Page 1

Washer-Extractor

Cabinet Hardmount

2-Speed, 3-Speed, and Variable-Speed

Model Numbers

HC18 SC18 UC18

HC25 SC25 UC25

HC27 SîC27 UC27

HC35 SC35 UC35

HC50 SC50 UC50

HC80 SC80 UC80

(See inside for complete model number list.)

Installation/Maintenance

NOTA: El manual en

español aparece después

del manual en inglés.

Part No. F232062R4

May 1999

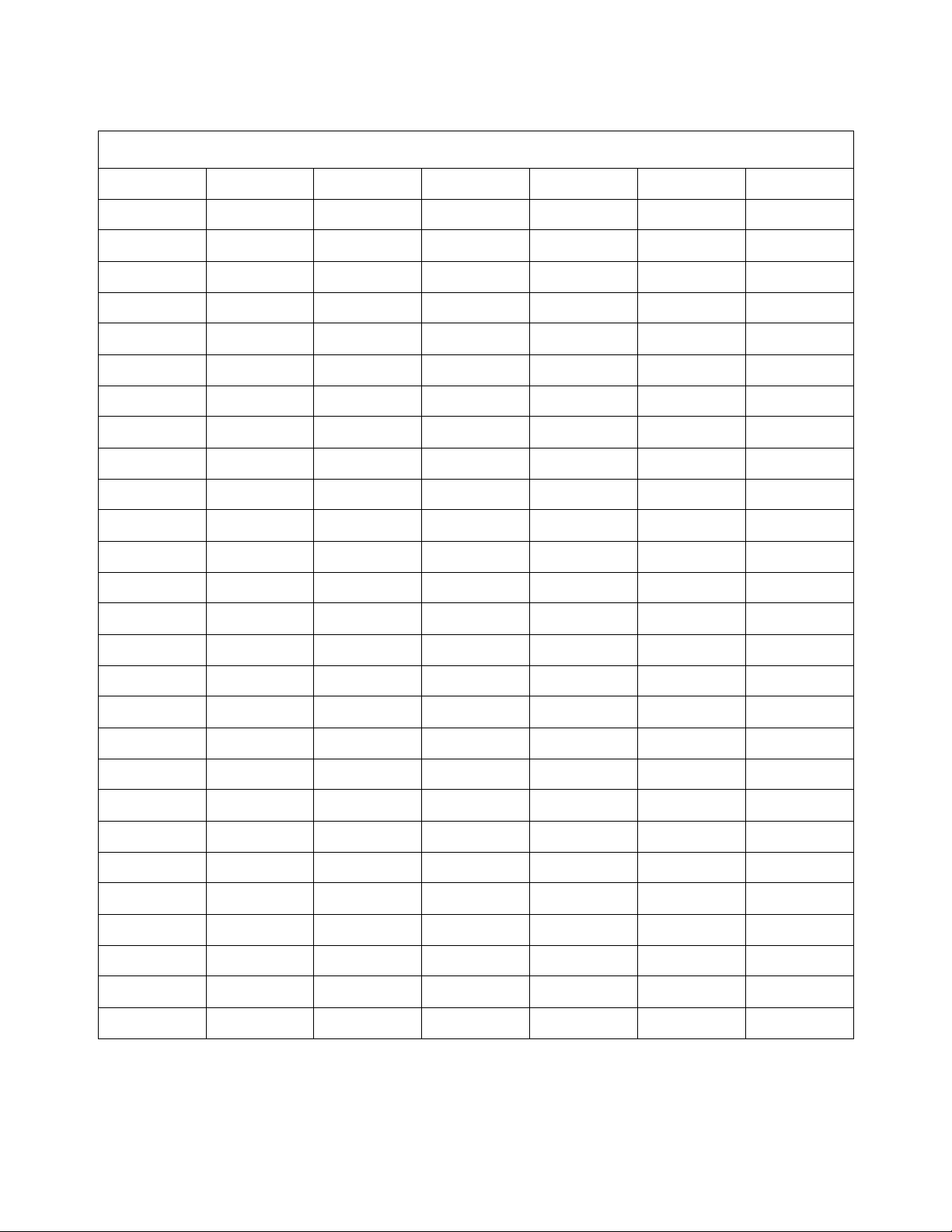

Page 2

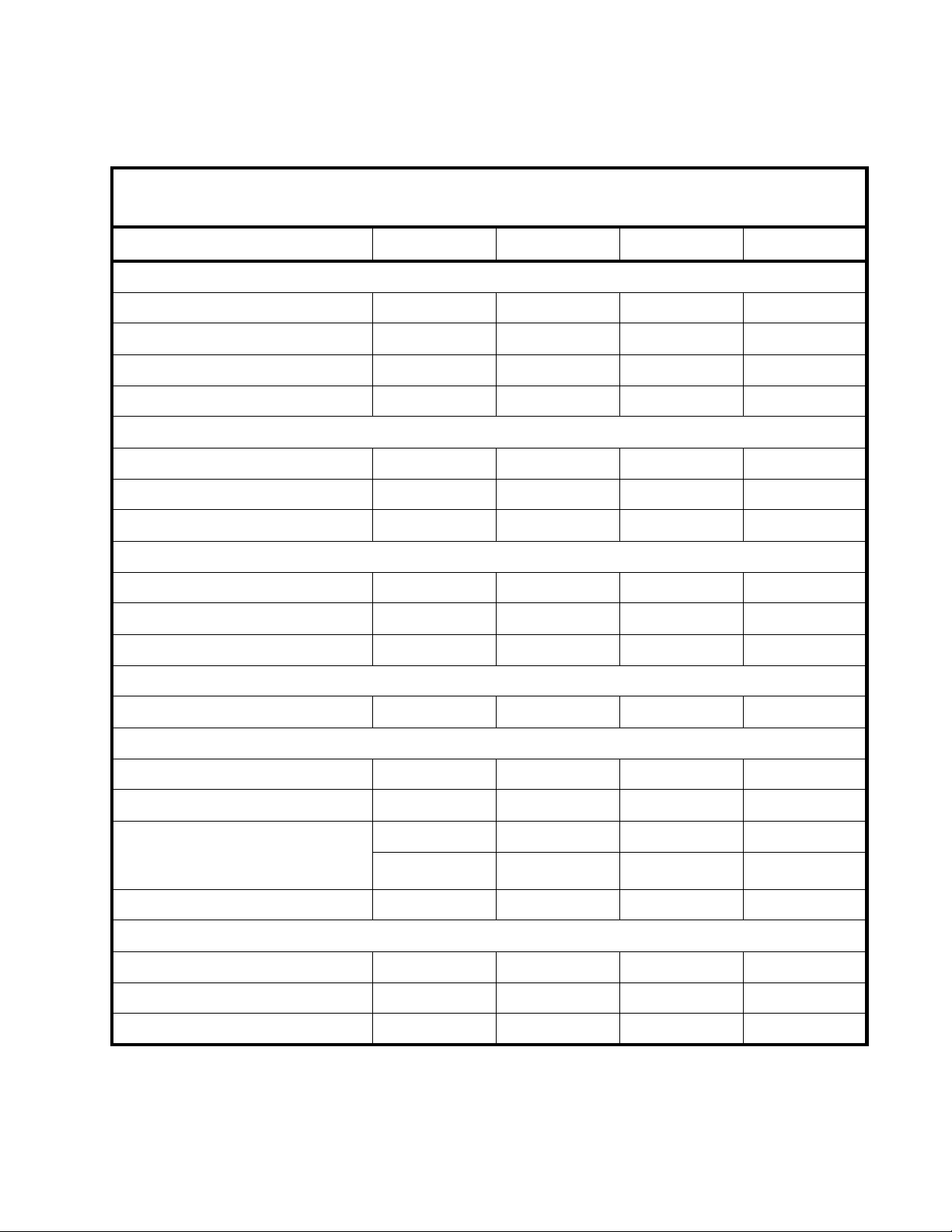

Model Number Chart

HC18EC2

HC18MC2

HC18MD2

HC18MH2

HC18MN2

HC18MV2

HC18PC2

HC18SN2

HC18VC2

HC25EC2

HC25MC2

HC25MD2

HC25MH2

HC25MN2

HC25MV2

HC35MD2

HC35MH2

HC35MN2

HC35MV2

HC35PC2

HC35SN2

HC35VC2

HC50EC2

HC50MC2

HC50MD2

HC50MH2

HC50MN2

HC50MV2

HC50PC2

HC50SN2

SC18MC3

SC18MD2

SC18MD3

SC18MH2

SC18MH3

SC18MN2

SC18MN3

SC18MV2

SC18MV3

SC18SN2

SC18SN3

SC18VN2

SC18VNV

SC25EC2

SC25EP2

SC27SN2

SC27VN2

SC27VNV

SC35EC2

SC35EP2

SC35MC2

SC35MC3

SC35MD2

SC35MD3

SC35MH2

SC35MH3

SC35MN2

SC35MN3

SC35MV2

SC35MV3

SC50MN3

SC50MV2

SC50MV3

SC50SN2

SC50VN2

SC50VNV

SC80ECV

SC80EPV

SC80MC3

SC80MD3

SC80MH3

SC80MN3

SC80MV3

SC80SN3

SC80VNV

UC18PN3

UC18VN2

UC18VNV

UC25MC2

UC25MD2

UC25MH2

UC25MN2

UC25MV2

UC25PC2

UC25PN2

UC27MN2

UC27PN2

UC27VN2

UC35MC2

UC35MC3

UC35VNV

UC50MC2

UC50MC3

UC50MD2

UC50MD3

UC50MH2

UC50MH3

UC50MN2

UC50MN3

UC50MV2

UC50MV3

UC50PC2

UC50PC3

UC50PN2

UC50PN3

HC25PC2

HC25SN2

HC25VC2

HC27EC2

HC27MC2

HC27MD2

HC27MH2

HC27MN2

HC27MV2

HC27SN2

HC27VC2

HC35EC2

HC35MC2

HC50VC2

HC80MC3

HC80MD3

HC80MH3

HC80MN3

HC80MV3

HC80PC3

HC80SN3

HC80VCV

HC80VNV

SC18EC2

SC18EP2

SC18MC2

SC25MC2

SC25MD2

SC25MH2

SC25MN2

SC25MV2

SC25SN2

SC27EC2

SC27EP2

SC27MC2

SC27MD2

SC27MH2

SC27MN2

SC27MV2

SC35SN2

SC35SN3

SC35VN2

SC35VNV

SC50EC2

SC50EP2

SC50MC2

SC50MC3

SC50MD2

SC50MD3

SC50MH2

SC50MH3

SC50MN2

UC18MC2

UC18MC3

UC18MD2

UC18MD3

UC18MH2

UC18MH3

UC18MN2

UC18MN3

UC18MV2

UC18MV3

UC18PC2

UC18PC3

UC18PN2

UC35MD2

UC35MD3

UC35MH2

UC35MH3

UC35MN2

UC35MN3

UC35MV2

UC35MV3

UC35PC2

UC35PC3

UC35PN2

UC35PN3

UC35VN2

UC50VN2

UC50VNV

UC80MC3

UC80MD3

UC80MH3

UC80MN3

UC80MV3

UC80PC3

UC80PN3

UC80VNV

Page 3

Table of Contents

Installation/Maintenance

Safety

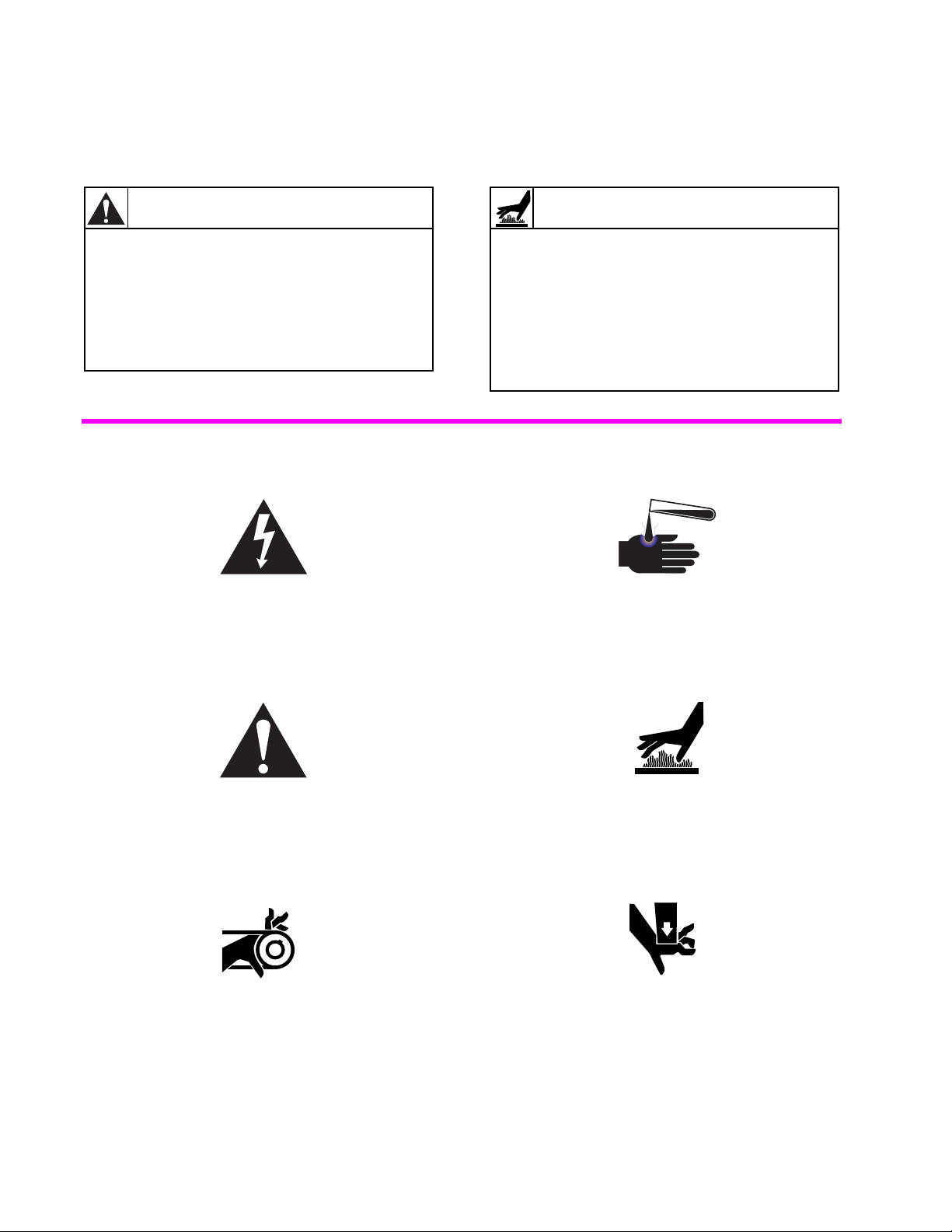

Key to Symbols ................................................ 4

Safety Decal Location ...................................... 5

Operator Safety ................................................ 6

Safe Operating Environment ............................ 7

Environmental Conditions ............................ 7

Machine Location ......................................... 8

Input and Output Services ............................ 8

AC Inverter Drive ......................................... 9

Misuse .............................................................. 9

Installation

Machine Overview ........................................... 11

Delivery Inspection .......................................... 12

Customer Service ............................................. 12

Model Number Familiarization Guide ............. 13

General Specifications ..................................... 14

Machine Dimensions ........................................ 20

Dimensional Clearances ................................... 27

Machine Foundation ........................................ 29

Mechanical Installation .................................... 31

Expansion Bolt Installation .......................... 31

Drain Connection ............................................. 42

Water Connection ............................................ 44

Electrical Installation ....................................... 45

Steam Requirements (Steam Heat

Option Only) .................................................... 52

Chemical Injection Supply System .................. 53

Control Function Test ...................................... 57

Maintenance

Daily ................................................................ 59

Beginning Of Day ........................................ 59

End Of Day .................................................. 60

Weekly ............................................................. 60

Monthly ........................................................... 60

Quarterly .......................................................... 64

Care Of Stainless Steel .................................... 65

Maintenance Checklists ................................... 66

Removal from Service

Decommissioning ............................................ 71

Elevated Base Frame Installation ................. 33

J-Bolt Installation ......................................... 35

Concrete Foundation Pad ............................. 39

F232062

1

Page 4

© Copyright 1999 Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232062

Page 5

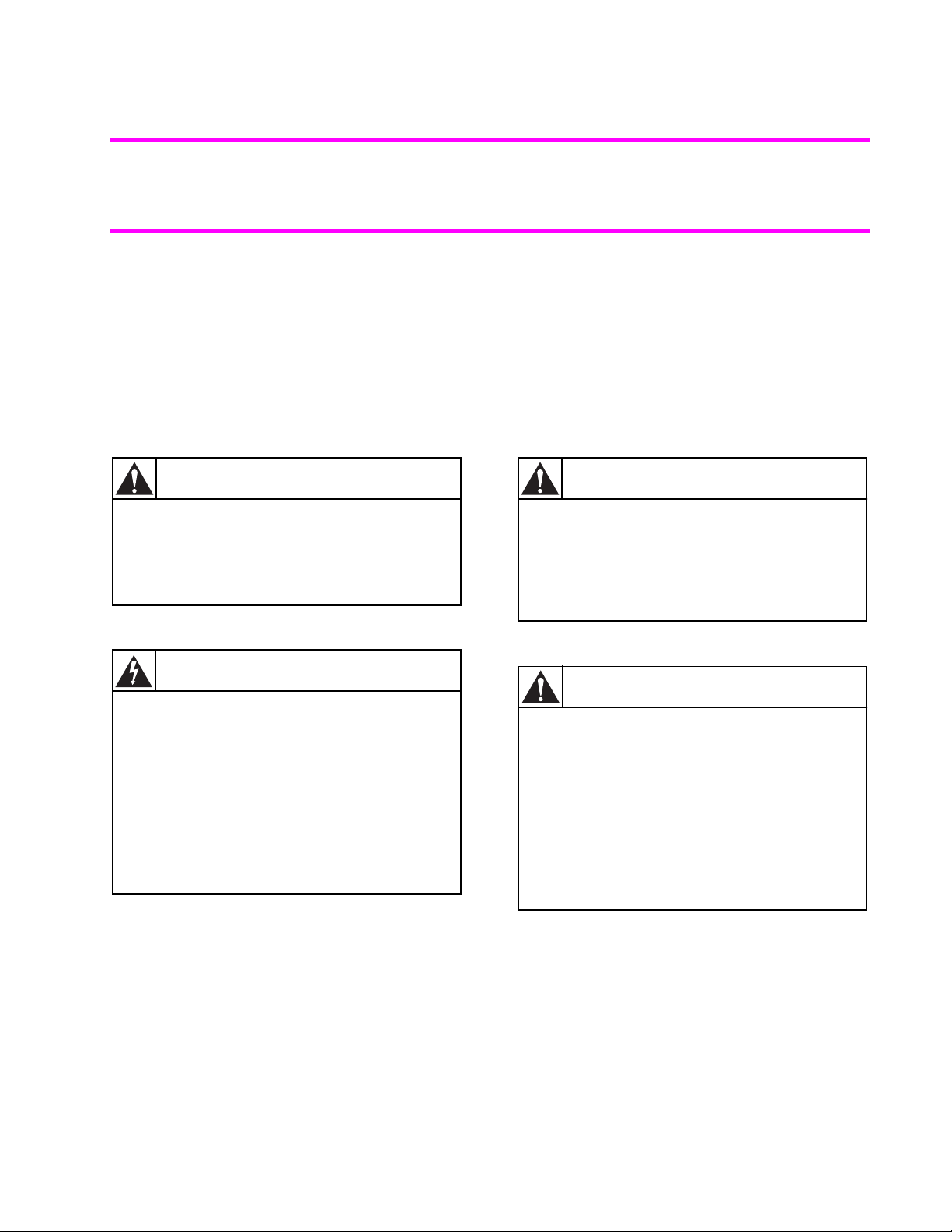

Section 1

Death or serious injury can result if children

become trapped in the machine. Do not

allow children to play on or around this

machine. Do not leave children unattended

while the machine door is open.

SW001

DANGER

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar with

the potential hazards involved. Failure to

observe this warning may result in personal

injury and/or equipment damage, and may

void the warranty.

SW004

WARNING

Safety

Anyone operating or servicing this machine

must follow the safety rules in this manual.

Particular attention must be paid to the

DANGER, WARNING

, and

CAUTION

blocks which appear throughout the manual.

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel familiar

with electrical test procedures, test

equipment, and safety precautions should

attempt adjustments and troubleshooting.

Disconnect power from the machine before

removing the control box cover, and before

attempting any service procedures.

SW005

The following warnings are general examples

that apply to this machine. Warnings specific

to a particular installation or maintenance

procedure will appear in the manual with the

discussion of that procedure.

F232062

3

Page 6

Safety

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that the

recommended clearances for inspection

and maintenance are provided. Never allow

the inspection and maintenance space to

be blocked.

SW020

Key To Symbols

The lightning flash and arrowhead within the

triangle is a warning sign indicating the

presence of dangerous voltage.

WARNING

Never touch internal or external steam

pipes, connections, or components. These

surfaces can be extremely hot and will

cause severe burns. The steam must be

turned off and the pipe, connections, and

components allowed to cool before the pipe

can be touched.

SW014

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper

precautions should be taken when handling

corrosive or caustic materials.

The exclamation point within the triangle is a

warning sign indicating important instructions

concerning the machine and possibly

dangerous conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms

within the machine. Guards should always be

in place when the machine is in operation.

4

This warning symbol indicates the presence of

hot surfaces that could cause serious burns.

Stainless steel and steam lines can become

extremely hot and should not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving

mechanical parts can crush and/or sever

body parts.

F232062

Page 7

Safety

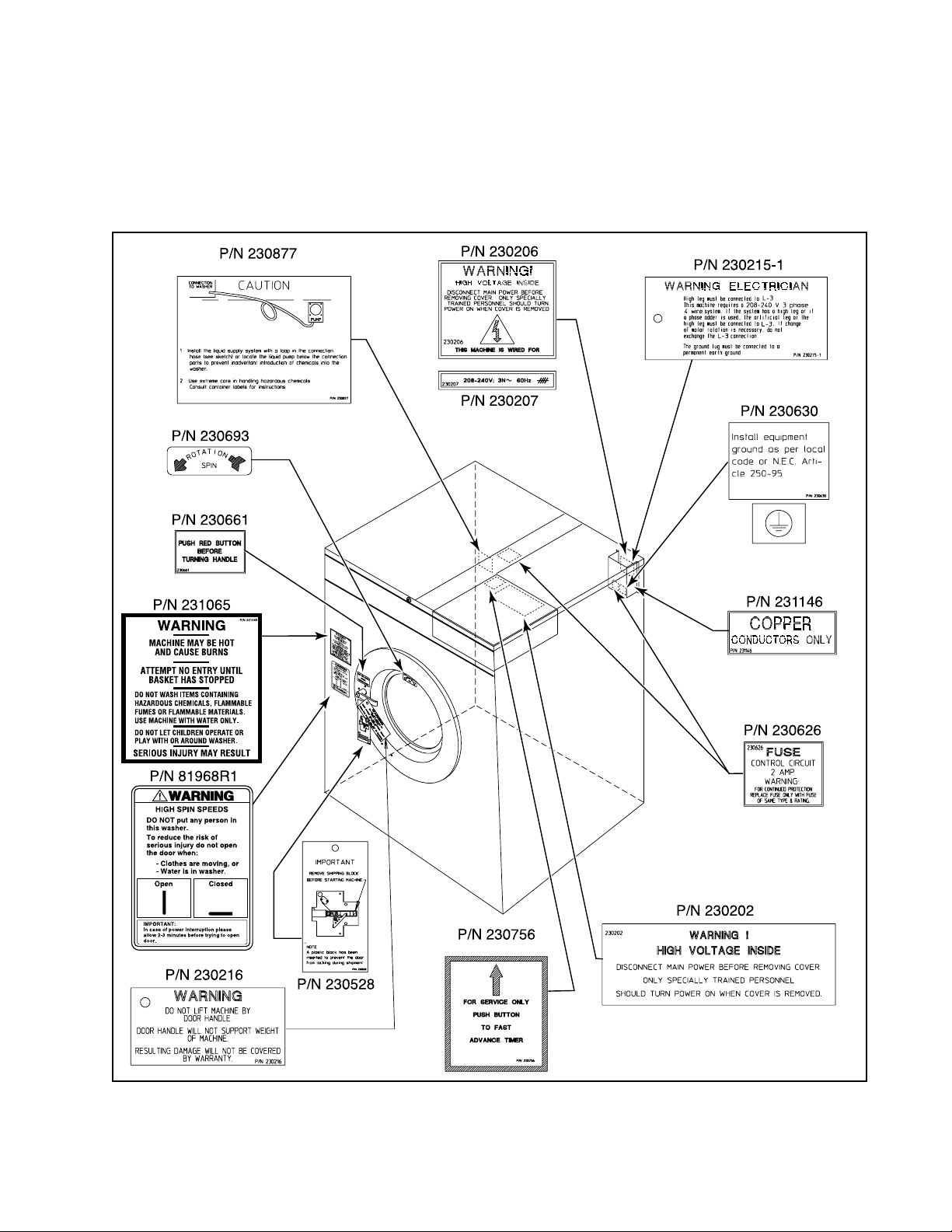

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety

(O.P.L. Only)

decals could result in injury to the operator or

service technician.

(Typical)

81968R1

8

1

96

8

R

1

(O.P.L. Only)

(80-pound models only)

(Not present on EDC models)

(MC Models Only)

H018IE3A

F232062

Figure 1

5

Page 8

Safety

To provide personal safety and keep the

machine in proper working order, follow all

maintenance and safety procedures presented

in this manual. If questions regarding safety

arise, contact the factory immediately.

Use factory-authorized spare parts to avoid

safety hazards.

Operator Safety

WARNING

NEVER insert hands or objects into basket

until it has completely stopped. Doing so

could result in serious injury.

SW012

To ensure the safety of machine operators,

the following maintenance checks must be

performed daily:

1. Prior to operating the machine, verify that

all warning signs are present and legible.

Missing or illegible signs must be replaced

immediately. Make certain that spares are

available.

If the door lock and interlock are

not functioning properly, call a

service technician.

3. Do not attempt to operate the machine

if any of the following conditions

are present:

a. The door does not remain securely

locked during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in

the machine.

WARNING

Never operate the machine with a bypassed

or disconnected balance system. Operating

the machine with severe out-of-balance

loads could result in personal injury and

serious equipment damage.

SW039

2. Check door interlock before starting

operation of the machine:

a. Attempt to start the machine with the

door open. The machine should not

start with the door open.

b. Close the door without locking it and

attempt to start the machine. The

machine should not start with the

door unlocked.

c. Close and lock the door and start a

cycle. Attempt to open the door while

the cycle is in progress. The door

should not open.

6

F232062

Page 9

Safety

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel reducers,

carbon tetrachloride, gasoline, benzene,

naptha, etc. Doing so could result in serious

personal injury and/or damage to

the machine.

SW002

DANGER

Safe Operating Environment

Safe operation requires an appropriate

operating environment for both the operator

and the machine. If questions regarding safety

arise, contact the factory immediately.

Environmental Conditions

•

Ambient Temperature

machine will freeze at temperatures of

32°F (0°C) or below.

Temperatures above 120°F (50°C) will

result in more frequent motor overheating

and, in some cases, malfunction or

premature damage to solid state devices

that are used in some models. Special

cooling devices may be necessary.

Water pressure switches are affected by

increases and decreases in temperature.

Every 25°F (10°C) change in temperature

will have a 1% effect on the water level.

.

Water in the

periodically. Louvers, screens, or other

separating devices may reduce the

available air opening significantly.

•

Radio Frequency Emissions

.

A filter is

available for machines in installations

where floor space is shared with

equipment sensitive to radio frequency

emissions.

•

Elevation

.

If the machine is to be operated

at elevations of over 3,280 feet (1,000

meters) above sea level, pay special

attention to water levels and electronic

settings (particularly temperature) or

desired results may not be achieved.

•

Chemicals

. Keep stainless steel surfaces

free of chemical residues.

•

Humidity

. Relative humidity above 90%

may cause the machine’s electronics or

motors to malfunction or may trip the

ground fault interrupter. Corrosion

problems may occur on some metal

components in the machine.

If the relative humidity is below 30%, belts

and rubber hoses may eventually develop

dry rot. This condition can result in hose

leaks, which may cause safety hazards

external to the machine in conjunction

with adjacent electrical equipment.

•

Ventilation

openings for such laundry room

accessories as dryers, ironers, water

heaters, etc., must be evaluated

F232062

. The need for make-up air

•

Water Damage

.

Do not spray the machine

with water. Short circuiting and serious

damage may result. Repair immediately all

seepage due to worn or damaged

gaskets, etc.

7

Page 10

Safety

Safe Operating Environment

(Continued)

Machine Location

•

Foundation

. The concrete floor must be of

sufficient strength and thickness to handle

the floor loads generated by the high

extract speeds of the machine.

•

Service/Maintenance Space

.

Provide

sufficient space to allow comfortable

performance of service procedures and

routine preventive maintenance.

This is especially important in connection

with machines equipped with an AC

inverter drive.

Consult installation instructions for specific

details.

CAUTION

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any

safety devices.

Input and Output Services

•

Water Pressure

. Best performance will be

realized if water is provided at a pressure

of 30 – 85 psi (2.0 – 5.7 bar). Although the

machine will function properly at lower

pressure, increased fill times will occur.

Water pressure higher than 100 psi

(6.7 bar) may result in damage to machine

plumbing. Component failure(s) and

personal injury could result.

SW019

•

Steam Heat (Optional) Pressure

.

Best

performance will be realized if steam is

provided at a pressure of 30 – 80 psi

(2.0 – 5.4 bar). Steam pressure higher

than 125 psi (8.5 bar) may result in

damage to steam components and may

cause personal injury.

For machines equipped with optional

steam heat, install piping in accordance

with approved commercial steam

practices. Failure to install the supplied

steam filter may void the warranty.

•

Compressed Air

.

For machines requiring

compressed air service, best performance

will be realized if air is provided at a

pressure of 80 – 100 psi (5.4 – 6.7 bar).

•

Drainage System

.

Provide drain lines or

troughs large enough to accommodate

the total number of gallons that could

be dumped if all machines on the site

drained at the same time from the highest

attainable level. If troughs are used,

they should be covered to support light

foot traffic.

•

Power

. For personal safety and for proper

operation, the machine must be grounded

in accordance with state and local codes.

The ground connection must be to a

proven earth ground, not to conduit or

water pipes. Do not use fuses in place of

the circuit breaker. An easy-access cutoff

switch should also be provided.

8

F232062

Page 11

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground lug

near the input power block on this machine.

Without proper grounding, personal injury

from electric shock could occur and machine

malfunctions may be evident.

SW008

Always disconnect power and water supplies

before a service technician performs any

service procedure. Where applicable, steam

and/or compressed air supplies should also be

disconnected before service is performed.

Safety

installations or above 440V for 400V

installations, a buckboost transformer is

recommended. If voltage is above 240 or

480, a buckboost transformer is required.

•

Sufficient space to perform service

procedures and routine preventive

maintenance is especially important for

machines equipped with the AC

inverter drive.

Misuse

Never use this machine for any purpose other

than washing fabric.

AC Inverter Drive

Machines equipped with the AC inverter drive

require special attention with regard to the

operating environment.

•

An especially dusty or linty environment

will require more frequent cleaning of the

AC inverter drive cooling fan filter and of

the AC inverter drive itself.

•

Power line fluctuations from sources such

as uninterruptible power supplies (UPS)

can adversely affect machines equipped

with the AC inverter drive. Proper

suppression devices should be utilized on

the incoming power to the machine to

avoid problems.

•

A clean power supply free from voltage

spikes and surges is absolutely essential

for machines equipped with the AC

inverter drive. Nonlinear inconsistencies

(peaks and valleys) in the power supply

can cause the AC inverter drive to generate

nuisance errors.

•

Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

•

Never wash machine parts or automotive

parts in the machine. This could result in

serious damage to the basket.

•

Never allow children to play on or around

this machine. Death or serious injury can

result if children become trapped in the

machine. Do not leave children unattended

while the machine door is open. These

cautions apply to animals as well.

If voltage is above 230V for 200V

F232062

9

Page 12

Safety

Notes

10

F232062

Page 13

Section 2

Installation

This manual is designed as a guide to the

installation and maintenance of the 18-pound,

25-pound, 27-pound, 35-pound, 50-pound,

and 80-pound capacity cabinet hardmount

washer-extractors.

Machine Overview

The design of the machine emphasizes

performance reliability and long service life.

In washer-extractor sizes up through the

50-pound capacity models, the cylinder is

supported with two sealed bearings mounted in

a machined cast iron trunnion. On 80-pound

capacity models, the cylinder and shaft

assembly is supported by two flange roller

bearing assemblies. Bearing housings are

bolted to a heavy gamma frame.

The 2-speed machines use one dual-speed

motor to drive the cylinder via a V-belt drive in

wash speed and extract speed.

The 3-speed 18-pound capacity models use

one triple-speed motor to drive the cylinder

at wash speed, medium extract speed, and

high extract speed. The 3-speed 35-pound,

50-pound, and 80-pound capacity models use

one single-speed and one dual-speed motor to

drive the cylinder at wash speed, medium

extract speed, and high extract speed.

flat belt drive. The 80-pound capacity machine

uses a 3V belt drive.

A door-lock system prevents opening of the

stainless steel door when a cycle is in progress.

It also prevents operation of the machine when

the door is open.

An electrically operated drain valve is used

to retain the water and wash solution in the

machine during the wash and rinse steps.

The drain valve closes when power is applied

and opens when power is removed, allowing

the machine to drain in the event of a

power failure.

The cylinder is designed with lifters or ribs

that lift the garments from the wash solution

when the cylinder rotates at slow speed and

allow the garments to tumble back into the

solution. The cylinder is perforated, allowing

the water to pass through and drain from

within during the wash process and extract.

Electrical controls for the machine are housed

in a separate enclosure located underneath the

top cover of the machine.

AC drive-controlled washer-extractors use one

motor to drive the cylinder. In all capacities

except the 80-pound, the motor is driven via a

F232062

11

Page 14

Installation

Machine Overview

The polypropylene supply dispenser is

located under a flexible cover on the left side

of the machine, viewed from the front. The

compartments are numbered 1 – 3, starting

from the left side of the machine. A nozzle

flushes dry supplies from the compartment

with water at the appropriate time in the cycle.

Liquid supplies can be injected directly into

the dispenser compartments by a customersupplied external chemical supply system.

Hose barbs on the rear of the machine facilitate

connection to an external chemical supply

system. A terminal strip in the input power

junction box provides control signals.

(Continued)

Delivery Inspection

Upon delivery, visually inspect crate,

protective cover, and unit for any visible

shipping damage. If the crate, protective cover,

or unit are damaged or signs of possible

damage are evident, have the carrier note the

condition on the shipping papers before the

shipping receipt is signed, or advise the carrier

of the condition as soon as it is discovered.

Customer Service

If literature or replacement parts are required,

contact the source from whom the machine

was purchased or contact Alliance Laundry

Systems LLC at (920) 748-3950 for the name

and address of the nearest authorized

parts distributor.

For technical assistance, call any of the

following numbers:

(850) 718-1035

(850) 718-1026

Marianna, Florida

(920) 748-3121

Ripon, Wisconsin

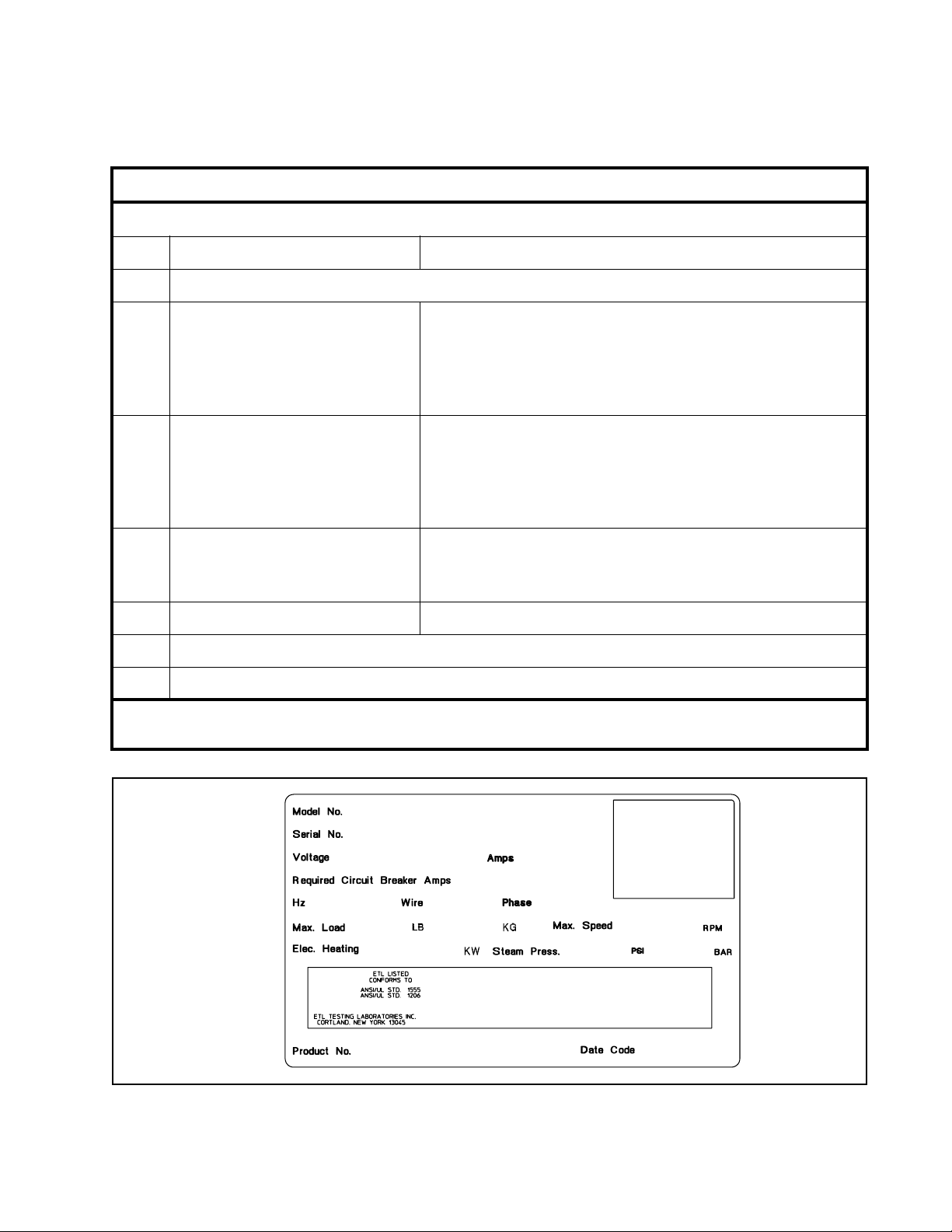

A record of each machine, including the serial

number, is on file with the manufacturer. The

serial number decal is located at the rear of the

machine. See Figure 2. Always provide the

machine’s serial number and model number

when ordering parts or when seeking

technical assistance.

Remove the crate and protective cover as soon

after delivery as possible. If any damage is

discovered upon removal of the crate and/or

protective cover, advise the carrier and file a

written claim immediately.

12

F232062

Page 15

Model Number Familiarization Guide

Installation

SC

35

M

(E)

(P)

(S)

(V)

N

(C)

(D)

(H)

(V)

2

(3)

(V)

C

U2

Sample Model Number:

Machine Type C = Cabinet

Machine Capacity (pounds dry weight)

Type of Electrical Control M = Mechanical Timer

E = WX/EDC Microcomputer

P = P-Series Microcomputer†

S = S-Series Microcomputer

V = V-Series Microcomputer

Coin Meter Option N = No Coin Meter

C = W2000 (Computer-controlled models only)‡

D = Digital (Mechanical Timer models only)

H = Horizontal Slide (Mechanical Timer models only)

V = Vertical Drop (Mechanical Timer models only)

Speed 2 = 2-Speed

3= 3-Speed

V = Variable-Speed

Electrical Characteristics See Voltage Designation Chart in this section.

Design Series

SC35MN2CU20001

0001

†Models designated “PN” use the S-Series Microcomputer.

‡Models designated “MC” are prepared for use with an aftermarket coin meter.

Option Identification (varies from machine to machine)

SC35MN2CU20001

00000000000

380 – 415

50

15

43

35 16

500000

Figure 2

5

470

H043I

F232062

13

Page 16

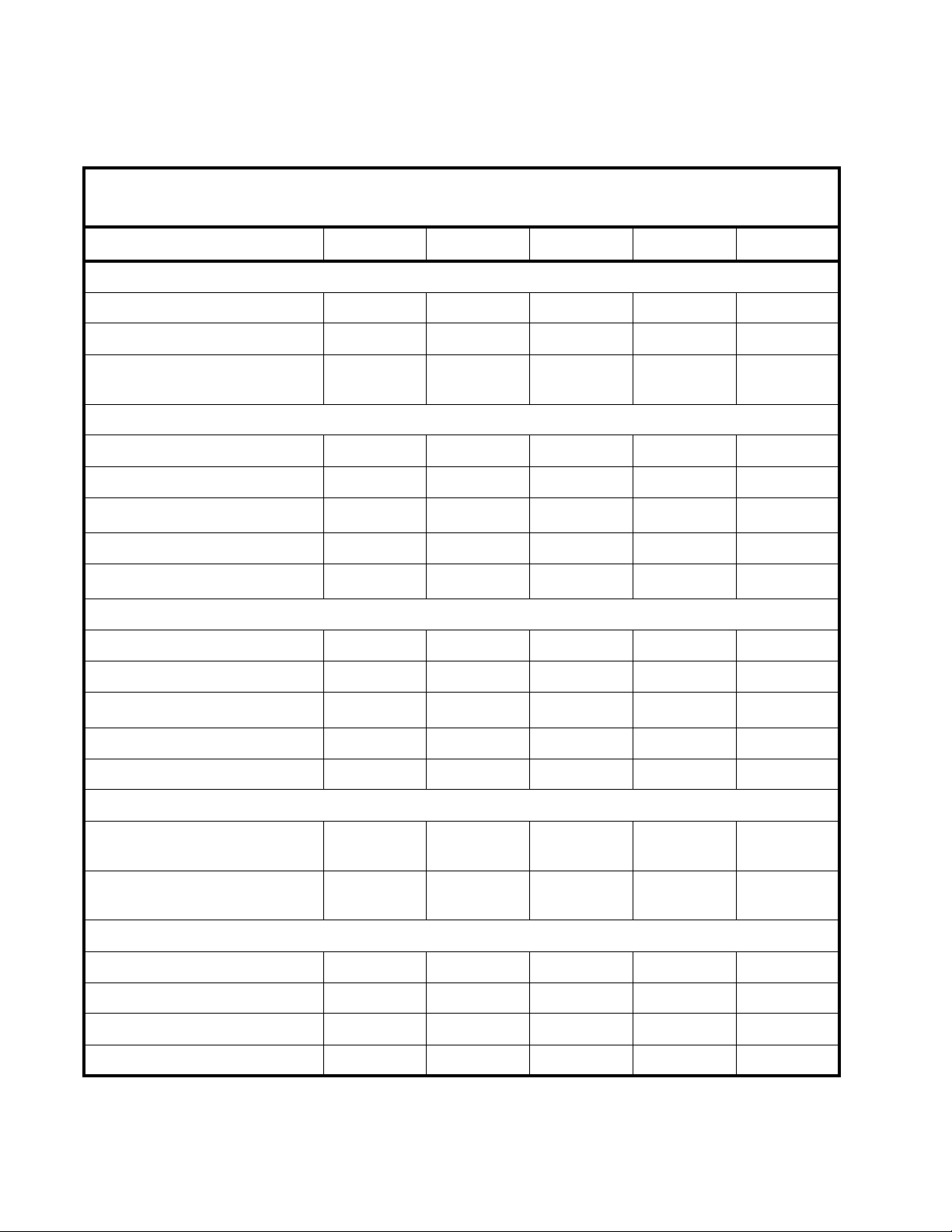

Installation

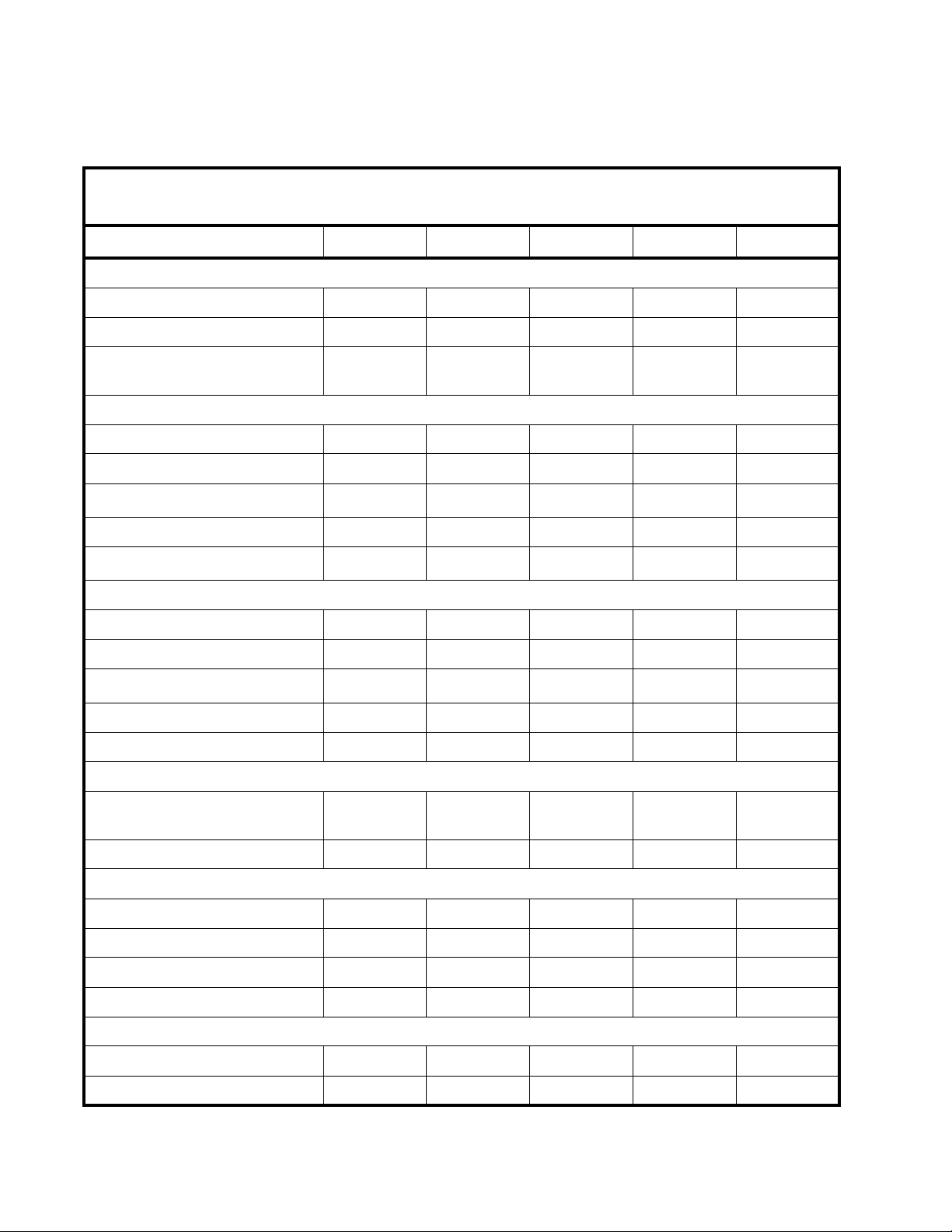

Cabinet Hardmount General Specifications

2-Speed Models

Specification 18 25 27 35 50

Overall Dimensions

Overall width, in (mm) 26 (660) 26 (660) 29 (737) 30-1/8 (765) 34-1/16 (865)

Overall height, in (mm) 42 (1067) 45 (1143) 45 (1143) 47-1/4 (1200) 49-3/4 (1265)

Overall depth, in (mm) 29-11/16

(754)

Weight and Shipping Information

Net weight, lb (kg) 390 (177) 435 (198) 495 (225) 650 (295) 820 (373)

Domestic shipping weight, lb (kg) 430 (194) 475 (214) 555 (250) 710 (320) 970 (437)

3

(m3)

3

(m3)

Domestic shipping volume, ft

Export shipping weight, lb (kg) 480 (218) 525 (236) 605 (272) 760 (345) 1020 (464)

Export shipping volume, ft

Cylinder diameter, in (mm) 21 (533) 21 (533) 24 (610) 26-1/4 (667) 30 (762)

Cylinder depth, in (mm) 13-3/4 (349) 18-3/4 (457) 16 (406) 18-3/8 (467) 20 (508)

Cylinder volume, ft

Perforation size, in (mm) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76)

Perforation open area,% 17 17 23 17 18

3

(l)

23.9 (0.669) 28.9 (0.809) 30.1 (0.852) 39.0 (1.09) 49.8 (1.39)

47.1 (1.32) 35.9 (1.01) 37.7 (1.07) 47.1 (1.32) 68.6 (1.92)

Wash Cylinder Information

2.76 (78.1) 3.76 (106) 4.19 (117.9) 5.76 (163.1) 8.18 (232)

Door Opening Information

33-11/16

(856)

34-13/16

(884)

38-1/2 (978) 42 (1067)

Door opening size, in (mm) 12 (305) 12 (305) 14-11/32

(364)

Ht. door bottom above floor, in

(mm)

Avg. power used per cycle, kW/hr 0.20 0.25 0.25 0.30 0.42

Nominal sound emission, dBA 60 63 63 64 66

Background noise level, dBA 48 51 51 49 49

Average HVAC load, Btu/hr 425 400 400 est. 510 700

14

17-1/4 (438) 17-1/4 (438) 17 (432) 19 (480) 18-1/4 (465)

Power Consumption

13-15/16

(354)

16-1/4 (413)

F232062

Page 17

Installation

Cabinet Hardmount General Specifications

2-Speed Models (Continued)

Specification 18 25 27 35 50

Drive Train Information

Number of motors in drive train 1 1 1 1 1

Wash/reverse power, hp (kW) 0.18 (0.13) 0.25 (0.19) 0.25 (0.19) 0.40 (0.30) 0.55 (0.41)

High extract power, hp (kW) 1.0 (0.746) 1.4 (1.04) 1.4 (1.04) 1.8 (1.3) 2.7 (2.01)

Cylinder Speeds

Wash/reverse speed, rpm 5355474744

High extract speed, rpm 525 540 480 470 450

Centrifugal Force Data

Wash/reverse centrifugal force, Gs 0.85 0.90 0.75 0.82 0.825

High extract centrifugal force, Gs 82.1 86.9 80 82.3 86.3

Balance Detection

Vibration safety switch installed N/A N/A N/A N/A N/A

Direct Steam Heating (Optional)

Steam inlet connection size, in (mm) 1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13)

Number of steam inlets 1 1 1 1 1

Steam req. to raise bath

temperature 10°F, l b

(10°C, kg)

Average steam use per cycle, BHP 0.66 0.87 0.94 1.4 1.9

Total electrical heating capacity, kW 7.8 7.8 7.8 15.6 23.4

Electrical heating elements 3 3 3 6 9

Electrical heat element size, kW 2.6 2.6 2.6 2.6 2.6

LOW 1.1 (0.50) 1.4 (0.64) 1.5 (0.68) 2.1 (0.95) 2.8 (1.3)

HIGH 1.2 (0.54) 1.6 (0.73) 1.7 (0.77) 2.8 (1.3) 3.7 (1.7)

Electrical Heating (Optional)

F232062

15

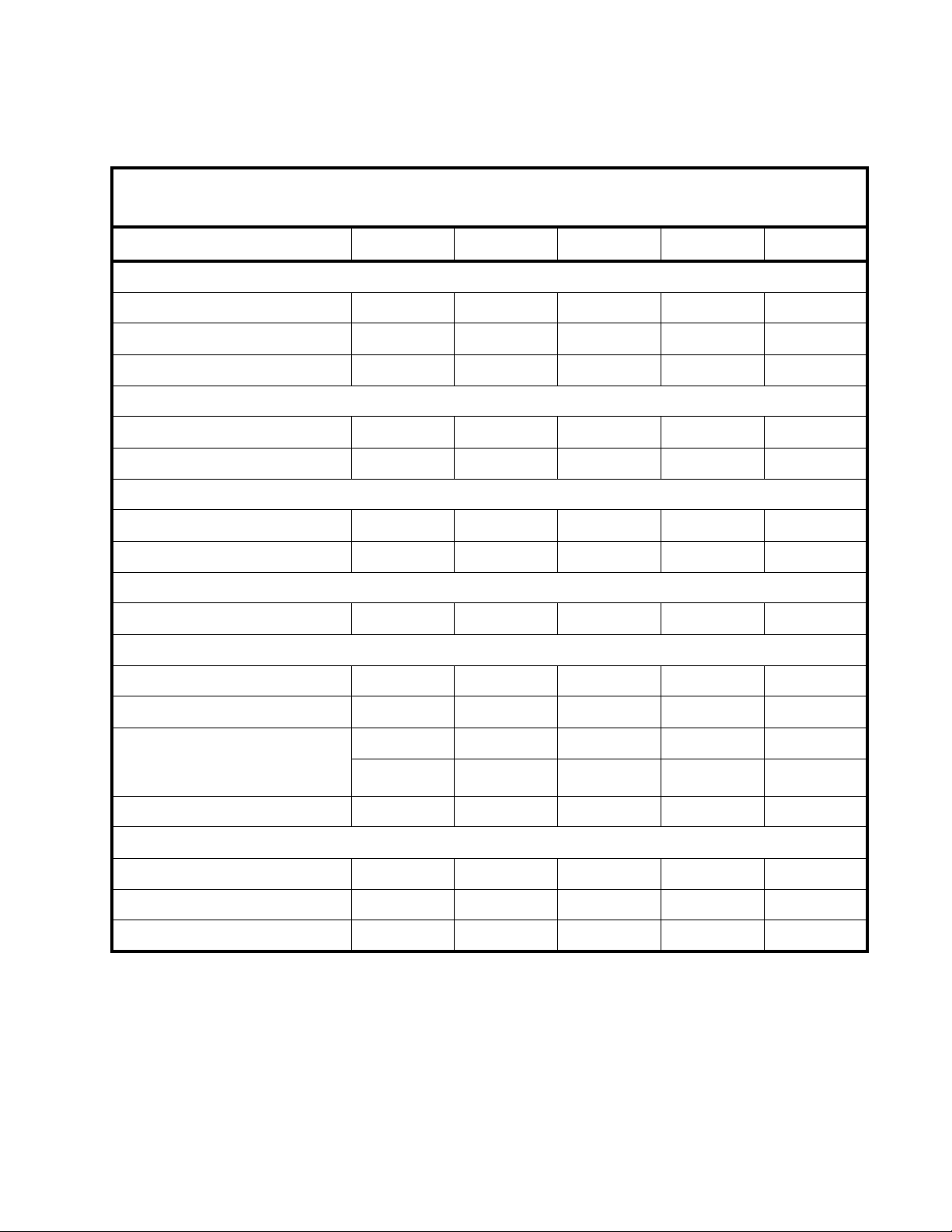

Page 18

Installation

Cabinet Hardmount General Specifications

3-Speed Models

Specification 18 35 50 80

Overall Dimensions

Overall width, in (mm) 26 (660) 30-1/8 (765) 34-1/16 (865) 41-1/2 (1054)

Overall height, in (mm) 42 (1067) 47-1/4 (1200) 49-3/4 (1265) 56 (1422)

Overall depth, in (mm) 29-11/16 (754) 38-1/2 (978) 42 (1067) 51-5/8 (1311)

Weight and Shipping Information

Net weight, lb (kg) 400 (182) 675 (307) 950 (432) 1600 (727)

Domestic shipping weight, lb (kg) 430 (195) 780 (355) 990 (450) 1650 (743)

3

(m3)

3

(m3)

Domestic shipping volume, ft

Export shipping weight, lb (kg) 490 (223) 785 (357) 1150 (523) 1700 (765)

Export shipping volume, ft

Cylinder diameter, in (mm) 21 (533) 26-1/4 (667) 30 (762) 36 (914)

Cylinder depth, in (mm) 13-3/4 (349) 18-3/8 (467) 20 (508) 22 (559)

Cylinder volume, ft

Perforation size, in (mm) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76)

Perforation open area,% 17 17 18 ---

Door opening size, in (mm) 12 (305) 13-15/16 (354) 16-1/4 (413) 18-1/2 (470)

Ht. door bottom above floor, in (mm) 17-1/4 (438) 19 (480) 18-1/4 (465) 21-1/2 (546)

Avg. power used per cycle, kW/hr 0.18 est 0.28 est 0.38 est 0.55 est.

Nominal sound emission, dBA 61 65 67 60 / 69

3

(l)

23.9 (0.669) 39.0 (1.09) 49.8 (1.39) 78.1 (2.19)

47.1 (1.32) 47.1 (1.32) 68.6 (1.92) ---

Wash Cylinder Information

2.76 (78.1) 5.76 (163.1) 8.18 (232) 12.4 (354)

Door Opening Information

Power Consumption

Background noise level, dBA 48 49 49 47

Average HVAC load, Btu/hr 440 525 725 900

16

F232062

Page 19

Installation

Cabinet Hardmount General Specifications

3-Speed Models (Continued)

Specification 18355080

Drive Train Information

Number of motors in drive train 1 2 2 2

Wash/reverse power, hp (kW) 0.18 (0.13) 0.40 (0.30) 0.90 ( 0.67) 1.0 (0.75)

Medium extract power, hp (kW) 1.2 (0.895) 0.45 (0.34) 1.0 (0.75) 1.2 (0.89)

High extract power, hp (kW) 1.5 (1.12) 3.0 (2.2) 3.5 (2.6) 4.5 (3.36)

Cylinder Speeds

Wash/reverse speed, rpm 46 47 44 40

Medium extract speed, rpm 330 75 60 64

High extract speed, rpm 661 591 561 530

Centrifugal Force Data

Wash/reverse centrifugal force, Gs 0.65 0.82 0.825 0.82

Medium extract centrifugal force, Gs 32.5 2.10 1.53 2.1

High extract centrifugal force, Gs 130 130 134 143

Balance Detection

Vibration safety switch installed N/A Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size, in (mm) 1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13)

Number of steam inlets 1 1 1 1

Steam req. to raise bath

temperature 10°F, l b

(10°C, kg)

Average steam use per cycle, BHP 0.66 1.4 1.9 3.1

Total electrical heating capacity, kW 7.8 15.6 23.4 31.2

Electrical heating elements 3 6 9 12

LOW 1.1 (0.5) 2.1 (0.95) 2.8 (1.3) 4.4 (2.0)

HIGH 1.2 (0.54) 2.8 (1.3) 3.7 (1.7) 6.3 (2.9)

Electrical Heating (Optional)

Electrical heat element size, kW 2.6 2.6 2.6 2.6

F232062

17

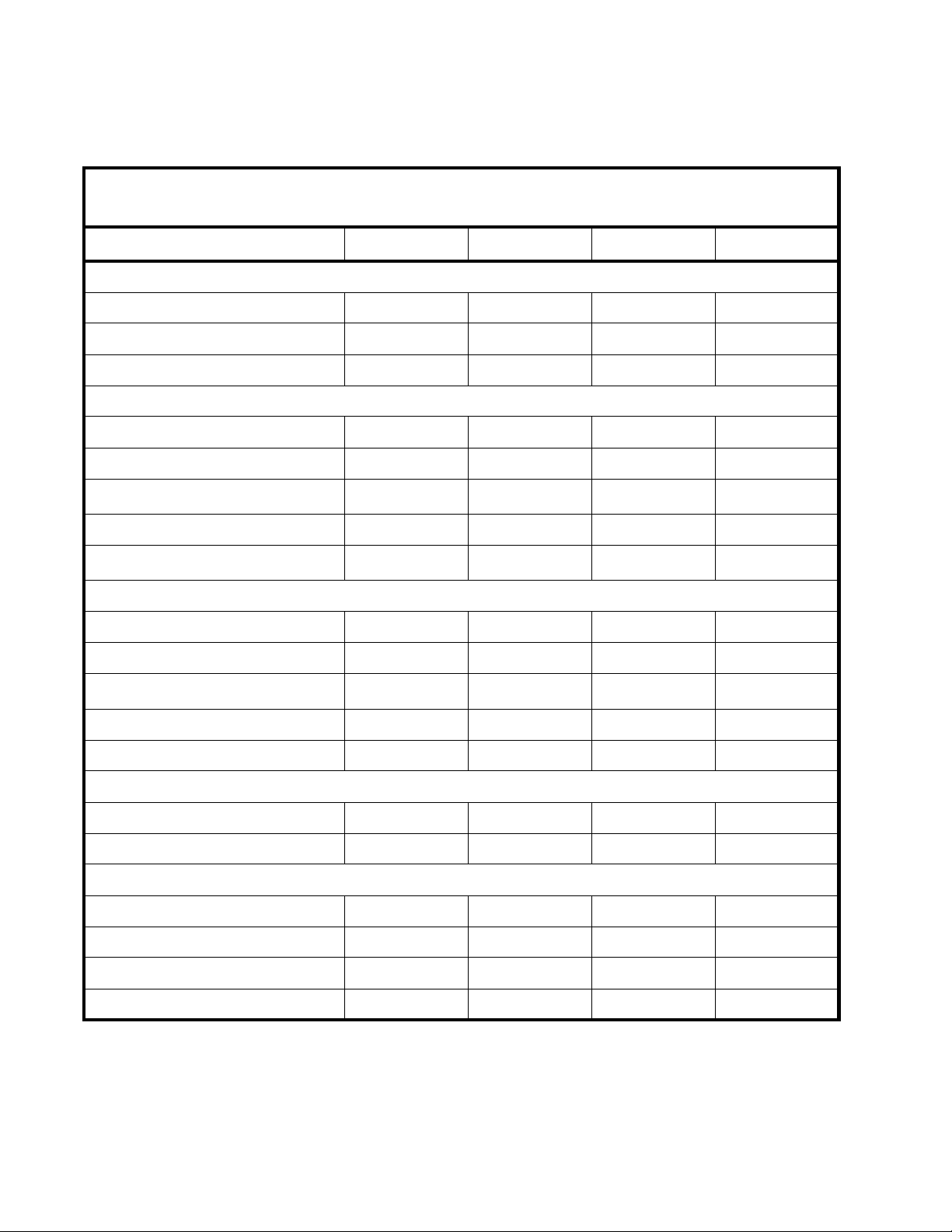

Page 20

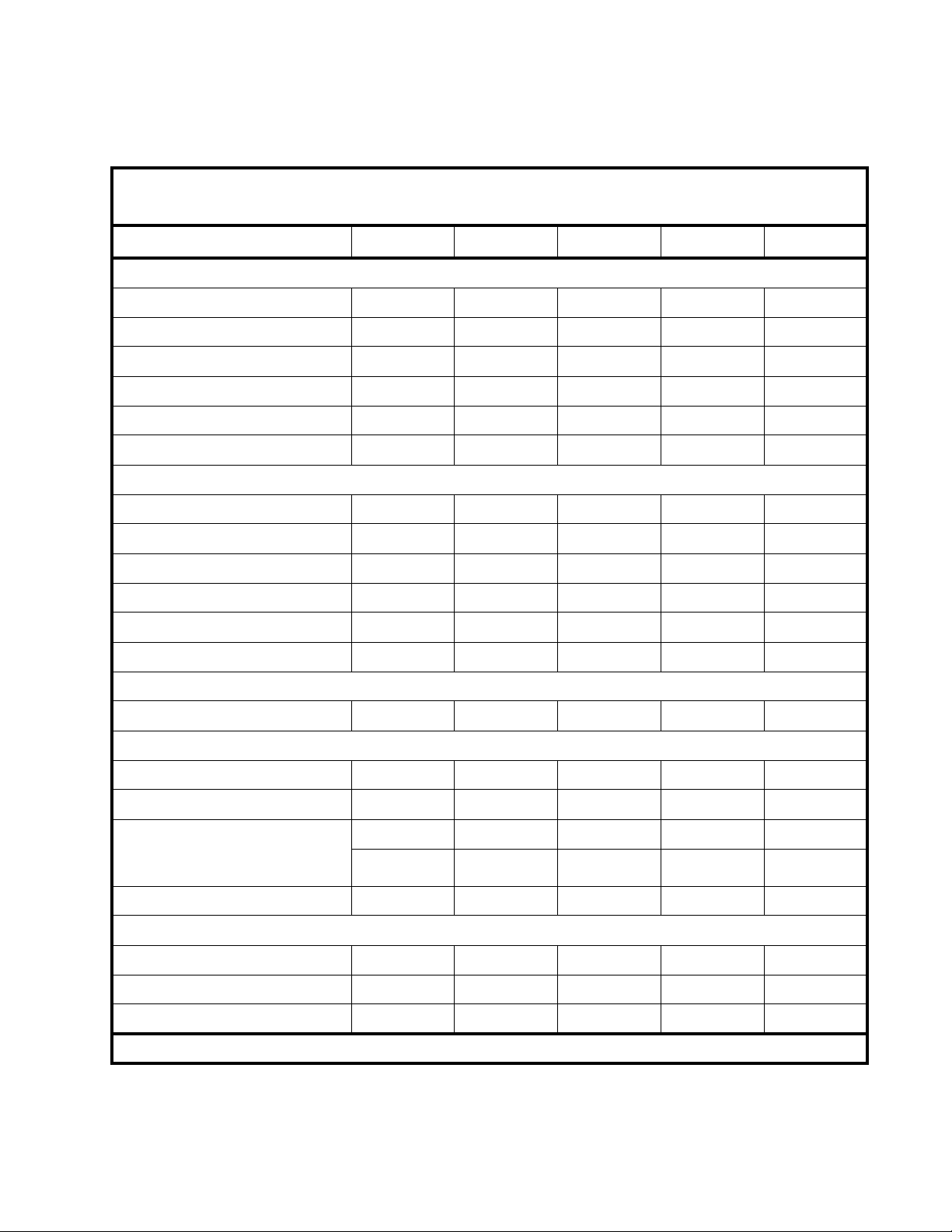

Installation

Cabinet Hardmount General Specifications

Variable-Speed Models

Specification 18 27 35 50 80

Overall Dimensions

Overall width, in (mm) 26 (660) 29 (737) 30-1/8 (765) 34-1/16 (865) 41-1/2 (1054)

Overall height, in (mm) 42 (1067) 45 (1143) 47-1/4 (1200) 49-3/4 (1265) 56 (1422)

Overall depth, in (mm) 29-11/16

(754)

Weight and Shipping Information

Net weight, lb (kg) 404 (182) 520 (234) 640 (288) 788 (355) 1406 (633)

Domestic shipping weight, lb (kg) 424 (191) 545 (245) 670 (301) 818 (371) 1456 (655)

3

3

(m3)

(m3)

Domestic shipping volume, ft

Export shipping weight, lb (kg) 494 (222) 610 (275) 750 (338) 988 (448) 1506 (678)

Export shipping volume, ft

Cylinder diameter, in (mm) 21 (533) 24 (610) 26-1/4 (667) 30 (762) 36 (914)

Cylinder depth, in (mm) 13-3/4 (349) 16 (406) 18-3/8 (467) 20 (508) 22 (559)

Cylinder volume, ft

Perforation size, in (mm) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76) 0.188 (4.76)

Perforation open area,% 17 23 17 18 27

Door opening size, in (mm) 12 (305) 14-11/32

3

(l)

23.9 (0.669) 30.1 (0.852) 39.0 (1.09) 49.8 (1.39) 96.18 (2.69)

47.1 (1.32) 37.7 (1.07) 47.1 (1.32) 68.6 (1.92) 109.4 (3.1)

Wash Cylinder Information

2.76 (78.1) 4.19 (117.9) 5.76 (163.1) 8.18 (232) 12.4 (354)

Door Opening Information

34-13/16

(884)

(364)

38-1/2 (978) 42 (1067) 51-5/8 (1311)

13-15/16

(354)

16-1/4 (413) 18-1/2 (470)

Ht. door bottom above floor, in (mm) 17-1/4 (438) 17 (432) 19 (480) 18-1/4 (465) 21-1/2 (546)

Power Consumption

Avg. power used per cycle, kW/hr 0.11 0.14 0.20 0.37

Nominal sound emission, dBA N/A N/A N/A N/A N/A

Background noise level, dBA N/A N/A N/A N/A N/A

Average HVAC load, Btu/hr 425 425 510 510 900

Drive Train Information

Number of motors in drive train 1 1 1 1 1

Drive motor power, hp (kW) 1 (0.75) 1 (0.75) 2 (1.5) 2 (1.5) 5 (3.7)

18

F232062

Page 21

Installation

Cabinet Hardmount General Specifications

Variable-Speed Models (Continued)

Specification 18 27 35 50 80

Cylinder Speeds

Gentle wash/reverse speed, rpm 29 27 26 24 22

Wash/reverse speed, rpm 5248464340

Distribution speed, rpm 8277736863

Low extract speed, rpm 366 343 328 307 280

Medium extract speed, rpm* 534 500 478 447 408

High extract speed, rpm 685 641 613 573 524

Centrifugal Force Data

Gentle wash centrifugal force, Gs 0.25 0.25 0.25 0.25 0.25

Wash/reverse centrifugal force, Gs 0.8 0.8 0.8 0.8 0.8

Distribution centrifugal force, Gs 2 2 2 2 2

Low extract centrifugal force, Gs 40 40 40 40 40

Med. extract centrifugal force, Gs 85 85 85 85 85

High extract centrifugal force, Gs 140 140 140 140 140

Balance Detection

Vibration safety switch installed N/A N/A Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size, in (mm) 1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13)

Number of steam inlets 1 1 1 1 1

Steam req. to raise bath

temperature 10°F, l b

(10°C, kg)

Average steam use per cycle, BHP 0.72 0.96 1.4 1.9 3.1

Total electrical heating capacity, kW 7.8 7.8 15.6 23.4 31.2

Electrical heating elements 3 3 6 9 12

LOW 1.1 (0.50) 1.4 (0.64) 2.1 (0.95) 2.8 (1.3) 4.4 (2.0)

HIGH 1.4 (0.64) 1.9 (0.86) 2.7 (1.2) 3.7 (1.7) 6.3(2.9)

Electrical Heating (Optional)

Electrical heat element size, kW 2.6 2.6 2.6 2.6 2.6

*Medium extract speed is not available on Electronic Control (EC) models.

F232062

19

Page 22

Installation

Machine Dimensions

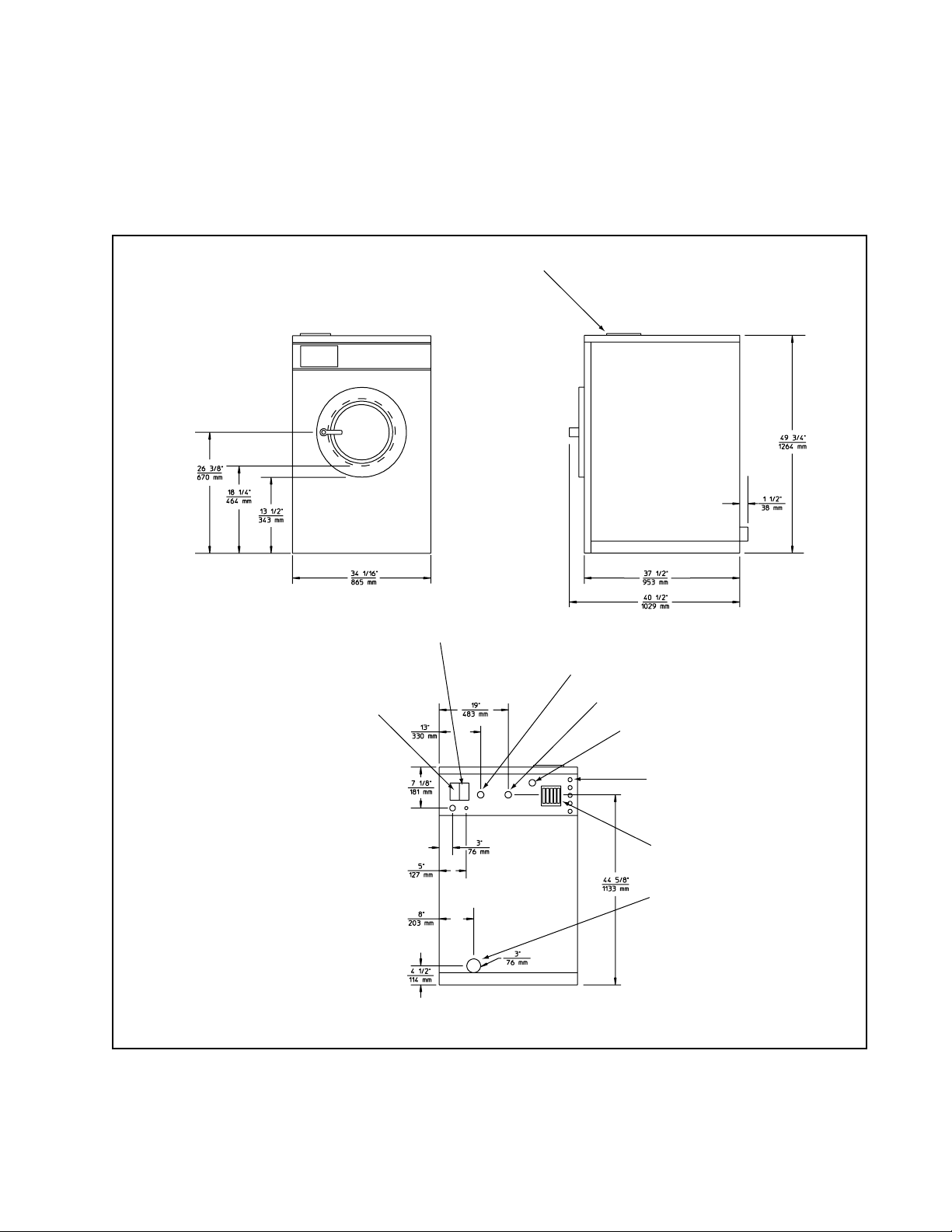

Figures 3 through 8 illustrate the machine

dimensions for each size of machine, starting

with the 18-pound model and finishing with

the 80-pound model.

Note:

purposes only. They are approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

The dimensions shown are for planning

20

F232062

Page 23

Supply Dispenser

Installation

External Chemical Supply Signal

Terminal Strip (OPL only)

Input Power Block

18-Pound Capacity Machines

Cold Water Inlet

Hot Water Inlet

Extra Water Inlet (optional)

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H001IE3A

Figure 3

F232062

21

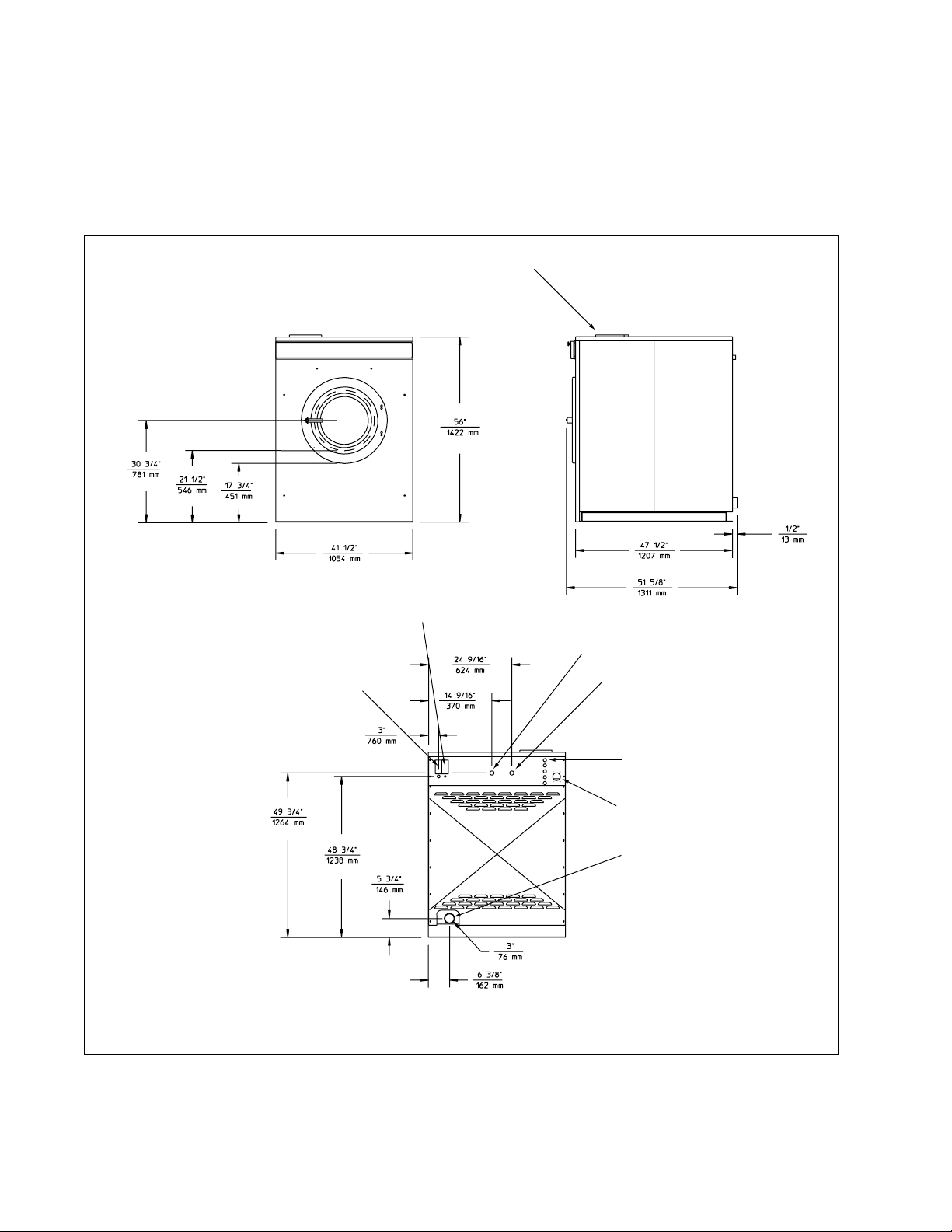

Page 24

Installation

Machine Dimensions

(Continued)

Supply Dispenser

External Chemical Supply Signal

Terminal Strip (OPL only)

Input Power Block

25-Pound Capacity Machines

Cold Water Inlet

Hot Water Inlet

Extra Water Inlet (optional)

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H002IE3A

Figure 4

22

F232062

Page 25

Supply Dispenser

Installation

External Chemical Supply Signal

Terminal Strip (OPL only)

Input Power Block

27-Pound Capacity Machines

Cold Water Inlet

Hot Water Inlet

Extra Water Inlet (optional)

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H003IE3A

Figure 5

F232062

23

Page 26

Installation

Machine Dimensions

(Continued)

Supply Dispenser

External Chemical Supply Signal

Terminal Strip (OPL only)

Input Power Block

35-Pound Capacity Machines

Cold Water Inlet

Hot Water Inlet

Extra Water Inlet (optional)

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H004IE3A

Figure 6

24

F232062

Page 27

Supply Dispenser

Installation

External Chemical Supply Signal

OPL only

Terminal Strip (OPL only)

Input Power Block

50-Pound Capacity Machines

Cold Water Inlet

Hot Water Inlet

Extra Water Inlet (optional)

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H005IE3A

Figure 7

F232062

25

Page 28

Installation

Machine Dimensions

External Chemical Supply Signal

Terminal Strip (OPL only)

(Continued)

Supply Dispenser

Cold Water Inlet

Input Power Block

80-Pound Capacity Machines

Hot Water Inlet

External Chemical

Supply Inlets (OPL only)

Vacuum Breaker

Drain Outlet

H049IE3A

Figure 8

26

F232062

Page 29

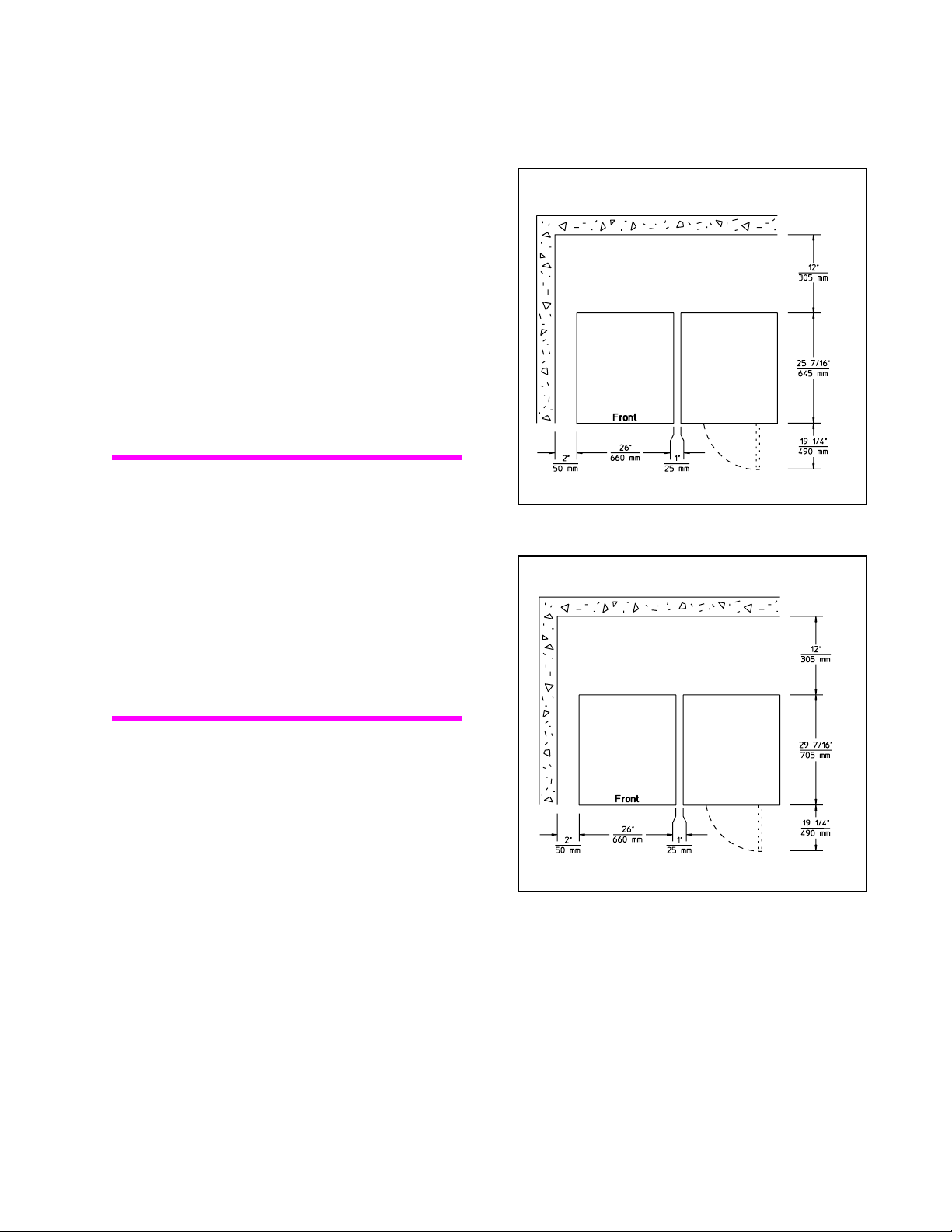

Installation

Dimensional Clearances

Allow a minimum of 12 inches (305 mm) at

the rear for 18-pound and 25-pound capacity

models and a minimum of 18 inches (457 mm)

at the rear for the larger machines. Allow

2 inches (51mm) at the sides and 1 inch

(25 mm) between machines in multiple

installations. Dimensional clearances are

indicated in Figures 9 through 14 for each size

of machine, starting with the 18-pound model

and finishing with the 80-pound model.

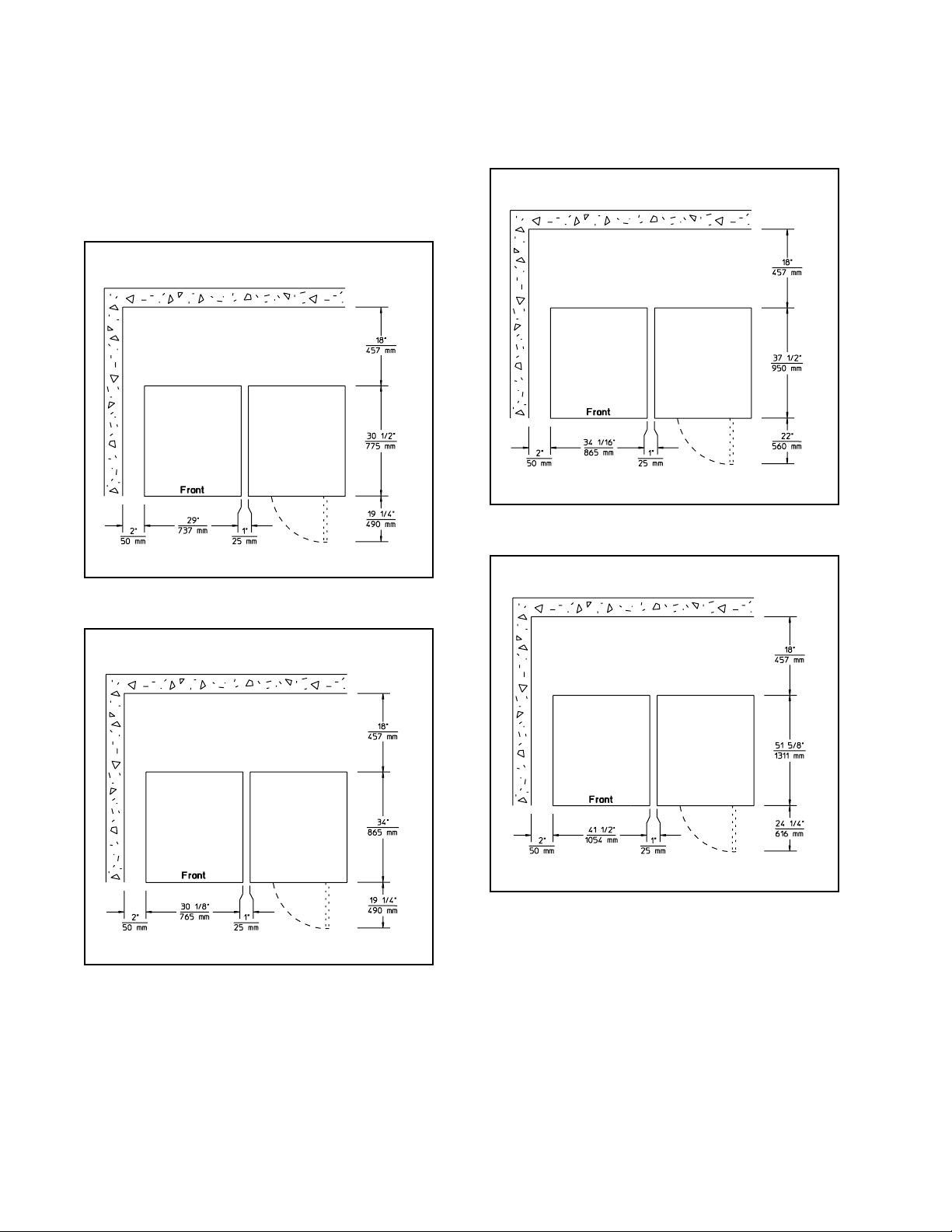

Note:

80-pound model are dependent upon which set

of mounting bolt holes is used. If the machine

is intended for close mounting (mounting bolt

pattern labeled "A" in Figure 28), follow the

clearances in Figure 14. If the machine is

intended for standard mounting (mounting bolt

pattern labeled "B" in Figure 28), provide a

minimum clearance of 8 inches (203 mm) at

each side of the machine in addition to the

clearances in Figure 14.

The dimensional clearances for the

18-Pound Capacity Machines

H019IE1A

Figure 9

25-Pound Capacity Machines

F232062

H020IE1A

Figure 10

27

Page 30

Installation

Dimensional Clearances

(Continued)

27-Pound Capacity Machines

Figure 11

50-Pound Capacity Machines

H023IE1A

Figure 13

H021IE1A

80-Pound Capacity Machines

35-Pound Capacity Machines

Figure 12

H048IE1A

Figure 14

H022IE1A

28

F232062

Page 31

Installation

Machine Foundation

Note:

above ground level, or over basements or

crawlspaces. Installation must be “slab on

grade” or equivalent.

Do not mount on wooden floors,

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that the

recommended clearances for inspection

and maintenance are provided. Never allow

the inspection and maintenance space to

be blocked.

A proper foundation is absolutely necessary

for all models because of the high extract

speed and the G-forces exerted.

SW020

The machine must be anchored to a smooth

level surface so that the entire base of the

machine is supported and rests on the

mounting surface. (Do not support the machine

on only four points.) Anchor bolts for machine

sizes up to the 50-pound capacity model must

be a minimum of 5/8-inch diameter, grade 2.

Anchor bolts for the 80-pound capacity model

must be a minimum of 3/4-inch diameter,

grade 2.

Care must be exercised in the design of the

mounting base due to the force exerted by the

machine during extract.

Static and dynamic loads on the floor or

foundation are shown in the Cabinet

Hardmount Floor Load Data tables in this

subsection. These tables can be used as a

reference when designing floors and

foundations.

Thoroughness of detail must be stressed with

all foundation work to insure a stable unit

installation, eliminating possibilities of

excessive vibration during extract.

The machine must be secured to a foundation

or floor of adequate construction. The floor

must be 3500 psi minimum reinforced

concrete embedded in clean, compacted fill

dirt. For 2-speed models, the floor must be at

least 4 inches (102 mm) thick. For 3-speed

and variable-speed models (except for the

80-pound capacity model), the floor must be at

least 6 inches (152 mm) thick. For 80-pound

capacity models, the floor must be at least 9

inches (229 mm) thick.

F232062

29

Page 32

Installation

Machine Foundation

(Continued)

Cabinet Hardmount Floor Load Data, 2-Speed Models

Specification 18 25 27 35 50

Static floor load, lbs (kN) 476 (2.12) 549 (2.44) 653 (2.90) 804 (3.58) 1041

(4.63)

Static pressure, lbs-ft2 (kN-m2)

Maximum dynamic load, lbs (kN) 296 (1.31) 420 (1.87) 427 (1.90) 581 (2.58) 860 (3.83)

Dynamic pressure, lbs-ft

Dynamic load frequency, Hz 8.75 9.00 8.00 7.83 7.50

Max. moment about machine base, lbs-ft (kN-m) 567

2

(kN-m2)

104 (4.96) 103 (4.94) 106 (5.07) 113 (5.41) 117 (5.62)

64.4 (3.08) 79.3 (3.80) 69.5 (3.33) 82 (3.91) 97 ( 4.64)

(0.769)

806 (1.12) 854 (1.16) 1261

(1.71)

1892

(2.57)

Cabinet Hardmount Floor Load Data, 3-Speed Models

Specification 18 35 50 80

Static floor load, lbs (kN) 486 (2.16) 829 (3.69) 1171 (5.21) 2047 ( 9.10)

2

Static pressure, lbs-ft

Maximum dynamic load, lbs (kN) 468 (2.08) 910 (4.05) 1340 (5.96) 2288 (10.2)

Dynamic pressure, lbs-ft

Dynamic load frequency, Hz 11.0 9.85 9.35 8.88

Max. moment about machine base, lbs-ft (kN-m) 899 (1.22) 1975 (2.68) 2948 (4.00) 5873 (7.98)

(kN-m2)

2

(kN-m2)

106 (5.07) 117 (5.58) 132 (6.32) 150 (7.18)

102 (4.88) 128 (6.13) 151 (7.23) 167 (8.03)

Cabinet Hardmount Floor Load Data, Variable-Speed Models

Specification 18 27 35 50 80

Static floor load, lbs (kN) 490 (2.18) 677 (3.01) 794 (3.53) 1009

(4.48)

Static pressure, lbs-ft2 (kN-m2)

Maximum dynamic load, lbs (kN) 512 (2.27) 755 (3.36) 979 (4.35) 1407

Dynamic pressure, lbs-ft

Dynamic load frequency, Hz 11.52 10.68 10.22 9.58 8.67

Max. moment about machine base, lbs-ft (kN-m) 983 (1.33) 1450

2

(kN-m2)

107 (5.11) 110 (5.26) 112 (5.35) 114 (5.46) 135 (6.46)

(6.25)

112 (5.35) 123 (5.88) 138 (6.60) 159 (7.61) 161 (7.71)

(1.97)

2125

(2.88)

3095

(4.19)

1853

(8.23)

2209

(9.80)

5678

(7.68)

30

F232062

Page 33

Mechanical Installation

H025I

H027I

This subsection provides four specific methods

of mechanical installation. Follow the

procedure most appropriate for your machine.

Installation

Note:

Improper installation may void the

warranty. Consult the manufacturer or your

distributor before deviating from the

appropriate procedure.

Expansion Bolt Installation

(2-Speed Models Only)

Note:

Expansion bolts are not suitable

for 3-speed or variable-speed machine

installations. Expansion bolts should not be

used in single-machine concrete foundation

pad installations.

Use the following instructions and Figures

15 through 20 as a step-by-step guide

to installation of the expansion bolts.

1. Verify that the floor is 3500 psi minimum

reinforced concrete embedded in clean,

compacted fill dirt and at least 4 inches

(102 mm) thick.

Figure 15

4. Set the drill depth gauge to 2-9/16 inches

(65 mm). See Figure 16.

H026I

Figure 16

5. Drill the holes to the set depth. See

Figure 17.

2. Verify that the mounting surface is level

and even. If the mounting surface fails to

meet these requirements, the machine

must be installed using J-bolts and

machinery grout.

3. Use the base of the machine as a template

by positioning the machine in the desired

location and marking the pre-drilled

mounting holes on the floor. See

Figure 15.

F232062

Figure 17

31

Page 34

Installation

Mechanical Installation

(Continued)

6. Use compressed air or a squeeze bulb to

clean out each hole. See Figure 18.

Figure 18

7. Install the machine anchors, using the

included tool.

8. Secure the machine to the floor, using the

bolts furnished with the anchors. Tighten

the locknuts by even increments—one

after the other—until all are tightened

evenly and the machine is fastened

securely to the floor. See Figure 19.

H028I

5/8 in. (19 mm)

diameter

Expansion

Bolt

H030IE1A

Locknut

Washer

Note:

Machine

Base

Figure 20

Check and retighten the locknuts after

five to ten days of operation and every three

months thereafter.

H029I

Figure 19

The completed expansion bolt installation is

shown in Figure 20.

32

F232062

Page 35

Installation

H025I

Elevated Base Frame Installation

(2-Speed Models Only)

Note:

The 3-speed and variable-speed

models should not be installed on elevated

base frames.

Factory-built elevated steel base frames are

designed to meet the specifications of the

2-speed model washer-extractor. See

Figure 21.

1. Verify that the floor is 3500 psi minimum

reinforced concrete embedded in clean,

compacted fill dirt. The floor must be at

least 4 inches (102 mm) thick.

2. Use the elevated base frame as a template

by positioning the frame in the desired

location and marking the pre-drilled

mounting holes on the floor. See

Figure 22.

H035I

Figure 21

Use the following instructions and Figures

22 through 26 as a step-by-step guide to

installation of the elevated base frame.

Figure 22

3. Adjust the drill depth gauge to match the

length of the J-bolt, minus 1-1/2 inches

(38 mm). See Figure 23.

H026I

Figure 23

F232062

33

Page 36

Installation

Mechanical Installation

(Continued)

4. Drill and chisel out a conical hole large

enough to accept the J-bolt. See

Figure 24.

Figure 24

5. Use compressed air or a squeeze bulb to

remove debris from each hole. Anchor

J-bolt in place, using an industry-accepted

anchoring compound. Verify that the

J-bolts are in the correct locations and that

1-1/2 inches (38 mm) of each J-bolt

protrude from the floor. See Figure 25.

H031I

7. Fill the space between the frame base

and the floor with a good quality

non-shrinking machinery grout to ensure a

stable installation. Grout completely under

all frame members.

8. Remove the spacers carefully, allowing the

base frame to settle into the wet grout.

9. Before grout sets completely, make a drain

opening in the rear of the base frame

grouting with a stiff piece of wire. This

opening should be approximately 1/2 inch

(13 mm) wide to allow any surface water

build-up under the base of the machine to

drain away.

Do not omit this step.

10. Position washers and locknuts on J-bolts

and fingertighten nuts to machine base.

11. After the grout is completely dry, tighten

locknuts by even increments—one after

the other—until all are tightened evenly

and the base frame is fastened securely to

the floor. See Figure 26.

Figure 25

6. Raise and level the base frame 1/2 inch

(13 mm) off the floor on three points,

using spacers such as nut fasteners.

34

H032IE1A

H033I

Figure 26

12. Position the machine over the base frame,

aligning the mounting holes on the

machine with the corresponding holes on

the frame.

F232062

Page 37

Installation

13. Install a bolt, lockwasher, and nut in each

mounting hole. Use 5/8" – 18 x 2 grade 5

mounting bolts with 5/8" – 18 grade B nuts

and 5/8" lockwashers.

14. Handtighten each nut.

15. Tighten the two rear nuts two turns.

16. Tighten the two front nuts two turns.

17. On 25-pound, 27-pound, 35-pound, and

50-pound capacity models, tighten the two

middle nuts firmly.

18. Tighten the two front nuts firmly; tighten

the two rear nuts firmly.

Note:

five to ten days of operation and every three

months thereafter.

Check and retighten the locknuts after

J-Bolt Installation

Install J-bolts in concrete per the mounting

bolt layouts in Figures 27 and 28. Use the

following instructions and Figures 29 through

33 as a guide to step-by-step installation of the

J-bolts.

1. Verify that the floor is 3500 psi minimum

reinforced concrete embedded in clean,

compacted fill dirt. For 2-speed models,

the floor must be at least 4 inches

(102 mm) thick. For 3-speed and variablespeed models (except for the 80-pound

capacity model), the floor must be at least

6 inches (152 mm) thick. For 80-pound

capacity models, the floor must be at least

9 inches (229 mm) thick.

F232062

35

Page 38

Installation

Mechanical Installation

18-Pound Capacity Machines 25-Pound Capacity Machines

(Continued)

36

27-Pound Capacity Machines 35-Pound Capacity Machines

50-Pound Capacity Machines

Figure 27

H024IE3A

F232062

Page 39

Installation

80-Pound Capacity Machines

Note:

There are two different mounting bolt

layouts which may be used for the 80-pound

capacity machine. See Figure 28. The bolt

holes marked A are to be used for close

mounting—machines installed with a 1-inch

(25.4 mm) clearance between machines.

The bolt holes marked B are to be used for

standard mounting—machines installed with

a minimum clearance of 8 inches (203 mm)

between machines.

2. Adjust the drill depth gauge to match the

length of the J-bolt, minus 1-1/2 inches

(38 mm). See Figure 29.

MI003FE1A

Figure 28

H026I

Figure 29

F232062

37

Page 40

Installation

Mechanical Installation

(Continued)

3. Drill and chisel out a conical hole large

enough to accept the J-bolt. See

Figure 30.

Figure 30

4. Use compressed air or a squeeze bulb to

remove debris from each hole. Anchor

J-bolt in place, using an industry-accepted

anchoring compound. Verify that the

J-bolts are in the correct locations and that

1-1/2 inches (38 mm) of each J-bolt

protrude from the floor. See Figure 31.

H031I

6. If the machine is a

2-speed

model and

the mounting surface is level and even,

grouting is optional.

If grouting is not desired, position washers

and locknuts on J-bolts and tighten the

locknuts by even increments—one after

the other—until all are tightened evenly

and the machine is fastened securely to the

floor. See Figure 26.

If grouting is desired (or required by the

condition of the mounting surface),

proceed to step 7.

If the machine is a

speed

model, the machine must be

3-speed

variable-

or

grouted. Proceed to step 7.

7. Raise and level the machine 1/2 inch off

the floor on three points, using spacers

such as nut fasteners.

8. Fill the space between the machine base

and the floor with a good quality

non-shrinking machinery grout to ensure a

stable installation. Grout completely under

all frame members.

Figure 31

5. Place the machine carefully over the

J-bolts. Never attempt to lift the machine

by the door handle or by pushing on the

cover panels.

38

H032IE1A

9. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

10. Before grout sets completely, make a drain

opening in the rear of the machine

grouting with a stiff piece of wire. This

opening should be approximately 1/2 inch

(13 mm) wide to allow any surface water

build-up under the base of the machine to

drain away.

Do not omit this step.

11. Position washers and locknuts on J-bolts

and fingertighten nuts to machine base.

12. After the grout is completely dry, tighten

the locknuts by even increments—one

after the other—until all are tightened

evenly and the machine is fastened

securely to the floor. See Figure 32.

F232062

Page 41

Installation

Concrete Foundation Pad

A concrete foundation pad may be constructed

to elevate the machines. See Figure 34 for a

typical concrete foundation pad installation.

H033I

Figure 32

Note:

Check and retighten the locknuts after

five to ten days of operation and every three

months thereafter.

Figure 33 shows the completed J-bolt

installation with grout.

Locknut

Machine

Base

1/2 in. (13 mm)

Machinery

Grout

J-Bolt

Note:

Expansion bolts should not be used

in single-machine concrete foundation

pad installations.

1. Verify that the floor is 3500 psi minimum

reinforced concrete embedded in clean,

compacted fill dirt. For 2-speed models,

the floor must be at least 4 inches

(102 mm) thick. For 3-speed and variablespeed models (except for the 80-pound

capacity model), the floor must be at least

6 inches (152 mm) thick. For 80-pound

capacity models, the floor must be at least

9 inches (229 mm) thick.

2. Break up and excavate the floor to a depth

of approximately 9 inches (230 mm)

below the floor surface, making certain

that the sides of the hole slope outwards

from top to bottom.The bottom of the hole

should be 5 inches (127 mm) larger all

around than the top.

F232062

Figure 33

H034IE1A

Note that when installation is complete,

the top of the pad should extend a

minimum of 4 inches (102 mm) out from

the machine on all sides.

3. Wet the hole well and brush the bottom

and sides with cement grout.

39

Page 42

Installation

Mechanical Installation

Pad height

must not exceed

8 in. (203 mm).

(Continued)

1 in. (25 mm) minimum

4 in. (102 mm)

minimum

4. Use rebar or other appropriate material to

ensure that the concrete foundation pad

will be sufficiently connected to the

existing floor.

5. Prepare a form for the above-ground

portion of the pad and fill form and

excavation with concrete to join the

foundation. Verify that top of pad is level.

The height of the pad must not exceed

8 inches (203 mm).

6. Use the mounting bolt layout in Figures

27 and 28 to properly position the

mounting bolts in the wet concrete.

When using J-bolts, allow 1-1/2 inches

(38 mm) to extend above the surface of

the concrete.

7. Allow concrete to dry.

Figure 34

H036IE3A

8. Place the machine carefully over the

mounting bolts. Never attempt to lift the

machine by the door handle or by pushing

on the cover panels.

9. If the machine is a

2-speed

model,

grouting is optional.

If grouting is not desired, position washers

and locknuts on J-bolts and tighten the

locknuts by even increments—one after

the other—until all are tightened evenly

and the machine is fastened securely to the

floor. See Figure 35.

If grouting is desired, proceed to step 10.

If the machine is a

speed

machine installed on a concrete

3-speed

variable-

or

foundation pad, the machine must be

grouted. Proceed to step 10.

40

F232062

Page 43

10. Raise and level the machine 1/2 inch off

the pad on three points, using spacers such

as nut fasteners.

11. Fill the space between the machine base

and the pad with a good quality

non-shrinking machinery grout to ensure a

stable installation. Grout completely under

all frame members.

12. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

13. Before grout sets completely, make a drain

opening in the rear of the machine

grouting with a stiff piece of wire. This

opening should be approximately 1/2 inch

(13 mm) wide to allow any surface water

build-up under the base of the machine to

drain away.

Do not omit this step.

Installation

Note:

five to ten days of operation and every three

months thereafter.

Check and retighten the locknuts after

14. Position washers and locknuts on J-bolts

and fingertighten nuts to machine base.

15. After the grout is completely dry, tighten

the locknuts by even increments—one

after the other—until all are tightened

evenly and the machine is fastened

securely to the concrete foundation pad.

See Figure 35.

H033I

Figure 35

F232062

41

Page 44

Installation

Drain Connection

A drain system of adequate capacity is

essential to machine performance. Ideally, the

water should empty through a vented pipe

directly into a sump or floor drain. Figures

36 and 37 show typical drain line and drain

trough configurations.

Drain Valve

Drain Hose

A flexible connection must be made to a

vented drain system to prevent an air lock and

to prevent siphoning. If proper drain size is not

available or practical, a surge tank is required.

A surge tank in conjunction with a sump pump

should be used when gravity drainage is not

possible, such as in below-ground-level

installations.

Overflow

Hose

Drain Tee

Floor

Open Drain Trough

Drain Valve

Drain Hose

H050IE3A

Figure 36

Vent Pipe

Overflow

Hose

Drain Tee

H051IE3A

Figure 37

42

F232062

Page 45

Installation

Before any deviation from specified

installation procedures is attempted,

the customer or installer should contact

See the Cabinet Hardmount Drain Information

table in this subsection for capacity-specific

drain information.

the distributor.

Installation of additional machines will require

Increasing the drain hose length, installing

elbows, or causing bends will decrease drain

flow rates and increase drain times, impairing

proportionately larger drain connections. See

the Cabinet Hardmount Drain Line Sizing

table in this subsection.

machine performance.

Cabinet Hardmount

Drain Information

18 25 27 35 50 80

Drain connection size, ID, in (mm) 2 (52) 2 (52) 2 (52) 2 (52) 3 (76) 3 (76)

Number of drain outlets 111111

Drain flow capacity, gal-min (l-min) 20 (76) 25 (95) 25 (95) 35 (132) 50 (189) 50 (189)

Recommended drain pit size, ft

3

(l)

1.80 (51) 2.36 (66.8) 2.50 (70.3) 3.14 (88.9) 4.52 (128) 5.90 (169)

Cabinet Hardmount

Drain Line Sizing

Minimum Drain I.D. [in (mm)]

Number Of Machines

Model

12345

18 2 (51) 3 (76) 3 (76) 4 (102) 4 (102)

25 2 (51) 3 (76) 3 (76) 4 (102) 4 (102)

27 2 (51) 3 (76) 3 (76) 4 (102) 4 (102)

35 3 (76) 3 (76) 3-1/2 (89) 4 (102) 4 (102)

50 3 (76) 4 (102) 6 (152) 6 (152) 6 (152)

80 4 (102) 6 (152) 6 (152) 8 (203) 8 ( 203)

F232062

43

Page 46

Installation

Water Connection

Cabinet Hardmount

Water Supply Information

Water inlet connection size, in (mm) 3/4 (19)

Number of water inlets (standard) 2

Recommended pressure, psi (bar) 30 – 85 (2 – 5.7)

Inlet flow capacity, gal-min/l-min (80psi) 12 (45)

Connections should be supplied by a hot and

a cold water line of at least the sizes shown

in the Water Supply Line Sizing table.

Installation of additional machines will require

proportionately larger water lines. See table.

To connect water service to machine with

rubber hoses, use the following procedure:

1. Before installing hoses, flush the water

system for at least 2 minutes.

2. Check filters in the machine’s inlet hoses

for proper fit and cleanliness before

connecting.

Cabinet Hardmount

Water Supply Line Sizing

Capacity

18 – 50

80

Number

Of

Machines

1 3/4 (19) 3/4 (19)

2 1 (25) 3/4 (19)

3 1-1/4 (32) 1 (25)

4 1-1/2 (38) 1 (25)

1 1 (25) 3/4 (19)

2 1-1/2 (38) 1 (25)

3 2 (50) 1-1/4 (32)

4 2 (50) 1-1/2 (38)

Supply Line Size

[in (mm)]

Main Hot/cold

Suitable air cushions should be installed in

supply lines to prevent “hammering.” See

Figure 38. If the water pressure is above

60 psi, flexible copper tubing should be used in

place of rubber hoses.

3. Hang hoses in a large loop; do not allow

them to kink.

If additional hose lengths are needed, use

flexible hoses with screen filters. Each hose

should have a screen filter installed to keep

rust and other foreign particles out of the water

inlet valves.

Pressure of 30 – 85 psi (2 – 5.7 bar) provides

best performance. Although the machine will

function properly at lower pressure, increased

fill times will occur.

44

Air Cushions

(Risers)

Water Supply

Faucets

MW008JE1A

Figure 38

F232062

Page 47

Installation

Never touch terminals or components of

the AC inverter drive unless power is

disconnected and the “CHARGE” indicator

LED is off. The AC inverter drive retains

potentially deadly voltage for some time

after the power is disconnected. There are

no user-serviceable parts inside the

AC inverter drive. Tampering with the drive

will void the warranty.

SW009

WARNING

When controlling the AC inverter drive with

a parameter unit, the machine’s computer

and its safety features are bypassed. This

would allow the basket to rotate at high

speeds with the door open. When using a

parameter unit to control the AC inverter

drive, a large sign should be placed on the

front of the machine warning people of the

imminent danger.

SW003

DANGER

Electrical Installation

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar with

the potential hazards involved. Failure to

observe this warning may result in personal

injury and/or equipment damage, and may

void the warranty.

SW004

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel familiar

with electrical test procedures, test

equipment, and safety precautions should

attempt adjustments and troubleshooting.

Disconnect power from the machine before

removing the control box cover, and before

attempting any service procedures.

SW005

Machines equipped with an AC inverter drive

require a clean power supply free from voltage

spikes and surges. A voltage monitor should be

used to check incoming power. The customer’s

local power company may provide such a

monitor.

If input voltage measures above 230V for a

200V drive or above 440V for a 400V drive,

ask the power company to lower the voltage.

As an alternative, a step-down transformer kit

is available from the distributor. Voltages

above 250V and 490V require additional

measures. Contact the distributor or the

manufacturer for assistance.

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground lug

near the input power block on this machine.

Without proper grounding, personal injury

from electric shock could occur and machine

malfunctions may be evident.

F232062

SW008

45

Page 48

Installation

Electrical Installation

The 2-speed and 3-speed machines have a

thermal overload protector in the drive motor

windings and a separate fuse for the control

circuit. Single-phase machines require a

single-phase inverse-time circuit breaker.

Three-phase machines require a three-phase

inverse-time circuit breaker.

On variable-speed machines, the AC drive

provides thermal overload protection for the

drive motor. However, a separate three-phase

inverse-time circuit breaker must be installed

for complete electrical overload protection.

This prevents damage to the motor by

disconnecting all legs if one should be lost

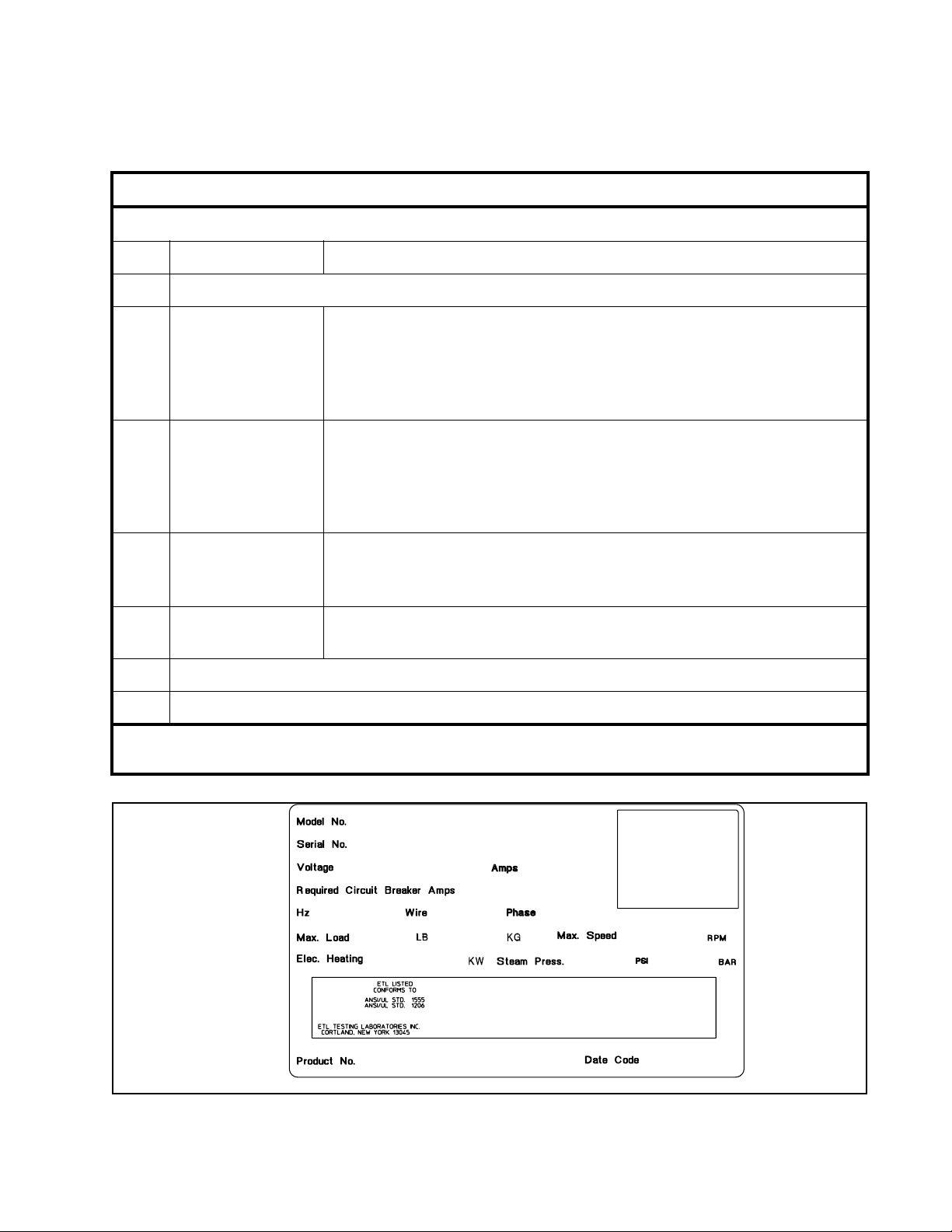

accidentally. Check the data plate on the back

of the washer-extractor or consult the

Electrical Specifications chart in this

subsection for model-specific circuit breaker

requirements.

(Continued)

Use wire sizes indicated in the Electrical

Specifications chart for runs up to 50 feet. Use

next larger size for runs of 50 to 100 feet. Use

two sizes larger for runs greater than 100 feet.

For personal safety and proper operation, the

machine must be grounded in accordance with

state and local codes. If such codes are not

available, grounding must conform with the

National Electric Code, article 250-95. The

ground connection must be made to a proven

earth ground, not to conduit or water pipes.

Do not connect the ground to the neutral

(N-white wire) leg at the terminal strip.

If three-phase service is unavailable for a

2-speed or 3-speed model and a Roto-Phase or

other phase adder is used, the artificial leg

must be connected to L3 in the input power

junction box.

Note:

breaker.

The machine should be connected to an

individual branch circuit not shared with

lighting or other equipment.

The connection should be shielded in a liquidtight or approved flexible conduit with proper

conductors of correct size installed in

accordance with the National Electric Code or

other applicable codes. The connection must

be made by a qualified electrician using the

wiring diagram provided with the machine, or

according to accepted European standards for

CE approved equipment.

Do NOT use fuses in place of a circuit

CAUTION

Do not use a phase adder on any variablespeed machine.

SW037

If the machine is intended for four-wire

service, a neutral leg must be provided by the

power company.

If a delta supply system is used on a four-wire

model, the high leg must be connected to L3.

Improper connections will result in equipment

damage and will void the warranty.

46

F232062

Page 49

Installation

Cabinet Hardmount

Electrical Specifications

18-Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Full Load

Voltag e

Cycle

Phase

Wire

Amps

Breaker

Circuit

AWG

mm

Full Load

Breaker

Amps

Circuit

AWG

mm

2

2

2-Speed Models

B 110-120 60 1 2 15 20 12 4.00 N/A

C380-41550344 15142.501415142.50

D220-24050335 15142.502425106.00

E 220-240 50 1 2 10 20 12 4.00 42 45 6 16.0

F440-48060334 15142.501620124.00

O208-24060335 15142.502425106.00

U

Y 208-240 60 1 2 10 20 12 4.00 N/A

380 50344 15142.501415142.50

240 50335 15142.502425106.00

3-Speed Models

A208-24060347 15142.502430106.00

C380-41550345 15142.501520124.00

D220-24050337 15142.502430106.00

F440-48060335 15142.501520124.00

O208-24060337 15142.502430106.00

Variable-Speed Models

O 208-240 60 3 3 3.84 15 14 2.50 N/A

Y 208-240 60 1 2 3.84 15 14 2.50 N/A

Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note:

F232062

47

Page 50

Installation

y)

Electrical Installation

(Continued)

Cabinet Hardmount

Electrical Specifications

25-Pound and 27-Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Full Load

Voltag e

Cycle

Phase

Wire

Amps

Breaker

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

mm

2

2-Speed Models

C380-41550344 15142.501515142.50

D220-24050336 15142.502425106.00

E 220-240 50 1 2 10 20 12 4.00 42 45 6 16.0

F440-48060334 15142.501620124.00

O208-24060337 15142.502525106.00

U

380 50344 15142.501515142.50

240 50336 15142.502425106.00

Y 208-240 60 1 2 10.5 20 12 4.00 N/A

Variable-Speed Models (27-pound capacity models onl

O 208-240 60 3 3 4.8 15 14 2.50 N/A

Y 208-240 60 1 2 4.8 15 14 2.50 N/A

Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note:

48

F232062

Page 51

Installation

Cabinet Hardmount

Electrical Specifications

35-Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Full Load

Voltag e

Cycle

Phase

Wire

Amps

Breaker

Circuit

AWG

mm

Full Load

Breaker

Amps

Circuit

AWG

mm

2

2

2-Speed Models

C380-41550345 15142.502630106.00

D 220-240 50 3 3 7 20 12 4.00 43 50 6 16.0

E 220-240 50 1 2 12 25 10 6.00 N/A

F440-48060335 15142.502630106.00

O 208-240 60 3 3 7 20 12 4.00 43 50 6 16.0

U

Y 208-240 60 1 2 12 25 10 6.00 N/A

380 50345 15142.502630106.00

240 50 3 3 7 20 12 4.00 43 50 6 16.0

3-Speed Models

A 208-240 60 3 4 12 30 10 6.00 44 50 6 16.0

C380-41550346 20124.002830106.00

D 220-240 50 3 3 10 30 10 6.00 44 50 6 16.0

F440-48060336 20124.002830106.00

O 208-240 60 3 3 12 30 10 6.00 44 50 6 16.0

Variable-Speed Models

O 208-240 60 3 3 5.86 15 14 2.50 N/A

Y 208-240 60 1 2 5.86 15 14 2.50 N/A

Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note:

F232062

49

Page 52

Installation

Electrical Installation

(Continued)

Cabinet Hardmount

Electrical Specifications

50-Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Full Load

Voltag e

Cycle

Phase

Wire

Amps

Breaker

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

2-Speed Models

C 380-415 50 3 4 6 15 14 2.50 39 50 6 16.0

D 220-240 50 3 3 10 20 12 4.00 64 70 4 25.0

E 220-240 50 1 2 15 30 10 6.00 N/A

F 440-480 60 3 3 6 15 14 2.50 39 50 6 16.0

O 208-240 60 3 3 10 20 12 4.00 64 70 4 25.0

Y 208-240 60 1 2 15 30 10 6.00 10 20 12 4.00

mm

2

3-Speed Models

A 208-240 60 3 4 13 30 10 6.00 64 70 4 25.0

C 380-415 50 3 4 7 20 12 4.00 39 50 6 16.0

D 220-240 50 3 3 13 30 10 6.00 62 70 4 25.0

F 440-480 60 3 3 7 20 12 4.00 39 50 6 16.0

O 208-240 60 3 3 13 30 10 6.00 64 70 4 25.0

Variable-Speed Models

O 208-240 60 3 3 10.9 15 14 2.50 66.5 70 4 2.50

Y 208-240 60 1 2 10.9 15 14 2.50 N/A

Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note:

50

F232062

Page 53

Installation

Cabinet Hardmount

Electrical Specifications

80-Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Full Load

Voltag e

Cycle

Phase

Wire

Amps

Breaker

Circuit

AWG

mm

Full Load

Breaker

Amps

Circuit

AWG

mm

2

3-Speed Models

A 208-240 60 3 4 15 40 6 16 90 100 1 45

C 380-415 50 3 4 9 20 12 4 41 45 6 16

D 220-240 50 3 3 14 40 6 16 89 90 2 35

F 440-480 60 3 3 9 20 12 4 46 50 6 16

O 208-240 60 3 3 15 40 6 16 90 100 1 45

W 380-415 50 3 3 9 20 12 4 41 45 6 16

Variable-Speed Models

F 440-480 60 3 3 4.49 15 14 2.50 N/A

O 208-240 60 3 3 12.4 20 12 4 87.46 90 2 35

Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note:

If the machine fails to operate after power is

connected, disconnect power and check the

control circuit fuse. Unlock and raise the top

cover. For mechanical timer, P-computer, and

S-computer models, the control circuit fuse is

on the center brace. For EDC and V-computer

models, dual control circuit fuses (1 primary

and 1 secondary) are in the control module. A

decal identifies the fuse (or fuses) in each case,

and provides the fuse rating appropriate to that

specific model.

2

If the control circuit fuse has blown, replace

with a fuse of the appropriate rating as

identified by the decal. Call a qualified

electrician if the replacement fuse blows.

F232062

51

Page 54

Installation