Alliance Laundry Systems HC18SN2, UC40VN2, SC35VN2, UC20PN2, HC18VC2 Operation & Maintenance Manual

...

Washer-Extractors

Cabinet Hardmount

S, P, and V-Series Microcomputers Coin and

Non-Coin Models

Refer to Page 3 for Model Identification

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Maintenance

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM166C

Part No. F232137R2

April 2002

Table of

Contents

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Nameplate Location.............................................................................. 4

Replacement Parts ................................................................................ 4

Customer Service.................................................................................. 4

Safety Information.............................................................................. 5

Important Safety Instructions ............................................................... 5

Operation............................................................................................. 7

Control Panel ........................................................................................ 7

Display Indications............................................................................... 8

Operating Instructions .......................................................................... 12

Maintenance ........................................................................................ 15

Daily ..................................................................................................... 15

Beginning of Day............................................................................. 15

End of Day ....................................................................................... 15

Weekly.................................................................................................. 16

Monthly................................................................................................. 16

Quarterly............................................................................................... 19

Care of Stainless Steel.......................................................................... 20

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Introduction

Model Identification

Information in this manual is applicable to these models:

HC18SN2 HC27VX2 HC50SN2 SC35VN2 UC20PN2 UC40VN2

HC18VC2 HC30SN2 HC50VC2 SC35VNV UC20VN2 UC40VNV

HC18VX2 HC30VC2 HC50VX2 SC40VN2 UC27PN2 UC50PN2

HC20SN2 HC30VX2 HC80VCV SC40VNV UC27VN2 UC50VN2

HC20VC2 HC35SN2 HC80VNV SC50VN2 UC30PN2 UC50VNV

HC20VX2 HC35VC2 HC80VXV SC50VNV UC30VN2 UC80VNV

HC25VC2 HC35VX2 SC18VN2 SC80VNV UC35PN2 UC125VNV

HC25VX2 HC40SN2 SC20VN2 SC125VNV UC35VN2

HC27SN2 HC40VC2 SC27VN2 UC18PN2 UC35VNV

HC27VC2 HC40VX2 SC30VN2 UC18VN2 UC40PN2

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Introduction

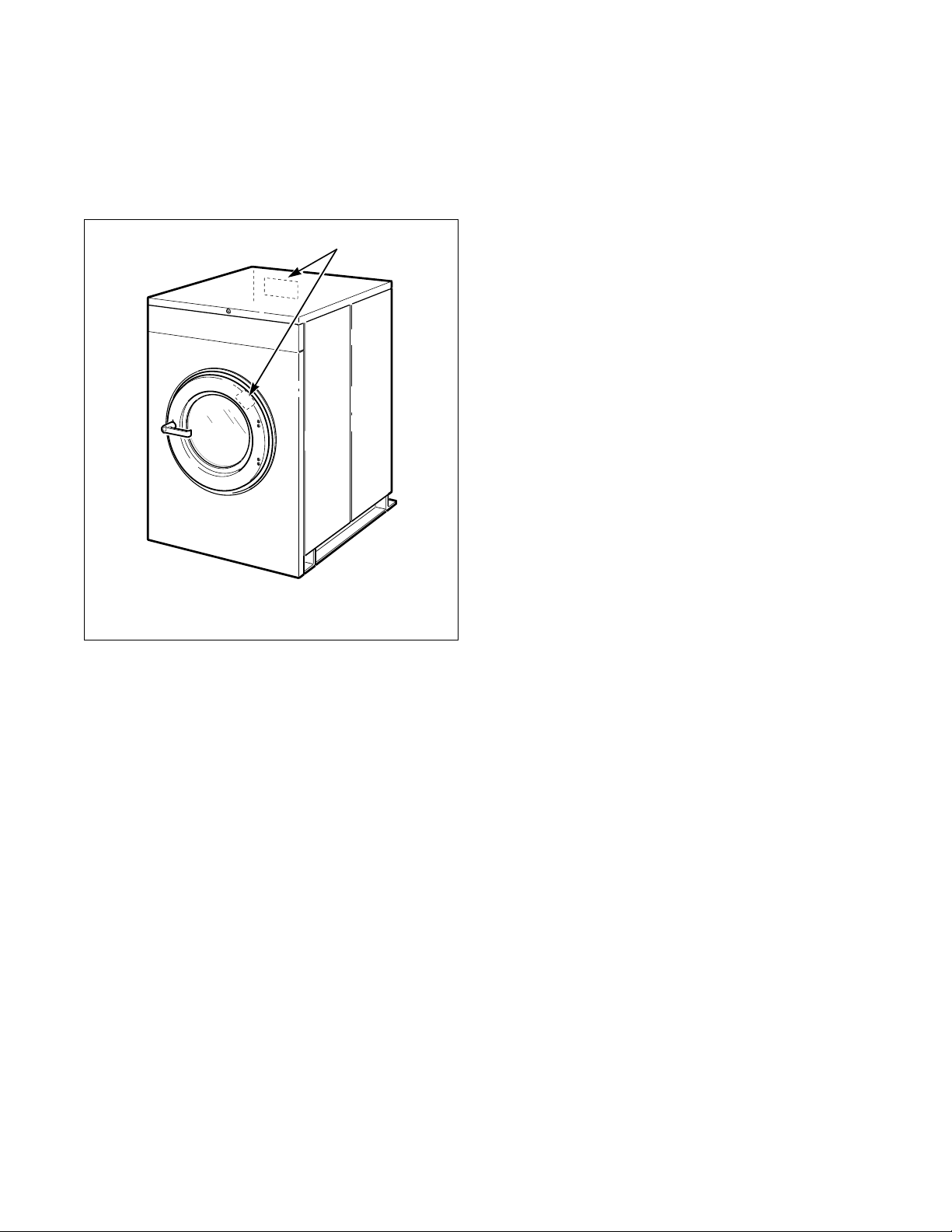

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

1

Replacement Parts

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call any of the following

numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida U.S.A.

(920) 748-3121

Ripon, Wisconsin U.S.A.

1 Nameplate

CHM167R

Figure 1

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Precautionary statements (“DANGER”, “WA R N I N G ”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer and those maintaining the

machine.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023E

1. Read all instructions before using the washer.

2. Refer to the Grounding Instructions in the

Installation Manual for the proper grounding of

the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply

with local codes and be made by licensed

personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Operation

Up Down Start Stop

1

2

3

4

5

6

8 7

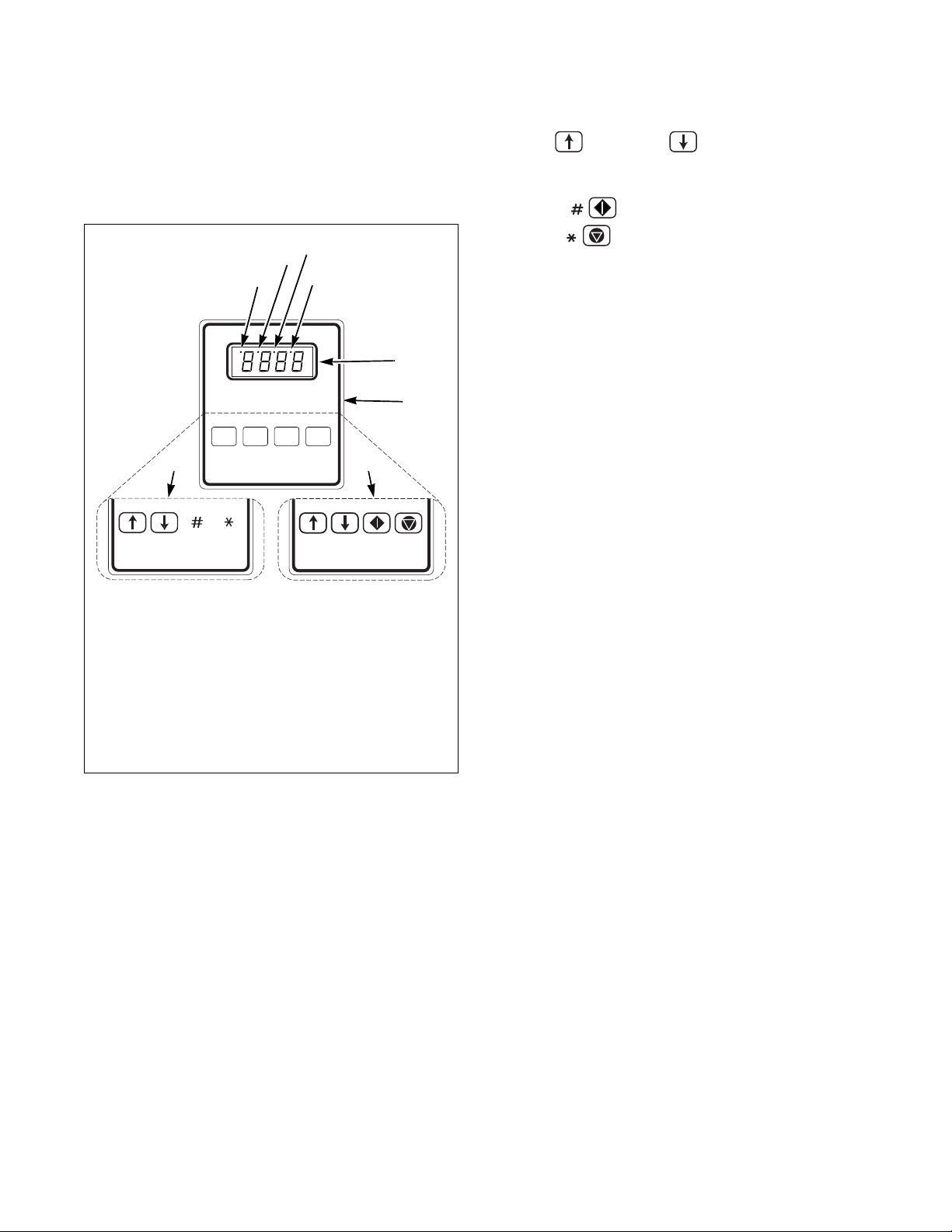

Control Panel

Figure 2 shows the control panel for S, P and

V-computer machines.

1 Out-of-Balance Condition for VCV, VXV

2 High Water Level

3 Medium Water Level for V-Series

4 Low Water Level

5 LED Display

6 Keys for Standard OPL

7 Keys for Icon OPL

8 Keys for VC2, VCV, VX2, VXV

The Up and Down keys are used in cycle

selection. Press these keys to move among cycles from

smaller to greater, or greater to smaller.

The Start key is used to start a cycle.

The Stop key is not active in normal Run

Mode. In Run Mode it is used only for stopping test

cycle.

The LED display informs operator of various

functions throughout operation of machine. Refer to

tables on the following pages for displays and their

meanings. Indicator lights in LED display indicate

out-of-balance conditions and water levels. Refer to

Figure 2.

B161R

Figure 2

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Operation

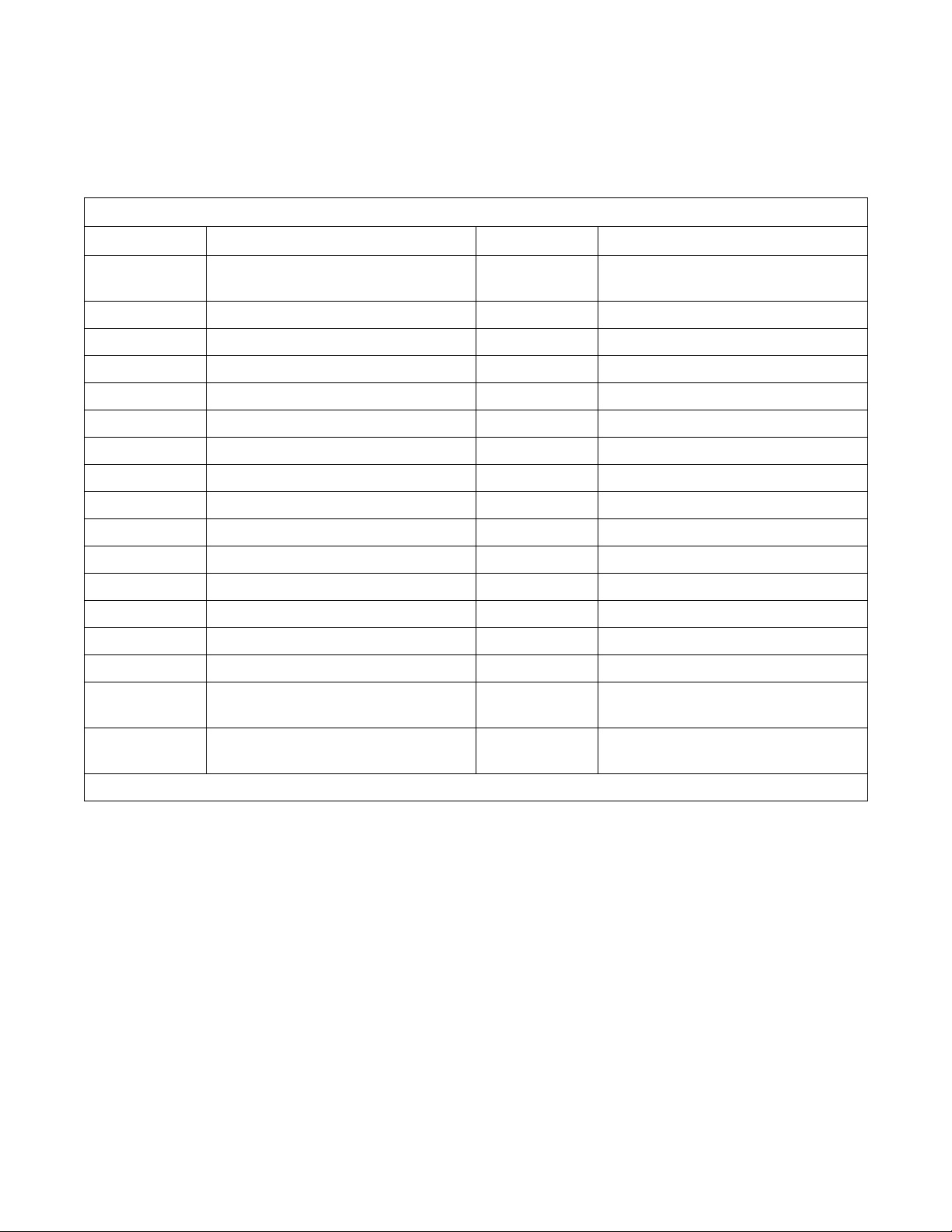

Display Indications

Table 1 through Ta b le 4 list the various displays and

what they mean. The operator should become familiar

with these computer displays.

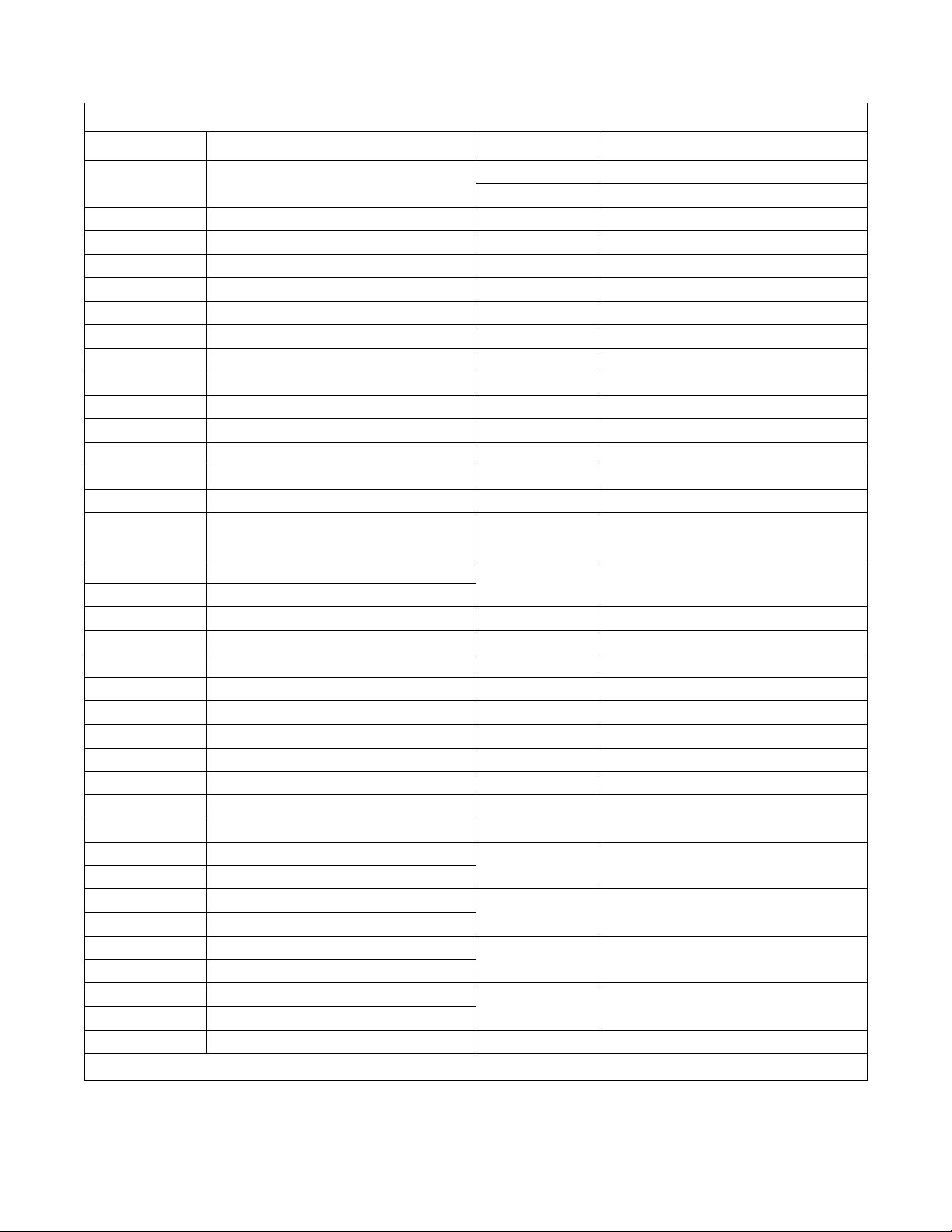

Display Indications for S-Series – Non-Coin

Display Meaning Display Meaning

S-05 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on HFIL Hot fill

CY Cycle (followed by two-digit number) LOLE Low water level

CHEC/CYC* Test cycle selected HILE High water level

FAr Degrees Fahrenheit SUP1 Supply 1

CEL Degrees Celsius SUP2 Supply 2

PrE Prewash segment (1st of 8 segments) SUP3 Supply 3

UASH Wash segment (2nd of 8 segments) SUP4 Supply 4

FIL1 First rinse (3rd of 8 segments) SUP5 Supply 5 (supply 1 and 2)

FIL2 Second rinse (4th of 8 segments) SUP6 Supply 6 (supply 2 and 3)

FIL3 Third rinse (5th of 8 segments) SUP7 Supply 7 (supply 3 and 4)

FIL4 Fourth rinse (6th of 8 segments) STOP Stop routine

FIL5 Fifth rinse (7th of 8 segments) SdLY Spin coast delay

FIL6 Sixth rinse (8th of 8 segments) donE Cycle and stop routine have ended

CFIL Cold fill door Door not properly closed

SPIn/tI

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

bFIL Warm fill (both hot and cold)

FILL/STOP* Programmed water level not reached

after 30 minutes

tSFL Temperature sensor failure or

temperature out of range

*Display indications separated by a slash (/) represent an alternating display.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FULL The computer detects low water level or

Table 1

higher when none should be present

F232137

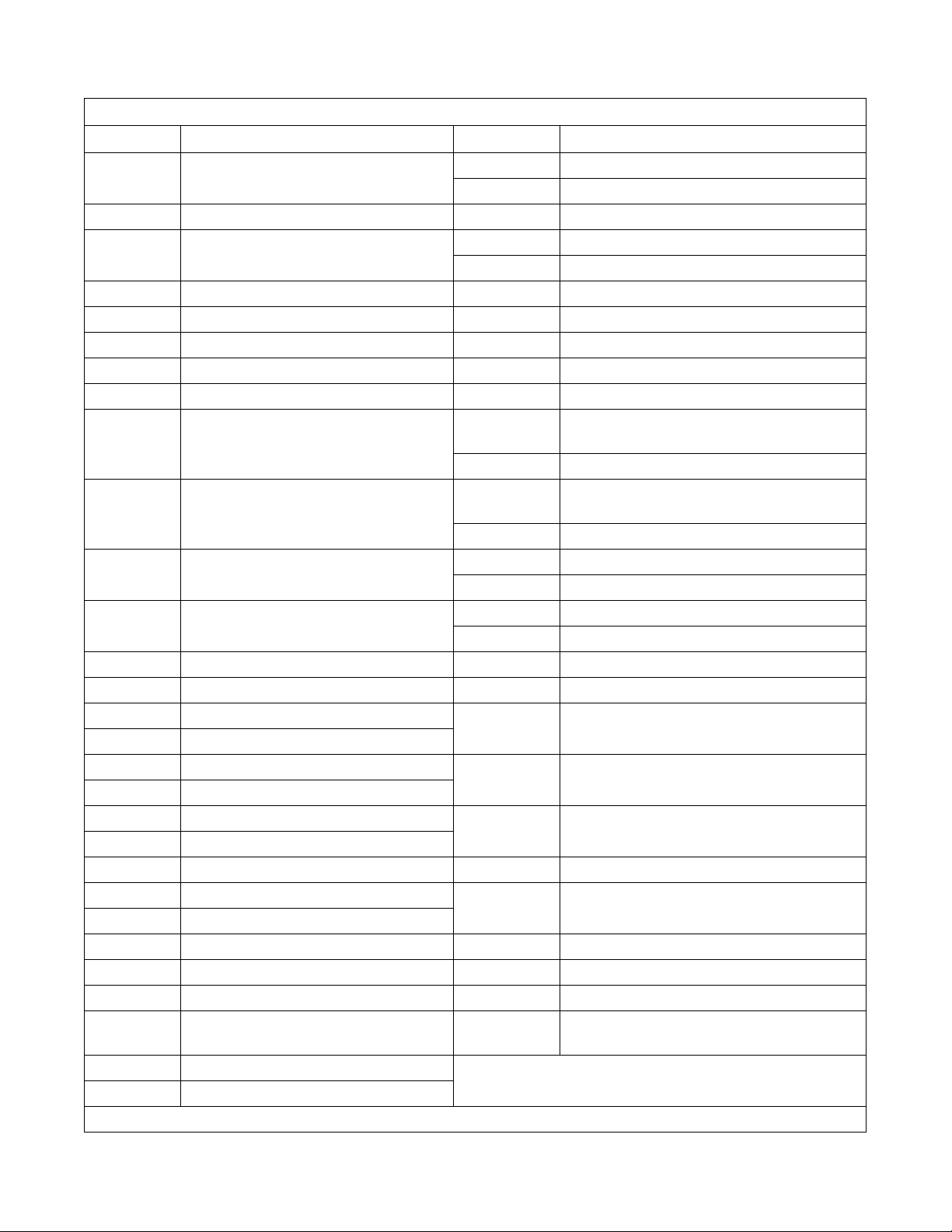

Operation

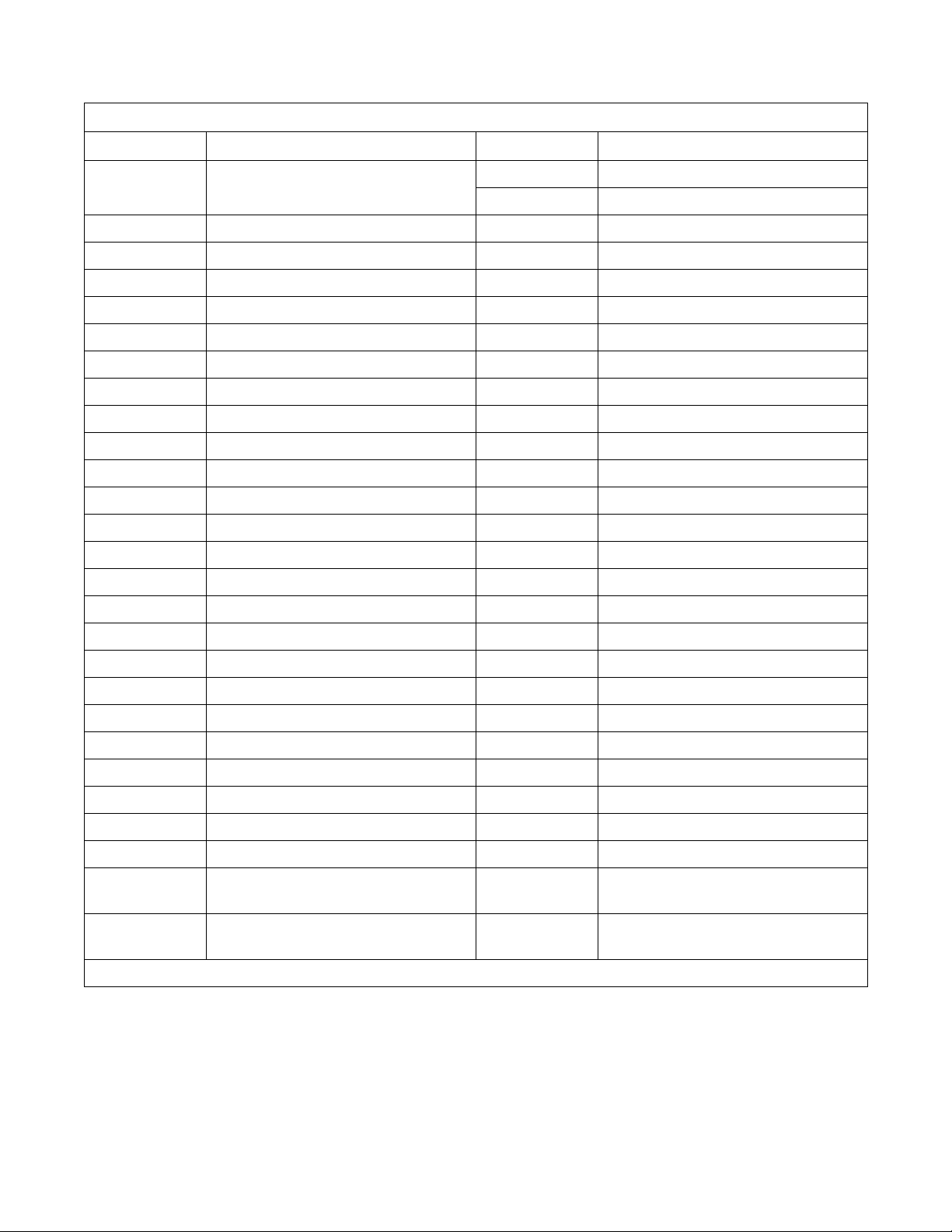

Display Indications for V-Series – Coin

Display Meaning Display Meaning

FC 5 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on

PAY/(price)* Pay (flashes alternately with start price if

“FLSH” SETUP option is enabled)

CY Cycle (followed by two-digit number) SUP1 Supply 1

tESt/CYC* Test cycle selected SUP2 Supply 2

FAr Degrees Fahrenheit SUP3 Supply 3

CEL Degrees Celsius SUP5 Supply 5 (supply 1 and 2)

HEAt Auxiliary heat enabled SUP6 Supply 6 (supply 2 and 3)

noHt Auxiliary heat disabled drAI/dISt* Distribution (load balancing before extract)

Strt/A

nt* Start amount – flashes briefly before

showing vend price in Setup Mode

Con1/deno* Coin 1 value – flashes briefly before

showing value of coin 1 in Setup Mode

Con2/deno* Coin 2 value – flashes briefly before

showing value of coin 2 in Setup Mode

PrE Prewash segment (1st of 8 segments) bAL/FAIL* Balance routine failed during test cycle

UASH Wash segment (2nd of 8 segments) SHUT/door* Door not properly closed

FIL1 First fill (3rd of 8 segments) CANt/OPEN* Computer cannot unlock door after five

FIL2 Second fill (4th of 8 segments)

FIL3 Third fill (5th of 8 segments) FILL/STOP* Programmed water level not reached after

FIL4 Fourth fill (6th of 8 segments)

FIL5 Fifth fill (7th of 8 segments) FULL The computer detects low water level or higher

FIL6 Sixth fill (8th of 8 segments)

AFIL Auxiliary fill dFLt Drive fault detected (Variable-speed only)

bFIL Warm fill (both hot and cold) tSFL Temperature sensor failure or temperature out

CFIL Cold fill

bLCH Add bleach (for supply 2 only) bAL? Special factory balance setup mode

1Pr One vend price – all cycles SPC? Special factory valve flush mode

16Pr 16 vend prices – one per cycle SPIN Spin in test cycle (2 speed only)

CHEC/

CYC*

For Wash speed forward in test cycle

FrEE “Free” cycle option

*Display indications separated by a slash (/) represent an alternating display.

Test cycle selected (same as tESt/CYC) rEv Reverse wash speed in test cycle

HFIL Hot fill

Lo Low water level

nEd Medium water level

HI High water level

SUP0 No supplies

(Variable-speed only)

drAI/For* Drain step (low speed forward in test cycle)

SPIn/tInE* Reads “SPIn” for one second, then “tInE”

followed by time for spin

SdLY Spin coast delay

STOP Stop routine

donE Cycle and stop routine have ended

HI 1 Low spin in test cycle (Variable-speed only)

HI 2 High spin in test cycle (Variable-speed only)

attempts

30 minutes

when none should be present

of range

F232137

Table 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Operation

Display Indications for V-Series – Non-Coin

Display Meaning Display Meaning

FP 1 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on SUP1 Supply 1

CY Cycle (followed by two-digit number) SUP2 Supply 2

tESt/CYC* Test cycle selected SUP3 Supply 3

FAr Degrees Fahrenheit SUP4 Supply 4

CEL Degrees Celsius SUP5 Supply 5 (Setup option)

HEAt Auxiliary heat enabled SUP6 Supply 6 (supply 1 and 5)

noHt Auxiliary heat disabled SUP7 Supply 7 (supply 3 and 4)

tFIL Temperature-controlled fill enabled SLo/For Gentle wash speed, forward direction

ntFL Temperature-controlled fill disabled SLo/rEv Gentle wash speed, reverse direction

CooL Automatic cool-down enabled nor

noCL Automatic cool-down disabled nor

Ag 1 Agitation 1 selected (90% agitation) drAI Drain enabled

Ag 2 Agitation 2 selected (33% agitation) nodr Drain disabled

Ag 3 Agitation 3 selected (10% agitation) dISt Distribution (load balancing before

Ag 4 Agitation 4 selected (6.7% agitation) SPIn/tI

AgSn Agitation speed normal

AgSL Agitation speed low SPn1 Lowest of three spins

PU

nP Pump output enabled (future use only) SPn2 Middle of three spins

nP

nP Pump output disabled (future use only) SPn3 Highest of three spins

PrE Prewash segment (1st of 11 segments) STOP Stop routine

UASH Wash segment (2nd of 11 segments) SdLY Spin coast delay

FIL1 First fill (3rd of 11 segments) donE Cycle and stop routine have ended

FIL2 Second fill (4th of 11 segments) dFLt Drive fault detected

FIL3 Third fill (5th of 11 segments) door Door not properly closed

FIL4 Fourth fill (6th of 11 segments) bAL/FAIL* Balancing routine failed during test cycle

FIL5 Fifth fill (7th of 11 segments)

FIL6 Sixth fill (8th of 11 segments) FILL/STOP* Programmed water level not reached

FIL7 Seventh fill (9th of 11 segments)

FIL8 Eighth fill (10th of 11 segments) FULL The computer detects low water level or

FIL9 Ninth fill (11th of 11 segments)

CFIL Cold fill rotA Computer detects possible rotation of

bFIL Warm fill (both hot and cold)

HFIL Hot fill tSFL Temperature sensor failure or

AFIL Auxiliary fill (Setup option)

Lo Low water level

*Display indications separated by a slash (/) represent a flashing display.

nEd Medium water level

HI High water level

n/For Normal wash speed, forward direction

n/rEv Normal wash speed, reverse direction

extract)

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

after 10 attempts to balance load

after 30 minutes

higher when none should be present

motor when there should be none

temperature out of range

10

Table 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Display Indications for V-Series Two Speed – Non-Coin

Display Meaning Display Meaning

Operation

F23n Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on FIL8 Eighth fill (10th of 11 segments)

CY Cycle (followed by two-digit number) FIL9 Ninth fill (11th of 11 segments)

tESt/CYC* Test cycle selected CFIL Cold fill

FAr Degrees Fahrenheit bFIL Warm fill (both hot and cold)

CEL Degrees Celsius HFIL Hot fill

HEAt Auxiliary heat enabled AFIL Auxiliary fill (Setup option)

noHt Auxiliary heat disabled Lo Low water level

tFIL Temperature-controlled fill enabled

ntFL Temperature-controlled fill disabled HI High water level

CooL Automatic cool-down enabled SUP1 Supply 1

noCL Automatic cool-down disabled SUP2 Supply 2

Ag 1 Agitation 1 selected (90% agitation) SUP3 Supply 3

Ag 2 Agitation 2 selected (33% agitation) SUP4 Supply 4

Ag 3 Agitation 3 selected (10% agitation) SUP5 Supply 5 (or Setup option)

Ag 4 Agitation 4 selected (6.7% agitation) SUP6 Supply 6 (supply 1 and 5)

FIL6 Sixth fill (8th of 11 segments)

FIL7 Seventh fill (9th of 11 segments)

nEd Medium water level

PU

nP Pump output enabled (future use only) SUP7 Supply 7 (supply 3 and 4)

nP Pump output disabled (future use only) For Wash speed, forward direction

nP

PrE Prewash segment (1st of 11 segments) rEv Wash speed, reverse direction

UASH Wash segment (2nd of 11 segments) drAI Drain enabled

FIL1 First fill (3rd of 11 segments) nodr Drain disabled

FIL2 Second fill (4th of 11 segments) STOP Stop routine

FIL3 Third fill (5th of 11 segments) SdLY Spin coast delay

FIL4 Fourth fill (6th of 11 segments) donE Cycle and stop routine have ended

FIL5 Fifth fill (7th of 11 segments) door Door not properly closed

FULL The computer detects low water level or

higher when none should be present

tSFL Temperature sensor failure or

temperature out of range

*Display indications separated by a slash (/) represent a flashing display.

FILL/STOP* Programmed water level not reached

after 30 minutes

SPIn/tI

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

Table 4

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Operation

Operating Instructions

1. Turn on main power source (circuit breaker).

For non-coin models: Turn on the On/Off switch

on the front panel to the On position.

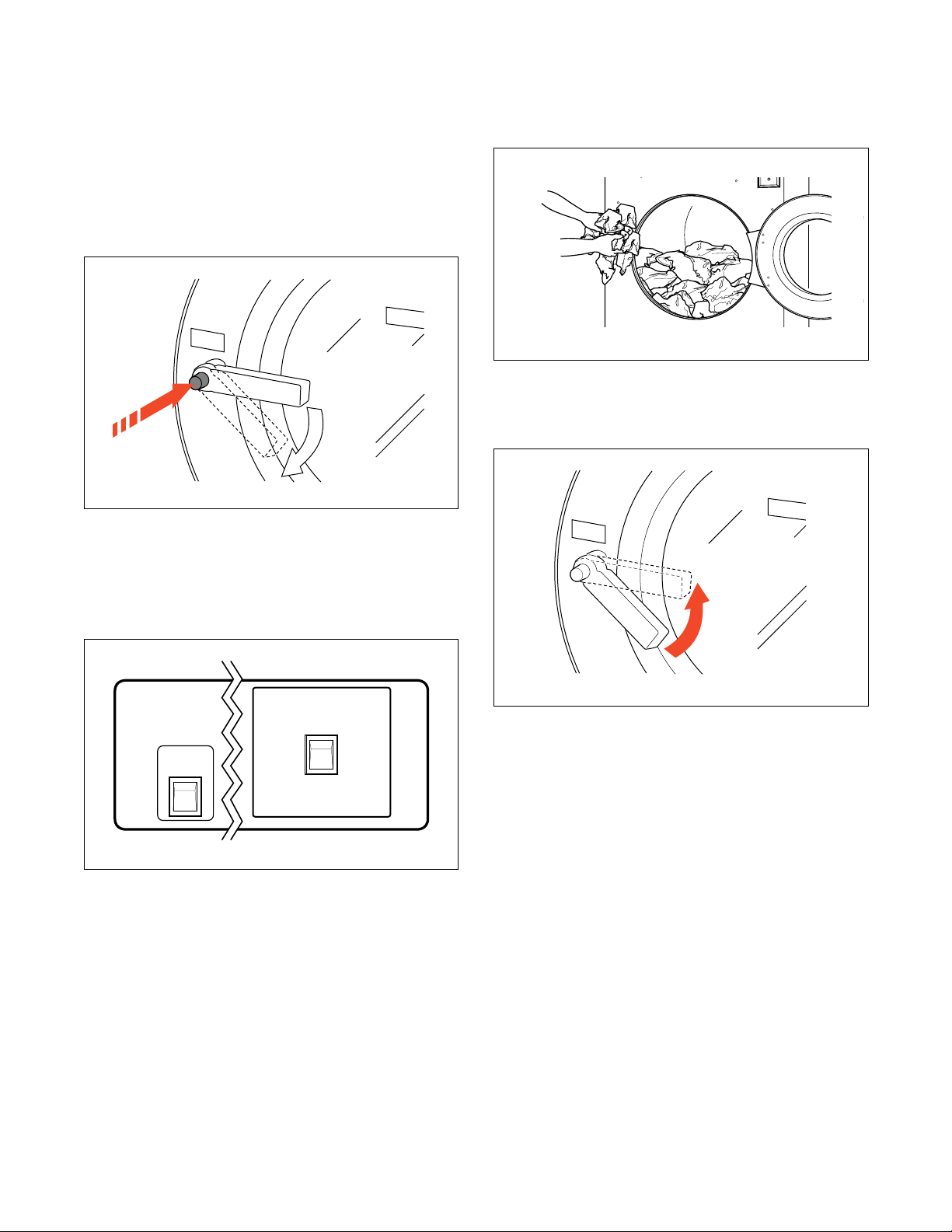

2. Push button and turn handle clockwise to open.

Refer to Figure 3.

U001I

Figure 3

For non-coin models: Press and hold the DOOR

UNLOCK button on the left side of the control

panel while performing the above step. Refer to

Figure 3 and Figure 4.

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 5.

U003I

Figure 5

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 6.

U001I

DOOR UNLOCK

Figure 4

U005I

U005I

On

Off

U135R

U135R

Figure 6

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Loading...

Loading...