Page 1

Frontload Washers

Metered Commercial

NOTA: El manual en

español aparece después

del manual en inglés.

Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

H264I

Part No. 801480R1

April 2004

Page 2

Page 3

WARNING

Failure to install, maintain, and/or operate this machine according to the manufacturer’s

instructions may result in conditions which can produce bodily injury and/or property

damage.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution, and

carefulness are factors which cannot be built into these washers. These factors MUST BE supplied by the

person(s) installing, maintaining, or operating the washer.

Always contact the distributor, service agent, or the manufacturer about any problems or conditions you do not

understand.

W030

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 5

Table of

Contents

Replacement Parts.............................................................................. 5

Safety Information.............................................................................. 7

Explanation of Safety Messages........................................................... 7

Important Safety Instructions ............................................................... 7

Installation........................................................................................... 9

Dimensions and Specifications............................................................. 9

Meter Case............................................................................................ 10

Before You Start................................................................................... 10

Tools ................................................................................................ 10

Electrical .......................................................................................... 10

Water................................................................................................ 10

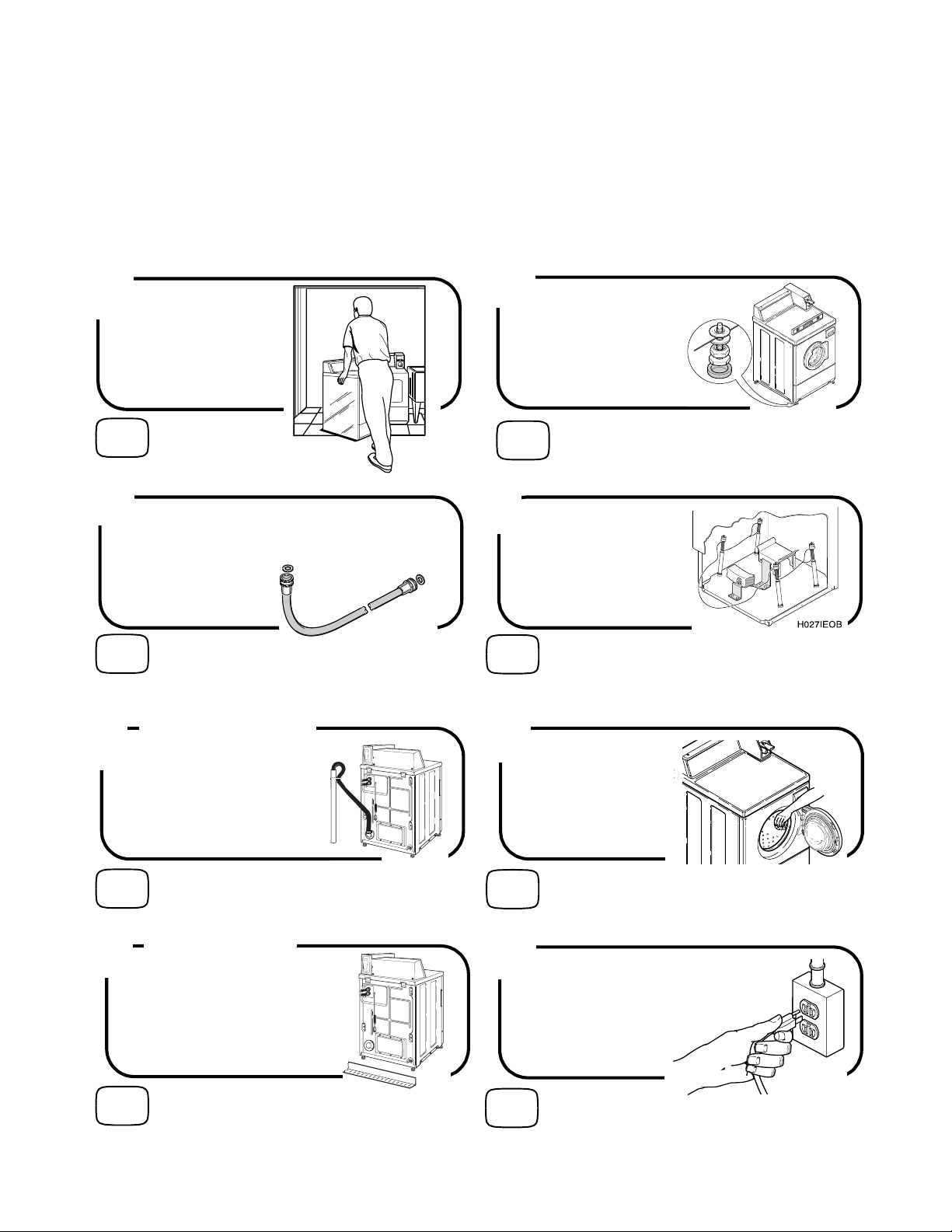

Installing the Washer............................................................................ 11

Step 1: Position Washer Near Installation Area .............................. 11

Step 2: Connect Water Inlet Hoses.................................................. 11

Step 3: (Non-Gravity Drain Models Only) Connect Drain Hose

to Drain Receptacle ........................................................................ 12

Step 4: (Gravity Drain Models Only) Connect Drain Outlet to Drain

System ............................................................................................ 13

Step 5: Position and Level the Washer ............................................ 14

Step 6: Remove the Shock Sleeves and Shipping Brace ................. 15

Step 7: Wipe Out Inside of Wash Drum.......................................... 15

Step 8: Plug In the Washer............................................................... 15

Step 9: Check Installation................................................................ 15

Moving Washer to a New Location................................................. 16

Electrical Requirements........................................................................ 17

Grounding Instructions .................................................................... 17

Water Supply Requirements................................................................. 18

Water Temperature .......................................................................... 18

Water Pressure ................................................................................. 19

Risers................................................................................................ 19

Operation............................................................................................. 21

Operation Instructions for Electromechanical Washers ....................... 21

Step 1: Load Laundry....................................................................... 21

Step 2: Close Loading Door............................................................. 21

Step 3: Add Laundry Supplies......................................................... 22

Step 4: Set Fabric Selector............................................................... 22

Step 5: Set WASH/RINSE Temperatures........................................ 22

Step 6: Insert Money........................................................................ 22

Indicator Lights................................................................................ 23

Rapid Advance................................................................................. 23

© Copyright 2004, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Operation Instructions for MDC Washers............................................ 24

Step 1: Set Fabric Selector and Wash Temperature......................... 24

Step 2: Add Laundry Supplies......................................................... 24

Step 3: Load Laundry....................................................................... 25

Step 4: Close Loading Door............................................................. 25

Step 5: Insert Coin(s) or Card.......................................................... 25

Step 6: Start Washer......................................................................... 26

Indicator Lights................................................................................ 26

Operation Instructions for NetMaster Washers.................................... 27

Step 1: Load Laundry....................................................................... 27

Step 2: Close Loading Door............................................................. 27

Step 3: Add Laundry Supplies......................................................... 28

Step 4: Set Fabric Selector............................................................... 28

Step 5: Set Wash Temperature......................................................... 28

Step 6: Insert Coin(s) or Card.......................................................... 29

Step 7: Start Washer......................................................................... 29

Indicator Lights................................................................................ 30

Maintenance ........................................................................................ 31

User-Maintenance Instructions............................................................. 31

Cold Weather Care........................................................................... 31

Care of Your Washer ....................................................................... 31

Replacing Hoses............................................................................... 31

Vacations and Extended Non-Use ................................................... 31

Before You Call for Service................................................................. 32

If Service Is Required........................................................................... 33

Information for Handy Reference......................................................... 34

Installer Checklist............................................................... Back Cover

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 7

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your washer, or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Notes

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 9

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING,” and “CAUTION”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Safety Information

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use your washer only for its intended purpose,

washing clothes.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

16. To reduce the risk of fire, clothes which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep your washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have your washer checked by a

qualified service person.

19. If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the garment manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Always contact your dealer, distributor, service agent

or the manufacturer about any problems or conditions

you do not understand.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 11

Installation

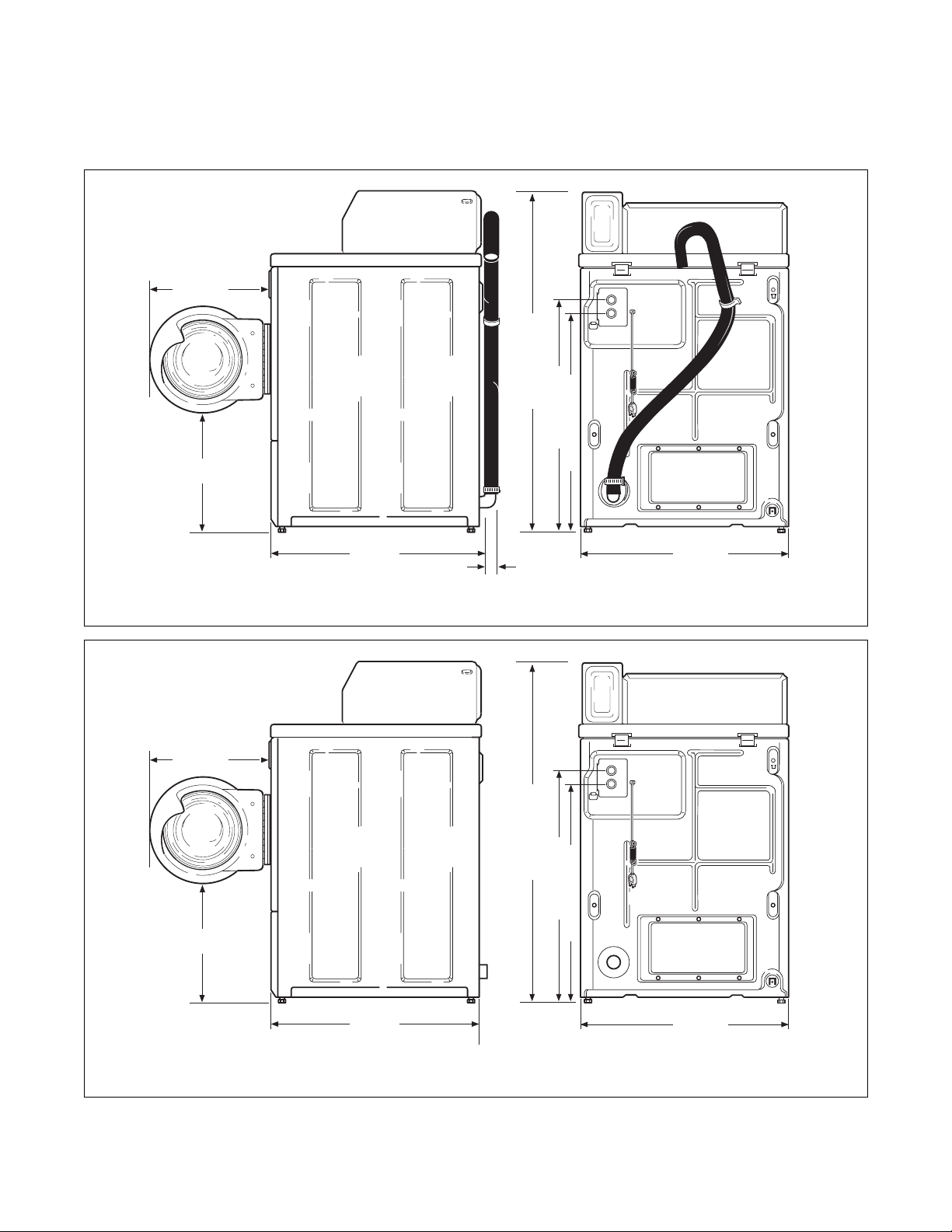

Dimensions and Specifications

17.5 in.

(44.8 cm)

14.3 in.

(36.3 cm)

43 in. (109.2 cm)

31.1 in. (79 cm)

29.6 in. (75.1 cm)

17.5 in.

(44.8 cm)

14.3 in.

(36.3 cm)

28 in.

(71.1 cm)

2 in.

(5.1 cm)

NON-GRAVITY DRAIN MODELS

43 in. (109.2 cm)

31.1 in. (79 cm)

26.9 in.

(68.3 cm)

FLW1975N

FLW1975N

29.6 in. (75.1 cm)

801480

28 in.

(71.1 cm)

2 in.

(5.1 cm)

GRAVITY DRAIN MODELS

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

26.9 in.

(68.3 cm)

FLW1976N

FLW1976N

9

Page 12

Installation

1

Meter Case

The factory mounted coin meter case does not include

the service door lock, slide, coin drawer, coin drawer

lock or keys. These parts must be ordered (at extra

cost) according to the purchaser’s requirements, direct

from the manufacturer of your choice.

NOTE: You have the option of using a screw type

lock or a 1/4 turn lock on the meter case service

door. If you choose to use a screw lock, then the

special bracket (located inside the meter case) must

be used. DO NOT use the special bracket if a

1/4 turn lock is used.

Coin Drawer Security – For additional security, drill

out the two pilot holes on each front side of the meter

case to 1/4 turn or 5/16 inch (6.4 or 7.9 mm) holes, and

install a bicycle lock through these holes.

Before You Start

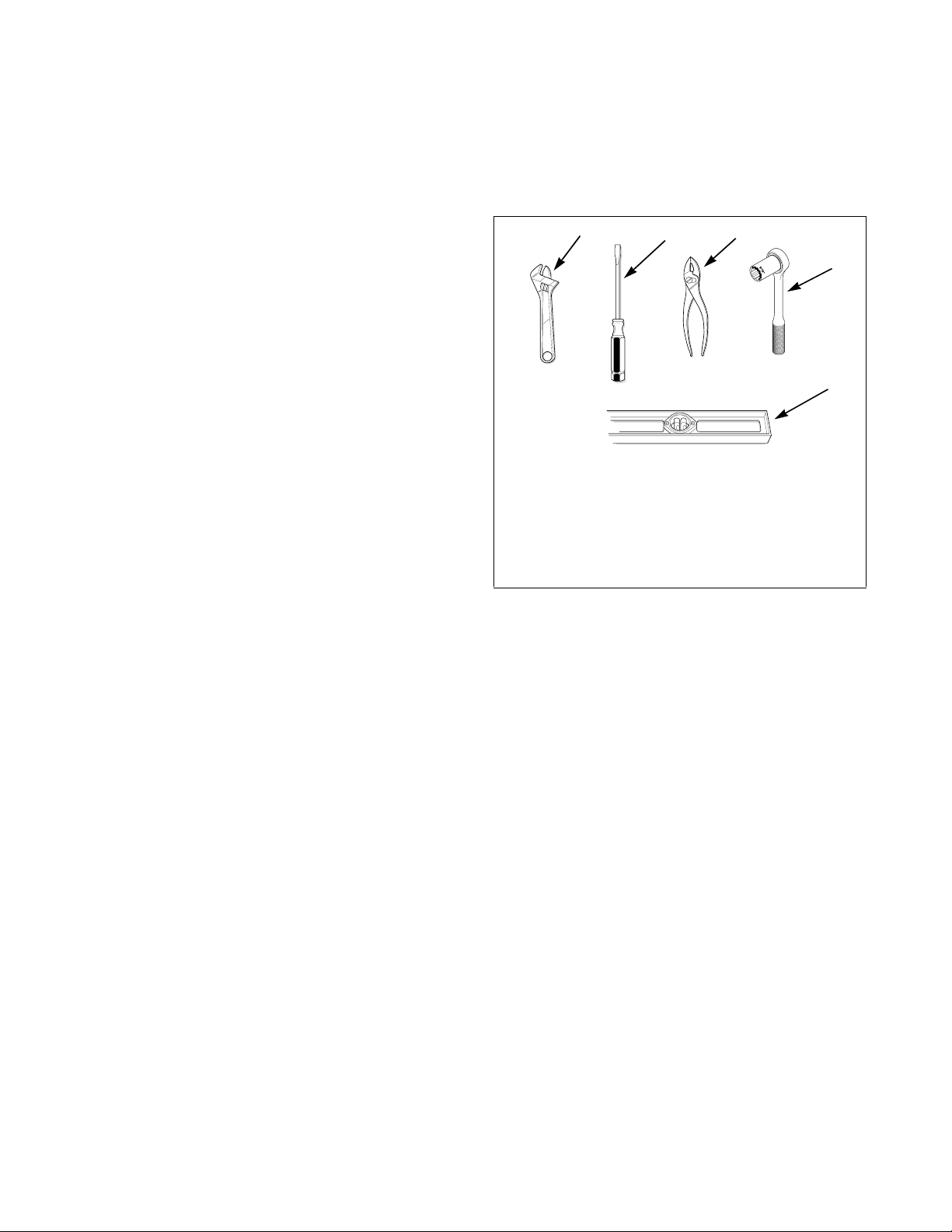

Tools

For most installations, the basic tools you will need

are:

2

1 Wrench

2 Screwdriver

3 Pliers

4 Socket Wrench

5 Level

3

4

5

D820I

Figure 1

Electrical

Refer to serial plate for specific electrical

requirements. For more detailed information, refer to

section on Electrical Requirements.

Water

Washer needs two standard 3/4 inch (19.1 mm) water

supply faucets with a pressure between 20 and

120 pounds per square inch (138 to 827 kPa). For

more detailed information refer to section on Wate r

Supply Requirements.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 13

Installation

Installing the Washer

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

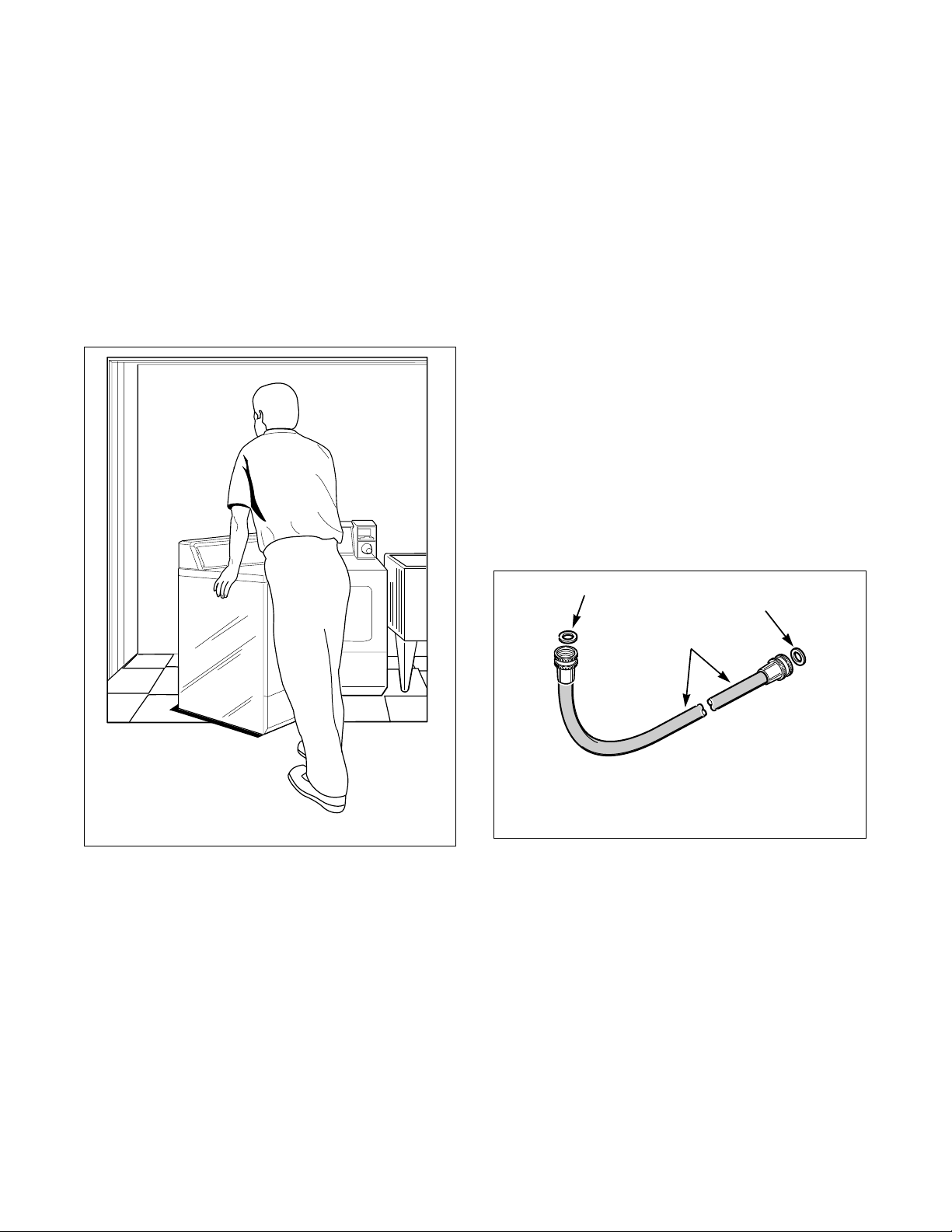

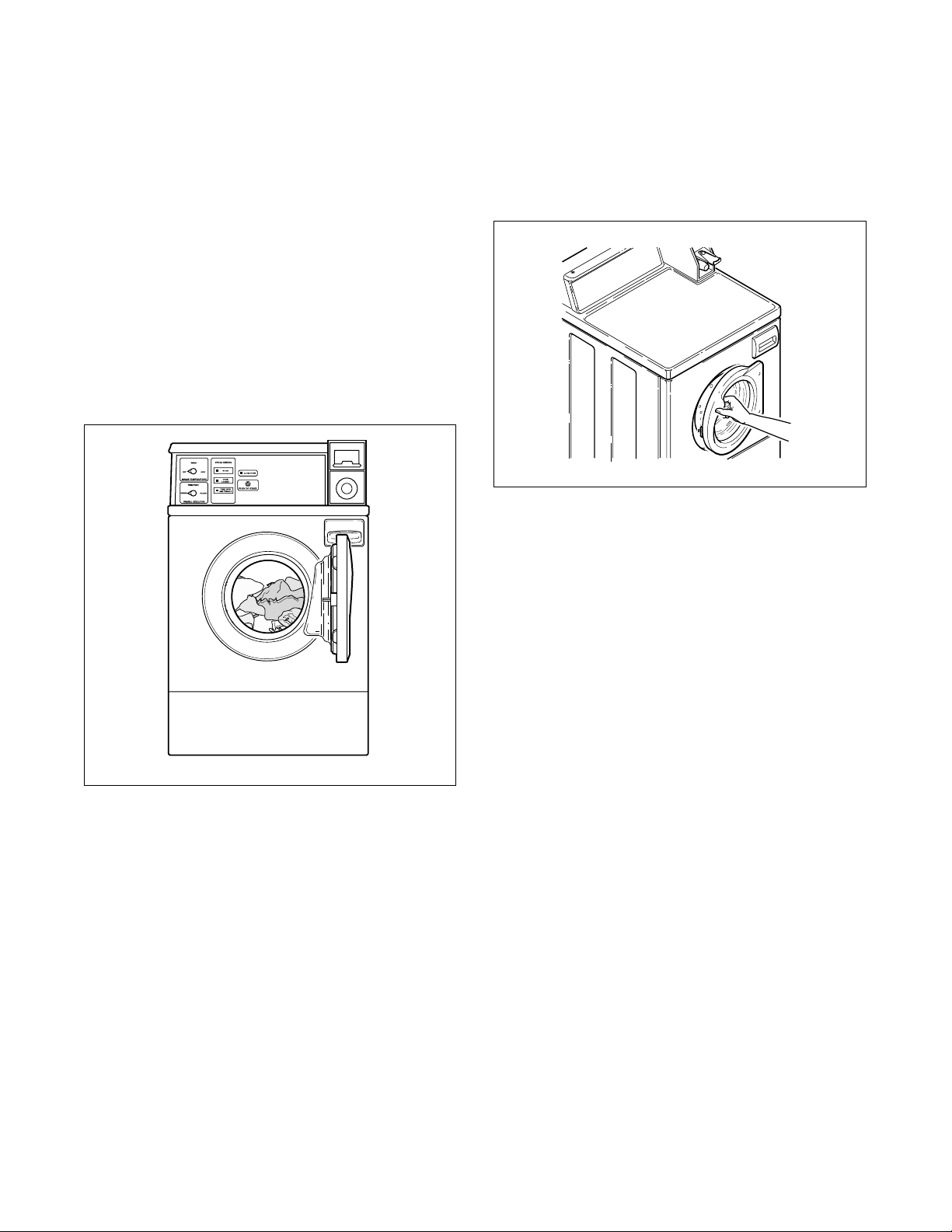

Step 1: Position Washer Near Installation

Area

Move washer so that it is within 4 feet (1.2 meters) of

the desired area of installation.

Step 2: Connect Water Inlet Hoses

NOTE: Refer to section on Water Supply

Requirements before connecting water inlet hoses.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the screens in the water

mixing valve.

NOTE: When installing in newly constructed or

renovated building, it is very important to flush the

lines since build-up may have occurred during

construction.

Remove the four plain rubber washers from accessories

bag, and install them according to Figure 3.

IMPORTANT: Thread hose couplings onto valve

connections finger-tight, then approximately

1/4 turn with pliers. DO NOT cross thread or

overtighten couplings.

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

Figure 2

H135I

1

1

2

H091I

1 Rubber Washer (Plain)

2 Inlet Hose

H135I

Figure 3

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

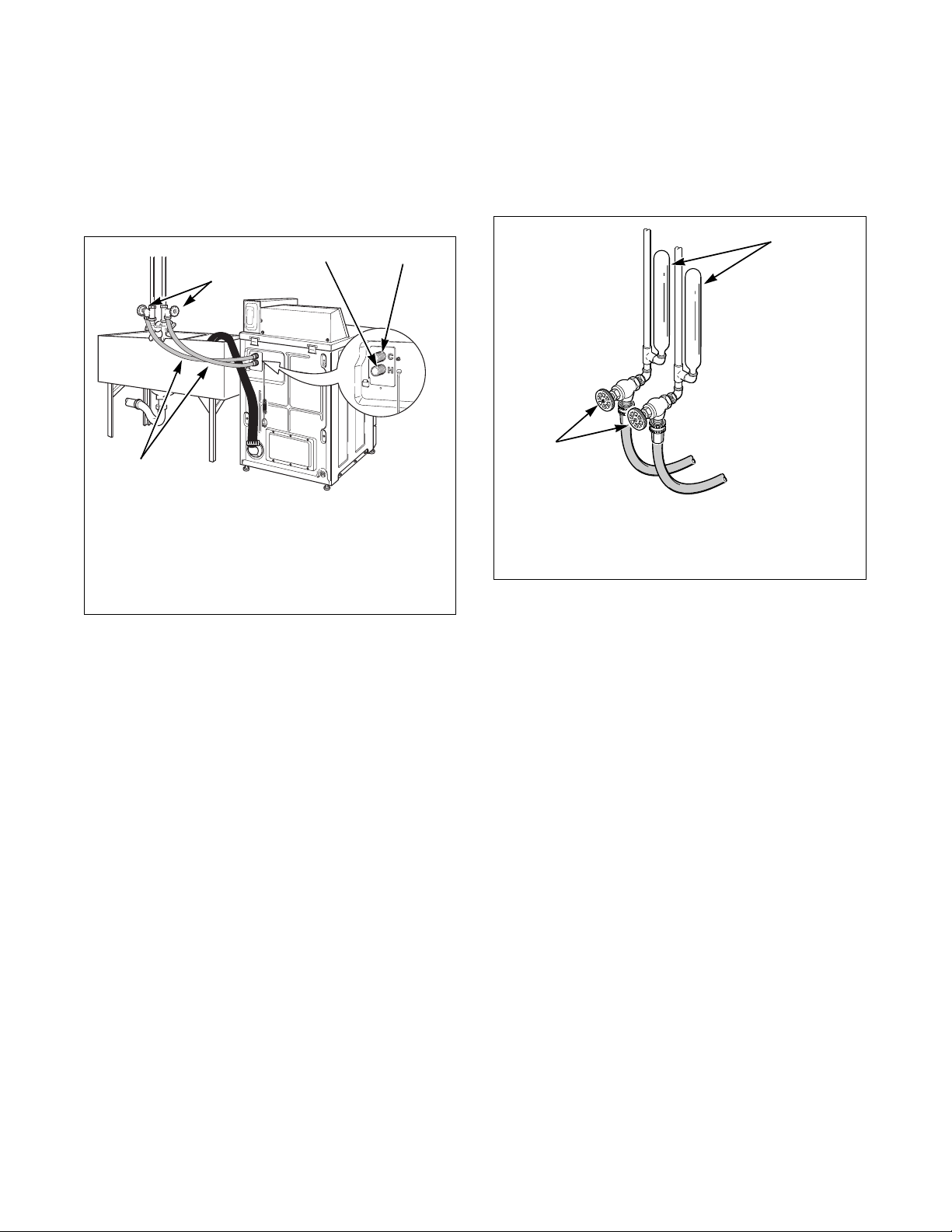

Installation

1

4

1 Water Supply Faucets

2 Hot Water Connection

3 Cold Water Connection

4 Water Inlet Hoses

Figure 4

2

3

WATER

MIXING

VALVE

FLW1977N

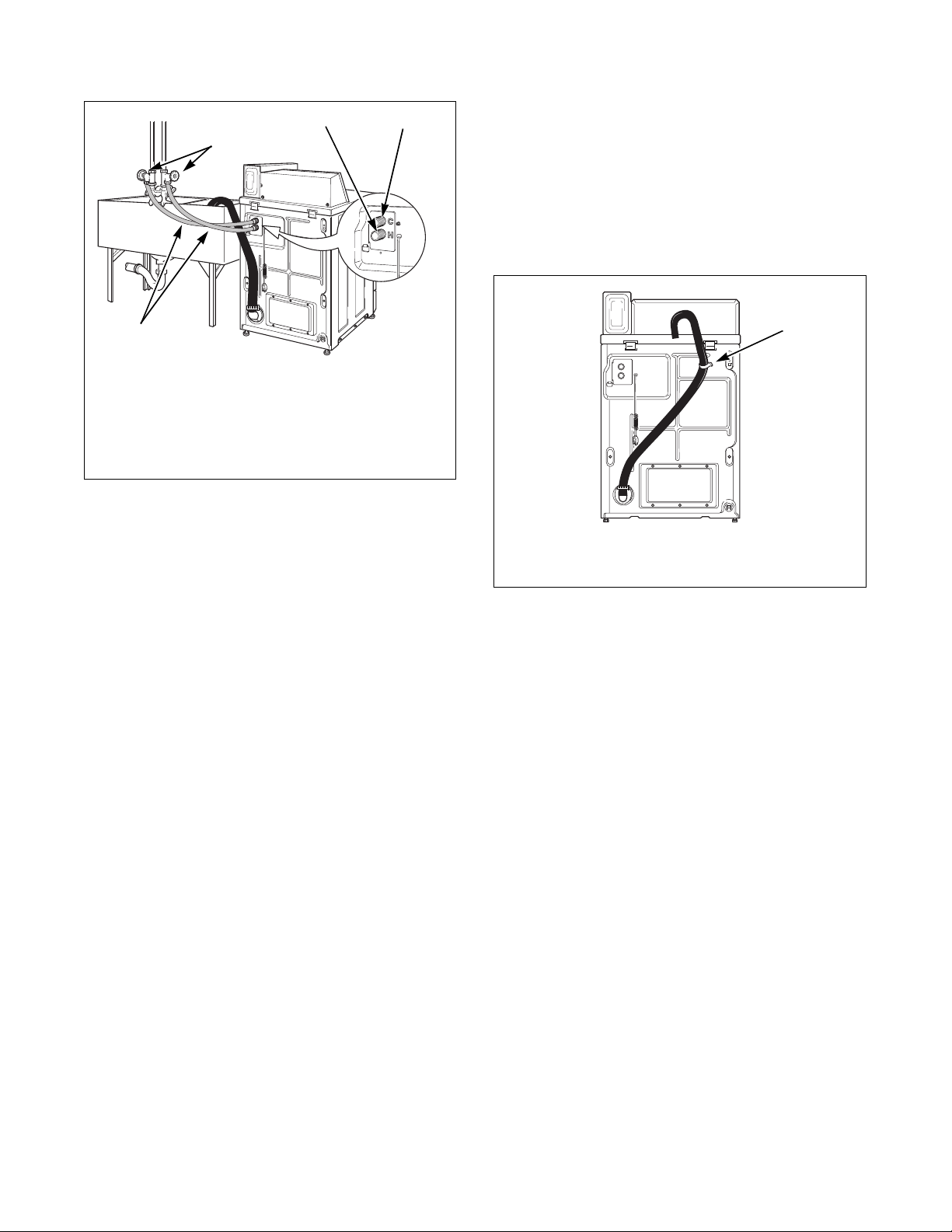

Connect Drain Hose to Drain Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by removing the shipping tape.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 1-3/8 inch (3.5 cm) outside

diameter drain hose.

1

FLW1978N

1 Shipping Tape

Step 3: (Non-Gravity Drain Models Only)

Figure 5

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 15

Installation

Standpipe Installation

Place the drain hose into the standpipe.

Remove the beaded tie-down strap from accessories

bag and place around standpipe and drain hose and

tighten strap to hold hose to standpipe. This will

prevent the drain hose from dislodging from drain

receptacle during use.

RECOMMENDED

HEIGHT

24 TO 36 in.

(61 TO 91.44 cm)

1

1 Standpipe – 2 in. (5.08 cm) or 1-1/2 in.

(4 cm)

FLW1979N

FLW1979N

Step 4: (Gravity Drain Models Only)

Connect Drain Outlet to Drain System

Remove drain fitting and hose clamp from accessories

bag, and clamp fitting onto drain outlet.

Connect the drain fitting to a vented drain system

using a flexible connection (obtain locally). The drain

system must be vented to prevent an air lock or

siphoning.

IMPORTANT: Increasing the drain hose length,

installing elbows, or causing bends will decrease

drain flow rates and increase drain times,

impairing machine performance.

2

1

Figure 6

FLW1980N

FLW1980N

1 Drain Trough

2 Drain Outlet

Figure 7

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation

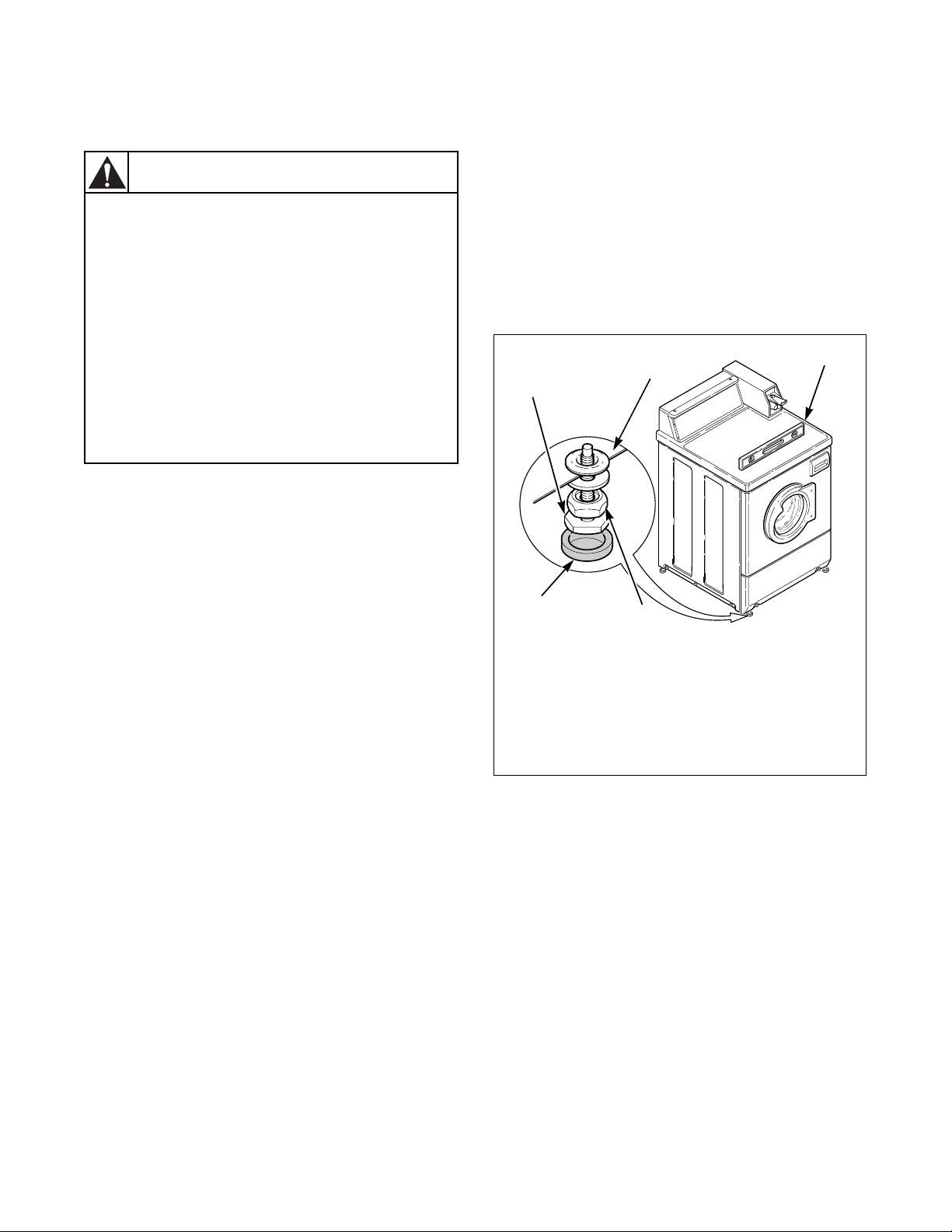

Washers elevated above floor level must

be anchored to that elevated surface,

base or platform. The material used to

elevate the washer should also be

anchored to the floor to ensure that the

washer will not walk or that the washer

can not be physically pulled, tipped or

slid from its installed position. Failure to

do so may result in conditions which can

produce serious injury, death and/or

property damage.

W306

WARNING

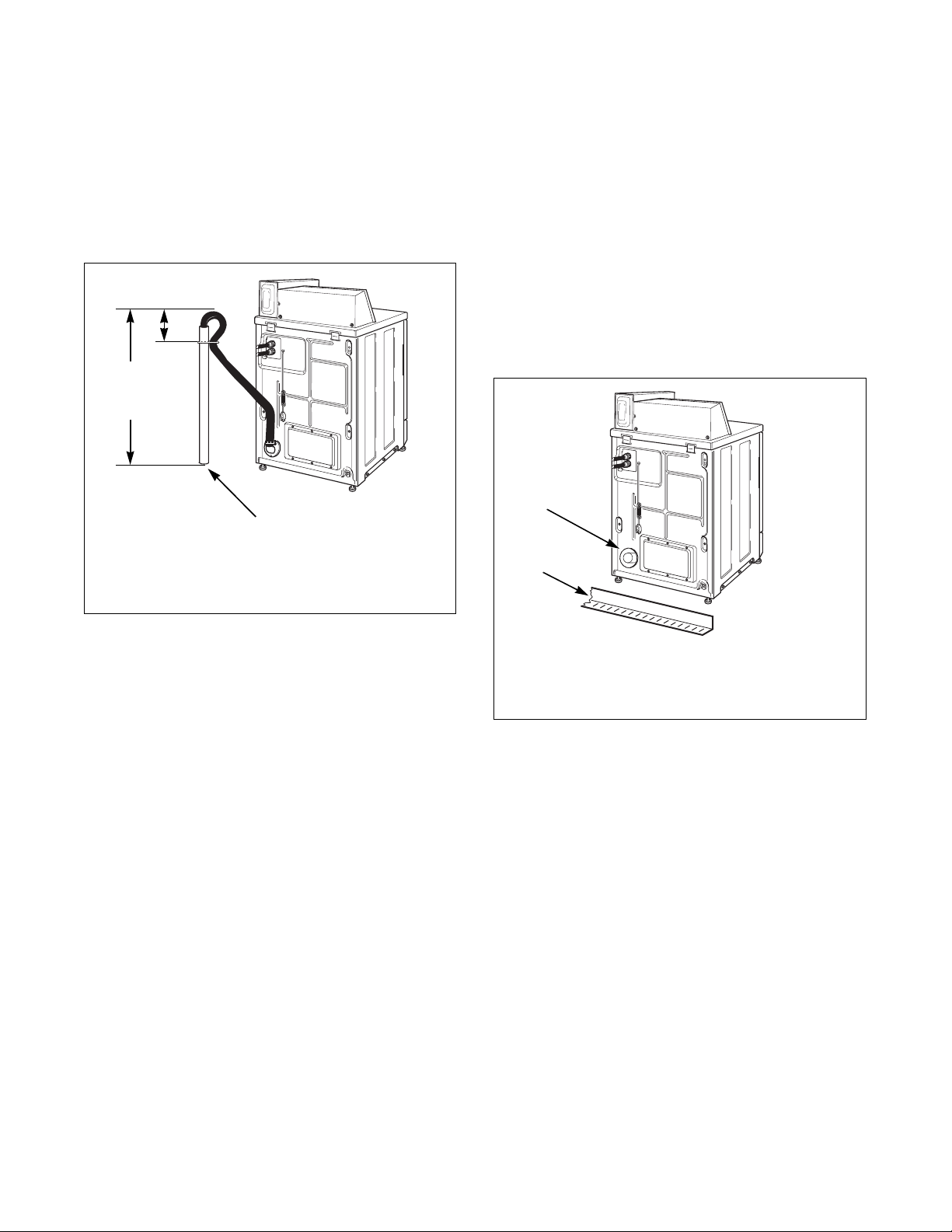

Step 5: Position and Level the Washer

Place washer in position on a clean, firm and

reasonably level floor. Installing the washer on any

type of carpeting is not recommended.

Loosen 7/8 inch locknut and adjust the front and rear

leveling legs until the washer is level from side to side

and front to back (using a level). Washer should not

rock.

NOTE: Level must rest on raised portion of top

panel. Refer to Figure 8.

Tighten the locknuts securely against the washer

base using the 7/8 inch wrench. If the locknuts are not

tight, washer will move out of position during

operation.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportation of the washer may

cause damage to the dispenser or door.

Remove rubber feet from accessories bag and place on

all four leveling legs.

Verify that washer does not rock.

3

2

1

5

1 Leveling Leg

2 Washer Base

3 Level

4 Locknut

5 Rubber Foot

4

H360I

Figure 8

NOTE: DO NOT slide washer across floor if the

leveling legs have been extended, as legs and base

could become damaged.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 17

Installation

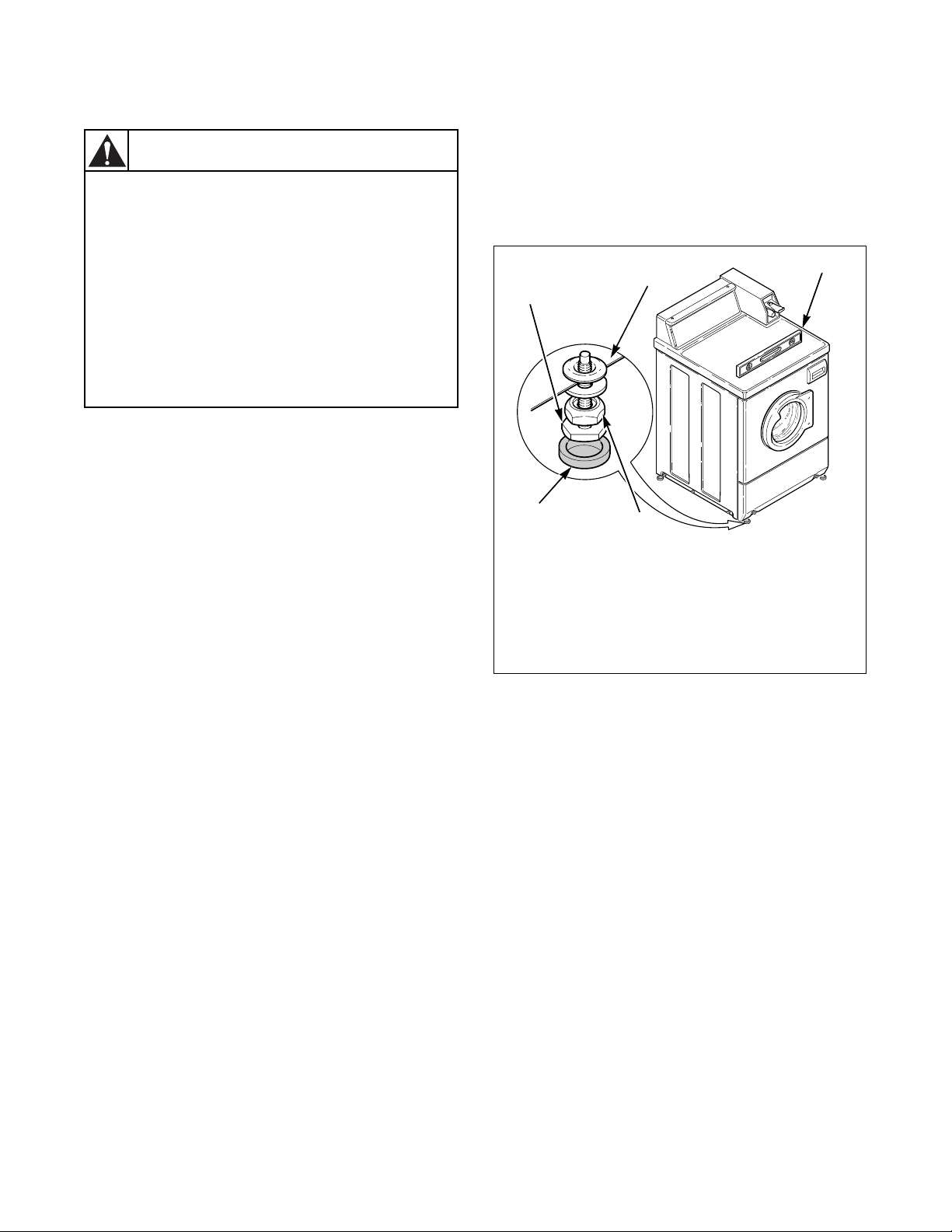

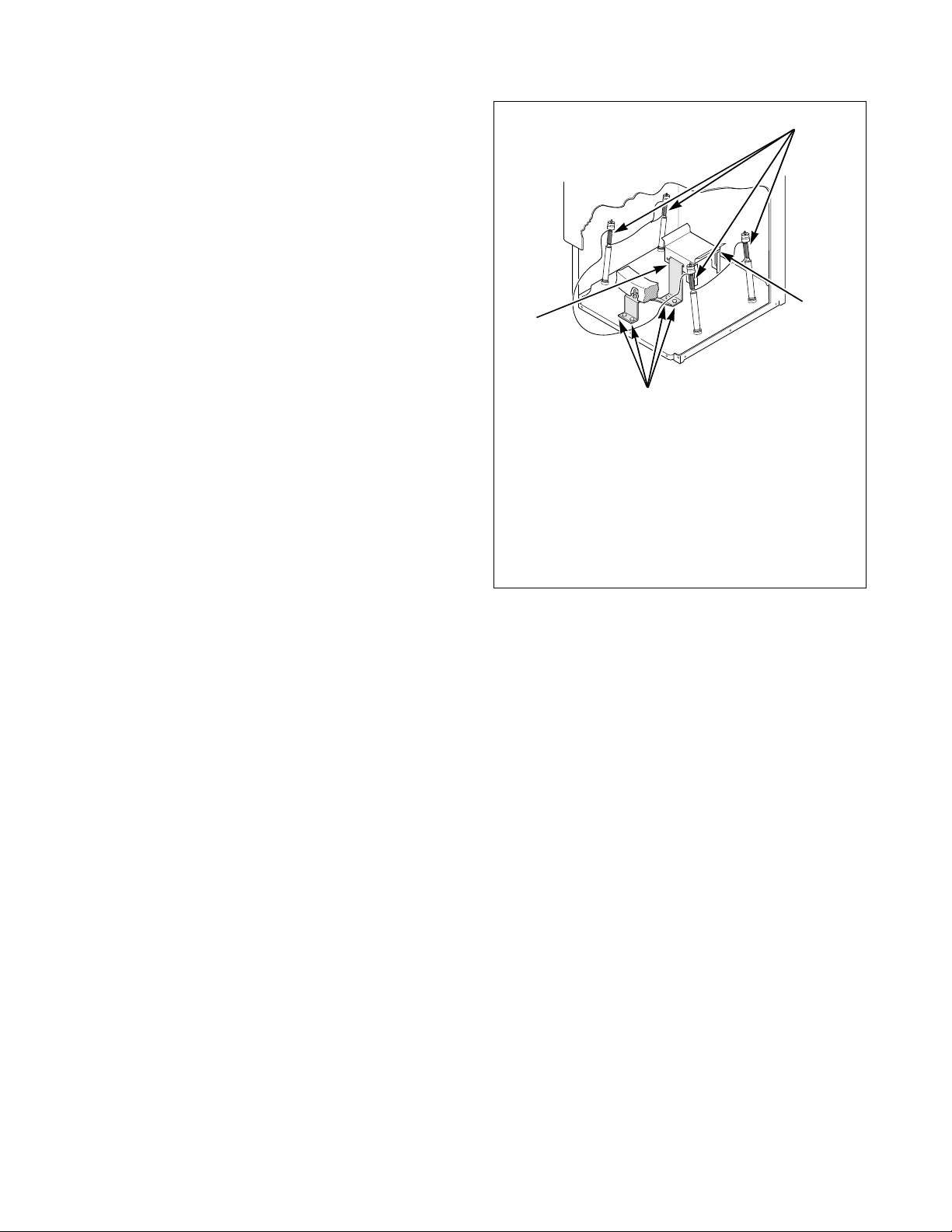

Step 6: Remove the Shock Sleeves and

Shipping Brace

Remove front access panel by removing the two

screws.

Remove bolts and lockwashers from shipping brace

with 9/16 inch wrench and remove brace. Remove

shock sleeves by pulling on the yellow rope. Remove

label from front side of front access panel and place on

backside of front access panel.

NOTE: The shipping brace, bolts, washers and

shock sleeves should be saved and MUST be

reinstalled whenever the washer is moved more

than four feet. Do not lift or transport washer from

front or without shipping materials installed.

Store the shipping materials in the bag provided in the

accessories bag. Save materials for use whenever the

washer is moved.

Reinstall front access panel.

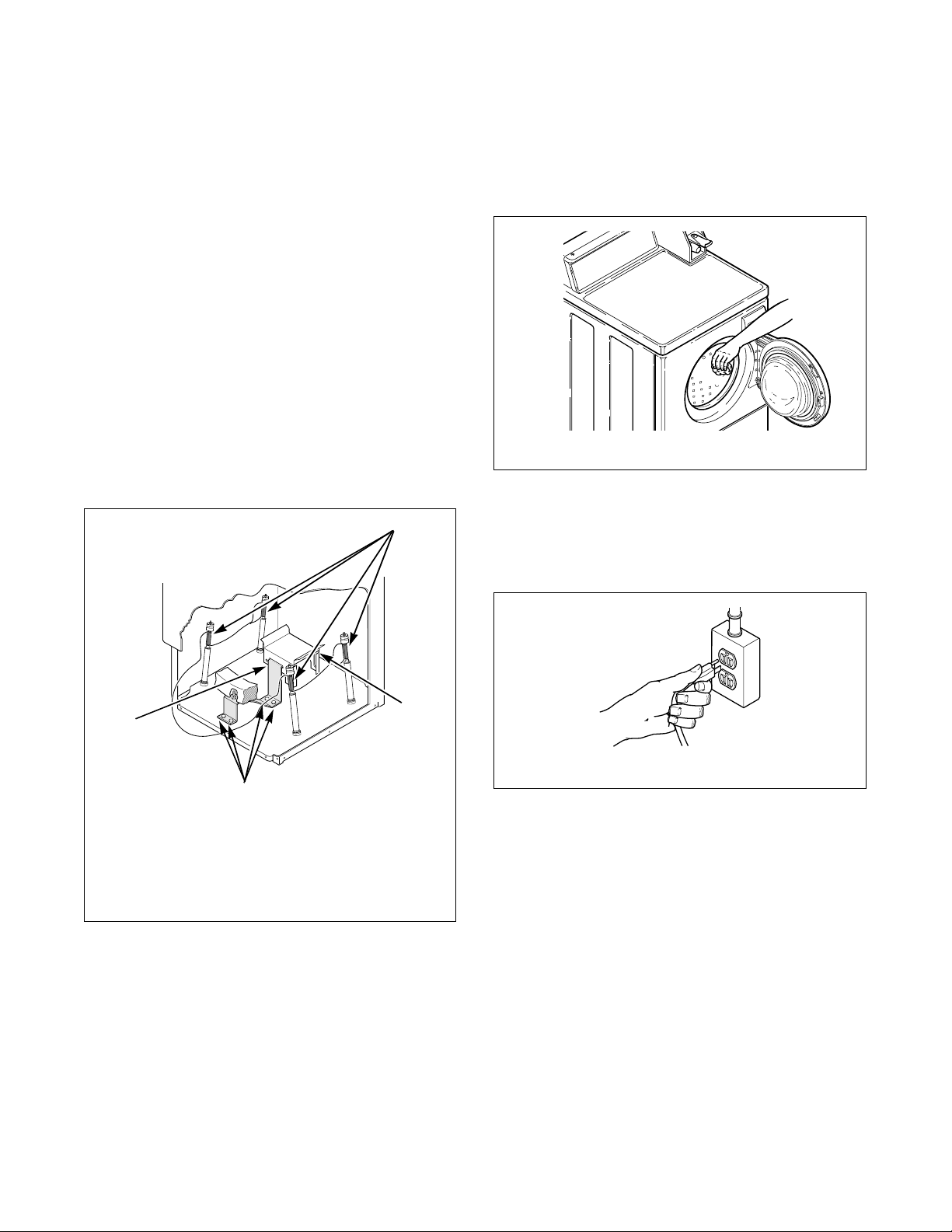

1

Step 7: Wipe Out Inside of Wash Drum

Before using washer for the first time, use an allpurpose cleaner, or a detergent and water solution, and

a damp cloth to remove shipping dust from inside

wash drum.

H227I

Figure 10

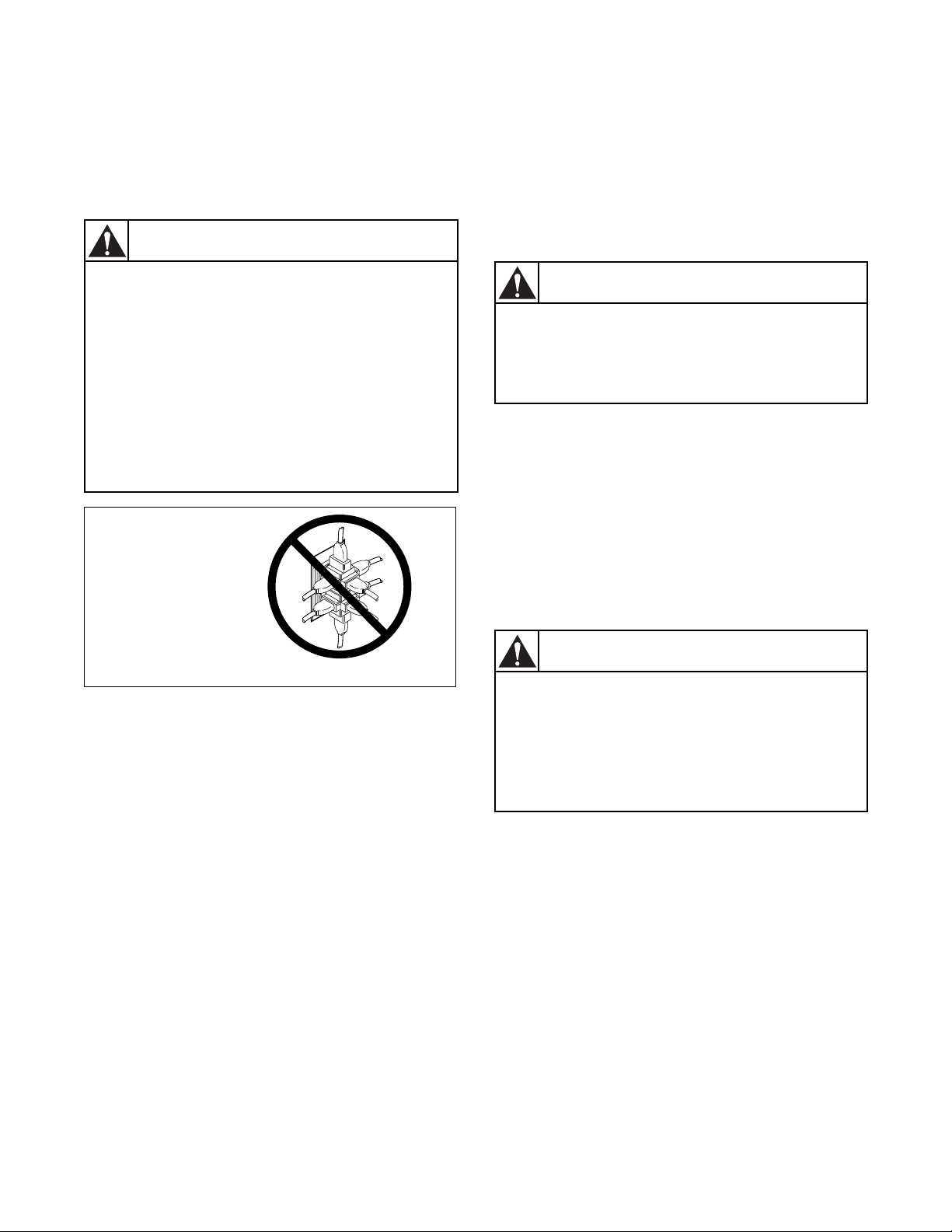

Step 8: Plug In the Washer

Refer to section on Electrical Requirements and plug

the washer in.

2

4

3

H336I

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

Figure 9

NOTE: The shipping materials MUST be

reinstalled whenever the washer is moved. Refer to

section on Moving Washer to a New Location for

instructions.

D254I

D254I

Figure 11

Step 9: Check Installation

Refer to Installer Checklist on the back cover and

make sure that washer is installed correctly.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Installation

Moving Washer to a New Location

To prevent damage while moving the washer, the

shipping materials MUST be reinstalled.

Reinstallation of Shipping Materials

Disconnect washer from electrical supply.

Remove front access panel by removing two screws.

Place the shock sleeves on all four shock absorbers.

Refer to Figure 12.

Insert hooked end of shipping brace into the open slot

of the motor mount. Attach with bolts and lockwashers.

Refer to Figure 12.

Reinstall front access panel.

1

2

4

3

H336I

1 Shock Sleeves

2 Motor Mount

3 Bolts and Lockwashers

4 Hooked End of Shipping Brace

Figure 12

Refer to step 6 for proper procedures whenever the

washer is moved.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 19

Installation

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA No. 70, and such local

regulations as might apply. It is the

customer’s responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure the laundry room

has adequate electrical power to operate

the washer.

W227

WARNING

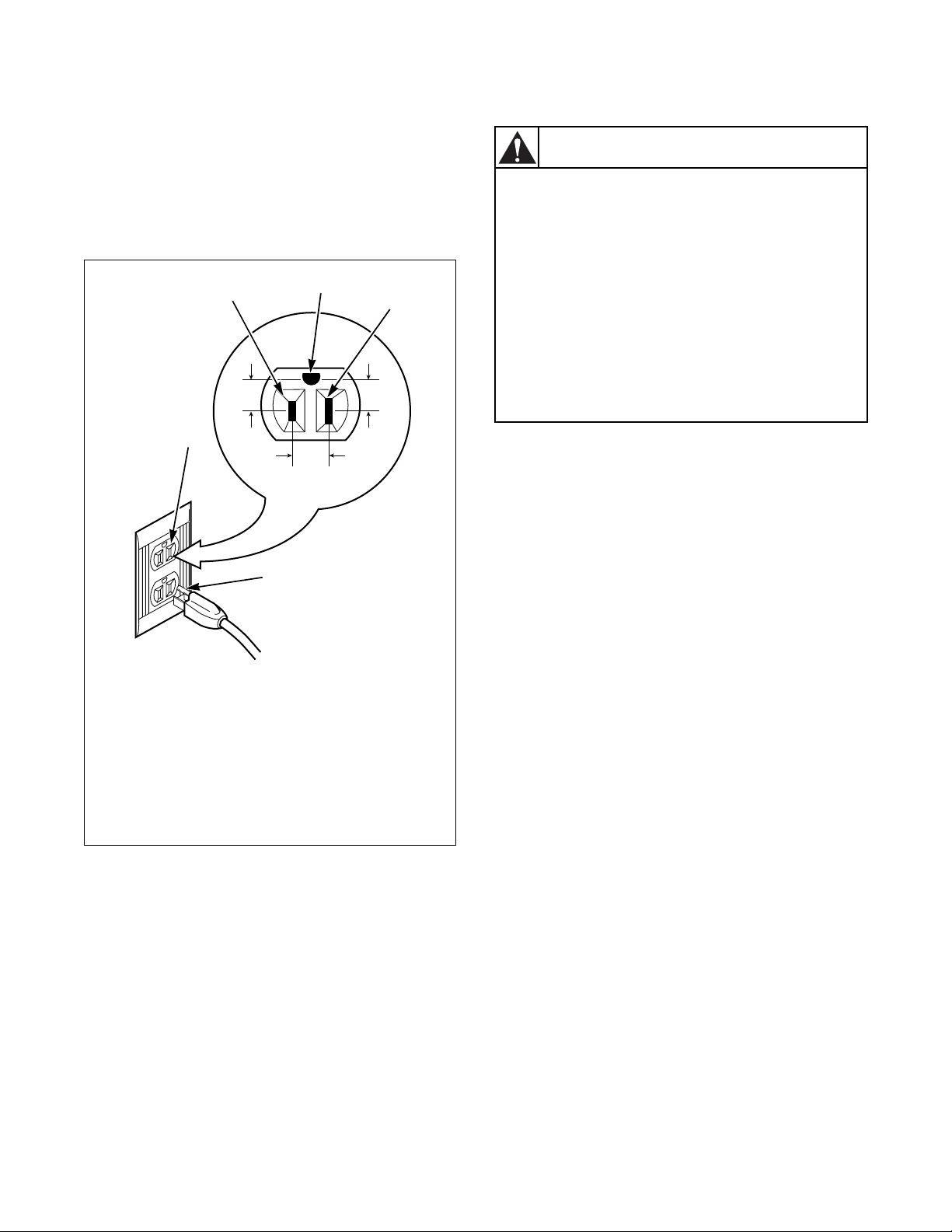

Electrical Requirements

(120 Volt, 60 Hertz with 3-Prong Grounding Plug)

NOTE: The wiring diagram is located in the

control cabinet.

DO NOT OVERLOAD

CIRCUITS

DO NOT USE

ADAPTER

DO NOT USE AN

EXTENSION CORD

D009I

Figure 13

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current) circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figure 14

to determine correct polarity of the wall receptacle.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

WARNING

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

Grounding Instructions

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-grounding conductor

and a 3-prong grounding plug. The plug must be

plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is

properly grounded.

W216

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Installation

Do not modify the plug provided with the washer – if

it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that illustrated, the

qualified electrician should correct the problem.

1

120 ± 12

V. A. C.

5

4

2

120 ± 12

V.A.C.

3

0

V.A.C.

Water Supply Requirements

WARNING

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used

for such a period and before using the

washer, turn on all hot water faucets and

let the water flow from each for several

minutes. This will release any

accumulated hydrogen gas. The gas is

flammable. Do not smoke or use an open

flame during this time.

W029

NOTE: Water supply faucets must fit standard

3/4 inch (19.1 mm) female garden hose couplings.

DO NOT USE SLIP-ON OR CLAMP-ON

CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

STANDARD 120 VOLT, 60 HERTZ,

3-WIRE EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

Figure 14

Water Temperature

Cold:

Recommended cold water temperature is 60° to

80° Fahrenheit (16° to 27° Celsius).

Hot:

D799I

Recommended hot water temperature is 120° to

140° Fahrenheit (49° to 60° Celsius).

Warm:

Mixture of hot and cold water. (Warm water

temperature is dependent upon the water temperature

and the pressure of both the hot and cold water supply

lines.)

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 21

Installation

NOTE: Longer inlet hoses are available (as

optional equipment at extra cost) if the hoses

supplied with the washer are not long enough for

the installation. Order hoses as follows:

No. 20617 Inlet Hose (8 feet) (2.44 m)

No. 20618 Inlet Hose (10 feet) (3.05 m)

2

1

4

1 Water Supply Faucets

2 Hot Water Connection

3 Cold Water Connection

4 Water Inlet Hoses

3

WATER

MIXING

VALVE

FLW1977N

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets (refer to Figure 16).

1

2

W005I

1 Risers (Air Cushions)

2 Water Supply Faucets

Figure 16

Figure 15

Water Pressure

Pressure must be a minimum of 20 to a maximum of

120 pounds per square inch (138 to 827 kPa) static

pressure measured at the faucet.

NOTE: Water pressure under 20 pounds per

square inch (138 kPa) will cause an extended fill

time in the washer and may not properly flush out

the detergent dispenser.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Notes

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 23

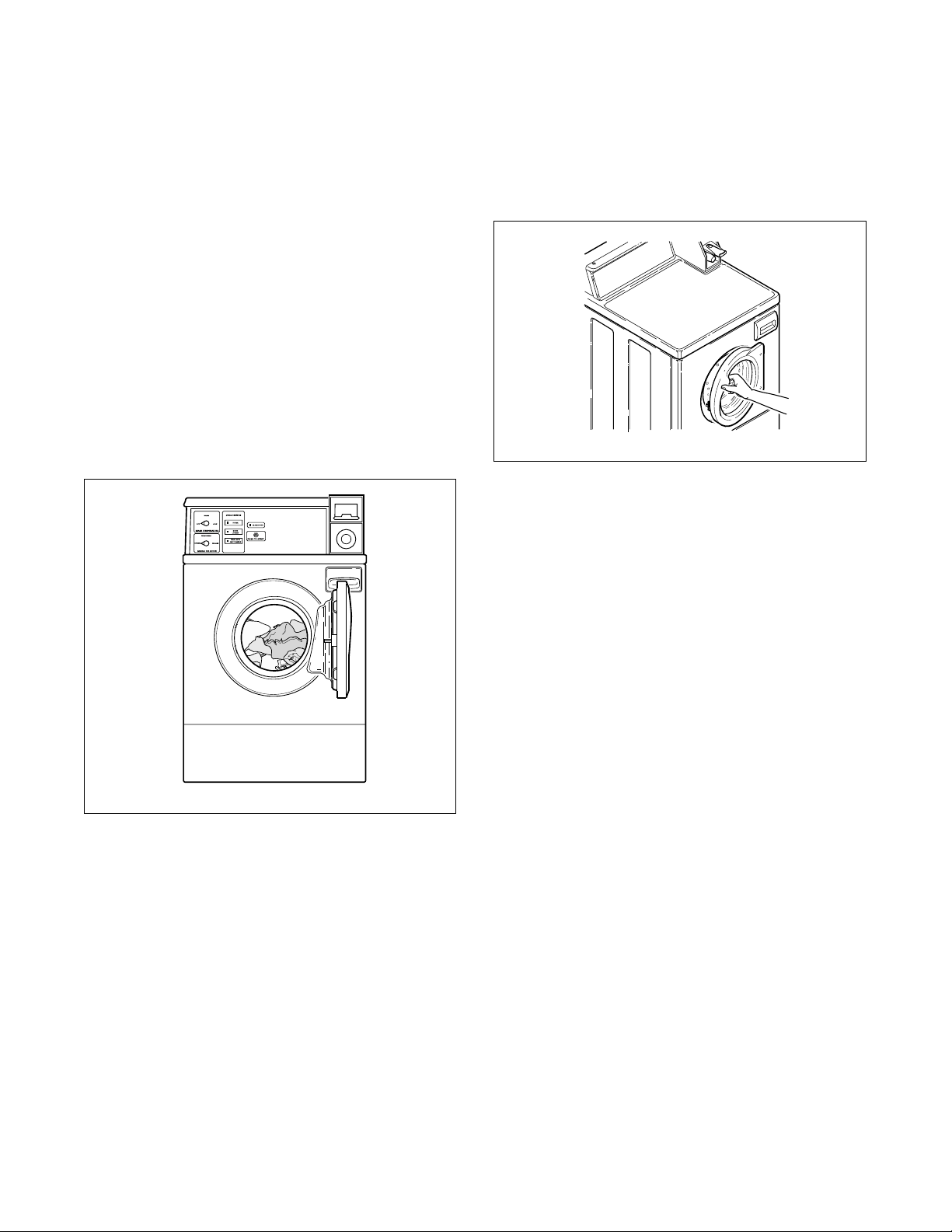

Operation

Operation Instructions for

Electromechanical Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washtub.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Load Laundry

Load items loosely into wash drum.

Step 2: Close Loading Door

Close the loading door tightly. The washer will not

operate with the loading door open.

D229I

Figure 18

801480

H228I

Figure 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Operation

Dispenser drawer requires a special tool

for removal. Contact a service person if

removal is necessary.

W236

CAUTION

Step 3: Add Laundry Supplies

Open dispenser drawer. Measure and add low sudsing

detergent (1), bleach (2) and fabric softener (3) to the

dispenser drawer (refer to Figure 19). Close dispenser

drawer.

IMPORTANT: If using detergents made for

topload washers, avoid oversudsing by using 1/2 of

the recommended amount.

3

1

2

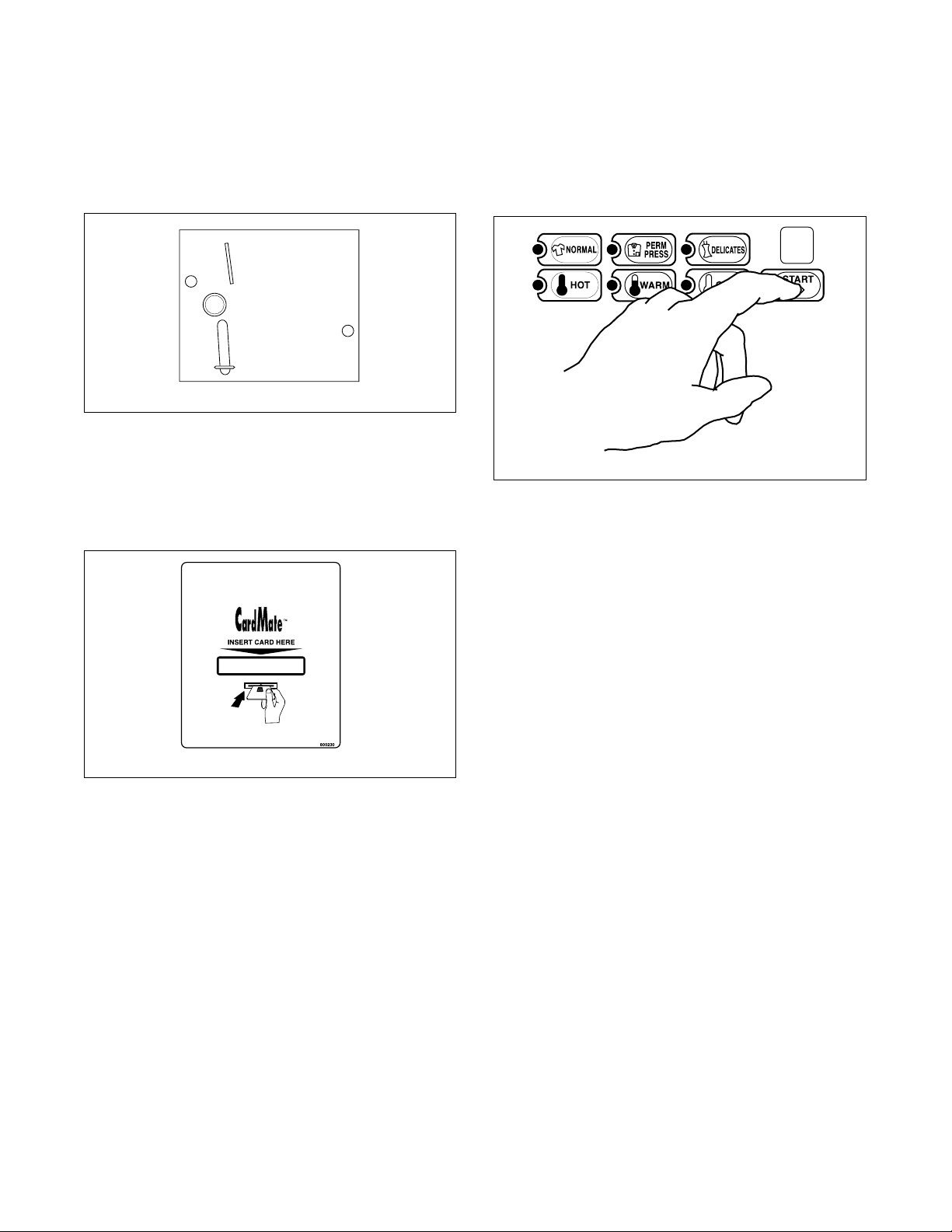

Step 4: Set Fabric Selector

Set regular loads at NORMAL or PERM PRESS. Set

delicate loads at DELICATE.

H171I

Figure 20

Step 5: Set WASH/RINSE Temperatures

Set at HOT (COLD rinse), WA RM (COLD rinse) or

COLD (COLD rinse).

NOTE: Always follow manufacturer’s care labels.

1 Detergent

2 Bleach

3 Fabric Softener

Figure 19

H226I

H170I

Figure 21

Step 6: Insert Money

Place coin(s) in slide and carefully push in as far as

possible and then pull slide out as far as possible. After

IN USE light comes on (indicating start of cycle),

press the PUSH-TO-START button.

1

W297I

1 Service Door

Figure 22

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 25

Operation

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

WARNING

Indicator Lights

IN USE

This light will remain on while washer is in use.

DOOR LOCKED

This light will come on after the PUSH-TO-START

button has been pressed and the washer door has

locked. It will remain on until the wash cycle has

ended.

FINAL SPIN AND TUMBLE

This light will come on at the start of the final spin and

remain on until the wash cycle has ended.

CLOSE DOOR

This light will come on if door is not closed tightly.

Firmly push door until light goes out.

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified service

person refer to the wiring diagram (located inside

of cabinet) and check for broken, loose or incorrect

wiring.

NOTE: Once a cycle has started, the door can only

be opened by first unplugging the power cord and

waiting one minute.

The washer will stop (pause) shortly before the first

spin and final spin.

Rapid Advance

The Rapid Advance feature allows the owner to

quickly advance through an active cycle to a specific

cycle step.

To enter Rapid Advance, open the service door long

enough for the IN USE light to turn on and close the

door. Refer to Figure 22.

NOTE: If service door remains open, rapid cycles

will be a free vend.

Press the PUSH-TO-START button to start the cycle.

Press PUSH-TO-START button again to advance

through each cycle step. Refer to Table 1 for cycle

steps.

Cycle Steps

Wash Fill/Agitate cycle step

Wash Distribute cycle step

Wash Pulse Spin cycle step

Rinse Fill/Agitate cycle step

Rinse Distribute cycle step

Rinse Pulse Spin cycle step

Extra Rinse Fill/Agitate cycle step (If extra rinse is

enabled)

Extra Rinse Distribute cycle step (If extra rinse is enabled)

Extra Rinse Pulse Spin cycle step (If extra rinse is enabled)

Final Fill/Agitate cycle step

Final Distribute cycle step

Final Pulse Spin cycle step

Final High Spin cycle step (Final Spin light on)

Breakaway cycle step (Final Spin light on)

End of cycle (door will remain locked for about 1 minute)

Table 1

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Operation

Operation Instructions for

MDC Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washtub.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

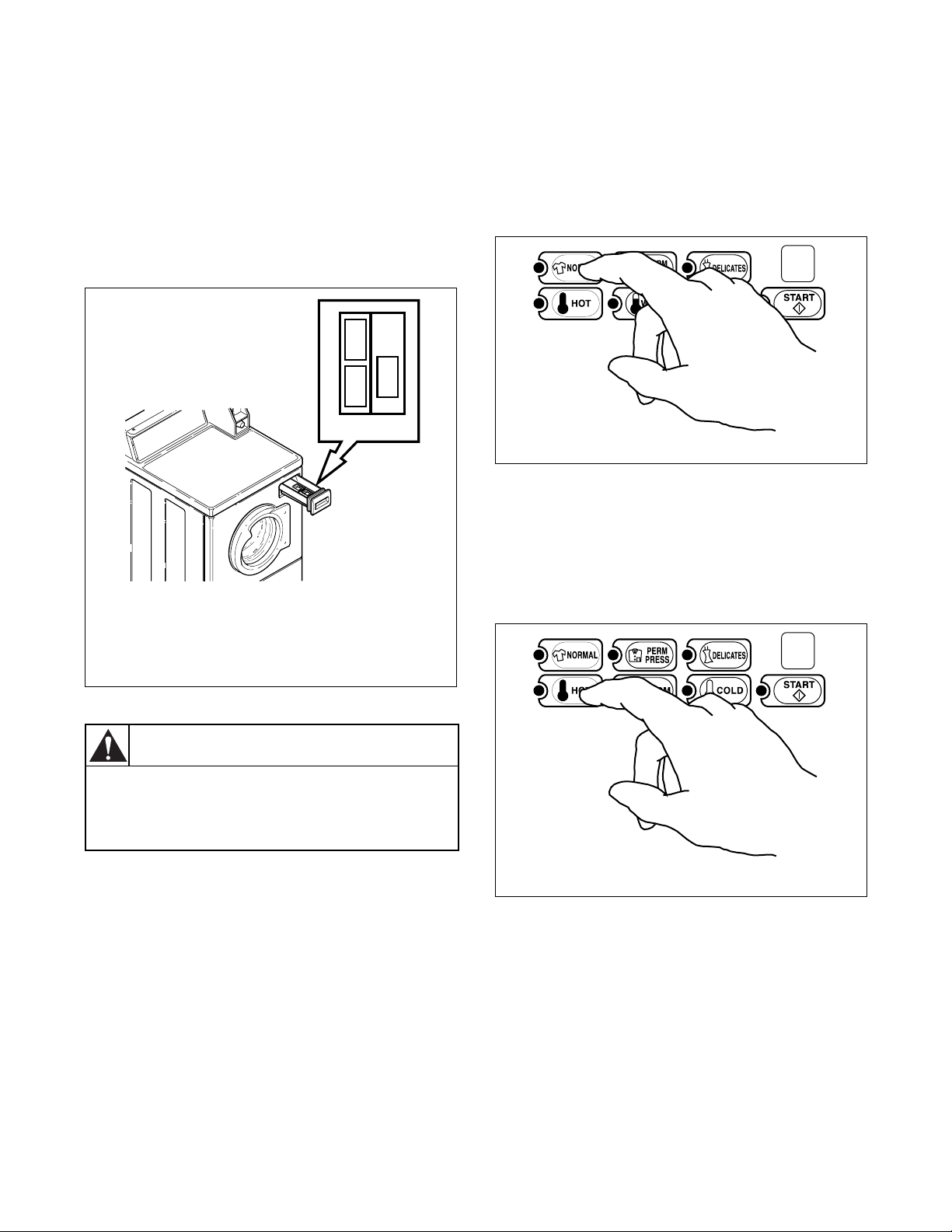

Step 1: Set Fabric Selector and Wash

Temperature

Push touchpad for NORMAL/HOT, NORMAL/

WARM, PERM PRESS/WARM or DELICATES/

COLD cycle. Light indicates selection.

NOTE: Changes can be made to Fabric Selector

setting up until the first fill is complete.

Step 2: Add Laundry Supplies

Open dispenser drawer. Measure and add low sudsing

detergent (1), bleach (2) and fabric softener (3) to the

dispenser drawer (refer to Figure 24). Close dispenser

drawer.

IMPORTANT: If using detergents made for

topload washers, avoid oversudsing by using 1/2 of

the recommended amount.

3

1

2

Figure 23

FLW1920N

FLW1920N

H284I

1 Detergent

2 Bleach

3 Fabric Softener

Figure 24

CAUTION

Dispenser drawer requires a special tool

for removal. Contact a service person if

removal is necessary.

W236

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 27

Operation

Step 3: Load Laundry

Load items loosely into wash drum.

Figure 25

Step 5: Insert Coin(s) or Card

To Insert Money

Check pricing as seen on digital display.

W387I

Figure 27

To Insert Card

Insert card into opening.

FLW1921N

Step 4: Close Loading Door

Close loading door tightly. The washer will not

operate with the loading door open.

H283I

Figure 26

DRY1927N

Figure 28

H283I

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Operation

9

Step 6: Start Washer

After vend price has been satisfied, push the START

pad. DOOR MUST BE CLOSED TO START

WA S HE R .

FLW1

FLW1923N

Figure 29

Indicator Lights

WA S H

WASH is lit at the beginning of a wash cycle and will

remain lit until the wash cycle is complete.

RINSE

RINSE is lit at the beginning of all RINSE cycles and

will remain lit until the rinse cycle is complete.

SPIN

SPIN is lit for all spin cycles.

DOOR LOCKED

DOOR LOCKED is lit whenever the door is locked.

The door cannot be opened when this light is on.

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified

serviceperson refer to the wiring diagram (located

inside of washer control hood) and check for

broken, loose or incorrect wiring.

NOTE: Once a cycle has started, the door can only

be opened by first unplugging the power cord and

waiting one minute.

WARNING

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 29

Operation

Operation Instructions for

NetMaster Washers

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washtub.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Load Laundry

Load items loosely into wash drum.

Step 2: Close Loading Door

Close loading door tightly. The washer will not

operate with the loading door open.

H283I

H283I

Figure 31

Figure 30

H282I

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Operation

Dispenser drawer requires a special tool

for removal. Contact a service person if

removal is necessary.

W236

CAUTION

Step 3: Add Laundry Supplies

Open dispenser drawer. Measure and add low sudsing

detergent (1), bleach (2) and fabric softener (3) to the

dispenser drawer (refer to Figure 32). Close dispenser

drawer.

IMPORTANT: If using detergents made for

topload washers, avoid oversudsing by using 1/2 of

the recommended amount.

3

1

2

Step 4: Set Fabric Selector

Push touchpad for NORMAL, PERM PRESS or

DELICATES cycle. Light indicates selection.

NOTE: Changes can be made to Fabric Selector

setting up until the first fill is complete.

H199I

H199I

Figure 33

Step 5: Set Wash Temperature

Push touchpad for HOT, WARM or COLD. Light

indicates selection.

1 Detergent

2 Bleach

3 Fabric Softener

Figure 32

H284I

NOTE: Always follow manufacturer’s care labels.

H200I

H200I

Figure 34

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 31

Operation

Step 6: Insert Coin(s) or Card

To Insert Money

Check pricing as seen on digital display.

W387I

Figure 35

To Insert Card

Insert card into opening. DO NOT REMOVE THE

CARD UNTIL REMOVE CARD LED IS LIT.

Step 7: Start Washer

After vend price has been satisfied, push the START

pad. DOOR MUST BE CLOSED TO START

WA S HE R .

H201I

H201I

Figure 37

801480

M343I

Figure 36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Operation

Indicator Lights

WA S H

WASH is lit at the beginning of a wash cycle and will

remain lit until the wash cycle is complete.

RINSE

RINSE is lit at the beginning of the RINSE or EXTRA

RINSE cycle and will remain lit until the rinse cycle is

complete.

SPIN

SPIN is lit for all spin cycles.

DOOR LOCKED

DOOR LOCKED is lit whenever the door is locked.

The door cannot be opened when this light is on.

INSERT COIN/CARD

INSERT COIN/CARD is lit to prompt the user to insert

coins or card to satisfy the vend price. When INSERT

COIN/CARD is lit, the digits and decimal point show

the vend price remaining to be satisfied.

REMOVE CARD (Card Models Only)

REMOVE CARD flashes after the START pad has

been pressed and the vend has been deducted from the

card.

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified

serviceperson refer to the wiring diagram (located

inside of washer control hood) and check for

broken, loose or incorrect wiring.

NOTE: Once a cycle has started, the door can only

be opened by first unplugging the power cord and

waiting one minute.

WARNING

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 33

Maintenance

User-Maintenance Instructions

Cold Weather Care

If the washer is delivered on a cold day (below

freezing), or is stored in an unheated room or area

during the cold months, do not attempt to operate it

until the washer has had a chance to warm up.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the

control panel. Some cleaning product sprays may

harm the finish on the control panel or damage the

interior of the hood.

Wipe the washer cabinet as needed. If detergent,

bleach or other washing products are spilled on the

cabinet, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Do not use scouring pads or abrasive cleansers.

The wash drum and window will need no particular

care although they may need rinsing or wiping after an

unusual load has been washed. Outside of window can

be cleaned with household window cleaner.

Replacing Hoses

Hoses and other natural rubber parts deteriorate after

extended use. Hoses may develop cracks, blisters or

material wear from the temperature and constant high

pressure they are subjected to.

All hoses should be checked on a yearly basis for any

visible signs of deterioration. Any hose showing the

signs of deterioration listed above should be replaced

immediately. All hoses should be replaced every 8 to

10 years.

Vacations and Extended Non-Use

IMPORTANT: To avoid possible property damage

due to flooding, turn off the water supply to the

washer whenever there will be an extended period

of non-use.

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Maintenance

Before You Call for Service

You may save time and money by checking the

following:

If the Washer:

Won’t

Fill

Won’t

Start

Won’t

Tumble

Won’t

Spin

•

••••

••••

•

••

••

••

•

•

•

Won’t

Drain

Possible Reason – Do This to Correct

Be sure power cord is plugged all the way into

the electrical outlet.

Close the loading door tightly.

Check the laundry room fuse or circuit breaker.

Turn on the hot and cold water faucets.

Are controls properly set?

Broken drive belt. Call the service person.

Foreign object trap clogged. Clean foreign object

trap.

Insert coin(s) or card.

Activate time accumulator. Push the coin slide all

the way in. (Coin Slide Models only)

Press the PUSH-TO-START button or START

pad.

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 35

Maintenance

If Service Is Required

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to locate an authorized service center

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Phone: (920) 748-3121

1

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS. The

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in Figure 38.

Please include a copy of your bill of sale and any

service receipts you have.

WARNING

To reduce the risk of serious injury or death,

DO NOT repair or replace any part of the unit

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have

the skills to carry out.

W329

1 Nameplate

H129P

Figure 38

801480

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Maintenance

Information for Handy Reference

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Date Purchased

Model Number Serial Number

Dealer’s Name

Dealer’s Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep your sales slip. Model and serial numbers are

located on the nameplate.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480

Page 37

Lavadoras con

carga frontal

comerciales con contador de monedas

Instalación/Operación

H264I

Guarde estas instrucciones para referencia en el futuro.

(Si la lavadora cambia de dueño, asegúrese de que este manual vaya con la misma).

www.comlaundry.com

Pieza No. 801480R1

Abril 2004

Page 38

Page 39

ADVERTENCIA

Si esta máquina no se instala, mantiene y opera según las instrucciones del fabricante,

podrían crearse condiciones peligrosas, que pueden derivar en lesiones personales o daño

a la propiedad.

NOTA: Las instrucciones rotuladas como ADVERTENCIA e IMPORTANTE que aparecen en este manual

no pretenden contemplar todas las posibles condiciones y situaciones que pueden presentarse. El sentido

común, la precaución y la cautela son factores que NO PUEDEN incluirse en el diseño de estas lavadoras.

Estos factores DEBERÁN SER aportados por la persona que realice la instalación, mantenimiento y

operación de la lavadora.

Comuníquese siempre con el concesionario, distribuidor, agente de servicios o fabricante cuando tenga problemas

o se encuentre en una situación que no comprenda.

W030S

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Notas

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 41

Tabla de

contenido

Piezas de repuesto............................................................................... 41

Información de seguridad.................................................................. 43

Explicación de los mensajes de seguridad............................................ 43

Instrucciones de seguridad importantes................................................ 43

Installación .......................................................................................... 47

Dimensiones y especificaciones ........................................................... 47

Contador de monedas ........................................................................... 48

Antes de comenzar................................................................................ 48

Herramientas.................................................................................... 48

Suministro eléctrico ......................................................................... 48

Requisitos de suministro de agua..................................................... 48

Instalación de la lavadora ..................................................................... 49

Paso 1: Coloque la lavadora cerca del área de instalación............... 49

Paso 2: Conecte las mangueras de suministro de agua.................... 49

Paso 3: (Únicamente modelos con desagüe sin gravedad)

Conecte la manguera de desagüe en el receptáculo de desagüe..... 50

Paso 4: (Únicamente modelos con desagüe con gravedad)

Conecte la salida del desagüe al sistema de desagüe ..................... 51

Paso 5: Coloque la lavadora en su lugar y nivélela ......................... 52

Paso 6: Saque los manguitos de amortiguador y el

tirante sujetador.............................................................................. 53

Paso 7: Limpie el interior del tambor de la lavadora....................... 53

Paso 8: Enchufe la lavadora............................................................. 53

Paso 9: Verifique la instalación ....................................................... 53

Desplazamiento de la lavadora a un nuevo sitio.............................. 54

Requisitos eléctricos............................................................................. 55

Instrucciones para la conexión a tierra............................................. 55

Requisitos de suministro de agua ......................................................... 56

Temperatura del agua....................................................................... 56

Presión del agua ............................................................................... 57

Tubos ascendentes ........................................................................... 57

Operación ............................................................................................ 59

Instrucciones de operación de lavadoras electromecánicas.................. 59

Paso 1: Cargue la lavadora............................................................... 59

Paso 2: Cierre la puerta de carga...................................................... 59

Paso 3: Agregue los suministros para lavar..................................... 60

Paso 4: Ajuste el selector de tela...................................................... 60

Paso 5: Seleccione las temperaturas de lavado y enjuague

(WASH/RINSE)............................................................................. 60

Paso 6: Deposite la(s) moneda(s)..................................................... 60

Luces indicadoras............................................................................. 61

Avance rápido .................................................................................. 61

© Copyright 2004, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede ser reproducida o transmitida en forma

alguna o a través de ningún medio sin el expreso consentimiento por escrito del editor.

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Instrucciones de funcionamiento de las lavadoras MDC ..................... 62

Paso 1: Ajuste el selector de tela y la temperatura de lavado .......... 62

Paso 2: Agregue los suministros para lavar..................................... 62

Paso 3: Cargue la lavadora............................................................... 63

Paso 4: Cierre la puerta de carga...................................................... 63

Paso 5: Inserte la(s) moneda(s)

o la tarjeta ....................................................................................... 63

Paso 6: Arranque la lavadora ........................................................... 64

Luces indicadoras............................................................................. 64

Instrucciones de funcionamiento de las lavadoras NetMaster.............. 65

Paso 1: Cargue la lavadora............................................................... 65

Paso 2: Cierre la puerta de carga...................................................... 65

Paso 3: Agregue los suministros para lavar..................................... 66

Paso 4: Ajuste el selector de tela...................................................... 66

Paso 5: Seleccione la temperatura de lavado................................... 66

Paso 6: Inserte la(s) moneda(s)

o la tarjeta ....................................................................................... 67

Paso 7: Arranque la lavadora ........................................................... 67

Luces indicadoras............................................................................. 68

Mantenimiento .................................................................................... 69

Instrucciones de mantenimiento para el usuario................................... 69

Cuidados en climas fríos.................................................................. 69

Cuidado de la lavadora..................................................................... 69

Reemplazo de mangueras ................................................................ 69

Vacaciones y falta de uso de la lavadora durante un

período prolongado......................................................................... 69

Antes de llamar para solicitar servicio de reparación........................... 70

Si la unidad necesita servicio................................................................ 71

Información de referencia..................................................................... 72

Lista de comprobación del instalador............................. Contraportada

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 43

Piezas de repuesto

Si necesita piezas de repuesto, llame al distribuidor

donde haya comprado su lavadora o póngase en

contacto con:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

Tel éfono: (920) 748-3950

para obtener el nombre y la dirección del distribuidor

autorizado de piezas de repuesto más cercano.

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Notas

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 45

Información de seguridad

Indica una situación de peligro inminente

que, si no se evita, ocasionará lesiones

personales de gravedad o la muerte.

PELIGRO

Indica una situación de peligro que, si no

se evita, podría ocasionar lesiones

personales de gravedad o la muerte.

ADVERTENCIA

Indica una situación de peligro que, si no

se evita, puede ocasionar lesiones

personales leves o moderadas, o daños a

la propiedad.

PRECAUCIÓN

Explicación de los mensajes de

seguridad

En este manual y en las calcomanías de la máquina

encontrará medidas de precaución (“PELIGRO”,

“ADVERTENCIA” y “PRECAUCIÓN”) seguidas por

instrucciones específicas. Estas precauciones sirven

para proteger la seguridad del operador, usuario y

aquellas personas responsables del mantenimiento de

dicha máquina.

Instrucciones de seguridad

importantes

Guarde estas instrucciones

ADVERTENCIA

Para reducir el riesgo de incendios,

electrocución y lesiones graves o

mortales cuando use la lavadora, tome

estas precauciones básicas:

W023SR1

1. Lea todas las instrucciones antes de utilizar la

lavadora.

2. Remítase a la sección de INSTRUCCIONES DE

CONEXIÓN A TIERRA del manual de

INSTALACIÓN para una correcta conexión a

tierra de su lavadora.

3. No lave prendas que se hayan limpiado, lavado,

sumergido o tratado con gasolina, solventes para

lavar al seco u otras sustancias inflamables o

explosivas, o que tengan rastros de dichas

sustancias. Estas sustancias despiden gases que

pueden encenderse o explotar.

Otras medidas de precaución tales como

(“IMPORTANTE” y “NOTA”) van seguidas de

instrucciones específicas.

IMPORTANTE: La palabra “IMPORTANTE” se

utiliza para informar al lector acerca de

procedimientos específicos donde se producirán

daños menores en caso de no seguirse el

procedimiento.

NOTA: La palabra “NOTA” se utiliza para

comunicar información de instalación, operación,

mantenimiento o servicio que sea importante pero

que no se relacione con un riesgo.

4. No agregue gasolina, solventes para lavar al seco

u otras sustancias explosivas o inflamables al

agua que utilizará para el lavado. Estas sustancias

despiden vapores que pueden encenderse o

explotar.

5. En ciertos casos, cuando no se utiliza el sistema

de agua caliente durante dos semanas o más,

puede almacenarse gas hidrógeno en dicho

sistema. EL GAS HIDRÓGENO ES

EXPLOSIVO. Si no ha utilizado el sistema de

agua caliente durante dos semanas o más, antes

de usar la lavadora o la combinación de lavadora

secadora, abra todos los grifos del agua caliente y

deje que el agua fluya por ellos durante un

tiempo. De esta manera, se liberará todo el gas

hidrógeno acumulado. Dicho gas es inflamable.

No fume ni utilice llama abierta durante este

lapso de tiempo.

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

43

Page 46

Información de seguridad

6. No deje que los niños jueguen sobre o dentro de

la lavadora. Debe supervisarse cuidadosamente a

los niños cuando se utiliza la lavadora cerca de

ellos. Esta es una medida de seguridad para todos

los artefactos eléctricos.

7. Antes de sacar de servicio la lavadora o

desecharla, saque la tapa del compartimiento de

lavado.

8. No introduzca la mano en la lavadora si la tina o

el agitador está en movimiento.

9. No instale ni coloque la lavadora en un lugar

donde esté expuesta al agua o a la intemperie.

10. No manipule indebidamente los controles de la

lavadora.

11. No repare ni cambie ninguna pieza de la

lavadora, ni trate de repararla, salvo que las

instrucciones de mantenimiento para el usuario lo

recomienden de manera expresa, o lo indiquen

las instrucciones de reparación del usuario que

usted está en capacidad de entender y llevar a

cabo.

12. Para reducir el riesgo de descarga eléctrica o

incendio, NO UTILICE extensiones ni

adaptadores para conectar la lavadora al

tomacorriente.

13. Utilice su lavadora sólo para la finalidad con la

que fue fabricada, es decir, para lavar ropa.

14. Desconecte SIEMPRE la lavadora del

tomacorriente antes de hacerle cualquier

mantenimiento. Desconecte el cable de

suministro de energía eléctrica sujetando el

tomacorriente en lugar de tirar del cable.

15. Instale la lavadora siguiendo las

INSTRUCCIONES DE INSTALACIÓN. Todas

las conexiones de agua, desagüe, suministro de

energía eléctrica y tierra deben cumplir con las

normas establecidas en los códigos locales y

deben ser realizadas por personal autorizado,

cuando el caso lo amerite. No realice las

conexiones usted mismo a menos que sepa cómo

hacerlo.

16. Para reducir los riesgos de incendios, no debe

introducirse en la lavadora ropa con rastros de

sustancias inflamables, como por ejemplo, aceite

vegetal, aceite de cocina, aceite para lubricar

máquinas, productos químicos inflamables,

diluyente de pinturas, etc., y prendas que

contengan ceras u otros productos químicos, tales

como mopas y paños de limpieza. Estas

sustancias inflamables pueden provocar que las

telas se prendan en fuego.

17. No utilice suavizadores de ropa o productos para

eliminar la estática, a menos que lo recomiende

el fabricante del suavizador o del producto.

18. Conserve su lavadora en buen estado. Golpear o

dejar caer la lavadora puede dañar los

dispositivos de seguridad. Si esto ocurre, haga

revisar la lavadora con personal de

mantenimiento calificado.

19. Si el cordón de alimentación eléctrica está

dañado, deberá ser reemplazado por un cordón o

conjunto especial, que puede adquirirse a través

del fabricante o du su agente de servicio.

20. Asegúrese de que las conexiones de agua tengan

una válvula de corte y que las conexiones de las

mangueras de llenado estén bien apretadas.

CIERRE las válvulas de corte cuando termine la

jornada.

21. La puerta de carga DEBERÁ ESTAR

CERRADA cuando la lavadora se esté llenando o

cuando esté funcionando el agitador o el ciclo de

centrifugado. NO anule el seguro de la puerta de

carga, permitiendo que la lavadora funcione

(lavado y centrifugado) con la puerta abierta.

22. Lea y aplique siempre las instrucciones del

fabricante que se encuentran en los paquetes de

productos para la limpieza y lavado. Respete las

advertencias o precauciones. Para reducir el

riesgo de envenenamiento o quemaduras con

productos químicos, mantenga en todo momento

dichos productos fuera del alcance de los niños

(guárdelos preferiblemente en un gabinete con

llave).

44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 47

Información de seguridad

23. Siga siempre las instrucciones para el cuidado de

la ropa suministradas por el fabricante de las

prendas de vestir.

24. Nunca ponga a funcionar la lavadora sin tener

todos los protectores o paneles colocados en su

posición.

25. NO ponga a funcionar la lavadora con piezas

dañadas o rotas.

26. NO anule ningún dispositivo de seguridad.

27. El incumplimiento de las instrucciones del

fabricante para la instalación, mantenimiento u

operación de la lavadora podría provocar lesiones

personales o daños a la propiedad.

NOTA: Las INSTRUCCIONES DE SEGURIDAD

IMPORTANTES y ADVERTENCIAS que se

presentan en este manual no pretenden contemplar

todas las posibles situaciones y condiciones que

pudieran presentarse. La instalación,

mantenimiento y operación de la lavadora deben

realizarse con sentido común, precaución y

cuidado.

Comuníquese siempre con el vendedor, distribuidor,

agente de servicios o fabricante cuando tenga

problemas o se encuentre en una situación que no

comprenda.

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

45

Page 48

Notas

46

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 49

Installación

Dimensiones y especificaciones

44,8 cm

(17,5 plg)

36,3 cm

(14,3 plg)

109,2 cm (43 plg)

79 cm (31,1 plg)

75,1 cm (29,6 plg)

44,8 cm

(17,5 plg)

36,3 cm

(14,3 plg)

71,1 cm (28 plg)

5,1 cm

(2 plg)

MODELOS CON DESAGÜE SIN GRAVEDAD

109,2 cm (43 plg)

79 cm (31,1 plg)

75,1 cm (29,6 plg)

68,3 cm (26,9 plg)

FLW1975N

FLW1975N

801480 (SP)

71,1 cm (28 plg)

5,1 cm

(2 plg)

68,3 cm (26,9 plg)

MODELOS CON DESAGÜE CON GRAVEDAD

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FLW1976N

FLW1976N

47

Page 50

Installación

Contador de monedas

El contador de monedas instalado de fábrica no

incluye el cerrojo de la puerta de servicio, el

deslizador, el cajón de monedas, el seguro del cajón de

monedas ni las llaves. Estas piezas deben ser pedidas

(a un costo adicional) de acuerdo a las necesidades del

comprador, directamente del fabricante de su elección.

NOTA: Usted tiene la opción de usar un seguro del

tipo que se atornilla o un seguro de 1/4 de vuelta en

la puerta de servicio del contador de monedas. Si

decide usar un seguro del tipo que se atornilla,

entonces debe usar una ménsula o soporte especial

(dentro de la caja del contador de monedas). NO

use la ménsula ni soporte especial si utiliza el

seguro de 1/4 de vuelta.

Seguridad del cajón para monedas – Para obtener

seguridad adicional, perfore los dos orificios piloto a

cada lado en la parte delantera de la caja del contador

de monedas a 6,4 ó 7,9 mm (1/4 de vuelta ó 5/16 plg) e

instale un seguro para bicicleta a través de estos

orificios.

Antes de comenzar

Herramientas

Éstas son las principales herramientas que necesitará

en la mayoría de las instalaciones:

1

1 Llave de tuercas

2 Destornillador

3 Alicates

4 Llave de cubo

5 Nivel

2

3

4

5

D820I

Figura 1

Suministro eléctrico

Consulte la placa de identificación para determinar los

requisitos eléctricos específicos. Para obtener más

detalles, consulte la sección de Requisitos eléctricos.

Requisitos de suministro de agua

La lavadora trabaja con dos grifos estándar de

19,1 mm (3/4 plg) para el suministro de agua con una

presión que oscile entre 138 a 827 kPa (20 y 120 libras

por pulgada cuadrada). Para obtener más detalles,

consulte la sección de Requisitos de suministro de

agua.

48

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 51

Installación

Instalación de la lavadora

NOTA: Si la lavadora se entrega en un día

extremadamente frío (temperatura por debajo del

nivel de congelamiento) o se coloca en un área o

salón sin calefacción durante los meses fríos, no

trate de poner a funcionar la lavadora antes de que

se caliente.

Paso 1: Coloque la lavadora cerca del

área de instalación

Mueva la lavadora hasta una distancia no mayor de

1,2 metros (4 pies) del área de instalación deseada.

Paso 2: Conecte las mangueras de

suministro de agua

NOTA: Consulte la sección de Requisitos de

suministro de agua antes de conectar las mangueras

de suministro de agua.

Abra los grifos de suministro de agua y limpie las

tuberías dejando que el agua fluya por

aproximadamente dos minutos para eliminar cualquier

material extraño que pueda obstruir las mallas de la

válvula para mezclar el agua.

NOTA: Cuando instale la lavadora en un local

recién construido o remodelado debe limpiar las

tuberías dejando que el agua fluya, ya que pudo

haberse acumulado material en las mismas durante

la construcción.

Saque las cuatro arandelas de goma planas de la bolsa

de accesorios e instálelas como se indica en la

Figura 3.

IMPORTANTE: Enrosque a mano las uniones en

las conexiones de válvula y seguidamente gire

aproximadamente un 1/4 de vuelta con la ayuda de

un alicate. Asegúrese de enroscar correctamente las

uniones y de NO apretarlas excesivamente.

Figura 2

H135I

H135I

Abra el grifo de agua y determine si hay fugas. Si

detecta alguna fuga, reajuste las uniones de la

manguera. Siga apretando y revise hasta eliminar las

fugas.

1

2

1 Arandela de goma (plana)

2 Manguera de suministro de agua

Figura 3

1

H091I

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

49

Page 52

Installación

2

1

3

4

VÁLVULA

PARA

MEZCLAR

EL AGUA

1 Grifos de suministro de agua

2 Conexión de agua caliente

3 Conexión de agua fría

4 Mangueras de suministro de agua

Figura 4

Paso 3: (Únicamente modelos con

desagüe sin gravedad) Conecte la

manguera de desagüe en el receptáculo

de desagüe

Saque la manguera del lugar de embarque en la parte

trasera de la lavadora, retirando la cinta de embarque.

IMPORTANTE: El receptáculo de desagüe debe

ser el apropiado para una manguera de desagüe

con un diámetro exterior de 3,5 cm (1-3/8 plg) como

mínimo.

FLW1977N

1

FLW1978N

1 Cinta de embarque

Figura 5

50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

801480 (SP)

Page 53

Installación

Instalación del tubo vertical de desagüe

Coloque la manguera de desagüe dentro del tubo

vertical de desagüe.

Saque la abrazadera perlada de la bolsa de accesorios,

colóquela alrededor del tubo vertical de desagüe y la

manguera de desagüe, y apriete la correa para sujetar

la manguera al tubo vertical de desagüe. Así se evita

que se salga la manguera del receptáculo de desagüe

cuando se esté utilizando.

61 A 91,44 cm

(24 A 36 plg)

ALTURA

RECOMENDADA

1

1 Tubo vertical de desagüe – 5,08 cm (2 plg)

ó 4 cm (1-1/2 plg)

Figura 6

FLW1979N

FLW1979N

Paso 4: (Únicamente modelos con

desagüe con gravedad) Conecte la salida

del desagüe al sistema de desagüe

Saque el empalme de desagüe y la abrazadera para

manguera de la bolsa de accesorios, y asegure el

empalme a la salida de desagüe.

Conecte el empalme de desagüe a un sistema de

desagüe sin obstrucciones por medio de una conexión

flexible (obténgala localmente). El sistema de desagüe

deberá ser ventilado para evitar que se produzca un

efecto de sifón o de bloqueo de aire.

IMPORTANTE: Al aumentar la longitud de la

manguera de drenado, instalar codos o doblar la

manguera se disminuye el flujo de drenado y se

aumenta el tiempo de drenado, impidiendo el buen

funcionamiento de la máquina.

2

1

1 Canaleta de desagüe

2 Salida de desagüe

Figura 7

FLW1980N

FLW1980N

801480 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51

Page 54

Installación

Las lavadoras elevadas sobre el nivel del

piso deberán fijarse mediante pernos de

anclaje a la superficie elevada, base o

plataforma. El material usado para elevar

la lavadora deberá estar también anclado

al piso para impedir que la lavadora se

desplace de su lugar al funcionar, y para

evitar que pueda ser empujada, inclinada

o deslizada de su posición de instalación.

De no hacerlo, pueden presentarse

condiciones peligrosas que podrian

ocasionar daños a la propiedad o

lesiones graves e incluso fatales.

W306S

ADVERTENCIA

Paso 5: Coloque la lavadora en su lugar y

nivélela

Coloque la lavadora en su posición sobre un piso

limpio, firme y suficientemente nivelado. No es

recomendable instalar la lavadora sobre alfombras de

ningún tipo.

NOTA: NO deslice la lavadora sobre el piso con las

patas niveladoras extendidas ya que podrían

resultar dañadas.

NOTA: El uso de la gaveta del surtidor o de la

puerta de la lavadora como agarradera al

transportar la lavadora puede dañar el surtidor o

la puerta.

Saque las patas de goma que vienen en la bolsa de

accesorios y colóquelas en las patas de nivelación.

Verifique que la lavadora no oscile.

3

2

1

Afloje las tuercas de seguridad de 7/8 plg y ajuste las

patas de nivelación frontales y posteriores hasta que la

lavadora quede nivelada, no solo en sentido lateral

sino también de atrás hacia adelante (use un nivel para

este procedimiento). La lavadora no debe cojear.

NOTA: El nivel deberá colocarse sobre la posición

elevada del panel superior. Consulte la Figura 8.

Apriete las tuercas de seguridad firmemente contra

la base de la lavadora con una llave de 7/8 plg. Si las

tuercas de seguridad no se aprietan debidamente, la

lavadora se moverá de su posición al funcionar.

52

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

1 Pata niveladora

2 Base de la lavadora

3 Nivel

4 Tuerca de seguridad

5 Tapa de goma

4

Figura 8

H360I

H360I

801480 (SP)

Page 55

Installación

Paso 6: Saque los manguitos de

amortiguador y el tirante sujetador

Desmonte el panel de acceso frontal sacando los dos

tornillos.

Saque los pernos y arandelas de seguridad del tirante

sujetador con una llave de tuercas de 9/16 plg y saque

el tirante sujetador. Desmonte los manguitos de

amortiguador tirando de la cuerda amarilla. Quite la

etiqueta de la parte lateral delantera del panel de

acceso frontal y colóquela en la parte posterior de

dicho panel.

NOTA: El tirante sujetador, pernos, arandelas y