Page 1

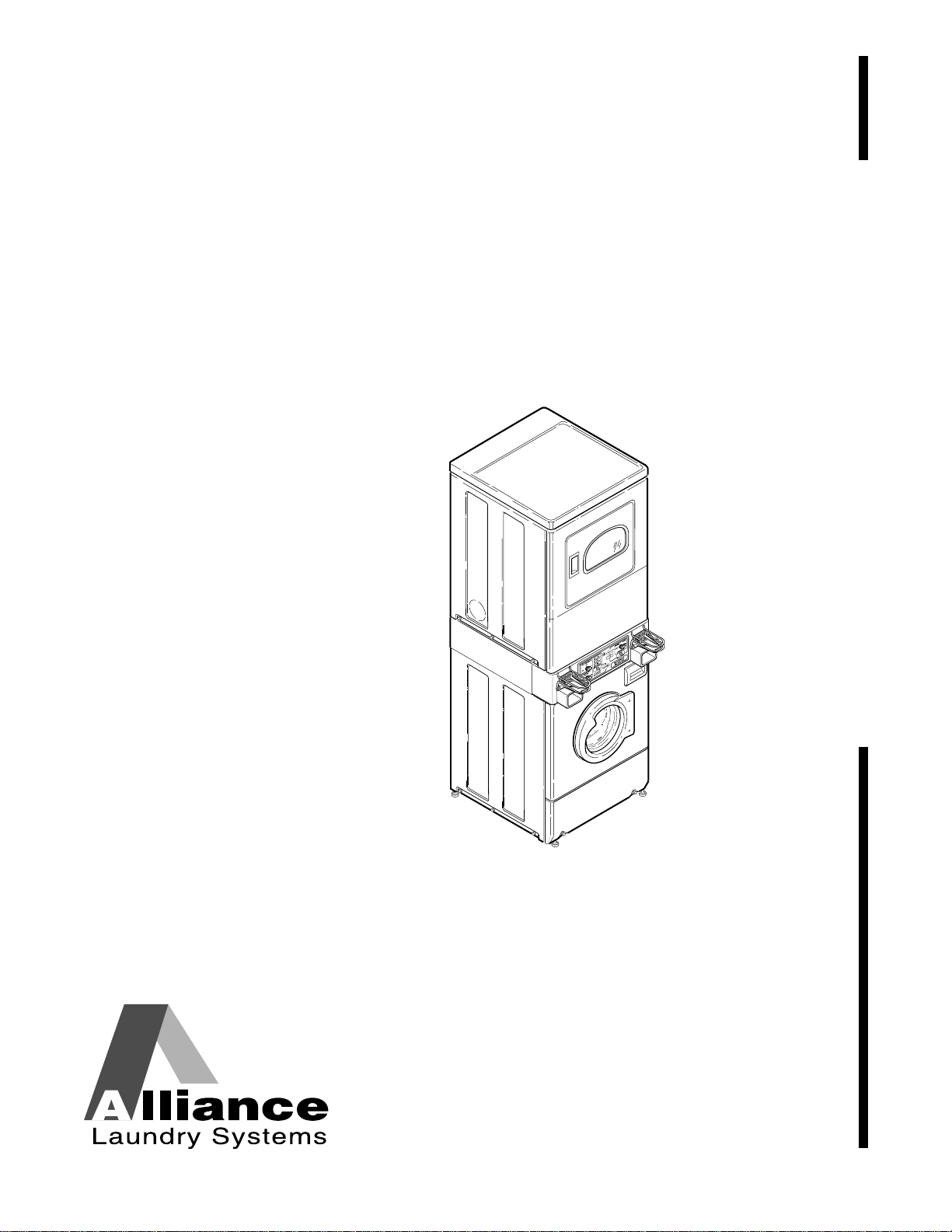

Stacked

Washer and Dryer

Metered

Electric and Gas Models

Installation and Operation

H242I

NOTA: El manual en español aparece después del manual en inglés.

Part No. 504509R7

October 1999

Page 2

Page 3

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE. (If the unit changes ownership, be

sure this manual accompanies the unit.)

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the

risk of fire or explosion or to prevent property damage, personal injury or death. W033

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

–Do not try to light any appliance.

–Do not touch any electrical switch; do not use any phone in your building.

–Clear the room, building or area of all occupants.

–Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

–If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or

the gas supplier. W052

IMPORTANT: Purchaser must consult the local gas supplier for suggested instructions to be

followed if the unit user smells gas. The gas utility instructions plus the SAFETY and

WARNING note directly above must be posted in a prominent location near the unit for

customer use.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids i n the vicinity of this or

any other appliance.

W053

504509 1

Page 4

Table of

Contents

Replacement Parts ...............................................................................2

Important Safety Instructions..............................................................3

Roughing In Dimensions .....................................................................5

Additional Security .............................................................................. 6

Washer Slide Extension ....................................................................... 6

Dryer Slide Extension .......................................................................... 7

Timer Cams...........................................................................................7

Coin Slide Guards ................................................................................ 7

Before You Start ...................................................................................8

Installing the Unit

Step 1: Position Unit Near Installation Area....................................9

Step 2: Connect Water Inlet Hoses...................................................9

Step 3: Connect Drain Hose to Drain Receptacle ..........................10

Step 4: Connect Gas Supply Pipe...................................................11

Step 5: Connect Electrical Plug......................................................12

Step 6: Connect Dryer Exhaust System..........................................13

Step 7: Remove the Shock Sleeves and Shipping Brace................ 13

Step 8: Position and Level the Unit................................................14

Step 9: Wipe Out Inside of Washer Drum and Dryer Drum...........15

Step 10: Plug In the Washer and Dryer ..........................................15

Step 11: Check Installation.............................................................15

Moving Unit to a New Location ........................................................16

Heat Source Check .............................................................................17

Water Supply Requirements ............................................................. 18

Washer Electrical Requirements ......................................................19

Electric Dryer Electrical Requirements ........................................... 20

Gas Dryer Electrical Requirements .................................................25

Gas Requirements .............................................................................27

Location Requirements .....................................................................28

Dryer Exhaust Requirements ...........................................................29

Multi-Dryer Installation Exhaust Requirements.............................32

Lint Filter.............................................................................................35

Dryer Motor Overload Protector.......................................................35

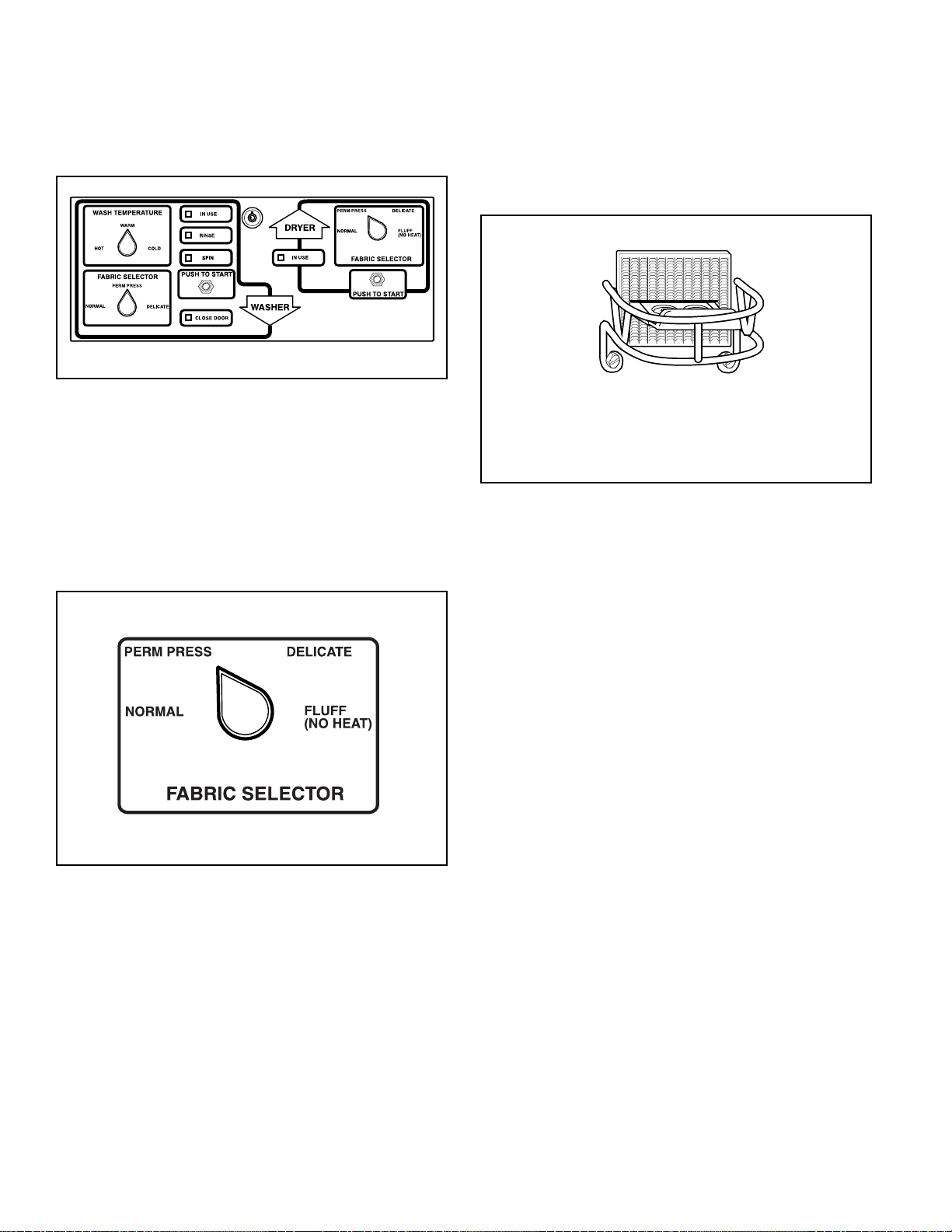

Operation Instructions for Electromechanical Washers ................ 36

Operation Instructions for Electromechanical Dryers ................... 39

Operation Instructions for Electronic Control Washers ................ 41

Operation Instructions for Electronic Control Dryers ................... 45

User-Maint enance Instructions .........................................................49

For Energy Conservation ...................................................................50

Before You Call for Service ................................................................51

Information for Handy Reference ....................................................53

Installer Check ....................................................................Back Cover

Replacement Parts

If replacement parts are required, contact the source

where you purchased your dryer, or contact

© Copyright 1999, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

2 504509

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Phone:

(920) 748-3950

for the name and address of the nearest authorized parts

distributor.

. . .

Page 5

IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

12. Do not use fabric softeners or products to

WARNING

To reduce the risk of fire, electric shock, or

injury to persons when using your dryer,

follow these basic precautions:

W034

1. Read all instructions before using the unit.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the unit.

3. Do not wash or dry articles that have been

previously cleaned in, washed in, soaked in, or

spotted with gasoline, dry-cleaning solvents, or

other flammable or explosive substances as they

give off vapors that could ignite or explode.

4. Under certain conditions, hydrogen gas may be

produced in a hot wate r s ystem that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumul ated h ydroge n gas. The gas is

flammable, do not smoke or use an open flame

during this time.

5. Do not allow children to play on or in the unit.

Close supervision of children is necessary when

the unit is used near children. This is a safety rule

for all appliances.

6. Before the unit is removed from service or

discarded, remove the doors to the washing and

drying compartments.

7. Do not reach into the washer or dryer if the

cylinders are revolving.

8. Do not install or store the unit where it will be

exposed to water and/or weather.

9. Do not tamper with the controls.

10. Do not repair or replace any part of the unit, or

attempt any servicing unless specifically

recommended in the User-Maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

11. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or expl ode.

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

13. To reduce the risk of an electri c shock o r f i r e, DO

NOT use an adapter to connect the unit to the

electrical power source.

14. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

15. ALWAYS clean the lint filter after every load. A

layer of lint in the filter reduces drying efficiency

and prolongs drying time.

16. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

17. T he interi or of the drye r and the exhaust duct

should be cleaned periodically by qualified

service pers onnel.

18. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

19. Washer and dryer will not operate with the

loading door open. DO NOT by-pass the door

safety switches by pe rmitting the wash er or dryer

to operate with the doors open. The washer and

dryer will stop tumbling when the doors are

opened. Do not use the washer or dry er if they do

not stop tumbling when the doors are opened or

start tumbling without pressing the START

mechanisms. Remove the unit from use and call

the service person.

20. Do not put articles soiled with vegetable or

cooking oil in the washer or dryer. Due to the oil,

the fabric ma y catch on fire by itself.

21. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc., or anything containing wax or

chemicals such as in mops a nd cleani ng clot hs, or

anything dry-cleaned at home with a drycleaning solvent in the dryer.

504509 3

Page 6

22. Use your washer only for its intended purpose,

washing clothes.

32. ALWAYS follow the fabric care instru ctions

supplied by the garment manufacturer.

23. Use the dryer only for its intended purpose,

drying clothes.

24. Always disconnect the electrical power to the

washer and dryer before attempting service to

either unit. Disconnect the power cords by

grasping the plug, not the cord.

25. I f the supply cord is damaged, it must be r eplaced

by a special cord or assembly available from the

manufactu rer or its service agent.

26. Install this unit according to the

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding and

gas supply must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

27. Keep your unit in good condition. Bumping or

dropping the unit can damage safety features. If

this occurs, ha ve your unit checke d by a qual if ied

service pers on.

28. Remove laundry immediately after the dryer

stops.

29. Always read and follow manufacturer’s

instructions on packa ges of l aundr y and cleaning

aids. Heed all warning s or pr ecautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

30. Do not tumble fiber glass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiber glass.

33. Never operate the unit with any guards and/or

panels removed.

34. DO NOT operate the unit wi th missing o r br oke n

parts.

35. DO NOT by-pass any safety devices.

36. Failure to install, maintain, and/or operate this

machine accor ding to the manufa cturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

37. D o not ope rate washer and dry er if t he units hav e

been separated.

IMPORTANT: Solvent vapors from dry-cleaning

machines create acids when drawn through the heater

of the drying unit. These acids are corrosive to the

dryer as well as to the laundry load being dried. Be

sure make-up air is free of solvent vapors.

IMPORTANT: Have your unit installed properly.

Don’t do it yourself unless you know how!

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this manual

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution

and care must be exercised when installing,

maintaining, or operating the dryer.

Always contact your dealer, distributor, service agent or

the manufacturer about any problems or conditions you

do not understand.

31. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

4 504509

Page 7

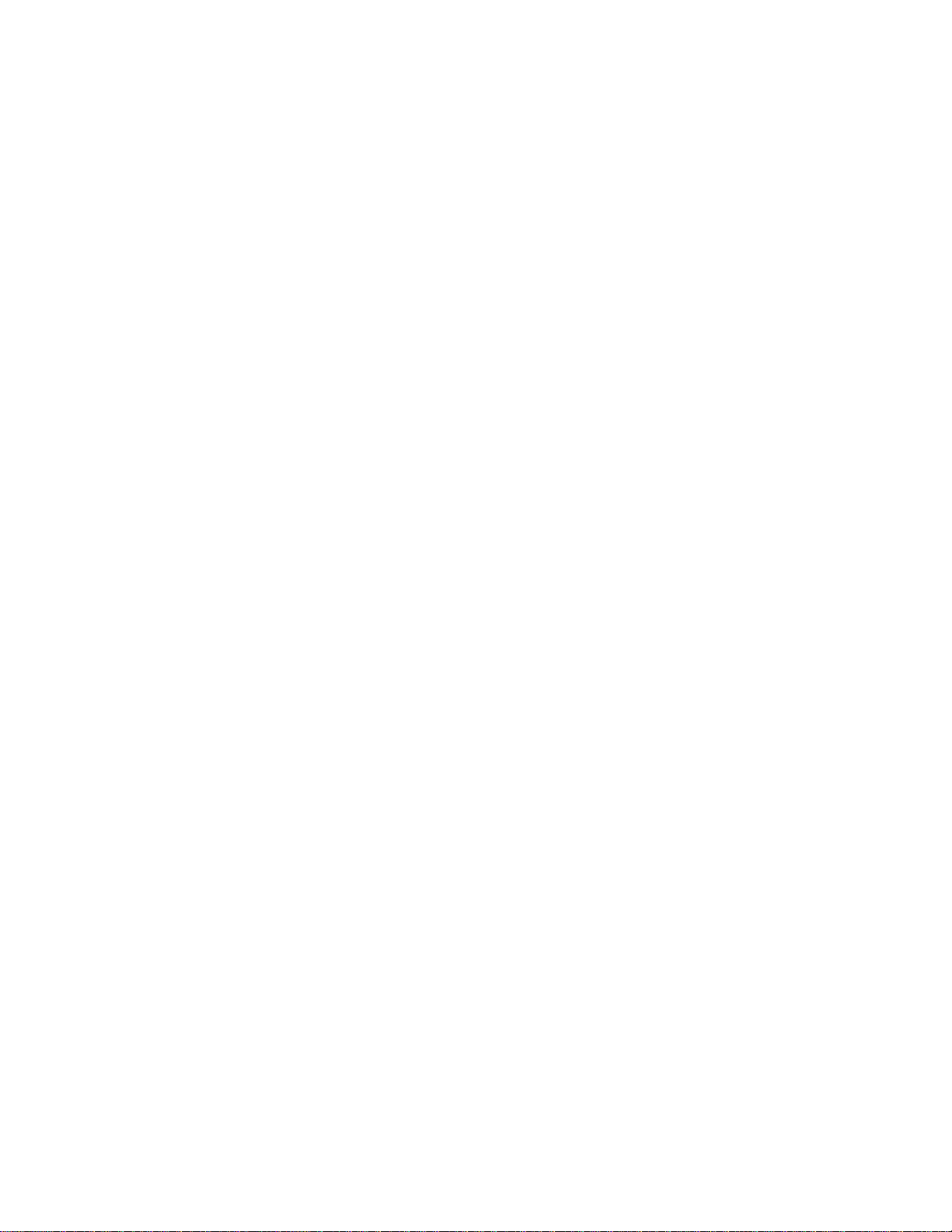

Roughing In Dimensions

23.5" (59.7 cm)

. . .

7.7"

(19.6 cm)

2.0"

(5.1 cm)

7.0"

(17.8 cm)

17.5"

(44.8 cm)

14.9"

(37.8 cm)

28" (71.1 cm) 26.9" (68.3 cm)

* WITH LEVELING LEGS TURNED INTO BASE.

ELECTRIC

23.5" (59.7 cm)

7.7"

(19.6 cm)

2.0"

(5.1 cm)

*77.1" (195.8 cm)

45.8" (116.3 cm)

2.0"

(5.1 cm)

15.4"

(39.1 cm)

31.1" (79 cm)

29.6" (75.1 cm)

H274IE3A

15.4"

(39.1 cm)

3/8"

NPT GAS

CONNECTION

7.0"

(17.8 cm)

17.5"

(44.8 cm)

*77.1" (195.8 cm)

45.8" (116.3 cm)

14.9"

(37.8 cm)

28" (71.1 cm) 26.9" (68.3 cm)

* WITH LEVELING LEGS TURNED INTO BASE.

2.0"

(5.1 cm)

31.1" (79 cm)

29.6" (75.1 cm)

H268IE3A

GAS

NOTE: Side and r ear exhaust openi ngs are four inch

(10.2 cm) ducting. Gas models cannot be vented out

left side of cabinet because of burner housing.

504509 5

IMPORTANT: The dryer should have sufficient

clearance around it fo r needed ventil ation and for the

ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

Page 8

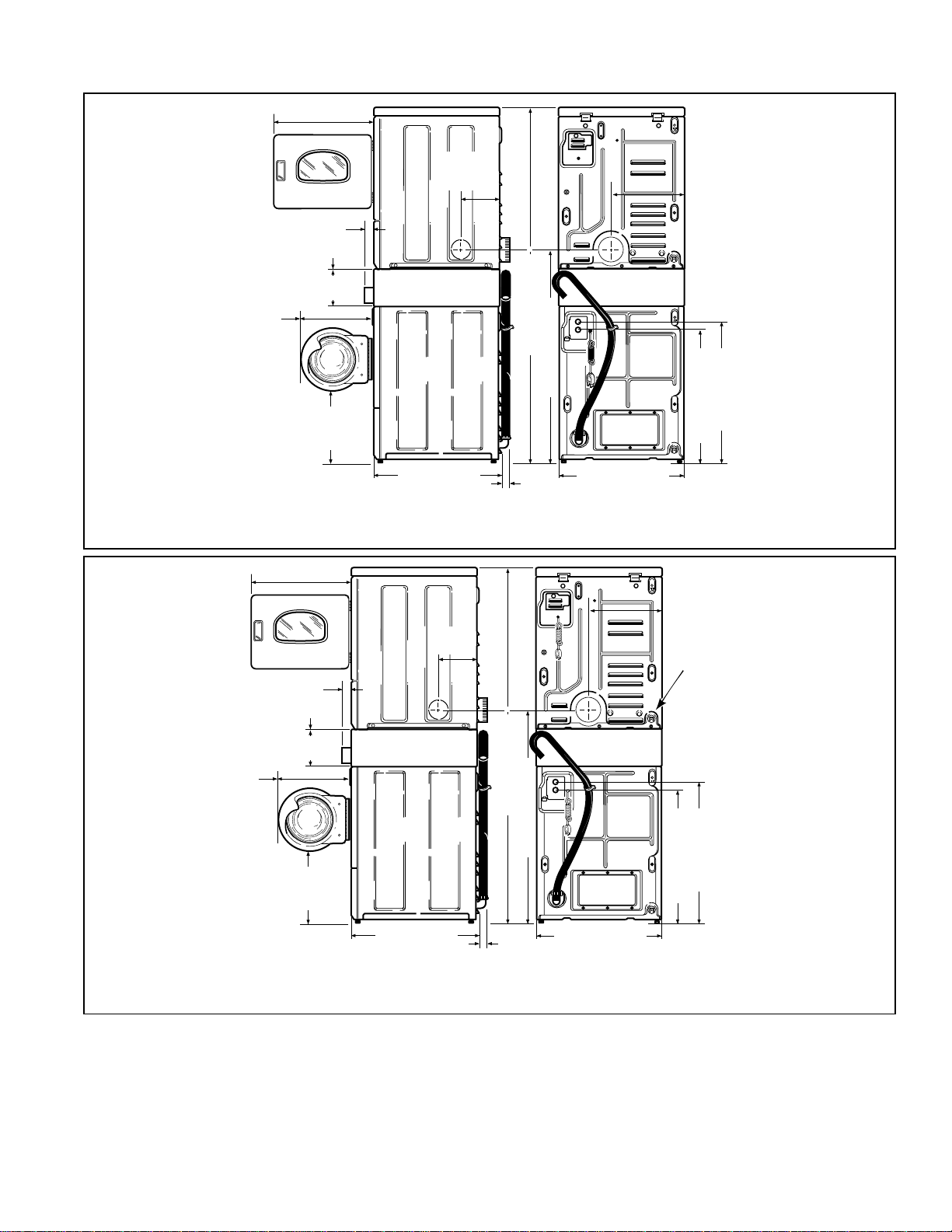

Additional Security

H067IE1A

. . .

T orx security screws are available (as optional equipment

at extra cost) for securing both lower access panels to

washer and dryer bases. Order part number 62853.

A Torx bit, part number 282P4, is available (as optional

equipment at extra cost) for installing the Torx security

screws.

Washer Slide Extension

(Coin Slide Models Only)

WARNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the washer and

dryer before servicing.

• Never start the washer and dryer with any

guards/panels removed.

• Whenever ground wires are removed during

servicing, these ground wires must be

reconnected to ensure that the washer and

dryer are properly grounded.

W251

A Torx bit holder, part number 24161, is available (as

optional equipment at extr a cost) to b e used with the T orx

bit.

. . .

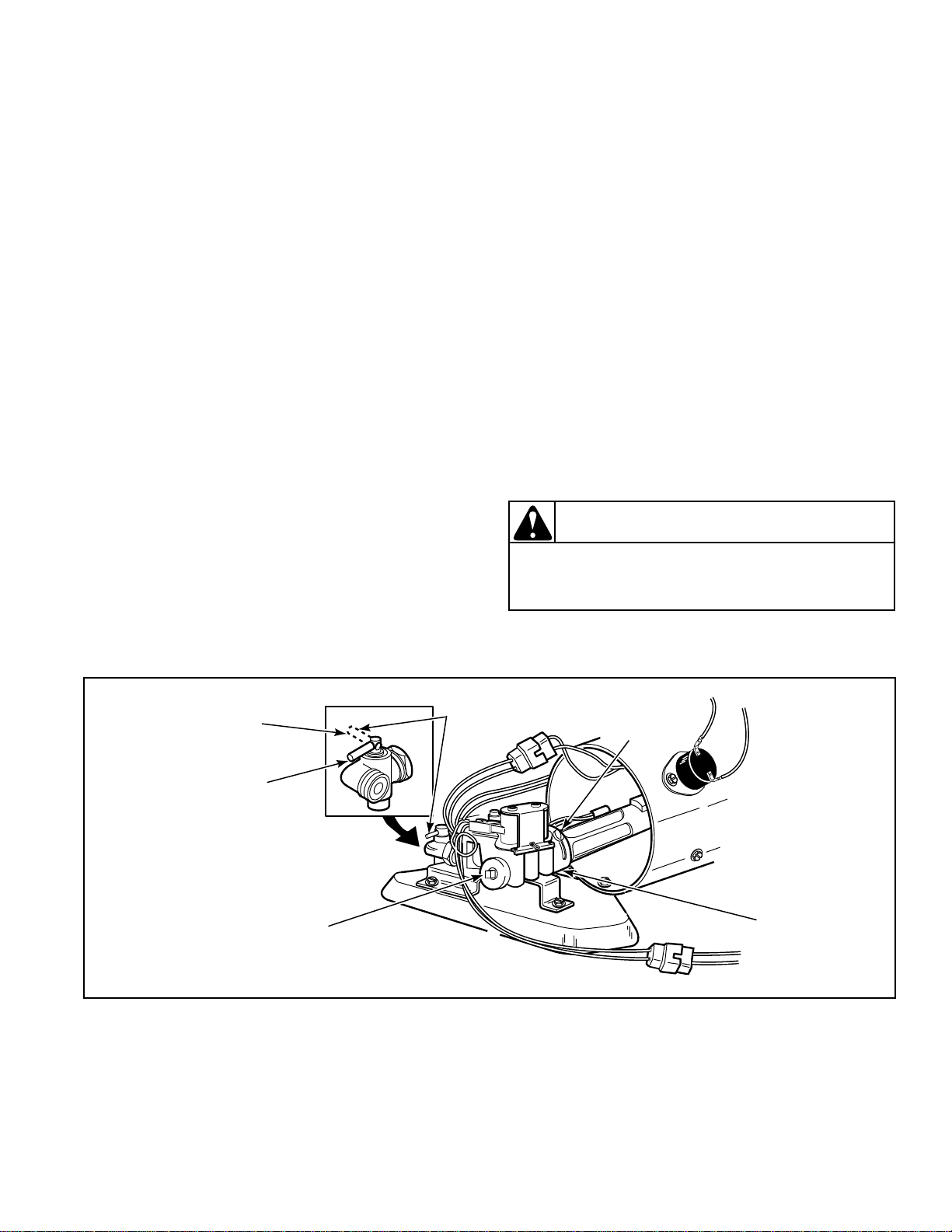

4. Place actuator and support assembly onto slide

extension, and install screw and lockwasher

(No. 03950).

5. Install assembed slide extension through coin slide

opening of security cabinet by reaching through

service door opening.

6. Ass emble slide e xtension (No. 685593) to top side of

coin slide using two screws and lockwashers

(No. 03950), and tighten firmly. See illustration

below.

Remove slide extension, shoulder screw, plastic boot,

actuator, actuator support, screws and lockwashers from

the accessories bag. Install slide extension as follows:

1. Unlock and open service door. Remove locking rod

holding coin slide to front of security cabinet.

NOTE: Refer to following illustration for steps 2

through 4 .

2. Assemble plastic boot (No. 36165) onto actuator

support (No. 685592).

3. Assemble actuator (No. 36164) to actuator support

(No. 685592) using shoulder screw (No. 36166).

H068IE1B

7. Reinstall assembled coin slide in security cabinet.

Close and lock service door.

After slide extension has been installed, check washer

operation as follows:

1. Connect electrical power to washer.

NOTE: To determine if slide functions properly,

allow washer to complete its cycle, and for timer to

stop, before starting evaluation process .

2. Pl ace required number of coins in slide. Push slide in

slowly and listen for coins to drop into coin drawer.

3. Push slide in a little farther and observe through

service door opening that actuator drops beyond

timer clutch. Continue pushing slide all the way in

and pull back. Confirm that the actuator will rotate

timer clutch and wash cycle starts.

NOTE: You must press Push-to-Start button to

initiate cycle after act iva tion of slide.

6 504509

Page 9

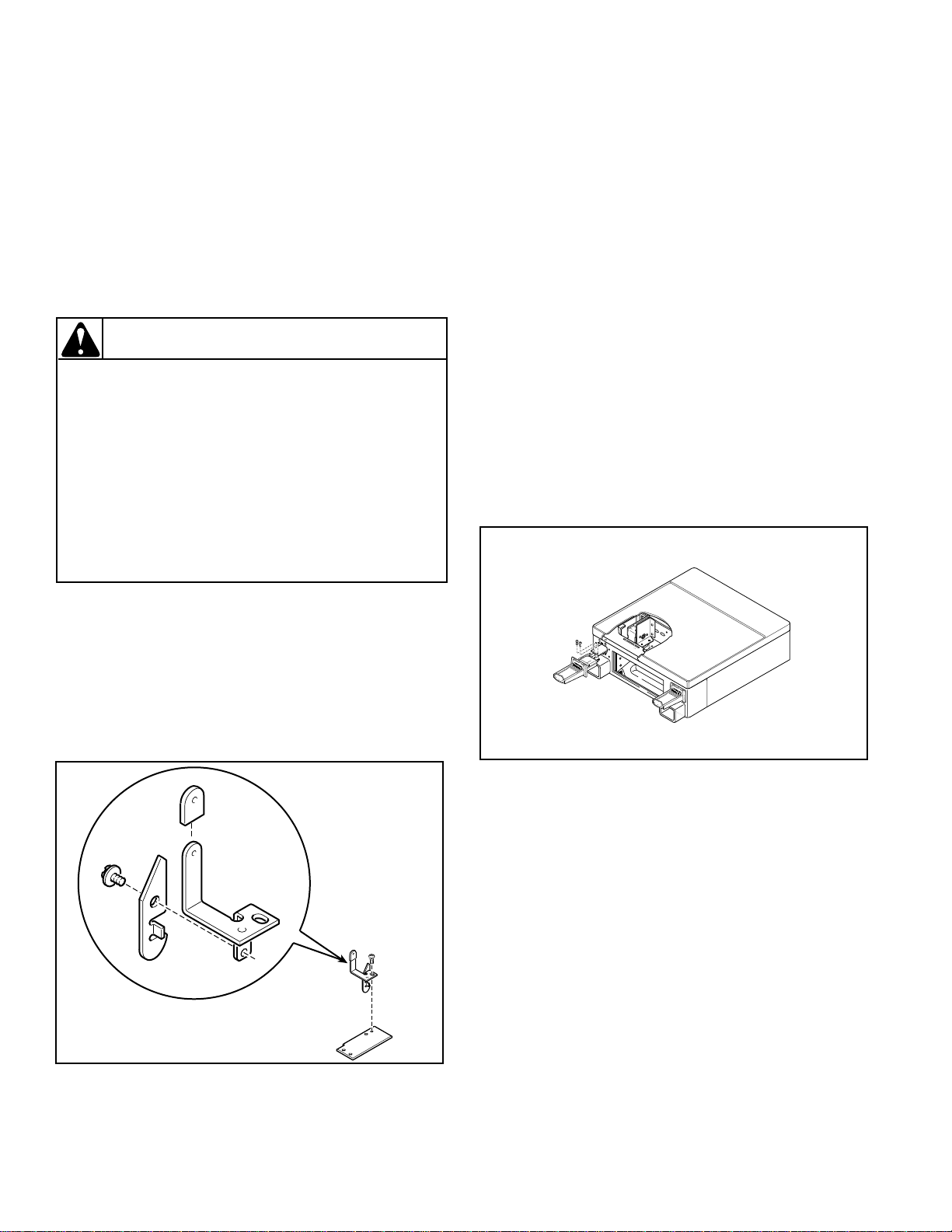

Dryer Slide Extension

(Coin Slide Models Only)

. . .

Remove two slide extensions, four screws and

lockwashers from the accesssories bag and install the

extension on the top of the coin slide.

IMPORTANT: Slide extension must be attached to

top side of the coin slides to make them long enough to

activate the accumulator (dryer) or timer (washer).

Timer Cams

The dryer timers are factory equipped with a 45 minute

timing cam. If this drying time is not suitable to your

installation, the following cams can be found in the

accessories bag.

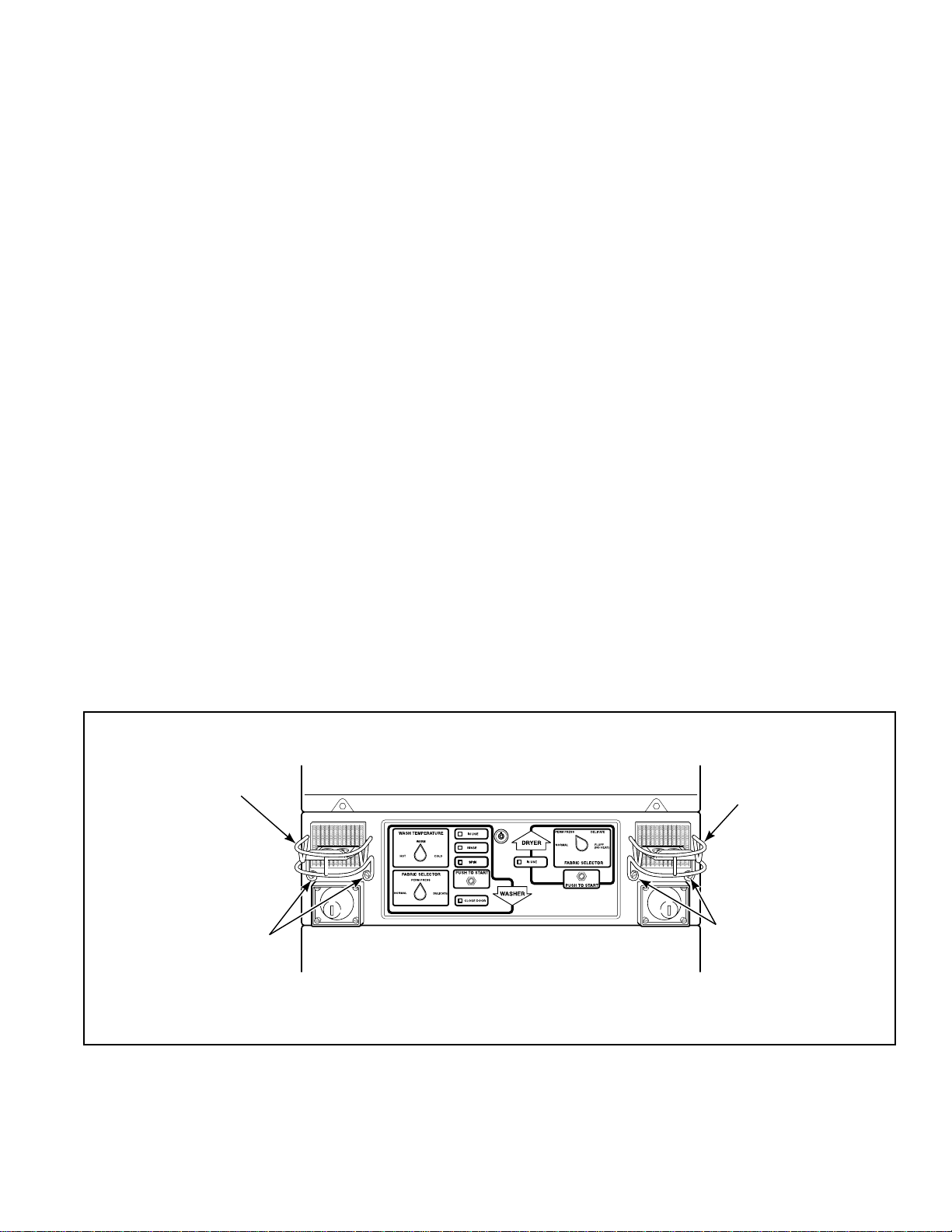

Coin Slide Guards

(Coin Slide Models Only)

NOTE: This unit, as shipped from the factory, does

not include the coin slide s, coin drawers , lock or keys.

These coin slide kits (or parts) must be ordered, at

extra cost, accordin g to the purchaser’s requirements

direct from the coin kit manufacturer of your choice.

. . .

ELECTRIC DRYERS

1-53242 Cams (30 Minutes)

1-53240 Cams (60 Minutes)

GAS DRYERS

1-53242 Cams (30 Minutes)

A 60 minute timing cam, Part No. 532 40, is a va ilable f or

the gas dryers as optional equipment at extra cost.

. . .

Using serrated hex head screws from accessories bag,

install coin slide guards (located in accessories bag), to

front of control cabinet. See illustration.

A special sec urity screw kit is available (as optional

equipment at extra cost) for securing the two coin slide

COIN

SLIDE

GUARD

SERRATED

HEX HEAD

SCREWS

guards and both fron t access panels to f ront of unit. Orde r

Security Kit No. 298P3. A special driver, part number

56217, is available (as optional equipment at extra cost)

for installing the special security screws.

COIN

SLIDE

GUARD

SERRATED

HEX HEAD

SCREWS

H151IE2A

NOTE: Coin slides and coin drawers are shown for illustration only. You must obtain them locally.

504509 7

Page 10

Before You Start

D074IE1G

LEVEL

SCREWDRIVERS

PLIERS

WRENCH

9

/

1

6

"

SOCKET

WRENCH

DUCT TAPE

TEFLON TAPE

H092IE1A

. . .

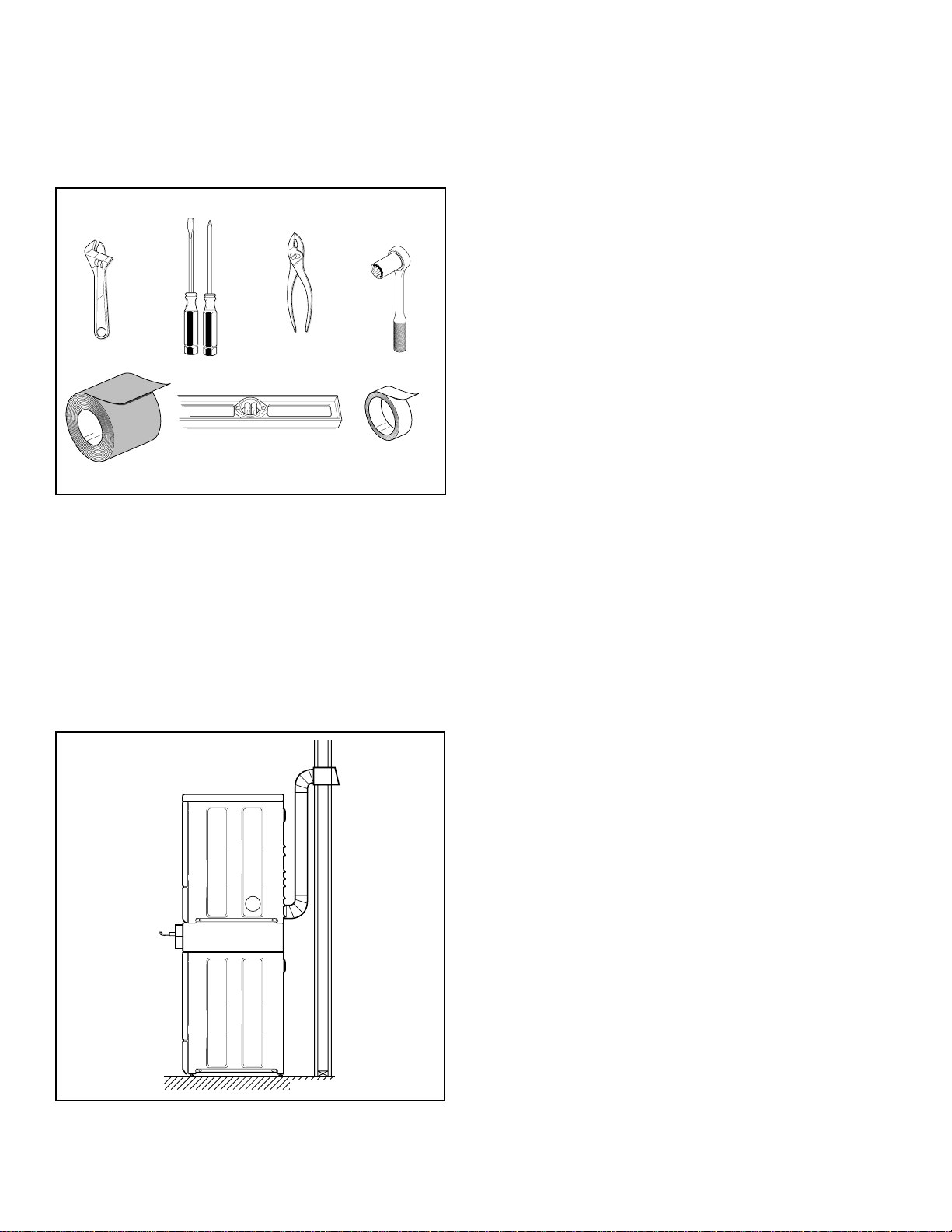

Tools

For most installations, the basic tools you will need are:

Water

Washer needs two standard 3/4 inch (19.1 mm) water

supply faucets with a pressure between 20-120 pounds

per square inch (138 to 827 kPa). For more detailed

information , refer to Section on Water Supply

Requirements.

Exhaust

Use rigid metal duct and exha ust the dryer to the outs ide

by the shortes t route possible.

Electrical

• WASHER

Refer to Seri al plate for sp ecific electrical

requirements. For more detailed information, refer to

Section on Washer Electrical Requirements.

• ELECTRIC DRYER

Dryer needs a 3 or 4 wire 120/240 or 120/208 Volt, 60

Hertz, AC single Phase electrical supply. For more

detailed information, refer to Sec t ion on Electric

Dryer Electrical Requirements.

• GAS DRYER

Dryer needs a 120 Volt, 60 Hertz, polarized 3-slot

effectively grounded receptacle. For more detailed

information, refer to Section on Gas Dryer Electrical

Requirements.

NOTE: 208 Volt heating element is available (as

optional equipment at extra cost).

Gas

Dryer is equipped for Natural Gas with a 3/8" NPT gas

supply connection. For more detailed information, refer

to Section on Gas Requirements.

Location

Place the dryer on a solid floor with an adequate air

supply . For more detai led information, refer to Secti on on

Location Requirements.

NOTE: For more detailed in formation, r efer to

Section on Dryer Exhaust Requirements.

8 504509

Page 11

Installing the Unit

. . .

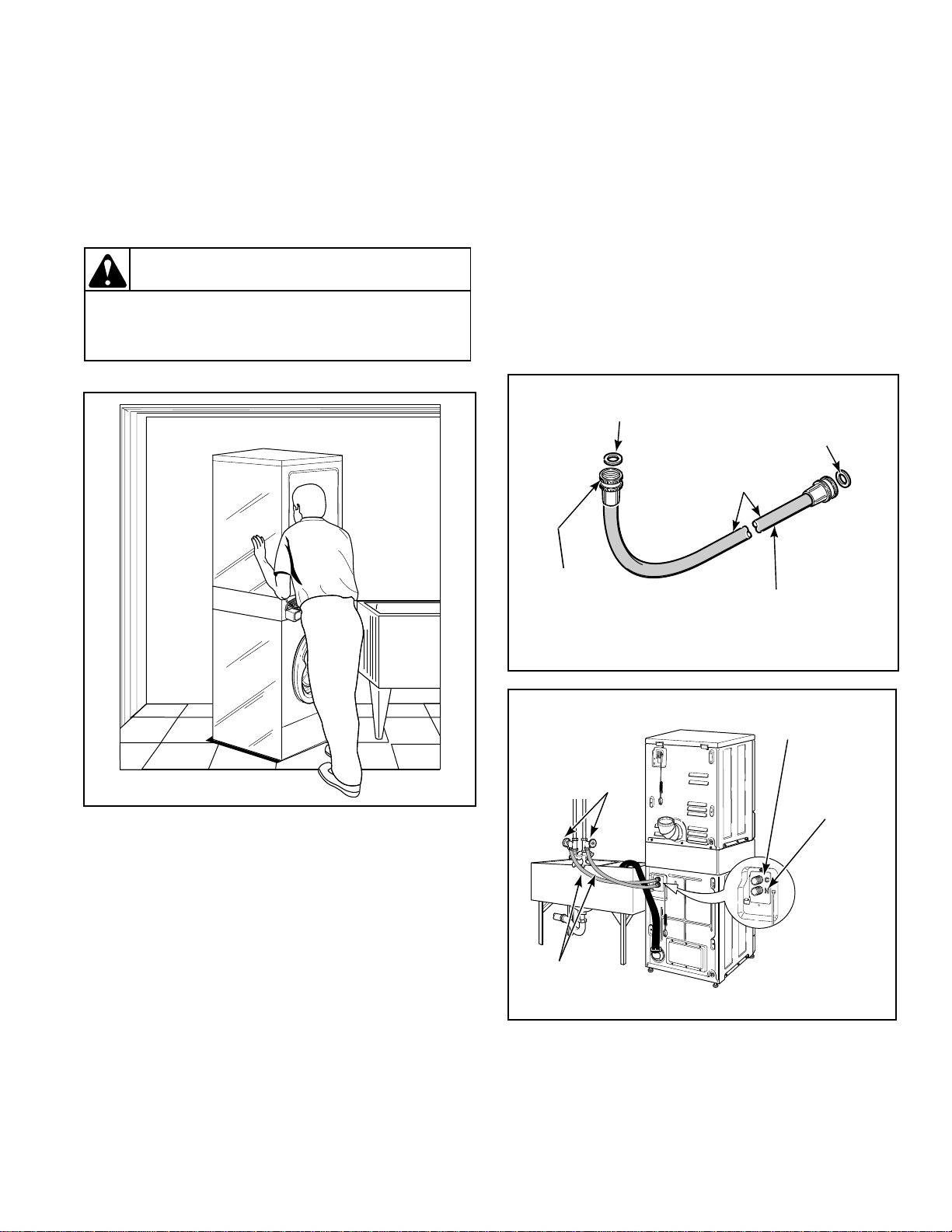

Step 1:

Position Unit Near Installation Area

Move unit so that it i s within four feet of the desired ar ea

of installation.

CAUTION

Washer and dryer are not designed to be

operated as separated, side-by-side units.

W187

NOTE: When installing in newly constructed or

renovated building, it is very important to flu sh the

lines since build-up may have occurred during

construction.

IMPORTANT: Thread hose couplings onto valve

connections finger-ti ght, then approximat ely 1/4 turn

with pliers. DO NOT cross thread or overtighten

couplings.

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

RUBBER WASHER

(Plain)

INSTALL THIS

END OF HOSE

TO WATER

SUPPLY FAUCET

INSTALL THIS END OF HOSE

TO VALVE CONNECTIONS

AT REAR OF WASHER

RUBBER WASHER

(Plain)

INLET

HOSE

H091IE1A

H243I

Step 2:

Connect Water Inlet Hoses

NOTE: Refer to Section on Water Supply

Requirements before connectin g water inlet hoses.

Remove the four plain rubber washers from accessories

bag, and install them according to the illustration.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that co uld cl og the screens in the water mixing

valve.

WATER

INLET

HOSES

COLD WATER

CONNECTION

WATER

SUPPLY

FAUCETS

HOT WATER

CONNECTION

WATER

MIXING VALVE

H096IE1A

504509 9

Page 12

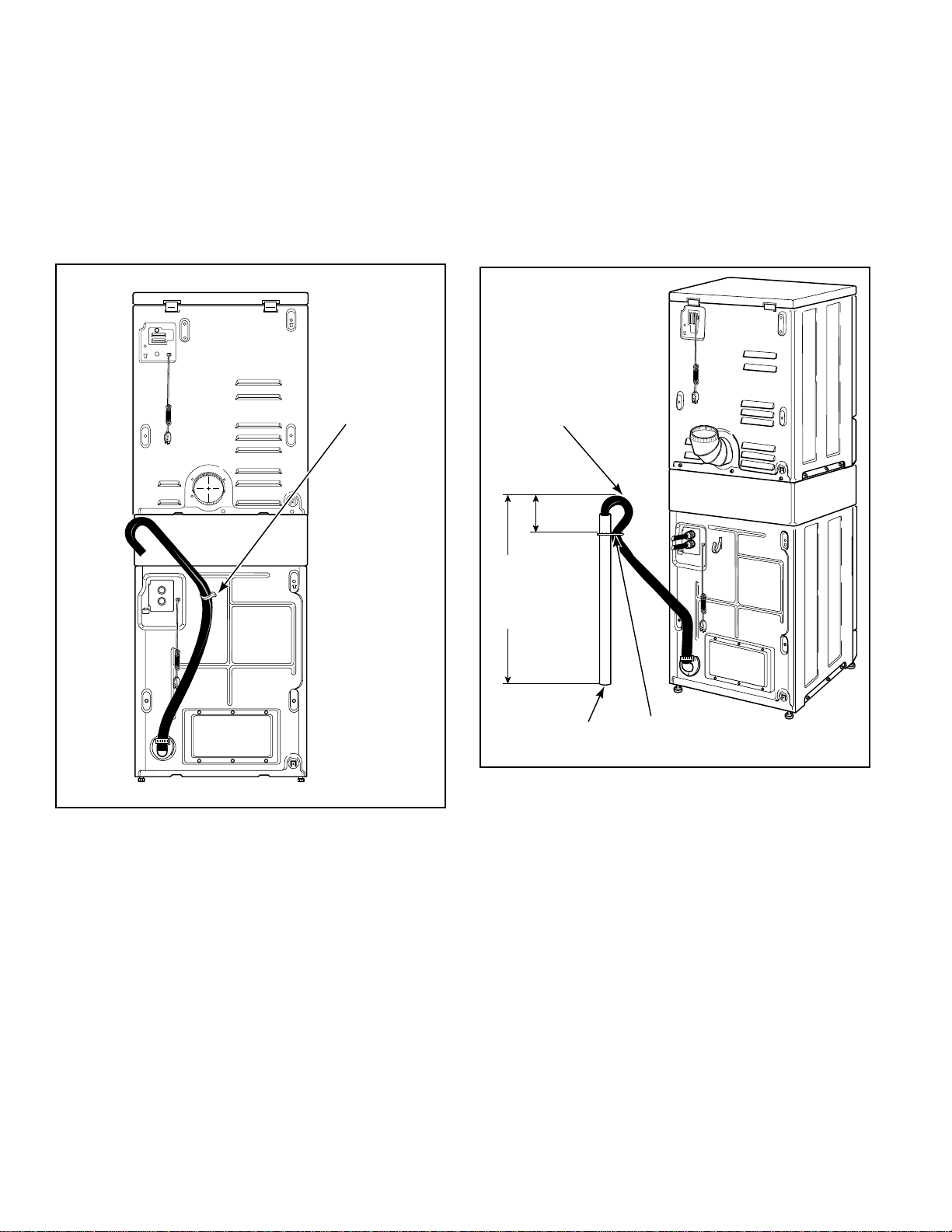

Step 3:

Connect Drain Hose to Drain Receptacle

Remove the drain hose from its shipping position on the

rear of the washer by unhooking the hose from the

retainer clam p.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 1-1/4 inch (32 cm) outside

diameter drain hose.

RETAINER

CLAMP

Standpipe Installation:

Place the drain hose into the standpipe.

Remove the beaded tie-down strap from accessories bag

and place around standpipe and drain hose and tighten

strap to hold hose to standpipe. This will pre vent the drai n

hose from dislodging from drain receptacle during use.

DRAIN

HOSE

24" to 36"

(91.44 cm

Recommended

Height)

D465IE1A

STANDPIPE

2" (5.08 cm) or

1-1/2" (4 cm)

BEADED

H097IE1A

TIE-DOWN

STRAP

10 504509

Page 13

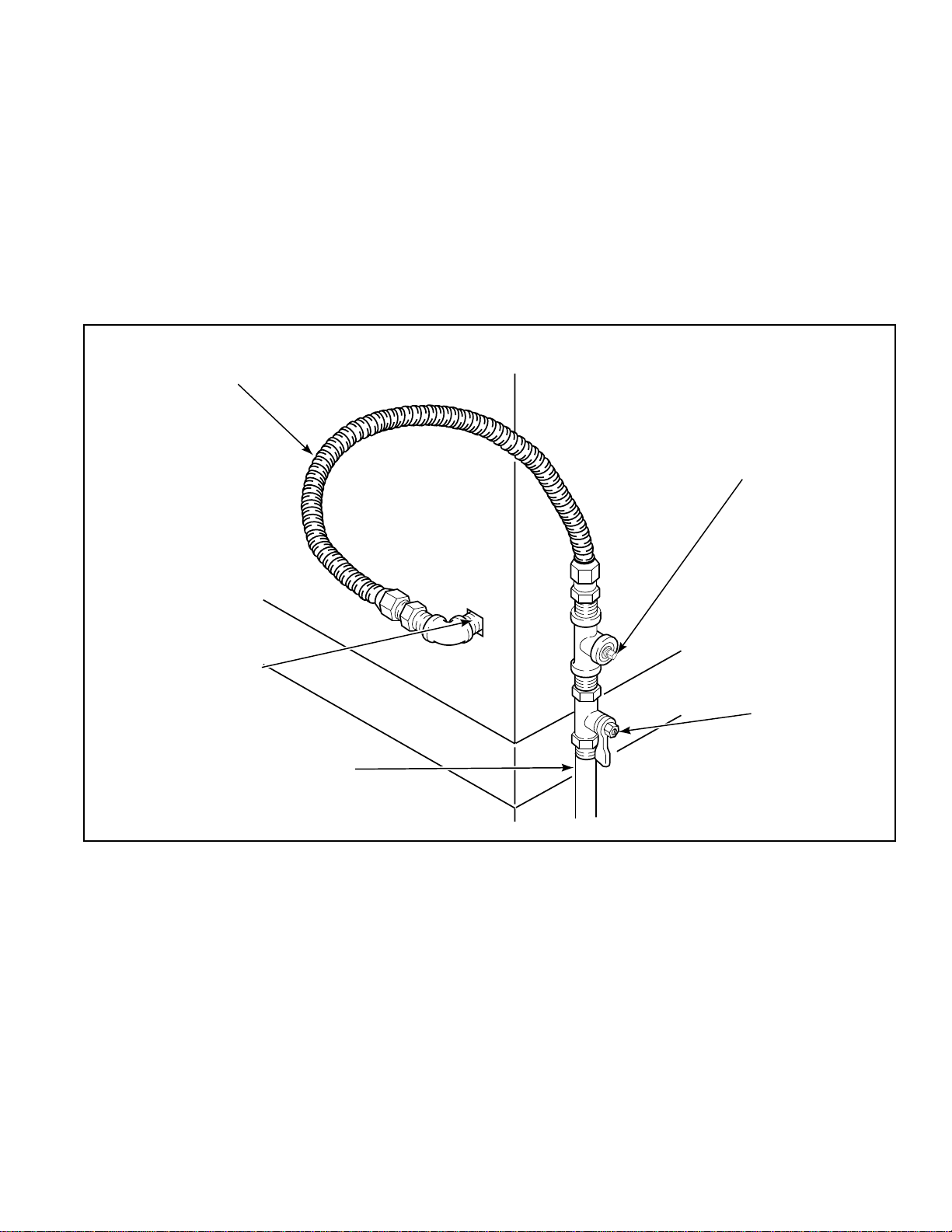

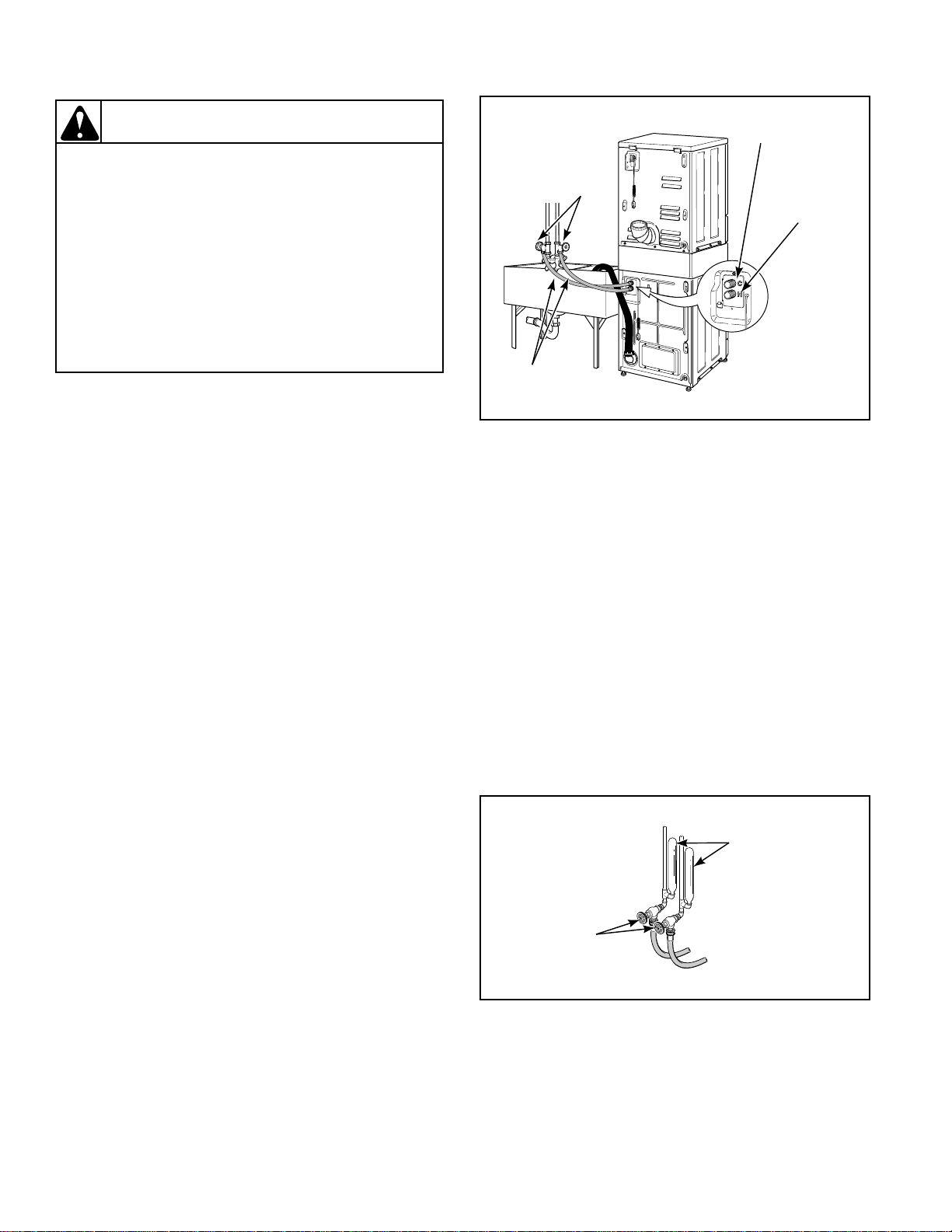

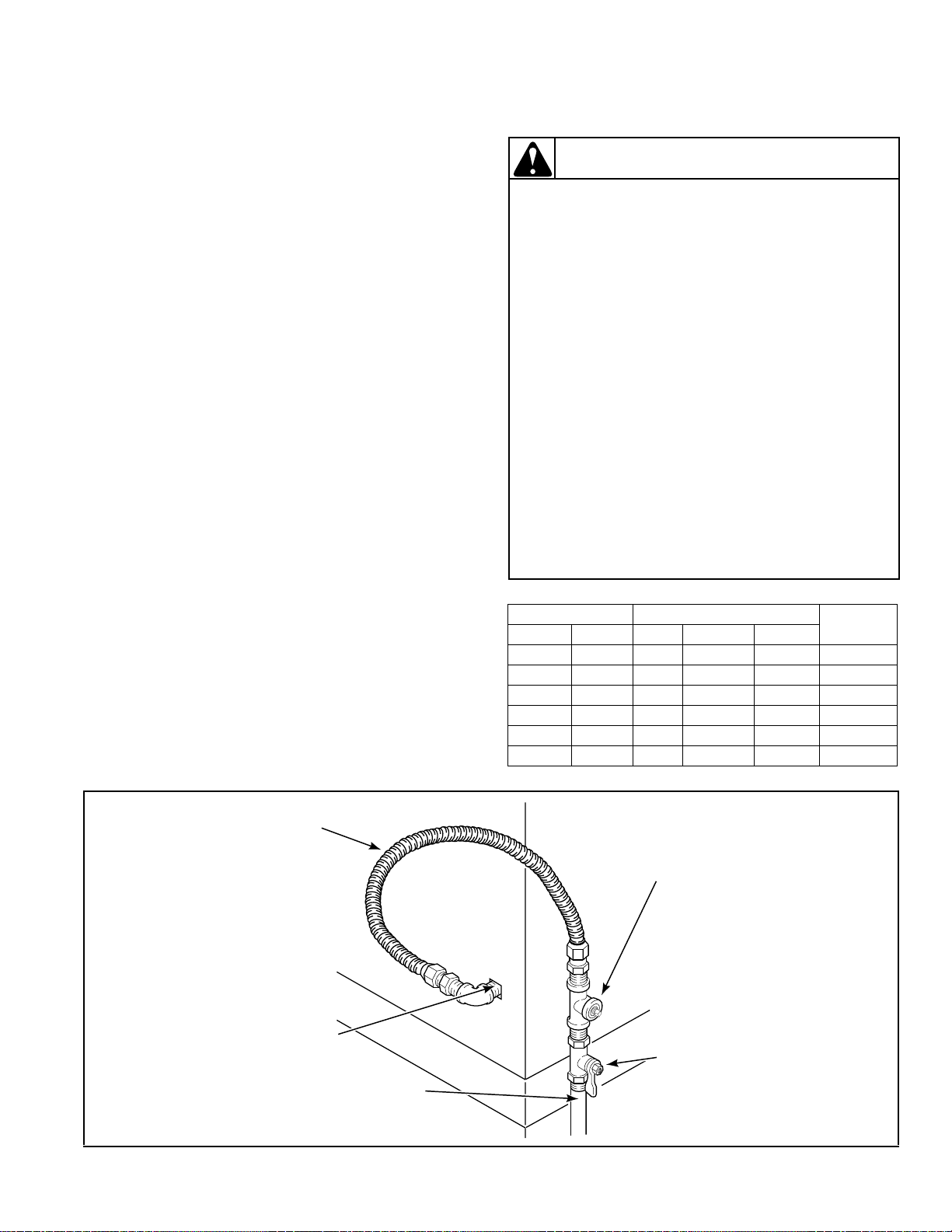

Step 4: (Gas Dryer ONLY)

Connect Gas Supply Pipe

For further assistance, refer to Section on Gas

Requirements.

1. Make certain dryer is equipped for use with t he type

of gas in laundry room. Dryer is equipped at the

factory for Natural Gas with a 3/8" NPT gas

connection.

2. Re mo ve the shi pping c ap from th e gas c onnecti on at

the rear of the dryer. Make sure you do not damage

the pipe threads when removing the cap.

NEW

STAINLESS STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3. Connect to gas supply pipe using a new flexible

stainless steel connector.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. F or L.P . (Propane) gas connection, refer to Section on

Gas Requir ements.

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

EQUIPMENT

SHUT-OFF

VALVE

Install within

6' (1.8 m) of dryer

D434IE3A

504509 11

Page 14

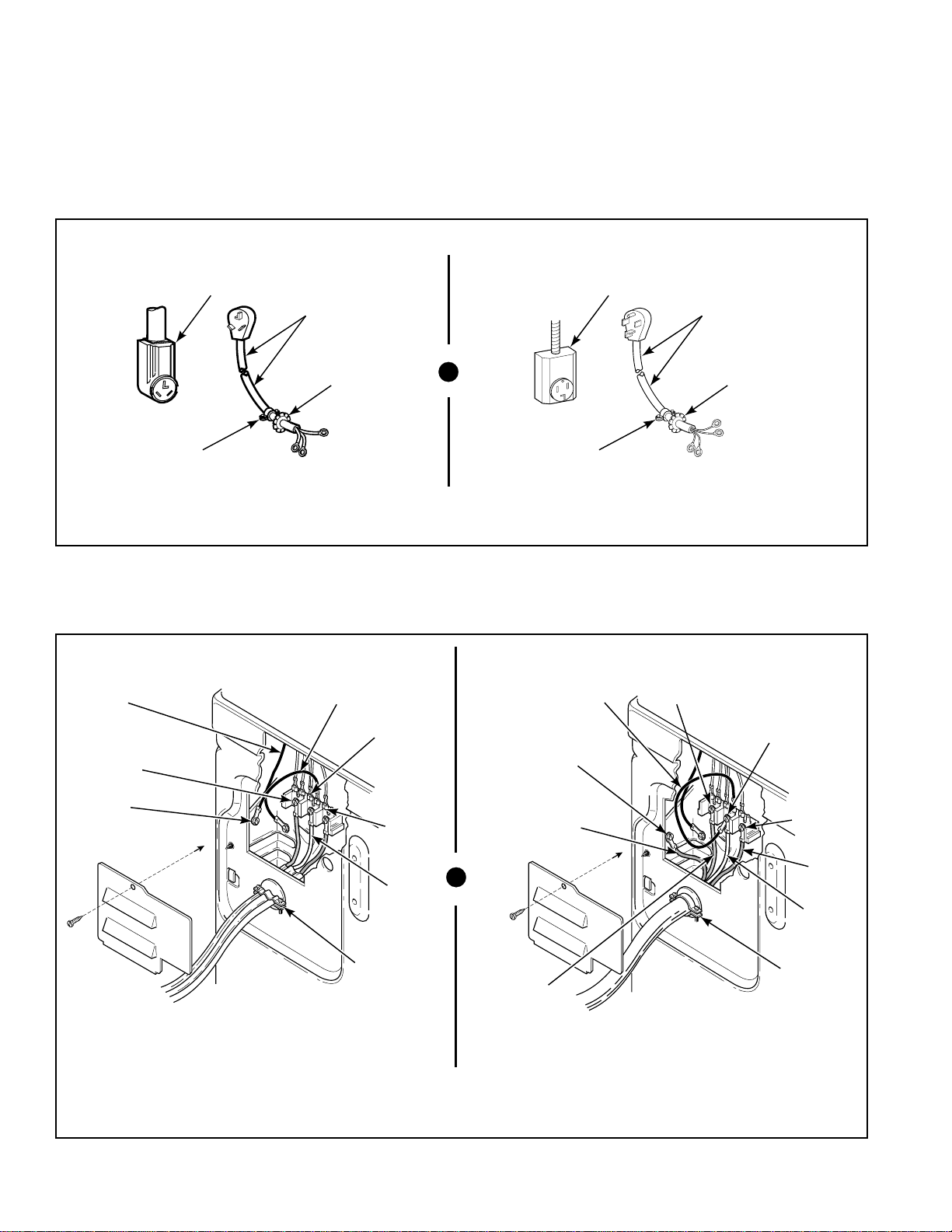

Step 5: (Electric Dryer ONLY)

D435IE1A

CENTER

WIRE

(NEUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

NEUTRAL

TERMINAL

GROUND

WIRE

“L2”

TERMINAL

“L1”

TERMINAL

GROUND

SCREW

GROUND

TO NEUTRAL

WIRE

Three-Wire Connection

Connect Electrical Plug

For further assistance, refer to Section on Electrical

Requirements.

TYPICAL

THREE-WIRE

RECEPTACLE

STRAIN

RELIEF

POWER CORD

- NOT SUPPLIED

WITH DRYER

(Three-Wire)

STRAIN

RELIEF

NUT

D275IE0H

Three Wire

NOTE: For more detailed information on connecting

three-wire or four-wire plugs, refer to Section on

Electric Dryer Electrical Requirements.

IMPORTANT: Use only a new U.L. listed No. 10

(copper wire only) three conduct or power supply cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a cloth es dryer.

TYPICAL

FOUR-WIRE

RECEPTACLE

STRAIN

RELIEF

POWER CORD

- NOT SUPPLIED

WITH DRYER

(Four-Wire)

STRAIN

RELIEF

NUT

D006IE0E

Four Wire

NOTE: Four-wire cord is required for mob il e homes

or where codes do not permit grounding through

neutral.

GROUND

WIRE

GROUND

SCREW

GROUND

NOTE: Dryer is shown with access cover removed f or illustration pur poses only. NEVER operate dr yer with

WIRE

RED

WIRE

Four-Wire Connection

“L1”

TERMINAL

NEUTRAL

TERMINAL

“L2”

TERMINAL

BLACK

WIRE

WHITE

WIRE

(NEUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

D436IE1A

access cover removed.

12 504509

Page 15

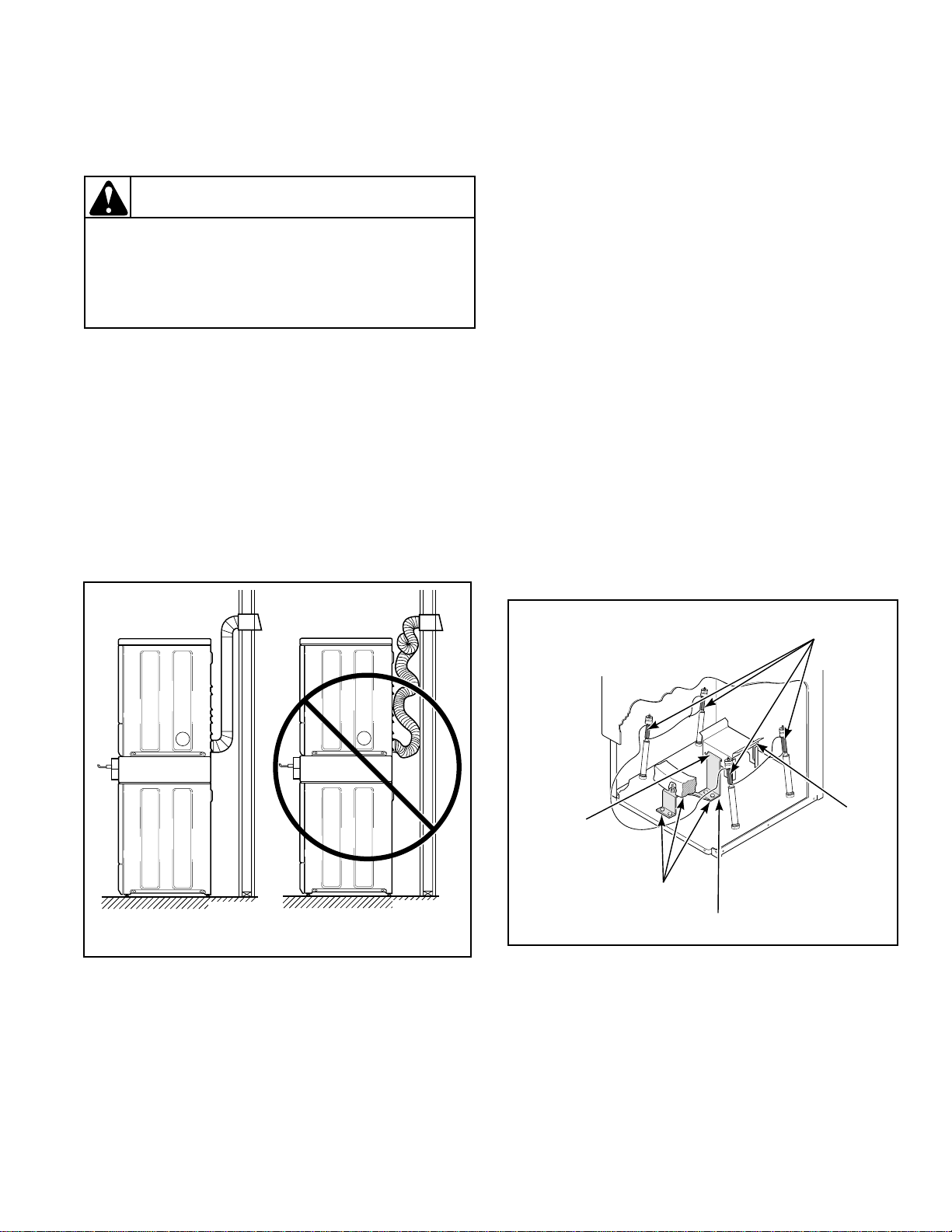

Step 6:

DO

H092IE1B

Step 7:

Connect Dryer Exhaust System

For further assis tance refer to Sections on Location

Requirements and Dryer Exhaust Requirements.

WARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted to

the outdoors.

W116

• DO NOT use plastic or thin foil flexible ducting.

• Locate unit so exhaust duct is as short as possible.

• Be certain old ducts are cleaned before installing your

new dryer.

• Use 4" (10.2 cm) diameter rigid or flexible metal duct.

• Use as few elbows as possible.

• Use duct tape on all joints.

• Failure to exhaust dryer properly will void

warranty.

Remove the Shock Sleeves and

Shipping Brace (Washer Only)

Remove front access panel by removing the two screws.

Remove bolts and washers from shipping brace with

9/16" wrench and remove brace. Remove shock sleeves

by pulling on the yellow rope.

Remove label from front side of front access panel and

place on backside of front access panel.

NOTE: The shipping brace, bolts, was hers and shock

sleeves should be saved and MUST be reinstalled

whenever the washer is moved more than four feet.

Do not lift or transport washer fr om front or withou t

shipping materials installed.

Store the shipping materials in the bag provided in the

Accessories Bag. Save materials for use whenever the

washer is moved.

NOTE: The shipping materials MUST be reinstalled

whenever the unit is moved. Refer to Moving Unit to a

New Location section for proper instructions on

reinstalling the shipping materials.

Reinstall front access panel.

H094IE1A

DON'T

NOTE: Venting materials are not supplied with the

unit (obtain locally).

HOOKED

END OF

SHIPPING

BRACE

BOLTS

WASHERS

SHOCK SLEEVES

MOTOR

MOUNT

H027IE1B

504509 13

Page 16

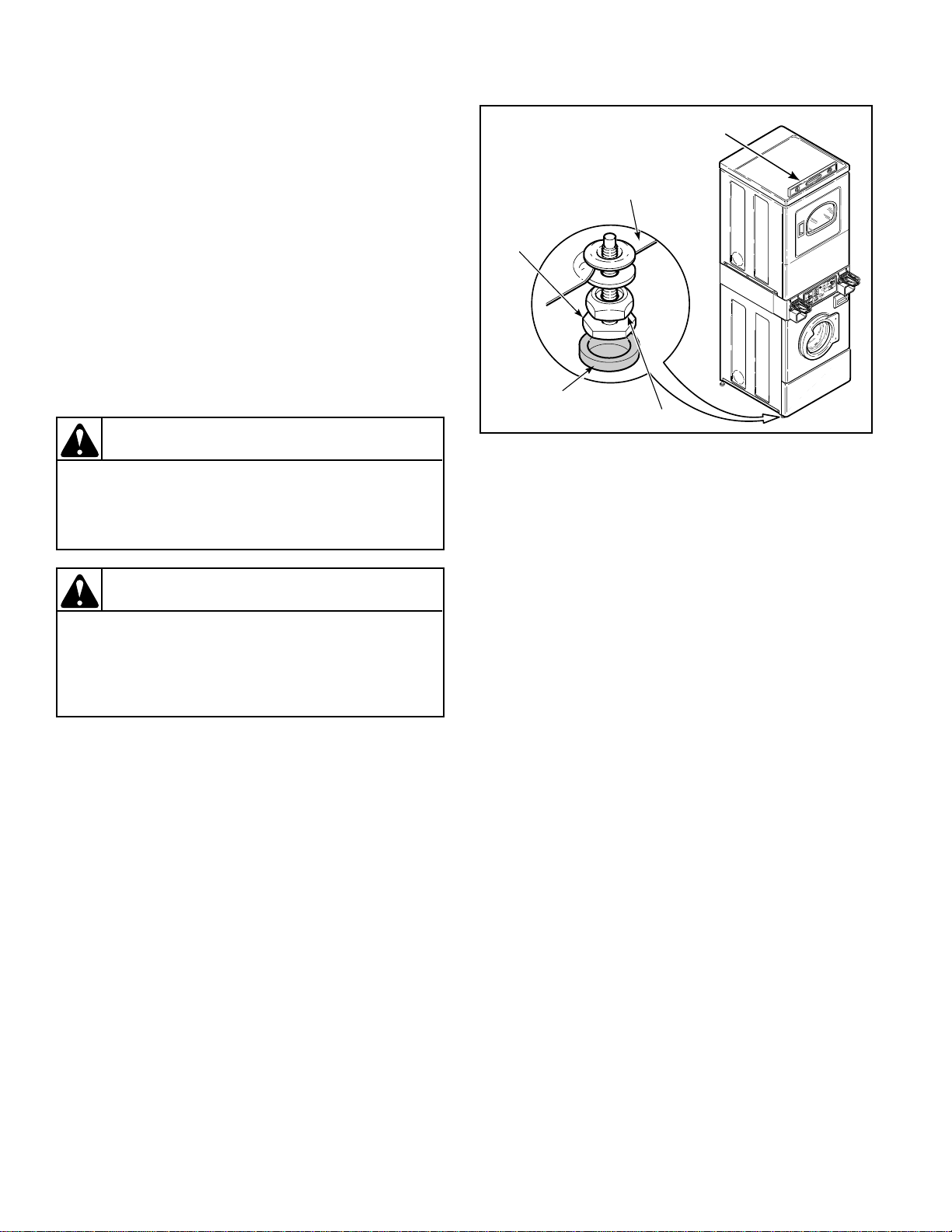

Step 8:

Position and Level the Unit

Place unit in position on a clean, firm and reasonably

level floor. Installing the unit on any type of carpeting is

not recommended.

Loosen 9/16" locknuts and adjust the leveling legs until

the unit does not rock and is level from side-to-side and

front-to-back. Hand tighten locknuts against unit base

and then securely tighten locknuts with 9/16" deep well

socket wrench. If the locknuts are not tight, the unit will

move out of positon during operation.

NOTE: Level must rest on raise portion of top panel.

See illustration.

Remove rubbe r feet from accessor ies bag and place on all

four leveling legs.

CAUTION

DO NOT slide unit more than four feet across

floor if the leveling legs have been extended,

as legs and base could become damaged.

W184

NOTE: For further assistance, refer to Section on

Location Requirements.

LEVEL

WASHER

BASE

LEVELING

LEG

RUBBER

CUP

LOCKNUT

H234IE1A

CAUTION

Use of the dispenser drawer or washer or

dryer doors as handles in the transportation

of the unit may cause damage to the

dispenser or doors.

W185

14 504509

Page 17

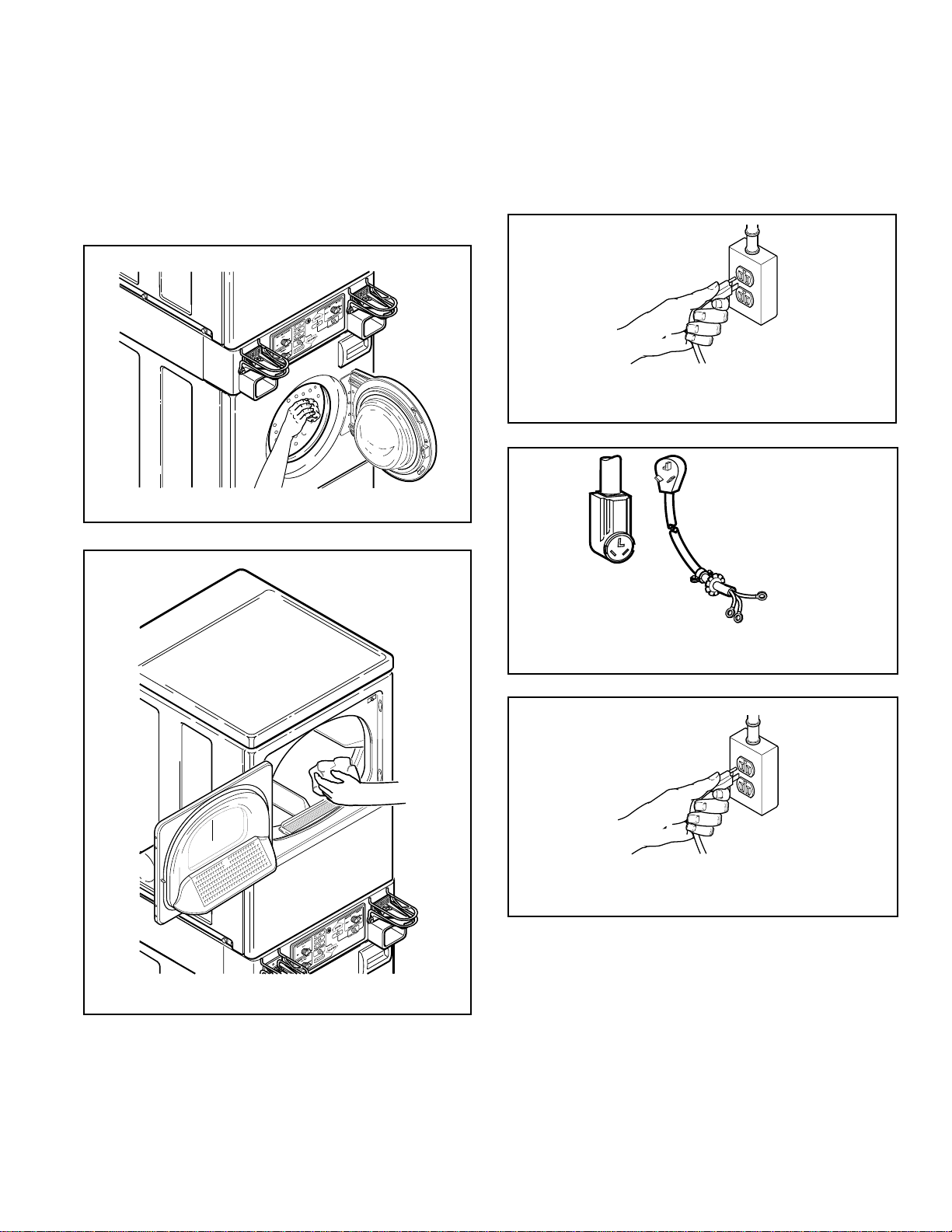

Step 9:

Step 10:

Wipe Out Inside of Washer Drum and

Dryer Drum

Before using the washer an d dryer for the first time, use

an all-purpose cleaner, or a detergen t and water sol ution,

and a damp cloth to remo ve shippin g dust from inside the

drums.

H244I

Plug In the Washer and Dryer

Refer to Sections on Electrical Requirements and

connect the washer and dryer to an electrical power

source.

D254IE0A

Washer

Plug cord into separately fused 15 Amp circuit.

H154IE1A

D275IE1B

Electric Dryer

Connect to 30 Amp circuit.

D254IE0A

Gas Dryer

Plug cord into separately fused 15 Amp circuit.

Step 11:

Check Installation

Refer to Installer Check on the back cover of this manua l

and make sure that unit is installed correctly.

504509 15

Page 18

Moving Unit to a New Location

. . .

To prevent damage while moving the washer, the

shipping materials MUST BE reinstalled.

Reinstallation of Shipping Materials

Remove front access panel by removing two screws.

Place the shock sleeves on all four shock absorbers. See

illustration.

Insert hooked end of shipping br ace i nto the open slot of

the motor mount. Attach with bolts and washers. See

illustration.

Reinstall front access panel.

SHOCK SLEEVES

HOOKED

END OF

SHIPPING

BRACE

BOLTS

MOTOR

MOUNT

H027IE1A

Refer to the I nstalling th e Unit for proper procedures

whenever the washer is moved.

16 504509

Page 19

Heat Source Check

(Electric Dryers)

. . .

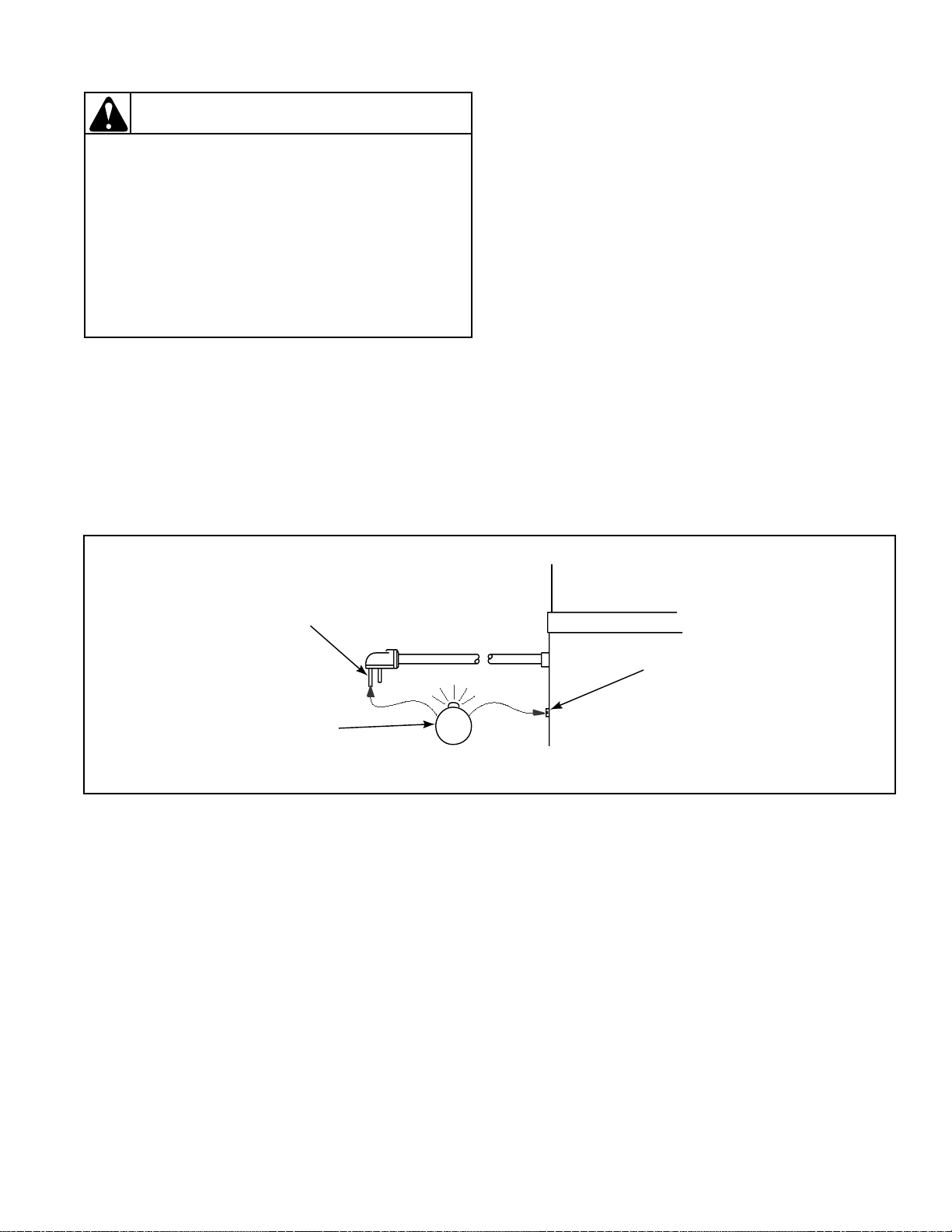

Metered Models

Set the proper FABRIC SELECTOR switch at

NORMAL. Place coins in the slide and carefully push

slide in as far as possible. IN USE light will come on

(Gas Dryers)

During the gas heat check, observ e the b urner fl ame. The

flame can be vie wed by r emoving the lo wer front panel of

the dryer.

Metered Models

Set FABRIC SELECTOR switch at NORMAL. Place

coins in the slide and carefully push slide in as far as

possible. IN USE light will come on indi cating the dryer

is ready to operate. Close the loading door and press the

PUSH-TO-START button f irmly . The dryer wil l start, the

igniter will glow red and the main burner will ignite.

IMPORTANT: If all air is not purged out of the gas

line, the gas igniter may go off before the gas is

ignited. If this happens, after approximately two

minutes the igniter will again attempt gas ignition.

After dryer has opera ted f or appr oximate ly f ive minutes,

observe burner flame. Adjust the air shutter to obtain a

soft, uniform blue flame. (A lazy, yellow tipped flame

indicating the dry er is ready to opera te. Close the lo ading

door and press the PUSH-TO-START button firmly to

start the dryer . Aft er dryer has operat ed for three minu tes,

the exhaust air or exhaust pipe should be warm.

indicates lack of air. A harsh, roaring, very blue flame

indicates too much air.) Adjust the air shutter as follows:

1. Loosen the air shutter lockscrew.

2. Turn the air shutter to the left to get a luminous

yellow tipped flame, then turn it back slowly to the

right to obtain a steady soft blue flame.

3. After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

4. Reinstall the lower front panel.

WARNING

For personal safety , lower front panel must be

in place during normal operation.

W046

After dryer has operat ed for approximately three minute s,

the exhaust air or exhaust pipe should be warm.

CLOSED

POSITION

OPEN

POSITION

1/8" (3.1 mm)

PIPE PLUG

(For checking

manifold pressure)

SHUT-OFF

VALVE

HANDLE

AIR SHUTTER

LOCKSCREW

AIR

SHUTTER

D157IE3C

504509 17

Page 20

Water Supply Requirements

. . .

WARNING

Under certain conditions, hydrogen gas may

be produced in a hot water system that has

not been used for two weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a

period and before using the washer, turn on

all hot water faucets and let the water flow

from each for several minutes. This will

release any accumulated hydrogen gas. The

gas is flammable, do not smoke or use an

open flame during this time.

NOTE: Water supply faucets must fit standard 3/4

inch (19.1 mm) female garden hose couplings.

DO NOT USE SLIP-ON OR CLAMP-ON

CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer is

not being used.

Water Temperature

Cold:

Recommended cold water temperature is 60° to 80°

Fahrenheit, 16° to 27° Celsius.

Hot:

Recommended hot water temperature is 120° to 140°

Fahrenheit, 49° to 60° Celsius.

Warm:

Mixture of hot and cold water. (Warm water temperature

is dependent upon the wat er temperature and the pre ssure

of both the hot and cold water supply lines.)

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should t urn off

water supply whenever there will be an extended

period of non-use.

NOTE: Longer inlet hoses are available (as optional

equipment at extra cost) if the hoses (supplied with

the washer) are not long enough for the installation.

Order hoses as follows:

W029

COLD WATER

CONNECTION

WATER

SUPPLY

FAUCETS

WATER

INLET

HOSES

HOT WATER

CONNECTION

WATER

MIXING VALVE

H096IE1A

Water Pressure

Pressure must be a minimum of 2 0 to a maximum of 1 20

pounds per square inch (138 to 827 kPa) static pressure

measured at the faucet.

NOTE: Water pressure under 20 pounds per square

inch (138 kPa ) will cause an extended fill time in the

washer and may not properly flu sh out the detergent

dispenser.

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets (see illustration

below).

RISERS

(Air cushions)

WATER SUPPLY

FAUCETS

W005IE1C

No. 20617 Inlet Hose (8 foot) (2.44m)

No. 20618 Inlet Hose (10 foot) (3.05m)

18 504509

Page 21

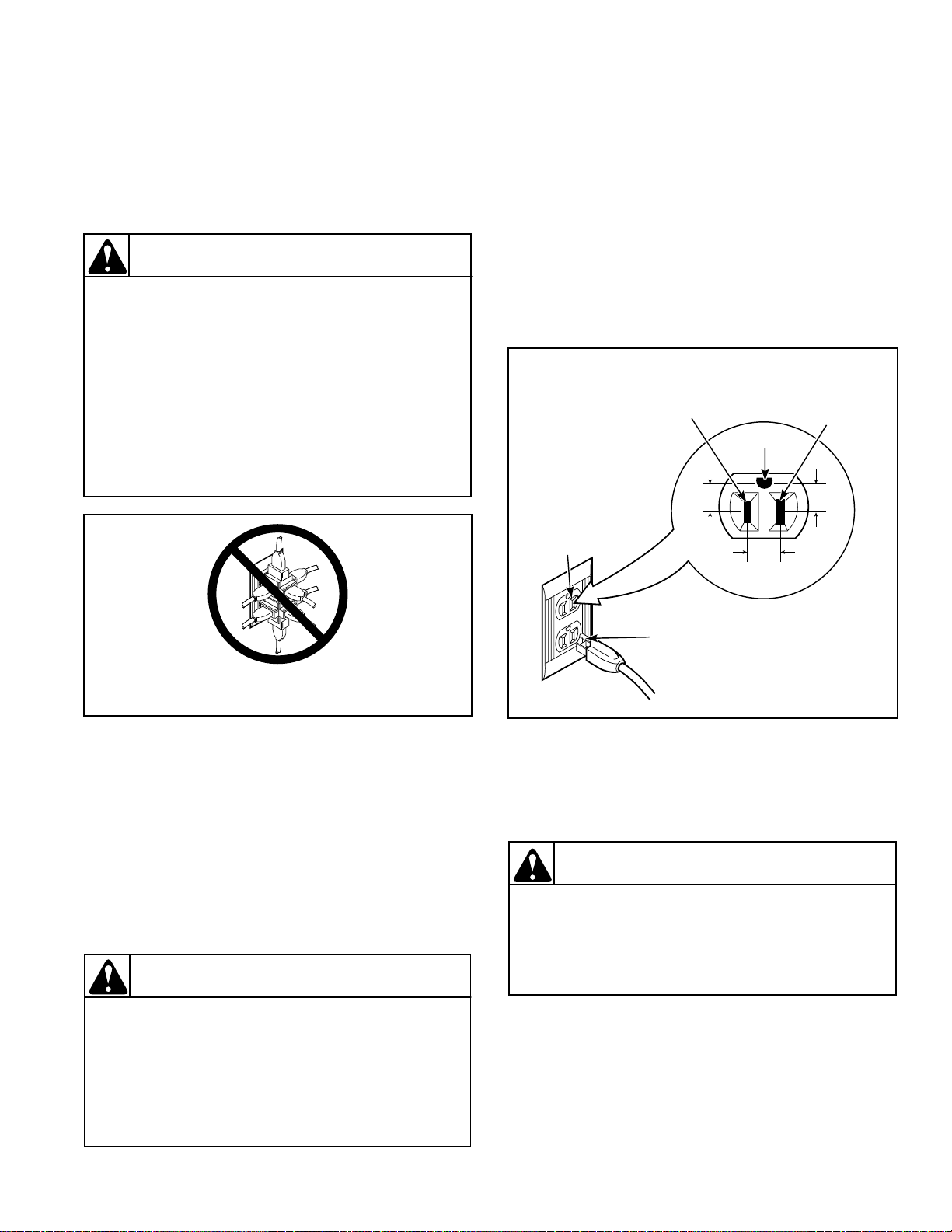

Washer

Electrical Requirements

(120 Volt, 60 Hertz with 3-Prong Grounding Plug)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code, ANSI/

NFPA No. 70, and such local regulations as

might apply. It is the customer’s

responsibility to have the wiring and fuses

checked by a qualified electrician to make

sure the laundry room has adequate

electrical power to operate the washer.

W227

. . .

Do not modify the plug provided with t he washer—if it

will not fit the outlet, have a proper outlet installed by a

qualified electrician.

NOTE: Have a qualified electrician check the polarity

of the wall receptacle. If a voltage reading is measured

other than that illustrated, the qualified electrician

should correct the problem.

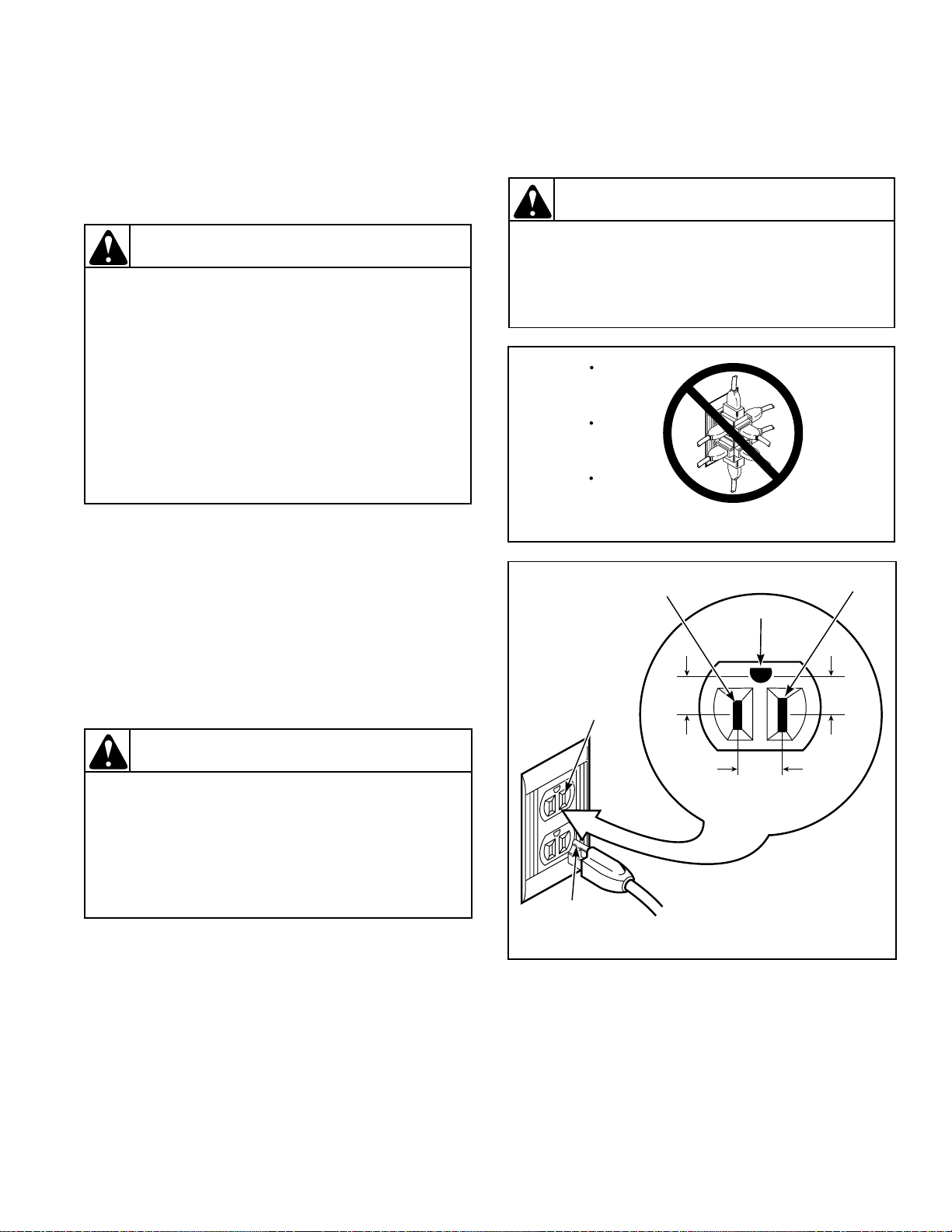

STANDARD 120 VOLT, 60 HERTZ,

3-WIRE EFFECTIVELY GROUNDED CIRCUIT

NEUTRAL

SIDE

0

V.A.C.

NEUTRAL

L1

120 ± 12

V.A.C.

GROUND

120 ± 12

V.A.C.

DO NOT OVERLOAD CIRCUITS

DO NOT USE ADAPTER

DO NOT USE AN EXTENSION CORD

D009IE1A

Grounding Instructions

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-grounding conductor

and a 3-prong groundi ng plug. The pl ug must be pl ugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or serviceman if you are in doubt

as to whether the washer is properly

grounded.

W032

ROUND

GROUNDING

PRONG

D090IE1A

Do not operate other app liances on the s ame circuit when

this appliance is operating.

Do not operate both a washer and gas dryer on the same

circuit. Use separately fu sed 15 Amp circuits.

WARNING

T o reduce the ri sk of electric shock or fi re, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

W031

504509 19

Page 22

Electric Dryer

Electrical Requirements

(120/240 Volt, 60 Hertz, 3-Wire Installation)

(120/208 Volt, 60 Hertz, 3-Wire Installation)*

*Alternative Heating Element Required

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply . It is the

customer’s responsibility to have the wiring

and fuses checked by a qualified electrician

to make sure the laundry room has adequate

electrical power to operate the dryer.

W035

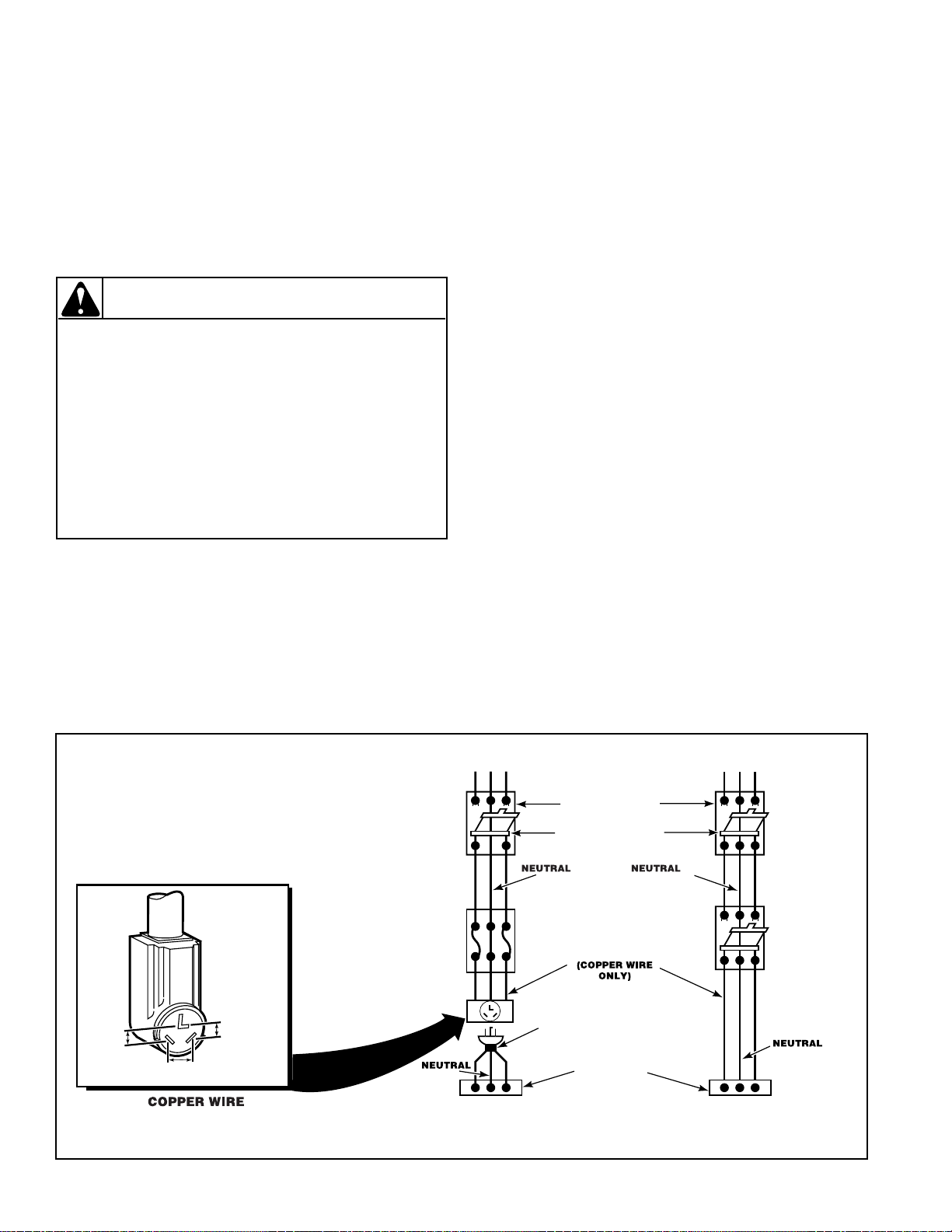

Grounding and Wiring Instructions

• The dryer must be connected to a grounded metal,

permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equ ipment-grounding ter minal or lead

on the dryer.

• The dryer has its own terminal block that must be

connected to a separat e br anc h, 60 Her tz , si ngl e pha se

. . .

circuit, AC (alternating current) circuit, fused at 30

Amperes (the circ uit must be fused on both sides of the

line). ELECTRICAL SERVICE FOR THE DR YER

SHOULD BE OF MAXIMUM RA TED VOLTAGE

LISTED ON THE NAMEPLATE. DO NOT

CONNECT DRYER TO 110, 115, OR 120 VOLT

CIRCUIT. Heating elements are available for field

installation in dryers which are to be connected to

electrical servi ce of dif ferent v oltage than tha t listed on

nameplate, such as 208 Volt.

• If branch circuit to dryer is fifteen feet (4.50 m) or less

in length, use U.L. (Underwriters Laboratories) listed

No. 10 A.W.G. wire (copper wire only), or as re qui red

by local codes. If over fifteen feet (4.50 m), use U.L.

(Underwriters Laboratories) listed No. 8 A.W.G. wire

(copper wire only), or as required b y local codes. Allo w

sufficient slack in wiring so dryer can be moved from

its normal location when necessary.

• The power cord (pigtail) connection between wall

receptacle and dryer ter minal block IS NOT supplied

with dryer. Type of pigtail and gauge of wire must

conform to local codes and wit h instructions mentioned

on the following pages.

The method of wiri ng the d ryer is opti onal and subject to

local code requirements. See examples below.

NOTE: The power cord (pigtail) is NOT supplied with the

electric dryer. Type of pigtail and gauge of wire must conform

to local codes and instructions.

The method of wiring the dryer is optional and subject to local

code requirements.

NOTE: Connect the dryer to the power supply with the

MAXIMUM RATED VOLTAGE listed on the nameplate.

A typical

30-Amp

Three-wire

Receptacle

NEMA Type

10-30R

120 ± 12

120 ± 12

VAC

240 ± 12

VAC

NOTE: Use only.

Shorter than 15' (4.5 m) use 10 A.W.G.

Longer than 15' (4.5 m) use 8 A.W.G.

VAC

INTERMEDIATE

FUSE BOX

(MAY BE

OMITTED IF

SERVICE

ENTRANCE

BOX IS FUSED)

RECEPTACLE

POWER SUPPLY POWER SUPPLY

WALL

L1 L2

PIGTAIL CONNECTION

3-WIRE GROUNDED NEUTRAL

120/240 VOLT, 60 HERTZ AC 1 PHASE

SERVICE ENTRANCE SWITCH BOX

(SEE NOTE BELOW)

30 AMPERE FUSES OR

CIRCUIT BREAKER

WIRE

METALLIC OR

NON-METALLIC

SHEATHED CABLE

PIGTAIL

TO DRYER

(SEE NOTE BELOW)

TERMINAL BLOCK

IN DRYER

WIRE

INTERMEDIATE

SHUT-OFF BOX

(MAY OR MAY

NOT BE FUSED)

L1 L2

DIRECT CONNECTION

D003IE3A

20 504509

Page 23

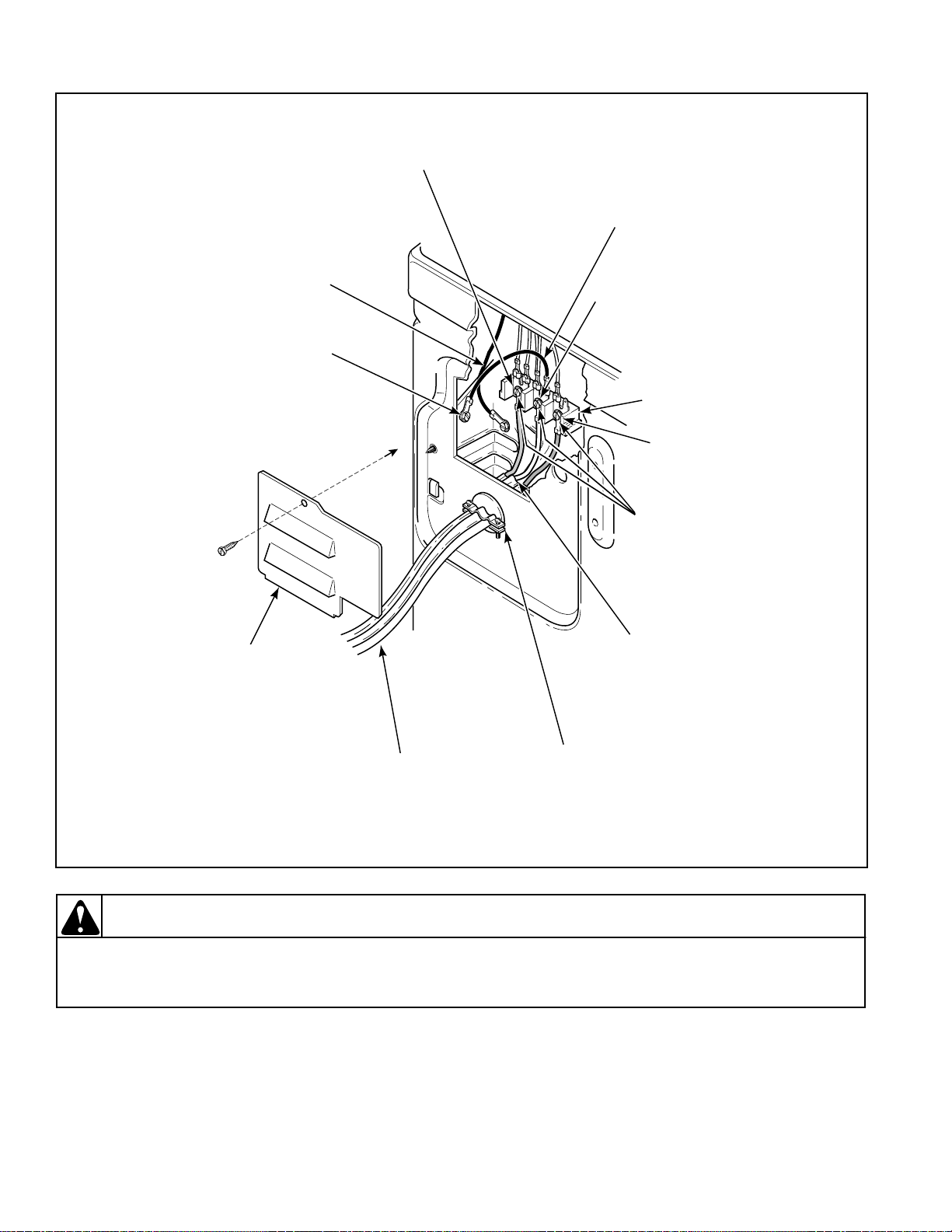

(Three-Wire Power Cord)

W ARNING

The dryer is grounded to neutral conductor

at the terminal block. If local codes do not

permit grounding through the neutral,

proceed as shown on

instructions.

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

before proceeding.

1. Remove the screw and terminal block access cover

from the rear of the dryer cabinet.

2. I nsert ends of direc t wire t hrough po wer su pply hol e

(containing proper strain relief) in re ar of dryer

cabinet. See follo wing page. Connect the po wer cord,

or direct wiring, to the appropriate terminal block

terminals using the three wire-binding screws from

the accessories pack in the envelope shipped

inside the dryer cylinder. If the dryer had prev iously

Four Wire Connection

W174

W135

been connected with a f our-wi re powe r cord, remo ve

the four-wire power cord by reversing procedures

under Four-Wire Power Cord instruction s.

IMPORTANT: Use only a U.L. listed No. 10 AWG

(copper wire only) three conduct or power supply cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a cloth es dryer.

3. Tighten these wire-binding screws firmly.

IMPORTANT: Failure to tighte n these sc rews firml y

may result in wire failure at the terminal block.

4. Secure the strain relief to the power cord, or wires,

where they enter the dryer cabinet.

5. Che ck the continuity of th e ground connection bef ore

plugging the cord into an outlet. Use an acceptable

indicating device connected to the center grounding

pin of the plug and the ground screw on the back of

the cabinet.

6. Reinstall access cover and screw.

GROUNDING

PIN

INDICATING

DEVICE

(MUST SHOW

CONTINUITY)

GROUND SCREW

ON BACK

OF CABINET

D357IE3A

504509 21

Page 24

Three-Wire Connection

“L1”

TERMINAL

GROUND

TO NEUTRAL

WIRE

TERMINAL

ACCESS

COVER

GROUND

WIRE

BRACKET

GROUND

SCREW

NEUTRAL

TERMINAL

TERMINAL

BLOCK

“L2”

TERMINAL

SLOTTED

HEX HEAD

SCREWS

(Shipped

inside

the dryer)

NEUTRAL

(WHITE

OR CENTER

WIRE)

POWER CORD

OR DIRECT WIRING -

NOT SUPPLIED

WITH DRYER

(Three-wire)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

D435IE2B

WARNING

Dryer unit is shown with the access cover removed for illustration purposes only. To reduce the

risk of an electric shock, NEVER operate the dryer unit with the access cover removed.

22 504509

W150

Page 25

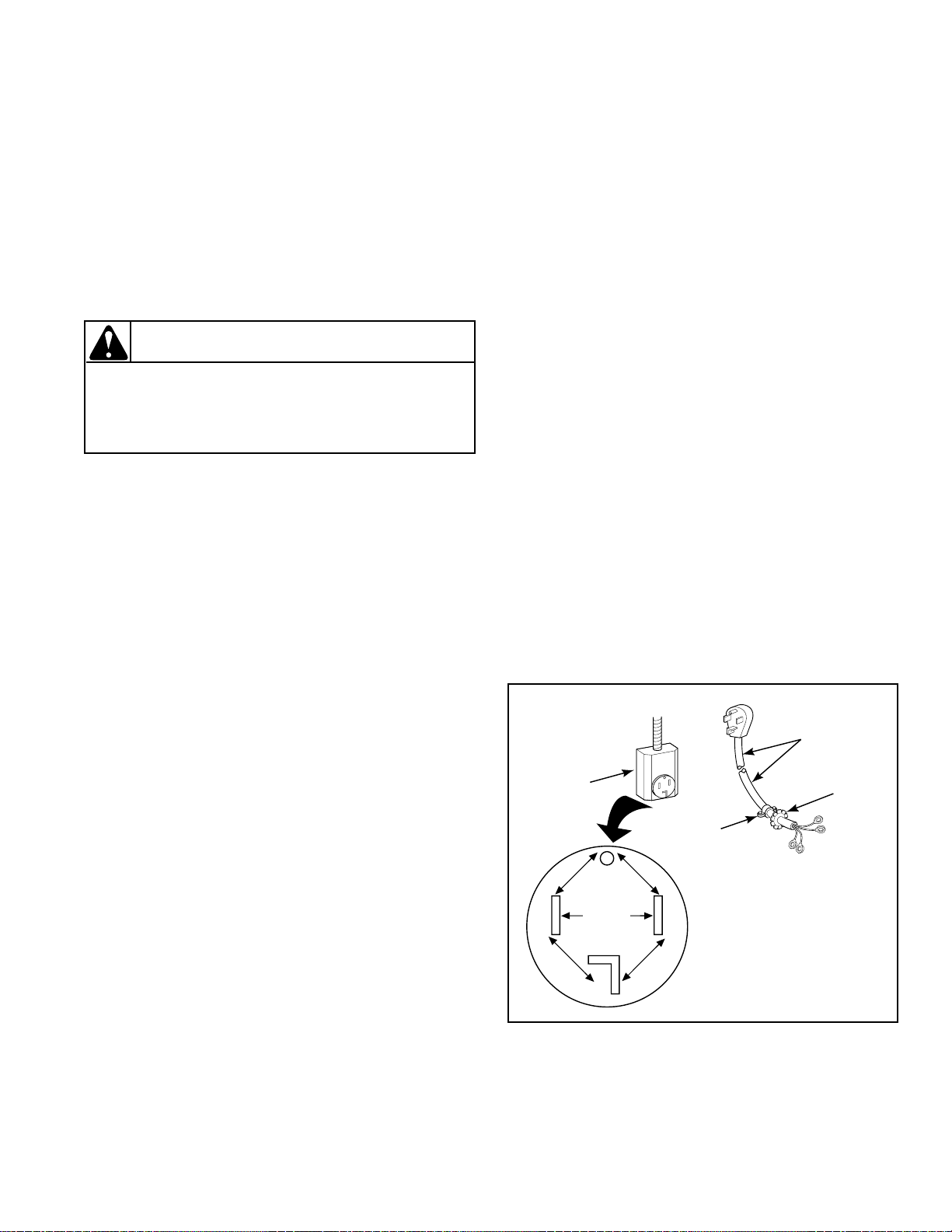

(Four-Wire Power Cord)

IMPORTANT: Use only a U.L. listed No. 10 AWG

(copper wire only) four conductor po wer suppl y cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a clothes dryer.

NOTE: The power cord is not suppli ed with the dryer

when the dryer is shipped from the factory, therefore,

disregard steps 2 and 3 below when conn ecting a fourwire power cord to a new dryer.

If the dryer has a three-wire cord attached, then

complete steps 1 through 12.

WARNING

To reduce the risk of electrical shock,

disconnect the electrical power to the dryer

before proceeding.

W137

1. Re move the scr ew holding t he access plate to the rear

of the dryer cabinet.

2. Remove the three screws holding the three wires to

the terminal block terminals. Save these screws.

3. Loosen the strain relief screw and pull the cord or

wires out through the rear of the dryer.

4. Remove the terminal bracket ground screw holding

the ground wire to the terminal block mounting

bracket. Save the screw.

NOTE: ON NEW DRYERS, this is the ground wire

that goes from the neutral (center) terminal on the

terminal block to the mounting bracket.

5. Route the end of the four-wire power cord through

the strain relief. DO NOT tighten th e strain relief

screws at this time.

6. I nsert the en d of power cor d and strain reli ef through

the hole in the rear of the dryer cabinet. Install the

strain relief nut from the inside of the cabinet and

tighten firmly.

7. Attach the green ground wire (from the four-wire

power cord) to the terminal block mounting bracket

using the hex head screw re moved in step 4 . Tighten

the screw firmly.

8. Usi ng the three wire-binding (10-32x3/8") screws

from the accessories envelope located inside the

cylinder (unless the scre ws were previous ly removed

in step 2), attach the po wer cord wir es to the terminal

block terminals as follows:

a.Red to Red

b.Black to Black

c. White to White (see NOTE below)

NOTE: When installing the white wire, loop the free

eyelet end of the ground wire (fr om s tep 4) and pla ce

it together with the white wire and attach both w i res

to the neutral (cen ter) terminal on t he terminal block.

See following page.

IMPORTANT: Failure to tighten the nuts firmly on

the terminal block may result in power cord wire

failure.

9. Tighten th e two strain relief screws to sec ure the

power cord.

10. Recheck all screws to be sure they are tight.

11. C heck the continuity of the ground connecti on before

plugging the cord into an outlet. Use an acceptable

indicating device connected to the center grounding

pin of the plug and the gre en screw on t he back of the

cabinet. See illustration on following page.

12. R einstal l the acc ess plat e and screw to the rear of the

dryer cabinet.

POWER CORD -

NOT SUPPLIED

WITH DRYER

(Four-Wire)

TYPICAL

FOUR-WIRE

RECEPTACLE

120 ± 12

V.A.C.

240 ± 12

120 ± 12

V.A.C.

V.A.C.

120 ± 12

V.A.C.

120 ± 12

V.A.C.

STRAIN

RELIEF

STRAIN

RELIEF

NUT

D006IE1C

504509 23

Page 26

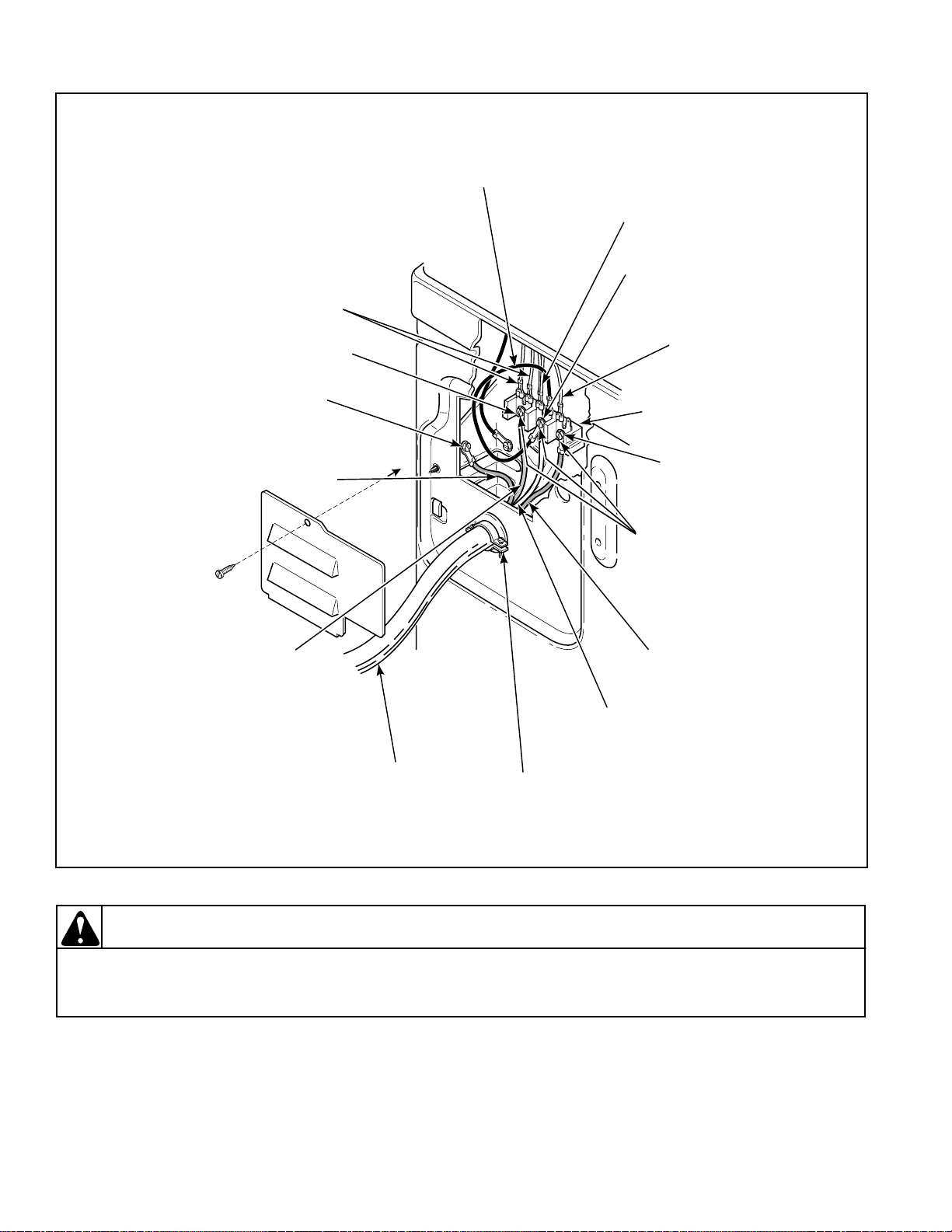

Four-Wire Connection

TERMINAL

BRACKET

GROUND

RED

WIRES

“L1”

TERMINAL

SCREW

GROUND

WIRE

WHITE

WIRES

NEUTRAL

TERMINAL

BLACK

WIRE

TERMINAL

BLOCK

GROUND

RED

WIRE

WIRE

POWER CORD -

NOT SUPPLIED

WITH DRYER

(FOUR-WIRE)

“L2”

TERMINAL

SLOTTED

HEX HEAD

SCREWS

(Shipped

inside

the dryer

or removed

in Step 2)

BLACK

WIRE

NEUTRAL

(WHITE

WIRE)

STRAIN

RELIEF

D436IE2B

WARNING

Dryer unit is shown with the access cover removed for illustration purposes only. To reduce the

risk of an electric shock, NEVER operate the dryer unit with the access cover removed.

24 504509

W150

Page 27

Gas Dryer

Electrical Requirements

(120 Volt, 60 Hertz, With 3-Prong Grounding Plug)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is the

customer’s responsibility to have the wiring

and fuses checked by a qualified electrician

to make sure the laundry room has adequate

electrical power to operate the dryer.

W035

• The dryer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hert z, AC (alternating current) cir cuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

• The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 120 Volts AC

(alternating current) 15 Amps. See illustration below

for determining correct polarity of the wall receptacle.

. . .

WARNING

T o reduce the ri sk of an el ectr ic shock or f ire,

DO NOT use an extension cord or an adapter

to connect the dryer to the electrical power

source.

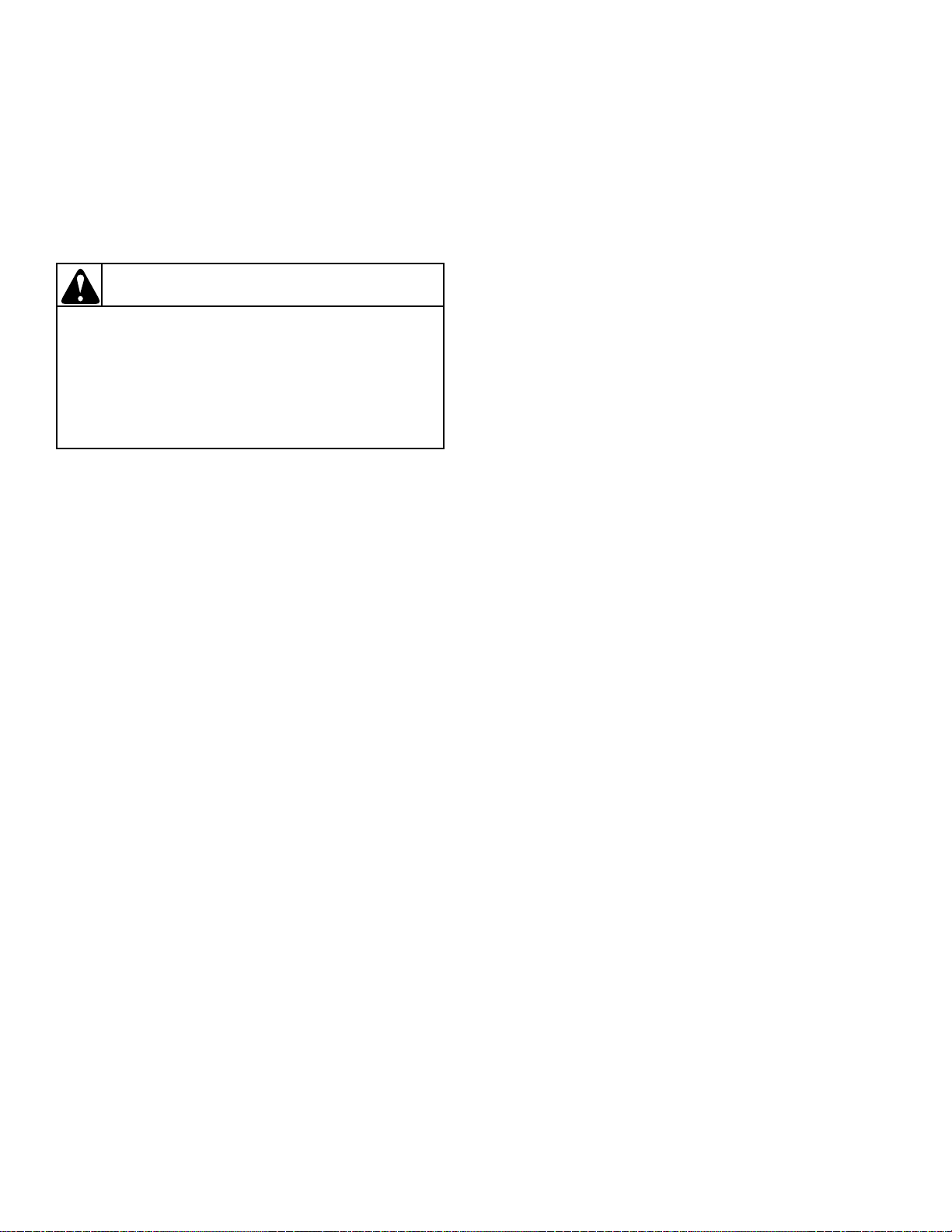

DO NOT

OVERLOAD

CIRCUITS

DO NOT

USE AN

ADAPTER

DO NOT

USE AN

EXTENSION

CORD

STANDARD

120 VOLT,

60 HERTZ,

3-WIRE EFFECTIVELY

GROUNDED CIRCUIT

NEUTRAL

SIDE

D009IE0C

L1

GROUND

115 ± 12

V.A.C.

W037

NEUTRAL

0

V.A.C.

WARNING

This dryer is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

W036

NOTE: A qualified electrician should check the

ROUND

GROUNDING

PRONG

polarity of the wa ll recep tacles. If a voltage reading is

measured other than that il lustrated, the qualified

electrician should correct the problem.

• DO NOT OPERATE OTHER APPLIANCES ON THE

SAME CIRCUIT WHEN THIS APPLIANCE IS

OPERATING. DO NOT OVERLOAD CIRCUITS!

• DO NOT operate both a washer and gas dryer on the

same ciruict. U se separate ly fused 15 Amp circuits.

504509 25

115 ± 12

V.A.C.

D090IE1B

Page 28

Grounding Instructions

• The dryer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The dryer is equipped

with a cord ha ving an equi pment-gro unding conduc tor

and a three prong grounding plug. The plug must be

plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the dryer is properly

grounded.

• DO NOT modify the plug provided with the dryer

unit—if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

• If the laundry room’s electrical supply does not meet

the above specifications and/or if you are not sure the

laundry room has an effectiv e ground, h a v e a qual if ie d

electrician or your local electrical utility company

check it and correct any problems.

W038

26 504509

Page 29

Gas Requirements

(Gas Dryers)

NOTE: The gas service to a gas dryer must conform

with the local codes and ordinances, or in the absence

of local codes and or dinances, with the l atest edition of

the National Fuel Gas Code ANSI Z223.1/NFPA 54 or

the CAN/CGA-B149, National Gas Installation Code.

3

Natural Gas, 1,000 Btu/ft

be supplied at 6.5 ± 1.5 inch water column pressure.

For proper op eration at altitudes ab ove 2,000 feet (610 m)

the natural g as v alv e spud orif ice si ze must b e redu ced to

ensure complete combustion. See table at right.

L.P. (Propane) Gas, 2,500 Btu/f t

must be supplied at 10 ± 1.5 inch w at er column pressure.

NOTE: DO NOT connect the dryer to L.P. (Propane)

Gas Service without convertin g the gas valve. A 458P3

L.P. (Propane) Gas Conversion Kit must be installed

by the Manufacturer’s Authorized Dealers,

Distributors, or local service personnel.

NOTE: The dryer and its individual shut-off valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 psi (3.45 kPa).

(37.3 MJ/m3), service must

3

(93.1 MJ/m3), service

. . .

W ARNING

To reduce the risk of gas leaks, fire or

explosion:

• The dryer must be connected to the type of

gas as shown on nameplate located in the

door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in LP

(propane) Gas, or Teflon tape, on all pipe

threads.

• Purge air and sediment from gas supply

line before connecting it to the dryer.

Before tightening the connection, purge

remaining air from gas line to dryer until

odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for gas

leaks. Use a non-corrosive leak detection

fluid.

W114R1

The dryer must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than

1/2 psi (3.45 kPa)

NOTE: When connecting to a gas line, an equi pment

shutoff valve must be installed within 6' (1.8 m) of the

dryer. An 1/8" N.P.T. pipe plug must be installed as

shown. See illustration.

NEW

STAINLESS

STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

Altitude Orifice Size Part

Numberft m # Inches mm

2000 610 41 0.0960 2.44 503776

3000 915 42 0.0935 2.37 503777

5500 168 0 43 0.0890 2.26 503778

7000 213 5 44 0.0860 2.18 58719

9000 274 5 45 0.0820 2.08 503779

10500 3200 46 0.0810 2.06 503780

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

EQUIPMENT

SHUT-OFF

VALVE

Installed within

6' (1.8 m) of dryer

D434IE2A

504509 27

Page 30

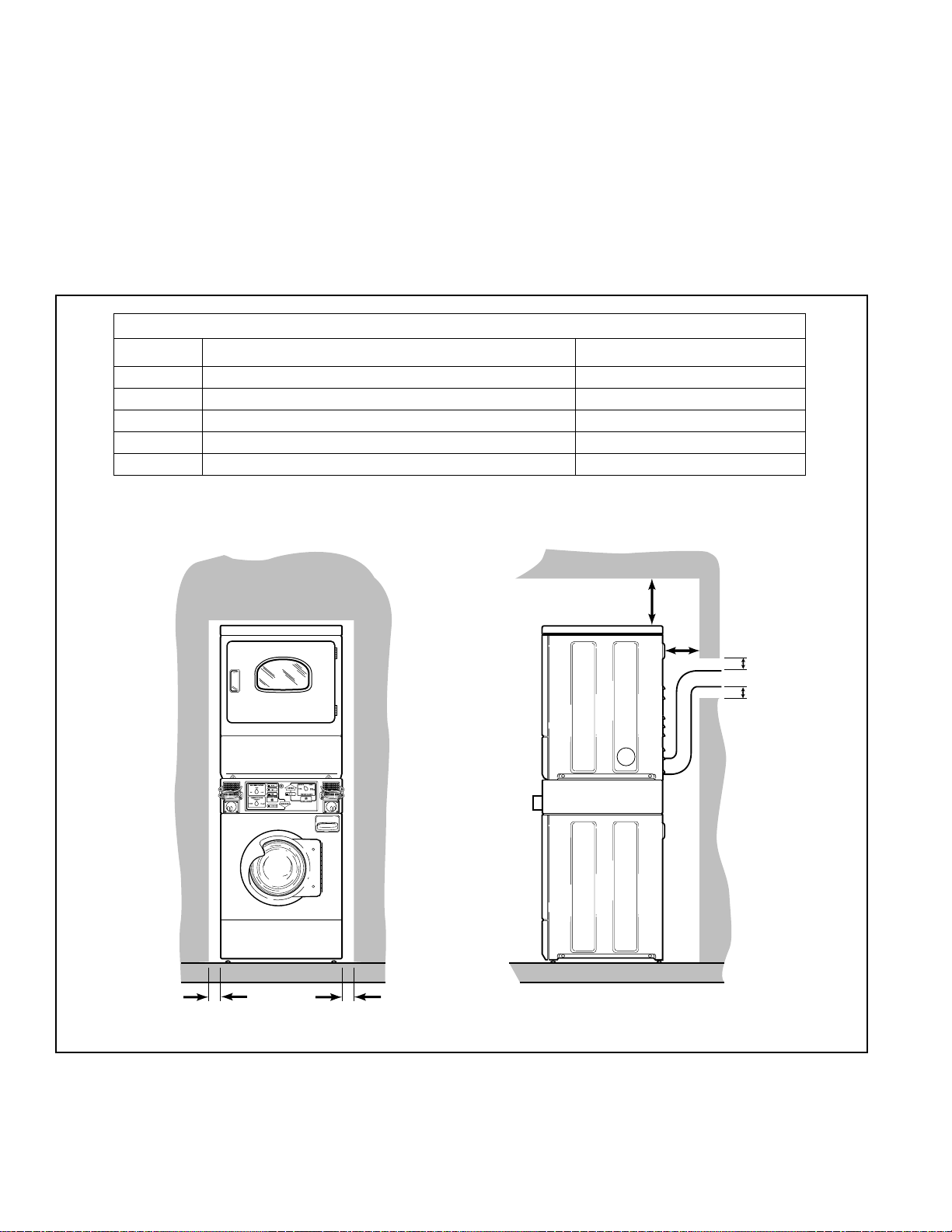

Location Requirements

. . .

Select a location with a solid floor.

The unit must not be instal le d or sto red in an area where

it will be exposed to water and/or weather.

Leveli ng l e gs can be adjusted from inside the un it wi th a

9/16" deep well socket . All four legs must rest fir mly on

the floor so the weight of the unit is evenly di stributed.

The unit must not rock and must be level from side-toside and front-to-back.

Dryer And Exhaust Duct Clearances

Area Description Minimum Clearance

A Left Dryer Side 0" (0 cm)

B Right Dryer Side 1" (2.54 cm)

C Dryer Top 6" (15.24 cm)

D Dryer Rear 2" (5.1 cm)

E Exhaust Duct Clearance to Combustible Materials 2" (5.1 cm)

NOTE: Shaded areas indicate adjacent structure.

IMPORTANT: Unless completely assembled, DO

NOT slide the unit acr oss the floor. DO NOT sl ide the

unit more than four feet once the leveling legs have

been extended, as the l egs and t h e base could become

damaged.

The unit needs sufficient clearance and an adequate air

supply for proper operation and vent ilation, and for easi er

installation and servicing. (Minimum clearances are

shown below.)

AB

C

D

E

E

H245IE1A

28 504509

Page 31

Dryer Exhaust Requirements

WARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted to

the outdoors.

W116

This gas appliance contains or produces a

chemical or chemicals which can cause death

or serious illness and which are known to the

State of California to cause cancer, birth

defects, or other reproductive harm. To

reduce the risk from substances in the fuel or

from fuel combustion, make sure this

appliance is installed, operated, and

maintained according to the instructions in

this manual.

W115

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas vent,

chimney or enclosed, unventilated area, such

as an attic, wall, ceiling, crawl space under a

building or concealed space of a building.

W045

To reduce the risk of fire, DO NOT use plastic

pipe or flexible plastic pipe to exhaust the

dryer .

W041

. . .

MAY BE

DESCRIPTION KIT P/N

Exhaust Duct

(4" Dia.)

Flexible Metal Duct

(4" Dia.)

Weather Hoods, with

hinged dampers (4")

Directional Exhaust

Kit

Tape Not Available Yes

NOTE: Kits described above are optional exhaust

system materials available at extra cost.

Not Available Yes

521P3 Yes

Not Available Yes

528P3 No

OBTAINED

LOCALLY

Never i nstal l flexible duct in concea led spa ces , such as a

wall or ceiling.

Exhaust System Materials

Exhaust system materials are not supplied with the unit.

Exhaust duct must be four inches (10.2 cm) in diameter

having no obstructions. Rigid metal duct is

recommended. Non-combustible semi-rigid flexible

metal duct is acceptable. Do not use plastic pipe or

flexible pl astic pipe, because it contributes to poor drying

performance and collects lint, wh ich can lead to a fire

hazard.

DO NOT use sheet meta l screws on ex haust pipe joints or

other fastening means which extend into the duct that

could catch lint and reduce the efficiency of the exhaust

system. Secure all joints w ith duct tape.

H094IE1A

DO

H092IE1B

DON'T

Make-Up Air Requirements

A dryer exhausts 214 cfm (measured at back of dryer)

and suff icient mak e-up air must be supplied to re place air

exhausted by dryer.

An unobstructed opening of at least 40 square inches

(260 cm

dryer. Protective louvers in the opening to the outdoors

can reduce air movement approxi mately 35 to 40 pe rcent.

Be sure the opening is large enough to compensate for

any louvers.

If it is necessary to duct make-up air to t he dryer, increase

the area of the ductwor k b y 25 perce nt to compen sate for

any reduction in air moveme nt . I n a ddi ti on, the make-up

air duct should extend down to within approximately two

feet from the floor, directly behind the dryer.

2

) of outdoor make-up air MUST be provide d for

504509 29

Page 32

Exhaust System

(

)

IMPORTANT: Keep exhaust duct as short as

possible.

NOTE: Be certain old ducts are cleaned before

installing your new unit.

For best drying results, recommended maximum length

of exhaust system is shown below.

T o prev ent backdra ft when dryer is no t in operation, outer

end of exhaust pipe must have a weather hood with

hinged dampers (obtain locally).

NOTE: Weather hood should be installed at least 12

inches (30.5 cm) above the gr ound. Larger clearanc es

may be necessary for installations where heavy

snowfall can occur.

Exhaust Direction

The dryer can be exhausted to the outdoors through the

back, left or right of the dryer. EXCEPTION: Gas

dryers cannot be v ented out the left side beca use of the

burner housing.

Unit is shipped from factory ready for rear exhaust; no

kits required.

Exhausting the dr yer through sides can be a ccomplished

by installing a Directional Exhaust Kit 528P 3 availabl e as

optional equipment at extra cost.

WEATHER HOOD

WITH HINGED

DAMPERS

RIGID OR

FLEXIBLE

METAL DUCT

H043IE1A

528P3 Directional Exhaust Kit

Number of

90° Elbows

Recommended Use only for sho rt run installations

4"

10.16 cm

Weather Hood Type

4"

(10.16 cm)

D011IE2D

2-1/2"

(6.35 cm)

Maximum length of 4" (10.2 cm) diameter rigid metal duct.

0 44 feet (13.4 m) 34 feet (10.4 m)

1 34 feet (10.4 m) 26 feet (7.9 m)

2 26 feet (7.9 m) 20 feet (6.1 m)

3 20 feet (6.1 m) 14 feet (4.3 m)

Maximum length of 4" (10.2 cm) diameter flexible meta l duct.

0 24 feet (7.3 m) 20 feet (6.1 m)

1 20 feet (6.1 m) 16 feet (4.9 m)

2 16 feet (4.9 m) 12 feet (3.7 m)

3 12 feet (3.7 m) 8 feet (2.4 m)

D011IE2E

NOTE: Deduct 6 feet (1.8 m) for each additional elbow.

30 504509

Page 33

Exhaust Sys tem Maintenance

521P3 Flexible Metal Vent Kit

Dryer Airflow

The dryer interior and the complete exhaust system

should be inspected after one year of use and cleaned if

necessary. Inspect and clean exhaust duct every one to

two years as required thereafter. The weather hood

should be checked frequently to make sure the dampers

move freely, dampers are not pushed in and that nothing

has been set against them. This main tenance work should

be done by a qualified service person.

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the dry er

before cleaning.

W043

Exhausting the dryer in hard-to-reach locations can be

accomplished by installing the 521P3 Flexible Metal

Vent Kit, available as optional equipment at extra cost.

The kit comes in two halves that can be separately

attached to the dryer and wall outlet. Once attached, the

unit can be slid back into position.

Efficient dryer operation requires proper dryer airflow.

Proper dryer airflow can be evaluated by measuring the

static pressure.

Static pressure in the dryer’s exhaust duct should be no

greater than that shown in the chart below. (Check with

dryer running and no load.)

NOTE: This can be measured with a manometer

placed on the exhaust duct approximately two feet (61

cm) from the dryer, see illustration below.

MAXIMUM STATI C

PRESSURE IN

WATER COLUMN

MANOMETER

.6 INCHES (1.5 cm)

D466IE1A

EXHAUST

DUCT

D012IE0A

Reduced Clearance Elbow

Installing the dryer in shallow closets can be

accomplished by usi ng an El bow, Part No. 62688, which

is one inch narrower than a standard venting elbow.

D319IE0A

504509 31

Page 34

Multi-Dryer Installation

Exhaust Requirements

• The illustration below shows a typical example of a

multiple dryer ins tallation. Not e how e ach dryer ha s its

own exhau st syst em vented to the central exhaust duct.

58786

BACKDRAFT

DAMPER

(Available

through

your local

authorized

parts source)

. . .

•

•

•

•

•

•

•

•

•

CLEAN-OUT

COVER

MUST BE

PROVIDED

E

T

A

IC

L

E

D

SS

E

T)

FF

R

A

U

P

E

M

FL

H

R

O

E

P

(N

L

R

A

O

M

T

R

C

O

E

N

R

L

E

E

T

Y

S

R

R

A

IC

T

D

R

S

B

O

A

F

T

H

S

U

P

E

S

U

E

IN

S

U

IN

E

S

E

IN

R

R

685559

U

T

A

R

E

P

IN

M

S

P

E

S

S

E

T

R

H

T

P

S

R

M

D

A

A

R

L

T

E

W

O

P

C

S

O

T

H

S

U

P

T

O

H

R

O

T

R

C

E

E

L

H

S

E

S

S

S

E

A

R

IC

P

W

R

M

B

TE

R

A

A

E

P

F

LIC

E

D

L

A

M

R

O

N

TE

A

IC

L

E

D

S

S

E

F

T)

F

A

PR

E

LU

M

F

H

R

O

E

P

(N

L

R

A

O

M

T

R

C

O

E

N

R

L

E

E

T

Y

S

R

R

A

IC

T

D

R

S

B

O

A

F

T

H

S

U

P

E

S

U

E

IN

S

U

IN

E

S

E

IN

R

R

685559

U

T

A

R

E

P

IN

M

S

E

S

SP

E

T

R

H

T

P

S

R

M

A

A

R

LD

T

E

W

O

P

C

S

O

T

H

S

U

P

T

O

H

R

O

T

R

C

E

E

L

H

S

E

S

S

S

E

A

R

IC

P

W

R

M

B

TE

R

A

A

PE

F

LIC

E

D

L

A

M

R

O

N

E

T

A

IC

L

E

D

S

S

E

T)

FF

R

A

P

E

LU

M

F

H

R

O

E

P

(N

L

R

A

O

M

T

R

C

O

E

N

R

L

E

E

T

Y

S

R

R

A

IC

T

D

R

S

B

O

A

F

T

H

S

U

P

E

S

U

E

IN

S

U

IN

E

S

E

IN

R

R

685559

U

T

A

R

E

P

IN

M

P

E

SS

S

E

T

R

H

T

P

S

R

M

A

A

R

LD

T

E

W

O

P

C

S

O

T

H

S

U

P

T

O

H

R

O

T

R

C

E

E

L

H

S

E

S

S

S

E

A

R

IC

P

W

R

M

B

TE

R

A

A

E

P

F

LIC

E

D

L

A

M

R

O

N

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

IMPORTANT: Static pressure in dryer’s exhaust

duct should be n o greater than t hat shown in th e chart

on Page 31. This can be measured with a manometer

placed on the exhaust duct approximately two feet

(61 cm) from the dryer. See Page 31. All dryers

connected to the main collector du ct should be in

operation when pressure is checked.

Installing an exhaust system does not eliminate the

necessity of cl eaning the dryer li nt filter before each load.

The dryer interior and the complete exhaust system

should be cleaned periodically by a qualified service

person to remove any lint build-up.

H246IE1A

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

before cleaning.

W043

32 504509

Page 35

• Dryer exhaust duct should enter the main duct at an

angle of no more than 30

° pointing in the direction of

the air flow. Ducts entering the main duct from

opposite sides s houl d be staggered so as not to o ppose

each other. See illustration below.

DRYER EXHAUST DUCT

AIR FLOW MAIN COLLECTOR DUCT

DRYER EXHAUST DUCT

30°

30° 30°

DRYER EXHAUST DUCT

• Provisions should be made for periodic lint removal

and cleaning of the main collector duct.

• The outside end of the main duct should ha ve a weather

hood (with hinged dampers) installed to prevent

passage of weather e lements, insects, d ust, and dirt into

the dryer.

• If a weather hood cannot be used, the outside end of the

main duct should hav e a s weep elbo w insta lled, and be

directed downward as shown on the fol lowing page. If

the main duct travels vertically through a roof rather

than through a wall, install 180

° sweep elbow on the

end of the duct with outlet at least 24 inches (61 cm)

above the highest part of the building.

DRYER EXHAUST DUCT

30°

D026IE3A

• Sufficient make-up air must be supplied to replace air

exhausted from dryer.

NOTE: Where the exhaust duct pierces the wall or

ceiling, an opening having a dia meter of 4 inches (10.2

cm) larger than the diameter of the exhau st duct shall

be provided, and the exhaust d uct centered within t he

opening.

• Damper, Part No. 5 8786, sh ould be in stalled in dryer ’s

exhaust system. This will prevent a backdraft when

dryer is not in use, and will keep the exhaust air in

balance within the central exhaust system.

IMPORTANT: Provisions must be made for make-up

air.

WARNING

IMPORTANT: If several dryers are exhau sted i nto a

main collector duct, it is essential that ductwork be

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

adequate in size and properly const ructed for efficient

operation.

exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated area,

such as an attic, wall, ceiling, crawl space

under a building or concealed space of a

building.

W045

504509 33

Page 36

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

180˚ SWEEP

ELBOW

(No cap

or screen)

PARAPET

MAIN COLLECTOR DUCT

WALL

• Main collector duct should be sized according to

specifications shown below.

Number

of Dryers

Minimum Diameter of

Horizontal Collector Duct

2 7 inch (17.8 cm) 8 inch (20.3 cm)

3 8 inch (20.3 cm) 9 inch (22.9 cm)

4 9 inch (22.9 cm) 10 inch (25.4 cm)

5 10 inch (25.4 cm) 11 inch (27.9 cm)

24" MIN.

(60.96 cm)

MAIN COLLECTOR DUCT

ROOF

Minimum Diameter of

Vertical Collector Duct

D039IE3A

6 11 inch (27.9 cm) 12 inch (30.5 cm)

7 12 inch (30.5 cm) 13 inch (32.6 cm)

8 12 inch (30.5 cm) 14 inch (35.6 cm)

9 13 inch (32.6 cm) 15 inch (38.1 cm)

10 14 inch (35.6 cm) 15 inch (38.1 cm)

11 14 inch (35.6 cm) 16 inch (40.6 cm)

NOTE: Main collector duct should be equipped with

an auxiliary fan that can mainta in the duct airf low at

a minimum of 1200 feet (366 m) pe r minute. If you do

not have a fan, clean the main collector duct at least

twice a year.

34 504509

Page 37

Lint Filter

. . .

CLEAN THE LINT FIL TER BEFORE DR YING EA CH

LOAD. (Refer to illustration below for lint filter

location.) Cleaning the lint filter is important because a

layer or pad of lint on th e filter will block the f low of air

through the dryer, thus reducing the efficiency of the

dryer . The cl othes will take l onger to dry and ener gy wil l

be wasted.

LINT

FILTER

H247IE1A

Dryer Motor Overload Protector

The motor ov erload protector stops the motor in the even t

of an over load. After co oling, the ov erload pr otector will

reset itself. The dryer can be restarted by pressing the

PUSH-TO-START button. If the overlo ad protector

cycles again, remove the unit from use and call the