Page 1

Frontload Washers

FLW1525C

Metered Commercial

NOTA: Para bajar una

copia de estas

instrucciones en

español, visite

www.comlaundry.com.

Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. 802951R3

August 2010

Page 2

Page 3

NOTE: The WARNING and IMPOR TANT instruct ions appearing i n this manual are no t meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution, and

carefulness are factors which cannot be built into these washers. These factors MUST BE supplied by the

person(s) installing, maintaining, or operating the washer.

Always contact the distributor, service agent, or the manufacturer about any problems or conditions you do not

understand.

Failure to install, maintain, and/or operate this machine according to the manufacturer's

instructions may result in conditions which can produce bodily injury and/or property

damage.

W030

WARNING

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Installation........................................................................................... 5

Dimensions and Specifications............................................................. 5

Before You Start................................................................................... 6

Tools ................................................................................................ 6

Installing the Washer............................................................................ 7

Step 1: Position Washer Near Installation Area .............................. 7

Step 2: Position and Level the Washer ............................................ 7

Step 3: Connect Fill Hoses............................................................... 8

Step 4: (Non-Gravity Drain Models Only)

Connect Drain Hose to Drain Receptacle....................................... 10

Step 5: (Gravity Drain Models Only)

Connect Drain Outlet to Drain System........................................... 11

Step 6: Remove the Shock Sleeves and Shipping Brace ................. 12

Step 7: Wipe Out Inside of Wash Drum.......................................... 12

Step 8: (Supply Injection Models Only)

Connect External Supplies to Washer............................................ 12

Control Function Test...................................................................... 13

Step 9: Plug In the Washer............................................................... 14

Step 10: Check Installation.............................................................. 15

Operation............................................................................................. 16

Operation Instructions .......................................................................... 16

Step 1: Load Laundry....................................................................... 16

Step 2: Close Loading Door............................................................. 16

Step 3: Add Laundry Supplies......................................................... 17

Step 4: Set Fabric Selector............................................................... 17

Step 5: Set Wash Temperature......................................................... 17

Step 6: Set Soil Level....................................................................... 18

Step 7: Insert Coin(s) or Card.......................................................... 18

Step 8: Start Washer......................................................................... 18

Indicator Lights................................................................................ 19

Maintenance........................................................................................ 20

User-Maintenance Instructions............................................................. 20

Lubrication....................................................................................... 20

Cold Weather Care........................................................................... 20

Care of Your Washer....................................................................... 20

Cleaning Glass Sealing Area ........................................................... 20

Replacing Hoses............................................................................... 20

Filter Screens ................................................................................... 20

Vacations and Extended Non-Use................................................... 20

Reinstallation of Shipping Materials ............................................... 21

Cleaning Foreign Object Trap ......................................................... 21

Troubleshooting.................................................................................. 22

Contact Information........................................................................... 24

Installer Checklist................................................................ Back Cover

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 5

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation t hat, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation t hat, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING ,” and “CAUTION”) followed by specif ic

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

Important Safety Instruction s

(Save These Instructi ons)

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash articles that have been previ ously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water . These substa nces give off vapors that

could ignite or explode.

Additional precauti ona ry statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used t o communic ate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this ti me.

6. Do not allow children to play on or i n the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances .

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

9. Do not install o r sto re th e washer where it wi ll be

exposed to water and/or weather.

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

10. Do not tamper with the controls.

3

Page 6

Safety Information

11. Do no t repair or re place any part of the washer , o r

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

12. T o redu ce the r isk of an electr ic sho ck or fi re, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use your washer only for its intended purpose,

washing clothes.

14. ALWAYS disconnect the washer from electrical

supply before att empting any se rvice. Discon nect

the power cord by gr aspi ng the plug, no t the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for wate r , drain, elect rical power and

grounding must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

16. To reduce the risk of fire, clothes which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or an ything

containing wax or chemical s such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep your washer in g ood conditio n. Bumping or

dropping the washer can damage safety features.

If this occurs, have your washer checked by a

qualified service person.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or sp in. DO NOT bypass

the loading door switch by pe rmitt ing the wash er

to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on pac kage s of l aund ry and cleaning

aids. Heed all warnin gs or pre cautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the garment manufacturer.

24. Never operate the wash er with any gua rds and/ or

panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that ma y occ ur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Always contact your dealer, distributor, service agent

or the manufacturer about any problems or conditions

you do not understand.

19. If the supply cord is damaged, it must be replac ed

by a special cord or assembly available from the

manufacturer or its service agent.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 7

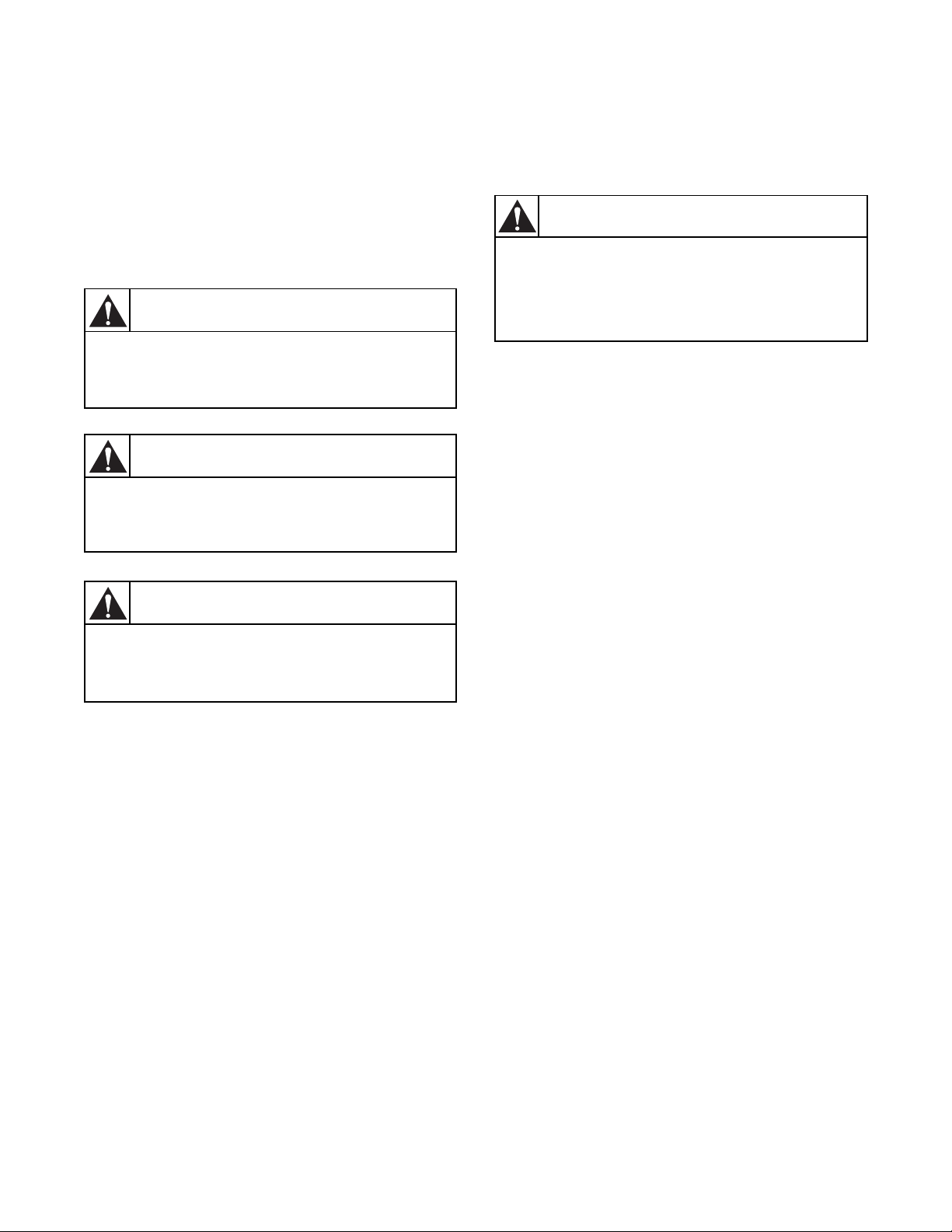

Installation

FLW2258N

2 in.

(5.1 cm)

42.25 in. (107.2 cm)

Stainless Stee l Models

Through Serial No. 100 501 87 19

43 in. (109.2 cm) All Other Models

29.6 in. (75.1 cm)

28 in. (71.1 cm)

24 in.

(61.0 cm)

26.9 in. (68.3 cm)

31.1 in. (79 cm)

2 in.

(5.1 cm)

36.94 in. (93.83 cm)

14.6 in.

(37.08 cm)

13.1 in.

(33.3 cm)

MODELS EQUIPPED WITH DRAIN HOSE

1.5 in.

(3.8 cm)

FLW2259N

2 in.

(5.1 cm)

29.6 in. (75.1 cm)

28 in. (71.1 cm)

24 in.

(61.0 cm)

26.9 in. (68.3 cm)

31.1 in. (79 cm)

4.1 in.

(10.41 cm)

36.94 in. (93.83 cm)

14.6 in.

(37.08 cm)

13.1 in.

(33.3 cm)

MODELS WITH GRAVITY DRAIN

4.2 in.

(10.67 cm)

1

1.5 in.

(3.8 cm)

42.25 in. (107.2 cm)

Stainless Steel Models

Through Serial No. 1005018719

43 in. (109.2 cm) All Other Models

Dimensions and Specifications

FLW2258N

1 1.5 in. (3.81 cm) Inside Diameter

1.86 in. (4.72 cm) Outside Diameter

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FLW2259N

5

Page 8

Installation

1

2

3

5

4

Before You Start

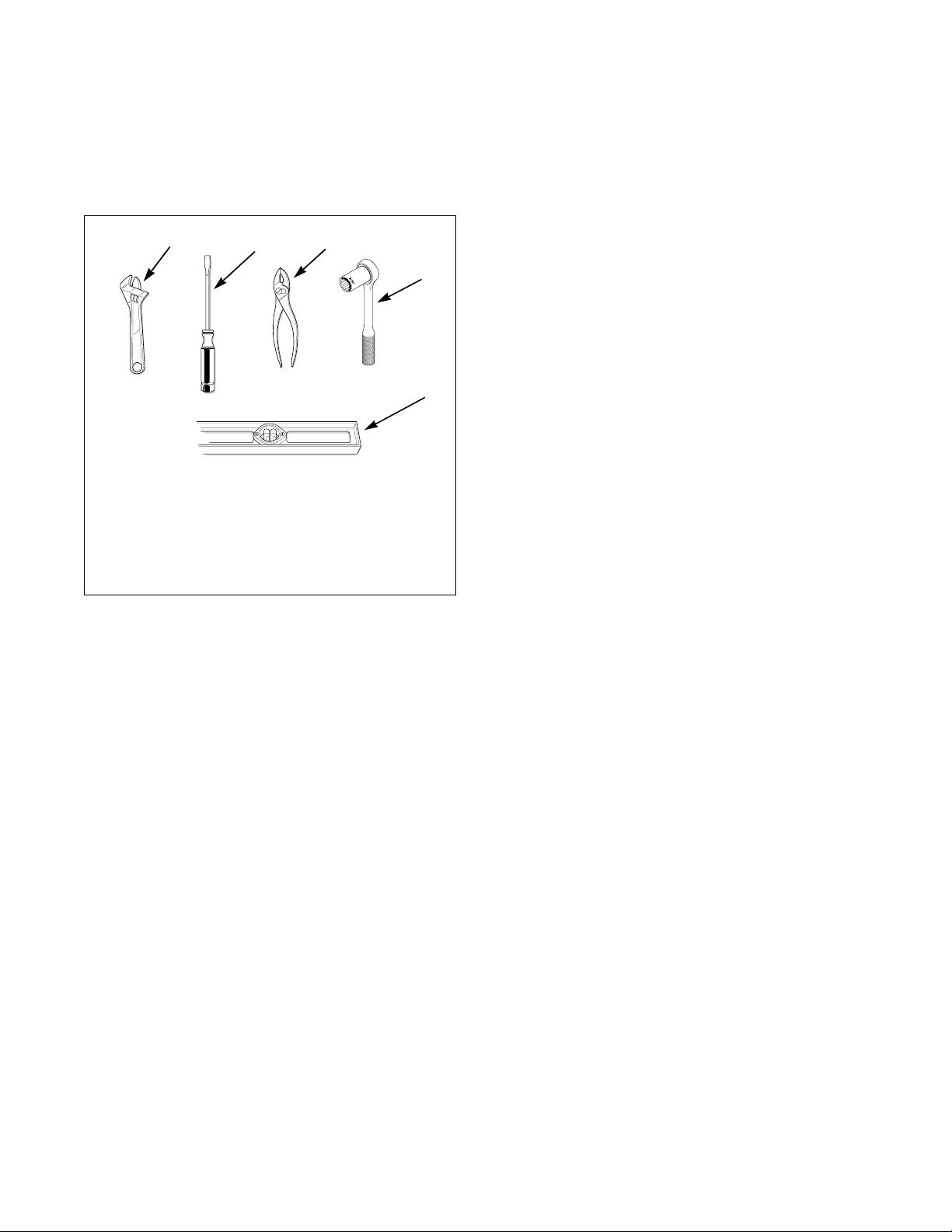

Tools

For most installations, the basic tools you will need

are:

D074I

1 Wrench

2 Screwdriver

3 Pliers

4 Socket Wrench

5 Level

NOTE: An 8 in. (20.32 cm) coin drawer i s required

for coin operated models.

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

NOTE: Install dryer before washer. This allows

room for attaching exhaust duct.

NOTE: Some moisture in th e wash drum is normal .

Water is used during testing at the manufacturer.

Figure 1

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 9

Installation

+,($

Washers elevated above floor level must

be anchored to that elevated surface,

base or platform. The material used to

elevate the washer should also be

anchored to the floor to ensure that the

washer will not walk or that the washer

can not be physically pulled, tipped or

slid from its installed position. Failure to

do so may result in conditions which can

produce serious injury, death and/or

property damage.

W306

WARNING

Installing the Washer

Step 1: Position Washer Near Installation

Area

Move washer so that it is within 4 feet (1.2 meters) of

the desired area of inst allation.

NOTE: For best performance and to minimize

vibration or movement, install washer on a solid,

sturdy and level floor. Some floors may need to be

reinforced, especially on a second floor or over a

basement. Do not install the washer on carpeting,

soft tile, a platform or other weakly supported

structures.

Step 2: Position and Level the Washer

Position washer so it has sufficient clearance for

installation and servicing.

NOTE: Use of the dispenser drawer or washer door

as a handle in the transportat ion of t he washer may

cause damage to the dispenser or door.

Place washer in position on a solid, sturdy and level

floor. Installing the washer on any type of carpeting,

soft tile, a platform or other weakly supported

structures is not recommended.

Figure 2

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

H054I

Place a level on the cabinet top and check if the

washer is level from side to side and front to back.

NOTE: Level must rest on raised portion of top

panel. Refer to Figure 3.

If washer is not level, tilt w asher to acce ss the front

and rear leveling legs. For easier access to leveling

legs, prop up washer with a wooden block. Refer to

Figure 3. Loosen 7/8 in. locknut and adjust legs until

the washer is level from side to side and front to back

(using a level). Washer should not rock.

Tighten the locknuts securely against the washer

base using the 7/8 in. wrench. If the locknuts are not

tight, washer will move out of positi on dur in g

operation.

7

Page 10

Installation

2

1

3

5

6

4

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used

for such a period and before using the

washer, turn on all hot water faucets and

let the water flow from each for several

minutes. This will release any

accumulated hydrogen gas. The gas is

flammable. Do not smoke or use an open

flame during this time.

W029

WARNING

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

NOTE: DO NOT slide washer across floor if the

leveling legs have been extended, as legs and base

could become damaged.

Remove rubber feet fr om accessori es bag and pl ace on

all four leveling legs.

Verify that unit doesn’t rock.

FLW2114N

FLW2114N

1 Leveling Leg

2 Washer Base

3 Level

4 Wood Block

5 Locknut

6 Rubber Foot

Figure 3

Step 3: Connect Fill Hoses

Water Supply

Water supply faucets must fit standard 3/4 inch

(19.1 mm) female garden hose couplings. DO NOT

USE SLIP-ON OR CLAMP-ON CONNECTIONS.

Water supply faucets should be readily accessible to

permit turning them off when washer is not being

used.

Recommended cold water temperature is 60° to 80°

Fahrenheit (16° to 27 Celsius). Recommended

maximum hot water temperature is 125° Fahrenheit

(51° Celsius). Warm water is a mixture of hot and cold

water. Warm water temperature is dependent upon

water temperature and pressure of both the hot and

cold water supply lines.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Water pressure must be a minimum of 20 to a

maximum of 120 pounds per square inch (138 to 827

kPa) static pressure measured at the faucet.

NOTE: Water pressure under 20 pounds per

square inch (138 kPa) will cause an extended fill

time in the washer and may not properly flush out

the detergent dispenser.

802951

Page 11

Installation

HOT

COLD

2

1

3

4

2

1

3

4

WATER

MIXING

VALVE

Turn on th e water supp ly faucets an d flush the li nes for

approximately two minutes to remove any foreign

materials t hat could clog the screen s in the water

mixing valve.

NOTE: When installing in newly constructed or

renovated building, it is very important to flush the

lines since build-up may have occurred during

construction.

Connecting Hoses

Insert each filter screen i nt o the end of each fill hose

that will connect to the water supply faucet. The screen

must be facing outward. Refer to Figure 4.

Insert each plain rubber washer into the other end of

each fill hose that will connect to the water mixing

valve at the rear of the washer. Refer to Figure 4.

Thread hose couplings onto valve connections fingertight, then approximately 1/4 turn with pliers.

IMPORTANT: DO NOT cross thread or

overtighten couplings.

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a monthly basis for

any visible signs of deterio ration. Any ho se showing

the signs of deterioration listed above should be

replaced immediatel y. All hoses should be replaced

every five years.

FLW1974N

FLW1974N

1 Water Supply Faucets

2 Hot Water Connection

3 Cold Water Connection

4 Fill Hoses

Figure 5

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water s upply whenever there will be an

extended period of non-use.

NOTE: Longer fill hoses are available (as optional

equipment at extra cost) if the hoses supplied with

the washer are not long enough for the i nst all at ion .

Order hoses as follows:

TLW1976N

1 Faucet

2 Fill Hoses

3 Plain Rubber Washe r

4 Filter Screens

Figure 4

No. 20617 Fill Hose (8 feet) (2.44 m)

No. 20618 Fill Hose (10 feet) (3.05 m)

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

W005I

2

1

1

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets (refer to

Figure 6).

W005I

1 Risers (Air Cushions)

2 Water Supply Faucets

Step 4: (Non-Gravity Drain Models Only)

Connect Drain Hose to Drain Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by removing the shipping tape.

IMPORTANT: Drain r eceptacle must be capabl e of

handling a minimum of 1-3/8 inch (3.5 cm) outside

diameter drain hose.

Figure 6

FLW1963N

1 Shipping Tape

Figure 7

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 13

Installation

Flw1964N

1

24 TO 36 in.

(61 TO 91.4 4 cm)

RECOMMENDED

HEIGHT

2

1

Standpipe Installation

Place the drain hose into the standpipe.

Remove the beaded tie-down strap from accessories

bag and place around standpipe and drain hose and

tighten strap to hold hose to standpipe. Refer to

Figure 8. This will prevent the drain hose from

dislodging from drain receptacle during use.

Step 5: (Gravity Drain Models Only)

Connect Drain Outlet to Drain System

Remove drain fitting (four inches long) and hose

clamp from accessories bag. Insert drain fitting into

drain outlet hose. Clamp hose and fitting.

Connect the drain fitting to a vented drain system

using a flexible connection (obtain locally). Inside

diameter of fitting is 1.53 in. (3.89 cm) and outside

diameter is 1.66 in. (4.22 cm). The drain system must

be vented to prevent an air lock or siphoning.

IMPORTANT: Increasing the drain hose length,

installing elbows, or causing bends will decrease

drain flow rates and increase drain times,

impairing machine performance.

FLW1964N

1 Standpipe 2 in. (5.08 cm) or 1-1/2 in. (4 cm)

Figure 8

Flw1935N

FLW1935N

1 Drain Trough

2 Drain Outlet Hose

Figure 9

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation

2

1

4

3

Step 6: Remove the Shock Sleeves and

Shipping Brace

Remove front access panel by removi ng the two s crews

at the bottom of the panel.

Remove the five bolts and lockwashers from shipping

brace with 9/16 in. wrench a nd remove br ace. Ref er to

Figure 10. One is holding the brace to the weight.

Remove this bolt first. Four bolts are located on the

washer base. Remove the two front bolts ne xt and the n

the two rear bolts. Remove all four shock sleeves by

pulling on the yellow rope. Remove label from front

side of front access panel or shipping brace and place

on backside of front ac cess panel for future reference.

NOTE: The shipping brace, bolts, washers and

shock sleeves should be saved and MUST be

reinstalled whenever th e washer is moved more

than four feet. Refer to User-Maintenance section

for instructions. Do not lift or transport washer

from front or without shipping materials installed.

Store the shipping materials in the accessories bag.

Save materials for use whenever the washer is moved.

Reinstall front access panel.

IMPORTANT: DO NOT tip washer more than

6 inches (152.4 mm) in any direc tion af te r shipping

brace has been removed. Shock absorbers may

separate and damage to washer may result. For

leveling purposes, the washer may be tilted a

maximum of 6 inches (152.4 mm) in any direction.

Step 7: Wipe Out Inside of Wash Drum

Before using washer for t he first time, use an all-purpose

cleaner , or a det ergent and water soluti on, an d a damp

cloth to remove shipping dust f rom in side wash dr um.

FLW2115N

Figure 11

Step 8: (Supply Injection Models Only)

Connect External Supplies to Washer

IMPORTANT: Undiluted chemical dripping can

damage the washer.

1. Remove two nozzles from accessories bag. Use

either the 3/8 inch or 1/ 4 inch nozzl es, dependi ng

on the diameter of the dispenser tubing used.

2. Attach nozzles to rear of machine. Connection

point located on cabinet, above water mixing

valve. Refe r to Figure 12.

3. Connect supply hoses to noz zle s and secure with

hose clamps (obtain locally). Refer to Figure 12.

NOTE: Hoses can be connected to either nozzle.

4. Refer to supply injection system instructions and

label inside washer junction box cover

(Figure 13) for electrical conn ection.

Do not attempt to make supply injection

electrical connections to points other than those

FLW2124N

1 Shock Sleeves

2 Motor Mount

3 Hooked End of Shipping Brace

4 Bolts and Lockwashers

Figure 10

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FLW2124N

provided specifically for that purpose by the

factory.

5. Refer to supply injection system instructions for

details on operation.

802951

Page 15

Installation

Wear eye and hand protection when

handling chemicals; always avoid direct

contact with raw chemicals. Read the

manufacturer’s directions for accidental

contact before handling chemicals. Ensure

an eye-rinse facility and an emergency

shower are within easy reach. Check at

regular intervals for chemical leaks.

SW016

WARNING

2

1

3

DETERGENT

DISPENSER

CONNECTION

SOFTENER

DISPENSER

CONNECTION

SOFTENER

RELAY

DETERGENT

RELAY

CHEMICAL INJECTION

ELECTRICAL INTERFACE

NO CONNECTION

TERMINAL

BLOCK

YELLOW

YELLOW/BLACK

RED

RED/BLACK

801653R1

NOTE: Normally Open Contacts.

Contacts Close to Start Chemical Injection.

Maximum Load Connection per Contact:

1A @ 120VAC/240VAC

Supply Injection System

Number of liquid supply connections

(1–Detergent and 2–Softener)

Liquid supply connection size,

in. (mm)

2

3/8 (9.52)

or

1/4 (6.35)

A junction box on the rear panel houses a terminal

strip which furnishes supply output signals for the

supply injection pumps. Refer to Figure 13 for the

injection interface label.

1 Injection Point

2 Nozzle

3 Supply Dispenser Pump Outlet

Figure 12

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FLW2028N

Figure 13

These terminals may be used to provide signals to the

supply injection system but must not be used to

provide power to the actual pump.

Any injection system pump which requires

110 VAC must be powered by a separate external

power source.

Control Function Test

The washer should be cleaned after the installation is

complete. A function test should then be executed on

the unloaded machine:

FLW2116N

1. Check the power supply for such characteristics

as correct volt age, pha se, and cyc les t o be cert ain

they are correct for the washer.

2. Open manual shut-off valves to the washer.

3. Apply power to the washer.

13

Page 16

Installation

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA No. 70, and such local

regulations as might apply. It is the

customer’s responsibility to have the

wiring, fuses and circuit breakers

installed by a quali fied electrician to make

sure adequate electrical power is

available to the washer.

W518

WARNING

1

2

3

4

5

Standard 120 Volt, 60 Hertz

3-Wire Effectively

Grounded Circuit

0 V.A.C.

120±12

V.A.C.

120±12

V.A.C.

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

WARNING

Step 9: Plug In the Washer

Electrical Requirements

(120 Volt, 60 Hertz with 3-Prong Grounding Plug)

NOTE: The wiring diagram is located in the

control cabinet.

When plugging in the washer:

DO NOT overload circuits.

DRY2022N

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

DO NOT use an extension cord.

DO NOT use an adapter.

DO NOT operate other appliances on the same

circuit. Use separately fused 15 Amp circuits.

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current), circuit

protected by a 15 amper e fus e, equivalent fusetron or

circuit breaker.

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figure 14

to determine correct polarity of the wall receptacle.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 14

802951

Page 17

Installation

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is

properly grounded.

W327

WARNING

Grounding Instructions

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current.

The washer is equipped with a cord having an

equipment-grounding conductor and a three-prong

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

DO NOT modify the plug provided with the washer –

if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

Step 10: Check Installation

Refer to Installer Checkl ist on the back cover of this

manual and make sure that washer is installed

correctly.

Run washer through one complete cycle to make sure

it is operating properly.

NOTE: Have a qualified electrician check the

polarity of the wall receptacle. If a voltage reading

is measured other than that in Figure 14, the

qualified electrician should correct the problem.

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Operation

Operation Instructions

IMPORTANT: Prior to first was h, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washtub.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Load Laundry

Load items loosely into wash drum.

NOTE: Small items such as baby socks may get

caught around the door. Place these articles insi de a

mesh garment bag.

Step 2: Close Loading Door

Close loading door tightly. The washer will not

operate with the loading door open.

FLW2227N

Figure 16

FLW2226N

Figure 15

When washing bulky items such as blankets and

comforters, use the DELICATES/BULKY cycle. The

cycle includes agitation and final spin speeds that

maintain the load’s balance and minimize wear to the

articles.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 19

Operation

Dispenser drawer requires a special tool

for removal. Contact a service person if

removal is necessary.

W236

CAUTION

Step 3: Add Laundry Supplies

Open dispenser drawer. Measure and add low sudsing,

high efficiency (HE) detergent (1), bleach (2) and

fabric softener (3) to the dispenser drawer (refer to

Figure 17). Close dispenser drawer.

IMPORTANT: If using non-HE detergent, avoid

oversudsing by using 1/2 of the detergent

manufacturer’ s recommended amount.

3

1

2

2

4

9

5

8

6

Step 4: Set Fabric Selector

Push touchpad for NORMAL, PERM PRESS or

DELICATES/BULKY cycle. Ligh t indicates

selection.

NOTE: Changes can be made to Fabric Selector

setting up until the first fill is complete.

FLW2228N

Figure 18

Step 5: Set Wash Temperature

Push touchpad for HOT, WARM or COLD. Light

indicates selection.

1 Detergent

2 Bleach

3 Fabric Softener

Figure 17

NOTE: Always follow manufacturer’s care labels.

FLW2236N

FLW2236N

FLW2229N

Figure 19

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Operation

Step 6: Set Soil Level

Push Soil Level touchpad to select LIGHT, MEDIUM

or HEAVY. Light indicates selection.

FLW2230N

Figure 20

Step 7: Insert Coin(s) or Card

To Insert Money

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

Step 8: Start Washer

After vend price has been satisfied, push the START

pad. DOOR MUST BE CLOSED TO START

WASHER.

FLW2231N

Figure 23

To Insert Card

Insert card into opening.

18

W387I

Figure 21

DRY1927N

Figure 22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 21

Operation

To reduce the risk of bodily injury, do not

remove laundry from washer until all

lights are out, and all moving parts have

stopped.

W092

WARNING

Indicator Lights

INSERT COINS/CARD

INSERT COINS/CARD is lit to prompt the user to

insert coins or card to satisfy the vend price. When

INSERT COINS/CARD is lit, the digits show the ven d

price remain ing to be satisfied.

WASH

WASH is lit during the WASH portions of the cycle.

RINSE

RINSE is lit during the RINSE portions of the cycle.

SPIN

SPIN is lit during the final spin portion of the cycle.

DOOR

DOOR is lit whenever the door is locked. The door

cannot be opened when this light is on.

LIGHT

LIGHT is lit when the LIGHT soil level is selected.

MEDIUM

IMPORTANT: If washer fails to operate properly

after installation, make sure electrical service and

water supply faucets are turned on. Are all the

controls properly set? Have a qualified service

person refer to the wiring diagram (located inside

of washer control cabinet) and check for broken,

loose or incorrect wiring.

NOTE: Once a cycle has started, the door can only

be opened by first unplugging the power cord and

waiting one minute.

MEDIUM is lit when the MEDIUM soil level is

selected.

HEAVY

HEAVY is lit when the HEAVY soil level is selected.

START

START flashes one second on and one second off

when the full vend price has been satisfied.

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Maintenance

User-Maintenance Instructions

Lubrication

All moving parts are sealed in a permanent supply of

lubricant or are equipped with oilless bearings.

Additional lubrication will not be necessary.

Do not lubricate the door hinge. If the hinge makes

noise, replace the hinge.

Cold Weather Care

If the washer is delivered on a cold day (below

freezing), or is stored in an unheated room or area

during the cold months, do not attempt to operate it

until the washer has had a chance to warm up.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the

control panel. Some cleaning product sprays may

harm the finish on the control panel or damage the

interior.

Wipe the washer cabinet as needed. If detergent,

bleach or other washing products are spilled on the

cabinet, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Do not use scouring pads or abrasive cleansers.

The wash drum will need no particula r care although it

may need rinsing or wiping after an unusual load has

been washed.

The outside of the door window can be cleaned with

household window cleaner.

Replacing Hoses

Hoses and other natural rubber parts deteriorate after

extended use. Hoses may develop cracks, blisters or

material wear from the temperature and constant high

pressure they are subjected to.

All hoses should be checked on a monthly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

Filter Screens

Check the filter screens in the fill hoses for debris or

damage annually. Clean or replace them if necessary.

If the washer is filling with water slowe r than normal,

check the filter screens. Clean or replace them if

necessary.

Order filter screen Part No. F270300 from the nearest

authorized parts distributor.

V acations and Extended Non-Use

IMPORTANT: To avoid possible property damage

due to flooding, turn off the water supply to the

washer whenever there will be an extended period

of non-use.

Leave the loading door open during extended periods

of non-use to allow the wash drum to dry out and

avoid a musty smell.

Running an occasional rinse cycle with bleach will

help to avoid a musty smell in the wash drum.

Cleaning Glass Sealing Area

In order to assure that the door properly seals against

water leaks, the following surfaces should be wiped

off periodically:

The outside peri meter of the do or glass where the

seal contacts the glass

The front surface of the door seal lip

Usually a mi ld soap solut ion will work. If there is an

extreme build-up of minerals from a hard water

supply, the surfaces may need to be cleaned with a

lime removal chemical.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 23

Maintenance

FLW2124N

2

1

4

3

Reinstallation of Shipping Materials

To prevent damage while moving the washer, the

shipping materials MUST be reinstalled.

Disconnect washer from electrica l supply.

While supporting the front access panel, remove

two screws from the bottom edge of the panel.

Gently lower the panel t o remove it fr om the

washer.

Place the shock sleeves on all four shock

absorbers. Refer to Figure 24.

Insert hooked en d of ship ping brac e into the ope n

slot of the motor mount. Refer to Figure 24.

Attach the brace with the five bolts and washers.

Refer to Figure 24.

Reinstall front access panel.

Cleaning Foreign Object Trap

The washer’s p ump ha s a trap that may collect foreign

objects. The trap may need to be cleaned if water is

draining slower than usual. To clean:

Disconne ct washer from electrical supply.

While supporting the front access panel, remove

two screws from the bottom edge of the panel.

Gently lower the panel to remove it from the

washer.

NOTE: The pump may have some water in it. Use a

rag or a container t o c atc h wat er. If the wash drum

is full of water, use a wet/dry shop vacuum to catch

the water.

With rag or vacuum ready, unscrew the cap on

the left side of the pump and remove trap.

Clean the debris from the trap.

Reinstall the trap and access panel.

Reconnect washer to electrical supply.

FLW2124N

1 Shock Sleeves

2 Motor Mount

3 Hooked End of Shipping Brace

4 Bolts and Lockwashers

Figure 24

Refer to Installation section, step 6 for proper

procedures whenever the washer is moved.

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Troubleshooting

Try these troubleshooting tips before making a service call. They may save time and money.

Washer Symptom Possible Cause/Solution

Won’t Fill

Won’t Start

Won’t Spin/Tumble

Stops/Pauses During

Cycle

• Make sure power cord is plugged all the way into the electrical outlet.

• Make sure hot and cold water faucets are turned on.

• Make sure that the fill hoses are not kinked or twisted.

•Press START keypad.

• Make sure that the controls are properly set.

• Make sure that the loading door is closed tightly.

• Check the laundry room fuse or circuit breaker.

• Clean the screens in the water mixing valve and the filter screens located at the faucet end

of the fill hoses.

• Make sure loading door is closed tightly.

•Press START keypad.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• Insert coin(s) or card.

• Make sure door latch is properly adjusted relative to door lock.

• Make sure loading door is closed tightly.

•Press START keypad.

• Make sure power cord is plugged all the way into the electrical outlet.

• Make sure controls are properly set.

• Check the laundry room fuse or circuit breaker.

• Broken drive belt. Call the service person.

• Foreign object trap in pump may be clogged. Clean the trap. Refer to

Maintenance section.

• Pauses are part of the washer’s normal operation.

• Wash load may be unbalanced. Washer will stop and then restart spin automatically.

• Check the laundry room fuse or circuit breaker.

Won’t Drain

Water Leaks

Too Many Soap Suds

• Make sure drain hose is not kinked or twisted.

• Make sure drain hose is not clogged.

• Make sure drain receptacle is not clogged.

• Refer to the Installation section to make sure that the drain hose has been properly

installed.

• Foreign object trap in pump may be clogged. Clean the trap. Refer to Maintenance

section.

• Check that fill hoses are properly installed on the faucets and the washer’s water mixing

valve.

• Check the condition of the fill hoses. Replace fill hoses every five years.

• Check the condition of the rubber door gasket for tears or holes.

• Make sure drain receptacle is not clogged.

• Check building plumbing.

• Laundry load may be oversudsing or overloaded. Make sure you are using low-sudsing,

high efficiency (HE) detergent and proper load sizes.

• Make sure outside perimeter of the door glass where seal contacts glass is clean.

• Laundry load may be oversudsing. Make sure you are using low sudsing, high efficiency

(HE) detergent.

• Make sure you are using the amount of detergent recommended on the detergent’s label.

If using non-HE detergent, use only 1/2 of the detergent manufacturer’s recommended

amount.

• Laundry load may be overloaded. Make sure you are using proper load sizes.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

802951

Page 25

Washer Symptom Possible Cause/Solution

Troubleshooting

Vibrates/Moves

Slightly

Is Noisy

Load is too Wet

Wrong Water

Temperature

• Make sure washer is level. Uneven leveling can cause vibration.

• Make sure washer is installed on a solid, sturdy and level floor. The washer should not be

installed on carpeting, soft tile, a platform or other weakly supported structures.

• Make sure rubber feet are installed on all four leveling legs. Refer to Installation section,

step 5.

• Make sure washer is level. Uneven leveling can cause vibration.

• Some sounds may be a par t of normal op eration for a frontload washer.

• Wash load may be unbalanced. The washer may have limited the spin speed to prevent

damage to the machine. Redistribute the load.

• Load is too small. Add items to make full load.

• Make sure that the controls are properly set.

• Check fill hoses. Make sure hot faucet hose is connected to hot mixing valve (indicated

with “H” on the valve bracket) and cold faucet is connected to cold mixing valve (indicated with “C” on the valve bracket).

• Make sure laundry room water heater is adjusted properly.

802951

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Contact Information

1

T o reduce t he risk of serious injur y or death,

DO NOT repair or replace any p art of the uni t

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have

the skills to carry out.

W329

WARNING

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to lo cate an aut horized s ervice ce nter

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.comlaundry.com

Phone: (920) 748-3121

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS. The

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in Figure 25.

Date Purchased ___________________________

Model Number ___________________________

Serial Number ___________________________

Please include a copy of your bill of sale and any

service receipts you have.

If replacement parts are required, contact the source

from where you purchased your washer or call

(920) 748-3950 for the name and address of the

nearest authorized parts distributor.

1 Nameplate

Figure 25

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FLW2123N

FLW2123N

802951

Page 27

Page 28

Installer Checklist

+,($

Flw1964N

Flw1935N

D254IE0A

FLW2115N

FLW2124N

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

• Position Washer

Near Installation

Area.

CHECK

• Position and Level

the Washer.

CHECK

• Connect Fill Hoses.

H054IE0A

FLW2114N

FLW2114N

COLD

HOT

• Remove the Shock

Sleeves and Shippi ng

Brace.

FLW2124N

CHECK

• Wipe Out Inside of

Wash Drum.

FLW2115N

CHECK

(Supply Injection Models Only)

• Connect External

Supplies to

Washer.

CHECK

(Non-Gravity Drain Models Only)

• Connect Drain Hose

to Drain Receptacle.

CHECK

(Gravity Drain Models Only)

• Connect Drain

Outlet to Drain

System.

CHECK

TLW1976N

FLW1964N

FLW1935N

TLW1976N

CHECK

•Plug In the

Washer.

CHECK

FLW2116N

FLW2116N

D254IE0A

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...