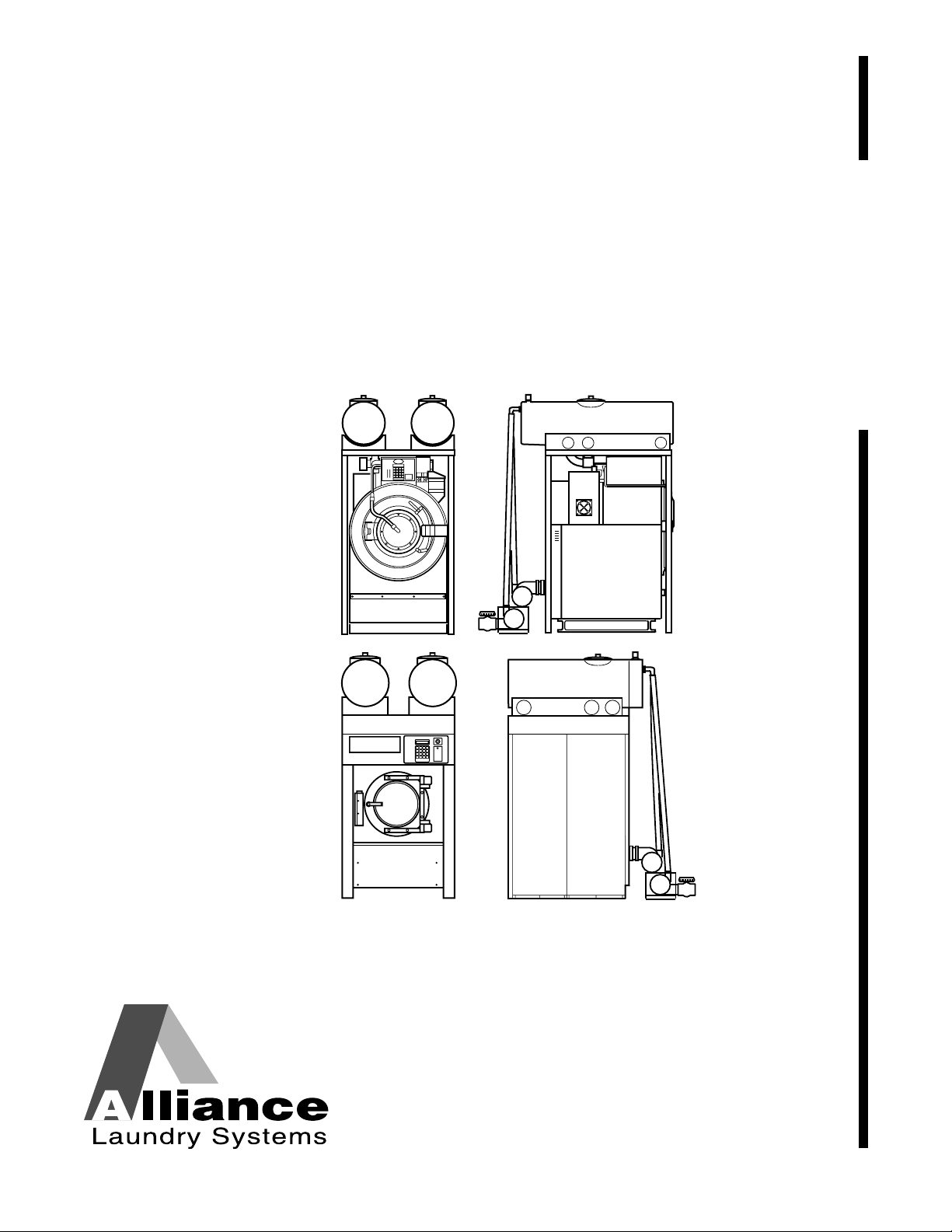

Page 1

Water Saving System

Installation, Maintenance,

Operation and Programming

Instructions Supplement

Refer to Page 3 for Model Identification

UW

NOTA: El manual en

español aparece después

del manual en inglés.

Supplement

UF

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

Q027I

Q027IE3A

Part No. F232122R3

October 2000

Page 2

Page 3

Table of

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Contents

Installation........................................................................................... 5

Dimensional Clearance......................................................................... 6

Machine Foundation ............................................................................. 8

Water Saving Tank Frame Foundation for Pocket

Hardmount Models (UWPV) ......................................................... 8

Mechanical Installation......................................................................... 9

Mounting Bolt Installation for Cabinet Freestanding

Models (UFPV) with

Water Saving System ..................................................................... 9

Mounting Bolt Installation for Pocket Hardmount

Models (UWPV) with Water Saving System................................. 9

Removing Top Section .................................................................... 11

Instructions for Installation of Pocket Hardmount

Models (UWPV) with Water Saving System..................................... 13

Tank Overflows ............................................................................... 18

Steam Heat Option........................................................................... 18

Instructions for Installation of Cabinet Freestanding

Models (UFPV) with Water Saving System ...................................... 19

Tank Overflows ............................................................................... 21

Maintenance ........................................................................................ 23

Daily ..................................................................................................... 23

Beginning of Day............................................................................. 23

End of Day ....................................................................................... 23

Weekly.................................................................................................. 23

Monthly................................................................................................. 23

Removal from Service ........................................................................ 25

Decommissioning ................................................................................. 25

Operation............................................................................................. 27

LED Display ......................................................................................... 27

Manual Mode Control Feature.............................................................. 27

Programming ...................................................................................... 29

Programming a Recovery Fill from Water Saving Tank(s).................. 29

Programming a Water Saving Drain Step ............................................ 29

Programming Cycles ............................................................................ 29

© Copyright 2000, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232122

1

Page 4

Notes

2

F232122

Page 5

Introduction

Model Identification

Information in this manual is applicable to these models:

UW 60 PV

UW 100 PV

UF 35 PV

UF 50 PV

UF 85 PV

F232122

3

Page 6

Notes

4

F232122

Page 7

Installation

This manual is designed as a supplement to the

installation, maintenance, operation and programming

of PV model Pocket Hardmount and Cabinet

Freestanding washer-extractors equipped with the

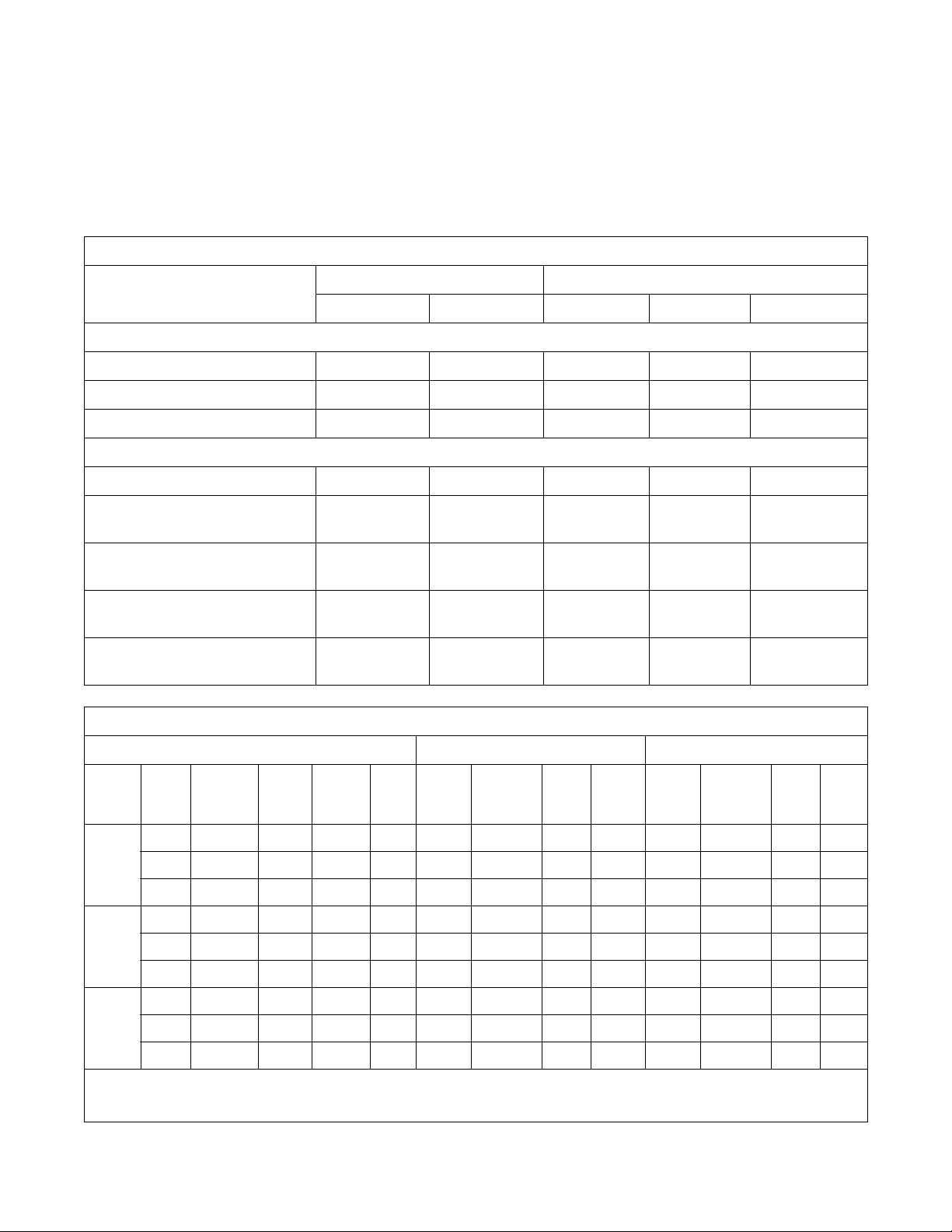

General Specifications for Models with Water Saving System

Models

Overall width, in (mm)

Overall height, in (mm)

Overall depth, in (mm)

Net weight, lb (kg)

Domestic shipping weight,

lb (kg)

Domestic shipping volume,

ft

3

(m3)

Pocket Hardmount Cabinet Freestanding

UW60PV UW100PV UF35PV UF50PV UF85PV

Overall Dimensions

41-7/16 (1053) 47-1/16 (1195) 35 (889) 39 (990.6) 46-1/2 (1181.1)

91 (2311) 95-5/8 (2429) 81-1/2 (2070) 85 (2159) 95-1/2 (2426)

61-3/4 (1568) 73-1/4 (1861) 54 (1392) 56.85 (1449) 65-3/4 (1670)

Weight and Shipping Information

1450 (657.7) 1810 (821) 1312 (595.1) 1700 (771.1) 3100 (1406.1)

1560 (707.6) 1935 (877.7) 1410 (639.6) 1800 (816.5) 3250 (1474.2)

207 (5.8) 212 (6.0) 137 (3.88) 143 (4.05) 201 (4.04)

Water Saving System (WSS). This manual should be

used in addition to the information found in manuals

with part numbers F232084, F232089, F232058 and

F232059 (supplied with the washer-extractor).

Export shipping weight,

lb (kg)

Export shipping volume,

Model Code Voltage Cycle Phase Wire

60

WSS

35

WSS

50

WSS

3

(m3)

ft

Electrical Specifications for Models with Water Saving System*

Voltage Designation Standard Electric Heat

N 440-480 50-60 3 3 6 15 14 3x2.5 33 40 8 3x10

P 380-415 50-60 3 3 6 15 14 3x2.5 29 40 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2.5 66 80 3 3x25

N 440-480 50-60 3 3 6 15 14 3x2.5 32 35 8 3x10

P 380-415 50-60 3 3 6 15 14 3x2.5 32 35 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2.5 50 50 8 3x10

N 440-480 50-60 3 3 6 15 14 3x2.5 43 50 8 3x10

P 380-415 50-60 3 3 6 15 14 3x2.5 43 50 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2.5 76 80 4 3x25

1600 (726) 2130 (967) 1500 (681) 1900 (863) 3350 (1521)

229 (6.5) 235 (6.7) 137 (3.88) 143 (4.05) 201 (5.69)

Full

Load

Amps

Breaker AWG mm

2

Full

Load

Amps

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Breaker AWG mm

2

*Voltage information for *UW80PVWSS mdoels is the same as that of standard UW80PV models.

F232122

5

Page 8

Installation

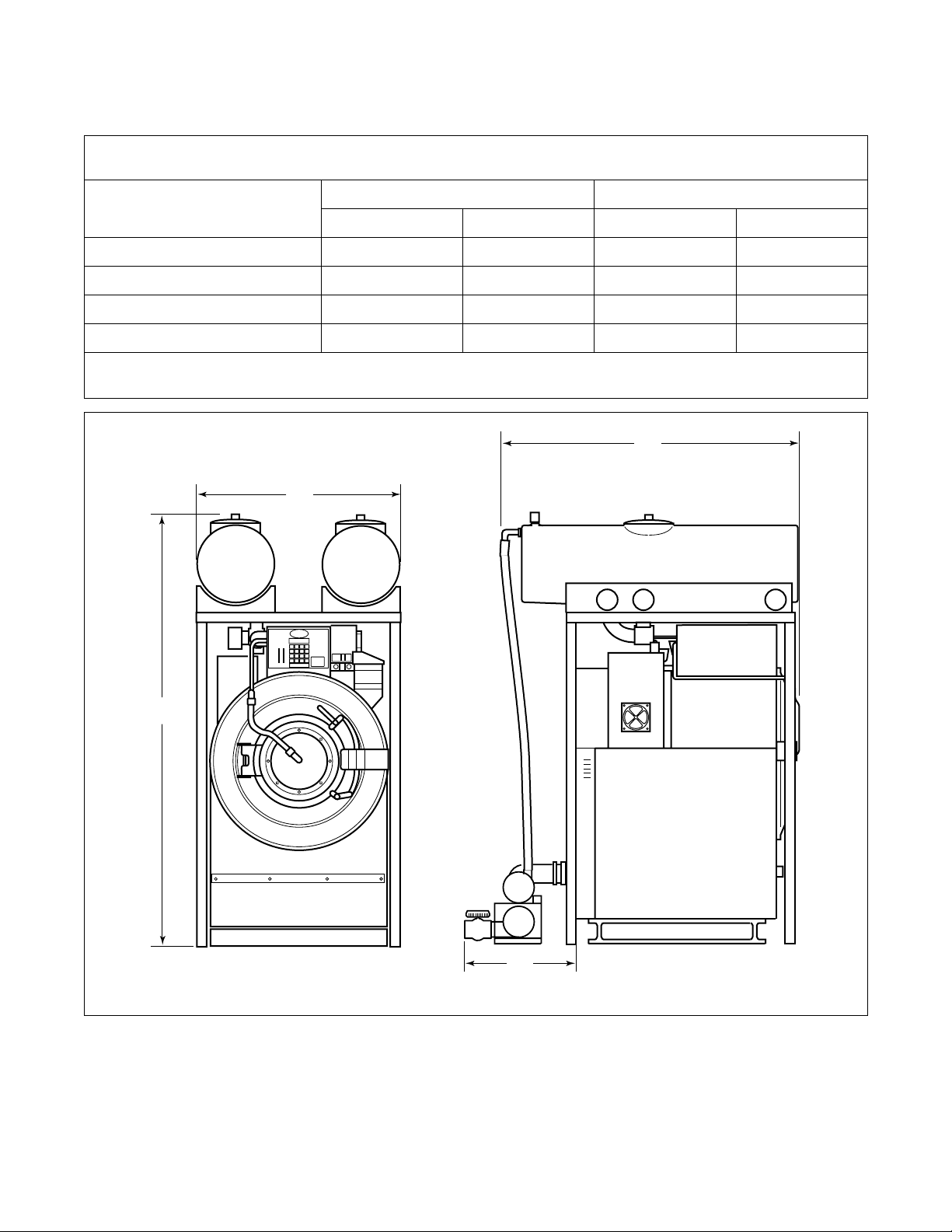

Dimensional Clearance

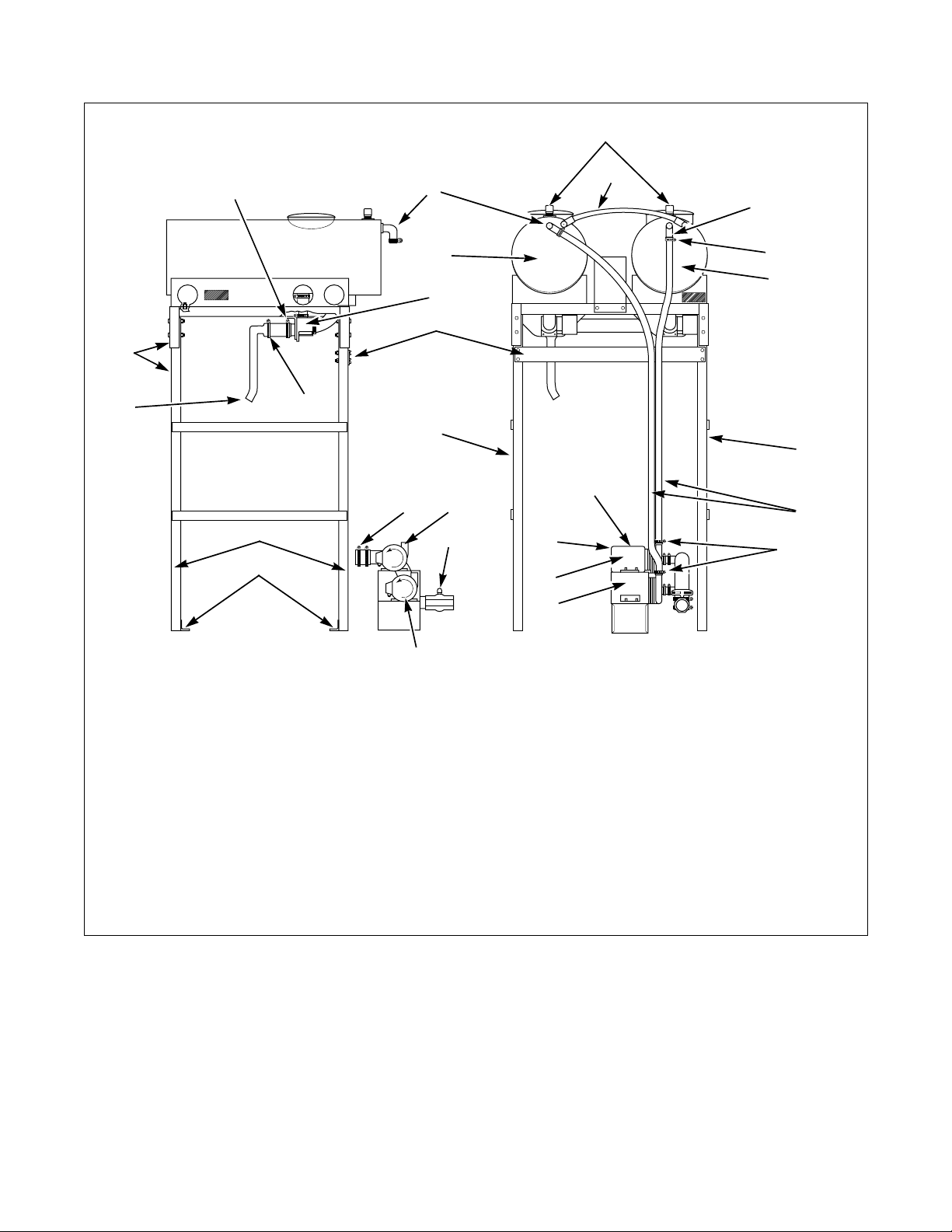

UWPV Pocket Hardmount with Water Saving System

Machine Dimensions*

Dimensions

60 100

in. mm in. mm

A

B

C

D

4-7/16 1052.5 47-1/16 1195.4

91 2311 95-5/8 2428.9

61-3/4 1568 73-1/4 1861

15-3/4 400 15-3/4 400

* Allow a minimum of 24 inches (610 mm) at the rear and 18 inches (460 mm) at the sides for maintenance, inspection and

adjustment. Allow at least 18 inches (460 mm) between machines in multiple installations.

C

A

B

D

Q020I

Q020I

6

F232122

Page 9

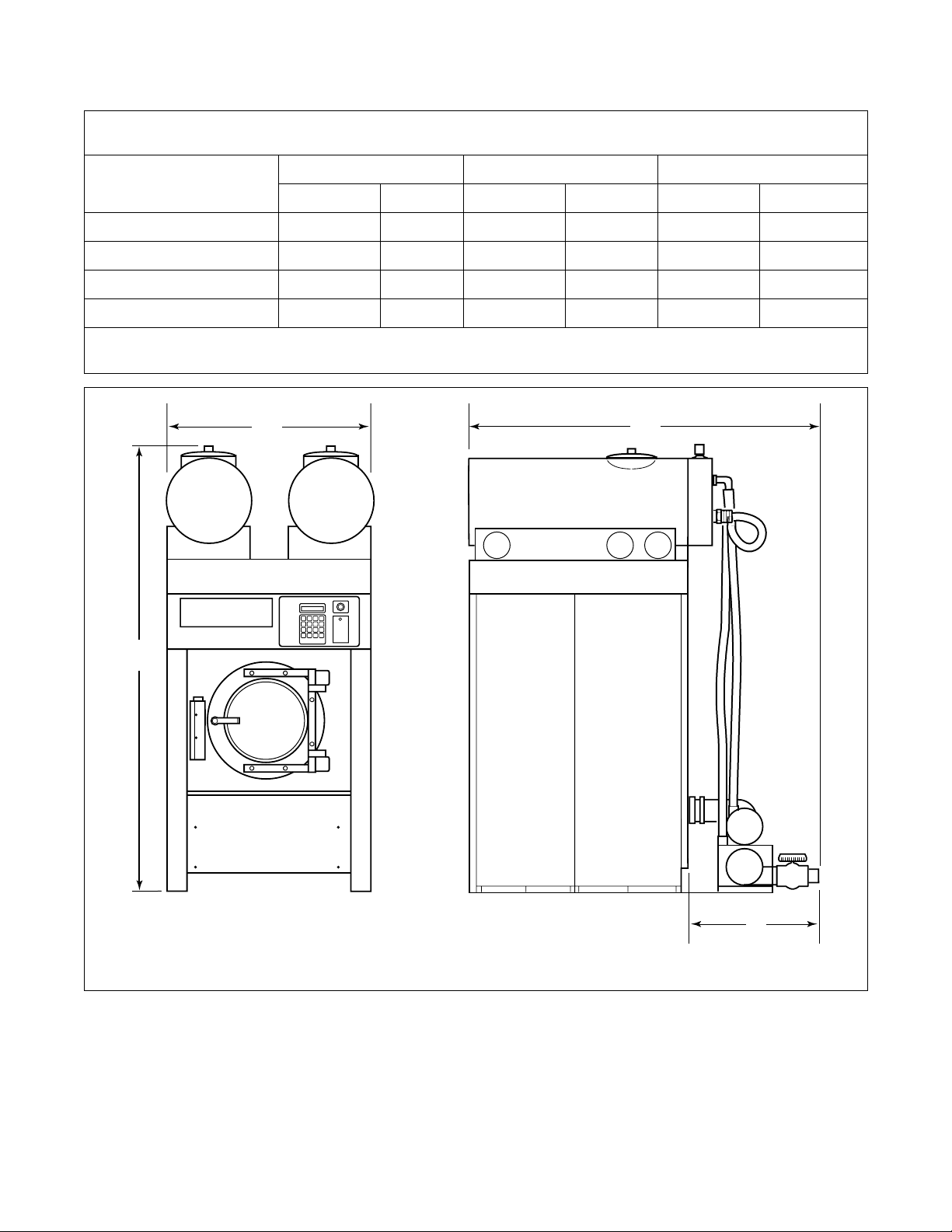

Installation

UFPV Cabinet Freestanding with Water Saving System

Machine Dimensions*

35 50 85

Dimensions

in. mm in. mm in. mm

A

B

C

D

35 889 39 990.6 46-1/2 1181.1

81-1/2 2070 85 2159 95-1/2 2426

57 1448 60-1/2 1537 68 1727

15-3/4 400 15-3/4 400 15-3/4 400

* Allow a minimum of 24 inches (610 mm) at the rear and 18 inches (460 mm) at the sides for maintenance, inspection and

adjustment. Allow at least 18 inches (460 mm) between machines in multiple installations.

A

C

B

D

Q002I

F232122

7

Page 10

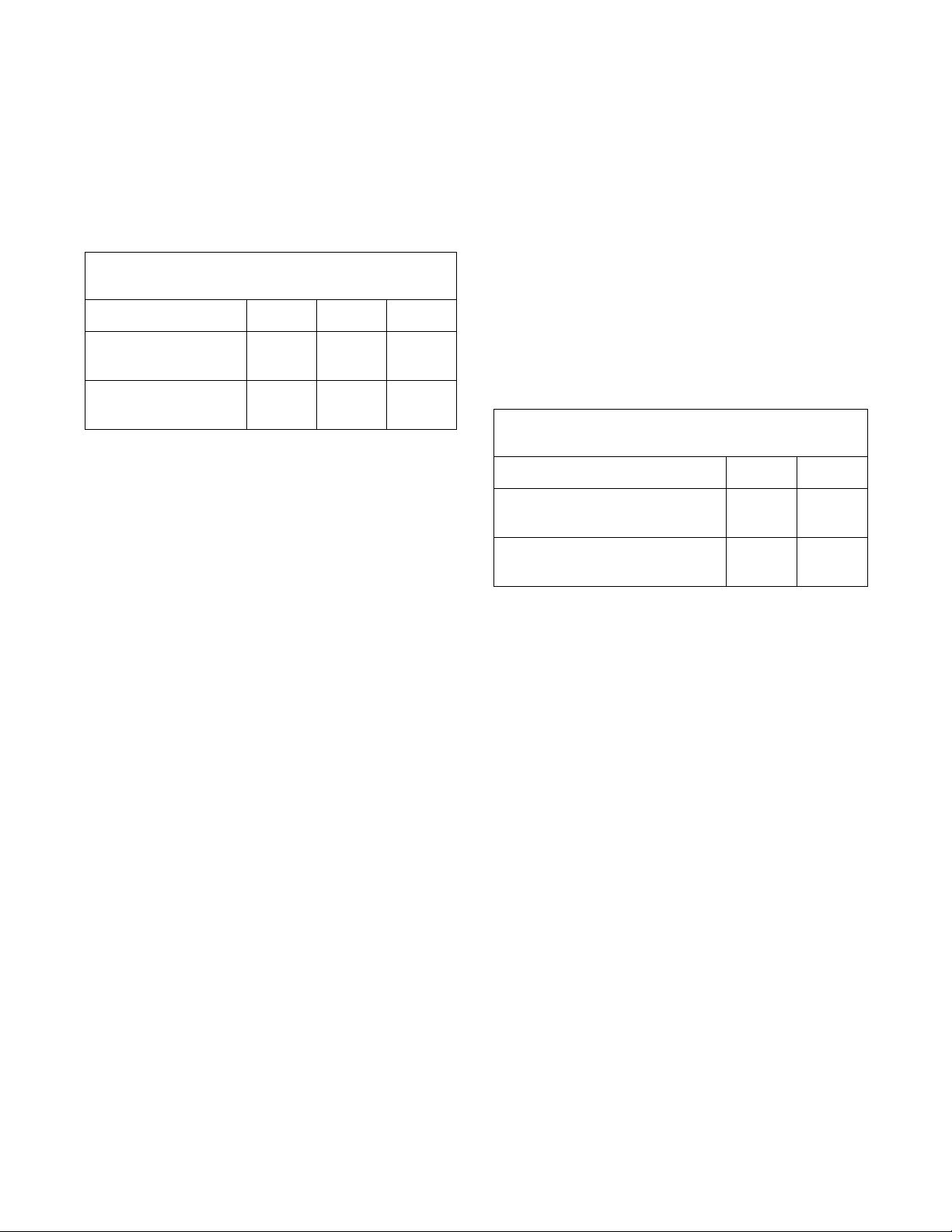

Installation

Machine Foundation

For machine foundation information for both UWPV

and UFPV models, refer to section in respective

installation/maintenance manuals.

For UFPV models with the Water Saving System, refer

to Table 1 for total floor load data.

UFPV Cabinet Freestanding

Floor Load Data

35 50 85

Static floor load,

lbs (kN)

Static Pressure,

2

lbs/ft

(kN/m2)

Water Saving Tank Frame Foundation for

Pocket Hardmount Models (UWPV)

A proper frame foundation is absolutely necessary for

all UWPV washer-extractors with WSS because of the

water weight at elevated heights.

2193

(9.755)

231

(11.07)

Table 1

2675

(11.899)

239

(11.45)

5052

(22.472)

313

(15.00)

IMPORTANT: Ensure that the tank frame is

installed on a level floor of sufficient strength and

that the recommended clearances for inspection

and maintenance are provided. Never allow the

inspection and maintenance space to be blocked.

The tank frame must be anchored to a smooth level

surface so that all four legs are supported and rest on

the mounting surface.

If the washer-extractor installation will include the

WSS, the elevated base must be designed to

accommodate the additional width of 4 inches on each

side of the washer-extractor and correct alignment.

Static washer-extractor, tank and frame load on the

floor or foundation is shown in Tab le 2.

UWPV Pocket Hardmount

Floor Load Data

60 100

Static floor load,

lbs (kN)

Static pressure per leg,

lbs/ft

2

(kN/m2)

2617

(11.7)

227

(10.9)

4341

(19.3)

271

(13.0)

NOTE: Do not mount on wooden floors, above

ground level, or over basements. Installation must

be “slab on grade” or equal.

Table 2

8

F232122

Page 11

Installation

Mechanical Installation

Mounting Bolt Installation for Cabinet

Freestanding Models (UFPV) with

Water Saving System

Refer to the Installation/Maintenance manual

(P/N F232059) for mounting bolt installation

information for UFPV models.

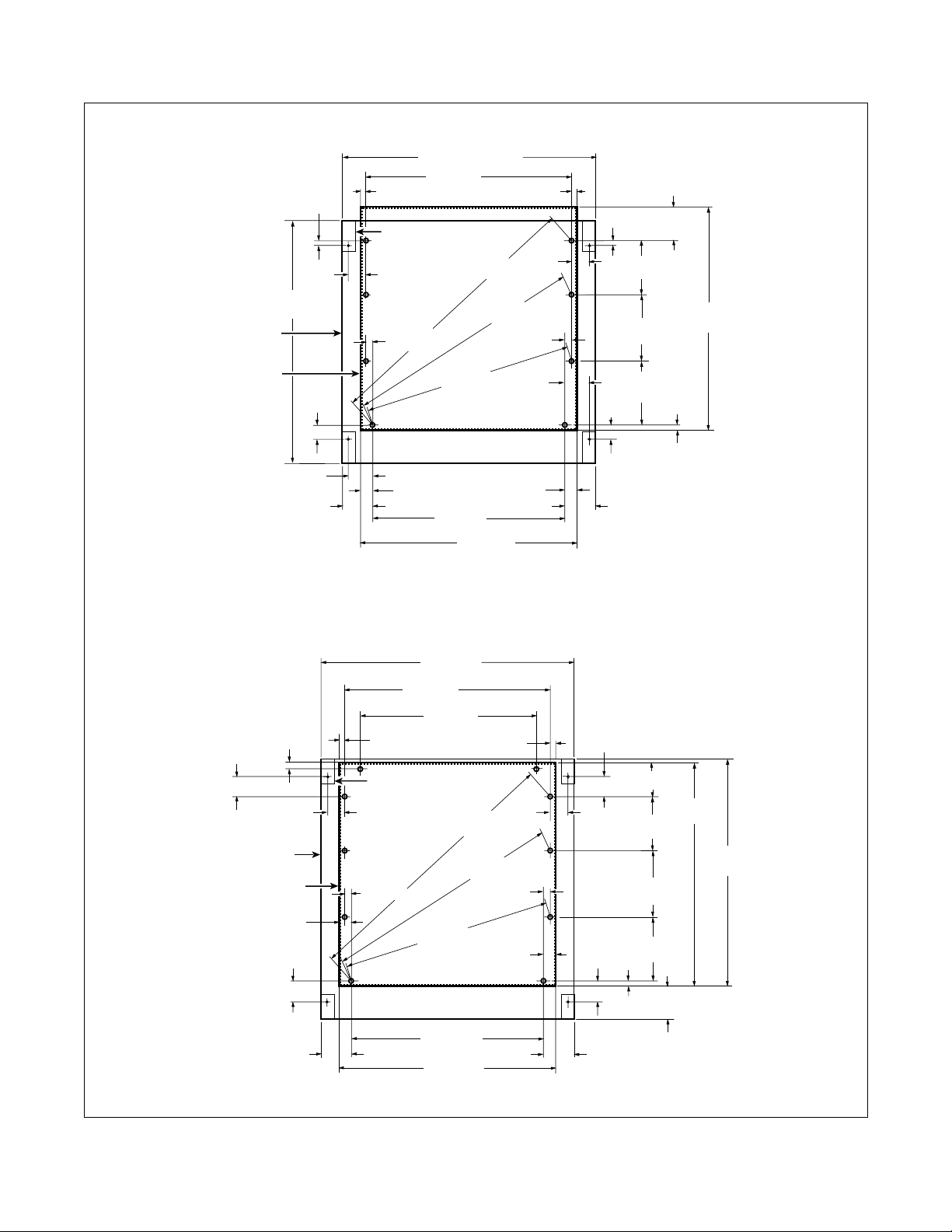

Mounting Bolt Installation for Pocket

Hardmount Models (UWPV) with Water

Saving System

NOTE: The WSS frame must be permanently

attached to the floor.

All UWPV machines use 5/16-18 x 6" bolts for

mounting the tank frame. Use the mounting bolt

layouts in Figure 2.

The threaded end of the bolts should extend 2 inches

above the surface of the floor.

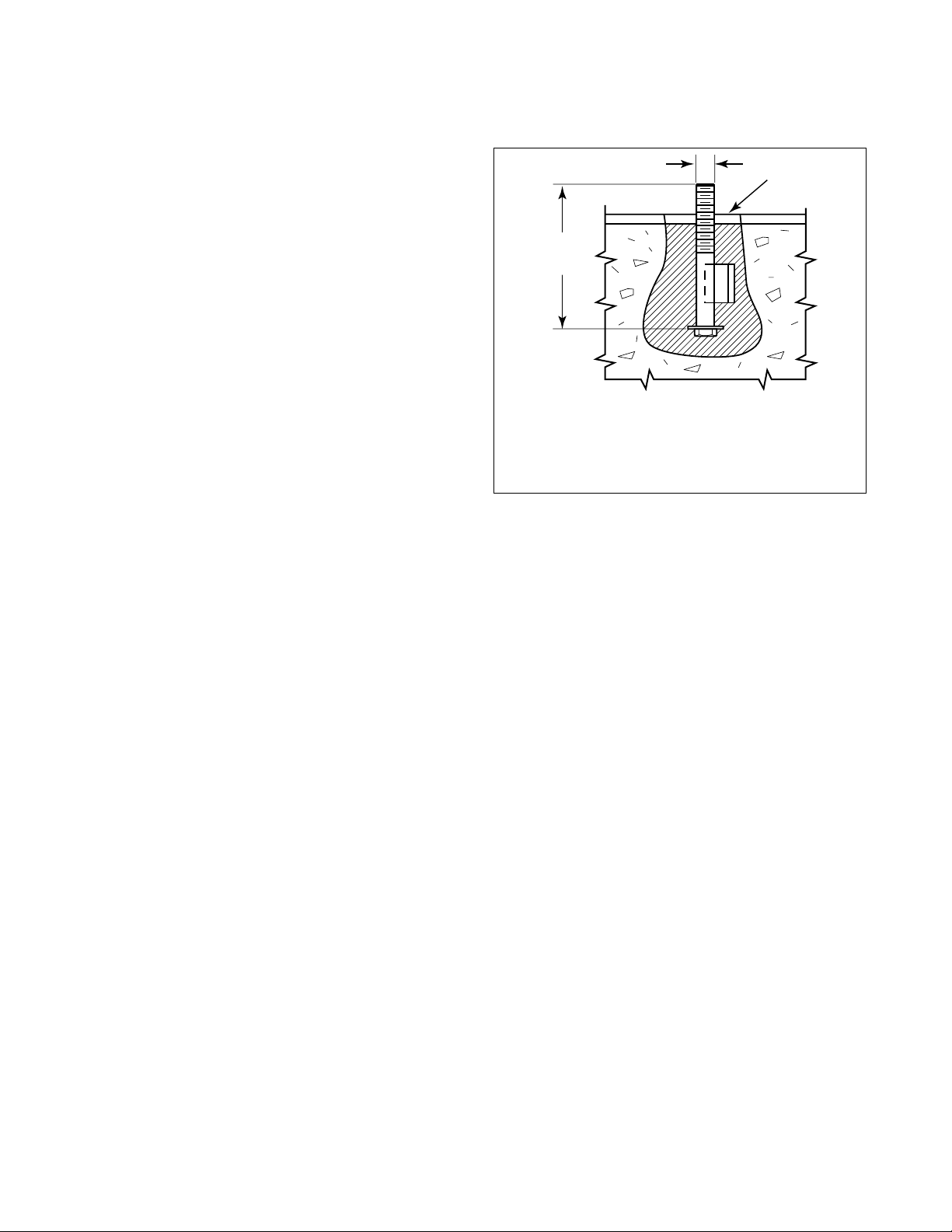

Refer to Figure 1 for a typical installation of individual

mounting bolts for the water saving frame.

1

2

1 5/16" (8 mm)

2 6" (52 mm)

3 Frame

Figure 1

3

Q028I

F232122

9

Page 12

Installation

UW60PV

9/16" (14 mm)

(962 mm)

Outline of

Stand Boundary

Outline of

Frame Base

37-7/8"

(51 mm)

2"

41-5/16" (1049 mm)

34-1/8"

(867 mm)

3/4"

(19 mm)

Outline of

Stand Leg

2-9/16"

(65 mm)

1-1/4"

(32 mm)

34-19/32"

(879 mm)

(997 mm)

34-19/32"

(879 mm)

39-1/4"

(32 mm)

3-13/16"

(97 mm)

Front Edge of Machine

3/4"

(19 mm)

2-9/16"

(65 mm)

1-1/4"

9/16" (14 mm)

9"

(229 mm)

10-3/4"

(273 mm)

10-11/16"

(271 mm)

2"

(51 mm)

4-13/16"

(106 mm)

3/4"

(19 mm)

36"

(914 mm)

UW100PV

4-3/16"

(106 mm)

Outline of

Stand Boundary

Outline of

Frame Base

3-13/16"

(97 mm)

4-27/32"

(123 mm)

3/4"

(19 mm)

2-11/16"

(69 mm)

3"

(76 mm)

2-9/16"

(65 mm)

2"

(51 mm)

3/4"

(19 mm)

31-5/8"

(803 mm)

47-1/16"

(1195 mm)

39-5/8"

(1006 mm)

35-1/8"

(892 mm)

35-5/8"

(905 mm)

3/4"

(19 mm)

Outline of

Stand Leg

2-11/16"

(69 mm)

46-9/32"

(1176 mm)

2-1/4"

(57 mm)

(76 mm)

2-1/4"

(57 mm)

52-1/16"

(1323 mm)

39-25/32"

(1010 mm)

Front Edge of Machine

2"

(51 mm)

3"

4-27/32"

(123 mm)

4-3/16"

(106 mm)

6-3/4" (171 mm)

2-9/16"

(65 mm)

9"

(229 mm)

13-5/8"

(346 mm)

13-5/8"

(346 mm)

Q023I

Q023I

43-3/4"

(1111 mm)

44-3/16"

(1122 mm)

10

4-15/16"

(126 mm)

35-1/8"

(892 mm)

41-1/8"

(1045 mm)

Figure 2

3/4" (19 mm)

4-15/16"

(126 mm)

4-13/16"

(106 mm)

Q024I

Q024I

F232122

Page 13

Installation

Refer to the Water Saving System (WSS) General

Specifications in this section to determine if there is

adequate clearance through the door for the machine.

If there is not and the WSS needs to be removed, refer

to the section “Removing the Top Section”. If

clearance is sufficient, proceed as follows:

NOTE: Allow concrete to cure before beginning

installation.

1. Place the WSS next to the concrete foundation.

IMPORTANT: Move the WSS by lifting from the

frame only. Never move by lifting, pulling or

pushing the tanks.

2. Remove the carriage bolts holding the wooden

skid to the WSS frame side legs.

3. Place the WSS over the mounting bolts.

4. Level the frame top section and sides. Align with

the washer-extractor.

NOTE: No part of the washer-extractor and the

WSS should be touching. If the machine requires

elevating during bolt down then the WSS will

require the same amount.

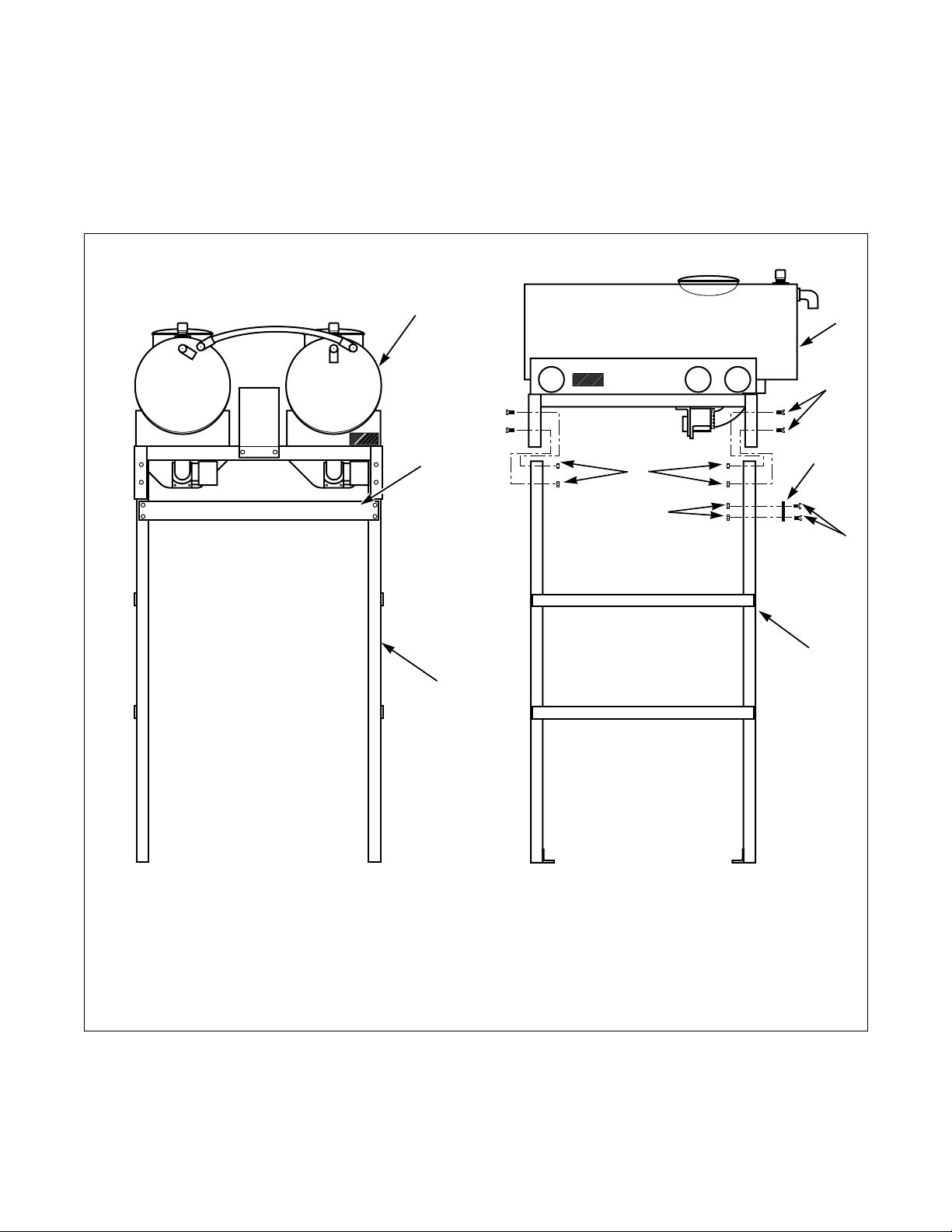

Removing Top Section

If removing the top section is necessary due to

insufficient clearance, refer to Figure 3 and proceed as

follows:

1. Place the WSS next to the concrete foundation.

IMPORTANT: Move WSS by lifting from the

frame only. Never move by lifting, pulling or

pushing the tanks.

2. Secure top section with lifting equipment.

3. Remove the eight nuts and bolts from the top

section that fasten the frame sides to the top

section. Refer to Figure 3.

4. Secure both frame sides in place and lift top

section with lifting equipment.

5. Remove the frame sides from the wooden skid by

removing the carriage bolts holding them to the

skid. Remove frame support bar. Refer to Figure 3.

6. Place both frame sides over the mounting bolts

and replace frame support bar. Snugly screw down

the mounting nuts. Do not tighten nuts at this time.

5. Tighten mounting nuts and washers to secure

frame to floor.

F232122

11

Page 14

Installation

7. Carefully lower top section over frame sides.

Insert the eight top section bolts and four frame

support bar bolts. Fully tighten the corresponding

nuts with the corresponding bolts.

8. Level the frame top section and sides. Align with

the washer-extractor.

1

2

NOTE: No part of the washer-extractor and the

WSS should be touching. If the machine requires

elevating during bolt down then the WSS will

require the same amount.

9. Tighten mounting nuts and washers to secure

frame to floor.

Top Section RemovedTop Section Not Removed

1

4

2

5

6

7

3

Side ViewRear View

1 To p S ec t io n 5 To p S ec t io n Nu t s

2 Frame Support Bar 6 Frame Support Bar Nuts

3 Frame Sides 7 Frame Support Bar Bolts

4 Top Section Bolts

Figure 3

3

Q042I

12

F232122

Page 15

Installation

Instructions for Installation of

Pocket Hardmount Models (UWPV)

with Water Saving System

Read the following instructions thoroughly before

proceeding. The installer must have a comprehensive

understanding of the instructions before attempting

installation of the WSS. Refer to Water Saving Tank

Frame Foundation section for frame boltdown.

WARNING

Lock out the main power panel and lock out

the power supply to the control box before

attempting any service procedures.

SW007

IMPORTANT: Ensure that the machine is installed

on a level floor of sufficient strength and that the

recommended clearances for inspection and

maintenance are provided. Never allow the

inspection and maintenance space to be blocked.

Refer to the WSS Electrical Specifications for voltage

information.

Refer to the WSS General Specifications in this

section to determine if there is adequate clearance for

the machine. If there is not and the WSS needs to be

removed, refer to the previous section “Removing Top

Section”.

1. Connecting the WSS to washer-extractor:

Tank Drain Hose Assembly

1

NOTE: Right and Left are as Viewed from the Rear

1 To R ig h t Ta n k D r ain Va l ve

2 To Left Tank Drain Valve

3 To Washer-Extractor Shell Pipe

Figure 4

2

Top View

Front View

3

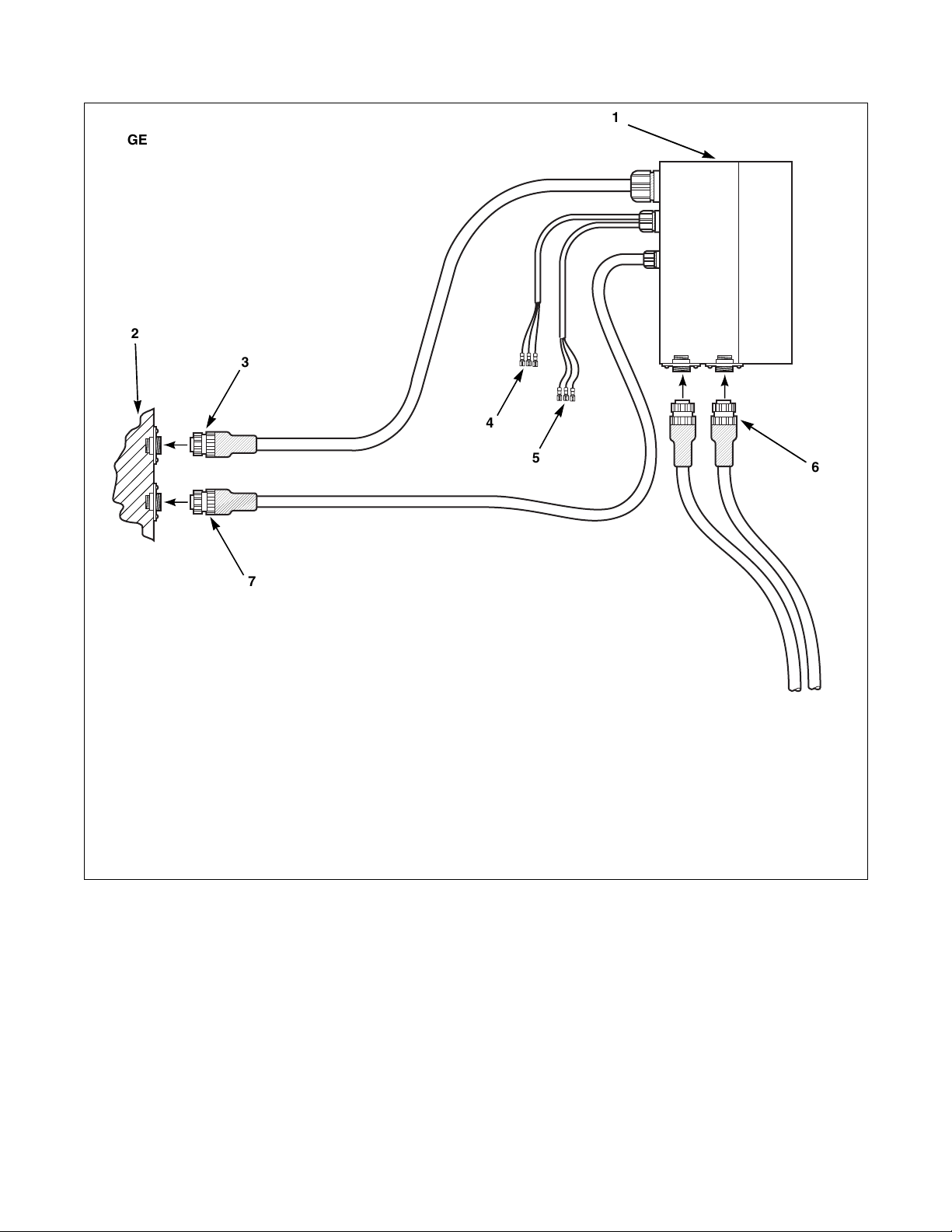

For 220V Machines:

a. For electrical hook-up, connect the control

signal cable to the “C1” (signal) quick

connect receptacle (top most plug on back of

washer-extractor control module). Connect

the power cable to the “C2” (power) quick

connect receptacle. Refer to Figure 7.

Q038I

NOTE: The tank drain hose assembly is packaged

inside washer-extractor basket.

a. Remove tank drain hose assembly from

packaging. Slide drain hose over tank drain

valves and washer-extractor shell pipe. Install

large hose clamps on drain valves and small

hose clamp on shell pipe and tighten. Refer to

Figures 4 and 5.

NOTE: Receptacles and plugs are keyed for proper

connection. For example, the control signal cable

will only fit in “C1”. Do not use excessive force

when connecting.

For 110V Machines:

a. Loosen the nut from the back of the PG9

strain relief found on the washer-extractor

control module rear. Thread 3-phase power

and green ground wires through the strain

relief and tighten the nut. Adjust extra wire

length through the strain relief, trimming off

extra length inside the control module leaving

enough to connect to input power terminal

block and ground.

b. Connect the 3-phase power wires to the input

power terminal block located inside the

washer-extractor control module.

F232122

13

Page 16

Installation

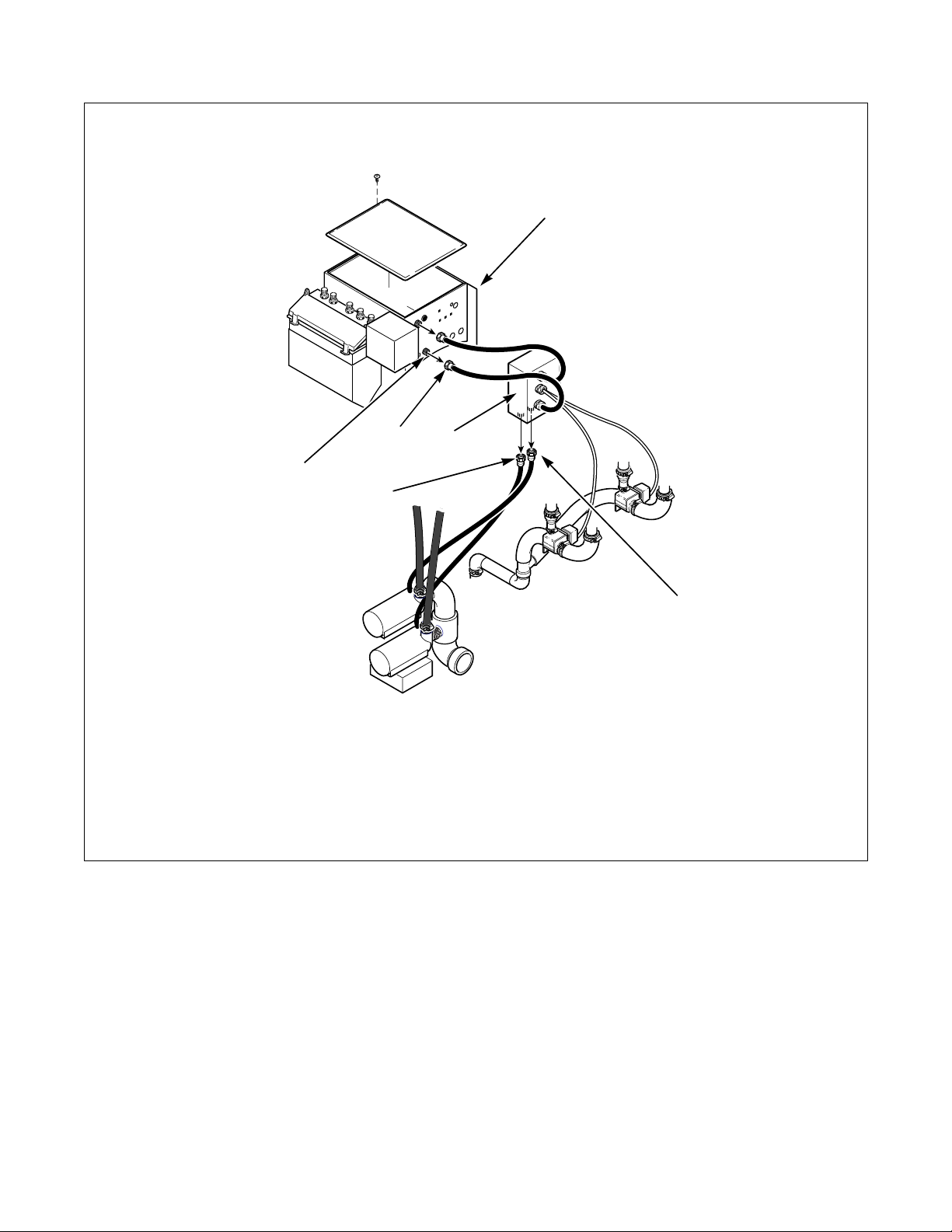

2. Installing the pump assembly (refer to Figure 5):

NOTE: The pump assembly is packaged inside

washer-extractor basket.

a. Remove the pump assembly from packaging

and place at the rear of the washer-extractor

resting flat on floor.

b. Route the two pump motor cable connections

to the WSS control housing (Figure 8). Slide

cable connectors in and twist to lock. Pump

cables and receptacles are marked “PA” and

“PB”. Refer to Figure 7.

c. Install large manifold hose clamp at the rear

of washer-extractor and tighten. Refer to

Figure 5.

d. Check ball valve for closed position. Before

operating machine, ball valve must be closed.

NOTE: Pump rotation must be counterclockwise

when pump is viewed from fan end or clockwise

when viewed from plastic pump head end.

Improper rotation will cause the pump to fail,

resulting in increased cycle time. Refer to rotation

arrow decal on pump and Figure 5. Rotation may

be corrected by exchanging two 3-phase power

wires on the load side of the respective contactor,

located in the remote-mounted WSS control

module.

3. Installing pump hose and vacuum vents:

NOTE: Pump hoses and vacuum vents are

packaged inside washer-extractor basket.

a. Remove pump hoses and four small hose

clamps from packaging.

b. Slide on the pump hose to the appropriate

pump (top pump to right tank, bottom pump

to left tank as viewed from rear) and tank

elbow at the rear of each tank. Refer to

Figure 5. Tighten the small hose clamps.

c. Apply Teflon tape to vacuum vent threads and

screw into top of each tank, tightening by

hand only.

d. Secure the two pump hoses and the two pump

motor cables with wire ties to frame side legs.

14

F232122

Page 17

Installation

4

20

19

1

2

2

3

6

5

7

11

8

18

8

8

10

10

17

16

9

11

12

13

9

21

14

Side View

15

Rear View

1 Large Hose Clamp 11 Ball Valve

2 Ta n k El bow 12 Pump Fan End

3 2" Tank Overflow 13 To p Pu m p

4 Vacuum Vent 14 Bottom Pump

5 Small Hose Clamp 15 Counterclockwise Pump Rotation

6 Left Tank 16 Carriage Bolts to Skid

7 Right Tank 17 Frame Side Legs

8 Frame Side 18 Tank Drain Hose Assembly

9 Pump Hoses 19 To Washer-Extractor Shell Pipe (Not Shown)

10 Pump Assembly 20 Frame

Figure 5

Q039I

F232122

15

Page 18

Installation

UW Integrated Water Saving System Machine Orientation

1

4

2

6

5

1 Washer-Extractor Control Module

2 Water Saving Control Housing

3 Quick Connect Receptacle for Tank “A” Pump Motor

4 Quick Connect Receptacle and Plug, C2 (Power)

5 Quick Connect Receptacle for Tank “B” Pump Motor

6 Quick Connect Receptacle and Plug, C1 (Signal)

Figure 6

3

Q043I

16

F232122

Page 19

GENERALIZED SKETCH OF ELECTRICAL

CONNECTIONS WATER SAVER SYSTEM (220V)

REFER TO INSTRUCTIONS AND DRAWING

#634148 FOR DETAILS

2

3

Installation

1

4

7

1 Remote Mounted Control Module for Water Saving System

2 Rear of Control Module on Host Machine

3 C1 (Signal) Quick Connect Receptacle and Plug

4 Cable 133 to Tank “A” Drain Valve

5 Cable 132 to Tank “B” Drain Valve

6 Pumps “A” and “B” Quick Connect Receptacle and Plug

7 C2 (Power) Quick Connect Receptacle and Plug

Figure 7

5

6

Q041I

F232122

17

Page 20

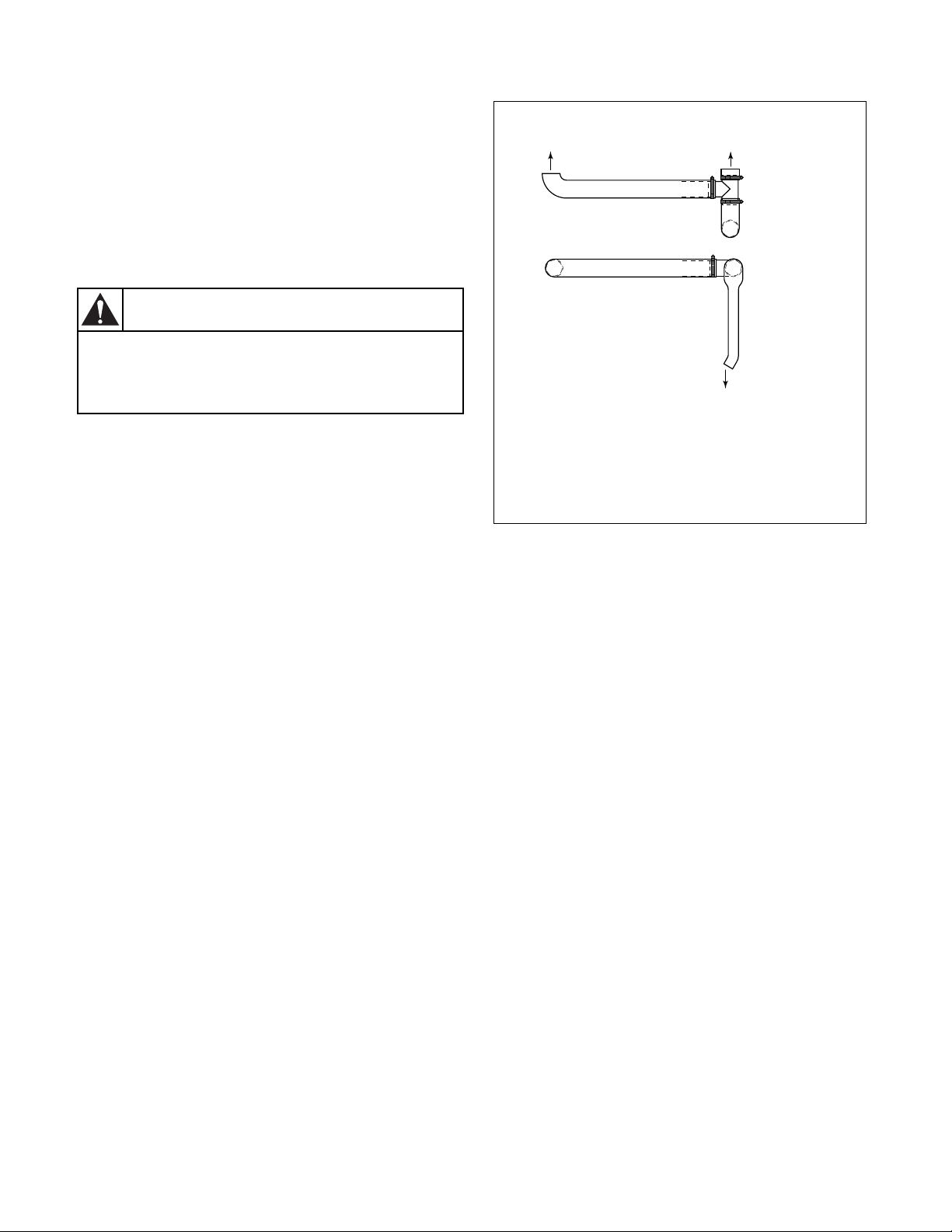

Installation

Tank damage. Connections made to the

overflow must point downward from the

tank. Routing plumbing upward will damage

tanks.

CAUTION

Tank Overflows

Some tank overflows have external 2" PVC

connections. These connections may be plumbed to an

open trough or floor drain.

IMPORTANT: Connections made to the overflow

must provide adequate support for weight of pipe

and fittings.

Steam Heat Option

WARNING

Hot Surfaces. Will cause severe burns. Turn

steam off and allow steam pipes, connections

and components to cool before touching.

If the washer-extractor is equipped with the steam heat

option, additional pipe fittings are not required.

IMPORTANT: Do not route any steam fittings or

pipes near WSS tanks. Wrap fittings and pipe with

steam plumbing insulation.

18

F232122

Page 21

Installation

Instructions for Installation of

Cabinet Freestanding Models

(UFPV) with Water Saving System

Read the following instructions thoroughly before

proceeding. The installer must have a comprehensive

understanding of the instructions before attempting

installation of the WSS.

Refer to the WSS Electrical Specifications for voltage

information.

Refer to the WSS General Specifications to determine

if there is adequate clearance through the door for the

machine. If not, removal of the water tanks is

necessary.

1

1. Removing the water tanks (if necessary):

a. Remove the three cap plugs located near the

rear and one located near the front on each

side of the tanks. Refer to Figure 8.

b. Loosen the two hose clamps attached at the

bottom rear of each tank. Refer to Figure 8.

c. Loosen the hoses clamps attached to the

elbow at the rear of each tank and slide off the

long black hoses that run from the tanks.

Refer to Figure 9.

d. Loosen the hose clamp to the short black hose

between each tank and remove from only one

tank.

2

3

5

1 Water Tanks

2 Vacuum Vents

3 Water Saving Control Housing

4 Cap Plug

5 Hose Clamps Under Tank, Behind Plug

4

Q007I

Figure 8

F232122

19

Page 22

Installation

Be extremely careful when removing tanks.

To prevent damage, always place tanks on a

level surface with clean-out access facing

up.

CAUTION

e. Remove the four bolts from each tank located

behind cap plug at each corner. Refer to

Figure 9.

f. Lift tanks off the washer-extractor.

2. Removing the pump assembly:

a. Remove manifold hose clamps connecting the

pump manifold to the drain valve found at the

1

rear of the washer-extractor to the right of the

pump assembly. Refer to Figure 9.

b. Unscrew the two pump motor electrical quick

disconnects from the water saving control

housing located at the rear of the washerextractor.

c. Slide off the long black hoses that run from

the water tanks. Refer to Figure 9.

d. Remove pump assembly and place to the side.

3. Positioning and bolting down the washerextractor:

Refer to Mechanical Installation Section for

boltdown instructions.

2

5

3

4

1 Corner Tank Bolts (4 per Tank) 4 Pump Assembly

2 Hose Clamps on Elbows 5 Cap Plug

3 Manifold Hose Clamps

Q008I

Q008I

20

Figure 9

F232122

Page 23

Installation

4. Reassembling the pump assembly:

a. Replace pump assembly at the rear of the

washer-extractor, resting flat on the floor.

b. Secure the two pump motor electrical quick

disconnects to the water saving control

housing.

c. Replace manifold hose clamp at rear of

washer-extractor.

d. Check ball valve for closed position. Before

operating machine, ball valve must be closed.

NOTE: Pump rotation must be counterclockwise

when pump is viewed from fan end or clockwise

when viewed from plastic pump head end.

Improper rotation will cause the pump to fail

resulting in increased cycle time. Refer to rotation

arrow on pump in Figure 5. Rotation may be

corrected by exchanging two 3-phase power wires

at input power terminal block then recheck each

pump separately.

5. Replacing the water tanks:

a. Carefully replace the tanks on top of the

washer-extractor.

b. Replace the four bolts behind cap plug at each

corner of tanks.

c. Slide on short black hose to the large tank

elbow at the rear of the tank. Refer to Figure 9.

Tighten hose clamp.

d. Slide on long black hoses to the appropriate

tank elbow at the rear of each tank – right tank

to top pump, left tank to bottom pump.

Tighten hose clamps.

e. Tighten the three clamps underneath each

tank.

f. Replace the three cap plugs on each side of

the tanks.

6. Installing the tank vacuum vents:

a. Remove tank vacuum vents from packaging.

b. Apply Teflon tape to vacuum vent threads and

screw into top of each tank, tightening by

hand only.

Tank Overflows

Some tank overflows have external 2" PVC

connections. These connections may be plumbed to an

open trough or floor drain.

CAUTION

Tank damage. Connections made to the

overflow must point downward from the

tank. Routing plumbing upward will damage

tanks.

IMPORTANT: Connections made to the overflow

must provide adequate support for weight of pipe

and fittings.

F232122

21

Page 24

Notes

22

F232122

Page 25

Maintenance

Daily

Beginning of Day

Inspect water saving tanks and all associated plumbing

connections for leaks.

End of Day

Run drain tank cycle.

Weekly

Clean tanks by removing cap on top of tanks and flush

out with a hose. Sanitize as needed.

Monthly

Flush drain ball valve, opening fully, to purge any lint

or debris from pump manifold.

Check top section nuts on tank frame to ensure they

are tightened to the specified torque (220 in. lb.).

F232122

23

Page 26

Notes

24

F232122

Page 27

Removal from Service

Decommissioning

Check water tanks to make sure all water has been

emptied from both tanks.

F232122

25

Page 28

Notes

26

F232122

Page 29

Operation

LED Display

The following table lists the various displays for the

Manual Mode Control Feature

WSS functions are not manually controllable.

Water Saving System (WSS) and what they mean.

These displays are the same for both models and are

displayed in the left two display digits. The operator

should become familiar with these computer displays.

Display Interpretations

aL

aM

aH

bL

bM

bH

Da

Db

Fill machine from tank A to low level

Fill machine from tank A to medium level

Fill machine from tank A to high level

Fill machine from tank B to low level

Fill machine from tank B to medium level

Fill machine from tank B to high level

Drain machine to tank A

Drain machine to tank B

NOTE: The left tank is designated as tank A as seen from the front of the machine, the right tank is tank B.

Table 3

NOTE: To prevent water hotter than 160°F from

draining into the water saving tanks, an alarm will

sound and “DRTEMP” will be displayed. If the

STOP key is not pressed within two minutes, the

machine will automatically stop.

F232122

27

Page 30

Notes

28

F232122

Page 31

Programming

NOTE: The following programming information is

for both Cabinet Freestanding and Pocket

Hardmount models with the Water Saving System

(WSS). Use in conjunction with respective

operating/programming manuals.

When programming steps using the WSS, the

computer must be in the PROGRAM mode and ready

for the next step. The display will read “nncc”, where

“nn” represents step number and “cc” represents cycle

number.

Programming a Recovery Fill from

Water Saving Tank(s)

1. Press the Auxiliary key. The display will read

“A-nncc”.

2. Press key 6 to select a fill from tank A. The

display will read “a-nncc”. To select a fill from

tank B, press key 7 instead. The display will read

“b-nncc”.

3. Press the Low, Medium, or High key to select a

water level. The second digit of the display will

read either “L”, “M,” or “H”, respectively for a

low, medium, or high water level. For example, if

a low level fill from tank A is selected, the

display will read “aLnncc”.

4. Press the Enter key. The display will now read

“M---S”.

5. Enter the desired maximum fill time. To program

5 minutes, press key 5. The display will read

“5M-00S”.

Programming a Water Saving

Drain Step

1. Press the Drain key. The display will read “D-nncc”.

2. Press key 2 to drain tank A or key 3 to drain to

tank B. The display will read “Danncc” if tank A

is selected and “Dbnncc” if tank B is selected.

3. Press the Enter key. The display will read “M---S.”

4. Enter the desired time for the drain step. For

example, to enter a time of five minutes, press

key 5. The display will show “5M-00S.”

NOTE: If machine does not empty in this amount

of time, “EMTY”, will be displayed.

5. Press the Enter key and go to the next step in the

cycle or the PROGRAM mode may be exited.

NOTE: When programming a drain step, it is

necessary to specify which type of drain is desired,

because water saving features are available at all

times.

NOTE: The WE-6 computer will not permit draining

into a tank if the water temperature exceeds 160

degrees Fahrenheit. In that event, the display will

show “DRTEMP”, the WE-6 will turn off all outputs

(except applicable drain[s]) and will sound the buzzer.

This will continue for up to two minutes. If the

operator does not respond within two minutes the

WE-6 aborts the cycle. The operator can press the

START key to begin the drain step again, or press

the STOP key to end the cycle.

6. Once the desired time had been entered, press the

Enter key to go to the next step of the cycle or to

exit PROGRAM mode.

F232122

Programming Cycles

Refer to the Programming section in the Operation/

Programming manuals (P/N F232059 for UF models,

P/N F232089 for UW models) for preprogrammed cycles.

29

Page 32

Page 33

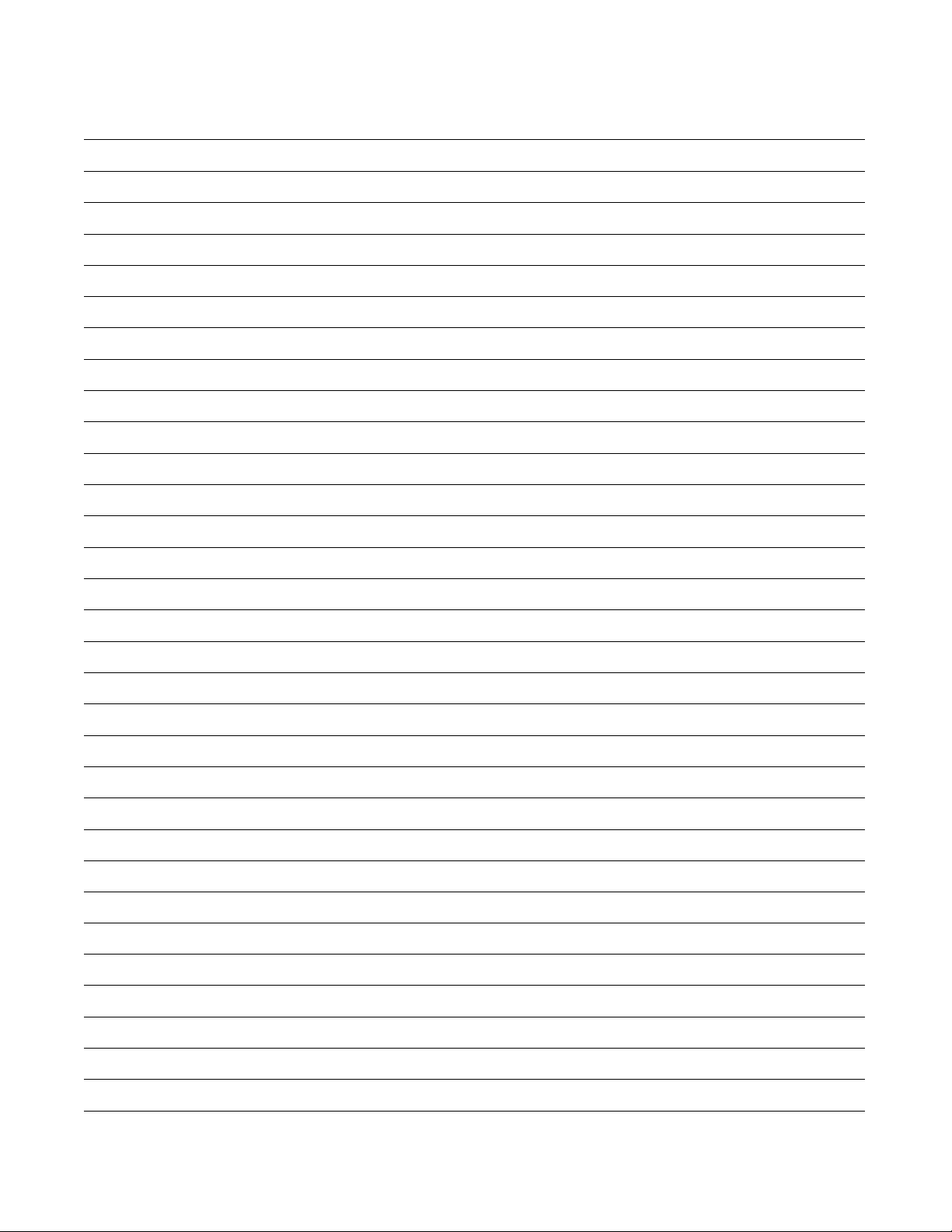

Sistema de ahorro

de agua

Suplemento de instrucciones de instalación,

mantenimiento, operación y programación

Refiérase a la identificación de modelos en la pagina 35

UW

Suplemento

UF

Guarde estas instrucciones para referencia futura.

(Si esta máquina cambia de dueño, este manual deberá ser entregado con la misma).

Q027I

Q027IE3A

Pieza No. F232122R3

Octubre 2000

Page 34

Page 35

Contenido

Introducción ........................................................................................ 35

Identificación de modelos..................................................................... 35

Instalación ........................................................................................... 37

Espacios libres ...................................................................................... 38

Cimientos para la máquina ................................................................... 40

Cimientos para la estructura de tanques del sistema de

ahorro de agua en modelos de lavadora extractora cilíndrica

de montaje permanente (UWPV) ................................................... 40

Instalación mecánica............................................................................. 41

Instalación de pernos de montaje para modelos de lavadora

extractora de gabinete autoestable (UFPV) con sistema de

ahorro de agua ................................................................................ 41

Instalación de pernos de montaje para modelos cilíndricos

de montaje permanente (UWPV) con sistema de ahorro de agua.. 41

Desmontaje de la sección superior................................................... 43

Instrucciones para instalación de modelos de lavadora

extractora cilíndrica de montaje permanente (UWPV) con

sistema de ahorro de agua .................................................................. 45

Agujeros de rebose de los tanques................................................... 50

Opción de calentamiento por vapor................................................. 50

Instrucciones para instalación de modelos de lavadora extractora de

gabinete autoestable (UFPV) con sistema de ahorro de agua ............ 51

Agujeros de rebose de los tanques................................................... 53

Mantenimiento .................................................................................... 55

Diariamente........................................................................................... 55

Al comienzo del día ......................................................................... 55

Al final del día ................................................................................. 55

Semanalmente....................................................................................... 55

Mensualmente....................................................................................... 55

Puesta fuera de servicio...................................................................... 57

Puesta fuera de servicio ........................................................................ 57

Operación ............................................................................................ 59

Pantalla de LED.................................................................................... 59

Función de control del modo manual ................................................... 59

Programación ...................................................................................... 61

Programación de un llenado de recuperación desde el(los)

tanque(s) del sistema de ahorro de agua............................................. 61

Programación de un paso de desagüe del sistema de ahorro de agua... 61

Ciclos preprogramados......................................................................... 61

© Copyright 2000, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede ser reproducida o transmitida en forma

alguna o a través de ningún medio, sin el expreso consentimiento por escrito del editor

.

F232122 (SP)

33

Page 36

Notas

34

F232122 (SP)

Page 37

Introducción

Identificación de modelos

La información contenida en este manual es aplicable

a los siguientes modelos:

UW 60 PV

UW 100 PV

UF 35 PV

UF 50 PV

UF 85 PV

F232122 (SP)

35

Page 38

Notas

36

F232122 (SP)

Page 39

Instalación

Este manual está diseñado como un suplemento para la

instalación, mantenimiento, operación y programación

de las lavadoras extractoras modelos PV de gabinete

autoestable y cilíndrica de montaje permanente,

equipadas con el sistema de ahorro de agua (WSS).

Especificaciones generales de modelos con sistema de ahorro de agua

Cilíndrico de montaje

Modelos

Anchura general, mm (plg)

Altura general, mm (plg)

Profundidad general, mm (plg)

Peso neto, kg (lb)

Peso de transporte

doméstico, kg (lb)

Volumen de transporte

doméstico, m

3

(pies3)

Peso de transporte de

exportación, kg (lb)

Volumen de de exportación,

3

m

(pies3)

1053 (41 7/16) 1195 (47 1/16) 889 (35) 990,6 (39) 1181,1 (46 1/2)

1568 (61 3/4) 1861 (73 1/4) 1392 (54) 1449 (56,85) 1670 (65 3/4)

657,7 (1450) 821 (1810) 595,1 (1312) 771,1 (1700) 1406,1 (3100)

707,6 (1560) 877,7 (1935) 639,6 (1410) 816,5 (1800) 1474,2 (3250)

726 (1600) 967 (2130) 681 (1500) 863 (1900) 1521 (3350)

permanente

UW60PV UW100PV UF35PV UF50PV UF85PV

Dimensiones generales

2311 (91) 2429 (95 5/8) 2070 (81 1/2) 2159 (85) 2426 (95 1/2)

Información de peso y transporte

5,8 (207) 6,0 (212) 3,88 (137) 4,05 (143) 4,04 (201)

6,5 (229) 6,7 (235) 3,88 (137) 4,05 (143) 5,69 (201)

Este manual debe usarse junto con la información que

aparece en los manuales con números de parte

F232084, F232089, F232058 y F232059 (que se

suministran con la lavadora extractora).

De gabinete autoestable

Especificaciones eléctricas para modelos con sistema de ahorro de agua*

Designación del voltaje Estándar Calor eléctrico

Modelo Código Voltaje Ciclo Fase Cable

Amperios

de plena

carga

Disyuntor

Galga

americana

para

alambres

mm

Amperios

2

de plena

carga

Disyuntor

Galga

americana

para

alambres

mm

N 440-480 50-60 3 3 6 15 14 3x2,5 33 40 8 3x10

60

WSS

P 380-415 50-60 3 3 6 15 14 3x2,5 29 40 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2,5 66 80 3 3x25

N 440-480 50-60 3 3 6 15 14 3x2,5 32 35 8 3x10

35

WSS

P 380-415 50-60 3 3 6 15 14 3x2,5 32 35 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2,5 50 50 8 3x10

N 440-480 50-60 3 3 6 15 14 3x2,5 43 50 8 3x10

50

WSS

P 380-415 50-60 3 3 6 15 14 3x2,5 43 50 8 3x10

Q 200-240 50-60 3 3 12 15 14 3x2,5 76 80 4 3x25

NOTA: Los tamaños de los cables que aparecen son para el conductor de cobre, THHN, de 90° para el artículo

NEC 310.

*La información de voltaje para los modelos *UW80PVWSS es igual a la de los modelos estándares UW80PV.

2

F232122 (SP)

37

Page 40

Instalación

Espacios libres

UWPV cilíndrica de montaje permanente con sistema de ahorro de agua

Dimensiones de la máquina*

Dimensiones

60 100

plg mm plg mm

A

B

C

D

41-7/16 1052,5 47-1/16 1195,4

91 2311 95-5/8 2428,9

61-3/4 1568 73-1/4 1861

15-3/4 400 15-3/4 400

* Deje una separación de por lo menos 610 mm (24 plg) por la parte trasera y 460 mm (18 plg) por los lados, para fines de

mantenimiento, inspección y ajuste. Deje por lo menos 460 mm (18 plg) entre una máquina y otra en instalaciones de

múltiples unidades.

C

A

38

B

D

Q020I

Q020I

F232122 (SP)

Page 41

Instalación

UFPV de gabinete autoajustable con sistema de ahorro de agua

Dimensiones de la máquina*

35 50 85

Dimensiones

mm plg mm plg mm plg

A

B

C

D

889 35 990,6 39 1181,1 46-1/2

2070 81-1/2 2159 85 2426 95-1/2

1448 57 1537 60-1/2 1727 68

400 15-3/4 400 15-3/4 400 15-3/4

* Deje una separación de por lo menos 610 mm (24 plg) por la parte trasera y 460 mm (18 plg) por los lados, para fines de

mantenimiento, inspección y ajuste. Deje por lo menos 460 mm (18 plg) entre una máquina y otra en instalaciones de

múltiples unidades.

A

C

B

D

Q002I

F232122 (SP)

39

Page 42

Instalación

Cimientos para la máquina

Para obtener la información relacionada con los

cimientos, tanto para el modelo UWPV como para el

modelo UFPV, consulte la sección correspondiente de

los manuales de instalación/mantenimiento

respectivos.

Para obtener la información sobre los modelos UFPV

con el sistema de ahorro de agua, consulte en la Tabl a 1

los datos de carga total sobre el piso.

Datos de carga sobre el piso de la lavadora

extractora UFPV de gabinete autoestable

35 50 85

Carga estática sobre el

piso, kN (lb)

Presión estática

2

kN-m

(lb-pie2)

Cimientos para la estructura de tanques

del sistema de ahorro de agua en

modelos de lavadora extractora cilíndrica

de montaje permanente (UWPV)

9,755

(2193)

11,07

(231)

Tabla 1

11,899

(2675)

11,45

(239)

22,472

(5052)

15,00

(313)

IMPORTANTE: Asegúrese de que la estructura de

los tanques quede instalada sobre un piso nivelado

con suficiente resistencia y de que se dejen los

espacios libres recomendados para inspección y

mantenimiento. Nunca permita que dichos espacios

queden bloqueados.

La estructura de los tanques debe ser anclada a una

superficie uniforme y nivelada, de tal forma que las

cuatro patas queden apoyadas y descansen sobre toda

la superficie de montaje.

Si la instalación de la lavadora extractora incluye el

WSS, la base elevada deberá diseñarse para aceptar

una anchura adicional de 10 cm (4 plg) pjor cada lado

de la lavadora extractora y corregir así la alineación.

En la Tabl a 2 se presenta la carga de la lavadora

extractora, de los tanques y de la estructura sobre el

piso o los cimientos.

Datos de carga sobre el piso de la lavadora

extractora UWPV cilíndrica de montaje

Carga estática sobre

el piso, kN (lb)

permanente

60 100

11,7

(2617)

19,3

(4341)

Unos cimientos apropiados son absolutamente

necesarios para todas las lavadoras extractoras UWPV

con sistemas de ahorro de agua debido al peso del agua

a alturas elevadas.

NOTA: No realice la instalación sobre pisos de

madera, en pisos superiores o sobre sótanos. La

instalación debe ser hecha sobre una losa rasante

de hormigón, o similar.

Presión estática por pata

kN-m

2

(lb-pie2)

Tabla 2

10,9

(227)

13,0

(271)

40

F232122 (SP)

Page 43

Instalación

Instalación mecánica

Instalación de pernos de montaje para

modelos de lavadora extractora de

gabinete autoestable (UFPV) con sistema

de ahorro de agua

Consulte el manual de instalación/mantenimiento

(N/P F232059) para obtener información sobre la

instalación de los pernos de montaje en los modelos

UFPV.

Instalación de pernos de montaje para

modelos cilíndricos de montaje

permanente (UWPV) con sistema de

ahorro de agua

NOTA: La estructura del WSS deberá quedar

fijada permanentemente al piso.

Todas las máquinas UWPV usan pernos de

5/16-18 x 6 plg para el montaje de la estructura de

tanques. Siga el esquema de montaje de los pernos que

aparece en la Figura 2.

En la Figura 1 se indica la instalación típica de los

pernos de montaje individuales en la estructura del

sistema de ahorro de agua.

1

2

1 8 mm (5/16")

2 52 mm (6")

3 Estructura

Figura 1

3

Q028I

El extremo con rosca de los pernos debe sobresalir

5 cm (2 plg) sobre la superficie del suelo.

F232122 (SP)

41

Page 44

Instalación

plg

Perfil del área ocupada

por la unidad

Perfil de la base

de la estructura

UW60PV

14 mm (9/16 plg)

962 mm

(37-7/8 plg)

51 mm

(2 plg)

97 mm

(3-13/16 plg)

123 mm

(4-27/32 plg)

1049 mm (41-5/16 plg)

867 mm

19 mm

(3/4plg)

(34-1/8 plg)

Perfil de la pata

de soporte

65 mm

(2-9/16 plg)

32 mm

(1-1/4 plg)

(34-19/32 plg)

879 mm

(34-19/32 plg)

Borde delantero

de la máquina

51 mm

(2 plg)

803 mm

(31-5/8 plg)

879 mm

997 mm

(39-1/4 plg)

905 mm

(35-5/8 plg)

19 mm

(3/4 plg)

65 mm

(2-9/16 plg)

32 mm

(1-1/4 plg)

97 mm

(3-13/16 plg)

51 mm

(2 plg)

106 mm

(4-13/16 plg)

14 mm (9/16 plg)

229 mm

(9 plg)

273 mm

(10-3/4 plg)

271 mm

(10-11/16 plg)

51 mm

(2 plg)

123 mm

(4-27/32 plg)

19 mm

(3/4 plg)

914 mm

(36 plg)

Q023I

UW100PV

19 mm

106 mm

(4-3/16 plg)

(3/4 plg)

69 mm

(2-11/16 plg)

Perfil del área

ocupada por la unidad

Perfil de la base de

la estructura

76 mm

(3 plg)

65 mm

(2-9/16 plg)

126 mm

(4-15/16 plg)

1195 mm

(47-1/16 plg)

1006 mm

(39-5/8 plg)

892 mm

19 mm

(3/4 plg)

(35-1/8 plg)

Perfil de la pata

de soporte

1323 mm

(52-1/16 plg)

57 mm

(2-1/4 plg)

1010 mm

(39-25/32 plg)

Borde delantero

de la máquina

892 mm

(35-1/8 plg)

1045 mm

(41-1/8 plg)

19 mm

(3/4 plg)

69 mm

(2-11/16 plg)

1176 mm

(46-9/32 plg)

57 mm

(2-1/4 plg)

76 mm

(3 plg)

106 mm

(4-3/16 plg)

171 mm (6-3/4 plg)

229 mm (9 plg)

65 mm

(2-9/16 plg)

19 mm (3/4 plg)

126 mm

(4-15/16 plg)

346 mm

(13-5/8 plg)

346 mm

(13-5/8 plg)

106 mm

(4-13/16 plg)

1111 mm

(43-3/4 plg)

(44-3/16 plg)

Q023I

1122 mm

Q024I

Q024I

42

Figura 2

F232122 (SP)

Page 45

Instalación

Consulte en esta sección las especificaciones generales

del sistema de ahorro de agua (WSS) para determinar

si hay una separación adecuada alrededor de la puerta

de la máquina. Si no la hay, y el WSS necesita ser

retirado, consulte la sección “Desmontaje de la

sección superior”. Si la separación es suficiente,

continúe como se indica a continuación:

NOTA: Espere a que el concreto (hormigón) se cure

antes de comenzar la instalación.

1. Coloque el WSS al lado del cimiento de

concreto.

IMPORTANTE: Mueva el WSS levantándolo por

la estructura únicamente. Nunca mueva el WSS

levantando, empujando o tirando de los tanques.

2. Saque los pernos de máquina sujetando la

plataforma de madera a las patas laterales de la

estructura del WSS.

3. Coloque el WSS sobre los pernos de montaje.

4. Nivele las secciones superior y laterales de la

estructura. Alinéela con la lavadora extractora.

Desmontaje de la sección superior

Si es necesario desmontar la sección superior debido a

que no hay espacio suficiente, consulte la Figura 3 y

proceda como se indica a continuación:

1. Coloque el WSS al lado del cimiento de

concreto.

IMPORTANTE: Mueva el WSS levantándolo por

la estructura únicamente. Nunca mueva el WSS

levantando, empujando o tirando de los tanques.

2. Sujete la sección superior con el equipo de izado.

3. Saque de la sección superior los ocho pernos y

tuercas que sujetan los lados de la estructura a la

parte superior. Consulte la Figura 3.

4. Asegure en su lugar ambos lados de la estructura

y levante la sección superior con el equipo de

izado.

5. Saque de la plataforma de madera los lados de la

estructura sacando para ello los pernos que los

mantienen unidos a la plataforma. Saque la barra

de soporte de la estructura. Consulte la Figura 3.

NOTA: La lavadora extractora y el WSS no deben

hacer contacto en ningún punto. Si es necesario

elevar la máquina para apretar los pernos, el WSS

deberá elevarse también a una altura equivalente.

5. Apriete las tuercas y arandelas de montaje para

asegurar la estructura al piso.

6. Coloque ambos lados de la estructura sobre los

pernos de montaje y vuelva a colocar la barra de

soporte de la estructura. Enrosque las tuercas de

montaje hasta que las piezas queden unidas, pero

lo apriete las tuercas todavía.

F232122 (SP)

43

Page 46

Instalación

7. Baje con cuidado la sección superior sobre los

lados de la estructura. Inserte los ocho pernos de

la sección superior, y los cuatro pernos de la

barra de soporte de la estructura. Coloque las

tuercas correspondientes y apriételas bien.

8. Nivele la sección superior y los lados de la

estructura. Alinéelos con la lavadora extractora.

1

2

NOTA: La lavadora extractora y el WSS no deben

hacer contacto en ningún punto. Si es necesario

elevar la máquina para apretar los pernos, el WSS

deberá elevarse también a una altura equivalente.

9. Apriete las tuercas y arandelas de montaje para

asegurar la estructura al piso.

Con la sección superior desmontadaCon la sección superior instalada

1

4

2

5

6

7

3

3

Vista lateralVista posterior

Q042I

1 Sección superior 5 Tuercas de la sección superior

2 Barra de soporte de la estructura 6 Tuercas de la barra de soporte de la estructura

3 Lados de la estructura 7 Pernos de la barra de soporte de la estructura

4 Pernos de la sección superior

44

Figura 3

F232122 (SP)

Page 47

Instalación

Cierre con llave el panel de alimentación

principal y en la fuente de corriente

eléctrica que llega a la caja de control antes

de realizar cualquiera de los

procedimientos de servicio.

ADVERTENCIA

SW007

Instrucciones para instalación de

modelos de lavadora extractora

cilíndrica de montaje permanente

(UWPV) con sistema de ahorro de

agua

Lea detenidamente las instrucciones siguientes antes

de proceder. El instalador deberá estar bien

familiarizado con las instrucciones antes de intentar la

instalación del WSS. Consulte la sección “Cimientos

para la estructura de tanques del sistema de ahorro de

agua” en lo relacionado con el apriete de los pernos.

IMPORTANTE: Asegúrese de que la máquina sea

instalada sobre un piso nivelado con la suficiente

resistencia y de que se mantengan los espacios

libres necesarios para inspección y mantenimiento.

Nunca permita que el espacio para inspección y

mantenimiento quede bloqueado.

Consulte las especificaciones generales del WSS en

esta sección para determinar si hay espacio suficiente

para la máquina. Si no lo hay, y es necesario retirar el

WSS, consulte la sección “Desmontaje de la sección

posterior”.

Consulte las Especificaciones eléctricas para modelos

con sistema de ahorro de agua (WSS) para obtener

información sobre el voltaje.

1. Conexión del WSS a la lavadora extractora:

NOTA: El conjunto de mangueras de desagüe viene

en un paquete dentro del cesto de la lavadora

extractora.

a. Saque del paquete el conjunto de mangueras

de desagüe del tanque. Coloque la manguera

de desagüe en las válvulas de desagüe del

tanque y en la tubería con revestimiento de la

lavadora extractora. Instale las abrazaderas de

manguera grandes en las válvulas de desagüe

y la abrazadera de manguera pequeña en la

tubería con revestimiento, y apriételas.

Consulte las Figuras 4 y 5.

F232122 (SP)

Montaje de manguera de desagüe de los tanques

1

NOTA: Las posiciones derecha e izquierda están

referidas a un observador ubicado en la parte

posterior de la máquina.

1 A la válvula de desagüe del tanque derecho

2 A la válvula de desagüe del tanque izquierdo

3 Al tubo del cilindro de la lavadora extractora

Figura 4

2

Vista

superior

Vista

frontal

3

Q038I

Para máquinas de 220V:

a. Para realizar una conexión eléctrica, conecte

el cable de señal de control al receptáculo de

desconexión rápida “C1” (señal) (la clavija

que se encuentra más arriba en la parte

posterior del módulo de control de la lavadora

extractora). Conecte el cable de alimentación

al receptáculo de desconexión rápida “C2”

(alimentación). Consulte la Figura 7.

NOTA: Los receptáculos y clavijas están marcados

para realizar una conexión correcta. Por ejemplo,

el cable de señal de control sólo encaja en “C1”. No

aplique demasiada fuerza al conectar.

Para máquinas de 110V:

a. Afloje la tuerca de la parte trasera del

protector contra tirones PG9, ubicado en la

parte posterior del módelo de control de la

lavadora extractora. Consulte la Figura 8.

Haga pasar los cables de alimentación

trifásica y el cable verde de tierra a través del

protector contra tirones, recogiendo el exceso

de cable dentro del módulo de control, y

dejando una longitud suficiente para la

conexión al boque de terminales de

alimentación de entrada y de tierra.

b. Conecte los cables de alimentación trifásica al

bloque de terminales de entrada de

alimentación, ubicado dentro del modulo de

control de la lavadora extractora.

45

Page 48

Instalación

2. Instalación del conjunto de bombas (consulte la

Figura 5):

NOTA: El conjunto de bombas viene en un paquete

dentro del cesto de la lavadora extractora.

a. Saque el conjunto de bombas del paquete y

colóquelo por la parte posterior de la lavadora

extractora, descansando en posición

horizontal sobre el suelo.

b. Encamine los dos cables de conexión del

motor al alojamiento de control del WSS (ver

Figura 8). Deslice los conectores hacia dentro

y enrósquelos hasta que queden bloqueados.

Los receptáculos y cables de bomba están

marcados “PA” y “PB”. Consulte la Figura 7.

c. Instale la abrazadera grande de la manguera

del distribuidor ubicada en la parte posterior

de la lavadora extractora y apriétela. Consulte

la Figura 5.

d. Compruebe que la válvula de bola está en la

posición cerrada. Antes de hacer funcionar la

máquina, la válvula de bola deberá estar

cerrada.

3. Instalación de la manguera de la bomba y las

bocas de ventilación:

NOTA: Las mangueras de bomba y las bocas de

ventilación vienen en un paquete dentro del cesto

de la lavadora extractora.

a. Saque del paquete las mangueras de las

bombas y cuatro abrazaderas de manguera

pequeñas.

b. Coloque la manguera en la bomba apropiada

(bomba superior al tanque derecho, bomba

inferior al tanque izquierdo, vistos desde la

parte posterior) y el codo del tanque a la parte

posterior de cada tanque. Consulte la Figura 5.

Apriete las abrazaderas de manguera pequeñas.

c. Coloque cinta de teflón a las roscas de las

bocas de ventilación y enrosque encima de

cada tanque; apriete con la mano solamente.

d. Asegure a las patas de la estructura las dos

mangueras de bomba y los dos cables de

motor de bomba con abrazaderas para cable.

NOTA: La bomba deberá girar en sentido

contrario al de las agujas del reloj cuando es vista

desde el extremo del ventilador, o en el sentido de

las agujas del reloj cuando es vista desde el extremo

del cabezal plástico de la bomba. La rotación

invertida hará fallar la bomba, lo cual alargaría el

tiempo de ciclo. Observe el rótulo con la flecha

indicadora del sentido de rotación sobre la bomba y

en la Figura 5. Para corregir el sentido de rotación,

intercambie dos de los cables de alimentación

trifásica en el lado de la carga del contactor

respectivo, ubicado en el módulo de control de

ahorro de agua (WSS) montado a distancia.

46

F232122 (SP)

Page 49

Instalación

4

20

19

1

2

2

3

6

5

7

11

8

18

8

8

10

10

17

16

9

11

12

13

9

21

14

Vista Lateral

15

Vista Posterior

1 Abrazadera de manguera larga 13 Bomba superior

2 Codo de tanque 14 Bomba inferior

3 Agujero de desagüe de tanque de 2 plg 15 Rotación de la bomba en sentido antihorario

4 Agujeros de ventilación de vacío 16 Pernos de máquina para sujeción de la

5 Abrazadera de manguera pequeña

plataforma de transporte

6 Tanque izquierdo 17 Patas laterales de la estructura

7 Tanque derecho 18 Conjunto de mangueras de desagüe de los

8 Lados de la estructura

tanques

9 Mangueras de bomba 19 Al tubo del cilindro de la lavadora extractora

10 Conjunto de bombas

(no mostrado)

11 Válvula de bola 20 Estructura

12 Extremo de ventilador de bomba

Figura 5

Q039I

F232122 (SP)

47

Page 50

Instalación

Orientación de la máquina con sistema de ahorro de agua integrado UW

1

4

2

6

5

1 Módulo de control de la lavadora extractora

2 Alojamiento del control de ahorro de agua

3 Receptáculo de conexión rápida para el motor de la bomba del Tanque “A”

4 Receptáculo y clavija de conexión rápida, C2 (Alimentación)

5 Receptáculo de conexión rápida para el motor de la bomba del Tanque “B”

6 Receptáculo y clavija de conexión rápida, C1 (Señal)

Figura 6

3

Q043I

48

F232122 (SP)

Page 51

ILUSTRACION GENERALIZADA DE CONEXIONES

ELECTRICAS DEL SISTEMA DE AHORRO DE AGUA (220V).

CONSULTE LAS INSTRUCCIONES Y LA GRAFICA #634148

PARA MAYORES DETALLES.

2

3

4

Instalación

1

5

7

1 Módulo de control de ahorro de agua montado a distancia

2 Parte posterior del módulo de control en la máquina principal

3 Receptáculo y clavija de conexión rápida C1 (Señal)

4 Cable 133 a la válvula de desagüe del Tanque “A”

5 Cable 132 a la válvula de desagüe del Tanque “B”

6 Receptáculo y clavija de conexión rápida de las bombas “A” y “B”

7 Receptáculo y clavija de conexión rápida C2 (Alimentación)

Figura 7

6

Q041I

F232122 (SP)

49

Page 52

Instalación

Daño al tanque. Las conexiones hechas a la

salida de desborde deberán apuntar hacia

abajo del tanque. El tendido de tubería

hacia arriba causará daño a los tanques.

PRECAUCIÓN

Agujeros de rebose de los tanques

Algunos agujeros de rebose tienen conexiones

externas de PVC de 2 plg. Estas conexiones pueden

desaguarse en una batea o desagüe en el piso.

IMPORTANTE: Las conexiones hechas a la salida

de desborde deberán proporcionar un soporte

adecuado proporcional al peso de la tubería y los

conectores.

Opción de calentamiento por vapor

ADVERTENCIA

Superficies calientes. Causará quemaduras

severas. Cierre la fuente de vapor y espere

a que se enfríen las tuberías de vapor,

conexiones y demás componentes antes de

tocarlos.

Si la lavadora extractora está equipada con la opción

de calentamiento por vapor, no es necesario usar

piezas de conexión de tuberías adicionales.

IMPORTANTE: No tienda conectores ni tuberías

cerca de los tanques del sistema de ahorro de agua.

Envuelva los conectores y las tuberías con aislante

de vapor para tuberías.

50

F232122 (SP)

Page 53

Instalación

Instrucciones para instalación de

modelos de lavadora extractora de

gabinete autoestable (UFPV) con

sistema de ahorro de agua

Lea detenidamente las instrucciones siguientes antes

de proceder. El instalador deberá estar bien

familiarizado con las instrucciones antes de intentar la

instalación del WSS.

Consulte las Especificaciones eléctricas para modelos

con sistema de ahorro de agua (WSS) para obtener

información sobre el voltaje.

Consulte las Especificaciones generales del WSS para

determinar si hay una separación adecuada alrededor

de la puerta de la máquina. Si no la hay, será necesario

desmontar los tanques de agua.

1. Desmontaje de los tanques de agua (si es

necesario):

1

a. Saque los tres tapones de sombrerete (dos de

ellos ubicados cerca de la parte posterior, y el

otro ubicado cerca de la parte frontal), por

cada lado de los tanques. Consulte la

Figura 8.

b. Afloje las dos abrazaderas de manguera

acopladas por la parte inferior trasera de cada

tanque. Consulte la Figura 8.

c. Afloje las dos abrazaderas de manguera

acopladas al codo que está ubicado en la parte

posterior de cada tanque, y saque las

mangueras negras largas conectadas a los

tanques. Consulte la Figura 9.

d. Afloje la abrazadera de manguera acoplada a

la manguera negra corta que interconecta los

tanques y desconecte solamente de uno de los

tanques.

4

5

1 Tanques de agua

2 Agujeros de ventilación de vacío

3 Alojamiento del control de ahorro de agua

4 Ta pón de sombrerete

5 Abrazaderas de manguera debajo del tanque, detrás del tapón

2

3

Q007I

F232122 (SP)

Figura 8

51

Page 54

Instalación

Tenga mucho cuidado al retirar los tanques.

Para evitar daños, coloque siempre los

tanques sobre una superficie nivelada con

acceso para limpieza por encima.

PRECAUCIÓN

e. Saque los cuatro pernos de cada tanque,

localizados detrás del tapón de sombrerete en

cada esquina. Consulte la Figura 9.

f. Levante los tanques de la lavadora extractora.

2. Desmontaje del conjunto de bombas:

a. Saque las abrazaderas de la manguera del

distribuidor que conecta el distribuidor de

bomba con la válvula de desagüe localizada

en la parte posterior de la lavadora extractora,

a la derecha del conjunto de bombas. Consulte

la Figura 9.

b. Desenrosque del alojamiento de control del

sistema de ahorro de agua (localizado en la

parte posterior de la lavadora extractora) las

dos piezas de desconexión eléctrica rápida de

los motores de bomba.

c. Saque las dos mangueras negras largas

conectadas a los tanques de agua. Consulte la

Figura 9.

d. Saque el conjunto de bombas y colóquelo a un

lado.

3. Ubicación de la lavadora extractora en su

posición definitiva y fijación mediante pernos:

Consulte las instrucciones de fijación mediante

pernos en la sección Instalación mecánica.

1

2

5

3

4

1 Pernos de esquina de los tanques (4 por tanque) 4 Conjunto de bombas

2 Abrazaderas de manguera en codos 5 Ta p ón de sombrerete

3 Abrazaderas de manguera en distribuidor

Q008I

Q008I

52

Figura 9

F232122 (SP)

Page 55

Instalación

4. Montaje del conjunto de bombas:

a. Reinstale el conjunto de bombas en la parte

posterior de la lavadora extractora, en

posición horizontal sobre el piso.

b. Asegure las dos piezas de conexión eléctrica

de los motores de bomba al alojamiento del

control del sistema de ahorro de agua.

c. Coloque la abrazadera de la manguera del

distribuidor en la parte posterior de la

lavadora extractora.

d. Compruebe que la válvula de bola está en la

posición cerrada. Antes de hacer funcionar la

máquina, la válvula de bola deberá estar

cerrada.

NOTA: La bomba deberá girar en sentido

contrario al de las agujas del reloj cuando es vista

desde el extremo del ventilador, o en el sentido de

las agujas del reloj cuando es vista desde el extremo

del cabezal plástico de la bomba. La rotación

invertida hará fallar la bomba, lo cual alargaría el

tiempo de ciclo. Observe el rótulo con la flecha

indicadora del sentido de rotación sobre la bomba y

en la Figura 5. Para corregir el sentido de rotación,

intercambie dos de los cables de alimentación

trifásica en el bloque de terminales de alimentación

de entrada, y compruebe cada bomba por

separado.

5. Reinstalación de los tanques de agua:

a. Coloque con cuidado los tanques encima de la

lavadora extractora.

b. Coloque los cuatro pernos detrás de los

tapones de sombreretes ubicados en cada una

de las esquinas de los tanques.

d. Coloque las mangueras negras largas en los

codos correspondientes, ubicados por la parte

trasera de cada tanque: el tanque de la derecha

con la bomba superior, y el tanque de la

izquierda con la bomba inferior. Apriete las

abrazaderas de las mangueras.

e. Apriete las tres abrazaderas debajo de cada

tanque.

f. Coloque los tres tapones de sombrerete por

cada lado de los tanques.

6. Instalación de las bocas de ventilación de

tanques:

a. Saque las bocas de ventilación del paquete.

b. Coloque cinta de teflón a las roscas de las

aberturas de ventilación y enrosque encima de

cada tanque; apriete con la mano solamente.

Agujeros de rebose de los tanques

Algunos agujeros de rebose tienen conexiones

externas de PVC de 2 plg. Estas conexiones pueden

desaguarse en una batea o desagüe en el piso.

PRECAUCIÓN

Daño al tanque. Las conexiones hechas a la

salida de desborde deberán apuntar hacia

abajo del tanque. El tendido de tubería

hacia arriba causará daño a los tanques.

IMPORTANTE: Las conexiones hechas a la salida

de desborde deberán proporcionar un soporte

adecuado proporcional al peso de la tubería y los

conectores.

c. Coloque la manguera negra corta en el codo

ubicado por la parte trasera del tanque grande.

Consulte la Figura 9. Apriete la abrazadera de

la manguera.

F232122 (SP)

53

Page 56

Notas

54

F232122 (SP)

Page 57

Mantenimiento

Diariamente

Al comienzo del día

Inspeccione que no haya fugas en los tanques del

sistema de ahorro de agua ni en ninguna de las

conexiones asociadas con los mismos.

Al final del día

Active el ciclo de desagüe de los tanques.

Semanalmente

Limpie los tanques; para ello, saque los tapones

ubicados encima de los tanques y aplique abundante

agua con una manguera. Desinfecte si es necesario.

Mensualmente

Enjuague con abundante agua la válvula de bola de

desagüe; para ello, ábrala completamente a fin de

purgar todas las pelusas y partículas que haya en el

distribuidor de bombas.

Compruebe que las tuercas de la sección superior de la

estructura de los tanques estén apretadas al par de

apriete especificado (220 lb-plg).

F232122 (SP)

55

Page 58

Notas

56

F232122 (SP)

Page 59

Puesta fuera de servicio

Puesta fuera de servicio

Asegúrese de que se ha vaciado toda el agua de los

tanques.

F232122 (SP)

57

Page 60

Notas

58

F232122 (SP)

Page 61

Operación

Pantalla de LED

En la siguiente tabla se presentan las diferentes

pantallas correspondientes al sistema de ahorro de

agua (WSS) y lo que éstas significan.

Estas pantallas son iguales para ambos modelos, y

aparecen en los dos dígitos izquierdos de la pantalla.

Es conveniente que el operador se familiarice con estas

pantallas.

Interpretación de la pantalla

aL

aM

aH

bL

bM

bH

Da

Db

NOTA: El tanque izquierdo (visto desde la parte delantera de la máquina) se designa tanque A, mientras

que el tanque derecho es el tanque B.

Llenar la máquina con agua del tanque A a nivel bajo

Llenar la máquina con agua del tanque A a nivel intermedio

Llenar la máquina con agua del tanque A a nivel alto

Llenar la máquina con agua del tanque B a nivel bajo

Llenar la máquina con agua del tanque B a nivel intermedio

Llenar la máquina con agua del tanque B a nivel alto

Desaguar la máquina hacia el tanque A

Desaguar la máquina hacia el tanque B

Función de control del modo

manual

No resulta posible el regular con la mano las funciones

del WSS (sistema de ahorro de agua).

NOTA: A fin de impedir que en los tanques de

ahorro de agua entre agua temperaturas más

elevadas de 71C (160F), sonará una alarma y en la

pantalla aparecerá “DRTEMP”. Si no se pulsa la

tecla de detención (STOP) en el transcurso de dos

minutos, la mánquina se detendrá

automáticamente.

Tabla 3

F232122 (SP)

59

Page 62

Notas

60

F232122 (SP)

Page 63

Programación

NOTA: La siguiente información de programación

se aplica a los modelos de gabinete autoestable y a

los modelos cilíndricos de montaje permanente de

lavadoras extractoras con sistema de ahorro de

agua (WSS). Emplee esta información junto con la

incluida en los respectivos manuales de operación/

programación.

Cuando programe pasos en los que intervenga el WSS,

el ordenador deberá estar en el modo de programa

(PROGRAM) y listo para el paso siguiente. Aparecerá

en pantalla “nncc”, donde “nn” representa el número

del paso y “cc” representa el número del ciclo.

Programación de un llenado de

recuperación desde el(los)

tanque(s) del sistema de ahorro de

agua

1. Oprima la tecla Auxiliary (auxiliar). Aparecerá

en pantalla “A-nncc”.

2. Oprima la tecla 6 para seleccionar un llenado con

agua del tanque A. Aparecerá en pantalla “a-

nncc”. Oprima la tecla 7 para seleccionar un

llenado con agua del tanque B. Aparecerá en

pantalla “b-nncc”.

3. Oprima la tecla Low (bajo), Medium

(intermedio) o High (alto) para seleccionar el

nivel de agua. Aparecerá en el segundo dígito de

la pantalla “L”, “M” o “H”, respectivamente. Por

ejemplo: si se selecciona un nivel bajo con agua

del tanque A, aparecerá en pantalla “aLnncc”.

4. Oprima la tecla Enter (introducir). Aparecerá en

pantalla “M---S”.

5. Introduzca el máximo tiempo de llenado. Para

programar 5 minutos, oprima la tecla 5.

Aparecerá en pantalla “5M-00S”.

6. Una vez introducido el tiempo deseado, oprima la

tecla Enter (introducir) para ir al paso siguiente

del ciclo o para salir del modo de programa

(PROGRAM).

Programación de un paso de

desagüe del sistema de ahorro de

agua

1. Oprima la tecla Drain (desagüe). Aparecerá en

pantalla “D-nncc”.

2. Oprima la tecla 2 para vaciar hacia el tanque A, o

la tecla 3 para vaciar hacia el tanque B.

3. Oprima la tecla Enter (introducir). Aparecerá en

pantalla “M---S”.

4. Introduzca el tiempo deseado para el paso de

desagüe. Por ejemplo: para introducir un tiempo

de 5 minutos, oprima la tecla 5. Aparecerá en

pantalla “5M-00S”.

NOTA: Si la máquina no se vacía en este intervalo

de tiempo, aparecerá en pantalla “EMTY”.

5. Oprima la tecla Enter (introducir) y vaya al paso

siguiente del ciclo. De lo contrario, saldrá del

modo de programa (PROGRAM).

NOTA: Al programar un paso de desagüe, hay que

especificar el tipo de desagüe que se desea, ya que

las funciones de ahorro de agua están disponibles

en todo momento.

NOTA: El ordenador WE-6 no permitirá el

desagüe hacia un tanque si la temperatura del agua

excede los 71ºC (160ºF). En ese caso, aparecerá en

pantalla “DRTEMP”, el WE-6 desactivará todas

las salidas (excepto los desagües aplicables) y se

escuchará un sonido de aviso. Este estado se

prolongará por hasta dos minutos. Si el operador

no responde durante el transcurso de dos minutos,

el WE-6 abortará el ciclo. El operador puede

oprimir la tecla de arranque (START) para volver

a comenzar el paso de desagüe, u oprimir la tecla

de parada (STOP) para finalizar el ciclo.

Ciclos preprogramados

Para obtener más información sobre los ciclos

preprogramados, consulte la sección Programación de

los manuales de Operación/programación (Pieza No.

F232059 para los modelos UF, y Pieza No. F232089

para los modelos UW).

F232122 (SP)

61

Page 64

Notas

62

F232122 (SP)

Loading...

Loading...