Page 1

Automatic

Washers

Metered and Nonmetered

Refer to Page 6 for Model Numbers

Service

www.comlaundry.com

W138P

Part No. 32918R2

February 2003

Page 2

Table of Contents

Section 1 – Safety Information

Locating an Authorized Servicer ............................4

Section 2 – Introduction

Customer Service ....................................................5

Nameplate Location ................................................5

Model Identification ................................................6

Section 3 – Troubleshooting

1. No Hot Water ...................................................7

2. No Cold Water .................................................7

3. No Warm Water ...............................................8

4. Water Fill Does Not Stop At Proper Level ......8

5. Timer Does Not Advance (Mechanical Timer

Models only) ....................................................8

6. No Agitation .....................................................9

7. Constant Agitation ...........................................9

8. Slow Spin Or No Spin ....................................10

9. Constant Spin .................................................10

10. Drive Motor Overload Protector Cycles

Repeatedly ......................................................10

11. Outer Tub Does Not Empty ...........................11

12. Excessive Vibration .......................................11

13. Water Leaking From Outer Tub ....................11

Section 4 – Grounding

14. Wall Receptacle Polarity Check ....................13

15. Power Cord to Control Hood, Control Hood to

the Control Panel Frame ................................13

16. Control Hood Wire Harness to Top Left Rear

Corner Gusset of Cabinet ...............................14

17. Motor to Mounting Bracket ...........................14

Section 5 – Service Procedures

18. Control Panel .................................................15

19. Speed or Wash Temperature Switch ..............15

20. Indicator Lights – Unbalanced Load, In Use,

Rinse or Spin ..................................................16

21. Timer Assembly – Metered Models ..............16

22. Timer Assembly (Nonmetered Models) ........17

23. Meter Case (Metered Models) .......................17

24. Timer Case (Nonmetered Models) .................18

25. Pressure Switch ..............................................19

26. Drain Hose Elbow ..........................................19

27. Loading Door .................................................20

28. Graphic Overlay .............................................22

29. Agitator ..........................................................22

30. Agitator, Drive Bell and Seal Assembly ........22

31. Front Panel .....................................................24

32. Pump Belt ......................................................25

33. Drive Belt .......................................................25

34. Motor and Mounting Bracket ........................26

35. Idler Lever and Pulley ....................................27

36. Motor Drive Pulley or Pump Pulley ..............29

37. Motor Switch .................................................29

38. Pump Assembly .............................................29

39. Cabinet Top Assembly ...................................30

40. Door/Out-Of-Balance Switch Assembly .......33

41. Mixing Valve Assembly ................................36

42. Washtub and Lint Filter or Clothes Guard .....37

43. Hub and Seal Kit Assembly ...........................42

To Install Drive Bell and No. 39508P

Seal Kit............................................................47

44. Outer Tub .......................................................48

45. Drive Pulley and Helix ..................................52

46. Brake Assembly .............................................53

47. Lower Bearing Housing .................................53

To Remove the Bearing ..................................56

48. Transmission Assembly .................................56

To Disassemble Transmission Assembly .......59

To Reassemble Transmission Assembly ........61

49. Balance Ring ..................................................62

50. Upper Bearing Assembly ...............................62

51. Snubber Pads ..................................................63

To Install the No. 434P3 Snubber Pad Kit......63

Section 6 – Adjustments

52. Leveling Legs ................................................67

53. Pressure Switch ..............................................68

54. Belt — Agitate and/or Spin ...........................68

55. Belt — Pump .................................................68

56. Out-of-Balance Switch Trigger – Through

Serial No. R8237277YK ................................69

© Copyright 2003, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

32918 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 3

Section 7 – Test Procedures

57. To Check Continuity Through Motor Harness

and Motor .......................................................71

58. To Check Continuity Through Base Harness,

Control Harness and Timer For Motor Start

Circuit .............................................................71

59. G.E. Motor Check (Start Windings) ..............72

60. G.E. Motor Check (High and Low

Windings) .......................................................73

Section 8 – Service Procedures Unique to the

Electronic Control Model Washers

61. Electrical Requirements .................................75

62. Grounding Instructions ..................................76

63. Washers Equipped with an Electronic

Control ...........................................................76

64. Functions of the Electronic Control ...............76

Cycles and Their Times ..................................77

Special Options (Programmable)....................77

Extra Rinse......................................................77

Hot Wash Charge............................................77

Coin Value ......................................................78

Vend Price.......................................................79

Unbalanced Light............................................79

Audit................................................................79

65. Power Outage or Interruption ........................79

66. Program Transfer ...........................................79

67. Handheld Programmer ...................................80

68. Cycle Programming .......................................82

69. Coin Acceptor ................................................83

To Wire a Coin Acceptor................................83

70. Loading Door Switch .....................................84

71. Troubleshooting Electronic Control ..............84

Diagnostic Mode.............................................84

Operation.........................................................85

72. Symptom: Indicator LEDs (i.e. Wash, Rinse,

Spin, Unbalanced) Do Not Light ..................87

73. Symptom: Tripped Circuit Breaker or Blown

Fuse ................................................................88

74. Symptom: Washer Will Not Fill or Wrong

Temperature Fill .............................................89

75. Symptom: Washer Will Not Agitate

Properly ..........................................................90

76. Symptom: Washer Will Not Spin Properly ...91

77. Transmit Light/Audit Control Board .............93

78. Cycle Count “C” ............................................94

79. No Slide Input “S” .........................................95

80. No Service Door Input “D” ............................96

81. No Coin Vault Input “V” ...............................97

82. Control Replacement .....................................98

Electronic Control Board Replacement Report ....99

Section 9 – Cycle Sequence Charts

Timer No. 28716 Cycle Sequence

(Long Cycle – Kingston) .....................................101

Timer No. 30464 Cycle Sequence

(Short Cycle)........................................................102

Timer No. 31111 Cycle Sequence

(Short Cycle)........................................................103

Timer No. 31682 Cycle Sequence

(Long Cycle) ........................................................104

Timer No. 33389 Cycle Sequence

(Long Cycle) ........................................................105

Timer No. 34601 Cycle Sequence

(Long Cycle) ........................................................106

Electronic Control Nos. 32005P or 33422P

Cycle Sequence....................................................107

Section 10 – Internal Wiring of Washer Motor

Switch ...................................................................109

Section 11 – Wiring Diagrams

Models EA1010 and EA1011

Through Serial No. R8237277YK ................112

Starting Serial No. R8237278YK..................113

Models EA1020 and EA1021

Through Serial No. R8237277YK ................114

Starting Serial No. R8237278YK..................115

Models EA1110 and EA1111

Through Serial No. R8237277YK ................116

Starting Serial No. R8237278YK..................117

Models EA1120 and EA1121

Through Serial No. R8237277YK ................118

Starting Serial No. R8237278YK..................119

Models EA1210 and EA1211

Through Serial No. R8237277YK ................120

Starting Serial No. R8237278YK..................121

Models EA1220 and EA1221

Through Serial No. R8237277YK ................122

Starting Serial No. R8237278YK..................123

Models EA1310 and EA1311

Through Serial No. R8237277YK ................124

Starting Serial No. R8237278YK..................125

Models EA1420 and EA1421..............................126

Model EA1510.....................................................127

Models EA1520 and EA1521

Through Serial No. R8237277YK ................128

Starting Serial No. R8237278YK..................129

2 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

Section 1

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING,” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer and those maintaining the machine.

a DANGER

Danger indicates the presence of a hazard that will cause severe personal injury, death or substantial property

damage if the danger is ignored.

a WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death or substantial property

damage if the warning is ignored.

a CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

WARNING

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

32918 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1 Safety Information

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

WARNING

W001R1

W007

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Section 2

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

NAMEPLATE

W363PE3A

32918 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

Section 2 Introduction

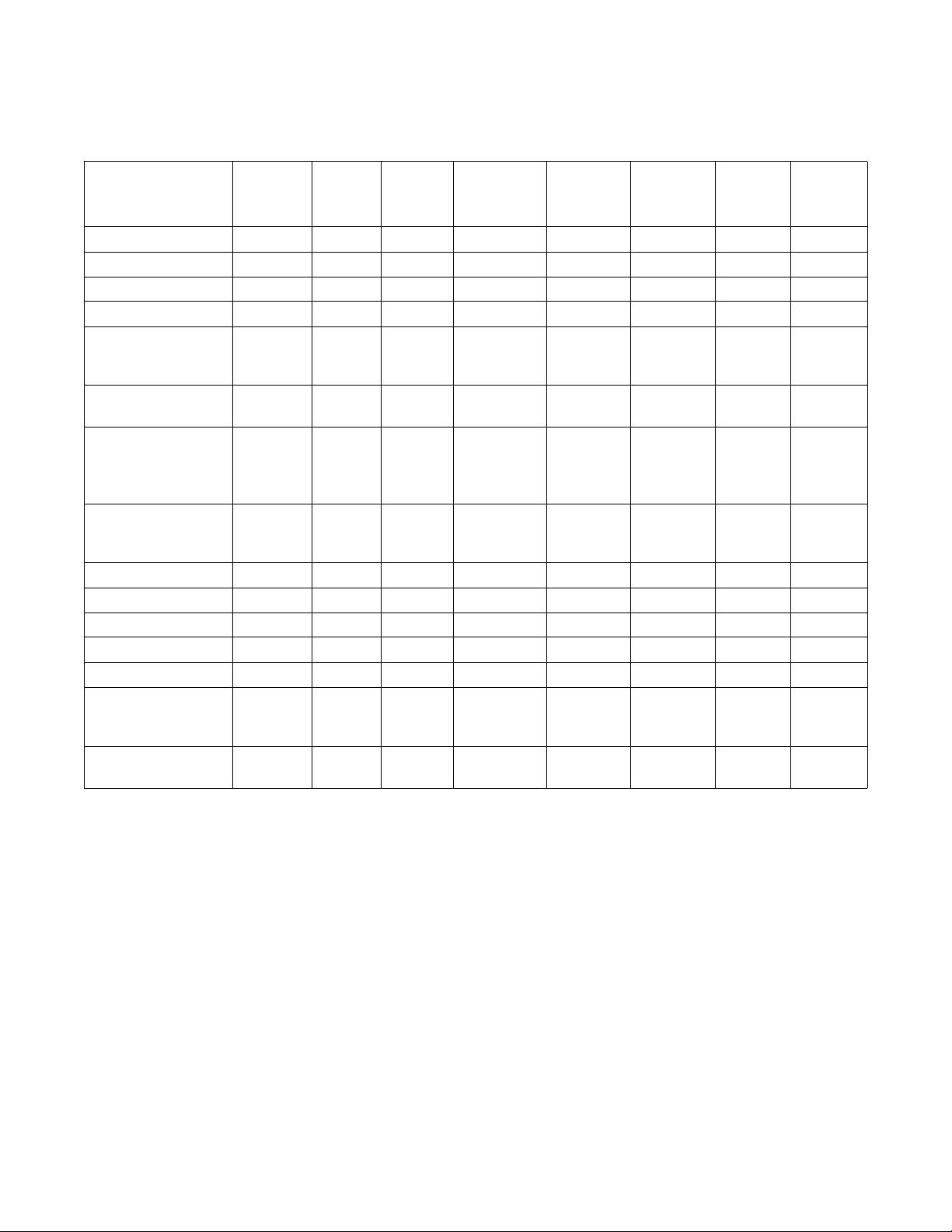

Model Identification

Information in this manual is applicable to these washers.

Model

Numbers

Electronic

Models

Card

Models

Metered

Models

Nonmetered

Models

One Speed

Motor

Two Speed

Motor

Porcelain

Was htub

Stainless

Steel

Was htub

EE1010

EA1011, EA1011G X X X

EA1020, EA1020G X X X

EA1021, EA1021G X X X

EA1110, EA1110P,

EA1110T, EA1210,

EA1210G, EA1710 X X X

EA1111, EA1111P,

EA1111T, EA1211 X X X

EA1120, EA1120P,

EA1120T, EA1220,

EA1220G, EA1220P,

EA1220T X X X

EA1121, EA1121P,

EA1121T, EA1221,

EA1221G, EA1721 X X X

EA1310, EA1310G X X X

EA1311, EA1311G X X X

EA1420 X X X

EA1421 X X X

EA1510G, EA1610 X X X

EA1520, EA1520G,

EA1520P, EA1520T,

EA1620 X X X

EA1521, EA1521G,

EA1621 X X X

XX X

6 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Section 3

Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

IMPORTANT: Refer to appropriate Wiring Diagram for aid in testing washer components.

1. NO HOT WATER

POSSIBLE CAUSE TO CORRECT

Hot water supply faucet is closed. • Open faucet.

Water supply is cold. • Check water heater.

Kinked hot water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or clogged screen in

outer end of inlet hose nearest water supply faucet.

Inoperative hot water mixing valve solenoid. • Test solenoid and replace if inoperative.

*Inoperative timer. • Test timer and replace if inoperative.

*Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control. • Refer to Section 8 to check out the electronic control.

• Disconnect hot water inlet hose, and clean or replace

screen(s).

W003

2. NO COLD WATER

POSSIBLE CAUSE TO CORRECT

Cold water supply faucet is closed. • Open faucet.

Kinked cold water inlet hose. • Straighten or replace hose.

Clogged mixing valve screen, or clogged screen in

outer end of inlet hose nearest water supply faucet.

Inoperative cold water mixing valve solenoid. • Test solenoid and replace if inoperative.

*Inoperative timer. • Test timer and replace if inoperative.

*Inoperative temperature switch. • Test switch and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Clogged pressure hose. • Remove and clean or replace hose.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control. • Refer to Section 8 to check out the electronic control

* Mechanical Timer Models only

† Electronic Control Models only

32918 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

• Disconnect cold water inlet hose, and clean or replace

screen(s).

operation.

Page 9

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

3. NO WARM WATER

POSSIBLE CAUSE TO CORRECT

No hot water. • Refer to Paragraph 1.

No cold water. • Refer to Paragraph 2.

4. WATER FILL DOES NOT STOP AT PROPER LEVEL

POSSIBLE CAUSE TO CORRECT

*Inoperative timer. • Test timer and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Air leak in pressure hose. • Replace hose.

Sediment on or under mixing valve diaphragm,

defective diaphragm, or armature binding in

armature guide.

Broken, weak or missing mixing valve armature

spring.

Siphoning action started in washer which will cause

water to be siphoned from washer during cycle due

to end of drain hose being lower than drain elbow at

rear of washer.

Water in pressure hose. • Blow air through hose to remove water.

Broken, loose, shorted or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control • Refer to Section 8 to check out the electronic control

• Disassemble and clean mixing valve. Replace

deteriorated or not-easily-cleaned components.

• Disassemble valve and replace spring, or replace

complete valve.

• Install No. 562P3 Siphon Break Kit.

operation.

W003

5. TIMER DOES NOT ADVANCE (Mechanical Timer Models only)

POSSIBLE CAUSE TO CORRECT

*Timer is designed to pause during fill periods. • Allow for completion of fill period.

*Inoperative timer. • Test timer and replace if inoperative.

Loading door is open. • Close loading door.

Washer will not fill. • Timer pauses until pressure switch is satisfied.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

* Mechanical Timer Models only

† Electronic Control Models only

8 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

6. NO AGITATION

POSSIBLE CAUSE TO CORRECT

*Inoperative timer. • Test timer and replace if inoperative.

Inoperative action switch. • Test switch and replace if inoperative.

Inoperative motor. • Test motor and replace if inoperative.

Inoperative pressure switch. • Test switch and replace if inoperative.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

Loose or broken drive belt. • Adjust or replace belt.

Inoperative transmission assembly. • Repair or replace transmission assembly.

Sheared motor pulley roll pin. • Remove drive motor and replace roll pin and any other

damaged parts.

Drive motor overload protector has cycled. • Refer to Paragraph 10.

Bind in pump. • Disassemble and clean pump or replace pump.

Loading door is open or door switch is inoperative. • Close door or test switch and replace if inoperative.

†Inoperative electronic control • Refer to Section 8 to check out the electronic control

operation.

W003

7. CONSTANT AGITATION

POSSIBLE CAUSE TO CORRECT

*Inoperative timer. • Test timer and replace if inoperative.

Inoperative speed switch. • Test switch and replace if inoperative.

Shorted or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control • Refer to Section 8 to check out the electronic control

operation.

* Mechanical Timer Models only

† Electronic Control Models only

32918 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

8. SLOW SPIN OR NO SPIN

POSSIBLE CAUSE TO CORRECT

*Inoperative timer. • Test timer and replace if inoperative.

Inoperative speed switch. • Test switch and replace if inoperative.

Loading door is open or door safety switch is

inoperative.

Bind in water pump. • Replace pump.

Inoperative drive motor. • Test motor and replace if inoperative.

Loose or broken drive belt. • Adjust or replace belt.

Washer has gone out of balance. • Open loading door to reset out-of-balance switch.

No clearance or stuck brake pads. • Free sticky brake pads or replace pads.

Broken, loose or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control • Refer to Section 8 to check out the electronic control

• Close loading door, or test switch and replace if

inoperative.

operation.

W003

9. CONSTANT SPIN

POSSIBLE CAUSE TO CORRECT

*Inoperative timer. • Test timer and replace if inoperative.

Inoperative drive motor. • Test motor and replace if inoperative.

Excessive wear on brake pads, or missing brake

• Replace brake pads.

pads.

Shorted or incorrect wiring. • Refer to appropriate wiring diagram.

†Inoperative electronic control • Refer to Section 8 to check out the electronic control

operation.

10. DRIVE MOTOR OVERLOAD PROTECTOR CYCLES REPEATEDLY

POSSIBLE CAUSE TO CORRECT

Excessive belt tension. • Adjust belts.

Inoperative motor overload protector. • Replace motor.

Bind in water pump. • Replace pump.

Bind in transmission. • Repair or replace transmission.

Brake pads binding. • Free binding pads, or replace pads.

* Mechanical Timer Models only

† Electronic Control Models only

10 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

11. OUTER TUB DOES NOT EMPTY

POSSIBLE CAUSE TO CORRECT

Kinked drain hose. • Straighten hose.

Obstruction in outer tub outlet hose. • Remove obstruction.

Inoperative water pump. • Dissassemble and clean pump or replace pump.

Loosen or broken pump belt. • Adjust or replace belt.

12. EXCESSIVE VIBRATION

POSSIBLE CAUSE TO CORRECT

Unbalanced load in tub. • Stop washer, redistribute load, then restart washer.

Broken, disconnected or incorrectly adjusted

centering spring(s) out of adjustment.

Washer is not properly leveled. • Adjust leveling legs.

Washer is installed on weak, “spongy”, carpeted or

built-up floor.

Incorrect or loose cabinet screws. • Replace with correct screws or tighten.

• Connect or replace centering spring(s). Spring should be

positioned as shown in Figure 56.

• Relocate washer, or support floor to eliminate weak or

“spongy” condition.

W003

13. WATER LEAKING FROM OUTER TUB

POSSIBLE CAUSE TO CORRECT

Leaking water seal in outer tub. • Replace hub and seal kit assembly, Paragraph 43

Hole in outer tub. • Replace outer tub.

Pressure hose or accumulator leaking. • Replace pressure hose and/or accumulator.

Outer tub cover gasket leaking. • Replace gasket.

Obstruction in drain causing water to come over top

• Remove obstruction.

of outer drain tub cover.

Tub-to-pump hose leaking at clamp. • Tighten clamp.

32918 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 13

Section 3 Troubleshooting

Notes

12 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 14

Section 4

Grounding

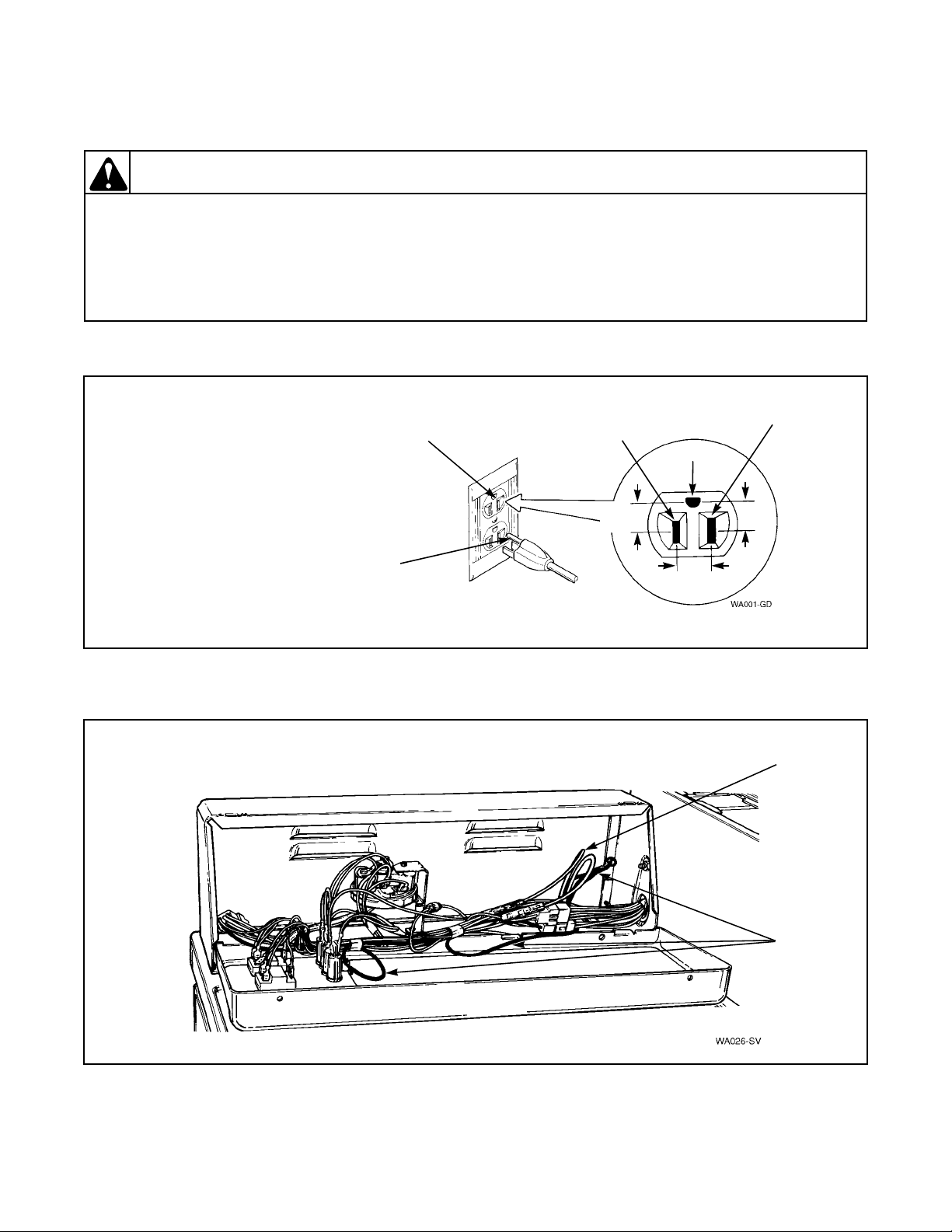

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

14. WALL RECEPTACLE POLARITY CHECK

W003

NOTE: Have a qualified

electrician check

polarity of wall

receptacle. If a voltage

Neutral

Side

L1

Ground

Neutral

reading is measured

other than that

illustrated, the qualified

electrician should

115 ± 12

VAC

0

VAC

correct the problem.

Round

Grounding

Prong

Figure 1

115 ± 12

VAC

15. POWER CORD TO CONTROL HOOD, CONTROL HOOD TO THE CONTROL PANEL FRAME

Power

Cord

Ground

Wires

Figure 2

32918 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

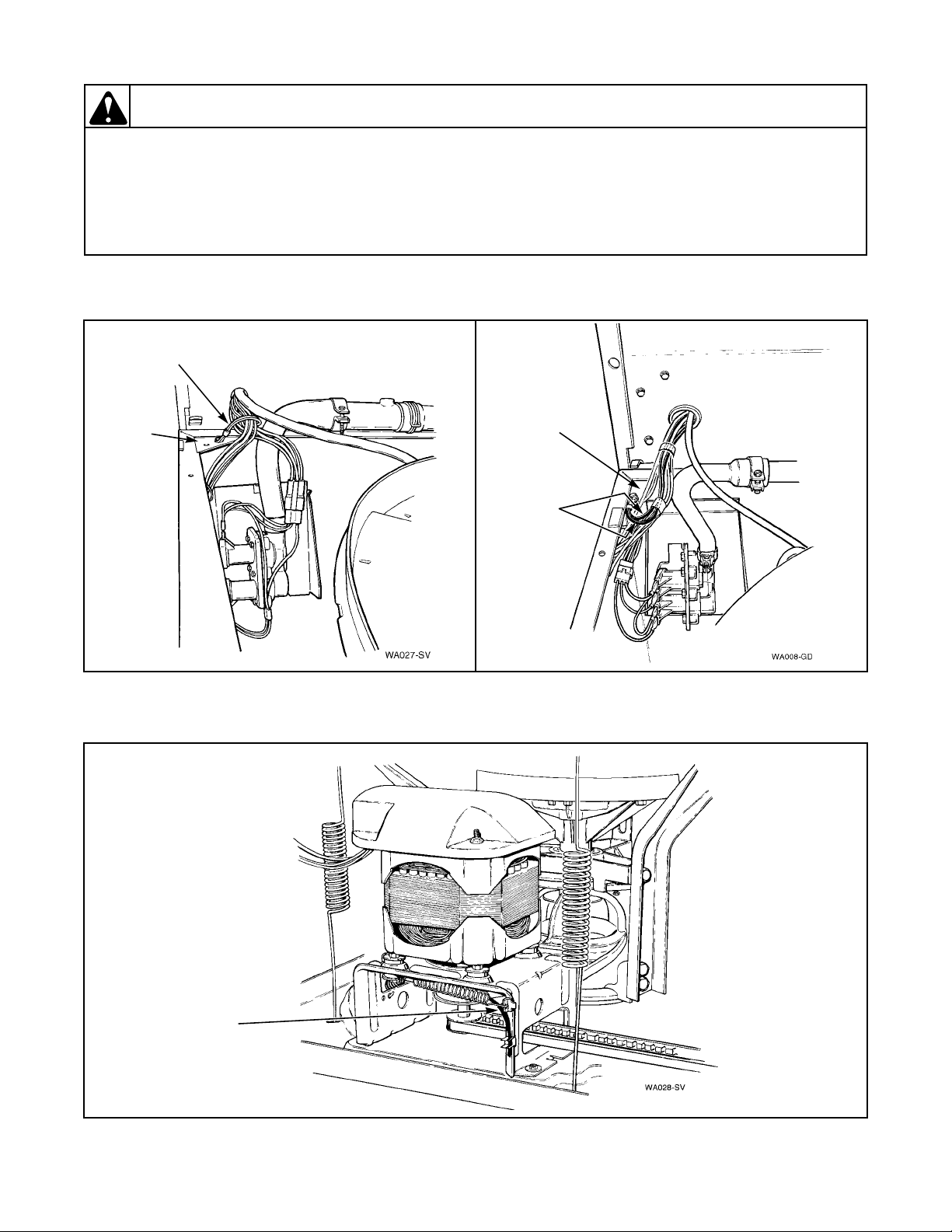

Section 4 Grounding

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

16. CONTROL HOOD WIRE HARNESS TO TOP LEFT REAR CORNER GUSSET OF CABINET

Ground

Wires

Corner

Corner

Gusset

Gusset

Ground

Wires

W003

17. MOTOR TO MOUNTING BRACKET

Ground

Wire

Figure 3

Figure 4

14 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

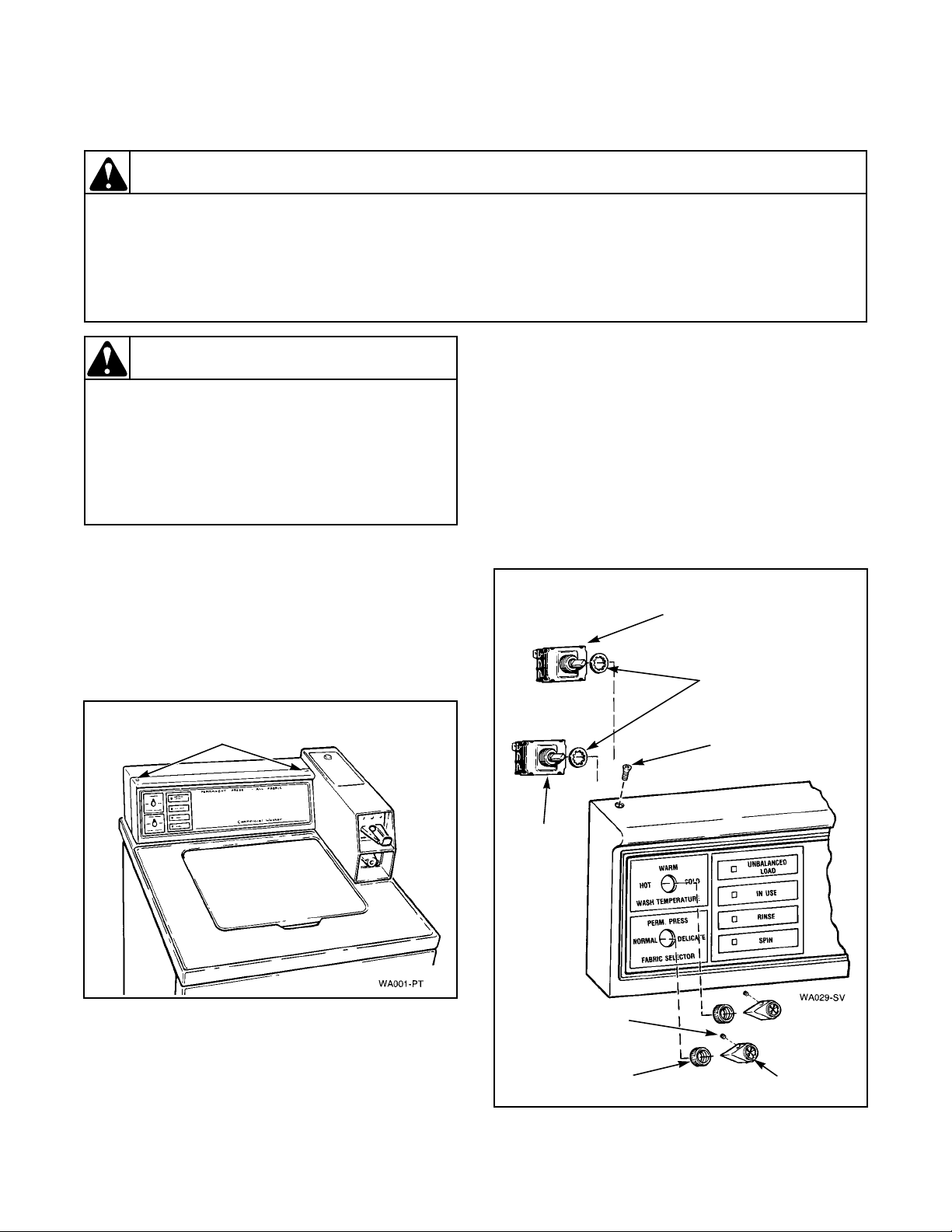

Page 16

Section 5

Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

b. Loosen setscrew holding switch knob to switch

WARNING

Do not repair or replace any part of the

washer or attempt any servicing unless

specifically recommended in the UserMaintenance Instructions or in published

user-repair instructions that you

understand and have the skills to carry

out.

IMPORTANT: When reference is made to

directions (right or left) in this manual, it is from

operator’s position facing front of washer.

18. CONTROL PANEL

Refer to Figure 5.

a. Remove two control panel attaching screws and

lift assembly off cabinet top.

NOTE: Lockwasher must be between switch and

control panel when installing switch. Refer to

Figure 6.

NOTE: Refer to appropriate wiring diagram when

rewiring switch.

shaft. Refer to Figure 6.

c. Remove knurled nut holding switch to control

panel. Refer to Figure 6.

d. Disconnect wires from switch.

Wash

Temperature

Switch

Lockwasher

W003

Panel

Attaching Screws

Figure 5

19. SPEED OR WASH TEMPERATURE

SWITCH

a. Remove two control panel attaching screws and

lift assembly off cabinet top. Refer to Figure 5.

Speed

Switch

Setscrew

Knurled

Nut

Panel Screw

Knob

Figure 6

32918 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 17

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

20. INDICATOR LIGHTS – UNBALANCED

LOAD, IN USE, RINSE OR SPIN

a. Remove two control panel attaching screws and

lift assembly off cabinet top.

b. Disconnect wires from light.

NOTE: Refer to wiring diagram when rewiring

light.

c. Squeeze locking tabs together and pull light out

from rear of panel.

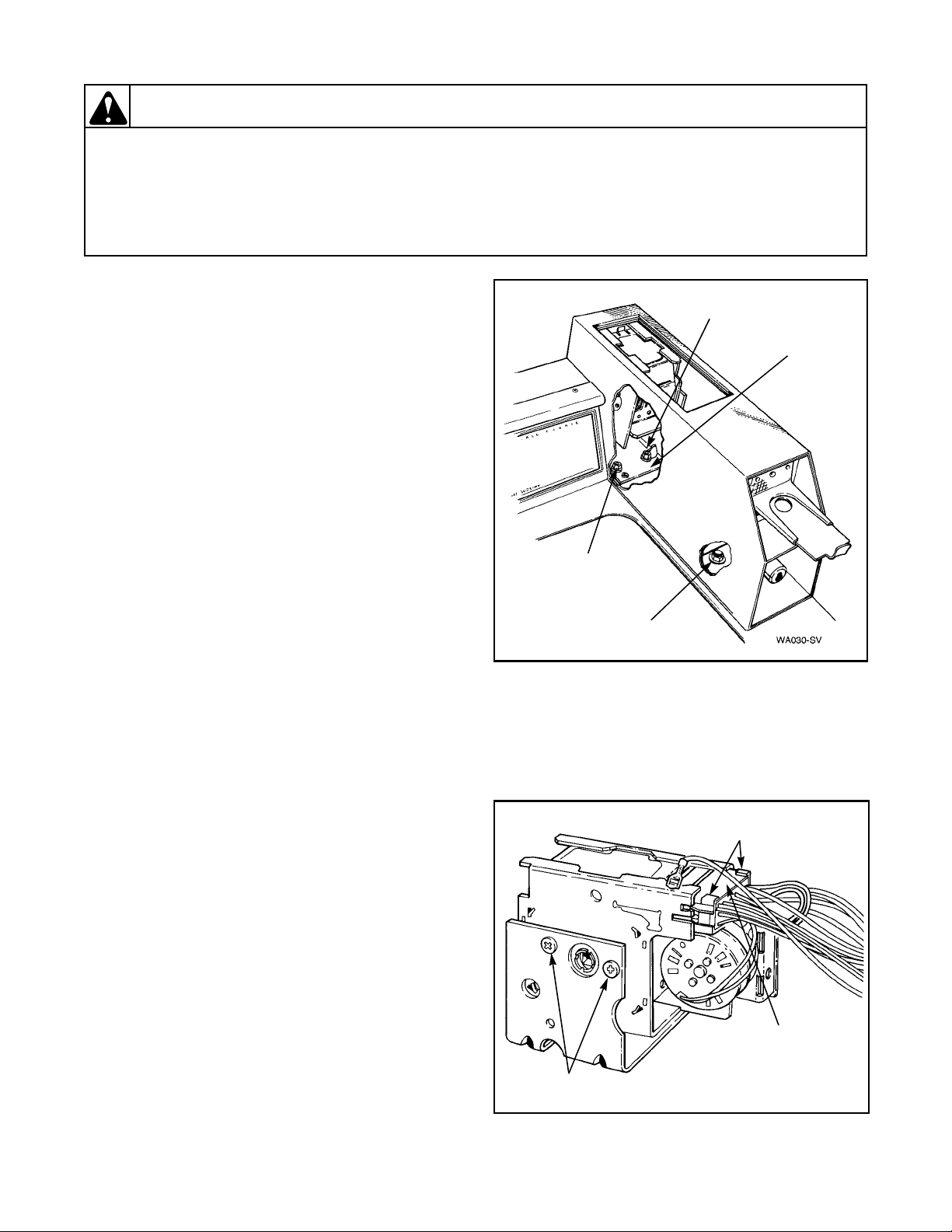

21. TIMER ASSEMBLY – Metered Models

a. Unlock and remove the service door.

b. Remove the inner timer bracket cap screw.

Refer to Figure 7.

c. Slide timer and bracket to the left to disengage

the bracket from shoulder screw. Lift timer and

bracket up and out of meter case through

service door opening as far as wires will permit.

NOTE: DO NOT attempt to repair the timer.

d. Disengage wire harness terminal block plug

from timer by pressing in movable locking tabs

(located on each side of terminal block plug).

Refer to Figure 8. Then pull terminal block

plug away from timer.

Shoulder

Screw

Timer

Bracket

Inner

Cap Screw

Meter Case

Bolt

Figure 7

NOTE: When installing clutch, be sure clutch

moves freely after setscrews are tightened.

IMPORTANT: Be careful not to dislodge or damage

two timer motor lead wires while handling timer.

IMPORTANT: To avoid an open circuit, DO NOT

pull on terminal block wires when removing block

Locking

Tabs

from timer as this could damage wires or terminal

crimpings. Before attaching wire harness terminal

blocks to timer, be sure all male terminals on timer

are straight and are capable of accepting terminals

from wire harness terminal blocks.

NOTE: To avoid timer damage, do not allow timer

to be struck on corners, edges of frame or on timer

shaft.

e. Remove two screws holding timer to bracket.

Refer to Figure 8.

f. Loosen setscrew holding clutch to timer shaft.

Refer to Figure 9.

16 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Timer Bracket

Attaching Screws

Figure 8

Terminal

Block

Plug

Page 18

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

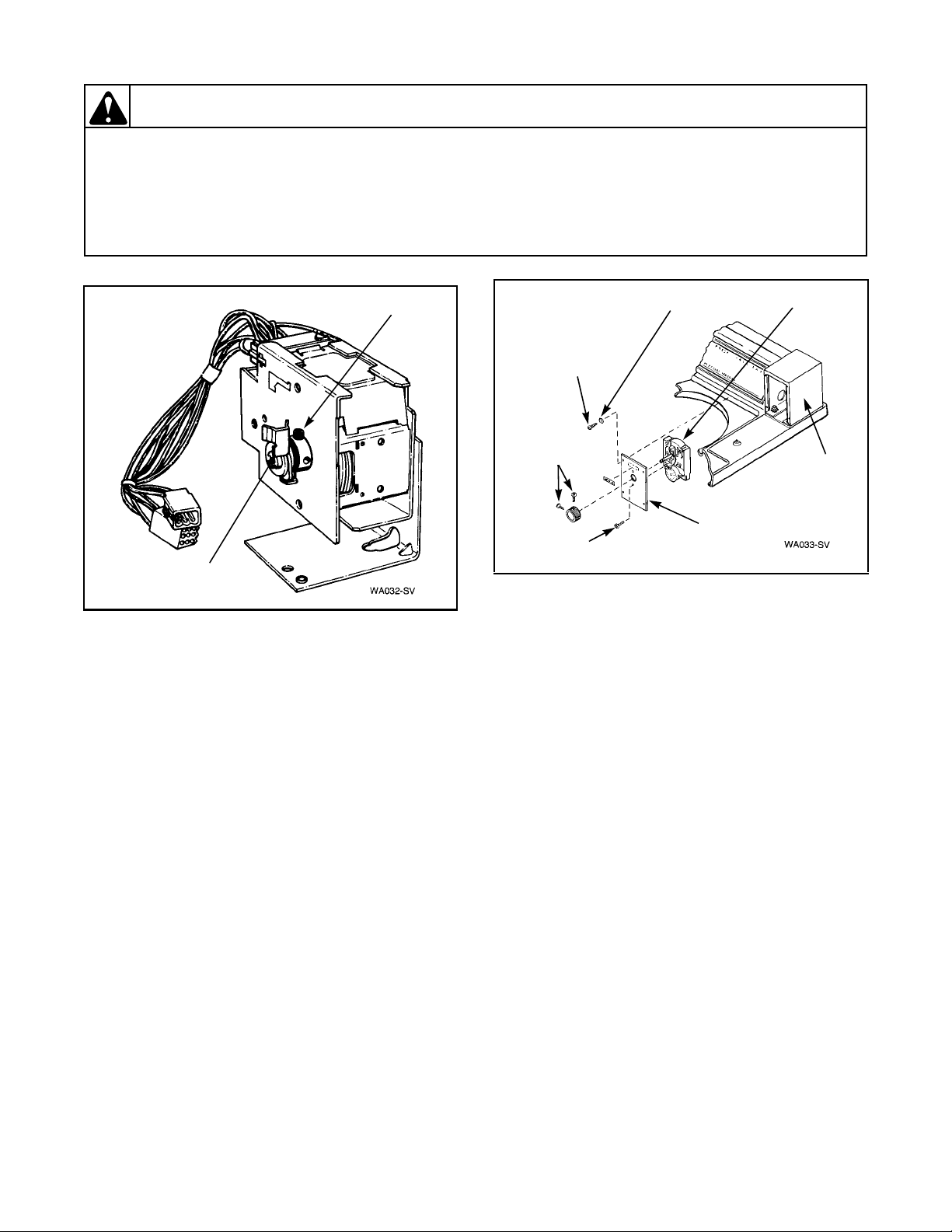

Setscrew

Clutch

Figure 9

22. TIMER ASSEMBLY (Nonmetered Models)

Refer to Figure 10.

a. Loosen two setscrews holding timer knob to

timer shaft.

b. Remove four screws and lockwashers holding

timer and plate to timer case.

NOTE: When reinstalling timer and plate,

lockwashers must be between head of screws and

timer plate.

c. Pull timer and plate out of timer case as far as

wires will permit.

NOTE: Disconnect ground wire from rear of timer.

d. Pull wire harness and blocks through into timer

housing; then disconnect timer harness from

control hood harness at quick disconnect block.

e. Remove two screws holding timer to timer

plate.

f. Disconnect wires from timer.

NOTE: Refer to appropriate wiring diagram when

rewiring timer.

Timer

Timer

Case

Timer Plate

Attaching

Screw

Timer Knob

Screws

Timer

Attaching Screw

Lockwasher

Timer

Plate

Figure 10

23. METER CASE (Metered Models)

a. Unlock and remove service door.

b. Remove the inner timer bracket cap screw.

Refer to Figure 7.

c. Slide timer and bracket to the left to disengage

bracket from shoulder screw.

d. Remove two control panel attaching screws and

lift assembly off cabinet top. Refer to Figure 5.

e. Disconnect timer harness from control hood

harness at disconnect blocks. Refer to

Figure 11.

f. Remove timer, bracket and harness out through

service door opening.

g. Remove cap screw, lockwashers and nut

holding meter case to end of control hood.

Refer to Figure 11.

h. Remove coin drawer.

i. Open loading door, hold hand under front meter

case bolt. Refer to Figure 7. Remove nut and

lockwasher.

j. Remove shoulder screw from inside meter case.

NOTE: When installing meter case, shoulder screw

must be installed in outer hole, refer to Figure 7, to

enable timer bracket to slide under screw head.

k. Carefully remove meter case from cabinet top.

32918 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Meter

Case

Meter Case

Screw

Disconnect

Blocks

Figure 11

24. TIMER CASE (Nonmetered Models)

a. Remove timer assembly. Refer to Paragraph

22.

b. Remove two control panel attaching screws and

lift assembly off cabinet top. Refer to Figure 5.

c. Remove cap screw, lockwashers and nut

holding timer case to control hood. Refer to

Figure 12.

d. Remove two screws from bottom edge of front

panel. Refer to Figure 9.

e. Pull bottom of panel away from washer until

hold-down clips (located on top flange of

panel) disengage from slots in cabinet top.

Refer to Figure 13.

f. Remove two cabinet top hold down screws.

Refer to Figure 13.

g. Tape loading door closed and lift cabinet top to

a vertical position.

h. Remove carriage bolts, washers, lockwashers

and nuts holding timer case to cabinet top.

i. Support timer case and remove screw and fiber

washer holding rear of case to cabinet top.

Timer Case

Screw

Timer Case

Attaching

Hardware

Figure 12

Cabinet Top

Hold-Down

Screws

Hold-Down

Clip

Front Panel

Screws

Figure 13

18 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

25. PRESSURE SWITCH

a. Remove two control panel attaching screws and

lift assembly off cabinet top.

b. Remove two screws holding switch to

mounting bracket.

c. Pull switch out of control hood far enough to

disconnect pressure hose and wires from

switch.

NOTE: Refer to appropriate wiring diagram when

rewiring pressure switch.

IMPORTANT: When installing pressure switch,

blow air into hose before connecting hose to switch

to remove any moisture that may have accumulated

in hose.

26. DRAIN HOSE ELBOW

Refer to Figure 14

a. Loosen hose clamp and remove drain hose from

elbow.

b. Remove screws holding elbow to rear of

washer cabinet.

c. Pull elbow out through opening in cabinet far

enough to permit loosening inner clamp, then

remove elbow from inner hose.

Elbow

Attaching

Screws

Hose

Clamp

Drain

Hose

Figure 14

NOTE: When installing elbow on inner hose, DO

NOT allow hose inside of washer to twist! Direct

elbow toward drain receptacle and secure elbow to

washer cabinet.

32918 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 21

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

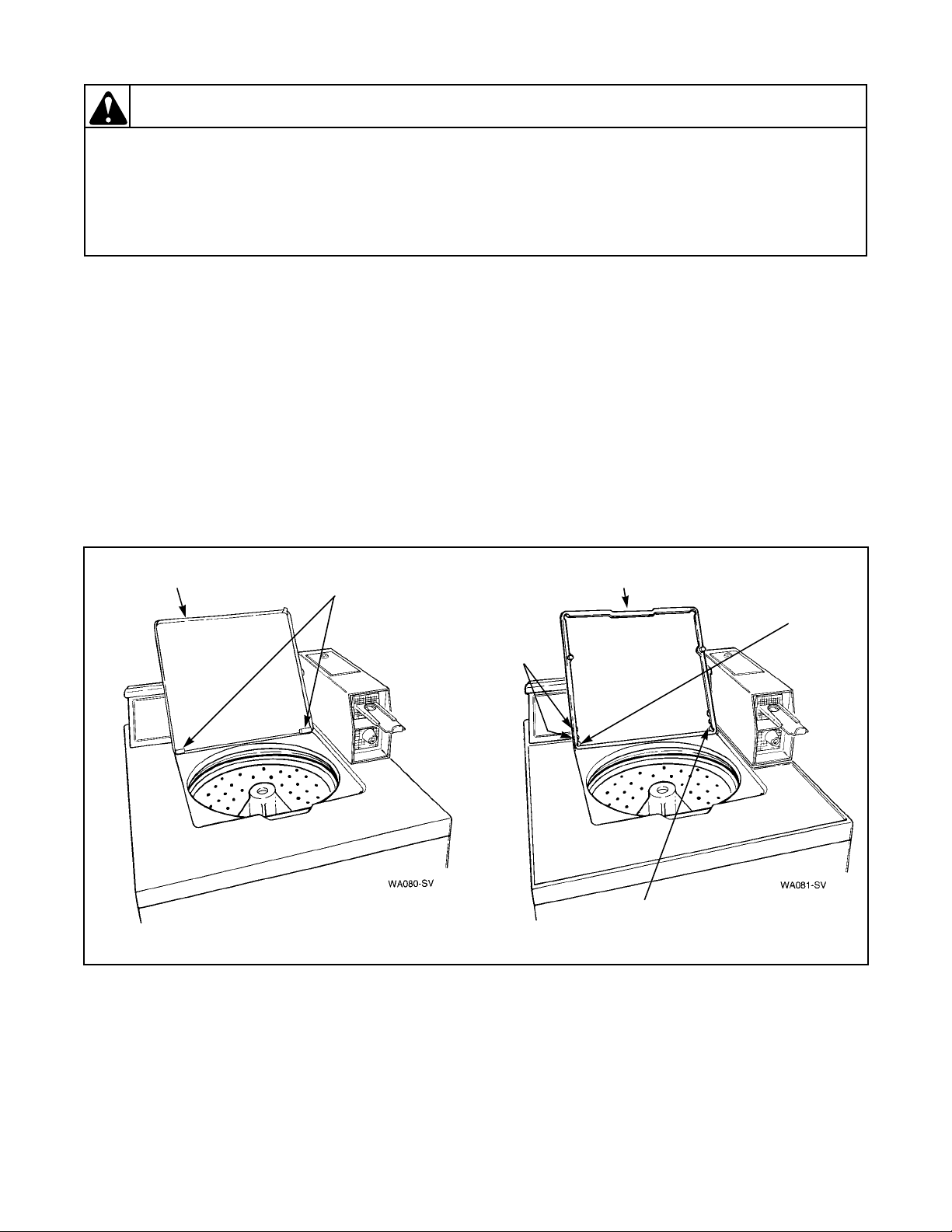

27. LOADING DOOR

Refer to Figure 15

a. Through Serial No. R8237277YK:

(1) Open loading door. Refer to Figure 15.

(2) Depress tab on either hinge, then slide

hinge out of loading door and bushing in

cabinet top.

(3) Tile loading door slightly and slide door

and hinge out of opposite bushing.

b. Starting Serial No. R8237278YK:

(1) Open loading door. Refer to Figure 15.

(2) Remove two screws holding left hinge to

door and remove hinge. Refer to Figure 15.

Loading

Door

Hinge

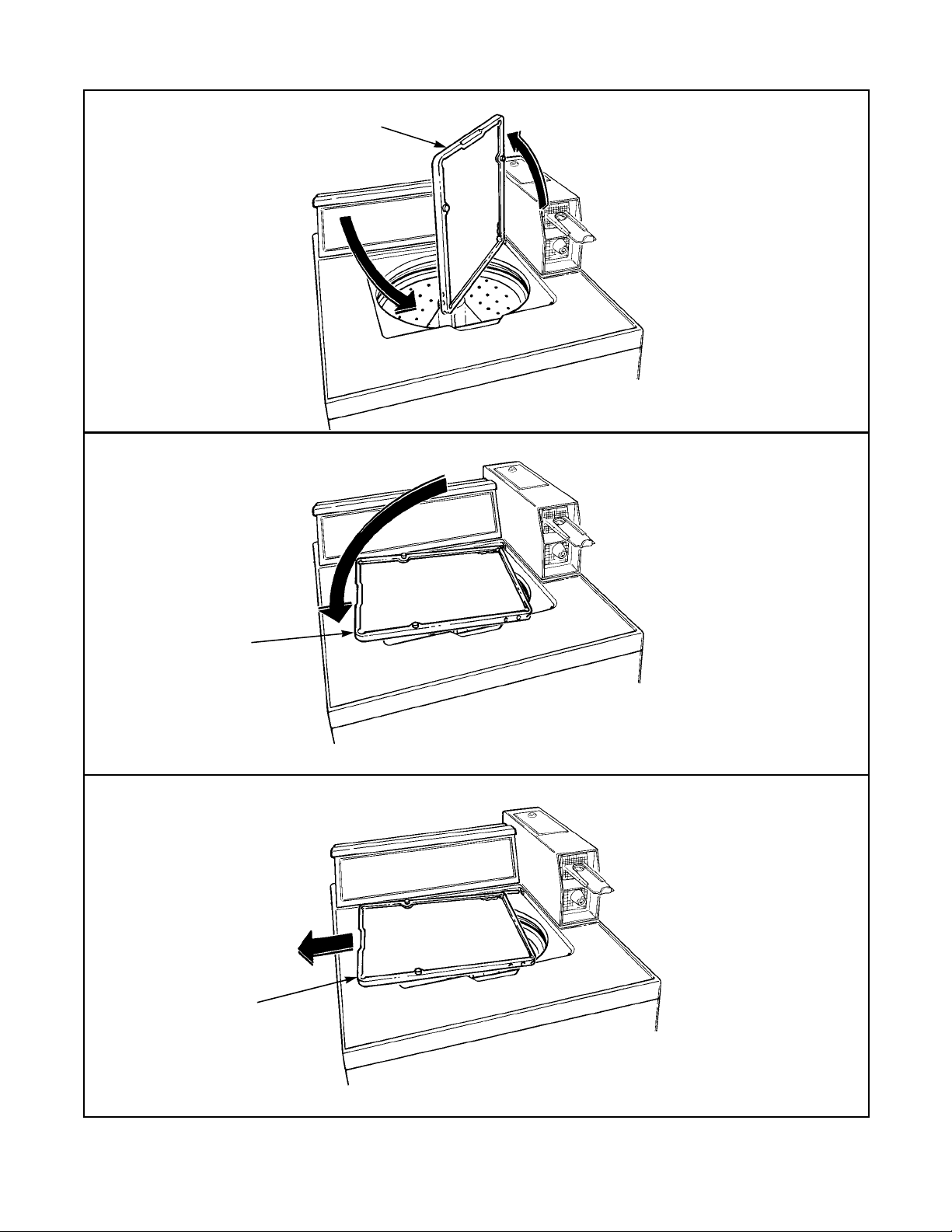

(3) With loading door raised to vertical

position, swing left side of door toward

front of washer. Refer to Figure 16,

procedure one.

(4) Rotate loading door so door is upside down.

Refer to Figure 16, procedure two.

(5) Remove loading door, right door hinge and

bushing from cabinet top. Refer to

Figure 16, procedure three.

NOTE: Reverse procedures when installing loading

door.

Loading

Door

Left

Hinge

Attaching

Screws

Hinge

Right

Hinge

THROUGH SERIAL NO. R8237277YK STARTING SERIAL NO. R8237278YK

Figure 15

20 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 22

Procedure One

Procedure Two

Section 5 Service Procedures

Door

Front

WA082a-SV

Door

Front

Procedure Three

Door

Front

WA082b-SV

WA082c-SV

Figure 16

32918 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 23

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

28. GRAPHIC OVERLAY

Refer to Figure 6

a. Loosen setscrews holding speed and wash

temperature switch knobs to switch shafts.

b. Remove knurled nuts holding each switch to

control panel.

NOTE: Lockwashers must be between switches and

control panel when installing switches.

c. Remove graphic overlay.

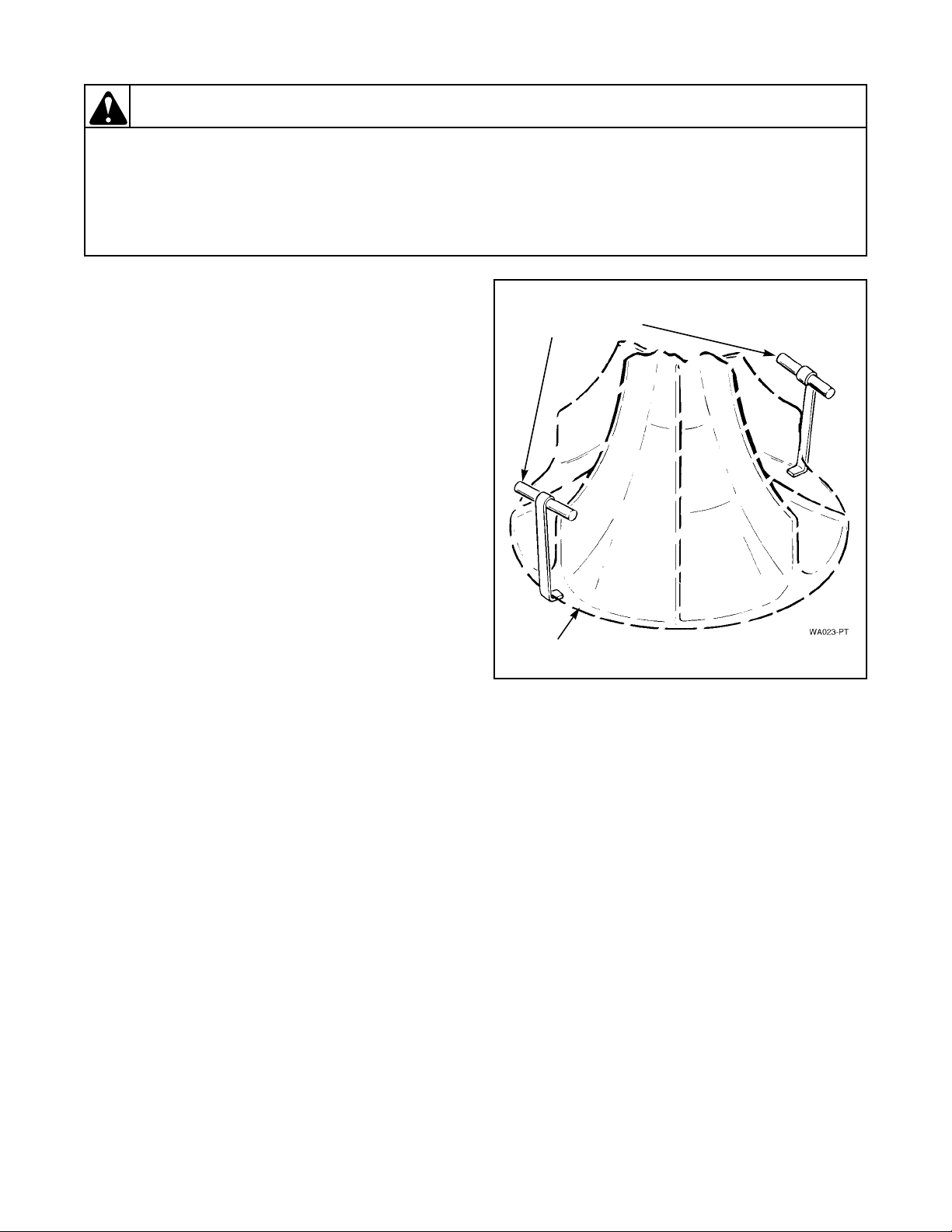

29. AGITATOR

a. Open loading door.

b. To remove agitator by hand, place two agitator

hooks, No. 254P4P, under bottom edge of

agitator. Refer to Figure 17.

No. 254P4P

Agitator Hooks

W003

NOTE: Hooks should be positioned 180 degrees of

each other, and must be placed under the agitator

vane for greater stability. If hooks are placed

between the vane area, damage to the agitator may

occur.

c. Using a rocking motion (back and forth)

carefully lift agitator off drive bell.

30. AGITATOR, DRIVE BELL AND SEAL

ASSEMBLY

a. Open loading door.

NOTE: If water is present in the washtub, spin and

pump out before attempting to remove the drive

bell and seal seat assembly.

b. To remove agitator by hand, place two agitator

hooks, No. 254P4P, under bottom edge of

agitator. Refer to Figure 17.

IMPORTANT: Hooks should be positioned 180

degrees of each other, and must be placed under

agitator vane for greater stability. If hooks are

placed between the vane area, damage to agitator

may occur.

Agitator

Figure 17

d. Remove the screw and o-ring washer from the

top side of the drive bell.

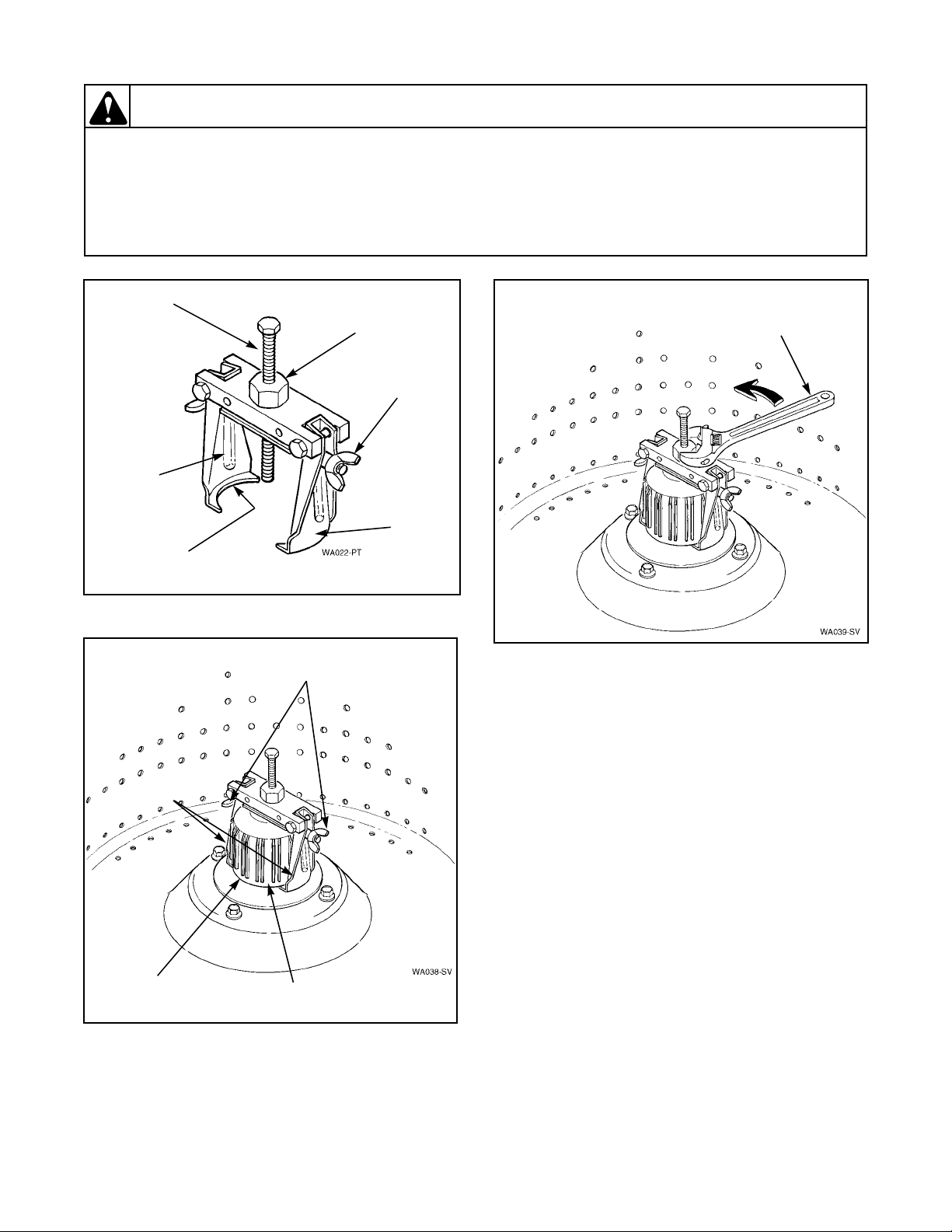

NOTE: To remove the drive bell from the

transmission shaft will require using the No. 294P4

Drive Bell Tool. Refer to Figure 18.

e. Back the one quarter inch bolt out of tool

approximately three quarters of the way.

f. Place tool over drive bell, making sure indent of

the jaw lines up with wide slots on drive bell.

Refer to Figure 19.

c. Using a rocking motion (back and forth)

carefully lift agitator off drive bell.

22 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 24

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Bolt

Indent

Jaws

Jaw

Lip

Figure 18

Wing

Nut

Large

Nut

Turn Adjustable

Wrench Counterclockwise

to Remove Drive Bell

Wing

Nut

Jaw

Figure 20

h. Place lip of each jaw under bottom edge of

drive bell, making sure indent on jaw lines up

with wide slots on drive bell. Then tighten wing

nuts to hold jaws firmly against drive bell.

Refer to Figure 19.

i. Use an adjustable wrench and turn large nut on

tool COUNTERCLOCKWISE to pull drive

bell from transmission shaft. Refer to

Figure 20.

IMPORTANT: If large nut is turned clockwise

when pulling drive bell, you will twist off the

quarter inch bolt.

j. Turn the one quarter inch bolt out of the

transmission shaft and remove tool and drive

Drive

Bell

Wide

Slot

Figure 19

bell from the washer.

k. Loosen the two wing nuts and remove drive bell

from tool.

l. Carefully pry the old seal out of the drive bell

and clean any foreign materials from the bell.

g. Screw the bolt down through hole in top of

drive bell until it bottoms out in the hole of the

shaft.

IMPORTANT: We recommend that both the seal

seat and the seal head be replaced together in pairs.

DO NOT replace only one of the two.

32918 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

m. Install the new seal into the drive bell.

n. Remove the seal head from the hub and clean

any foreign material from the hub seal

mounting area.

o. Place the new seal head on hub and carefully

push the seal head into position.

IMPORTANT: Make sure the seal is pressed down

against the shoulder on the hub.

NOTE: Soapy water will aid in the assembly of the

seal onto the hub.

IMPORTANT: DO NOT apply any type of

lubricants to the sealing surfaces of either the seal

seat or seal head as you will damage the seals.

TO REINSTALL DRIVE BELL

a. Position drive bell over transmission shaft.

Rotate drive bell until splines in drive bell line

up with splines on transmission shaft.

b. Place No. 294P4 Bell Tool over top of bell.

Screw bolt into transmission shaft until it

bottoms out.

NOTE: It is not necessary to use the tool jaws on

drive bell during this operation.

g. A sharp blow on top of agitator, with palm of

your hand, will force agitator down onto drive

bell, allowing fingers on underside of agitator

to lock under bottom edge of drive bell.

NOTE: Do not push agitator onto drive bell any

further than necessary.

31. FRONT PANEL

Refer to Figure 21

a. Remove two screws from bottom edge of front

panel.

b. Pull bottom of panel away from washer until

hold down clips (located on top flange of panel)

disengage from slots in cabinet top.

Hold-Down Clips

Compress hold-down clips enough to remove

them from slots in top flange of panel.

Guide Lugs

Remove screws holding guide lugs to side flanges

of front panel.

Cabinet Top

Hold-Down

Screws

c. Use an adjustable wrench and turn large nut on

tool CLOCKWISE to force drive bell down

onto transmission shaft until bell bottoms out

on shaft.

d. Turn bolt out of transmission shaft and remove

Hold-Down

Clip

tool.

e. Place new o-ring gasket onto new screw.

Thread the new screw down through hole in top

of drive bell and into transmission shaft. DO

NOT reuse the old screw and o-ring gasket!

NOTE: Torque new screw down between 45 to 55

inch pounds (5 to 6.2 Nm). Over torque will

mushroom the plastic bell.

f. Place agitator on top of drive bell. Slowly rotate

Front Panel

Screws

Figure 21

agitator until fingers on underside of agitator

line up with large slots on drive bell.

24 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

32. PUMP BELT

a. Remove front panel. Refer to Paragraph 31.

b. Remove two front mounting screws and loosen

the rear mounting screw holding pump and

bracket to washer base. Refer to Figure 22.

Pivot entire assembly toward motor to loosen

belt tension.

c. Run belt off motor pulley, then remove belt

from pump pulley.

NOTE: After installing pump belt, adjust belt.

Refer to Paragraph 55.

d. While holding idler lever, reach in and around

right side of motor and run belt off right side of

large drive pulley. Refer to Figure 23.

e. Remove belt from motor pulley and pull belt

out through front of motor mount.

IMPORTANT: Drive belt MUST be replaced with

belt No. 28808 (special clutch-type belt) for proper

washer operation.

TO INSTALL NO. 28808 DRIVE BELT

NOTE: If the new belt is replacing a burned belt,

the motor pulley “V” groove must be polished with

a fine (320 grit) emery cloth to remove the rubber

residue. The residue will affect the washer spin

operation.

a. Push belt in through front of motor mount and

place belt on motor pulley.

b. Reach in and around right side of motor,

starting with belt on right side of large drive

pulley, run belt onto pulley.

c. Reach in through front of motor mount and

move idler lever to the left.

Pump

Attaching

Screws

Pump

Belt

Figure 22

33. DRIVE BELT

a. Remove front panel. Refer to Paragraph 31.

b. Remove two front mounting screws and loosen

the rear mounting screw holding pump and

bracket to washer base. Refer to Figure 22.

Pivot entire assembly toward motor to loosen

belt tension.

c. Reach in through front of motor mount and

move idler lever to the left to release tension on

belt.

IMPORTANT: Use care when releasing the idler

lever tension. If the idler spring or helper spring is

overstretched, washer operation will be affected.

d. While holding idler lever, reach around right

side of motor and place belt on idler pulley.

IDLER PULLEY MUST RIDE ON OUTSIDE

OF BELT.

NOTE: There is no belt adjustment after installing

new drive belt. Check to be sure motor and

mounting bracket have been shifted toward rear of

washer to its limit of travel within the mounting

bracket attaching screws. If the motor and

mounting bracket must be repositioned, loosen the

four motor attaching screws and shift motor and

mounting bracket toward rear of washer to its limit

of travel. Retighten the four attaching screws. Refer

to Figure 24.

e. Install pump belt, adjust per Paragraph 32.

lever tension. If the idler spring or helper spring is

overstretched, washer operation will be affected.

IMPORTANT: Use care when releasing the idler

32918 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

Drive

Pulley

Wire harness

must be installed

ahead of spring.

W003

Helper

Spring

Idler

Spring

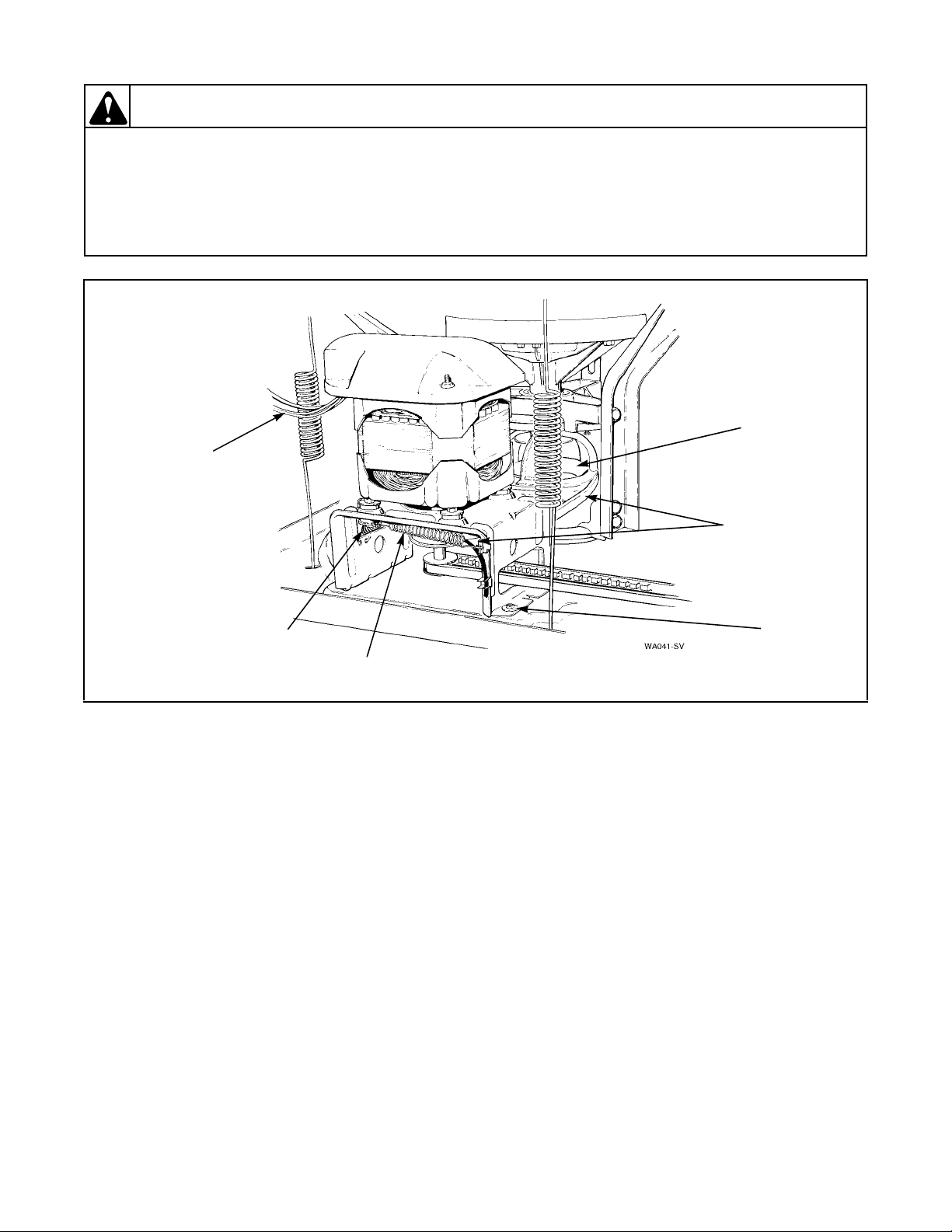

34. MOTOR AND MOUNTING BRACKET

a. Remove front panel. Refer to Paragraph 31.

b. Disconnect motor wire harness from base wire

harness at disconnect blocks. Refer to

Figure 28.

c. Remove pump belt. Refer to Paragraph 32.

Then remove drive belt. Refer to Paragraph 33.

NOTE: When installing belts, adjust pump belt.

Refer to Paragraph 55. There is no drive belt

adjustment.

d. Remove four screws holding motor and

mounting bracket to washer base. Refer to

Figure 24. Then lift complete assembly out of

washer.

Drive

Belt

Motor

Attaching

Screws

Figure 23

NOTE: When installing motor and mounting

bracket, tab on right bottom flange of mounting

bracket must be placed in hole in base. Mounting

bracket must be shifted toward rear of washer to its

limit of travel within the mounting bracket

attaching screws.

e. Remove nuts, steel washers, spacers and rubber

mounts holding motor to mounting bracket.

Refer to Figure 25. Lift motor off mounting

bracket and remove balance of rubber mounts

and steel washers from motor mounting studs.

IMPORTANT: When installing motor on mounting

bracket, position motor with switch facing toward

left side of mounting bracket.

NOTE: Refer to Figure 25 for motor and mounting

bracket assembly sequence.

26 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

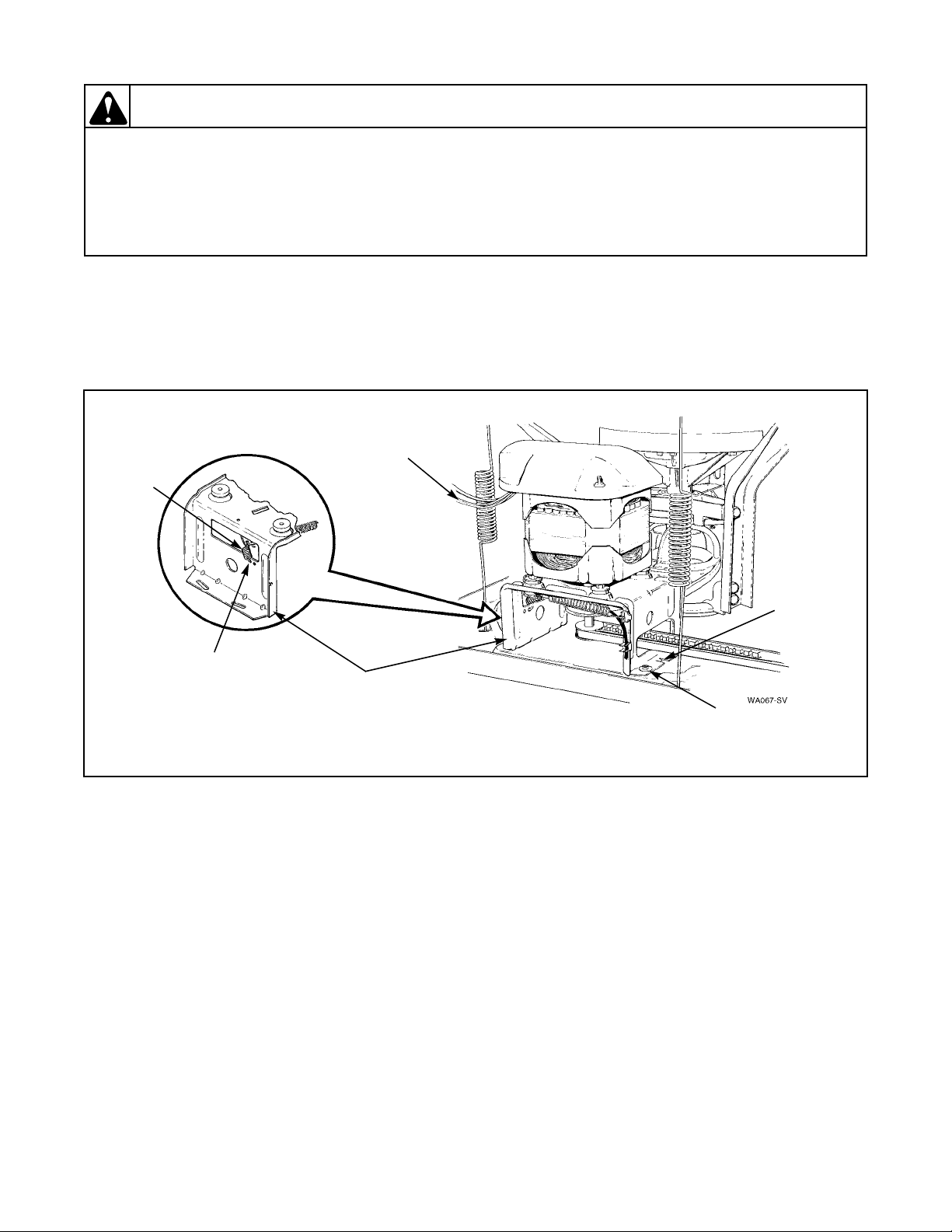

35. IDLER LEVER AND PULLEY

a. Remove motor and mounting bracket. Refer to

Paragraph 34, steps “a” through “d”.

b. Remove nut, washer and bolt holding idler

lever and pulley to motor mounting bracket.

Wire harness

must be installed

ahead of spring.

Helper

Spring

The round spring hook

must be hooked in

rear hole for proper

idler lever operation.

Motor Mounting

Bracket

NOTE: Refer to Figure 25 for idler lever and pulley

assembly sequence.

c. Apply No. 03637P Lubricant to the area of idler

lever that makes contact with motor mounting

bracket.

Positioning

Tab

Motor

Attaching

Screws

Figure 24

32918 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

Section 5 Service Procedures

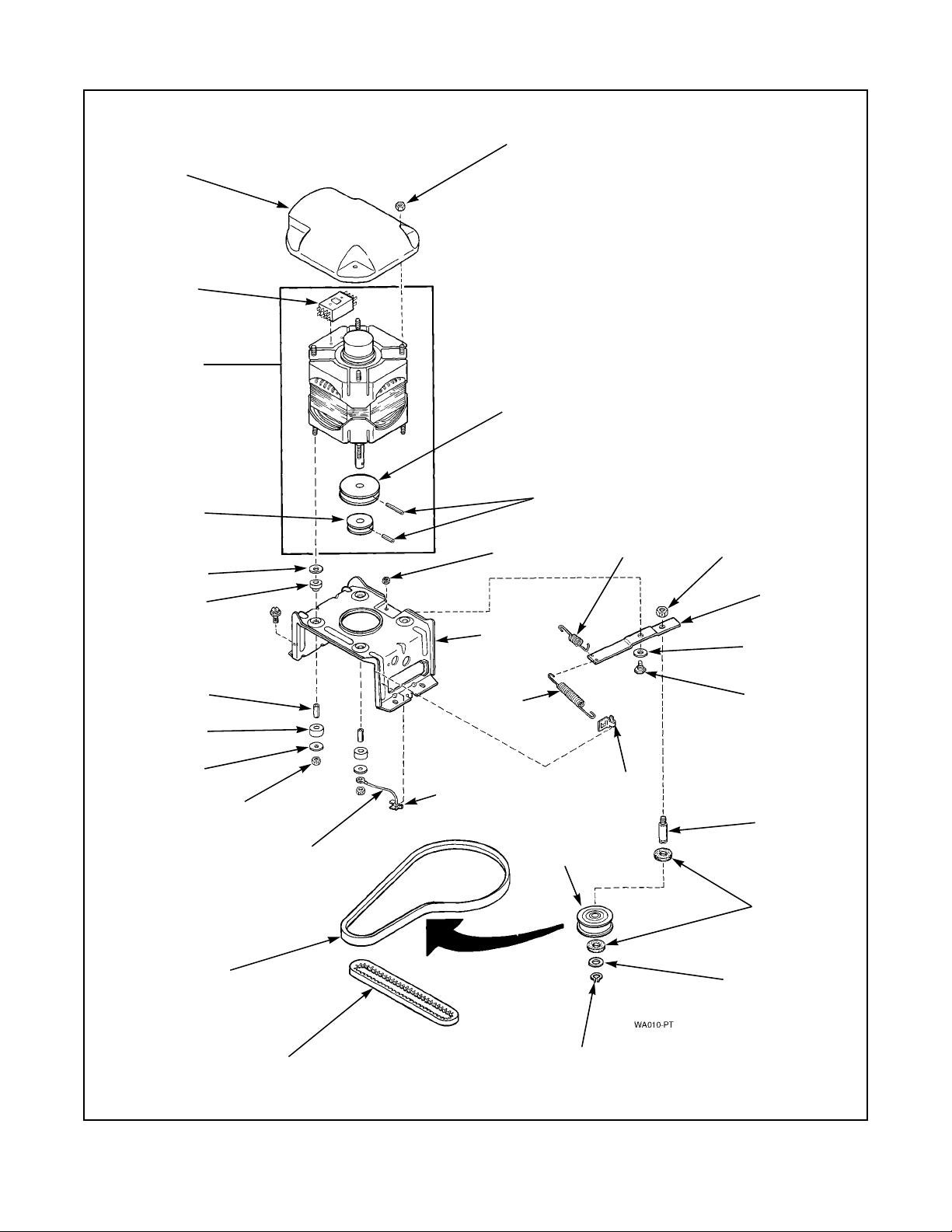

Motor

Shield

Motor

Switch

Motor

Pulley

(Pump)

Steel

Washer

Rubber

Mount

Nut

Pulley

(Agitate and Spin)

Roll

Pin

Nut

Motor

Mounting

Bracket

Helper

Spring

Locknut

Idler

Lever

Washer

Spacer

Rubber

Mount

Steel

Washer

Nut

Ground Wire

(Green)

Belt

(Agitate and Spin)

(Pump)

Belt

Spring

Ground Clip

(Clips to the motor

mounting bracket)

Idler

Pulley

Figure 25

Shoulder

Bolt

Clip

Idler

Shaft

Felt

Washers

Nylatron

Washer

Retainer

Ring

28 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

36. MOTOR DRIVE PULLEY OR PUMP

PULLEY

a. Remove motor and mounting bracket. Refer to

Paragraph 34, steps “a” through “d”.

b. Lay motor and mounting bracket on its side.

NOTE: To remove pulleys, support motor shaft (to

prevent bending shaft) and drive out pulley roll

pins.

37. MOTOR SWITCH

a. Remove front panel. Refer to Paragraph 31.

b. Remove nut holding motor shield to motor.

Refer to Figure 25.

c. Disconnect external wires from motor switch

terminals.

NOTE: Refer to appropriate wiring diagram when

rewiring external switch wires.

d. Remove two screws holding switch to motor.

Refer to Figure 25.

e. Disconnect internal motor leads from switch

terminals.

38. PUMP ASSEMBLY

a. Remove front panel. Refer to Paragraph 31.

b. Remove pump belt. Refer to Paragraph 32.

IMPORTANT: There will always be some water

that will remain in the outer tub; therefore, before

removing hoses from the pump, the hoses will have

to be pinched off or drained to prevent water

spillage on the floor.

NOTE: Rear screw hole in pump mounting bracket

is keyhole shaped; therefore, it is not necessary to

remove the rear screw.

c. Slide pump and mounting bracket toward rear

of washer and lift assembly out of washer.

d. Loosen hose clamps and remove hoses from

pump assembly. Refer to Figure 26.

Pump Mounting Bracket

Remove four screws holding pump to mounting

bracket.

NOTE: Refer to Figure 27 for pump and mounting

bracket assembly sequence.

NOTE: Refer to wiring schematics, Section 10, for

rewiring internal switch wires.

Outer Tub

to Pump

Hose

Drain

Hose

Pump

Attaching

Screws

Figure 26

32918 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Pump

Assembly

Pump

Mounting

Bracket

Hex Head

Screw

Figure 27

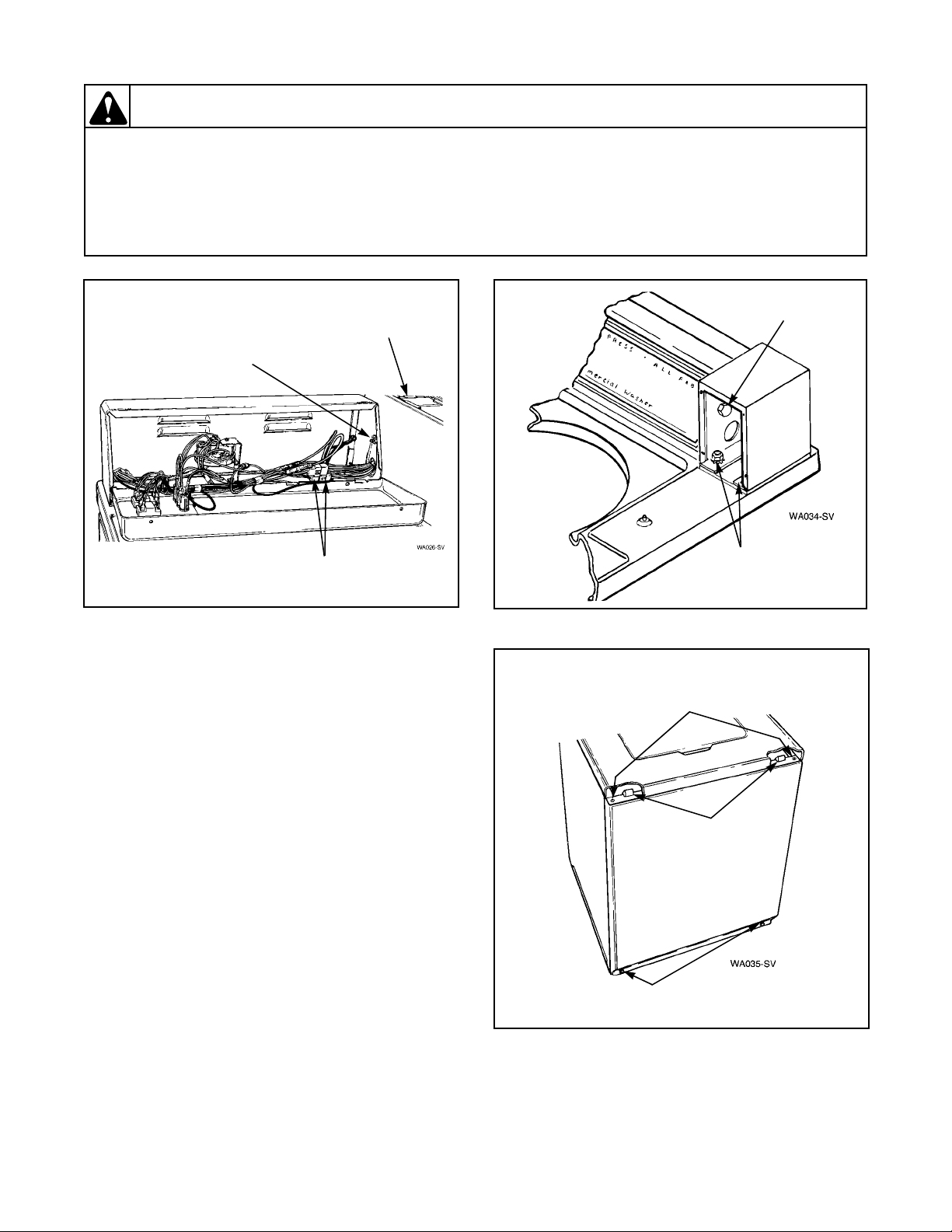

Page 31

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Wire

Harness

Clip

Disconnect

Blocks

THROUGH SERIAL NO. R8237277YK STARTING SERIAL NO. R8237278YK

Cabinet Top

Hold-Down

Screw

Door Switch and

Out-of-Balance

Switch Assembly

39. CABINET TOP ASSEMBLY

a. Remove two screws from bottom edge of front

panel. Refer to Figure 21.

b. Pull bottom of panel away from washer until

hold down clips (located on top flange of panel)

disengage from slots in cabinet top. Refer to

Figure 28.

c. Remove two cabinet top hold-down screws.

Refer to Figure 28.

d. Metered Models:

(1) Unlock and open meter case service door.

(2) Remove inner cap screw holding the timer

and bracket to the cabinet bracket.

(3) Slide timer and bracket to the left to

disengage bracket from shoulder screw.

Lift timer and bracket out of meter case

through service door opening as far as wires

will permit.

(4) Remove shoulder screw from inside meter

case.

Figure 28

NOTE: Cabinet top is self supporting, however, a

small chain may be used for additional support.

Refer to Figure 29.

Cabinet Top

Wire

Harness

Clip

Disconnect

Blocks

Hold-Down

Screw

e. If area or space permits, tape loading door

closed and lift cabinet top to a vertical position

by hinging it on the rear hold-down bracket.

TO REMOVE CABINET TOP FROM

WASHER

a. Metered Models – Unlock and remove the

service door. Remove the inner cap screw

holding the timer and bracket to the cabinet

bracket.

b. Slide the timer and bracket to the left to

disengage the bracket from the shoulder screw.

Lift timer and bracket out of the meter case

through the service door opening as far as the

wires will permit.

c. Remove the shoulder screw from inside the

meter case.

NOTE: When installing the shoulder screw, it must

be installed in the outer hole to enable the timer

bracket to slide under the screw head. Refer to

Figure 7.

30 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

IMPORTANT: When installing pressure hose, blow

air into hose before connecting hose to switch to

Chain

remove any moisture that may have accumulated in

the hose.

k. Push base wire harness block and pressure hose

down through hole in cabinet top.

l. Tape loading door closed.

m. Lift front of cabinet top slightly and pull

forward to disengage from the rear hold-down

bracket.

W003

Figure 29

NOTE: When reinstalling the shoulder screw, it

must be installed in the outer hole to enable the

timer bracket to slide under the screw head. Refer

to Figure 7.

d. Remove two screws from bottom edge of front

panel. Refer to Figure 21.

e. Pull bottom of panel away from washer until

hold-down clips (located on top flange of

panel) disengage from slots in cabinet top.

f. Remove two cabinet top hold down screws.

Refer to Figure 28.

g. Remove two control panel attaching screws.

Refer to Figure 5.

h. Lift control panel up and out of the slots in the

cabinet top. Lay the control panel face down on

some protective padding on the cabinet top.

i. Disconnect control hood harness from base

wire harness at the quick disconnect blocks.

Refer to Figure 30.

j. Disconnect pressure hose from pressure switch.

WARNING

To reduce the risk of personal injury, be

careful not to damage door switch and outof-balance switch assembly when removing

cabinet top.

n. Pull top forward far enough to permit

disconnecting the green ground wires from top

rear corner gusset of washer cabinet. Refer to

Figure 31. Disconnect wires from mixing valve

solenoids at rear of washer.

NOTE: Refer to appropriate wiring diagram when

rewiring mixing valve solenoids.

o. Carefully lift cabinet top off washer and set

alongside the washer cabinet on protective

padding.

p. Starting Serial No. R8237278YK:

WARNING

To reduce the risk of personal injury, be

careful not to damage door switch and outof-balance switch assembly when removing

cabinet top.

IMPORTANT: When reinstalling cabinet top and

before lowering top into position, pivot outer tub

forward far enough to prevent damaging (bending)

out-of-balance switch lever.

32918 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Control Hood

and Base

Wire Harness

Disconnect

Blocks

Ground Wires

(Green)

Pressure

Hose

Pressure

Switch

Control Panel

Assembly

Figure 30

Pressure

Hose

Pressure

Hose

Mixing Valve

Assembly

Corner

Gusset

Mixing Valve

Wire Harness

Mixing Valve

Assembly

THROUGH SERIAL NO. R8237277YK

Disconnect

Blocks

Corner

Gusset

Ground

Wires

(Green)

Mixing Valve

Disconnect

Blocks

STARTING SERIAL NO. R8237278YK

Figure 31

32 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 34

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

40. DOOR/OUT-OF-BALANCE SWITCH

ASSEMBLY

Through Serial No. R8237277YK:

a. Hinge cabinet top or remove. Refer to

Paragraph 39.

b. Remove two screws holding switch and bracket

assembly to the underside of the right front

flange of the cabinet top. Refer to Figure 32.

c. Disconnect wires from switch.

Shield

Lever

Swtich

Attaching

Screw

NOTE: Refer to appropriate wiring diagram when

rewiring switch.

d. Through Serial No. R8237277YK – Remove

two screws holding switch to bracket. Refer to

Figure 32.

NOTE: After installing switch assembly, adjust per

Paragraph 56.

Cabinet

Top

Switch

Switch

Clip

Bracket

Switch

Screw

Switch

Holder

Spring

Spring

Cabinet

Top

Lever

Attaching

Screws

Actuator

Arm

THROUGH SERIAL NO. R8237277YK STARTING SERIAL NO. R8237278YK

Figure 32

32918 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Starting Serial No. R8237278YK:

a. Remove screws holding the control panel to the

hood or back panel.

b. Disconnect wires from switch.

c. Move the switch lever off the switch plunger by

moving the lever back under the cabinet top.

Refer to Figure 33.

Cabinet

Top

Push

Here

Switch

Lever

Cabinet

Top

Clip Tabs

Switch

Screwdriver

Switch

Holder

Figure 34

Figure 33

d. Place the blade of a small screwdriver, or

similar device, between front of switch and

Switch

Switch

Clip

switch holder. Refer to Figure 34.

e. Slide the blade to the left to disengage the

switch clip tab holding the switch to the switch

holder. Refer to Figure 34.

f. Disengage the opposite end of the switch clip

tab from the holder and remove switch out

through opening in cabinet top.

g. Remove the switch clip from the old switch and

place through holes in new switch. Refer to

Figure 35.

h. Place the switch tool, Part No. 272P4, over the

switch clip tabs as shown in Figure 36.

i. Carefully place switch down into switch holder.

Refer to Figure 37. Line up the switch clip tabs

with the slots in the switch holder. Refer to

Figure 37.

34 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

j. Place a putty knife, or similar device, on

backside of switch clip. Refer to Figure 38.

Push on switch clip as you carefully pull the

switch tool out between switch and holder,

allowing the switch clip tabs to engage with

slots in holder. Refer to Figure 38.

Figure 35

Page 36

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

NOTE: Make sure the switch is secure within the

272P4

Switch

Tool

holder by wiggling it back and forth.

k. Reset the switch lever by raising and lowering

the loading door.

NOTE: Be sure the switch lever tab locates itself on

top of the switch plunger.

l. Reconnect wires to switch terminals.

NOTE: Refer to wiring diagram located in hood

area.

W003

Switch

Clip Tabs

Cabinet

Top

Figure 36

Switch

272P4

Switch Tool

Switch

Clips

m. Reinstall the control panel to the hood or back

panel.

272P4

Switch

Too l

Cabinet

Top

Slot

Putty

Knife

Switch

Holder

Slots

Switch

Holder

Switch

Clip Tabs

Slot

Switch

Holder

Figure 38

Figure 37

32918 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 37

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Water Inlet

Hose

Mixing Valve

Attaching

Screw

Backflow

Preventer

Center

Line

Hose

Clamp

THROUGH SERIAL NO. R8237277YK STARTING SERIAL NO. R8237278YK

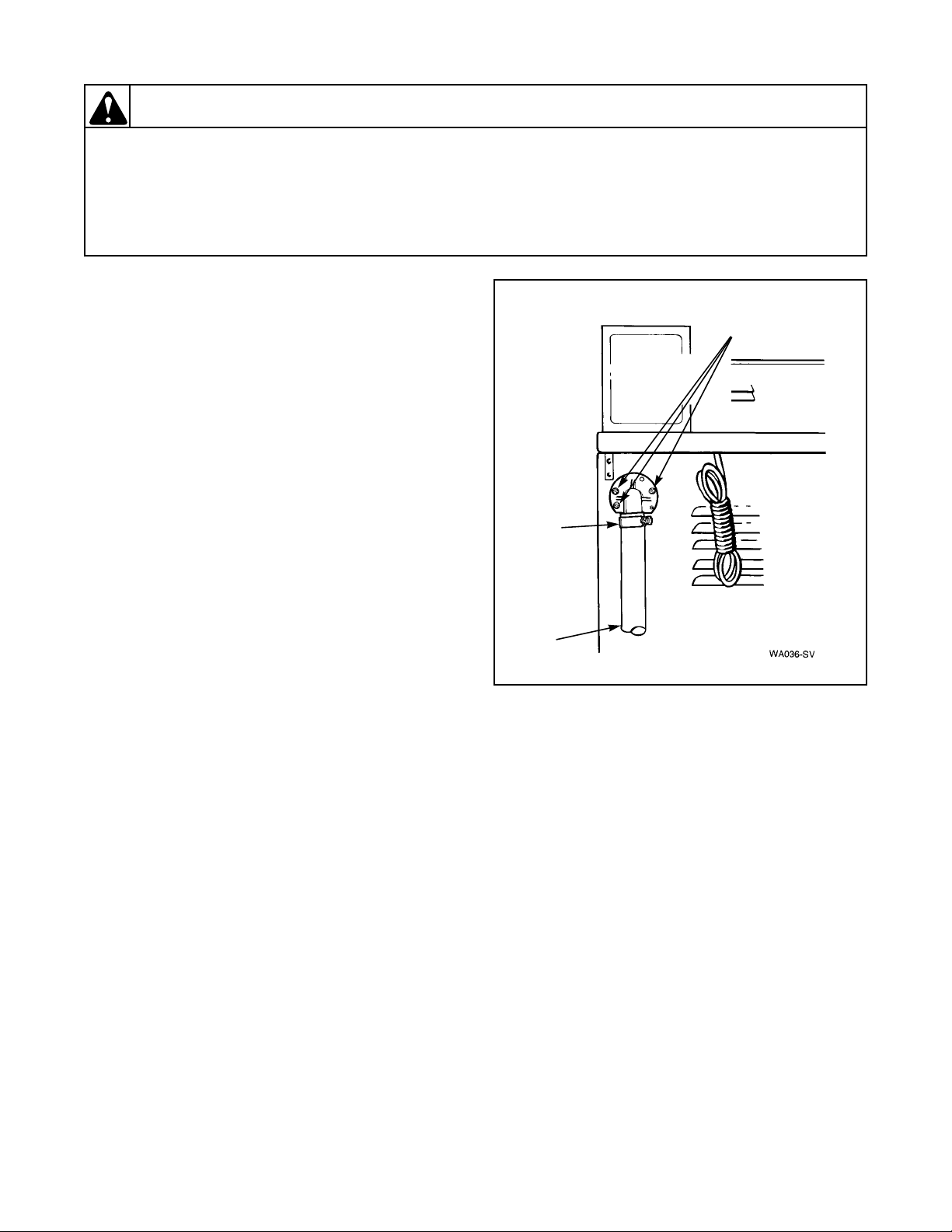

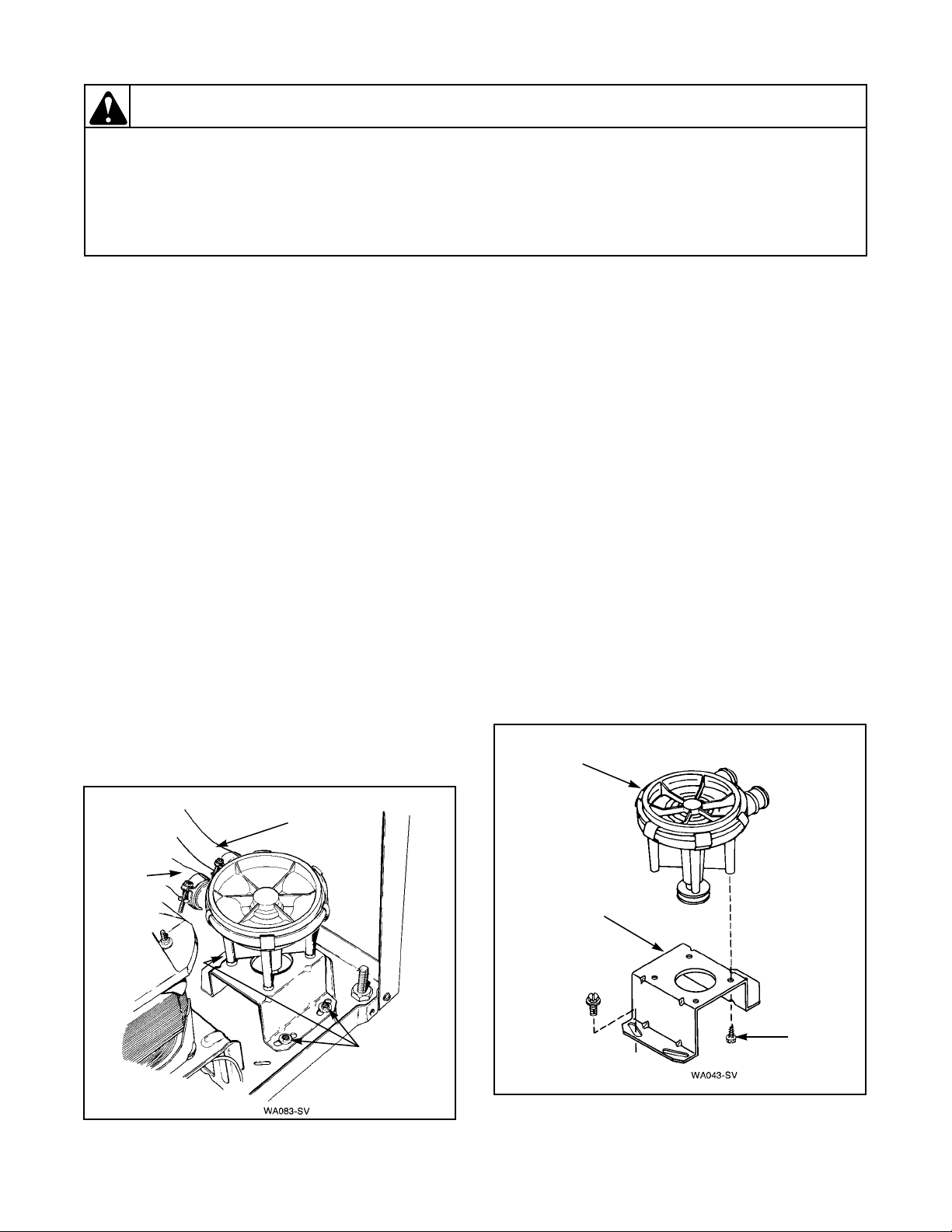

41. MIXING VALVE ASSEMBLY

a. Hinge cabinet top or remove. Refer to

Paragraph 39.

b. Remove screw holding mixing valve to

mounting bracket at rear of washer cabinet.

Refer to Figure 39.

White

Line

Filler

Hose

Mixing Valve

Wire Harness

Disconnect

Blocks

Mixing Valve

Wire Harness

Disconnect

Figure 39

Blocks

Water Inlet

Hose

Mixing Valve

Backflow

Preventer

Arrow

Attaching

Screw

Center

Line

Hose

Clamp

White

Line

Filler

Hose

Line on

Tub Cover

NOTE: When installing mixing valve, tab on

bottom flange must be placed in positioning hole in

mounting bracket.

c. Pull mixing valve out toward front of washer

far enough to permit disconnecting water inlet

and fill hoses from mixing valve. Refer to

Figure 39.

d. Disconnect solenoid wires at disconnect

blocks. Refer to Figure 39.

NOTE: Refer to appropriate wiring diagram when

rewiring solenoid.

36 32918

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 38

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

42. WASHTUB AND LINT FILTER OR

CLOTHES GUARD

a. Remove agitator. Refer to Paragraph 29.

b. Hinge cabinet top or remove. Refer to

Paragraph 39.

c. Disconnect filler hose from backflow

preventer. Refer to Figure 39.

NOTE: Through Serial No. R8237277YK – When

installing filler hose, white line on the hose must be

aligned with center line of the backflow preventer.

Refer to Figure 39. A one eighth inch clearance is

necessary to prevent the hose from rubbing on the

flange of the tub cover. Refer to Figure 40. Loosen

the hose clamp and move the hose to obtain the

proper clearance.

Starting Serial No. R8237278YK – When installing

filler hose, white dot on the hose must be aligned

with arrow on backflow preventer and white line on

hose that connects to tub cover must be aligned with

line located on top side of outer tub cover. Refer to

Figure 39. Make sure the hose is in its natural

position (not kinked or twisted) and is parallel to the

rear edge of the washer cabinet. If it is not, loosen

hose clamp and straighten the hose.

d. Starting Serial No. R8237278YK – Unhook the

pressure hose from the retainer clips located on

the left rear edge of the outer tub cover. Refer to

Figure 39.

e. Through Serial No. R8237277YK – Remove

eight clips holding outer tub cover to tub. Refer

to Figure 40. Lift cover off tub and set beside

washer cabinet.

Starting Serial No. R8237278YK – There are

eight tub cover hold-down tabs which snap over

outer tub flange. Using the special tub cover

tool, Part No. 273P4, insert the two prongs of

the tool underneath each side of the tandem

tabs. Refer to Figure 40. Tilt the tool toward the

center of the tub cover and at the same time lift

upward on cover to unsnap hold-down tabs

from outer tub flange. One by one, disengage

each of the eight hold-down tabs from outer tub

flange and remove cover.

NOTE: Through Serial No. R8237277YK – When

installing the outer tub cover, always use a new

cover gasket. Lubricate the gasket with liquid soap

to aid in the assembly. Cover must be placed on the

outer tub so the notch on the top edge of the outer

tub cover is directly over the left front clip hole in

the tub. Refer to Figure 40. Starting with this hole,

place each spring clip in its respective hole and snap

in place. Refer to Figure 40 for proper clip

installation.

Starting Serial No. R8237278YK – When installing

outer tub cover, always use a new cover gasket.

Before installing the new gasket, clean and remove

any foreign material that is in the gasket groove of

the cover. The outer tub flange must also be cleaned.

Starting at the positioning pin that is located

between the two bleach drain tabs, lay gasket into