Alliance Laundry Systems JT30XG, JT30WE, JT30EG, STB30EG, JTB30EG Installation Operation & Maintenance

...Page 1

Drying Tumblers

30 Pound Capacity (28" Wide)

30 Pound Capacity (31.5" Wide)

50 Pound Capacity

75 Pound Capacity

120 Pound Capcity

170 Pound Capacity

Model Numbers in this manual

are shown on page 5

Installation/Operation/Maintenance

NOTA: El manual en

español aparace después

del manual en inglés.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

(If this tumbler changes ownership, be sure this manual accompanies

the tumbler.)

Part No. M413620R3

November 1998

Page 2

Page 3

TABLE OF CONTENTS

SECTION I

SAFETY

Important Safety Instructions . . . . . . . . . . . . . . . . . . 5

SECTION II

INTRODUCTION

Information For Handy Reference . . . . . . . . . . . . . . 7

Nameplate Location . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replacement Parts Information . . . . . . . . . . . . . . . . 8

Cabinet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exhaust Thimble Locations. . . . . . . . . . . . . . . . . . . . 10

Steam Connection Locations. . . . . . . . . . . . . . . . . . . 11

Gas Connection Locations . . . . . . . . . . . . . . . . . . . . 12

Electrical Connection Locations . . . . . . . . . . . . . . . . 13

Tumbler Specifications . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION III

INSTALLATION INSTRUCTIONS

Receiving Inspection. . . . . . . . . . . . . . . . . . . . . . . . . 23

Materials Required (Obtain Locally) . . . . . . . . . . . . 23

Positioning the Drying Tumbler . . . . . . . . . . . . . . . . 24

Leveling the Drying Tumbler . . . . . . . . . . . . . . . . . . 24

Drying Tumbler Enclosure Construction . . . . . . . . . 25

Facilities Required. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Make-Up Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Gas Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Steam Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . 42

Accessory Timing Cam Installation . . . . . . . . . . . . . 49

SECTION IV

ADJUSTMENTS

Main Gas Burner Air Shutter. . . . . . . . . . . . . . . . . . . 53

Air Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Air Flow Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cylinder Door Switch . . . . . . . . . . . . . . . . . . . . . . . . 58

Cylinder Door Strike . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cylinder Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SECTION V

OPERATING INSTRUCTIONS

Manual Dual Timer Tumbler. . . . . . . . . . . . . . . . . . . 66

Coin-Operated Tumbler. . . . . . . . . . . . . . . . . . . . . . . 67

Electronically Controlled OPL Tumbler . . . . . . . . . . 69

SECTION VI

PREVENTIVE MAINTENANCE

INSTRUCTIONS

Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Lint Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Lint Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Every Three Months . . . . . . . . . . . . . . . . . . . . . . . . . 81

Lint Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Belt Tension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Every Six Months . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Overall Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Maintenance Check Chart . . . . . . . . . . . . . . . . . . . . . 82

Energy Saving Tips . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Service Savers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Troubleshooting the Tumbler. . . . . . . . . . . . . . . . . . . 84

Preliminary Operating Checks . . . . . . . . . . . . . . . . . 50

Final Operating Checks . . . . . . . . . . . . . . . . . . . . . . 51

©Copyright 1998, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in an y form or b y any means

without the expressed written consent of the publisher.

M413620

1

Page 4

Notes

2

M413620

Page 5

SECTION I

Safety

IMPORTANT: Warranty is void unless drying tumbler is installed according to instructions in this manual.

Compliance with minimum specifications and requirements detailed herein, and with applicable local gas fitting

regulations, municipal building codes, water supply regulations, electrical wiring regulations, and any other

relevant statutory regulations. Because of varied requirements, applicable local codes should be thoroughly

understood and all pre-installation work arranged for accordingly.

In the U.S.A., installation must conform to the latest edition of the American National Standard Z223.1 “National

Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code”.

In Canada, installation must comply with Standards CAN1-B149.1 or CAN1-B149.2 codes for gas burning

appliances and equipment and CSA C22.1, latest edition, Canadian Electric Code, Part I.

In Australia, installation must comply with the Australian Gas Association Installation Code for Gas Burning

Appliances and Equipment.

WARNING

Failure to install, maintain, and/or operate this machine according to manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution and

carefulness are factors which CANNOT be built into this tumbler. These factors MUST BE supplied by the

person(s) installing, maintaining or operating the tumbler.

W051

Always contact your dealer, distributor, service agent or the manufacturer on any problems or conditions you do

not understand.

M413620

3

Page 6

IMPORTANT: Information must be obtained from your local gas supplier on instructions to be followed if the

user smells gas. These instructions must posted in a prominent location. Step-by-step instructions of the safety

information below must be posted in a prominent location near the tumbler for customer use.

WARNING

FOR YOUR SAFETY, the information in

this manual must be followed to minimize

the risk of fire or explosion or to prevent

property damage, personal injury or

death.

W033

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical sw itch; do not

use any phone in your building.

– Clear the room, building or area of all

occupants.

– Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’ s instructions.

– If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

W052

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

W053

AVERTISSEMENT

Assurez-vous de bien suivre les

instructions données dans cette notice

pour réduire au minimum le risque

d’incendie ou d’explosion ou pour

éviter tout dommage matérial, toute

blessure ou la mort.

W033Q

• Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables

dans le voisinage de cet appareil ou de

tout autre appareil.

• QUE FAIRE SI V OUS SENTEZ UNE ODEUR

DE GAZ

– Ne pas tenter d’allumer d’apareil.

– Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous vous trouvez.

– Évacuez la pièce, le bâtiment ou la zone.

– Appelez immédiatement votre

fournisseur de gas depuis un voisin.

Suivez les instructions du fournisseur.

– Si vous ne pouvez rejoindre le

fournisseur de gas, appelez le service

des incendies.

• L’installation et l’entretien doivent être

assurés par un installateur ou un service

d’entretien qualifié ou par le fournisseur

de gaz.

W052Q

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de tout autre appareil.

W053Q

4

M413620

Page 7

IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using

your tumbler, follow these basic precautions:

1. Read all instructions before using the tumbler.

2. Refer to the GROUNDING INSTRUCTIONS for the proper grounding of the tumbler.

3. Do not dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, drycleaning solvents, other flammable or explosive substances as they give off vapors that could ignite or explode.

4. Do not allow children to play on or in the tumbler. Close supervision of children is necessary when the tumbler is

used near children. This is a safety rule for all appliances.

5. Before the tumbler is removed from service or discarded, remove the door to the drying compartment.

6. Do not reach into the tumbler if the cylinder is revolving.

7. Do not install or store the tumbler where it will be exposed to water and/or weather.

W054

8. Do not tamper with the controls.

9. Do not repair or replace any part of the tumbler, or attempt any servicing unless specifically recommended in the

User-Maintenance instructions or in published user-repair instructions that you understand and have the skills to

carry out.

10. Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric

softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics or articles containing foam ru bber or similarly textured

rubberlike materials.

12. Always clean the lint filter before every load. A layer of lint in the filter reduces drying efficiency and prolongs

drying time.

13. Keep area around the exhaust opening and adjacent surrounding area free from the accumulation of lint, dust and

dirt.

14. The interior of the tumbler and the exhaust duct should be cleaned periodically by qualified service personnel.

15. If not installed, operated and maintained in accordance with the manufacturer’ s instructions or if the re is damage to

or mishandling of this product’s components, use of this prod uct could e xpose yo u to substances in the fuel or fro m

fuel combustion which can cause death or serious illness and which are known to the State of California to cause

cancer, birth defects or other reproductive harm.

16. Tumbler will not operate with the loading door open. DO NOT bypass the door safety switch by permitting the

tumbler to operate with the door open. The tumbler will stop tumbling when the door is opened. Do not use the

tumbler if it does not stop tumbling when the door is opened or starts tumbling without pressing or turning the

START mechanism. Remo ve the tumbler from use and call the serviceman. Tumbler will not operate with lint

panel open. DO NOT bypass lint panel safety switch by permitting the tumbler to operate with the lint panel open.

M413620

5

Page 8

17. Do not put articles soiled with vegetable or cooking oil in the tumbler, as these oils may not be removed during

drying. Due to the remaining oil, the fabric may catch on fire by itself.

18. To reduce the risk of fire, DO NOT put clothes which have traces of any flammable substances such as machine

oil, flammable chemicals, thinner, etc. or anything containing wax or chemicals such as in mops and cleaning

cloths, or anything dry-cleaned at home with a dry-cleaning solvent in the tumbler.

19. Use the tumbler only for its intended purpose, drying fabrics.

20. ALWAYS disconnect the electrical power to the tumbler before servicing. Disconnect power by shutting of f

appropriate breaker or fuse.

21. Install this tumbler according to these INSTALLATION INSTRUCTIONS. All connections for electrical power,

grounding, and gas supply must comply with local codes and be made b y licensed personnel when required. Do not

do it yourself unless you know how!

22. Remove laundry immediately after the tumbler stops.

23. Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Heed all warnings

or precautions. To reduce the risk of poisoning or chemical burns, keep them out of reach of children at all times

(preferably in a locked cabinet).

24. Do not tumble fiberglass curtains and draperies unless the label says it can be done. If they are dried, wipe out the

cylinder with a damp cloth to remove particles of fiberglass.

25. Always follow the fabric care instructions supplied by the garment manufacturer.

26. Never operate the tumbler with any guards and/or panels removed.

27. DO NOT operate the tumbler with missing or broken parts.

28. DO NOT by-pass any safety devices.

29. Failure to install, maintain, and/or operate this machine according to the manufacturer’s instructions may result in

conditions which can produce bodily injury and/or property damage.

30. Run tumbler with a load before putting tumbler into service.

WARNING

To reduce the risk of serious injury, install lockable door(s) to prevent public access to

rear of tumblers.

This machine is intended for commercial use.

W055

6

M413620

Page 9

SECTION II

Introduction

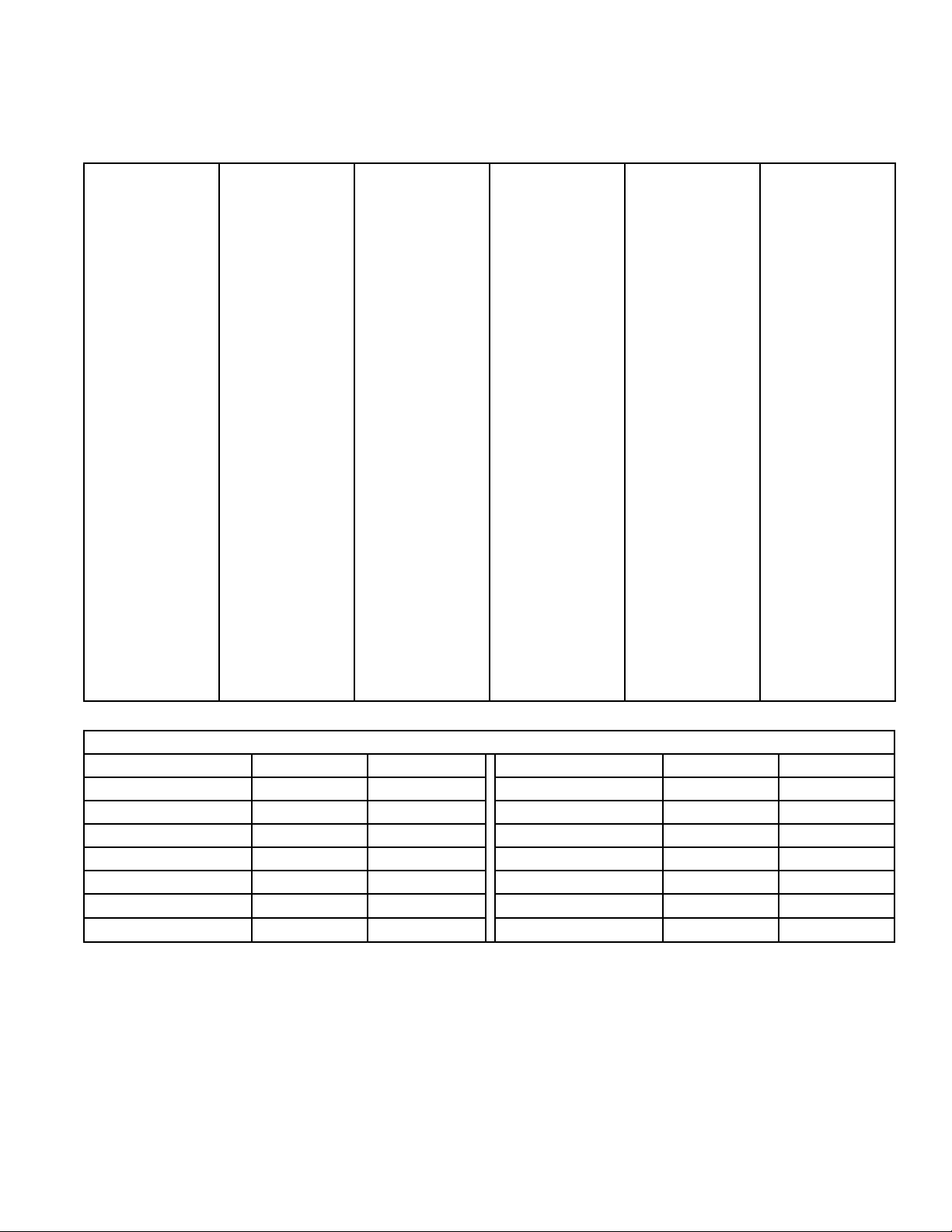

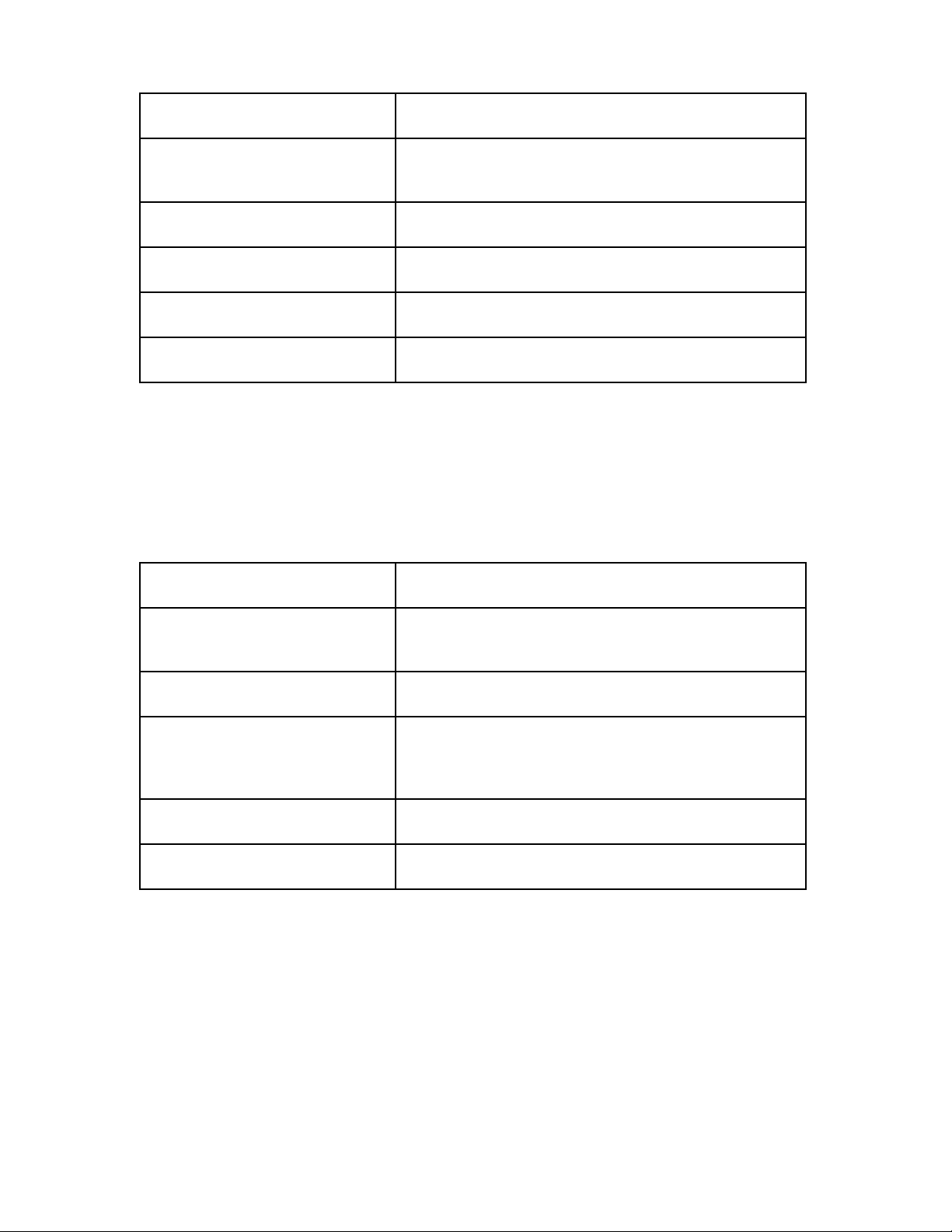

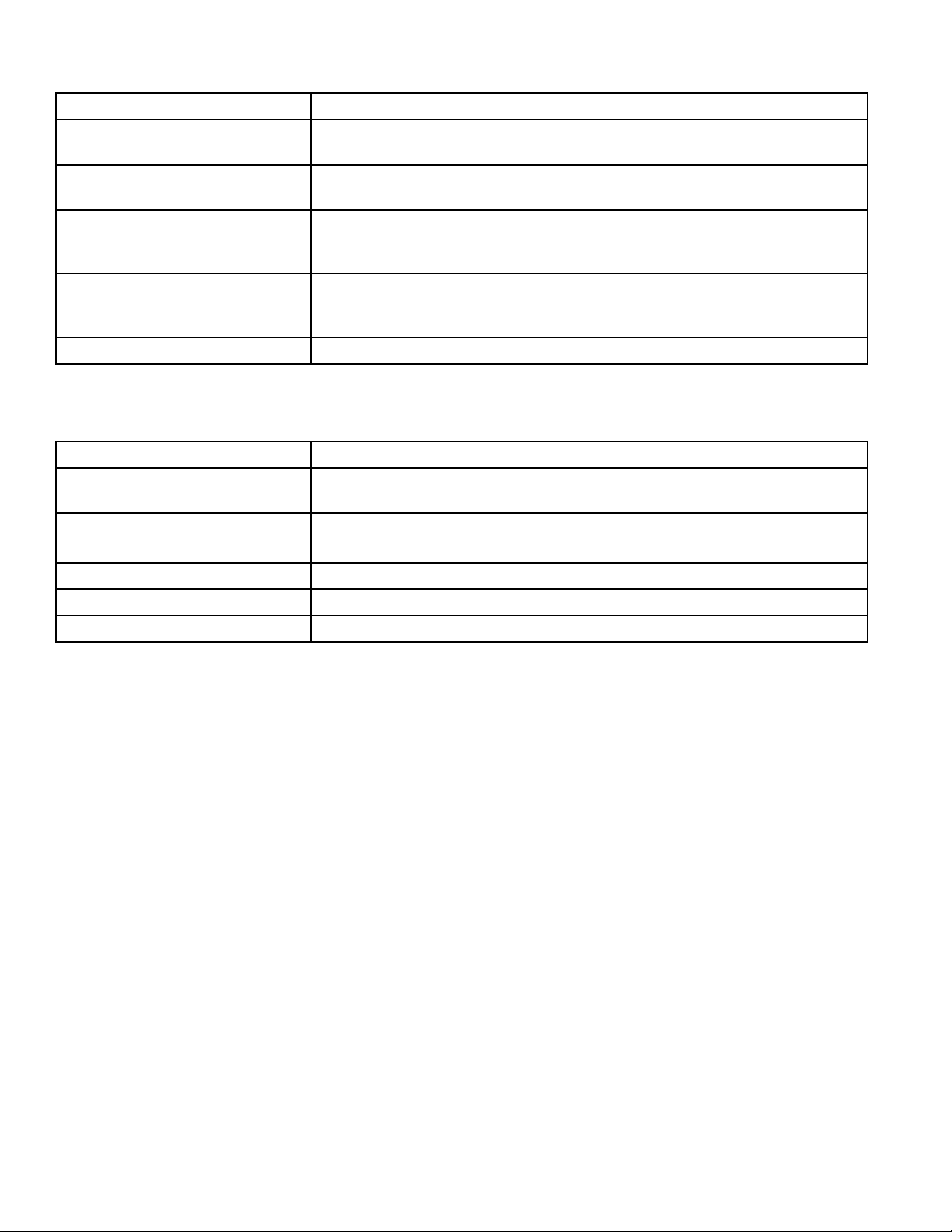

Information in this manual is applicable to these tumbler models.

30 Pound

(28" Wide)

JT30XG

JT30WE

30 Pound

(31.5" Wide) 50 Pound 75 Pound 120 Pound 170 Pound

JT30CG

STB30CG

JTB30CG

DTB30CG

JT30EG

STB30EG

JTB30EG

DTB30EG

JT30CE

STB30CE

JTB30CE

DTB30CE

JT30CSH

STB30CSH

JTB30CSH

DTB30CSH

JT30CSL

STB30CSL

JTB30CSL

DTB30CSL

JT50CG

STB50CG

JTB50CG

DTB50CG

JT50EG

STB50EG

JTB50EG

DTB50EG

JT50CE

STB50CE

JTB50CE

DTB50CE

JT50CSH

STB50CSH

JTB50CSH

DTB50CSH

JT50CSL

STB50CSL

JTB50CSL

DTB50CSL

JT75CG

STB75CG

JTB75CG

DTB75CG

JT75EG

STB75EG

JTB75EG

DTB75EG

JT75CE

STB75CE

JTB75CE

DTB75CE

JT75CSH

STB75CSH

JTB75CSH

DTB75CSH

JT75CSL

STB75CSL

JTB75CSL

DTB75CSL

ST120FG

JT120FG

DT120FG

ST120CSH

JT120CSH

DT120CSH

ST170FG

JT170FG

DT170FG

ST170CSH

JT170CSH

DT170CSH

STB634

DTB634

Conversion Table

Multiply By To Obtain Multiply By To Obtain

BTU .252 kCal Pounds / sq. in. .06895 Bars

BTU 1055 Joules Pounds / sq. in. .070 kg / sq. cm.

Inch 2.54 Centimeters Pounds (lbs.) .454 Kilograms

Inches W.C. .036 Pounds / sq. in. Boiler Horsepower 33479 BTU

Inches W.C. .249 kPa Boiler Horsepower 34.5 lbs. Steam / hr.

lbf / inch2 (psi)

3

ft

.0369 kPa CFM .471 liters / second

28.32 Liters KW 3414 BTU / hr.

INFORMATION FOR HANDY REFERENCE

Date Purchased _________________________________________________________

Model No. _________________________ Serial No. __________________________

Dealer’s Name _____ ___________________ __ __ ___________________ __ __ ______

NOTICE: For your own convenience and protection, record the above

information and retain your sales slip for this appliance. The model and serial

numbers will be found on the nameplate located on the tumbler, see Figure 1.

M413620

7

Page 10

NAMEPLATE LOCATION

FOR THE 30, 50

AND 75 POUND

TUMBLER

FOR THE

120 POUND

TUMBLER

T276IE3B

INFORMATION

When writing for information

on any tumbler, be sure to

mention model and serial

numbers. The model and serial

numbers will be found on

the nameplate as shown.

JUNCTION BOX

COVER

T228IE3D

FOR THE

170 POUND

TUMBLER

T238IE3B

JUNCTION

BOX

COVER

T281IE3B

Figure 1

PARTS ORDERING INFORMATION

If literature or replacement parts are required, contact the source from whom the machine was purchased or contact

Alliance Laundry Systems at (920) 748-3950 for the name and address of the nearest authorized parts distributor. For

technical assistance, call (920) 748-3121.

8

M413620

Page 11

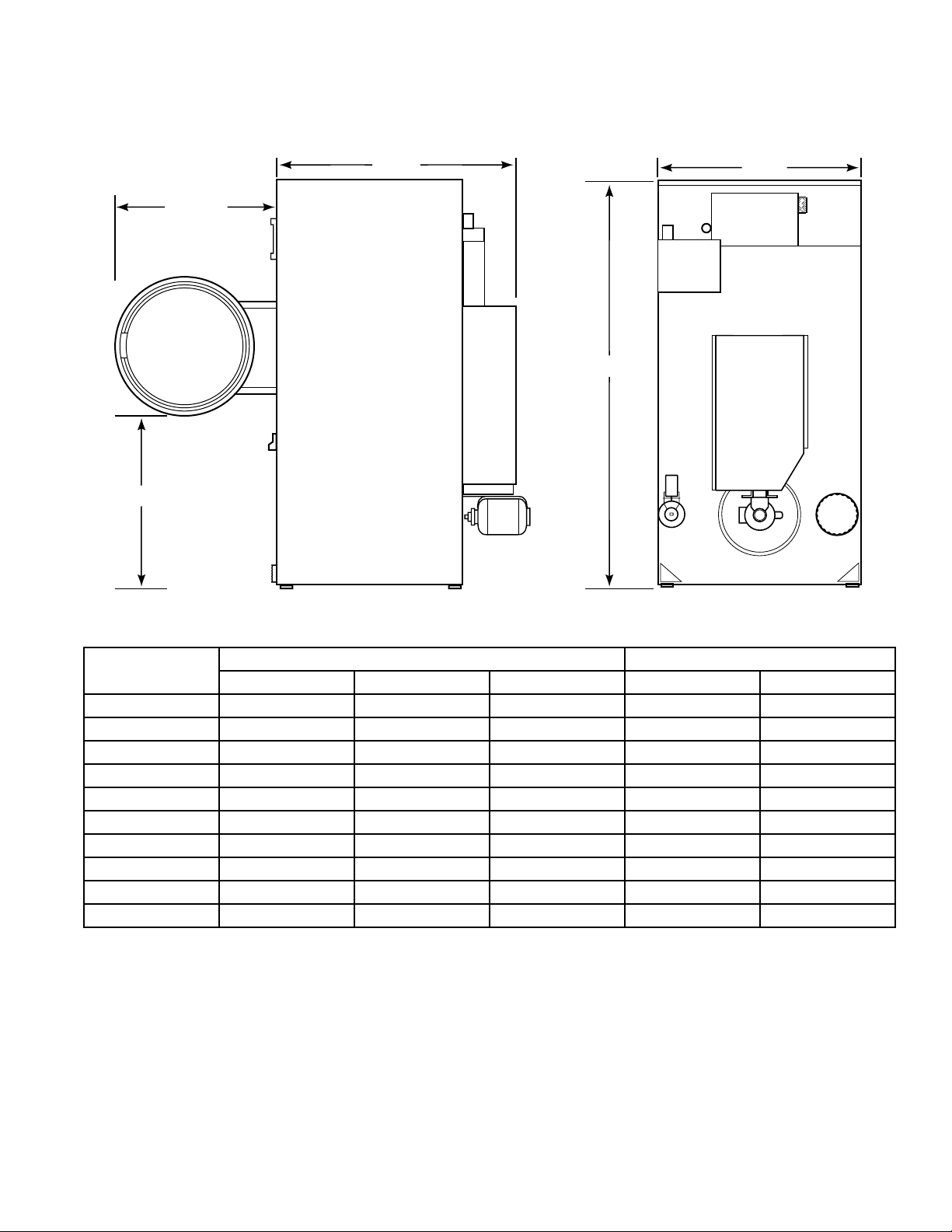

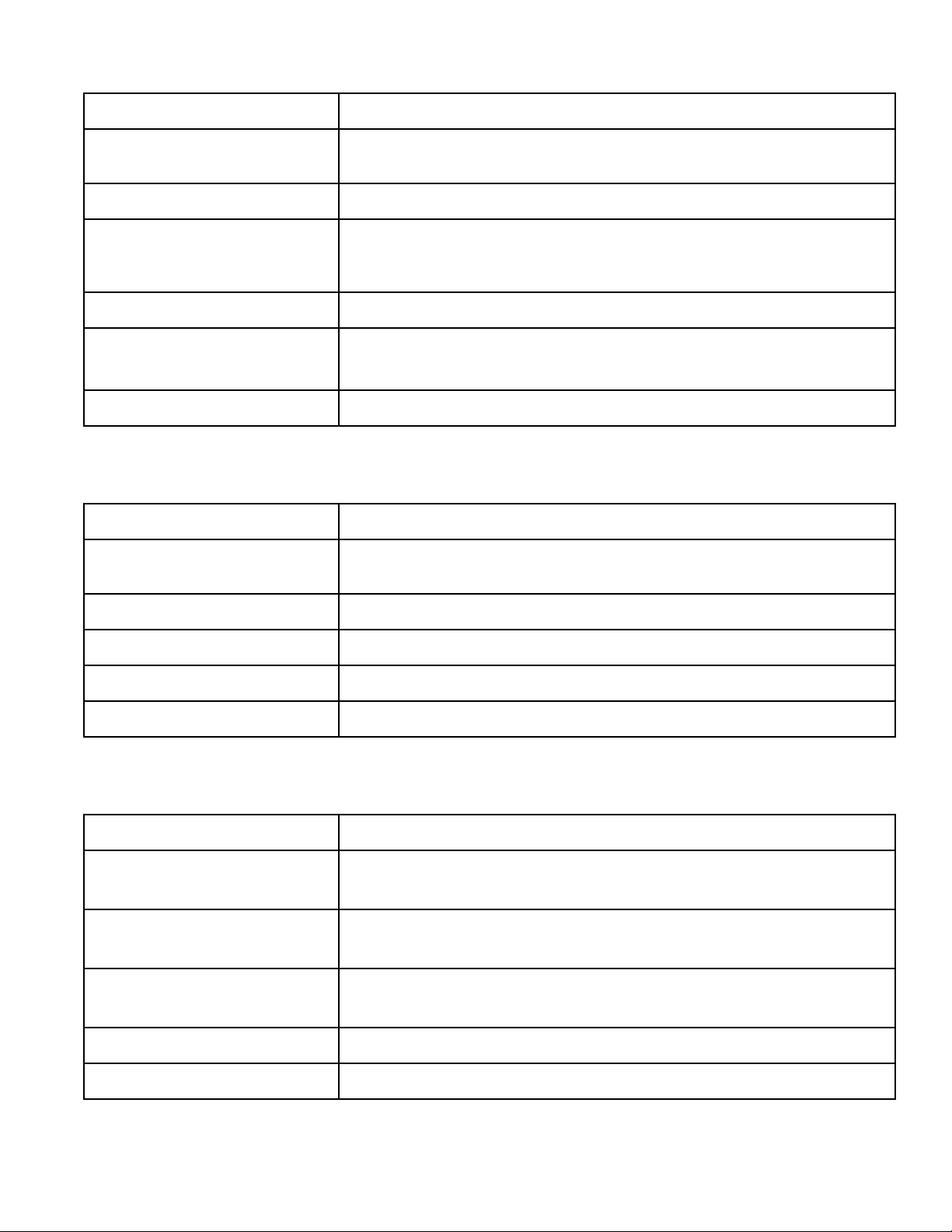

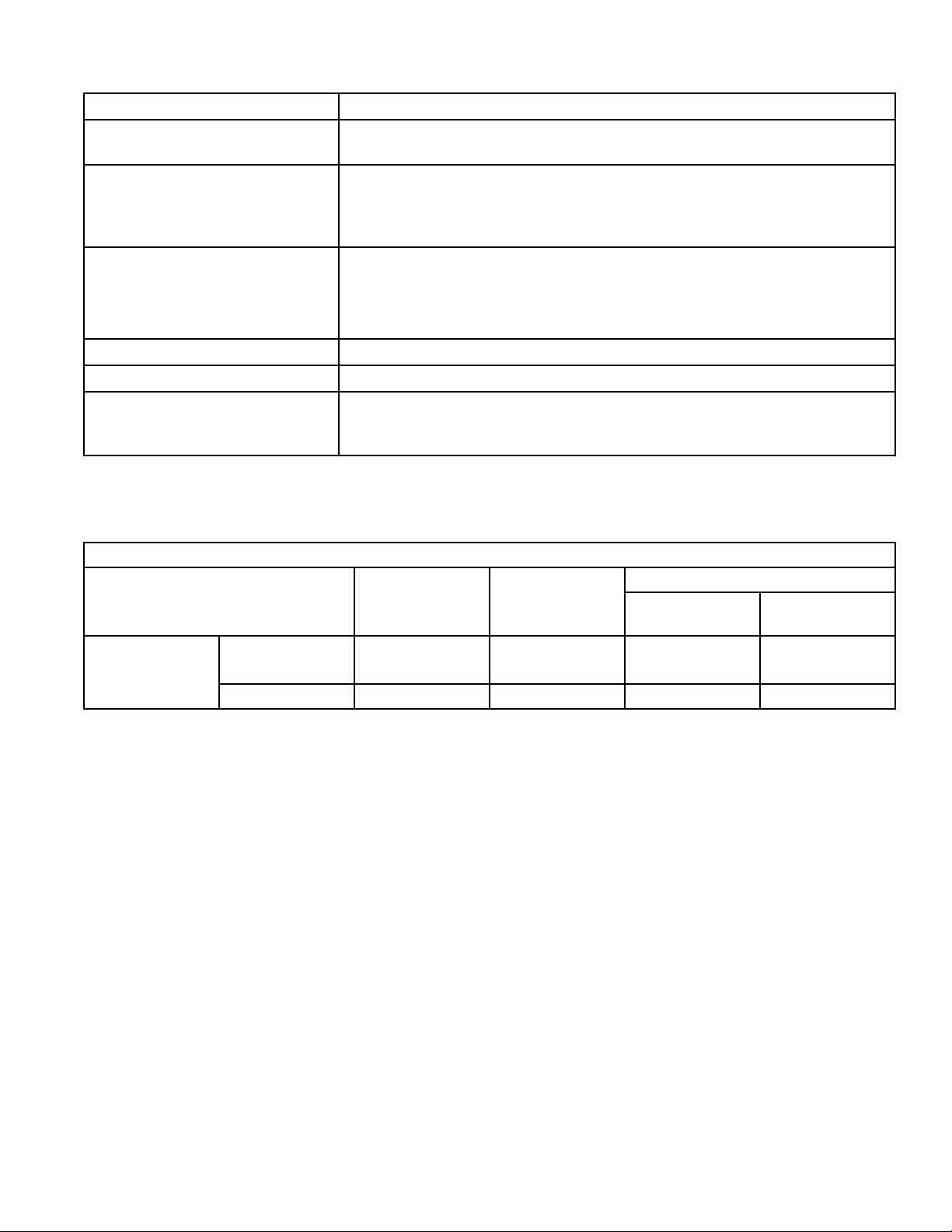

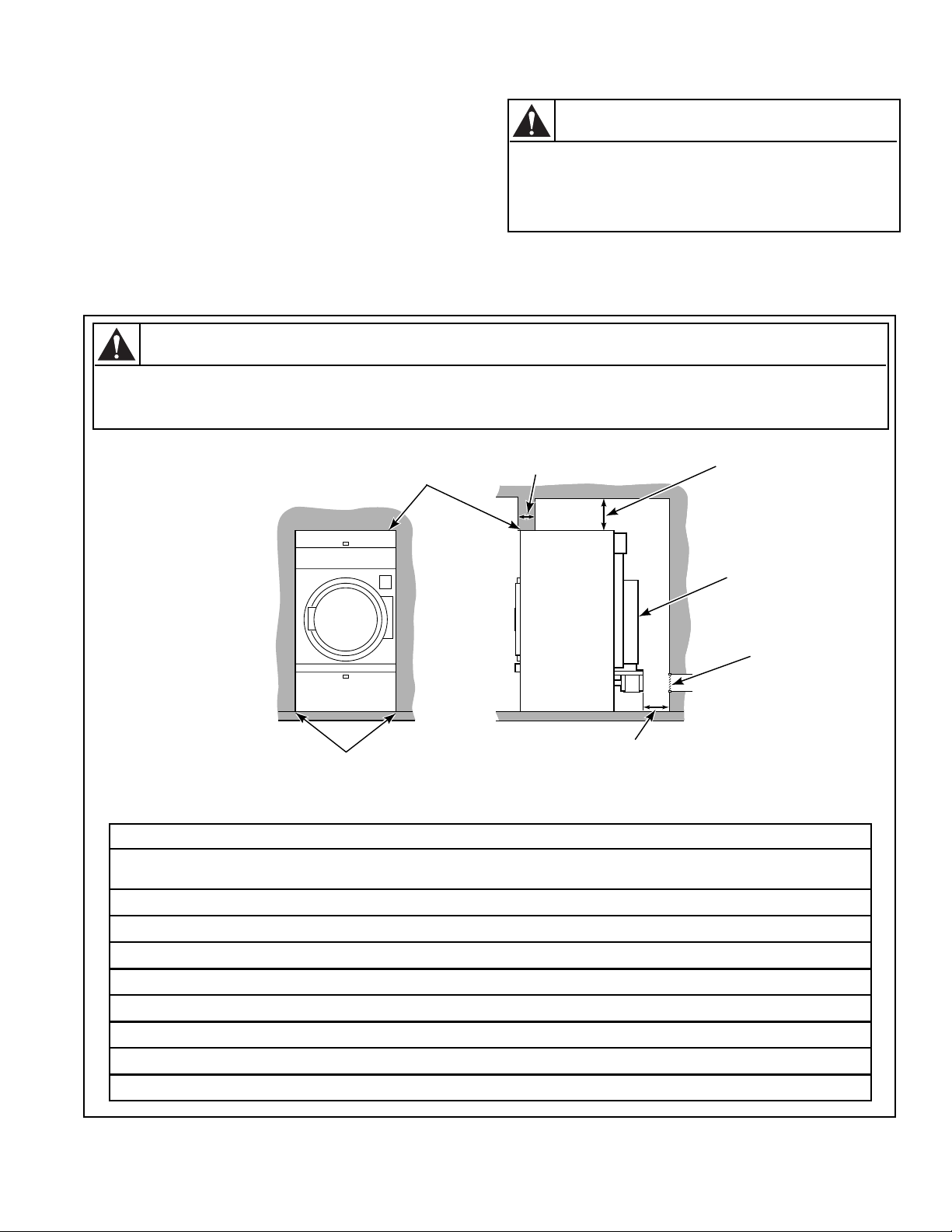

Roughing-In Dimensions and Specifications

Cabinet Dimensions

OPENING

CLEARANCE

DEPTH

WIDTH

HEIGHT

T326IE3A

TUMBLER MODELS

30XG/30WE 72-1/4" (1835 mm) 28" (711 mm) 44-7/8" (1140 mm) 26-3/4" (679 mm) 30-3/4" (781 mm)

30CG/30EG 72-1/4" (1835 mm) 31-1/2" (800 mm) 46-11/16" (1186 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

30CE/30CSH 72-1/4" (1835 mm) 31-1/2" (800 mm) 44-7/8" (1140 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

30CSL 72-1/4" (1835 mm) 31-1/2" (800 mm) 45-1/32" (1144 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

50CG/50EG/50CE 76-5/8" (1946 mm) 38-5/8" (981 mm) 47" (1194 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

50CSL/50CSH 80" (2032 mm) 38-5/8" (981 mm) 47" (1194 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

75CG/75EG/75CE/634 76-5/8" (1946 mm) 38-5/8" (981mm) 53" (1346 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

75CSL/75CSH 80" (2032 mm) 38-5/8" (981 mm) 53" (1346 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

120FG*/120CSH* 85-1/2" (2172 mm) 46-1/2" (1181 mm) 65" (1235 mm) 30-1/2" (775 mm) 31-5/16" (795 mm)

170FG*/170CSH* 94" (2390 mm) 53-1/8" (1349 mm) 66-1/8" (1679 mm) 30-1/2" (775 mm) 33-5/16" (857 mm)

HEIGHT WIDTH DEPTH OPENING CLEARANCE

OVERALL DOOR

* See Section III “Positioning the Drying Tumbler” for temporarily reducing the height of these models.

M413620

9

Page 12

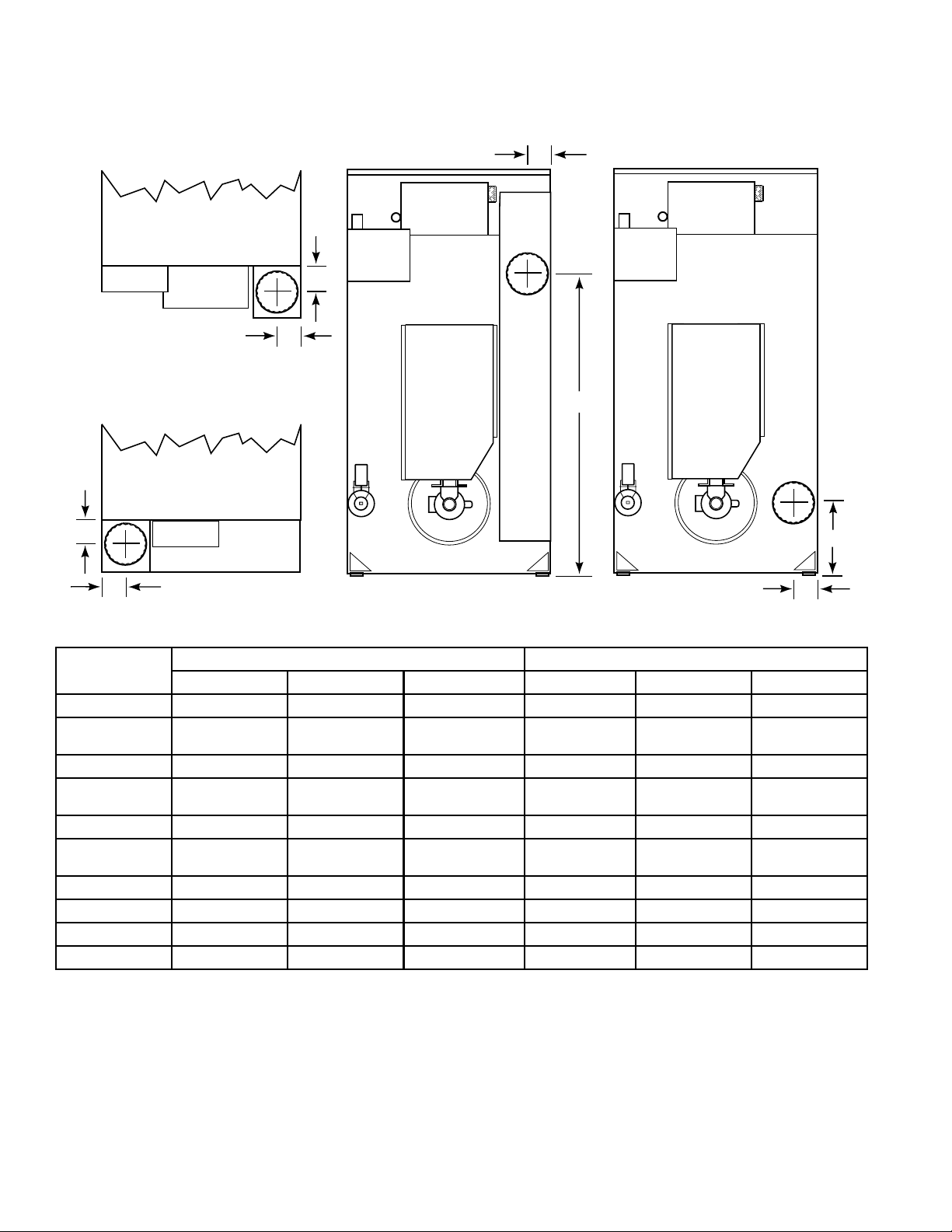

Roughing-In Dimensions and Specifications

Exhaust Thimble Locations

DEPTH

30XG, 30WE & 75EG

ACROSS

120FG, 120CSH,

170FG & 170CSH

ACROSS

ACROSS

DEPTH

HEIGHT

HEIGHT

ACROSS

T327E3A

TUMBLER MODELS

30XG/30WE N/A N/A N/A 6" (152 mm) 3-3/8" (86 mm) 3-3/8" (86 mm)

30CG/30CE

30CSL/30CSH

30EG 8" (203 mm) 4-7/16" (113 mm) 55-3/8" (1407 mm) N/A N/A N/A

50CG/50CE

50CSL/50CSH

50EG 8" (203 mm) 5-3/8" (137 mm) 57-5/8" (1464 mm) N/A N/A N/A

75CG/75CE

75CSL/75CSH

75EG N/A N/A N/A 8" (203 mm) 5-5/8" (143 mm) 5" (127 mm)

634 10" (254 mm) 6-1/2" (165 mm) 6-1/2" (165 mm) N/A N/A N/A

120FG/120CSH N/A N/A N/A 10" (254 mm) 203 mm (8") 7-1/2" (185 mm)

170FG/170CSH N/A N/A N/A 12" (305 mm) 7" (178 mm) 9-3/8" (238 mm)

DIAMETER ACROSS HEIGHT DIAMETER ACROSS HEIGHT

8" (203 mm) 4-7/16" (113 mm) 21-7/8" (556 mm) N/A N/A N/A

8" (203 mm) 5-3/8" (137 mm) 13-3/8" (340 mm) N/A N/A N/A

8" (203 mm) 5-3/8" (137 mm) 13-3/8" (340 mm) N/A N/A N/A

HORIZONTAL EXHAUST VERTICAL EXHAUST

10

M413620

Page 13

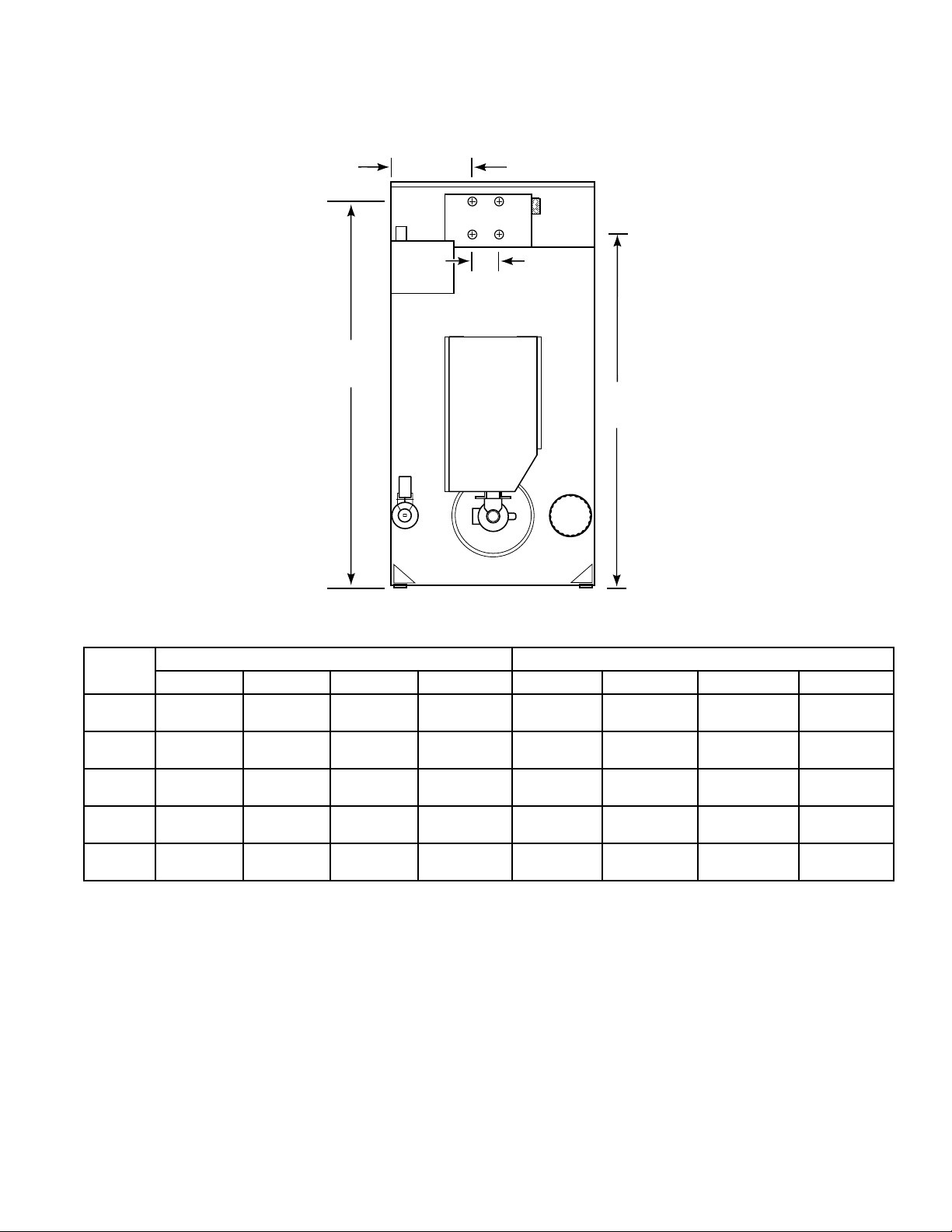

Roughing-In Dimensions and Specifications

Steam Connection Locations

ACROSS

SPAN

STEAM

INLET

HEIGHT

STEAM

OUTLET

HEIGHT

TUMBLER

MODELS

30CSL

30CSH

50CSL

50CSH

75CSL

75CSH

120CSH 3/4" (19 mm)

170CSH 3/4" (19 mm)

DIAMETER ACROSS HEIGHT SPAN DIAMETER ACROSS HEIGHT SPAN

3/4" (19 mm)

I.D.

3/4" (19 mm)

I.D.

3/4" (19 mm)

I.D.

I.D.

I.D.

STEAM INLET STEAM OUTLET

14" (356 mm) 68-3/4"

15-1/4"

(387 mm)

15-1/4"

(387 mm)

21-1/4"

(540 mm)

15-3/4"

(400 mm)

(1746 mm)

72-3/4"

(1848 mm)

72-3/4"

(1848 mm)

82-3/4"

(2102 mm)

88"

(2235 mm)

7-1/2"

(190 mm)

7-1/2"

(190 mm)

7-1/2"

(190 mm)

N/A (Manifold) 1" (25 mm)

21-5/8"

(549 mm)

3/4" (19 mm)

I.D.

3/4" (19 mm)

I.D.

3/4" (19 mm)

I.D.

N.P.T.

1" (25 mm)

N.P.T.

T328E3A

14" (356 mm) 61-1/4"

15-1/4"

(387 mm)

15-1/4"

(387 mm)

11-7/8"

(302 mm)

8-3/4"

(222 mm)

(1556 mm)

64-3/4"

(1645 mm)

64-3/4"

(1645 mm)

68-1/2"

(1739 mm)

71-3/4"

(1822 mm)

7-1/2"

(190 mm)

7-1/2"

(190 mm)

7-1/2"

(190 mm)

21-1/2"

(546 mm)

35-5/8"

(905 mm)

M413620

11

Page 14

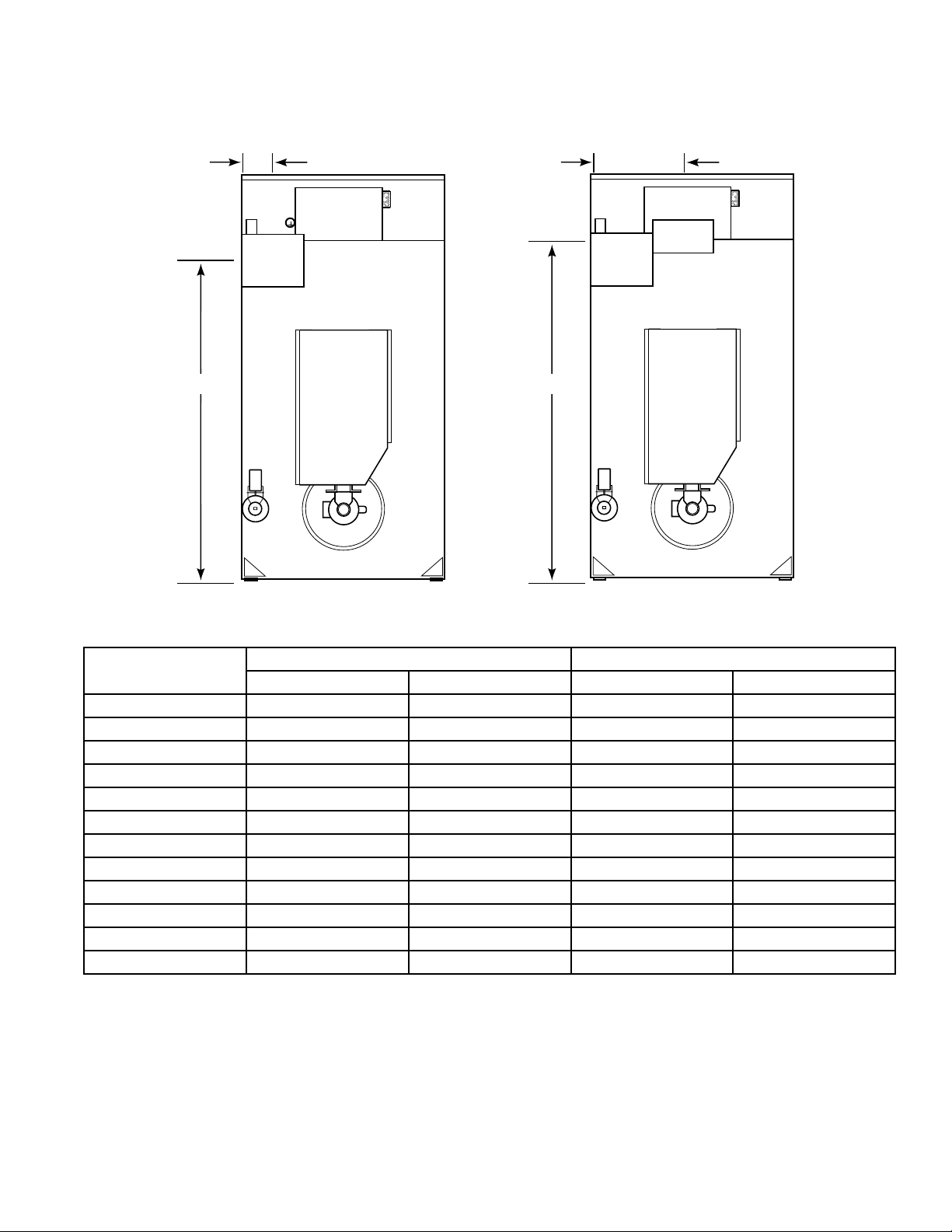

Roughing-In Dimensions and Specifications

Gas Connection Locations

ACROSS

HEIGHT

T329E3A

TUMBLER

MODELS

30XG 1/2" (12.7 mm) 12-1/4" (311 mm) 62-1/8" (1578 mm)

30CG/30EG 1/2" (12.7 mm) 15" (381 mm) 62-1/8" (1578 mm)

50CG/50EG 1/2" (12.7 mm) 15-1/2" (394 mm) 65-3/4" (1670 mm)

75CG/75EG 1/2" (127 mm) 15-3/4" (400 mm) 65-3/4" (1670 mm)

634 3/4" (19 mm) 15-3/4" (400 mm) 65-3/4" (1670 mm)

120FG 3/4" (19 mm) 33-1/2" (851 mm) 70-1/4" (1784 mm)

170FG 1" (25 mm) 38-5/8" (979 mm) 77-3/8" (1965 mm)

DIAMETER (N.P.T.) ACROSS HEIGHT

GAS CONNECTION

12

M413620

Page 15

Roughing-In Dimensions and Specifications

Electrical Connection Locations

HEIGHT

ACROSS

Gas & Steam

HEIGHT

Electric

ACROSS

T330iE3A

TUMBLER

MODELS

30XG/30CG/30EG 65" (1651 mm) 3" (76 mm) N/A N/A

30WE N/A N/A 60" (1524 mm) 14" (356 mm)

30CE N/A N/A 60" (1524 mm) 16" (406 mm)

30CSL/30CSH 65" (1651 mm) 3" (76 mm) N/A N/A

50CG/50EG 68" (1727 mm) 3" (76 mm) N/A N/A

50CE N/A N/A 64" (1626 mm) 19" (483 mm)

50CSL/50CSH 68" (1727 mm) 3" (76 mm) N/A N/A

75CG/75EG 68" (1727 mm) 3" (76 mm) N/A N/A

75CE N/A N/A 64" (1626 mm) 19" (483 mm)

75CSL/75CSH/634 68" (1727 mm) 3" (76 mm) N/A N/A

120FG/120CSH 65" (1651 mm) 24" (610 mm) N/A N/A

170FG/170CSH 68" (1727 mm) 27" (686 mm) N/A N/A

ELECTRICAL SERVICE - GAS & STEAM MODELS ELECTRICAL SERVICE - ELECTRIC MODELS

HEIGHT ACROSS HEIGHT ACROSS

NOTE: These are approximate dimensions only.

M413620

13

Page 16

30 Pound, 28" wide Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Gas Consumption: 75,000 BTU per hour (79.1 MJ/hr.)

Max. Air Flow: 370 C.F.M. (175 liters/sec.)

Net Weight: 350 Pounds (159 kg) (approximate)

30 Pound, 28" wide Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Element: 21,000 Watts (60 Hz models)

Long life nichrome wire

18,000 Watts (50 Hz models)

Max. Air Flow: 625 C.F.M. (295 liters/sec.)

Net Weight: 410 Pounds (184.5 kg) (approximate)

14

M413620

Page 17

30 Pound Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 cm x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Energy Saver Models — 80,000 BTU per hour (84.4 MJ/hr.)

Gas Consumption:

Standard Models — 105,000 BTU per hour (110.8 MJ/hr.)

Gas Connection: 1/2 inch N.P. T.

Max. Air Flow: Energy Saver Models — 250 C.F.M. (118 liters/sec.)

Standard Models — 625 C.F.M. (295 liters/sec.)

Net Weight: 450 Pounds (204 kg) (approximate)

30 Pound Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 cm x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Element: 21,000 Watts (all voltages)

Max. Air Flow: 625 C.F.M. (295 liters/sec.)

Net Weight: 450 Pounds (204 kg) (approximate)

30 Pound Steam Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds dry weight (13.6 kg) (cotton load)

Motor: High Pressure (4 coils) 1/2 H.P.

Low Pressure (4 coils) 3/4 H.P.

Boiler Horsepower: 4 coil High Pressure – 3.7 Bhp (123,950 BTU/hr., 58 kg/hr, 31,235 kCal/hr.)

4 coil Low Pressure – 2.6 Bhp (87,100 BTU/hr., 40 kg/hr, 21,949 kCal/hr.)

Max. Air Flow: 625 C.F.M. (295 liters/sec.)

Net Weight: 470 Pounds (214 kg) (approximate)

M413620

15

Page 18

50 Pound Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 30" (94 cm x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor:

(Nonreversing Models)

Gas Consumption:

Max. Air Flow: Energy Saver Models — 390 C.F.M. (184 liters/sec.)

Net Weight: 545 Pounds (247 kg) (approximate)

1/2 H.P., lifetime lubricated, internal overload protected

(See below for reversing models.)

Energy Saver Models — 95,000 BTU per hour (100.2 MJ/hr.)

Standard Models — 120,000 BTU per hour (126.6 MJ/hr.)

Standard Models — 750 C.F.M. (354 liters/sec.)

50 Pound Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 30" (94 cm x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor:

(Nonreversing Models)

1/2 H.P., lifetime lubricated, internal overload protected

(See below for reversing models.)

Element: 21,000 watts (240 VAC 50 Hz.) Long life nichrome wire

30,000 watts (all other voltages) Long life nichrome wire

Max. Air Flow: 750 C.F.M. (354 liters/sec.)

Net Weight: 550 Pounds (250 kg) (approximate)

16

M413620

Page 19

50 Pound Steam Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 30" (94 x 76.2 cm) perforated galvanized steel with four baffles;

50 pounds (22.7 kg) dry weight (cotton load)

Motor:

(Nonreversing Models)

Boiler Horsepower: High Pressure Steam (6 Coil) — 4.60 B.H.P.

Max. Air Flow: 750 C.F.M. (354 liters/sec)

Net Weight: 4 Coil Tumbler — 565 pounds (257 kg) (approximate)

High Pressure Steam — 1/2 H.P.

Low Pressure Steam — 3/4 H.P

Both motors are lifetime lubricated, internal overload protected

See below for reversing models.

Low Pressure Steam (4 Coil) — 3.00 B.H.P.

6 Coil Tumbler — 580 pounds (263 kg) (approximate)

REVERSING MOT OR SIZES

STEAM

GAS ELECTRIC

HIGH

PRESSURE

LOW

PRESSURE

50 LB.

FAN 1/3 H.P. 1/3 H.P. 1/3 H.P. 1/2 H.P.

CYLINDER 1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

M413620

17

Page 20

75 Pound Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 36" (94 x 91.4 cm) perforated galvanized steel cylinder with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: 3/4 H.P., lifetime lubricated, internal overload protected. See below for

reversing models.

Standard Models: 165,000 B.T.U. per hour (174.1 MJ/hr.)

Gas Consumption:

Max. Air Flow: Standard Models: 920 C.F.M. (434 liters/sec.)

Net Weight: 575 Pounds (261 kg) (approximate)

Energy Saver Models: 140,000 B.T.U. per hour (147.7 MJ/hr.)

DTB634 Models: 215,000 B.T.U. per hour (227 MJ/hr.)

Energy Saver Model: 500 C.F.M. (236 liters/sec.)

634 Models: 1100 C.F.M. (519 liters/sec.)

75 Pound, Electric, Non-reversing Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 36" (94 x 91.4 cm) perforated galvanized steel with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: 3/4 H.P., lifetime lubricated, internal overload protected. See below for

reversing models.

Element: 30,0 00 watts (all models)

Max. Air Flow: (C.F.M.) 750 C.F.M. (354 liters/sec.)

Net Weight: 555 Pounds (252 kg) (approximate)

18

M413620

Page 21

75 Pound Steam Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 37" x 36" (94 x 91.4 cm) perforated galvanized steel with four baffles;

75 pounds (34.1 kg) dry weight (cotton load)

Motor: High Pressure Steam — 3/4 H.P.

Low Pressure Steam — 3/4 H.P.

Both motors are lifetime lubricated, internal overload protected.

See below for reversing models.

Electrical Boiler Horsepower: High Pressure Steam — 4.60 BPH (154,100 BTU/hr.)

(72.1 kg/hr., 38,833 kCal/hr.)

Low Pressure Steam — 4.00 BHP (134,000 BTU/hr.)

(62.7 kg/hr., 33,768 kCal/hr.)

Max. Air Flow: 750 C.F.M. (354 liters/sec)

Net Weight: 6 Coil Tumbler — 615 pounds (280 kg) (approximate)

Electrical Requirements:

(Reversing Models)

75 LB.

* 634 Models

208-240 Volt, 60 Hertz, 3 Phase, 4 Amp.

480 Volt, 60 Hertz, 3 Phase, 2 Amp

240 Volt, 50 Hertz, 1 Phase, 8 Amp

REVERSING MOT OR SIZES

STEAM

GAS ELECTRIC

FAN

CYLINDER 1/3 H.P. 1/3 H.P. 1/3 H.P. 1/3 H.P.

1/3 H.P.

1 H.P.*

1/3 H.P. 1/3 H.P. 1/2 H.P.

HIGH

PRESSURE

LOW

PRESSURE

M413620

19

Page 22

120 Pound Gas Tumbler

Cylinder: 44" diameter x 41" deep (111.8 cm x 104.1 cm)

Perforated galvanized steel with four baffles;

120# dry weight (cotton load).

Cylinder Motor: 3/4 H.P., lifetime lubricated, internal overload protected.

Fan motor: 1 H.P. lifetime lubricated, internal overload protected.

Gas Consumption: 300,000 BTU/hr (316 MJ/hr)

Air Flow: 2000 CFM at .3" W.C. (944 liters/sec at .76 cm W.C.)

Net Weight (approx.): 1275 pounds (580 kg)

120 Pound Steam Tumbler

(Not Agency Listed)

Cylinder: 44" diameter x 41" deep (111.8 cm x 104.1 cm)

Perforated galvanized steel with four baffles;

120# dry weight (cotton load).

Cylinder Motor: 3/4 H.P. lifetime lubricated,

internal overload protected

Fan Motor: 1 H.P. lifetime lubricated,

internal overload protected

Steam Consumption (maximum): 10 B.H.P (156.8 kg/hr)

335,000 BTU/hr (84,419 kCal/hr)

Operating Steam Pressure

(maximum):

Air Flow: 2000 CFM at .3" W.C. (944 liters/sec at .76 cm W.C.)

Net Weight (approx.): 1375 pounds (625 kg)

125 psi (8.79 kg/sq cm)

20

M413620

Page 23

170 Pound Gas Tumbler

Cylinder: 50-3/4" diameter x 42-1/2" deep (128.9 cm x 108. 9 cm)

Perforated galvanized steel with four baffles;

170# dry weight (cotton load).

Cylinder Motor: 3/4 H.P. lifetime lubricated

Fan Motor: 3 H.P. lifetime lubricated

Gas Consumption: 395,000 BTU/hr (401 MJ/hr)

Air Flow: 2300 CFM at .3" W.C. (1083.3 liters/sec at .76 cm W.C.)

Net Weight (approx.): 1575 pounds (716 kg)

170 Pound Steam Tumbler

(Not Agency Listed)

Cylinder: 50-3/4" diameter x 42-1/2" deep (128.9 cm x 108. 9 cm)

Perforated galvanized steel with four baffles;

170# dry weight (cotton load).

Cylinder Motor: 3/4 H.P. lifetime lubricated

Fan Motor: 3 H.P. lifetime lubricated

Steam Consumption (maximum): 15 B.H.P (235.2 kg/hr)

502,500 BTU/hr (126,630 kcal/hr)

Operating Steam Pressure

(maximum):

125 psi (8.79 kg/sq cm)

Air Flow: 2300 CFM at .3" W.C. (1083.3 liters/sec at .76 cm W.C.)

Net Weight (approx.): 1675 pounds (761 kg)

M413620

21

Page 24

Notes

22

M413620

Page 25

SECTION III

Installation Instructions

RECEIVING INSPECTION

Upon delivery, visually inspect crate carton and parts for

any visible shipping damage. If the crate, carton or co ver

are damaged or signs of possible damage are evident,

have the carrier n ote the condition on the shipping p apers

before the shipping receipt is signed, or advise the carrier

of the condition as soon as it is discovered.

Remove the crate and protecti ve cover as soon as possible

and check the items listed on the packing list. Advise the

carrier of any damaged or missing articles as soon as

possible. A written claim should be filed with the carrier

immediately if articles are damaged or missing.

IMPORTANT: Remove the shipping tape from the

two back draft dampers located in the exhaust

thimble.

MATERIALS REQUIRED

(Obtain Locally)

GAS, ELECTRIC OR STEAM DRYING

TUMBLERS

• One fused disconnect switch or circuit breaker.

GAS DRYING TUMBLERS ONLY

• One gas shut-off valve for gas service line to each

tumbler.

STEAM DRYING TUMBLERS ONLY

• One steam shut-off valve for steam service line to be

connected upstream of solenoid steam valve.

• Two steam shut-off valves for each condensate return

line.

• Flexible steam hoses with a 125 psig (pounds per

square inch gauge) (8.79 kg/sq. cm) working pressure

for connecting steam coils. See Figure 25, 26 and 27

for sizing and connection configurations.

• Two steam traps for steam coil outlet to condensate

return line. (Three for 120 and 170 pound tumblers. )

• Two vacuum breakers for condensate return lines.

(Three for 120 and 170 pound tumblers.)

M413620

23

Page 26

POSITIONING THE DRYING

LEVELING THE DRYING

TUMBLER

The tumbler may be removed from the skid before

moving it to the installation location or it may be moved

while still attached to the skid. To remove tumbler from

the skid, unscrew the four shipping capscrews (one at

each corner) and remove the tumbler from the skid. The

lint panel door will have to be removed in order to remove

the two front capscrews.

NOTE: Do not throw these four capscrews away —

they are the leveling legs.

Screw the four lev eling le gs back into the le v el adjusting

fittings from the top.

To fit a 170 pound tumbler (with shipping skid) through

an 8-foot high door, you must remove the front access

panel. The upper 3 inches of the stove must also be

removed on 170 pound gas tumblers. Removing the

entire gas or steam heater assembly and the shipping skid,

will reduce the height of the 120 pound tumbler to 70

inches, and the 170 pound tumbler to 75 inches.

To remove tumbler from the skid, unscrew the four

shipping capscrews (one at each corner) and remove the

tumbler from the skid.

Slide the tumbler to its permanent location and level.

Keep the tumbler as close to the floor as possible. The

tumbler must rest firmly on the floor so weight of tumbler

is evenly distrib uted. T umbler must not rock. Shim under

the corners to level and stabilize the unit.

TUMBLER

Each tumbler should be leveled within 1/8 inch (3.2 cm)

from front to rear, and 1/8 inch (3.2 cm) from side to side.

Check front to rear level by rotating the clothes cylinder

until one rib is at the bottom, then place a level on the rib .

Side to side level should be checked by placing a le vel on

the front and rear of the top panel.

24

M413620

Page 27

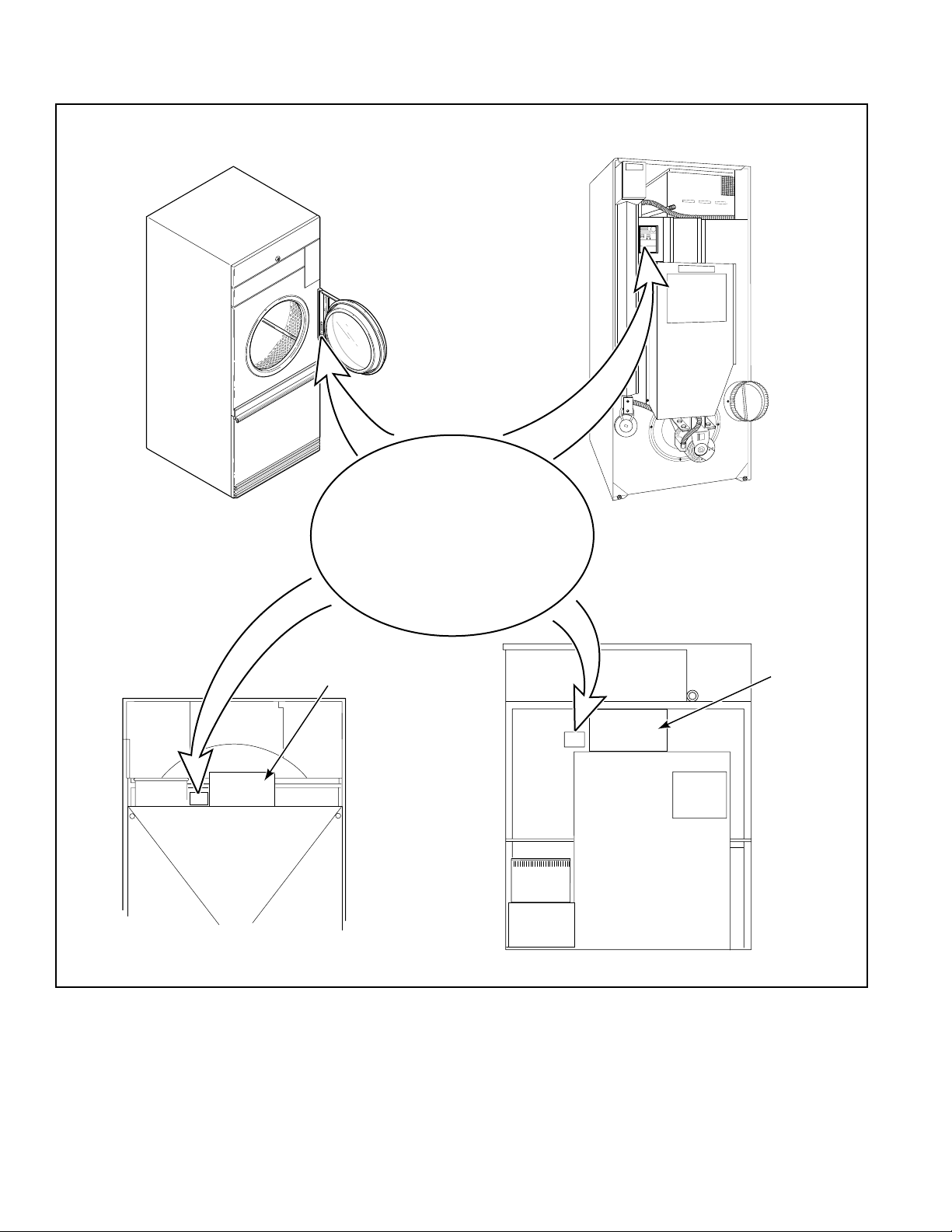

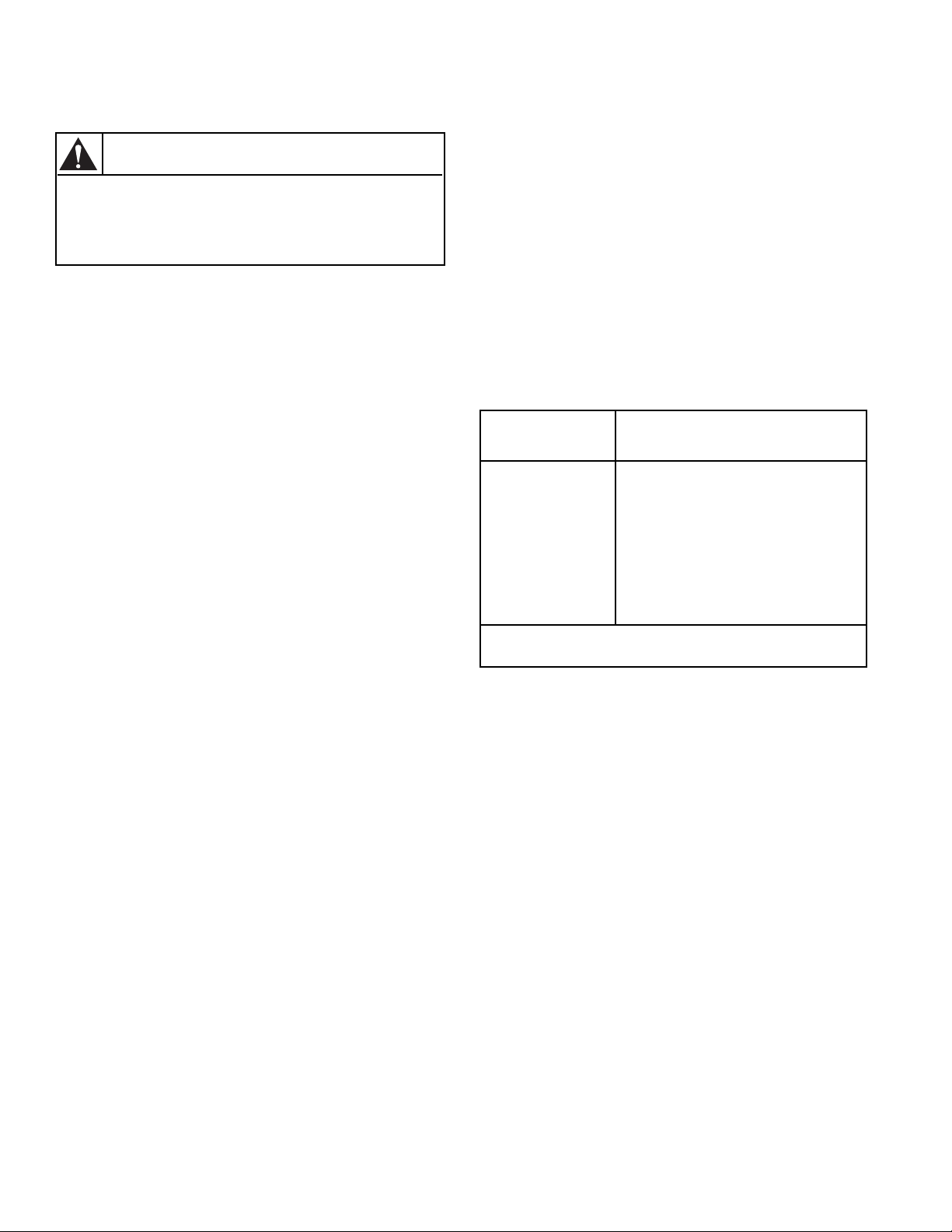

DRYING TUMBLER ENCLOSURE CONSTRUCTION

IMPORTANT: DO NOT block the air flow at the rear

of the tumbler with laundry or other articles. Doing

so would prevent adequate air supply to the

combustion chamber of the tumbler.

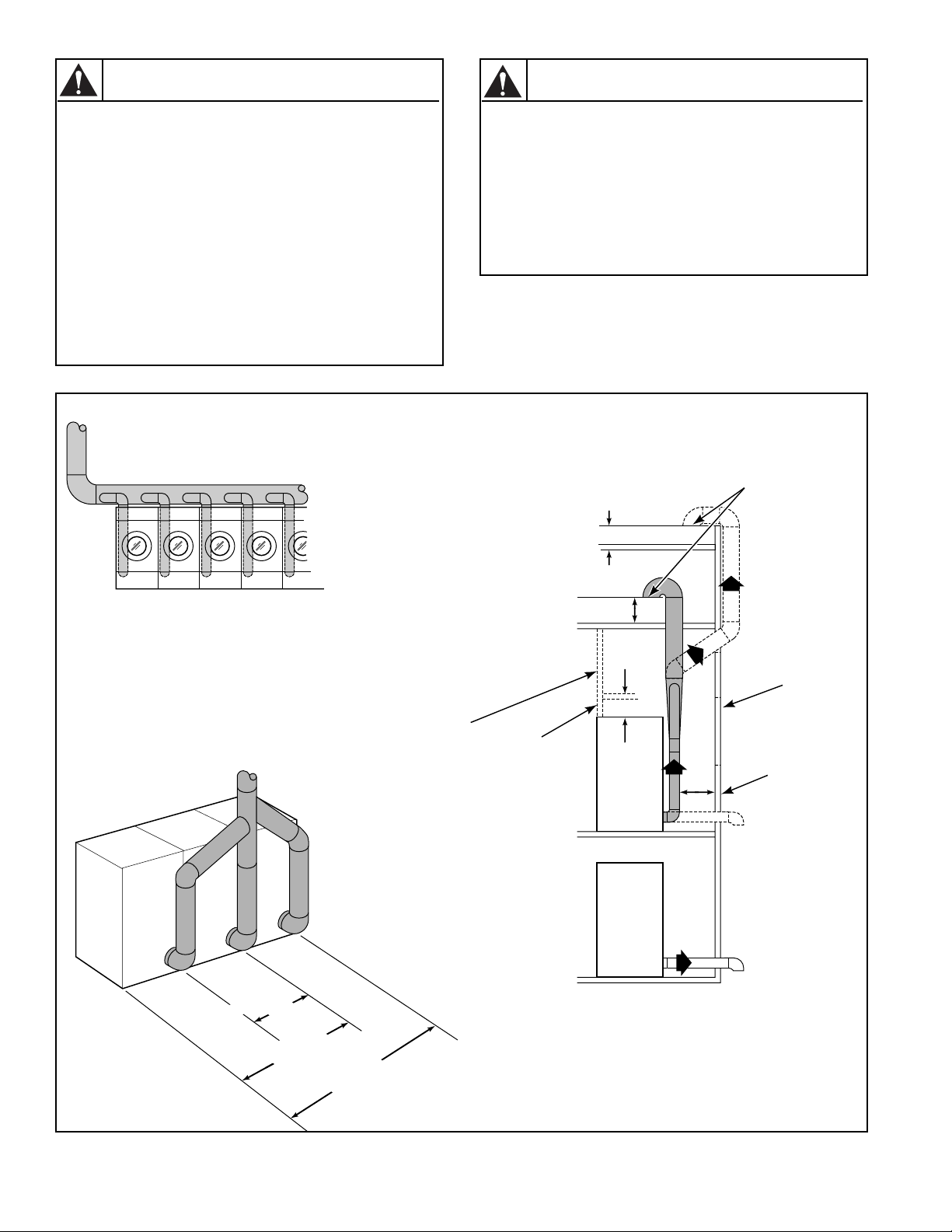

A typical tumbler enclosure is shown in Figure 2. Note

that the enclosure touches the tumbler top and side

T o reduce the risk of serious injury, install

lockable door(s) to prevent public access

to rear of tumblers.

panels. Also, note the minimum and maximum

dimensions. Be aware that there may be local codes and

ordinances which must be complied with.

IMPORTANT: Install tumblers with sufficient

clearance for servicing and operation, see Figure 2.

WARNING

To reduce the risk of severe injury, clearance of tumbler cabinet from combustible

construction must conform to the minimum clearances.

WARNING

W055

W056

12" (30.5 cm)

MINIMUM

CLEARANCE

PERMITTED

FOR REMAINDER

GUARD

PROVISION

MAKE-UP

T038IE3D

NOTE: Shaded areas

indicate adjacent

structure.

0" CLEARANCE PERMITTED

FOR FIRST 4" (10.16 cm)

0" CLEARANCE

4" (10.16 cm)

MAXIMUM

24" (61 cm) MINIMUM

36" (91.4 cm) RECOMMENDED

FOR MAINTENANCE PURPOSES

Minimum Recommended Clearances

Model Top

First 4" (10.2 cm)

Top

(Remainder)

Back Sides

All 30# (28") 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

FOR

AIR

All 30# (31.5") 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

All 50# 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

All 75# 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

Gas 120# 0" (0.0 cm) 4" (10.2 cm) 24" (61 cm) 0" (0 cm)

Steam 120# 0" (0.0 cm) 18" (45.7 cm) 24" (61 cm) 0" (0 cm)

Gas 170# 0" (0.0 cm) 4" (10.2 cm) 24" (61 cm) 0" (0 cm)

Steam 170# 0" (0.0 cm) 18" (45.7 cm) 24" (61 cm) 0" (0 cm)

Figure 2

M413620

25

Page 28

FACILITIES REQUIRED

To assure compliance, consult local building code

requirements.

WARNING

A drying tumbler produces combustible

lint. To reduce the risk of fire, the tumbler

must be exhausted to the outdoors.

W057

FLOOR

The drying tumbler must be installed on a level floor

capable of supporting 100 pounds per square fo ot (488.3

kg/sq. m) for 30, 50 and 75 pound tumblers. The floor

must be capable of supporting 120 pound s per square foot

(585.8 kg/sq. m) for 120 and 1 70 poun d tumblers. Floor

covering materials such as carpeting or tile should be

removed.

• Individual Venting

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to the

outdoors. At no point may the cross area of installed

venting be less than the cross area of the exhaust

thimble of the tumbler.

The maximum allowable length venting is 14 feet (4.3

m) and two 90° elbo ws o r equivalent. If the equivalent

length of a duct required for an installation exceeds the

maximum allowable equiv alent length, the diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 m). Cross section area of a

rectangular duct must be increased by 20% for each

addtional 20 feet (6.1 m). Table below shows how to

determine equiv a lent venting:

DUCT

DIAMETER

EQUIVALENT LENGTH OF

STRAIGHT DUCT

LAYOUT

Whenever possible, tumblers should be installed along an

outside wall where duct length can be kept to a minimum,

and make-up air can be easily accessed. Construction

must not block the airflow at the top rear of the tumbler.

Doing so would prevent adequate air supply to the

tumbler’s combustion chamber.

VENTING

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to the

outdoors by the shortest possible route.

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth, so the joints do not permit the accumulation of

lint. Do not use sheet metal screws to join vent sections.

Improperly sized or assembled ductwork causes excess

back pressure which results in slow drying, lint collecting

in the duct, lint blowing back into the room, and

increased fire hazard.

Exhaust ducts shall be constructed of sheet metal or

other noncombustible material. Such ducts must be

equivalent in strength and corrosion resistance to

ducts made of galvanized sheet steel not less than

0.0195 inches (0.495 mm) thick.

6" (15.2 cm)

8" (20.3 cm)

10" (25.40 cm)

12" (30.48 cm)

14" (35.56 cm)

16" (40.64 cm)

18" (45.72 cm)

Equivalent Length (feet) = 1.7 x Duct Diameter

(inches)

Example: A 12" diameter duct’s equivalent

length of 14 feet of duct and two 90° elbows is:

Equivalent Length = 14 feet + (2) 90° elbows

With the tumbler in operation, airflow at any point in

the duct must be at least 1200 feet per minute (366 m./

min.) to insure that the lint remains airborne.

One 90° elbow = 7 feet (2.1 m)

One 90° elbow = 9.3 feet (2.83 m)

One 90° elbow = 11.6 feet (3.5 m)

One 90° elbow = 14 feet (4.3 m)

One 90° elbow = 16 feet (4.9 m)

One 90° elbow = 18.7 feet (5.7 m)

One 90° elbow = 21 feet (6.4 m)

Table 1

= 14 feet + 14 feet + 14 feet

= 42 feet (12.8 m)

Where the exhaust duct pierces a combustible wall or

ceiling, an opening having a diameter of 4 inches (10.2

cm) larger than the diameter of the exhaust duct shall be

provided, with the duct centered in the opening. When

ducts pass through walls, ceilings, floors or partitions, the

space around the duct shall be sealed with noncombustible material. See Figures 3, 4 and 5.

26

M413620

Page 29

• Collector Venting

While it is preferable to exhaust tumblers individually

to the outdoors, a main collector duct may be used if it

is sized according to Figure 5. This illustration

indicates minimum diameters, and should be increased

if the collector length exceeds 20 feet (6.1 m). The

collector duct may be rectangular in cross section, as

long as the area is not reduced. Provisions should be

made for lint removal and cleaning of the collector

duct.

The collector duct must be tapered, as shown in Figur e

5. The individual tumbler ducts must enter the

collector duct at a 45° angle in the direction of air flow .

Never connect a tumbler duct at a 90° angle to the

collector duct. Doing so will cause excessive back

pressure, resulting in poor perf ormance. Never

connect two tumbler exhaust ducts directly across

from each other at the point of entry to the collector

duct.

The collector system must be designed so the static

back pressure measured 12 inches (30.5 cm) from the

exhaust thimble does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of the tumbler. This must be measured with

all tumblers running that are vented into the collector.

At a minimum, the National Fuel Gas Code requires

tumblers to have at least one square inch (6.5 sq. cm)

of opening for every 1000 BTU/hr. of input rating for

proper combustion.

Example: A tumbler with a rated input of 120,000

BTU/hr. requires 120 square inches of free

opening.

The additional opening recomended by the

manufacturer is required for optimum drying and

reliability.

Protective louvers in the opening to the outdoors can

reduce air movement by approximately 40 percent. The

opening must compensate for the area taken up by the

louvers.

The make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased sufficiently

to prevent downdrafts in any of the vents when all

tumblers are in operation. Do not locate gravity vented

appliances between tumbler(s) and make-up air

openings. If it is necessary to duct make-up air to the

tumbler(s), increase the area of the duct work by 25

percent to compensate for any restriction in air

movement.

MAKE-UP AIR

A tumbler is forced air exhausted and requires provisions

for make-up air to replace the air exhausted by the

tumbler.

IMPORTANT: Do not obstruct the flow of

combustion and ventilation air.

Recommended Make-Up Air Opening

(to the outside) for Each Tumbler

Model

30#

50#

75EG

75EG

634 250 (1613)

120#

170#

Opening

2

(cm2)

Inches

144 (928)

195 (1258)

300 (1936)

free air

395 (2548)

free air

M413620

27

Page 30

WARNING

WARNING

Solvent gases and vapors from dry

cleaning machines create acids when

drawn through the heater of a drying

tumbler. These acids are corrosive to the

drying tumbler as well as to the laundry

load being dried. Be sure make-up air is

free of solvent gases and vapors.

If the dry cleaning machines are in the

same area as the tumbler, then the

tumbler make-up air must come from a

source free of solvent gases and vapors.

W058

FOR BEST PERFORMANCE

provide an individual exhaust

duct for each drying tumbler.

Do not install a hot water heater

in room containing drying

tumblers. It is better to have

the water heater in a separate

room with a separate air inlet.

To reduce the risk of fire and

accumulation of combustible gases, DO

NOT exhaust tumbler air into a window

well, gas vent, chimney or enclosed,

unventilated area such as an attic wall,

ceiling, crawl space under a building, or

concealed space of a building.

W059

NOTE: Do not install wire

mesh or screen in this

opening as lint will build up

and prevent proper discharge

of air from drying tumblers.

ROOF 30" (76.2 cm)

T108IE3A

T075IE3A

REMOVABLE STRIP OF PANEL IN FRAMING WALL

TO PERMIT REMOVAL OF DRYING TUMBLER

FROM FRAMING WALL

ONE

DRYING

TUMBLER

TWO

DRYING

TUMBLERS

TUMBLERS

THREE

DRYING

ROOF 30" (76.2 cm)

PARTITION OR

BULKHEAD

CONSULT YOUR LOCAL BUILDING

CODE FOR REGULATIONS WHICH

MAY ALSO APPLY

NOTE: Inside of duct shall be

smooth. Do not use sheet

metal screws to join sections.

CEILING

WALL

36 INCHES

(91.4 cm)

RECOMMENDED

SERVICE AREA

24 INCHES

(61.0 cm)

MINIMUM

T108IE3B

28

Figure 3

M413620

Page 31

VERTICAL EXHAUST INSTALLATION

HORIZONTAL EXHAUST INSTALLATION

WALL

CONNECT TO

TUMBLER

2" (5.1 cm)

MINIMUM

WALL

2" (5.1 cm)

MINIMUM

WALL

CONNECT TO

TUMBLER

EXHAUST AIR FLOW

MAXIMUM LENGTH OF

DUCT 14 FEET

(4.3 m)

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

Figure 4

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

T030IE3B

2" (5.1 cm)

MINIMUM

EXHAUST

OUTLET

NO SCREEN

OR CAP

INSPECTION OR

CLEANOUT COVER

ALKJ I HGFEDCB

NO SCREEN

OR CAP

DUCT

STATION

A

B

C

D

E

F

G

H

I

J

K

L

45˚

AIR OUT

MINIMUM DIAMETER

30 LB. 28" WIDE

GAS & ELEC.

30, 50, 75 LB.

GAS & ELEC.

30, 50, 75 LB.

STEAM, DTB634

120 LB.

GAS & STEAM

170 LB.

GAS & STEAM

7" (17.8 cm) 10" (25.4 cm) 10" (25.4 cm) 10" (25.4 cm) 12" (30.5 cm)

10" (25.4 cm) 12" (30.5 cm) 14" (35.6 cm) 15" (38.1 cm) 17" (43.2 cm)

12" (30.5 cm) 15" (38.1 cm) 17" (43.2 cm) 18" (45.7 cm) 21" (53.3 cm

14" (35.6 cm) 17" (43.2 cm) 20" (50.8 cm) 21" (53.3 cm) 24" (60.1 cm)

16" (40.6 cm) 19" (48.3 cm) 22" (55.9 cm) 24" (61.0 cm) 27" (68.6 cm)

18" (45.7 cm) 21" (53.3 cm) 24" (61.0 cm) 26" (66.0 cm) 30" (76.2 cm)

19" (48.3 cm) 23" (58.4 cm) 26" (66.0 cm) 28" (71.1 cm) 32" (81.3 cm)

20" (50.8 cm) 25" (63.5 cm) 28" (71.1 cm) 30" (76.2 cm) 34" (86.4 cm)

22" (55.9 cm) 26" (66.0 cm) 30" (76.2 cm) 32" (81.3 cm) 36" (91.4 cm)

23" (58.4 cm) 27" (68.6 cm) 31" (78.0 cm) 33" (83.8 cm) 38" (96.5 cm)

24" (61.0 cm) 29" (73.9 cm) 33" (83.8 cm) 35" (88.9 cm) 40" (101.6 cm)

25" (63.5 cm) 30" (76.2 cm) 34" (86.4 cm) 36" (91.4 cm) 42" (106.7 cm)

Figure 5

T056IE3B

M413620

29

Page 32

GAS REQUIREMENTS

WARNING

To reduce the risk of fire or explosion, DO

NOT CONNECT THE GAS LINE TO THE

TUMBLER IF THE GAS SERVICE IS NOT

THE SAME AS THAT SPECIFIED ON THE

TUMBLER SERIAL PLATE! It will first be

necessary to convert the gas burner

orifice and gas valve. Appropriate

conversion kits are available.

W060

IMPORTANT: Any product re visions or conversions

must be made by the Manufacturer’s Authorized

Dealers, Distributors or local service personnel.

WARNING

The tumbler and its individual shut-off

valve must be disconnected from the gas

supply piping system during an y pressure

testing of that system at test pressures in

excess of 1/2 psig (3.45 kPa).

The size of gas service pipe is dependent upon many

variables (lengths, tees, etc.). Specific pipe size

information should be obtained from the ga s supplier.

Refer to Tables 2 and 3 for general pipe size.

A dirt and water vapor pipe trap must be furnished and

installed by customer, see Figure 6.

It is important that equal pressure be maintained at all

tumbler gas connections. This can best be done by

installing a one inch (2.54 cm) pipe gas loop as shown in

Figures 7, 9 and 11.

WARNING

To reduce the risk of fire or explosion, if

the tumbler is to be connected to

Liquefied Petroleum (L.P.) gas, a vent to

the outdoors must be provided in the

room where the tumbler is installed.

W062

The tumbler must be isolat ed fr om the gas

supply piping system by closing its

individual manual shut-off valve during

any pressure testing of the gas supply

piping system at test pressure equal to or

less than 1/2 psig (3.45 kPa).

IMPORTANT: The installation must comply with

local codes or, in the absence of local codes:

• with the latest edition of the “National Fuel

Gas Code”, ANSI Z223.1 in the U.S.A.

• with CAN1-B149.1 or CAN1-B149.2 in

Canada

• and Australian Gas Association/Australian

L.P. Gas Association requirements in Australia

W061

30

M413620

Page 33

FOR 30, 50 AND 75 POUND

TUMBLERS

WARNING

NATURAL GAS service must be supplied at 6-1/2 ±

1-1/2 inch water column pressure (1.62 ± .37 kPa).

L.P. GAS service must be supplied at 11 ± .3 inch water

column pressure (2.74 ± .07 kPa).

FOR 120 AND 170 POUND

TUMBLERS

NATURAL GAS service must be supplied at 7 ± 1 inch

water column pressure (1.74 ± .23 kPa).

L.P. GAS service must be supplied at 11 ± .3 inch water

column pressure (2.74 ± .07 kPa).

Pressure checks can be made at the shut-off valve, see

Figure 6.

Purge air and sediment from the gas service line before

connecting it loosely to the tumbler. Purge remaining air

until odor of gas is detected, then tighten connection. Use

pipe compound, resistant to actions of L.P. gas, on all

pipe threads.

Check all pipe connections, internal and

external, for gas leaks using a soapy

solution. To reduce the risk of explosion

or fire, DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS! Gas

connections should be checked annually

for leakage.

W063

GAS LINE

TO

DRYER

CONTROLS

SHUT-OFF

VALVE

1/8" (.32 cm) N.P.T. plugged

tapping accessible for

pressure testing. Gauge

connection located upstream

from dryer main manual

shut-off

GAS SUPPLY

PIPING SYSTEM

GAS

“T” FITTING

6 INCHES (15.2 cm)

MINIMUM GAS PIPE

DIRT AND

WATER VAPOR

TRAP

GAS

PIPE CAP

T135IE1A

Figure 6

M413620

31

Page 34

Example of Gas Loop Piping

For 30, 50, and 75 Pound Tumblers

IMPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

MAIN

REGULATOR

GAS

SHUT-OFF

VALVES

GAS SPACE HEATER

TUMBLERS

GAS LINE

PRESSURE TAP

GAS

METER

IMPORTANT: Line pressure must be maintained at 6-1/2 ± 1-1/2 water column inches (1.62 ± .37 kPa) for Natural Gas

(11 ± .3 water column inches [2.74 ± .07 kPa] for L.P. Gas) with all gas appliances running (tumblers, water heaters, space heaters,

furnace, etc.).

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches

(2.00 kPa) pressure with all gas appliances firing.

GAS WATER

HEATERS

PRESSURE

REGULATOR

(If required)

NOTE: Minimum pipe size to

tumbler is 1/2" (12.7 mm)

T034IE3D

ONE INCH

(2.54 cm)

PIPE

GAS LOOP

Figure 7

Example of Gas Supply Piping

For 30, 50, and 75 Pound Tumblers

NOTE: See BTU/HR. rating

on dryer nameplate.

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

GAS TUMBLER DRYERS

(75,000 BTU/HR. each)

123456789

FURNACE

(120,000 BTU/HR.)

MAIN

REGULATOR

GAS

GAS WATER

HEATERS

(400,000 BTU/HR. each)

GAS

METER

25' (7.6 m)

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m) gas supply pipe.

= 44' (13.4 m) Total Gas Liner

Using the table in

Table 2,

the main supply pipe diameter should be 2" (5.08 cm).

Figure 8

32

PRESSURE

REGULATOR

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 75,000

= 675,000 BTU/HR.

19' (5.8 m)

19' (5.8 m)

T035IE3E

M413620

Page 35

Example of Gas Loop Piping

For 120 Pound Tumblers

IMPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

MAIN

REGULATOR

GAS SPACE HEATER

TUMBLERS

GAS

SHUT-OFF

VALVES

GAS LINE

PRESSURE TAP

GAS

METER

IMPORTANT: Line pressure must be maintained at 7" ± 1" water column inches (1.74 ± .23 kPa) for Natural Gas (11 ± .3 water

column inches [2.74 ± .07 kPa] for L.P. Gas) with all gas appliances running (tumblers, water heaters, space heaters, furnace,

etc.).

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches

pressure with all gas appliances firing.

GAS WATER

HEATERS

PRESSURE

REGULATOR

(If required)

NOTE: Minimum pipe size to

tumbler is 3/4" (1.9 cm)

T034IE3E

Figure 9

Example of Gas Supply Piping

For 120 Pound Tumblers

NOTE: See BTU/HR. rating

on dryer serial plate.

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

GAS TUMBLER DRYERS

(300,000 BTU/HR. each)

123456789

FURNACE

(120,000 BTU/HR.)

MAIN

REGULATOR

GAS

GAS WATER

HEATERS

(400,000 BTU/HR. each)

GAS

METER

1" (2.5 cm)

PIPE

GAS LOOP

25' (7.6 m)

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m) gas supply pipe.

= 44' (13.4 m) Total Gas Line

Using the table in

Table 3,

the main supply pipe diameter should be 3" (7.6 cm).

Figure 10

M413620

PRESSURE

REGULATOR

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 300,000

= 2,700,000 BTU/HR.

19' (5.8 m)

19' (5.8 m)

T035IE3F

33

Page 36

Example of Gas Loop Piping

For 170 Pound Tumblers

MPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

GAS SPACE HEATER

MAIN

REGULATOR

GAS

METER

IMPORTANT: Line pressure must be maintained at 7" ± 1" water column inches (1.74 ± .23 kPa) for Natural Gas (11 ± .3 water

column inches [2.74 ± .07 kPa] for L.P. Gas) with all gas appliances running (tumblers, water heaters, space heaters, furnace,

etc.)

GAS WATER

HEATERS

PRESSURE

REGULATOR

(If required)

GAS

SHUT-OFF

VALVES

NOTE: Minimum pipe size to

tumbler is 1" (2.5 cm)

TUMBLERS

GAS

LINE

PRESSURE

TAP

1" (2.5 cm)

PIPE

GAS LOOP

T034IE3F

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches

pressure with all gas appliances firing.

Figure 11

Example of Gas Supply Piping

For 170 Pound Tumblers

GAS

FURNACE

(120,000 BTU/HR.)

GAS WATER

MAIN

REGULATOR

GAS

METER

HEATERS

(400,000 BTU/HR. each)

25' (7.6 m)

PRESSURE

REGULATOR

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

GAS TUMBLER DRYERS

(395,000 BTU/HR. each)

123456789

19' (5.8 m)

19' (5.8 m)

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m)

= 44' (13.4 m) Total Gas Line

Using the table in

Table 3,

the main supply pipe diameter should be 3-1/2" (8.9 cm).

Figure 12

34

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 395,000

= 3,555,000 BTU/HR.

T035IE3G

M413620

Page 37

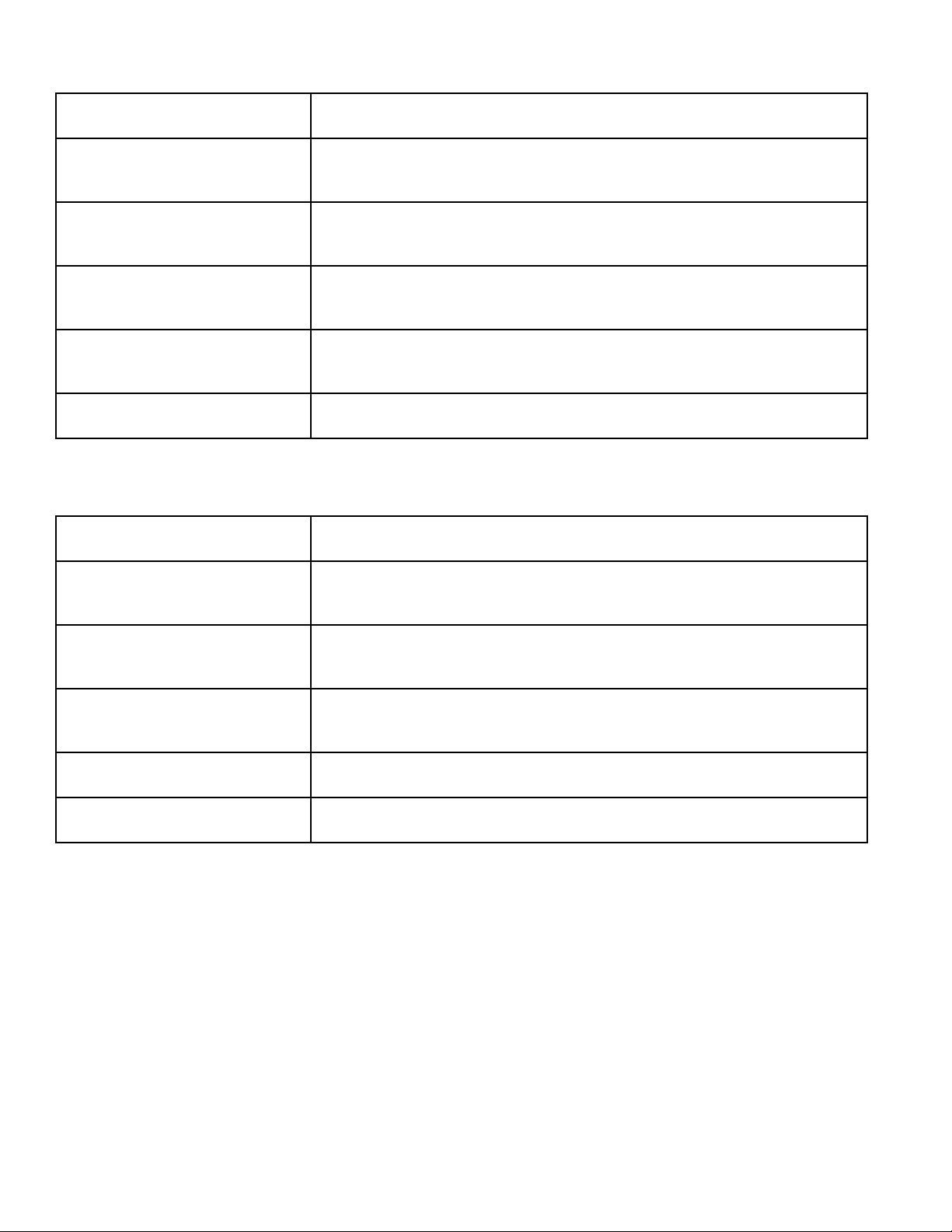

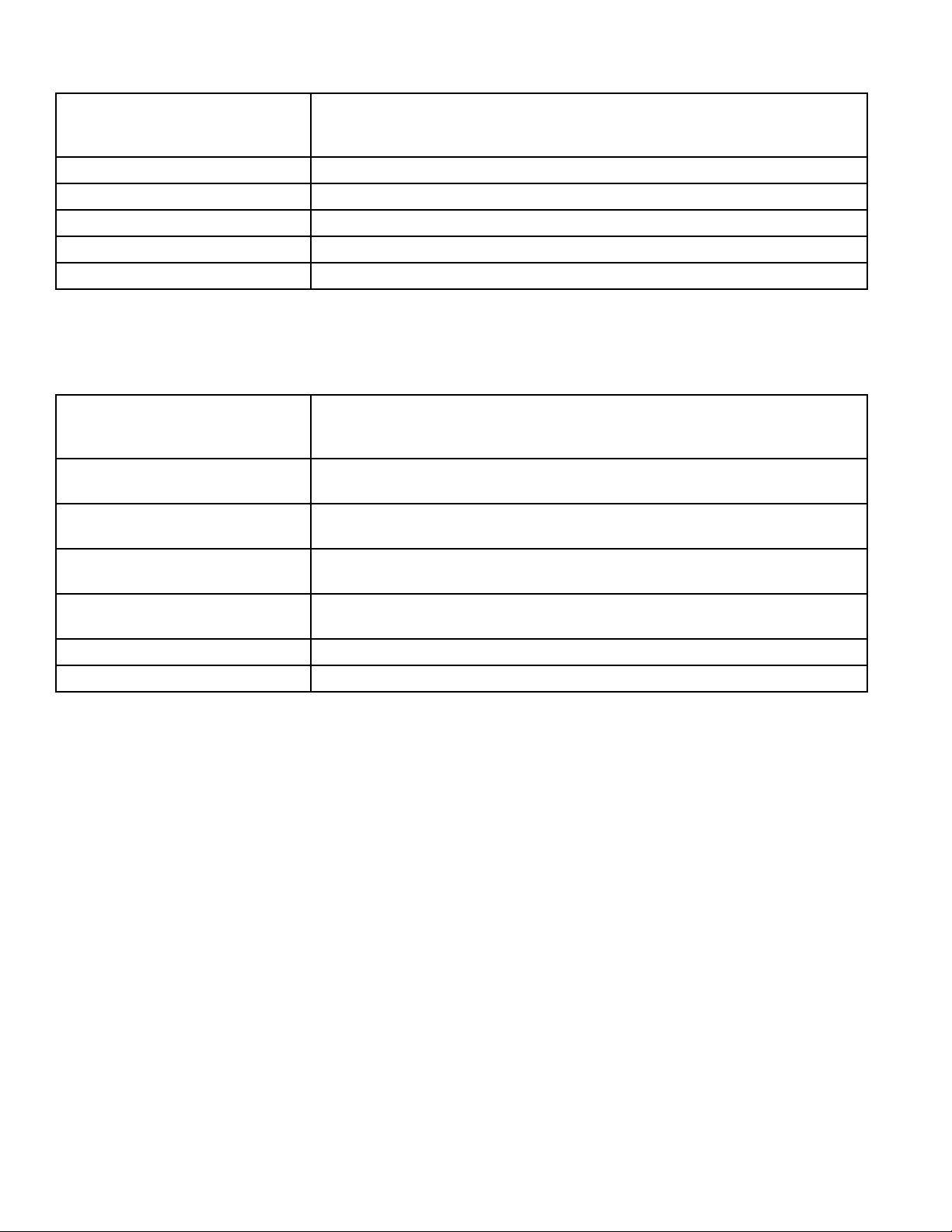

For 30, 50 and 75 Pound Tumblers

GAS PIPE SIZE REQUIRED FOR 1,000 BTU NATURAL GAS — .64 SPECIFIC GRAVITY

AT 6½ ± 1½ INCH (1.62 ± .37 kPa) WATER COLUMN PRESSURE

EQUIVALENT LENGTH

GAS

APPLIANCES

TOTAL

BTU/HR.

100,000

120,000

140,000

160,000

180,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

1,500,000

1,600,000

1,700,000

1,800,000

1,900,000

2,000,000

2,200,000

2,400,000

2,600,000

2,800,000

3,000,000

FOR L. P. GAS, CORRECT THE TOTAL BTU/HR. BY MULTIPLYING IT BY 0.6. THE ANSWER IS THE

EQUIVALENT BTU ON THE ABOVE CHART.

25 FT.

(7.63 m)

BASED ON 0.3" WATER COLUMN PRESSURE DROP FOR LENGTH GIVEN

¾" (19.05mm)

¾" (19.05mm)

¾" (19.05mm)

¾" (19.05mm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

50 FT.

(15.25 m)

¾" (19.05mm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

75 FT.

(22.88 m)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

100 FT.

(30.50 m)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

125 FT.

(38.13 m)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

4" (10.16cm)

150 FT.

(45.75 m)

1" (2.54cm)

1" (2.54cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

IMPORTANT: The installation must conform with local codes or, in the absence of local codes:

• with the latest edition of the “National Fuel Gas Code”, ANSI Z223.1 i n the U.S.A.,

• with CAN1-B149.1 or CAN1-B149.2 in Canada,

•

and Australian Gas Associa t ion / Australian LP Gas Association requirements in Australia

.

Table 2

M413620

35

Page 38

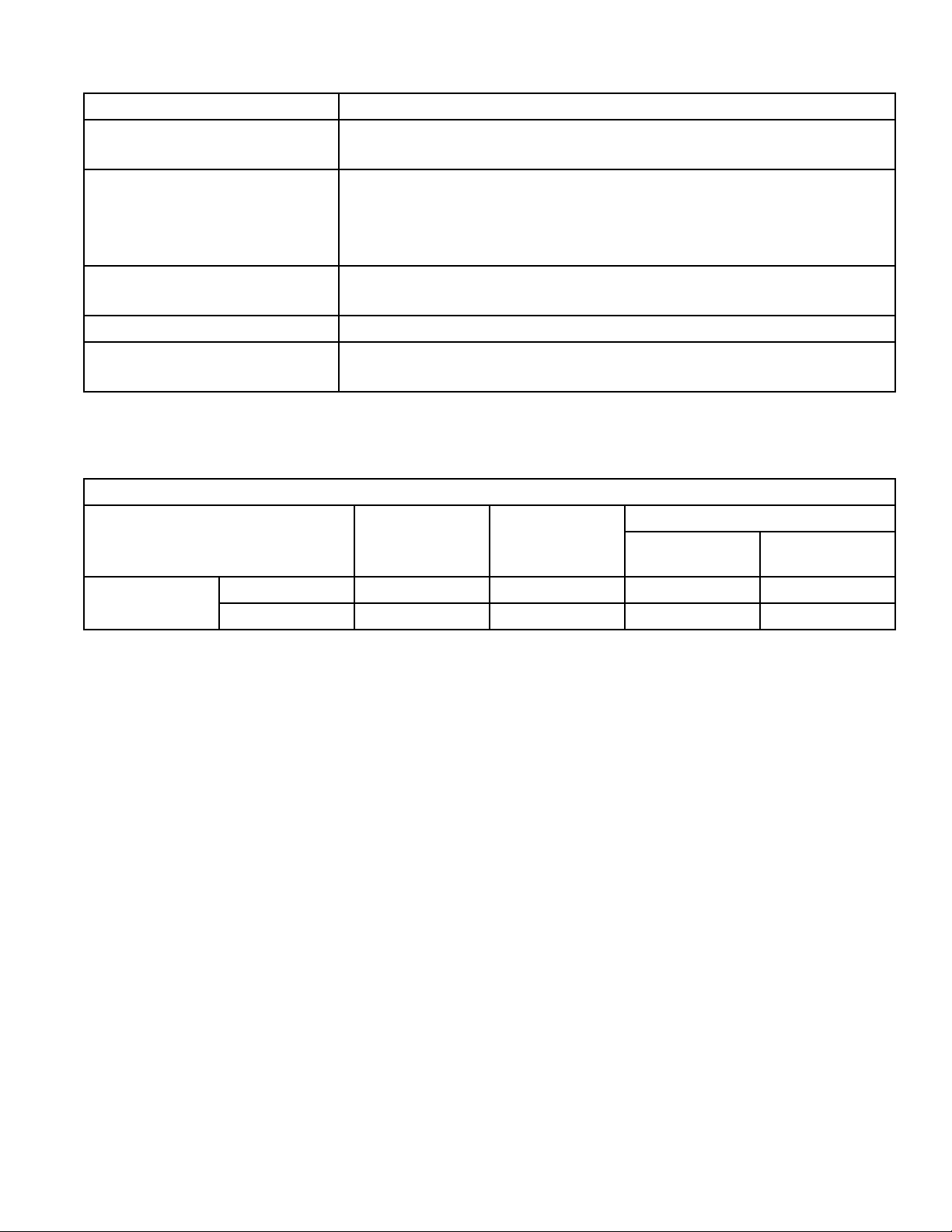

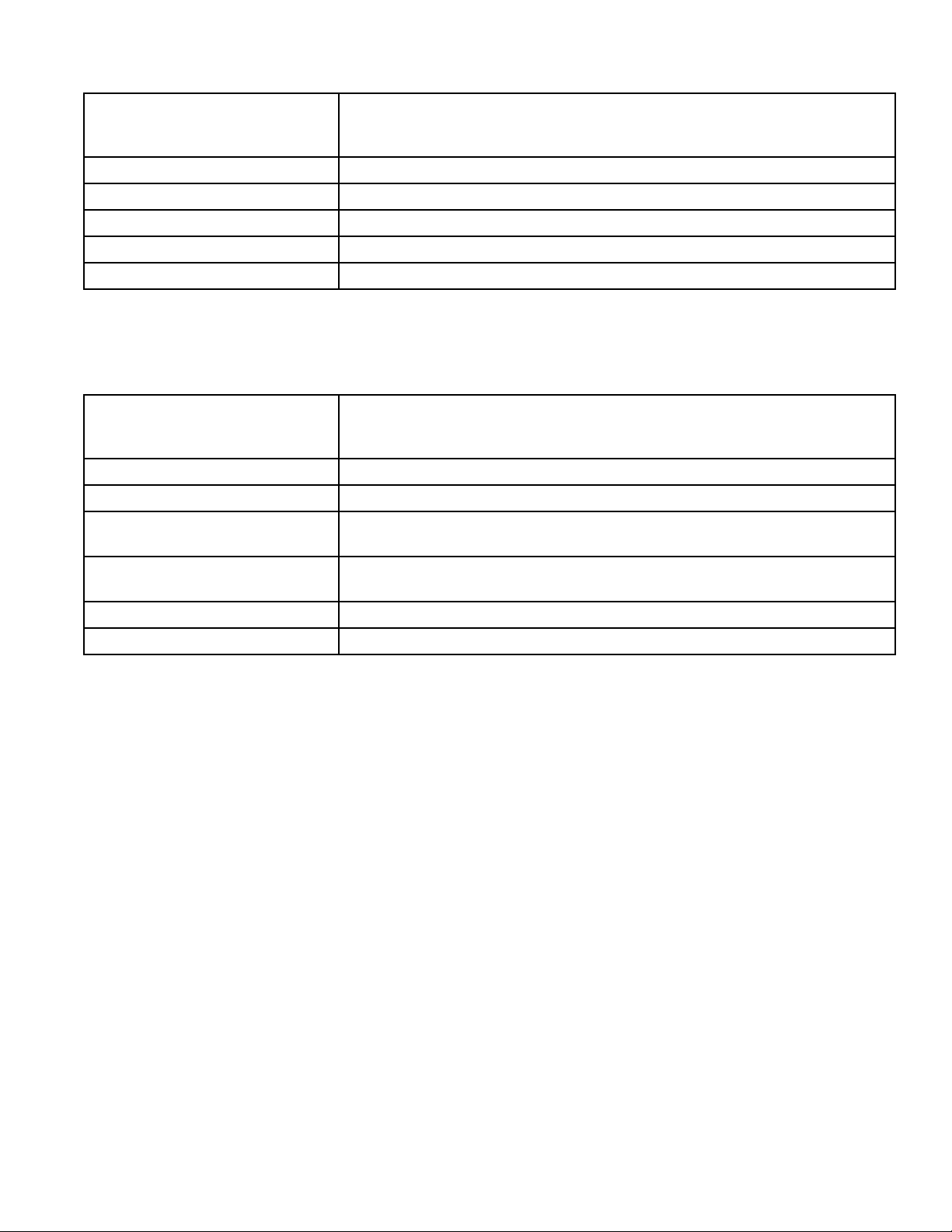

For 120 and 170 Pound Tumblers

GAS PIPE SIZE REQUIRED FOR 1,000 BTU NATURAL GAS — .64 SPECIFIC GRAVITY

AT 7 TO 9 INCH WATER COLUMN PRESSURE (1.74 to 2.241 kPa)

EQUIVALENT LENGTH

GAS

APPLIANCES

TOTAL

BTU/HR.

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

1,500,000

1,600,000

1,700,000

1,800,000

1,900,000

2,000,000

2,200,000

2,400,000

2,600,000

2,800,000

3,000,000

3,200,000

3,400,000

3,600,000

3,800,000

4,000,000

FOR L. P. GAS, CORRECT THE TOTAL BTU/HR. BY MULTIPLYING IT BY 0.6. THE ANSWER IS THE

EQUIVALENT BTU ON THE ABOVE CHART.

25 FT.

(7.63 m)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½” (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

50 FT.

(15.25 m)

BASED ON 0.3" WA TER COLUMN PRESSURE DROP FOR LENGTH GIVEN

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" 3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

75 FT.

(22.88 m)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

100 FT.

(30.50 m)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

4" (10.16cm)

4" (10.16cm)

125 FT.

(38.13 m)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

1½" (3.81cm)

1½" (3.81cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

4" (10.16cm)

150 FT.

(45.75 m)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

IMPORTANT: The installation must conform with local codes or, in the absence of local codes:

• with the latest edition of the “National Fuel Gas Code”, A NSI Z223.1 in the U.S.A.,

• with CAN1-B149.1 or CAN1-B149.2 in Canada,

• and Australian Gas Association / Australian LP Gas Associat ion requirements in Australia.

Table 3

36

M413620

Page 39

STEAM REQUIREMENTS (Steam Drying Tumblers)

The size of the steam service pipe is dependent upon

many variables (length, tees, high pressure system, low

pressure system, etc.). Specific pipe size information

should be obtained from the steam system supplier or a

qualified steam fitter.

1. Refer to F igur es 13, 14, and 15 for proper steam pipe

configurations.

2. To prevent condensate draining from headers to

tumbler, piping should ha v e a minimum 12 inch rise

(30.5 cm) above respective header. Do not make

steam connection to header with a horizontal or

downward facing tee or elbow.

3. Whenever possible, horizontal runs of steam lines

must drain, by gravity, to respective steam header.

Water pockets, or an improperly drained steam

header will provide wet steam, causing improper

operation of tumbler . If pockets or improper drainage

cannot be eliminated, install a by-pass trap to drain

condensate from the low point in the steam header to

the return.

4. In both steam supply and steam return line, it is

recommended that each have a pipe union and globe

valve. This will enable you to disconnect the steam

connections and service the tumbler while your plant

is in operation.

5. Before connecting trap and check valve to tumbler,

open shutoff valve in steam supply line and allow

steam to flow through tumbler to flush out any dirt

and scale from tumbler. This will assure proper

operation of trap when connected.

6. After flushing system, install vacuum breaker , bucket

trap (with built-in strainer) and check valve. For

successful operation of tumbler, install trap 18 inches

(45.7 cm) below coil and as near to the tumbler as

possible. Inspect trap carefully for inlet and outlet

markings and install according to trap manufacturer's

instructions. If steam is gravity returned to boiler,

omit trap but install vacuum breaker and check v alve

in return line near tumbler.

PIPING RECOMMENDATIONS

1. Trap each steam coil individually. Always keep the

trap clean and in good working condition.

2. When tumbler is on the end of a line of equipment,

extend header at least 4 feet (1.2 m) beyond tumbler.

Install shutoff v alve, union, check valve and by -pass

trap at end of line. If gravity return to boiler, omit

trap.

3. Insulate steam supply and return line for safety of

operator and safety while servicing tumbler.

4. Keep tumbler in good working condition. Repair or

replace any worn or defective parts.

NOTE: Steam heated tumbler models are not

certified by the American Gas Association or the

Canadian Gas Association.

WARNING

The flexible steam hoses connecting the

coil outlet connections and steam traps

must have a minimum of 172 psig (12.04

kg/cm2) (pounds per square inch gauge)

working pressure. A shutoff v alve m ust be

installed downstream from each steam

trap so the condensate return line can be

isolated in event a steam trap requires

maintenance.

W064

STEAM VALVE ELECTRICAL

CONNECTIONS

Refer to wiring diagram for steam valve electrical

connections in J-Box.

7. Install union and shutoff valve in return line and

make final pipe connections to return header.

M413620

37

Page 40

INSTALLING STEAM SOLENOID

VALVE AND MAKING STEAM INLET

CONNECTIONS

INSTALLING STEAM TRAP AND

MAKING CONDENSATE RETURN

CONNECTIONS

High pressure machines require a (constant) 80 to 100

psig (pounds per square inch gauge) (5.62 to 7.03 kg/s q.

cm) steam service for optimum operation. Low pressure

machines require a (constant) 10 to 15 psig (pounds per

square inch gauge) (.70 to 1.05 kg/sq. cm) steam service

for optimum operation. The following steps outline the

procedure for installing the steam solenoid valve and

connecting the steam service.

a. Install a manual shut-of f gate v alv e in the condensate

return line after the steam trap for each coil.

b. Connect the steam solenoid valve to the related steam

coil inlet connection with nipples, flex hoses, unions,

and tee. See Figures 13, 14, and 15 for typical

installations.

c. Install a gate shut-off valve in the steam supply line.

Connect the shut-off gate valve outlet to th e solenoid

steam valve inlet connection. See F igures 13, 14, and

15 for typical installations.

WARNING

The flexible steam hoses connecting the

solenoid steam valve to the coil inlets

must have a 125 psig (pounds per square

inch gauge) (8.79 kg/sq. cm) working

pressure. A shut-off gate valve must be

installed upstream from the solenoid

steam valve. This way, steam can be shut

off for maintenance purposes, or in the

event the hose ruptures.

The steam solenoid valve must be

supported so minimum load is exerted on

the steam coil inlet connections.

W065

The steam trap must be installed and the coil outlet

connections must be connected to the condensate return

lines. The following steps outline the procedure for

installing the steam trap and connecting the condensate

return lines. See Figures 13, 14, and 15 for typical

installations.

a. Connect a flexible hose to each steam coil outlet.

b. Install a strainer to the ends of each flexible hose.

c. Install a steam trap to each strainer.

IMPORTANT: Steam trap must be installed a

minimum of 10 inches (25.4 cm) below the steam coil

outlet connections.

d. Install a gate shut-off valve to each steam trap.

e. Connect to the condensate return lines.

WARNING

The flexible steam hoses connecting the

coil outlet connections and steam traps

must have a minim um of 125 psig (pounds

per square inch gauge) (8.79 kg/sq. cm.)

working pressure. A shutoff gate valve

must be installed downstream from each

steam trap so the condensate return line

can be isolated in event a steam trap

requires maintenance.

Each steam trap must be supported so

minimum load is exerted on the coil outlet

connection.

W066

38

M413620

Page 41

STEAM REQUIREMENTS

For 30, 50, and 75 Pound Steam DryingTumblers Only

NOTE: See Table 4 for sizing of steam

lines. Piping must also be sized

accordingly for length of runs, and

number of elbows.

SUPPLY

RETURN

12" (30.5 cm)

RISERS

UNION

CHECK

STEAM

BONNET

SOLENOID

VALVE

(Supplied with

machine)

VACUUM

BREAKER

CONDENSATE