Page 1

Drying Tumblers

75 Pound Capacity

634 Liter Capacity

Refer to Page 5 for Model Numbers

Service

www.comlaundry.com

T012C

T012c

Part No. M411433R1

October 2001

Page 2

Table of Contents

Section 1 – Safety Information

Locating An Authorized Service Person..................4

Section 2 – Introduction

Model Identification.................................................5

Customer Service.....................................................6

Serial Plate Location................................................6

Safety Warnings and Decals....................................7

Safety Precautions for Servicing Tumblers .............7

How A Tumbler Works ...........................................8

Section 3 – Troubleshooting

1. Motor Does Not Start......................................11

2. Motor Overload Protector Cycles Repeatedly12

3. Motor Runs But Cylinder Does Not Turn.......12

4. Motor Does Not Stop......................................12

5. Heating Element Does Not Heat

Or Burner Does Not Ignite..............................13

6. Igniter Glows, Flame Sensor Opens But No

Ignition - Gas Models .....................................15

7. Burner Ignites And Goes Out Repeatedly

- Gas Models...................................................15

8. Heating Element Or Burner Shuts-off

Prematurely.....................................................16

9. Heating Element Or Burner Repeatedly

Cycles Off On High Limit Thermostat...........16

10. Heating Element Or Burner

Does Not Shut-off ..........................................17

11. Clothes Do Not Dry ........................................17

12. Tumbler Overheating......................................17

13. Burners Not Burning Properly - Gas Models .18

14. Cylinder Door Opens During Operation.........18

15. Tumbler Runs But No Steam To Coils

- Steam Models ...............................................18

16. Water In Steam Line - Steam Models.............19

17. Troubleshooting Electronic Control Models ..19

18. Tumbler Will Not Start, Time On Drying Timer,

Door Closed (Manual Timer Models).............20

19. Motor Runs, Time On Drying Timer But No

Heat .................................................................21

20. Igniter Does Not Glow....................................22

21. Igniter Glows Constantly................................22

22. Igniter Glows, Cycles Off But Burner Does Not

Ignite ...............................................................22

23. Igniter Does Not Spark ...................................23

Section 4 – Grounding

Grounding Instructions ..........................................25

Section 5 – Service Procedures

24. Control Panel ..................................................27

25. Push-to-Start Switch .......................................27

26. Cooling, Drying, or Run Light........................27

27. Relay (Manual Timers Models)......................29

28. Resistor 208 or 240 Volt/60 Hertz..................29

29. Cooling or Drying Timer................................29

30. Cooling or Drying Timer Motor.....................30

31. Coin Meter ......................................................31

32. Coin Meter Timer Motor ................................32

33. Coin Meter Run or Heat Switch .....................32

34. Electronic Control (MM Models) ...................33

35. Reversing/nonreversing Switch ......................33

36. Battery (MM Model) ......................................33

37. Control Thermostat.........................................35

38. Thermistor.......................................................37

39. Gas Valve........................................................38

40. Diode Logic Board..........................................38

41. Main Coil ........................................................38

42. Igniter Bracket ................................................38

43. Sensor..............................................................40

44. Igniter..............................................................40

45. Ignition Control...............................................40

46. Gas Valve........................................................40

47. Main Coil ........................................................41

48. Burner Tube ....................................................41

49. Contactors And Terminal Block.....................41

50. Heater Element ...............................................42

51. Stove High Limit Thermostat .........................44

52. Cabinet High Limit Thermostat......................45

53. High Limit Thermostat ...................................46

54. Steam Coils.....................................................46

55. Loading Door Assembly.................................47

56. Loading Door Hinge.......................................47

57. Loading Door Handle .....................................48

58. Front Panel......................................................49

59. Loading Door Switch......................................50

60. Loading Door Switch Rod..............................50

61. Airflow Switch Assembly...............................51

62. Wire-Way Cover.............................................51

63. Drive Guard ....................................................52

© Copyright 2001, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

M411433 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 3

64. Drive Belt........................................................52

65. Drive Chain.....................................................53

66. Idler Housing Assembly .................................53

67. Idler Sprocket..................................................56

68. Sheave.............................................................56

69. Drive Sprocket/Pulley.....................................56

70. Idler Shaft........................................................56

71. Cylinder Sprocket/Upper Sheave....................57

72. Cylinder Assembly..........................................57

73. Trunnion Housing Assembly..........................58

74. Trunnion Shaft Assembly ...............................59

75. Motor And Fan Assembly...............................60

76. Cylinder Drive Motor .....................................62

77. Reversing Control Electrical Components......64

Section 6 – Adjustments

78. Leveling Legs..................................................67

79. Main Gas Burner Air Inlet Shutters................68

80. Airflow Switch................................................69

81. Loading Door Switch......................................71

82. Loading Door Strike .......................................72

83. Drive Belt Tension..........................................72

84. Drive Tension..................................................75

85. Cylinder Clearance..........................................76

2 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

Section 1

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION”,

“WARNING”, and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer, and those maintaining the machine.

a DANGER

Danger indicates the presence of a hazard that will cause severe personal injury, death, or substantial property

damage if the danger is ignored.

a WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death, or substantial property

damage if the warning is ignored.

a CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

WARNING

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and that you understand and have the

skills to carry out.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R1

M411433 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1 Safety Information

IMPORTANT INFORMATION: During the lifetime of your tumbler, it may require service. The information

contained in this manual was written and is intended for use by qualified service technicians who are familiar

with the safety procedures required in the repair of your tumbler, and who are equipped with the proper tools

and testing equipment.

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W240

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you, or the inexperienced person making such

repairs, to the risk of serious injury, electrical shock or death.

W007

CAUTION

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution and

carefulness are factors which CANNOT be built into this tumbler. These factors MUST BE supplied by the

person(s) installing, maintaining or operating the tumbler.

Always contact your dealer, distributor, service agent or the manufacturer on any problems or conditions you do not

understand.

Locating An Authorized Service Person

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service

is required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

:

W008

4 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Section 2

Introduction

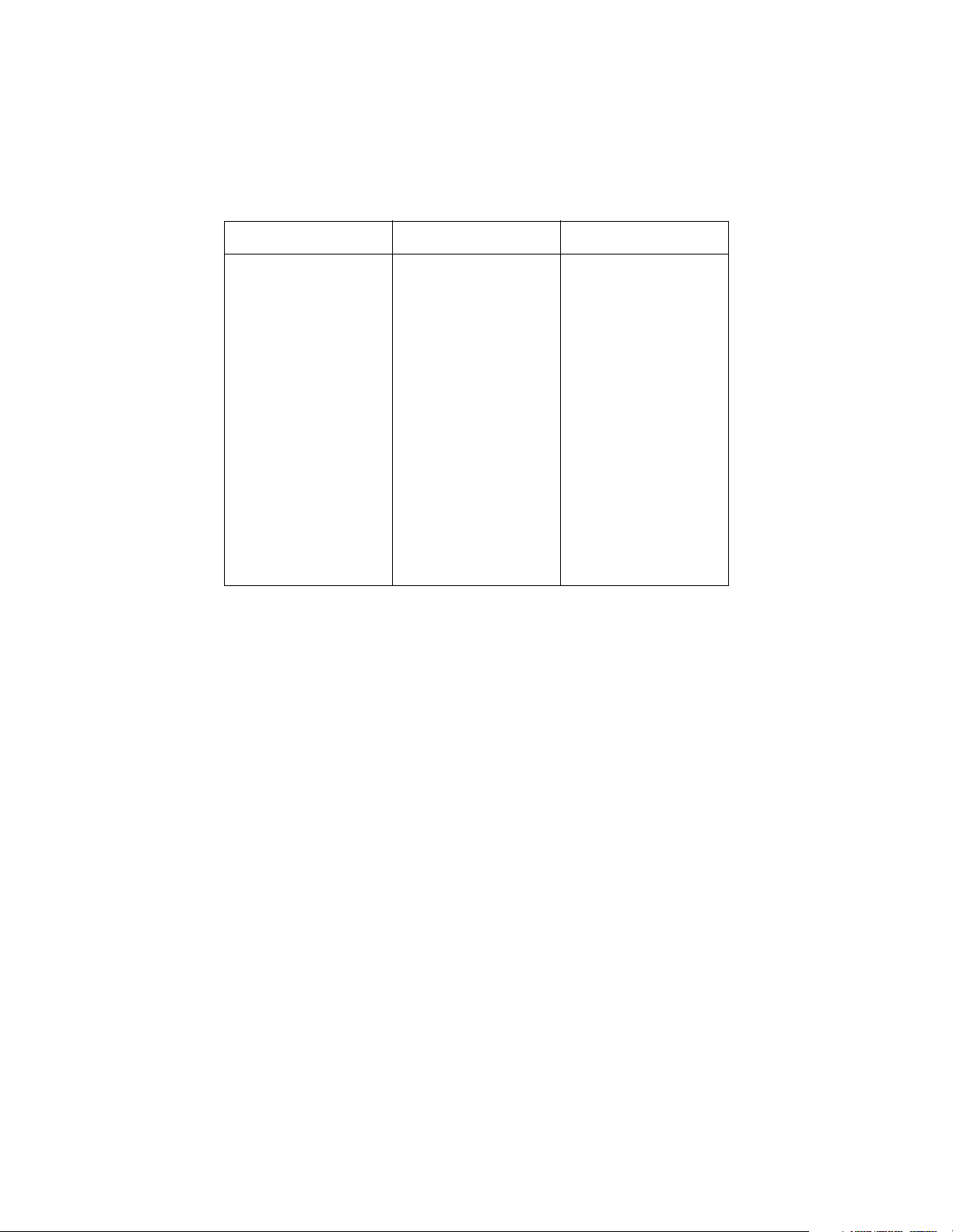

Model Identification

Information in this manual is applicable to these models:

Gas Steam Electric

AT B7 5C G

DCB75CG

DCB75FG

DTB634

DTB75CG

DTB75EG

DTB75FG

JCB75CG

JT75CG

JT75EG

JTB75CG

JTB75EG

SCB75CG

ST75CG

STB75CG

STB75EG

STB634

AT B7 5C S H

DCB75CSH

DCB75CSL

DTB75CSH

DTB75CSL

JCB75CSH

JCB75CSL

JT75CSH

JT75CSL

JTB75CSH

JTB75CSL

SCB75CSH

SCB75CSL

ST75CSH

ST75CSL

STB75CSH

STB75CSL

DCB75CE

DTB75CE

JCB75CE

JT75CE

JTB75CE

SCB75CE

ST75CE

STB75CE

M411433 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

Section 2 Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

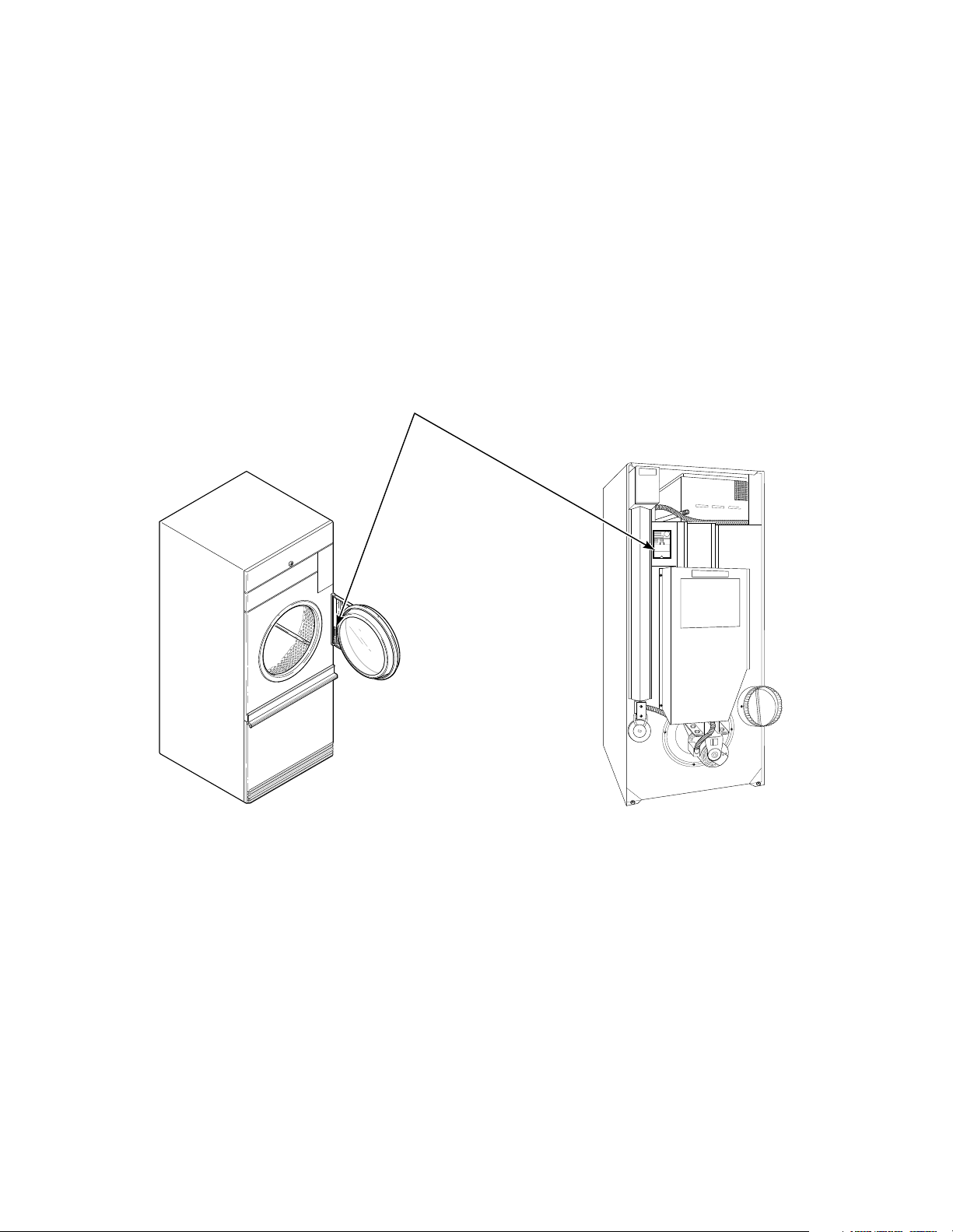

Serial Plate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on serial plate(s) as shown.

T419IE3B

6 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Safety Warnings and Decals

SAFETY WARNINGS and decals have been provided

in key locations to remind you of important precautions

for the safe operation and maintenance of your tumbler.

Please take the time to review these warnings before

proceeding with service work.

All decals have been designed and applied to withstand

washing and cleaning. Decals should be checked

periodically to be sure they have not been damaged,

removed, or painted. Refer to Parts Manual for

ordering replacement decals.

Safety Precautions for Servicing Tumblers

• Disconnect electrical service.

• Shut off supply gas valve before servicing gas

components.

Section 2 Introduction

• Control panel and access panel MUST be

reinstalled after inspection or servicing of

tumbler is completed.

• Use a non-corrosive leak detection solution to

check all pipe connections for gas leaks. DO NOT

USE AN OPEN FLAME TO CHECK FOR GAS

LEAKS!

• Chain/Drive guard MUST be reinstalled after

inspection or servicing of tumbler is completed.

• Belt guard MUST be reinstalled after inspection

or servicing of tumbler is completed.

• Contactor box cover MUST be reinstalled after

inspection or servicing of electric and/or reversing

tumbler is completed.

• Loading door switch MUST be operational before

putting tumbler into service.

• Junction box cover MUST be reinstalled after

inspection or servicing of tumbler is completed.

M411433 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

Section 2 Introduction

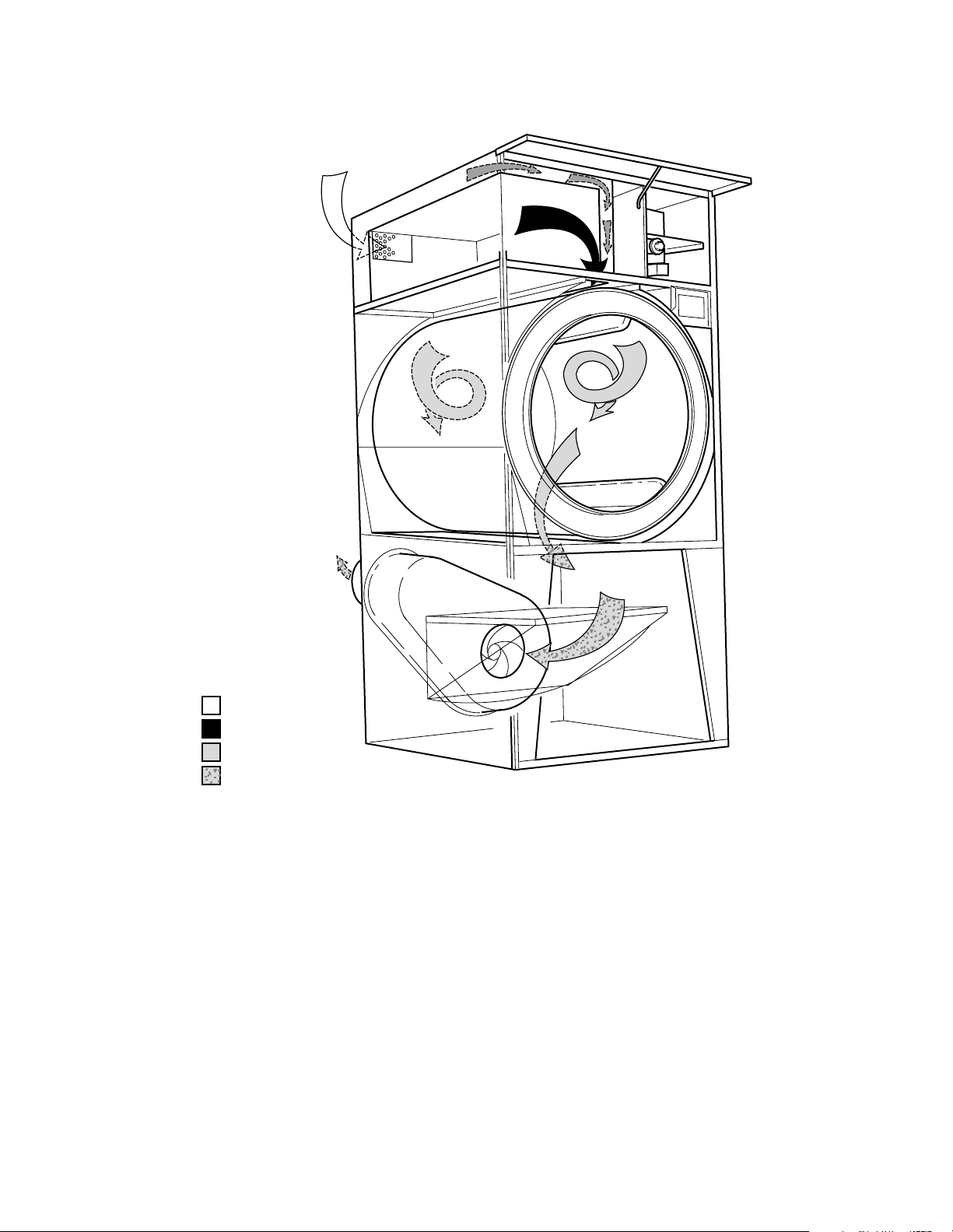

How A Tumbler Works

Fresh Air

Combustion Air

Mixed Air

T008CE1A

Exhaust Air

Standard Models

The tumbler uses heat, air and movement to dry loads of laundry.

When the motor is started, the exhaust fan pulls air in through the air intake and over the heat source

(burner flame for gas, heating element for electric, and coil for steam).

The heated air moves into the cylinder, where it is circulated through the laundry by the tumbling action

of the cylinder.

The air then passes through the lint filter, exhaust fan, and is vented to the outdoors.

NOTE: In Energy Saver Models, some of the exhaust air is recirculated. Refer to illustration on page 9.

8 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

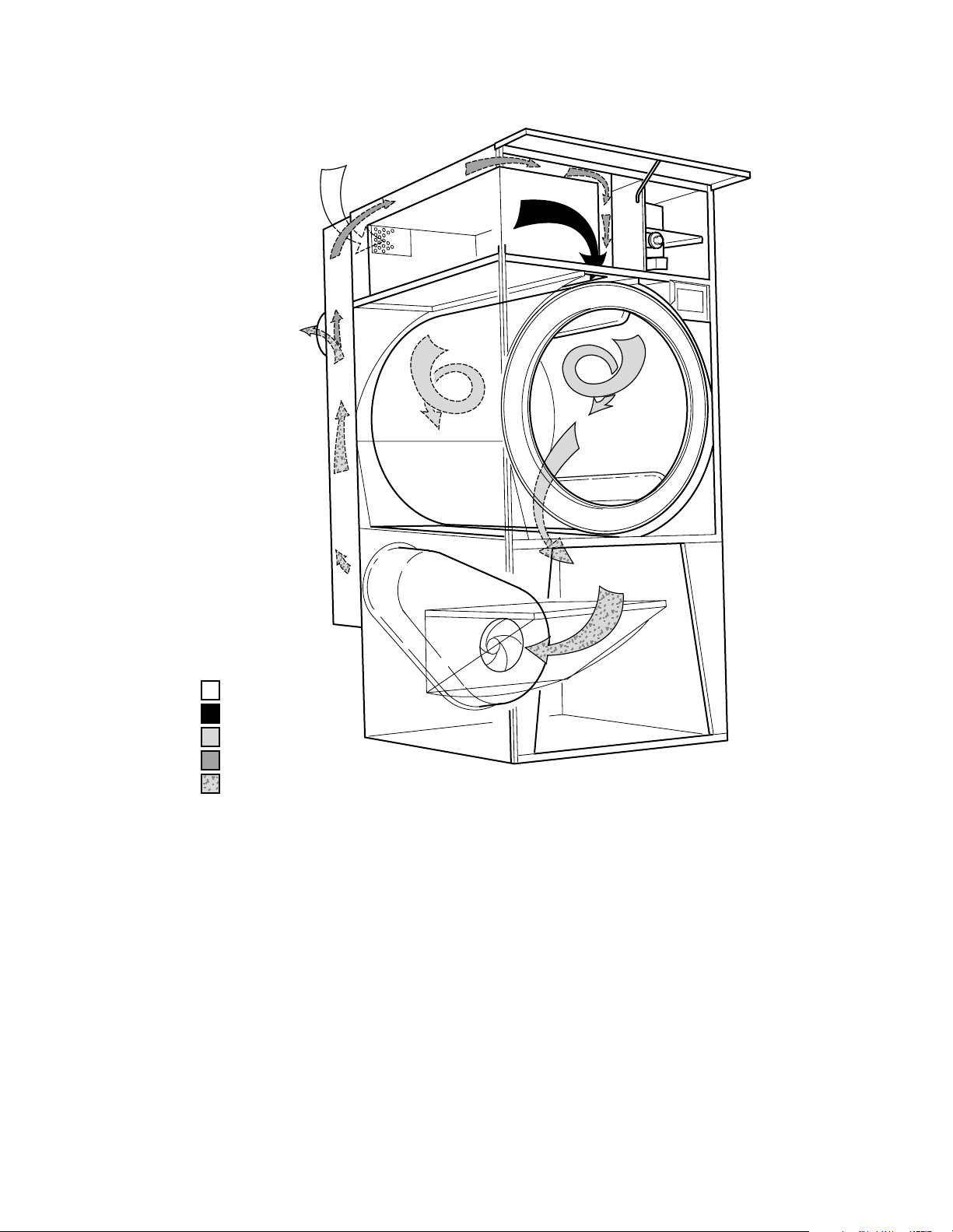

Section 2 Introduction

Fresh Air

Combustion Air

Mixed Air

Recirculating Air

Exhaust Air

T007CE1A

Energy Saver Models

M411433 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

Section 3

Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

IMPORTANT: Refer to appropriate wiring diagram for aid in testing tumbler components.

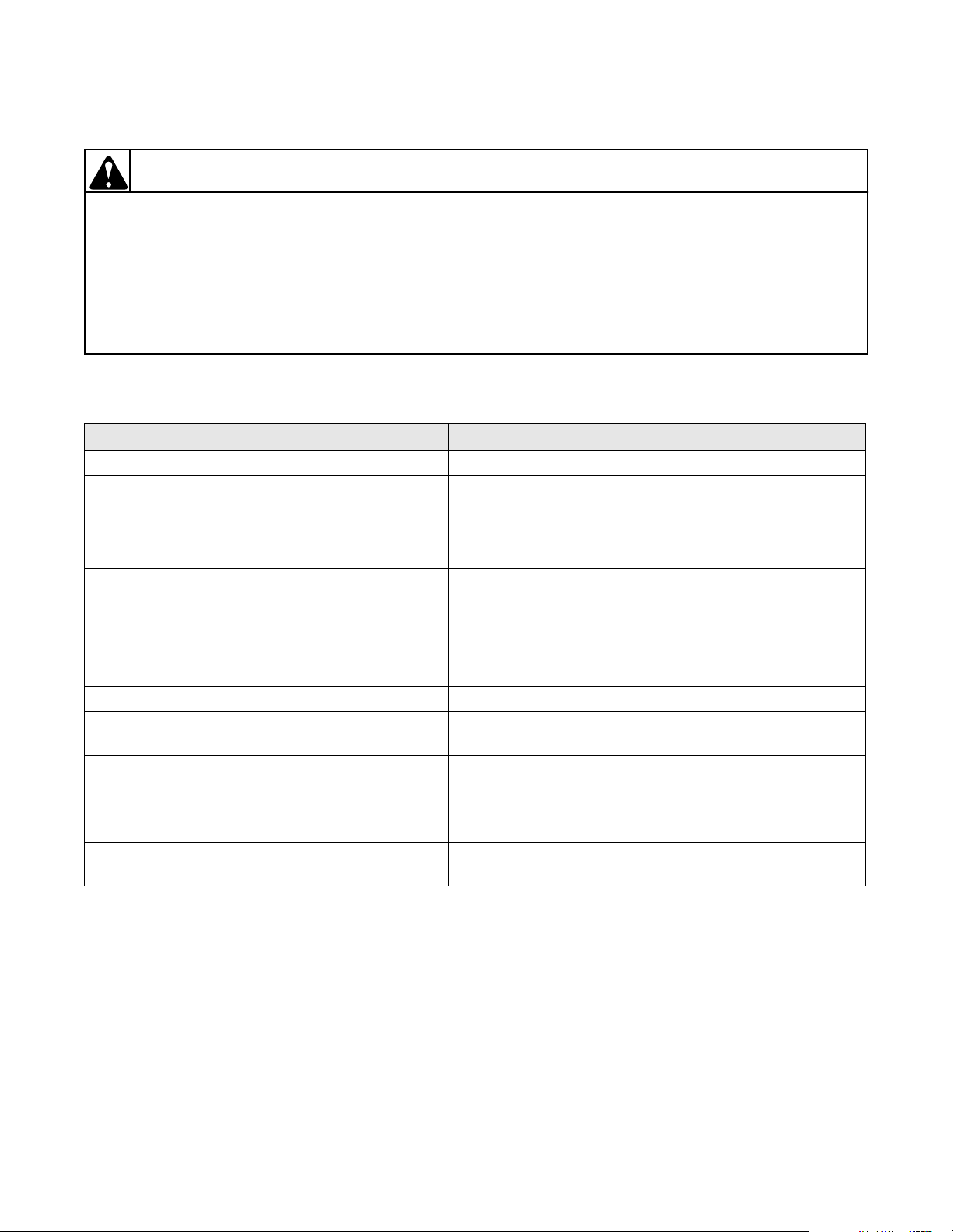

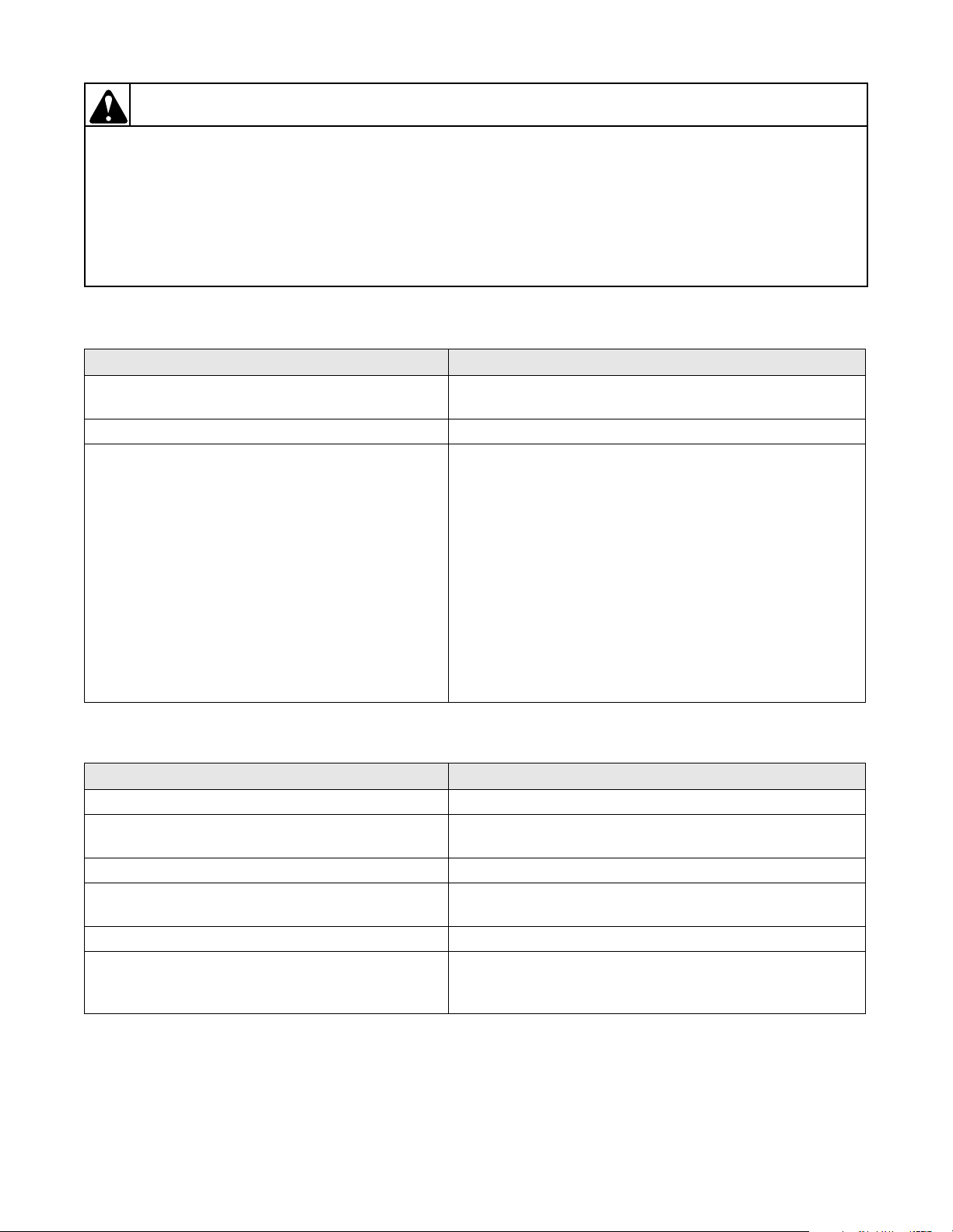

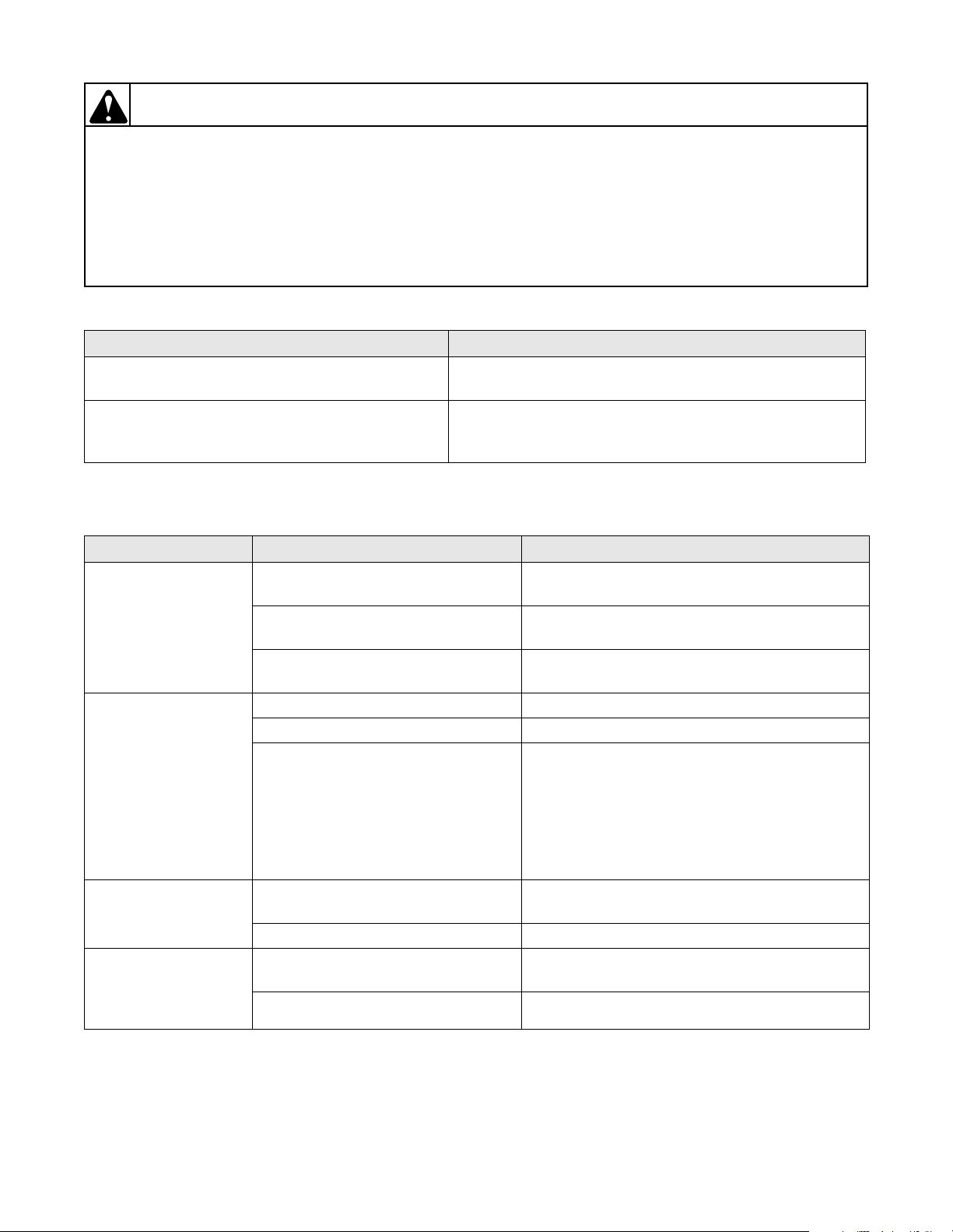

1. MOTOR DOES NOT START

POSSIBLE CAUSE TO CORRECT

Electrical power off or fuses blown. • Check power and fuses, replace fuses if necessary

Loading door not closed or inoperative door switch. • Close door, or test switch and replace if inoperative.

Door switch improperly adjusted. • Refer to Adjustment Section for door switch adjustment.

Trunnion shaft assembly binding in

trunnion housing bearings.

Start circuit not completed. • Press start switch, or test switch and replace if

Idler shaft binding in idler housing bearings. • Replace bearings.

Inoperative motor. • Have motor tested and replace if inoperative.

Non-Metered Models: Timer improperly set. • Turn drying timer clockwise to desired setting.

Non-Metered Models: Inoperative timer. • Test timer and replace if inoperative.

Metered Models: Improper coins inserted in

accumulator.

Metered Models: Accumulator knob improperly

set after coins were inserted.

Metered Models: Inoperative run switch

(accumulator).

Broken, loose, or incorrect wiring. • Refer to wiring diagram located on back of tumbler or in

• Replace trunnion housing bearings.

inoperative.

• Check that proper coins are inserted.

• Turn knob clockwise to its full limit of travel.

• Test run switch and replace if inoperative.

literature packet.

W002

M411433 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

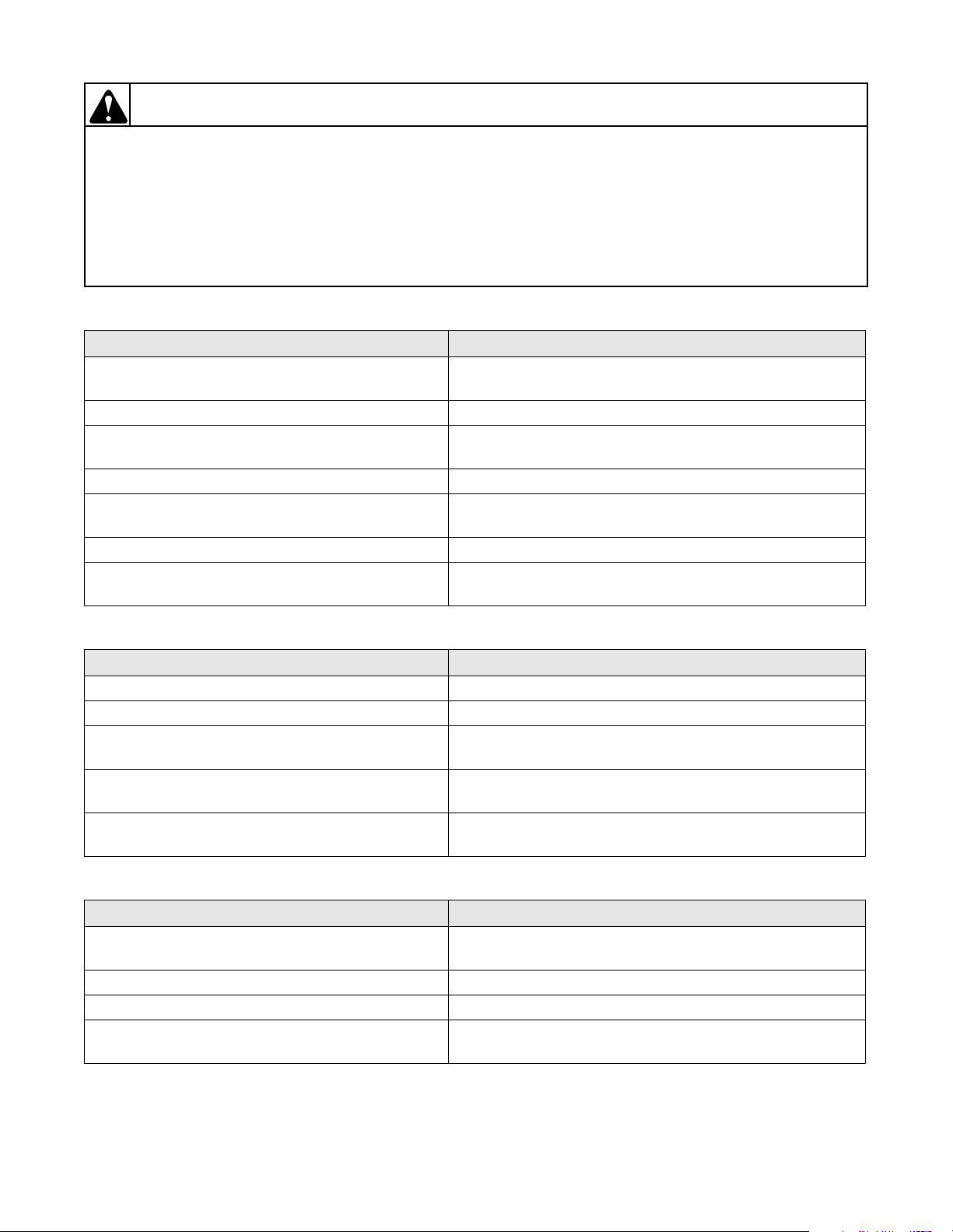

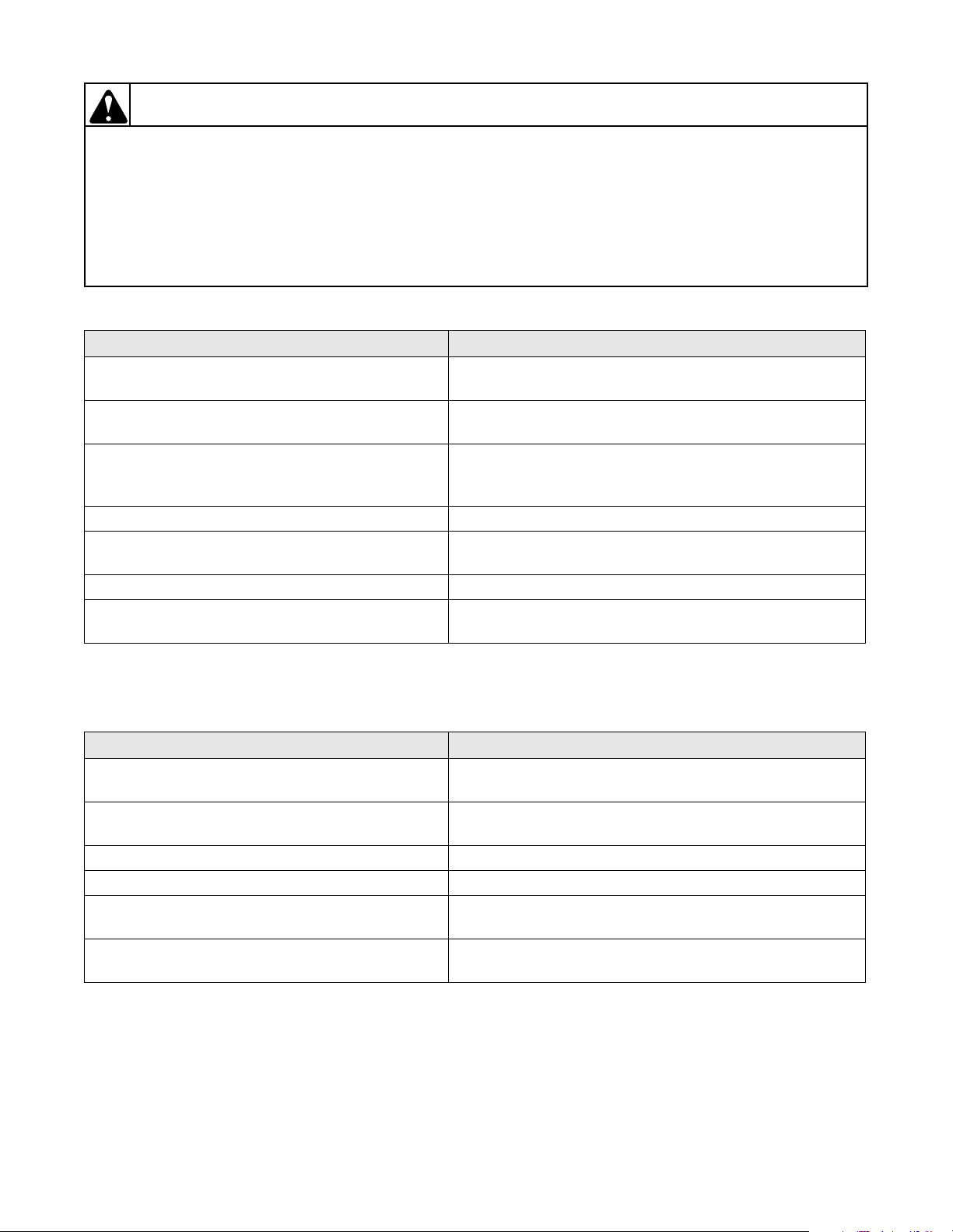

2. MOTOR OVERLOAD PROTECTOR CYCLES REPEATEDLY

POSSIBLE CAUSE TO CORRECT

Incorrect voltage. • Refer to the Installation Manual (supplied with tumbler)

for electrical requirements.

Clothes load too large. • Remove part of load.

Cylinder is binding. • Check cylinder for binding. Refer to Adjustment Section

for cylinder adjustment.

Inadequate wiring. • Check with electrician to ensure that wiring is adequate.

Inadequate make-up air. • Refer to Installation Manual (supplied with tumbler) for

make-up air requirements.

Poor housekeeping. • Clean lint accumulation on and around the motor.

Broken, loose, or incorrect wiring. • Refer to wiring diagram located on back of tumbler or in

literature packet.

W002

3. MOTOR RUNS BUT CYLINDER DOES NOT TURN

POSSIBLE CAUSE TO CORRECT

Motor drive pulley loose. • Tighten setscrews.

Sheave loose. • Tighten setscrews.

Broken or loose belt. • Replace or adjust belt. Refer to Adjustment Section for

proper belt adjustment.

Broken or loose drive chain. • Replace or adjust chain. Refer to Adjustment Section for

proper chain adjustment.

Cylinder is binding. • Check cylinder for binding. Refer to Adjustment Section

for proper cylinder adjustment.

4. MOTOR DOES NOT STOP

POSSIBLE CAUSE TO CORRECT

Inoperative door switch or switch is out-ofadjustment.

• Test switch and replace if inoperative. Refer to

Adjustment Section for proper switch adjustment.

Non-Metered Models: Inoperative timer. • Test timer and replace if inoperative.

Metered Models: Inoperative accumulator. • Test accumulator and replace if inoperative.

Incorrect wiring. • Refer to wiring diagram located on the back of tumbler or

in literature packet.

12 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 13

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

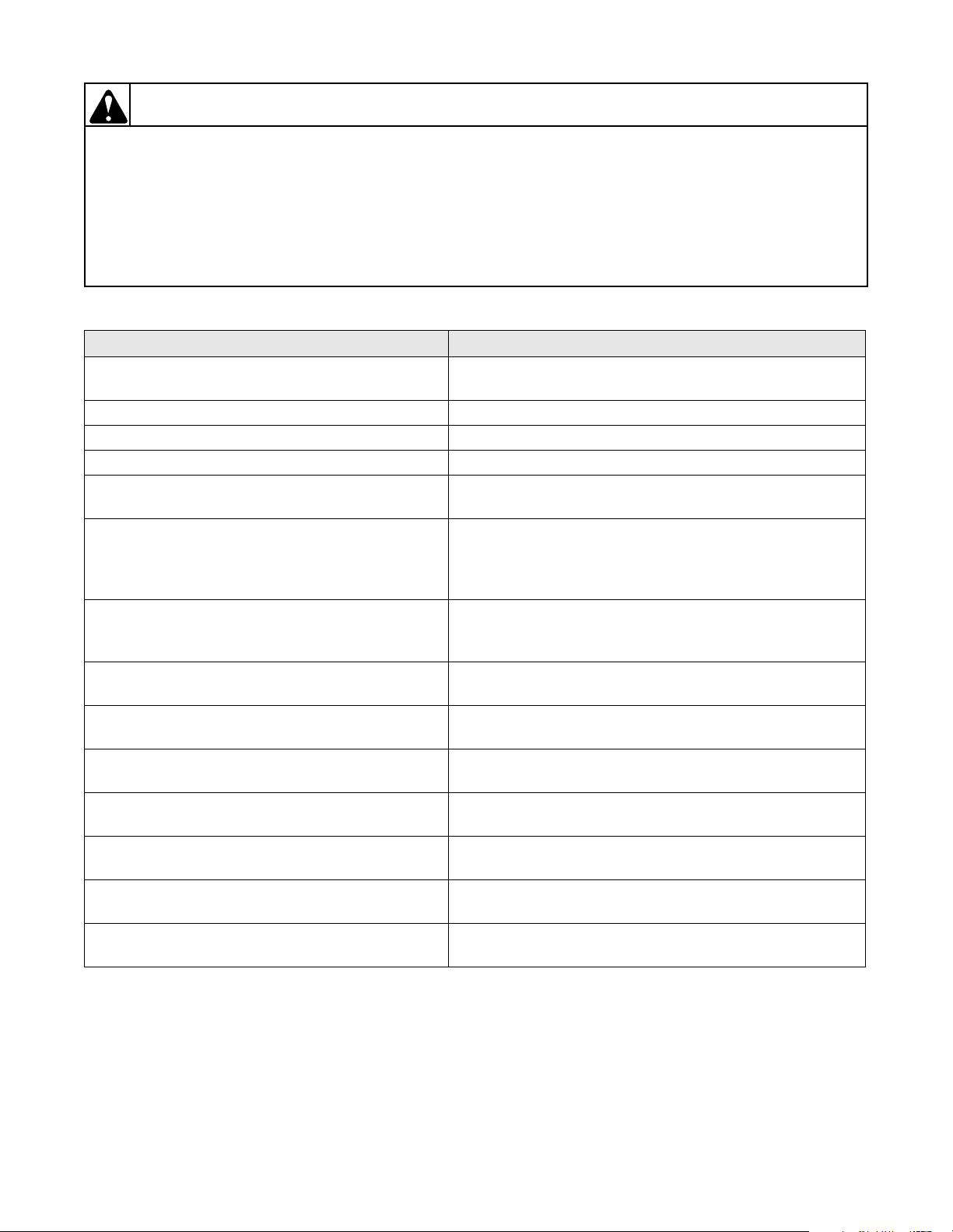

5. HEATING ELEMENT DOES NOT HEAT OR BURNER DOES NOT IGNITE

POSSIBLE CAUSE TO CORRECT

Improper or inadequate exhaust system. • Refer to the Installation Manual (supplied with tumbler)

for exhaust system requirements.

Blown fuses or tripped circuit breakers. • Check fuses or circuit breakers.

Drying timer not selected or inoperative. • Set drying timer or replace if inoperative.

Inoperative thermostat. • Test thermostat and replace if inoperative.

Electric Models:

• Check heat contactors and elements. Replace if necessary.

Inoperative heating elements.

Gas Models:

Insufficient gas supply.

• Open partially closed gas shut-off valve, or correct low

gas pressure. Check inlet pressure and compare to

pressure specified on serial plate. If pressure cannot be

obtained, contact gas supplier.

Gas Models:

Incorrect orifices.

• Tumbler is equipped for type of gas specified on serial

plate. If orifices are different from that specified on serial

plate, obtain and install proper orifices.

Gas Models: (IEI Ignition)

• Test igniter and replace if inoperative.

Inoperative igniter.

Gas Models: (IEI Ignition)

• Test igniter control and replace if inoperative.

Inoperative igniter control.

Gas Models:

• Test main coil and replace if inoperative.

Inoperative Main Coil

Gas Models:

Inoperative Redundant Coil

Gas Models: (Glow Bar Ignition)

• Test redundant coil and replace complete gas valve if

inoperative.

• Test igniter and replace if inoperative.

Inoperative igniter.

Gas Models: (Glow Bar Ignition)

• Test sensor and replace if inoperative.

Inoperative sensor.

Gas and Electric Models:

• Test thermostat and replace if inoperative.

Inoperative high limit thermostat.

W002

(continued on next page)

M411433 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 14

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

5. HEATING ELEMENT DOES NOT HEAT OR BURNER DOES NOT IGNITE (cont.)

POSSIBLE CAUSE TO CORRECT

Gas and Electric Models:

Inoperative airflow switch

• Clean lint compartment after every eight hour shift.

• Check back draft damper for foreign objects, lint

accumulation, or other causes that may prevent damper

from opening.

• Check ductwork for lint build-up. Refer to Installation

Manual (supplied with tumbler) to ensure that ductwork

and make-up air openings are sized properly.

W002

• Check exhaust outlet. If a screen has been improperly

installed on the outlet, it may be clogged with lint or

frozen over in winter.

Gas and Electric Models:

Airflow switch out of adjustment.

• Refer to Adjustment Section for airflow switch

adjustment.

Lint door panel not closed properly. • Open lint door panel, place lint door panel back on

tumbler (ensuring a tight fit) then latch.

Broken, loose, or incorrect wiring. • Refer to wiring diagram located on back of tumbler or in

literature packet.

14 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

6. IGNITER GLOWS, FLAME SENSOR OPENS BUT NO IGNITION - GAS MODELS

(White Rodgers Glow-bar Ignition)

POSSIBLE CAUSE TO CORRECT

Insufficient gas supply. • Is manual shut-off valve in full open position? Check gas

pressure.

Gas flow, but no ignition. • Gap between igniter and burner must be 1/8 – 1/4 inch.

No gas flow through gas valve. • Check for 80 – 120 Volts between red and white wires on

gas valve.

• If correct voltage is present and redundant coil does not

click open, replace complete gas valve.

W002

• If correct voltage is not present, replace diode logic board.

• If correct voltage is present and redundant coil clicks

open, check for 40 – 60 Volts across the purple wires on

the main coil after the igniter cycles off.

• If voltage is present and main coil does not click open,

replace main coil.

• If no voltage is present, replace diode logic board.

7. BURNER IGNITES AND GOES OUT REPEATEDLY - GAS MODELS

(Glow-Bar Ignition)

POSSIBLE CAUSE TO CORRECT

Burner heat not holding sensor contacts open. • Replace sensor.

Insufficient gas pressure. • Check gas supply and pressure. A low flame will not

maintain radiation to sensor.

Burner ports plugged or dirty. • Check burner tubes for build-up.

Improper or inadequate exhaust system or make-up

air.

• Refer to Installation Manual (supplied with tumbler) for

exhaust and make-up air requirements.

Inoperative high limit thermostat. • Test thermostat and replace in inoperative.

Improper orifices. • Tumbler is equipped for type of gas specified on serial

plate. If orifices are different from that specified on serial

plate, obtain and install proper orifices.

M411433 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 16

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

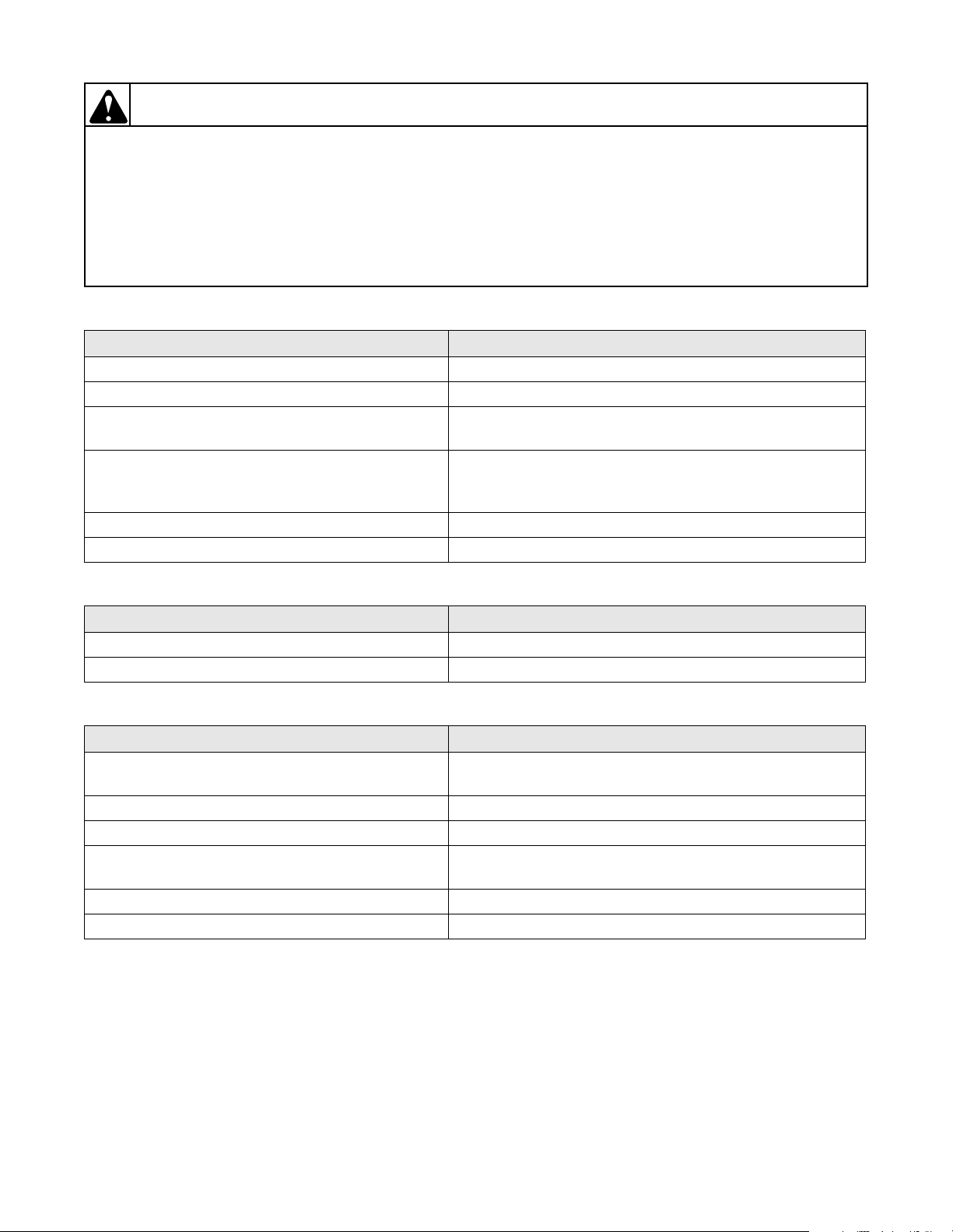

8. HEATING ELEMENT OR BURNER SHUTS-OFF PREMATURELY

POSSIBLE CAUSE TO CORRECT

Improper or inadequate exhaust and/or make-up air

system.

• Refer to Installation Manual (supplied with tumbler) for

exhaust and make-up air requirements.

Gas Models: Insufficient gas supply • Open partially closed gas shut-off valve, or correct low

pressure.

Gas Models: Tumbler not properly equipped for

type of gas used.

• Tumbler is equipped for type of gas specified on serial

plate. If orifices are different from that specified on serial

plate, obtain and install proper orifices.

Gas Models: Improperly adjusted burner flame. • Refer to Adjustment Section for burner flame adjustment.

Gas Models: (Glow-Bar Ignition) Sensor contact

• Replace sensor.

closing.

Cycling off on limit thermostat. • Refer to Paragraph 9.

Broken, loose or incorrect wiring. • Refer to wiring diagram located on back of tumbler or in

literature packet.

W002

9. HEATING ELEMENT OR BURNER REPEATEDLY CYCLES OFF ON HIGH LIMIT

THERMOSTAT

POSSIBLE CAUSE TO CORRECT

External exhaust system is longer than

recommended or inadequate make-up air.

• Refer to Installation Manual (supplied with tumbler) for

exhaust and make-up air requirements.

Clogged lint screen. • Remove screen and clean. Lint screen and compartment

should be cleaned after every eight hour shift.

Lint in tumbler ducts. • Clean tumbler ducts

Lint in external exhaust system. • Disassemble exhaust system and clean.

High limit thermostat cycling at too low a

• Replace thermostat.

temperature.

Lint door panel not closed properly. • Remove lint door panel, place lint door panel back on

tumbler (ensuring a tight fit) then latch.

16 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 17

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

10. HEATING ELEMENT OR BURNER DOES NOT SHUT-OFF

POSSIBLE CAUSE TO CORRECT

Gas Models:

• Replace gas valve.

Impurities on gas valve seat, preventing valve from

closing.

Inoperative drying timer, relay or contactor. • Replace timer, relay or contactor.

Incorrect wiring. • Refer to wiring diagram located on back of tumbler or in

literature packet.

W002

11. CLOTHES DO NOT DRY

POSSIBLE CAUSE TO CORRECT

Heat source inoperative. • Refer to Paragraph 5.

Too much water in articles being dried. • Remove excess water.

Clothes load too large. • Remove part of load.

Improper or inadequate exhaust system. • Refer to Installation Manual (supplied with tumbler) for

exhaust requirements.

Heat source shuts-off prematurely. • Refer to Paragraph 8.

Drying timer improperly set. • Set selector for higher setting.

Incorrect voltage. • Refer to Installation Manual (supplied with tumbler) for

electrical requirements.

Inadequate make-up air. • Refer to Installation Manual (supplied with tumbler) for

make-up air requirements.

12. TUMBLER OVERHEATING

POSSIBLE CAUSE TO CORRECT

Gas Models: Incorrect main burner orifices. • Replace orifices.

Gas Models: Gas pressure too high. • Gas pressure must be as specified on serial plate.

Inadequate make-up air. • Refer to Installation Manual (supplied with tumbler) for

make-up air requirements.

Lint accumulation. • Remove lint.

Restricted or inadequate exhaust system. • Remove obstruction or lint build-up from exhaust

ductwork. Refer to the Installation Manual (supplied

with tumbler) for exhaust system requirements.

Inoperative thermostat. • Replace thermostat.

M411433 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 18

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

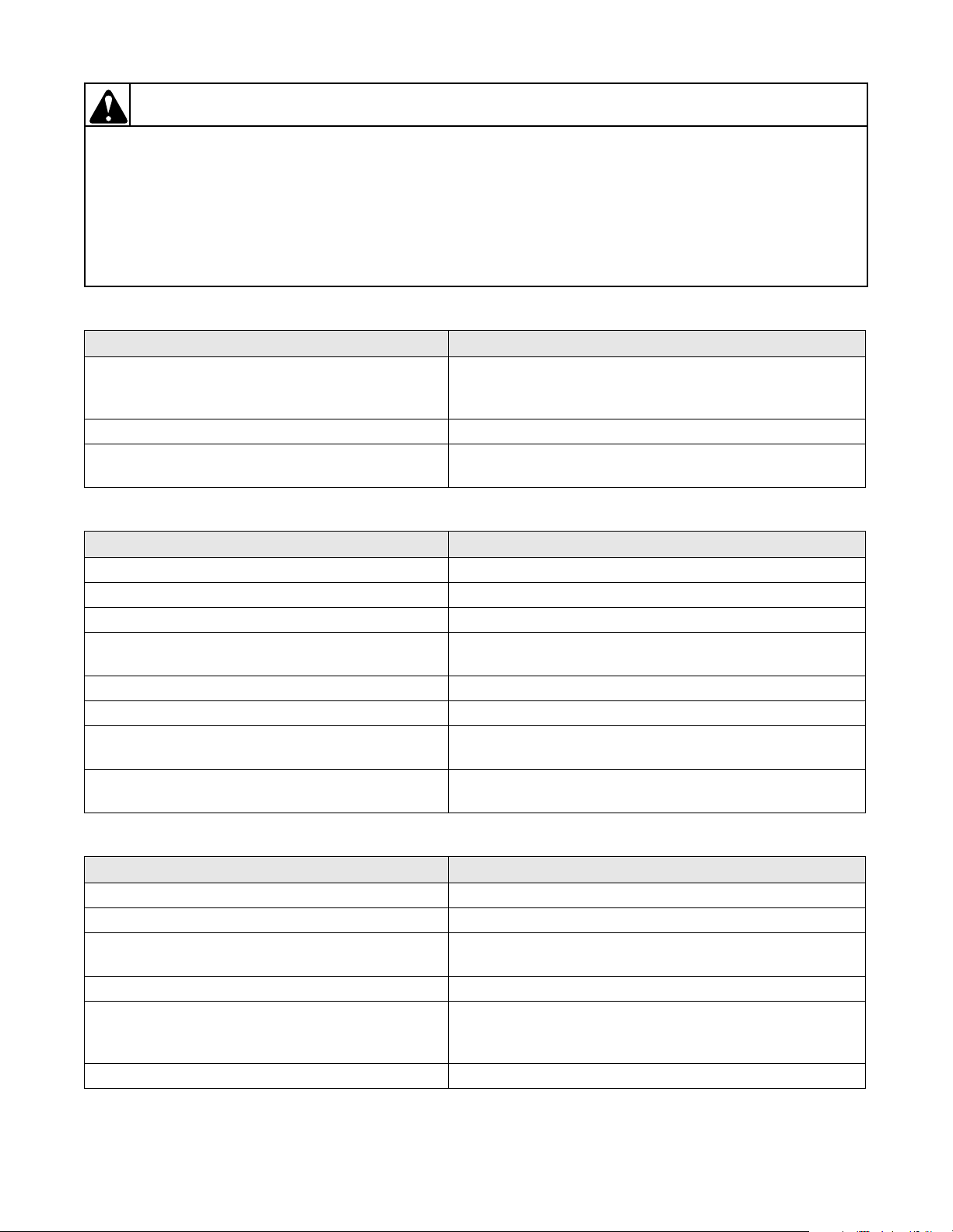

13. BURNERS NOT BURNING PROPERLY - GAS MODELS

POSSIBLE CAUSE TO CORRECT

Burner air shutters incorrectly adjusted. • Refer to Adjustment Section for proper flame adjustment.

Dirt in burners. • Disassemble burners and blow out the dirt.

Gas pressure too high. • Check serial plate on back of the tumbler for correct gas

pressure.

Incorrect orifices. • Tumbler is equipped for type of gas specified on serial

plate. If orifices are different from that specified on serial

plate, obtain and install proper orifices.

Restricted or blocked exhaust duct. • Disassemble and clean exhaust system.

Airflow switch not functioning properly. • Check adjustment and replace airflow switch if necessary.

W002

14. CYLINDER DOOR OPENS DURING OPERATION

POSSIBLE CAUSE TO CORRECT

Door strike improperly adjusted. • Refer to Adjustment Section for door strike adjustment.

Tumbler improperly leveled. • Refer to Adjustment Section for leveling leg adjustment.

15. TUMBLER RUNS BUT NO STEAM TO COILS - STEAM MODELS

POSSIBLE CAUSE TO CORRECT

Valves closed. • Check all valves in supply and return lines, make sure

they are open.

Blocked steam trap. • Remove trap and clean. Replace if inoperative.

Inoperative solenoid valve. • Check operation of solenoid valve.

Incorrect installation of check valve. • Check for inlet and outlet markings on check valve, and

invert is necessary.

Clogged strainer. • Remove strainer and clean.

Inoperative timer or thermostat. • Test timer or thermostat, replace if inoperative.

18 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

16. WATER IN STEAM LINE - STEAM MODELS

POSSIBLE CAUSE TO CORRECT

Incorrect installation of steam piping. • Refer to Installation Manual (supplied with tumbler) for

steam requirements.

Trap functioning improperly. • Check trap for size and capacity. If trap is dirty or

sluggish, clean thoroughly or replace. Check return line

for high back pressure.

W002

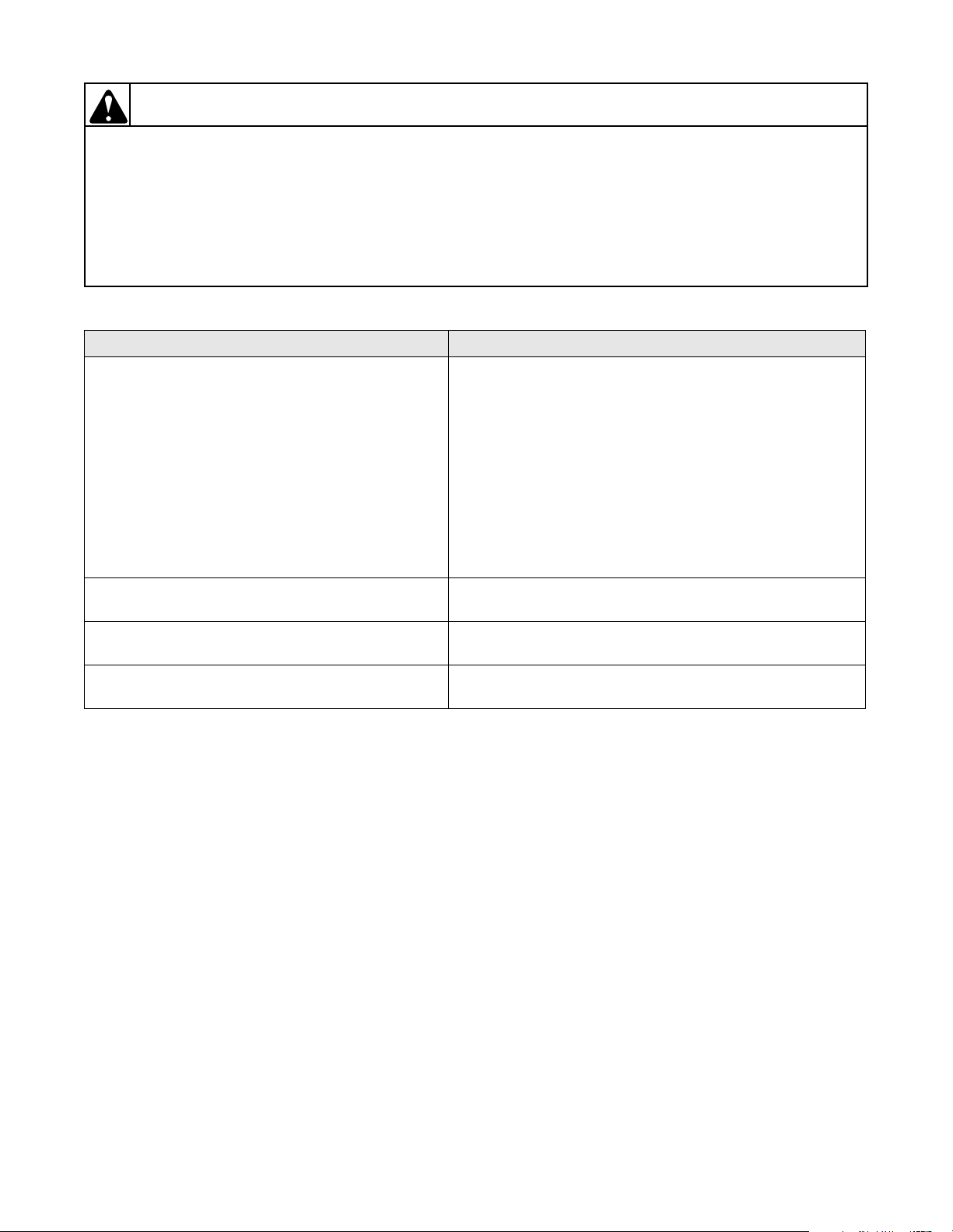

17. TROUBLESHOOTING ELECTRONIC CONTROL MODELS

PROBLEM POSSIBLE CAUSE TO CORRECT

Display shows “PF”

(MM models)

Tumbler has not been run in last six

days.

A custom cycle has not been

Power tumbler for at least two continuous days to

recharge battery.

Enter a custom cycle into memory.

programmed into memory.

Discharged battery. If tumbler has been powered for at least two

continuous days, replace battery.

Door Open light and

display flash with door

closed

Door switch needs adjustment. Adjust and test door switch.

Door switch faulty. Replace door switch.

Electrical service connected

incorrectly.

Check service connections to terminal block in

junction box. For 120 or 240 Volt tumblers,

neutral wire must be connected to terminal

marked “NEUT”. On single phase tumblers, hot

wire must be connected to terminal marked “L1”.

A ground wire must be secured to the ground

screw in the junction box.

Display shows “SH”

and signals sounds

Temperature at sensor is over 191°F

(88.3°C).

Allow tumbler to cool and press ON/SELECT

pad. If display still shows “SH”, replace sensor.

Temperature sensor shorted. Replace temperature sensor.

Display shows “OP”

and signal sounds

three minutes after

Temperature at sensor is under 24°F

(-4.4°C).

Temperature sensor open. Replace temperature sensor.

If the temperature of the tumbler is above 24°F

(-4.4°C), replace temperature sensor.

tumbler is started

M411433 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

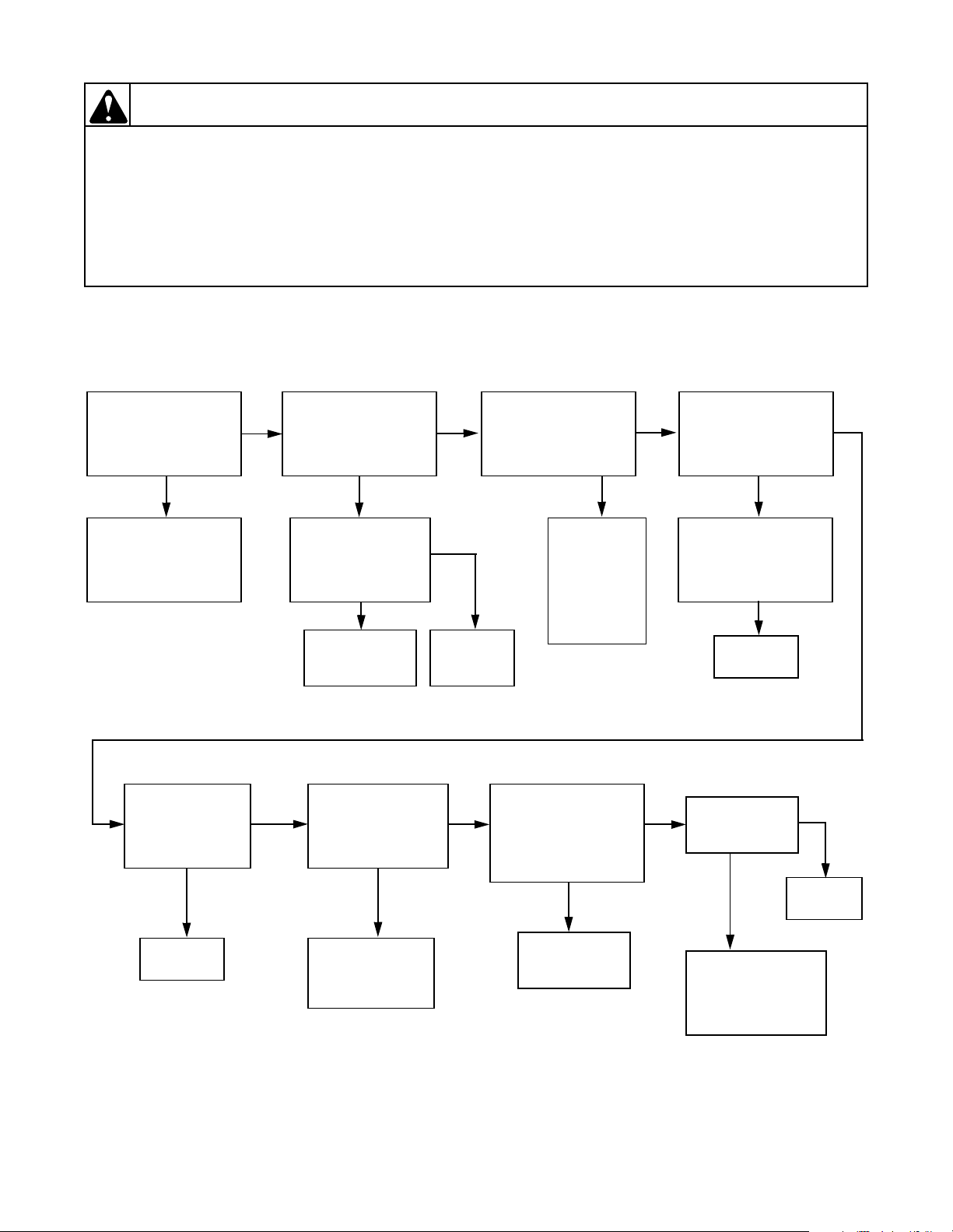

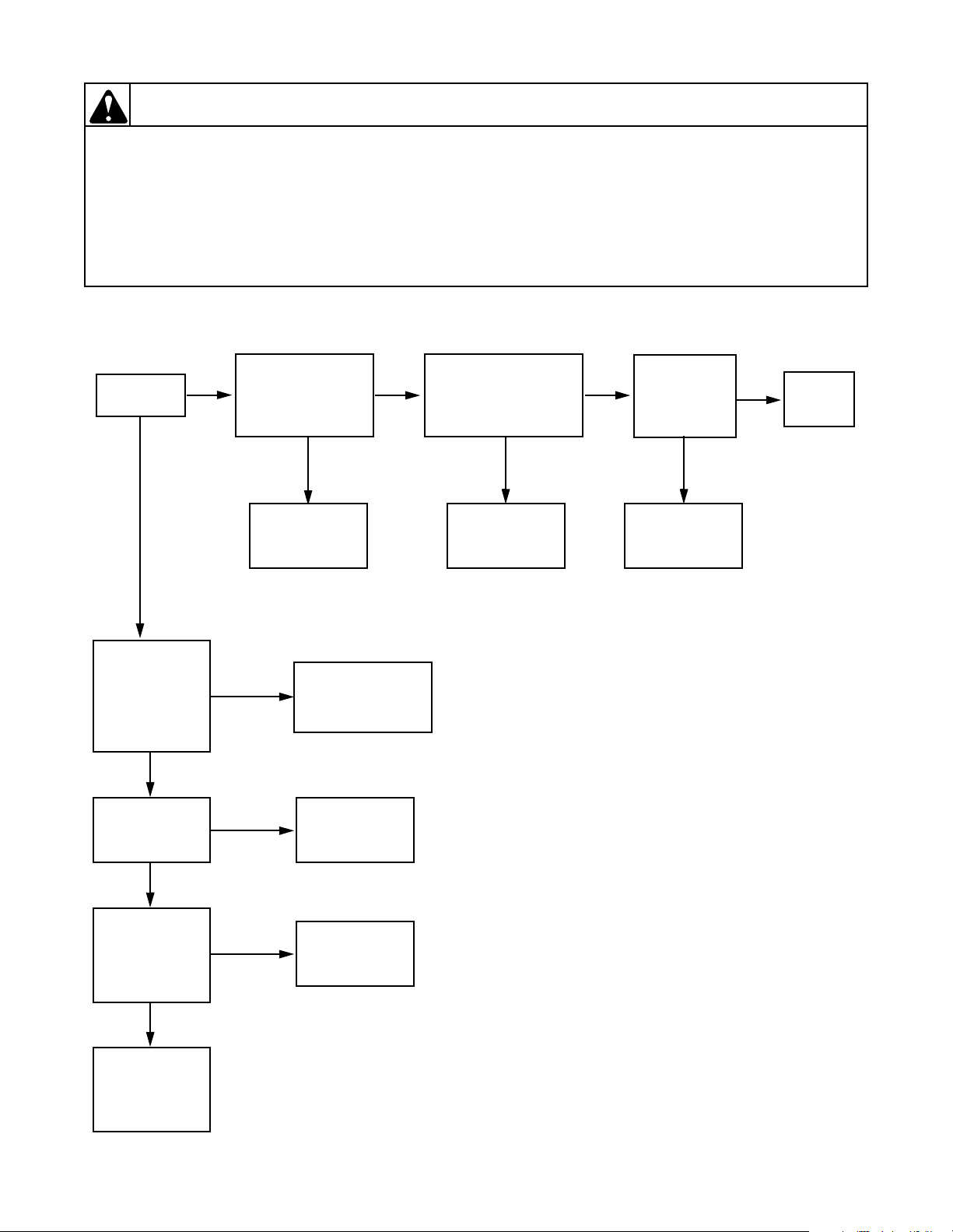

18. TUMBLER WILL NOT START, TIME ON DRYING TIMER, DOOR CLOSED

(MANUAL TIMER MODELS)

W002

CHECK FOR

LINE VOLTAGE

INTO DOOR SWITCH

NO

CHECK

ELECTRICAL SERVICE

TO TUMBLER

(Fuses/Circuit Breaker)

CHECK FOR

LINE VOLTAGE ON

TERMINAL 1 OF

CONTROL RELAY

NO

CHECK FOR

LINE VOLTAGE

OUT OF

DOOR SWITCH

NO NO

HAS SWITCH ROD

MECHANICALLY

ACTUATED

DOOR SWITCH?

NO

ADJUST

DOOR SWITCH

ROD

YES YES YES

CHECK FOR

LINE VOLTAGE INTO

PUSH-TO-START

SWITCH

NO NO

YES

YES

REPLACE

DOOR

SWITCH

CHECK FOR

LINE VOLTAGE AT

TERMINAL 3 OF

CONTROL RELAY

CHECK FOR

BROKEN

WIRE

OR POOR

CONNECTION

AT

HARNESS

PLUG

PRESS

PUSH-TO-START

SWITCH. CHECK FOR

LINE VOLTAGE OUT

OF PUSH-TO-START

SWITCH

YESYES

CHECK FOR

LINE VOLTAGE ACROSS

COIL TERMINALS

OF CONTROL RELAY

NO

CHECK FOR

LINE VOLTAGE ON

TERMINAL B

OF DRYING TIMER

NO

REPLACE

TIMER

CHECK FOR

LINE VOLTAGE

TO MOTOR

NO

YES

REPLACE

MOTOR

YES

REPLACE

RELAY

20 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHECK FOR

BROKEN WIRE

FROM CONTROL

RELAY TERMINAL 1

REPLACE

PUSH-TO-START

SWITCH

CHECK FOR

BROKEN WIRE

OR POOR

CONNECTION

AT HARNESS PLUG

Page 21

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

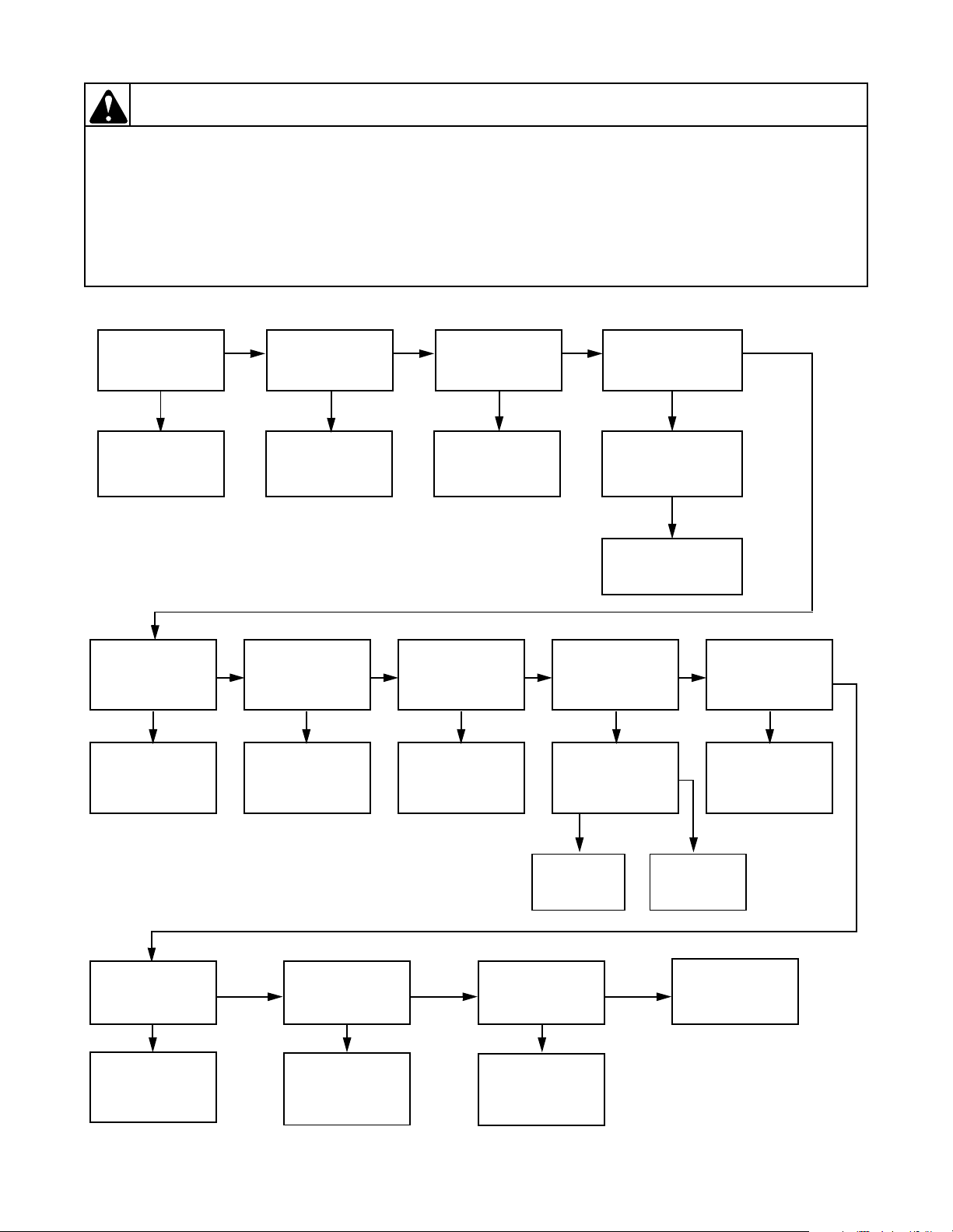

19. MOTOR RUNS, TIME ON DRYING TIMER BUT NO HEAT

W002

POWER OUT OF

MAIN CONTROL

THERMOSTAT

YES

CHECK THE

IGNITION CIRCUIT

CHECK FOR

BROKEN OR

LOOSE WIRE AT

HARNESS PLUG

YES NO NO NO NO

REPAIR

WIRE

NO

NO YES YES YES

POWER INTO

MAIN CONTROL

THERMOSTAT

YES

REPLACE

MAIN CONTROL

THERMOSTAT

POWER ON

RED WIRE

FROM MOTOR

REPLACE

MOTOR

NO

TERMINAL 6 OF

CONTROL RELAY

BROKEN WIRE TO

MAIN CONTROL

THERMOSTAT

POWER INTO

AIRFLOW

SWITCH

CHECK FOR

LOOSE OR

BROKEN WIRE

FROM MOTOR

POWER ON

YES YES

LOOSE OR

NO

POWER OUT OF

AIRFLOW

SWITCH

AIRFLOW

SWITCH

CLOSED

POWER ON

TERMINAL 4 OF

CONTROL RELAY

POWER ACROSS

COIL TERMINALS OF

CONTROL RELAY

YES

REPLACE

CONTROL RELAY

NO

POWER INTO

CABINET

HIGH LIMIT

THERMOSTAT

CHECK FOR

BROKEN WIRE

FROM

AIRFLOW SWITCH

YES

NO

ADJUST

AIRFLOW

SWITCH

POWER OUT OF

CABINET

HIGH LIMIT

THERMOSTAT

NO NO NO

REPLACE

THERMOSTAT

M411433 21

POWER INTO

BURNER

HIGH LIMIT

THERMOSTAT

CHECK FOR

BROKEN WIRE

FROM CABINET

HIGH LIMIT

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

YES YESYES

POWER OUT OF

BURNER

HIGH LIMIT

THERMOSTAT

REPLACE

BURNER

HIGH LIMIT

THERMOSTAT

YES

REPLACE

AIRFLOW

SWITCH

CHECK FOR LOOSE

OR BURNED

CONNECTION

AT HARNESS PLUG

Page 22

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

20. IGNITER DOES NOT GLOW

(White Rodgers Glow-Bar System)

W002

ARE 80 - 120 VOLTS

PRESENT BETWEEN

BLACK WIRE AND

GROUND ON MAIN

THERMOSTAT?

NO

CHECK

HEAT CIRCUIT

YES

ARE 80 - 120 VOLTS

PRESENT BETWEEN

WIRES OF IGNITER

BRACKET?

YES

REPLACE

IGNITER

NO

21. IGNITER GLOWS CONSTANTLY

REPLACE

SENSOR

22. IGNITER GLOWS, CYCLES OFF BUT BURNER DOES NOT IGNITE

ARE 80 - 120 VOLTS

PRESENT BETWEEN

EACH OF THE PURPLE

WIRES OF SENSOR AND

GROUND?

NO

REPLACE

DIODE LOGIC BOARD

ARE 80 - 120 VOLTS

PRESENT ACROSS

THE RED AND WHITE

WIRES OF THE

REDUNDANT COIL?

NO

REPLACE DIODE

LOGIC BOARD

YES YES YES

22 M411433

CAN YOU

HEAR THE

REDUNDANT

COIL

OPEN?

NO

REPLACE

COMPLETE

GAS VALVE

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

ARE 40 - 60 VOLTS

PRESENT ACROSS

THE PURPLE WIRES

TO THE

MAIN COIL?

NO

REPLACE DIODE

LOGIC BOARD

CAN YOU

HEAR THE

MAIN COIL

CLICK

OPEN?

NO

REPLACE

MAIN COIL

IS GAP BETWEEN

YES

AND BURNER

1/8 IN. TO 1/4 IN.?

IGNITER GAP TO

1/8 IN. TO 1/4 IN.

IGNITER

NO

ADJUST

Page 23

Section 3 Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

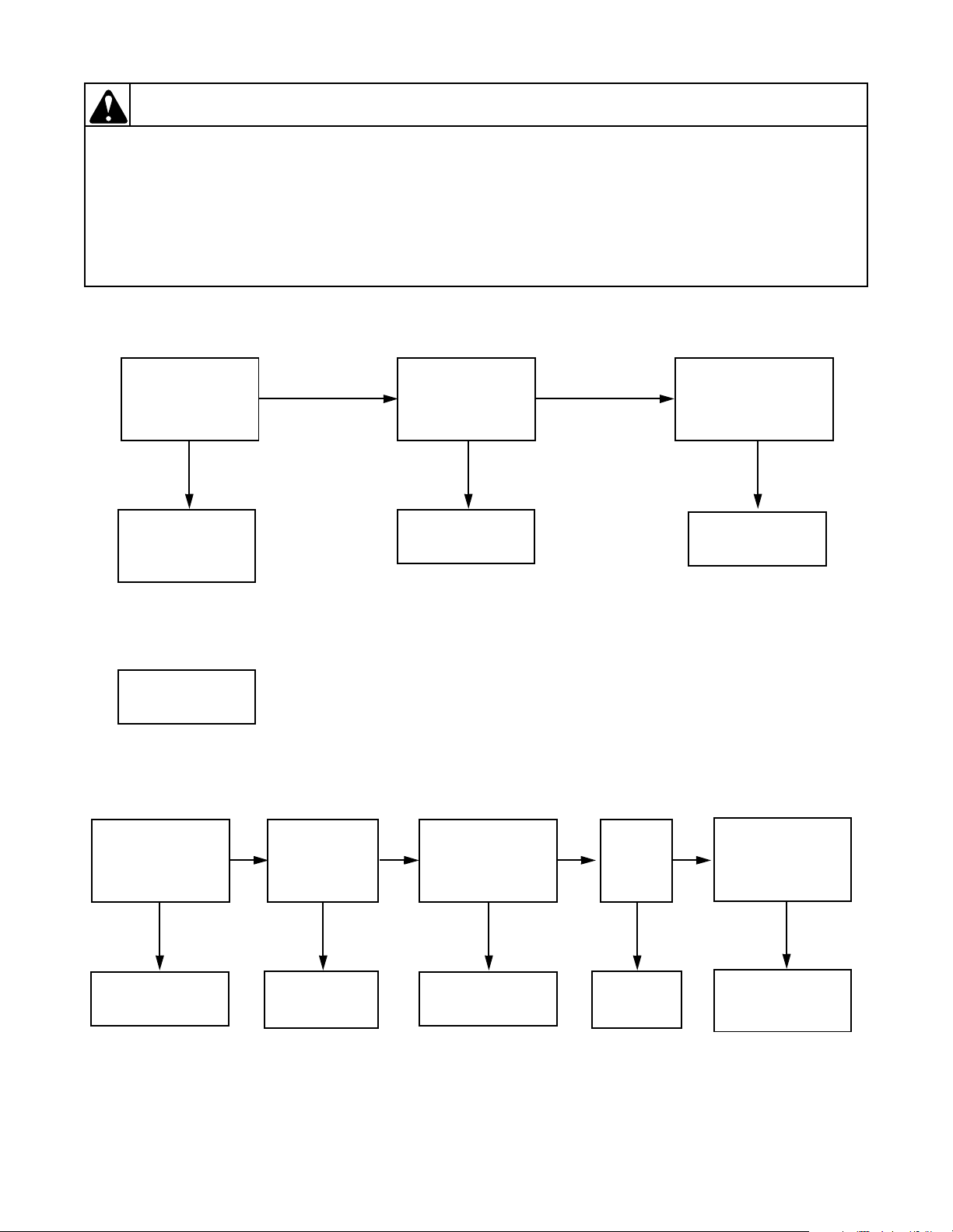

23. IGNITER DOES NOT SPARK

(White Rodgers Instant Electronic Ignition)

W002

IGNITER

SPARKING

YES

GREEN WIRE

FROM

IEI CONTROL

CONNECTED TO

GROUND

TERMINAL?

YES

GAS SHUT-OFF

VALVE

OPEN?

NO

IEI CONTROL IN

SAFETY LOCKOUT

RESET BY OPENING

AND CLOSING DOOR

YES

OPEN AND

CLOSE DOOR

NO

NO

CONNECT

GREEN WIRE TO

GROUND TERMINAL

OPEN GAS

SHUT-OFF

VAL VE

NO

RESISTANCE OF

HIGH VOLTAGE LEAD

GREATER THAN 25,000

OHMS OR LESS THAN

5,000 OHMS

YES YES

REPLACE

HIGH VOLTAGE

LEAD

NO

IGNITER GAP IS

NOT 5/32 IN.

(.397 CM)

OR CERAMIC

CRACKED

RE-GAP OR

REPLACE

IGNITER

NO

REPLACE

IEI

CONTROL

YES

120 VOLTS

PRESENT ON

BLACK WIRE

FROM

IEI CONTROL

YES

CHECK GAS

VALVE COILS

REPLACE

AS REQUIRED

M411433 23

NO

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

REPLACE

IEI

CONTROL

Page 24

Section 4

Grounding

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

WARNING

To reduce the risk of fire and electric shock, check with a qualified serviceperson for proper

grounding procedures. Improper connection of the equipment grounding conductor may result

in a risk of electric shock.

W002

W068R1

WARNING

To reduce the risk of fire and electric shock, if electrical supply is coming from a three phase

service, DO NOT connect a “High Leg” or “Stinger Leg” to a single phase machine. On a three

phase machine, if there is a “High Leg” or “Stinger Leg” it should be connected to L3.

Grounding Instructions

Tumbler must be grounded. In the event of malfunction

or breakdown, grounding will reduce the risk of electric

shock by providing the path of least resistance for

electric current. Tumbler must be connected to a

grounded metal, permanent wiring system; or an

equipment grounding conductor must be run with the

circuit conductors and connected to the appropriate

ground location.

NOTE: To ensure protection against shock,

tumbler MUST be electrically grounded in

accordance with local codes, or in the absence of

local codes, with the latest edition of the National

Electrical Code ANSI/NFPA No. 70. In Canada, the

electrical connections are to be made in accordance

with CSA C22.1 or the latest edition of the

Canadian Electrical Code, Part I and/or local codes.

Electrical work should be done by a qualified

electrician.

WARNING

All electrical connections should be made

by a qualified electrician.

To reduce the risk of electrical shock, deenergize the electrical circuit being

connected to the tumbler before making any

electrical connections. Never attempt to

connect a live circuit.

W070

W069

M411433 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

Section 5

Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

IMPORTANT: References made to the left or right

hand direction are taken from the operator’s

position facing the front of the tumbler.

24. CONTROL PANEL

Refer to Figure 1.

a. Unlock and open access panel. To hold panel

open, swing support rod under panel.

b. Manual Timer and Coin Meter Models

(1) Remove two screws holding control panel

to cabinet.

(2) Lift control panel off top edge of front

panel and pull panel forward just far

enough to disconnect wire harness at the

plug.

25. PUSH-TO-START SWITCH

a. Remove control panel.

b. Remove two screws holding switch, and

mounting bracket (if applicable), to control

panel. Refer to Figure 1.

c. Disconnect wires from switch terminals and

remove switch.

NOTE: Refer to wiring diagram when rewiring

switch.

26. COOLING, DRYING, OR RUN LIGHT

a. Remove control panel.

b. Disconnect light wire leads.

NOTE: On Coin Meter Models, the run light white

lead must be joined to the wire harness white lead

using a double spade connector. Remove the single

spade lug from the replacement run light white

wire.

c. Compress locking tabs on sides of light and

push light out through front of control panel

Refer to Figure 2 for Coin Drop Models or

Figure 3 for Manual Timer Models.

NOTE: Refer to wiring diagram when rewiring

light.

M411433 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Section 5 Service Procedures

ACCESS

PANEL

ATTACHING SCREWS

SUPPORT

ROD

CONTROL PANEL

PUSH-TO-START

SWITCH

TERMINAL

BOARD

SCREWS

T056SE3D

WIRE HARNESS

PLUG

T057SE3A

CONTROL PANEL

BRACKETS

PUSH-TO-START

SWITCH ASSEMBLY

CONTROL

PANEL BRACKET

Figure 1

28 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

27. RELAY (MANUAL TIMERS MODELS)

a. Remove control panel.

COIN DROP

MODEL

TAB

TAB

b. Remove two screws holding relay to mounting

bracket. Refer to Figure 3.

c. Disconnect wires from relay.

NOTE: Refer to wiring diagram when rewiring

relay.

28. RESISTOR 208 or 240 Volt/60 Hertz

(Models with Control Circuit)

a. Remove control panel.

b. Disconnect resistor leads. Refer to Figure 3.

W002

RUN LIGHT

LOCKING

TAB

CONTROL

Figure 2

PANEL

T005SE1C

NOTE: Refer to wiring diagram when rewiring

resistor.

29. COOLING OR DRYING TIMER

(New Style)

a. Remove control panel.

b. Pull timer knob off timer shaft. Refer to

Figure 3.

c. Remove three screws holding timer to control

panel or mounting bracket.

d. Remove wires from timer terminal board, and

timer motor lead from terminal block.

IMPORTANT: Be sure barrier is installed in proper

position when reinstalling drying timer. Refer to

Figure 3.

NOTE: Refer to wiring diagram when rewiring

timer.

M411433 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

MANUAL TIMER

MODELS

TIMER

DRYING

LIGHT

W002

LOCKING

TA BS

COOLING

LIGHT

TIMER

KNOB

30. COOLING OR DRYING TIMER MOTOR

(Old Style Timers)

NOTE: Cooling and drying timers used prior to

January 1985 were supplied by Greenwald and

have serviceable timer motors. After January 1985,

Robert Shaw or Mallory timers are used, which do

not have serviceable timer motors. These later

timers must be replaced as complete assemblies if

the timer motor fails.

a. Remove control panel.

b. Disconnect motor leads.

RESISTORS

RELAY

MOUNTING

BRACKET

T341S

Figure 3

c. Remove screws holding timer motor to

mounting bracket, Figure 4.

NOTE: Refer to wiring diagram when rewiring

timer motor.

d. Replacing Greenwald timer assembly with

Mallory timer assembly:

(1) Remove Greenwald timer assembly.

(2) Connect timer terminal wire 3 to terminal

board terminal B.

(3) Connect timer terminal 5 wire to terminal

board terminal C.

30 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

HEAT

SWITCH

SCREW

TIMER

MOTOR

W002

RUN

SWITCH

TIMER

ASSEMBLY

TU001-SV

Figure 4

31. COIN METER

Refer to Figure 5.

a. Remove control panel.

b. Disconnect wires from heat and run switches.

c. Cut remaining motor wire and joining white

wire at wire nut.

d. Remove four speed nuts holding coin meter to

coin meter frame.

NOTE: Refer to wiring diagram when rewiring coin

meter. Connect wires cut in step “c” above with

new wire nut.

TIMER

MOTOR

Figure 5

SPEED

NUT

COIN

METER

TU060-SV

M411433 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

32. COIN METER TIMER MOTOR

a. Remove control panel.

b. Remove two screws holding motor to mounting

bracket. Refer to Figure 6.

c. Hold cam and drive fork against inside face of

motor mounting bracket and pull timer motor

free of cam and drive fork.

d. Disconnect motor leads.

e. Slide cam and drive fork out from under motor

mounting bracket.

NOTE: Refer to wiring diagram when rewiring

timer motor.

MOTOR

MOUNTING

BRACKET

SCREW

remove the switches and actuating bracket

parts.

d. Assemble the two switches and the two parts

making up the switch actuating bracket.

e. Actuate the switches a number of times by

manually pressing the actuating plate against

the switch lever and plunger to ensure that the

actuating parts do not bind. If binding occurs,

reposition the actuating plate slightly until the

binding stops.

NOTE: Refer to wiring diagram when rewiring

switches.

TIMER

SWITCH

ACTUATOR

BRACKET

CAM AND

DRIVE FORK

T007SE1B

TIMER

MOTOR

Figure 6

33. COIN METER RUN OR HEAT SWITCH

Refer to Figure 7.

RUN

SWITCH

HEAT

SWITCH

T008SE1B

a. Remove control panel.

b. Disconnect wires from switches on timer.

Figure 7

c. Hold switches and actuating bracket under

switches tightly together with one hand while

removing two screws holding switches to

timing motor mounting bracket. Carefully

32 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 31

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

34. ELECTRONIC CONTROL (MM Models)

a. Unlock and open access panel.

b. Remove retaining screw and swing electronic

control out from control area. Refer to Figure 8.

c. Disconnect battery plug from control plug.

d. Carefully remove the wire harness wires from

the back of the electronic control.

e. Remove the four mounting screws holding the

electronic control to the bracket. Refer to

Figure 3.

NOTE: Refer to the wiring diagram when

reconnecting the wire harness to the electronic

control.

IMPORTANT: Due to the sensitivity of the

electronic control, careful handling is required. As a

precautionary measure, we recommend using a

ground wrist strap when handling the electronic

control. Wrist strap, cord and alligator clip are

designed to carry away any electrostatic charge

from your body and to direct charge to an available

ground. By using this static protection device,

potential electrostatic discharge problems

associated with handling of electronic control will

be minimized. Always handle electronic control by

its metal edges. If a wrist strap is not available,

touch tumbler while it is plugged in before handling

control to dissipate any charge.

35. REVERSING/NONREVERSING SWITCH

Refer to Figure 8.

a. Unlock and open access panel.

b. Remove retaining screw and swing electronic

control out from control area.

c. Disconnect the wires from the back of the

switch.

d. Remove nut holding switch to electronic

control bracket. For OM Models, depress

locking tabs on rectangular switch.

36. BATTERY (MM Model)

(Electronic Control Models)

Refer to Figure 8.

a. Unlock and open access panel.

b. Remove retaining screw and swing electronic

control out from control area.

c. Disconnect battery plug from control plug.

d. Unsnap plastic clamp holding battery to control

bracket.

M411433 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Section 5 Service Procedures

ELECTRONIC

CONTROL BRACKET

ELECTRONIC

CONTROL

RETAINING

SCREW

MOUNTING

SCREWS

NUT

REVERSING/

NON REVERSING

SWITCH

(4)

Figure 8

BATTERY

PLUG

BATTERY

PLASTIC

CLAMP

WIRE

HARNESS

CONTROL

PLUG

T094SE3C

ELECTRONIC

CONTROL

BRACKET

SWITCH

(Reversing)

SWITCH PLATE

(Reversing)

CONTROL

PLUG

T332PE3C

Figure 9

34 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

37. CONTROL THERMOSTAT

a. Remove control panel.

b. Pull off thermostat knob. Refer to Figure 10.

c. Disconnect wires from thermostat.

d. Remove two screws holding thermostat to

bracket.

THERMOSTAT

THERMOSTAT

KNOB

SCREWS

Figure 10

SENSING

TUBE

BRACKET

j. Carefully remove thermostat, tube and probe.

IMPORTANT: Do not kink sensing tube when

installing thermostat.

NOTE: Refer to wiring diagram when rewiring

thermostat.

JUNCTION

BOX

WIRE

TIES

T012SE1B

e. Remove wire-way attaching screws. Refer to

Figure 11.

f. Remove screws, wire clips and/or retaining

straps securing thermostat sensing tube in wire-

WIRE

WAY

way.

g. Remove junction box cover attaching screws.

Refer to Figure 11.

IMPORTANT: When reinstalling thermostat, be

sure to install all screws and wire clips and replace

all retaining straps removed in step “f” and “g”.

h. Unlock and remove lint panel.

i. Spread locking tabs on sensing probe bracket

TU013-SV

and disengage probe from bracket. Refer to

Figure 12.

THERMOSTAT

IMPORTANT: When reinstalling thermostat, be

SENSING TUBE

sure to secure sensing probe with locking tabs on

bracket.

M411433 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 11

Page 34

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

SENSING

PROBE

LOCKING

TABS

SENSING PROBE

Figure 12

THERMOSTAT

LINT

SCREEN

THERMOSTAT

SENSING TUBE

WARNING

T014SE3A

36 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

38. THERMISTOR

(Electronic Control Models Only)

Refer to Figure 13.

a. Unlock and remove the lint panel.

b. Remove the two screws holding the perforated

cover to the thermistor bracket.

c. Disconnect the wires from the back of the

thermistor.

THERMISTOR

d. Remove the two screws holding the thermistor

to the bracket.

OM Models: Unthread thermistor from

bracket.

NOTE: Refer to the wiring diagram when

reconnecting the wires to the thermistor.

OM Models

THERMISTOR

WIRES

T345P

SCREW

LINT

PANEL

PERFORATED

COVER

T093SE3C

Figure 13

M411433 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 36

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

39. GAS VALVE

(White Rodgers Glow-Bar Models)

Refer to Figure 15.

a. Remove control panel.

b. Close gas shut-off valve. Refer to Figure 14.

c. Disconnect all wires from gas valve terminals

and disconnect gas valve pipe unions.

d. Remove screws holding gas valve and bracket

to stove assembly.

e. Remove gas valve from mounting bracket.

f. Remove spudholder and nipple from left side of

valve. Use 1/2 inch Allen wrench to remove

plug from right side of valve.

IMPORTANT: Purge air from the gas service line

by operating tumbler in drying mode. Use pipe

compound resistant to action of L.P. gas on all pipe

threads.

WARNING

To reduce risk of fire or explosion, check

pipe connections for gas leaks with a noncorrosive leak detection fluid. Do not use an

open flame to check for gas leaks!

W310

NOTE: Refer to wiring diagram when rewiring gas

valve.

40. DIODE LOGIC BOARD

(White Rodgers Glow-Bar Models)

a. Remove control panel.

b. Disconnect wires from diode logic board

terminals. Refer to Figure 14.

NOTE: Refer to wiring diagram when rewiring

diode logic board.

c. Compress tabs on back ends of diode logic

board standoffs and push standoffs through

holes in cabinet wall to free the diode logic

board.

41. MAIN COIL

(White Rodgers Glow-Bar Models)

Refer to Figure 15.

NOTE: The redundant coil cannot be purchased

separately. Replace the complete gas valve.

a. Remove control panel.

b. Close gas shut-off valve. Refer to Figure 14.

c. Disconnect wires from main coil terminals.

d. Remove screws holding main coil to gas valve.

NOTE: Refer to wiring diagram when rewiring gas

valve main coils.

42. IGNITER BRACKET

(White Rodgers Glow-bar Models)

Refer to Figure 14.

a. Remove control panel.

b. Insert tips of 90 degree Tru-Arc pliers into

holes in each igniter mounting clip and spread

clips just far enough for igniter removal.

IMPORTANT: Use extreme care when handling the

igniter as it is very fragile. Handle igniter by

grasping the white wings only. Do not handle the

silicon carbide portion of the igniter with hands or

allow any oil, grease, or other foreign material to

contaminate it. Hairline cracks, oil, grease, or other

impurities will cause igniter to burn out.

c. Remove screw holding igniter bracket to stove

assembly.

d. Disconnect igniter wires from diode logic

board.

38 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 37

STAND-OFFS

GLOWBAR

IGNITER

SENSOR

IGNITER

BRACKET

SPUD HOLDER

GAS

SHUT-OFF

VALV E

UNION

NUTS

NIPPLE

VALV E

White Rodgers Glow-Bar Ignition Burner

WHITE RODGERS

GLOW-BAR IGNITION BURNER

GAS

DIODE

LOGIC

BOARD

GAS

OFF

PLUG

GAS

ON

T019SE1A

Section 5 Service Procedures

MANIFOLD

IGNITOR

NIPPLE

UNION

NUT

GAS

VALV E

HIGH VOLTAGE

LEAD

T021SE1B

GAS

ON

WHITE RODGERS

INSTANT ELECTRONIC IGNITION BURNER

GAS

OFF

GAS

SHUT-OFF

VALV E

MAIN

COIL

REDUNDANT

COIL

WHITE RODGERS

White Rodgers Glow-Bar

GLOW-BAR GAS VALVE

GAS

VALV E

BODY

Figure 14

MAIN

COIL

GAS

VALV E

BODY

REDUNDANT

COIL

White Rodgers

Instant Electronic System (IEI)

INSTANT ELECTRONIC IGNITION GAS VALVE

WHITE RODGERS

T002SE3D

Figure 15

M411433 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 38

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

43. SENSOR

(White Rodgers Glow-Bar Models)

Refer to Figure 14.

a. Remove control panel.

b. Disconnect wires from sensor, (on left side of

burner housing).

c. Remove screw holding sensor to side of stove

assembly.

NOTE: Refer to wiring diagram when rewiring

flame sensor.

44. IGNITER

(Instant Electronic Ignition Models)

Refer to Figure 14.

a. Remove control panel.

b. Disconnect high voltage lead from igniter.

c. Remove two screws attaching igniter bracket to

stove assembly.

45. IGNITION CONTROL

(Instant Electronic Ignition Models)

Refer to Figure 14.

a. Remove control panel.

b. Disconnect wire harness.

c. Remove high voltage lead.

46. GAS VALVE

(Instant Electronic Ignition Models)

Refer to Figure 15.

a. Remove control panel.

b. Close gas shut-off valve. Refer to Figure 14.

c. Disconnect all wires from gas valve terminals

and disconnect gas valve pipe unions.

d. Remove screw holding gas valve bracket to

stove.

e. Remove spudholder and manifold from left

side of valve and plug from right side of valve.

f. Remove gas valve from mounting bracket.

IMPORTANT: Purge air from the gas service line

by operating tumbler in drying mode. Use pipe

compound resistant to action of L.P. Gas on all pipe

threads.

WARNING

To reduce risk of fire or explosion, check

pipe connections for gas leaks with a noncorrosive leak detection fluid. Do not use an

open flame to check for gas leaks!

W310

IMPORTANT: Remove circuit board and plastic

back as a unit. Handle ignition control unit by sides

of board only. Do not contact circuit boards with

hands or metal objects. Place unit in clean, dry area

away from work area to avoid damage. Do not

attempt field repair of the ignition control unit.

Attempted repair or tampering with the ignition

control unit will void its warranty.

d. Remove two screws attaching ignition control

unit to cabinet frame.

e. Remove ignition control unit.

40 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

W002

47. MAIN COIL

(Instant Electronic Ignition Models)

Refer to Figure 15.

NOTE: The redundant coil cannot be purchased

separately. Replace complete gas valve.

a. Remove control panel.

b. Close gas shut-off valve. Refer to Figure 14.

c. Disconnect wires from main coil terminals.

d. Remove screws holding main coil to gas valve.

48. BURNER TUBE

a. Remove control panel.

b. Close gas shut-off valve. Refer to Figure 14.

c. Disconnect union nuts attaching nipple to

spudholder and remove spudholder.

d. Remove screws holding gas and valve bracket

to stove assembly.

e. Remove screws holding burner tubes to stove

frame and remove burner tubes.

WARNING

b. Remove wires from contactor terminals and

terminal blocks.

NOTE: Refer to wiring diagram when rewiring

contactors or terminal blocks.

c. Remove screws attaching contactor to box.

d. Remove two screws holding terminal block to

box.

NOTE: Terminal block consists of two terminal

section (one phase) or three terminal sections (three

phase) and an end piece snapped together. Later

models use a one-piece three position terminal block

mounted on a din rail.

TERMINAL

CONTACTOR

BLOCKS

CONTACTOR

To reduce risk of fire or explosion, check

pipe connections for gas leaks with a noncorrosive leak detection fluid. Do not use an

open flame to check for gas leaks!

W310

IMPORTANT: Make sure that spudholder and

orifices are positioned such that gas will be injected

directly down the center of the burner.

Figure 16

T182SE1A

49. CONTACTORS AND TERMINAL BLOCK

(Electric Models)

Refer to Figure 16.

NOTE: Contactors and terminal blocks are located

in contactor box at the rear of the tumbler.

a. Remove screw holding cover to contactor box

and remove cover.

M411433 41

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 40

Section 5 Service Procedures

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumbler is properly grounded.

50. HEATER ELEMENT

(Electric Tumbler)

Refer to Figure 17.

a. Remove two screws holding wire hood to top of

cabinet and remove.

b. Remove nuts, wires and bus bars from element

terminals.

c. Remove four screws holding heater housing to

top of cabinet and remove heater from tumbler.

d. Turn heater housing upside down and remove

bottom guard retaining screws.

e. Remove two retaining screws from each of the

elements to be replaced.

W002

NOTE: To remove top element, all elements must

be removed. To remove center element, both center

and bottom element must be removed.

f. Slide element forward until terminals clear rear

of heater housing.

g. Tilt element up and gently slide it out of

housing.

IMPORTANT: Bottom guard must be put back on

bottom of housing before reinstalling heater on

tumbler.

42 M411433

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

Older Models:

BOTTOM GUARD

ATTACHING SCREW

SCREW

HIGH LIMIT

THERMOSTAT

Section 5 Service Procedures

HEATER

HOUSING

WIRES

NUT

BOTTOM

GUARD

BUS BAR

Newer Models:

JUMPER

WIRES

BUS BAR

NUT

HEATER

HOUSING

HEATER

ELEMENT

T231PE3D

SCREW

HIGH LIMIT

THERMOSTAT

HEATER

ELEMENT