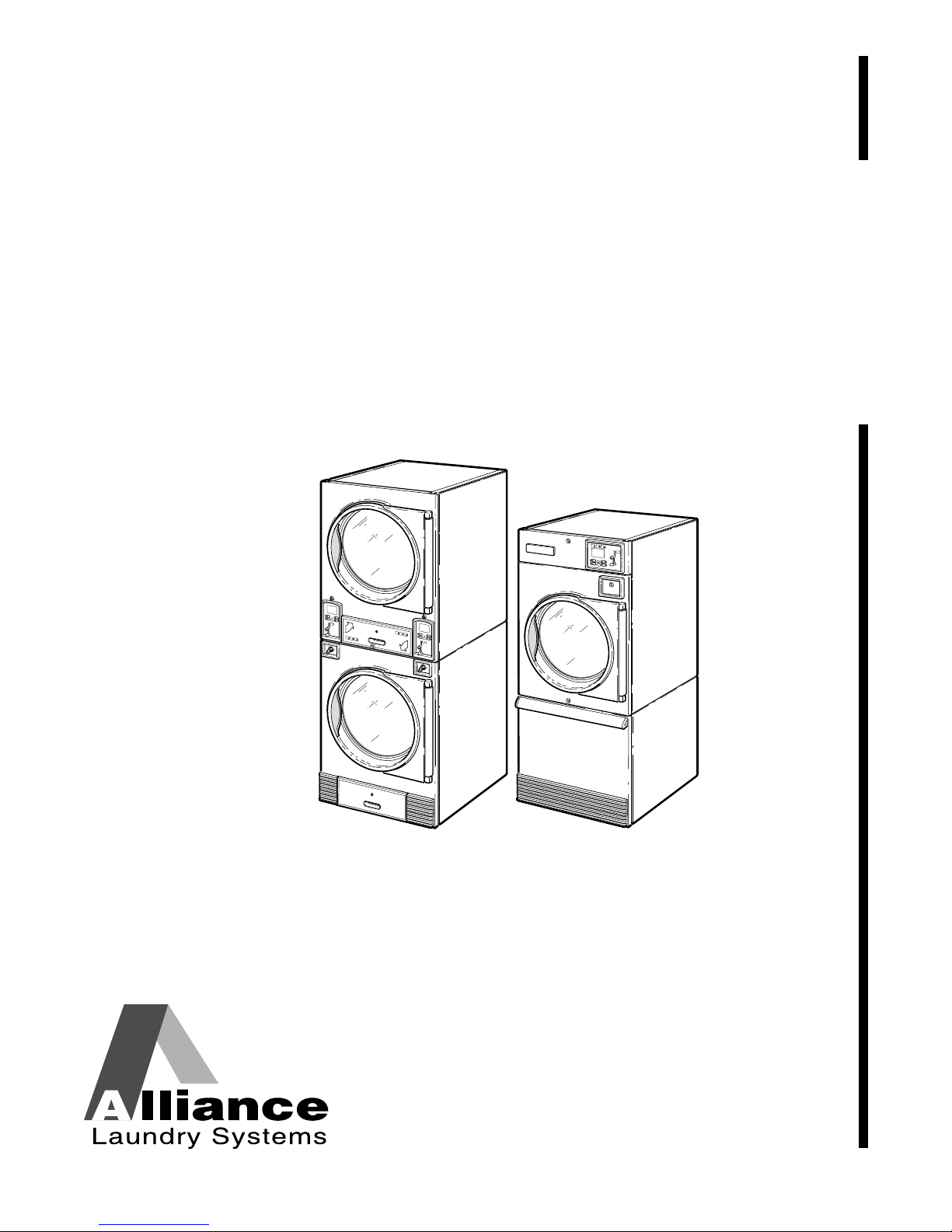

Alliance Laundry Systems DT0220SFG, DA0220SRG, JT0300DRG, DC0220SRG, DT0220SRG Installation Manual

...Page 1

Drying Tumblers

Stacked 30 Pound (300 Liter) Capacity

Refer to Page 5 for Model Identification

NOTA: El manual en

español aparece después

del manual en inglés.

25 Pound (220 Liter) Capacity

30 Pound (270 Liter) Capacity

35 Pound (350 Liter) Capacity

H

I

G

H

T

E

M

P

S

T

A

R

T

L

O

W

T

E

M

P

M

E

D

T

E

M

P

N

O

H

E

A

T

C

25

1

S

E

L

E

C

T

T

E

M

P

1

S

E

L

2

E

C

T

T

I

E

N

M

S

E

P

3

R

T

C

O

P

I

H

U

N

I

S

G

H

H

S

T

T

E

A

M

R

P

T

S

T

A

R

T

L

O

W

T

E

M

P

M

E

2

I

N

S

E

3

R

T

C

O

P

I

U

N

S

H

S

T

A

R

T

D

T

E

M

P

N

O

H

E

A

T

C

25

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

T477C

T477C T478C

www.comlaundry.com

T478C

Part No. 70223701R2

June 2002

Page 2

Page 3

Installation must conform with local codes or, in the absence of local codes, with:

FOR YOUR SAFETY, the information in

this manual must be followed to minimize

the risk of fire or explosion or to prevent

property damage, personal injury or

death.

W033

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do

not use any phone in your building.

– Clear the room, building or area of all

occupants.

– Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

– If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

W052

WARNING

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

W053

In the U.S.A.

, installation must conform to the latest edition of the American National Standard Z223.1/

NFPA 54 “National Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code.”

In Canada

, installation must comply with Standards CSA-B149.1 or Natural Gas and Propane Installation

Code and CSA C22.1, latest edition, Canadian Electric Code, Part I.

In Australia

, installation must comply with the Australian Gas Association Installation Code for Gas

Burning Appliances and Equipment.

IMPORTANT: Information must be obtained from a local gas supplier on instructions to be followed if the

user smells gas. These instructions must be posted in a prominent location. Step-by-step instructions of the

above safety information must be posted in a prominent location near the tumbler for customer use.

AVERTISSEMENT

POUR VOTRE SÉCURITÉ il est impératif

de suivre les instructions de ce manuel

pour minimiser les risques d’incendie ou

d’explosion et pour éviter les dommages

matériels, les blessures corporelles ou la

mort.

W033Q

• Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de tout autre appareil.

• QUE FAIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ :

– Ne pas tenter d’allumer d’apareil.

– Ne touchez à aucun interrupteur. Ne

pas vous servir des téléphones se

trouvant dans le bâtiment où vous

vous trouvez.

–Évacuez la pièce, le bâtiment ou la

zone.

– Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du

fournisseur.

– Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

• L’installation et l’entretien doivent être

assurés par un installateur ou un

service d’entretien qualifié ou par le

fournisseur de gaz.

W052Q

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de tout autre appareil.

W053Q

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 5

Table of

Contents

Introduction......................................................................................... 5

Model Identification ............................................................................. 5

Customer Service.................................................................................. 6

Wiring Diagram.................................................................................... 6

Serial Plate Location............................................................................. 7

Safety Information .............................................................................. 9

Important Safety Instructions ............................................................... 10

Specifications and Dimensions........................................................... 13

Cabinet Dimensions.............................................................................. 14

Cabinet Dimensions – Stacked Model.................................................. 15

Exhaust Outlet Locations...................................................................... 16

Gas Connection Locations.................................................................... 17

Electrical Connection Locations........................................................... 18

Steam Connection Locations................................................................ 19

Installation........................................................................................... 21

Pre-Installation Inspection.................................................................... 21

Location Requirements......................................................................... 21

Tumbler Enclosure................................................................................ 22

Position and Level the Tumbler............................................................ 23

Installing Accessory Timing Cam ........................................................ 24

Removal of Existing Timing Cam................................................... 24

Installation of New Timing Cam ..................................................... 24

Before Placing Tumbler into Service ................................................... 25

Required for CE Marked (European) Models Only......................... 26

Installing Gas Drying Tumblers in the European Union...................... 27

General Information......................................................................... 27

Basic Configuration ......................................................................... 28

Specific Conversion Procedures...................................................... 29

Exhaust Requirements ....................................................................... 37

Layout................................................................................................... 37

Make-Up Air......................................................................................... 37

Venting ................................................................................................. 37

Individual Venting ........................................................................... 38

Manifold Venting............................................................................. 39

Gas Requirements............................................................................... 43

Gas Supply Pipe Sizing and Looping ................................................... 45

High Altitude Orifice Sizing................................................................. 47

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Electrical Requirements..................................................................... 49

Grounding Instructions......................................................................... 49

Service/Ground Location...................................................................... 50

Connecting Electrical Service............................................................... 51

Configuring Your Tumbler for Other Service Voltages.................. 51

Stacked Tumbler Electrical Connections......................................... 52

For CE Marked Models Only .......................................................... 52

Conversion Instructions........................................................................ 53

Ferrite Ring Installation........................................................................ 56

Electrical Requirements for Gas and Steam Models............................ 57

Electrical Requirements for Electric Models........................................ 59

Steam Requirements........................................................................... 63

Piping Recommendations..................................................................... 63

Adjustments......................................................................................... 65

Loading Door Switch............................................................................ 65

Airflow Switch...................................................................................... 66

Door Strike............................................................................................ 66

Removing Tumbler from Service...................................................... 67

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 7

Introduction

Model Identification

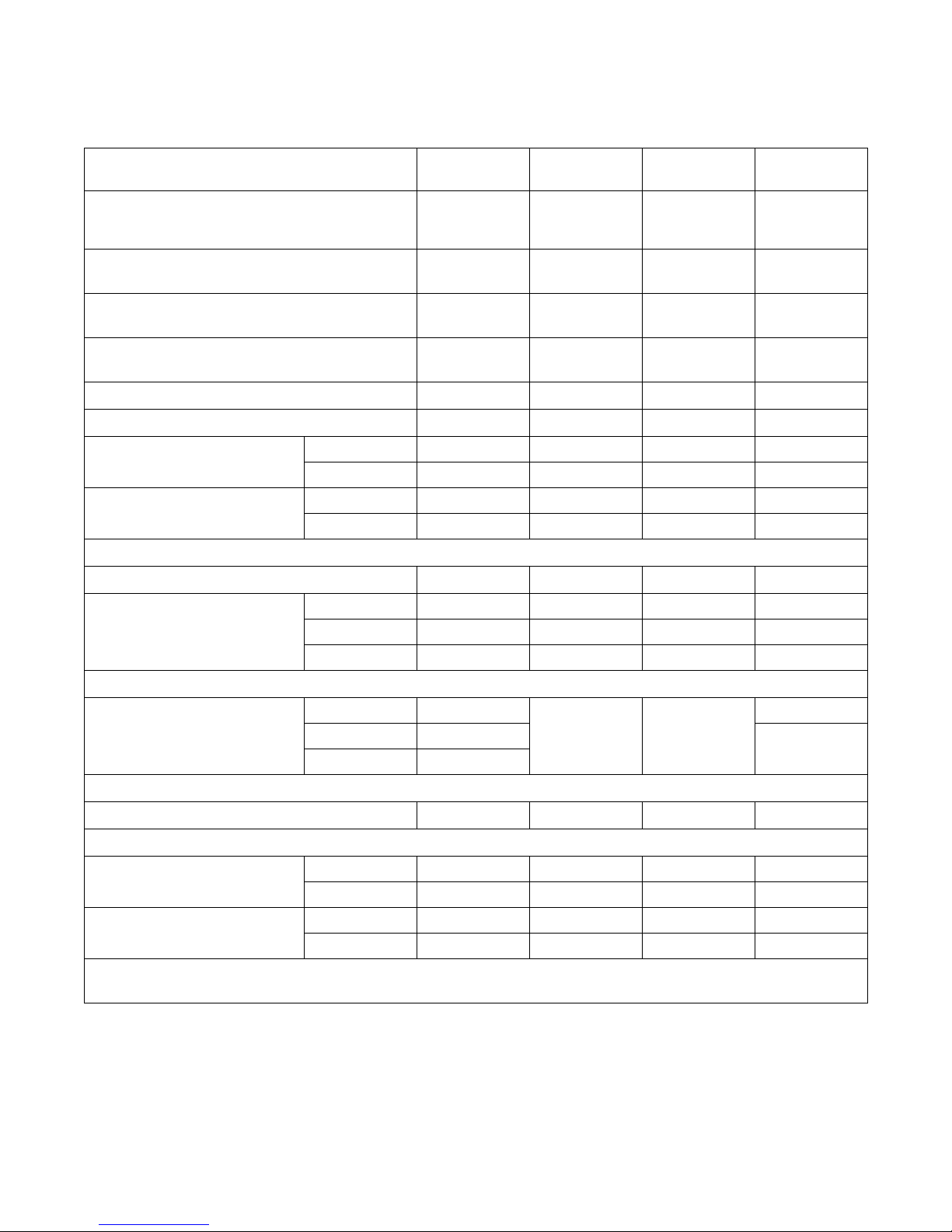

Information in this manual is applicable to these models. †

Gas Steam Electric

25 Pound

(220 Liter)

30 Pound

(270 Liter)

30 Pound

Stacked

(300 Liter)

35 Pound

(350 Liter)

DA0220SRG

DC0220SFG

DC0220SRG

DT0220SFG

DT0220SRG

GC0220SRG

GT0220SRG

JA0220SRG

JC0220SFG

DA0270SRG

DC0270SFG

DC0270SRG

DT0270SFG

DT0270SRG

GC0270SFG

GC0270SRG

GT0270SFG

GT0270SRG

JA0270SRG

DC0300DFG

DC0300DRG

DT0300DFG

DT0300DRG

JA0300DRG

JC0300DFG

JC0300DRG

JT0300DFG

AT0350SRG

DA0350SRG

DC0350SFG

DC0350SRG

DT0350SFG

DT0350SRG

JA0350SRG

JC0350SFG

JC0220SRG

JT0220SFG

JT0220SRG

SA0220SRG

SC0220SFG

SC0220SRG

ST0220SFG

ST0220SRG

JC0270SFG

JC0270SRG

JT0270SFG

JT0270SRG

SA0270SRG

SC0270SFG

SC0270SRG

ST0270SFG

ST0270SRG

JT0300DRG

NT0300DRG

SA0300DRG

SC0300DFG

SC0300DRG

ST0300DFG

ST0300DRG

JC0350SRG

JT0350SFG

JT0350SRG

SA0350SRG

SC0350SFG

SC0350SRG

ST0350SFG

ST0350SRG

DC0220SSH

DC0220SSL

DT0220SSH

DT0220SSL

GC0220SSL

GT0220SSL

JC0220SSH

DC0270SSH

DC0270SSL

DT0270SSH

DT0270SSL

GC0270SSH

GC0270SSL

GT0270SSH

GT0270SSL

DC0300DSH

DC0300DSL

DT0300DSH

DT0300DSL

JC0300DSH

JC0300DSL

AT0350SSH

AT0350SSL

DC0350SSH

DC0350SSL

DT0350SSH

DT0350SSL

JC0350SSH

JC0220SSL

JT0220SSH

JT0220SSL

SC0220SSH

SC0220SSL

ST0220SSH

ST0220SSL

JC0270SSH

JC0270SSL

JT0270SSH

JT0270SSL

SC0270SSH

SC0270SSL

ST0270SSH

ST0270SSL

JT0300DSH

JT0300DSL

SC0300DSH

SC0300DSL

ST0300DSH

ST0300DSL

JC0350SSL

JT0350SSH

JT0350SSL

SC0350SSH

SC0350SSL

ST0350SSH

ST0350SSL

DC0220SEL

DT0220SEL

GC0220SEL

JC0220SEL

DC0270SEL

DT0270SEL

GC0270SEL

GT0270SEL

DC0300DEL

DT0300DEL

JC0300DEL

DC0350SEL

DT0350SEL

JC0350SEL

JT0220SEL

SC0220SEL

ST0220SEL

JC0270SEL

JT0270SEL

SC0270SEL

ST0270SEL

JT0300DEL

SC0300DEL

ST0300DEL

JT0350SEL

SC0350SEL

ST0350SEL

† Includes models with the following control suffixes:

CD – rotary coin drop EY – EDC card ready NX – NetMaster coin ready ZC – NetMaster coin network

EC – EDC electronic coin MT – manual timer NY – NetMaster card ready ZR – NetMaster card network

EP – EDC control NC – NetMaster coin OM – OPL micro ZX – NetMaster coin ready network

EX – EDC coin ready NR – NetMaster card RM – reversing OPL micro ZY – NetMaster card ready network

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call the following number:

(920) 748-3121

Ripon, Wisconsin U.S.A.

Wiring Diagram

The wiring diagram is inside the junction or contactor box.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 9

Serial Plate Location

When calling or writing for information about your

product, be sure to mention model and serial numbers.

Model and serial numbers are found on serial plate on

rear of machine, and inside door hinge.

MODEL NO:

SERIAL NO:

V-/ HERTZ/ PHASE

AMPS, WIRES + GROUND

TOTAL kW, MOTOR kW

REQ'D CIRCUIT BREAKER: AMPS

FAN OUTPUT:

@MAX "WC STATIC PRESSURE

EQUIPPED FOR: GAS@ "WC MANIFOLD PRESS.

MIN SUPPLY

PRESSURE:

INPUT: BTU/hr @ BTU/cu.ft.

MADE IN U.S.A./FABRIQUE AU ETATS UNIS/FABRICADO EN LOS ESTADOS UNIDOS 70051001

MODEL NO:

SERIAL NO:

MAX SUPPLY

"WC. "WC.

PRESSURE:

ANS 72152

CLOTHES DRYER.

VOL II

TESTED FOR NATURAL &

LIQUID PETROLEUM GASSES

CGA 72

AMPLFIEDRER

Introduction

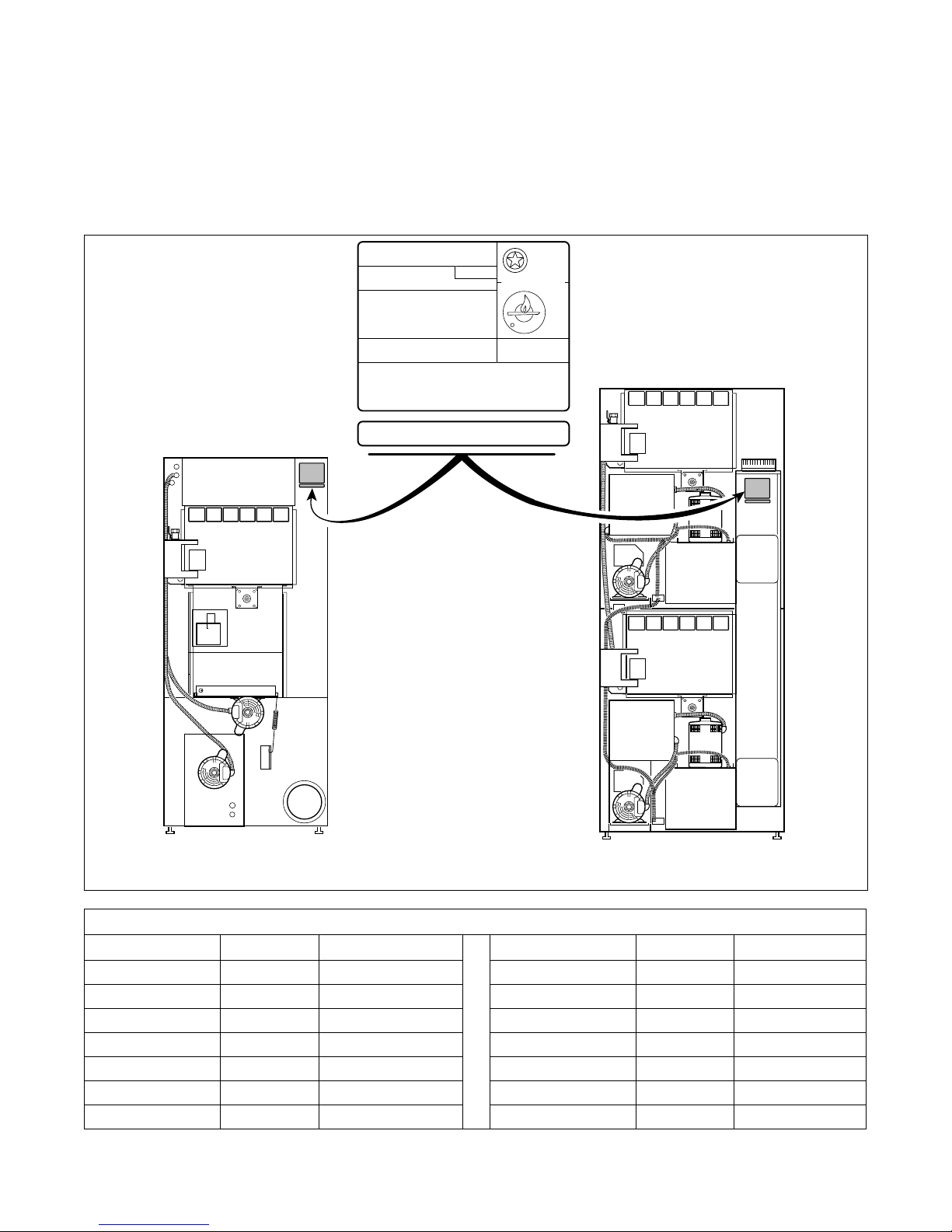

25, 30 AND 35 POUND 30 POUND STACKED

Multiply By To Obtain Multiply By To Obtain

Btu .252 kCal Pounds/sq. inch .06895 Bars

Btu 1055 Joules Pounds/sq. inch .070 kg/sq. cm

Inch 25.4 Millimeters Pounds (lbs.) .454 Kilograms

Inches W.C. .036 Pounds/sq. inch Boiler Horsepower 33,479 Btu/hr.

Inches W.C. .249 kPa Boiler Horsepower 34.5 lbs. Steam/hr.

lbf/inch

ft

70223701

2

(psi) .0369 kPa CFM .471 liters/second

3

28.32 Liters kW 3414 Btu/hr.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

T448I

T448I

Conversion Table

7

Page 10

Notes

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 11

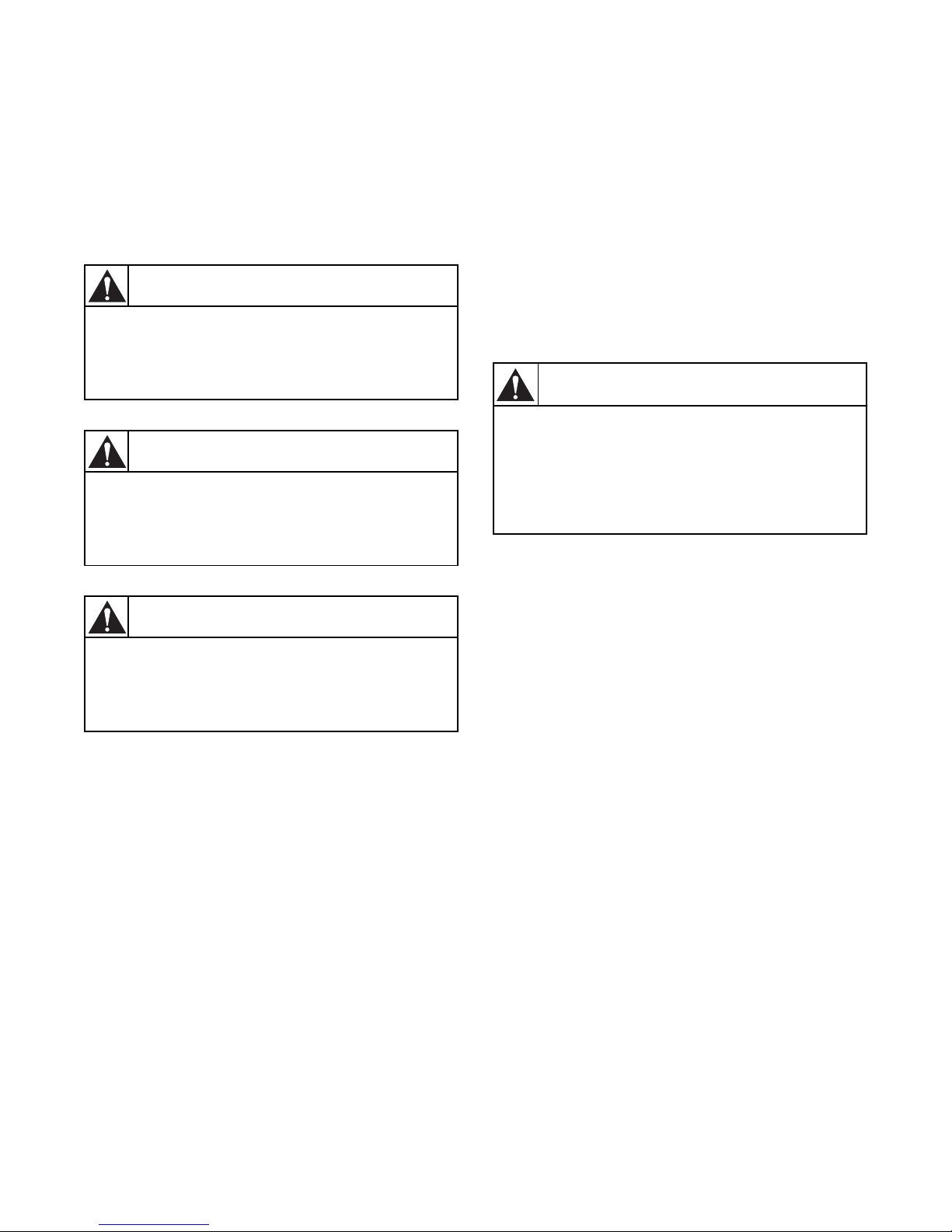

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Precautionary statements (“DANGER,”

“WARNING,” and “CAUTION ”), followed by

specific instructions, are found in this manual and on

machine decals. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

IMPORTANT: Warranty is void unless tumbler is

installed according to instructions in this manual.

Installation should comply with minimum

specifications and requirements detailed in this

manual and applicable local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, and any other

relevant statutory regulations. Due to varied

requirements, applicable local codes should be

thoroughly understood and all pre-installation

work arranged for accordingly.

WARNING

Failure to install, maintain, and/or operate

this machine according to manufacturer’s

instructions may result in conditions which

can produce serious injury, death and/or

property damage.

W051

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not meant

to cover all possible conditions and situations that

may occur. It must be understood that common

sense, caution and carefulness are factors which

CANNOT be built into this tumbler. These factors

MUST BE supplied by the person(s) installing,

maintaining or operating the tumbler.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Always contact your dealer, distributor, service agent

or the manufacturer on any problems or conditions you

do not understand.

9

Page 12

Safety Information

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your tumbler, read and follow these

basic precautions:

W359

WARNING

Save These Instructions

Important Safety Instructions

1. Read all instructions before using the tumbler.

2. Refer to the Grounding Instructions for the

proper grounding of the tumbler.

3. Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not allow children to play on or in the

tumbler. Close supervision of children is

necessary when the tumbler is used near children.

This is a safety rule for all appliances.

5. Before the tumbler is removed from service or

discarded, remove the door to the drying

compartment and the door to the lint

compartment.

6. Do not reach into the tumbler if the cylinder is

revolving.

7. Do not install or store the tumbler where it will

be exposed to water and/or weather.

8. Do not tamper with the controls.

9. Do not repair or replace any part of the tumbler,

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

10. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

12. Always clean the lint filter daily.

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust, and dirt.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

14. The interior of the tumbler and the exhaust duct

should be cleaned periodically by qualified

service personnel.

15. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Tumbler will not operate with the loading door

open. DO NOT bypass the door safety switch to

permit the tumbler to operate with the door open.

The tumbler will stop tumbling when the door is

opened. Do not use the tumbler if it does not stop

rotating when the door is opened or starts rotating

without pressing or turning the START

mechanism. Remove the tumbler from use and

call the service person.

17. Tumbler will not operate with lint panel open.

DO NOT bypass lint panel safety switch to

permit the tumbler to operate with the lint panel

open.

18. Do not put articles soiled with vegetable or

cooking oil in the tumbler, as these oils may not

be removed during washing. Due to the

remaining oil, the fabric may catch on fire by

itself.

19. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc. or anything containing wax or

chemicals such as in mops and cleaning cloths, or

anything dry-cleaned at home with dry-cleaning

solvent in the tumbler.

20. Use the tumbler only for its intended purpose,

drying water-washed fabrics.

21. ALWAYS disconnect the electrical power to the

tumbler before servicing. Disconnect power by

shutting off appropriate breaker or fuse.

22. Install this tumbler according to these

Installation Instructions. All connections for

electrical power, grounding, and gas supply must

comply with local codes and be made by licensed

personnel when required.

70223701

Page 13

Safety Information

23. Remove laundry immediately after tumbler stops.

24. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiberglass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiberglass.

26. Always follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the tumbler with any guards and/or

panels removed.

28. DO NOT operate the tumbler with missing or

broken parts.

29. DO NOT bypass any safety devices.

30. Solvent vapors from dry-cleaning machines

create acids when drawn through the heater of the

drying unit. These acids are corrosive to the

tumbler as well as to the laundry load being

dried. Be sure make-up air is free of solvent

vapors.

31. Failure to install, maintain, and/or operate this

machine according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

WARNING

To reduce the risk of serious injury, install

lockable door(s) to prevent public access to

rear of tumblers.

W055

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Notes

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 15

Specifications and Dimensions

Specifications 25 Pound 30 Pound

Noise Level Measured during Operation at

Operator Position of 1 meter in Front of

Machine and 1.6 meters from Floor

Net Weight (approximate):

pounds (kg)

Cylinder Size:

inches (mm)

Cylinder Capacity (dry weight):

pounds (kg)

Drive Motor Horsepower

Fan Motor Horsepower

Maximum Airflow per

Pocket: C.F.M. (L/sec)

Maximum Static Back

Pressure: Inches W.C. (mbar)

Gas Connection

Gas Consumption

50 Hertz 410 (194) 410 (194) 320 (151) 470 (222)

60 Hertz 450 (212) 450 (212) 350 (165) 470 (222)

50 Hertz 0.6 (1.5) 0.6 (1.5) 0.8 (2.0)* 0.5 (1.3)

60 Hertz 0.8 (2.0) 0.8 (2.0) 0.9 (2.3)* 0.6 (1.5)

kW 18.7 21.4 21.4** 26.4

Mj/hr67.57777**95

Btu/hr 64,000 73,000 73,000** 90,000

30 Pound

Stacked

60 dBA 61 dBA 63 dBA 66 dBA

330

(150)

26.5 x 24

(673 x 610)

25

(11.3)

1/4 1/4 1/4** 1/4

1/4 1/4 1/4** 1/4

Gas Models

1/2 in. NPT 1/2 in. NPT 1/2 in. NPT 1/2 in. NPT

350

(159)

26.5 x 30

(673 x 762)

30

(13.6)

575

(261)

30 x 26

(762 x 660)

2 x 30

(2 x 13.6)

35 Pound

360

(163)

30 x 30

(762 x 762)

35

(15.9)

Heating Element

Steam Plumbing

At 80 psig (5.5 bar)

At 15 psig (1.03 bar)

*with both pockets running

**for each pocket

Electric Models

380/50/3 9 kW

400/50/3 10 kW

Standard 12 kW

Steam Models

3/4 in. NPT 3/4 in. NPT 3/4 in. NPT 3/4 in. NPT

Steam Consumption Boiler Horsepower (Btu/hr)

SH Models 3.0 (100,000) 3.0 (100,000) 2.3 (77,000)** 3.4 (113,800)

SL Models 2.4 (80,300) 2.4 (80,300) 1.9 (63,600)** 2.8 (93,700)

SH Models 2.1 (70,300) 2.1 (70,300) 1.6 (53,500)** 2.4 (80,300)

SL Models 1.7 (56,900) 1.7 (56,900) 1.3 (43,500)** 2.0 (67,000)

21 kW 21 kW**

21 kW

24 kW

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

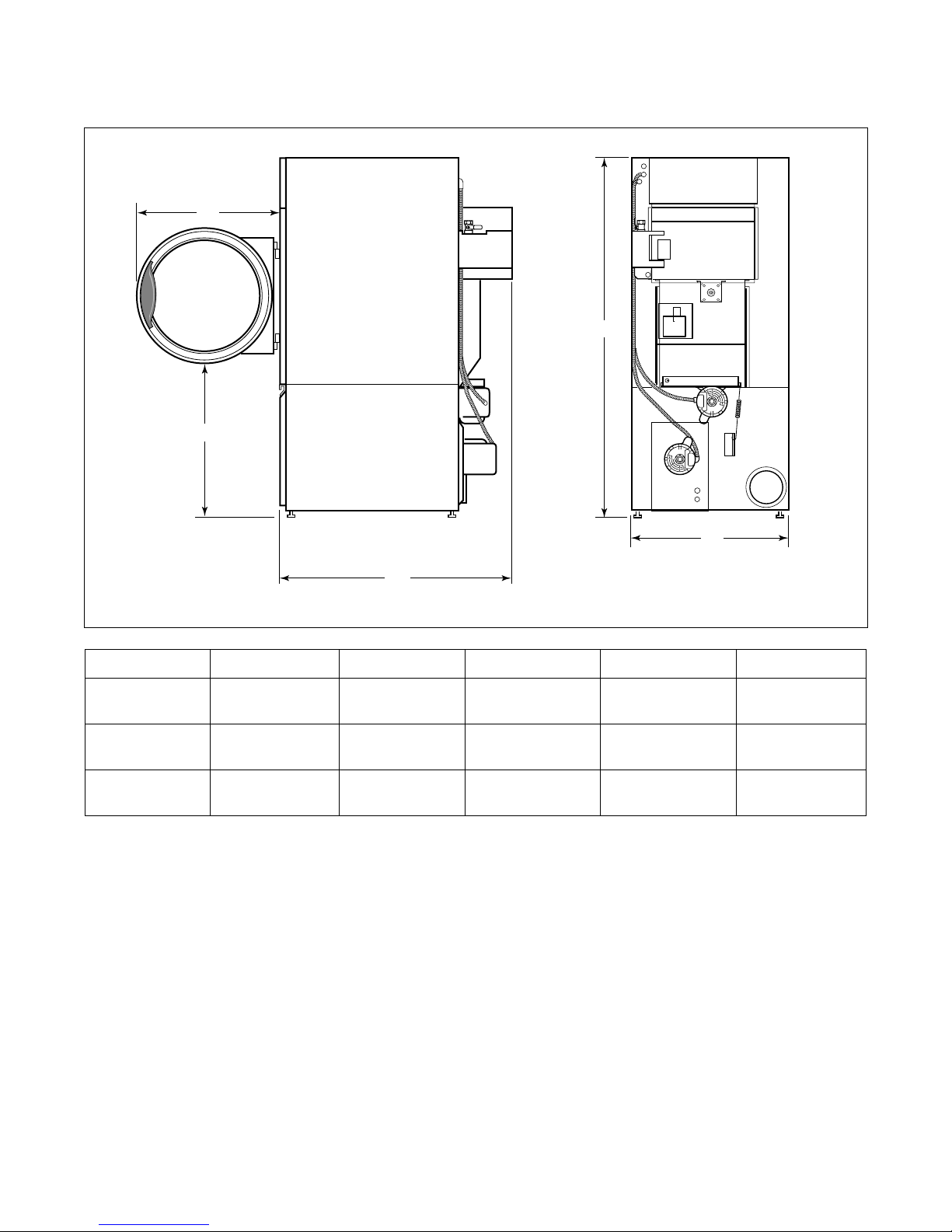

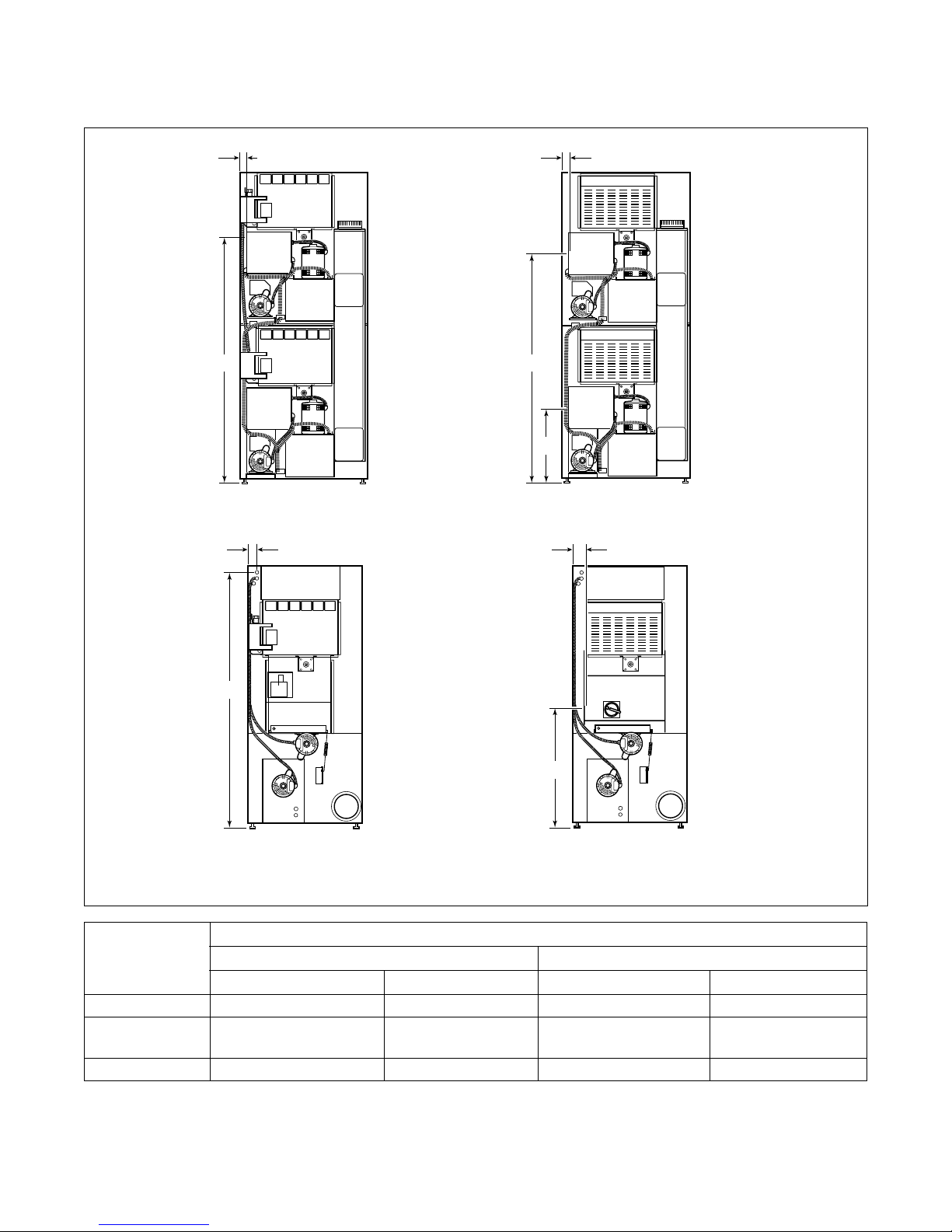

Specifications and Dimensions

Cabinet Dimensions

A

B

D

E

C

Models A B C D E

25 Pound 26.25 in.

(667 mm)

30 Pound 26.25 in.

(667 mm)

35 Pound 28 in.

(711 mm)

27.5 in.

(699 mm)

27.5 in.

(699 mm)

27.5 in.

(699 mm)

38.875 in.

(987 mm)

44.875 in.

(1140 mm)

44.875 in.

(1140 mm)

63.875 in.

(1622 mm)

63.875 in.

(1622 mm)

63.875 in.

(1622 mm)

NOTE: Facia panels available to increase height of

single pocket models to 72.25 inches (1835 mm) and

76.25 inches (1938 mm).

T370I

T370I

28 in.

(711 mm)

28 in.

(711 mm)

31.5 in.

(800 mm)

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 17

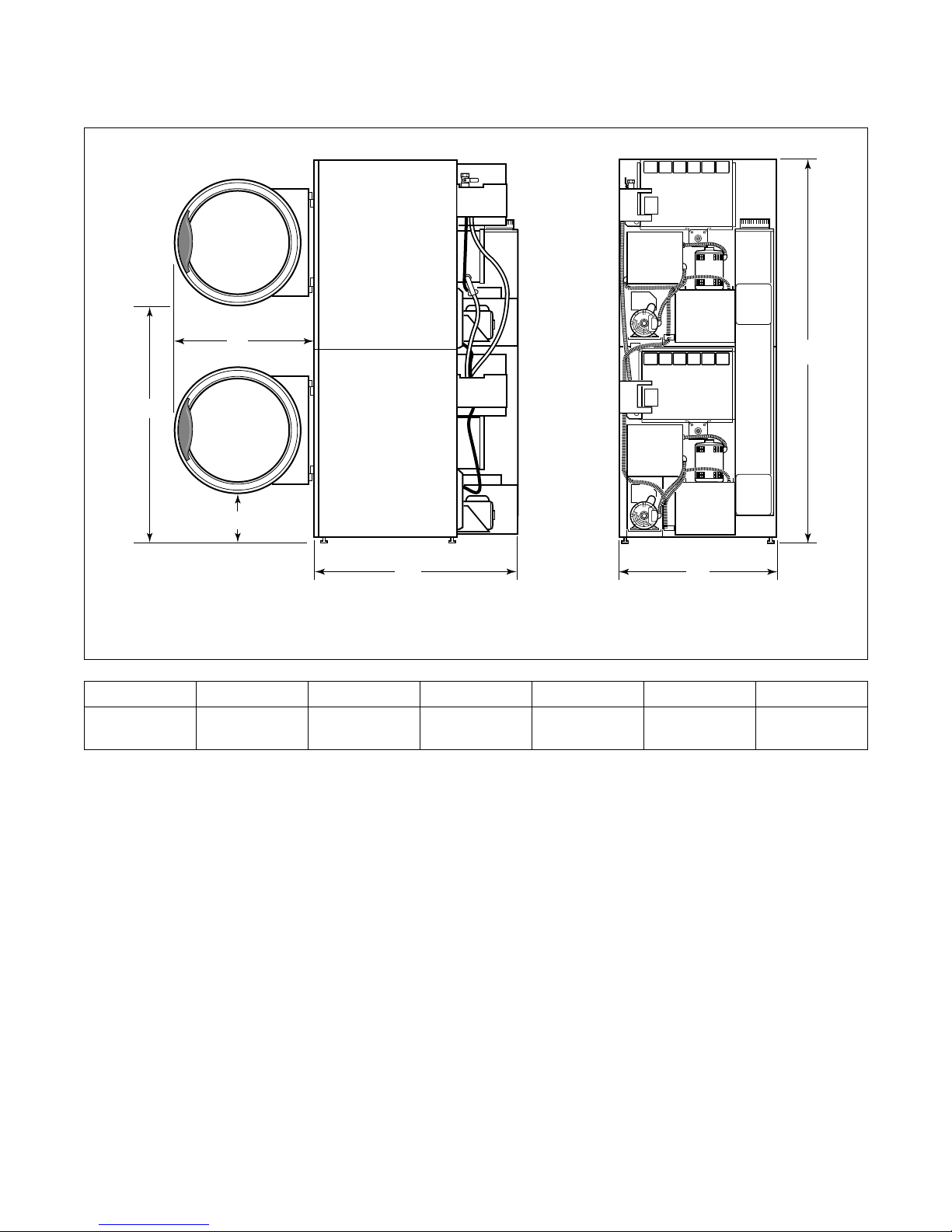

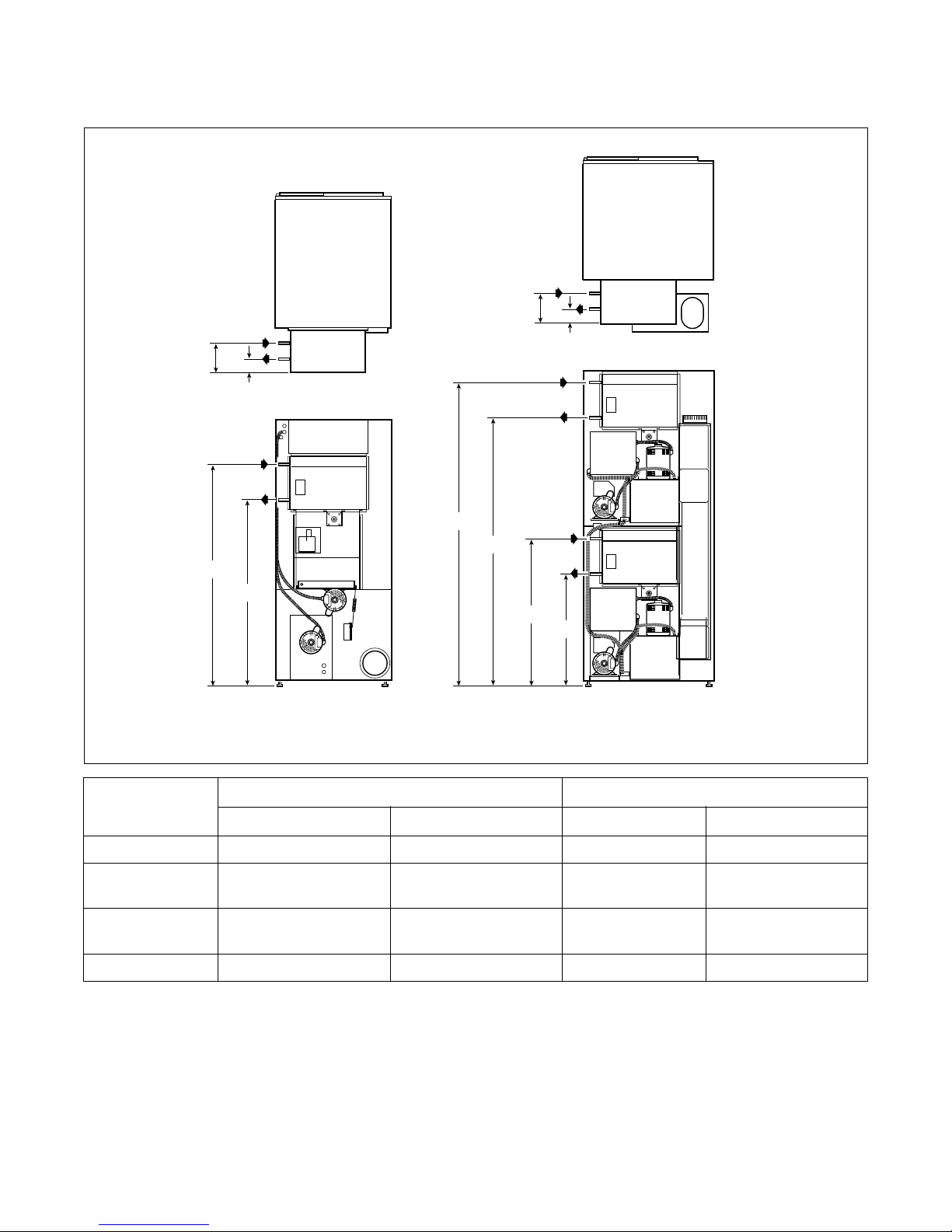

Cabinet Dimensions – Stacked Model

Specifications and Dimensions

B

A

C

D

30 POUND STACKED

E

F

T439I

T439I

ModelsABCDEF

30 Pound

Stacked

48 in.

(1219 mm)

28 in.

(711 mm)

10 in.

(254 mm)

42.875 in.

(1090 mm)

31.5 in.

(800 mm)

76.25 in.

(1937 mm)

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

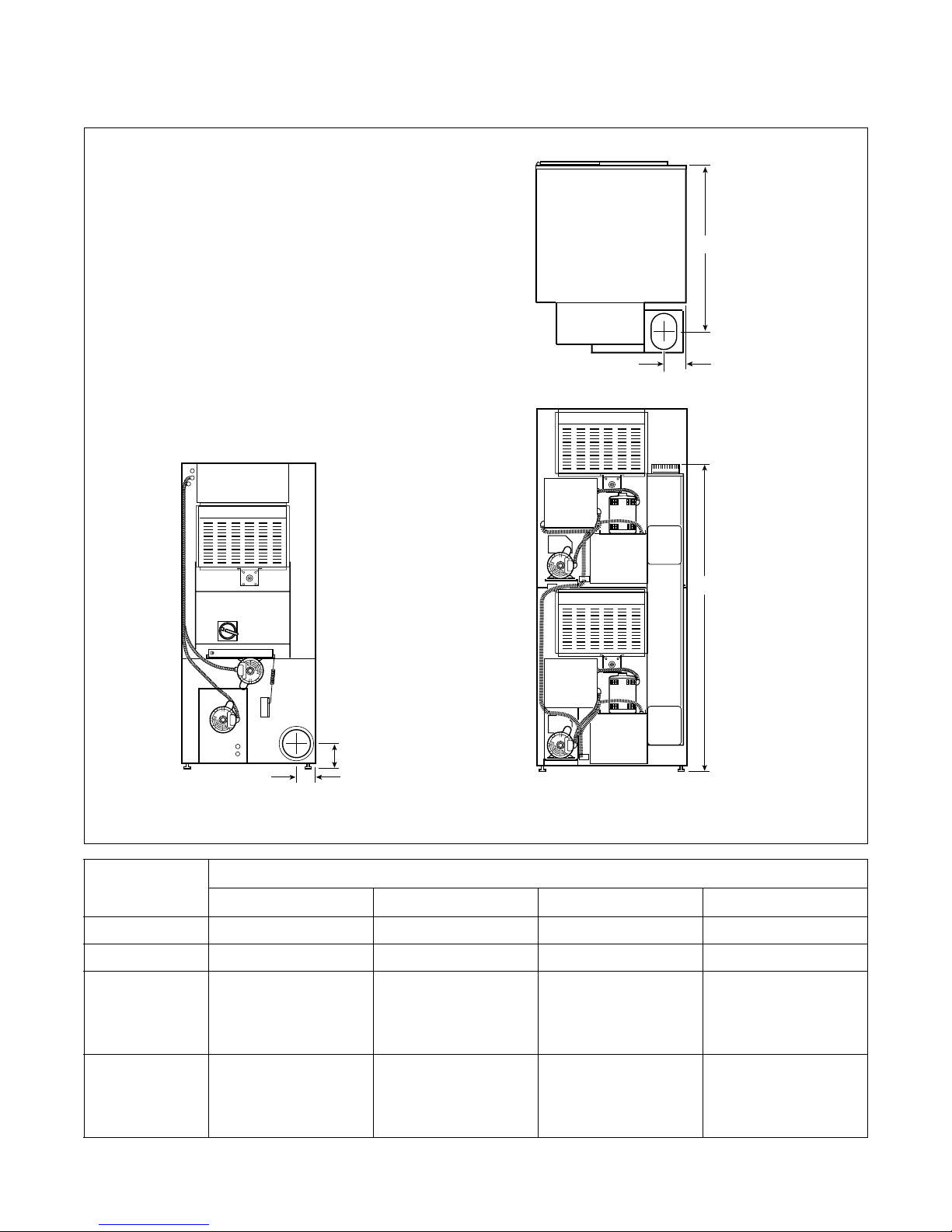

Page 18

Specifications and Dimensions

Exhaust Outlet Locations

C

A

B

B

A

25, 30 AND 35 POUND 30 POUND STACKED

Rear Exhaust

Models

Diameter A B C

25/30 Pound 6 in. (152 mm) 3.875 in. (99 mm) 4.625 in. (117 mm) N/A

35 Pound 8 in. (203 mm) 4.875 in. (124 mm) 5.625 in. (143 mm) N/A

30 Pound

8 in. (203 mm) 4.875 in. (124 mm) 66.25 in. (1683 mm) 32.63 in. (829 mm)

Stacked

(Manufactured

Before 3/22/99)

T479I

30 Pound

Stacked

Elliptical

Fits 8 in. (203 mm)

(Manufactured

After 3/22/99)

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4.325 in. (110 mm) 64.25 in. (1632 mm) 35.75 in. (908 mm)

70223701

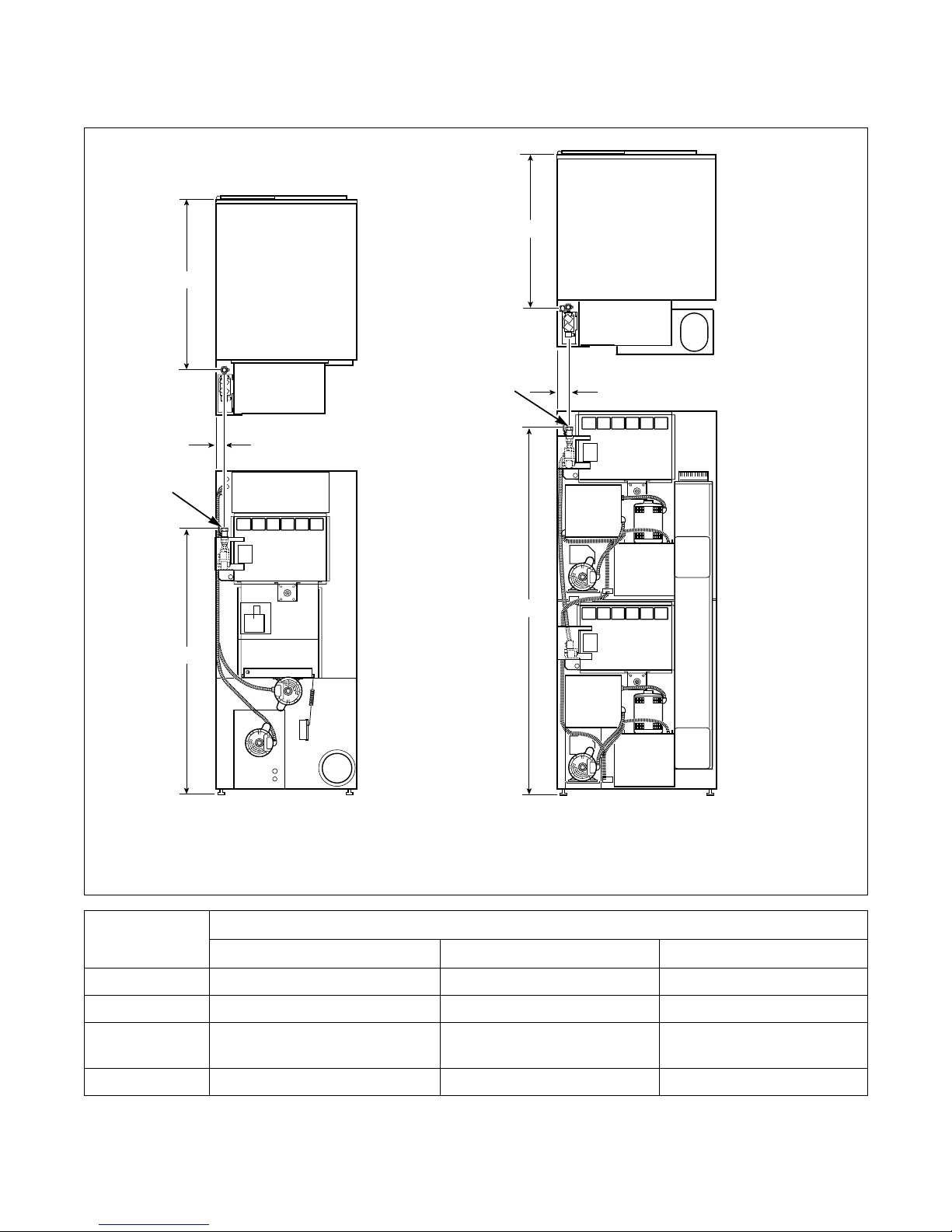

Page 19

Gas Connection Locations

C

Specifications and Dimensions

C

1

B

1

A

A

25, 30 AND 35 POUND 30 POUND STACKED

B

T482 I

1 1/2 in. NPT

Models

ABC

25 Pound 59 in. (1500 mm) 1.5 in. (38.1 mm) 29 in. (737 mm)

30 Pound 59 in. (1500 mm) 1.5 in. (38.1 mm) 35 in. (889 mm)

30 Pound

80 in. (2032 mm) 2.5 in. (64 mm) 30.5 in. (775 mm)

Stacked

35 Pound 59 in. (1500 mm) 2.5 in. (64 mm) 35 in. (889 mm)

NOTE: All connections use 1/2 inch NPT pipe.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

T482I

Gas Connection

17

Page 20

Specifications and Dimensions

Electrical Connection Locations

B

A

30 POUND STACKED

GAS AND STEAM

D

C

C

30 POUND STACKED

ELECTRIC

DB

A

C

T480I

25, 30 AND 35 POUND

GAS AND STEAM

25, 30 AND 35 POUND

ELECTRIC

Electrical Service

Models

Gas and Steam Models Electric Models

ABCD

25/30 Pound 62.25 in. (1581 mm) 2 in. (51 mm) 28 in. (711 mm) 3.25 in. (83 mm)

30 Pound

Stacked

57 in. (1448 mm) 2 in. (51 mm) 48.5 in. (1232 mm)

11.5 in. (292 mm)

7 in. (178 mm)

35 Pound 62.25 in. (1581 mm) 3 in. (76 mm) 28 in. (711 mm) 4.25 in. (108 mm)

T480I

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 21

Steam Connection Locations

Specifications and Dimensions

C

C

D

A

B

A

B

25, 30 AND 35 POUND

D

A

B

30 POUND STACKED

T481I

Models

ACBD

25/30 Pound 53.75 in. (1365 mm) 7.8 in. (198 mm) 42.5 in. (1080 mm) 6.5 in. (165 mm)

30 Pound Stacked

74.15 in. (1883 mm) 11.6 in. (295 mm) 62.9 in. (1598 mm) 10.25 in. (260 mm)

(Upper)

30 Pound Stacked

36.6 in. (930 mm) 11.6 in. (295 mm) 25.3 in. (643 mm) 10.25 in. (260 mm)

(Lower)

35 Pound 53.75 in. (1365 mm) 7.8 in. (198 mm) 42.5 in. (1080 mm) 6.5 in. (165 mm)

NOTE: All connections use 3/4 inch NPT pipe.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Inlet Outlet

19

Page 22

Notes

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 23

Installation

IMPORTANT: Warranty is void unless tumbler is

installed according to instructions in this manual.

Installation should comply with minimum

specifications and requirements detailed herein,

and with applicable local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, and any other

relevant statutory regulations. Due to varied

requirements, applicable local codes should be

thoroughly understood and all pre-installation

work arranged for accordingly.

Pre-Installation Inspection

Upon delivery, visually inspect crate carton and parts

for any visible shipping damage. If the crate, carton, or

cover is damaged or signs of possible damage are

evident, have the carrier note the condition on the

shipping papers before the shipping receipt is signed,

or advise the carrier of the condition as soon as it is

discovered.

Remove the crate and protective cover as soon as

possible and check the items listed on the packing list.

Advise the carrier of any damaged or missing articles

as soon as possible. A written claim should be filed

with the carrier immediately if articles are damaged or

missing.

Location Requirements

The tumbler must be installed on a level floor capable

of supporting 100 pounds per square foot

(488.3 kg/sq. m). Floor covering materials such as

carpeting or tile should be removed.

To assure compliance, consult local building code

requirements. The tumbler must not be installed or

stored in an area where it will be exposed to water

and/or weather.

IMPORTANT: DO NOT block the airflow at the

rear of the tumbler with laundry or other articles.

Doing so would prevent adequate air supply to the

combustion chamber of the tumbler.

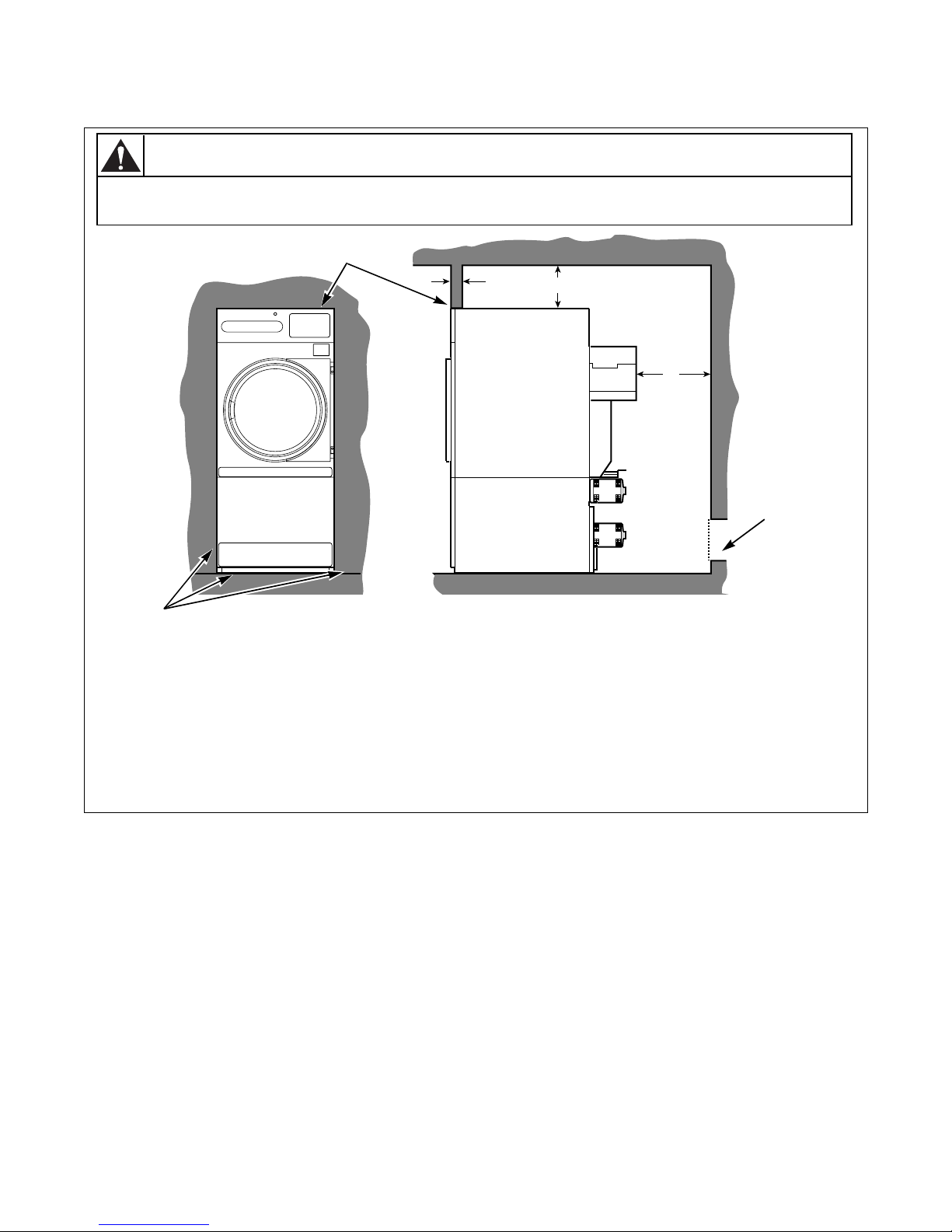

A typical tumbler enclosure is shown in Figure 1. Note

that the enclosure touches the tumbler top and side

panels. Also, note the minimum and maximum

dimensions. Be aware that there may be local codes

and ordinances which must be complied with.

WARNING

To reduce the risk of serious injury, install

lockable door(s) to prevent public access to

rear of tumblers.

W055

Material Required (Obtain Locally)

All Models

Gas Models

Steam

Models

One fused disconnect switch or circuit

breaker.

One gas shut-off valve for gas service

line to each tumbler.

One steam shut-off valve for steam

service line to be connected upstream of

solenoid steam valve.

Two steam shut-off valves for each

condensate return line.

Flexible steam hoses with a 125 psig

(pounds per square inch gauge)

(8.78 kg/sq. cm) working pressure for

connecting steam coils. Refer to

Figure 18 for sizing and connection

configurations.

Two steam traps for steam coil outlet to

condensate return line.

Two vacuum breakers for condensate

return lines.

Table 1

IMPORTANT: Install tumblers with sufficient

clearance for servicing and operation. Refer to

Figure 1.

IMPORTANT: Keep tumbler area clear and free

from combustible materials, gasoline and other

flammable vapors and liquids.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Installation

Tumbler Enclosure

WARNING

To reduce the risk of severe injury, clearance of tumbler cabinet from combustible

construction must conform to the minimum clearances.

1

W056

2

6

1 Zero Clearance Permitted

2 4 in. (102 mm)

3 12 in. (305 mm) Minimum Clearance

4 24 in. (610 mm) minimum – 36 in. (914 mm) recommended for maintenance purposes.

5 Provision for make-up air: Minimum 1 square foot required per tumbler (2 square feet for stacked model) –

Location for reference only. May be anywhere behind tumbler.

6 Zero Clearance Permitted

NOTE: Shaded areas indicate adjacent structure.

3

4

T484I

5

T484I

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 1

70223701

Page 25

Installation

1

2

Position and Level the Tumbler

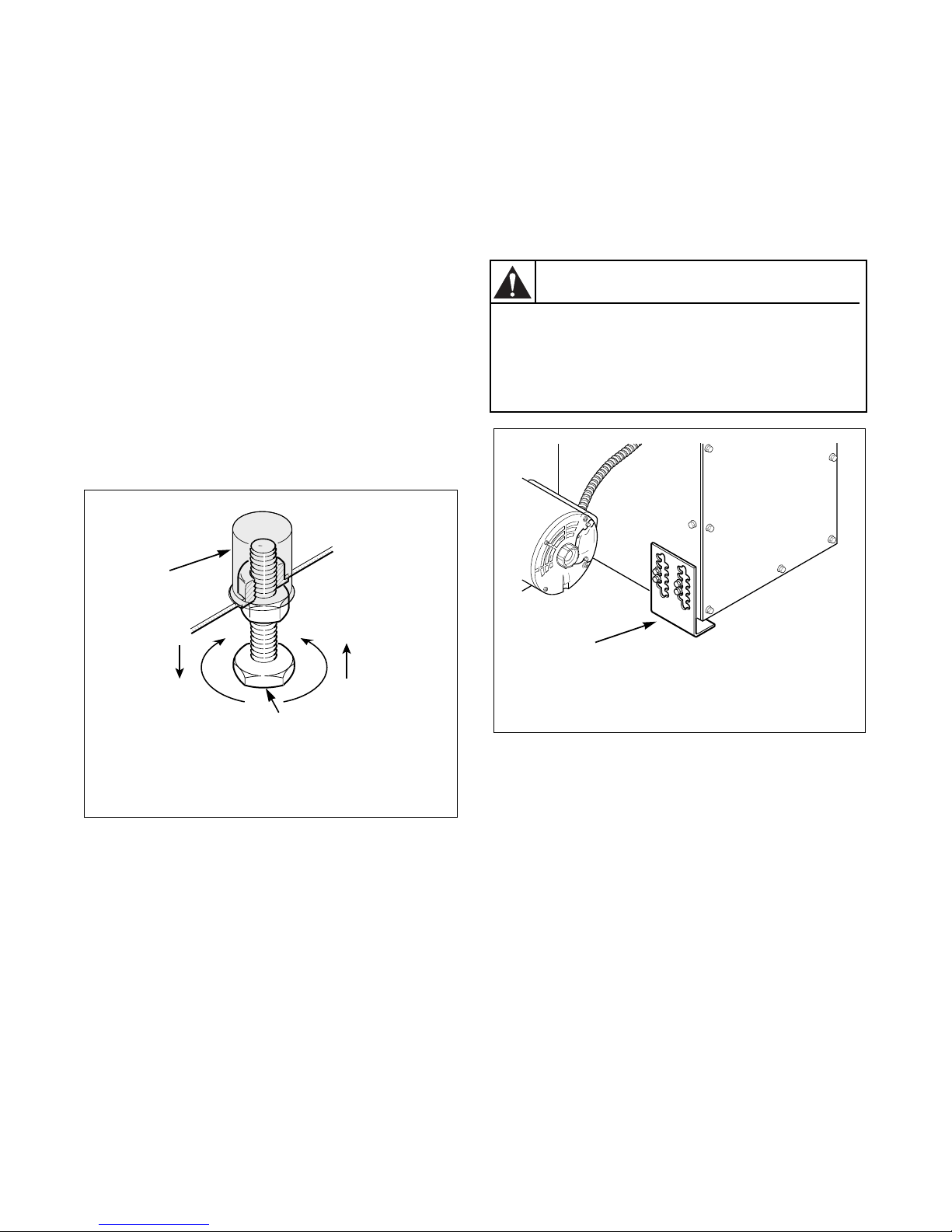

Remove lint panel door, and unscrew the four shipping

bolts (one at each corner). Remove tumbler from skid.

NOTE: Do not throw bolts away – they are the

leveling legs.

Remove four nuts from the literature packet, and screw

one fully onto each leveling leg.

Screw the four leveling legs (bolts) back into the level

adjusting fittings from the bottom.

Slide tumbler to its permanent location. Adjust the

leveling legs until the unit is level within 1/8 inch

(32 mm). Tumbler must not rock. Lock leveling legs

with nuts installed.

IMPORTANT: Keep tumbler as close to floor as

possible. The unit must rest firmly on floor so

weight of tumbler is evenly distributed.

Stacked Tumblers Only:

The stacked tumbler (300D) has a fifth leveling leg

which is enclosed with this manual. It MUST BE

installed on the lower left side of the blower housing to

stabilize the tumbler. Refer to Figure 3.

After leveling with the four cabinet leveling legs,

install the fifth so that it contacts the floor.

CAUTION

The stacked drying tumbler has a 5th

leveling leg on the blower housing. It is

very important to properly adjust this leg.

Unit is back heavy and could rock or tip.

W250

1

T467I

T467I

T451I

T451I

1 Plastic Cap

2 Leveling Leg

Figure 2

1 Fifth Leg

Figure 3

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Installation

Installing Accessory Timing Cam

(Metered Models)

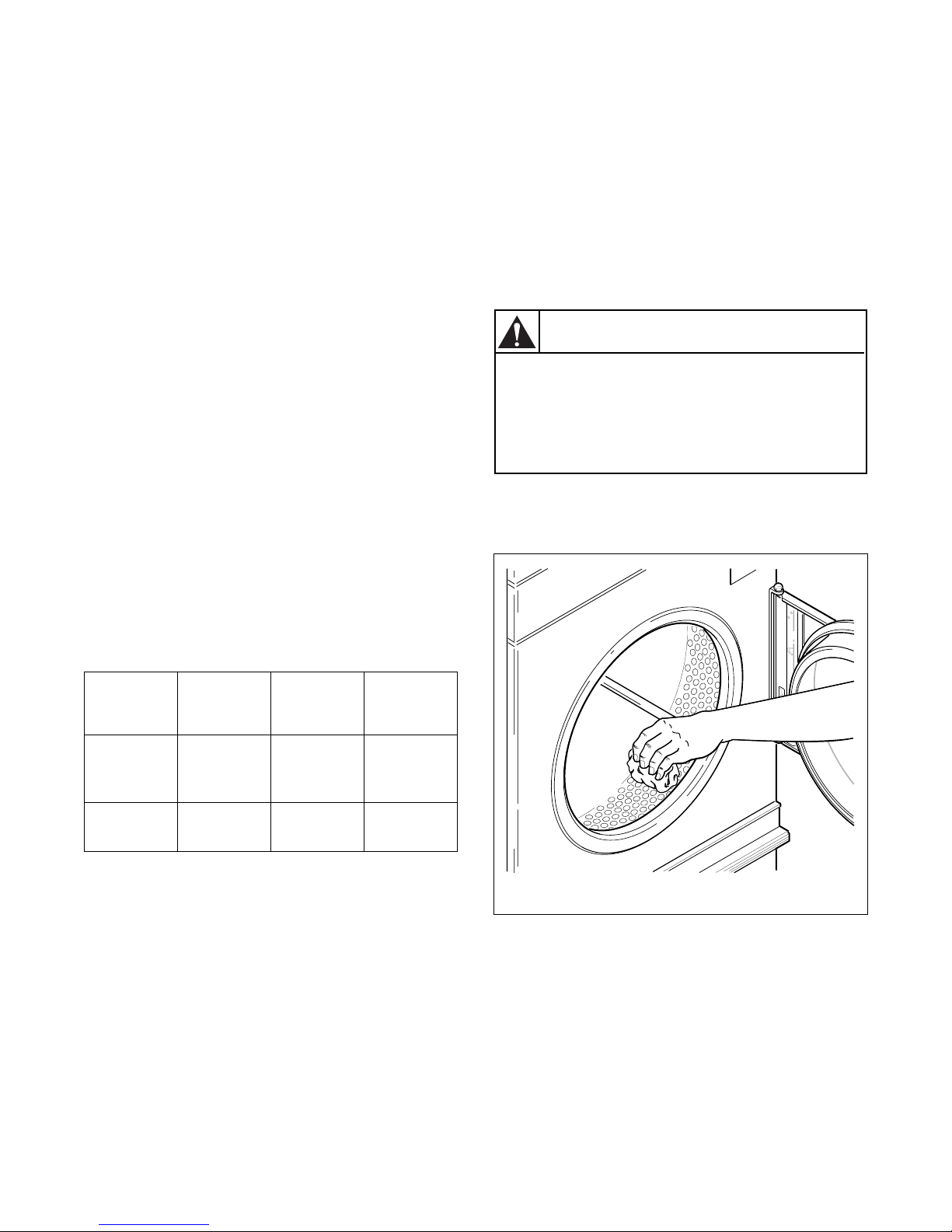

Coin Drop tumblers have eight accessory cams in the

literature packet. These allow you to change your

vending times. Refer to Table 2. Timer motor RPM is

printed on the timer motor.

Cam Pins

21530

31020

47.515

5612

6510

8 3.75 7.5

10 3 6

12 2.5 5

1/30 RPM

Timer Motor

Table 2

1/60 RPM

Timer Motor

Installation of New Timing Cam

1. Insert drive into timing cam with wide prong in

wide hole of cam.

2. Position timing cam and drive fork over the timer

shaft, aligning the timer flat with the drive fork

and the “V” notch with one of the ratchet teeth.

3. Press timing cam down firmly to seat timing cam

onto the motor shaft.

1

2

T039I

T039I

1 Line up notch to clear ratchet tooth.

2 Lift gently with narrow blade.

Removal of Existing Timing Cam

1. Rotate cam by hand until “V” notch lines up

beneath the ratchet tooth. Refer to Figure 4.

2. Insert narrow screwdriver under nylon cam, close

to the clock shaft. Lift gently off shaft. Make sure

that pressure is directed upward and that the “V”

notch clears the ratchet tooth.

Figure 4

4. Remove all accumulated time by turning cam

counterclockwise until switch shuts off. Apply

moderate clockwise pressure to fully seated

timing cam and drive against the timing motor

shaft. Meter must be advanced electrically for

one cycle before an accurate measure of time can

be made.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 27

Installation

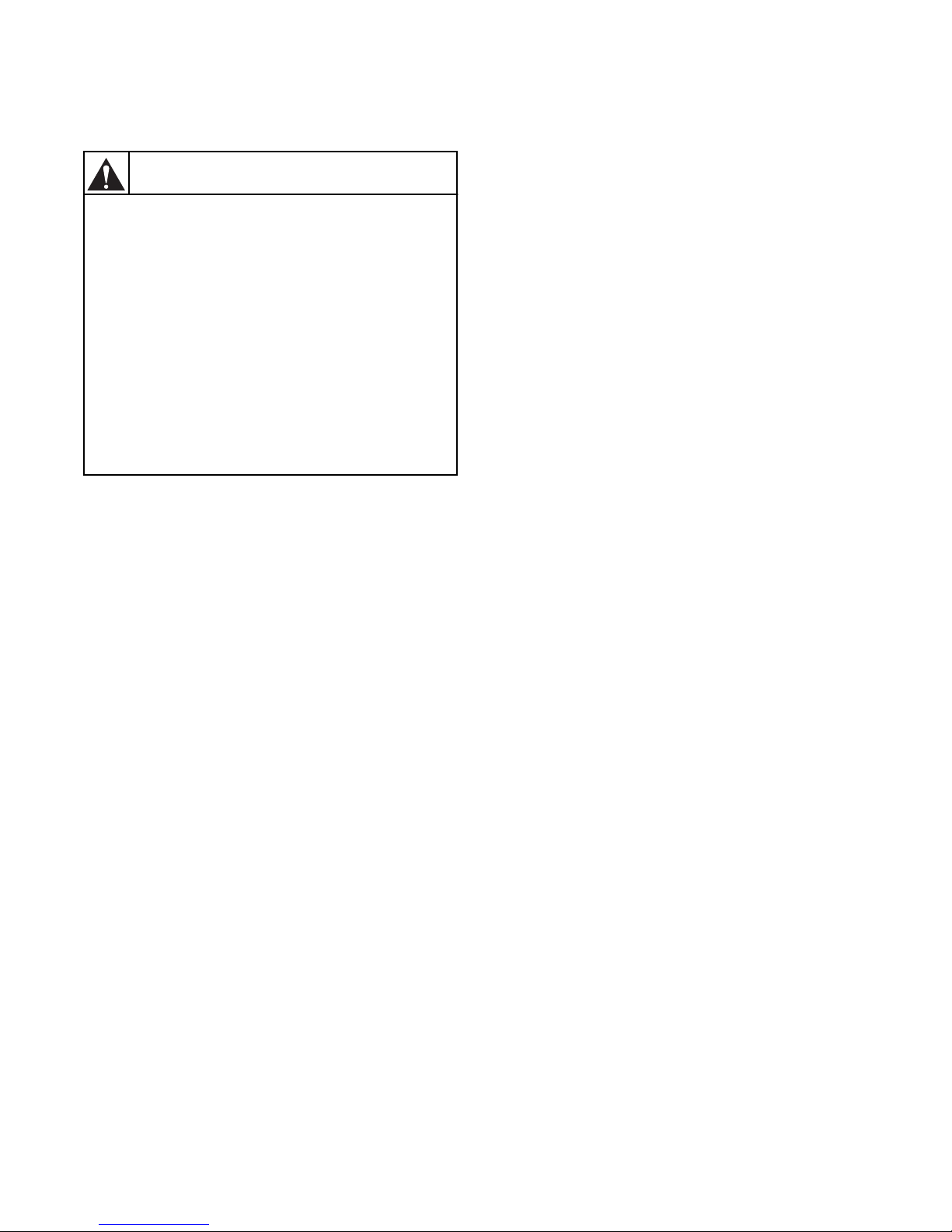

Before Placing Tumbler into Service

1. Remove or open all panels and check accessible

bolts, nuts, screws, terminals, and fittings for

tightness.

2. Replace all panels and guards.

3. Turn on electrical supply to tumbler.

4. Open the supply valve for gas or steam heated

tumblers.

5. After performing the previous checks, start the

tumbler by pressing START. (Refer to the

Operating Manual for detailed instructions.)

Release the start button and open the cylinder

door. The cylinder should stop rotating within

seven seconds after the door is opened a

maximum of 2 inches (51 mm). If it does not,

adjust the cylinder door switch. Refer to

Adjustments section.

IMPORTANT: The electronic ignition system will

attempt to light the gas by sparking for the “trial

for ignition” period (refer to Tab le 3). If gas does

not ignite within this period, the ignition control

will go into a safety lockout and the valve will no

longer open until the control is reset. It may be

necessary to retry several times to bleed air from

the gas lines. To reset, open and close the loading

door and restart tumbler.

7. Check the airflow switch operation by opening

the lint panel. The heating systems should shut

off when the lint panel is opened a maximum of

1-1/2 inches (38 mm).

The airflow switch operation may be affected by

shipping tape still in place, lack of make-up air,

or an obstruction in the exhaust duct. These

should be checked and the required corrective

action taken before attempting to adjust the

airflow switch.

WARNING

The tumbler must not be operated if the

airflow switch does not operate properly.

Faulty airflow switch operation may cause

an explosive gas mixture to collect in the

tumbler.

W072

8. Wipe out the cylinder using an all-purpose

cleaner or detergent and water solution. Refer to

Figure 5.

Location

Europe and

Australia

All others 1-3 10 Open loading

Prepurge

Time

(seconds)

18 10 Press reset

Trial for

Ignition

(seconds)

Table 3

To Reset

Lockout

Condition:

button on rear

of machine

door

If lockout condition persists, check that the manual

gas shut-off valve is in the “ON” position and that

the gas service is properly connected. If condition

still persists, remove tumbler from service.

6. Load the cylinder with a full load of clean rags

and run to remove oil or dirt from cylinder.

T452I

T452I

Figure 5

If the tumbler does not meet ANY of the above

requirements, remove tumbler from use. Refer to

Removing Tumbler from Service section.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Installation

Required for CE Marked (European)

Models Only

Once machine is installed, please be sure to complete

the following items:

● Review and verify machine operation with

customer.

● Leave Operating Instructions and a signed

Declaration of Conformity with customer.

● Leave Model Number Insert with customer, if

applicable.

● Review machine warranty information with

customer.

● Apply warning sticker on front panel of machine,

in language appropriate to country of sale (found

in literature packet).

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 29

Installation

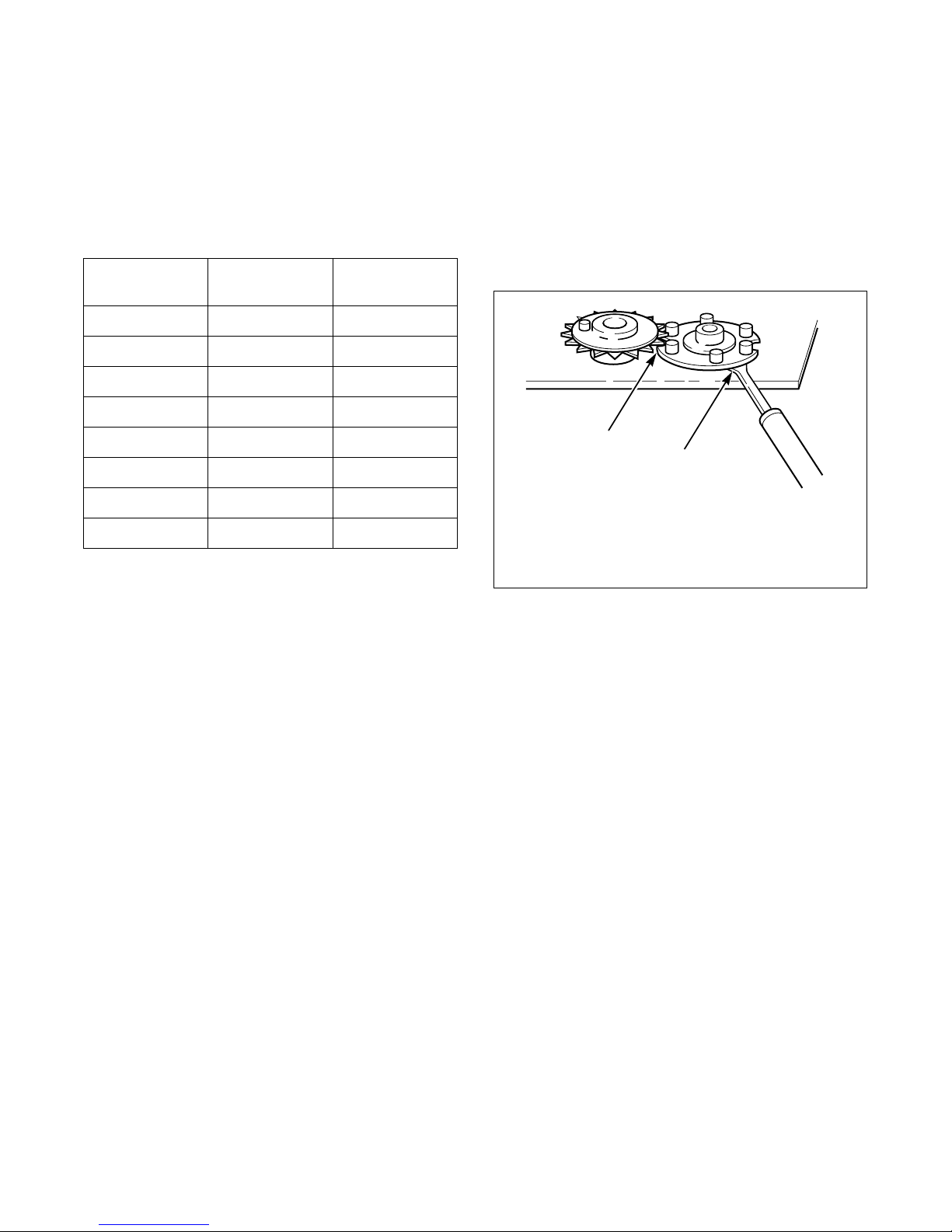

WARNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the

tumbler before servicing.

• Close gas shut-off valve to gas tumbler

before servicing.

• Close steam valve to steam tumbler

before servicing.

• Never start the tumbler with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumbler is properly grounded.

W002

Installing Gas Drying Tumblers in

the European Union

General Information

This information is to be used when installing gas

tumblers in countries, and/or on gases, different than

the machine’s factory configuration. Tumblers are

supplied from the factory for operation on Natural Gas

or L.P. Gas in the countries of GB/IE/PT/ES/IT. To

install machines in any other country, or on any other

gas, requires some level of modification.

Orifices, stickers, block-open kits, regulator springs

and other parts needed for conversions are to be

ordered separately.

Models are built in three different configurations:

● Regulated Natural Gas – Injector is sized for

Natural Gas, second family, group H (E) at

20 mbar inlet pressure. Regulator/governor is

operational. Gas valve CAN be field-converted to

a non-regulating type.

● Unregulated Natural Gas – Injector is sized for

Natural Gas, second family, group E+ at

20.25 mbar inlet pressure. Regulator/governor is

blocked open. Gas valve CANNOT be fieldconverted to a regulating type.

● Unregulated L.P. (Liquefied Petroleum) Gas –

Injector is sized for L.P., third family, group 3+ at

28.37 mbar inlet pressure. Regulator/governor is

blocked open. Gas valve CANNOT be fieldconverted to a regulating type.

Serial plates supplied from the factory are configured

for the countries of GB/IE/PT/ES/IT. These

instructions pertain to the situations when the country

of use or gas supply is different than that on the serial

plate.

The tables referred to describe the different gases that

are available in different EU countries, and how the

machines need to be configured to operate with those

gases. In the EU, there are Natural Gases that do not

allow for machine regulation, and L.P. Gases that must

be regulated. For L.P. Gas, third family B/P at

50 mbar, order Regulated Natural Gas machines and

convert according to tables.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Installation

WARNING

When converting the tumbler to a

different gas or pressure, first verify that

the supply inlet pressure is equipped with

a pressure regulator (located ahead of the

tumbler) that will maintain the gas supply

at the inlet pressure specified.

W430

Basic Configuration

1. Determine the necessary conversion operations to

convert from the factory-supplied configuration

to the desired configuration.

2. Perform the conversions required so the machine

is properly configured for the desired country and

gas (refer to Specific Conversion Procedures

section):

● How to Convert Gas Valve from Regulated to

Unregulated

NOTE: Conversion from regulated to unregulated

is only needed when regulated tumblers were

ordered, but unregulated tumblers were needed.

● How to Change Injector (Orifice) Size

● How to Adjust Gas Valve Governor/Regulator

● How to Change Regulator Spring DE/AT

Only.

3. If applicable, peel off the appropriate country

sticker from Part No. 503382 or M413919

(included with machine) and apply it to the serial

plate over the existing country information. Refer

to Figure 9.

4. If applicable, peel off the appropriate conversion

sticker from Part No. M413800 or M413919

(included with machine) and apply it to the serial

plate over the “ADJUSTED FOR ______ GAS:

______” information. Refer to Figure 9.

SPECIFIED

LOCAL INLET

PRESSURE

2

3

1

1 Gas Shut-Off Valve (Ahead of pressure tap)

2 Pressure Tap

3 Gas Shut-Off Valve (Shown in closed position)

Figure 6

T103K

5. Commission tumbler for use.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 31

Installation

Specific Conversion Procedures

How to Convert Gas Valve from Regulated to

Unregulated

Johnson GM7000 gas valve:

1. Disconnect electrical power from tumbler. Close

gas shut-off valve to tumbler. Refer to Figure 7.

2. Follow instructions in Conversion Kit, Part No.

431485 (Johnson Part No. GM-70 CBP).

11

10

NOTE: This kit does not contain any orifices.

3. Change injector size as required by the

appropriate table according to How to Change

Injector (Orifice) Size.

4. For 220 steam models, L.P. Gas only. Install 220

steam L.P. orifice plate (Part No. 70201901) onto

gas valve bracket. Refer to Figure 7.

5. Commission tumbler for use.

1

2

3

4

9

5

8

7

6

T154K

T154K

1 Gas Shut-Off Valve (Shown in closed position) 7 Part No. 70201901 220 Steam LP Orifice Plate

2 Shut-Off Valve

3 Gas Valve 8 Required Orifice/Injector Pressure

4 Orifice/Injector 9 Manometer

5 Regulator Adjusting Housing and Gasket

(Regulated version shown)

6 Gas Valve Bracket 11 Spud Holder

10 Connect Over Loosened Slotted Pressure Tap

(For use on 220 steam models LP only)

in Bottom of Gas Valve

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 7

29

Page 32

Installation

1

BURNER INJECTOR

(ORIFICE)

How to Change Injector (Orifice) Size

1. Disconnect electrical power from tumbler. Close

gas shut-off valve to tumbler. Refer to Figure 7.

2. For Johnson GM7000 gas valve:

Remove spud holder assembly from gas valve

and remove burner orifice from the spud holder.

Refer to Figure 7.

3. Install the new, correct injector(s) (orifices).

Refer to Figure 8. Torque each to 9 – 10 Nm.

4. Reinstall spud holder assembly to gas valve,

making certain orifice is in line with burner tube

opening, and flange gasket is in place in flange

groove. Refer to Figure 7 or Figure 8.

5. Commission tumbler for use.

NOTE: Blank injectors (orifices) are available as

Part No. M400995.

How to Adjust Gas Valve Governor/Regulator

1. Check gas injector (manifold) pressure as

follows. Refer to Figure 7.

How to Change Regulator Spring, DE/AT

Only

1. Disconnect electrical power from tumbler. Close

gas shut-off valve to tumbler. Refer to Figure 6

and Figure 7.

2. Follow instructions in kit Part No. 431559.

3. Adjust injector (manifold) pressure according to

applicable table and How to Adjust Gas Valve

Governor/Regulator section.

4. Install old regulator cap.

5. Commission tumbler for use.

Loosen screw plug inside pressure tap located on

underside of valve.

Connect a “U”-tube manometer (or similar

pressure gauge) to the injector (manifold)

pressure tap.

2. Start tumbler and note pressure once flame is

burning. Remove regulator cap and adjust

regulator screw until the injector pressure per

applicable table is achieved. Replace regulator

cap.

3. Commission tumbler for use.

T025K

T025KE1D

1 Size Stamped on Orifice

Figure 8

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 33

Installation

NOTE: In addition to directions below, follow all

instructions in this section, including verification

and adjustment of injector pressure.

1 – Order as Regulated Natural Gas. No modification

needed.

2 – Order as Regulated Natural Gas. Apply

appropriate country sticker.

3 – Order as Regulated Natural Gas. Apply

appropriate country and gas stickers.

4 – Order as Unregulated with Unregulated Natural

Gas injector. Apply appropriate country sticker.

5 – Order as Unregulated with L.P. Gas injectors.

Apply appropriate country sticker.

6 – Order as Regulated Natural Gas. Apply

appropriate country and gas stickers.

Model 0220SFG: Convert with (1) 50 mbar

regulator spring kit Part No. 431559 and (1)

2.3 mm injector Part No. M406184.

Model 0220SRG: Convert with (1) 50 mbar

regulator spring kit Part. No. 431559 and (1)

2.1 mm injector Part No. M401003.

Model 0270SFG: Convert with (1) 50 mbar

regulator spring kit Part No. 431559 and (1)

2.45 mm injector Part No. M401015.

Model 0270SRG: Convert with (1) 50 mbar

regulator spring kit Part. No. 431559 and (1)

2.2 mm injector Part No. M401011.

Model 0300DFG: Convert with (2) 50 mbar

regulator spring kits Part No. 431559 and (2)

2.45 mm injectors Part No. M401015.

Model 0300DRG: Convert with (2) 50 mbar

regulator spring kits Part No. 431559 and (2)

2.2 mm injectors Part No. M401011.

Model 0350SFG: Convert with (1) 50 mbar

regulator spring kit Part No. 431559 and (1)

2.7 mm injector Part No. M411375.

Model 0350SRG: Convert with (1) 50 mbar

regulator spring kit Part No. 431559 and (1)

2.5 mm injector Part No. M406361.

7 – Order as Unregulated with L.P. Gas injectors. No

modification needed.

8 – Order as Unregulated with L.P. Gas injectors.

Apply appropriate country sticker.

OPEN – No Approval available.

Special Cases – Regulated Gas Valve may be

converted to Unregulated with block-open kit Part

No. 431485.

Model: 0220SFG Input: 21.9 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

Table 4

44

Gas

Family &

Group

2nd family

Group H

(E)

2nd family

Group L

(LL)

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

22

Inject. 0

4.0 mm

4.0 mm

3.3 mm

2.3 mm

2.3 mm

2.3 mm

Inject. Qty &

Part. No.

1

M402996

1

M402996

1

M410021

1

M406184

1

M406184

1

M406184

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Press.

20 mbar Yes 8.9 mbar

25 mbar Yes 13.5 mbar

30 mbar No Unreg.

50 mbar Yes 28.7 mbar

Inject.

Press.

No Unreg.

No Unreg.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Installation

Model: 0270SFG Input: 25.8 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

44

Family &

Group

2nd family

Group H

2nd family

Group L

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

Table 5

Model: 0300DFG Input: 2 x 25.8 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

Table 6

44

Family &

Group

2nd family

Group H

2nd family

Group L

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

Gas

(E)

(LL)

Gas

(E)

(LL)

22

22

Inject. 0

4.6 mm

4.6 mm

3.6 mm

2.45 mm

2.45 mm

2.45 mm

Inject. 0

4.6 mm

4.6 mm

3.6 mm

2.45 mm

2.45 mm

2.45 mm

Inject. Qty

& Part. No.

1

M411511

1

M411511

1

M401014

1

M401015

1

M401015

1

M401015

Inject. Qty

& Part. No.

2

M411511

2

M411511

2

M401014

2

M401015

2

M401015

2

M401015

Inlet

20.25

mbar

28.37

mbar

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Gvnr./

Regltr.

Press.

20 mbar Yes 7.6 mbar

25 mbar Yes 11 mbar

30 mbar No Unreg.

50 mbar Yes 28 mbar

Press.

20 mbar Yes 7.6 mbar

25 mbar Yes 11 mbar

30 mbar No Unreg.

50 mbar Yes 28 mbar

Inject.

Press.

No Unreg.

No Unreg.

Inject.

Press.

No Unreg.

No Unreg.

Model: 0350SFG Input: 31.4 kW Flue Code: B

Gas

32

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

Table 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

44

Family &

2nd family

2nd family

2nd family

3rd family

Group B/P

3rd family

Group B/P

3rd family

22

Gas

Group

Group H

(E)

Group L

(LL)

Group E+

Group 3+

Inject. 0

5.0 mm

5.0 mm

4.0 mm

2.7 mm

2.7 mm

2.7 mm

Inject. Qty

& Part. No.

1

70070901

1

70070901

1

M402996

1

M411375

1

M411375

1

M411375

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Press.

20 mbar Yes 8.9 mbar

25 mbar Yes 12.5 mbar

30 mbar No Unreg.

50 mbar Yes 28.3 mbar

Inject.

Press.

No Unreg.

No Unreg.

70223701

Page 35

Installation

Model: 0220SRG Input: 18.8 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

44

Family &

Group

2nd family

Group H

2nd family

Group L

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

Table 8

Model: 0270SRG Input: 21.4 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

Table 9

44

Family &

Group

2nd family

Group H

2nd family

Group L

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

Gas

(E)

(LL)

Gas

(E)

(LL)

22

22

Inject. 0

3.9 mm

3.9 mm

3.1 mm

2.1 mm

2.1 mm

2.1 mm

Inject. 0

4.0 mm

4.0 mm

3.3 mm

2.2 mm

2.2 mm

2.2 mm

Inject. Qty

& Part. No.

1

M402980

1

M402980

1

70202701

1

M401003

1

M401003

1

M401003

Inject. Qty

& Part. No.

1

M402992

1

M402992

1

M401021

1

M401011

1

M401011

1

M401011

Inlet

20.25

mbar

28.37

mbar

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Gvnr./

Regltr.

Press.

20 mbar Yes 8.0 mbar

25 mbar Yes 11.5 mbar

30 mbar No Unreg.

50 mbar Yes 28.7 mbar

Press.

20 mbar Yes 8.0 mbar

25 mbar Yes 11.8 mbar

30 mbar No Unreg.

50 mbar Yes 28.9 mbar

Inject.

Press.

No Unreg.

No Unreg.

Inject.

Press.

No Unreg.

No Unreg.

Model: 0300DRG Input: 2 x 21.4 kW Flue Code: B

Gas

Typ e

Nat.

Gas

L.P.

Gas

70223701

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

1111122222 2

3

44

555555

66

77777 88

Tab le 1 0

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Family &

2nd family

2nd family

2nd family

3rd family

Group B/P

3rd family

Group B/P

3rd family

22

Gas

Group

Group H

(E)

Group L

(LL)

Group E+

Group 3+

Inject. 0

4.0 mm

4.0 mm

3.3 mm

2.2 mm

2.2 mm

2.2 mm

Inject. Qty

& Part. No.

2

M402992

2

M402992

2

M401021

2

M401011

2

M401011

2

M401011

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Press.

20 mbar Yes 8.0 mbar

25 mbar Yes 11.8 mbar

30 mbar No Unreg.

50 mbar Yes 28.9 mbar

Inject.

Press.

No Unreg.

No Unreg.

33

Page 36

Installation

Model: 0350SRG Input: 26.4 kW Flue Code: B

Gas

GB IE PT ES IT DK NO SE FI DE NL BE FR AT

Typ e

1111122222 2

Nat.

Gas

555555

L.P.

Gas

77777 88

3

66

Tab le 1 1

44

Family &

Group

2nd family

Group H

2nd family

Group L

2nd family

Group E+

3rd family

Group B/P

3rd family

Group B/P

3rd family

Group 3+

Gas

(E)

(LL)

22

Inject. 0

4.6 mm

4.6 mm

3.7 mm

2.5 mm

2.5 mm

2.5 mm

Inject. Qty

& Part. No.

1

M411511

1

M411511

1

M400998

1

M406361

1

M406361

1

M406361

Inlet

20.25

mbar

28.37

mbar

Gvnr./

Regltr.

Press.

20 mbar Yes 8.0 mbar

25 mbar Yes 12.0 mbar

30 mbar No Unreg.

50 mbar Yes 28.1 mbar

Inject.

Press.

No Unreg.

No Unreg.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 37

LOCATED

HERE

Installation

44001907

T369IE1A

APPLICATION OF STICKERS TO SERIAL PLATE

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 9

35

Page 38

Notes

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 39

Exhaust Requirements

A drying tumbler produces combustible

lint. To reduce the risk of fire, the tumbler

must be exhausted to the outdoors.

W057

To reduce the risk of fire and accumulation

of combustible gases, DO NOT exhaust

tumbler air into a window well, gas vent,

chimney or enclosed, unventilated area

such as an attic wall, ceiling, crawl space

under a building, or concealed space of a

building.

W059

WARNING

Make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased

sufficiently to prevent downdrafts in any of the vents

when all tumblers are in operation. Do not locate

gravity vented appliances between tumbler(s) and

make-up air openings. If it is necessary to duct makeup air to the tumbler(s), increase the area of the

ductwork by 25% to compensate for any restriction in

air movement.

Venting

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to the

outdoors by the shortest possible route.

Layout

Whenever possible, install tumblers along an outside

wall where duct length can be kept to a minimum, and

make-up air can be easily accessed. Elbows and long

vents tend to increase drying time. Construction must

not block the airflow at the rear of the tumbler. Doing

so would prevent adequate air supply to the tumbler’s

combustion chamber.

Make-Up Air

A tumbler is forced air exhausted and requires

provisions for make-up air to replace the air exhausted

by the tumbler.

IMPORTANT: Do not obstruct the flow of

combustion and ventilation air.

Make-up air openings should be as close to the

tumbler(s) as possible.

The required make-up air opening to the outside for

each

tumbler is:

144 square inches (928 sq. cm) for 25, 30 and

35 pound tumbler models

288 square inches (1856 sq. cm) for 30 pound

stacked tumbler models

Make-up air openings with louvers will restrict

airflow. The opening must be increased to compensate

for area taken up by louvers.

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth, so the joints do not permit the accumulation

of lint.

DO NOT use plastic or thin foil flexible ducts. Use

exhaust ducts made of sheet metal or other

noncombustible material. Use metal duct tape on all

joints.

Verify that old ducts are thoroughly cleaned out before

installing new tumbler.

Improperly sized or assembled ductwork causes

excess back pressure which results in slow drying, lint

collecting in the duct, lint blowing into the room, and

increased fire hazard.

Exhaust ducts shall be constructed of sheet metal

or other noncombustible material. Such ducts must

be equivalent in strength and corrosion resistance

to ducts made of galvanized sheet steel not less than

0.0195 inches (0.495 mm) thick.

Where the exhaust duct pierces a combustible wall,

ceiling, floor or partition an opening having a diameter

of 4 inches (102 mm) larger than the diameter of the

exhaust duct shall be provided, with the duct centered

in the opening. The space around the duct may be

sealed with noncombustible material. Refer to

Figure 10.

IMPORTANT: For best performance provide an

individual exhaust duct for each tumbler. Do not

install a hot water heater in room containing

tumblers. It is better to have the water heater in a

separate room with a separate air inlet.

37

Page 40

Exhaust Requirements

Individual Venting

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to the

outdoors.

IMPORTANT: At no point may the cross sectional

area of installed venting be less than the cross

sectional area of the exhaust outlet of the tumbler.

The exhaust duct must be designed so the static back

pressure measured 12 inches (305 mm) from the

exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of the tumbler. Static back pressure must be

measured with the tumbler running (both pockets on

stacked models).

Duct

Diameter

6 in. (152 mm)

8 in. (203 mm)

10 in. (254 mm)

12 in. (305 mm)

14 in. (355.6 mm)

16 in. (406.4 mm)

18 in. (457.2 mm)

Equivalent Length of

Straight Duct

One 90° elbow = 7 ft. (2.1 m)

One 90° elbow = 9.3 ft. (2.83 m)

One 90° elbow = 11.6 ft. (3.5 m)

One 90° elbow = 14 ft. (4.3 m)

One 90° elbow = 16 ft. (4.9 m)

One 90° elbow = 18.7 ft. (5.7 m)

One 90° elbow = 21 ft. (6.4 m)

Equivalent Length (feet) = 1.17 x Duct Diameter (inches)

Table 12

Example: A 12 inch diameter duct’s equivalent

length of 14 feet of duct and two 90° elbows is:

The maximum allowable length venting of the same

diameter as the exhaust thimble is 14 feet (4.3 meters)

and two 90° elbows or equivalent. If the equivalent

length of a duct required for an installation exceeds the

maximum allowable equivalent length, the diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 meters). Cross section area of a

rectangular duct must be increased by 20% for each

additional 20 feet (6.1 meters). Table 12 shows how to

determine equivalent venting.

1

6

2

CONNECT TO

TUMBLER

Equivalent Length = 14 feet + (2) 90° elbows

= 14 feet + 14 feet + 14 feet

= 42 feet (12.8 meters)

With the tumbler (both pockets on stacked models) in

operation, airflow at any point in the duct should be at

least 1200 feet per minute (366 meters per meter) to

ensure that lint remains airborne. If 1200 feet per

minute cannot be maintained, schedule a regular

inspection and cleaning of the ductwork.

2

CONNECT TO TUMBLER

5

4

EXHAUST

OUTLET

3

1

3

VERTICAL EXHAUST INSTALLATION HORIZONTAL EXHAUST INSTALLATION

1 No Screen or Cap

2 Wall

3 2 in. (51 mm) Minimum Clearance

4 NOTE: Where exhaust duct pierces a combustible wall or ceiling, an opening having a diameter 4 in. (102 mm)

larger than diameter of exhaust duct shall be provided, with exhaust duct centered in opening.

5 Exhaust Airflow – Maximum Length of Duct: 14 ft. (4.3 m)

6 Minimum Distance Between Opening and Roof: 36 in. (914 mm)

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

4

TMB1379N

TMB1379N

Figure 10

70223701

Page 41

Exhaust Requirements

Manifold Venting

While it is preferable to exhaust tumblers individually

to the outdoors, a main collector duct may be used if it

is sized according to Figure 12. This illustration

indicates minimum diameters, which should be

increased if the collector length exceeds 14 feet and

two 90° elbows. The diameter of a round duct must be

increased by 10% for each additional 20 feet

(6.1 meters). Cross sectional area of a rectangular or

square duct must be increased 20% for each additional

20 feet (6.1 meters). Refer to Table 12 to determine

equivalent ducting sizing. The collector duct may be

rectangular or square in cross section, as long as the

area is not reduced. Provisions MUST be made for lint

removal and cleaning of the collector duct.

The vent collector system must be designed so the

static back pressure measured 12 inches (305 mm)

from the exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of tumbler. Static back pressure must be

measured with all tumblers vented into the collector

operating.

Never connect a tumbler duct at a 90° angle to the

collector duct (refer to Figure 11). Doing so will

cause excessive back pressure, resulting in poor

performance. Never connect two tumbler exhaust

ducts directly across from each other at the point of

entry to the collector duct.

With the tumbler (both pockets on stacked models) in

operation, airflow at any point in the duct should be at

least 1200 feet per minute (366 meters per minute) to

ensure that lint remains airborne. If 1200 feet per

minute cannot be maintained, schedule a regular

inspection and cleaning of the ductwork.

The collector system must be designed so the static

back pressure measured 12 inches (305 mm) from

the exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of tumbler. This must be measured with all

tumblers vented into the collector operating.

T438I

Figure 11

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Exhaust Requirements

;

;

;

;

1

2

;;;

;;;

D1

D2

;;;;;;;;;

;;;;;;;;;

3

LKJ I HG F E D CB A

L

4

1 Clearance

NOTE: Where the exhaust duct pierces a combustible wall or ceiling, the opening must be sized per local codes.

2 Outlet Duct Diameter for One Battery Same as Largest Station Used

3 Outlet Duct Diameter for Two Batteries

4 45° Ty pi c al

Figure 12

Duct

Station

25, 30 Pound* 30 Pound Stacked, 35 Pound**

Minimum Diameter

T472I

D1 D2 D1 D2

A

B

C

D

E

F

G

H

I

J

K

L

7 in. (178 mm) 10 in. (254 mm) 9 in. (229 mm) 12 in. (305 mm)

10 in. (254 mm) 14 in. (356 mm) 12 in. (305 mm) 17 in. (432 mm)

12 in. (305 mm) 18 in. (457 mm) 15 in. (381 mm) 21 in. (533 mm)

14 in. (356 mm) 20 in. (508 mm) 17 in. (432 mm) 24 in. (610 mm)

16 in. (406 mm) 23 in. (584 mm) 19 in. (483 mm) 27 in. (686 mm)

18 in. (457 mm) 25 in. (635 mm) 21 in. (533 mm) 30 in. (762 mm)

19 in. (483 mm) 27 in. (686 mm) 23 in. (584 mm) 32 in. (813 mm)

20 in. (508 mm) 29 in. (737 mm) 24 in. (610 mm) 34 in. (864 mm)

22 in. (559 mm) 31 in. (787 mm) 26 in. (660 mm) 36 in. (914 mm)

23 in. (584 mm) 32 in. (813 mm) 27 in. (686 mm) 38 in. (965 mm)

24 in. (610 mm) 34 in. (864 mm) 28 in. (711 mm) 40 in. (1016 mm)

25 in. (635 mm) 36 in. (914 mm) 30 in. (762 mm) 42 in. (1067 mm)

* Requires 6 inch diameter duct from tumbler to manifold

** Requires 8 inch diameter duct from tumbler to manifold

Tab le 1 3

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 43

Exhaust Requirements

5

1

4

CEILING

3

2

Consult your local building code for regulations which may also apply.

NOTE: Inside of duct shall be smooth. Do not use sheet metal screws to join sections.

T493I

1 NOTE: Do not install wire mesh or screen in this opening as lint will build up and prevent proper discharge of air

from tumblers.

2 Wall

3 Removable Strip of Panel in Framing Wall to Permit Removal of Tumbler from Framing Wall

4 Partition or Bulkhead

5 Minimum Distance Between Opening and Roof: 36 in. (914 mm)

Figure 13

70223701

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Notes

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70223701

Page 45

Gas Requirements

To reduce the risk of fire or explosion, DO

NOT CONNECT THE GAS LINE TO THE

TUMBLER IF THE GAS SERVICE IS NOT

THE SAME AS THAT SPECIFIED ON THE

TUMBLER SERIAL PLATE! It will first be

necessary to convert the gas burner

orifice and gas valve. Appropriate

conversion kits are available.

W060

WARNING

IMPORTANT: Any product revisions or

conversions must be made by the manufacturer’s

authorized dealers, distributors, or local service

personnel.

IMPORTANT: The tumbler must be isolated

the gas supply piping system by closing its

individual manual shut-off valve during any

pressure testing of the gas supply piping system at

test pressure equal to or less than

1/2 psig

(3.45 kPa, 34.5 mbar).

IMPORTANT: The tumbler and its manually

operated appliance gas valve must be disconnected

from the gas supply piping system during any

pressure testing of that system at test pressures in

excess of

1/2 psi (3.45 kPa, 34.5 mbar).

IMPORTANT: The installation must comply with

local codes or, in the absence of local codes:

from

A dirt and water vapor pipe trap must be furnished and

installed by customer, refer to Figure 14. One gas

shut-off valve must also be supplied for gas service

line to each tumbler (obtain locally).

It is important that equal pressure be maintained at all

tumbler gas connections. This can best be done by

installing a one inch (25 mm) pipe gas loop as shown

in Figure 15.

WARNING

To reduce the risk of fire or explosion, if the

tumbler is to be connected to Liquefied

Petroleum (L.P.) gas, a vent to the outdoors

must be provided in the room where the

tumbler is installed.

NATURAL GAS service must be supplied at

7 ± 1-1/2 inch water column pressure (17.4 ± 4 mbar,

1.74 ± 0.37 kPa). An in-line pressure regulator may be