Page 1

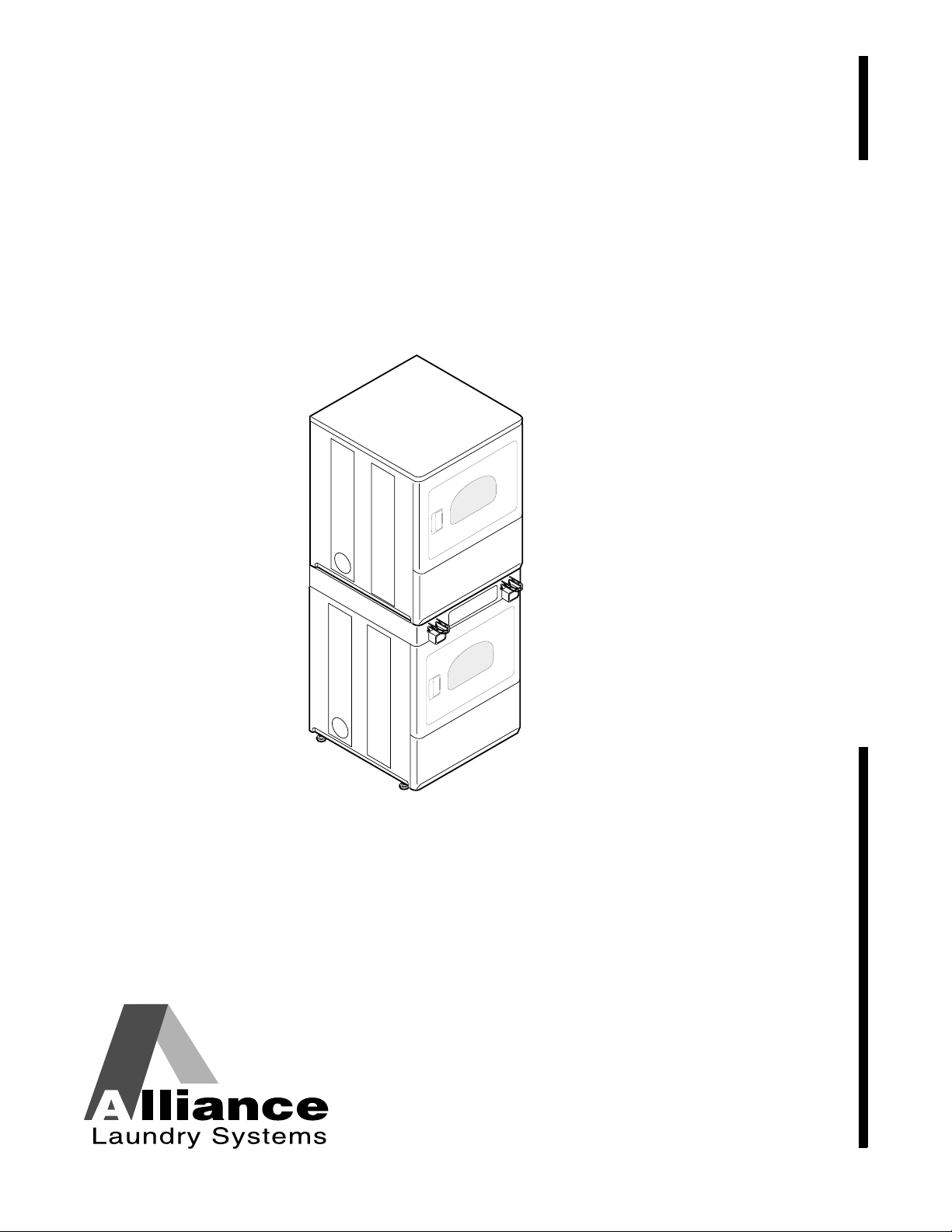

Stacked Dryer

Metered and Nonmetered

Electric and Gas Models

Installation and Operation

D355IE1B

NOTA: El manual en español aparece después del manual en inglés.

Part No. 504524R3

June 1998

Page 2

Page 3

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE. (If the dryer changes ownership, be

sure this manual accompanies the dryer.)

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the

risk of fire or explosion or to prevent property damage, personal injury or death.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your building.

– Clear the room, building or area of all occupants.

– Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

W033

W052

IMPORTANT: Purchaser must consult the local gas supplier for suggested instructions to be

followed if the dryer user smells gas. The gas utility instructions plus the SAFETY and

WARNING note directly above must be posted in a prominent location near the dryer for

customer use.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

W053

504524

1

Page 4

Table of

Contents

Replacement Parts ...............................................................................2

Important Safety Instructions..............................................................3

Roughing In Dimensions .....................................................................5

Additional Security ..............................................................................7

Slide Extension .....................................................................................7

Timer Cams ........................................................................................... 7

Lower Front Panel Security ................................................................7

Coin Slide Guards ................................................................................ 8

Before You Start ...................................................................................9

Installing the Dryer

STEP 1 – Position and Level the Dryer Unit.................................. 10

STEP 2 – Connect Dryer Exhaust System .....................................10

STEP 3 – Connect Gas Supply Pipe...............................................11

STEP 4 – Connect Electrical Plug..................................................12

STEP 5 – Wipe Out Inside of Each Dryer...................................... 13

STEP 6 – Plug in the Dryer Unit....................................................13

STEP 7 – Check Installation...........................................................13

Heat Source Check ............................................................................. 14

Reversing Door Procedure ................................................................15

Electrical Requirements (Electric Dryers) ....................................... 16

Electrical Connection .........................................................................17

Three-wire Power Cord .................................................................17

Four-Wire Power Cord ..................................................................19

Electrical Requirements (Gas Dryers) .............................................21

Gas Requirements .............................................................................23

Location Requirements .....................................................................24

Dryer Exhaust Requirements ........................................................... 25

Multi-Dryer Installation Exhuast Requirements............................. 28

Lint Filter.............................................................................................31

Motor Overload Protector..................................................................31

User-Maintenance Instructions .........................................................32

For Energy Conservation ................................................................... 32

Before Your Call for Service...............................................................33

Operation Instructions For Electromechanical Dryers ..................34

Operation Instructions for Electronic Control Dryers....................36

Information for Handy Reference ....................................................39

Installer Check .................................................................... Back Cover

Replacement Parts . . .

If replacement parts are required, contact the source

where you purchased your dryer, or contact

Copyright 1998, Alliance Laundry Systems LLC

©

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the written permission of the publisher.

2

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Phone:

(920) 748-3950

for the name and address of the nearest authorized parts

distributor.

504524

Page 5

IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

14. The interior of the dryer and the exhaust duct

WARNING

To reduce the risk of fire, electric shock, or

injury to persons when using your dryer,

follow these basic precautions:

W034

1. Read all instructions before using the dryer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the dryer.

3. Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable

or explosive substances as they give off vapors

that could ignite or explode.

4. Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children. This is a safety

rule for all appliances.

5. Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

6. Do not reach into the dryer if the cylinder is

revolving.

7. Do not install or store the dryer where it will be

exposed to water and/or weather.

8. Do not tamper with the controls.

9. Do not repair or replace any part of the dryer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

10. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

12. ALWAYS clean the lint filter after every load. A

layer of lint in the filter reduces drying efficiency

and prolongs drying time.

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

should be cleaned periodically by qualified

service personnel.

15. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Dryer will not operate with the loading door

open. DO NOT by-pass the door safety switch by

permitting the dryer to operate with the door

open. The dryer will stop tumbling when the door

is opened. Do not use the dryer if it does not stop

tumbling when the door is opened or starts

tumbling without pressing the START

mechanism. Remove the dryer from use and call

the service person.

17. Do not put articles soiled with vegetable or

cooking oil in the dryer, as these oils may not be

removed during washing. Due to the remaining

oil, the fabric may catch on fire by itself.

18. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc., or anything containing wax or

chemicals such as in mops and cleaning cloths, or

anything dry-cleaned at home with a drycleaning solvent in the dryer.

19. Use the dryer only for its intended purpose,

drying clothes.

20. Always disconnect the electrical power to the

dryer before attempting service. Disconnect the

power cord by grasping the plug, not the cord.

21. Replace worn power cords and/or loose plugs.

22. Install this dryer according to the

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding and

gas supply must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

23. Remove laundry immediately after the dryer

stops.

504524

3

Page 6

24. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiber glass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiber glass.

26. ALWAYS follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the dryer with any guards and/or

panels removed.

28. DO NOT operate the dryer with missing or

broken parts.

29. DO NOT by-pass any safety devices.

30. Failure to install, maintain, and/or operate this

machine according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

IMPORTANT: Solvent vapors from dry-cleaning

machines create acids when drawn through the heater

of the drying unit. These acids are corrosive to the

dryer as well as to the laundry load being dried. Be

sure make-up air is free of solvent vapors.

IMPORTANT: Have your dryer installed properly.

Don’t do it yourself unless you know how!

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this manual

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution

and care must be exercised when installing,

maintaining, or operating the dryer.

Always contact your dealer, distributor, service agent or

the manufacturer about any problems or conditions you

do not understand.

4

504524

Page 7

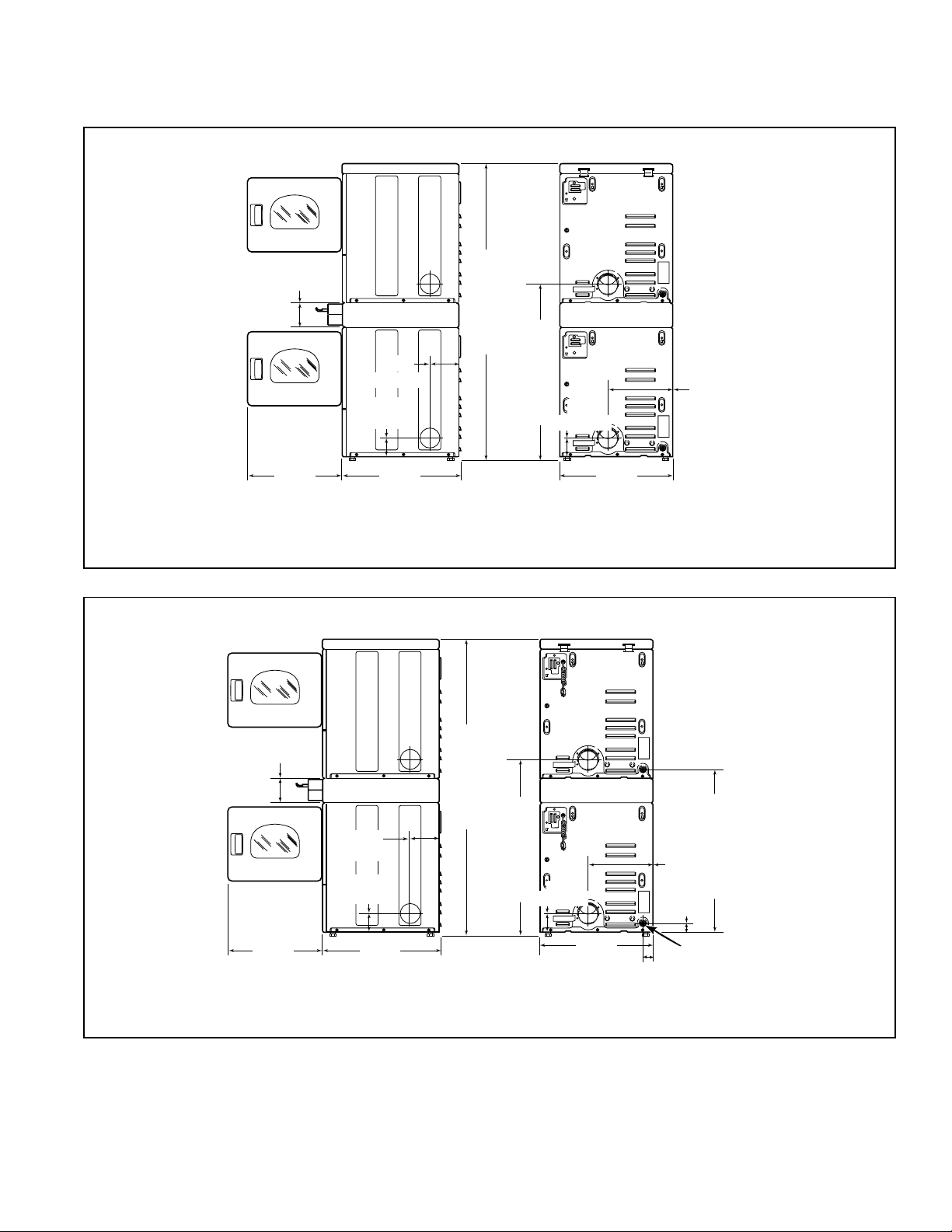

Roughing In Dimensions . . .

(Metered Models)

7.0"

(17.8 cm)

*76.5" (194.3 cm)

7.7"

(19.6 cm)

4.0"

(10.2 cm)

4.0"

*45.2" (114.8 cm)

(10.2 cm)

15.4"

(39.1 cm)

23.5"

(59.7 cm)

* WITH LEVELING LEGS TURNED INTO BASE.

28.0"

(71.1 cm)

ELECTRIC MODELS

7.0"

(17.8 cm)

*76.5" (194.3 cm)

7.7"

(19.6 cm)

4.0"

(10.2 cm)

26.9"

(68.3 cm)

4.0"

*45.2" (114.8 cm)

(10.2 cm)

15.4"

(39.1 cm)

2.8"

(7.1 cm)

D350IE2A

43.5" (110.5 cm)

23.5"

(59.7 cm)

*WITH LEVELING LEGS TURNED INTO BASE.

28.0"

(71.1 cm)

GAS MODELS

NOTE: Side, rear and bottom exhaust openings are

four inch (10.2 cm) ducting. Gas models cannot be

vented out left side of cabinet because of burner

housing.

504524

26.9"

(68.3 cm)

2.3"

(6 cm)

3/8"

NPT GAS

CONNECTION

D351IE2A

IMPORTANT: The dryer should have sufficient

clearance around it for needed ventilation and for the

ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

5

Page 8

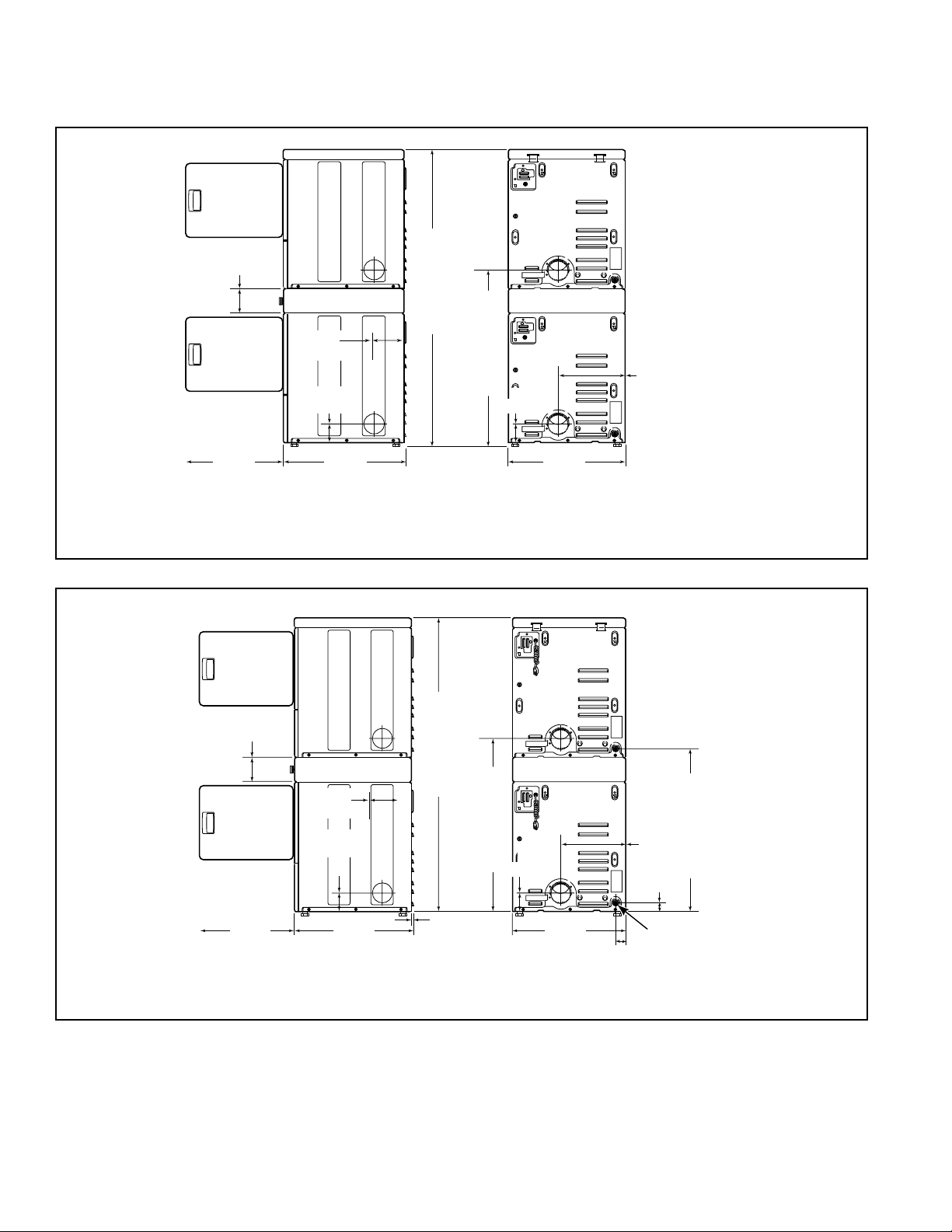

Roughing In Dimensions . . .

(Nonmetered Models)

7.0"

(17.8 cm)

7.7"

(19.6 cm)

4.0"

(10.2 cm)

23.5"

(59.7 cm)

*WITH LEVELING LEGS TURNED INTO BASE.

28.0"

(71.1 cm)

*76.5" (194.3 cm)

ELECTRIC MODELS

7.0"

(17.8 cm)

*45.2" (114.8 cm)

4.0"

(10.2 cm)

26.9"

(68.3 cm)

15.4"

(39.1 cm)

D353IE2A

7.7"

(19.6 cm)

4.0"

(10.2 cm)

23.5"

(59.7 cm)

*WITH LEVELING LEGS TURNED INTO BASE.

28.0"

(71.1 cm)

GAS MODELS

NOTE: Side, rear and bottom exhaust openings are

four inch (10.2 cm) ducting. Gas models cannot be

vented out left side of cabinet because of burner

housing.

6

*76.5" (194.3 cm)

4.0"

*45.2" (114.8 cm)

(10.2 cm)

26.9"

(68.3 cm)

15.4"

(39.1 cm)

(7.1 cm)

2.3"

CONNECTION

(6 cm)

2.8"

3/8"

NPT GAS

D352IE2A

43.5" (110.5 cm)

IMPORTANT: The dryer should have sufficient

clearance around it for needed ventilation and for the

ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

504524

Page 9

Additional Security . . .

Torx security screws are available (as optional equipment

at extra cost) for securing both lower access panels to

each dryer base. Order part number 62853.

A Torx bit, part number 282P4, is available (as optional

equipment at extra cost) for installing the Torx security

screws.

Slide Extension . . .

(Metered Models)

Remove two slide extensions, four screws and

lockwashers from the accesssories bag (located in lower

cylinder) and install the extension on the top of the coin

slide.

IMPORTANT: Slide extension must be attached to

top side of the coin slides to make them long enough to

activate the accumulator.

Timer Cams . . .

A Torx bit holder, part number 24161, is available (as

optional equipment at extra cost) to be used with the Torx

bit.

NOTE: This dryer unit, as shipped from the factory,

does not include the coin slides, coin drawers, lock or

keys. These coin slide kits (or parts) must be ordered,

at extra cost, according to the purchaser’s

requirements direct from the coin kit manufacturer

of your choice.

(Metered Models)

The dryer timers are factory equipped with a 45 minute

timing cam. If this drying time is not suitable to your

installation, the following cams can be found in the

accessories bag (located in lower cylinder).

ELECTRIC DRYERS

2-53242 Cams (30 Minutes)

Lower Front Panel Security . . .

(Optional)

(Metered Models)

For added security, remove the two screws (with

lockwashers) from accessories bag (located in lower

cylinder). Install screws as follows:

1. Unlock control panel.

2. Lift up on control panel and swing bottom of panel

out, then pull down and away from control cabinet.

2-53240 Cams (60 Minutes)

GAS DRYERS

2-53242 Cams (30 Minutes)

A 60 minute timing cam, Part No. 53240, is available for

the gas dryers as optional equipment at extra cost.

3. Install the two screws down through holes in lower

flange of control cabinet and into top flange of lower

front panel.

504524

7

Page 10

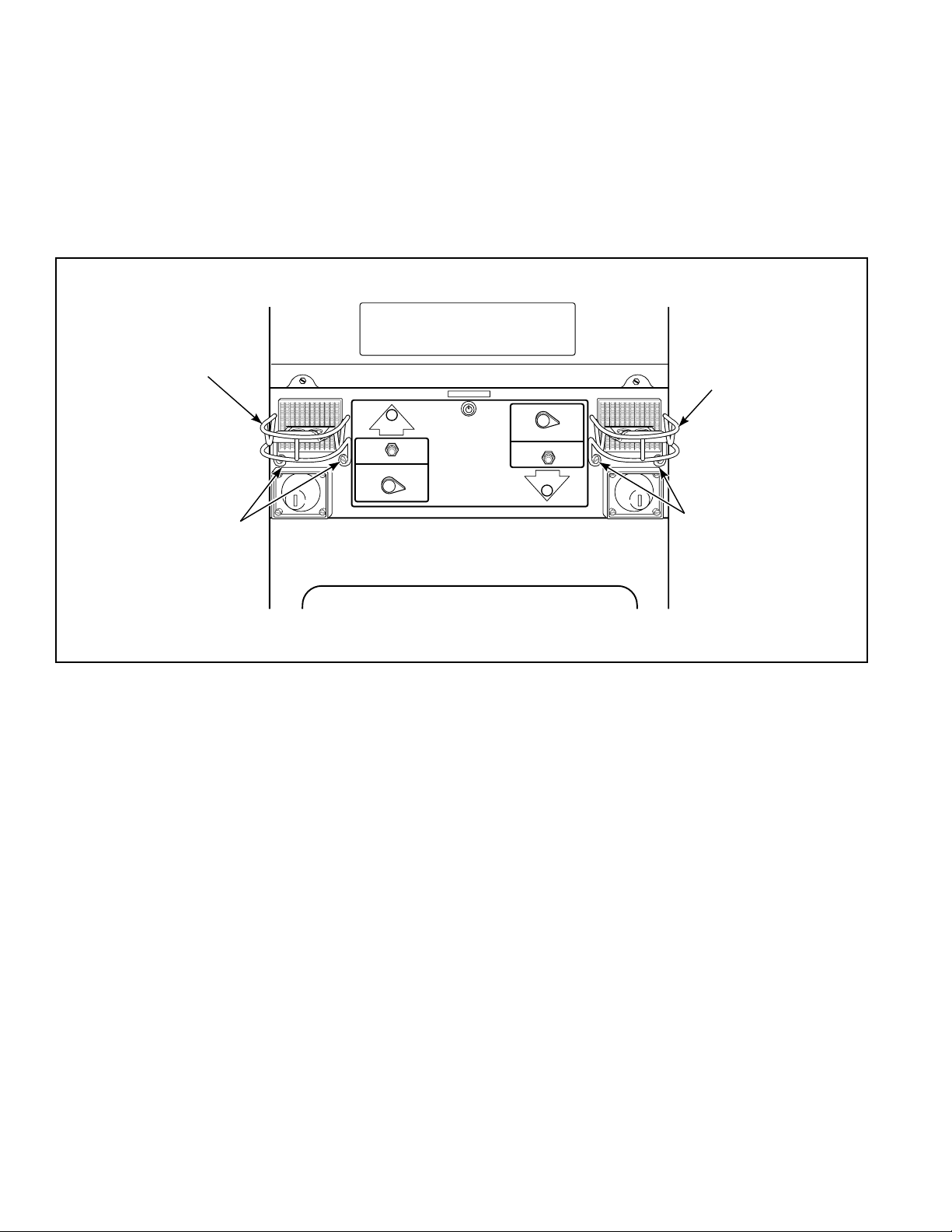

Coin Slide Guards . . .

(Metered Models)

Using serrated hex head screws from accessories bag

(located in lower cylinder), install coin slide guards

(located in accessories bag in lower cylinder), to front of

dryer’s control cabinet. See illustration below.

A special security screw kit is available (as optional

equipment at extra cost) for securing the two coin slide

COIN

SLIDE

GUARD

IN USE

PUSH TO START

PERM PRESS

DELICATE

FABRIC SELECTOR

FLUFF

(NO HEAT)

NORMAL

SERRATED

HEX HEAD

SCREWS

guards and both front panels to front of dryer unit. Order

Security Kit No. 298P3. A special driver, part number

56217, is available (as optional equipment at extra cost)

for installing the special security screws.

COIN

SLIDE

GUARD

PERM PRESS

DELICATE

NORMAL

FLUFF

(NO HEAT)

FABRIC SELECTOR

PUSH TO START

IN USE

SERRATED

HEX HEAD

SCREWS

D193IE3A

NOTE: Coin slides and coin drawers are shown for illustration only. You must obtain them locally.

8

504524

Page 11

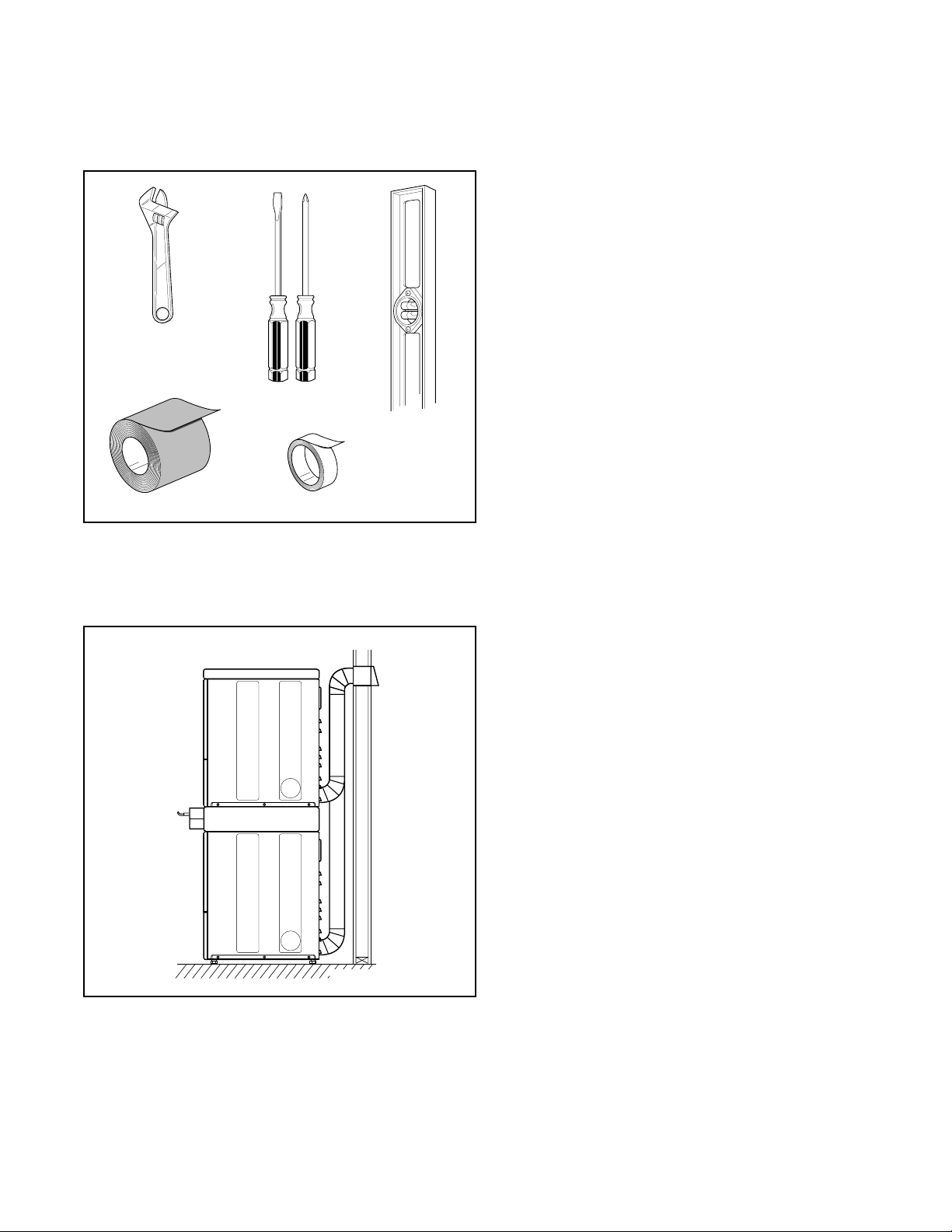

Before You Start . . .

Tools

For most installations, the basic tools you will need are:

WRENCH

SCREWDRIVERS

LEVEL

DUCT TAPE

TEFLON TAPE

D074IE1F

Exhaust

Electrical

• ELECTRIC DRYER Dryer needs a 3 or 4 wire 120/

240 or 120/208 Volt, 60 Hertz, AC single Phase

electrical supply.

• GAS DRYER

Dryer needs a 120 Volt,

60 Hertz, polarized 3-slot effectively grounded

receptacle.

NOTE: For more detailed information, refer to

Section on Electrical Requirements.

Gas

Dryer is equipped for Natural Gas with a 3/8" NPT gas

supply connection. For more detailed information, refer

to Section on Gas Requirements.

Location

Place the dryer on a solid floor with an adequate air

supply. For more detailed information, refer to Section on

Location Requirements.

Use rigid metal duct and exhaust the dryer to the outside

by the shortest route possible.

D354IE0A

NOTE: For more detailed information, refer to

Section on Dryer Exhaust Requirements.

504524

9

Page 12

Installing the Dryer . . .

(continued)

)

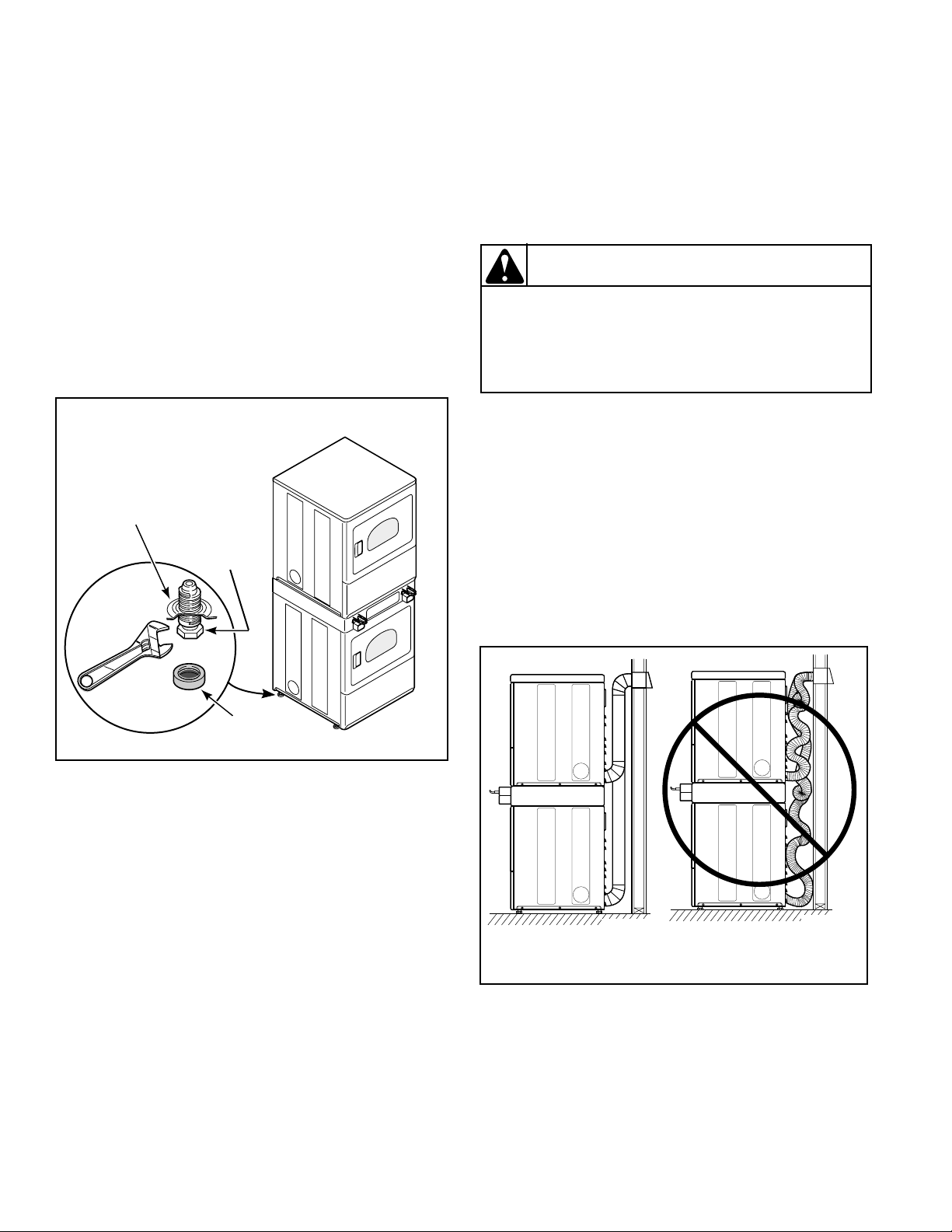

STEP 1:

Position and Level

the Dryer Unit

For further assistance refer to Section on Location

Requirements.

Install dryer before washer. This allows room for

attaching exhaust duct.

Install the four rubber cups found in the accessory bag.

Place the dryer in position, and adjust the legs until the

dryer is level.

DRYER

BASE

LEVELING

LEG

STEP 2:

Connect Dryer Unit Exhaust System

For further assistance refer to Sections on Location

Requirements and Dryer Exhaust Requirements.

WARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted to

the outdoors.

• DO NOT use plastic or thin foil flexible ducting.

• Locate dryer so exhaust duct is as short as possible.

• Be certain old ducts are cleaned before installing your

new dryer.

• Use 4" (10.2 cm) diameter rigid or flexible metal duct.

• Use as few elbows as possible.

• Use duct tape on all joints.

RUBBER

CUP

D355IE1A

• Failure to exhaust dryer properly will void

warranty.

D354IE0C

DO

NOTE: Venting materials are not supplied with the

dryer (obtain locally).

DON'T

D356IE0B

10

504524

Page 13

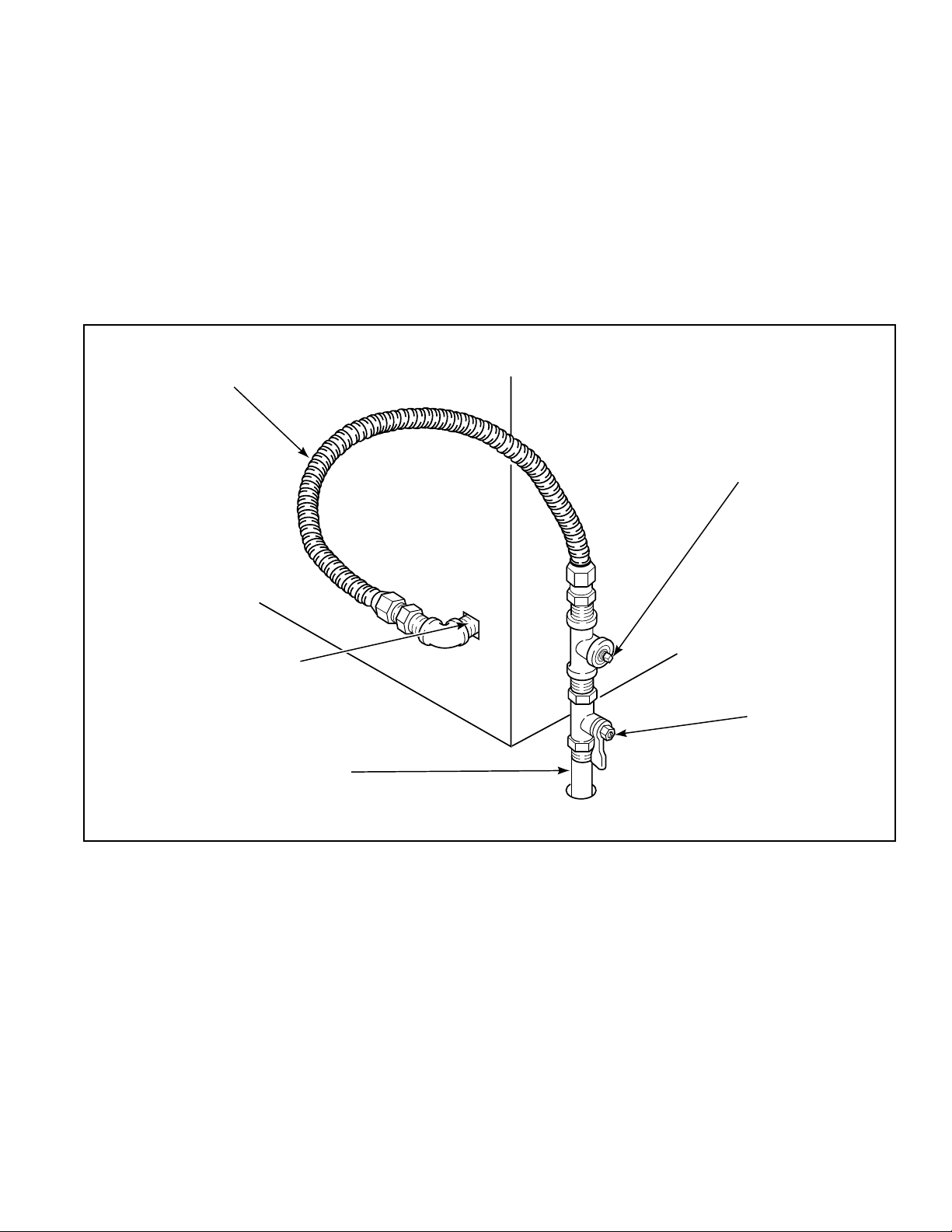

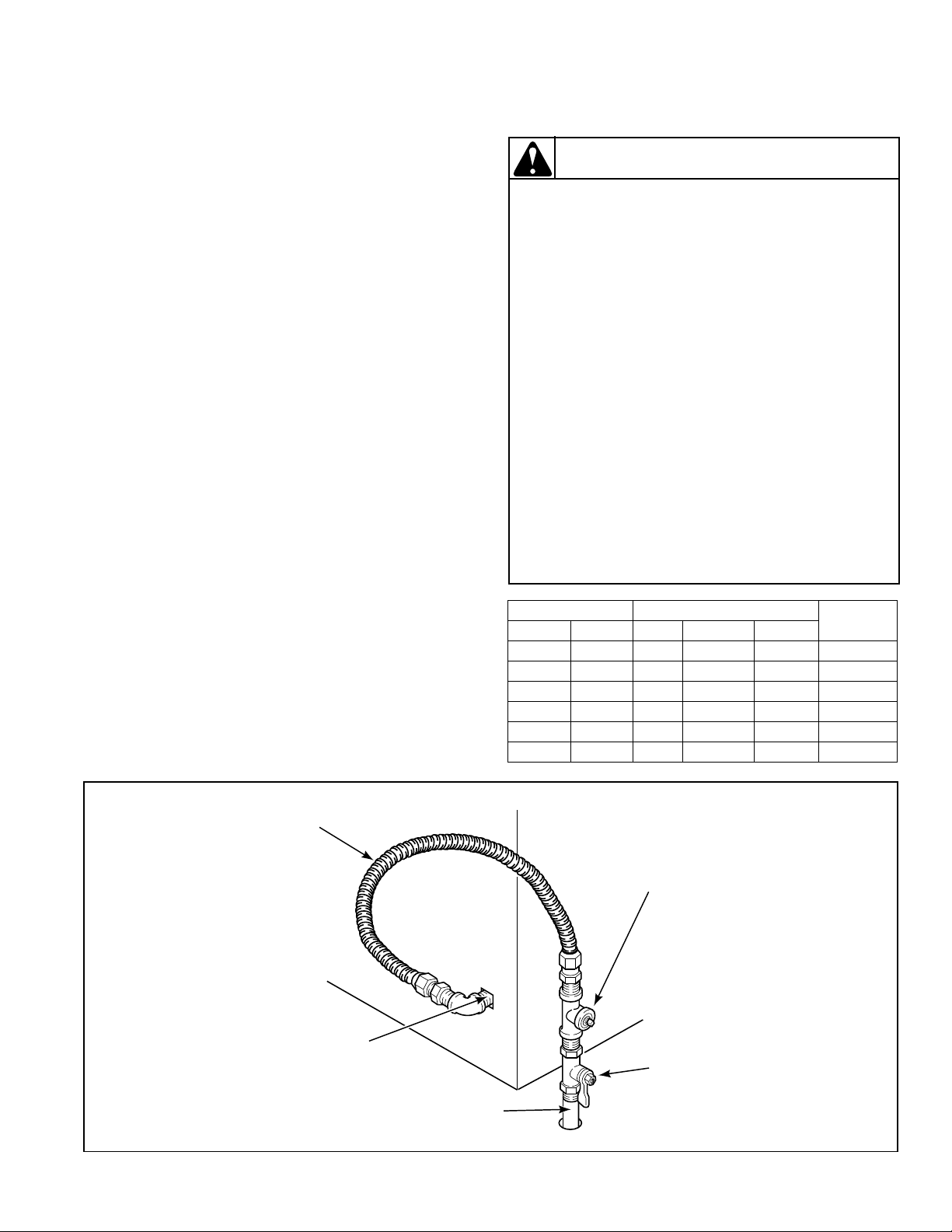

STEP 3: (Gas Dryer ONLY)

Connect Gas Supply Pipe

For further assistance, refer to Section on Gas

Requirements.

1. Make certain dryer is equipped for use with the type

of gas in laundry room. Dryer is equipped at the

factory for Natural Gas with a 3/8" NPT gas

connection.

2. Remove the shipping cap from the gas connection at

the rear of the dryer. Make sure you do not damage

the pipe threads when removing the cap.

NEW

STAINLESS STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3. Connect to gas supply pipe.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. For L.P. (propane) gas connection, refer to Section on

Gas Requirements.

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

EQUIPMENT

SHUT-OFF

VALVE

Install within

6' (1.8 m) of dryer

D233IE3D

504524

11

Page 14

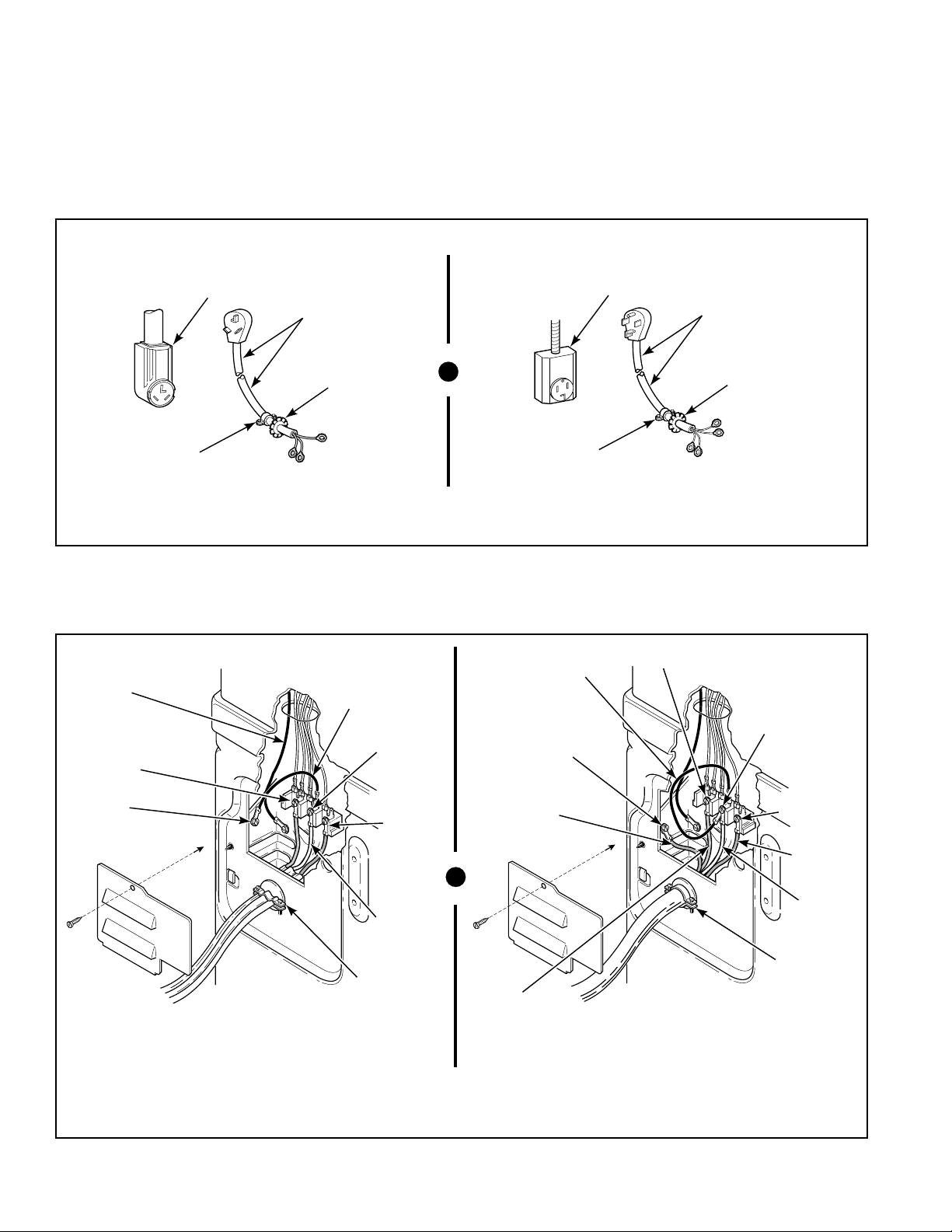

STEP 4: (ELECTRIC DRYER ONLY)

Connect Electrical Plug

For further assistance, refer to Section on Electrical

Requirements.

TYPICAL

THREE-WIRE

RECEPTACLE

STRAIN

RELIEF

Three Wire

Three Wire

POWER CORD

(Three-Wire)

STRAIN

RELIEF

NUT

D275IE0D

NOTE: For more detailed information on connecting

three-wire or four-wire plugs, refer to Section on

Electrical Plug Connection.

IMPORTANT: Use only a new U.L. listed No. 10

(copper wire only) three conductor power supply cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a clothes dryer.

TYPICAL

FOUR-WIRE

RECEPTACLE

STRAIN

RELIEF

POWER CORD

(Four-Wire)

STRAIN

RELIEF

NUT

D006IE0A

Four Wire

NOTE: Four-wire cord is required for mobile homes

or where codes do not permit grounding through

neutral.

"L1"

TERMINAL

NEUTRAL

TERMINAL

"L2"

TERMINAL

BLACK

WIRE

WHITE

WIRE

(NEUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

D171IE1A

GROUND

WIRE

"L1"

TERMINAL

GROUND

SCREW

GROUND

TO NEUTRAL

WIRE

NEUTRAL

TERMINAL

TERMINAL

CENTER

(NEUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

Three-Wire Connection

"L2"

WIRE

D276IE1A

GROUND

WIRE

GROUND

SCREW

GROUND

WIRE

RED

WIRE

Four-Wire Connection

NOTE: Dryer is shown with access cover removed for illustration purposes only. NEVER operate dryer with

access cover removed.

12

504524

Page 15

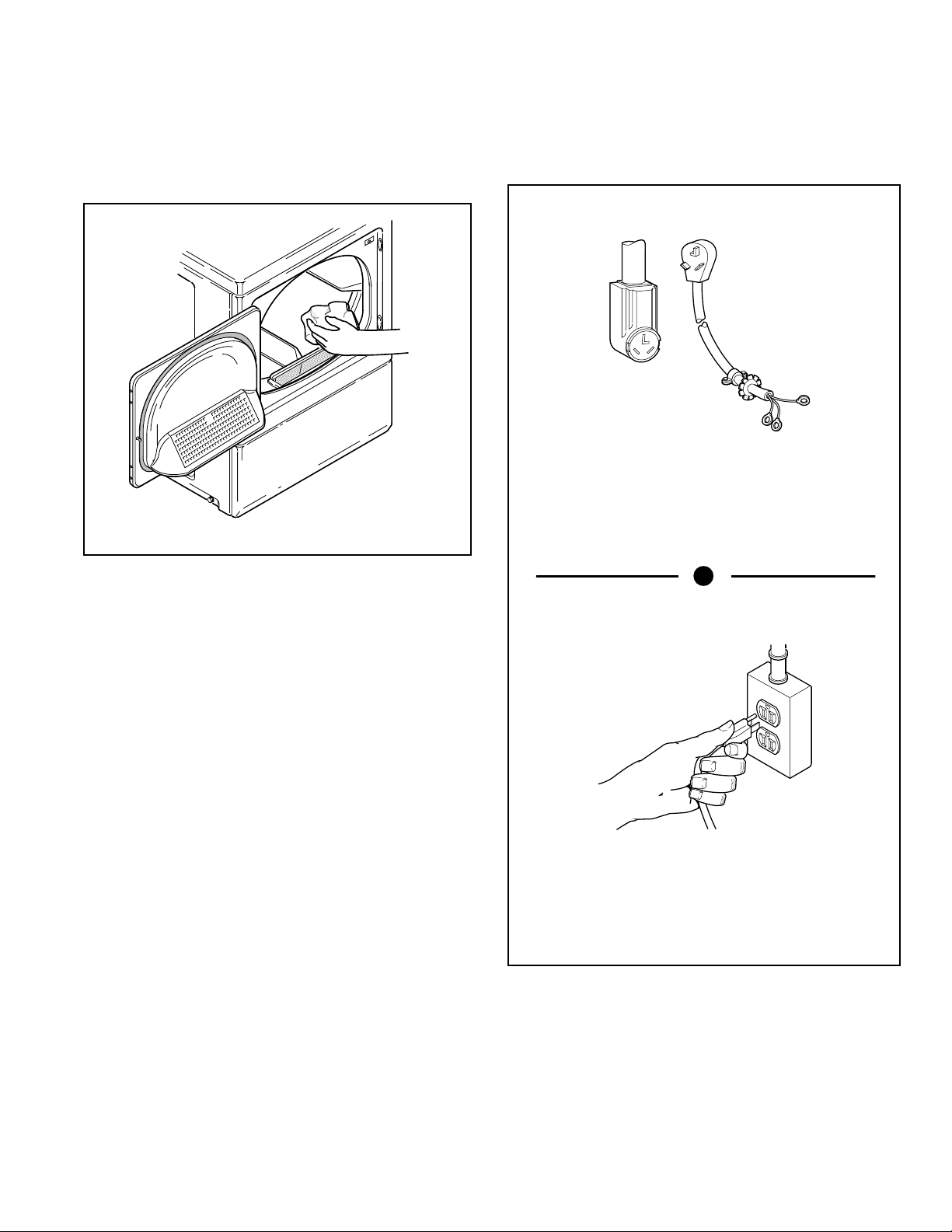

STEP 5:

STEP 6:

Wipe Out Inside Of Each Dryer

Before using dryer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside dryer drum.

D340IE2A

Plug in the Dryer Unit

Refer to Section on Electrical Requirements, and

connect the dryer to an electrical power source.

D275IE0F

ELECTRIC

Connect each unit to 30 Amp

circuit.

504524

D254IE0D

GAS

Plug each cord into separately

fused 15 Amp circuit.

STEP 7:

Check Installation

Refer to Installer Check on the back cover of this manual

and make sure that dryer is installed correctly.

13

Page 16

Heat Source Check . . .

(Electric Dryers)

Metered Models

Set the proper FABRIC SELECTOR switch at

NORMAL. Place coins in the slide and carefully push

slide in as far as possible. IN USE light will come on

indicating the dryer is ready to operate. Close the loading

door and press the PUSH-TO-START button firmly to

start the dryer. After either dryer has operated for three

minutes, the exhaust air or exhaust pipe should be warm.

(Gas Dryers)

During the gas heat check, observe the burner flame. The

flame can be viewed by removing the lower front panel of

the dryer.

Metered Models

Set FABRIC SELECTOR switch at NORMAL. Place

coins in the slide and carefully push slide in as far as

possible. IN USE light will come on indicating the dryer

is ready to operate. Close the loading door and press the

PUSH-TO-START button firmly. The dryer will start, the

igniter will glow red and the main burner will ignite.

Nonmetered Models

Set FABRIC SELECTOR switch at NORMAL and turn

timer knob to 50. Close the loading door and press the

PUSH-TO-START button. IN USE light will come on

indicating start of cycle, igniter will glow red and main

burner will ignite.

Nonmetered Models

Set FABRIC SELECTOR switch at NORMAL and turn

timer knob to 50. Close the loading door and press the

PUSH-TO-START button. IN USE light will come on

indicating start of cycle. After either dryer has operated

for three minutes, the exhaust air or exhaust pipe should

be warm.

All Models

After either dryer has operated for approximately five

minutes, observe burner flame. Adjust the air shutter to

obtain a soft, uniform blue flame. (A lazy, yellow tipped

flame indicates lack of air. A harsh, roaring, very blue

flame indicates too much air.) Adjust the air shutter as

follows:

1. Loosen the air shutter lockscrew.

2. Turn the air shutter to the left to get a luminous

yellow tipped flame, then turn it back slowly to the

right to obtain a steady soft blue flame.

3. After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

4. Reinstall the lower front panel.

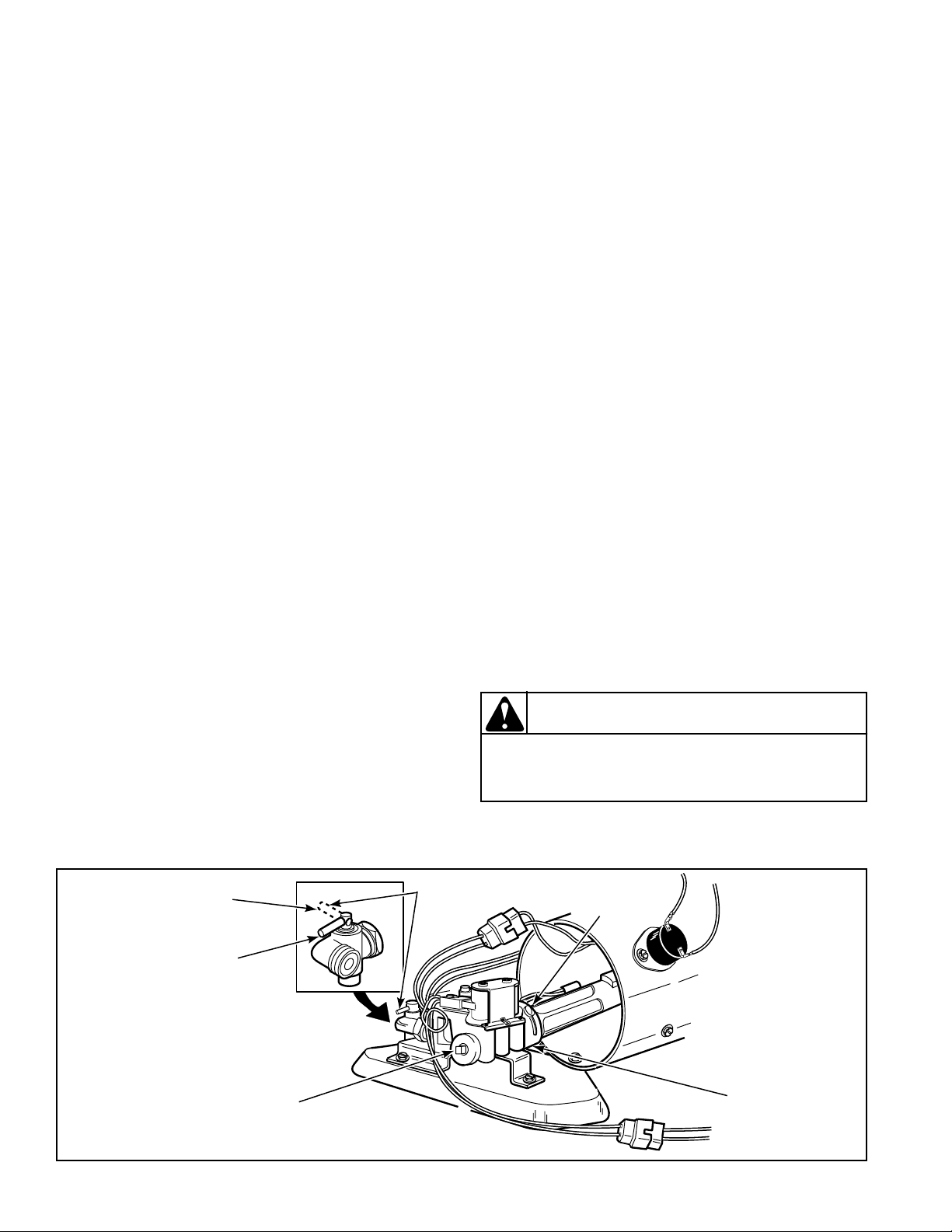

WARNING

IMPORTANT: If all air is not purged out of the gas

line, the gas igniter may go off before the gas is

ignited. If this happens, after approximately two

minutes the igniter will again attempt gas ignition.

CLOSED

POSITION

OPEN

POSITION

1/8" (3.1 mm)

PIPE PLUG

(For checking

manifold pressure)

14

SHUT-OFF

VALVE

HANDLE

For personal safety, lower front panel must be

in place during normal operation.

W046

After either dryer has operated for approximately three

minutes, the exhaust air or exhaust pipe should be warm.

AIR SHUTTER

LOCKSCREW

AIR

SHUTTER

D157IE3C

504524

Page 17

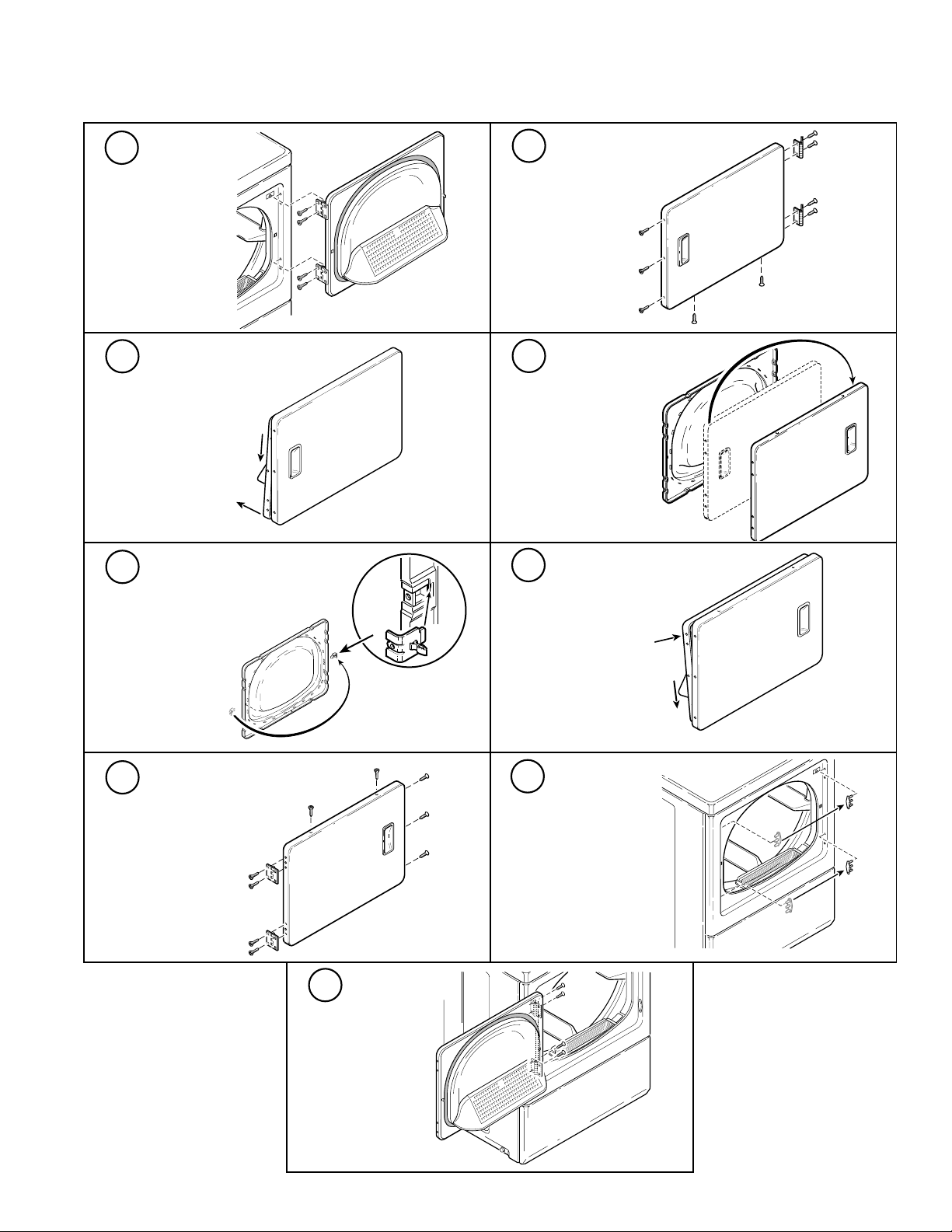

Reversing Door Procedure . . .

D273PE1B

4

Rotate door panel

180 degrees

as shown.

D269PE1D

6

Insert liner under

flange on bottom of

door, then push

top of door

liner into place.

B

A

8

D345IE1B

Using a screwdriver,

remove two door

plugs, and reinstall

on opposite side

of door opening.

The door on this dryer is completely reversible. To reverse door proceed as follows:

1

Remove four

hinge attaching

screws.

3

Pull bottom of

door liner out,

then pull down,

removing door

liner from door

panel.

5

2

Remove all

nine screws.

D347IE1A

B

A

D268PE1C

D348IE1C

Remove door strike

from door liner

and reinstall on

opposite side.

7

Reinstall nine screws

removed in Step 2.

504524

D276PE1B

D270PE1B

9

Reinstall four

hinge attaching

screws removed

in Step 1.

D346IE1A

15

Page 18

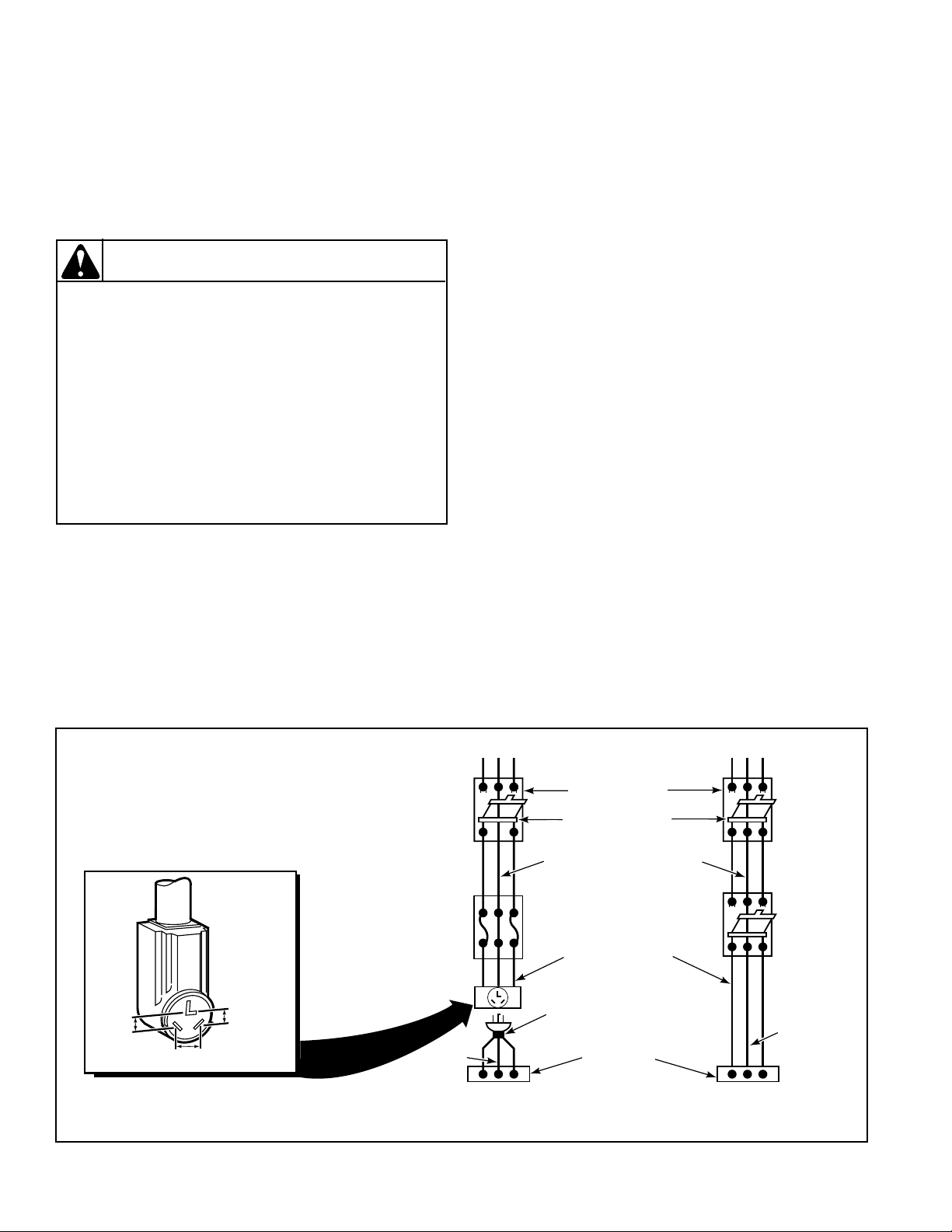

Electrical Requirements . . .

(Electric Dryers)

(120/240 Volt, 60 Hertz, 3-Wire Installation)

(120/208 Volt, 60 Hertz, 3-Wire Installation)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is the

customer’s responsibility to have the wiring

and fuses checked by a qualified electrician

to make sure the laundry room has adequate

electrical power to operate the dryer.

W035

Grounding And Wiring Instructions

• Each dryer must be connected to a grounded metal,

permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on each dryer.

• Each dryer has its own terminal block that must be

connected to a separate branch, 60 Hertz, single phase

circuit, AC (alternating current) circuit, fused at 30

Amperes (the circuit must be fused on both sides of the

line). ELECTRICAL SERVICE FOR THE DRYER

UNIT SHOULD BE OF MAXIMUM RATED

VOLTAGE LISTED ON THE NAMEPLATE. DO

NOT CONNECT DRYER TO 110, 115, OR 120

VOLT CIRCUIT. Heating elements are available for

field installation in dryer units which are to be

connected to electrical service of different voltage than

that listed on nameplate, such as 208 Volt.

• If branch circuit to dryer unit is fifteen feet (4.50 m) or

less in length, use U.L. (Underwriters Laboratories)

listed No. 10 A.W.G. wire (copper wire only), or as

required by local codes. If over fifteen feet (4.50 m),

use U.L. (Underwriters Laboratories) listed No. 8

A.W.G. wire (copper wire only), or as required by local

codes. Allow sufficient slack in wiring so dryer can be

moved from its normal location when necessary.

• The power cord (pigtail) connection between wall

receptacle and dryer unit terminal block IS NOT

supplied with dryer unit. Type of pigtail and gauge of

wire must conform to local codes and with instructions

mentioned on the following pages.

The method of wiring the dryer unit is optional and

subject to local code requirements. See examples below.

NOTE: The power cord (pigtail) is NOT supplied with the

electric dryer. Type of pigtail and gauge of wire must conform

to local codes and instructions.

The method of wiring the dryer is optional and subject to local

code requirements.

NOTE: Connect the dryer to the power supply with the

MAXIMUM RATED VOLTAGE listed on the nameplate.

A typical

30-Amp

Three-wire

Receptacle

NEMA Type

10-30R

120 ± 12

120 ± 12

VAC

240 ± 12

VAC

NOTE: Use COPPER WIRE only.

Shorter than 15' (4.5 m) use 10 A.W.G.

Longer than 15' (4.5 m) use 8 A.W.G.

VAC

INTERMEDIATE

16

FUSE BOX

(MAY BE

OMITTED IF

SERVICE

ENTRANCE

BOX IS FUSED)

WALL

RECEPTACLE

NEUTRAL

POWER SUPPLY POWER SUPPLY

L1 L2

PIGTAIL CONNECTION

3-WIRE GROUNDED NEUTRAL

120/240 VOLT, 60 HERTZ AC 1 PHASE

SERVICE ENTRANCE SWITCH BOX

(SEE NOTE BELOW)

30 AMPERE FUSES OR

CIRCUIT BREAKER

NEUTRAL WIRE NEUTRAL WIRE

METALLIC OR

NON-METALLIC

SHEATHED CABLE

(COPPER WIRE

ONLY)

PIGTAIL

TO DRYER

(SEE NOTE BELOW)

TERMINAL BLOCK

IN DRYER

DIRECT CONNECTION

L1 L2

INTERMEDIATE

SHUT-OFF BOX

(MAY OR MAY

NOT BE FUSED)

NEUTRAL

D003IE3A

504524

Page 19

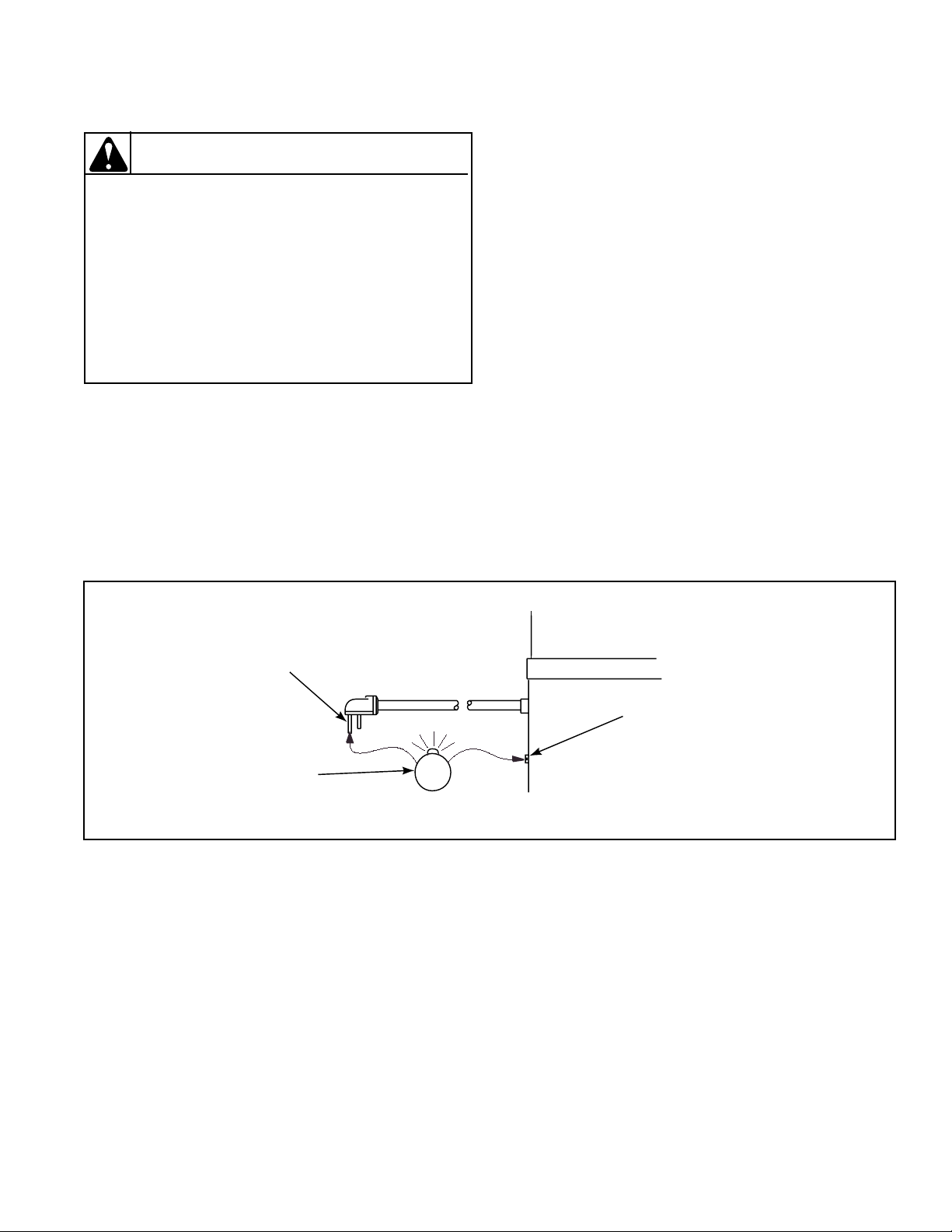

Electrical Connection . . .

(Three-Wire Power Cord)

WARNING

The dryer unit is grounded to neutral

conductor at the terminal block. If local

codes do not permit grounding through the

neutral, proceed as shown on Four Wire

Connection instructions.

W148

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

unit before proceeding.

W149

cylinder. If the dryer unit had previously been

connected with a four-wire power cord, remove the

four-wire power cord by reversing procedures under

Four-Wire Power Cord instructions.

IMPORTANT: Use only a U.L. listed No. 10 AWG

(copper wire only) three conductor power supply cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a clothes dryer unit.

3. Tighten these wire-binding screws firmly.

IMPORTANT: Failure to tighten these screws firmly

may result in wire failure at the terminal block.

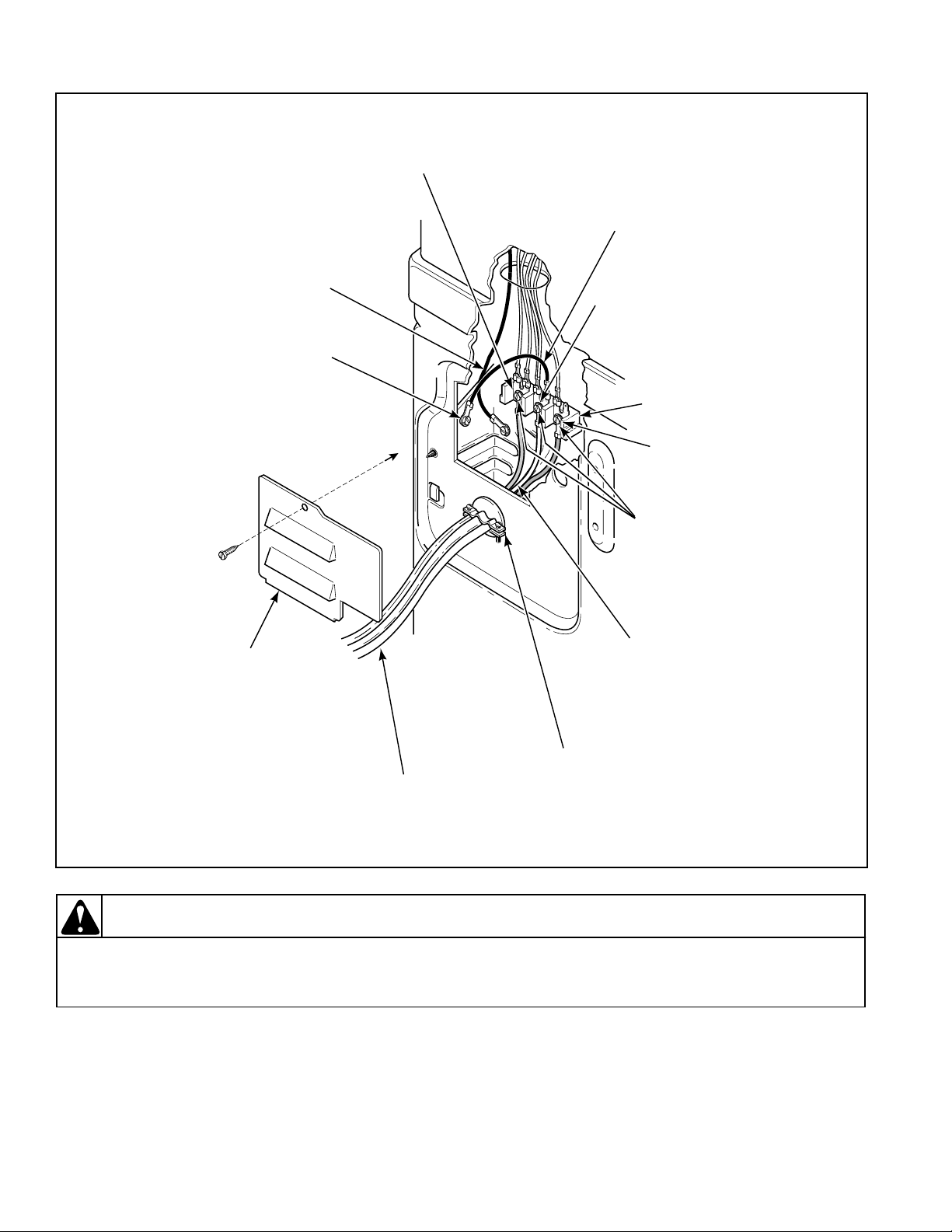

1. Remove the screw and terminal block access cover

from the rear of the dryer unit cabinet.

2. Insert ends of direct wire through power supply hole

(containing proper strain relief) in rear of dryer unit

cabinet. See following page. Connect the power

cord,or direct wiring, to the appropriate terminal

block terminals using the three wire-binding

(10-32x3/8") screws from the accessories pack in

the envelope shipped inside the dryer unit

GROUNDING

PIN

INDICATING

DEVICE

(MUST SHOW

CONTINUITY)

4. Secure the strain relief to the power cord, or wires,

where they enter the dryer unit cabinet.

5. Check the continuity of the ground connection before

plugging the cord into an outlet. Use an acceptable

indicating device connected to the center grounding

pin of the plug and the green screw on the back of the

cabinet.

6. Reinstall access cover and screw.

GROUND SCREW

ON BACK

OF CABINET

D357IE3A

504524

17

Page 20

Three Wire Connection

"L1"

TERMINAL

GROUND

TO NEUTRAL

WIRE

TERMINAL

ACCESS

COVER

GROUND

WIRE

BRACKET

GROUND

SCREW

NEUTRAL

TERMINAL

TERMINAL

BLOCK

"L2"

TERMINAL

SLOTTED

HEX HEAD

SCREWS

(Shipped

inside

the dryer)

NEUTRAL

(WHITE

OR CENTER

WIRE)

STRAIN

RELIEF

POWER CORD

OR DIRECT

WIRING

(Three-wire)

(NOT SUPPLIED

WITH DRYER)

D170IE2D

WARNING

Dryer unit is shown with the access cover removed for illustration purposes only. To reduce the

risk of an electric shock, NEVER operate the dryer unit with the access cover removed.

18

W150

504524

Page 21

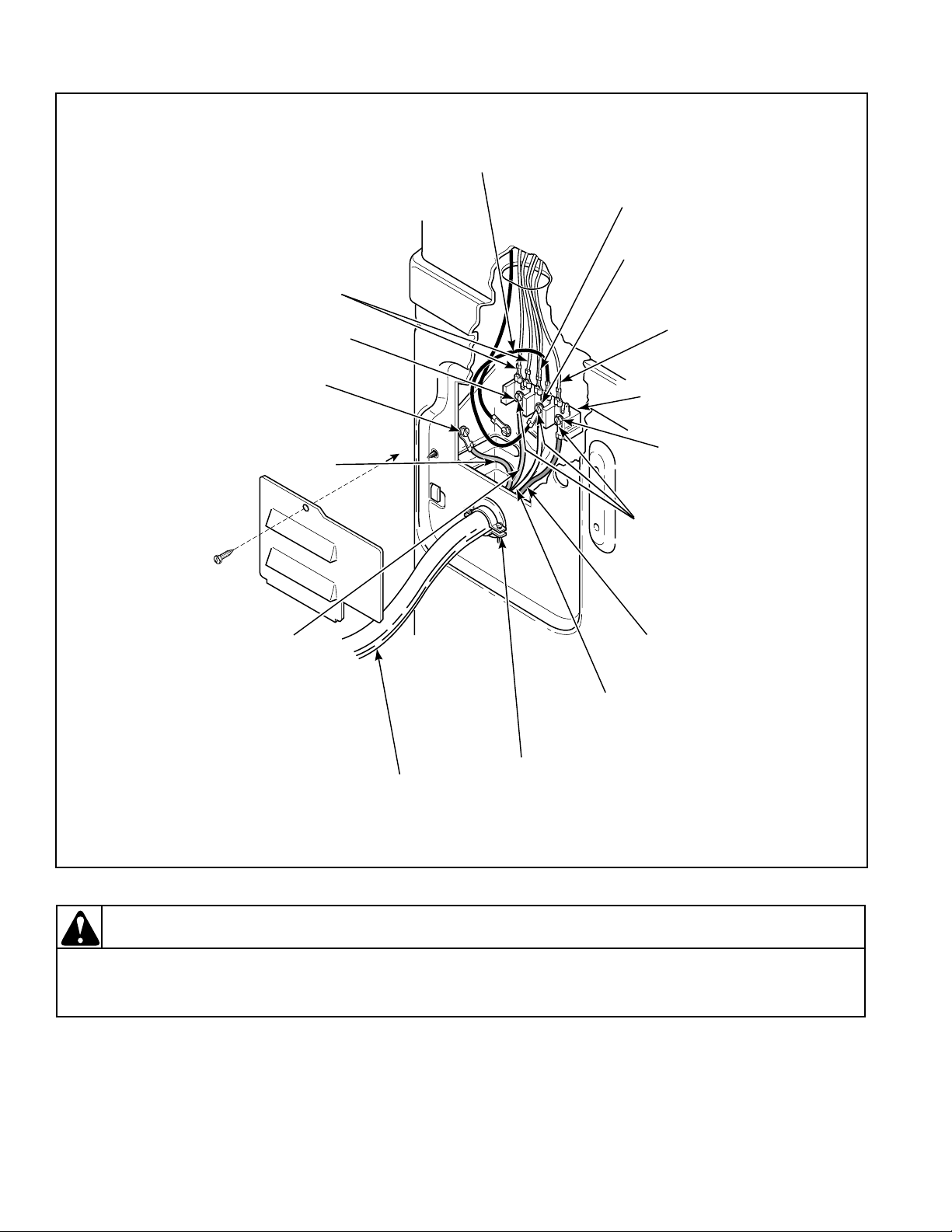

(Four-Wire Power Cord)

IMPORTANT: Use only a U.L. listed No. 10 AWG

(copper wire only) four conductor power supply cord

kit rated 240 Volts (minimum) 30 Amperes and

labeled as suitable for use in a clothes dryer unit.

NOTE: The power cord is not supplied with the dryer

unit when the dryer unit is shipped from the factory,

therefore, disregard steps 2 and 3 below when

connecting a four-wire power cord to a new dryer

unit.

If the dryer unit has a three-wire cord attached, then

complete steps 1 through 12.

WARNING

To reduce the risk of electrical shock,

disconnect the electrical power to the dryer

unit before proceeding.

W151

1. Remove the screw holding the access plate to the rear

of the dryer unit cabinet.

2. Remove the three screws holding the three wires to

the terminal block terminals. Save these screws.

3. Loosen the strain relief screw and pull the cord or

wires out through the rear of the dryer unit.

4. Remove the terminal bracket ground screw holding

the ground wire to the terminal block mounting

bracket. Save the screw.

8. Using the three wire-binding (10-32x3/8") screws

from the accessories envelope located inside the

cylinder (unless the screws were previously removed

in Step 2), attach the power cord wires to the terminal

block terminals as follows:

a. Red to Red

b.Black to Black

c. White to White (see NOTE below)

NOTE: When installing the white wire, loop the free

eyelet end of the ground wire (from Step 4) and place

it together with the white wire and attach both wires

to the neutral (center) terminal on the terminal block.

See following page.

IMPORTANT: Failure to tighten the nuts firmly on

the terminal block may result in power cord wire

failure.

9. Tighten the two strain relief screws to secure the

power cord.

10. Recheck all screws to be sure they are tight.

11. Check the continuity of the ground connection before

plugging the cord into an outlet. Use an acceptable

indicating device connected to the center grounding

pin of the plug and the green screw on the back of the

cabinet. See illustration on following page.

12. Reinstall the access plate and screw to the rear of the

dryer unit cabinet.

NOTE: ON NEW DRYER UNITS, this is the ground

wire that goes from the neutral (center) terminal on

the terminal block to the mounting bracket.

Install four-wire power cord

5. Route the end of the four-wire power cord through

the strain relief. DO NOT tighten the strain relief

screws at this time.

6. Insert the end of power cord and strain relief through

the hole in the rear of the dryer unit cabinet. Install

the strain relief nut from the inside of the cabinet and

tighten firmly.

7. Attach the green ground wire (from the four-wire

power cord) to the terminal block mounting bracket

using the hex head screw removed in Step 4. Tighten

the screw firmly.

TYPICAL

FOUR-WIRE

RECEPTACLE

120 ± 12

V.A.C.

240 ± 12

120 ± 12

V.A.C.

V.A.C.

120 ± 12

V.A.C.

120 ± 12

V.A.C.

STRAIN

RELIEF

POWER CORD -

NOT SUPPLIED

WITH DRYER

(Four-Wire)

STRAIN

RELIEF

NUT

D006IE1C

504524

19

Page 22

Four Wire Connection

TERMINAL

BRACKET

GROUND

RED

WIRES

"L1"

TERMINAL

SCREW

GROUND

WIRE

WHITE

WIRES

NEUTRAL

TERMINAL

BLACK

WIRE

TERMINAL

BLOCK

GROUND

RED

WIRE

WIRE

POWER CORD

(FOUR-WIRE)

"L2"

TERMINAL

SLOTTED

HEX HEAD

SCREWS

(Shipped

inside

the dryer

or removed

in Step 2)

BLACK

WIRE

NEUTRAL

(WHITE

WIRE)

STRAIN

RELIEF

D171IE2D

WARNING

Dryer unit is shown with the access cover removed for illustration purposes only. To reduce the

risk of an electric shock, NEVER operate the dryer unit with the access cover removed.

20

W150

504524

Page 23

Electrical Requirements . . .

D090IE1B

STANDARD

120 VOLT,

60 HERTZ,

3-WIRE EFFECTIVELY

GROUNDED CIRCUIT

NEUTRAL

SIDE

ROUND

GROUNDING

PRONG

GROUND

NEUTRAL

L1

0

V.A.C.

115 ± 12

V.A.C.

115 ± 12

V.A.C.

(Gas Dryers)

(120 Volt, 60 Hertz, With 3-Prong Grounding Plug)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is

the customer’s responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure the laundry room

has adequate electrical power to operate the

dryer.

W035

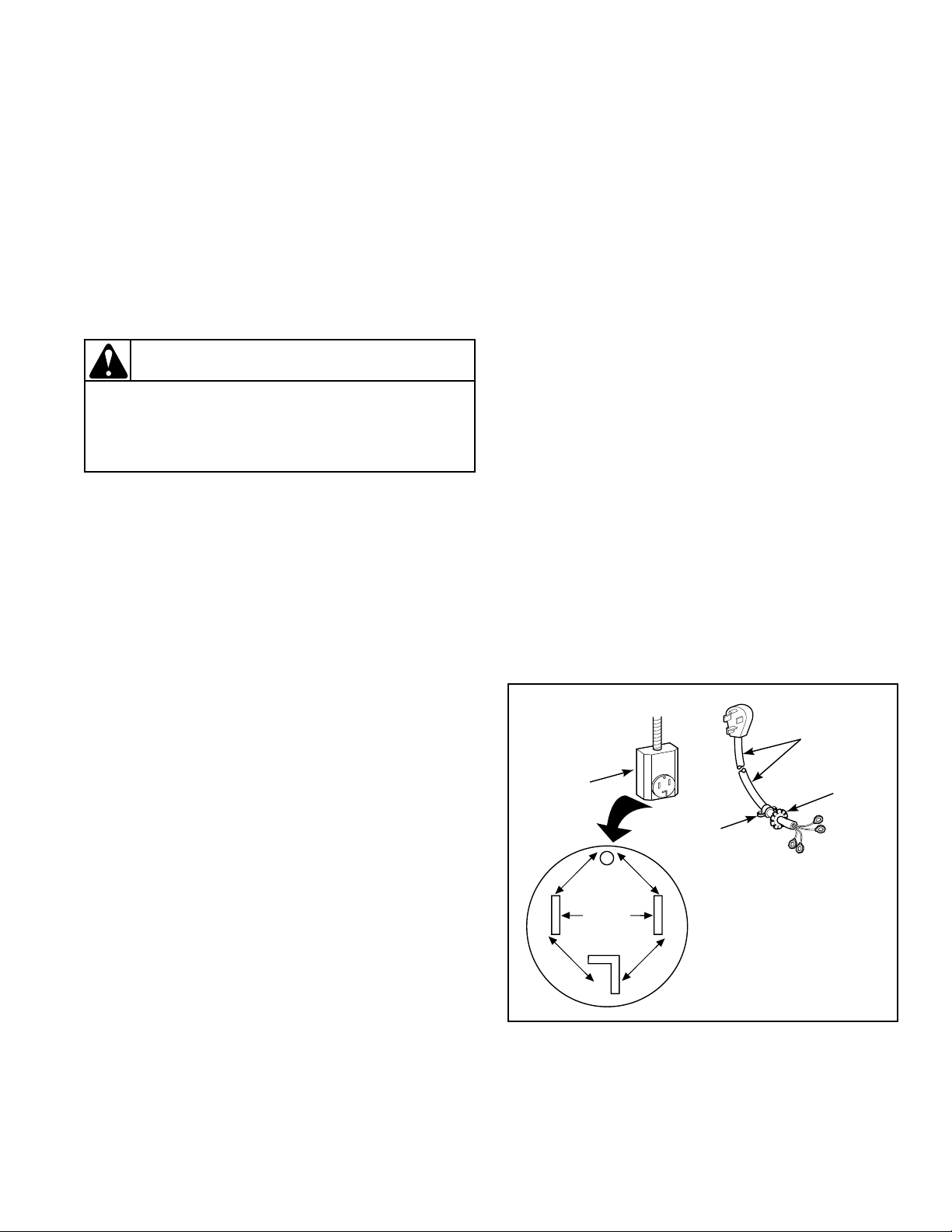

• Each dryer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current) circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

• The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 120 Volts AC

(alternating current) 15 Amps. See illustration below

for determining correct polarity of the wall receptacle.

See illustration below.

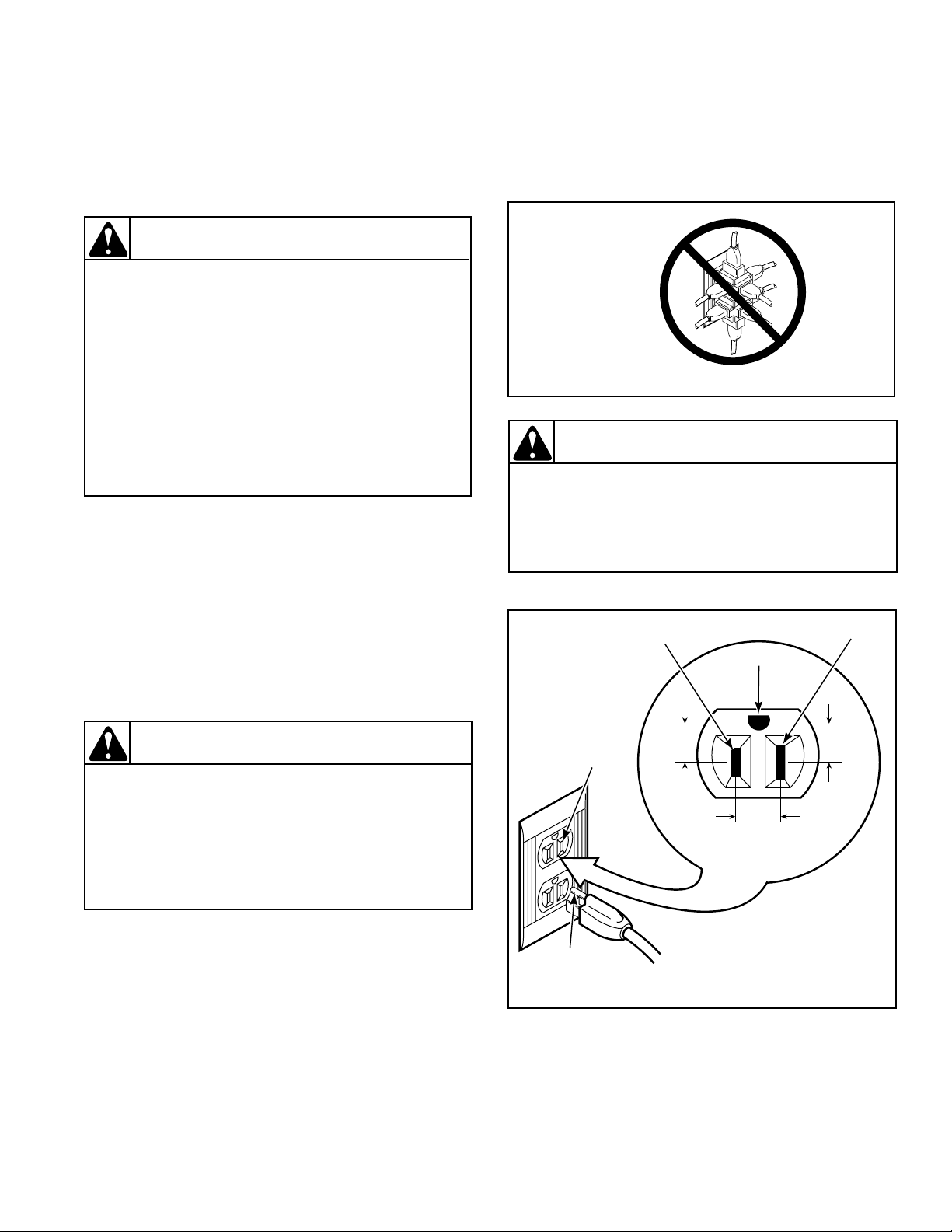

DO NOT

OVERLOAD

CIRCUITS

D009IE0B

\

WARNING

To reduce the risk of an electric shock or fire,

DO NOT use an extension cord or an adapter

to connect the dryer unit to the electrical

power source.

W152

This dryer is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

NOTE: A qualified electrician should check the

polarity of the wall receptacles. If a voltage reading is

measured other than that illustrated, the qualified

electrician should correct the problem.

• DO NOT OPERATE OTHER APPLIANCES ON THE

SAME CIRCUIT WHEN THIS APPLIANCE IS

OPERATING. DO NOT OVERLOAD CIRCUITS!

504524

WARNING

W036

21

Page 24

Grounding Instructions

• The dryer unit must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The dryer unit is

equipped with a cord having an equipment-grounding

conductor and a three prong grounding plug. The plug

must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all

local codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the dryer unit is properly

grounded.

• DO NOT modify the plug provided with the dryer

unit—if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

• If the laundry room’s electrical supply does not meet

the above specifications and/or if you are not sure the

laundry room has an effective ground, have a qualified

electrician or your local electrical utility company

check it and correct any problems.

W153

22

504524

Page 25

Gas Requirements . . .

(Gas Dryers)

NOTE: The gas service to a gas dryer unit must

conform with the local codes and ordinances, or in the

absence of local codes and ordinances, with the latest

edition of the National Fuel Gas Code ANSI Z223.1/

NFPA 54 or the CAN/CGA-B149, National Gas

Installation Code.

3

Natural Gas, 1,000 Btu/ft

be supplied at 6.5 ± 1.5 inch water column pressure.

For proper operation at altitudes above 2,000 feet (610 m)

the natural gas valve spud orifice size must be reduced to

ensure complete combustion. See table at right.

L.P. (propane) Gas, 2,500 Btu/ft

must be supplied at 10 ± 1.5 inch water column pressure.

NOTE: DO NOT connect the dryer unit to L.P.

(propane) Gas Service without converting the gas

valve. A 458P3 L.P. (propane) Gas Conversion Kit

must be installed by the Manufacturer’s Authorized

Dealers, Distributors, or local service personnel.

NOTE: The dryer unit and its individual shut-off

valve must be disconnected from the gas supply

piping system during any pressure testing of that

system at test pressures in excess of 1/2 psi (3.45 kPa).

(37.3 MJ/m3), service must

3

(97.1 MJ/m3), service

WARNING

To reduce the risk of gas leaks, fire or

explosion:

• The dryer unit must be connected to the

type of gas as shown on nameplate located

in the door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in LP

(propane) Gas, or Teflon tape, on all pipe

threads.

• Purge air and sediment from gas supply

line before connecting it to the dryer unit.

Before tightening the connection, purge

remaining air from gas line to dryer unit

until odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for gas

leaks. Use a non-corrosive leak detection

fluid.

W154R2

The dryer unit must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than

1/2 psi (3.45 kPa)

NOTE: When connecting to a gas line, an equipment

shutoff valve must be installed within 6' (1.8 m) of the

dryer. An 1/8" N.P.T. pipe plug must be installed as

shown. See illustration.

NEW

STAINLESS

STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

Altitude Orifice Size Part

Numberft m # Inches mm

2000 610 41 0.0960 2.44 503776

3000 915 42 0.0935 2.37 503777

5500 1680 43 0.0890 2.26 503778

7000 2135 44 0.0860 2.18 58719

9000 2745 45 0.0820 2.08 503779

10500 3200 46 0.0810 2.06 503780

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

EQUIPMENT

SHUT-OFF

VALVE

Installed within

6' (1.8 m) of dryer

D233IE2E

504524

23

Page 26

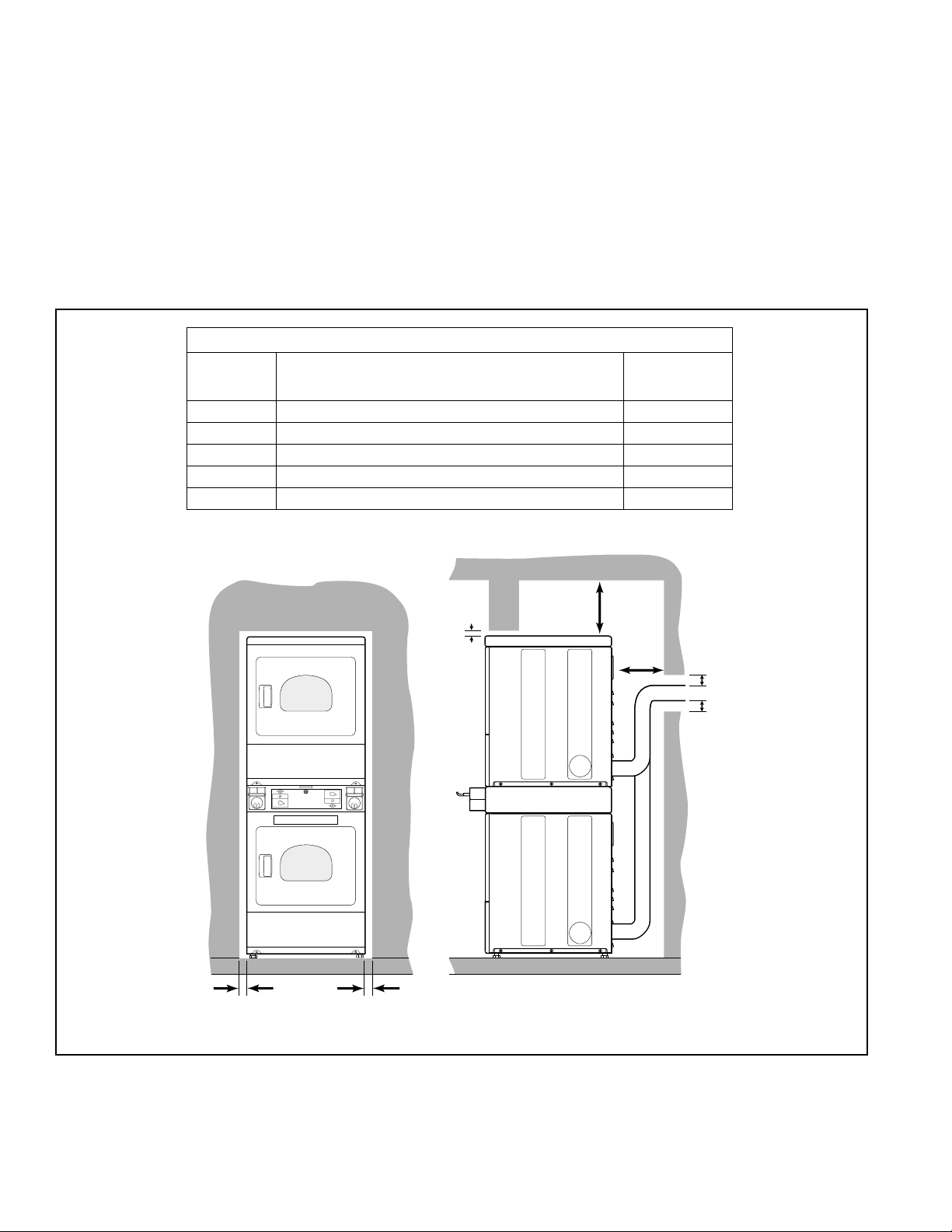

Location Requirements . . .

Select a location with a solid floor.

No other fuel burning appliance should be installed in the

same closet with the dryer unit.

The dryer unit must not be installed or stored in an area

where it will be exposed to water and/or weather.

Leveling legs can be adjusted from inside the dryer unit

with a 1/4" driver. All four legs must rest firmly on the

floor so the weight of the dryer is evenly distributed. The

dryer unit must not rock.

Dryer And Exhaust Duct Clearances

Area Description

A Dryer Sides 0" (0 cm)

B Dryer Top (Rear 24") 2" (5.1 cm)

C Dryer Rear 4" (10.2 cm)

D Dryer Top (Front 4") 0" (0 cm)

E Exhaust Duct from Combustible Construction 2" (5.1 cm)

NOTE: Shaded areas

indicate adjacent structure.

IMPORTANT: Unless completely assembled, DO

NOT slide the dryer unit across the floor. DO NOT

slide the unit once the leveling legs have been

extended, as the legs and the base could become

damaged.

The dryer unit needs sufficient clearance and an adequate

air supply for proper operation and ventilation, and for

easier installation and servicing. (Minimum clearances

are shown below.)

Minimum

Clearance

D

AA

B

C

E

E

D358IE2A

24

504524

Page 27

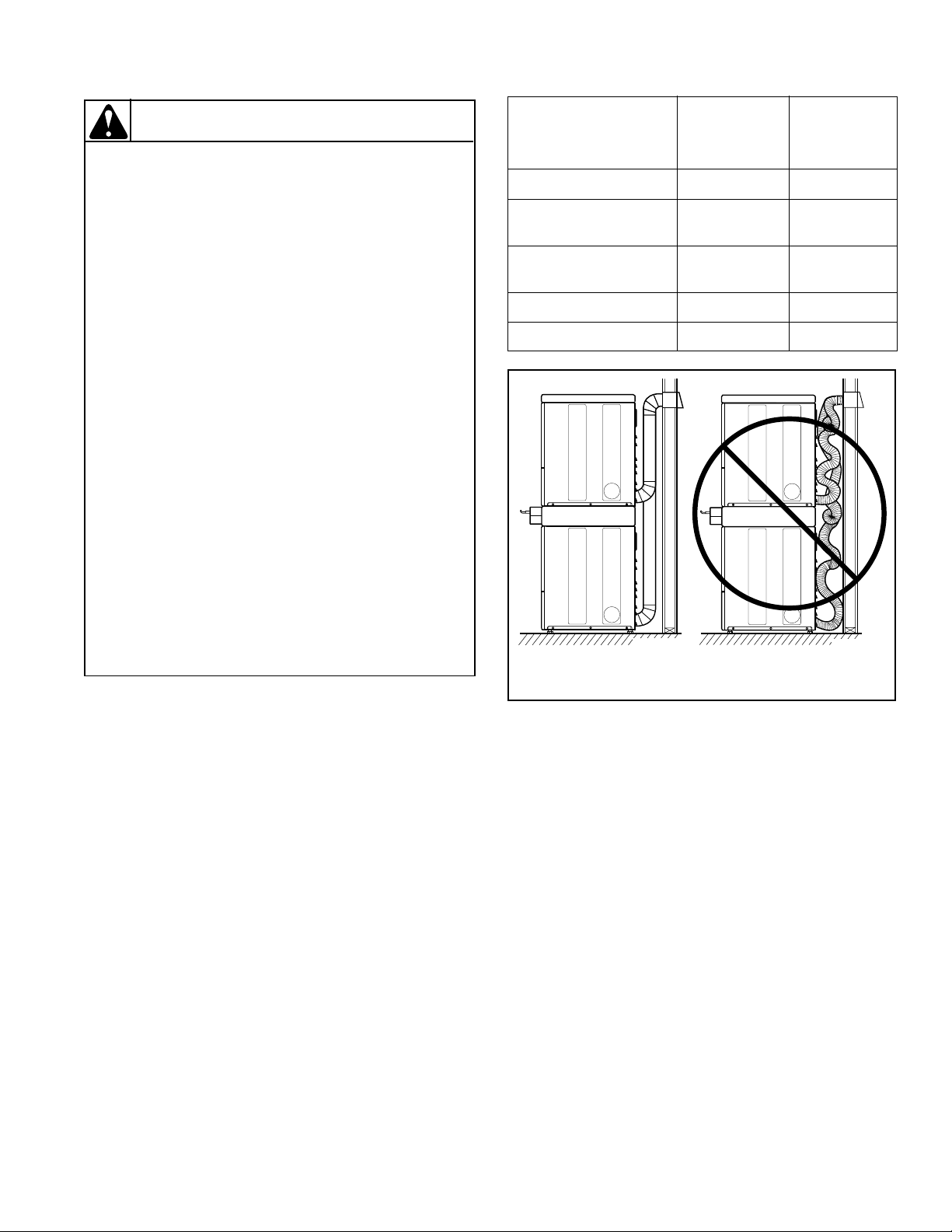

Dryer Exhaust Requirements . . .

DON'T

D356IE0B

D354IE0C

DO

WARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted to

the outdoors.

W116

This gas appliance contains or produces a

chemical or chemicals which can cause death

or serious illness and which are known to the

State of California to cause cancer, birth

defects, or other reproductive harm. To

reduce the risk from substances in the fuel or

from fuel combustion, make sure this

appliance is installed, operated, and

maintained according to the instructions in

this manual.

W115

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas vent,

chimney or enclosed, unventilated area, such

as an attic, wall, ceiling, crawl space under a

building or concealed space of a building.

W045

To reduce the risk of fire, DO NOT use plastic

pipe or flexible plastic pipe to exhaust the

dryer.

W041

MAY BE

DESCRIPTION KIT P/N

Exhaust Duct (4" Dia.) Not Available Yes

Flexible Metal Duct

(4" Dia)

Weather Hoods, with

hinged dampers (4")

Directional Exhaust Kit 528P3 No

Tape Not Available Yes

521P3 Yes

Not Available Yes

OBTAINED

LOCALLY

Never install flexible duct in concealed spaces, such as a

wall or ceiling.

Exhaust System Materials

Exhaust system materials are not supplied with the dryer

unit.

Exhaust duct must be four inches (10.2 cm) in diameter

having no obstructions. Rigid metal duct is

recommended. Non-combustible semi-rigid flexible

metal duct is acceptable. Do not use plastic pipe or

flexible plastic pipe, because it contributes to poor drying

performance and collects lint, which can lead to a fire

hazard.

DO NOT use sheet metal screws on exhaust pipe joints or

other fastening means which extend into the duct that

could catch lint and reduce the efficiency of the exhaust

system. Secure all joints with duct tape.

NOTE: Kits described above are optional exhaust

system materials available at extra cost.

Make-Up Air Requirements

A dryer unit exhausts 214 cfm (measured at back of dryer

unit) and sufficient make-up air must be supplied to

replace air exhausted by each dryer unit.

An unobstructed opening of at least 40 square inches

(260 cm

each dryer unit. Protective louvers in the opening to the

outdoors can reduce air movement approximately 35 to

40 percent. Be sure the opening is large enough to

compensate for any louvers.

If it is necessary to duct make-up air to the dryer unit,

increase the area of the ductwork by 25 percent to

compensate for any reduction in air movement. In

addition, the make-up air duct should extend down to

within approximately two feet from the floor, directly

behind the dryer unit.

2

) of outdoor make-up air MUST be provided for

504524

25

Page 28

Exhaust System

(

)

D011IE2E

2-1/2"

(6.35 cm)

(continued)

)

IMPORTANT: Keep exhaust duct as short as

possible.

NOTE: Be certain old ducts are cleaned before

installing your new dryer unit.

For best drying results, recommended maximum length

of exhaust system is shown below.

To prevent backdraft when dryer unit is not in operation,

outer end of exhaust pipe must have a weather hood with

hinged dampers (obtain locally).

NOTE: Weather hood should be installed at least 12

inches (30.5 cm) above the ground. Larger clearances

may be necessary in areas where heavy snowfall can

occur.

Exhaust Direction

The dryer unit can be exhausted to the outdoors through

the back, left, right or bottom of the dryer unit.

EXCEPTION: Gas dryers cannot be vented out the

left side because of the burner housing.

Exhausting the dryer through sides or bottom (lower

dryer only) can be accomplished by installing a

Directional Exhaust Kit 528P3 available as optional

equipment at extra cost.

WEATHER

HOOD

WITH

HINGED

DAMPERS

RIGID OR

FLEXIBLE

METAL

DUCT

D186IE0A

528P3 Directional Exhaust Kit

Dryer unit is shipped from factory ready for rear exhaust;

no kits required.

Number of

90° Elbows

10.16 cm

Recommended Use only for short run installations

4"

Maximum length of 4" (10.2 cm) diameter rigid metal duct.

0 44 feet (13.4 m) 34 feet (10.4 m)

1 34 feet (10.4 m) 26 feet (7.9 m)

2 26 feet (7.9 m) 20 feet (6.1 m)

3 20 feet (6.1 m) 14 feet (4.3 m)

Maximum length of 4" (10.2 cm) diameter flexible metal duct.

Weather Hood Type

4"

(10.16 cm)

D011IE2D

26

0 24 feet (7.3 m) 20 feet (6.1 m)

1 20 feet (6.1 m) 16 feet (4.9 m)

2 16 feet (4.9 m) 12 feet (3.7 m)

3 12 feet (3.7 m) 8 feet (2.4 m)

NOTE: Deduct 6 feet (1.8 m) for each additional elbow.

504524

Page 29

Exhaust System Maintenance

Reduced Clearance

Elbow

The dryer unit interior and the complete exhaust system

should be inspected after one year of use and cleaned if

necessary. Inspect and clean exhaust duct every one to

two years as required thereafter. The weather hood

should be checked frequently to make sure the dampers

move freely, dampers are not pushed in and that nothing

has been set against them. This maintenance work should

be done by a qualified service person.

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

before cleaning.

W043

Exhausting the dryer unit in hard-to-reach locations can

be accomplished by installing the 521P3 Flexible Metal

Vent Kit, available as optional equipment at extra cost.

The kit comes in two halves that can be separately

attached to the dryer unit, the wall outlet and to each

other. Once attached, the dryer can be slid back into

position.

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer unit’s front panel with laundry,

rugs, etc. Blockage will decrease airflow through the

dryer unit, thus reducing the efficiency of the dryer

unit.

Reduced Clearance Elbow

Installing the dryer unit in shallow closets can be

accomplished by using an Elbow, Part No. 62688, which

is one inch narrower than a standard venting elbow.

D319IE0A

Reduced Clearance Elbow

Dryer Airflow

Efficient dryer unit operation requires proper dryer

airflow. Proper dryer unit airflow can be evaluated by

measuring the static pressure.

Static pressure in the dryer unit’s exhaust duct should be

no greater than that shown in the chart below. (Check

with dryer unit running and no load.)

NOTE: This can be measured with a manometer

placed on the exhaust duct approximately two feet (61

cm) from the dryer unit, see illustration below.

MAXIMUM STATIC

PRESSURE IN

MANOMETER

WATER COLUMN

.6 INCHES (1.5 cm)

EXHAUST

DUCT

Measuring Static Pressure

504524

Measuring Static Pressure

D012IE0A

27

Page 30

Multi-dryer Installation

(continued))

Exhaust Requirements . . .

• The illustration below shows a typical example of a

multiple dryer installation. Note how each dryer has its

own exhaust system vented to the central exhaust duct.

58786

BACKDRAFT

DAMPER

(Available

through

your local

authorized

parts source)

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

CLEAN-OUT

COVER

MUST BE

PROVIDED

D359IE2A

IMPORTANT: Static pressure in each dryer’s

exhaust duct should be no greater than that shown in

the chart on Page 28. This can be measured with a

manometer placed on the exhaust duct approximately

two feet (61 cm) from the dryer. See Page 28. All

dryers connected to the main collector duct should be

in operation when pressure is checked.

Installing an exhaust system does not eliminate the

necessity of cleaning the dryer lint filter before each load.

The dryer interior and the complete exhaust system

should be cleaned periodically by a qualified service

person to remove any lint build-up.

28

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

before cleaning.

W043

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer’s front panel with laundry, rugs,

etc. Blockage will decrease airflow through the dryer,

thus reducing the efficiency of the dryer.

504524

Page 31

• Dryer unit exhaust duct should enter the main duct at an

angle of no more than 30

pointing in the direction of

°

the air flow. Ducts entering the main duct from

opposite sides should be staggered so as not to oppose

each other. See illustration below.

• Provisions should be made for periodic lint removal

and cleaning of the main collector duct.

DRYER EXHAUST DUCT

AIR FLOW MAIN COLLECTOR DUCT

DRYER EXHAUST DUCT

30°

30° 30°

• The outside end of the main duct should have a weather

hood (with hinged dampers) installed to prevent

passage of weather elements, insects, dust, and dirt into

the dryer units.

• If a weather hood cannot be used, the outside end of the

main duct should have a sweep elbow installed, and be

directed downward as shown on the following page. If

the main duct travels vertically through a roof rather

than through a wall, install 180

sweep elbow on the

°

end of the duct with outlet at least 24 inches (61 cm)

above the highest part of the building.

DRYER EXHAUST DUCT

DRYER EXHAUST DUCT

30°

D026IE3A

• Sufficient make-up air must be supplied to replace air

exhausted from dryer units.

NOTE: Where the exhaust duct pierces the wall or

ceiling, an opening having a diameter of 4 inches (10.2

cm) larger than the diameter of the exhaust duct shall

be provided, and the exhaust duct centered within the

opening.

• Damper, Part No. 58786, should be installed in each

dryer’s exhaust system. This will prevent a backdraft

when dryer unit is not in use, and will keep the exhaust

air in balance within the central exhaust system.

WARNING

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated area,

such as an attic, wall, ceiling, crawl space

under a building or concealed space of a

building.

504524

IMPORTANT: Provisions must be made for make-up

air.

IMPORTANT: If several dryer units are exhausted

into a main collector duct, it is essential that ductwork

be adequate in size and properly constructed for

efficient operation.

W045

29

Page 32

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

180˚ SWEEP

ELBOW

(No cap

or screen)

PARAPET

MAIN COLLECTOR DUCT

WALL

• Main collector duct should be sized according to

specifications shown below.

Number

of Dryers

Minimum Diameter of

Horizontal Collector Duct

1 stack 7 inch (17.8 cm) 8 inch (20.3 cm)

1 stack 8 inch (20.3 cm) 9 inch (22.9 cm)

2 stacks 9 inch (22.9 cm) 10 inch (25.4 cm)

2 stacks 10 inch (25.4 cm) 11 inch (27.9 cm)

24" MIN.

(60.96 cm)

MAIN COLLECTOR DUCT

VERTICAL DUCTHORIZONTAL DUCT

Minimum Diameter of

Vertical Collector Duct

ROOF

D039IE3A

3 stacks 11 inch (27.9 cm) 12 inch (30.5 cm)

3 stacks 12 inch (30.5 cm) 13 inch (32.6 cm)

4 stacks 12 inch (30.5 cm) 14 inch (35.6 cm)

4 stacks 13 inch (32.6 cm) 15 inch (38.1 cm)

5 stacks 14 inch (35.6 cm) 15 inch (38.1 cm)

5 stacks 14 inch (35.6 cm) 16 inch (40.6 cm)

NOTE: Main collector duct should be equipped with

an auxiliary fan that can maintain the duct airflow at

a minimum of 1200 feet (366 m) per minute. If you do

not have a fan, clean the main collector duct at least

twice a year.

30

504524

Page 33

Lint Filter . . .

CLEAN THE LINT FILTER BEFORE DRYING EACH

LOAD. (Refer to illustration below for lint filter

location.) Cleaning the lint filter is important because a

layer or pad of lint on the filter will block the flow of air

through the dryer, thus reducing the efficiency of the

dryer. The clothes will take longer to dry and energy will

be wasted.

LINT

FILTER

Motor Overload Protector . . .

The motor overload protector stops the motor and shuts

the heat off automatically in the event of an overload.

After cooling, the overload protector will reset itself. The

dryer can be restarted by pressing the PUSH-TO-START

D349IE3B

button. If the overload protector cycles again, remove the

dryer from use and call the service person to correct the

problem.

504524

31

Page 34

User-Maintenance Instructions . . .

Lubrication

All moving parts are sealed in a permanent supply of

lubricant or are equipped with oilless bearings.

Additional lubrication will not be necessary.

Care of Your Dryer

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

W049

Clean the lint filter before drying each load. The lint filter

may be washed if needed. Occasionally remove lint filter

and vacuum the area under it.

Ordinarily, the dryer cylinder will need no care.

Wipe each dryer cabinet as needed. If detergent, bleach or

other washing products have been spilled on the dryer

unit, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Do not allow sharp or rough objects to lean against the

dryer unit. The finish could be damaged.

Use only a damp or sudsy cloth for cleaning the control

panel. Some spray prewash products may harm the finish

on the control panel.

NOTE: The wiring diagram is located inside the

control panel.

For Energy Conservation . . .

• Make sure the lint filter is always clean.

• Do not overload dryer unit.

• Do not overdry clothes.

• Remove items to be ironed while still damp.

• Large loads of similar fabrics dry the most efficiently.

However, dry permanent press in smaller loads to

prevent wrinkling.

Exhaust System

The exhaust duct should be inspected after one year of

use and cleaned if necessary by a qualified service person

to remove any lint build-up. Inspect and clean exhaust

duct every one to two years as required thereafter.

The weather hood should be checked frequently to make

sure the dampers move freely, dampers are not pushed in

and that nothing has been set against them.

Keep dryer area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

Do not obstruct the flow of combustion and ventilation

air.

NOTE: Verify proper operation after servicing.

• Use the correct temperature FABRIC SELECTOR

setting for the type of fabric being dried.

• Locate your dryer so the exhaust duct is as short and

straight as possible.

• Do not open the door during the drying cycle.

• Plan to do your laundry on low humidity days; your

clothes will dry faster.

Should you plan to dry several loads, do them one after

another, then you do not have to reheat the dryer unit’s

interior parts each time.

32

504524

Page 35

Before You Call For Service . . .

You may save time and money by checking the following:

•If Your Dryer:

Does

Not

Start

•

•

•

•

•

•

•

•

Does

Not

Heat

•

•

•

•

•

Does not Dry

Clothes

Satisfactorily

Possible Reason — Do This To Correct

Metered models—Insert coin(s) or card.

Nonmetered models—Turn the timer knob further into the cycle.

Be sure the cord is plugged all the way into the electrical outlet.

Close the loading door.

Make sure the controls are in a HEAT setting.

Metered models—Activate time accumulator. Push the coin slide all the

way in.

Press the PUSH-TO-START button.

Has the laundry room fuse blown or become loosened, or is a circuit

breaker OFF? The dryer unit itself does NOT have an electrical fuse.

Has the motor overload protector cycled? Wait 10 minutes and try again.

Gas Dryers Only—Check to see if the gas valve in the dryer (behind the

lower front panel) and the main gas line valve are turned on.

•

••

••

•

Clean the lint filter.

Check the exhaust duct to the outside to see if it is kinked, blocked or

needs cleaning.

Check the weather hood to make sure the flappers move freely, are not

pushed in or have not been blocked.

Is the load too small? Small loads may not tumble properly or dry

evenly.

504524

33

Page 36

Operation Instructions for

PUSH TO START

IN USE

IN USE

PUSH TO START

FABRIC SELECTOR

FABRIC SELECTOR

PERM PRESS

NORMAL

DELICATE

FLUFF

(NO HEAT)

PERM PRESS

NORMAL

DELICATE

FLUFF

(NO HEAT)

D360IE2A

Electromechanical Dryers . . .

(Metered and Nonmetered Models)

IMPORTANT: Before using dryer unit for the first

time, use an all-purpose cleaner, or a detergent and

water solution, and a damp cloth to remove shipping

dust from inside of each dryer drum.

STEP 1:

Clean Lint Filter

Clean lint filter before each use.

D349IE2B

STEP 3:

Close Loading Door

Close loading door. Dryer will not operate with the door

open.

D326IE2A

STEP 4:

Determine Proper Dryer

STEP 2:

Load Laundry

Load clothes loosely into dryer drum. Add fabric softener

sheet if desired.

34

D339IE2B

The direction of the arrow indicates which dryer is being

used.

504524

Page 37

STEP 5:

D363IE2A

STEP 6:

Set Fabric Selector

Select NORMAL for cottons, PERM PRESS for

permanent press, DELICATE for sensitive items or

FLUFF (NO HEAT) for items that require no heat.

Always follow Manufacturer’s Care Label

instructions.

PERM

DELICATE

PRESS

NORMAL

FLUFF

(NO HEAT)

FABRIC SELECTOR

D342IE2A

Start Dryer

METERED MODELS:

Place coin(s) in slide and carefully push in as far as

possible and then pull slide out as far as possible. After

IN USE light comes on (indicating start of cycle), press

the PUSH-TO-START button.

Metered Models

NONMETERED MODELS:

Rotate timer knob to desired time setting (up to 60

minutes). After IN USE light comes on (indicating start

of cycle), press the PUSH-TO-START button.

D365IE1A

Nonmetered Models

Remove knits when slightly damp because overdrying

may cause shinkage. Do not tumble dry knit woolens.

Should dryer stop before cycle is completed, the motor

overload protector may have cycled. See page 32.

504524

35

Page 38

Operation Instructions for

D280IE2A

INSERT COINS

PRICE

NORMAL

HIGH

TEMP

DELICATES

LOW

TEMP

PERM

PRESS

MED TEMP

TUMBLE

NO

HEAT

START

FABRICS AND TEMPERATURES

INSERT COINS

PRICE

NORMAL

HIGH

TEMP

DELICATES

LOW

TEMP

PERM

PRESS

MED TEMP

TUMBLE

NO

HEAT

START

FABRICS AND TEMPERATURES

LOWER

UPPER

Electronic Control Dryers . . .

(Metered and Nonmetered Models)

IMPORTANT: Before using dryer unit for the first

time, use an all-purpose cleaner, or a detergent and

water solution, and a damp cloth to remove shipping

dust from inside of each dryer drum.

STEP 1:

Clean Lint Filter

Clean lint filter before each use.

D349IE2B

STEP 3:

Close Loading Door

Close loading door. Dryer will not operate with the door

open.

D326IE2A

STEP 4:

Determine Proper Dryer

STEP 2:

Load Laundry

Load clothes loosely into dryer drum. Add fabric softener

sheet if desired.

D339IE2B

The direction of the arrow indicates which dryer is being

used.

36

504524

Page 39

STEP 5:

Set Fabric Selector

Select NORMAL (High Temp), PERM PRESS (Med

Temp), DELICATES (Low Temp) or TUMBLE (No

Heat) by pushing touchpad.

Always follow Manufacturer’s Care Label

instructions.

To Insert Card:

Insert card into opening. Follow directions on display.

DO NOT REMOVE THE CARD UNTIL DISPLAY

READS "Remove Card."

Remove knits when slightly damp because overdyring

may cause shrinkage. Do not tumble dry knit woolens.

STEP 6:

Insert Coin(s) or Card

To Insert Money.

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

If Additional Time Feature is turned on, additional dryer

time may be purchased at cycle start or while dryer is

running.

W387IE0A

STEP 7:

Start Dryer

To start dryer, push START pad.

To stop dryer at any time, open the door. To restart the

dryer, close door and push START pad.

Cycle is completed when time remaining reaches 00

minutes.

504524

37

Page 40

Indicator Lights

INSERT COINS

INSERT COINS is lit to prompt the user to insert coins to

satisfy the vend price for the chosen cycle. When INSERT

COINS is lit, the three digits and decimal point will

display the vend price remaining to be satisfied.

PUSH START

PUSH START is lit whenever the dryer is not in a cycle,

the full vend price has been satisfied and the dryer door is

closed. When the START pad is pressed, the cycle will

begin or resume. The PUSH START status word flashes at

one-second intervals when activated.

DRYING

DRYING is lit to indicate that one of the heated cycles

(HIGH TEMP, MED TEMP, LOW TEMP) is currently in

operation. The status word DRYING goes off at the end of

a heated cycle or when the COOL DOWN cycle begins.

DOOR OPEN

DOOR OPEN is lit and flashes at one-second intervals

whenever the dryer door is open.

COOL DOWN

COOL DOWN is lit whenever the COOL DOWN portion

of a heated cycle is active. It is also lit when the NO

HEAT cycle is in operation.

PRICE

PRICE is lit to indicate that the value displayed is the

vend pricing remaining to be satisfied. Once the vend

price is satisfied, the word PRICE will go off.

TIME REMAINING

TIME REMAINING is lit to indicate that the time

displayed by two digits and the colon is the time

remaining (in minutes) in the active cycle. The colon

flashes at one-second intervals and time continually

counts down in an active cycle.

Should dryer stop before cycle is completed, the motor

overload protector may have cycled. See

page 32.

38

504524

Page 41

Information for Handy Reference . . .

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Date Purchased

Model Number Serial Number

Dealer’s Name

Dealer’s Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep your sales slip. Model and serial numbers are located on

the nameplate.

504524

39

Page 42

Notes

40

504524

Page 43

Secadoras de

montaje vertical

con contador de monedas

y sin él

Modelos eléctricos y a gas

Instalación y operación

D355IE1B

No. de pieza 504524R3

Junio 1998

Page 44

GUARDE ESTAS INSTRUCCIONES PARA CONSULTARLAS EN EL FUTURO. (Si vende esta secadora,

asegúrese de entregarle este manual al nuevo propietario.)

ADVERTENCIA

POR SU PROPIA SEGURIDAD, la información que aparece en este manual debe

tomarse en cuenta para mantener a un mínimo el riesgo de incendio o explosión y

para evitar daños a la propiedad, lesiones personales o la muerte.

• No almacene ni use gasolina u otros vapores o líquidos inflamables cerca de éste ni en

cualquier otro aparato electrodoméstico.

• QUÉ DEBE HACER SI DETECTA OLOR A GAS:

– No trate de usar ningún aparato electrodoméstico.

– No toque ningún interruptor eléctrico; no use ningún teléfono en el edificio.

– Asegúrese de que todas las personas salgan de la habitación, edificio o área.

– Llame de inmediato a su proveedor de gas desde el teléfono de algún vecino. Siga las

instrucciones que le dé el proveedor de gas.

– Si no puede ponerse en contacto con su proveedor de gas, llame a los bomberos.

• Un instalador calificado, una agencia de servicio o el proveedor de gas debe hacer la

instalación y proporcionar el servicio.

W033S

W052S

IMPORTANTE: El comprador debe consultar al proveedor de gas para obtener instrucciones acerca

de los pasos a seguir en caso de que el usuario detecte olor a gas. Las instrucciones del proveedor de gas

y las notas de SEGURIDAD y ADVERTENCIA directamente arriba deben ser colocadas en algún lugar

visible cerca de la secadora, para que las vea fácilmente la persona que use la secadora.

POR SU PROPIA SEGURIDAD

No almacene ni use gasolina ni vapores o líquidos inflamables cerca de esta secadora ni

de cualquier otro aparato electrodoméstico.

W05S3

42

504524

Page 45

Contenido

Piezas de repuesto

Importantes instrucciones de seguridad

Dimensiones para la preparación de instalación

Seguridad adicional

Extensión para deslizador

Levas de regulación de tiempo

Seguridad para el panel delantero inferior

Protectores para los deslizadores para monedas

Antes de comenzar

Instalación de la unidad de secadoras

PASO 1: Coloque la unidad de secadoras en su lugar y nivélela....51

PASO 2: Conecte el sistema de escape de la unidad de secadoras .51

PASO 3: Conecte las tuberías de suministro de gas........................52

PASO 4: Conecte las clavijas eléctricas..........................................53

PASO 5: Limpie el interior de cada una de las secadoras...............54

PASO 6: Conecte cada una de las secadoras...................................54

PASO 7: Revise la instalación.........................................................54

Revisión de la fuente de calor

Procedimiento para invertir la posición de cada puerta

Requisitos eléctricos (Secadoras eléctricas)

Conexión eléctrica

Cable de corriente de tres conductores ...........................................59

Cable de corriente de cuatro conductores.......................................61

Requisitos eléctricos (Secadoras a gas)

Requisitos de gas

Requisitos de ubicación

Requisitos para el escape de las secadoras

Requisitos para el escape de instalaciones múltiples de secadoras

Filtro de pelusa

Protector de sobrecarga del motor

Instrucciones de mantenimiento para el usuario

Para conservar energía

Antes de llamar para solicitar servicio de reparación

Instrucciones de uso para secadoras electromecánicas

Instrucciones de uso para secadoras con controles electrónicos

Información de referencia

Revisión de la instalación