Alliance Laundry Systems CP040PMN1, CPC40M, CP040PMQ1, CP040PMX2, IP040PMN1 Installation Operation & Maintenance

...Page 1

Washer-Extractors

PHM1397C

PHM1397C

Pocket Hardmount Variable-Speed

Refer to Page 6 for Model Identification

Installation/Operation/Maintenance

Original Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. C003292ENR1

November 2013

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Safety Decals ........................................................................................ 5

Operator Safety..................................................................................... 5

Model Identification ............................................................................. 6

Introduction......................................................................................... 7

Delivery Inspection............................................................................... 7

Nameplate Location.............................................................................. 7

Replacement Parts ................................................................................ 7

Customer Service.................................................................................. 7

Specifications and Dimensions........................................................... 8

High Speed Models............................................................................... 8

Medium Speed Models......................................................................... 10

Machine Dimensions ............................................................................ 12

40 Pound Models ............................................................................ 13

60 Pound Models ............................................................................ 14

80 Pound Models ............................................................................. 15

100 Pound Models ........................................................................... 16

125 Pound Models ........................................................................... 17

140 Pound Models ........................................................................... 18

175 Pound Models ........................................................................... 19

Floor Load Data.................................................................................... 20

Installation Instructions ........................................................................ 21

Surface ............................................................................................. 21

Anchors ............................................................................................ 21

Mounting.......................................................................................... 21

Mounting Bolt Installation Requirements ............................................ 21

Location ........................................................................................... 21

Clearances ........................................................................................ 22

Mounting Bolt Hole Locations ............................................................. 23

Installing Anchors............................................................................ 23

Grouting and Setting Machine ......................................................... 23

Mounting Bolt Hole Locations ............................................................. 24

40 Pound Models ............................................................................. 24

60, 80 and 100 Pound Models.......................................................... 26

125, 140 and 175 Pound Models...................................................... 28

Water Connection ................................................................................. 30

Drain Connection Requirements........................................................... 31

Electrical Installation Requirements..................................................... 33

Circuit Breakers ............................................................................... 34

Grounding ........................................................................................ 34

Wire Size.......................................................................................... 34

Making Connections to Machine..................................................... 36

Adjusting Control Transformer Taps............................................... 36

Provisions for 50 Hz Installations.................................................... 36

Steam Requirements (Steam Heat Option Only).................................. 37

Chemical Injection Supply System....................................................... 38

© Copyright 2013, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Chemical Service Connections ........................................................ 38

Connection of Chemical Supply Hoses ........................................... 38

Connection of Chemical Pump Signals ........................................... 39

First Start-Up ...................................................................................... 40

Operation............................................................................................. 41

General Operation Instructions............................................................. 41

Maintenance ........................................................................................ 43

Daily ..................................................................................................... 43

Beginning of Day............................................................................. 43

End of Day ....................................................................................... 43

Weekly.................................................................................................. 44

Monthly................................................................................................. 44

Quarterly ............................................................................................... 45

Care of Stainless Steel .......................................................................... 46

Disposal of Unit................................................................................... 47

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

C003292ENR1

Page 5

Safety Information

DANGER indicates an imminently

hazardous situation that, if not avoided,

will cause severe personal injury or

death.

DANGER

WARNING indicates a hazardous situation

that, if not avoided, could cause severe

personal injury or death.

WARNING

CAUTION indicates a hazardous situation

that, if not avoided, may cause minor or

moderate personal injury or property

damage.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Install the washer according the

INSTALLATION instructions. Refer to the

GROUNDING instructions in the

INSTALLATION manual for the proper

grounding of the washer. All connections for

water, drain, electrical power and grounding must

comply with local codes and be made by licensed

personnel when required. It is recommended that

the machine be installed by qualified technicians.

3. Do not install or store the washer where it will be

exposed to water and/or weather.

4. To prevent fire and explosion, keep the area

around machine free from flammable and

combustible products. Do not add the following

substances or textiles containing traces of the

following substances to the wash water: gasoline,

kerosene, waxes, cooking oils, vegetable oils,

machine oils, dry-cleaning solvents, flammable

chemicals, thinners, or other flammable or

explosive substances. These substances give off

vapors that could ignite, explode or cause the

fabric to catch fire by itself.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

6. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

3

Page 6

Safety Information

7. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This appliance

is not intended for use by young children or

infirm persons without supervision. Young

children should be supervised to ensure that they

do not play with the appliance. This is a safety

rule for all appliances.

8. DO NOT reach and/or climb into the tub or onto

the washer, ESPECIALLY if the wash drum is

moving. This is an imminently hazardous

situation that, if not avoided, will cause severe

personal injury or death.

9. Never operate the washer with any guards, panels

and/or parts removed or broken. DO NOT bypass

any safety devices or tamper with the controls.

10. Use washer only for its intended purpose,

washing textiles. Never wash machine parts or

automotive parts in the machine. This could

result in serious damage to the basket or tub.

11. Use only low-sudsing, no-foaming types of

commercial detergent. Be aware that hazardous

chemicals may be present. Wear hand and eye

protection when adding detergents and

chemicals. Always read and follow

manufacturer’s instructions on packages of

laundry and cleaning aids. Heed all warnings or

precautions. To reduce the risk of poisoning or

chemical burns, keep them out of the reach of

children at all times (preferably in a locked

cabinet).

12. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

13. Always follow the fabric care instructions

supplied by the textile manufacturer.

14. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open. Do not

attempt to open the door until the washer has

drained and all moving parts have stopped.

15. Be aware that hot water is used to flush the

supply dispenser. Avoid opening the dispenser lid

while the machine is running.

16. Do not attach anything to the supply dispenser’s

nozzles, if applicable. The air gap must be

maintained.

18. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

20. DANGER: Before inspecting or servicing

machine, power supply must be turned OFF. The

servicer needs to wait for at least 3 minutes after

turning the power OFF and needs to check for

residual voltage with a voltage meter. The

inverter capacitor or EMC filter remains charged

with high voltage for some time after powering

OFF. This is an imminently hazardous situation

that, if not avoided, will cause severe personal

injury or death.

21. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out. ALWAYS disconnect the

washer from electrical, power and water supplies

before attempting any service.

22. Disconnect the power cord by grasping the plug,

not the cord. Replace worn power cords and/or

loose plugs. If the supply cord is damaged, it

must be replaced by a special cord or assembly

available from the service agent.

23. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

24. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

17. Do not operate the machine without the water

reuse plug or water reuse system in place, if

applicable.

4

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 7

IMPORTANT: Ensure that the recommended

Machine installations must comply with

minimum specifications and

requirements stated in the applicable

Installation Manual, any applicable

municipal building codes, water supply

requirements, electrical wiring

regulations and any other relevant

statutory regulations. Due to varied

requirements and applicable local codes,

this machine must be installed, adjusted,

and serviced by qualified maintenance

personnel familiar with applicable local

codes and the construction and operation

of this type of machinery. They must also

be familiar with the potential hazards

involved. Failure to observe this warning

may result in personal injury, property

damage, and/or equipment damage, and

will void the warranty.

W820

WARNING

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Operating the machine with severe out-ofbalance loads could result in personal

injury and serious equipment damage.

W728

WARNING

clearances for inspection and maintenance are

provided. Never allow the inspection and

maintenance space to be blocked.

Safety Information

Operator Safety

The following maintenance checks must be performed

daily:

1. Verify that all warning signs are present and

legible, replace as necessary.

2. Check door interlock before starting operation of

machine:

a. Attempt to start machine with door open.

Machine should not start.

b. Close door without locking it and attempt to

start machine. Machine should not start.

c. Attempt to open door while the cycle is in

progress. The door should not open.

If door lock and interlock are not functioning

properly, disconnect power and call a service

technician.

3. Do not attempt to operate machine if any of the

following conditions are present:

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

Use manufacturer-authorized spare parts to avoid

safety hazards.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

a. Door does not remain securely locked during

entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in machine.

5

Page 8

Safety Information

Model Identification

Information in this manual is applicable to these models:

Medium Speed High Speed

IP040PMQ1

IP040PMX2

IPH40M

IPH180

IPH270

JP060PMQ1

IP080PMQ1

IP080PMQ2

IPH80M

IPH370

IP100PMQ1

IPH100M

IPH460

JP100PMQ1

IP140PMQ1

IPH140M

IPH640

JP140PMQ1

40

Pound

60

Pound

80

Pound

100

Pound

125

Pound

140

Pound

175

Pound

CP040PMN1

CP040PMQ1

CP040PMX2

CPC40M

IP040PMN1

IP040PMN2

CP060PMN1

CP060PMQ1

CP060PMX2

CPC60M

IP060PMN1

IP060PMQ1

IP060PMX2

IPH60M

CP080PMN1

CP080PMN2

CP080PMQ1

CPC80M

IP080PMN1

IP080PMN2

CP100PMN1

CP100PMN2

CP100PMQ1

CPC100M

IP100PMN1

IP100PMN2

Not Applicable

CP140PMN1

CP140PMQ1

CPC140M

IP140PMN1

Not Applicable

CP040PHN1

CP040PHQ1

CP040PHX2

CPC40H

IP040PHN1

IP040PHN2

CP060PHN1

CP060PHN2

CP060PHQ1

CP060PHQ2

CP060PHX1

CP060PHX2

CPC60H

IP060PHN1

CP080PHN1

CP080PHN2

CP080PHQ1

CP080PHQ2

CPC80H

IP080PHN1

CP100PHN1

CP100PHN2

CP100PHQ1

CP100PHQ2

CPC100H

IP100PHN1

CP125PHN1

CP125PHN2

CP125PHQ1

CP125PHQ2

CPC125H

IP125PHN1

IP125PHN2

CP140PHN1

CP140PHQ1

CPC140H

IP140PHN1

CP175PHN1

CPC175H

IP175PHN1

IPH175H

IP040PHQ1

IP040PHX2

IPH40H

JP040PHN1

JP040PHQ1

IP060PHN2

IP060PHQ1

IP060PHX2

IPH60H

JP060PHN1

JP060PHN2

JP060PHQ1

IP080PHN2

IP080PHQ1

IPH80H

JP080PHN1

JP080PHN2

JP080PHQ1

IP100PHN2

IP100PHQ1

IPH100H

JP100PHN1

JP100PHN2

JP100PHQ1

IP125PHQ1

IP125PHQ2

IPH125H

IPH570

JP125PHN1

JP125PHN2

IP140PHQ1

IPH140H

JP140PHN1

JP140PHQ1

IPH790

JP175PHN1

JP175PHN2

6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 9

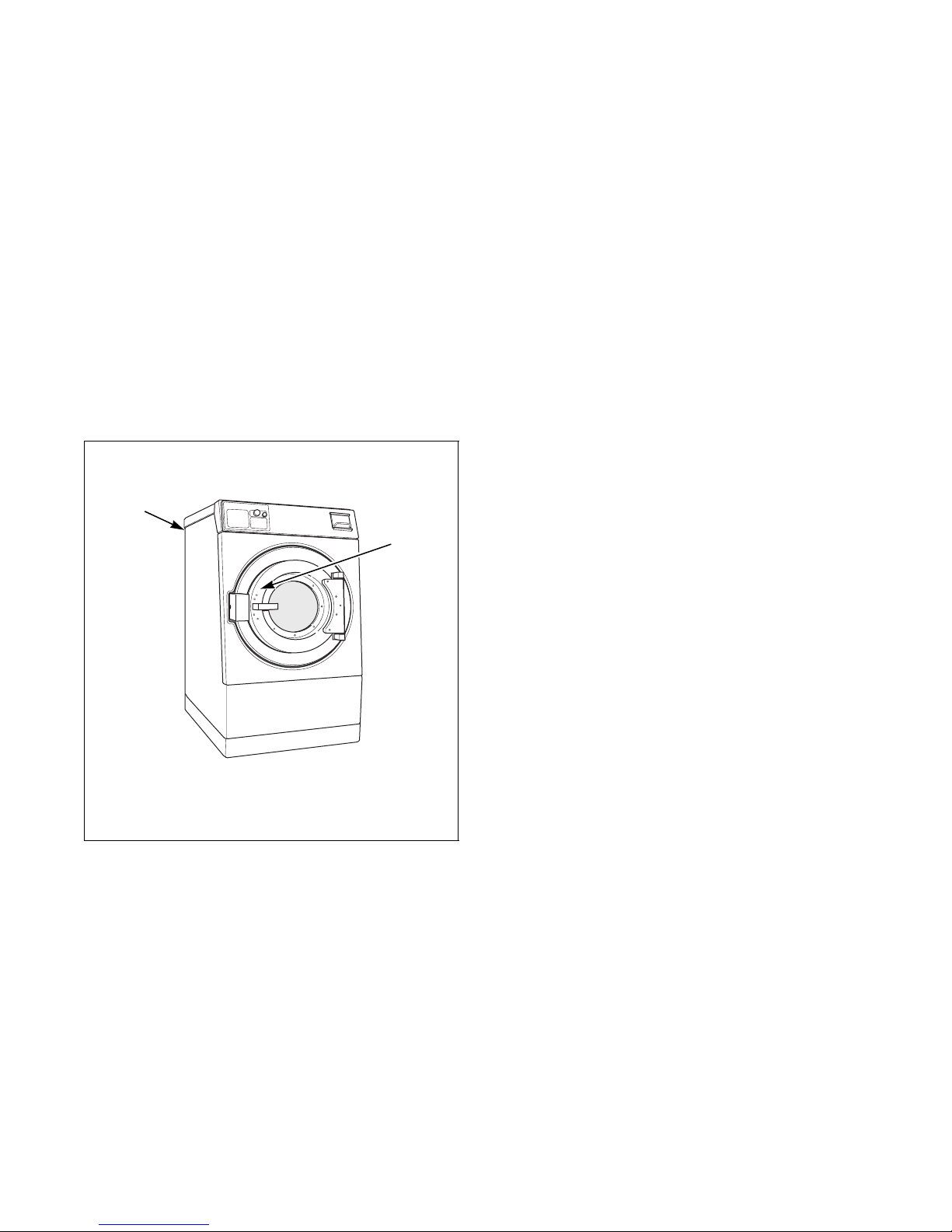

Introduction

PHM1397C

1

2

Delivery Inspection

Upon delivery, visually inspect crate, protective cover

and unit for any visible shipping damage. If the crate,

protective cover or unit is damaged or signs of

possible damage are evident, have the carrier note the

condition on the shipping papers before the shipping

receipt is signed or advise the carrier of the condition

as soon as it is discovered.

Nameplate Location

The nameplate is located inside the door and on the

upper rear panel. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance. Refer to Figure 1.

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems LLC at

+1 (920) 748-3950 for the name of the nearest

authorized parts distributor.

Customer Service

For technical assistance, contact your local distributor

or contact:

Alliance Laundry Systems

Shepard Street

P. O . B ox 99 0

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

+32 56 41 20 54 Wevelgem, Belgium

1 Inside the Door

2 On Upper Rear Panel

Figure 1

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

PHM1397N

7

Page 10

Specifications and Dimensions

High Speed Models

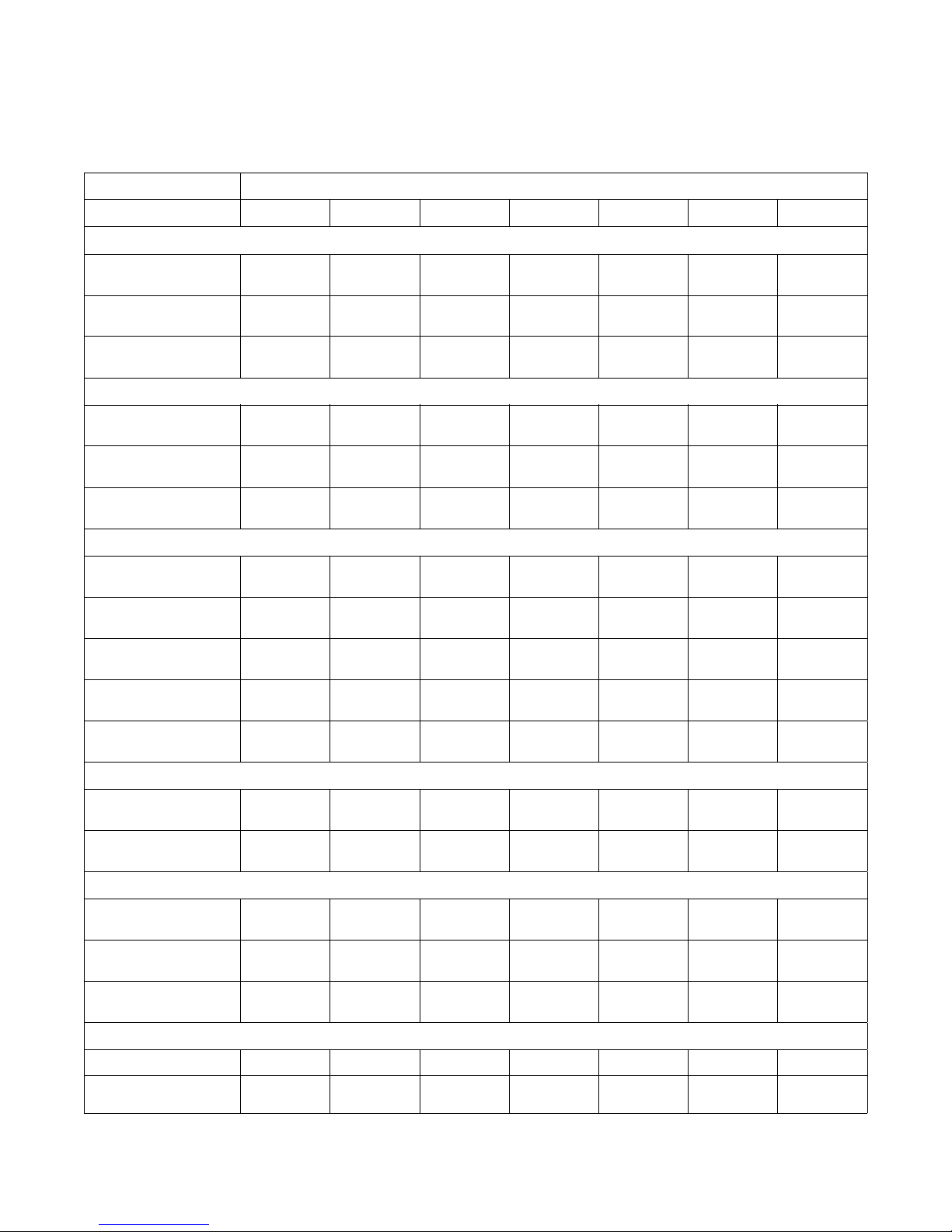

Models

Specifications 40H 60H 80H 100H 125H 140H 175H

Overall Dimensions

Overall Width,

in. (mm)

Overall Height,

in. (mm)

Overall Depth,

in. (mm)

Weight and Shipping Information

Net Weight,

lbs. (kg)

Domestic Shipping

Weight, lbs. (kg)

Domestic Shipping

Volume , f t

3

(m3)

Wash Cylinder Information

Cylinder Diameter,

in. (mm)

Cylinder Depth,

in. (mm)

Cylinder Volume,

ft3 (l)

Perforation Size,

in. (mm)

Cylinder Capacity 1:10

Fill Ratio, lbs. (kg)

32

(813)

57

(1448)

45.6

(1158)

1093

(496)

1150

(522)

63

(1.78)

27

(686)

19

(483)

6.3

(178.4)

0.19

(4.83)

39.3

(17.8)

34.5

(876)

62.6

(1590)

47.8

(1214)

1367

(620)

1424

(646)

76.9

(2.18)

31

(787)

22

(559)

9.6

(271.8)

0.19

(4.83)

60

(27.2)

42.5

(1080)

70

(1778)

51.4

(1306)

1908

(865)

2001

(908)

110

(3.11)

37

(940)

21

(533)

13.1

(371.0)

0.19

(4.83)

81.6

(37)

42.5

(1080)

70

(1778)

56.4

(1433)

1979

(898)

2072

(940)

122

(3.45)

37

(940)

26

(660)

16.2

(458.7)

0.19

(4.83)

101

(45.8)

50.3

(1278)

77.1

(1958)

56.1

(1425)

2459

(1115)

2557

(1160)

160

(4.53)

43

(1092)

24

(610)

20.1

(569.2)

0.19

(4.83)

125

(56.7)

50.3

(1278)

77.1

(1958)

59.1

(1501)

2725

(1236)

2823

(1280)

167

(4.73)

43

(1092)

27

(686)

22.7

(642.8)

0.19

(4.83)

141.7

(64.3)

50.3

(1278)

77.1

(1958)

64.1

(1628)

2963

(1344)

3064

(1390)

179

(5.07)

43

(1092)

32

(813)

26.8

(758.9)

0.19

(4.83)

175

(79.4)

Door Opening Information

Door Opening Size,

in. (mm)

Height of Door Bottom

Above Floor, in. (mm)

15

(381)

22.5

(572)

Drain System

Overflow Size,

in. (mm)

Drain Outlet Size,

in. (mm)

Number of Drain Outlets,

(std/opt)

1.5

(38.1)

3

(76.2)

1/2 1/2 1/2 1/2 1/2 1/2 1/2

Water Inlet

Connection Size

Number of Inlets,

(std/opt)

8

3/4 NPT 3/4 NPT 3/4 NPT 3/4 NPT 3/4 NPT 1-1/4 NPT 1-1/4 NPT

2/3 2/3 2/3 2/3 2/3 2/3 2/3

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

17

(432)

25.8

(655)

1.5

(38.1)

3

(76.2)

20

(508)

26.6

(676)

1.5

(38.1)

3

(76.2)

Table 1 (continued)

20

(508)

27.1

(688)

1.5

(38.1)

3

(76.2)

24.5

(622)

31.3

(795)

3

(76.2)

3

(76.2)

24.5

(622)

31.3

(795)

3

(76.2)

3

(76.2)

24.5

(622)

31.3

(795)

3

(76.2)

3

(76.2)

C003292ENR1

Page 11

Specifications and Dimensions

Table 1 (continued)

Models

Specifications 40H 60H 80H 100H 125H 140H 175H

Chemical Supply System

Number of Dry Chemical

Compartments,

(std/opt)

Number of Liquid Supply

Connections, (std/opt)

1/5 1/5 1/5 1/5 1/5 1/5 1/5

6/12 6/12 6/12 6/12 6/12 6/12 6/12

Cylinder Speeds/Centrifugal Force Data

Possible Wash Speeds,

RPM (G-Force)

Preset Wash Speed,

RPM (G-Force)

Balance Speed,

RPM (G-Force)

Preset Low Extract

Speed, RPM (G-Force)

Preset Medium Extract

Speed, RPM (G-Force)

Preset High Extract

Speed, RPM (G-Force)

Maximum SmartSpin

Speed, RPM (G-Force)

10-60

(0.05-1.4)

46

(0.8)

81

(2.5)

511

(100)

605

(140)

775

(230)

885

(300)

10-60

(0.04-1.6)

43

(0.8)

75

(2.5)

477

(100)

564

(140)

723

(230)

826

(300)

10-60

(0.05-1.9)

39

(0.8)

69

(2.5)

437

(100)

516

(140)

662

(230)

756

(300)

10-60

(0.05-1.9)

39

(0.8)

69

(2.5)

437

(100)

516

(140)

662

(230)

756

(300)

10-55

(0.06-1.9)

36

(0.8)

69

(2.5)

405

(100)

479

(140)

573

(200)

701

(300)

10-55

(0.06-1.9)

36

(0.8)

64

(2.5)

405

(100)

479

(140)

573

(200)

640

(250)

10-55

(0.06-1.9)

36

(0.8)

64

(2.5)

405

(100)

479

(140)

573

(200)

640

(250)

Drive Train Information

Number of Motors In

Drive Train

Drive Motor Power,

hp (kW)

(2.2)

Balance Detection

Vibration Switch

Installed

STD STD STD STD STD STD STD

Electrical Heating (Optional)

Total Electrical Heating

Capacity, kW

Number of Electrical

Heating Elements

Electrical Heating

Element Size, kW

21.5@240V

21.5@480V

6 – 240V

6 – 480V

Noise Emission

Not

Applicable

1111111

3

3333Not

5

(3.7)

32.2@240V

21.5@480V

9 – 240V

6 – 480V

Not

Applicable

7.5

(5.6)

32.2@240V

21.5@480V

9 – 240V

6 – 480V

Not

Applicable

7.5

(5.6)

32.2@240V

21.5@480V

9 – 240V

6 – 480V

Not

Applicable

10

(7.5)

Not

Applicable

Not

Applicable

Applicable

Not

Applicable

7.5

(5.6)

Not

Applicable

Not

Applicable

Not

Applicable

Not

Applicable

15

(11.2)

Not

Applicable

Not

Applicable

Not

Applicable

Not

Applicable

Table 1

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

9

Page 12

Specifications and Dimensions

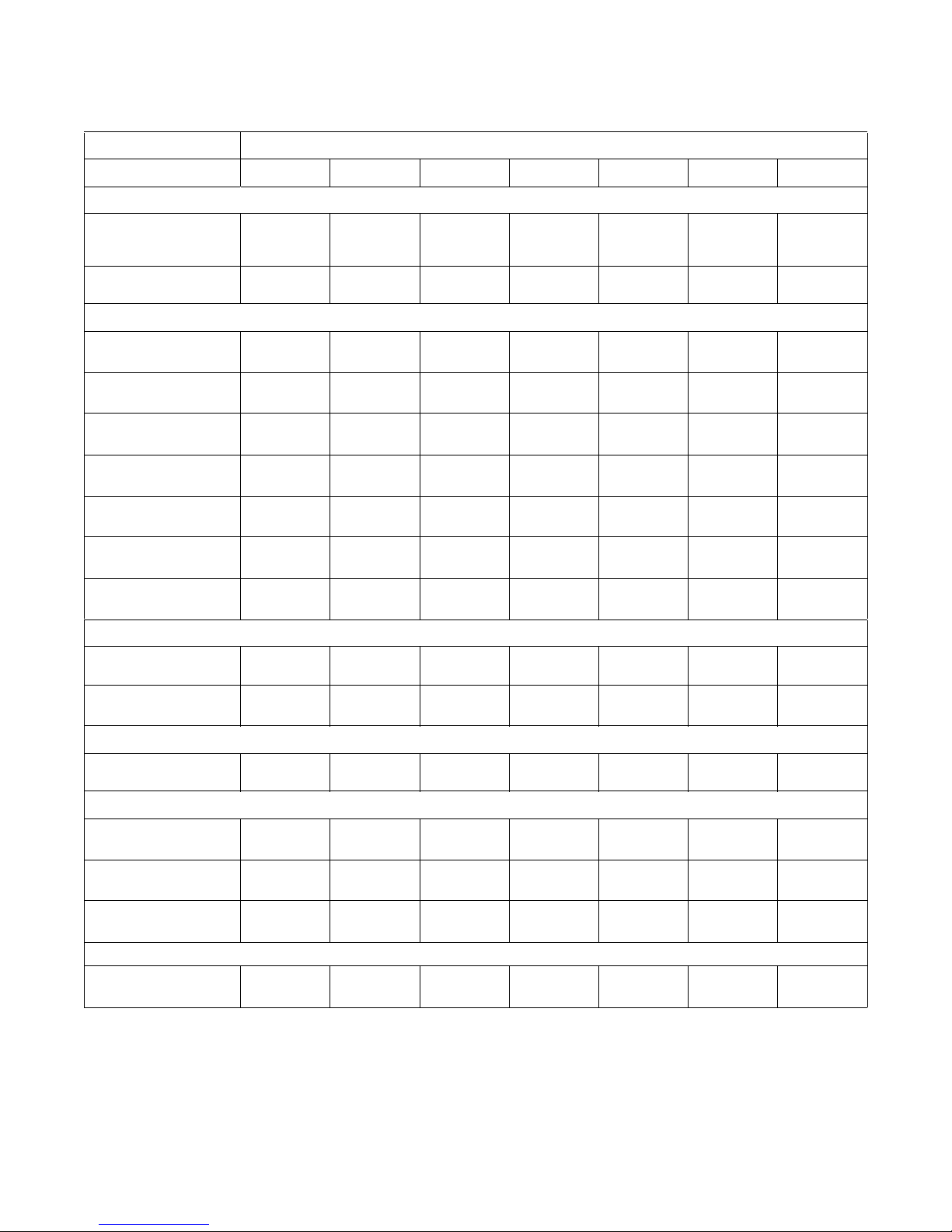

Medium Speed Models

Models

Specifications 40M 60M 80M 100M 140M

Overall Dimensions

Overall Width,

in. (mm)

Overall Height,

in. (mm)

Overall Depth,

in. (mm)

Weight and Shipping Information

Net Weight,

lbs. (kg)

Domestic Shipping Weight,

lbs. (kg)

Domestic Shipping Volume,

ft.3 (m3)

Wash Cylinder Information

Cylinder Diameter,

in. (mm)

Cylinder Depth,

in. (mm)

Cylinder Volume, ft.3 (l)

Perforation Size,

in. (mm)

Cylinder Capacity 1:10 Fill

Ratio, lbs. (kg)

32

(813)

57

(1448)

45.6

(1158)

1093

(496)

1150

(522)

63

(1.78)

27

(686)

19

(483)

6.3

(178.4)

0.19

(4.83)

39.3

(17.8)

34.5

(876)

62.6

(1590)

47.8

(1214)

1367

(620)

1424

(646)

76.9

(2.18)

31

(787)

22

(559)

9.6

(271.8)

0.19

(4.83)

60

(27.2)

42.5

(1080)

70

(1778)

51.4

(1306)

1908

(865)

2001

(908)

110

(3.11)

37

(940)

21

(533)

13.1

(370.1)

0.19

(4.83)

81.6

(37)

42.5

(1080)

70

(1778)

56.4

(1433)

1979

(898)

2072

(940)

122

(3.45)

37

(940)

26

(660)

16.2

(458.7)

0.19

(4.83)

101

(45.8)

50.3

(1278)

77.1

(1958)

59.1

(1501)

2725

(1236)

2823

(1280)

167

(4.73)

43

(1092)

27

(686)

22.7

(642.8)

0.19

(4.83)

141.7

(64.3)

Door Opening Information

Door Opening Size,

in. (mm)

Height of Door Bottom

Above Floor,

in. (mm)

Drain System

Overflow Size,

in. (mm)

Drain Outlet Size,

in. (mm)

Number of Drain Outlets,

(std/opt)

Water Inlet

Connection Size

Number of Inlets, (std/opt)

10

15

(381)

22.5

(572)

1.5

(38.1)

3

(76.2)

17

(432)

25.8

(655)

1.5

(38.1)

3

(76.2)

20

(508)

26.6

(676)

1.5

(38.1)

3

(76.2)

20

(508)

27.1

(688)

1.5

(38.1)

3

(76.2)

1/2 1/2 1/2 1/2 1/2

3/4 NPT 3/4 NPT 3/4 NPT 3/4 NPT 1-1/4 NPT

2/3 2/3 2/3 2/3 2/3

Table 2 (continued)

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

24.5

(622)

31.3

(795)

3

(76.2)

3

(76.2)

C003292ENR1

Page 13

Specifications and Dimensions

Table 2 (continued)

Models

Specifications 40M 60M 80M 100M 140M

Chemical Supply System

Number of Dry Chemical

compartments, (std/opt)

Number of Liquid Supply

Connections, (std/opt)

Liquid Supply Connection

Size

1/5 1/5 1/5 1/5 1/5

6/12 6/12 6/12 6/12 6/12

1/2 NPT1/2 NPT1/2 NPT1/2 NPT1/2 NPT

Drive Train Information

Number of Motors In Drive

Train

Drive Motor Power,

hp (kW)

11111

3

(2.3)

3

(2.3)

5

(3.7)

5

(3.7)

Cylinder Speeds/Centrifugal Force Data

Possible Wash Speed,

RPM (G-Force)

Preset Wash Speed,

RPM (G-Force)

Balance Speed,

RPM (G-Force)

Preset Low Extract Speed,

RPM (G-Force)

Preset Medium Extract

Speed, RPM (G-Force)

Preset High Extract Speed,

RPM (G-Force)

Maximum SmartSpin

Speed,

RPM (G-Force)

10-60

(0.05-1.4)

46

(0.8)

81

(2.5)

361

(50)

443

(75)

511

(100)

626

(150)

10-60

(0.04-1.6)

43

(0.8)

75

(2.5)

337

(50)

413

(75)

477

(100)

584

(150)

10-60

(0.05-1.9)

39

(0.8)

69

(2.5)

309

(50)

378

(75)

437

(100)

535

(150)

10-60

(0.05-1.9)

39

(0.8)

69

(2.5)

309

(50)

378

(75)

437

(100)

535

(150)

7.5

(5.6)

10-55

(0.06-1.9)

36

(0.8)

64

(2.5)

286

(50)

351

(75)

405

(100)

496

(150)

Balance Detection

Vibration Switch Installed

STD STD STD STD STD

Electrical Heating (Optional)

Total Electrical Heating

Capacity, kW

Number of Electrical

Heating Elements

Electrical Heating Element

Size, kW

21.5@240V

21.5@480V

6 – 240V

6 – 480V

3333Not Applicable

Noise Emission

Not Applicable Not Applicable Not Applicable Not Applicable Not Applicable

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

32.2@240V

21.5@480V

9 – 240V

6 – 480V

Table 2

32.2@240V

21.5@480V

9 – 240V

6 – 480V

32.2@240V

21.5@480V

9 – 240V

6 – 480V

Not Applicable

Not Applicable

11

Page 14

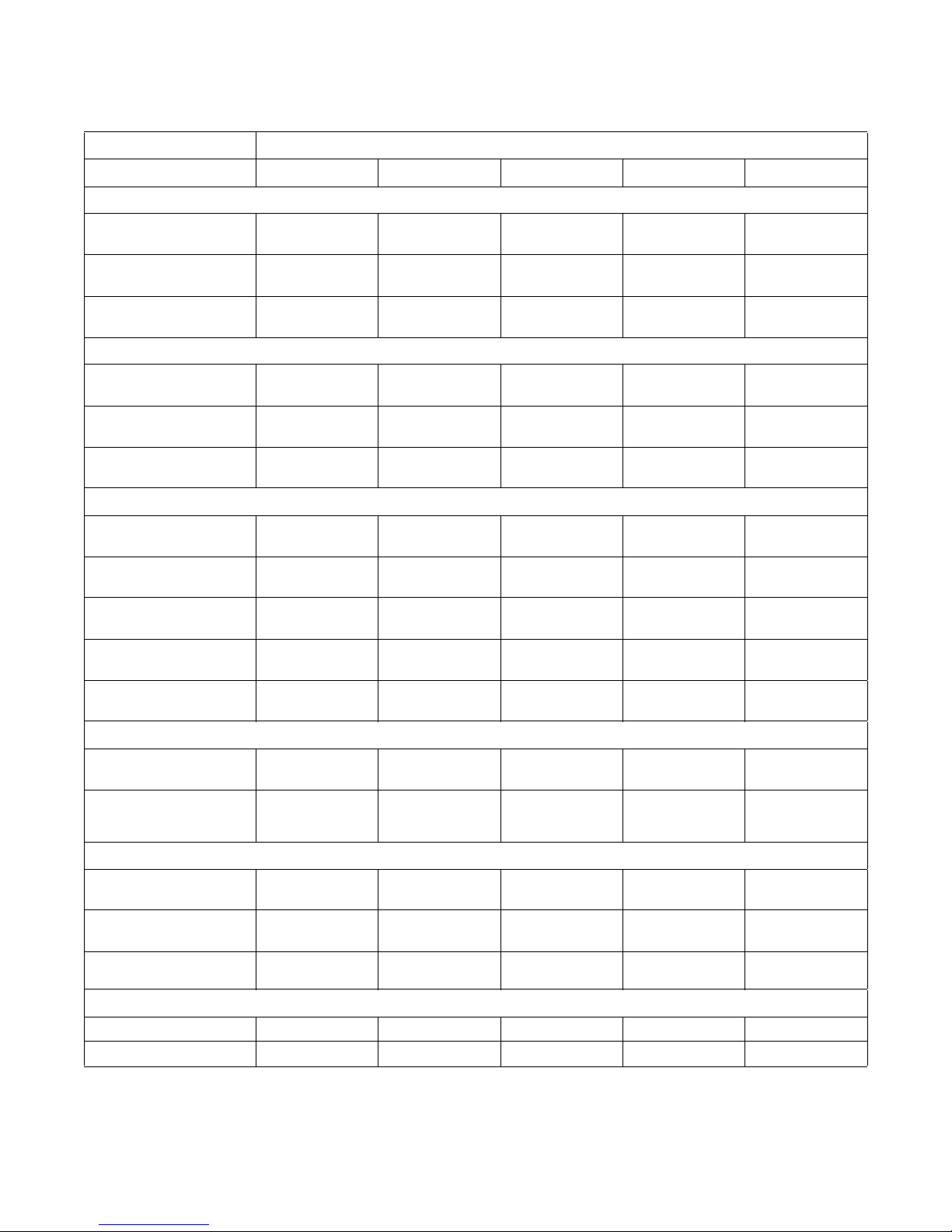

Specifications and Dimensions

Machine Dimensions

Dimensional Clearances

Allow 24 inches (600 mm) at the rear of the machine

and 18 inches (450 mm) is recommended at the sides

for maintenance, inspection and adjustment.

In multiple installations, allow 18 inches (450 mm)

between machines. Machine dimensions are indicated

in Figure 2 through Figure 8. For minimum

clearances, refer to Figure 9.

12

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 15

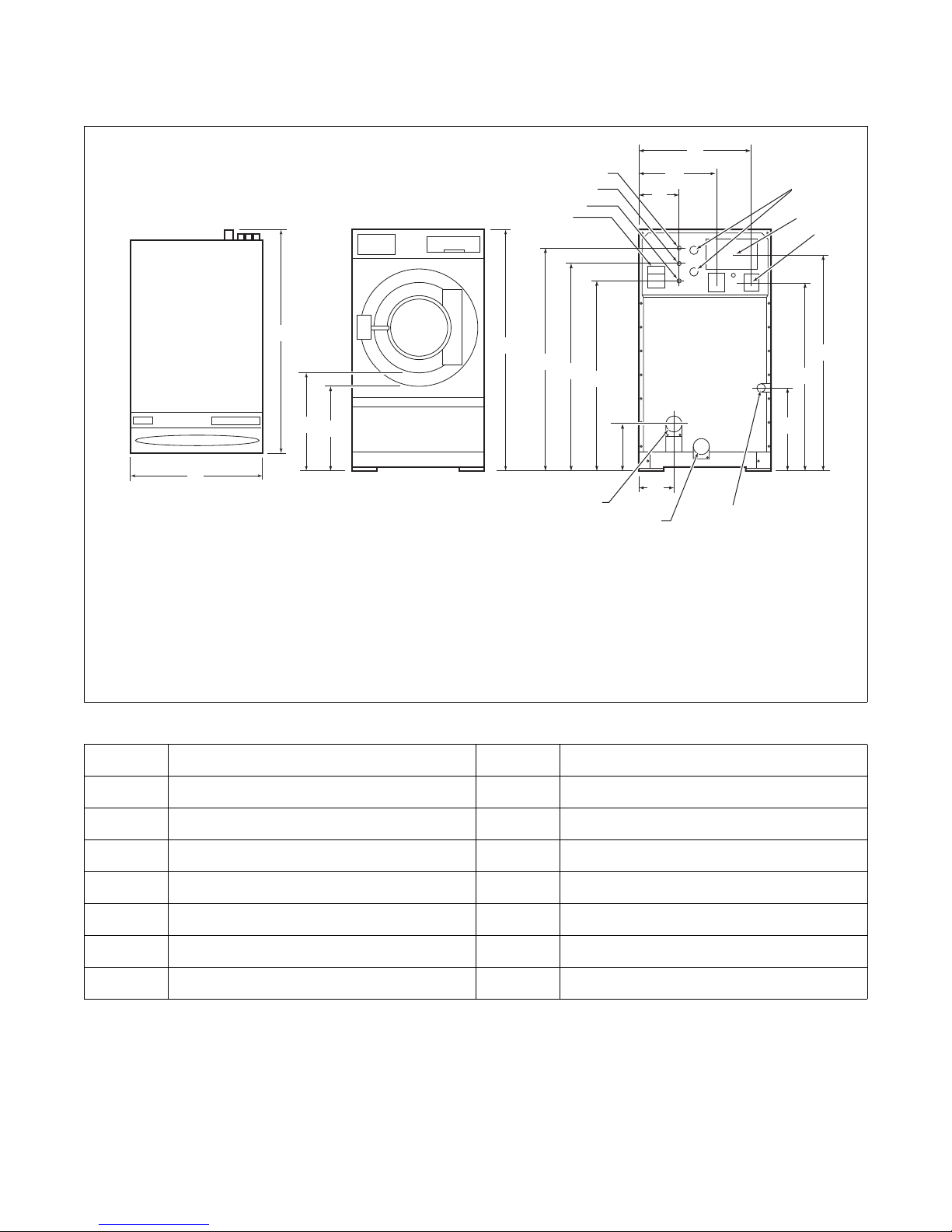

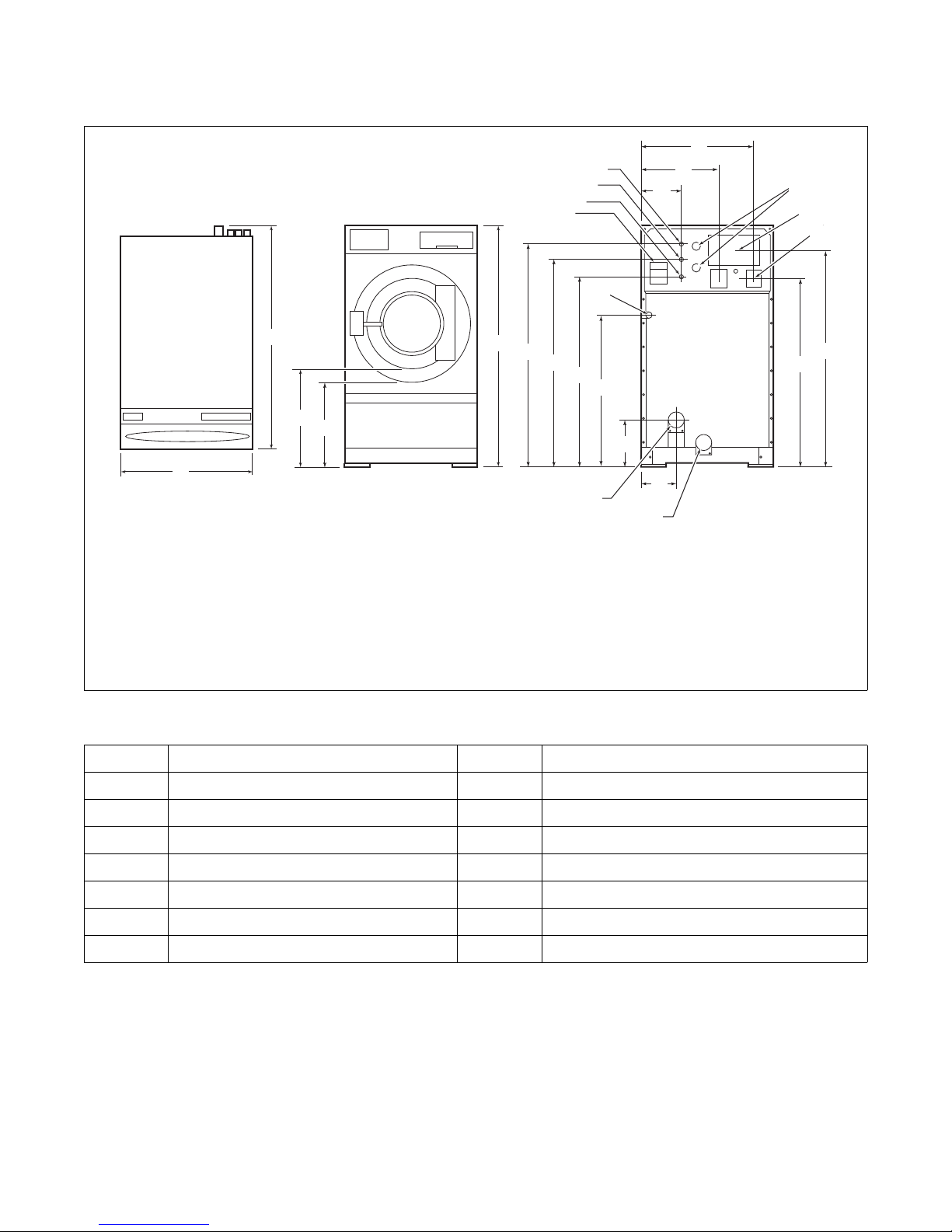

40 Pound Models

PHM727N

FRONT

REAR

TOP

D

E

F

A

B

C

G

H

I

J

K

L

M

N

O

P

4

6

7

5

1

2

3

9

8

10

Specifications and Dimensions

1 External Supply Connection 6 External Supply Wiring Connection

2 Auxiliary 7 Power Inlet

3 Hot Water 8 Steam Inlet

4 Cold Water 9 Auxiliary Drain

5 Greasing Points 10 Drain

Figure 2

A

B

C

D

E

F

G

H

45.6 in. (1158 mm)

32 in. (813 mm)

25.5 in. (648 mm)

22.5 in. (572 mm)

57 in. (1448 mm)

52 in. (1321 mm)

48 in. (1219 mm)

44 in. (1118 mm)

Table 3

I

J

K

L

M

N

O

P

11.7 in. (297 mm)

10.25 in. (260 mm)

19.35 in. (491 mm)

27.93 in. (709 mm)

21.8 in. (554 mm)

43 in. (1092 mm)

51.4 in. (1306 mm)

8.88 in. (226 mm)

PHM727N

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

13

Page 16

Specifications and Dimensions

PHM728N

REAR

FRONT

TOP

D

E

F

A

B

C

G

H

I

J

K

L

M

N

O

P

4

6

7

5

1

2

3

9

8

10

60 Pound Models

1 External Supply Connection 6 External Supply Wiring Connection

2 Auxiliary 7 Power Inlet

3 Hot Water 8 Auxiliary Drain

4 Cold Water 9 Drain

5 Greasing Points 10 Steam Inlet

Figure 3

A

B

C

D

E

F

G

H

47.8 in. (1214 mm)

34.5 in. (876 mm)

28.8 in. (732 mm)

25.8 in. (655 mm)

62.6 in. (1590 mm)

57.62 in. (1464 mm)

53.62 in. (1362 mm)

49.62 in. (1260 mm)

Table 4

K

L

M

N

O

P

I

J

38.5 in. (978 mm)

11.7 in. (297 mm)

11.5 in. (292 mm)

21.1 in. (536 mm)

29.69 in. (754 mm)

48.6 in. (1234 mm)

57.1 in. (1450 mm)

9.63 in. (245 mm)

PHM728N

14

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 17

80 Pound Models

FRONT

D

E

F

A

B

C

G

H

I

J

K

L

M

N

P

4

6

5

2

3

9

8

10

1

R

O

Q

TOP

REAR

S

7

Specifications and Dimensions

PHM729N

1 External Supply Connection 6 External Supply Wiring Connection

2 Auxiliary 7 Power Inlet

3 Hot Water 8 Auxiliary Drain

4 Cold Water 9 3 in. (76.2 mm) Drain

5 Greasing Points 10 Steam Inlet

Figure 4

A

B

C

D

E

F

G

H

I

J

51.4 in. (1306 mm)

42.5 in. (1080 mm)

29.6 in. (752 mm)

26.6 in. (676 mm)

52 in. (1321 mm)

61.5 in. (1562 mm)

70 in. (1778 mm)

66 in. (1676 mm)

62 in. (1575 mm)

58 in. (1473 mm)

K

L

M

N

O

P

Q

R

S

38.4 in. (975 mm)

11.7 in. (297 mm)

12.25 in. (311 mm)

29 in. (737 mm)

37.7 in. (958 mm)

56 in. (1422 mm)

64.4 in. (1636 mm)

12 in. (305 mm)

6 in. (152 mm)

PHM729N

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Table 5

15

Page 18

Specifications and Dimensions

FRONT

D

E

F

A

B

C

G

H

I

J

K

L

M

N

P

4

6

5

2

3

9

8

10

1

R

O

TOP

REAR

7

Q

S

100 Pound Models

I

PHM730N

1 External Supply Connection 6 External Supply Wiring Connection

2 Auxiliary 7 Power Inlet

3 Hot Water 8 Auxiliary Drain

4 Cold Water 9 3 in. (76.2 mm) Drain

5 Greasing Points 10 Steam Inlet

Figure 5

A

B

C

D

E

F

G

H

I

J

56.4 in. (1433 mm)

42.5 in. (1080 mm)

30.12 in. (765 mm)

27.13 in. (689 mm)

52 in. (1321 mm)

61.5 in. (1562 mm)

70 in. (1778 mm)

66 in. (1676 mm)

62 in. (1575 mm)

58 in. (1473 mm)

K

L

M

N

O

P

Q

R

S

38.4 in. (975 mm)

11.7 in. (297 mm)

12.25 in. (311 mm)

29 in. (737 mm)

37.7 in. (958 mm)

56 in. (1422 mm)

64.4 in. (1636 mm)

12 in. (305 mm)

6 in. (152 mm)

PHM730N

16

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Table 6

C003292ENR1

Page 19

125 Pound Models

FRONT

D

E

F

A

B

C

G

H

I

J

K

L

M

N

P

4

6

5

2

3

9

8

1

R

O

S

TOP

REAR

7

Q

U

T

Specifications and Dimensions

1 External Supply Connection 6 Power Inlet

2 Hot Water 7 3 in. (76.2 mm) Drain

3 Cold Water 8 Auxiliary Drain

4 Auxiliary 9 Steam Inlet

5 External Supply Wiring Connection

Figure 6

A

B

C

D

E

F

G

H

I

J

56.1 in. (1425 mm)

50.3 in. (1278 mm)

34.3 in. (871 mm)

31.3 in. (795 mm)

58 in. (1473 mm)

67.6 in. (1717 mm)

77.1 in. (1958 mm)

71.7 in. (1821 mm)

67.7 in. (1720 mm)

64.5 in. (1638 mm)

M

O

Q

L

N

P

R

S

T

U

45.3 in. (1151 mm)

11.6 in. (295 mm)

6.7 in. (170 mm)

18.1 in. (460 mm)

28.8 in. (732 mm)

31.1 in. (790 mm)

63.8 in. (1621 mm)

70.2 in. (1783 mm)

19.4 in. (493 mm)

6 in. (152 mm)

PHM731N

K

C003292ENR1

63.7 in. (1618 mm)

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Table 7

17

Page 20

Specifications and Dimensions

REAR

FRONT

TOP

D

E

F

A

B

C

G

H

I

J

K

L

M

N

P

4

6

5

2

3

9

8

1

R

O

S

7

Q

T

10

140 Pound Models

1 External Supply Connection 6 Power Inlet

2 Cold Water 7 Greasing Points

3 Hot Water 8 Auxiliary Drain

4 Auxiliary 9 3 in. (76.2 mm) Drain

5 External Supply Wiring Connection 10 Steam Inlet

Figure 7

A

B

C

D

E

F

G

H

I

J

59.1 in. (1501 mm)

50.3 in. (1278 mm)

34.3 in. (871 mm)

31.3 in. (795 mm)

58 in. (1473 mm)

67.6 in. (1717 mm)

77.1 in. (1958 mm)

70.8 in. (1798 mm)

65.7 in. (1669 mm)

45.5 in. (1156 mm)

K

L

M

N

O

P

Q

R

S

T

11.7 in. (297 mm)

12 in. (305 mm)

15.18 in. (386 mm)

17 in. (432 mm)

36.7 in. (932 mm)

45.26 in. (1150 mm)

56 in. (1422 mm)

64.4 in. (1636 mm)

19.3 in. (490 mm)

6 in. (152 mm)

PHM732N

18

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Table 8

C003292ENR1

Page 21

175 Pound Models

REAR

FRONT

TOP

D

E

F

A

B

C

G

H

I

J

K

L

M

N

P

4

6

5

2

3

9

8

1

R

O

S

7

Q

T

10

Specifications and Dimensions

1 External Supply Connection 6 Power Inlet

2 Cold Water 7 Greasing Points

3 Hot Water 8 Auxiliary Drain

4 Auxiliary 9 3 in. (76.2 mm) Drain

5 External Supply Wiring Connection 10 Steam Inlet

Figure 8

A

B

C

D

E

F

G

H

I

J

64.1 in. (1628 mm)

50.3 in. (1278 mm)

34.3 in. (871 mm)

31.3 in. (795 mm)

58 in. (1473 mm)

67.6 in. (1717 mm)

77.1 in. (1958 mm)

73.2 in. (1859 mm)

66.2 in. (1681 mm)

45.3 in. (1151 mm)

K

L

M

N

O

P

Q

R

S

T

Table 9

11.6 in. (295 mm)

15.6 in. (396 mm)

21.6 in. (549 mm)

18.6 in. (472 mm)

28.8 in. (732 mm)

31.1 in. (790 mm)

63.8 in. (1621 mm)

70.2 in. (1783 mm)

19.4 in. (493 mm)

6 in. (152 mm)

PHM733N

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

19

Page 22

Specifications and Dimensions

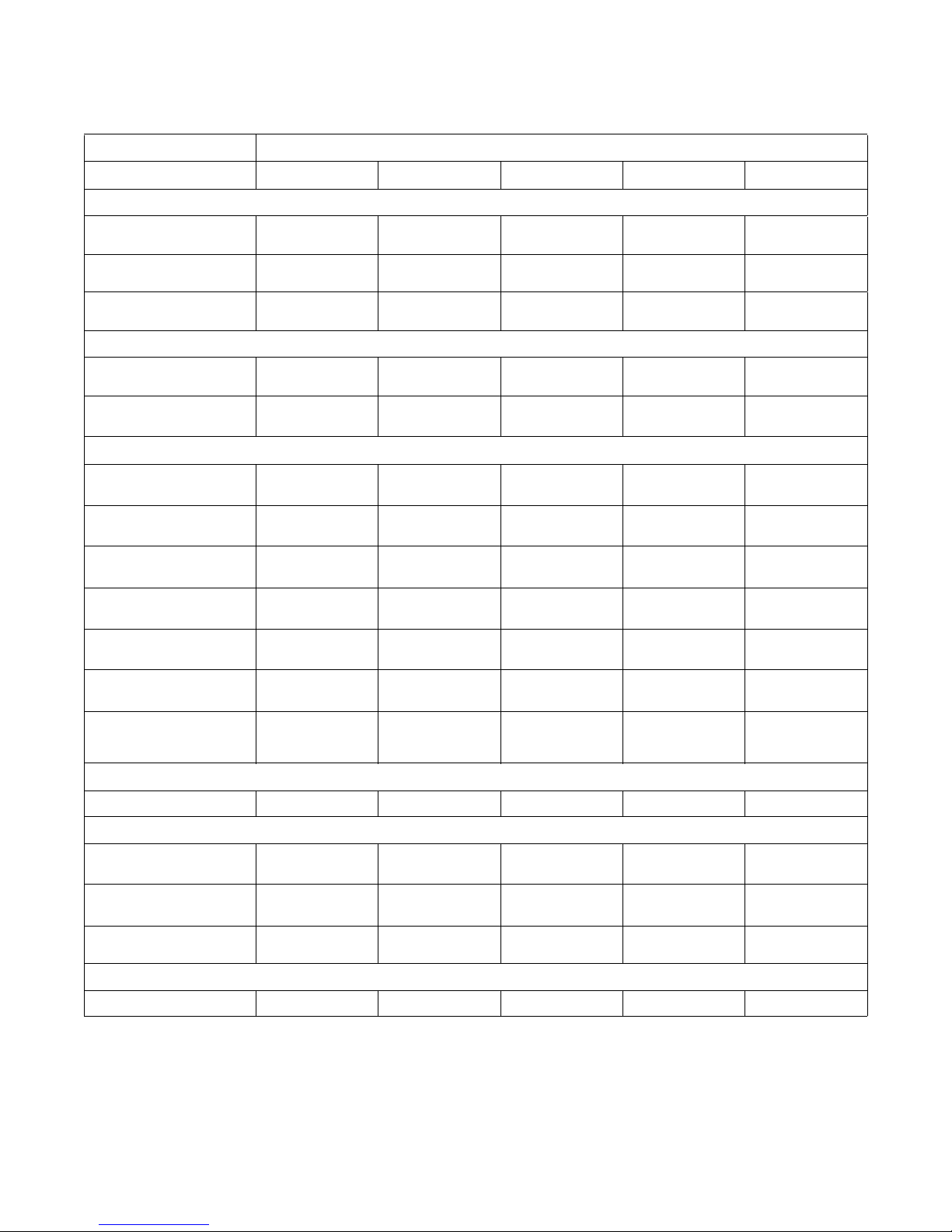

Floor Load Data

Size

Machine

40M 100G

40M 150G

40H 230G

40H 300G

60M 100G

60M 150G

60H 230G

60H 300G

80M 100G

80M 150G

80H 230G

)

2

Net Wt. of

(lbs.)

Machine

Basket

Height of

Center (in.)

Max RPM

Basket

Diameter

27 1583 33.35 511 100 1701 179 786 2440 256.8 2185 8.52

27 1583 33.35 625 149.6 1701 179 706 2359 248.3 1961 10.42

27 1690 33.35 775 230 1808 190.3 1808 3569 375.7 5025 12.92

27 1690 33.35 885 300 1808 190.3 1415 3175 334.2 3931 14.75

31 1627 37.2 477 100 1807 170.9 1201 2936 277.7 3722 7.95

31 1627 37.2 585 150.5 1807 170.9 1083 2818 266.6 3359 9.75

31 1795 37.2 723 229.9 1975 186.8 2758 4661 440.9 8551 125

31 1795 37.2 826 300 1975 186.8 2160 4063 384.3 6696 13.77

37 1766 40 437 100.2 2011 139.2 1636 3549 245.7 5452 7.28

37 1766 40 535 150.2 2011 139.2 1471 3384 234.3 4903 8.92

37 1926 40 662 230 2171 150.3 3754 5826 403.5 12512 11.03

G Cal-

culated

(lbs.)

Static Load

Static Floor

(lbs./ft

Pressure

Dynamic

Load (lbs.)

Load (lbs.)

Max Vertical

)

2

(lbs./ft

Max Dynamic

Floor Pressure

(lbs./ft.)

Load Freq

Base Moment

(Hz)

80H 300G

100M 100G

100M 150G

100H 230G

100H 300G

125H 200G

125H 300G

140M 100G

140M 150G

140H 200G

140H 250G

175H 200G

175H 250G

37 1926 40 756 300 2171 150.3 2937 5010 346.9 9791 12.6

37 2007 40.3 437 100.2 2310 145.1 2025 4213 264.7 6799 7.28

37 2007 40.3 535 150.2 2310 145.1 1821 4009 251.9 6114 8.52

37 2167 40.3 662 230 2470 155.2 4646 6995 439.4 15603 11.03

37 2167 40.3 756 300 2470 155.2 3635 5984 375.9 2209 12.6

43 2749 46.5 573 200.3 3124 165.8 5006 7980 423.6 19400 9.55

43 2749 46.5 701 299.7 3124 165.8 4496 7470 396.5 17421 11.68

43 2749 46.8 405 100 3174 155.5 2835 5839 286 11057 6.75

43 2749 46.8 500 152.5 3174 155.5 2593 5597 274.2 10112 8.33

43 3027 46.8 573 200.3 3452 169.1 5675 8957 438.8 22134 9.55

43 3027 46.8 640 249.8 3452 169.1 4248 7530 368.9 16567 10.67

43 3450 46.8 573 200.3 3975 166.6 7009 10774 451.5 27335 9.56

43 3450 46.8 640 249.8 3975 166.6 5246 9011 377.6 20461 10.67

Table 10

20

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 23

Specifications and Dimensions

• Always mount this machine on a solid,

stable ground floor.

• Never install a hard mount washerextractor on an above ground floor or

over a basement.

• Never use any material between the

machine and floor except grout. The use

of rubber pads, neoprene or other

materials will make the installation

unsafe, noisy and will void all

warranties.

W706

WARNING

To reduce the risk of fire, serious injury,

property damage and/or death, install the

machine on a level (within 3/8 inch),

uncovered concrete floor of sufficient

strength at grade.

W787

WARNING

Installation Instructions

Surface

These machines must be securely anchored on a solid,

flat reinforced concrete surface capable of

withstanding the weight of the machine and the

considerable forces generated during the spin/extract

cycle. Surface should be a high quality concrete

(minimum 3500 psi test strength) and at least 12 in.

(305 mm) thickness for all models. The surface should

be clean, flat and free of irregularities. The pad should

be 12 in. (305 mm) larger than the footprint of the

machine on all sides, beveling out towards the bottom

of the pad.

Anchors

The use of a minimum Grade 5 SAE rated 3/4 inch (19

mm) anchor bolt is recommended for installing

machines.

Mounting

Mounting Bolt Installation

Requirements

Location

Plan the location of the machines. When placing

machines consider the following:

• The loading door is easily accessible to your

workers and does not interfere with other

equipment.

• Make sure that the machine does not block

emergency exits, open doors, work traffic paths,

etc.

• There is adequate clearance in front of the

machine for operation.

• There is clearance behind and above the machine

to safely perform periodic maintenance. Always

check local codes. Refer to Clearances section.

On Metal Base

NOTE: Installation on a raised metal base is not

recommended.

On Concrete

Refer to Grouting and Setting Machine section.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

21

Page 24

Specifications and Dimensions

PHM692N

24 in.

(610 mm)

24 in.

(610 mm)

18 in. (recommended)

(457 mm)

1* in. (minimum)

(25 mm)

18 in. (recommended)

(457 mm)

6* in. (minimum)

(152 mm)

Clearances

IMPORTANT: If the machines are to be mounted

less than 18 in. (457 mm) from each other or less

than 18 in. (457 mm) from a side wall, only the

inside bolt holes will be accessible. If the machines

are to be mounted less than 6 in. (152 mm) from

each other, a wall or other equipment, they must be

installed without using the skirt around the bottom,

as it cannot be reinstalled after the machines are in

place.

* When using minimum clearances for installing 80 pound or larger machines, adjustments must be made to include the width of the

single-cup (standard) or 5-cup (optional) dispenser mounted on the side of the machine. Refer to Figure 5 through Figure 8.

Figure 9

PHM692N

22

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 25

Specifications and Dimensions

1

2

2 in.

(51 mm)

8 in.

(203 mm)

0.75 in.

(19 mm)

Be very careful when lifting and moving

machine. If machine falls, serious

personal injury or death may result.

W707

WARNING

Mounting Bolt Hole Locations

Use a sturdy template to guide hammer-drill into floor.

A heavy steel template/drill guide is available from

your distributor.

Make sure to follow bolt manufacturer’s

recommendation for bit size for the particular anchors

you are using.

The dimensions shown in Figures 11 through 13 are

patterns for various models.

Installing Anchors

1. Measure holes to verify that they match bolt hole

pattern in base of frame.

2. Drill holes for anchor bolts. Refer to Figure 10.

Grouting and Setting Machine

After concrete has cured and anchor bolts are properly

set, proceed as follows:

1. Remove two 1/4-20 bolts that secure trim skirt

and remove skirt.

2. Carefully position machine over anchor bolts and

lower it into place – all anchor bolts should pass

through the frame holes easily.

3. Using 4 removable spacers, raise machine about

1/2 in. (13 mm) and level it both front to rear and

side-to-side. The machine should rest on 4 points

when this operation is completed.

4. Remove rear panel so inside is accessible for

grouting.

PHM178N

1 Frame

2 Grout

Figure 10

3. Clean out anchor holes and floor around them.

4. Insert anchors and secure them per their

manufacturer’s installation instructions.

5. Mix enough machinery grout to fill all spaces

between machine base and floor. Grout

completely under all frame members. Force grout

under machine base until all voids are filled.

6. Before grout has set and become stiff, carefully

remove spacers, allowing machine to settle into

wet grout.

7. When grout is fully cured, place lock-washers

and nuts on anchor studs. Tighten nuts in even

increments using a diagonal pattern. This will

help insure equal tension at all anchor points.

NOTE: After machine has been in place and

operated for a day, retighten anchor bolts.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

23

Page 26

Specifications and Dimensions

F

A

L

C

G

J

M

H

K

D

E

B

I

FRONT OF MACHINE

REAR OF MACHINE

WALL

N

P

O

24 in. (610 mm) min. recommended for service

PHM763N

Mounting Bolt Hole Locations

IMPORTANT: All drawings are not to scale.

40 Pound Models

24

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Figure 11

C003292ENR1

Page 27

Model 40 Pound

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

4 in. (102 mm)

1 in. (25 mm)

5.5 in. (140 mm)

30.5 in. (775 mm)

17.5 in. (445 mm)

9 in. (229 mm)

5.5 in. (140 mm)

31.32 in. (796 mm)

22.85 in. (580 mm)

34.73 in. (882 mm)

27.34 in. (694 mm)

37.03 in. (941 mm)

42.78 in. (1087 mm)

21 in. (533 mm)

30 in. (762 mm)

32 in. (813 mm)

Specifications and Dimensions

Tab le 11

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

25

Page 28

Specifications and Dimensions

PHM764N

F

A

L

C

G

J

M

H

K

D

E

B

I

FRONT OF MACHINE

REAR OF MACHINE

WALL

Q

S

R

24 in. (610 mm) min. recommended for service

O

P

N

60, 80 and 100 Pound Models

26

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Figure 12

PHM764N

C003292ENR1

Page 29

Specifications and Dimensions

Model 60 Pound 80 Pound 100 Pound

A

B

C

D

E

F

G

H

I

J

4 in.

(102 mm)

1.5 in.

(38 mm)

5.5 in.

(140 mm)

35 in.

(889 mm)

26.25 in.

(667 mm)

17.5 in.

(445 mm)

8.75 in.

(222 mm)

4 in.

(102 mm)

32.69 in.

(830 mm)

25.07 in.

(637 mm)

1.5 in.

(38 mm)

1.5 in.

(38 mm)

7 in.

(178 mm)

41.5 in.

(1054 mm)

33 in.

(838 mm)

22 in.

(559 mm)

11 in.

(279 mm)

4 in.

(102 mm)

41 in.

(1041 mm)

30.55 in.

(776 mm)

6.5 in.

(165 mm)

1.5 in.

(38 mm)

7 in.

(178 mm)

41.5 in.

(1054 mm)

33 in.

(838 mm)

22 in.

(559 mm)

11 in.

(279 mm)

4 in.

(102 mm)

41 in.

(1041 mm)

30.55 in.

(776 mm)

M

N

O

Q

R

K

L

36.03 in.

(915 mm)

29.3 in.

(744 mm)

35.23 in.

(895 mm)

41 in.

(1041 mm)

47.09 in.

(1196 mm)

P

41.16 in.

(1045 mm)

23.5 in.

(597 mm)

31.5 in.

(800 mm)

S

34.5 in.

(876 mm)

45.21 in.

(1148 mm)

36 in.

(914 mm)

43.6 in.

(1107 mm)

51.47 in.

(1307 mm)

57.29 in.

(1455 mm)

50.34 in.

(1279 mm)

28.5 in.

(724 mm)

39.5 in.

(1003 mm)

42.5 in.

(1080 mm)

45.21 in.

(1148 mm)

36 in.

(914 mm)

43.6 in.

(1107 mm)

51.47 in.

(1307 mm)

57.29 in.

(1455 mm)

50.34 in.

(1279 mm)

28.5 in.

(724 mm)

39.5 in.

(1003 mm)

42.5 in.

(1080 mm)

Table 12

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

27

Page 30

Specifications and Dimensions

F

A

L

C

G

J

M

H

K

D

E

B

I

FRONT OF MACHINE

REAR OF MACHINE

Q

S

R

24 in. (610 mm) min. recommended for service

O

P

N

WALL

125, 140 and 175 Pound Models

28

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Figure 13

PHM762N

C003292ENR1

Page 31

Specifications and Dimensions

Model 125 Pound 140 Pound 175 Pound

H-Series H-Series H-Series

A

B

C

D

E

F

G

H

I

J

3.93 in.

(100 mm)

1.5 in.

(38 mm)

7 in.

(178 mm)

47.5 in.

(1207 mm)

27 in.

(686 mm)

18 in.

(457 mm)

9 in.

(229 mm)

3.5 in.

(89 mm)

48.1 in.

(1222 mm)

37.35 in.

(949 mm)

3.5 in.

(89 mm)

1.5 in.

(38 mm)

7 in.

(178 mm)

49 in.

(1245 mm)

27 in.

(686 mm)

18 in.

(457 mm)

9 in.

(229 mm)

3.5 in.

(89 mm)

48.1 in.

(1222 mm)

37.35 in.

(949 mm)

2.5 in.

(64 mm)

1.5 in.

(38 mm)

7 in.

(178 mm)

54 in.

(1372 mm)

27 in.

(686 mm)

18 in.

(457 mm)

9 in.

(229 mm)

1.5 in.

(38 mm)

48.1 in.

(1222 mm)

37.35 in.

(949 mm)

M

K

L

50.56 in.

(1284 mm)

40.47 in.

(1028 mm)

45.2 in.

(1148 mm)

N

O

P

Q

R

S

54.42 in.

(1382 mm)

67 in.

(1702 mm)

59.75 in.

(1518 mm)

36.25 in.

(921 mm)

47.25 in.

(1200 mm)

50.25 in.

(1276 mm)

50.56 in.

(1284 mm)

40.47 in.

(1028 mm)

45.2 in.

(1148 mm)

54.42 in.

(1382 mm)

68.07 in.

(1729 mm)

60.95 in.

(1548 mm)

36.25 in.

(921 mm)

47.25 in.

(1200 mm)

50.25 in.

(1276 mm)

50.56 in.

(1284 mm)

40.47 in.

(1028 mm)

45.2 in.

(1148 mm)

54.42 in.

(1382 mm)

71.75 in.

(1822 mm)

68.27 in.

(1734 mm)

36.25 in.

(921 mm)

47.25 in.

(1200 mm)

50.25 in.

(1276 mm)

Table 13

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

29

Page 32

Specifications and Dimensions

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

P038I

1

2

Water Connection

Water service should have the following:

• Hot water temperature should be a maximum of

190°F (88°C).

• Water pressure should be between 30 and 85 psi

(2 to 7 bar).

• Install screen filters in water supply lines to keep

rust, grit or other foreign material out of solenoid

valves.

• Suitable air cushions (risers) should be installed

in supply lines to prevent “hammering.” Refer to

Figure 14.

To connect water feeders to rear of machine, use

flexible hoses. Because this is a vibrating machine,

water lines must allow for movement or leaks may

result. Hang hoses in a large loop behind machine so

that they are not kinked or pinched.

P038I

1 Air Cushions (Risers)

2 Water Supply Faucets

Figure 14

For machines labeled with the CE mark, backsiphon

protection devices must be installed previous of all

machine water inlet valves in accordance with

accepted European standards.

30

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 33

Specifications and Dimensions

Drain Connection Requirements

A flexible connection must be made to a vented drain

system to prevent an air lock and to prevent siphoning.

IMPORTANT: Machines must be installed in

accordance with all local codes and ordinances.

IMPORTANT: The top of the vent must be 12

inches (304.8 mm) lower than bottom of inlet

valves.

Drain Information

Specifications

Overflow Size,

in. (mm)

Drain connection size, I.D.,

in. (mm) with second drain

Number of drain outlets*

Drain flow capacity,

gal/min. (l/min.)

Recommended drain pit

size, ft3 (l) †

†Sized for one machine using high level.

*Data reflects single drain, dual drain is optional.

IPH40

IPM40

1.5

(38.1)

2

(50.8)

1111111

30

(114)

5

(142)

IPH60

IPM60

1.5

(38.1)

3

(76.2)

70

(265)

12

(340)

If proper drain size is not available or practical, a surge

tank is required. A surge tank along with a sump pump

should be used when gravity drainage is not possible.

Increasing drain hose length, installing elbows or

causing bends will decrease drain flow rate and

increase drain times, impairing machine performance.

IPH80

IPM80

1.5

(38.1)

3

(76.2)

60

(227)

9

(255)

IPH100

IPM100

1.5

(38.1)

3

(76.2)

65

(246)

11

(311)

IPH125

3

(76.2)

3

(76.2)

125

(473)

36

(1019)

IPH140

IPM140

3

(76.2)

3

(76.2)

125

(473)

36

(1019)

IPH175

3

(76.2)

3

(76.2)

125

(473)

36

(1019)

Table 14

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

31

Page 34

Specifications and Dimensions

4

1

2

5

6

7

3

1 Rear of Machine

2 Drain Pipe

3 1 in. (25.4 mm) Minimum Air Gap

4 Steel Grate

5 Drain Trough

6 Strainer

7 Waste Line

PHM621N

Figure 15

NOTE: Installation of additional machine will

require proportionately larger drain connections.

32

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 35

Specifications and Dimensions

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

WARNING

Never touch terminals or components of

the AC inverter drive unless power is

disconnected and the “CHARGE”

indicator LED is off. The AC inverter drive

retains potentially deadly voltage for some

time after the power is disconnected.

There are no user-serviceable parts inside

the AC inverter drive. Tampering with the

drive will void the warranty.

SW009

WARNING

When controlling the AC inverter drive

with a parameter unit, the machine’s

computer and its safety features are

bypassed. This would allow the basket to

rotate at high speeds with the door open.

When using a parameter unit to control the

AC inverter drive, a large sign should be

placed on the front of the machine

warning people of the imminent danger.

SW003

DANGER

This machine must be protected by a

circuit breaker. DO NOT USE FUSES!

W691

WARNING

Electrical Installation Requirements

IMPORTANT: Electrical ratings are subject to

change. Refer to serial decal for electrical ratings

information specific to your machine.

The AC inverter drive requires a clean power supply

free from voltage spikes and surges. Use a voltage

monitor to check incoming power.

If input voltage measures above 230V for a 200V

drive or above 460V for a 400V drive, ask the power

company to lower the voltage. As an alternative, a

step-down transformer kit is available from the

distributor. Voltages above 240 and 480 require

additional measures. Contact a qualifiied electrical

maintenance person for assistance.

Electrical connections are made at the rear of the

machine. The machine must be connected to the

proper electrical supply shown on the identification

plate attached to the side of the control module.

IMPORTANT: Alliance Laundry Systems

warranty does not cover components that fail as a

result of improper input voltage.

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

33

Page 36

Specifications and Dimensions

Do not use a phase adder on any variablespeed machine.

SW037

CAUTION

Failure to provide this equipment with a

proper proven earth ground may result in

a severe shock hazard and may increase

EMI emissions.

W708

WARNING

The AC drive provides thermal overload protection for

the drive motor. However, a separate circuit breaker or

electrical supply disconnecting device must be

installed for complete electrical overload protection.

This prevents damage to the AC drive by

disconnecting all legs if one should be lost

accidentally.

IMPORTANT: Do NOT use fuses in place of a

circuit breaker.

The machine should be connected to an individual

branch circuit not shared with lighting or other

equipment.

The connection should be shielded in a liquid-tight or

approved flexible conduit with proper conductors of

correct size installed in accordance with the National

electric Code or with applicable codes. The connection

must be made by a qualified electrician using the

wiring diagram provided with the machine or

according to accepted European standards for

machines labeled with the CE mark.

Use wire sizes indicated in Table 15 for runs up to

50 feet (15.24 meters). Use next larger size for runs of

50 to 100 feet (15.24 to 30.48 meters). Use 2 sizes

larger for runs greater than 100 feet (30.48 meters).

For personal safety and for proper operation, the

machine must be grounded in accordance with local

codes. If such codes are not available, grounding must

conform with the National Electric Code, article

205-95 or accepted European standards for machines

labeled with the CE mark. The ground connection

must be made to a proven earth ground, not to conduit

or water pipes.

Circuit Breakers

The machines are to be connected to individual

common trip circuit breakers. Use only UL 489 rated

circuit breakers. Fuses are not to be used in any

installations. (Fuses may fail separately causing a

single-phase voltage condition.) A single-phase

condition will cause the other lines to have a

considerable change in current draw suddenly, which

may cause the inverter to fail. Do not install more than

one machine per breaker and do not install any other

equipment on the breaker supplying the machine. If

there is a “stinger” leg (also known as high leg, red

leg, etc.) it must be connected to L3 of the terminal

block of the machine. A line reactor is highly

recommended.

Grounding

All equipment should be grounded with a proven earth

ground. Do not use water pipes or electrical conduit as

an earth ground path. All grounding and wiring must

conform to local and national electrical codes.

Wire Size

Wire size must meet or exceed all codes for breaker

size.

Use either SO type cord or flex conduit with stranded

copper conductors of prescribed size for power supply

between machine and wall. Because this machine

vibrates in normal operation, hard conduit may

become loose and cause wire abrasion and solid

conductor wires may break during normal operation

on vibrating machines.

34

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

C003292ENR1

Page 37

Specifications and Dimensions

Pocket Hardmount

Electrical Specifications

Voltage Designation Standard Electric Heat

Model

40H

60H

80H

100H

125H

140H

175H

2

Code

Voltag e

Cycle

Phase

Wire

Full Load

Amps

Breaker

AWG

mm

Full Load

Amps

Breaker

AWG

N 380 – 480 50/60 3 3 4 15 14 2.5 29 35 8 10

Q 200 – 240 50/60 3 3 8 15 14 2.5 56 60 6 16

X 200 – 240 50/60 1/3 2/3 11 15 14 2.5 56 60 6 16

N 380 – 480 50/60 3 3 6 15 14 2.5 29 35 8 10

Q 200 – 240 50/60 3 3 11 15 14 2.5 84 90 3 25

X 200 – 240 50/60 1/3 2/3 12 15 14 2.5 84 90 3 25

N 380 – 480 50/60 3 3 8 15 14 2.5 31 35 8 10

Q 200 – 240 50/60 3 3 15 20 12 4 87 110 2 35

N 380 – 480 50/60 3 3 8 15 14 2.5 32 40 8 10

Q 200 – 240 50/60 3 3 15 20 12 4 88 110 2 35

N 380 – 480 50/60 3 3 10 15 14 2.5

Not Available

Q 200 – 240 50/60 3 3 19 30 10 6

N 380 – 480 50/60 3 3 11 15 14 2.5

Not Available

Q 200 – 240 50/60 3 3 20 30 10 6

N 380 – 480 50/60 3 3 15 20 12 4 Not Available

2

mm

N 380 – 480 50/60 3 3 3 15 14 2.5 29 35 8 10

40M

Q 200 – 240 50/60 3 3 5 15 14 2.5 56 60 6 16

X 200 – 240 50/60 1/3 2/3 9 15 14 2.5 56 60 6 16

N 380 – 480 50/60 3 3 5 15 14 2.5 29 35 8 10

60M

Q 200 – 240 50/60 3 3 9 15 14 2.5 84 90 3 25

X 200 – 240 50/60 1/3 2/3 11 15 14 2.5 84 90 3 25

N 380 – 480 50/60 3 3 6 15 14 2.5 31 35 8 10

80M

Q 200 – 240 50/60 3 3 11 15 14 2.5 87 110 2 35

N 380 – 480 50/60 3 3 7 15 14 2.5 32 40 8 10

100M

Q 200 – 240 50/60 3 3 12 15 14 2.5 88 110 2 35

N 380 – 480 50/60 3 3 8 15 14 2.5

140M

Q 200 – 240 50/60 3 3 16 20 12 4

Not Available

NOTE: Wire-size based on: NFPA 70 (NEC), Table 310.16, 75°C Column. No more than three current carrying

conductors per raceway. Use copper conductors only. Use circuit breakers only. Do not use fuses. Suggested breaker

size based on NFPA 70, Section 240.6. Contact local authority having jurisdiction for additional information. Local

electrical codes supersede all suggestions of this table. Follow all local electrical codes. Local is defined as place of

machine installation.

Table 15

C003292ENR1

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

35

Page 38

Specifications and Dimensions

50Hz

60Hz

N

1

Making Connections to Machine

After electrical service feeder has been installed and

electrical service voltage verified by a volt meter,

follow this procedure to connect service to the

equipment.

1. Remove screw securing electrical service

connection panel and remove panel from

machine.

2. Install an appropriate strain relief or conduit

connector in cover.

3. Feed wire through connector leaving about 6 in.

(150 mm) pigtails on inside of cover. Strip about

3/8 in. (10 mm) insulation off the end of each

wire.

4. Tighten strain relief or conduit connector in

place.

5. Connect ground wire to ground terminal at

electrical service connections on machine.

6. Connect L1, L2 and L3 to terminal block

provided at electrical service connections on

machine.

7. Reinstall panel onto rear of machine and tighten

cover screw.

Adjusting Control Transformer Taps

Adjust control transformer to deliver correct voltage to

machine controls.

7. Power up machine temporarily and, using a volt

meter, verify the voltage on transformer

secondary is between 100 and 130 VAC.

Provisions for 50 Hz Installations

If machine is to be installed on a 50 Hz power system,

adjust control transformer taps as described in

Adjusting Control Transfer Taps section. Then

change drain valve wiring as follows:

1. Disconnect power from machine. Follow lockout/tag-out procedures.

2. Remove lower rear panel to access drain valves.

3. Snap black plastic cover off of each drain valve

motor by locating and squeezing two tabs on

each cover.

4. On each drain valve motor there are three

terminals (labeled 60 Hz, 50 Hz and N). Locate

these terminals.

5. On each drain valve motor, move wire from 60

Hz tap to 50 Hz tap. There should be wires on 50

Hz terminal and N terminal.

6. Reinstall black plastic motor covers.

7. Reinstall rear panel.

8. Reconnect power to machine.

NOTE: If the proper tap on drain valve motor is

not selected it will run hot and will be damaged.

1. Measure line-to-line voltage to be supplied to

machine with a volt meter.

2. Refer to the schematic supplied with machine

and locate transformer terminal chart.

3. In this chart, locate the primary voltage range,

which corresponds to line voltage measured

above, and note terminals which would be used

on primary.

4. In the chart, locate the secondary terminals

corresponding to line voltage. If line voltage is

not in chart, round it up to the next higher

voltage, which is in the chart, or contact a service

technician for assistance.

5. Remove two screws holding rear electrical

enclosure in place and remove rear electrical

enclosure cover.

6. Locate control transformer in enclosure – the

primary is on the right of the transformer and the

secondary terminals are on the left. Make sure

terminals are connected to primary and

secondary terminals selected in steps 3 and 4.

36

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

PHM695N

1 Cover

Figure 16

C003292ENR1

Page 39

Specifications and Dimensions

Hot Surfaces. Will cause severe burns.

Turn steam off and allow steam pipes,

connections and components to cool

before touching.

W505

WARNING

Steam Requirements

(Steam Heat Option Only)

Steam inlet connection, in. (mm)

Number of steam inlets

Recommended pressure,

psi (bar)

Maximum pressure,

psi (bar)

1/2 (DN13) 1/2 (DN13) 1/2 (DN13) 1/2 (DN13) 3/4 (DN19) 3/4 (DN19)

For machines equipped with optional steam heat,

install piping in accordance with approved commercial

steam practices. Steam requirements are shown in

Table 16.

NOTE: Failure to install supplied steam filter may

void warranty.

Steam Supply Information

40 60 80 100 125 140/175