Page 1

Stacked Clothes

REMARQUE : Le guide

est rédigé en anglais et

en français. La version

francaise figure à la

suite de la version

anglaise.

Installation/Operation

Dryers

Metered

Electric and Gas Models

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

D009C

Part No. 512686R4

September 2009

Page 2

Page 3

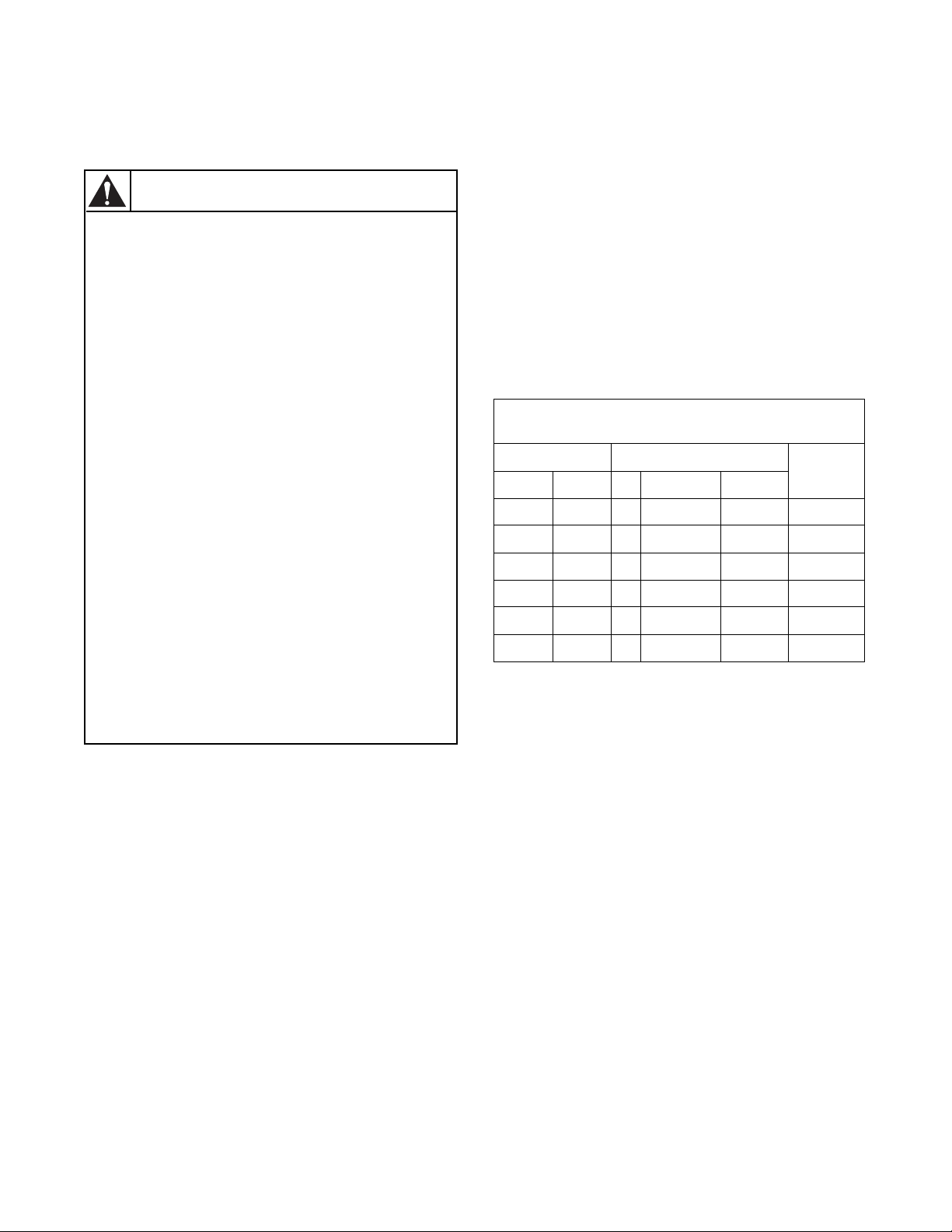

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize

the risk of fire or explosion or to prevent property damage, personal injury or

death. Keep this manual for future reference. If this machine changes ownership,

this manual must accompany machine.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your building.

– Clear the room, building or area of all occupants.

– Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

IMPORTANT: Purchaser must consult the local gas supplier for suggested instructions to be followed if the

unit user smells gas. The gas utility instructions plus the SAFETY and WARNING note directly above must

be posted in a prominent location near the unit for customer use.

W755

W052

WARNING

• Installation of unit must be performed by a qualified installer.

• Install clothes dryer according to manufacturer’s instructions and local codes.

• DO NOT install a clothes dryer with flexible plastic venting materials. If flexible metal (foil

type) duct is installed, it must be of a specific type identified by the appliance manufacturer

as suitable for use with clothes dryers. Refer to section on connecting exhaust system.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These

conditions will obstruct clothes dryer airflow and increase the risk of fire.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

W729R1

W053

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT512686

1

Page 4

Table of

Contents

Safety Information.............................................................................. 4

Explanation of Safety Messages........................................................... 4

Important Safety Instructions ............................................................... 4

Installation........................................................................................... 6

Dimensions ........................................................................................... 6

Before You Start................................................................................... 7

Tools ................................................................................................ 7

Additional Security............................................................................... 7

Installing the Dryer............................................................................... 8

Step 1: Position and Level the Dryer ............................................... 8

Step 2: Connect Dryer Unit Exhaust System................................... 9

Step 3: (Gas Dryer Only) Connect Gas Supply Pipe ....................... 14

Step 4: Reverse Door, if Desired ..................................................... 15

Step 5: Wipe Out Inside of Dryer .................................................... 17

Step 6: Connect Unit to Electrical Power ........................................ 17

Step 7: Recheck Steps 1-6................................................................ 20

Step 8: Check Heat Source .............................................................. 20

Vending................................................................................................ 22

Coin Slide Guards................................................................................. 22

Coin Slide Control ................................................................................ 23

Power-Up Mode............................................................................... 23

Ready Mode..................................................................................... 23

Start Mode........................................................................................ 23

Run Mode......................................................................................... 23

Door Open Mode ............................................................................. 23

End of Cycle Mode .......................................................................... 23

Topoffs............................................................................................. 23

Temperature Selector Switch........................................................... 23

Error Display Mode ......................................................................... 24

Setting Dry Time Dipswitches.............................................................. 24

Models Through Serial No. 0908..................................................... 24

Models Starting Serial No. 0909...................................................... 24

All Models ....................................................................................... 24

Models Starting Serial No. 0909...................................................... 24

Dipswitch Settings................................................................................ 25

Models Through Serial No. 0908..................................................... 26

Models Starting Serial No. 0909...................................................... 27

Slide Extension ..................................................................................... 28

Operation............................................................................................. 30

Operation Instructions for Coin Slide Dryers....................................... 30

Step 1: Clean Lint Filter................................................................... 30

Step 2: Load Laundry....................................................................... 30

Step 3: Close Loading Door............................................................. 30

Step 4: Determine Proper Dryer ...................................................... 31

Step 5: Set Fabric Selector............................................................... 31

Step 6: Start Dryer ........................................................................... 31

© Copyright 2009, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 5

Operation Instructions for MDC Dryers............................................... 32

Step 1: Clean Lint Filter................................................................... 32

Step 2: Load Laundry....................................................................... 32

Step 3: Close Loading Door............................................................. 32

Step 4: Determine Proper Dryer ...................................................... 33

Step 5: Set Fabric Selector............................................................... 33

Step 6: Insert Coin(s) or Card .......................................................... 33

Step 7: Start Dryer ........................................................................... 34

Indicator Lights................................................................................ 34

Operation Instructions for NetMaster Dryers....................................... 35

Step 1: Clean Lint Filter................................................................... 35

Step 2: Load Laundry....................................................................... 35

Step 3: Close Loading Door............................................................. 35

Step 4: Determine Proper Dryer ...................................................... 36

Step 5: Set Fabric Selector............................................................... 36

Step 6: Insert Coin(s) or Card .......................................................... 36

Step 7: Start Dryer ........................................................................... 36

Indicator Lights................................................................................ 37

Maintenance ........................................................................................ 38

Lubrication............................................................................................ 38

Care of Your Dryer............................................................................... 38

Dryer Interior ................................................................................... 38

Cabinet ............................................................................................. 38

Control Panel ................................................................................... 38

Exhaust System................................................................................ 38

Lint Filter.............................................................................................. 39

Motor Overload Protector..................................................................... 39

For Energy Conservation...................................................................... 39

Troubleshooting .................................................................................. 40

Contact Information........................................................................... 41

Installer Checklist................................................................. Back Cover

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING,” and “CAUTION”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

DANGER

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

CAUTION

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of fire, electric shock,

or injury to persons when using your

dryer, follow these basic precautions:

W034

1. Read all instructions before using the dryer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the dryer.

3. Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable

or explosive substances as they give off vapors

that could ignite or explode.

4. Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children. This is a safety

rule for all appliances.

5. Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

6. Do not reach into the dryer if the cylinder is

revolving.

7. Do not install or store the dryer where it will be

exposed to water and/or weather.

8. Do not tamper with the controls.

9. Do not repair or replace any part of the dryer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

10. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

12. ALWAYS clean the lint filter after every load. A

layer of lint in the filter reduces drying efficiency

and prolongs drying time.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 512686

Page 7

Safety Information

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

14. The interior of the dryer and the exhaust duct

should be cleaned periodically by qualified

service personnel.

15. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Dryer will not operate with the loading door

open. DO NOT bypass the door safety switch by

permitting the dryer to operate with the door

open. The dryer will stop tumbling when the door

is opened. Do not use the dryer if it does not stop

tumbling when the door is opened or starts

tumbling without pressing the START

mechanism. Remove the dryer from use and call

the service person.

17. Do not put articles soiled with vegetable or

cooking oil in the dryer, as these oils may not be

removed during washing. Due to the remaining

oil, the fabric may catch on fire by itself.

18. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc., or anything containing wax or

chemicals such as in mops and cleaning cloths, or

anything dry-cleaned at home with a drycleaning solvent in the dryer.

23. Remove laundry immediately after the dryer

stops.

24. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiberglass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiberglass.

26. ALWAYS follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the dryer with any guards and/or

panels removed.

28. DO NOT operate the dryer with missing or

broken parts.

29. DO NOT bypass any safety devices.

30. DO NOT operate dryers if the units have been

separated.

31. Failure to install, maintain, and/or operate this

machine according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

IMPORTANT: Solvent vapors from dry-cleaning

machines create acids when drawn through the

heater of the drying unit. These acids are corrosive

to the dryer as well as to the laundry load being

dried. Be sure make-up air is free of solvent vapors.

IMPORTANT: Have your dryer installed properly.

Don’t do it yourself unless you know how!

19. Use the dryer only for its intended purpose,

drying clothes.

20. Always disconnect the electrical power to the

dryer before attempting service. Disconnect the

power cord by grasping the plug, not the cord.

21. If supply cord is damaged, it must be replaced by

a special cord or assembly available from the

manufacturer or its service agent.

22. Install this dryer according to the

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding and

gas supply must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the dryer.

Always contact your dealer, distributor, service agent

or the manufacturer about any problems or conditions

you do not understand.

5

Page 8

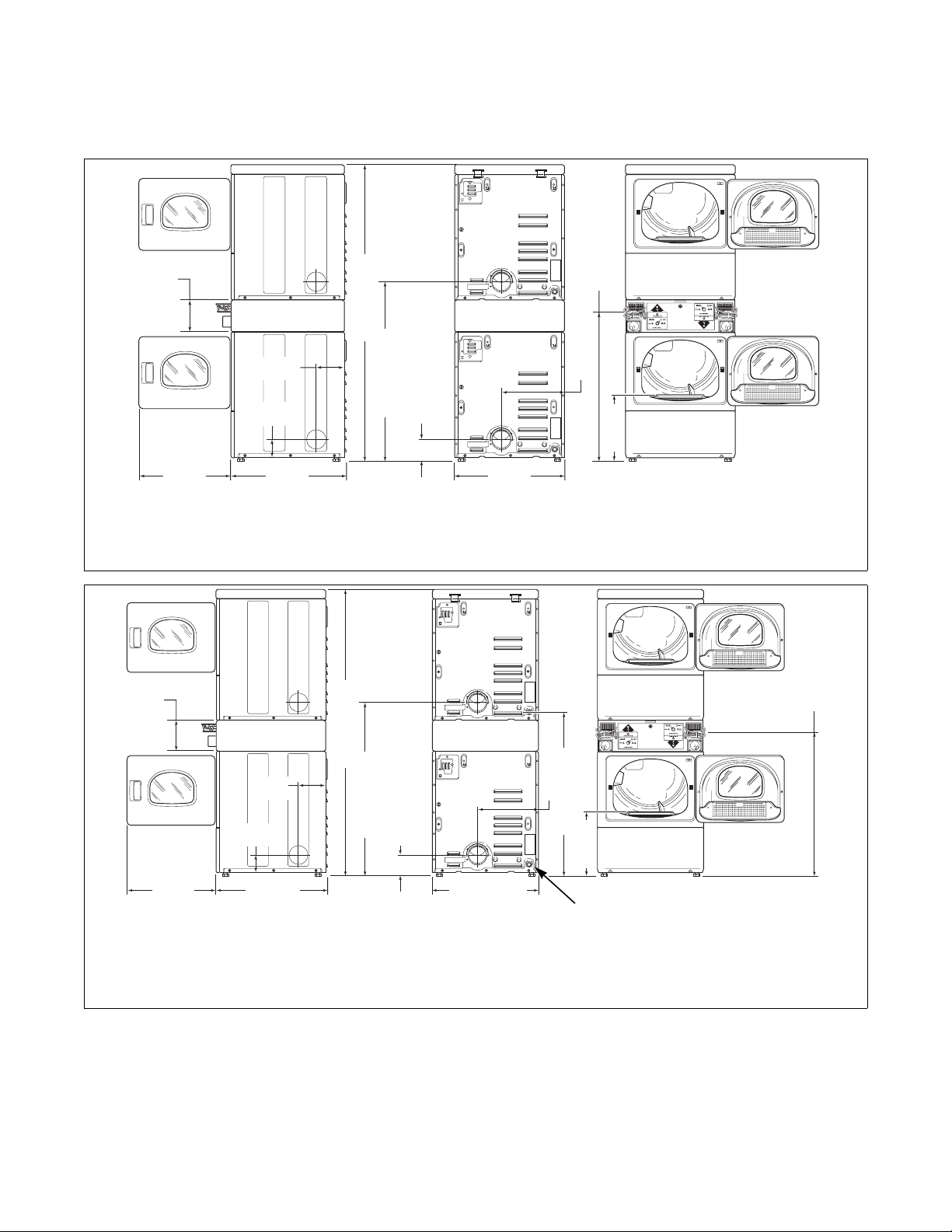

Dimensions

Installation

17.8 cm

(7 in.)

59.7 cm

(23.5 in.)

20.3 cm

(8 in.)

11.4 cm

(4.5 in.)

71.1 cm

(28.0 in.)

*194.3 cm (76.5 in.)

10.2 cm

*113.8 cm (44.8 in.)

(4 in.)

68.3 cm

(26.9 in.)

*100 cm (39.38 in.)

Coin Slide Models

*93.8 cm (36.94 in.)

Electronic Control Models

39.4 cm (15.5 in.)

32.2 cm

(15.44 in.)

ELECTRIC MODELS

*With leveling legs turned into base. NOTE: Not all models have windows.

17.8 cm

(7 in.)

DRY2245N

*100 cm (39.38 in.)

Coin Slide Models

*93.8 cm (36.94 in.)

Electronic Control Models

*194.3 cm (76.5 in.)

20.3 cm

59.7 cm

(23.5 in.)

(8 in.)

11.4 cm

(4.5 in.)

71.1 cm

(28.0 in.)

*113.8 cm (44.8 in.)

10.2 cm

(4 in.)

68.3 cm (26.9 in.)

39.4 cm (15.5 in.)

110.5 cm (43.5 in.)

32.2 cm

(15.44 in.)

1

GAS MODELS

*With leveling legs turned into base. NOTE: Not all models have windows.

1 3/8 in. N.P.T. Gas Connection

NOTE: Side, rear and bottom exhaust openings are

10.2 cm (4 in.) ducting. Gas models cannot be

vented out left side of cabinet because of burner

housing.

IMPORTANT: The dryer should have sufficient

clearance around it for needed ventilation and for

the ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 512686

DRY2246N

DRY2246N

Page 9

Installation

Before You Start

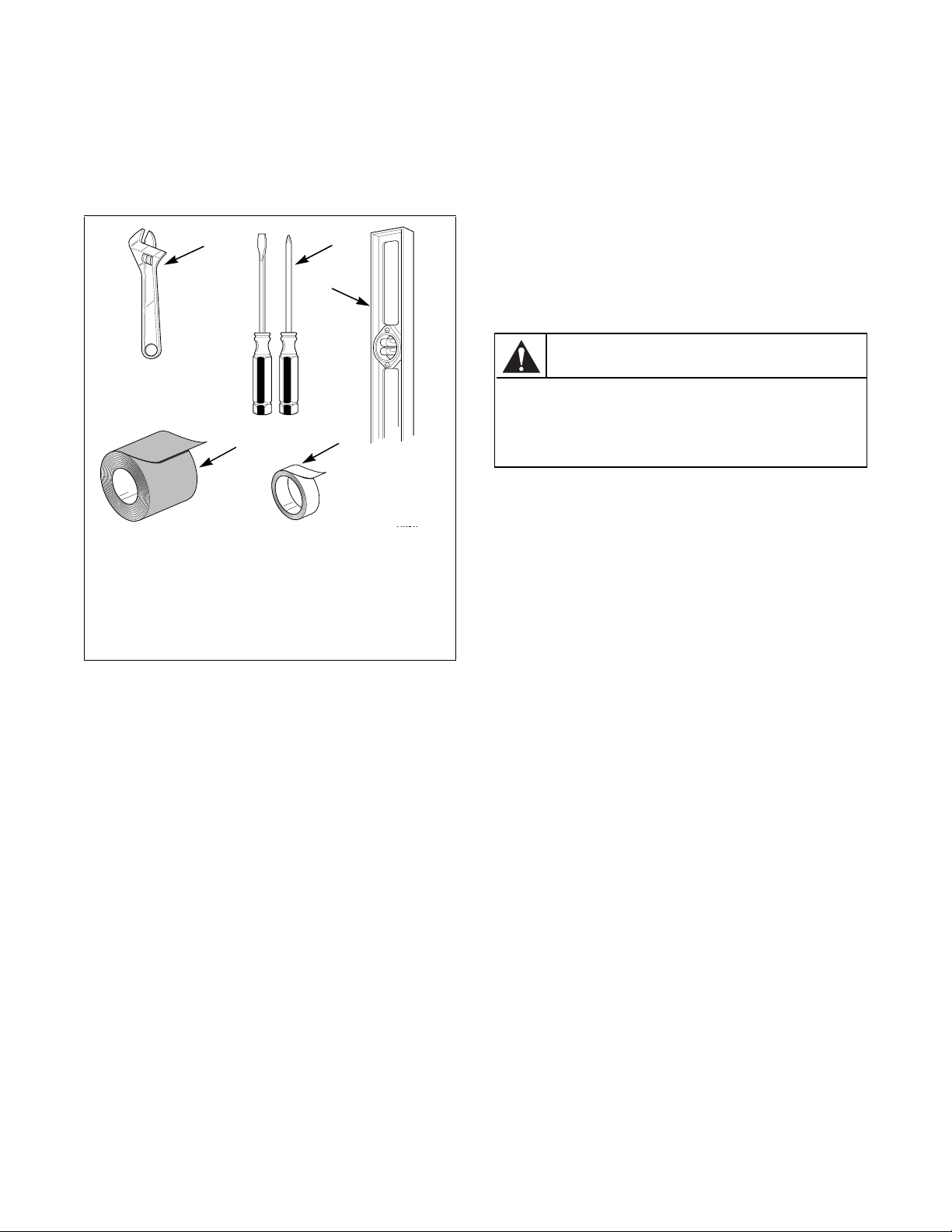

Tools

For most installations, the basic tools you will need

are:

1

5

1 Wrench

2 Screwdrivers

3 Level

4 Teflon Tape

5 Duct Tape

2

3

4

D818I

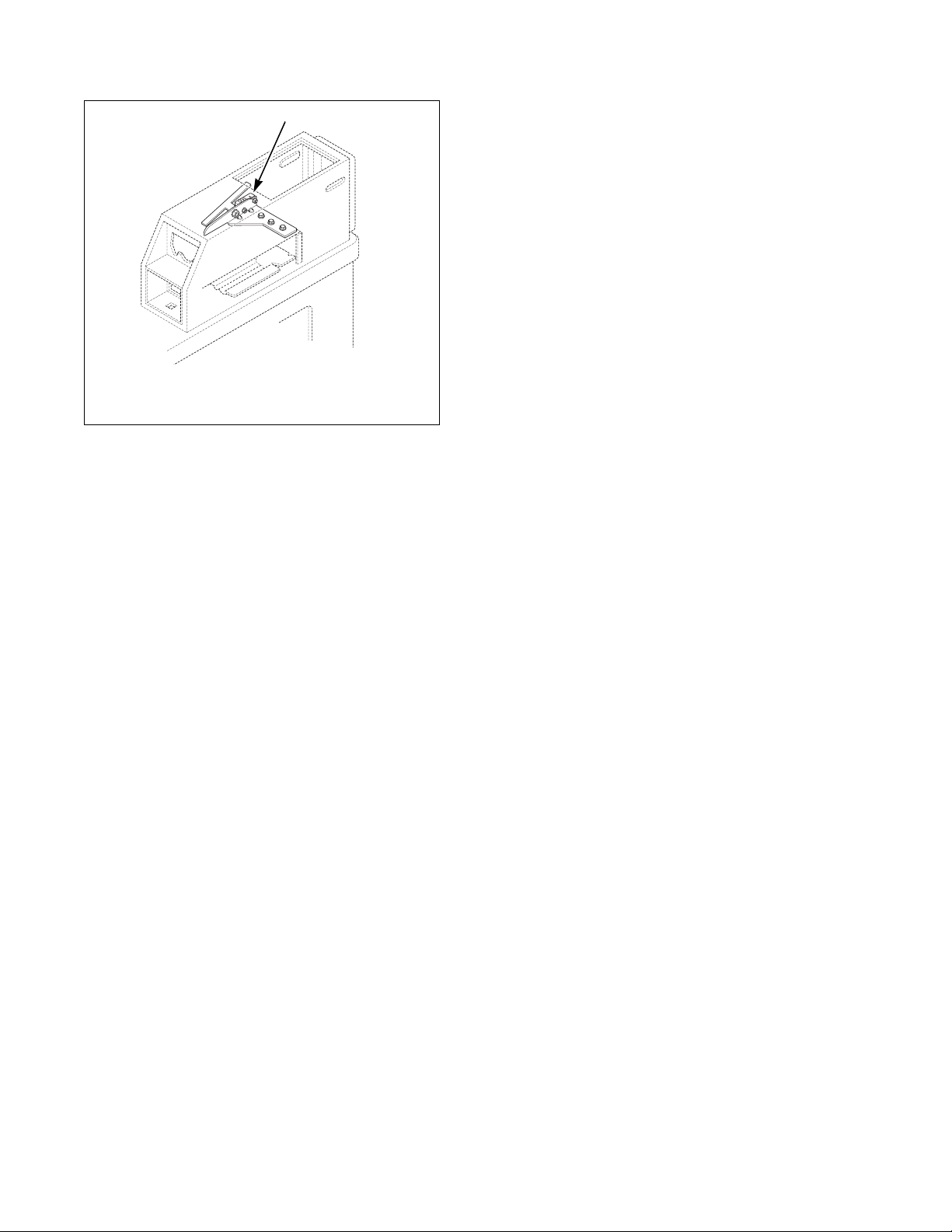

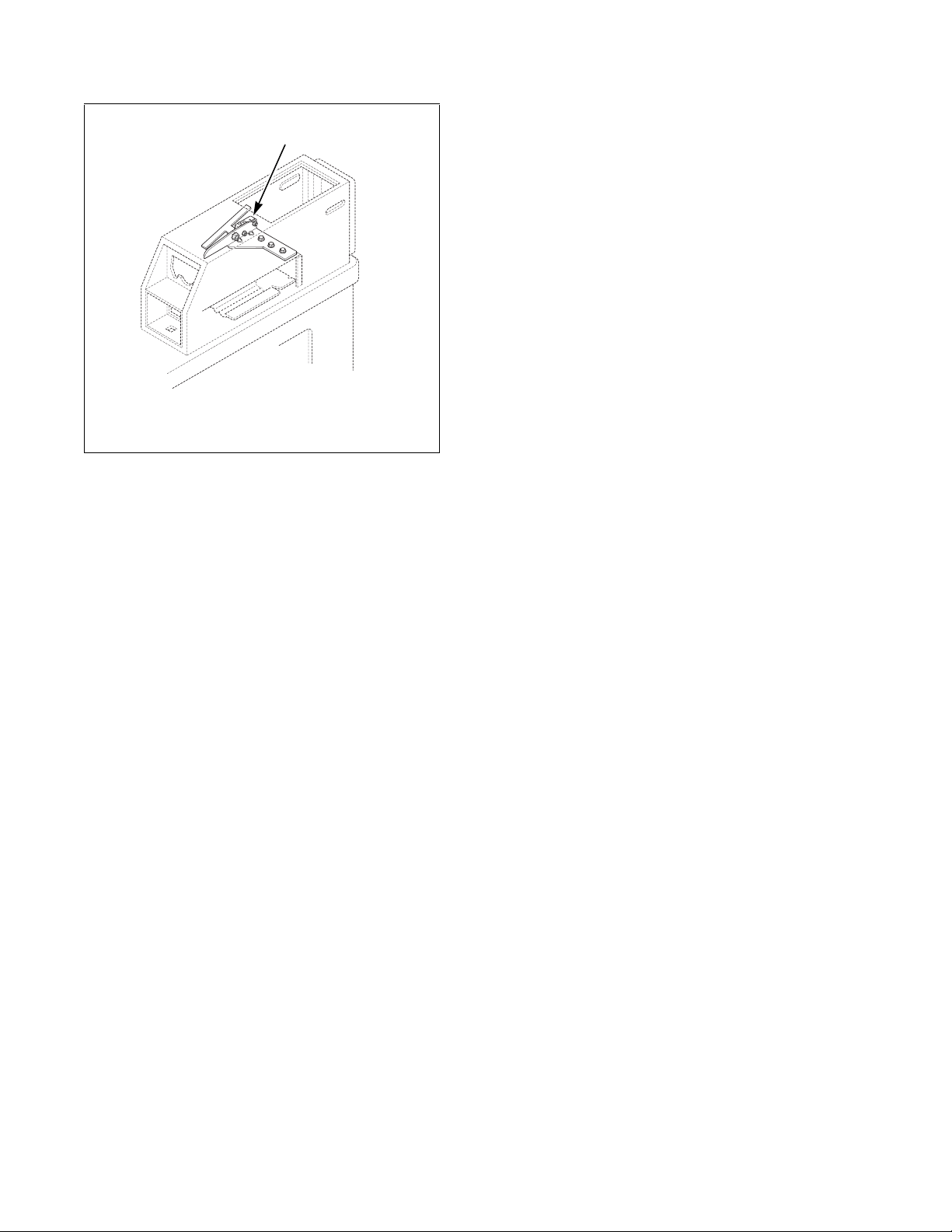

Additional Security

Torx security screws are available (as optional

equipment at extra cost) for securing both lower access

panels to each dryer base. Order Part No. 62853.

A Torx bit, Part No. 282P4, is available (as optional

equipment at extra cost) for installing the Torx security

screws.

A Torx bit holder, Part No. 24161, is available (as

optional equipment at extra cost) to be used with the

Torx bit.

WARNING

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

Figure 1

NOTE: An 20.32 cm (8 in.) coin drawer is required

for coin operated MDC and NetMaster models.

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Installation

Installing the Dryer

Step 1: Position and Level the Dryer

Install dryer before washer. This allows room for

attaching exhaust duct.

Install the four rubber feet (in accessories bag).

Select a location with a solid floor. Dryers installed in

residential garages must be elevated 46 cm (18 inches)

above the floor.

No other fuel burning appliance should be installed in

the same closet with the dryer.

The dryer unit must not be installed or stored in an

area where it will be exposed to water and/or weather.

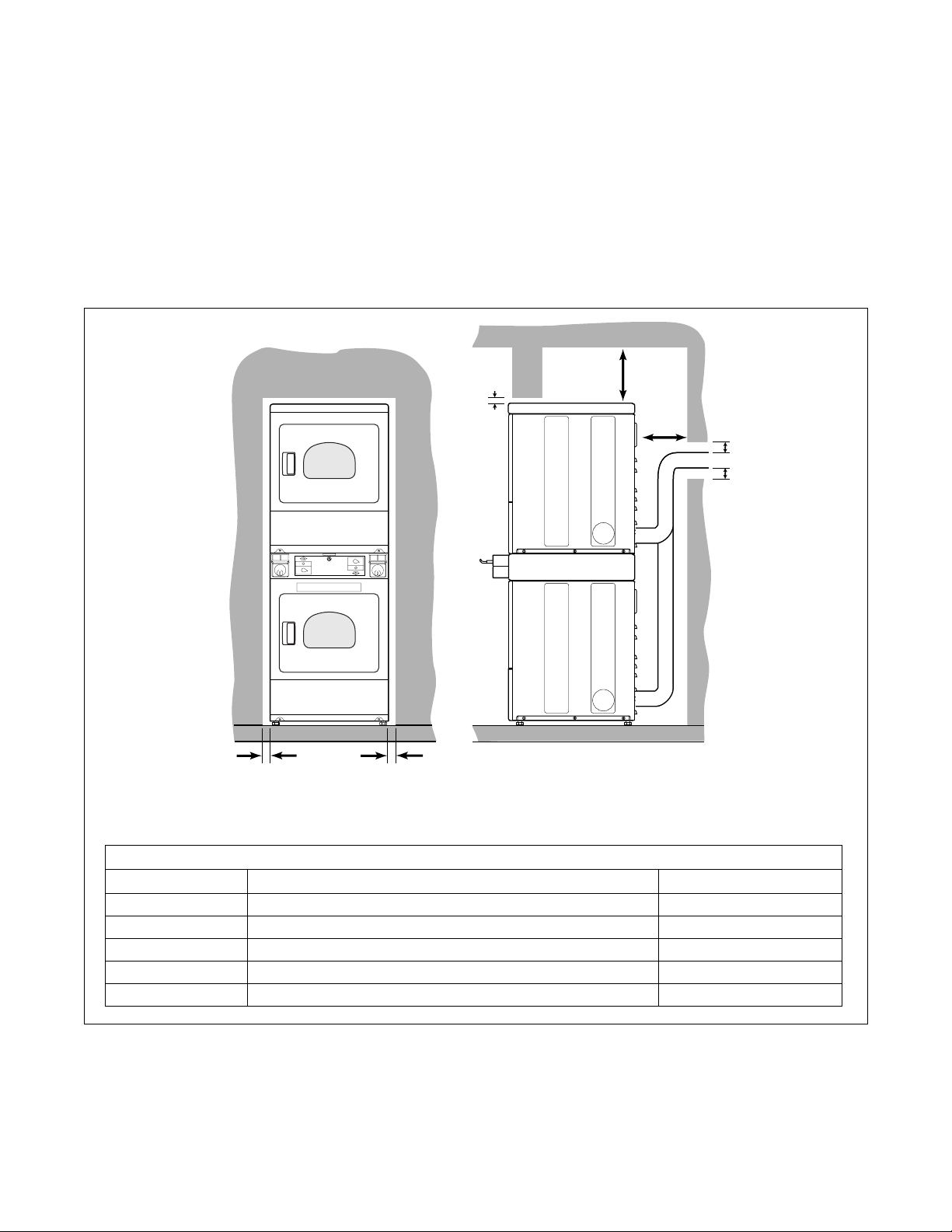

The dryer needs sufficient clearance and an adequate

air supply for proper operation and ventilation, and for

easier installation and servicing. (Minimum clearances

are shown in Figure 2).

B

A

NOTE: Shaded areas indicate adjacent structure.

Area

A Dryer Sides 0 cm (0 in.)

B Dryer Top (Rear 24 in.) 30.5 cm (12 in.)

C Dryer Rear 10.2 cm (4 in.)

D Dryer Top (Front 4 in.) 1.3 cm (0.5 in.)

E Exhaust Duct from Combustible Construction 5.1 cm (2 in.)

A

Dryer and Exhaust Duct Clearances

D

Description Minimum Clearance

C

E

E

D358I

D358I

Figure 2

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 11

Installation

Place the dryer in position, and adjust the legs until the

dryer is level from side to side and front to back.

Leveling legs can be adjusted from inside the dryer

with a 1/4 in. driver. All four legs must rest firmly on

the floor so the weight of the dryer is evenly

distributed. The dryer must not rock.

2

1

3

4

1 Dryer Base

2 Level

3 Leveling Leg

4 Rubber Foot

Figure 3

D690I

D690I

IMPORTANT: In mobile home installations, gas

dryers MUST be permanently attached to the floor

at the time of installation. Order No. 526P3 Hold

Down Kit (available at extra cost) for a

manufactured (mobile) home installation. Follow

the instructions supplied with the kit.

Installation of unit must conform to the Manufactured

Home Construction and Safety Standards, Title 24

CF4, Part 32-80 or Standard CAN/CSA-Z240 MH.

IMPORTANT: Unless completely assembled, DO

NOT slide the dryer unit across the floor. DO NOT

slide the unit once the leveling legs have been

extended, as the legs and the base could become

damaged.

Step 2: Connect Dryer Unit Exhaust

System

WARNING

To reduce the risk of fire and combustion

gas accumulation the dryer MUST be

exhausted to the outdoors.

W604

To reduce the risk of fire and the

accumulation of combustion gases, DO

NOT exhaust dryer air into a window well,

gas vent, chimney or enclosed, unventilated

area, such as an attic, wall, ceiling, crawl

space under a building or concealed space

of a building.

W045

17

WARNING

This gas appliance contains or produces a

chemical or chemicals which can cause

death or serious illness and which are

known to the State of California to cause

cancer, birth defects, or other reproductive

harm. To reduce the risk from substances in

the fuel or from fuel combustion, make sure

this appliance is installed, operated, and

maintained according to the instructions in

this manual.

W115

To reduce the risk of fire, DO NOT use

plastic or thin foil ducting to exhaust the

dryer.

W354

To reduce the risk of fire, the exhaust duct

and weather hood MUST be fabricated of a

material that will not support combustion.

Rigid or flexible metal pipe is recommended

for a clothes dryer.

W048

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

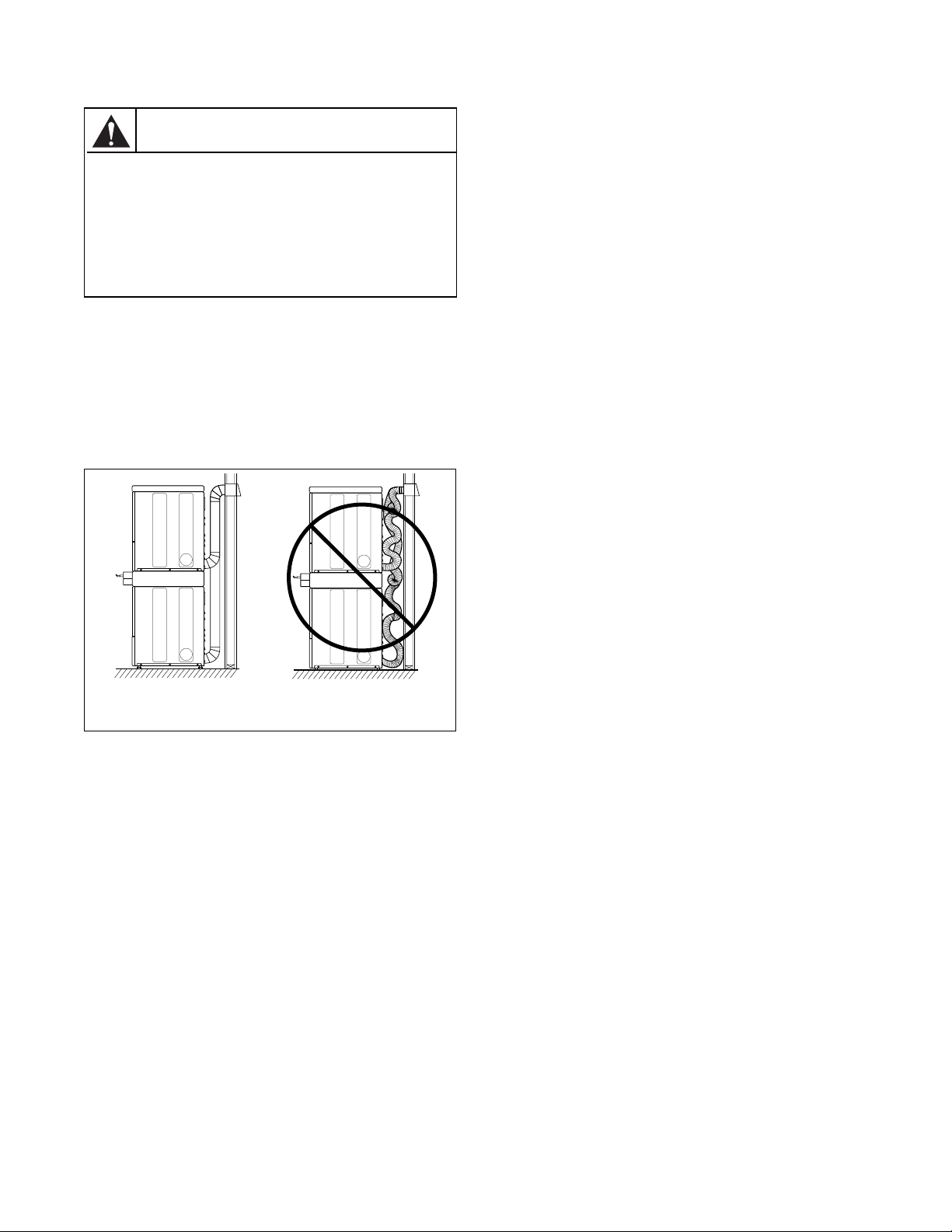

WARNING

To reduce the risk of fire due to increased

static pressure, we do not recommend

installation of in-line secondary lint filters

or lint collectors. If secondary systems

are mandated, frequently clean the

system to assure safe operation.

W749

IMPORTANT: Installing in-line filters or lint

collectors will cause increased static pressure.

Failure to maintain the secondary lint system will

decrease dryer efficiency and may void machine

warranty.

• DO NOT use plastic or thin foil ducting. Rigid

metal duct is recommended.

• Install backdraft dampers in multi-dryer

installations.

• In mobile home installations, dryer exhaust duct

must be secured to mobile home structure.

• Dryer exhaust duct MUST NOT terminate under

mobile home.

• Dryer exhausts 220 cfm (measured at back of

dryer).

• DO NOT install flexible duct in concealed

spaces, such as a wall or ceiling.

• Static pressure in exhaust duct should not be

greater than 1.5 cm water column (.6 inches),

measured with manometer placed on exhaust

duct 61 cm (two feet) from dryer (check with

dryer running and no load). In multi-dryer

installations, all dryers connected to the main

collector duct should be operating when pressure

is checked.

• Exhausting dryer in hard-to-reach locations can

be done by installing 521P3 Flexible Metal Vent

Kit (available as optional equipment at extra

cost).

DON’TDO

D354I D356I

Figure 4

• Locate dryer so exhaust duct is as short as

possible.

• Be certain old ducts are cleaned before installing

your new dryer.

• Use 102 mm (4 inch) diameter rigid or flexible

metal duct.

• The male end of each section of duct must point

away from the dryer.

• Use as few elbows as possible.

• Use duct tape or pop-rivets on all duct joints. DO

NOT use sheet metal screws or fasteners on

exhaust pipe joints which extend into the duct

and catch lint.

• Sufficient make-up air must be supplied to

replace the air exhausted by the dryer. The free

area of any opening for outside air must be at

least 260 cm

2

(40 in2).

• Energy efficient buildings with low air

infiltration rates should be equipped with an air

exchanger that can accommodate on demand

make-up air needs in the laundry room. These

devices can be obtained through your building

contractor or building material suppliers.

• Do not draw make-up air from a room containing

a gas fired water heater, a dry cleaner or a hair

salon.

• Failure to exhaust dryer properly will void

warranty.

NOTE: Venting materials are not supplied with the

dryer (obtain locally).

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer’s front panel with laundry,

rugs, etc. Blockage will decrease airflow through

the dryer, thus reducing the efficiency of the dryer.

• Ductwork that runs through unheated areas must

be insulated to help reduce condensation and lint

build-up on pipe walls.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 13

Installation

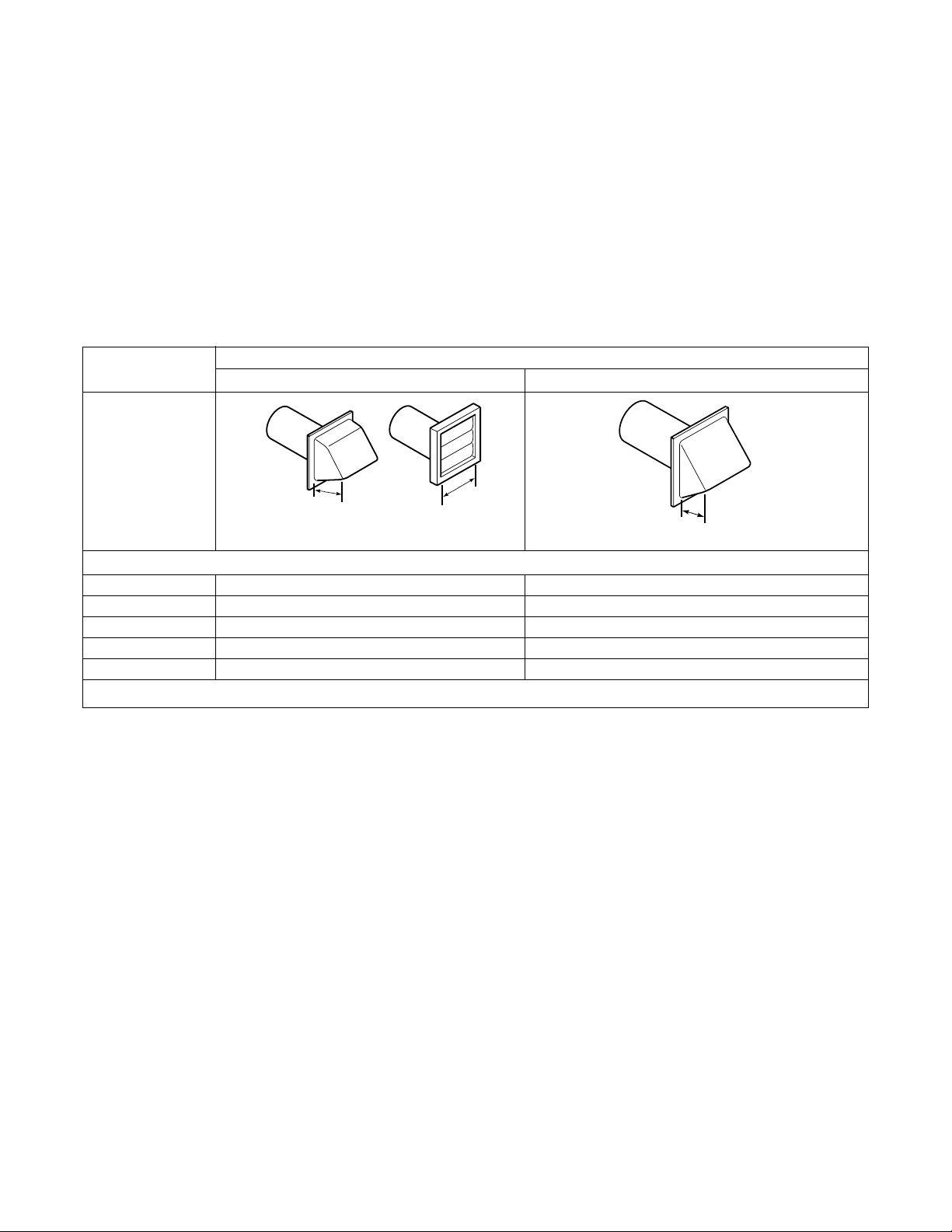

Exhaust Direction

The dryer can be exhausted to the outdoors through the

back, left, right or bottom of the dryer. EXCEPTION:

Gas dryers cannot be vented out the left side

because of the burner housing.

Dryer is shipped from factory ready for rear exhaust.

Exhausting the dryer through sides or bottom can be

accomplished by installing a Directional Exhaust Kit,

528P3 (available as optional equipment at extra cost).

Number of

90° Elbows

Maximum length of 10.2 cm (4 in.) diameter rigid metal duct.

0 19.8 m (65 feet) 16.8 m (55 feet)

1 16.8 m (55 feet) 14.3 m (47 feet)

2 14.3 m (47 feet) 12.5 m (41 feet)

3 11.0 m (36 feet) 9.1 m (30 feet)

4 8.5 m (28 feet) 6.7 m (22 feet)

Recommended Use Only for Short Run installations

10.2 cm

(4 in.)

Exhaust System

For best drying results, recommended maximum

length of exhaust system is shown in Table 1.

To prevent backdraft when dryer is not in operation,

outer end of exhaust pipe must have a weather hood

with hinged dampers (obtain locally).

NOTE: Weather hood should be installed at least

30.5 cm (12 inches) above the ground. Larger

clearances may be necessary for installations where

heavy snowfall can occur.

Weather Hood Type

10.2 cm

(4 in.)

D673I

6.35 cm

(2-1/2 in.)

D802I

NOTE: Deduct 1.8 m (6 feet) for each additional elbow.

Table 1

NOTE: The maximum length of a 10.2 cm (4 in.)

diameter flexible metal duct must not exceed 2.4 m

(7.87 ft.), as required to meet UL2158, clause

7.3.2A.

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation

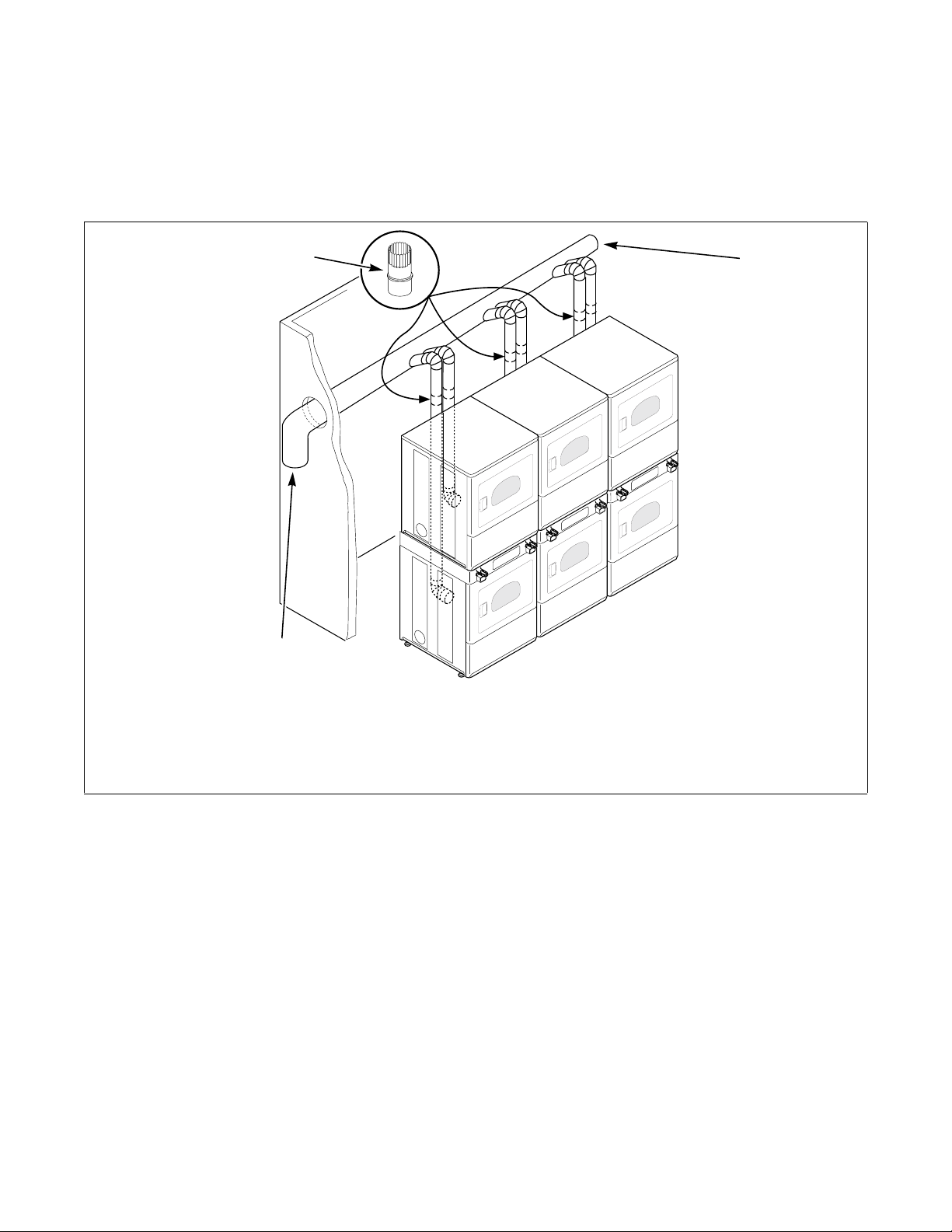

Multi-Dryer Installation Exhaust

Requirements

Figure 5 shows a typical example of a multiple dryer

installation. Note how each dryer has its own exhaust

system vented to the central exhaust duct.

1

61 cm (24 in.)

MINIMUM

CLEARANCE TO

ROOF/GROUND

3

1 58786 Backdraft Damper (Available through

your local authorized parts source)

2 Clean Out Cover (Must be provided). Inspect

monthly.

2

METERED MODELS

ILLUSTRATED

D359I

3 Weather Hood or Sweep Elbow

(No cap or screen)

12

Figure 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

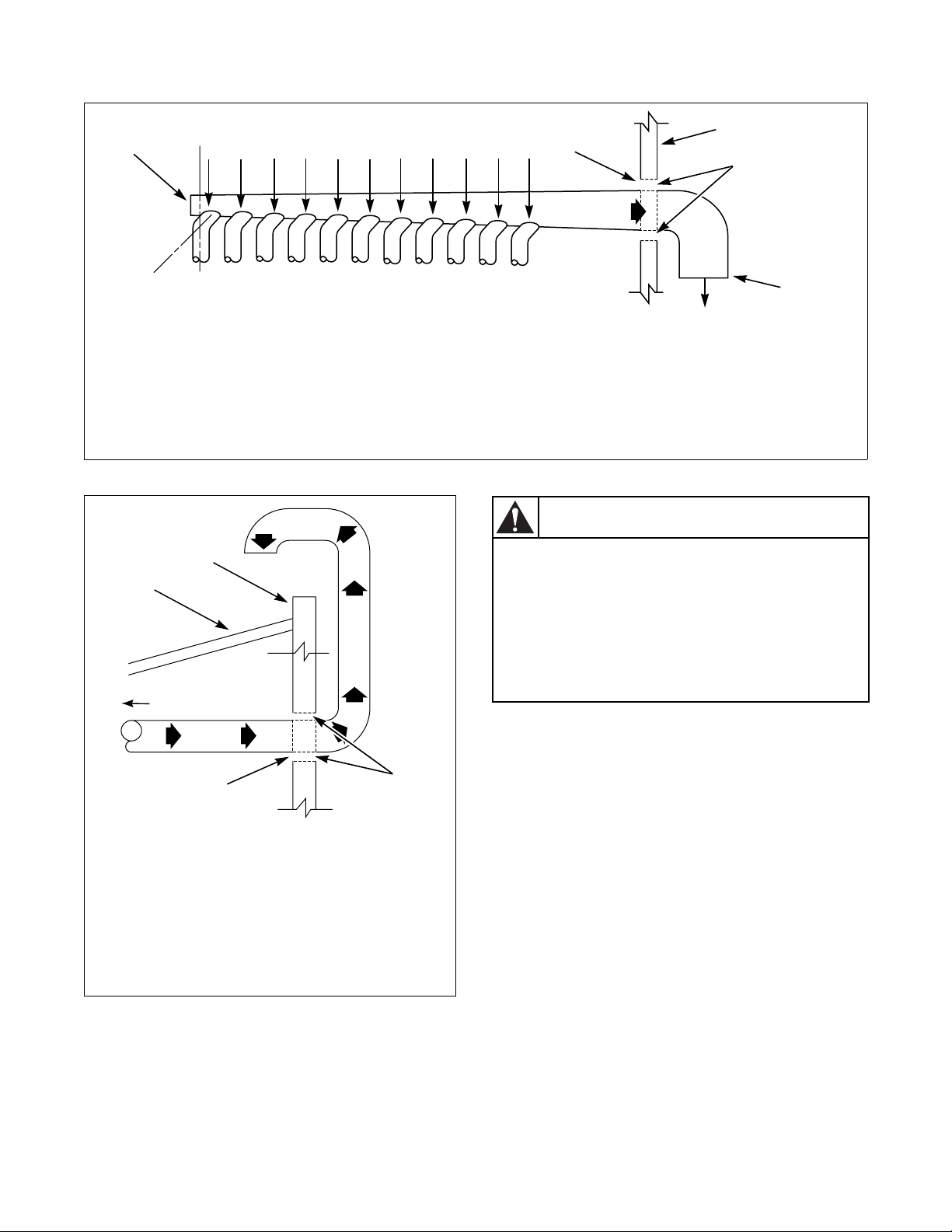

Page 15

Installation

2

5

B

A

CD

EF

GH

IJ

1

K

3

AIR

FLOW

30°

HORIZONTAL EXHAUST INSTALLATION

1 NOTE: Where the exhaust duct pierces a

combustible wall or ceiling, the opening must be

sized per local codes.

2 Wall

.

2

1

CONNECT TO DRYER

Figure 6

EXHAUST AIR FLOW

MAXIMUM LENGTH OF

DUCT 9.1 m (30 feet)

EXHAUST

OUTLET

4

H318I

3 Clearance per Local Codes

4 No Screen or Cap

5 Clean Out Cover – Inspect Monthly

WARNING

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated

area, such as an attic, wall, ceiling, crawl

space under a building or concealed space

of a building.

W045

4

VERTICAL EXHAUST INSTALLATION

1 Roof

2 Wall

3 5 cm (2 in.) Minimum

4 NOTE: Where the exhaust duct pierces a

combustible wall or ceiling, an opening must

be sized as shown or per local codes.

Figure 7

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

H319I

13

Page 16

Installation

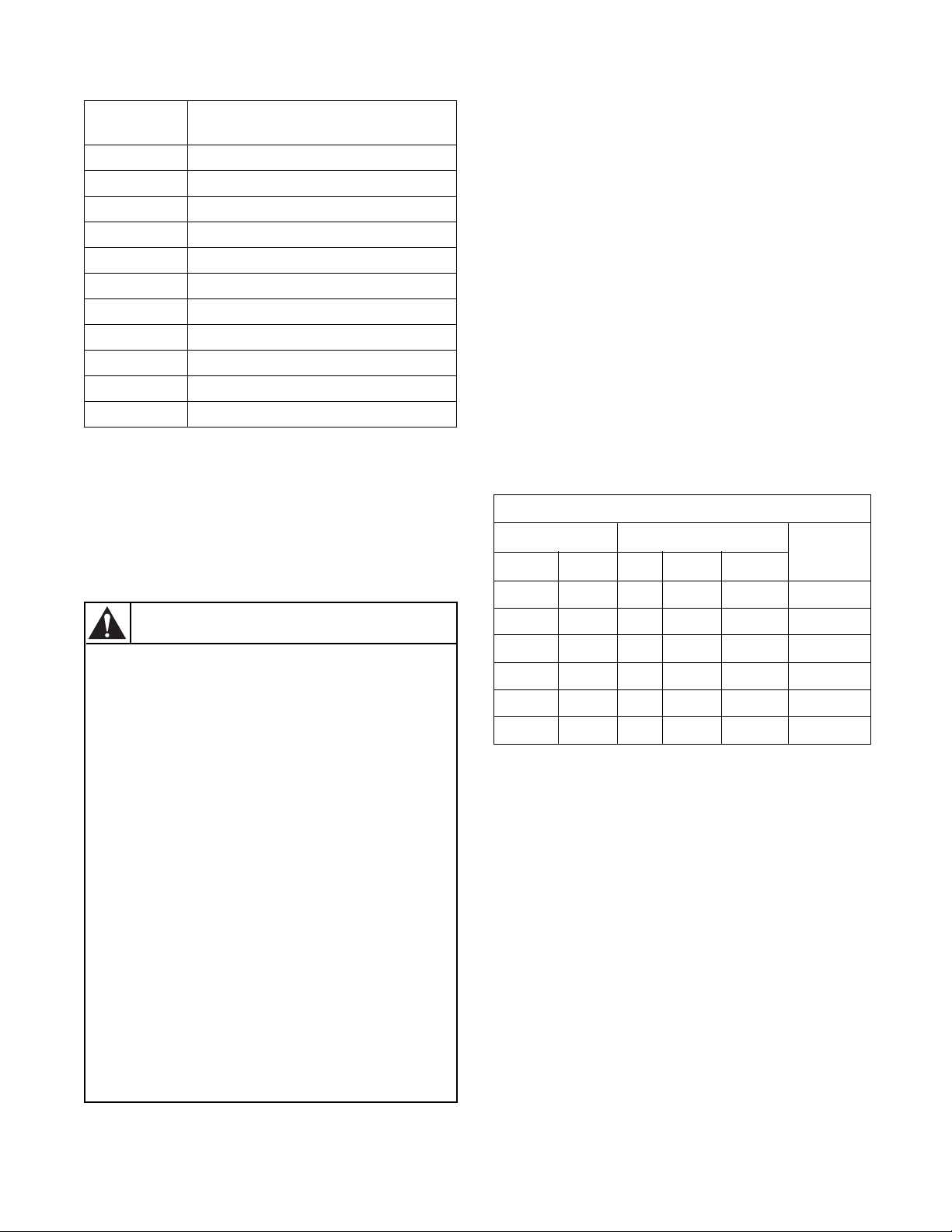

Duct Station

A 10.2 cm (4 inches)

B 20.3 cm (8 inches)

C 22.9 cm (9 inches)

D 25.4 cm (10 inches)

E 27.9 cm (11 inches)

F 30.5 cm (12 inches)

G 32.6 cm (13 inches)

H 35.6 cm (14 inches)

I 38.1 cm (15 inches)

J 38.1 cm (15 inches)

K 40.6 cm (16 inches)

Minimum Diameter of

Collector Duct

A Backdraft Damper, Part No. 58786 (obtain locally),

should be installed in a 10.2 cm (4 inch) diameter

VERTICAL duct system. This will prevent a backdraft

when dryer is not in use, and will keep the exhaust air

in balance within the central exhaust system.

Step 3: (Gas Dryer Only) Connect Gas

Supply Pipe

1. Make certain your dryer is equipped for use with

the type of gas in your laundry room. Dryer is

equipped at the factory for Natural Gas with a

3/8 inch NPT gas connection.

NOTE: The gas service to a gas dryer must

conform with the local codes and ordinances, or in

the absence of local codes and ordinances, with the

latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or the CAN/CSA-B149.1 Natural

Gas and Propane Installation Code.

3

Natural Gas, 37.3 MJ/m

(1000 Btu/ft3), service must

be supplied at minimum 5.0 inch water column

pressure to maximum 10.5 inch water column

pressure.

For proper operation at altitudes above 610 m

(2000 feet) the natural gas valve spud orifice size must

be reduced to ensure complete combustion. Refer to

Tabl e 2 .

Natural Gas Altitude Adjustments

Altitude Orifice Size

m feet # mm inches

610 2,000 41 2.44 0.0960 503776

Part

Number

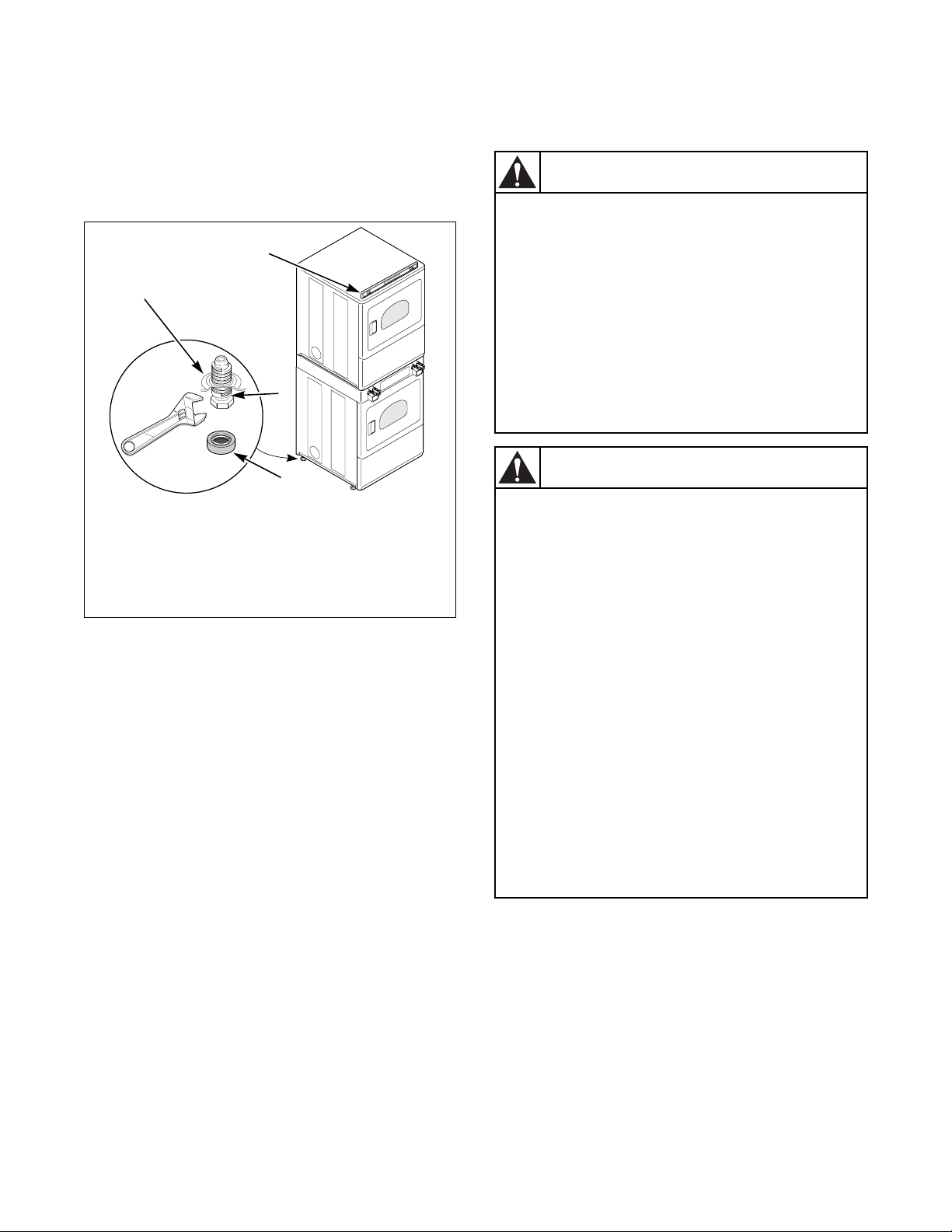

WARNING

To reduce the risk of gas leaks, fire or

explosion:

• Each dryer must be connected to the type

of gas as shown on nameplate located in

the door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in L.P.

(Liquefied Petroleum) Gas, or Teflon tape,

on all pipe threads.

• Purge air and sediment from gas supply

line before connecting it to a dryer. Before

tightening the connection, purge

remaining air from gas line to each dryer

until odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for gas

leaks. Use a non-corrosive leak detection

fluid.

• Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W315

915 3,000 42 2.37 0.0935 503777

1,680 5,500 43 2.26 0.0890 503778

2,135 7,000 44 2.18 0.0860 58719

2,745 9,000 45 2.08 0.0820 503779

3,200 10,500 46 2.06 0.0810 503780

Table 2

2. Remove the shipping cap from the gas

connection at the rear of the dryer. Make sure you

do not damage the pipe threads when removing

the cap.

3. Connect to gas supply pipe.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 17

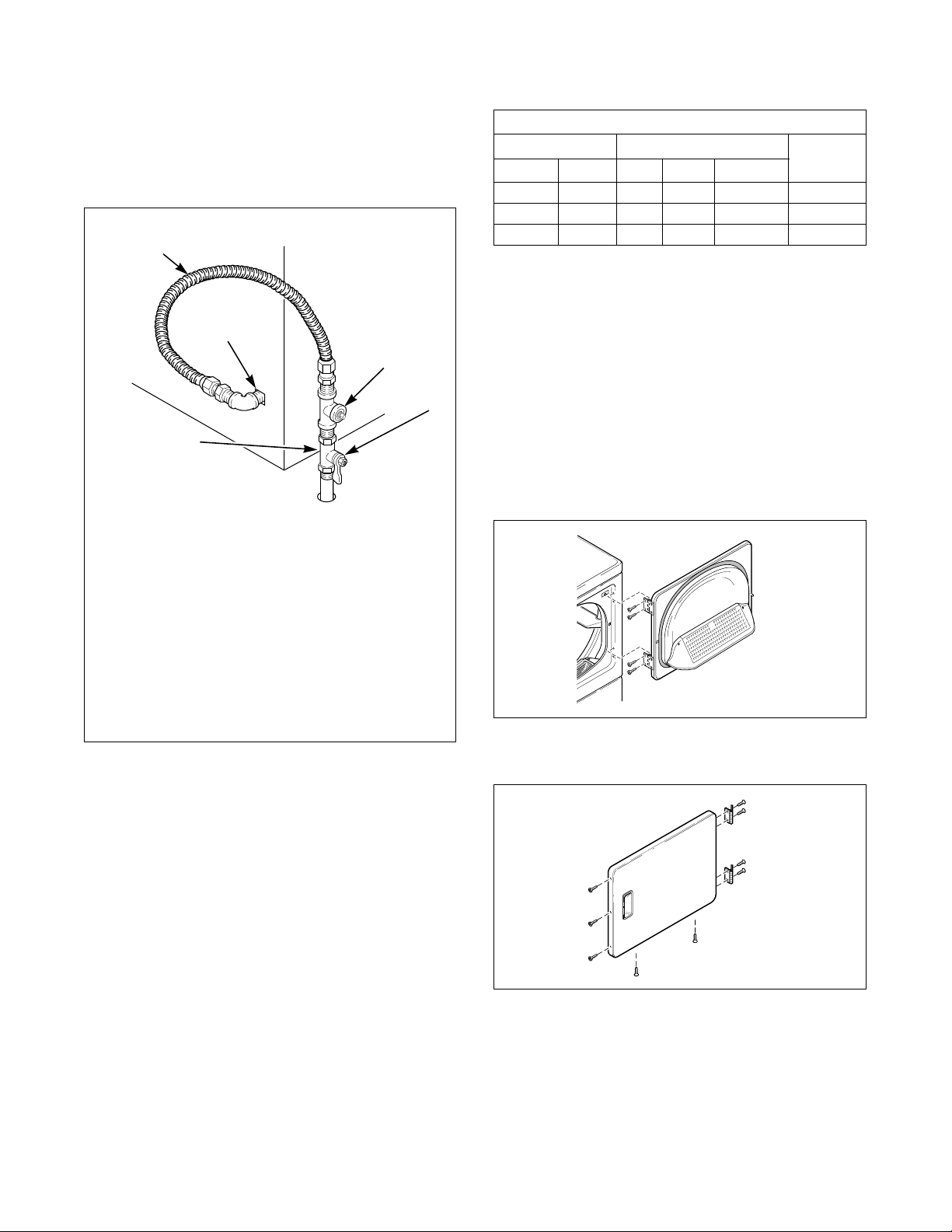

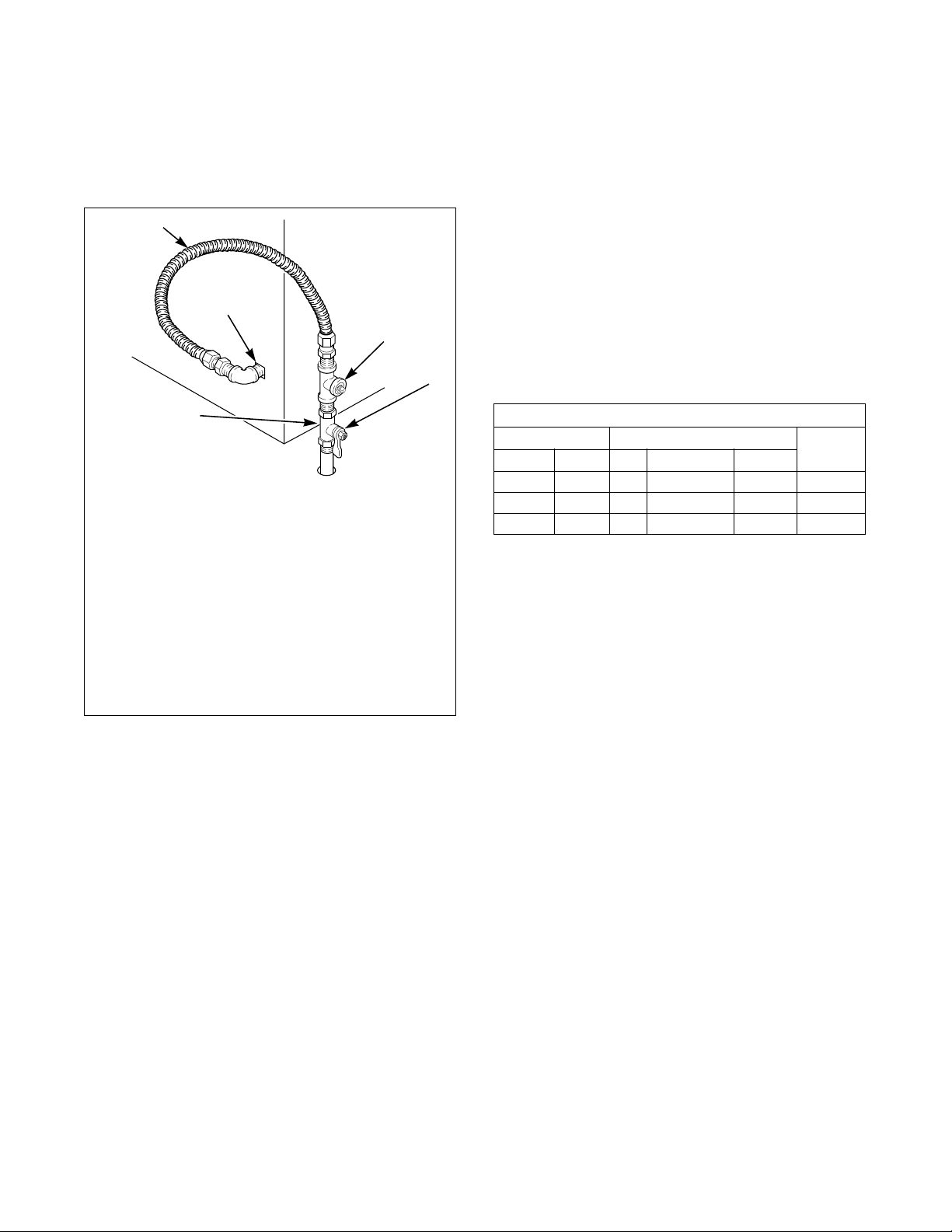

NOTE: When connecting to a gas line, an

equipment shut-off valve must be installed within

1.8 m (6 feet) of the dryer. An 1/8 in. NPT pipe plug

must be installed as shown for checking inlet

pressure. Refer to Figure 8.

1

5

2

3

4

Installation

L.P. Altitude Adjustments

Altitude Orifice Size

m feet No. mm inches

1070 3500 54 1.40 0.0550 503785

2290 7500 55 1.32 0.0520 58755

3355 11000 56 1.18 0.0465 503786

Part

No.

Table 3

NOTE: DO NOT connect the dryer to L.P. Gas

Service without converting the gas valve. Install

L.P. Gas Conversion Kit 458P3 (available at extra

cost).

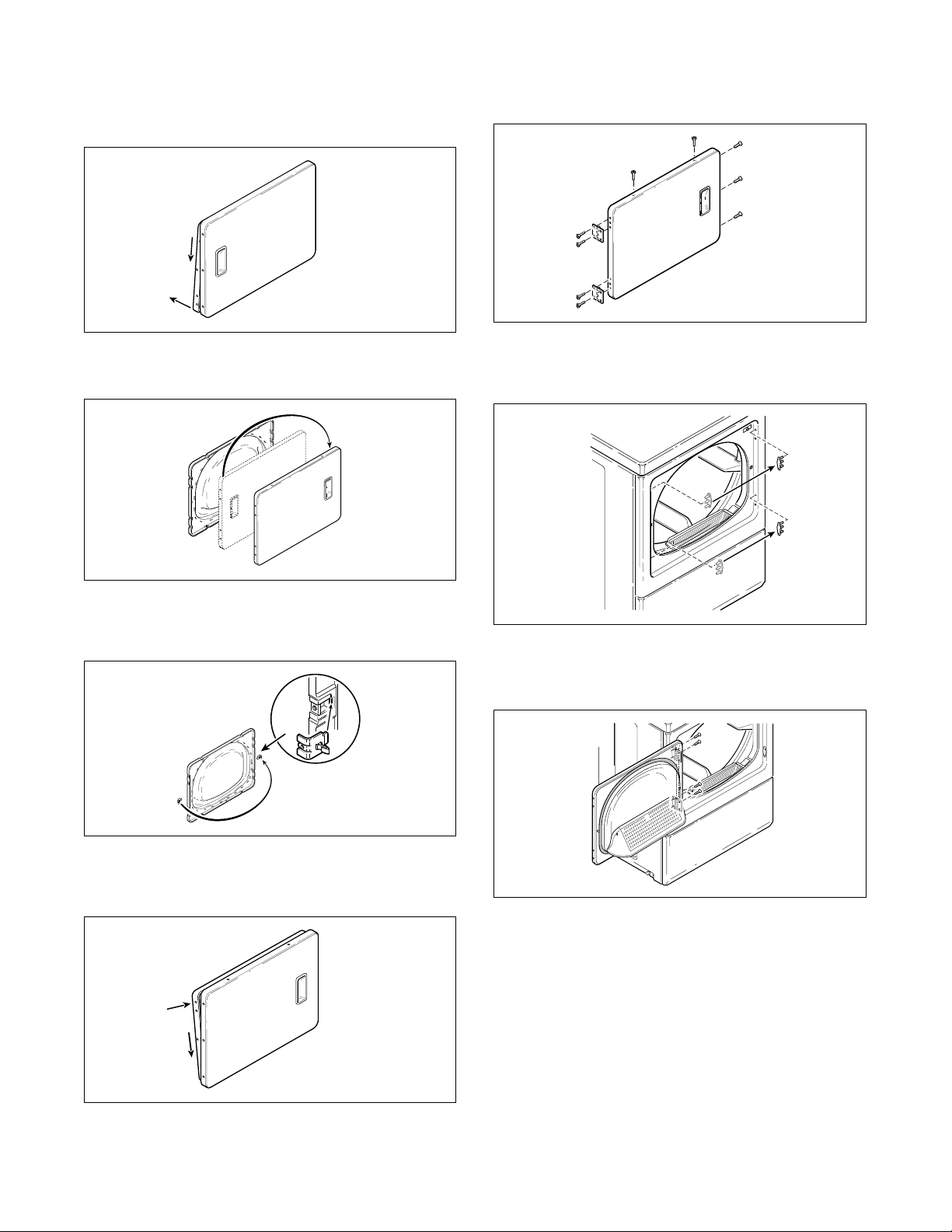

Step 4: Reverse Door, if Desired

NOTE: Doors with windows cannot be reversed.

The door on this dryer is completely reversible. To

reverse door proceed as follows:

D233I

D233I

1 New Stainless Steel Flexible Connector -

(Use design CSA certified connector)

Use only if allowed by local codes

2 1/8 in. NPT Pipe Plug

3 Equipment Shut Off Valve

4 Black Iron Pipe

Shorter than 6.1 m (20 ft.) - 9.5 mm

(Use 3/8 in.) pipe

Longer than 6.1 m (20 ft.) - use 12.7 mm (1/2

in.) pipe.

5 3/8 in. NPT Gas Connection

Figure 8

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external)

for gas leaks with a non-corrosive leak detection

fluid.

NOTE: The dryer and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 3.45 kPa (1/2 lb./in.

2

).

Refer to Step 8 (Check Heat Source).

3

L.P. (Liquefied Petroleum) Gas, 93.1 MJ/m

(2500 Btu/ft

3

), service must be supplied at 10 ± 1.5

inch water column pressure.

1. Remove four hinge attaching screws.

D675I

Figure 9

2. Remove all nine screws.

Figure 10

D675I

D272P

For proper operation at altitudes above 1070 m

(3500 feet) the L.P. gas valve spud orifice size must be

reduced to ensure complete combustion. Refer to

Tabl e 3 .

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Installation

3. Pull bottom of door liner out, then pull down,

removing door liner from door panel.

B

A

DRY1916N

DRY1916N

Figure 11

4. Rotate door panel 180 degrees as shown.

7. Reinstall nine screws removed in Step 2.

DRY1919N

Figure 15

DRY1919N

8. Using screwdriver, remove two door plugs, and

reinstall on opposite side of door opening.

D273P

Figure 12

5. Remove door strike from door liner and reinstall

on opposite side.

DRY1917N

Figure 13

DRY1917N

6. Insert liner under flange on bottom of door, then

push top of door liner into place.

B

D317S

Figure 16

9. Reinstall four hinge attaching screws, removed in

Step 1.

D606I

Figure 17

D606I

16

A

DRY1918N

DRY1918N

Figure 14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 19

Installation

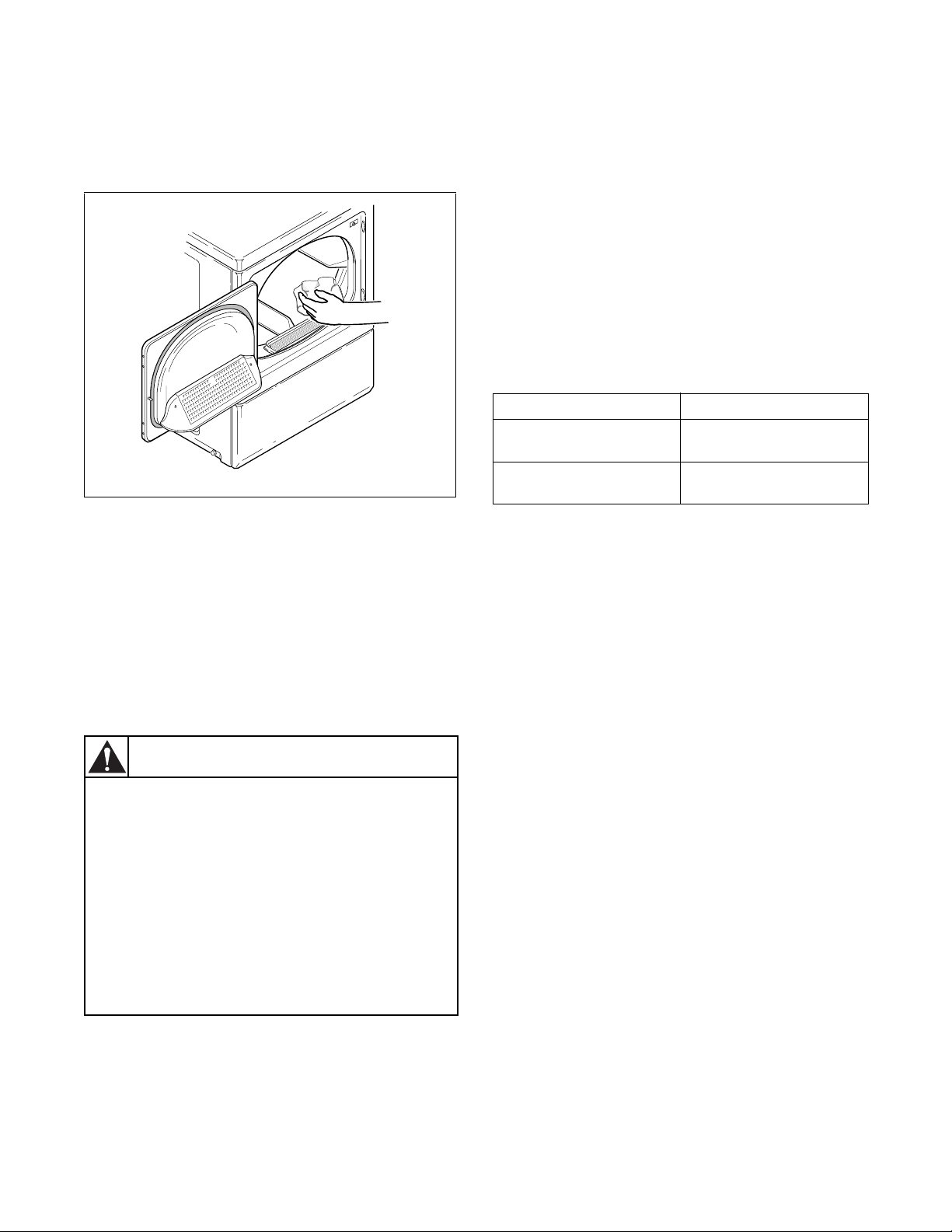

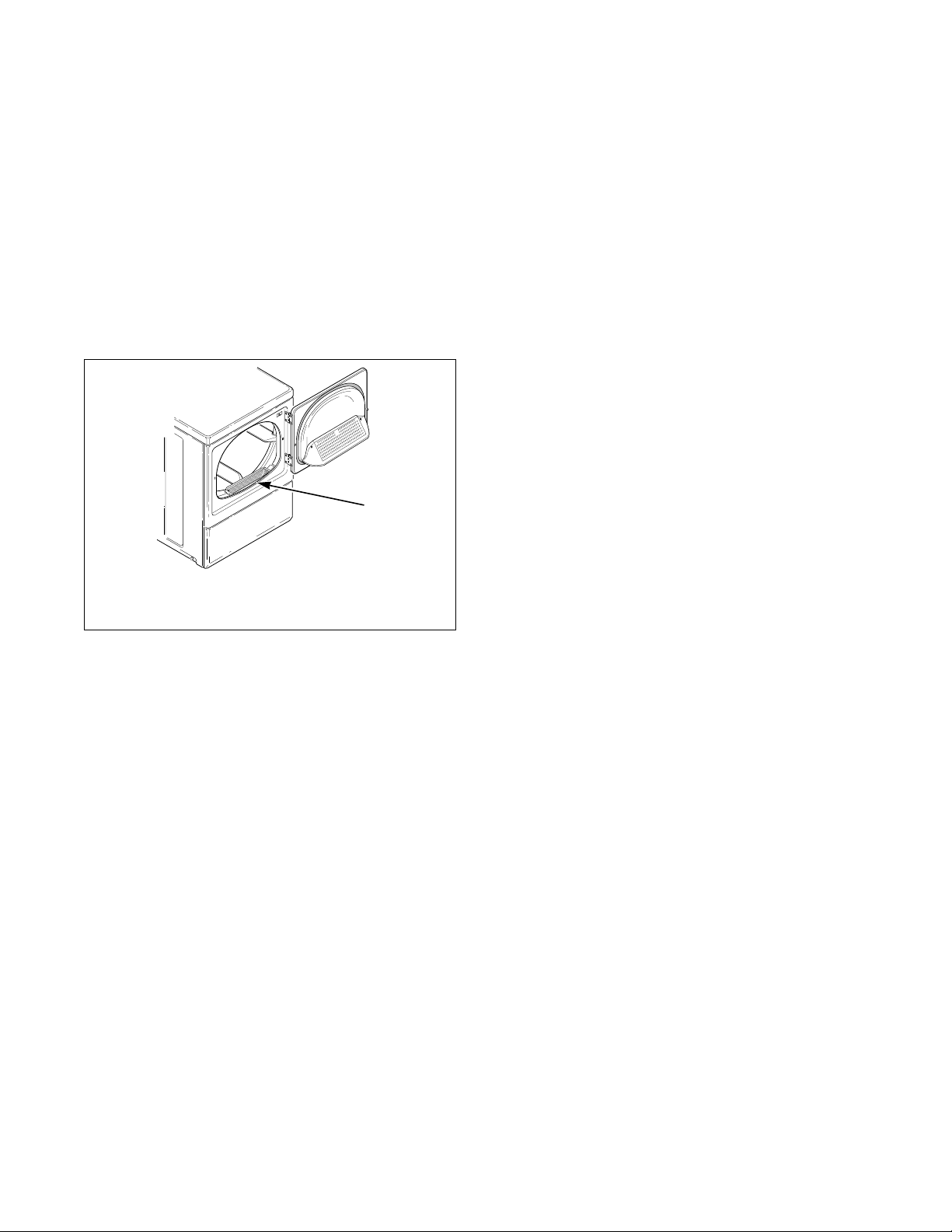

Step 5: Wipe Out Inside of Dryer

Before using dryer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside dryer drum.

D604I

D604I

Figure 18

Step 6: Connect Unit to Electrical Power

Grounding Instructions

The electric service must be a separate branch,

polarized, three-wire and ground, 120/240 Volt, or

120/208 Volt, 60 Hertz, AC single phase circuit fused

with 60 Ampere fuses.

The cord (supplied with dryer) and plug assembly

(obtain locally) should be plugged into an approved

receptacle that is mounted on the wall adjacent to the

dryer. This receptacle should be accessible to the user

or service person when the dryer is in position, to

permit disconnecting when necessary.

NOTE: Branch circuit wire size requirements to

laundry room outlet are shown in Tabl e 4.

Wire Length Wire

Less than 4.5 m (15 ft.) Listed No. 10 AWG

Copper wire only

Longer than 4.5 m (15 ft.) Listed No. 8 AWG

Copper wire only

Table 4

Electric Dryers Equipped with Lead-In Cord

(120/240 Volt, 60 Hertz, 3-Wire and Ground

Installation)

(120/208 Volt, 60 Hertz, 3-Wire and Ground

Installation)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

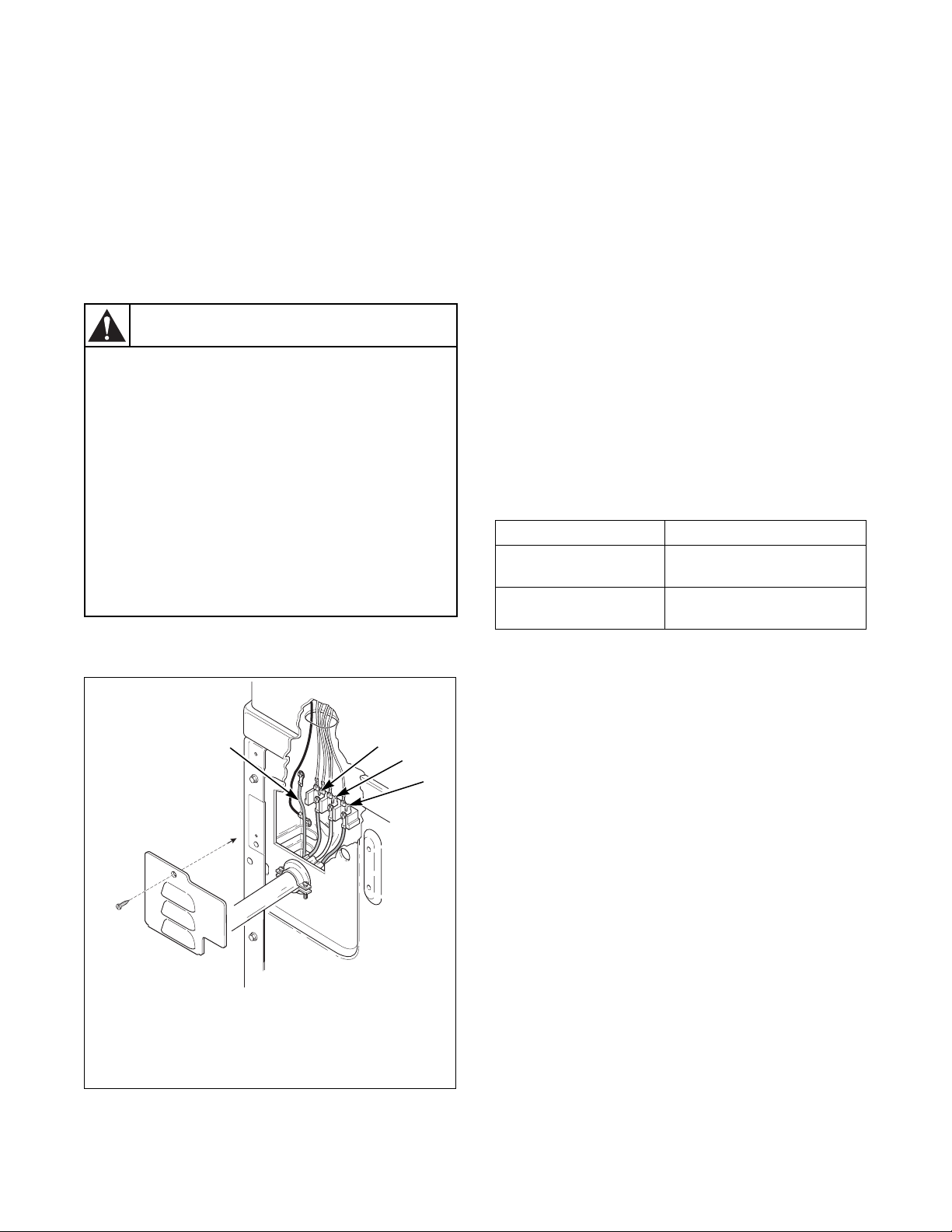

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer’s responsibility to have the

wiring and fuses installed by a qualified

electrician to make sure adequate

electrical power is available to the dryer.

W521

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Installation

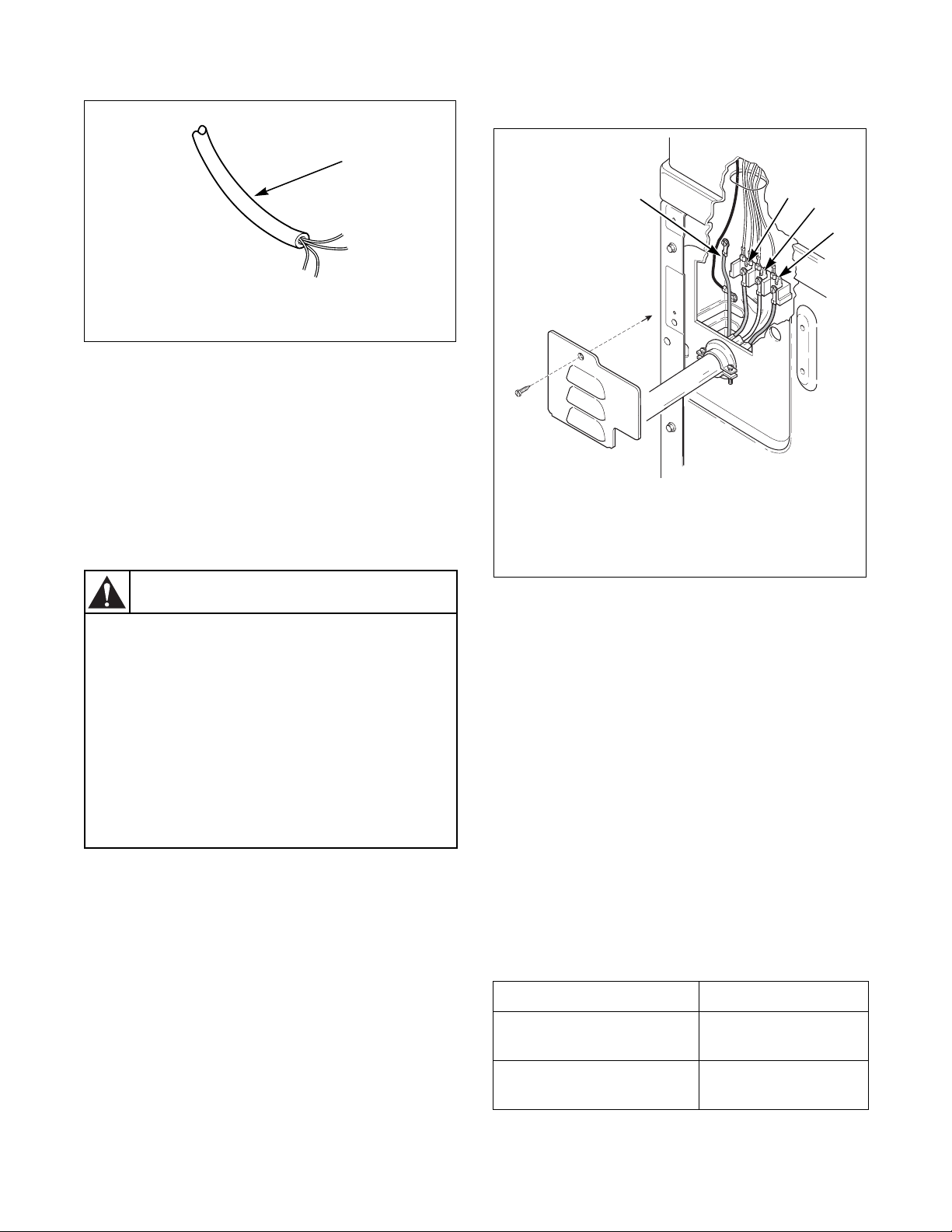

Grounding and Wiring Instructions

1

D373I

1 Power Cord (Four-Wire)

Figure 19

Electric Dryers Not Equipped with Lead-In

Cord

(120/240 Volt, 60 Hertz, 3-Wire and Ground

Installation)

(120/208 Volt, 60 Hertz, 3-Wire and Ground

Installation)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer’s responsibility to have the wiring

and fuses installed by a qualified electrician

to make sure adequate electrical power is

available to the dryer.

W521

1

1 Ground Wire

2 “L1” Terminal

3 Neutral Terminal

4 “L2” Terminal

Figure 20

2

3

4

DRY2377N

The dryer must be connected to a grounded metal,

permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or

lead on the dryer.

IMPORTANT: DO NOT connect ground wire to

neutral terminal.

Only flexible metal conduit, rigid metal conduit or

armored cable wiring systems are recommended.

Refer to Figure 20 for terminal block connections.

Electrical service for the dryer should be of maximum

rated voltage (208 or 240 Volt, depending on heating

element), listed on nameplate with a 60 Amp circuit

breaker or time delay fuse. Do not connect dryer to

110, 115 or 120 Volt circuit.

18

NOTE: Branch circuit wire size requirements are

shown in Table 5 .

Wire Length Wire

Less than 15 ft. (4.5m) Listed No.8 AWG

Longer than 15 ft. (4.5m) Listed No.6 AWG

Table 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Copper wire only

Copper wire only

512686

Page 21

Installation

Gas Dryers

(120 Volt, 60 Hertz, With 3-Prong Grounding

Plug)

NOTE: The wiring diagram is located behind the

control panel, inside the control cabinet.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

to the dryer unit MUST conform with the

local codes, or in the absence of local

codes, with the latest edition of the

National Electrical Code ANSI/NFPA 70 or

the Canadian Electrical Code, CSA C22.1,

and such local regulations as might

apply. It is the customer’s responsibility

to have the wiring and fuses checked by a

qualified electrician to make sure the

laundry room has adequate electrical

power to operate the dryer unit.

W084

• Each dryer is designed to be operated on a

separate branch, polarized, three-wire, effectively

grounded, 120 Volt, 60 Hertz, AC (alternating

current) circuit protected by a 20 Ampere fuse,

equivalent fusetron or circuit breaker.

• The three-prong grounding plug on the power

cord should be plugged directly into a polarized

three-slot effectively grounded receptacle rated

120 Volts AC (alternating current) 20 Amps.

Refer to Figure 21 to determine correct polarity

of the wall receptacle.

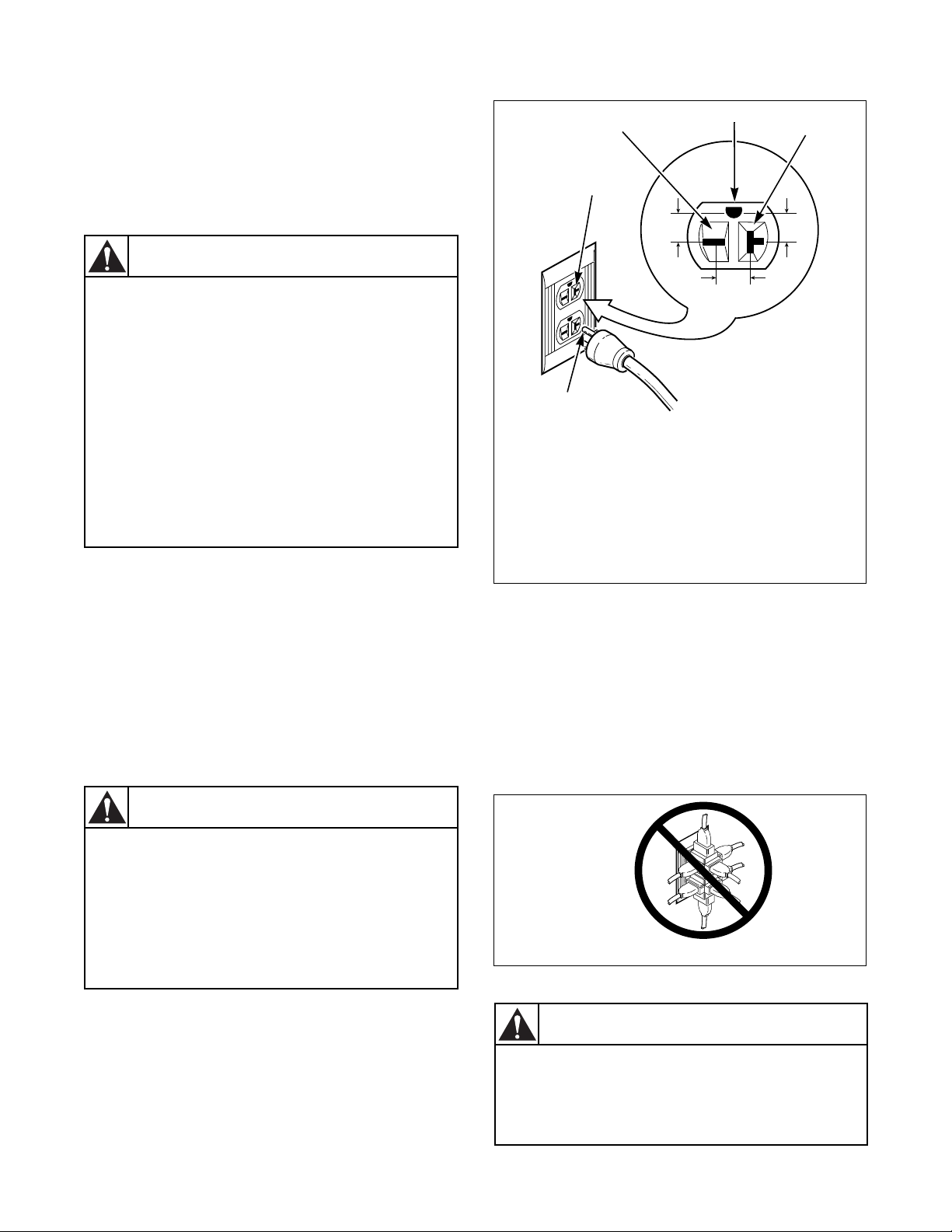

WARNING

This dryer is equipped with a three-prong

(grounding) plug for your protection

against shock hazard and should be

plugged directly into a properly grounded

three-prong receptacle. Do not cut or

remove the grounding prong from this

plug.

W036

1

5

115 ± 12

V.A.C.

4

STANDARD 120 VOLT, 60 HERTZ,

3-WIRE EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral

4 Round Grounding Prong

5 Neutral Side

2

115 ± 12

V.A .C .

0

V.A.C.

D739I

3

D739I

Figure 21

NOTE: A qualified electrician should check the

polarity of the wall receptacles. If a voltage reading

is measured other than that illustrated, the

qualified electrician should correct the problem.

• DO NOT OPERATE OTHER APPLIANCES

ON THE SAME CIRCUIT WHEN THIS

APPLIANCE IS OPERATING. DO NOT

OVERLOAD CIRCUITS! Refer to Figure 22.

.

DO NOT

OVERLOAD

CIRCUITS

D009I

Figure 22

512686

WARNING

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the dryer unit to the

electrical power source.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

W152

19

Page 22

Installation

Grounding Instructions

• The dryer unit must be grounded. In the event of

malfunction or breakdown, grounding will

reduce the risk of electric shock by providing a

path of least resistance for electric current. The

dryer unit is equipped with a cord having an

equipment-grounding conductor and a three

prong grounding plug. The plug must be plugged

into an appropriate outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the dryer unit is

properly grounded.

W153

• DO NOT modify the plug provided with the

dryer unit – if it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

• If the laundry room’s electrical supply does not

meet the above specifications and/or if you are

not sure the laundry room has an effective

ground, have a qualified electrician or your local

electrical utility company check it and correct

any problems.

Step 7: Recheck Steps 1-6

Refer to Installer Checklist on the back cover of this

manual and make sure that dryer is installed correctly.

Step 8: Check Heat Source

Electric Dryers

Close the loading door and start the dryer in a heat

setting (refer to the Operation section). After the dryer

has operated for three minutes, the exhaust air or

exhaust pipe should be warm.

Gas Dryers

IMPORTANT: This operation is to be conducted

by qualified personnel only.

To view the burner flame, remove the lower front

panel of the dryer.

Close the loading door, start the dryer in a heat setting

(refer to the Operation section). The dryer will start,

the igniter will glow red and the main burner will

ignite.

IMPORTANT: If all air is not purged out of gas

line, gas igniter may go off before gas is ignited. If

this happens, after approximately two minutes

igniter will again attempt gas ignition.

IMPORTANT: If igniter does not light, make sure

gas is turned on.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 23

After either dryer has operated for approximately five

minutes, observe burner flame through lower front

panel. Adjust the air shutter to obtain a soft, uniform

blue flame. (A lazy, yellow-tipped flame indicates lack

of air. A harsh, roaring, very blue flame indicates too

much air.) Adjust the air shutter as follows:

Installation

WARNING

For personal safety, lower front panel must

be in place during normal operation.

W046

1. Loosen the air shutter lockscrew.

2. Turn the air shutter to the left to get a luminous

After either dryer has operated for approximately three

minutes, exhaust air or exhaust pipe should be warm.

yellow-tipped flame, then turn it back slowly to

the right to obtain a steady, soft blue flame.

3. After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

4. Reinstall the lower front panel.

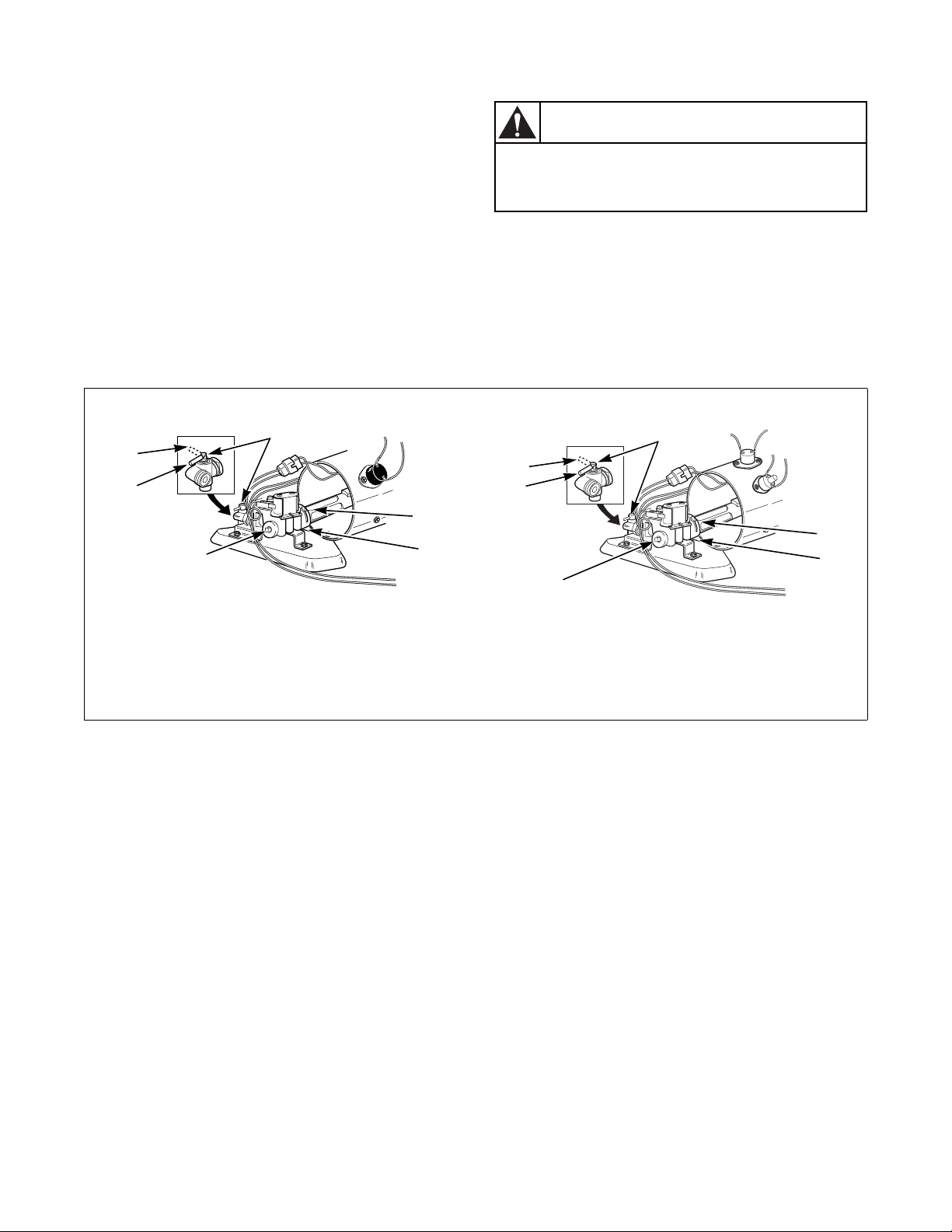

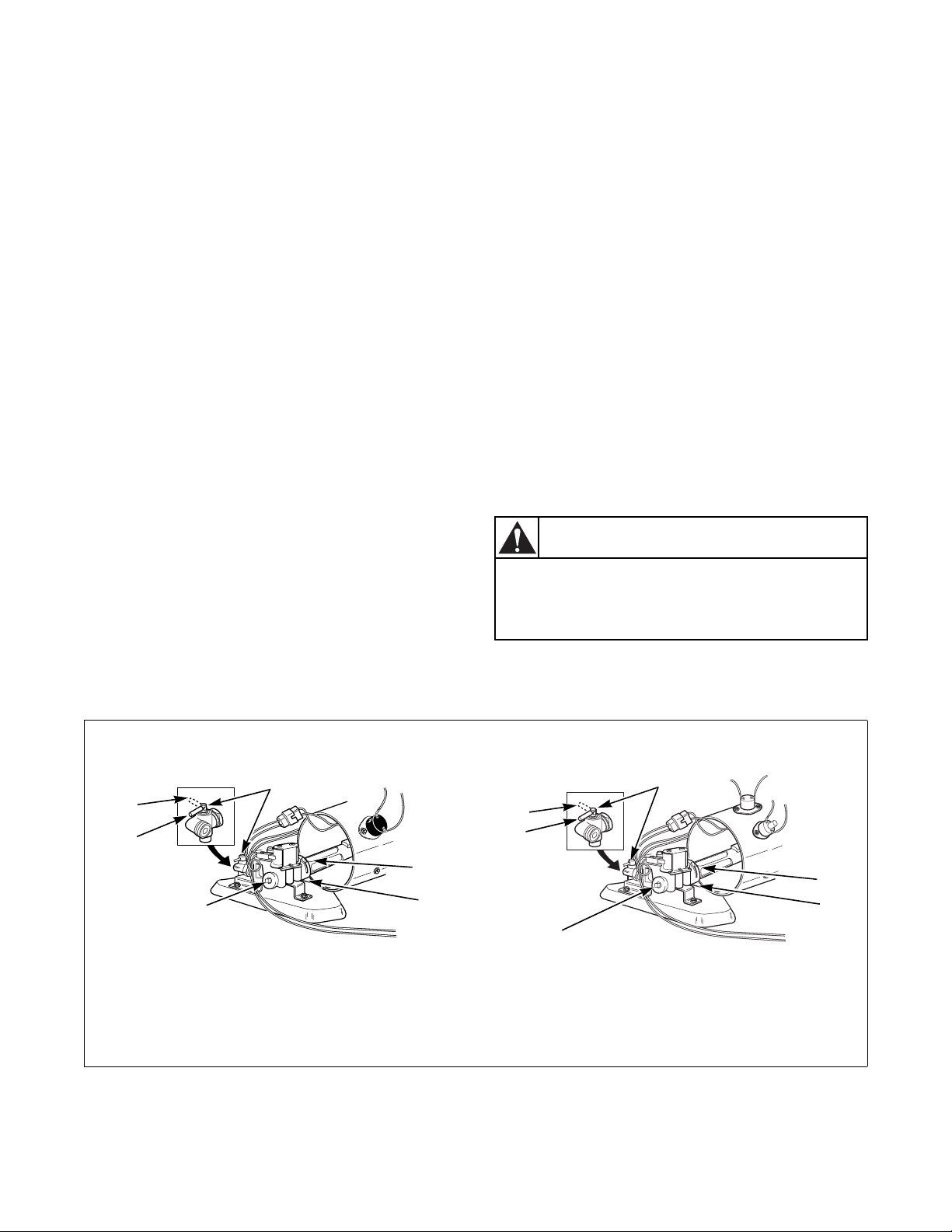

COIN SLIDE, MDC, AND NETMASTER MODELS THROUGH

SERIAL NO. 0803 AND NONMETERED MODELS

2

1

6

3

5

1 Closed Position 5 3.1 mm (1/8 in.) Pipe Plug

2 Shut-Off Valve Handle (For checking manifold pressure)

3 Air Shutter Lockscrew 6 Open Position

4 Air Shutter

4

D700I DRY2235N

COIN SLIDE, MDC, AND NETMASTER MODELS

STARTING SERIAL NO. 0804

2

1

6

5

3

4

512686

Figure 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

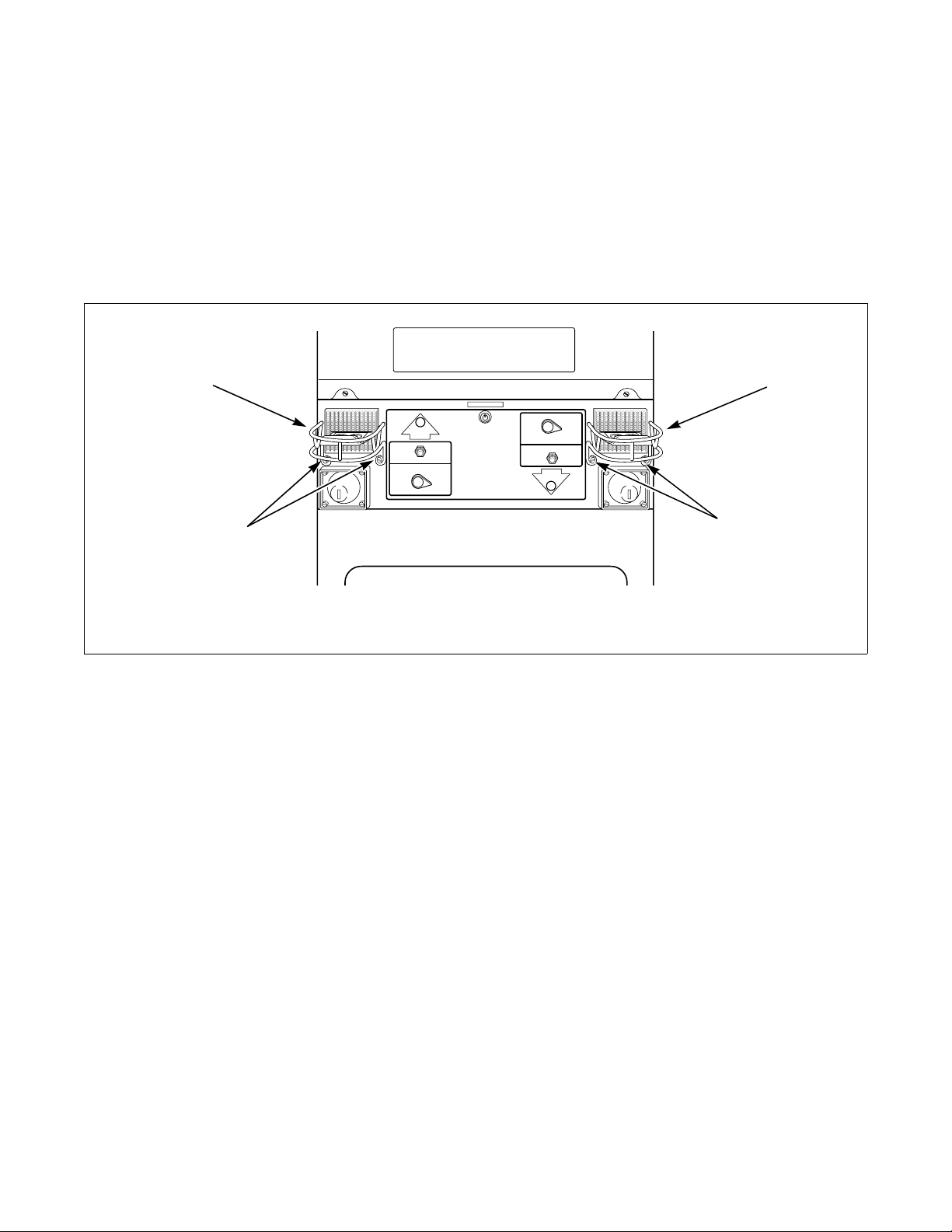

Vending

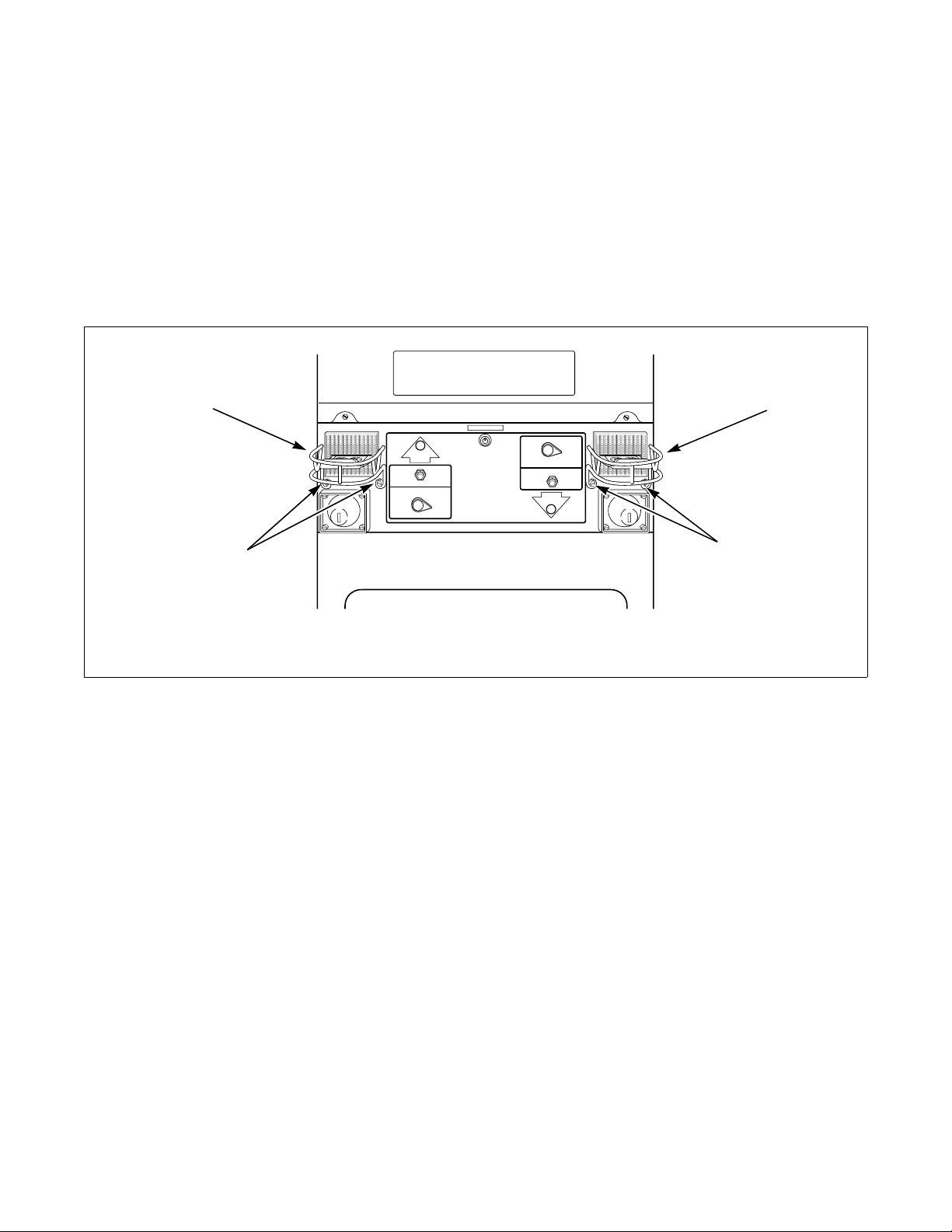

Coin Slide Guards

(Metered Models)

Using sheet metal screws from accessories bag

(located in lower cylinder), install coin slide guards

(located in accessories bag in lower cylinder) to front

of dryer’s control cabinet. Refer to Figure 24.

1

PERM PRESS

DELICATE

FLUFF

NORMAL

IN USE

PUSH TO START

PERM PRESS

NORMAL

FABRIC SELECTOR

DELICATE

FLUFF

(NO HEAT)

FABRIC SELECTOR

PUSH TO START

IN USE

(NO HEAT)

2

1 Coin Slide Guard 2 Sheet Metal Screws

Figure 24

NOTE: Coin slides and coin drawers are shown for

illustration only. You must obtain them locally.

1

2

D784I

D784I

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 512686

Page 25

Vending

Coin Slide Control

(Coin Slide Models Only)

Power-Up Mode

When power is applied to the dryer, the control will

enter the Ready Mode. If the control was powered

down during a running a cycle, the IN USE LED will

flash once and the control will enter Start Mode. If the

dry time dipswitch settings have not been changed

from factory default, the IN USE LED will flash once.

Ready Mode

In Ready Mode, the control waits for the vend to be

satisfied before entering Start Mode.

Start Mode

In Start Mode, the vend has been satisfied, but the

Start button has not been pressed. The IN USE LED

will be lit. The timer will not count down until the

Start button is pressed.

Run Mode

In Run Mode, the control is running a cycle. The

IN USE LED is lit.

Door Open Mode

In Door Open Mode, the control turns off the heater

and motor when the door is opened during a run cycle.

The timer will continue to count down time and the

IN USE LED is lit.

End of Cycle Mode

In End of Cycle Mode, a cycle is complete and the

IN USE LED is off. The control remains in this mode

until the door is opened or additional vend has been

satisfied.

Topoffs

Any time the control receives a coin slide pulse during

a cycle it will add the programmed dry time to the time

currently remaining in the cycle. The IN USE LED

will flash briefly to indicate the coin input. The

maximum cycle time is 99 minutes. The control will

not add time beyond 99 minutes. The cool down time

will not change. If the control receives a coin slide

pulse during cool down it will exit cool down and start

heating with the cycle time equal to the programmed

time.

Temperature Selector Switch

For five minutes after the control is powered up, there

is a diagnostic feature that allows the temperature

selector switches to be tested. When the temperature

selector is changed, the new setting is displayed by

flashing the IN USE LED as follows:

High/Normal: 4 flashes

Medium/PP: 3 flashes

Low/Delicate: 2 flashes

No Heat: 1 flash

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Vending

Error Display Mode

The control enters Error Display Mode to display

thermistor errors. The heater is turned off, the IN USE

LED flashes to indicate the error (refer to paragraphs

below), and the timer will continue to count down

time. The control remains in Error Display Mode until

the control senses the thermistor has returned to an

acceptable heating range, the cycle ends or machine is

powered down.

Open Thermistor

If the control senses a temperature less than 0

the heat has been on for at least three minutes it will

set an open thermistor error. The control will flash the

IN USE LED twice separated by a one and a half

second pause. This sequence is repeated as long as the

Open Thermistor error is sensed.

Shorted Thermistor

If the control senses a temperature greater than 210 ±

°F during an active cycle it will set a Shorted

4

Thermistor error. The control will flash the IN USE

LED three times separated by a one and a half second

pause. This sequence is repeated as long as the Shorted

Thermistor error is sensed.

°F when

Setting Dry Time Dipswitches

Models Starting Serial No. 0909

The seventh switch is used to program the amount of

additional cool down time. The additional cool down

time is added to the factory default minimum cool

down time of 3 minutes. A value of 3 additional

minutes is available.

The eighth switch is used for the cycle reset. If the

switch is OFF (default), the control will save the time

left on a cycle in case of a power failure. If the switch

is ON, the control will clear the cycle and return to

Ready Mode if there is a power failure.

All Models

The control is shipped from the factory programmed

with 1 minute of minimum heat time, preset with 41

additional minutes of drying time (dipswitches 1, 4

and 6 in ON position) and 3 minutes of minimum cool

down time for a total time of 45 minutes for a coin

pulse. Refer to Table 6 for dipswitch settings.

The control reads the dipswitch settings at power-up.

The control must be powered down to change the

dipswitch settings.

To change the heat or cool down time for a coin pulse,

the desired dry time dipswitches must be set to ON

position. All other dipswitches must be in OFF

position.

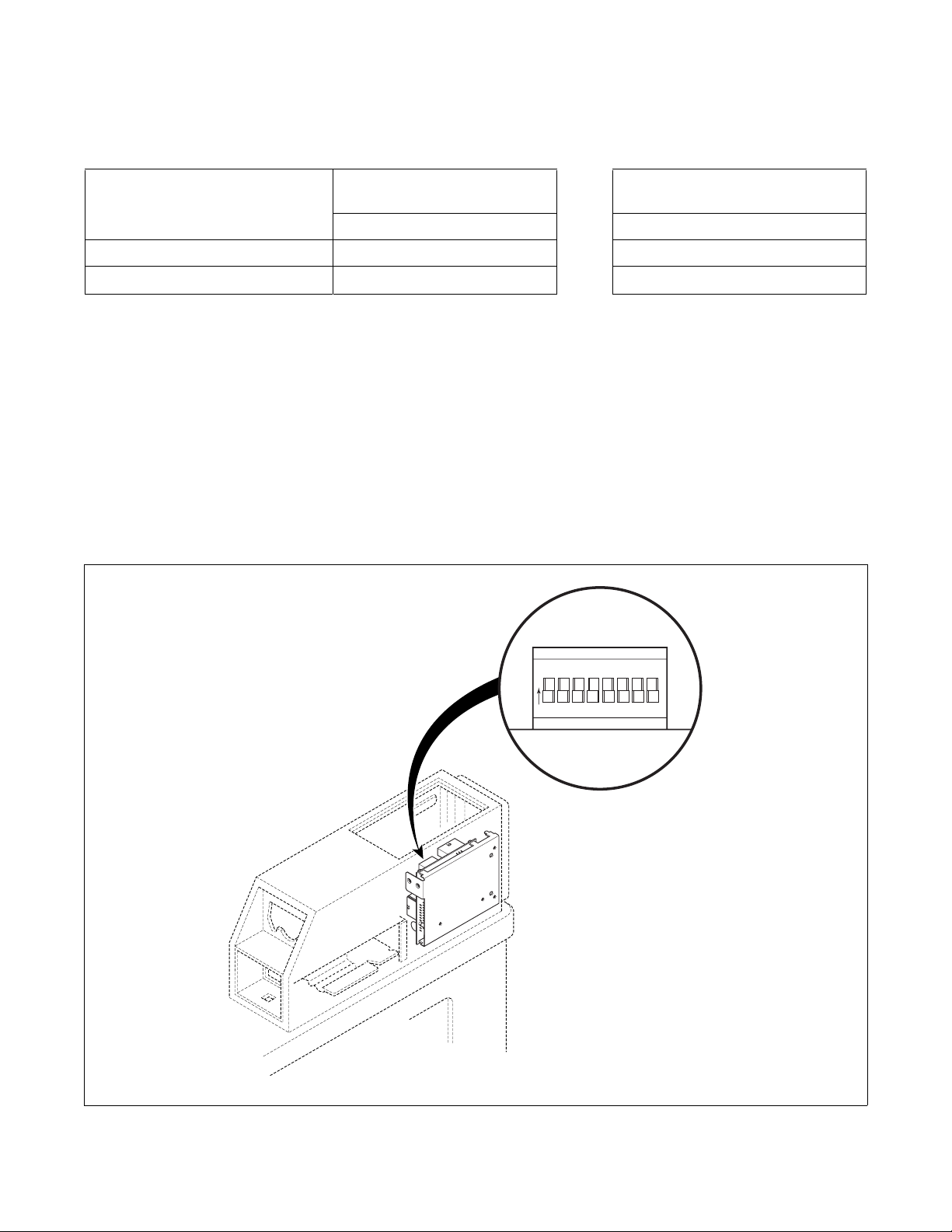

To change the dry time on the dryer, combinations of

dipswitches can be set on the control. Refer to

Figure 25.

There are eight dipswitches on the dryer control. The

first six switches are used to program the amount of

additional heat time given for each coin pulse. The

additional drying time is added to the factory default

minimum heat time of one minute. A value of 1 to 63

minutes of additional drying time is available for each

coin slide pulse.

Models Through Serial No. 0908

The last two switches are used to program the amount

of additional cool down time. The additional cool

down time is added to the factory default minimum

cool down time of 3 minutes. A value of 1 to 3

additional minutes is available.

NOTE: The control must be powered down for 10

seconds before the dipswitch can be changed.

Models Starting Serial No. 0909

Resetting Cycle Time to Zero

To remove any cycle time that may have accumulated

on the control during setup, the cycle time on the

control can be reset to zero.

To reset the time, unplug the dryer and set dipswitch 8

to ON position. Restore power to the dryer for 10

seconds and once again unplug dryer. Set dipswitch 8

to OFF position and restore power to the dryer.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 27

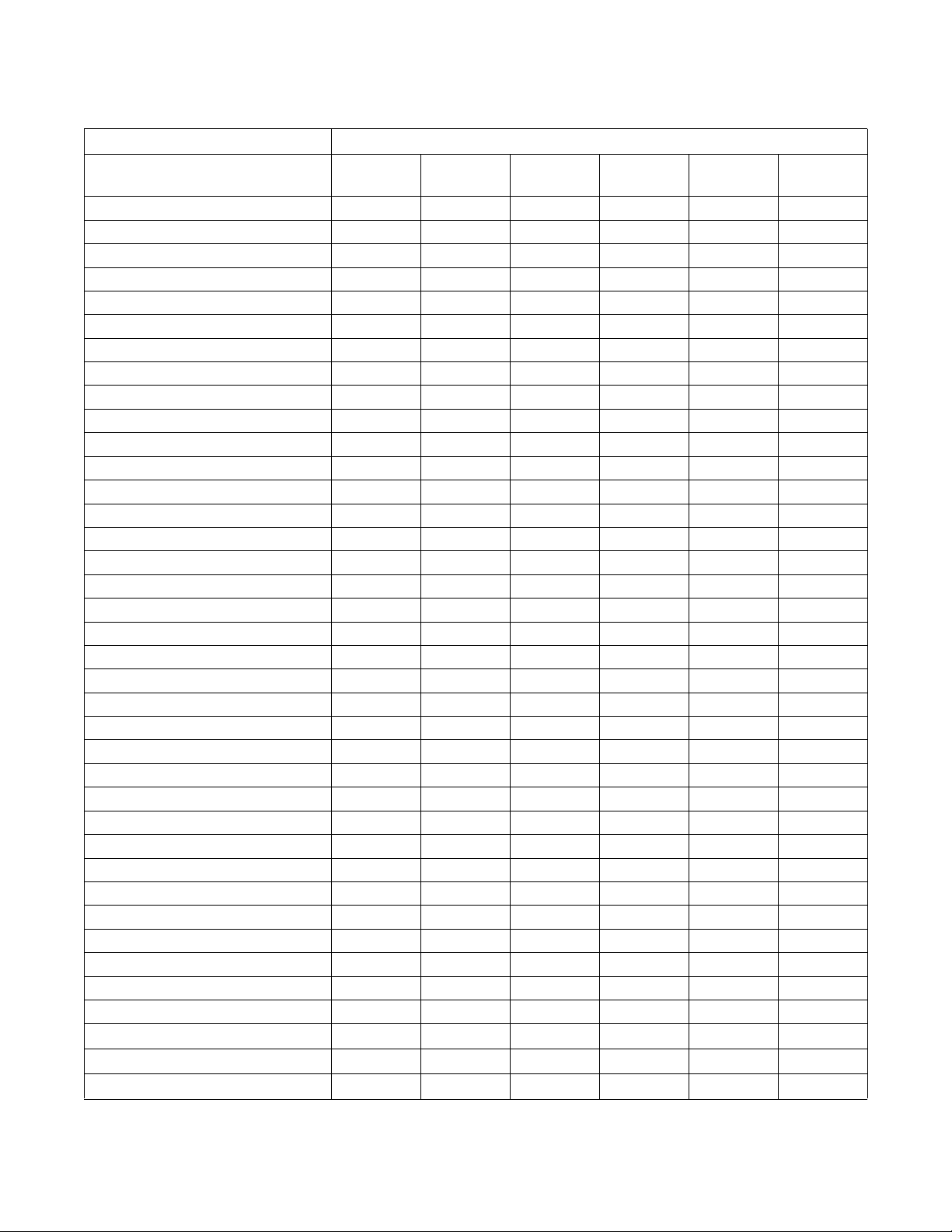

Dipswitch Settings

Heat Time Per Coin Pulse

(in minutes)

1 OFF OFF OFF OFF OFF OFF

2 ON OFFOFFOFFOFFOFF

3 OFF ON OFF OFF OFF OFF

4 ON ON OFF OFF OFF OFF

5 OFF OFF ON OFF OFF OFF

6 ON OFF ON OFF OFF OFF

7 OFF ON ON OFF OFF OFF

8 ON ON ON OFF OFF OFF

9 OFF OFF OFF ON OFF OFF

10 ON OFF OFF ON OFF OFF

11 OFF ON OFF ON OFF OFF

12 ON ON OFF ON OFF OFF

13 OFF OFF ON ON OFF OFF

14 ON OFF ON ON OFF OFF

15 OFF ON ON ON OFF OFF

16 ON ON ON ON OFF OFF

17 OFF OFF OFF OFF ON OFF

18 ON OFF OFF OFF ON OFF

19 OFF ON OFF OFF ON OFF

20 ON ON OFF OFF ON OFF

21 OFF OFF ON OFF ON OFF

22 ON OFF ON OFF ON OFF

23 OFF ON ON OFF ON OFF

24 ON ON ON OFF ON OFF

25 OFF OFF OFF ON ON OFF

26 ON OFF OFF ON ON OFF

27 OFF ON OFF ON ON OFF

28 ON ON OFF ON ON OFF

29 OFF OFF ON ON ON OFF

30 ON OFF ON ON ON OFF

31 OFF ON ON ON ON OFF

32 ON ON ON ON ON OFF

33 OFF OFF OFF OFF OFF ON

34 ON OFFOFFOFFOFF ON

35 OFF ON OFF OFF OFF ON

36

37

38

Vending

Heat Switch Number

123456

ON ON OFF OFF OFF ON

OFF OFF ON OFF OFF ON

ON OFF ON OFF OFF ON

Table 6 (continued)

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

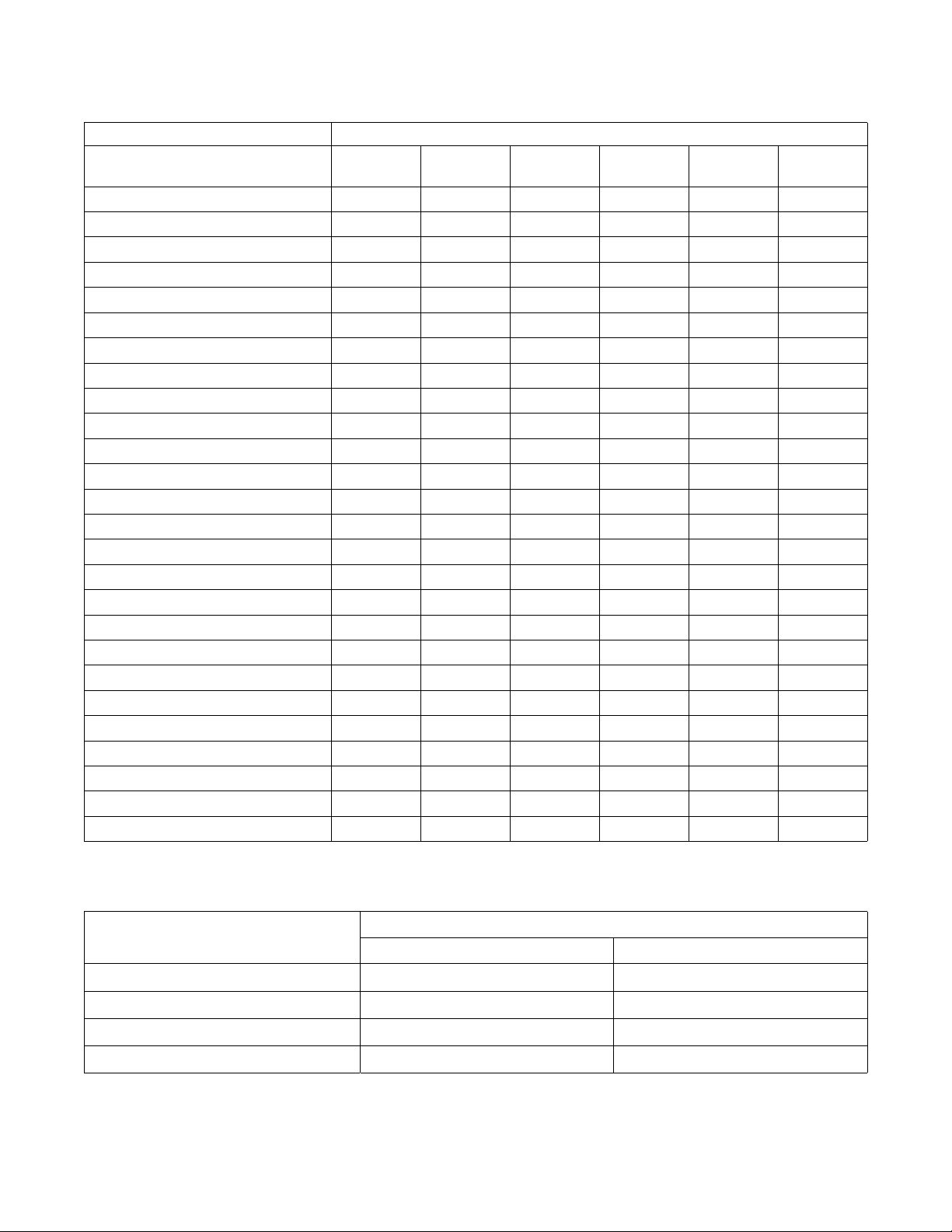

Vending

Heat Time Per Coin Pulse

(in minutes)

39

40

41

42 (preset at factory)

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Table 6 (continued)

Heat Switch Number

123456

OFF ON ON OFF OFF ON

ON ON ON OFF OFF ON

OFF OFF OFF ON OFF ON

ON OFF OFF ON OFF ON

OFF ON OFF ON OFF ON

ON ON OFF ON OFF ON

OFF OFF ON ON OFF ON

ON OFF ON ON OFF ON

OFF ON ON ON OFF ON

ON ON ON ON OFF ON

OFF OFF OFF OFF ON ON

ON OFF OFF OFF ON ON

OFF ON OFF OFF ON ON

ON ON OFF OFF ON ON

OFF OFF ON OFF ON ON

ON OFF ON OFF ON ON

OFF ON ON OFF ON ON

ON ON ON OFF ON ON

OFF OFF OFF ON ON ON

ON OFF OFF

OFF ON OFF ON ON ON

ON ON OFF ON ON ON

OFF OFF ON ON ON ON

ON OFF ON ON ON ON

OFF ON ON ON ON ON

ON ON ON ON ON ON

ON ON ON

Models Through Serial No. 0908

Cool Down Per Cycle Cool Down Switch Number

(in minutes)

3 (preset at factory)

4

5

6

Total Cycle Time = Heat Time + Cool Down Time

Table 6 (continued)

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

78

OFF OFF

ON OFF

OFF ON

ON ON

512686

Page 29

Models Starting Serial No. 0909

Vending

Table 6 (continued)

Cool Down Per Cycle

Cool Down

Switch Number

(in minutes)

3 (preset at factory)

6

OFF OFF

ON ON

Total Cycle Time = Heat Time + Cool Down Time

Test Setting

When testing coin slide operation or other

troubleshooting, set dipswitch with this shorter cycle:

1. Unplug the machine power cord.

2. Record the machine control dipswitch settings.

Then set them all to the off position. Refer to

Figure 25.

3. Plug in the machine and initiate a cycle.

Cycle Reset

Switch Number

78

Tab le 6

NOTE: With all the control dipswitches off, the

total cycle time will be four minutes long.

4. Once all the testing is complete, unplug the

machine and re-set the dipswitches to their

original settings.

5. Plug in the machine.

2345678

O

1

N

DRY2225P

DRY2225P

512686

Figure 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Vending

Slide Extension

(Coin Slide Models Only)

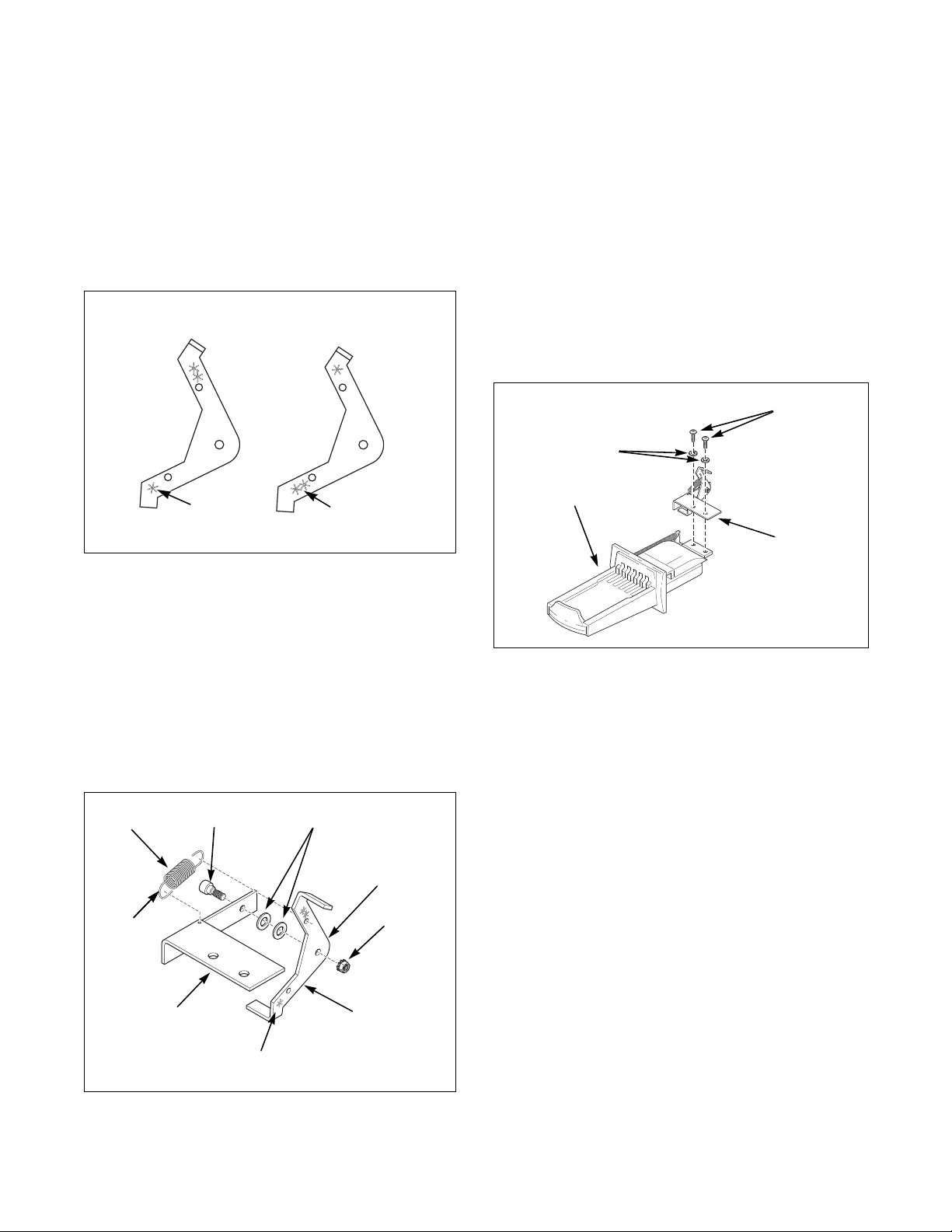

1. Remove slide extension parts from parts

accessories bag included in unit.

2. If installing a Greenwald coin slide, position

extension lever (to be installed on extension

bracket) with arm that has one star facing down.

Refer to Figure 26.

Greenwald

Coin Slide

One Star

Monarch or

ESD Coin Slide

Two Stars

5. Torque nut between 2 and 2.26 Nm (18 and 20

inch-pounds), or tighten nut firmly.

6. Install extension spring in bracket hole and hole

in upper arm of lever. Refer to Figure 27.

7. Bend loops closed after installation.

8. Check to make sure the lever swings freely.

Installing Extension Onto Coin Slide:

Option 1

1. Install slide extension onto top of coin slide using

two remaining screws and lockwashers. Refer to

Figure 28.

Attaching

Screws

Lockwashers

Coin Slide

Slide

Extension

TLW2088N

Figure 26

3. If installing a Monarch or ESD coin slide,

position lever with arm that has two stars facing

down. Refer to Figure 26.

4. Install extension lever with rounded corner

facing away from extension bracket using bolt,

one or two flat washers (shims) (use number of

washers included in kit) and nut. Refer to

Figure 27. Make sure washers are flat against

bracket.

Spring

Loops

Extension Bracket

Bolt

One or Two

Flat Washers (Shims)

Rounded Corner

Nut

Extension Lever

TLW2089N

TLW1564K

Figure 28

2. Insert coins and partially extend coin slide.

3. Insert coin slide on its side through meter case

opening. Then rotate 90 degrees to its proper

orientation.

4. Return coin slide and hook slide pins onto meter

case.

5. Continue coin slide installation according to

manufacturer’s instructions.

NOTE: During coin slide installation, make sure

activation lever is up and off the switch. Refer to

Figure 29.

28

Star(s) Facing Down

TLW2089N

Figure 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 31

Vending

1

TLW2090N

TLW2090N

1 Lever Off Switch

Figure 29

6. Check to make sure coin slide is operating

properly by inserting coins and starting a cycle.

The IN USE light will turn on, or flash if it is

already on, to indicate proper operation.

NOTE: To avoid long run-down time (45 minutes

factory default) when testing operation, refer to

Test Setting section.

Installing Extension Onto Coin Slide:

Option 2

1. Install coin slide according to manufacturer’s

instructions.

2. Insert coins into coin slide and slowly push slide

in. Stop before coins fall into coin box. This will

allow installing extension through meter case

service door opening.

3. Install slide extension onto top of coin slide using

two screws and lockwashers. Refer to Figure 28.

NOTE: Make sure extension lever is above switch

activation lever.

4. Check to make sure coin slide is operating

properly by inserting coins and starting a cycle.

The IN USE light will turn on, or flash if it is

already on, to indicate proper operation.

NOTE: To avoid long run-down time (45 minutes

factory default) when testing operation, refer to

Test Setting section.

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Operation

Operation Instructions for Coin

Slide Dryers

WARNING

To reduce the risk of fire, electric shock, or

injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS before operating

this appliance.

W727

IMPORTANT: Before using dryer for the first

time, use an all-purpose cleaner, or a detergent and

water solution, and a damp cloth to remove

shipping dust from inside of dryer drum.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Clean Lint Filter

Clean lint filter before each use.

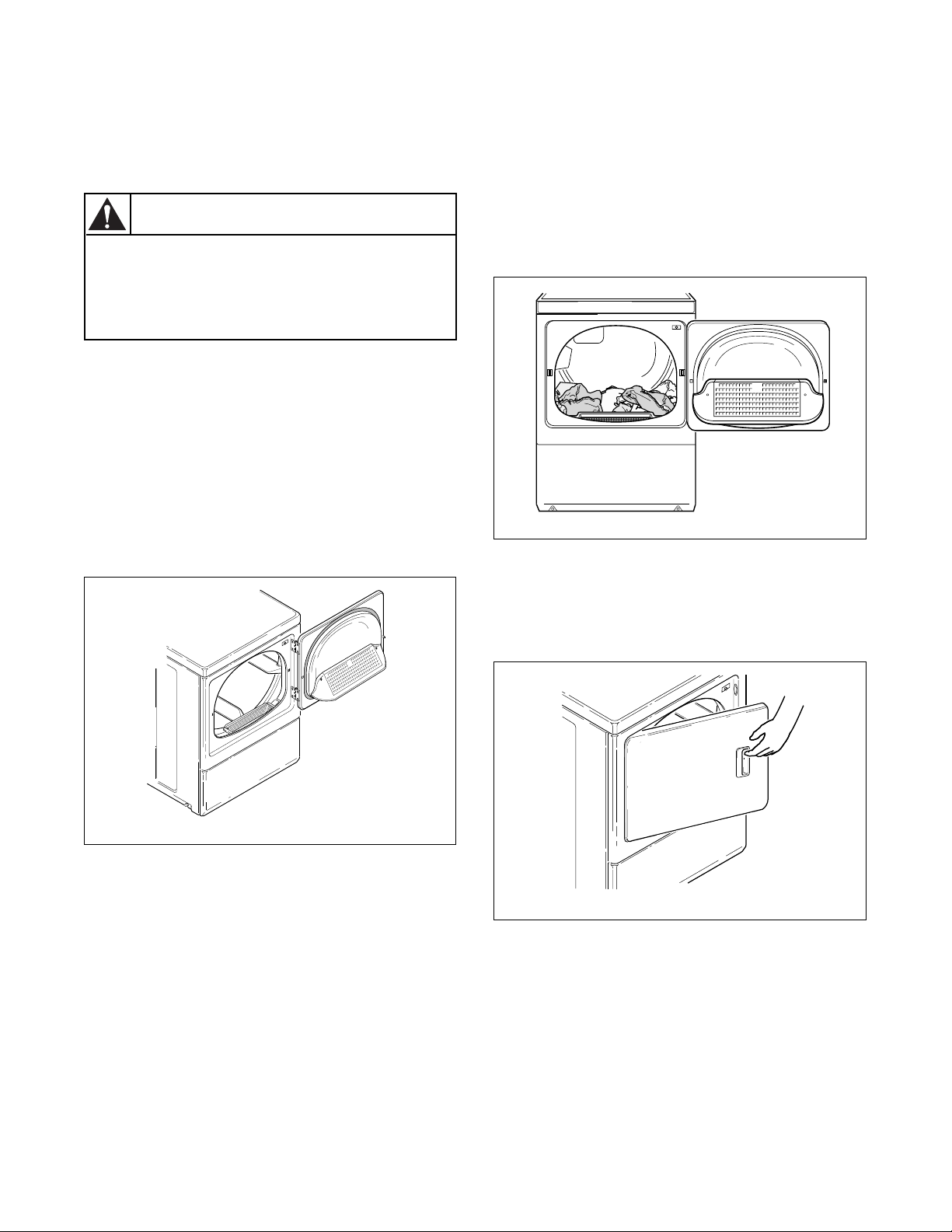

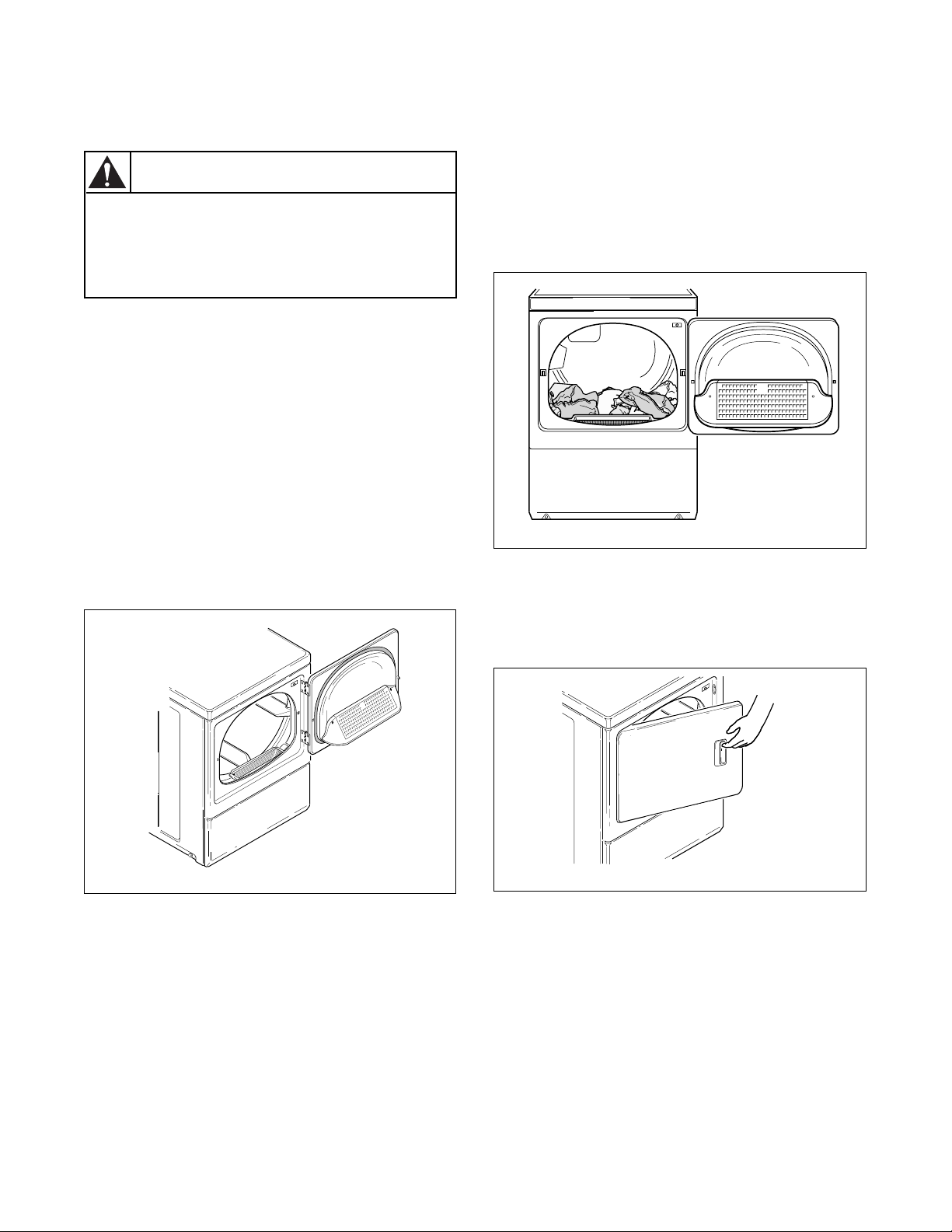

Step 2: Load Laundry

Load clothes loosely into dryer drum. Add fabric

softener sheet if desired.

IMPORTANT: To avoid damage to dryer, do not

use more than one fabric softener sheet per load.

D609I

D609I

Figure 31

Step 3: Close Loading Door

Figure 30

Close loading door. Dryer will not operate with the

door open.

D608I

D608I

D688I

D688I

Figure 32

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 512686

Page 33

Operation

Step 4: Determine Proper Dryer

The direction of the arrow indicates which dryer is

being used.

DRY2140N

Figure 33

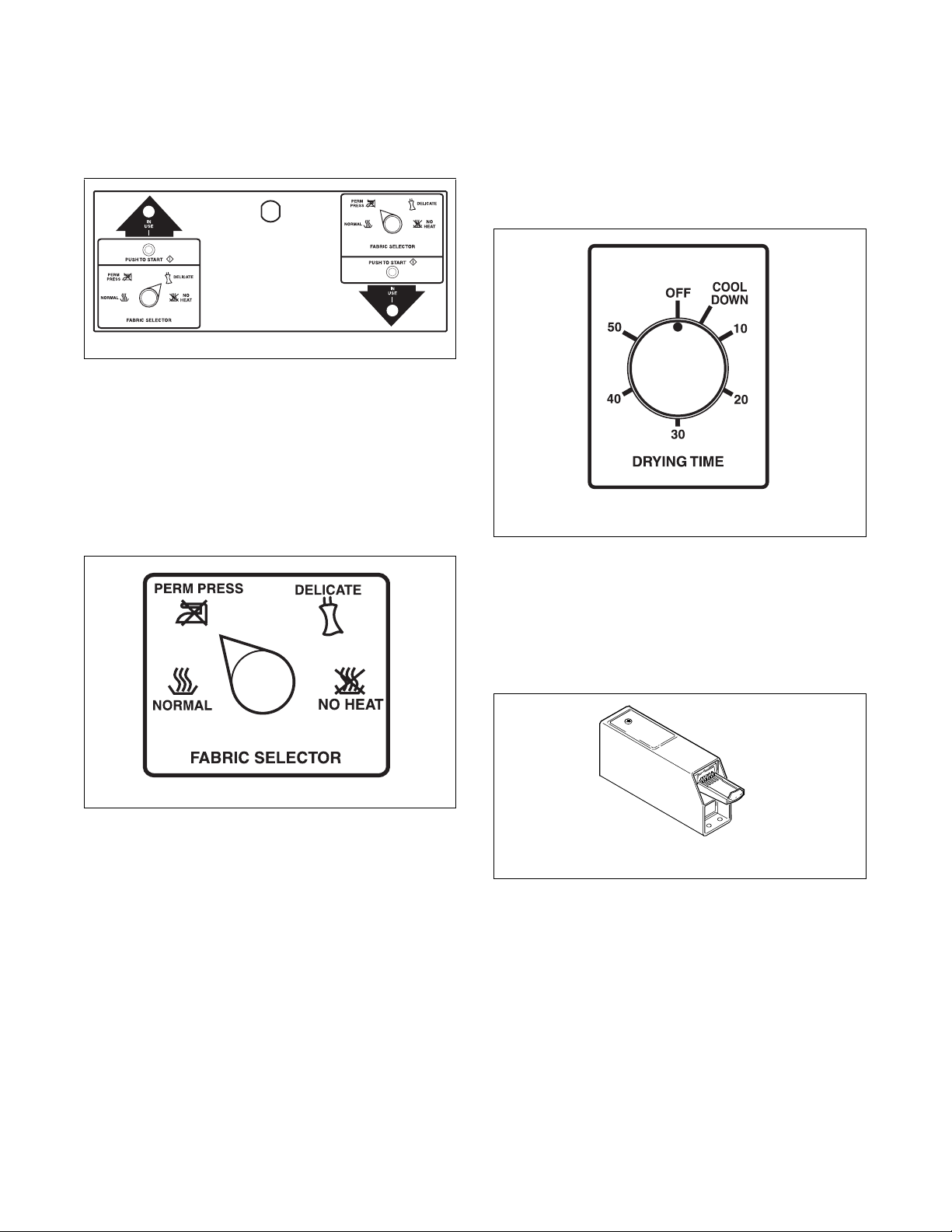

Step 5: Set Fabric Selector

Select NORMAL for cottons, PERM PRESS for

permanent press, DELICATE for sensitive items or

FLUFF (NO HEAT) for items that require no heat.

NOTE: Always follow manufacturer’s care label

instructions.

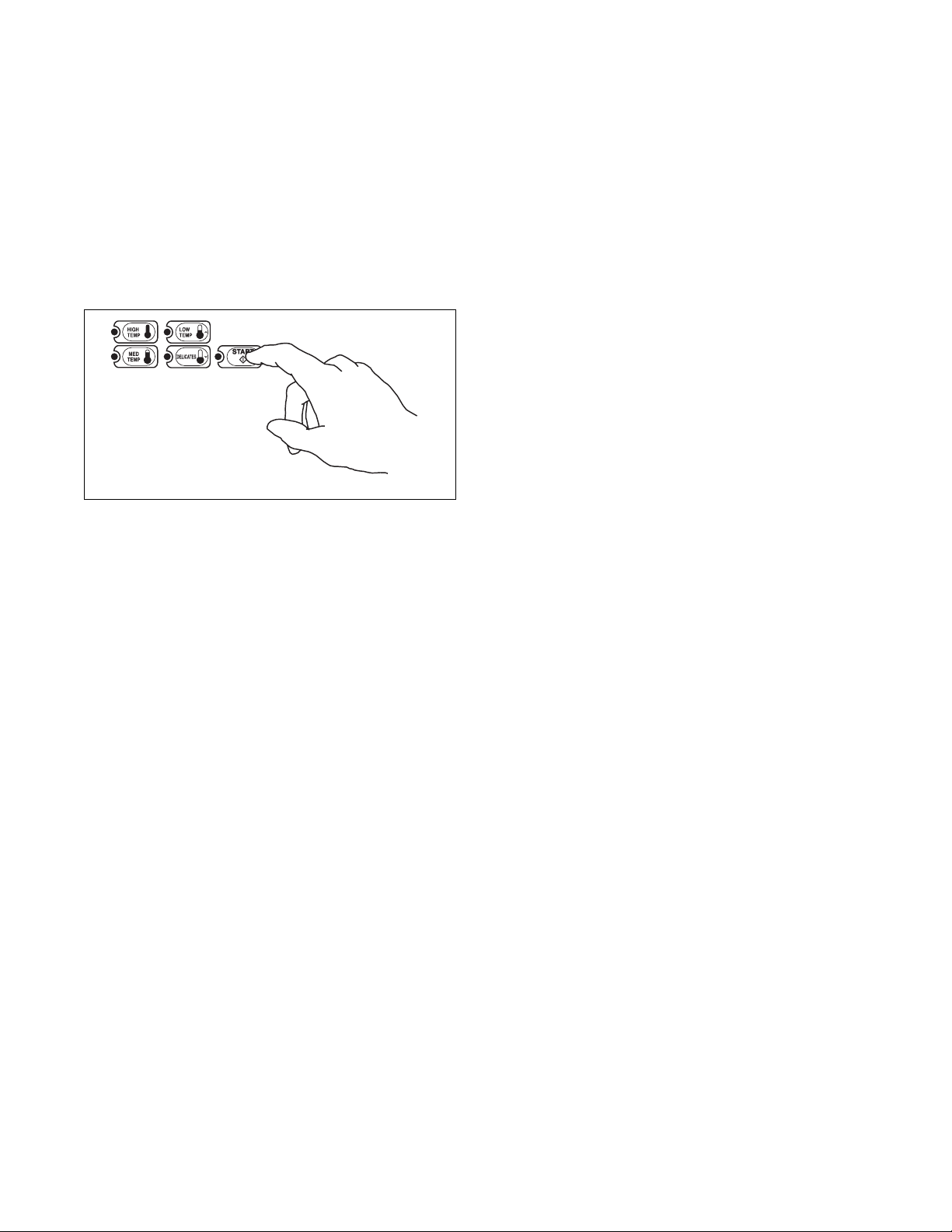

Step 6: Start Dryer

Nonmetered Models

Rotate timer knob to desired time setting (up to

60 minutes). Press the PUSH-TO-START button.

IN USE light will come on (indicating start of cycle).

NONMETERED MODELS

DRY2101N

Figure 35

Figure 34

DRY2100N

Coin Slide Models

Place coin(s) in slide and carefully push in as far as

possible and then pull slide out as far as possible. After

IN USE light comes on (indicating start of cycle),

press the PUSH-TO-START button.

METERED MODELS

Figure 36

Remove knits when slightly damp because overdrying

may cause shrinkage. Do not tumble dry knit woolens.

Should dryer stop before cycle is completed, the motor

overload protector may have cycled. Refer to

Maintenance section.

W297I

D363I

512686

NOTE: This machine includes an extended tumble

feature. Starting 20 minutes after a cycle ends, the

cylinder will tumble for two minutes every hour

without heat, up to 18 hours or until door is

opened.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Operation

Operation Instructions for MDC

Dryers

WARNING

To reduce the risk of fire, electric shock, or

injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS before operating

this appliance.

W727

IMPORTANT: Before using dryer for the first

time, use an all-purpose cleaner, or a detergent and

water solution, and a damp cloth to remove

shipping dust from inside of dryer drum.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Clean Lint Filter

Clean lint filter before each use.

Step 2: Load Laundry

Load clothes loosely into dryer drum. Add fabric

softener sheet if desired.

IMPORTANT: To avoid damage to dryer, do not

use more than one fabric softener sheet per load.

D609I

D609I

Figure 38

Step 3: Close Loading Door

Figure 37

Close loading door. Dryer will not operate with the

door open.

D608I

D608I

D688I

D688I

Figure 39

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 35

Operation

Step 4: Determine Proper Dryer

The direction of the arrow indicates which dryer is

being used.

DRY1929N

Figure 40

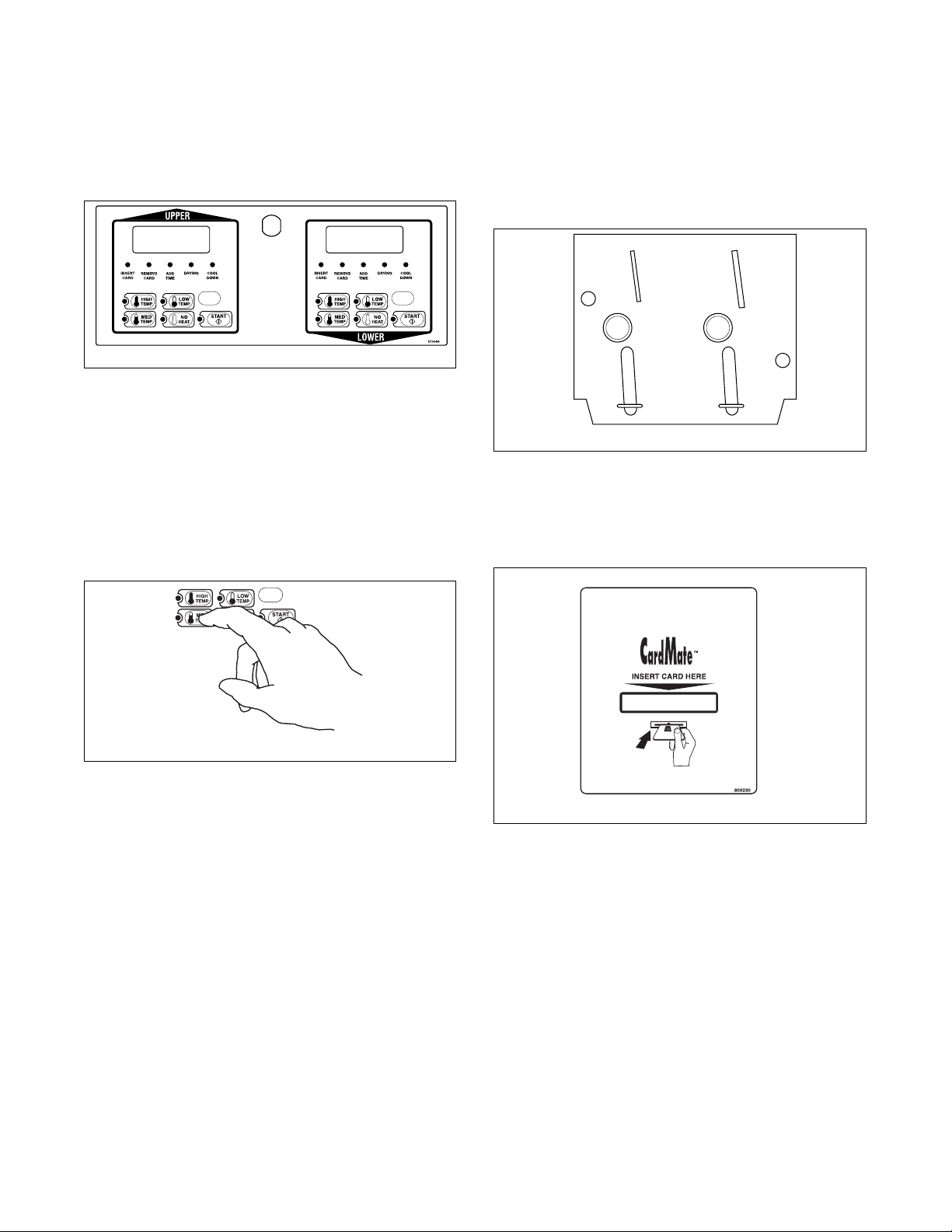

Step 5: Set Fabric Selector

Select HIGH TEMP, MED TEMP, LOW TEMP or

DELICATES by pushing touchpad.

NOTE: Always follow manufacturer’s care label

instructions.

Step 6: Insert Coin(s) or Card

To Insert Money

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

W388I

Figure 42

To Insert Card

Insert card into opening.

Figure 41

DRY1926N

DRY1926N

DRY1927N

Figure 43

If Additional Time Feature is turned on, additional

dryer time may be purchased at cycle start or while

dryer is running.

Remove knits when slightly damp because overdrying

may cause shrinkage. Do not tumble dry knit woolens.

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Operation

Step 7: Start Dryer

To start dryer, push START pad.

To stop dryer at any time, open the door. To restart the

dryer, close door and push START pad.

Cycle is completed when time remaining reaches

00 minutes.

DRY1928N

DRY1928N

Figure 44

Indicator Lights

START

START is lit whenever the dryer is not in a cycle, the

full vend price has been satisfied and the dryer door is

closed. When the START pad is pressed, the cycle

will begin or resume.

DRYING

DRYING is lit to indicate that one of the heated cycles

(HIGH TEMP, MED TEMP, LOW TEMP or

DELICATES) is currently in operation. DRYING will

turn off at the end of a heated cycle or when the COOL

DOWN cycle begins.

COOL DOWN

COOL DOWN is lit whenever the COOL DOWN

portion of a heated cycle is active. It is also lit when no

heat is programmed for a cycle in operation.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 37

Operation

Operation Instructions for

NetMaster Dryers

WARNING

To reduce the risk of fire, electric shock, or

injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS before operating

this appliance.

W727

IMPORTANT: Before using dryer for the first

time, use an all-purpose cleaner, or a detergent and

water solution, and a damp cloth to remove

shipping dust from inside of dryer drum.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Clean Lint Filter

Clean lint filter before each use.

Step 2: Load Laundry

Load clothes loosely into dryer drum. Add fabric

softener sheet if desired.

IMPORTANT: To avoid damage to dryer, do not

use more then one fabric softener sheet per load.

D609I

D609I

Figure 46

Figure 45

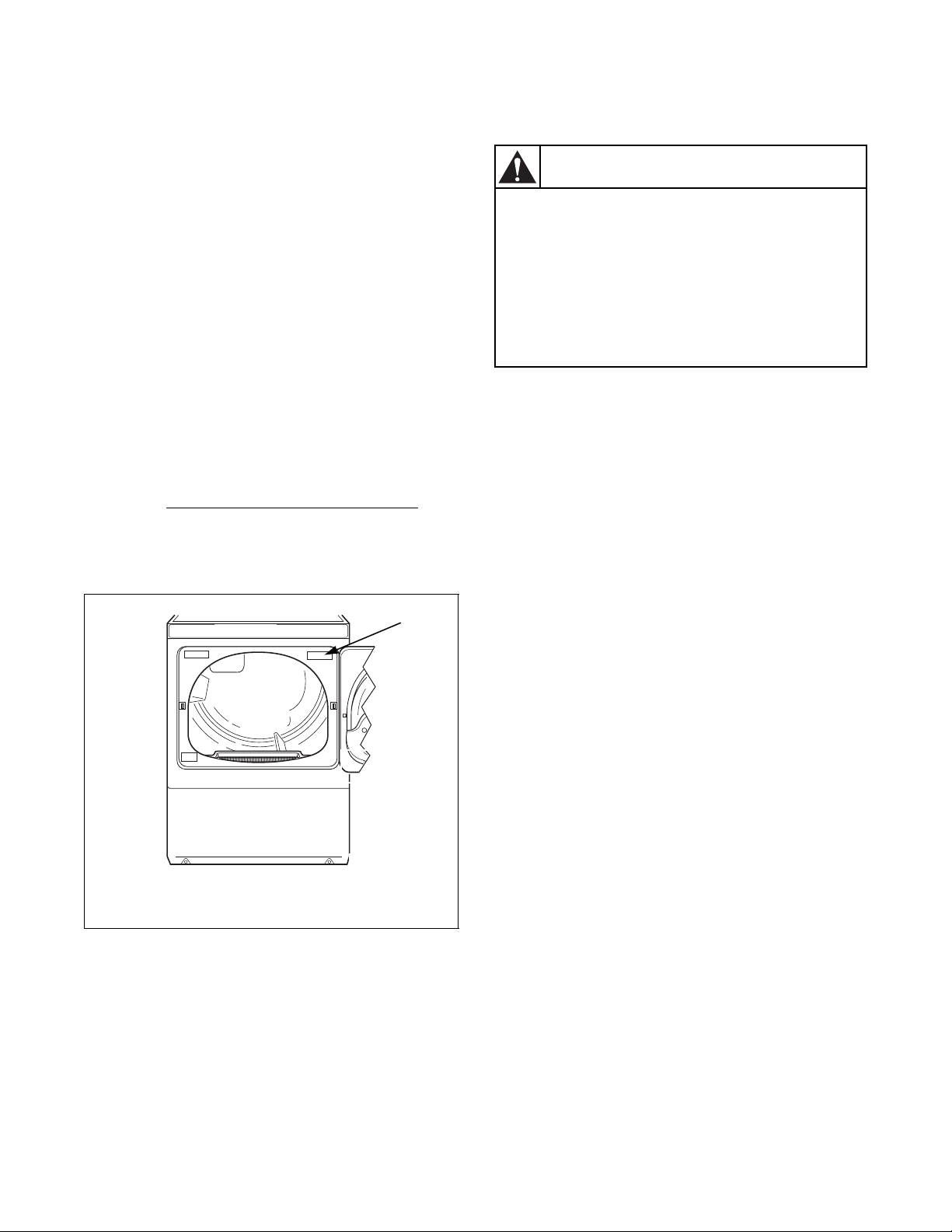

Step 3: Close Loading Door

Close loading door. Dryer will not operate with the

door open.

D608I

D608I

D688I

D688I

Figure 47

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Operation

Step 4: Determine Proper Dryer

The direction of the arrow indicates which dryer is

being used.

D779I

Figure 48

Step 5: Set Fabric Selector

Select HIGH TEMP, MED TEMP, LOW TEMP or

NO HEAT by pushing touchpad.

NOTE: Always follow manufacturer’s care label

instructions.

To Insert Card

Insert card into opening. Do not remove the card until

the REMOVE CARD LED is lit.

M343I

Figure 51

If Additional Time Feature is turned on, additional

dryer time may be purchased at cycle start or while

dryer is running.

Remove knits when slightly damp because overdrying

may cause shrinkage. Do not tumble dry knit woolens.

D777I

Figure 49

Step 6: Insert Coin(s) or Card

To Insert Money

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

Step 7: Start Dryer

To start dryer, push START pad.

To stop dryer at any time, open the door. To restart the

dryer, close door and push START pad.

Cycle is completed when time remaining reaches

00 minutes.

D778I

Figure 52

36

W388I

Figure 50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

512686

Page 39

Operation

Indicator Lights

INSERT COINS/CARD

INSERT COINS/CARD is lit to prompt the user to

insert coins or a card to satisfy the vend price. When

INSERT COINS/CARD is lit, the three digits and

decimal point will display the vend price remaining to

be satisfied.

START

START is lit whenever the dryer is not in a cycle, the

full vend price has been satisfied and the dryer door is

closed. When the START pad is pressed, the cycle

will begin or resume.

DRYING

DRYING is lit to indicate that one of the heated cycles

(HIGH TEMP, MED TEMP, or LOW TEMP) is

currently in operation. DRYING will turn off at the end

of a heated cycle or when the COOL DOWN cycle

begins.

COOL DOWN

COOL DOWN is lit whenever the COOL DOWN

portion of a heated cycle is active. It is also lit when

the NO HEAT cycle is in operation.

ADD TIME (Card Models Only)

ADD TIME flashes when a card is inserted while a

cycle is running or when a card is left in the reader for

at least five seconds after cycle has started.

REMOVE CARD (Card Models Only)

REMOVE CARD flashes when a card is inserted or left

in the reader after a transaction is complete. It will also

flash alternately with ADD TIME when a card is

inserted while a cycle is running or when a card is left

in the reader.

512686

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Maintenance

Lubrication

All moving parts are sealed in a permanent supply of

lubricant or are equipped with oilless bearings.

Additional lubrication will not be necessary.

Care of Your Dryer

WARNING

To reduce the risk of an electric shock,

serious injury or death, disconnect the

electrical service to the dryer before

cleaning the interior.

W132

Dryer Interior

Wipe the surfaces using a soft cloth and household

cleaner or a non-abrasive paste of powdered laundry

detergent and hot water, followed by a short heat cycle

with a load of rags.

To remove crayon or ball point ink off the dryer drum,

put the heat on high and use old rags in the dryer to

absorb the crayon or ink. If unsuccessful, contact the

appliance dealer. DO NOT use any chemicals in the

dryer.

Exhaust System

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the

dryer before cleaning.

W043

The exhaust duct should be inspected after one year of

use and cleaned if necessary by a qualified service

person to remove any lint build-up. Inspect and clean

exhaust duct every one to two years as required

thereafter.

The weather hood should be checked frequently to

make sure the dampers move freely, dampers are not

pushed in and that nothing has been set against them.

Keep dryer area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

Do not obstruct the flow of combustion and ventilation

air.

NOTE: Verify proper operation after servicing.

IMPORTANT: The use of chlorine bleach for

removing any discolorations should be avoided

because bleach could damage the finish.

Cabinet

Wipe the dryer cabinet as needed. If detergent, bleach

or other washing products have been spilled on the

dryer, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Control Panel

Use only a damp or sudsy cloth for cleaning the

control panel. Some spray pretreat products may harm

the finish on the control panel.

NOTE: The wiring diagram is located inside the

control panel.

WARNING

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation.

W049

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 512686

Page 41

Maintenance

Lint Filter

CLEAN THE LINT FILTER BEFORE DRYING