Page 1

Cylinder ironer

CI 1650/325

CI 2050/325

Technical specifications

Installation instructions

Operating instructions

Maintenance

Instruction manual

Part No. D1273

Code: B12340801

September 2010

Page 2

Page 3

Contents

Safety Information ..........................................................................................4

1

Explanation of Safety Messages ...................................................................4

Safety notice .................................................................................................. 6

2

3

4

5

6

7

Important Safety Instructions ......................................................................... 7

Product description ........................................................................................ 9

Intended use .................................................................................................. 9

Description of structural components ..........................................................10

Workplaces and noise level ......................................................................... 11

Technical data CI1650/325, CI2050/325 ..................................................... 12

Warranty and service instructions ................................................................ 14

Initial setup of the machine .........................................................................15

Transport and machine fastening ................................................................ 15

Setting up the machine ................................................................................ 16

Basic checks ................................................................................................ 22

Operation ....................................................................................................... 24

Operating devices and their position ...........................................................24

Starting the machine .................................................................................... 25

Functions ..................................................................................................... 26

Failure and information signals .................................................................... 28

Machine function, adjustment and troubleshooting .................................32

Description of machine functions ................................................................. 32

Adjustments of the machine ........................................................................37

Troubleshooting ........................................................................................... 42

Description of the control system ...............................................................44

General description of the control system ...................................................44

Control panel and function keys ..................................................................46

Menu structure and how to enter ................................................................. 47

"Manu" adjusting menu ................................................................................ 49

"Coin" adjusting menu .................................................................................50

Technical menu ............................................................................................52

Display menu ............................................................................................... 55

Central panel ............................................................................................... 55

Sigma explorer ............................................................................................55

Maintenance .................................................................................................. 56

Safety advice ............................................................................................... 56

Maintenance scheme ..................................................................................56

Contents

Page 4

Safety Information

Explanation of Safety Messages

Throughout this manual and on machine decals, you will nd precautionary statements (“DANGER”, “WARNING” and

“CAUTION”) followed by specic instructions. These precautions are intended for the personal safety of the operator,

user, servicer, and those maintaining the machine.

Indicates an imminently hazardous situation that, if not

avoided, will cause severe personal injury or death.

Indicates a hazardous situation that, if not avoided, could

cause severe personal injury or death.

1

DANGER

WARNING

CAUTION

Indicates a hazardous situation that, if not avoided, may

cause minor or moderate personal injury or property

damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specic instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specic procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing

information that is important but not hazard related.

4

Page 5

Safety signs and labels are also placed on the unit. Those signs and labels are limited messages.

Where needed, further explanations are provided below. These signs are to be inspected for readability and

replaced when missing, damaged, or unreadable. Refer to the Maintenance section of this manual for the

periodic maintenance schedule. Refer to the parts manual for ordering information.

WARNING

Electric hazard inside.

Can cause death or serious injury.

Turn off and lock out/tag out all electric power

before opening.

1

WARNING

Moving parts hazard.

Can cause serious injury.

Do not operate unless all guards and covers are

in place.

Do not put hands/ngers beyond guard/cover.

WARNING

Burn hazards.

Contact with machine components or hot goods

can burn you.

Do not operate unless all guards are in place.

Use care when handling recently processed or

dried goods.

5

Page 6

WARNING

Failure to install, maintain, and/or operate this machine according to the manufacturer's

instructions may result in conditions which can produce serious injury, death, and/or

property damage.

Do not repair or replace any part of the machine or attempt any servicing unless specically

recommended or published in this Installation/Operation Manual and that you are qualied

to carry out.

Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded and to reduce the risk of re,

electric shock, serious injury, or death.

WARNING

Toxic and re hazards.

Machine produces gases, fumes and lint which may be toxic or catch

re and could result in serious injury or death.

Vent exhaust outdoors and regularly clean lint away from machine.

1

WARNING

Burn and crash hazards.

Push red nger guard bar daily to test. If ironer does not stop,

do not use.

Turn off and lock out/tag out all power until repaired.

Safety notice

CAUTION: Note for installation

The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the NATIONAL ELECTRICAL CODE, ANSI/NFPA 70, or Canadian Electrical Code, CSA C22.1.

The installation must comply with local codes or, in the absence of local codes, with the current National Fuel Gas Code,

ANSI Z22.1, or the current CAN/CSA B149, Installation Codes.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing the equipment shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

There must be provisions for adequate combustion and ventilation air, clearance around air openings and accessibility

clearances for servicing and operation.

6

Page 7

1

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of re, electric shock, serious injury or

death to persons when using your cylinder ironer, read

and follow these basic precautions:

1. Read all instructions before using the ironer.

2. Refer to the Grounding Instructions for the proper grounding of the ironer.

3. Do not iron articles that have been previously cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other ammable or explosive substances as they give off vapors

that could ignite or explode.

4. Do not allow children to play on or around the ironer. Close supervision of children is necessary when

the ironer is used near children. This is a safety rule for all appliances.

5. Check the operation of the safety nger guard at the beginning of every shift. Operating the safety

guard should stop the ironer immediately. If this safety feature is not working properly, employees must

shut off the ironer and notify the supervisor. Do not operate the ironer until the safety nger guard is

repaired and working properly. Be sure that all other safety features, including guards and panels, are

in place before operating the ironer.

6. Never service the ironer while it is running. Never reach over, under, or behind the safety nger guard

or into any area near hot surfaces or moving parts without rst shutting off the ironer at the switch and

power source. Follow this rule whenever working on the ironer to avoid serious injury from the ironer's

heat and/or pressure.

7. Never try to remove, adjust, or straighten jammed or misfed linen while the ironer is running.

Attempting to clear the jammed linen item can result in the user being caught in the linen and pulled

into the ironer. If something is jammed in the ironer, turn off the power before attempting to correct the

problem. Avoid contact with heated parts.

8. Protect yourself and fellow workers by making sure that everyone follows all the rules. Read and follow

all safety labels and warnings. Learn all aspects of the equipment such as what is hot, which parts

move, all safety shutoffs, and all emergency procedures. Do not come close to moving or heated

parts. Do not wear loose clothing, sweaters, jewelry or neck ties when near the ironer.

9. Frequent scheduled safety meetings are a must to review and update rules. If anyone is observed

breaking the rules, the supervisor or manager should be notied immediately. Reporting people for

rule breaking could save their lives or limbs.

10. Emergency shutoffs such as nger bars and emergency stop switches, should be painted red and

clearly labeled.

11. Maintenance personnel should work in a buddy system for mutual protection when working on a

ironer.

12. If in doubt, don't. Do not do anything until the supervisor or service-maintenance department has been

contacted. Only qualied personnel should service the ironer.

13. Do not install or store the ironer where it will be exposed to water and/or weather.

14. Do not tamper with the controls.

15. Do not repair or replace any part of the ironer, or attempt any servicing unless specically

recommended in this installation/operation manual.

16. To reduce the risk of re, DO NOT IRON plastics or articles containing foam rubber or similarly

textured rubber-like materials.

17. Keep area around the exhaust opening and adjacent surrounding area free from the accumulation of

lint, dust, and dirt.

18. The interior of the ironer and the exhaust duct should be cleaned periodically by qualied service

personnel.

7

Page 8

1

19. If not installed, operated, and maintained in accordance with the manufacturer's instructions or if

there is damage to or mishandling of this product's components, use of this product could expose

you to substances in the fuel or from fuel combustion which can cause death or serious illness and

which are known to the State of California to cause cancer, birth defects, or other reproductive harm.

20. Do not put articles soiled with vegetable or cooking oil in the ironer, as these oils may not be

removed during washing. Due to the remaining oil, the fabric may catch on re by itself.

21. To reduce the risk of re, DO NOT put articles which have traces of any ammable substances such

as machine oil, ammable chemicals, thinner, etc., or anything containing wax or chemicals such as

in mops and cleaning cloths, or anything dry-cleaned at home with dry-cleaning solvent in the ironer.

22. ALWAYS disconnect the electrical power to the ironer before servicing. Disconnect power by shutting

off appropriate breaker of use.

23. Install this ironer according to the Installation Instructions in this manual.

All connections for electrical power, grounding, and gas supply must comply with local codes and be

made by licensed personnel when required.

WARNING

To prevent serious injury or death, read ironer

manuals before installing, operating, maintaining,

or cleaning the ironer.

8

Page 9

Product description

2

Intended use

The machine, described in this manual is solely intended to use it for ironing of

sheets, small pieces of linen, pillowcases, table linen and other at linen.

It is not suitable for garments or other thick linen.

WARNING

Any other use of the machine may involve risks to persons

and must therefore only take place after previously

obtained written approval from the manufacturer.

Equipment and components on the machine, which are important to safety and

health, have been constructed in preparation for an expected life of 15,000 operating

hours - however max. 10 years from the time of manufacture.

WARNING

The correct function of such equipment and components

within this period implies that the prescribed maintenance

is carried out.

Normally the ironed pieces are coming into the outlet tray after ironing, where the

operator can take them without any danger.

WARNING

It may involve risk of burning to the operator when taking

the sheets directly from the roll, deeper into the machine

at the outlet tray. Jams should always be taken away by

authorized personnel.

The normal, permanent working places of the operating personnel (operator) have

been marked on the layout.

WARNING

It may involve risk to the operator to work on or under

the machine. Work Stay in these areas is only allowed for

authorized personnel, and only when the machine has been

stopped, cooled down and the main switch has been locked

in position "0".

Important

This manual is a part of the delivered machine volume, and is to be handed

over to the new owner if the machine is sold.

If any doubt should occur about the contents in the manuals in your local

language, which you should have received at the time the machine was rst

installed, it will always be the English text, which is valid.

9

Page 10

Description of structural components

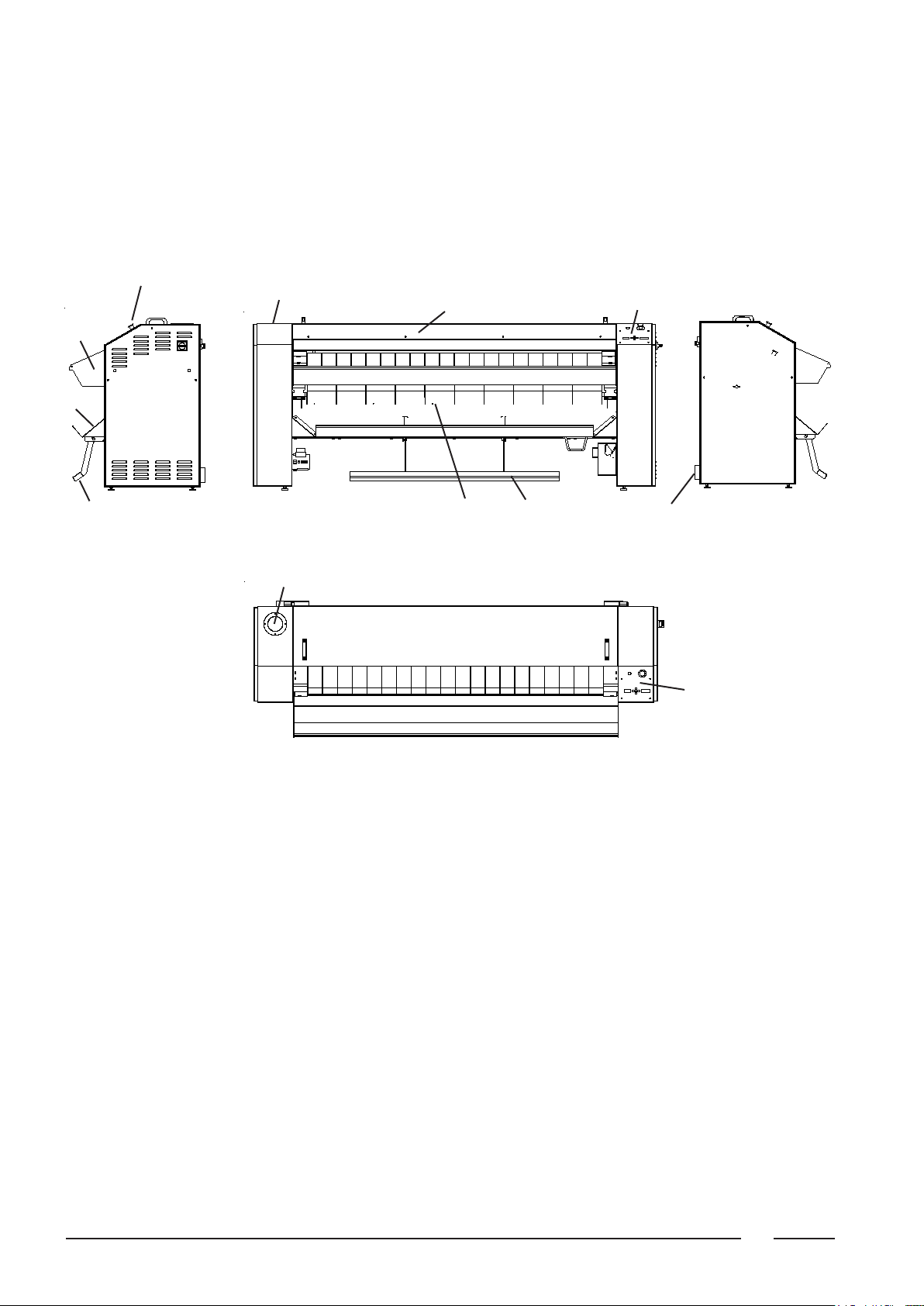

This machine is delivered in various types adjusted to the needs of the individual

laundry. The principal components of the machine are the following:

2

2

5

4

6

7

7

3

4

6

1

7

1

1. Operation panel

2. Emergency stop

3. Input conveyor

4. Outlet tray

5. Tray for wet linen

6. Foot stop (option)

7. Exhaust pipe (top or back / option)

Further information about the construction of this machine will appear from the

"Techical data" paragraph in the manual.

10

Page 11

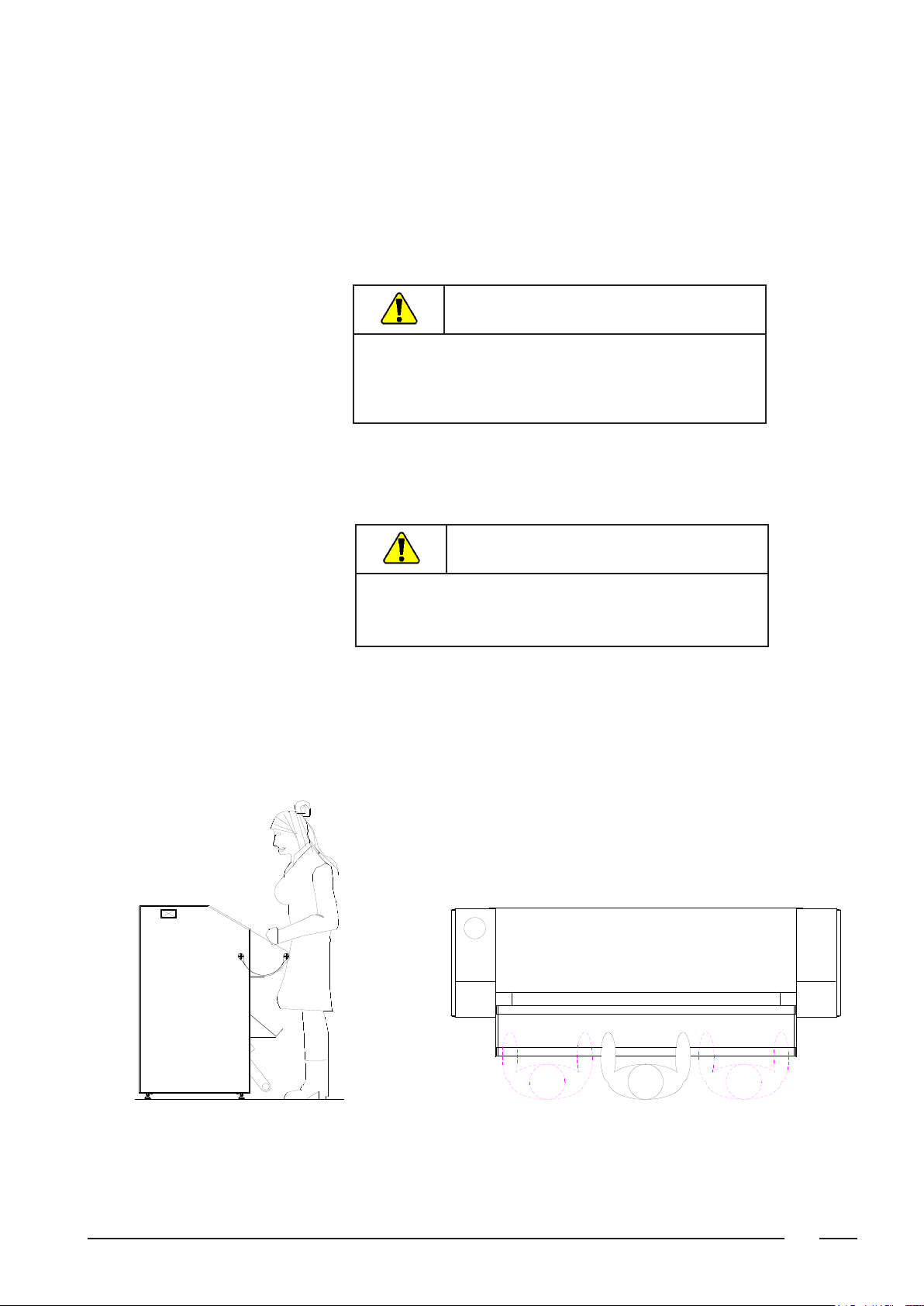

Workplaces and noise level

2

The construction and appearance of the machine are illustrated on the layout below.

On the layout, the operators’ workplaces during normal operation are indicated by the

human gures, which are sketched in.

WARNING

It may involve risk to the operator to work on or under

the machine. Work Stay in these areas is only allowed for

authorized personnel, and only when the machine has been

stopped, cooled down and the main switch has been locked

in position "0".

Normally the ironed pieces are coming into the outlet tray after ironing, where the

operator can take them without any danger.

WARNING

It may involve risk of burning to the operator when taking

the sheets directly from the roll, deeper into the machine

at the outlet tray. Jams should always be taken away by

authorized personnel.

The sound pressure levels of the machine have been measured at a height of 1.6 m

at the indicated workplaces of the operator. The value for the workplace is 60dB.

side view

top view

11

Page 12

Technical data CI1650/325, CI2050/325

Roller

Diameter 323 mm 323 mm

Length 1740 mm 2140 mm

Working width 1600 mm 2000 mm

Dimensions

Height 1140 mm 1140 mm

Width 2328 mm 2728 mm

Depth (excl. feeding bag) 886 (650) mm 886 (650) mm

Net weight

Gas-heated 625 kg 710 kg

Electrical heated 665 kg 760 kg

Electrical connection

Electric 400V 3p + 0 50Hz 35A 35A

Electric 230V 3p + 0 50Hz 50A 65A

Gas 230V 1p + 0 50Hz 10A 10A

Gas 120V 1p + 60Hz 10A 10A

Other connections

Gas 1/2"

Motor drive main roll 0.18 kW

Motor ventilator 0.13 kW

Adjustable speed 1.4 -> 6 m/min.

Airow ventilator 570m³/h

Exhaust Ø 100 mm

Use of power

Electrical heated 18 kW 22.5 kW

Gas-heated 28 kW 35 kW

Electric consumption of gas-

heated ironer

Electric consumption of electrical

ironer

Capacity linen (percentage of moisture 50%)

Electrical 33 Kg/h 42 Kg/h

Gas 42.5 Kg/h 53.5 Kg/h

Ambient conditions

Permitted max. ambient temperature +40°C

Permitted max. relative moisture

of the atmosphere

2

1650/325 2050/325

0.6 kW 0.6 kW

18.6 kW 23.1 kW

85%

12

Page 13

Sound level measurement

Measuring points

The measuring points are dened as workplaces on the machine in question during normal operation.

Measuring method

The measuring result is an average of a measurement for 60 seconds, measured on the actual machine or on a

corresponding machine. The measuring result will appear as a LpA value. The result will have an uncertainty of ± 2 dB.

The LpA value is the reference workplace emission.

Measuring conditions

During the measurements, the machine will be equipped with legs or transport wheels and be located on a concrete oor.

Measuring equipment

The measurements are carried out with a noise meter approved for DIN IEC 651 Class 3.

2

Conversion table

Length: 1 m = 1,000 mm = 3.2808 ft = 39.3701 in

Weight: 1 kg = 1,000 g = 2.2046 lb

Area: 1 m² = 10.7639 ft² = 1.550 . 10³ in²

Volume: 1 m³ = 1,000 l = 35.3145 ft³ = 60.976 . 10³ in³

Temperature: °C = 0.556 . (°F - 32)

(0 °C = 32.0 °F)

Force: 1 N = 0.2248 lbf

Pressure: 1 Pa = 0.145 . 10-3 psi

1 bar = 14.50 psi

Tension, mechanical: 1 N/mm² = 106 Pa = 145.0 lbf/in²

Energy, mechanical: 1 J = 947.8 . 10-6 Btu

Energy, electrical: 1 kWh = 3.412 . 10³ Btu

Effect: 1 kW = 3413 Btu/h = 1.341 hp

Momentum: 1 Nm = 737.1 . 10-3 lb-ft

13

Page 14

Warranty and service instructions

The manufacturer undertakes to replace defective parts resulting from faulty design, materials or

workmanship for a period not exceeding 12 months from contractual delivery time, or max. 2,500

operating hours. The warranty is only valid if the product is correctly installed and maintained in

accordance with the manufacturer's instruction and common practice. No warranty claim can be made

as a result of inappropriate operation, improper use, and use of force.

The manufacturer's warranty does not include damage that is due to insufcient maintenance, changes

or repair made without the written consent of the manufacturer, normal wear or defects due to war,

strike, lockout, and other force majeure or political conditions, which the manufacturer cannot control.

The same applies to damage to products, which are not supplied by the manufacturer or a construction

ordered by the buyer.

Wearing parts such as transport belts, drive belts or similar are not included in the warranty.

The manufacturer is not liable for production losses due to machine malfunctions.

Faulty parts will be replaced by the manufacturer upon receipt of the faulty components.

Transport costs to the manufacturer and back to the buyer, transport insurance and installation costs

are for the buyer's account.

2

14

Page 15

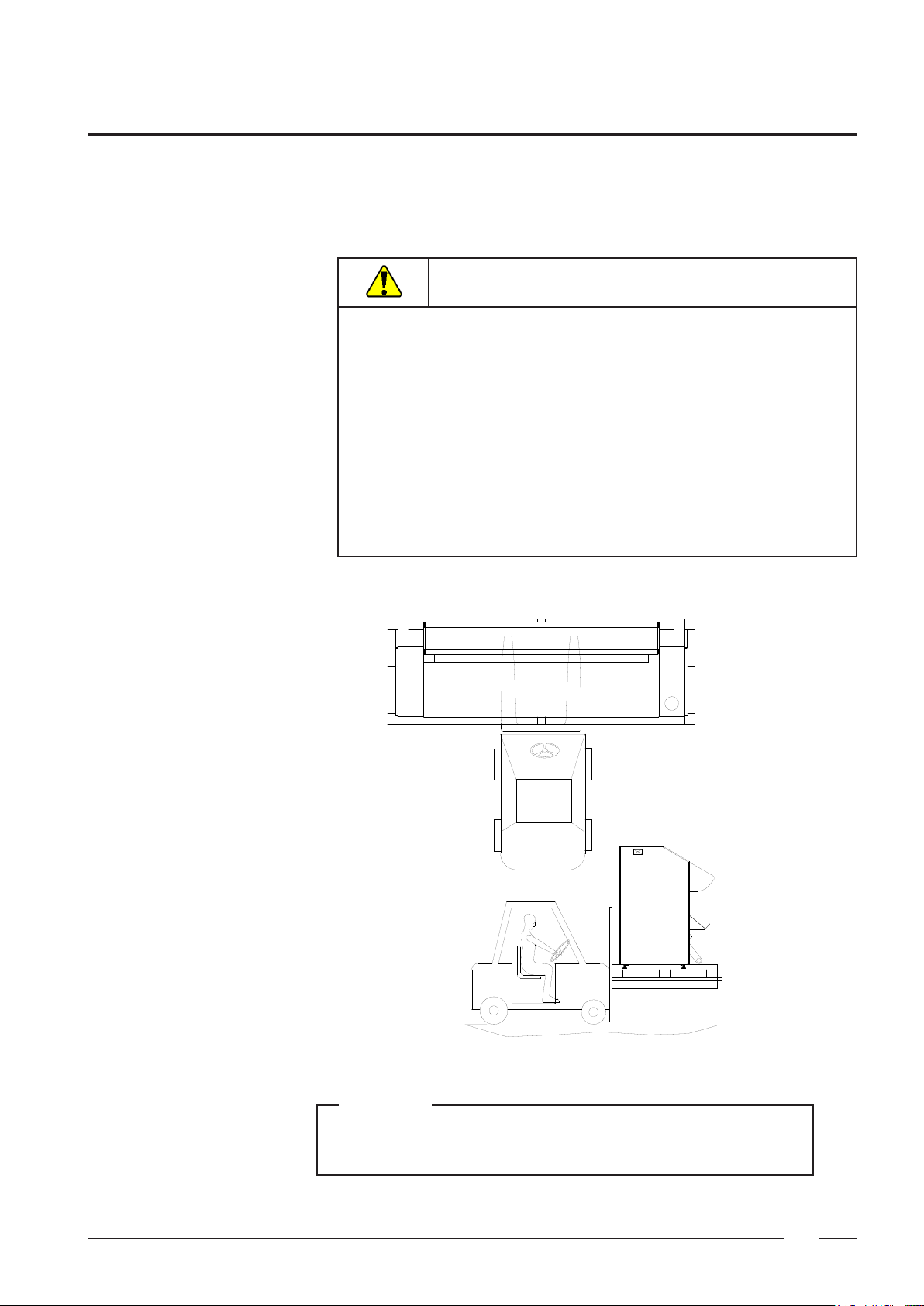

Initial setup of the machine

Transport and machine

fastening

The machine has been secured with bolts on a solid wooden frame and has been

safely packed in plastic sheeting from the factory.

During all transport and handling of the machine, there is a risk of the

machine tipping over or falling over onto persons. In order to avoid

accidents, the following should therefore be observed:

During transport and handling with a fork-lift truck, the forks should be

situated proportional to the center of gravity as shown below and on the

packing of the machine.

Never use lifting and hoisting material with a too small lifting capacity.

See paragraph 'Technical data' concerning the weight of the machine.

The max. weight of the machine including packing is stated on the packing

of the machine.

Never move the machine on inclined or uneven surfaces.

3

WARNING / DANGER

Important

We recommend to let the wooden frame remain bolted for the use of

transport with fork-lift truck, until the machine is near the place of setting up.

15

Page 16

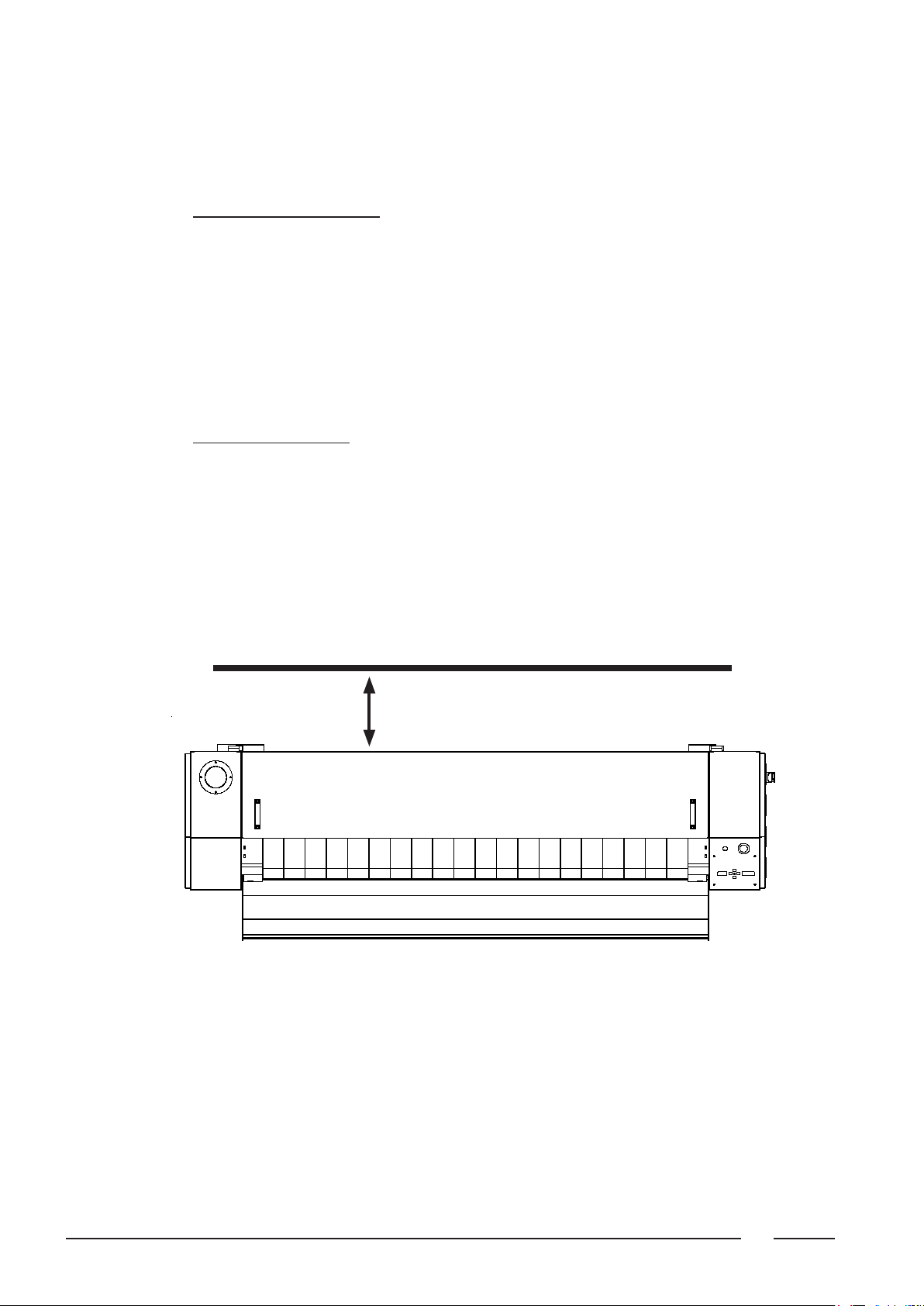

Setting up the machine

Preparation of the machine

- Inspect the machine by delivery on any damage.

- The machine can be moved by a manual pallet lifter.

- Remove the packing carefully and remove the parts on top of the machine.

- Place the machine on its nal position. Keep in mind that the sides of the

machine have to be free of any surroundings of at least 1 meter.

- The back must be at least 30 cm from the wall because of the turning cover.

Mechanical installation

- The machine has to be level. To check this, use a spirit level.

- The machine can be levelled by adjusting the four bolts under the machine.

Loosen the lock nuts, adjust the four bolts so the machine is level and fasten

the lock nuts.

3

/ / / / / / / / / / / / / / / / / / / / / / / / / /

30 cm

16

Page 17

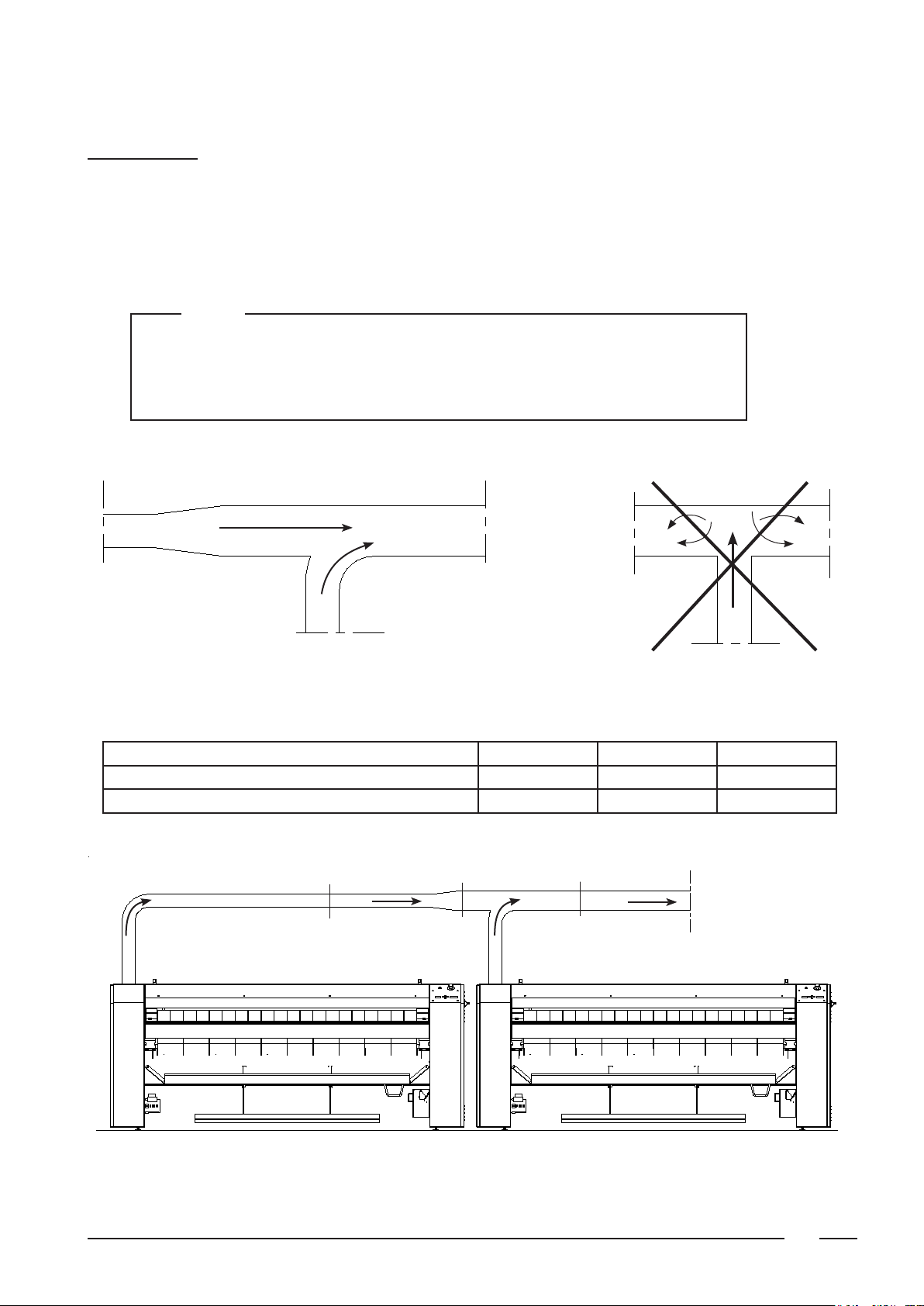

Exhaust system

Whenever possible, install the ironer along an outside wall where duct length can be kept to a minimum, and

make-up air can be easily accessed. The construction must not block the airow at the rear of the ironer.

Doing so would prevent adequate air supply to the ironer combustion.

For maximum efciency, ironer air must be exhausted to the outdoors by the shortest possible route.

Note

Never connect an ironer duct at a 90° angle to the collector dust (see picture below).

Doing so will cause excessive back pressure, resulting in poor performance.

Never connect two ironer exhaust ducts directly across from each other at the point of

entry to the collector dust.

3

Number of ironers D1 D2 D3

Diameter of the exhaust pipe (in mm) 100 150 225

Ventilation aperture required section (in dm²) 0,8 1,8 4

D1

D2

D2

1 2

17

Page 18

3

In order to ensure a satisfactory function of the machine exhaust system, the subsequent pipe system that is

installed in the laundry, should as minimum be dimensioned according to the following guidelines. If the pressure

loss in the piping system is increased as a result of dimensioning faults, this will cause a reduction of the exhaust

and thus the machine capacity.

In case of short distances between the ironer and the outlet to the outside, i.e. less than 15m including allowance

for bends, the exhaust pipe can be made as a channel with diameter 125mm for all machine types.

In case of longer distances, we recommend to use a larger pipe diameter. When judging the exhaust channel,

see the following tables that deal with pressure loss and the dynamic pressure by different pipe dimensions and

also deal with the equivalent pipe lengths for different part elements in an exhaust channel.

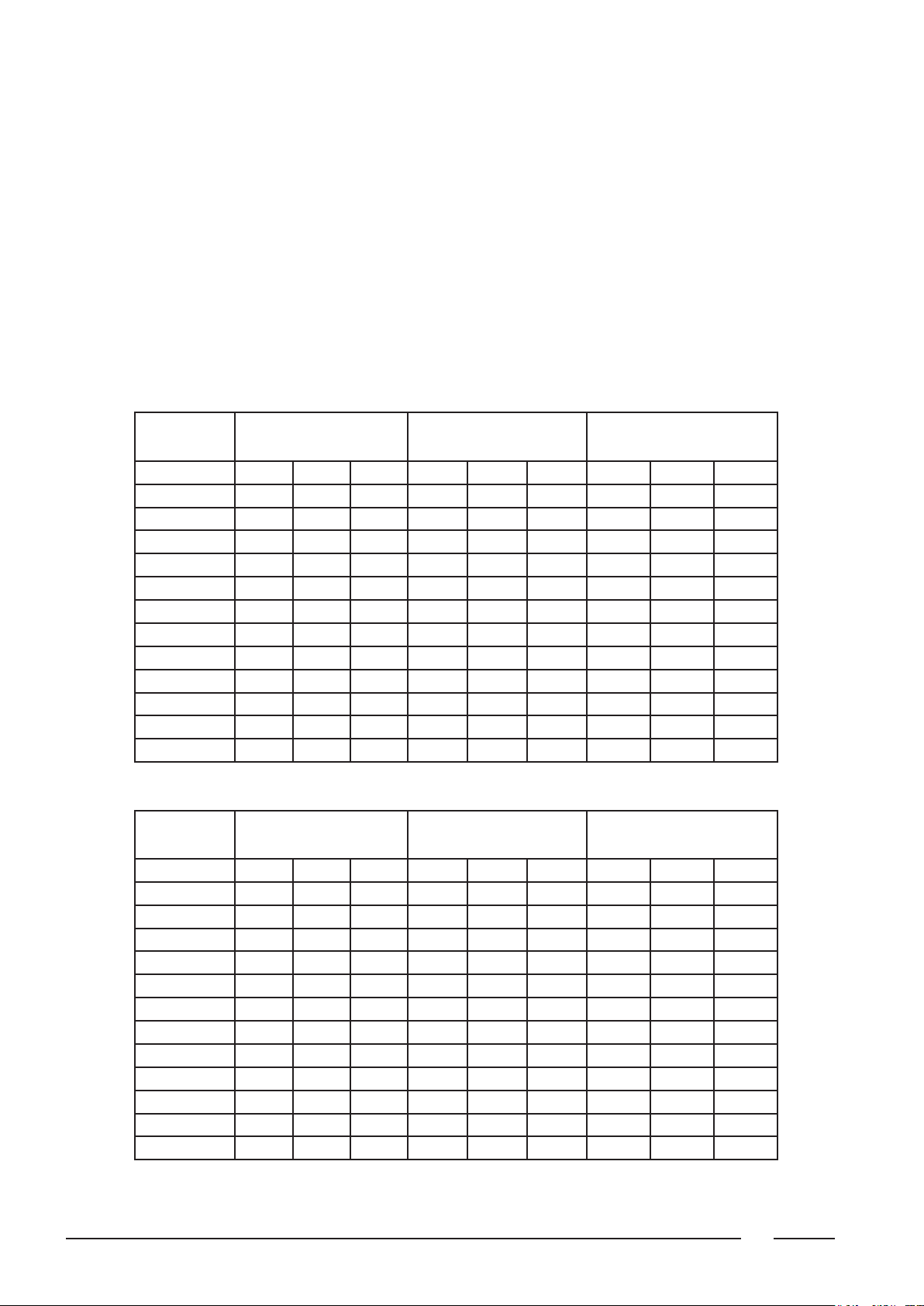

Dynamic pressure (Pd) in [Pa] and specic pressure loss (∆p) in [Pa/m] dependent on volume ow in m³/h and

pipe diameter (dia) in mm. S is the speed in m/s.

Diameter

Volume

m³/hour Pa Pa m/s Pa Pa m/s Pa Pa m/s

250 47 14 8,8 19 4 5,7 9 2 3,9

350 93 26 12,4 38 8 7,9 18 3 5,5

450 153 42 15,9 63 13 10,2 30 5 7,1

550 229 62 19,5 94 19 12,4 45 7 8,6

650 320 85 23,0 131 26 14,7 63 10 10,2

750 426 112 26,5 174 34 17,0 84 13 11,8

850 547 143 30,1 224 44 19,2 108 17 13,4

950 683 178 33,6 280 54 21,5 135 21 14,9

1050 834 217 37,1 342 66 23,8 165 25 16,5

1150 1001 259 40,7 410 79 26,0 198 30 18,1

1250 1182 305 44,2 484 92 28,3 234 35 19,6

1350 1379 355 47,7 565 107 30,6 272 41 21,2

Diameter

Volume

m³/hour Pa Pa m/s Pa Pa m/s Pa Pa m/s

250 7 1 3,5 5 1 2,7 3 0 2,2

350 14 2 4,8 9 1 3,8 6 1 3,1

450 23 4 6,2 15 2 4,9 10 1 4,0

550 35 5 7,6 22 3 6,0 14 2 4,9

650 49 7 9,0 30 4 7,1 20 2 5,7

750 65 10 10,4 41 5 8,2 27 3 6,6

850 83 12 11,7 52 7 9,3 34 4 7,5

950 104 15 13,1 65 8 10,4 43 5 8,4

1050 127 18 14,5 79 10 11,5 52 6 9,3

1150 153 22 15,9 95 12 12,6 63 7 10,2

1250 180 25 17,3 113 14 13,6 74 8 11,1

1350 210 29 18,7 131 16 14,7 86 9 11,9

Pd ∆p S

Pd ∆p S

100

160

125

Pd ∆p S

180

Pd ∆p S

150

Pd ∆p S

200

Pd ∆p S

18

Page 19

Equivalent pipe length in m for selected single resistances :

Right-angled corner : 13.4

90 degrees smooth bend R/D = 2 : 2.1

90 degrees angular bend R/D = 2 (three sections) : 2.6

90 degrees angular bend R/D = 2 (ve sections) : 2.1

In general, we recommend that the pressure loss in the exhaust pipe is kept as low as possible.

If more machines are to be connected to the same exhaust channel, it is necessary to contact a ventilating rm that can

advise you with regard to the correct dimensioning of the exhaust channel.

The pressure loss in the exhaust channel can be calculated in the following way :

Pchannel = Pd + Iength channel x ∆p

If Pchannel > 300 Pa, we recommend to increase the pipe dimension.

For this purpose, a prefabricated transfer piece is to be used.

To avoid noise, we advise to keep the maximum velocity in the pipe under 12 m/sec.

3

19

Page 20

Electrical installation

The customer must install a circuit breaker for each machine.

Compare the type of network and its voltage with the data mentioned on the machine and pay attention

to the instructions. For the connection, regulations according to VDE 0100 as well as the local valid

regulations of the energy providing premises are to be taken into consideration.

It is very important to have the electric connections done by a qualied technician, in order to make sure

that the installation is effected in accordance with the prevailing standards and instructions and the valid

instructions where the machine is to be installed.

Make sure that the voltage, which is to be connected, corresponds to the voltage mentioned on the

indication plate of the ironer inside the righthanded frame. The selected network connection cannot

be less powerful than the H07RNF according to the VDE 0282 and should have a minimum diameter,

which corresponds to the nominal electric power mentioned on the ironer.

Each machine must have a main switch. With this main switch, it is possible to cut the electrical

equipment from the mains, also by persons who have not been trained in the eld of electrotechnics.

This is necessary for cleaning, maintenance and reparation activities, both for the machine itself and for

the corresponding electrical equipment. In the guidance from the feeding to the electrical equipment, the

main switch is always behind the proper mains connection.

3

The main switch can also be applied in the supply guidance separately. It needs to be placed very close

to the machine so that there cannot be misunderstandings that the switch belongs to the machine.

When there are two or more main switches, there may not exist a dangerous situation when not all

the main switches are disconnected at the same time. For each main switch, there must be a warning,

which says that there is more than one feeding. If the main switches are placed far from each other

(not usual and not recommended), a supply will have to be made which separates the main switches by

disconnecting one of them. The control of this supply is in fact a safety-related control which applies

EN 954-1. In practice, the supply will often be executed in category 1 (EN 954-1) with bipolar contacts.

Overview circuit breakers and wire section feeding cable per machine

Circuit breaker size Cable section Fuse

CI325 gas 25A 1,5mm² 16A

CI325 elec 3x230V 80A 16mm² 63A

CI325 elec 3x400V 63A 6mm² 40A

20

Page 21

Gas tube installation

- It is important to have the connections performed by an authorized mechanic in order

to be sure that the installation corresponds to the current rules and guidelines of the

country where the ironer will be installed.

- The gas supply pipe must be tted with a stop valve, which is easily to reach.

- The ironer must be connected to the type of gas, which is stated on the apparatus.

The inlet gas pressure must correspond to the specication on the type plate, as well.

- Using a gas pipe that is too small can lead to insufcient gas supply, which results in a

poor heating and a poor ironing result.

WARNING

Test all clutches and connections for possible

leaks by means of a soap solution. NEVER by

means of a ame.

3

Gas supply DN16

(1/2" BSP)

- The customer must install a lter and a manual stop valve on the supply side of the machine.

- Gas installation and connection must be done by qualied personnel only.

21

Page 22

Basic checks

3

Important

The rst start-up of the machine should only be performed by an authorized

service engineer or a distributor.

In special cases, it may be allowed that the rst start-up is performed by the

customer, but only after thorough instruction.

WARNING

If the rst start-up is performed on one's own

initiative, this may cause damage to persons,

things, or environment.

- Check if all safety guards with interlocking device are closed, and that all emergency stop devices

have been deactivated.

- Start the machine.

All machines have been tested and adjusted from the factory. However, factors such as temperatures,

moisture of the atmosphere etc. may imply that an adjustment is necessary at the set-up place.

Ventilation of the room

The machine is tted with a ventilator. This ventilator ensures vaporized moisture, and with a gasheated ironer the ue gases, being exhausted.

It is important that the room, in which the ironer has been installed, is sufciently ventilated. You have

to take the universal rules for laundry environments into account together with the fact that the ironer

exhausts 350 m³/h. It is also important that sufcient fresh air can enter the room.

Check this before you start the machine!

22

Page 23

3

Air lters

Before operating the machine, the air lter(s) must be checked.

By removing the right door, you can check if the lter on the venturi of the gas valve is not blocked by

something.

Important

Do not cover this lter at any time!

Exhaust gases

The exhaust gases of a gas-heated ironer must be inspected by an authorized mechanic.

The gas burner needs to be adjusted at prevailing rules, gas sort and gas pressure.

The measured exhaust gases may not be higher than the current rules.

Check the exhaust pipe on leaks and repair this, if so.

23

Page 24

Operation

Operating devices and their position

The machine is equipped with the following operating devices:

4

1: Emergency stop button

2: Gas failure reset button

3: Start/stop button

4: “+” Button

5: “-“ Button

6: Return button

7: Left display (temperature)

8: Right display (speed)

When the power is switched to the machine by the main switch, then “ ” and the program version will

appear for 5 seconds.

Then the left display will give the actual temperature (in °C or °F) and the right display will give the actual

speed (in M/min or ft/min).

24

Page 25

Starting the machine

4

After switching the power to the machine, the display will show:

After 2 seconds:

After 5 seconds:

X.XX

The ironer starts running and the heating is activated.

The small dot in the left display shows that the heating power is activated.

If the small dot is blinking, only 1 set of elements is activated (only electrical heated ironers).

X.XX = number software version

25

Page 26

Functions

4

Set the iron temperature

The left display shows the previous setting of the temperature in a blinking mode when the - button is

pressed.

Now the setting is changeable by pushing the - or + button. Once the setting is done, press the return

button to conrm.

Set the ironing speed

The right display shows the previous setting of the speed in a blinking mode when the + button is

pressed.

Now the setting is changeable by pushing the + or - button. Once the setting is done, press the return

button to conrm.

Pedal

The pedal can be used to spread out the linen.

The feeding and ironing belts stop turning while this pedal is being stepped on and the display will show

during 30 seconds:

WARNING

Do not use this pedal more and longer than necessary to

avoid damage of the linen by overheating. The machine

gives an acoustical signal after some seconds to warn.

Finger protection panel

For safety reasons, the feeding and ironing belts stop turning if the nger protection panel is pushed

backwards. The buzzer is activated and on the display will appear:

Important

This panel may also be pushed back due to accumulation or multiple folding

of linen, as a result of which the machine also stops and the same warning is

coming on the display. Take the linen away and reset the emergency circuit

and start the machine again.

26

Page 27

Return button (not with guiding ribbons)

In case a piece is xated inside the ironer, it is possible to let the feeding belts and the main roll with

the belts turn backwards by pressing the return button continuously. It is necessary to pull the

linen tightly backwards when doing so. After having released this button, press the start button again,

otherwise the ironing process will be ended.

WARNING

Do not use this button when the linen has already

completely disappeared from the feeding belts into the

ironer. This could cause a jam inside the ironer and damage

the linen and/or the ironer.

Ironing

4

Now it is possible to start ironing as the temperature is high enough.

Put the linen as at as possible on the feeding belts in order to avoid creasing.

The linen will be carried on into the ironer by the feeding belts.

Always spread open the linen by hand as at as possible and make sure that it does not get stuck

anywhere.

Ending

The ironing process is stopped by pressing the start button.

The heating is switched off. However, in order not to get overheated, the feeding* and ironing belts,

as well as the fan keep running until the cooldown temperature has been reached.

(*) With a coin ironer, the feeding belts are not running.

The speed and “ ” are alternately displayed on the right display during this cooldown period.

After the cooldown temperature is reached, the drive and the ventilator are switched off.

27

Page 28

Failure and information signals

If the procedure described here does not rectify

the operational failure, the technical personnel of

the laundry should be called in.

Activate hand protection

4

WARNING

The foot pedal is pressed

There is a failure in the gas control (with a gas-heated ironer)

There is a failure in the relays for the heating elements

Important

When this signal is coming, press the reset button in case of a gas-heated

ironer (see drawing p. 15). If this problem continues, an engineer must be

consulted.

28

Page 29

There is an overheat problem (more than 190° detected).

There is a short circuit in the temperature sensor 1.

There is a broken wire in the temperature sensor 1.

There is an overheat problem (more than 190° detected).

There is a short circuit in the temperature sensor 2.

There is a broken wire in the temperature sensor 2.

4

Cool down situation

The foot pedal is pressed and there is an overheat situation.

Important

The foot pedal has to be released as soon as possible. It is possible that

linen in the ironer or the belts of the ironer will be damaged by burning if the

machine is not quick started up again.

After 30 seconds, the roll will start again automatically.

29

Page 30

The pressure switch is not activated (ventilator is not running or too much counterpressure in

exhaust pipe).

The pressure switch is activated when the ventilator is not active (pressure switch is damaged

or bypassed).

4

Important

An engineer must check the working of the switch and replace it in case of

malfunction.

The speed sensor is not giving signals and the motor is activated (speed sensor is damaged

or motor is not running).

Important

The foot pedal has to be released as soon as possible to prevent that linen in

the ironer will be damaged by burning.

30

Page 31

4

The heating elements are switched off but the relay stays on (contacts of the relay are burnt together).

WARNING

The relays have to be replaced to prevent

overheating of the ironer and damage to linen

and ironer.

31

Page 32

Machine function, adjustment and troubleshooting

Description of machine functions

General description of machine function

The ironer is intended to iron and dry sheets and towels. This happens by means of a heated roller,

across which the sheet is transported. The roller heats the sheet, which evaporates the residual moisture

in the sheet. After that, the sheet leaves the machine where a plate collects the sheet.

The sheet can now be taken away.

Feeding sheets and towels

The sheets have to be laid on the feeding belts in a level way. The sheet is taken into the machine

because of the running belts.

If the sheet does not cover the entire width of the feeding belts, you have to feed the sheet at the right

or left side alternately. This improves the effective function of the machine and prevents the ironing roller

from locally becoming too hot.

5

If a sheet that is too thick or creased, is fed, the plate above the feeding belts will be pressed in. This will

stop the machine in order to prevent the machine from being jammed. The sheet has to be laid properly

before you can start the machine with the start button. If this is not possible, you let the machine run

backwards so that the sheet comes out of the machine. This can be done by means of the control or with

the optional handle.

WARNING

A sheet being too long in the machine can burn.

Firmly deal with this matter and remove the sheet

in time.

32

Page 33

5

Operating the foot pedal (option)

The machine is equipped with a foot pedal (see picture below). This foot pedal is located in the middle of

the machine between the two side frames underneath the outlet plate.

The foot pedal is used for feeding sheets in an easy way.

By pressing down the foot pedal when the machine is running, the machine will stop during 30 seconds.

In this way, you can easily and properly lay down the sheet on the feeding belts.

After releasing the foot pedal, the machine will start to run again.

33

Page 34

5

Setting the temperature

The ironing temperature of the machine can be set on the control panel. Standard, this can vary between

130 and 175°C and is adjustable per degree. The range of the temperature setting can be changed in the

technical menu of the machine. This is shown on the left window of the control panel (see 7 on the picture

below).

Advice

At the rst start up of the ironer, set the ironing

temperature to max. 160°C. When start ironing,

increase the temperature to the desired level.

The temperature can be changed as follows:

Press the “–“ key (5) to enter the temperature

window (7). With the “+” (4) and “–“ (5) key, you can

set the temperature. Press the ↓ key (6) to leave

the menu.

WARNING

Always watch the temperature setting when

different sorts of textile are being processed.

The temperature may not be too high, otherwise

the textile could catch re.

Important

If you have set a new temperature that is lower than the actual ironing

roller temperature of the machine, you have to take into account that it may

take some time before the ironing roller has cooled down to the lower (set)

temperature.

34

Page 35

5

Setting the speed

The speed of the ironing roller is shown on the right display (8) of the control panel.

The speed of the ironing roller can be set on the control panel. This can vary between 1.4 m/min and

6 m/min and is adjustable per 0.1 m/min. The range of the speed setting can be changed in the technical

menu of the machine.

The speed can be changed as follows:

Press the “+“ key (4) to enter the speed

window (8). With the “+” (4) and “–“ (5) key,

you can set the speed.

Press the ↓ key (6) to leave the menu.

The speed has to be set in combination with the temperature. The speed is set correctly if the sheet

leaves the machine dry and the heating device is able to remain the wanted temperature.

Take into account that it takes some time for the heating control to create a stable working point of the

machine.

35

Page 36

5

Manual drive

The machine can be driven by means of the optional manual drive with manpower. This can be useful

after a voltage drop. If, during the voltage drop, a sheet is in the machine, it could catch re. If you use

the manual drive in this case, it is possible to let the sheet come out of the machine.

If the manual drive has to be used, you need the handle, which can be found at the front machine beam

underneath the collecting plate (see 1 on the picture below).

This handle can be coupled to the motor of the machine by turning the lid (3) to the left so that a hole

becomes visible. Put the handle in this hole and turn the handle in such a way that it meshes in the bush,

which is behind the lid.

The handle is now in position 2. You can now drive the machine by turning the handle either forward or

backward.

The machine can be started with the emergency unlocking button and the start button (if it’s live again) by

closing the lid (3) (turn to the right).

Put the handle back in its original position (1), so you can always nd it when you need it.

36

Page 37

Adjustments of the machine

Guiding ironing belts

The ironing belts are guided by plates on a beam, which is placed between the ironing belts.

On the outlet side, a beam, which has a xed position, guides these ironing belts

(see 1 on the picture below).

There is also a beam on the back side of the machine (see 2 on the picture below).

If the guiding of the ironing belts is not adjusted correctly, it will effect the life of the ironing belts in a

negative way. If the ironing belts have been dismounted/replaced, you have to recheck the guiding of

the ironing belts. Beam 2 can be reached if you remove the plating on the rear side of the machine.

5

37

Page 38

5

Tightening the drive chain

A chain drives the machine. In the course of time, this chain will extend. It is important that the chain’s

tension is checked every month. You can check the chain’s tension by moving the left part of the chain,

at half-height, to the left and the right.

The total motion of freedom of the chain may horizontally not be more than 30mm. If it is more than

30mm, you have to tighten the chain. This can be done by slackening the four bolts B (see B on the

picture below) a few turns. By doing so, the motor becomes loose and it will move downwards.

If the motor is not moving downwards by itself, you can do this by hand. After that, screw the four bolts B

again. Check the chain tension once again. Repeat the procedure, if necessary.

Never tighten the chain too much.

WARNING

Only do this when the machine has been

stopped, cooled down and the main switch has

been locked in position "0".

38

Page 39

5

Tightening the ironing belts

The ironing belts ensure the contact of the sheet with the ironing roller. These ironing belts will extend and

will become thinner in course of time. Therefore, it is important to tighten the ironing belts in time, in order

to remain the ironing effectivity of the machine.

The ironing belts are tensioned by means of springs. There is a spring on each side of the machine

(see S on the picture below).

A bolt with a nut is fastened to this spring. The position of the nut on the bolt determines the spring

force of the tensioner. The further you screw the nut on the bolt, the tauter the spring is pulled. It is

important that the spring remains tensioned permanently. This means that the nut may not come loose

from the clamping plate while the machine is running. Check the spring tension each month and adjust if

necessary.

39

Page 40

5

1) Tightening the feeding belts

The feeding belts transport the sheet into the machine. The feeding belts are driven by the feeding roller.

If the contact of the feeding belts with this feeding roller is unsatisfactory, the belts will slip, which results

in a poor sheet transport. In this case, it is necessary to tighten the feeding belts.

WARNING

Only do this when the machine has been

stopped, cooled down and the main switch has

been locked in position "0".

In order to tighten the feeding belts, you rst have to unscrew a number of bolts.

First loosen the bolt B1 one turn (1x on the left side and 1x on the right side of the machine) (see B1 on

the following page). Then loosen the bolts B2 one turn (2x on the left side and 2x on the right side of the

machine) (see B2 on the following page). Attention: the back bolts B2 are situated underneath the hand

protection plate. These bolts can be reached by means of a wrench.

Now the feeding bed is loose, you have to tighten the back part of the feeding bridge. Do this by

tightening the hexagon socket screws, using a socket head wrench with wrench width 6 (see T on the

following page), until the belts are tightened sufciently.

These screws (see H_S on the following page) are each situated behind a cover plate and they are

accessible through a hole at the front of the stainless steel cover plate above the feeding roller, at the left

and right of the machine.

ATTENTION

The cover plates do not have to be removed in

order to be able to tighten the feeding belts.

After the belts have been tightened, you rst have to tighten bolts B2, then bolts B1.

40

Page 41

2) Adjusting the gap between input table and main roll

The gap between main roll and input table can be adjusted by pins coming out from the input table.

To adjust: follow the procedure on the previous page, except for bolt B1.

To move the pins forward: screw B3 until desired.

To move the pins backward: unscrew B3.

Tighten bolts B2.

5

H_S

H_S

B2

B1

B3

T

41

Page 42

Troubleshooting

Starting problems

Fault Cause Remedy

"No air" on display

"No speed" on

display

"No heat" on

display

"Foot" on display

"Heat1" or

"Heat2" on display

(number of the

defective sensor)

No air has been exhausted.

Fan blocked.

Vacuum valve does not connect.

Plug of vacuum valve is not inserted.

Malfunction frequency converter.

Frequency converter out of order.

Plug of drive is not inserted.

Speed sensor does not detect pulses.

Burner in reset.

Ionization follow-up cable not inserted well in

contact of burner.

Plug of heating is plugged out of the burner.

No gas in pipe at rst set-up.

Overheat switch tripped.

Fuse gas control broken.

Foot pedal is operated. Release the foot pedal.

Temperature sensor cable interrupted.

Temperature sensor out of order.

Input on control out of order.

Clean fan.

Clean outlet tube.

Eliminate the fault.

Check if the valve’s switch connects.

Check position/switching point of the switch.

Insert the plug in the right input of the control.

See page 44.

See page 44.

Insert the plug in the right input of the control.

Adjust distance chain wheel and sensor to 1mm.

Out of order, replace sensor.

Open gas tap and reset burner.

Insert plug well in burner and control print.

Insert plug in right input of the control.

Make many start attempts, with resets in the

meantime, so that air is removed from the pipes.

Check system and reset switch.

Replace fuse after controlling system.

Readjust the switch.

Tighten the springs.

Check cable and repair defects.

Replace the sensor by a new one.

Replace the control by a new one.

5

Frequency converter

Fault Condition Possible cause

OI.AC**

It.AC

HFxx trip

Drive output instantaneous over current. Insufcient ramp times.

Phase to phase or phase to ground short circuit on the drives

output.

Drive requires autotuning to the motor.

Motor or motor connections changed, re-autotune drive to motor.

I²t on drive output current. Excessive mechanical load.

High impedance phase to phase or phase to ground short circuit

at drive output.

Drive requires re-autotuning to motor.

Hardware faults. Internal drive hardware fault.

42

Page 43

Fault Condition Solution

OVL.d

hot

br.rS

AC.Lt

I x t overload (I = current, t = time). Reduce motor current (Load).

Heatsink/IGBT temperature high. Reduce ambient temperature or reduce motor current.

Braking resistor overload. Call Customer Service.

Drive is in current limit. Call Customer Service.

Burner

Fault Cause Remedy

Continuous

malfunction

after reset

Malfunction

burner after

2 start

attempts

No supply voltage so also no burning

reset lamp.

Overheat.

Short-circuit electrode to earth.

No gas supply.

No ignition spark.

Check fuses and wiring.

Check overheat thermostat (see Fig. 1).

Adjust electrode properly -> ignition probe: 3 mm from burner

(see Fig. 2).

Check gas supply, gas tap and function of the gas valves.

Adjust electrode properly.

Machine has no contact with earth.

Check electrical connection of the machine.

Check overheat thermostat.

5

thermostat

No ignition while there is a spark.

Fig. 1

No gas supply.

Wrong adjustment gas valve.

No PWM signal on ventilator (turns full at spark).

3 mm

Fig. 2

43

Page 44

Description of the control system

General description of the control system

The control system consists of a microprocessor board with built-on display and push-buttons.

Electric heating control

For the electric heated version, the relays for the heating elements are controlled by a time related P.I.D.

controlled function built in the program of the processor, which has the opportunity of a quick reaction with

limited overshoot. The elements are activated by relays.

Gas heating

With the gas version, a PWM controlled ventilator is used, which is controlled by the microprocessor.

This ventilator blows the mix of gas and air into the burner, which means that the power of the burner is

controlled by the microprocessor. The advantage is that also here the burner is controlled with a P.I.D.

controlled function from 20-40 to 100% so that there is a quick reacting system with a low overshoot.

When the need of power is lower than 15%, the burner will be temporarily switched off.

6

Temperature control

The temperature of the roll is measured by Pt1000 elements that are mounted on a contact plate on the

roll. The Pt1000 are directly connected to the microprocessor board.

To prevent overheating when there is a malfunction of the Pt1000 or the microprocessor board,

a maximum temperature switch is placed, which switches off the power of the relay of the elements or the

power of the gas control unit.

temp2: left sensor

temp1: right sensor

44

Page 45

Control of exhaust ventilator

The exhaust ventilator always turns on maximum when the ironer is switched on. An underpressure

switch is mounted, which controls the working of the exhaust ventilator. The function of this

underpressure switch is controlled when starting up the machine and will give a warning sign when the

function is not correct.

Speed control

The speed is controlled by means of a frequency regulator, which is controlled by a feedback system

through the microprocessor board.

The speed is checked by an approximated switch, which is activated by the teeth of a detection wheel.

approximated switchteeth of a detection wheel

6

Start/stop function

The ironer can be started and stopped by pressing the 0/I button.

The foot pedal can temporarily stop the ironer.

45

Page 46

Control panel and function keys

The machine is equipped with the following operating devices:

6

1: Emergency stop button

2: Reset gas

3: Start/stop button

4: “+” Button

5: “-“ Button

6: Return button

7: Left display (temperature)

8: Right display (speed)

When the power is switched to the machine by the main switch, “ ” and the program version will

appear during 5 seconds.

Then the left display will give the actual temperature (in °C or °F) and the right display will give the actual

speed (in M/min).

46

Page 47

+ -

- +

- +

5 sec

I

I/0 +

Menu structure and how to enter

After installation, each ironer needs to be congured.

There are 2 different systems: Manual and Coin version.

Manual version

When the main switch is switched on, " " appears on the right display during 5 seconds.

To enter the adjusting menus, press the I/0 button and ↓ button simultaneously until " " appears on

the right display. With the + and - button, it is possible to switch between the menus , and

. By pressing the ↓ button, you choose a specic menu.

6

Coin version: hidden buttons

The hidden buttons (A) normally have no function in the coin version.

However, during the conguration, they have the same function as the manual version.

A

47

Page 48

6

5 sec

I

5 sec

+ -

- +

- +

2 sec

5 sec

Menu structure

When the main switch is switched on, " " appears on the right display during 5 seconds.

To enter the adjusting menus, activate the microswitch inside the coin box casing.

When " " appears, keep pressing the microswitch (approximately 5 sec.) until " " appears

on the display. Then press the “I” button to reset the emergency stop, after which the blinking " "

menu will appear on the right display.

Then press the hidden ↓ button until 3 blinking dashes appear on the left display (approximately 2 sec.).

Release the ↓ button and press the microswitch again (approximately 5 sec.) until " " lights up on

the right display.

With the + and - button, it is possible to switch between the menus , and .

By pressing the ↓ button, you choose a specic menu.

48

Page 49

-

+

+

-

+

-

+

-

+

-

+

-

+

"Manu" adjusting menu

This is the group of parameters for the manual ironer with start button action.

Manu

Press the return button to continue.

6

t °C or t °F [default: °C]

Change, if necessary, by means of the + button and then press the

return button.

XX Cool [default: 80°C]

This cool down temperature can be adjusted between 80 and 100°C

by pressing the + or - button.

Then press the return button.

Iron

The following settings determine the 2 temperatures in between which

it will be possible to set the temperature during operation.

XXX Low [default: 130°C]

This is the low limit temperature.

It can be changed by pressing the + or - button.

Then press the return button.

XXX High [default: 175°C]

This is the high limit temperature.

It can be changed by pressing the + or - button.

Then press the return button.

X X X

SP.L X.X [default: 1,4 m/min]

This is the low limit of the speed.

It can be changed by pressing the + or - button.

Then press the return button.

SP.H X.X [default: 6 m/min]

This is the high limit of the speed.

It can be changed by pressing the + or - button.

Then press the return button.

A.St X.X [default: 0.0]

In order to avoid that the ironer remains unused at temperature for a

long time, it is possible to enter a switch off time.

In case of “0.0”, the cycle must be stopped manually.

Then press the return button.

End

Press the return button to conrm the setting of this parameter group.

49

Page 50

6

+

+

+

+

-

+

-

+

-

+

-

+

"Coin" adjusting menu

This is the group of parameters for the coin operated ironer.

Coin

Press the return button to continue.

on t °C [default : °C]

By selecting this parameter, the temperature will be calculated and

shown in °C. Press the return button to choose this option.

Off t °C [default : °C]

By selecting this parameter, the temperature will be calculated in °C

but not shown during operation. Press the return button to choose this

option.

On t °F [default : °F]

By selecting this parameter, the temperature will be calculated and

shown in °F. Press the return button to choose this option.

Off t °F [default : °F]

By selecting this parameter, the temperature will be calculated in °F

but not shown during operation. Press the return button to choose this

option.

XX Cool [default : 80°C]

This cool down temperature can be adjusted between 80 and 100°C

by pressing the + or - button.

Then press the return button.

XXX Iron [default : 160°C]

This is the operating temperature of the ironer. This can be adjusted

between 130 and 175°C with the + and - button. Then press the return

button.

SP X.X [default : 1.4 m/min]

This is the operating speed of the ironer belts. It can be changed with

the + and - button.

Then press the return button.

C1L (coin 1 low)

Here, you can adjust the time in minutes and seconds with the + and button for low tariff coin 1. Then press the return button.

50

Page 51

6

-

+

-

+

-

+

-

+

-

+

-

+

+

+

+

+

C1M (coin 1 Medium)

Here, you can adjust the time in minutes and seconds with the + and button for middle tariff coin 1. Then press the return button.

C1H (coin 1 High)

Here, you can adjust the time in minutes and seconds with the + and button for high tariff coin 1. Then press the return button.

C2L (coin 2 low)

Here, you can adjust the time in minutes and seconds with the + and button for low tariff coin 2. Then press the return button.

C2M (coin 2 Medium)

Here, you can adjust the time in minutes and seconds with the + and button for middle tariff coin 2. Then press the return button.

C2H (coin 2 High)

Here, you can adjust the time in minutes and seconds with the + and button for high tariff coin 2. Then press the return button.

Add XX [default : 00]

This parameter determines the minimum amount to be inserted (in

minutes) before the machine will start. It can be changed with the

+ and - button. Then press the return button.

Y/n ti.St

If the ironing temperature drops below 130°C, the feeding belts stop

running. Select "Yes" or "no" with the + button whether the remaining

time should count down or not. Then press the return button.

Y/n rEmo

Select y (yes) or n (no) by means of the + button if a central operating

system is provided. Then press the return button.

Y/n rM.St. (only if rEmo = Yes)

Select y (yes) or n (no) by means of the + button if a central operating

system is provided, by which a running cycle can be stopped (via

coin 2). Then press the return button.

Y/n Pr.cY (only if rEmo = Yes)

Select y (yes) or n (no) by means of the + button if the cycle contact

musn’t be closed continuously during the cycle. As a result, the contact

can open when the temperature is too low (see ti.St).

End

Press the return button to conrm.

51

Page 52

6

-

+ + +

+

-

+

+

+

Technical menu

This is the group of parameters, which effect the technical operation of the ironer. They are programmed in the factory

and normally do not need to be changed.

tEch

Press the return button to continue.

X . X

Adr X.X [default : 1]

This is the serial address of the ironer when connected in a network.

Only change when placed in a network. Press the return button to

choose this option.

Dia XXX [default : 325]

Select the roller diameter by means of this parameter. Press the return

button to choose this option.

X X X X

Len XXXX [default : 1650-2050]

Select the ironer length by means of this parameter. Press the return

button to choose this option.

Elec (Electric heating)

This parameter indicates which heating system is used in the ironer.

Press the return button to choose this option.

52

Page 53

6

-

+

-

+

-

+

-

+

-

+

-

+

+

X X X X

X X X X

X X . X

X X

X X

kp XXXX [default: gas 300] [default: elec 400]

Value of the proportion of the P.I.D. regulator for the burner.

Press the return button to choose this option.

kd XXXX [default: gas 1000] [default: elec 3000]

Differential value of the P.I.D. regulator for the burner. Press the return

button to choose this option.

ki XXXX [default: gas 0.5] [default: elec 2.0]

Integrator value of the P.I.D. regulator for the burner. Press the return

button to choose this option.

Start PWM [default: 40]

At the moment of ignition of the burner: as long as there is no

feedback measured, this value will be sent (only with gas heating).

Minimum PWM (default: 25)

When the measured signal is smaller, this value will be sent (only with

gas heating).

X X

Remark:

Settings kp, kd, ki, SPW, MPW and PWM are not possible when heat = steam.

PWM XX

Test signal to check the PWM of the burner. The chosen value (25%,

50% or 100%) will be sent during normal operation, independently of

the temperature. After a voltage interruption, PWM will automatically

be put on "none" (only with gas heating).

L.r or Lr.SS [default: L.r]

This parameter affects the function of the frequency converter and

must therefore never be changed, unless another type of converter is

built in. Press the return button to choose this option.

53

Page 54

6

rEv Y/n [default: YES] (not adjustable with coin)

Depending on the used guiding ribbon of the pressure roller, the roller

can be reversed (only with manually operated machine).

tMP 1

Temperature of probe 1.

tMP 2

Temperature of probe 2.

End

Press the return button to conrm the settings of this parameter group.

54

Page 55

Display menu

This group contains the data of total operating hours and the total number of inserted coins.

DiSP

Press the return button to continue.

6

X X X

Central panel

X X X X

X X X

X X X

Id. XXXX

This is the index concerning the total operating hours of the ironer.

This may be an interesting indicator in view of maintenance.

Press the return button to continue.

C1 XXX

This is the total number of coins inserted in coin meter 1 (max. 999).

Press the return button to continue.

C2 XXX

This is the total number of coins inserted in coin meter 2 (max. 999).

Press the return button to continue.

End

Press the return button to continue.

Optional, it is possible to operate the coin version through a central panel.

In this case, not a coin selector is built in, but instead of that, an extra PC board with a relay that gives impulses

instead of the coin selector contacts.

Sigma explorer

It is possible to connect the machine to a PC with Sigma Explorer software together with other IPSO machines in a

bus system. This can be used for different coin tariffs and parameter functions.

55

Page 56

Maintenance

Safety advice

When starting the maintenance work on the ironer, the following should be observed:

1. Turn off the gas tap in case of a gas-heating ironer.

2. Ensure that the ironer has cooled down until it has reached the environmental temperature.

3. Use proper tools in order to avoid damage to the machine, which can result in personal injury.

Maintenance scheme

7

The cleaning and maintenance intervals mentioned below are based on a use of 8 hours a day and 5 days a

week. If the use of this machine differs, the intervals given below can be adjusted linearly.

Daily maintenance

Cleaning:

Surrounding area

Daily clean the surrounding area of the machine. Keep it free from dust as much as possible. A clean workroom

will prolong the life of the machine as less dust and dirt will be drawn in the machine.

Filter for gas-heated ironer

Gas-heated ironers are equipped with an air lter. This lter is located in the right-hand door of the machine.

Clean it manually or with a vacuum cleaner after the machine has been turned off.

WARNING

Maintenance on the machine is solely reserved

for the maintenance personnel.

56

Page 57

7

Weekly maintenance

Waxing

To prevent laundry from adhering to the ironing roller and to avoid corrosion of the ironing roller, this roller has

to be "waxed“ every week. Follow the instructions below.

Important

Only use a normal sheet or table-cloth for a grease cloth.

Set the machine to 150°C and with a speed of 1.6 mtr. per minute. Take a grease cloth and check its state.

If the grease cloth has sufcient wax, you can feed the cloth. The width of the grease cloth has to be equal to

the width of the feeding conveyor, otherwise, the ironing roller will not be fully waxed.

If the machine is not going to be used for a longer period, you have to wax the ironing roller.

With this waxing, you can prevent the ironing roller from being corroded during this particular period.

Monthly maintenance

Fan

The vapour exhaust fan on the left side of the machine will become lthy during operation. Check the fan on

this. By removing the left door, you can see the suction opening of the fan. Any lth accumulation is to be found

in the impeller of the fan. Remove this by means of the vacuum cleaner.

While cleaning this part, do not forget to clean the frame space.

fan

fan impeller

57

Page 58

Filter gas mixture

Check lter on dust. Clean if dirty.

7

Frame right side

This space has to be cleaned every month (also gas-heated ironers).

Vapour exhaust beam

As a result of the laundry being ironed, dust will remain in the machine. This dust accumulates at a

certain number of places. One place is the vapour exhaust beam on top of the machine.

By removing the left door of the machine, you can see the vapour exhaust beam. Shine with an electric

torch through the hole at the left on top of the left side frame. Here, you can see the internal pollution of

the vapour exhaust beam.

If this is seriously polluted, you can open the top and clean it.

Important

If the inside of the beam is clean, it will not

guarantee that the bottom and the outside of the

vapour exhaust beam are clean. Therefore, open

the top and check it each month thoroughly.

58

Page 59

Opening the top: unscrew bolts on the left and right side before opening the top.

7

Subplating dust accumulation

As a result of the laundry being ironed, dust will remain in the machine. This dust accumulates at a

certain number of places. One place is the subplating on the machine.

The plating has to be removed each month to wipe away the dust. Loosen the bolts, which fasten the

three parts of the subplating.

The easiest way is to loosen the bolts on one side (front/back) a few turns and to remove the other side

completely. The plates can now be pulled out from the remaining bolts. Placing back the bottom cover is

simplied by doing this. Clean the plates and place them back in the machine. The slot holes in the subplating have to be positioned on the inlet and outlet of the machine.

59

Page 60

Half-yearly maintenance

Runners and axial bearing

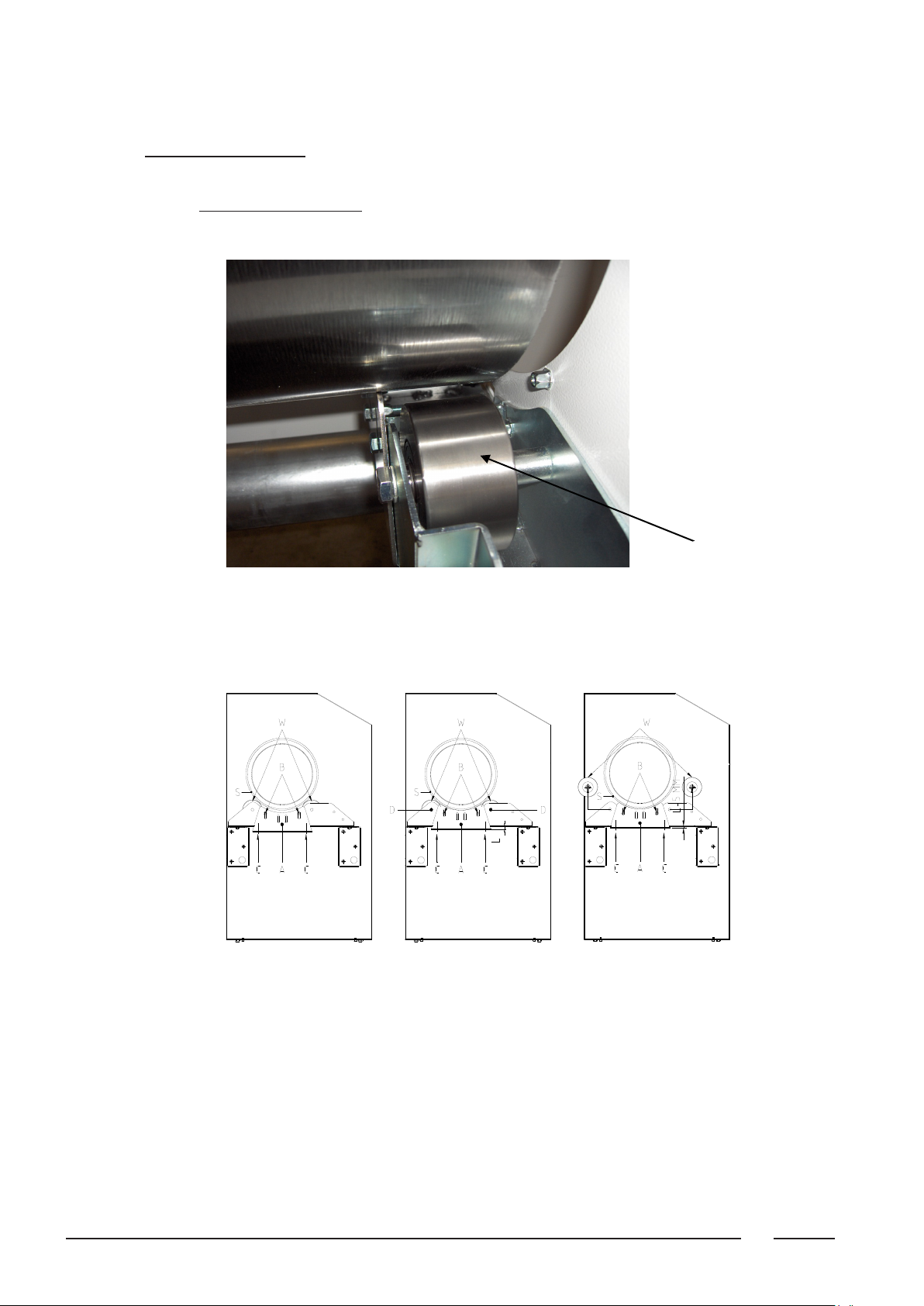

7

runner

The ironing roller (S) is supported by 4 runners (W). These runners are placed on the outer end of the

ironing roller. Using the machine will wear these runners on the outside.

60

Page 61

7

Check each half year the surface quality of the runners (W). If you do not check this, it can inuence the

ironing roller (S) in a negative way.

Remove debris.

The runners can be dismounted if the ironing roller is not resting upon the runners. A tool is available,

which can lift the ironer roller. This tool (A) can be ordered with your IPSO dealer.

The two small screening plates underneath the machine (1 on the left and 1 on the right) have to be taken

away.

Then you have to mount the "ironing lifting plates“ (A) on both sides with 2 bolts (B), which have to be

tightened manually. Also the two bolts (C) have to be mounted. These bolts (C) have to be tightened in

such a way that the lifting plate (A) supports the roller evenly.

To prevent that the ironing roller (S) is lifted too high and so would damage internal components,

you have to determine the position of the lifting plates (A) if they just touch the roller. If so, measure (L).

The plate may not be screwed up more than 5mm (for the 8 bolts, it means not more than 4 turns from

the moment, the plate just touches the ironing roller).

The ironing roller is now lifted by the plates. The runners can be removed.

The runners are tted with M12 bolts (D).

By removing these bolts, the runners become free and can be taken out.

Mount the runners in reverse order.

Feeding belts

The tension of the feeding belts has to be increased if the belts are not driven properly.

Exchanging the belts:

- Slacken the belts (see page 40).

- Turn the belt by hand in such a way that the connector is in front of you.

- Then pull the pin out of the belt and hold both ends of the belt.

- Now connect the new belt to the old belt by putting back the pin in the connector.

- By pulling the free end of the old belt, the new belt will be pulled through the machine.

- If the pin is in front of you again, you disconnect the old belt from the new belt and connect both ends of

the new belt.

- Do this for all belts and then tension the feeding belts (see page 40).

61

Page 62

7

Ironer belts

For tensioning the ironer belts, see page 39.

Using the machine will pollute the ironing belts so that they will become smaller, longer and thinner.

If the ironing effect has become unacceptable, you have to exchange the ironing belts by new ones.

Slacken the belt tensioners by reducing the spring tension of the tensioners to zero and remove the tension nut

of the springs so that the tensioner can move freely.

Do this on the left and right side of the machine (see page 39).

Push (inside the side frame, on both sides) by means of a beam (or some other tool) the tensioner to its highest

possible position. Place the small beams vertically underneath the spanner.

Now remove the top plating, the rear plating as well as the vapour exhaust beam (see page 39) of the machine.

The pressure roll of the ironer (roll straight above the ironing roller) has to be lifted up. This can be done by

putting wooden beams from the feeding side between the main roll and the shaft of the pressure roll on both

sides (left and right). The beams can be used as a lever for lifting the roller.

Mounting new ironing belts happens in reverse order. For this purpose, please note the following points:

- The ap on the ironing belts has to be on one side of the ironing roller. Also the ironing belt has to be placed

in such a way that the ap is dragged by the ironing belt.

- Connect the ends of the ironing belt in such a way that the ends are in line. This means that the pulled part of

the belts may not protrude on a side. This could cause a mechanical load to the machine, which does not

help its life of the machine.

Drive

The chain tension has to be checked biannually as described on page 38.

The condition of the chain wheels has to be checked biannually, as well. If the chain wheels are worn down,

they have to be exchanged.

Slacken the chain by placing the motor in its top position. Loosen the hexagon socket screw of the chain wheel

that has to be exchanged one turn and remove the chain.

Important