Page 1

Washer-Extractors

CHM1772C

CHM1772C

Cabinet Hardmount

Refer to Page 6 for Model Identification

Operation/Maintenance

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. F8208401R3

February 2011

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 2

Explanation of Safety Messages........................................................... 2

Important Safety Instructions ............................................................... 2

Safety Decals ........................................................................................ 4

Operator Safety..................................................................................... 5

Introduction......................................................................................... 6

Model Identification ............................................................................. 6

Nameplate Location.............................................................................. 9

Replacement Parts ................................................................................ 9

Customer Service.................................................................................. 9

Operation............................................................................................. 11

Operating Instructions .......................................................................... 11

Maintenance ........................................................................................ 13

Daily ..................................................................................................... 13

Beginning of Day............................................................................. 13

End of Day ....................................................................................... 13

Weekly.................................................................................................. 14

Monthly................................................................................................. 14

Quarterly ............................................................................................... 16

Care of Stainless Steel .......................................................................... 17

© Copyright 2011, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer and those maintaining the

machine.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 5

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

20. If the supply cord is damaged, it must be replaced

by a special cord or assembly, available from the

manufacturer or its service agent.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards

and/or panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

3

Page 6

Safety Information

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Install the machine on a level floor of

sufficient strength. Failure to do so may

result in conditions which can produce

serious injury, death and/or property

damage.

W703

WARNING

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

IMPORTANT: Ensure that the recommended

clearances for inspection and maintenance

are provided. Never allow the inspection and

maintenance space to be blocked.

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 7

Safety Information

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Operating the machine with severe out-ofbalance loads could result in personal

injury and serious equipment damage.

W728

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door and start the machine. The

machine should not start with the door

unlocked.

Do not bypass any safety devices in the machine.

c. Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, disconnect power and call a service

technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

Model Identification

Information in this manual is applicable to these models:

HCD020GD2

HCD020JD2

HCD020LD2

HCL020GD2

HCL020GN2

HCL020HDF

HCL020HN2

HCL020KD2

HCL020LD2

HCN020GC2

HCN020GD2

HCN020GE2

HCN020GN2

20 POUND

HCN020GX2

HCN020GY2

HCN020HC2

HCN020HCF

HCN020HD2

HCN020HN2

HCN020HNF

HCN020HY2

HCN020HYF

HCN020KC2

HCD030LD2

HCL030GN2

HCL030HDF

HCL030HN2

HCL030HNF

HCN030GC2

HCN030GD2

HCN030GE2

HCN030GN2

HCN030GX2

HCN030GY2

HCN030HC2

HCN030HCF

HCN030HD2

30 POUND

HCN030HN2

HCN030HNF

HCN030HY2

HCN030HYF

HCN030KC2

HCN030KCF

HCN030KCV

HCN030KD2

HCN030KDV

HCN030KEF

HCN030KY2

HCN020KCF

HCN020KCV

HCN020KD2

HCN020KDV

HCN020KEF

HCN020KEV

HCN020KY2

HCN020KYF

HCN020KYV

HCU020GC2

HCU020GD2

HCU020GE2

HCU020GL2

HCU020GN2

HCU020GX2

HCU020GY2

HCU020HC2

HCU020HN2

HCU020HNF

HCU020HX2

HCU020KCF

HCU020KCV

HCU020KE2

HCN030KYF

HCN030KYV

HCU030GC2

HCU030GD2

HCU030GE2

HCU030GL2

HCU030GN2

HCU030GX2

HCU030GY2

HCU030HC2

HCU030HN2

HCU030HNF

HCU030HX2

HCU030KCF

HCU030KCV

HCU030KE2

HCU030KY2

HCU030KYF

HCU030KYV

HCZ030GN2

SCD030GD2

SCD030LD2

SCL030GC2

SCL030GN2

SCL030HN2

HCU020KL2

HCU020KY2

HCU020KYF

HCU020KYV

HCZ020GN2

HCZ020HN2

SCL020GCZ

SCL020GN2

SCL020HNF

SCL020JC2

SCL020JD2

SCL020JDF

SCL020JE2

SCL020JEF

SCL020JX2

SCN020GC2

SCN020GD2

SCN020GE2

SCN020GN2

SCN020GX2

SCN020GY2

SCN020HN2

SCN020HNF

SCL030HNF

SCL030JC2

SCL030JCF

SCL030JD2

SCL030JDF

SCL030JE2

SCL030JEF

SCL030JX2

SCL030JXF

SCL030JY2

SCL030KN2

SCL030KNF

SCL030KNV

SCL030LD2

SCL030LEV

SCN030GC2

SCN030GD2

SCN030GE2

SCN030GN2

SCN030GX2

SCN030GY2

SCN030HN2

SCN030HNF

SCN030JC2

SCN030JCF

(Continued)

Model

SCN020JC2

SCN020JCF

SCN020JCV

SCN020JD2

SCN020JEF

SCN020JXF

SCN020JY2

SCN020JYF

SCN020JYV

SCN020KN2

SCN020KNF

SCN020LC2

SCN020LCF

SCN020LCV

SCN020LD2

SCN020LX2

SCN020LY2

SCN020LYF

SCN020LYV

SCN020WC2

SCN020WCF

SCN020WCV

SCN020WD2

SCN030JCV

SCN030JD2

SCN030JE2

SCN030JEF

SCN030JX2

SCN030JY2

SCN030JYF

SCN030JYV

SCN030KN2

SCN030KNF

SCN030LC2

SCN030LCF

SCN030LCV

SCN030LD2

SCN030LE2

SCN030LY2

SCN030LYF

SCN030LYV

SCN030WC2

SCN030WCF

SCN030WCV

SCN030WD2

SCN030WDV

SCN030WY2

SCN030WYF

SCN020WDV

SCN020WY2

SCN020WYF

SCN020WYV

SCU020GC2

SCU020GD2

SCU020GE2

SCU020GL2

SCU020GN2

SCU020GX2

SCU020GY2

SCU020HN2

SCU020HNF

SCU020JC2

SCU020JCF

SCU020JCV

SCU020JD2

SCU020JDF

SCU020JDV

SCU020JE2

SCU020JEF

SCU020JEV

SCU020JL2

SCN030WYV

SCU030GC2

SCU030GD2

SCU030GE2

SCU030GL2

SCU030GN2

SCU030GX2

SCU030GY2

SCU030HN2

SCU030HNF

SCU030JC2

SCU030JCF

SCU030JCV

SCU030JD2

SCU030JDF

SCU030JDV

SCU030JE2

SCU030JEF

SCU030JEV

SCU030JL2

SCU030JLF

SCU030JLV

SCU030JX2

SCU030JXF

SCU030JXV

SCU020JLF

SCU020JLV

SCU020JX2

SCU020JXF

SCU020JXV

SCU020JY2

SCU020JYF

SCU020JYV

SCU020KN2

SCU020KNF

SCU020WEV

UCL020GNZ

UCL020HN2

UCL020KN2

UCN020GN2

UCN020HN2

UCN020HNF

UCN020KN2

UCU020GN2

UCU020HN2

UCU020HNF

UCU020KN2

UCZ020GN2

SCU030JY2

SCU030JYF

SCU030JYV

SCU030KN2

SCU030KNF

SCU030WCV

SCU030WE2

UCL030GN2

UCL030HN2

UCL030HNF

UCL030KN2

UCN030GN2

UCN030HN2

UCN030HNF

UCN030KN2

UCN030KNF

UCU030GN2

UCU030HN2

UCU030HNF

UCU030KN2

UCZ030GN2

VCU030GN2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 9

HCD040LD2

HCL040GN2

HCL040HC2

HCL040HDF

HCL040HE2

HCL040HN2

HCN040GC2

HCN040GD2

HCN040GE2

HCN040GN2

HCN040GX2

HCN040GY2

HCN040HC2

HCN040HCF

40 POUND

HCN040HN2

HCN040HNF

HCN040HY2

HCN040HYF

HCN040KC2

HCN040KCF

HCN040KCV

HCN040KD2

HCN040KDF

HCN040KDV

HCN040KEF

HCD060LD2

HCL060GN2

HCL060HCF

HCL060HN2

HCN060GC2

HCN060GD2

HCN060GE2

HCN060GN2

HCN060GX2

HCN060GY2

HCN060HC2

HCN060HCF

HCN060HDF

HCN060HN2

60 POUND

HCN060HNF

HCN060HY2

HCN060HYF

HCN060KC2

HCN060KCF

HCN060KCV

HCN060KD2

HCN060KDF

HCN060KDV

HCN060KEF

HCN060KEV

HCN040KEV

HCN040KY2

HCN040KYF

HCN040KYV

HCU040GC2

HCU040GD2

HCU040GE2

HCU040GL2

HCU040GN2

HCU040GX2

HCU040GY2

HCU040HC2

HCU040HN2

HCU040HNF

HCU040HX2

HCU040KCF

HCU040KCV

HCU040KE2

HCU040KY2

HCU040KYF

HCU040KYV

SCD040GD2

SCD040LD2

SCL040GC2

SCL040GN2

HCN060KY2

HCN060KYF

HCN060KYV

HCU060GC2

HCU060GD2

HCU060GE2

HCU060GL2

HCU060GN2

HCU060GX2

HCU060GY2

HCU060HC2

HCU060HN2

HCU060HNF

HCU060HX2

HCU060KCF

HCU060KCV

HCU060KEV

HCU060KY2

HCU060KYF

HCU060KYV

SCD060GD2

SCD060LD2

SCL060GC2

SCL060GN2

SCL060HN2

(Continued)

Model

SCL040HN2

SCL040HNF

SCL040JC2

SCL040JD2

SCL040JDF

SCL040JE2

SCL040JEF

SCL040JX2

SCL040JXF

SCL040JXV

SCL040KN2

SCL040KNF

SCL040KNV

SCL040LE2

SCN040GC2

SCN040GD2

SCN040GE2

SCN040GN2

SCN040GX2

SCN040GY2

SCN040HN2

SCN040HNF

SCN040JC2

SCN040JCF

SCN040JCV

SCL060HNF

SCL060JC2

SCL060JCF

SCL060JD2

SCL060JE2

SCL060JX2

SCL060KN2

SCL060KNV

SCL060LE2

SCN060GC2

SCN060GD2

SCN060GE2

SCN060GN2

SCN060GNF

SCN060GX2

SCN060GY2

SCN060HN2

SCN060HNF

SCN060JC2

SCN060JCF

SCN060JCV

SCN060JD2

SCN060JDF

SCN060JEF

SCN060JX2

(Continued)

SCN040JD2

SCN040JE2

SCN040JEF

SCN040JY2

SCN040JYF

SCN040JYV

SCN040KN2

SCN040KNF

SCN040KNV

SCN040LC2

SCN040LCF

SCN040LCV

SCN040LD2

SCN040LDV

SCN040LE2

SCN040LY2

SCN040LYF

SCN040LYV

SCN040WC2

SCN040WCF

SCN040WCV

SCN040WDV

SCN040WY2

SCN040WYF

SCN040WYV

SCN060JY2

SCN060JYF

SCN060JYV

SCN060KN2

SCN060KNF

SCN060KNV

SCN060LC2

SCN060LCF

SCN060LCV

SCN060LD2

SCN060LDV

SCN060LE2

SCN060LY2

SCN060LYF

SCN060LYV

SCN060WC2

SCN060WCF

SCN060WCV

SCN060WD2

SCN060WDV

SCN060WY2

SCN060WYF

SCN060WYV

SCU060GC2

SCU060GD2

SCU040GC2

SCU040GD2

SCU040GE2

SCU040GL2

SCU040GN2

SCU040GX2

SCU040GY2

SCU040HN2

SCU040HNF

SCU040JC2

SCU040JCF

SCU040JCV

SCU040JD2

SCU040JDF

SCU040JDV

SCU040JE2

SCU040JEF

SCU040JEV

SCU040JL2

SCU040JLF

SCU040JLV

SCU040JX2

SCU040JXF

SCU040JXV

SCU040JY2

SCU060GE2

SCU060GL2

SCU060GN2

SCU060GX2

SCU060GY2

SCU060HN2

SCU060HNF

SCU060JC2

SCU060JCF

SCU060JCV

SCU060JD2

SCU060JDF

SCU060JDV

SCU060JE2

SCU060JEF

SCU060JEV

SCU060JL2

SCU060JLF

SCU060JLV

SCU060JX2

SCU060JXF

SCU060JXV

SCU060JY2

SCU060JYF

SCU060JYV

Introduction

SCU040JYF

SCU040JYV

SCU040KN2

SCU040KNF

SCU040KNV

SCU040WEV

UCL040GN2

UCL040HN2

UCL040HNF

UCL040KN2

UCL040KNF

UCL040KNV

UCN040GN2

UCN040HN2

UCN040HNF

UCN040KN2

UCN040KNF

UCN040KNV

UCU040GN2

UCU040HN2

UCU040HNF

UCU040KN2

UCU040KNV

VCU040GN2

SCU060KN2

SCU060KNF

SCU060KNV

SCU060WEV

UCL060GN2

UCL060HN2

UCL060HNF

UCL060KN2

UCL060KNF

UCL060KNV

UCN060GN2

UCN060HN2

UCN060HNF

UCN060KN2

UCN060KNF

UCN060KNV

UCU060GN2

UCU060HN2

UCU060HNF

UCU060KN2

UCU060KNV

VCU060GN2

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Introduction

HCD080LDV

HCL080HNF

HCN080GCF

HCN080GDF

HCN080GEF

HCN080GNF

HCN080GXF

HCN080GYF

HCN080HCF

80 POUND

HCN080HDF

HCN080HNF

HCN080HYF

HCN080KCF

HCN080KCV

HCN080KDF

SCL125KNV

SCN125KNV

SCN125LYV

SCU125KNV

UCL125KNV

125 POUND

UCU125KNV

HCN080KDV

HCN080KEV

HCN080KYF

HCN080KYV

HCU080GCF

HCU080GDF

HCU080GEF

HCU080GLF

HCU080GNF

HCU080GXF

HCU080GYF

HCU080HCF

HCU080HNF

HCU080HXF

HCU080KCF

(Continued)

Model

HCU080KCV

HCU080KYF

HCU080KYV

SCL080GNF

SCL080HNF

SCL080KNV

SCN080GCF

SCN080GDF

SCN080GEF

SCN080GNF

SCN080GXF

SCN080GYF

SCN080HNF

SCN080JCF

SCN080JCV

SCN080JDF

SCN080JYF

SCN080JYV

SCN080KNV

SCN080LCV

SCN080LDV

SCN080LYV

SCN080WCV

SCN080WDV

SCN080WYV

SCU080GCF

SCU080GDF

SCU080GEF

SCU080GLF

SCU080GNF

SCU080GXF

SCU080GYF

SCU080HNF

SCU080JCF

SCU080JCV

SCU080JDF

SCU080JDV

SCU080JEF

SCU080JEV

SCU080JLF

SCU080JLV

SCU080JXF

SCU080JXV

SCU080JYF

SCU080JYV

SCU080KNV

UCL080GNF

UCL080HNF

UCL080KNV

UCN080GNF

UCN080HNF

UCN080KNV

UCU080GNF

UCU080HNF

UCU080KNV

VCU080GNF

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 11

Introduction

1

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

Replacement Parts

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call:

(920) 748-3121

Ripon, Wisconsin

+32 56 41 2054

Wevelgem, Belgium

1 Nameplate

CHM2233N

Figure 1

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Introduction

CHM2286N

*CN040GC2OUID01

00000000000

208 – 240

3

HzHz PhasePhase

Supply Water: Supply Water: BARBAR

Number of wires :Number of wires : FLA :FLA : ampsamps

3

Circuit Breaker Size :Circuit Breaker Size : ampsamps

60 3

Serial No.Serial No.

Model No.Model No.

VoltageVoltage

40

30 - 85 psi, 2 - 5.7

Max. Load :Max. Load :

Schematic :Schematic :

KGKG

18.2

LBLB

EXAMPLE OF NAMEPLATE

Model Number Familiarization Guide

*C

N

040

G

C

2

O

U

1

D

01

* Denotes Brand

Product Family

Agency Approval

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Control

Actuation (C = Coin drop)

Washer-Extractor Speed Capability (2 = 2 speed)

Electrical Characteristics

Panel Type

Design Series

Heat Feature (D = Direct Steam)

Option Identification (varies from machine to machine)

Sample Model Number:

*CN040GC2OU1D01

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM2286N

Figure 2

F8208401

Page 13

Operation

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

Operating Instructions

1. Turn on main power source (circuit breaker).

2. Turn handle clockwise to open. Refer to

Figure 3.

NOTE: For 125 capacity models through 1/31/11,

press the Unlock/Stop keypad, push the button on

door handle and turn handle counter clockwise to

open.

For 125 capacity models starting 2/1/11, turn

handle clockwise to open.

CHM2243N

4. Close door and turn handle counter clockwise.

Refer to Figure 5.

NOTE: For 125 capacity models through 1/31/11,

close door and turn handle clockwise.

For 125 capacity models starting 2/1/11, close door

and turn handle counter clockwise.

CHM2244N

Figure 5

5. The default wash cycle will display.

Figure 3

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 4.

NOTE: Underloading can cause out-of-balance

conditions that can shorten machine life.

Figure 4

6. Select the desired soil setting (select models

only), cycle setting (select models only) and

cycle/temperature. The LED indicator(s) for that

cycle will light.

U003I

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Powder

a. DETERGENT

CHM2228N

Liquid

b. BLEACH

CHM2230N

Powder

CHM2229N

Liquid

c. SOFTENER

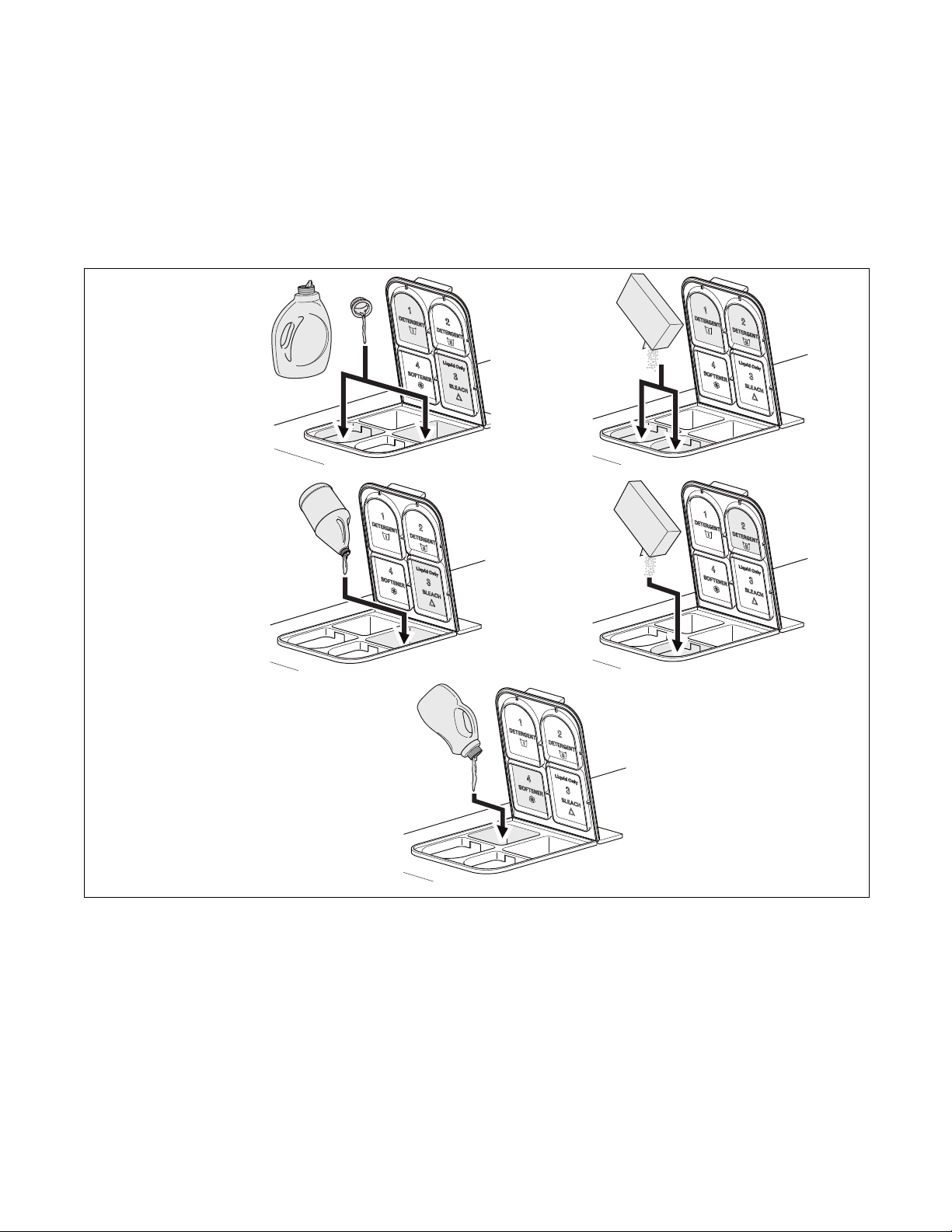

7. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 6.

a. Detergent:

• Liquid - Compartment 1 (prewash) +

Compartment 3

• Powder - Compartment 1 (prewash) +

Compartment 2

b. Bleach:

• Liquid - Compartment 3

• Powder - Compartment 2

c. Softener:

• Liquid - Compartment 4

CHM2227N

8. For vended models only. Insert coin(s) or card

• If the machine is a coin operated unit, add coins.

• If the machine is a card operated unit, insert and

• If the unit is interfaced to a central/remote pay

as necessary.

As each coin is added, the vend counts down to

the amount remaining.

remove card per card system instructions.

system, go to the central/remote pay console,

CHM2231N

Figure 6

make payment and select the machine and follow

central/remote pay system instructions.

9. Press the START keypad.

10. During first fill, the desired wash cycle can be

changed. After first fill has ended, the wash cycle

active at that moment remains the chosen wash

cycle.

11. When cycle is complete, display shows “00”.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 15

Maintenance

Sharp edges can cause personal injury.

Wear safety glasses and gloves, use

proper tools and provide lighting when

handling sheet metal parts.

W366R1

WARNING

3. Check door interlock before starting operation:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door and start the machine. The

machine should not start with the door

unlocked.

IMPORTANT: Replace all panels that are removed

to perform service and maintenance procedures.

Do not operate the machine with missing guards or

with broken or missing parts. Do not bypass any

safety devices.

Daily

IMPORTANT: Door lock should be checked daily

to ensure proper operation. Also check that all

safety and instruction stickers are on the machine.

Any missing or illegible safety instructions stickers

should be replaced immediately.

Beginning of Day

1. Inspect water inlet valve hose connections on the

back of the machine for leaks.

2. Inspect steam hose connections for leaks (where

applicable).

c. Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, disconnect power and call a service

technician.

End of Day

1. Clean the door gasket of residual detergent and

all foreign matter.

2. Clean the door glass with a damp cloth.

3. Clean automatic supply dispenser lid and general

area.

4. Clean the machine’s top, front and side panels

with mild detergent. Rinse with clean water.

5. Leave loading door open at the end of each day to

allow moisture to evaporate.

NOTE: Unload the machine promptly after each

completed cycle to prevent moisture buildup. Leave

loading door open after each completed cycle to

allow moisture to evaporate.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Maintenance

1

2

3

4

Weekly

1. Check the machine for leaks.

a. Start an unloaded cycle to fill the machine.

b. Verify that door and door gasket do not leak.

c. Verify that the drain valve is operating and

that the drain system is free from obstruction.

If water does not leak out during the first

wash segment, the drain valve is closed and

functioning properly.

For F and variable-speed models only, clean the AC

drive box filter(s) weekly or more frequently as

needed:

1. Wash the filter with warm water and allow filter

to air dry. As an alternative, the filter may be

vacuumed clean.

IMPORTANT: The control module cover and fan

filter must be in place for the fan to properly cool

the AC inverter drive. Failure to observe this

warning will void the warranty and could lead to

expensive AC inverter drive repair.

Monthly

NOTE: Disconnect power to the machine at its

source before performing the monthly maintenance

procedures.

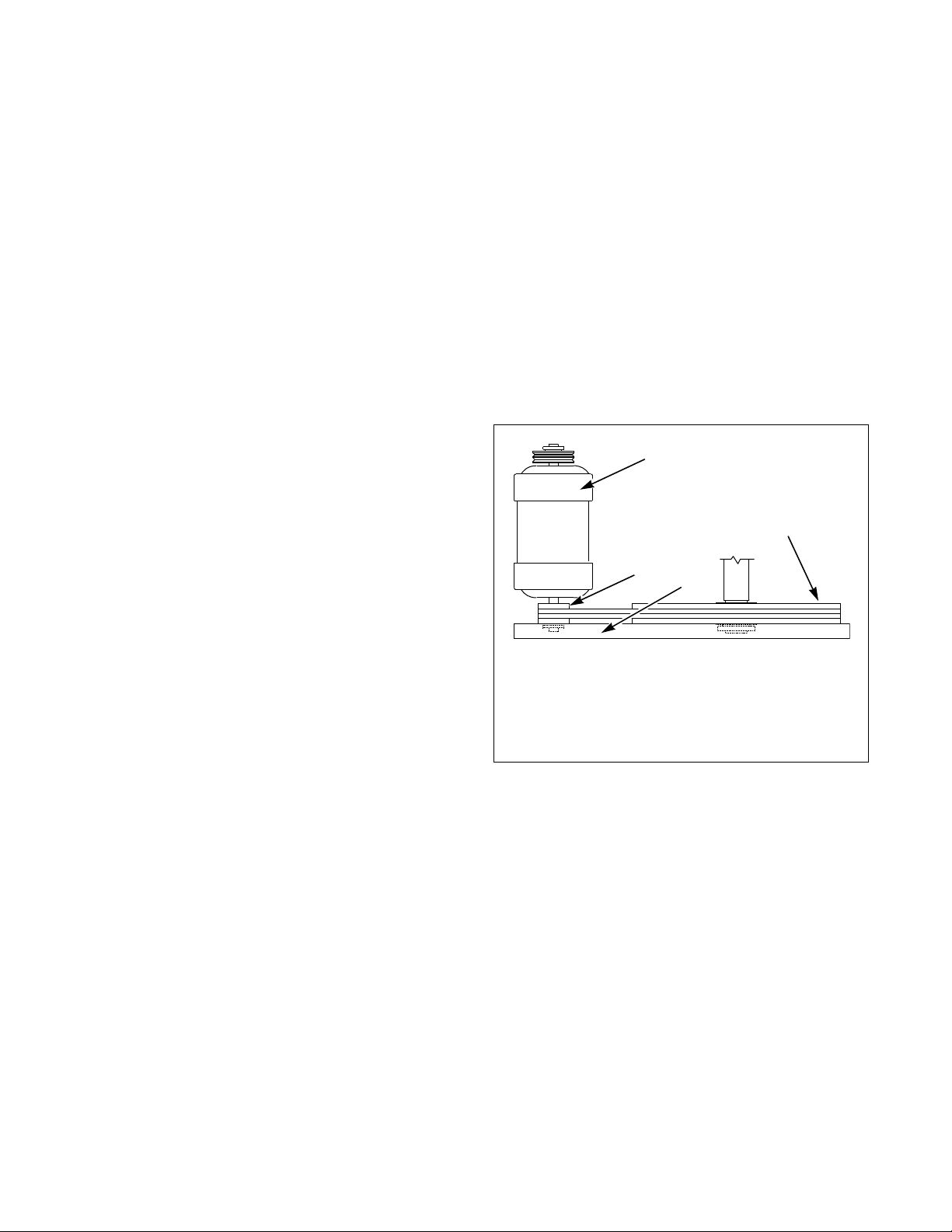

1. Use the following procedures to determine if

V-belt(s) require replacement or adjustment. Call

a qualified service technician in either case.

a. Check V-belt(s) for uneven wear and frayed

edges.

b. For groove-pulley drive systems, verify

alignment by placing a straightedge across

both pulley faces. The straightedge should

make contact with the pulleys in four places.

Refer to Figure 7.

H040I

1 Motor

2 Motor Pulley

3 Straightedge

4 Basket Pulley

Figure 7

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 17

c. For flat-pulley drive systems, verify allowable

1

2

distance of belt from edge of pulley. Refer to

Tab l e 1 below.

Flat-Pulley Alignment

Maintenance

Model

20 .09 in. (2 mm)

30 .09 in. (2 mm)

40 .09 in. (2 mm)

60 .38 in. (10 mm)

Table 1

d. For F and variable-speed models only,

verify that V-belts are properly tensioned by

Allowable

Distance from Edge

1 Deflection

2 Span Length

applying a set force to the belts and measuring

the deflection to determine the belt tension.

Refer to Table 2 for the acceptable belt’s

tension ranges. Belt tension measurements

should be taken as close to the center of the

belt span as possible. Refer to Figure 8.

Belt Tension Testing for Variable-Speed Models

Model Belt Belt Span Deflection Range

H039I

Figure 8

Force

Min – Max

40 Motor-Basket 16.9 in. (428 mm) .31 – .34 in. (7.9 – 8.7 mm) 6.1 – 7.4 lbs. (27 – 33 N)

60 Motor-Basket 16.8 in. (426 mm) .28 – .31 in. (7.1 – 7.9 mm) 6.1 – 7.4 lbs. (27 – 33 N)

80 Motor-Basket

Banded Belt

2. For 80 and 125 pound capacity models only,

lubricate bearings and seals each month OR after

every 200 hours of operation.

a. Use a premium-grade lithium-based #2

grease. Never mix two types of grease, such

as petroleum and silicone.

b. Pump the grease gun slowly, permitting only

the following number of strokes:

• Bearing grease fitting, 2 strokes

• Seal grease fitting, 2 stroke

NOTE: Do not pump the grease gun until grease

comes out of the bearing housing. This can result in

overlubrication, causing damage to bearings and

22.1 in. (561 mm) .22 – .25 in. (5.08 – 6.35 mm) 23 – 26 lbs. (102.3 – 115.6 N)

Table 2

3. Remove back panel and check overflow hose and

drain hose for leaks.

4. Unlock and remove the top cover and check the

supply dispenser hoses and hose connections.

5. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

6. Tighten motor mounting bolt locknuts and

bearing bolt locknuts. Check to see that the pin is

in place.

seals.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Maintenance

H042I

1

2

7. Use compressed air to clean lint from motor.

8. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

9. Use compressed air to clean all electrical

components of moisture and dust.

10. Verify the insulation is intact on all external wires

and that all connections are secure. If bare wire is

evident, call a service technician.

11. For F and variable-speed models only, clean

AC drive cooling fan blades monthly (more often

if required by the condition of the air).

Quarterly

NOTE: Disconnect power to the machine at its

source before performing the quarterly

maintenance procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

H042I

1 Cap

2 Filter Element

3. Verify that the drain motor shield is in place and

secure, if so equipped.

4. Check all painted surfaces for exposed metal.

(Matching paint is available from the

manufacturer.)

• If bare metal is showing, paint with primer or

solvent-based paint.

• If rust appears, remove it with sandpaper or by

chemical means and then paint with primer or

solvent-based paint.

5. Clean customer-supplied steam filter, where

applicable. Refer to Figure 9.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew cap.

c. Remove element and clean.

d. Replace element and cap.

Figure 9

6. Check the bearing mounting bolts to make sure

they are torqued properly. Refer to Tab l e 3 for

specifications.

Machine

Capacity

20 All 75 ft-lbs.

30-60 All 105 ft-lbs.

80 Front 200 ft-lbs.

80 Rear 97 ft-lbs.

Bearing Torque

Table 3

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208401

Page 19

Maintenance

Care of Stainless Steel

• Remove dirt and grease with detergent and water.

Thoroughly rinse and dry after washing.

• Avoid contact with dissimilar metals to prevent

galvanic corrosion when salty or acidic solutions

are present.

• Do not allow salty or acidic solutions to

evaporate and dry on stainless steel. Wipe clean

of any residues.

• Rub in the direction of the polish lines or “grain”

of the stainless steel to avoid scratch marks when

using abrasive cleaners. Use stainless steel wool

or soft, non-metal bristle brushes. Do not use

ordinary steel wool or steel brushes.

• If the stainless steel appears to be rusting, the

source of the rust may be an iron or steel part not

made of stainless steel, such as a nail or screw.

Tip: Paint all carbon steel parts with a heavy

protective coating. Stainless steel fasteners

should be used whenever possible.

• Remove discoloration or heat tint from

overheating by scouring with a powder or by

employing special chemical solutions.

• Do not leave sterilizing solutions on stainless

steel equipment for prolonged periods of time.

• When an external chemical supply is used,

ensure no siphoning of chemicals occurs when

the washer-extractor is not in use. Highly

concentrated chemicals can cause severe damage

to stainless steel and other components within the

machine. Damage of this kind is not covered by

the manufacturer’s warranty. Locate the pump

and tubing below the washer-extractor’s injection

point to prevent siphoning of chemicals into the

machine.

F8208401

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Loading...

Loading...