Page 1

Washer-Extractors

CHM1772C

CHM1772C

Cabinet Hardmount

Refer to Page 6 for Model Identification

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. F8208301R8

October 2012

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 2

Explanation of Safety Messages........................................................... 2

Important Safety Instructions ............................................................... 2

Safety Decals ........................................................................................ 4

Operator Safety..................................................................................... 5

Introduction......................................................................................... 6

Model Identification ............................................................................. 6

Delivery Inspection............................................................................... 11

Nameplate Location.............................................................................. 11

Replacement Parts ................................................................................ 13

Customer Service.................................................................................. 13

Specifications and Dimensions........................................................... 14

Dimensional Clearances ....................................................................... 23

Installation........................................................................................... 24

Machine Foundation ............................................................................. 24

Concrete Foundation Installation..................................................... 26

Machine Anchoring .............................................................................. 29

Direct-to-Finished-Floor Installation ............................................... 29

Elevated Base Frame Installation..................................................... 30

Mounting Bolt Hole Locations (Without Elevated Base Frames)........ 32

Mounting Bolt Hole Locations (With Elevated Base Frames)............. 38

Drain Connection.................................................................................. 42

Water Connection Requirements.......................................................... 44

Electrical Installation Requirements..................................................... 45

Input Power Conditioning..................................................................... 46

Input Voltage Requirements ............................................................ 47

Circuit Breakers and Quick Disconnects ......................................... 47

Connection Specifications ............................................................... 47

Grounding ........................................................................................ 47

Phase Adder ..................................................................................... 48

Thermal Overload Protector ............................................................ 48

Steam Requirements (Steam Heat Option Only).................................. 54

Supply Dispensing ................................................................................ 54

External Supplies.................................................................................. 55

Connection of External Liquid Supplies.......................................... 56

Start Up................................................................................................ 57

Basket Rotation..................................................................................... 57

© Copyright 2012, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Install the washer according the

INSTALLATION instructions. Refer to the

GROUNDING instructions in the

INSTALLATION manual for the proper

grounding of the washer. All connections for

water, drain, electrical power and grounding must

comply with local codes and be made by licensed

personnel when required. It is recommended that

the machine be installed by qualified technicians.

3. Do not install or store the washer where it will be

exposed to water and/or weather.

4. To prevent fire and explosion, keep the area

around machine free from flammable and

combustible products. Do not add the following

substances or textiles containing traces of the

following substances to the wash water: gasoline,

kerosene, waxes, cooking oils, vegetable oils,

machine oils, dry-cleaning solvents, flammable

chemicals, thinners, or other flammable or

explosive substances. These substances give off

vapors that could ignite, explode or cause the

fabric to catch fire by itself.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

6. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

F8208301

Page 5

Safety Information

7. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This appliance

is not intended for use by young children or

infirm persons without supervision. Young

children should be supervised to ensure that they

do not play with the appliance. This is a safety

rule for all appliances.

8. DO NOT reach and/or climb into the tub or onto

the washer, ESPECIALLY if the wash drum is

moving. This is an imminently hazardous

situation that, if not avoided, will cause severe

personal injury or death.

9. Never operate the washer with any guards, panels

and/or parts removed or broken. DO NOT bypass

any safety devices or tamper with the controls.

10. Use washer only for its intended purpose,

washing textiles. Never wash machine parts or

automotive parts in the machine. This could

result in serious damage to the basket or tub.

11. Use only low-sudsing, no-foaming types of

commercial detergent. Be aware that hazardous

chemicals may be present. Wear hand and eye

protection when adding detergents and

chemicals. Always read and follow

manufacturer’s instructions on packages of

laundry and cleaning aids. Heed all warnings or

precautions. To reduce the risk of poisoning or

chemical burns, keep them out of the reach of

children at all times (preferably in a locked

cabinet).

12. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

13. Always follow the fabric care instructions

supplied by the textile manufacturer.

14. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open. Do not

attempt to open the door until the washer has

drained and all moving parts have stopped.

15. Be aware that hot water is used to flush the

supply dispenser. Avoid opening the dispenser lid

while the machine is running.

16. Do not attach anything to the supply dispenser’s

nozzles, if applicable. The air gap must be

maintained.

18. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

20. DANGER: Before inspecting or servicing

machine, power supply must be turned OFF. The

servicer needs to wait for at least 3 minutes after

turning the power OFF and needs to check for

residual voltage with a voltage meter. The

inverter capacitor or EMC filter remains charged

with high voltage for some time after powering

OFF. This is an imminently hazardous situation

that, if not avoided, will cause severe personal

injury or death.

21. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out. ALWAYS disconnect the

washer from electrical, power and water supplies

before attempting any service.

22. Disconnect the power cord by grasping the plug,

not the cord. Replace worn power cords and/or

loose plugs. If the supply cord is damaged, it

must be replaced by a special cord or assembly

available from the service agent.

23. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

24. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

17. Do not operate the machine without the water

reuse plug or water reuse system in place, if

applicable.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Install the machine on a level floor of

sufficient strength. Failure to do so may

result in conditions which can produce

serious injury, death and/or property

damage.

W703

WARNING

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

IMPORTANT: Ensure that the recommended

clearances for inspection and maintenance are

provided. Never allow the inspection and

maintenance space to be blocked.

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 7

Safety Information

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Operating the machine with severe out-ofbalance loads could result in personal

injury and serious equipment damage.

W728

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door and start the machine. The

machine should not start with the door

unlocked.

Do not bypass any safety devices in the machine.

c. Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, disconnect power and call a service

technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

Model Identification

Information in this manual is applicable to these

models:

HCD020GD2

HCD020JD2

HCD020LD2

HCL020GD2

HCL020GN2

HCL020HDF

HCL020HN2

HCL020KD2

HCL020KDF

HCL020KDV

HCL020LD2

HCN020GC2

HCN020GD2

HCN020GE2

HCN020GN2

20 POUND

HCN020GX2

HCN020GY2

HCN020HC2

HCN020HCF

HCN020HD2

HCN020HN2

HCN020HNF

HCN020HY2

HCN020HYF

HCN020KC2

HCN020KCF

HCN020KCV

HCN020KD2

HCN020KDV

HCN020KDV

HCN020KEF

HCN020KEV

HCN020KY2

HCN020KYF

HCN020KYV

HCU020GC2

HCU020GD2

HCU020GE2

HCU020GL2

HCU020GN2

HCU020GX2

HCU020GY2

HCU020HC2

HCU020HN2

HCU020HNF

HCU020HX2

HCU020KCF

HCU020KCV

HCU020KE2

HCU020KEV

HCU020KL2

HCU020KY2

HCU020KYF

HCU020KYV

HCZ020GN2

HCZ020HN2

SCL020GC2

SCL020GN2

SCL020HN2

SCL020HNF

SCL020JC2

SCL020JD2

SCL020JDF

SCL020JE2

SCL020JEF

SCL020JX2

SCN020GC2

SCN020GD2

SCN020GE2

SCN020GN2

SCN020GX2

SCN020GY2

SCN020HN2

SCN020HNF

SCN020JC2

SCN020JCF

SCN020JCV

SCN020JD2

SCN020JEF

SCN020JXF

SCN020JY2

Model

(Continued)

SCN020JYF

SCN020JYV

SCN020KN2

SCN020KNF

SCN020LC2

SCN020LCF

SCN020LCV

SCN020LD2

SCN020LX2

SCN020LY2

SCN020LYF

SCN020LYV

SCN020WC2

SCN020WCF

SCN020WCV

SCN020WD2

SCN020WDV

SCN020WY2

SCN020WYF

SCN020WYV

SCU020GC2

SCU020GD2

SCU020GE2

SCU020GL2

SCU020GN2

SCU020GX2

SCU020GY2

SCU202HN2

SCU020HNF

SCU020JC2

SCU020JCF

SCU020JCV

SCU020JD2

SCU020JDF

SCU020JDV

SCU020JE2

SCU020JEF

SCU020JEV

SCU020JL2

SCU020JLF

SCU020JLV

SCU020JX2

SCU020JXF

SCU020JXV

SCU020JY2

SCU020JYF

SCU020JYV

SCU020KN2

SCU020KNF

SCU020LC2

SCU020LCV

SCU020LD2

SCU020LDV

SCU020LE2

SCU020LEV

SCU020LX2

SCU020LXV

SCU020LY2

SCU020LYV

SCU020WC2

SCU020WCV

SCU020WD2

SCU020WDV

SCU020WE2

SCU020WEV

SCU020WX2

SCU020WXV

SCU020WY2

SCU020WYV

UCL020GN2

UCL020HN2

UCL020KN2

UCN020GN2

UCN020HN2

UCN020HNF

UCN020KN2

UCU020GN2

UCU020HN2

UCU020HNF

UCU020KN2

UCZ020GN2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 9

HCD030LD2

HCL030GN2

HCL030HDF

HCL030HN2

HCL030HNF

HCL030KD2

HCL030KDF

HCL030KDV

HCN030GC2

HCN030GD2

HCN030GE2

HCN030GN2

HCN030GX2

HCN030GY2

HCN030HC2

HCN030HCF

30 POUND

HCN030HD2

HCN030HN2

HCN030HNF

HCN030HY2

HCN030HYF

HCN030KC2

HCN030KCF

HCN030KCV

HCN030KD2

HCN030KDV

HCN030KEF

HCN030KY2

HCN030KYF

HCN030KYV

HCU030GC2

HCU030GD2

HCU030GE2

HCU030GL2

HCU030GN2

HCU030GX2

HCU030GY2

HCU030HC2

HCU030HN2

HCU030HNF

HCU030HX2

HCU030KCF

HCU030KCV

HCU030KE2

HCU030KEV

HCU030KY2

HCU030KYF

HCU030KYV

HCZ030GN2

SCD030GD2

SCD030LD2

SCL030GC2

SCL030GN2

SCL030HN2

SCL030HNF

SCL030JC2

SCL030JCF

SCL030JD2

(Continued)

Model

SCL030JDF

SCL030JE2

SCL030JEF

SCL030JX2

SCL030JXF

SCL030JY2

SCL030KN2

SCL030KNF

SCL030KNV

SCL030LD2

SCL030LEV

SCN030GC2

SCN030GD2

SCN030GE2

SCN030GN2

SCN030GX2

SCN030GY2

SCN030HN2

SCN030HNF

SCN030JC2

SCN030JCF

SCN030JCV

SCN030JD2

SCN030JE2

SCN030JEF

SCN030JX2

SCN030JY2

SCN030JYF

SCN030JYV

(Continued)

SCN030KN2

SCN030KNF

SCN030LC2

SCN030LCF

SCN030LCV

SCN030LD2

SCN030LE2

SCN030LY2

SCN030LYF

SCN030LYV

SCN030WC2

SCN030WCF

SCN030WCV

SCN030WD2

SCN030WDV

SCN030WLV

SCN030WX2

SCN030WY2

SCN030WYF

SCN030WYV

SCU030GC2

SCU030GD2

SCU030GE2

SCU030GL2

SCU030GN2

SCU030GX2

SCU030GY2

SCU030HN2

SCU030HNF

SCU030JC2

SCU030JCF

SCU030JCV

SCU030JD2

SCU030JDF

SCU030JDV

SCU030JE2

SCU030JEF

SCU030JEV

SCU030JL2

SCU030JLF

SCU030JLV

SCU030JX2

SCU030JXF

SCU030JXV

SCU030JY2

SCU030JYF

SCU030JYV

SCU030KN2

SCU030KNF

SCU030LC2

SCU030LCV

SCU030LD2

SCU030LDV

SCU030LE2

SCU030LEV

SCU030LX2

SCU030LXV

SCU030LY2

Introduction

SCU030LYV

SCU030WC2

SCU030WCV

SCU030WD2

SCU030WDV

SCU030WE2

SCU030WEV

SCU030WX2

SCU030WXV

SCU030WY2

SCU030WYV

UCL030GN2

UCL030HN2

UCL030HNF

UCL030KN2

UCN030GN2

UCN030HN2

UCN030HNF

UCN030KN2

UCN030KNF

UCU030GN2

UCU030HN2

UCU030HNF

UCU030KN2

UCZ030GN2

VCU030GN2

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Introduction

HCD040LD2

HCL040GN2

HCL040HC2

HCL040HDF

HCL040HE2

HCL040HN2

HCL040KD2

HCL040KDF

HCL040KDV

HCN040GC2

HCN040GD2

HCN040GE2

HCN040GN2

HCN040GX2

HCN040GY2

HCN040HC2

40 POUND

HCN040HCF

HCN040HD2

HCN040HN2

HCN040HNF

HCN040HY2

HCN040HYF

HCN040KC2

HCN040KCF

HCN040KCV

HCN040KD2

HCN040KDF

HCN040KDV

HCN040KEF

HCN040KEV

HCN040KY2

HCN040KYF

HCN040KYV

HCU040GC2

HCU040GD2

HCU040GE2

HCU040GL2

HCU040GN2

HCU040GX2

HCU040GY2

HCU040HC2

HCU040HN2

HCU040HNF

HCU040HX2

HCU040KCF

HCU040KCV

HCU040KE2

HCU040KEV

HCU040KY2

HCU040KYF

HCU040KYV

SCD040GD2

SCD040LD2

SCL040GC2

SCL040GN2

SCL040HN2

SCL040HNF

SCL040JC2

(Continued)

Model

SCL040JD2

SCL040JDF

SCL040JE2

SCL040JEF

SCL040JX2

SCL040JXF

SCL040JXV

SCL040KN2

SCL040KNF

SCL040KNV

SCL040LE2

SCN040GC2

SCN040GD2

SCN040GE2

SCN040GN2

SCN040GX2

SCN040GY2

SCN040HN2

SCN040HNF

SCN040JC2

SCN040JCF

SCN040JCV

SCN040JD2

SCN040JE2

SCN040JEF

SCN040JY2

SCN040JYF

SCN040JYV

SCN040KN2

(Continued)

SCN040KNF

SCN040KNV

SCN040LC2

SCN040LCF

SCN040LCV

SCN040LD2

SCN040LDV

SCN040LE2

SCN040LY2

SCN040LYF

SCN040LYV

SCN040WC2

SCN040WCF

SCN040WCV

SCN040WDV

SCN040WX2

SCN040WY2

SCN040WYF

SCN040WYV

SCU040GC2

SCU040GD2

SCU040GE2

SCU040GL2

SCU040GN2

SCU040GX2

SCU040GY2

SCU040HN2

SCU040HNF

SCU040JC2

SCU040JCF

SCU040JCV

SCU040JD2

SCU040JDF

SCU040JDV

SCU040JE2

SCU040JEF

SCU040JEV

SCU040JL2

SCU040JLF

SCU040JLV

SCU040JX2

SCU040JXF

SCU040JXV

SCU040JY2

SCU040JYF

SCU040JYV

SCU040KN2

SCU040KNF

SCU040KNV

SCU040LC2

SCU040LCV

SCU040LD2

SCU040LDV

SCU040LE2

SCU040LEV

SCU040LX2

SCU040LXV

SCU040LY2

SCU040LYV

SCU040WC2

SCU040WCV

SCU040WD2

SCU040WDV

SCU040WE2

SCU04WEV

SCU040WX2

SCU040WXV

SCU040WY2

SCU040WYV

UCL040GN2

UCL040HN2

UCL040HNF

UCL040KN2

UCL040KNF

UCL040KNV

UCN040GN2

UCN040HN2

UCN040HNF

UCN040KN2

UCN040KNF

UCN040KNV

UCU040GN2

UCU040HN2

UCU040HNF

UCU040KN2

UCU040KNV

VCU040GN2

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 11

HCD060LD2

HCL060GN2

HCL060HCF

HCL060HN2

HCL060KD2

HCL060KDF

HCL060KDV

HCN060GC2

HCN060GD2

HCN060GE2

HCN060GN2

HCN060GX2

HCN060GY2

HCN060HC2

HCN060HCF

HCN060HDF

60 POUND

HCN060HN2

HCN060HNF

HCN060HY2

HCN060HYF

HCN060KC2

HCN060KCF

HCN060KCV

HCN060KD2

HCN060KDF

HCN060KDV

HCN060KEV

HCN060KEF

HCN060KY2

HCD080LDV

HCL080HNF

HCL080KDF

HCL080KDV

HCN080GCF

HCN080GDF

HCN080GEF

HCN080GNF

HCN080GXF

HCN080GYF

80 POUND

HCN080HCF

HCN080HCV

HCN080HDF

HCN080HNF

HCN080HYF

HCN080HYV

HCN080KCF

SCL125KNV

SCN125KNV

SCN125LYV

SCN125WYV

SCU125KNV

125 POUND

HCN060KYF

HCN060KYV

HCU060GC2

HCU060GD2

HCU060GE2

HCU060GL2

HCU060GN2

HCU060GX2

HCU060GY2

HCU060HC2

HCU060HN2

HCU060HNF

HCU060HX2

HCU060KCF

HCU060KCV

HCU060KEV

HCU060KY2

HCU060KYF

HCU060KYV

SCD060GD2

SCD060LD2

SCL060GC2

SCL060GN2

SCL060HN2

SCL060HNF

SCL060JC2

SCL060JCF

SCL060JD2

SCL060JE2

HCN080KCV

HCN080KDF

HCN080KDV

HCN080KEV

HCN080KYF

HCN080KYV

HCU080GCF

HCU080GDF

HCU080GEF

HCU080GLF

HCU080GNF

HCU080GXF

HCU080GYF

HCU080HCF

HCU080HNF

HCU080HXF

HCU080KCF

UCL125KNV

UCU125KNV

(Continued)

Model

SCL060JXF

SCL060KN2

SCL060KNV

SCL060LE2

SCN060GC2

SCN060GD2

SCN060GE2

SCN060GN2

SCN060GNF

SCN060GX2

SCN060GY2

SCN060HN2

SCN060HNF

SCN060JC2

SCN060JCF

SCN060JCV

SCN060JD2

SCN060JDF

SCN060JEF

SCN060JX2

SCN060JY2

SCN060JYF

SCN060JYV

SCN060KN2

SCN060KNF

SCN060KNV

SCN060LC2

SCN060LCF

SCN060LCV

HCU080KCV

HCU080KYF

HCU080KYV

SCD080LDV

SCL080GNF

SCL080HNF

SCL080KNV

SCN080GCF

SCN080GDF

SCN080GEF

SCN080GNF

SCN080GXF

SCN080GYF

SCN080HNF

SCN080JCF

SCN080JCV

SCN080JDF

SCN060LD2

SCN060LDV

SCN060LE2

SCN060LY2

SCN060LYF

SCN060LYV

SCN060WC2

SCN060WCF

SCN060WCV

SCN060WD2

SCN060WDV

SCN060WEV

SCN060WY2

SCN060WYF

SCN060WYV

SCU060GC2

SCU060GD2

SCU060GE2

SCU060GL2

SCU060GN2

SCU060GX2

SCU060GY2

SCU060HN2

SCU060HNF

SCU060JC2

SCU060JCF

SCU060JCV

SCU060JD2

SCU060JDF

SCN080JYF

SCN080JYV

SCN080KNV

SCN080LCV

SCN080LDV

SCN080LYV

SCN080WCV

SCN080WDV

SCN080WYV

SCU080GCF

SCU080GDF

SCU080GEF

SCU080GLF

SCU080GNF

SCU080GXF

SCU080GYF

SCU080HNF

SCU060JDV

SCU060JE2

SCU060JEF

SCU060JEV

SCU060JL2

SCU060JLF

SCU060JLV

SCU060JX2

SCU060JXF

SCU060JXV

SCU060JY2

SCU060JYF

SCU060JYV

SCU060KN2

SCU060KNF

SCU060KNV

SCU060LC2

SCU060LCV

SCU060LD2

SCU060LDV

SCU060LE2

SCU060LEV

SCU060LX2

SCU060LXV

SCU060LY2

SCU060LYV

SCU060WC2

SCU060WCV

SCU060WD2

SCU080JCF

SCU080JCV

SCU080JDF

SCU080JDV

SCU080JEF

SCU080JEV

SCU080JLF

SCU080JLV

SCU080JYF

SCU080JYV

SCU080JXF

SCU080JXV

SCU080KNV

SCU080LCV

SCU080LDV

SCU080LEV

SCU080LXV

Introduction

SCU060WDV

SCU060WE2

SCU060WEV

SCU060WX2

SCU060WXV

SCU060WY2

SCU060WYV

UCL060GN2

UCL060HN2

UCL060HNF

UCL060KN2

UCL060KNF

UCL060KNV

UCN060GN2

UCN060HN2

UCN060HNF

UCN060KN2

UCN060KNF

UCN060KNV

UCU060GN2

UCU060HN2

UCU060HNF

UCU060KN2

UCU060KNV

VCU060GN2

SCU080LYV

SCU080WCV

SCU080WDV

SCU080WEV

SCU080WXV

SCU080WYV

UCL080GNF

UCL080HNF

UCL080KNV

UCN080GNF

UCN080HNF

UCN080KNV

UCU080GNF

UCU080HNF

UCU080KNV

VCU080GNF

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Introduction

1

This manual is designed as a guide to the installation

of the Cabinet Hardmount Washer-Extractor.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

Delivery Inspection

Upon delivery, visually inspect crate, protective cover,

and unit for any visible shipping damage. If the crate,

protective cover, or unit is damaged or signs of

possible damage are evident, have the carrier note the

condition on the shipping papers before the shipping

receipt is signed, or advise the carrier of the condition

as soon as it is discovered.

Remove the crate and protective cover as soon after

delivery as possible. If any damage is discovered upon

removal of the crate and/or protective cover, advise the

carrier and file a written claim immediately.

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance. Refer to Figure 1.

CHM2233N

1 Nameplate

Figure 1

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 13

Model Number Familiarization Guide

Hz

Phase

Supply Water:

BAR

Number of wires :

FLA :

amps

Circuit Breaker Size :

amps

Serial No.

Model No.

Voltage

Max. Load :

Schematic :

KG

LB

EXAMPLE OF NAMEPLATE

Sample Model Number: *CN040GC2OU1D01

Introduction

*C

N

040

G

C

2

O

U

1

D

01

* Denotes Brand

Product Family

Agency Approval

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control

Actuation (C = Coin drop)

Washer-Extractor Speed Capability (2 = 2 speed)

Electrical Characteristics

Panel Type

Design Series

Heat Feature (D = Direct Steam)

Option Identification (varies from machine to machine)

Model No.

Serial No.

Voltage

Number of wires :

Circuit Breaker Size :

Max. Load :

Schematic :

Supply Water:

208 – 240

40

*CN040GC2OUID01

00000000000

Hz

60 3

3

amps

3

LB

FLA :

18.2

KG

30 - 85 psi, 2 - 5.7

Figure 2

Phase

amps

BAR

CHM2286N

CHM2286N

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Introduction

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, contact your local distributor

or contact:

Alliance Laundry Systems

Shepard Street

P. O . B ox 99 0

Ripon, Wisconsin 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121

+3256412054

Wevelgem, Belgium

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 15

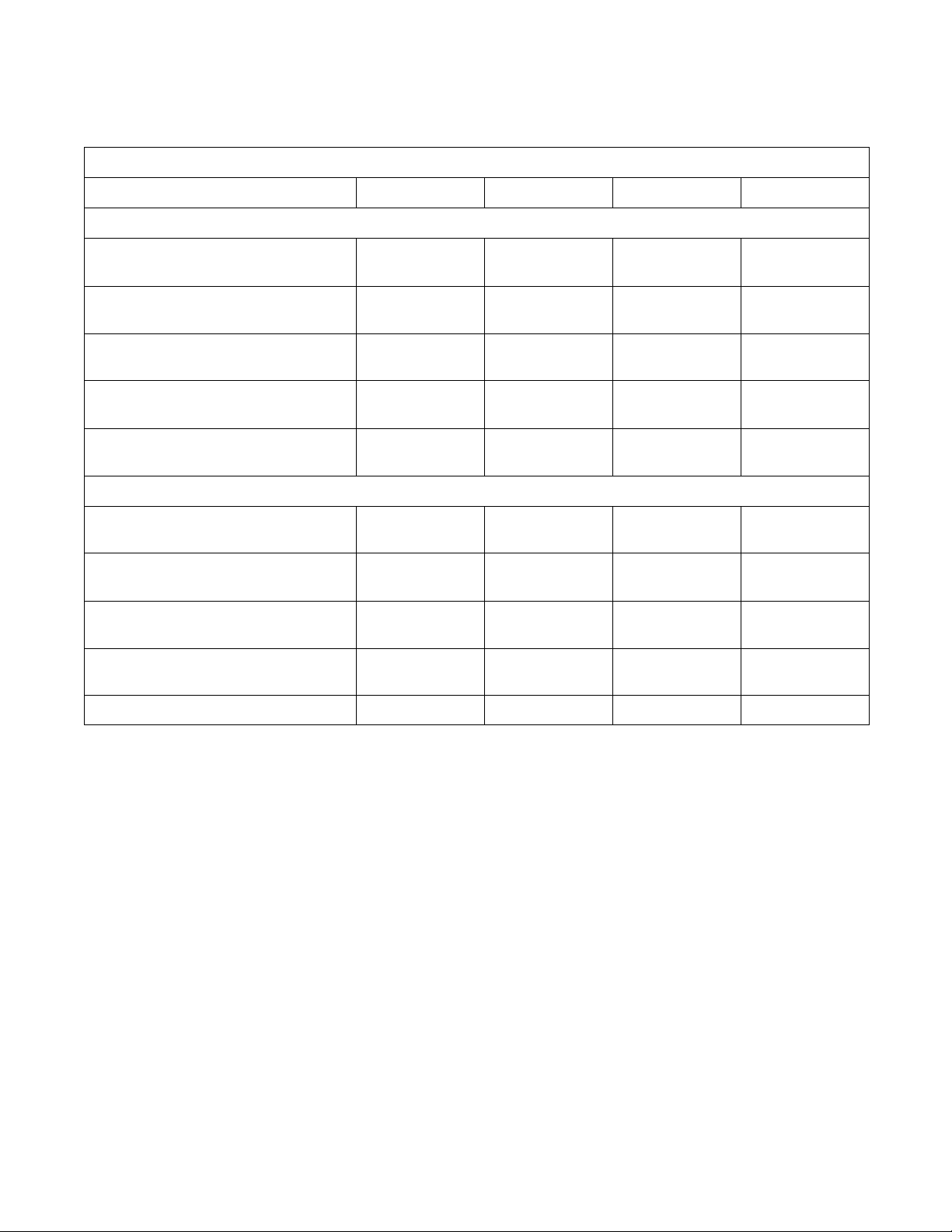

Specifications and Dimensions

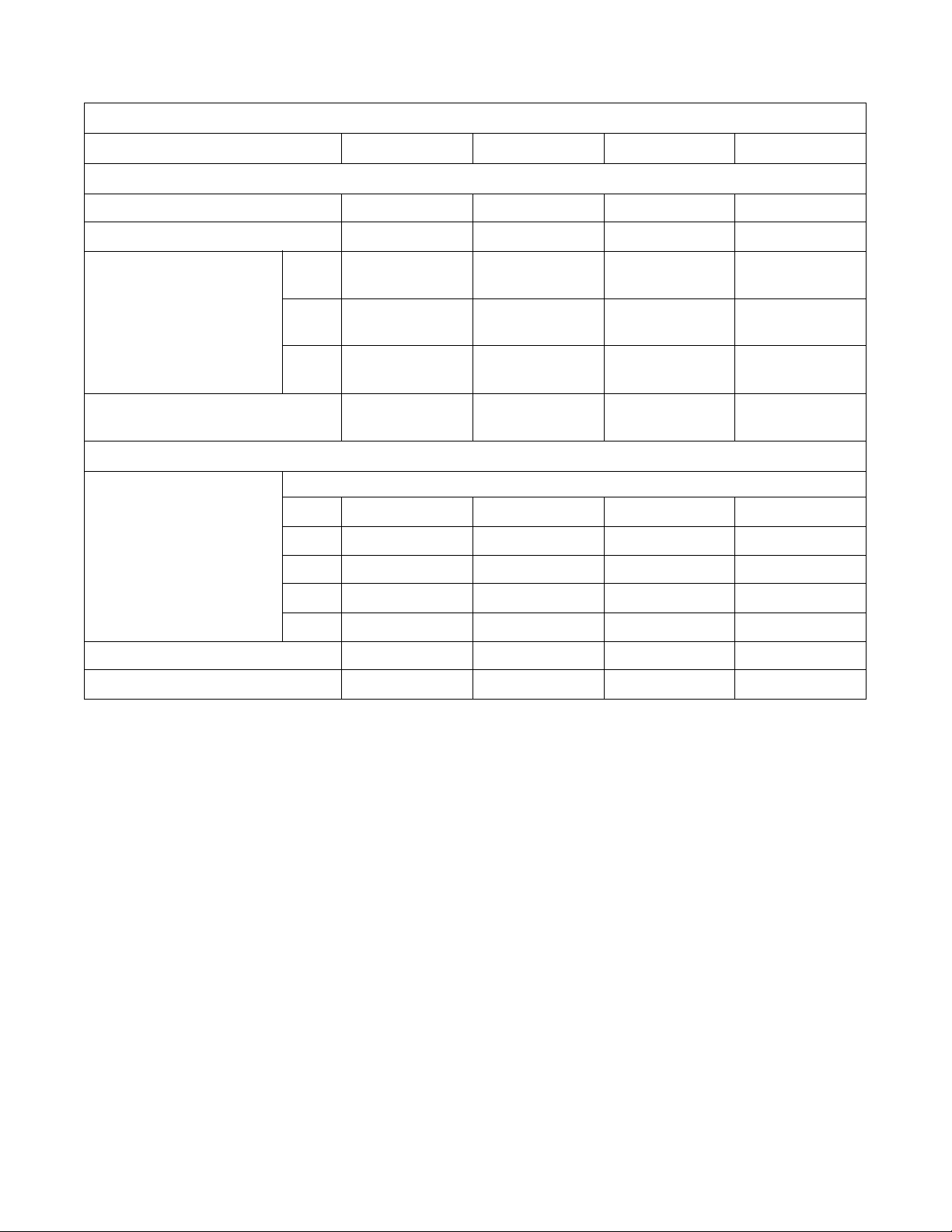

Specification 20 30 40 60

Weight and Shipping Information

2 Speed Models

Net weight, lbs. (kg) 387

(176)

Domestic shipping weight, lbs. (kg) 420

(191)

Domestic shipping volume, ft.

Export shipping weight, lbs. (kg) 475

Export shipping volume, ft.

Wash Cylinder Information

Cylinder diameter, in. (mm) 21

Cylinder depth, in. (mm) 13.75

Cylinder volume, ft.

Perforation size, in. (mm) 0.188

3

(l) 2.76

3

(m3) 30.5

(.86)

(215)

3

(m3) 36.2

(1.03)

(533)

(349)

(78.1)

(4.76)

489

(222)

530

(240)

40.75

(1.15)

593

(269)

49.9

(1.41)

24

(610)

16

(406)

4.19

(118.6)

0.188

(4.76)

692

(314)

734

(333)

50

(1.42)

816

(370)

60

(1.70)

26.25

(667)

20.25

(514)

6.34

(180)

0.188

(4.76)

812

(368)

854

(387)

64

(1.81)

948

(430)

75.8

(2.15)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

Perforation open area, % 17 23 17.5 18

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

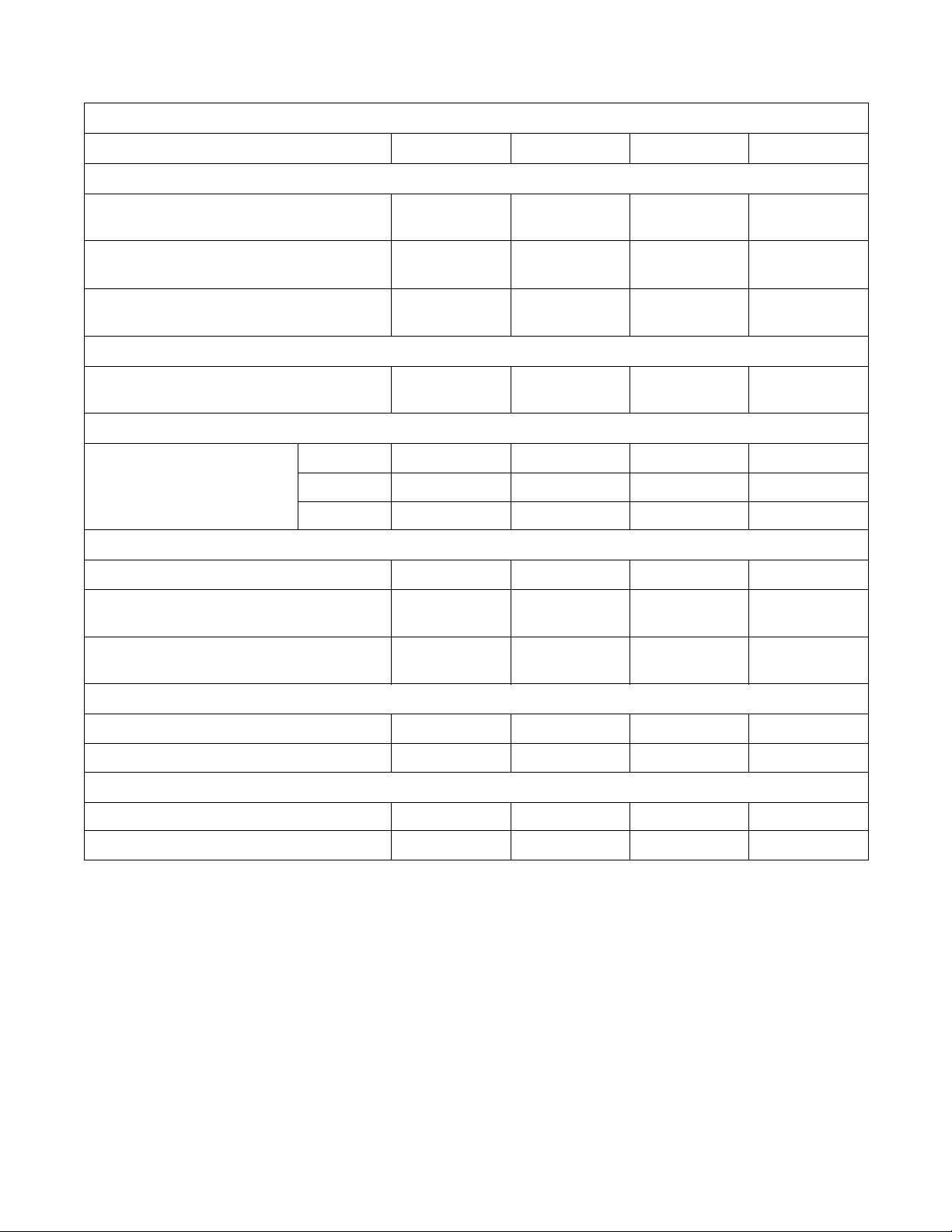

Specifications and Dimensions

Specification 20 30 40 60

Door Opening Information

2 Speed Models (Continued)

Door opening diameter, in. (mm)

Height of door bottom above floor, in. (mm)

Height of door opening above floor, in. (mm)

11.63

(295)

14.38

(365)

17.19

(437)

14.34

(364)

14

(356)

17

(431)

16.25

(413)

14.5

(368)

19

(483)

16.25

(413)

(381)

(470)

Estimated Building Heat Load

HVAC load, BTU/hr. (Kcal./hr.)

400

(101)

450

(113)

510

(129)

(189)

Power Consumption

Average power used per cycle,

kW-hr.

No load .06 .13 .196 .25

Sheets .10 .14 .195 .26

Towels .11 .16 .213 .33

Drive Train Information

Number of motors in drive train 1 1 1 1

Wash/reverse power, HP (kW) 0.15

(0.11)

High extract power, HP (kW) 0.74

(0.55)

0.24

(0.18)

1.34

(1.00)

0.40

(0.30)

1.8

(1.3)

(0.41)

(2.01)

15

18.5

750

0.55

2.7

Cylinder Speeds

Wash/reverse speed, RPM 57 49 51 44

High extract speed, RPM 528 464 491 469

Centrifugal Force Data

Wash/reverse centrifugal force, G 0.9 0.8 0.8 0.9

High extract centrifugal force, G 80.3 72.1 78.1 85.4

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 17

Specifications and Dimensions

2 Speed Models (Continued)

Specification 20 30 40 60

Direct Steam Heating (Optional)

Steam inlet connection size, NPT N/A N/A 1/2 1/2

Number of steam inlets N/A N/A 1 1

Steam required to raise bath

water temperature,

LOW N/A N/A

2.09

(0.84)

3.6

(0.895)

10°F (10°C), lbs. (kg)

Average steam use per cycle,

bhp (kg)

MED N/A

HIGH N/A

N/A

N/A 2.40

(1.15)

N/A 2.84

(1.48)

0.73

(6.9)

1.43

(12.2)

4.4

(1.384)

5.5

(1.916)

2.32

(15.4)

Electrical Heating (Optional)

Total electrical heating

capacity, kW

Input Voltage

200V 5.4 5.4 10.8 10.8

240V 7.8 7.8 15.6 15.6

380V 6.5 6.5 13.0 13.0

415V 7.8 7.8 15.5 15.5

480V 10.4 10.4 15.6 15.6

Electrical heating elements 3 3 6 6

Electrical heat element size, kW 2.6 2.6 2.6 2.6

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Specifications and Dimensions

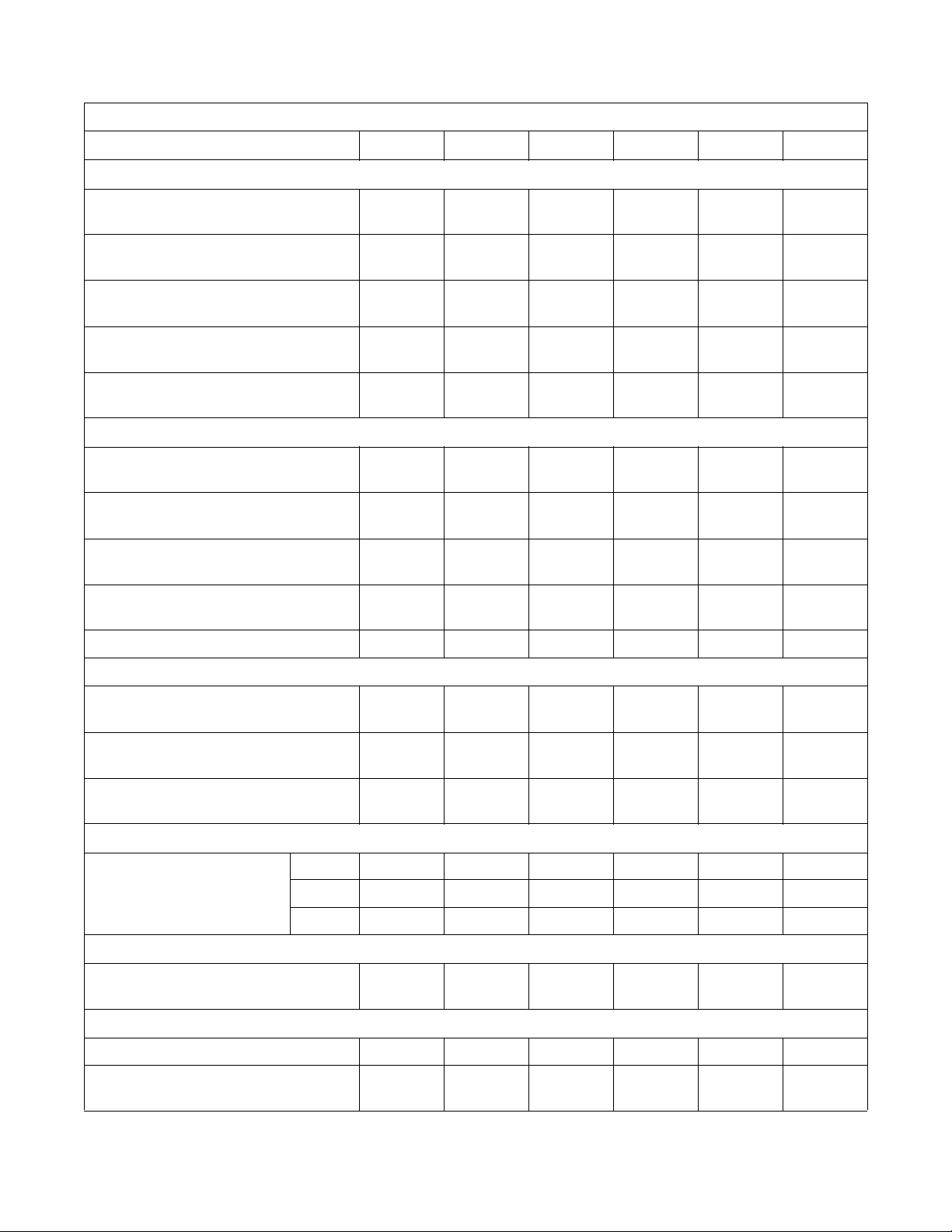

Specification 20 30 40 60 80 125

Weight and Shipping Information

V-Speed and F-Speed Models

Net weight, lbs. (kg) 386

(175)

Domestic shipping weight, lbs. (kg) 424

(191)

Domestic shipping volume, ft.

3

(m3)27

(0.76)

Export shipping weight, lbs. (kg) 476

(215)

Export shipping volume, ft.

3

(m3) 36.7

(1.04)

498

(226)

545

(245)

34.4

(.98)

588

(267)

49.5

(1.40)

706

(321)

744

(338)

43.6

(1.24)

846

(385)

65.6

(1.86)

773

(350)

824

(373)

52.2

(1.48)

1020

(463)

74.7

(3.35)

1374

(623)

1461

(663)

102.2

(2.89)

1573

(714)

118.3

(3.35)

2301

(1044)

2384

(1081)

163

(4.3)

2492

(1130)

173

(4.8)

Wash Cylinder Information

Cylinder diameter, in. (mm) 21

(533)

Cylinder depth, in. (mm) 13.75

(349)

Cylinder volume, ft.

3

(l) 2.76

(78.1)

Perforation size, in. (mm) 0.188

(4.76)

24

(610)

16

(406)

4.19

(118)

0.188

(4.76)

26.25

(667)

20.25

(514)

6.34

(180)

0.188

(4.76)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

36

(914)

22

(559)

12.4

(354)

0.188

(4.76)

42

(1067)

24

(610)

19.2

(544)

0.188

(4.76)

Perforation open area, % 17 23 17.5 18 18 24

Door Opening Information

Door opening size, in. (mm) 11.63

(295)

Height of door bottom above floor,

in. (mm)

Height of door opening above floor,

in. (mm)

14.38

(365)

17.19

(437)

14.34

(364)

14

(356)

17

(431)

16.25

(413)

14.5

(368)

18

(457)

16.25

(413)

18.25

(445)

18.5

(470)

18.5

(470)

17.75

(451)

21.63

(549)

(508)

(737)

30.25

(768)

Power Consumption

Average power used per cycle,

kW-hr.

No load .06 .13 .196 .25 .30 .63

Sheets .10 .14 .195 .26 .28 .64

Towels .11 .16 .213 .33 .34 .83

Estimated Building Heat Load

HVAC load, BTU/hr. (Kcal./hr.) 400

(101)

450

(113)

510

(129)

750

(189)

950

(239)

1200

(302)

Drive Train Information

Number of motors in drive train 1 1 1 1 1 1

Drive motor power, hp (kW) 1

(.75)

1

(.75)

2

(1.7)

3

(2.2)

5

(3.7)

7.5

(5.6)

20

29

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 19

Specifications and Dimensions

V-Speed and F-Speed Models (Continued)

Specification 20 30 40 60 80 125

Cylinder Speeds

Gentle wash/reverse speed, RPM 292726262226

Wash/reverse speed, RPM 525246434037

Distribution speed, RPM 929282777065

Low extract speed, RPM 366 366 328 307 280 260

Medium extract speed, RPM (Not

534 534 478 447 408 378

available on Electronic Control models)

High extract speed, RPM 686 686 613 574 524 485

Centrifugal Force Data

Gentle wash centrifugal force, G 0.25 0.25 0.25 0.25 0.25 0.43

Wash/reverse centrifugal force, G 0.8 0.8 0.8 0.8 0.8 0.8

Distribution centrifugal force, G 2.5 2.5 2.5 2.5 2.5 2.6

Extract Speed 1, G 808080808080

Extract Speed 2, G 100 100 100 100 100 100

Extract Speed 3 (V-Speed only), G 120 120 120 120 120 120

Extract Speed 4 (V-Speed only), G 140 140 140 140 140 140

Direct Steam Heating (Optional)

Steam inlet connection size, NPT N/A N/A 1/2 1/2 1/2 3/4

Number of steam inlets N/AN/A1111

Steam required to raise bath

water temperature

10°F (10°C), lbs. (kg)

LOW N/A N/A

MED N/A N/A

2.09

(0.94)

2.40

(1.09)

3.6

(1.63)

4.4

(2.00)

2.58

(1.17)

4.65

(2.11)

3.64

(1.65)

5.17

(2.35)

HIGH N/A N/A

Average steam use per cycle, bhp (kg) N/A 0.73

(6.9)

2.84

(1.29)

1.43

(12.2)

5.5

(2.50)

2.32

(15.4)

5.79

(2.63)

1.34

(20.9)

(31.45)

Electrical Heating

Total electrical heating capacity, kWInput Voltage

200V 5.4 5.4 10.8 10.8 21.7 N/A

240V 7.8 7.8 15.6 15.6 31.2 N/A

380V 6.5 6.5 13.0 13.0 19.6 34.4

415V 7.8 7.8 15.5 15.5 23.3 41

480V 10.4 10.4 15.6 15.6 31.2 54.8

Electrical heating elements 3 3 3 9 12 12

Electrical heat element size, kW 2.6 2.6 5.2 2.6 2.6 4.2

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7.78

(3.52)

1.14

17

Page 20

Specifications and Dimensions

1

2

3

5

6

B

C

D

E

F

H

I

O

P

N

Q

R

20, 30, 40, 60 and 80 POUND CAPACITY MACHINES

M

L

J

A

G

K

4

NOTE: The dimensions shown are for planning

purposes only. They are approximate and subject

to normal manufacturing tolerances. If exact

dimensions are required for construction purposes,

contact the distributor or manufacturer. We

reserve the right to make changes at any time

without notice.

CHM2278N

CHM2278N

1 Supply Dispenser 4 Cold Water Inlet

2 Input Power Block Compartment 5 Vacuum Breaker

3 Hot Water Inlet 6 Drain Outlet

Figure 3

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 21

Specifications and Dimensions

Machine Capacity Dimensions

Dimensions 20 30 40 60 80

A

B

C

D

Standard

E

Electric Heat

F

G

H

I

J

35.15 in.

(893 m)

34.52 in.

(877 mm)

1.81 in.

(46 mm)

4.5 in.

(114 mm)

5.88 in.

(149 mm)

5.88 in.

(149 mm)

8.82 in.

(224 mm)

15.10 in.

(384 mm)

15.6 in.

(396 mm)

1.58 in.

(40 mm)

30.21 in.

(767 mm)

38.03 in.

(966 mm)

37.46 in.

(951 mm)

1.73 in.

(44 mm)

4.5 in.

(114 mm)

5.88 in.

(149 mm)

5.88 in.

(149 mm)

8.82.in.

(224 mm)

15.19 in.

(386 mm)

15.6 in.

(396 mm)

1.18 in.

(30 mm)

34.57 in.

(878 mm)

40.31 in.

(1024 mm)

39.71 in.

(1009 mm)

2.97 in.

(75 mm)

4.81 in.

(122 mm)

6.35 in.

(161 mm)

6.03 in.

(153 mm)

8.82.in.

(224 mm)

15.15 in.

(385 mm)

15.65 in.

(398 mm)

1.47 in.

(37 mm)

39.72 in.

(1009 mm)

43.31 in.

(1100 mm)

42.4 in.

(1077 mm)

2.42 in.

(61 mm)

4.69 in.

(119 mm)

5.5 in.

(140 mm)

6.27 in.

(159 mm)

8.82.in.

(224 mm)

19.85 in.

(504 mm)

20.35 in.

(517 mm)

1.34 in.

(34 mm)

42.54 in.

(1081 mm)

51.87 in.

(1317 mm)

48.68 in.

(1236 mm)

2.71 in.

(69 mm)

5.71 in.

(145 mm)

6.38 in.

(162 mm)

7.15 in.

(182 mm)

8.82 in.

(224 mm)

21.62 in.

(549 mm)

26.12 in.

(663 mm)

0.97 in.

(25 mm)

51.5 in.

(1308 mm)

K

M

N

O

P

Q

R

25.5 in.

(648 mm)

L

23.01 in.

(584 mm)

17 in.

(432 mm)

14.38 in.

(365 mm)

26 in.

(660 mm)

1.5 in.

(38 mm)

42 in.

(1067 mm)

9 in.

(229 mm)

30.42 in.

(773 mm)

24 in.

(610 mm)

17 in.

(432 mm)

14 in.

(356 mm)

29 in.

(737 mm)

1.5 in.

(38 mm)

44.95 in.

(1142 mm)

9 in.

(229 mm)

35.28 in.

(896 mm)

26 in.

(660 mm)

17.74 in.

(451 mm)

14.56 in.

(370 mm)

30.63 in.

(778 mm)

1.5 in.

(38 mm)

47.20 in.

(1199 mm)

9 in.

(229 mm)

38.23 in.

(971 mm)

26.38 in.

(670 mm)

18.12 in.

(460 mm)

14.94 in.

(379 mm)

34.06 in.

(865 mm)

1.5 in.

(38 mm)

49.89 in.

(1267 mm)

9 in.

(229 mm)

47.52 in

(1207 mm).

30.91 in.

(785 mm)

20.77 in.

(528 mm)

17.91 in.

(455 mm)

41.5 in.

(1054 mm)

1.5 in.

(38 mm)

56.16 in.

(1426 mm)

9 in.

(229 mm)

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Specifications and Dimensions

P

6

1

4

7

A

B

C

D

E

F

O

5

125 POUND CAPACITY MACHINES

8

2

3

Q

H

G

N

J

K

L

M

9

I

1 Dry Chemical Dispenser (Optional) 6 Hot Water Inlet

2 Input Power Block Compartment 7 Liquid Chemical Inlet

3 Fans 8 Steam Inlet (Optional)

4 Valve Panel 9 Drain Outlet

5 Cold Water Inlet

CHM2279N

CHM2279N

Figure 4

Machine Capacity Dimensions for 125 Pound Models through 1/31/11

A

B

C

D

E

F

G

H

I

78.8 in. (2002 mm)

14.62 in. (371 mm)

6.27 in. (159 mm)

29.56 in. (751 mm)

41.28 in. (1049 mm)

51.26 in. (1302 mm)

75.15 in. (1909 mm)

83.4 in. (2118 mm)

2.86 in. (73 mm)

J

K

L

M

N

O

P

Q

61.28 in. (1557 mm)

70.81 in. (1799 mm)

50.2 in. (1275 mm)

38.96 in. (990 mm)

35.74 in. (908 mm)

60 in. (1524 mm)

9.92 in (252 mm)

88.09 in. (2237 mm)

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 23

Specifications and Dimensions

CHM2345N

P

6

1

4

7

A

B

C

D

E

F

O

5

125 POUND CAPACITY MACHINES

8

2

3

Q

H

G

N

J

K

L

M

9

I

CHM2345N

1 Dry Chemical Dispenser (Optional on OPL 5 Cold Water Inlet

Models) 6 Hot Water Inlet

2 Input Power Block Compartment 7 Liquid Chemical Inlet

3 Fans 8 Steam Inlet (Optional)

4 Valve Panel 9 Drain Outlet

Figure 5

Machine Capacity Dimensions for 125 Pound Models starting 2/1/11

A

B

C

D

E

F

G

H

I

63.04 in. (1601 mm)

11.69 in. (297 mm)

5.01 in. (127 mm)

23.65 in. (601 mm)

33.03 in. (839 mm)

39.28 in. (998 mm)

60.21 in. (1529 mm)

65.77 in. (1671 mm)

2.29 in. (58 mm)

J

K

L

M

N

O

P

Q

49.02 in. (1245 mm)

56.06 in. (1424 mm)

40.16 in. (1020 mm)

30.16 in. (766 mm)

28.28 in. (718 mm)

48 in. (1219 mm)

7.94 in (202 mm)

70.47 in. (1790 mm)

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Specifications and Dimensions

A

B

C

FRONT

Dimensional Clearances

CHM2280N

Figure 6

Machine Capacity Dimensional Clearances

Dimensions 20 30 40 60 80 125

Recommended

C

Minimum

A

B

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

6 in.

(152 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

18 in.

(457 mm)

(600 mm)

(12.5 mm)

(914 mm)

(610 mm)

24 in.

.5 in.

36 in.

24 in.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 25

Installation

To reduce the risk of fire, this appliance

must be bolted to an uncovered concrete

floor.

W731

WARNING

Machine Foundation

NOTE: Do not mount on wooden floors, tile floors,

above ground level, or over basements or crawl

spaces because of the high extract speed and the

G-forces exerted.

Thoroughness of detail must be stressed with all

foundation work to ensure a stable unit installation,

eliminating possibilities of excessive vibration during

the extract cycle.

Machine Foundation Requirements

Models

2 Speed and F-Speed

(20-60 Models)

Foundation

Thickness

(minimum)

4 in.

(102 mm)

Mounting

Bolt

depth

2.75 in.

(70 mm)

The floor and foundation must be minimum 4000 psi

reinforced concrete set firmly in clean, compacted fill

dirt.

The machine must be anchored to a smooth, level

surface so that the entire base of the machine is

supported and rests on the mounting surface. (Do not

support the machine on only four points.)

Grouting is required.

An elevated foundation must not exceed 8 inches

(203 mm).

Refer to Tab l e 1 for foundation and anchoring

requirements.

Anchoring

Installation

Foundation

Method(s)

Direct-to-floor, elevated

base frame, or concrete

foundation

Anchoring

Method(s)

Requirement*

Expansion bolt

or Epoxy bolt

Bolt

Diameter

Size

(minimum)

5/8 in.

Variable-Speed

(20-60 Models)

80 Models

VariableSpeed

125 Models

* Recommend SAE 495 Grade 5 or higher strength bolts.

6 in.

(152 mm)

9 in.

(229 mm)

12 in.

(304 mm)

2.75 in.

(70 mm)

3.25 in.

(83 mm)

3.25 in.

(83 mm)

Direct-to-floor, elevated

base frame or concrete

foundation

Direct-to-floor or

concrete foundation

Table 1

Epoxy bolt 5/8 in.

Epoxy bolt or

rebar frame

3/4 in.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Installation

Refer to Table 2 and Tab le 3 for static and dynamic

loads on the floor or foundation.

Floor Load Data, 2 Speed Models

Specification 20 30 40 60

Static floor load, lbs. (kN) 449

(1.99)

Static pressure, lbs.-ft.

2

(kN-m2)97.8

(4.68)

Dynamic load, lbs. (kN) 374

(1.66)

Dynamic pressure,

2

lbs.-ft.

(kN-m2)

165.3

(7.91)

Dynamic load frequency, Hz 8.8 7.7 8.2 7.8

Maximum moment about

machine base, lbs.-ft. (kN-m)

714

(0.97)

Maximum vertical load, lbs. (kN) 759

(3.37)

622

(2.76)

101

(4.84)

495

(2.2)

169

(8.09)

989

(1.34)

1038

(4.62)

903

(4.0)

118

(5.65)

898

(3.99)

216

(10.3)

1926

(2.61)

1653

(7.4)

1099

(4.9)

(5.75)

1404

(6.3)

(12.11)

3086

(4.2)

2322

(10.3)

120

253

Table 2

Floor Load Data, Variable-Speed Models

Specification 2030406080125

Static floor load, lbs. (kN) 482

(2.14)

Static pressure, lbs.-ft.

2

(kN-m2) 105

(5.02)

Dynamic load, lbs. (kN) 532

(2.37)

Dynamic pressure, lbs.-ft.

2

(kN-m

)

2

207

(9.98)

624

(2.78)

102

(4.87)

767

(3.41)

214

(10.22)

923

(4.11)

121

(5.78)

1049

(4.67)

238

(11.37)

1061

(4.22)

116

(5.54)

1514

(6.73)

261

(12.47)

1738

(7.73)

126.9

(6.07)

3310

(14.72)

350.5

(16.78)

2839

(12.6)

177.5

(8.5)

4364

(19.4)

431.5

(20.6)

Dynamic load frequency, Hz 11.5 10.7 10.2 9.6 8.95 8.1

Maximum moment about

machine base, lbs.-ft. (kN-m)

Maximum vertical load, lbs. (kN) 950

1016

(1.38)

(4.23)

1535

(2.08)

1313

(5.84)

2252

(3.05)

1824

(8.11)

3328

(4.51)

2394

(10.65)

8482

(11.5)

4799

(21.35)

14547

(19.7)

6904

(30.7)

Table 3

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 27

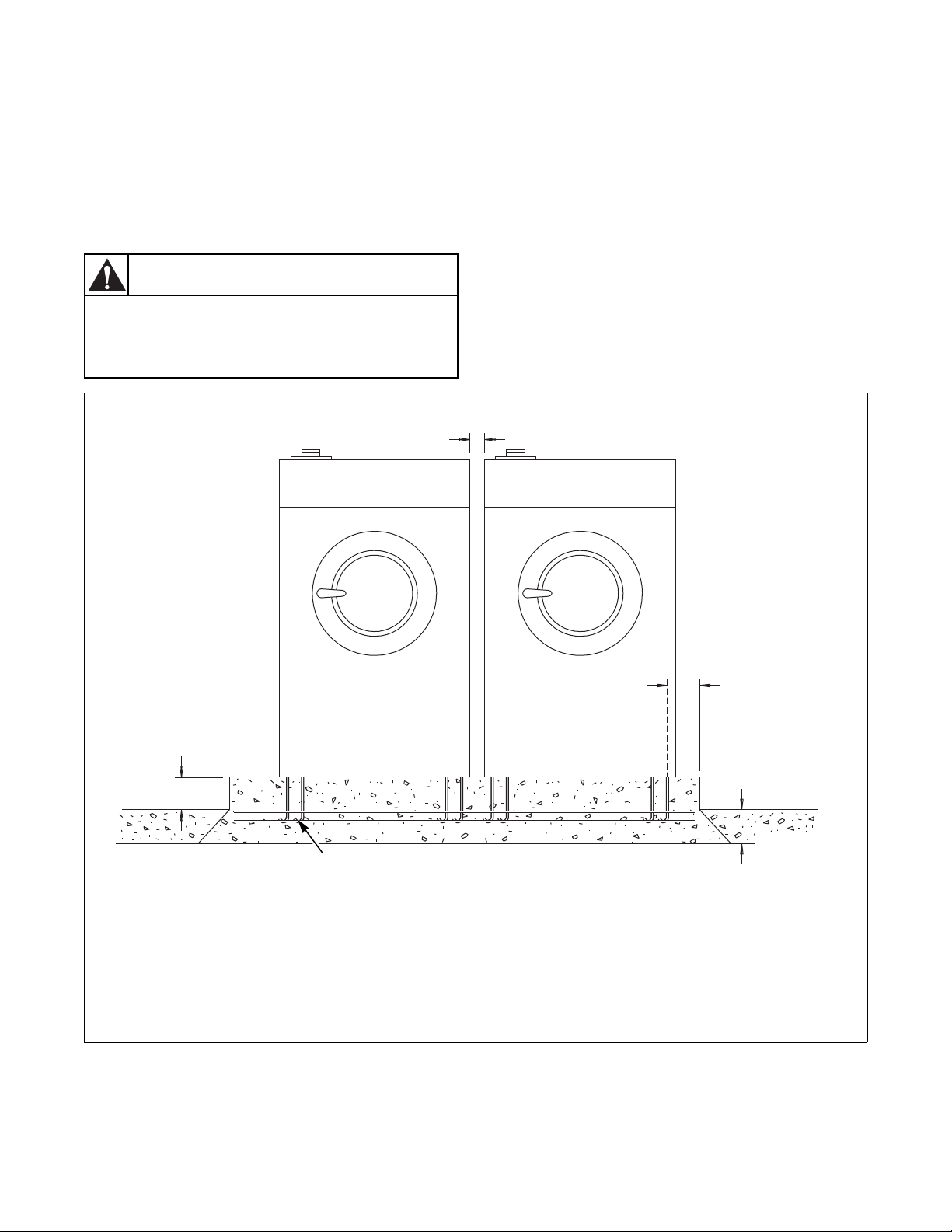

Installation

To reduce the risk of fire, this appliance

must be bolted to an uncovered concrete

floor.

W731

WARNING

CHM2281N

B

C

20, 30, 40 AND 60 MODELS

A

D

E

Concrete Foundation Installation

A concrete foundation pad may be constructed to

elevate the machines. The concrete foundation pad

must be poured, reinforced with rebar and tied to the

existing floor with reinforcing bars. Refer to Figure 7,

Figure 8 or Figure 9 for a typical concrete foundation

pad installation.

1. Verify that the floor meets the requirements given

in the Machine Foundation section.

2. Excavate the floor to a depth of approximately

9 inches (230 mm) below the floor surface,

making certain that the sides of the hole slope

outwards from top to bottom. The bottom of the

hole should be 6 inches (152 mm) larger all

around than the top.

3. Wet the hole well and brush the bottom and sides

with cement grout.

A Pad height must not exceed 8 in. (203 mm) D 4 in. (102 mm) minimum

above existing floor (2 and F-Speed Models)

B .5 in. (13 mm) minimum 6 in. (152 mm) minimum (V-Speed Models)

C 4 in. (102 mm) minimum E Concrete reinforcing bar

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM2281N

Figure 7

25

Page 28

Installation

4. Use rebar or other appropriate material to ensure

that the concrete foundation will be sufficiently

connected to the existing floor.

5. If desired, prepare a form for the above-ground

portion of the foundation and fill form and

excavation with concrete to join the foundation.

Verify that top of foundation is level. The height

of the foundation must not exceed 8 inches

(203 mm).

6. Use the mounting bolt layout to properly position

the mounting bolts in the wet concrete.

NOTE: When using any anchoring bolts, allow 1.5

inches (38 mm) to extend above the surface of the

concrete. Refer to the Machine Anchoring section.

7. Allow concrete to dry and cure before machine is

placed into service.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 29

A 9 in. (229 mm) C 47.5 in. (1207 mm)

CHM2282N

80 MODELS

A

B

B

CD

LENGTH FOR ONE MACHINE

COMPACTED FILL DIRT 18 in. (457 mm) DEPTH

COMPACTED FILL DIRT 18 in. (457 mm) DEPTH

B

CHM2283N

125 MODELS

COMPACTED FILL DIRT 24 in. (609 mm) DEPTH

A

B

C

D

LENGTH FOR ONE MACHINE

A

A

COMPACTED FILL DIRT 24 in. (609 mm) DEPTH

B 6 in. (152 mm) D 4 ft. 6 in. (1372 mm)

Installation

CHM2282N

Figure 8

CHM2283N

A 12 in. (305 mm) C 48 in. (1219 mm)

B 6 in. (152 mm) D 6 ft. (1829 mm)

Figure 9

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Installation

CHM

B

C

A

Machine Anchoring

Before anchoring the machine, refer to Tabl e 4 to

determine the appropriate method of anchoring for the

machine.

NOTE: Improper installation may void the

warranty. Consult the manufacturer or distributor

before varying from a procedure.

Direct-to-Finished-Floor Installation

Installing With Expansion Bolts for

2 Speed Models

NOTE: Expansion bolts are not suitable for

variable-speed machine installations.

1. Verify the floor meets the requirements given in

the Machine Foundation section.

2. Mounting surface should be level and machine

must be properly grouted.

3. Use the base of the machine as a template by

positioning the machine in the desired location

and marking the pre-drilled mounting holes on

the floor. Mounting Bolt templates are available

through Alliance Laundry Systems.

13. Position washers and nuts on bolts and finger

tighten nuts to machine base.

14. Before grout sets completely, make a drain

opening in the grouting at the rear center of the

machine with a stiff piece of wire. This opening

should be approximately .5 inch (13 mm) wide to

allow any surface water build-up under the base

of the machine to drain away. Do not omit this

step.

15. Allow machine grout to set, but not cure.

16. Remove the spacers carefully, allowing the

machine to settle into the grout.

17. Tighten the nuts by even increments – one after

the other using the specified torque – until all are

tightened evenly and the machine is fastened

securely to the floor. Refer to Tab l e 4.

4. Refer to Figure 10 and Tabl e 4 to set the drill

depth gauge.

5. Drill the holes to the set depth. Refer to Table 4.

6. Use compressed air or a squeeze bulb to clean out

debris from each hole.

7. Fill half the hole depth with an industry-accepted

adhesive anchoring system.

8. Insert expansion bolt until it reaches the bottom

of the hole and 1.5 inches (38 mm) of the bolt

extends above the surface.

9. Allow adhesive around bolt to cure properly.

NOTE: Select the proper size and strength anchor

system. Follow the manufacturer’s installation

instructions and recommended cure times.

10. Position machine over anchoring bolts.

11. Raise and level the machine .5 inch (13 mm) off

the floor on three points, using spacers such as

nut fasteners.

12. Fill the space between the machine base and the

floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

Anchor Specifications

(refer to Figure 10)

Models A

20-60 5/8 in.

80-125 3/4 in.

Figure 10

B

(minimum)

2.75 in.

(69.9 mm)

3.25 in.

(82.6 mm)

Table 4

C

.625 in.

(15.9 mm)

.75 in.

(19 mm)

CHM2285N

Torque

(ft.- lbs.)

90

(ft.-lbs.)

175

(ft.-lbs.)

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 31

The completed expansion bolt installation is shown in

CHM2284

Refer to

Tab l e 4

1

5

3

2

4

6

1.5 in.

(38.1 mm)

Figure 11.

NOTE: Check and retighten the nuts after five to

ten days of operation and every three months

thereafter.

CHM2284N

1 Washer

2 Locknut

3 Machine Base or Base Frame

4 Machinery Grout

5 Adhesive

6 Expansion Bolt

Figure 11

Elevated Base Frame Installation

Factory-built elevated steel base frames are designed

to meet the specifications of the 20-60 2 speed,

F-speed and V-speed model washer-extractors only.

Refer to Figure 12. The spacing between two

machines provided by an elevated base is .38 inch

(9.5 mm) in 20, 30 and 60 pound models and .25 inch

(6.3 mm) in 40 pound models.

Installation

H035I

Figure 12

Installing With Elevated Base Frame

1. Verify the floor meets the requirements given in

the Machine Foundation section.

2. Use the elevated base frame as a template by

positioning the frame in the desired location and

marking the pre-drilled mounting holes on the

floor.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Installation

1

2

3

4

3. Refer to Figure 10 and Tabl e 4 to set the drill

depth gauge.

4. Drill the holes to the set depth. Refer to Table 4.

5. Use compressed air or a squeeze bulb to remove

debris from each hole.

6. Fill half the hole depth with an industry accepted

adhesive anchoring system.

7. Insert bolt until it reaches the bottom of the hole

and 1.5 inches (38 mm) of the bolt extends above

the base frame. Refer to Figure 11.

8. Allow adhesive around the bolt to cure properly.

9. Position base frame over anchoring bolts.

10. Raise and level the base frame .5 inch (13 mm)

off the floor on three points, using spacers such

as nut fasteners.

11. Fill the space between the base frame and the

floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

12. Position washers and locknuts on bolts and finger

tighten nuts to base frame.

17. Position the machine over the base frame, aligning

the mounting holes on the machine with the

corresponding holes on the frame.

18. Install a bolt, lockwasher, and nut in each

mounting hole. Use 5/8 inch – 18 x 2.00 grade 5

mounting bolts with 5/8 inch – 18 grade B nuts

and 5/8 inch lockwashers.

19. Hand tighten each nut.

20. Tighten the two rear nuts two turns.

21. Tighten the two front nuts two turns.

22. On 30, 40 and 60 models, tighten the two middle

nuts firmly.

23. Tighten the two front nuts firmly; tighten the two

rear nuts firmly.

NOTE: Check and retighten the locknuts after five

to ten days of operation and every three months

thereafter.

NOTE: For 80 and 125 pound models, a

bolt-locator fixture or rebar frame is available as

an option. This is designed to be embedded in

concrete. Refer to Figure 13.

13. Before grout sets completely, make a drain

opening in the grouting at the rear of the base

IMPORTANT: Do not install any 80 or 125

machines on an elevated base frame.

frame with a stiff piece of wire. This opening

should be approximately .5 inch (13 mm) wide to

allow any surface water build-up under the base

of the machine to drain away. This drain opening

must not be near frame mounting bolts. Do not

omit this step.

14. Allow machine grout to set, but not cure.

15. Remove the spacers carefully, allowing the base

frame to settle into the wet grout.

16. Tighten nuts by even increments – one after the

other using the specified torque – until all are

tightened evenly and the base frame is fastened

securely to the floor. Refer to Table 4.

P035I

1 Machine Base

2 Mounting Bolt Threads

3 Grouting

4 Bolt-Locator Fixture or Rebar Frame

Figure 13

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 33

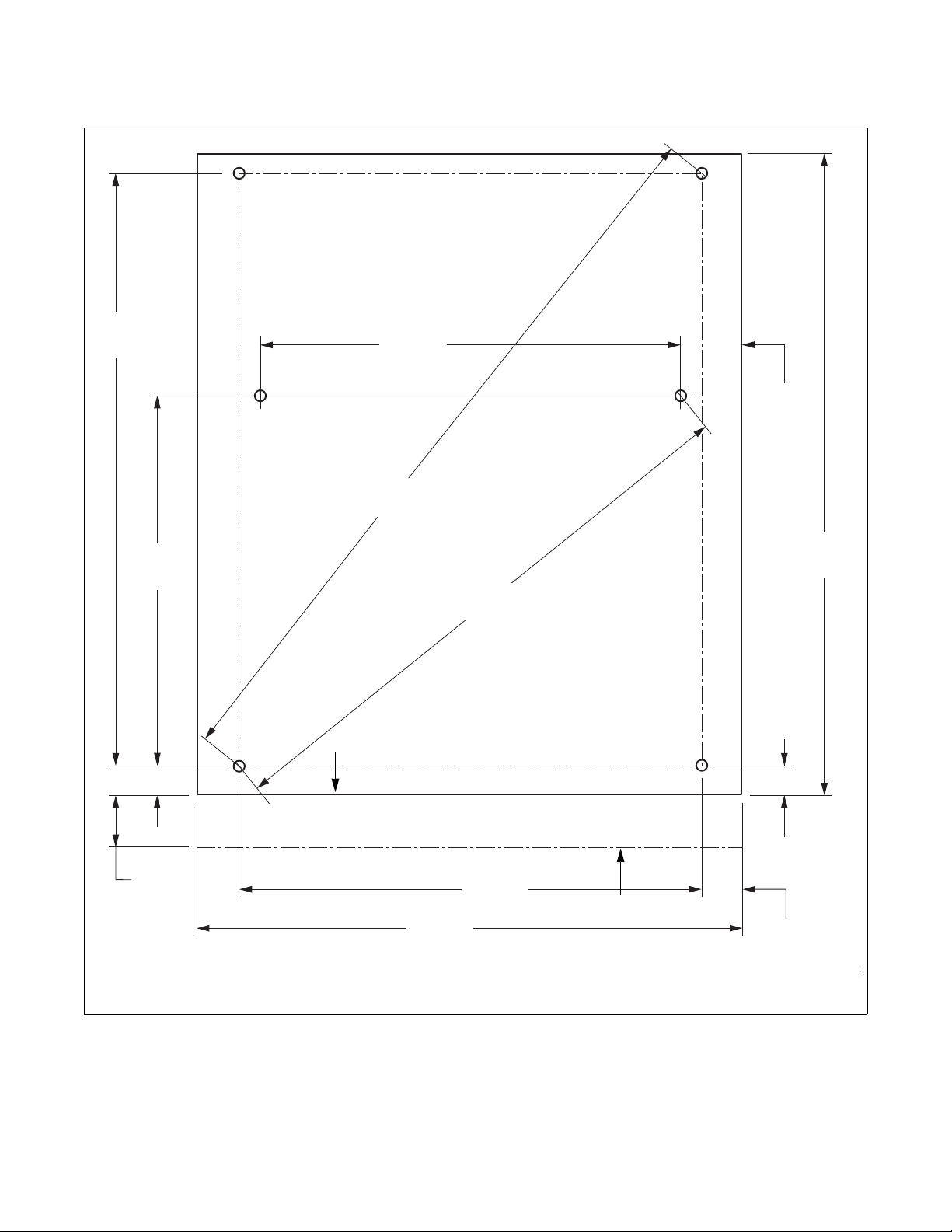

Mounting Bolt Hole Locations (Without Elevated Base Frames)

26 in.

(660 mm)

20 Models

20.66 in.

(525 mm)

23.94 in.

(608 mm)

25-44 in.

(646 mm)

20.88 in.

(530 mm)

0.75 in.

(19 mm)

2.56 in.

(65 mm)

Front of Front Panel

2.56 in.

(65 mm)

2.67 in.

(68 mm)

2.67 in.

(68 mm)

14.31 in.

(363 mm)

31.75 in.

(806 mm)

25.22 in.

(641 mm)

Installation

Figure 14

CHM2224N

IMPORTANT: Drawing is not to scale.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Installation

30 Models

23.88 in.

(607 mm)

28.94 in.

(735 mm)

18.44 in.

(468 mm)

2.75 in.

(70 mm)

2.75 in.

(70 mm)

29 in.

(737 mm)

23.5 in.

(597 mm)

37.52 in.

(953 mm)

30.02 in.

(762 mm)

2.56 in.

(65 mm)

2.56 in.

(65 mm)

30.5 in.

(775 mm)

0.75 in.

(19 mm)

Front of Front Panel

Front of Frame

Mounting Bolt Hole Locations (Without Elevated Base Frames)

IMPORTANT: Drawing is not to scale.

Figure 15

CHM2063N

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 35

Mounting Bolt Hole Locations (Without Elevated Base Frames)

CHM206

32.5 in.

(826 mm)

20 in.

(508 mm)

23.63 in.

(600 mm)

41.63 in.

(1057 mm)

31.88 in.

(810 mm)

3.5 in.

(89 mm)

36 in.

(914 mm)

26 in.

(660 mm)

30.63 in.

(778 mm)

0.75 in.

(19 mm)

40 Models

2.32 in.

(59 mm)

0.75 in.

(19 mm)

1.75 in.

(45 mm)

Front of Front Panel

Front of Frame

Installation

Figure 16

CHM2067N

IMPORTANT: Drawing is not to scale.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Installation

CH

60 Models

34.06 in.

(865 mm)

3.28 in.

(83 mm)

3.28 in.

(83 mm)

27.5 in.

(700 mm)

46.88 in.

(1191 mm)

37.44 in.

(951 mm)

36 in.

(914 mm)

24.07 in.

(611 mm)

0.75 in.

(19 mm)

2.03 in.

(52 mm)

2.03 in.

(52 mm)

30 in.

(760 mm)

37.5 in.

(953 mm)

1.25 in.

(32 mm)

Front of Front Panel

Mounting Bolt Hole Locations (Without Elevated Base Frames)

IMPORTANT: Drawing is not to scale.

Figure 17

CHM2065N

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 37

Mounting Bolt Hole Locations (Without Elevated Base Frames)

CHM2334

80 Models*

33.5 in.

(851 mm)

40 in.

(1016 mm)

4 in.

(102 mm)

5 in.

(127 mm)

17 in.

(432 mm)

0.75 in.

(19 mm)

4 in.

(102 mm)

28.5 in.

(724 mm)

41.5 in.

(1054 mm)

33.5 in.

(851 mm)

31.5 in.

(800 mm)

4 in.

(102 mm)

4 in.

(102 mm)

0.75 in.

(19 mm)

5 in.

(127 mm)

9.5 in.

(241 mm)

11 in.

(279 mm)

47.5 in.

(1207 mm)

25 in.

(635 mm)

1 in.

(25 mm)

A

A

B

B

B

B

AB

A

1 in.

(25 mm)

A

AB

Front of Front Panel

56.5 in.

(1435 mm)

43.22 in.

(1098 mm)

Installation

*For close mounting, use mounting bolt pattern labeled “A”; for standard mounting, use “B.”

Figure 18

CHM2334N

IMPORTANT: Drawing is not to scale.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Installation

125 Models

46.5 in.

(1181 mm)

0.75 in.

(19 mm)

0.75 in.

(19 mm)

10 in.

(254 mm)

15 in.

(381 mm)

15.25 in.

(388 mm)

0.75 in.

(19 mm)

23.25 in.

(591 mm)

23.25 in.

(591 mm)

48 in.

(1219 mm)

48.94 in.

(1243 mm)

61.5 in.

(1562 mm)

48 in.

(1219 mm)

55.47 in.

(1409 mm)

Front of Front Panel

Mounting Bolt Hole Locations (Without Elevated Base Frames)

IMPORTANT: Drawing is not to scale.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 19

CHM2069N

F8208301

Page 39

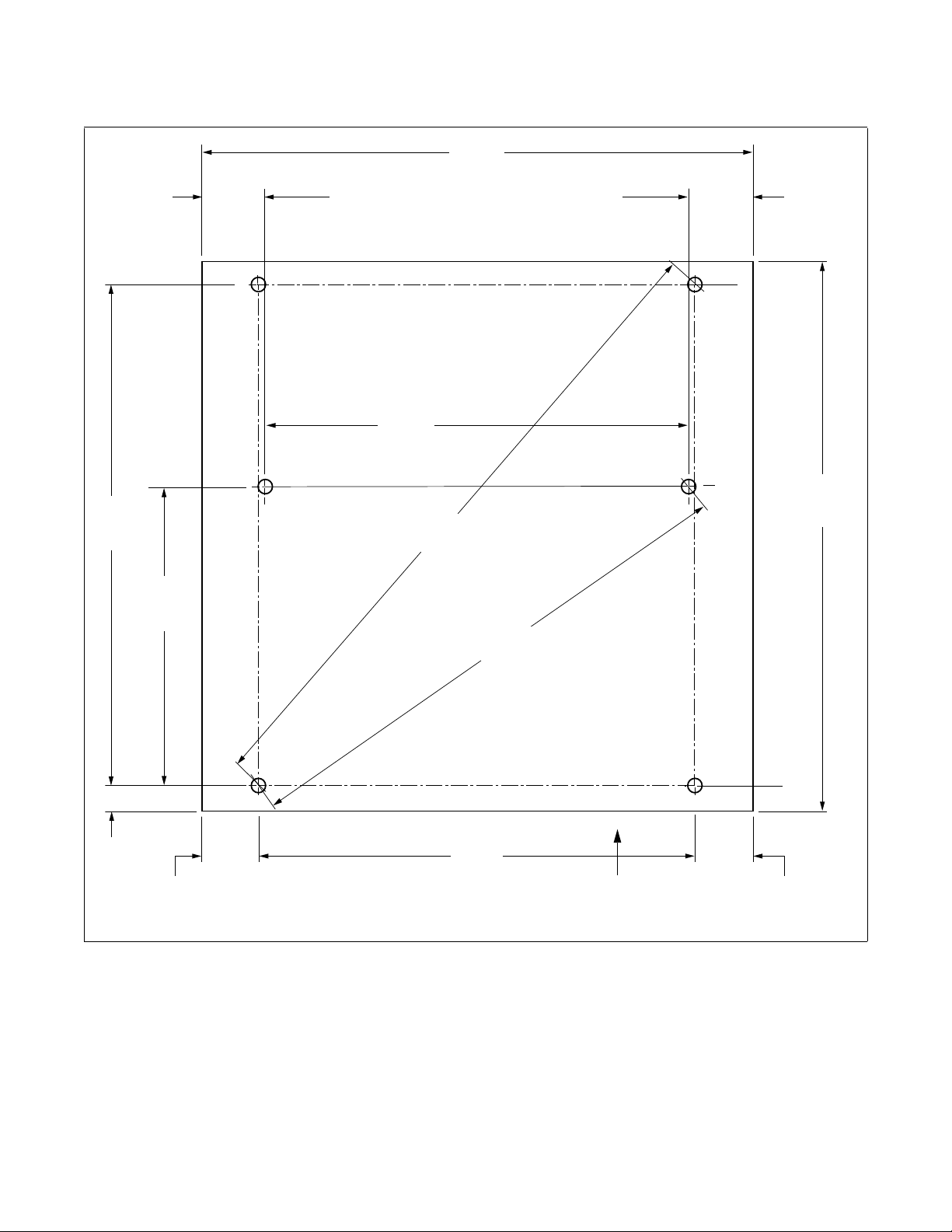

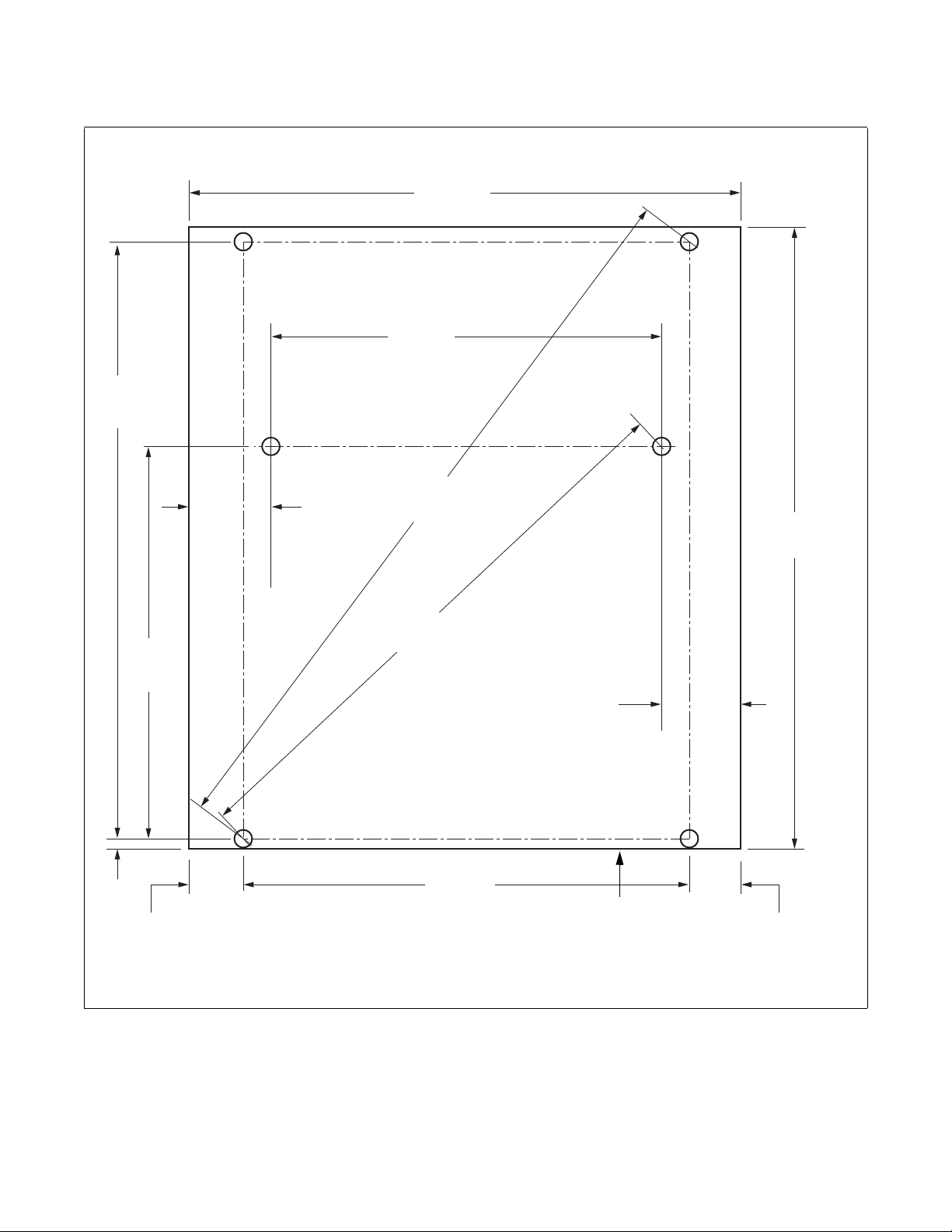

Mounting Bolt Hole Locations (With Elevated Base Frames)

20 Models

26.4 in.

(670 mm)

31.75 in.

(806 mm)

23.94 in.

(608 mm)

26.2 in.

(665 mm)

20.88 in.

(530 mm)

2.75 in.

(70 mm)

1.13 in.

(29 mm)

2.75 in.

(70 mm)

20.66 in.

(525 mm)

2.87 in.

(73 mm)

2.87 in.

(73 mm)

14.31 in.

(363 mm)

25.22 in.

(640 mm)

Front of Front Panel

Installation

CHM2070N

IMPORTANT: Drawing is not to scale.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 20

37

Page 40

Installation

30 Models

23.88 in.

(607 mm)

28.94 in.

(735 mm)

18.44 in.

(468 mm)

2.94 in.

(75 mm)

2.94 in.

(75 mm)

29.4 in.

(747 mm)

23.5 in.

(597 mm)

37.52 in.

(953 mm)

30.02 in.

(762 mm)

2.75 in.

(70 mm)

2.75 in.

(70 mm)

31.2 in.

(792 mm)

1.13 in.

(29 mm)

Front of Front Panel

Mounting Bolt Hole Locations (With Elevated Base Frames)

Figure 21

CHM2072N

IMPORTANT: Drawing is not to scale.

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 41

Mounting Bolt Hole Locations (With Elevated Base Frames)

40 Models

23.63 in.

(600 mm)

31.88 in.

(810 mm)

30.88 in.

(784 mm)

2.38 in.

(61 mm)

2.44 in.

(62 mm)

20 in.

(508 mm)

32.5 in.

(826 mm)

3.62 in.

(92 mm)

26 in.

(660 mm)

41.63 in.

(1057 mm)

36 in.

(914 mm)

Front of Front Panel

Installation

IMPORTANT: Drawing is not to scale.

F8208301

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 22

CHM2074N

39

Page 42

Installation

60 Models

30 in.

(762 mm)

36 in.

(914 mm)

24 in.

(610 mm)

3.47 in.

(88 mm)

3.47 in.

(88 mm)

34.5 in.

(876 mm)

27.5 in.

(700 mm)

46.88 in.

(1191 mm)

2.22 in.

(56 mm)

2.22 in.

(56 mm)

38.9 in.

(988 mm)

2.13 in.

(54 mm)

37.44 in.

(951 mm)

Front of Front Panel

Mounting Bolt Hole Locations (With Elevated Base Frames)

Figure 23

CHM2076N

IMPORTANT: Drawing is not to scale.

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

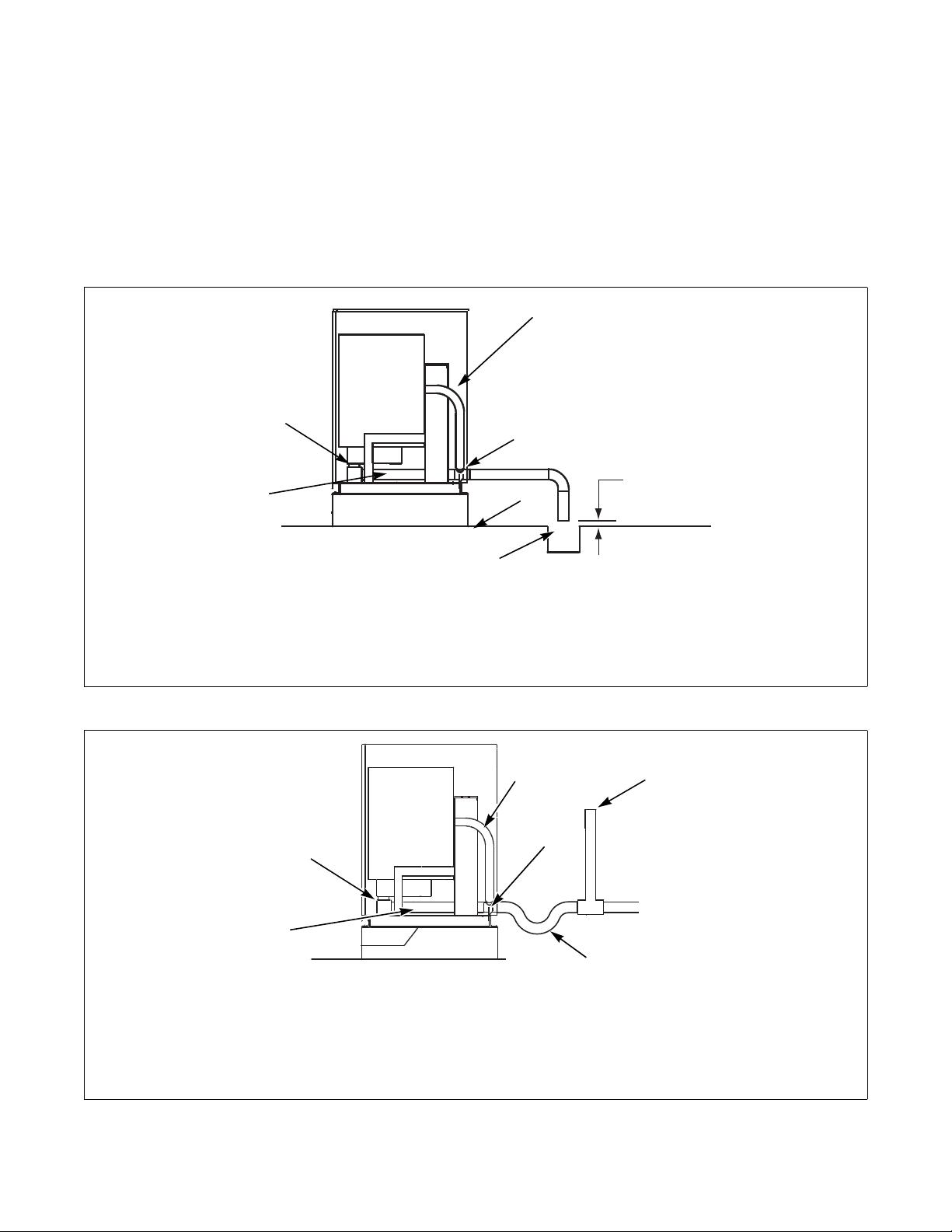

Page 43

Installation

1

2

3

4

5

7

DRAIN TROUGH

6

1

2

3

4

5*

DRAIN LINE

6

Drain Connection

Figure 24 and Figure 25 show typical drain trough and

drain line installations.

Connect the drain outlet to a vented drain system using

only a flexible connection. The drain system must be

vented to prevent an air lock or siphoning.

Use the supplied black rubber adapter and clamps to

transition from the machine drain outlet to the 2 inches

schedule 40 PVC plumbing (20 and 30 models) and

the 3 inches schedule 40 PVC plumbing (40, 60, 80

and 125 models).

If proper drain size is not available or practical, a surge

tank is required. A surge tank along with a sump pump

should be used when gravity drainage is not possible,

such as in below-ground-level installations.

CHM2058N

CHM2058N

F8208301

1 Drain Hose 5 Floor

2 Drain Valve 6 Open Drain Trough

3 Overflow Hose 7 1 in. Minimum Gap

4 Drain Tee

Figure 24

1 Drain Hose 4 Overflow Hose

2 Drain Valve 5 Ven t Pip e*

3 Drain Tee 6 Trap (as required by local codes)

* Drain line must be vented to meet local plumbing codes.

CHM2335N

Figure 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM2058N

CHM2335N

41

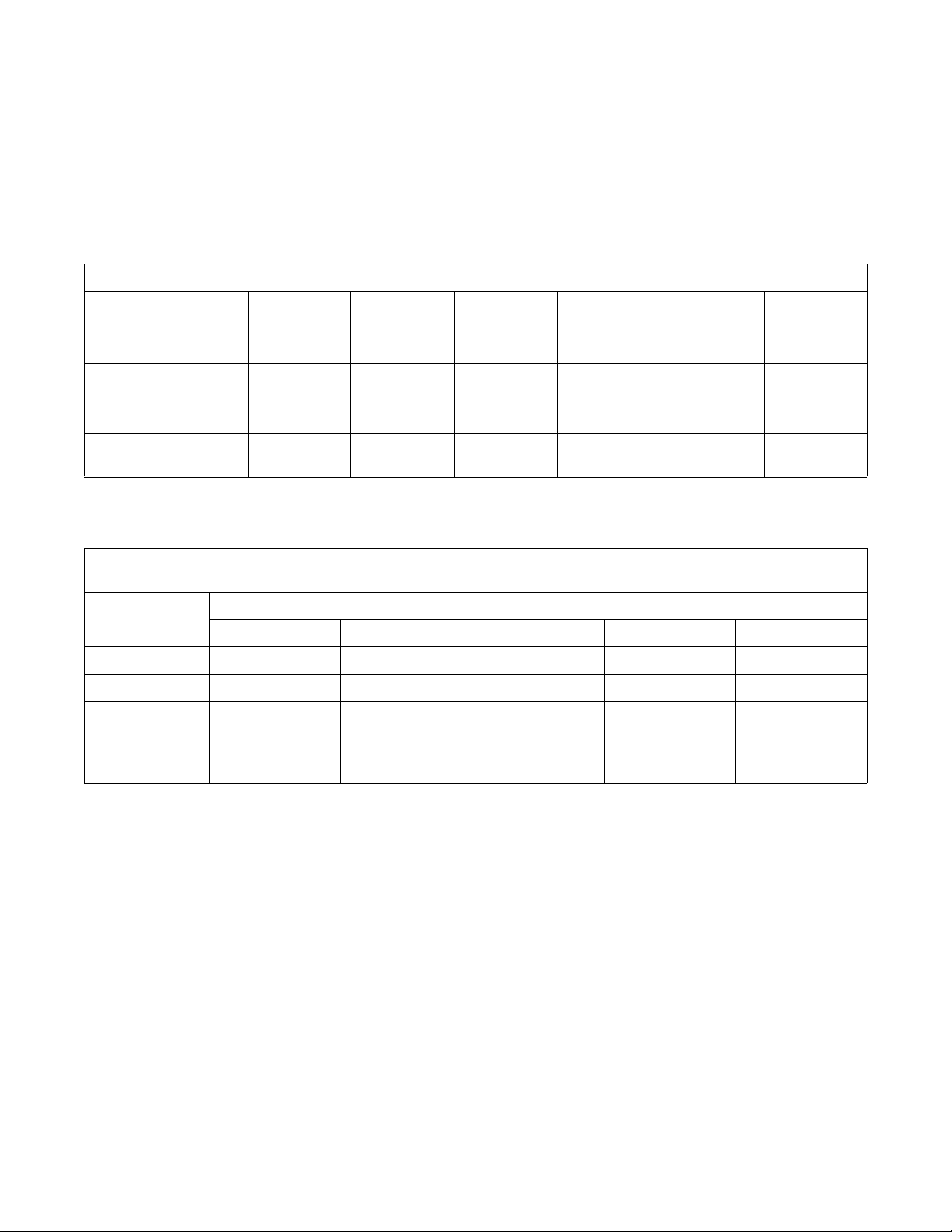

Page 44

Installation

Before any deviation from specified installation

procedures is attempted, the customer or installer

Refer to Tab l e 5 for capacity-specific drain

information.

should contact the distributor.

NOTE: Installation of additional machines will

IMPORTANT: Increasing the drain hose length,

require larger drain connections. Refer to Tab le 6.

installing elbows, or causing bends will decrease

drain flow rates and increase drain times,

impairing machine performance.

Drain Information

20 30 40 60 80 125

Drain connection size,

OD

Number of drain outlets111111

Drain flow capacity 20 gal/min

Recommended

drain pit size

* Also works with 3 in. OD PVC pipe if connected to inside of drain tee connector.

2 in.

(51 mm)

(76 l/min)

3

1.8 ft.

(51 l)

2 in.

(51 mm)

25 gal/min

(95 l/min)

3

2.5 ft.

(71 l)

3 in.*

(76 mm)

45 gal/min

(170 l/min)

4.52 ft.

(128 l)

Table 5

3 in.*

(76 mm)

55 gal/min

(208 l/min)

3

4.52 ft.

3

(128 l)

3 in.*

(76 mm)

50 gal/min

(189 l/min)

3

5.9 ft.

(167 l)

3.5 in.*

(89 mm)

70 gal/min

(265 l/min)

3

13 ft.

(368 l)

Model

20

30

40

60

80, 125

Drain Line Sizing

Minimum Drain ID

Number of Machines

12345

2 in. (51 mm) 3 in. (76 mm) 3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm)

2 in. (51 mm) 3 in. (76 mm) 3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm)

3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm)

3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm)

4 in. (102 mm) 6 in. (152 mm) 6 in. (152 mm) 8 in. (203 mm) 8 in. (203 mm)

Table 6

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8208301

Page 45