Page 1

Washer-Extractors

Cabinet Hardmount Operating Instructions

Basic Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM1772C

Part No. F8321401R1EN

April 2010

Page 2

Page 3

Basic Installation/Operation

Table of

Content s

Safety Information.............................................................................. 2

Important Safety Instructions ............................................................... 2

Safety Decals........................................................................................ 4

Operator Safety....................................................................... ..... ......... 5

Specifications and Dimensions........................................................... 6

Dimensional Clearances ....................................................................... 10

Dimensions........................................................................................... 11

20, 30, 40, 60 and 80 Models........................................................... 11

125 Model........................................................................................ 13

Electrical Specifications ....................................................................... 14

Operation............................................................................................. 17

Operating Instructions, Vend Models Only.......................................... 18

Operating Instructions, OPL Models Only........................................... 20

Disposal of Unit................................................................................... 22

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Basic Installation/Operation

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Safety Information

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Refer to the

INSTALLATION Manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils,

dry-cleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

GROUNDING INSTRUCTIONS in the

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORT ANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable; do not smoke o r us e an open flam e

during this time.

6. Do not allow children to play on or in the washer .

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8321401 (EN)

Page 5

Basic Installation/Operation

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer , or

attempt any servicing unless specifically

recommended in the user-maintenance instructions

or in published user-repair instructions that the

user understands and has the skills to carry out.

12. T o reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

20. If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

service agent.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. T o reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards and/or

panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Basic Installation/Operation

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Install the machine on a level floor of

sufficient strength. Failure to do so may

result in conditions which can produce

serious injury, death and/or property

damage.

W703

WARNING

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

IMPORTANT: Ensure that the recommended

clearances for inspection and maintenance

are provided. Never allow the inspection and

maintenance space to be blocked.

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide person al safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 7

Basic Installation/Operation

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

Do not bypass any safety devices in the machine.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locke d

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Basic Installation/Operation

Specifications and Dimensions

Specification 20 30 40 60

Weight and Shipping Information

2 Speed Models

Net weight, lbs. (kg) 387

(176)

Domestic shipping weight, lbs. (kg) 420

(191)

Domestic shipping volume, ft

Export shipping weight lbs., (kg) 475

Export shipping volume, ft

Wash Cylinder Information

Cylinder diameter,

in. (mm)

Cylinder depth, in. (mm) 13.75

Cylinder volume, ft

Perforation size, in. (mm) 0.188

Perforation open area, % 17 23 17.5 18

3

(l) 2.76

3

(m3) 30.5

(0.86)

(215)

3

(m3) 36.2

(1.03)

(533)

(349)

(78.1)

(4.76)

21

489

(222)

530

(240)

40.75

(1.15)

593

(269)

49.9

(1.41)

24

(610)

16

(406)

4.19

(118.6)

0.188

(4.76)

692

(314)

734

(333)

50

(1.42)

816

(370)

60

(1.70)

26.25

(667)

20.25

(514)

6.34

(180)

0.188

(4.76)

812

(368)

854

(387)

64

(1.81)

948

(430)

75.8

(2.15)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

Door Opening Information

Door opening diameter, in. (mm)

Height of door bottom above floor, in. (mm)

Height of door opening above floor, in. (mm)

Power Consumption

Average power used per cycle,

kW-hr

Average HVAC load, Btu/hr. (Kcal./Hr.) 425

No load

Sheets

Towels

11.63

(295)

14.38

(365)

17.19

(437)

0.06 0.13 0.196 0.25

0.10 0.14 0.195 0.26

0.11 0.16 0.213 0.33

(107)

Table 1 (Continued)

14.34

(364)

14

(356)

17

(431)

463

(117)

16.25

(413)

14.5

(368)

19

(483)

510

(129)

16.25

(413)

15

(381)

18.5

(470)

700

(176)

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8321401 (EN)

Page 9

Basic Installation/Operation

Table 1 (Continued)

2 Speed Models (Continued)

Specification 20304060

Drive Train Information

Number of motors in drive train 1 1 1 1

Wash/reverse power, HP (kW) 0.15

(0.11)

High extract power, HP (kW) .74

(0.55)

0.24

(0.18)

1.34

(1.00)

0.40

(0.30)

1.8

(1.3)

0.55

(0.41)

2.7

(2.01)

Cylinder Speeds

Wash/reverse speed, RPM 57 49 51 44

High extract speed, RPM 528 464 491 469

Centrifugal Force Data

Wash/reverse centrifugal force, Gs 0.9 0.8 0.8 0.9

High extract centrifugal force, Gs 80.3 72.1 78.1 85.4

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

N/A N/A 1/2

(13)

1/2

(13)

Number of steam inlets N/A N/A 1 1

Steam required to raise bath water

temperature 10°F (10°C), lbs. (kg)

LOW N/A N/A 2.09

(0.84)

MED N/A N/A 2.40

(1.15)

3.6

(0.895)

4.4

(1.384)

HIGH N/A N/A 2.84

Average steam use per cycle,

bhp (kg)

N/A 0.73

(6.9)

(1.48)

1.43

(12.2)

(1.916)

(15.4)

Electrical Heating (Optional)

Total electrical heating capacity,

kW

Input Voltage

200V

240V

380V

415V

480V

5.4 5.4 10.8 10.8

7.8 7.8 15.6 15.6

6.5 6.5 13.0 13.0

7.8 7.8 15.5 15.5

N/A N/A 15.6 15.6

Electrical heating elements 3 3 6 6

Electrical heat element size, kW 2.6 2.6 2.6 2.6

Table 1

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5.5

2.32

7

Page 10

Basic Installation/Operation

Variable-Speed and Fixed-Speed Models

Specification 20 30 40 60 80 125

Weight and Shipping Information

Net weight, lbs. (kg) 386

(175)

Domestic shipping weight, lbs. (kg) 424

(191)

Domestic shipping volume, ft

3

(m3)27

(0.76)

Export shipping weight, lbs. (kg) 476

(215)

Export shipping volume, ft

3

(m3) 36.7

(1.04)

Wash Cylinder Information

Cylinder diameter, in. (mm) 21

(533)

Cylinder depth, in. (mm) 13.75

(349)

Cylinder volume, ft

3

(l) 2.76

(78.1)

Perforation size, in. (mm) 0.188

(4.76)

Perforation open area, % 17 23 17.5 18 18 24

498

(226)

545

(245)

34.4

(0.98)

588

(267)

49.5

(1.40)

24

(610)

16

(406)

4.19

(118)

0.188

(4.76)

706

(321)

744

(338)

43.6

(1.24)

846

(385)

65.6

(1.86)

26.25

(667)

20.25

(514)

6.34

(180)

0.188

(4.76)

773

(350)

824

(373)

52.2

(1.48)

1020

(463)

74.7

(3.35)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

1374

(623)

1461

(663)

102.2

(2.89)

1573

(714)

118.3

(3.35)

36

(914)

22

(559)

12.4

(354)

0.188

(4.76)

(1044)

(1081)

(1130)

(1060)

2301

2384

163

(4.3)

2492

173

(4.8)

42

24

(609)

19.2

(544)

0.188

(4.76)

Door Opening Information

Door opening size, in. (mm) 11.63

(295)

Height of door bottom above floor, in. (mm) 14.38

(365)

Height of door opening bottom, in. (mm) 17.19

(437)

14.34

(364)

14

(356)

17

(431)

16.25

(413)

14.5

(368)

18

(457)

16.25

(413)

18.25

(445)

18.5

(470)

17.75

(451)

N/A 21.63

(549)

20

(508)

29

(737)

30.25

(768)

Estimated Building Heat Load

Average power used per cycle, kW-hr 0.05 0.07 0.34 0.21 0.40 0.60

A verage HVAC load, Btu/hr 400 450 510 750 950 1200

Drive Train Information

Number of motors in drive train 1 1 1 1 1 1

Drive motor power, HP (kW) 1

(.75)

1

(.75)

2

(1.7)

3

(2.2)

5

(3.7)

7.5

(5.6)

Table 2 (Continued)

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 11

Basic Installation/Operation

Table 2 (Continued)

Variable-Speed and Fixed-Speed Models (Continued)

Specification 20 30 40 60 80 125

Cylinder Speeds

Gentle wash/reverse speed, RPM 292726262226

Wash/reverse speed, RPM 52 52 46 43 40 37

Distribution speed, RPM 92 92 82 77 70 65

Low extract speed, RPM 366 366 328 307 280 260

Medium extract speed, RPM

(Not available on Electronic Control models.)

High extract speed, RPM 686 686 613 574 524 485

Centrifugal Force Data

Gentle wash centrifugal force, Gs 0.25 0.25 0.25 0.25 0.25 0.43

Wash/reverse centrifugal force, Gs 0.8 0.8 0.8 0.8 0.8 0.8

Distribution centrifugal force, Gs 2.5 2.5 2.5 2.5 2.5 2.6

Low extract centrifugal force, Gs 40 40 40 40 40 40

Medium extract centrifugal force, Gs 85 85 85 85 85 85

High extract centrifugal force, Gs 140 140 140 140 140 140

534 534 478 447 408 378

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

Number of steam inlets N/A N/A 1 1 1 1

Steam required to raise bath water

temperature 10°F (6°C), lbs. (kg)

Average steam use per cycle, bhp (kg) N/A 0 .73

Electrical Heating (Optional)

Total electrical heating capacity, kW

Electrical heating elements

Electrical heat element size, kW

LOW N/A N/A 2.09

MED N/A N/A 2.40

HIGH N/A N/A 2.84

Input Voltage

200V 5.4 5.4 10.8 10.8 21.7 N/A

240V 7.8 7.8 15.6 15.6 31.2 N/A

380V 6.5 6.5 13.0 13.0 19.6 N/A

415V 7.8 7.8 15.5 15.5 23.3 N/A

480V N/A N/A 15.6 15.6 31.2 N/A

N/A N/A 1/2

(13)

(0.94)

(1.09)

(1.29)

1.43

(11.3)

333912N/A

2.6 2.6 5.2 2.6 2.6 N/A

(12.2)

1/2

(13)

3.6

(1.63)

4.4

(2.00)

5.5

(2.50)

2.32

(15.4)

1/2

(13)

2.58

(1.17)

4.65

(2.11)

5.79

(2.63)

1.34

(20.9)

(1.65)

(2.35)

(3.52)

(31.45)

3/4

(19)

3.64

5.17

7.78

1.14

F8321401 (EN)

Table 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Basic Installation/Operation

C

B

A

FRONT

Dimensional Clearances

CHM2280N

CHM2280N

Figure 1

Machine Capacity Dim e nsional Clearances

Dimensions 20 30 40 60 80 125

A

B

C

(recommended)

C

(minimum)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

2 in.

(51 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

12 in.

(305 mm)

6 in.

(152 mm)

.5 in.

(12.5 mm)

24 in.

(610 mm)

18 in.

(457 mm)

(600 mm)

(12.5 mm)

(914 mm)

(610 mm)

Table 3

24 in.

.5 in.

36 in.

24 in.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 13

Dimensions

2

H

G

F

C

A

B

D

E

3

4

5

6

1

R

I

K

J

L

M

N

P

O

Q

20, 30, 40, 60 AND 80 POUND CAPACITY MACHINES

20, 30, 40, 60 and 80 Pound Models

Basic Installation/Operation

CHM2278N

CHM2278N

1 Supply Dispenser 4 Cold Water Inlet

2 Input Power Block 5 Vacuum Breaker

3 Hot Water Inlet 6 Drain Outlet

Figure 2

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Basic Installation/Operation

Dimensions 20 30 40 60 80

A

B

C

D

Standard

E

Electric Heat

F

G

H

I

J

35.15 in.

(893 m)

34.52 in.

(877 mm)

1.81 in.

(46 mm)

4.5 in.

(114 mm)

5.88 in.

(149 mm)

5.88 in.

(149 mm)

8.82 in.

(224 mm)

15.10 in.

(384 mm)

15.6 in.

(396 mm)

1.58 in.

(40 mm)

30.21 in.

(767 mm)

Machine Capacity Dimensions

38.03 in.

(966 mm)

37.46 in.

(951 mm)

1.73 in.

(44 mm)

4.5 in.

(114 mm)

5.88 in.

(149 mm)

5.88 in.

(149 mm)

8.82.in.

(224 mm)

15.19 in.

(386 mm)

15.6 in.

(396 mm)

1.18 in.

(30 mm)

34.57 in.

(878 mm)

40.31 in.

(1024 mm)

39.71 in.

(1009 mm)

2.97 in.

(75 mm)

4.81 in.

(122 mm)

6.35 in.

(161 mm)

6.03 in.

(153 mm)

8.82.in.

(224 mm)

15.15 in.

(385 mm)

15.65 in.

(398 mm)

1.47 in.

(37 mm)

39.72 in.

(1009 mm)

43.31 in.

(1100 mm)

42.4 in.

(1077 mm)

2.42 in.

(61 mm)

4.69 in.

(119 mm)

5.5 in.

(140 mm)

6.27 in.

(159 mm)

8.82.in.

(224 mm)

19.85 in.

(504 mm)

20.35 in.

(517 mm)

1.34 in.

(34 mm)

42.54 in.

(1081 mm)

51.87 in.

(1317 mm)

48.68 in.

(1236 mm)

2.71 in.

(69 mm)

5.71 in.

(145 mm)

6.38 in.

(162 mm)

7.15 in.

(182 mm)

8.82 in.

(224 mm)

21.62 in.

(549 mm)

26.12 in.

(663 mm)

0.97 in.

(25 mm)

51.5 in.

(1308 mm)

K

M

N

O

P

Q

R

25.5 in.

(648 mm)

L

23.01 in.

(584 mm)

17 in.

(432 mm)

14.38 in.

(365 mm)

26 in.

(660 mm)

1.5 in.

(38 mm)

42 in.

(1067 mm)

9 in.

(229 mm)

30.42 in.

(773 mm)

24 in.

(610 mm)

17 in.

(432 mm)

14 in.

(356 mm)

29 in.

(737 mm)

1.5 in.

(38 mm)

44.95 in.

(1142 mm)

9 in.

(229 mm)

35.28 in.

(896 mm)

26 in.

(660 mm)

17.74 in.

(451 mm)

14.56 in.

(370 mm)

30.63 in.

(778 mm)

1.5 in.

(38 mm)

47.20 in.

(1199 mm)

9 in.

(229 mm)

38.23 in.

(971 mm)

26.38 in.

(670 mm)

18.12 in.

(460 mm)

14.94 in.

(379 mm)

34.06 in.

(865 mm)

1.5 in.

(38 mm)

49.89 in.

(1267 mm)

9 in.

(229 mm)

47.52 in

(1207 mm).

30.91 in.

(785 mm)

20.77 in.

(528 mm)

17.91 in.

(455 mm)

41.5 in.

(1054 mm)

1.5 in.

(38 mm)

56.16 in.

(1426 mm)

9 in.

(229 mm)

Table 4

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 15

125 Model

125 POUND CAPACITY MACHINES

F

E

D

4

5

6

7

8

3

2

A

B

C

9

G

H

I

J

K

L

M

N

Q

P

O

1

Basic Installation/Operation

CHM2279N

CHM2279N

1 Dry Chemical Dispenser (Optional) 6 Hot Water Inlet

2 Input Power Block 7 Liquid Chemical Inlet

3 Fans 8 Steam Inlet (Optional)

4 Valve Panel 9 Drain Outlet

5 Cold Water Inlet

Figure 3

Machine Capacity Dimensions for 125 Pound Models

A

B

C

D

E

F

G

H

I

78.8 in. (2002 mm)

14.62 in. (371 mm)

6.27 in. (159 mm)

29.56 in. (751 mm)

41.28 in. (1049 mm)

51.26 in. (1302 mm)

75.15 in. (1909 mm)

83.4 in. (2118 mm)

2.86 in. (73 mm)

J

K

L

M

N

O

P

Q

Table 5

61.28 in. (1557 mm)

70.81 in. (1799 mm)

50.2 in. (1275 mm)

38.96 in. (990 mm)

35.74 in. (908 mm)

60 in. (1524 mm)

9.92 in (252 mm)

88.09 in. (2237 mm)

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Basic Installation/Operation

Electrical Specifications

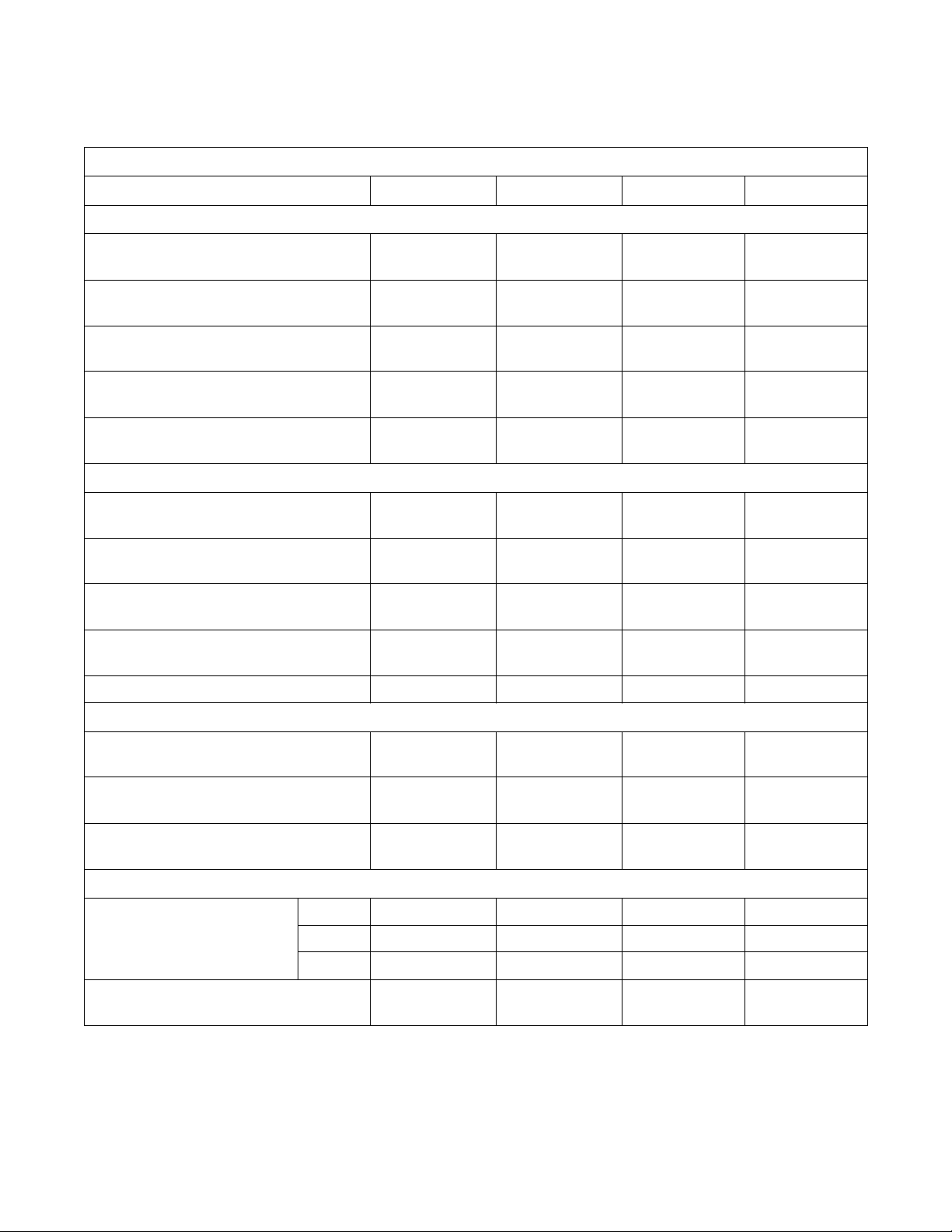

Electrical Specifications

20 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Voltage

Cycle

Phase

Wire

Full Load

Amps

Breaker

Full Load

Circuit

AWG

mm

2

Amps

Breaker

Circuit

AWG

2 Speed Models

B 120 60 1 2 16 20 12 4.0 N/A

C 380 – 415 50 3 4 4 15 14 2.5 14 15 14 2.5

F 440 – 480 60 3 3 4 15 14 2.5 N/A

J 200 50 3 3 5 15 14 2.5 N/A

O 208 – 240 60 3 3 5 15 14 2.5 23 30 10 6.0

Y 208 – 240 60 1 2 8 15 14 2.5 N/A

Variable-Speed Models

Q 200 – 240 50/60 3 3 4 15 14 2.5 21 30 10 6.0

R 380 – 480 50/60 3 3 4 15 14 2.5 N/A

X 200 – 240 50/60 1/3 2/3 6/4 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 6

Electrical Specifications

30 Pound Capacity Models

mm

2

Voltage Designation Standard Electric Heat

Code

Voltage

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

2 Speed Models

C 380 – 415 50 3 4 4 15 14 2.5 15 20 12 4.0

F 440 – 480 60 3 3 4 15 14 2.5 N/A

J 200 50 3 3 7 15 14 2.5 N/A

O 208 – 240 60 3 3 7 15 14 2.5 25 30 10 6.0

Y 208 – 240 60 1 2 10 20 12 4.0 N/A

Variable-Speed Models

Q 200 – 240 50/60 3 3 5 15 14 2.5 22 30 10 6.0

R 380 – 480 50/60 3 3 4 15 14 2.5 N/A

X 200 – 240 50/60 1/3 2/3 7/5 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 7

mm

2

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 17

Electrical Specifications

40 Pound Capacity Models

Basic Installation/Operation

Code

Voltage Designation Standard Electric Heat

Voltage

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

2 Speed Models

C 380 – 415 50 3 4 5 15 14 2.5 27 30 10 6.0

F 440 – 480 60 3 3 5 15 14 2.5 24 30 10 6.0

J 200 50 3 3 7 20 12 4.0 N/A

O 208 – 240 60 3 3 7 20 12 4.0 45 50 8 10.0

Y 208 – 240 60 1 2 14 30 10 6.0 N/A

Variable-Speed Models

R 380 – 480 50/60 3 3 5 15 14 2.5 22 30 10 6.0

Q 200 – 240 50/60 3 3 6 15 14 2.5 42 50 8 10.0

X 200 – 240 50/60 1/3 2/3 10/6 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 8

Electrical Specifications

60 Pound Capacity Models

mm

2

Code

Voltage Designation Standard Electric Heat

Voltage

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

AWG

mm

2

Full Load

Amps

Breaker

Circuit

AWG

2 Speed Models

C 380 - 415 50 3 4 5 15 14 2.5 27 30 10 6.0

F 440 - 480 60 3 3 5 15 14 2.5 24 30 10 6.0

J 200 50 3 3 10 20 12 4.0 N/A

O 208 - 240 60 3 3 10 20 12 4.0 48 50 8 10.0

Variable-Speed Models

R 380 - 480 50/60 3 3 6 15 14 2.5 23 30 10 6.0

Q 200 - 240 50/60 3 3 8 15 14 2.5 43 50 8 10.0

X 200 - 240 50/60 1/3 2/3 11/8 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 9

mm

2

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Basic Installation/Operation

Electrical Specifications

80 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Voltage

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Amps

Breaker

Circuit

AWG

Variable-Speed Models

R 380 – 480 50/60 3 3 8 15 14 2.5 40 50 8 10.0

Q 200 – 240 50/60 3 3 11 15 14 2 .5 82 90 3 25.0

X 200 – 240 50/60 1/3 2/3 16/11 20/15 12/14 4.0/2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 10

Electrical Specifications

125 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Voltage

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

Variable-Speed Models

R 380 – 480 50/60 3 3 10 15 14 2.5 N/A

Q 200 – 240 50/60 3 3 11 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

mm

2

mm

2

Tabl e 11

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 19

Operation

CHM2253N

CHM2254N

CHM2255N

CHM2256N

CHM2257N

CHM507N

CHM2258N

CHM509N

CHM510N

CHM2259N

CHM2260N

CHM2261N

CHM2262N

CHM2263N

CHM2264N

CHM2264N

CHM1988N

CHM1988N

CHM2265N

CHM2266N

Basic Installation/Operation

NOTE: Available settings vary by model.

Symbol Description

Stop

Start

Up Edit

Down Edit

Back

Table 12 (Continued)

Symbol Description

Extra Wash

Extra Rinse

Normal Wash

Permanent Press

Gentle Wash

Add Bleach

Door Lock

Table 12 (Continued)

Time

Wash

Start/Enter

Vend Price/Actuation

Rinse

Table 12

Spin

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Basic Installation/Operation

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

Operating Instructions, Vend

Models Only

1. Turn on main power source (circuit breaker).

2. Turn handle clockwise to open. Refer to Figure

4.

CHM2243N

Figure 4

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 5.

NOTE: Underloading can cause out-of-balance

conditions that can shorten machine life.

4. Close door and turn handle counter clockwise.

Refer to Figure 6.

CHM2244N

Figure 6

5. The default wash cycle will display.

6. Select the desired soil setting (select models

only), cycle setting (select models only) and

cycle/temperature. The LED indicator(s) for that

cycle will light.

Figure 5

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8321401 (EN)

U003I

Page 21

Basic Installation/Operation

CHM2227N

Powder

a. DETERGENT

CHM2228N

Liquid

b. BLEACH

CHM2230N

Powder

CHM2229N

Liquid

c. SOFTENER

7. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 7.

a. Detergent:

• Liquid - Compartment 1 (prewash) +

Compartment 3

• Powder - Compartment 1 (prewash) +

Compartment 2

b. Bleach:

• Liquid - Compartment 3

• Powder - Compartment 2

c. Softener:

• Liquid - Compartment 4

8. Insert coin(s) or card as necessary.

• If the machine is a coin operated unit, add coins.

• If the machine is a card operated unit, insert and

• If the unit is interfaced to a central/remote pay

As each coin is added, the vend counts down to

the amount remaining.

remove card per card system instructions.

system, go to the central/remote pay console,

make payment and select the machine and follow

central/remote pay system instructions.

CHM2231N

Figure 7

9. Press the START keypad.

10. During first fill, the desired wash cycle can be

changed. After first fill has ended, the wash cycle

active at that moment remains the chosen wash

cycle.

11. Whe n cycle is complete, display shows “00”.

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Basic Installation/Operation

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

Operating Instructions, OPL Models

Only

1. Turn on main power source (circuit breaker).

2. Turn door handle clockwise to open.

NOTE: For 125 models, press the Unlock/Stop

keypad. Turn door handle counter clockwise to

open.

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 8.

NOTE: Underloading can cause out-of-balance

conditions that can shorten machine life.

4. Close door and turn handle counter clockwise.

Refer to Figure 9.

NOTE: For 125 models, close door and turn handle

clockwise.

CHM2244N

Figure 9

5. The default wash cycle will display.

Figure 8

U003I

6. If desired, select a different wash cycle

temperature (select models only) or a different

wash cycle number. The LED indicator for that

cycle will light or the display will indicate the

current cycle.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Page 23

Basic Installation/Operation

CHM2227N

Powder

a. DETERGENT

CHM2228N

Liquid

b. BLEACH

CHM2230N

Powder

CHM2229N

Liquid

c. SOFTENER

7. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 10.

a. Detergent:

• Liquid - Compartment 1 (prewash) +

Compartment 3

• Powder - Compartment 1 (prewash) +

Compartment 2

b. Bleach:

• Liquid - Compartment 3

• Powder - Compartment 2

c. Softener:

• Liquid - Compartment 4

8. Press the START keypad.

9. During first fill, the desired wash cycle can be

changed on some models. After first fill has

ended, the wash cycle active at that moment

remains the chosen wash cycle.

CHM2231N

Figure 10

10. When cycle is complete, display shows “00”.

F8321401 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Basic Installation/Operation

Disposal of Unit

This appliance is marked according to the European

directive 2002/96/EC on Waste Electrical and

Electronic Equipment (WEEE).

This symbol on the product or on its packaging

indicates that this product shall not be treated as

household waste. Refer to Figure 1 1. Instead it shall be

handed over to the applicable collection point for the

recycling of electrical and electronic equipment.

Ensuring this product is disposed of correctly will help

prevent potential negative consequences for the

environment and human health which could otherwise

be caused by inappropriate waste handling of this

product. The recycling of materials will help to

conserve natural resources. For more detailed

information about recycling of this product, please

contact the local city office, household waste disposal

service, or the source from which the product was

purchased.

MIX1N

Figure 11

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F8321401 (EN)

Loading...

Loading...