Page 1

Washer-Extractors

This manual is only a

Supplement. Refer to

Installation Manual and

Operation/Maintenance

Manual for full

instructions.

Installation/Operation Supplement

Cabinet Hardmount Operating Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM166C

Part No. F232145R6EN

November 2005

Page 2

Page 3

Installation/Operation Supplement

Table of

Contents

Safety Information .............................................................................. 3

Important Safety Instructions ............................................................... 3

Specifications and Dimensions........................................................... 5

Gap Setting for Vibration Switch

(Variable-Speed and Fixed-Speed

Models)............................................................................................... 8

Dimensional Clearances ....................................................................... 16

Dimensions ........................................................................................... 17

18, 20, 25, 27, 30, 35, 40, 50, 60 and 80 Models............................. 17

125 Model ........................................................................................ 19

Electrical Specifications ....................................................................... 20

Operation............................................................................................. 25

Instructions for EDC Control................................................................ 27

Instructions for Mechanical Timer ....................................................... 29

Instructions for S, P and V Series Microcomputers ............................. 31

Instructions for B Series Microcomputer ............................................. 33

Instructions for A Series Microcomputer ............................................. 35

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Installation/Operation Supplement

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 5

Installation/Operation Supplement

Safety Information

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

DANGER

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

WARNING

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

CAUTION

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

1. Read all instructions before using the washer.

2. Refer to the

Installation Manual for the proper grounding of

the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils,

dry-cleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Grounding Instructions in the

W023

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Installation/Operation Supplement

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer,

or attempt any servicing unless specifically

recommended in the user-maintenance instructions

or in published user-repair instructions that the

user understands and has the skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing clothes.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply

with local codes and be made by licensed

personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: Underloading can cause out-of-balance

conditions that can shorten life of machine.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 7

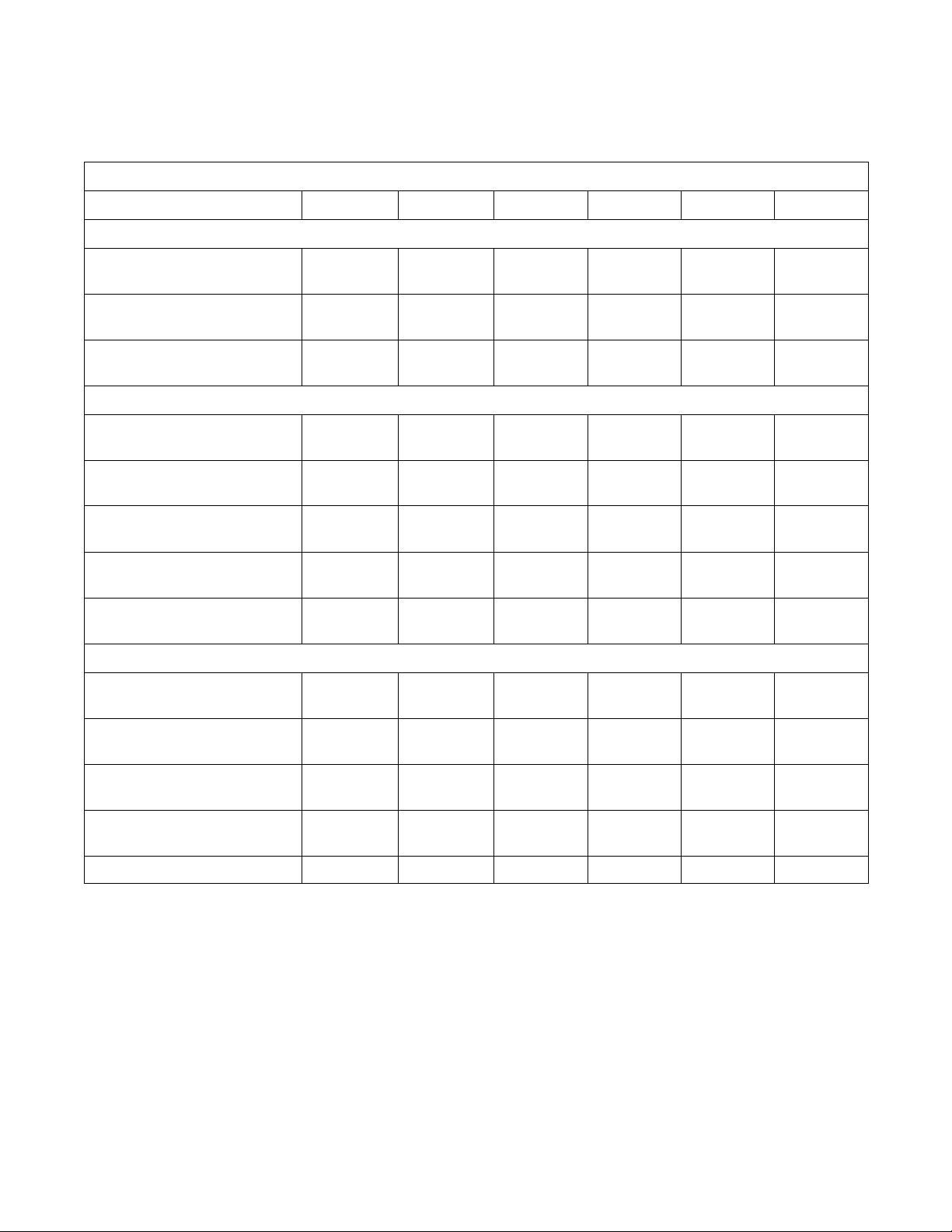

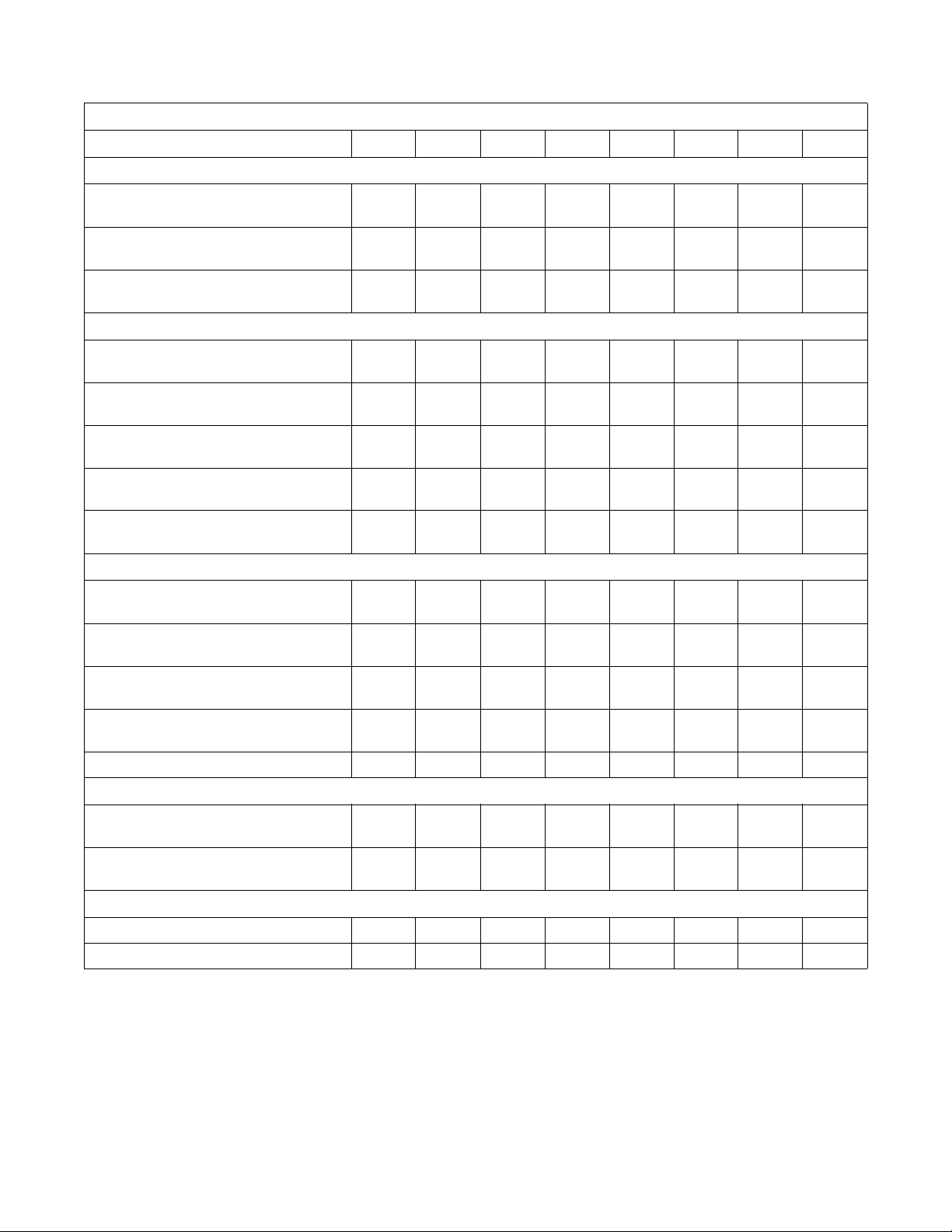

Specifications and Dimensions

Specification 18, 20 25 27, 30 35 40 50

Overall Dimensions

Installation/Operation Supplement

2 Speed Models

Overall width, in. (mm) 26

(660)

Overall height, in. (mm) 42-7/8

(1089)

Overall depth, in. (mm) 29-13/16

(757)

Weight and Shipping Information

Net weight, lbs. (kg) 390

(177)

Domestic shipping weight, lbs.

(kg)

Domestic shipping volume, ft

3

(m

)

Export shipping weight lbs., (kg) 480

Export shipping volume, ft

Wash Cylinder Information

Cylinder diameter,

in. (mm)

3

3

(m3)30.1

428

(194)

28

(0.8)

(218)

(0.86)

21

(533)

26

(660)

45

(1143)

33-7/8

(860)

435

(198)

470

(214)

33

(0.9)

530

(241)

36.7

(1.03)

21

(533)

29

(737)

45-7/8

(1165)

34-13/16

(884)

498

(226)

545

(245)

35

(1.0)

588

(267)

39.6

(1.11)

24

(610)

30-1/8

(765)

47-1/4

(1200)

38-1/2

(978)

650

(295)

680

(309)

39

(1.09)

760

(345)

47.1

(1.32)

26-1/4

(667)

30-5/8

(778)

47-7/8

(1216)

40-3/16

(1021)

706

(321)

744

(338)

42.6

(1.19)

846

(385)

54.1

(1.51)

26-1/4

(667)

34-1/16

(865)

50-13/16

(1291)

41-13/16

(1087)

820

(373)

875

(398)

53

(1.5)

1020

(464)

58.7

(1.67)

30

(762)

Cylinder depth, in. (mm) 13-3/4

(349)

Cylinder volume, ft

Perforation size, in. (mm) 0.188

Perforation open area, % 17 17 23 17 17.5 18

F232145 (EN)

3

(l) 2.76

(78.1)

(4.76)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

18-3/4

(476)

3.76

(106.5)

0.188

(4.76)

Table 1 (Continued)

(406)

4.19

(118.6)

0.188

(4.76)

16

18-3/8

(467)

5.76

(163.1)

0.188

(4.76)

20-1/4

(514)

6.34

(180)

0.188

(4.76)

20

(508)

8.18

(231.6)

0.188

(4.76)

5

Page 8

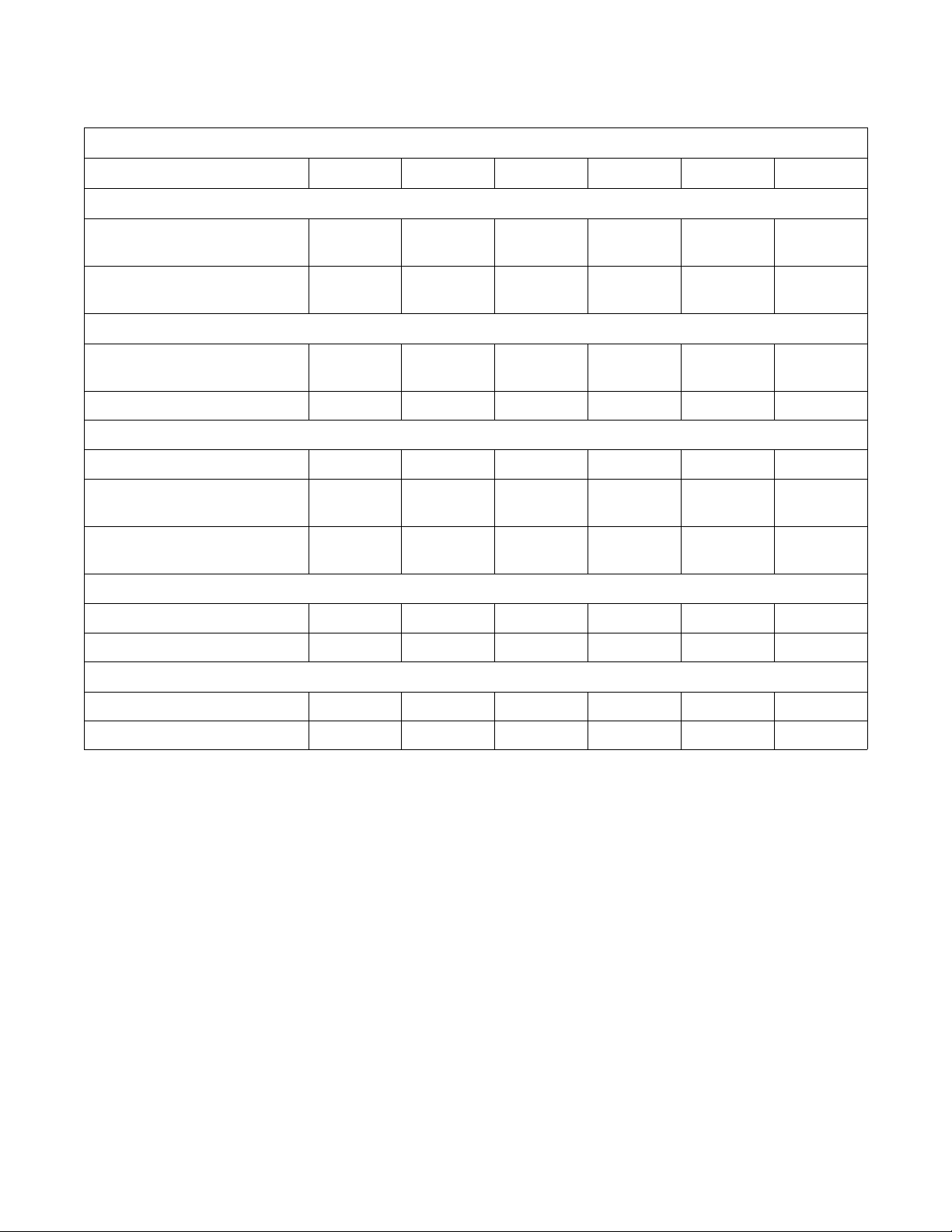

Installation/Operation Supplement

T

Table 1 (Continued)

2 Speed Models (Continued)

Specification 18, 20 25 27, 30 35 40 50

Door Opening Information

Door opening diameter,

in. (mm)

Height of door bottom above floor,

in. (mm)

12

(305)

14-3/8

(365)

12

(305)

14-3/8

(365)

14-11/32

(364)

14

(356)

14-11/32

(364)

16

(406)

16-1/4

(413)

14-1/2

(368)

16-1/4

(413)

13-1/2

(343)

Power Consumption

Average power used per cycle,

0.20 0.25 0.25 0.30 0.34 0.42

kW-hr

Average HVAC load, Btu/hr 425 400 400 510 510 700

Drive Train Information

Number of motors in drive train 1 1 1 1 1 1

Wash/reverse power, HP (kW) 0.18

(0.13)

High extract power, HP (kW) 1.0

(0.746)

0.25

(0.19)

1.4

(1.04)

0.25

(0.19)

1.4

(1.04)

0.40

(0.30)

1.8

(1.3)

0.40

(0.30)

1.8

(1.3)

0.55

(0.41)

(2.01)

2.7

Cylinder Speeds

Wash/reverse speed, RPM 53 55 47 47 47 44

High extract speed, RPM 525 540 480 470 470 450

Centrifugal Force Data

Wash/reverse centrifugal force, Gs 0.85 0.90 0.75 0.82 0.82 0.825

High extract centrifugal force, Gs 82.1 86.8 78.4 82.3 82.3 86.3

Table 1 (Continued)

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 9

Installation/Operation Supplement

Table 1 (Continued)

2 Speed Models (Continued)

Specification 18, 20 25 27, 30 35 40 50 60

Balance Detection

Vibration switch installed N/A N/A N/A N/A N/A N/A N/A

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

Number of steam inlets 1111111

Steam required to raise

bath water temperature

10°F (6°C)

Average steam use per cycle,

bhp (kg)

LOW 1.05 (0.75) 1.4 (1.01) 1.44 (1.03) 2.06 (1.48) 2.09 (1.51) 2.76 (1.99) 2.76 (1.99)

HIGH 1.4 (1.01) 1.59 (1.15) 1.91 (1.37) 2.69 (1.94) 2.84 (2.04) 3.59 (2.59) 3.59 (2.59)

0.71

(11.1)

0.87

(13.6)

0.97

(15.2)

1.4

(21.6)

1.43

(22.4)

1.84

(28.9)

1.84

(28.9)

Electrical Heating (Optional)

Total electrical heating capacity,

7.8 7.8 7.8 15.6 15.6 23.4 23.4

kW

Electrical heating elements 3336399

Electrical heat element size, kW 2.6 2.6 2.6 2.6 5.2 2.6 2.6

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

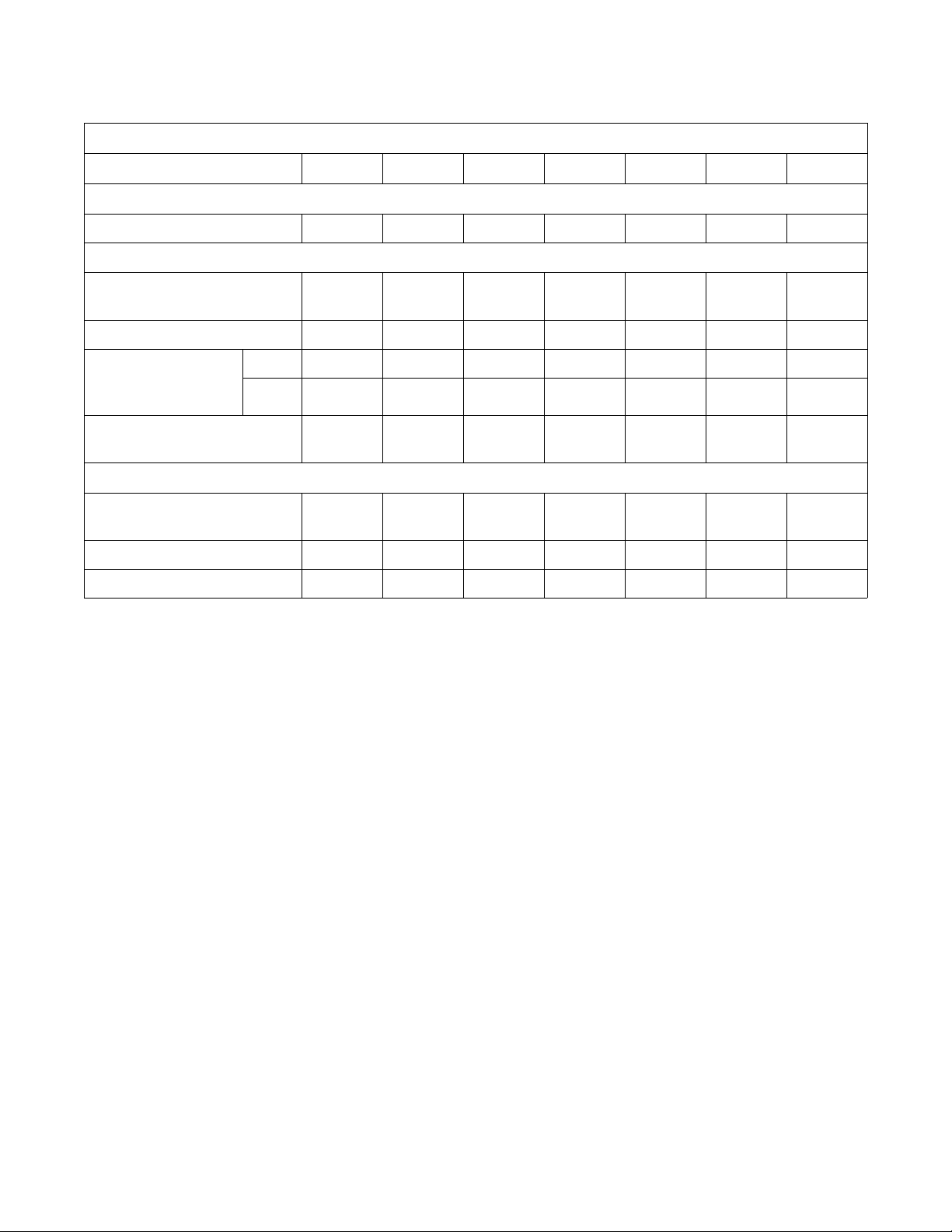

Page 10

Installation/Operation Supplement

Gap Setting for Vibration Switch

(Variable-Speed and Fixed-Speed

Models)

18, 20 27, 30 35 40 50 60 80 125

Switch gap

setting*

* Gap setting should be made with “GO-NO-GO” type feeler gauge. Lower value must not trip switch. Upper value must trip switch.

After the machine has been properly installed, the

vibration switch gap must be measured before

conducting the Control Function Test. Locate the gap

found between the vibration switch and the machine

structure. Refer to Figures 1, 2, 3, 4 and 5. To check

the gap setting of the switch, proceed as follows:

1. Remove the front panel on 18-50 models.

Remove the rear panel on 60-80 models. Remove

the top cover on the 125 model. The switch can

be seen inside the bottom right corner of the Aframe, mounted on a bracket. Refer to Figures 1,

2, 3, 4 and 5.

0.015-

0.025 in.

(0.38-

0.64 mm)

0.025-

0.035 in.

(0.64-

0.89 mm)

0.030-

0.040 in.

(0.76-

1.02 mm)

0.020-

0.030 in.

(0.51-

0.64 mm)

Tab le 2

0.025-

0.035 in.

(0.64-

0.89 mm)

0.013-

0.015 in.

(0.20-

0.25 mm)

0.009-

0.011 in.

(0.23-

0.28 mm)

0.008 in.

0.20 mm)

0.006-

(0.15-

2. Measure the gap distance when the switch is in

both the open and closed positions. The

specifications should be at the minimum switch

gap setting when the switch is open and at the

maximum switch gap setting when the switch is

closed. If these distances are not correct, adjust

the balance switch to these specifications.

NOTE: The standard position of the switch is open,

or non-tripped.

3. Tighten nuts on switch extension after adjusting

the gap. Measure the gap distance to verify

accurate setting.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 11

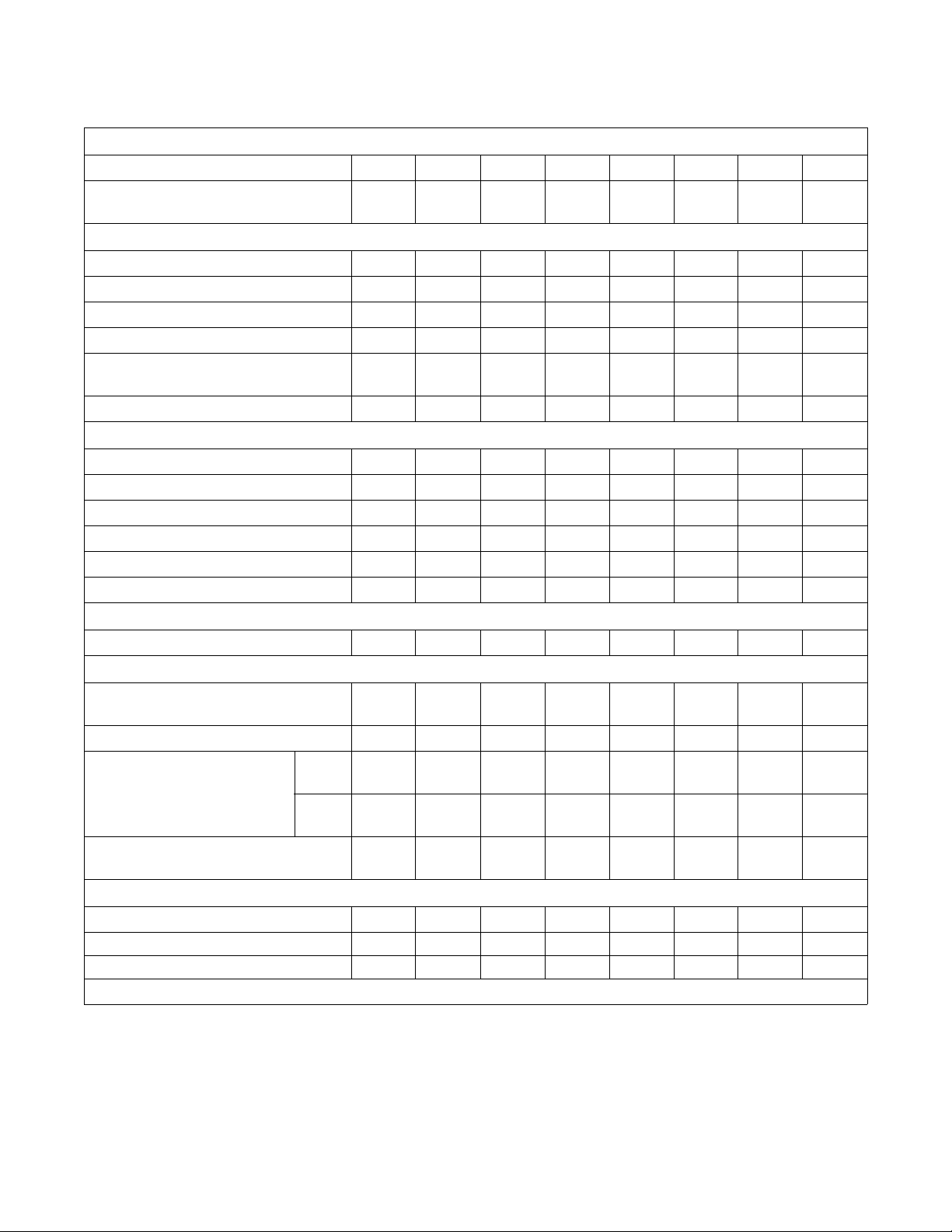

Variable-Speed and Fixed-Speed Models

Specification 20 30 35 40 50 60 80 125

Overall Dimensions

Overall width, in. (mm) 26

(660)

Overall height, in. (mm) 42-7/8

(1089)

Overall depth, in. (mm) 29-13/16

(757)

Weight and Shipping Information

Net weight, lbs. (kg) 386

(175)

Domestic shipping weight, lbs. (kg) 424

(191)

3

Domestic shipping volume, ft

(m3)28

(0.8)

Export shipping weight, lbs. (kg) 476

(215)

Export shipping volume, ft

3

(m3)30.1

(0.86)

29

(737)

45-7/8

(1165)

34-13/16

(884)

498

(226)

545

(245)

35

(1.0)

588

(267)

39.6

(1.11)

30-1/8

(765)

47-1/4

(1200)

38-1/2

(978)

621

(282)

670

(301)

39

(1.09)

731

(332)

47.1

(1.32)

30-5/8

(778)

47-7/8

(1216)

40-3/16

(1021)

706

(321)

744

(338)

42.6

(1.19)

846

(385)

54.1

(1.51)

Installation/Operation Supplement

34-1/16

(865)

50-13/16

(1291)

42-13/16

(1087)

767

(348)

818

(371)

53

(1.5)

967

(439)

58.7

(1.67)

34-1/16

(865)

41-1/2

(1054)48(1219)

50-13/16

(1291)56(1422)

42-13/16

(1087)

773

(350)

824

(373)

53

(1.5)

1020

(463)

58.7

(1.67)

51-5/8

(1311)

1406

(633)

1456

(655)

97

(2.7)

1506

(678)

109.5

(3.1)

70-1/2

(1791)

56-3/4

(1441)

2346

(1066)

2421

(1098)

153

(4.3)

2701

(1225)

173

(4.8)

Wash Cylinder Information

Cylinder diameter, in. (mm) 21

(533)

Cylinder depth, in. (mm) 13-3/4

(349)

3

Cylinder volume, ft

(l) 2.76

(78.1)

Perforation size, in. (mm) 0.188

(4.76)

24

(610)

16

(406)

4.19

(118)

0.188

(4.76)

26-1/4

(667)

18-3/8

(467)

5.76

(163.1)

0.188

(4.76)

26-1/4

(667)

20-1/4

(514)

6.34

(180)

0.188

(4.76)

30

(762)

20

(508)

8.18

(232)

0.188

(4.76)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

36

(914)

22

(559)

12.96

(367)

0.188

(4.76)

42

(1060)

24

(609)

19.24

(545)

0.188

(4.76)

Perforation open area, % 17231717.518182717

Door Opening Information

Door opening size, in. (mm) 12

(305)

Height of door bottom above floor, in. (mm) 14-3/8

(365)

14-11/32

(364)

14

(356)

14-11/32

(364)

16

(406)

16-1/4

(413)

14-1/2

(368)

16-1/4

(413)

13-1/2

(343)

16-1/4

(413)

13-1/2

(343)

18-1/2

(470)

17-3/4

(451)

20

(508)

29

(737)

Power Consumption

Average power used per cycle, kW-hr 0.05 0.07 0.20 0.34 0.37 0.21 0.40 0.60

Average HVAC load, Btu/hr 400 450 510 510 750 750 950 1200

Table 3 (Continued)

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation/Operation Supplement

Table 3 (Continued)

Drive Train Information

Number of motors in drive train 11111111

Drive motor power, HP (kW) 2

(1.5)

Cylinder Speeds

Gentle wash/reverse speed, RPM 2927262624242227

Wash/reverse speed, RPM 5248464743434037

Distribution speed, RPM 8286737368776362

Low extract speed, RPM 366 343 328 328 307 307 280 260

Medium extract speed, RPM

(Not available on Electronic Control models.)

High extract speed, RPM 685 641 613 614 573 574 524 485

Centrifugal Force Data

Gentle wash centrifugal force, Gs 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.43

Wash/reverse centrifugal force, Gs 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8

Distribution centrifugal force, Gs 22222222

Low extract centrifugal force, Gs 40 40 40 40 40 40 40 40

Medium extract centrifugal force, Gs 85 85 85 85 85 85 85 85

High extract centrifugal force, Gs 140 140 140 140 140 140 140 140

534 500 478 478 447 447 408 380

2

(1.5)

2

(1.5)

2

(1.5)

2

(1.5)

3

(2.2)

5

(3.7)

7.5

(5.6)

Balance Detection

Vibration switch installed* Standard Standard Standard Standard Standard Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

Number of steam inlets 11111111

Steam required to raise bath water

temperature 10°F (6°C), lbs. (kg)

Average steam use per cycle, bhp (kg) 0.54

Electrical Heating (Optional)

Total electrical heating capacity, kW 7.8 7.8 15.6

Electrical heating elements 33639912N/A

Electrical heat element size, kW 2.6 2.6 2.6 5.2 2.6 2.6 2.6 N/A

* Refer to Gap Setting for Vibration Switch (Variable-Speed and Fixed-Speed Models) section for specifications.

LOW 0.62

HIGH 0.88

1/2

(13)

(0.28)

(0.4)

(8.3)

1/2

(13)

0.92

(0.42)

1.31

(0.6)

0.73

(11.3)

1/2

(13)

2.1

(1.51)

2.69

(1.96)

1.4

(21.6)

1/2

(13)

2.09

(1.51)

2.84

(2.04)

1.43

(22.4)

15.6

1/2

(13)

2.8

(2.0)

3.6

(2.59)

1.8

(28.9)

23.4 23.4 31.2 N/A

1/2

(13)

3.6

(1.63)

5.5

(2.49)

2.32

(36.4)

1/2

(13)

4.1

(2.93)

6.0

(4.34)

2.93

(45.9)

(19)

(4.9)

(6.4)

(71)

3/4

6.8

8.9

4.5

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 13

For 18, 20, 25, 27, 30 and 35 Pound

Capacity Machines

Installation/Operation Supplement

3

2

1 Sump 3 Vibration Switch

2 Gap Distance 4 Switch Extension

1

4

Figure 1

CHM1995N

CHM1995N

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation/Operation Supplement

For 40 and 50 Pound Capacity Variable-Speed

and Fixed-Speed Machines

3

2

1

3

4

4

1 Sump 3 Vibration Switch

2 Gap Distance 4 Switch Extension

Figure 2

CHM2000N

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 15

For 60 Pound Capacity Variable-Speed and

Fixed-Speed Machines

Installation/Operation Supplement

2

3

2

1

6

4

5

1 Lower Bracket 4 Balance Bolt

2 Upper Bracket 5 Lock Nut

3 Vibration Switch 6 Gap Distance

CHM1999N

CHM1999N

F232145 (EN)

Figure 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation/Operation Supplement

For 80 Pound Capacity Machines

1

2

3

1 Switch Extension 3 Vibration Switch

2 Gap Distance

Figure 4

CAB1998N

CHM1998N

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 17

For 125 Pound Capacity Machines

3

2

1

1 Vibration Switch 3 Switch Extension

2 Gap Distance

Installation/Operation Supplement

CHM1993N

Figure 5

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

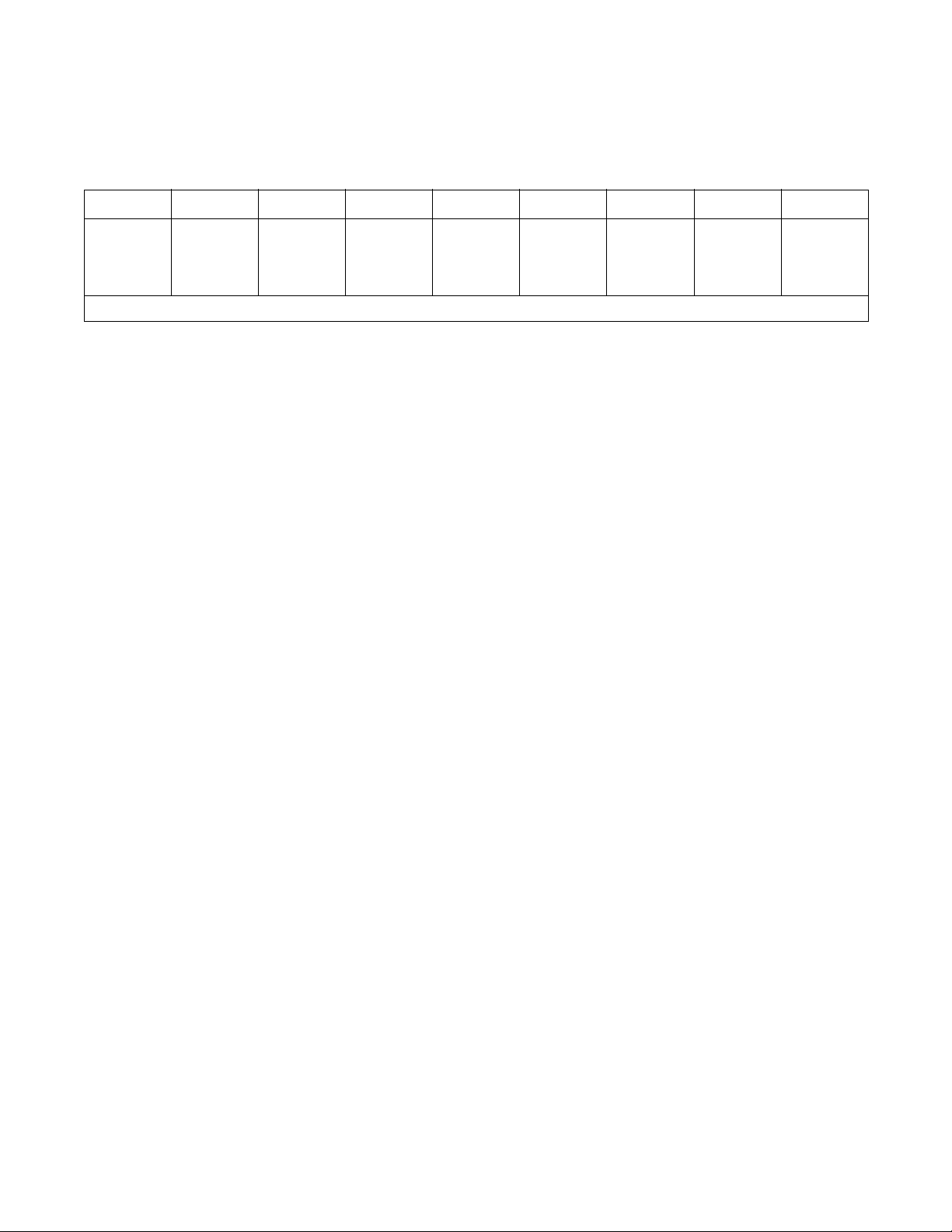

Page 18

Installation/Operation Supplement

Dimensional Clearances

F

E

FRONT

A

B

C

D

Figure 6

Machine Capacity Dimensional Clearances

Dimensions 18, 20 25 27, 30 35 40 50 60 80 125

A

B

C

D

E

F

*For 80 pound models intended for standard mounting, clearance should be 6 in. (150 mm).

2 in.

(50 mm)

26 in.

(660 mm)

1 in.

(25 mm)

16-3/8 in.

(416 mm)

25-5/8 in.

(650 mm)

12 in.

(305 mm)

2 in.

(50 mm)

26 in.

(660 mm)

1 in.

(25 mm)

16-3/8 in.

(416 mm)

29-7/16 in.

(705 mm)

12 in.

(305 mm)

2 in.

(50 mm)

29 in.

(737 mm)

1 in.

(25 mm)

19-1/4 in.

(490 mm)

30-1/2 in.

(775 mm)

12 in.

(305 mm)

2 in.

(50 mm)

30-1/8 in.

(765 mm)

1 in.

(25 mm)

19-1/4 in.

(490 mm)

34 in.

(864 mm)

18 in.

(457 mm)

2 in.

(50 mm)

30-5/8 in.

(778 mm)

1 in.

(25 mm)

22 in.

(560 mm)

36 in.

(914 mm)

12 in.

(305 mm)

2 in.

(50 mm)

34-1/16 in.

(865 mm)

1 in.

(25 mm)

22 in.

(560 mm)

37-1/2 in.

(953 mm)

12 in.

(305 mm)

2 in.

(50 mm)

34-1/16 in.

(865 mm)

1 in.

(25 mm)

22 in.

(560 mm)

38-3/4 in.

(984 mm)

12 in.

(305 mm)

2 in.

(50 mm)

41-1/2 in.

(1054 mm)

1 in.*

(25 mm)

25 in.

(635 mm)

51-5/8 in.

(1311 mm)

24 in.

(610 mm)

24 in.

(600 mm)

48 in.

(1219 mm)

12 in.

(300 mm)

26-1/4 in.

(667 mm)

56-3/4 in.

(1441 mm)

24 in.

(610 mm)

U158M

16

Tab le 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 19

Dimensions

18, 20, 25, 27, 30, 35, 40, 50, 60 and

80 Models

1

Installation/Operation Supplement

4

3

2

S

R

I

J

5

6

7

8

H

A

B

C

D

1 Supply Dispenser 5 Hot Water Inlet

2 Input Power Block 6 Extra Inlet Valve

3 External Chemical Supply Signal Terminal Strip

(OPL only)

4 Cold Water Inlet 9 Drain Outlet

E

F

G

7 External Chemical Supply Inlet (OPL only)

8 Vacuum Breaker

L

N

Figure 7

K

M

O

9

Q

P

CHM2019N

CHM2019N

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Installation/Operation Supplement

Machine Capacity Dimensions

Dimensions 18, 20 25 27, 30 35 40 50 60 80

A

B

C

D

E

F

G

H

K

L

M

N

O

P

Q

R

S

22-15/16 in.

(583 mm)

17-1/4 in.

(438 mm)

14-3/8 in.

(365 mm)

26 in.

(660 mm)

25-5/8 in.

(650 mm)

29-13/16 in.

(757 mm)

0 0 0 1-1/8 in.

42 in.

(1062 mm)

I

J

12-1/2 in.

(318 mm)

11-1/2 in.

(292 mm)

3-1/2 in.

(89 mm)

34-1/2 in.

(876 mm)

5-3/4 in.

(146 mm)

4-1/2 in.

(114 mm)

2 in.

(51 mm)

36-3/16 in.

(919 mm)

38-1/2 in.

(978 m)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

23 in.

(584 mm)

17-1/4 in.

(438 mm)

14-3/8 in.

(365 mm)

26 in.

(660 mm)

30 in.

(762 mm)

34-3/16 in.

(868 mm)

45 in.

(1143 mm)

12-1/2 in.

(318 mm)

11-1/2 in.

(292 mm)

3-1/2 in.

(89 mm)

37-1/2 in.

(952 mm)

5-3/4 in.

(146 mm)

4-1/2 in.

(114 mm)

2 in.

(51 mm)

39-3/16 in.

(995 mm)

41-1/2 in.

(1054 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

24 in.

(610 mm)

17 in.

(432 mm)

14 in.

(356 mm)

29 in.

(737 mm)

30-5/8 in.

(775 mm)

34-13/16 in.

(884 mm)

45 in.

(1143 mm)

15-1/4 in.

(387 mm)

14-3/4 in.

(375 mm)

3-3/4 in.

(95 mm)

37-11/16 in.

(957 mm)

5-7/8 in.

(149 mm)

4 in.

(102 mm)

2 in.

(51 mm)

38-15/16 in.

(989 mm)

41 in.

(1041 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26 in.

(660 mm)

19 in.

(483 mm)

16 in.

(406 mm)

30-1/8 in.

(765 mm)

34 in.

(864 mm)

38-1/8 in.

(968 mm)

(29 mm)

47 in.

(1194 mm)

14-1/4 in.

(362 mm)

10-13/16 in.

(275 mm)

2-3/4 in.

(70 mm)

40-1/8 in.

(1020 mm)

7-5/16 in.

(186 mm)

4-3/4 in.

(121 mm)

2 in.

(51 mm)

41-15/16 in.

(1064 mm)

41-15/16 in.

(1064 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

25-3/4 in.

(654 mm)

18 in.

(457 mm)

14-1/2 in.

(368 mm)

30-5/8 in.

(778 mm)

36 in.

(914 mm)

40-3/16 in.

(1021 mm)

1/2 in.

(13 mm)

47 in.

(1194 mm)

15-7/16 in.

(392 mm)

14-7/16 in.

(367 mm)

3-13/16 in.

(97 mm)

39 in.

(990 mm)

5-1/2 in.

(140 mm)

4-3/4 in.

(121 mm)

3 in.

(76 mm)

42-1/8 in.

(1070 mm)

43-3/16 in.

(1097 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26-3/8 in.

(670 mm)

18-1/4 in.

(464 mm)

13-1/2 in.

(343 mm)

34-1/16 in.

(865 mm)

37-3/4 in.

(959 mm)

41-13/16 in.

(1062 mm)

1/2 in.

(13 mm)

49-15/16 in.

(1268 mm)

20-3/4 in.

(527 mm)

19-3/4 in.

(502 mm)

3-1/2 in.

(89 mm)

41-1/2 in.

(1054 mm)

6-7/16 in.

(163 mm)

5 in.

(127 mm)

3 in.

(76 mm)

43-3/16 in.

(1097 mm)

45-1/2 in.

(1156 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26-3/8 in.

(670 mm)

18-1/4 in.

(464 mm)

15 in.

(381 mm)

34-1/16 in.

(865 mm)

38-3/4 in.

(984 mm)

42-13/16 in.

(1087 mm)

1/2 in.

(13 mm)

49-15/16 in.

(1268 mm)

20-3/4 in.

(527 mm)

19-3/4 in.

(502 mm)

3-1/2 in.

(89 mm)

41-1/2 in.

(1054 mm)

6-7/16 in.

(163 mm)

5 in.

(127 mm)

3 in.

(76 mm)

43-3/8 in.

(1102 mm)

45-1/2 in.

(1156 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

30-5/8 in.

(777 mm)

21-5/8 in.

(549 mm)

17-3/4 in.

(451 mm)

41-1/2 in.

(1054 mm)

48 in.

(1219 mm)

51 in.

(1295 mm)

1/2 in.

(13 mm)

56 in.

(1422 mm)

22-1/4 in.

(572 mm)

14-7/16 in.

(378 mm)

3-7/16 in.

(87 mm)

44-1/2 in.

(1130 mm)

6-3/8 in.

(162 mm)

5-3/4 in.

(146 mm)

(76 mm)

42-3/4 in.

(1086 mm)

50 in.

(1270 mm)

1-3/16 in.

(30 mm)

(76 mm)

3 in.

3 in.

18

Table 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 21

125 Model

1

Installation/Operation Supplement

J

K

L

M

N

O

I

2

3

4

5

6

R

S

A

B

C

D

1 Dry Chemical Dispenser (Optional) 5 Liquid Chemical Inlet

2 Cold Water Inlet 6 Steam Inlet (Optional)

3 Extra Water Inlet (Optional) 7 Drain Outlet

4 Hot Water Inlet

E

F

G

P

H

Figure 8

Machine Capacity Dimensions

A

B

C

D

1016 mm (40 in.)

768 mm (30.12 in.)

737 mm (29 in.)

203 mm (8 in.)

K

L

M

N

Q

7

B023I

1041 mm (41 in.)

978 mm (38.5 in.)

851 mm (33.5 in.)

756 mm (29.75 in.)

T

B023I

E

F

G

H

I

J

F232145 (EN)

1219 mm (48 in.)

1283 mm (50.5 in.)

1422 mm (56.75 in.)

25 mm (1 in.)

1791 mm (70.5 in.)

1130 mm (44.5 in.)

O

P

Q

R

S

T

124 mm (4.88 in.)

1622 mm (63.88 in.)

1648 mm (64.88 in.)

1692 mm (66.63 in.)

Tab le 6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

610 mm (24 in.)

330 mm (13 in.)

19

Page 22

Installation/Operation Supplement

Electrical Specifications

Electrical Specifications

18 and 20 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

mm

2

2 Speed Models

B 110 – 120 60 1 2 15 20 12 4 N/A

C 380 – 415 50 3 4 4 15 14 2.5 14 15 14 2.5

D 220 – 240 50 3 3 5 15 14 2.5 24 25 10 6

E220 – 2405012102012 4 4245 6 16

F 440 – 480 60 3 3 4 15 14 2.5 16 20 12 4

H 380 60 3 3 4 15 14 2.5 13 15 14 2.5

J 200 50 3 3 5 15 14 2.5 24 25 10 6

O 208 – 240 60 3 3 5 15 14 2.5 24 25 10 6

Y208 – 2406012102012 4 4245 6 16

Variable-Speed Models

Q 200 – 240 50/60 3 3.8 3.8 15 14 2.5 N/A N/A N/A N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Table 7

25, 27 and 30 Pound Capacity Models

Electrical Specifications

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

Full Load

Breaker

AWG

mm

2

Amps

Circuit

AWG

mm

2

2 Speed Models

C 380 – 415 50 3 4 4 15 14 2.5 15 20 12 4

D 220 – 240 50 3 3 6 15 14 2.5 24 25 10 6

E220 – 2405012102012 4 4245 6 16

F 440 – 480 60 3 3 4 15 14 2.5 16 20 12 4

H 380 60 3 3 4 15 14 2.5 14 15 14 2.5

J 200 50 3 3 6 15 14 2.5 20 25 10 6

O 208 – 240 60 3 3 7 15 14 2.5 25 30 10 6

Y 208 – 240 60 1 2 10 20 12 4 43

45616

Variable-Speed Models

Q 200 – 240 50/60 3 3 4.8 15 14 2.5 N/A N/A N/A N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

20

Table 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 23

Electrical Specifications

35 Pound Capacity Models

Installation/Operation Supplement

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Amps

Full Load

Breaker

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

2 Speed Models

C 380 – 415 50 3 4 5 15 14 2.5 26 30 10 6

D 220 – 240 50 3 3 7 20 12 4 43 50 6 16

F 440 – 480 60 3 3 5 15 14 2.5 26 30 10 6

O 200 – 240 60 3 3 7 20 12 4 43 50 6 16

Y 208 – 240 60 1 2 12 25 10 6 N/A

Variable-Speed Models

N 440 – 480 50/60 3 3 2.3 15 14 2.5 27.3 30 10 6

P 380 – 415 50/60 3 3 2.3 15 14 2.5 24 25 10 6

Q 208 – 240 50/60 3 3 5.9 15 14 2.5 43.4 45 6 16

T 200 – 240 50/60 1 2 5.9 15 14 2.5 N/A

X 200 – 240 50/60 1 or 3 2 or 3 5.9/5.9 15 14 2x2.5

N/A

3x2.5

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Tab le 9

mm

2

Electrical Specifications

40 Pound Capacity Models

Voltage Designation Standard Electric Heat

Code

Volt age

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Amps

Breaker

Circuit

AWG

2 Speed Models

C 380 – 415 50 3 4 5 15 14 2.5 26 30 10 6

D 220 – 240 50 3 3 7 20 12 4 45 50 6 16

F 440 – 480 60 3 3 5 15 14 2.5 29 30 10 6

H 380 60 3 3 3 15 14 2.5 25 30 10 6

J 200 50 3 3 7 20 12 4 38 40 6 16

O 208 – 240 60 3 3 7 20 12 4 45 50 6 16

Y 208 – 240 60 1 2 13.5 30 10 6 N/A

Variable-Speed Models

N 440 – 480 50/60 3 3 6 15 14 2.5 30 30 10 6

P 380 – 415 50/60 3 3 6 15 14 2.5 29 30 10 6

Q 200 – 240 50/60 3 3 5 15 14 2.5 48 60 6 16

X 200 – 240 50/60 1 or 3 2 or 3 11/11 15 14 2.5 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

mm

2

F232145 (EN)

Tab l e 1 0

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Installation/Operation Supplement

Electrical Specifications

50 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

Full Load

Breaker

AWG

mm

2

Amps

Circuit

AWG

mm

2

2 Speed Models

C 380 – 415 50 3 4 6 15 14 2.5 39 50 6 16

D220 – 2405033122012 4 6470 4 25

E220 – 2405012153010 6 3740 8 10

F 440 – 480 60 3 3 6 15 14 2.5 39 50 6 16

J 200 50 3 3 10 20 12 3 x 4 N/A

O208 – 2406033102012 4 6470 4 25

Y*208 – 2406012153010 6 3740 8 10

Variable-Speed Models

N 440 – 480 50/60 3 3 4 15 14 2.5 41.6 45 8 10

P 380 – 415 50/60 3 3 4 15 14 2.5 36.5 40 8 10

Q 200 – 240 50/60 3 3 6.3 15 14 2.5 62.6 70 4 25

T 200 – 240 50/60 1 2 6.3 15 14 2.5 N/A

X 200 – 240 50/60 1 or 3 2 or 3 6.3/6.3 15 14 2x2.5

N/A

3x2.5

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

*Coin models only.

Tab l e 1 1

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 25

Electrical Specifications

60 Pound Capacity Models

Installation/Operation Supplement

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Breaker

Amps

Circuit

AWG

mm

2

Full Load

Breaker

Amps

Circuit

AWG

2 Speed Models

C 380-415 50 3 4 4 15 14 2.5 37 50 8 10.0

D 220-240 50 3 3 7 20 12 4.0 64 70 4 25.0

F 440-480 60 3 3 4 15 14 2.5 41 50 8 10.0

H 380 60 3 3 3 20 12 4.0 33 50 8 10.0

J 200 50 3 3 8 20 12 4.0 55 60 6 16.0

O 208-240 60 3 3 7 20 12 4.0 64 70 4 25.0

X 200-240 50/60 1/3 2/3 9 20 12 4.0 N/A N/A N/A N/A

Variable-Speed Models

N 440-480 50/60 3 3 4 15 14 2.5 42 50 8 10.0

P 380-415 50/60 3 3 5 15 14 2.5 37 40 8 10.0

Q 200-240 50/60 3 3 6 15 14 2.5 65 60 6 16.0

X 200-240 50/60 1/3 2/3 10 20 12 4.0 N/A N/A N/A N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

mm

2

Tab l e 1 2

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Installation/Operation Supplement

Electrical Specifications

80 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

Full Load

Breaker

AWG

mm

2

Amps

Circuit

AWG

Variable-Speed Models

N 440 – 480 50/60 3 3 4.5 15 14 2.5 42 45 8 10

P 380 – 415 50/60 3 3 4.5 15 14 2.5 37 40 8 10

Q 200 – 240 50/60 3 3 12.4 20 12 4 87.4 90 2 35

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Tab l e 1 3

Electrical Specifications

125 Pound Capacity Models

Code

Voltage Designation Standard Electric Heat

Volt age

Cycle

Phase

Wire

Full Load

Amps

Breaker

Circuit

AWG

mm

2

Full Load

Amps

Breaker

Circuit

AWG

Variable-Speed Models

N 440 – 480 50/60 3 3 5.1 15 14 2.5 N/A

P 380 – 415 50/60 3 3 5.1 15 14 2.5 N/A

Q 200 – 240 50/60 3 3 7.9 25 10 6 N/A

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

mm

2

mm

2

Tab l e 1 4

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 27

Operation

Installation/Operation Supplement

Table 15 (Continued)

Symbol Description

Start

CHM493N

CHM493N

Special Wash

(Owner programming

CHM494N

CHM494N

required – See Cycle Charts

in programming manual)

Normal Cycle

CHM495N

CHM495N

Delicate Cycle

CHM496N

CHM496N

Permanent Press Cycle

CHM497N

CHM497N

Cold Wash

CHM498N

CHM498N

Symbol Description

Edit Down

CHM504N

CHM504N

CHM505N

CHM506N

CHM505N

CHM506N

Start

Select Mode

Wash

CHM507N

CHM507N

Add Bleach

CHM508N

Rinse

CHM509N

CHM509N

CHM499N

CHM499N

CHM500N

CHM500N

CHM501N

CHM502N

CHM503N

Warm Wash

Table 15 (Continued)

Hot Wash

Stop

Start

Edit Up

CHM510N

CHM510N

CHM511N

CHM512N

CHM2003N

CHM2003N

CHM2004N

CHM2004N

Table 15 (Continued)

Spin

Door Open

Clean Filter

Reduced Spin

(∨) keypad

Extra Wash

(∧) keypad

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Installation/Operation Supplement

Table 15 (Continued)

Symbol Description

95C

95C

60C

60C

40C

40C

*

<

CHM1980N

CHM1980N

CHM1981N

CHM1981N

CHM1982N

CHM1982N

CHM1983N

CHM1983N

CHM1984N

CHM1984N

CHM1985N

CHM1985N

CHM1986N

CHM1986N

Normal Wash

Hot

Permanent Press

Hot

Normal Wash

Warm

Permanent Press

Warm

Normal Wash

Cold

Permanent Press/Exit

Cold

Hand Wash/Edit Up

30C

<

CHM1987N

CHM1987N

CHM1988N

CHM1988N

CHM1989N

CHM1989N

CHM1990N

CHM1990N

Gentle Wash/Edit Down

Cold

Time

Start/Enter/

Wash Temperature Display

Vend Price/Actuation

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 29

Installation/Operation Supplement

Instructions for EDC Control

1. Turn on the main power source (circuit breaker).

2. Push button and turn handle clockwise to open.

Refer to Figure 9.

U001IE1B

U001IE1B

Figure 9

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 10.

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 11.

U005IE1B

U005IE1B

Figure 11

5. Select cycle and temperature. Refer to Figure 12.

6. For machines equipped with a coin meter: Insert

coins. Refer to Figure 12.

Figure 10

U003IE1A

WASH

RINSE

INSERT

COIN/CARD

CLOSE

DOOR

ADD

SPIN

BLEACH

NORMAL

HOT

PERM

PRESS

WARM

DELICATE

COLD

SPECIAL

WASH

B148R

Figure 12

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Installation/Operation Supplement

7. For machines equipped with a cardreader:

Insert card into cardreader and follow the

instructions. Refer to Figure 13. DO NOT

REMOVE CARD UNTIL DISPLAY ON

CARDREADER READS “Remove Card”.

INSERT

WASH

COIN/CARD

CLOSE

RINSE

DOOR

ADD

SPIN

BLEACH

NORMAL

HOT

PERM

PRESS

WARM

DELICATE

DELICATES

COLD

COLD

*

START

SPECIAL

WASH

B149R

Figure 13

8. Add detergent to container 1 and softener to

container 3. Press the START key. Refer to

Figure 14.

B149R

NOTE: If a higher-priced cycle is selected, after the

full price has been satisfied for current cycle,

display will show additional price required and the

INSERT COIN/CARD light will flash. Insert coins/

card to satisfy price for special cycle. If price is not

satisfied, the previous cycle selected will begin after

one minute.

9. If display flashes “SPEC” then “CYCL”, extra

options such as high-speed extract or extra rinse

are available. If desired, insert coins/card to meet

additional price shown on display. If not desired,

wait 30 seconds for earlier cycle selection to

continue.

10. Add bleach to container 2 when ADD BLEACH

light is lit. Refer to Figure 15.

1

2

3

L

IA

C

E

P

H

S

S

A

W

*

T

R

S

A

E

T

T

A

S

C

I

L

E

D

M

R

E

S

P

S

COLD

E

R

P

M

L

R

A

M

R

WA

O

N

D

T

R

R

A

E

S

C

/

N

I

N

I

O

C

OT

H

E

S

O

L

R

C

O

H

O

S

D

A

W

H

D

C

D

A

A

E

E

L

S

B

N

I

R

N

I

P

S

1

SPECIAL

WASH

*

START

1 Detergent

2 Bleach

3 Softener

T

R

R

A

E

S

C

/

N

I

N

I

O

C

E

S

O

L

R

C

O

H

O

S

D

A

W

H

D

C

D

A

A

E

E

L

S

B

N

I

R

N

I

P

S

2

Figure 14

3

WASH

RINSE

SPIN

L

A

I

C

E

P

H

S

S

A

W

*

S

E

T

A

START

C

I

L

E

D

M

D

R

L

E

S

O

P

S

C

E

R

P

M

L

R

A

M

R

WA

O

N

D

T

O

H

1 Detergent

INSERT

COIN/CARD

CLOSE

DOOR

ADD

BLEACH

B156R

2 Bleach

B155R

3 Softener

Figure 15

B155R

11. Cycle is complete when display reads “:00”.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 31

Installation/Operation Supplement

Instructions for Mechanical Timer

1. Turn on the main power source (circuit breaker).

For non-coin models: Turn on the On/Off switch

on the front panel to the On position.

2. Push button and turn handle clockwise to open.

Refer to Figure 16.

Figure 16

For non-coin models: Press and hold the DOOR

UNLOCK button on the left side of the control

panel while performing the above step. Refer to

Figure 17.

U001IE1B

U001IE1B

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 18.

U003IE1A

Figure 18

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 19.

On

U005IE1B

Figure 19

DOOR UNLOCK

Off

U135R

U135R

Figure 17

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Installation/Operation Supplement

5. Select wash cycle. Refer to Figure 20.

CYCLE INDICATOR WASH CYCLES

P

R

E

W

N

A

I

S

H

HOT WARM WARM COLD

H

HEAVILY

PERM-

NORMAL

S

A

SOILED

W

PRESS

WASH

DELICATE

KNITS

ON

ADD BLEACH

WHEN LIT

P

S

R

I

N

S

E

Figure 20

6. At start of cycle, add liquid and/or powder

supplies to supply dispenser. Refer to Figure 21.

a. Add detergent to container 1.

b. Add softener to container 3.

For non-coin models: Liquid supplies may be

injected directly into the supply dispenser by an

external chemical supply dispenser. Refer to

Installation and Programming Manuals.

U002IE1A

For non-coin models: Press the Start button.

Refer to Figure 22.

DELICATE

KNITS

WARM COLD

Figure 22

On Start

Off

U136R

U136R

8. Add bleach to container 2 when ADD BLEACH

light is lit. Refer to Figure 23.

3

1

7. For coin models: Insert required number of coins

to start machine. Refer to Figure 21.

3

2

1

B157R

1 Detergent

2 Bleach

3 Softener

Figure 21

ON

ADD BLEACH

WHEN LIT

1 Detergent

2 Bleach

3 Softener

2

B158R

B159R

Figure 23

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 33

Installation/Operation Supplement

Instructions for S, P and V Series

Microcomputers

1. Turn on main power source (circuit breaker).

For non-coin models: Turn the On/Off switch on

the front panel to the On position.

2. Push button and turn handle clockwise to open.

Refer to Figure 24.

U001IE1B

U001IE1B

Figure 24

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 26.

U003IE1A

Figure 26

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 27.

For non-coin models: Press and hold the DOOR

UNLOCK button on the left side of the control

panel while performing the above step. Refer to

Figure 25.

On

DOOR UNLOCK

Off

U135R

U135R

Figure 25

U005IE1B

Figure 27

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Installation/Operation Supplement

5. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 28.

a. Add detergent to container 1.

b. Add softener to container 3.

For non-coin models: Liquid supplies may be

injected directly into the supply dispenser by an

external chemical supply dispenser. Refer to

Installation and Programming Manuals.

6. Press the Up and Down keys to select wash cycle.

Refer to Figure 29.

7. For coin models: Insert required number of coins

to start machine. Refer to Figure 28.

3

2

1

B157R

1 Detergent

2 Bleach

3 Softener

9. When applicable, add beach to container 2 when

the display reads “bLCH”. Refer to Figure 30.

2

1

1 Up

2 Down

3 Start

4 Stop

CYCLE SELECTION

Figure 30

3

4

B160R

NOTE: To stop a cycle at any time, press the Stop

key. Non-coin models only.

NOTE: To display the temperature of the water

while a cycle is running, press the Up key. To

display the number of the cycle in progress, press

the Start key.

Figure 28

8. For non-coin models: Press the Start key. Refer

to Figure 29.

2

1

CYCLE SELECTION

1 Up

2 Down

3 Start

4 Stop

Figure 29

3

4

B159R

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 35

Installation/Operation Supplement

Instructions for B Series

Microcomputer

NOTE: Opening the coin box while in Run Mode

and before a cycle has started will put control into

Audit Mode. Display will show “Audt”. To revert

back to Run Mode, close coin box and press START

keypad.

1. Turn on main power source (circuit breaker).

2. Push button and turn handle clockwise to open.

Refer to Figure 31.

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 33.

U005I

Figure 33

5. The default wash cycle will display. Refer to

Figure 34.

NOTE: Perm Press Cold is the default cycle for

coin models if none is selected. Perm Press Hot is

the default cycle for OPL models.

U001I

Figure 31

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 32.

U003I

Figure 32

WASH

ADD

BLEACH

RINSE

SPIN

DOOR

CLEAN

FILTER

START

Figure 34

NORMAL

HOT

LIGHT SOIL

HOT

HEAVY SOIL

HOT HOT

STAINED

HOT

95C 95C

60C 60C

40C 40C

<

PERM PRESS

HOT

TM

VISA

WARM

UNIFORMS

DELICATE

COLD

30C

CHM522N

CHM522N

<

CHM1764C

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Installation/Operation Supplement

6. If desired, select a different cycle at this point or

after satisfying vend. The LED indicator for that

cycle will light.

7. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 35.

a. Add detergent to compartment 1.

b. Add softener to compartment 3.

3

2

1

B157R

1 Detergent

2 Bleach

3 Softener

9. If the machine is a card operated unit, insert and

remove card. Contact the card reader

manufacturer for details.

10. If the unit is interfaced to a central/remote pay

system, go to the central/remote pay console,

make payment and select the machine. Contact

the pay system manufacturer for more details.

11. When applicable, add bleach to compartment 2

when the ADD BLEACH LED is lit.

12. Press the desired wash cycle key.

13. Press the START keypad.

14. During first fill, the desired wash cycle can be

changed. After first fill has ended, the wash cycle

active at that moment remains the chosen wash

cycle.

15. When cycle is complete, display shows “donE”.

Figure 35

8. If the machine is a coin operated unit, add coins.

As each coin is added, the display counts down to

the amount remaining.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Page 37

Installation/Operation Supplement

Instructions for A Series

Microcomputer

NOTE: Opening the coin box while in Run Mode

and before a cycle has started will put control into

Audit Mode. Display will show “Audt”. To revert

back to Run Mode, close coin box and press START

keypad.

1. Turn on main power source (circuit breaker).

2. Push button and turn handle clockwise to open.

Refer to Figure 36.

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 38.

U005I

Figure 38

5. The default wash cycle will display. Refer to

Figure 39.

NOTE: The default cycle is Perm Press 60°C for

coin models if no cycle is selected.

U001I

Figure 36

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 37.

U003I

Figure 37

CHM1759C

Figure 39

F232145 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Installation/Operation Supplement

6. If desired, select a different cycle at this point or

after satisfying vend. The LED indicator for that

cycle will light.

7. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 40.

a. Add detergent to compartment 1.

b. Add softener to compartment 3.

.

3

2

1

1 Detergent

2 Bleach

3 Softener

B157R

10. If the unit is interfaced to a central/remote pay

system, go to the central/remote pay console,

make payment, select the machine, and follow

central/remote pay system instructions.

11. Press the desired wash cycle key if it hasn’t

already been selected.

NOTE: Once START keypad is pressed, the

selected wash cycle is locked in and wash cycle will

begin.

12. Press the START keypad.

13. Add bleach if and when prompted (display will

show “bLCH”, signal will sound on and off for

45 seconds and Add Bleach indicator lights).

NOTE: If the version of the control in machine is

capable of reading temperature and control is not

in Audit Mode, pressing the START keypad while a

cycle is running will cause display to show

temperature. Press START keypad again to revert

to minutes remaining shown in display.

14. When cycle is complete, display shows “dOnE”,

the Door Open LED lights and door can be

opened.

Figure 40

8. If the machine is a coin operated unit, add coins.

As each coin is added, the display counts down to

the amount remaining.

9. If the machine is a card operated unit, insert and

remove card per card system instructions.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232145 (EN)

Loading...

Loading...