Alliance Laundry Systems MG030N, HUT30R, GJT30S, BA025E, SA025E Original Instructions Manual

...Page 1

Tumble Dryer

Dual Digital Control

Refer to Page 8 for Model Numbers

Programming

Original Instructions

Keep These Instructions for Future Refer

CAUTION: Read the instructions before using the machine.

(If this machine changes ownership, this manual must accompany machine.)

ence.

www.alliancelaundry.com

Part No. 70579901EN

January 2018

Page 2

Page 3

Installation must conform with local codes or, in the absence of

local codes, with:

In the U.S.A., installation must conform to the latest edition of

the American National Standard Z223.1/ NFP

Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric

Code.”

In Canada, installation must comply with Standards CAN/CSAB149.1 or Natural Gas and Propane Installation Code and CSA

C22.1, latest edition, Canadian Electric Code, Part I.

A 54 “National

IMPORTANT: Information must be obtained from a local gas supplier on instructions to be followed if the

user smells gas. These instructions must be posted in

a prominent location. Step-by-step instructions of the

above safety information must be posted in a prominent location near the tumble dryer for customer use.

IMPORT

dryer after installation and demonstrate to the owner

how to operate the machine.

ANT: The installer must fully test the tumble

In Australia and New Zealand, installation must comply with the

Gas Installations Standard AS/NZS 5601 Part 1: General Installations.

WARNING

FOR YOUR SAFETY, the information in this manual

must be followed to minimize the risk of fire or explosion or to prevent property damage, personal injury or death.

W033

WARNING

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS:

•

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Clear the room, building or area of all occu-

pants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

W052

WARNING

To reduce the risk of electric shock, fire, explosion,

serious injury or death:

• Disconnect electric power to the tumble dryer before servicing.

• Close gas shut-off valve to gas tumble dryer before servicing.

• Close steam valve to steam tumble dryer before

servicing.

• Never start the tumble dryer with any guards/

panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected to

ensure that the tumble dryer is properly grounded.

W002R1

WARNING

• Installation of unit must be performed by a qualified installer

• Install tumble dryer according to manufacturer’s

instructions and local codes.

• DO NOT install a tumble dryer with flexible plastic

venting materials. If flexible metal (foil type) duct

is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use

with tumble dryer. Refer to section on connecting

exhaust system. Flexible venting materials are

known to collapse, be easily crushed, and trap

lint. These conditions will obstruct tumble dryer

airflow and increase the risk of fire.

.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

W752R1

The following information applies to the state of Massachusetts,

USA.

3 Part No. 70579901EN

Page 4

• This appliance can only be installed by a Massachusetts licensed plumber or gas fitter

.

• This appliance must be installed with a 36 inch [91 cm] long

flexible gas connector.

• A “T-Handle” type gas shut-off valve must be installed in the

gas supply line to this appliance.

• This appliance must not be installed in a bedroom or bathroom.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

4 Part No. 70579901EN

Page 5

Table of Contents

Introduction........................................................................................... 7

Model Identification........................................................................................7

Preliminary Information.......................................................................20

About the Control......................................................................................... 20

Glossary of Terms......................................................................................... 20

Power Fail Recovery..................................................................................... 20

Control Identification........................................................................... 21

Select Cycle Keypads....................................................................................21

Display Identification............................................................................24

Light Emitting Diodes (LEDs)....................................................................... 24

CYCLE LED............................................................................................ 24

REVERSING LED (reversing models only).................................................24

Four 7-Segment Digits.................................................................................. 24

Special Features....................................................................................25

Collecting Audit Information......................................................................... 25

Testing the Machine Using Diagnostic Functions............................................. 25

Rapid Advance Feature................................................................................. 25

Machine Operation...............................................................................26

Power Up.....................................................................................................26

System Check Mode..................................................................................... 26

Start Mode................................................................................................... 26

Run Mode.................................................................................................... 26

End of Cycle Mode....................................................................................... 26

Changing Cycles...........................................................................................26

OPL Power Save...........................................................................................26

Power Failure Display Mode..........................................................................26

Error Display Mode...................................................................................... 26

Extended Tumble Mode.................................................................................26

Opening the Service Door .................................................................... 27

Stacked Tumble Dryer...................................................................................27

Stand Alone Tumble Dryer............................................................................ 27

©

Copyright 2017, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

.

5 Part No. 70579901EN

Page 6

Entering the Manual Mode................................................................... 28

How to Enter the Manual Mode......................................................................28

How to Exit Manual Mode.............................................................................28

Rapid Advance Feature.........................................................................29

Manual Rapid Advance Menu........................................................................ 29

Collecting Audit Information................................................................ 30

Manual Read Audit Mode Menu.................................................................... 30

Machine Diagnostic Functions.............................................................. 31

Manual Diagnostic Mode Menu..................................................................... 31

Diagnostic (Testing) Mode – Quick Reference................................................. 31

Diagnostic Test Descriptions.......................................................................... 32

Front-End Control Software Version Number d 01 .......................................32

Input/Output Board Software Version Number d 02...................................... 32

Drive Board Software Version Number d 03................................................ 32

Fan Board Software Version Number d 04................................................... 32

Ignition Control Software Version Number d 05 (gas models only)................ 32

Service Door Switch Input Test d 08 ...........................................................32

Dryer on Temperature Test d 14..................................................................33

Door Switch Input Test d 15 ...................................................................... 33

Lint Door Switch Input Test d 16................................................................ 33

Temperature Sensor Display Test d 19 ........................................................ 33

12.5VDC Voltage Test d 20 ....................................................................... 33

24VDC Voltage Test d 21 .......................................................................... 33

AC Mains Voltage Test d 28 ...................................................................... 33

Machine Configuration #1 Display Test d 29 ...............................................33

Machine Configuration #2 Display Test d 30 ...............................................34

Machine Configuration #3 Display Test d 31 ...............................................34

Machine Configuration #4 Display Test d 32 ...............................................34

Machine Configuration #5 Display Test d 33................................................44

ICM Alarm Status d 34 (gas models only)................................................... 44

ICM Reset Test d 35 (gas models only)....................................................... 44

Heat Interlock Test d 36............................................................................. 44

Air Flow Switch Test d 37.......................................................................... 45

Fan Motor Test d 38...................................................................................45

Damper Motor Test d 39 (steam models only).............................................. 45

Drive Motor Test d 40................................................................................45

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Factory Test Cycle................................................................................ 46

Factory Test Quick Reference Chart................................................................46

Error Codes..........................................................................................48

6 Part No. 70579901EN

Page 7

Introduction

Model Identification

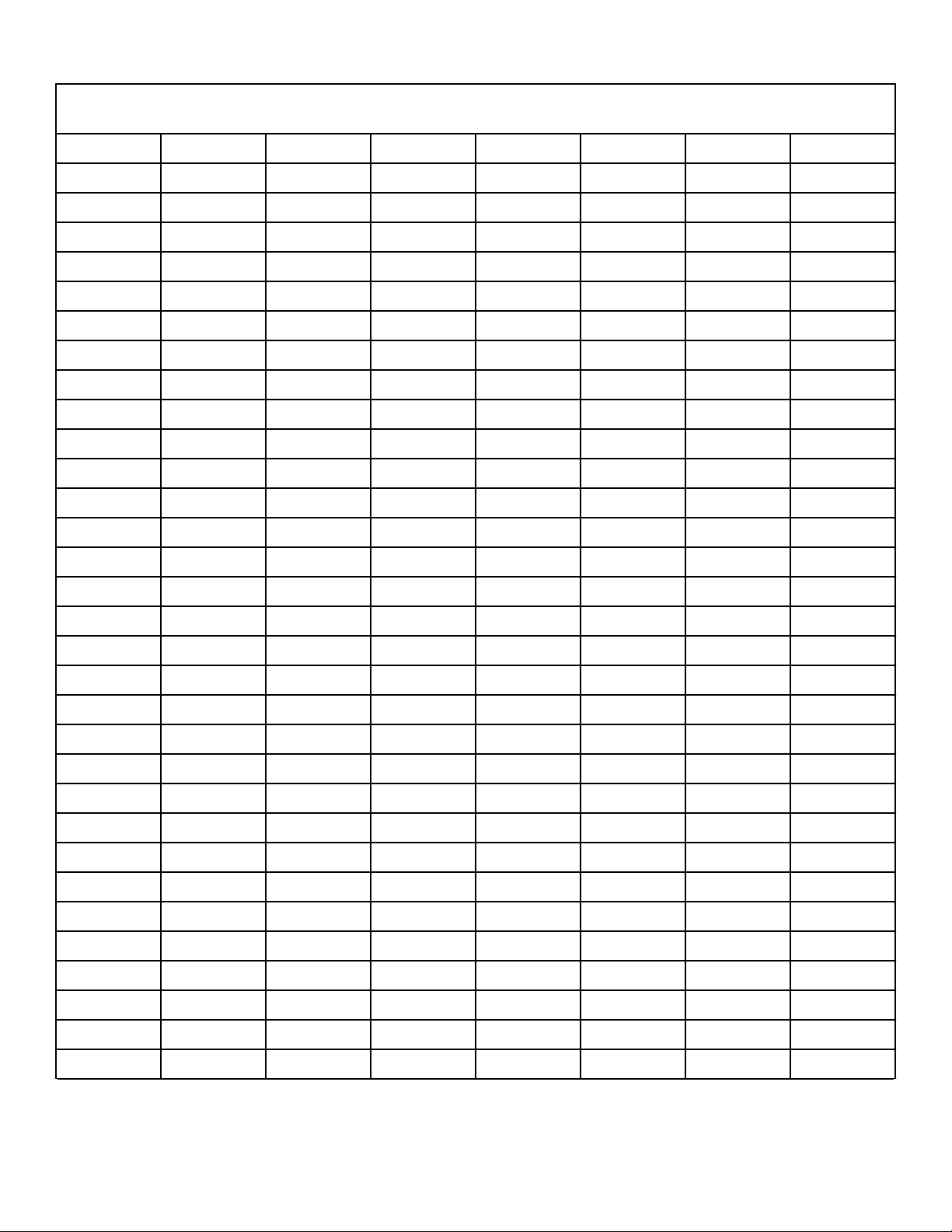

Information in this manual is applicable to these models. Refer

to the machine serial plate for the model number

.

Introduction

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

7 Part No. 70579901EN

Page 8

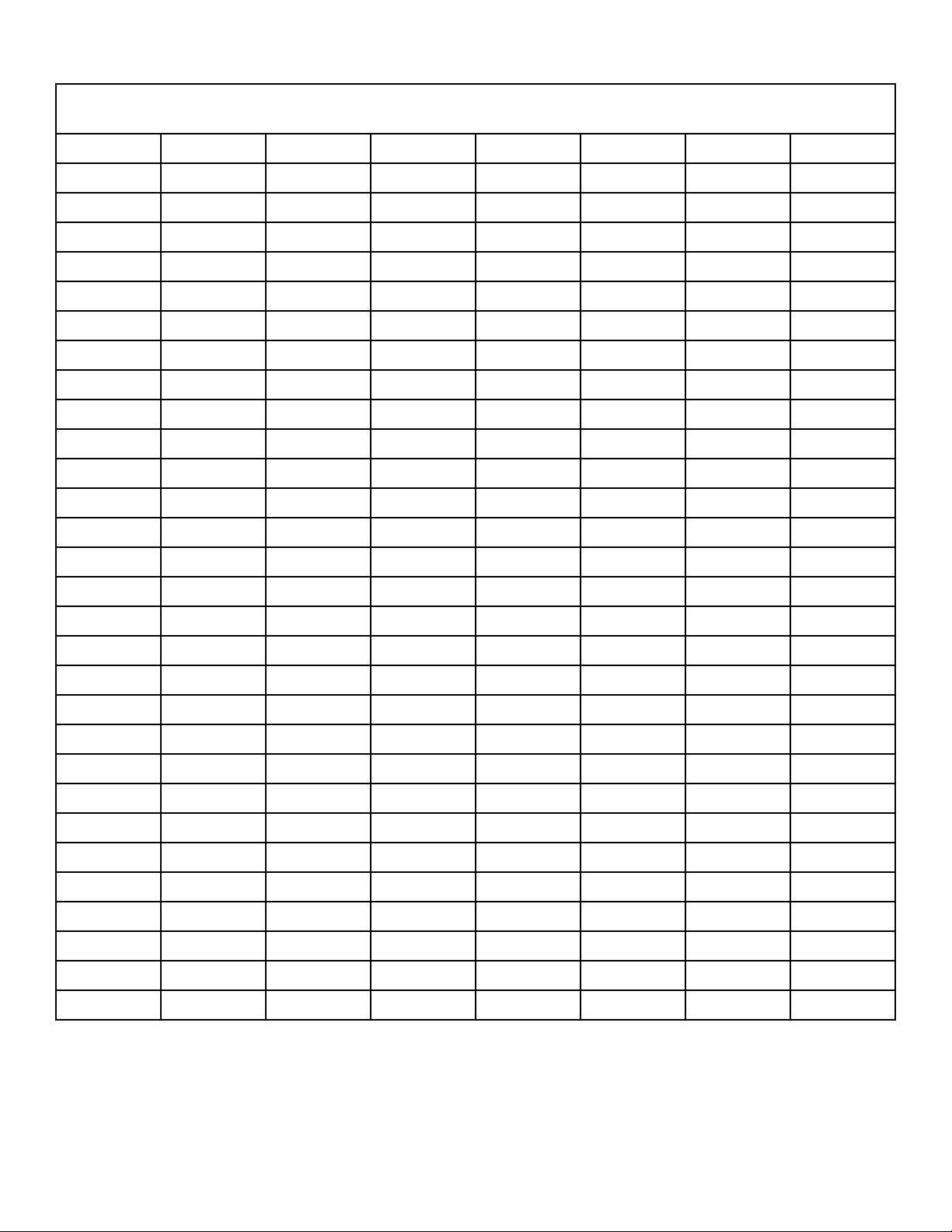

Introduction

25 Series (11 Kg)

BA025E BU025L HA025S HU025F NG025S PK025N SJ025F UG025R

BA025F BU025N HG025D HU025L NH025E PT025E SJ025L UG025S

BA025L BU025R HG025E HU025N NH025L PT025L SJ025N UH025E

BA025N BU025S HG025F HU025R NH025N PT025N SJ025R UH025F

BA025R GA025E HG025L HU025S NH025S PT025S SJ025S UH025L

BA025S GA025L HG025N KT025E NJ0205E PU025E SK025N UH025N

BG025D GA025N HG025R KT025L NJ025L PU025L SK025R UH025R

BG025E GA025S HG025S KT025N NJ025N PU025N ST025E UH025S

BG025F GG025E HH025E KT025S NJ025S PU025S ST025F UJ025D

BG025L GG025L HH025F MG025D NK025N SA025E ST025L UJ025E

BG025N GG025N HH025L MG025E NU025E SA025F ST025N UJ025F

BG025R GG025S HH025N MG025F NU025L SA025L ST025R UJ025L

BG025S GH025E HH025R MG025L NU025N SA025N ST025S UJ025N

BH025E GH025L HH025S MG025N NU025S SA025R SU025E UJ025R

BH025F GH025N HJ025D MG025R PA025E SA025S SU025F UJ025S

BH025L GH025S HJ025E MG025S PA025L SG025D SU025L UK025N

BH025N GJ025E HJ025F MJ025D PA025N SG025E SU025N UK025R

BH025R GJ025L HJ025L MJ025E PA025S SG025F SU025R UT025E

BH025S GJ025N HJ025N MJ025F PG025E SG025L SU025S UT025F

BJ025D GJ025S HJ025R MJ025L PG025L SG025N UA025E UT025L

BJ025E GK025N HJ025S MJ025N PG025N SG025R UA025F UT025N

BJ025F GU025E HK025N MJ025R PG025S SG025S UA025L UT025R

BJ025L GU025L HK025R MJ025S PH025E SH025E UA025N UT025S

BJ025N GU025N HT025E NA025E PH025L SH025F UA025R UU025E

BJ025R GU025S HT025F NA025L PH025N SH025L UA025S UU025F

BJ025S HA025E HT025L NA025N PH025S SH025N UG025D UU025L

BK025N HA025F HT025N NA025S PJ025E SH025R UG025E UU025N

BK025R HA025L HT025R NG025E PJ025L SH025S UG025F UU025R

BU025E HA025N HT025S NG025L PJ025N SJ025D UG025L UU025S

BU025F HA025R HU025E NG025N PJ025S SJ025E UG025N

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

8 Part No. 70579901EN

Page 9

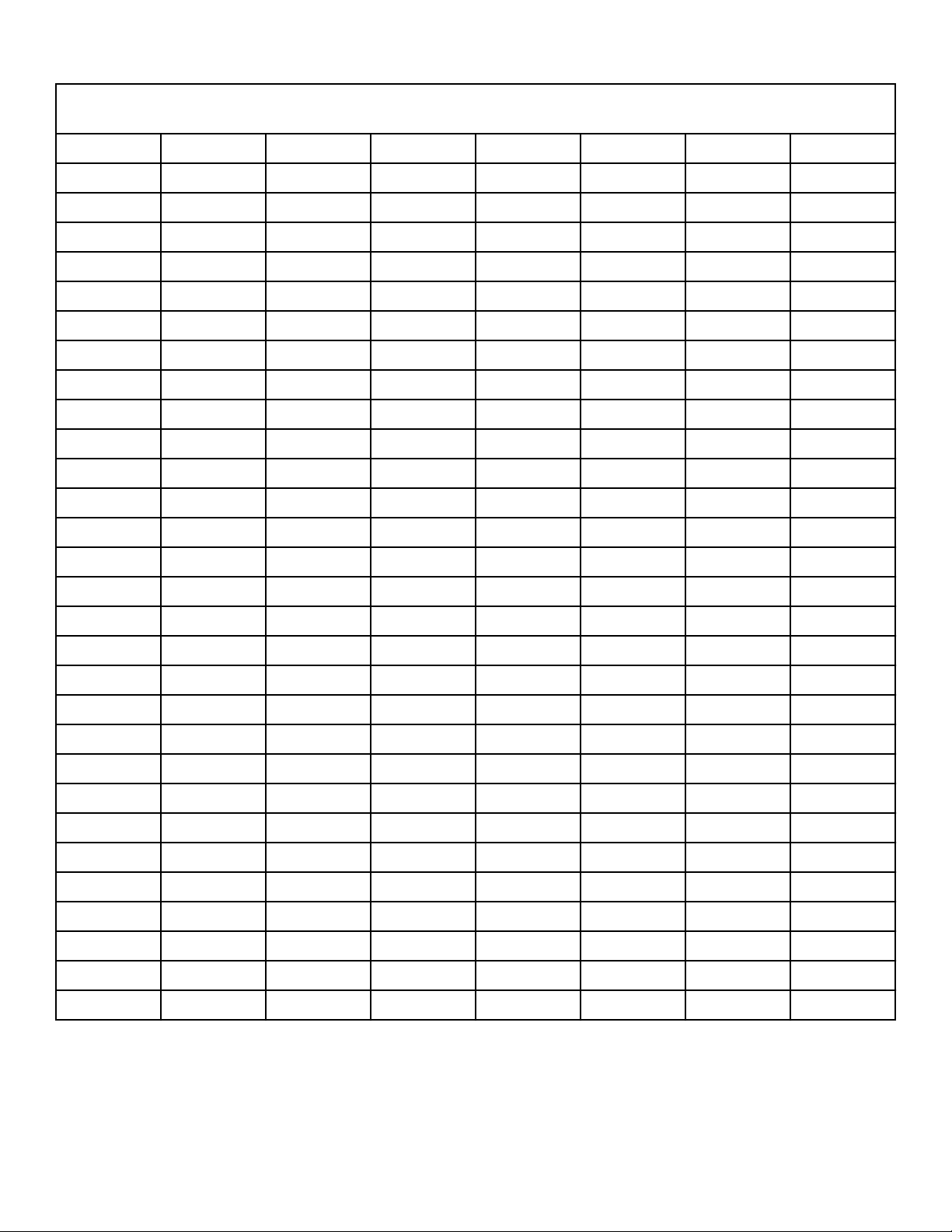

Introduction

30 Series (13 Kg)

BA030E BU030L HA030S HU030F NG030S PK030N SJ030F UG030R

BA030F BU030N HG030D HU030L NH030E PT030E SJ030L UG030S

BA030L BU030R HG030E HU030N NH030L PT030L SJ030N UH030E

BA030N BU030S HG030F HU030R NH030N PT030N SJ030R UH030F

BA030R GA030E HG030L HU030S NH030S PT030S SJ030S UH030L

BA030S GA030L HG030N KT030E NJ030E PU030E SK030N UH030N

BG030D GA030N HG030R KT030L NJ030L PU030L SK030R UH030R

BG030E GA030S HG030S KT030N NJ030N PU030N ST030E UH030S

BG030F GG030E HH030E KT030S NJ030S PU030S ST030F UJ030D

BG030L GG030L HH030F MG030D NK030N SA030E ST030L UJ030E

BG030N GG030N HH030L MG030E NU030E SA030F ST030N UJ030F

BG030R GG030S HH030N MG030F NU030L SA030L ST030R UJ030L

BG030S GH030E HH030R MG030L NU030N SA030N ST030S UJ030N

BH030E GH030L HH030S MG030N NU030S SA030R SU030E UJ030R

BH030F GH030N HJ030D MG030R PA030E SA030S SU030F UJ030S

BH030L GH030S HJ030E MG030S PA030L SG030D SU030L UK030N

BH030N GJ030E HJ030F MJ030D PA030N SG030E SU030N UK030R

BH030R GJ030L HJ030L MJ030E PA030S SG030F SU030R UT030E

BH030S GJ030N HJ030N MJ030F PG030E SG030L SU030S UT030F

BJ030D GJ030S HJ030R MJ030L PG030L SG030N UA030E UT030L

BJ030E GK030N HJ030S MJ030N PG030N SG030R UA030F UT030N

BJ030F GU030E HK030N MJ030R PG030S SG030S UA030L UT030R

BJ030L GU030L HK030R MJ030S PH030E SH030E UA030N UT030S

BJ030N GU030N HT030E NA030E PH030L SH030F UA030R UU030E

BJ030R GU030S HT030F NA030L PH030N SH030L UA030S UU030F

BJ030S HA030E HT030L NA030N PH030S SH030N UG030D UU030L

BK030N HA030F HT030N NA030S PJ030E SH030R UG030E UU030N

BK030R HA030L HT030R NG030E PJ030L SH030S UG030F UU030R

BU030E HA030N HT030S NG030L PJ030N SJ030D UG030L UU030S

BU030F HA030R HU030E NG030N PJ030S SJ030E UG030N

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

9 Part No. 70579901EN

Page 10

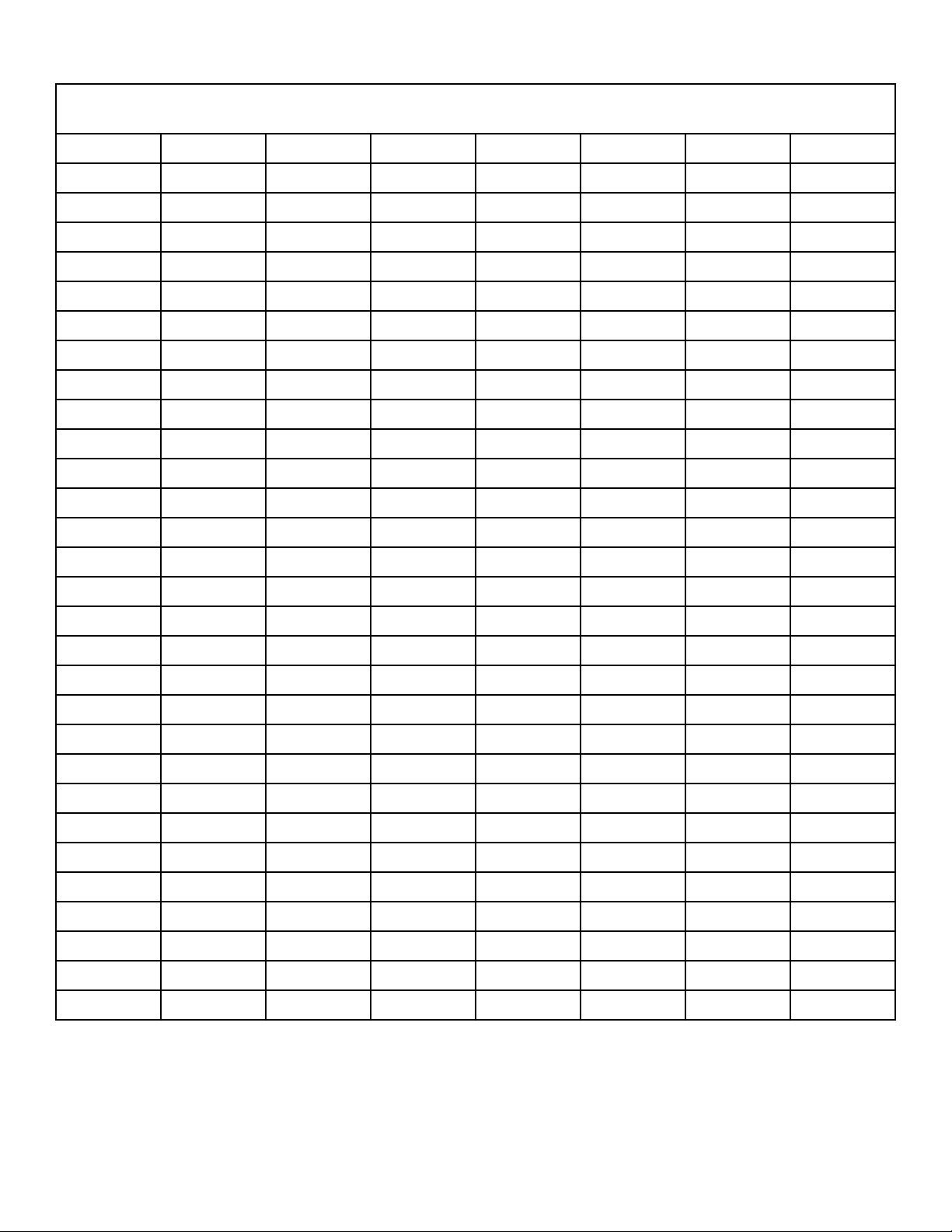

Introduction

T30 Series (13/13 Kg)

BAT30E BUT30L HAT30S HUT30F NGT30S PKT30N SJT30F UGT30R

BAT30F BUT30N HGT30D HUT30L NHT30E PTT30E SJT30L UGT30S

BAT30L BUT30R HGT30E HUT30N NHT30L PTT30L SJT30N UHT30E

BAT30N BUT30S HGT30F HUT30R NHT30N PTT30N SJT30R UHT30F

BAT30R GAT30E HGT30L HUT30S NHT30S PTT30S SJT30S UHT30L

BAT30S GAT30L HGT30N KTT30E NJT30E PUT30E SKT30N UHT30N

BGT30D GAT30N HGT30R KTT30L NJT30L PUT30L SKT30R UHT30R

BGT30E GAT30S HGT30S KTT30N NJT30N PUT30N STT30E UHT30R

BGT30F GGT30E HHT30E KTT30S NJT30S PUT30S STT30F UJT30D

BGT30L GGT30L HHT30F MGT30D NKT30N SAT30E STT30L UJT30E

BGT30N GGT30N HHT30L MGT30E NUT30E SAT30F STT30N UJT30F

BGT30R GGT30S HHT30N MGT30F NUT30L SAT30L STT30R UJT30L

BGT30S GHT30E HHT30R MGT30L NUT30N SAT30N STT30S UJT30N

BHT30E GHT30L HHT30S MGT30N NUT30S SAT30R SUT30E UJT30R

BHT30F GHT30N HJT30D MGT30R PAT30E SAT30S SUT30F UJT30S

BHT30L GHT30S HJT30E MGT30S PAT30L SGT30D SUT30L UKT30N

BHT30N GJT30E HJT30F MJT30D PAT30N SGT30E SUT30N UKT30R

BHT30R GJT30L HJT30L MJT30E PAT30S SGT30F SUT30R UTT30E

BHT30S GJT30N HJT30N MJT30F PGT30E SGT30L SUT30S UTT30F

BJT30D GJT30S HJT30R MJT30L PGT30L SGT30N UAT30E UTT30L

BJT30E GKT30N HJT30S MJT30N PGT30N SGT30R UAT30F UTT30N

BJT30F GUT30E HKT30N MJT30R PGT30S SGT30S UAT30L UTT30R

BJT30L GUT30L HKT30R MJT30S PHT30E SHT30E UAT30N UTT30S

BJT30N GUT30N HTT30E NAT30E PHT30L SHT30F UAT30R UUT30E

BJT30R GUT30S HTT30F NAT30L PHT30N SHT30L UAT30S UUT30F

BJT30S HAT30E HTT30L NAT30N PHT30S SHT30N UGT30D UUT30L

BKT30N HAT30F HTT30N NAT30S PJT30E SHT30R UGT30E UUT30N

BKT30R HAT30L HTT30R NGT30E PJT30L SHT30S UGT30F UUT30R

BUT30E HAT30N HTT30S NGT30L PJT30N SJT30D UGT30L UUT30S

BUT30F HAT30R HUT30E NGT30N PJT30S SJT30E UGT30N

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

10 Part No. 70579901EN

Page 11

Introduction

35 Series (16 Kg)

BA035E BU035N HA035S HU035L NG035S PJ035N SJ035D UG035M

BA035F BU035R HG035D HU035M NH035E PJ035S SJ035E UG035N

BA035L BU035S HG035E HU035N NH035L PK035N SJ035F UG035R

BA035M GA035E HG035F HU035R NH035M PT035E SJ035L UG035S

BA035N GA035L HG035L HU035S NH035N PT035L SJ035M UH035E

BA035R GA035M HG035M KT035E NH035S PT035M SJ035N UH035F

BA035S GA035N HG035N KT035L NJ035E PT035N SJ035S UH035L

BG035D GA035S HG035R KT035M NJ035L PT035S SK035N UH035M

BG035E GG035E HG035S KT035N NJ035M PU035E SK035R UH035N

BG035F GG035L HH035E KT035S NJ035N PU035L ST035E UH035R

BG035L GG035M HH035F MG035D NJ035S PU035M ST035F UH035S

BG035M GG035N HH035L MG035E NK035N PU035N ST035L UJ035D

BG035N GG035S HH035M MG035F NU035E PU035S ST035M UJ035E

BG035R GH035E HH035N MG035L NU035L SA035E ST035N UJ035F

BG035S GH035L HH035R MG035M NU035M SA035F ST035R UJ035L

BH035E GH035M HH035S MG035N NU035N SA035L ST035S UJ035M

BH035F GH035N HJ035D MG035R NU035S SA035M SU035E UJ035N

BH035L GH035S HJ035E MG035S PA035E SA035N SU035F UJ035R

BH035M GJ035E HJ035F MJ035D PA035L SA035R SU035L UJ035S

BH035N GJ035L HJ035L MJ035E PA035M SA035S SU035M UK035N

BH035R GJ035M HJ035M MJ035F PA035N SG035D SU035N UK035R

BH035S GJ035N HJ035N MJ035L PA035S SG035E SU035P UT035E

BJ035D GJ035S HJ035R MJ035M PG035E SG035F SU035R UT035F

BJ035E GK035N HJ035S MJ035N PG035L SG035L SU035S UT035L

BJ035F GU035E HK035N MJ035R PG035M SG035M UA035E UT035M

BJ035L GU035L HK035R MJ035S PG035N SG035N UA035F UT035N

BJ035M GU035M HT035E NA035E PG035S SG035R UA035L UT035R

BJ035N GU035N HT035F NA035L PH035E SG035S UA035M UT035S

BJ035R GU035S HT035L NA035M PH035L SH035E UA035N UU035E

BJ035S HA035E HT035M NA035N PH035M SH035F UA035R UU035F

BK035N HA035F HT035N NA035S PH035N SH035L UA035S UU035L

BK035R HA035L HT035R NG035E PH035S SH035M UG035D UU035M

Table continues...

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

11 Part No. 70579901EN

Page 12

Introduction

35 Series (16 Kg)

BU035E HA035M HT035S NG035L PJ035E SH035N UG035E UU035N

BU035F HA035N HU035E NG035M PJ035L SH035R UG035F UU035R

BU035L HA035R HU035F NG035N PJ035M SH035S UG035L UU035S

BU035M

T45 Series (20/20 Kg) * Only available in gas

BAT45L BUT45N HGT45L HUT45N NHT45L PTT45L SJT45N UGT45R

BAT45N BUT45R HGT45N HUT45R NHT45N PTT45N SJT45R UHT45L

BAT45R GAT45L HGT45R KTT45L NJT45L PUT45L SKT45N UHT45N

BGT45D GAT45N HHT45L KTT45N NJT45N PUT45N SKT45R UHT45R

BGT45L GGT45L HHT45N MGT45D NKT45N SAT45L STT45L UJT45D

BGT45N GGT45N HHT45R MGT45L NUT45L SAT45N STT45N UJT45L

BGT45R GHT45L HJT45D MGT45N NUT45N SAT45R STT45R UJT45N

BHT45L GHT45N HJT45L MGT45R PAT45L SGT45D SUT45L UJT45R

BHT45N GJT45L HJT45N MJT45D PAT45N SGT45L SUT45N UKT45N

BHT45R GJT45N HJT45R MJT45L PGT45L SGT45N SUT45R UKT45R

BJT45D GKT45N HKT45N MJT45N PGT45N SGT45R UAT45L UTT45L

BJT45L GUT45L HKT45R MJT45R PHT45L SHT45L UAT45N UTT45N

BJT45N GUT45N HTT45L NAT45L PHT45N SHT45N UAT45R UTT45R

BJT45R HAT45L HTT45N NAT45N PJT45L SHT45R UGT45D UUT45L

BKT45N HAT45N HTT45R NGT45L PJT45N SJT45D UGT45L UUT45N

BKT45R HAT45R HUT45L NGT45N PKT45N SJT45L UGT45N UUT45R

BUT45L HGT45D

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

12 Part No. 70579901EN

Page 13

Introduction

50 Pound (25 Kg)

BA050E GA050E HG050L KT050L NJ050N PK050N SH050S UG050L

BA050L GA050L HG050N KT050N NJ050S PR050E SJ050D UG050N

BA050N GA050N HG050S KT050S NK050N PR050L SJ050E UG050S

BA050S GA050S HH050E MG050D NR050E PR050N SJ050L UH050E

BG050D GG050E HH050L MG050E NR050L PR050S SJ050N UH050L

BG050E GG050L HH050N MG050L NR050N PT050C SJ050S UH050N

BG050L GG050N HH050S MG050N NR050S PT050E SK050N UH050S

BG050N GG050S HJ050D MG050S NU050E PT050L SR050E UJ050D

BG050S GH050E HJ050E MJ050D NU050L PT050N SR050L UJ050E

BH050E GH050L HJ050L MJ050E NU050N PT050S SR050N UJ050L

BH050L GH050N HJ050N MJ050L NU050S PU050E SR050S UJ050N

BH050N GH050S HJ050S MJ050N PA050E PU050L ST050C UJ050S

BH050S GJ050E HK050N MJ050S PA050L PU050N ST050E UK050N

BJ050D GJ050L HR050E NA050E PA050N PU050S ST050L UR050E

BJ050E GJ050N HR050L NA050L PA050S SA050E ST050N UR050L

BJ050L GJ050S HR050N NA050N PG050E SA050L ST050S UR050N

BJ050N GK050N HR050S NA050S PG050L SA050N SU050E UR050S

BJ050S GU050E HT050C NG050E PG050N SA050S SU050L UT050C

BK050N GU050L HT050E NG050L PG050S SG050D SU050N UT050E

BR050E GU050N HT050L NG050N PH050E SG050E SU050S UT050L

BR050L GU050S HT050N NG050S PH050L SG050L UA050E UT050N

BR050N HA050E HT050S NH050E PH050N SG050N UA050L UT050S

BR050S HA050L HU050E NH050L PH050S SG050S UA050N UU050E

BU050E HA050N HU050L NH050N PJ050E SH050E UA050S UU050L

BU050L HA050S HU050N NH050S PJ050L SH050L UG050D UU050N

BU050N HG050D HU050S NJ050E PJ050N SH050N UG050E UU050S

BU050S HG050E KT050E NJ050L PJ050S

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

13 Part No. 70579901EN

Page 14

Introduction

55 Series (24 Kg) * Only available in gas and electric

BA055E BU055F HG055D HU055F NH055E PT055N SJ055N UG055R

BA055F BU055L HG055E HU055L NH055L PU055E SJ055R UH055E

BA055L BU055N HG055F HU055N NH055N PU055L SK055N UH055F

BA055N BU055R HG055L HU055R NJ055E PU055N SK055R UH055L

BA055R GA055E HG055N KT055E NJ055L SA055E ST055E UH055N

BG055D GA055L HG055R KT055L NJ055N SA055F ST055F UH055R

BG055E GA055N HH055E KT055N NK055N SA055L ST055L UJ055D

BG055F GG055E HH055F MG055D NU055E SA055N ST055N UJ055E

BG055L GG055L HH055L MG055E NU055L SA055R ST055R UJ055F

BG055N GG055N HH055N MG055F NU055N SG055D SU055E UJ055L

BG055R GH055E HH055R MG055L PA055E SG055E SU055F UJ055N

BH055E GH055L HJ055D MG055N PA055L SG055F SU055L UJ055R

BH055F GH055N HJ055E MG055R PA055N SG055L SU055N UK055N

BH055L GJ055E HJ055F MJ055D PG055E SG055N SU055R UK055R

BH055N GJ055L HJ055L MJ055E PG055L SG055R UA055E UT055E

BH055R GJ055N HJ055N MJ055F PG055N SH055E UA055F UT055F

BJ055D GK055N HJ055R MJ055L PH055E SH055F UA055L UT055L

BJ055E GU055E HK055N MJ055N PH055L SH055L UA055N UT055N

BJ055F GU055L HK055R MJ055R PH055N SH055N UA055R UT055R

BJ055L GU055N HT055E NA055E PJ055E SH055R UG055D UU055E

BJ055N HA055E HT055F NA055L PJ055L SJ055D UG055E UU055F

BJ055R HA055F HT055L NA055N PJ055N SJ055E UG055F UU055L

BK055N HA055L HT055N NG055E PK055N SJ055F UG055L UU055N

BK055R HA055N HT055R NG055L PT055E SJ055L UG055N UU055R

BU055E HA055R HU055E NG055N PT055L

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

14 Part No. 70579901EN

Page 15

Introduction

75 Pound (34 Kg)

BA075E BU075L HG075L HU075N NJ075M PT075E SK075R UH075F

BA075F BU075M HG075M HU075R NJ075N PT075L SR075E UH075L

BA075L BU075N HG075N HU075S NJ075S PT075M SR075F UH075M

BA075M BU075R HG075R KT075E NK075N PT075N SR075L UH075N

BA075N BU075S HG075S KT075L NR075E PT075S SR075M UH075R

BA075R GA075E HH075E KT075M NR075L PU075E SR075N UH075S

BA075S GA075L HH075F KT075N NR075M PU075L SR075R UJ075D

BG075D GA075M HH075L KT075S NR075N PU075M SR075S UJ075E

BG075E GA075N HH075M MG075D NR075S PU075N ST075C UJ075F

BG075F GA075S HH075N MG075E NU075E PU075S ST075E UJ075L

BG075L GG075E HH075R MG075F NU075L SA075E ST075F UJ075M

BG075M GG075L HH075S MG075L NU075M SA075F ST075L UJ075N

BG075N GG075M HJ075D MG075M NU075N SA075L ST075M UJ075R

BG075R GG075N HJ075E MG075N NU075S SA075M ST075N UJ075S

BG075S GG075S HJ075F MG075R PA075E SA075N ST075R UK075N

BH075E GH075E HJ075L MG075S PA075L SA075R ST075S UK075R

BH075F GH075L HJ075M MJ075D PA075M SA075S SU075E UR075E

BH075L GH075M HJ075N MJ075E PA075N SG075D SU075F UR075F

BH075M GH075N HJ075R MJ075F PA075S SG075E SU075L UR075L

BH075N GH075S HJ075S MJ075L PG075E SG075F SU075M UR075M

BH075R GJ075E HK075N MJ075M PG075L SG075L SU075N UR075N

BH075S GJ075L HK075R MJ075N PG075M SG075M SU075R UR075R

BJ075D GJ075M HR075E MJ075R PG075N SG075N SU075S UR075S

BJ075E GJ075N HR075F MJ075S PG075S SG075R UA075E UT075C

BJ075F GJ075S HR075L NA075E PH075E SG075S UA075F UT075E

BJ075L GK075N HR075M NA075L PH075L SH075E UA075L UT075F

BJ075M GU075E HR075N NA075M PH075M SH075F UA075M UT075L

BJ075N GU075L HR075R NA075N PH075N SH075L UA075N UT075M

BJ075R GU075M HR075S NA075S PH075S SH075M UA075R UT075N

BJ075S GU075N HT075C NG075E PJ075E SH075N UA075S UT075R

BK075N GU075S HT075E NG075L PJ075L SH075R UG075D UT075S

BK075R HA075E HT075F NG075M PJ075M SH075S UG075E UTF75L

Table continues...

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

15 Part No. 70579901EN

Page 16

Introduction

75 Pound (34 Kg)

BR075E HA075F HT075L NG075N PJ075N SJ075D UG075F UTF75N

BR075F HA075L HT075M NG075S PJ075S SJ075E UG075L UU075E

BR075L HA075M HT075N NH075E PK075N SJ075F UG075M UU075F

BR075M HA075N HT075R NH075L PR075E SJ075L UG075N UU075L

BR075N HA075R HT075S NH075M PR075L SJ075M UG075R UU075M

BR075R HA075S HU075E NH075N PR075M SJ075N UG075S UU075N

BR075S HG075D HU075F NH075S PR075N SJ075R UGF75L UU075R

BU075E HG075E HU075L NJ075E PR075S SJ075S UGF75N UU075S

BU075F HG075F HU075M NJ075L PT075C SK075N UH075E

120 Pound (55 Kg)

BA120E GA120L HA120N HU120N NK120N PT120C SJ120E UG120N

BA120L GA120N HA120S HU120S NU120E PT120E SJ120L UG120S

BA120N GA120S HG120E KT120E NU120L PT120L SJ120N UH120E

BA120S GG120E HG120L KT120L NU120N PT120N SJ120S UH120L

BG120E GG120L HG120N KT120N NU120S PT120S SK120N UH120N

BG120L GG120N HG120S KT120S PA120E PU120E ST120C UH120S

BG120N GG120S HH120E NA120E PA120L PU120L ST120E UJ120D

BG120S GH120E HH120L NA120L PA120N PU120N ST120L UJ120E

BH120E GH120L HH120N NA120N PA120S PU120S ST120N UJ120L

BH120L GH120N HH120S NA120S PG120E SA120E ST120S UJ120N

BH120N GH120S HJ120E NG120E PG120L SA120L SU120E UJ120S

BH120S GJ120E HJ120L NG120L PG120N SA120N SU120L UK120N

BJ120E GJ120L HJ120N NG120N PG120S SA120S SU120N UT120C

BJ120L GJ120N HJ120S NG120S PH120E SG120E SU120S UT120E

BJ120N GJ120S HK120N NH120E PH120L SG120L UA120E UT120L

BJ120S GK120N HT120C NH120L PH120N SG120N UA120L UT120N

BK120N GU120E HT120E NH120N PH120S SG120S UA120N UT120S

BU120E GU120L HT120L NH120S PJ120E SH120E UA120S UU120E

BU120L GU120N HT120N NJ120E PJ120L SH120L UG120D UU120L

BU120N GU120S HT120S NJ120L PJ120N SH120N UG120E UU120N

BU120S HA120E HU120E NJ120N PJ120S SH120S UG120L UU120S

GA120E HA120L HU120L NJ120S PK120N

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

16 Part No. 70579901EN

Page 17

Introduction

170 Pound (77 Kg) *Only available in gas and steam

BA170L GA170N HA170S HU170S NU170L PT170L SJ170N UG170S

BA170N GA170S HG170L KT170L NU170N PT170N SJ170S UH170L

BA170S GG170L HG170N KT170N NU170S PT170S SK170N UH170N

BG170L GG170N HG170S KT170S PA170L PU170L ST170C UH170S

BG170N GG170S HH170L NA170L PA170N PU170N ST170L UJ170D

BG170S GH170L HH170N NA170N PA170S PU170S ST170N UJ170L

BH170L GH170N HH170S NA170S PG170L SA170L ST170S UJ170N

BH170N GH170S HJ170L NG170L PG170N SA170N SU170L UJ170S

BH170S GJ170L HJ170N NG170N PG170S SA170S SU170N UK170N

BJ170L GJ170N HJ170S NG170S PH170L SG170L SU170S UT170C

BJ170N GJ170S HK170N NH170L PH170N SG170N UA170L UT170L

BJ170S GK170N HT170C NH170N PH170S SG170S UA170N UT170N

BK170N GU170L HT170L NH170S PJ170L SH170L UA170S UT170S

BU170L GU170N HT170N NJ170L PJ170N SH170N UG170D UU170L

BU170N GU170S HT170S NJ170N PJ170S SH170S UG170L UU170N

BU170S HA170L HU170L NJ170S PK170N SJ170L UG170N UU170S

GA170L HA170N HU170N NK170N PT170C

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

17 Part No. 70579901EN

Page 18

Introduction

200 Pound (90 Kg) *Only available in gas and steam

BA200L GA200N HA200S HU200S NU200L PT200L SJ200N UG200S

BA200N GA200S HG200L KT200L NU200N PT200N SJ200S UH200L

BA200S GG200L HG200N KT200N NU200S PT200S SK200N UH200N

BG200L GG200N HG200S KT200S PA200L PU200L ST200C UH200S

BG200N GG200S HH200L NA200L PA200N PU200N ST200L UJ200D

BG200S GH200L HH200N NA200N PA200S PU200S ST200N UJ200L

BH200L GH200N HH200S NA200S PG200L SA200L ST200S UJ200N

BH200N GH200S HJ200L NG200L PG200N SA200N SU200L UJ200S

BH200S GJ200L HJ200N NG200N PG200S SA200S SU200N UK200N

BJ200L GJ200N HJ200S NG200S PH200L SG200L SU200S UT200C

BJ200N GJ200S HK200N NH200L PH200N SG200N UA200L UT200L

BJ200S GK200N HT200C NH200N PH200S SG200S UA200N UT200N

BK200N GU200L HT200L NH200S PJ200L SH200L UA200S UT200S

BU200L GU200N HT200N NJ200L PJ200N SH200N UG200D UU200L

BU200N GU200S HT200S NJ200N PJ200S SH200S UG200L UU200N

BU200S HA200L HU200L NJ200S PK200N SJ200L UG200N UU200S

GA200L HA200N HU200N NK200N PT200C

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

18 Part No. 70579901EN

Page 19

Heater Digit (Position 6)

C - Steam (CRN)

D - Liquid Petroleum (L.P.) Gas, Japan

E - Electric

F - Reduced Electric (Eco Line)

L - L.P. Gas

M - Medium Electric

N - Natural Gas

R - Reduced Gas, Natural Gas (Eco Line)

S - Steam

OPL Control Suffixes

Control Digit (position 7) Actuation Digit (position 8)

Introduction

Example Control Suffix Combination

F - Dual Digital Control N - OPL FN- Dual Digital Control, OPL

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

19 Part No. 70579901EN

Page 20

Preliminary Information

About the Control

This control is an advanced, programmable computer that allows

the owner to control most machine features by pressing a sequence of keypads. Refer to

The control allows the owner to retrieve audit information and

run diagnostic tests. Refer to Entering the Manual Mode for a full

list of features.

IMPORTANT: In the event of a power failure, the control

will not have to be reprogrammed. It is designed with a

memory system that will remember how it was programmed until the electrical power is restored.

IMPORTANT: It is extremely important that the machine

has a good ground connection and that all mechanical

and electrical connections to the control are made before applying power to or operating the machine.

Glossary of Terms

Control Identification.

Preliminary Information

The following are a few terms and abbreviations to learn. These

are referred to throughout the instructions.

Display – This term refers to the window area of the control that

displays words and values.

LED (Light Emitting Diode) – This term refers to the lights next

to the keypads and status words of the control.

Power Fail Recovery

If a cycle is in progress and the power fails, the cycle status is

saved in memory

sume into the previously active cycle (if so programmed by the

owner), by pressing the START pad. If the power failure occurs

while the control is in a fatal error mode, it will return to Start

Mode upon recovery.

. When the power recovers, the dryer will re-

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

20 Part No. 70579901EN

Page 21

Control Identification

TMB1783R_SVG

1

2

3

4

5

6

7

8

TMB1784R_SVG

1

2

3

4

5

6

7

8

Control Identification

Select Cycle Keypads

The SELECT keypad is used to select the specific machine cycle.

The default cycle is set at the previously selected cycle. The selected cycle is indicated by the light (LED) on the control. Pressing the STAR

cycle will begin.

NOTE: The reversing feature is not available on all

models.

S Models

T (enter) keypad will confirm the selection and the

H Models

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. START (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. START (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

21 Part No. 70579901EN

Page 22

TMB1785R_SVG

1

2

3

4

5

6

7

8

TMB1786R_SVG

1

2

3

4

5

6

7

8

TMB1787R_SVG

1

2

3

4

5

6

7

8

TMB1788R_SVG

1

2

3

4

5

6

7

8

Control Identification

U Models

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. START (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

I Models

P Models

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. START (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

N Models

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. STAR

5. REVERSING Keypad

6. DISPLAY Keypad

T (enter) Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. STAR

T (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

22 Part No. 70579901EN

Page 23

G and K Models

TMB1789R_SVG

1

2

3

4

5

6

7

8

1. Display

2. 7-segment Digits

3. Increase/Decrease COOL DOWN TIME

4. START (enter) Keypad

5. REVERSING Keypad

6. DISPLAY Keypad

7. SELECT Temperature Keypad

8. Increase/Decrease HEAT TIME

Control Identification

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

23 Part No. 70579901EN

Page 24

Display Identification

Light Emitting Diodes (LEDs)

LIGHT EMITTING DIODES (LEDs) are used to indicate the

chosen cycle and cycle status. See below for information on each

LED.

CYCLE LED

(High, Medium, Low, No Heat)

Cycle LED will remain lit the entire cycle.

REVERSING LED (reversing models only)

Any time a cycle or cycle step is set for reversing, the REVERSING LED will be lit.

Four 7-Segment Digits

The 7-Segment Digits are used to display the time remaining in a

cycle, error messages and descriptive codes. During diagnostic

testing, these digits will display descriptive codes and values (as

described in How to Enter the Manual Mode).

Display Identification

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

24 Part No. 70579901EN

Page 25

Special Features

Collecting Audit Information

The control will store audit information in its memory that can be

retrieved by pressing various combinations of keypads. The control will record total machine cycles, total hours run and total rapid advance cycles.

For more information on the audit features, refer to Manual Read

Audit Mode Menu.

Testing the Machine Using Diagnostic

Functions

Special diagnostic features built into the control allow the owner

to run specific diagnostic tests. By opening and closing the service door and then pressing various sequences of keypads, the

owner may perform diagnostic tests.

For detailed information on running diagnostic tests, refer to

Manual Diagnostic Mode Menu.

Special Features

Rapid Advance Feature

This feature allows the owner to manually advance through active cycles. This feature is useful when tests must be performed

immediately on a machine currently in an active cycle. In this

case, the owner can manually advance through the cycles to Start

Mode. At this point, the owner can perform the required tests and

then return the machine to the point it was interrupted.

For information on using the Rapid Advance feature, refer to Run

Mode.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

25 Part No. 70579901EN

Page 26

Machine Operation

Machine Operation

Power Up

When power is applied to the machine, the control becomes active and will display its machine type ( td), followed by the

software version ( SX XX ), and then by the software subversion

)

number (

.XX

System Check Mode

The front end control enters this mode after Power-Up Mode.

System Check Mode acts as an extension to Power-Up Mode and

during this mode, the control will check if the correct drive motor, fan motor and ignition control (for gas machines only) are

connected to the machine. If the motor type checks have successfully been completed or if the door is not closed prior to the five

(5)

second timer expiring, the front end control will continue to

the next mode. The mode that is entered after System Check

Mode completes is determined in Power-Up Mode. If the door

was not closed and the motor type check was not completed, this

check will be done the next time the motor drive contactor is enabled. If the test detects an incorrect drive motor, fan motor or ignition control, a Board ID Error will be set.

Start Mode

The control enters this mode when it is ready to start or resume a

cycle. The control will display the last cycle that was run and the

remaining cycle time.

If the DISPLA

operator for 4.25 minutes (i.e., keypad presses, opening or closing the loading door), the display will turn off. Operator input

(i.e., keypad presses opening or closing the loading door) will

turn on the display.

After pressing the START (enter) keypad if the door is closed, the

cycle will begin. The cycle time in minutes will be displayed.

keypad is pressed or if there is no input from the

Y

Run Mode

The control enters this mode when a cycle is running. The time

remaining appears in the display

.

curs, the control reverts back to Start Mode. If enough time elapses and the door is not opened or a keypad is pressed, the control

will enter Extended Tumble Mode.

Changing Cycles

Cycles can be changed anytime by pressing the SELECT keypad

to change temperature, press the up or down keypads to change

heat and cool down times and press the REVERSING keypad to

turn reversing on and off.

OPL Power Save

When in Start Mode, if the display keypad is pressed or if there is

no input from the operator for 4.25 minutes, (i.e., keypad presses,

opening or closing the loading door), the display will turn off.

Operator input (i.e., keypad presses, opening or closing the loading door) will turn on the display

.

Power Failure Display Mode

In Power Failure Display Mode the control will show Pr FL.

This informs the user that a cycle was interrupted and did not

complete normally. This mode is entered from System Check

Mode

if a power failure occurred during a cycle and the cycle is

not able to automatically resume. If the user presses any key,

Start Mode is entered. Refer to Power Failure Recovery.

Error Display Mode

This feature is used to display a machine error. Refer to Machine

Errors for more details on errors and their displays.

Extended Tumble Mode

If the door hasn't been opened and no keys have been pressed 20

minutes after the cycle has ended, the control increments the Total Number Extended T

tended Tumble. The cylinder will tumble for two minutes every

60 minutes for up to 18 hours or until the door is opened or a key

is pressed.

umble Cycles audit counter and enters Ex-

Upon the start of a cycle, the control will display the heat cycle

time and cool down cycle time. When the heat portion of the cycle ends, the cool down portion begins.

Rapid Advance Feature is enabled, press the START (enter)

If the

keypad to decrement one minute per key press.

Once the cycle is complete, the control will proceed to the End of

Cycle Mode.

End of Cycle Mode

When a cycle is complete, the control displays 00 until the door

is opened or a keypad is pressed. When one of these options oc-

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

26 Part No. 70579901EN

Page 27

Opening the Service Door

TMB1790R_SVG

25

C

1

2

3

SELECT

TEMP

INSERT

COIN

PUSH

ST

ART

1

2

3

SELECT

TEMP

INSERT

COIN

PUSH

ST

ART

1

TMB1791R_SVG

1

Opening the Service Door

Stacked Tumble Dryer

To open the service door, unlock it. Push down and in on bottom

of control so that the top of the control tilts forward.

Stand Alone Tumble Dryer

Unlock access panel over control and remove.

1. Control

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 1

27 Part No. 70579901EN

Page 28

Entering the Manual Mode

Entering the Manual Mode

Manual Mode allows audit and diagnostic control functions to be

accessed manually from the control.

How to Enter the Manual Mode

1. Open the service door. Refer to Opening the Service Door.

Press and hold the SELECT (∧) and DISPLAY (∨) keypads at

2.

the same time.

Manual Modes

Display Description

rA Pd

AU dt

di Ag

How to Exit Manual Mode

3.

The display will shows rA Pd.

4. Press the SELECT (∧) or the DISPLAY (∨) keypad to scroll

through the options until the desired option appears in the display. Refer to Table 1 .

5. Press the START (enter) keypad to enter the option.

Manual Rapid Advance Mode (Refer to Manual Rapid Advance

Menu)

Manual Read Audit Mode (Refer to Manual Read Audit Mode

Menu)

Manual Diagnostic Mode (Refer to Manual Diagnostic Mode

Menu)

Table 1

Simultaneously press the SELECT (∧) and

pads until the control returns to the mode that was active before

Manual Mode was entered.

DISPLAY (∨) key-

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

28 Part No. 70579901EN

Page 29

Rapid Advance Feature

Manual Rapid Advance Menu

This feature allows the user to quickly advance through a running

cycle (reduce time remaining in the cycle).

While in Rapid Advance Mode, the cycle time may be reduced

by pressing the ST

pad is pressed and held in, the time remaining will be reduced at

a rate of 4 minutes per second.

1. From Manual Mode (refer to How to Enter the Manual

Mode), select rA Pd and press the START (enter) keypad.

2. Press the SELECT (∧) or DISPLAY (∨) keypads to advance

the cycle by reducing the time.

3. Press the START (enter) keypad to select the desired time.

4. Simultaneously press the SELECT (∧) and DISPLAY (∨) keypads or press the START (enter) keypad to exit the rapid advance option.

5. Simultaneously press the SELECT (∧) and DISPLAY (∨) keypads to return to the Manual Mode menu.

ART (enter) keypad. If the START (enter) key-

Rapid Advance Feature

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

29 Part No. 70579901EN

Page 30

Collecting Audit Information

Manual Read Audit Mode Menu

The Manual Read Audit Mode menu allows an operator to view

the audit data listed in T

1. From Manual Mode (refer to How to Enter the Manual

Mode), select AU dt and press the START (enter) keypad.

2. Press the SELECT (∧) or DISPLAY (∨) keypads to scroll

through the available audit data.

3. Press the START (enter) keypad to select the desired audit data option. The audit data is displayed.

4. Simultaneously press the SELECT (∧) and DISPLAY (∨) keypads or press the START (enter) keypad to exit the audit data

option.

5. Simultaneously press the SELECT (∧) and DISPLAY (∨) keypads to return to the Manual Mode menu.

Display Description

able 2 .

Collecting Audit Information

Cy C

ru hr

rA Pd

Total number of cycles

Total number of run hours

Total number of rapid advance

cycles

Table 2

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

30 Part No. 70579901EN

Page 31

Machine Diagnostic Functions

Machine Diagnostic Functions

Manual Diagnostic Mode Menu

The Manual Diagnostic Mode allows an operator to run diagnostic tests on various machine operations (refer to T

servicing the machine.

1. From Manual Mode (refer to How to Enter the Manual

Mode), select di Ag and press the START (enter) keypad.

2. Press the SELECT (∧) or DISPLAY (∨) keypads to scroll

through the diagnostic test options until the desired option is

displayed.

3. Press the START (enter) keypad to select the desired option.

4. Press the SELECT (∧) or DISPLAY (∨) keypads to scroll

through the diagnostic test option steps.

Test Number Diagnostic Mode Display

d 01

d 02

d 03

d 04

able 3 ) without

Front-End Control Software Version Number

Input/Output Board Software Version

Number

Drive Board Software Version Number

Fan Board Software Version Number

5. Press the START (enter) keypad to run the diagnostic test.

NOTE: Press the SELECT (∧) and DISPLAY (∨) keypads

at the same time to cancel a diagnostic test before it is

complete.

6. To exit the Manual Diagnostic Mode, simultaneously press

the SELECT (∧) and DISPLAY (∨) keypads to return to the

Manual Mode menu.

Diagnostic (Testing) Mode – Quick

Reference

SX XX, XX

ob XX, XX

db XX

Fb XX

d 05

d 08

d 14*

d 15*

d 16*

d 19

d 20

d 21

d 28

d 29

d 30

d 31

d 32

d 33

d 34*

Ignition Control Software Version Number

(gas models only)

Service Door Switch Input Test

Dryer On Temp Test

Door Switch Input Test

Lint Door Switch Input Test

Temperature Sensor Display Test

12.5VDC Voltage Test

24VDC Voltage Test

AC Mains Voltage Test

Machine Configuration #1 Display Test

Machine Configuration #2 Display Test

Machine Configuration #3 Display Test

Machine Configuration #4 Display Test

Machine Configuration #5 Display Test

ICM Alarm Status (gas models only)

iC XX

S oP, S CL

XX XF or XX XC, NN

dr oP, dr CL

Lt oP, Lt CL

XX XF or XX XC, SH, oP

XX XX

XX XX

X XX

AX XX

bX XX

CX XX

dX XX

EX XX

A on, AoFF

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table 3 continues...

31 Part No. 70579901EN

Page 32

Machine Diagnostic Functions

Test Number Diagnostic Mode Display

d 35*

d 36*

- Cabinet Limit Thermostat

- Stove Limit Thermostat 1

- Stove Limit Thermostat 2

- Manual Reset Limit Thermostat

d 37*

d 38*

d 39*

d 40*

*Diagnostic test only available in Start Mode.

Diagnostic Test Descriptions

Front-End Control Software Version Number d 01

This option displays the control software version number. To start

test, control must be in the Manual Diagnostic Mode Menu.

T

o enter, press the START (enter) keypad. The display will show

SX XX, where X XX is the software version number, then XX,

where XX is the software subversion number if the subversion is

not 0.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Input/Output Board Software Version Number d

02

ICM Reset Test (gas models only)

Heat Interlock Test -

Air Flow Switch Test

Fan Motor Test

Damper Motor Test (steam models only)

Drive Motor Test

Table 3

To enter, press the START (enter) keypad. The display will show

db XX where XX is the software version of the drive.

T

o exit the test, simultaneously press the SELECT (∧) and DIS-

PLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Fan Board Software Version Number d 04

This option displays the fan board software version number. To

start test, control must be in the Manual Diagnostic Mode Menu.

To enter, press the START (enter) keypad. The display will show

Fb XX, where XX is the drive parameter version number.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Ignition Control Software Version Number d 05

This option displays the input/output board software version

number

Mode Menu.

To enter, press the START (enter) keypad. The display will show

ob XX, where XX is the board software version number, then XX,

where XX is the software subversion number if the subversion is

not 0.

. To start test, control must be in the Manual Diagnostic

(gas models only)

This option displays the current ignition control software version

number

Mode Menu.

To enter, press the START (enter) keypad. The display will show

iC XX where XX is the software version of the drive.

rS Et

C oP, C CL

S1 oP, S1 CL

S2 oP, S2 CL

NL oP, NL CL

Af oP, AF CL

FA n

dA NP

Fr d, PA US, rE v

. To start test, control must be in the Manual Diagnostic

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Drive Board Software Version Number d 03

This option displays the drive board software version number. To

start test, control must be in the Manual Diagnostic Mode Menu.

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Service Door Switch Input Test d 08

This option tests the service door switch. To start test, control

must be in the Manual Diagnostic Mode Menu.

32 Part No. 70579901EN

Page 33

Machine Diagnostic Functions

To enter, press the START (enter) keypad. The display will show

S oP when the service door switch is open and S CL when the

service door switch is closed.

The service door switch has to be closed for at least one second

and opened for at least one second for the display to change. This

test will add a count to the service door opening counter for the

audit and save the date/time for each opening.

o exit the test, simultaneously press the SELECT (∧) and DIS-

T

PLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Dryer on Temperature Test d 14

This option tests the temperature inside the cylinder while running a cycle. T

o start test, control must be in the Manual Diag-

nostic Mode Menu.

To enter, press the START (enter) keypad. The machine will run

until it has reached the selected cycle temperature. The display

will show XX XF for degrees in Fahrenheit or XX XC for degrees in Celsius. The XX X will show the degrees. During cool

down, the control will display the time remaining as NN (minutes)

or NN SS (minutes and seconds).

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Door Switch Input Test d 15

This test will display whether the loading door is open or closed.

T

o start test, control must be in the Manual Diagnostic Mode

Menu.

To enter, press the START (enter) keypad. If the door is open, the

display will show dr oP. If the door is closed, the display will

show dr CL.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Lint Door Switch Input Test d 16

This test will display whether the lint door switch is open or

closed. T

o start test, control must be in the Manual Diagnostic

Mode Menu.

To enter, press the START (enter) keypad. If the lint door switch

is open, the display will show Lt oP. If the lint door switch is

closed, the display will show Lt CL.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Temperature Sensor Display Test d 19

To enter, press the START (enter) keypad. If the door is closed,

the display will show XX XF or XX XC. The F will show Fahrenheit, the C will show Celsius and the XXX will show degrees.

If control senses a shorted thermistor

, the display will show SH. If

the control senses an open thermistor, the display will show oP.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

12.5VDC Voltage Test d 20

This test displays the value of the 12.5VDC supply. To start test,

control must be in the Manual Diagnostic Mode Menu.

T

o enter, press the START (enter) keypad. The display will show

XX XX where XXX is the voltage.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

24VDC Voltage Test d 21

This test will display whether the washer door is open or closed.

T

o start test, control must be in the Manual Diagnostic Mode

Menu.

To enter, press the START (enter) keypad. The display will show

XX XX where XXX in the voltage. The 24V supply is charged

when the door is closed. If the door is open the supply will discharge to a near zero (0) value.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

AC Mains Voltage Test d 28

This will display the AC Mains Voltage. To start test, control

must be in the Manual Diagnostic Mode Menu.

T

o enter, press the START (enter) keypad. The display will show

XXX which is the voltage in 1 Volt precision.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads.

Machine Configuration #1 Display Test d 29

This option shows the machine configuration values. To start test,

control must be in the Manual Diagnostic Mode Menu.

o enter, press the START (enter) keypad. For configuration val-

T

ue #1, the display will show AX XX. XX is a number corresponding to whether or not the network board or the life-test jumper is

present. Refer to Table 4 .

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads.

This option displays the temperature sensed at the thermistor. To

start test, control must be in the Manual Diagnostic Mode Menu.

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

33 Part No. 70579901EN

Page 34

Machine Diagnostic Functions

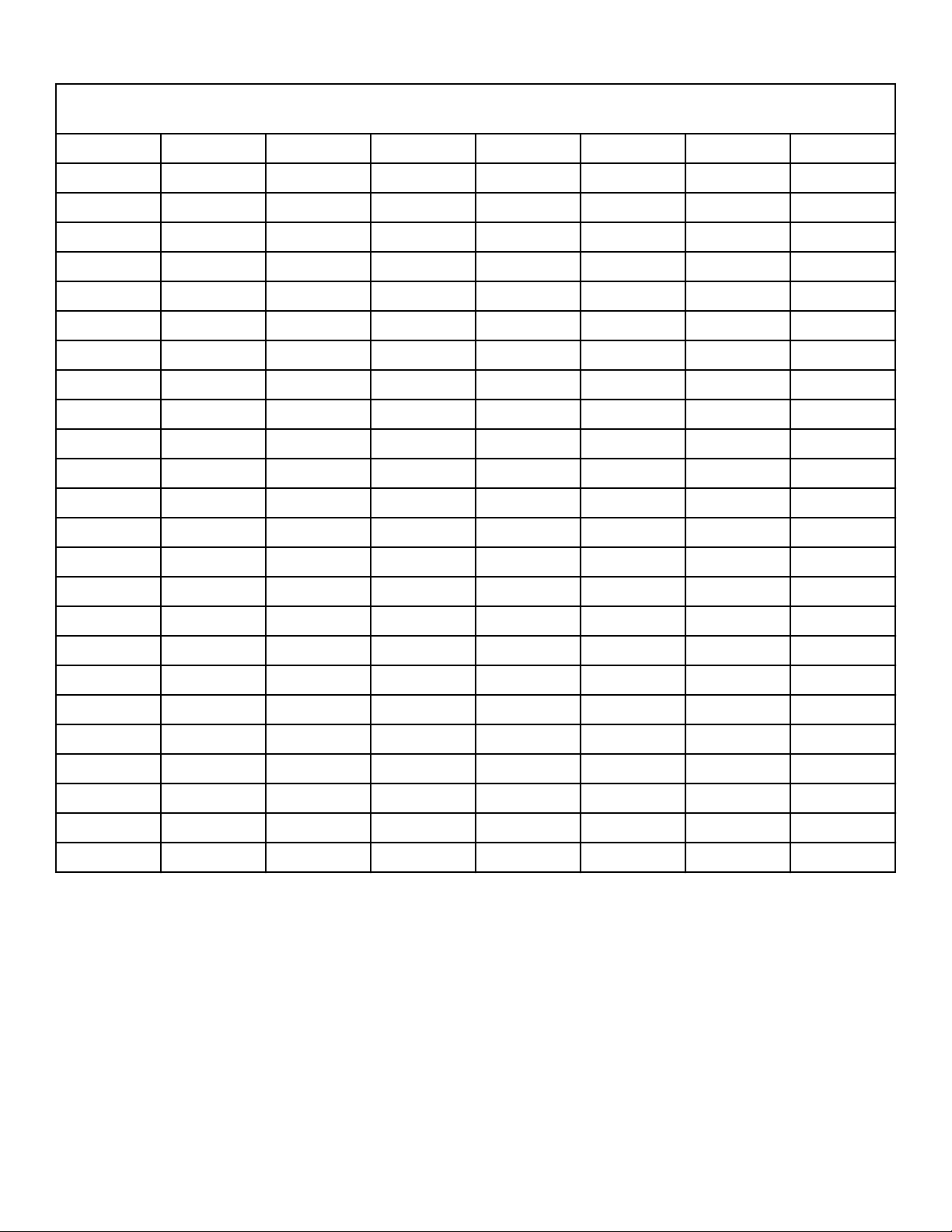

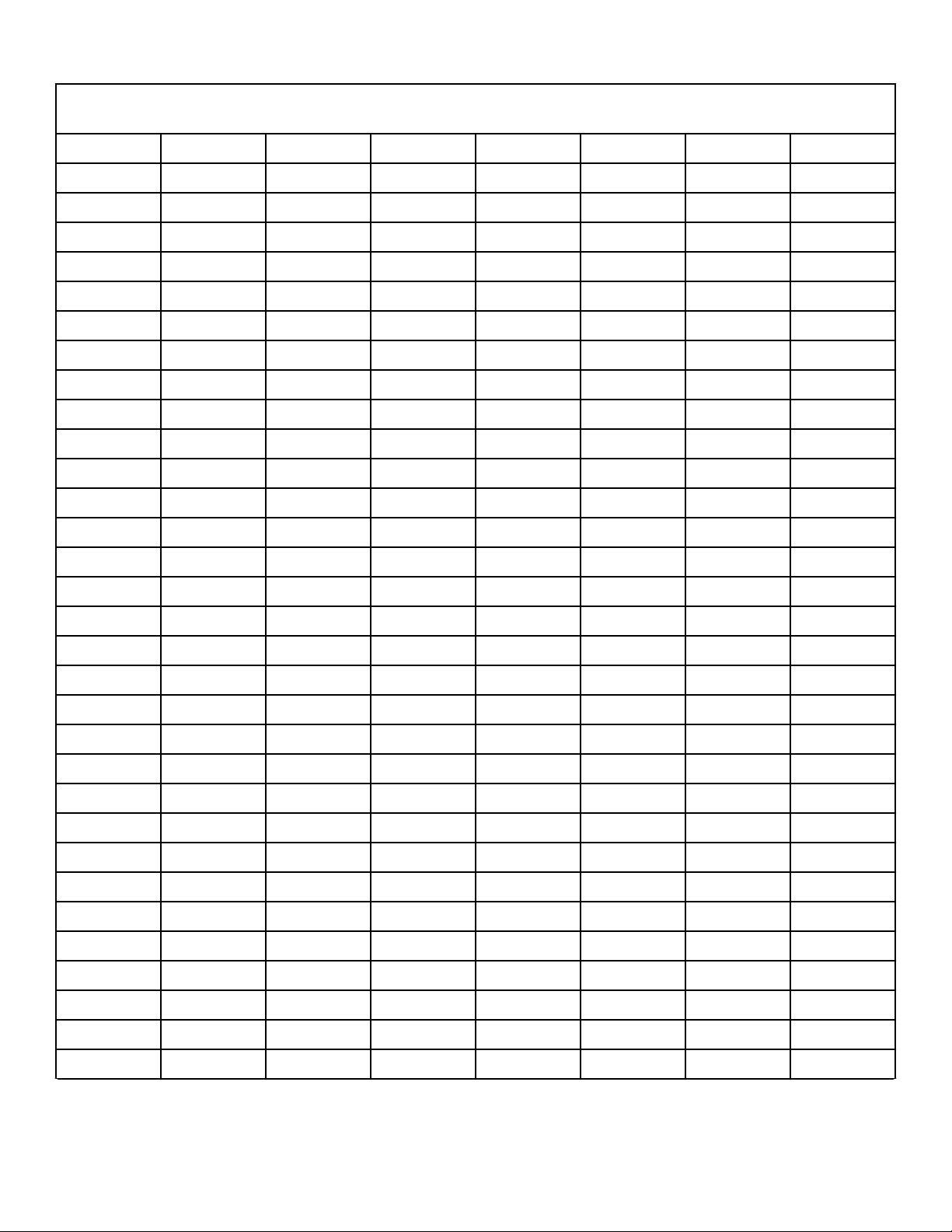

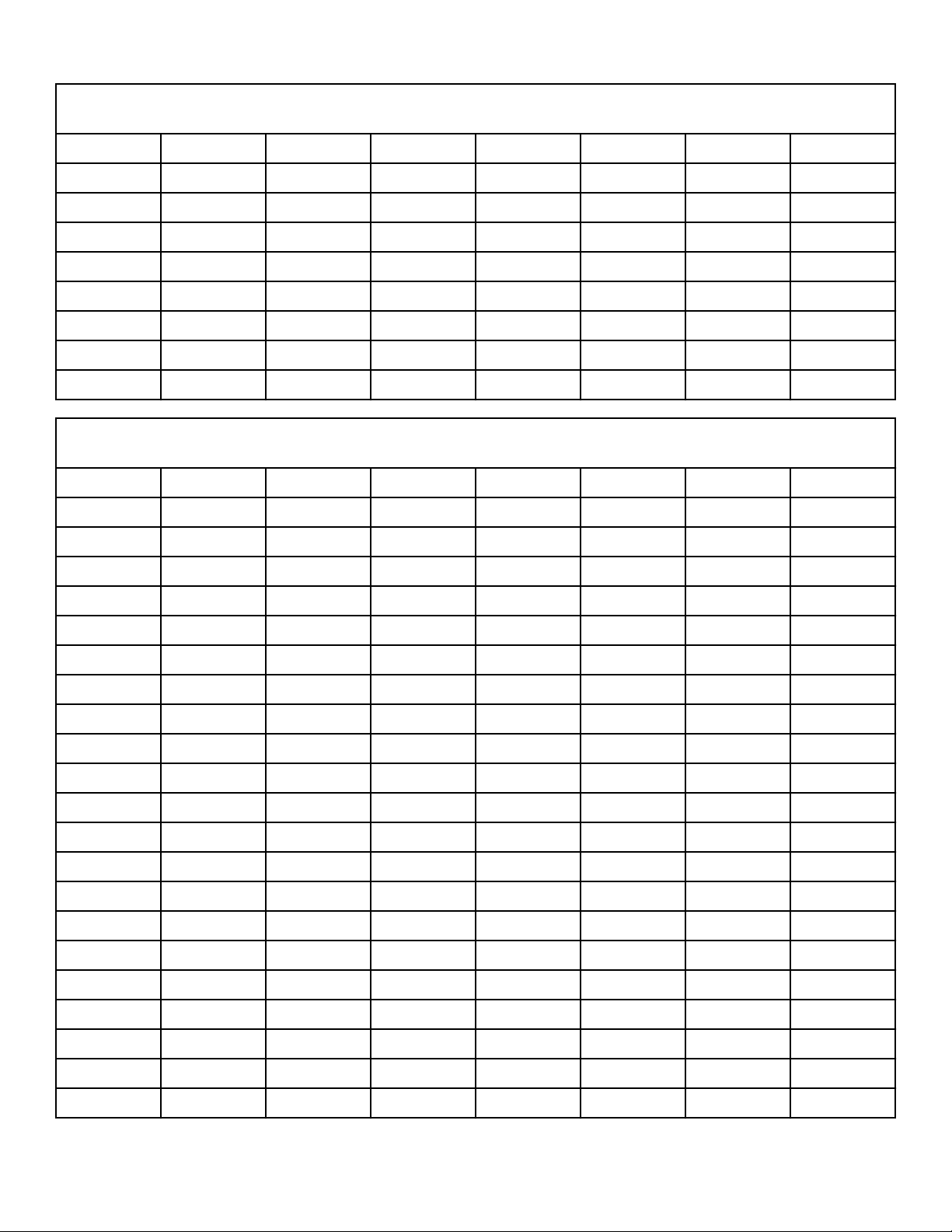

Each column of the table below contains a unique combination of

the words YES and NO that indicates if that column’

s connection

is present.

Comm Board "B" Head-

Configuration Value

er Present

0 NO

16 YES

Table 4

Machine Configuration #2 Display Test d 30

This option shows the machine configuration values. To start test,

control must be in the Manual Diagnostic Mode Menu.

T

o enter, press the START (enter) keypad. For configuration value #2, the display will show bX XX. XXX is a number corresponding to the capacity size of the machine. Refer to Table 5 .

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Option Description

Option Description

7 55 Pound Tumble Dryer

9 75 Pound Tumble Dryer

10 F75 Pound Tumble Dryer

14 120 Pound Tumble Dryer

15 170 Pound Tumble Dryer

16 200 Pound Tumble Dryer

Table 5

Machine Configuration #3 Display Test d 31

This option is not used on this model. 0 is always displayed.

Machine Configuration #4 Display Test d 32

This option shows the user which dipswitches are set on the con-

To start test, control must be in the Manual Diagnostic Mode

trol.

Menu.

To Enter, press the START (enter) keypad. The display will show

dX XX with X XX representing a configuration value as shown

in Table 6 .

0 Invalid

1 25 Pound Tumble Dryer

2 30 Pound Tumble Dryer

3 35 Pound Tumble Dryer

If supply voltage is 100-127 Volt per phase, the voltage configuration should be 120 Volt.

If supply voltage is 200-240 Volt per phase, the voltage configuration should be 240 Volt.

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

4 T30 Pound Stack Tumble Dryer

5 T45 Pound Stack Tumble Dryer

6 50 Pound Tumble Dryer

nostic Mode Menu.

Each column in the table below contains a unique combination of

the words ON and OFF that indicates if that column’s dipswitch

is set on or off when the value is displayed.

Table 5 continues...

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

Dipswitch 8

0 OFF OFF OFF OFF OFF OFF OFF OFF

1 OFF OFF OFF OFF OFF OFF OFF ON

Dipswitch 1

(Volt Supply)**

2 OFF OFF OFF OFF OFF OFF ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

34 Part No. 70579901EN

Page 35

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

3 OFF OFF OFF OFF OFF OFF ON ON

4 OFF OFF OFF OFF OFF ON OFF OFF

5 OFF OFF OFF OFF OFF ON OFF ON

6 OFF OFF OFF OFF OFF ON ON OFF

7 OFF OFF OFF OFF OFF ON ON ON

8 OFF OFF OFF OFF ON OFF OFF OFF

9 OFF OFF OFF OFF ON OFF OFF ON

10 OFF OFF OFF OFF ON OFF ON OFF

11 OFF OFF OFF OFF ON OFF ON ON

Dipswitch 1

(Volt Supply)**

12 OFF OFF OFF OFF ON ON OFF OFF

13 OFF OFF OFF OFF ON ON OFF ON

14 OFF OFF OFF OFF ON ON ON OFF

15 OFF OFF OFF OFF ON ON ON ON

16 OFF OFF OFF ON OFF OFF OFF OFF

17 OFF OFF OFF ON OFF OFF OFF ON

18 OFF OFF OFF ON OFF OFF ON OFF

19 OFF OFF OFF ON OFF OFF ON ON

20 OFF OFF OFF ON OFF ON OFF OFF

21 OFF OFF OFF ON OFF ON OFF ON

22 OFF OFF OFF ON OFF ON ON OFF

23 OFF OFF OFF ON OFF ON ON ON

24 OFF OFF OFF ON ON OFF OFF OFF

25 OFF OFF OFF ON ON OFF OFF ON

26 OFF OFF OFF ON ON OFF ON OFF

27 OFF OFF OFF ON ON OFF ON ON

28 OFF OFF OFF ON ON ON OFF OFF

29 OFF OFF OFF ON ON ON OFF ON

30 OFF OFF OFF ON ON ON ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

35 Part No. 70579901EN

Page 36

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

31 OFF OFF OFF ON ON ON ON ON

32 OFF OFF ON OFF OFF OFF OFF OFF

33 OFF OFF ON OFF OFF OFF OFF ON

34 OFF OFF ON OFF OFF OFF ON OFF

35 OFF OFF ON OFF OFF OFF ON ON

36 OFF OFF ON OFF OFF ON OFF OFF

37 OFF OFF ON OFF OFF ON OFF ON

38 OFF OFF ON OFF OFF ON ON OFF

39 OFF OFF ON OFF OFF ON ON ON

Dipswitch 1

(Volt Supply)**

40 OFF OFF ON OFF ON OFF OFF OFF

41 OFF OFF ON OFF ON OFF OFF ON

42 OFF OFF ON OFF ON OFF ON OFF

43 OFF OFF ON OFF ON OFF ON ON

44 OFF OFF ON OFF ON ON OFF OFF

45 OFF OFF ON OFF ON ON OFF ON

46 OFF OFF ON OFF ON ON ON OFF

47 OFF OFF ON OFF ON ON ON ON

48 OFF OFF ON ON OFF OFF OFF OFF

49 OFF OFF ON ON OFF OFF OFF ON

50 OFF OFF ON ON OFF OFF ON OFF

51 OFF OFF ON ON OFF OFF ON ON

52 OFF OFF ON ON OFF ON OFF OFF

53 OFF OFF ON ON OFF ON OFF ON

54 OFF OFF ON ON OFF ON ON OFF

55 OFF OFF ON ON OFF ON ON ON

56 OFF OFF ON ON ON OFF OFF OFF

57 OFF OFF ON ON ON OFF OFF ON

58 OFF OFF ON ON ON OFF ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

36 Part No. 70579901EN

Page 37

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

59 OFF OFF ON ON ON OFF ON ON

60 OFF OFF ON ON ON ON OFF OFF

61 OFF OFF ON ON ON ON OFF ON

62 OFF OFF ON ON ON ON ON OFF

63 OFF OFF ON ON ON ON ON ON

64 OFF ON OFF OFF OFF OFF OFF OFF

65 OFF ON OFF OFF OFF OFF OFF ON

66 OFF ON OFF OFF OFF OFF ON OFF

67 OFF ON OFF OFF OFF OFF ON ON

Dipswitch 1

(Volt Supply)**

68 OFF ON OFF OFF OFF ON OFF OFF

69 OFF ON OFF OFF OFF ON OFF ON

70 OFF ON OFF OFF OFF ON ON OFF

71 OFF ON OFF OFF OFF ON ON ON

72 OFF ON OFF OFF ON OFF OFF OFF

73 OFF ON OFF OFF ON OFF OFF ON

74 OFF ON OFF OFF ON OFF ON OFF

75 OFF ON OFF OFF ON OFF ON ON

76 OFF ON OFF OFF ON ON OFF OFF

77 OFF ON OFF OFF ON ON OFF ON

78 OFF ON OFF OFF ON ON ON OFF

79 OFF ON OFF OFF ON ON ON ON

80 OFF ON OFF ON OFF OFF OFF OFF

81 OFF ON OFF ON OFF OFF OFF ON

82 OFF ON OFF ON OFF OFF ON OFF

83 OFF ON OFF ON OFF OFF ON ON

84 OFF ON OFF ON OFF ON OFF OFF

85 OFF ON OFF ON OFF ON OFF ON

86 OFF ON OFF ON OFF ON ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

37 Part No. 70579901EN

Page 38

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

87 OFF ON OFF ON OFF ON ON ON

88 OFF ON OFF ON ON OFF OFF OFF

89 OFF ON OFF ON ON OFF OFF ON

90 OFF ON OFF ON ON OFF ON OFF

91 OFF ON OFF ON ON OFF ON ON

92 OFF ON OFF ON ON ON OFF OFF

93 OFF ON OFF ON ON ON OFF ON

94 OFF ON OFF ON ON ON ON OFF

95 OFF ON OFF OFF ON ON ON ON

Dipswitch 1

(Volt Supply)**

96 OFF ON ON OFF OFF OFF OFF OFF

97 OFF ON ON OFF OFF OFF OFF ON

98 OFF ON ON OFF OFF OFF ON OFF

99 OFF ON ON OFF OFF OFF ON ON

100 OFF ON ON OFF OFF ON OFF OFF

101 OFF ON ON OFF OFF ON OFF ON

102 OFF ON ON OFF OFF ON ON OFF

103 OFF ON ON OFF OFF ON ON ON

104 OFF ON ON OFF ON OFF OFF OFF

105 OFF ON ON OFF ON OFF OFF ON

106 OFF ON ON OFF ON OFF ON OFF

107 OFF ON ON OFF ON OFF ON ON

108 OFF ON ON OFF ON ON OFF OFF

109 OFF ON ON OFF ON ON OFF ON

110 OFF ON ON OFF ON ON ON OFF

111 OFF ON ON OFF ON ON ON ON

112 OFF ON ON ON OFF OFF OFF OFF

113 OFF ON ON ON OFF OFF OFF ON

114 OFF ON ON ON OFF OFF ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

38 Part No. 70579901EN

Page 39

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

115 OFF ON ON ON OFF OFF ON ON

116 OFF ON ON ON OFF ON OFF OFF

117 OFF ON ON ON OFF ON OFF ON

118 OFF ON ON ON OFF ON ON OFF

119 OFF ON ON ON OFF ON ON ON

120 OFF ON ON ON ON OFF OFF OFF

121 OFF ON ON ON ON OFF OFF ON

122 OFF ON ON ON ON OFF ON OFF

123 OFF ON ON ON ON OFF ON ON

Dipswitch 1

(Volt Supply)**

124 OFF ON ON ON ON ON OFF OFF

125 OFF ON ON ON ON ON OFF ON

126 OFF ON ON ON ON ON ON OFF

127 OFF ON ON ON ON ON ON ON

128 ON OFF OFF OFF OFF OFF OFF OFF

129 ON OFF OFF OFF OFF OFF OFF ON

130 ON OFF OFF OFF OFF OFF ON OFF

131 ON OFF OFF OFF OFF OFF ON ON

132 ON OFF OFF OFF OFF ON OFF OFF

133 ON OFF OFF OFF OFF ON OFF ON

134 ON OFF OFF OFF OFF ON ON OFF

135 ON OFF OFF OFF OFF ON ON ON

136 ON OFF OFF OFF ON OFF OFF OFF

137 ON OFF OFF OFF ON OFF OFF ON

138 ON OFF OFF OFF ON OFF ON OFF

139 ON OFF OFF OFF ON OFF ON ON

140 ON OFF OFF OFF ON ON OFF OFF

141 ON OFF OFF OFF ON ON OFF ON

142 ON OFF OFF OFF ON ON ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

39 Part No. 70579901EN

Page 40

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

143 ON OFF OFF OFF ON ON ON ON

144 ON OFF OFF ON OFF OFF OFF OFF

145 ON OFF OFF ON OFF OFF OFF ON

146 ON OFF OFF ON OFF OFF ON OFF

147 ON OFF OFF ON OFF OFF ON ON

148 ON OFF OFF ON OFF ON OFF OFF

149 ON OFF OFF ON OFF ON OFF ON

150 ON OFF OFF ON OFF ON ON OFF

151 ON OFF OFF ON OFF ON ON ON

Dipswitch 1

(Volt Supply)**

152 ON OFF OFF ON ON OFF OFF OFF

153 ON OFF OFF ON ON OFF OFF ON

154 ON OFF OFF ON ON OFF ON OFF

155 ON OFF OFF ON ON OFF ON ON

156 ON OFF OFF ON ON ON OFF OFF

157 ON OFF OFF ON ON ON OFF ON

158 ON OFF OFF ON ON ON ON OFF

159 ON OFF OFF ON ON ON ON ON

160 ON OFF ON OFF OFF OFF OFF OFF

161 ON OFF ON OFF OFF OFF OFF ON

162 ON OFF ON OFF OFF OFF ON OFF

163 ON OFF ON OFF OFF OFF ON ON

164 ON OFF ON OFF OFF ON OFF OFF

165 ON OFF ON OFF OFF ON OFF ON

166 ON OFF ON OFF OFF ON ON OFF

167 ON OFF ON OFF OFF ON ON ON

168 ON OFF ON OFF ON OFF OFF OFF

169 ON OFF ON OFF ON OFF OFF ON

170 ON OFF ON OFF ON OFF ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

40 Part No. 70579901EN

Page 41

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

171 ON OFF ON OFF ON OFF ON ON

172 ON OFF ON OFF ON ON OFF OFF

173 ON OFF ON OFF ON ON OFF ON

174 ON OFF ON OFF ON ON ON OFF

175 ON OFF ON OFF ON ON ON ON

176 ON OFF ON ON OFF OFF OFF OFF

177 ON OFF ON ON OFF OFF OFF ON

178 ON OFF ON ON OFF OFF ON OFF

179 ON OFF ON ON OFF OFF ON ON

Dipswitch 1

(Volt Supply)**

180 ON OFF ON ON OFF ON OFF OFF

181 ON OFF ON ON OFF ON OFF ON

182 ON OFF ON ON OFF ON ON OFF

183 ON OFF ON ON OFF ON ON ON

184 ON OFF ON ON ON OFF OFF OFF

185 ON OFF ON ON ON OFF OFF ON

186 ON OFF ON ON ON OFF ON OFF

187 ON OFF ON ON ON OFF ON ON

188 ON OFF ON ON ON ON OFF OFF

189 ON OFF ON ON ON ON OFF ON

190 ON OFF ON ON ON ON ON OFF

191 ON OFF ON ON ON ON ON ON

192 ON ON OFF OFF OFF OFF OFF OFF

193 ON ON OFF OFF OFF OFF OFF ON

194 ON ON OFF OFF OFF OFF ON OFF

195 ON ON OFF OFF OFF OFF ON ON

196 ON ON OFF OFF OFF ON OFF OFF

197 ON ON OFF OFF OFF ON OFF ON

198 ON ON OFF OFF OFF ON ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

41 Part No. 70579901EN

Page 42

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

199 ON ON OFF OFF OFF ON ON ON

200 ON ON OFF OFF ON OFF OFF OFF

201 ON ON OFF OFF ON OFF OFF ON

202 ON ON OFF OFF ON OFF ON OFF

203 ON ON OFF OFF ON OFF ON ON

204 ON ON OFF OFF ON ON OFF OFF

205 ON ON OFF OFF ON ON OFF ON

206 ON ON OFF OFF ON ON ON OFF

207 ON ON OFF OFF ON ON ON ON

Dipswitch 1

(Volt Supply)**

208 ON ON OFF ON OFF OFF OFF OFF

209 ON ON OFF ON OFF OFF OFF ON

210 ON ON OFF ON OFF OFF ON OFF

211 ON ON OFF ON OFF OFF ON ON

212 ON ON OFF ON OFF ON OFF OFF

213 ON ON OFF ON OFF ON OFF ON

214 ON ON OFF ON OFF ON ON OFF

215 ON ON OFF ON OFF ON ON ON

216 ON ON OFF ON ON OFF OFF OFF

217 ON ON OFF ON ON OFF OFF ON

218 ON ON OFF ON ON OFF ON OFF

219 ON ON OFF ON ON OFF ON ON

220 ON ON OFF ON ON ON OFF OFF

221 ON ON OFF ON ON ON OFF ON

222 ON ON OFF ON ON ON ON OFF

223 ON ON OFF ON ON ON ON ON

224 ON ON ON OFF OFF OFF OFF OFF

225 ON ON ON OFF OFF OFF OFF ON

226 ON ON ON OFF OFF OFF ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

42 Part No. 70579901EN

Page 43

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

227 ON ON ON OFF OFF OFF ON ON

228 ON ON ON OFF OFF ON OFF OFF

229 ON ON ON OFF OFF ON OFF ON

230 ON ON ON OFF OFF ON ON OFF

231 ON ON ON OFF OFF ON ON ON

232 ON ON ON OFF ON OFF OFF OFF

233 ON ON ON OFF ON OFF OFF ON

234 ON ON ON OFF ON OFF ON OFF

235 ON ON ON OFF ON OFF ON ON

Dipswitch 1

(Volt Supply)**

236 ON ON ON OFF ON ON OFF OFF

237 ON ON ON OFF ON ON OFF ON

238 ON ON ON OFF ON ON ON OFF

239 ON ON ON OFF ON ON ON ON

240 ON ON ON ON OFF OFF OFF OFF

241 ON ON ON ON OFF OFF OFF ON

242 ON ON ON ON OFF OFF ON OFF

243 ON ON ON ON OFF OFF ON ON

244 ON ON ON ON OFF ON OFF OFF

245 ON ON ON ON OFF ON OFF ON

246 ON ON ON ON OFF ON ON OFF

247 ON ON ON ON OFF ON ON ON

248 ON ON ON ON ON OFF OFF OFF

249 ON ON ON ON ON OFF OFF ON

250 ON ON ON ON ON OFF ON OFF

251 ON ON ON ON ON OFF ON ON

252 ON ON ON ON ON ON OFF OFF

253 ON ON ON ON ON ON OFF ON

254 ON ON ON ON ON ON ON OFF

Table 6 continues...

©

Copyright, Alliance Laundry Systems LLC DO NOT COPY or TRANSMIT

43 Part No. 70579901EN

Page 44

Machine Diagnostic Functions

Dipswitch 8

Configuration Value

(Heat Source)

Dipswitch 7

(Heat Source)

Dipswitch 6

(Reserved)

Dipswitch 5

(Unused)

Dipswitch 4

(Temp Units)*

Dipswitch 3

(Reserved)

Dipswitch 2

(Unused)

255 ON ON ON ON ON ON ON ON

*OFF = Fahrenheit, ON = Celsius

**OFF = 120 VAC, ON = 240 VAC

Table 6

Dipswitch 1

(Volt Supply)**

Machine Configuration #5 Display Test d 33

This option shows the voltage configuration of the machine and

the fan speed type.

Diagnostic Mode Menu.

To enter, press the START (enter) keypad. For configuration value #5, the display will show EX XX. XXX is a number corresponding to the voltage parameter and fan speed. Refer to Table

7 .

To exit the test, simultaneously press the SELECT (∧) and DISPLAY (∨) keypads. The control will return to the Manual Diag-

nostic Mode Menu.

Config Value

2 Gas/Steam OFF

3 Gas/Steam ON

4 Electric OFF

5 Electric ON

6 Eco Gas OFF

7 Eco Gas ON

To start test, control must be in the Manual

Adjust Fan

Speed for

Heat Type

480V Motor

Drives