Alliance Laundry Systems AWN432SP111TW01, AWN402PP111TW01, AWN432SP113CW04, AWN432SP113TW01, AWN542SP111TW01 Troubleshooting Manual

...Page 1

Home

Topload

Washers

Refer to Page 5 for Model Numbers

Troubleshooting

www.alliancelaundry.com

TLW2C

Part No. 201520R6

November 2016

Page 2

Page 3

Table of

Content s

Section 1 – Safety Information ...............................................................3

Section 2 – Introduction..........................................................................5

Model Identification..............................................................................5

How Your Washer Works .....................................................................6

Customer Service...................................................................................8

Nameplate Location...............................................................................8

Section 3 – Troubleshooting....................................................................9

1. Low Water Level on High Fill Setting..........................................9

2. Clicking Noise During Operation on NEWLY Installed Units....9

3. Motor Hums................................................................................10

4. No Hot Water..............................................................................11

5. No Cold Water............................................................................12

6. No Warm Water..........................................................................13

7. Slow Hot Fill or Warm Fill is Too Cold.....................................14

8. Water Fill Does Not Stop At Proper Level.................................15

9. Washer Fills, Motor Hums.................................................. ..... ...16

10. Timer Does Not Advance ...........................................................17

11. Motor Does Not Run...................................................................18

12. No Agitation................................................................................19

13. Constant Agitation ..................................................... ..... .... ........20

14. Washer Overheats, Cycles On Motor Thermal Protector,

Switch Actuator Kicks In And Out.............................................21

15. Slow Spin Or No Spin.................................................................22

16. Constant Spin..............................................................................23

17. Washer Stops In Cycle; Quits After A Couple Loads;

Is Intermittent..............................................................................24

18. Washer Is Locked Up Or Binding...............................................25

19. Outer Tub Does Not Empty........................................................26

20. Excessive Vibration ................................................... ..... .... ........27

21. Water Leaking From Outer Tub..................................................28

Section 4 – Control Troubleshooting

Model AWNA11SP111TW01 ...............................................................29

22. Error Mode..................................................................................29

23. Washer Will Not Fill (Pressure Switch Diagnostic). ..................30

24. Washer Will Not Fill (Mixing Valve Diagnostic) ......................32

25. Washer Over Fills (Pressure Switch Open)................................34

26. No Agitation – Low and High Speed..........................................36

27. Washer Will Not Spin – Low Speed...........................................38

28. Washer Will Not Spin – High Speed..........................................40

Section 5 – Adjustments........................................................................42

29. Leveling Legs..............................................................................42

30. Belt (Agitate And Spin) ...................................................... ..... ...42

© Copyright 2016, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

201520R6 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

Section 6 – Test Procedures..................................................................43

31. Motor Test Procedure..................................................................43

32. Mixing Valve Solenoid Test Procedure......................................44

33. Temperature Switch Test Procedure...........................................44

Section 7 – Cycle Sequence Charts....................................................... 45

Section 8 – Internal Wiring of Washer Motor Switch........................55

2 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer, and those maintaining the machine.

DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

CAUTION

Caution indicates a hazardous situation that, if not avoided, may cause minor or moderate person al injury or property

damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

201520R6 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you, or the inexperienced person making such

repairs, to the risk of serious injury, electrical shock, or death.

W007

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer , distributor , service agent or the manufactu rer about any prob lems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 7

Section 2

Introduction

Model Identification

Information in this manual is applicable to these washer models.

AWNA11SP111TW01

AWN311SP111TW01

AWN402PP111TW01

AWN412SP111TW01

AWN432SP111TW01

AWN432SP113CW04

AWN432SP113TW01

AWN432SP113TW04

AWN542SP111TW01

AWN542SP111TWAH

AWS01NW

AWS17NW

AWS44NW

AWS45NW

AWS48NW

AWS51NW

AWS52NW

AWS53NW

AWS75NW

AWS76NW

201520R6 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Introduction

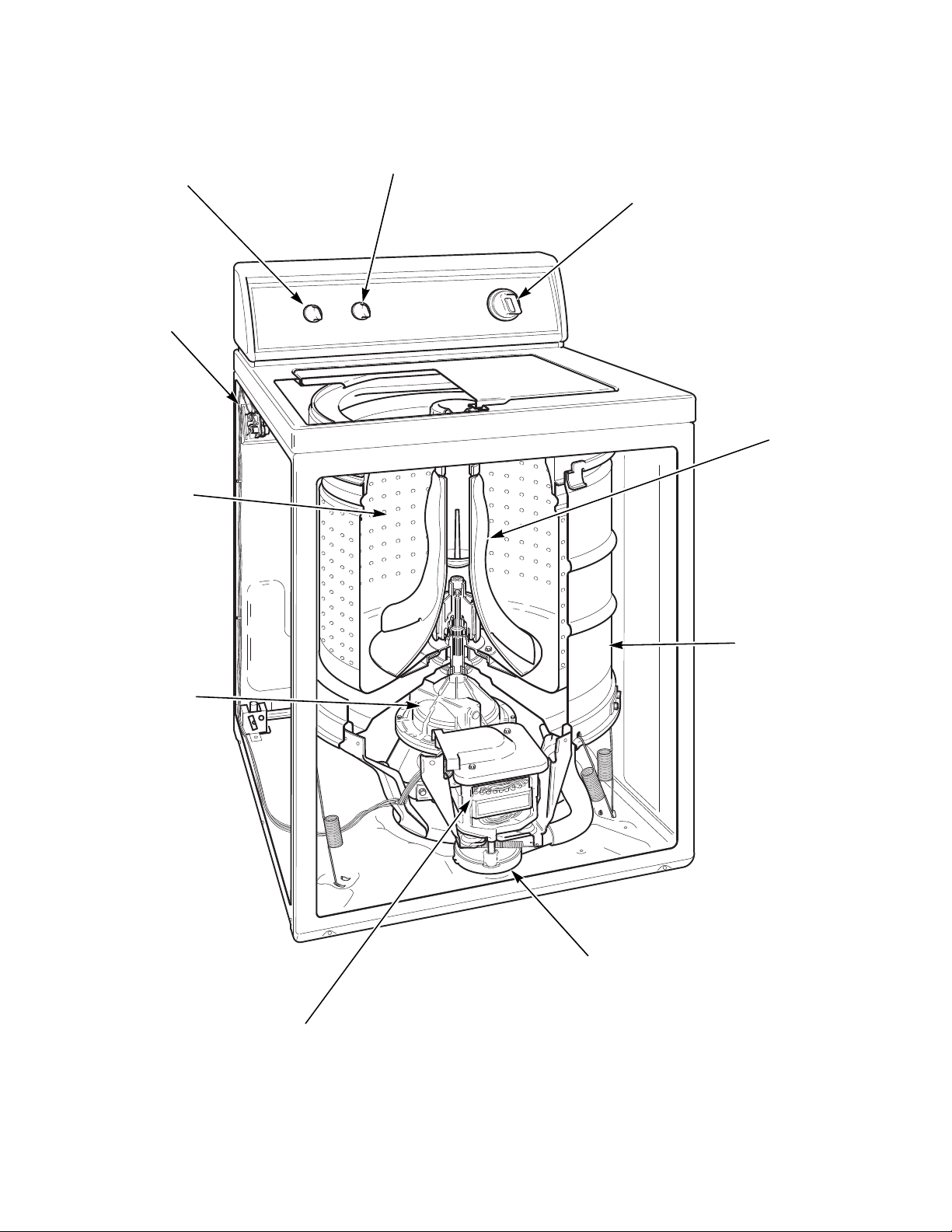

Temperature

Switch

Pressure

Switch

Timer

Agitator

Outer

Tub

Mixing

Valve

Washtub

Transmission

Motor

Pump

How Your Washer Works

TLW306S

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 9

Introduction

The cycle begins with a wash fill. The water

temperature is determined by the temperature selector.

While water fills the washtub, a column of air is

trapped in a pressure bulb and hose. The air pressure

continues to increase as the washtub fills with water

until it is great enough to activate the pressure switch.

The pressure switch then causes the wash fill to stop

and wash agitation to begin. However, the loading door

must be closed for the washer to agitate or spin.

The washer uses a reversing type motor, a special drive

belt and an idler assembly. The idler assembly applies

tension to the outside of the drive belt.

During agitation, the motor runs in the

counterclockwise direction. The spring tension on the

idler pulley applies the tension required to reduce the

slack on the drive belt and maintain maximum belt to

motor pulley contact. This eliminates belt slippage and

ensures an efficient wash action, even with extra large

loads.

The belt drives the transmission drive pulley in the

counterclockwise direction. The pulley drives the helix

which is splined to the input shaft of the transmission.

This causes the input shaft to turn inside of a roller

clutch which is pressed into the transmission cover.

This roller clutch acts as a bearing in the

counterclockwise direction allowing the transmission

gears to operate. The transmission’s rack and pinion

gear design produces a 210 degree agitation st roke at

the output shaft of the transmission which drives the

agitator. The brake assembly remains locked during the

agitation mode since no pressure is applied to it by the

transmission drive pulley.

As water is removed by the pump and the momentum

of the washtub increases, the idler spring tension

gradually overcomes the belt tension removing the belt

slack. This eventually increases the belt to pulley

contact until maximum spin speed is achieved.

The drive pulley turns clockwise riding up the ramps of

the helix, exerting pressure on the brake and forcing it

to release from brake pads. The helix drives the input

shaft of the transmission, and when the input shaft turns

in the clockwise direction the roller clutch locks onto

the shaft causing the entire transmission assembly to

turn. None of the gears in the transmission are

operating at this time. The hub of the washtub is splined

to the transmission tube and rotates with the

transmission assembly. The centrifugal force created

by the spinning washtub causes water to be extracted

from the clothes.

Water is introduced during the first spin to “SPRAY”

the garments and remove suds from them. The initial

spin is followed by rinse agitation to rinse away any

detergent residue. The washer fills and then agitates

like the wash portion of the cycle. Following rinse

agitation, a final spin extracts the rinse water from the

clothes preparing them for the dryer.

After the wash agitation is completed, the timer

advances into the first spin. During spin, the motor

reverses turning in the clockwise direction to spin the

water out of the washtub. The combination of water,

washtub and load weight cause the drive belt tension on

the idler side of the belt to overtake the idler spring

pressure allowing the belt to become slack on the

opposite side. This reduces the belt to pulley contact

and allows slipping between the belt and pulley.

201520R6 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

Introduction

W429SE1B

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized parts

distributor.

For technical assistance, call (920) 748-3121.

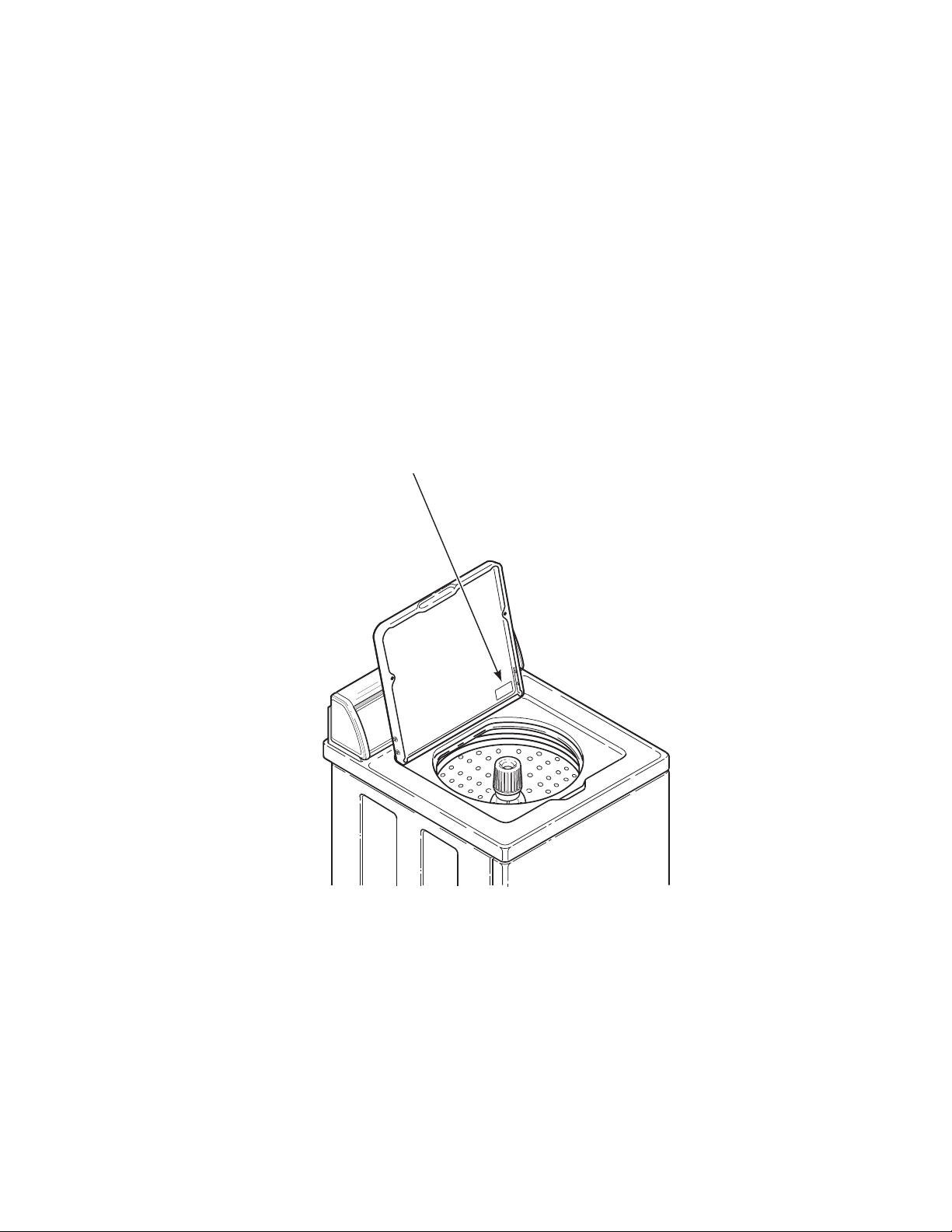

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 11

Section 3

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Troubleshooting

IMPORTANT: Refer to Wiring Diagram for aid in

testing washer components.

1. Low Water Level on High Fill

Setting

a. If there is an instance of a low water level on the

highest fill setting, check that the high setting

water level is approximately 1.5 inches below

the top row of washtub holes.

b. If the water level is within .5 inch of this level

without clothes, it is performing as designed.

Recent new mandates from the Department of

Energy (DOE) call for certain efficiencies to be

met by all washer manufacturers which require

the use of a different pressure switch to meet

these requirements. No modification can be

made to the washer to fill higher on this setting.

2. Clicking Noise During Operation

on NEWLY Installed Units

If a clicking noise is heard when first starting up a new

topload washer, the noise is related to the belt taking a

temporary “set” around the idler pulley . The set causes

a slight bump in the belt which in turn causes the idler

lever to tap the motor bracket making the clicking

noise. THE BELT DOES NOT NEED TO BE

REPLACED.

To correct this condition please perform the following

break-in procedure:

1. After installing the unit start a fill cycle to

make sure the seals have been lubricated.

2. Stop the fill cycle and place the unit into a

spin cycle.

3. Run the cycle for several minutes until the

belt has warmed up. This will remove the

“set.”

4. Normal use will keep the belt from

resetting.

5. For extended periods of non-use (three to

four weeks), this procedure might need to

be repeated.

201520R6 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Troubleshooting

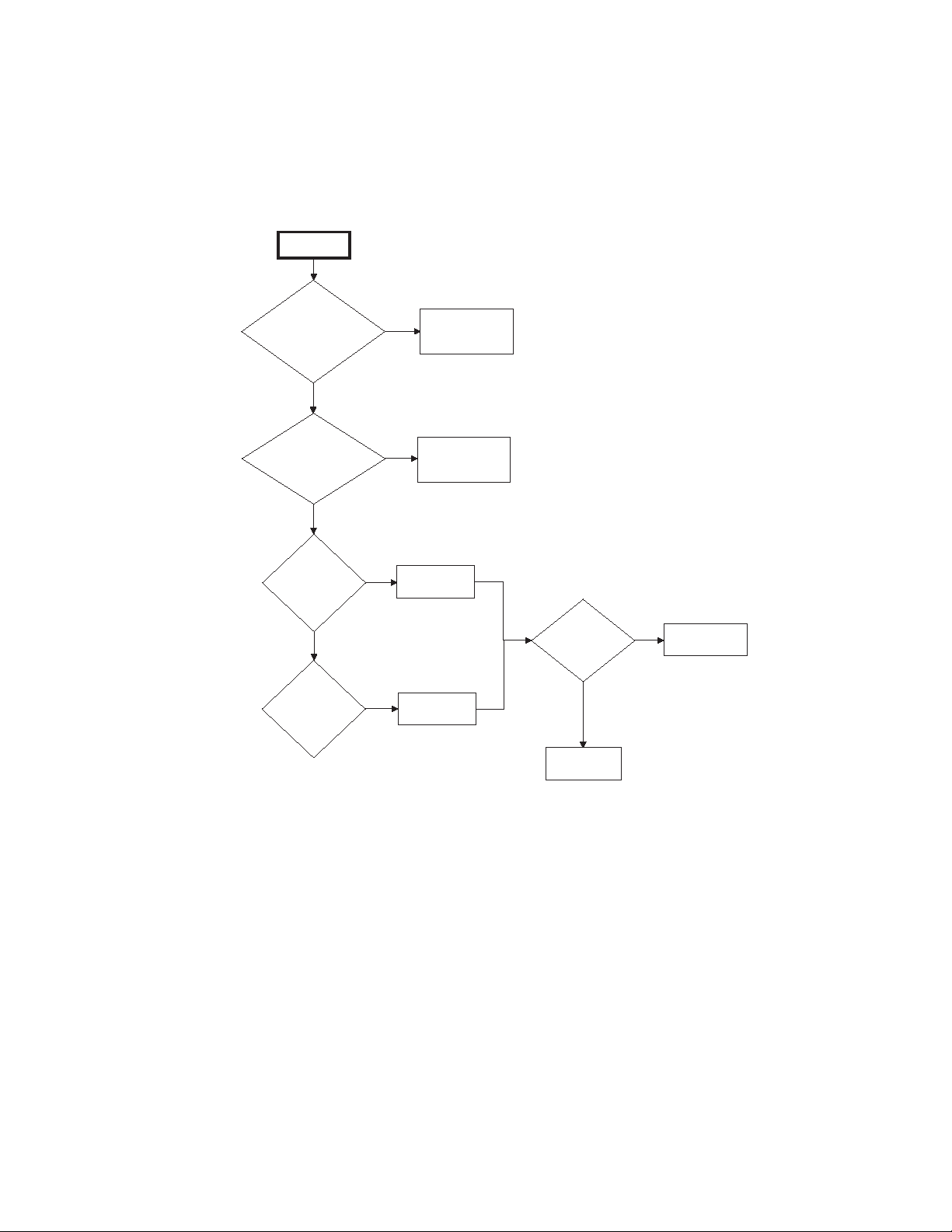

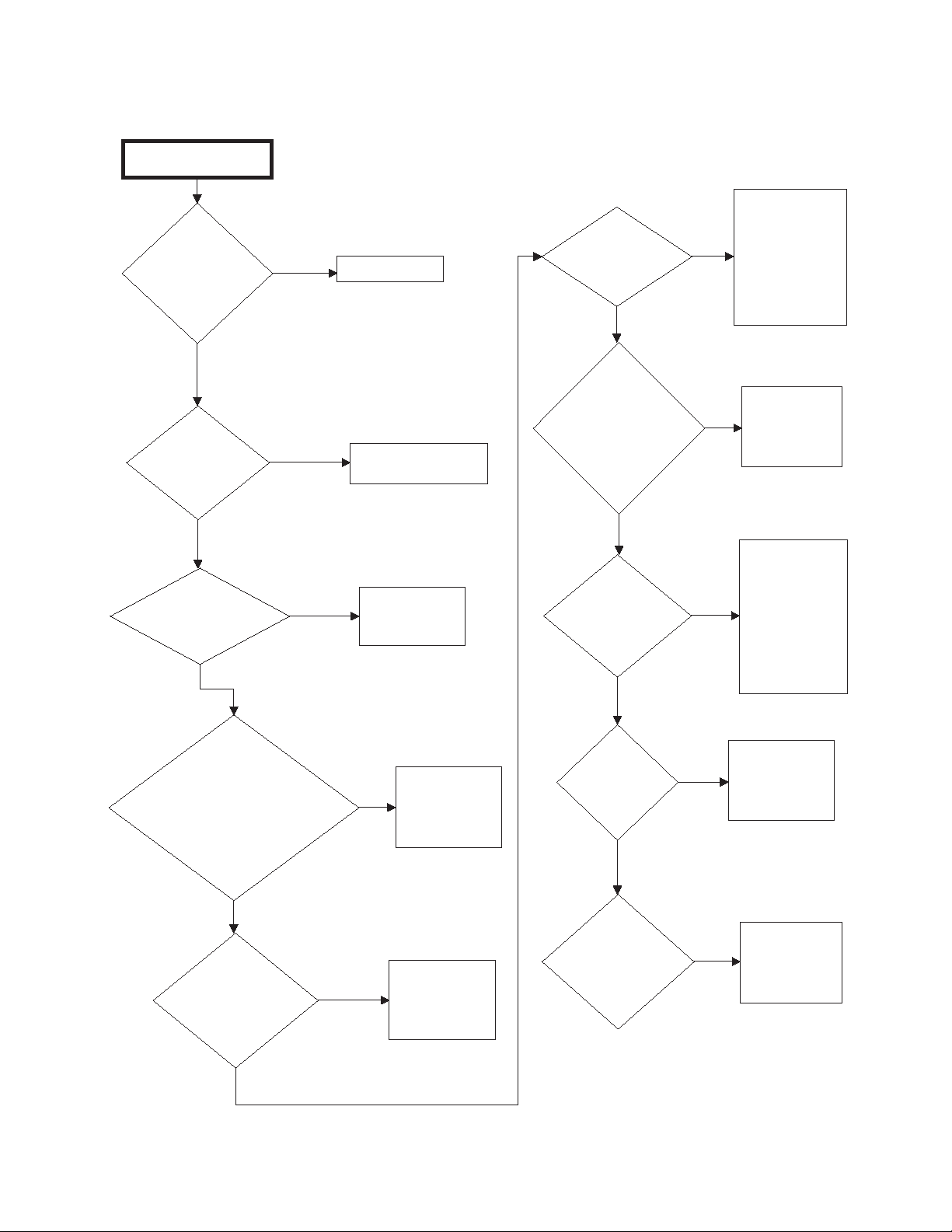

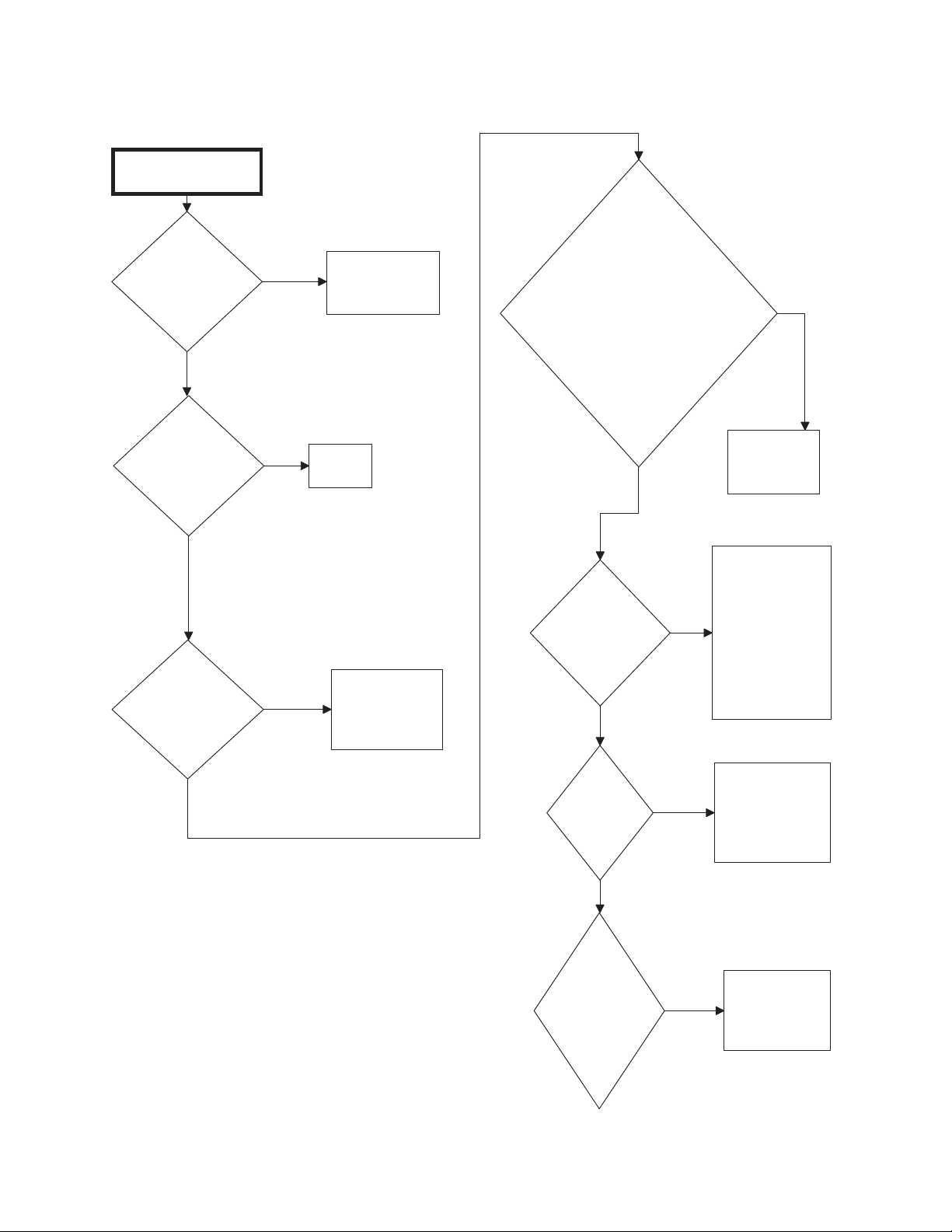

3. Motor Hums

A topload washer exhibiting a humming motor in

agitation or spin may require the timer or motor to be

replaced. Refer to flow chart below to determine if the

motor or timer needs to be replaced.

Motor Hums.

Does belt turn

freely in

counterclockwise

direction?

Yes

Does belt turn

freely in clockwise

direction?

Yes

Does the

motor hum in

the agitate

step?

No

Does the

motor hum in

the spin

step?

No

No

Yes

Start washer in

spin step.

Yes

Start washer in

agitate step.

Check

transmission for

proper operation.

Check brakes for

proper operation.

Does motor

continue to

hum?

No

Yes

Replace motor.

10

Replace timer.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW403S

201520R6

Page 13

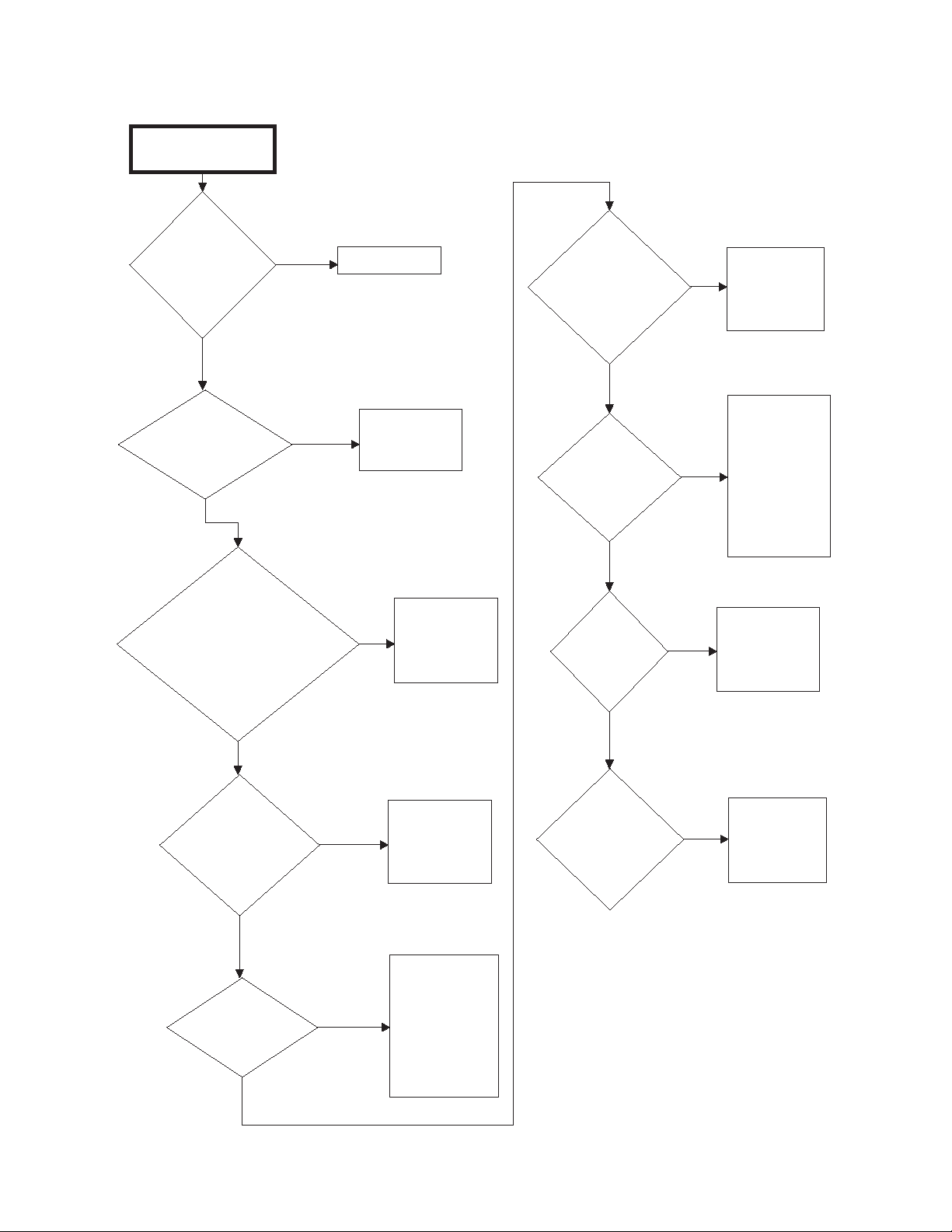

4. No Hot Water

TLW346S

There is no hot water.

Is the water

supply faucet

closed?

No

Yes

Open faucet.

Is timer

inoperative?

No

Troubleshooting

Test for

continuity

through timer

Yes

circuits (refer to

wiring diagram)

and replace if

inoperative.

Is the water

supply cold?

No

Is the hot water

fill hose kinked?

No

Is the mixing valve

screen or screen in

outer end of fill hose

nearest water supply

faucet clogged?

Yes

Yes

Check water heater.

Straighten or

replace hose.

Disconnect hot

Yes

fill hose and

clean or

replace screen.

Is temperature

switch

inoperative?

No

Is pressure

switch

inoperative?

No

Is pressure

hose

clogged?

No

Yes

Yes

Yes

Remove and

clean or

replace hose.

Test switch

and replace if

inoperative.

Test switch.

Must have

continuity from

terminal 1 to 2

when empty or

1-3 when full.

Replace if

inoperative.

No

Is there

broken, loose

Is hot water

mixing valve

solenoid

inoperative?

Yes

Test solenoid

and replace if

necessary.

or incorrect

wiring?

No

201520R6 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Yes

Refer to

appropriate

wiring

diagram.

TLW346S

Page 14

Troubleshooting

TLW347S

5. No Cold Water

There is no cold

water.

Is the water

Yes

supply faucet

closed?

No

Is the cold

water fill hose

kinked?

No

Is the mixing valve

screen or screen in

outer end of fill hose

nearest water supply

faucet clogged?

Yes

Open faucet.

Straighten or

replace hose.

Disconnect

Yes

cold fill hose

and clean or

replace screen.

Is temperature

switch

inoperative?

No

Is pressure

switch

inoperative?

No

Is pressure

hose

clogged?

Yes

Yes

Yes

Test switch

and replace if

inoperative.

Test switch.

Must have

continuity from

terminal 1 to 2

when empty or

1-3 when full.

Replace if

inoperative.

Remove and

clean or

replace hose.

12

No

Is cold water

mixing valve

solenoid

inoperative?

No

Is timer

inoperative?

No

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Yes

Yes

Test solenoid

and replace if

necessary.

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

No

Is there

broken, loose

or incorrect

wiring?

Yes

Refer to

appropriate

wiring

diagram.

TLW347S

201520R6

Page 15

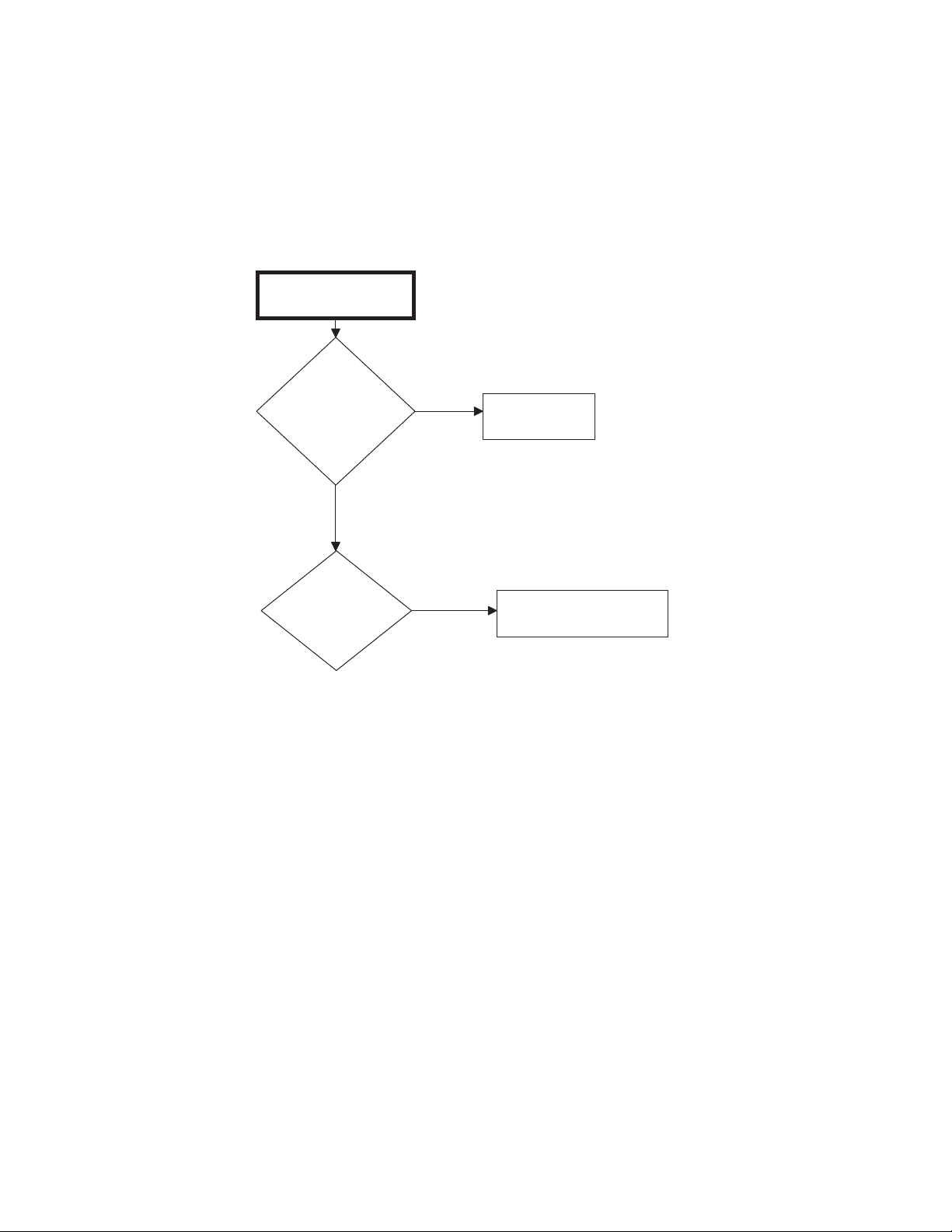

6. No Warm Water

There is no warm

water.

Is there no

hot water?

Refer to

Paragraph 1.

Yes

Is there no

cold water?

No

Refer to Paragraph 2.

Yes

TLW328S

TLW328S

Troubleshooting

201520R6 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 16

Troubleshooting

Hot fill is slow or warm fill

is too cold.

Are fill hose

filter screens

plugged with

debris?

Clean or replace

screens.

Is water

pressure too

low?

Check water pressure.

Recommended water

pressure is 20 to 120 psi.

Yes

TLW378S

Are mixing valve

screens plugged

with debris?

Clean or replace

screens.

Yes

No

No

Yes

Unit is filling properly. Recent new mandates from the

Department of Energy (DOE) call for certain efficiencies to be

met by all washer manufacturers which require the use of a

different fill valve to meet these requirements. No

modification can be made to the washer to fill faster on these

settings.

No

TLW378S

7. Slow Hot Fill or Warm Fill is Too Cold

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 17

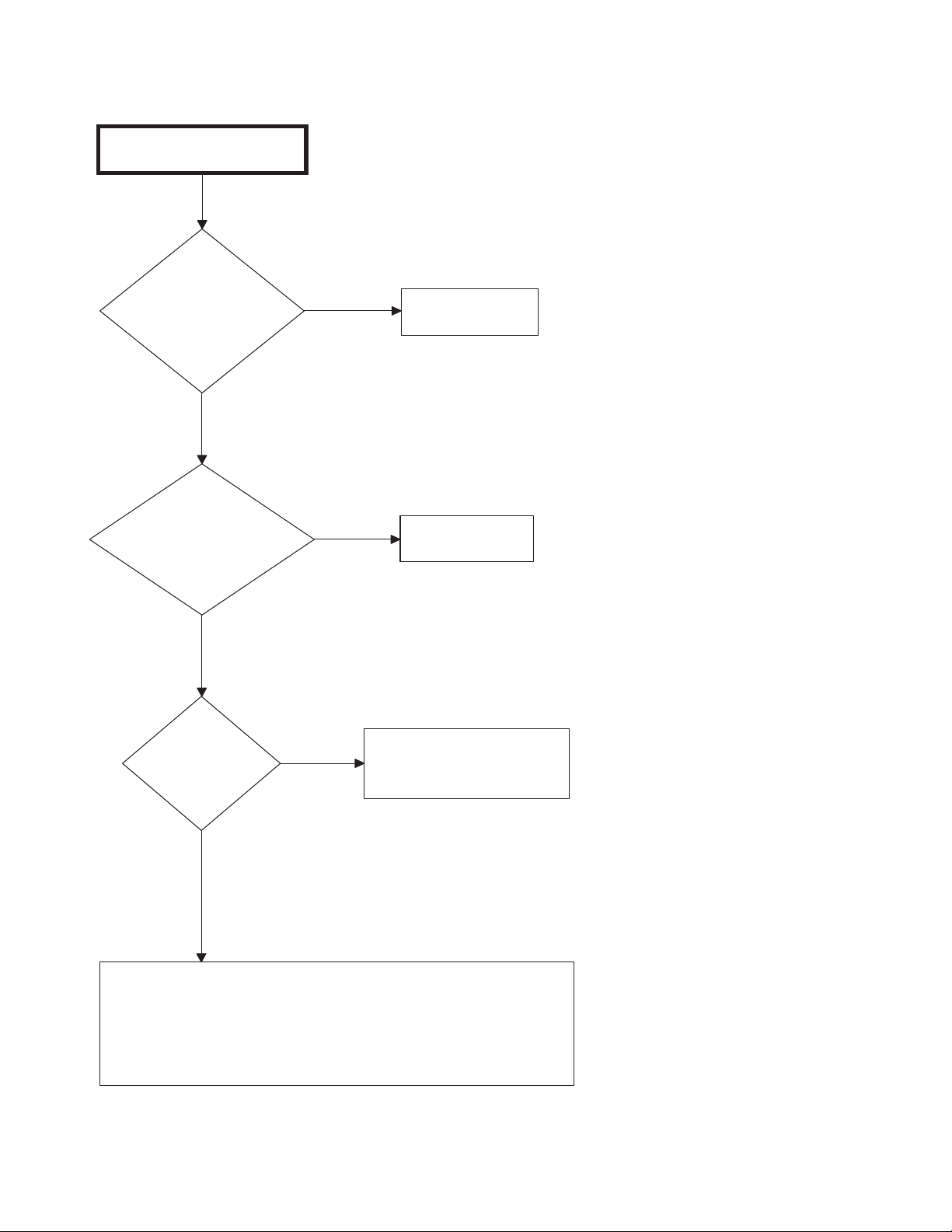

8. Water Fill Does Not Stop At Proper Level

Water fill does not

stop at proper level.

Is pressure

switch

inoperative?

Test switch and

replace if

inoperative.

Yes

Is mixing

valve

inoperative?

Test valve and

replace if

inoperative.

Yes

Was there a siphoning

action started in washer

causing water to be

siphoned from washer

during cycle due to end

of drain hose being

lower than cabinet top of

washer?

Install 562P3

Siphon

Break Kit.

TLW348S

Yes

Is there

water in

pressure

hose?

Blow air through

hose to remove

water or replace

hose.

Yes

Is there

broken,

loose,

shorted or

incorrect

wiring?

Refer to

appropriate

wiring diagram.

No

Yes

Is there an

air leak in

pressure

hose?

Replace

hose.

Yes

No

Does drain

hose fit tight

in standpipe

or drain?

Provide an air

gap around drain

hose and drain

receptacle.

Install No. 36878

Standpipe

Adapter (optional

on some

models).

No

No

No

Yes

No

TLW348S

Troubleshooting

201520R6 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 18

Troubleshooting

TLW377S

9. Washer Fills, Motor Hums

Washer fills, motor hums

in wash portion of cycle.

Advance timer to

spin. Close

loading door. Pull

timer knob out.

Does machine

start to spin?

Yes

Motor checks OK and

pump is clear.

No

Does motor hum

in wash and spin

portions of cycle?

Yes

Unplug machine.

Remove front

panel. Rotate main

drive pulley in both

directions. Does

pulley freely rotate

in both directions?

No

Does pulley

rotate in

clockwise

direction

(spin) only?

Yes

Replace

timer

only.

Unplug machine.

Remove front

panel. Rotate

main drive pulley

in both

directions. Is

pulley locked in

both directions?

No

Replace

motor

and

timer.

Yes

Something

is jammed in

pump. Clean

or replace

pump.

16

Yes

Replace transmission.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW377S

201520R6

Page 19

10.Timer Does Not Advance

Timer does not advance.

Is pause part

of normal

operation?

Timer is designed to

pause during fill

periods and when

going from agitate to

spin. Allow completion

of those steps. Some

cycles (delicate) have

additional pauses.

Refer to diagram for

information on time

required.

Yes

Is timer

inoperative?

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Yes

Is lid

open?

No

Close lid. Lid

MUST be closed

any time the

washer is set to

agitate or spin.

Yes

Washer

will not fill?

Timer pauses

until pressure

switch is

satisfied.

TLW349S

No

Has washer

drive motor

over loaded

and motor

thermal

overload been

tripped?

Timer is designed

to stop under

these conditions.

Motor thermal

proctor reset time

may vary

depending upon

the reason for

washer overload,

however, it should

reset within 15

minutes. Check to

ensure washer

was not

overloaded with

clothes.

Yes

Is circuit breaker

to washer tripped,

disconnecting

power to washer?

Reset circuit

breaker.

No

Yes

Timer is designed to

pause when going

from spin into rinse

to allow the washtub

to stop spinning

before filling. Make

sure timer has

advanced into fill

portion of rinse

cycle.

No

Yes

Is timer

motor lead

wire off timer

terminal?

Refer to

appropriate

wiring diagram

and reattach

wire.

No

Yes

Is there broken,

loose or

incorrect wiring?

Refer to

appropriate

wiring diagram.

Yes

Washer

will not fill?

No

Yes

Is washer

siphoning

during rinse

fill?

Install siphon

break kit, Part

No. 562P3.

No

No

No

Yes

TLW349S

Troubleshooting

201520R6 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Troubleshooting

Motor does not run.

Is electrical

power off, fuse

blown or power

cord not

plugged in?

Check laundry

room for blown or

loose fuse(s) or

open circuit

breakers.

(Washer itself

does not have an

electrical fuse.)

Yes

Is lid open or

lid switch

inoperative?

Close lid or

test switch and

replace if

inoperative.

Yes

Is timer

improperly

set?

No

Reset timer or

try another

cycle.

Yes

Are motor

starting

functions

inoperative; no

start or motor

hums only?

Refer to Test

Procedures

section to check

start switch and

start windings.

TLW474S

No

Is timer

inoperative?

Test for

continuity

through timer

circuits (refer

to wiring

diagram) and

replace if

inoperative.

Yes

Is there

broken,

loose or

incorrect

wiring?

Refer to

appropriate

wiring diagram.

Yes

Refer to

appropriate wiring

diagram for

correct wiring.

Yes

Is motor dead,

won't run?

Refer to Test

Procedures

section to

check switch

and windings.

Yes

Is there a bind in

upper or lower

motor bearing?

Remove belt and

determine if

motor shaft will

spin. Replace

motor if shaft is

locked up.

Yes

Is power

cord

miswired?

No

Yes

Has motor

overload

protector

cycled?

No

Yes

No

No

No

No

Is there a

bind in

pump?

Replace pump.

No

No

Yes

Wait two or three minutes

for overload protector to reset.

If protector cycles repeatedly,

refer to Washer Overheats,

Cycles On Motor Thermal

Protector, Switch Actuator

Kicks In And Out paragraph.

TLW474S

11.Motor Does Not Run

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 21

12.No Agitation

No agitation.

Is timer

inoperative?

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Yes

Motor

won't run?

Refer to Test

Procedures section

to check switch

and windings.

Yes

Is pressure

switch

inoperative?

Test switch. Must

have continuity

from terminal 1 to

3. Replace if

inoperative.

TLW475S

Has drive

motor

overload

protector

cycled?

Yes

Is there a

bind in

pump?

Replace pump.

No

Yes

Close lid or test

switch and

replace if

inoperative.

Yes

Is there

broken, loose

or incorrect

wiring?

Refer to

appropriate

wiring diagram.

No

Yes

Is lid open

or lid switch

inoperative?

No

Yes

Is transmission

assembly

inoperative?

Repair or

replace

transmission

assembly.

Yes

Is drive

belt

broken or

loose?

Replace belt.

No

Yes

Are pauses

part of

normal cycle?

Timer is

designed to

pause (SOAK)

during

DELICATE

cycle. Allow

completion of

SOAK period.

Yes

No delicate

cycle

agitate?

Refer to Test

Procedures

section to check

low speed switch

and windings.

No

No

No

Yes

No

No

No

Wait two or three minutes

for overload protector to reset.

If protector cycles repeatedly,

refer to Washer Overheats,

Cycles On Motor Thermal

Protector, Switch Actuator

Kicks In And Out paragraph.

TLW475S

Troubleshooting

201520R6 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 22

Troubleshooting

TLW352S

13.Constant Agitation

Constant agitation.

Is timer

inoperative?

No

Yes

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Is there

shorted or

incorrect

wiring?

No

Is transmission

assembly

inoperative?

Yes

Yes

Refer to appropriate

wiring diagram.

Repair or

replace

transmission

assembly.

TLW352S

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 23

14.Washer Overheats, Cycles On Motor Thermal Protector, Switch Actuator

Washer overheats, cycles on

motor thermal protector, switch

actuator kicks in and out.

Is belt tacky,

not allowing

proper slip?

Check belt and

replace if

defective.

Yes

Is belt tension

too great, not

allowing

proper slip?

Make sure idler

spring is

properly

connected.

Yes

Is timer

inoperative?

No

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Yes

Are motor

switch

functions

inoperative?

Refer to Test

Procedures

section to check

switch

functions.

TLW353S

No

Are brake

pads or

brake

assembly

binding?

Free binding

pads, or replace

pads and brake

assembly.

Yes

Have

bearings,

transmission

or motor

locked up and

will not turn?

Check that all

these

components are

able to move

freely. Correct

or replace

binding

component.

No

Yes

Contact local

utility company,

or have a

qualified

electrician check

power supply.

No

Yes

Is there a bind

in water pump?

Replace pump.

Yes

Is voltage

incorrect?

No

Yes

No

No

TLW353S

Kicks In And Out

Troubleshooting

201520R6 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 24

Troubleshooting

TLW476S

15.Slow Spin Or No Spin

Slow spin or no spin.

Test for

continuity

through timer

Is timer

inoperative?

No

Is lid open

or lid switch

inoperative?

Yes

Yes

circuits (refer

to wiring

diagram) and

replace if

inoperative.

Close lid or test

switch and

replace if

inoperative.

Has drive

motor

overload

protector

cycled?

No

Yes

Wait two or three minutes

for overload protector to reset.

If protector cycles repeatedly,

refer to Washer Overheats,

Cycles On Motor Thermal

Protector, Switch Actuator

Kicks In And Out paragraph.

No

Is there a

bind in

pump?

No

Is drive

belt

broken or

loose?

No

Motor

won't run?

No

Yes

Yes

Yes

Replace pump.

Replace belt.

Refer to Test

Procedures

section to

check switch

and windings.

Is there no

clearance

between

brake pads

and discs?

No

Is there

broken, loose

or incorrect

wiring?

No

Is there oil

on belt?

Yes

Yes

Yes

Replace pads

and brake

assembly.

Refer to

appropriate

wiring diagram.

Replace belt.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW476S

201520R6

Page 25

16.Constant Spin

Constant spin.

Is timer

inoperative?

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Yes

Is there

shorted or

incorrect

wiring?

Refer to appropriate

wiring diagram.

Yes

TLW355S

Is there

excessive wear

on brake pads

or missing

brake pads?

Replace brake

pads and brake

assembly.

Yes

Washtub does

not stop spinning

within seven

seconds after lid

is opened.

Replace brake

pads and brake

assembly.

No

No

No

Yes

Is lid switch

inoperative?

Replace lid

switch.

No

Yes

TLW355S

Troubleshooting

201520R6 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Troubleshooting

Washer stops in cycle, quits

after a couple loads or is

intermittent.

Is belt tacky,

not allowing

proper slip?

Check belt and

replace if

defective.

Yes

Is belt tension

too great, not

allowing

proper slip?

Make sure idler

spring is

properly

connected.

Yes

Is timer

inoperative?

No

Test for

continuity

through timer

circuits (refer to

wiring diagram)

and replace if

inoperative.

Yes

Are motor

switch

functions

inoperative?

Refer to Test

Procedures

section to check

switch functions.

TLW477S

No

Has motor

overload

protector

cycled?

Yes

Has brake,

transmission

or motor

locked up and

will not turn?

Check that all

these

components

are able to

move freely.

Yes

Refer to

appropriate wiring

diagram.

Yes

Is there

broken, loose

or incorrect

wiring?

Yes

No

No

No

No

Wait two or three minutes

for overload protector to reset.

If protector cycles repeatedly,

refer to Washer Overheats,

Cycles On Motor Thermal

Protector, Switch Actuator

Kicks In And Out paragraph.

TLW477S

17.Washer Stops In Cycle; Quits After A Couple Loads; Is Intermittent

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 27

18.Washer Is Locked Up Or Binding

Washer is locked up or binding.

Is there

excessive

belt tension?

Replace belt

and/or idler

spring.

Yes

Is there a bind

in upper or

lower bearing?

Replace bearing.

Yes

Is there a

bind in water

pump?

No

Replace pump.

Yes

Is voltage

incorrect?

Contact local

utility company

or have a

qualified

electrician

check power

supply.

No

Are brake

pads

binding?

Free binding

pads or

replace pads.

Yes

Repair or replace

transmission.

Yes

Is there a

bind in

transmission?

Yes

No

No

No

TLW338S

Troubleshooting

201520R6 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Troubleshooting

TLW339S

19.Outer Tub Does Not Empty

Outer tub does

not empty.

Is drain hose

kinked?

No

Is drain hose out

of hose retainer

clip in back of

cabinet.

No

Is water pump

inoperative?

Yes

Straighten hose.

Yes

Yes

Replace pump.

Remove washer

front panel and

install drain hose

into hose retainer

clip in back of

cabinet.

26

No

Is there an

obstruction

in outer tub

Yes

Remove obstruction.

outlet hose?

TLW339S

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 29

20.Excessive Vibration

Excessive vibration.

Is there an

unbalanced

load in tub?

Stop washer,

redistribute

load, then

restart washer.

Yes

Is there a

broken or

disconnected

centering

spring(s)?

Connect or

replace centering

spring(s).

Yes

Is washer

unleveled?

No

Adjust leveling

legs.

Yes

Is base

damaged

(washer was

dropped)?

Replace base

assembly.

TLW357S

No

Are cabinet

screws

incorrect or

loose?

Replace with

correct screws

or tighten.

Yes

Is friction

ring

broken?

Replace

friction ring.

Yes

Relocate washer or

support floor to

eliminate weak or

"spongy" condition.

Yes

Is washer

installed on

weak, "spongy",

carpeted or

built-up floor?

Yes

No

No

No

Is there

lubricant on

pivot dome

and/or base

friction ring?

Remove

lubricant or

replace

parts.

No

Yes

Is partial

liquid filled

balance ring

leaking?

Replace

balance ring.

No

Yes

No

TLW357S

Troubleshooting

201520R6 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Troubleshooting

Water leaking from

outer tub.

Is water seal

in outer tub

leaking?

Replace hub

and seal kit

assembly.

Yes

Is there a

hole in outer

tub?

Replace outer

tub.

Yes

Is pressure

hose or

accumulator

leaking?

No

Replace

pressure hose

and/or

accumulator.

Yes

Is tub-to-

pump hose

leaking at

clamp?

Tighten clamp.

TLW341S

No

Is there an

obstruction in

drain causing

water to come

over top of outer

tub cover?

Remove

obstruction.

Yes

Replace gasket.

Yes

Is outer tub

cover

gasket

leaking?

Yes

No

No

No

TLW341S

21.Water Leaking From Outer Tub

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 31

Control Troubleshooting

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

Model AWNA11SP111TW01

22.Error Mode

In Error Mode, the IN USE LED flashes to display

fill and drain errors (refer to paragraphs below).

Error Mode can only be exited by powering down

washer.

Fill Error

A Fill Error will occur if the tub does not fill

within 62 minutes of the start of the cycle. A Fill

Error is indicated by the control repeatedly

flashing the IN USE LED twice separated by a one

and a half second pause until the control is

powered down. If Error Mode is turned off, the fill

error will not occur and the control will continue

to wait for the fill level to be reached.

Section 4

Drain Error

A Drain Error will occur if the tub is not empty

after a spin cycle. A Drain Error is indicated by the

control repeatedly flashing the IN USE LED three

times separated by a one and a half second pause

until the control is powered down. If Error Mode

is turned off, the drain error will not occur and the

machine cycle will advance to the next cycle step

as though the water had been pumped out.

201520R6 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Control Troublesh ooting Model AWNA11SP111TW01

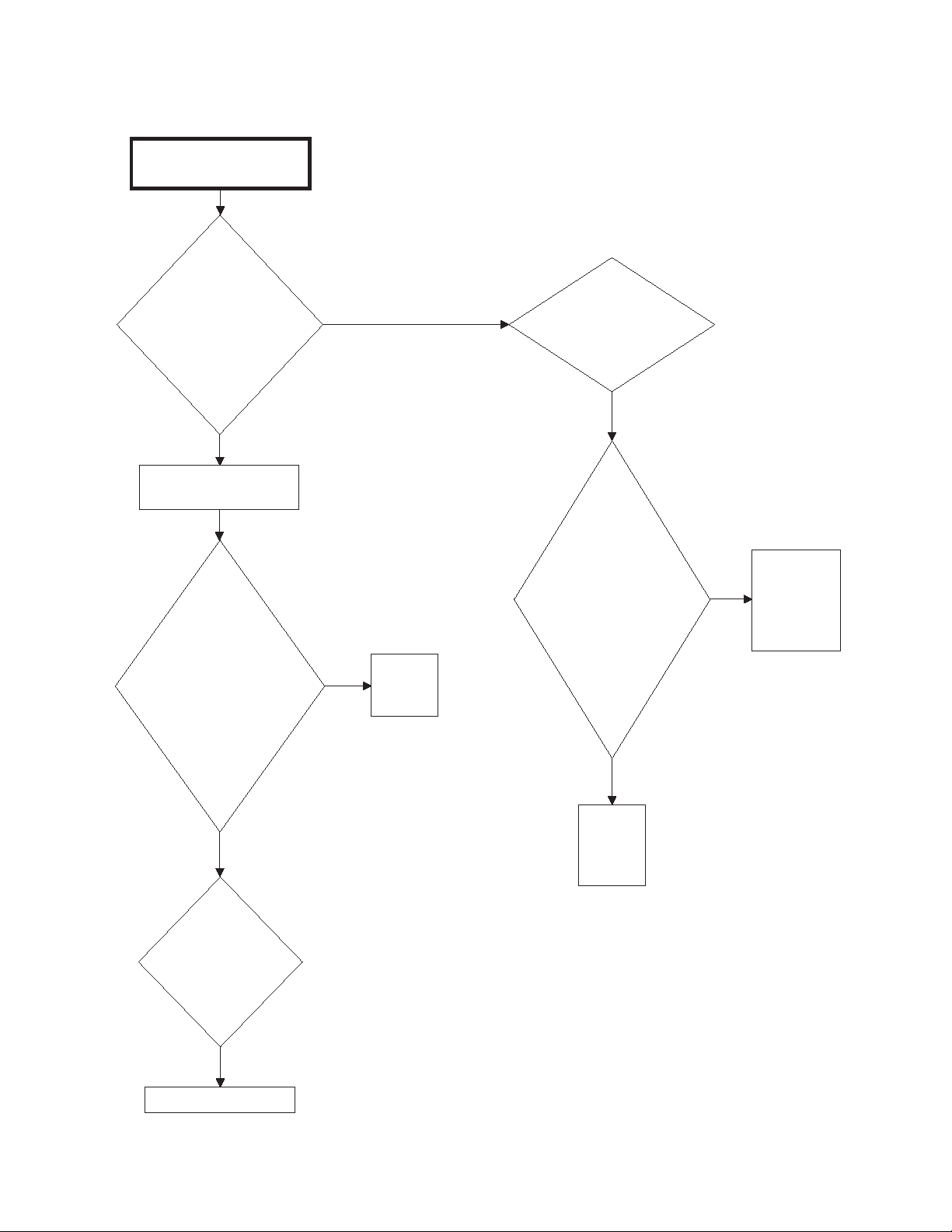

Is the lid closed?

Is there 120 volts AC

between terminal

“H3-5” on the control

and neutral?

Is there 120 volts AC

between pressure

switch terminal 2 and

neutral?

Is there 120 volts AC

between pressure

switch terminal 1 and

neutral?

Close lid and

check switch for

continuity.

Refer to Washer

will not fill (mixing

valve diagnostics).

Check wiring

between control

board and

pressure switch.

Check for proper

function of

pressure switch,

pressure hose and

accumulator.

Replace if

necessary.

Check wiring

between pressure

switch and lid

switch.

Yes

No

Yes

Yes

No

Yes

No

No

TLW343S

(1)

(2)

(3)

(4)

Note: Assuming water is turned on.

TLW343S

23.Washer Will Not Fill (Pressure Switch Diagnostic)

30 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

Control Troubleshooting Model AWNA11SP111TW01

TLW466S

1

2

3

4

Washer Will Not Fill (Pressure Switch Diagnostic)

201520R6 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 34

Control Troublesh ooting Model AWNA11SP111TW01

TLW344S

24.Washer Will Not Fill (Mixing Valve Diagnostic)

Note: Assuming No Fill (pressure

switch diagnostics) checks out okay, and

cycle is started and “In Use” light is lit.

(1)

Is there voltage from

either “H3-4” or “H3-1” (based

on temperature selection)

to the Neutral wire?

Yes

(2)

Is there voltage

across either the hot

or cold coil to

neutral?

Yes

(3)

Is there 120 volts AC

across the coil of

either the hot or cold

valve?

No

No

No

Yes

Replace control.

Correct wiring

between mixing

valve and control.

Does water flow

through the mixing

valve?

Yes

No

Replace mixing

valve.

(4)

Is there 120 volts AC

between either the

hot or cold coil to

terminal 4 on the

motor?

Yes

(5)

Is there 120 volts AC

between either the

hot or cold coil to

terminal 8 on the

motor?

Yes

Correct wiring

between terminal 8

of the motor and

neutral side of the

hot/cold coil.

No

No

Unit operates

properly.

Correct wiring

between motor

and neutral wire.

Thermal protector

in motor open.

Replace motor.

TLW344S

32 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

Control Troubleshooting Model AWNA11SP111TW01

TLW466S

1

5

3

2

4

Washer Will Not Fill (Mixing Valve Diagnostic)

201520R6 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 36

Control Troublesh ooting Model AWNA11SP111TW01

With power

disconnected, does

the unit still over

flow?

Washer Over Fills.

Is there voltage

on either the orange

wire of the hot valve

or gray wire of the cold

valve to neutral?

Replace mixing

valve.

Check for

incorrect or

damaged wiring

between water

valve and L1.

Yes

No

Yes

No

Reconnect

power.

(1)

Unit works

properly.

TLW287S

TLW287S

25.Washer Over Fills (Pressure Switch Open)

34 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 37

Control Troubleshooting Model AWNA11SP111TW01

TLW466S

1

Washer Over Fills (Pressure Switch Open)

201520R6 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 38

Control Troublesh ooting Model AWNA11SP111TW01

TLW345S

26.No Agitation – Low and High Speed

(1)

Is there voltage

between “H6-1” on

control to terminal 4

on the motor?

Yes

(2)

Low speed

Is there voltage

between “H6-6” and

terminal 4 on the

motor?

Yes

(3)

Low speed

Is there voltage

across terminals 3 &

4 on the motor?

Yes

(4)

Low speed

Is there voltage

across terminals 3 &

8 on the motor?

Yes

(5)

Is there voltage at

“H6-4” on the control

to terminal 8 on the

motor?

Yes

(6)

Is there voltage

across terminal 1 & 8

of the motor?

High speed

High speed

High speed

(2a)

No

No

No

No

No

No

Check operation of

lid switch, check

wiring to control.

Replace control

Correct wiring

between control

and motor.

Check operation of

thermal protector

in the motor.

Replace motor if

necessary.

Replace control.

Correct wiring

between control

and motor. Check

capacitor, replace

if necessary.

Is there voltage

between “H6-5” and

terminal 4 on the

motor?

No

Is there voltage

across terminals 7 &

4 on the motor?

Is there voltage

across terminals 8 &

7 on the motor?

(7)

Is there voltage

between terminal 1

of the motor and

“H6-2” on the control?

Yes

(8)

Is there voltage

between “H6-3” on

control to terminal 1

on the motor?

Yes

Yes

(3a)

Yes

No

(4a)

Yes

No

No

No

Correct wiring

between motor

terminal 8 and

control.

Replace control.

Yes

Replace motor.

TLW345S

36 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

No Agitation – Low and High Speed

TLW466S

2

1

3

7

4

2a

8

3a

5

6

4a

Control Troubleshooting Model AWNA11SP111TW01

201520R6 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 40

Control Troublesh ooting Model AWNA11SP111TW01

Is there voltage

across “H6-1” on the

control and terminal

4 on the motor?

Is there voltage

across terminals 3 &

8 of the motor?

Is there voltage

across terminals 3 &

4 on the motor?

Is there voltage

across “H6-6” on the

control and terminal

4 on the motor?

Check lid switch

for proper

operation. Check

wiring from control

to lid switch to

supply.

Replace control.

Correct wiring

between motor

and control.

Check operation of

motor

thermal protector.

Replace motor if

necessary.

Yes

No

Yes

No

Yes

No

Yes

No

Is there voltage

across “H6-3” on

control to terminal 8

of the motor?

Is there voltage from

“H6-4” on control to

terminal 1 of the

motor?

Is there voltage from

“H6-2” on control to

terminal 6 of the

motor?

Is there voltage

across terminals 6 &

8 of the motor?

Replace the

control.

Correct wiring to

the motor.

Replace control.

Yes

No

Yes

No

Yes

No

Yes

No

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Unit should

operate properly.

TLW293S

TLW293S

27.Washer Will Not Spin – Low Speed

38 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

Washer Will Not Spin – Low Speed

TLW466S

2

1

3

7

4

8

5

6

Control Troubleshooting Model AWNA11SP111TW01

201520R6 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 42

Control Troublesh ooting Model AWNA11SP111TW01

Is there voltage

across “H6-1” on the

control and terminal

4 on the motor?

Is there voltage

across terminals 7 &

8 of the motor?

Is there voltage

across terminals 7 &

4 on the motor?

Is there voltage

across “H6-5” on the

control and terminal

4 on the motor?

Check lid switch

for proper

operation. Check

wiring from control

to lid switch to

supply.

Replace control.

Correct wiring

between motor

and control.

Check operation of

motor

thermal protector.

Replace motor if

necessary.

Yes

No

Yes

No

Yes

No

Yes

No

Is there voltage

across “H6-3” on

control to terminal 8

of the motor?

Is there voltage from

“H6-4” on control to

terminal 1 of the

motor?

Is there voltage from

“H6-2” on control to

terminal 6 of the

motor?

Is there voltage

across terminals 6 &

8 of the motor?

Replace the

control.

Correct wiring to

the motor.

Replace control.

Yes

No

Yes

No

Yes

No

Yes

No

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Unit should

operate properly.

TLW291S

TLW291S

28.Washer Will Not Spin – High Speed

40 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 43

Washer Will Not Spin – High Speed

TLW466S

2

1

3

7

6

8

5

4

Control Troubleshooting Model AWNA11SP111TW01

201520R6 41

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 44

Section 5

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

W456SE3A

Level

Washer

Base

Locknut

Leveling

Leg

Rubber

Foot

Adjustments

29.Leveling Legs

Refer to Figure 1.

a. Place rubber feet on all four leveling legs.

b. Place washer in position on a clean, dry, and

reasonably firm floor.

c. Loosen locknuts and adjust two front leveling

legs. Once adjusted, tilt washer forward on

front legs and lower back down into position to

set the rear self-leveling legs.

d. Washer must not rock. After washer is at

desired height, tighten locknuts securely

against bottom of washer base. If these locknuts

are not tight, washer will not remain stationary

during operation.

NOTE: Improper installation, installation on

carpet or flexing of a weak floor will cause

excessive vibration.

IMPORTANT: Do not slide washer across floor

once leveling legs have been extended, as legs and

base could become damaged.

30.Belt (Agitate And Spin)

No belt adjustment is required.

42 201520R6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 1

Page 45

Section 6

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

WARNING

Disconnect electric power to washer before performing the following steps:

W188

Test Procedures

31.Motor Test Procedure

IMPORTANT: Disconnect base wire harness plug from motor.

Motor test procedures using an Ohm meter.

NOTE: Resistance readings slightly out of given ranges may be due to meter conditions. These readings DO

NOT necessarily indicate motor failure.

Meter Connections

1. Ground to Each Other Terminal Open Terminal shorted to ground.

2. White to Yellow Closed Open thermal overload.

Red to Brown

3.

Blue to White

4.

Violet to White (2-speed motor) 2.5 Ohms

5.

6. “R” to Red Closed Open start (auxiliary) switch.

7. “P” to Blue (2-speed motor) Closed Open start switch 4 pole winding.

NOTE: Steps 8, 9 and 10 are with motor centrifugal mechanism in the run position.

8. “R” to Red Open Start auxiliary switch.

“P” to Blue (2-speed motor) 3 Ohms

9.

10. “P” to Blue (2-speed motor) Closed Open low (6 pole) winding run switch.

Reading

Should Be

2-8 Ohms

1-2 Ohms

(Approximate)

(approximate)

If Not

Start winding open or resistance too high or too

low.

High speed winding (4 pole) open or resistance

too high or too low.

Low winding opening; High speed winding open;

or resistance too high or too low.

Refer to Blue to White and Violet to White.

201520R6 43

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 46

Test Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

32.Mixing Valve Solenoid Test Procedure

Mixing valve test procedures using an Ohm meter.

NOTE: Resistance readings slightly out of given ranges may be due to meter conditions. These readings DO

NOT necessarily indicate mixing valve failure.

120 Volt coils 900 - 1100 Ohms

240 Volt coils 3200 - 4000 Ohms

33.Temperature Switch Test Procedure

Check for continuity between the following terminal connections:

3 Position Switches

Temperature

Wash Rinse

Hot Cold L - 3

Warm Cold L - 3- 4

Cold Cold L - 4

4 Position Switches

Temperature

Wash Rinse

Hot Cold L1 - 2

Warm Warm

Warm Cold L1 - 2, L1 - 1, 1 - 2

Cold Cold L1 - 1

L1 - 1, L1 - 2, L2 - 2, L2 - 1,

L2 - L1, 1 - 2

Connection

Connection

44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 47

Section 7

TIMER NO. 37927P CYCLE SEQUENCE

*On Single Speed Model Washers, All Speeds are

Fast.

KEY:

H = HOT W = WARM C = COLD

Cycle Sequence Charts

NOTE: Times listed are approximate.

WATER

TEMP.

CYCLE

SOAK, FILL & AGITATE H,W,C SLOW 4:00

SOAK, FILL H,W,C 12:00

SOAK

OFF 4:00

REGULAR

OFF 4:00

PRESS

PERMANENT

OFF 4:00

DELICATE

OFF 4:00

SPIN SLOW 4:00

WASH, FILL & AGITATE H,W,C FAST 15:30

SPIN FAST 2:00

SPIN & SPRAY C FAST :30

SPIN FAST 1:30

RINSE FILL & AGITATE W,C FAST 4:00

SPIN FAST 6:00

WASH, FILL & AGITATE H,W,C FAST 9:30

SPIN SLOW 2:00

SPIN & SPRAY C SLOW :30

SPIN SLOW 1:30

RINSE FILL & AGITATE W,C FAST 4:00

SPIN FAST 6:00

WASH, FILL & SOAK H,W,C 3:00

WASH, FILL & AGITATE H,W,C SLOW :30

WASH, FILL & SOAK H,W,C 1:30

WASH FILL & AGITATE H,W,C SLOW :30

WASH FILL & SOAK H,W,C 1:30

WASH FILL & AGITATE H,W,C SLOW :30

WASH FILL & SOAK H,W,C 1:30

WASH FILL & AGITATE H,W,C SLOW :30

WASH FILL & SOAK H,W,C 1:30

SPIN SLOW 2:00

SPIN & SPRAY C SLOW :30

SPIN SLOW 1:30

RINSE FILL & AGITATE C SLOW 4:00

SPIN SLOW 4:00

FUNCTION

SELECT

*MOTOR

SPEED

TIME (Min.

& Sec.)

201520R6 45

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 48

Cycle Sequence Charts

TIMER NO. 38881P CYCLE SEQUENCE

NOTE: Times listed are approximate.

WATER

CYCLE

SOAK, FILL & AGITATE H,W,C SLOW 3:00

SOAK, FILL H,W,C 12:00

SOAK

OFF 3:00

SPIN SLOW 3:00

WASH, FILL & AGITATE H,W,C FAST 6:00

FUNCTION

SELECT

TEMP.

*MOTOR

SPEED

TIME (Min.

& Sec.)

PRE-

REGULAR

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

EXTRA

OFF OFF

PRESS

PERMANENT

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

SPIN FAST 3:00

WASH

WASH, FILL & AGITATE H,W,C FAST 15:30

SPIN FAST 3:00

SPIN & SPRAY C FAST :25

SPIN FAST 2:35

RINSE FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

RINSE, FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

RINSE

WASH, FILL & AGITATE H,W,C FAST 9:30

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :25

SPIN SLOW 2:35

RINSE FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

RINSE, FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

RINSE

EXTRA

OFF 3:00

WASH, FILL & SOAK H,W,C 3:00

WASH, FILL & AGITATE H,W,C SLOW :25

WASH, FILL & SOAK H,W,C 2:35

WASH FILL & AGITATE H,W,C SLOW :25

WASH FILL & SOAK H,W,C 2:35

SPIN SLOW 3:00

DELICATE

46

SPIN & SPRAY C SLOW :25

SPIN SLOW 2:35

RINSE FILL & AGITATE C SLOW 3:00

SPIN SLOW 3:00

(continued on next page)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 49

Cycle Sequence Charts

*On Single Speed Model Washers, All Speeds are

Fast.

KEY:

H = HOT W = WARM C = COLD

TIMER NO. 38881P CYCLE SEQUENCE

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

RINSE, FILL & AGITATE C S LOW 3:00

SPIN SLOW 3:00

RINSE

EXTRA

OFF 3:00

201520R6 47

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 50

Cycle Sequence Charts

*On Single Speed Model Washers, All Speeds are

Fast.

KEY:

H = HOT W = WARM C = COLD

TIMER NO. 200927P CYCLE SEQUENCE

NOTE: Times listed are approximate.

WATER

CYCLE

WASH, FILL & AGITATE H,W,C FAST 15:00

SPIN FAST 1:30

SPIN & SPRAY C FAST :25

SPIN FAST 2:35

REGULAR

OFF 3:00

PRESS

PERMANENT

OFF 3:00

DELICATE

OFF 3:00

RINSE FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

WASH, FILL & AGITATE H,W,C FAST 9:00

SPIN FAST 1:30

SPIN & SPRAY C FAST :25

SPIN FAST 2:35

RINSE FILL & AGITATE W,C FAST 3:00

SPIN FAST 6:00

WASH, FILL & SOAK H,W,C 1:30

WASH, FILL & AGITATE H,W,C FAST :25

WASH, FILL & SOAK H,W,C 2:35

WASH FILL & AGITATE H,W,C FAST :25

WASH FILL & SOAK H,W,C 2:35

WASH FILL & AGITATE H,W,C FAST :25

WASH FILL & SOAK H,W,C 1:05

SPIN FAST 1:30

SPIN & SPRAY C FAST :25

SPIN FAST 2:35

RINSE FILL & AGITATE C FAST 3:00

SPIN FAST 3:00

FUNCTION

SELECT

TEMP.

*MOTOR

SPEED

TIME (Min.

& Sec.)

48

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 51

Cycle Sequence Charts

TIMER NO. 37922P CYCLE SEQUENCE

NOTE: Times listed are approximate.

WATER

CYCLE

SOAK, FILL & AGITATE H,W,C SELECT 3:00

SOAK, FILL H,W,C 12:00

SOAK

OFF 3:00

SPIN SELECT 3:00

WASH, FILL & AGITATE H,W,C SELECT 6:00

FUNCTION

SELECT

TEMP.

*MOTOR

SPEED

TIME (Min.

& Sec.)

PRE-

REGULAR

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

EXTRA

OFF OFF

PRESS

PERMANENT

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

SPIN SELECT 3:00

WASH

WASH, FILL & AGITATE H,W,C SELECT 15:00

SPIN SELECT 3:00

SPIN & SPRAY C SELECT :25

SPIN SELECT 2:35

RINSE FILL & AGITATE W,C SELECT 3:00

SPIN SELECT 6:00

RINSE, FILL & AGITATE W,C SELECT 3:00

SPIN SELECT 6:00

RINSE

WASH, FILL & AGITATE H,W,C SELECT 9:00

SPIN MEDIUM 3:00

SPIN & SPRAY C MEDIUM :25

SPIN MEDIUM 2:35

RINSE FILL & AGITATE W,C SELECT 3:00

SPIN SELECT 6:00

RINSE, FILL & AGITATE W,C SELECT 3:00

SPIN SELECT 6:00

RINSE

EXTRA

OFF 3:00

WASH, FILL & SOAK H,W,C 3:00

WASH, FILL & AGITATE H,W,C MEDIUM :25

WASH, FILL & SOAK H,W,C 2:35

WASH FILL & AGITATE H,W,C MEDIUM :25

WASH FILL & SOAK H,W,C 2:35

SPIN MEDIUM 3:00

DELICATE

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

201520R6 49

SPIN & SPRAY C MEDIUM :25

SPIN MEDIUM 2:40

RINSE FILL & AGITATE C MEDIUM 3:00

SPIN MEDIUM 3:00

(continued on next page)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 52

Cycle Sequence Charts

*On Single Speed Model Washers, All Speeds are

Fast.

KEY:

H = HOT W = WARM C = COLD

TIMER NO. 37922P CYCLE SEQUENCE

RINSE, FILL & AGITATE C MEDIUM 3:00

SPIN MEDIUM 3:00

RINSE

EXTRA

OFF 3:00

WASH, FILL & SOAK H,W,C 3:00

WASH, FILL & AGITATE H,W,C SLOW :25

WASH, FILL & SOAK H,W,C 2:35

WASH FILL & AGITATE H,W,C SLOW :25

WASH FILL & SOAK H,W,C 2:35

SPIN MEDIUM 3:00

HANDWASH

OFF 3:00

SPIN & SPRAY C MEDIUM :25

SPIN MEDIUM 2:40

RINSE FILL & AGITATE C SLOW 3:00

SPIN MEDIUM 3:00

50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 53

CYCLE

TIMER NO. 202705 AND 203387 CYCLE SEQUENCE

Cycle Sequence Charts

NOTE: Times listed are approximate.

WATER

TEMP.

FUNCTION

SOAK FILL & AGITATE H,W,C SLOW 3:00

SOAK FILL H,W,C 12:00

SELECT

*MOTOR

SPEED

TIME (Min.

& Sec.)

SOAK/

SPIN SLOW 3:00

PREWASH

OFF 6:00

WASH FILL & AGITATE H,W,C FAST 15:00

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :24

SPIN SLOW 3:00

PRESS

PERMANENT

HEAVY DUTY/

OFF/PAUSE CYCLE END OR PAUSE FOR EXTRA RINSE 3:00

EXTRA

OFF 6:00

ECO

NORMAL

OFF 6:00

DELICATE

OFF/PAUSE

RINSE FILL & AGITATE C FAST 3:00

SPIN FAST 6:00

RINSE FILL & AGITATE C 3:00

SPIN FAST 6:00

RINSE

WASH FILL & AGITATE C FAST 9:00

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :24

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :24

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :24

SPIN SLOW 3:00

SPIN FAST 9:00

WASH FILL & SOAK H,W,C 3:00

WASH FILL & AGITATE H,W,C SLOW :24

WASH FILL & SOAK H,W,C 2:30

WASH FILL & AGITATE H,W,C SLOW :24

WASH FILL & SOAK H,W,C 2:30

SPIN SLOW 3:00

SPIN & SPRAY C SLOW :24

SPIN SLOW 3:00

RINSE FILL & AGITATE C SLOW 3:00

SPIN SLOW 3:00

CYCLE END OR PAUSE FOR EXTRA RINSE

RINSE FILL & AGITATE C 3:00

3:00

SPIN SLOW 3:00

RINSE

EXTRA

OFF OFF 6:00

201520R6 51

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 54

Cycle Sequence Charts

*On Single Speed Model Washers, All Speeds are

Fast.

KEY:

H = HOT W = WARM C = COLD

TIMER NO. 202705 AND 203387 CYCLE SEQUENCE

52

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 55

Cycle Sequence Charts

CYCLE SEQUENCE FOR MODEL AWNA11SP111TW01 – NORMAL, PERMANET PRESS, DELICATE CYCLES

LIGHTS

TIME

FUNCTION IN USE RINSE SPIN

WATER

TEMP.

CYCLE & MOTOR

SPEED *

(Minutes and Seconds)

FILL X H, W, C 2:00

AGITATE X

PAUSE X **

AGITATE X

PAUSE X **

WASH

AGITATE X

PAUSE X **

N & PP = FAST

D = SLOW

N & PP = FAST

D = SLOW

N & PP = FAST

D = SLOW

N & PP = 4:00

N & PP = 1:30

N & PP = 4:00

N & PP = 1:30

N & PP = 4:00

N & PP = 0:15

SPIN 1 X FAST 1:00

PAUSE X 0:30

SPIN/FILL 1 X X C FAST 0:16

SPIN X X FAST 0:16

PAUSE 1 X X 0:30

SPIN/FILL 2 X X C FAST 0:16

SPIN X X FAST 0:16

RINSE

PAUSE 2 X X 0:30

SPIN/FILL 3 X X C FAST 0:16

PAUSE 3 X X 0:30

SPIN/FILL 4 X X C FAST 0:16

PAUSE 4 X X 0:30

D = 0:25

D = 2:30

D = 0:25

D = 2:30

D = 0:25

D = 2:30

FINAL SPIN X X FAST 5:00

SPIN

TOTAL

N & PP = 25:26

*On single speed models, all speeds are fast.

**On delicate cycle, all LEDs flashing during soak period.

KEY:

H = HOT PP = PERMANENT PRESS CYCLE

W = WARM D = DELICATE CYCLE

C = COLD X = INDICATOR LIGHT GLOWS

N = NORMAL

CYCLE

D = 18:51

201520R6 53

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 56

Cycle Sequence Charts

CYCLE SEQUENCE FOR MODEL AWNA11SP111TW01 – RINSE & SPIN AND SPIN ONLY CYCLES

LIGHTS

FUNCTION IN USE RINSE SPIN

WATER

TEMP.

CYCLE &

MOTOR SPEED *

TIME (Minutes and Seconds)

RINSE &

SPIN CYCLE

FILL X X C 2:00 0:00

AGITATE X X FAST 4:00 0:00

RINSE

PAUSE X X 0:10 0:00

SPIN 1 X X FAST 0:45 0:00

SPIN

SPIN

AND

SPRAY

FINAL

SPIN

XX C FAST 0:15 0:00

X X FAST 4:00 5:00

TOTAL 9:10 5:00

KEY:

C = COLD

X = INDICATOR LIGHT

GLOWS

SPIN ONLY

CYCLE

54

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

201520R6

Page 57

Section 8

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

White

W310SE3A

Brown

Blue

Yellow

Red

R

W

BR

BU

Y

P

AUX.

RED

WHITE

RUN

START

G

Y

BU

BR

W

R

4P M

YELLOW

BROWN

BLUE

YELLOW

OVERLOAD

PROTECTOR

W211SE3A

Internal Wiring of Washer Motor Switch

201520R6 55

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

MOTOR ASSEMBLY

(1 Speed Motors)

Page 58

Internal Wiring of Washer Motor Switch

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

W311SE3B

Wire

Harness

Connection

Block

White

Brown

Blue

Yellow

Violet

Red

R

P

Y

BU

BR

W

RUN

START

G

Y

BR

BU

RED

VIOLET

BLUE

4P M

6P M

W224SE3A

OVERLOAD

PROTECTOR

R

WHITE

YELLOW

P

BROWN

W

YELLOW

AUX.

56

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

MOTOR ASSEMBLY

(2 Speed Motors)

201520R6

Page 59

Page 60

Loading...

Loading...