Page 1

Preliminary Installation Information

Subject 200 Pound Tumble Dryer

Use With 70420801 Installation Manual

Model Identification

Gas Steam/Thermal Oil

200 Pound

DR200G2-BA200L

DR200G2-BA200N

DR200G2-BT200L

DR200G2-BT200N

DR200G2-BU200L

DR200G2-BU200N

CA200L

CA200N

CT200L

CT200N

CU200L

CU200N

HA200L

HA200N

HT200L

HT200N

HU200L

HU200N

IT200L

IT200N

SA200L

SA200N

ST200L

ST200N

SU200L

SU200N

UA200L

UA200N

UT200L

UT200N

UU200L

UU200N

DR200S2-BT200S

DR200S2-BT200T

DR200S2-BU200S

DR200S2-BU200T

CT200S

CT200T

CU200S

CU200T

HT200S

HT200T

HU200S

HU200T

IT200S

IT200T

ST200S

ST200T

SU200S

SU200T

UT200S

UT200T

UU200S

UU200T

Includes models with the following control suffixes:

R3 – reversing DX4 OPL RE – reversing OPL Micro RQ – reversing dual digital timer

RD – reversing DMP OPL RM – reversing OPL Micro RU – reversing UniLinc OPL

Page 1 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Part No. 70470101

September 2011

Page 2

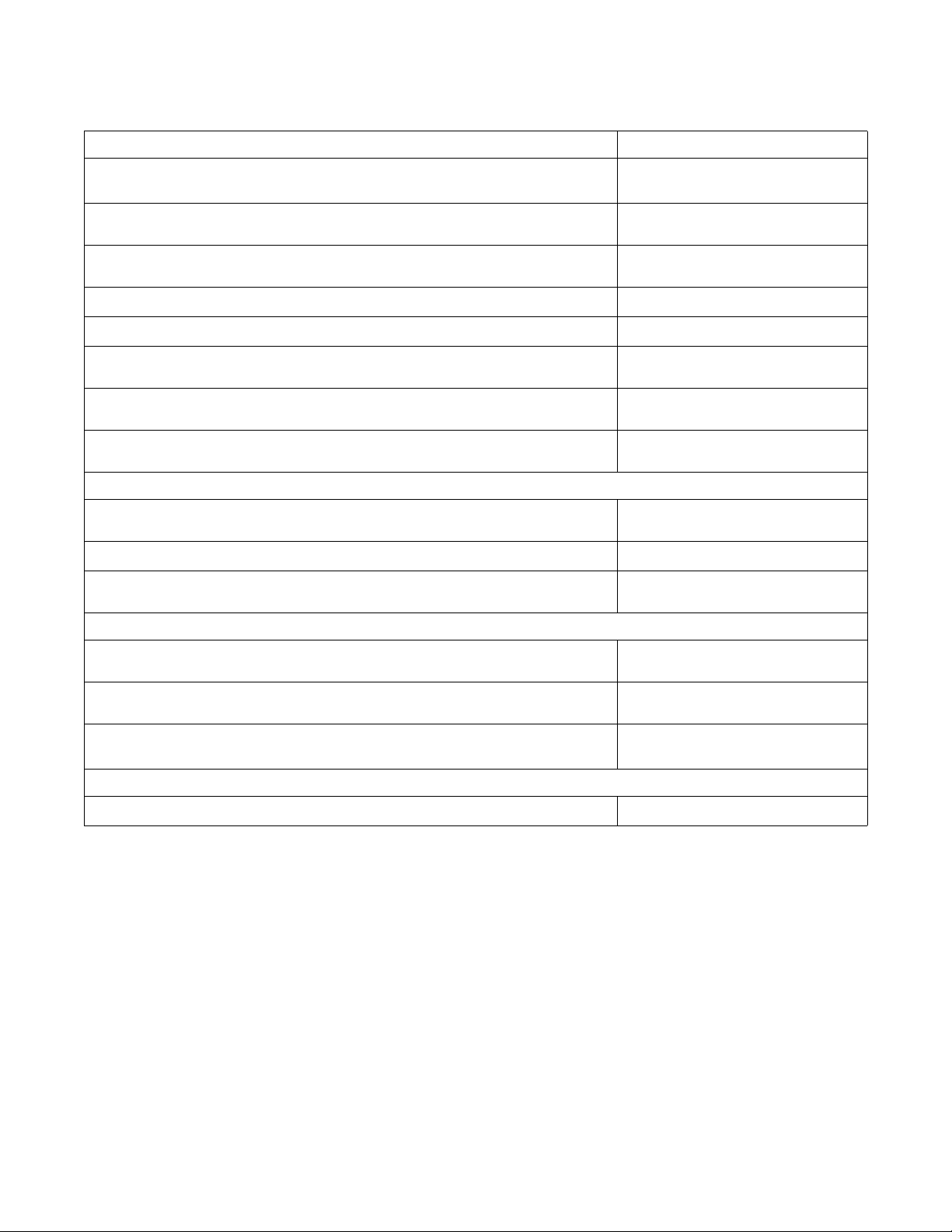

Specifications and Dimensions

Specifications 200 Pound

Noise level measured during operation at operator position of 3.3 feet

(1

meter) in front of machine and 5.2 feet (1.6 meters) from floor.

Cylinder Size: Inches (mm)

Cylinder Capacity dry weight: Pounds (kg)

Cylinder Motor Horsepower

66 dBA

50.75 x 50

(1289 x 1270)

200

(90.7)

0.75

Fan Motor Horsepower

Air Outlet Diameter: Inches (mm)

Maximum Static Back Pressure: W.C.I. (mbar)

Maximum Airflow: C.F.M (L/sec.)

Gas Models

Net Weight (approximate): Pounds (kg)

Gas Connection

Gas Burner Rating: Btu/hr. (Mj/hr.)

Steam Models

Net Weight (approximate): Pounds (kg)

Steam Connection

Steam Coil Rating at 100 psig:Boiler Horsepower (Btu/hr.)

(recommended operating pressure 80-100 psig)

3

12

(300)

0.3

(0.8)

2450

(1156)

1707

(774)

1 in. NPT

425,000

(448)

1807

(820)

3/4 in. NPT inlet

1 in. NPT outlet

18.8

(648,000)

Heating Element Rating:Kilowatts (kW)

N/A = Not Applicable

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Electric Models

N/A

Page 2 of 12

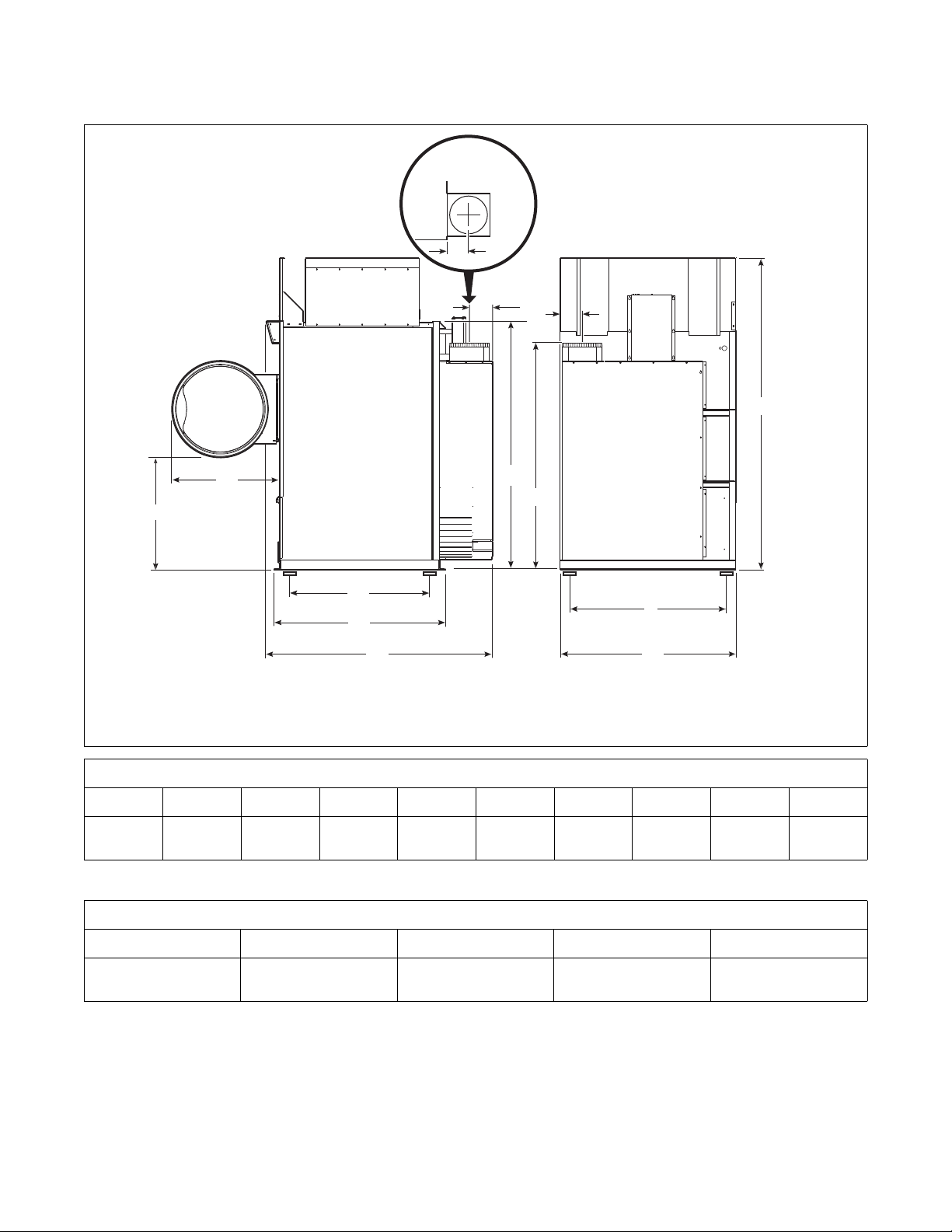

Page 3

200 Pound Tumble Dryer

A

B

C

D

W

H

F

Y

X

V

TOP VIEW OF

EXHAUST

DUCT

E

G

I

Dimensions and Exhaust Outlet

Locations

Cabinet Dimensions

TMB2363N

Models A B C D E F G H I

200L/N/S

32.1 in.

(815 mm)

35.6 in.

(904 mm)

58 in.

(1473 mm)

59.25 in.

(1505 mm)

76.18 in.

(1935 mm)

52.12 in.

(1324 mm)

53.12 in.

(1349 mm)

94 in.

(2388 mm)

Refer to Position and Level the Tumble Dryer to temporarily reduce the heights of these models.

Exhaust Outlet Dimensions and Locations

Models V W X Y

200L/N/S

67.19 in.

(1707 mm)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7.03 in.

(179 mm)

Page 3 of 12

(229 mm)

9 in.

TMB2363N

75.12 in.

(1908 mm)

7 in.

(178 mm)

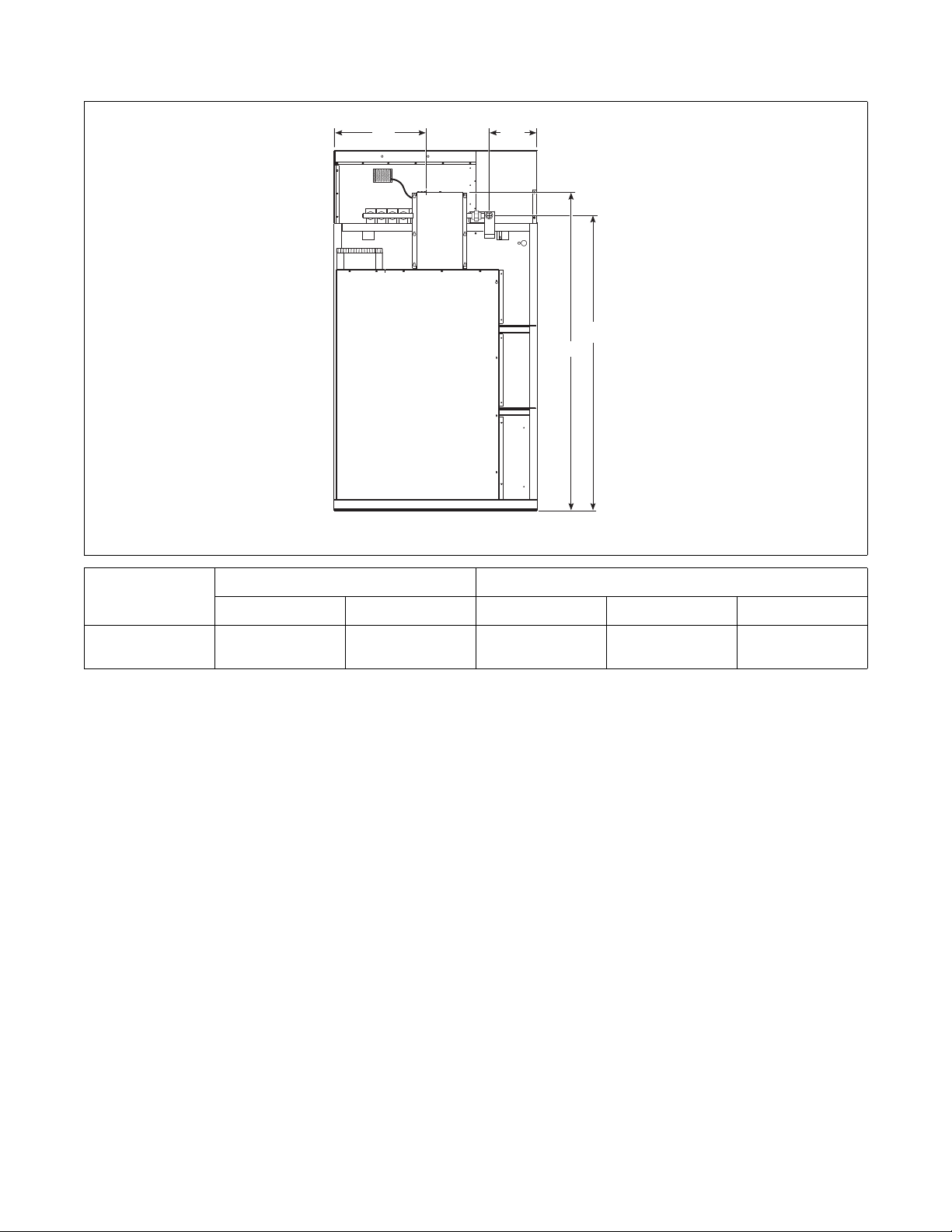

Page 4

Electric and Gas Connection

C

A

B

D

Locations for Gas Models

Models

Electrical Connection Gas Connection

A B C D Diameter

200L/N

21 in.

(533 mm)

81 in.

(2057 mm)

NOTE: These figures are approximate dimensions only.

13.7 in.

(348 mm)

77.4 in.

(1966 mm)

TMB2357N

1 in. NPT

Page 4 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Electric and Steam Connection

A1

B1

B2

A2

D

E

F

C

Locations for Steam Models

Models

200S

Models

200S

Models

200S

Steam Inlet

Diameter A1 A2 F

3/4 in. NPT 37.625 in.

(956 mm)

15.25 in.

(387 mm)

88 in.

(2235 mm)

Steam Outlet

Diameter B1 B2 D

1 in. NPT 44.625 in.

(1133 mm)

Electrical Connection

8.75 in.

(222 mm)

71.75 in.

(1822 mm)

C E

21 in.

(533 mm)

81 in.

(2057 mm)

TMB2358N

Page 5 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Position and Level the Tumble Dryer

The tumble dryer may be moved with or without the

skid. To remove the skid, unscrew the four shipping

bolts, and discard them.

To fit a 200 pound tumble dryer (with shipping skid)

through an 8 foot (2.43 meters) high door, you must

remove the front access panel. The upper 3 inches

(76

mm) of the stove must also be removed on

200

pound gas tumble dryers. Removing the entire gas

or steam heater assembly and the shipping skid will

reduce the height to 75

inches (1905 mm).

Level the tumble dryer to within 0.125 inch (3 mm)

from front-to-rear (level on cylinder rib), and side-toside (level on top panel). Shim under corners to level

and stabilize unit. Tumble dryer must not rock.

Make-Up Air

Required Make-Up Air Opening

(to the outside) for Each Tumble Dryer

Models Opening

200 Pound

525 in.2 (3710 cm2)

free air

Table 1

Page 6 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

Exhaust Requirements

LKJ I HG F

E

D

C

BA

3

1

2

ONE MANIFOLD ASSEMBLY

1 NOTE: Where the exhaust duct pierces a

combustible wall or ceiling, the opening

MUST be sized per local codes.

TMB2019N

2 Outlet Duct Diameter

3 45° Typical

Duct

Stations

A

B

C

D

E

F

G

H

I

J

K

L

Figure 1

12 in. (305 mm) Duct

Table 2

200 Pound

12 in. (305 mm)

17 in. (432 mm)

21 in. (533 mm)

24 in. (610 mm)

27 in. (686 mm)

30 in. (762 mm)

32 in. (813 mm)

34 in. (864 mm)

36 in. (914 mm)

38 in. (965 mm)

40 in. (1016 mm)

42 in. (1067 mm)

Page 7 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

1 NOTE: Where the exhaust duct pierces a

1

2

3

L

K

J

I

L

K

J

I

CONTINUE

TO A

CONTINUE

TO A

TWO MANIFOLD ASSEMBLIES

combustible wall or ceiling, the opening

MUST be sized per local codes.

TMB2018N

2 Outlet Duct Diameter

3 45° Typical

Figure 2

Duct

Stations

A

B

C

D

E

F

G

H

I

J

K

L

200 Pound

12 in. (305 mm) Duct

17 in. (432 mm)

24 in. (610 mm)

30 in. (762 mm)

34 in. (864 mm)

38 in. (965 mm)

42 in. (1067 mm)

45 in. (1143 mm)

45 in. (1143 mm)

52 in. (1321 mm)

54 in. (1372 mm)

57 in. (1448 mm)

60 in. (1524 mm)

Table 3

Page 8 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

Gas Requirements

For converting Non-CE Models from Natural Gas to

L.P. Gas:

200 Pound Models - M4975P3

High Altitude Orifice Sizing

For proper operation at altitudes above 2000 feet (610

meters), the gas orifice size must be reduced to ensure

complete combustion. Refer to

For CE models, consult local gas supplier.

Table 4.

Non-CE Models

Model Gas

2001 – 4000 610 – 1220 19 .1660 4.2

Natural

Gas

200L/N

L.P.

Gas

* Btu/hr. derate of 4% per 1000 ft. (305 m) of altitude.

4001 – 6000 1221 – 1830 20 .1610 4.1 M401002 357,000

6001 – 8000 1831 – 2440 22 .1570 4.0 M402996 323,000

8001 – 10,000 2441 – 3050 24 .1520 3.9 M402980 289,000

2001 – 4000 610 – 1220 33 .1130 2.9

4001 – 6000 1221 – 1830 34 .1110 2.8 M411512 357,000

6001 – 8000 1831 – 2440 7/64 .1094 2.8 70070902 323,000

8001 – 10,000 2441 – 3050 37 .1040 2.6 M401024 289,000

Altitude Orifice

feet m No. inches mm Quantity Part No. (Btu/hr.)*

New

Rate

M402995 391,000

5

M401022 391,000

4

Table 4

Page 9 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

Electrical Requirements

For 200 Pound Tumble Dryer Models

Serial Plate Rating

200-208V/60Hz/3ph

240V/60Hz/3ph

380V/50 or 60Hz/3ph

400-415V/50Hz/3ph

440V/60Hz/3ph

460-480V/60Hz/3ph

L1, L2, L3 and ground 14 20A - 3 pole

L1, L2, L3 and ground 14 20A - 3 pole

L1, L2, L3 and ground 8 15A - 3 pole

L1, L2, L3 and ground 8 15A - 3 pole

L1, L2, L3 and ground 7 15A - 3 pole

L1, L2, L3 and ground 7 15A - 3 pole

Terminal Block

Connections Required

* Current ratings vary slightly depending on model; refer to serial plate.

Table 5

Rated

Current*

Breaker

Rating

Recommended Wire

Size

12 AWG (3.31 mm2)

12 AWG (3.31 mm2)

14 AWG (2.08 mm2)

14 AWG (2.08 mm2)

14 AWG (2.08 mm2)

14 AWG (2.08 mm2)

Page 10 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

Steam Requirements

TMB2024N

SUPPLY

2

1

9

3

RETURN

2

3

7

10

4

5

8

6

NOTE: Refer to Table 6 for sizing of steam lines. Piping must also be sized accordingly for length of runs and number

of elbows.

1

2

3

4

5

Risers 12 in. (305 mm)

Shut-Off Valve

Check Valve

Vacuum Breaker (optional)

Condensate Return Line from Supply Line

6

7

8

9

10

18 in. Drop (457 mm)

Steam Bonnet

Solenoid Valve (Supplied with machine)

Union

Trap with Built-In Strainer

Figure 3

Model

200S

Steam Pressure

PSI (bar)

80-100 (5.3-6.9) 1-1/4 in. NPT 517

Minimum

Supply Pipe Diameter

Steam Trap Size *

(Pounds Condensate/Hour)

* Based on maximum psi.

Table 6

Page 11 of 12

TMB2024N

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Loading Door Strike

1

2

Belt Drive

The loading door strike must be adjusted to have

sufficient tension to hold loading door closed against

force of load tumbling against it. Proper adjustment is

when 8-15 pounds (35.6-66.7 N) pull is required to

open door.

If adjustment is required, refer to Figure 4 and proceed

as follows:

To adjust, open door, loosen adjustment screws and

position strike for desired magnet engagement.

retighten screws.

NOTE: Proper tensions for new belts are

45-55

pounds for the motor belt, 55-65 pounds for

the final drive and 65-70 pounds for 200 pound

blower, measured with a Borroughs Belt Tension

Gauge. Using a Browning Belt Tension Gauge, the

motor belt deflection should be 0.31

inch at five

pounds pressure, and final drive belt deflection

should be 0.25

inch at five pounds pressure.

TMB2359N

1 Door Strike

2 Adjustment Screws

Figure 4

Page 12 of 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...