Page 1

Metered and

Nonmetered

Commercial Single

Dryers

(Electric and Gas Models)

Installation and Operation

REMARQUE: Le guide

est rédigé en anglais et en

français. La version

française figure à la suite

de la version anglaise.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE. (If the

dryer changes ownership, be sure this manual accompanies the dryer.)

Part No. 504523R3

November 1998

Page 2

Page 3

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the

risk of fire or explosion or to prevent property damage, personal injury or death.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

–Do not try to light any appliance.

–Do not touch any electrical switch; do not use any phone in your building.

–Clear the room, building or area of all occupants.

–Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

–If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids i n the vicinity of this or

any other appliance.

W033

IMPORTANT: Purchaser must consult the local gas supplier for suggested instructions to be followed

if the dryer user smells gas. The gas utility instructions plus the SAFETY and WARNING note directly

above must be posted in a prominent location near the dryer for customer use.

Electric models are not approved by the Canadian Gas Association.

504523 1

Page 4

Table of

Contents

Replacement Parts ...............................................................................3

Important Safety Instructions .............................................................4

Roughing In Dimensions .....................................................................6

Meter Case ............................................................................................ 8

Timer Cams .......................................................................................... 8

Dryer Slide Extension .......................................................................... 9

Before You Start

Tools ..............................................................................................10

Exhaust ...........................................................................................10

Electrical.........................................................................................10

Gas..................................................................................................10

Location..........................................................................................10

Installing the Dryer

STEP 1 (Position and Level the Dryer) .........................................11

STEP 2 (Connect Dryer Exhaust System)......................................11

STEP 3 (Connect Gas Supply Pipe)...............................................12

STEP 4 (Wipe Out Inside of Dryer)............................................... 13

STEP 5 (Plug in the Dryer)............................................................13

STEP 6 (Check Installation)...........................................................13

Heat Source Check ............................................................................. 14

Reversing Door Procedure ................................................................15

Electrical Requirements (Electric Dryers) .......................................16

Electrical Requirements (Gas Dryers) .............................................17

Gas Requirements .............................................................................19

Location Requirements .....................................................................20

Dryer Exhaust Requirements

Exhaust System Materials..............................................................21

Make Up Air Requirements............................................................22

Exhaust System ..............................................................................22

Exhaust Direction...........................................................................22

Exhaust System Maintenance.........................................................23

Dryer Airflow.................................................................................23

Reduced Clearance Elbow..............................................................23

Multi-Dryer Installation Exhaust Requirements ............................ 24

Manufactured (Mobile) Home Installation ......................................27

Lint Filter ............................................................................................ 28

Motor OverLoad Protector ...............................................................28

User-Maint enance Instructions

Lubrication .....................................................................................29

Care of Your Dryer.........................................................................29

Exhaust System ..............................................................................29

For Energy Conservation ..................................................................29

Before You Call for Service ...............................................................30

Additional Dryer Security ................................................................. 31

Operation Instructions for Electromechanical Dryers ................... 32

Operation Instructions for Electronic Control Dryers ................... 34

Information for Handy Reference ....................................................37

Installer Check .................................................................... Back Cover

© Copyright 1998, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

2 504523

Page 5

Replacement Parts . . .

If replacement parts are required, contact the source

where you purchased your dryer, or contact

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Phone: (920) 748-3950

for the name and address of the nearest authorized parts

distributor.

504523 3

Page 6

IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

14. The interior of the dryer and the exhaust duct

WARNING

To reduce the risk of fire, electric shock, or

injury to persons when using your dryer,

follow these basic precautions:

W034

1. Read all instructions before using the dryer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the dryer.

3. Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable

or explosive substances as they give off vapors

that could ignite or explode.

4. Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children. This is a safety

rule for all appliances.

5. Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

6. Do not reach into the dryer if the cylinder is

revolving.

7. Do not install or store the dryer where it will be

exposed to water and/or weather.

8. Do not tamper with the controls.

9. Do not repair or replace any part of the dryer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

10. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

12. ALWAYS clean the lint filter after every load. A

layer of lint in the filter reduces drying efficiency

and prolongs drying time.

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

should be cleaned periodically by qualified

service pers onnel.

15. If not installed, operated and ma intained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Dryer will not operate with the loading door

open. DO NOT by-pass the door safety switch by

permitting the dryer to operate with the door

open. The dryer will st op tumbling when the doo r

is opened. Do not use the dryer if it does not stop

tumbling when the door is opened or starts

tumbling without pressing the START

mechanism. Remove the dryer from use and call

the service person.

17. Do not put articles soiled with vegetable or

cooking oil in the dryer, as these oils may not be

removed during washing. Due to the remaining

oil, the fabric may catch on fire by itself.

18. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc., or anything containing wax or

chemicals such as in mops a nd cleani ng clot hs, or

anything dry-cleaned at home with a drycleaning solvent in the dryer.

19. Use the dryer only for its intended purpose,

drying clothes.

20. Always disconnect the electrical power to the

dryer before attemp ting service. Disconnect the

power cord by grasping the plug, not the cord.

21. Replace worn power cords and/or loose plugs.

22. Install this dryer according to the

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding and

gas supply must comply with local codes and be

made by licensed personnel when required. Do

not do it yourself unless you know how!

23. R emo v e laundry immedi ate ly aft er the drye r

stops.

4 504523

Page 7

24. Always read and follow manufacturer’s

instructions on packa ges of l aundr y and cleaning

aids. Heed all warning s or pr ecautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiber glass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiber glass.

26. ALWAYS follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the dryer with any guards and/or

panels removed.

28. DO NOT operate the dryer with missing or

broken parts.

29. DO NOT by-pass any safety devices.

30. Failure to install, maintain, and/or operate this

machine accor ding to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

IMPORTANT: Solvent vapors from dry-cleaning

machines create acids when drawn through the heater

of the drying unit. These acids are corrosive to the

dryer as well as to the laundry load being dried. Be

sure make-up air is free of solvent vapors.

IMPORTANT: Have your dryer installed properly.

Don’t do it yourself unless you know how!

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this manual

are not meant to cover all possible conditions and

situations that may occur. Common sense, caution

and care must be exercised when installing,

maintaining, or operating the dryer.

Always contact your dealer, distributor, service agent or

the manufacturer about any problems or conditions you

do not understand.

504523 5

Page 8

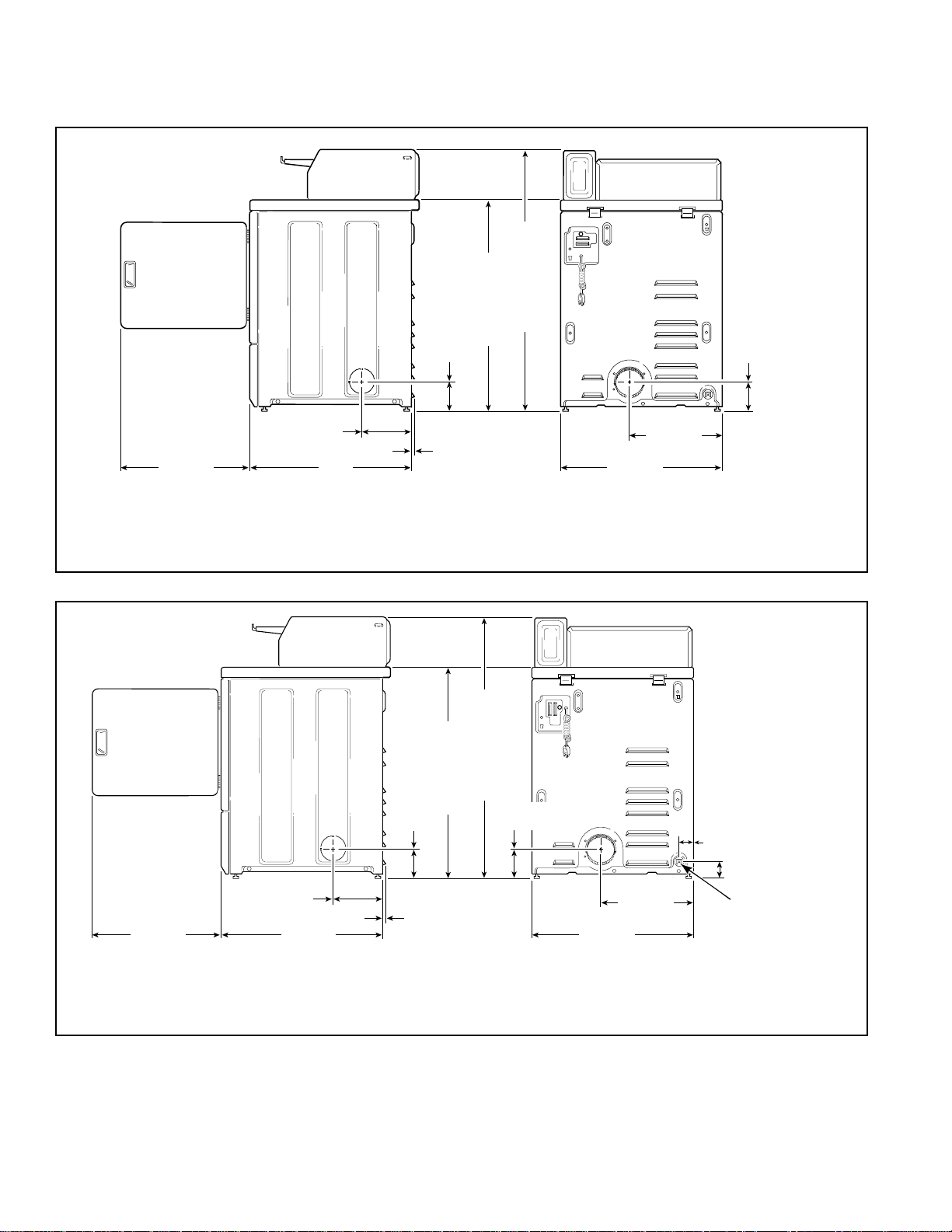

Roughing In Dimensions . . .

(Metered Models)

*109.7 cm (43.2")

10.2 cm

(4.0")

*91.4 cm (36")

10.2 cm

(4.0")

19.6 cm

(7.7")

59.7 cm

(23.5")

* WITH LEVELING LEGS TURNED INTO BASE.

19.6 cm

59.7 cm

(23.5")

* WITH LEVELING LEGS TURNED INTO BASE.

71.1 cm

(28")

(7.7")

71.1 cm

(28")

1.0 cm

(.4")

ELECTRIC MODELS

*109.7 cm (43.2")

1.0 cm

(.4")

*91.4 cm (36")

10.2 cm

(4.0")

10.2 cm

(4.0")

68.3 cm

(26.9")

68.3 cm

(26.9")

39.1 cm

(15.4")

39.1 cm

(15.4")

D329IE3F

6 cm

(2.3")

7 cm

(2.8")

3/8"

NPT GAS

CONNECTION

D330IE3F

GAS MODELS

NOTE: Side, rear and bottom exhaust openings are

10.2 cm (four inch) ducting. Gas models cannot be

vented out left side of cabinet because of burner

housing.

6 504523

IMPORTANT: The dryer should have sufficient

clearance around it fo r needed ventil ation and for the

ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

Page 9

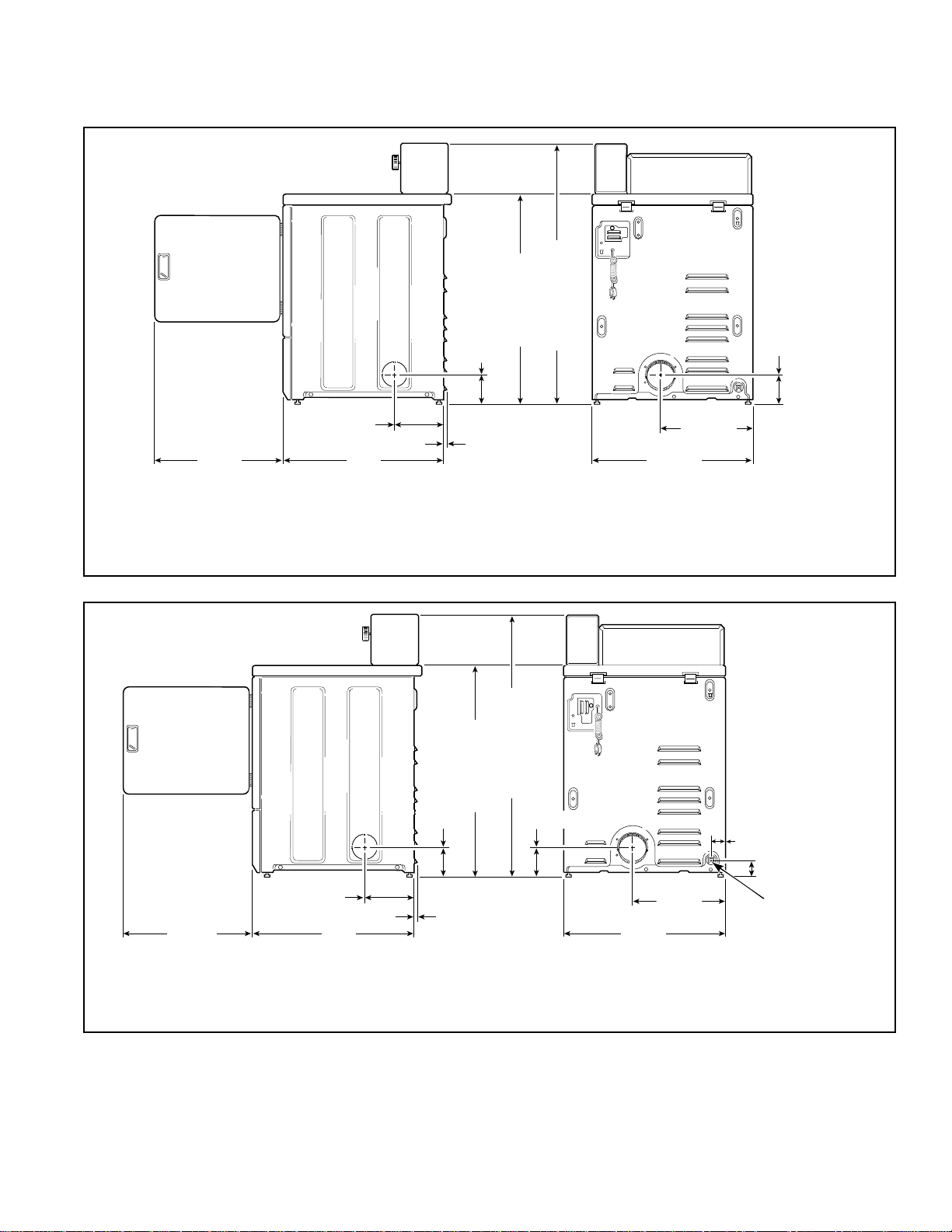

Roughing In Dimensions . . .

(Nonmetered Models)

19.6 cm

(7.7")

59.7 cm

(23.5")

* WITH LEVELING LEGS TURNED INTO BASE.

71.1 cm

(28")

ELECTRIC MODELS

10.2 cm

(4.0")

1.0 cm

(.4")

*91.4 cm (36")

*109.7 cm (43.2")

10.2 cm

(4.0")

39.1 cm

(15.4")

68.3 cm

(26.9")

D331IE3D

*109.7 cm (43.2")

1.0 cm

(.4")

*91.4 cm (36")

68.3 cm

(26.9")

39.1 cm

(15.4")

6 cm

(2.3")

10.2 cm

(4.0")

3/8"

NPT GAS

CONNECTION

D332IE3D

19.6 cm

(7.7")

59.7 cm

(23.5")

* WITH LEVELING LEGS TURNED INTO BASE.

71.1 cm

(28")

10.2 cm

(4.0")

GAS MODELS

NOTE: Side, rear and bottom exhaust openings are

10.2 cm (four inch) ducting. Gas models cannot be

vented out left side of cabinet because of burner

housing.

504523 7

IMPORTANT: The dryer should have sufficient

clearance around it f or needed v entilation and f or the

ease of installation and servicing. For maximum

drying performance, we recommend that more

clearance be allowed around the dryer than the

clearances that are listed throughout this manual.

Page 10

Meter Case . . .

(Metered Models)

The factory mou nted coin meter cas e does not includ e the

service door lock, coin drawer, coin drawer lock and

keys. These parts must be ordered (at extra cost)

according to the purch aser’ s requirements direct from the

manufacturer of your choice.

Timer Cams . . .

(Metered Models)

The dryer timer is factory equipped with a 45 minute

timing cam. If this drying time is not suitable to your

Electric Dryers Gas Dryers

1-53242 Cams (30 Minutes) 1-53242 Cams (30 Minutes)

1-53240 Cams (60 Minutes)

A 60 minute timing cam, Part No. 53240, is available for gas

dryers as optional equipment at extra cost.

NOTE: You have the option of us ing a screw type lock

or a 1/4 turn lock on the meter case service door. If

you choose to use a screw lock, then the special

bracket (loc ated inside th e meter case) must be used.

DO NOT use the special bracket if a 1/4 turn lock is

used.

Coin Drawer Security — for additional security, drill

out the two pilot ho les on each front side of the meter case

to 1/4 or 5/16 inch (6.4 or 8.0 mm) holes and install a

bicycle lock through these holes.

installation, the following cams can be found in the

envelope located in the cylinder:

8 504523

Page 11

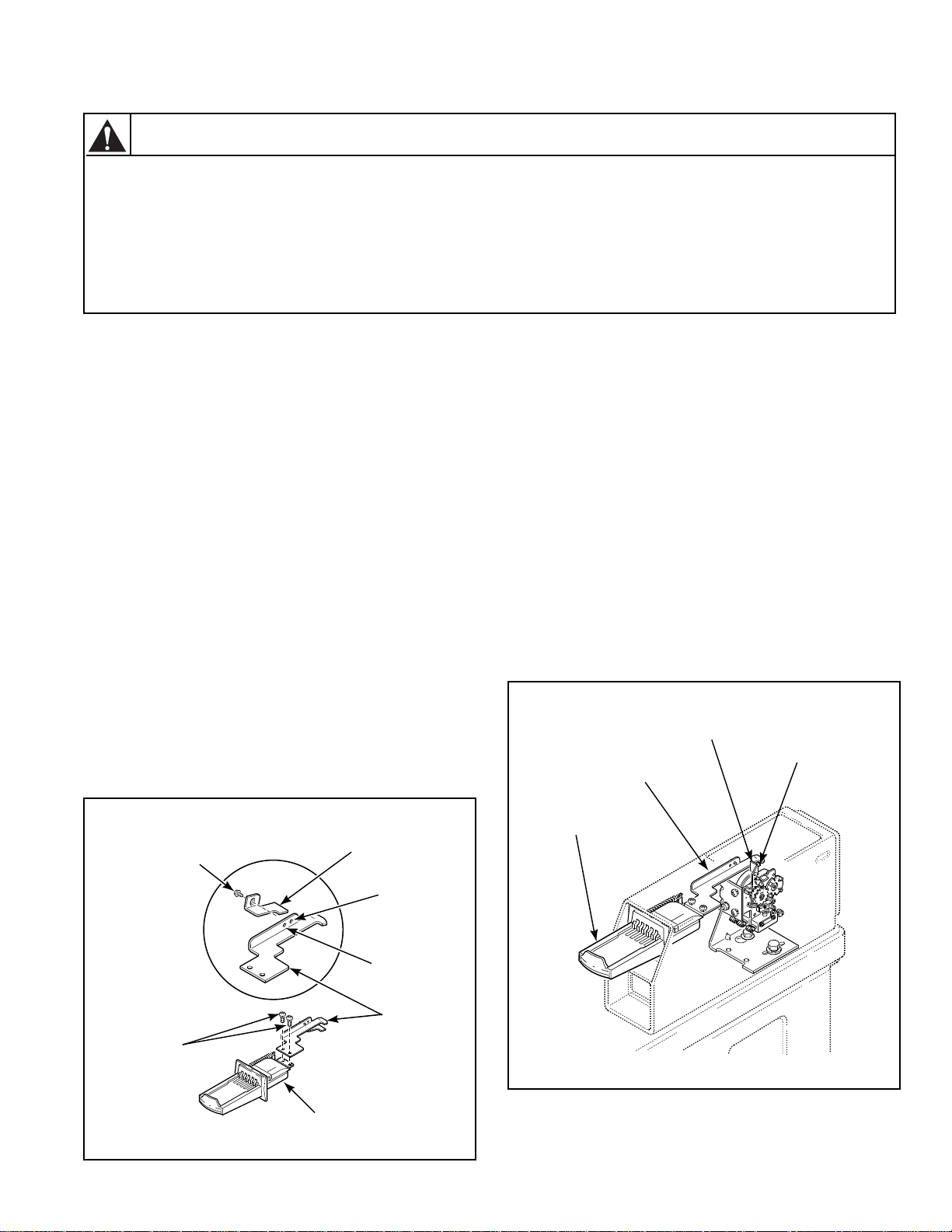

Dryer Slide Extension . . .

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

1. Assemble coin slide extension, No. 503733, to top

side of coin sli de usi ng tw o Phillip s head screws and

lockwashers, No. 03950. Tighten firmly.

2. Install slide extension modifier, No. 501796, as

follows:

NOTE: Dryers equipped with Greenwald coin slides

(except for Greenwald Comet Slide or Greenwald

Tokette Slide) do not require the use of the slide

extension modifier.

• ESD Coin Slide – Mount slide extension

modifier, No. 501796, to the underside of slide

extension, No. 503733. Align the hol e in the slide

extension modifier with hole “A” in the slide

extension and install self-tapping screw, No.

501086. Tighten firmly.

• GREENWALD Comet Slide, GREENWALD

Tokette Slide or MONARCH Coin Slide –

Mount slide extension modifier, No. 501796, to

the underside of slide extension, No. 503733.

Align the hole in the slid e extension modif ier with

hole “B” in the slide extension and install selftapping screw, No. 501086. Tighten firmly.

3. Reinstall coin slide in dryer meter case.

4. CHECK DRYER OPERA TION – Conne ct electrical

power to dryer. Place required number of coins in

coin slide. Push s lide in, and observ e through service

door opening in meter case. The slide extension

should be contacting the accumulator actuator arm

and moving back with slide travel.

When slide is pushed all the way in, slide is retracted.

Accumulator actuator arm should remain back until

slide extension is moved forward and contacts

actuator arm ag ian, returning arm t o starting position .

5. After completing the dryer check, reinstall service

door on top of meter case.

NOTE: When reinstalling service door, front of door

must be inserted at about a 45

° angle in order to engag e

notched tabs with internal rib at top of meter case.

ACCUMULATOR

ACTUATOR ARM

SLIDE

EXTENSION

SLIDE

EXTENSION

MODIFIER

COIN

501086

SELF-TAPPING

SCREW

03950

PHILLIPS

HEAD

SCREWS

AND

LOCKWASHERS

COIN

SLIDE

504523 9

501796

SLIDE EXTENSION

MODIFIER

HOLE "A"

HOLE "B"

503733

SLIDE

EXTENSION

D019KE1C

SLIDE

D044KE1A

Page 12

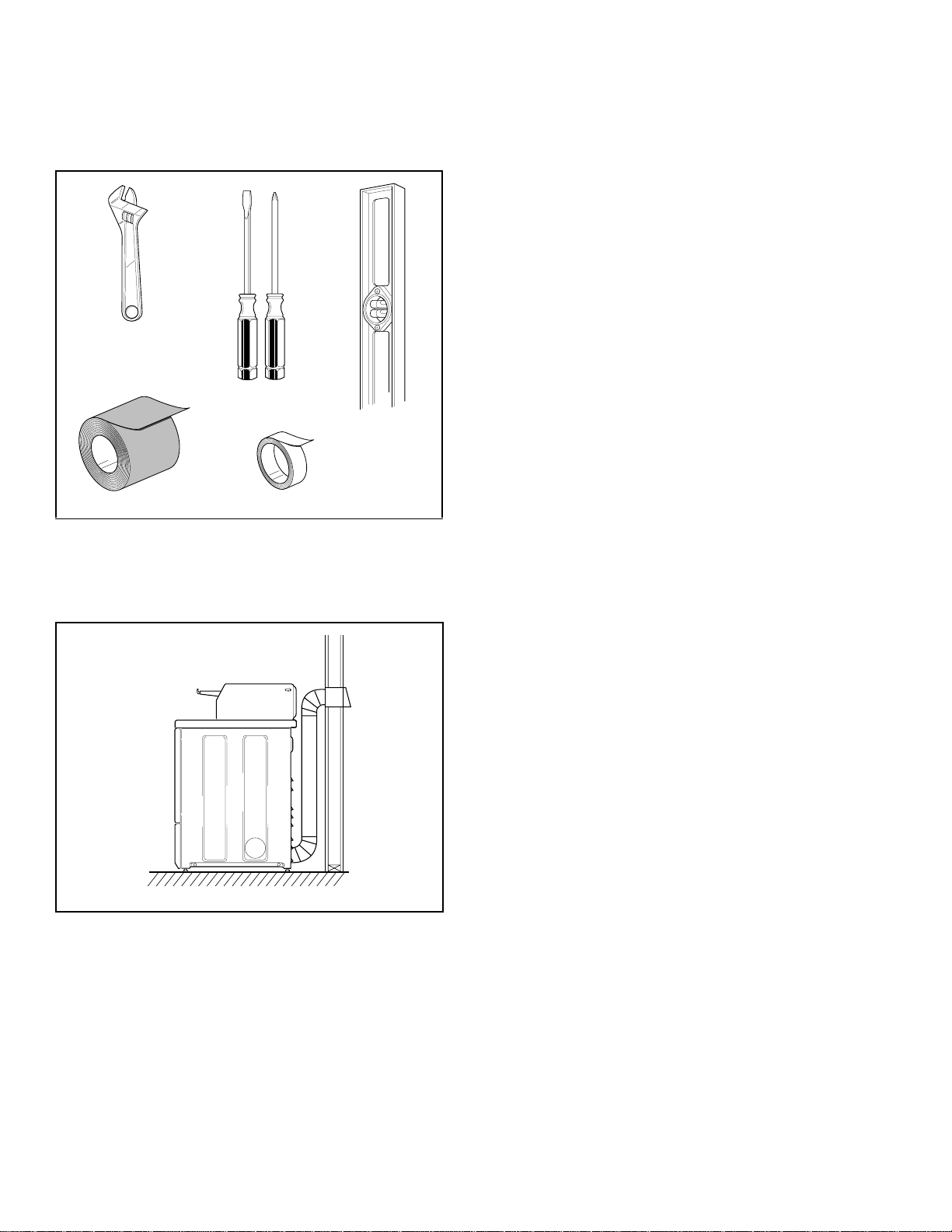

Before You Start . . .

D074IE1F

DUCT TAPE

TEFLON TAPE

WRENCH

LEVEL

SCREWDRIVERS

Tools

For most installations, the basic tools you will need are:

Exhaust

Use rigid metal duct and exha ust the dryer to the outs ide

by the shortes t route possible.

Electrical

• ELECTRIC DRYER

Dryer needs a 3 wire and ground, 120/240 or 120/208

Volt, 30Amp., 60 Hertz, AC single Phase electrical

supply.

• GAS DRYER

Dryer needs a 120 Volt, 15 Amp., 60 Hertz, polarized

3-slot effectively grounded receptacle.

NOTE: For more detailed information, refer to

Section on Electrical Requirements.

Gas

Dryer is equipped for Natural Gas with a 3/8"NPT gas

supply connection. For more detailed information, refer

to Section on Gas Requirements.

Location

Place the dryer on a solid floor with an adequate air

supply . For more detai led information, refer to Secti on on

Location Requirements.

D333I

NOTE: For more detailed information, refer to

Section on Dryer Exhaust Requirements.

10 504523

Page 13

Installing the Dryer . . .

STEP 1:

Position and Level

the Dryer

For further assistance refer to Section on Location

Requirements.

Install dryer before washer. This allows room for

attaching exhaust duct.

Install the four rubber cups found in the accessory bag.

Place the dryer in position, and adjust the legs until the

dryer is level.

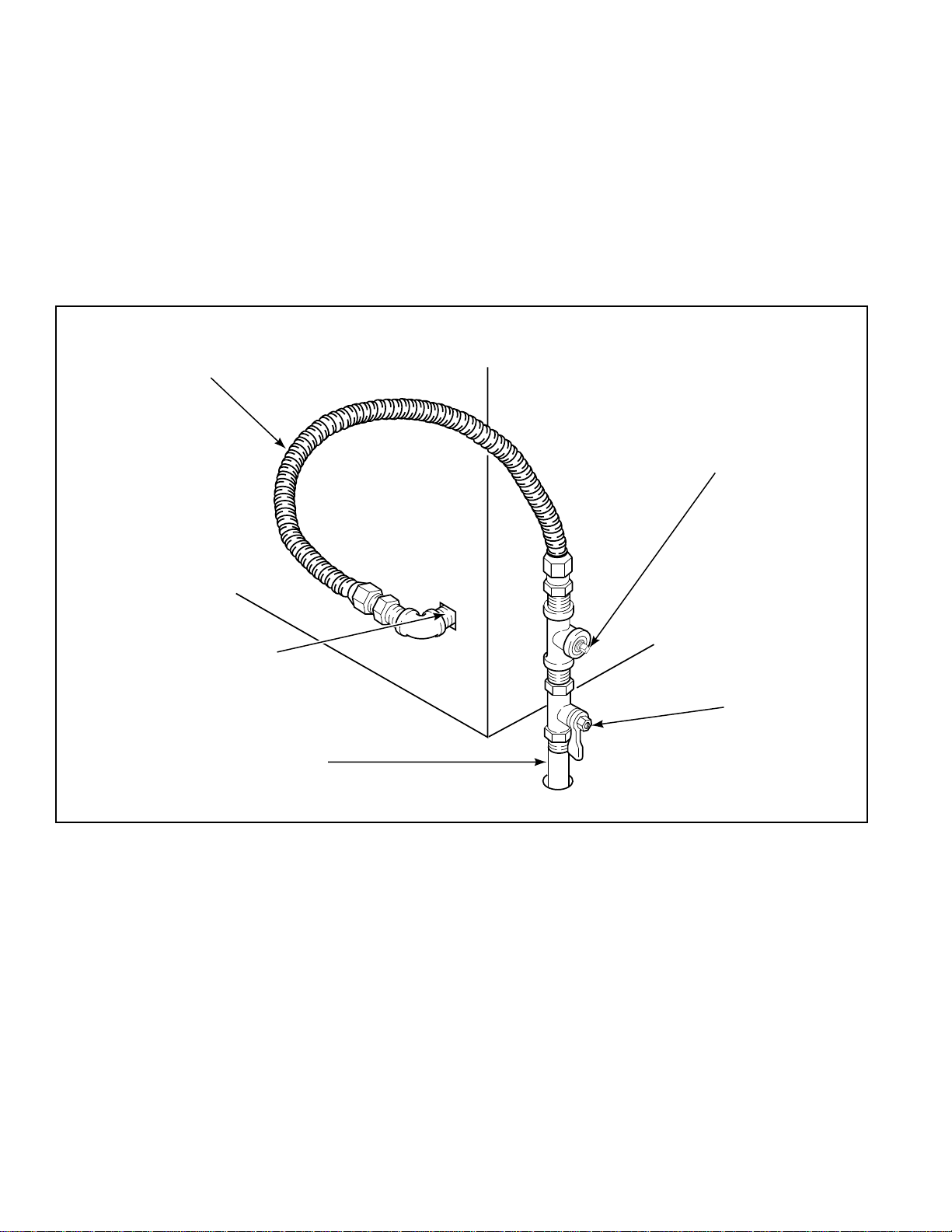

STEP 2:

Connect Dryer Exhaust System

For further assis tance refer to Sections on Location

Requirements and Dryer Exhaust Requirements.

DRYER

BASE

LEVEL

RUBBER

CUP

LEVELING

LEG

D334IE1A

WARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted to

the outdoors.

W116

• DO NOT use plastic or thin foil flexible ducting.

• Locate dryer so exhaust duct is as short as possible.

• Be certain old ducts are cleaned before installing your

new dryer.

• Use 10.2 cm (4") diameter rigid or flexible metal duct.

• Use as few elbows as possible.

• Use duct tape on all joints.

• Failure to exhaust dryer properly will void

warranty.

D333IE1A

DO

NOTE: Venting materials are not supplied with the

dryer (obtain locally).

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer’s front panel with laundr y, rug s,

etc. Blockage will de crease airf low through the dryer,

thus reducing the efficiency of the dryer.

DON’T

D335IE1A

504523 11

Page 14

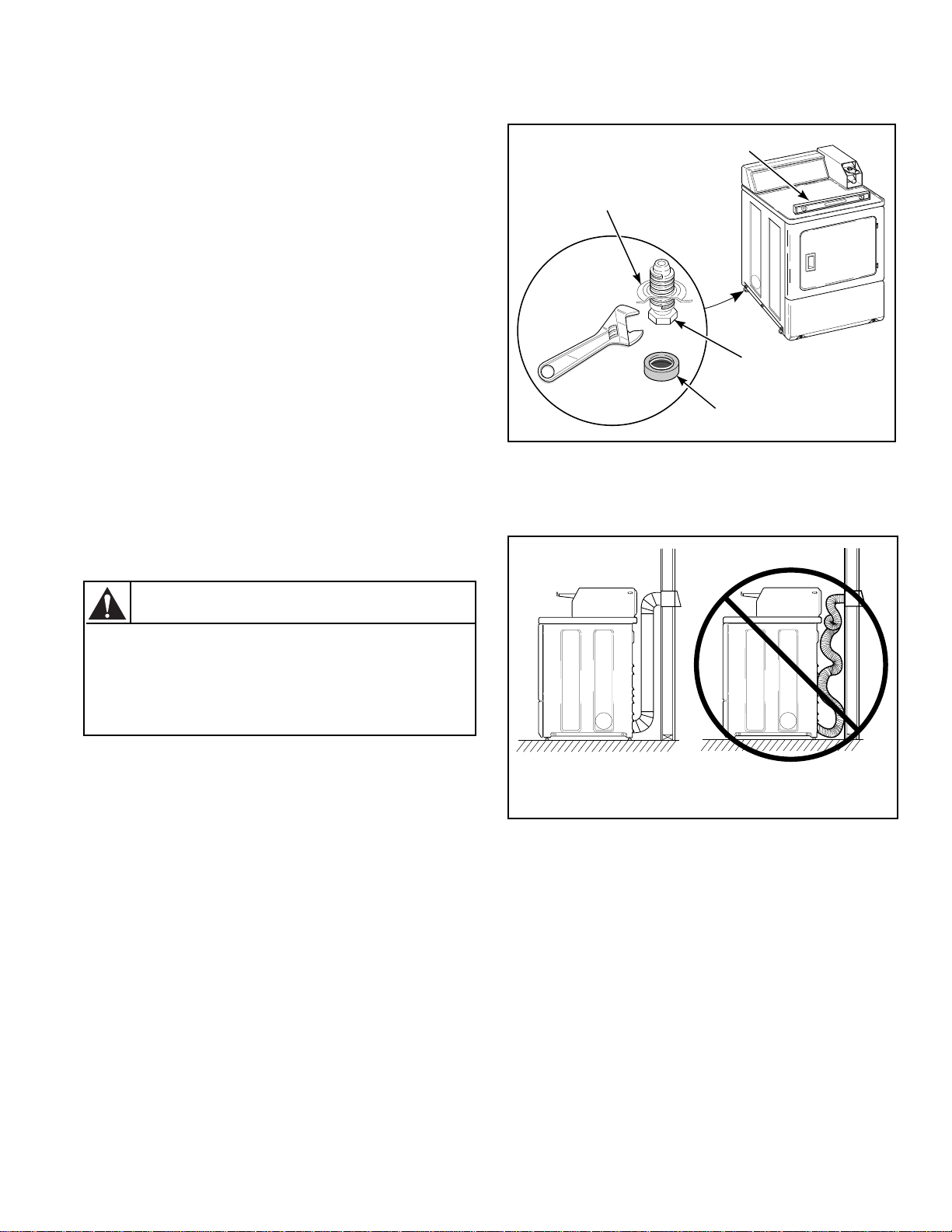

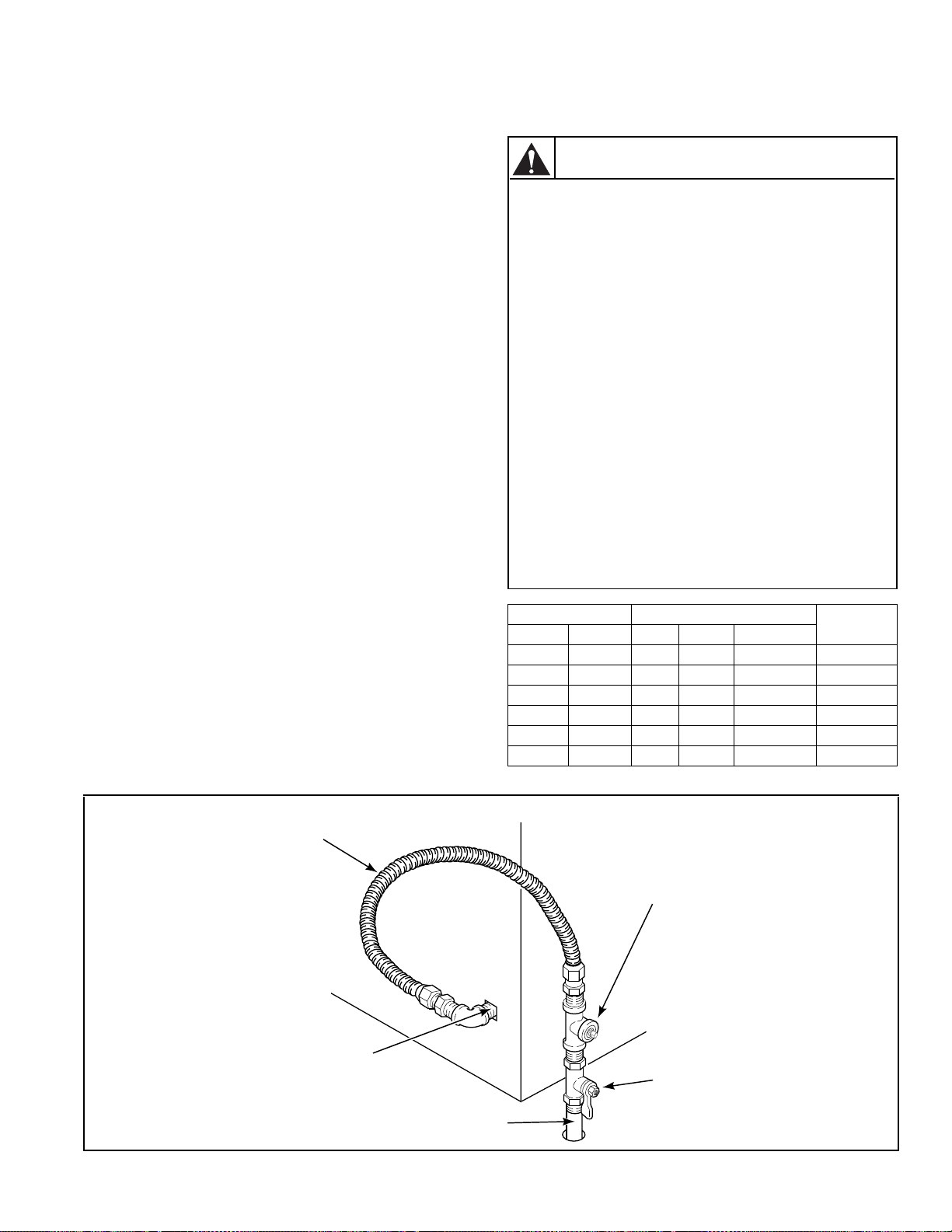

STEP 3: (Gas Dryer ONLY)

Connect Gas Supply Pipe

For further assistance, refer to Section on Gas Requirements.

1. Make certain dr yer is equipped for use with the type

of gas in laundry room. Dryer is equipped at the

factory for Natural Gas with a 3/8" NPT gas

connection.

2. Re mo ve the shi pping c ap from th e gas c onnecti on at

the rear of the dryer. Make sure you do not damage

the pipe threads when removing the cap.

NEW

STAINLESS STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3. Connect to gas supply pipe.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. F or L.P . (Propane) gas connection, refer to Section on

Gas Requir ements.

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 6.1 m (20') - use 3/8" pipe

Longer than 6.1 m (20') - use 1/2" pipe

EQUIPMENT

SHUT-OFF

VALVE

Install within

1.8 m (6') of dryer

D233IE3H

12 504523

Page 15

STEP 4:

Wipe Out Inside Of Dryer

Before using dryer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside dryer drum.

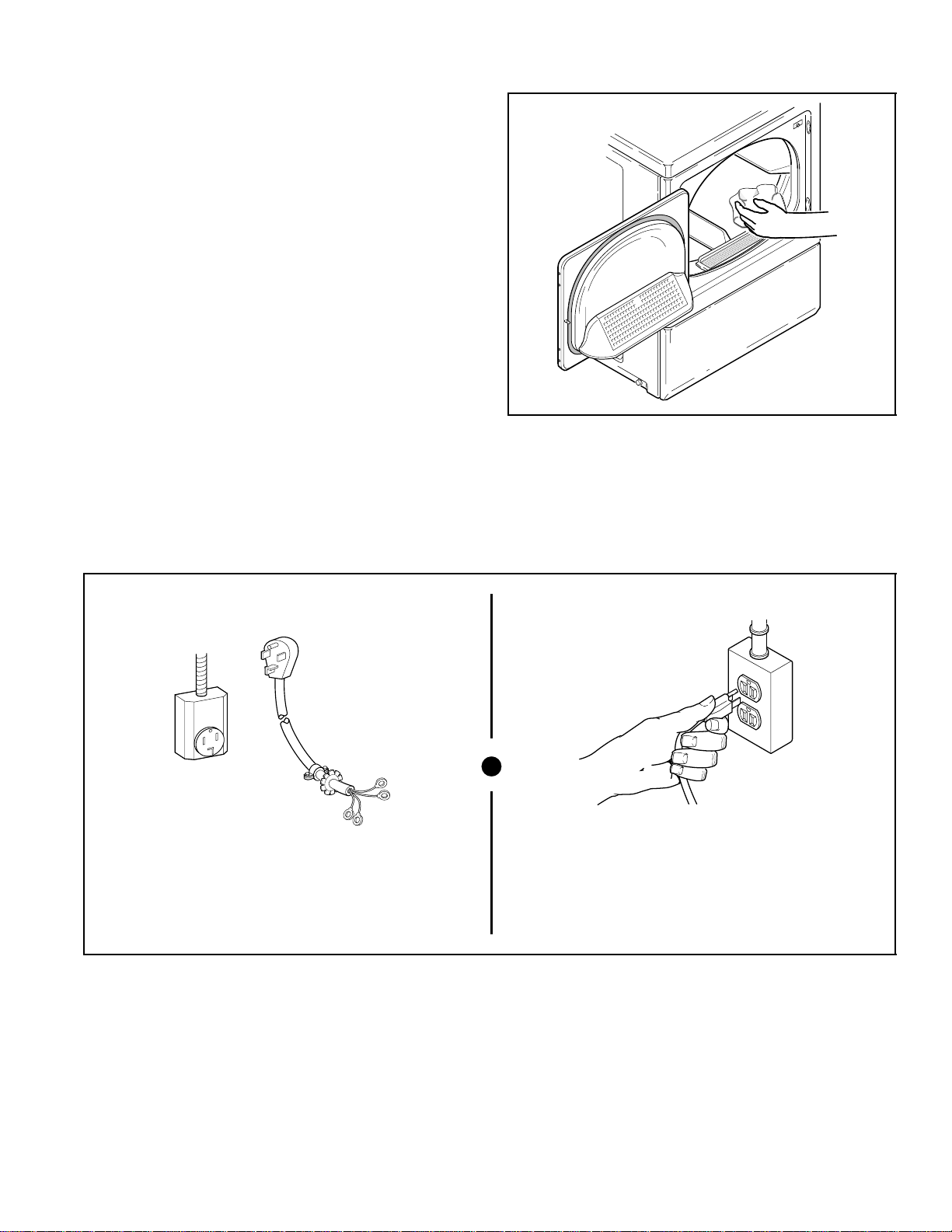

STEP 5:

Plug in the Dryer

D340I

Refer to Section on Elec trical Requ irements, and

connect the dryer to an electrical power source.

D006IE0B

ELECTRIC

Connect to 30 Amp circuit.

D254IE0B

GAS

Plug core into seperately fused

15 Amp circuit.

STEP 6:

Check Installation

Refer to Installer Chec k on the back cov er of this manual

and make sure that dryer is installed correctly.

504523 13

Page 16

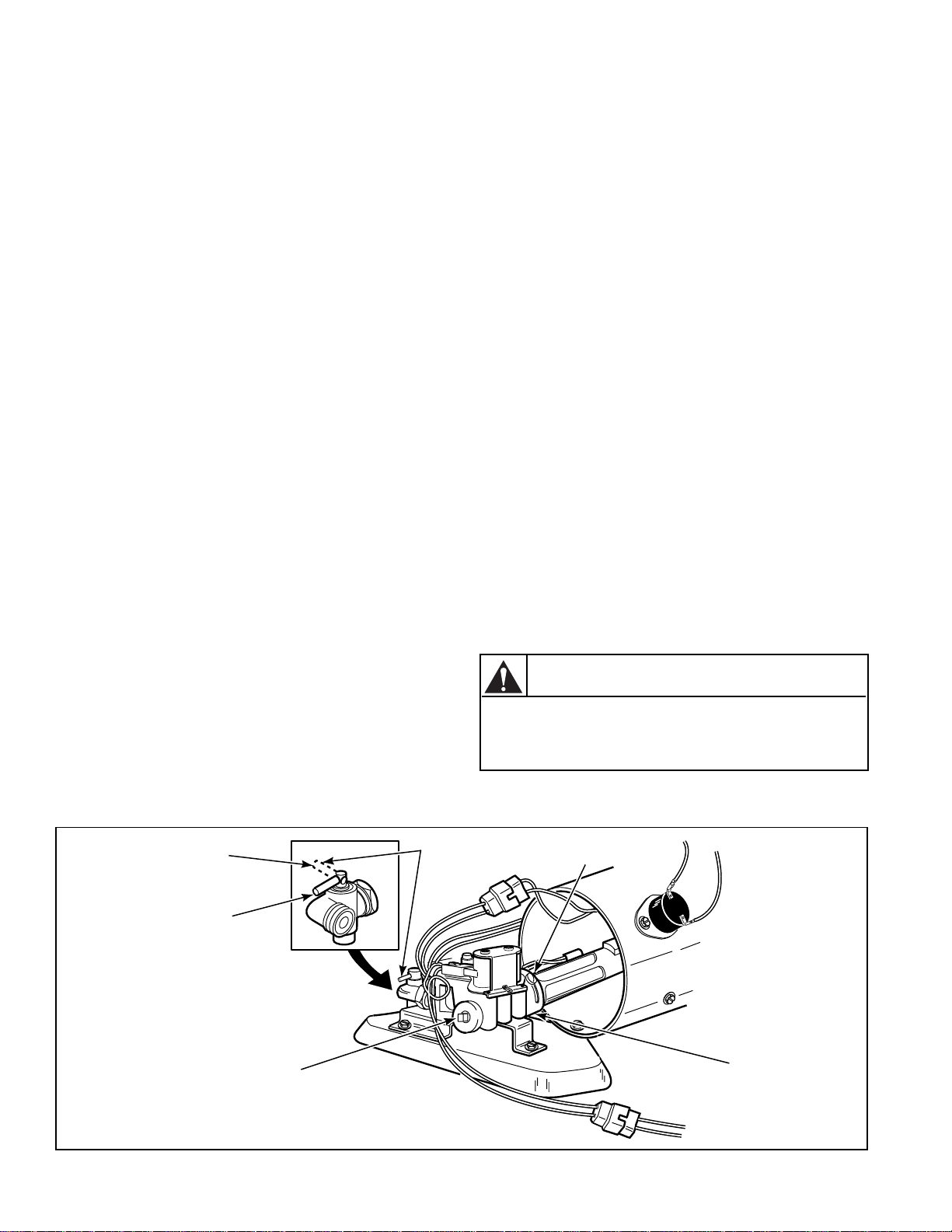

Heat Source Check . . .

(Electric Dryers)

Metered Models

Set the proper FABRIC SELECTOR switch at

NORMAL. Place coins in the slide and carefully push

slide in as far as possible. IN USE light will come on

indicating the dr yer is ready to oper ate. Close the loadi ng

door and press the PUSH-TO-START button firmly to

start the dryer. After the dryer has operated for three

minutes, the exha ust air or exhaust pipe should be warm.

(Gas Dryers)

During the gas heat check, observ e the b urner fl ame. The

flame can be vie wed by r emoving the lo wer front panel of

the dryer.

Metered Models

Set FABRIC SELECTOR switch at NORMAL. Place

coins in the slide and carefully push slide in as far as

possible. IN USE light will come on indicating the dryer

is ready to operate. Close the loading door and press the

PUSH-TO-START b utton fir mly . The dryer will start, the

igniter will glow red and the main burner will ignite.

Nonmetered Models

Set FABRIC SELECTOR switch at NORMAL and turn

timer knob to 50. Close the loading door and press the

PUSH-TO-START button. IN USE light will come on

indicating start of cycle, igniter will glow red and main

burner will ignite.

Nonmetered Models

Set FABRIC SELECTOR switch at NORMAL and turn

timer knob to 50. Close the loading door and press the

PUSH-TO-START button. IN USE light will come on

indicating star t o f cycle. After the dryer has operated for

three minutes, the exhaust air or exhaust pipe should be

warm.

All Models

After the dryer has operated for approximately five

minutes, observe burner flame. Adjust the air shutter to

obtain a soft, uniform bl ue fl ame. (A lazy, yellow tipped

flame indicates lack of air. A harsh, roaring, very blue

flame indicates too much air.) Adjust the air shutter as

follows:

1. Loosen the air shutter lockscrew.

2. Turn the air shutter to the left to get a lumino us

yellow tipped flame, then turn it back slowly to the

right to obtain a steady soft blue flame.

3. After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

4. Reinstall the lower front panel.

WARNING

IMPORTANT: If all air is not purged out of the gas

line, the gas igniter may go off before the gas is

ignited. If this happens, after approximately two

minutes the igniter will again attempt gas ignition.

CLOSED

POSITION

OPEN

POSITION

1/8"

PIPE PLUG

(For checking

manifold pressure)

SHUT-OFF

VALVE

HANDLE

For personal safety, lower front panel must

be in place during normal operation.

W046

After the dryer has operated for approximately three

minutes, the exhaust air or exhaust pipe should be warm.

AIR SHUTTER

LOCKSCREW

AIR

SHUTTER

D157IE3B

14 504523

Page 17

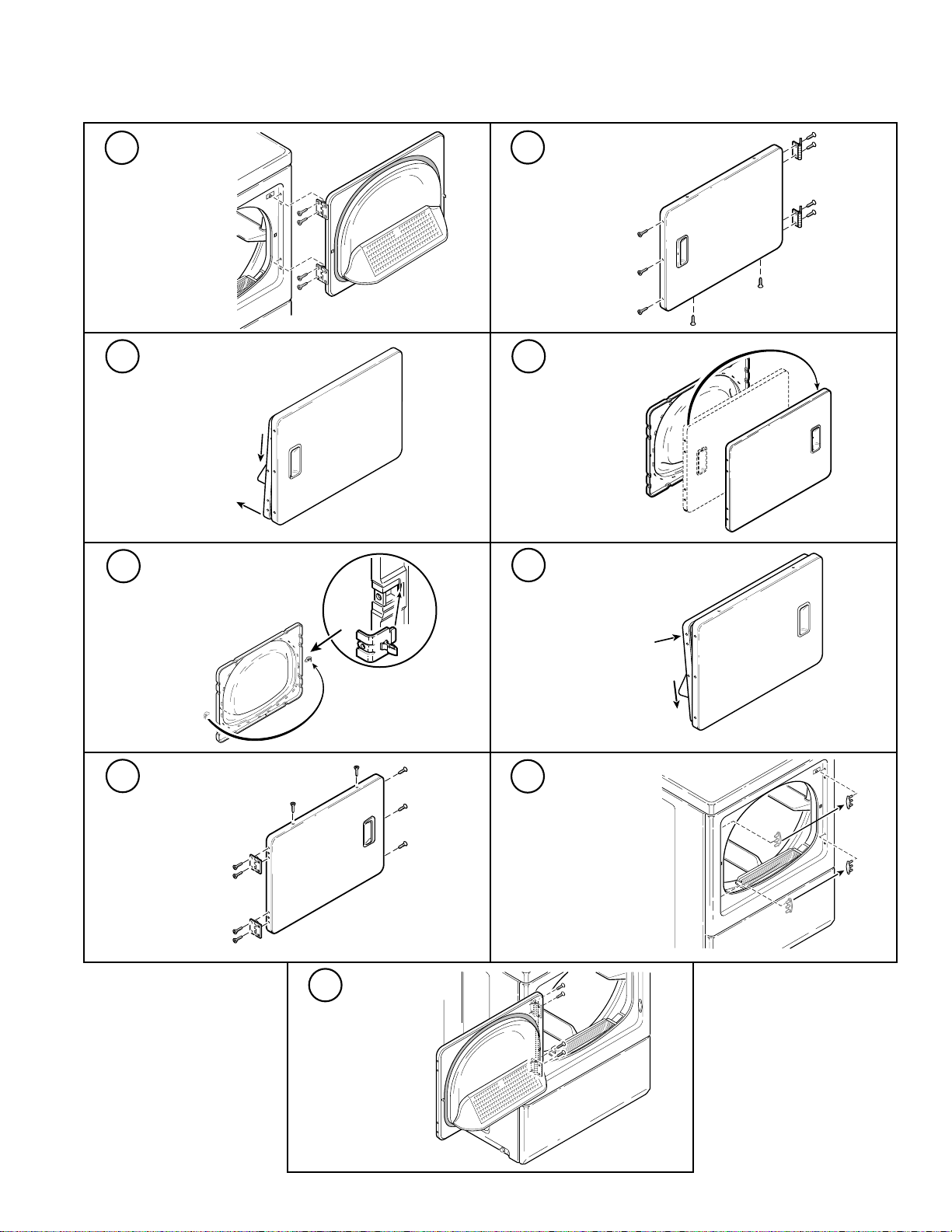

Reversing Door Procedure . . .

The door on this dryer is completely reversible. To reverse door proceed as follows:

1

Remove four

hinge attaching

screws.

3

Pull bottom of

door liner out,

then pull down,

removing door

liner from door

panel.

5

2

Remove all

nine screws.

D347IE1B

D348IE1B

4

Rotate door panel

180 degrees

as shown.

B

A

D268PE1C

D273PE1B

6

Remove door strike

from door liner

and reinstall on

opposite side.

7

Reinstall nine screws

removed in Step 2.

D276PE1B

D270PE1B

9

Reinstall four

hinge attaching

screws removed

in Step 1.

Insert liner under

flange on bottom of

door, then push

top of door

liner into place.

8

Using a screwdriver,

remove two door

plugs, and reinstall

on opposite side

of door opening.

B

A

D269PE1D

D345IE1B

D346IE1A

504523 15

Page 18

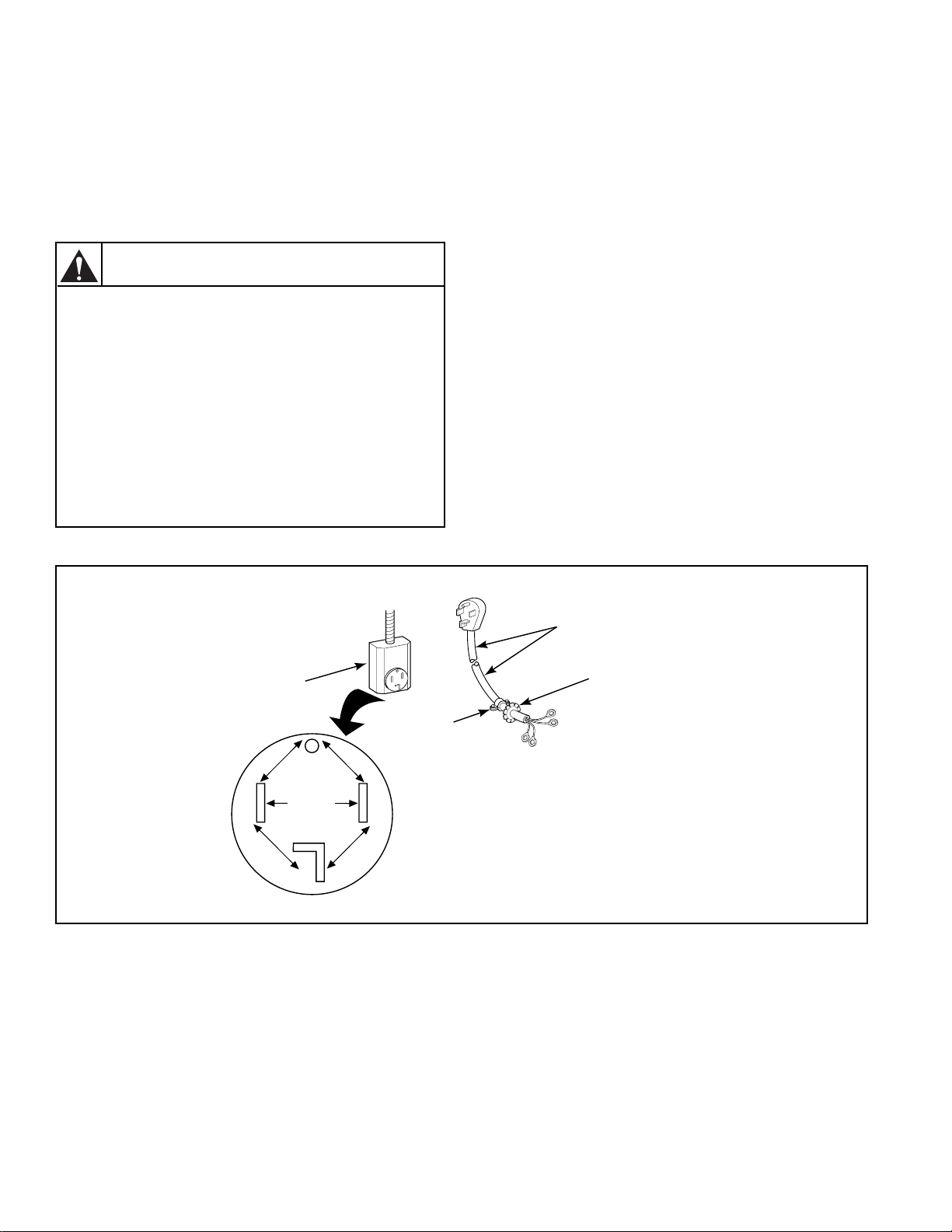

Electrical Requirements . . .

(Electric Dryers)

(120/240 Volt, 60 Hertz, 3-Wire and Ground Installation)

(120/208 Volt, 60 Hertz, 3-Wire and Ground Installation)

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is

the customer’s responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure the laundry room

has adequate electrical power to operate the

dryer.

Grounding and Wiring Instructions

The electric service must be a separate branch,

polarized, three-wire and ground, 120/240 Volt, or 120/

208 Volt, 60 Hz, AC single phase circuit fused with

30 ampere fuses.

The cord and plug assembly (sup plied with dryer) shoul d

be plugged into an approved receptacle that is mounted

on the wall adjacent to the dryer. This receptacle should

be accessible to th e user or service pe rson when the dryer

is in position, to permit disconnecting when necessary.

If the branch circ uit to the dryer is 4.57 mt (15 f ee) or less

in length, use No. 10 AWG wire or as required by local

codes. If ov er 4.57 m (15 feet), a No. 8 AWG wire should

be used, or as required by local codes.

W035

POWER CORD

(Four-Wire)

TYPICAL

FOUR-WIRE

RECEPTACLE

120 ± 12

V.A.C.

240 ± 12

V.A.C.

120 ± 12

V.A.C.

120 ± 12

V.A.C.

120 ± 12

V.A.C.

D106GE2A

STRAIN

RELIEF

STRAIN

RELIEF

NUT

D006IE2B

16 504523

Page 19

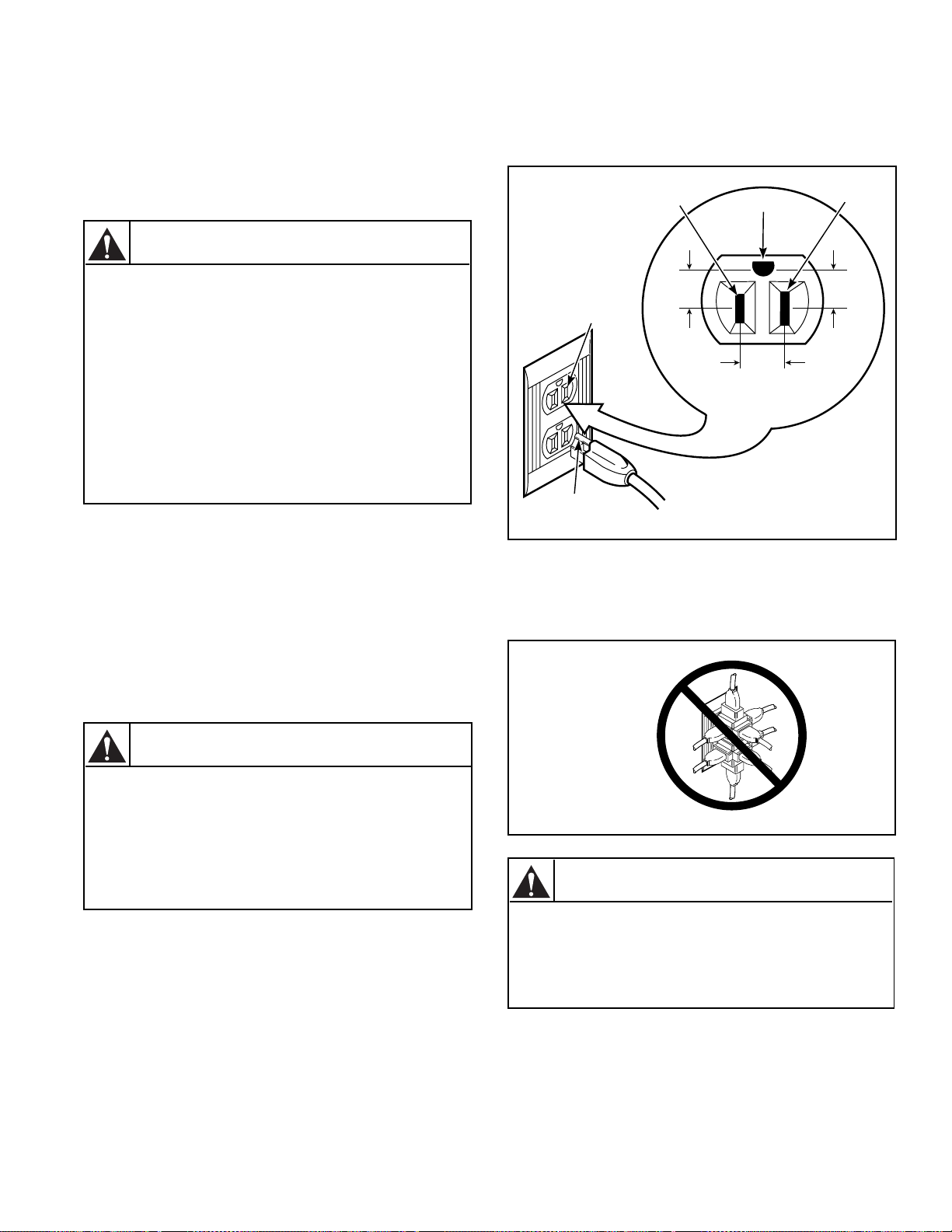

Electrical Requirements . . .

(Gas Dryers)

(120 Volt, 60 Hertz, With 3-Prong Grounding Plug)

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and grounding

MUST conform with the latest edition of the

National Electrical Code ANSI/NFPA 70 or the

Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is

the customer’s responsibility to have the

wiring and fuses checked by a qualified

electrician to make sure the laundry room

has adequate electrical power to operate the

dryer.

W035

• The dryer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current) circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

• The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 120 Volts AC

(alternating current) 15 Amps. See illustration for

determining correct polarity of the wall receptacle.

WARNING

STANDARD

120 VOLT,

60 HERTZ,

3-WIRE EFFECTIVELY

GROUNDED CIRCUIT

NEUTRAL

SIDE

ROUND

GROUNDING PRONG

L1

115 ± 12

V.A.C.

GROUND

115 ± 12

V.A.C.

NEUTRAL

0

V.A.C.

D090IE1C

• DO NOT OPERA TE OTHER APPLIANCES ON THE

SAME CIRCUIT WHEN THIS APPLIANCE IS

OPERATING. DO NOT OVERLOAD CIRCUITS!

See illustration below.

DO NOT

OVERLOAD

CIRCUITS

This dryer is equipped with a three-prong

(grounding) plug for your protection against

D009IE0B

shock hazard and should be plugged direc tly

into a properly grounded three-prong

receptacle. Do not cut or remove the

grounding prong from this plug.

.

NOTE: A qualified electrician should check the

polarity of the wa ll recep tacles. If a voltage reading is

measured other than that illustrated, the qualified

electrician should correct the problem.

504523 17

W036

T o reduc e the risk of an ele ctric s hock or fire ,

DO NOT use an extension cord or an adapter

to connect the dryer to the electrical power

source.

WARNING

W037

Page 20

Grounding Instructions

• The dryer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The dryer is equipped

with a cord ha ving an equi pment-gro unding conduc tor

and a three prong grounding plug. The plug must be

plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the dryer is properly

grounded.

• DO NOT modify the plug provided with the dryer—if

it will not fi t the outlet, ha ve a proper outlet i nstalled by

a qualified electrician.

• If the laundry room’s electrical supply does not meet

the above specifications and/or if you are not sure the

laundry room has an effective ground, ha v e a qualified

electrician or your local electrical utility company

check it and correct any problems.

W038

18 504523

Page 21

Gas Requirements . . .

(Gas Dryers)

NOTE: The gas service to a gas dryer must conform

with the local codes and ordinances, or in the absence

of local codes and or dinances, with the l atest edition of

the National Fuel Gas Code ANSI Z223.1/NFPA 54 or

the CAN/CGA-B149, National Gas Installation Code.

3

Natural Gas, 37.3 MJ/m

be supplied at 6.5 ± 1.5 inch water column pressure.

For proper oper ation at altitudes abo ve 610 m (2,000 feet)

the natural g as v alv e spud orif ice si ze must b e redu ced to

ensure complete combustion. See table at right.

L.P. (Propane) Gas, 93.1 MJ/m

must be supplied at 10 ± 1.5 inch water column pr es sur e.

NOTE: DO NOT connect the dryer to L.P. (Propane)

Gas Service without convertin g the gas valve. A 458P3

L.P. (Propane) Gas Conversion Kit must be installed

by the Manufacturer’s Authorized Dealers,

Distributors, or local service personnel.

NOTE: The dryer and its individual shut-off valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 3.45 kPa (1/2 psi).

(1,000 Btu/ft3), service must

3

(2,500 Btu/ft3), service

WARNING

To reduce the risk of gas leaks, fire or

explosion:

• The dryer must be connected to the type of

gas as shown on nameplate located in the

door recess.

• Use a new flexible stainless steel

connector.

• Use pipe joint compound insoluble in LP

(propane) Gas, or Teflon tape, on all pipe

threads.

• Purge air and sediment from gas supply

line before connecting it to the dryer.

Before tightening the connection, purge

remaining air from gas line to dryer until

odor of gas is detected. This step is

required to prevent gas valve

contamination.

• Do not use an open flame to check for gas

leaks. Use a non-corrosive leak detection

fluid.

W114R1

The dryer must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than

3.45 kPa (1/2 psi)

NOTE: When connecting to a gas line, an equi pment

shutoff valve must be installed within 1.8 m (6') of the

dryer. An 1/8" N.P.T. pipe plug must be installed as

shown. See illustration.

NEW

STAINLESS

STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 6.1 m (20') - use 3/8" pipe

Longer than 6.1 m (20') - use 1/2" pipe

Altitude Orifice Size Part

Numberm ft # mm Inches

610 2000 41 2.44 0.0960 503776

915 3000 42 2.37 0.0935 503777

1680 5500 43 2.26 0.0890 503778

2135 7000 44 2.18 0.0860 58719

2745 9000 45 2.08 0.0820 503779

3200 10500 46 2.06 0.0810 503780

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

EQUIPMENT

SHUT-OFF

VALVE

Installed within

1.8 m (6') of dryer

D233IE2G

504523 19

Page 22

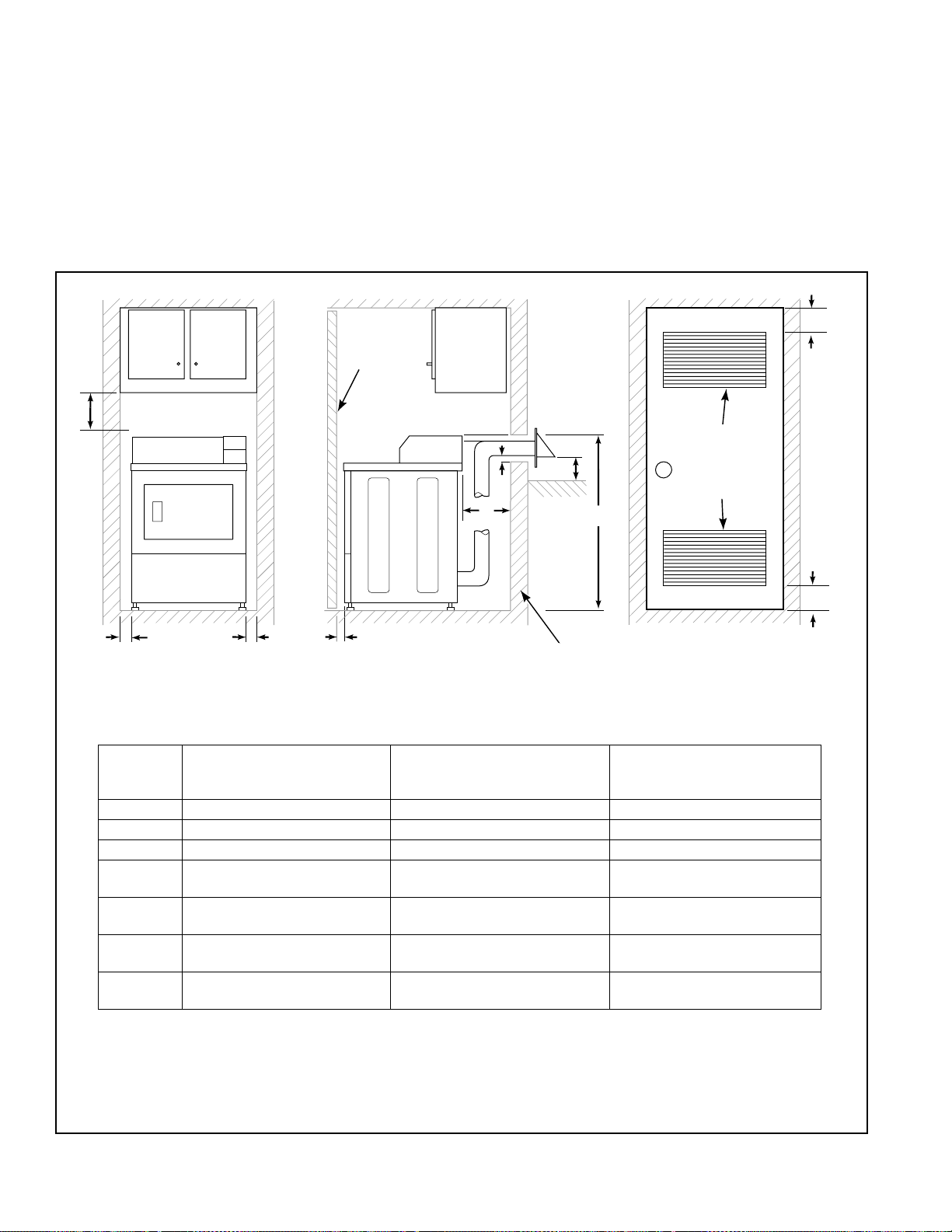

Location Requirements . . .

Select a location with a solid floor.

No other fuel b urning appl iance should b e installed i n the

same closet with the dryer.

The dryer must not be ins talled or stored in an area where

it will be exposed to water and/or weather.

Leveling legs can be adjusted from inside the dryer with

a 1/4" driver. All four legs must rest firmly on the floor so

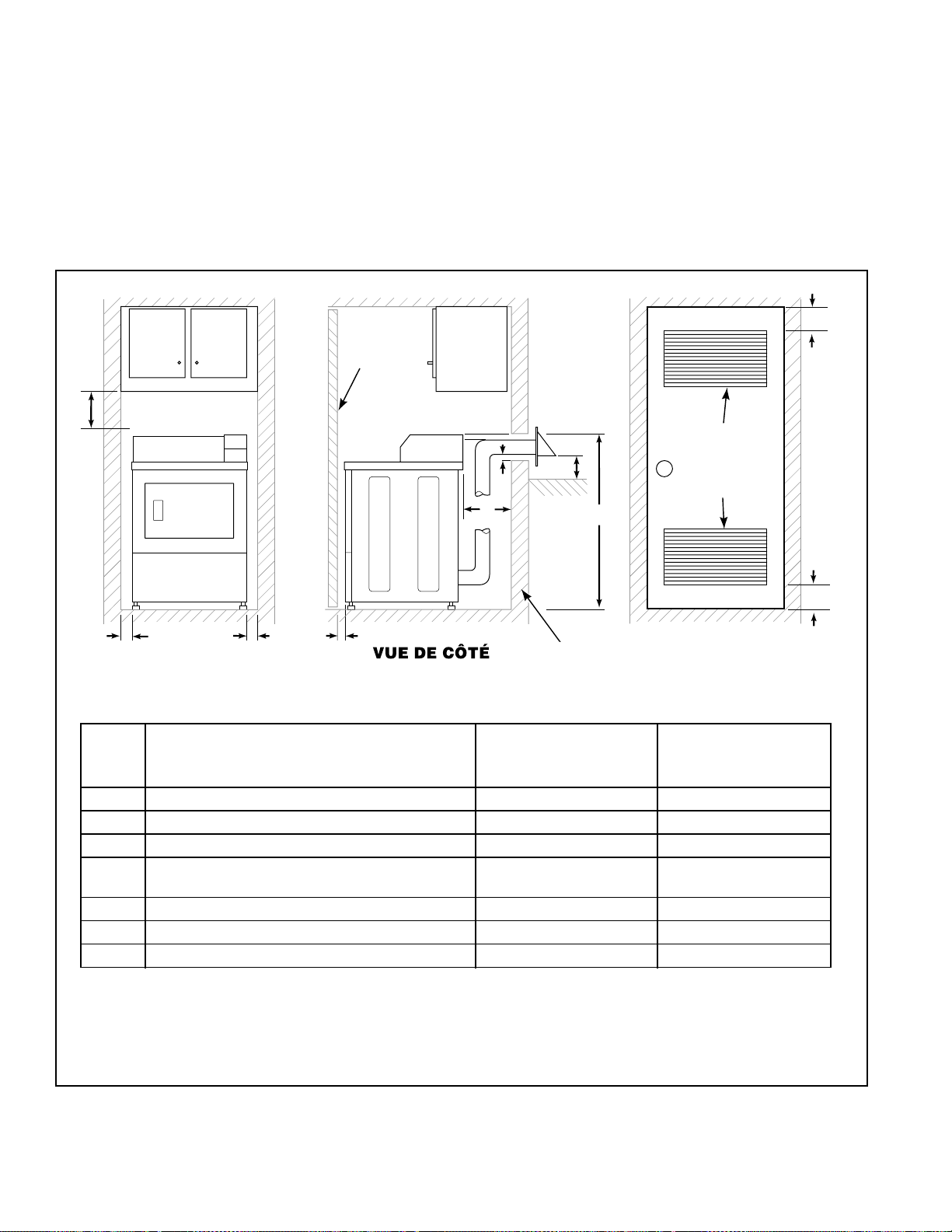

CLOSET

DOOR

B

the weight of the dryer is evenly distributed. The dryer

must not rock.

The dryer needs sufficient clearance and an adequate air

supply for proper operation and vent ilation, and for easi er

installation and servicing. (Minimum clearances are

shown below.)

F

CENTERED

AIR

D

A

E

**42"

OPENINGS (G)

(2 Openings

Minimum)

A

FRONT VIEW

(w/o Closet Door)

AREA DESCRIPTION FREE STANDING /

AC

SIDE VIEW

ALCOVE INSTALLATION

OUTER

WALL OF

ENCLOSURE

FRONT VIEW

(Closet Door)

CLOSET INSTALLATION

(See Illustration)

(See Illustration)

A Dryer sides and rear clearance 0 cm (0") 0 cm (0")

B Dryer top clearance 30.5 cm (12") 30.5 cm (12")

C Dryer front clearance Not Applicable 5.1 cm (2")

D Exhaust duct clearance to

5.1 cm (2") 5.1 cm (2")

combustible material

E Weather hood to ground

30.5 cm (12") 30.5 cm (12")

clearance

F Distance from floor or ceiling

Not Applicable 7.6 cm (3")

to hole edge

G* Area of centered air openings

Not Applicable 260 sq. cm/open (40 sq. in.)

in closet door

*Louvered door with equivalent air openings is acceptable. (Minimum clearances are shown.)

F

D337IE3A

**NOTE: For new installations, locate top of wall vent 106 cm (42 inches) above floor to make venting

easier to connect.

20 504523

Page 23

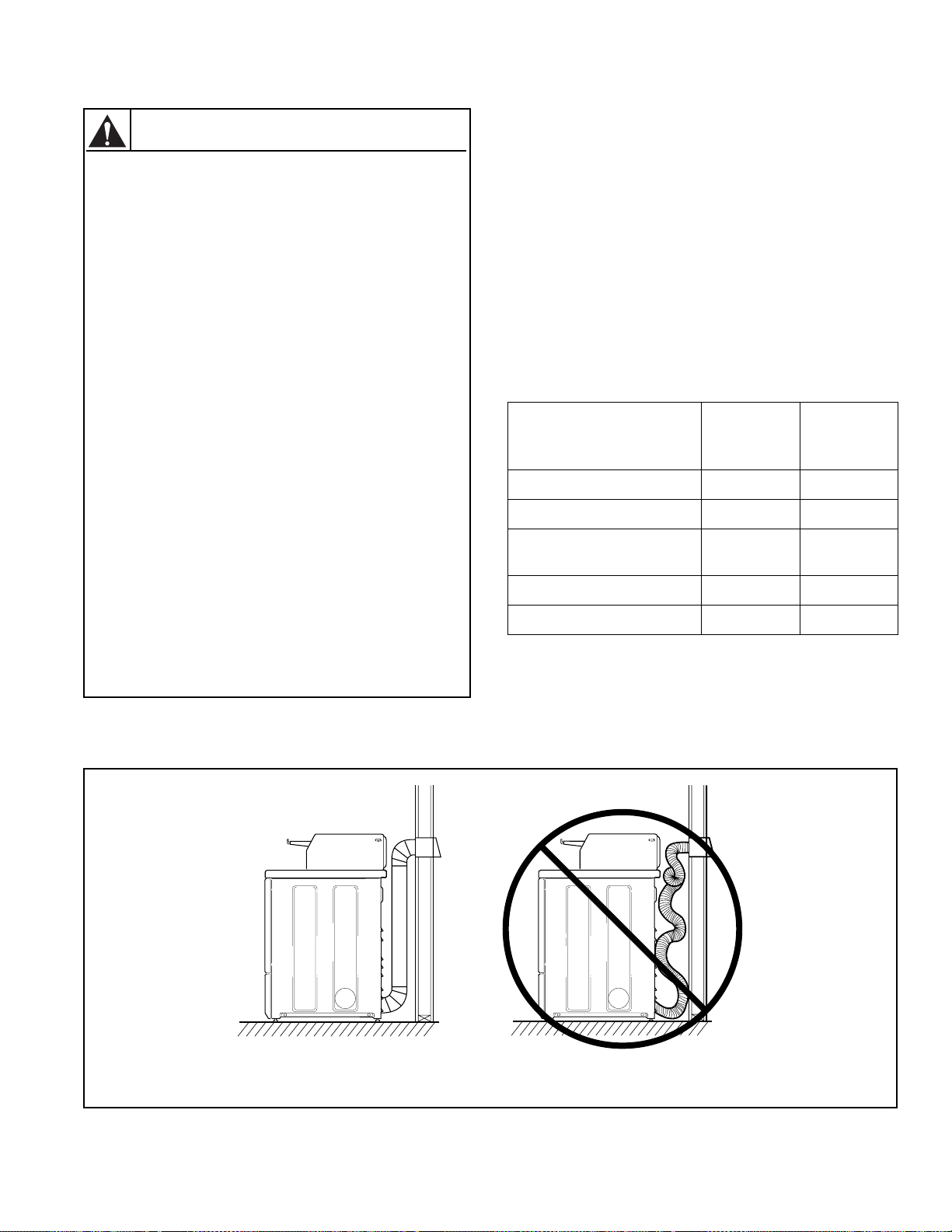

Dryer Exhaust Requirements . . .

W ARNING

A clothes dryer produces combustible lint. To

reduce the risk of fire and combustion gas

accumulation the dryer MUST be exhausted

to the outdoors.

W116

This gas appliance contains or produces a

chemical or chemicals which can cause

death or serious illness and which are known

to the State of California to cause cancer,

birth defects, or other reproductive harm. To

reduce the risk from substances i n the fuel or

from fuel combustion, make sure this

appliance is installed, operated, and

maintained according to the instructions in

this manual.

W115

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated ar ea,

such as an attic, wall, ceiling, crawl space

under a building or concealed space of a

building.

W045

To reduce the risk of fire, DO NOT use plastic

pipe or flexible plastic pipe to exhaust the

dryer .

W041

Exhaust System Materials

Exhaust system materia ls ar e not s uppli ed with the dr yer.

Exhaust duct must be 10.2 cm (four inches) in

diameter having no obstructions. Rigid metal duct is

recommended. Non-combustible semi-rigid flexible

metal duct is acceptable. Do not use plastic pipe or

flexible plast ic pipe, because it contr ibutes to poor dryi ng

performance and collects lint, which can lead to a fire

hazard.

DO NOT use sheet meta l screws on exh aust pipe joints or

other fastening means which extend into the duct that

could catch lint and reduce the efficiency of the exhaust

system. Secure all joints with duct tape.

MAY BE

DESCRIPTION KIT P/N

Exhaust Duct (4" Dia.) Not Available Yes

Flexible Metal Duct (4" Dia) 521P3 Yes

Weather Hoods, with hinged

dampers (4")

Directional Exha ust Kit 528P3 No

Tap e Not Available Yes

Not Available Yes

NOTE: Kits described above are optional exhaust

system materials available at extra cost.

OBTAINED

LOCALLY

Never i nstal l flexible duct in concealed spaces, such as a

wall or ceiling.

D333IE0B

DO

D335IE0A

DON’T

504523 21

Page 24

Make-Up Air Requirements

A dryer exhausts 214 cfm (measured at back of dryer)

and suff icient mak e-up air must be supplied to re place air

exhausted by each dryer.

2

An unobstructed opening of at least 260 cm

inches) of outdoor make-up air MUST be provided for

each dryer. Protective louvers in the opening to the

outdoors can reduce air movement approximately 35 to

40 percent. Be sure the opening is large enough to

compensate for any louvers.

(40 square

clearances may be necessary for installations where

heavy snowfall can occur.

Exhaust Direction

The dryer can be exhausted to the outdoors through the

back, left, right or bottom of the dryer. EXCEPTION:

Gas dryers cannot be vented out the lef t s ide becaus e

of the burner housing.

Dryer is shipped from factory ready for rear exhaust; no

kits required.

If it is necessary to duct make-up air to t he dryer, increase

the area of the ductw ork b y 25 perce nt to compensate for

any reduction i n air movement. In addition, the make-up

air duct should ext end down to wit hin approximately tw o

feet from the floor, directly behind the dryer.

Exhaust System

IMPORTANT: Keep exhaust duct as short as

possible.

NOTE: Be certain old ducts are cleaned before

installing your new dryer.

For best drying results, recommended maximum length

of exhaust system is shown below.

T o prev ent backdra ft when dryer is no t in operation, outer

end of exhaust pipe must have a weather hood with

hinged dampers (obtain locally).

NOTE: Weather hood should be installed at least

30.5 cm (12 inches) above the ground. Larger

Number of

90° Elbows

Recommended Use only for short run installations

Exhausting the dryer through sides or bottom can be

accomplished by installing a Directional Exhaust Kit

528P3 available as optional equipment at extra cost.

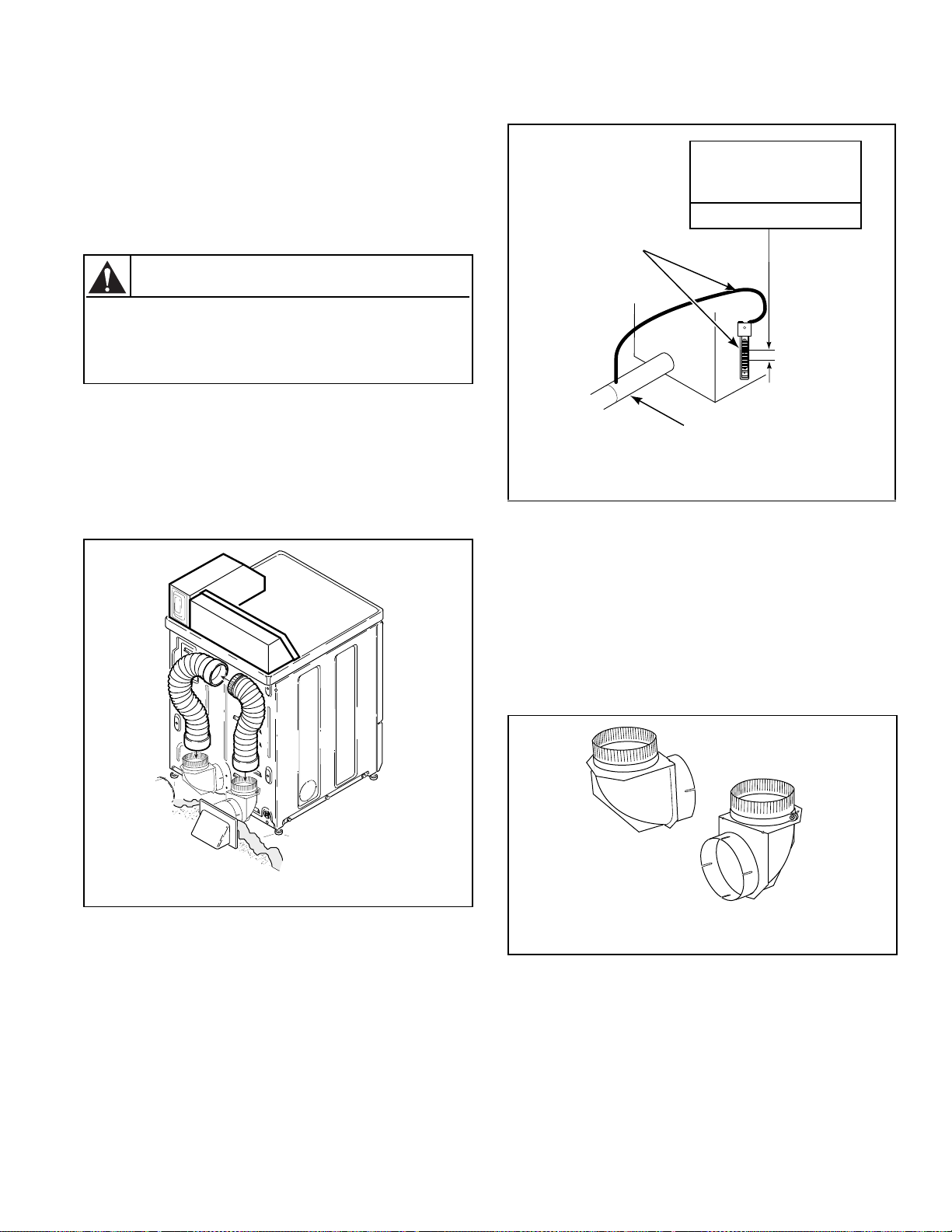

D361IE0A

528P3 Directional Exhaust Kit

Weather Hood Type

10.16 cm

(4")

10.16 cm

(4")

D011IE2P

6.35 cm

(2-1/2")

D011IE2Q

Maximum length of 10.2 cm (4") diameter rigid metal duct.

0 13.4 m (44 feet) 10.4 m (34 feet)

1 10.4 m (34 feet) 7.9 m (26 feet)

2 7.9 m (26 feet) 6.1 m (20 feet)

3 6.1 m (20 feet) 4.3 m (14 feet)

Maximum length of 10.2 cm (4") diameter flexible meta l duct.

0 7.3 m (24 feet) 6.1 m (20 feet)

1 6.1 m (20 feet) 4.9 m (16 feet)

2 4.9 m (16 feet) 3.7 m (12 feet)

3 3.7 m (12 feet) 2.4 m (8 feet)

NOTE: Deduct 1.8 m (6 feet) for each additional elbow.

22 504523

Page 25

Exhaust Sys tem Maintenance

The dryer interior and the complete exhaust system

should be inspected after one year of use and cleaned if

necessary. Inspect and clean exhaust duct every one to

two years as required thereafter. The weather hood

should be checked frequently to make sure the dampers

move freely, dampers are not pushed in and that nothing

has been set against them. This main tenance work should

be done by a qualified service person.

WARNING

To reduce the risk of electric shock,

disconnect the electrical service to the dry er

before cleaning.

W043

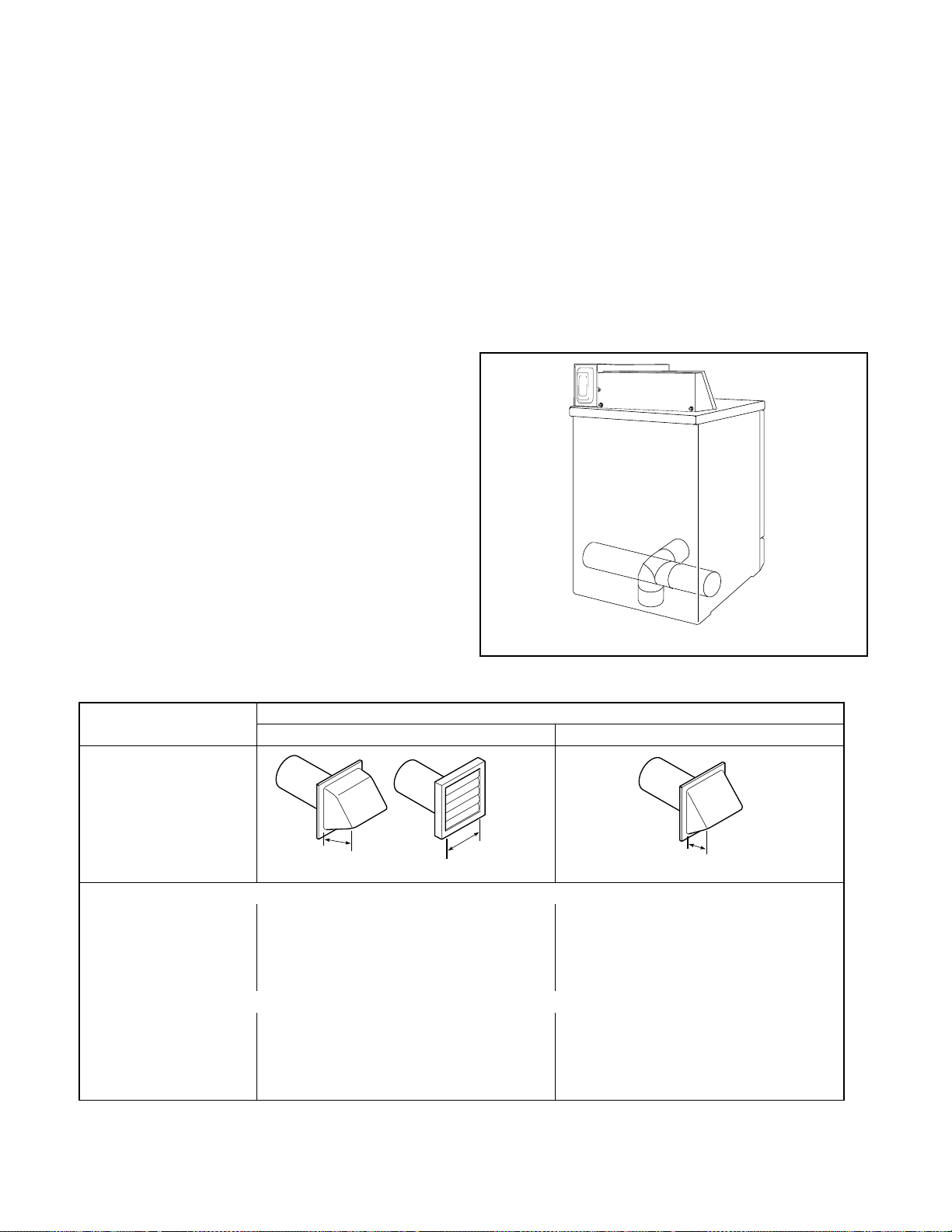

Exhausting the dryer in hard-to-reach locations can be

accomplished by installing the 521P3 Flexible Metal

Vent Kit, available as optional equipment at extra cost.

The kit comes in two halves that can be separately

attached to the dryer and wall outlet. Once attached, the

dryer can be slid back into position and the two halves

can be connected from the front.

NOTE: This can be measured with a manometer

placed on the exhaust duct approximately 61 cm

(two feet) from the dryer, see illustration below.

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

1.5 cm (.6 INCHES)

MANOMETER

EXHAUST

DUCT

Measuring Static Pressure

D012IE0A

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer’s front panel with laundr y, rugs,

etc. Blockage will de crease airf low through the dryer,

thus reducing the efficiency of the dryer.

D362IE1A

521P3 Flexible Metal Vent Kit

Dryer Airflow

Efficient dryer operation requires proper dryer airflow.

Proper dryer airflow can be evaluated by measuring the

static pressure.

Static pressure in the dryer’s exhaust duct should be no

greater than that shown in the chart below. (Check with

dryer running and no load.)

Reduced Clearance Elbow

Installing the dryer in shallow closets can be

accomplished by usi ng an El bow, Part No. 62 688, whic h

is one inch narrower than a standard venting elbow.

D319IE0A

Reduced Clearance Elbow

504523 23

Page 26

Multi-dryer Installation

Exhaust Requirements

• The illustration below shows a typical example of a

multiple dryer ins tallation. Not e how e ach dryer ha s its

own exhau st syst em vented to the centra l exhaust duct.

BACKDRAFT DAMPER

58786

(Available through your

local authorized parts source)

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

CLEAN OUT

COVER MUST

BE PROVIDED

METERED MODELS

ILLUSTRATED

D164IE3B

IMPORTANT: Static press ure in the dryer’ s exhaust

duct should be n o greater than t hat shown in th e chart

WARNING

on Page 23. This can be measured with a manometer

placed on the exhaust duct approximately 60.96 cm

(two feet) from the dryer. See Page 23. All dryers

connected to the main collector duct should be in

operation when pressure is checked.

Installing an exhaust system does not eliminate the

necessity of cl eaning the dryer li nt filter before each load.

The dryer interior and the complete exhaust system

should be cleaned periodically by a qualified service

person to remove any lint build-up.

24 504523

To reduce the risk of electric shock,

disconnect the electrical service to the dryer

before cleaning.

W043

IMPORTANT: DO NOT block the airflow at the

bottom of the dryer’s front panel with laundry, rugs,

etc. Blockage will de crease airf low through the dryer,

thus reducing the efficiency of the dryer.

Page 27

• Dryer exhaust duct should enter the main duct at an

angle of no more than 30

° pointing in the direction of

the air flow. Ducts entering the main duct fro m

opposite sides s houl d be staggered so as not to o ppose

each other. See illustration below.

• Provisions should be made for periodic lint removal

and cleaning of the main collector duct.

DRYER EXHAUST DUCT

AIR FLOW MAIN COLLECTOR DUCT

DRYER EXHAUST DUCT

30°

• The outside end of the main duct should have a

weather hood (with hinged dampers) installed to

prevent passage of weather elements, insects, dust,

and dirt into the dryers.

• If a weather hood cannot be used, the outside end of

the main duct should have a sweep elbow installed,

and be directed do wnw ard as sh o wn on pa ge 24. If the

main duct travels vertically through a roof rather than

through a wall, install 180

° sweep elbow on the end

of the duct with outlet at least 60.96 cm (24 inches)

above the highe st part of the building.

30° 30°

DRYER EXHAUST DUCT

DRYER EXHAUST DUCT

30°

• Sufficient make-up air must be supplied to replace air

exhausted from dryers.

NOTE: Where the exhaust duct pierces the wall or

ceiling, an opening having a diameter of 10.2 cm

(4 inches) larger than the diameter of the exhaust

duct shall be provided, and the exhaust duct centered

within the opening.

• Damper, Part No. 58786, should be installed in each

dryer’s exhaust system. This will prevent a backdraft

when dryer is not in use, and will keep the exhaust air

in balance within the central exhaust system.

D026IE3A

W ARNING

IMPORTANT: Provisions must be made for make-up

air.

To reduce the risk of fire and the

accumulation of combustion gases, DO NOT

exhaust dryer air into a window well, gas

vent, chimney or enclosed, unventilated

area, such as an attic, wall, ceiling, crawl

IMPORTANT: If several dryers are exhau sted i nto a

main collector duct, it is essential that ductwork be

adequate in size and properly const ructed for efficient

operation.

space under a building or concealed space

of a building.

W045

504523 25

Page 28

WEATHER HOOD

OR SWEEP ELBOW

(No cap or screen)

180˚ SWEEP

ELBOW

(No cap

or screen)

PARAPET

MAIN COLLECTOR DUCT

WALL

• Main collector duct should be sized according to

specifications shown below.

Number of Dryers

2 17.8 cm (7 inches) 20.3 cm (8 inches)

3 20.3 cm (8 inches) 22.9 cm (9 inches)

4 22.9 cm (9 inches) 25.4 cm (10 inches)

5 25.4 cm (10 inches) 27.9 cm (11 inches)

Minimum Diameter of

Horizontal Collector Duct

60.96 cm

(24") MIN.

MAIN COLLECTOR DUCT

VERTICAL DUCTHORIZONTAL DUCT

Minimum Diameter of

Vertical Collector Duct

ROOF

D039IE3D

6 27.9 cm (11 inches) 30.5 cm (12 inches)

7 30.5 cm (12 inches) 32.6 cm (13 inches)

8 30.5 cm (12 inches) 35.6 cm (14 inches)

9 32.6 cm (13 inches) 38.1 cm (15 inches)

10 35.6 cm (14 inches) 38.1 cm (15 inches)

11 35.6 cm (14 inches) 40.6 cm (16 inches)

NOTE: Main collector duct should be equipped with

an auxiliary fan that can mainta in the duct airf low at

a minimum of 366 m (1200 feet ) per min ute. If you do

not have a fan, clean the main collector duct at least

twice a year.

26 504523

Page 29

Manufactured (Mobile) Home

Installation . . .

IMPORTANT: Installation must conform to

the Manufactured Home Construction and

Safety Standards, Title 24 CFR, Part 32-80 or

Standard CAN/CSA-Z240 MH.

The dryer can be installed in a manufactured (mobile)

home by following these instructions:

1. IMPORTANT: Gas dryers MUST be

permanently attached to the floor at the time of

installation. Order No. 526P3 Dryer Installation

Kit for a manufactured (mobile) home

installation. F ollow th e instructions supplied with

the kit.

2. Venting— Dryer MUST be e xhausted to the outdoors.

WARNING

T o red uce the risk of fire and combustion gas

accumulation, the dryer MUST BE

EXHAUSTED TO THE OUTDOORS. Refer to

Section on Dryer Exhaust Requirements.

W047

• The dryer can be exhausted to the outdoors through

the back, left, right or bottom panel. Gas dryers

cannot be exhausted out the left side be cause of the

burner housing.

• Dryer exhaust MUST NOT terminate under the

mobile home.

• For proper operation, it is important that the dryer has

an ample amount of out side mak e-up air. The free area

of any opening for the in tr oducti on of out side ai r must

be at least 163 cm

• When exhausting the dryer to the outdoors, the dryer

can be installed with “0” inch clearance at the sides

and rear. Clearance of the duct from combustible

construction must be a minimum of 5.1 cm (2 inches).

• Venting materials are not supplied with the dryer

(obtain locally).

2

(25 in2).

W ARNING

To reduce the risk of fire, the exhaust duct

and weather hood MUST be fabricated of a

material that will not support combustion.

Rigid or flexible metal pipe is recommended

for a clothes dryer.

W048

• Exhaust duct must be secured to the mobile home

structure.

• Exhaust ducts MUST NOT be connected with sheet

metal screws or faste ners which exten d into the duct.

• Exhaust duct MUST NOT be connected to any other

duct, vent or chimney.

504523 27

Page 30

Lint Filter . . .

CLEAN THE LINT FIL TER BEFORE DR YING EA CH

LOAD. (Refer to illustration below for lint filter

location.) Cleaning the lint filter is important because a

layer or pad of lint on th e filter will block the flow of air

through the dryer, thus reducing the efficiency of the

dryer . The cl othes will take l onger to dry and ener gy wil l

be wasted.

LINT

FILTER

Motor Overload Protector . . .

The motor overload protector stops the motor and shuts

the heat off automa tically in the event of an overload.

After cooling, the overload protector will reset itself.

The dryer can be restarted by pressing or turning the

D349IE3B

PUSH-TO-START button. If the overload protector

cycles again, remove the dryer from use and call the

service person to correct the problem.

28 504523

Page 31

User-Maintenance Instructions . . .

Lubrication

All moving parts are sealed in a permanent supply of

lubricant or are equipped with oilless bearings.

Additional lubrication will not be necessary.

Care of Your Dryer

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

W049

Clean the lint fi lter before drying each loa d. The lint filter

may be washed if neede d. Occasionally remo ve li nt fil ter

and vacuum the area under it.

Ordinarily, the dryer cylinder will need no care.

Wipe the dryer cabin et as needed. If det ergent, bleach or

other washing products have been spilled on the dryer,

wipe immediately. Some products will cause permanent

damage if spilled on the cabinet.

Do not allow sharp or rough objects to lean against the

dryer. The finish could be damaged.

Use only a damp or sudsy cloth for cleaning the control

panel. Some spray prew ash products may harm th e finish

on the control panel.

NOTE: The wiring diagram is located inside the

control panel.

For Energy Conservation . . .

• Make sure the lint filter is always clean.

• Do not overload dryer.

• Do not overdry clothes.

• Remove items to be ironed wh ile still damp.

• Large loads of similar fabrics dry the most efficiently.

However, dry permanent press in smaller loads to

prevent wrinkling.

• Use the correct temperature FABRIC SELECTOR

setting for the type of fabric being dried.

Exhaust System

The exhaust duct should be inspected after one year of

use and cleaned if nece ssary by a qualif ied service pers on

to remove any lint build-up. Inspect and clean exhaust

duct every one to two years as required thereafter.

The weather hood should be check ed f requent ly t o make

sure the dampers mov e freel y, dampers are not pushed in

and that nothing has been set against them.

Keep dryer area clear and free from combustible

materials, gasoline and other flammable vapors and

liquids.

Do not obstruct the flow of combustion and ventila tion

air.

NOTE: Verify proper operation after servicing.

• Locate your dryer so the exhaust duct is as short and

straight as possible.

• Do not open the door during the drying cycle.

• Plan to do your laundry on low humidity days; your

clothes will dry faster.

• Should you plan to dry sev eral loads , do them one a fter

another, then you do not have to reheat the dryer’s

interior parts each time.

504523 29

Page 32

Before You Call For Service . . .

You may save time and money by checking the following:

•If Your Dryer:

Does

Not

Start

•

•

•

•

•

•

•

•

Does

Not

Heat

•

•

•

•

•

Does not Dry

Clothes

Satisfactorily

Possible Reason — Do This To Correct

Metered models—Insert coin(s) or card.

Nonmetered models—Turn the timer knob further into the cycle.

Be sure the cord is plugged all the way into the electrical outlet.

Close the loading door.

Make sure the controls are in a HEAT setting.

Metered models—Activate time accumulator. Push the coin slide all the

way in.

Press the PUSH-TO-START button.

Has the laundry room fuse blown or become loosened, or is a circuit

breaker OFF? The dryer itself does NOT have an electrical fu se.

Has the motor overload protector cycled? Wait 10 minutes and try again.

Gas Dryers Only—Check to se e if the gas valve in the drye r (behind the

lower front panel) and the main gas line valve are turned on.

•

••

••

•

Clean the lint filter.

Check the exhaust duct to the outside to see if it is kinked, blocked or

needs cleaning.

Check the weather hood to make sure the flappers move freely, are not

pushed in or have not been blocked.

Is the load too smal l? Small loads may not tumble properly or dry

evenly.

30 504523

Page 33

Additional Dryer Security . . .

(Metered Models)

WARNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the dryer

before servicing.

• Never start the dryer with any guards/

panels removed.

• Close gas shut-off valve to gas dryer before

servicing.

• Whenever ground wires are removed

during servicing, these ground wires must

be reconnected to ensure that the dryer is

properly grounded.

W138

7. While supporting lower access panel, remove two

screws from bo ttom edge. Gen tly lower a ccess panel

to disengage guide lugs from bottom edge of front

panel.

8. Remove two screws holding bottom tabs on front

panel to dryer cabinet. Swing bottom of front panel

away from dryer f ar enough to disenga ge hold-do wn

clips and guide lugs from cabinet top.

9. Disconnect wires from door switch.

NOTE: Refer to wiring diagram when rewiring

switch.

10. Remove two cabinet top hold-down scerws and

install two #10 tamper-resistant screws, Part No.

62853.

Enclosed in the shipping bag are four tamper-resistant

screws. When used , these scre ws will pro vide add itional

security for your dryer.

Located on the service door of the dryer is a flat Phillips

head scre w . During shipme nt, this scre w is used t o attach

the service door to the meter case. For additional

security, this screw can be reinstalled inside the control

hood of your washer.

The follo wi ng li st is the procedure re quired to install the

Phillips head screw and tamper-resis ta nt screws:

1. Remove the Phillips head screw from service door

(see illustration).

2. Re mo ve two scr e ws holdi ng contro l panel to control

hood.

3. T il t control panel forward and la y on a protecti ve p ad

to prevent scratching of cabinet top.

4. I nsert philli ps head screw do wn throu gh double “D”

hole in left rear corner of cabinet top (inside co ntrol

hood) until it enga ges retainer nut located on left re ar

corner gusset of cabinet.

5. Finger tighten screw.

IMPORTANT: Do not use a power driver to tighten

screw. Torque of a power driver could over-tighten

screw causing damage to cabinet assembly.

6. Se cure control panel to control hood using tw o No. 8

tamper-resistant screws, Part No . 35528.

11. R ei nstall door switch and front p ane l and install two

#10 tamper-resistant screws, Part No. 62853 to

secure lower access panel.

NOTE: Tamper-resistant bits and bit holder, for

installation of tamper-resistant screws, are available

as optional equipment at extra cost.

DOUBLE

“D” HOLE

#8 SCREWS

35528

#10 SCREWS

62853

#10 SCREWS

62853

D237IE1A

Bit (No. 8 screws)...................Part No. 281P4

Bit (No. 10 screws)................. Part No. 282P4

Bit Holder (3/8 drive).............. Part No. 24161

504523 31

Page 34

Operation Instructions for

D339I

Electromechanical Dryers . . .

(Metered and Nonmetered Models)

IMPORTANT: Before using dryer for the first time,

use an all-purpose cleaner, or a detergent and water

solution, and a damp cloth to remove shipping dust

from inside of dryer drum.

STEP 1:

Clean Lint Filter

Clean lint filter before each use.

D349I

STEP 3:

Close Loading Door

Close loading door. Dryer will not operate with the door

open.

D326I

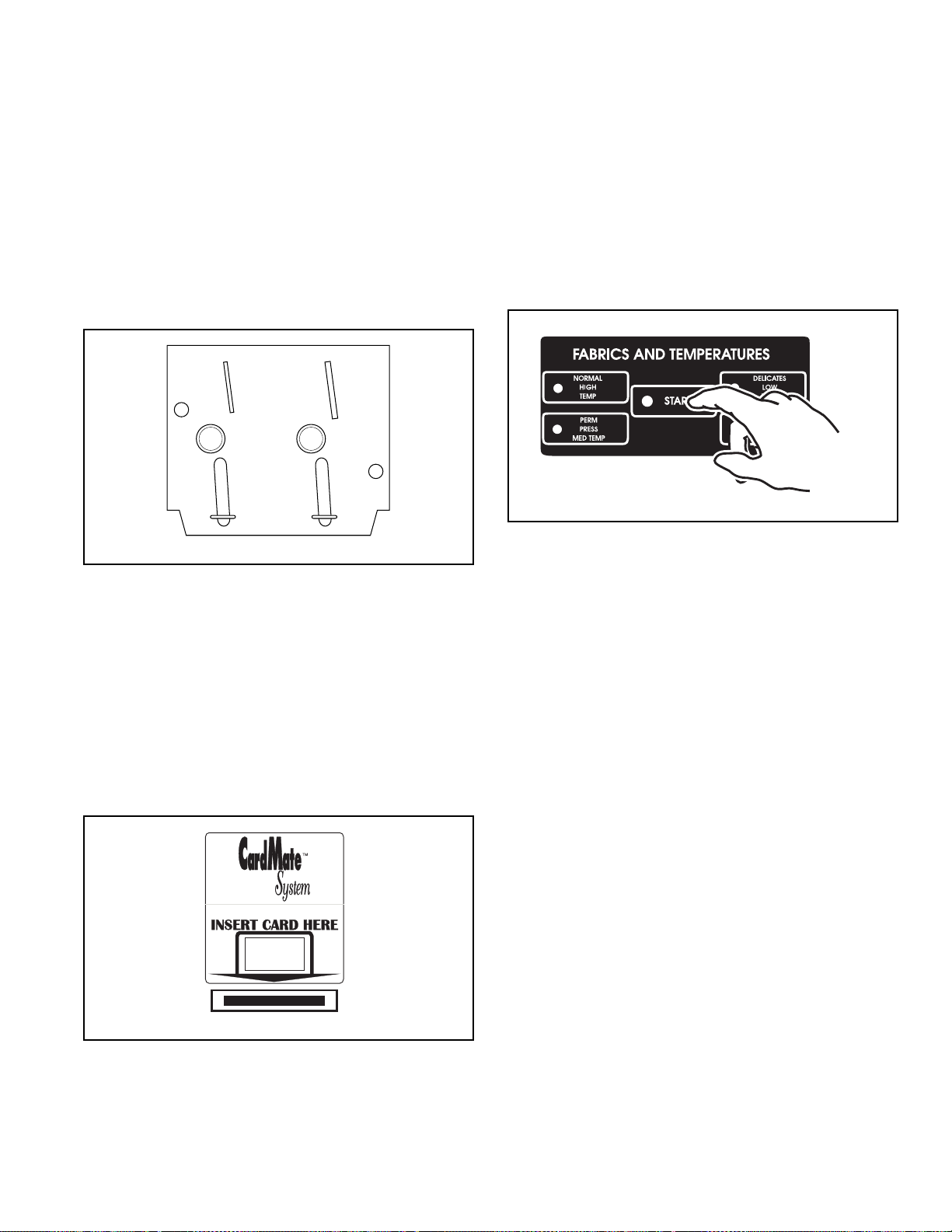

STEP 4:

Set Fabric Selector

STEP 2:

Load Laundry

Load clothes l oosely into dryer drum. Add fabric softener

sheet if desired.

Select NORMAL for cottons, PERM PRESS for

permanent press, DELICATE for sensitive items or

FLUFF NO HEAT for items that require no heat.

Always follow Manufacturer’s Care Label

instructions.

PERM

DELICATE

PRESS

NORMAL

FLUFF

(NO HEAT)

FABRIC SELECTOR

D342I

32 504523

Page 35

STEP 5:

W297IE0A

Metered Models

Start Dryer

METERED MODELS:

Place coin(s) in slide and carefully push in as far as

possible and then pull slide out as far as possible. After

IN USE light comes on (indicating start of cycle), press

the PUSH-TO-STA RT button.

NONMETERED MODELS:

Rotate timer knob to desired time setting (up to 60

minutes). After IN USE light comes on (indicating start

of cycle), press the PUSH-TO-START button.

Remove knits when slightly damp because overdrying

may cause shrinkage. Do not tumble dry knit woolens.

Should dryer stop before cycle is completed, the motor

overload prot ector may have cycled. See page 28.

D365IE1A

Nonmetered Models

504523 33

Page 36

Operation Instructions for

D339I

Electronic Control Dryers . . .

(Metered and Nonmetered Models)

IMPORTANT: Before using dryer for the first time,

use an all-purpose cleaner, or a detergent and water

solution, and a damp cloth to remove shipping dust

from inside of dryer drum.

STEP 1:

Clean Lint Filter

Clean lint filter before each use.

D349I

STEP 3:

Close Loading Door

Close loading door. Dryer will not operate with the door

open.

D326I

STEP 4:

STEP 2:

Load Laundry

Load clothes l oosely into dryer drum. Add fabric softener

sheet if desired.

Set Fabric Selector

Select NORMAL (High Temp), PERM PRESS (Med

Temp), DEL ICATES (Low Temp) or TUMBLE (No

Heat) by pushing touchpad.

Always follow Manufacturer’s Care Label

instructions.

D294I

34 504523

Page 37

STEP 5:

M330I

STEP 6:

Insert Coin(s) or Card

To Insert Money.

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

If Additional Time Feature is turned on, additional dryer

time may be purchased at cycle start or while dryer is

running.

W388I

To Insert Card:

Start Dryer

To start dryer, push START pad.

To stop dryer at any time, open the door. To restart the

dryer, close door and push START pad.

Cycle is completed when time remaining reaches 00

minutes.

D296I

Insert card into opening. Follow directions on display.

DO NOT REMOVE THE CARD UNTIL DISPLAY

READS “Remove Card.”

Remove knits when slightly damp because overdyring

may cause shrinkage. Do not tumble dry knit woolens.

504523 35

Page 38

Indicator Lights

INSERT COINS

INSERT COINS is lit to prompt the user to inser t coins to

satisfy the v end price for the chos en cycle. When INSERT

COINS is lit, the three digits and decimal point will

display the vend price remaining to be satisfied.

PUSH START

PUSH START is lit whenever the dryer is not in a cycle,

the full ve nd price has bee n satisf ied and the d ryer door is

closed. When the START pad is pressed, the cycle will

begin or res ume. The PUSH ST ART status word flashes at

one-second intervals when activated.

DRYING

DRYING is lit to indicate that one of the heated cycles

(HIGH TEMP, MED TEMP , LOW TEMP) i s currently in

operation. The s tatus word DR YING goes off at the end of

a heated cycle or when the COOL DOWN cycle begins.

DOOR OPEN

DOOR OPEN is lit and flashes at one-second intervals

whenever the dryer door is open.

COOL DOWN

COOL DOWN is lit whenev er the COOL DO WN port ion

of a heated cycle is active. It is also lit when the NO

HEAT cycl e is in operation.

PRICE

PRICE is lit to indicate that the value displayed is the

vend pricing remaining to be satisfied. Once the vend

price is satisfied, the word PRICE will go off.

TIME REMAINING

TIME REMAINING is lit to indicate that the time

displayed by two digits and the colon is the time

remaining (in minutes) in the active cycle. The colon

flashes at one-second intervals and time continually

counts down in an active cycle.

Should dryer stop before cycle is completed, the motor

overload prot ector may have cycled. See page 28.

36 504523

Page 39

Information for Handy Reference . . .

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 59471-0990

Date Purchased

Model Number Serial Number

Dealer’s Name

Dealer’s Address Phone Number

Service Agency

Service Agency Address Phone Number

NOTE: Record the above information and keep y our sales slip. Model and serial numbers are located on the

nameplate.

504523 37

Page 40

38 504523

Page 41

Sécheuses

commerciales

individuels payantes

ou non payantes

(modèles électriques et à gaz)

D’installation et de fonctionnement

CONSERVER CES INSTRUCTIONS POUR REFERENCE FUTURE.

(Si la sécheuse change de propriétaire, veillez à ce que ce manuel accompagne

la sécheuse.)

Réf. n° 504523R3

Novembre 1998

Page 42

AVERTISSEMENT

Assurez-vous de bien suivre les instructions données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou pour éviter tout dommage matérial,

toute blessure ou la mort.

• Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables

dans le voisinage de cet appareil ou de tout autre appareil.

• QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

–Ne pas tenter d’allumer d’appareil.

–Ne toucher à aucun interrupteur. Ne pas vous servir des téléphones se trouvant dans

le bâtiment où vous vous trouvez.

–Évacuer la pièce, le bâtiment ou la zone.

–Appeler immédiatement votre fournisseur de gas depuis un voisin. Suivre les

instructions du fournisseur.

–Si vous ne pouvez rejoindre le fournisseur de gas, appeler le service des incendies.

• L’installation et l’entretien doivent être assurés par un installateur ou un service

d’entretien qualifié ou par le fournisseur de gaz.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflam mables dans

le voisinage de cet appareil ou de tout autre appareil.

W033

IMPOR TANT : L’acheteur d oit con sulter le f our nisseur en gaz loca l af in de connaî tre l es instru ctions à

suivre au cas où l’utilisateur sentirait des émanations de gaz. Les instructions du service de

distribution de gaz ainsi que les avis de SÉCURITÉ et d’AVERTISSEMENTS indiqués ci-dessus

doivent être affichés dans un endroit bien visible près de la sécheuse à l’utilisation du client.

Les modèles électriques ne sont pas certifies CGA.

40 504523 (QU)

Page 43

Table des

matières

Pièces de rechange...............................................................................42

Consignes de sécurité importantes ...................................................43

Dimensions pour l’installation...........................................................45

Boîte à monnaie ..................................................................................47

Came du compteur ............................................................................. 47

Installation de l’extension d’une glissière sur sécheuse .................. 48

Avant de commencer

Outils ..............................................................................................49

Évacuation......................................................................................49

Électricité........................................................................................49

Gaz..................................................................................................49

Emplacement..................................................................................49

Installation de la sécheuse

ÉTAPE 1 (Placer la sécheuse et la mettre à niveau).......................50

ÉTAPE 2 (Raccorder le système d’évacuation de la sécheuse)...... 50

ÉTAPE 3 (Raccorder le tuyau d’alimentation de gaz)....................51

ÉTAPE 4 (Nettoyer l’intérieur de la sécheuse)...............................52

ÉTAPE 5 (Brancher la sécheuse)....................................................52

ÉTAPE 6 (Vérifier l’installation)....................................................52

Vérification de la source de chaleur ..................................................53

Instructions d’inversion de porte.......................................................55

Installation électri que (séc heus es éle ct ri ques )..................................56

Installation électri que (séc heus es à gaz)........ ......... ......... ......... .........57

Installation au gaz...............................................................................59

Dimensions de l’emplacement............................................................60

Critères d’évacuation de la sécheuse

Matériaux du système d’évacuation...............................................61

Exigences d’air neuf d’appoint.......................................................62

Système d’évacaution.....................................................................62

Direction d’évacuation ...................................................................62

Maintenance du système d’évacuation...........................................63

Flux d’air de la sécheuse................................................................63

Coude pour espace réduit...............................................................63

Critères d’installation d’évacuation pour plusieurs sécheuses ...... 64

Installation en maison préfabriquée (mobile)..................................67

Filtre a charpie ...................................................................................68

Dispositif protecteur de surcharge du moteur .................................68

Instructions d’entretien à l’intention de l’usager

Lubrification...................................................................................69

Soins de votre sécheuse..................................................................69

Système d’évacuation.....................................................................69

Pour economiser l’energie ................................................................. 69

Avant de faire venir le technicien d’entretien .................................. 70

Mesures de sécurité supplémentaires ............................................... 71

Mode d’emploi pour les sécheuses électromécaniques ...................72

Mode d’emploi pour les sécheuses à commande électronique ....... 74

Informations servant de référence rapide.........................................77

Vérification de l’installation......................................Couverture arrière

© Droit d’auteur 1998, Alliance Laundry Systems LLC

T out droits réservés. T o ute reproduction, m ême partielle, de cet o uvrage est interdi te. Une copie ou dif fusion par quelq ue procédé

que ce soit sans le consentement ecrit de l’éditor constitu e une contrefacon.

41 504523 (QU)

Page 44

Pièces de rechange . . .

Pour obtenir des pièces de rechange, prière de contacter

le distribu teur aupr ès duquel la sécmheus e à été achetée ,

ou contacter :

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Phone: (920) 748-3950

pour obtenir les nom et adresse du distributeur e pièces

agréé local.

504523 (QU) 42

Page 45

CONSIGNES DE SÉCURITÉ IMPORTANTES

(CONSERVER CES INSTRUCTIONS)

12. T OUJOURS nettoyer le f iltr e à charpie à la fi n de

MISE EN GARDE

Pour éviter tout risque d’incendie, de choc

électrique ou de dommages corporels pour

les personnes utilisant la sécheuse, suivre

ces précautions fondamentales :

W034Q

1. Lire toutes les instructions avant d’utiliser la

sécheuse.

2. Consulter les INSTRUCTIONS RELATIVES A

LA MISE A TERRE présentées dans le

MANUEL D’INSTALLATION pour assurer la

mise à terre correcte de la sécheuse.

3. Ne pas faire sécher d’articles ayant été lavés,

trempés ou tachés d’essence, de solvants pour

nettoyage à sec ou d’autres produits

inflammables ou explosifs puisqu’ils produisent

des vapeurs qui risquent de prendre feu ou

d’exploser.

4. Ne pas permettre aux enfants de jouer sur ou

dans la sécheuse. Il faut l es surveiller de très près

lorque’ils sont à proximité de l’appareil. Cette

consigne de sécurité s’applique à tous les

appareils ménagers.

5. Avant de retirer la sécheuse du service ou de la

mettre au reb ut, démonte r la porte donnant acc ès

au compartiment de séchage.

6. Ne pas mettre le bras dans la sécheuse si le

tambour tourne.

7. Ne pas installer ou remiser la sécheuse dans un

endroit où elle sera exposée à l’eau et aux

intempéries.

8. Ne pas abuser les commandes.

9. N’effectuer aucune réparation ni aucun

entretien, et ne changer aucune pièce de la

sécheuse à moins que l’actio n soit spé cifiquement

conseillée dans les instructions d’entretien pour

l’utilisateur ou autre manuel pertinent, que ces

instructions soient convenablement lues et

comprises, et que l’on soit qualifié pour les

effectuer.