Page 1

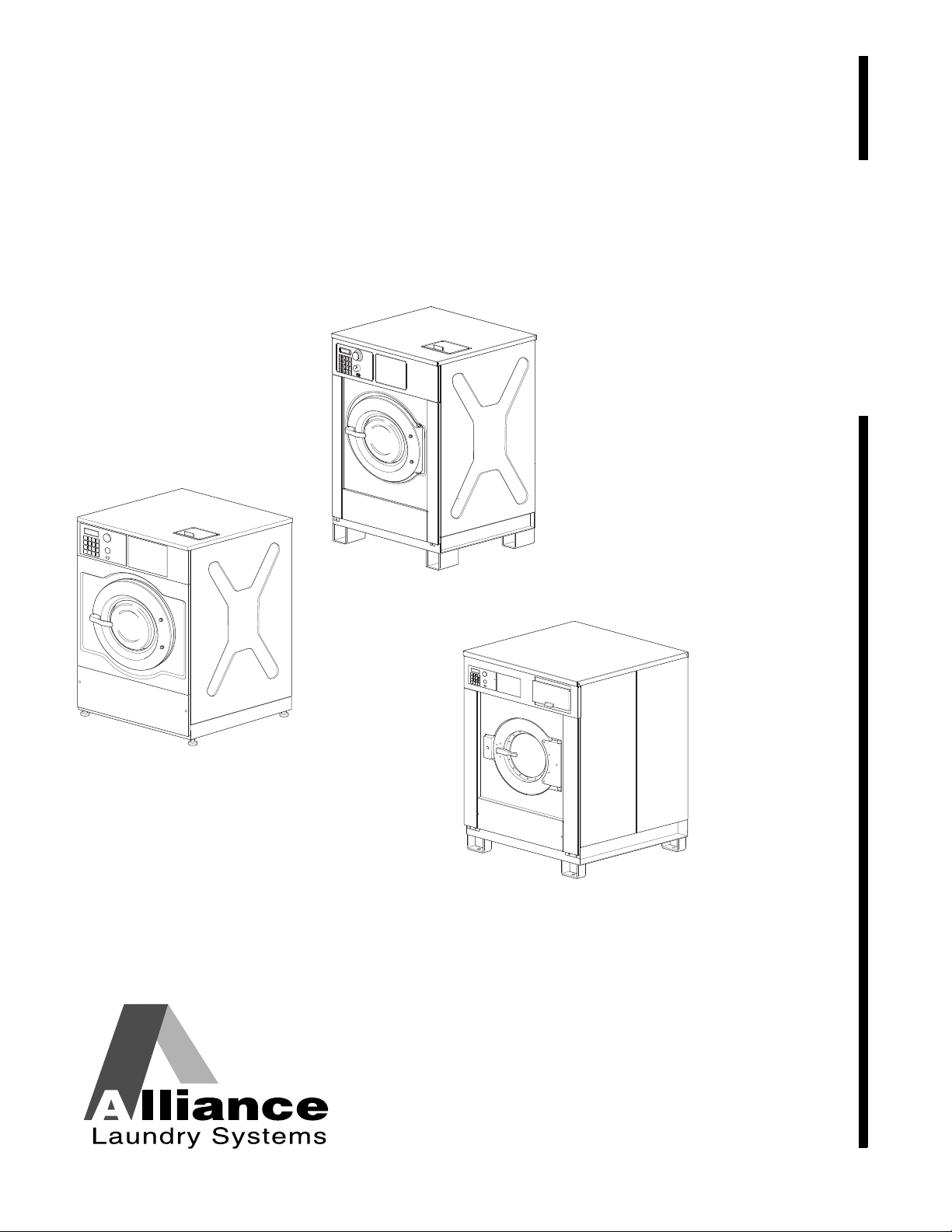

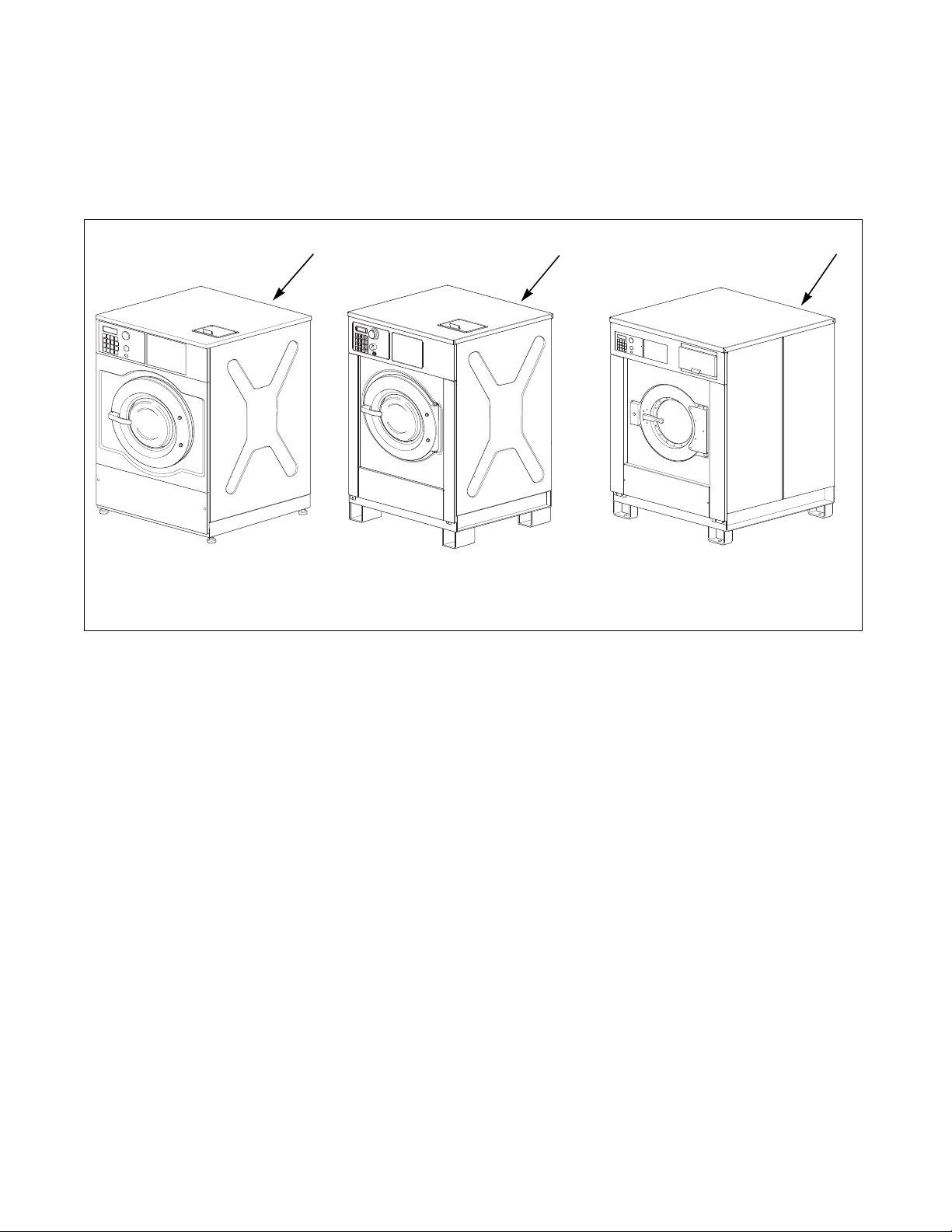

Washer-Extractors

CFD19C

CFD20C

100, 135, 165 and 200 Models

CFD20C

33, 40, 55 and 75 Models

Cabinet Freestanding

Refer to Page 6 for Model Identification

CFD15C

Installation

CFD19C

18, 25 and 35 Models

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. 9001000R13

July 2010

Page 2

Page 3

Table of

Content s

Safety Information.............................................................................. 2

Explanation of Safety Messages........................................................... 2

Important Safety Instructions ............................................................... 2

Safety Decals........................................................................................ 4

Operator Safety....................................................................... ..... ......... 5

Introduction......................................................................................... 6

Model Identification ............................................................................. 6

Nameplate Location.............................................................................. 8

Replacement Parts ................................................................................ 8

Customer Service.................................................................................. 8

Specifications and Dimensions........................................................... 10

Installation........................................................................................... 25

Dimensional Clearances................................................................... 25

Machine Foundation ............................................ ..... .... ................... 26

Mechanical Installation......................................................................... 27

Frame Dimensions and Mounting Bolt Location............................. 27

Mounting Bolt Installation (If Required).............................................. 41

Removing the Transport Brackets........................................................ 42

Drain Connection.................................................................................. 44

Water Connection................................................................................. 46

Electrical Installation............................................................................ 47

Electrical Connection......................................................... ..... .............. 50

Remote Liquid Supply Connection ...................................................... 50

Chemical Injection Supply System.................................................. 50

Steam Requirements (Steam Heat Option Only).................................. 51

Supply Programming Table............................................................. 52

Supply Relay Configuration (No Wiring)........................................ 52

Primary 220 Volt Remote Liquid Supply Connection..................... 52

Out-of-Balance Switch ......................................................................... 54

Automatic Lubricator............................................................................ 54

Control Function Test........................................................................... 55

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Precautionary statements (“DANGER,” “W ARNING ,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT : The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer .

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001000

Page 5

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer , or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. T o reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

20. If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. T o reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards and/or

panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

3

Page 6

Safety Information

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Install the machine on a level floor of

sufficient strength. Failure to do so may

result in conditions which can produce

serious injury, death and/or property

damage.

W703

WARNING

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

IMPORTANT: Ensure that the recommended

clearances for inspection and maintenance

are provided. Never allow the inspection and

maintenance space to be blocked.

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 7

Safety Information

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

Do not bypass any safety devices in the machine.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technicia n.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locke d

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

Model Identification

Information in this manual is applicable to these

models:

HX18PVQM6 SX18PVPA7 UX18PVNA6 HX18PVQU6 SX18PVQU6 UX18PVNU6

HX18PVQM7 SX18PVQM6 UX18PVNA7 HX18PVXU6 SX18PVXU6 UX18PVPU6

HX18PVXM6 SX18PVQM7 UX18PVPA6 UX18PVQU6

HX18PVXM7 SX18PVXM6 UX18PVPA7 UX18PVXU6

SX18PVXM7 UX18PVQA6

18

HX25PVQM6 SX25PVQM6 UX25PVNA6 HX25PVQU6 SX25PVQU6 UX25PVNU6

HX25PVQM7 SX25PVQM7 UX25PVNA7 HX25PVXU6 SX25PVXU6 UX25PVPU6

HX25PVXM6 SX25PVXM6 UX25PVPA6 UX25PVQU6

HX25PVXM7 SX25PVXM7 UX25PVPA7 UX25PVXU6

25

33

HX35PVQM6 SX35PVQM6 UX35PVNA6 HX35PVQU6 SX35PVQU6 UX35PVNU6

HX35PVQM7 SX35PVQM7 UX35PVNA7 HX35PVXU6 SX35PVXU6 UX35PVPU6

HX35PVXM6 SX35PVXM6 UX35PVPA6 UX35PVQU6

HX35PVXM7 SX35PVXM7 UX35PVPA7 UX35PVXU6

SX35PVNM7 UX35PVQA6

35

UX18PVQA7

UX18PVQM6

UX18PVQM7

UX18PVXA6

UX18PVXA7

UX18PVXM6

UX18PVXM7

UX25PVQA6

UX25PVQA7

UX25PVQM6

UX25PVQM7

UX25PVXA6

UX25PVXA7

UX25PVXM6

UX25PVXM7

UX33PVNA7

UX33PVPA7

UX33PVQA7

UX33PVQM7

UX33PVXA7

UX33PVXM7

UX35PVQA7

UX35PVQM6

UX35PVQM7

UX35PVXA6

UX35PVXA7

UX35PVXM6

UX35PVXM7

continued

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001000

Page 9

40

55

75

100

135

165

200

Introduction

continued

UX40PVNA7

UX40PVPA7

UX40PVQA7

UX40PVQM7

UX40PVXA7

UX40PVXM7

HX55PVNU6 SX55PVNU6 UX55PVNU6

HX55PVNU7 SX55PVNU7 UX55PVNU7

HX55PVQU6 SX55PVPU6 UX55PVPU6

HX55PVQU7 SX55PVPU7 UX55PVPU7

HX55PVXU6 SX55PVQU6 UX55PVQU6

HX55PVXU7 SX55PVQU7 UX55PVQU7

SX55PVXU6 UX55PVXU6

SX55PVXU7 UX55PVXU7

HX75PVNU6 SX75PVNU6 UX75PVNU6

HX75PVNU7 SX75PVNU7 UX75PVNU7

HX75PVPU7 SX75PVPU7 UX75PVPU6

HX75PVQU6 SX75PVQU6 UX75PVPU7

HX75PVQU7 SX75PVQU7 UX75PVQU6

UX75PVQU7

HX100PVNU6 SX100PVNU6 UX100PVNU6

HX100PVNU7 SX100PVNU7 UX100PVNU7

HX100PVPU7 SX100PVPU7 UX100PVPU6

HX100PVQU6 SX100PVQU6 UX100PVPU7

HX100PVQU7 SX100PVQU7 UX100PVQU6

UX100PVQU7

HX135PVNU6 SX135PVNU6 UX135PVNU6

HX135PVNU7 SX135PVNU7 UX135PVNU7

HX135PVPU7 SX135PVPU7 UX135PVPU6

HX135PVQU6 SX135PVQU6 UX135PVPU7

HX135PVQU7 SX135PVQU7 UX135PVQU6

UX135PVQU7

HX165PVNU6 SX165PVNU6 UX165PVNU6

HX165PVNU7 SX165PVNU7 UX165PVNU7

HX165PVPU7 SX165PVPU7 UX165PVPU6

HX165PVQU6 SX165PVQU6 UX165PVPU7

HX165PVQU7 SX165PVQU7 UX165PVQU6

UX165PVQU7

HX200PVNU7 SX200PVNU7 UX200PVNU7

HX200PVPU7 SX200PVPU7 UX200PVPU7

HX200PVQU7 SX200PVQU7 UX200PVQU7

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Introduction

1

18, 25 AND 35 MODELS

1

33, 40, 55 AND 75 MODELS

CFD20C

1

CFD20C

100, 135, 165 AND 200 MODELS

CFD19C

CFD15C

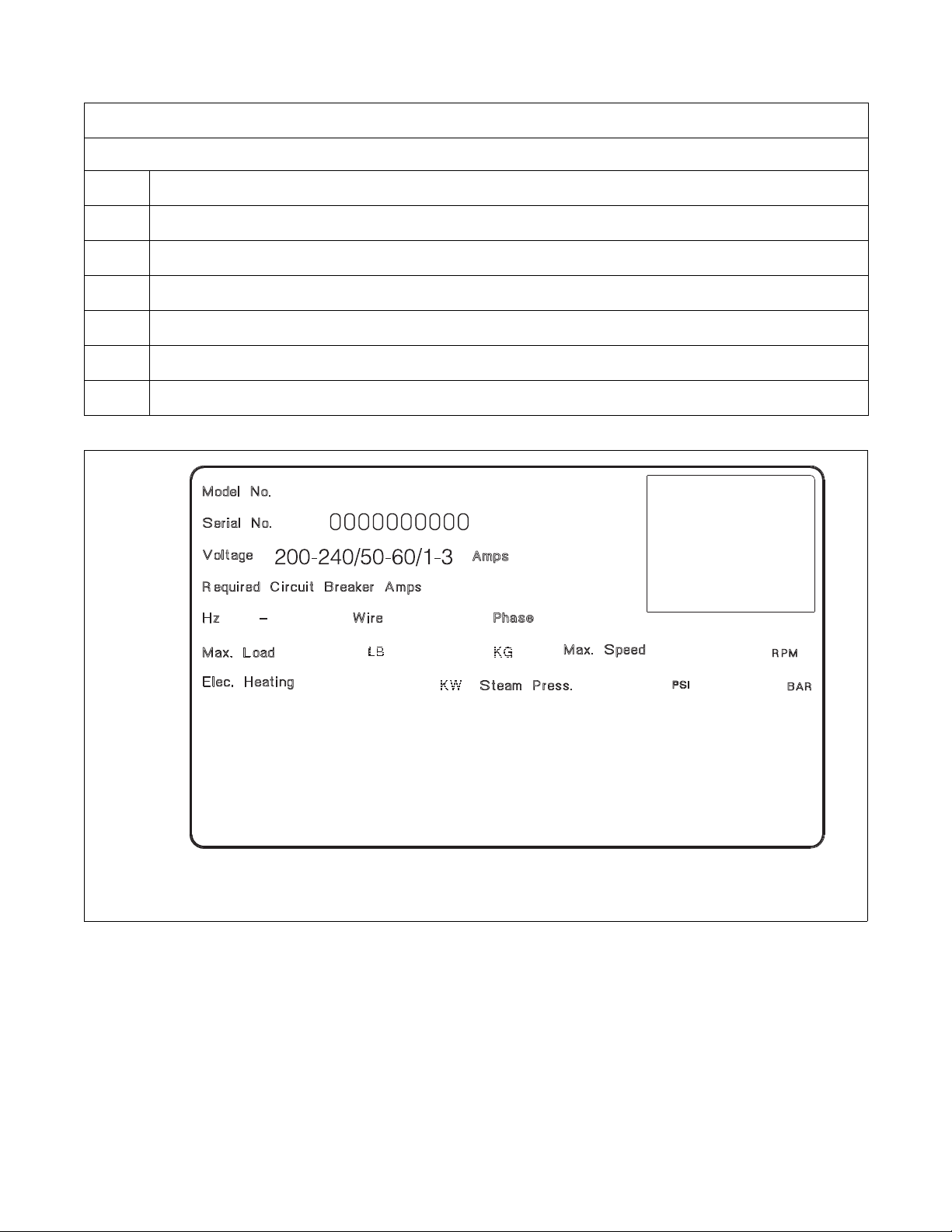

Nameplate Location

The nameplate is located at the rear of the machine.

Always provide the machine’s serial number and

model number when ordering parts or when seeking

technical assistance.

CFD19C

1 Nameplate

Figure 1

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call (920) 748-3121.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 11

Model Number Familiarization Guide

CFD29N

X55PVXM60001

12

55

25

50 60

15

2/3+PE 1/3

1000

*

EXAMPLE OF NAMEPLATE

Sample Model Number: *X55PVXM60001

Introduction

*X

55

P

V

X

M6

0001

* Denotes Brand

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control (P = WE-6 Computer)

Washer-Extractor Speed Capabilities

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

9001000

Figure 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD29N

9

Page 12

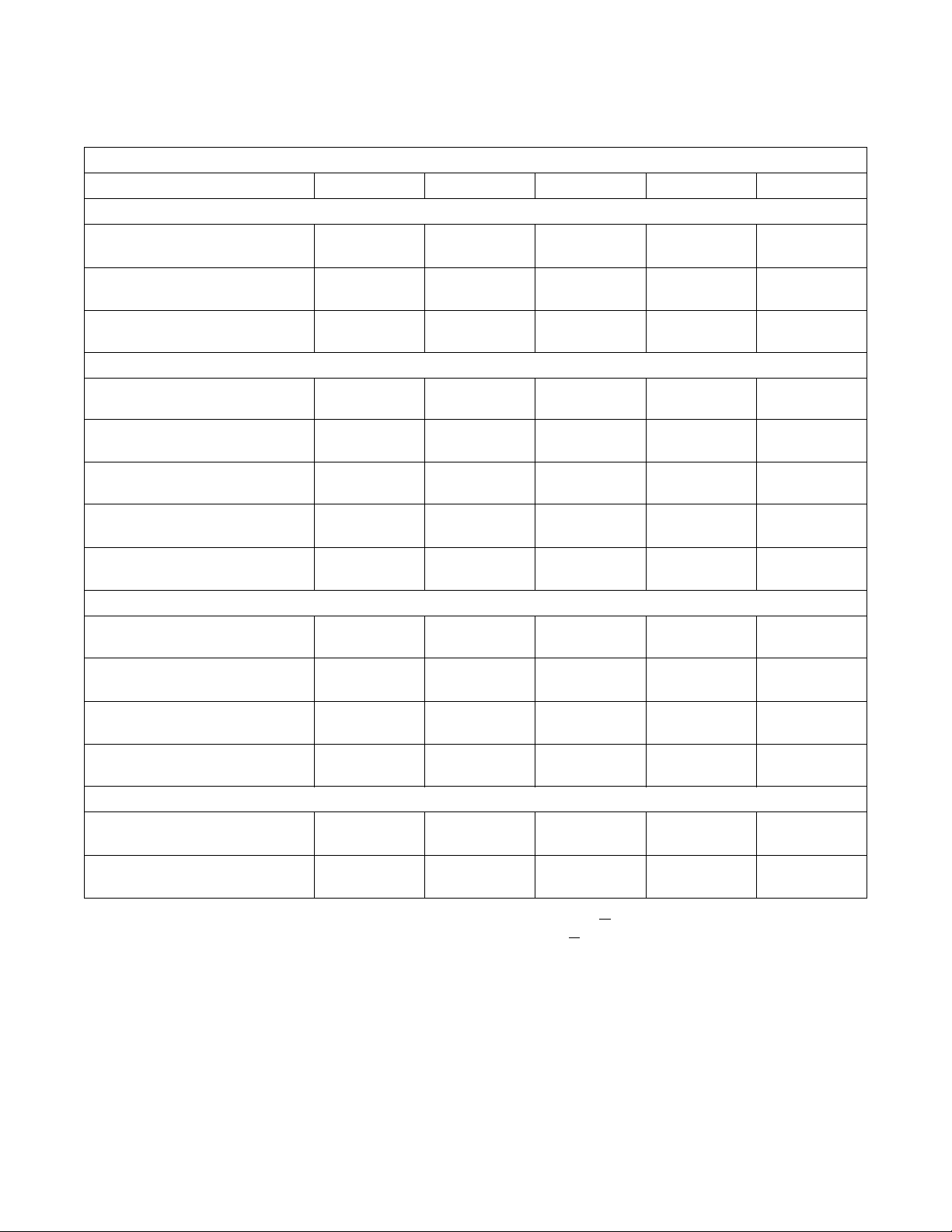

Specifications and Dimensions

Model 1825333540

Overall Dimensions

Overall width 26 in.

(660 mm)

Overall height 40.6 in.

(1031 mm)

Overall depth 30.7 in.

(780 mm)

Weight and Shipping Information

Net weight †

Net weight †† 520 lb.

Shipping weight † 514 lb.

Shipping weight †† 624 lb.

Shipping volume 22.5 ft

Wash Cylinder Information

Cylinder diameter 20.9 in.

Cylinder depth 13.6 in.

Cylinder volume 2.7 ft

Perforation size 0.1 in.

Door Opening Information

Door opening size

Height of door bottom above floor

465 lb.

(211Kg)

(236 kg)

(233 Kg)

(283 kg)

(0.8 m

(530 mm)

(345 mm)

(76 l)

(3 mm)

11.8 in.

(300 mm)

11 in.

(279 mm)

General Specifications

26 in.

(660 mm)

40.6 in.

(1031 mm)

34.3 in.

(870 mm)

520 lb.

(236 Kg)

531 lb.

(241 kg)

569 lb.

(258 Kg)

639.5 lb.

(290 kg)

3

3

)

24.5 ft

(0.9 m

3

3

)

20.9 in.

(530 mm)

17.3 in.

(440 mm)

3

3.43 ft3

(97 l)

0.1 in.

(3 mm)

11.8 in.

(300 mm)

11 in.

(279 mm)

30.71 in.

(780 mm)

54.15 in.

(1376 mm)

33.07 in.

(840 mm)

811.30 lb.

(368 Kg)

N/A

844.37 lb.

(383 Kg)

N/A

42.83 ft

(1.21 m

3

3

26.77 in.

(680 mm)

15.75 in.

(400 mm)

5.12 ft3

(145 l)

0.1 in.

(3 mm)

15.75 in.

(400 mm)

18.58 in.

(472 mm)

30.8 in.

(783 mm)

47 in.

(1194 mm)

37.8 in.

(960 mm)

789 lb.

(358 Kg)

765 lb.

(347 kg)

855 lb.

(388 Kg)

1030 lb.

(467 kg)

)

34.7 ft

(1.3 m

3

3

)

25.6 in.

(650 mm)

19.7 in.

(500 mm)

5.9 ft3

(167 l)

0.1 in.

(3 mm)

11.8 in.

(300 mm)

15.6 in.

(395 mm)

30.71 in.

(780 mm)

54.15 in.

(1376 mm)

37.01 in.

(940 mm)

862.01 lb.

(391 Kg)

N/A

921.53 lb.

(418 Kg)

N/A

45.98 ft

(1.3 m

3

3

)

26.77 in.

(680 mm)

19.69 in.

(500 mm)

6.39 ft3

(181 l)

0.1 in.

(3 mm)

15.75 in.

(400 mm)

18.58 in.

(472 mm)

† For Models with A or M in the 8th position in the model number (e.g. *X18PVXA

†† For Models with U in the 8th position in the model number (e.g *X18PVXU

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001000

6)

6)

Page 13

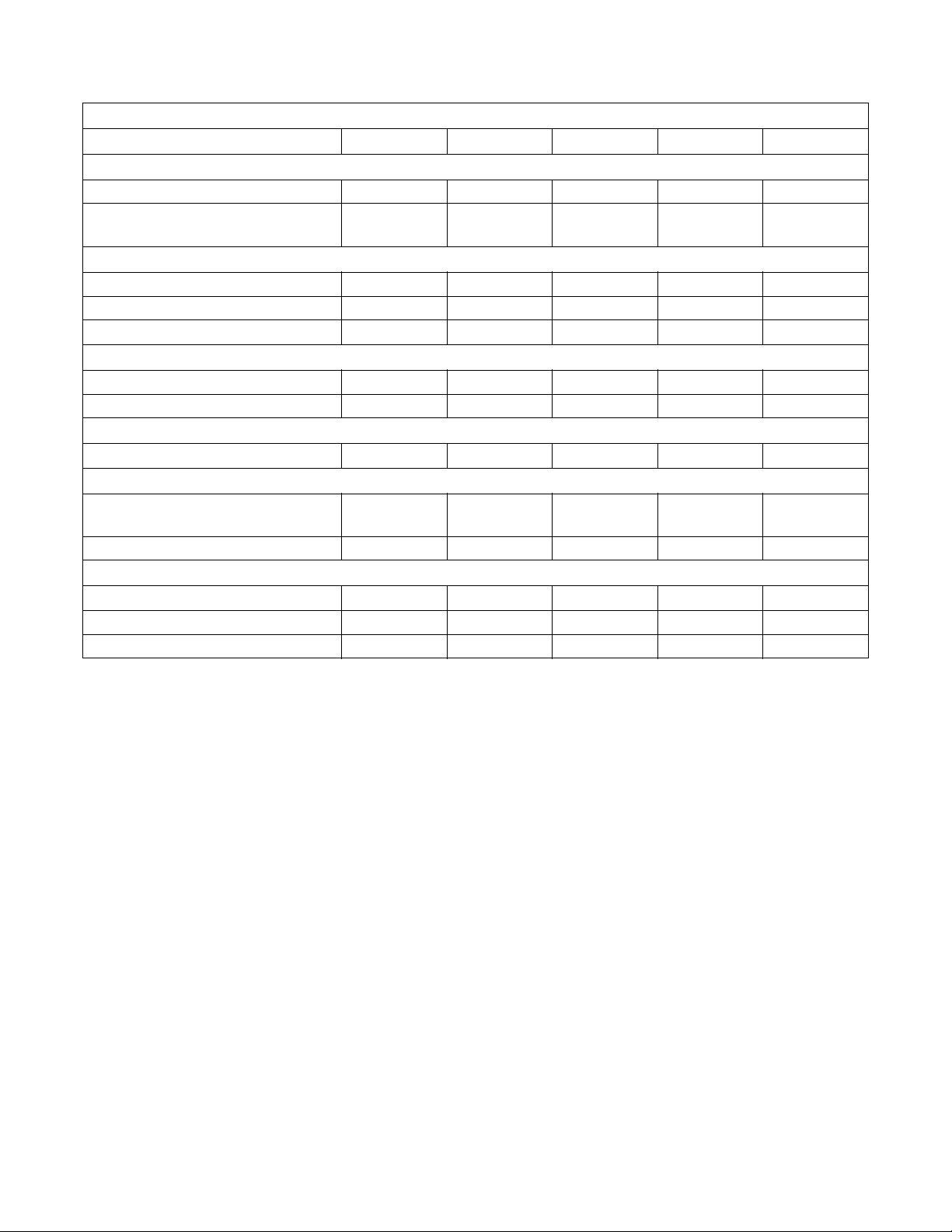

Specifications and Dimensions

General Specifications

Model 1825333540

Drive Train Information

Number of motors in drive train 1 1 1 1 1

Drive motor power 1 HP

(0.75 kW)

1 HP

(0.75 kW)

2.95 HP

(2.2 kW)

2 HP

(1.5 kW)

2.95 HP

(2.2 kW)

Cylinder Speeds

Wash/reverse speed 10-50 RPM 1 0-5 0 RPM 10-50 RPM 10-50 RPM 10-50 RPM

Distribution/drain speed 82 RPM 82 RPM 85 RPM 74 RPM 85 RPM

Extract speed 250-1000 RPM 250-1000 RPM 250-1000 RPM 250-1000 RPM 250-1000 RPM

Centrifugal Force Data

Wash/reverse centrifugal force 0.03-0.74 Gs 0.03-0.74 Gs 0.37-0.94 Gs 0.04 -0.91 Gs 0.37-0.94 Gs

Extract centrifugal force 19-296 Gs 19-296 Gs 24-377 Gs 23-363 Gs 24-377 Gs

Balance Detection

Vibration safety switch installed Standard Standard Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size 0.38 in.

(10 mm)

0.38 in.

(10 mm)

.375 in.

(10 mm)

0.38 in.

(10 mm)

.375 in.

(10 mm)

Number of steam inlets 1 1 1 1 1

Electrical Heating (Optional)

Total electrical heating capacity 9 kW 9 kW 18 kW 18 kW 18 kW

Electrical heating elements 3 3 6 6 6

Electrical heat element size 3 kW 3 kW 3 kW 3 kW 3kW

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

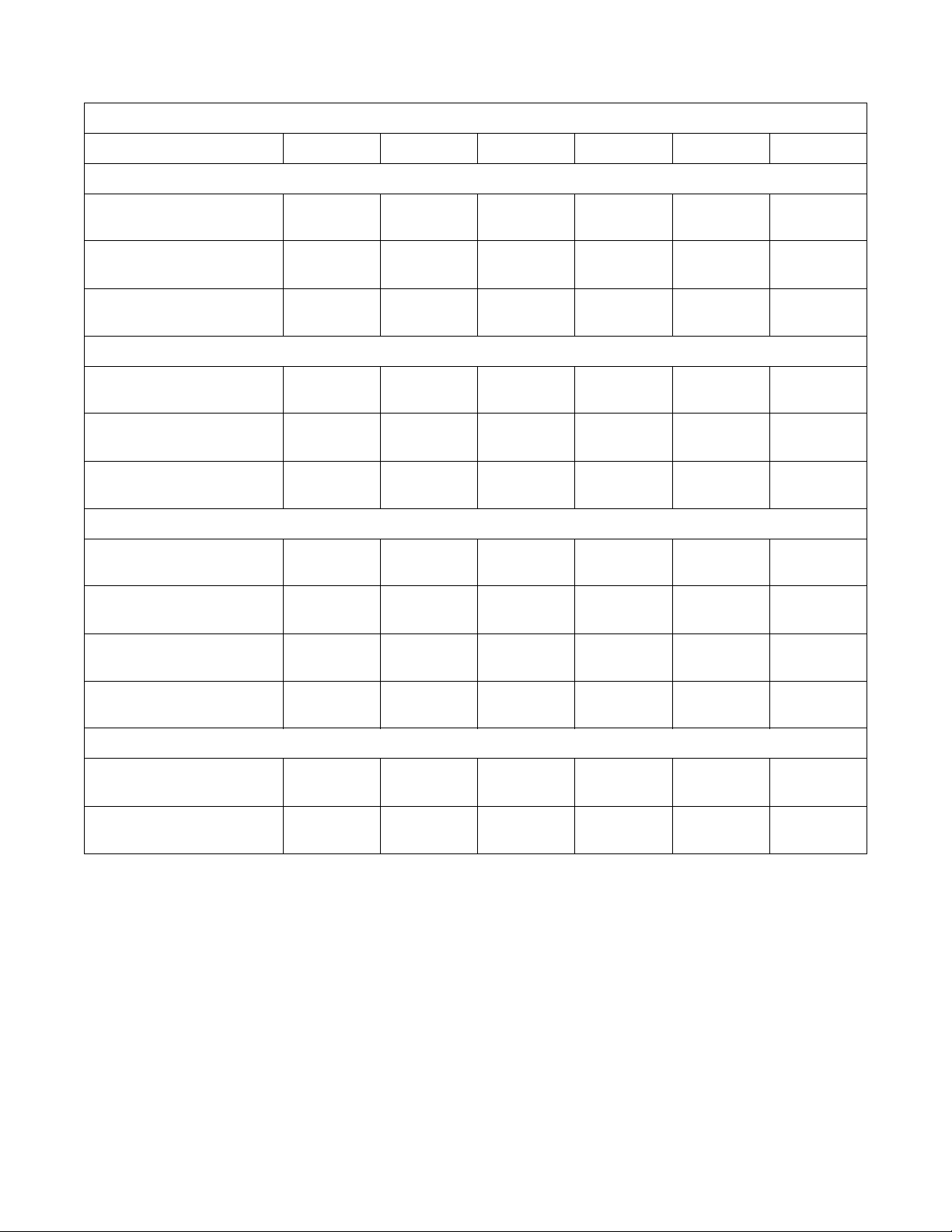

Specifications and Dimensions

Model 55 75 100 135 165 200

Overall Dimensions

General Specifications

Overall width 35.4 in.

(900 mm)

Overall height 60.8 in.

(1544 mm)

Overall depth 40 in.

(1016 mm)

Weight and Shipping Information

Net weight 1247 lb.

(570 kg)

Shipping weight 1380 lb.

(630 kg)

Shipping volume 54.9 ft

3

(1.5 m

Wash Cylinder Information

Cylinder diameter 29.5 in.

(750 mm)

Cylinder depth 20.9 in.

(530 mm)

Cylinder volume 8.27 ft

(234 l)

3

)

3

41.8 in.

(1060 mm)

61.4 in.

(1560 mm)

46 in.

(1168 mm)

1907 lb.

(865 kg)

2194 lb.

(995 kg)

3

74 ft

3

(2.1 m

)

33.5 in.

(850 mm)

21.1 in.

(537 mm)

10.76 ft3

(305 l)

47.3 in.

(1200 mm)

75.6 in.

(1920 mm)

52.4 in.

(1330 mm)

3351 lb.

(1520 kg)

3741 lb.

(1697 kg)

3

115 ft

3

(3.3 m

)

38.6 in.

(980 mm)

23.5 in.

(597 mm)

15.92 ft3

(451 l)

47.3 in.

(1200 mm)

75.6 in.

(1920 mm)

59.1 in.

(1500 mm)

3626 lb.

(1645 kg)

4017 lb.

(1822 kg)

3

131 ft

3

(3.7 m

)

38.6 in.

(980 mm)

30.5 in.

(775 mm)

20.66 ft3

(585 l)

51.8 in.

(1300 mm)

82.7 in.

(2100 mm)

63.8 in.

(1620 mm)

4630 lb.

(2100 kg)

5113 lb.

(2319 kg)

3

162 ft

(4.4 m3)

43.1 in.

(1095 mm)

30.5 in.

(775 mm)

25.8 ft3

(730 l)

51.8 in.

(1300 mm)

82.68 in.

(2100 mm)

71.18 in.

(1808 mm)

6393.41 lb.

(2900 kg)

6613.86 lb.

(3000 kg)

217.89 ft

(6.17 m3)

43.11 in.

(1095 mm)

37.68 in.

(957 mm)

31.748 ft3

(9001 l)

3

Perforation size 0.1 in.

(3 mm)

Door Opening Information

Door opening size

15.6 in.

(395 mm)

Height of door bottom above

floor

22 in.

(559 mm)

0.1 in.

(3 mm)

15.6 in.

(395 mm)

22 in.

(559 mm)

0.1 in.

(3 mm)

19.7 in.

(500 mm)

25.5 in.

(648 mm)

0.1 in.

(3 mm)

19.7 in.

(500 mm)

25.5 in.

(648 mm)

0.1 in.

(3 mm)

24.5 in.

(622 mm)

28 in.

(710 mm)

0.1 in.

(3 mm)

24.5 in.

(622 mm)

23.74 in.

(603 mm)

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 15

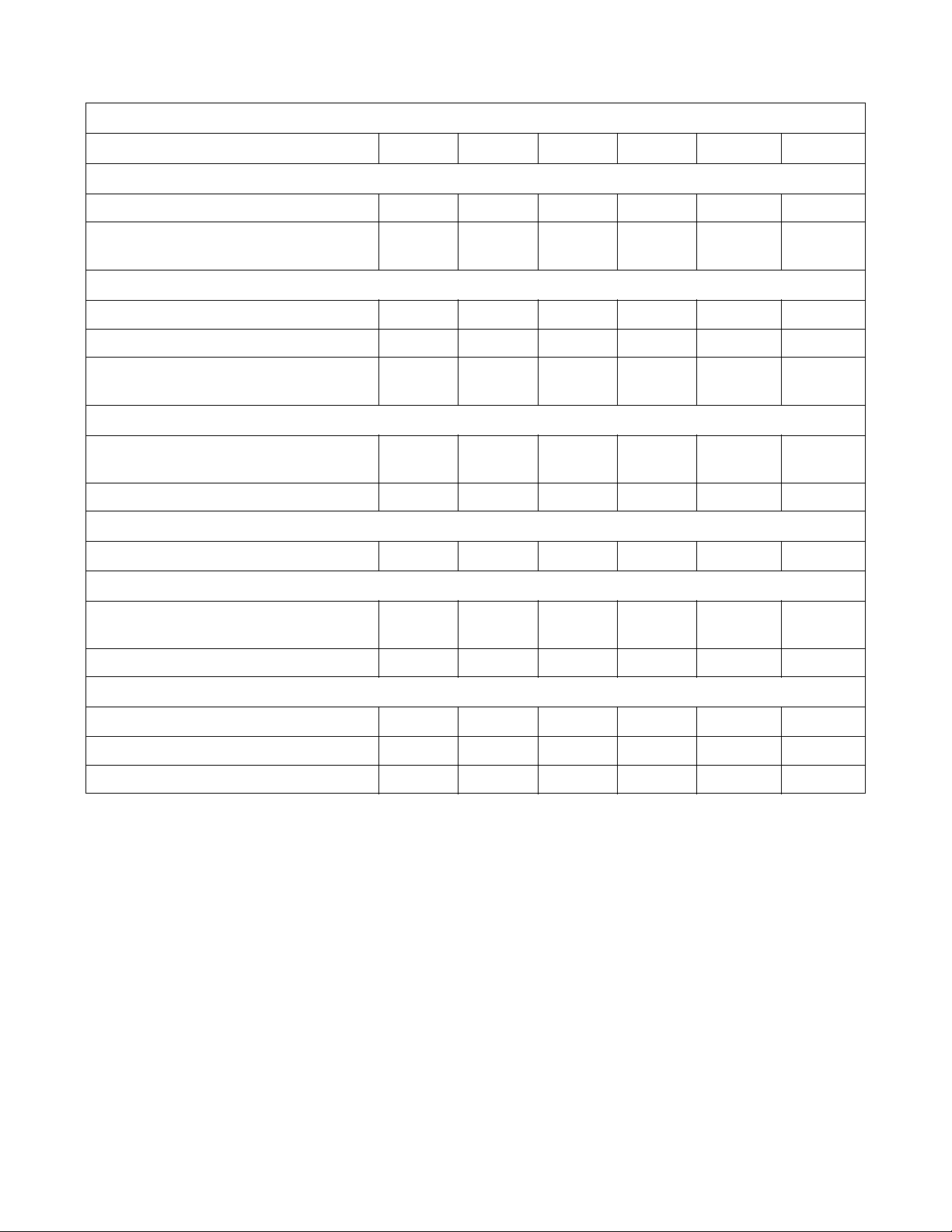

Specifications and Dimensions

General Specifications

Model 55 75 100 135 165 200

Drive Train Information

Number of motors in drive train 11111 1

Drive motor power 4 HP

(3 kW)

5.4 HP

(4 kW)

7.4 HP

(5.5 kW)

10 HP

(7.5 kW)

15 HP

(11.5 kW)

20 HP

(15 kW)

Cylinder Speeds

Wash/reverse speed 10-50 RPM 10-50 RPM 10-50 RPM 10-50 RPM 10-50 RPM 10-50 RPM

Distribution/drain speed 69 RPM 65 RPM 61 RPM 61 RPM 100 RPM 80 RPM

Extract speed 250-1000

RPM

250-1000

RPM

250-800

RPM

250-800

RPM

250-750

RPM

250-750

RPM

Centrifugal Force Data

Wash/reverse centrifugal force 0.04-1.05 Gs0.05-1.19 Gs0.06-1.37 Gs0.06-1.37 Gs0.06-1.52 Gs0.06-1.52

Gs

Extract centrifugal force 26-418 Gs 30-475 Gs 34-350 Gs 34-350 Gs 34-344 Gs 34-342 Gs

Balance Detection

Vibration safety switch installed Standard Standard Standard Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size 0.38 in.

(10 mm)

0.38 in.

(10 mm)

0.38 in.

(10 mm)

0.38 in.

(10 mm)

0.75 in.

(19 mm)

0.75 in.

(19 mm)

Number of steam inlets 11111 1

Electrical Heating (Optional)

Total electrical heating capacity 18 kW 18 kW 27 kW 27 kW N/A 36 kW

Electrical heating elements 6699N/A9

Electrical heat element size 3 kW 3 kW 3 kW 3 kW N/A 4 kW

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Specifications and Dimensions

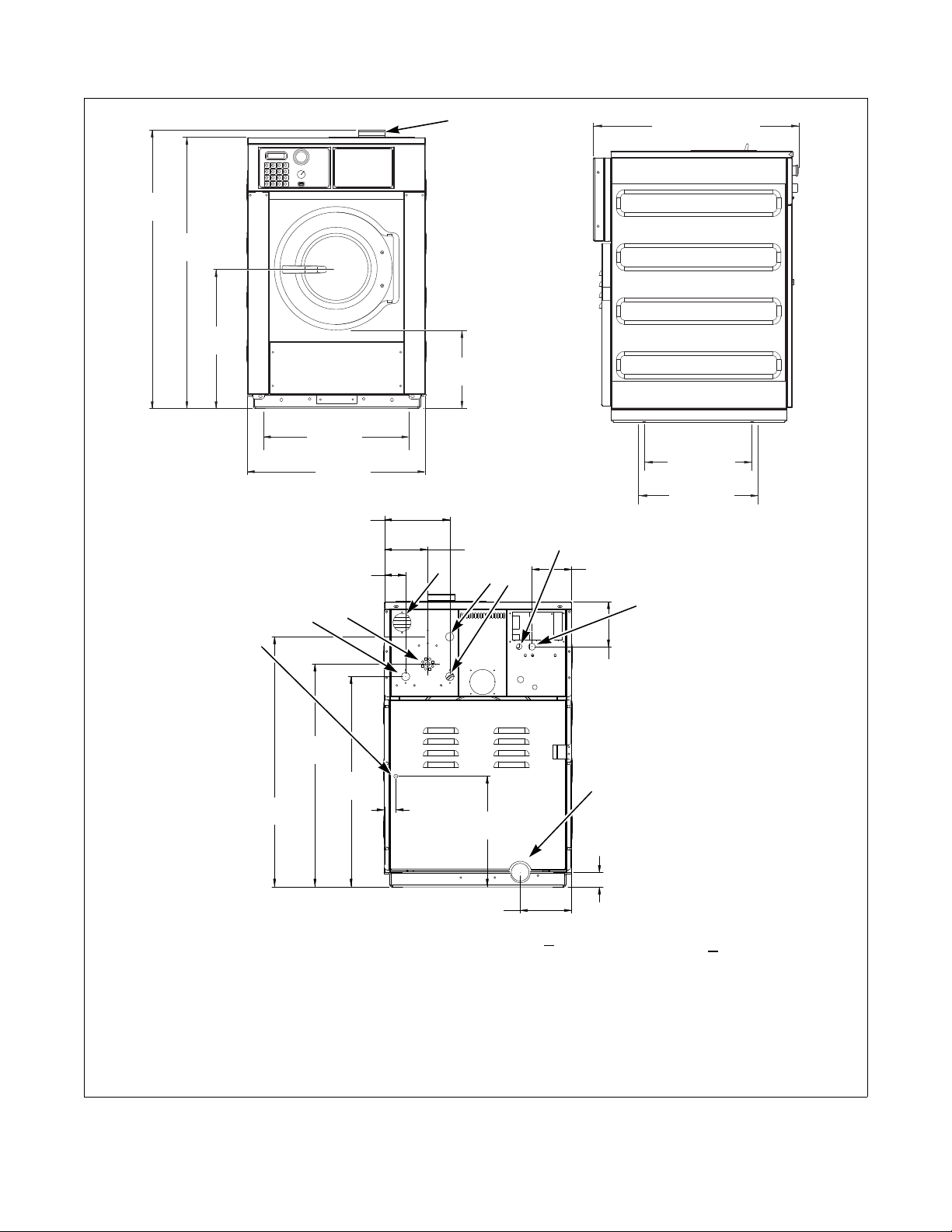

CFS464N

CFS465N

40.6 in.

(1031 mm)

39.8 in.

(1011 mm)

26 in.

(660 mm)

CFD530N

CFS464N

CFS465N

9 in.

(229 mm)

6 in.

(152 mm)

2.9 in.

(74 mm)

5.5 in.

(140 mm)

30.7 in.

(780 mm)

29.2 in.

(742 mm)

1.6 in.

(41 mm)

15.3 in.

(389 mm)

6.2 in.

(158 mm)

2 in.

(51 mm)

7.1 in.

(181 mm)

1

4

6

3

2

10

11 in.

(279 mm)

18: 31 in. (787 mm)

25: 34.8 in. (884 mm)

34.7 in.

(881 mm)

7

9

5

19.13 in.

(486 mm)

18: 22.05 in.

(560 mm)

25: 25.98 in.

(660 mm)

8

20.4 in.

(518 mm)

18 and 25 Pound Capacity Models with U in the 8th Position (e.g. *X18PVXU6)

CFD530 N

1 Fill and Supply Ventilation 6 External Liquid Supply Inlets

Figure 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

2 Cold Water Inlet (Required) 7 Electrical Power Input

3 Hot Water Inlet (Required) 8 External Supply Signal Input

4 Cold Water Inlet (Required) 9 Drain Outlet

5 Flushing Supply Dispenser 10 Steam Connection Input (Optional)

14

9001000

Page 17

Specifications and Dimensions

CFD528N

40.87 in. (1038 mm)

39.8 in. (1011 mm)

10.98 in.

(279 mm)

20.87 in. (530 mm)

2.56 in.

(65 mm)

25.98 in. (660 mm)

2.56 in.

(65 mm)

34.92 in. (887 mm)

31.14in. (791 mm)

19.1 in. (485 mm)

2.76 in. (70 mm)

1.73 in.

(44 mm)

7.09 in. (180 mm)

25.98 in. (660 mm)

11

10

4

2

1

9

1.3 in.

(33 mm)

18: 23.23 in. (590 mm)

25: 27.17 in. (690 mm)

29.41 in. (747 mm)

8

3

1.3 in.

(33 mm)

1.18 in.

(30 mm)

8.66 in.

(220 mm)

7

CFD521N

18: 26.38 in. (670 mm)

25: 30.31 in. (770 mm)

18: 28.62 in. (727 mm)

25: 32.56 in. (827 mm)

1.18 in.

(30 mm)

27.41 in. (696.2 mm)

4.3 in.

(109 mm)

8.9 in. (226 mm)

5.94 in. (151 mm)

2.95 in. (75 mm)

2.72 in.

(69 mm)

CFD522N

6

5

18 and 25 Pound Capacity Models with A or M in the 8th Position (e.g. *X18PVXM6)

CFD528N

CFD521N

CFD522N

1 Fill and Supply Ventilation 7 Electrical Power Input

2 Cold Water Inlet (Required) 8 Drain Outlet

3 External Liquid Supply Inlets 9 Steam Connection Input (Optional)

4 Hot Water Inlet (Required) 10 Cold Water Inlet (Required)

5 Ventilation Tub 11 Flushing Supply Dispenser

6 Main Switch

Figure 4

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

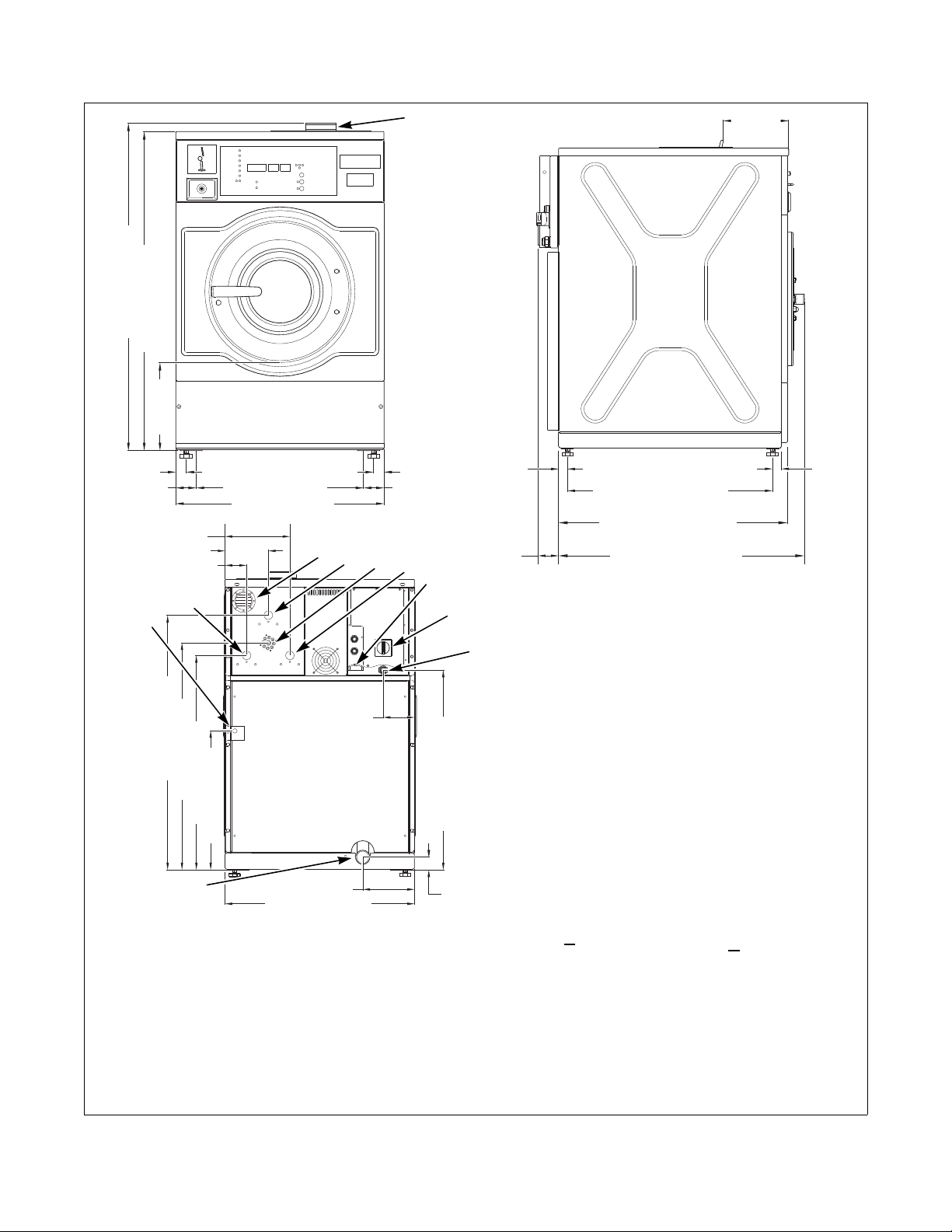

Specifications and Dimensions

CFD539N

CFD539N

CFD537N

54.15 in. (1376 mm)

53.07 in. (1348 mm)

18.58 in. (472 mm)

26.77 in. (680 mm)

1.97 in.

(50 mm)

30.71 in. (780 mm)

1.97 in.

(50 mm)

44.9 in. (1141 mm)

43.6 in. (1108 mm)

27.7 in. (704 mm)

7.29 in. (185 mm)

6.69 in. (170 mm)

3

2

1

10

26.18 in. (665 mm)

41.95 in. (1066 mm)

9

4

3.41 in.

(86.5 mm)

8.66 in.

(220 mm)

7

CFD537N

1.34 in.

(34 mm)

39.96 in. (1015 mm)

1.38 in.

(35 mm)

13.05 in. (332 mm)

10.49 in. (267 mm)

7.93 in. (202 mm)

4.3 in.

(109 mm)

CFD538N

6

5

33 Pound Capacity Mode ls

3.47 in.

(88 mm)

1.34 in.

(34 mm)

28.86 in. (733 mm)

29.65 in. (753 mm)

4.13 in. (105 mm)

8

CFD538N

1 Fill and Supply Ventilation 6 Connection Clamps

2 External Liquid Supply Inlets 7 Ventilation Tub

3 Cold Water Inlet (Required) 8 Electrical Power Inputs

4 Cold Water Inlet (Required) 9 Drain Valve

5 Hot Water Inlet (Required) 10 Steam Connection Input (Optional)

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 5

9001000

Page 19

Specifications and Dimensions

CFD531N

CFS467N

CFD531N

CFS467N

47 in.

(1194 mm)

24.4 in.

(620 mm)

30.8 in.

(782 mm)

CFS468N

12.9 in.

(328 mm)

10.4 in.

(264 mm)

36.75 in.

(934 mm)

37.8 in.

(960 mm)

6.1 in.

(155 mm)

35 in.

(889 mm)

39.4 in.

(1001 mm)

4.4 in.

(112 mm)

15.5 in.

(394 mm)

5

20 in.

(508 mm)

38 in.

(965 mm)

41 in.

(1041 mm)

3.5 in.

(89 mm)

1

3

2

4

8

7

9

10

6

25.16 in.

(639 mm)

30.31 in.

(770 mm)

8 in.

(203 mm)

35 Pound Capacity Models with U in the 8th Position (e.g. *X35PVXU6)

46.3 in.

(1176 mm)

1 Fill and Supply Ventilation 6 External Liquid Supply Inlets

2 Cold Water Inlet (Required) 7 Electrical Supply Signal Input

3 Hot Water Inlet (Required) 8 External Supply Signal Input

4 Cold Water Inlet (Required) 9 Drain Outlet

5 Flushing Supply Dispenser 10 Steam Connection Input (Optional)

Figure 6

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Specifications and Dimensions

CFD524N

CFD529N

CFD524N

CFD525N

47.32 in. (1202 mm)

46.3 in. (1176 mm)

2.6 in.

(66 mm)

CFD529N

1.34 in.

(34 mm)

10.49 in. (267 mm)

35.16 in. (893 mm)

3.47 in.

(88 mm)

13.05 in. (332 mm)

20.87 in. (530 mm)

7.87 in.

(200 mm)

2.76 in. (70 mm)

33.17 in. (843 mm)

14.78 in.

(376 mm)

11

2.36 in.

(60 mm)

36.81 in. (935 mm)

38.11 in. (968 mm)

7.93 in. (202 mm)

1

3

2

4

7

9

10

6

25.51 in. (648 mm)

1.44 in.

(36.5 mm)

35 Pound Capacity Models with A or M in the 8th Position (e.g. *X35PVXM6)

30.71 in.(780 mm)

2.6 in.

(66 mm)

1.34 in.

(34 mm)

8.66 in.

(220 mm)

1.44 in.

(36.5 mm)

30.12 in. (765 mm)

33.86 in. (860 mm)

36.06 in. (916 mm)

3.23 in.

82 mm)

4.13 in. (105 mm)

4.3 in.

(109.2 mm)

8

5

1.38 in (35 mm)

CFD525N

1 Fill and Supply Ventilation 7 Drain Outlet

2 Hot Water Inlet (Required) 8 Steam Connection Input (Optional)

3 Cold Water Inlet (Required) 9 External Liquid Supply Inlets

4 Main Switch 10 Cold Water Inlet (Required)

5 Ventilation Tub 11 Flushing Supply Dispenser

6 Electrical Power Input

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 7

9001000

Page 21

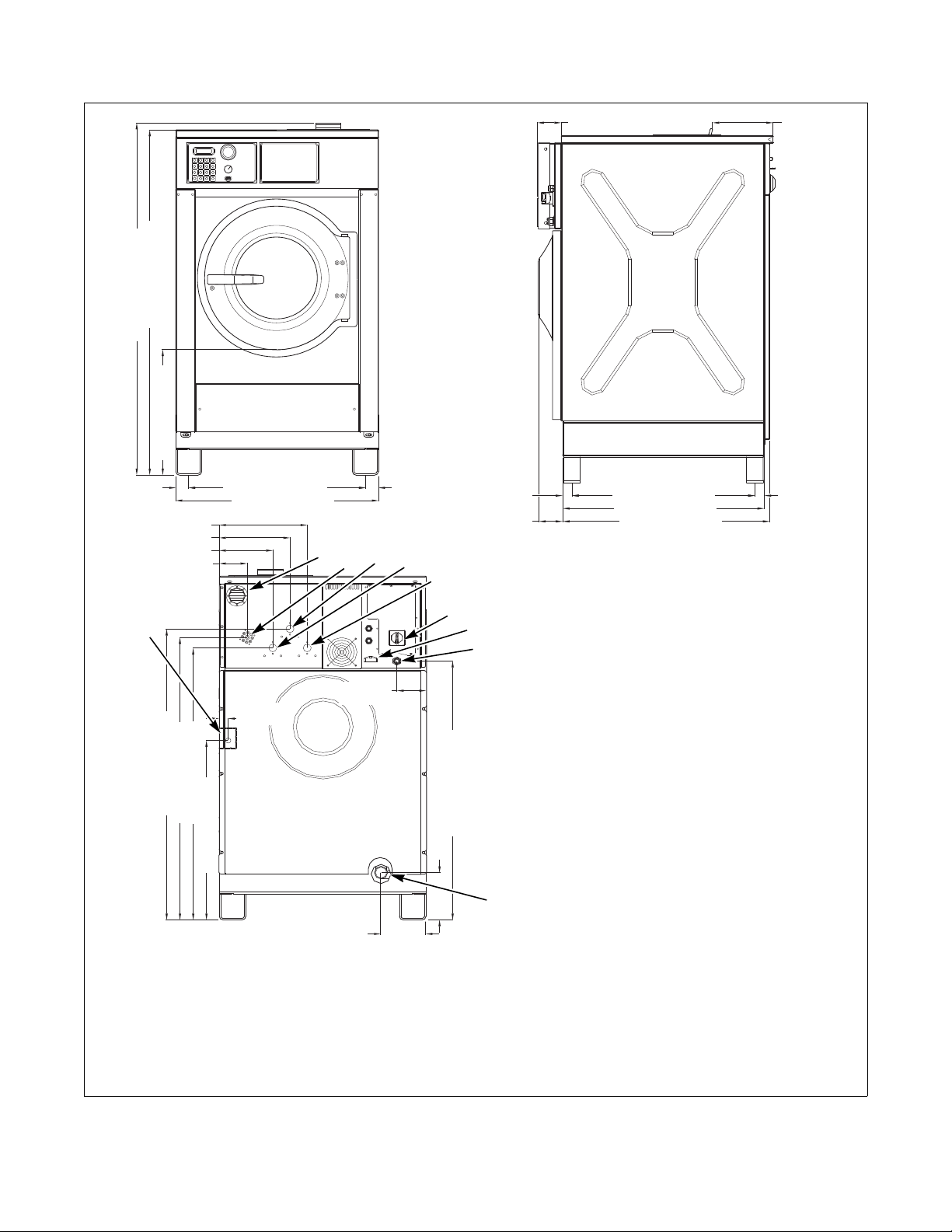

Specifications and Dimensions

CFD539N

CFD539N

CFD537N

54.15 in. (1376 mm)

53.07 in. (1348 mm)

18.58 in. (472 mm)

26.77 in. (680 mm)

1.97 in.

(50 mm)

30.71 in. (780 mm)

1.97 in.

(50 mm)

44.9 in. (1141 mm)

43.6 in. (1108 mm)

27.7 in. (704 mm)

7.29 in. (185 mm)

6.69 in. (170 mm)

3

2

1

10

30.12 in. (765 mm)

41.95 in. (1066 mm)

9

4

3.41 in.

(86.5 mm)

8.66 in.

(220 mm)

7

CFD537N

1.34 in.

(34 mm)

39.96 in. (1015 mm)

1.38 in.

(35 mm)

13.05 in. (332 mm)

10.49 in. (267 mm)

7.93 in. (202 mm)

4.3 in.

(109 mm)

CFD538N

6

5

40 Pound Capacity Mode ls

3.47 in.

(88 mm)

1.34 in.

(34 mm)

32.8 in. (833 mm)

33.58 in. (853 mm)

4.13 in. (105 mm)

8

CFD538N

1 Fill and Supply Ventilation 6 Connection Clamps

2 External Liquid Supply Inlets 7 Ventilation Tub

3 Cold Water Inlet (Required) 8 Electrical Power Inputs

4 Cold Water Inlet (Required) 9 Drain Valve

5 Hot Water Inlet (Required) 10 Steam Connection Input (Optional)

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 8

19

Page 22

Specifications and Dimensions

CFD509N

CFS471N

CFD509N

60.8 in.

(1544 mm)

33.8 in.

(859 mm)

35.43 in.

(900 mm)

59 in.

(1499 mm)

CFS470N

40 in.

(1016 mm)

CFS471N

55 MODEL

6.2 in.

(158 mm)

10 in.

(254 mm)

13.6 in.

(91 mm)

3.9 in.

(99 mm)

7.5 in.

(191 mm)

6.5 in.

(165 mm)

4.1 in.

(104 mm)

54.7 in.

(1389 mm)

28.4 in.

(721 mm)

1.4 in.

(36 mm)

1

3

4

9

11

22 in.

(559 mm)

5

2

4.1 in.

(104 mm)

6.5 in.

(165 mm)

50.5 in.

(1283 mm)

8

7

10

4 in.

(102 mm)

6

9.9 in.

(252 mm)

29.13 in.

(740 mm)

32.68 in.

(830 mm)

CFS470N

1 Fill and Supply Ventilation 7 Electrical Power Input

2 Cold Water Inlet (Required) 8 External Supply Signal Input

3 Hot Water Inlet (Required) 9 Drain Outlet

4 Cold Water Inlet (Required) 10 Reuse Drain Outlet (Optional)

5 Flushing Supply Dispenser 11 Steam Connection Input (Optional)

6 External Liquid Supply Inlets

Figure 9

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 23

Specifications and Dimensions

CFS474N

CFD510N

CFD510N

62 in.

(1575 mm)

33.6 in.

(853 mm)

60.3 in.

(1532 mm)

46 in.

(1168 mm)

CFS473N

CFS474N

75 MODEL

9 in.

(229 mm)

14.4 in.

(366 mm)

19.2 in.

(488 mm)

3.7 in.

(94 mm)

6.9 in.

(175 mm)

6.7 in.

(170 mm)

4.1 in.

(104 mm)

55.4 in.

(1407 mm)

22.9 in.

(582 mm)

1.7 in.

(43 mm)

2

3

4

9

11

5

4 in.

(102 mm)

22 in.

(559 mm)

41.73 in.

(1060 mm)

1

7

8

4.1 in.

(104 mm)

10

9.7 in.

(246 mm)

6

51.75 in.

(1315 mm)

34.25 in.

(870 mm)

37.8 in.

(960 mm)

CFS473N

1 Fill and Supply Ventilation 7 Electrical Power Input

2 Cold Water Inlet (Required) 8 External Supply Signal Input

3 Hot Water Inlet (Required) 9 Drain Outlet

4 Cold Water Inlet (Required) 10 Reuse Drain Outlet (Optional)

5 Flushing Supply Dispenser 11 Steam Connection Input (Optional)

6 External Liquid Supply Inlets

Figure 10

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Specifications and Dimensions

CFD511N

76.8 in.

(1951 mm)

37.8 in.

(960 mm)

40.94 in.

(1040 mm)

47.24 in.

(1200 mm)

CFS477N

12 in.

(305 mm)

9.3 in.

(2362 mm)

6.9 in.

(175 mm)

4.1 in.

(104 mm)

4.5 in.

(114 mm)

6.5 in.

(165 mm)

8.7 in.

(221 mm)

6.7 in.

(170 mm)

2 in.

(51 mm)

9.8 in.

(249 mm)

27.4 in.

(696 mm)

8.5 in.

(216 mm)

8.5 in.

(216 mm)

7.3 in.

(185 mm)

6

25.5 in.

(648 mm)

3.5 in.

(89 mm)

62 in.

(1575 mm)

12

2

3

5

4

1

9

13

8

10

11

7

CFS476N

100: 39.76 in.

(1010 mm)

135: 46.65 in.

(1185 mm)

4 in.

(102 mm)

100: 52.4 in. (1331 mm)

135: 59.3 in. (1506 mm)

CFS476N

CFD511N

100 AND 135 MODELS

1 Fill and Supply Ventilation 8 Electrical Power Input

2 Cold Water Inlet (Required) 9 External Supply Signal Input

3 Hot Water Inlet (Required) 10 Drain Outlet

4 Cold Water Inlet (Required) 11 Reuse Drain Outlet (Optional)

5 Cold Water Inlet (Required) 12 Steam Connection Input (Optional)

6 Flushing Supply Dispenser 13 Service Power Disconnect

7 External Liquid Supply Inlets

22

Figure 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 25

Specifications and Dimensions

CFD511N

CFD511N

82.7 in.

(2100 mm)

40.2 in.

(1020 mm)

44.9 in.

(1140 mm)

51.2 in.

(1300 mm)

CFS477N

14.25 in.

(360 mm)

10.75 in.

(273 mm)

7.8 in.

(198 mm)

4.5 in.

(114 mm)

4.5 in.

(114 mm)

6.75 in.

(172 mm)

8.7 in.

(221 mm)

7.75 in.

(197 mm)

2 in.

(51 mm)

10.24 in.

(260 mm)

27.4 in.

(696 mm)

10 in.

(254 mm)

9.3 in.

(236 mm)

6

25.25 in.

(641 mm)

4.8 in.

(122 mm)

73 in.

(1854 mm)

12

2

3

5

4

1

9

13

8

10

11

7

10 in.

(254 mm)

CFD15N

63.8 in.

(1620 mm)

4 in.

(102 mm)

46.7 in.

(1185 mm)

1 Fill and Supply Ventilation 8 Electrical Power Input

2 Cold Water Inlet (Required) 9 External Supply Signal Input

3 Hot Water Inlet (Required) 10 Drain Outlet (S tandard)

4 Cold Water Inlet (Required) 11 Dual Drain Outlet (Optional)

165 MODEL

5 Cold Water Inlet (Required) 12 Steam Connection Input (Optional)

6 Flushing Supply Dispenser 13 Service Power Disconnect

7 External Liquid Supply Inlets

CFD15N

9001000

Figure 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Specifications and Dimensions

CFD533N

82.7 in.

(2100 mm)

39 in.

(993 mm)

44.8 in.

(1138 mm)

CFD535N

3.19 in.

(81 mm)

51.18 in.

(1300 mm)

12.72 in.

(323 mm)

9.76 in.

(248 mm)

10.12 in.

(257 mm)

19.13 in.

(486 mm)

35.37 in.

(899.5)

6

23.75 in.

(603 mm)

16.06 in.

(408 mm)

12

2

3

5

4

1

9

13

8

10

11

7

CFD534N

CFD534N

1.73 in.

(44 mm)

68.96 in.

(175.2 mm)

10.24 in.

(260 mm)

10.24 in.

(260 mm)

3.19 in.

(81 mm)

6.67 in.

(169.5 mm)

6.81 in.

(173 mm)

9.33 in.

(237 mm)

4.61 in.

(117 mm)

10.31 in.

(262 mm)

6.97 in.

(117 mm)

3.19 in.

(81 mm)

57.2 in.

(1453 mm)

53.74 in.

(1365 mm)

1.04 in.

(26.5 mm)

1.73 in.

(44 mm)

10.71 in.

(272 mm)

2.23 in.

(56.5 mm)

6.85 in.

(174 mm)

24

CFD533N

1 Fill and Supply Ventilation 8 Electrical Power Input

2 Cold Water Inlet (Required) 9 External Supply Signal Input

3 Hot Water Inlet (Required) 10 Drain Outlet (S tandard)

4 Cold Water Inlet (Required) 11 Dual Drain Outlet (Optional)

200 MODEL

5 Cold Water Inlet (Required) 12 Steam Connection Input (Optional)

6 Flushing Supply Dispenser 13 Service Power Disconnect

7 External Liquid Supply Inlets

Figure 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 27

Installation

Dimensional Clearances

Table 1 shows recommended minimum clearances on

all sides of the washer-extractor.

Recommended Minimum Clearances

Model 18253335405575100135165200

Minimum rear

clearance

Minimum

clearance between

machine and wall

Minimum

clearance between

machines (side)

Minimum front

clearance (door

swing)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

16.5 in.

(419 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

16.5 in.

(419 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

21 in.

(533 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

16.5 in.

(419 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

21 in.

(533 mm)

Table 1

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

21 in.

(533 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

21 in.

(533 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

26 in.

(660 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

26 in.

(660 mm)

24 in.

(600 mm)

6 in.

(150 mm)

1.2 in.

(30 mm)

26 in.

(660 mm)

(600 mm)

(150 mm)

(30 mm)

(660 mm)

24 in.

6 in.

1.2 in.

26 in.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Installation

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

W488

CAUTION

Machine Foundation

Thoroughness of detail must be stressed with all

foundation work to ensure a stable unit installation,

eliminating possibilities of excessive vibration during

extract.

Floor Load Data

Model 18253335405575100135165200

Kinetic Energy of the

Cylinder, (N/m)

Dynamic Bottom

Load, (N/Hz)

1386 1730 2736 3240 4105 6640 12404 18361 23257 29581 29581

700/16 750/16 1200/16 1200/16 1200/16 1700/15 2000/15 2960/13 3900/13 4960/13 6100/13

The washer-extractor must be placed on a smooth

level surface so that the entire base of the machine is

supported and rests on the mounting surface.

The standard installation does not require anchoring

unless mandated by state or local codes.

Static and dynamic loads on the floor or foundation are

shown in Table 2.

Table 2 can be used as a reference when designing

floors and foundations.

IMPORTANT: Mounting bolts MUST be us ed for

installation on the 18, 25 and 35 models equipped

with steam heat and models installed on metal base

frames. Refer to Mounting Bolt Installation.

Table 2

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 29

Mechanical Installation

CFD42N

18 MODEL

26 in.

(660 mm)

22.59 in.

(650 mm)

1.3 in.

(33 mm)

23.23 in.

(590 mm)

1.81 in.

(30 mm)

1.81 in.

(30 mm)

2.56 in.

(65 mm)

23.38 in.

(594 mm)

20.87 in.

(530 mm)

Frame Dimensions and Mounting Bolt

Location

18, 25, 35, 55, 75, 100, 135 and 165 Pound

Capacity with U in the 8th position of the

Model Number (e.g. *X18PVXU6)

Installation

IMPORTANT: Drawing is not to scale.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD42N

Figure 14

27

Page 30

Installation

CFD44N

25 POUND

26 in.

(660 mm)

27.17

in.

(690 mm)

30.79 in.

(782 mm)

1.3 in.

(33 mm)

2.56 in.

(65 mm)

1.81 in.

(30 mm)

23.38 in.

(594 mm)

20.87 in.

(530 mm)

1.81 in.

(30 mm)

IMPORTANT: Drawing is not to scale.

Figure 15

CFD44N

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 31

Installation

CFD541N

28.86 in.

(733 mm)

26.77 in.

(680 mm)

1.97 in.

(50 mm)

.87 in.

(22 mm)

1.97 in.

(50 mm)

33 MODEL

1.34 in.

(34 mm)

26.18 in.

(665 mm)

1.34 in.

(34 mm)

30.71 in.

(780 mm)

IMPORTANT: Drawing is not to scale.

Figure 16

CFD541N

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Installation

30.70 in.

(780 mm)

1.34 in.

(34 mm)

1.44 in.

(36.5 mm)

2.6 in.

66 mm)

1.34 in.

(34 mm)

1.44 in.

(36.5 mm)

2.6 in.

(66 mm)

28 in.

(712 mm)

25.51 in.

(648 mm)

30.12 in.

(765 mm)

33 in.

(838 mm)

35 MODEL

Figure 17

CFD43N

CFD43N

IMPORTANT: Drawing is not to scale.

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 33

1.34 in.

(34 mm)

30.12 in.

(765 mm)

26.77 in.

(680 mm)

1.97 in.

(50 mm)

.87 in.

(22 mm)

1.97 in.

(50 mm)

40 MODEL

328 in.

(833 mm)

1.34 in.

(34 mm)

30.71 in.

(780 mm)

Installation

IMPORTANT: Drawing is not to scale.

Figure 18

CFD542N

CFD542N

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Installation

35.35 in.

(898 mm)

32.68 in.

(830 mm)

36.61 in.

(930 mm)

29.13 in.

(740 mm)

3.15 in.

(80 mm)

1.97 in.

(50 mm)

1.97 in.

(50 mm)

3.15 in.

(80 mm)

55 MODEL

CFD45N

IMPORTANT: Drawing is not to scale.

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD45N

Figure 19

9001000

Page 35

Installation

75 MODEL

41.73 in.

(1060 mm)

42.52 in.

(1080 mm)

3.74 in.

(95 mm)

37.8 in.

(960 mm)

2.36 in.

(60 mm)

34.25 in.

(870 mm)

2.36 in.

(60 mm)

3.74 in.

(95 mm)

CFD46N

IMPORTANT: Drawing is not to scale.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD46N

Figure 20

33

Page 36

Installation

100 MODEL

47.24 in.

(1200 mm)

42.91 in.

(1090 mm)

3.15 in.

(80 mm)

39.76 in.

(1010 mm)

40.94 in.

(1040 mm)

1.57 in.

(40 mm)

1.57 in.

(40 mm)

3.15 in.

(80 mm)

CFD48N

IMPORTANT: Drawing is not to scale.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD48N

Figure 21

9001000

Page 37

Installation

CFD47N

135 MODEL

47.24 in.

(1200 mm)

50 in.

(1270 mm)

46.65 in.

(1185 mm)

3.15 in.

(80 mm)

40.94 in.

(1040 mm)

3.15 in.

(80 mm)

1.67 in.

(42.5 mm)

1.67 in.

(42.5 mm)

IMPORTANT: Drawing is not to scale.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 22

CFD47N

35

Page 38

Installation

CFD47N

165 POUND

51.2 in.

(1300 mm)

49.25 in.

(1251 mm)

3.15 in.

(80 mm)

3.15 in.

(80 mm)

46.7 in.

(1185 mm)

44.9 in.

(1140 mm)

1.3 in.

(33 mm)

1.3 in.

(33 mm)

IMPORTANT: Drawing is not to scale.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD47N

Figure 23

9001000

Page 39

200 POUND

3.19 in.

(81 mm)

3.19 in.

(81 mm)

1.73 in.

(44 mm)

44.8 in.

(1138 mm)

1.73 in.

(44 mm)

51.18 in.

(1300 mm)

51.18 in.

(1300 mm)

44.8 in.

(1138 mm)

Installation

IMPORTANT: Drawing is not to scale.

Figure 24

CFD536N

CFD536N

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Installation

CFD49N

18 MODEL

26 in.

(660 mm)

22.05 in.

(560 mm)

26.38 in.

(670 mm)

2.17 in.

(55 mm)

19.13 in.

(486 mm)

3.43 in.

(87 mm)

2.17 in.

(55 mm)

3.43 in.

(87 mm)

18, 25 and 35 Pound Capacity with A or M in

the 8th position of the Model Number (e.g.

*X18PVXA6)

IMPORTANT: Drawing is not to scale.

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 25

CFD49N

9001000

Page 41

Installation

25 MODEL

26 in.

(660 mm)

25.98

in.

(660 mm)

3.43 in.

(87 mm)

2.17 in.

(55 mm)

30.31 in.

(770 mm)

3.43 in.

(87 mm)

19.13 in.

(486 mm)

2.17 in.

(55 mm)

CFD51N

IMPORTANT: Drawing is not to scale.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 26

CFD51N

39

Page 42

Installation

CFD50N

35 MODEL

30.8 in.

(782 mm)

33.85 in.

(860 mm)

2.78 in.

(71 mm)

1.77 in.

(45 mm)

30.31 in.

(770 mm)

25.16 in.

(639 mm)

1.77 in.

(45 mm)

2.78 in.

(71 mm)

IMPORTANT: Drawing is not to scale.

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 27

CFD50N

9001000

Page 43

Installation

CFS485N

6 in.

(152 mm)

1

2

4

3

Mounting Bolt Installation

(If Required)

1 Base Frame

2 Bolt

3 Washer

4 Anchor Bolt/Plug

CFS485N

3. Put bolts through the machine in the anchors and

fasten them. (For the 18, 25, and 35 models, the

diameter of the bolt must be minimum 1/2-13 or

12 mm; for the 33, 40, 55, 75, 100, 135, 165 and

200 models, the diameter of the bolt must be

minimum 5/8-11 or 16 mm.)

4. To level machine, fill the spaces between the

machine base and floor with machinery grout.

Grout completely under all frame members.

Remove front and rear panels to gain access to all

frame members. Force grout under the machine

base until all voids are filled.

5. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

6. Position washers and locknuts on machinery

anchor bolts and finger-tighten to machine base.

7. After the grout is completely dry, tighten the

locknuts by even increments – one after the

other – until all are tightened evenly and the

machine is fastened securely to the floor.

8. Remove the four red transport brackets which

secure the moving components of the machine

during shipping. Refer to Figures 29, 31 and 32

for typical transport bracket locations.

Figure 28

After the concrete has cured and the anchors are

installed, proceed as follows:

1. Place the washer-extractor adjacent to the

foundation. Do not attempt to move it by pushing

on the sides. Always insert a pry bar or other

device under the bottom of the frame of the

washer-extractor to move it.

2. Place the washer-extractor carefully over the

anchors.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Installation

The machine must never be activated

before removing these transport

brackets.

W489

WARNING

CFD65N

CFD65N

1

18, 25 AND 35 MODELS WITH U IN THE 8TH

POSITION IN THE MODEL NUMBER

(E. G. *X18PVXU

6)

CFD34N

1

18, 25 AND 35 MODELS WITH A OR M IN THE 8TH

POSITION IN THE MODEL NUMBER

(E. G. *X18PVXM

6)

Removing the Transport Brackets

To prevent damage during transportation, the machine

has been equipped with four red transport brackets

(refer to Figure 29 for 18, 25 and 35 models; refer to

Figure 30 for 33 and 40 models; refer to Figure 31 for

55 and 75 models [depending on model number]; refer

to Figure 32 for 100, 135, 165 and 200 models) to

eliminate every possible movement of the tub.

After the machine has been placed level, take off the

service panels and the back panel to remove these

transport brackets.

CFD34N

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1 Transport Brackets

Figure 29

9001000

Page 45

1 Transport Brackets

1

FRONT

REAR

33 AND 40 MODELS

1

1

1

CFS487N

1

FRONT

REAR

55 AND 75 MODELS

CFS488N

1

1

100, 135, 165 AND 200 MODELS

FRONT

REAR

Figure 30

Installation

CFD543N

CFS488N

1 Transport Brackets

Figure 32

1 Transport Brackets

Figure 31

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFS487N

43

Page 46

Installation

4

REAR OF MACHINE

3

5

6

1

7

8

2

Drain Connection

A drain system of adequate capacity is essential to

washer-extractor performance.

Ideally, the water should empty through a vented pipe

directly into a sump or floor drain.

Figure 33 shows drain line and drain trough

configurations.

A flexible connection must be made to a vented or air

gap drain system to prevent an air lock and to prevent

siphoning. If proper drain size is not available or

practical, a surge tank is required. A surge tank in

conjunction with a sump pump should be used when

gravity drainage is not possible, such as in belowground-level installations.

Before any deviation from specified installation

procedures is attempted, the customer or installer

should contact the distributor.

Increasing the drain hose length, installing elbows, or

causing bends will impair washer-extractor

performance.

Refer to Table 3 for capacity-specific drain

information.

Installation of additional washer-extractors will

require proportionately larger drain connections. Refer

to Table 4.

1 Water Inlet

2 Water Inlet Air Gap

3 Drain Pipe

4 1-Inch Minimum Waste Line Air Gap

5 Steel Grate

6 Drain Trough

7 Strainer

8 Waste Line

44

(Per local code)

Figure 33

CFS490N

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 47

Installation

Drain Information

Model 18 25 33 35 40 55 75 100 135 165 200

Drain

connection

size, ID

2 in.

(51 mm)

2 in.

(51 mm)

2 in.

(50 mm)

2 in.

(51 mm)

2 in.

(50 mm)

3 in.

(76.2

mm)

3 in.

(76.2

mm)

3 in.

(76.2

mm)

3 in.

(76.2

mm)

3 in.

(76.2

mm)

Number of

drain

111111 1 1 1 2 2

outlets

Drain flow

capacity

32

gal/min

(120

l/min)

32

gal/min

(120

l/min)

21.13

gal/min

(160

l/min)

32

gal/min

(120

l/min)

21.13

gal/min

(160

l/min)

73

gal/min

(280

l/min)

73

gal/min

(280

l/min)

73

gal/min

(280

l/min)

73

gal/min

(280

l/min)

73

gal/min

(280

l/min)

Recommended

drain pit

2.5 ft

(72 l)

3

3.3 ft

(95 l)

3

5.1 ft

(1451)

3

5.8 ft

(165 l)

3

6.4 ft

(1811)

3

8.3 ft

(235 l)

3

11 ft

(304 l)

3

16 ft

(455 l)

3

20 ft

(575 l)

3

24 ft

3

(679 l)

size

Table 3

3 in.

(76.2

mm)

73

gal/min

(280

l/min)

31.8 ft

(9001)

3

Model

18

25

33

35

40

55

75

100

135

165

200

Drain Line Sizing

Minimum Drain ID

Number of Machines

1234567

2 in.

(51 mm)

2 in.

(51 mm)

2 in.

(51 mm)

2 in.

(51 mm)

2 in.

(51 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

3 in.

(76.2 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

3.5 in.

(88 mm)

3.5 in.

(88 mm)

3.5 in.

(88 mm)

3.5 in.

(88 mm)

3.5 in.

(88 mm)

5 in.

(131 mm)

5 in.

(131 mm)

6 in.

(152 mm)

6 in.

(152 mm)

6 in.

(152 mm)

6 in.

(152 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

4 in.

(102 mm)

6 in.

(152 mm)

6 in.

(152 mm)

7 in.

(177.8 mm)

7 in.

(177.8 mm)

7 in.

(177.8 mm)

7 in.

(177.8 mm)

4.5 in.

(114 mm)

4.5 in.

(114 mm)

4.5 in.

(114 mm)

4.5 in.

(114 mm)

4.5 in.

(114 mm)

6.7 in.

(170 mm)

6.7 in.

(170 mm)

8 in.

(203 mm)

8 in.

(203 mm)

8 in.

(203 mm)

8 in.

(203 mm)

5 in.

(124 mm)

5 in.

(124 mm)

5 in.

(124 mm)

5 in.

(124 mm)

5 in.

(124 mm)

7.3 in.

(186 mm)

7.3 in.

(186 mm)

10 in.

(254 mm)

10 in.

(203 mm)

10 in.

(203 mm)

10 in.

(203 mm)

5.5 in.

(140 mm)

5.5 in.

(140 mm)

5.5 in.

(140 mm)

5.5 in.

(140 mm)

5.5 in.

(140 mm)

8 in.

(203 mm)

8 in.

(203 mm)

12 in.

(305 mm)

12 in.

(305 mm)

12 in.

(305 mm)

12 in.

(305 mm)

9001000

Table 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

45

Page 48

Installation

To avoid personal injury, recommended

inlet water temperature should be no

higher than 125° Fahrenheit (51° Celsius).

W709

WARNING

Water Connection

The 18-135 models are delivered with hoses with

3/4 inch hose connectors. The 165 model is delivered

with 3 x 1 inch and 1 x 3/4 inch hose connectors.

These hoses fit the water inlet valves of the machine

and the main water inlet taps. To ensure the optimal

functioning of the water inlet valves, the water

pressure on the inlet should be between 30-85 psi

(2-5.7 bar). If the pressure is too low, the cycle time

will increase considerably. In case of boiler fed

machines, a maximum of hot water of 194°F (90°C)

should be available:

Connections should be supplied by a hot and a cold

water line per national and local codes.

Water Supply Information

To connect water service to machine with rubber

hoses, use the following procedure:

1. Before installing hoses, flush the water system

for at least two minutes.

2. Check filters in the washer-extractor’s inlet hoses

for proper fit and cleanliness before connecting.

3. Hang the hoses in a large loop, do not allow them

to kink.

If additional hose length is needed use flexible hoses

with screen filters. Each hose should have a screen

filter installed to keep rust and other foreign particles

out of the water inlet valves.

Pressure of 30-85 psi (2-5.7 bar) provides best

performance. Although the washer-extractor will

function at lower pressures, increased fill times will

occur with some loss of supply flushing.

Suitable air cushions should be installed in supply

lines to prevent “hammering.”

Model18253335405575100135165200

Water inlet

connection

size

Number of

water inlets

(standard)

Recommended

pressure

Inlet flow

capacity

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

5.3 gal/

min

(20 l/

min)

0.75 in.

(19 mm)

33333334444

30-85 psi

(2-5.7

bar)

5.3 gal/

min

(20 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

5.3 gal/

min

(20 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

5.3 gal/

min

(20 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

5.3 gal/

min

(20 l/

min)

Table 5

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

12 gal/

min

(45 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

12 gal/

min

(45 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

12 gal/

min

(45 l/

min)

0.75 in.

(19 mm)

30-85 psi

(2-5.7

bar)

12 gal/

min

(45 l/

min)

1.0 in.

(25 mm)

30-85 psi

(2-5.7

bar)

25 gal/

min

(95 l/

min)

0.75 and

1.0 in.

(19 and

25 mm)

30-85 psi

(2-5.7

bar)

25 gal/

min

(95 l/

min)

46

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 49

Electrical Installation

Hazardous Voltage. Can cause shock,

burn or cause death. Allow machine

power to remain off for two minutes prior

to working in and around AC inverter

drive.

W359

WARNING

Hazardous Voltage. Can cause shock,

burn or death. Verify that a ground wire

from a proven earth ground is connected

to the lug near the input power block on

this machine.

W360

WARNING

Do not use a phase adder on any variablespeed machine.

W490

DANGER

The AC inverter drive requires a clean power supply

free from voltage spikes and surges. A voltage monitor

should be used to check incoming power. The

customer’s local power company may provide such a

monitor.

If input voltage measures above 240V for a 220V

drive or above 480V for a 400V drive, ask the power

company to lower the voltage. As an alternative, a

step-down transformer kit is available from the

distributor.

The AC drive provides overload protection for the

drive motor. However, a separate single or three phase

circuit breaker must be installed for complete

electrical overload protection. This prevents damage

to the motor by disconnecting all legs if one should be

lost accidentally. Check the data plate on the back of

the washer-extractor or consult Table 6 for circuit

breaker requirements.

Installation

The washer-extractor should be connected to an

individual branch circuit not shared with lighting or

other equipment.

The connection should be shielded in a liquid tight or

approved flexible conduit with proper conductors of

correct size installed in accordance with the National

Electric Code or other applicable codes. The

connection must be made by a qualified electrician

using the wiring diagram provided with the washerextractor, or according to accepted European standards

for CE-approved equipment.

Use wire sizes indicated in Table 6 for runs up to

50 feet.

Use next larger size for runs of 50 to 100 feet. Use two

sizes larger for runs greater than 100 feet.

For personal safety and proper operation, the washerextractor must be grounded in accordance with state

and local codes. If such codes are not available,

grounding must conform with the National Electric

Code, article 250-95. The ground connection must be

made to a proven earth ground, not to conduit or water

pipes.

IMPORTANT: Alliance Laundry Systems

Warranty does not cover components that fail as a

result of improper input voltage.

IMPORTANT: Do NOT use fuses in place of a

circuit breaker.

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

47

Page 50

Installation

Electrical Specifications

Voltage Designation Standard Electric Heat

Model

Code

Voltage

Cycle

Phase

Wire

Full

Load

Amps

Circuit

Breaker

AWG

/mm2Full Load

Amps

(Heating

Element

kW)

Circuit

Breaker

18 N 440-480 50/60 3 3+PE 6 15 14/2.5 20 25 10/6.0

P 380-415 50/60 3 3+N+PE Not available 17 20 12/4.0

Q 200-240 50/60 3 3+PE Not available 28 30 10/6.0

X 200-240 50/60 1/3 2/3+PE 10 15 14/2.5 Not available

25 N 440-480 50/60 3 3+PE 6 15 14/2.5 21 25 10/6.0

P 380-415 50/60 3 3+N+PE Not available 18 20 12/4.0

Q 200-240 50/60 3 3+PE Not available 29 30 10/6.0

X 200-240 50/60 1/3 2/3+PE 10 15 14/2.5 Not available

N 440-480 50/60 3 3+PE 6 15 14/2.5 32 40 8/10.0

P 380-415 50/60 3 3+N+PE 18 20 12/4.0 44 50 8/10.0

33

Q 200-240 50/60 3 3+PE 18 20 12/4.0 63 70 4/25.0

X 200-240 50/60 1/3 2/3+PE 18 20 12/4.0 Not available

N 440-480 50/60 3 3+PE 12 15 14/2.5 41 50 8/10.0

P 380-415 50/60 3 3+N+PE Not available 36 40 8/10.0

35

Q 200-240 50/60 3 3+PE Not available 58 60 6/16.0

X 200-240 50/60 1/3 2/3+PE 12 15 14/2.5 Not available

N 440-480 50/60 3 3+PE 6 15 14/2.5 32 40 8/10.0

P 380-415 50/60 3 3+N+PE 18 20 12/4.0 44 50 8/10.0

40

Q 200-240 50/60 3 3+PE 18 20 12/4.0 63 70 4/25.0

X 200-240 50/60 1/3 2/3+PE 18 20 12/4.0 Not available

N 440-480 50/60 3 3+PE 12 15 14/2.5 41 50 8/10.0

P 380-415 50/60 3 3+N+PE Not available 36 40 8/10.0

55

Q 200-240 50/60 3 3+PE Not available 58 60 6/16.0

X 200-240 50/60 1/3 2/3+PE 16 20 14/2.5 Not available

N 440-480 50/60 3 3+PE 12 15 14/2.5 41 50 8/10.0

75

P 380-415 50/60 3 3+N+PE 12 15 14/2.5 36 40 8/10.0

Q 200-240 50/60 3 3+PE 15 20 12/4.0 58 60 6/16.0

N 440-480 50/60 3 3+PE 17 20 12/4.0 62 70 4/25.0

100

P 380-415 50/60 3 3+N+PE 17 20 12/4.0 55 60 6/16.0

Q 200-240 50/60 3 3+PE 18 25 10/6.0 88 90 3/35.0

N 440-480 50/60 3 3+PE 17 25 10/6.0 62 70 4/25.0

135

P 380-415 50/60 3 3+N+PE 17 25 10/6.0 55 60 6/16.0

Q 200-240 50/60 3 3+PE 20 30 10/6.0 88 90 3/35.0

Table 6 (continued)

AWG

2

/mm

48

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 51

Table 6 (continued)

Electrical Specifications

Voltage Designation Standard Electric Heat

Model

Code

N 440-480 50/60 3 3+PE 20 25 10/6.0

165

P 380-415 50/60 3 3+N+PE 20 25 10/6.0

Voltage

Cycle

Phase

Wire

Full

Load

Amps

Circuit

Breaker

AWG

/mm2Full Load

Amps

(Heating

Element

kW)

41 (9x3 kW) 63 8/10.0

52 (9x4 kW) 63 8/10.0

50 (9x3 kW) 63 8/10.0

61 (9x4 kW) 80 6/16.0

Q 200-240 50/60 3 3+PE 32 40 8/10.0 76 (9x3 kW) 100 4/25.0

N 440-480 50/60 3 3+PE 19 25 10/6.0

200

P 380-415 50/60 3 3+N+PE 18 25 10/6.0

42 (9x3 kW) 63 8/10.0

53 (9x4 kW) 63 8/10.0

51 (9x3 kW) 63 8/10.0

62 (9x4 kW) 80 6/16.0

Q 200-240 50/60 3 3+PE 27 40 8/10.0 77 (9x3 kW) 100 4/25.0

Table 6

Installation

Circuit

Breaker

AWG

2

/mm

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

49

Page 52

Installation

Dangerous Chemicals. May damage eyes

and skin. Wear eye and hand protection

when handling chemicals; always avoid

direct contact with raw chemicals. Read

the manufacturer’s directions for

accidental contact before handling

chemicals. Ensure an eye-rinse facility

and an emergency shower are within easy

reach. Check at regular intervals for

chemical leaks.

W363

WARNING

CONNECTION OF THE LIQUID SUPPLY HOSES

Drill out plugs and nipples before making

supply hose connection. Failure to do so

can cause buildup of pressure and risk a

tubing rupture.

W491

CAUTION

Electrical Connection

Remove the cover plate at the back of the machine.

Using copper conductors only, connect the power

cable to the connectors. Refer to the instructions listed

on the machine’s decal on how to connect the

machine.

After electrical installation is complete, run the

machine through a test cycle and check for clockwise

basket rotation during the extract step. If rotation is not

clockwise, disconnect the power from the machine and

have a qualified electrician reverse any 2 motor leads

at the AC drive terminal block.

Remote Liquid Supply Connection

Chemical Injection Supply System

Undiluted chemical dripping can damage the machine.

Therefore, all chemical supply dispenser pumps

should be mounted below the washer’s injection point.

All dispenser tubing should also run below the

injection point. Loops do not prevent drips if these

instructions are not followed. Failure to follow these

instructions could damage the machine and void the

warranty.

CFS492N

Figure 34

A connection has been placed at the back of the

machine. There are nine holes in this connection, through

each of which a liquid supply hose can be connected.

50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001000

Page 53

Installation

Never touch internal or external steam

pipes, connections, or components. These

surfaces can be extremely hot and will

cause severe burns. The steam must be

turned off and the pipe, connections, and

components allowed to cool before the

pipe can be touched.

SW014

WARNING

Steam Requirements

(Steam Heat Option Only)

For washer-extractors equipped with optional steam

heat, install piping in accordance with approved

commercial steam practices. Steam requirements are

shown in Table 7.

Steam Supply Information

18-75 100/135 165/200

Steam inlet connection, in (mm) 3/8 (10) 1/2 (13) 3/4 (19)

Number of steam inlets 1 1 1

Recommended pressure, psi (bar) 30 – 80 (2.0 – 5.5) 30 – 80 (2.0 – 5.5) 30 – 80 (2.0 – 5.5)

Maximum pressure, psi (bar) 80 (5.5) 80 (5.5) 80 (5.5)

Table 7

9001000

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51

Page 54

Installation

CFS7N

Supply

Relay

1

12

Supply

Relay

2

34

Supply

Relay

3

56

Supply

Relay

4

78 910

Supply

Relay

5

Supply

Relay

6