Page 1

Drying Tumblers

30 Pound Capacity (28" Wide)

30 Pound Capacity (31.5" Wide)

Refer to Page 7 for Model Numbers

Installation/Operation/Maintenance

NOTA: El manual en

español aparace después

del manual en inglés.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

(If this tumbler changes ownership, be sure this manual accompanies

the tumbler.)

www.comlaundry.com

Part No. M414545

September 2002

Page 2

Page 3

TABLE OF CONTENTS

SECTION I

Safety

Important Safety Instructions . . . . . . . . . . . . . . . . . . 5

SECTION II

Introduction

Information for Handy Reference . . . . . . . . . . . . . . 7

Parts Ordering Information . . . . . . . . . . . . . . . . . . . 8

Nameplate Location . . . . . . . . . . . . . . . . . . . . . . . . . 8

Roughing-In Dimensions and Specifications

Cabinet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 9

Roughing-In Dimensions and Specifications

Exhaust Thimble Locations . . . . . . . . . . . . . . . . . . . 10

Roughing-In Dimensions and Specifications

Steam Connection Locations . . . . . . . . . . . . . . . . . . 11

Roughing-In Dimensions and Specifications

Gas Connection Locations . . . . . . . . . . . . . . . . . . . . 12

Roughing-In Dimensions and Specifications

Electrical Connection Locations . . . . . . . . . . . . . . . 13

28" wide Gas Tumbler . . . . . . . . . . . . . . . . . . . . . . . 14

28" wide Electric Tumbler . . . . . . . . . . . . . . . . . . . . 14

Gas Tumbler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electric Tumbler . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Example of Gas Supply Piping . . . . . . . . . . . . . . . . . 26

Steam Requirements (Steam Drying Tumblers) . . . . 28

Piping Recommendations . . . . . . . . . . . . . . . . . . 28

Steam Valve Electrical Connections . . . . . . . . . . 28

Installing Steam Solenoid Valve

and Making Steam Inlet Connections . . . . . . . . 29

Installing Steam Trap and Making Condensate

Return Connections . . . . . . . . . . . . . . . . . . . . . . 29

Steam Requirements

Steam Drying Tumblers Only . . . . . . . . . . . . . . . . . . 30

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . 31

Grounding Instructions . . . . . . . . . . . . . . . . . . . . 31

Jumper Configuration Instructions

(OPL Micro Control Models Only) . . . . . . . . . . 33

Ring Ferrite Installation

(Gas and Steam OPL Micro Control

Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrical Requirements

For 28" wide Tumblers . . . . . . . . . . . . . . . . . . . . . . . 34

Electrical Requirements

For 31.5" wide Tumblers . . . . . . . . . . . . . . . . . . . . . 35

Accessory Timing Cam Installation

(Coin Meter Models) . . . . . . . . . . . . . . . . . . . . . . . . 36

Steam Tumbler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SECTION III

Installation Instructions

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . 17

Materials Required (Obtain Locally) . . . . . . . . . . . . 17

Gas, Electric or Steam Drying Tumblers . . . . . . 17

Gas Drying Tumblers Only . . . . . . . . . . . . . . . . 17

Steam Drying Tumblers Only . . . . . . . . . . . . . . 17

Positioning the Tumbler . . . . . . . . . . . . . . . . . . . . . . 18

Leveling the Tumbler . . . . . . . . . . . . . . . . . . . . . . . . 18

Tumbler Enclosure Construction . . . . . . . . . . . . . . . 19

Facilities Required . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Make-Up Air . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Gas Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 24

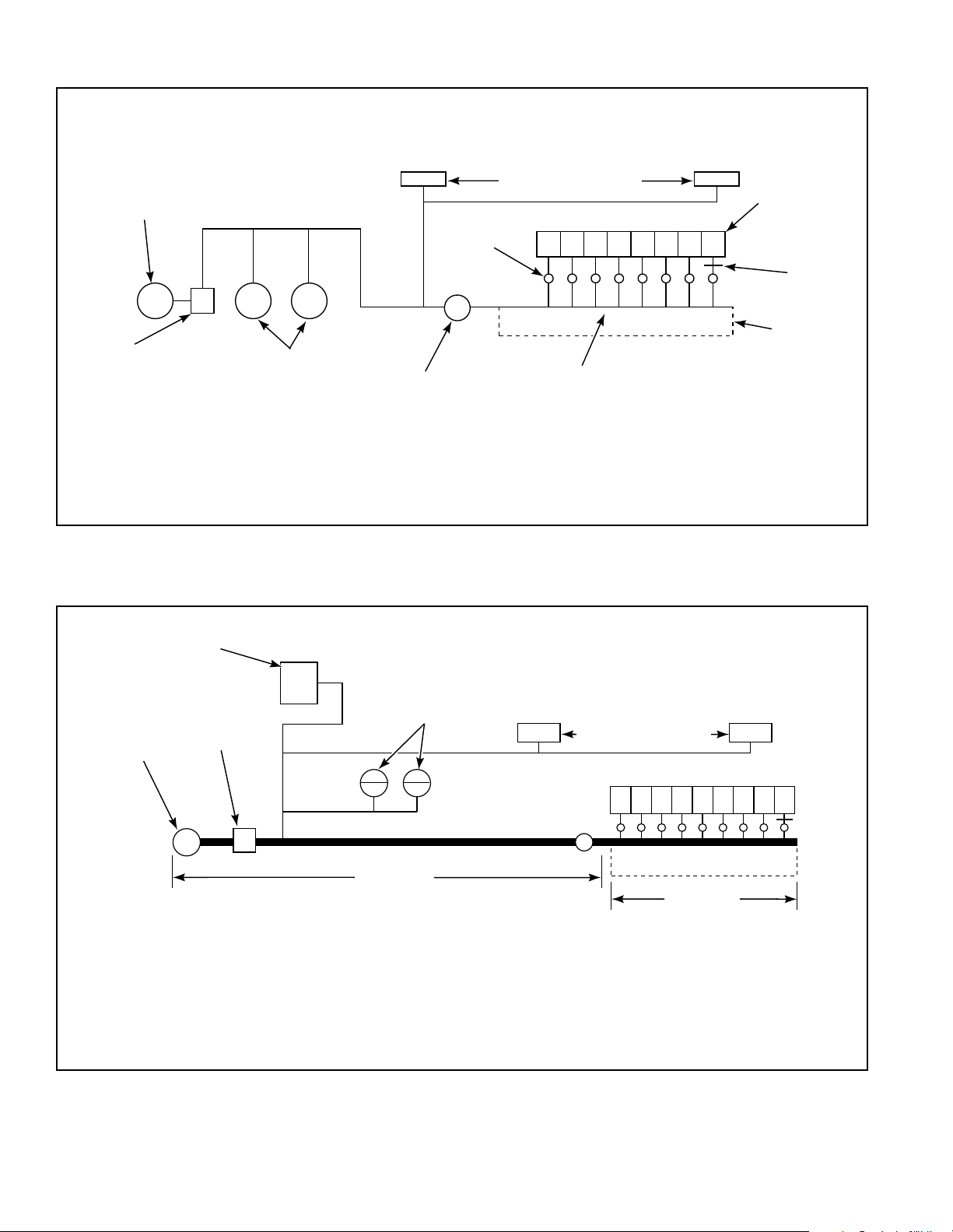

Example of Gas Loop Piping . . . . . . . . . . . . . . . . . . 26

Removal of Existing Timing Cam . . . . . . . . . . . 36

Installation of New Timing Cam . . . . . . . . . . . . 36

Preliminary Operating Checks . . . . . . . . . . . . . . . . . 37

Final Operating Checks . . . . . . . . . . . . . . . . . . . . . . 38

OPL Micro Control Tumbler . . . . . . . . . . . . . . . 38

Manual Dual Timer Tumbler . . . . . . . . . . . . . . . 38

Coin-Operated Tumbler . . . . . . . . . . . . . . . . . . . 38

SECTION IV

Adjustments

Main Gas Burner Air Shutter

All Gas Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Airflow Switch

For Gas and Electric Tumblers . . . . . . . . . . . . . . . . . 42

Loading Door Switch . . . . . . . . . . . . . . . . . . . . . . . . 43

Loading Door Strike . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chain Drive Nonreversing Models . . . . . . . . . . . . . . 45

Belt Drive Nonreversing Models . . . . . . . . . . . . . . . 45

Belt Drive Reversing Models . . . . . . . . . . . . . . . . . . 46

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

SECTION V

Operating Instructions

SECTION VI

Preventive Maintenance Instructions

Manual Dual Timer Tumbler . . . . . . . . . . . . . . . . . . 51

Coin-Operated Tumbler . . . . . . . . . . . . . . . . . . . . . . 52

Reversing Operation . . . . . . . . . . . . . . . . . . . . . . 53

Reverse Control Switch . . . . . . . . . . . . . . . . . . . 53

Electronically Controlled OPL Tumbler . . . . . . . . . . 54

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Status Lights, Signal and Reversing . . . . . . . . . . 56

Drying Laundry . . . . . . . . . . . . . . . . . . . . . . . . . 56

Security Lock-Out . . . . . . . . . . . . . . . . . . . . . . . 60

Temperature Adjustment . . . . . . . . . . . . . . . . . . 60

Show Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . 60

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Lint Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Lint Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Every Three Months . . . . . . . . . . . . . . . . . . . . . . . . .66

Lint Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Every Six Months . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Overall Check . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Energy Saving Tips . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Service Savers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting the Tumbler . . . . . . . . . . . . . . . . . .69

©Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means

without the expressed written consent of the publisher.

2 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section I

Safety

IMPORTANT: Warranty is void unless drying tumbler is installed according to instructions in this manual.

Compliance with minimum specifications and requirements detailed herein, and with applicable local gas fitting

regulations, municipal building codes, water supply regulations, electrical wiring regulations, and any other

relevant statutory regulations. Because of varied requirements, applicable local codes should be thoroughly

understood and all pre-installation work arranged for accordingly.

In the U.S.A., installation must conform to the latest edition of the American National Standard Z223.1 “National

Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code”.

In Canada, installation must comply with Standards CAN1-B149.1 or CAN1-B149.2 codes for gas burning

appliances and equipment and CSA C22.1, latest edition, Canadian Electric Code, Part I.

In Australia, installation must comply with the Australian Gas Association Installation Code for Gas Burning

Appliances and Equipment.

WARNING

Failure to install, maintain, and/or operate this machine according to manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution and

carefulness are factors which CANNOT be built into this tumbler. These factors MUST BE supplied by the

person(s) installing, maintaining or operating the tumbler.

W051

Always contact your dealer, distributor, service agent or the manufacturer on any problems or conditions you do

not understand.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

IMPORTANT: Information must be obtained from your local gas supplier on instructions to be followed if the

user smells gas. These instructions must posted in a prominent location. Step-by-step instructions of the safety

information below must be posted in a prominent location near the tumbler for customer use.

WARNING

FOR YOUR SAFETY, the information in

this manual must be followed to minimize

the risk of fire or explosion or to prevent

property damage, personal injury or

death.

W033

• Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not

use any phone in your building.

– Clear the room, building or area of all

occupants.

– Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’s instructions.

– If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

W052

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

W053

AVERTISSEMENT

POUR VOTRE SÉCURITÉ il est

impératif de suivre les instructions de

ce manuel pour minimiser les risques

d’incendie ou d’explosion et pour

éviter les dommages matériels, les

blessures corporelles ou la mort.

W033Q

• Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables

dans le voisinage de cet appareil ou de

tout autre appareil.

• QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ :

– Ne pas tenter d’allumer d’apareil.

– Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous vous trouvez.

–Évacuez la pièce, le bâtiment ou la zone.

– Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

– Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

• L’installation et l’entretien doivent être

assurés par un installateur ou un service

d’entretien qualifié ou par le fournisseur

de gaz.

W052Q

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables dans le voisinage de cet

appareil ou de tout autre appareil.

W053Q

4 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using

your tumbler, follow these basic precautions:

1. Read all instructions before using the tumbler.

2. Refer to the GROUNDING INSTRUCTIONS for the proper grounding of the tumbler.

3. Do not dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, drycleaning solvents, other flammable or explosive substances as they give off vapors that could ignite or explode.

4. Do not allow children to play on or in the tumbler. Close supervision of children is necessary when the tumbler is

used near children. This is a safety rule for all appliances.

5. Before the tumbler is removed from service or discarded, remove the door to the drying compartment.

6. Do not reach into the tumbler if the cylinder is revolving.

7. Do not install or store the tumbler where it will be exposed to water and/or weather.

W054

8. Do not tamper with the controls.

9. Do not repair or replace any part of the tumbler, or attempt any servicing unless specifically recommended in the

User-Maintenance instructions or in published user-repair instructions that you understand and have the skills to

carry out.

10. Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric

softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics or articles containing foam rubber or similarly textured

rubberlike materials.

12. Always clean the lint filter before every load. A layer of lint in the filter reduces drying efficiency and prolongs

drying time.

13. Keep area around the exhaust opening and adjacent surrounding area free from the accumulation of lint, dust and

dirt.

14. The interior of the tumbler and the exhaust duct should be cleaned periodically by qualified service personnel.

15. If not installed, operated and maintained in accordance with the manufacturer’s instructions or if there is damage to

or mishandling of this product’s components, use of this product could expose you to substances in the fuel or from

fuel combustion which can cause death or serious illness and which are known to the State of California to cause

cancer, birth defects or other reproductive harm.

16. Tumbler will not operate with the loading door open. DO NOT bypass the door safety switch by permitting the

tumbler to operate with the door open. The tumbler will stop tumbling when the door is opened. Do not use the

tumbler if it does not stop tumbling when the door is opened or starts tumbling without pressing or turning the

START mechanism. Remove the tumbler from use and call the serviceman. Tumbler will not operate with lint

panel open. DO NOT bypass lint panel safety switch by permitting the tumbler to operate with the lint panel open.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

17. Do not put articles soiled with vegetable or cooking oil in the tumbler, as these oils may not be removed during

drying. Due to the remaining oil, the fabric may catch on fire by itself.

18. To reduce the risk of fire, DO NOT put clothes which have traces of any flammable substances such as machine

oil, flammable chemicals, thinner, etc. or anything containing wax or chemicals such as in mops and cleaning

cloths, or anything dry-cleaned at home with a dry-cleaning solvent in the tumbler.

19. Use the tumbler only for its intended purpose, drying fabrics.

20. ALWAYS disconnect the electrical power to the tumbler before servicing. Disconnect power by shutting off

appropriate breaker or fuse.

21. Install this tumbler according to these INSTALLATION INSTRUCTIONS. All connections for electrical power,

grounding, and gas supply must comply with local codes and be made by licensed personnel when required. Do not

do it yourself unless you know how!

22. Remove laundry immediately after the tumbler stops.

23. Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Heed all warnings

or precautions. To reduce the risk of poisoning or chemical burns, keep them out of reach of children at all times

(preferably in a locked cabinet).

24. Do not tumble fiberglass curtains and draperies unless the label says it can be done. If they are dried, wipe out the

cylinder with a damp cloth to remove particles of fiberglass.

25. Always follow the fabric care instructions supplied by the garment manufacturer.

26. Never operate the tumbler with any guards and/or panels removed.

27. DO NOT operate the tumbler with missing or broken parts.

28. DO NOT bypass any safety devices.

29. Failure to install, maintain, and/or operate this machine according to the manufacturer’s instructions may result in

conditions which can produce bodily injury and/or property damage.

30. Run tumbler with a load before putting tumbler into service.

WARNING

To reduce the risk of serious injury, install lockable door(s) to prevent public access to

rear of tumblers.

This machine is intended for commercial use.

W055

6 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

Section II

Introduction

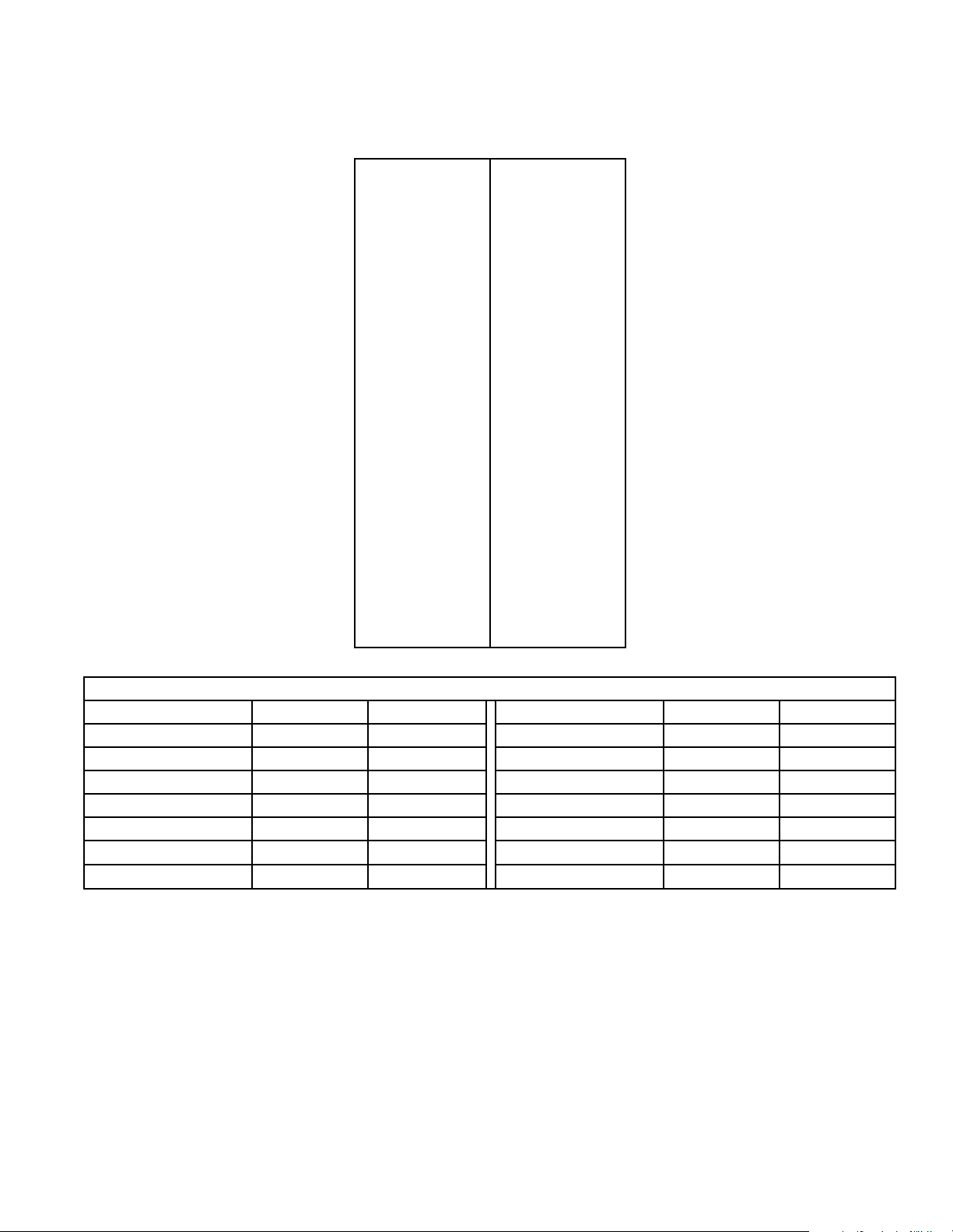

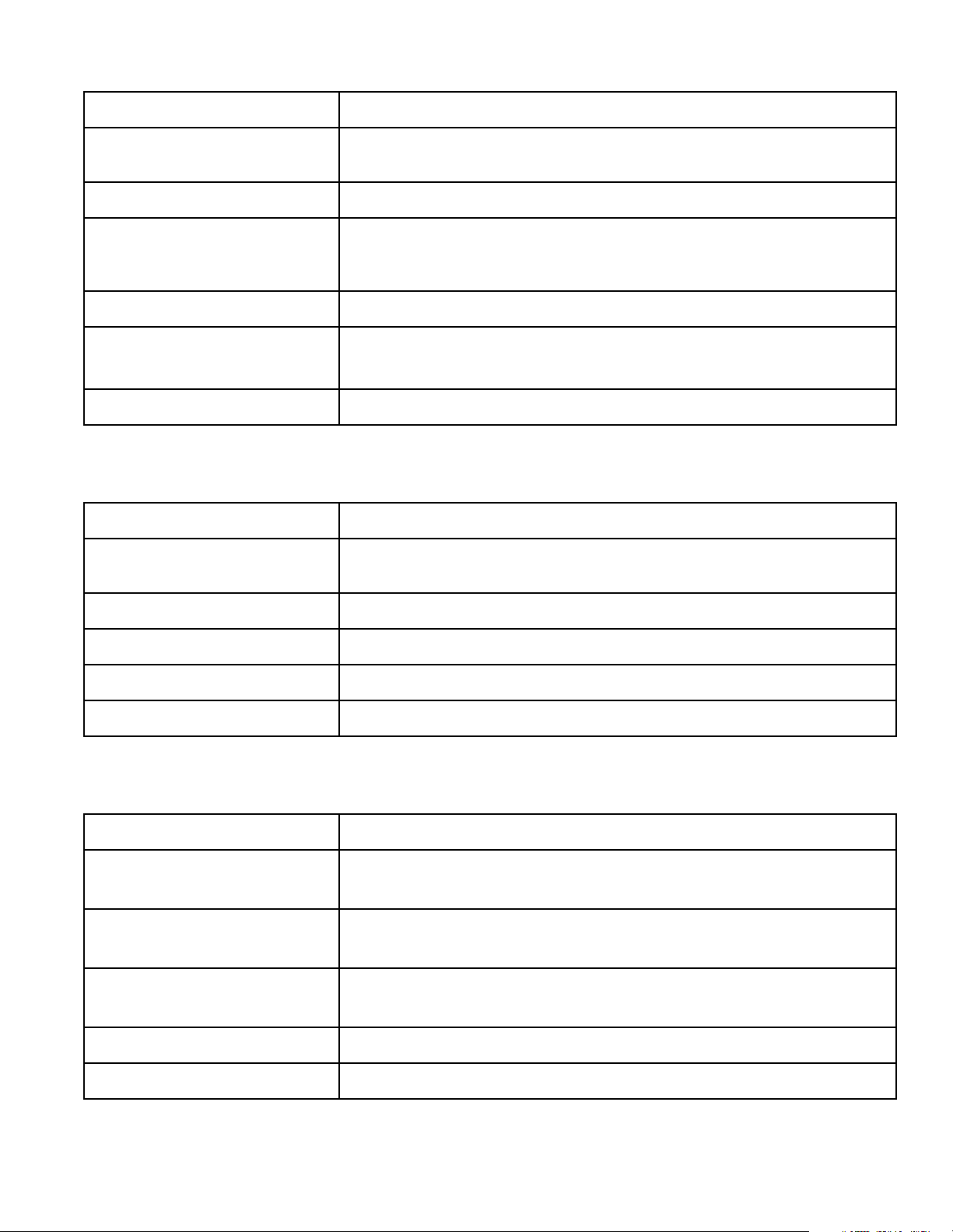

Information in this manual is applicable to these tumbler models.

30 Pound

(28" Wide)

JT30XG

JT30WE

ST30WE

ST30WG

ST30XG

30 Pound

(31.5" Wide)

JT30CG

STB30CG

JTB30CG

DTB30CG

JT30EG

STB30EG

JTB30EG

DTB30EG

JT30CE

STB30CE

JTB30CE

DTB30CE

JT30CSH

STB30CSH

JTB30CSH

DTB30CSH

JT30CSL

STB30CSL

JTB30CSL

DTB30CSL

Conversion Table

Multiply By To Obtain Multiply By To Obtain

BTU .252 kCal Pounds / sq. in. .06895 Bars

BTU 1055 Joules Pounds / sq. in. .070 kg / sq. cm.

Inch 2.54 Centimeters Pounds (lbs.) .454 Kilograms

Inches W.C. .036 Pounds / sq. in. Boiler Horsepower 33479 BTU

Inches W.C. .249 kPa Boiler Horsepower 34.5 lbs. Steam / hr.

lbf / inch

3

ft

2

(psi)

.0369 kPa CFM .471 liters / second

28.32 Liters KW 3414 BTU / hr.

Information For Handy Reference

Date Purchased _________________________________________________________

Model No. _________________________ Serial No. __________________________

Dealer’s Name _________________________________________________________

NOTICE: For your own convenience and protection, record the above

information and retain your sales slip for this appliance. The model and serial

numbers will be found on the nameplate located on the tumbler. Refer to

Figure 1.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

PARTS ORDERING INFORMATION

If literature or replacement parts are required, contact the

source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950 for

the name and address of the nearest authorized parts

distributor.

For technical assistance, call (920) 748-3121.

NAMEPLATE LOCATION

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate as shown.

Nameplate

TMB1961N

Figure 1

8 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

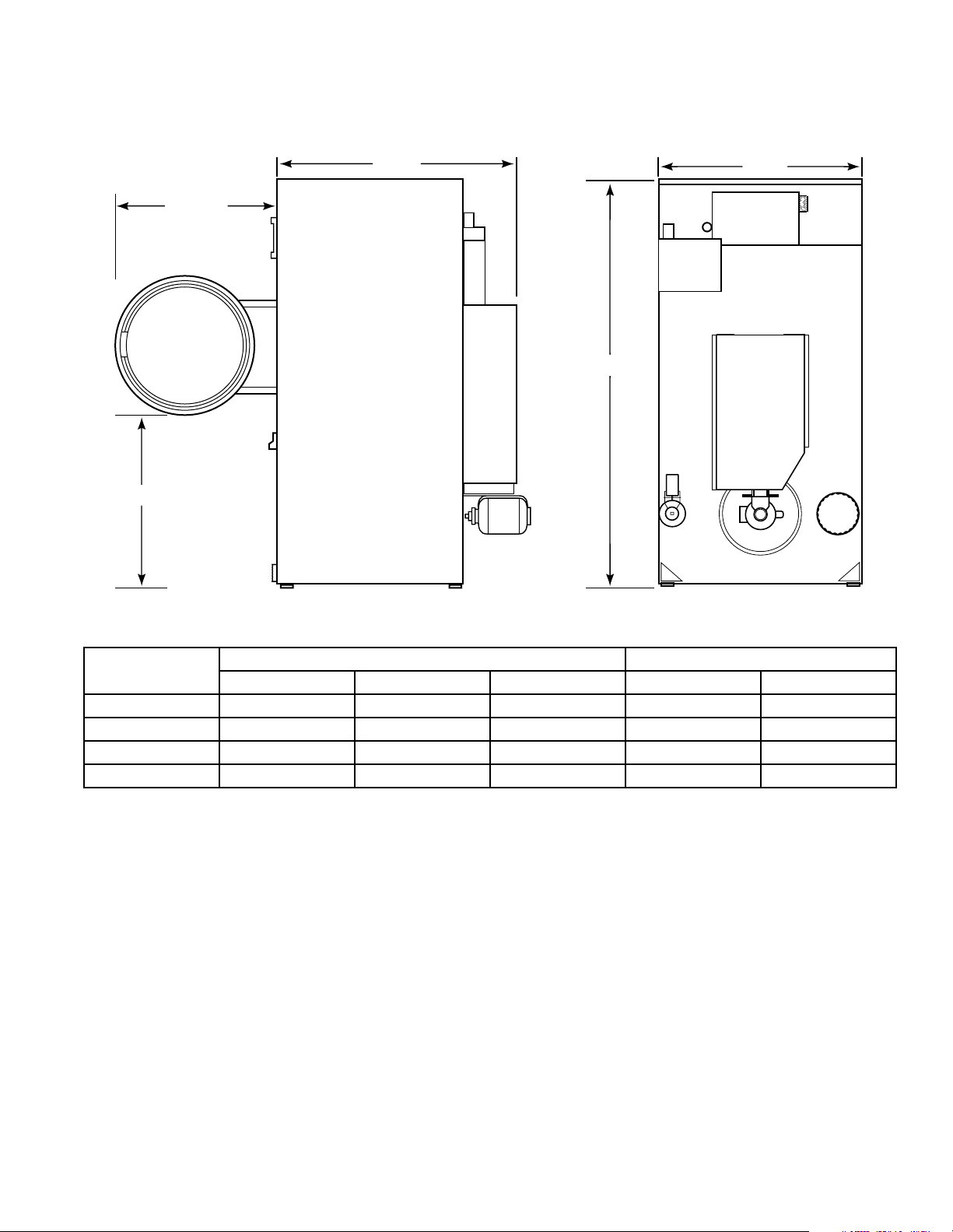

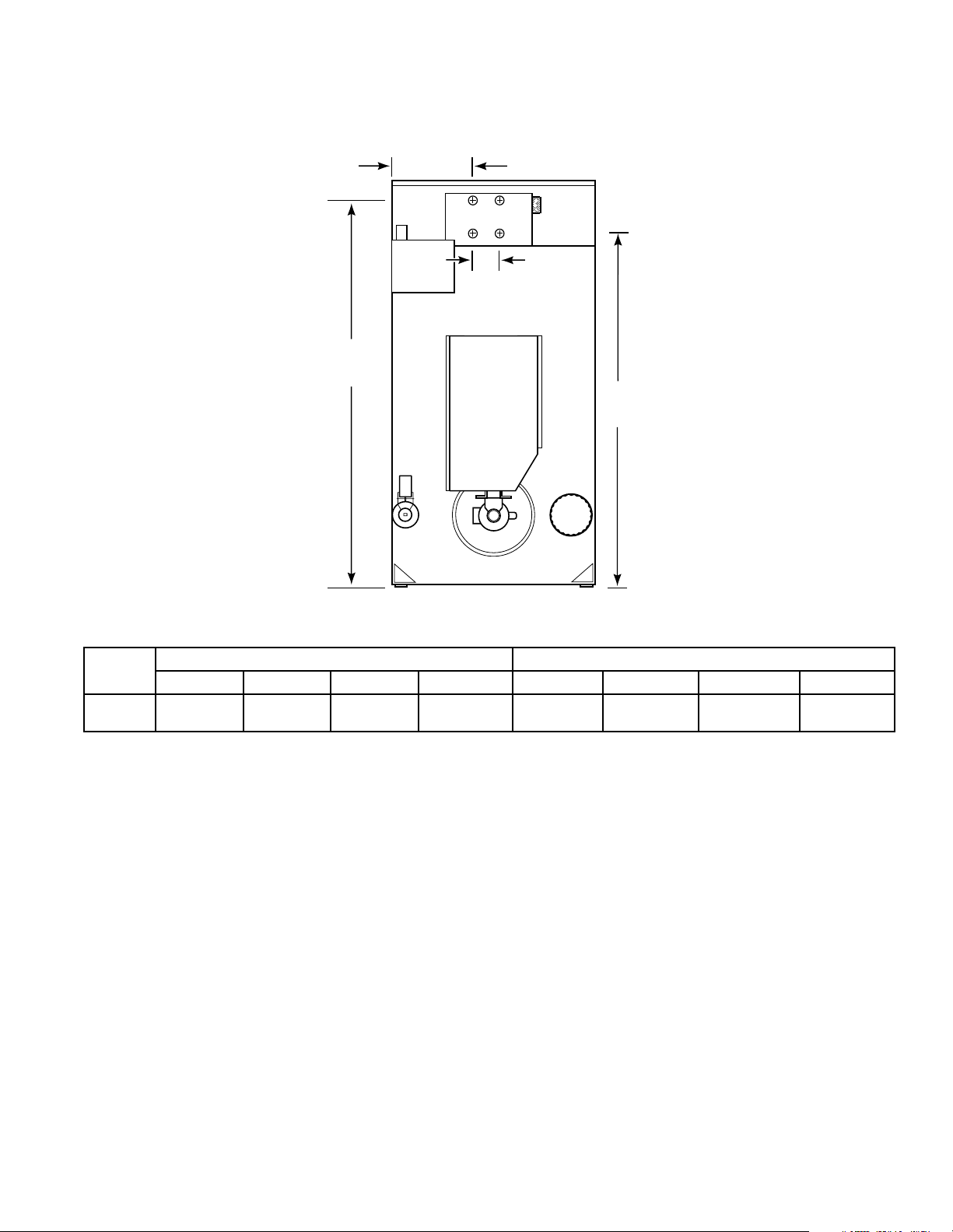

ROUGHING-IN DIMENSIONS AND SPECIFICATIONS

CABINET DIMENSIONS

OPENING

CLEARANCE

DEPTH

WIDTH

HEIGHT

T326IE3A

TUMBLER MODELS

30XG/30WE 72-1/4" (1835 mm) 28" (711 mm) 44-7/8" (1140 mm) 26-3/4" (679 mm) 30-3/4" (781 mm)

30CG/30EG 72-1/4" (1835 mm) 31-1/2" (800 mm) 46-11/16" (1186 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

30CE/30CSH 72-1/4" (1835 mm) 31-1/2" (800 mm) 44-7/8" (1140 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

30CSL 72-1/4" (1835 mm) 31-1/2" (800 mm) 45-1/32" (1144 mm) 28-1/4" (717 mm) 30-3/4" (781 mm)

HEIGHT WIDTH DEPTH OPENING CLEARANCE

OVERALL DOOR

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

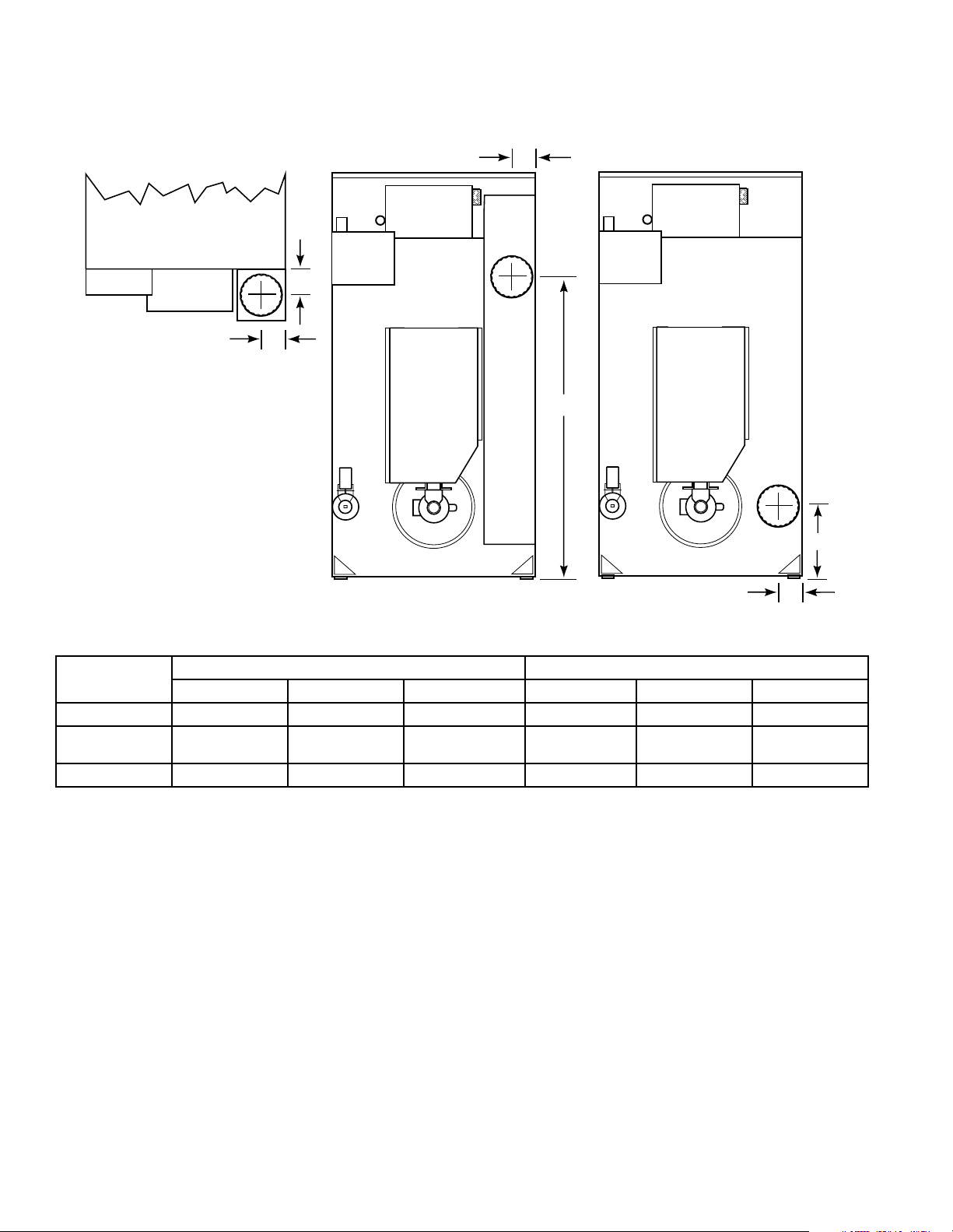

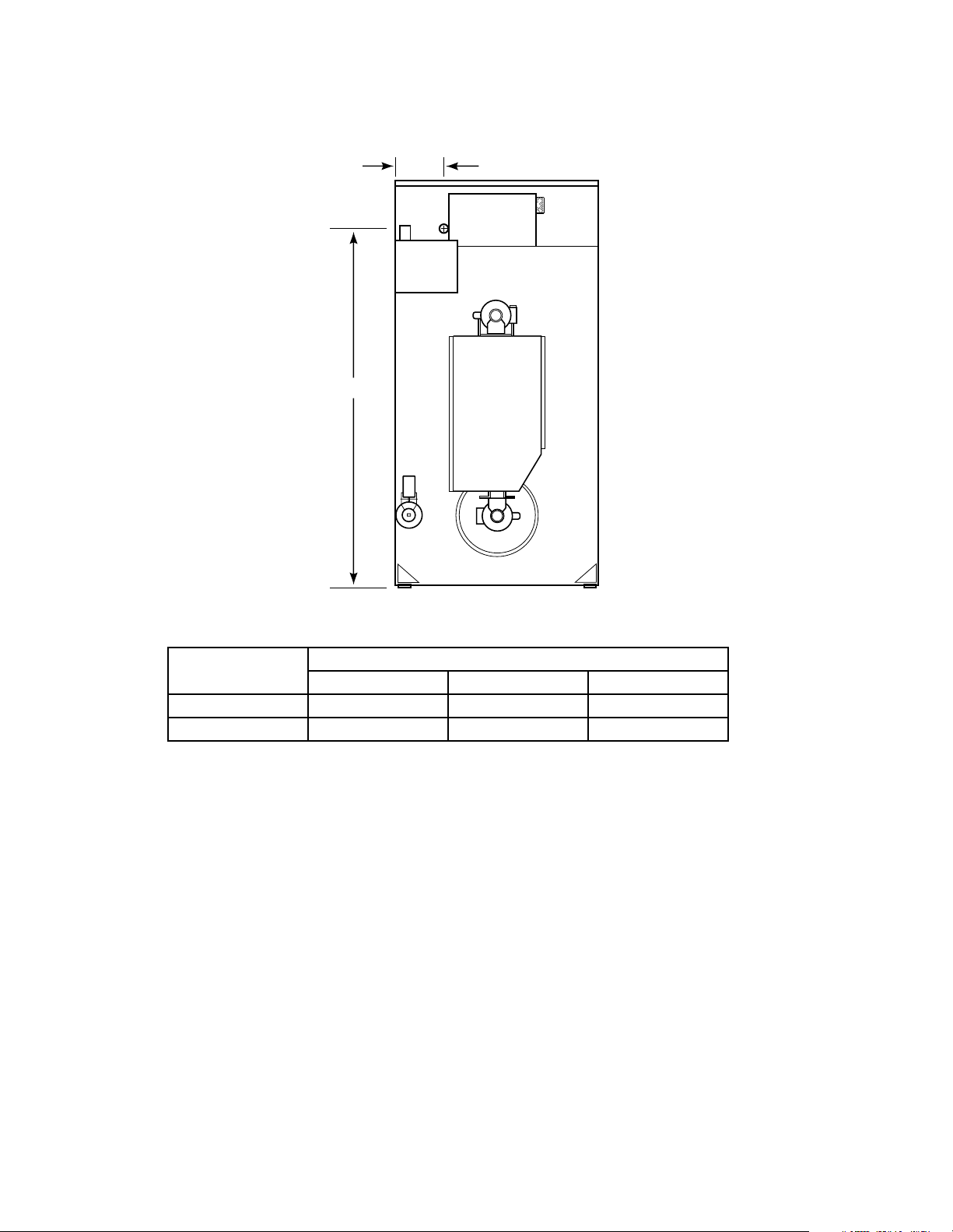

Roughing-In Dimensions and Specifications

Exhaust Thimble Locations

30XG and 30WE

ACROSS

ACROSS

DEPTH

HEIGHT

HEIGHT

ACROSS

TMB1959N

TUMBLER MODELS

30XG/30WE N/A N/A N/A 6" (152 mm) 3-3/8" (86 mm) 3-3/8" (86 mm)

30CG/30CE

30CSL/30CSH

30EG 8" (203 mm) 4-7/16" (113 mm) 55-3/8" (1407 mm) N/A N/A N/A

DIAMETER ACROSS HEIGHT DIAMETER ACROSS HEIGHT

8" (203 mm) 4-7/16" (113 mm) 21-7/8" (556 mm) N/A N/A N/A

HORIZONTAL EXHAUST VERTICAL EXHAUST

10 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 13

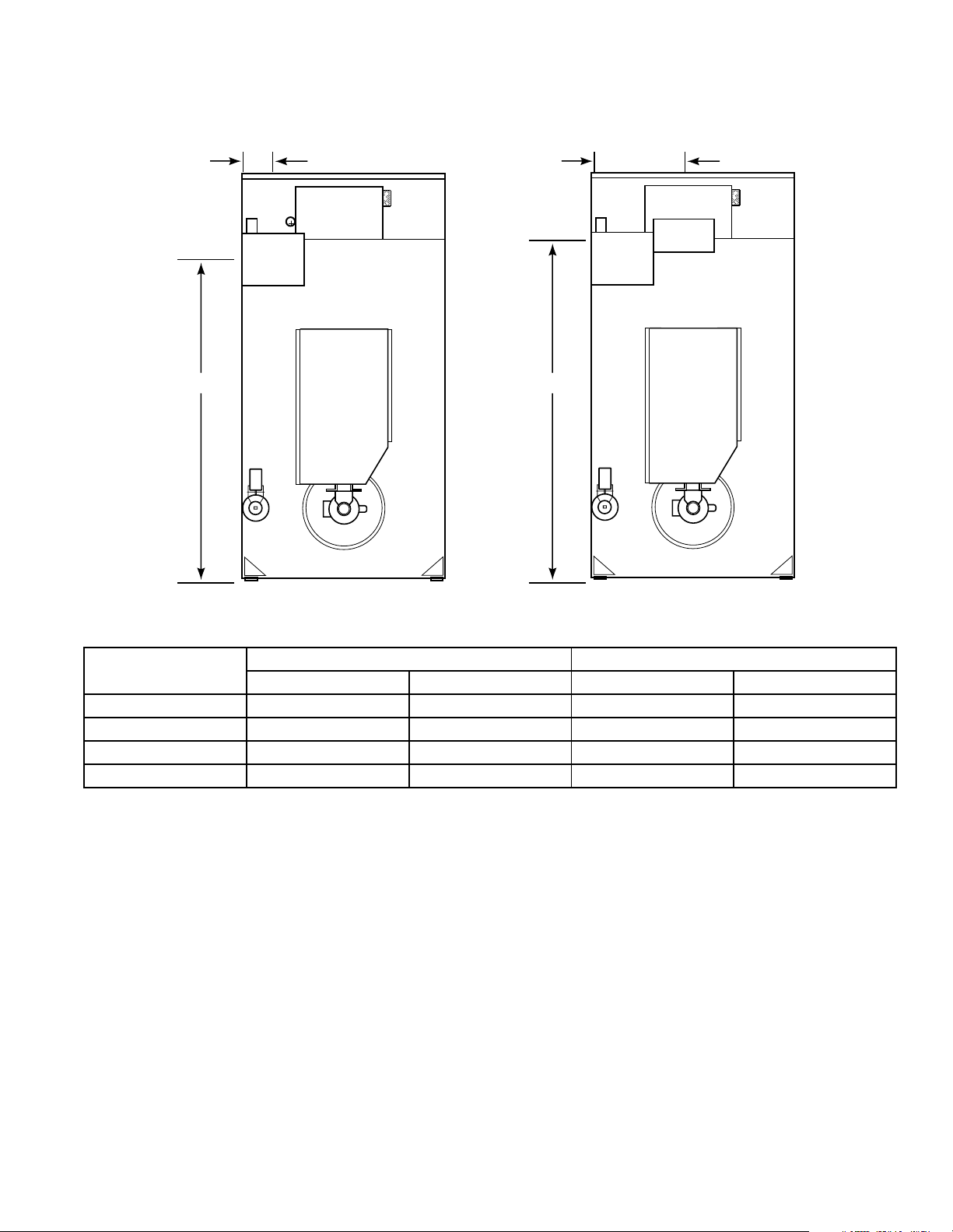

Roughing-In Dimensions and Specifications

Steam Connection Locations

ACROSS

SPAN

STEAM

INLET

HEIGHT

STEAM

OUTLET

HEIGHT

TUMBLER

MODELS

30CSL

30CSH

T328IE3A

STEAM INLET STEAM OUTLET

DIAMETER ACROSS HEIGHT SPAN DIAMETER ACROSS HEIGHT SPAN

3/4" (19 mm)

I.D.

14" (356 mm) 68-3/4"

(1746 mm)

7-1/2"

(190 mm)

3/4" (19 mm)

I.D.

14" (356 mm) 61-1/4"

(1556 mm)

7-1/2"

(190 mm)

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

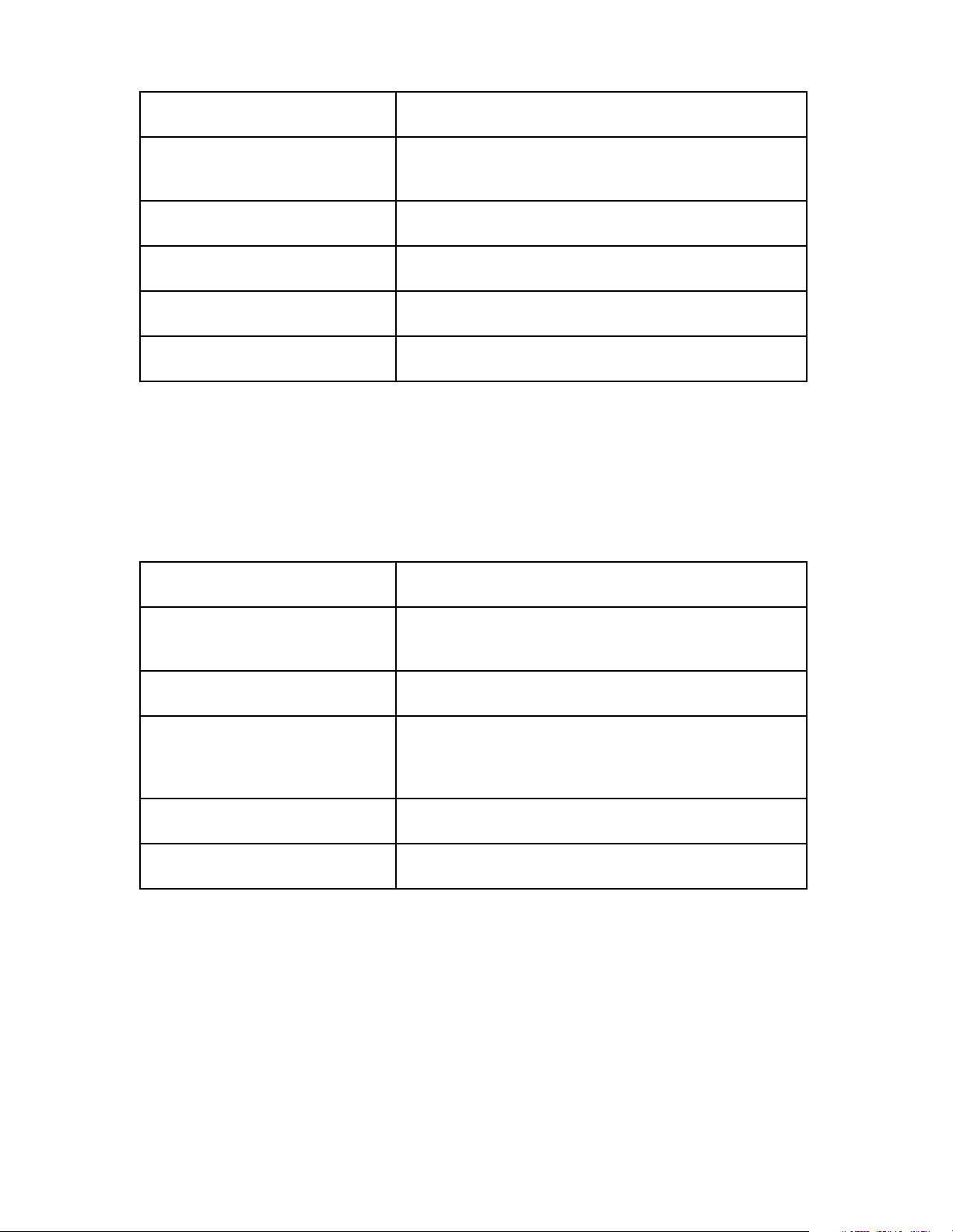

Roughing-In Dimensions and Specifications

Gas Connection Locations

ACROSS

HEIGHT

T329IE3A

TUMBLER

MODELS

30XG 1/2" (12.7 mm) 12-1/4" (311 mm) 62-1/8" (1578 mm)

30CG/30EG 1/2" (12.7 mm) 15" (381 mm) 62-1/8" (1578 mm)

DIAMETER (N.P.T.) ACROSS HEIGHT

GAS CONNECTION

12 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

Roughing-In Dimensions and Specifications

330IE3

Electrical Connection Locations

HEIGHT

ACROSS

Gas & Steam

HEIGHT

Electric

ACROSS

T

A

TUMBLER

MODELS

30XG/30CG/30EG 65" (1651 mm) 3" (76 mm) N/A N/A

30WE N/A N/A 60" (1524 mm) 14" (356 mm)

30CE N/A N/A 60" (1524 mm) 16" (406 mm)

30CSL/30CSH 65" (1651 mm) 3" (76 mm) N/A N/A

ELECTRICAL SERVICE - GAS & STEAM MODELS ELECTRICAL SERVICE - ELECTRIC MODELS

HEIGHT ACROSS HEIGHT ACROSS

NOTE: These are approximate dimensions only.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

28" wide Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Gas Consumption: 75,000 BTU per hour (79.1 MJ/hr.)

Max. Airflow

Net Weight: 350 Pounds (159 kg) (approximate)

: 370 C.F.M. (175 liters/sec.)

28" wide Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 26.5" x 30" (67.3 cm x 76.2 cm)

perforated galvanized steel with three baffles

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Element: 21,000 Watts (60 Hz models)

Long life nichrome wire

18,000 Watts (50 Hz models)

Max. Airflow

Net Weight: 410 Pounds (184.5 kg) (approximate)

14 M414545

: 625 C.F.M. (295 liters/sec.)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 17

Gas Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 cm x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Energy Saver Models — 80,000 BTU per hour (84.4 MJ/hr.)

Gas Consumption:

Standard Models — 105,000 BTU per hour (110.8 MJ/hr.)

Gas Connection: 1/2 inch N.P.T.

Max. Airflow: Energy Saver Models — 250 C.F.M. (118 liters/sec.)

Standard Models — 625 C.F.M. (295 liters/sec.)

Net Weight: 450 Pounds (204 kg) (approximate)

Electric Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 cm x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds (13.6 kg) dry weight (cotton load)

Motor: 1/3 H.P., lifetime lubricated, internal overload protected

Element: 21,000 Watts (all voltages)

Max. Airflow

Net Weight: 450 Pounds (204 kg) (approximate)

: 625 C.F.M. (295 liters/sec.)

Steam Tumbler

Cabinet Finish: Electrostatically applied thermosetting polyester.

Cylinder: 30" x 30" (76.2 x 76.2 cm) perforated galvanized steel with three baffles;

30 pounds dry weight (13.6 kg) (cotton load)

Motor: High Pressure (4 coils) 1/2 H.P.

Low Pressure (4 coils) 3/4 H.P.

Boiler Horsepower: 4 coil High Pressure – 3.7 Bhp (123,950 BTU/hr., 58 kg/hr, 31,235 kCal/hr.)

4 coil Low Pressure – 2.6 Bhp (87,100 BTU/hr., 40 kg/hr, 21,949 kCal/hr.)

Max. Airflow

Net Weight: 470 Pounds (214 kg) (approximate)

M414545

: 625 C.F.M. (295 liters/sec.)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Notes

16 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

Section III

Installation Instructions

RECEIVING INSPECTION

Upon delivery, visually inspect crate carton and parts for

any visible shipping damage. If the crate, carton or cover

are damaged or signs of possible damage are evident,

have the carrier note the condition on the shipping papers

before the shipping receipt is signed, or advise the carrier

of the condition as soon as it is discovered.

Remove the crate and protective cover as soon as possible

and check the items listed on the packing list. Advise the

carrier of any damaged or missing articles as soon as

possible. A written claim should be filed with the carrier

immediately if articles are damaged or missing.

IMPORTANT: Remove the shipping tape from the

two back draft dampers located in the exhaust

thimble.

MATERIALS REQUIRED (Obtain Locally)

GAS, ELECTRIC OR STEAM DRYING TUMBLERS

• One fused disconnect switch or circuit breaker.

GAS DRYING TUMBLERS ONLY

• One gas shut-off valve for gas service line to each

tumbler.

STEAM DRYING TUMBLERS ONLY

• One steam shut-off valve for steam service line to be

connected upstream of solenoid steam valve.

• Two steam shut-off valves for each condensate return

line.

• Flexible steam hoses with a 125 psig (pounds per

square inch gauge) (8.79 kg/sq. cm) working pressure

for connecting steam coils. Refer to Figure 9 and

Table 3.

• Two steam traps for steam coil outlet to condensate

return line.

• Two vacuum breakers for condensate return lines.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

POSITIONING THE TUMBLER

LEVELING THE TUMBLER

The tumbler may be removed from the skid before

moving it to the installation location or it may be moved

while still attached to the skid. To remove tumbler from

the skid, unscrew the four shipping capscrews (one at

each corner) and remove the tumbler from the skid. The

lint panel door will have to be removed in order to remove

the two front capscrews.

NOTE: Do not throw these four capscrews away —

they are the leveling legs.

Screw the four leveling legs back into the level adjusting

fittings from the top.

Slide the tumbler to its permanent location and level.

Keep the tumbler as close to the floor as possible. The

tumbler must rest firmly on the floor so weight of tumbler

is evenly distributed. Tumbler must not rock.

Each tumbler should be leveled within 1/8 inch (3.2 cm)

from front to rear, and 1/8 inch (3.2 cm) from side to side.

Check front to rear level by rotating the clothes cylinder

until one rib is at the bottom, then place a level on the rib.

Side to side level should be checked by placing a level on

the front and rear of the top panel.

18 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 21

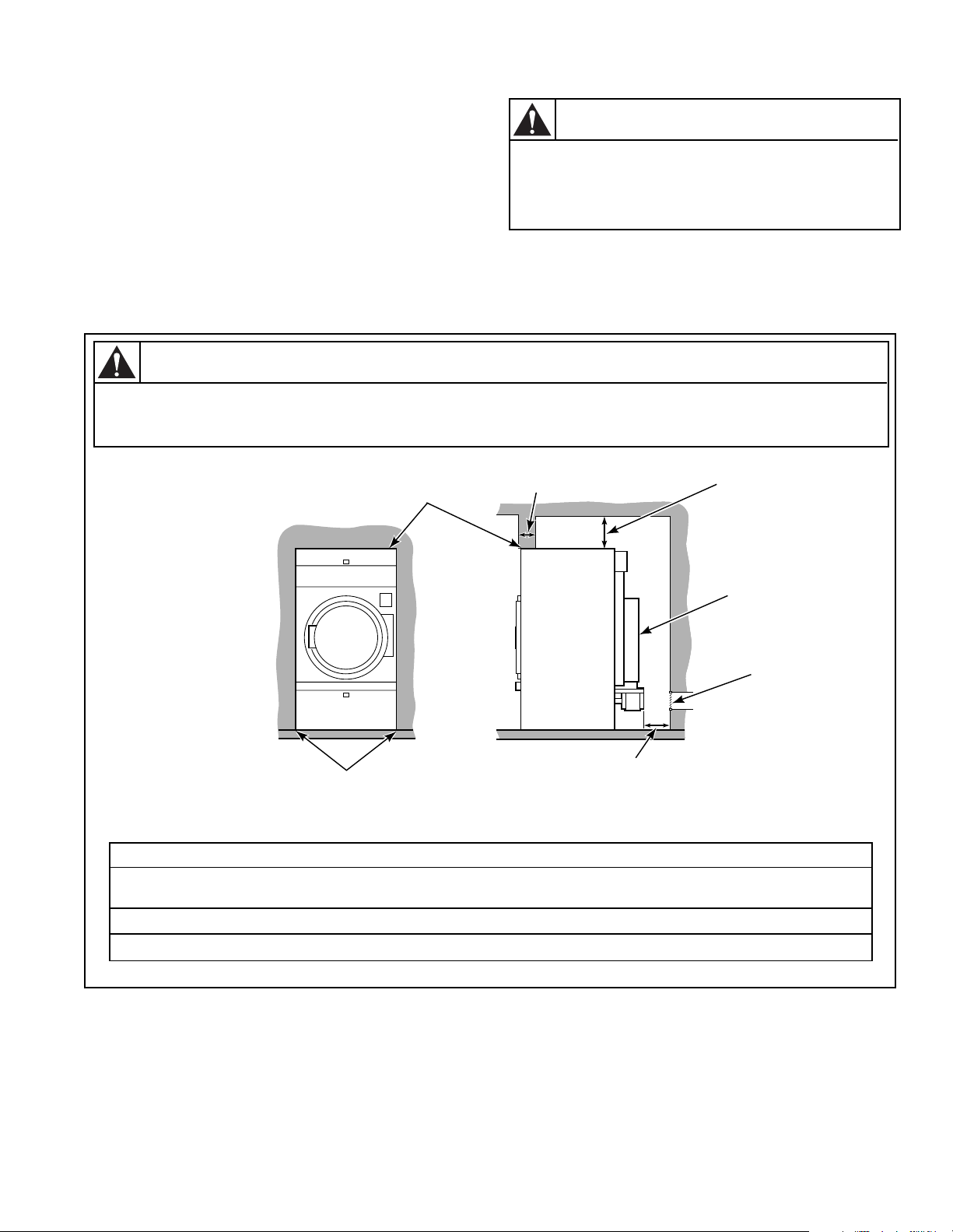

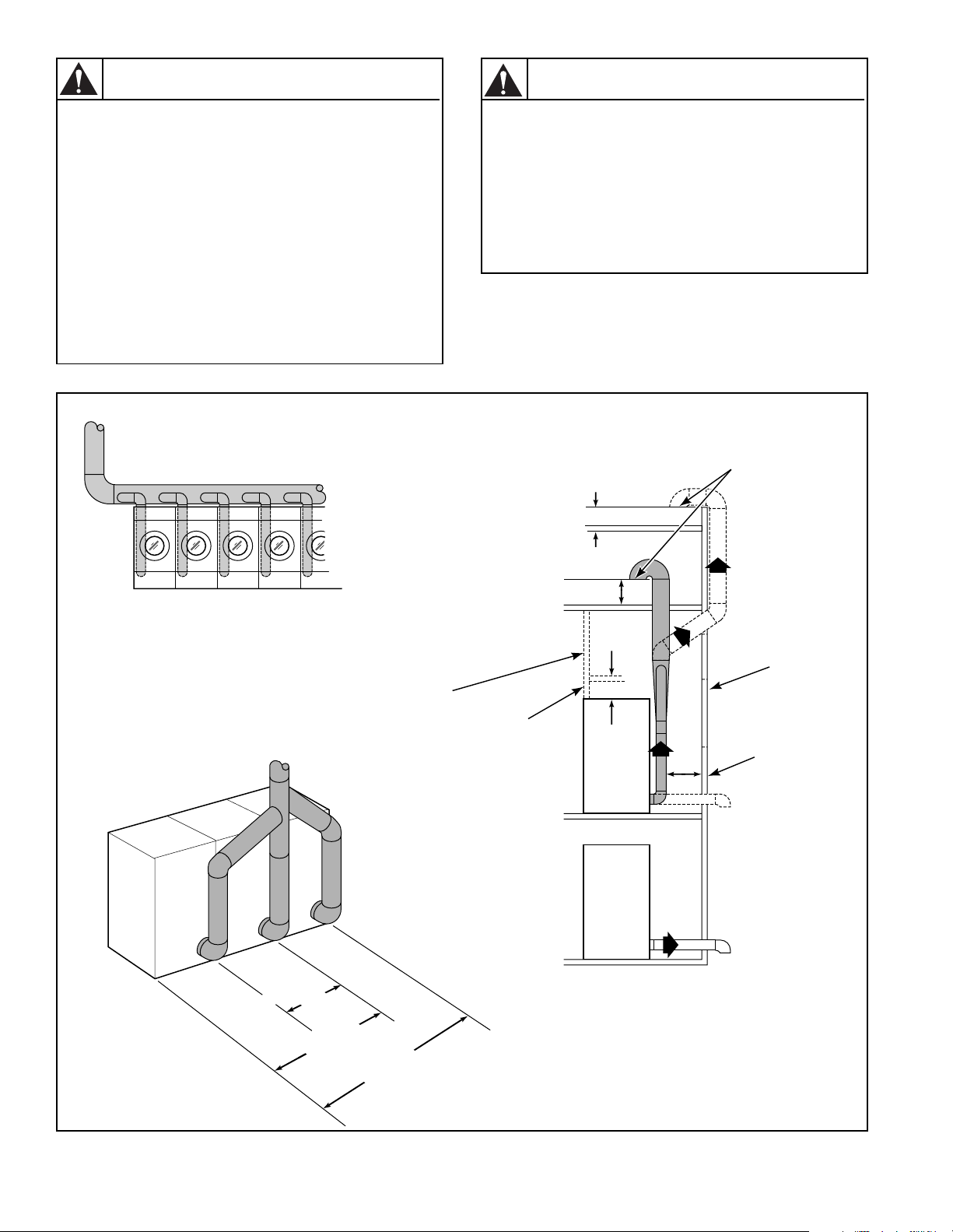

TUMBLER ENCLOSURE CONSTRUCTION

IMPORTANT: DO NOT block the airflow at the rear

of the tumbler with laundry or other articles. Doing

so would prevent adequate air supply to the

combustion chamber of the tumbler.

A typical tumbler enclosure is shown in Figure 2. Note

that the enclosure touches the tumbler top and side

To reduce the risk of serious injury, install

lockable door(s) to prevent public access

to rear of tumblers.

panels. Also, note the minimum and maximum

dimensions. Be aware that there may be local codes and

ordinances which must be complied with.

IMPORTANT: Install tumblers with sufficient

clearance for servicing and operation. Refer to

Figure 2.

WARNING

To reduce the risk of severe injury, clearance of tumbler cabinet from combustible

construction must conform to the minimum clearances.

WARNING

W055

W056

12" (30.5 cm)

MINIMUM

CLEARANCE

PERMITTED

FOR REMAINDER

GUARD

PROVISION

MAKE-UP

T038IE3D

NOTE: Shaded areas

indicate adjacent

structure.

0" CLEARANCE PERMITTED

FOR FIRST 4" (10.16 cm)

0" CLEARANCE

4" (10.16 cm)

MAXIMUM

24" (61 cm) MINIMUM

36" (91.4 cm) RECOMMENDED

FOR MAINTENANCE PURPOSES

Minimum Recommended Clearances

Model Top

First 4" (10.2 cm)

To p

(Remainder)

Back Sides

28" 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

FOR

AIR

31.5" 0" (0.0 cm) 12" (30.5 cm) 24" (61 cm) 0" (0 cm)

Figure 2

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

FACILITIES REQUIRED

To assure compliance, consult local building code

requirements.

WARNING

A drying tumbler produces combustible

lint. To reduce the risk of fire, the tumbler

must be exhausted to the outdoors.

W057

FLOOR

The tumbler must be installed on a level floor capable of

supporting 100 pounds per square foot (488.3 kg/sq. m).

Floor covering materials such as carpeting or tile must be

removed.

LAYOUT

Whenever possible, tumblers should be installed along an

outside wall where duct length can be kept to a minimum,

and make-up air can be easily accessed. Construction

must not block the airflow at the top rear of the tumbler.

Doing so would prevent adequate air supply to the

tumbler’s combustion chamber.

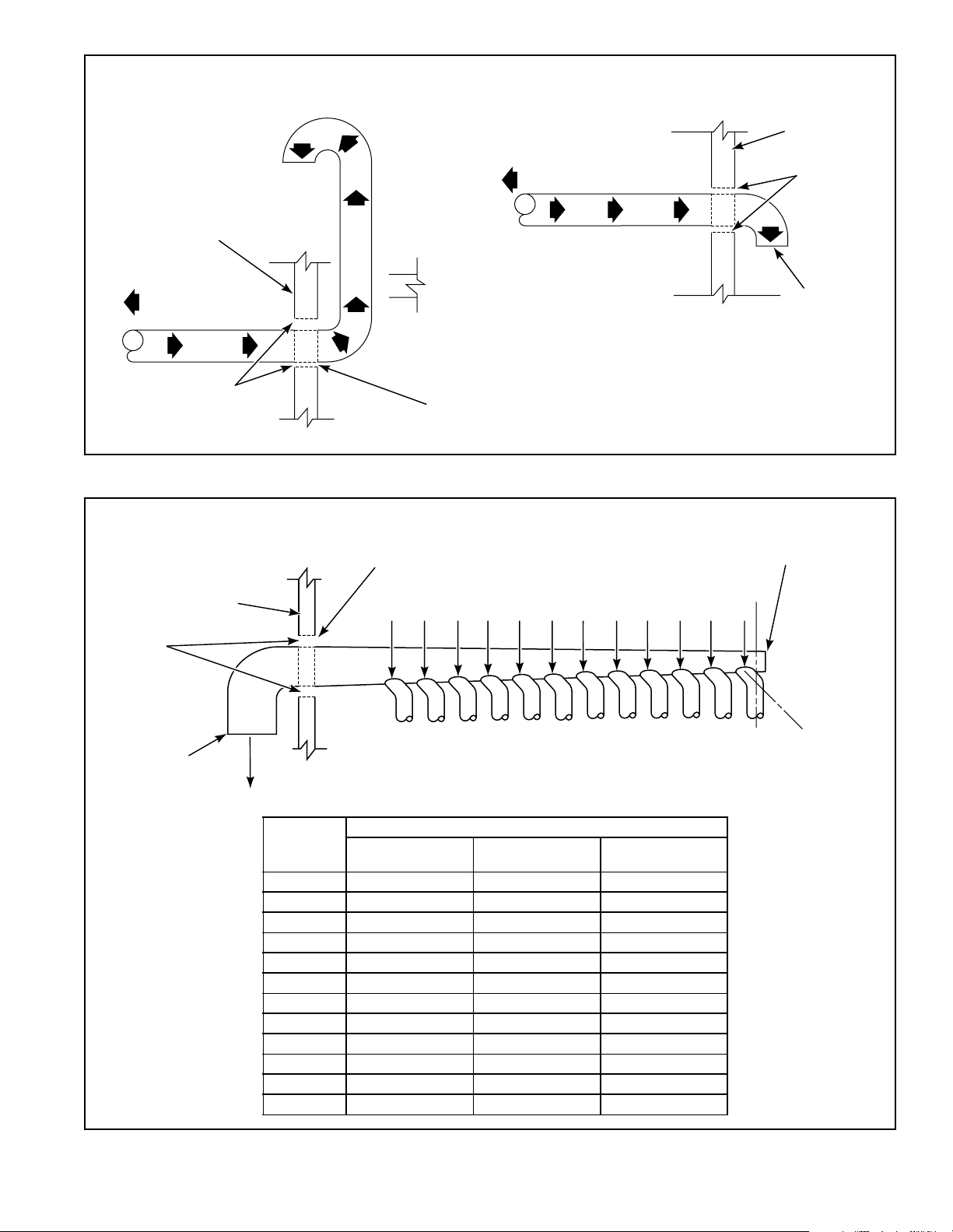

VENTING

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to the

outdoors by the shortest possible route.

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth, so the joints do not permit the accumulation of

lint. Do not use sheet metal screws to join vent sections.

Improperly sized or assembled ductwork causes excess

back pressure which results in slow drying, lint collecting

in the duct, lint blowing back into the room, and

increased fire hazard.

preferred to exhaust tumbler(s) individually to the

outdoors. At no point may the cross area of installed

venting be less than the cross area of the exhaust

thimble of the tumbler.

The maximum allowable length venting is 14 feet (4.3

m) and two 90° elbows or equivalent. If the equivalent

length of a duct required for an installation exceeds the

maximum allowable equivalent length, the diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 m). Cross section area of a

rectangular duct must be increased by 20% for each

addtional 20 feet (6.1 m). To determine equivalent

venting, Refer to Tabl e 1 .

DUCT

DIAMETER

6" (15.2 cm)

8" (20.3 cm)

10" (25.40 cm)

12" (30.48 cm)

14" (35.56 cm)

16" (40.64 cm)

18" (45.72 cm)

Equivalent Length (feet) = 1.7 x Duct Diameter

(inches)

Example: A 12" diameter duct’s equivalent

length of 14 feet of duct and two 90° elbows is:

Equivalent Length = 14 feet + (2) 90° elbows

With the tumbler in operation, airflow at any point in

the duct must be at least 1200 feet per minute (366 m./

min.) to insure that the lint remains airborne.

EQUIVALENT LENGTH OF

STRAIGHT DUCT

One 90° elbow = 7 feet (2.1 m)

One 90° elbow = 9.3 feet (2.83 m)

One 90° elbow = 11.6 feet (3.5 m)

One 90° elbow = 14 feet (4.3 m)

One 90° elbow = 16 feet (4.9 m)

One 90° elbow = 18.7 feet (5.7 m)

One 90° elbow = 21 feet (6.4 m)

Table 1

= 14 feet + 14 feet + 14 feet

= 42 feet (12.8 m)

Exhaust ducts shall be constructed of sheet metal or

other noncombustible material. Such ducts must be

equivalent in strength and corrosion resistance to

ducts made of galvanized sheet steel not less than

0.0195 inches (0.495 mm) thick.

Where the exhaust duct pierces a combustible wall or

ceiling, an opening having a diameter of 4 inches (10.2

cm) larger than the diameter of the exhaust duct shall be

provided, with the duct centered in the opening. When

ducts pass through walls, ceilings, floors or partitions, the

space around the duct shall be sealed with noncombustible material. Refer to Figures 3, 4 and 5.

• Individual Venting

For maximum efficiency and performance, it is

20 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 23

• Collector Venting

While it is preferable to exhaust tumblers individually

to the outdoors, a main collector duct may be used if it

is sized accordingly. Refer to Figure 5. This

illustration indicates minimum diameters, and should

be increased if the collector length exceeds 20 feet

(6.1 m). The collector duct may be rectangular in cross

section, as long as the area is not reduced. Provisions

should be made for lint removal and cleaning of the

collector duct.

The collector duct must be tapered. Refer to Figure 5.

The individual tumbler ducts must enter the collector

duct at a 45° angle in the direction of airflow. Never

connect a tumbler duct at a 90° angle to the collector

duct. Doing so will cause excessive back pressure,

resulting in poor performance. Never connect two

tumbler exhaust ducts directly across from each

other at the point of entry to the collector duct.

The collector system must be designed so the static

back pressure measured 12 inches (30.5 cm) from the

exhaust thimble does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of the tumbler. This must be measured with

all tumblers running that are vented into the collector.

At a minimum, the National Fuel Gas Code requires

tumblers to have at least one square inch (6.5 sq. cm)

of opening for every 1000 BTU/hr. of input rating for

proper combustion.

Example: A tumbler with a rated input of 120,000

BTU/hr. requires 120 square inches of free

opening.

The additional opening recomended by the

manufacturer is required for optimum drying and

reliability.

Protective louvers in the opening to the outdoors can

reduce air movement by approximately 40 percent. The

opening must compensate for the area taken up by the

louvers.

The make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased sufficiently

to prevent downdrafts in any of the vents when all

tumblers are in operation. Do not locate gravity vented

appliances between tumbler(s) and make-up air

openings. If it is necessary to duct make-up air to the

tumbler(s), increase the area of the duct work by 25

percent to compensate for any restriction in air

movement.

MAKE-UP AIR

A tumbler is forced air exhausted and requires provisions

for make-up air to replace the air exhausted by the

tumbler.

IMPORTANT: Do not obstruct the flow of

combustion and ventilation air.

Recommended make-up air opening to the outside is

144 inches

2

(928 cm2).

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

WARNING

WARNING

Solvent gases and vapors from dry

cleaning machines create acids when

drawn through the heater of a drying

tumbler. These acids are corrosive to the

drying tumbler as well as to the laundry

load being dried. Be sure make-up air is

free of solvent gases and vapors.

If the dry cleaning machines are in the

same area as the tumbler, then the

tumbler make-up air must come from a

source free of solvent gases and vapors.

W058

FOR BEST PERFORMANCE

provide an individual exhaust

duct for each drying tumbler.

Do not install a hot water heater

in room containing drying

tumblers. It is better to

have the water heater in

a separate room with a

separate air inlet.

To reduce the risk of fire and

accumulation of combustible gases, DO

NOT exhaust tumbler air into a window

well, gas vent, chimney or enclosed,

unventilated area such as an attic wall,

ceiling, crawl space under a building, or

concealed space of a building.

W059

NOTE: Do not install wire

mesh or screen in this

opening as lint will build up

and prevent proper discharge

of air from drying tumblers.

ROOF 30" (76.2 CM)

T075IE3A

REMOVABLE STRIP OF PANEL IN FRAMING WALL

TO PERMIT REMOVAL OF DRYING TUMBLER

T108IE3A

FROM FRAMING WALL

ONE

DRYING

TUMBLER

TWO

DRYING

TUMBLERS

THREE

DRYING

TUMBLERS

ROOF 30" (76.2 cm)

PARTITION OR

BULKHEAD

CONSULT YOUR LOCAL BUILDING

CODE FOR REGULATIONS WHICH

MAY ALSO APPLY

NOTE: Inside of duct shall be

smooth. Do not use sheet

metal screws to join sections.

CEILING

WALL

36 INCHES

(91.4 cm)

RECOMMENDED

SERVICE AREA

24 INCHES

(61.0 cm)

MINIMUM

T108IE3C

Figure 3

22 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

VERTICAL EXHAUST INSTALLATION

HORIZONTAL EXHAUST INSTALLATION

WALL

CONNECT TO

TUMBLER

2" (5.1 cm)

MINIMUM

WALL

2" (5.1 cm)

MINIMUM

WALL

CONNECT TO

TUMBLER

EXHAUST AIR FLOW

MAXIMUM LENGTH OF

DUCT 14 FEET

(4.3 m)

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

Figure 4

NOTE: WHERE THE EXHAUST DUCT PIERCES A COMBUSTIBLE WALL

OR CEILING, AN OPENING HAVING A DIAMETER FOUR INCHES (10.2 cm)

LARGER THAN THE DIAMETER OF THE EXHAUST DUCT SHALL BE

PROVIDED, AND THE EXHAUST DUCT CENTERED WITHIN THE OPENING.

T030IE3B

2" (5.1 cm)

MINIMUM

EXHAUST

OUTLET

NO SCREEN

OR CAP

INSPECTION OR

CLEANOUT COVER

ALKJ I HGF E DCB

NO SCREEN

OR CAP

AIR OUT

DUCT

STATION

28" WIDE

GAS & ELEC.

MINIMUM DIAMETER

30 LB.

GAS & ELEC.

30 LB. STEAM

A 7" (17.8 cm) 10" (25.4 cm) 10" (25.4 cm)

B 10" (25.4 cm) 12" (30.5 cm) 14" (35.6 cm)

C 12" (30.5 cm) 15" (38.1 cm) 17" (43.2 cm)

D 14" (35.6 cm) 17" (43.2 cm) 20" (50.8 cm)

E 16" (40.6 cm) 19" (48.3 cm) 22" (55.9 cm)

F 18" (45.7 cm) 21" (53.3 cm) 24" (61.0 cm)

G 19" (48.3 cm) 23" (58.4 cm) 26" (66.0 cm)

H 20" (50.8 cm) 25" (63.5 cm) 28" (71.1 cm)

I 22" (55.9 cm) 26" (66.0 cm) 30" (76.2 cm)

J 23" (58.4 cm) 27" (68.6 cm) 31" (78.0 cm)

K 24" (61.0 cm) 29" (73.9 cm) 33" (83.8 cm)

L 25" (63.5 cm) 30" (76.2 cm) 34" (86.4 cm)

Figure 5

45˚

T056IE3B

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

GAS REQUIREMENTS

WARNING

To reduce the risk of fire or explosion, DO

NOT CONNECT THE GAS LINE TO THE

TUMBLER IF THE GAS SERVICE IS NOT

THE SAME AS THAT SPECIFIED ON THE

TUMBLER SERIAL PLATE! It will first be

necessary to convert the gas burner

orifice and gas valve. Appropriate

conversion kits are available.

W060

IMPORTANT: Any product revisions or conversions

must be made by the Manufacturer’s Authorized

Dealers, Distributors or local service personnel.

WARNING

The tumbler and its individual shut-off

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psig (3.45 kPa).

The size of gas service pipe is dependent upon many

variables (lengths, tees, etc.). Specific pipe size

information should be obtained from the gas supplier.

Refer to Ta b le 2 for general pipe size.

A dirt and water vapor pipe trap must be furnished and

installed by customer. Refer to Figure 6.

It is important that equal pressure be maintained at all

tumbler gas connections. This can best be done by

installing a one inch (2.54 cm) pipe gas loop. Refer to

Figure 7.

WARNING

To reduce the risk of fire or explosion, if

the tumbler is to be connected to

Liquefied Petroleum (L.P.) gas, a vent to

the outdoors must be provided in the

room where the tumbler is installed.

W062

NATURAL GAS service must be supplied at 6-1/2 ±

1-1/2 inch water column pressure (1.62 ± .37 kPa).

L.P. GAS service must be supplied at 11 ± .3 inch water

column pressure (2.74 ± .07 kPa).

The tumbler must be isolated from the gas

supply piping system by closing its

individual manual shut-off valve during

any pressure testing of the gas supply

piping system at test pressure equal to or

less than 1/2 psig (3.45 kPa).

IMPORTANT: The installation must comply with

local codes or, in the absence of local codes:

• with the latest edition of the “National Fuel

Gas Code”, ANSI Z223.1 in the U.S.A.

• with CAN1-B149.1 or CAN1-B149.2 in

Canada

• and Australian Gas Association/Australian

L.P. Gas Association requirements in Australia

W061

24 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

WARNING

Check all pipe connections, internal and

external, for gas leaks using a soapy

solution. To reduce the risk of explosion or

fire, DO NOT USE AN OPEN FLAME TO

CHECK FOR GAS LEAKS! Gas

connections should be checked annually

for leakage.

W063

GAS LINE

TO

DRYER

CONTROLS

SHUT-OFF

VALVE

DIRT AND

WATER VAPOR

TRAP

1/8" (.32 cm) N.P.T. plugged

tapping accessible for

pressure testing. Gauge

connection located upstream

from dryer main manual

shut-off

Figure 6

GAS SUPPLY

PIPING SYSTEM

GAS

“T” FITTING

6 INCHES (15.2 cm)

MINIMUM GAS PIPE

GAS

PIPE CAP

T135IE1A

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Example of Gas Loop Piping

IMPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

MAIN

REGULATOR

GAS SPACE HEATER

TUMBLERS

GAS

SHUT-OFF

VALVES

GAS LINE

PRESSURE TAP

GAS

METER

IMPORTANT: Line pressure must be maintained at 6-1/2 ± 1-1/2 water column inches (1.62 ± .37 kPa) for Natural Gas

(11 ± .3 water column inches for L.P. Gas) (2.74 ± .07 kPa) with all gas appliances running (tumblers, water heaters, space heaters,

furnace, etc.).

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches (2.00

kPa) pressure with all gas appliances firing.

GAS WATER

HEATERS

PRESSURE

REGULATOR

(If required)

NOTE: Minimum pipe size to

tumbler is 1/2" (12.7 mm)

T034IE3D

ONE INCH

(2.54 cm)

GAS LOOP

Figure 7

Example of Gas Supply Piping

NOTE: See BTU/HR. rating

on dryer nameplate.

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

GAS TUMBLER DRYERS

(75,000 BTU/HR. each)

123456789

FURNACE

(120,000 BTU/HR.)

MAIN

REGULATOR

GAS

GAS WATER

HEATERS

(400,000 BTU/HR. each)

GAS

METER

PIPE

PRESSURE

25' (7.6 m)

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m) gas supply pipe.

= 44' (13.4 m) Total Gas Liner

The main supply pipe diameter should be 2" (5.08 cm). Refer to Table 2.

REGULATOR

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 75,000

= 675,000 BTU/HR.

19' (5.8 m)

19' (5.8 m)

TMB1960N

Figure 8

26 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

GAS PIPE SIZE REQUIRED FOR 1,000 BTU NATURAL GAS — .64 SPECIFIC GRAVITY

GAS

APPLIANCES

TOTAL

BTU/HR.

100,000

AT 6½ ± 1½ INCH (1.62 ± .37 kPa) WATER COLUMN PRESSURE

25 FT.

(7.63 m)

BASED ON 0.3" WATER COLUMN PRESSURE DROP FOR LENGTH GIVEN

¾" (19.05mm)

50 FT.

(15.25 m)

¾" (19.05mm)

EQUIVALENT LENGTH

75 FT.

(22.88 m)

1" (2.54cm)

100 FT.

(30.50 m)

1" (2.54cm)

125 FT.

(38.13 m)

1" (2.54cm)

150 FT.

(45.75 m)

1" (2.54cm)

120,000

140,000

160,000

180,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

1,100,000

1,200,000

1,300,000

1,400,000

1,500,000

¾" (19.05mm)

¾" (19.05mm)

¾" (19.05mm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

1" (2.54cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

1" (2.54cm)

1¼" (3.18cm)

1¼" (3.18cm)

1¼" (3.18cm)

1½" (3.81cm)

1½" (3.81cm)

2" (5.08cm)

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

1,600,000

1,700,000

1,800,000

1,900,000

2,000,000

2,200,000

2,400,000

2,600,000

2,800,000

3,000,000

FOR L. P. GAS, CORRECT THE TOTAL BTU/HR. BY MULTIPLYING IT BY 0.6. THE ANSWER IS THE

EQUIVALENT BTU ON THE ABOVE CHART.

IMPORTANT: The installation must conform with local codes or, in the absence of local codes:

• with the latest edition of the “National Fuel Gas Code”, ANSI Z223.1 in the U.S.A.,

• with CAN1-B149.1 or CAN1-B149.2 in Canada,

2" (5.08cm)

2" (5.08cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

2½" (6.35cm)

2½" (6.35cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

3½" (8.89cm)

• and Australian Gas Association / Australian LP Gas Association requirements in Australia.

Table 2

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

3" (7.62cm)

4" (10.16cm)

27

Page 30

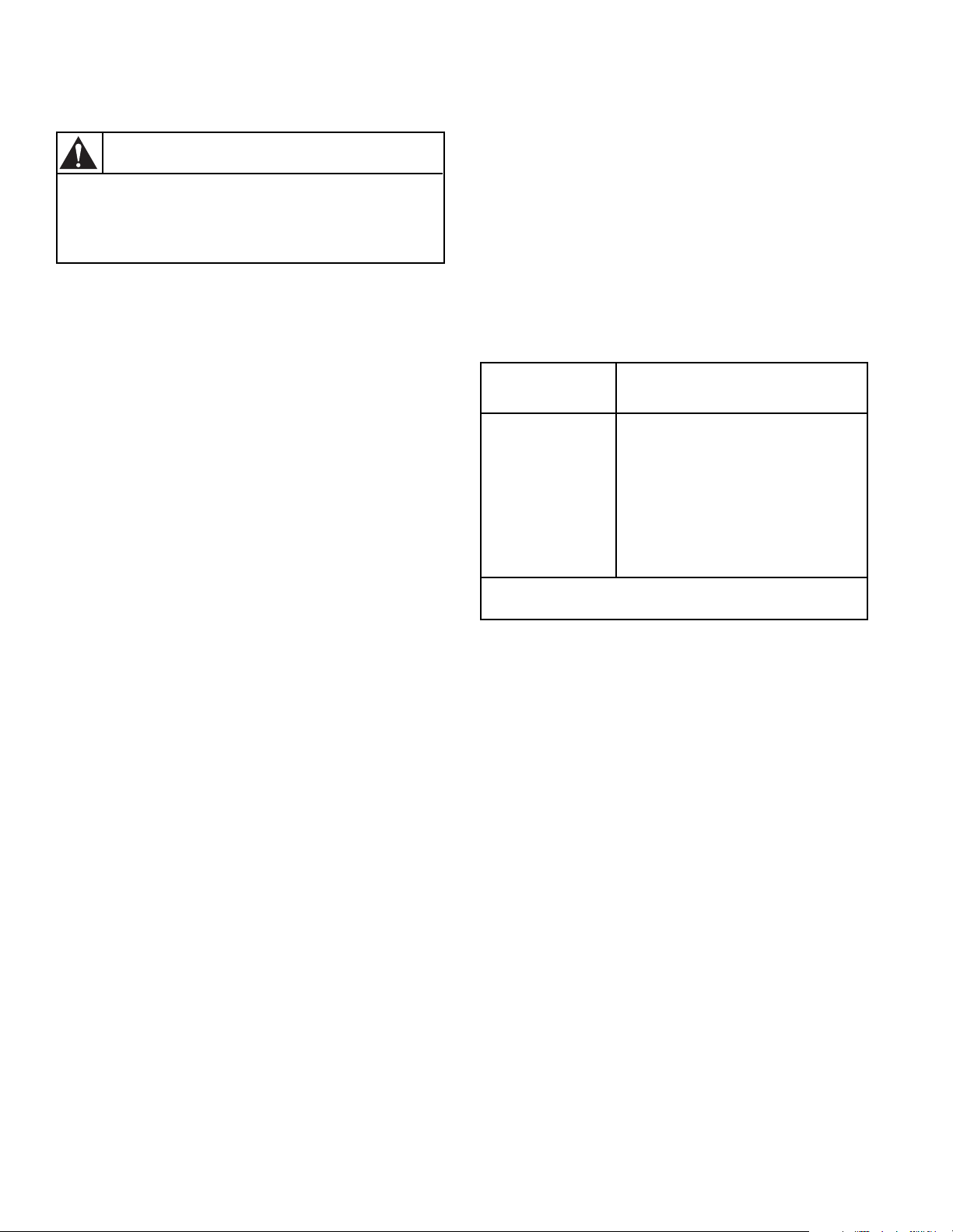

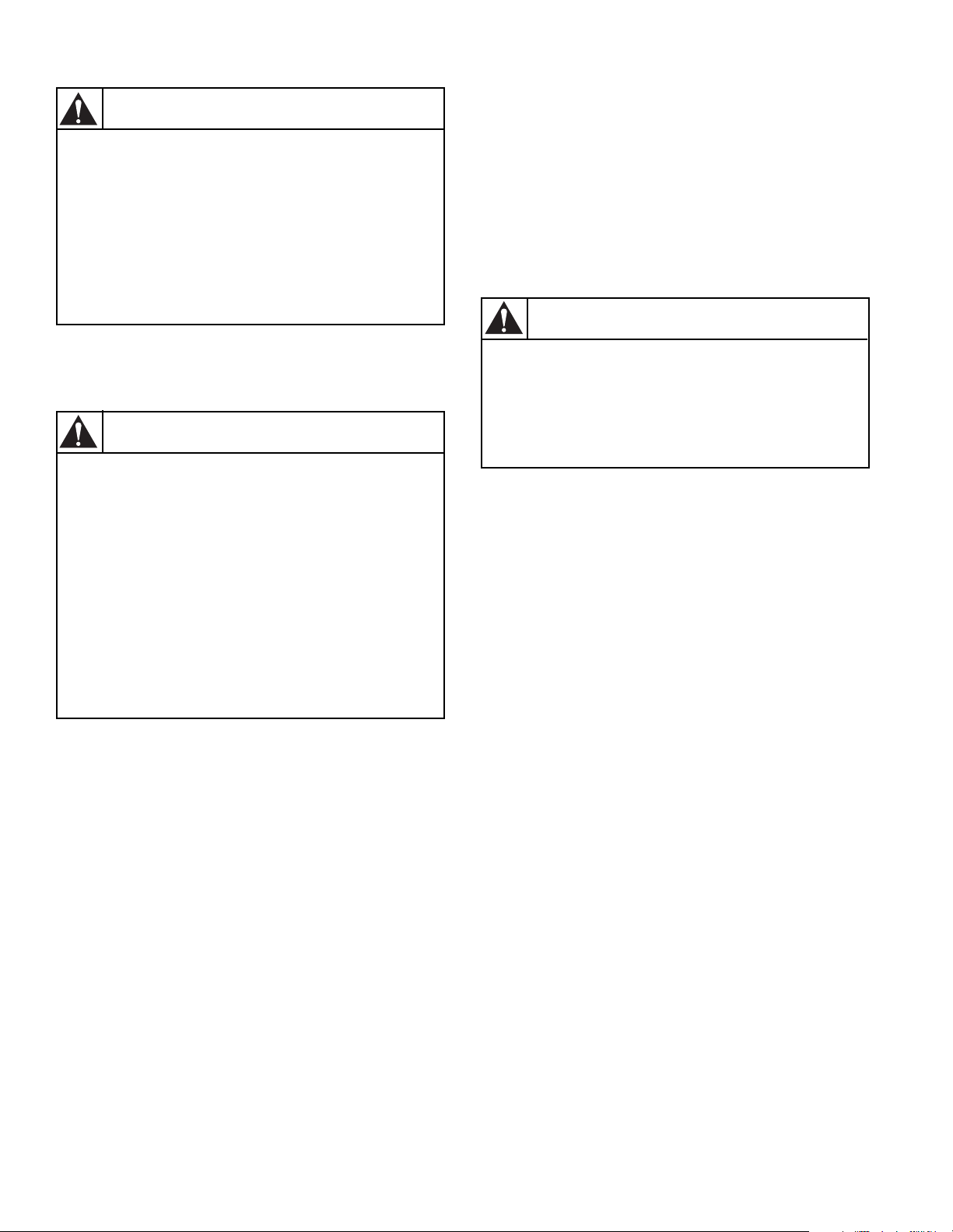

STEAM REQUIREMENTS (Steam Drying Tumblers)

The size of the steam service pipe is dependent upon

many variables (length, tees, high pressure system, low

pressure system, etc.). Specific pipe size information

should be obtained from the steam system supplier or a

qualified steam fitter.

1. Refer to Figure 9 for proper steam pipe

configurations.

2. To prevent condensate draining from headers to

tumbler, piping should have a minimum 12 inch rise

(30.5 cm) above respective header. Do not make

steam connection to header with a horizontal or

downward facing tee or elbow.

3. Whenever possible, horizontal runs of steam lines

must drain, by gravity, to respective steam header.

Water pockets, or an improperly drained steam

header will provide wet steam, causing improper

operation of tumbler. If pockets or improper drainage

cannot be eliminated, install a bypass trap to drain

condensate from the low point in the steam header to

the return.

4. In both steam supply and steam return line, it is

recommended that each have a pipe union and globe

valve. This will enable you to disconnect the steam

connections and service the tumbler while your

facility is in operation.

5. Before connecting trap and check valve to tumbler,

open shut-off valve in steam supply line and allow

steam to flow through tumbler to flush out any dirt

and scale from tumbler. This will assure proper

operation of trap when connected.

6. After flushing system, install vacuum breaker, bucket

trap (with built-in strainer) and check valve. For

successful operation of tumbler, install trap 18 inches

(45.7 cm) below coil and as near to the tumbler as

possible. Inspect trap carefully for inlet and outlet

markings and install according to trap manufacturer’s

instructions. If steam is gravity returned to boiler,

omit trap but install vacuum breaker and check valve

in return line near tumbler.

PIPING RECOMMENDATIONS

1. Trap each steam coil individually. Always keep the

trap clean and in good working condition.

2. When tumbler is on the end of a line of equipment,

extend header at least 4 feet (1.2 m) beyond tumbler.

Install shutoff valve, union, check valve and bypass

trap at end of line. If gravity return to boiler, omit

trap.

3. Insulate steam supply and return line for safety of

operator and safety while servicing tumbler.

4. Keep tumbler in good working condition. Repair or

replace any worn or defective parts.

NOTE: Steam heated tumbler models are not

certified by the American Gas Association or the

Canadian Gas Association.

WARNING

The flexible steam hoses connecting the

coil outlet connections and steam traps

must have a minimum of 172 psig (pounds

per square inch gauge) (12.04 kg/sq. cm)

working pressure. A shut-off valve must

be installed downstream from each steam

trap so the condensate return line can be

isolated in event a steam trap requires

maintenance.

W064

STEAM VALVE ELECTRICAL CONNECTIONS

Refer to wiring diagram for steam valve electrical

connections in J-Box.

7. Install union and shut-off valve in return line and

make final pipe connections to return header.

28 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 31

INSTALLING STEAM SOLENOID VALVE AND MAKING STEAM INLET CONNECTIONS

INSTALLING STEAM TRAP AND MAKING CONDENSATE RETURN CONNECTIONS

High pressure machines require a (constant) 80 to 100

psig (pounds per square inch gauge) (5.62 to 7.03 kg/sq.

cm) steam service for optimum operation. Low pressure

machines require a (constant) 10 to 15 psig (pounds per

square inch gauge) (.70 to 1.05 kg/sq. cm) steam service

for optimum operation. The following steps outline the

procedure for installing the steam solenoid valve and

connecting the steam service.

a. Install a manual shut-off gate valve in the condensate

return line after the steam trap for each coil.

b. Connect the steam solenoid valve to the related steam

coil inlet connection with nipples, flex hoses, unions,

and tee. Refer to Figure 9.

c. Install a gate shut-off valve in the steam supply line.

Connect the shut-off gate valve outlet to the solenoid

steam valve inlet connection. Refer to Figure 9.

WARNING

The flexible steam hoses connecting the

solenoid steam valve to the coil inlets

must have a 125 psig (pounds per square

inch gauge) (8.79 kg/sq. cm) working

pressure. A shut-off valve must be

installed upstream from the solenoid

steam valve. This way, steam can be shut

off for maintenance purposes, or in the

event the hose ruptures.

The steam solenoid valve must be

supported so minimum load is exerted on

the steam coil inlet connections.

W065

The steam trap must be installed and the coil outlet

connections must be connected to the condensate return

lines. The following steps outline the procedure for

installing the steam trap and connecting the condensate

return lines. Refer to Figure 9.

a. Connect a flexible hose to each steam coil outlet.

b. Install a strainer to the ends of each flexible hose.

c. Install a steam trap to each strainer.

IMPORTANT: Steam trap must be installed a

minimum of 10 inches (25.4 cm) below the steam coil

outlet connections.

d. Install a gate shut-off valve to each steam trap.

e. Connect to the condensate return lines.

WARNING

The flexible steam hoses connecting the

coil outlet connections and steam traps

must have a minimum of 125 psig (pounds

per square inch gauge) (8.79 kg/sq. cm.)

working pressure. A shut-off valve must

be installed downstream from each steam

trap so the condensate return line can be

isolated in event a steam trap requires

maintenance.

Each steam trap must be supported so

minimum load is exerted on the coil outlet

connection.

W066

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

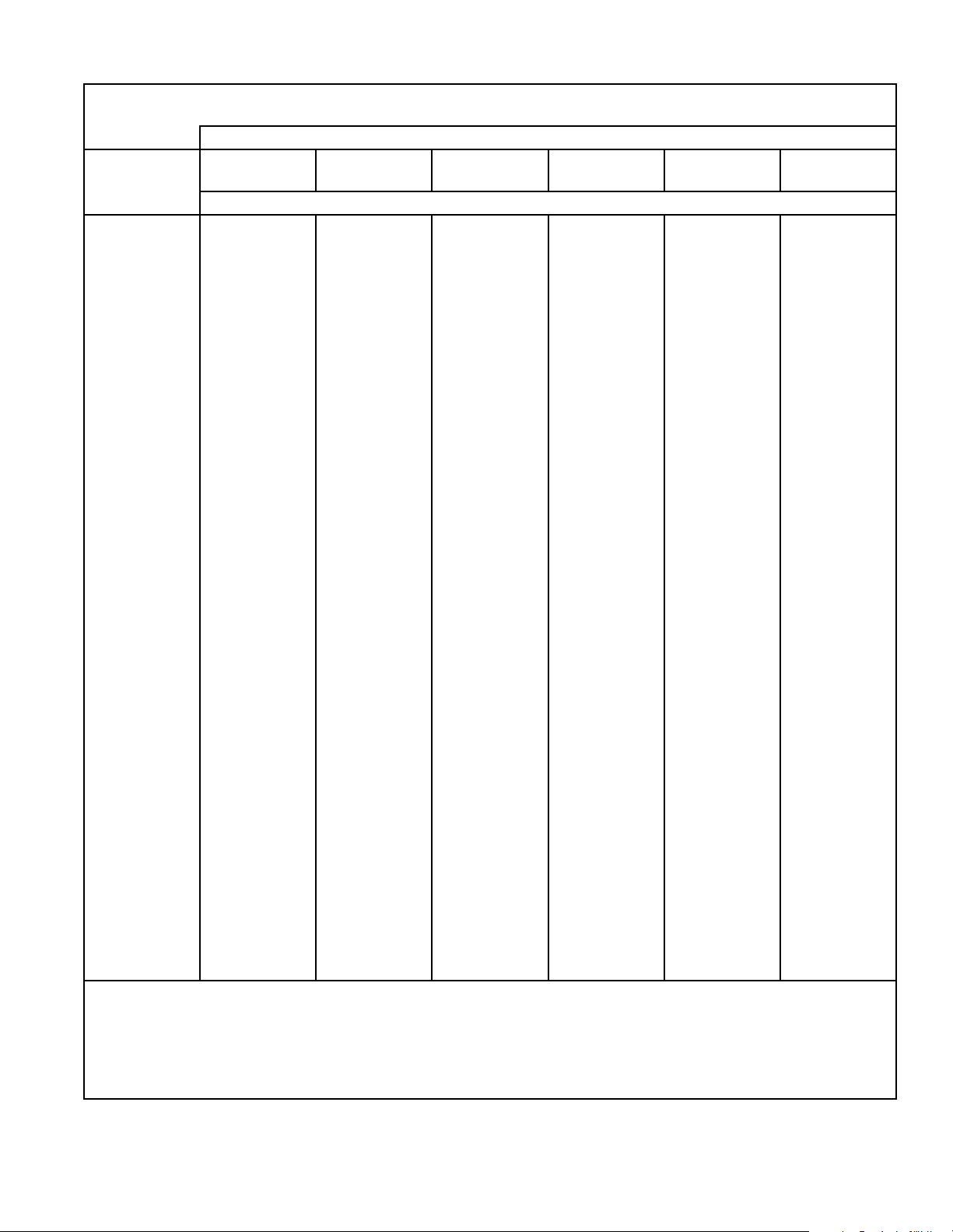

STEAM REQUIREMENTS STEAM DRYING TUMBLERS ONLY

NOTE: For sizing of steam lines. Piping

must also be sized accordingly for length

of runs, and number of elbows. Refer to

Table 3.

SUPPLY

RETURN

12" (30.5 cm)

RISERS

UNION

CHECK

VALVE

TRAP WITH

BUILT-IN

STRAINER

STEAM

BONNET

SOLENOID

VALVE

(Supplied with

machine)

VACUUM

BREAKER

CONDENSATE

RETURN LINE

FROM

SUPPLY LINE

CHECK

VALVE

Figure 9

TUMBLER

MODEL

STEAM PRESSURE

(PSI)

MINIMUM PIPE

DIAMETER

STEAM TRAP SIZE

(Pounds Condensate/Hour)

30CSL 7-15 3/4" (1.9 cm) 140

30CSH 80-100 3/4" (1.9 cm) 140

GATE

VALVE

T221IE3H

Table 3

30 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

ELECTRICAL REQUIREMENTS

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected

to ensure that the tumbler is properly grounded.

WARNING

To reduce the risk of fire and electric shock, check with a qualified serviceman for proper

grounding procedures. Improper connection of the equipment grounding conductor may

result in a risk of electric shock.

To reduce the risk of fire and electric shock, if electrical supply is coming from a three

phase service, DO NOT connect a “High Leg” or “Stinger Leg” to a single phase machine.

On a three phase machine, if there is a “High Leg” or “Stinger Leg” it should be

connected to L3.

W002

W068

W069

GROUNDING INSTRUCTIONS

This tumbler must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current. This tumbler must be

connected to a grounded metal, permanent wiring

system; or an equipment grounding conductor must be

run with the circuit conductors and connected to the

appropriate ground location.

WARNING

All electrical connections should be

made by a qualified electrician.

To reduce the risk of electrical shock, deenergize the electrical circuit being

connected to the tumbler before making

any electrical connections. Never attempt

to connect a live circuit.

W070

NOTE: To ensure protection against shock, this

tumbler MUST be electrically grounded in

accordance with the local codes, or in the absence of

local codes, with the latest edition of the National

Electrical Code ANSI/NFPA No. 70. In Canada the

electrical connections are to be made in accordance

with CSA C22.1 latest edition Canadian Electrical

Code, Part I and/or local codes. Electrical work

should be done by a qualified electrician.

CAUTION

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation. Verify proper operation after

servicing.

W071

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

The following steps outline the procedure for connecting

the electrical service to the tumbler.

3. Check the electrical service phase sequence (three

phase only) as follows:

NOTE: The wiring diagram is supplied in material

packet in cylinder.

1. Install a circuit breaker as close to the tumbler as

possible. If more than one tumbler is being installed,

a disconnect switch or circuit breaker should be

provided for each. This will make it possible to

disconnect each tumbler for maintenance purposes.

2. Connect the conduit-encased leads to the disconnect

switch, or circuit breaker. Connect the wire leads to

the appropriately labeled terminal on the terminal

block. The ground wire must be connected to the

ground connection. Refer to Figure 10.

ELECTRICAL SERVICE

(Gas & Steam Models)

a. Energize the electrical service (on reversing

tumblers, ensure nonreversing is selected)and

momentarily start the tumbler. Check the direction

of the cylinder rotation. If the cylinder rotates

clockwise (viewed from the front), the phase

sequence is correct. If the cylinder rotates

counterclockwise, proceed with step “b”.

NOTE: On reversing tumblers, the fan motor should

also rotate clockwise (viewed from the front) on all

models.

b. Disconnect and reverse any two leads at

connections.

ELECTRICAL SERVICE

(Electric Models)

CONTACTOR

BOX

ACCESSORY

BOX

GROUND LUG

(Electric Models)

FUSES

GROUND SCREW

(Gas & Steam Models Only)

T224SE3A

Figure 10

32 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

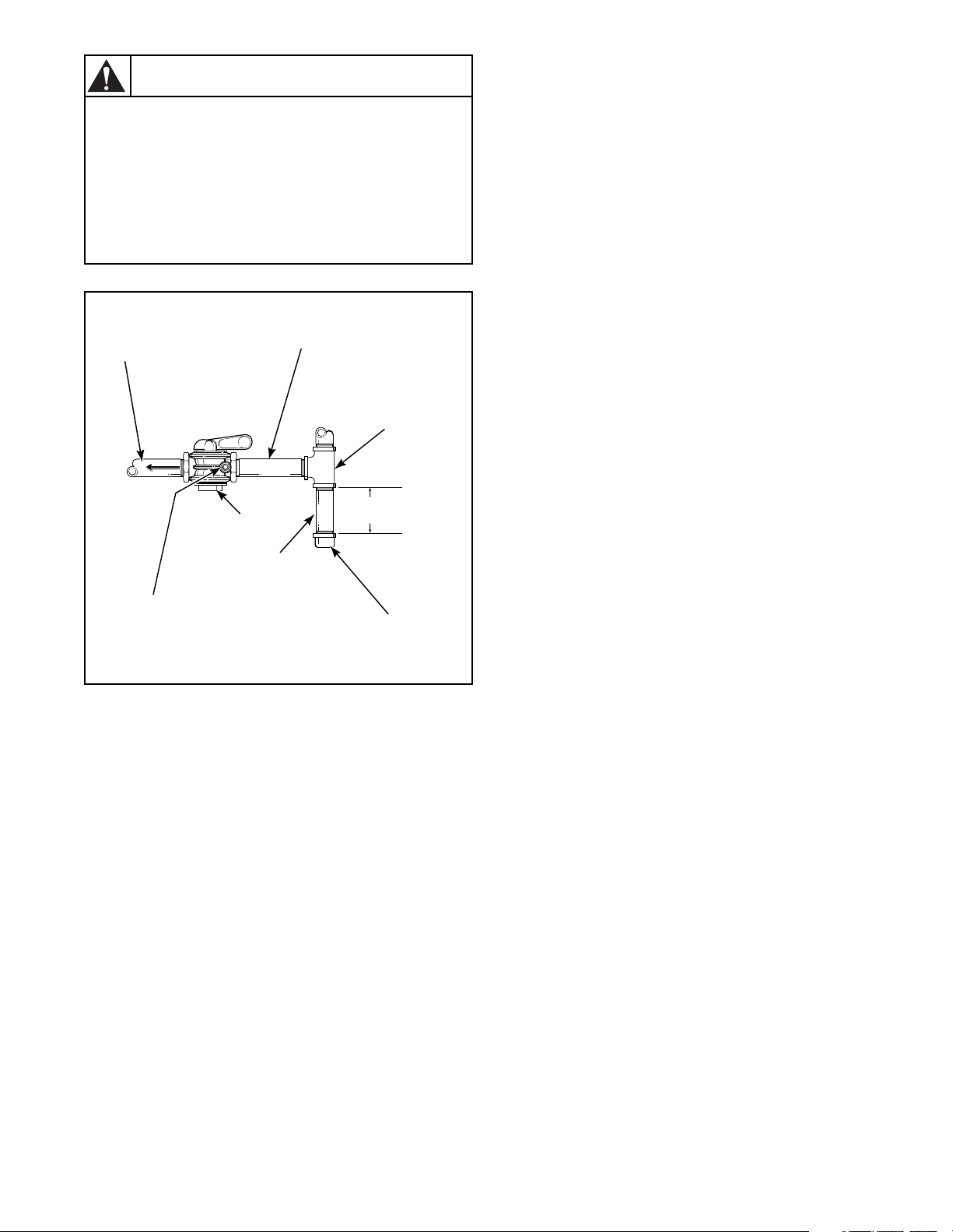

JUMPER CONFIGURATION INSTRUCTIONS (OPL MICRO CONTROL MODELS ONLY)

RING FERRITE INSTALLATION (GAS AND STEAM OPL MICRO CONTROL MODELS ONLY)

Changing the transformer configuration jumper is

required if any of the following apply:

• You have 208V service and are connecting a gas or

steam model rated for 208 or 240V.

• You have 415V service and are connecting a gas or

steam model rated for 380 or 415V.

To configure your 208V or 240V tumbler for 208V

operation, you must remove the 240V configuration

jumper located in the contactor box and replace it with

the 208V jumper supplied with the information packet.

This must be done prior to supplying power to machine.

Failure to install proper configuration jumper may result

in damage to sensitive electronic controls and may void

warranty.

To configure your 380V or 415V tumbler for 415V

operation, you must remove the 380V configuration

jumper located in the contactor box and replace it with

the 415V jumper supplied with the information packet.

This must be done prior to supplying power to machine.

Failure to install proper configuration jumper may result

in damage to sensitive electronic controls and may void

warranty.

The ring ferrite provided in the information packet must

be installed over the power leads during connection of

electrical service. The ferrite protects the sensitive

electronic controls from destructive electrical

disturbances which may be present on power lines to the

machine. Failure to properly install the ring ferrite may

result in damage to the electronic controls and will void

control warranty.

Installation Instructions:

1. Immediately after connection of power leads and

before applying power to machine, locate each of the

incoming service leads including ground.

2. Snap the ring ferrite closed over all of the service

leads inside of the contactor box as shown. It is

important that the ferrite ring be installed inside the

contactor box as shown. Do not install the ferrite

outside of the box or other area. Make sure that

service leads are in the center of the ferrite before

closing the ring so not to pinch or damage leads.

CONTACTOR

BOX

JUMPER

Figure 11

FERRITE

RING

T225SE1A

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

ELECTRICAL REQUIREMENTS For 28" wide Tumblers

NOTE: Minimum wire sizes are obtained from Canadian Electrical Code and are intended for use as a guideline

only. Electrical connections should be made only by a qualified electrical contractor in accordance with all

applicable local and national requirements.

NOTE: DO NOT use aluminum wire.

Heat Source

Gas 120/60/1 L1, Neutral, and ground

Gas 208-240/60/1 L1, L2, Neutral, and ground

Gas 240/50/1 L1, Neutral, and ground

Gas 120/50/1 L1, Neutral, and ground

Electric 208/60/1 L1, L2, and ground

Electric 240/60/1 L1, L2, and ground

Electric 240/50/1 L1, Neutral, and ground

Electric 208/60/3 L1, L2, and ground

Electric 240/50/3 L1, L2, L3, and ground

Electric 240/60/3 L1, L2, L3, and ground

Electric 380/50/3 L1, L2, L3, Neutral, and ground

Electric 415/50/3 L1, L2, L3, Neutral, and ground

Electric 480/60/3 L1, L2, L3, and ground

Amp Rating 104 AMP 92 AMP 62 AMP 55 AMP 27 AMP 91 AMP 55 AMP 34 AMP 31 AMP

Circuit Breaker 125 AMP 100 AMP 70 AMP 60 AMP 30 AMP 100 AMP 60 AMP 40 AMP 35 AMP

Poles 223332333

Minimum Wire Size

Per Canadian Elec.

Code C22.1

Electrical Specs

ELECTRIC DRYING TUMBLERS

208V

60 HZ

1 PH

1 AWG 2 AWG 4 AWG 6 AWG 10 AWG 2 AW G 6 AWG 8 AWG 8 AWG

240V

60 HZ

1 PH

208V

60 HZ

3 PH

Wires Required and Terminal Block Connections

Table 4

240V

60 HZ

3 PH

480V

60 HZ

3 PH

240V

50 HZ

1 PH

240V

50 HZ

3 PH

380V

50 HZ

3 PH

415V

50 HZ

3 PH

Table 5

GAS DRYING TUMBLERS

120V 1 Phase

60 Hz.

Minimum Wire Size Per

Canadian Elec. Code C22.1

Disconnect Switch 15 AMP

Fusetron 15 AMP

Circuit Breaker 15 AMP 15 AMP 15 AMP 15 AMP

No. of Poles 1222

34 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

14 AWG 16 AWG 16 AWG 14 AWG

208/240V 1 Phase

60 Hz.

USE CIRCUIT BREAKER ONLY

Table 6

240V 1 Phase

50 Hz.

120V 1 Phase

30 Hz.

Page 37

ELECTRICAL REQUIREMENTS For 31.5" wide Tumblers

NOTE: Minimum wire sizes are obtained from Canadian Electrical Code and are intended for use as a guideline

only. Electrical connections should be made only by a qualified electrical contractor in accordance with all

applicable local and national requirements.

NOTE: DO NOT use aluminum wire.

Heat Source Serial Plate Voltage

Steam CSL 120V/60Hz/1ph L1, Neutral and ground * 20 Amps 1 12 AWG

Gas & CSH 120V/60Hz/1ph L1, Neutral and ground * 15 Amps 1 14 AWG

Gas & Steam 208 or 240V/60Hz/1ph L1, L2 and ground * 15 Amps 2 14 AWG

Gas & Steam 230-240V/50Hz/1ph L1, Neutral and ground * 15 Amps 1 14 AWG

Gas & Steam 208 or 240V/60Hz/3ph L1, L2, L3, and ground * 15 Amps 3 14 AWG

Gas & Steam 380 or 415V/50Hz/3ph L1, L2, L3, and ground * 15 Amps 3 14 AWG

Gas & Steam 460-480V/60Hz/3ph L1, L2, L3, and ground * 15 Amps 3 14 AWG

Electric 208V/60Hz/1ph L1, L2, and ground 104 Amps 125 Amps 2 0 AWG

Electric 240V/60Hz/1ph L1, L2, and ground 92 Amps 100 Amps 2 2 AWG

Electric 240V/50Hz/1ph L1, Neutral and ground 90 Amps 100 Amps 1 2 AWG

Electric 208V/60Hz/3ph L1, L2, L3, and ground 62 Amps 70 Amps 3 4 AWG

Electric 240V/60Hz/3ph L1, L2, L3, and ground 55 Amps 60 Amps 3 4 AWG

Electric 240V/50Hz/3ph L1, L2, L3, and ground 53 Amps 60 Amps 3 4 AWG

Electric 380V/50Hz/3ph L1, L2, L3, and ground 33 Amps 40 Amps 3 8 AWG

Electric 415V/60Hz/3ph L1, L2, L3, and ground 30 Amps 35 Amps 3 8 AWG

Electric 480V/60Hz/3ph L1, L2, L3, and ground 28 Amps 35 Amps 3 8 AWG

* Current Ratings vary slightly depending on model, see nameplate.

Terminal Block

Connections Required

Rated

Current

Breaker

Rating

Breaker

Poles

Recommended

Wire Size

Table 7

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

ACCESSORY TIMING CAM INSTALLATION (Coin Meter Models)

The tumbler is shipped with two accessory cams which

allow you to change your vending times.

The coin slide tumbler accumulator will have a 60 minute

timer motor. The accumulator will operate with a two pin

cam (30 minutes). The cams furnished with the tumbler

will be three pin (20 minutes) and four pin (15 minutes).

The 25¢ meter will have a 60 minute timer motor. Refer

to Table 8.

No. of Pins in Cam Cycle Length (Minutes)

6

5

4

10

12

15

Table 8

Cams that allow other timer increments are available

through your distributor.

To figure time increments, use this formula: Timer Motor

Speed (60) divided by number of pins on cam = Cycle

Length (minutes). Cams are available with 1 to 12 pins.

Example: 60

÷ 5 (Pin cam) = 12 minute cycle.

INSTALLATION OF NEW TIMING CAM

1. Insert drive into timing cam with wide prong in wide

hole of cam.

2. Position timing cam and drive fork over the timer

shaft, aligning the timer flat with the drive fork and

the “V” notch with one of the ratchet teeth.

3. Press timing cam down firmly to seat timing cam

onto the motor shaft.

LINE UP NOTCH

TO CLEAR RATCHET

TOOTH

LIFT GENTLY

WITH NARROW

BLADE

REMOVAL OF EXISTING TIMING CAM

1. Rotate cam by hand until “V” notch lines up beneath

the ratchet tooth. Refer to Figure 12.

2. Insert narrow screwdriver under nylon cam, close to

the clock shaft. Lift gently off shaft. Make sure that

pressure is directed upward and that the “V” notch

clears the ratchet tooth.

Figure 12

4. Remove all accumulated time by turning cam

counterclockwise until switch shuts off. Apply

moderate clockwise pressure to fully seated timing

cam and drive against the timing motor shaft. Meter

must be advanced electrically for one cycle before an

accurate measure of time can be made.

36 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

PRELIMINARY OPERATING CHECKS

1. Remove or open all panels and check accessible

bolts, nuts, screws, terminals and fittings for

tightness.

2. Check V-belt tension and adjust if necessary. Refer to

appropriate paragraphs in Section IV.

3. Steam tumblers: Open the steam service shut-off

valves.

4. After performing the previous checks, start the

tumbler by pressing START (hold for approximately

three seconds). Release the start button and open the

cylinder door. The cylinder should stop rotating

within seven seconds after the door is opened a

maximum of two inches (5.01 cm) plus or minus ¹⁄₄

inch (.63 cm). If it does not, adjust the loading door

interlock. Refer to the appropriate paragraph in

Section IV.

5. Gas tumblers: Start the tumbler and check the burner

flame. Adjust the gas inlet shutter as required. Refer

to the appropriate paragraph in Section IV.

IMPORTANT: The one wire igniter Instant

Electronic Ignition system will attempt to light the gas

by sparking for approximately 15 seconds (5 seconds

for 2 wire igniters). If gas ignition does not take place

within 15 seconds (5 seconds for 2 wire igniters) the

Instant Electronic Ignition control will go into safety

lockout and the valve will no longer open until Instant

Electronic Ignition control is reset. To reset Instant

Electronic Ignition control, remove power from

control by opening and closing the tumbler door. If

condition persists, check, that the gas shut-off valve is

in “on” position and that the gas service is properly

connected. If condition still persists, remove tumbler

from service.

6. Load the cylinder with a full load of clothes or clean

rags and run to remove oil or dirt from cylinder.

7. Gas and electric tumblers: Check the airflow switch

operation by opening the lint panel. The heating

systems should shut off when the lint panel is opened

a maximum of 1-1/2 inches (3.81 cm).

WARNING

The tumbler must not be operated if the

airflow switch does not operate properly.

Faulty airflow switch operation may cause

an explosive gas mixture to collect in the

tumbler.

W072

The airflow switch operation may be affected by shipping

tape still in place, lack of make-up air, or an obstruction

in the exhaust duct. These should be checked and the

required corrective action taken before attempting to

adjust the airflow switch. To adjust the airflow switch

refer to appropriate paragraph in Section IV.

M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

FINAL OPERATING CHECKS

OPL MICRO CONTROL TUMBLER

Refer to OPL micro-control section to check control for

proper operation.

MANUAL DUAL TIMER TUMBLER

Refer to Figure 13.

1. Set the TEMPERATURE selector to the desired

temperature, and set the DRYING and COOLING

selectors to maximum.

2. Press the PUSH-TO-START button in and hold it in

for approximately three seconds. The motor will

start, the heat system will come on and the DRYING

indicator will light.

3. During the drying period the DRYING selector

rotates counterclockwise. When the DRYING

selector reaches “0” the heat system will shut off, the

DRYING indicator will go out and the COOLING

indicator will light.

During the cooling period the COOLING selector rotates

to the left. When the COOLING selector reaches “0” the

motor will stop and the COOLING indicator will go out

indicating the end of the cycle.

COIN-OPERATED TUMBLER

Refer to Figure 14.

1. Set the TEMPERATURE selector to the desired

temperature.

2. Insert required number of coins in the coin slot and

turn the knob fully clockwise and release it. The

RUN indicator (option) will light.

For Coin Slide Models — Place required number of

coins in coin slide and push slide in as far as possible,

then release.

3. Press the PUSH-TO-START button in and hold it in

for approximately three seconds. The motor will start

and the heat circuit will come on.

4. An automatic preset 2-1/2 minute cool-down period

occurs near the end of the cycle. During this period

the heat system is off and encompassing air circulates

through the load to cool it.

5. When the coin metered time expires, the cycle is

completed.

38 M414545

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

TEMPERATURE

SELECTOR

MANUAL DUAL TIMER

DURABLE PRESS CONTROL PANEL

TEMPERATURE

HIGH LOW