Page 1

PS40 F

Part No. D0892R1

Programming and adapting

wash programs

Manual

Alliance International bvba - Nieuwstraat 146 - B-8560 Wevelgem (Belgium)

Tel. +32 56 41 20 54 - Fax +32 56 41 86 74 - info@alliancels.eu - www.alliancels.eu

Page 2

Page 3

Contents

1 Introduction ..................................................................................... 5

Programmer PS40 ..................................................................................... 5

Circuit diagrams ......................................................................................... 5

2 Division .......................................................................................... 7

3 Pre-programming mode ................................................................ 9

Pre-programming ....................................................................................... 9

4 Programming mode ........................................................................ 18

Programming ............................................................................................. 18

Inserting and deleting a program part ........................................................ 34

5 Copying mode ................................................................................. 36

Copying mode ............................................................................................ 36

6 Operating mode .............................................................................. 38

Selecting a program ................................................................................... 38

Starting a program ..................................................................................... 38

Course of the program ............................................................................... 38

Programmed start ...................................................................................... 39

Changing the program ............................................................................... 39

Changing the level, the washing time and the temperature once .............. 39

Controlling the temperature of the bath and the number of revolutions..... 39

Controlling the program during functioning ................................................ 40

Running through the program quicly .......................................................... 40

Programmed stop ...................................................................................... 40

Soaking ...................................................................................................... 40

Time stop ................................................................................................... 41

Interrupting and stopping the program ....................................................... 41

Filling up with water ................................................................................... 41

Discharging the water ................................................................................ 41

Heating the bath ........................................................................................ 41

Adding soap ............................................................................................... 42

Error messages ......................................................................................... 42

7 Test mode ....................................................................................... 45

8 Liquid soap connection ................................................................ 46

Standard programs .................................................................................... 47

Version 3.22 ß

Code: 249/00247/00

03/03/2009

Contents

Page 4

4

Index

$C (( 21

$F (( 21

A

A (( 21

A2 42

A4 42

A5 42

A7 42

A8 42

A9 42

Ab 42

Ad 42

AH 42

ACCL 17,40

Add 17,27

ALArM ((( 17 27 33

B

Bu% 17

C

Cd'& (( 27

Cdn (( 27

Cdn& (( 27

Cdu (( 27

CLoSE 41

Cold 39

Cool 27

CoPY PrG 7,37

D

d1 13

d2 13

Data(((( 33

dAtA(((( 7

dEFaul 17

dESt.)) 37

dI 29,31

DiSt 31

diSt 31

door. oPEN 38

DrAin 31

dt ((( 31

E

EMEr 17

End 33

EntEr 40

F

F5 42

F6 42

FC 9

FrEE%((( 33

G

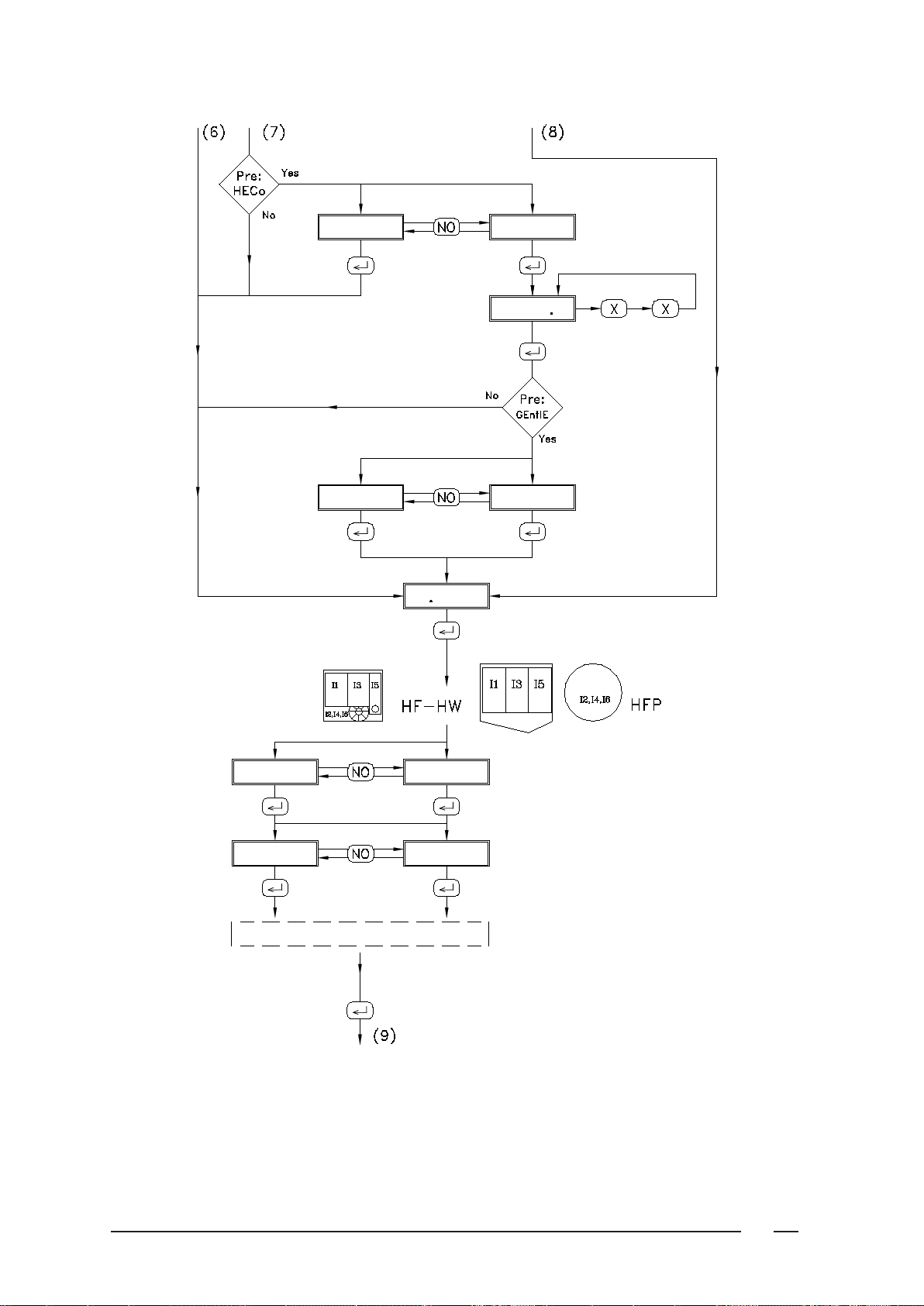

GEntlE 15,23

Good(((( 7

H

HEAt 15,21

HEAt-Mod 15,21

HEAt-SYS 15,21

HECo 15,23,39

HourS 7

HF 9

HYSt 17

I

i1 11,23

i2 11,13,23

i3 11

i4 11

i5 11

i6 11

iI 11

ir1 13

J

Jolt 31

L

L (( 39

L XX 39

LE (( 25

LECo 9,25,39

LoG 7

LS (( 25

M

Mod 15,21

N

no Add 27

O

oPEn door 41

P

P(( End 38

PrE 7,9

ProG 19

ProG (( 7,38

ProGcopY 7

ProGEdit 7

ProGList 7

ProG PC 7

ProGr 7

ProGrAM 7

ProM((((. 7

R

RaM full 19,35,37

rd1 13

rd2 13

S

S (( 21

SE-i 9,7,25,29,44

SoAk 27,40

SoAk ((( 27

SoAktiME 40

SoAP (( 15,25

SourCE.(( 37

SP (( 21

SP ((( 29

SPI- ( 29

SPin 29

SPit 29

StArt 7,43

StoP 27,40

StoP ((( 27

StoPtiME 40

T

t $C 15

t (( 39

t $F 15

t= (((( 31

t=(($C 39

t1 25

td ((( 29

tESt 7,43,45

tiHold 17

tu ((( 33

W

WASh 31

X

(( dEti 29

(( CYti 19

(( del 35

(( id (( 19

(( rotE 19

(( SE-i 23

(( SE-L 25

(( tEMP 21,25

((--)) 37

((tistop 41

Page 5

5

Introduction 1

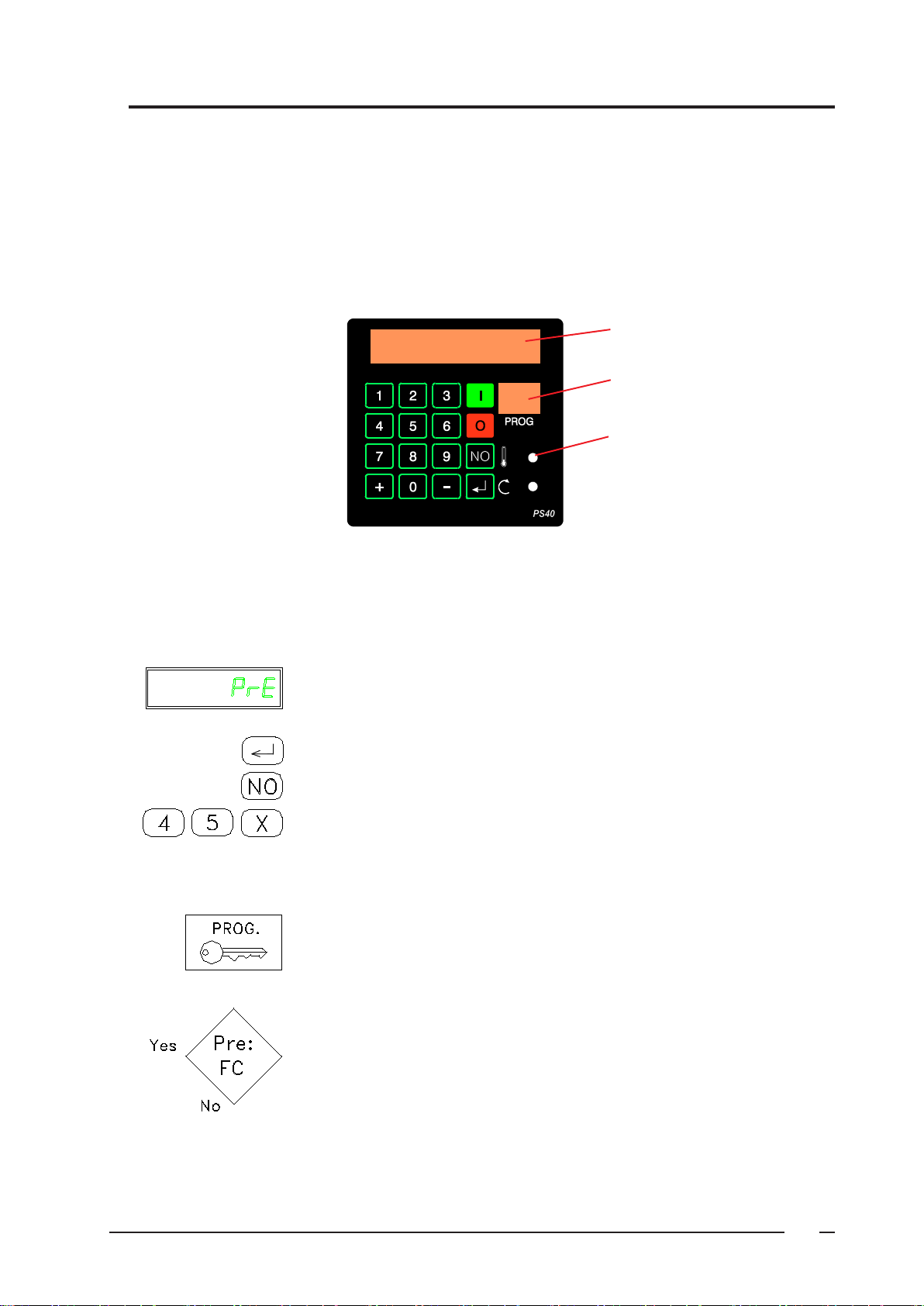

PS40F Programmer

On machines with an electronic freely programmable programmer PS40F, it is possible to program

40 programs of your choice (0 to 39). 10 standard programs (40 to 49) are also at your disposal.

Operating the machine, as well as entering the data in order to obtain a washing program, can be done by means

of the keyboard on the control panel or by optical downloading from the PC.

You can also download existing programs from the machine into the PC in order to modify or transfer them to

another machine.

Information

Program number

Windows of optical

download

Circuit diagrams

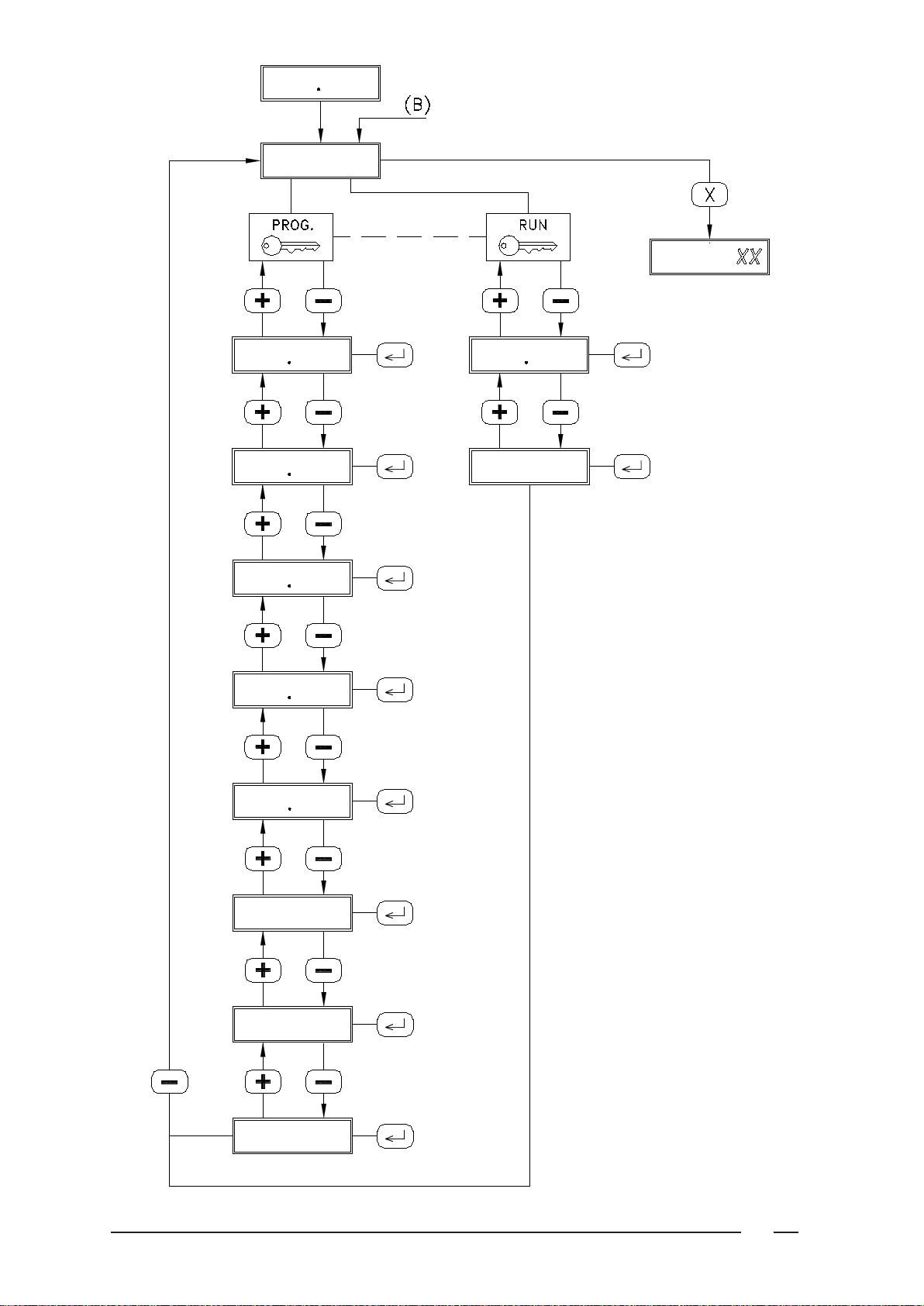

In this manual you will nd several circuit diagrams. Below is an explanation

of the symbols used.

Represents a text that appears on the display.

These symbols with rounded edges represent the pressing of certain keys, to

be found on the keyboard.

Ex. Digits, Start, Stop, etc. (X stands for a digit of your choice).

The symbols in rectangles represent mechanical actions to be executed.

Ex. Switch key switch in front

A symbol in a window represents a needed software implementation.

Ex. If a frequency controlled motor was chosen in the preprogram, a machine

with coin switch was selected, or not, etc.

Page 6

6

data((((

Good((((

ProM((((

start

Prog

ProGEdit

ProG PC

ProgCopy

ProgList

ProG PrE

LoG

HourS

tESt

Hours

ProGList

Page 7

7

Division 2

When a machine is placed under pressure, a so-called “Eprom test” is executed. “ ProM((((” and “

Good((((” appear temporarily on the display (XXXX stands for the serial number of the Eprom). Then

‘dAtA((((” appears temporarily. This is the “checksum” of all data. This value modies each time, that

there are changes in the programmation.

“StArt” appears afterwards.

By entering a program number, you can select a washing program (“ ProG ((" is shown) or you can proceed

to other modes by pushing the “-” or “+” button.

Remark :

When a machine is put under pressure for the rst time, or when an error occurs in the Ram memory (memory of

the washing program), “A3” will appear. Press “ENTER”.

When the switch is put in “Run” level, you can only select out of “ProGList” and “Hours”.

ProGEdit (programmation mode) (E455)

You can insert step by step the necessary data to obtain a full washing cycle of your choice.

To program a washing program : see further in chapter 4.

ProG PC (download mode) (E938)

Programs composed in a PC can be downloaded in the machine, or programs from the machine can be downloaded

in the PC.

To copy a program : see manual “WPS40”.

ProGcoPY(copy mode) (E328)

Existing programs can be programmed to another program number.

This can save you a lot of programmation work for similar programs.

To copy a program : see further in chapter 5.

ProGList(list mode) (E788)

You can check how many steps and programs are still available (free).

Push “Enter” and the programs are shown in turns with its respectively steps, at the end “FrEE%(((” shows

the number of still available steps.

By keeping the “NO” button pressed, you do not proceed automatically and the display stays.

By pressing “ENTER”, the reading process is stopped and the number of free steps is indicated.

ProG PrE (pre-programmation mode) (E619)

Here you can initialize the machine to its own technical caracteristics (f.ex. coin meter or manual machine, number

of water inlet valves, machine with or without heating, etc.) as well as certain free programmable options (f.ex.

temperature in °C or in °F, temperature readable during the cycle on the display or not, etc.)

To modify the “preprogram” : see further in chapter 3.

Remark :

The “preprogram” is programmed by the constructor and should normally not be modied.

LoG (error indications) (E605)

Here you can recall the last 20 error indications. Press “-” or “+” each time in order to return or proceed to the

previous or following error indication. Press “0” to leave the menu.

Hours(working hours)(E223)

Press “Enter” to see the number of working hours of a machine.

tESt (test mode) (E217)

Here you can technically test the machine (see chapter 7).

Page 8

8

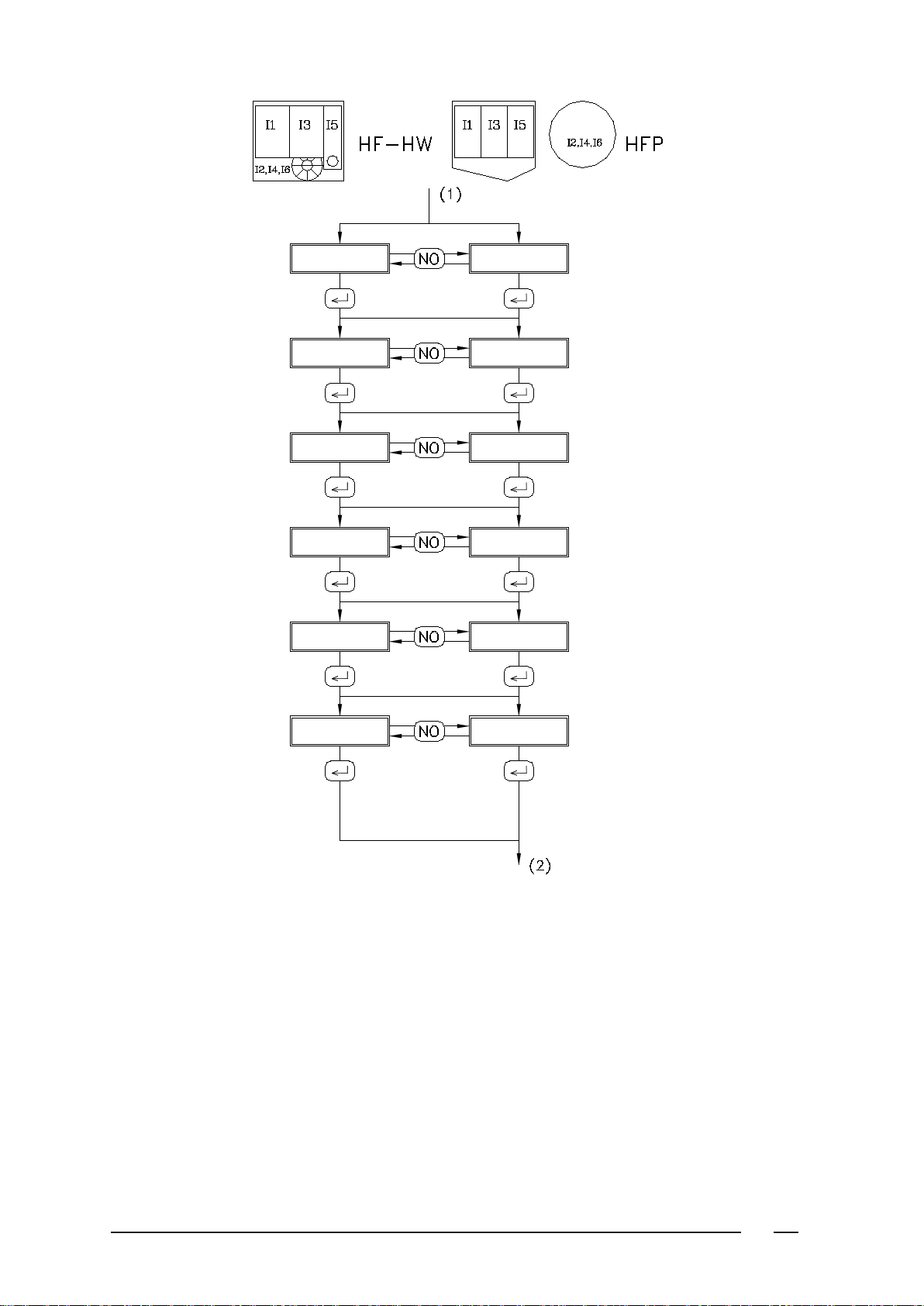

PrE

no HF HF

no FC FC

no LECo LECo

SE-i

Page 9

9

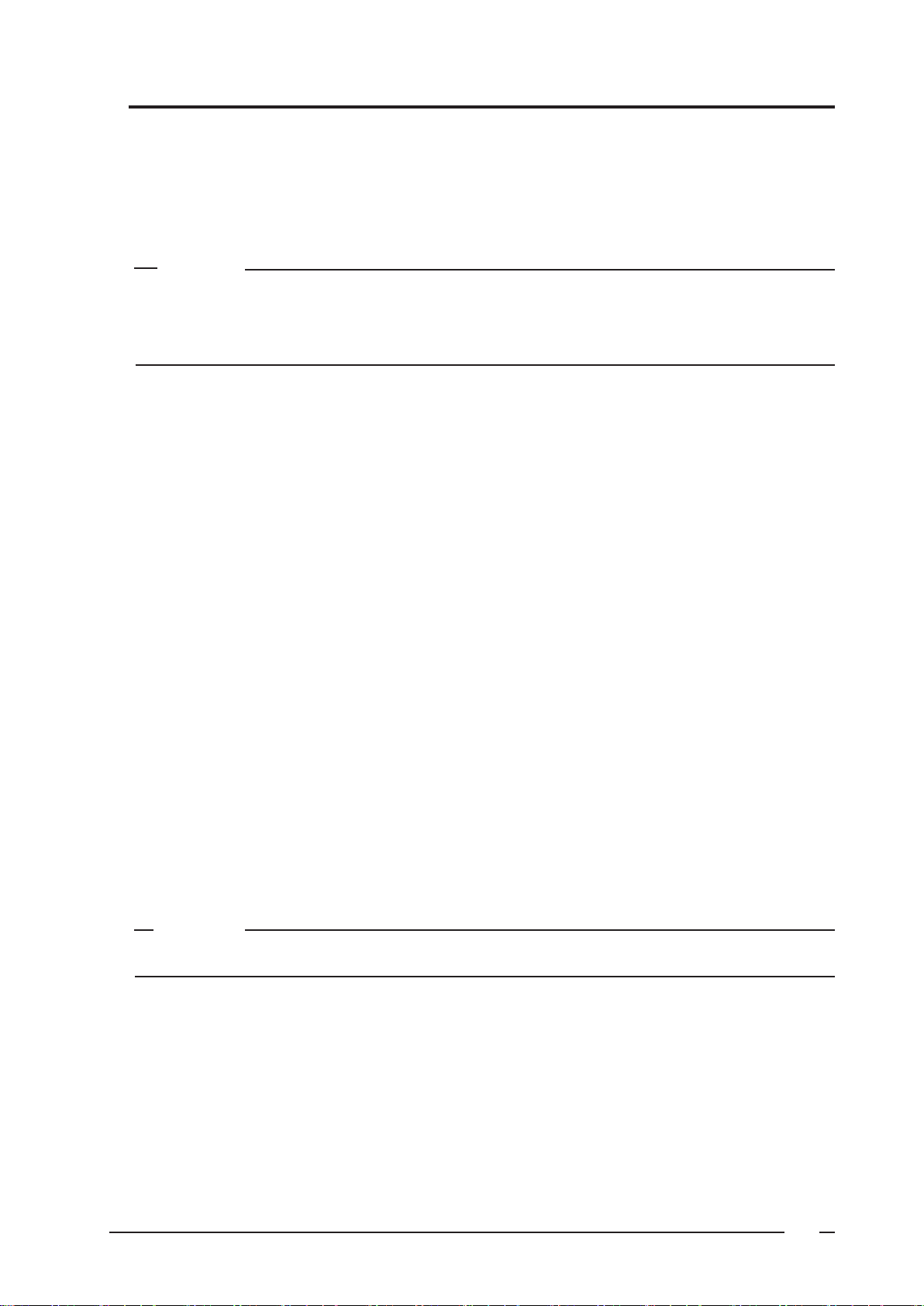

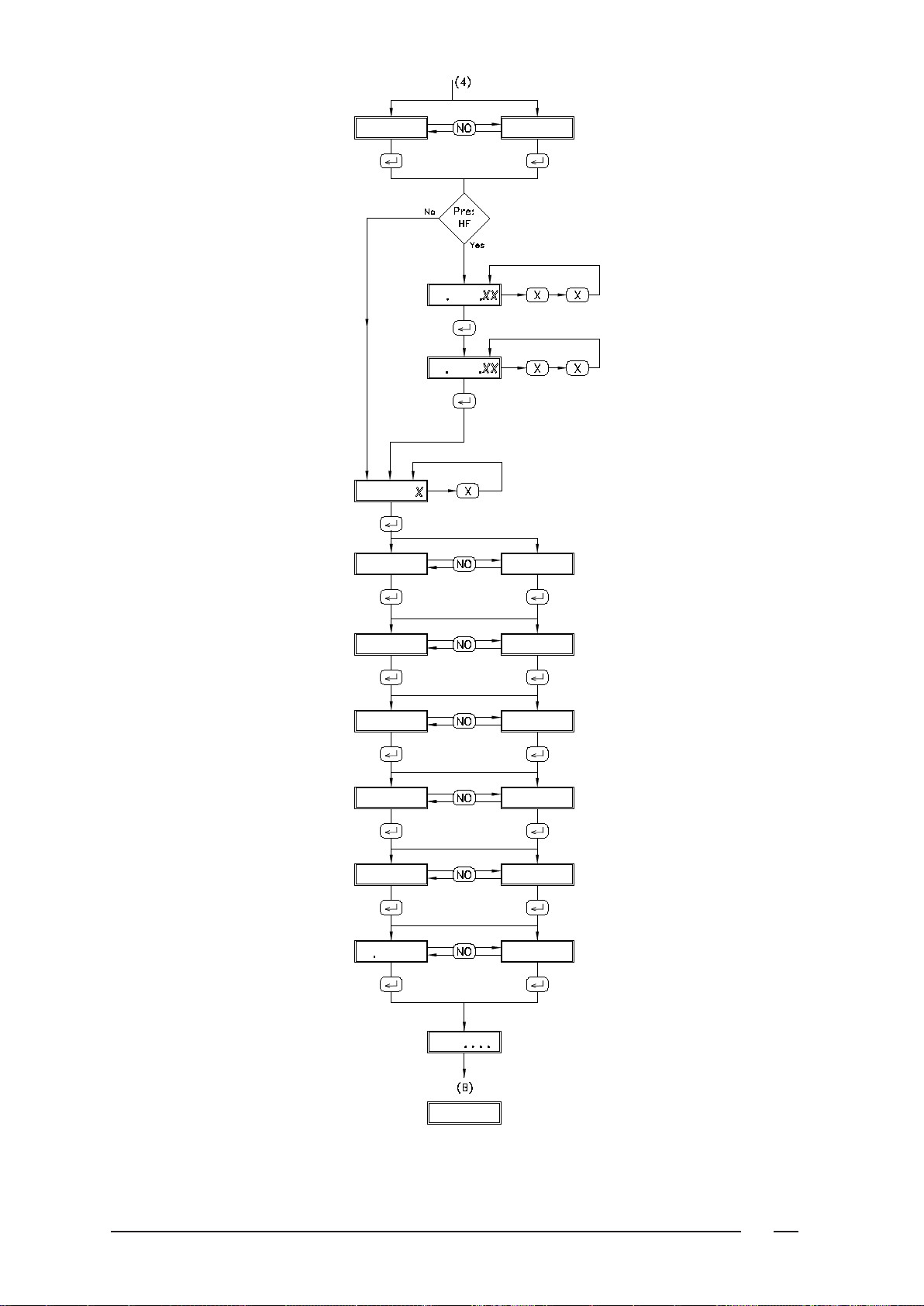

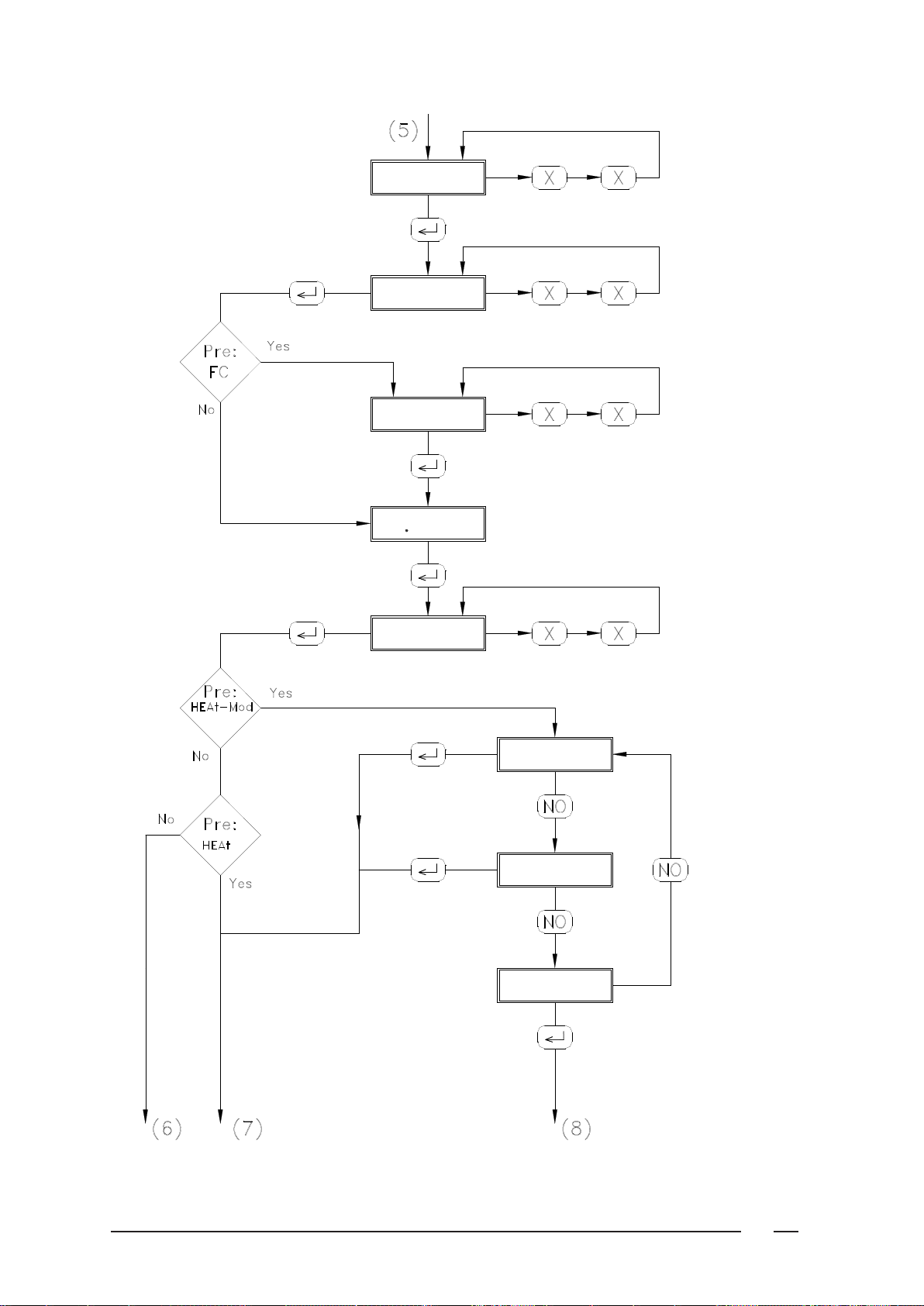

Pre-programming mode 3

Pre-programming

To open the "pre-programming mode": see 2. Division in modes.

In most cases, the selection is done by changing the order on the display if necessary by " NO "

(ex. " no FC " and after pressing " NO ": " FC ") and conrming this with "ENTER".

While pre-programming, it is possible to return step by step by pressing ‘0’ ( stop-key ).

PrE = Preprogram (altering the "Preprogram" )

Press "ENTER".

HF = Machine type HF, WE 245/304, or WE of the "washer extractors"

FC = Frequency controlled (with frequency controlled motor)

LECo = Level control (water level control)

Temporarily stopping the program until the correct water level is reached.

SE-i = Select inlet (selection of the water inlet valves).

Page 10

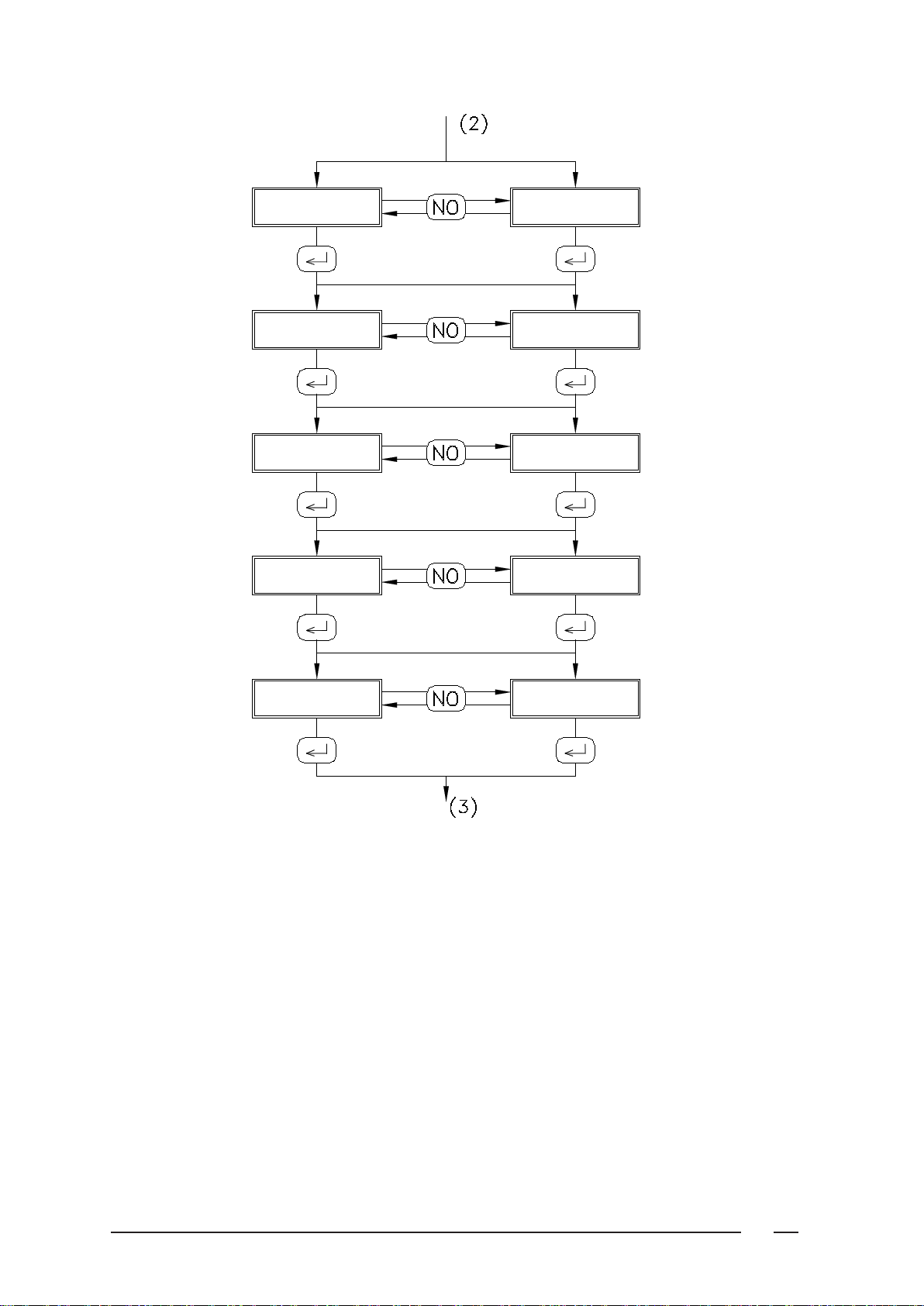

10

no i2 i2

no i4 i4

i6no i6

i1no i1

no i3 i3

no i5 i5

Page 11

11

Pre-programming mode 3

HF - HW - HFP 3 soap supplies

i2 Soft (tub)

i4 Warm (tub)

i6 Hard (tub)

iI Soft (prewash)

i3 Warm (main wash)

i5 Hard (softener)

Page 12

12

no ir1

no dI

dI VALVE

no d2

ir1

dI

dI PuMP

d2

d2 VALVE d2 PuMP

Page 13

13

Pre-programming mode 3

ir1 Recuperation valve 1

d1 Discharge valve 1

d1 Discharge valve 1 or pump

d2 Discharge valve 2

d2 Discharge valve 2 or pump

Page 14

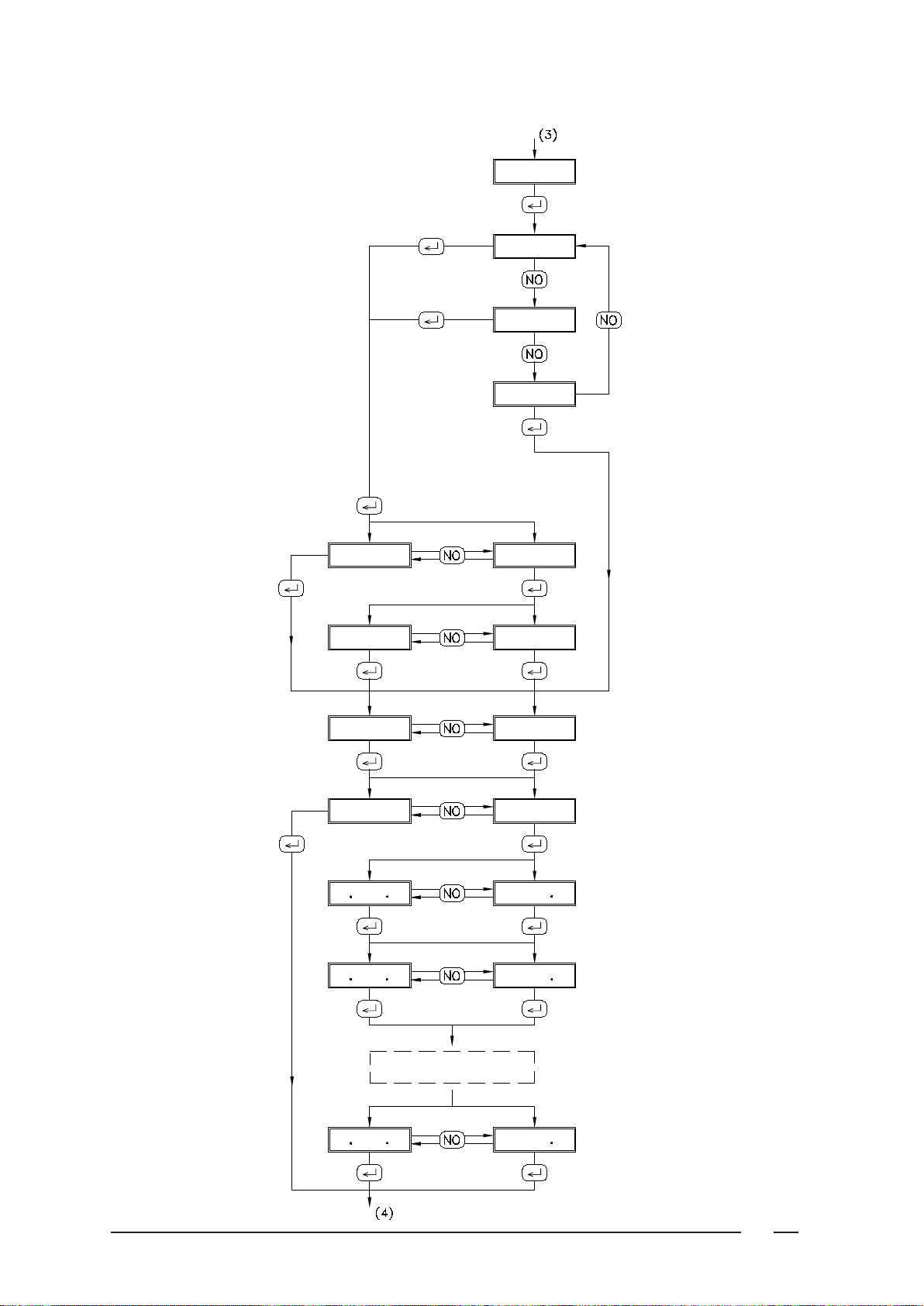

14

HEAT-SYS

HEAT

HEAT-Mod

Mod

HECo

GEntLE

t $Ft $C

noGEntLE

no HECo

noSoAP01 SoAP01

noSoAP02 SoAP02

noSoAP12 SoAP12

SoAP03-----SoAP11

no SoAP SoAP

Page 15

15

Pre-programming mode 3

HEAt-SYS = Heating system

On machines with hot water supply, the modulation technique can be used. For this purpose, a controlled

water mixing is applied during water supply, as a result of which the temperature of the bath after loading is

perfect in most cases. If this option is not used, a traditional mixing system is used.

In following steps, you have to enter whether this modulation technique will be used or not.

Therefore, select from the following:

HEAt (heating system without modulation)

HEAt-Mod (heating system and modulation)

Mod (no heating system, only modulation)

If no hot water inlet valves are selected (see SE-i) " HEAt " is automatically selected and " HEAt-SYS"

will not be displayed.

HECo = Execute heating control (temperature control)

This means stopping the program temporarily during warm up, until the right temperature is reached.

GEntlE = Converting the movement time and the dwell time of the tumbler during temperature control.

If the machine is not equipped with a heating system ( Mod at HEAt-SYS), the functions HECo and

GEntlE will not be displayed.

t $C of t $F = temperature selection in °C or °F.

SoAP = Injection pumps for liquid soap

If no liquid soap supplies are provided, continue with Add

SoAP 01 = Soap pump 1

Soap injection via pump 1

On PS40, a maximum of 12 liquid soap supplies can be connected (standard 6 + 6 optional).

Select the desired soap supplies from Soap 01 to SoAP 12 inclusive.

SoAP 12 = Soap pump 12

Page 16

16

no Add Add

HYSt=

no bu%

no t

no ALArM no ALArm

no t

bu%

no ACCL ACCL

no EMEr EMEr

WAIT

iStilt

EStilt

StArt

nodefaul dEFAul

Page 17

17

Pre-programming mode 3

Add = Additional programs

These are 3 options (Cool-down, time stop and a soaking program), which can be set later while

programming. (see chapter 4)

On a machine type WE , you proceed directly to "HYST".

iS.tilt.XX (Intermediate spin tilts)

With " X,X " you can enter the number of tilting breaks that may occur during intermediate spinning

(1 to 15) before skipping this spinning cycle.

ES.tilt.XX (End spin tilts)

With " X,X " you can enter the number of tilting breaks that may occur during intermediate spinning

(1 to 15) before skipping this spinning cycle.

HYSt = Hysterisis

Here you can set the hysteresis (in °C) on the heating. The smaller the value, the more constant the water

temperature will be, but the more frequent the heating element will switch off and on.

Enter the hysterisis with " X,X " (1-5°C).

Bu% Buzzer (signal) at the end of the program

t = Temperature

Reading the temperature, visible on the display.

ACCL = Acceleration (to accelerate)

This allows running through the program quickly by means of the " E " key (in the "operation mode").

EMEr = Emergency stop

The " STOP " key functions as emergency switch in the "operating mode".

ALArm

This way, an external source (horn or light) will be commanded, via outlet " SOAP 6 ", which will

announce f. ex. the end of a program or soaking cycle. This way, the number of soap exits will be reduced from

12 to 11.

dEFaul= default

This parameter has no inuence yet.

The pre-programming has nished now. " WAit" appears temporarily. You’ll return to " StArt ".

Page 18

18

ProG

ProG ((

id

CYti

t ((((

(( rotE

(( ((

((

Page 19

19

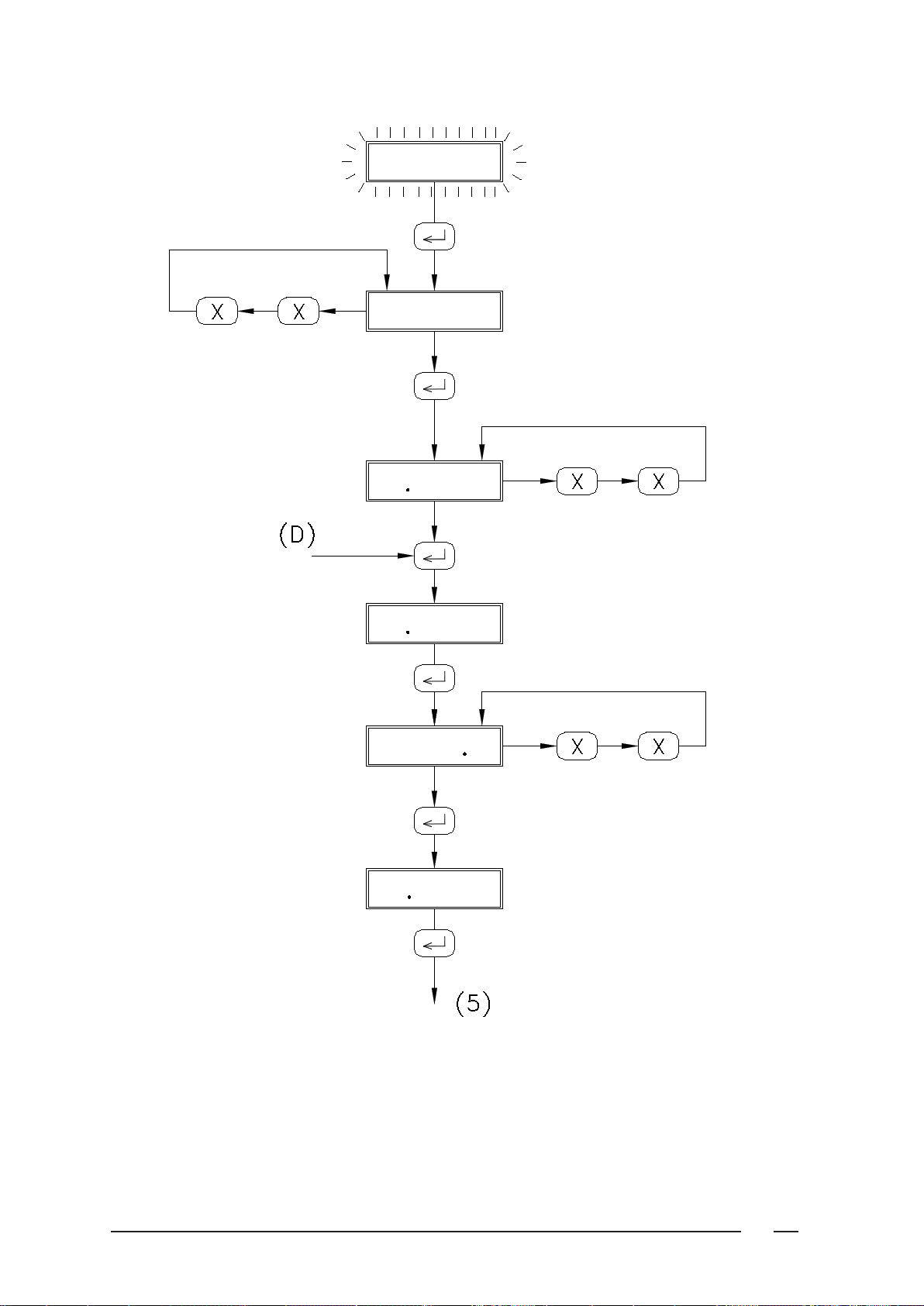

Programming mode 4

Programming

To open the "programming mode" , see 2. division in modes.

The selection can often be done by changing the order on the display if necessary with " NO "

(f. ex. " no HECo " and after pressing " NO ": " HECo "), and conrming this with "ENTER".

While programming, it is possible to return step by step by pressing " STOP " (stop-key).

ProG (blinking) = Programming

Press " ENTER ".

ProG (( = the program number that has to be programmed

Enter the desired program number with " X,X ".

On the program number display, the program number is displayed. In order to select a program number above

9, the number should be formed with a combination of keys.

Press " ENTER " again.

(( id (( = "program number" and "program part number".

The rst XX represent the program number entered at " ProG ".

The second XX represent the "program part number".

Example:

" 02id 03 " represents program 2, program part 3.

A program part is a part of a program (prewash, main wash cycle, rinsing etc.) and is ended by a water

discharge in each case. In order to obtain a full wash cycle, several program parts should be entered

consecutively. (max. 99 per wash cycle ).

Enter a program part number with " X,X " and press " ENTER ".

If during programming, there is insufcient space in the " RAM memory ", the error message

" RaM full " will appear.

(( CYti = Cycle time

This is the duration of the washing time in this program part ( XX) ( without taken into account the temperature

and level control )

From now on, " XX " stands for the program part number that has been entered.

Press " ENTER ".

t XX.XX = Time (Washing time in minutes and seconds)

Enter the time with " X,X " ( 0 to 60 minutes ) and press " ENTER ".

If " 0 " is entered, the program will proceed with " SPin " (or " no SPin ").

(( rotE = Rotation (Dwell - and washing movement times)

Press " ENTER ".

Page 20

20

$C ((

A ((

S ((

SP ((

(( tEMP

HEAt

HEAt-Mod

Mod

Page 21

21

Programming mode 4

A (( = Action time (movement time)

Enter the movement time with " X,X " (0 to 60 seconds).

When the motor frequency is controlled, a digit will appear after the decimal point and the time can be set

accurately to 0.1 sec.

When "0" seconds is entered (cycle without movement of the drum), the following step (" S XX " ) is

skipped.

Press "E ".

S (( = Stop time (dwell time)

Enter the dwell time with " X,X " (1 to 60 seconds).

When the motor frequency is controlled, a digit will appear after the decimal point and the time can be set

accurately to 0.1 sec. (minimum 0.5 sec).

Press "E ".

The next step depends on the selection during the "pre-programming".

- Without " FC " (frequency controlled motor ): change to " XX. tEMP ".

- With " FC " ( frequency controlled motor ): change to " SP XX ".

SP (( = Speed

Enter the revolutions per minute of the washing movement with " X,X " (10 to 50 revs/min)

Press " ENTER ".

(( tEMP = Temperature (of the bath)

Press " ENTER ".

$C (( = Temperature (Or " $F (( " °C or °F according to your selection in pre-programming ).

Enter with " X,X " the temperature (maximum 95°C) and press " ENTER ".

In case of a cold bath, enter "0". Proceed with " XX. SE-i " immediately.

The following step depends on the selection made in "preprogram" during " HEAt-SYS ".

If " HEAt-Mod " was selected, you can now make a selection with " NO " switched off:

HEAt (heating without modulation) transition to " HECo " or " (( SE-i ".

HEAt-Mod (modulation with supplementary heating) transition to " HECo " or " (( SE-i ".

Mod (modulation without supplementary heating) transition to " (( SE-i ".

Press " ENTER ".

If " HEAt " was selected, there will be an immediate transition to " HECo " or " (( SE-i ".

If " Mod " was selected, there will be an immediate transition to " (( SE-i ".

Page 22

22

no HECo HECo

t ((((

noGEntLE GEntLE

(( SE-i

no i2

i2

no i4

i4

i6-i1-i3-i5-ir1

Page 23

23

Programming mode 4

HECo = Heating control

If no heating control is wanted, select " no HECo " and press " ENTER ".

If heating control is desired, select " HECo " and press " ENTER ".

If " no HECo " is selected, there will be a transfer to " (( SE-i ".

t XX = Time (duration of temperature control)

With " X,X ", enter the time when the control should be performed (value between 0 and the washing time

entered at " (( CYTi " ) and press " ENTER ".

GEntlE = converting the movement and dwell time (set at " A XX " and " S XX ") during temperature

control.

" (( SE-i ". = Select inlet (select water inlet valves)

Press " ENTER ".

i2 = Inlet 2 (inlet valve 2) (HF) or i1 = Inlet 1 (inlet valve 1) (HFP machine)

With " NO ", select whether an inlet valve should be selected or not.

Press " ENTER " to continue with the next inlet valve.

To save space, not all valves have been drawn. The action is the same for each one of them.

You can nd the function of the valves in chapter 3.

If, by mistake, you selected the wrong inlet valve and the temperature should rise above the

" $C XX " set, cold water will automatically ow through inlet valve " i2 " (HF) or " i4 "

(HFP) for safety.

The following step depends on the selection made at "preprogram"

- without " SoAP " (liquid soap supply) : transfer to " (( SE L ".

- with " SoAP " (liquid soap supply) : transfer to " SoAP " (or " no SoAP ").

Page 24

24

no SoAP SoAP

no So1

SoAP 01

So1

t1 (((

So2-S03-So4-------So12

(( SE-LE

LE ((

no LECo LECo

LS ((

Page 25

25

Programming mode

Programming mode 4

SoAP= Liquid soap supply

If no soap injection is desired, select " no SoAP " and press " ENTER ". (Transfer to " (( SE-L ")

If soap injection is desired, select" SoAP " and press " ENTER ".

The program will proceed with the rst soap inlet activated in the "preprogram".

Example: "So1" (Soap 1)

SoI = Liquid soap injection 1

Use " NO " to choose whether a soap inlet pump should be selected or not.

Then press " ENTER ".

t1 (((= Time 1 (duration of soap injection 1)

Enter the duration with " X,X,X " (maximum 999 seconds).

Press " ENTER " to proceed to the next soap injection.

Depending on the selection in "preprogram", the soap inlets can be programmed one after the other (from So1

to So12 included).

In order to save space, only SO 1 was drawn, the others are identical.

Press " Enter " after setting the soap inlets.

(( SE-L = Select level (select water level)

Press " ENTER "

LE (( = Level (Water level)

Use " X,X " to enter the level (5 to 50) (experimental) and press " ENTER ".

The next step depends on the selection made during " pre-programming "

- without " LECo " (level control) : transfer to " Add " (or " no Add ")

- with " LECo " (level control): transfer to " LECo " (or " no LECo ")

When " 0$" is entered at " (( tEMP", you can enter a level between 0 and 50.

Overow (extremely soiled linen).

- enter " 0$C " (or " $F ") at " ((tEMP "

- select " no HECo " and enter the level " 00 " at " L (( ".

During the complete washing time, water will be supplied and discharged via the overow.

LECo = Level control

If no level control is desired, select " no LECo " and press " ENTER ".

If level control is desired, select " LECo " and press " ENTER ".

LS (( = Level stop (level control)

With " X,X ", enter the level where the program time should stop (automatically limited) till the set value is

reached at " LE (( ").

When this level is reached, the programmer continues and the bath is lled till the level set at "L (( " is

reached. Press " ENTER ".

Page 26

26

no Add Add

Cool Cd'& ((

Cd' ((

Cdu ((

Cdu& ((

StoP

StoP (((

SoAk SoAk (((

AlArM(((

no Add

Page 27

27

Programming mode 4

The next step depends on the selection during " pre-programming ".

- Without " Add "(help program), transition to " SPin " (or " no SPin ").

- With " Add " (help program), transition to " Add " (or " no Add ").

Add = Additional program (program extension)

When no program extension is desired, select " no Add " and press " ENTER " (transition to " SPin").

If a program extension is desired , select " Add " and press " ENTER ".

With "NO" switched off select: " Cool ", " StoP ", " STOP ((( ", " SoAH ((( ", or once more

" no Add " and press " ENTER " to conrm your selection.

Cool = Cool-down

Cd'& (( = degree of temperature drop to the highest cool-down temperature

Enter the degrees of temperature drop at " X,X " (1 to 99 °/minute) and press " ENTER ".

Cdu (( = highest cool-down temperature

Witht " X,X " enter the temperature (30 to 85) and press " ENTER ".

Cdn& (( = degree of temperature drop to the lowest cool-down temperature

With " X,X " enter the degree of temperature drop (1 to 99 °/ minute) and press " ENTER ".

Cdn (( = lowest cool-down temperature

With " X,X " enter the temperature (30 to 85 and automatically limited to the value set at

" Cdu (( ") and press " ENTER ".

StoP = Stop

In the " operating mode " , the program will stop here, so f.ex. extra soap could be added manually (the

water remains in the bath). See operating mode: " programmed stop "

A " stop time " up to 999 minutes can be entered. After this stop time has expired, the program will

automatically restart.

StoP (((

With " X,X,X " enter the stop time (0 to 999 minutes) and press "ENTER".

If "0 " was entered, the program will be stopped until "START " is pressed.

SoAk = Soak

In the ‘ operating mode, the program will stop here, the level will be brought to " 25 " and every

3 minutes, a left - right movement will be performed (temperature will remain constant).

See operating mode: " soak ".

You can enter a " soaking time " from up to 999 minutes. After this soaking time is up, the program will

automatically restart.

SoAk (((

With " X,X,X " you can enter the soaking time (0 to 999 minutes) and press " ENTER ".

If "0" was entered, the program will be stopped until " START " is pressed..

ALArM (((

In the beginning of this soaking time you can activate the alarm signal.

With " X,X,X " you can enter the time (0 to 250 secs) during which you want to hear the signal.

This option can only be displayed if the preprogram is selected ( see "ALARM").

If " 999 " was entered, the alarm will be active during the complete soaking time!

no Add = No additional (no program extension)

Page 28

28

no SPin SPin

SPit ((

SP (((

d1

d2

(( dEti

td (((

Page 29

29

Programming mode 4

SPin = Spinning (extraction)

If spinning is desired, select " SPin" and press " ENTER ".

If no spinning is desired, select " no SPin" and press " ENTER ". (transition to " dO "," d1 " or

" d2", ...).

The next step is dependent upon the type of machine:

With frequency controlled motor

SPit (( = Spin time (duration of spinning)

With " X " enter the duration of the spinning

(1 to 15 minutes) and press " ENTER ".

SP ((( = Speed (spinning speed)

With " X,X,X,X " enter the number of revolutions

of low spinning (250 to 1000 revs / min) and

press " ENTER ".

On machines with drum diameter higher than

850 mm, this value is limited to 800.

dI = Drain 1 (drain valve 1)

Select " d1" , " d2 " with

" NO" " and conrm with " ENTER ".

The number of drain valves from which you

can choose, is dependent upon the setting of

the pre-program.

Without frequency controlled motor

SPI- ( = Low spin time

With " X " enter the duration of low spinning

(1 to 9 minutes) and press " ENTER ".

dI = Drain 1 (drain valve 1)

Select " d1" of " d2 ",or " NO" " and conrm

with " ENTER ".

The number of drain valves of which you can

choose, is dependent upon the settings of the

pre-program.

(( dEti = Delay time (clearance time after

spinning)

Press " ENTER ".

td ((( = time delay (clearance time)

With " X,X,X ", enter the time and press

" ENTER ".

Time to enter:

30 to 180 secs after low spinning.

60 to 180 secs after high spinning.

(( dEti = Delay time (clearance after

spinning )

Press " ENTER ".

td ((( = time delay (clearance time)

With " X,X,X " enter the time and press

" ENTER ".

Time to enter:

30 to 180 secs after spinning below

500 revs /min

60 to 180 secs after spinning above

500 revs / min

Page 30

30

d2

d1

dO

dt (((

Wash

dist

Jolt

drain

t% (((

Page 31

31

Programming mode 4

dI = Drain 1

Select " d1 ", " d2" of " dO"met " NO " and conrm "ENTER ".

When "dO" is selected, the water will not be discharged (transition to the next program part)

The number of drain valves of which you can choose, is dependent upon the setting of the preprogram.

dt ((( = Drain time

With " X,X,X " enter the drain time (max 180 secs) and press " ENTER ". With " NO " select from

" WASh ", " diSt ", " JoLt" and " DrAin " which action should be performed in between two

discharges and conrm with " ENTER " .

WASh = Washing movement

Washing movement of the drum during water discharge.

diSt = Distribution (distribution speed) (not on machines of the type WE (no HF))

Distribution movement of the drum during water discharge.

Jolt = Short spinning ( after distribution, low spinning for 10 secs )

At " dt ((( " enter a minimum of 60 secs

drAin = discharge

Water discharge without movement of the drum

t= (((( = Time

This is the duration of the program part.

Press " ENTER ".

Page 32

32

((id ))

FrEE%(((

End

tu ((

AlArM(((

data((((

Start

Page 33

33

Programming mode 4

FrEE%((( = the maximum number program parts to program.

You can program 400 program parts at the most .

Press " ENTER ".

End = end of a program part.

Press "NO " to proceed with the next program part ( transfer to " ((.id )) "). ))stands for the

following program part number.

Press " ENTER " to set the end of the program.

tu (((= Tumble (untwining)

This is being executed in a washing rhythm of 60 secs of action and 9 secs of stop time. The lowest speed

that occurs in this program is being used (on frequency controlled machines).

With " X, X, X ", enter the tumble time (30 to 999 secs) and press " ENTER ".

If no untwining is needed, you can enter 0. A dwell time of 1 minute is then performed.

ALArm(((

Here is where you can activate the alarm signal.

With " X,X,X ", enter the time (0 to 250 secs) during which you want to hear the alarm.

This option is only displayed when selected in pre- program (see "ALARM").

If " 999 " was entered, the alarm will remain activated until the door is opened.

Data((((

At the end of the programming, the new " checksum " is displayed ‘ during a couple of seconds, then you

proceed with " StArt " .

Page 34

34

((id ((

(( inS

((id ((

((id ((

(( dEL

Page 35

35

Programming mode 4

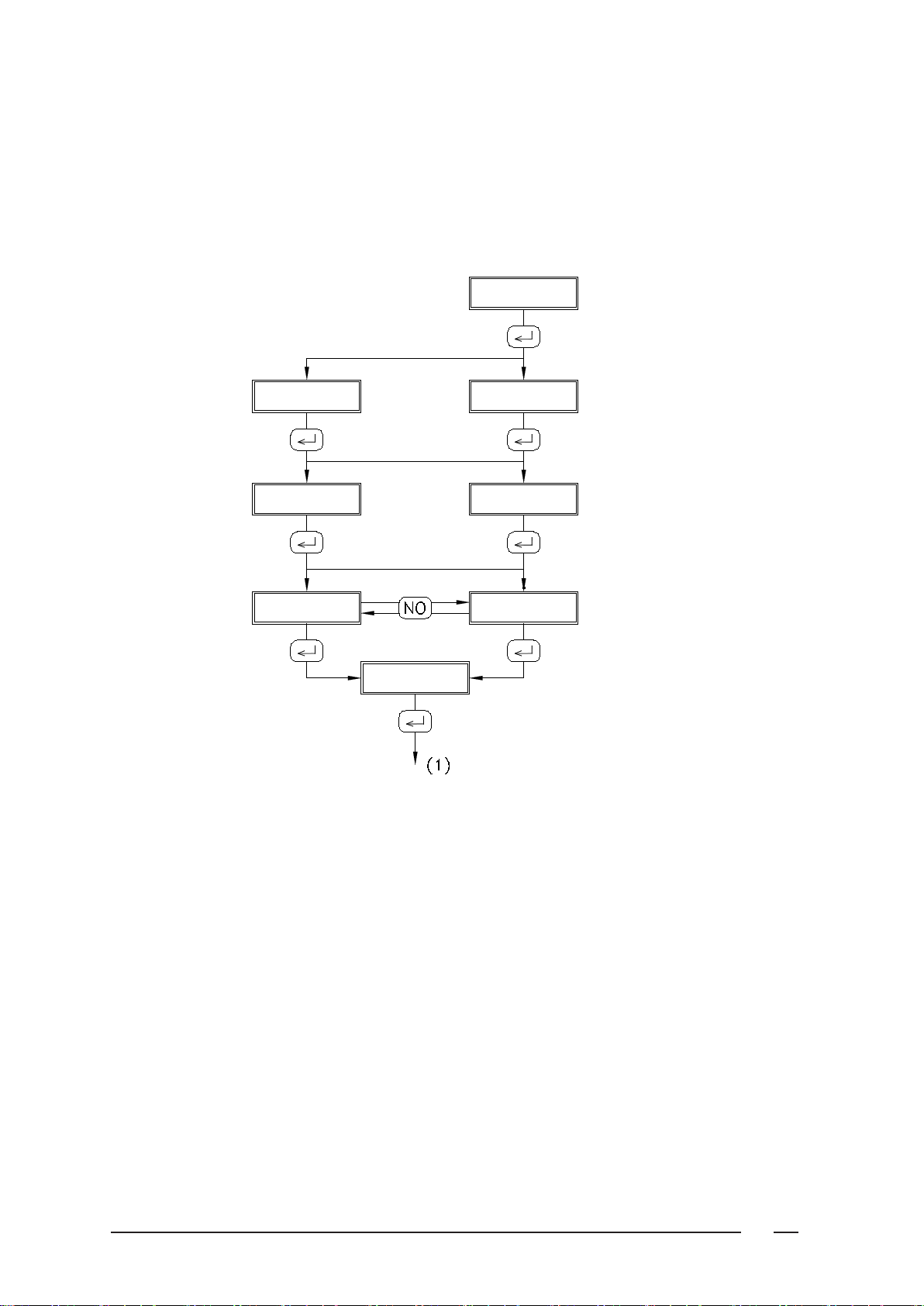

Inserting and deleting a program part

Start the programming procedure till " ((id (( ".

Inserting a program part.

Press " START ".

XX. inS = Insert

Press " ENTER ".

The program part " XX " is advanced with one position. " ((id (( " reappears on the display. This

program part can now be re-entered.

Example:

Program " 01 " with 4 program parts (01,02,03,04)

Between 02 and 03, one program part has to be inserted.

Select " 01id 03 " and press " START ". " 03ins "reappears on the display . Press " ENTER " .

" 01id 03 " reappears. Program part " 03 " should now be re-entered. The previous part " 03 " has

moved on to " 04 " and " 04 " has moved on to " 05 " .

If there should be insufcient space in the Ram memory, the error message " Ram full " will

appear.

Deleting a program part

Press " STOP ".

(( del (blinking) = Delete

Press " ENTER ".

The program part " XX " is being deleted. The following program parts are moved back with one

position.

Example:

Program " 01 " with 4 program parts (01,02,03,04,)

Part 02 has to be deleted.

Select " 01id 02 " and press " STOP ". On the display appears " 02 del ". Press " ENTER ".

Now, "01id02 " reappears. This used to be program part " 03 ".

Program part 04 has been moved back to 03.

Program tables

The table on the following pages shows how the programmed data have been saved.

Copy the blank tables on the pages for as many times as there are programs to be set. Fill them in and save

them carefully.

Page 36

36

CopY PrG

SourCE((

deSt ))

(( ))

StArt

Page 37

37

Copying mode 5

Copying mode

To go to the " copying mode ", see 2. Division in modes.

The PC40 programmer is tted with 10 xed standard programs (40 to 49). These programs can be executed

directly.

At these locations however, it is impossible to change them. If you want to change them or use them as the

basis of another program, you need to copy them rst to a new program number between 0 and 39.

(see further).

Other already self-programmed programs can also be copied to another number (between 0 and 39)in the same

way and then be used as a basis for other programs. In this way, you can save a lot of time when creating programs

that are much alike.

CoPY PrG = Copy program

To conrm, press " ENTER ".

To cancel, press any key ( transition to " StArt")

SourCE.(( = program to copy

With " X,X " , enter the program number and conrm with " ENTER ".

dESt.)) = Destination (destination of the copied program)

With " Y,Y ", enter a program number and conrm with " ENTER ".

((--)) = Conrmation of copy

To conrm: press " ENTER " (transition to " StArt ")

To cancel: press any key ( transition to " StArt")

If there should be insufcient space in the RAM memory, the error message " Ramfull " will appear.

Standard programs

On the pages at the back of the manual, you’ll nd the composition of the standard programs according

to the different machine types.

Page 38

38

ProG ((

(( ((*((

ProG ((

ProG ((

(( ((*((

(( ((*((

(( ((*((

(( ((*((

(( ((*((

P(( End

Operating mode 6

To go to "operating mode": see 2. Division in modes.

Selecting a program

ProG ((= Program XX (ex. program 01)

If necessary, select another program number.

The program number is shown on the display.

To select a program number above 9, you need to enter the number as a combination.

Example: Program 25 : enter " 2 " + " 5 "

Starting a program

Press " I ".

The program is now started.

" XX. XX' XX " appears on the display ( f. ex. " 01.41’15 " ).

01 = program part number

41' 15 = total resting programming time

When the door hasn’t been shut properly, the message " door. oPEN " appears.

When a program number has been selected, which isn’t linked with a program yet, " A2 " is blinking

on the display during 10 seconds.

Course of the program

During the program, the program time will count down per seconds.

After a program part has been performed, the next program part number appears.

" XX. XX' XX. " (e.g.: " 01. 41' 15. ")

When water is being supplied, the rst decimal point will illuminate.

As long as a level control is being performed at the same time, this decimal

point will blink.

" XX. XX' X.X " (e.g.: " 01. 41' 1.5 ")

When the water is heated, the second decimal point will illuminate.

As long as a temperature control is being performed at the same time, the

decimal point will blink

" XX. XX' .XX " (e.g.: " 01. 41' .15 ")

When the water is being discharged, the third decimal point will illuminate.

As long as a distribution control is being performed at the same time, the decimal

point will blink.

" XX. XX' .XX " (e.g.: " 01. 41'. 15 ")

When high spinning, the fourth decimal point will illuminate.

When low spinning, this decimal point will blink.

" P(( End "

When the entire program has been executed " P(( End " appears (f.ex.: " P01 End") and the buzzer will be activated for about 10 seconds (if the buzzer " bu%"has been selected " in "preprogram ").

On programs where an alarm signal has been programmed, (ALArM((() this is now being executed.

When the door is opened, " StArt " appears.

Page 39

39

Operating mode 6

Programmed start

Press " START " and keep it pressed for more than 5 seconds after a program has been selected.

" dELAY .XX " appears on the display.

By entering a digit between 0 and 99, the start can be postponed per hour.

Press " START " again to start the count down (the decimal point blinks).

In the last hour, the minutes are blinking on the display.

Remark:

To stop the countdown: press " STOP ".

Changing the program

The rst 3 minutes after starting, you still have the possibility to change the program. Enter another

program number.

" P.((.StArt" will appear on the display. " P.(( " represents a new program number.

Press " START " to conrm.

Remark:

On machines with coin (if a more expensive program has been selected), the amount due " (((.(( " appears.

The rst program keeps running till the coins are inserted. If this doesn’t happen, the program will continue

3 minutes after the rst start.

Changing the level, the washing time and the temperature settings once.

Select the program number.

Before starting the program, press " NO " and " ENTER " at the same time.

Per program part, rst the level "L ((", the washing time " t (( " and then the temperature " $C (("

appear on the display. Change these data if necessary and press " ENTER " to proceed with the washing time

and temperature settings of the next program part.

Start the program with " START " after the setting have been modied.

Remark:

The value of " LECo" en " HECo" is being changed downward with the same value till a minimum of

"00 " is reached.

The program will only be executed once with the settings modied in this manner. This function cannot be

realized on machines with coins.

Controlling the temperature of the bath and the number of revolutions

By pressing the " NO ", you can read the temperature of the bath and the number of revs for 5 seconds.

These functions are only operative if temperature reading ("t") has been selected in "preprogram".

Press once:

The temperature of the bath is given, followed by a horizontal line. (t=(($C_ ) .

Press twice:

The highest temperature in the program is given, followed by two horizontal lines (t=(($C%).

Press three times:

The highest temperature in the program is given, followed by three horizontal lines (t=(($C%).

Remark:

When the temperature measured is less than 25 °C, the message " Cold " is displayed.

Press four times:

On machines with frequency controlled motor ( " FC " in "preprogram", the number of revolutions

is given ).

_

Page 40

40

Operating mode 6

Controlling the program during functioning

By pressing " NO " longer than 3 seconds and then releasing it, all set steps per program part are displayed

one after the other during 1 second.

By pressing and holding " NO " once more, the step performed last is displayed. After releasing the " NO

", the next steps are given.

At the end of the program part, " EntEr " appears during 3 seconds. In order to proceed with the reading

of the next program part, " ENTER " should be pressed within that time. If not, the normal course of the

program is displayed.

Running through the program quickly

While pressing , the program will be accelerated (if accelerate (" ACCL") was selected in

"preprogram").

The seconds are counted down faster. The acceleration is interrupted at every major step of the program

(discharge, cool down, etc.) Press the acceleration key once more to continue more rapidly.

In this way, you have the possibility not to execute certain parts or the rest of the program.

During tumble, the program cannot be accelerated.

Programmed stop

When a " stop " has been programmed, the program will stop there. The water remains in the drum, there are

no drum movements and " StoP " appears on the display.

After pressing " START ", the program continues

Stop with stop time

If a stop time has been programmed, " StoPtiME " and the counting down remaining stop time will

alternately appear on the display. After the stop time has expired, the program time will continue automatically.

The machine stops until " START " is pressed again.

Alarm signal.

If an alarm has been programmed, this will be activated at the beginning of the stop. This signal can be stopped

by pressing " START " or " STOP ".

.

Soaking

If " SoAk " has been programmed, the program will stop there. The bath will be brought to level 25, kept at

the right temperature and every 3 minutes there will be a left - right movement.

The soaking continues till " START " is pressed.

Soaking with soak time.

If a soak time has been programmed, " SoAktiME " and the counting down remaining soak time will

appear alternately on the display. After the soak time has expired, the program time shall continue automatically.

If, during this soak time, the START - key is being pressed, the program will be proceeded immediately.

Alarm signal.

If an alarm has been programmed, this will be activated at the beginning of the soak time. This signal can be

stopped by pressing " START " or " STOP " .

Page 41

41

Operating mode 6

Time stop (not on machines with coins)

By pressing the “STOP” button longer than 3 seconds, the program comes in “time stop” (if “ EMEr” was

selected in the “pre-program”).

With this you can for instance extend a program for very dirty linen. The time is stopped and the step is continuously

executed. The programmed water level and temperature are maintained. During the “time stop”, “ ((tistop”

is indicated.

Now you can possibly program the stop time. Therefore, press “ENTER”. Now, “(( ti ((” is indicated.

Program by means of “X,X,X” the stop time (from 1 to 999) minutes and press “E”.

The display shows by turns “((tisto” and the counting stop time left. Once the stop time is passed, the

program time continues automatically.

If no stop time is programmed, the stop will be executed continuously until “START” is pressed.

A "time stop" during the spin is automatically broken off after 20 minutes.

Break off or stop a program

When the “STOP” button is shortly pressed, the display text blinks and the water is evacuated after 5 seconds

(only if emergency stop (“EMEr”) was selected in the “pre-program”). The buzzer starts after 30 seconds,

“oPEn door” appears and the door has to be opened. Afterwards “CloSe” appears.

When the door is locked again, you can :

- continue the program by pressing “START”

- stop the program permanently by pressing “STOP”.

The stop function operates during spin1 with 60 seconds delay and during spin2 with 120 seconds delay.

Add water

By pressing rst button “1” and then one of the buttons from “1” till “9” during a program, the corresponding

inlet valve is opened.

By pressing rst button “2” and then one of the buttons from “1” till “3” during a program, the corresponding

inlet valve is opened.

While pressing, the chosen inlet valve and level are shown ,“ i( l((”. This indication lasts for 3 seconds after

releasing.

These functions do not operate during the rst 3 minutes of the program.

Water exhausts

By pressing rst the “0” button and then one of the buttons from “1” till “4” during a program, the corresponding

exhaust valve is opened.

While pressing, the chosen exhaust valve and level are shown “d( l((”. This indication lasts for 3 seconds

after releasing.

This function does not operate during the rst 3 minutes of the program.

Warm up the bath

By keeping the button “4” pressed during a program, the heating is activated (max. 95 °C). While pressing, the

temperature of the bath “$C ((” (or “of $F ((”) is shown.

This function does not operate during the rst 3 minutes of the program.

Page 42

42

Operating mode 6

Adding soap (not on machines with coins)

By pressing rst button “3” and then the “+” button, “SO(t((” is indicated. By keeping one of the buttons from

“1” to “9” pressed then, soap is added through this entry. With button “0”, “-”, "+”, soap can be added through

entry 10 till 12. While pressing, the selected soap entry and time when the soap has been added are indicated.

This function does not operate during the rst 3 minutes of the program.

Error indications

When there has been a technical failure during a program, " A( " or " F( " will be indicated at the end instead

of " P(( End ".

" A0 " : the program key was in the wrong position when trying to access the programming mode.

" A3 " : the machine has not been set up (preprogram) or the memory has been lost.

" A4 " : the lling time was longer than 15 minutes.

" A5 " : the requested temperature was not achieved after 60 minutes of heating.

" A6 " : the temperature in the cylinder is unsafe at the end of a program (Temperature > TES in conguration

le). Wait until the load cools to prevent burns.

" F6 " : the doorlock was unbolted.

" A7 " : there is still water in the tub at the end of the program (door cannot be opened).

" A8 " : the temperatur sensor was not operating.

" A9 " : the heat motor security was switched on during the program (not for frequency controlled

machines).

" Ac " : the water was not evacuated after 3 minutes : there was no further heating.

" Ad " : no rpm were measured during the spin (only for frequency controlled machines).

" AH " : the spin was not executed (max. number of tilts was exceeded).

These indications disappear after opening the door.

Certain error indications are directly shown and prevent the start of the cycle or stop the cycle.

" A2 " : an unknown program was chosen.

" F1 " : invalid control conguration / wrong conguration le / corrupted PS40 rmware.

" F5 " : the door was opened during the program.

" Ab " : water level has still been detected at the start of the program.

" F6 " : the doorlock was unbolted during the program.

" FA " : the tilt switch is blocked.

" FH " : hardware error (fault at printed circuit board).

These error indications disappear when the error is repaired.

Page 43

43

Test mode 7

The test mode is set up to help nding technical failures and is rather made for specialists.

To enter “test mode”, you have to :

- Put in front the key switch in position “PROG”.

Press “+” or “-” button until the display indicates" tESt ".

Give a number from 1 to 7 to choose one of the below mentioned test functions.

To leave test mode : press the “STOP” button

Test 1 : check the 8 inlets

Here it is indicated if the inlet contacts are opened (o) or closed (c).

To check the next inlet : press “ENTER”.

To check the previous inlet : press “NO”.

To stop this test, press “STOP”.

inP.tHEr.o : heat motor security

inP.hEY .o : key switch

inP.LOCh.o : doorlock S2

inP.door.o : doorlock S1

inP.tiLt.c : tilt switch

inP.SEnS.c : sensor for rpm

inP.tiHo.o: not applicable

inP.bS .o : not applicable

Example :

" t1.tHEr.o " : heat motor security open

" t1.tHEr.c " : heat motor security closed

Test 2 : check the rpm

Step by step the basic speeds of the machine are executed.

Press “ENTER” each time to go to the next step.

P000u0.00

P000u0.00 the door is locked

Lo((u0.41 the drum turns left at wash speed. The target rpm are indicated on the right, whereas the

control signal (XX) is indicated on the left.

P000u0.00 Pause

ro((u0.41 the drum turns right at wash speed. The target rpm are indicated on the right, whereas

the control signal (XX) is indicated on the left.

do((u0.84 the drum turns right at distribution speed. The target rpm are indicated on the right,

whereas the control signal is indicated on the left.

lo((u5.00 the drum turns right at low spin. The target rpm are indicated on the right, whereas the

control signal (XX) is indicated on the left.

Ho((u1.00 the drum turns right at high spin. The target rpm are indicated on the right, whereas the

control signal (XX) is indicated on the left.

Page 44

44

Test mode 7

Test 4 : Calibrate the water level sensor

In this program, you can program the 0-level, maximum level and the number of divisions.

Wait to start the program until the water is out of the tub.

The display indicates “t4.LEV ((.(”.

By pressing “0”, the 0-level is calibrated.

Then press the “START” button.

Now the valve will be closed and water will be taken. The display shows the respective water level.

When the value does not longer increase on the display, this means that the highest level is achieved.

Press the “STOP” button now. Through this, the water inlet is stopped.

Then press “1”. Through this, the highest level is calibrated.

Now program at “t4.LEV ((.(” the number of divisions (maximum 99) and press “ENTER”.

To stop the test , press the “STOP” button again.

Test 5 : check the temperature sensor

The display shows " t5.((.( ". " XX.X " means the respective temperature in the tub.

To stop this test, press the “STOP” button.

Test 6 : check the 24 outlets.

Here you can activate by turns the outlet contacts.

To check the next outlet, press “ENTER”.

By pressing “0” or “1”, the contact is opened or closed and the last display shows respectively “o” (open) or

“c”

To check the previous outlet, press “NO”.

To stop this test, press the “STOP” button.

Out.door.o: door lock

Out.heat.o: heating

Out.irI .o: recycling inlet valve 1

Out.i6 .o: inlet valve 6

Out.i5 .o: inlet valve 5

Out.i4 .o: inlet valve 4

Out.i3 .o: inlet valve 3

Out.i2 .o: inlet valve 2

Out.i1 .o: inlet valve 1

Out.SO1 .o: soap pump 1

Out.S12 .o: soap pump 12

Out.drA1.o: exhaust valve 1

Out.drA2.o: exhaust valve 2

Page 45

45

Test mode 7

Test 7 : keyboard

The display shows : “t8.--”

Each time you push a button now, the respective function is shown.

To stop this test, press the “STOP” button twice.

Ram reset

Through this function, you can delete all date from the Ram memory.

Press o at “test”.

The display shows “Code”.

Enter “ 7 5 3 “ (quickly one after the other).

By doing a ram reset, all self programmed program parts are deleted.

Page 46

46

Liquid soap connection 8

Connection of the liquid soap

hoses

Electrical connection of the

liquid soap pumps

The liquid soap connection consists of 8 connections for liquid

soap.

The central opening is used for ventilation.

On machines equipped with a liquid soap connection, connect the

wires directly on the print board next to the ground wire connection

(option). Connect as indicated on the wiring diagram.

The two connectors on the right give a tension of 220V ~ (max. 4A)

which can be applied to drive 220V ~ soap pumps. If more than 4A

is required, an external tension will have to be used. 6 connections

have been provided, of which one (S6) can be used to drive a waterproong pump (e.g. for rain coats, etc.).

The 220V can be transformed to other values to drive other type

soap pumps.

Example: pumps 24V ~.

Also, pumps with different operating tension can be combined.

Example: 5 pumps 220V ~ and 1 pump 24V ~.

With an external tension 24V DC.

Page 47

47

Standard programs 9

The table on the next page shows how the programmed data are registered.

Standard programs

You can see on the next pages the composition of the standard programs.

Program 40: Hot wash 1 40° - 90°

Program 41: Warm wash 40° - 60°

Program 42 : Synthetics 1 35° - 40°

Program 43 : Synthetics 2 40°

Program 44 : Gentle wash 30° - 30°

Program 45 : Cold wash 20°

Program 46 : Duvet 30° - 40°

Program 47 : Curtains 30° - 40°

Program 48 : Starch

Program 49 : Hot wash 2 40° - 90° (hot intermediate rinse)

For every type of machine a blanc table is foreseen in which all the information of the own programs can be

lled in. Copy the blanc tables as many times as programs will be made. Fill them in and store them carefully.

Page 48

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

Soap injection

Level

Level control

Additionel program

Spin

Drain

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

48

Page 49

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

Soap injection

Level

Level control

Additionel program

Spin

Drain

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

49

Page 50

Program : 40 Total time : 41' 30" Name: Hot wash 1

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

41 41 41 41 41

40 90 0 0 0

/////

XX///

/////

37///

/////

X/X//

XX///

///XX

X////

/X///

////X

/ / ///

13 10 20 20 16

10 10 13 13 13

1/118

500 / 500 500 1000

X 30XXX

/ / ///

/ / ///

/ X///

/////

/X///

/ / ///

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

30 / 303060

8.30 14.30 3.30 3.30 11

30

50

Page 51

Program : 41 Total time : 41' 30" Name: Warm wash

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

7 14222

12 12 15 15 15

3 3 333

41 41 41 41 41

40 60 0 0 0

/////

XX///

/////

37///

/////

X/X//

XX///

///XX

XX///

/X///

////X

/////

13 10 20 20 16

10 10 13 13 13

1/118

500 / 500 500 1000

X30XXX

/////

/////

/X///

/////

/////

/////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

30 / 30 30 60

8.30 14.30 3.30 3.30 11

30

51

Page 52

Program : 42 Total time : 27' 30" Name: Synthetics 1

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

410222

10 10 12 12 12

44444

41 41 41 41 41

35 40 0 0 0

/////

XXXXX

/////

24///

/////

XXX//

XX///

///XX

X////

/X///

////X

/////

13 13 20 20 16

10 10 13 13 13

////4

/ / / / 800

30 30 30 30 X

/////

/////

XXXX/

/////

/////

////2

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

////60

4.30 10.30 2.30 2.30 7

30

52

Page 53

Program : 43 Total time : 19'30" Name: Synthetics 2

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

8222

10 10 10 10

5555

35 35 35 35

35 0 0 0

////

X///

////

3///

////

XX//

X///

//XX

X///

////

///X

////

13 20 20 16

10 13 13 13

///3

/ / / 500

30 30 30 X

////

XXX/

////

////

////

////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

///30

8.30 2.30 2.30 5.30

30

53

Page 54

Program : 44 Total time : 22' Name: Gentle wash

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

47222

33555

10 10 10 10 10

30 30 30 30 30

30 30 0 0 0

/////

XX///

/////

23///

/////

XXX//

/////

///XX

X////

/X///

////X

/////

20 20 20 20 16

13 13 13 13 13

////2

/ / / / 500

30 30 30 30 X

/////

/////

XXXX/

/////

/////

/////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

////30

4.30 7.30 2.30 2.30 4.30

30

54

Page 55

Program : 45 Total time : 18' 30" Name: Cold wash

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

9222

3336

12 12 12 12

25 25 25 25

20 0 0 0

////

X///

////

3///

////

XX//

////

//XX

X///

////

///X

////

18 18 18 16

13 13 13 13

///1

/ / / 400

30 30 30 X

////

////

XXXX

////

////

////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

///30

9.30 2.30 2.30 3.30

30

55

Page 56

Program : 46 Total time : 22' Name: Duvet

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

66222

55555

10 10 10 10 10

30 30 30 30 30

35 40 0 0 0

/////

XX///

/////

22///

/////

XXX//

X////

///XX

X////

/X///

////X

/////

20 20 20 20 20

10 10 15 15 15

////1

/ / / / 500

30 30 30 30 X

/////

/////

XXXX/

/////

/////

/////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

/////

////30

6.30 6.30 2.30 2.30 3.30

30

56

Page 57

Program : 47 Total time : 26' Name: Curtains

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

14 2 222

2 2 222

10 10 10 10 10

25 25 25 25 25

30 0 000

/////

XX///

/////

7////

/////

XX///

/////

//XXX

X////

/////

////X

/////

20 20 20 20 20

8 8 10 10 10

////1

/ / / / 350

30 30 30 30 X

/////

/////

XXXX/

/////

/////

/////

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

////30

14.30 2.30 2.30 2.30 3.30

30

57

Page 58

Program : 48 Total time : 12' 30" Name: Starch

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

3

15

2

41

0

/

/

/

/

/

X

/

/

X

/

/

/

9

9

8

1000

X

/

/

/

/

/

/

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

60

12

30

58

Page 59

Program : 49 Total time : 44' Name: Hot wash 2

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

721422 2

12 10 12 15 15 15

3 4 333 3

42 42 42 42 42 42

40 90 90 0 0 0

///// /

X XX/ / /

///// /

3/7// /

///// /

X//X/ /

X XX/ / /

////XX

X//// /

//X// /

/////X

///// /

13 10 10 20 20 16

10 10 10 13 13 13

1//118

500 / / 500 500 1000

X3030XX X

///// /

/XX// /

///// /

///// /

///// /

///// /

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

30 / / 30 30 60

8.30 2.30 14.30 3.30 3.30 11

59

Page 60

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

Soap injection

Level

Level control

Additionel program

Spin

Drain

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

60

Page 61

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (tub)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

Soap injection

Level

Level control

Additionel program

Spin

Drain

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

61

Page 62

Program : 40 Total time : 41' 30" Name: Hot wash 1

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (kuip)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT

HEAt-Mod

Mod

HECo t

GenTlE

SE-i i2

i4

i6

i1

i3

i5

ir1

SoAP so t1

SoAP so t2

SoAP so t3

SoAP so t4

SoAP so t5

SoAP so t6

SoAP so t7

SoAP so t8

SoAP so t9

SoAP so t10

SoAP so t11

SoAP so t12

SE-L LE

LECo LS

Add Cool '&

Cool '

Add Cool n&

Cool n

StoP t

SoAk t

AlarM t

Spin t

Sp

d1 dt

d2 dt

d0

Wash

diSt

Jolt

drain

01 02 03 04 05 06 07 08

7 14 2 2 2

12 12 15 15 15

3 3 3 3 3

28 28 28 28 28

40 90 0 0 0

/ / / / /

X X / / /

/ / / / /

3 7 / / /

/ / / / /

X / X / /

X X / / /

/ / / X X

X / / / /

/ X / / /

/ / / / X

/ / / / /

20 20 25 25 20

20 20 25 25 20

1 / 1 1 8

400 / 400 400 800 *

X 30 X X X

/ / / / /

/ / / / /

/ X / / /

/ / / / /

/ / / / /

/ / / / /

Delay

Time

Tumble

Alarm

deTi Td

t%

tu

AlarM t

N.B: HF730 (*) = SP 750

60 / 60 60 60

8.30 14.30 3.30 3.30 11

30

62

Page 63

Program : 41 Total time : 41' 30" Name: Warm wash

Segment

Wash time

Temperature

Heating system

Heating control

Wash action

Soft (tub)

Warm (tub)

Hard (tub)

Soft (prewash)

Warm (main wash)

Hard (conditioner)

Recuperation 1

Soap injection

Level

Level control

Additionel program

Spin

Drain

id

CYti t

rotE A

S

sp

TemP $C

HEAT