Page 1

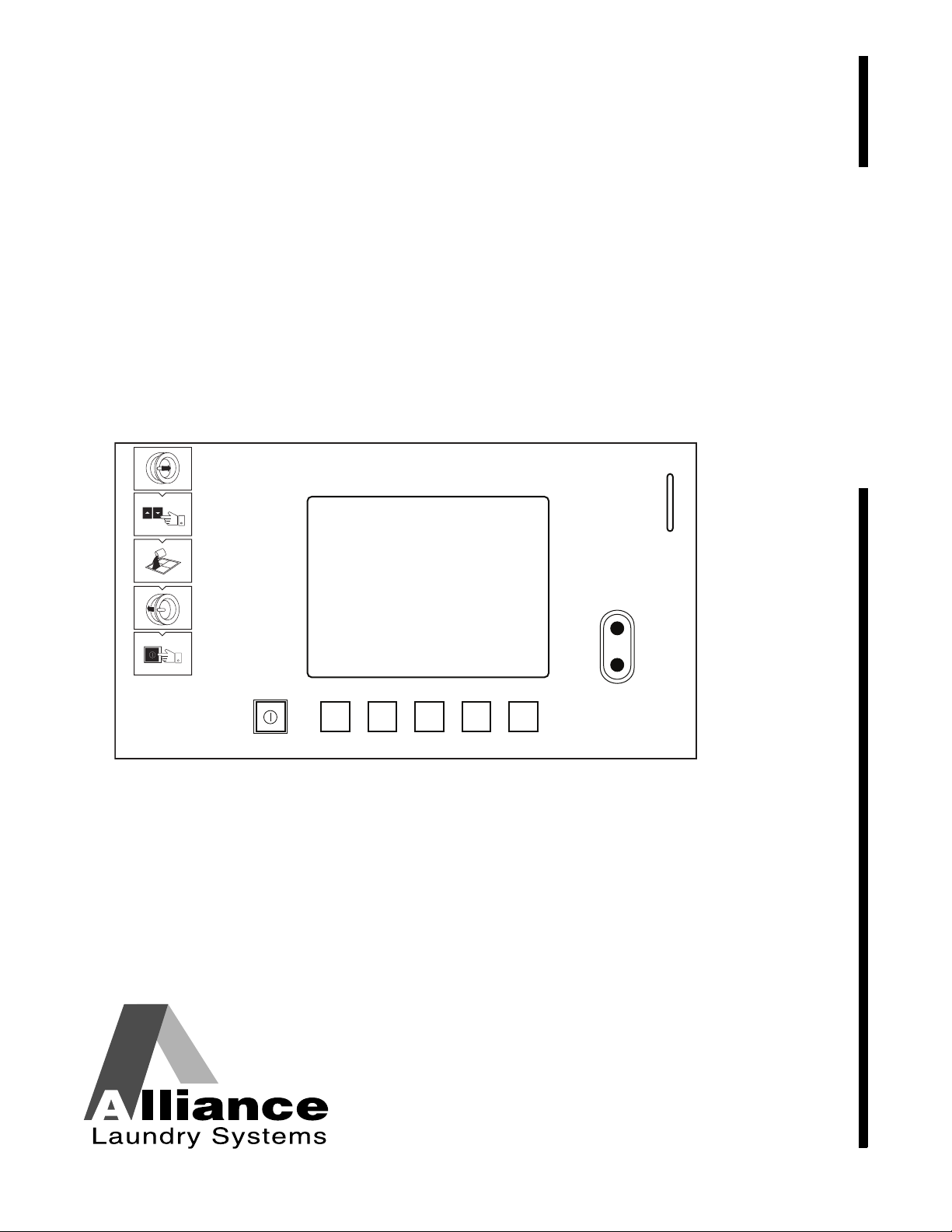

Washer-Extractor

CFD198R

CFD198R

Cygnus Professional

Refer to Page 3 for Model Numbers

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. D1353ENR1

September 2012

Page 2

Page 3

NOTE: The WARNING and IMPORTANT

Failure to install, maintain, and/or operate

this machine according to the

manufacturer's instructions may result in

conditions which can produce bodily injury

and/or property damage.

W030

WARNING

instructions appearing in this manual are not meant

to cover all possible conditions and situations that

may occur. It must be understood that common

sense, caution, and carefulness are factors which

cannot be built into these washer-extractors. These

factors MUST BE supplied by the person(s)

installing, maintaining, or operating the washerextractor.

Always contact the distributor, service agent, or the

manufacturer about any problems or conditions you do

not understand.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Table of

Contents

Model Identification ........................................................................... 3

Preliminary Information.................................................................... 6

About the Control ................................................................................. 6

Glossary of Terms................................................................................. 6

Power Failure Recovery ....................................................................... 6

Communications ................................................................................... 6

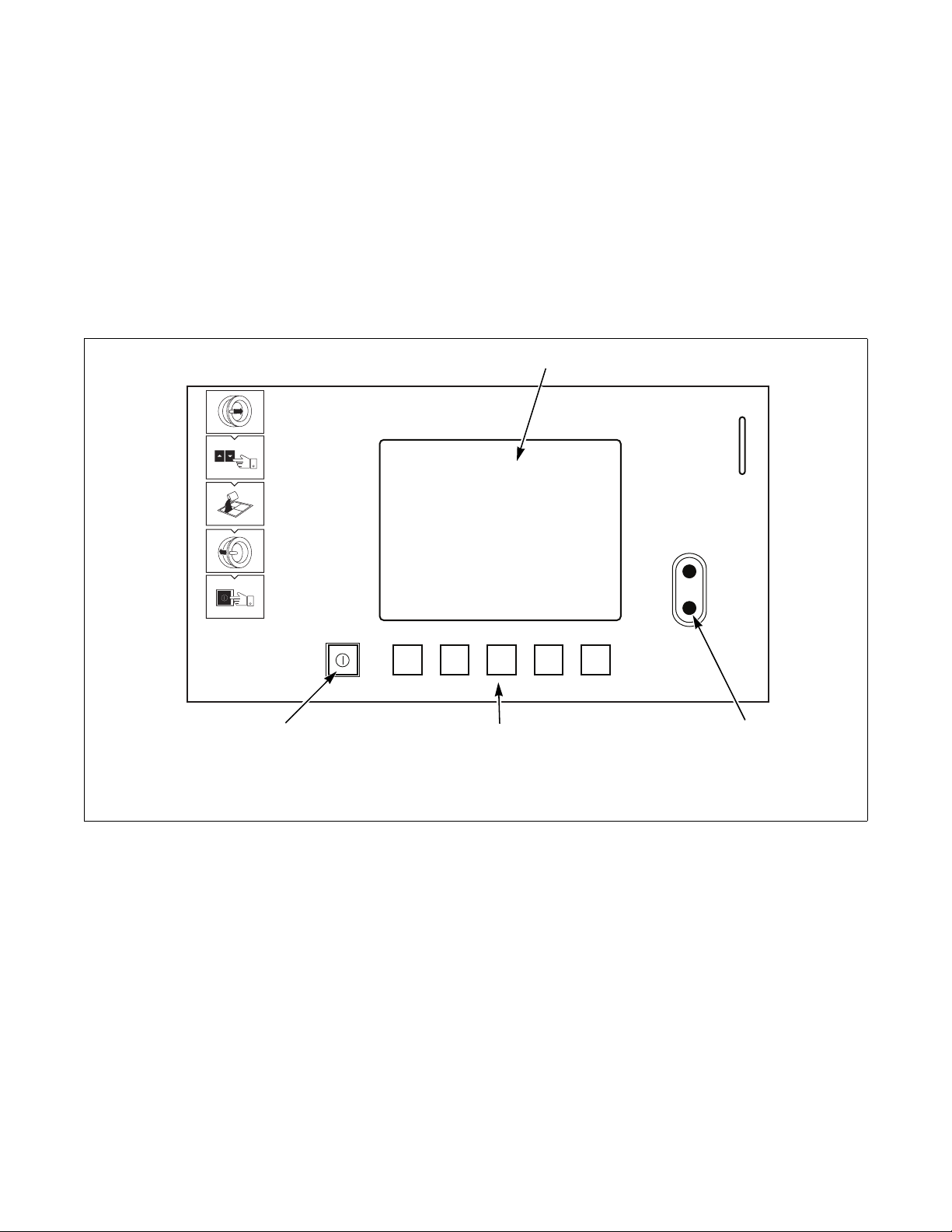

Control Identification......................................................................... 7

Selection Keypads ................................................................................ 7

Display Identification ......................................................................... 8

Cycle Screen ......................................................................................... 8

Special Features .................................................................................. 11

Programming Control ........................................................................... 11

Viewing Control Information ............................................................... 11

Testing Machine Components .............................................................. 11

Rapid Advance Feature......................................................................... 11

Communication Mode .......................................................................... 11

Washer-Extractor Operation ............................................................ 12

Start Up................................................................................................. 12

Start Mode ............................................................................................ 12

Run Mode ............................................................................................. 12

Stop Mode............................................................................................. 12

End of Cycle Mode............................................................................... 12

The Non-Active Menu ........................................................................ 13

What is Available in the Non-Active Menu? ....................................... 13

Non-Active Menu Navigation.......................................................... 14

Non-Active Menu Options ................................................................... 16

1. Logbook Sub-Menu ..................................................................... 16

2. Info Sub-Menu ............................................................................. 17

3. Advanced Functions Sub-Menu................................................... 20

3.1 Test Menu .................................................................................. 21

3.2 Edit Menu................................................................................... 28

3.3 Edit Menu Subroutine ................................................................ 34

3.4 Data Transfer Menu ................................................................... 35

3.5 Settings Menu ............................................................................ 44

Error Messages ................................................................................... 50

Events................................................................................................... 53

Rapid Advance Feature...................................................................... 55

How to Use Rapid Advance............................................................. 55

Communication Mode........................................................................ 56

Infra-red Communications.................................................................... 56

© Copyright 2012, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 5

Model Identification

Information in this manual is applicable to these

washer-extractor models:

CHF455

CHF575

CHF730

CHG065Z

CHG075Z

CHG100Z

CHG135Z

CHG150Z

CHG165Z

CHG185Z

CHG235Z

CHG305Z

CHG400Z

CHN065Z

CHN075Z

CHN100Z

CHN135Z

CHW065Z

CHW075Z

CHW100Z

CHW135Z

CHW150Z

CHW165Z

CHW185Z

CHW235Z

CHW305Z

CHW400Z

CHZ065Z

CHZ075Z

CHZ100Z

CHZ135Z

CHZ150Z

CHZ165Z

CHZ185Z

CXN165Z

CXN235Z

CXN305Z

CXU060Z

CXU065Z

CXU075Z

CXU100Z

CXU135Z

CXU165Z

CXU235Z

CXU305Z

CXW060Z

CXW065Z

CXW075Z

CXW100Z

CXW135Z

CXW165Z

CHN150Z

CHN165Z

CHN185Z

CHN235Z

CHN305Z

CHN400Z

CHU065Z

CHU075Z

CHU100Z

CHU135Z

CHU150Z

CHU165Z

CHU185Z

CHU235Z

CHU305Z

CHU400Z

CHZ235Z

CHZ305Z

CHZ400Z

CXG060Z

CXG065Z

CXG075Z

CXG100Z

CXG135Z

CXG165Z

CXG235Z

CXG305Z

CXN060Z

CXN065Z

CXN075Z

CXN100Z

CXN135Z

CXW235Z

CXW305Z

CXZ060Z

CXZ065Z

CXZ075Z

CXZ100Z

CXZ135Z

CXZ165Z

CXZ235Z

CXZ305Z

HD100_CYGNUS-PRO

HD135_CYGNUS-PRO

HD165_CYGNUS-PRO

HD235_CYGNUS-PRO

HD305_CYGNUS-PRO

HD60_CYGNUS-PRO

(Continued)

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Model Identification

HD65_CYGNUS-PRO

IHU185Z

(Continued)

XN100Z

HD75_CYGNUS-PRO

HF455_CYGNUS-PRO_OPL

HF575_CYGNUS-PRO_OPL

HF730_CYGNUS-PRO_OPL

HF900_CYGNUS-PRO_OPL

IHF455

IHF575

IHF730

IHG065Z

IHG075Z

IHG100Z

IHG135Z

IHG150Z

IHG165Z

IHG185Z

IHG235Z

IHG305Z

IHU235Z

IHU305Z

IHU400Z

IHW065Z

IHW075Z

IHW100Z

IHW135Z

IHW150Z

IHW165Z

IHW185Z

IHW235Z

IHW305Z

IHW400Z

IHZ065Z

IHZ075Z

IHZ100Z

IHZ135Z

IXN135Z

IXN165Z

IXN235Z

IXN305Z

IXU060Z

IXU065Z

IXU075Z

IXU100Z

IXU135Z

IXU165Z

IXU235Z

IXU305Z

IXW060Z

IXW065Z

IXW075Z

IXW100Z

IXW135Z

IHG400Z

IHN065Z

IHN075Z

IHN100Z

IHN135Z

IHN150Z

IHN165Z

IHN185Z

IHN235Z

IHN305Z

IHN400Z

IHU065Z

IHU075Z

IHU100Z

IHU135Z

IHU150Z

IHU165Z

IHZ150Z

IHZ165Z

IHZ185Z

IHZ235Z

IHZ305Z

IHZ400Z

IXG060Z

IXG065Z

IXG075Z

IXG100Z

IXG135Z

IXG165Z

IXG235Z

IXG305Z

IXN060Z

IXN065Z

IXN075Z

IXW165Z

IXW235Z

IXW305Z

IXZ060Z

IXZ065Z

IXZ075Z

IXZ100Z

IXZ135Z

IXZ165Z

IXZ235Z

IXZ305Z

JHW065Z

JHW075Z

JHW100Z

JHW135Z

JHW150Z

JHW165Z

(Continued)

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 7

JHW185Z

JXW100Z

Model Identification

(Continued)

WD150_CYGNUS-PRO

JHW235Z

JHW305Z

JHW400Z

JXW060Z

JXW065Z

JXW075Z

JXW135Z

JXW165Z

JXW235Z

JXW305Z

WD100_CYGNUS-PRO

WD135_CYGNUS-PRO

WD165_CYGNUS-PRO

WD185_CYGNUS-PRO

WD235_CYGNUS-PRO

WD400_CYGNUS-PRO

WD65_CYGNUS-PRO

WD75_CYGNUS-PRO

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Preliminary Information

About the Control

This control is an advanced, programmable computer

that lets the operator control machine features by

pressing a sequence of keypads. Refer to Figure 1.

The control allows the operator to obtain information

from the machine, run test cycles, modify the control’s

programmable features, set the service counters and

view the error code history. Refer to The Non-Active

Menu section for a list of features.

IMPORTANT: In the event of a power failure, the

control will not have to be reprogrammed. It is

designed with a memory system that will remember

how it was programmed until the electrical power

is restored.

IMPORTANT: It is extremely important that the

washer-extractor has a good ground connection and

that all mechanical and electrical connections to the

control are made before applying power to or

operating the washer-extractor.

Glossary of Terms

Communications

The control may be programmed manually or by infrared communication with an external device.

Infra-red Communications

A PC allows the owner to program and retrieve

information from the control without using the

machine’s keypad, which greatly expands the

programming options available to the owner. However,

it is not required to program and operate the washerextractor. The operation of a PC and the advanced

features available are covered separately in the

instructions included with the PC programming

software, Cygnus Assist.

The following are a few terms and abbreviations to

learn. These are referred to throughout the instructions.

Display – This term refers to the window area of the

control that displays words and values.

Power Failure Recovery

If a cycle is in progress and the power fails, the water

will be drained from the machine and the door can be

opened after approximately 3 minutes. If the door is not

opened and the power failure is shorter than 2 weeks,

the washer-extractor will resume the previously active

cycle.

If the door is opened or if the length of the power failure

is longer than 2 weeks, the control will end the cycle

and the display will revert back to Start Mode.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 9

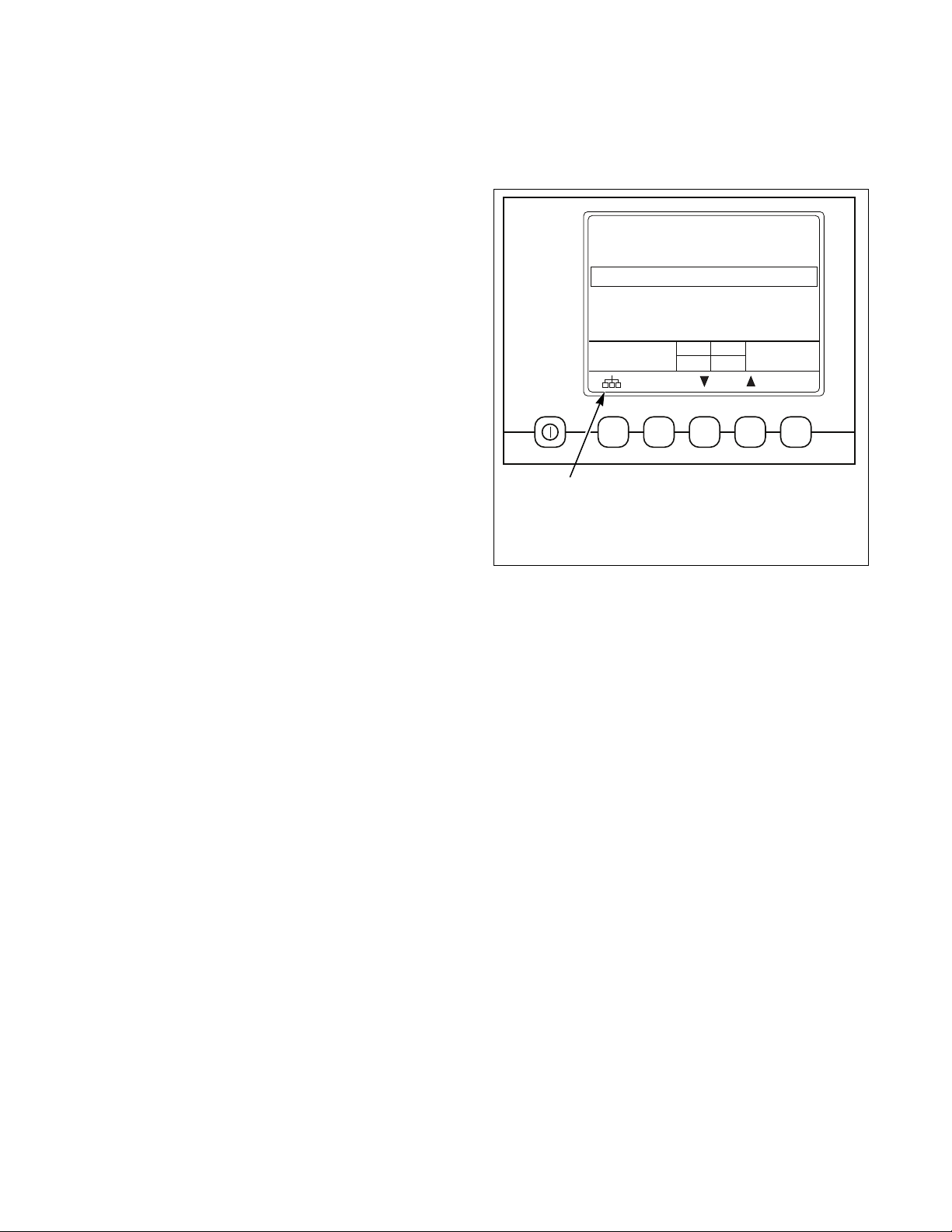

Control Identification

1

3

2

4

Selection Keypads

(Refer to Figure 1)

The Selection keypads are used in various combinations

to obtain information from the machine, run wash

cycles, run test cycles, modify the control’s

programmable features, set the service counters and

view the error code history. These instructions cover

the manual programming and data retrieval options.

1 Display 3 Selection keypads

2 Optical Download Window 4 Start/Stop keypad

Figure 1

CFD198R

CFD198R

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Display Identification

CFD936R

Hot wash 30°-90°C

40 °C

26.0cm

27°C

1h 09

1

2

3

4

5

6

7

8

9

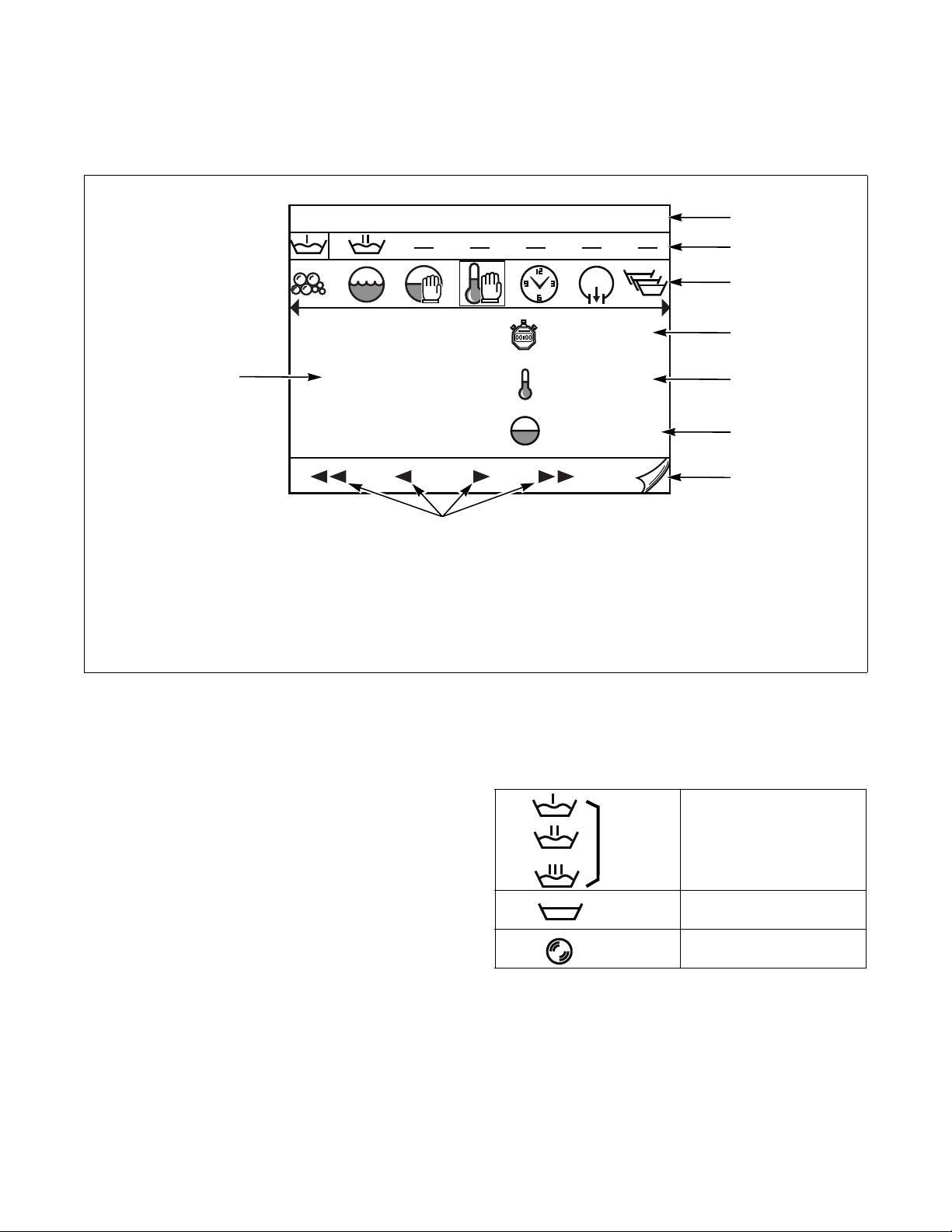

Cycle Screen

1 Title Bar 6 Water Level

2 Cycle Phase Bar 7 Next Screen

3 Step Bar 8 Navigation

4 Cycle Time Remaining 9 Info

5 Water Temperature

CFD936R

Title Bar (Refer to Figure 2, Item 1)

Displays the cycle.

Figure 2

Cycle Phase Bar (Refer to Figure 2, Item 2)

Displays how the various phases of the cycle are

progressing. The active phase is highlighted.

CFD203R

CFD202R

CFD201R

CFD204R

CFD205R

Wash C y cl e

Rinse Cycle

Spin Cycle

Ta bl e 1

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 11

Display Identification

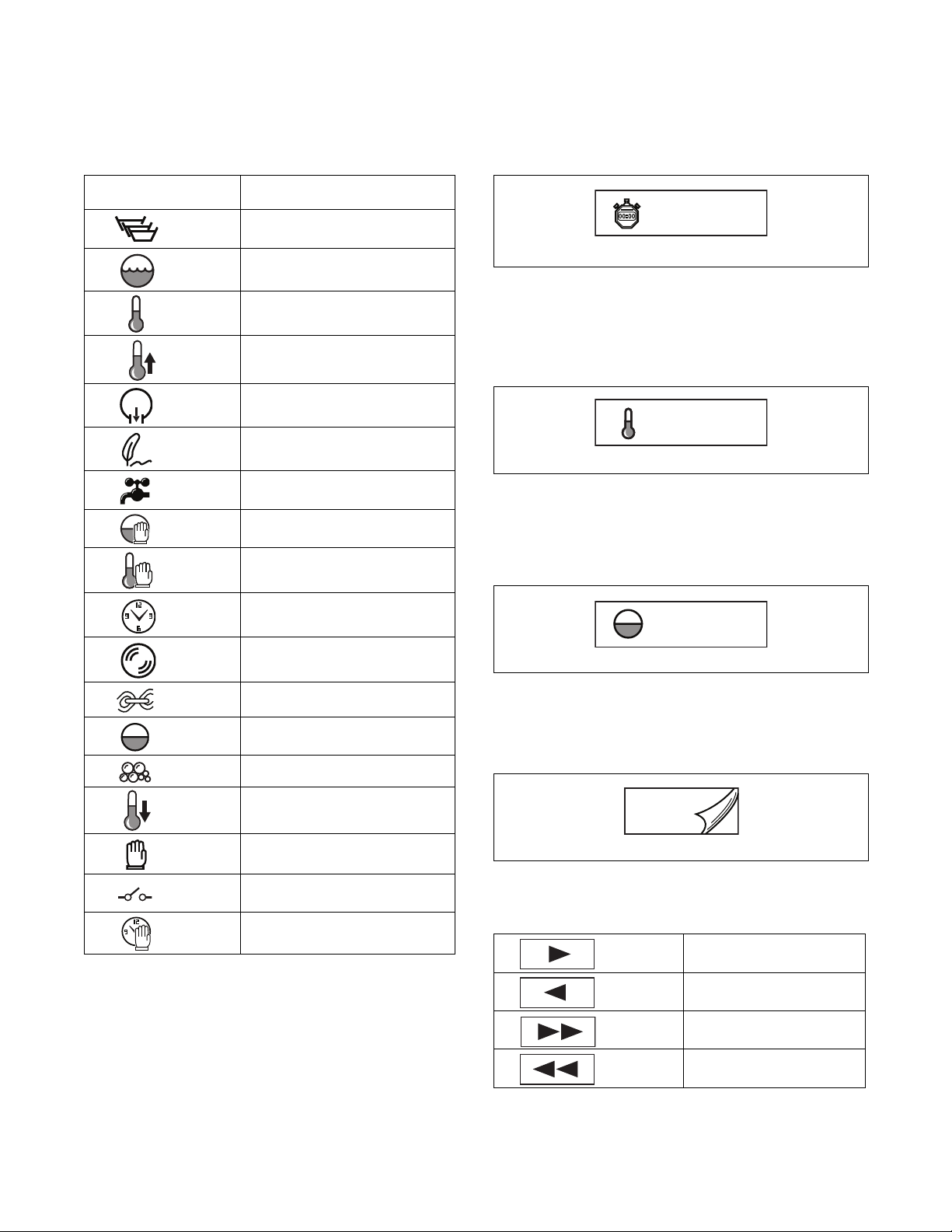

Step Bar (Refer to Figure 2, Item 3)

Displays the phase components. The active component

appears in the selection box.

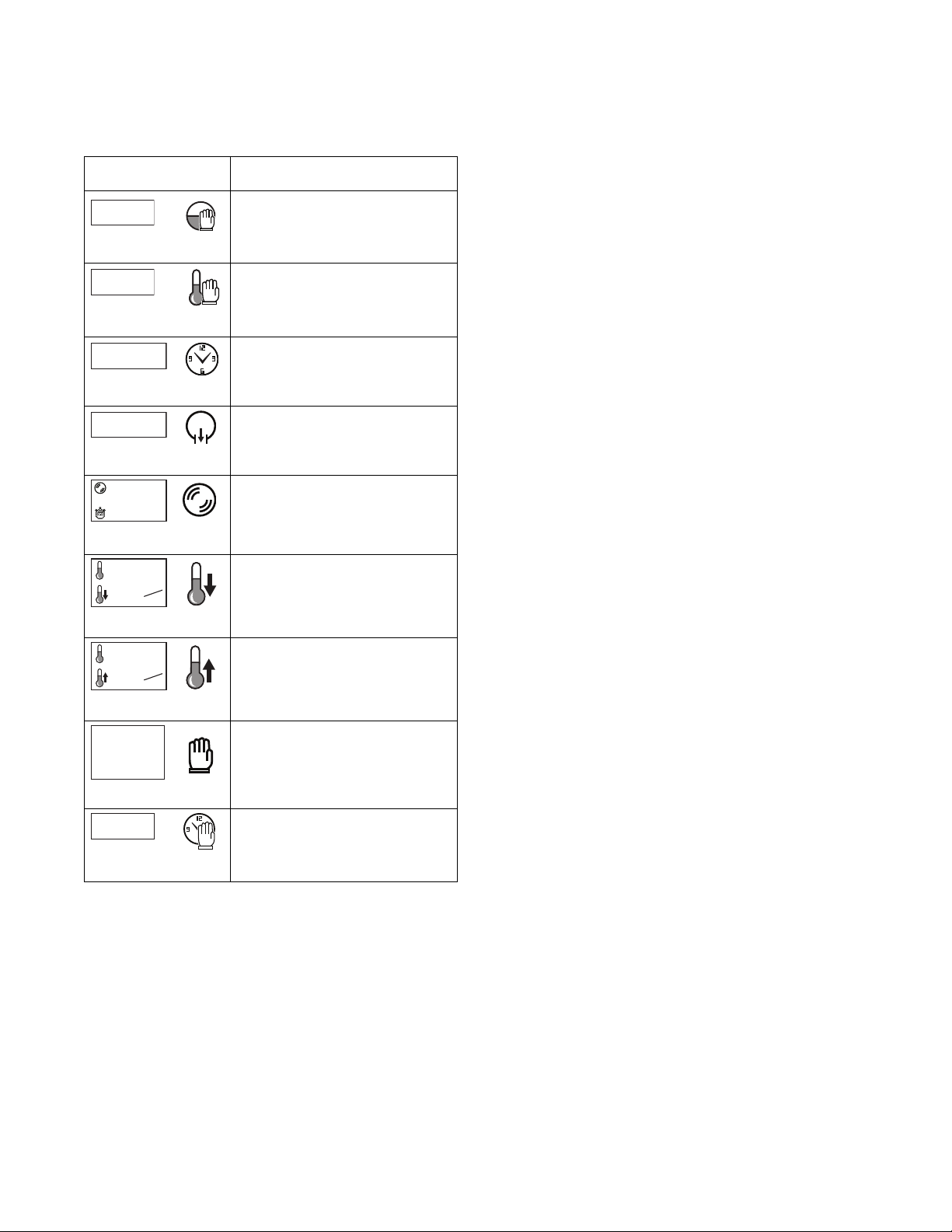

Symbol Description

CFD206R

CFD207R

CFD208R

CFD209R

CFD210R

CFD211R

CFD213R

CFD214R

CFD215R

Wash Phas e

Wash Action

Heating

Controlled Heating

Drain

Label

Water Inlet

Water Level Time Stop

Heating Time Stop

Cycle Time Remaining

(Refer to Figure 2, Item 4)

Displays the remaining program time.

1h 27

CFD226R

Figure 3

Water Temperature (Refer to Figure 2, Item 5)

Displays the temperature of the water. This symbol is

flashing when heating is activated.

13°C

CFD227R

Figure 4

Water Level (Refer to Figure 2, Item 6)

Displays the water level in the wash tub. This symbol

is flashing when machine is filling.

CFD216R

CFD217R

CFD218R

CFD219R

CFD220R

CFD221R

CFD222R

CFD224R

CFD224R

Time

Spin

Subroutine

Water Level

Soap Inlet

Cool Down

Hold

Relay Contact

Predefined Start

Tab le 2

23.0cm

CFD228R

Figure 5

Next Screen (Refer to Figure 2, Item 7)

View the next screen.

CFD426R

Figure 6

Proceed - Return (Refer to Figure 2, Item 8)

Go to the next component.

CFD261R

Restart the current phase.

CFD423R

Start the next phase.

CFD424R

Resume the previous or first

CFD425R

phase.

Ta bl e 3

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Display Identification

1

500

min

rpm

00

40 °C

2.0

°C

min

40 °C

2.0

°C

min

1h59

Explanation

Explanation

Explanation

8:00

Info (Refer to Figure 2, Item 9)

Displays information on the active component:

Symbol Description

15 cm

CFD229R CFD214R

Level Stop: Target level is

displayed.

40 °C

CFD230R CFD215R

12min25

CFD231R CFD216R

1

CFD232R CFD210R

CFD233R CFD217R

CFD234R CFD221R

CFD235R CFD209R

Heat Stop: Target temperature.

Time: Time remaining.

Drain: Selected drain.

Spin: Set spin speed and remaining

spin time.

Cool-down: Target temperature

and drop in temperature per minute.

Controlled Heating: Ta rget

temperature and rise in temperature

per minute.

CFD236R CFD222R

CFD237R CFD224R

Waiting: Remaining waiting time

and self-composed comment.

Predefined Start: Time at which

the program will start or resume.

Tab le 4

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 13

Special Features

Programming Control

The control allows the washer-extractor’s operator to

program the control with the use of the keypad.

For details on programming select cycle options, refer to

the Advanced Functions Sub-menu section.

Viewing Control Information

The control will store information in its memory that

can be retrieved by pressing various combinations of

keypads. The control will record machine cycles and

hours of operation.

For more information, refer to the Logbook Sub-menu

section.

Testing Machine Components

By entering the Non-Active Menu’s Test Menu under

the Advanced Functions Sub-menu, the operator may

perform the following tests:

• Water Level Test

• Water Inlet Test

• Motor Test

• Temperature Sensor Test and Calibration

• Water Outlet Valve or Drain Pump Test

• Expansion Relay Test

• Rotation Sensor Door Lock and Out-Of-Balance

Switch Test

Rapid Advance Feature

This feature allows the operator to manually advance

through an active cycle. This feature is useful when

tests must be performed immediately on a washerextractor currently in an active cycle.

For detailed information on using the Rapid Advance

feature, refer to the Rapid Advance Feature section.

Communication Mode

This feature allows the control to communicate with a

PC equipped with the Cygnus Assist software using

infra-red communication. This allows the control to be

programmed and have its data read without using the

machine’s keypad.

For more detailed information on using the

Communication Mode feature, refer to the

Communication Mode section.

For detailed information, refer to the Test Menu

section under the Advanced Functions Sub-menu.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Washer-Extractor Operation

Start Up

When power is applied to the washer-extractor, if the

control was not powered down during a running cycle,

it will enter Start Mode.

Start Mode

The control enters this mode when the machine is ready

for operation. The display will show the available

cycles.

After pressing the Start/Stop keypad with the door

closed and locked, the cycle will begin.

Run Mode

Upon the start of a cycle, the control displays detailed

information about the cycle and current phase.

Stop Mode

The control enters this mode if the operator ends the

cycle before it is completed by pressing the Start/Stop

keypad. Once the control does not detect water or

cylinder rotation, it will enter End of Cycle mode.

End of Cycle Mode

When a cycle is complete, the control will display

“End” until the door is opened. When the door is

opened, the control will return to Start Mode.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 15

The Non-Active Menu

1

What is Available in the Non-Active

Menu?

The Non-Active menu can be used to obtain

information from the machine, run test cycles, modify

the control’s programmable features, set the service

counters and view the error code history.

NOTE: To enter the Non-Active Menu, a cycle must

not be in process.

To enter the Non-Active Menu, press and hold the

keypad below the Menu icon.

Normal wash 40º-40ºC

War m wash 30º-60ºC

Hot wash 30º-90ºC

Delicate 30ºC

Synthetic 1 40ºC

1h00

CFD937R

CFD937R

1

Menu

Figure 7

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

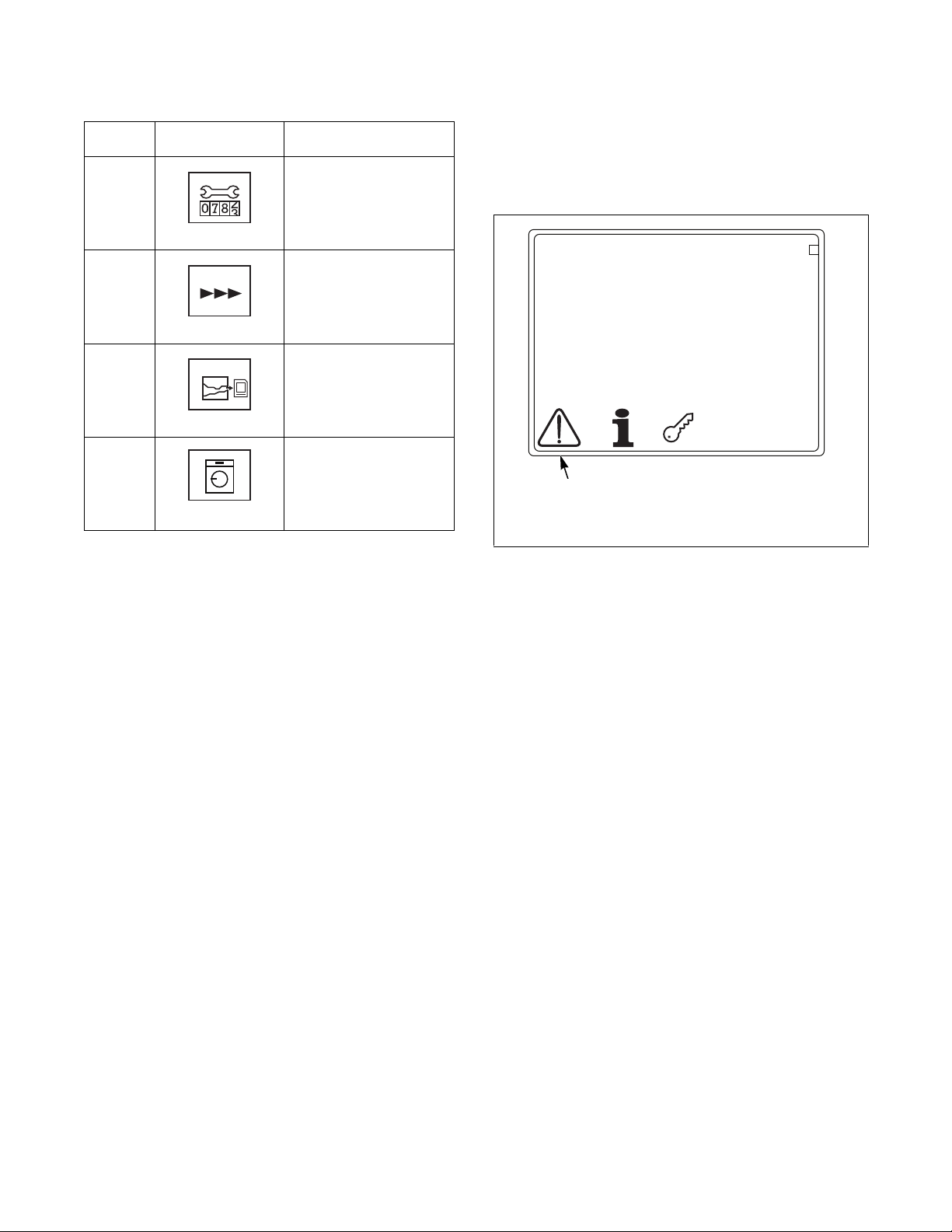

The Non-Active Menu

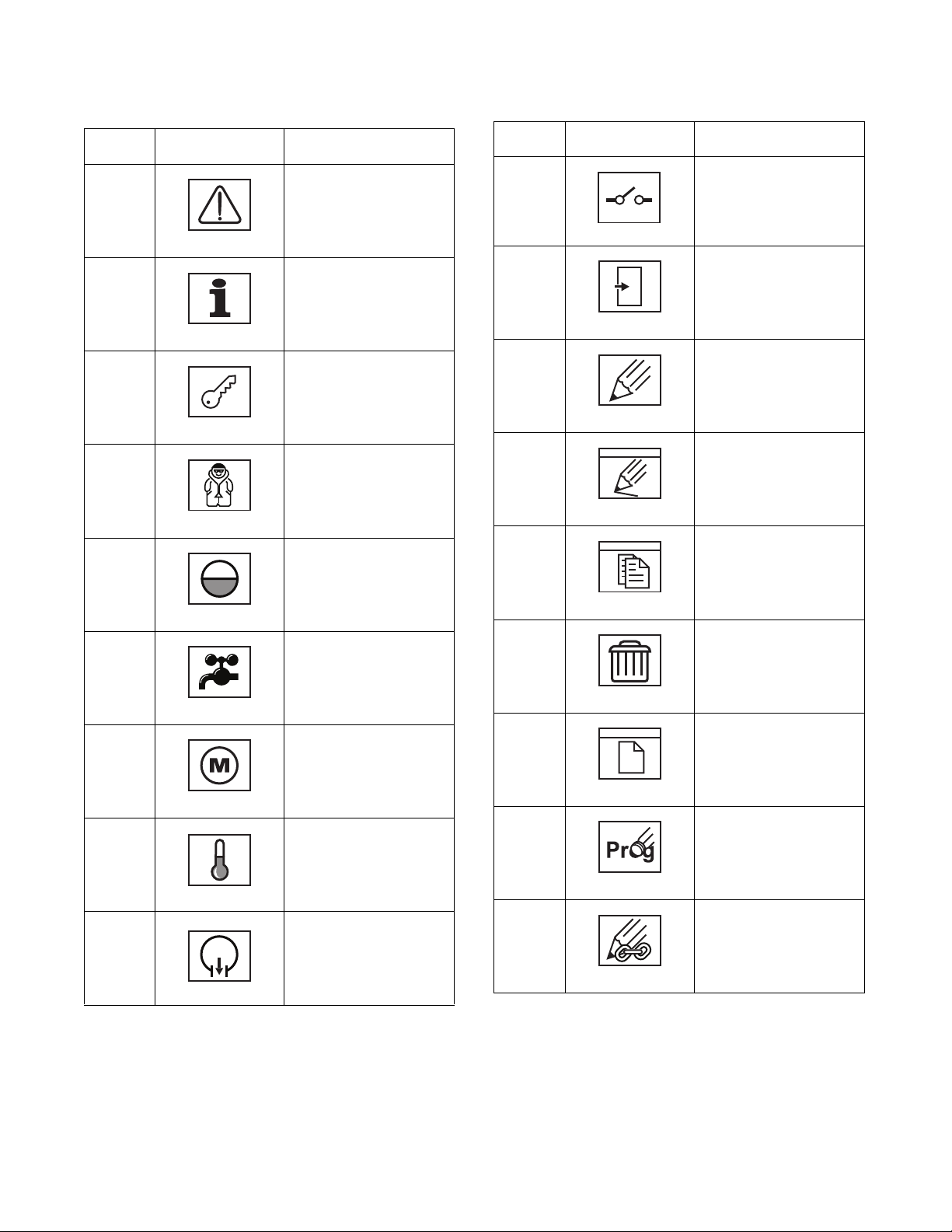

Non-Active Menu Navigation

Option

Number

1

2

3

a.

i.

Option

Icon

CFD272R

CFD275R

CDF284R

CFD293R

Logbook Sub-Menu:

displays information

about cycles that have

been run.

Info Sub-Menu: displays

technical information

about the machine,

configurations and cycle

programs.

Advanced Functions

Sub-Menu: run test

program, create or edit

cycle programs.

Tes t Me nu : test operation

of certain electrical

components

Water Level Sensor: set

0 level and calibrate

Description

Option

Number

vii.

b.

vi.

ii.

(Continued Table 5)

Option

Icon

Description

Expansion Relay:

activate the (optional)

expansion relay

CFD327R

Inputs: test inputs

CFD329R

Edit Menu: create, edit,

copy or delete cycle

programs

CFD333R

Edit Program

i.

CFD335R

Copy Program

ii.

iii.

iv.

CFD296R

Water Inlet Valves:

activate valves

CFD300R

iii.

Motor: test motor and

frequency inverter

CFD308R

iv.

Temperature Sensor:

test sensor

CFD319R

v.

Water Outlet Valve or

Pump: test operation and

v.

CFD323R

seal of valves or pump

c.

(Continued Table 5)

CFD336R

Delete Program

CFD337R

Create Program

CFD338R

Modify Program Title

CFD339R

Edit Menu Subroutine:

create, edit, copy or delete

subroutines

CFD376R

(Continued Table 5)

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 17

The Non-Active Menu

Option

Number

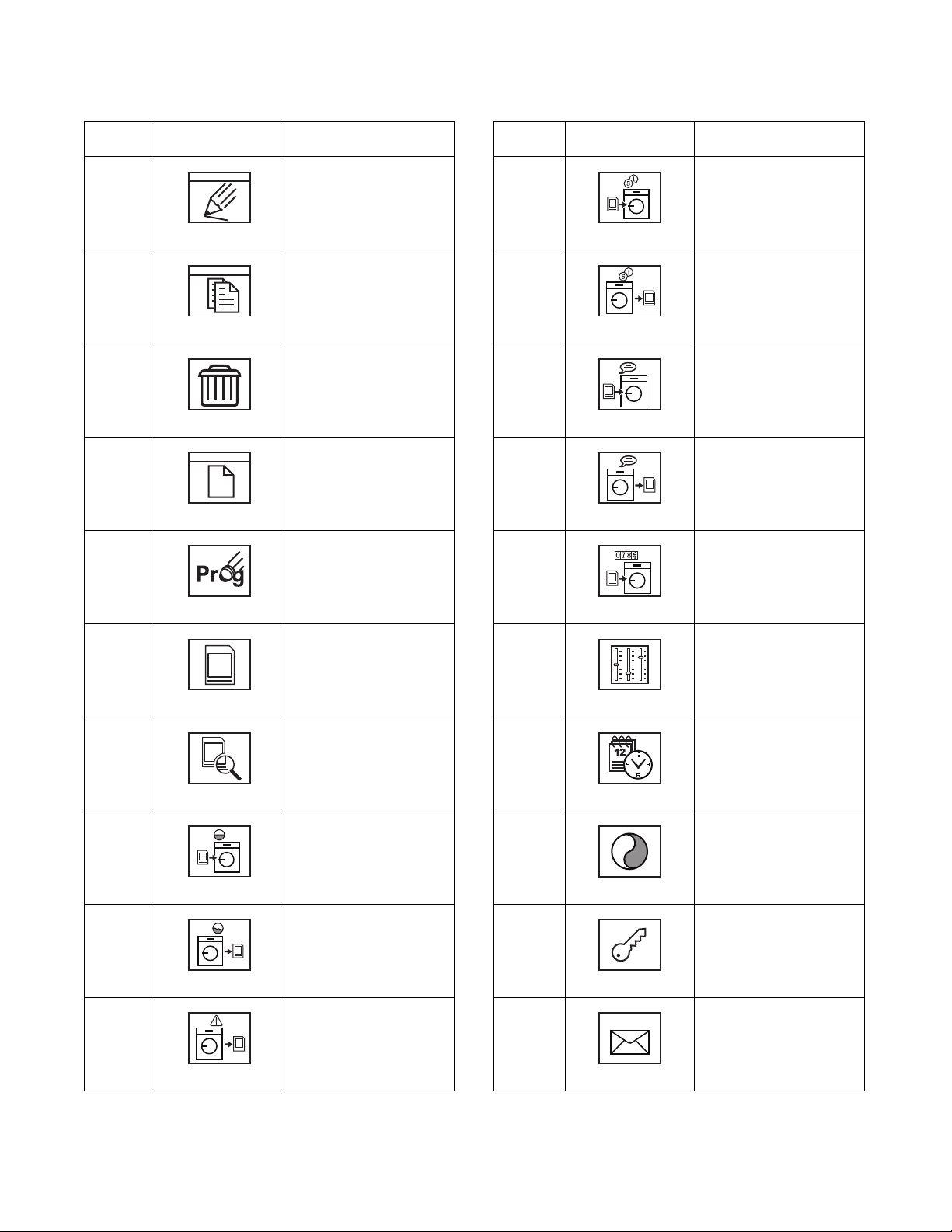

d.

iii

iv.

(Continued Table 5)

Option

Icon

Edit Subroutine

Description

Option

Number

(Continued Table 5)

Option

Icon

Upload Price and Time

Description

File to Machine: load

i.

CFD385R

v.

CFD398R

Copy Subroutine

price and time file

Download Price and

Time File from

ii

vi.

Machine: write price and

time files to data card

CFD386R

Delete Subroutine

CFD401R

Upload Help File to

Machine: load help file to

machine

Download Help File

CFD387R

vii.

CFD402R

Create Subroutine

from Machine: write help

file to data card

Upload Firmware

CFD338R

viii.

CFD403R

Modify Subroutine Title

(*.csp) to Machine: load

v.

ix.

firmware and updates to

machine

CFD339R

Data Transfer Menu:

upload software or

download data from the

e.

CFD404R

Setting Menu: edit user

settings

machine using a data card

CFD379R

Content of Data Card:

CFD405R

Date and Time

read content of data card

i.

i.

D1353 (EN)

ii.

iii.

iv.

CFD385R

Upload Wash Data to

Machine: load cycle

programs to machine

CFD392R

Download Wash Data

form Machine: write

cycle programs to data

card

CFD395R

Download Logbook

from Machine: write

logbook contents to data

card

CFD397R

(Continued Table 5)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD408R

Display: contrast

ii.

CFD410R

Password/Access Code:

change access code

iii.

CFD284R

Address: set network

address number

iv.

CFD413R

(Continued Table 5)

15

Page 18

The Non-Active Menu

12oC

20

10

0

CFD271R

2

1

Option

Number

vii.

viii.

vi.

(Continued Table 5)

Option

Icon

Description

Maintenance Counters:

set maintenance warning

v.

CFD415R

times

Non-Active Menu Options

1. Logbook Sub-Menu

The Logbook Sub-Menu allows the operator to view

information about cycles that have been run.

Advance: activate/

deactivate rapid advance

CFD419R

History Overview

(graph): write to a data

card

CFD420R

Put Out of Order:

disable machine

CFD271R

CFD421R

1 Logbook Sub-Menu

Tab le 5

Figure 8

To access the Logbook Sub-Menu, press the keypad

below the Logbook Sub-Menu icon. Refer to Figure 8.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 19

CFD935R

CFD935R

?

Time Date Event Prog

15:46

15:46

15:43

15:43

15:41

15:41

15:40

15:40

15:38

10/09

10/09

10/09

10/09

10/09

10/09

10/09

10/09

10/09

159

159

102

100

159

159

159

159

159

03

03

03

03

01

01

01

01

01

0001

0002

0003

0005

0006

0007

0008

0009

0010

007

Injector communication error

#

15:43 10/09 007 030004

2

1

7: Inverter communication error

Error during communication with

invertor:

- no communication / reaction from

the mainboard

- missing communication between

inverter and mainboard

- check connection and

wiring with inverter board

- check functioning inverter board

(art.209/02006/00)

CFD271R

2

1

1 Navigation

2 Call Info

Figure 9

The overview shows the history of a cycle program.

# Number of the event

Time: Time of the event

Date: Date of the event

Event: Indication of the specific event (see page 53)

The Non-Active Menu

2. Info Sub-Menu

The Info Sub-Menu allows the operator to view

technical information about the machine,

configurations and cycle programs.

CFD271R

1 Info Sub-menu

Figure 11

To access the Info Sub-Menu, press the keypad below

the Info Sub-Menu icon. Refer to Figure 11.

Prog: Program number

Select an action using the keypads below the

Navigation icons and press keypad below the Call Info

icon. Action details will be displayed.

Press the Start/Stop keypad to return.

D1353 (EN)

CFD938R

Figure 10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

The Non-Active Menu

CFD276R

Software

Package

Mainboard

Boot

Display

Boot

Washdata

Machine info

D. O. M.

D. O. I.

Type

Serial nr

Counters

Cycles

Hours

Freestanding

:

:

:

:

:

:

:

:

:

:

:

1/2007

0H6 (HC165)

1002

:

:

: yes

4987

48553

V 1 . 3 . 3

V 1 . 3 . 3

V 1 . 3 . 3

V 1 . 3 . 3

V 1 . 3 . 3

HC165 PROF 1-16 r e l a . cgs

*

18/02/2011, at 08:55

1/7

CFD276R

CFD277R

:

:

:

:

:

:

:

:

:

:

:

:

:

Configuration 1

Capacity

Diam tub

Depth tub

Diam drum

Level offset

Min level

Overflow level

Motor voltage

Motor power

Heat 1 : electric

Heat 2 : none

Min spin speed

Max spin speed

16.5 kg

710 mm

565 mm

650 mm

-90 mm

130 mm

405 mm

230 v

1500 v

( 10 kw )

250 rpm

1000 rpm

2/7

CFD277R

CFD278R

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Configuration 2

Max current

Stall prev wash

Stall prev jump

Stall prev spin

Max prev

Prev ratio

Prev offset

Stall ratio

Wash accel

Wash accel

Dist accel

Jump accel

Spin accel

Spin accel

Pulses/rev

6.5 A

140 A

63 A

68 A

165 Hz

15.00 Hz / 100 rpm

1.00 Hz

16.58 Hz / 100 rpm

5 s/50Hz

8 s/50Hz

40 s/50Hz

25 s/50Hz

0.75 Hz/g

40 s/50Hz

3

3/7

CFD278R

CFD279R

Hints : edited - measured

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

0.00

0.00

0.00

0.00

0.27

0.00

0.00

0.00

0.00

0.00

0.22

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

1:

2:

3:

4:

5:

6:

7:

8:

9:

10:

11:

12:

13:

14:

15:

16:

17:

18:

19:

20:

4/7

CFD279R

Screen 1/7:

Software version

Machine info (date of manufacture, serial number, etc.) and

counters

Press the keypads below the Navigation icon to view the next or previous

screen.

Press the Start/Stop keypad to return.

Screen 2/7:

Configuration 1

Machine configuration

Press the keypads below the Navigation icons to view the next or previous

screen.

Press the Start/Stop keypad to return.

Screen 3/7:

Configuration 2

Data relating to the frequency inverter.

Press the keypads below the Navigation icons to view the next or previous

screen.

Press the Start/Stop keypad to return.

Screen 4/7:

Edited and measured times of the cycle programs.

(Continued Table 6)

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 21

The Non-Active Menu

CFD280R

5/7

Hints : edited

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

21:

22:

23:

24:

25:

26:

27:

28:

29:

30:

31:

32:

33:

34:

35:

36:

37:

38:

39:

40:

CFD280R

CFD281R

6/7

Hints : edited

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

Prog

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

4:15

41:

42:

43:

44:

45:

46:

47:

48:

49:

40:

51:

52:

53:

54:

55:

56:

57:

58:

59:

60:

CFD281R

CFD282R

7/7

Weekly program counter

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

0

0

1

1

0

0

4

0

0

0

0

0

0

0

0

0

0

0

0

0

1:

2:

3:

4:

5:

6:

7:

8:

9:

0:

11:

12:

13:

14:

15:

16:

17:

18:

19:

20:

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

21:

22:

23:

24:

25:

26:

27:

28:

29:

30:

31:

32:

33:

34:

35:

36:

37:

38:

39:

40:

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

Pr

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

41:

42:

43:

44:

45:

46:

47:

48:

49:

50:

51:

52:

53:

54:

55:

56:

57:

58:

59:

60:

0

CFD282R

CFD283R

CFD283R

(Continued Table 6)

Screen 5/7:

Edited and measured times of the cycle programs (continued).

Screen 6/7:

Edited and measured times of the cycle programs (continued).

Screen 7/7:

Overview of the weekly counts per cycle (the number of times that each

cycle has been executed during the last 7 days).

Press the keypad below the 0 in order to reset the counters.

Press the keypad below the Check icon to confirm the reset, or press the

keypad below the X to cancel.

Tab le 6

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

The Non-Active Menu

CFD271R

2

1

1000_

3. Advanced Functions Sub-Menu

The Advanced Functions Sub-Menu allows the

operator to test machine components, create or edit a

cycle or modify the machine’s settings.

CFD271R

1 Advanced Functions Sub-Menu

Figure 12

To access the Advanced Functions Sub-Menu, press

the keypad below the Advanced Functions Sub-Menu,

icon. Refer to Figure 12.

“Advanced functions” Access Code Menu

The operator must have the security code to access

advanced functions.

Enter the password using the keypads below the

Navigation icons and press the keypad below the

Check icon to confirm.

CFD285R

Figure 13

The security code is 1000 by default.

The Advanced Functions Sub-Menu is now displayed.

Press the Start/Stop keypad to return.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 23

The Non-Active Menu

CFD292R

3

54321

CFD294R

4

54321

6

7 8 5

3.1 Test Menu

1 Test Menu

2 Edit Menu: Edit, copy or delete cycle

programs (see page 28).

3 Edit Menu Subroutine: Edit, copy or delete

subroutines (see page 34).

4 Data Transfer Menu: Upload software or

download data from the machine using a data

card (see page 35).

5 Settings Menu: Edit the user setting

(see page 44).

The Test Menu allows the operator to test the operation

of certain electrical components of the machine.

To access the Test Menu from the Advanced Functions

Sub-Menu, press the keypad below the corresponding

icon.

NOTE: Empty the drum completely before running

the test program.

CFD292R

Figure 14

5

CFD239R

CFD294R CFD939R

1 Water Level Sensor (see page 22) 5 Navigation

2 Water Inlet Valves (see page 22) 6 Water Outlet Valve or Pump (see page 25)

3 Motor (see page 23) 7 Expansion Relay (see page 25)

4 Temperature Sensor (see page 24) 8 Inputs (see page 26)

Figure 15

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

The Non-Active Menu

4

WATER LEVEL SENSOR

CFD297R

440

44.5 rpm

0.0 cm

0

CFD297R

CFD298R

440

4.0 cm

44.5 rpm

CFD298R

Measured

Level

Theoretical

Level

CFD299R

4

WATER INLET VALVES

HOT 1

CFD301R

CFD302R

CFD303R

CFD304R

CFD305R

CFD306R

CFD307R

Advanced Functions Sub-Menu/Test Menu/

Water Level Sensor

CFD294R

Figure 16

To access the Water Level Sensor display, from the

Test Menu, press the keypad below the corresponding

icon. Refer to Figure 16.

Allows the operator to set the zero level and calibrate

the water level sensor.

Setting the Zero Level

Make sure all the water has been

emptied.

If necessary, stop the power to the

machine for a few minutes.

Then press the keypad below the 0

to establish the “zero level”.

Calibrating the Sensor

To do this, first place a marker in

the middle of the door window.

Then press the keypad below the

Water Inlet icon to fill the

machine. Press the keypad again

to stop filling when the water

reaches the marker.

Compare the measured level

against the theoretical level and, if

44.5 rpm

44.5 cm

necessary, adjust the measured

439

value using the keypads below the

Navigation icons and confirm by

presing the keypad below the

Check icon.

CFD299R

Press the Start/Stop keypad to exit

this test.

Tab le 7

Advanced Functions Sub-Menu/Test Menu/

Water Inlet Valves

CFD294R

Figure 17

To access the Water Inlet Valves display, from the Test

Menu, press the keypad below the corresponding icon.

Refer to Figure 17.

Allows the operator to activate the water inlet valves.

Use the keypads below the

Navigation icons to select one

or more valves and press the

keypad below the Check icon

to activate the selected valve.

Press the Start/Stop keypad to

exit this test.

Hot water - pre-wash

compartment

Hot water - softener

compartment

Hot water - main wash

compartment

Cold water - pre-wash

compartment

Cold water - bleach

compartment

Cold water - main wash

compartment

22

Ta bl e 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 25

The Non-Active Menu

4

MOTOR

0

rpm

frequency : 0.00 Hz

current : 0.00 A

voltage : 0.0 V

FR D720

0.4 KW

1 2

3

CFD310R

44

rpm

frequentie: 6.35 Hz

current : 3.13 A

CFD310R

CFD311R

45

rpm

frequentie : 6.50 Hz

current : 3.11 A

on / off : 90/350 msec (20%)

CFD311R

CFD312R

CFD313R

Spin

Speed

Spin

Time

CFD315R

306

rpm

CFD315R

Advanced Functions Sub-Menu/Test Menu/

Motor

CFD294R

Figure 18

To access the Motor display, from the Test Menu, press

the keypad below the corresponding icon. Refer to

Figure 18.

Allows the operator to test the operation of the motor

and frequency inverter.

Checking the wash speed

Checking the spin speed

265

rpm

500

rpm

ratio : 1443

27.8g _ 40.50Hz _ 2.92A

500

rpm

500

rpm

ratio : 1418

90.6g _ 70.90Hz _ 2.09AA

1

0

Press the keypad below the Wash

icon (refer to Figure 14) to bring

the drum up to wash speed.

Press the keypad below the

Rotation icon (as shown).

The system will display the time it

takes the rotation sensor to detect

a spoke of the belt pulley.

on = detect

off = do not detect

The system also displays the

detection ratio as a percentage.

Press the keypad below the Spin

Speed icon (refer to Figure 19) to

bring the drum to a spin speed of

500 rpm.

mm56

If the machine has a maximum

spin speed of less than 500 rpm,

CFD312R

this number will be rounded down

to the nearest lower one hundred.

Once the drum has spun for a few

seconds at 500 rpm (to measure

the revolution frequency ratio),

press the keypad below the left

mm07

Up/Down icons to increase the

spin speed (depending on the

machine type).

CFD313R

Press the keypads below the right

Up/Down icons to adjust the spin

time, if necessary.

Once the spin time has passed, the

drum will slow down and the spin

speed will be displayed.

D1353 (EN)

1 Wash

2 Spin Speed

3 Inverter

(Continued Table 9)

Figure 19

CFD940R

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

The Non-Active Menu

CFD317R

Resetting invertor...

CFD317R

CFD318R

Auto tuning in progress...

CFD318R

4

TEMPERATURE SENSOR

CFD320R

21 oC

100%

CFD320R

CFD321R

CFD322R

(Continued Table 9)

Tuning the frequency invertor to the motor

This will need to be performed

every time a new motor or

frequency invertor is fitted.

Press the keypad below the

Inverter icon to start the

adjustment. Refer to Figure 19.

The frequency invertor is first

reset (Resetting invertor...), then

the motor and invertor are tuned

(Auto tuning in progress...).

Press the Start/Stop keypad to exit

the motor test.

Table 9

Advanced Functions Sub-Menu/Test Menu/

Temperature Sensor

CFD294R

Figure 20

To access the Temperature Sensor display, from the

Test Menu, press the keypad below the corresponding

icon. Refer to Figure 20.

Allows the operator to test the operation of the

temperature sensor.

Press the keypad below the

Water Inlet icon (as shown) to

start the test.

The temperature measured by

the sensor is displayed.

Water will fill until it reaches

the safety level.

19 oC

100%

The Heat icon will appear (as

shown).

CFD321R

Press the keypad below the Heat

icon to switch the heating

elements on or off.

30 oC

While the heating elements are

100%

on, the temperature will reach a

maximum of 90°C.

CFD322R

Press the Start/Stop keypad to

exit this test.

Table 10

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 27

The Non-Active Menu

WATER INLET VALVES

5

WATER OUTLET VALVE OR PUMP

CFD324R

0.0 cm

1 2

CFD324R

CFD325R

CFD326R

22.5 cm

1 2

CFD326R

WATER INLET VALVES

5

EXPANSION RELAY

O Clax Activ

O Clax Star

O Eco Star

O Eco Break

O Flashing lig

O Horn

O Lanadol

O Clip Combi

O Viva Deo Plu

O Potan Ole

O Recy. Pump

O No function

O No function

Advanced Functions Sub-Menu/Test Menu/

Water Outlet Valve or Drain Pump

CFD939R

Figure 21

To access the Water Outlet Valve or Drain Pump

display, from the Test Menu, press the keypad below

the corresponding icon. Refer to Figure 21.

Allows the operator to test the operation and seal of the

outlet valves or pump.

Advanced Functions Sub-Menu/Test Menu/

Expansion Relay

CFD939R

Figure 22

To access the Expansion Relay display, from the Test

Menu, press the keypad below the corresponding icon.

Refer to Figure 22.

Allows the operator to activate the (optional)

expansion relay.

11.5 cm

1 2

The water level is displayed.

Press the keypad below the

Water Inlet (as shown) icon to

fill the tub.

Press again to stop filling.

CFD326R

Press the keypad below the 1 or

2 (option) to allow the tub to

empty (drain symbol appears).

Press this keypad again to stop

the tub from emptying.

Press the Start/Stop keypad to

exit the outlet test.

Table 11

CFD328R

Figure 23

Use the keypads below the Navigation icons to select

one or more expansion relays and activate each one

using the keypad below the Checkbox icon. Refer to

Figure 23.

Press the Start/Stop keypad to exit the relay test.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

The Non-Active Menu

5

INPUTS

rotation:

tilt:

door:

lock:

1

3 6

2

5

4

CLOSED

OPEN

Advanced Functions Sub-Menu/Test Menu/

Inputs

CFD939R

Figure 24

To access the Inputs display, from the Test Menu, press

the keypad below the corresponding icon. Refer to

Figure 24.

Allows the operator to test the inputs.

An input contact is displayed as open or closed,

depending on its current status. Refer to Figure 26.

CFD331R

Figure 26

Test the inputs

1. Door closed input: while observing the Door

Relay display (refer to Figure 25), open and close

the machine’s door. The Door Relay display

should change from close to open as the door is

opened and from open to close as the door is

closed.

Door lock input: close the machine’s door.

While observing the Lock Switch display (refer

to Figure 25), press the keypad below the Door

Lock icon (refer to Figure 25), to lock and unlock

the door. The Lock Switch display should change

from open to close as the door is locked and close

to open as the door is unlocked.

Tilt input: while observing the Tilt Switch

display (refer to Figure 25

), manually move the

tilt switch. The Tilt Switch display should change

from close to open as the tilt switch comes into

contact with the cutout in the tilt switch bracket.

1 Door Relay

2 Lock Switch

3 Lock Door

4 Tilt Switch

5 Rotation Sensor

6 Next

Figure 25

2. Rotation input: open the machine’s door. While

observing the Rotation Sensor display (refer to

Figure 25

), manually rotate the machine’s basket.

The Rotation Sensor display should change from

open to close as the basket is rotated and the

RPM sensor detects a pulley spoke.

Press the Start/Stop keypad to exit the inputs test.

CFD330R

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

26

D1353 (EN)

Page 29

Input Relay Card

INPUTS

In 1

In 10

In 7

In 5

In 4

No function

CFD332R

Figure 27

Press the keypad below the Next icon to view the Input

Relay Card display. More or less inputs may be

displayed, depending on the model of machine.

When an input is activated, “●” is displayed. When an

input is not activated, “

○” is displayed.

The Non-Active Menu

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

The Non-Active Menu

CFD292R

3

EDIT MENU

Thermal Dis./Sluice 75

o

Hot with Prewash 60oC

Fast Hot 60

o

C

Chemical Sluice 40

o

C

Warm with Prewash 40

Warm wash 40

o

C

1

2

3

CFD335R

CFD336R

CFD337R

CFD338R

CFD339R

3.2 Edit Menu

CFD292R

Figure 28

To access the Edit Menu, from the Advanced Functions

Sub-Menu, press the keypad below the corresponding

icon. Refer to Figure 28.

Allows the operator to create, edit, copy or delete cycle

programs.

Edit, copy, delete or create a cycle program

1. Select a program to edit by pressing the keypads

below the Navigation icons. Refer to Figure 29.

2. Press the keypad below the Function Option icon

to change the function. Refer to Tab l e 12 .

Edit a program (see page 29)

Copy a program (see page 32)

Delete a program (see page 32)

Create a new program (see page 33)

Modify a program title (see page 33)

1 Function Option

2 Navigation

3 Check

Figure 29

Table 12

3. Press the keypad below the Check icon to

confirm the function. Refer to Figure 29.

4. When finished editing, press the Start/Stop

keypad to exit the Edit Menu.

CFD533R

CFD375R

Figure 30

Confirm to save any changes made by pressing the

keypad below the Check icon, or cancel by pressing the

keypad below the X. Refer to Figure 30.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 31

Edit Menu/Edit Program

Warm Wash 30 -60oC

Synthetic 1 40

o

C

60

o

C

25

o

C

Synthetic 2

Handwash

Delicate

Hot Wash 30 -90oC

30

o

C

2

3

1

1

2

3

5

6

7

8

4

CFD942R

1 Function Option

2 Navigation

3 Check

Figure 31

To access the Edit Program function, from the Edit

Menu display, press the keypad below the Function

Option until the Edit Program icon appears (as shown).

Press the keypad below the Check icon. Refer to

Figure 31.

The Non-Active Menu

Delicate 30oC

CFD943R

CFD943R

1 Function Option

2 Navigate Phases

3 Navigate Steps

4 Check

5 Title Bar

6 Program Phase Bar

7 Step Bar

8 Edit Field

Figure 32

Allows the operator to edit the selected cycle program.

All values for water level, water temperature, wash

movement, etc., can be changed. The operator can also

add, move or delete cycle phases and steps.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

The Non-Active Menu

CFD335

CFD343

CFD344

CFD345

CFD347

Edit program steps

1. Press the keypads below the Navigate Phases

icons until the correct phase is highlighted in the

Program Phase Bar.

2. Press the keypads below the Navigate Steps icons

until the correct step is highlighted in the Step

Bar.

3. Press the keypad below the Function Option to

change the function. Refer to Figure 13.

Edit settings for the selected step

Delete the selected step

Insert a step before the selected step

4. Press the keypad below the Check icon to

confirm the function.

Insert a step behind the selected step

Move the selected step

Table 13

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 33

The Non-Active Menu

CFD348R

CFD348R

CFD349R

HOT 1

CFD349R

15 cm

CFD350R

CFD351R

12

.sec

3

.sec

43

rpm

CFD351R

CFD352R

15 cm

CFD352R

0min25

OClax Activ

OClax Star

OEco Star

OEco Break

OLanadol

OClip Combi

OViva Deo Plu

OPotan Ole

Flashing lig

Horn

Recy. pump

Relais 12

Relais 13

Relais 14

Relais 15

Relais 16

CFD353R

CFD354R

40 oC

CFD354R

CFD355R

40 oC

CFD355R

CFD356R

40 oC

0.1

oc

mm

CFD356R

CFD357R

40 oC

1.0

oc

mm

CFD357R

CFD358R

CFD359R

0h10

Explanation 1

CFD359R

R

CFD360R

R

dist

1

CFD361R

CFD255R

O Clax Activ

O Clax Star

O Eco Star

O Eco Break

O Flashing lig

O Horn

O Lanadol

O Clip Combi

O Viva Deo Plu

O Potan Ole

O Recy. Pump

O No function

O No function

CFD362R

CFD363R

Hot Wash 40 -90oC

Label

CFD363R

1

CFD364R

R

CFD365R

Edit step values

Every step has its own values which can be selected

and changed as shown using the selection keypads

(refer to Figure 32.)

Description of the values for each step

Description of the values for each step

Wash phase:

Indication of the step.

Water inlet:

The water inlet valves.

Water level:

The water level and loaddependent filling.

Wash action:

The wash action time, the wash

stop time and the wash speed.

Water level time stop:

The water level to be reached

before the cycle program

continues.

Soap inlet:

The soap inlets via the powder

tray and activation of the liquid

soap pumps (time).

Heating:

The target temperature for the

tub and controlled fill via hot

and cold water mix.

(Continued Table 14)

Time:

The duration of the last step.

13min00

CFD358 R

Wai ting:

The time during which the cycle

program will temporarily stop

and the explanation.

Drain:

The drain valve or drain pump.

1

CFD360

Spin:

500

rpm

1min00

11

CFD361

Relay contact:

The number of relay contacts

available.

Comment:

Info text.

• Spin speed.

• Spin time.

• Maximum number of

attempts to resume spin

after a tilt.

• Wool washing: immediate

start with distribution speed

in the spin cycle.

• Outlet valve: selection of

outlet valve 1 or 2.

or

• Spin with distribution

speed only.

• Outlet valve: selection of

outlet valve 1 or 2.

D1353 (EN)

Heating time stop:

The temperature the tub has to

reach before the cycle program

continues.

Controlled cool down:

The temperature to which the

tub must drop via controlled

cool down and the speed of

cooling.

Controlled heating:

The temperature to which the

tub must rise via controlled

heating and the speed of

heating.

(Continued Table 14)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Subroutine:

The available subroutines.

Programmed start time:

7H30

The time when the program

starts.

CFD365

Table 14

Press the Start/Stop keypad to return to the Edit Menu

display.

31

Page 34

The Non-Active Menu

Warm Wash 30 -60oC

Synthetic 1 40

o

C

60

o

C

25

o

C

Synthetic 2

Handwash

Delicate

Hot Wash 30 -90oC

30

o

C

2

1

3

Starch Cold

Spin

Prg 11

CFD946R

Warm Wash 30 -60oC

Synthetic 1 40

o

C

60

o

C

25

o

C

Synthetic 2

Handwash

Delicate

Hot Wash 30 -90oC

30

o

C

2

1

3

Advanced Functions/Edit Menu/Copy

Program

CFD944R

1 Function Option

2 Navigation

3 Check

Figure 33

To access the Copy Program function, from the Edit

Menu display, press the keypad below the Function

Option until the Copy Program icon appears (as

shown). Press the keypad below the Check icon. Refer

to Figure 33.

Allows the operator to create a new program by

copying a selected program and then editing the copied

program.

Advanced Functions/Edit Menu/Delete

Program

CFD946R

1 Function Option

2 Navigation

3 Check

Figure 35

To access the Delete Program function, from the Edit

Menu display, press the keypad below the Function

Option until the Delete Program icon appears (as

shown). Press the keypad below the Check icon. Refer

to Figure 35.

Allows the operator to delete a selected program.

Figure 34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

The copy program will be placed at the end of the program

list.

32

CFD370R

CFD945R

Figure 36

Confirm by pressing the keypad below the Check icon

or cancel by pressing the keypad below the X. Refer to

Figure 36.

When this is done, the Edit Menu will appear.

D1353 (EN)

Page 35

The Non-Active Menu

Warm Wash 30 -60oC

Synthetic 1 40

o

C

60

o

C

25

o

C

Synthetic 2

Handwash

Delicate

Hot Wash 30 -90oC

30

o

C

CFD372R

CFD373R

Prg 12

CFD373R

Warm Wash 30 -60oC

Synthetic 1 40

o

C

60

o

C

25

o

C

Synthetic 2

Handwash

Delicate

Hot Wash 30 -90oC

30

o

C

Advanced Functions/Edit Menu/Create New

Program

CFD947R

Figure 37

To access the Create New Program function, from the

Edit Menu display, press the keypad below the

Function option until the Create New Program icon

appears (as shown). Press the keypad below the Check

icon. Refer to Figure 37.

Allows the operator to create a new program.

Advanced Functions/Edit Menu/Modify

Program Title

CFD948R

Figure 38

To access the Modify Program Title function, from the

Edit Menu display, press the keypad below the

Function Option until the Modify Program title icon

appears (as shown). Press the keypad below the Check

icon. Refer to Figure 38.

Allows the operator to modify the title of a program.

The new program will

automatically be placed at the

end of the program list.

The new program has been

given a basic structure of a

default program (2 washes +

3 rinses).

The new program can be edited as described under Edit

Program (see page 29).

NOTE: Modifying the program’s title is only possible

when the text is not a bitmap. When copying or

creating new cycles on the marhine, these cycles will

have a text title. Refer to Figure 34.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

The Non-Active Menu

CFD292R

3

EDIT MENU SUBROUTINE

Sub 01

Sub 02

Sub 03

1

3

2

CFD335R

CFD336R

CFD337R

CFD338R

CFD339R

3.3 Edit Menu Subroutine

CFD292R

Figure 39

To access the Edit Menu Subroutine, from the

Advanced Functions Sub-Menu, press the keypad

below the corresponding icon. Refer to Figure 39.

Allows the operator to edit, copy, delete or create new

subroutines. A subroutine is a block of steps grouped

together for insertion into a program. This enables the

operator to create programs faster by placing identical

program phases (such as rinses) in a subroutine.

Edit, copy, delete or create a subroutine

1. Select a subroutine to edit by pressing the kepads

below the Navigation icons. Refer to Figure 40.

2. Press the keypad below the Function Option to

change the function. Refer to Figure 40 and

Tab l e 15 .

Edit subroutine

Copy subroutine

Create a new subroutine

Delete subroutine

Modify a subroutine title

1 Function Option

2 Navigation

3 Check

Figure 40

Table 15

3. Press the keypad below the Check icon to

confirm the function. Refer to Figure 40.

4. Subroutines can be built, edited, copied or

deleted in the same way as wash programs (see

Edit Menu).

However, one subroutine cannot be inserted

into another.

CFD949R

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 37

CFD378R

Sub 06

DATA TRANSFER MENU

Figure 41

To create a new subroutine, start a basic subroutine. It

can then be edited in the same way as a cycle program

(see Edit Program).

The steps bar displays the content.

Press the Start/Stop keypad to exit the Edit Subroutine

Menu.

5. Save changes (refer to Figure 41).

The Non-Active Menu

3.4 Data Transfer Menu

3

CFD292R

CFD292R

Figure 42

To access the Data Transfer Menu, from the Advanced

Functions Sub-Menu, press the keypad below the

corresponding icon. Refer to Figure 42.

Allows the user to upload software or download data

from the machine using an SD card.

1. The “insert card” display will appear. Refer to

Figure 43.

# Type Filename Size

CFD381R

Figure 43

2. Put the SD card into the slot at the front of the

control panel. Refer to Figure 44.

CFD380R

Figure 44

If there is no slot, the operator can insert the SD

card into the card holder on the inside of the

control panel. To do this, the operator must

remove the cover from the machine.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

The Data Transfer Menu will appear. Refer to

Figure 45.

35

Page 38

The Non-Active Menu

CFD382R

3.1

8:09

5432

1

CFD384

3.8

8:09

59876 10

8:09

CEF382R CFD383R CFD384R

3.7

CFD383R

1 Content of data card 7 Write price and time file from the machine to the

2 Write cycle data from the data card to the data card (see page 37).

machine. 8 Write help file from the data card to the machine

3 Write cycle data from the machine to the data (see page 38).

card (see page 35). 9 Write help file from the machine to the data card

4 Write logbook contents to the data card (see page 40).

(see page 36). 10 Write machine firmware (*.csp) from a data card

5 Navigation to the machine (see page 41).

6 Write price and time file from the data card to

the machine (see page 37).

Figure 45

An hourglass symbol will appear while data is being

transfered.

IMPORTANT: Do not remove the SD card while

the hourglass is present.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 39

The Non-Active Menu

CFD382R

3.1

8:09

WRITE DATA TRANSFER

FROM THE MACHINE TO THE DATA CARD

HC165_00000

2

HC165_00000

1

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Cycle Data from the

Machine to the Data Card

CFD382R

Figure 46

To access the Write Data from the Machine to the Data

Card function, from the Data Transfer Menu, press the

keypad below the corresponding icon. Refer to

Figure 46.

Changing the File Name

1. Move the cursor using the keypads below the

Left/Right icons to select a letter or figure or to

add a letter or figure. Refer to Figure 47.

2. Change the letters and figures using the keypads

below the Up/Down icons. Refer to Figure 47.

3. Press the keypad below the Check icon to write

the data to the data card. Refer to Figure 47.

An hourglass symbol will appear while writing.

4. Press the Start/Stop keypad to return to the Data

Transfer Menu.

Allows the operator to write cycle date (cycle

programs) from the machine to the data card.

1 Cycle Data

2 Cursor

Figure 47

The cycle data is displayed as shown. Refer to

Figure 47. If necessary, the name of the file can be

changed.

CFD396R

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

The Non-Active Menu

CFD382R

3.1

8:09

WRITE LOGBOOK CONTENTS

TO THE DATA CARD

HC165_00000

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Logbook Contents to

the Data Card

CFD382R

Figure 48

To access the Write Logbook Contents to the Data Card

function, from the Data Transfer Menu, press the

keypad below the corresponding icon. Refer to

Figure 48.

Changing the File Name

1. Move the cursor using the keypads below the

Left/Right icons to select a letter or figure or to

add a letter or figure. Refer to Figure 49.

2. Change the letters and figures with using the

keypads below the Up/Down icons. Refer to

Figure 49.

3. Press the keypad below the Check icon to write

the data to the data card. Refer to Figure 49.

An hourglass symbol will appear while writing.

4. Press the Start/Stop keypad to return to the Data

Transfer Menu.

Allows the operator to write the logbook contents from

the macine to the data card.

1 Logbook Content

2 Cursor

Figure 49

The logbook content file is displayed as shown. Refer

to Figure 49. If necessary, the name of the file can be

changed.

CFD529R

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 41

Advanced Functions Sub-Menu/Data

3.1

8:09

CONTENT OF DATA CARD

CFD386R

# Type Filename Size

001

002

003

004

005

006

007

1266 kB in 7 file(s)

Free space: 769 kB

WF235 wet clean

HF234 - Initial

HC165 Coin

April 2009

Cygnus 1.2.5

Coin store BXL

Help Francais

10171

10171

8915

23472

1233678

451

10221

II0I0I

CFD386R

DELETE

Several types of data

can be stored.

CFD387R

CFD951R

CFD389R

CFD390R

CFD391R

CFD375R

Transfer Menu/Content of Data Card

CFD382R

Figure 50

To access the Content of Data Card display, from the

Data Transfer Menu, press the keypad below the

corresponding icon. Refer to Figure 50.

The Non-Active Menu

Allows the operator to read the content of the data card.

Refer to Table 16.

Press the keypad below the Delete icon (above) to delete all the data from the data

card. Confirm by pressing the keypad below the Check icon.

Cycle programs (.cgs)

Machine operating software (firmware) (.csp)

History (.chi)

Price and time file (.cpr)

Help file (.chf)

D1353 (EN)

Cancel deletion by pressing the keypad below the X.

Press the Start/Stop keypad to return to the Data Transfer Menu.

Table 16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

The Non-Active Menu

CFD383R

3.7

8:09

WRITE HELP FILE FROM THE

DATA CARD TO THE MACHINE

# Type Filename Size

001

002

003

004

38 kB in 4 file(s)

Free space: 7562 kB

New Medic HC165.chf

New Medic WFH150.chf

New Medic WFH65.chf

HC165_00000

10001

10001

9861

10001

CFD383R

3.7

8:09

WRITE PRICE AND TIME FILE FROM THE DATA

CARD TO THE MACHINE

# Type Filename Size

001

002

003

004

38 kB in 4 file(s)

Free space: 7562 kB

New Medic HC165.cpr

New Medic WFH150.cpr

New Medic WFH65.cpr

HC165_00000

10001

10001

9861

10001

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Help File from the Data

Card to the Machine

CFD583R

Figure 51

To access the Write Help File, from the Data Card to

the machine function, press the keypad below the

corresponding icon. Refer to Figure 51.

Allows the operator to load Help files from the data

card to the machine.

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Price and Time File

from the Data Card to the Machine

CFD383R

Figure 53

To access the Write Price and Time File, from the Data

Card to the Machine function from the Data Transfer

Menu, press the keypad below the corresponding icon.

Refer to Figure 53.

Allows the operator to load price and time files from

the data card to the machine.

1. Use the keypads below the Navigation icons to

select the Help file to write to the machine. Refer

to Figure 52.

2. Confirm by pressing the keypad below the Check

icon. Refer to Figure 52.

An hour glass symbol will appear while writing.

3. Press the Start/Stop keypad to return to the Data

Transfer Menu.

40

CFD930R

Figure 52

1. Use the keypads below the Navigation icons to

select the price and time file to write to the

machine. Refer to Figure 54.

2. Confirm by pressing the keypad below the Check

icon. Refer to Figure 54.

An hourglass symbol will appear while writing.

3. Press the Start/Stop keypad to return to the Data

Transfer Menu.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CFD530R

Figure 54

D1353 (EN)

Page 43

The Non-Active Menu

CFD383R

3.7

8:09

WRITE PRICE AND TIME FILE FROM THE

MACHINE TO THE DATA CARD

HC165_00000

2

1

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Price and Time File

from the Machine to the Data Card

CFD383R

Figure 55

To access the Write Price and Time File, from the

Machine to the Data Card function from the Data

Transfer Menu, press the keypad below the

corresponding icon. Figure 55.

The price and time file is displayed as shown. If

necessary, the name of the file can be changed.

1. Move the cursor using the keypads below the

Left/Right icons to select a letter or figure or to

add a letter or figure. Refer to Figure 56.

2. Change the letters and figures with using the

keypads below the Up/Down icons. Refer to

Figure 56.

3. Press the keypad below the Check icon to write

the data to the data card. Refer to Figure 56.

An hourglass symbol will appear while writing.

4. Press the Start/Stop keypad to return to the Data

Transfer Menu.

Allows the operator to write price and time files from

the machine to the data card.

1 Price and time file

2 Cursor

Figure 56

CFD531R

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

The Non-Active Menu

CFD383R

3.7

8:09

WRITE HELP FILE FROM THE

MACHINE TO THE DATA CARD

HC165_00000

1

2

Advanced Functions Sub-Menu/Data

Transfer Menu/Write Help File from the

Machine to the Data Card

CFD383R

Figure 57

To access the Write Help File from the Machine to the

Data Card display, from the Data Transfer Menu, press

the keypad below the corresponding icon. Refer to

Figure 57.

1. Move the cursor using the keypads below the

Left/Right icons to select a letter or figure or to

add a letter or figure. Refer to Figure 58.

2. Change the letters and figures with using the

keypads below the Up/Down icons. Refer to

Figure 58.

3. Press the keypad below the Check icon to write

the data to the data card. Refer to Figure 58.

An hourglass symbol will appear while writing

4. Press the Start/Stop keypad to return to the Data

Transfer Menu.

Allows the operator to load Help files from the Data

Card to a machine.

1 Help file

2 Cursor

Figure 58

The help file is displayed as shown. If necessary, the

name of the file can be changed.

CFD941R

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 45

Advanced Functions Sub-Menu/Data

CFD952R

3.8

8:09

WRITE MACHINE FIRMWARE FROM A DATA

CARD TO THE MACHINE

Transfer Menu/Write Machine Firmware from

a Data Card to the Machine

The Non-Active Menu

CFD953R

Figure 60

1. Cancel load and replace by pressing the keypad

below the X. Refer to Figure 60.

CFD952R

Figure 59

To Write Machine Firmware from a Data Card to the

Machine, from the Data Transfer Menu, press the

keypad below the corresponding icon. Refer to

Figure 59.

Allows the operator to load and replace firmware from

the data card to the machine.

2. Confirm by pressing the keypad below the Check

icon. Refer to Figure 60.

3. Press the Start/Stop keypad to return to the Data

Transfer Menu.

D1353 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

43

Page 46

The Non-Active Menu

CFD292R

3

SETTINGS MENU

CFD950R

6.2

9.37

4 - 1

5

4321

6

7

8

5

3.5 Settings Menu

CFD292R

Figure 61

To access the Settings Menu, from the Advanced

Functions Sub-Menu, press the keypad below the

corresponding icon. Refer to Figure 61.

Allows the operator to edit the user settings. Refer to

Figure 62.

CFD406R CFD950R

1 Date and time 6 Maintenance Counters

2 Display Contract 7 Advance

3 Password Access Code 8 Put Out of Order

4 Address Network

5 Navigation

Figure 62

44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

D1353 (EN)

Page 47

The Non-Active Menu

5

4 - 1

DATE AND TIME

14:42:00

07/04 2006

5/7

1

2

3

4 - 1

DISPLAY CONTRAST

!"#$%&'( )*+,_./0123456789:;<=>?@ABCDEFGH

IJKLMNOPQRSTUVWXYZ[\]^_'abcdefghijklmnop

qrstuvwxyz{ | } >< !"#$%&'( )

*+,_./0123456789

Advanced Functions Sub-Menu/Settings

Menu/Date and Time

Figure 63

To access the Date and Time function, from the

Settings Menu, press the keypad below the

corresponding icon. Refer to Figure 63.

CFD406R

Advanced Functions Sub-Menu/Settings

Menu/Display Contrast

CFD406R

Figure 65

To access the Display Contrast function, from the

Settings Menu, press the keypad below the

corresponding icon. Refer to Figure 65.

Allows the operator to set the time, date and day.

1 Time

2 Date

3 Day

Figure 64

1. Press the keypads below the Left/Right icons to

select the time, date or day, and edit these, if

necessary.

2. Confirm by pressing the keypad below the Check

icon. Refer to Figure 64.

CFD292R

Allows the operator to display contrast.

CFD411R

Figure 66

1. Increase or decrease contrast by pressing the

keypads below the Navigation icons and confirm

by pressing the keypad below the Check icon.

Refer to Figure 66.

2. Press the Start/Stop keypad to return to the

Settings Menu.

3. Press the Start/Stop keypad to return to the

Settings Menu.

D1353 (EN)