Page 1

1234567890123456789012

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1234567890123456789012

Part No. D0247

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

IPSO - LSG n.v.

Instruction manual

HF145, HF176

HF205, HF234

Technische gegevens

Technical specifications

Installation instructions

Operating instructions

Gebruiksaanwijzing

Maintenance

Nieuwstraat 146 - B-8560 Wevelgem (Belgium)

Tel. 056/41 20 54 - Fax 056/41 86 74

Installatie

Onderhoud

Page 2

Contents

1 General safety instructions .............................................................. 3

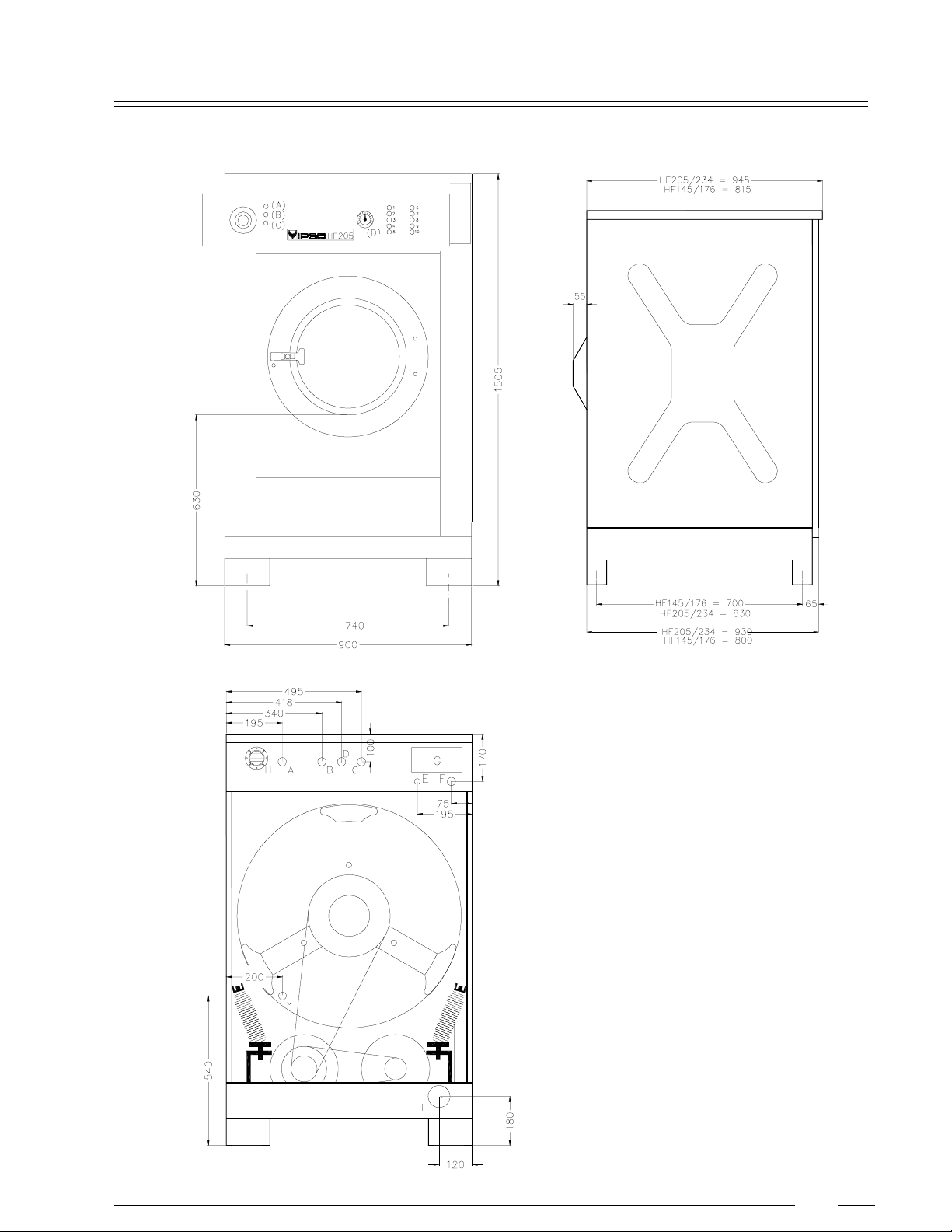

2 Technical data and dimensions ....................................................... 4

Technical data ................................................................................ 4

Dimensions ..................................................................................... 5

3 Installation and connection ............................................................. 6

Ground ............................................................................................ 6

Removing the transport brackets .................................................... 6

Water connection ............................................................................ 6

Water drain ..................................................................................... 7

Main power connection .................................................................... 7

Steam connection ........................................................................... 8

4 Operating instructions ..................................................................... 9

Machine with CAM-timer and 10 buttons ......................................... 9

Machine with electronical PLC-9 microprocessor and start button ... 12

5 Technical remarks ............................................................................ 16

Program time (Machine with CAM-timer) .......................................... 16

Internal connection of the electrical heating .................................... 17

Internal connections of the motor .................................................... 17

Thermo-magnetic motor protection .................................................. 18

Tilt switch and electronical repetition system .................................. 19

6 Maintenance of the machine ........................................................... 20

Code: 249/00026/01

08/09/94

Contents

Page 3

General safety instructions

Ignoring any of the safety instructions can cause serious personal injury and can also cause damage to the linen or the

machine

Read the installation and instruction manual carefully before connecting the

p

machine.

It is recommended that the machine be installed by qualified technicians.

p

The machine should be installed according to the installation instructions. (See

p

chapter 3)

The machine should be grounded according to the instructions in order to

p

eliminate the risk of electrocution.

Do not expose the machine to high humidity or extreme high or low tempera-

p

tures.

Cut off all main water inlets, steam and electrical supplies at the end of each

p

operating day.

1

Before starting repairs or maintenance, shut off all power and water supplies.

p

To prevent fire and explosion:

p

Keep the area around the machine free from inflammable or combustible

products.

Do not put fabrics that are treated with inflammable products into the machine.

These fabrics should be hand-washed or air-dried first.

Always carefully read and follow the instructions on the packing of detergents.

p

Store these products out of the reach of children.

Always take into account the instructions on the labels of clothes.

p

Never allow children to play in the surroundings of a machine.

p

Remark:

These instructions surely cannot prevent all risks of accidents. It is up to the user to act with the utmost

p

precaution.

Do not hesitate to contact the dealer in case of a problem.

p

3

Page 4

Technical data and dimensions

Technical data

HF 145 HF 176 HF 205 HF 234

Capacity (dry weight)

1/11 13,2 kg 16 kg 18,6 kg 21,3 kg

1/10 14,5 kg 17,6 kg 20,5 kg 23,4 kg

1/9 16,1 kg 19,5 kg 22,7 kg 26 kg

Cylinder

Diameter 750 mm 750 mm 750 mm 750 mm

Depth 329 mm 399 mm 464 mm 530 mm

Volume 145 Lit. 176 Lit. 205 Lit. 234 Lit.

Cabinet

Height 1505 mm 1505 mm 1505 mm 1505 mm

Width 900 mm 900 mm 900 mm 900 mm

Depth 855 mm 855 mm 855 mm 855 mm

Front loading

Diameter door opening 395 mm 395 mm 395 mm 395 mm

Door height - loxer edge 630 mm 630 mm 630 mm 630 mm

Door height - center 820 mm 820 mm 820 mm 820 mm

speed

Wash 40 rpm

Distribution 110 rpm

Spin 420 rpm

High spin 900 rpm

G-force

Spin 74/343

Motors (3-phase)

Wash18p. 290 rpm. 220 W 280 W 370 W 370 W

Distribution 18p. 290 rpm 220 W 280 W 370 W 370 W

Spin 2p. 2900 rpm. 1100 W 1300 W 1800 W 1800 W

High spin 2p. 2900 rpm. 1100 W 1300 W 1800 W 1800 W

Drain

Depend-O-Drai 3"

Option 2"

Water-inlet

Hard, soft, hot warer & cool down 3/4"

Steam connection

steam connection 3/8"

Heating

Electric 220/380V 12/15/18 kW

Electric 380V 24 kW

Steam X

Boliler fed X

Boiler fed (with auxiliary heating) X

Packing dimensions

(H x W x D) 1650x1020x1150 mm

Weight

Net 380 kg 455 kg 561 kg 570 kg

Gross 450 kg 524 kg 621 kg 630 kg

2

4

Page 5

Dimensions

2

A. Hard water connection 3/4"

p

B. Warm water connection 3/4"

p

C. Soft water connection 3/4"

p

D. Water connection cool-down (option)

p

E. Electrical power connection motor drive

p

F. Electrical connection heating

p

G. Electrical connection clamps

p

H. Ventilation soap dispenser

p

I. Water drain

p

J. Steam connection

p

5

Page 6

Installation and connection

Ground

The machine must be placed on a flat, solid surface (metal base, concrete or solid

ground). It is recommended that the machine be anchored on the provided places

(A) in the base, especially in case of a plinth. (See Dimensions 2)

The machine must be placed entirely level. For easy maintenance it is recommended to keep a minimal distance of 600 mm between the wall and the back of the

machine.

If several machines are placed next to each another, there should be a minimal

distance of 30 mm between each machine.

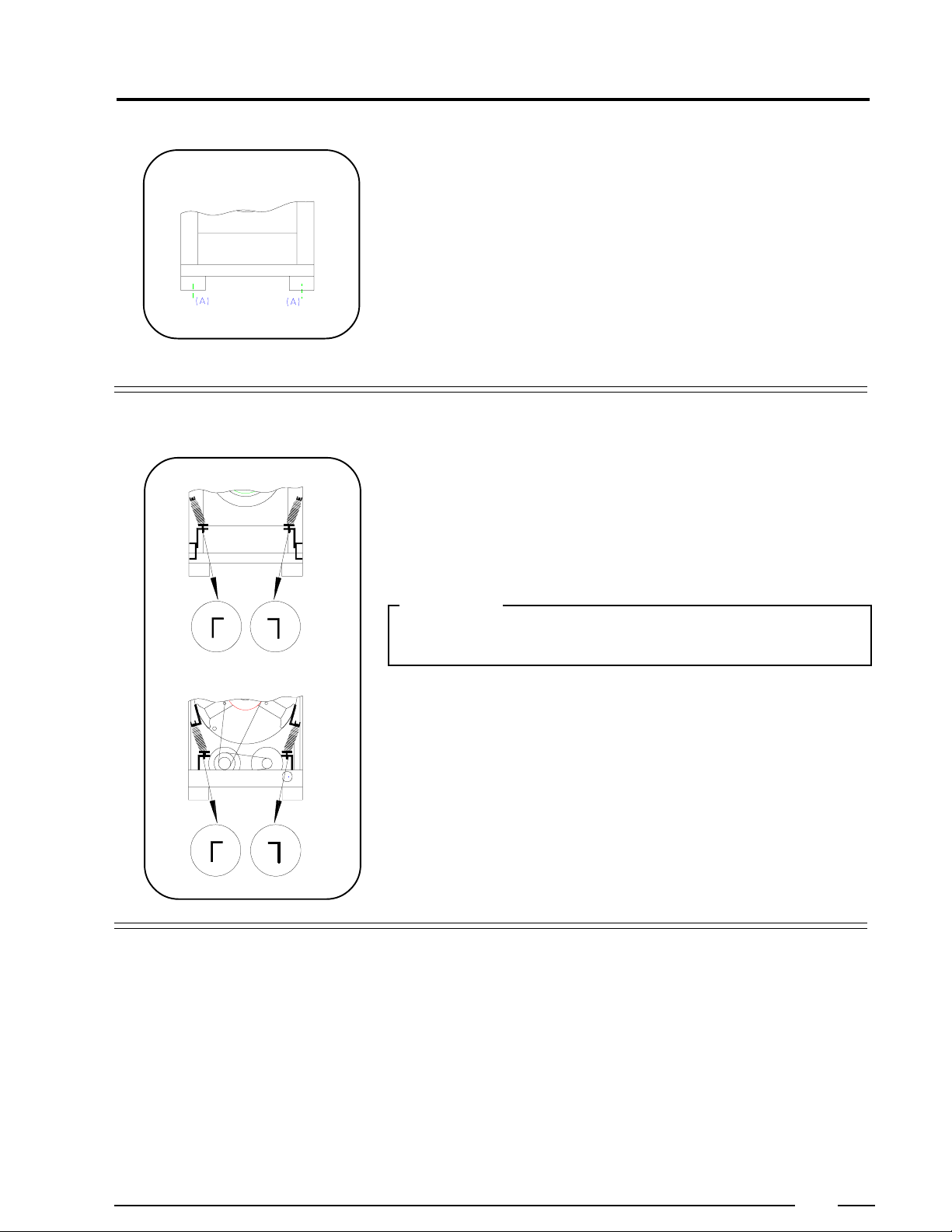

Removing the transport brackets

To prevent damage during transportation, the machine has been equipped with

two red transport brackets (D) to eliminate every possible movement of the tub.

After the machine has been placed level, take off the service panel and remove

these transport brackets.

3

Water connection

Important

The machine must never be activated before removing these transport

brackets.

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet

should be between 0,5 and 10 kg/cm² (7 and 145 psi). If the pressure is too low,

the cycle time will increase considerably.

In case of boiler fed machines, a minimum of hot water of 90°C should be available:

For the HF145: 110l. HF205: 135l.

For the HF176: 125l. HF234: 150l.

6

Page 7

3

Water drain

Main power connection

The machine is equipped with a drain valve with 6/4" outer diameter (50 mm). This

drain valve should be connected to the drain by means of the drain elbow which

is delivered with the machine.

The diameter of the main drain should be adapted to the water flow and the

p

number of machines. It should be sufficient to handle at least 80L/min. per

machine.

It is necessary to connect the main drain at least on one side to an open air-

p

brake to allow ventilation.

When the main drain has not been sufficiently deodorized, every machine

p

should be installed seperately with a deodorizer.

In case of machines with electrical heating two seperate connections

p

should always be used. One for the motor circuit, one for the heating.

After connection, check the spin direction. The cylinder must spin in the

p

direction of the arrow, showed on the sticker on the door window

(clockwise).

A wrong spin direction can damage the motor, and can also cause water

to spurt from the soap dispenser.

In case of wrong spin direction: switch the terminal clamps of the motor

p

circuit R and S of the connecting cable.

Motor

Motor

Machine with electrical

heating

Heating

Machine with steam heating or boiler fed machine

without additional electrical heating

Value of mains fuses:

Motor circuit: 220V 3AC 380V 3AC + N

16A 16A

Value of the mains fuses:

Motor circuit:220V 3AC380V 3AC + N

16A 16A

Heating: 220V 3AC 380V 3AC + N

12kw ---- 25A

15 kw 50A 25 A

18 kw 50 A 32 A

21 kw ---- 40 A

24 kw ---- 40 A

7

Page 8

3

Steam connection

Machines with steam heating must have a steam valve between the steam

installation and the machine.

With direct steam injection into the machine

1. Steam pipe

2. steam cut-off valve 3/8"

3. Pipe coupling 3/8"

3. Steam filter 3/8"

5. Magnetic steam valve 3/8"

6. Curve MF 3/8"

7. Steam hose with appropriate pipe coupling 3/8"

Added parts for steam heating with heat exchanger

3. Double pipe coupling 1/2"

9. Condensation accumulator with filter 1/2"

10. Conical coupling MM 1/2"

11. Single window 1/2"

12. One-way valve 1/2"

M = inner wire, F = outer wire

The manufacturer is not responsible for damage or accidents caused by not following the installation instructions!

8

Page 9

Operating instructions

Machine with CAM-timer and 10 buttons

4

Open the door

Fill the drum

Close the door

Select program

Press the red button on the doorhandle and open the door.

The machines have 5 wash programs. Sort the linen according to the quality and

the allowed wash temperature. Remove all nails, coins, etc. that can damage the

linen or the machine during the wash cycle. Turn sleeves of overcoats, shirts and

blouses inside out. To increase the wash action and thus the quality of the wash,

it is recommended to mix large and small pieces.

If the machine is filled less than 80% of the capacity, this could prevent a good

operation and can even damage the machine.

Overloading the machine can be the cause of low wash quality.

Press the button of the desired program: (1-5)

1. Hot wash (2 baths)(40°/90°C)

2. Warm wash (2 baths)(40°/60°C)

3. Synthetics (2 baths)(40°/40°C) (No final spin 1000rpm)

4. Synthetics (1 bath)(40°C) (No final spin 1000rpm)

5. Gentle/Wool (1 bath)(30°C or cold) (No final spin 1000rpm)

Add detergents

Remark:

Program 4 & 5 low water level and normal wash action. For high water level and

reduced wash action, press button 8.

It is recommended to use only those detergents with reduced foam. These are

often available in the laundrette, and are also easily found in shops. The dose you

should use is normally indicated on the packing.

Overdosing of soap can lead to poor wash results and foam bubbling out of the

machine can damage it.

Left compartment A: Pre-wash (1st bath)

Middle compartment B: Main wash (2nd bath)

Right compartment C: Final rinse (conditioner)

Compartment D: Directly in tub

9

Page 10

4

Choose temperature

Start the machine

Orange pilot lights

thermostat with 2 adjustable temperatures can be installed.

The choice of temperature via the switch buttons can then be replaced by the input

of T1/T2

- T2 = Highest adjustable temperature (Main wash)

- T1 = Lowest adjustable temperature (Pre-wash)

Press the start button (6). When the machine is started, the red control lamp on

the fascia panel (A) will light up.

When the middle orange pilot light (B) lights up, the liquid bleach may be added

manually (Compartment D).

When the bottom orange pilot light (C) lights up, the linen softener is automatcally

added or the starch pay be added manually (compartment D)

End of the cycle

Remarks

Function buttons (6-10)

When the red pilot light on the fascia panel turns off, the wash cycle has come

to an end and you can open the door.

Button 6: START.

p

Press this button and release immediately to start a program.

Button 7: STARCH.

p

To starch at the end of a wash cycle proceed as follows:

- In case you dont want to starch some of the linen, remove these first.

- Dissolve the starch in some water.

- Press button 7.

- Press button 6 and release it.

- Add the dissolved starch (in compartment D) when water flows into the

soap dispenser.

- Program sequence: Water inlet - Starch:2' - Drain:30" - Spin:130 - Tumble:30".

- After ending the starch program, press out button 7.

p

Button 8: HIGH WATER LEVEL (reduced wash action)

If you want to wash in a certain program with high water level and reduced wash

action, press button 8. After ending the program, press out button 8.

p

Button 9: NO SPIN

If you want to run a program without spinning, press the button 9 before

you press the start button. After ending that program press out this button

9. You can also choose 8 & 9 at the same time to wash with reduced wash

action, high water level and without spinning.

p

Button 10: RAPID ADVANCE.

With this button you can at any time skip a part or the rest of the program.

10

Page 11

4

Button Soak

(Option!)

Opening the door in case

of an emergency

Choose a program (1...5) (Dont press button 7)

- Press the pause switch so the light turns on.

- Add detergent and start the machine.

The bath is filled to high water level. A reduced wash action of 3 sec. wash and

12 sec. pause is engaged while the bath is heated to 30° or 40°C, depending on

the selected program 1-4: 40°C, program 5: 30°C.

When the required temperature is reached, the wash action stops until the bath

is cooled down and heating starts again. When the desired pause time is passed,

press out the pause switch. The machine will automatically proceed with its

normal program.

When you want to open the door in case of an emergency (power breakdown,

deficiencies, etc...) remove the service panel (A) at the bottom and pull the left

suspended ring (B) while you press the red button on the doorhandle and open

the door.

Important:

Before opening the door, be sure there is no water left in the tub, and that

the drum has come to a complete stop.

11

Page 12

Machine with electronical microprocessor and start button

4

Open the door

Fill the drum

Close the door

Select program

Press the red button on the doorhandle and open the door.

Sort the linen according to the quality and the allowed wash temperature. Remove

all nails, coins, etc. that can damage the linen or the machine during the wash cycle.

Turn sleeves of overcoats, shirts and blouses inside out. To increase the wash

action and thus the quality of the wash, it is recommended to mix large and small

pieces.

If the machine is filled less than 80% of the capacity, this could prevent a good

operation and can even damage the machine.

Overloading the machine can be the cause of low wash quality.

The machine has at least 6 programs (IPSO Belgium). Press the program selection

button (SELECT) as many times until the desired program number appears:

1. Hot wash (2 baths)(40°/90°C)

2. Warm wash (2 baths)(40°/60°C)

3. Synthetics (2 baths)(40°/40°C) (No final spin 1000rpm)

4. Synthetics (1 bath)(40°C) (No final spin 1000rpm)

5. Gentle/Wool (1 bath)(30°C or cold) (No final spin 1000rpm)

6. Starch (1 bath)(cold) (No final spin 1000rpm)

Add detergents

Remark:

These programs can be modified. Other programs can be added. (Max. 9). If this

is desired, contact your distributor.

It is recommended to use only those detergents with reduced foam. These are

often available in the laundrette, and are also easily found in shops. The dose you

should use is normally indicated on the packing.

Overdosing of soap can lead to poor wash results and foam bubbling out of the

machine can damage it.

Left compartment A: Pre-wash (1st bath)

Middle compartment B: Main wash (2nd bath)

Right compartment C: Final rinse (conditioner)

Compartment D: Directly in tub

12

Page 13

4

Choose temperature

Start the machine

As an option, a thermometer or thermostat with 2 or 3 adjustable temperatures can

be installed.

- T3 = Highest adjustable temperature

- T2 = Middle adjustable temperature

- T1 = Lowest adjustable temperature

Press the start button. When the machine is started, the green pilot light on the

fascia panel will turn off.

End of a cycle

Remarks

During the program, the selected program number remains visible on the left

display. The other two show the remaining program segments of 1 minute. You

can stop the cycle prematurely by pressing the START/STOP button.

When the green pilot light on the fascia panel lights up and the two displays on

the right turn off, the wash cycle has ended and you can open the door.

Rapid Advance

Keep the program select button (SELECT) pressed and then press the START/

STOP button at the same time. By doing this action twice, the middle and right

decimal point will flash at the same time. By pressing the program select button

now you can advance to the following step of the program. By keeping the

program select button pressed it is possible to advance rapidly through a part or

the rest of the program.

To continue normally with the program, press the START/STOP button.

Programmable start

It is possible to start a machine with PLC-9 automatically after a maximum of 99

hours.

Select a program.

p

By keeping the program select button (SELECT) pressed and then pressing the

p

START/STOP button at the same time, -01 appears. Every time you press

the program select button (SELECT) one hour is added to the delay. The

program will only start after the programmed delay has passed.

To undo the programmed start, press START/STOP button.

p

13

Page 14

4

Special functions

By keeping the program select button (SELECT) pressed and then pressing the

START/STOP button at the same time, it is possible to use special functions.

After a while, the left decimal point starts to flash. (A)

p

This means that the program will keep repeating the segment that is now

active (Time stop).

To continue the program normally, press the START/STOP button. Or

if you want to select the following function, press the program select

button (SELECT) once again.

The middle decimal point lights up and the left keeps flashing (B). Now

p

the time will be stopped and the water will be heated to 40°C with reduced

wash action and high water level. By means of this soak program you can

prolongue the pre-wash in case of very dirty linen.

To continue the program normally, press the START/STOP button. Or

if you want to select the following special function, press the program

select button (SELECT) once again.

The right decimal point now lights up (C).

p

This means that all wash actions are being executed at reduced wash

action.

To continue the program normally, press the START/STOP button. Or

if you want to select the following special function, press the program

select button (SELECT) once again.

The right decimal point lights up and the left flashes.

p

Now the program activates a time stop during the wash cycle but in

this case with a reduced wash action.

To continue the program normally, press the START/STOP button.

Test program

By keeping the program select button (SELECT) pressed, when selecting the

program, for more than 5 seconds, you enter the test program (0). This was

specially designed to help the technical service in case of malfunction.

Thermo-magnetic motor protection

When the thermo-magnetic motor protection is activated, the red control pilot

light on the fascia panel will light up and the display will turn off. When the

protection (manually or automatically) is being reset, a flashing S will appear

on the display. This means that you should select again the program.

14

Page 15

Special messages

When starting the program and the door is not closed properly, cdo will

p

appear (Close door).

When starting the program and something is wrong with the water level

p

switches, HLE (high level), LLE (low level) or alternating SLE - tilt

(safety level) will appear.

When one of the required temperatures was not reached during the program,

p

1tE, 2tE, 3tE or 4tE will appear at the end.

When one of the required water levels was not reached during the program,

p

HLE (high level), LLE (low level) or alternating SLE - tilt (safety level)

will appear at the end.

Extra switches and buttons. (Option)

Button adding water

p

With this button the water level in the tub will rise for as long as you press the

button.

Button drain water

p

With this button the water level in the tub will fall for as long as you press the

button.

Switch no high spin

p

By turning this switch to the right, high spin is executed as low spin.

4

Opening the door in

case of an emergency

Switch lowered water level

p

By turning this switch to the right, you can lower the water level in case of a

smaller wash-load. This can save time, water and energy.

When you want to open the door in case of an emergency (power breakdown,

deficiencies, etc...) remove the service panel (A) at the bottom and pull the left

suspended ring (B) while you press the red button on the doorhandle and open

the door.

Important:

Before opening the door, be sure there is no water left in the tub, and that

the drum has come to a complete stop.

15

Page 16

Technical remarks

Program time (Machine with CAM-timer)

Code 10.1126 - 220 V (50Hz with brown CAM-timer)

There are several possibilities according to cabling, microprocessor, type of heating, tempe-

rature control, water level control, etc.... For your information you can find the details of the

programs for a machine with standard programs, boiler fed (without temperature control nor

water level controls).

12345

Hot Warm Synth. 1 Synth. 2 Wool

water inlet cold+warm cold+warm cold+warm cold+warm cold

pre-wash 630" 630" 430" 630" 630"

water drain 130" 130" 130" 130" 1'30"

spin 230" 230" 230" 130" 130"

water inlet warm 33% cold+ 50%cold+

main wash 12' 12' 9'

water drain 130" 130" 130"

water inlet cold cold cold cold cold

rinse1 2' 2' 2' 2' 2'

water drain 130" 130" 130" 130" 130"

spin 230" 230" 130" 130" 130"

water inlet cold cold cold cold cold

rinse 22'2'2'2'2'

water drain 130" 130" 130" 130" 130"

spin 230" 230" 130" 130" 130"

water inlet cold cold cold cold cold

rinse 3 230" 230" 230" 230" 230"

water drain 130" 130" 130" 130" 130"

low spin 250" 250" 250" 250" 250"

high spin 440" 440"

delay 30" 30" 30" 30" 30"

tumble 30" 30" 30" 30" 30"

total 4830" 4830" 3650" 2720" 2720"

5

66% warm 50%warm

Remark

In the programs 1 & 2 the pre-wash is installable on 430" or 630" and the main wash installable

on 9' or 12',according to the cabling.

Every time the machine is out of balance during the spin 1 minute is added to the program. (See

electronical repetition system)

16

Page 17

Internal connection of the electrical heating

s

Vermogen 3x220V R5 3x380V R5

Heating

12kW 3x2kW s LC1D253 H LC1D0901

3x2kW

15kW 3x2kW s LC1D253 H LC1D1810

3x3kW

18kW 3x3kW s LC1D323 H LC1D1810

3x3kW

5

H

B = Black

GY = Grey

R = Red

PU = Purple

Br = Brow

BU = Blue

W = White

W/B = White/Black

21kW 3x3kW ------ ------ H LC1D1810

3x4kW ------ ------ s LC1D1810

24kW 3x4kW ------ ------ s LC1D1810

3x4kW ------ ------ s LC1D1810

Internal connections of the motors

Remark:

Other executions are available as option

220V 380V

Low speed High Speed Lo w speed High speed

17

Page 18

HF205/HF234

220V

5

380V

Grey

Brown

Black

Yellow/green

Washmotor: White/black

spinmotor: purple

Washmotor: Blue

Spinmotor: White/red

Grey

Thermo-magnetic motor protection

Brown

Black

Grey

Brown

Black

Yellow/green

Washmotor: White/black

spinmotor: purple

Grey

Brown

Black

Washmotor: Blue

Spinmotor: White/red

Autom. reset

Man. reset

The thermic overload relay turns off in case of overloading. Because this relay

is installed on automatical reset, after a while the motors are switched back on

automatically.

Installation and type of overload relay

220V

Machine Type value installation

HF145 LR2D13149 7-10A 7A

HF176 LR2D13149 7-10A 8A

HF205 LR2D13149 7-10A 10A

HF234 LR2D13149 7-10A 10A

380V

Machine Type value installation

HF145 LR2D13109 4-6A 4A

HF176 LR2D13109 4-6A 4A

HF205 LR2D13149 7-10A 7A

HF234 LR2D13149 7-10A 7A

18

Page 19

Tilt switch and electronical repetition system

5

Tilt switch

window

probe

Electronical

repetition system

The tilt switch is mounted on the solid part of the machine. There is a window

around the probe of the tilt switch that is mounted on the movable part of the

machine.

When the machine goes out of balance by overloading or uneven distribution of

the linen, the tilt switch will interrupt this action to prevent damage to the machine.

Important

To guarantee good functioning, the probe should be centered horizontally

and vertically at 1/3 from the bottom of the tilt window (when machine drum

is empty).

The spin is controlled by the electronical repetition system. This system is

responsible for the drive of the different motors during high and low spin.

Operation:

The printboard will be activated during the drain, and the following actions occur:

a) The micromotor of the programmer stops.

b) The distribution speed is activated and the drain valve opened.

c) After the water is drained completely, the machine starts low spin at 500 rpm.

d) After 240" low spin, high spin starts at 1000 rpm.

Remarks:

The duration of the high spin (1000rpm) is determined by the programmer.

p

In case the machine is out of balance during spinning, the spin motor will stop while

p

the linen is redistributed via the wash action. After 30 sec. the machine will try again

to spin.

Every time the machine is out of balance the spin time shortens by 30 sec. (Not with

p

PLC-9).

When the drain valve is obstructed, the same things happen as when the machine

p

is out of balance.

After a power failure during spinning, the machine starts at point a) (see operation).

p

After an interruption by the thermo-magnetic motor protection during spinning,

the machine starts at point a) of the described operation.

p

Machines with electronical microprocessor PLC-9 have the repetition system

printboard integrated on the main printboard. In this case the repetition process

p

will be executed no more than 15 times without shortening the spin time.

19

Page 20

Maintenance of the machine

6

General maintenance

Periodical maintenance

Clean the entire cabinet of the machine regularly and remove all traces of soap,

p

etc....

Remove all detergent residue in the soap dispenser with hot water.

p

p

Clean the door gasket and remove all detergents and other products.

Shut off the main water, steam and power connections at the end of each day.

p

Do not change the setting of the water inlet taps on boiler fed machines once

these have been installed.

p

It is recommended to leave the door and the soap dispenser open after use,

to ventilate the machine.

The V-belts of the motors should be retightened after two to three months

p

when first used. This is necessary because these belts are subject to a onetime stretching when first used. By ignoring this instruction, the belt starts

to slip after a few months and will brake shortly afterwards.

Check regularly if the filters of the water inlet are not blocked by calcification.

p

If a machine frequently skips the final spin, check whether the probe of the

out of balance switch is still in the appropriate position, that is horizontally

p

centered and vertically 1/3 from the bottom inside the window. (When the

drum is empty).

Repair and after-sales

service

Gegevens verdeler:

Gegevens machine:

An obstructed drain can cause frequent interruption of spinning for safety

reasons.

p

In case of important malfunctions and deficiencies which you cannot resolve

p

yourself, do not hesitate to contact the technical service of your distributor.

Name: ...................................................................................

Address: ...............................................................................

Tel.: ......................................................................................

Type: .....................................................................................

Program: ...............................................................................

Date of installation: ...............................................................

Installed by: ..........................................................................

Serial number: .......................................................................

Operation voltage and frequency: ..........................................

The manufacturer reserves the right to change the content of this instruc-

tion manual, at all times and without previous notice.

20

Loading...

Loading...