ALLIANCE PK120N, NK120N, SJ120E, UG120N, BA120L Installation Manual

...

Tumble Dryers

TMB1282C_SVG

120 Pound (55 Kilogram) Capacity

170 Pound (77 Kilogram) Capacity

200 Pound (90 Kilogram) Capacity

Models with 0 or 3 in 13th Position of Model Number

Refer to Page 8 for Model Identification

Installation

Original Instructions

Keep These Instructions for Future Reference.

CAUTION: Read the instructions before using the machine.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. 70532501ENR7

December 2018

Installation must conform with local codes or, in the absence of

local codes, with:

In the U.S.A., installation must conform to the latest edition of

the American National Standard Z223.1/ NFPA 54 “National

Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric

Code.”

In Canada, installation must comply with Standards CAN/CSAB149.1 Natural Gas and Propane Installation Code and CSA

C22.1, latest edition, Canadian Electric Code, Part I.

In Australia and New Zealand, installation must comply with the

Gas Installations Standard AS/NZS 5601 Part 1: General Installations.

In Europe, before installation, check that the local distribution

conditions, nature of gas and pressure, and the adjustment of the

appliance are compatible.

This equipment has been designed and certified to comply with

IEC/EN 60335 electrical safety standards for tumble dryers.

Read all instructions before using tumble dryer.

IMPORTANT: If it is unavoidable that fabrics that contain vegetable or cooking oil or have been contaminated by hair care products be placed in a tumble dryer,

they should first be washed in hot water with extra detergent. This will reduce, but not eliminate, the hazard.

WARNING

FOR YOUR SAFETY, the information in this manual

must be followed to minimize the risk of fire or explosion or to prevent property damage, personal injury or death.

W033

WARNING

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

• WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Clear the room, building or area of all occu-

pants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

• Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

W052

IMPORTANT: Information must be obtained from a local gas supplier on instructions to be followed if the

user smells gas. These instructions must be posted in

a prominent location. Step-by-step instructions of the

above safety information must be posted in a prominent location near the tumble dryer for customer use.

IMPORTANT: Post the following statement in a prominent location

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

DANGER

Electric shock hazard will result in death or serious

injury. Disconnect all electric power to appliance and

accessories and wait five (5) minutes before servicing.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

IMPORTANT: The installer must fully test the tumble

dryer after installation and demonstrate to the owner

how to operate the machine.

IMPORTANT: The machine shall only be installed in a

room separated from inhabited rooms, incorporating

appropriate ventilation specified in the National Installation Regulations.

W925

IMPORTANT: The tumble dryer is not to be used if industrial chemicals have been used for cleaning.

3 Part No. 70532501ENR7

WARNING

WARNING

To reduce the risk of electric shock, fire, explosion,

serious injury or death:

• Disconnect electric power to the tumble dryer before servicing.

• Close gas shut-off valve to gas tumble dryer before servicing.

• Close steam valve to steam tumble dryer before

servicing.

• Never start the tumble dryer with any guards/

panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected to

ensure that the tumble dryer is properly grounded.

W002R1

WARNING

• Installation of unit must be performed by a qualified installer.

• Install tumble dryer according to manufacturer’s

instructions and local codes.

• DO NOT install a tumble dryer with flexible plastic

venting materials. If flexible metal (foil type) duct

is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use

with tumble dryer. Refer to section on connecting

exhaust system. Flexible venting materials are

known to collapse, be easily crushed, and trap

lint. These conditions will obstruct tumble dryer

airflow and increase the risk of fire.

Electrical shock hazard can cause death or serious

injury. To reduce the risk of electric shock, disconnect all electric power to appliance and accessories

before servicing.

W929

WARNING

Moving parts hazard can cause serious injury. Disconnect electric power to unit before servicing. Unexpected start of machinery will occur if the units

equipped with the extended tumble feature.

W937

WARNING

Lint compartment must be cleaned daily

To avoid the risk of fire:

• Use for drying water washed fabrics only.

• DO NOT dry articles containing foam rubber, plastic, or similarly textured rubber like materials.

• DO NOT put articles soiled with cooking oil in dryer as cooking oil may not be removed during

washing. Due to the remaining oil the fabric may

catch on fire by itself.

• DO NOT put articles soiled with flammable liquids

or flammable cleaning solvents in dryer.

W930

CAUTION

TO AVOID THE RISK OF FIRE THIS DRYER MUST BE

EXHAUSTED OUTDOORS.

WARNING

To reduce the risk of serious injury: Avoid contact

with hot surfaces.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

W752R1

W928

W927

CAUTION

• Risk of fire, a clothes dryer produces combustible

lint. Exhaust outdoors. Care should be taken to

prevent the accumulation of lint around the exhaust opening and in the surrounding area.

• DO NOT reach into the dryer until all moving parts

have stopped.

• DO NOT let children play on or in the dryer.

W931

In Australia and New Zealand:

4 Part No. 70532501ENR7

WARNING

• DO NOT operate this appliance before reading the

instruction booklet.

• DO NOT place articles on or against this appliance.

• DO NOT store chemicals or flammable materials

or spray aerosols near this appliance.

• DO NOT operate with panels, covers or guards removed from this appliance.

• DO NOT load materials containing flammable solvents into this appliance.

• If repeated ignition reset is required, the dryer

should not be used and a service call booked.

Risk of fire/flammable material.

W926

The following information applies to the state of Massachusetts,

USA.

• This appliance can only be installed by a Massachusetts licensed plumber or gas fitter.

• This appliance must be installed with a 36 inch [91 cm] long

flexible gas connector.

• A “T-Handle” type gas shut-off valve must be installed in the

gas supply line to this appliance.

• This appliance must not be installed in a bedroom or bathroom.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

5 Part No. 70532501ENR7

Table of Contents

Introduction........................................................................................... 9

Model Identification .......................................................................................9

Contact Information...................................................................................... 11

Manufacturing Date...................................................................................... 12

Safety Information................................................................................13

Explanation of Safety Messages..................................................................... 13

Important Safety Instructions......................................................................... 13

Specifications and Dimensions.............................................................. 15

Specifications and Dimensions ...................................................................... 15

Cabinet Dimensions and Exhaust Outlet Locations ..........................................17

Electric and Gas Connection Locations for Gas Models ...................................19

Electric and Steam Connection Locations for Steam Models ............................ 20

Electric Connection Location for Electric Models............................................ 22

Installation........................................................................................... 23

Pre-Installation Inspection............................................................................. 23

Location Requirements..................................................................................23

Remove Shipping Materials........................................................................... 24

Position and Level the Tumble Dryer..............................................................25

Mounting..................................................................................................... 25

Fire Suppression System (Optional Equipment)............................................... 25

Check Local Codes and Permits..................................................................25

Water Requirements...................................................................................25

Water Connections.....................................................................................26

Electrical Requirements............................................................................. 27

Auxiliary Alarm........................................................................................ 27

Before Placing Tumble Dryer into Service.......................................................28

Required for IEC Models Only .................................................................. 29

Exhaust Requirements..........................................................................30

Exhaust Requirements...................................................................................30

Layout......................................................................................................... 30

Make-Up Air................................................................................................30

Venting........................................................................................................ 30

Individual Venting..................................................................................... 32

Manifold Venting...................................................................................... 33

©

Copyright 2018, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

6 Part No. 70532501ENR7

Gas Requirements.................................................................................36

Gas Requirements.........................................................................................36

How to Change Burner Orifice Size............................................................ 39

How to Adjust Gas Valve Governor/Regulator............................................. 40

Installing CE Gas Tumble Dryer.....................................................................41

Adjusting Manifold Pressure for Natural Gas G20 or G25................................ 41

Adjusting Supply Pressure for L.P.G. G30 or G31............................................41

Converting From Natural Gas to L.P.G. or From Unregulated L.P.G. to Regulated

L.P.G........................................................................................................41

Start-Up Procedure........................................................................................41

Gas Supply Pipe Sizing and Looping.............................................................. 42

Low Pressure Gas Pipe Sizes......................................................................43

High Pressure Gas Pipe Sizes..................................................................... 45

High Altitude Orifice Sizing ......................................................................... 47

Electrical Requirements........................................................................51

Electrical Requirements.................................................................................51

Wiring Diagram............................................................................................51

Grounding Instructions..................................................................................51

For On Premises Laundry (OPL) Models Only.............................................52

Service/Ground Location........................................................................... 52

To Connect Electrical Service To The Tumble Dryer........................................ 52

Electrical Specifications ............................................................................... 53

Steam Requirements.............................................................................56

Steam Requirements......................................................................................56

Piping Recommendations.............................................................................. 60

Installing Steam Trap and Making Condensate Return Connections...................60

Adjustments......................................................................................... 61

Adjustments................................................................................................. 61

Gas Burner Air Shutter.................................................................................. 61

Airflow Switch ............................................................................................ 62

Loading Door Switch.................................................................................... 62

Loading Door Catch (120 and 170 Series Models)........................................... 62

Loading Door Strike (200 Series Models)........................................................63

Manual Resettable Thermostat....................................................................... 63

Belt Drive.................................................................................................... 63

Upper Belt Tension....................................................................................64

Lower Belt Tension................................................................................... 64

Before You Call for Service................................................................... 65

Removing Tumble Dryer from Service.................................................. 66

Disposal of Unit.................................................................................... 67

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

7 Part No. 70532501ENR7

China Restriction of hazardous substances (RoHS)............................... 68

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

8 Part No. 70532501ENR7

Introduction

Model Identification

Information in this manual is applicable to these models. Refer

to the machine serial plate for the model number.

120 Pound (55 Kg)

BA120E GA120L HA120S HU120N NR120E PJ120S SH120N UG120L

BA120L GA120N HG120E HU120S NR120S PK120E SH120S UG120N

BA120N GA120S HG120L KT120E NT120E PK120L SJ120E UG120S

BA120S GG120E HG120N KT120L NT120L PK120N SJ120L UH120E

BG120E GG120L HG120S KT120N NT120N PR120E SJ120N UH120L

BG120L GG120N HH120E KT120S NT120S PR120S SJ120S UH120N

BG120N GG120S HH120L NA120E NU120E PT120C SK120E UH120S

BG120S GH120E HH120N NA120L NU120L PT120E SK120L UJ120E

Introduction

BH120E GH120L HH120S NA120N NU120N PT120L SK120N UJ120L

BH120L GH120N HJ120E NA120S NU120S PT120N SR120E UJ120N

BH120N GH120S HJ120L NG120E PA120E PT120S SR120S UJ120S

BH120S GJ120E HJ120N NG120L PA120L PU120E ST120C UK120E

BJ120E GJ120L HJ120S NG120N PA120N PU120L ST120E UK120L

BJ120L GJ120N HK120E NG120S PA120S PU120N ST120L UK120N

BJ120N GJ120S HK120L NH120E PG120E PU120S ST120N UR120E

BJ120S GK120E HK120N NH120L PG120L SA120E ST120S UR120S

BK120E GK120L HR120E NH120N PG120N SA120L SU120E UT120C

BK120L GK120N HR120S NH120S PG120S SA120N SU120L UT120E

BK120N GU120E HT120C NJ120E PH120E SA120S SU120N UT120L

BR120E GU120L HT120E NJ120L PH120L SG120E SU120S UT120N

BR120S GU120N HT120L NJ120N PH120N SG120L UA120E UT120S

BU120E GU120S HT120N NJ120S PH120S SG120N UA120L UU120E

BU120L HA120E HT120S NK120E PJ120E SG120S UA120N UU120L

BU120N HA120L HU120E NK120L PJ120L SH120E UA120S UU120N

BU120S HA120N HU120L NK120N PJ120N SH120L UG120E UU120S

GA120E

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

9 Part No. 70532501ENR7

Introduction

170 Pound (77 Kg) *Only available in gas and steam

BA170L GA170N HG170L KT170L NT170L PK170L SH170S UG170N

BA170N GA170S HG170N KT170N NT170N PK170N SJ170L UG170S

BA170S GG170L HG170S KT170S NT170S PR170S SJ170N UH170L

BG170L GG170N HH170L NA170L NU170L PT170C SJ170S UH170N

BG170N GG170S HH170N NA170N NU170N PT170L SK170L UH170S

BG170S GH170L HH170S NA170S NU170S PT170N SK170N UJ170L

BH170L GH170N HJ170L NG170L PA170L PT170S SR170S UJ170N

BH170N GH170S HJ170N NG170N PA170N PU170L ST170C UJ170S

BH170S GJ170L HJ170S NG170S PA170S PU170N ST170L UK170L

BJ170L GJ170N HK170L NH170L PG170L PU170S ST170N UK170N

BJ170N GJ170S HK170N NH170N PG170N SA170L ST170S UR170S

BJ170S GK170L HR170S NH170S PG170S SA170N SU170L UT170C

BK170L GK170N HT170C NJ170L PH170L SA170S SU170N UT170L

BK170N GU170L HT170L NJ170N PH170N SG170L SU170S UT170N

BR170S GU170N HT170N NJ170S PH170S SG170N UA170L UT170S

BU170L GU170S HT170S NK170L PJ170L SG170S UA170N UU170L

BU170N HA170L HU170L NK170N PJ170N SH170L UA170S UU170N

BU170S HA170N HU170N NR170S PJ170S SH170N UG170L UU170S

GA170L HA170S HU170S

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

10 Part No. 70532501ENR7

Introduction

200 Pound (90 Kg) *Only available in gas and steam

BA200L GA200N HG200L KT200L NT200L PK200L SH200S UG200N

BA200N GA200S HG200N KT200N NT200N PK200N SJ200L UG200S

BA200S GG200L HG200S KT200S NT200S PR200S SJ200N UH200L

BG200L GG200N HH200L NA200L NU200L PT200C SJ200S UH200N

BG200N GG200S HH200N NA200N NU200N PT200L SK200L UH200S

BG200S GH200L HH200S NA200S NU200S PT200N SK200N UJ200L

BH200L GH200N HJ200L NG200L PA200L PT200S SR200S UJ200N

BH200N GH200S HJ200N NG200N PA200N PU200L ST200C UJ200S

BH200S GJ200L HJ200S NG200S PA200S PU200N ST200L UK200L

BJ200L GJ200N HK200L NH200L PG200L PU200S ST200N UK200N

BJ200N GJ200S HK200N NH200N PG200N SA200L ST200S UR200S

BJ200S GK200L HR200S NH200S PG200S SA200N SU200L UT200C

BK200L GK200N HT200C NJ200L PH200L SA200S SU200N UT200L

BK200N GU200L HT200L NJ200N PH200N SG200L SU200S UT200N

BR200S GU200N HT200N NJ200S PH200S SG200N UA200L UT200S

BU200L GU200S HT200S NK200L PJ200L SG200S UA200N UU200L

BU200N HA200L HU200L NK200N PJ200N SH200L UA200S UU200N

BU200S HA200N HU200N NR200S PJ200S SH200N UG200L UU200S

GA200L HA200S HU200S

Heater Digit (Position 6)

C - Steam (CRN)

E - Electric

L - Liquid Petroleum (L.P.) Gas

N - Natural Gas

S - Steam

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

11 Part No. 70532501ENR7

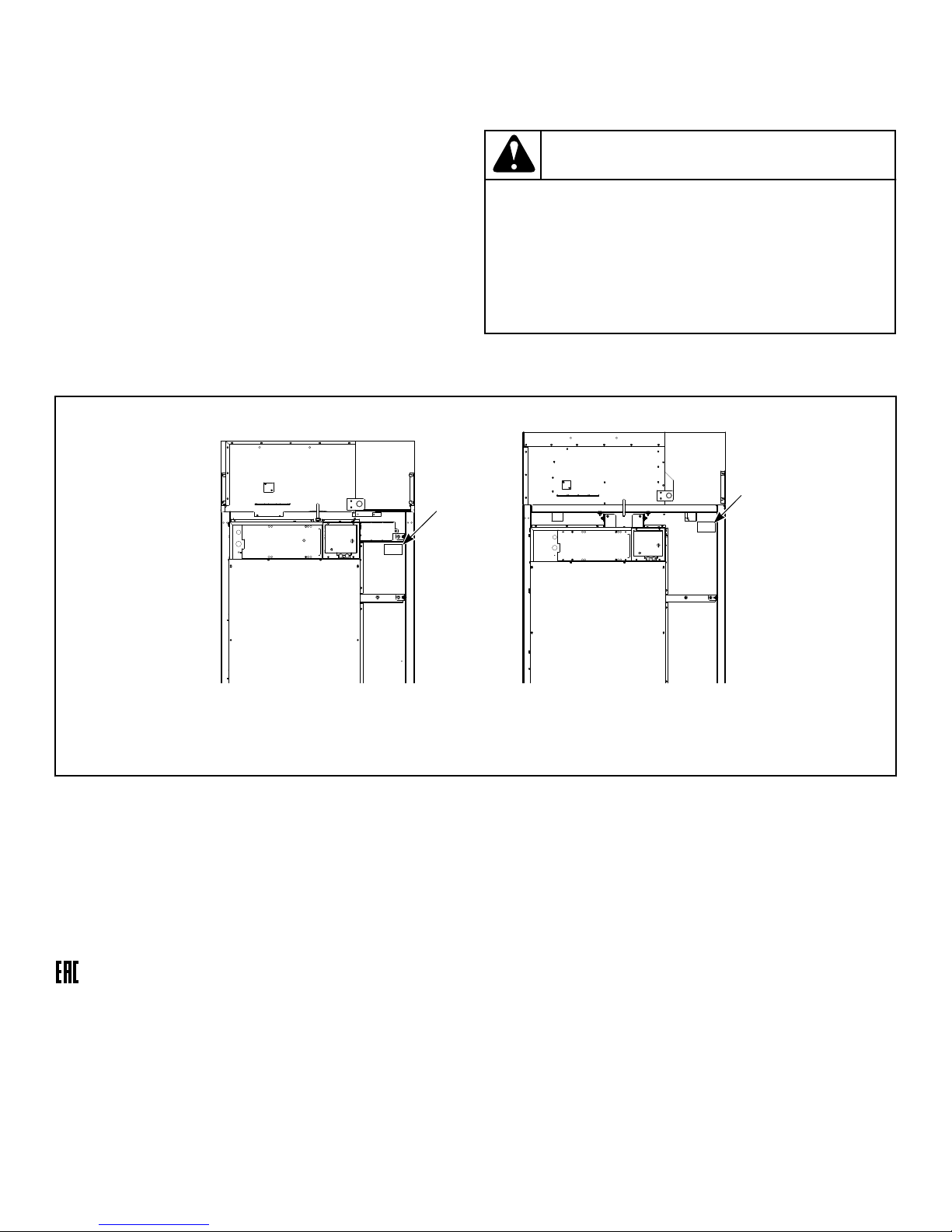

TMB2427N_SVG

120 170/200

1

1

Introduction

Contact Information

If service is required, contact the nearest Factory Authorized

Service Center.

If you are unable to locate an authorized service center or are unsatisfied with the service performed on your unit, contact the

source from which you purchased your unit.

When calling or writing about your unit, PLEASE GIVE THE

MODEL AND SERIAL NUMBERS. The model and serial numbers are located on the serial plate. The serial plate will be in the

location shown in Figure 1 .

Date Purchased ______________________________

Model Number ______________________________

Serial Number _______________________________

Please include a copy of your bill of sale and any service receipts

you have.

WARNING

To reduce the risk of serious injury or death, DO NOT

repair or replace any part of the unit or attempt any

servicing unless specifically recommended in the

user-maintenance instructions or in published userrepair instructions that you understand and have the

skills to carry out.

W329

If replacement parts are required, contact the source from where

you purchased your unit.

NOTE: An alternate serial plate is located on the front of the machine on the inside of the loading door hinge.

1. Serial Plate

Figure 1

Manufacturing Date

The manufacturing date for your unit can be found on the serial

number. The first two digits indicate the year. The third and

fourth digits indicate the month. For example, a unit with serial

number 1505000001 was manufactured in May 2015.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

12 Part No. 70532501ENR7

Safety Information

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,” and

“CAUTION”), followed by specific instructions, are found in this

manual and on machine decals. These precautions are intended

for the personal safety of the operator, user, servicer, and those

maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if

not avoided, will cause severe personal injury or

death.

WARNING

Indicates a hazardous situation that, if not avoided,

could cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided,

may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and

“NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specific procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is important but not hazard related.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your tumble

dryer, follow these basic precautions.

W776R1

Save These Instructions

• Read all instructions before using the tumble dryer.

• Install the tumble dryer according to the INSTALLATION instructions. Refer to the EARTHING (grounding) instructions

for the proper earthing (grounding) of the tumble dryer. All

connections for electrical power, earthing (grounding) and gas

supply must comply with local codes and be made by licensed

personnel when required. It is recommended that the machine

be installed by qualified technicians.

• Do not install or store the tumble dryer where it will be exposed to water and/or weather. The tumble dryer cannot be

used in a closed room where the air supply is insufficient. If

necessary, ventilation grids must be installed in the doors or

the windows.

• This tumble dryer must not be activated without lint screen

filter.

• When you perceive a gas odor, immediately shut off the gas

supply and ventilate the room. Do not power on electrical appliances and do not pull electrical switches. Do not use

matches or lighters. Do not use a phone in the building. Warn

the installer, and if so desired, the gas company, as soon as

possible.

• To avoid fire and explosion, keep surrounding areas free of

flammable and combustible products. Regularly clean the cylinder and exhaust tube should be cleaned periodically by

competent maintenance personnel. Daily remove debris from

lint screen filter and inside of filter compartment.

• Do not use or store flammable materials near this appliance.

• Do not place into tumble dryer articles that have been previously cleaned in, washed in, soaked in or spotted with gasoline or machine oils, vegetable or cooking oils, cleaning waxes or chemicals, dry-cleaning solvents, thinner or other flammable or explosive substances as they give off vapors that

could ignite, explode or cause fabric to catch on fire by itself.

• Do not spray aerosols in the vicinity of this appliance while it

is in operation.

• Items such as foam rubber (latex foam), shower caps, waterproof textiles, rubber backed articles and clothes or pillows

filled with foam rubber pads should not be dried in the tumble

dryer. Do not use the appliance to dry materials with a low

melting temperature (PVC, rubber, etc.).

• Do not tumble fiberglass curtains and draperies unless the label says it can be done. If they are dried, wipe out the cylinder

with a damp cloth to remove particles of fiberglass.

• Do not allow children to play on or in the dryer. Close supervision of children is necessary when the dryer is used near

children. This appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning the use

of the appliance by a person responsible for their safety. This

is a safety rule for all appliances.

• Cleaning and user maintenance shall not be made by children

without supervision.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

13 Part No. 70532501ENR7

Safety Information

• Children less than three years should be kept away unless

continuously supervised.

• Do not reach into the tumble dryer if the cylinder is revolving.

• Use tumble dryer only for its intended purpose, drying fabrics. Always follow the fabric care instructions supplied by

the textile manufacturer and only use the dryer to dry textiles

that have been washed in water. Only insert spin-dried linen

in the dryer to avoid damage to dryer.

• Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Follow all warnings or precautions. To reduce the risk of poisoning or chemical burns,

keep them out of the reach of children at all times (preferably

in a locked cabinet).

• Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener

or product.

• Remove laundry immediately after tumble dryer stops.

• DO NOT operate the tumble dryer if it is smoking, grinding

or has missing or broken parts or removed guards or panels.

DO NOT tamper with the controls or bypass any safety devices.

• Tumble dryer will not operate with the loading door open. DO

NOT bypass the door safety switch to permit the tumble dryer

to operate with the door open. The tumble dryer will stop rotating when the door is opened. Do not use the tumble dryer if

it does not stop rotating when the door is opened or starts

tumbling without pressing the START mechanism. Remove

the tumble dryer from use and call for service.

• Tumble dryer will not operate with lint panel open. DO NOT

bypass lint panel door safety switch to permit the tumble dryer to operate with the lint panel door open.

• Do not alter this tumble dryer from factory construction except as otherwise described in the technical instructions.

• Always clean the lint filter daily. Keep area around the exhaust opening and adjacent surrounding area free from the accumulation of lint, dust and dirt. The interior of the tumble

dryer and the exhaust duct should be cleaned periodically by

qualified service personnel.

• Solvent vapors from dry-cleaning machines create acids when

drawn through the heater of the drying unit. These acids are

corrosive to the tumble dryer as well as the laundry load being

dried. Be sure make-up air is free of solvent vapors.

• At the end of each working day, close off all main supplies of

gas, steam and electricity.

IMPORTANT: For fire suppression equipped tumble

dryers, electricity and water should NOT be turned

off.

• Do not repair or replace any part of the tumble dryer, or attempt any servicing unless specifically recommended in the

user-maintenance instructions or in published user-repair instructions that the user understands and has the skills to carry

out. ALWAYS disconnect and lockout the electrical power to

the tumble dryer before servicing. Disconnect power by shutting off appropriate breaker or fuse.

• Activation of the emergency stop switch stops all tumble dryer control circuit functions, but DOES NOT remove all electrical power from tumble dryer.

• Exhaust ductwork should be examined and cleaned annually

after installation.

• Before the tumble dryer is removed from service or discarded,

remove the door to the drying compartment and the door to

the lint compartment.

• Failure to install, maintain, and/or operate this tumble dryer

according to the manufacturer’s instructions may result in

conditions which can produce bodily injury and/or property

damage.

NOTE: The WARNINGS and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Observe and be aware of other labels and precautions that are located on the machine. They are intended to provide instruction for safe use of the machine. Common sense, caution and care must be exercised when installing, maintaining, or operating the

tumble dryer.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do not understand.

NOTE: All appliances are produced according the EMCdirective (Electro-Magnetic-Compatibility). They can be

used in restricted surroundings only (comply minimally

with class A requirements). For safety reasons there

must be kept the necessary precaution distances with

sensitive electrical or electronic device(s). These machines are not intended for domestic use by private

consumers in the home environment.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

14 Part No. 70532501ENR7

Specifications and Dimensions

Specifications and Dimensions

Specifications and Dimensions

Refer to machine serial plate for additional specifications.

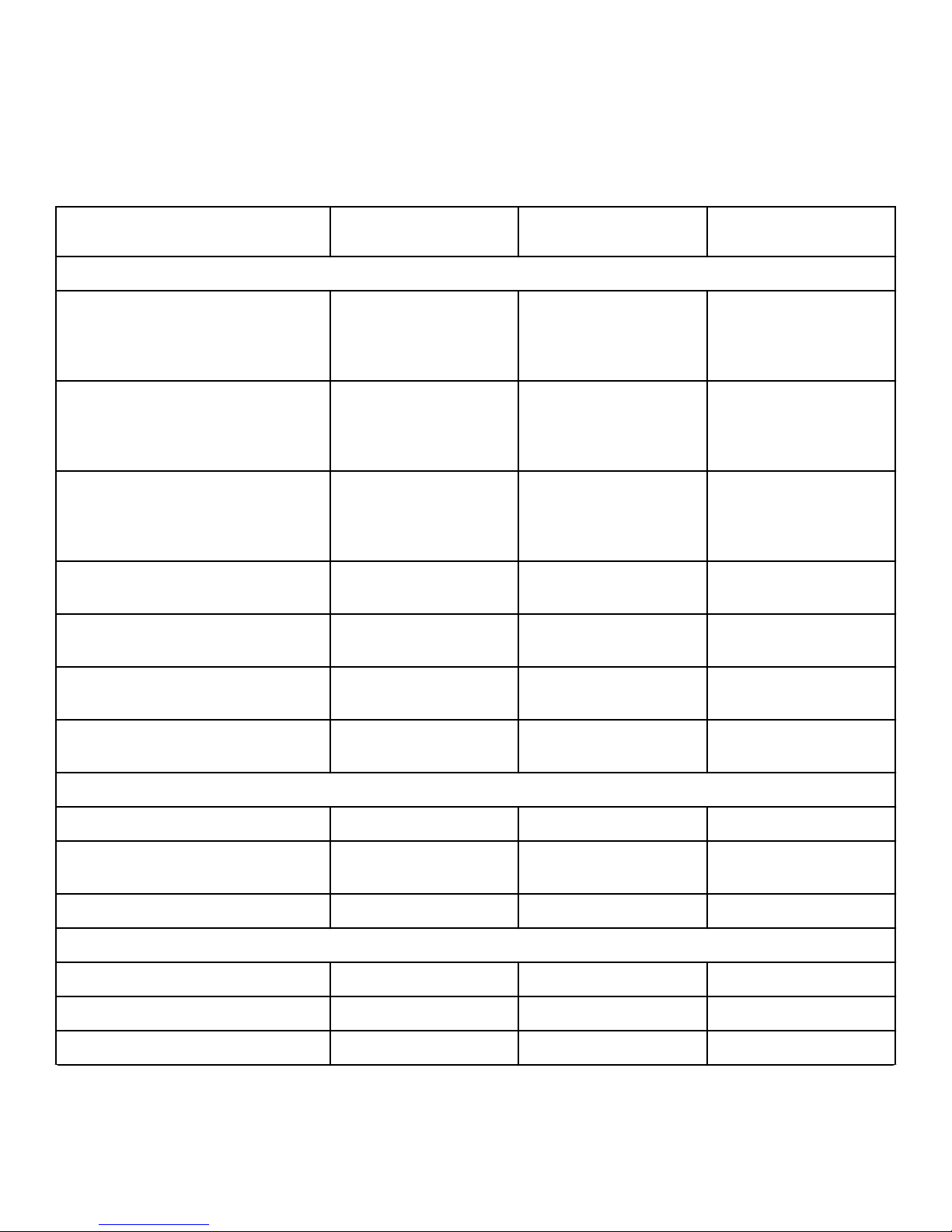

Specifications 120 Series 170 Series 200 Series

Weights and Shipping Information

Net Weight (approximate):

Pounds [Kilograms ]

Standard Packaging Weight: Pounds

[Kilograms]

Slat Crate Packaging Weight: Pounds

[Kilograms]

Standard Packaging Shipping Dimensions: Inches [Millimeters ]

Standard Packaging Shipping Volume:

ft3 [m3]

Slat Crate Packagine Shipping Dimensions: Inches [Millimeters ]

Slat Crate Packaging Shipping Volume:

ft3 [m3]

Gas 1220 [555]

Steam 1330 [605]

Electric 1250 [565]

Gas 1290 [585]

Steam 1400 [635]

Electric 1320 [600]

Gas 1460 [660]

Steam 1570 [710]

Electric 1490 [675]

48.0 x 71.5 x 90.0 [1220 x

1820 x 2290]

179 [5.1] 220 [6.2] 243 [6.9]

53.0 x 74.5 x 90.9 [1350 x

1890 x 2310]

208 [5.9] 268 [7.6] 294 [8.3]

Gas 1400 [635]

Steam 1550 [705]

Gas 1480 [670]

Steam 1630 [740]

Gas 1670 [755]

Steam 1820 [825]

52.1 x 73.8 x 99.0 [1320 x

1870 x 2510]

60.1 x 76.8 x 100.3 [1530

x 1950 x 2550]

Gas 1550 [705]

Steam 1700 [770]

Gas 1630 [740]

Steam 1780 [805]

Gas 1820 [825]

Steam 1970 [895]

52.1 x 81.3 x 99.0 [1320 x

2070 x 2510]

60.1 x 84.3 x 100.3 [1530

x 2140 x 2550]

Cylinder Information

Cylinder Size: Inches [mm] 44.0 x 41.0 [1120 x 1040] 50.8 x 42.5 [1290 x 1080] 50.8 x 50.0 [1290 x 1270]

Cylinder Capacity dry weight: Pounds

[kg]

Cylinder Volume: ft3 [liter] 36.1 [1020] 49.8 [1410] 58.6 [1660]

Operational Information

Cylinder Motor: HP [kW] 1.5 [1.1] 1.5 [1.1] 1.5 [1.1]

Fan Motor: HP [kW] 1.5 [1.1] 1.5 [1.1] 1.5 [1.1]

Air Outlet Diameter: Inches [mm] 10.0 [254] 12.0 [305] 12.0 [305]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

120 [55] 170 [77] 200 [90]

Table continues...

15 Part No. 70532501ENR7

Specifications and Dimensions

Specifications 120 Series 170 Series 200 Series

Maximum Static Back Pressure: W.C.I.

0.80 [2.0, 0.20] 0.80 [2.0, 0.20] 0.80 [2.0, 0.20]

[mbar, kPa]

Minimum Static Back Pressure:

0.0 [0.0, 0.0] 0.0 [0.0, 0.0] 0.0 [0.0, 0.0]

W.C.I. [Millibar, kPa]

Maximum Airflow: C.F.M. [L/sec.] 1400 [660] 2150 [1,010] 2150 [1,010]

Heat dissipation of surface area exposed

60 [680,000] 60 [680,000] 60 [680,000]

to conditioned air: Btu/ft2 [Joules/m2]

Noise level measured during operation

60 dBA 69 dBA 69 dBA

at operator position of 3.3 feet [1 meter]

in front of machine and 5.2 feet [1.6 meters] from floor.

Door Opening Information

Door Opening Diameter: Inches [Milli-

27.0 [686] 27.0 [686] 27.0 [686]

meter]

Door Hinge Side Right Right Right

Door Maximum Open Angle: Degrees 180 180 180

Gas Models

Gas Connection 1 NPT 1 NPT 1 NPT

Gas Burner Rating:

270,000 [79, 290] 395,000 [116, 417] 425,000 [125, 448]

Btu/hr. [kW, Mj/hr.]

Steam Models

Steam Connection 3/4 NPT inlet

3/4 NPT outlet

Steam Coil Rating at 100 psig:

187,500 [88.8] 265,500 [125.7] 265,500 [125.7]

3/4 NPT inlet

1 NPT outlet

3/4 NPT inlet

1 NPT outlet

Btu/hr. [kg/hr.] (recommended operating

pressure 80-100 psig)

Electric Models

Heating Element Rating: Kilowatts

60 Not Applicable Not Applicable

(kW)

NOTE: All IEC machines are shipped with an adapter to

convert the gas connection threads to BSPT (from

NPT).

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

16 Part No. 70532501ENR7

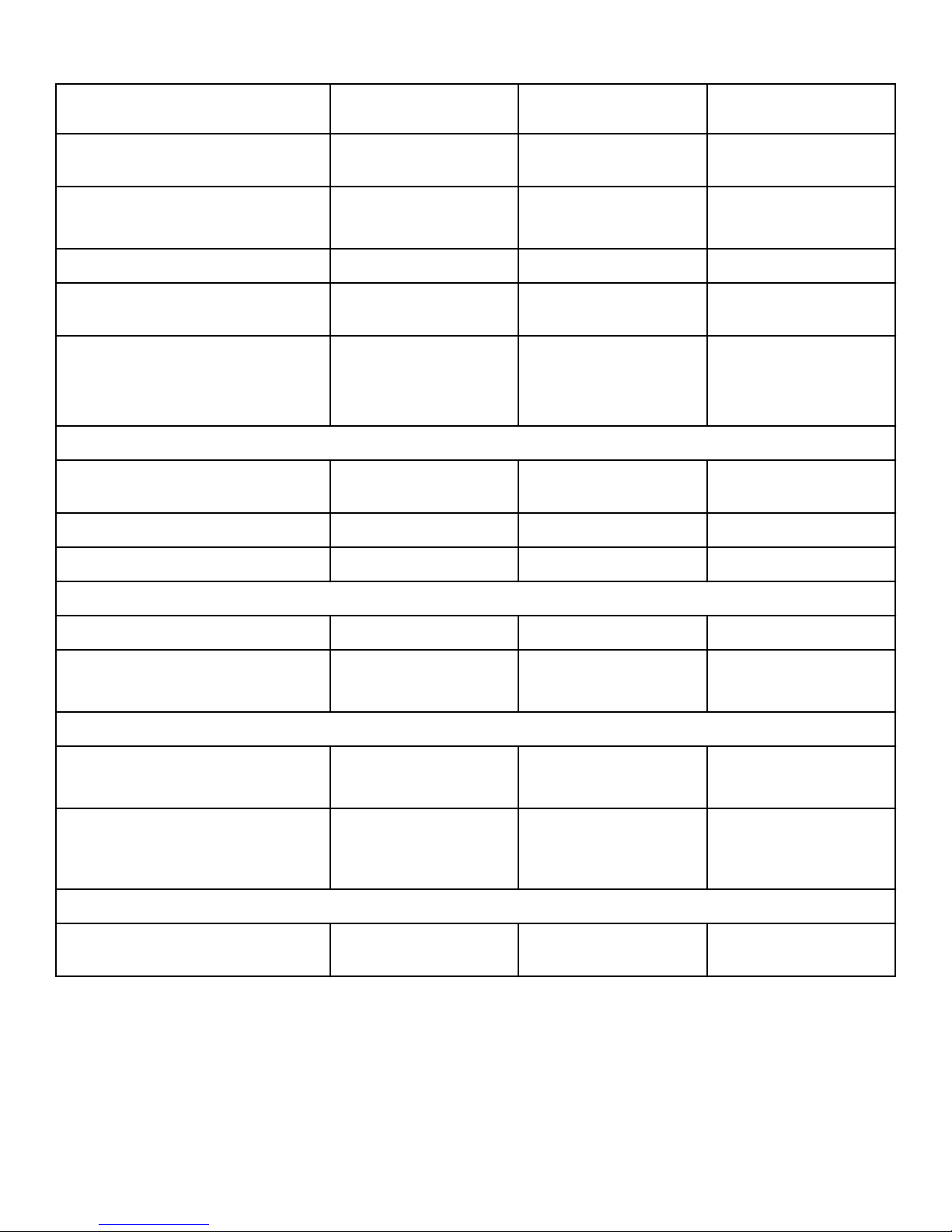

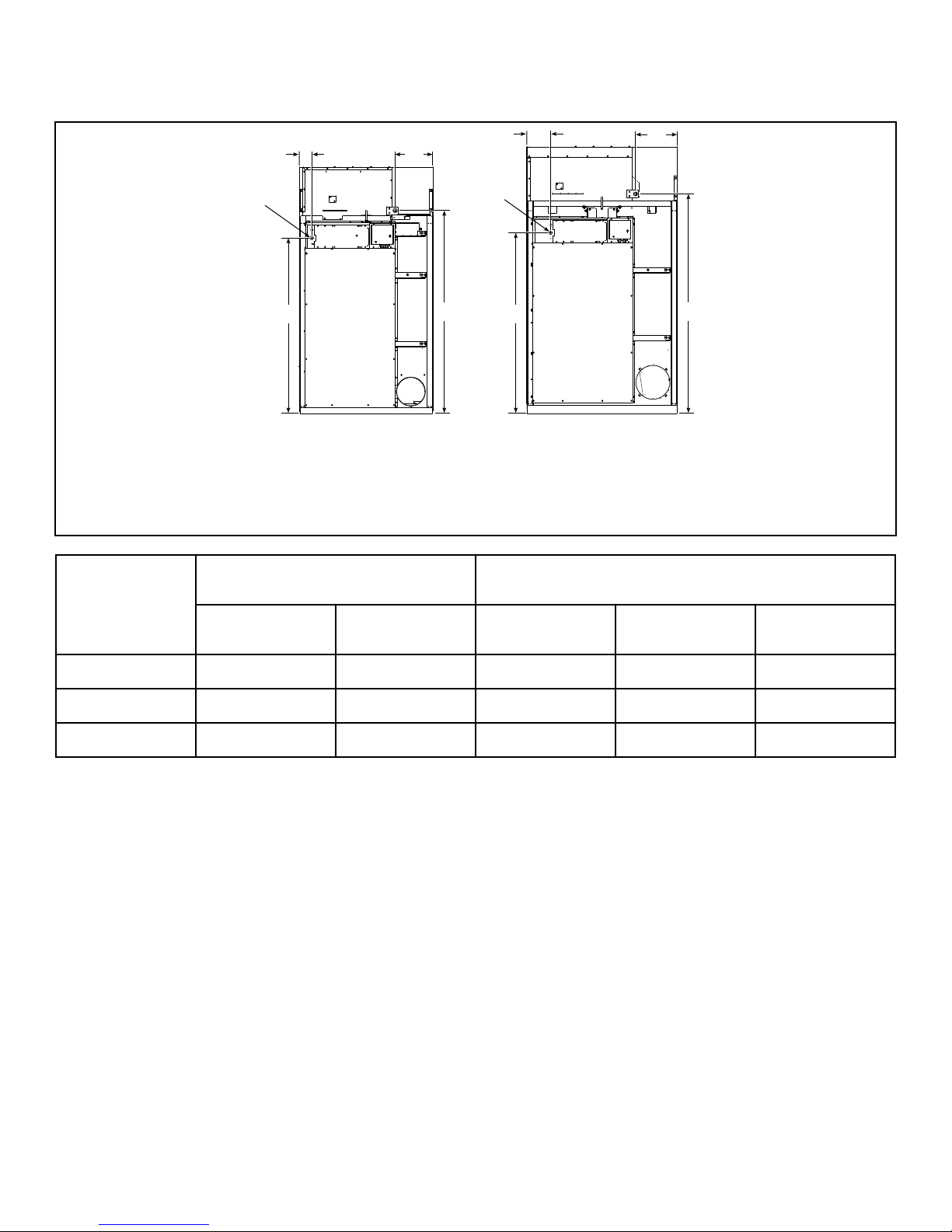

Cabinet Dimensions and Exhaust Outlet Locations

TMB2428N_SVG

Y

Z

H

C

D

E

F

K

G

J

I

B

A

Specifications and Dimensions

Cabinet Dimensions, in. [mm]

Models A B C D E

120 31.4 [800] 32.5 [825] 46.5 [1180] 49.9 [1270] 67.9 [1725]

170 33.9 [860] 32.5 [825] 48.3 [1125] 51.8 [1315] 69.8 [1775]

200 32.1 [815] 34.0 [865] 55.8 [1420] 59.3 [1505] 77.3 [1965]

Cabinet Dimensions, in. [mm]

Models F G H I* J* K*

120 46.1 [1170] 85.7 [2175] 70.0 [1780] 28.6 [725] 30.1 [765] 58.0 [1475]

170 52.9 [1345] 94.0 [2390] 75.0 [1905] 32.7 [830] 34.3 [870] 60.8 [1545]

200 52.9 [1345] 94.0 [2390] 75.0 [1905] 32.7 [830] 34.3 [870] 60.8 [1545]

* Fire suppression system optional - may not be on machine. Refer to Position and Level the Tumble Dryer to temporarily re-

duce the heights of these models.

Rear Exhaust Dimensions, in. [mm]

Models Diameter Y Z

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table continues...

17 Part No. 70532501ENR7

Specifications and Dimensions

Rear Exhaust Dimensions, in. [mm]

120 10.0 [250] 7.6 [195] 7.6 [195]

170 12.0 [305] 8.8 [225] 11.0 [280]

200 12.0 [305] 8.8 [225] 11.0 [280]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

18 Part No. 70532501ENR7

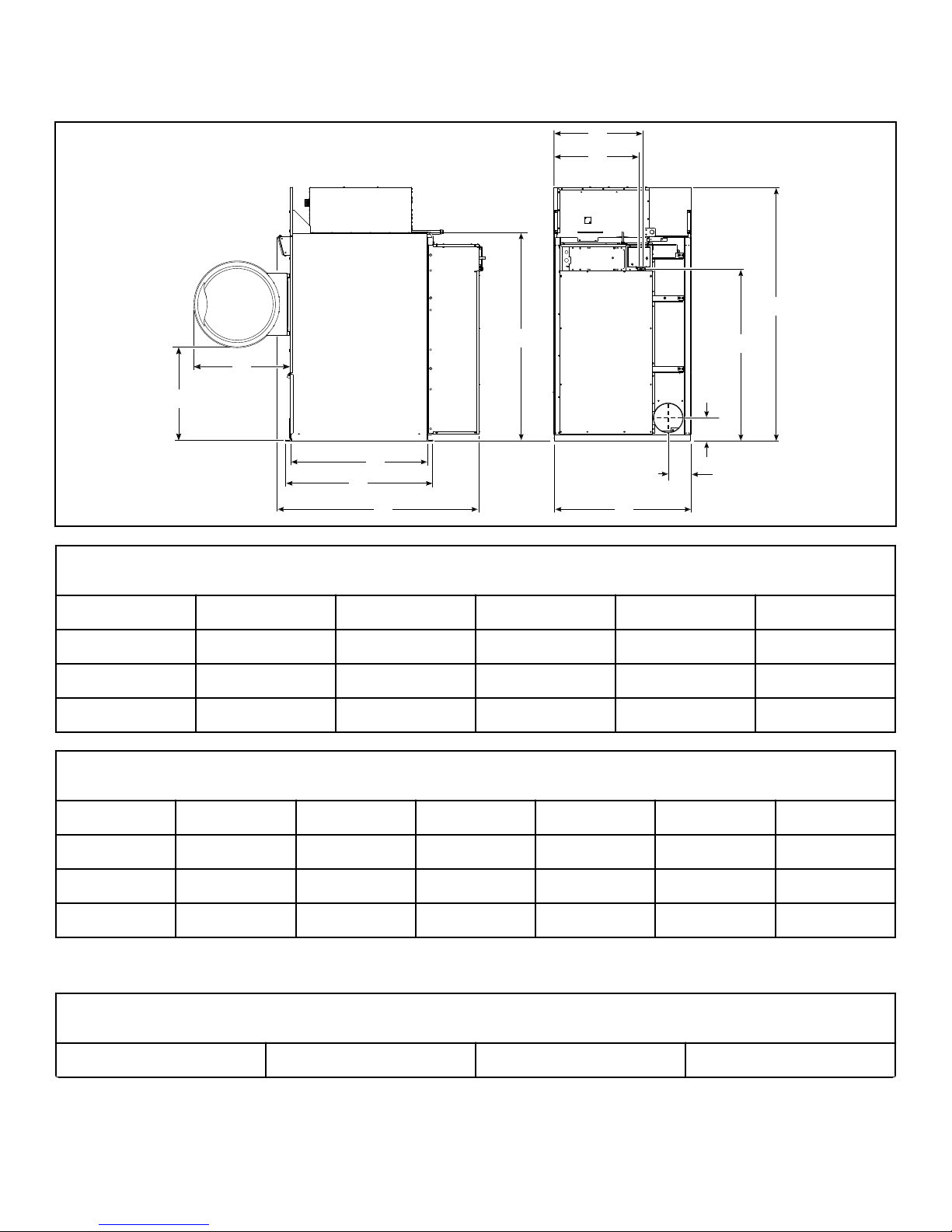

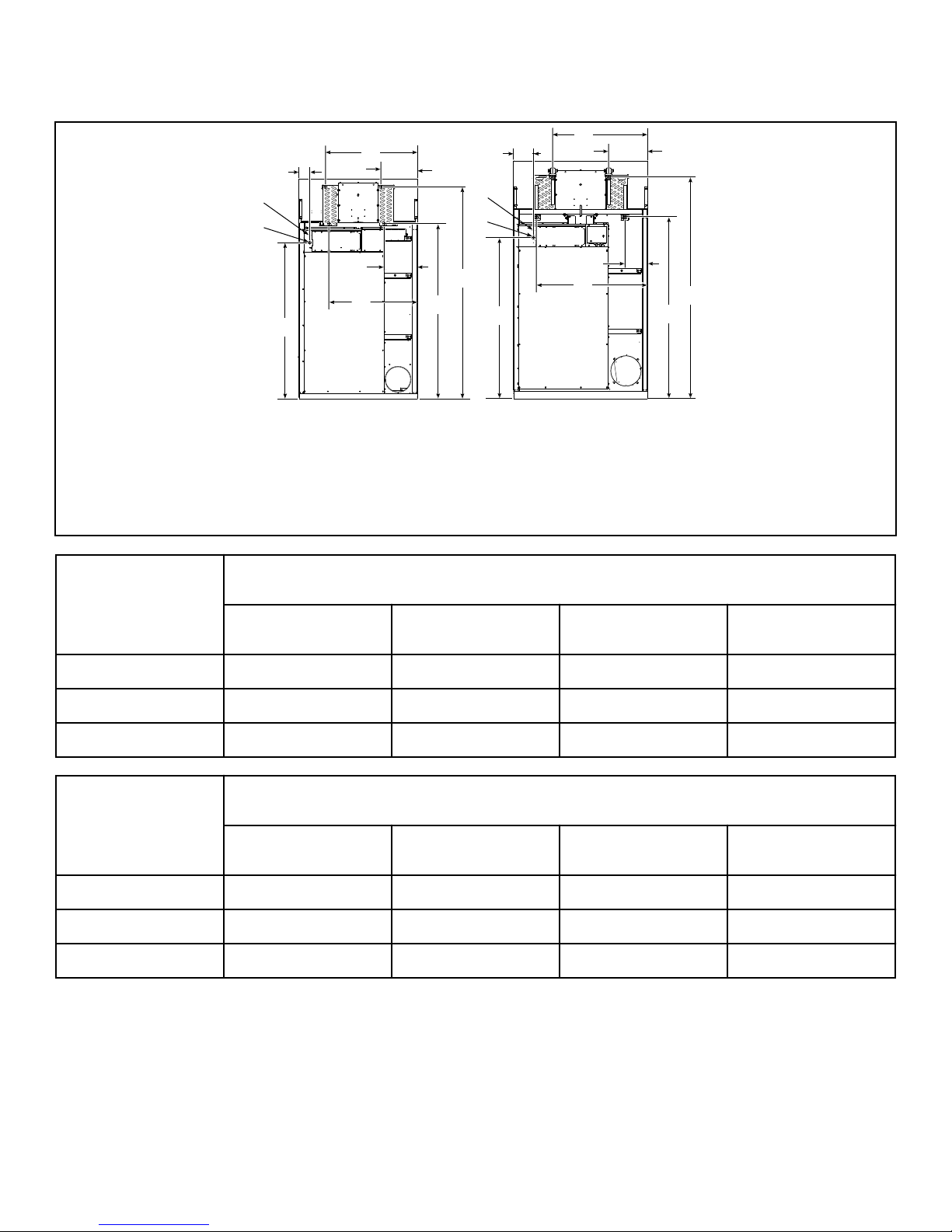

Electric and Gas Connection Locations for Gas Models

TMB2430N_SVG

D

B

C

A

D

B

C

A

21

3

3

1. 120

2. 170 and 200

3. Electrical Connection 1.125 in. [29 mm] Diameter

Specifications and Dimensions

Electrical Connection, in. [mm] Gas Connection, in. [mm]

Models

A B C D Diameter

120 3.9 [100] 60.9 [1545] 12.9 [330] 70.2 [1785] 1 NPT

170 8.0 [205] 63.7 [1620] 14.6 [370] 77.4 [1965] 1 NPT

200 8.0 [205] 63.7 [1620] 14.6 [370] 77.4 [1965] 1 NPT

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

19 Part No. 70532501ENR7

TMB2577N_SVG

B2

B2

B1

B1

D

D

E

E

F

F

A2

A2

A1

A1

C

C

21

3

3

4

4

Specifications and Dimensions

Electric and Steam Connection Locations for Steam Models

1. 120

2. 170 and 200

3. Electrical Connection 0.875 in. [22 mm] Diameter

4. Electrical Connection 1.125 in. [29 mm] Diameter

Steam Inlet, in. [mm]

Models

Diameter A1 A2 F

120 3/4 NPT 35.9 [910] 14.3 [365] 82.5 [2095]

170 3/4 NPT 37.6 [955] 15.5 [395] 87.6 [2225]

200 3/4 NPT 37.6 [955] 15.5 [395] 87.6 [2225]

Steam Outlet, in. [mm]

Models

Diameter B1 B2 D

120 3/4 NPT 34.6 [880] 13.1 [335] 68.5 [1740]

170 1 NPT 44.0 [1120] 9.0 [230] 72.0 [1830]

200 1 NPT 44.0 [1120] 9.0 [230] 72.0 [1830]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

20 Part No. 70532501ENR7

Electrical Connection, in. [mm]

Specifications and Dimensions

Models

C E

120 3.9 [100] 60.9 [1545]

170 8.0 [205] 63.7 [1620]

200 8.0 [205] 63.7 [1620]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

21 Part No. 70532501ENR7

Loading...

Loading...