ALLIANCE CK025N, CHD25G2-CT025L, CHD25G2-CA025N, CHD25G2-CT025N, CHD25G2-CU025N Installation Operation & Maintenance

...

Tumble Dryers

S

TA

R

T

25

C

H

I

G

H

T

E

M

P

M

E

D

T

E

M

P

L

O

W

T

E

M

P

N

O

H

E

A

T

1

2

3

S

E

L

E

C

T

T

E

M

P

I

N

S

E

R

T

C

O

I

N

P

U

S

H

S

T

A

R

T

1

2

3

S

E

L

E

C

T

T

E

M

P

I

N

S

E

R

T

C

O

I

N

P

U

S

H

S

T

A

R

T

S

T

A

R

T

2

5

C

H

IG

H

T

E

M

P

M

E

D

T

E

M

P

L

O

W

T

E

M

P

N

O

H

E

A

T

T477C

T478C

25 Pound (11,3 Kilogram) Capacity

30 Pound (13,6 Kilogram) Capacity

35 Pound (16 Kilogram) Capacity

Stacked 30 Pound (13,6 Kilogram) Capacity

Stacked 45 Pound (20,4 Kilogram) Capacity

55 Pound (25 Kilogram) Capacity

Starting Serial No. 0602004144

Refer to Page 6 for Model Identification

Installation/Operation/Maintenance

Original Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. 70458301ENR6

June 2013

Installation must conform with local codes or, in the absence of local codes, with:

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your building.

– Clear the room, building or area of all occupants.

– Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

W052

FOR YOUR SAFETY, the information in this manual must be followed to minimize the risk

of fire or explosion or to prevent property damage, personal injury or death.

W033

WARNING

In the U.S.A.

, installation must conform to the latest edition of the American National Standard Z223.1/

NFPA 54 “National Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code.”

In Canada

, installation must comply with Standards CAN/CSA-B149.1 or Natural Gas and Propane

Installation Code and CSA C22.1, latest edition, Canadian Electric Code, Part I.

In Australia and New Zealand

, installation must comply with the Gas Installations Standard AS/NZS 5601

Part 1: General Installations.

IMPORTANT: Information must be obtained from a local gas supplier on instructions to be followed if the

user smells gas. These instructions must be posted in a prominent location. Step-by-step instructions of the

above safety information must be posted in a prominent location near the tumble dryer for customer use.

IMPORTANT: The installer must fully test the tumble dryer after installation and demonstrate to the owner

how to operate the machine.

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

1

The following information applies to the state of Massachusetts, USA.

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumble dryer before servicing.

• Close gas shut-off valve to gas tumble dryer before servicing.

• Close steam valve to steam tumble dryer before servicing.

• Never start the tumble dryer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the tumble dryer is properly grounded.

W002R1

WARNING

• Installation of unit must be performed by a qualified installer.

• Install tumble dryer according to manufacturer’s instructions and local codes.

• DO NOT install a tumble dryer with flexible plastic venting materials. If flexible metal (foil

type) duct is installed, it must be of a specific type identified by the appliance manufacturer

as suitable for use with tumble dryer. Refer to section on connecting exhaust system.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These

conditions will obstruct tumble dryer airflow and increase the risk of fire.

W752R1

WARNING

This appliance can only be installed by a Massachusetts licensed plumber or gas fitter.

This appliance must be installed with a 91 cm (36 inch) long flexible gas connector.

A “T-Handle” type gas shut-off valve must be installed in the gas supply line to this appliance.

This appliance must not be installed in a bedroom or bathroom.

2

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Table of

Content s

Introduction......................................................................................... 6

Model Identification ............................................................................. 6

Contact Information.................................................. ............................ 9

Safety Information.............................................................................. 10

Important Safety Instructions ............................................................... 11

Specifications and Dimensions........................................................... 13

Cabinet Dimensions – 025, 030, 035 and 055 Series........................... 15

Cabinet Dimensions – T30 and T45 Series .......................................... 16

Exhaust Outlet Locations – 025, 030, 035 and 055 Series................... 17

Exhaust Outlet Locations – T30 and T45 Series.................................. 18

Gas Connection Locations – 025, 030, 035 and 055 Series................. 19

Gas Connection Locations – T30 and T45 Series ................................ 20

Electrical Connection Locations – 025, 030, 035 and 055 Series........ 21

Electrical Connection Locations – T30 and T45 Series ....................... 22

Steam Connection Locations – 025, 030 and 035 Series...................... 23

Steam Connection Locations – T30 Series........................................... 24

Installation........................................................................................... 25

Pre-Installation Inspection.................................................................... 25

Location Requirements......................................................................... 25

Position and Level the Tumble Dryer................................................... 27

Fire Suppression System....................................................................... 28

Check Local Codes and Permits...................................................... 28

Water Requirements......................................................................... 28

Water Connections........................................................................... 28

Electrical Requirements.......................................................... .... ..... 29

Auxiliary Alarm............................................................................... 30

To Reverse the Loading Door – 025, 030, 035 and 055 Series............ 30

Before Placing Tumble Dryer into Service .......................................... 33

Required for CE Models Only......................................................... 35

Installing CE Gas Tumble Dryer.......................................................... 36

General Information......................................................................... 36

CE Orifices....................................................................................... 37

Properties of CE Gases .................................................................... 38

Basic Configuration ......................................................................... 39

Specific Conversion Procedures ...................................................... 39

Exhaust Requirements ....................................................................... 42

Layout................................................................................................... 42

Make-Up Air........................................................................... ..... .... ..... 42

Venting ................................................................................................. 42

Individual Venting........................................................................... 43

Manifold Venting............................................................................. 45

Gas Requirements............................................................................... 48

Gas Supply Pipe Sizing and Looping................................................... 50

High Altitude Burner Orifice Sizing..................................................... 52

© Copyright 2013, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

3

Electrical Requirements..................................................................... 54

Wiring Diagram.................................................................................... 54

Grounding Instructions......................................................................... 55

For CE Models Only........................................................................ 55

Service/Ground Location................................................................. 56

To Connect Electrical Service To The Tumble Dryer.......................... 59

Configuring Your Tumble Dryer for Other Service Voltages......... 59

Electrical Connections for T30 and T45 Only................................. 59

Conversion Instructions........................................................................ 60

Ferrite Ring Installation (025, 030, 035 and 055 Series Only)............. 62

Electrical Specifications .................................................... ..... .............. 63

Steam Requirements........................................................................... 68

Piping Recommendations..................................................................... 68

Installing Steam Trap and Making Condensate Return

Connections........................................................................................ 69

Single Drop Timer .............................................................................. 71

Power-Up Mode........................................................ ..... .... ................... 71

Ready Mode.......................................................................................... 71

Start Mode ............................................................................................ 71

Run Mode ............................................................................................. 71

Setting Dry Time Dipswitches.............................................................. 71

Resetting Cycle Time to Zero............................................................... 71

Dipswitch Settings................................................................................ 72

Operating Instructions....................................................................... 74

Emergency Stop Button on CE Models................................................ 74

Operating Instructions .......................................................................... 75

Control Instructions.............................................................................. 76

Dual Digital Timer Control.............................................................. 76

Electronic OPL Micro Control......................................................... 78

Single Drop Control......................................................................... 79

MDC Coin and Card Control........................................................... 81

Quantum Control ............................................................................. 82

Galaxy 600 Control.......................................................................... 83

LED OPL Control............................................................................ 84

UniLinc Control............................................................................... 85

DX4 Coin Control............................................................................ 86

DX4 OPL Control............................................................................ 86

Diagnostic Microprocessor Control................................................. 87

DMP OPL Models ........................................................................... 88

DMP Coin........................................................................................ 90

Ignition Control Operation and Troubleshooting for

Models Starting 3/11/13..................................................................... 94

Internal Control Failure.................................................................... 94

Troubleshooting............................................................................... 94

Proper Electrode Location ............................................................... 95

Flame Current Measurement............................................................ 95

Ignition Control Operation for

Non-CE Models Through 3/10/13...................................................... 96

Ignition Control Operation for

CE Models Through 3/10/13.............................................................. 97

4

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Adjustments......................................................................................... 99

Airflow Switch...................................................................................... 99

Loading Door Switch............................................................................ 99

Door Strike............................................................................................ 100

Maintenance........................................................................................ 101

Daily ..................................................................................................... 101

Monthly................................................................................................. 102

Quarterly............................................................................................... 102

Bi-Annually .......................................................................................... 102

Annually ............................................................................................... 102

Fire Suppression System Maintenance Test.................................... 103

Before You Call for Service............................................................... 105

Removing Tumble Dryer from Service............................................. 105

Disposal of Unit................................................................................... 106

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

5

Introduction

Model Identification

Information in this manual is applicable to these models:

Gas Steam Electric

ST025N

SU025L

SU025N

UA025L

UA025N

UK025N

UT025L

UT025N

UU025L

UU025N

YT025L

YT025N

YU025L

YU025N

ST030L

ST030N

SU030L

SU030N

UA030L

UA030N

UK030N

UT030L

UT030N

UU030L

UU030N

YT030L

YT030N

YU030L

YU030N

SKT30N

STT30D

STT30L

STT30N

SUT30L

SUT30N

UAT30L

UAT30N

UKT30N

UTT30L

UTT30N

UUT30L

UUT30N

(Continued)

025

Series

030

Series

T30

Series

CHD25G2-CA025L

CHD25G2-CA025N

CHD25G2-CT025L

CHD25G2-CT025N

CHD25G2-CU025L

CHD25G2-CU025N

CK025N

DR25G2-BA025L

DR25G2-BA025N

DR25G2-BK025N

DR25G2-BT025L

DR25G2-BT025N

DR25G2-BU025L

DR25G2-BU025N

CHD30G2-CA030L

CHD30G2-CA030N

CHD30G2-CT030L

CHD30G2-CT030N

CHD30G2-CU030L

CHD30G2-CU030N

CK030N

DR30G2-BA030L

DR30G2-BA030N

DR30G2-BK030N

DR30G2-BT030D

DR30G2-BT030L

DR30G2-BT030N

DR30G2-BU030L

DR30G2-BU030N

CHD30STG2-CAT30L

CHD30STG2-CAT30N

CHD30STG2-CTT30L

CHD30STG2-CTT30N

CHD30STG2-CUT30L

CHD30STG2CUT30N

CKT30N

DR335

DR335G2-BKT30N

DRST30G2-BAT30L

DRST30G2-BAT30N

DRST30G2-BTT30D

DRST30G2-BTT30L

DRST30G2-BTT30N

DRST30G2-BUT30L

DRST30G2-BUT30N

HA025L

HA025N

HK025N

HT025L

HT025N

HU025L

HU025N

IPD25G2

IT025L

IT025N

SA025L

SA025N

SK025N

ST025L

HA030L

HA030N

HK030N

HT030D

HT030L

HT030N

HU030L

HU030N

IPD30G2

IT030L

IT030N

SA030L

SA030N

SK030N

ST030D

HAT30L

HAT30N

HKT30N

HTT30D

HTT30L

HTT30N

HUT30L

HUT30N

IPD30STG2

ITT30L

ITT30N

MTT30N

NTT30N

SAT30L

SAT30N

CHD25S2-CT025S

CHD25S2-CU025S

DR25S2-BT025S

DR25S2-BU025S

HT025S

HU025S

IPD25S2

CHD30S2-CT030S

CHD30S2-CU030S

DR30S2-BT030S

DR30S2-BU030S

HT030S

HU030S

IPD30S2

CHD30STS2-CTT30S

CHD30STS2-CUT30S

DRST30S2-BTT30S

DRST30S2-BUT30S

HTT30S

HUT30S

IPD30STS2

IT025S

ST025S

SU025S

UT025S

UU025S

YT025S

YU025S

IT030S

ST030S

SU030S

UT030S

UU030S

YT030S

YU030S

ITT30S

STT30S

SUT30S

UTT30S

UUT30S

CHD25E2-CT025E

CHD25E2-CU025E

DR25E2-BT025E

DR25E2-BU025E

HT025E

HU025E

IPD25E2

CHD30E2-CT030E

CHD30E2-CU030E

DR30E2-BT030E

DR30E2-BU030E

HT030E

HU030E

IPD30E2

CHD30STE2-CTT30E

CHD30STE2CUT30E

DRST30E2-BTT30E

DRST30E2-BUT30E

HTT30E

HUT30E

IPD30STE2

IT025E

ST025E

SU025E

UT025E

UU025E

YT025E

YU025E

IT030E

ST030E

SU030E

UT030E

UU030E

YT030E

YU030E

ITT30E

STT30E

SUT30E

UTT30E

UUT30E

6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

035

Series

T45

Series

055

Series

AT035L

AT035N

CHD35G2-CA035L

CHD35G2-CA035N

CHD35G2-CT035L

CHD35G2-CT035N

CHD35G2-CU035L

CHD35G2-CU035N

CK035N

DR35G2-BA035L

DR35G2-BA035N

DR35G2-BK035N

DR35G2-BT035L

DR35G2-BT035N

DR35G2-BU035L

DR35G2-BU035N

CKT45N

CTT45L

CTT45N

DR445G2-BAT45L

DR445G2-BAT45N

DR445G2-BKT45N

DR445G2-BTT45D

DR445G2-BTT45L

DR445G2-BTT45N

DR445G2-BUT45L

DR445G2-BUT45N

DRST45G2-BAT45L

DRST45G2-BAT45N

DRST45G2-BTT45D

DRST45G2-BTT45L

DRST45G2-BTT45N

DRST45G2-BUT45L

DRST45G2-BUT45N

CA055L

CA055N

CK055N

CT055L

CT055N

CU055L

CU055N

DR55SG2-BA055L

DR55SG2-BA055N

DR55SG2-BK055N

DR55SG2-BT055D

DR55SG2-BT055L

DR55SG2-BT055N

DR55SG2-BU055L

DR55SG2-BU055N

Introduction

(Continued)

Gas Steam Electric

HA035L

HA035N

HK035N

HT035L

HT035N

HU035L

HU035N

IPD35G2

IT035L

IT035N

SA035L

SA035N

SU035N

UA035L

UA035N

UK035N

UT035L

UT035N

UU035L

UU035N

YT035L

YT035N

YU035L

YU035N

AT035S

CHD35S2-CT035S

CHD35S2-CU035S

DR35S2-BT035S

DR35S2-BU035S

HT035S

HU035S

IPD35S2

IT035S

ST035S

SU035S

UT035S

UU035S

YT035S

YU035S

AT035E

CHD35E2-CT035E

CHD35E2-CU035E

DR35E2-BT035E

DR35E2-BU035E

HT035E

HU035E

IPD35E2

SK035N

ST035L

ST035N

SU035L

HAT45L

HAT45N

HKT45N

HTT45D

HTT45L

HTT45N

HUT45L

HUT45N

IPD45STG2

ITT45L

STT45N

SUT45L

SUT45N

UAT45L

UAT45N

UKT45N

UTT45L

UTT45N

UUT45L

UUT45N

Not Applicable Not Applicable

ITT45N

MTT45N

NTT45N

SAT45L

SAT45N

SKT45N

STT45D

STT45L

HA055L

HA055N

HK055N

HT055D

HT055L

HT055N

HU055L

HU055N

IPD55G2

IT055L

IT055N

ST055L

ST055N

SU055L

SU055N

UA055L

UA055N

UK055N

UT055L

UT055N

UU055L

UU055N

Not Applicable

CT055E

CU055E

DR55SE2-BT055E

DR55SE2-BU055E

HT055E

HU055E

SA055L

SA055N

SK055N

ST055D

(see next page for suffixes)

IT035E

ST035E

SU035E

UT035E

UU035E

YT035E

YU035E

IPD55E2

IT055E

ST055E

SU055E

UT055E

UU055E

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

7

Introduction

Includes models with the following control suffixes:

3B – reversing DX4 vended

3O – DX4 OPL

3V – DX4 vended

3W – reversing DX4 prep for coin

3X – DX4 prep for coin

BB – reversing basic electronic, coin

BC – basic electronic, coin

BG – basic electronic, OPL mode

BL – basic electronic, central pay

BW – reversing basic electronic, prep

for coin

BX – basic electronic, prep for coin

BY – basic electronic, prep for card

BZ – reversing basic electronic, prep

for card

DO – DMP OPL

DV – DMP vended

DX – DMP prep for coin

EO – LED OPL

KB – reversing single coin

KC – single coin

KW – reversing prep for coin

KX – prep for coin

KY – prep for card

KZ – reversing prep for card

LB – reversing network adaptable

coin

LC – network adaptable coin

LW – reversing network adaptable,

prep for coin

LX – network adaptable, prep for

coin

LY – network adaptable, prep for

card

LZ – reversing network adaptable,

prep for card

NC – NetMaster coin

NR – NetMaster card

NX – NetMaster, prep for coin

NY – NetMaster, prep for card

OM – OPL micro

QT – dual digital timer

R3 – reversing DX4 OPL

RE – reversing LED OPL

RQ – reversing dual digital timer

RU – reversing UniLinc OPL

SD – single drop

SX – single drop, prep for coin

UO – UniLinc OPL

WB – reversing network ready coin

WC – network ready coin

WW –reversing network ready, prep

for coin

WX – network ready, prep for coin

WY – network ready, prep for card

WZ – reversing network ready, prep

for card

ZC – NetMaster network coin

ZR – NetMaster network card

ZX – NetMaster network, prep for

coin

ZY – NetMaster network, prep for

card

8

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Contact Information

T o reduce the risk of serious injury or death,

DO NOT repair or replace any p art of the unit

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have

the skills to carry out.

W329

WARNING

1

1

TMB2098N

TMB1974N

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to locate an authorized service center

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

+32 56 41 20 54 Wevelgem, Belgium

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS.

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in Figure 1.

Date Purchased _____________ __ __ __ ___ __ __ ____

Model Number ______________________________

Serial Number _______________________________

The

Introduction

If replacement parts are required, contact the source

from where you purchased your tumble dryer or call

+1 (920) 748-3950 or +32 56 41 20 54 for the name

and address of the nearest authorized parts distributor.

Please include a copy of your bill of sale and any

service receipts you have.

1 Serial Plate

Figure 1

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

9

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

Failure to install, maintain, and/or operate

this machine according to manufacturer’s

instructions may result in conditions which

can produce serious injury, death and/or

property damage.

W051R1

WARNING

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not

meant to cover all possible conditions and

situations that may occur. It must be understood

that common sense, caution and carefulness are

factors which CANNOT be built into this tumble

dryer. These factors MUST BE supplied by the

person(s) installing, maintaining or operating the

tumble dryer.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

Always contact your dealer, distributor, service agent

or the manufacturer on any problems or conditions you

do not understand.

10

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Save These Instructions

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your tumbler, follow these basic

precautions.

W776

WARNING

Safety Information

Important Safety Instructions

1. Read all instructions before using the tumble

dryer.

2. Install the tumble dryer according to the

INSTALLATION instructions. Refer to the

EARTHING (grounding) instructions for the

proper earthing (grounding) of the tumble dryer.

All connections for electrical power, earthing

(grounding) and gas supply must comply with

local codes and be made by licensed personnel

when required. It is recommended that the

machine be installed by qualified technicians.

3. Do not install or store the tumble dryer where it

will be exposed to water and/or weather. The

tumble dryer cannot be used in a closed room

where the air supply is insufficient. If necessary,

ventilation grids must be installed in the doors or

the windows.

4. This appliance must not be activated without lint/

foam filter.

5. When you perceive a gas odor, immediately

switch off the gas supply and ventilate the room.

Do not switch on electrical appliances and do not

pull electrical switches. Do not use matches or

lighters. Do not use a phone in the building. Warn

the fitter, and if so desired, the gas company, as

soon as possible.

6. To avoid fire an d explosion, keep surrounding

areas free of flammable and combustible

products. Regularly clean the dryer drum and

exhaust tube should be cleaned periodically by

competent maintenance personnel. Daily remove

piled up dust from filter and inside of filter

compartment.

7. Do not use or store flammable materials near this

appliance.

8. Do not dry articles that have been previously

cleaned in, washed in, soaked in or spotted with

gasoline or machine oils, vegetable or cooking

oils, cleaning waxes or chemicals, dry-cleaning

solvents, thinner or other flammable or explosive

substances as they give off vapors that could

ignite, explode or cause fabric to catch on fire by

itself.

9. Do not spray aerosols in the vicinity of this

appliance while it is in operation.

10. Items such as foam rubber (latex foam), shower

caps, waterproof textiles, rubber backed articles

and clothes or pillows filled with foam rubber

pads should not be dried in the tumble dryer. Do

not use the appliance to dry materials with a low

melting temperature (PVC, rubber, etc.).

11. Do not tumble fiberglass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiberglass.

12. Do not allow children on or in the tumble dryer.

This appliance is not intended for use by young

children or infirm persons without supervision.

Young children should be supervised to ensure

that they do not play with the appliance.

13. Do not reach into the tumble dryer if the cylinder

is revolving.

14. Use tumble dryer only for its intended purpose,

drying fabrics. Always follow the fabric care

instructions supplied by the textile manufacturer

and only use the dryer drum to dry textiles that

have been washed in water. Only insert spindried linen in the dryer.

15. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. T o reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

16. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

17. Remove laundry immediately after tumble dryer

stops.

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

11

Safety Information

18. DO NOT operate the tumble dryer if it is

smoking, grinding or has missing or broken parts

or removed guards or panels. DO NOT tamper

with the controls or bypass any safety devices.

19. Tumble dryer will not operate with the loading

door open. DO NOT bypass the door safety

switch to permit the tumble dryer to operate with

the door open. The tumble dryer will stop

tumbling when the door is opened. Do not use the

tumble dryer if it does not stop tumbling when

the door is opened or starts tumbling without

pressing or turning the START mechanism.

Remove the tumble dryer from use and call for

service.

20. Tumble dryer(s) will not operate with lint panel

open. DO NOT bypass lint panel safety switch to

permit the tumble dryer to operate with the lint

panel open.

21. Do not modify this appliance.

22. Always clean the lint filter daily. Keep area

around the exhaust opening and adjacent

surrounding area free from the accumulation of

lint, dust and dirt. The interior of the tumble

dryer and the exhaust duct should be cleaned

periodically by qualified service personnel.

23. Solvent vapors from dry-cleaning machines

create acids when drawn through the heater of the

drying unit. These acids are corrosive to the

tumble dryer as well as the laundry load being

dried. Be sure make-up air is free of solvent

vapors.

24. At the end of each working day, close off all main

supplies of gas, steam and current.

25. Do not repair or replace any part of the tumble

dryer, or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out. ALWAYS disconnect and

lockout the electrical power to the tumble dryer

before servicing. Disconnect power by shutting

off appropriate breaker or fuse.

26. Before the tumble dryer is removed from service

or discarded, remove the door to the drying

compartment and the door to the lint

compartment.

27. Failure to install, maintain, and/or operate this

tumble dryer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the tumble

dryer.

Always contact your dealer, distributor, service agent

or the manufacturer on any problems or conditions you

do not understand.

12

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

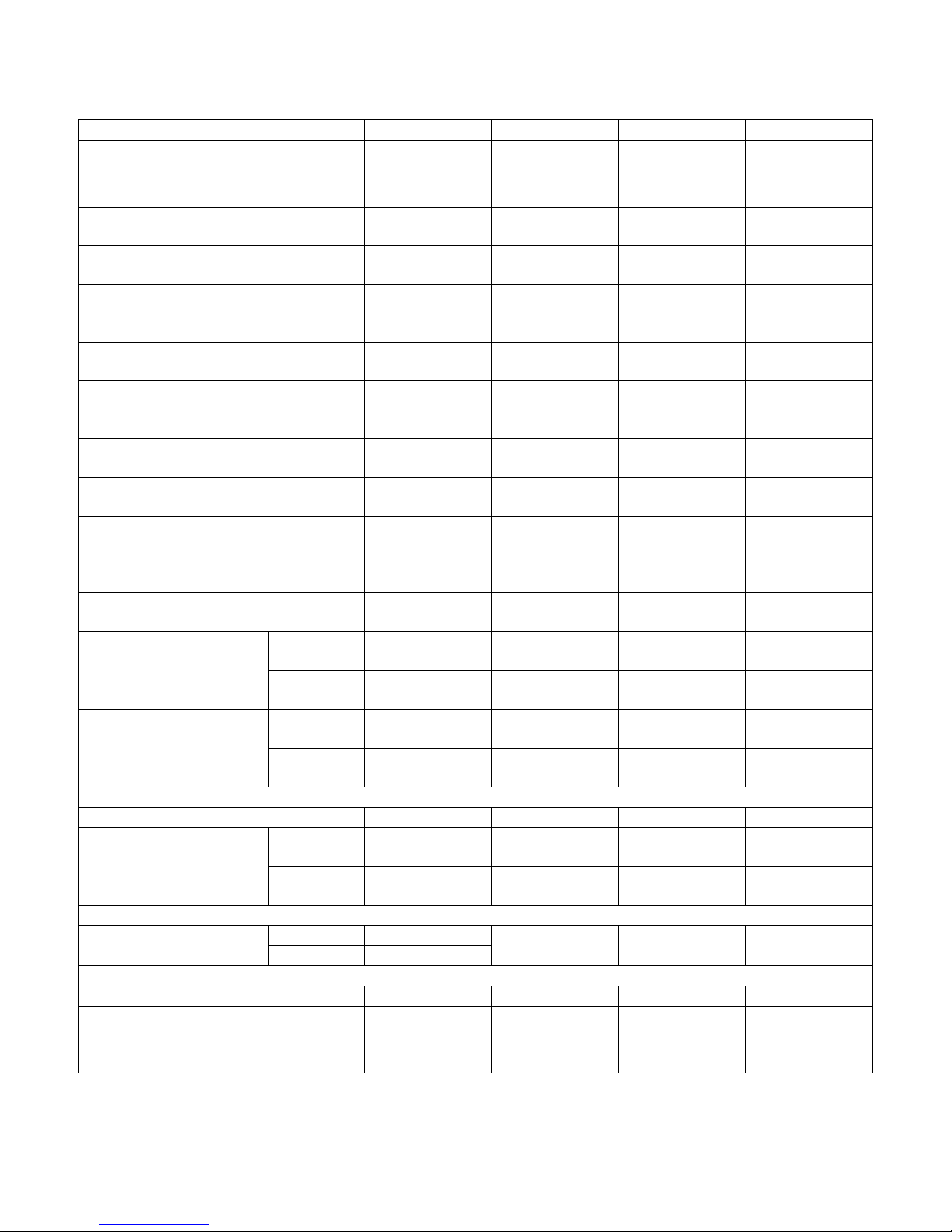

Specifications and Dimensions

Specifications 025 Series 030 Series 035 Series 055 Series

Noise level measured during

operation at operator position of

3.3 feet (1 meter) in front of machine

and 5.2 feet (1.6 meters) from floor

Net Weight (approximate):

Pounds (kg )

Standard Packaging Weight:

Pounds (kg )

Standard Packaging Shipping

Dimensions:

Inch (mm)

Slat Crate Packaging Weight:

Pounds (kg )

Slat Crate Shipping Dimensions:

Inch (mm)

Cylinder Size:

Inch (mm)

Cylinder Capacity (dry weight):

Pounds (kg )

Drive Motor:

Horsepower (kW)

Fan Motor:

Horsepower (kW)

50 Hertz 430

Maximum Airflow per

Pocket: C.F.M. (l/sec)

Maximum Static Back

Pressure:

Inch W.C. (mbar, kPa)

Gas Connection 1/2 in. NPT 1/2 in. NPT 1/2 in. NPT 1/2 in. NPT

Gas Burner Rating:

Btu/hr. (kW, Mj/hr.)

Heating Element Rating:

Steam Connection 3/4 in. NPT 3/4 in. NPT 3/4 in. NPT N/A

Steam Coil Rating at 100 psig:

Boiler Horsepower (Btu/hr.)

(recommended operating

pressure 80-100 psig)

N/A = Not Applicable

60 Hertz 500

50 Hertz 0.6

60 Hertz 0.8

50 Hertz 64,000

60 Hertz 64,000

400/50/3 10 kW

Standard 12 kW

60 dBA 61 dBA 63 dBA 63 dBA

300

(137)

332

(151)

30 x 43 x 69

(762 x 1,092 x

1,753)

406

(184)

34.5 x 46 x 87.75

(876 x 1,168 x

2,229)

26.5 x 24

(673 x 610)

25

(11.3)

1/4

(0.1865)

1/4

(0.1865)

(203)

(236)

(1.5, 0.15)

(2.0, 0.2)

Gas Models

(18.7, 67.5)

(18.7, 67.5)

Electric Models

Steam Models

3.9

(134,700)

330

(150)

364

(165)

30 x 49 x 69

(762 x 1,245 x

1,753)

446

(202)

34.5 x 52 x 87.75

(876 x 1,321 x

2,229)

26.5 x 30

(673 x 762)

30

(13.6)

1/4

(0.1865)

1/4

(0.1865)

430

(203)

500

(236)

0.6

(1.5, 0.15)

0.8

(2.0, 0.2)

73,000

(21.4, 77)

73,000

(21.4, 77)

21 kW 24 kW 27 kW

3.9

(134,700)

360

(163)

394

(179)

33 x 49 x 69

(838 x 1,245 x

1,753)

480

(218)

37.5 x 52 x 87.75

(953 x 1,321 x

2,229)

30 x 30

(762 x 762)

35

(15.9)

1/4

(0.1865)

1/4

(0.1865)

550

(260)

650

(307)

0.5

(1.3, 0.13)

0.6

(1.5, 0.15)

90,000

(26.4, 95)

90,000

(26.4, 95)

4.8

(166,000)

40 x 60 x 87.25

(1,016 x 1,524 x

435

(197)

476

(216)

35.5 x 59 x 72

(902 x 1,499 x

1,829)

506

(230)

2,216)

33 x 35

(838 x 889)

55

(24.9)

Nonreversing

1/2 (0.373)

Reversing

1/4 (0.1865)

1/2

(0.373)

600

(283)

700

(330)

0.5

(1.3, 0.13)

0.6

(1.5, 0.15)

102,000

(29.9, 107.6)

112,000

(32.8, 118.2)

N/A

NOTE: All machines are shipped with extra nipple

to convert to metric thread (from Standard).

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

13

Specifications and Dimensions

Specifications T30 Series T45 Series

Noise level measured during operation at operator

position of 3.3 feet (1 meter) in front of machine and

5.2 feet (1.6 meters) from floor

Net Weight (approximate):

Pounds (kg)

Standard Packaging Weight:

Pounds (kg)

Standard Packaging Shipping Dimensions:

Inch (mm)

Slat Crate Packaging Weight:

Pounds (kg)

Slat Crate Shipping Dimensions:

Inch (mm)

Cylinder Size:

Inch (mm)

Cylinder Capacity (dry weight):

kg (Pounds)

Drive Motor**:

Horsepower (kW)

Fan Motor**:

Horsepower (kW)

50 Hertz 340

Maximum Airflow per Pocket**:

C.F.M. (l/sec)

60 Hertz 400

50 Hertz 0.8

Maximum Static Back Pressure*:

Inch W.C. (mbar, kPa)

60 Hertz 0.9

Gas Models

Gas Connection

50 Hertz 73,000

Gas Burner Rating**:

Btu/hr. (kW, Mj/hr.)

60 Hertz 73,000

Electric Models

Heating Element Rating**:

Steam Models

Steam Connection

Steam Coil Rating at 100 psig**:

Boiler Horsepower (Btu/hr.) (recommended operating

pressure 80-100 psig)

* with both pockets running

** for each pocket

N/A = Not Applicable

NOTE: All machines are shipped with extra nipple

to convert to metric thread (from Standard).

66 dBA 67 dBA

544

(247)

582

(264)

32.5 x 47 x 81

(826 x 1,194 x 2,057)

35.5 x 54 x 85

(902 x 1,372 x 2,159)

661

(300)

37 x 50 x 87.75

(940 x 1,270 x 2,229)

40 x 57 x 87.25

(1,016 x 1,448 x 2,216)

30 x 26

(762 x 660)

2 x 30

(2 x 13.6)

1/4

(0.1865)

1/4

(0.1865)

(160)

(189)

(2.0, 0.2)

(2.3, 0.23)

1/2 in. NPT 1/2 in. NPT

(21.4, 77)

(21.4, 77)

(27.8, 100.2)

21 kW N/A

3/4 in. NPT N/A

3.2

(111,000)

673

(305)

718

(326)

748

(339)

33 x 30

(838 x 762)

2 x 45

(2 x 20.5)

1/2

(0.373)

1/2

(0.373)

500

(236)

600

(283)

0.8

(2.0, 0.2)

0.9

(2.3, 0.23)

87,000

(25.5, 91.8)

95,000

N/A

14

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

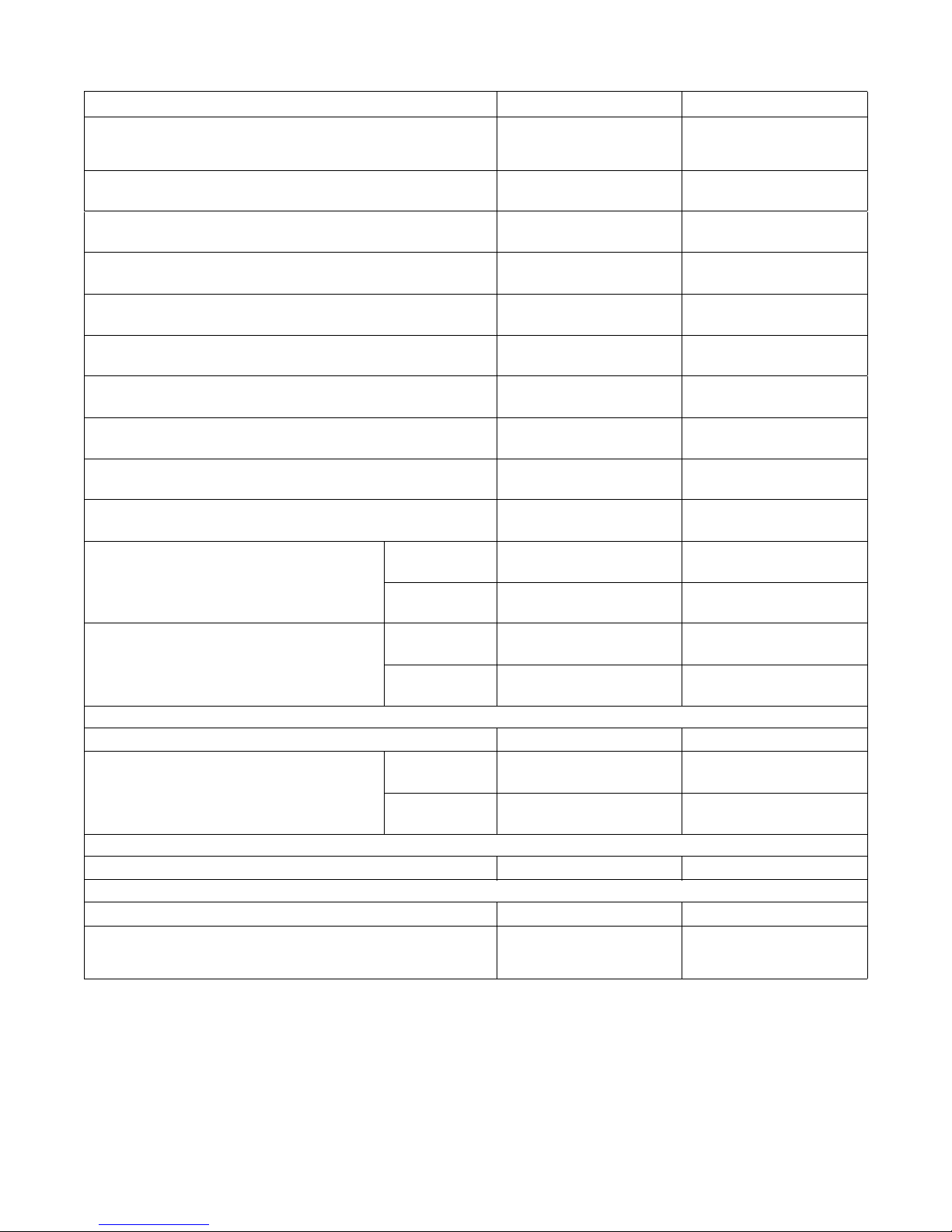

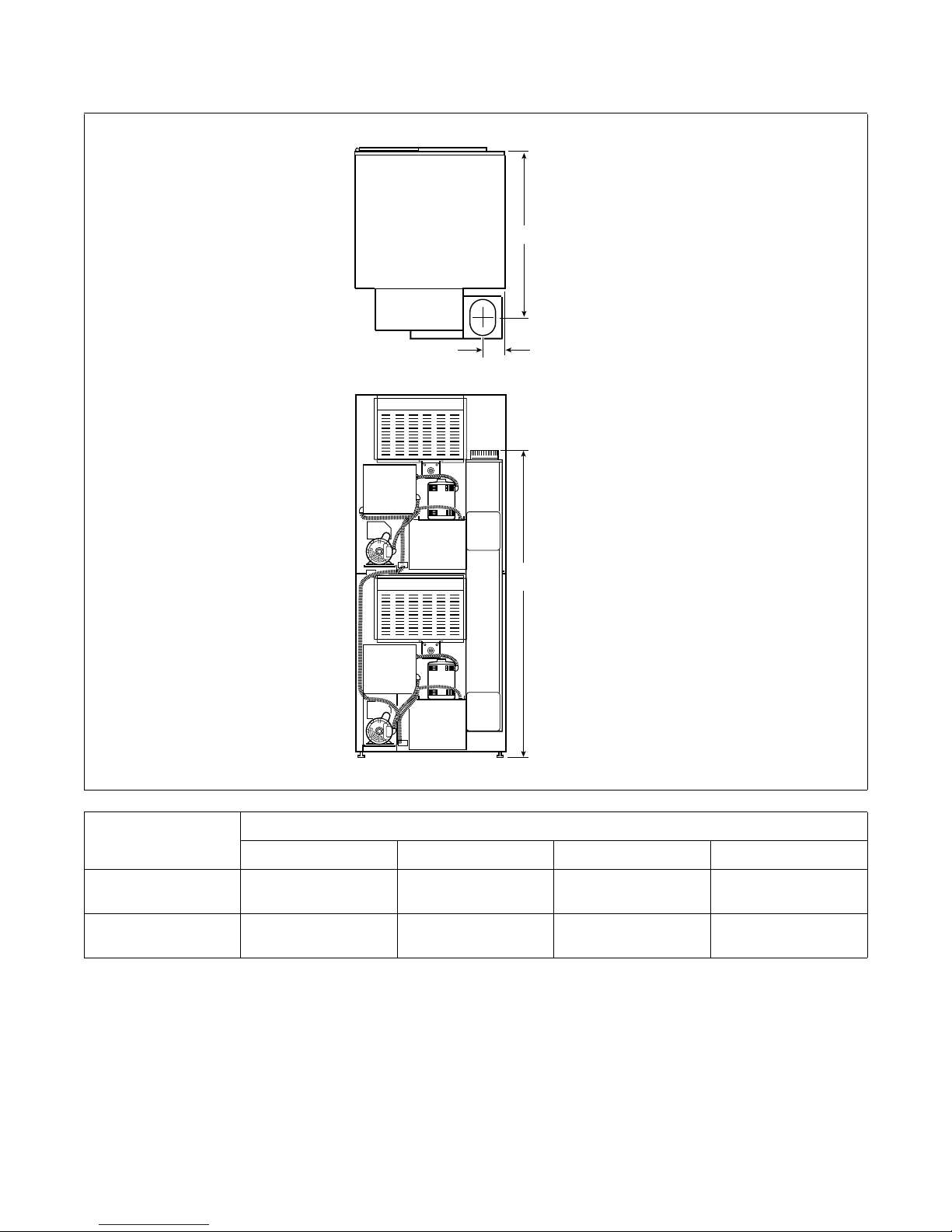

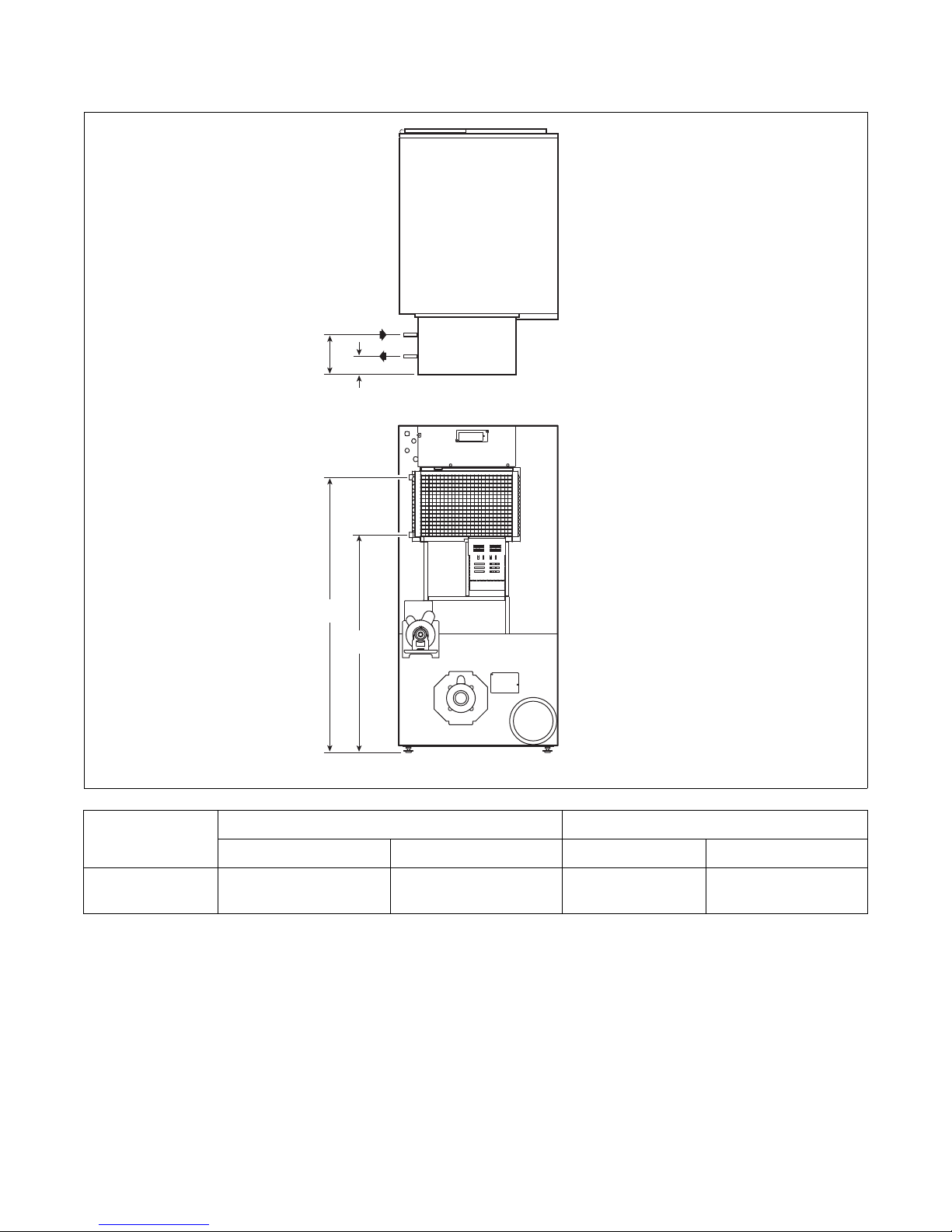

Cabinet Dimensions – 025, 030, 035 and 055 Series

B

A

C

H

E

F

D

G

J

I

K

L

Specifications and Dimensions

Models A B C D E F*

025 Series

030 Series

035 Series

055 Series

26.25 in.

(667 mm)

26.25 in.

(667 mm)

28 in.

(711 mm)

31.88 in.

(810 mm)

27.5 in.

(669 mm)

27.5 in.

(669 mm)

27.5 in.

(669 mm)

26.87 in.

(682.5 mm)

23.35 in.

(593 mm)

28.35 in.

(720 mm)

28.35 in.

(720 mm)

33.75 in.

(857.25 mm)

25.75 in.

(654 mm)

31.75 in.

(806 mm)

31.75 in.

(806 mm)

38.25 in.

(971.5 mm)

40.875 in.

(1,038 mm)

46.875 in.

(1,191 mm)

46.875 in.

(1,191 mm)

53.62 in.

(1,365 mm)

Models G H* I* J* K L

025 Series

030 Series

035 Series

055 Series

* Fire suppression system optional - may not be on machine.

NOTE: Facia panels available to increase height of

models to 72.25 inches (1,835 mm) and 76.25 inches

63.875 in.

(1,622 mm)

63.875 in.

(1,622 mm)

63.875 in.

(1,622 mm)

66.72 in.

(1,694.7 mm)

(1,938 mm).

16.48 in.

(419 mm)

16.48 in.

(419 mm)

16.48 in.

(419 mm)

17.75 in.

(451 mm)

15.41 in.

(391 mm)

15.41 in.

(391 mm)

19.59 in.

(497.5 mm)

18.65 in.

(474 mm)

1.59 in.

(40 mm)

1.59 in.

(40 mm)

1.59 in.

(40 mm)

1.59 in.

(40 mm)

24.64 in.

(626 mm)

24.64 in.

(626 mm)

27.38 in.

(695 mm)

30.5 in.

(774.7 mm)

TMB2292N

6.53 in.

(166 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

28 in.

(711 mm)

28 in.

(711 mm)

31.5 in.

(800 mm)

34.5 in.

(876 mm)

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

15

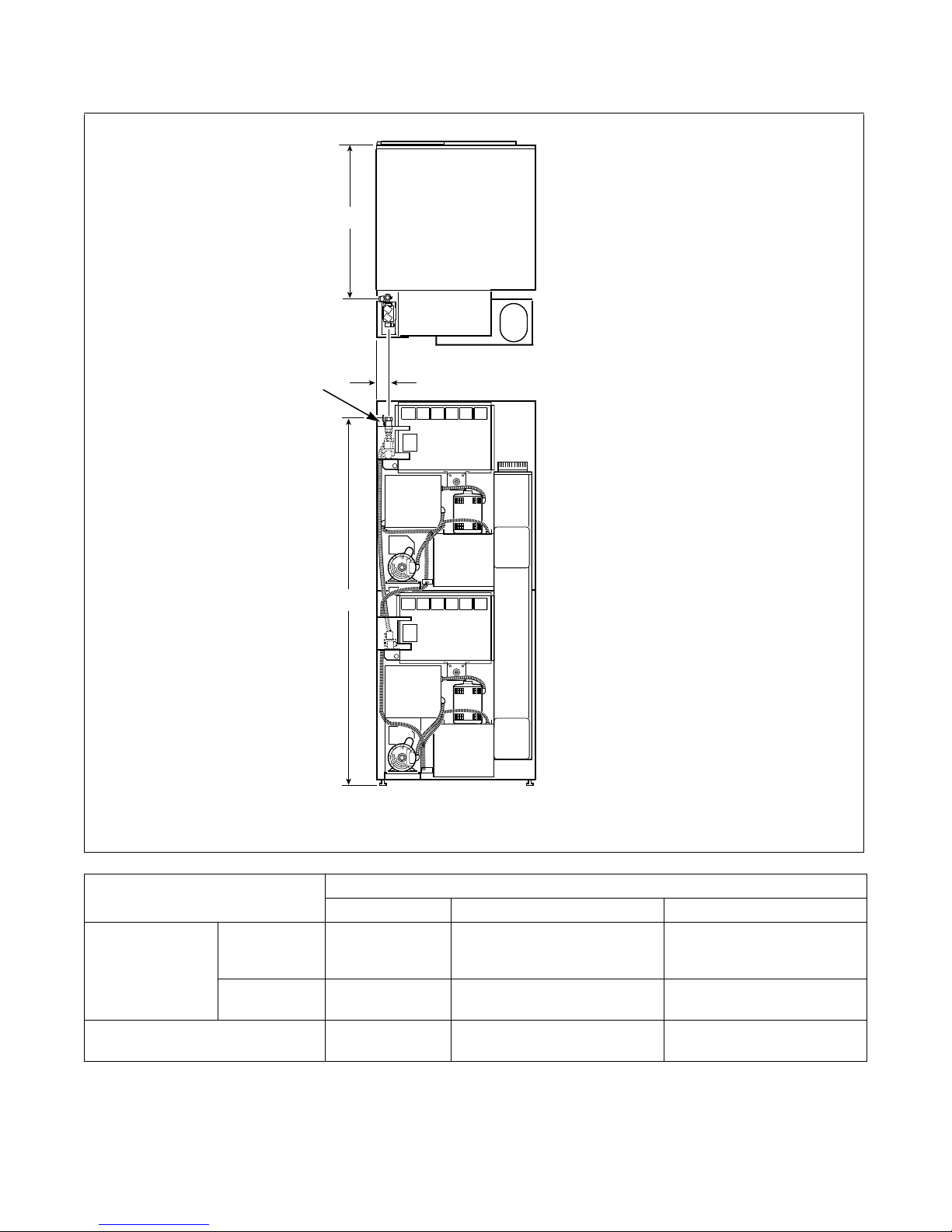

Specifications and Dimensions

TMB2332N

C

E

F

H

J

B

D

G I

A

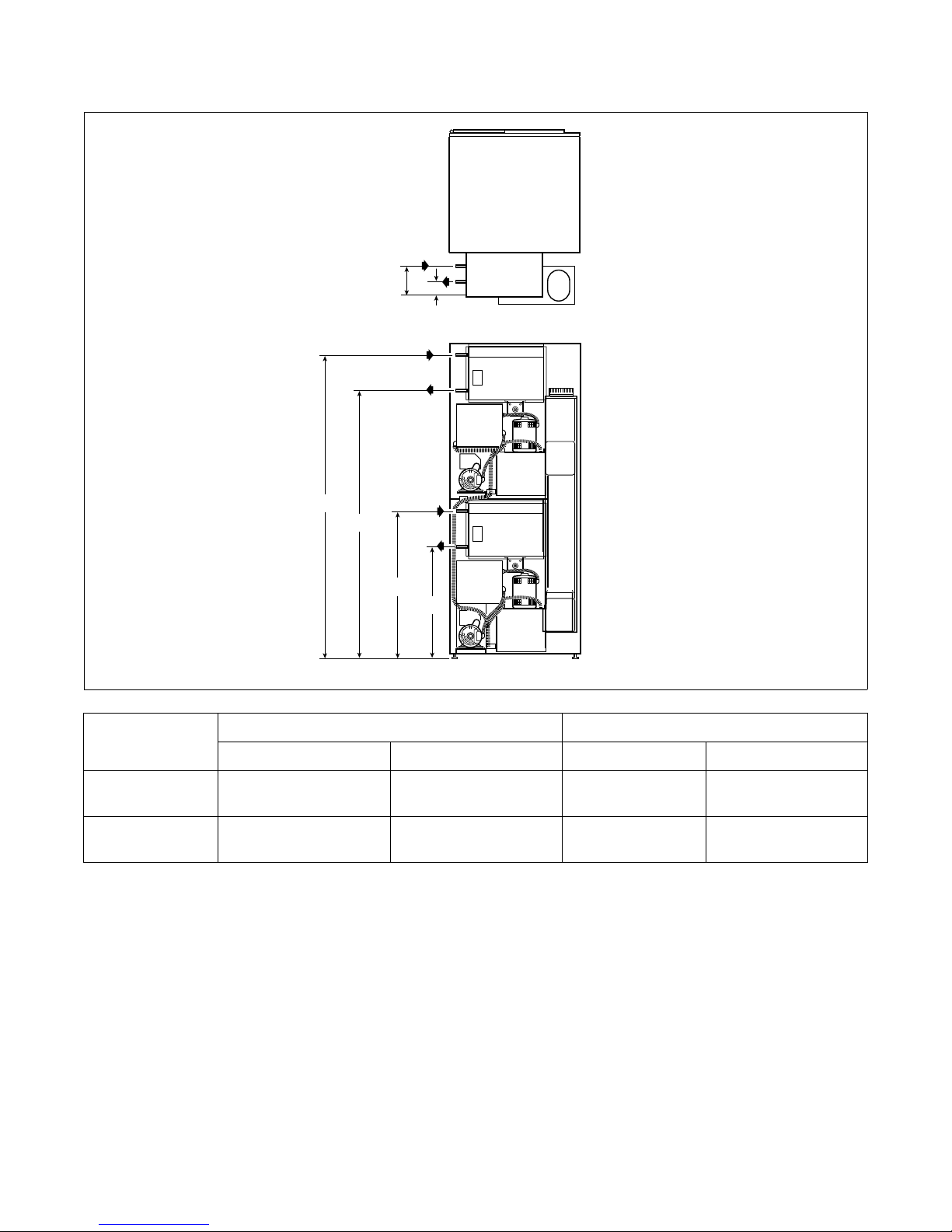

Cabinet Dimensions – T30 and T45 Series

TMB2332N

ModelsABCDE

T30 Series

T45 Series

28 in.

(711 mm)

31.88 in.

(810 mm)

49 in.

(1,245 mm)

50.4 in.

(1,280 mm)

48.25 in.

(1,226 mm)

49.3 in.

(1,252 mm)

11.4 in.

(290 mm)

10.3 in.

(262 mm)

10.7 in.

(272 mm)

9.3 in.

(236 mm)

Models F G H I J

T30 Series

T45 Series

25.02 in.

(636 mm)

29.37 in.

(746 mm)

42.76 in.

(1,086 mm)

48.62 in.

(1,235 mm)

27.38 in.

(695 mm)

30.50 in.

(775 mm)

31.5 in.

(800 mm)

34.5 in.

(876 mm)

76.25 in.

(1,937 mm)

81.25 in.

(2,063.75 mm)

NOTE: To meet ADA compliance, install a 4 inch

(102 mm) riser on T30 models only.

16

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

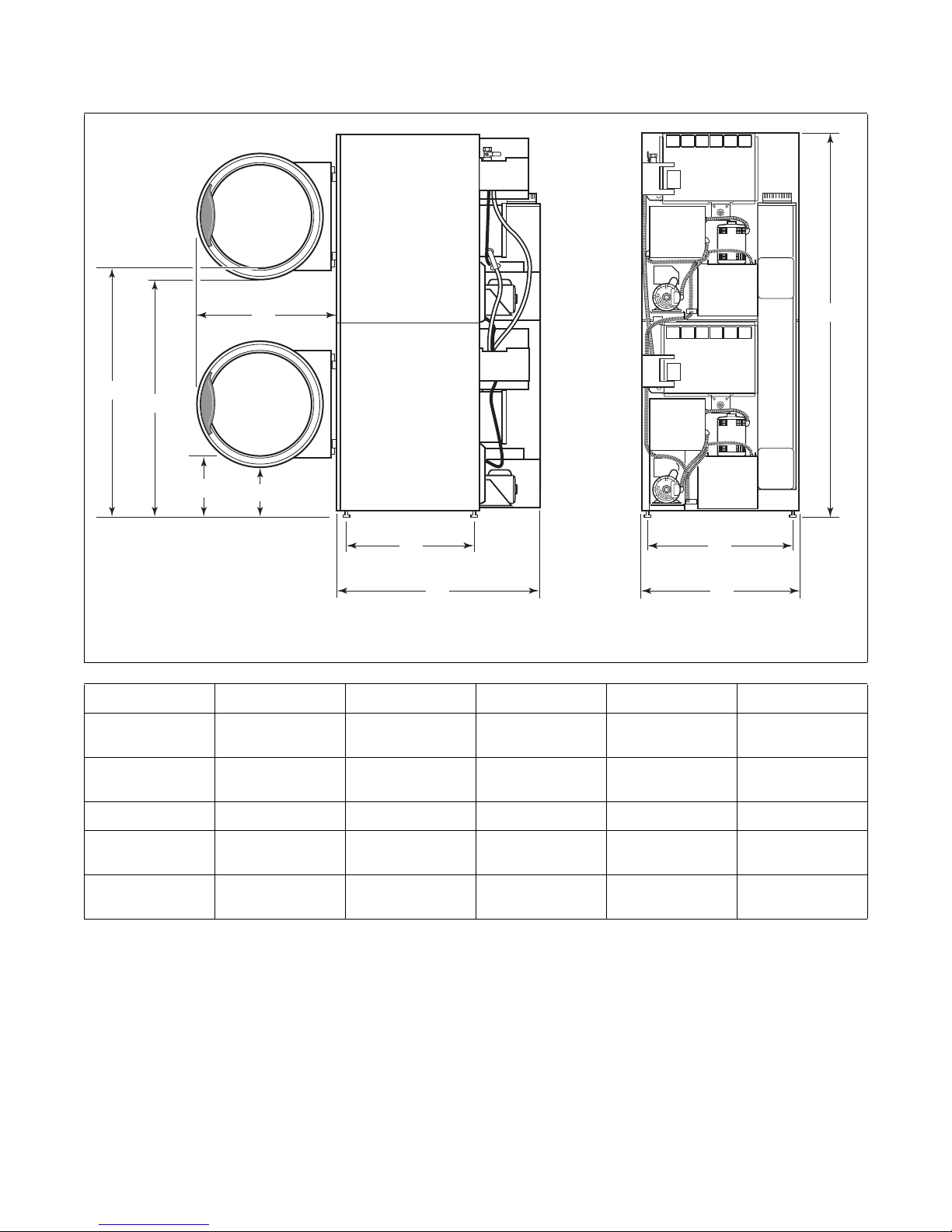

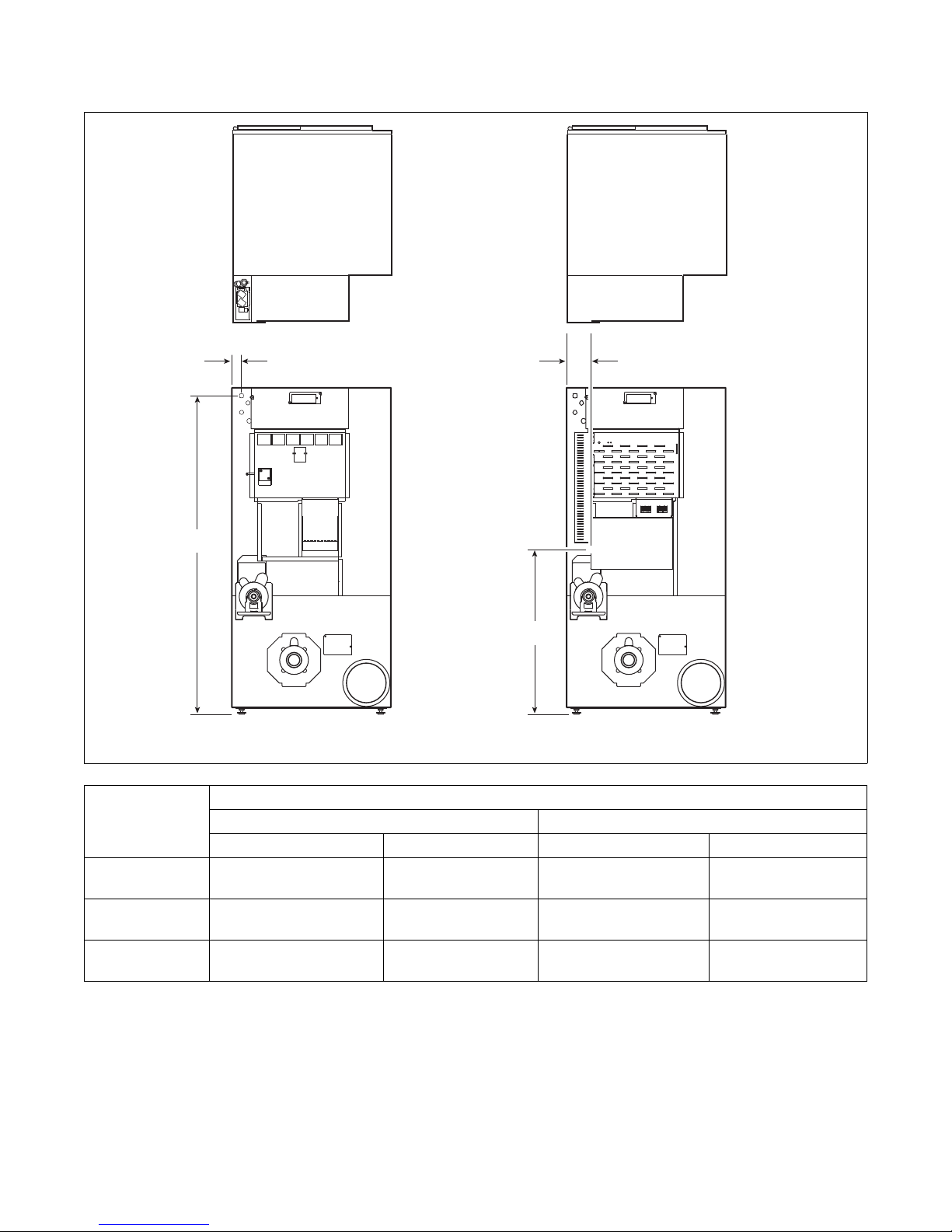

Specifications and Dimensions

B

A

Exhaust Outlet Locations – 025, 030, 035 and 055 Series

Models

025/030 Series

035 Series

055 Series

70458301ENR6

Rear Exhaust

Diameter A B

6 in.

(152 mm)

8 in.

(203 mm)

8 in.

(203 mm)

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

3.875 in.

(99 mm)

4.875 in.

(124 mm)

4.808 in.

(122 mm)

TMB2132N

4.625 in.

(117 mm)

5.625 in.

(143 mm)

6.156 in.

(156.3 mm)

17

Specifications and Dimensions

TMB1969N

B

C

A

Exhaust Outlet Locations – T30 and T45 Series

Models

T30 Series

T45 Series

Rear Exhaust

Diameter A B C

Elliptical

Fits 8 in. (203 mm)

Elliptical

Fits 10 in. (254 mm)

36.54 in.

(928 mm)

40.88 in.

(1,038 mm)

4.25 in.

(108 mm)

4.75 in.

(121 mm)

TMB1969N

62.42 in.

(1,585 mm)

66.00 in.

(1,676 mm)

18

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

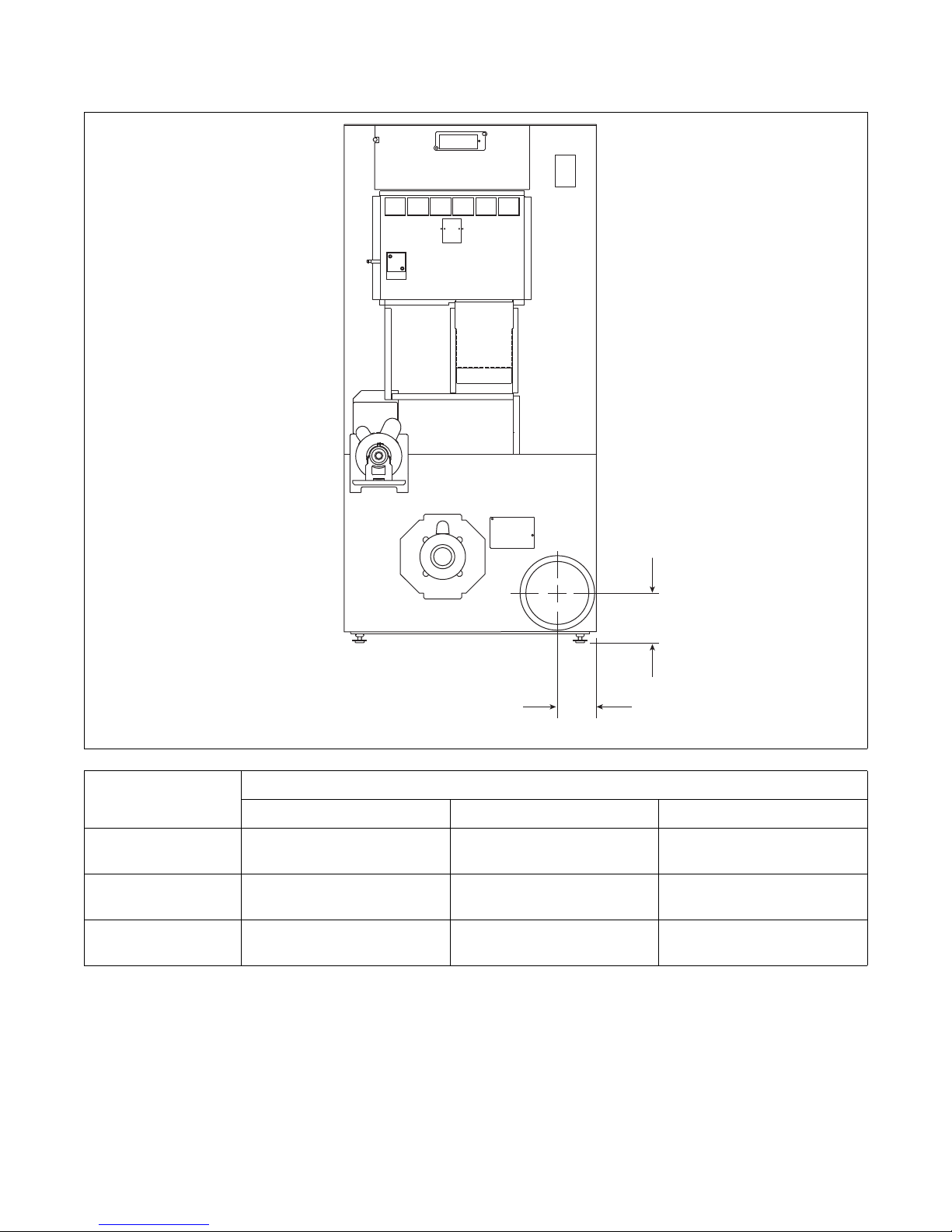

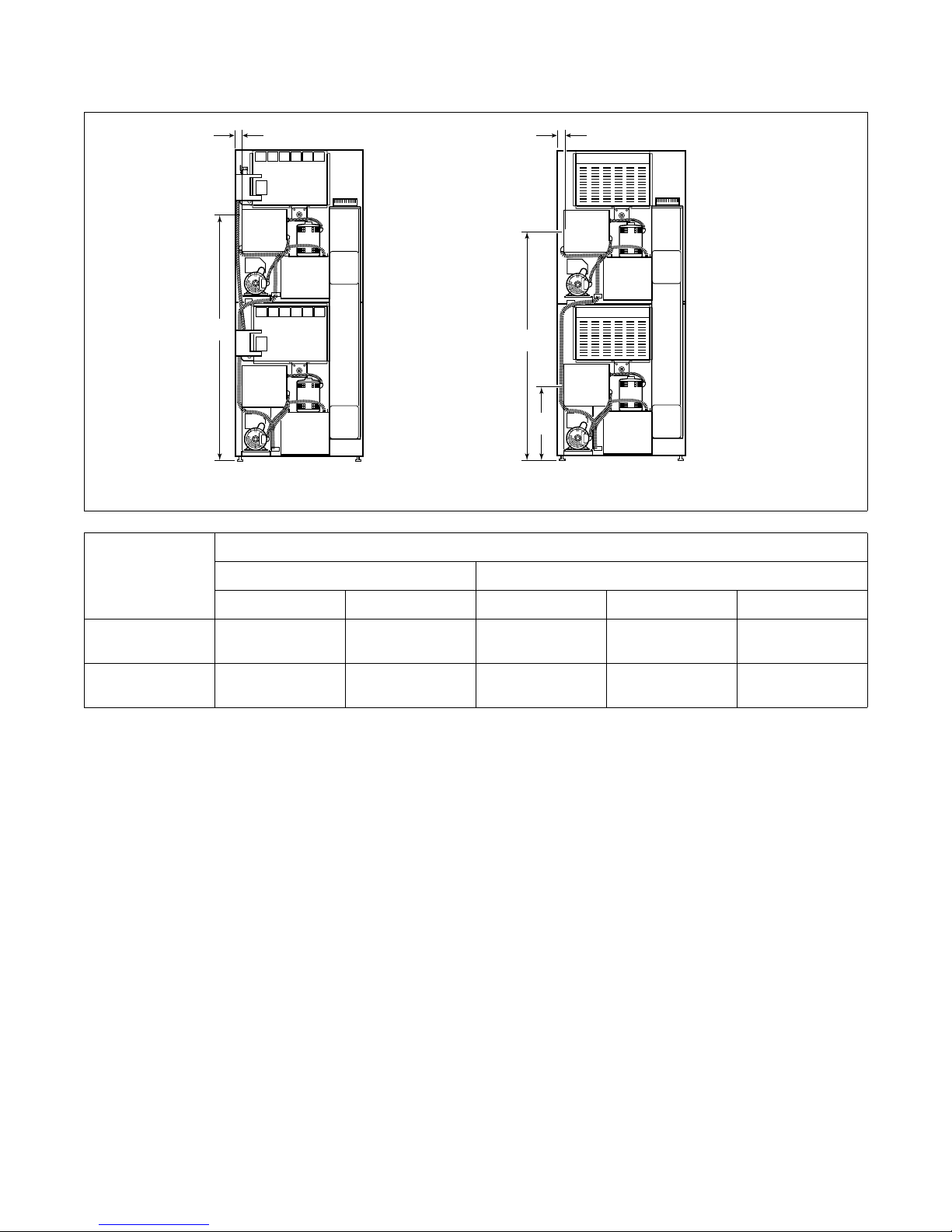

Specifications and Dimensions

B

C

A

1

Gas Connection Locations – 025, 030, 035 and 055 Series

1 1/2 in. NPT

Models

25 Series

30 Series

35 Series

55 Series

Models

25 Series

30 Series

35 Series

55 Series

TMB2106N

Gas Connection – CE and Australian Units

ABC

59 in.

(1,500 mm)

59 in.

(1,500 mm)

59 in.

(1,500 mm)

59 in.

(1,500 mm)

1.5 in.

(38.1 mm)

1.5 in.

(38.1 mm)

2.5 in.

(64 mm)

2.5 in.

(64 mm)

29 in.

(737 mm)

35 in.

(889 mm)

35 in.

(889 mm)

35 in.

(889 mm)

Gas Connection – Non-CE and Non-Australian Units

ABC

57 in.

(1,450 mm)

57 in.

(1,450 mm)

57 in.

(1,450 mm)

55.285 in.

(1,404 mm)

2.5 in.

(64 mm)

2.5 in.

(64 mm)

4 in.

(101.6 mm)

1.621 in.

(41.17 mm)

35.5 in.

(927 mm)

43 in.

(1,092 mm)

43 in.

(1,092 mm)

46.75 in.

(1,187.45 mm)

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

19

Specifications and Dimensions

TMB1970N

A

B

C

1

Gas Connection Locations – T30 and T45 Series

1 1/2 in. NPT

Models

T30 Series

T45 Series

Non-CE and

Non-

Australian

CE and

Australian

TMB1970N

Gas Connection

AB C

75.20 in.

(1,910 mm)

75.28 in.

(1,912 mm)

78.75 in.

(2,000 mm)

1.74 in.

(44 mm)

2.5 in.

(64 mm)

4.12 in.

(105 mm)

36.84 in.

(936 mm)

30.60 in.

(777 mm)

42.88 in.

(1,089 mm)

20

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Specifications and Dimensions

B

D

A

C

ELECTRIC

GAS AND STEAM

Electrical Connection Locations – 025, 030, 035 and 055 Series

Models

025/030 Series

035 Series

055 Series

70458301ENR6

TMB2204N

Electrical Service

Gas and Steam Models Electric Models

ABCD

62.25 in.

(1,581 mm)

62.25 in.

(1,581 mm)

65.187 in.

(1,655.75 mm)

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

2 in.

(51 mm)

3 in.

(76 mm)

1.765 in.

(44.83 mm)

28 in.

(711 mm)

28 in.

(711 mm)

32.526 in.

(826.16 mm)

3.25 in.

(83 mm)

4.25 in.

(108 mm)

6.547 in.

(166.3 mm)

21

Specifications and Dimensions

A

B

E

D

C

GAS AND STEAM ELECTRIC

Electrical Connection Locations – T30 and T45 Series

TMB1971N

Models

T30 Series

T45 Series

N/A = Not Applicable

Electric Service

Gas and Steam Models Electric Models

ABCDE

59 in.

(1,498 mm)

62.5 in.

(1,588 mm)

1.75 in.

(44 mm)

1.75 in.

(44 mm)

35.63 in.

(905 mm)

73.21 in.

(1,859 mm)

N/A N/A N/A

2.28 in.

(58 mm)

22

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Steam Connection Locations – 025, 030 and 035 Series

C

D

B

A

Specifications and Dimensions

Models

ACBD

025/030/035

Series

53.75 in.

(1,365 mm)

NOTE: All connections use 3/4 in. NPT pipe.

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

Inlet Outlet

6.29 in.

(160 mm)

42.5 in.

(1,080 mm)

TMB2108N

2.39 in.

(61 mm)

23

Specifications and Dimensions

C

D

A

B

A

B

Steam Connection Locations – T30 Series

Models

Inlet Outlet

ACBD

T30 Series

(Upper)

T30 Series

(Lower)

NOTE: All connections use 3/4 in. NPT pipe.

73.93 in.

(1,877 mm)

36.35 in.

(923 mm)

6.29 in.

(160 mm)

6.29 in.

(160 mm)

62.71 in.

(1,592 mm)

25.13 in.

(638 mm)

TMB1972N

2.39 in.

(61 mm)

2.39 in.

(61 mm)

24

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Installation

Pre-Installation Inspection

Upon delivery, visually inspect the crate, carton and

parts for any visible shipping damage. If the crate,

carton, or cover is damaged or signs of possible

damage are evident, have the carrier note the condition

on the shipping papers before the shipping receipt is

signed, or advise the carrier of the condition as soon as

it is discovered.

Remove the crate and protective cover as soon as

possible and check the items listed on the packing list.

Advise the carrier of any damaged or missing articles

as soon as possible. A written claim should be filed

with the carrier immediately if articles are damaged or

missing.

IMPORTANT: Remove the shipping tape from the

two back draft dampers located in the exhaust

outlet.

IMPORTANT: Warranty is void unless tumble

dryer is installed according to instructions in this

manual. Installation should comply with minimum

specifications and requirements detailed in this

manual and applicable local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, and any other

relevant statutory regulations. Due to varied

requirements, applicable local codes should be

thoroughly understood and all pre-installation

work arranged for accordingly.

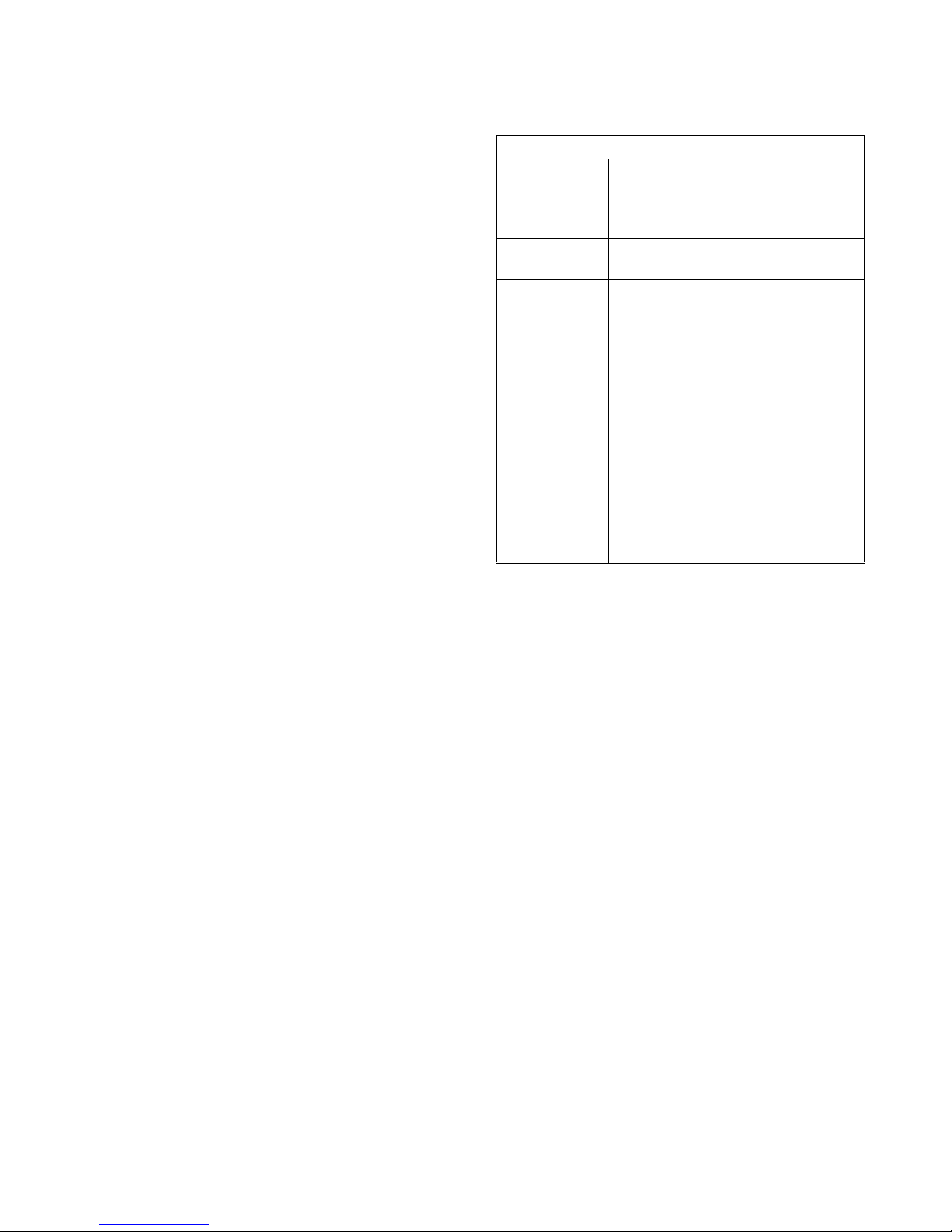

Materials Required (Obtain Locally)

One Single Pole fused disconnect

All Models

Gas Models

Steam Models

switch or circuit breaker on 1 Phase

models.

Circuit breaker on 3 Phase models.

One gas shut-off valve for gas service

line to each tumble dryer.

One steam shut-off valve for steam

service line to be connected upstream of

solenoid steam valve.

Two steam shut-off valves for each

condensate return line.

Flexible steam hoses with a

125 psig (pounds per square inch gauge)

(8.79 kg/sq. cm) working pressure for

connecting steam coils. Refer to

Figure 27 for sizing and co nnecti on

configurations.

T wo steam traps for steam coil outlets to

condensate return line.

Optional – Two vacuum breakers for

condensate return lines.

NOTE: 3 Phase Only – Each tumble dryer must be

connected to its own individual branch circuit

breaker, not fuses, to avoid the possibility of “single

phasing” and causing premature failure of the

motor(s).

Location Requirements

The tumble dryer must be installed on a level floor.

Floor covering materials such as carpeting or tile

should be removed.

To assure compliance, consult local building code

requirements. The tumble dryer must not be installed

or stored in area where it will be exposed to water and/

or weather.

IMPORTANT: DO NOT block the airflow at the

rear of the tumble dryer with laundry or other

articles. Doing so would prevent adequate air

supply to the combustion chamber of the tumble

dryer.

A typical tumble dryer enclosure is shown in Figure 2.

IMPORT ANT : Install tumble dryers with sufficient

clearance for servicing and operation, refer to

Figure 2.

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

25

Installation

TMB2021N

1

7

2

To reduce the risk of severe injury, clearance of tumbler cabinet from combustible

construction must conform to the minimum clearances, and/or local codes and

ordinances.

W770

WARNING

4

5

6

3

NOTE: Shaded areas indicate adjacent structure.

1 0.5 in. (13 mm) recommended between machines for removal or installations.

2 Allow 2-4 in. (51-102 mm) opening at top of machine to aid in removal or installation. A removable trim piece

may be used to conceal the opening; zero clearance allowed for trim.

3 4 in. (102 mm) Maximum Header Thickness

4 12 in. (305 mm) Minimum Clearance

5 24 in. (610 mm) minimum, 36 in. (914 mm) recommended for maintenance purposes.

6 Provision for make-up air.

7 0.25 in. (6 mm) recommended for removal or installation purposes, zero clearance allowed.

Figure 2

TMB2021N

26

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

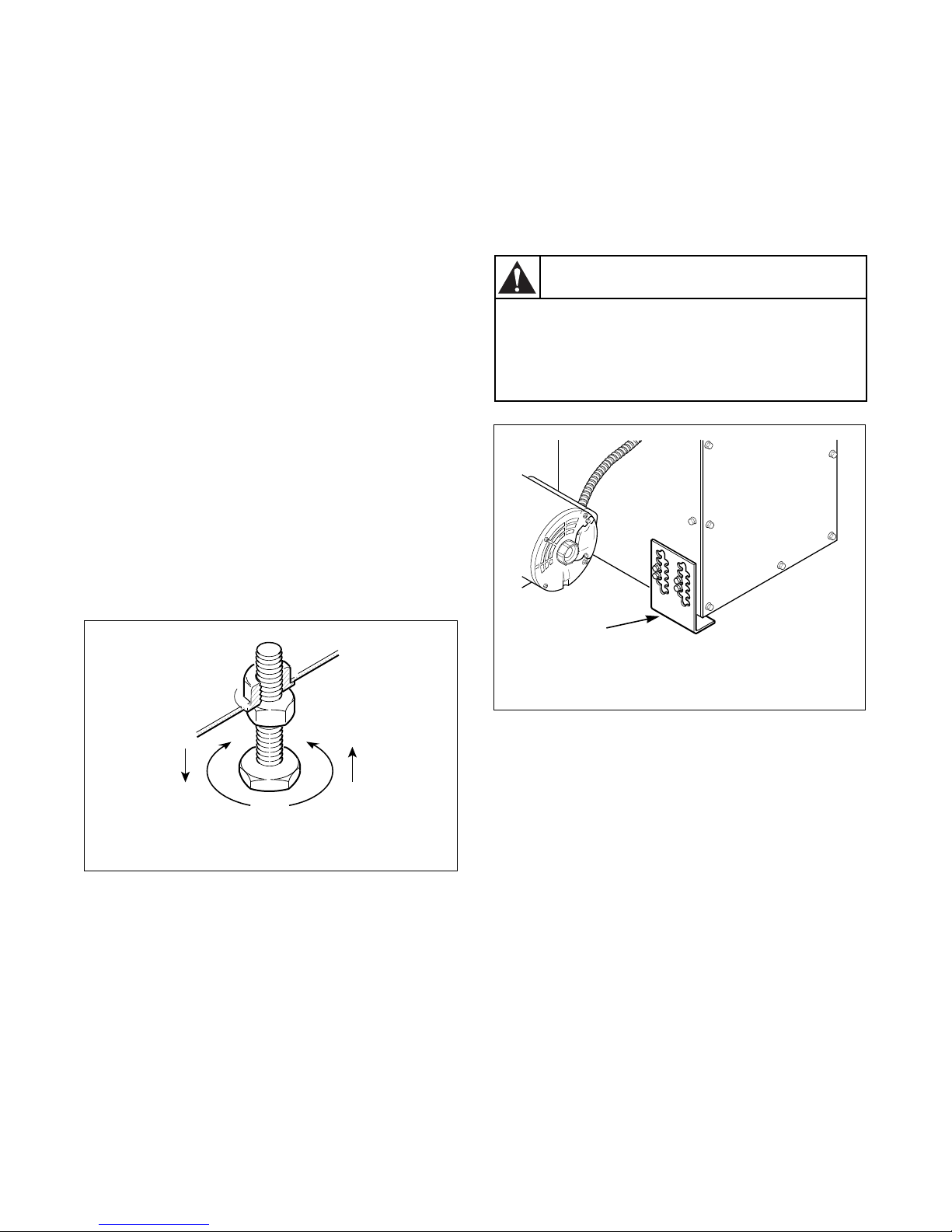

Installation

T483I

The stacked tumble dryer has a 5th leveling

leg on the blower housing. It is very

important to properly adjust this leg. Unit is

back heavy and could rock or tip.

W250R1

CAUTION

1

Position and Level the Tumble Dryer

Remove lint panel door, an d unscrew the four shipping

bolts (one at each corner). Remove tumble dryer from

skid.

NOTE: Do not throw bolts away – they are the

leveling legs.

Remove four nuts from the literature package, and

screw one fully on to each leveling leg.

Screw the four leveling legs (bolts) back into the level

adjusting fittings from the bottom.

Slide tumble dryer to its permanent location. Adjust

the leveling legs until the unit is level, or no more than

0.125 inch (3.18 mm) higher in the front. Refer to

Figure 3. Tumble Dryer must not rock. Lock leveling

legs with nuts previously installed.

NOTE: The front of the tumble dryer should be

slightly higher than the rear (approximately

0.125 inch [3.18 mm]). This will prevent the clothes,

while tumbling, from wearing on the door glass

gasket.

The stacked tumble dryer has a fifth leveling leg which

is shipped in the up position. The fifth leveling leg

MUST BE installed properly on the lower left side of

the blower housing to stabilize the tumble dryer . Refer

to Figure 4.

After leveling with the four cabinet leveling legs,

lower the fifth leveling leg so it contacts the floor, and

then secure the screws.

IMPORTANT: Keep tumble dryer as close to floor

as possible. The unit must rest firmly on floor so

weight of tumble dryer is evenly distributed.

T483I

Figure 3

T467I

1 Fifth Leg

Figure 4

70458301ENR6

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

27

Installation

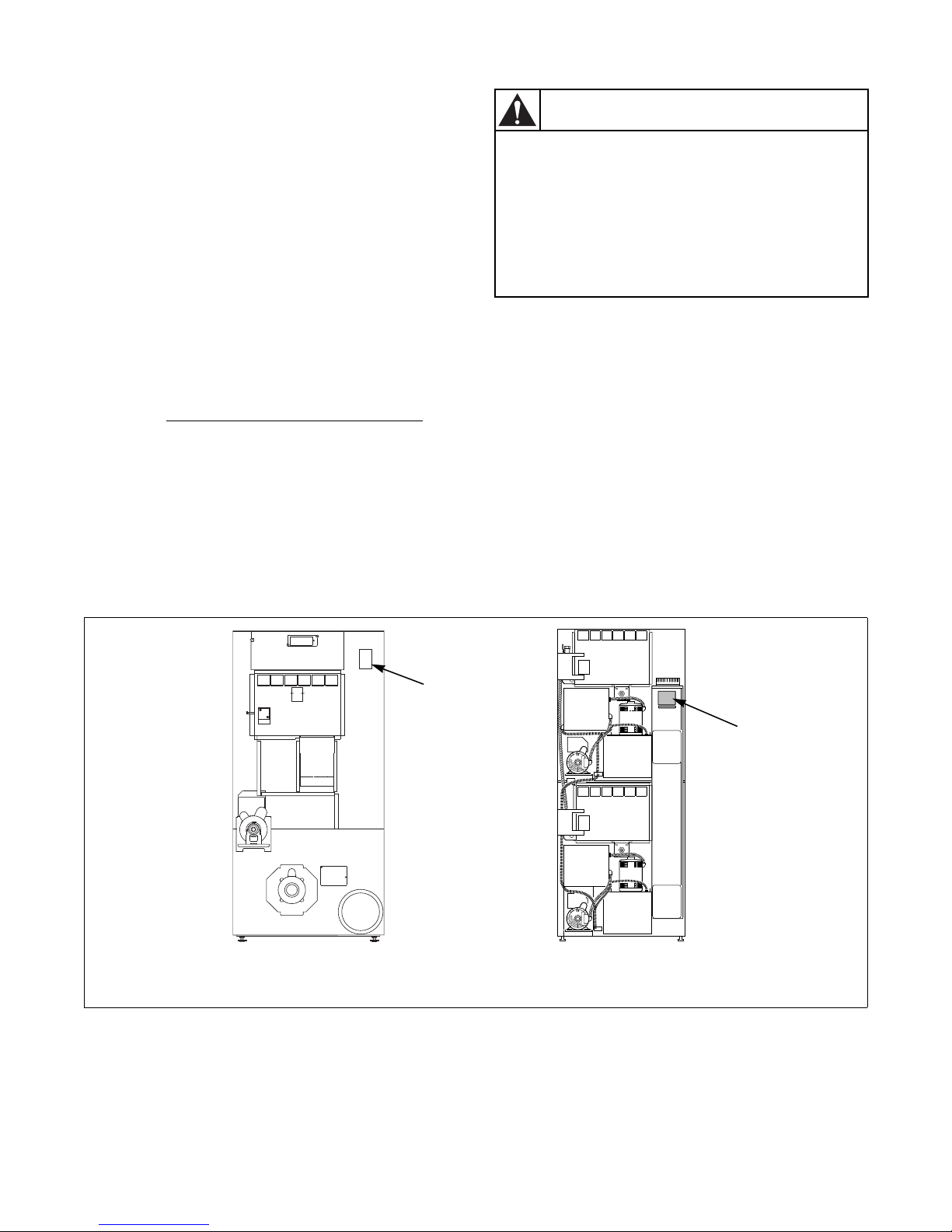

TMB2248N

1

2

Fire Suppression System

Check Local Codes and Permits

Call your local water company or the proper municipal

authority for information regarding local codes.

IMPORTANT: It is your responsibility to have

ALL plumbing connections made by a qualified

professional to assure that the plumbing is

adequate and conforms to local, state, and federal

regulations or codes.

IMPORTANT: It is the installation or owner’s

responsibility to see that the necessary or required

water, water pressure, pipe size, or connections are

provided. Manufacturer assumes no responsibility

if the fire suppression system is not connected,

installed, or maintained properly.

Water Requirements

IMPORTANT: Water must be supplied to the fire

suppression system, or the fire suppression system

will not operate as intended.

Connection point to the electric water solenoid valve is

a 3/4 inch (19 mm) hose. The fire suppression system

equipped tumble dryer must be supplied with a

minimum water pipe size of 1/2 inch (12.7 mm) and be

provided with a

maximum of 120 psi (827 kPa) of pressure at all times.

Flowrate must be no less than, but approximately

15 gallons (57 liters) per minute.

minimum of 20 psi (138 kPa) and a

IMPORTANT: If temperature sensors inside the

tumble dryer register a temperature below 40°F

(4.4°C), the fire suppression system control will

lock out. This feature protects against operation of

the tumble dryer with a possible frozen water

supply. Only when the temperatur e sensors register

a temperature above 40°F (4.4°C) will the machine

reset for operation.

IMPORTANT: Flexible supply line/coupling must

be used. Solenoid valve failure due to hard

plumbing connections will void the warranty. It is

recommended that a filter or strainer be installed

in the water supply line.

Water Connections

T wo hoses and a Y-valve are provided with the tumble

dryer to allow for connection of water supply to

tumble dryer. The water connections are made to the

bushings of the water solenoid valve, located on the

rear of the tumble dryer. The Y-valve provides a single

female hose connection (Standard US 3/4-11 1/2 NH

thread). Refer to Figure 5 and Figure 6.

NOTE: Water pressure under 20 psi (138 kPa) will

cause low flow and water leakage at water solenoid

valve.

If the rear of the tumble dryer or the water supply is

located in an area where it will be exposed to cold/

freezing temperatures, provisions must be made to

protect these water lines from freezing.

IMPORTANT: Temperature of the water supply

must be kept between 40°F and 120°F (4.4°C and

48.9°C). If water in the supply line or water

solenoid valve freezes, the fire suppression system

will not operate.

TMB2248N

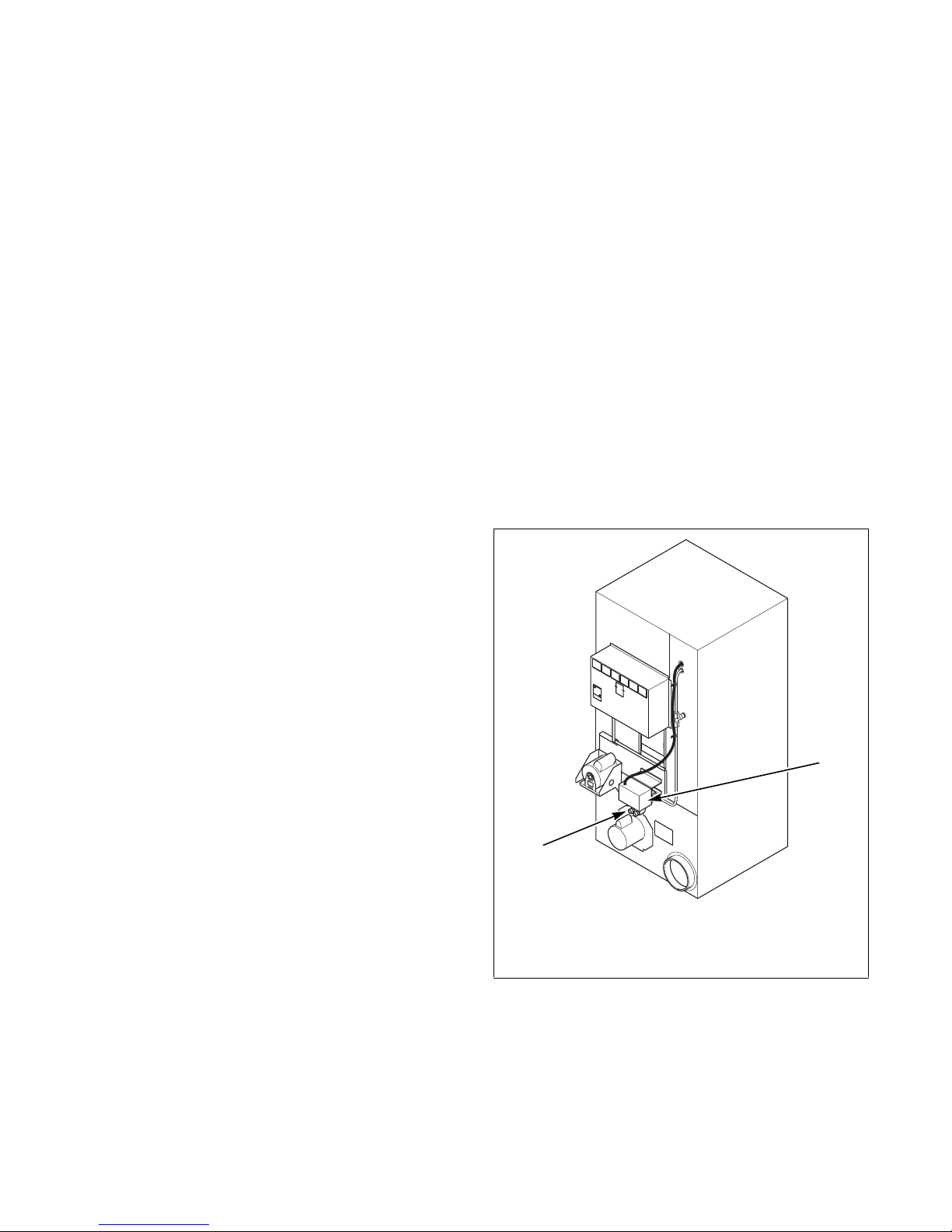

1 Fire Suppression System Control Box

2 Water Solenoid Valve

Figure 5

To connect the two hoses (supplied with tumble

dryer), insert rubber washers (from literature pack) in

water inlet hose couplings. Refer to Figure 6.

28

© Copyright, Alliance Laundry Systems LLC - DO NOT COPY or TRANSMIT

70458301ENR6

Loading...

Loading...