ALLIANCE A135 ARIES, A180 ARIES, A105, IA80 ARIES, A80 ARIES Installation Operation & Maintenance

...Page 1

Washer-Extractors

Cabinet Hardmount

Refer to Page 8 for Model Identification

Installation/Operation/Maintenance

Original Instructions

Keep These Instructions for Futur

(If this machine changes ownership, this manual must accompany machine.)

e Reference.

www.alliancelaundry.com

Part No. D1634ENR4

January 2016

Page 2

Page 3

Table of Contents

Safety Information..................................................................................5

Explanation of Safety Messages....................................................................... 5

Important Safety Instructions........................................................................... 5

Safety Decals................................................................................................. 7

Operator Safety.............................................................................................. 7

Introduction........................................................................................... 8

Model Identification........................................................................................8

Delivery Inspection.........................................................................................8

Replacement Parts ......................................................................................... 8

Customer Service............................................................................................9

Specifications and Dimensions.............................................................. 10

General Specifications...................................................................................10

Machine Dimensions.....................................................................................15

Mounting Bolt Hole Locations – 8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L and 14

kg / 30 lb. / 135L; 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and 28 kg / 70

lb. / 280 L with 100 G Extraction................................................................17

Mounting Bolt Hole Locations – 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and

28 kg / 70 lb. / 280 L with 175 G Extraction; 35 kg / 80 lb. / 332 L and 52 kg /

115 lb. / 520 L...........................................................................................18

Floor Mounting Layout .................................................................................19

Installation........................................................................................... 20

Pallet Removal............................................................................................. 20

Machine Installation......................................................................................21

Machine Foundation and Pad Installation.....................................................21

Machine Installation on Floor or Steel Base................................................. 23

Drain Connection..........................................................................................25

Drain Valve...............................................................................................26

Drain Pump, 8 kg / 20 lb. / 80 L Models...................................................... 29

Water Connection Requirements.....................................................................30

Water Reuse Connection............................................................................ 31

Reused Water Treatment............................................................................ 32

Water Reuse Tank Properties...................................................................... 32

Electrical Installation Requirements................................................................33

Residual Current Device (RCD) - Models Outside of North America............. 34

Supply Protection Device...........................................................................34

Supply Cable............................................................................................ 35

Machine Protective Earth Connection and Equipotential Bonding.................. 37

Input Power Conditioning..............................................................................38

©

Copyright 2016, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

3 Part No. D1634ENR4

Page 4

Input Voltage Requirements........................................................................38

Circuit Breakers and Quick Disconnects......................................................... 38

Connection Specifications..............................................................................39

Single Phase Connection............................................................................39

Three Phase Connection.............................................................................39

Phase Adder..............................................................................................40

Thermal Overload Protector....................................................................... 40

Electrical Specifications.............................................................................40

Steam Requirements (Steam Heat Option Only)...............................................50

Steam Valve Installation.............................................................................51

Supply Dispensing........................................................................................ 51

Connection of External Liquid Supplies.......................................................... 51

Electrical Connection of External Liquid Soap Supply System.......................... 52

Operation............................................................................................. 53

Operating Instructions................................................................................... 53

Power Cut.................................................................................................... 54

Automatic Door-lock Unlocking Module........................................................ 54

Maintenance......................................................................................... 55

Maintenance.................................................................................................55

Daily........................................................................................................... 55

Beginning of Day...................................................................................... 55

End of Day............................................................................................... 55

Quarterly......................................................................................................56

Every 6 Months............................................................................................ 56

Care of Stainless Steel...................................................................................58

Disposal of Unit.................................................................................... 59

Disconnecting the Machine............................................................................59

Disposal of Unit............................................................................................59

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

4 Part No. D1634ENR4

Page 5

Safety Information

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,” and

“CAUTION”), followed by specific instructions, are found in this

manual and on machine decals. These precautions are intended

for the personal safety of the operator, user, servicer, and those

maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if

not avoided, will cause severe personal injury or

death.

WARNING

Indicates a hazardous situation that, if not avoided,

could cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided,

may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and

“NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specific procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is important but not hazard related.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your washer,

follow these basic precautions:

W023

• Read all instructions before using the washer.

• Install the washer according to the INSTALLATION instructions. Refer to the Earthing (grounding) instructions in the INSTALLATION manual for the proper earthing (grounding) of

the washer. All connections for water, drain, electrical power

and earthing (grounding) must comply with local codes and

be made by licensed personnel when required. It is recommended that the machine be installed by qualified technicians.

• Do not install or store the washer where it will be exposed to

water and/or weather.

• To prevent fire and explosion, keep the area around machine

free from flammable and combustible products. Do not add

the following substances or textiles containing traces of the

following substances to the wash water: gasoline, kerosene,

waxes, cooking oils, vegetable oils, machine oils, dry-cleaning solvents, flammable chemicals, thinners, or other flammable or explosive substances. These substances give off vapors

that could ignite, explode or cause the fabric to catch fire by

itself.

• Under certain conditions, hydrogen gas may be produced in a

hot water system that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using a

washing machine or combination washer-dryer, turn on all hot

water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. The

gas is flammable, do not smoke or use an open flame during

this time.

• To reduce the risk of an electric shock or fire, DO NOT use an

extension cord or an adapter to connect the washer to the electrical power source.

• Do not allow children to play on or in the washer. Close supervision of children is necessary when the washer is used

near children. This appliance is not intended for use by young

children or infirm persons without supervision. Young children should be supervised to ensure that they do not play with

the appliance. This is a safety rule for all appliances.

• DO NOT reach and/or climb into the tub or onto the washer,

ESPECIALLY if the wash drum is moving. This is an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

• Never operate the washer with any guards, panels and/or parts

removed or broken. DO NOT bypass any safety devices or

tamper with the controls.

• Use washer only for its intended purpose, washing textiles.

Never wash machine parts or automotive parts in the machine. This could result in serious damage to the basket or

tub.

• Use only low-sudsing, no-foaming types of commercial detergent. Be aware that hazardous chemicals may be present.

Wear hand and eye protection when adding detergents and

chemicals. Always read and follow manufacturer’s instruc-

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

5 Part No. D1634ENR4

Page 6

Safety Information

tions on packages of laundry and cleaning aids. Heed all

warnings or precautions. To reduce the risk of poisoning or

chemical burns, keep them out of the reach of children at all

times [preferably in a locked cabinet].

• Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener

or product.

• To avoid machine corrosion and component failure, do not

use corrosive chemicals in the machine. Warranty claims related to damage caused by corrosive chemicals will be denied.

• Always follow the fabric care instructions supplied by the textile manufacturer.

• Loading door MUST BE CLOSED any time the washer is to

fill, tumble or spin. DO NOT bypass the loading door switch

by permitting the washer to operate with the loading door

open. Do not attempt to open the door until the washer has

drained and all moving parts have stopped.

• Be aware that hot water is used to flush the supply dispenser.

Avoid opening the dispenser lid while the machine is running.

• Do not attach anything to the supply dispenser's nozzles, if

applicable. The air gap must be maintained.

• Do not operate the machine without the water reuse plug or

water reuse system in place, if applicable.

• Be sure water connections have a shut-off valve and that fill

hose connections are tight. CLOSE the shut-off valves at the

end of each wash day.

• Keep washer in good condition. Bumping or dropping the

washer can damage safety features. If this occurs, have washer checked by a qualified service person.

• DANGER: Before inspecting or servicing machine, power

supply must be turned OFF. The servicer needs to wait for at

least 10 minutes after turning the power OFF and needs to

check for residual voltage with a voltage meter. The inverter

remains charged with high voltage for some time after powering OFF. This is an imminently hazardous situation that, if not

avoided, will cause severe personal injury or death. Before

starting inspection of the inverter, check for residual voltage

across main circuit terminals + and -. This voltage must be

below 30 VDC before the servicer can access the inverter for

inspection.

• Do not repair or replace any part of the washer, or attempt any

servicing unless specifically recommended in the user-maintenance instructions or in published user-repair instructions that

the user understands and has the skills to carry out. ALWAYS

disconnect the washer from electrical, power and water supplies before attempting any service.

• Disconnect the power by turning off the circuit breaker or by

unplugging the machine. Replace worn power cords.

• Before the washer is removed from service or discarded, remove the door to the washing compartment.

• Failure to install, maintain, and/or operate this washer according to the manufacturer’s instructions may result in conditions

which can produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Observe and be aware of other labels and precautions that are located on the machine. They are intended to provide instruction for safe use of the machine. Common sense, caution and care must be exercised when installing, maintaining, or operating the

washer.

Always contact your dealer, distributor, service agent or the manufacturer on any problems or conditions you do not understand.

NOTE: For European Union member states only: Electrical safety of the washers described in this manual is

in compliance with the requirements of the European

standard EN60204-1.

DANGER

Electrical shock hazard will result in death or serious

injury. Disconnect electric power and wait ten (10)

minutes before servicing.

W911

WARNING

Dangerous voltages are present inside the machine.

Only qualified personnel should attempt adjustments

and troubleshooting. Disconnect power from the machine before removing any cover and guards, and

before attempting any service procedures.

W736

WARNING

Machine installations must comply with minimum

specifications and requirements stated in the applicable Installation Manual, any applicable municipal

building codes, water supply requirements, electrical

wiring regulations and any other relevant statutory

regulations. Due to varied requirements and applicable local codes, this machine must be installed, adjusted, and serviced by qualified maintenance personnel familiar with applicable local codes and the

construction and operation of this type of machinery.

They must also be familiar with the potential hazards

involved. Failure to observe this warning may result

in personal injury, property damage, and/or equipment damage, and will void the warranty.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

W820

6 Part No. D1634ENR4

Page 7

IMPORTANT: Ensure that the machine is installed on a

level floor of sufficient strength. Ensure that the recommended clearances for inspection and maintenance are

provided. Never allow the inspection and maintenance

space to be blocked.

WARNING

Safety Information

WARNING

NEVER insert hands or objects into basket until it

has completely stopped. Doing so could result in serious injury.

SW012

Never touch internal or external steam pipes, connections, or components. These surfaces can be extremely hot and will cause severe burns. The steam

must be turned off and the pipe, connections, and

components allowed to cool before the pipe can be

touched.

SW014

WARNING

Install the machine on a level floor of sufficient

strength. Failure to do so may result in conditions

which can produce serious injury, death and/or property damage.

W703

WARNING

NEVER INTERFERE WITH THE SETTING OF THE

DOOR HANDLE. NEVER TRY TO MODIFY THE SETTING OR REPAIR THE HANDLE! ANY INTERFERENCE WITH ITS SETTING MAY LEAD TO SERIOUS

RISK FOR THE OPERATOR! A DAMAGED OR INCORRECTLY FUNCTIONING DOOR HANDLE MUST ALWAYS BE IMMEDIATELY REPLACED WITH A NEW

ORIGINAL PART.

C014

The following maintenance checks must be performed daily:

1. Verify that all warning labels are present and legible, replace

as necessary.

2. Check door interlock before starting operation of the machine:

a. Attempt to start the machine with the door open. The ma-

chine should not start.

b. Close the door without locking it and start the machine.

The machine should not start.

c. Attempt to open the door while a cycle is in progress. The

door should not open.

If the door lock and interlock are not functioning properly, disconnect power and call a service technician.

3. Do not attempt to operate the machine if any of the following

conditions are present:

a. The door does not remain securely locked during the en-

tire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly grounded circuit.

Do not bypass any safety devices in the machine.

WARNING

Operating the machine with severe out-of-balance

loads could result in personal injury and serious

equipment damage.

W728

Safety Decals

Safety decals appear at crucial locations on the machine. Failure

to maintain legible safety decals could result in injury to the operator or service technician.

Use manufacturer-authorized spare parts to avoid safety hazards.

Operator Safety

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

7 Part No. D1634ENR4

Page 8

Introduction

Model Identification

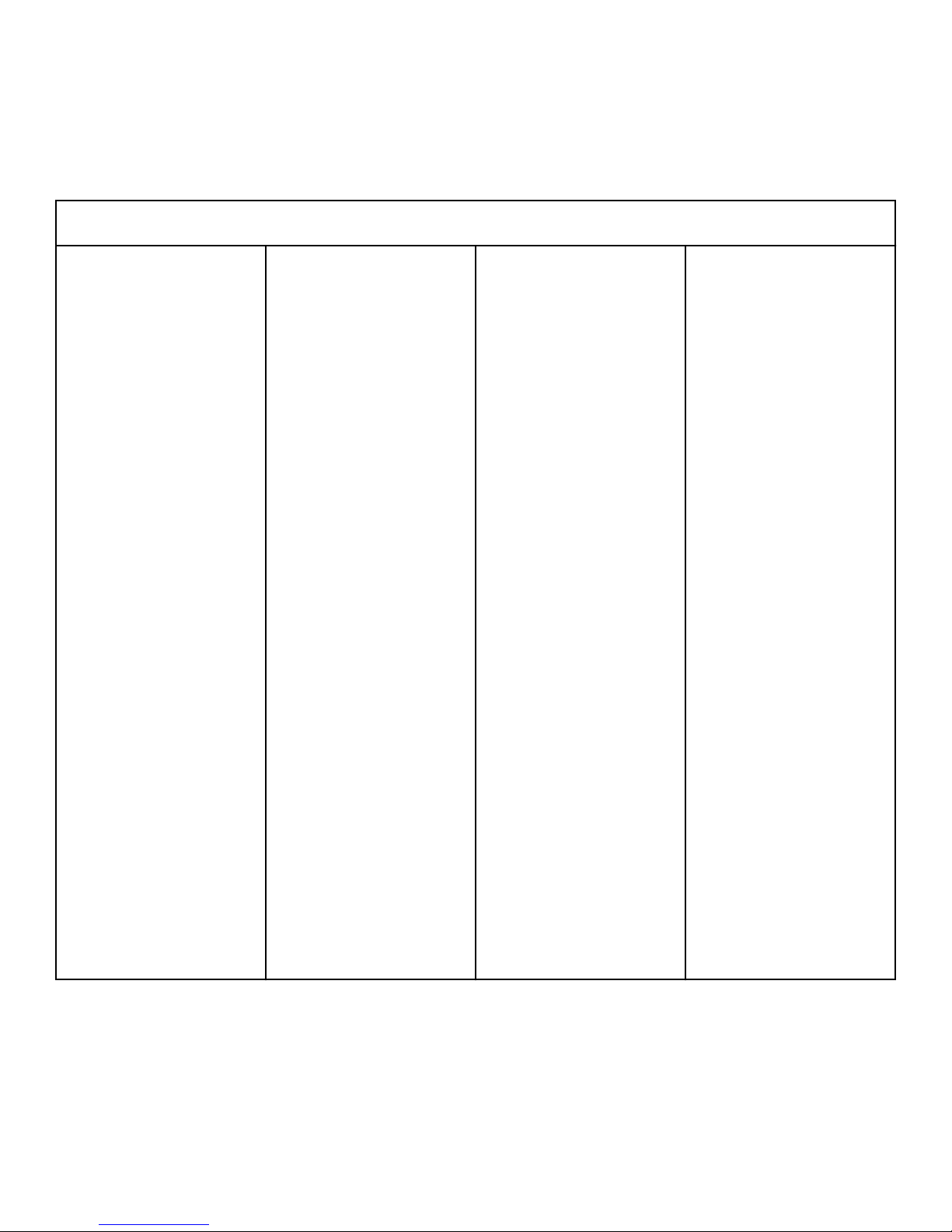

Information in this manual is applicable to these models:

Introduction

Models

A105

A105_ARIES

A135

A135_ARIES

A180

A180_ARIES

A80

A80_ARIES

IA80_ARIES

IA80_ARIES-ELITE

IA105_ARIES

IA105_ARIES-ELITE

IA135_ARIES

IA135_ARIES-ELITE

IA180_ARIES

IA180_ARIES-ELITE

IA240_ARIES

IAB180J

IAB180R

IAG080J

IAG080R

IAG105J

IAG105R

IAG135J

IAG135R

IAG180J

IAG180R

IAG240J

IAG240R

IAG280J

IAG280R

IAG332J

IAG332R

IAG520J

IAU080J

IAU080R

IAU105J

IAU105R

IAU135J

IAU135R

IAU180J

IAU180R

IAU240J

IAU240R

IAU280J

IAU280R

IAU332J

IAU332R

IAU520J

IAU520R

IAW080J

WMA103E

WMA103E_ARIES

WMA123E

WMA123E_ARIES

WMA153E

WMA153E_ARIES

WMA203E

WMA203E_ARIES

WMA253E

WMA253E_ARIES

WMA303E

WMA303E_ARIES

WMA403E

WMA403E_ARIES

WMA73E

WMA73E_ARIES

WMA83E

IA240_ARIES-ELITE

IA280_ARIES

IA280_ARIES-ELITE

IA332_ARIES

IA332_ARIES-ELITE

IA520_ARIES

IA520_ARIES-ELITE

IAG520R

IAGU080J

Delivery Inspection

Upon delivery, visually inspect crate, protective cover, and unit

for any visible shipping damage. If signs of possible damage are

evident, have the carrier note the condition on the shipping papers before the shipping receipt is signed, or advise the carrier of

the condition as soon as it is discovered.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

IAW080R

IAW105J

IAW105R

IAW135J

IAW135R

IAW180J

IAW180R

IAW240J

IAW240R

WMA83E_ARIES

Replacement Parts

If literature or replacement parts are required, contact the source

from which the machine was purchased or contact Alliance Laundry Systems at +1 (920) 748-3950 for the name and address of

the nearest authorized parts distributor.

8 Part No. D1634ENR4

Page 9

Customer Service

For technical assistance, contact your local distributor or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

Alliance International: +32 56 41 20 54 Wevelgem, Belgium

Introduction

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

9 Part No. D1634ENR4

Page 10

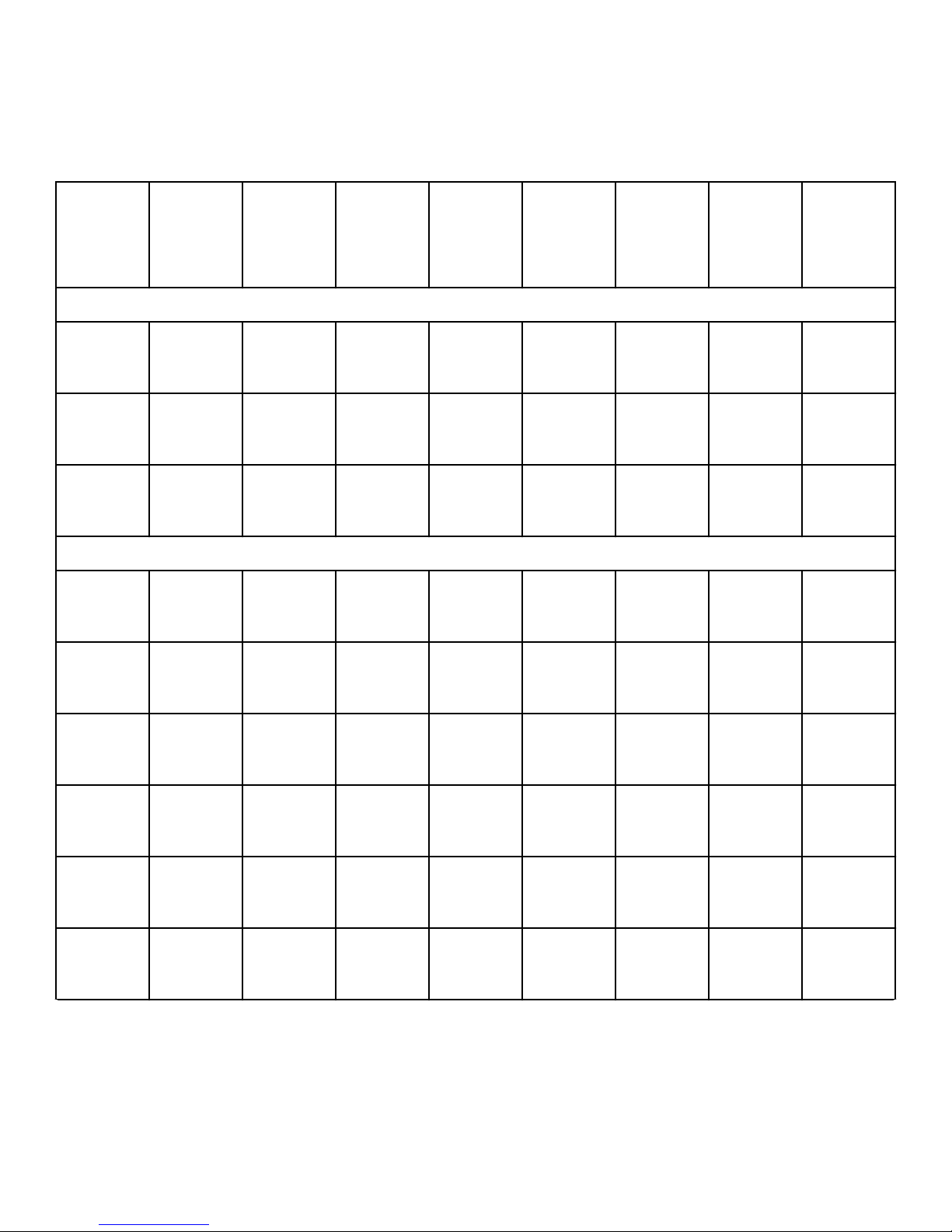

Specifications and Dimensions

General Specifications

Specifications and Dimensions

8 kg /

20 lb. /

Specifications

Overall Dimensions

Overall

width, in.

[mm]

Overall

height, in.

[mm]

Overall

depth, in.

[mm]

Weight and Shipping Information

Net weight,

lbs. [kg]

(100G)

80 L

Models

25.98 [660] 29.53 [750] 29.53 [750] 35.03 [890] 35.03 [890] 35.03 [890] 41.73

43.89

[1115]

30.91 [785] 30.91 [785] 35.43 [900] 36.02 [915] 41.73

298 [135] 375 [170] 419 [190] 563 [255] 606 [275] 639 [290] 904 [410] 1146 [520]

11 kg /

25 lb. /

105 L

Models

48.22

[1225]

14 kg /

30 lb. /

135 L

Models

48.22

[1225]

18 kg /

40 lb. /

180 L

Models

55.51

[1410]

24 kg /

55 lb. /

240 L

Models

55.51

[1410]

[1060]

28 kg /

70 lb. /

280 L

Models

55.51

[1410]

44.68

[1135]

35 kg /

80 lb. /

332 L

Models

[1060]

59.05

[1500]

40.55

[1030]

52 kg /

115 lb. /

520 L

Models

41.73

[1060]

59.05

[1500]

51.77

[1315]

Net weight,

lbs. [kg]

(150G)

Net weight,

lbs. [kg]

(175G)

Shipping

weight, lbs.

[kg](100G)

Shipping

weight, lbs.

[kg](150G)

Shipping

weight, lbs.

[kg](175G)

N/A N/A N/A N/A N/A N/A 904 [410] N/A

298 [135] 375 [170] 419 [190] 695 [315] 728 [330] 783 [355] N/A N/A

320 [145] 408 [185] 441 [200] 595 [270] 639 [290] 672 [305] 992 [450] 1257 [570]

N/A N/A N/A N/A N/A N/A 1147 [520] N/A

320 [145] 408 [185] 441 [200] 739 [335] 783 [355] 849 [385] N/A N/A

Table continues...

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

10 Part No. D1634ENR4

Page 11

Specifications and Dimensions

8 kg /

20 lb. /

Specifications

Shipping

dimensions

(WxDxH),

in. [mm]

80 L

Models

27.95 x

32.87 x

49.02 [710

x 835 x

1245]

Wash Cylinder Information

Cylinder

20.87 [530] 24.40 [620] 24.40 [620] 29.53 [750] 29.53 [750] 29.53 [750] 35.98 [914] 35.98 [914]

diameter

in. [mm]

Cylinder

13.78 [350] 13.78 [350] 17.72 [450] 16.14 [410] 21.46 [545] 24.41 [620] 19.88 [505] 31.10 [790]

depth in.

[mm]

Cylinder

volume ft

2.6 [75] 3.7 [105] 4.8 [135] 6.4 [180] 8.5 [240] 9.9 [280] 11.7 [332] 20.47 [520]

3

[l]

11 kg /

25 lb. /

105 L

Models

31.50 x

32.87 x

53.35 [800

x 835 x

1355]

14 kg /

30 lb. /

135 L

Models

31.50 x

37.40 x

53.35 [800

x 950 x

1355]

18 kg /

40 lb. /

180 L

Models

36.42 x

38.19 x

61.02 [925

x 970 x

1550]

24 kg /

55 lb. /

240 L

Models

36.42 x

44.49 x

61.02 [925

x 1130 x

1550]

28 kg /

70 lb. /

280 L

Models

36.42 x

46.85 x

61.02 [925

x 1190 x

1550]

35 kg /

80 lb. /

332 L

Models

43.31 x

43.31 x

66.93

[1100 x

1100 x

1700]

52 kg /

115 lb. /

520 L

Models

43.31 x

54.53 x

66.93

[1100 x

1385 x

1700]

Door Opening Information

Door open-

13 [330] 16.14 [410] 16.14 [410] 18.11 [460] 18.11 [460] 18.11 [460] 19.84 [504] 19.84 [504]

ing size, in.

[mm]

Height of

13.74 [349] 13.46 [342] 13.46 [342] 18.31 [465] 18.31 [465] 18.31 [465] 18.31 [465] 18.31 [465]

door bottom above

floor, in.

[mm]

Drive Train Information

Number of

1 1 1 1 1 1 1 1

motors in

drive train

Motor Size,

0.67 [0.5] 0.67 [0.5] 1 [0.75] 1 [0.75] 1.48 [1.1] 1.5 [2.01] 2.95 [2.2] 5.36 [4]

hp [kW]

(100G)

Motor Size,

N/A N/A N/A N/A N/A N/A 2.95 [2.2] N/A

hp [kW]

(150G)

Motor Size,

0.67 [0.5] 0.67 [0.5] 1 [0.75] 1.48 [1.1] 2.01 [1.5] 2.01 [1.5] N/A N/A

hp [kW]

(175G)

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table continues...

11 Part No. D1634ENR4

Page 12

Specifications and Dimensions

Specifications

Motor Size,

0.67 [0.5] 0.74 [0.55] 1 [0.75] 1.48 [1.1] 2.01 [1.5] 2.01 [1.5] N/A N/A

hp [kW]

(200G)

Cylinder Speeds

Wash,

50 46 46 42 42 42 38 38

RPM

Extraction,

580 540 540 490 490 490 440 440

RPM

(100G)

Extraction,

N/A N/A N/A N/A N/A N/A 540 N/A

RPM

(150G)

Extraction,

770 710 710 645 645 645 N/A N/A

RPM

(175G)

8 kg /

20 lb. /

80 L

Models

11 kg /

25 lb. /

105 L

Models

14 kg /

30 lb. /

135 L

Models

18 kg /

40 lb. /

180 L

Models

24 kg /

55 lb. /

240 L

Models

28 kg /

70 lb. /

280 L

Models

35 kg /

80 lb. /

332 L

Models

52 kg /

115 lb. /

520 L

Models

Heating

Electric,

kW

Steam, psi

[bar]

Hot water,

°F [°C]

Noise Emissions

Wash sequence, dB

(100 G)

Wash sequence, dB

(150 G)

Wash sequence, dB

(175 G)

Extract sequence, dB

(100G)

6 / 9 (4.6) 6 / 9 / 12 9 / 12 12 / 18 18 21.9 27 40.6

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

15-116

[1-8]

90 [194] 90 [194] 90 [194] 90 [194] 90 [194] 90 [194] 90 [194] 90 [194]

49 49 50 48 50 50 50 50

N/A N/A N/A N/A N/A N/A 50 N/A

49 49 50 50 50 50 N/A N/A

53 53 65 55 65 65 65 65

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table continues...

12 Part No. D1634ENR4

Page 13

Specifications and Dimensions

Specifications

Extract se-

N/A N/A N/A N/A N/A N/A 65 N/A

quence, dB

(150G)

Extract se-

53 53 65 65 65 65 N/A N/A

quence, dB

(175G)

Floor Load Data

Maximum

427 [1.9] 495 [2.2] 607 [2.7] 764 [3.4] 877 [3.9] 944 [4.2] 1461 [6.5] 1888 [8.4]

static load

on floor,

lbs. [kN]

(100G)

Maximum

N/A N/A N/A N/A N/A N/A 1461 [6.5] N/A

static load

on floor,

lbs. [kN]

(150G)

8 kg /

20 lb. /

80 L

Models

11 kg /

25 lb. /

105 L

Models

14 kg /

30 lb. /

135 L

Models

18 kg /

40 lb. /

180 L

Models

24 kg /

55 lb. /

240 L

Models

28 kg /

70 lb. /

280 L

Models

35 kg /

80 lb. /

332 L

Models

52 kg /

115 lb. /

520 L

Models

Maximum

static load

on floor,

lbs. [kN]

(175G)

Maximum

dynamic

load on

floor, lbs.

[kN]

(100G)

Maximum

dynamic

load on

floor, lbs.

[kN]

(150G)

Maximum

dynamic

load on

floor, lbs.

[kN]

(175G)

427 [1.9] 495 [2.2] 607 [2.7] 899 [4.0] 1012 [4.5] 1101 [4.9] N/A N/A

360 ± 337

[1.6 ± 1.5]

N/A N/A N/A N/A N/A N/A 1191

427 ± 450

[1.9 ± 2.0]

495 ± 562

[2.2 ± 2.5]

607 ± 719

[2.7 ± 3.2]

674 ± 967

[3.0 ± 4.3]

719 ± 1124

[3.2 ± 5.0]

1191

± 1866 [5.3

± 5.5]

1506

± 1843 [6.7

± 8.2]

N/A

± 1866 [5.3

± 8.3]

360 ± 562

[1.6 ± 2.5]

427 ± 764

[1.9 ± 3.4]

495 ± 989

[2.2 ± 4.4]

764 ± 1259

[3.4 ± 5.6]

832 ± 1664

[3.7 ± 7.4]

877 ± 1956

[3.9 ± 8.7]

N/A N/A

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table continues...

13 Part No. D1634ENR4

Page 14

Specifications and Dimensions

Specifications

Frequency

of dynamic

load, Hz

(100G)

Frequency

of dynamic

load, Hz

(150G)

Frequency

of dynamic

load, Hz

(175G)

General Data

Ambient

Temperature, °F

[°C]

8 kg /

20 lb. /

80 L

Models

11 kg /

25 lb. /

105 L

Models

14 kg /

30 lb. /

135 L

Models

18 kg /

40 lb. /

180 L

Models

24 kg /

55 lb. /

240 L

Models

28 kg /

70 lb. /

280 L

Models

35 kg /

80 lb. /

332 L

Models

52 kg /

115 lb. /

520 L

Models

9.7 8.9 8.9 8.2 8.2 8.2 9 7.4

N/A N/A N/A N/A N/A N/A 9 N/A

12.8 11.8 11.8 10.8 10.8 10.8 N/A N/A

41-95 [5-35]

Relative

Humidity

Height

above sea

level ft.

[m]

Storage

Temperature, °F

[°C]

30%-90% without condensation

up to 3280 [up to 1000]

34-131 [1-55]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

14 Part No. D1634ENR4

Page 15

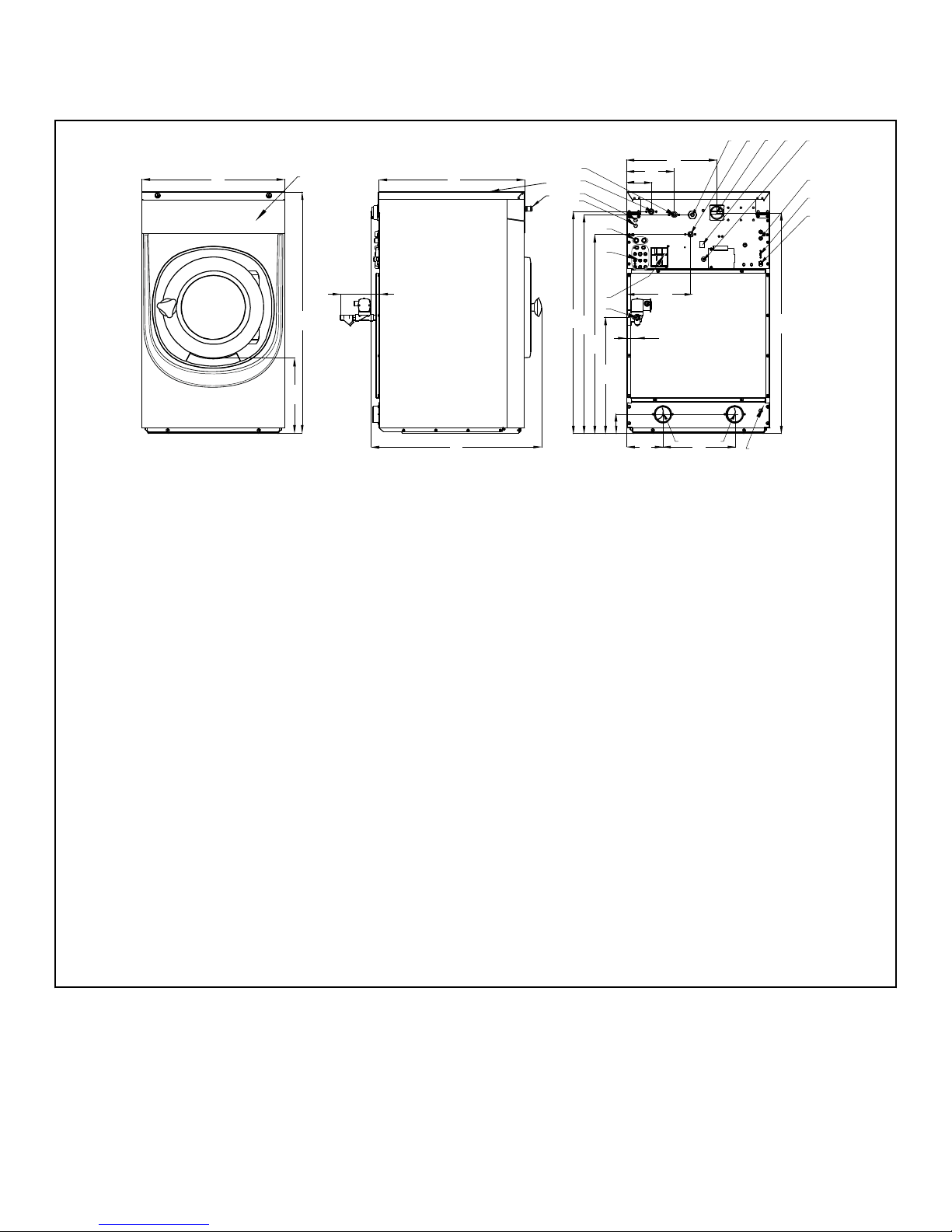

Machine Dimensions

1

A

B

C

D

E

F

2

3

G

H

I

J

K

L

M

N

O

P

Q

R

S

4

5

6

7

8

9

10

11

121314 15 16

17

18

19

20

21

22

CHM2465N_SVG

Specifications and Dimensions

1. Control panel

2. Soap dispenser

3. Centralstop button

4. Steam connection

5. Air relieve

6. Liquid soap connection

7. Recyled water inlet

8. Steam valve connection

9. Recycled water valve cable inlet

10. Cold water inlet, soft

11. Cold water inlet, hard

12. Electrical connection

13. Hot water inlet

14. Main switch

15. Heating change-over switch

16. Liquid soap pump eletrical connection

17. Fuses

18. USB port

19. PC programming connection

20. Discharge water cable inlet

21. Drain valve - 3 in. 76 mm

22. Drain valve - 3 in. 76 mm (80 and 115 lb. [332 and 520 L] Models only)

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 1

15 Part No. D1634ENR4

Page 16

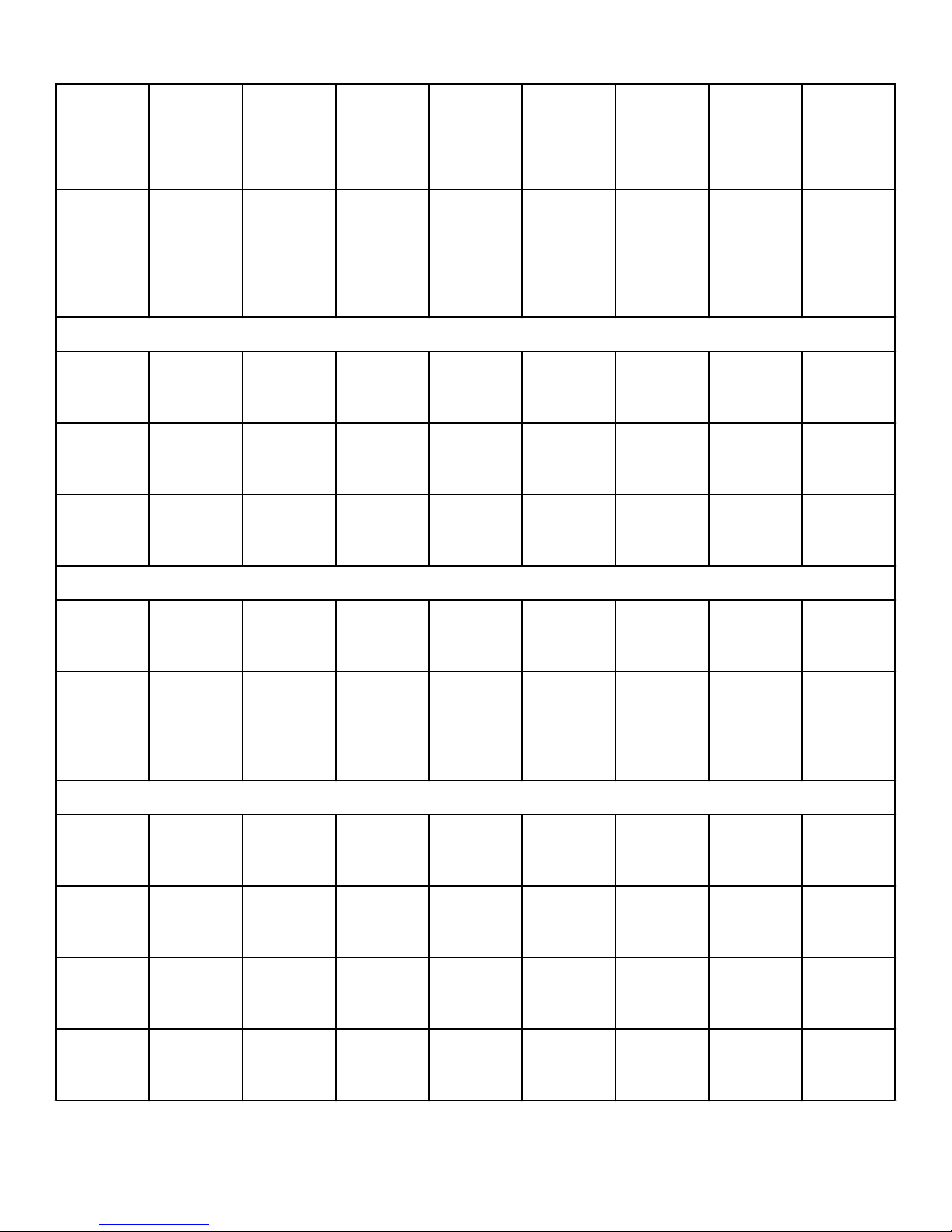

Specifications and Dimensions

8 kg /

20 lb. /

80 L

Models,

Specification

in.

[mm]

A 25.98 [660] 29.53 [750] 29.53 [750] 35.03 [890] 35.03 [890] 35.03 [890] 41.73

11 kg /

25 lb. /

105 L

Models,

in.

[mm]

14 kg /

30 lb. /

135 L

Models,

in.

[mm]

18 kg /

40 lb. /

180 L

Models,

in.

[mm]

24 kg /

55 lb. /

240 L

Models,

in.

[mm]

28 kg /

70 lb. /

280 L

Models,

in.

[mm]

35 kg /

80 lb. /

332 L

Models,

in.

[mm]

[1060]

52 kg /

115 lb. /

520 L

Models,

in.

[mm]

41.73

[1060]

B 13.74 [349] 13.46 [342] 13.46 [342] 18.31 [465] 18.31 [465] 18.31 [465] 18.31 [465] 18.31 [465]

C 43.89

[1115]

48.22

[1225]

48.22

[1225]

55.51

[1410]

55.51

[1410]

55.51

[1410]

59.05

[1500]

59.05

[1500]

D 7.08 [180] 7.56 [192] 7.56 [192] 4.72 [120] 4.72 [120] 4.72 [120] 5.71 [145] 5.71 [145]

E 30.91 [785] 30.91 [785] 35.43 [900] 36.02 [915] 41.73

[1060]

F 26.61 [676] 26.61 [676] 31.14 [791] 32.13 [816] 37.83 [961] 40.79

G 40.35

[1025]

44.68

[1135]

44.68

[1135]

51.85

[1317]

51.85

[1317]

44.68

[1135]

[1036]

51.85

[1317]

40.55

[1030]

51.77

[1315]

36.89 [937] 48.11

[1222]

55.63

[1413]

52.44

[1332]

H 39.76

[1010]

I 36.22 [920] 40.55

44.09

[1120]

[1030]

44.09

[1120]

40.55

[1030]

51.06

[1297]

47.72

[1212]

51.06

[1297]

47.72

[1212]

51.06

[1297]

47.72

[1212]

53.78

[1366]

52.21

[1326]

54.09

[1374]

55.67

[1414]

J 21.06 [535] 18.89 [480] 18.89 [480] 20.79 [528] 20.79 [528] 20.79 [528] 20.79 [528] 20.79 [528]

K 3.46 [88] 3.85 [98] 3.95 [98] 5.12 [130] 5.12 [130] 5.12 [130] 4.72 [120] 4.72 [120]

L 6.53 [166] 8.85 [225] 8.85 [225] 11.02 [280] 11.02 [280] 11.02 [280] 12.52 [318] 12.52 [318]

M N/A N/A N/A N/A N/A N/A 18.98 [482] 18.98 [482]

N 40.15

[1020]

44.48

[1130]

44.48

[1130]

50 [1270] 50 [1270] 50 [1270] 53.11

[1349]

53.11

[1349]

O 1.89 [48] 1.65 [42] 1.65 [42] 2.13 [54] 2.13 [54] 2.13 [54] 2.60 [66] 2.60 [66]

P 11.53 [293] 13.31 [338] 13.31 [338] 11.93 [303] 11.93 [303] 11.93 [303] 15.08 [383] 14.29 [363]

Q 16.34 [415] 19.88 [505] 19.88 [505] 24.61 [625] 24.61 [625] 24.61 [625] 26.42 [671] 26.41 [671]

R 8.58 [218] 8.58 [218] 8.58 [218] 8.58 [218] 8.58 [218] 8.58 [218] 9.76 [248] 8.78 [223]

S 4.44 [113] 4.44 [113] 4.44 [113] 4.44 [113] 4.44 [113] 4.44 [113] 4.45 [113] 3.46 [88]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Table 1

16 Part No. D1634ENR4

Page 17

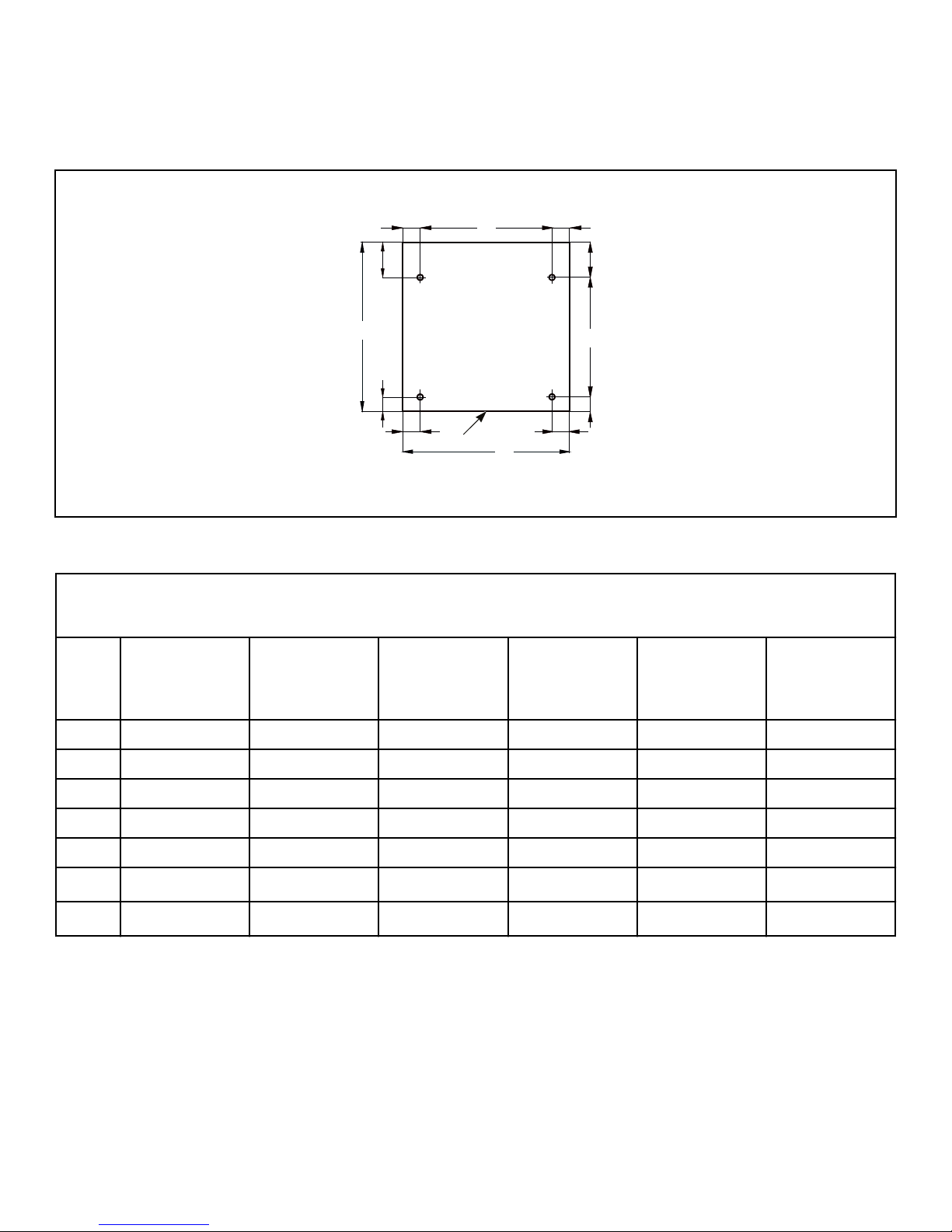

CHM2467N_SVG

F

EE

D D

C C

B

A

1

G

C C

Specifications and Dimensions

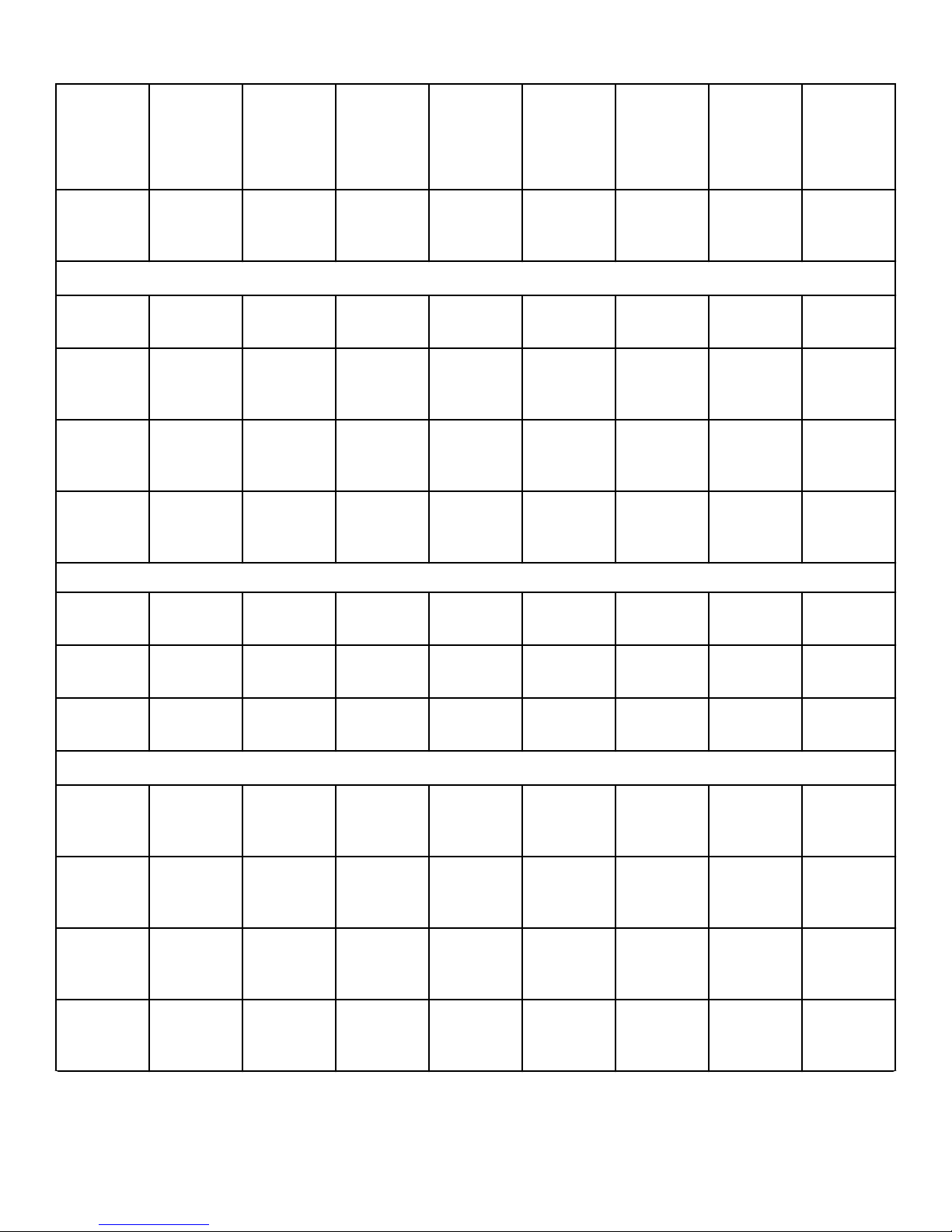

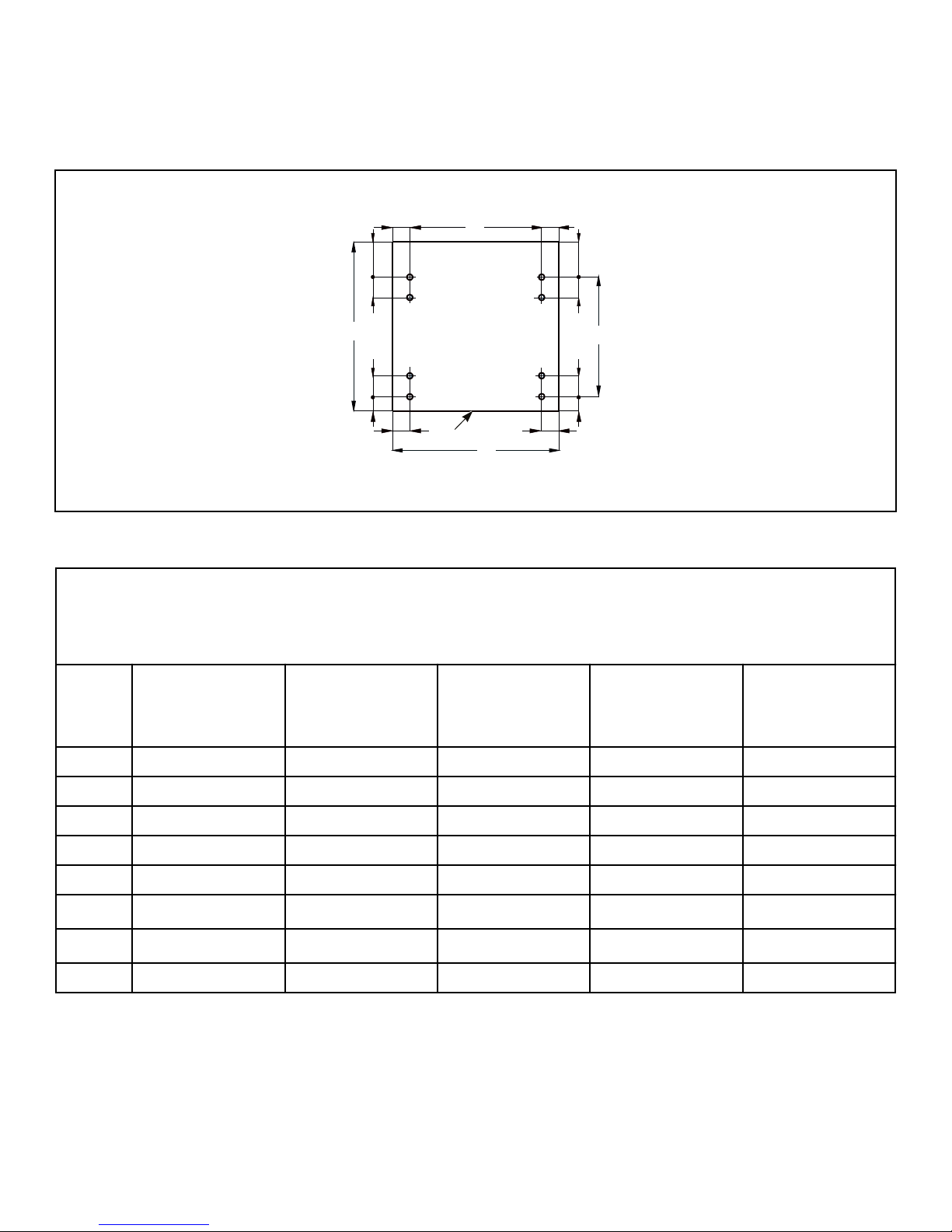

Mounting Bolt Hole Locations – 8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L and 14

kg / 30 lb. / 135L; 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and 28 kg / 70 lb. / 280

L with 100 G Extraction

8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L and 14 kg / 30 lb. / 135 L; 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and

28 kg / 70 lb. / 280 L with 100 G Extraction)

1. Front of machine

Figure 2

Mounting Bolt Hole Locations – 8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L and 14 kg / 30 lb. / 135 L; 18 kg / 40 lb. /

180L, 24 kg / 55 lb. / 240 L and 28 kg / 70 lb. / 280 L with 100 G Extraction, in. [mm]

Spec

ifica-

tion

8 kg / 20 lb. /

80 L

11 kg / 25 lb. /

105 L

14 kg / 30 lb. /

135 L

18 kg / 40 lb. /

180 L (100G)

24 kg / 55 lb. /

240 L (100G)

28 kg / 70 lb. /

280 L (100G)

A 20.55 [522] 24.21 [615] 24.21 [615] 29.57 [751] 29.57 [751] 29.57 [751]

B 18.66 [474] 18.66 [474] 22.59 [574] 22.40 [569] 28.11 [714] 31.06 [789]

C 2.71 [69] 2.85 [67.5] 2.65 [67.5] 2.74 [69.5] 2.74 [69.5] 2.74 [69.5]

D 5.47 [139] 5.47 [139] 6.06 [154] 8.68 [220.5] 8.68 [220.5] 8.68 [220.5]

E 2.26 [57.5] 2.26 [57.5] 2.26 [57.5] 1.97 [50] 1.97 [50] 1.97 [50]

F 25.98 [660] 29.52 [750] 29.52 [750] 35.04 [890] 35.04 [890] 35.04 [890]

G 26.39 [670.5] 26.39 [670.5] 30.92 [785.5] 33.01 [838.5] 38.76 [984.5] 41.71 [1059.5]

Table 2

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

17 Part No. D1634ENR4

Page 18

CHM2468N_SVG

G

F

E E

D D

C C

C C

B

A

1

H H

H H

Specifications and Dimensions

Mounting Bolt Hole Locations – 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and 28

kg / 70 lb. / 280 L with 175 G Extraction; 35 kg / 80 lb. / 332 L and 52 kg / 115 lb. /

520 L

18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and 28 kg / 70 lb. / 280 L with 175 G Extraction; 35 kg / 80 lb. / 332 L

and 52 kg / 115 lb. / 520 L

1. Front of machine

Mounting Bolt Hole Locations – 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. / 240 L and 28 kg / 70 lb. / 280 L with 175 G

Extraction; 35 kg / 80 lb. / 332 L and 52 kg / 115 lb. / 520 L

in. [mm]

Speci-

fica-

tion

18 kg / 40 lb. /

180 L (175G)

A 29.57 [751] 29.57 [751] 29.57 [751] 36.22 [920] 36.22 [920]

B 22.40 [569] 28.11 [714] 31.06 [789] 25.16 [639] 36.38 [924]

C 2.74 [69.5] 2.74 [69.5] 2.74 [69.5] 2.76 [70] 2.76 [70]

D 8.68 [220.5] 8.68 [220.5] 8.68 [220.5] 10.69 [271.5] 10.69 [271.5]

E 1.97 [50] 1.97 [50] 1.97 [50] 1.97 [50] 1.97 [50]

F 35.04 [890] 35.04 [890] 35.04 [890] 41.73 [1060] 41.73 [1060]

G 33.01 [838.5] 38.76 [984.5] 41.71 [1059.5] 37.82 [960.5] 49.04 [1245.5]

H 3.23 [82] 3.23 [82] 3.23 [82] 3.23 [82] 3.23 [82]

24 kg / 55 lb. /

240 L (175 G)

Figure 3

28 kg / 70 lb. /

280 L (175G)

Table 3

835 kg / 80 lb. /

332 L

52 kg / 115 lb. /

520 L

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

18 Part No. D1634ENR4

Page 19

Floor Mounting Layout

CHM2466N_SVG

A

B

Dimensional Clearances

Figure 4

Dimensional Clearances, in. [mm]

A Distance to wall (minimum) 20 [500]

Specifications and Dimensions

B Distance of machine to side wall or other machine (mini-

mum)

Table 4

0.79 [20]

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

19 Part No. D1634ENR4

Page 20

Installation

Pallet Removal

The machine is delivered bolted onto the transport pallet and

packed in shrink-wrap foil or box.

1. Remove packing from machine.

2. Remove front and rear panel.

3. Remove bolts between machine and pallet.

4. When machine is lifted off pallet, make sure the machine does

not come down on the floor with either of the rear corners

first. The machine's side panel can be damaged.

NOTE: Two self-adhesive ruber stop-blocks are supplied with the machine. They may be applied as

paint protection when opening the door.

Installation

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

20 Part No. D1634ENR4

Page 21

Machine Installation

CHM2469N_SVG

B

A

Installation

Install the machine close to a floor drain or open drain.

Machine Foundation and Pad Installation

A concrete pad may be constructed to elevate a machine. Care

must be exercised in the design of the pad due to the force exer-

ted by the machine during extract. This concrete pad, recommended not to exceed 7.87 inches [200 mm] above existing floor,

must be placed, reinforced with rebar and tied to the existing

floor.

Figure 5

Specification in. [mm]

A 5.9 - 7.87 [150 - 200]

B 1.58 [40]

Table 5

IMPORTANT: Do NOT install a pad on top of the existing floor. The foundation and pad must be constructed

and tied together as one piece.

If the existing floor is not reinforced concrete at least of minimum thickness 4.72 in [120 mm] or an elevated pad is desired,

the following steps must be performed:

1. Cut a hole larger than the machine base through the existing

floor, refer to Figure 6 .

2. Excavate to a depth as indicated in Table 6 from the top of the

existing floor.

3. Wet the excavated area and spread over with cement.

4. Drill holes [refer to manufacturer’s requirements for drill hole

size] for the perimeter reinforcing bar into the existing floor.

5. Clean out debris from each reinforcing bar hole.

6. Fill half the hole depth with acrylic adhesive.

7. Using #4 (60 ksi) reinforcing bar, tie new pad to existing floor

making sure to tie reinforcing bars at the intersections and using proper reinforcing bar supports to hold bars at the proper

depth in the pad.

NOTE: When inserting the reinforcing bar, note the

locations (and space requirements) for drilling holes

for chemical anchor bolts.

8. Allow adhesive around reinforcing bar to cure properly, refer

to adhesive manufacturer for recommended cure times.

9. Pour concrete into the prepared base.

10. Level the surface carefully into a horizontal plane.

11. Allow concrete to cure for at least one week before installa-

tion of the machine.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

21 Part No. D1634ENR4

Page 22

CHM2470N_SVG

E

D

C

B

A

Installation

Figure 6

Specifi-

cation,

in. [mm]

8 kg / 20

lb. / 80 L

Models

11 kg /

25 lb. /

105 L

Models

14 kg /

30 lb. /

135 L

Models

18 kg /

40 lb. /

180 L

Models

24 kg /

55 lb. /

240 L

Models

28 kg /

70 lb. /

280 L

Models

35 kg /

80 lb. /

332 L

Models

52 kg /

115 lb. /

520 L

Models

A 30.71 [780] 34.25 [870] 34.25 [870] 39.76 [1010] 39.76 [1010] 39.76 [1010] 46.46 [1180] 46.46 [1180]

B Refer to Table 2 or Table 3 , Specification F

C Refer to Table 2 or Table 3 , Specification G

D 2.95 [75]

E 31.12

[790.5]

31.12

[790.5]

35.65

[905.5]

37.74

[958.5]

43.48

[1104.5]

46.44

[1179.5]

42.54

[1080.5]

53.76

[1365.5]

Table 6

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

22 Part No. D1634ENR4

Page 23

CHM2471N_SVG

6

5

4

3

2

1

Installation

Machine Installation on Floor or Steel Base

The drum of rigid-mount machines is fixed to the frame. The

floor and steel base (if used) underneath the machine MUST be

stable enough to be able to absorb the dynamic loads which are

created during the spin sequence. Refer to General Specifica-

tions. M16 anchor bolts and washers and M16 self-locking nuts

must be used so the machine, the steel base (if used) and floor

form one integral unit. Refer to Figure 7 and Figure 8 .

Installation on floor

NOTE: Anchor bolts are not supplied with machine.

Washers and nuts are supplied with machines. Torque

is 100Nm. For anchoring dimensions, refer to Mounting

Bolt Hole Locations – 8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L

and 14 kg / 30 lb. / 135L; 18 kg / 40 lb. / 180 L, 24 kg / 55 lb. /

240 L and 28 kg / 70 lb. / 280 L with 100 G Extraction and

Mounting Bolt Hole Locations – 18 kg / 40 lb. / 180 L, 24 kg /

55 lb. / 240 L and 28 kg / 70 lb. / 280 L with 175 G Extraction;

35 kg / 80 lb. / 332 L and 52 kg / 115 lb. / 520 L.

1. Nut

2. Washer

3. Spacing washer

4. Anchor bolt

5. Washer

6. Concrete floor

Figure 7

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

23 Part No. D1634ENR4

Page 24

CHM2472N_SVG

7

6

5

4

3

2

1

2

2

1

Installation

Installation on a steel base and floor

1. Nut

2. Washer

3. Spacing washer

4. Anchor bolt

5. Washer

6. Concrete floor

7. Bolt (supplied with steel base)

Figure 8

NOTE: The existing concrete floor must be at least 4.72

in. [120 mm] thick.

1. Check that the machine is installed in a level and stable manner in all its corners.

2. If necessary, level the machine up by means of stainless or

galvanized spacing washers inserted between the machine

frame and the floor. Refer to Figure 9 and Figure 10 . The di-

mensions of the spacers must be the same as the dimension of

the machine frame in the place where the anchor bolts are located (80 x 80 mm).

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

24 Part No. D1634ENR4

Page 25

CHM2473N_SVG

3

2

1

CHM2474N_SVG

3

2

1

CHM2480N_SVG

1

Installation

20 lb. (80 L), 25 lb. (105 L) and 30 lb. (135 L); 40 lb.

(180 L), 55 lb. (240 L) and 70 lb. (280 L) with 100 G

Extraction

1. Washer

2. Spacing washers, as needed

3. Concrete floor

Figure 9

NOTE: Mounting bolts are not included with the machine.

Drain Connection

40 lb. (180 L), 55 lb. (240 L) and 70 lb. (280 L) with

175 G Extraction; 80 lb. (332 L) and 115 lb. (520 L)

1. Washer

2. Spacing washers, as needed

3. Concrete floor

Figure 10

3. Fit a washer and self-locking nut on the anchor bolt and tighten with a torque wrench to 100Nm.

NOTE: It is advisable to recheck the torque after a

short period of machine operation.

4. Using the bottom frame of the machine, lift the whole machine and place over the four drilled holes.

5. Check that the machine is seated in a perfectly level manner.

6. Using mechanical or chemical anchor bolts, mount the ma-

chine to the floor or steel base.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

1. Drain connection

Figure 11

25 Part No. D1634ENR4

Page 26

CHM2479N_SVG

A

4

D

C

3

B

2

1

Installation

Drain Valve

IMPORTANT: Machine must be installed in accordance

with all local codes and ordinances.

All drain systems must be vented to prevent an air lock or siphoning.

Connect a 3 inch [76 mm] pipe or rubber hose to the machine's

drain pipe, ensuring a downward flow from the machine. Avoid

sharp bends which may prevent proper draining.

The drainage pipe should be located over a floor drain, drainage

channel.

Drainage Pipe Information, in. [mm]

52 kg /

Specification

8 kg /

20 lb. /

80 L

Models

11 kg /

25 lb. /

105 L

Models

14 kg /

30 lb. /

135 L

Models

18 kg /

40 lb. /

180 L

Models

24 kg /

55 lb. /

240 L

Models

28 kg /

70 lb. /

280 L

Models

35 kg /

80 lb. /

332 L

Models

115

lb. /

520 L

Models

A 3 [75] 3 [75] 3 [75] 3 [75] 3 [75] 3 [75] 3 [75] 3 [75]

B 3.46 [88] 3.85 [98] 3.95 [98] 5.12 [130] 5.12 [130] 5.12 [130] 4.72 [120] 4.72 [120]

C mini-

0.79 [20] 0.79 [20] 0.79 [20] 0.79 [20] 0.79 [20] 0.79 [20] 0.79 [20] 0.79 [20]

mum

D mini-

3.94 [100] 3.94 [100] 3.94 [100] 3.94 [100] 3.94 [100] 3.94 [100] 3.94 [100] 3.94 [100]

mum

1. Clamp

2. Drain elbow 3 in. [76 mm]

3. Waste channel

4. Waste channel cover

Specification Model Requirement

Drain connection number 8 kg / 20 lb. / 80 L - 28 kg / 70 lb. / 280 L 1

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 12

Table 7 continues...

26 Part No. D1634ENR4

Page 27

Specification Model Requirement

CHM2481N_SVG

2

C

B

A

1

Installation

Drain connection number 35 kg / 80 lb. / 332 L - 52 kg / 115 lb. /

520 L)

Drain connection size, in. [mm] All 3 [76]

Average flow rate of draining gal/min. [l/

8 kg / 20 lb. / 80 L - 28 kg / 70 lb. / 280 L 55.48 [210]

min.]

Average flow rate of draining gal/min. [l/

min.]

Drain pump with hose - internal diameter

35 kg / 80 lb. / 332 L - 52 kg / 115 lb. /

520 L

8 kg / 20 lb. / 80 L 0.75 [19]

of hose, in [mm]

Flow rate of drain pump, gal/min. [l/

8 kg / 20 lb. / 80 L 9.51 [36]

min.]

Table 7

The main drain channel-pipe must have the capacity to be able to

handle the total output of all connected machines. In a drainpipe,

a vent must be provided every 65.62 ft. [20 m] to assure the drain

pipe will work. If the main drain pipe cannot be sufficiently ven-

on the drainpipe, the diameter of the tube or the width of the

waste channel must increase. Refer to Figure 13 .

The diameters of drain pipe for machines with two drain valves

must have dimensions suitable for double the value of water flow.

ted, install a vent per machine. Every time a machine is coupled

2

110 [420]

1. Vent

2. Flow

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 13

27 Part No. D1634ENR4

Page 28

Installation

Drain Line Sizing / Minimum Drain ID, in. [mm]

A - 1 Machine B - 2 Machines C - 3 Machines

3 [75] 4 [100] 5 [125]

Table 8

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

28 Part No. D1634ENR4

Page 29

CHM2482N_SVG

1

Installation

Drain Pump, 8 kg / 20 lb. / 80 L Models

Connect a flexible hose to a drain pipe so that the hose bend must

not be located lower than the water level to provide sufficient si-

phon effect. In order to achieve good draining, the hose must not

bend at a sharp angle. Refer to Figure 14 .

1. Drain hose bend

Figure 14

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

29 Part No. D1634ENR4

Page 30

CHM2475N_SVG

21

CHM2476N_SVG

3

2

1

Installation

Water Connection Requirements

WARNING

To prevent personal injury, avoid contact with inlet

water temperatures higher than 125° Fahrenheit [51°

Celsius] and hot surfaces.

W748

NOTE: For 8 kg / 20 lb. / 80 L, 11 kg / 25 lb. / 105 L, 14

kg / 30 lb. / 135 L, 18 kg / 40 lb. / 180 L and 24 kg / 55

lb. / 240 L Models, to connect cold water, use a hose

with plastic elbow. To connect hot water, use a hose

with metal elbow.

Do not re-use water hoses; only use new water hoses.

The appliance has been designed with a built-in "AB" airgap system according to EN1717. Nevertheless, when potable water will

be connected to the appliance, an approved double check valve or

some other no less effective device providing backflow prevention protection to at least fluid category three shall be fitted at the

point of connections between the water supply and the appliance.

All intake connections to the machine are to be fitted with manual shut-off valves and filters, to facilitate installation and servicing.

All water connectors present on the machine must be connected

or the wash program will not function correctly. Refer to Table 9

for possible connection options, which will depend on the water

types to be connected to the machine, which can be found by

checking the machine plates.

2 Water Connection Models

3 Water Connection Models

1. Refer to Table 9 .

2. Refer to Table 9 .

3. Refer to Table 9 .

Figure 16

Water

type Water connection

1 2 3

Cold and Hot Cold Hot N/A

Cold soft,

Cold soft Hot Cold hard

Cold hard and

Hot

Table 9

WARNING

1. Refer to Table 9 .

2. Refer to Table 9 .

Figure 15

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

If the water pressure is below the minimum value,

the wash result can not be guaranteed for a selected

program.

W914

The maximum water inlet temperature for vended models is

194°F [90°C]and the recommended maximum water inlet temperature for on-premises models is 150°F [66°C] (standard models) or 140°F [60°C] (WRAS approved models) .

Connections should be supplied by a hot and a cold water line of

at least the sizes shown in Water Supply Line Sizing . Installation

of additional machines will require proportionately larger water

lines.

Connections should be supplied by a hot and a cold water line per

national and local codes and in accordance with IEC 61770.

30 Part No. D1634ENR4

Page 31

Installation

To connect water service to a machine with hoses, use the following procedure:

1. Before installing hoses, flush the building’s water system at

the machine connection valves for at least two (2) minutes.

3. Hang hoses in a large loop; do not allow them to kink.

If additional hose lengths are needed or using hoses other than

those supplied by manufacturer, flexible hoses with screen filters

are required.

2. Check filters in the machine’s inlet hoses for proper fit and

cleanliness before connecting.

Specification Model Requirement

Water inlet connection size, in. BSP 8 kg / 20 lb. / 80 L - 35 kg / 80 lb. / 332 L 3/4

Water inlet connection size, in. BSP 52 kg / 115 lb. / 520 L 1

Recommended pressure, PSI [bar] All 44-73 [3-5]

Inlet flow capacity per inlet, gal/min [l/

8 kg / 20 lb. / 80 L - 24 kg / 55 lb. / 240 L 5.28 [20]

min.]

Inlet flow capacity per inlet, gal/min at

15 PSI [l/min. at 1 bar]

Inlet flow capacity per inlet, gal/min at

28 kg / 70 lb. / 280 L - 35 kg / 80 lb. /

17.44 [66]

332 L

52 kg / 115 lb. / 520 L 48.34 [183]

15 PSI [l/min. at 1 bar]

Inlet flow capacity per inlet, gal/min at

116 PSI [l/min. at 8 bar]

18 kg / 40 lb. / 180 L - 35 kg / 80 lb. /

332 L)

49.66 [188]

Inlet flow capacity per inlet, gal/min at 116

52 kg / 115 lb. / 520 L 136.846 [518]

PSI [l/min. at 8 bar]

Table 10

Suitable air cushions (risers) should be installed in supply lines to

prevent “hammering.”

Alliance Laundry Systems, LLC ranges of front loading commercial clothes washing machines have solenoid valves at the inlets.

The water supply to the washing machines is supplied with an

AB air gap between the soap tray and the drum. Minimum and

maximum working pressure 1 bar and 8 bar. The machines are

supplied with approved inlet hoses.

NOTE: This machine has a fluid category 5 backflow

prevention device built in between the soap tray and

drum.

To comply with WRAS (IRN R150), European standard EN1717,

an approved double check valve backflow prevention device with

the watermark is provided with the unit and must be fitted at the

point of connection(s) between the supply and the fitting.

NOTE: No more than two (2) water connection hoses

should be used on WRAS-approved models.

Figure 17

Water Reuse Connection

WARNING

Disconnect the machine power supply. When the

main switch is turned off, the inlet terminals of the

machine main switch are still under current.

W900

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

1. Drill out the protective screens of the water reuse inlet using a

drill bit of .59 in. [15 mm] diameter. Refer to Figure 18 .

IMPORTANT: Do not pierce the screens open. It

could lead to blockage of the water channel.

31 Part No. D1634ENR4

Page 32

CHM2477N_SVG

2

1

Installation

1. Cable inlet for control of water reuse valve or pump

2. Water reuse inlet

Figure 18

2. Connect the control of your reuse valve or pump onto the conductor of inlet valve I5 or I7 provided by the manufacturer,

which will disconnect the valve in question from standard

function.

IMPORTANT: The manufacturer waives all responsibility for malfunction of the washing machine if a

different valve than the specified I5 or I7 is used as

the water recycle valve.

3. Fit a cable bushing into the opening, and pull the cable

through the bushing. Refer to Figure 18 .

4. Connect the coil for control of the recuperated water inlet (the

coil is not supplied with the machine), operating voltage

208-240V 50/60 Hz.

5. Secure the cable so that it cannot be pulled out of the machine

or inlet valve.

Water Reuse Specifications

Temperature range, °F [°C] 41 to 194 [5 to 90]

Maximum pressure, PSI

116 [8]

[bar]

Reused Water Treatment

The reused water must be filtered before entering the water reuse

tank. A mechanical filter must be installed which filters off small

particles (fluff, buttons, paper, etc.) of sizes 0.0079 in. [0.2 mm]

or smaller. The denser the mesh, the better. There must also be a

filter installed on the pressure side of the pump. It is also possible

to install an additional, chemical filter. The manufacturer advises

to consult a specialist in filter systems.

Water Reuse Tank Properties

WARNING

It is prohibited to heat the water in the reuse tank.

This would disturb the temperature balance of the

washer and make the remaining chemicals in the recuperated water more active, which would lead to

corrosion of the entire installation.

W901

The reuse tank must meet the following minimum requirements:

• The tank must be made according to national standards.

• Tank capacity varies depending on multiple factors, so it must

be calculated by an authorized engineer. The factors are:

• The number of washing steps per washer, in which the wa-

ter will be re-used.

• The programmable amount of water that will be re-used in

a washing step (to find this amount, please refer to the

Programming Manual).

• The number of washers that will deliver water to the re-

use tank.

• The use of recuperated water per washer.

The tank must have an overflow to the sewer. Water from the

sewer must not be able to flow back into the reuse tank.

The network of pipes and hoses, the water pump and the reuse

tank must be of a non-corroding material. It must be resistant to

water and chemicals used for washing.

Connection - outside diam-

0.75 [19]

eter, in. [mm]

The hose and the connector must be resistant to chemical substances which are used for the washing process. It is also possible

to use a hose with enhanced performance such as the rubber

EPDM hose.

The water reuse system must be fitted with a filter which must be

regularly and thoroughly cleaned (based on water quality). This

cleaning prevents prolongation of filling up times and malfunction of water valves.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

The tank must be equipped with a system that fills the tank with

clean water to a minimum required working level, in case the water level drops below this minimum. If this requirement is not met

and an insufficient or no amount of recuperated water is fed into

the washer, it will not function properly.

A pump must transport the recuperated water from the tank to the

washer. The requirements for the pump depend on the number

and type of washers that are connected to the water re-use system. The maximum pump pressure is 116 psi [8 bar].

It is advisable to install a level switch. This level switch must be

connected to the microprocessor by means of a potential-free

contact. Refer to Figure 19 .

32 Part No. D1634ENR4

Page 33

CHM2560N_SVG

7

6

5

4

3

2

1

1. L

2. Level switch

3. K1

4. Terminal A

5. Terminal B

6. K1

7. N

Figure 19

The relay contact K1 has to close when the water level is too low.

Terminal B is positioned on the left side, in the lower part of the

microprocessor. Terminal A is positioned directly above Terminal

B. The microprocessor is positioned inside the washer. If the

"Check signal recycle" parameter is set to "yes" in the configuration menu, the timer will send a signal if the water level of the

reuse tank is too low.

Electrical Installation Requirements

IMPORTANT: Electrical ratings are subject to change.

Refer to serial plate for electrical ratings information

specific to your machine.

DANGER

Installation

WARNING

Hazardous Voltage. Can cause shock, burn or death.

Verify that a ground wire from a proven earth ground

is connected to the lug near the input power block

on this machine.

W360

IMPORTANT: If the machine is not equipped with a

main switch, supply disconnecting devices need to be

provided in the installation for all electrical supplies

connected to the machine, in accordance with EN

60204-1 standard, point 5.3.

IMPORTANT: Make sure the supply voltage is always

within the limits specified. When you have long distances in the electrical installation, it may be necessary to

use bigger cables to reduce the voltage drop.

Models outside of North America:

IMPORTANT: When the machine is connected near a

large capacity power supply transformer (500kVA or

more, wiring length shorter than 32.81 ft [10 m]) or

there is a power capacitor switch-over, a power supply

improving reactor must be installed. If you do not install this, the inverter may get damaged. Contact your

distributor for more information.

Models outside of North America: For electrical protection, if local regulations allow, there must be installed a residual current

device (RCD) and a circuit breaker in the electrical installation of

the building (laundry switchboard). Refer to Figure 20 .

Electrical connections are made at the rear of the machine. The

machine must be connected to the proper electrical supply shown

on the serial plate on the rear of the machine, using copper conductors only.

Electrical shock hazard will result in death or serious

injury. Disconnect electric power and wait ten (10)

minutes before servicing.

WARNING

Dangerous voltages are present inside the machine.

Only qualified personnel should attempt adjustments

and troubleshooting. Disconnect power from the machine before removing any cover and guards, and

before attempting any service procedures.

©

DO NOT COPY or TRANSMIT

Copyright, Alliance Laundry Systems LLC -

WARNING

Grounding: In event of malfunction, breakdown or

W911

W736

leakage current, grounding will reduce the risk of

electrical shock and serve as a protecting device by

providing a path of least resistance of electrical current. Therefore, it is very important and the responsibility of the installer to assure the washer is adequately grounded at installation, following all national and local requirements.

33 Part No. D1634ENR4

W902

Page 34

CHM2486N_SVG

8

7

6

5

4

3

2

1

Installation

• Maximum of 2 machines installed on each RCD (for 30mA,

only 1 machine)

Some washer control circuits are supplied with a separating transformer. Therefore, the RCD may not detect faults in the control

circuits (but the fuse(s) on the separating transformer will).

Supply Protection Device

A supply protection device protects the machine and wiring

against short circuits. (Glow-wire) fuses or (automatic) circuit

breakers may be used as supply protection devices.

Protection must be the "slow" type, which means curve D for circuit breakers.

1. Residual current device (RCD)

2. Laundry electrical switchboard

3. Supply protection device

4. Washing machine

5. Phase conductors

6. Protective conductor

7. Main switch inlet terminal switchboard

8. Neutral conductor

Figure 20

IMPORTANT: Alliance Laundry Systems warranty does

not cover components that fail as a result of improper

input voltage.

Residual Current Device (RCD) - Models Outside

of North America

In some countries, an RCD is known as an Earth Leakage Trip,

Ground Fault Circuit Interrupter (GFCI), Appliance Leakage

Current Interrupter (ALCI) or Earth (Ground) Leakage Current

Breaker.

When locally allowed, an RCD must be installed. In some power

network earthing systems, an RCD may not be allowed.

The RCD must have the following specifications:

• Tripping current of 100mA (if not locally available/allowed,

use a 30mA trip current, preferably selective type with small

time delay set)

• Type B (components inside the machine which make use of

DC voltages and require this better performance RCD)

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

34 Part No. D1634ENR4

Page 35

CHM2487N_SVG

7

6

5

4

3

2

1

Installation

Supply Cable

• For crossection size, refer to Table 11 Determining AWG Sizes

• Route the supply cable as short as possible, directly from the

The supply cable is not delivered with the machine. The supply

cable must have the following specifications:

• Conductors with copper cores (For wire size details, refer to

supply protection device to the washer without branching off

• Do not use a plug or extensions cords (the machine is intended to be permanently connected to the electrical network)

Electrical Specifications)

• Stranded conductors (flexible wiring) that can withstand vibration from machine

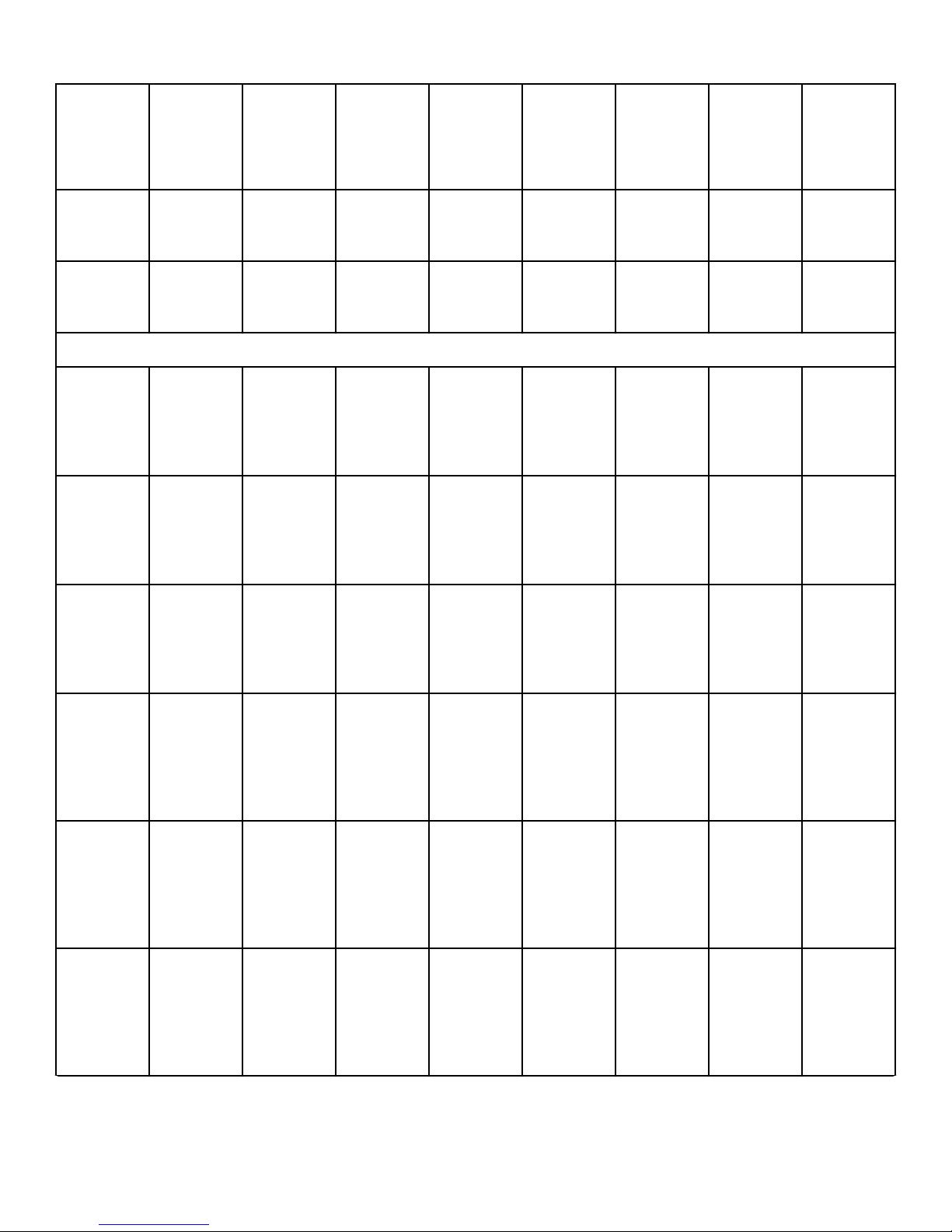

Min. phase conductor

Power supply protection device nominal current (US)

section, AWG [mm2]

Automatic circuit break-

ers Fuses

16A (15A) 10A (10A) 15 [1.5] 15 [1.5]

20A (20A) 16A (15A) 13 [2.5] 13 [2.5]

25A (-) 20A (20A) 11 [4] 11 [4]

40A (40A) 32A (30A) 9 [6] 9 [6]

63A (-) 50A (50A) 7 [10] 7 [10]

Min. protection conductor section, AWG [mm2]

80A 63A 5 [16] 5 [16]

100A 80A 3 [25] 5 [16]

125A 100A 2 [35] 3 [25]

Table 11 Determining AWG Sizes

To connect the supply cable, the following steps must be performed:

1. Insert cable through opening on rear panel. Insure a strain relief is used so the supply cable can not move.

2. Strip the conductor ends. Refer to Figure 21 . The protection

conductor must be longer so it can be routed to the machine

without tension.

1. Protection conductor

2. Phase conductor

3. Phase conductor

4. Phase conductor

5. Neutral conductor

6. Molded tube

7. Stripped length of conductors

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 21

3. With stranded conductors, use wire end tubes with an insulated sleeve (6) for L1/U, (L2/V), (L3/W), (N) conductors.

Make sure there is no accidental contact, since the supply cable stays under voltage even when the main switch is off.

35 Part No. D1634ENR4

Page 36

CHM2488N_SVG

7

6

5

4

3

2

1

Installation

4. Crimp a ring terminal to the protection conductor so it stays

fixed to the PE terminal.

5. Connect the supply cable conductors to the incoming terminals (main switch [1]), marked with L1/U, (L2/V), (L3/W),

(N) and the terminal marked with PE. Refer to Figure 22 .

1. Main switch

2. Strain relief

3. Sag of inlet cable

4. N

5. W

6. V

7. U

Figure 22

Provide a sag in the cable, in front of the strain relief. This

will prevent condensed water from dripping into the machine.

Refer to Figure 22 .

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

36 Part No. D1634ENR4

Page 37

Machine Protective Earth Connection and Equipo-

tential Bonding

If there are other washers or appliances with exposed conductive

parts, which can touch simultaneously, make sure to make equipotential bonding between all these appliances. The external protective terminal for this purpose is located on the rear panel of the

machine frame. The minimum protection conductor's cross section depends on the supply cable cross section (refer to Table 11

Determining AWG Sizes). However, for the protection purposes,

with the supply cable cross section of a min. 4 mm2, select a larger conductor section, i.e., 6 mm2.

Installation

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

37 Part No. D1634ENR4

Page 38

Installation

Input Power Conditioning

The drive is suitable for direct connection to input power within

the rated voltage of the drive. Listed in Input Power Condition

are certain input power conditions which may cause component

damage or reduction in product life. If any of the conditions exist,

Input Power Condition Possible Corrective Action(s)

Low Line impedance (less than 1% line reactance) • Install Line Reactor

Greater than 120 kVA supply transformer

Line has power factor correction capacitors • Install Line Reactor

Line has frequent power interruptions

Line has intermittent noise spikes in excess of 6000V (lightning)

Phase to ground voltage exceeds 125% of normal line to line

voltage

Ungrounded distribution system

240V open delta configuration (stinger leg)* • Install Line Reactor

* For drives applied on an open delta with a middle phase grounded neutral system, the phase opposite the phase that is tapped in the

middle to the neutral or earth is referred to as the “stinger leg,” “high leg,” “red leg,” etc. This leg should be identified throughout

the system with red or orange tape on the wire at each connection point. The stinger leg should be connected to the center Phase B

on the reactor.

install one of the devices listed under the Possible Corrective Action(s).

IMPORTANT: Only one device per branch circuit is required. It should be mounted closest to the branch and

sized to handle the total current of the branch circuit.

• Isolation Transformer

• Isolation Transformer

• Remove MOV jumper to ground

• Install Isolation Transformer with grounded secondary (if

necessary)

Table 12

Input Voltage Requirements

For voltages above or below listed specifications, contact your

power company or local electrician.

If machine is intended for four-wire service, a neutral leg must be

provided by power company.

If a delta supply system is used on a four-wire model, connect

high leg to L3.

IMPORTANT: Improper connections will result in equipment damage and will void warranty.

DANGER

Electrical shock hazard will result in death or serious

injury. Disconnect electric power and wait five (5) minutes before servicing.

W810

DANGER

Hazardous Rotation Speed. Will cause serious injury

when controlling AC inverter drive with a parameter

unit, safety features are bypassed allowing basket to

rotate at high speeds with the door open. Place large

sign on front of machine to warn people of imminent

danger.

W361

Circuit Breakers and Quick Disconnects

Single-phase machines require a single-phase inverse-time circuit

breaker. Three-phase machines require a separate, three-phase inverse-time circuit breaker to prevent damage to the motor by disconnecting all legs if one should be lost accidentally. Refer to

section for model-specific circuit breaker requirements.

IMPORTANT: All quick disconnects should comply with

the specifications. DO NOT use fuses instead of circuit

breakers.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

38 Part No. D1634ENR4

Page 39

N

CHM2499N_SVG

PE U N

PE

N

U

CHM2500N_SVG

V W N

CHM2501N_SVG

Installation

Connection Specifications

IMPORTANT: Connection must be made by a qualified

electrician using wiring diagram provided with machine, or according to accepted European Union standards.

Connect machine to an individual branch circuit not shared with

lighting or other equipment. Shield connection in a liquid-tight or

approved flexible conduit. Copper conductors of correct size

must be installed in accordance with National Electric Code

(NEC) or other applicable codes.

Use wire sizes indicated in the Electrical Specifications chart for

runs up to 50 feet [15 m]. Use next larger size for runs of 50 to

100 feet [15 to 30 m]. Use two (2) sizes larger for runs greater

than 100 feet [30 m].

Single Phase Connection

Connect the electrical service's wires to the machine's electrical

connection terminal as shown.

Machine's Electrical

Electrical Service Wire

U U

Neutral N

PE PE (Ground)

Connection Terminal

Single-Phase Connection

Figure 24

Three Phase Connection

Connect the electrical service's wires to the machine's electrical

connection terminal as shown.

Machine's Electrical

Electrical Service Wire

Connection Terminal

Table 13

Electrical Connection Terminal Block

Figure 23

U U

V V

W W

PE PE (Ground)

Table 14

Electrical Connection Terminal Block

Figure 25

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

39 Part No. D1634ENR4

Page 40