All-Flo SB-05 User Manual

1

⁄2˝ PERFORMANCE PLUS

METALLIC MAINTENANCE MANUAL

CHECK VALVE AND O-RING MAINTENANCE

1. Flush and neutralize the pump to be certain all corrosives or hazardous materials

are removed prior to any maintenance. This procedure should always be

followed when returning pumps for factory service also.

2. Remove bolts (19) in both the discharge and suctions manifolds. Suction check

valve seats and check balls (26, 27) are located inside of the bottom of the outer

chamber (28). Gently remove and inspect for excessive wear, pitting or other

signs of degradation. Inspect valve seat and manifold o-rings (38). Replace if

necessary. Discharge check valves are located inside of the bottom of the

discharge manifold (32). Repeat procedure for inspection of discharge check

valves and o-rings.

3. When re-assembling, the check ball should fit within the ball cavity of the chamber

and discharge manifold. Press fit the valve seats into position with the curved

portion facing the ball. Lightly tighten fasteners. Tighten all external fasteners to

final torque requirement after pump is completely assembled.

NOTE: When using pumps built with PTFE o-rings always replace with new

PTFE o-rings, since the original o-rings may not reseal the pump.

DIAPHRAGM AND PILOT SLEEVE ASSEMBLY MAINTENANCE

4. To inspect diaphragms remove nuts (18) from bolts (16) from the outer pumping

chambers (28). If replacement is necessary due to abrasion or rupture, unscrew

the outer diaphragm plates (29). Models that are built with PTFE elastomers will

have a PTFE overlay (30) that faces the outer pumping chamber and a back-up

diaphragm (31) on the air side of pump. Pumps without PTFE will contain only

the back-up diaphragms.

5. If there has been a diaphragm rupture and corrosive or viscous fluid has entered

the air side of pump the complete air system should be inspected. After

removing diaphragms and inner diaphragm plate (33), the pilot sleeve assembly

(14, 40, 42, 45-47) and diaphragm rod assembly (13, 15) may be removed by

removing the retaining plates (41) and pushing the entire unit out through the

bore in the intermediate (34). Diaphragm rod assembly must be unscrewed to

remove pilot sleeve.

NOTE: To aid in reassembly use a non-synthetic, petroleum based lubricating

grease without EP additives. Carleton-Stuart MagnaLube G is recommended.

6. Clean or replace any components that have excessive wear, dirt build-up, or

chemical attack. Lube all components prior to reassembling. Reassemble pilot

sleeve spacers, o-rings and lip seals (40) within bore of intermediate. Make sure

that the open sides of the lip seals iare facing outward toward the diaphragms.

Also make sure that the end spacers (14) are at the end on either side of the pilot

sleeve assembly and all inner spacers (47) are separated by o-rings. Next, carefully insert the diaphragm rod assembly with pilot sleeve inside the assembly in

the bore. Reattach retaining plates. Do not over tighten self-tapping screws (24).

7. Take one diaphragm and invert (reverse the natural bow of the material) and

with the curved side of the inner diaphragm plate facing the diaphragm

assemble onto outer diaphragm plate stud and then screw assembly into

diaphragm rod. Push diaphragm rod to the opposite side of the intermediate

and add the opposite diaphragm assembly. Tighten the outer diaphragm

plates to 70 in-lbs (7,91 NM) of torque. After tightening, reverse the inverted

diaphragm back to its original state, allowing the outer bead to seat in the

groove of the intermediate.

NOTE: Inverting the first diaphragm aids reassembly.

8. Position outer diaphragm chambers onto intermediate making sure that witness

lines are matching.

NOTE: If air valve has been removed, proper orientation of air system with

fluid chambers must be observed. The bottom of the intermediate has the

smaller hook shaped air passage slot on the air valve mounting face, and

the outer chamber check ball cavity should be pointing downward.

9. Tighten all external fasteners to final torque requirement after pump is

completely assembled.

10. Position the manifolds making sure of the proper orientation in relation to the air

valve for your application. Also make sure that the manifold o-rings do not shift

from their grooves during reassembly. Tighten all external fasteners to final torque

requirement after pump is completely assembled.

EXTERNAL FASTENER TORQUE REQUIREMENTS

NOTE: When reassembling, loosely tighten all external fasteners adjusting

and aligning and gradually, in an alternating fashion, tighten to torque

requirements listed below.

AIR VALVE CAP SCREWS 40 in-lbs (4,52 NM)

MANIFOLD BOLTS, 90-100 in-lbs (10,17-11,3 NM)

OUTER CHAMBER CAP SCREWS, 75-85 in-lbs (8,48-9,61 NM)

AIR VALVE MAINTENANCE

11. To evaluate air valve components, remove the four cap screws (11), washers,

(25, 10) and nuts (17) from the air valve body (7). The shuttle plate (5) and

shuttle (6) can be inspected by removing them from their location in the slot in

the back of the air valve. Inspect for scratches or surface irregularities. Replace

if necessary. Remove the plug (1) at the bottom of the air valve. Next, push the

air valve spool (2) out of the air valve body. Gently reach in and pull lip seals

(43) out of inside bore of the air valve body. Check for cracks, splitting or

scratches. Clean components if replacement is not necessary. Inspect plug

o-ring (44) for any damage, replace if necessary and reposition o-ring into

groove in air valve body.

NOTE: Make sure that the open sides of the two lip seals face each other

when reassembling air valve. Lube all components with suggested maintenance grease as an aid in reassembly.

12. Reinsert air valve spool inside of air valve body. Place shuttle on middle rib of air

valve spool through the square slot in back of air valve. Lubricate side of plate

that faces the shuttle and reposition valve plate over shuttle. Press the valve

plug into air valve body, chamfered end first.

13. Check that gasket (4) is not cracked. If damaged replace.

14. After gasket is pressed back into position align air valve onto intermediate and

reinsert the four cap screws with lock washer and flat washers. Apply 40 in-lbs

(4,52 NM) of torque to fasteners.

U.S. Patent Number 5232352

SPECIFICATIONS

TOTAL HEAD IN FEET (METERS)

CAPACITY:

Adjustable 0-17 GPM (64,6 LPM)

MAXIMUM TEMP:

Metallic models – 200˚F (93˚C)

MAXIMUM AIR PRESSURE:

120 psi (8,2 bar)

MINIMUM AIR PRESSURE:

20 psi (1,3 bar)

DRY LIFT:

Models with PTFE balls – 10 feet (3 meters)

Other models – 15 feet (4,5 meters)

WEIGHT:

Aluminum models – 10 pounds (4,5 kg)

Stainless Steel models – 19 pounds (8,6 kg)

MAXIMUM SOLIDS:

1/8 ˝ (3,2 mm) Ball Check Valve

AIR SUPPLY:

Inlet – 1/4˝ NPT Female (BSP compatible)

Outlet – 3/8˝ NPT Female

FLUID INLET/DISCHARGE:

1/2 ˝ NPS Female (NPT or BSP compatible)

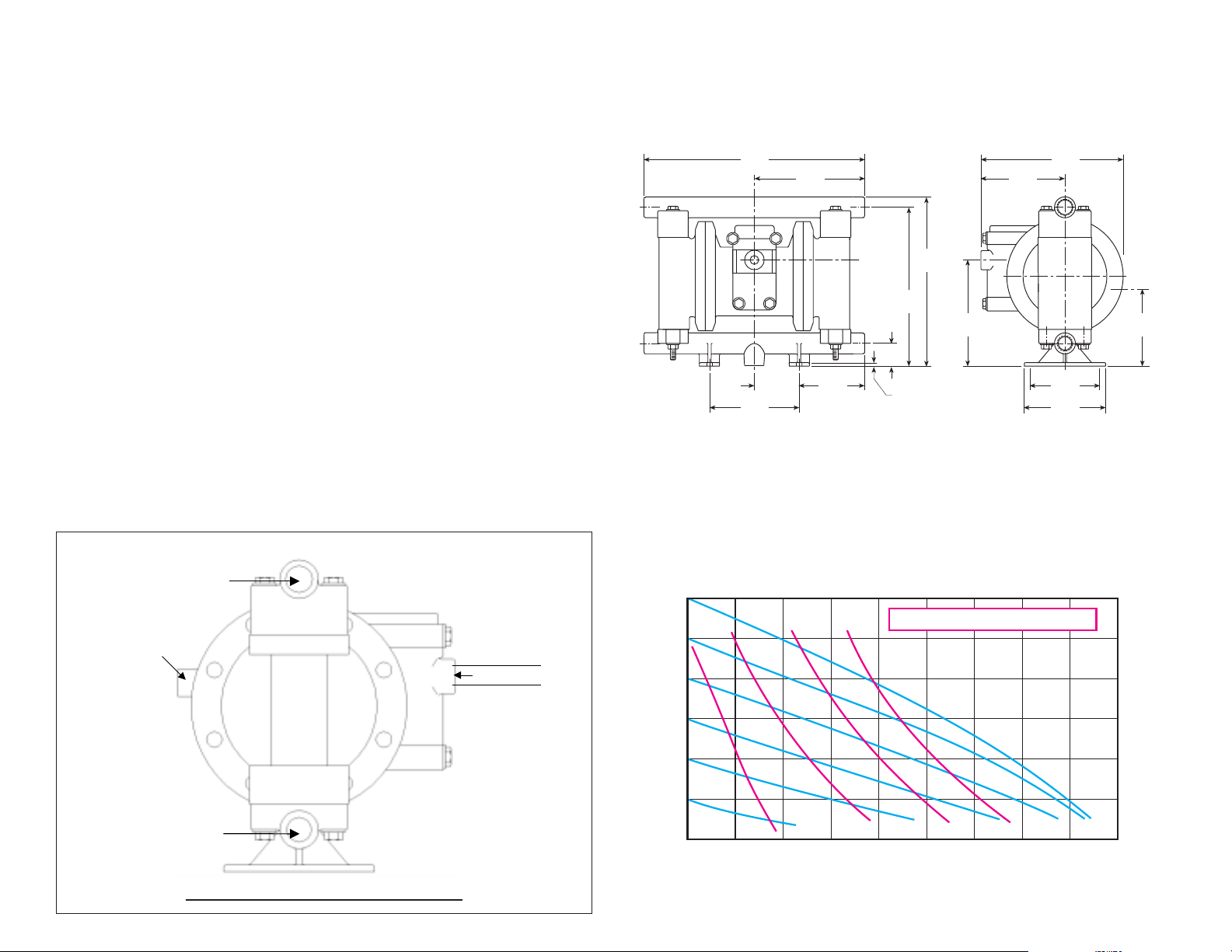

DIMENSIONS

Dimensions in inches and (mm)

10.86

(276,0)

4.40

(112,0)

DISCHARGE

INLET

2.20

(56,0)

5.43

(138,0)

3.23

(82,0)

PERFORMANCE CURVE

(Based on water-flooded suction)

1.13

(28,6)

7.82

(198,6)

5.43

(138,0)

8.34

(212,0)

5.21

(132,0)

AIR

SUPPLY

4.12

(105,0)

7.37*

(187,2)

3.24

(82,0)

4.00

(102,0)

EXHAUST

3.80

(96,5)

AIR

Typical Installation

DISCHARGE

Muffler (air exhaust)

is supplied with

each pump.

SUCTION

DO NOT USE AIR LINE LUBRICATION

Flexible Airline

AIR FLOW CONTROL

VALVE IS OPTIONAL

(USE TO MAINTAIN

MAXIMUM AIR

EFFICIENCY)

AIR FLOW CONTROL

VALVE PART NO:

13400-30

SUCTION AND DISCHARGE PORTS

CAN BE REPOSITIONED TO SUIT

THE APPLICATION

DISCHARGE FLOW-Liters/Min.

120

(8,2)

100

7,6 15,1 22,7 30,3 37,9 45,4 53,0 60,6 68,1

2

5

10

15

AIR CONSUMPTION - SCFM

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BARS)

0 2 4 6 8 1012141618

DISCHARGE FLOW-U.S. Gals./Min.

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

Loading...

Loading...