All-Flo P300 Operation & Maintenance Manual

A-

ALL-F

PUMP OPERATION & MAINTENANCE MANUAL

(

P300 High Density Polyethylene Air Diaphragm Pump

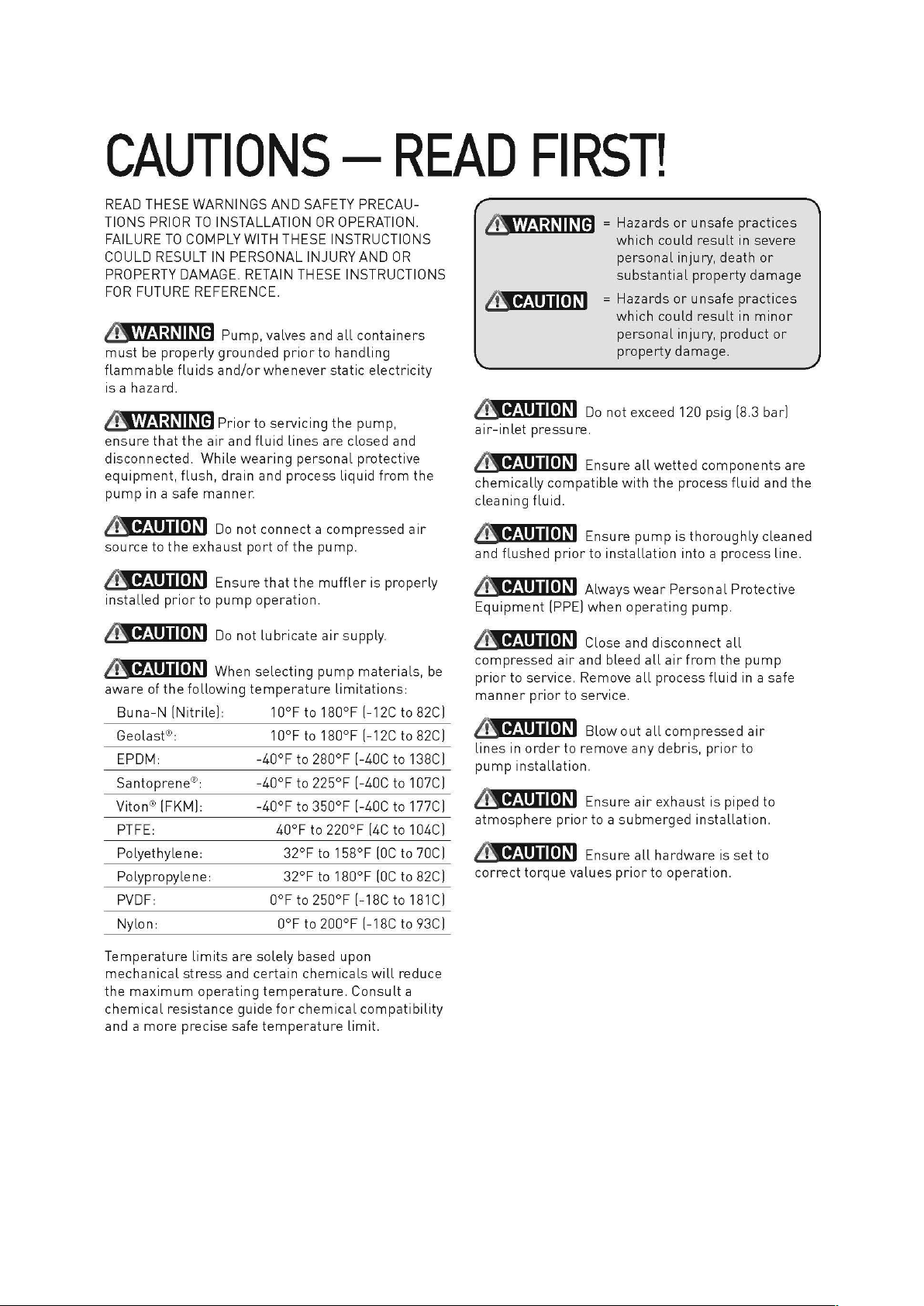

1. Warnings and Caution _______________________________________________________________________ 3

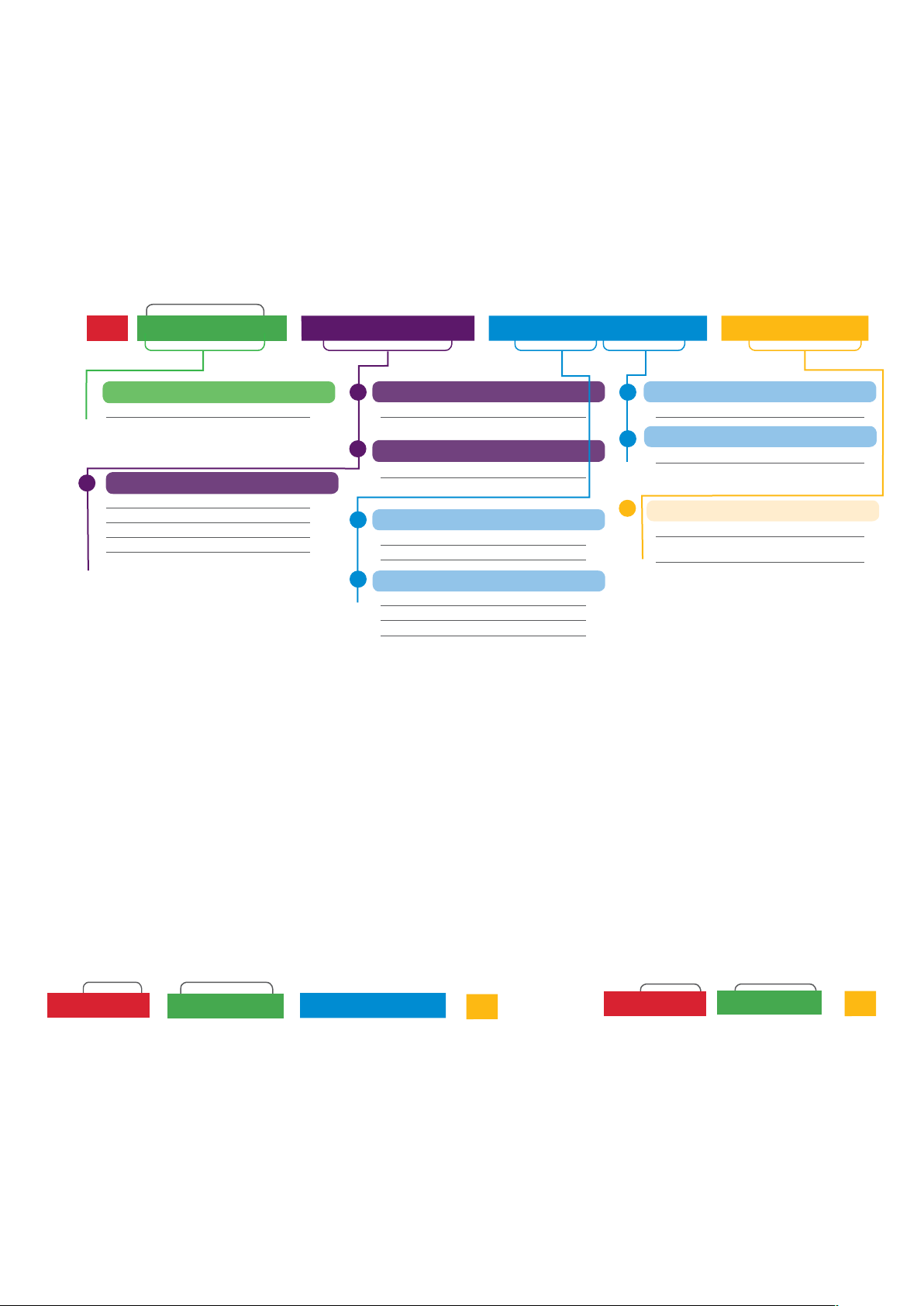

2. Pump Model Matrix __________________________________________________________________________4

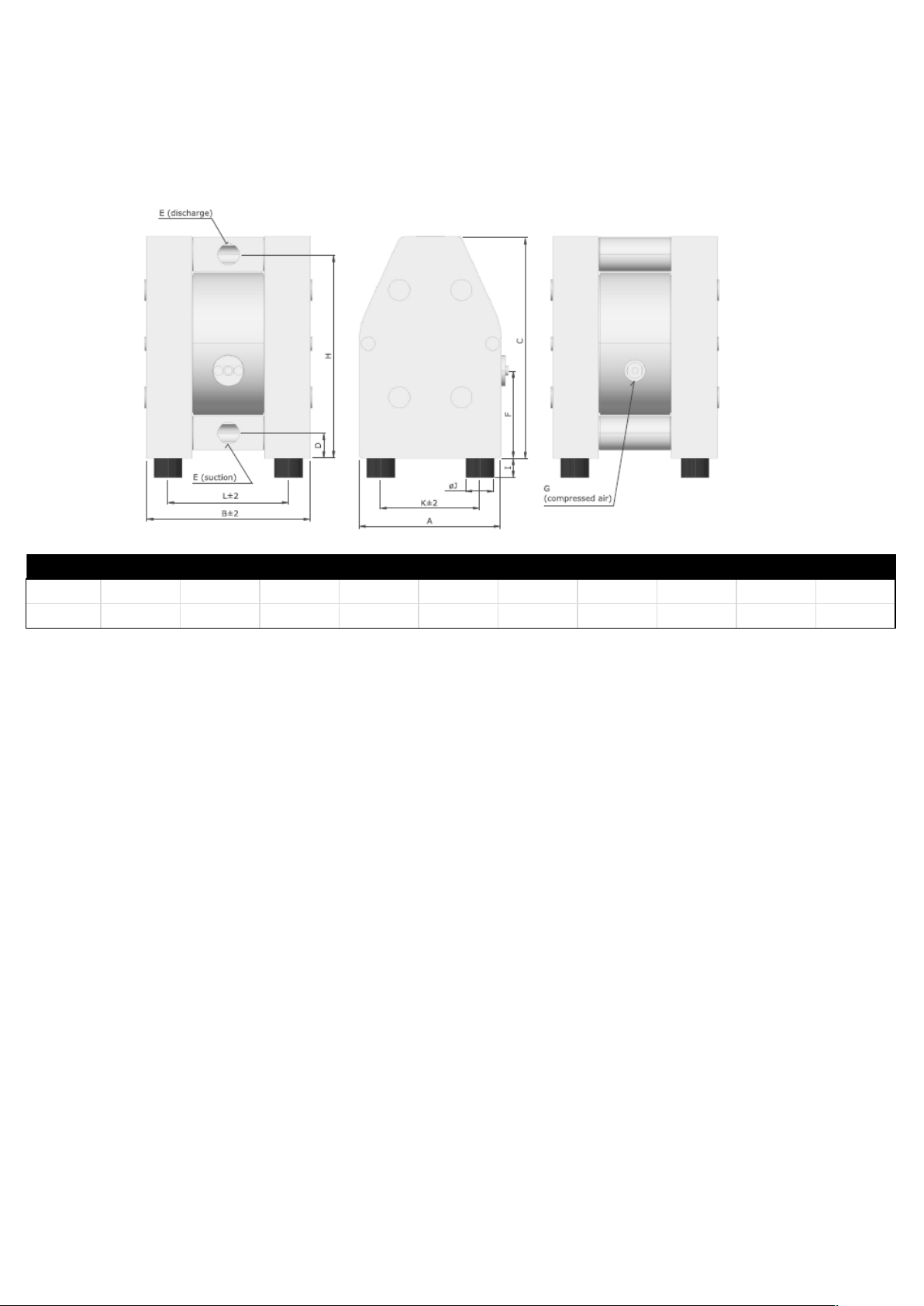

3. Pump Dimensions ___________________________________________________________________________5

4. Pump Integrated with Pulsation Dampener Dimensions ______________________________________________6

5. Pump Specifications and Performance Curve ______________________________________________________7

6. Installation, Troubleshooting and Maintenance _____________________________________________________8-12

Installation ______________________________________________________________________________ 8-9

Troubleshooting __________________________________________________________________________10

Operation _______________________________________________________________________________11

Maintenance _____________________________________________________________________________12

7. Torque Specifications _________________________________________________________________________13

8. Exploded View and Parts List ___________________________________________________________________14-15

9. High Pressure System (Option Code HP) __________________________________________________________16

10. High Pressure System Appearance and Dimensions _________________________________________________ 17

11. High Pressure System Exploded Views ___________________________________________________________ 18

12. High Pressure System Performance Curves ________________________________________________________19

13. Warranty and Registration ______________________________________________________________________20

2 I All-Flo Pump Co.

3I All-Flo Pump Co.

Model Designation Matrix

PRODUCT SERIES

1

FLUID CONNECTI

FLUID C

INTERM

PUMP SIZE

NER CHAMIN

ON TYPE

HAMBER

MANIFOLDS

EDI

A

TE/

BER

S/

DIAPHRAGM

VALVE/BAL

L

VAL

VE SEAT

O-RINGS

P X X X - 1 2 3 - 4 5 6 7

PUMP SIZE

300 = 3 Inch

FLUID CONNECTION TYPE

N = FNPT

B = FBSPT

A = ANSI Flange

D = DIN Flange

INTERMEDIATE / INNER CHAMBER

2

H = High Density Polyethylene

J = Conductive Polyethylene

3

FLUID CHAMBER / MANIFOLDS

H = High Density Polyethylene

J = Conductive Polyethylene

DIAPHRAGMS

4

E = EPDM

P = Integral PTFE

VALVE/BALL

5

E = EPDM

T = PTFE

3 = Stainless Steel

VALVE SEAT

6

H = High Density Polyethylene

O-RINGS

7

E = EPDM

T = PTFE

0

SPECIAL OPTION

G

Z001 = Pump Integrated with Pulsation

70 = Standard

Dampener

SPECIAL (HA

SPE

MUFFLER)

(P )

OR

CIAL

TING

- 8 9

RD

SPE

W

ARE,

CIAL (

O

THER)

10

WET END REPAIR KIT

Wet end kits are available and

consist of diaphragms, (back-up

diaphragms if required), balls,

seats and seat O-Rings.

See matrix below.

WET END

REPAIR KITS

PRODUCT

SERIES

P W E

Bold indicates recommended options

PUMP SIZE

-

-

0

3 0

DIAPHR

0 03

V

AL

VE/

BALL

A

GM

4 5 6 7

-

-

VAL

VE SEAT

O

-RINGS

MATERIAL

-

P

AIR END REPAIR KIT

Air end repair kit contains pilot sleeve

assembly and main air valve.

AIR END

EP

ODPR

S

AIRR KIT

UCT

SERIE

P A K

-

PUMP SIZE

3

0

0

MATERIAL

-

P

4 I All-Flo Pump Co.

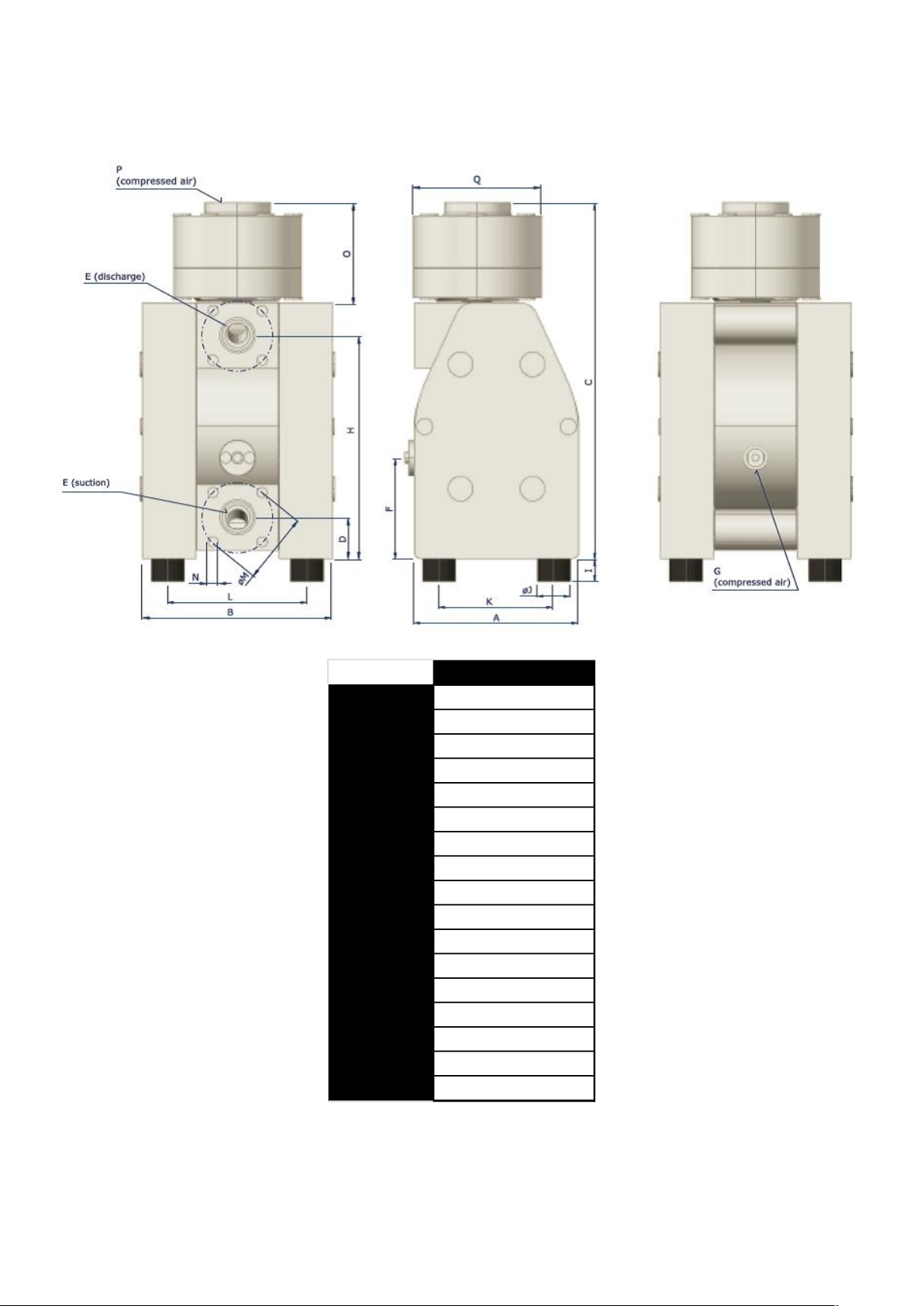

Pump Dimensions

A B C D F H I J K L

P300 18.90" 22.83" 31.50" 3.94" 15.28" 27.17" 1.57" 2.95" 15.55" 19.49"

(480 mm) (580 mm) (800 mm) (100 mm) (388 mm) (690 mm) (40 mm) (75 mm) (395 mm) (495 mm)

5 I All-Flo Pump Co.

Pump Integrated with Pulsation Dampener Dimensions

P300

A 18.90”(480 mm)

B 22.83”(580 mm)

C 31.50”(800 mm)

D 3.94”(100 mm)

E 15.28”(388 mm)

F 3”

G 27.17”(690 mm)

H 3/4”

I 1.57”(40 mm)

ØJ 2.95”(75 mm)

K 15.55”(395 mm)

L 19.49”(495 mm)

M 6.30”(160 mm)

N 5/8”

O 10.28”(261 mm)

P 1/2”

Q 14.17”(360 mm)

6 I All-Flo Pump Co.

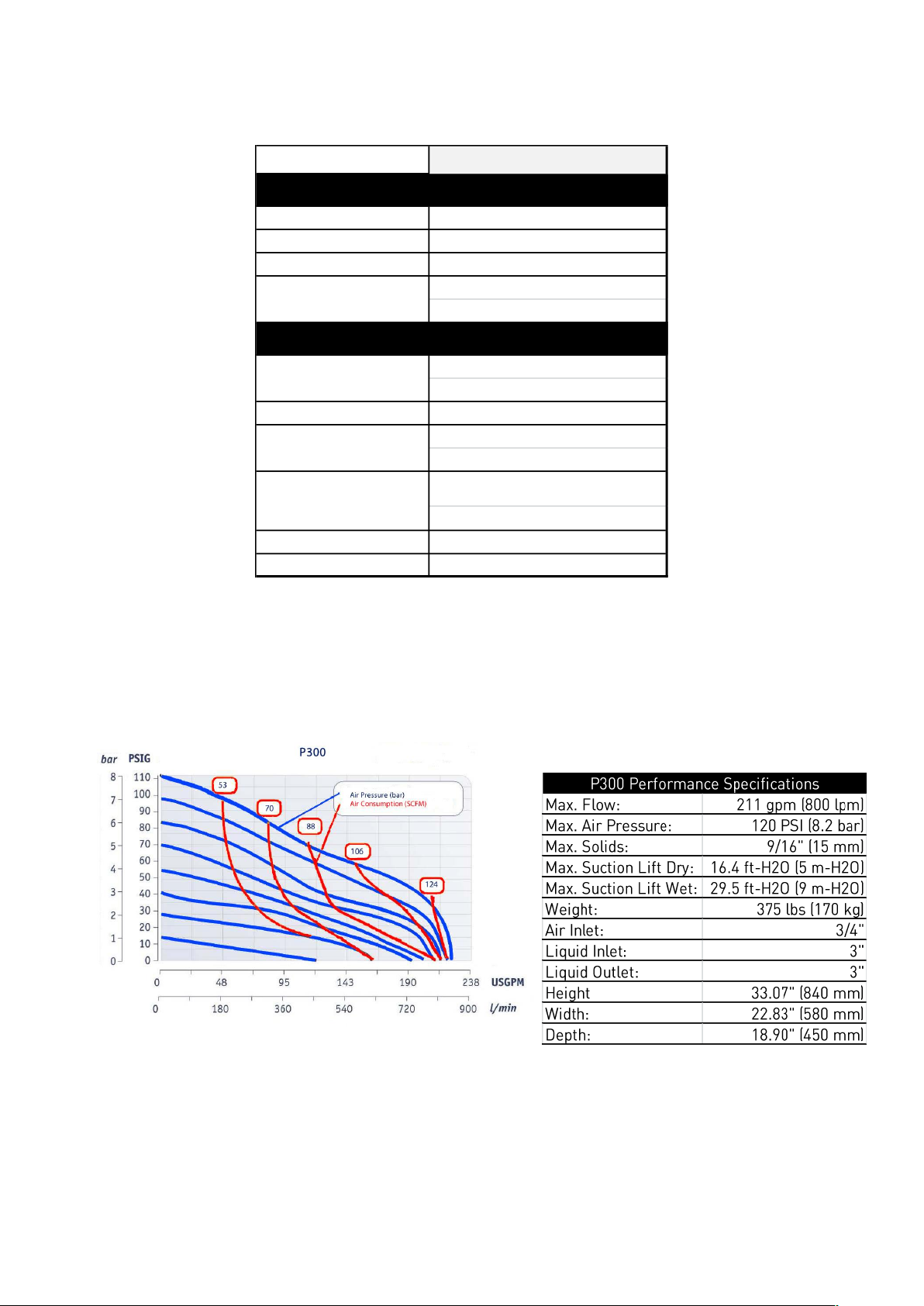

Pump Specifications

P300

Dimension

Air Inlet

3/4”

Liquid Inlet

3”

Liquid Outlet

3”

375 lbs

(170 kg)

Performance

211 gpm

(800 lpm)

Max pressure

120 PSI (8.2 bar)

9/16”

(12 mm)

16.4 ft-H

2

O

(5 m-H

2

O)

Suction lift wet

29.5 ft-H

2

O (9.0 m-H2O)

Temperature limits

158 °F (70° C)

Max Solids

Suction lift dry

Weight

Max capacity

Performance Curves

7 I All-Flo Pump Co.

Loading...

Loading...