All-Flo KN-025 User Manual

1

⁄4˝CLASSIC PERFORMANCE

MAINTENANCE MANUAL

CHECK VALVE, GASKET AND O-RING MAINTENANCE

1. Flush and neutralize the pump to be certain all corrosives or hazardous materials are removed prior to any maintenance. This procedure should always be

followed when returning pumps for factory service also. Remove suction,

discharge and air supply lines.

2. Remove the 1/4-20 nuts (28) and slide the six cap screws (27) that hold the

pump together out of the pump. Remove the #8 screws (5) from the left and right

manifold plates (1,19) and inspect the gaskets (2). The suction (or lower) check

valves are an integral part of the left and right chambers and should not be

dismantled. If replacement of the valve seats is necessary, the left and right

chambers (6, 18) which contain the valves must be replaced. The upper

discharge disks (3) are not sealed into the chambers and may be inspected for

wear. If any components are worn or scratched, replace. Note: Due to the

distortion of gaskets under pressure, gaskets may need to be replaced after

pump has been disassembled to assure a positive seal

3. To inspect manifold tube o-rings (17) remove right chamber.

4. Both diaphragms (9) can be inspected after removing the left and right chamber.

If diaphragms appear worn or ruptured go to step 7. If diaphragms do not need

replacing, proceed with steps 5 and 6.

5. To reassemble: Insert the discharge valve disks into place. Press gaskets into

grooves in chambers.

6. Align left and right manifolds on

the bosses of the chambers.

Secure to each chamber with the

ten #8 screws. Tighten to 12 ft-

lbs (16,3 NM). Slide left chamber tubes through intermediate.

Position o-rings on the end of the

tubes. Lubricate o-rings and right

chamber holes. Slide a flat

Discharge

Valve Disk

Suction Valve Disk

is part of right and

left chambers

DIAPHRAGM MAINTENANCE

7. Remove outer diaphragm plates (7) by holding one diaphragm plate and twisting

off the other plate.

8. The diaphragm o-ring (8) is used only with PTFE diaphragms. Replace

diaphragms if ruptured or worn. Inspect inner diaphragm plates (10). If diaphragm

rod needs replacing go to step 10.

washer (26) onto each of the six

capscrews and insert through

the entire assembly. Secure with

a flat washer (26) and a tension

washer (29) under each nut.

Tighten to 5 ft-lbs (6,8 NM).

Apply torque evenly.

9. If no further inspection is necessary reassemble inner diaphragm plates and

diaphragms onto stud of outer diaphragm plates and screw each assembly into

diaphragm rod. (Make sure optional diaphragm o-ring is in position in the o-ring

groove on either side of the intermediate if using PTFE diaphragms. When positioning PTFE diaphragms make sure that the concave side is facing the wet

ends of pump.) Tighten outer diaphragm plates to 40 in-lbs (4,5 NM). Reassemble pump according to steps 5 and 6.

AIR VALVE AND DIAPHRAGM ROD MAINTENANCE

10. To remove the diaphragm rod twist the two rod halves apart by using a 7/16”

wrench on the flats at the end of each half. Pull each half out of the pump. Inspect for corrosion.

11. To inspect diaphragm rod lip seals (14) remove the two self tapping screws (12)

from the retaining plates (13). Gently remove lip seals and inspect for damage.

To reassemble, lubricate diaphragm rod lip seals (14) and insert into bore with

the u-cup portion facing inward. Note: Since the diaphragm rod passes through

the spring clip assembly (23), spring clip assembly must be removed prior to

reinsertion of the diaphragm rod into bore in intermediate.

12. To remove spring clip assembly firmly pull air valve plug (25) from pump.

13. Inspect spring clip assembly and shuttle (22) for damage. Surface of intermediate around air ports and flat surface of shuttle must be smooth, no scratches or

debris. Replace or clean if necessary.

14. Attach retainer plate with flat surface toward lip seals. Do not over tighten self

tapping screws.

15. To reinsert diaphragm rod halves, drop shuttle into intermediate over ports. Groove

in shuttle should be aligned vertically in pump and should face outward. Insert

spring side of spring clip assembly into groove in shuttle. At this point the assembly is not affixed to anything. Press down as shown below to insert long half of

diaphragm rod (16) through spring clip assembly and position under spring ends.

16. While continuing to apply pressure to spring clip assembly,

screw short half of diaphragm

rod (11) into long half.

17. Follow instructions for assembly of diaphragms in step 9.

Apply

pressure with

finger while

inserting and

assembling

the

diaphragm

rods.

19. Follow procedure for final assembly of pump in step 6.

Final tightening of diaphragm

rod will occur when outer

diaphragm plates are tightened.

18. Make sure valve plug o-ring (21)

is well lubed, position o-ring and

press air valve plug into the

intermediate making sure that

tab and indentation are aligned.

If o-ring is not well lubricated, it

will not permit reinsertion.

SPECIFICATIONS

CAPACITY:

Adjustable . . . 0 to 4.3 GPM (16,3 liters/min.)

MAXIMUM TEMPERATURE:

KN-025 Model . . . . . . . . . . . . . 200°F (93°C)

Other Models . . . . . . . . . . . . . . 150°F (66°C)

MAXIMUM AIR PRESSURE:

All Models . . . . . . . . . . . . . 100 PSI (6,8 bar)

DRY LIFT:

Other Models . . . . . . . . . . . . 17 ft. (5 meters)

WEIGHT:

KN-025 Model . . . . . . . . . . . . 7 lbs. (3,2 kg.)

Other Models . . . . . . . . . . . . . 5 lbs. (2,3 kg.)

Maximum Solids: . . . . . . 1/16” or (1,6 mm)

AIR SUPPLY:

Inlet . . . 1/4” NPT Female (BSP Compatible)

Outlet . . . . . . . . . . . . . . . . . 1/4” NPT Female

Fluid Inlet/Discharge: . . . . . . . . . .1/4” NPT

* Geolast properties are similar to that of

Nitrile (Buna-N)

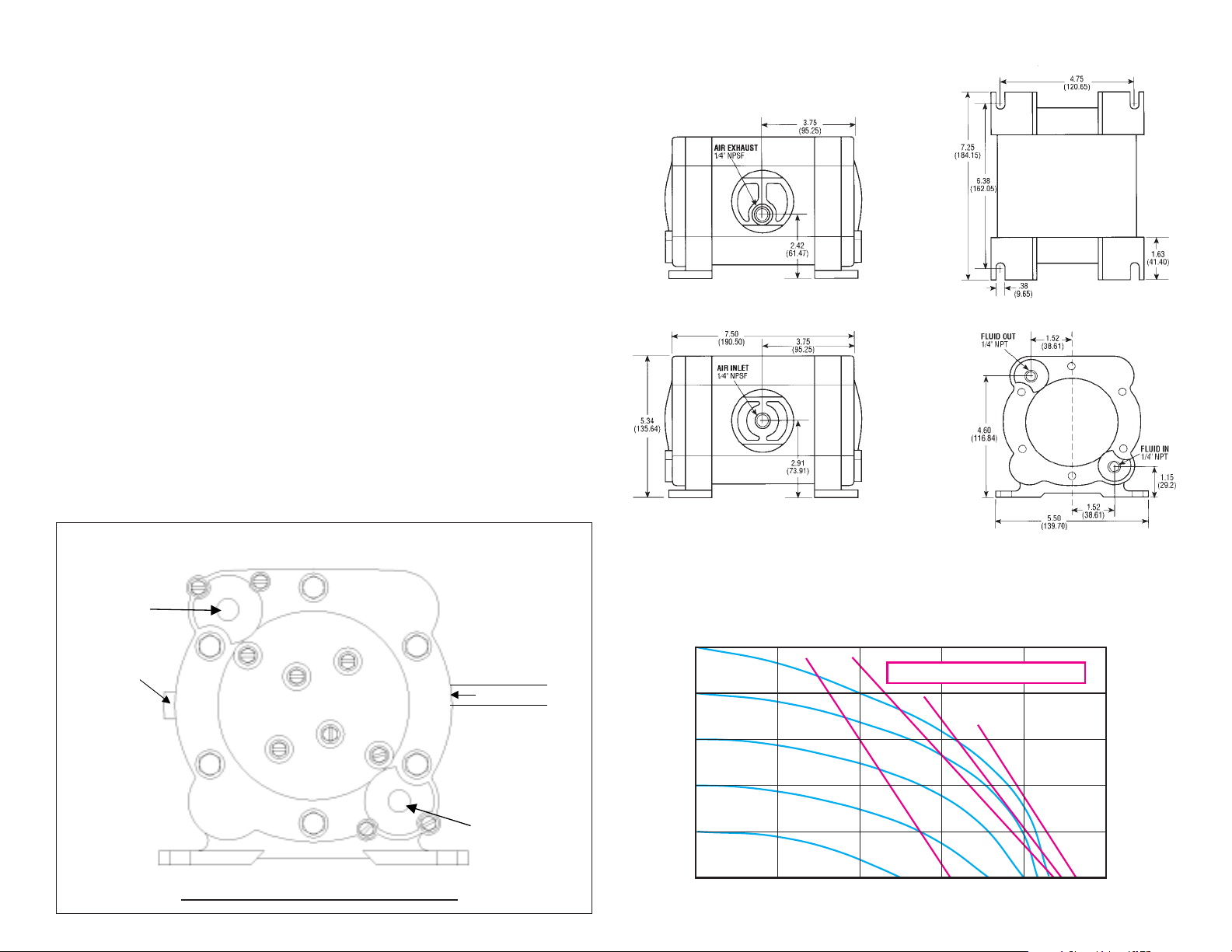

DIMENSIONS

Dimensions in inches and (mm)

Rear View

Front View

Footprint

Typical Installation

DISCHARGE

Muffler (air exhaust)

is supplied with

each pump.

DO NOT USE AIR LINE LUBRICATION

Flexible Airline

AIR FLOW CONTROL

VALVE IS OPTIONAL

(USE TO MAINTAIN

MAXIMUM AIR

EFFICIENCY)

AIR FLOW CONTROL

VALVE PART NO:

134000-30

SUCTION

PERFORMANCE CURVE

(Based on water-flooded suction)

DISCHARGE FLOW-Liters/Min.

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BAR)

02

3,8

DISCHARGE FLOW-U.S. Gals./Min.

7,6

2

1

Side View

11,4

AIR CONSUMPTION - SCFM

3

3

15,2

4

4

19,0

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

TOTAL HEAD IN FEET (METERS)

51

Loading...

Loading...