All-Flo KE-038-B3 User Manual

3

⁄8˝SPECIALTY PERFORMANCE

MAINTENANCE MANUAL

BEFORE YOU BEGIN

Flush and neutralize the pump to be certain all corrosive or hazardous materials are removed prior to any maintenance. This procedure should always be

followed when performing maintenance, transporting used pumps or returning

pumps for factory service.

VALVE AND O-RING MAINTENANCE

1. Remove the nuts (3) and washers (4) from the bolts (23) in manifolds. Remove the

manifolds (20), (11). Two of the four max pass valves and back-ups (13, 14) are

located inside of the bottom of the outer chambers (16). Gently remove and inspect

for excessive wear, pitting or other signs of degradation. Inspect manifold o-ring (12)

as well and replace if necessary.

2. The other two max-pass valves are located inside of the bottom of the discharge

manifold (20). Repeat the procedure for inspection of discharge valves, back-ups

and o-rings. (Some pumps such as those built with PTFE have ball valves in place of

the max pass valves. Repeat the procedure—inspect valve seat (28), balls (29), ball

cage (27) and o-ring (12)).

3. When re-assembling the max-pass pump, the sleeve (15) should be assembled into

the valve cavity first, followed by the max-pass valve (13), the valve back-up (14) and

finally the o-ring (12). For pumps with balls valves, the cage (27) should be assembled into the valve cavity first, followed by the ball (29), valve seat (28), and

finally the o-ring (12). Lightly tighten all external fasteners when assembling, torquing

them to their requirements after pump is completely assembled.

NOTE: When using pumps built with PTFE o-rings, always replace with new

PTFE o-rings, since the original o-rings may not reseal the pump.

DIAPHRAGM MAINTENANCE

4. To inspect diaphragms, remove the nuts (7) from the carriage bolts (8) on the band

clamps (16) surrounding the outer pump chambers (16). If replacement is necessary

due to abrasion or rupture, unscrew the outer diaphragm plates (17). Only models

that have PTFE elastomers will have both a PTFE overlay (18) that faces the outer

pump chamber and an o-ring (25) on the air side of pump. (NOTE: Pumps that do not

contain PTFE will not have o-ring (25) – they are built with diaphragms (19) only.)

5. To inspect the diaphragm rod’s lip seals, remove diaphragm rod and carefully pick out the

lip seals from inside the intermediate (22). Replace if necessary. Be sure to reinsert the

lip seals with open cup facing the inside of the pump. Make sure that the rod guide is

facing the air valve assembly and slide the diaphragm rod back into intermediate.

6. Take one diaphragm and with the curved side of the inner diaphragm plate facing the

diaphragm, assemble onto the outer diaphragm plate stud. Screw the assembly into

the end of the diaphragm rod. Repeat for the other side. Torque the outer diaphragm

plates to requirements.

7. Position outer diaphragm chambers onto the intermediate, making sure that the witness line of the intermediate matches with the parting line of the chamber.

8. When positioning band clamps, use soapy water or a compatible lubricating spray on

the inside of the band clamps to aid assembly. Tap with a mallet on the outside of the

clamp to help position it while tightening the fasteners. The band clamp fasteners are

stainless steel. To prevent galling, apply an anti-seize compound to the thread. Tighten

to final torque requirements.

9. Position the manifolds, making sure of their orientation in relation to the air valve for your application.

Also, make sure that the manifold o-rings do not shift from their grooves during reassembly.

Tighten all external fasteners to final torque requirements after the pump is completely assembled.

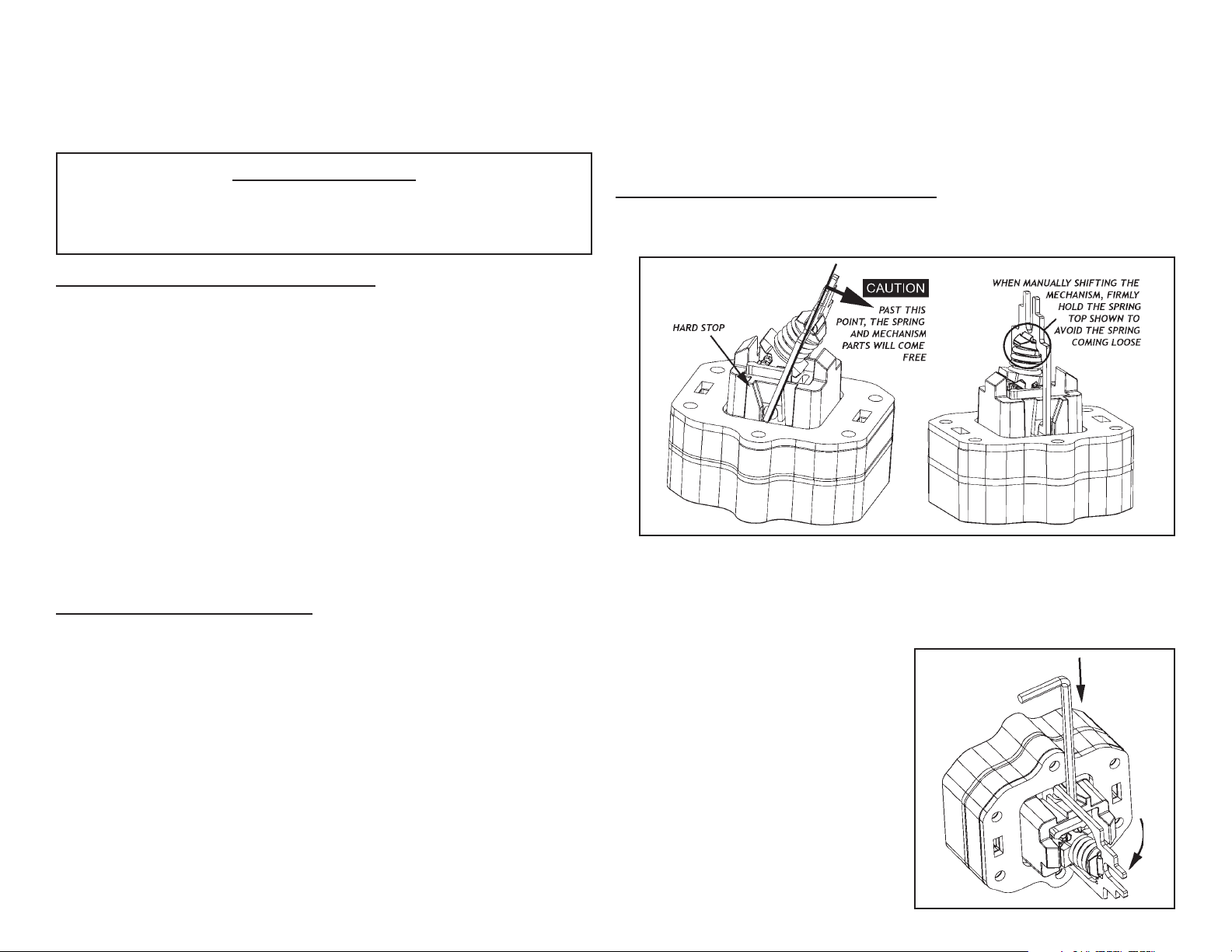

AIR VALVE ASSEMBLY INSPECTION

CAUTION: Only one side of the mechanism has a hard-stop. Shifting the mechanism past its operating position can cause the spring to pop free and internal

components to come loose. Use caution when shifting the mechanism manually.

10. If there has been a diaphragm rupture and fluid has entered the air side of the pump, the

complete air system should be inspected. Remove the air valve assembly (2) by

unscrewing the six long hex-head air valve assembly screws (9).

11. Clean or replace the air valve assembly if there is excessive wear, dirt build-up or chemical attack. Inspect for proper shifting of the spring mechanism by manually pushing the

metal spring retainer from one side to the other.

12. To reinstall the air valve, first shift the spring

mechanism to the side with the hard-stop.

Next, prop the spring retainer into a more

neutral position by inserting a 7/64” or 3mm

hex key as shown between the hard-stop

and the spring retainer.

13. With the rod guide (1) positioned such that

the opened end is facing the air valve assembly opening, slide the air valve assembly in place so that the forks slide into the

rod guide. Once the fork of the spring retainer is in the rod guide, pull the hex key

free and push the air valve assembly fully

into place. Finally, reinsert and tighten the

air valve assembly screws to the torque

listed on the specs sheet.

(Over)

FASTENER TORQUE REQUIREMENTS

NOTE: When reassembling, loosely tighten all external fasteners adjusting and

aligning. Then gradually, in an alternating fashion, tighten to the torque

requirements listed below.

AIR VALVE ASSEMBLY SCREWS 12 in-lbs (1,35 NM)

BAND CLAMPS 13.3 ft-lbs (18,8 NM)

MANIFOLD BOLTS, 10 in-lbs (1,13 NM)

OUTER DIAPHRAGM PLATES, 40 in-lbs (4,5 NM)

U.S. Patent Number 5232352

DIMENSIONS

Dimensions in inches and (mm)

8.55

(217,2)

AIR

INLET

DISCHARGE

4.82

(122,4)

7.19

(182,6)

SPECIFICATIONS

CAPACITY:

Adjustable 0-9 GPM (34,0 LPM)

MAXIMUM TEMP:

PVDF models – 200˚F (93˚C)

Other models –150˚F (66˚C)

MAXIMUM AIR PRESSURE:

120 psi (8,2 bar)

MINIMUM AIR PRESSURE:

20 psi (1,3 bar)

DRY LIFT:

Models with PTFE balls –

10 feet (3 meters)

Models with Max-Pass™ valves –

17 feet (5,2 meters)

Typical Installation

DISCHARGE

Muffler (air exhaust)

is supplied with

each pump.

SUCTION

DO NOT USE AIR LINE LUBRICATION

WEIGHT:

PVDF models – 5 pounds (2,3 kg)

Other models – 3.8 pounds (1,7 kg)

MAXIMUM SOLIDS:

Models with Max-Pass™ valves – 1/4˝

(6,4 mm)

Other models – 1/16˝ (3,2 mm)

AIR SUPPLY:

Inlet – 1/4˝ NPS Female

(BSP or NPT compatible)

Outlet – 3/8˝ NPS Female

(BSP or NPT compatible)

FLUID INLET/DISCHARGE:

3/8˝ NPS Female

(BSP or NPT compatible)

AIR INLET IS ON

SIDE WITH S.S.

INSERT AND

OPPOSITE AIR

VALVE ASSEMBLY

Flexible Airline

AIR FLOW CONTROL

VALVE IS OPTIONAL

(USE TO MAINTAIN

MAXIMUM AIR EFFICIENCY)

AIR FLOW CONTROL VALVE

PART NO: 13400-30

SUCTION AND DISCHARGE PORTS

CAN BE REPOSITIONED TO SUIT

THE APPLICATION

1.06

(26,9)

EXHAUST

3.86

(98,0)

6.63

(168,4)

4.06

(103,1)

4.21

(106,9)

R .15

(3,8mm)

SUCTION

2.40

(61,0)

NOTE: AIR INLET IS ON THE SIDE WITH STAINLESS STEEL

INSERT. THE AIR VALVE ASSEMBLY IS ON THE

OPPOSITE SIDE OF THE PUMP.

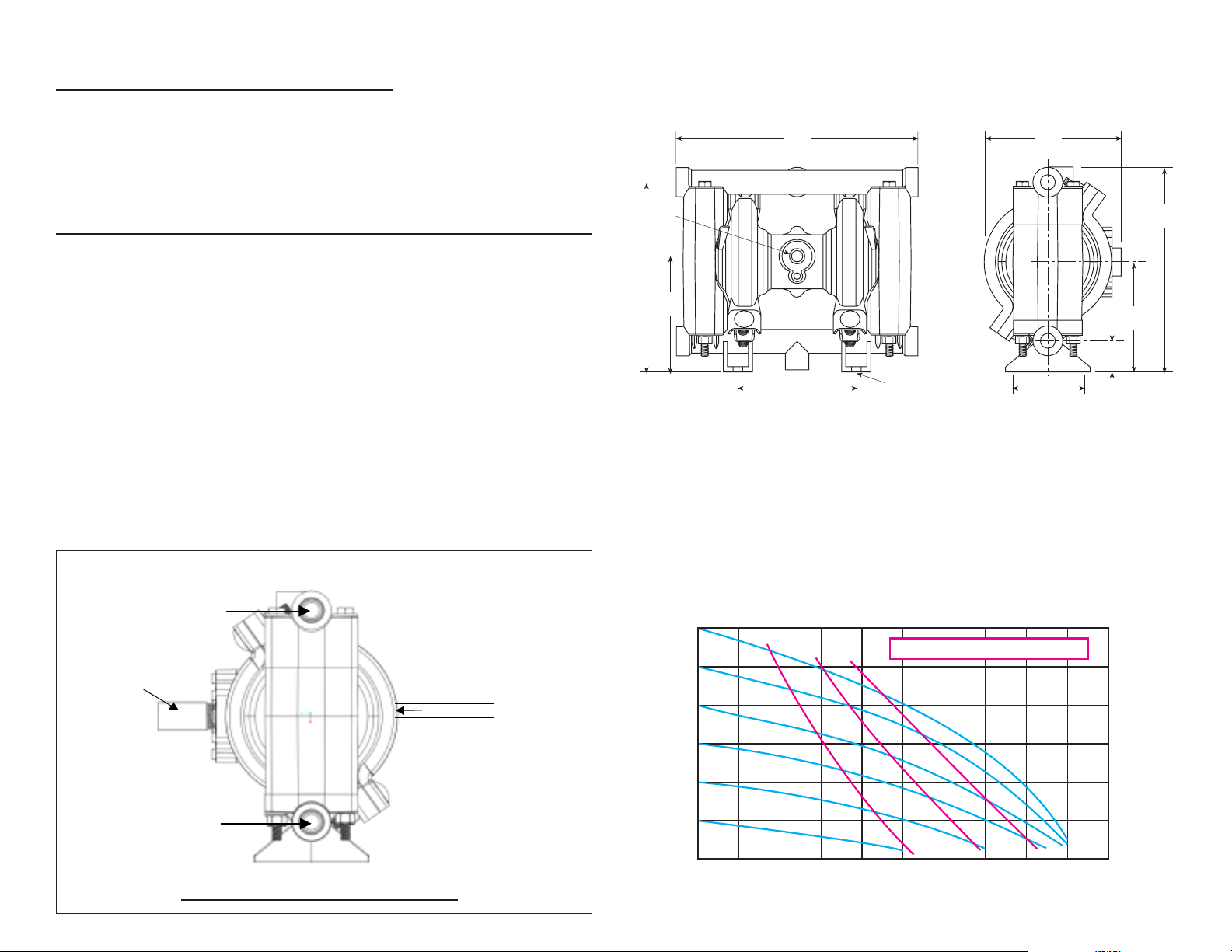

PERFORMANCE CURVE

(Based on water-flooded suction)

DISCHARGE FLOW-Liters/Min.

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BAR)

3,8 7,6 11,4 15,1 18,9 22,7 26,5 30,3 34,1 37,9

3

10

6

AIR CONSUMPTION - SCFM

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

012345678910

DISCHARGE FLOW-U.S. Gals./Min.

TOTAL HEAD IN FEET (METERS)

Loading...

Loading...