All-Flo A050 User Manual

PUMP OPERATIONS & MAINTENANCE MANUAL

A050 - 1/2 INCH AIR OPERATED DOUBLE DIAPHRAGM PUMP

all-o.com

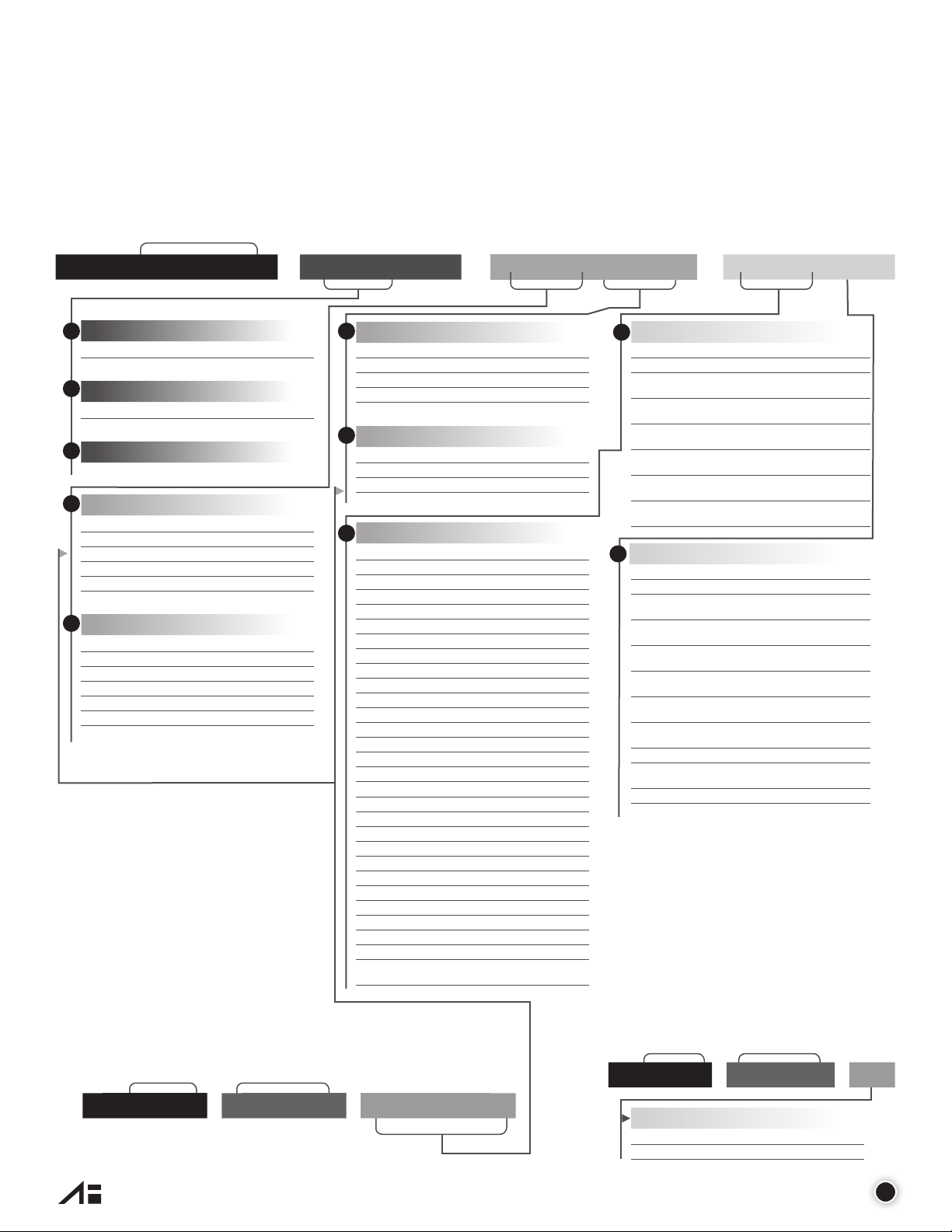

TABLE OF

CONTENTS

SECTION 1 WARNINGS AND SAFETY PRECAUTIONS 3

SECTION 2 MODEL DESIGNATION MATRIX 4-5

SECTION 3 PRINCIPLES OF OPERATION 6

SECTION 4 DIMENSIONAL DRAWINGS 7-8

SECTION 5 PERFORMANCE CURVES

RUBBER DIAPHRAGMS ..............................................................9

TPE DIAPHRAGMS ........................................................................9

PTFE DIAPHRAGMS .....................................................................9

SECTION 6 INSTALLATION, TROUBLESHOOTING AND MAINTENANCE

OPERATION ..................................................................................... 13

MAINTENANCE ............................................................................14

SECTION 7 REPAIR, ASSEMBLY AND TORQUE SPECIFICATIONS

PUMP WET END REMOVAL ............................................ 14-15

AIR VALVE REMOVAL .........................................................16-17

PILOT VALVE REMOVAL .................................................. 18-19

TORQUE SPECIFICATIONS ....................................................... 19

SECTION 8 EXPLODED VIEWS AND PARTS LISTS 20-25

SECTION 9 ELASTOMERS AND REPAIR KITS 26

SECTION 10 WARRANTY AND REGISTRATION 27

INSTALLATION ................................................................................... 10-11

TROUBLESHOOTING ..................................................................12

2

all-o.com

CAUTIONS — READ FIRST!

READ THESE WARNINGS AND SAFETY PRECAUTIONS PRIOR TO INSTALLATION OR OPERATION.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND OR

PROPERTY DAMAGE. RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

WARNING

must be properly grounded prior to handling

flammable fluids and/or whenever static electricity

is a hazard.

Pump, valves and all containers

WARNING

CAUTION

= Hazards or unsafe practices

which could result in severe

personal injury, death or

substantial property damage

= Hazards or unsafe practices

which could result in minor

personal injury, product or

property damage.

SECTION

1

WARNING

ensure that the air and fluid lines are closed and

disconnected. While wearing personal protective

equipment, flush, drain and process liquid from the

pump in a safe manner.

CAUTION

source to the exhaust port of the pump.

CAUTION

installed prior to pump operation.

CAUTION

CAUTION

aware of the following temperature limitations:

Buna-N (Nitrile): 10°F to 180°F (-12C to 82C)

Geolast®: 10°F to 180°F (-12C to 82C)

EPDM: -40°F to 280°F (-40C to 138C)

Santoprene®: -40°F to 225°F (-40C to 107C)

Viton® (FKM): -40°F to 350°F (-40C to 177C)

PTFE: 40°F to 220°F (4C to 104C)

Prior to servicing the pump,

Do not connect a compressed air

Ensure that the muffler is properly

Do not lubricate air supply.

When selecting pump materials, be

CAUTION

air-inlet pressure.

CAUTION

chemically compatible with the process fluid and the

cleaning fluid.

CAUTION

and flushed prior to installation into a process line.

CAUTION

Equipment (PPE) when operating pump.

CAUTION

compressed air and bleed all air from the pump

prior to service. Remove all process fluid in a safe

manner prior to service.

CAUTION

lines in order to remove any debris, prior to

pump installation.

CAUTION

atmosphere prior to a submerged installation.

Do not exceed 120 psig (8.3 bar)

Ensure all wetted components are

Ensure pump is thoroughly cleaned

Always wear Personal Protective

Close and disconnect all

Blow out all compressed air

Ensure air exhaust is piped to

Polyethylene: 32°F to 158°F (0C to 70C)

Polypropylene: 32°F to 180°F (0C to 82C)

PVDF: 0°F to 250°F (-18C to 181C)

Nylon: 0°F to 200°F (-18C to 93C)

Temperature limits are solely based upon

mechanical stress and certain chemicals will reduce

the maximum operating temperature. Consult a

chemical resistance guide for chemical compatibility

and a more precise safe temperature limit. Always

use minimum air pressure when pumping at elevated

temperatures.

CAUTION

correct torque values prior to operation.

Ensure all hardware is set to

all-o.com

3

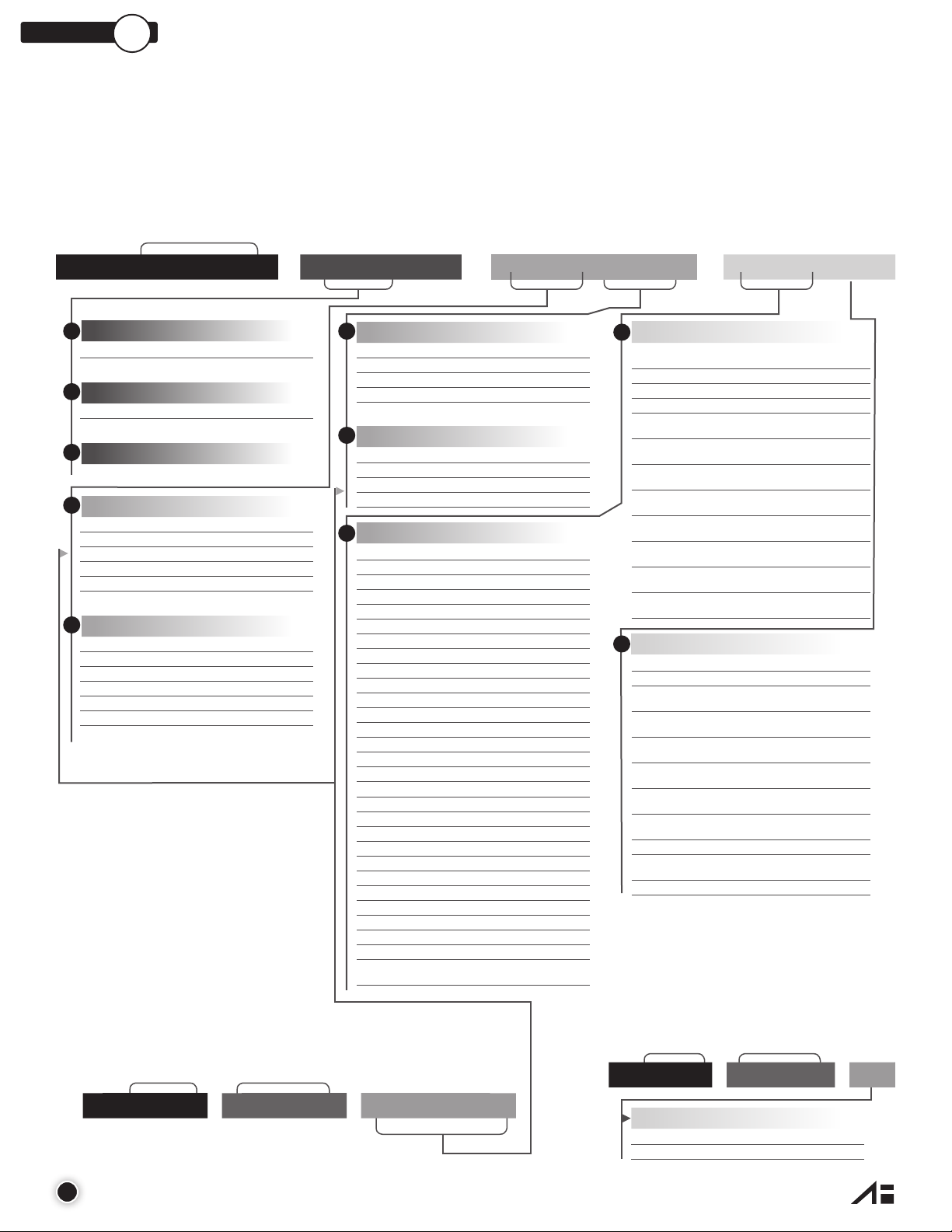

SECTION

2

MODEL DESIGNATION MATRIX - ALUMINUM

PRODUCT SERIES

FLUID CONNECTION TYPE

FLUID CHAMBERS/

INTERMEDIATE/

INNER CHAMBER

SIZE

MANIFOLDS

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

A 0 5 0 - 1 2 3 - 4 5 6 7 - 8 9 10

SPECIAL (HARDWARE,

MUFFLER, LUG)

PORTING

SPECIAL (OTHER)

FLUID CONNECTION TYPE

1

N = NPT

B = BSP

INTERMEDIATE / INNER CHAMBER

2

A = Aluminum

P = Polypropylene (Glass Filled)

FLUID CHAMBER / MANIFOLDS

3

A = Aluminum

DIAPHRAGMS

4

G = Geolast

S = Santoprene

T = PTFE with Santoprene® Backup

N = Buna – N

E = EPDM

V = Viton

VALVE/BALL

5

G = Geolast

S = Santoprene

T = PTFE

E = EPDM

V = Viton

3 = 316 Stainless Steel

®

®

®

®

®

®

WET END REPAIR KIT

Wet end kits are available and

consist of diaphragms, (back-up

diaphragms if required), balls,

seats and seat o-rings.

See matrix below.

PRODUCT

SERIES

WET END

REPAIR KIT

PUMP SIZE

VALVE SEAT

6

P = Polypropylene

3 = 316 Stainless Steel

A = Aluminum

K = PVDF

Y = Nylon

O-RINGS

7

N = Buna-N

E = EPFM

T = PTFE

®

V = Viton

PORTING

8

0 = Standard (Suction Right / Discharge Right)

T = Suction Right / Discharge Left

X = Suction Left / Discharge Right

Y = Suction Left / Discharge Left

A = Suction Center Front / Discharge Center Front

B = Suction Center Front / Discharge Center Rear

C = Suction Center Front / Discharge Top

D = Suction Center Front / Discharge Right

E = Suction Center Front / Discharge Left

F = Suction Center Rear / Discharge Center Front

G = Suction Center Rear / Discharge Center Rear

H = Suction Center Rear / Discharge Top

I = Suction Center Rear / Discharge Right

J = Suction Center Rear / Discharge Left

K = Suction Bottom / Discharge Center Front

L = Suction Bottom / Discharge Center Rear

M = Suction Bottom / Discharge Top

N = Suction Bottom / Discharge Right

O = Suction Bottom / Discharge Left

P = Suction Right / Discharge Center Front

Q = Suction Right / Discharge Center Rear

R = Suction Right / Discharge Top

U = Suction Left / Discharge Center Front

V = Suction Left / Discharge Center Rear

W = Suction Left / Discharge Top

1 = Dual Suction

2 = Dual Suction / Dual Discharge

3 = Dual Discharge

4 = All Ports Open (Standard ports will be left

un-plugged)

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

SPECIAL OPTION (HARDWARE, MUFFLER, LUG)

9

0 = Standard (Zinc Plated Steel Hardware, Plastic

Muffler)

4 = Zinc Plated Steel Hardware, Metal Muffler

7= Stainless Steel Hardware, Plastic Muffler

8 = Stainless Steel Hardware, Metal Muffler

B = PTFE Coated Stainless Steel Hardware,

Plastic Muffler

C = PTFE Coated Stainless Steel Hardware,

Metal Muffler

D = Zinc Plated Steel Hardware, Plastic Muffler,

Grounding Lug Installed

E = Zinc Plated Steel Hardware, Metal Muffler,

Grounding Lug Installed

F = Stainless Steel Hardware, Plastic Muffler,

Grounding Lug Installed

G = Stainless Steel Hardware, Metal Muffler,

Grounding Lug Installed

H = PTFE Coated Stainless Steel Hardware,

Plastic Muffler, Grounding Lug Installed

I = PTFE Coated Stainless Steel Hardware,

Metal Muffler, Grounding Lug Installed

SPECIAL OPTION (OTHER)

10

0 = Standard (None)

1 = Cycle Counter Valve

2 = Solenid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC

3 = Solenid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC Explosion Proof

4 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC

5 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC Explosion Proof

6 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC

7 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC Explosion Proof

8 = Solenid Adaptor Valve 24 Volt DC

9 = Solenid Adaptor Valve 24 Volt DC,

Explosion Proof

A = Grease Free (No Lubrication Assembly)

AIR END REPAIR KIT

Air end repair kit contains pilot sleeve assembly, diaphragm rod and main air valve.

AIR END

PRODUCT

SERIES

REPAIR KIT

PUMP SIZE

MATERIAL

AWE - 050- 4567

Bold indicates recommended options

* Solenid Adaptor Valves only available on select pump models with polypropylene intermediate

all-o.com

4

AAK- 050-2

INTERMEDIATE / INNER CHAMBER

A = Aluminum

P = Polypropylene (Glass Filled)

MODEL DESIGNATION MATRIX - STAINLESS STEEL

PRODUCT SERIES

FLUID CONNECTION TYPE

FLUID CHAMBERS/

INTERMEDIATE/

INNER CHAMBER

SIZE

MANIFOLDS

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

A 0 5 0 - 1 2 3 - 4 5 6 7 - 8 9 10

SPECIAL (HARDWARE,

MUFFLER, LUG)

SPECIAL (OTHER)

PORTING

FLUID CONNECTION TYPE

1

N = NPT

B = BSP

2

INTERMEDIATE / INNER CHAMBER

P = Polypropylene (Glass Filled)

A = Aluminum

3

FLUID CHAMBER / MANIFOLDS

3 = CF8M Stainless Steel

4

DIAPHRAGMS

S = Santoprene

T = PTFE with Santoprene® Backup

N = Buna – N

E = EPDM

V = Viton

G = Geolast

5

VALVE/BALL

S = Santoprene

T = PTFE

E = EPDM

V = Viton

G = Geolast

3 = Stainless Steel

®

®

®

®

®

®

WET END REPAIR KIT

Wet end kits are available and

consist of diaphragms, (back-up

diaphragms if required), balls,

seats and seat o-rings.

See matrix below.

PRODUCT

SERIES

WET END

REPAIR KIT

PUMP SIZE

VALVE SEAT

6

3 = 316 Stainless Steel

P = Polypropylene

A = Aluminum

K = PVDF

Y = Nylon

O-RINGS

7

E = EPDM

T = PTFE

N = Buna-N

®

V = Viton

PORTING

8

0 = Standard (Suction Right / Discharge Right)

T = Suction Right / Discharge Left

X = Suction Left / Discharge Right

Y = Suction Left / Discharge Left

A = Suction Center Front / Discharge Center Front

B = Suction Center Front / Discharge Center Rear

C = Suction Center Front / Discharge Top

D = Suction Center Front / Discharge Right

E = Suction Center Front / Discharge Left

F = Suction Center Rear / Discharge Center Front

G = Suction Center Rear / Discharge Center Rear

H = Suction Center Rear / Discharge Top

I = Suction Center Rear / Discharge Right

J = Suction Center Rear / Discharge Left

K = Suction Bottom / Discharge Center Front

L = Suction Bottom / Discharge Center Rear

M = Suction Bottom / Discharge Top

N = Suction Bottom / Discharge Right

O = Suction Bottom / Discharge Left

P = Suction Right / Discharge Center Front

Q = Suction Right / Discharge Center Rear

R = Suction Right / Discharge Top

U = Suction Left / Discharge Center Front

V = Suction Left / Discharge Center Rear

W = Suction Left / Discharge Top

1 = Dual Suction

2 = Dual Suction / Dual Discharge

3 = Dual Discharge

4 = All Ports Open (Standard ports will be left

un-plugged)

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

SPECIAL OPTION (HARDWARE, MUFFLER, LUG)

9

0 = Standard (Stainless Steel Hardware, Plastic Muffler)

8 = Stainless Steel Hardware, Metal Muffler

B = PTFE Coated Stainless Steel Hardware,

Plastic Muffler

C = PTFE Coated Stainless Steel Hardware,

Metal Muffler

F = Stainless Steel Hardware, Plastic Muffler,

Grounding Lug Installed

G = Stainless Steel Hardware, Metal Muffler,

Grounding Lug Installed

H = PTFE Coated Stainless Steel Hardware,

Plastic Muffler, Grounding Lug Installed

I = PTFE Coated Stainless Steel Hardware,

Metal Muffler, Grounding Lug Installed

SPECIAL OPTION (OTHER)

10

0 = Standard (None)

1 = Cycle Counter Valve

2 = Solenid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC

3 = Solenid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC Explosion Proof

4 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC

5 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC Explosion Proof

6 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC

7 = Solenid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC Explosion Proof

8 = Solenid Adaptor Valve 24 Volt DC

9 = Solenid Adaptor Valve 24 Volt DC,

Explosion Proof

A = Grease Free (No Lubrication Assembly)

AIR END REPAIR KIT

Air end repair kit contains pilot

sleeve assembly, diaphragm rod

and main air valve.

AIR END

PRODUCT

SERIES

REPAIR KIT

PUMP SIZE

MATERIAL

AWE - 050- 4567

Bold indicates recommended options

* Solenid Adaptor Valves only available on select pump models with polypropylene intermediate

AAK- 050-2

INTERMEDIATE / INNER CHAMBER

P = Polypropylene (Glass Filled)

A = Aluminum

all-o.com

5

SECTION

3

PRINCIPLES OF OPERATION

HOW AN AIR OPERATED DOUBLE

DIAPHRAGM PUMP WORKS

The air-valve directs pressurized air behind the diaphragm on the right,

causing the diaphragm on the right to move outward (to the right).

Since both the right diaphragm and the left diaphragm are connected

via a diaphragm rod, when the right diaphragm moves to the right, the

left diaphragm (through the action of the diaphragm rod) moves to the

right also.

When the diaphragm on the left side is moving to the right, it is referred

to as suction stroke. When the left diaphragm is in its suction stroke,

the left suction ball moves upward (opens) and the left discharge ball

moves downward (closes). This action creates suction and draws liquid

into the left side chamber.

The air-valve directs pressurized air behind the left diaphragm, causing

the left diaphragm to move outward (to the left).

Since both the left diaphragm and the right diaphragm are connected

via a diaphragm rod, when the left diaphragm moves to the left, the

right diaphragm (through the action of the diaphragm rod) moves to

the left also.

When the diaphragm on the left side moves outward, the left discharge ball

moves upward (opens) and the left suction ball moves downward (closes).

This causes the liquid to leave the left side liquid outlet of the pump.

Simultaneously, the right diaphragm moves inward (to the left), which

causes the right suction ball to open and the right discharge to close,

which in turn causes suction, drawing liquid into the right chamber.

The process of alternating right suction / left discharge (and vice-versa)

continues as long as compressed air is supplied to the pump.

6

all-o.com

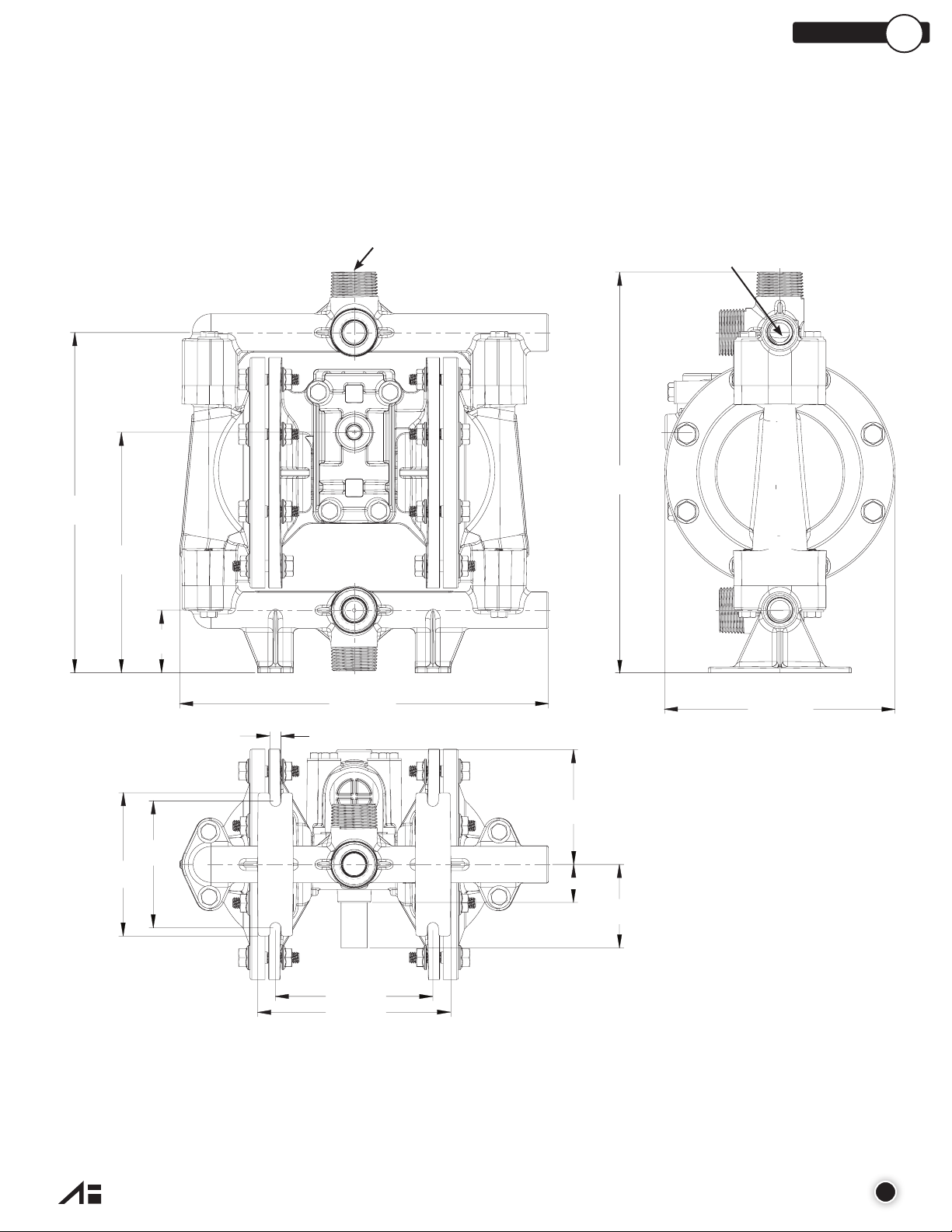

1/2” PUMP DIMENSIONS

(241mm)

5.4” (137mm)

ALUMINUM CENTER SECTION

SECTION

4

9.5”

6.7”

(170mm)

1.8”

(46mm)

1” MNPT OR 1” MBSP (x4)

1/2” FNPT or FBSP

11.2”

(284mm)

10.3” (262mm)

0.3” (8mm)

3.2”

(81mm)

3.6”

(91mm)

4.0”

(102mm)

4.4” (112mm)

1.1” (28mm)

Note - Suction Right / Discharge Right are default ports. See part number

matrix option code for additional porting options.

2.3”

(58mm)

6.4” (163mm)

all-o.com

7

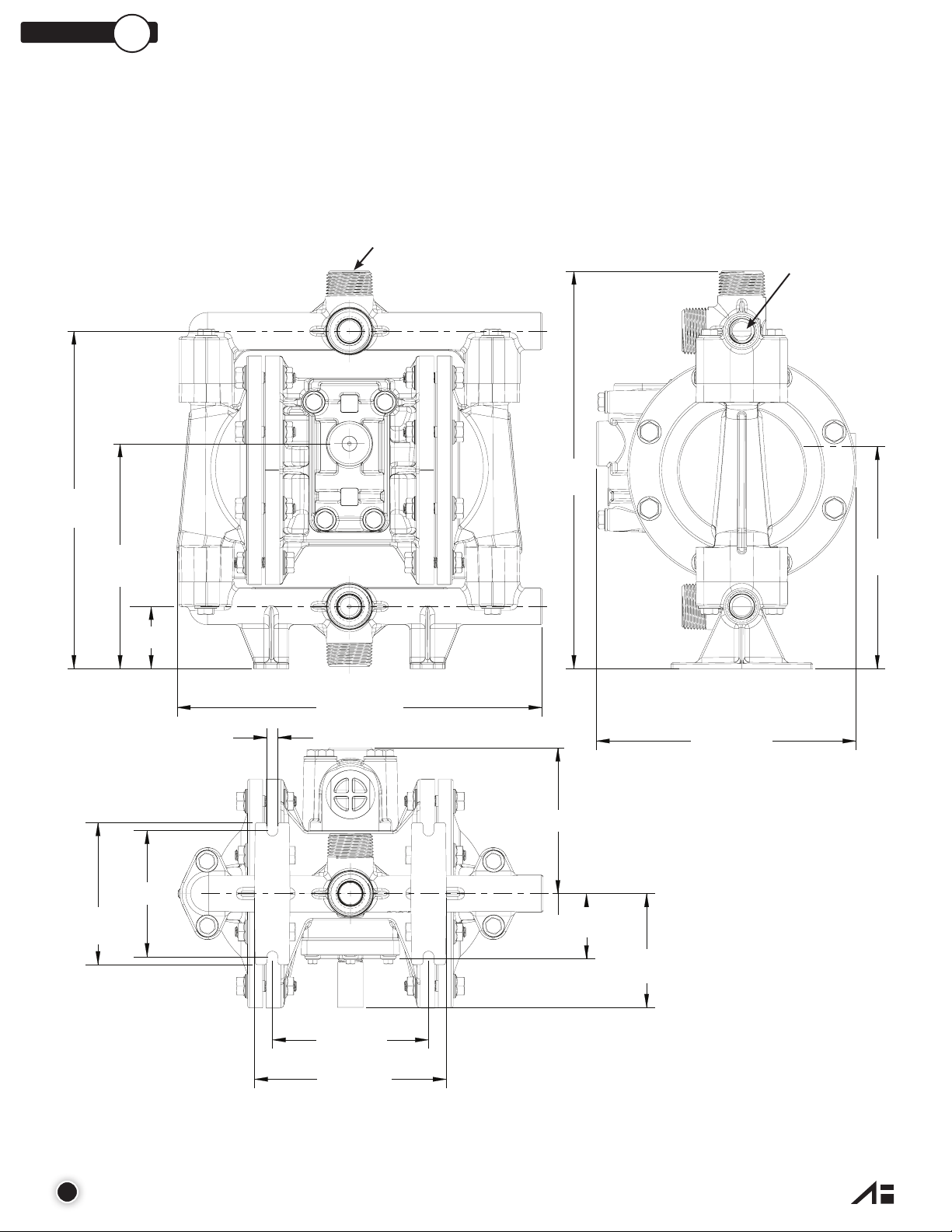

SECTION

(241mm)

(160mm)

4

1/2” PUMP DIMENSIONS

POLYPROPYLENE CENTER SECTION

9.5”

6.3”

(160mm)

1.8”

(46mm)

1” MNPT OR 1” MBSP (x4)

11.2”

(284mm)

1/2” FNPT or FBSP

6.3”

10.3” (261.62mm)

0.3”

(8mm)

4.1” (104mm)

3.6”(91mm)

4.0”

(102mm)

4.4” (112mm)

5.4” (137mm)

1.8” (46mm)

Note - Suction Right / Discharge Right are default ports. See part number

matrix option code for additional porting options.

3.2”

(81mm)

7.3” (185mm)

8

all-o.com

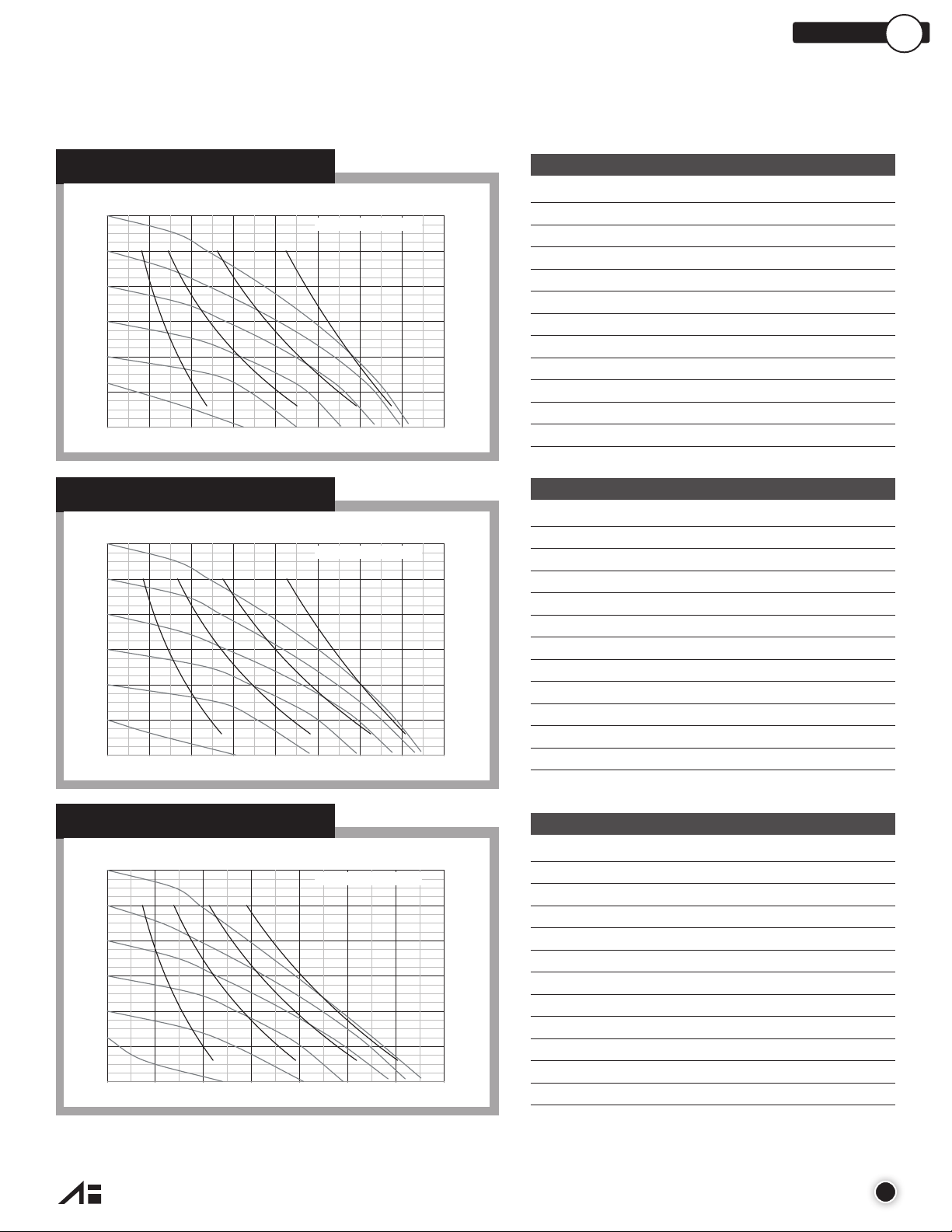

PERFORMANCE CURVES

SECTION

5

PERFORMANCE CURVE (1/2” RUBBER)*

DISCHARGE FLOW-Liters/Min.

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BARS)

7.5 15.1 22.7 30.337.945.45360.6

02 46810121416

DISCHARGE FLOW-U.S. Gals./Min.

AIR CONSUMPTION (SCFM)

20 5 10 15

PERFORMANCE CURVE (1/2” TPE)*

DISCHARGE FLOW-Liters/Min.

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BARS)

7.5 15.1 22.7 30.337.945.45360.6

02 46810121416

DISCHARGE FLOW-U.S. Gals./Min.

AIR CONSUMPTION (SCFM)

20 5 10 15

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

(27,9)

(13,9)

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

(27,9)

(13,9)

Performance Specifications

Max. Flow: 14 gpm (53.0 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids:

1

/8” (3.2 mm)

Max. Suction Lift Dry: 15 ft-H2O (4.5 m-H2O)

Max. Suction Lift Wet: 31 ft-H2O (9.4 m-H2O)

Weight: AL-10 lbs (4.5 kg)/SS-20 lbs (9.1 kg)

Air Inlet: 1/4” FNPT

92

Liquid Inlet: ½” FNPT/BSP

Liquid Outlet: ½” FNPT/BSP

46

TOTAL HEAD IN FEET (METERS)

Height: 11.2” (284 mm)

Width: 10.3” (262 mm)

Depth: 6.4” (163 mm)**

Performance Specifications

Max. Flow: 15 gpm (56.8 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids:

1

/8” (3.2 mm)

Max. Suction Lift Dry: 15 ft-H2O (4.5 m-H2O)

Max. Suction Lift Wet: 31 ft-H2O (9.4 m-H2O)

Weight: AL-10 lbs (4.5 kg)/SS-20 lbs (9.1 kg)

Air Inlet: 1/4” FNPT

92

Liquid Inlet: ½” FNPT/BSP

Liquid Outlet: ½” FNPT/BSP

46

TOTAL HEAD IN FEET (METERS)

Height: 11.2” (284 mm)

Width: 10.3” (262 mm)

Depth: 6.4” (163 mm)**

PERFORMANCE CURVE (1/2” PTFE)*

DISCHARGE FLOW-Liters/Min.

20 5 10 15

(8,2)

(6,8)

120

100

7.5 15.1 22.730.3

37.9

AIR CONSUMPTION (SCFM)

45.4

53

276

(83,9)

230

(69,9)

Performance Specifications

Max. Flow: 13 gpm (49.2 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids:

1

/8” (3.2 mm)

Max. Suction Lift Dry: 14 ft-H2O (4.3 m-H2O)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

PRESSURE INLET/OUTLET PSIG (BARS)

184

(55,9)

138

(41,9)

(27,9)

(13,9)

Max. Suction Lift Wet: 31 ft-H2O (9.4 m-H2O)

Weight: AL-10 lbs (4.5 kg)/SS-20 lbs (9.1 kg)

Air Inlet: 1/4” FNPT

92

46

TOTAL HEAD IN FEET (METERS)

Liquid Inlet: ½” FNPT/BSP

Liquid Outlet: ½” FNPT/BSP

Height: 11.2” (284 mm)

Width: 10.3” (262 mm)

02 468101214

DISCHARGE FLOW-U.S. Gals./Min.

*Flow rates indicated on all three charts shown were determined by pumping water at flooded suction, using an aluminum intermediate fitted pump.

For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump performance curve.

**Polypropylene intermediate is 7.3” (185mm) deep.

Depth: 6.4” (163 mm)**

all-o.com

9

Loading...

Loading...