Page 1

ALLEN&HEATH

WARNING – HIGH VOLTAGES

Power Supply Unit (PSU) work should only

be carried out by qualified personnel.

We recommend that you use an approved Allen & Heath

service centre for all power supply work.

Please contact your local Allen & Heath distributor for more details.

http://www.allen-heath.com/

Page 2

SERVICE INFORMATION

Publication AP6047

Page 3

Introduction

This publication provides technical information on servicing the Allen & Heath XONE VF-1 Analogue Filter

unit. Included are internal layout drawings, block diagrams and circuit schematics with board layouts.

Whilst we believe this information to be reliable we do not assume responsibility for inaccuracies. We also

reserve the right to make changes in the interest of further product development.

Additional Resources

Allen & Heath web site www.allen-heath.com Product information

Technical downloads

Distribution contacts

Company contacts

Technical support support@allen-heath.com

See web for local contact

XONE VF-1 user guide AP5917 Operating instructions

Performance specification

XONE VF-1 Service Information

Issue status: xonevf-1_ap6047_1.doc

Print date: 07 December 2004

Copyright © 2004 Allen & Heath. All rights reserved

Manufactured in the United Kingdom by Allen & Heath

Kernick Industrial Estate, Penryn, Cornwall, TR10 9LU, UK

http://www.allen-heath.com

2 xonevf-1_ap6047_1.doc

Page 4

Servicing Precautions – General Notes

Service personnel: Service work should be carried out by technically qualified service personnel only.

Mains power is dangerous and can kill. Do not attempt to work on a linear or switched

mode power supply if you are not suitably qualified to do so. Do not attempt to repair

surface mount circuit assemblies unless you are suitably qualified and have the

necessary facilities to do so. Replacement circuit assemblies can be ordered.

Service facilities: Ensure a suitably sized work surface is available. Ensure this is clear of dirt, debris

and obstructions which may damage the equipment surfaces. Ensure adequate

lighting. Use the correct tools for the job and ensure they are in good working order.

Ensure all workshop safety requirements are adhered to.

Service information: Check that you have all the information you need before starting the service job. Refer

to the Allen & Heath web site or contact Allen & Heath technical support for details on

the latest information. Full technical information can be downloaded from the web site

Distributor Zone (password required).

Mains power: Connect the equipment to mains power only of the type described in the user guide

and marked on the rear panel. The power source must provide a good ground

connection. Ensure you always use an isolation transformer when working on any

mains power supply unit.

Mains cord and fuse: Use the correct power cord as supplied with the equipment. Do not remove or tamper

with the ground connection in the power cord. Heed the Important Mains Plug Wiring

Instructions printed in the user guide if it is necessary to rewire the mains cord.

Always replace the equipment mains fuse with the correct type and rating as

described in the user guide and marked on the equipment panel.

Opening the unit: Switch off and remove the mains power cord before opening the equipment. Ensure

all power supply covers and safety shields are in place before applying power with the

unit open for diagnostic fault finding.

Closing the unit: Before finishing, check the quality and accuracy of the service work carried out.

Remove any dirt or debris as this may cause equipment failure in the future. Ensure all

assemblies, harnesses and connectors are correctly aligned and plugged in. Ensure

that jumper settings and control configurations are correctly set according to the

requirements of the customer.

Testing the unit: Before operating the equipment, read and adhere to the Important Safety Instructions

printed in the user guide. Test that the service work has been successfully carried out.

Shipping the unit: Use adequate packing such as the original packaging or purpose designed flight case

if you need to ship the unit. To avoid injury to yourself or damage to the equipment

take care when lifting, moving or carrying the equipment.

Servicing Notes – XONE VF-1

User maintenance: There are no user serviceable parts inside. Refer any service work to competent

technical personnel only.

Technology: The XONE VF-1 uses SMT (surface mount) PCB technology. In certain cases it may

be better to replace a faulty assembly rather than try to fix it without the appropriate

tools and training. The power supply is a built-in universal mains input, switched

mode circuit which should be serviced by suitably qualified personnel only.

Operation: The XONE VF-1 is an analogue filter unit. To ensure optimum performance and

reliability it should be connected and operated as described in the user guide.

Fault finding: Refer to the system block diagram and circuit drawings to follow through the signal

path during fault diagnosis. Replace suspected faulty components only with those

specified by Allen & Heath. The use of lower grade alternatives may degrade the

performance.

xonevf-1_ap6047_1.doc

3

Page 5

Contents Log

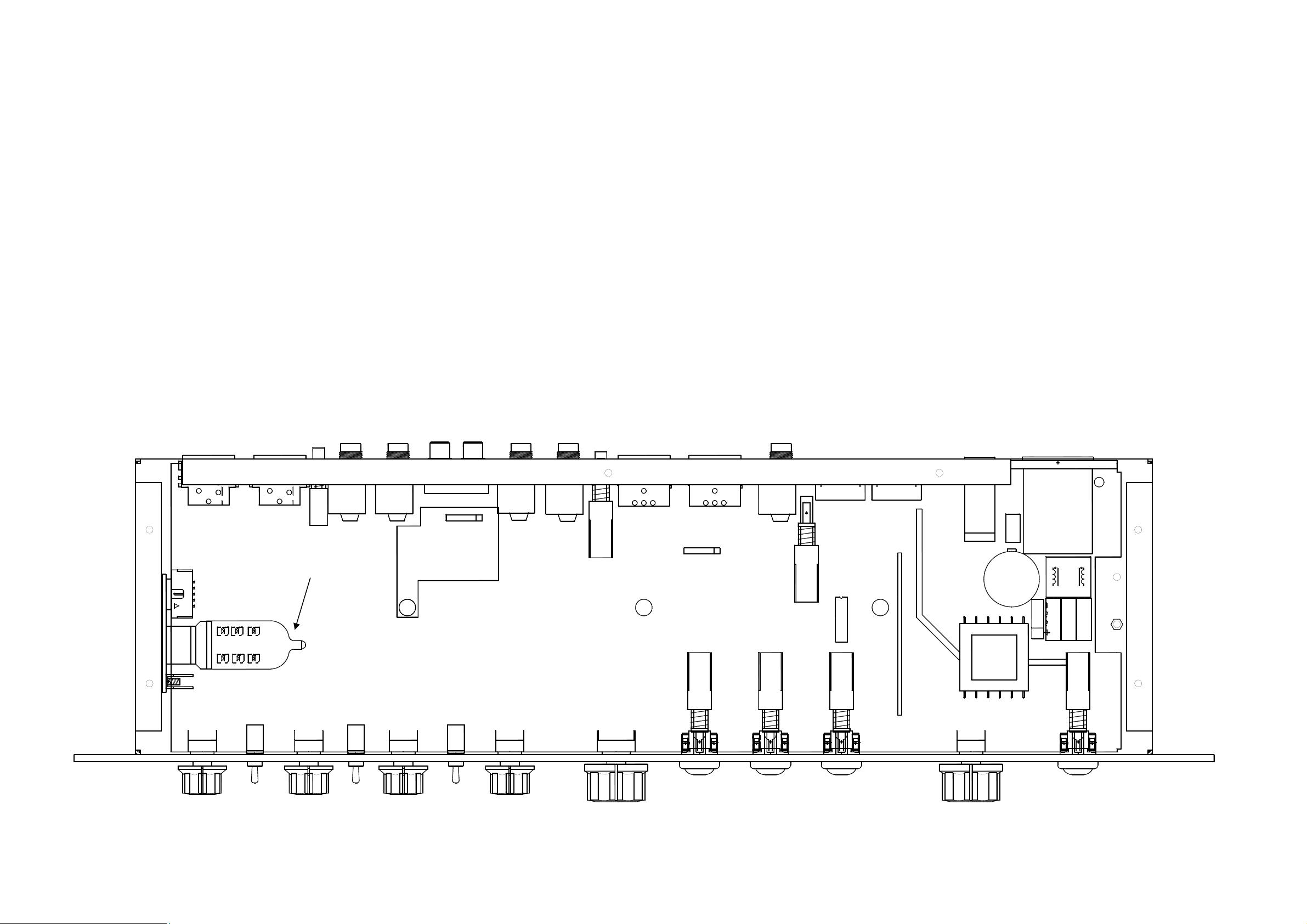

Internal Layout Drawing .............................................xonevf-1_layout_1.pdf

Surface and Main Parts................................................xonevf-1_parts_1.pdf

System Block Diagram ................................. xonevf-1_blockdiagram_1.pdf

Main PCB Assembly iss.1 .............................xonevf-1_003-358_main_1.pdf

Main PCB Assembly iss.4 .............................xonevf-1_003-358_main_4.pdf

RIAA Option PCB ............................................ xonevf-1_003-360_riaa_a.pdf

RIAA Option Fitting Instructions ......................... xonevf-1_riaa_fitting_1.pdf

4 xonevf-1_ap6047_1.doc

Page 6

Product .........................XONE:VF-1/120

.....................................XONE:VF-1/220

.....................................XONE:VF-1/240

.................................. XONE:VF-1R/120

.................................. XONE:VF-1R/220

.................................. XONE:VF-1R/240

Main Assembly ......................... 003-357

PCB Assembly ......................... 003-358

Pack Assembly......................... 003-359

RIAA Option PCB Assy ............ 003-360

Valve ECC82 ............................AE5139

21

3

CN12

CN16

12

3

CN7CN8 CN9

SW10

CN2CN3 CN4

CN1

AB

CN1

1

CN5

G

123

SW1

RIAA OPTION

VALVE ECC82 AE5139

LD1LD2LD3

LD4LD5LD6

FH1 FH2

-

PCB ASSY

003-358

G

CN10

321

CN6

CN17

1

SW5

PIC SKT

CN13CN14

WARNING HIGH VOLTAGE!

SW8

SW7

SW9

F1

NTC1

TX1

CN15

LN

L1

C117

BR1

R207

P1

C113C114 C115

SW6

SW2

VR1 VR2

LD8

SW4

VR3

SW3

VR4 VR6

VR5

LD9

LD12

LP4

LD11

LD7

LD10

LD13

LD14

LP1 LP2 LP3

xone_vf-1_layout_1.doc Sheet 1 of 1

Page 7

R15

003-358 iss.1

R64

R65

R60

R61

U4A

2

3

6

5

2

3

6

5

10K 1%

U3A

R16

R17

10K 1%

U3B

R23

10K 1%

R6

10K 1%

U2A

R7

10K 1%

R8

10K 1%

U2B

R9

10K 1%

TL072D

R24

3K9

C5

15P

C43

100P_S

TL072D

10K 1%

C44

100P_S

C45

100P_S

C46

100P_S

C39

100P_S

TL072D

C40

100P_S

C41

100P_S

C42

100P_S

1

TL072D

1

7

TL072D

C19

47/25

1

7

100N

R68

47R

R69

47R

R66

47R

R67

47R

C36

R45

47K

R1

10K 1%

6

5

R4

10K 1%

2

3

R13

10K 1%

R5

10K 1%

U1B

TL072D

R14

10K 1%

U1A

TL072D

C2

15P

C4

15P

PRE_OUT_L

7

1

C30

100N

C9

47/25

OFF_CTRL

PRE_OUT_R

SW10B

4

6

R39

47K

R226

10K

C14

5

47/25

C141

22N

100N

MMBFJ111

R22710K

C33

R42

47K

Q11

FILT_OUT_L

R230

10K

10K

OFF_CTRL

C133

47/25

R220

47K

Q13

MMBFJ111

R231

FILT_OUT_R

C31

100N

C10

47/25

6

5

R223

47K

U29B

C136

47/25

R41

10K 1%

C11

15P

TL072D

R40

47K

ON_CTRL

C34

100N

C15

47/25

R228

10K

2

3

7

C139

100N

R229

10K

R216

10K 1%

U29A

R221

47K

C134

47/25

C142

22N

C32

15P

TL072D

R232

10K

R43

47K

R44

10K 1%

Q12

MMBFJ111

1

C140

100N

R233

10K

R224

47K

C137

47/25

C135

47/25

R222

47K

MMBFJ111

CN2

R

T

e

CN1A

A

W

OUT_LEFT

R

CN3

d

B

W

OUT_RIGHT

R

CN1B

CN7

1 2

R

T

CN8

1 2

R2

12K 1%

R32

20K 1%

R3

12K 1%

3

XLR NC3FAH20

0

R10

10K 1%

R11

12K 1%

R34

R12

12K 1%

3

XLR NC3FAH20

0

R33

20K 1%

20K 1%

R35

20K 1%

C1

15P

C3

15P

6

5

R217

10K 1%

Q14

OUT_LEFT

R215

10K 1%

C16

15P

U30B

TL072D

OUT_RIGHT

C138

47/25

R225

47K

R50

47R 1%

7

R51

47R 1%

R218

10K 1%

C35

2

3

15P

U30A

TL072D

1

3

1

LEFT

SW10A

RIGHT

R63

4K71%

4K71%

2

4K71%

R62

4K71%

R59

4K71%

4K71%

4K71%

R58

4K71%

c

ON_CTRL

SW1A

PRE_OUT_L

FILT_OUT_L

R18

10K 1%

R19

10K 1%

1

3

2

R234

100K 1%

3

2

R22

15K 1%

C12

47/25

R72

2K2 1%

R73

2K2 1%

C13

47/25

C49

100N

C17

47/25

R70

2K2 1%

R71

2K2 1%

C18

47/25

C50

100N

C47

100N

C48

100N

L_OUT_-

R75

100K 1%

R76

100K 1%

L_OUT_+

R_OUT_-

R77

100K 1%

R78

100K 1%

R_OUT_+

R52

47R 1%

R53

47R 1%

LIP

LEFT JACK OUT

3

0

LEFT BALANCED OUT

3

0

RIGHT BALANCED OUT

T

R

CN9

XLR NC3MAH20

12

CN10

XLR NC3MAH20

12

CN4

b

+15V

-15V

R84

10R PF RAD

R83

10R PF RAD

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

C55

100/25

C54

100/25

8

U1C

V+

V-

TL072D

4

ISSUE BY DATE

1 ARJ 30-07-04

8

V+

V-

TL072D

4

SW1B

4

PRE_OUT_R

FILT_OUT_R

8

V+

V-

TL072D

4

+VIO

U29C

-VIO

8

V+

V-

4

U30C

TL072D

+VIO

U2C

CHK

BY

8

U3C

V+

V-

TL072D

4

-VIO

FILE: AG5877_1 SHEET 1.Sch 14:45:17 4-Nov-2004

8

V+

V-

4

U4C

TL072D

R20

10K 1%

R21

10K 1%

6

5

R235

100K 1%

PRINTED:

5

6

R26

15K 1%

U4B

TL072D

R25

3K9 0805

C6

15P

7

FILT_OUT_L

FILT_OUT_R

RIGHT JACK OUT

MONITOR OUT

100N

C20

47/25

C37

TITLE:

R54

47R 1%

R55

47R 1%

R46

47K

C21

47/25

C22

47/25

R56

47R 1%

R57

47R 1%

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 1 5

1

CN5

T

R

CN6

T

R

Page 8

e

003-358 iss.1

d

c

b

FILT_IN_L

FILT_IN_R

R211

10K 1%

R212

10K 1%

C23

47/25

R93

47K

R29

10K 1%

C24

47/25

R94

47K

R30

10K 1%

R96

10K

R97

10K

2

U5A

3

TL072D SMD

R95

10K 1%

25

3

VR5B

20KK

R118

1K8

R121

R104

10K

R105

10K

6

U5B

5

TL072D SMD

R31

10K 1%

16

4

VR5A

20KK

R119

1K8

R122

U22B

NSL32

NSL32

39K

U23B

NSL32

1

7

NSL32

U23A

39K

U22A

C62

10/16

10/16

C63

R124

1K0 1%

R125

1K0 1%

D17

LL4148

D18

LL4148

12

JP2

ARC DISABLE

FILT_OUT_L

ARC DISABLE

1 2

JP3

JUMP 2 STRT

FILT_OUT_R

C64

C65

C66

C67

470P

470P

470P

470P

R130

R138

R131

R139

R132

R140

R133

R141

470R

30K1%

470R

30K1%

470R

30K1%

470R

30K1%

-VF

+15V

-15V

VCF_DC

3

2

6

7

11

10

14

15

9

8

R86

10R PF RAD

R85

10R PF RAD

U9

VCA1

VCA2

VCA3

VCA4

VGND

SSM2164S_1(16)

+VF

MD

V+

4

5

12

13

1

16

C57

100/25

C56

100/25

8

V+

V-

4

2

3

6

5

6

5

2

3

U5C

TL072D

C68

1N0 0805

U6A

TL072D SMD

C69

1N0 0805

U6B

TL072D SMD

C70

1N0 0805

U7B

TL072D SMD

C71

1N0 0805

U7A

TL072D SMD

8

U6C

V+

V-

TL072D

4

1

7

7

1

8

U7C

V+

V-

TL072D

4

C72

10/50

C73

10/50

C74

10/50

C75

10/50

C76

10/50

C77

10/50

+VF

-VF

R98

10K

R99

10K

R100

10K

R106

10K

R107

10K

R108

10K

8

V+

V-

4

U8C

TL072D

R101

10K

R102

10K

R103

10K

R109

10K

R110

10K

R111

10K

Q1

Q2

Q3

Q5

Q4

Q6

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

HP_DC_CNTRL

BP_DC_CNTRL

LP_DC_CNTRL

LP_DC_CNTRL

BP_DC_CNTRL

HP_DC_CNTRL

C7

15P

R142

10K1%

2

U8A

3

6

U8B

5

TL072D

C8

15P

R143

10K1%

TL072D

1

7

FILT_OUT_L

FILT_OUT_R

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

1 ARJ 30-07-04

CHK

BY

VR5C

BRKT

8

9

20KK

FILE: AG5877_1 SHEET 2.Sch 14:45:18 4-Nov-2004

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 2 5

1

Page 9

PRE_OUT_L

003-358 iss.1

PRE_OUT_R

R144

68K 1%

R145

68K 1%

e

d

c

1

3

5

7

9

1

3

5

7

9

2

4

6

8

10

2

4

6

8

10

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

R47

47K

C25

47/25

R126

1K0 1%

+VS

2

3

VHT

GRID_L

CATH_L

CN11

IDC 5X2 F STRT

-15V_VPCB

GRID _R

CATH_R

HEATER

R79

100K 1%

D2

LL4148

2

U10A

3

D1

LL4148

C81

330N

C82

330N

U13A

TL072D

R168

1M0 1%

R169

1M0 1%

ISSUE BY DATE

1 ARJ 30-07-04

+5V

2

1

7

R171

TL072D

3

R170

4K7 1%

8

4K7 1%

R49

47K

1

4

FREQUENCY

20KK

D5

LL4148

D6

LL4148

C38

100N

R180

30K 1%

C26

47/25

C27

47/25

R184

30K 1%

BRKT

13

VR6A

VR1A

2

EF FOLLOWER

20KK

1 3

R165

30K 1%

R166

30K 1%

4

SW4B

2

1

3

MIDI_Fc

Fc_SND

EF_LEVEL

R150

120K 1%

LFO DEPTH

VR4A

20KK

1 3

6

U15B

5

TL072D

2

U16A

3

TL072D

SW5A

2

C98

PRINTED:

R152

2

9K1

R151

6K8 1%

R164

30K 1%

C103 22P_S

7

C104

R186

R190

680P

C105

R187

R181

680P

C106

R188

R182

680P

C107

R189

680P

22P

1

VD_R

VD_L

560R 1%

+5V

EVELOPE FOLLOWER SIDE-CHAIN

1

R48

47K

LFO

EF_LEVEL

V1A

ECC82

69

V1B

ECC82

5

CHK

BY

D3

LL4148

5

6

R160

220R

D4

LL4148

LFO SPEED

VR3A

2

20KK

1 3

R80

100K 1%

U13B

TL072D

EF TO OVERDRIVE

R162

47K

VD_L

BRKT

5

6

VR1B

FILE: AG5877_1 SHEET 3.Sch 14:45:18 4-Nov-2004

R127

1K0 1%

7

R

SW4A

2

L

+5V

VR2A

2

20KK

1 3

OVERDRIVE DEPTH

C83

R173

33K 1%

330N

C99

10N

+15V

-15V

5

BRKT

R90

10R PF RAD

R89

10R PF RAD

6

VR2B

R163

15K

C85

1/63

1

3

R179

56K 1%

LD1

LD2

LD3

VO_L

VALVE_HT

BRKT

5

R146

330K 1%

C86

1/63

100/25

6

VR3B

C61

C60

100/25

R147

1M2 1%

1

3

WAVEFORM

1

3

2

3

RD

RD

RD

CN12

BRKT

5

R

L

R

L

SW3A

R155

10K1%

10N

U14A

TL072D

112

334

556

778

9910

8

4

6

VR4B

SW2A

C93

U14C

V+

V-

TL072D

R148

220K

2

2

RD

RD

RD

DECAY

1

2

4

6

8

10

BRKT

5

+5V

R159

10K1%

LD4

LD5

LD6

VO_R

-VO

+10V

C88

47N

10K1%

8

V+

V-

TL072D

4

6

VR6B

R149

220K

R156

LL4148

U15C

D20

6

5

C84

330N

+VO

-VO

LL4148

U14B

TL072D

5

C89

47N

2

3

D21

R157

10K1%

10N

R174

33K 1%

C100

10N

8

4

BRKT

R158

10K1%

D22

LL4148

C94

U16C

V+

V-

TL072D

4

SW2B

U11A

7

VD_R

5

6

C92

TL072D

10N

5

U10B

TL072D

1

R120

470R

LL4148

BRKT

7

HP_DC

BP_DC

-5

VALVE OVERDRIVE CIRCUIT

CV_1

CV_2

D19

PRE_OUT_L

VO_L

VO_R

PRE_OUT_R

4

5

SW3B

D7

LL4148

2

3

R183

30K 1%

560R 1%

27K 1%

560R 1%

27K 1%

560R 1%

30K 1%

6

5

R36

20K 1%

U12A

R153

10K1%

C91

10N

TL072D

U12B

1

3

2

6

7

11

10

14

15

9

8

10R PF RAD

10R PF RAD

7

5

6

10K1%

R88

R87

U17

VCA1

VCA2

VCA3

VCA4

VGND

SSM2164S_1(16)

U11B

R37

20K 1%

C95

NF

7

TL072D

C90

NF

TL072D

+15V

-15V

-VO +VO

R154

-VS

R123

39K

C101

10N

MD

V+

C102

10N

TITLE:

R167

2K7

C59

100/25

C58

100/25

R175

33K 1%

4

5

12

13

1

16

R178

33K 1%

XONE VF-1 MAIN PCB

8

V+

V-

4

R185

VCF_DC

U10C

TL072D

2

3

30K 1%

C96

R176

33K 1%

U15A

TL072D

22P

8

V+

V-

TL072D

4

6

5

U11C

1

R177

C97

U16B

TL072D

+VS

-VS

33K 1%

22P

8

U12C

V+

V-

TL072D

4

FILT_IN_L

7

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 3 5

1

8

4

-5

FILT_IN_R

U13C

V+

V-

TL072D

Page 10

C118

003-358 iss.1

100NMLC

+5V

R112

SW6B

5

4

6

e

SW7B

SW8B

SW9B

4

6

4

6

4

6

5

5

d

5

SW6A

2

FILTER ON

SW7A

2

HIGH PASS

SW8A

2

BAND PASS

SW9A

2

LOW PASS

10K

1

3

+5V

R113

10K

1

3

1

3

1

3

R114

10K

Fc_SND

R115

10K

C143

4N7

10

RC0/AN4

9

RC1/AN5

8

RC2/AN6

7

RC3/AN7

6

TX

5

RX

+5V

1

VDD

VSS

14

U18

RA0/AN0

RA1/AN1

RA2/AN2

RA3

RA4/AN3

RA5

PIC16F688

CN17

6

13

12

11

4

3

2

12345

+5V

LD7GNLD10

C87

GN

GN

GN

1/63

R134

470R

R135

470R

R136

470R

R137

470R

R116

10K

MIDI_Fc

HP_DC

BP_DC

LP_DC

FILT_ON

+5V

R191

4K7 1%

R192

4K7 1%

5

4

9

8

11

10

7

6

U20A

LM2901 SMD

U20C

LM2901 SMD

U20D

LM2901 SMD

U20B

LM2901 SMD

R81

100K 1%

R74

3K9

R193

4K7 1%

2

14

13

1

R196

1M0 1%

R194

4K7 1%

R197

1M0 1%

R195

4K7 1%

R198

1M0 1%

R237

4K7 1%

R238

4K7 1%

Q9

BC848B

-VMID

R236

1M0 1%

D23

LL4148

R201

1M0 1%

D8

LL4148

HP_DC_CNTRL

C108

22N

BP_DC_CNTRL

C109

22N

LP_DC_CNTRL

C110

22N

ON_CTRL

R239

220K

OFF_CTRL

R202

220K

R219

10K 1%

8

1

R241

10R

FILT_ON

CR

2

C111

4N7

LP_DC

BP_DC

HP_DC

7

3

R199

82K

LD8GNLD11

LD9GNLD12

LD13

BL

LD14

BL

6

4 5

R200

680K 2%

+VMID

U19

LM2907

c

+15V

-15V

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

R92

10R PF RAD

R91

10R PF RAD

ISSUE BY DATE

1 ARJ 30-07-04

C28

47/25

C29

47/25

3

V+

V-

12

Fc_SND

+VMID

U20E

LM2901 SMD

-VMID

R240

9K1

CHK

BY

+5V

R128

1K0 1%

Q8

R117

10K

VCC

BASE

COLL

GND

U21

6N138

NC

NC

A

K

R172

+5V

+5V

8

7

6

5

LOCAL OFF

SW5B

5

FILE: AG5877_1 SHEET 4.Sch 14:45:19 4-Nov-2004

5K6

4

6

R203

1K2 1%

Q7

BC848B

1

2

3

4

BC848B

R161

220R

D9

LL4148

R27

220R

3

1

0

0

425

CN13

1

425

CN14

3

R28

MIDI OUT

220R

MIDI IN

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 4 5

1

Page 11

CN15

003-358 iss.1

N

L

E

LP1 LP2 LP3 LP4 FID1 FID2AI4AI1 AI2

FH4

CN16

123

FID3 FID4

4

INLET

FILTERED IEC

MAINS

NTC1

INRUSH SUPP NTC20R

F1

12

AI3

EMC SCREEN

FH1 FH2 FH3

e

T500mA

E

N

2

P1

PIN

d

c

b

L

3

1

3

C113

L1

100N 275V

1

C78

CHOKE 20MH

100N 100V/MLC

10/50

L_GND

L2

4.7uH

R204

6K8 1%

C112

4N7

2 4

C120

1

8

6

L_GND

COMP

VREF

OUT

C121

150P

R205

7

VCC

GND

5

L_GND

23

BR1

150K 1%

U24

ISEN

VFB

RT/CT

UC3842D1

FUSE HOLDER 20MM

2KBP206

3

2

4

C114

100N 275V

14

C115

100N 275V

L_GND

R38

20K 1%

R206

3K3 1%

C117

L_GND

C51

100N

L_GND

68/400

L_GND

C132

330P

C127

2N2 250V/PEM

R207

82K 1W

D10

C122

120/63 LESR

R208

68R

L_GND

R129

1K0 1%

BYG80G

R82

100K 1%

R209

1R0 1W

C116

100N 275V

D15

P6KE200A

D16

BYV26E

Q10

STB4NC80ZT4

R210

1R0 1W

L_GND L_GND

TX1

1

PRIMARYBIAS

2

3

5 8

XFRMR E/30/15/7A (UNI) (AM5547)

12

10

7

11

9

D11

BYG80G

D13

BYG80G

BYG80G

D14

D12

BYG80G

C129

470/25 LESR

C128 470/25 LESR

C123

120/63 LESR

GND_PSU

C125

120/63 LESR

GND_PSU

L3

L4

L5

L6

4.7uH

4.7uH

4.7uH

4.7uH

4.7uH

U25

1

2

C79

10/50

3

Vin

2

1

Vin

U27

1

Vin

U28

Vin

C131

470/25 LESR

C130

470/25 LESR

C124

120/63 LESR

L7

C126

120/63 LESR

+15V

GND

7815

U26

-15V

GND

+5V

GND

7805

2

ADJ

TL783

1

Vout

7915

3

3

3

C52

100N

C53

100N

2

+15V

C144

10/50

-15V

+10V

+5V

C80

10/50

VALVE_HT

R213

1K0 1%

R214

39K 1%

C119

47/63

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

1 ARJ 30-07-04

CHK

BY

FILE: AG5877_1 SHEET 5.Sch 14:45:19 4-Nov-2004

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 5 5

1

Page 12

003-358 iss.1

Page 13

e

003-358 iss.4

d

B

c

CN1A

A

LH_RCA_OUT

CN2

LH_RCA_IN

W

OUT_LEFT

R

RH_RCA_OUT

CN3

RH_RCA_IN

W

OUT_RIGHT

R

CN1B

R

T

R

T

C134

R1

10/50

R2

R32

20K 1%

R3

10K 1%

3

CN7

1 2

XLR NC3FAH20

0

C135

CN8

1 2

R10

10/50

R11

R34

R12

10K 1%

3

XLR NC3FAH20

0

10K 1%

10K 1%

10K 1%

10K 1%

20K 1%

R33

20K 1%

R35

20K 1%

R5

10K 1%

C2

CN18

U1B

TL072D

1

2

3

4

5

6

U1A

TL072D

15P

LH_RCA_OUT

LH_RCA_IN

+15V

-15V

RH_RCA_IN

RH_RCA_OUT

R14

10K 1%

C4

15P

6

5

C1

R4

10K 1%

15P

RIAA OPTION CONNECTOR

2

3

C3

R13

10K 1%

15P

PRE_OUT_L

7

1

C30

100N

C9

100/35

PRE_OUT_R

4

6

R39

47K

OFF_CTRL

SW10B

R226

10K

C141

22N

100N

C14

5

100/35

MMBFJ111

R22710K

C33

R42

47K

Q11

R220

47K

FILT_OUT_L

R230

10K

10K

OFF_CTRL

C133

330/10

C31

100N

C10

100/35

Q13

MMBFJ111

R231

R223

47K

FILT_OUT_R

R15

10K 1%

C43

2

R22

10K 1%

R18

10K 1%

R63

4K71%

4K71%

4K71%

R62

4K71%

R59

4K71%

4K71%

4K71%

R58

4K71%

R234

10K 1%

R64

R65

2

3

R60

R61

6

5

3

U4A

2

OUT_LEFT

R41

10K 1%

C11

U29B

C136

330/10

15P

TL072D

R228

10K

R40

47K

ON_CTRL

C34

100N

C15

100/35

C142

22N

C32

15P

TL072D

R232

10K

R43

47K

R44

10K 1%

Q12

MMBFJ111

1

R233

10K

ON_CTRL

Q14

MMBFJ111

R217

10K 1%

7

R229

10K

R216

10K 1%

2

U29A

3

6

5

6

5

R215

10K 1%

C16

15P

U30B

TL072D

OUT_RIGHT

PRE_OUT_L

R50

47R 1%

7

R51

47R 1%

R218

10K 1%

C35

2

3

15P

U30A

TL072D

LEFT

SW10A

1

3

RIGHT

1

SW1A

1

3

2

2

3

6

5

U3A

R16

R17

10K 1%

U3B

R23

10K 1%

R6

10K 1%

U2A

R7

10K 1%

R8

10K 1%

U2B

R9

10K 1%

TL072D

R24

10K 1%

C5

15P

100P_S

TL072D

10K 1%

C44

100P_S

C45

100P_S

C46

100P_S

C39

100P_S

TL072D

C40

100P_S

C41

100P_S

C42

100P_S

1

TL072D

1

7

TL072D

C19

47/25

1

7

100N

R68

47R

R69

47R

R66

47R

R67

47R

C36

R45

47K

C12

47/25

R72

2K2 1%

R73

2K2 1%

C13

47/25

C49

100N

C17

47/25

R70

2K2 1%

R71

2K2 1%

C18

47/25

C50

100N

C47

100N

C48

100N

L_OUT_-

R75

100K 1%

R76

100K 1%

L_OUT_+

R_OUT_-

R77

100K 1%

R78

100K 1%

R_OUT_+

R52

47R 1%

R53

47R 1%

LIP

LEFT JACK OUT

3

0

LEFT BALANCED OUT

3

0

RIGHT BALANCED OUT

T

R

CN9

XLR NC3MAH20

12

CN10

XLR NC3MAH20

12

CN4

b

+15V

-15V

R84

10R PF RAD

R83

10R PF RAD

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

C55

100/25

C54

100/25

8

U1C

V+

V-

TL072D

4

ISSUE BY DATE

1 ARJ 30-07-04

2 ARJ 17-08-04

8

V+

V-

TL072D

4

R21

10K 1%

SW1B

4

PRE_OUT_R

8

V+

V-

TL072D

4

+VIO

U29C

-VIO

8

V+

V-

4

U30C

TL072D

+VIO

U2C

CHK

BY

8

U3C

V+

V-

TL072D

4

-VIO

FILE: AG5877_4 SHEET 1.Sch 11:50:14 2-Nov-2004

8

V+

V-

4

U4C

TL072D

6

PRINTED:

R20

5

10K 1%

R235

10K 1%

5

6

U4B

TL072D

R25

10K 1%

C6

15P

7

FILT_OUT_L

FILT_OUT_R

RIGHT JACK OUT

MONITOR OUT

100N

C20

47/25

C37

TITLE:

R54

47R 1%

R55

47R 1%

R46

47K

C21

47/25

C22

47/25

R56

47R 1%

R57

47R 1%

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 1 5

4

CN5

T

R

CN6

T

R

Page 14

e

003-358 iss.4

d

c

b

FILT_IN_L

FILT_IN_R

R211

10K 1%

R212

10K 1%

C23

330/10

R93

47K

R29

10K 1%

C24

330/10

R94

47K

R30

10K 1%

R96

10K

R97

10K

2

U5A

3

TL072D SMD

R95

10K 1%

25

3

VR5B

20KK

R118

1K8

R121

R104

10K

R105

10K

6

U5B

5

TL072D SMD

R31

10K 1%

16

4

VR5A

20KK

R119

1K8

R122

U22B

NSL32

NSL32

39K

U23B

NSL32

1

7

NSL32

U23A

39K

U22A

C62

10/16

10/16

C63

R124

1K0 1%

R125

1K0 1%

D17

LL4148

D18

LL4148

12

JP2

ARC DISABLE

FILT_OUT_L

ARC DISABLE

1 2

JP3

JUMP 2 STRT

FILT_OUT_R

C64

C65

C66

C67

470P

470P

470P

470P

R130

R138

R131

R139

R132

R140

R133

R141

470R

30K1%

470R

30K1%

470R

30K1%

470R

30K1%

-VF

+15V

-15V

VCF_DC

3

2

6

7

11

10

14

15

9

8

R86

10R PF RAD

R85

10R PF RAD

U9

VCA1

VCA2

VCA3

VCA4

VGND

SSM2164S_1(16)

+VF

MD

V+

4

5

12

13

1

16

C57

100/25

C56

100/25

8

V+

V-

4

2

3

6

5

6

5

2

3

U5C

TL072D

C68

1N0 0805

U6A

TL072D SMD

C69

1N0 0805

U6B

TL072D SMD

C70

1N0 0805

U7B

TL072D SMD

C71

1N0 0805

U7A

TL072D SMD

8

U6C

V+

V-

TL072D

4

1

7

7

1

8

U7C

V+

V-

TL072D

4

C72

47/25

C73

47/25

C74

47/25

C75

47/25

C76

47/25

C77

47/25

+VF

-VF

R98

10K

R99

10K

R100

10K

R106

10K

R107

10K

R108

10K

8

V+

V-

4

U8C

TL072D

R101

10K

R102

10K

R103

10K

R109

10K

R110

10K

R111

10K

Q1

Q2

Q3

Q5

Q4

Q6

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

MMBFJ111

HP_DC_CNTRL

BP_DC_CNTRL

LP_DC_CNTRL

LP_DC_CNTRL

BP_DC_CNTRL

HP_DC_CNTRL

C7

15P

R142

10K1%

2

U8A

3

6

U8B

5

TL072D

C8

15P

R143

10K1%

TL072D

1

7

FILT_OUT_L

FILT_OUT_R

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

1 ARJ 30-07-04

2 ARJ 17-08-04

CHK

BY

VR5C

BRKT

8

9

20KK

FILE: AG5877_4 SHEET 2.Sch 11:50:14 2-Nov-2004

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 2 5

4

Page 15

PRE_OUT_L

003-358 iss.4

PRE_OUT_R

R144

68K 1%

R145

68K 1%

e

d

c

1

3

5

7

9

1

3

5

7

9

2

4

6

8

10

2

4

6

8

10

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

R47

47K

C25

47/25

R126

1K0 1%

+VS

2

3

VHT

GRID_L

CATH_L

CN11

IDC 5X2 F STRT

-15V_VPCB

GRID _R

CATH_R

HEATER

R79

100K 1%

D2

LL4148

2

U10A

3

D1

LL4148

C81

330N

C82

330N

U13A

TL072D

R168

1M0 1%

R169

1M0 1%

ISSUE BY DATE

1 ARJ 30-07-04

2 ARJ 17-08-04

+5V

2

1

7

R171

TL072D

3

R170

4K7 1%

8

4K7 1%

R49

47K

1

4

FREQUENCY

20KK

D5

LL4148

D6

LL4148

C38

100N

R180

30K 1%

C26

47/25

C27

47/25

R184

30K 1%

BRKT

13

VR6A

VR1A

2

EF FOLLOWER

20KK

1 3

R165

30K 1%

R166

30K 1%

4

SW4B

2

1

3

MIDI_Fc

Fc_SND

EF_LEVEL

R150

120K 1%

LFO DEPTH

VR4A

20KK

1 3

6

U15B

5

TL072D

2

U16A

3

TL072D

SW5A

2

C98

PRINTED:

R152

2

9K1

R151

6K8 1%

R164

30K 1%

C103 22P_S

7

C104

R186

R190

680P

C105

R187

R181

680P

C106

R188

R182

680P

C107

R189

680P

22P

1

VD_R

VD_L

560R 1%

+5V

EVELOPE FOLLOWER SIDE-CHAIN

1

R48

47K

LFO

EF_LEVEL

V1A

ECC82

69

V1B

ECC82

5

CHK

BY

D3

LL4148

5

6

R160

220R

D4

LL4148

LFO SPEED

VR3A

2

20KK

1 3

R80

100K 1%

U13B

TL072D

EF TO OVERDRIVE

R162

47K

VD_L

BRKT

5

6

VR1B

FILE: AG5877_4 SHEET 3.Sch 11:50:14 2-Nov-2004

R127

1K0 1%

7

R

SW4A

2

L

+5V

VR2A

2

20KK

1 3

OVERDRIVE DEPTH

C83

R173

0R0

470N_S

C99

NF

+15V

-15V

5

BRKT

R90

10R PF RAD

R89

10R PF RAD

6

VR2B

R163

15K

C85

1/63

1

3

R179

56K 1%

LD1

LD2

LD3

VO_L

VALVE_HT

BRKT

5

R146

330K 1%

C86

1/63

100/25

6

VR3B

C61

C60

100/25

R147

1M2 1%

1

3

WAVEFORM

1

3

2

3

RD

RD

RD

CN12

BRKT

5

R

L

R

L

SW3A

R155

10K1%

10N

U14A

TL072D

112

334

556

778

9910

8

4

6

VR4B

SW2A

C93

U14C

V+

V-

TL072D

R148

220K

2

2

RD

RD

RD

DECAY

1

2

4

6

8

10

BRKT

5

+5V

R159

10K1%

LD4

LD5

LD6

VO_R

-VO

+10V

C88

47N

10K1%

8

V+

V-

TL072D

4

6

VR6B

R149

220K

R156

LL4148

470N_S

U15C

D20

6

5

C84

+VO

-VO

5

D21

LL4148

R157

10K1%

10N

U14B

TL072D

R174

0R0

8

4

BRKT

C89

47N

10K1%

2

3

C94

C100

NF

U16C

V+

V-

TL072D

4

SW2B

R158

U11A

D22

LL4148

7

VD_R

5

6

C92

TL072D

10N

5

U10B

TL072D

1

R120

470R

LL4148

BRKT

7

HP_DC

BP_DC

-5

VALVE OVERDRIVE CIRCUIT

CV_1

CV_2

D19

PRE_OUT_L

VO_L

VO_R

PRE_OUT_R

4

5

SW3B

D7

LL4148

2

3

R183

30K 1%

560R 1%

27K 1%

560R 1%

27K 1%

560R 1%

30K 1%

6

5

R36

20K 1%

U12A

R153

10K1%

C91

10N

TL072D

U12B

1

3

2

6

7

11

10

14

15

9

8

10R PF RAD

10R PF RAD

7

5

6

10K1%

R88

R87

U17

VCA1

VCA2

VCA3

VCA4

VGND

SSM2164S_1(16)

U11B

R37

20K 1%

C95

NF

7

TL072D

C90

NF

TL072D

+15V

-15V

-VO +VO

R154

-VS

R123

39K

C101

MD

V+

C102

NF

TITLE:

R167

2K7

C59

100/25

C58

100/25

R175

NF

NF

4

5

12

13

1

16

R178

NF

XONE VF-1 MAIN PCB

8

V+

V-

4

R185

VCF_DC

U10C

TL072D

2

3

30K 1%

C96

R176

33K 1%

U15A

TL072D

22P

8

V+

V-

TL072D

4

6

5

U11C

1

R177

C97

U16B

TL072D

+VS

-VS

33K 1%

22P

8

U12C

V+

V-

TL072D

4

FILT_IN_L

7

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 3 5

4

8

4

-5

FILT_IN_R

U13C

V+

V-

TL072D

Page 16

C118

003-358 iss.4

100NMLC

+5V

R112

SW6B

5

4

6

e

SW7B

SW8B

SW9B

4

6

4

6

4

6

5

5

d

5

SW6A

2

FILTER ON

SW7A

2

HIGH PASS

SW8A

2

BAND PASS

SW9A

2

LOW PASS

10K

1

3

+5V

R113

10K

1

3

1

3

1

3

R114

10K

Fc_SND

R115

10K

C143

100N

10

RC0/AN4

9

RC1/AN5

8

RC2/AN6

7

RC3/AN7

6

TX

5

RX

+5V

100NMLC

1

VDD

VSS

14

C145

U18

RA0/AN0

RA1/AN1

RA2/AN2

RA3

RA4/AN3

RA5

PIC16F688

CN17

6

13

12

11

4

3

2

12345

+5V

LD7GNLD10

C87

GN

GN

GN

1/63

R134

470R

R135

470R

R136

470R

R137

470R

R116

10K

MIDI_Fc

HP_DC

BP_DC

LP_DC

FILT_ON

+5V

R191

4K7 1%

R192

4K7 1%

5

4

9

8

11

10

7

6

U20A

LM2901 SMD

U20C

LM2901 SMD

U20D

LM2901 SMD

U20B

LM2901 SMD

R81

100K 1%

R74

3K9

R193

4K7 1%

2

14

13

1

R196

1M0 1%

R194

4K7 1%

R197

1M0 1%

R195

4K7 1%

R198

1M0 1%

R237

4K7 1%

R238

4K7 1%

Q9

BC848B

-VMID

R236

1M0 1%

D23

NF

R201

1M0 1%

D8

NF

HP_DC_CNTRL

C108

22N

BP_DC_CNTRL

C109

22N

LP_DC_CNTRL

C110

22N

ON_CTRL

R239

220K

OFF_CTRL

R202

220K

R219

10K 1%

8

1

R241

10R

FILT_ON

CR

2

C111

4N7

LP_DC

BP_DC

HP_DC

7

3

R199

82K

LD8GNLD11

LD9GNLD12

LD13

BL

LD14

BL

6

4 5

R200

680K 2%

+VMID

U19

LM2907

c

+15V

-15V

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

R92

10R PF RAD

R91

10R PF RAD

ISSUE BY DATE

1 ARJ 30-07-04

2 ARJ 17-08-04

C28

47/25

C29

47/25

3

V+

V-

12

Fc_SND

+VMID

U20E

LM2901 SMD

-VMID

R240

9K1

CHK

BY

+5V

R128

1K0 1%

Q8

R117

10K

VCC

BASE

COLL

GND

U21

6N138

NC

NC

A

K

R172

+5V

+5V

8

7

6

5

LOCAL OFF

SW5B

5

FILE: AG5877_4 SHEET 4.Sch 11:50:15 2-Nov-2004

5K6

4

6

R203

1K2 1%

Q7

BC848B

1

2

3

4

BC848B

R161

220R

D9

LL4148

R27

220R

3

1

0

0

425

CN13

425

1

CN14

3

MIDI IN

R28

MIDI OUT

220R

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 4 5

4

Page 17

CN15

003-358 iss.4

N

L

E

LP1 LP2 LP3 LP4 FID1 FID2AI4AI1 AI2

FH4

CN16

123

FID3 FID4

4

INLET

FILTERED IEC

MAINS

NTC1

INRUSH SUPP NTC20R

F1

12

AI3

EMC SCREEN

FH1 FH2 FH3

e

T500mA

E

N

2

P1

PIN

d

c

b

L

3

1

3

C113

L1

100N 275V

1

C78

CHOKE 20MH

100N 100V/MLC

10/50

L_GND

L2

4.7uH

R204

6K8 1%

C112

4N7

2 4

C120

1

8

6

L_GND

COMP

VREF

OUT

C121

150P

R205

7

VCC

GND

5

L_GND

23

BR1

150K 1%

U24

ISEN

VFB

RT/CT

UC3842D1

FUSE HOLDER 20MM

2KBP206

3

2

4

C114

100N 275V

14

C115

100N 275V

L_GND

R38

20K 1%

R206

3K3 1%

C117

L_GND

C51

100N

L_GND

68/400

L_GND

C132

330P

C127

2N2 250V/PEM

R207

82K 1W

D10

C122

120/63 LESR

R208

68R

L_GND

R129

1K0 1%

BYG80G

R82

100K 1%

R209

1R0 1W

C116

100N 275V

D15

P6KE200A

D16

BYV26E

Q10

STB4NC80ZT4

R210

1R0 1W

L_GND L_GND

TX1

1

PRIMARYBIAS

2

3

5 8

XFRMR E/30/15/7A (UNI) (AM5547)

12

10

7

11

9

D11

BYG80G

D13

BYG80G

BYG80G

D14

D12

BYG80G

C129

470/25 LESR

C128 470/25 LESR

C123

120/63 LESR

GND_PSU

C125

120/63 LESR

GND_PSU

L3

L4

L5

L6

4.7uH

4.7uH

4.7uH

4.7uH

4.7uH

U25

1

2

C79

10/50

3

Vin

2

1

Vin

U27

1

Vin

U28

Vin

C131

470/25 LESR

C130

470/25 LESR

C124

120/63 LESR

L7

C126

120/63 LESR

+15V

GND

7815

U26

-15V

GND

+5V

GND

7805

2

ADJ

TL783

1

Vout

7915

3

3

3

C52

100N

C53

100N

2

+15V

C144

10/50

-15V

+10V

+5V

C80

10/50

VALVE_HT

R213

1K0 1%

R214

39K 1%

C119

47/63

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

ISSUE BY DATE

1 ARJ 30-07-04

2 ARJ 17-08-04

CHK

BY

FILE: AG5877_4 SHEET 5.Sch 11:50:15 2-Nov-2004

PRINTED:

TITLE:

XONE VF-1 MAIN PCB

PAGE:

DRG No: ISSUE: SHEET: OF

C5877 5 5

4

Page 18

003-358 iss.4

Page 19

e

003-360 iss.A

XONE VF-1 RIAA OPTION

A

C5936

R2

47K 1%

3

C1

330P_S

CN1

LH_RCA_OUT

1

LH_RCA_IN

d

R18

0R0 1206

R19

0R0 1206

R20

0R0 1206

2

3

4

5

6

SIL 6 F STRT

+15V

-15V

RH_RCA_IN

RH_RCA_OUT

R1

47K 1%

C2

330P_S

c

2

R3

1K2 1%

5

6

R5

1K2 1%

TL072D SMD

U1A

R7

22K 1%

C7

15P

TL072D SMD

U1B

R9

22K 1%

C9

15P

1

7

R11

4K7 1%

R12

4K7 1%

C11

150N

C12

150N

C13

470N

R13

680R 1%

C14

470N

R14

680R 1%

3

2

R4

1K2 1%

5

6

R6

1K2 1%

TL072D SMD

U2A

R8

22K 1%

C8

15P

TL072D SMD

U2B

R10

22K 1%

C10

15P

1

7

b

a

ALLEN&HEATH

Kernick Industrial Estate,

Penryn, Cornwall,

England. TR10 9LU

+44 (0)8707 556250

Tel:

+44 (0)8707 556251

Fax:

ABCDEFGH

FID1

FIDUCIAL

FID3

FIDUCIAL

ISSUE BY DATE

FID2

FIDUCIAL

FID4

FIDUCIAL

+15V

-15V

CHK

BY

FILE: AG5936_A.Sch 17:00:18 1-Nov-2004

R15

R16

47R

47R

FH1

C4

33/25_S

C6

33/25_S

8

U1C

V+

V-

TL072D SMD

4

+15RIAA

8

U2C

V+

V-

TL072D SMD

4

-15RIAA

PRINTED:

TITLE:

PAGE:

DRG No: ISSUE: SHEET: OF

11

Page 20

003-360 iss.A

Loading...

Loading...