Page 1

ALLEN&H

EATH

WARNING – HIGH VOLTAGES

Power Supply Unit (PSU) work should only

e carried out by qualified personnel.

b

We recommend that you use an approved Allen & Heath

service centre for all power supply work.

Please contact your local Allen & Heath distributor for more details.

http://www.allen-heath.com/

Page 2

Page 3

INTRODUCTION

The information presented in this manual is intended for competent technical personnel to carry out service and product

support for the MixWizard WZ 20:8:2. We assume that the reader is familiar with the related electronic theory and audio

terminology, and is able to carry out basic servicing, fault-finding and repair of audio equipment of this type. Service

personnel should also be familiar with audio systems, mains earthing and power requirements, as well as handling

precautions.

For further information on the operation and application of the MixWizard WZ 20:8:2 please refer to the USER GUIDE

publication AP2932 supplied with each console.

Whilst we believe the information in this manual to be reliable we do not assume responsibility for inaccuracies. We also

reserve the right to make changes in the interest of further product development.

SERVICE AND TECHNICAL SUPPORT

Under normal conditions the MixWizard WZ 20:8:2 does not require user maintenance or internal calibration. Any

service work required should be carried out by qualified technical personnel only.

We are able to offer further product support through our worldwide distribution network. To help us provide the most

efficient service please would you quote the console serial number in any communication regarding this product.

SAFETY WARNING !

Mains electricity is dangerous and can kill. Mains voltage is present within the unit. Do not remove any

covers with mains connected. Do not carry out any work within the unit while it is powered. High voltage

components are insulated for safety but should not be touched with power applied. The mains voltage

setting is indicated on the on the rear panel next to the mains socket. Check that this matches your local

mains supply. Check your mains wiring and earthing before switching on.

DO NOT REMOVE THE MAINS EARTH CONNECTION!

The chassis is always connected to mains earth. Audio 0V connects to the chassis internally. Should

problems be encountered with ground loops operate the audio ground lift switches on other equipment

connected to the unit or disconnect the cable screens at one end. Refer to the section on 'EARTHING'

in the User Guide.

INTRODUCTION, SERVICE AND TECHNICAL SUPPORT ............................................................................. 2

TECHNICAL DESCRIPTION .............................................................................................................................3

SPECIFICATION & CONNECTIONS................................................................................................................. 4

DIMENSIONS FOR FLIGHTCASING, INSTALLING THE CONSOLE.............................................................. 5

REMOVING THE CONNECTOR CIRCUIT BOARD.......................................................................................... 6-7

REMOVING A MONO or STEREO INPUT, LEFT or RIGHT CIRCUIT BOARD .............................................. 8-9

INTERNAL LINK OPTIONS ...............................................................................................................................10-11

ORDERING A CONSOLE, SPARE PARTS & ASSEMBLIES .......................................................................... 12-14

FRONT & REAR PANELS ................................................................................................................................. 15

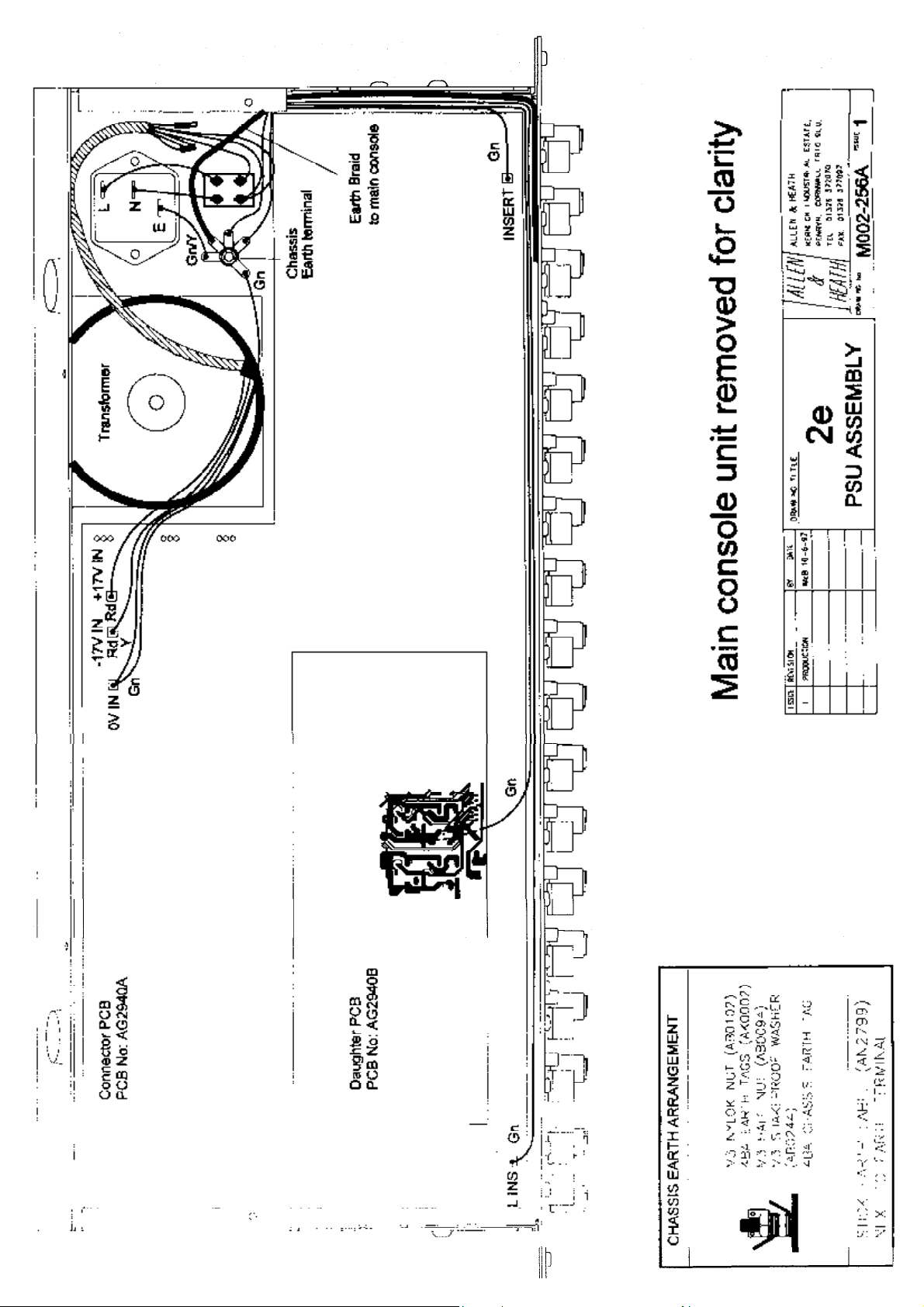

TRANSFORMER & POWER WIRING ............................................................................................................... 16-17

MONO INPUT CIRCUIT BOARD COMPONENT IDENT .................................................................................. AG2894

MONO INPUT CIRCUIT DIAGRAM ...................................................................................................................C2894

STEREO INPUT CIRCUIT BOARD COMPONENT IDENT .............................................................................. AG2937

STEREO INPUT CIRCUIT DIAGRAM ............................................................................................................... C2937

LEFT CIRCUIT BOARD COMPONENT IDENT................................................................................................. AG2938

LEFT CIRCUIT BOARD CIRCUIT DIAGRAM sheet 1 ......................................................................................C2938

LEFT CIRCUIT BOARD CIRCUIT DIAGRAM sheet 2 ......................................................................................C2938

RIGHT CIRCUIT BOARD COMPONENT IDENT .............................................................................................. AG2939

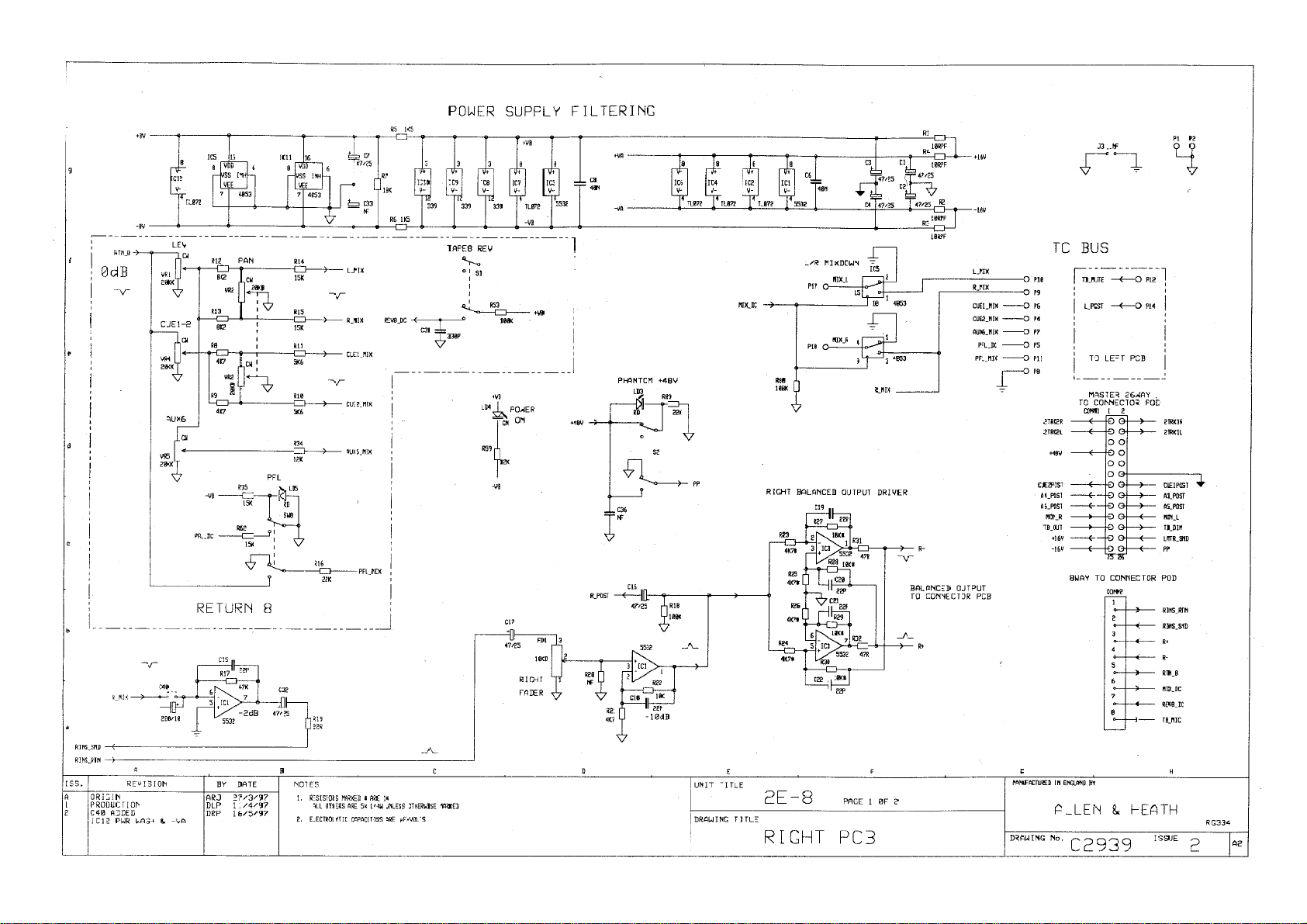

RIGHT CIRCUIT BOARD CIRCUIT DIAGRAM sheet 1 .................................................................................... C2939

RIGHT CIRCUIT BOARD CIRCUIT DIAGRAM sheet 2 .................................................................................... C2939

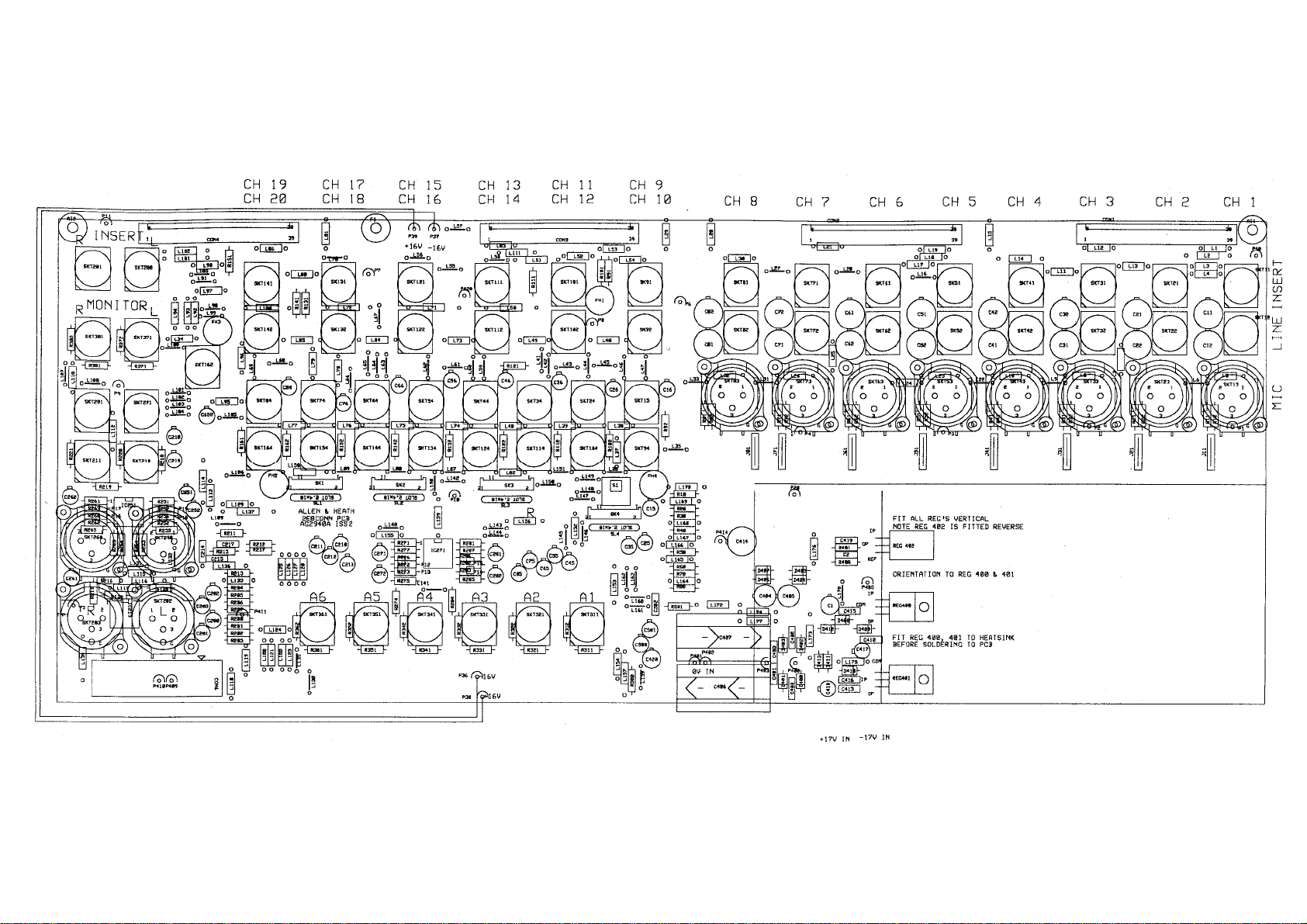

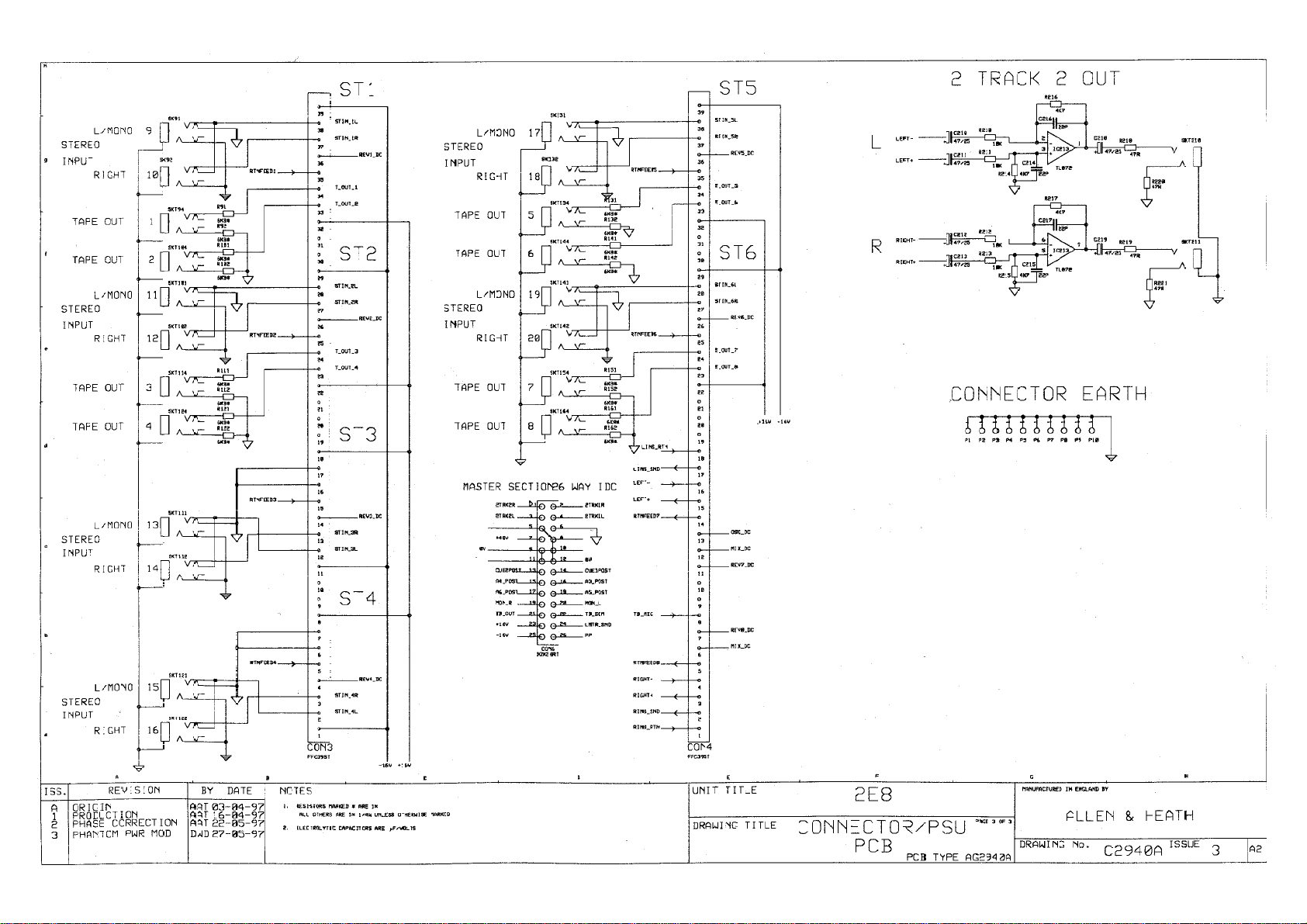

CONNECTOR CIRCUIT BOARD COMPONENT IDENT .................................................................................. AG2940A

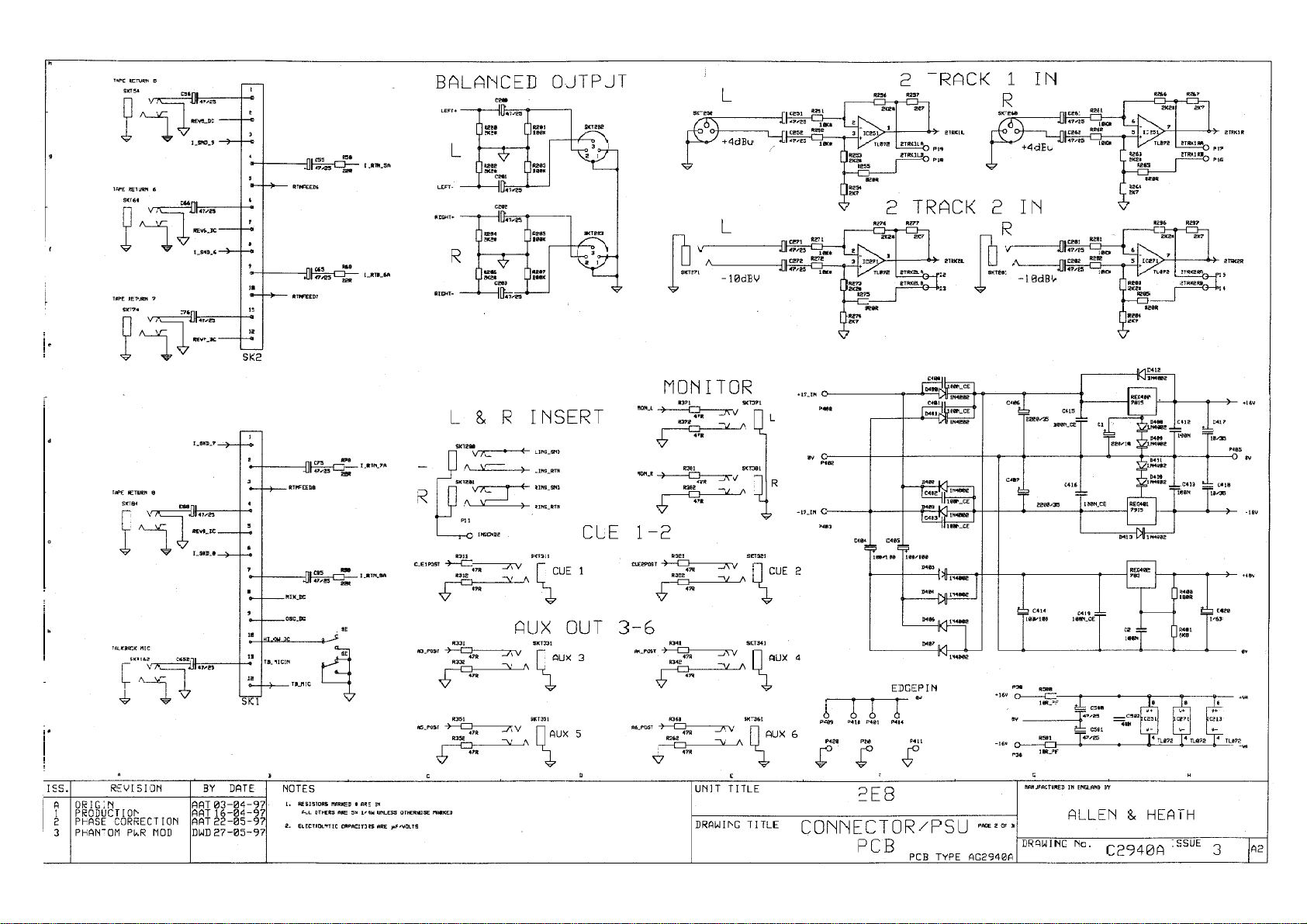

CONNECTOR CIRCUIT BOARD CIRCUIT DIAGRAM sheet 1 ........................................................................ C2940A

CONNECTOR CIRCUIT BOARD CIRCUIT DIAGRAM sheet 2 ........................................................................ C2940A

CONNECTOR CIRCUIT BOARD CIRCUIT DIAGRAM sheet 3 ........................................................................ C2940A

CONNECTOR CIRCUIT DAUGHTER BOARD COMPONENT IDENT............................................................. AG2940B

CONNECTOR CIRCUIT DAUGHTER BOARD CIRCUIT DIAGRAM ............................................................... C2940B

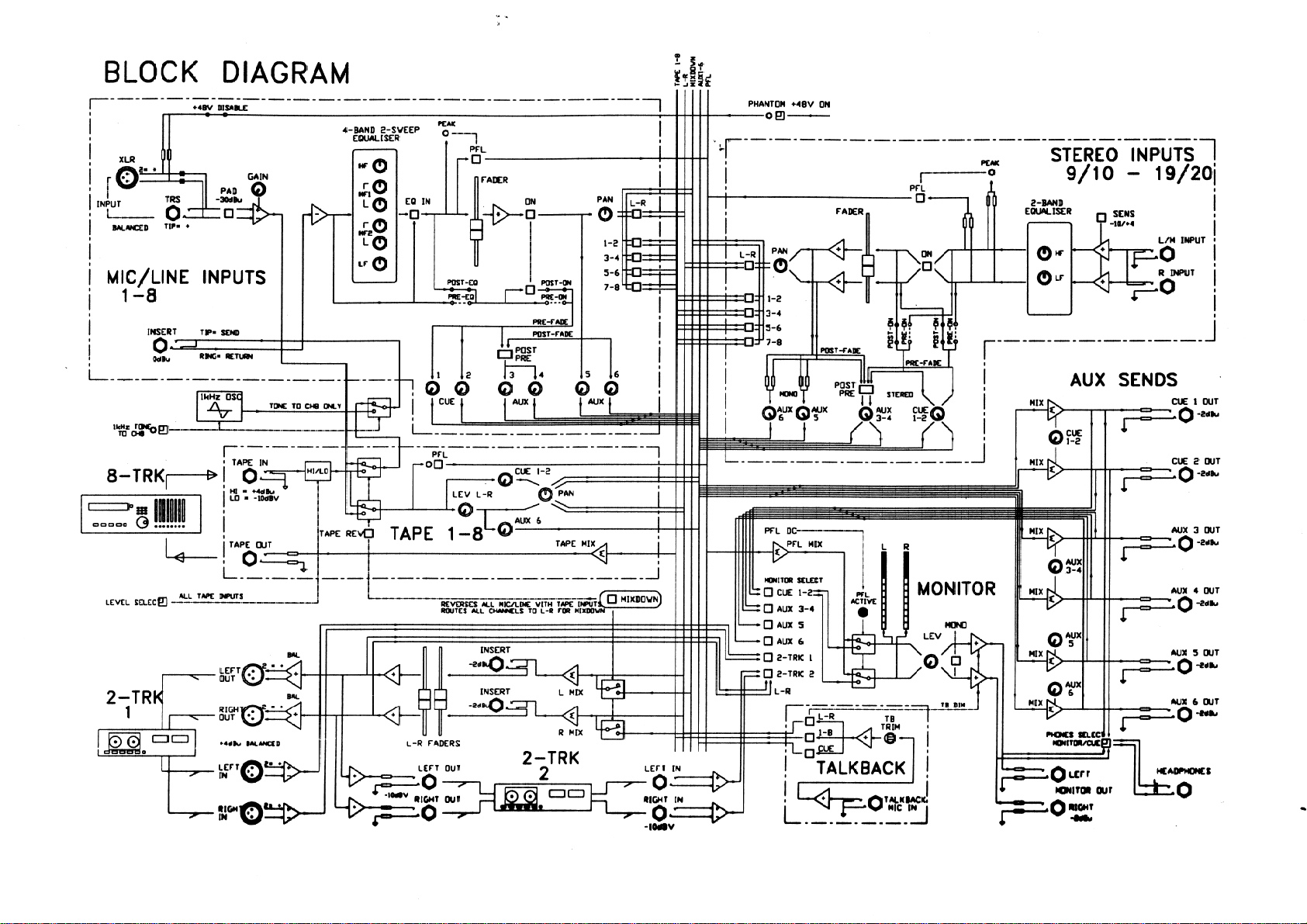

BLOCK DIAGRAM.............................................................................................................................................. 34

copyright © 1997 ALLEN & HEATH. All rights reserved

ALLEN & HEATH

CONTENTS

Publication .....................AP2933 Issue 1

2 2E-8SM

Page 4

TECHNICAL DESCRIPTION

The ALLEN & HEATH MixWizard WZ 20:8:2 is a dedicated 8-track rack mount or desk standing mixer with 8 mono

inputs and 6 stereo inputs. All mono input channels have a 4 band 2-sweep EQ with 6 individual aux sends and Direct

output. The 6 stereo inputs have a 2 band EQ with 2 stereo cue/aux sends and 2 mono aux sends. The 8 tape return inputs

have individual level and pan controls with a stereo cue facility . In addition the MixWizard WZ 20:8:2 also has extensive

talkback facilities and an internal 1kHz sinewave oscillator for level checking The internal power supply unit is located

in the rotating connector module.

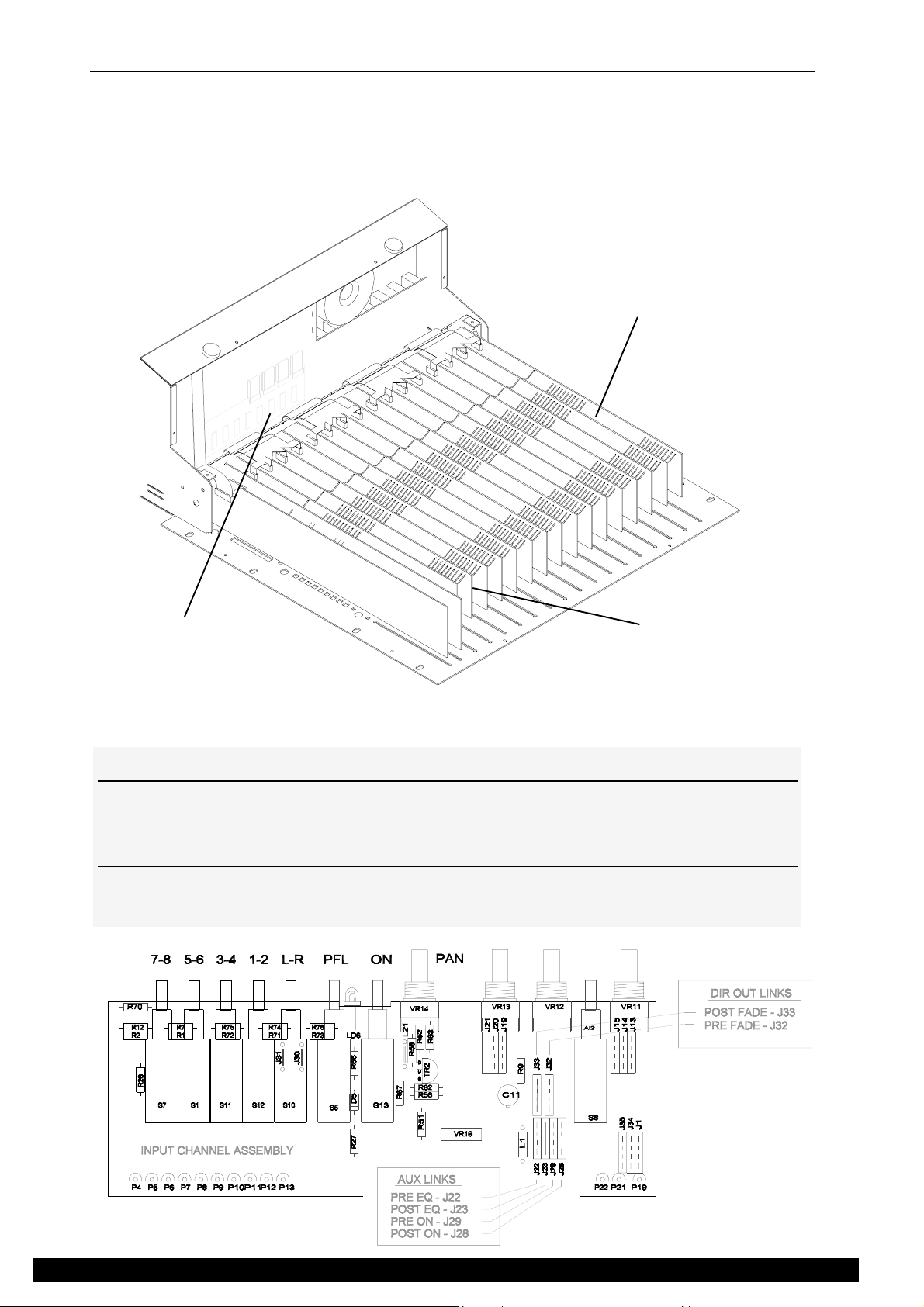

CONSTRUCTION

All metal chassis for 19" rack mount in 10U space. Comprises a 16swg steel front panel housing individual channel

circuit assemblies interconnected by means of soldered copper wire busbars. The connectors are housed in a rotating

connector module for either rack or desk mounted applications. Access to the channel internal assemblies is by removal

of the 18swg folded steel base. Access to the connectors and power supply components is by removal of the rear cover

of the connector module without the need to remove the console base. The channel assemblies may be removed for

servicing.

THE CIRCUIT COMPONENTS

The MixWizard WZ 20:8:2 is manufactured using high performance industry standard linear op-amp and discrete

semiconductor circuit devices. In particular the switches and potentiometers have proven to be durable and problem free.

When operated correctly the normal performance of the unit introduces no noticeable audio signal degradation.

AUDIO INPUTS AND OUTPUTS

All XLR connector inputs and outputs are balanced (differential) with high impedance inputs and low impedance

outputs. To use these with unbalanced equipment the -ve signal should be linked to 0V in the cable or input connector.

All unbalanced connections are line level 3-pole TRS ¼" jack sockets. All outputs are low impedance and thus capable

of driving several high impedance inputs simultaneously. All inputs and outputs are in phase.

THE PFL SYSTEM

The console PFL switches send pre-fade signals to the PFL mix bus. These signals are switched with 4053 CMOS gates

located on the RIGHT circuit board (PCB No: AG2939). The supply for the 4053 is ± 8V DC and is derived locally from

the ±16V. The gates are switched when a PFL switch is selected.

EARTHING THE AUDIO SYSTEM

The console chassis is connected to mains earth via the mains power cable. Console audio 0V is also connected to chassis.

FOR SAFETY REASONS NEVER REMOVE THE EARTH WIRE FROM THE MAINS PLUG.

Multiple earth paths cause earth (ground) loops which may result in audible hum and interference. These may be avoided

by making sure that there is only one path to earth from each piece of equipment, disconnecting audio cable screens at

one end if necessary.

INTERCONNECTIONS

Where possible use balanced connections for the CHANNEL inputs, AUX/CUE SENDs, and both L/R outputs to

minimise noise pick-up. Avoid running audio cables near to mains or lighting cables, thyristor dimmer units or power

supplies etc. These may cause audible hum and buzz. The use of low impedance sources significantly reduces

interference pick-up. Check the cables for correct wiring to avoid problems with phase reversal and unreliable

connection. The MixWizard WZ 20:8:2 follows the convention for XLR pin 2 and jack tip = signal hot (+).

ALWAYS USE BALANCED CABLES WHEN CONNECTING TO PHANTOM POWERED MICROPHONES.

WHEN USING NON-PHANTOM POWERED OR UNBALANCED MICROPHONES OR UNBALANCED LINE

SOURCES, MAKE SURE THAT THE +48V IS DISABLED TO PREVENT ACCIDENTAL DAMAGE.

INDIVIDUAL CHANNELS CAN HAVE +48V DISABLED, REFER TO THE LINK OPTIONS SECTION IN THE USER

GUIDE OR SERVICE MANUAL.

If ground loops cause problems, connect the cable screen at one end only. Balanced outputs may be connected to

unbalanced inputs and vice versa by linking the signal cold (-) to 0V ground.

2E-8SM

3

ALLEN & HEATH

Page 5

SPECIFICATIONS

0 dBu = 0.775 Volts rms 0 dBV = 1 Volt rms

HEADROOM: .............................. +21dB channels

+23dB mix to output

MAX OUTPUT: XLR ................... +27dBu 2kohm max load

jack.................... +21dBu 2kohm max load

METERS:........ L, R..................... peak reading 12 bar LED

PEAK LEDs: ............................... Turn on 5dB before clipping

FREQUENCY RESPONSE:........ 20Hz to 50kHz +0/-1dB

DISTORTION: THD+Noise at +14dBu 1kHz

Channel to mix output ....................................... 0.008%

WEIGHT: unpacked 11kg, packed 14kg

CROSSTALK: Referred to driven channel at 1kHz

Channel fader off ......................... <-90dB

Channel off ........................... <-90dB

NOISE: Measured rms 22Hz to 22kHz bandwidth

Mic input EIN (150 ohm source) . <-128dB

LR output residual noise ...............<-97dBu 101dBS/N

LR faders unity mix noise............ <-82dBu 86dB S/N

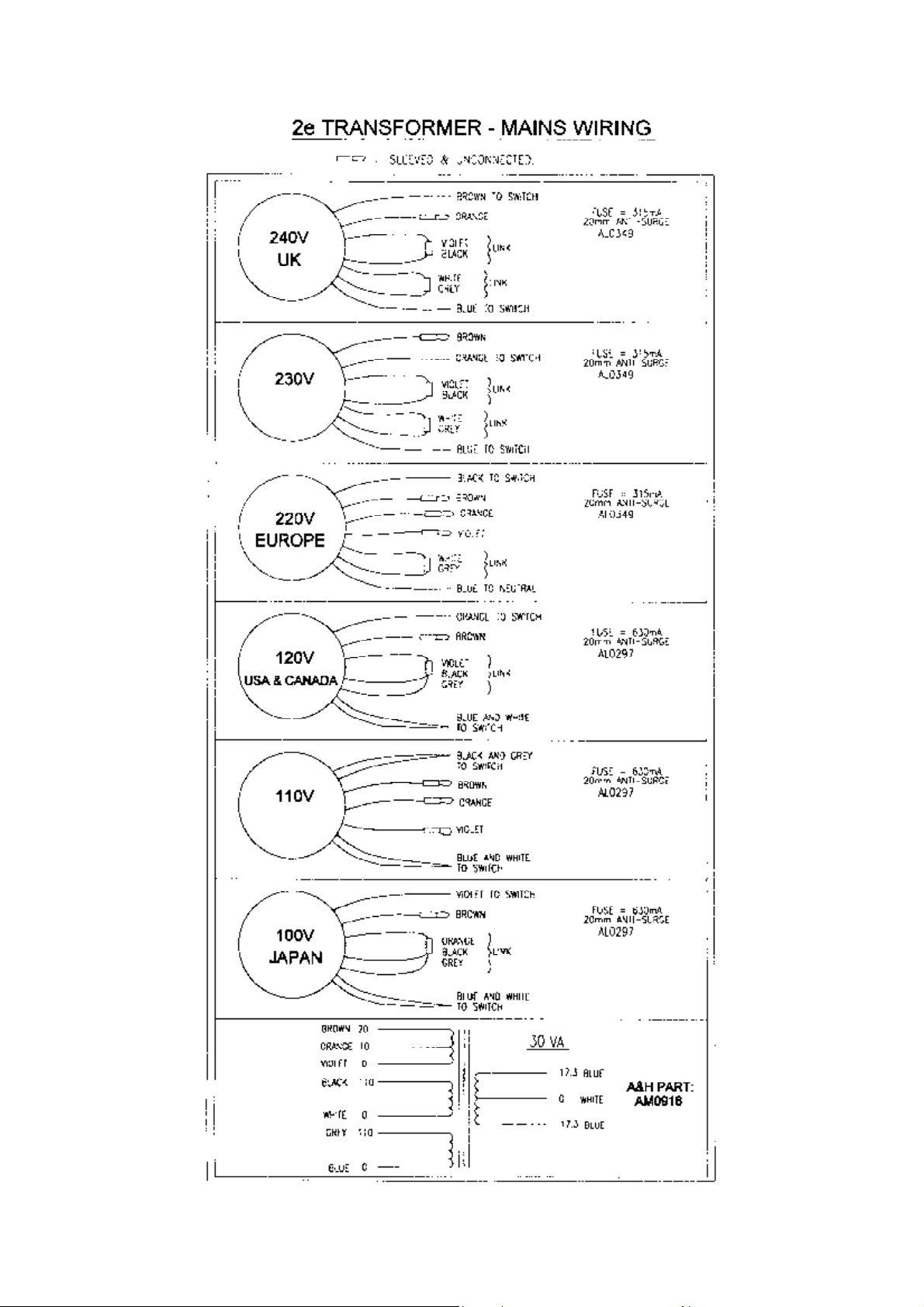

POWER SUPPLY: ...................... internal, linear regulated

AC Mains input: ........................... IEC socket with lead supplied

100 to 240V AC @ 50/60Hz

factory wired to country voltage

Power consumption ..................... 35W max

Mains Fuse rating:....................... 100-120V AC T630mA 20mm

220-240V AC T315mA 20mm

CONNECTIONS

INPUTS:

Channel 1-8 IN ..............XLR ........................... pin 2 hot, 3 cold, bal PAD out .......... 2k ohm variable -60 to -20dBu

TRS jack.................... tip hot, ring cold, bal PAD in............. >10k ohm variable -30 to +10dBu

Stereo 9/10-19/20 IN TRS jack (L/M,R) ...... tip sig, ring gnd, unbal ........... >10k ohm ........-10dBV / +4dBu

Tape 1-8 IN....................TRS jack.................... tip sig, ring gnd, unbal .............. >10k ohm ........ -10dBV / +4dBu

2-Track 1 IN ...................XLR ........................... pin 2 hot, 3 cold, balanced ....... >10k ohm ........+4dBu

2-Track 2 IN ...................TRS jack.................... tip hot, ring cold, balanced ....... >10k ohm ........ -10dBV

Talkback mic IN .............TRS jack.................... tip sig, ring gnd, unbalanced .... 2k ohm ............ variable -50 to -20dBu

INSERTS:

Channel 1-8 Insert .........TRS jack .................... tip send, ring return, unbal ....................<75 ohm, >3k ohm...... 0dBu

L-R mix ..........................TRS jack.................... tip send, ring return, unbal ....................<75 ohm, >7k ohm...... -2dBu

OUTPUTS:

2-Track 1 OUT...............XLR ........................... pin 2 hot, 3 cold, balanced....................<75 ohm .......... +4 dBu

2-Track 2 OUT...............TRS jack.................... tip hot, ring cold, impedance bal ........... <75 ohm ..........-10dBV

Tape 1-8 OUT................TRS jack.................... tip hot, ring cold, impedance bal ........... <75 ohm ..........-10dBV / +4dBu

Cue 1-2 OUT ................. TRS jack.................... tip hot, ring cold, impedance bal ........... <75 ohm ..........-2dBu

Aux 1-4 OUT.................. TRS jack.................... tip hot, ring cold, impedance bal ........... <75 ohm ..........-2dBu

Monitor L,R OUT ...........TRS jack.................... tip hot, ring cold, impedance bal ........... <75 ohm ..........-2dBu

PHONES OUT...............TRS jack.................... tip left, ring right........... for stereo headphones 30 to 600 ohms

ALLEN & HEATH

4

2E-8SM

Page 6

DIMENSIONS

The diagrams below give the dimensions for flightcasing the console.

INSTALLING THE CONSOLE

The MixWizard Series features the ALLEN & HEATH Quick Change Connector (QCC) system. The rear connector

module may be hinged and locked into either of two positions: Rear connectors for desktop operation with the control

panel sloped at a convenient 15 degrees, or Underside connectors for 19" rack mounting in a compact 10U space. The

connector position can be easily changed at any time to fit your application.

Do not transport or carry

To change the position

remove the crosshead

locking screw on each side,

swing the connector pod into

position, and refit the two

screws.

the console with the locking

screws removed.

Do not attempt to remove

the connector pod from the

console.

19" Rack Mounting

Mount the console in the rack

using 4x M6 bolts each side for

maximum strength. We

recommend you fit the bolts with

plastic cup washers to protect the

panel, and they look good... These

should be available from the

supplier of the rack unit or a good

hardware store.

2E-8SM

Desktop Operation

The console is fitted with rubber feet to

ensure it does not slip or scratch the

work surface. The control panel is

angled at 15 degrees for operating

convenience.

5

ALLEN & HEATH

Page 7

REMOVING THE CONNECTOR CIRCUIT BOARD ASSEMBLY

Before beginning any service work, remove all power to the unit and disconnect any signal cables where necessary. The

rotating connector module must be set for desk top operation to gain access to the cover screws. It is not necessary to

disconnect the connector module from the main unit. Service work is best carried out with the unit inverted on a clean

work surface suitably covered to protect the mixer cosmetics. Ensure adequate lighting and use the correct tools. Access

to the connector circuit board options can be achieved without the complete removal of the circuit board.

1.) Working from the rear of the console remove screws (A) fixing the XLR connectors to the panel and using

a 12mm Nutdriver, remove jack nuts (B). Also remove the 2 screws indicated.

Remove 2 screws

B

B

A

B

B

B

A

A

2.) With the unit inverted, remove the 4 connector cover screws (C) and remove the cover.

C

Access to the connector circuit board options can be achieved at this stage by carefully easing

the circuit board assembly from the rear panel with the harnesses still connected.

It is not necessary to completely remove the circuit board assembly to change the options.

Refer to the section INTERNAL LINK OPTIONS for more details.

ALLEN & HEATH

REAR COVER

BASE

6

2E-8SM

Page 8

To completely remove the connector circuit board assembly

4.) First remove the base cover of the main unit to gain more access. Refer to 2 and 3 in the section

REMOVING AN INPUT, LEFT or RIGHT CIRCUIT BOARD for details on the removal of the base

cover.

5.) Cut the cable ties along the bottom edge of the connector circuit board fixing the harness to the connector

circuit board assembly and lift the circuit board assembly from the chassis.

6.) Then carefully disconnect the ribbon cable and the 4 flexible flat cables plugged into the circuit board

assembly.

7.) Before desoldering the wires connected to the circuit board, make a note of their colour and locations.

8.) The circuit board can now be completely removed from the chassis.

When all service work is complete, remove all debris such as solder, component legs and wire clippings from inside the

console and check your work carefully before reassembly. To refit the connector circuit assembly follow the above

procedure in reverse order. Make sure all harnesses are correctly aligned and plugged on. Test for correct operation.

CONNECTOR CIRCUIT

BOARD ASSEMBLY

Flexible flat cables

2E-8SM

Unit inverted with the base and connector cover removed.

7

ALLEN & HEATH

Page 9

REMOVING AN INPUT, LEFT or RIGHT CIRCUIT BOARD ASSEMBLY

Before beginning any service work, remove all power to the unit and disconnect any signal cables where necessary. The

rotating connector module must be set for desk top operation to gain access to the cover. Service work is best carried

out with the unit inverted on a clean work surface suitably covered to protect the mixer cosmetics. Ensure adequate

lighting and use the correct tools. Access to the channel circuit board options can be achieved without the removal of

the circuit board.

1.) If completely removing a circuit board assembly, pull off the knobs and remove the pot nuts and fader screws

from the circuit assembly to be removed. The switch caps can remain in place. If removing the LEFT circuit

board assembly remove the nut on the headphone socket.

2.) Working from the front of the mixer remove screws and nuts (A) fixing the base cover to the front panel.

A

3.) With the unit inverted, remove the 2 remaining screws (B) in the base cover and remove the base.

B

BASE

ALLEN & HEATH

8

2E-8SM

Page 10

Access to the input channel circuit board options can be achieved at this stage by carefully cutting

and resoldering the link options as necessary. It is not necessary to completely remove the circuit

board assembly to change the options.

Refer to the section INTERNAL LINK OPTIONS for more details.

To completely remove a circuit board assembly

4.) Identify the circuit board assembly to be removed and then cut the buss wires half way between each circuit

board. Disconnect the flexible flat cable (C) plugged into the connectors mounted along the edge of the circuit

board. If removing the LEFT or RIGHT circuit board assembly, the ribbon cable (D) and flexible flat cable

(E) will have to be carefully unplugged as well.

5.) The circuit board can now be removed.

When all service work is complete, remove all debris such as solder, component legs and wire clippings from inside the

console and check your work carefully before reassembly. To refit the circuit assembly follow the above procedure in

reverse order. Make sure all harnesses are correctly aligned and plugged on. Test for correct operation.

C

Buss wires

Cut each wire

in the centre

MONO

STEREO

LEFT

RIGHT

D

Unit inverted with the base and connector cover removed.

Overlap

and

solder

BUSS WIRES

2E-8SM

9

ALLEN & HEATH

Page 11

INTERNAL LINK OPTIONS

The console is set to satisfy most applications that should be encountered. However, the following internal link options

are offered to provide alternative settings for those applications that may require them. Access to the options requires

the removal of the rear covers depending on which option settings are to be altered. Refer to the section for removing

circuit board assembly on which the link option is located. Some options involve the cutting of circuit board tracks and

soldering of circuit board links and should only be carried out by competent technical personnel. Further information

is available from ALLEN & HEATH if required.

MONO INPUT CIRCUIT BOARD

ASSEMBLIES

X8

CONNECTOR CIRCUIT

BOARD ASSEMBLY

LEFT

RIGHT

DAUGHTER CIRCUIT BOARD

ASSEMBLY

X1

Unit inverted with the base and connector cover removed.

STEREO INPUT CIRCUIT BOARD

ASSEMBLIES

X6

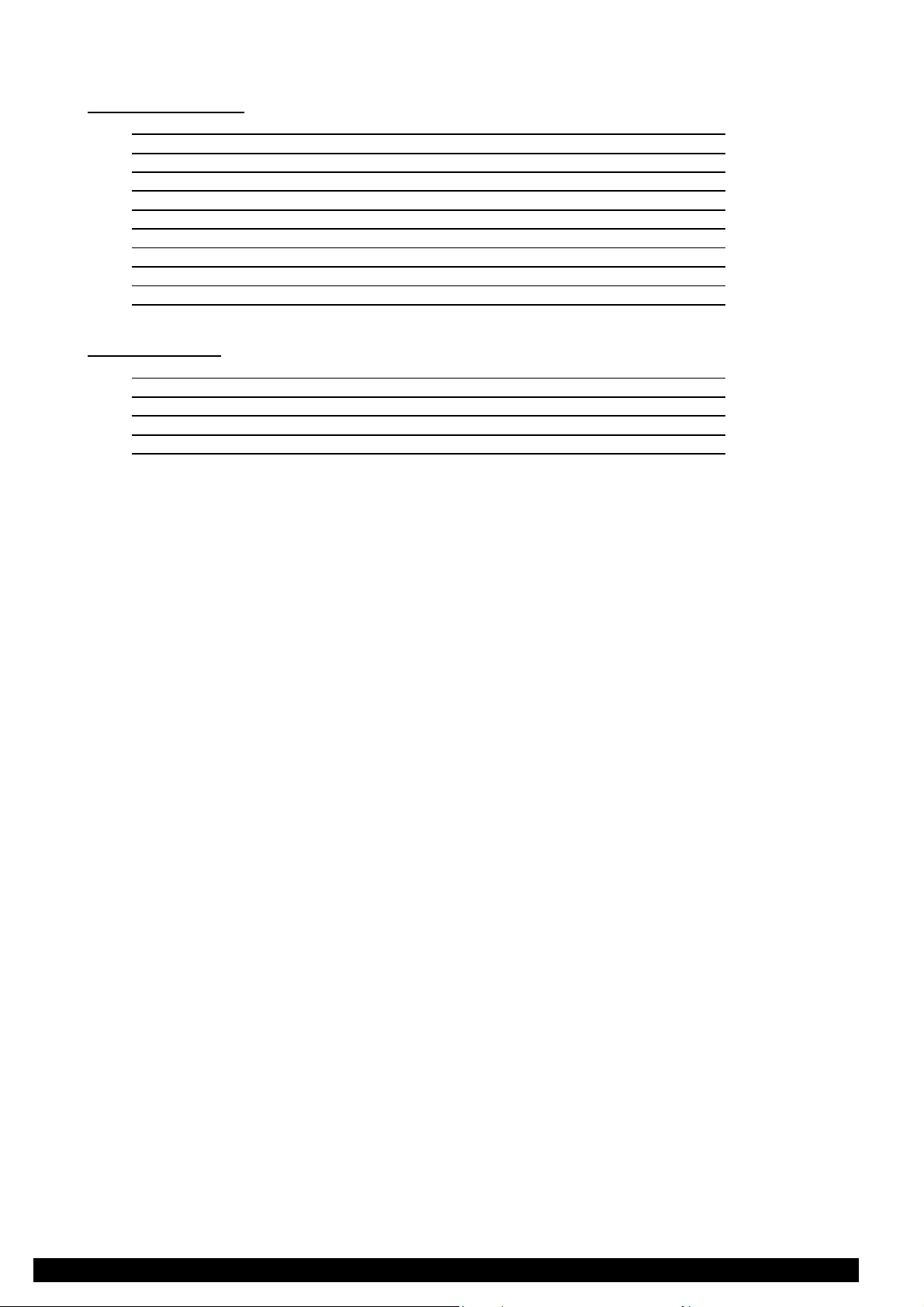

Channel Pre-Fade Aux Send Options

The pre-fade sends are set post-EQ and post-ON as standard. However, link options on each channel assembly allow

pre-EQ and/or pre-ON if required. Refer to the diagram below.

Channel Direct Output Source

The direct outputs are sourced post-fader as standard. A link option is available per channel to select a pre-fade

source. Refer to the diagram below.

ALLEN & HEATH

10

2E-8SM

Page 12

1234567890123456789012

1

2

1

2

1

2

1

2

1

2

1

2

1234567890123456789012

Phantom Power Disable

It is perfectly safe to connect non-phantom powered sources such as dynamic microphones to powered XLR sockets

providing that balanced leads and sources are used. The +48V supply is current limited through 6.8k ohm resistors

to each XLR to prevent damage. However, you can disable phantom power to selected channels by cutting out links

on the rear connector circuit assembly.

8 7 6 5 4 3 2 1

Phantom power

links

Connector circuit board assembly.

component side view

2 Track 1 & 2 Track 2 Input Sensitivity

Both 2 track inputs can be set for nominal high level +4dBu operation or low level -10dBV operation as is common

with much of the external equipment available today. The factory default setting for 2 track 1 is nominal high level

+4dBu operation and for 2 track 2 the factory default setting is low level -10dBV operation. Most outboard

equipment includes output level adjustment but if you wish to change the input sensitivity, the rear connector circuit

board assembly can be reconfigured.

23456789012345678901

23456789012345678901

23456789012345678901

2 Track1 & 2 level

23456789012345678901

23456789012345678901

Option location

23456789012345678901

Connector circuit board assembly

trackside view

Solder link between square

pads for -10dBV operating

2E-8SM

level on 2 Track 1.

Cut tracks between square

pads for +4dBu operating

level on 2 Track 2.

11

ALLEN & HEATH

Page 13

ORDERING SPARE PARTS

ORDERING A CONSOLE

To order a new console unit please specify the model number and AC mains voltage required.

MODEL DESCRIPTION ORDER CODE

MixWizard 20:8:2 8 Mono + 6 Stereo Input channels WZ 2082/volts

MixWizard 16:2 16 Mono Input channels WZ 1602/volts

MANUALS AND SUPPORT DOCUMENTATION

DESCRIPTION ORDER CODE

MixWizard 20:8:2 User Guide AP2932

MixWizard 20:8:2 Service Manual AP2933

MixWizard 20:8:2 Brochure AP2941

SERVICE TOOLS

The tools required to service the MixWizard range of products are standard to an electronics service workshop and are

easily obtainable. The following items are necessary for disassembly and service access:

1-point Crosshead screwdriver (M3, 4AB) AT0004

2-point Crosshead screwdriver (M4, 6AB) AT0002

11mm AF Nutdriver (potentiometer nuts, headphone socket nuts)

12mm AF Nutdriver (jack nuts)

ORDERING AN ASSEMBLY

The following assemblies for the MixWizard 20:8:2 are supplied fully tested. Please quote the description and order

code for the part required.

Printed circuit (PCB) assemblies:

Mono Input PCB assembly 002-257

Stereo Input PCB assembly chans 13/14, 15/16 002-258

Stereo Input PCB assy chans 9/10, 11/12, 17/18, 19/20 002-270

Left PCB assembly 002-259

Right PCB assembly 002-260

Connector & Daughter PCB assembly 002-261

IDC connector harnesses:

MixWizard WZ 20:8:2 26 way Master harness AL2978

ORDERING A SPARES KIT

It is recommended that the spares kit order code 002-247 is held and maintained by the service agent to enable in-field

service repairs to the MixWizard WZ 20:8:2 independent of the ALLEN & HEATH factory. Commonly available items

such as resistors, capacitors, tools and soldering equipment are not included. The contents of the kit is listed below.

Individual spare parts may be ordered. Please quote the description and order code for the part required.

ALLEN & HEATH

12

2E-8SM

Page 14

DESCRIPTION ORDER CODE QTY

Fixings:

Screw 4AB x 5/16" Pan Pozi Black AB0057 10

Screw M2.5 x 4mm Pan Pozi Black AB2944 10

Screw M3 x 4mm Pan Pozi Black AB0233 10

Screw M3 x 8mm Pan Pozi Black AB0073 5

Screw M3 x 6mm TT Pan Pozi Black AB0071 5

Screw M3 x 10mm CSK Pozi Black AB0093 5

Screw M3 x 10mm Pan Pozi Black AB0076 5

Screw M3 x 12mm Pan Pozi Black AB0078 5

Nylock Nut M3 AB0102 5

Knobs and caps:

Knob Yellow & Grey 11mm D AJ2079 10

Knob Dark Grey & Grey 11mm D AJ2078 10

Knob Green & Grey 11mm D AJ2077 10

Knob Blue & Grey 11mm D AJ2075 10

Knob Brown & Grey 11mm D AJ2080 10

Knob Red & Grey 11mm D AJ2074 10

Knob L./blue & Grey 11mm D AJ2076 10

Fader Knob 11mm White+Black line AJ8078 10

Fader Knob 11mm Yellow+White line AJ8080 5

Fader Knob 11mm Blue+Black line AJ8081 5

Button 5.5mm Square Grey AJ0363 10

Button 5.5mm Square Red AJ0364 10

Button 5.5mm Square White AJ0373 10

Faders, Potentiometers, switches, and connectors:

10KD fader 100mm AI8108 5

10KD x 2 fader 100mm AI8116 5

20KK (203K) AI8003 5

20KB (203B) centre click AI8004 5

200KC x 2 (204C) AI8005 5

20KB x 2 (203B 14mm wide) AI8006 5

20KK x 2 (203K 14mm wide) AI8007 5

10KAC x 2 (103KAC 14mm wide) AI8008 5

5KD reverse (502RD) AI8111 5

5KB (502B) AI8112 5

Pot Nut 9mm AB8050 10

Switch 2PCO Latching AL0162 5

Jack Socket Vert PCB+nut (IN, INSERTS, ST1/2) AL8082 10

Jack Socket Vertical PCB + nut AL8114 10

Jack Socket Headphone AL0328 1

XLR 3 Pin Female Vertical PCB Mount AL2410 5

XLR 3 Pin Male Vertical PCB Mount AL2411 5

LEDs and Semiconductors:

LED 3mm T1 Yellow AE0084 5

LED 3mm T1 Green AE0085 5

LED 3mm T1 Red AE0086 5

LED Bar Rectangular 8Green/3Yellow/1Red AE2701 2

Transistor 2N4403 PNP AE0273 5

Transistor BC214C PNP AE0031 2

Transistor BC549 NPN AE0020 2

IC TL072CP Dual Op Amp AE0046 5

IC NE5532N OP-AMP AE0221 1

IC LM339N Quad Comparator AE0071 2

IC CMOS 4053B AE0117 3

IC SSM2142P Balanced output driver AE0302 -

2E-8SM

13

ALLEN & HEATH

Page 15

POWER SUPPLY:

Mains lead IEC-2pin EURO AH0205 Mains lead IEC-3pin UK AL0206 Mains lead IEC-3pin US (C33) AL0323 Mains Fuse 20mm T315mA (UK,EU) AL0349 5

Mains Fuse 20mm T630mA (USA,CAN) AL0297 5

Transformer 30VA AM0918 IC Adjustable Regulator 783 (+48V DC) AE0214 2

IC Regulator 7815 (+15V DC) AE0047 2

IC Regulator 7915 (-15V DC) AE0048 2

Insulating kit TO220 AA0693 2

Miscellaneous:

MixWizard WZ 16:2 Packing assembly 002-245 -

MixWizard WZ 20:8:2 Packing assembly 002-271 -

Flex cable 39 way 200mm AH2900 2

Flex socket 39 way straight AL2902 Flex socket 8 way 90deg AL2901 -

ALLEN & HEATH

14

2E-8SM

Page 16

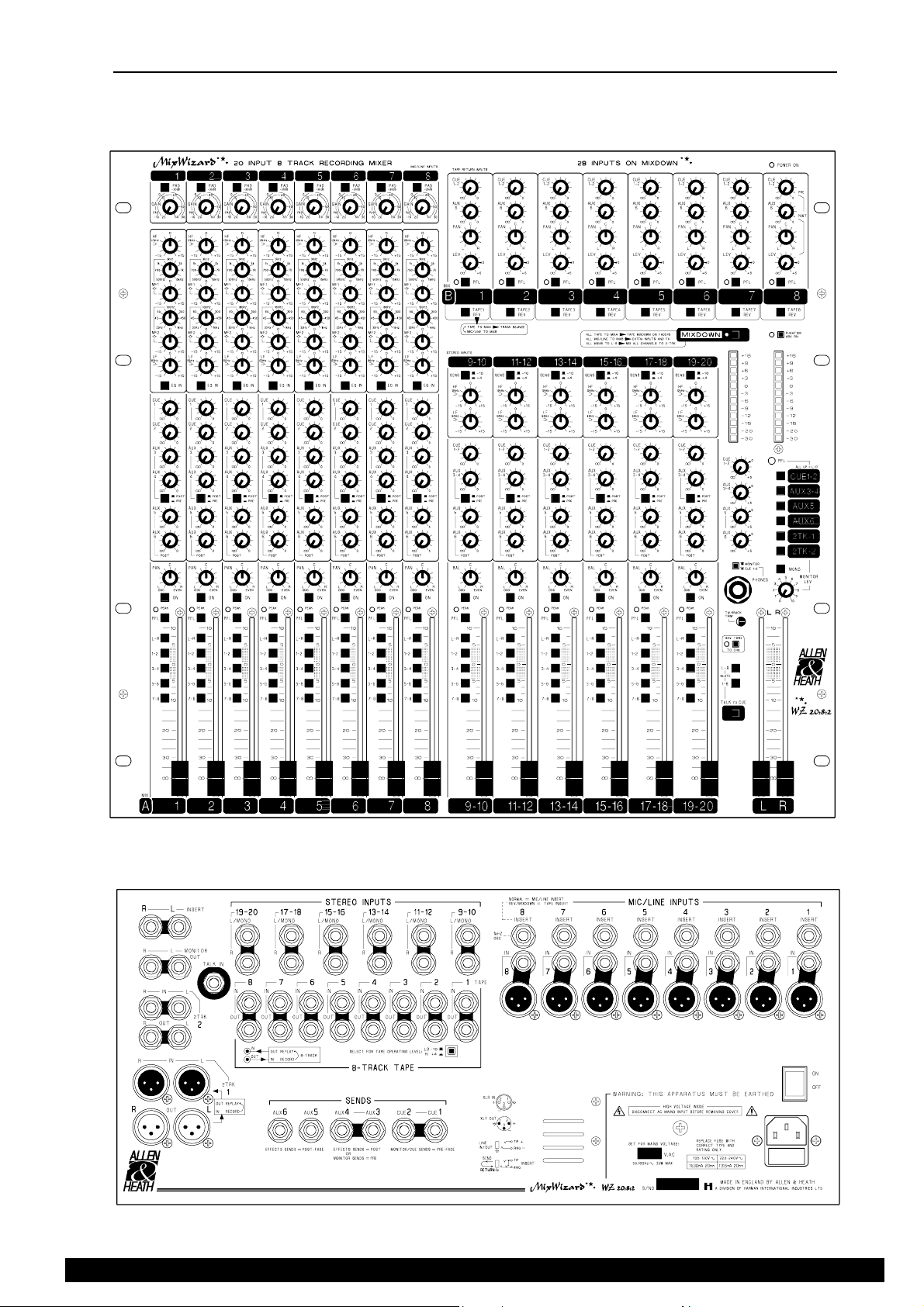

FRONT & REAR PANELS

2E-8SM

15

ALLEN & HEATH

Page 17

XXX SWITCH

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Loading...

Loading...