OPERATOR’S

MANUAL

REVISED 9-4-6 for Version 3 build 27

http://www.allendatagraph.com/

Limited Warranty Agreement........................................................... 1

Technical Support............................................................................. 1

Installation........................................................................................2

SET-UP.......................................................................................................... 2

i-TECH Cutter Stand..................................................................................... 2

Computer Connection.................................................................................... 2

Communications Port Setup................................................................................3

Setup for Window XP............................................................................................................3

Setup for Windows 2000.......................................................................................................4

Setup for Windows 95/98......................................................................................................6

Loading Allen i-TECH Software .................................................................. 7

The Remote Panel Utility Program......................................................................7

XP Installation Instructions ...................................................................................................7

Other Windows Operating Systems Installations..................................................................7

Installing Firmware..............................................................................................7

Windows XP / Windows 2000 Driver.................................................................8

Optional SmartMarkTM Sensor......................................................... 9

Registration Mark.......................................................................................... 9

Operation..................................................................................................... 10

SmartMark™ Setup...................................................................................... 11

Sensitivity ..........................................................................................................11

Sensor Offsets....................................................................................................12

Control Panel..................................................................................14

Remote Panel.................................................................................. 18

Remote Panel Functions.............................................................................. 18

Action menu ................................................................................................ 18

Send HPGL File.................................................................................................18

Cancel, Continue, Pause ....................................................................................18

Save Settings from Cutter to File, Load Settings from File To Cutter..............18

Save Calibration/Restore Calibration................................................................18

Open Com Port ..................................................................................................19

Close Com Port..................................................................................................19

Upload Firmware...............................................................................................19

Save to EEROM and Restore from EEROM.....................................................19

Setup Menu.................................................................................................. 19

Main Menu.........................................................................................................19

State Tab..............................................................................................................................19

Knife Settings Tab...............................................................................................................20

Rubber Tab ..........................................................................................................................20

Line Sensor........................................................................................................21

Line Sensor Tab...................................................................................................................21

Skew Tab.............................................................................................................................23

Scale Tab .............................................................................................................................24

Settings Menu....................................................................................................24

Options Menu ....................................................................................................27

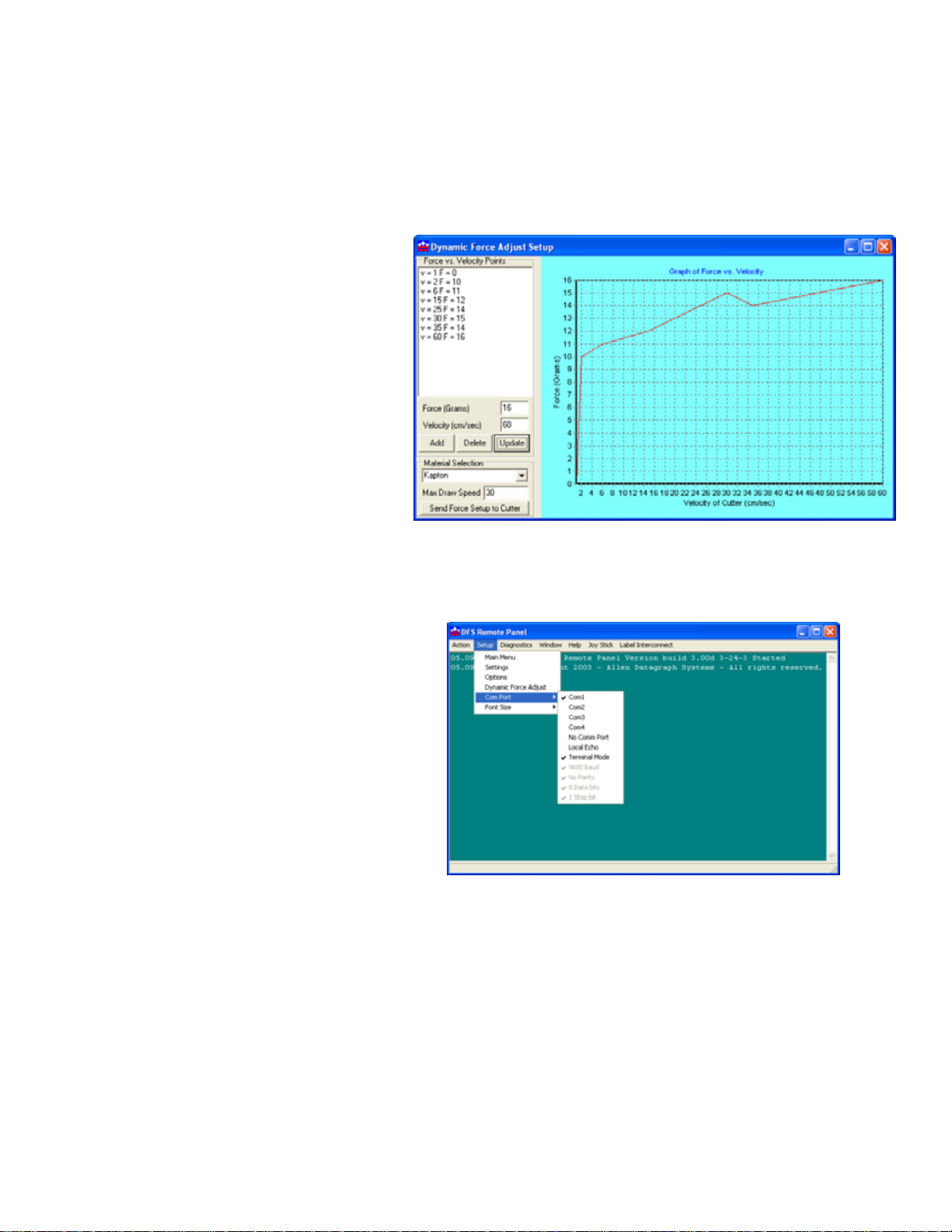

Dynamic Force Adjust.......................................................................................28

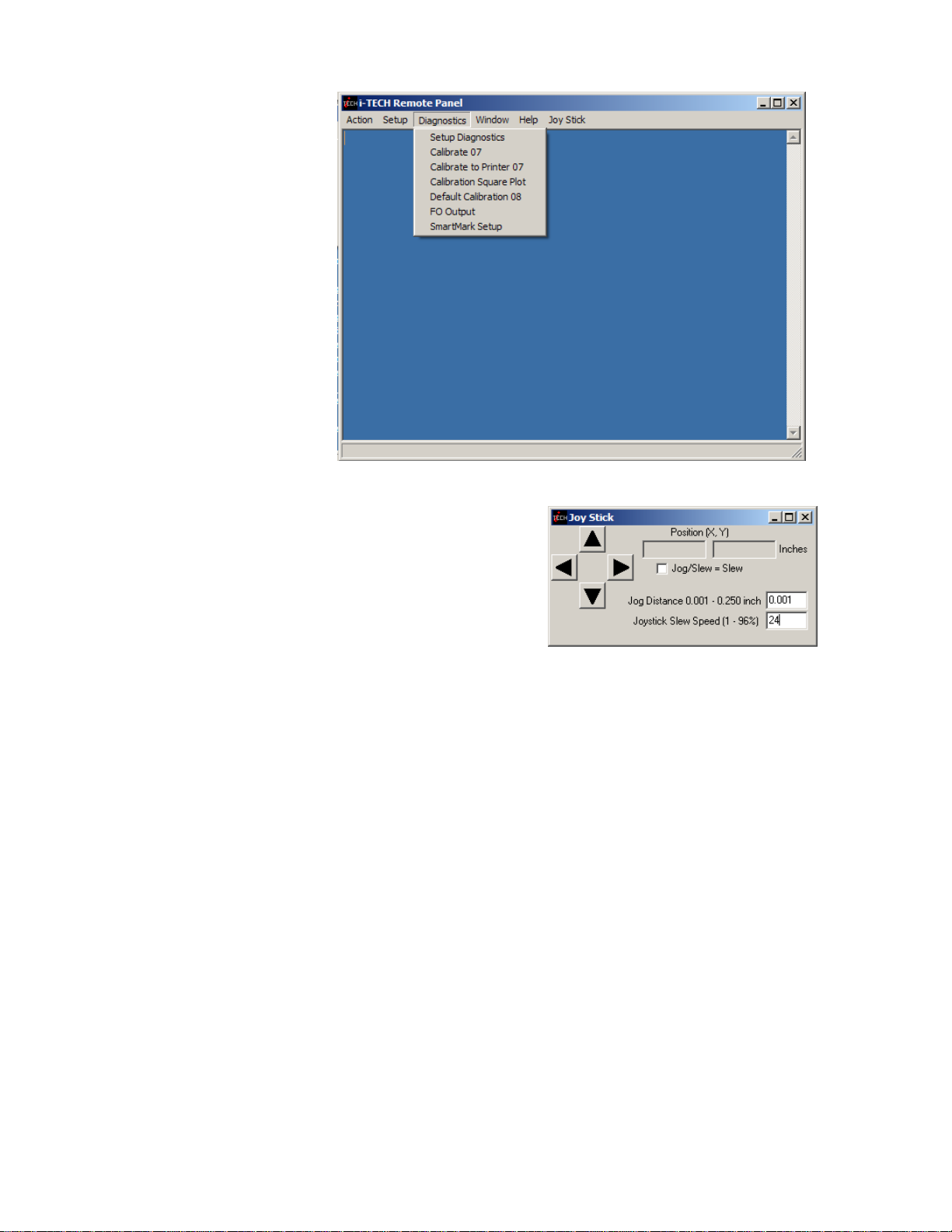

Diagnostics.................................................................................................. 29

Joy Stick ...................................................................................................... 29

i-TECH Cutter Loading Instructions.............................................. 29

Installing Knife Blades...................................................................30

Tutorial Using Adobe Illustrator and SmartMarkTM.......................31

Calibration......................................................................................33

Maintenance ................................................................................... 34

Cleaning....................................................................................................... 34

Pinch Wheel Maintenance ........................................................................... 34

Mechanical Adjustments............................................................................. 34

Belt Tension.......................................................................................................34

Diagnostics..................................................................................... 35

Diagnostic Operation................................................................................... 36

Control panel operation .....................................................................................36

Remote panel operation.....................................................................................36

Setup Diagnostics........................................................................................ 36

Customer Diagnostics.................................................................................. 37

Set Model Number 03........................................................................................37

Button Diagnostic 31.........................................................................................37

Confidence Test 02............................................................................................37

Flag Monitor / Adjust 34 ...................................................................................38

Flag Setup - Z Axis 58.......................................................................................38

LED and Hex display 29....................................................................................38

Line Sensor 21...................................................................................................38

Motor Balance 51...............................................................................................38

PWM Amplifier Status ......................................................................................39

Reed Switch 24..................................................................................................39

Trouble Shooting............................................................................ 39

Error Codes..................................................................................... 40

Appendix A Installation And Assembly Instructions..................... 41

Appendix B SmartMarkTM setup.................................................... 41

Appendix C Loading Diagram ....................................................... 41

Appendix D Cart Assembly Instructions........................................ 41

Appendix E Radio and Television Interference..............................42

Appendix F Model i-536 Addendum.............................................. 42

Appendix G Model i-536 Adjustable Parameters........................... 42

Appendix H Hot Tip Instructions...................................................42

Appendix I Template Maker Supplement.......................................42

Limited W arranty Agreement

ALLEN DATAGRAPH i-TECH cutters are warranted to be free of defects in both materials and

workmanship. Should any part of this equipment be defective, it will be repaired or replaced, at the

option of the manufacturer, at no charge for parts or factory labor for a period of one (2) years from

the date of installation. All warranty services are performed at the Allen Datagraph factory. Replacement parts not installed at the factory will be billed to the customer at regular prices and credit

will be issued when the defective parts are returned. The customer is responsible for freight on warranty parts and repairs.

This warranty is void if:

1. The equipment has been damaged by negligence, accident or mishandling, or has not been

operated in accordance with the procedures described in the operating instructions;

or:

2. The equipment has been altered or repaired by other than an approved service station or

factory service center, or adaptations or accessories have been attached to the equipment that shall

have adversely affected the performance, safety, or reliability of the equipment.

NO OTHER WARRANTY, EXPRESSED OR IMPLIED, APPLIES to the equipment. Allen

Datagraph does not assume any responsibility for consequential damages occasioned by the

equipment, or inconvenience or interruption in operation.

In case of unsatisfactory operation, Allen Datagraph or its Dealer should be notified immediately.

Technical Support

Up to 4 hours of call in technical support is available at no charge during the warranty period.

Technical support is available during business hours based on Eastern Time Monday thru Friday.

Technical support outside the limits stated will be billed at current rates.

For Technical support call: 603-216-6344

There are many online documents available to help you to use the Cutter at our technical support

page at

http://www.allendatagraph.com.

1

Installation

SET-UP

Some Allen Datagraph products require specialized installation in order for the limited warranty to

remain in effect, ask your dealer or contact technical support at Allen Datagraph for details.

Unpack all accessories and the unit. See installation and assembly instructions in Appendix A.

Power Connection

Important Note: Use of a HIGH QUALITY surge protector or uninterruptible power supply is

REQUIRED by Allen Datagraph Systems. Failure to do so could affect your warranty coverage if a

problem arises due to improper power connection.

CAUTION: The power cord is a three-conductor cable that incorporates a safety (earth) ground

connection. For the machine to operate safely and correctly, the power cord must be plugged into

an outlet that has an earth ground contact. Never plug the power cord into a two-prong outlet by

using a 3=2 cord adapter.

CAUTION: Never allow roll or sheet goods to rub on the power cord because the material can cut

the cord causing an electrical fire hazard!

Allen Products can be configured to operate from any of the following power sources:

115 VAC / 48-66 Hz or 230 VAC / 48-66 Hz

ALLEN DATAGRAPH products are normally factory preset for the power requirements of the

destination country. The machine's configuration is indicated on the power input module as either

115V or 230V. To change the configuration:

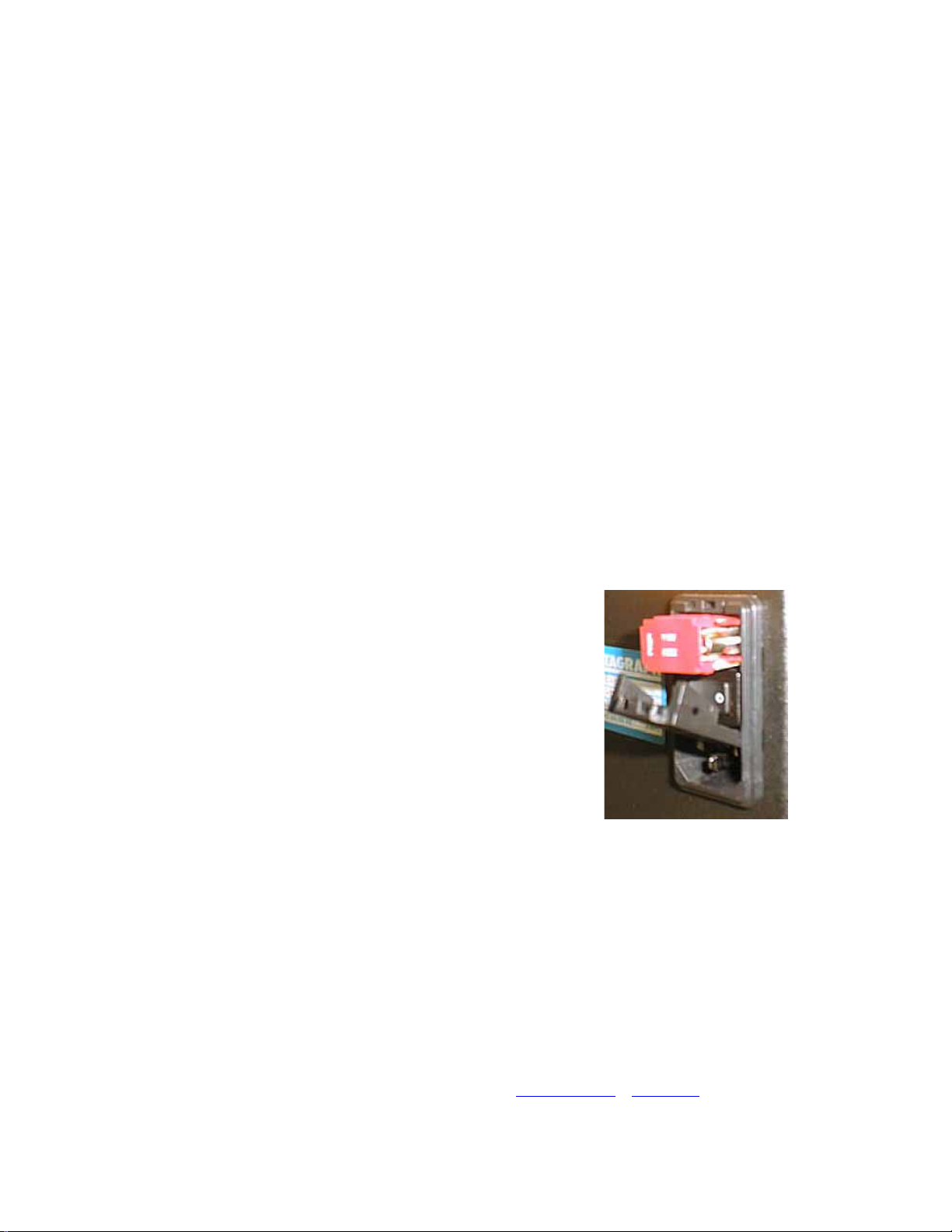

a. Disconnect the AC power cord from the fuse

block on the power input end panel. This is

located at the lower left end of cutter.

b. Open the fuse block cover with a small flat

screwdriver and remove the red fuse block.

c. Orient the fuse block so that the desired voltage

appears in the fuse block cover.

d. Close the fuse block cover and verify that the

desired voltage is showing.

i-TECH Cutter Stand

The i-TECH CUTTER comes equipped with a deluxe stand. Assembly instructions for the stand

are packaged inside the stand box that arrived with your cutter.

Note: The material rollers and associated brackets are packaged inside the cutter box, under the

packaging foam. It is necessary to remove the foam in order remove the parts.

Computer Connection

System Interfacing

All Allen Datagraph products utilize serial (RS-232) interface or optionally USB (universal serial

bus) interface. Use of the USB requires a USB to Serial converter. The recommended USB to

serial converters are described in Title: Usb Interface

support page of the Allen Datagraph web site.

Website Copy / CD Copy on the technical

2

The serial interface is factory preset for 9600 baud, no parity, 8 bits, 1 stop bit. The i-TECH, when

used with the supplied plotter cable, automatically supports both HARDWIRE and XON / XOFF

software handshaking.

Connect the plotter cable supplied with the i-TECH to serial port and to the communications port

on the host computer. A "null modem" cable may be used on serial XON / XOFF communications

only and is available at computer supply stores.

Because of the high degree of bi-directional communications required by the i-TECH and the

SmartMark™ system we recommend the use of the supplied communications cable and one of the

com ports on the host computer.

See your computer documentation for proper set-up of the communications port.

In general the communications port should be set up as follows:

Communications Port Setup

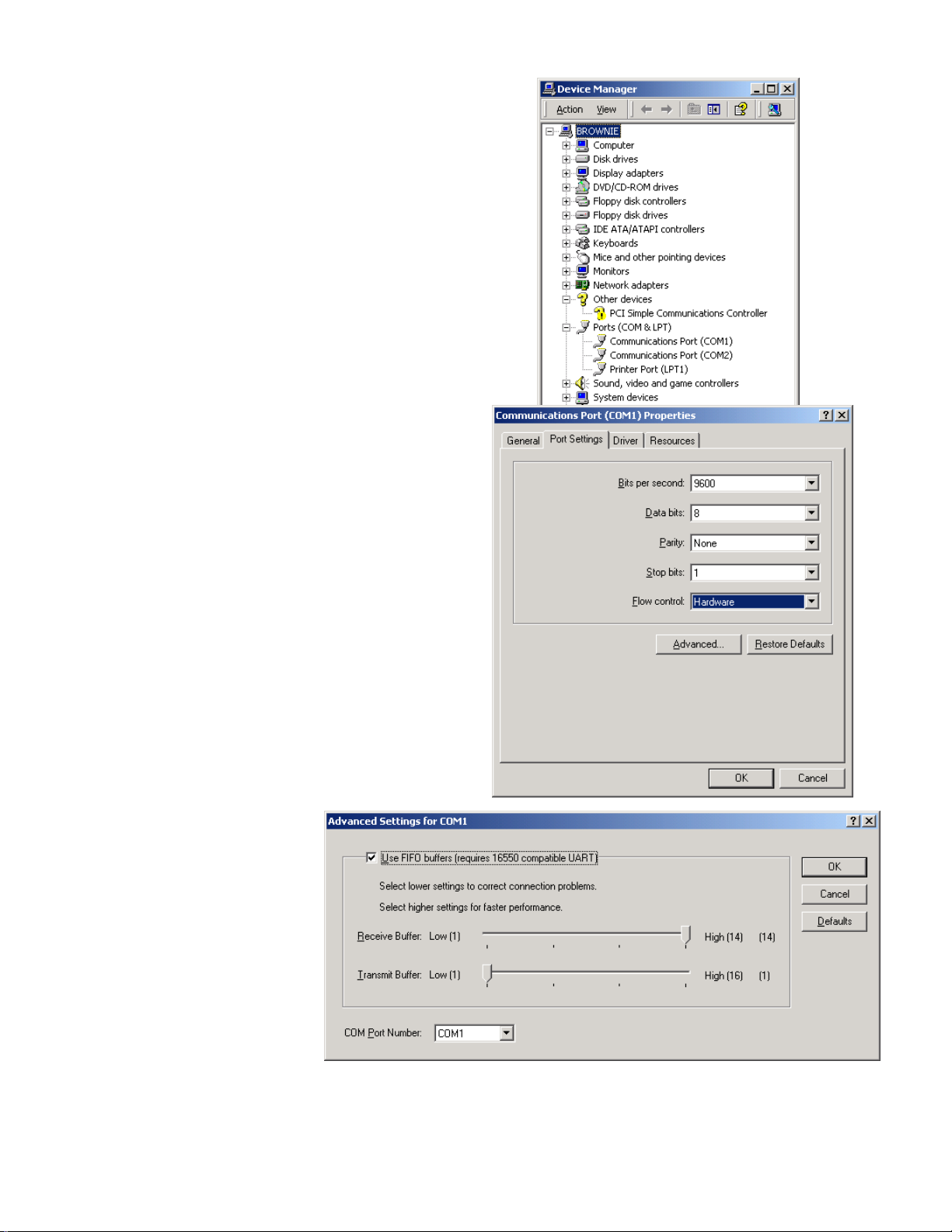

Setup for Window XP

Windows XP default for communications port connected to

cutter causes E56 errors. You need to change this default

before cutter will operate properly.

Start Window Explorer

Right click on properties

Select Hardware tab

and click on Device

Manager. Click on + in

front of Ports (COM &

LPT). Right click on

selected com port

3

Select port settings and configure port as

shown.

Click on Advanced and

configure port as

shown.

Setup for Windows 2000

Right click on My Computer icon on desktop

and select properties

Select Hardware page

Select device manager

4

Click on the + in front of Ports (COM & LPT)

Right click on com port that is connected to cutter and

select properties

Select Port Settings page

Select bits per second = 9600

data bits = 8

Parity = none

stop bit 1

flow control hardware

Click on advanced

Check use FIFO buffers

Set Receive buffer = 14

Set Transmit buffer = 1

click on OK

click on OK

close device manage

(click on x in top right

corner)

click on OK

5

Setup for Windows 95/98

Right click on My Computer icon on

desktop and select properties. Select

Hardware page. Click on + in front of

Ports (COM & LPT). Click on Communication port connected to cutter.

Click on Properties button

Select Port Settings page

Select bits per second = 9600

data bits = 8

Parity = none

stop bit 1

flow control hardware

Click on advanced

UnCheck use FIFO buffers

click on OK

click on OK

click on OK

6 7

Loading Allen i-TECH Software

The Firmware Utility CD contains:

1. The Remote Panel Utility program for managing machine settings.

2. A current revision of firmware.

"Firmware" is software that controls the machine functions. The

firmware on this disk is provided for update purposes only and

should not be installed on new machines.

3. Manual and sample jobs.

4. Cutter driver for Window XP or Windows 2000.

The Remote Panel Utility Program

In order to easily control the many settings of the i-TECH CUTTER, it is necessary to install the

Remote Panel Utility Program.

If connected to a computer running under the Windows operating system, your Allen Datagraph

product has many settings for machine control that can be accessed by the Remote Panel Utility

program.

NOTE: Before running the setup program, be sure to exit the older version of the Remote Panel.

To install and run the Remote Panel Utility program - Open Windows Explorer by right clicking on

the Start Button. Find the CD-ROM drive and find the setup file Setupi-TECHBuildXX.zip (the

XX reflects the numeric version number of the software and firmware). Run the setup program by

double clicking on the file. Follow the onscreen prompts.

XP Installation Instructions

The downloaded file is a .zip file. You can run the setup program just by double clicking on the

*.zip file then double click on the setup *.exe file.

Other Windows Operating Systems Installations

If you have not already installed Winzip on your computer, download and install the Winzip program from

and drop the contents of the zip file to your desktop.

The setup program will run to install the Remote Panel and the firmware on your Windows computer. If instructed by the factory to upgrade your firmware, follow the firmware upgrade instructions below. If you were only instructed to upgrade to a new remote panel you have already completed this task and do not need to install the firmware.

http://www.winzip.com. Then you can open the zip file by double clicking on it. Drag

Installing Firmware

The firmware on this disk is provided for update purposes only and should not be installed on

new machines. In general you should not install a firmware update unless directed by a member

of the technical support staff. Firmware updates are available on the technical support page of

the Allen Datagraph web site at

This procedure details the firmware upgrade procedure. Normally firmware is only sent to customers when a software problem is reported that has been fixed in a later version of the software.

From time to time Allen Datagraph will recommend that you upgrade your firmware in your Allen

Datagraph i-TECH. A file can be downloaded from the Allen Datagraph web site and saved to the

desktop.

http://www.allendatagraph.com.

Before running the setup program be sure to exit the older version of the Remote Panel.

Firmware Installation Instructions:

Only install new firmware if instructed to do so by Allen Datagraph.

Refer to Title : Printer Conflict

Website Copy / CD Copy if you

have installed some other printer

driver other than the Allen Datagraph printer driver.

Turn on the Allen Datagraph

equipment to be upgraded and

connect it to your computer with

the supplied serial cable. Start

the Remote Panel by clicking on

start, program, Allen Datagraph,

Remote Panel. Click on Setup,

Com Port and verify that the correct Com port has a check next to

its name. Click on Setup -> Options and select Advanced on the menus. Click

on

Action, Upload Firmware. Select

I960a.hex file and click

fails, you will be given a backup procedure to

follow on the computer screen.

Open. If the upload

Windows XP / Windows 2000 Driver

This printer driver has been tested with CorelDRAW, Adobe Illustrator, Flexisign, and PowerCAD.

It should work with any program that sends vectors rather than bitmaps to the printer. Allows cutting directly from windows graphics programs without requiring additional software purchases.

Note: Driver requires ownership of Allen Datagraph Equipment to use. Requires: Windows XP or

Windows 2000. The setup program for the printer driver is available on the supplied CD or on the

tech support page at the Allen Datagraph web site at

http://www.allendatagraph.com/.

Installation instructions

Run Setup. The setup is named SetupCutterDriverxx.EXE on the supplied CD. A shortcut to the

installation instructions will be placed on the desktop. (DirectCut Help File). Documentation for

the printer driver is included in the help file.

8

Optional SmartMarkTM Sensor

The SmartMarkTM option that is available for Allen i-TECH cutters is an optical registration system

that allows cutting of pre-printed graphics. The SmatMark system has the capability of recognizing

up to three registration marks, and adjusting for scale and skew discrepancies the may occur.

TM

The SmartMark

tic transmit/receive leads that connect to the amplifier, a lens assembly that is attached to the tool

block assembly of the cutting head, and associated internal cutter wiring.

The SmartMarkTM sensor recognizes changes in contrast from the background media to the printed

mark. The “sensitivity” of the sensor must be set in order for the system to recognize the contrast

reliably and be able to cut accurately.

option consists of an amplifier that is mounted to the cutting head, two fiber op-

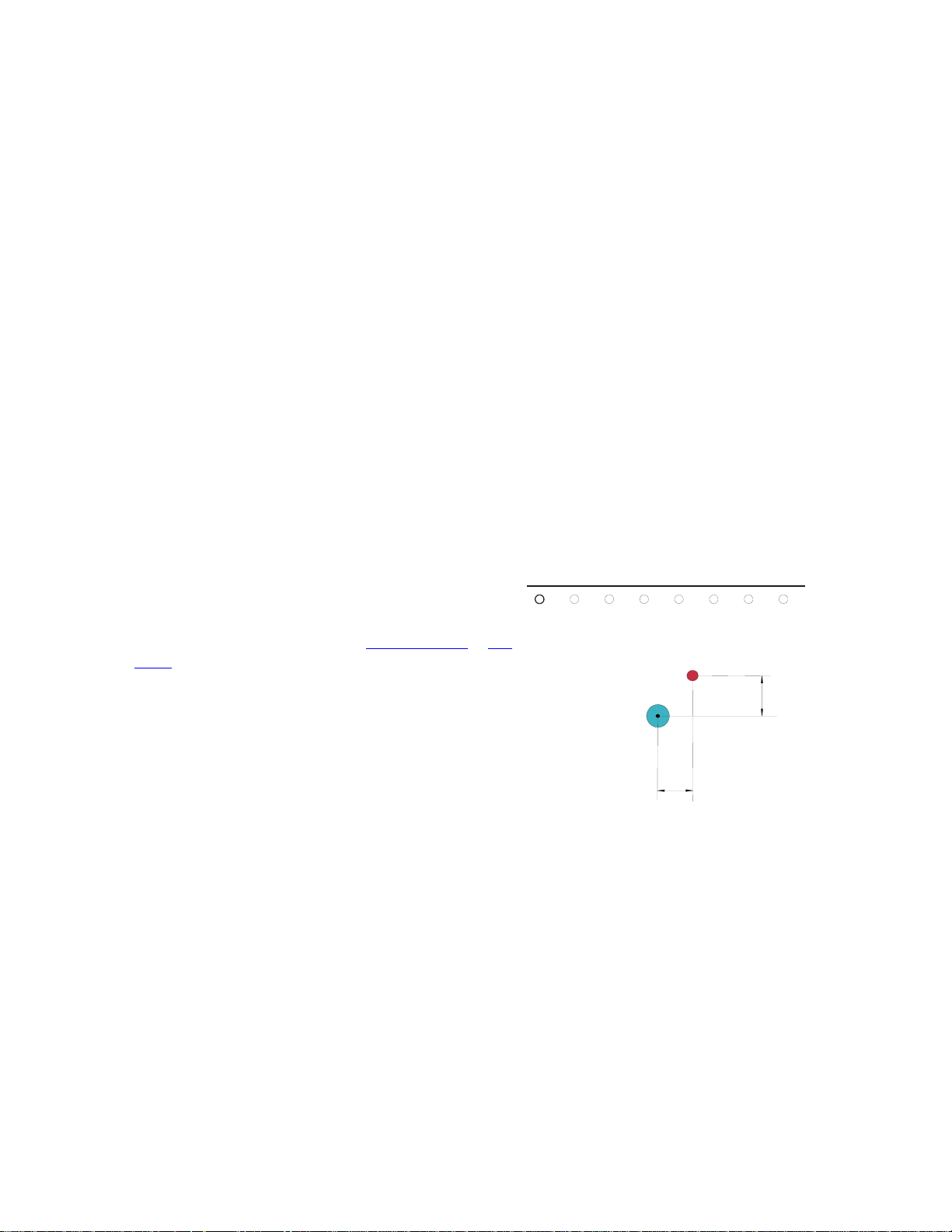

Registration Mark

MARK SIZE

LABEL

LIN E SIZE

Standard SmartMarkTM Registration Mark Origin Point

The recommended target is available for Adobe Illustrator and CorelDraw for download on the

technical support page of the Allen Datagraph web site (

designing a target for scanning, read the Title: Why thick lines don’t work

http://www.allendatagraph.com). When

Website Copy / CD

Copy. The recommended Mark Size is 0.5 inch (12.7mm) the size can be as small as 0.25 inch

(6.35 mm) or as large as 1 inch (25.4mm) The recommended line size is 0.13 (3.3mm) and can be

as small as 0.07 inch (1.8mm). The registration mark should be printed with as high a contrast as

possible. The sensor relies on reading the change in intensity of the reflection of the red LED

pointer. When printing process colors on white media the best color is usually black. Certain spot

colors are difficult. For example silver spot on white, while to the eye there is contrast the reflectivity of the two is sometimes nearly the same. Different medias also have different reflectivity and

will on occasion require adjusting the sensor sensitivity (see below). If there is trouble with certain

materials detecting the target you can print the target in a yellow or white field. The size of the

yellow field should be double the scan distance. (Note: in order to get an accurate scan no other

printed marks may appear in the yellow scan area. The printer color alignment marks can appear

on the inside edge of the target or the other side of the media.)

9

The mark should be placed at least 0.5 inches (12.7mm) from the edge of the media and the spacing between jobs should be at least 0.5 inch (12.7mm). (Advanced usage: You can place the target

closer to the edge of the material if the area of the platen that is scanned by the sensor is covered

with the same color material as the background material.)

The number of rows and columns of labels between registration marks defines a set or

page of labels. A page of labels can be one row or several

rows of labels. There are several aspects to consider when

deciding on how many rows of

labels to print on one page. The

main consideration is the trade

off between speed (it takes a

couple of seconds to perform

the FO command and scan the

registration mark) and registration accuracy. The more often

you scan the registration mark

(the closer the marks) the more

accurate the cut registration will

be. If the job allows for overprinting the cut line, then registration may be less critical and eliminating some of the registration marks can speed the job. Generally registration marks should be placed at least every 24 inches (610mm). Most users print registration marks for each row then adjust the cut job to skip one or more marks if desired. This procedure also insures equal spacing of the labels and gives complete flexibility for cutting. The distance between the last cut line of the previous page and the target on the next page must be between

0 and 1 inch (2.54 cm). If the distance between frames is less than the scan length, then the target

must be outside of the area where the labels are printed. (Note: every page of a label run must be

identical or you won’t be able to use the copy command).

ONE PAGE

Operation

The theory of operation relies on the sensor sending a signal to the i-TECH embedded computer

when the SmartMark™ senses a change in reflected light from the media as it would when the sensor scans the printed registration mark. The i-TECH scans the mark in both directions and registers

the intersection of the mark. The i-TECH computer then assigns that intersection as the 0,0 point

of the cutter coordinate system and matches that to the origin point of the HPGL cut file.

The i-TECH uses a special HPGL command, FO, to start the registration mark sensing function. It

can automatically re-register the coordinate each time the FO HPGL command is received. As part

of the setup a “x move between jobs” is input via the remote panel which moves the sensor to the

approximate position of the next copy’s or next job’s registration mark. The space between jobs in

the printer driver also affects the where the next target is located. These two parameters are added

together. The i-TECH expects the target for the next frame to be within ½ the scan distance of the

end of the job.

The Red LED pointer must be manually positioned with the joystick buttons at the approximate 0,0 coordinate position prior to

sending the first job. The SmartMark™ system automatically repositions the sensor for

subsequent copies.

10

(0,0 POINT)

LED POINTER

The positioning process must be repeated if the joystick buttons are used. This is helpful because it

allows the system to be reinitialized when needed. Some printers require a leader between jobs and

this feature is a very easy way to deal with the issue.

Once the LED pointer is positioned as shown, the SmartMark™ is ready to operate and will scan

the registration mark when it receives a FO command in the job stream whether on the first copy or

on subsequent copies. Since the FO command is embedded in the beginning of the cut file the scan

of the registration mark is performed at the beginning of each copy or set of labels and on subsequent copies.

SmartMark™ Setup

There are several adjustable parameters built in to the SmartMarkTM sensor that give the system its

extreme flexibility. Some of the parameters can be automatically set by the microprocessors embedded in the system and some require manual intervention.

Sensitivity

1. In order to accurately sense the registration mark the SmartMark™ System operates using very fast signals at fairly low signal levels. All systems operating in this manner

are subject to interference from outside electro magnetic sources. In order to limit the

effects of outside interference the SmartMark™ system uses a high logic signal when

the sensor is off the mark and a low logic signal when the sensor is on the mark. In

normal operation the sensor sends a high logic signal when the sensor is on a light

background and a low logic signal when on a dark registration mark (L on). The sensor allows for sensing light registration marks on dark backgrounds by changing its

state so that the sensor sends a high logic signal when on a dark background and a low

logic signal when on a light registration mark (D on). The (L / D On) operation is set

by pressing the mode key 3 times. The current setting will be displayed. If the jog

switch is moved, the opposite setting for the output operation will be displayed. If the

jog switch is pressed, the digital display will blink quickly 3 times and the selected

output operation will be confirmed. Press the “MODE” key 3 times or keep it pressed

for 2 seconds or more to return to “RUN” mode.

2. ective value passes the set threshold

The sensor changes its logic state when the refl

level. The sensor utilizes a self-teaching program to set this threshold level. There are

multiple methods for setting the threshold level. The preferred is the Two Level

11

X

Teaching Mode, which will allow you to set a middle ground threshold value. Select

the “TEACH” mode by pressing the Mode Key once. Press the jog switch when the red

dot is on the material background. The display will blink then the “TEACH” (yellow

light) will blink. This indicates that the second point is now ready for input. Move the

sensor over the registration mark and press the jog switch, again the display will blink.

The display will either indicate the word “GOOD” which indicates that stable sensing

can be performed or “HARD” indicating stable sensing cannot be performed. The

threshold value setting will be displayed then the display will blink with the characters

“——“. The incident light intensity will again be displayed, indicating that configuration is now complete. Press the “MODE” key 5 times or keep it pressed for 2 seconds

or more to return to “RUN” mode.

3. r should be: As the LED moves into the registra-

The performance you are looking fo

tion mark from the background area the Operation Indicator (orange light) will activate

(ON), and then deactivate (OFF) when moved back into the material background area,

all the while the green light (Stability Indicator) will remain lit. If you have the “Loff” selected on the operation selection, the operation of the orange Operation Indicator

will be opposite.

4. ation regarding advanced programming and operation of the sensor

Additional inform

can be found in Appendix D “SmartMark™ setup”.

Sensor Offsets

The SmartMark™ sensor is offset from t e. The red dot indicates the LED point

and the blue circle represent the knife. This value is normally setup at the factory or during installation of the i-TECH. The offset distance is preset at the factory, but may need to be adjusted on

occasion. You may follow this procedure only if you

own a digitizing site (Allen p/n PL-00-11-500). Otherwise you must follow the manual procedure described in the TSB Calibration

Copy .

he center of the knif

Website Copy / CD

Y OFFSET

OFFSET

12

To automatically reprogram the SmartMark™ sensor

offset and sensor size parameters: Open the i-TECH

Remote Panel. Open the

click on

SmartMarkTM Setup

Diagnostics Menu and

1. Before running this procedure run the Calibrate to Printer diagnostic.

2. Print the 6x3 rectangle in c:\Program Files\Allen Datagraph\Sample directory on the same

printer you ran the “calibrate to printer diagnostic”.

3. Enter the designed size of the rectangle in the Rectangle Size boxes

4. Load Media into cutter.

TM

5. Move the SmartMark

6. Click on Find Sensor Size and Offset. This determines the size of sensor based on the fo-

cal length and the current setting of the threshold.

7. After scanning the scale, skew, and origin points you will be asked to joystick the carriage

to the lower right corner of the rectangle. Use either the optional fiber optic bombsite so

that the center of the bombsite is directly above the lower right hand corner of the printed

rectangle.

8. Click on OK to save new values or Cancel to restore original values.

You can review the numbers by opening the

section describing the line sensor menu.

Sensor beam near the lower right corner of the 6x3 rectangle

Setup Menu, click on Line Sensor Menu. See

13

Control Panel

The front control panel is the primary user interface for the i-TECH cutter. It is used for input of

speed and force as well as several other functions.

LOAD The load key is used to ini-

tialize the system and to load or

automatically fill the supply dancer

bar. Once the material is fed thru

the media path and the nip rollers

are engaged (see media loading section), press the load key and the

supply roller will start feeding media into the supply dancer bar and

will automatically stop once the

supply dancer bar reaches the bottom and the loop is full. If the media height sensor is off, the load

light will then come on to indicate

the system is ready to operate. If

the media height sensor is turned o

the system will scan the digital die

cutter station pinch rollers to dete

mine the media width (see Label

Remote section). Be sure that the

label frame you want to cut is at

least 2 inches behind the knife blade

before pressing load.

n,

r-

L P

LOAD

PAUSE COPY

S

P

E

E

D

F1

F

O

R

C

E

C

TC

TEST

CUT

SELECT

PAUSE The pause key will halt the

operation of the system at any point.

It is used to pause the system for

inspection, media jams or to pause

the machine for any other reason.

Press the pause key to re-start the system. The system can be jogged while paused and will remember where it was and restart from where it was stopped regardless of where it was jogged.

This is very helpful for inspecting the cut. You can pause the system and joystick the media or cut

head away from its position to inspect the cutting or registration. After inspecting the media, simply press the pause key again and the i-TECH will return to the point where it was paused and resume cutting. The pause light will flash while the system is paused. You can also use the pause

button to enter the unload state (press Pause followed by Load).

F3

COPY The copy key is used to input the quantity of copies the i-TECH will digitally die cut. It is

used after the first copy of the job is cut. Once the first copy is cut and you are happy with the results, press the copy key. The display will read 0002. The number represents the total number

of copies including the first one run. Increase the number of copies by pressing the up arrow key

of the joystick or the force up button. Hold the key down and the numbers will start moving slowing then more quickly. Press the down arrow key to lower the number. Alternatively the force

keys will increment the single digits and the speed keys will increment the 10’s digits. Remember

the number displayed includes the first copy run before the copy key was pressed. Input the copy

quantity and start the cutting by pressing the

SELECT KEY.

SPEED The speed keys are used for controlling the cut speed (the speed the knife travels around

the periphery of the items being cut). Increase the speed by pressing the up arrow key. Decrease

the speed by pressing the down arrow key. Hold the key down and the numbers will start moving

14

slowing then more quickly. The i-TECH will also self adjust the speed within certain limits based

on the speed of the device feeding the unit. The range for speed is 1 to 100.

FORCE The force key is used in conjunction with the test cut key to set the depth of cut. The

factory default for cutting is set at 12. The range of force is 1 to 100 when the system is in the

normal force range and 1 to 1000 when in the 1000 step mode. For most applications the normal

force range is adequate (see dynamic force and 1000-step mode in the Remote Panel section). In

the normal force range mode, the force is adjustable between 10 and 550 grams of force in 100

steps.

The force is set by test cutting the media to be cut using the test cut function. Using the joystick, position the knife in an unused portion of the me-

dia and press the

similar to the diagram to the right. With a sharp knife or tweezers you

should be able to individually remove each part of the test cut pattern working from the ring to the triangle without affecting the remaining parts. A

properly set force will leave a very slight scratch or mark on the liner.

The force may need to be adjusted due to blade wear during use if problems with weeding occur.

Simply increase the force setting by one until satisfactory weeding occurs. If the knife blade is

changed, revert back to the original setting or perform the test cut procedure again. The blade may

need to be replaced if the force is increased by more than 20 percent from when the blade was new.

TEST CUT key. The system will cut a test cut pattern

F1 This key puts the pen up or down during digitizing mode.

F2 This key is not used and has no function

F3 This key is a short cut to the OPER mode. It is equivalent to pressing select, left/right until

OPEr is displayed and pressing select.

RESET the cutter by pressing the F1, F2 and F3 keys in order.

JOYSTICK The joystick is used for positioning the knife

and media in the die cutting station and for several other functions.

The four

cutter carriage that holds the knife blade and the SmartMark™

sensor. Press the key once to move the material or carriage

slowly and press it a second time within ½ second to move at

a faster speed. Tap the key to jog the cutter a fixed distance.

The distance is adjustable (see Joy section below or joystick in

the Remote Panel section).

SELECT

will change to indicate the last used menu item. To select a menu item press the select key and

then press the right or left arrow key to scroll thru the various menu items. With the desired menu

item displayed, press the up or down arrow key to select the state. When the desired state is displayed press the select key to input the menu item and state. The menu items are: ACCL, CAd,

diA, indE, JOY, OPEr, and Set.

ARROW KEYS are used to jog the material or

SELECT

The select key is used to invoke the menu system. Press the select key and the display

Menu Items:

ACCL allows setting the acceleration in ¼ G increments. Acceleration is the rate of in-

crease/decrease of speed of the motors along a vector. Higher G values increase throughput however higher G values also increase the likelihood of experiencing repeatability problems. Recommended values are (2-8) for standard labels.

15 16

CAd override menu function enables or disables the CAD override function. With the function

On the cutter will ignore some HPGL control commands sent from the cutting software. With the

function Off the CAD software can control these HPGL commands.

The commands affected by CAd override are:

AS set acceleration

FS set force

KA set minimum a ngle

KN set knife offset

IP input P1/P2

RO rotate

SC set scale

SP select pen

ST select tool

UV up velocity (move speed)

VS down velocity (cut speed)

Press the select key to initiate the menu function. Press the left or right arrow key to display CAd,

then press the up or down key to toggle between off and on. Press the select key to lock in the

desired menu setting.

diA is used for entering into the diagnostic mode. Press the select key to initiate the menu func-

tion, then press the left or right arrow key to display diA. Press the up or down key to scroll thru

the diagnostic numbers (0002 – 0099). Press the select key to start the diagnostic. (see diagnostics

section) . To exit from a diagnostic mode select 0099 and press select.

IndE indexes the x-axis. One of the uses for this function is for metering material. Press the se-

lect key to initiate the menu function, then press the left or right arrow key to display IndE.

Press the select key. Press the up or down arrow to toggle between inches (InCH) or centimeters

(cEnt). When the desired unit of measure is displayed press the select key. The display will read

0001. The number represents the number of inches or centimeters to be metered in the x-axis.

Increase the number by pressing the up arrow key of the joystick. Hold the key down and the

numbers will start moving slowing then more quickly. Press the down arrow key to lower the

number. Alternatively the force keys will increment the single digits and the speed keys will increment the 10’s digits. Input the length and start by pressing the select key.

JOy allows changing the joystick parameters: of jog distance or slew speed. Press the select key

to enter the menu system. Press the left or right joystick buttons until JOy is displayed. Press up

or down on the joystick to select (Sped or Jog). Press select. Press up or down on the joystick to

select a value for joystick speed (1-100%) or jog distance (0.01 inch increments). Press select to

save the displayed value.

This menu item has 2 sub-menus:

Sped- Allows the user to set the maximum speed that the joystick will move the material

or head when pressed twice. Range 1-60.

Jog- Allows the user to set the distance that the head or material will move when a joystick

button is pressed and released. Range is 1-100 in 1/1000

100=.100”

th

inch increments. i.e., 1=.001”,

OPEr is used to select the operation mode between cutting (CUt), pen plotting/drawing (drA) or

pouncing (POUn). Press the select key to initiate the menu function, then press the left or right arrow key to display OPEr. Press the up or down key to select the desired function. Press the select

key to lock the desired menu setting.

SEt loads or saves a custom set-up or power up default. Press the select key to initiate the menu

function. Press the left or right arrow key to display SEt. Press the up or down key to scroll thru

(LOAd, Save), press select, press the up or down key to scroll thru the settings (1 – 6). Press the

select key to load or are save the setting. Setting #1 is loaded when the machine is powered up.

(see also factory and custom set-up section)

The set menu item has 2 sub-menus:

Load- loads a setup.

To load a setting:

Press select

Press left or right arrow until SET menu is displayed.

Press up or down arrow to display Load.

Press select

Press up or down arrow to display the number of the setting you want to

load (1-6)

Press select.

Save- saves a customized setting.

To save a setting:

Adjust force, speed, acceleration as needed.

Press select

Press left or right arrow until SET menu is displayed.

Press up or down arrow to display Save.

Press select

Press up or down arrow to display the number of the setting you want to

customize (1-6) (# 1 is the setting that is loaded on power up.)

Press select.

The display will blink FFFF, and then return back to your setting.

17

Remote Panel

The Remote Panel program is used to address all i-TECH CUTTER functions. It should be loaded

onto the computer that is directly connected to the i-TECH CUTTER. We recommend that you

place a shortcut on the Windows Desktop so that you can easily start the program when needed. It

can be run in the background with most cad programs.

If running a design program that utilizes a compliant windows printer driver or when using the Allen Datagraph Windows XP / 2000

driver, be aware that all windows

printer drivers can grab hold of the

COM port and keep programs that

talk directly to com port from

working. Symptoms: E56, funny

characters on LCD display, plots

not finishing, slow send. To

eliminate the problem read the

Title Communication Failure

Website Copy / CD Copy

Remote Panel Functions

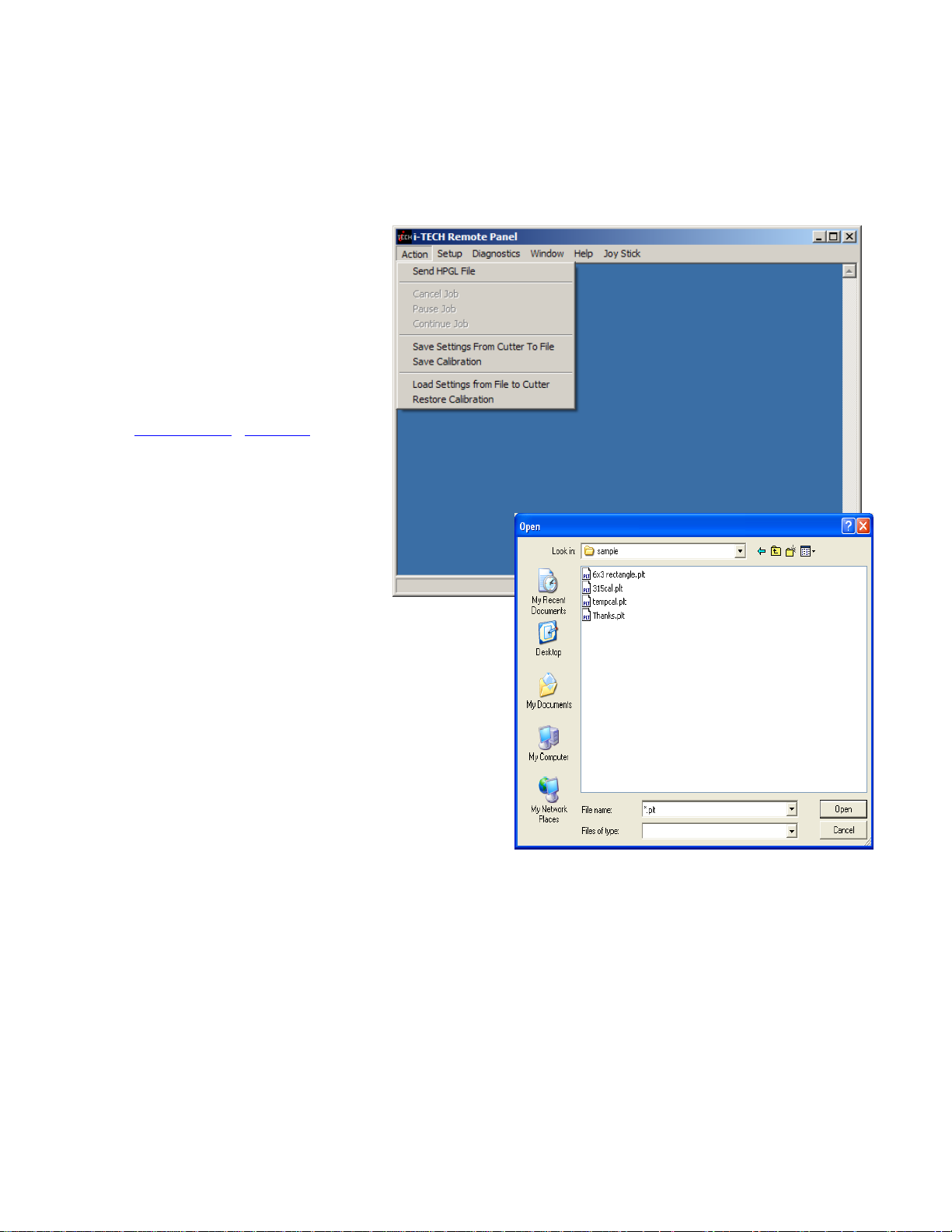

Action menu

Send HPGL File

Send HPGL File will send a HPGL

plotter file directly to the Cutter.

Typical origins HPGL files include the Allen Driver,

CorelDraw or some other design software. To send a

HPGL plotter file from the remote panel program

click the Send HPGL File menu item to open the select file window. Select the files desired and click

the Open button. This will send the file directly to

the Cutter.

Cancel, Continue, Pause

These commands will cancel, continue, or pause a

job being sent by the Send HPGL command. For

jobs sent by other programs you can use the Pause

button on the cutter and the (F1, F2, F3) combo to

cancel the currently cutting job.

Save Settings from Cutter to File, Load Settings from File To Cutter

These commands save the settings (see setup settings menu) and some line sensor parameters that

are in the i-TECH to a disk file or loads settings saved by this command from a file and sends them

to the i-TECH. This allows you to have more than 6 setups for different materials and it allows

backing up your settings to your hard drive in case of failure of the CPU board.

Save Calibration/Restore Calibration

This command saves line sensor parameters that depend on the calibration and calibration of the

cutter or allows loading the calibration parameters from a file. This command allows calibration of

the i-TECH to multiple printers.

18

Advanced menu items (These menu items appear if you select the advanced menu

on the Setup Option menu)

Open Com Port

Will initialize the communications port.

Close Com Port

Closes the communications port so that other programs can use the port. The remote panel program will automatically close the port in most instances when it is not actively communicating with

the i-TECH.

Upload Firmware

Should your firmware ever need to be updated, this command will locate the firmware file and send

it to the i-TECH.

Save to EEROM and Restore from EEROM

These commands are used to save custom settings and factory settings to the computer when certain electronic components need to be replaced.

Setup Menu

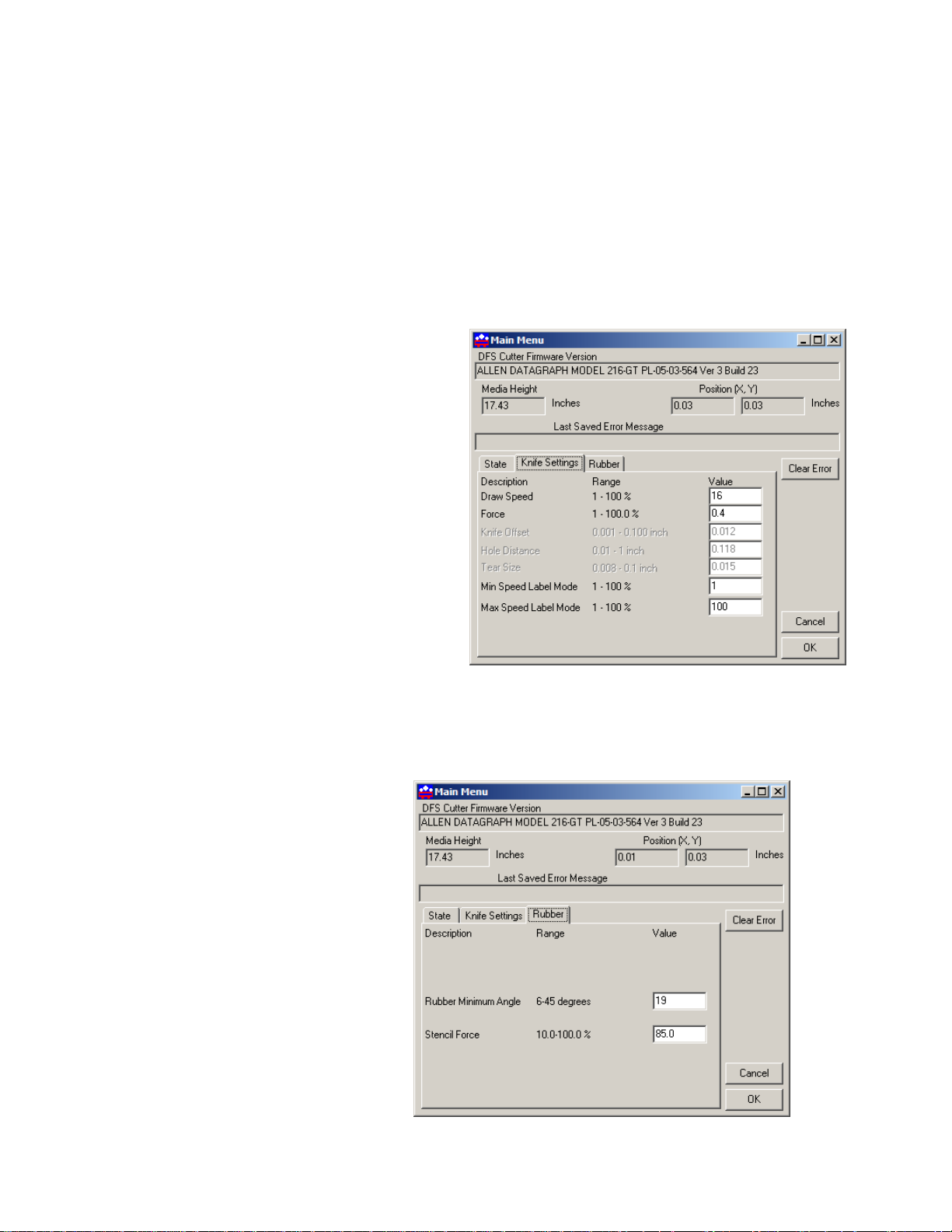

Main Menu

The Main menu opens the main menu window. The top window shows the model number and

firmware version (build 23 in the sample). The media height window shows the maximum dimension the i-TECH is set to cut. With the media height sensors enabled, the i-TECH will scan the

pinch wheel magnets to determine the loaded media size and will calculate the maximum cut size.

The i-TECH will send this dimension (called the clip limits) to many software programs so that the

software program can determine if the specified cut file will fit. If a file with dimensions larger

than the clip limit is sent to the i-TECH, the cut will be truncated. If the media height sensor is

disabled, the default clip limits will be used and it is possible to cut off the edge of the media. The

position window shows the current location of the knife in the cutter coordinate system. The Last

Saved Error Message window displays the last error. Errors displayed here may be old. The error

may have occurred earlier in the cutters life. The

saved error notification.

Clear Error button clears the memory of the

State Tab

The

State radio buttons allow the user to set the condition of the cutter. Unload means the cutter

is not loaded and is not ready to receive a cut file. The Pause radio button means the cutter is currently paused and the Ready button means the cutter is loaded and ready to receive the cut file and

proceed with cutting. This set of buttons duplicates the Load and Pause buttons on the front panel.

The CAd Override radio buttons enables or disables the CAD override function. With the

function

software. With the function

tems will work correctly only when this feature is set to on.

These commands include:

AS set acceleration

FS set force

KA set minimum a ngle

KN set knife offset

IP input P1/P2

RO rotate

SC set scale

SP select pen

On, the cutter will ignore some of the HPGL control commands sent from the cutting

Off, the software can control these HPGL functions. Some CAD sys-

19

ST select tool

UV up velocity (move speed)

VS down velocity (cut speed)

The Mode radio butons sets the operation. Select cutting, pen plotting/drawing or pouncing.

The i-TECH will normally only use the Cut function.

The Dynamic Force radio buttons (an advanced option) engages the dynamic force function,

which instantaneously adjusts the force on the fly based on the actual velocity of the knife blade.

All cutters must accelerate and decelerate as they cut around corners. Some medias require different force settings for different speeds. This parameter allows for building a database for these materials and when enabled will greatly improve the cutting on these materials. (See the Dynamic

Force Section for more details).

Knife Settings Tab

Draw Speed displays and sets the velocity

of the knife when it is actually drawing or

cutting. The draw speed is the speed the knife

travels around the periphery of the items being

cut. The i-TECH will also self adjust the

speed within certain limits based on the speed

of the device feeding the unit. The range for

speed is 1 to 100%.

Force displays and sets the cutting force.

The default force for cutting is set at 12. The

range of force is 1 to 100%.

Knife Offset is the distance between the

center of the knife blade and the knife tip.

Standard blades have a 0.012 inch (.030 cm)

offset. If you have objects that do not close

correctly, you might have to adjust the knife offset to correct the problem.

Hole Distance and Tear Size are used when the cutter is in the Pounce Mode. The hole dis-

tance setting is the distance between holes and the tear size is the distance the cutter moves with the

pounce tool down to tear the media and enlarge the pounced hole.

Min Speed Label Mode and Max

Speed Label Mode

the limits for the automatic speed

setting function of the i-TECH. The

cutting speed will automatically

increase or decrease, within the limits

set here, to keep pace with the in feed

device. Normally you set the Max to

100 and the min to 1.

are used to set

Rubber Tab

Rubber Minimum Angle displays

and sets the angle between consecutive vectors that when exceeded will

invoke the tangential emulation mode.

At angles less than the value set in

this parameter the cutter will move

between vectors without evoking the tangential emulation mode.

20

Stencil Force is the force separation between drag knife mode and tangential emulation cut

mode. Tangential emulation cut mode is normally used for rubber or very heavy material.

Advanced menu items (These menu items appear if you select the advanced menu

on the Setup Option menu)

Rubber Scratch Force displays and sets the down force used during tangential emulation.

This is primarily used when cutting thick materials such as sandblast rubber. Tangential emulation

simulates a tangential or servo controlled rotating knife by moving to a position short of the vector

to be cut and putting the knife blade down with a very light force while moving toward the direction of cut to align the knife before applying the full cutting force. This improves the cut quality in

thick materials. (default 0.1%)

Rubber Backup Multiplier (default 20) displays and sets the distance the knife will be dragged

at the light force used to align it. This parameter is used with and is additive to the

Backup Offset

between vectors and the Rubber Backup Offset is a constant added to the distance calculated based

on angle.

(default 0.02). The Rubber Backup Multiplier is based on the change of angle

Rubber

Rubber Minimum Angle (default 19) is the rotation angle between two vectors that enables

tangential emulation. Subsequent vectors that have angle between them exceeding this parameter

cause the pen to be picked up, dragged along the surface to align the knife and plunged into the

media at the beginning of the next vector. Subsequent vectors that have angle between them less

than this parameter will perform a drag rotation.

Max Motion Vector Length (default 0.001) (Named after the driver that outputs very small

vectors) Allen Cutters very accurately replicate the vectors in the HPGL plot file. Some design

programs output vectors that are very short. It is sometimes desirable to combine some of these

vectors into a longer vector to eliminate jagged edges or slow cutting. This parameter works like a

curve-smoothing algorithm and is used to improve poor HPGL files.

Anticipation Rubber (default 0.002) and Anticipation Vinyl (default 0.0004) is a parame-

ter that adjusts the backlash compensation in the cutter. The Anticipation Rubber is the parameter

used when the cutter is in tangential emulation mode and the Anticipation Vinyl is the parameter

used when not in tangential emulation

mode. Heavier materials require more

backlash compensation. These numbers

are individually set at the factory and

should not require adjustment except

when cutting heavy materials. If you are

experiencing thick and thin lines or

misshaped letters, adjust the anticipation

parameter to obtain satisfactory results.

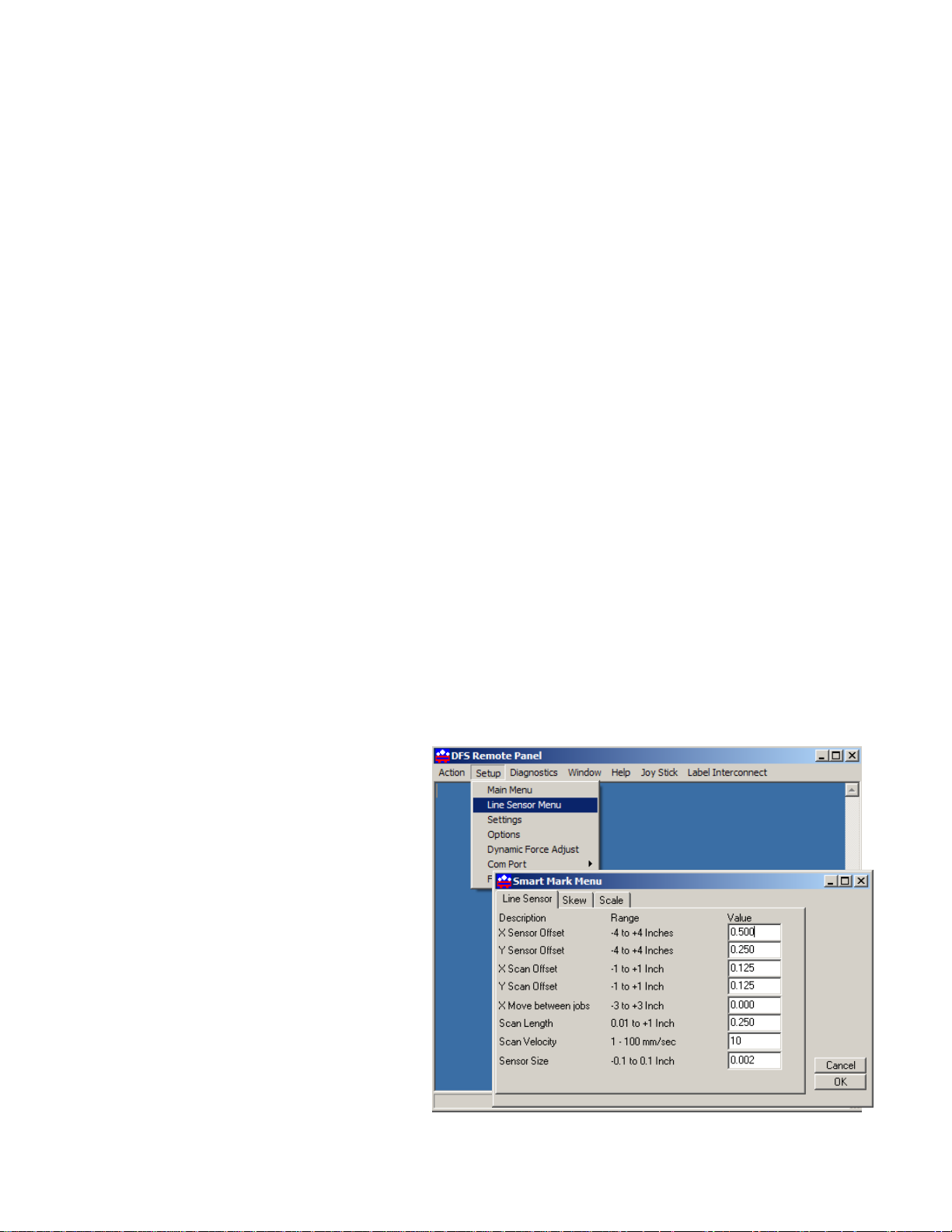

Line Sensor

Clicking on Setup Line Sensor menu

opens the SmartMark

Line Sensor Tab

TM

Menu.

Sensor Offsets - The SmartMark™

sensor is offset from the center of the

knife. The offset distance is preset at the

factory or during installation, but may

need to be adjusted on occasion. The i-

21

TECH will automatically calculate and set the SmartMark™ offset and sensor size parameters. See

drawing for definition of sensor offsets. Title: Calibration

Website Copy / CD Copy.

Sensor size is the offset from the exact

center of the red dot of the SmartMark™

sensor to the sense radius and may

change based on sensor sensitivity or

media reflectivity. This parameter is best

set using the procedure in the TSB. The

Sensor Size parameter is only useful in

three target scanning. If you are not

using three-target scanning you can set

the size to 0 and the sensor size is included in the sensor-offset parameter.

Scanning Parameters

The i-TECH SmartMark™ system has adjustable scanning

parameters to allow for different size and style of registration

marks. The primary parameters are the scan offset and

length. The ideal X and Y offsets are one-half the mark size

and the ideal scan length is two

times the scan offset.

To set the parameters type in the desired numbers in the

Offset, Y Scan Offset

entered the desired values click on

and Scan Length.When you have

LABEL

OK. (see also registration mark section)

MARK SIZE

LIN E SIZE

X Scan

X OFFSET

`

Y OFFSET

SCAN LENGTH

Scan Velocity (default 10) sets the speed of the scanning. Depending on the media and registra-

tion mark contrast, this parameter may need to be adjusted. The better the contrast in reflectivity

the faster the scan velocity can be set. If you are experiencing missed registration marks, you may

need to reduce the scan velocity.

X move between jobs is the distance after the farthest excursion of the x-axis during a frame

that the i-TECH should advance to find the target in the next frame of labels. This item is duplicated in the DirectCut printer driver as the space between jobs. These two parameters are added

together so if the printer driver is normally used, the parameter is set to 0. Since the two parameters

are added together you can also use this parameter to allow cutting labels whose distance between

frames is between 1 and 2 inches.

Advanced menu item (This menu item appears if you select the advanced menu on

the Setup Option menu)

Target Scan Direction sets the direction of the scanning operation. For single mark origin

scanning the default target scan direction is

be desirable to reverse the scan direction. For instance, the mark might be printed to close to the

trailing edge of the preceding labels limiting the distance available for scanning. In this instance, it

might be desirable to reverse the scan direction in the X-axis. Consideration must be given in the

+X, +Y. There may be circumstances where it might

22

cut file because the inside edge of the mark will be considered as the 0,0 point for the cutter coordinate system.

Skew Tab

The SmartMark™ system can use one, two

or three registration marks. In standard

operation the i-TECH only requires one

registration mark to accurately cut the die

lines of most labels. If, however, there is a

problem with the printing it may become

desirable to use multiple registration

marks. (see also discussion about marks in

Tutorial Using Adobe Illustrator section)

When using two registration marks the

embedded computer in the i-TECH will

automatically scan both the Origin Point and the

Skew Point. This is helpful if the printing is skewed

in relationship to the media.

When using multiple registration points it is helpful

to understand the FO command and its parameters.

Note: scaling without skew is not implemented.

X, Y Scan offset. This is the distance from the

skew point to perform the Y and X scans to find the

skew point. With the targets defined as above, the X, +Y is the correct signs for the scan offset for the

skew mark.

Scan Skew Point - A fourth scanning mode is

implemented that performs scaling and skewing by scanning only two marks (origin and scale).

This method assumes there is no scaling error in the Y-axis. (Specify the Origin, Skew, and Scale

mode in the printer driver). By checking the scan skew mark off, the i-TECH will only scan the

Scale and Skew mark and perform X-axis scaling and skew correction.

Advanced menu items (These menu items appear if you select the advanced menu

on the Setup Option menu)

Y Target Location. This is the distance between the origin target and the skew target when the

nd

2

parameter of the FO command is –1. This command is used on CAD systems that do not emit

the FO HPGL command. You set up the initialization string to have

BJ1;FO-1,-1; <for origin skew and scale processing>

or

BJ1;FO0,-1; <for origin and skew processing>

This causes the cutter to look at the Y Target Location parameter from this menu item.

Target Scan Direction sets the direction of the scanning operation. The skew mark is normally

scanned

document.

+X,-Y. Changing the direction of the skew scan direction is beyond the scope of this

23

Scale Tab

X, Y Scan Offset. This is the distance

from the scale point to perform the Y and

X scans to find the scale point. With the

targets defined as above, the -X, +Y are

the correct signs of scan offset for the

scale target.

Advanced menu items (These

menu items appear if you select

the advanced menu on the Setup

Option menu)

X Target Location. This is the distance between the origin target and the scale target when the

st

1

parameter of the FO command is –1. This command is used on CAD systems that do not emit

the FO hpgl command. You set up the initialization string to have:

BJ1;FO-1,-1; <for origin skew and scale processing>

This causes the cutter to look at the X target location parameter from this menu item.

Target Scan Direction sets the direction of the scanning operation. The scale mark is normally

scanned

tion. Changing the scale

scan direction is beyond the

scope of this document.

-X,+Y. There may be circumstances where it might be desirable to reverse the scan direc-

Settings Menu

The i-TECH allows six factory or custom set-ups.

Set-Up 1, whether standard

or modified, is automatically

loaded at power up. A user

may modify the speed,

force, (or any feature) on the

control panel. See key

command summary.

Changes to a Set-Up, unless

saved, will be in effect only

until changed from the control panel, CAS software, the unit is

turned off or reloaded.

Any of the features shown in the Setup

Form may be saved to one of the systems 6 memory locations.

To save a custom set-up simply fill in the desired value(s) in the appropriate window, including the

Setup Number, click on the

To load the edit boxes with the current system parameters, input the setup number in the

Save Setup button.

Setup

Number window and then click the Load Setup button.

Setup Number sets the memory position.

Draw Speed is the velocity of the knife when cutting (e.g. while the knife is down).

24

Move Speed is the velocity of the knife when in the up position (not cutting).

Force controls the down force or pressure on the knife.

Knife Offset

with the tip offset from the center of rotation. As the

cutter moves the knife trails behind it, just like a caster

on an office chair. In order to accurately cut the outlines, the computer embedded in the cutter

compensates for the offset of the knife. This parameter sets the offset for those calculations. The figure to

the right shows the path the knife follows; the radius

move at the corner allows for the knife offset. The standard blade (Allen P/N H20-007) available

at our online store at

cm).

All drag knife cutters use a knife blade

http://www.allendatagraph.com has a knife offset of (0.012 inch or 0.0304

CUTTER PATH

Minimum Angle The cutter must stop and then accelerate whenever it makes a sharp turn. At

shallow angles the cutter can continue at the cut velocity without decelerating then accelerating.

This parameter sets the angle where below which the cutter can continue without stopping. High

values increase throughput and lower value increase quality. Good quality can be obtained at reasonable speed at the default value of 12°.

Hole Distance displays and sets the distance between holes when the cutter is used in the pounce

mode.

Tear Size displays and sets the hole size created when the cutter is in the pounce mode.

Acceleration displays and sets the servo acceleration. The unit of measurement is 1/4 g’s or 8

feet per second. This parameter is more important in small graphics than in large labels or text. A

setting of 2 to 8 is generally the best for most label cutting. This parameter does affect throughput

speed on graphics with short vectors. As the graphics get larger the effect of higher acceleration

diminishes. Higher acceleration can degrade cut quality.

Load Speed displays and sets the speed of the material loading and the speed of the material pull

off in the service loop mode.

Load Length displays and sets the length of the material that is pulled during the load cycle and

service loop if the cutter service loop mode is on. This should be turned off on the i-TECH when

the cutter is in the Label Mode.

Dynamic Force (an advanced feature) engages the dynamic force function that instantaneously

adjusts the force on the fly based on the actual velocity of the knife blade. All cutters must accelerate and decelerate as they cut around corners. Some medias require different force settings for

different speeds. This parameter allows for building a database for these materials and when enabled will greatly improve the cutting on these materials. (See the Dynamic Force Section for more

details)

CAd Override On or OFF enables or disables the CAD function. With the function On (dis-

, the cutter will ignore some of the HPGL control commands sent from the cutting software.

abled)

With the function

These commands include:

AS set acceleration

FS set force

KA set minimum angle

KN set knife offset

Off, the software can control these HPGL functions.

25

IP input P1/P2

RO rotate

SC set scale

SP select pen

ST select tool

UV up velocity (move speed)

VS down velocity (cut speed)

Mode sets the operation mode. Select the operation mode cutting, pen plotting/drawing or pounc-

ing.

Coordinate System Allen Sys-

tems have four origins to allow for

flexibility when using various

CAD/CAS systems. The i-TECH is

shipped with the Long X coordinate

system in all factory set-ups and is

compatible with most plotter or printer

drivers. The choice of coordinate systems other than Long X is beyond the

scope of this document.

To restore the factory default to all

setups click the

Restore Default

button.

LOWER LEFT ORI GIN

(LONG Y)

+Y

A a

0,0

TOOL

+X

LOWER RIGHT ORIGIN

(LONG X)

+Y

TOOL

+X

A a

0,0

CENTER ORIGIN

TOOL

A a

-Y

+X

CENTER, ROTATED 180

-X

0,0

+Y

-X

+Y

0,0

+X

DFS COORDINATE SYSTEMS

-Y

A a

TOOL

26

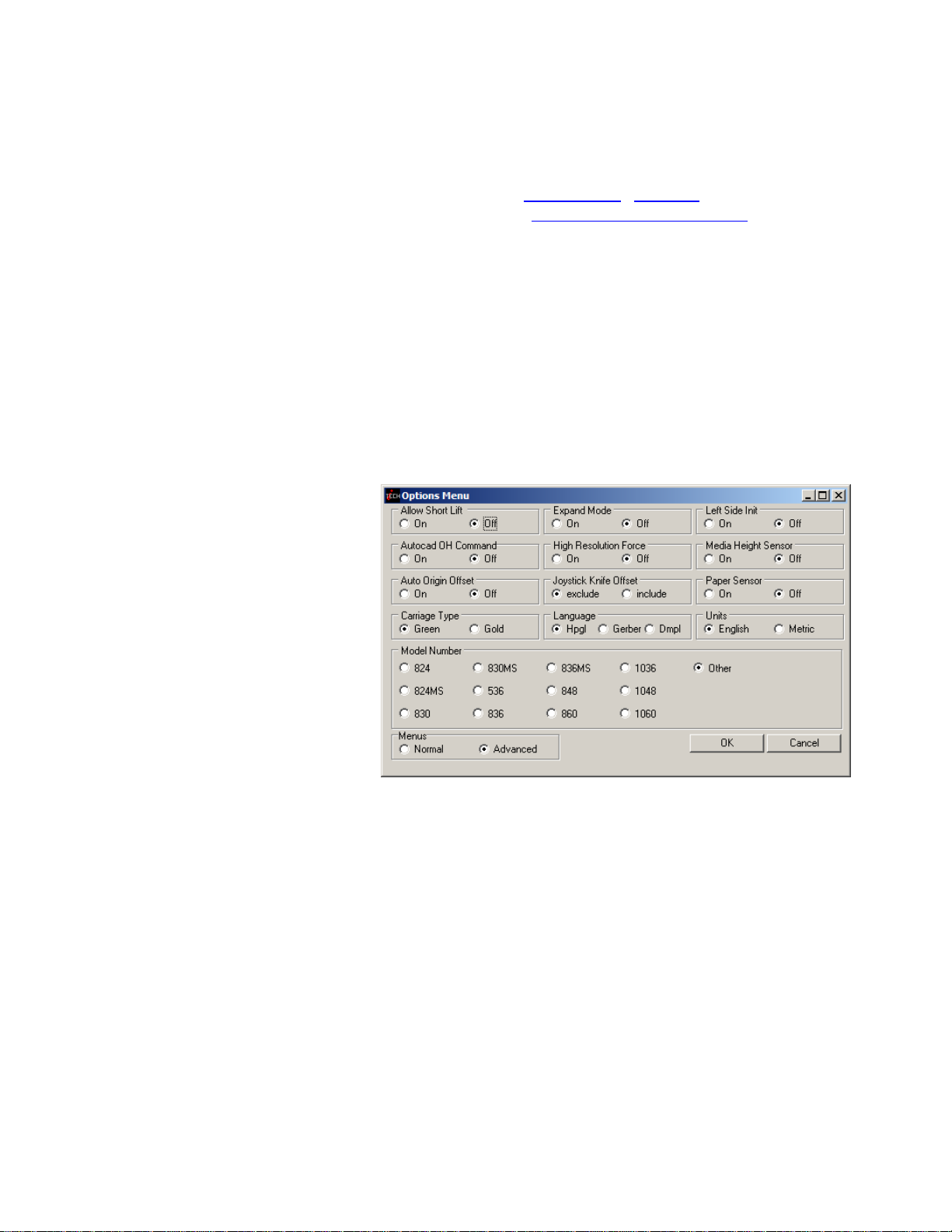

Options Menu

The options menu displays and sets

the following parameters:

Auto Origin Offset determines

whether moving the joystick automatically sets the origin to (0,0).

Most CAD systems and the Allen

DirectCut printer driver require this

option to be set On. Set to Off when

cutting from a CAD system that

does not use the SmartMark™ sensor

such as the Gerber Omega software.

Language determines which lan-

guage the cutter uses. Select Hpgl

for most cad systems and the

DirectCUT

are using Gerber Omega select

Gerber. If your cad system only

output dmpl you can select this language.

TM

Printer Driver. If you

Media Height Sensor turns on or off the load function that senses the width of the media based

on the set up of the pinch wheels. With this function enabled, the cutter head will scan a magnet on

the pinch wheels to establish the height of the media. With the function off, the cutter is loaded

with the maximum width. This option is normally set to Off for label cutting.

Units sets the units of measure to English or Metric units.

Model sets the model number.

Menus option offers the more

advanced features of the

software. It is recommended

this be set to Normal until a

more advance feature is

understood or is required by

your operation. The menu

items below are displayed when

the menus is set to Advanced.

Autocad OH Command

determines how the system will

respond to the HPGL OH

command.

Expand Mode allows the cutter to cut past the normal clip limits in the Y-axis. This function

allows cutting and extra 1/2 inch wide.

High Resolution Force sets the force resolution to 1 to 1000 steps instead of 1 to 100 steps. It

is useful when cutting very hard to cut medias. It allow setting the force between two of the standard force settings. A force of 112 is equivalent to 11.2 % force. (also see the Dynamic Force Section)

Joystick Knife Offset this option controls whether the cutting data point includes or excludes

the knife offset. The normal setting is include. Exclude is used for CadLink’s SignCad program

27

when digitizing only. The SmartMark™ system ignores this setting and properly calculates the location regardless of the setting.

Language sets the computer to either the HPGL (normal) or DMPL language for the plot file.

Dynamic Force Adjust

This feature is considered an advanced feature and does not appear on the Setup menu unless the

menu is set to advanced on the option page. Dynamic Force Adjust sets up the dynamic force parameters and database. To establish a

new material database type in the

name of the new material in the

terial Selection

box and click

Ma-

Add. In the Force and Velocity Win-

dow, type in the desired force vs. velocity that you have established for the

material. The recommended method

for establishing the various force vs.

velocity numbers is to run the test cut

at various velocities and record the

results for entry here.

Enter the Maximum cut speed for the

media in the

window.

Max Draw Speed

Before using Dynamic Force Adjust, it is necessary to send the force setup to the cutter memory by

clicking the

loaded or reset.

Send Force to Cutter button. This needs to be done after each time the cutter is

Com Port menu is used to set the com-

munications port to the Remote Panel only.

It does not set the communications port for

the design software or Allen Windows

Driver. The

communicating directly from the remote

panel while in

Local Echo mode is used in

Terminal Mode.

Font Size sets the font size for the Re-

mote Panel Program.

28

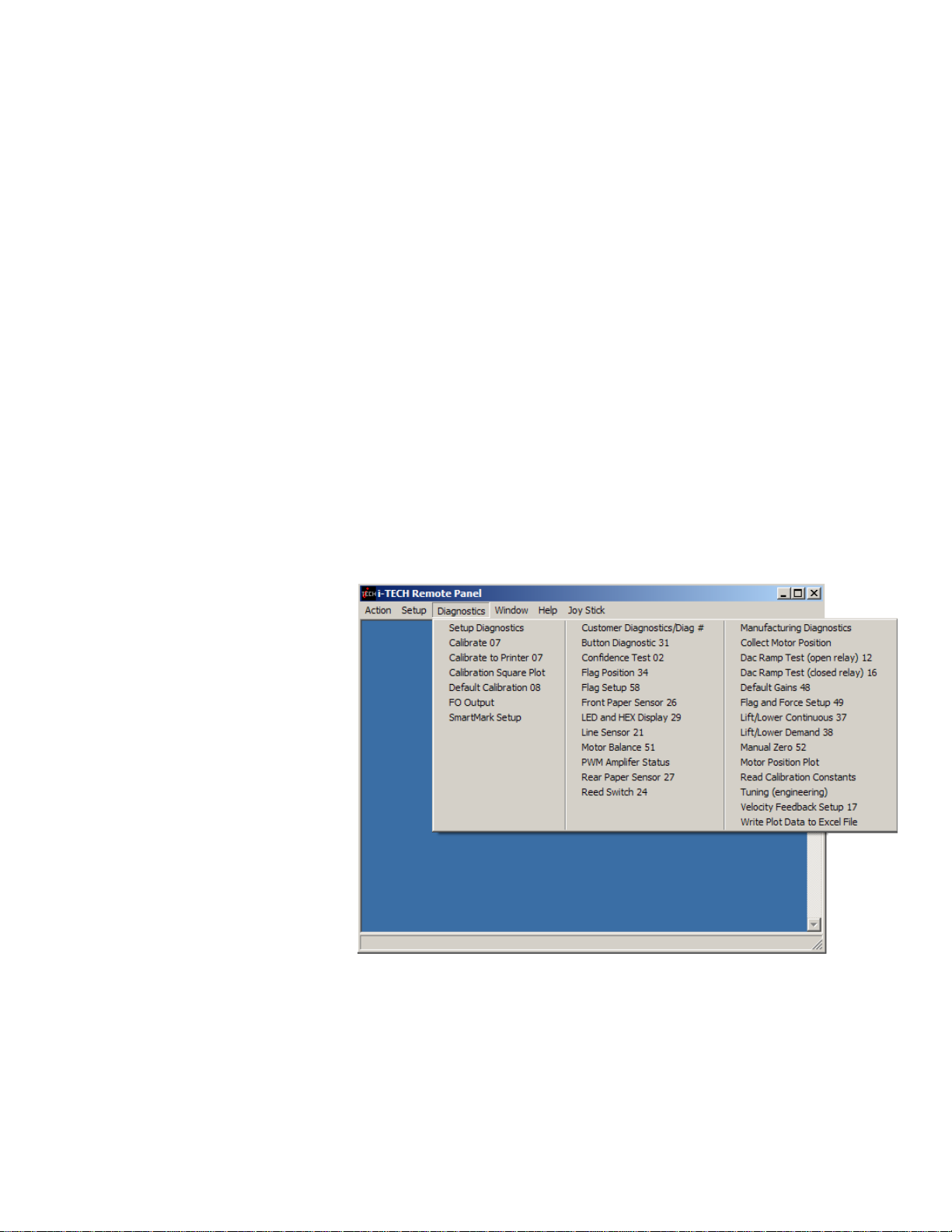

Diagnostics

See the diagnostics section

of this manual. Additional

diagnostics are available if

advanced menus are used.

Joy Stick

JOYSTICK The joystick is used for positioning the

knife and media in the die cutting station.

The four

or cutter carriage that holds the knife blade and the

SmartMark™ sensor. With the Jog/Slew box unchecked

so that Jog/Slew = Slew, the joystick speed will be the

speed set in the Joystick Speed Window. Left Click and hold the arrow button to move the material or carriage. With the Jog/Slew box checked so that Jog/Slew = Jog, the arrow buttons will jog

the cutter that fixed distance each time the button is clicked.

The setting in the Jog Distance Window also sets the jog distance for the Front Panel Joystick buttons.

ARROW KEYS are used to jog the material

i-TECH Cutter Loading Instructions

1. Power on i-TECH CUTTER unit. Allow system to initialize.

2. Insert media from the back of the cutter, passing the media over the lower roller that

has the large black disks, and under the upper roller that has the black rubber o-rings.

3. Pass the media under the pinch wheels.

4. Pass the media through the front rollers in the same fashion as you did in the

rear.

5. Align the right side of the media to the large black disks (front and rear tracking

guides). NOTE:These guides are factory set to be square with the grit wheel, and

should not be relocated unless directed to do so by Allen Datagraph.

6. Using 2 fingers, slide left side tracking guides to within 1/16” of material edge. These

guides have a tension spring in them, which can be adjusted with the 1/8” Allen

wrench supplied in your accessory kit. They should have enough tension to stay in

place during operation, but not so much that they can’t be moved by placing a finger

on each side of the roller and pushing toward the material.

29

7. Manually spool off some material from the roll into the rear media basket. Using the

joystick buttons, move the material forward and back to be sure that proper tracking

can be achieved. Raise the pinch wheels and make any material adjustments necessary.

8. Once proper tracking is achieved, retract the material to the first tracking guide and

press the LOAD button.

SEE APPENDIX C FOR LOADING DIAGRAMS

Installing Knife Blades

Summary

1. Insure plastic groove filler is in.

2. Install knife blade in knife holder.

3. Insure blade is out from depth guide.

4. Load material.

5. Install knife assembly.

6. Set machine to C

7. Perform cut test pattern.

8. Adjust force, offset and depth guide.

CAUTION: To avoid personal injury, keep hands, hair, clothing and jewelry away from

the cutter's moving parts at all times.

UT MODE.

Installing replacement blades

The knife blade should be replaced when the force has been increased by more than 20 percent or

the cut quality has degraded. The first sign of blade degradation usually occurs in the corners of

the cut and may lead to poor weeding.

New blades slide into the holder to a preset height and are held in magnetically. No tools or adjustments are required. To replace the blade, first remove the blade holder from the tool holder by

loosening the brass thumbscrew and pulling up on the silver knife holder. To remove the used

blade, grasp it with a pair of tweezers and pull it out of the knife holder (discard the blade safely).

Remove the new blade from the plastic case and remove the protective cap. Insert the blade into

the holder and let the magnet pull it into the preset position. Reinsert the knife holder into the tool

holder and tighten the brass thumbscrew.

Replacement blades are available from several sources including from Allen Datagraph Systems,

Inc. They can be purchased online @

(Allen P/N H20-007 45° for vinyl, H20-008 60° for thick materials and heavy laminates)

http://www.allendatagraph.com/ or by calling 603-893-1983.

Tool Holder Block

The knife blade holder is installed in the tool holder block with a thumbscrew. The tool holder

block is held to the cutting head by two hex drive screws.

Knife blade holder Assembly

The blade holder is designed for use with Allen Datagraph’s 45 and 60-degree blades. Solvents and

lubricants should

not be used, as they will diminish cutting accuracy.

30

Knife Blades

Knifes blades for the Allen Datagraph i-TECH Unit are made with tungsten carbide and are designed specifically for digital die cutting. The tip is offset from the center of the shaft so that the

blade has a caster action when pulled. Blades are available in 45 and 60-degree tip angles. The 60degree is intended only for thick materials such as sandblast mask or thick over-laminates. For best

cutting results, protect the knife tip from damage when not in use.

Knife Blades Depth Guide

Allen Datagraph's controlled depth knife holder has a depth guide that is adjustable to control the

depth of cut the cutter makes. Correct adjustments allow the blade to cut the material and lightly

mark the backer (carrier) material. Too much cut depth can cause cut through and premature blade

wear. Not enough cut depth will make "weeding" of media difficult.

Use the cut test, force and depth adjustment to establish good cutting (see setting cut force – cut

depth section)

Use the cut test and force to establish good cutting (see setting cut force – cut depth section)

Groove Filler

Clean any debris from the groove before installing a new groove filler. The filler simply snaps into

and out of place with no special tools required. It is important that the groove filler be installed

fully and evenly, otherwise material cut through may occur in some sections across the plotter. The groove filler should be installed for knives and pen plotting, but must be removed for

Pouncing

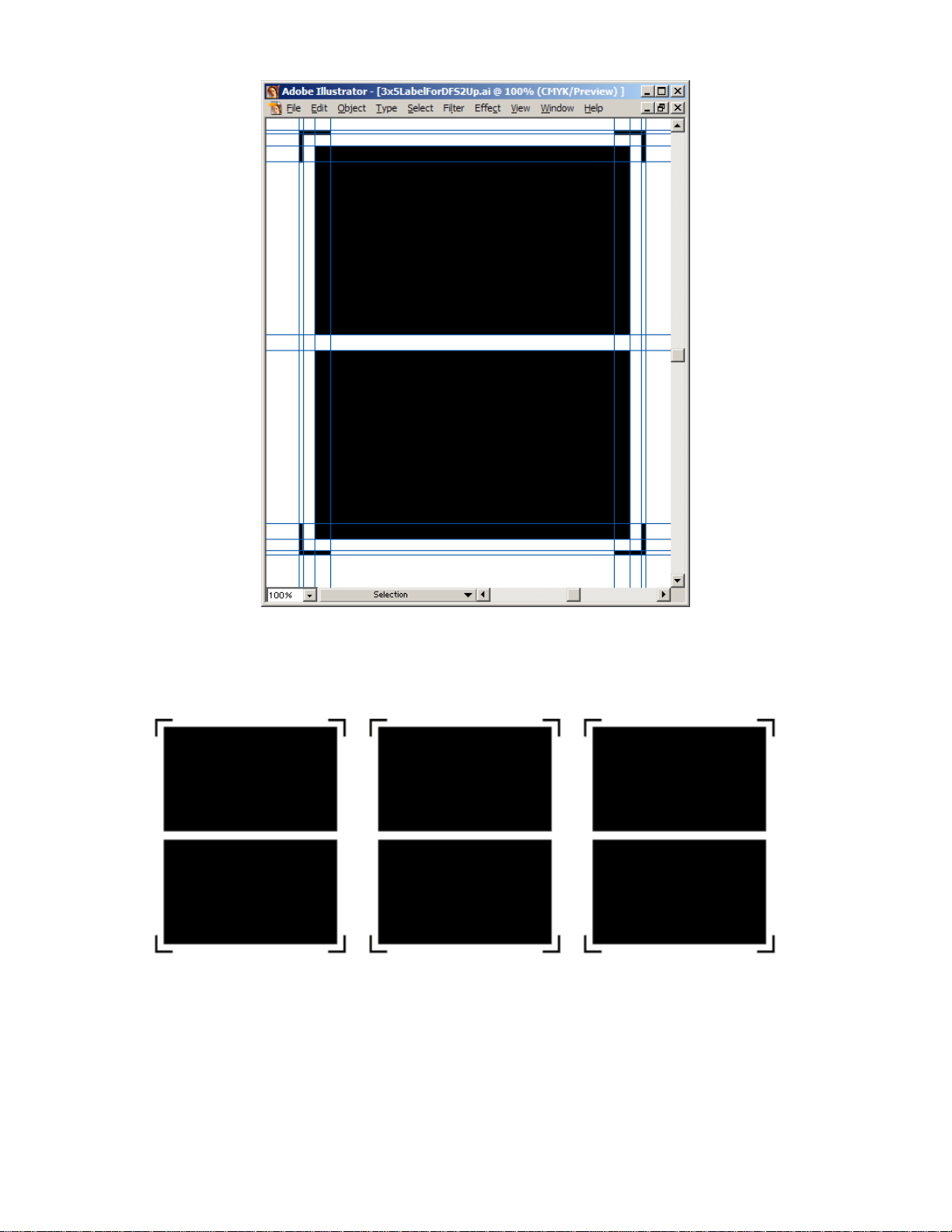

Tutorial Using Adobe Illustrator and SmartMark

Several additional documents have been written for using the printer driver with various CAD programs. They are on the tech support page of the Allen Datagraph web site.

http://www.allendatagraph.com.

TM

The most common CAD program used by our customers for label design and cut line preparation is

Adobe Illustrator 10. Other programs can be used as well as long as they send vectors rather than

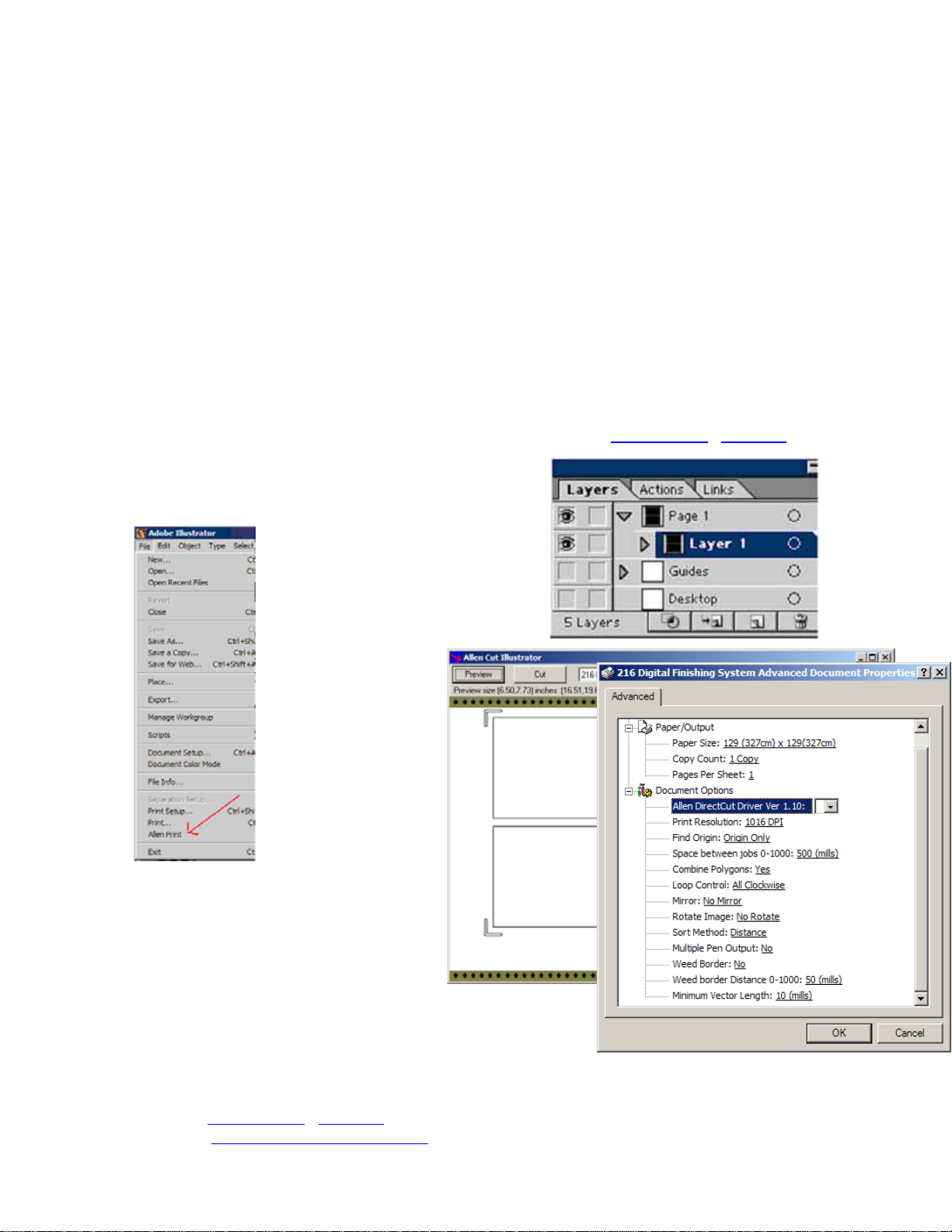

raster images to the printer driver. Allen Datagraph has implemented the Allen Print utility for