Allen-Bradley 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix Programming Manual

...Page 1

Programming Manual

Logix 5000 Controllers Produced and

Consumed Tags

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069 CompactLogix,

5069 Compact GuardLogix, Studio 5000 Logix Emulate

Page 2

Important user information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this

equipment before you install, configure, operate, or maintain this product. Users ar e required to familiarize themselves with installation and

wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried

out by suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described

in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerat ions.

WARNING: Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a

hazard, and recognize the consequence

Important:

Labels may also be on or inside the equipment to provide specific precautions.

Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to

alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control

center, to alert people to potential Arc Flash. Arc Flash will cause severe injury or death. Wear

proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradle y, Rockwell Software, Rockwell Automation, and TechConnect ar e t r ademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Auto mat ion are property of their respective companies.

Page 3

The graphical user interface has been updated in

Summary of Changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table identifies changes that apply to all information about a subject in

the manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that

subject.

Subject Reason

Updated screen shots

throughout.

Updated supported controllers . Logix Designer supports new 5069 Compact

release 31 of the Logix Designer application.

GuardLogix controllers.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Topic Name Reason

Additional Resources on page 7 Added controller user manuals as additional

resources

Controllers and networks that support

produced/consumed tags on page 12

Considerations when migrating projects that cont ain

multicast produce tags on page 13

Considerations when migrating projects that contain

multicast produce tags on page 13

Organize tags for produced or consumed data on

page 14

Create a produced tag on page 16 Renamed Produce a tag to Create a produce tag

Create a consumed ta g on page 18 Minor changes to the Create a consumed tag

Set RPI limits, default for producer tag on page 25 Updated the RPI limits and default procedure

Updated information on networks that support

produced and consumed tags

Added safety consumed tags on Compact

GuardLogix 5380 and GuardLogix 5580 controllers

considerations

Updated the versions of software for multicast

consumers running releases v18 and later

Updated the controller projects to be verified to

include Compact GuardLogix 5380 and GuardLogix

5580 controllers

Minor changes to the Create a produced tag

procedure

procedure

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 3

Page 4

Summary of Changes

Consideration when migrating projects that contain

multicast produ ce tag s on page 13

Organize tags for produced or consumed data on

page 14

RPI limitations and negotiated default on page 23

Set RPI limits, default for producer tag on page 25

RPI I/O faults on page 37

Set up the consuming controller on page 28 Renamed Set up the consumer tag to Set up the

Renamed Allow Consumed Tags to Use RPI

Provided by Consumer to Allow Consumed Tags to

Use RPI Provided by Producer parameter

consuming controller and updated the procedure

4 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 5

Preface

Produce and

Produce a Large

Index

Table of contents

Consume a Tag

Additional Resources ...................................................................................... 7

Legal notices ................................................................................................... 8

Chapter 1

Introduction ................................................................................................... 11

Controllers and networks that support produced/consumed tags .................. 12

Connection requirements of a produced or consumed tag ............................ 12

Considerations when migrating projects that contain multicast produce tags

...................................................................................................................... 13

Organize tags for produced or consumed data .............................................. 14

Adjust for bandwidth limitations ............................................................ 15

Create a produced tag ................................................................................... 16

Create a consumed tag .................................................................................. 18

Additional steps for a PLC-5C controller ............................................... 22

RPI limitations and negotiated default .......................................................... 23

Set RPI limits, de fault for produc er ta g ........................................................ 25

Unicast connection option ...................................................................... 27

Set up the consuming controller ................................................................... 28

Verify consumed tag acceptance .................................................................. 29

Produced and consumed RPI scenarios ........................................................ 32

Scenario 1 ............................................................................................... 32

Scenario 2 ............................................................................................... 33

Scenario 3 ............................................................................................... 34

Scenario 4 ............................................................................................... 35

1769-L2x and 1769-L3x RPI limits .............................................................. 35

RPI I/O faults ................................................................................................ 37

Array

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 5

Chapter 2

Introduction ................................................................................................... 39

Produce a large array .................................................................................... 40

Page 6

Page 7

Additional

Preface

This manual details how, with a Logix 5000 controller, to produce and

consume standard tags and produce a large array. For information on

produced/consumed safety tags, refer to the documentation specific to your

controller.

This manual is one of a set of related manuals that show common procedures

for programming and operating Logix 5000™ controllers.

Resources

For a complete list of common procedures manuals, refer to the

Logix 5000

Controllers Common Procedures Programming Manual , publication 1756PM001 .

The term Logix 5000 controller refers to any controller that is based on the

Logix 5000 operating system.

These documents contain additional information concerning related

Rockwell Automation products.

Resource Description

Replacement Guidelines: Logix5000

Controllers Reference Manual ,

publication 1756-RM100

ControlLogix 5580 and GuardLogix

5580 Controllers User Manual ,

publication 1756-UM543

CompactLogix 5380 and Compact

GuardLogix 5380 Controllers User

Manual , publication 5069-UM001

GuardLogix 5570 Controllers User

Manual , publication 1756-UM022

Compact GuardLogix 5370 Controllers

User Manual , publication 1769-UM022

Industrial Automation Wiring and

Grounding Guidelines , publication

1770-4.1

Product Certifications webpage,

available at

http://ab.rockwellautomation.com

Provides guidelines for migrating

projects from ControlLogix 5560/5570

controllers to ControlLogix 5580

controllers, and from CompactLogix

5370 controllers to CompactLogix 5380

controllers.

Provides information about designing a

system, operating a ControlLogix or

GuardLogix-based 5580 contr oller s

system, and developing applications.

Explains how to use the CompactLogix

and Compact GuardLogix 5380

Controllers.

Describes the GuardLogix-specific

procedures to configure, operate, and

troubleshoot your controller.

Describes the necessary tasks to install,

configure, program, and operate a

Compact GuardLogix 5370 controller.

Provides general guidelines for

installing a Rockwell Automation

industrial system.

Provides declarations of conformity,

certificates, and other certification

details.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 7

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor

or sales representative.

Page 8

Preface

Legal notices

Copyright notice

Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights

Reserved. Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement

for details.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement

("EULA") by opening the License.rtf file located in your product's install

folder on your hard drive.

Other Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product can be located at their respective web

site(s).

You may alternately obtain complete Corresponding Source code by

contacting Rockwell Automation via our Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page .

Please include "Open Source" as part of the request text.

The following open source software is used in this product:

Software Copyright License Name License Text

AngularJS Copyright 2010-2017 Google, Inc. MIT License AngularJS 1.5.9 License

Bootstrap Copyright 2011-2017 Twitter, Inc.

Copyright 2011-2017 The Bootstrap Authors

jQuery Copyright 2005, 2014 JS Foundation and

other contributors

OpenSans Copyright 2017 Google, Inc. Apache License,

MIT License Bootstrap 3.3.7 License

MIT License jQuery 2.1.1 License

OpenSans License

Version 2.0

Trademark Notices

Allen-Bradley, ControlBus, ControlFLASH, Compact GuardLogix, Compact

I/O, ControlLogix, CompactLogix, DCM, DH+, Data Highway Plus,

DriveLogix, DPI, DriveTools, Explorer, FactoryTalk, FactoryTalk

Administration Console, FactoryTalk Alarms and Events, FactoryTalk Batch,

FactoryTalk Directory, FactoryTalk Security, FactoryTalk Services Platform,

FactoryTalk View, FactoryTalk View SE, FLEX Ex, FlexLogix, FLEX I/O,

8 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 9

Preface

Guard I/O, High Performance Drive, Integrated Architectu r e, K in e tix,

Logix5000, Logix 5000, Logix5550, MicroLogix, DeviceNet, EtherNet/IP,

PLC-2, PLC-3, PLC-5, PanelBuilder, PowerFlex, PhaseManager, POINT

I/O, PowerFlex, Rockwell Automation, RSBizWare, Rockwell Software,

RSEmulate, Historian, RSFieldbus, RSLinx, RSLogix, RSNetWorx for

DeviceNet, RSNetWorx for EtherNet/IP, RSMACC, RSView, RSView32,

Rockwell Software Studio 5000 Automation Engineering & Design

Environment, Studio 5000 View Designer, SCANport, SLC, SoftLogix,

SMC Flex, Studio 5000, Ultra 100, Ultra 200, VersaView, WINtelligent,

XM, SequenceManager are trademarks of Rockwell Automation, Inc.

Any Rockwell Automation logo, software or hardware product not

mentioned herein is also a trademark, registered or otherwise, of Rockwell

Automation, Inc.

Other Trademarks

CmFAS Assistant, CmDongle, CodeMeter, CodeMeter Control Center, and

WIBU are trademarks of WIBU-SYSTEMS AG in the United States and/or

other countries. Microsoft is a registered trademark of Microsoft Corporation

in the United States and/or other countries. ControlNet is a trademark of

ControlNet International. DeviceNet is a trademark of the Open DeviceNet

Vendors Association (ODVA). Ethernet/IP is a trademark of ControlNet

International under license by ODVA.

All other trademarks are the property of their respective holders and are

hereby acknowledged.

Warranty

This product is warranted in accordance with the product license. The

product’s performance may be affected by system configuration, the

application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors.

The instructions in this document do not cover all the details or variations in

the equipment, procedure, or process described, nor do they provide

directions for meeting every possible contingency during installation,

operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however,

the accompanying software may have changed since the release. Rockwell

Automation, Inc. reserves the right to change any information contained in

this document or the software at any time without prior notice. It is your

responsibility to obtain the most current information available from Rockwell

when installing or using this product.

Environmental compliance

Rockwell Automation maintains current product environmental information

on its website at

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 9

Page 10

Preface

http://www.rockwellautomation.com/rockwellautomation/aboutus/sustainability-ethics/product-environmental-compliance.page

Contact Rockwell Automation

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

10 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 11

must match the data type (including any array dimensions) of the produced tag. The

Introduction

Chapter 1

Produce and Consume a Tag

A Logix 5000™ controller lets you produce (broadcast) and consume

(receive) system-shared tag s.

Term Definition

Produced tag A tag that a controller makes available for use by other controllers. Multiple

controllers can simultaneously consu me (receiv e) t he data. A produced tag sends

its data to one or more consumed tags (consumers) without using logic.

Consumed tag A tag that receives the data of a produced tag. The data type of the consumed tag

RPI of the consumed tag determines the period at which the data updates.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 11

Page 12

Chapter 1

Produce and Consume a Tag

Example:

Controllers and

Connection

networks that

support

produced/consumed

tags

requirements of a

produced or

consumed tag

For two controllers to share produced or consumed tags, both controllers

must be in the same backplane or attached to the same control network,

such as ControlNet or EtherNet/IP network. Although produced and

consumed tags can be bridged over two networks, Rockwell Automation®

does not support this configuration. Check the documentation specific to

your controller to determine which network connections it supports.

Produced and consumed tags each require connections. As the number of

controllers that can consume a produced tag increases, the number of

connections the controller has available for other operations, like

communication and I/O, is reduced.

Important:

Each produced or consumed tag uses the following connections.

This Type of Tag Uses This Many Connections

Produced tag number_of_consumers + 1

Consumed tag 1

Communication Paths to Compact GuardLogix 5380, CompactLogix

5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580

controllers

If a controller running release v24 or earlier is to consume tag data from

Compact GuardLogix 5380, CompactLogix 5380, CompactLogix 5480,

ControlLogix 5580, or GuardLogix 5580 controller, it must have a target

device in its I/O configuration for the connection. However, releases v24 and

earlier do not have profiles for Compact GuardLogix 5380, CompactLogix

5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580

controllers, so a substitute must be used.

If a consumed-tag connection fails, all of the other tags being consumed

from that remote controller stop receiving new data.

Connection Requirements of a Produced or Consumed Tag

• A ControlLogix controller producing 4 tags for 1 controller uses 8

connections:

• Each tag uses 2 connections (1 consumer + 1 = 2).

• 2 connections per tag x 4 tags = 8 connections.

• Consuming 4 tags from a controller uses 4 connections (1 connection

per tag x 4 tags = 4 connections).

12 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Rockwell recommends the following substitutes:

• To consume tags through the embedded Ethernet port on Compact

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480,

ControlLogix 5580, or GuardLogix 5580 controller, represent the

controller as a CompactLogix 5370 Controller, such as the 1769-

Page 13

Produce and Consume a Tag

Chapter 1

Considerations

when migrating

projects that

L36ERM, in the consuming controller’s I/O configuration. These

controllers have a built-in Ethernet port and therefore can be addressed

using an EtherNet/IP Address.

• To consume tags through the backplane port on a GuardLogix 5580 or

ControlLogix 5580 controller, represent the controller as a

ControlLogix 5570, such as the 1756-L75, in the consuming

controller’s I/O configuration. This process allows connection using

the backplane.

When you migrate projects from an earlier controller model to Compact

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix

5580, or GuardLogix 5580 controller, you need to verify that projects

containing multicast produce tags are configured correctly.

contain multicast

produce tags

Compact GuardLogix 5380 and GuardLogix 5580 controllers in v31

only produce safety tags as unicast

Compact GuardLogix 5380 and GuardLogix 5580 controllers only produce

safety tags as unicast. They can consume safety tags as either unicast or

multicast. When configuring a consumed safety tag, consider the capabilities

of the producer.

• If the producer in the I/O configuration of this controller is a Compact

GuardLogix 5380 or GuardLogix 5580 controller, and you are

consuming a safety tag, configure the consumed tag to use unicast.

• If the producer in the I/O configuration of this controller is a Compact

GuardLogix 5370 or GuardLogix 5570 or 5560 controller, the safety

consumed tag can be configured as wither unicast or multicast.

RPI limitation s

In releases before v28, produced tags produce data at the requested packet

interval (RPI) of the fastest requesting consumer. This behavior allows

multiple consumers, with different RPI settings, to successfully connect to a

producer. In releases v28 and later, the first consumer of a produced tag

determines the RPI at which data is produced. All subsequent consumers

must request the same RPI value as the first consumer or they fail to connect

and display error code 0112.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 13

The first consumer of a produced tag is the device that sends the fi rs t

consumer connection to the producing controller. The first consumer request

is based on the order in which the producer and consumer control system

powers up, so the first consumer can change if power is cycled to the system.

You cannot configure a device to be the first consumer. It can be difficult to

tell which consumer will send the first request to the producing controller, so

you should plan accordingly when configuring multicast produced tags.

Page 14

Chapter 1

Produce and Consume a Tag

Organize tags for

To make sure consumers of produced tags can connect to Compact

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix

5580, and GuardLogix 5580 controllers, take the following steps:

• For consumers running releases v17 and earlier that are consumers of a

produced tag from Compact GuardLogix 5380, CompactLogix 5380,

CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580

controllers:

• Verify that all multicast consumed tags of a produced tag are

configured with the same RPI. If they are not, some consumers will

fail to connect.

• For multicast consumers running releases v18 and later, take one of

these steps:

• Verify that all multicast consumed tags of a produce tag are

configured with the same RPI, or

• Verify that all multicast consumers are configured to Allow

Consumed Tags To Use RPI Provided By Producer.

For more information on replacing a ControlLogix 5560/5570 controller with

a ControlLogix 5580 controller or a CompactLogix 5370 controller with a

CompactLogix 5380 controller, refer to the following publication in the

Rockwell Literature Library

:

produced or

consumed data

Guideline Details

Create the tags at the controller

scope.

Use one of these data types:

• DINT

• REAL

• Array of DINTs or REALs

• User-defined

To share tags with a PLC-5C

controller, use a user-defined

data type.

Only controller-scoped tags can be shared.

To share other data types, create a user-defined data type that contains the required

data.

Use the same data type for the produced tag and corresponding consumed tag or tags.

To This Then

Produce Integers Create a user-defined data type that contains an array of INTs

Replacement Guidelines: Logix5000 Controllers Reference Manual (1756RM100).

Follow these guidelines when organizing tags for produced or consumed

data (shared data).

with an even number of elements, such as INT[2]. (When you

produce INTs, you must produce two or more.)

Only one

REAL value

More than

one REAL

value

Use the REAL data type.

Create a user-defined data type that contains an array of

REALs.

14 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 15

Produce and Consume a Tag

Chapter 1

defined data types. (This uses fewer connections than producing

Adjust for bandwidth

Guideline Details

Consume Integers Create a user-defined data type that contains these members.

Limit the size of the standard tag

to 500 bytes.

Use the highest permissible RPI

for your application.

Verify that Compact GuardLogix

5380, CompactLogix 5380,

CompactLogix 5480,

ControlLogix 5580, or

GuardLogix 5580 controller

projects containing multicast

produce tags are configured

correctly.

Combine data that goes to the

same controller.

If you must transfer more than 500 bytes, create logic to transfer the data in packets.

If the produced tag is over a ControlNet network, the tag may need to be less than 500

bytes.

Important: Produced and consum ed safety tags are lim ited to 128 bytes.

If the controller consumes the tag over a ControlNet network, use a binary multiple of the

ControlNet network update time (NUT). For example, if the NUT is 5 ms, use an RPI of 5,

10, 20, 40 ms, and so forth.

Take the following steps to make sure consumers of produce tags can connect:

• For consumers running Logix Designer releases v17 and earlier that are consumers of

a producer from a Compact GuardLogix 5380, CompactLogix 5380, CompactLogix

5480, ControlLogix 5580, or GuardLogix 5580 controller:

• For multicast consumers running Logix Designer releases v18 and later, take one of

these steps:

If you are producing several tags for the same controller, group the data:

• Into one or more usereach tag separately.)

• According to similar update intervals. (To conserve network bandwidth, use a greater

RPI for less critical data.)

For example, you could create one tag for data that is critical and another tag for data

that is not as critical.

Data Type Description

DINT Status

INT[x], where x is the output size of the

data from the PLC-5C controller. (If you

are consuming only one INT, omit x.)

• Verify that all multicast consumed tags of a produce tag are configured with

the same RPI. If they are not, some consumers will fail to connect.

• Verify that all multicast consumed tags of a produce tag are configured with

the same RPI, or

• Verify that all multicast consumers are configured to Allo w Consumed Tag s

To Use RPI Provided By Producer.

Data produced by

a PLC-5C

controller

limitations

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 15

When a tag is shared over a ControlNet network, the tag must fit within the

bandwidth of the network.

• As the number of connections over a ControlNet network increases,

several connections, including produced or consumed tags, may need

to share a network update time (NUT).

• Since a ControlNet network can pass only 500 bytes in one NUT, the

data of each connection must be less than 500 bytes to fit into the

NUT.

Depending on the size of the system, there may not be enough bandwidth on

the ControlNet network for a tag of 500 bytes. If a tag is too large for the

ControlNet network, make one or more of these adjustments.

Page 16

Chapter 1

Produce and Consume a Tag

timestamp, or schedule data require direct con nections and cannot take advantage

Create a produced

Adjustment Description

Reduce your NUT. At a faster NUT, less connections have to share an update slot.

Increase the requested packet interval

(RPI) of your connections.

For a ControlNet bridge module (CNB)

in a remote chassis, choose the most

efficient communication format for that

chassis:

Separate the tag into two or more

smaller tags.

Create logic to transfer the data in

smaller sections ( packets).

At higher RPIs, connections can take turns sending data during an update slot.

Are most of the modules in the

chassis non-diagnostic, digital I/O

modules?

Yes Rack Optimization

No None

The Rack Optimization format uses an additional 8 bytes for each slot in its

chassis . Analog modules or modules that are sending or getting diagnostic, fuse,

of the rack optimized form. Choosing None frees up the 8 bytes per slot for other

uses, such as produced or consumed tags.

1. Group the data according to similar update rates. For example, create one tag

for data that is critical and another tag for data that is not as critical.

2. Assign a different RPI to each tag.

See Produce a Large Array.

Then choose this communication

format for the remote CNB module.

tag

The produced tag sends its data to one or more consumed tags without using

logic, and can be used simultaneously by multiple controllers.

To create a produced tag:

1. Open the Logix Designer application and choose a controller.

Important:

A controller can have both producing and consuming tags, but a

producer cannot consume its own data. The local controller is the

consumer, and the remote controller is the producer.

2. In the Controller Organizer, right-click Controller Tags and click Edit

Tags.

Only controller-scoped tags can be shared.

3. In the Tag Editor, right-click the tag that you want to be a producer,

and click Edit (name of tag) Properties.

16 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 17

Produce and Consume a Tag

Chapter 1

4. In the Type box, click Produced.

The Connection button becomes available when Type is either

Produced or Consumed.

5. Click Connection to define the produced tag. The Produced Tag

Connection dialog box opens.

6. In the Max Consumers box, type the number of controllers to

consume (receive) this tag.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 17

7. (optional) Click Advanced to open the Advanced Options dialog box

to change the RPI range limitation, negotiated default, or unicast

connection.

Page 18

Chapter 1

Produce and Consume a Tag

Important:

Create a consumed

tag

Tip: The Advanced button is available for controllers using version 18

and later of the application.

8. Click OK to close the Produced Tag Connection dialog box.

9. Click OK to close the Tag Properties dialog box.

The consumed tag receives data of a produced tag. The data type of the

consumed tag must match the data type (including any array dimensions) of

the produced tag.

Before you begin:

• Add the controller that is producing the data to the Controller

Organizer I/O Configuration folder.

To create a consumed tag:

1. Open the Logix Designer application and choose a controller.

A controller can have both producing and consuming tags, but a

producer cannot consume its own data. The local controller is the

consumer, and the remote controller is the producer.

2. In the Controller Organizer, right-click Controller Tags and click

Edit Tags.

You can consume only controller-scoped tag s.

18 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 19

Produce and Consume a Tag

Chapter 1

3. In the Tag Editor, right-click the tag that will consume the data, and

then click Edit (name of tag) Properties.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 19

4. In the Type box, click Consumed.

The Connection button becomes available when Type is either

Produced or Consumed.

5. In the Data Type box, select the data type.

If the producing

controller is

Logix5000 controller Same data type as the produced tag.

PLC-5C controller User-defined data type with these members.

Then the data type should be

Data type Description

Page 20

Chapter 1

Produce and Consume a Tag

If the producing

controller is

Then the data type should be

DINT Status

INT[x], where x is the output size of the data from

the PLC-5C controller. (If you are consuming only

one INT, omit x.)

Data produced by a PLC-5C

controller

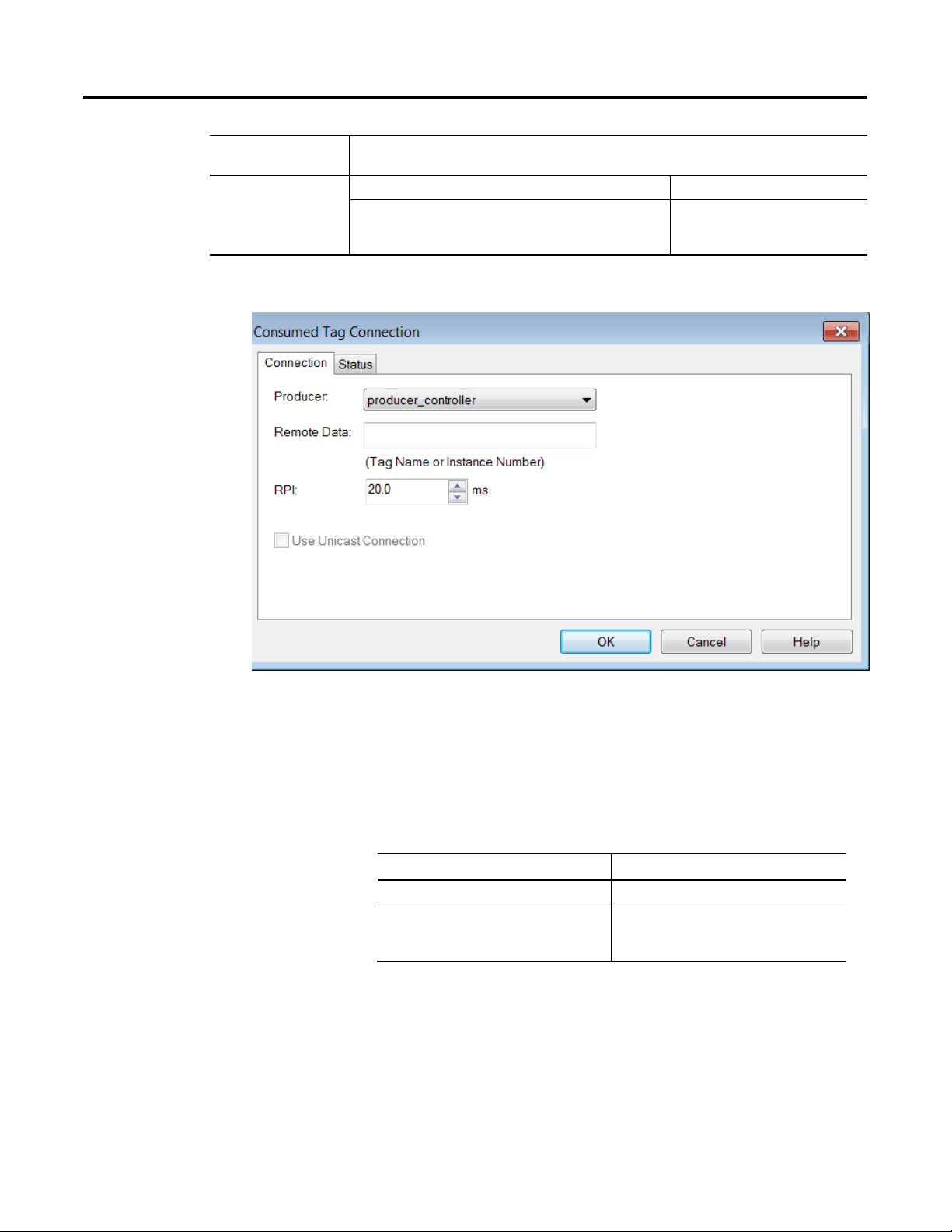

6. Click Connection to define the consumed tag.

7. In the Producer box, select the controller that produces the data.

If the list is empty, add a remote controller to the Controller Organizer

I/O Configuration folder.

8. In the Remote Data box, type the name or the instance number of the

produced tag.

If the producing controller is Then type or choose

Logix5000 controller Tag name of the produced tag

PLC-5C controller Message number from the

ControlNet configuration of the

PLC-5C controller

9. In the RPI box, enter the requested packet interval (RPI) for the

connection.

20 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 21

Produce and Consume a Tag

Chapter 1

Consuming controllers have additional setup to allow its consuming

Important:

tags to use an RPI provided by a producing controller. Refer to Set

RPI Limits, Default for Producer Tag for details.

10. If applicable, clear the Use Unicas t Connec tion check box to use a

Multicast connection.

A Unicast connection is the default unless you are configuring a

standard consumed tag and the communication path between the

producer and consumer does not cross EtherNet/IP or is across the

backplane. Then the check box is cleared and unavailable.

11. Click the Status tab to configure the status properties for the consumed

tags.

12. In the Data Type box, select the data type that allows for connection

status.

13. Click OK to close the Consumed Tag Connection dialog box.

14. Click OK to close the Tag Properties dialog box.

Tip:

If you consume the tag over a ControlNet network, use RSNetWorx for

ControlNet software to schedule the network.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 21

Page 22

Chapter 1

Produce and Consume a Tag

Action

Details

In the Message size, enter two times the number of REALs

Additional steps for a

PLC-5C controller

When sharing data with a PLC-5C controller, do the following.

In the ControlNet configuration

of the PLC-5C controller,

schedule a message.

If the PLC-5C controller

consumes REALs, reconstruct

the values.

If the PLC-5C controller

consumes REALs, reconstruct

the values.

If the PLC-5C

controller

Produces Integers In the ControlNet configuration of the PLC-5C contr oll er ,

Consumes

When you produce REALs (32-bit floating-point values) for a PLC-5C controller, the PLC-5C

controller stores the data in consecutive 16-bit integers.

• The first integer contains the upper (leftmost) bits of the value.

• The second integer contains the lower (rightmost) bits of the value.

This pattern continues for each floating-point value.

When you produce REALs (32-bit floating-point values) for a PLC-5C controller, the PLC-5C

controller stores the data in consecutive 16-bit integers.

• The first integer contains the upper (leftmost) bits of the value.

• The second integer contains the lower (rightmost) bit s of the value.

This pattern continues for each floating-point value.

This Then in RSNetWorx software

insert a Send Scheduled Message.

Integers Do these steps in the ControlNet configuration of the PLC-5C

controller.

• Insert a Receive Scheduled Message.

• In the Message size, enter the number of integers in the

produced tag.

REALs Do these steps in the ControlNet configuration of the PLC-5C

controller.

• Insert a Receive Scheduled Message.

•

in the produced tag. For example, if the produced tag

contains

10 REALs, enter 20 for the Message size.

The following example shows how to reconstruct a REAL (floating-point

value) in the PLC-5C controller.

22 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 23

Produce and Consume a Tag

Chapter 1

Example:

RPI limitations and

Reconstruct a floating point value.

The two MOV instructions reverse the order of the integers as the

integers move to a new location. Because the destination of the COP

instruction is a floating-point address, it takes two consecutive

integers, for a total of 32 bits, and converts them to a single floatingpoint value.

negotiated default

RPI limitations and negotiated behavior vary depending on the version of the

Logix Designer application that is running on your controllers.

Behavior in releases v28 and later

In releases v28 and later, the first consumer of a produce tag determines the

RPI at which data is produced. All subsequent consumers must request the

same RPI value as the first consumer or they fail to connect and display error

code 0112.

The first consumer of a produce tag is the device that sends the first

consumer connection to the producing controller. The first consumer request

is based on the order in which the producer and consumer control system

powers up, so the first consumer can change if power is cycled to the system.

You cannot configure a device to be the first consumer. There is no way to

tell which consumer will send the first request to the producing controller, so

you must plan accordingly when configuring multicast produce tags. See

Considerations when migrating projects that contain multicast produce tags

on page 13 for more information.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 23

Page 24

Chapter 1

Produce and Consume a Tag

Tip:

The controller’s backplane and Ethernet ports can support different RPIs. If

multiple consumers need to connect to the controller at different RPIs, you

can configure them to connect through the backplane or the Ethernet port.

See Connection requirements of a produced or consumed tag on page 12

more information.

for

Behavior in releases v18 to v27

In versions 18 and earlier, controllers can be programmed to enhance the

requested packet interval (RPI) acceptance between producing and

consuming tags within specified limitations for multicast connections. A

producing controller verifies that the RPI of incoming connections are within

the produced tag settings. If the consuming tag’s RPI falls outside the

configured range, a producing controller will reject the incoming RPI and

may provide an RPI (default) to the consuming controller.

This optional default RPI applies only if the consuming controller is set up to

allow its consumed tags to use an RPI provided by the producer. You can

choose to not use the default value. However, you will have to manually

change a rejected RPI to make the value within the limitation settings for the

produced tag.

Tip:

1769-L2x and 1769-L3x controllers have additional RPI information. See

1769-L2x and 1769-L3x RPI Limits on page 35

for details.

If you have multicast consumers running Logix Designer releases v18 and

later, take the following steps to make sure consumers of produce tags can

connect:

• Verify that all multicast consumed tags of a produce tag are configured

with the same RPI, or

• Verify that all multicast consumers are configured to Allow

Consumed Tags To Use RPI Provided By Producer.

Behavior in releases v17 and earlier

When using releases v17 and earlier of the application, an incoming RPI of a

consuming controller will be accepted by the producer. No default RPI is

offered by the producing controller. The packet intervals of existing

connections from other consumers could be sped up on multicast

connections.

The RPI limitations (the range set on the produced tag) and the default

process applies only to multicast connections on unscheduled networks. This

feature is unavailable for controllers on the ControlNet network or unicast

connections. Scheduled bandwidths on the ControlNet network transmit

critical data at pre-determined intervals of time.

24 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 25

Produce and Consume a Tag

Chapter 1

Set RPI limits,

default for producer

tag

Important:

RPI limits and default values are not supported for safety tags and

AXIS tags. AXIS produced tags are produced at a rate equal to the

Coarse Update Period of the associated motion group. Safety

produced tags are produced at a rate specified by the Safety Task

Period.

If you have controllers running releases v17 or earlier that are consumers of a

producer from a Compact GuardLogix 5380, CompactLogix 5380,

CompactLogix 5480, ControlLogix 5580, or GuardLogix 5580 controller,

take the following step to make sure consumers of produce tags can connect:

• Verify that all multicast consumed tags of a produce tag are configured

with the same RPI. If they are not, some consumers will fail to connect.

Use the Advanced Options dialog box to establish RPI limitations (range)

and default values when setting up a producing tag for multicast connections.

The RPI Limits configuration, which is disabled when online, must be

within:

• Minimum RPI: 0.2 ms for ControlLogix controllers and for

CompactLogix 5380 controllers, and 1.0 ms for all other

CompactLogix controllers.

• Maximum RPI: 536870.911 ms.

• Default RPI: configurable within the minimum/maximum range.

• 1769-L2x and 1769-L3x controllers: refer to 1769-L2x and 1769-L3x

RPI Limits for additional instructions.

The RPI limits apply only to multicast connections on unscheduled networks. This

functionality is not supported on the ControlNet network.

Important: The Advanced Options dialog box is also used to set up the unicast connection

between a consumer and producer controller. Even though the Unicast check box

is selected by default, multicast connections can be changed to a produced tag

whether or not the box is checked. The check box dictates only whether this

produced tag can accept a unicast connection. The consuming controller

determines if the connection is unicast.

To set RPI limits for multicast connections:

1. Open the Tag Properties dialog box of the produced tag if it isn't

already opened, and then click Connection. The Produced Tag

Connection dialog box opens.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 25

Page 26

Chapter 1

Produce and Consume a Tag

2. On the Connection tab in the Produced Tag Connections dialog box,

click Advanced. The Advanced Options dialog box opens.

3. In the Minimum RPI box, enter the smallest requested packet interval

(fastest rate) at which consumers may consume data from the tag.

4. In the Maximum RPI box, enter the largest packet interval (slowest

rate) at which consumers may consume data from the tag. Rockwell

Automation recommends using the default value of 536870.9 ms.

5. Select the Provide Default RPI to Consu mer for Out-of-Range

Requests check box to enable the producing tag to provide an RPI to a

consuming tag whenever a consuming tag has an RPI outside the range

of the producer's Minimum and Maximum RPI, and then in the

Default RPI box, enter the value that the producer provides to the

consumer.

Important: Select Allow Consumed Tags to Use RPI Provided by Producer on the

Advanced tab in the Controller Properties dialog box to allow negotiations

to use the RPI provided by the producer.

6. Click OK to close the Advanced Options dialog box.

7. Click OK to close the Produced Tag Connections dialog box.

26 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 27

Produce and Consume a Tag

Chapter 1

Unicast connection

option

Unicast connections are point-to-point connections between a producing

controller and consuming controller; no multiple connections. Unicast

connections do not require a minimum or maximum RPI range or default

RPI value.

The Allow Unicast Consumer Connections check box at the bottom of the

Advanced Options dialog box is selected by default to allow multiple

unicast consumers to consume from the produced tag.

Clear the Allow Unicast Consumer Connections check box if you are not

using Unicast and the controller is running low on controller memory.

Additional producer resources are allocated for each potential consumer

when the check box is selected.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 27

Page 28

Chapter 1

Produce and Consume a Tag

Set up the

consuming

controller

The Consuming controller must be set up to allow its consumed tags to

accept an RPI provided by the producer. Use the Advanced tab in the

Controller Properties dialog box to set up the controller.

Important:

For controllers running Logix Designer releases v17 or earlier that

contain consumers of a producer from Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, or

GuardLogix 5580 controller, verify that all multicast consumed tags of

a produce tag are configured with the same RPI. If they are not, some

consumers will fail to connect. See

default on page 23 for more information.

RPI limitations and negotiated

To set up the consuming controller:

1. In the Controller Organizer, right-click the controller that has been

set up with a consuming tag and click Properties.

The Controller Properties dialog box opens.

28 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 29

Produce and Consume a Tag

Chapter 1

Verify consumed

2. Click the Advanced tab.

tag acceptance

3. Select the Allow Consumed Tags to Use RPI Provided by Producer

check box to allow for the RPI negotiation.

Important:

The check box is only available when the controller is offline. If the

check box is not checked, the consuming controller does not

accept the RPI provided by the producer if the consuming

controller requests an RPI that is out of the producer’s configured

RPI range. As a result, an out-of-range RPI request results in a

failed connection.

4. Click OK.

When a consuming controller accepts a default RPI by a producing

controller, you can verify the acceptance and the RPI value on the

Consumed Tag Connection dialog box.

Before you begin:

• The controller must be online and the consumed tag is connected with

the producer providing the RPI.

To verify consumed tag acceptance and RPI value:

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 29

1. In the Controller Organizer, right-click the Controller Tags folder

and click Edit Tags.

Page 30

Chapter 1

Produce and Consume a Tag

2. In the Tag Editor, right-click a consuming tag and click Edit (name

of tag) Properties. The Tag Properties dialog box opens.

30 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

3. In the Type box, click Connection.

Page 31

Produce and Consume a Tag

Chapter 1

The Consumed Tag Connection dialog box opens. On the

Connection tab, a flag to the right of the RPI box indicates the

consuming controller has accepted an RPI provided by the producer.

The time interval of the RPI also is indicated.

4. Click Cancel to exit.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 31

Page 32

Chapter 1

Produce and Consume a Tag

Produced and

Scenario 1

consumed RPI

scenarios

The following scenarios explain how producing and consuming tags

exchange RPI for controllers.

The RPI is within range of the producing con tr o ll er ’s R PI Limits.

There is no default RPI that is set up for the producing controller.

32 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Version 17 and earlier: The consuming controller is brought online with an

RPI configured at 3 ms. The producer accepts the RPI requested by the

consuming tag. All controllers on the multicast connection will be increased

to 3 ms for the API, which is the interval the data is actually being produced.

Version 18 and later: The consuming controller is brought online with an

RPI configured at 3 ms. The producing controller verifies the requested RPI

by the consumer is within the RPI limits set up for the producer. Since the

request is within the range, the producing controller accepts the RPI of the

consumer.

Tip:

If you use all the default settings of version 18 and later, you have the

same behavior as version 17 and earlier.

Page 33

Produce and Consume a Tag

Chapter 1

Scenario 2

The RPI is outside the range of the producing controller’s RPI Limits.

There is no default RPI that is set up for the producing controller.

Version 17 and earlier: The RPI requested by the consumed tag is not

within the range of the producer. The connection is rejected and a 0111 error

is reported that the connection failed. You must re-enter an RPI that is within

the range configured on the produced tag. If a version 17 consumer is trying

to connect with a version 18 producer and the RPI is outside the range of the

producer and there is no default set up, a 0111 error reports the connection

failed.

Tip:

See RPI I/O Faults on page 37

for an explanation of the error messages.

Version 18 and later: The RPI requested by the consumed tag is not within

the RPI limitation range of the producer. The producer is not set up to

provide a default RPI, so a 0111 error message is reported that the

connection failed. You must re-enter an RPI that is within the range

configured for the producer because there is no RPI default negotiation with

the consumer.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 33

Page 34

Chapter 1

Produce and Consume a Tag

Scenario 3

The RPI is outside the range of the producing controller’s RPI Limits. A

default RPI is set up for the producing controller. But, the network path

contains a bridge that blocks the negotiated RPI to prevent an interruption to

other controllers on the network.

Version 17 and earlier: The RPI requested by the consumed tag is not

within the range of the producer. The connection is rejected and a 0112 error

is reported that the connection failed. You must re-enter an RPI that is within

the range configured on the produced tag. If a version 17 consumer is trying

to connect with a version 18 producer and the RPI is outside the range of the

producer, a 0112 error reports the connection fail ed.

Tip:

See RPI I/O Faults on page 37

for an explanation of the error messages.

Version 18 and later: The RPI requested by the consumed tag is not within

the RPI limitation range of the producer. The producer is configured to

provide an RPI default. The producer sends the default RPI to the consumer,

but the consumer controller is not set up to accept a default RPI from the

producer. The negotiated RPI is disabled to prevent an interruption to the

multicast connection. A 0112 error message is reported and you must reenter an RPI within the range of the producer’s limits.

34 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 35

Produce and Consume a Tag

Chapter 1

Scenario 4

1769-L2x and 1769-

The RPI is outside the range of the producing controller’s RPI Limits. A

default RPI is set up for the producing controller. The consumer is set up to

accept the RPI provided by the producer.

L3x RPI limits

Version 17 and earlier: The RPI requested by the consumed tag is not

within the range of the producer. The connection is rejected and a 0112 error

is reported that the connection failed. You must re-enter an RPI that is within

the range configured on the produced tag. If a version 17 consumer is trying

to connect with a version 18 producer and the RPI is outside the range of the

producer, a 0112 error reports the connection failed.

Version 18 and later: The RPI requested by the consumed tag is not within

the RPI limitation range of the producer. The producer is configured to

provide an RPI default. The producer sends the default RPI to the consumer.

The consumer is set up to accept the RPI provided by the producer. The

connection is successful and the multicast connection accepts the new RPI of

5 ms.

All controllers, with the exception of the CompactLogix 1769-L2x and 1769-

L3x controllers, produce data in packet intervals ranging from

0.196…536870.911 ms. The 1769-L2x and 1769-L3x controllers produce

only in packet intervals of 2, 4, 8, 16, 32, 64, 128, 256, 512, or 1024 ms.

You are not confined to entering these exact values when configuring an RPI

limitation range and default RPI for the 1769-L2x and 1769-L3x controllers.

However, if an unsupported packet interval is entered, then the Logix

Designer application may override the unsupported packet interval with a

supported packet interval. When this occurs, the new ‘effective’ value is

displayed separately next to the unsupported value that was entered.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 35

Page 36

Chapter 1

Produce and Consume a Tag

Similar to other controllers, the 1769-L2x and 1769-L3x controllers will

verify that the RPI of incoming connections are within the produced tag

settings. If the consuming tag’s RPI falls outside the configured range, a

producing controller will reject the incoming RPI and then provide an RPI

(default) to the consuming controller.

Important:

The producing and consuming controllers must be set up to allow

the consumed tags to use an RPI provided by the producer.

See RPI Limitations and Negotiated Default on page 23 and

the consuming controller on page 28 for procedures to set up the

producer and consumer tags to accept a negotiated default RPI.

Set up

For the 1769-L2x and 1769-L3x controllers, the Effec t ive Minimum RPI,

when present, is used to determine the fastest packet interval allowed by the

tag. When the Effective Default RPI is present, it is the larg est packet

interval (slowest rate) at which negotiated connections will be produced for

the tag.

The effective RPI limit values are presented with a flag on the Advanced

Options dialog box to indicate that RPI limits are set to values other than

what you entered.

36 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 37

Produce and Consume a Tag

Chapter 1

Scenario Description

Software

I/O Fault Message

RPI I/O faults

The following table provides a description of error messages for situations

where an RPI is not accepted.

Version

RPI of consumed tag is not within the range of the

producer. Producer does not support RPI

negotiation or is not configured to provide a default

RPI to the consumer.

RPI of consumed tag is not within the range of the

producer. Producer is returning default RPI.

Consumer does not support negotiation or is not

configured to accept RPI from producer.

Any (Code 0111) Requested Packet Interval

(RPI) out of range.

18 and later (Code 0112) Requested Packet Interval

(RPI) out of range.

17 and earlier (Code 0112) Unknown Error.

RPI of consumer is out of range, but producer

provides a default RPI and consumer can accept

default RPI. Network path contains bridge that does

not support extended error information. For I/O

connectivity between two controllers, such as

consuming a tag from a producing controller, both

controllers must be attached to the same

EtherNet/IP subnet. Two controllers cannot bridge

produced or consumed tags over two subnets. For

more information on setting up your network, refer to

the following publication in the

Library :

EtherNet/IP Network Configuration User Manual

(ENET-UM001)

RPI of consumer is out of range, but producer

provides a default RPI and consumer can accept

RPI provided by producer. Network path contains

scheduled network update time (NUT).

Rockwell Literature

Prevent connection failures with Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and

GuardLogix 5580 controllers

If a consumer displays error code 0112 and fails to connect to a Compact

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix

5580, or GuardLogix 5580 controller that provides produce tags, take the

following steps to make sure consumers of produce tags can connect:

18 and later (Code 0112) Requested Packet Interval

(RPI) out of range. Producer provided

RPI blocked by the network path.

18 and later (Code 0112) Requested Packet Interval

(RPI) out of range. Cannot use producer

provided RPI over a path containing a

scheduled network.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 37

• For consumers running Logix Designer releases v17 and earlier that are

consumers of a producer from a Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, or

GuardLogix 5580 controller:

Page 38

Chapter 1

Produce and Consume a Tag

• Verify that all multicast consumed tags of a produce tag are

configured with the same RPI. If they are not, some consumers will

fail to connect.

• For multicast consumers running Logix Designer releases v18 and

later, take one of these steps:

• Verify that all multicast consumed tags of a produce tag are

configured with the same RPI, or

• Verify that all multicast consumers are configured to Allow

Consumed Tags To Use RPI Provided By Producer.

38 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 39

Introduction

Chapter 2

Produce a Large Array

The Logix5000 controller can send as many as 500 bytes of data over a

single scheduled connection. This corresponds to 125 DINT or REAL

elements of an array. To transfer an array of more than 125 DINTs or

REALs, use a produced/consumed tag of 125 elements to create a packet of

data. You can then use the packet to send the array piecemeal to another

controller.

When you send a large array of data in smaller packets, you must be sure that

the transmission of a packet is complete before the data is moved into the

destination array.

• Produced data over the ControlLogix backplane is sent in 50 byte

segments.

• Data transmission occurs asynchronous to a program scan.

The logic that this section includes uses an acknowledge word to make sure

that each packet contains new data before the data moves to the destination

array. The logic also uses an offset value to indicate the starting element of

the packet within the array.

Because of the offset and acknowledge elements, each packet carries 123

elements of data from the array, as shown in the following.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 39

Page 40

Chapter 2

Produce a Large Array

Produce a large

In addition, the array must contain an extra 122 elements. In other words, it

must be 122 elements greater than the greatest number of elements that you

want to transfer.

• These elements serve as a buffer.

• Because each packet contains the same number of elements, the buffer

prevents the controller from copying beyond the boundaries of the

array.

• Without the buffer, this would occur if the last packet contained fewer

than 123 elements of actual data.

Follow these steps to produce a large array.

array

1. In the Controller Tags folder of the controller project that produces

the array, create these tags.

P Tag Name Type

array_ack DINT[2]

X

array_packet DINT[125]

2. Convert array_ack to a consumed tag.

For Specify

Controller Name of the controller that is receiving the

packet.

Remote Tag Name array_ack

Both controllers use the same name for this

data.

3. In either the Controller Tags folder or the tags folder of the program

that will contain the logic for the transfer, crea te these tag s.

Tag Name Type

array DINT[x] where x equals the number of

elements to transfer plus 122 elements

array_offset DINT

array_size DINT

array_transfer_time DINT

array_transfer_time_max DINT

array_transfer_timer TIMER

40 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

4. In the array_size tag, enter the number of elements of real data.

The value of x from step 3 minus the 122 elements of buffer.

5. Create or open a routine for the logic that creates packets of data.

Page 41

Produce a Large Array

Chapter 2

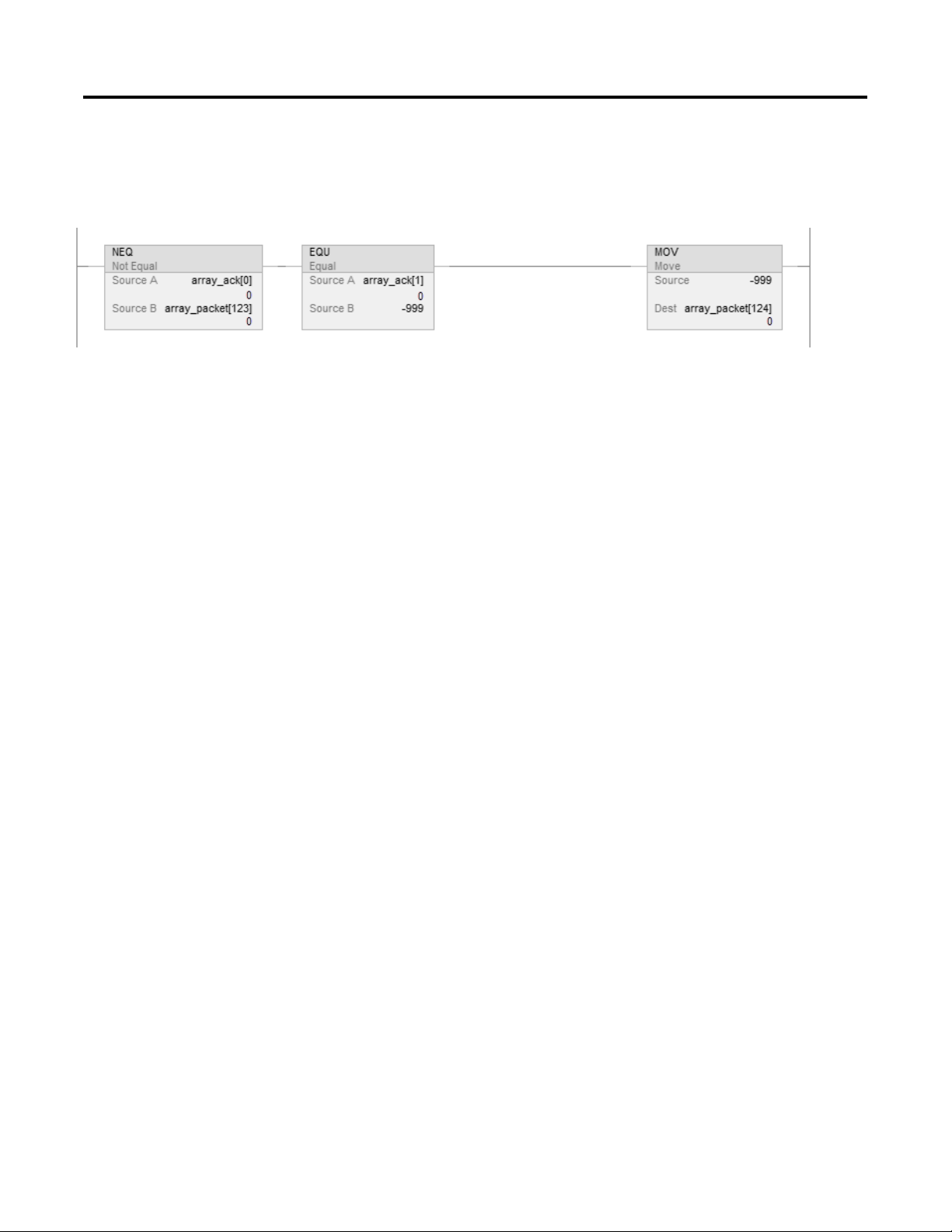

6. Enter this logic.

When the offset value in array_ack[0] is not equal to the current offset value but array_ack[ 1] equal s -999, the consumer has

begun to receive a new packet, so the rung moves -999 into the last element of the packet. The consumer waits until it receives

the value -999 before it copies the packet to the array. This guarantees that the consumer has new data.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 41

Page 42

Chapter 2

Produce a Large Array

When the offset value in array_ack[0] is equal to the current offset value, the consumer has copied the packet to the array; so

the rung checks for more data to transfer. If the offset value plus 123 is less than the size of the array, there is more data to

transfer; so the rung increases the offset by 123. Otherwise, there is no more data to transfer; so the rung resets the offset

value, logs the transfer time, and resets the timer. In either case, the rung uses the new offset value to create a new packet of

data, appends the new offset value to the packet, and clears the acknowledge element of the packet (packet[124]).

If the current transfer time is greater than the maximum transfer time, update the maximum transfer time. This maintains a

record of the longest time to transfer data.

42 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Page 43

Produce a Large Array

Chapter 2

P

Tag Name

Type

7. In the Controller Tags folder of the controller project that consumes

the array, create these tags.

X

array_ack DINT[2]

array_packet DINT[125]

8. Convert array_packet to a consumed tag.

For Specify

Controller Name of the controller that is sending the

packet.

Remote tag name array_packet

Both controllers use the same name for this

data.

9. In either the Controller Tags folder or the tags folder of the program

that will contain the logic for the transfer, crea te these tag s.

Tag Name Type

array DINT[x] where x equals the number of

elements to transfer plus 122 elements

array_offset DINT

10. Create or open a routine for the logic that will move the data from the

packets to the destination array.

11. Enter this logic.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 43

Page 44

Chapter 2

Produce a Large Array

When the offset value in array_packet[123] is different than the offset value in array_ack[0], the controller has begun to receive a

new packet of data; so the rung checks for the value of -999 in the last element of the packet.

If the last element of the packet equals -999, the controller has received an entire packet of new data and begins the copy

operation.

• The offset value moves from the packet to array_offset.

• The COP instructions copy the data from the packet to the destination array, starting at the offset value.

• The offset value moves to array_ack[0], which signals that the copy is complete.

• Array_ack[1] resets to zero and waits to signal the arrival of a new packet.

If the last element of the packet is not equal to -999, the transfer of the packet to the controller may not be complete; so -999

moves to array_ack[1]. This signals the producer to return the value of -999 in the last element of the packet to verify the

transmission of the packet.

44 Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Transferring a large array as smaller packets improves system performance

over other methods of transferring the data.

• Fewer connections are used than if you broke the data into multiple

arrays and sent each as a produced tag. For example, an array with

5000 elements would take 40 connections (5000/125=40) by using

individual arrays.

• Faster transmission times are achieved than if you used a message

instruction to send the entire array.

Page 45

Produce a Large Array

Chapter 2

• Messages are unscheduled and are executed only during the

‘system overhead’ portion of the Logix5550 execution. Therefore,

messages can take a fairly long time to complete the data transfer.

• You can improve the transfer time by increasing the system

overhead time slice, but this diminis hes the per form ance of the

continuous task.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 45

Page 46

Page 47

A

Index

adjust

bandwidth limitations 15

array

defining data packets 39

RPI limits 34

L3x controller

RPI limits 34

limitations

bandwidth 15

RPI 23

B

bandwidth

adjust limitations 15

C

communicate

other controllers 11

connection

produced or consumed tag 12

consumed tag

connection requirements 12

consumer

creating tag 18

RPI scenarios 31

using producer RPI 27

verifying RPI 29

ControlNet

bandwidth limits 15

create

produced tag 16

D

default

RPI 23

E

error messages

RPI 36

P

PLC-5C

share data 22

produced tag

connection requirements 12

create 16

producer

creating tag 16

RPI scenarios 31

R

RPI

I/O faults 36

limitations, setting default 23

S

scenarios

RPI acceptance 31

T

tag

array 40

consumer RPI verification 29

consumer using producer RPI 27

creating consumer 18

creating producer 16

produce 16

I

I/O faults 36

L

L2x controller

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018 47

Page 48

Rockwell Automation support

Rockwell Automation provides technical information on the web to assist you in using its products. At

http://www.rockwellautomation.com/support you can find technical and application notes, s ampl e code, and links to software service

packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com for software updates, support chats and forums,

technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact your

local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone.

Installation assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual. You can

contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide Locator available at http://www.rockwellautomation.com/locations,

or contact your local Rockwell Automation representative.

New product satisfaction return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the

phone number above to obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete the feedback form, publication RA-DU002

.

Rockwell Automation Publication 1756-PM011J-EN-P - February 2018

Supercedes Publication 1756-PM011I-EN-P - December 2016 Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights Reserved. Printed in the U.S.A.

Loading...

Loading...