Page 1

SLC 500 Hardware Migration

Bulletins 1746, 1747, 1769, 5069

Reference Manual

Original Instructions

Page 2

SLC 500 Hardware Migration Reference Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 3

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Overview Product Lifecycle Status Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SLC 500 System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CompactLogix 5370 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CompactLogix 5380 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Compact I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compact 5000 I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SLC 500 Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CompactLogix 5380 Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sensor Actuator Power for CompactLogix 5380 . . . . . . . . . . . . . . . . . 13

Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Replace an SLC 500 Controller Upgrade to a CompactLogix 5370 Controller . . . . . . . . . . . . . . . . . . . . . . . 15

Upgrade to a CompactLogix 5380 Controller . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3

Replace an SLC 500 I/O Module Upgrade an SLC I/O Installation by Replacing it with Compact I/O . . 17

Upgrade an SLC I/O Installation by Replacing it with

Compact 5000 I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SLC I/O Installation Using a Conversion Kit. . . . . . . . . . . . . . . . . . . . 23

Appendix A

Wiring Diagram Comparisons Replace an SLC 5 Processor Serial Port with a Compact I/O

Serial Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SLC 5/03, SLC 5/04, or SCL 5/05 to 5069-SERIAL . . . . . . . . . . . . . 25

Replace an SLC 500 I/O with a Compact I/O . . . . . . . . . . . . . . . . . . . . . . . 26

1746-IA4 to 1769-IA8I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1746-IA8 to 1769-IA8I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1746-IA16 to 1769-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1746-IB8 to 1769-IQ16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1746-IB16 to 1769-IQ16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1746-IG16 to 1769-IG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1746-IM4 to 1769-IM12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1746-IM8 to 1769-IM12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1746-IM16 to 1769-IM12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 3

Page 4

Table of Contents

1746-ITB16 to 1769-IQ16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1746-ITV16 to 1769-IQ16F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1746-IV8 to 1769-IQ16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1746-IV16 to 1769-IQ16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1746-OA8 to 1769-OA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1746-OA16 to 1769-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1746-OB8 to 1769-OB8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1746-OB16 to 1769-OB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1746-OB16E to 1769-OB16P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1746-OBP8 to 1769-OB8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1746-OG16 to 1769-OG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1746-OV8 to 1769-OV16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1746-OV16 to 1769-OV16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1746-OW4 to 1769-OW8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1746-OW8 to 1769-OW8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1746-OW16 to 1769-OW16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1746-IO2DC to 1769-IQ6XOW4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1746-NI4 to 1769-IF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1746-NIO4I to 1769-IF4XOF2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1746-NIO4V to 1769-IF4XOF2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1746-NI8 to 1769-IF8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1746-NO4I to 1769-OF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1746-NO4V to 1769-OF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replace an SLC 500 I/O with a Compact 5000 I/O . . . . . . . . . . . . . . . . . . 42

1746-IA4 to 5069-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1746-IA8 to 5069-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1746-IA16 to 5069-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1746-IM4 to 5069-IA16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1746-IM8 to 5069-IA16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1746-IM16 to 5069-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1746-IB8 to 5069-IB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1746-IB16 to 5069-IB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1746-ITB16 to 5069-IB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1746-OA8 to 5069-OA16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1746-OA16 to 5069-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1746-OB8 to 5069-OB8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1746-OBP8 to 5069-OB8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1746-OBP16 to 5069-OB16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1746-OB16 to 5069-OB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1746-OB16E to 5069-OB16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1746-OW4 to 5069-OW4I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1746-OW8 to 5069-OW4I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1746-OW16 to 5069-OW16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1746-OX8 to 5069-OX4I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1746-NI4 to 5069-IY4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1746-NI8 to 5069-IF8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1746-NO4I to 5069-OF4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1746-NO4V to 5069-OF4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 5

Preface

About This Publication

This document serves as a guide for replacing your existing SLC™ 500 modules

with other products such as Compact I/O™ modules, or Compact 5000™ I/O

modules.

The SLC 500 Control system hardware was redesigned to be RoHS compliant.

As a result, several of the products will continue to be available for years to

come, however, some products, such as less capable controllers and lower

density I/O, have been discontinued.

The SLC™ control platform in general is in the Active Mature lifecycle state, as

the newer CompactLogix™ and Compact 5000 platforms provide greater

functionality and connectivity.

The following chapters of this document describe the many SLC,

CompactLogix, and I/O options available for active management of your

installed base of control products. You have the option of maintaining,

migrating, or replacing that installed base in a phased manner to meet your

needs.

This document focuses on hardware migration. For more detailed

information, including instructions for

Logix program, see SLC to CompactLogix Programming Migration

Application Profile, publication 5069-AP001.

converting an SLC program to a

Audience

Required Software

This document is intended for users of SLC 500 controllers and I/O modules

who are familiar with the RSLogix 500® programming software.

If the replacement is an SLC 500 controller or I/O module, no additional

software is required.

If the replacement is a CompactLogix 5370 controller, CompactLogix 5380

controller, Compact I/O module, or Compact 5000 I/O module, the following

are required:

• Studio 5000 environment

The Studio 5000® environment combines elements of design into one

standard framework that optimizes productivity and reduces time to

commission.

With the Studio 5000 Applications you can:

- Build and maintain a system layout in a central place with

Studio 5000 Architect®

- Configure, program, and maintain your Logix 5000™ family of

controllers with Studio 5000 Logix Designer®

- Create intuitive, modern screens for the PanelView™ 5000 graphic

terminals with Studio 5000 View Designer®

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 5

Page 6

Preface

- Create and leverage reusable libraries of content for rapid project

development with Application Code Manager

The following CompactLogix controllers are compatible with

Studio 5000 Applications:

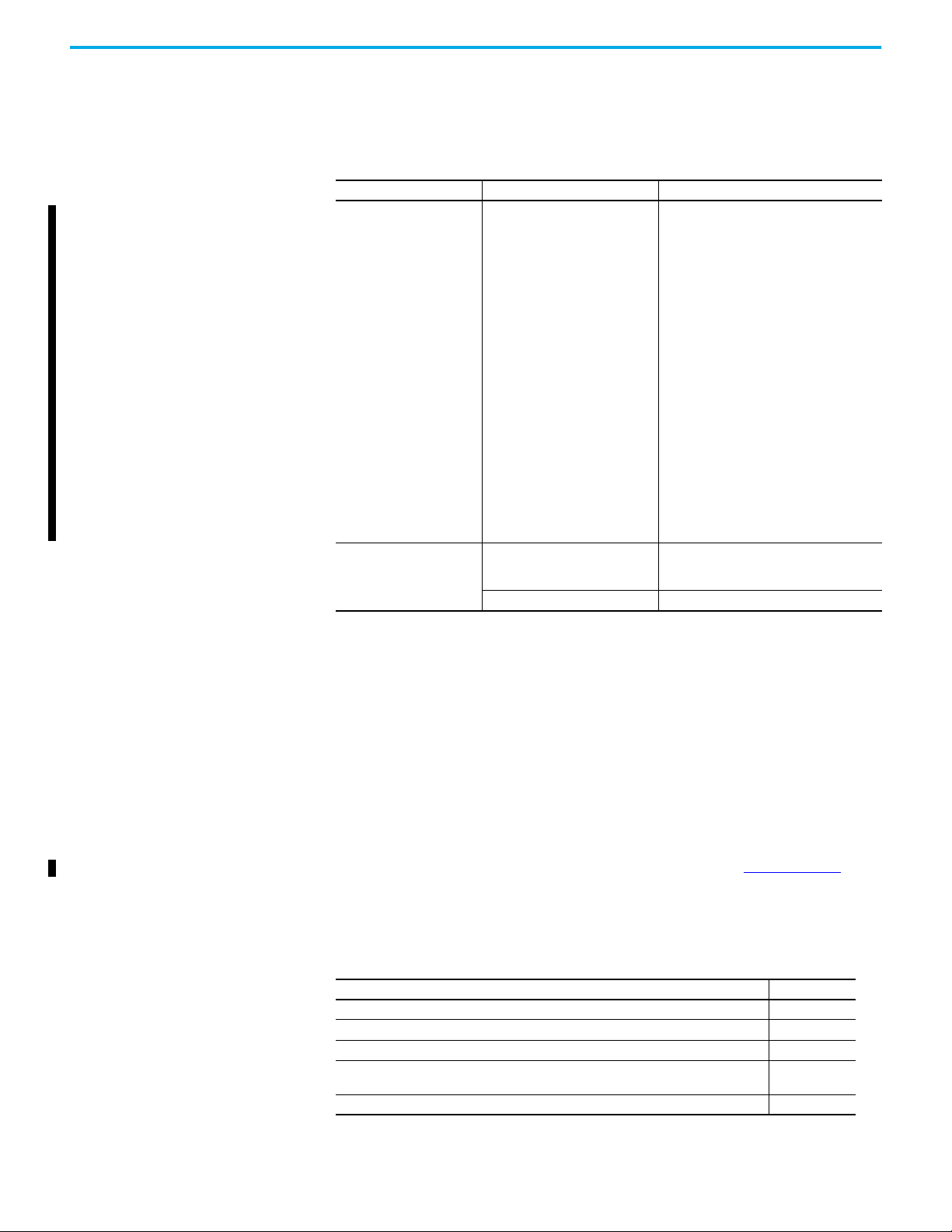

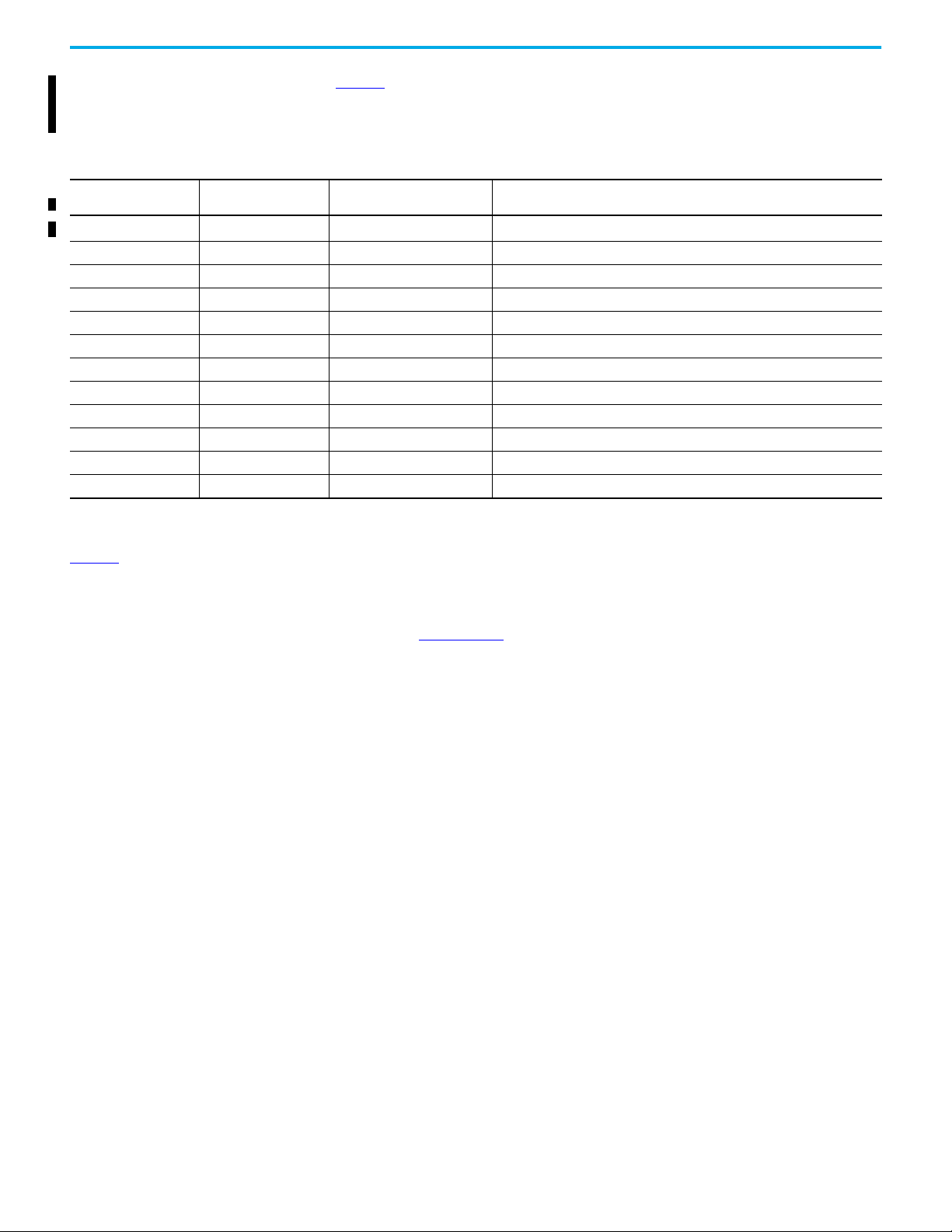

Controllers Cat. No. Studio 5000 Logix Designer Application

CompactLogix 5380 /

Compact GuardLogix 5380

CompactLogix 5370 For CompactLogix 5370 controllers

5069-L306ER, 5069-L306ERM, 5069L310ER, 5069-L310ERM, 5069-L310ERNSE,

5069-L320ER, 5069-L320ERM, 5069L320ERMK, 5069-L330ER, 5069L330ERM,

5069-L330ERMK, 5069-L340ER, 5069L340ERM, 5069-L350ERM, 5069L350ERMK,

5069-L380ERM, 5069-L3100ERM

5069-L306ERS2, 5069-L306ERMS2,

5069-L310ERS2, 5069L310ERMS2,5069-L320ERS2,

5069-L320ERMS2, 5069-L330ERS2,

5069-L330ERMS2, 5069-L340ERS2,

5069-L340ERMS2, 5069-L350ERS2,

5069-L350ERMS2, 5069-L380ERS2,

5069-L380ERMS2, 5069-L3100ERS2,

5069-L3100ERMS2, 5069-L320ERS2K,

5069-L320ERMS2K, 5069-L330ERS2K,

5069-L330ERMS2K, 5069-L350ERS2K,

5069-L350ERMS2K

using firmware revision 21.00.00 or

later

1769-L19ER-BB1B Version 28.00.00 or later

Version 29.00.00 or later

Version 21.00.00 or later

Summary of Changes

• RSLogix 500/RSLogix Micro version 12 or RSLogix Project Migrator

The RSLogix 500/RSLogix™ Micro version 12 software includes an

integrated SLC to CompactLogix program converter tool. To convert,

simply perform a Save Program As, then select file type as *.ACD, and

fill out the menu prompts.

For older versions of RSLogix 500/RSLogix Micro, the RSLogix Project

Migrator tool is a free, standalone software tool for converting an

RSLogix 5 or RSLogix 500 project export file for import into Studio

5000 Logix Designer application.

The standalone converter tool is available for download at: rok.auto/pcdc

.

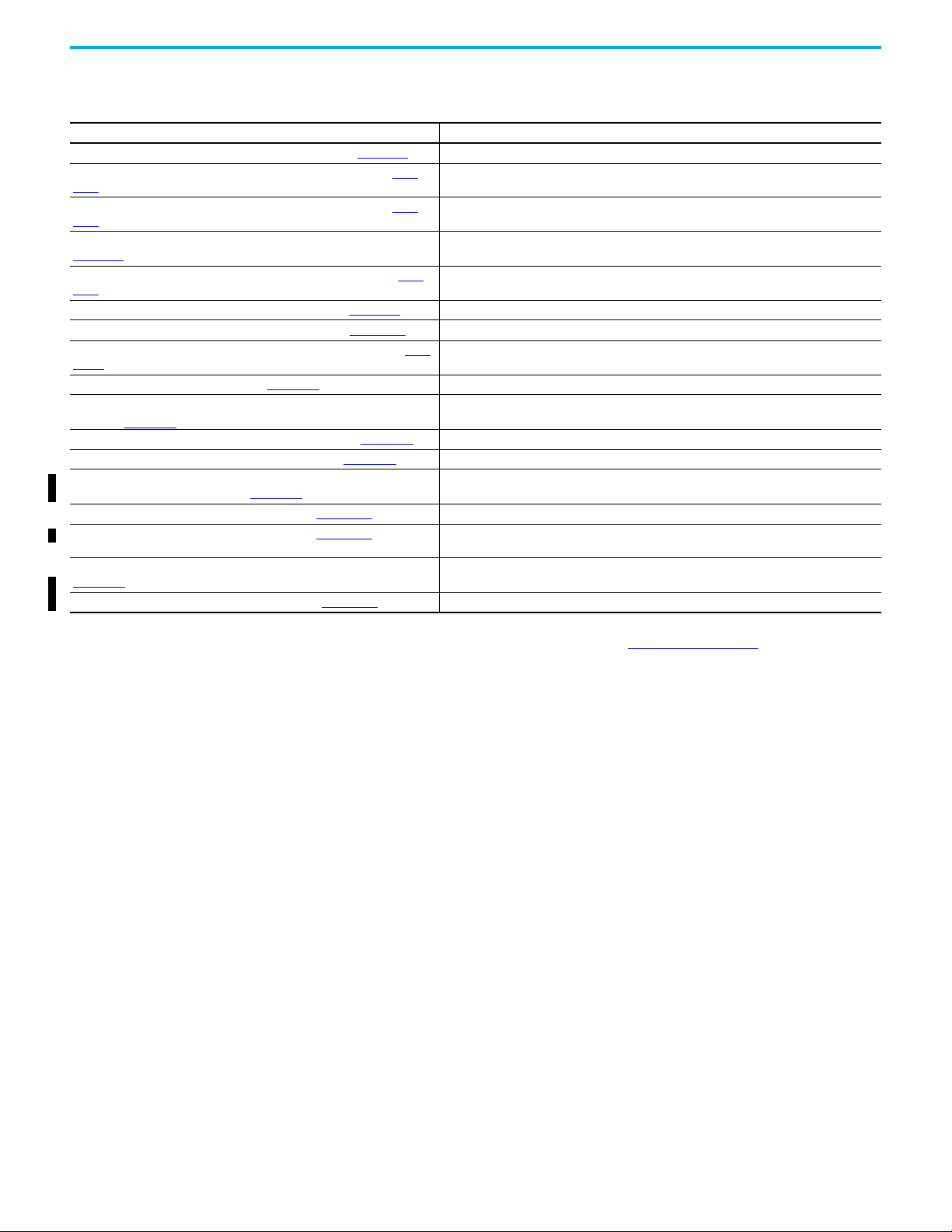

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Top i c Page

Added compatible list of CompactLogix 5380 controllers. 6

Updated reference documents. 7

Added a section on other considerations for migration. 14

Added a section for SLC 500 I/O to Compact 5000 I/O replacement using

conversion modules.

Updated wire diagrams and warnings in Wiring Diagrams chapter. 25

23

6 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 7

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

SLC 500 Analog Input Module Installation Instructions, publication 1746-IN006

SLC 500 RTD/Resistance Input Module Installation Instructions, publication 1746-

IN007

SLC 500 RTD/Resistance Input Module Installation Instructions, publication 1746-

IN012

SLC 500 Thermocouple/mV Analog Input Module Installation Instructions, publication

1746-IN015

SLC 500 8-Point Analog Output Module Installation Instructions, publication 1746-

IN026

SLC 500 Digital I/O Modules Installation Instructions, publication 1746-IN027

SLC 500 4-Channel Analog I/O Modules User Manual, publication 1746-UM005 A more detailed description on how to configure the SLC 500 analog I/O modules.

SLC 500 4-Channel Thermocouple/mV Input Module User Manual, publication 1746-

UM007

SLC 500 Systems Selection Guide, publication 1747-SG001

SLC to CompactLogix Programming Migration Application Profile,

publication 5069-AP001

CompactLogix Controllers Specifications Technical Data, publication 1769-TD005

Compact I/O Modules Specifications Technical Data, publication 1769-TD006

CompactLogix 5380, Compact GuardLogix 5380, and CompactLogix 5480 Controllers

Specifications Technical Data, publication 5069-TD002

CompactLogix 5370 Controllers User Manual, publication 1769-UM021

CompactLogix 5380 Controllers User Manual, publication 5069-UM001

Compact 5000 I/O Modules and EtherNet/IP Adapters Technical Data, publication

5069-TD001

Compact 5000 I/O Serial Module User Manual, publication 5069-UM003

Installation instructions for the SLC 500 Analog Input Module (Cat. No. 1746-NI8).

Installation instructions for the SLC 500 RTD/Resistance Input Module (Cat. No. 1746-NR8).

Installation instructions for the SLC 500 RTD/Resistance Input Module (Cat. No. 1746-NR4).

Installation instructions for the SLC 500 Thermocouple/mV Analog Input Module.

Installation instructions for SLC 500 8-point analog output modules.

Installation Instructions for SLC 500 digital I/O modules.

A more detailed description on how to configure the SLC 500 4-Channel Thermocouple/mV Input

Module.

An overview of the SLC 500 family of products.

Provides information on converting an SLC program to a Logix program and migrating the existing SLC

I/O to an Ethernet network.

Provides CompactLogix controllers specifications.

Provides Compact I/O Modules specifications.

Provides CompactLogix, Compact GuardLogix, and CompactLogix controllers specifications.

Describes how to install, use, and troubleshoot CompactLogix 5370 controllers.

Describes how to install, use, and troubleshoot CompactLogix 5380 controllers and Compact

GuardLogix 5380 controllers.

Provides Compact 5000 I/O and EtherNet/IP adapter specifications.

Describes how to install, use, and troubleshoot a Compact 5000 I/O serial module.

You can view or download publications at rok.auto/literature

.

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 7

Page 8

Preface

Notes:

8 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 9

Overview

Chapter 1

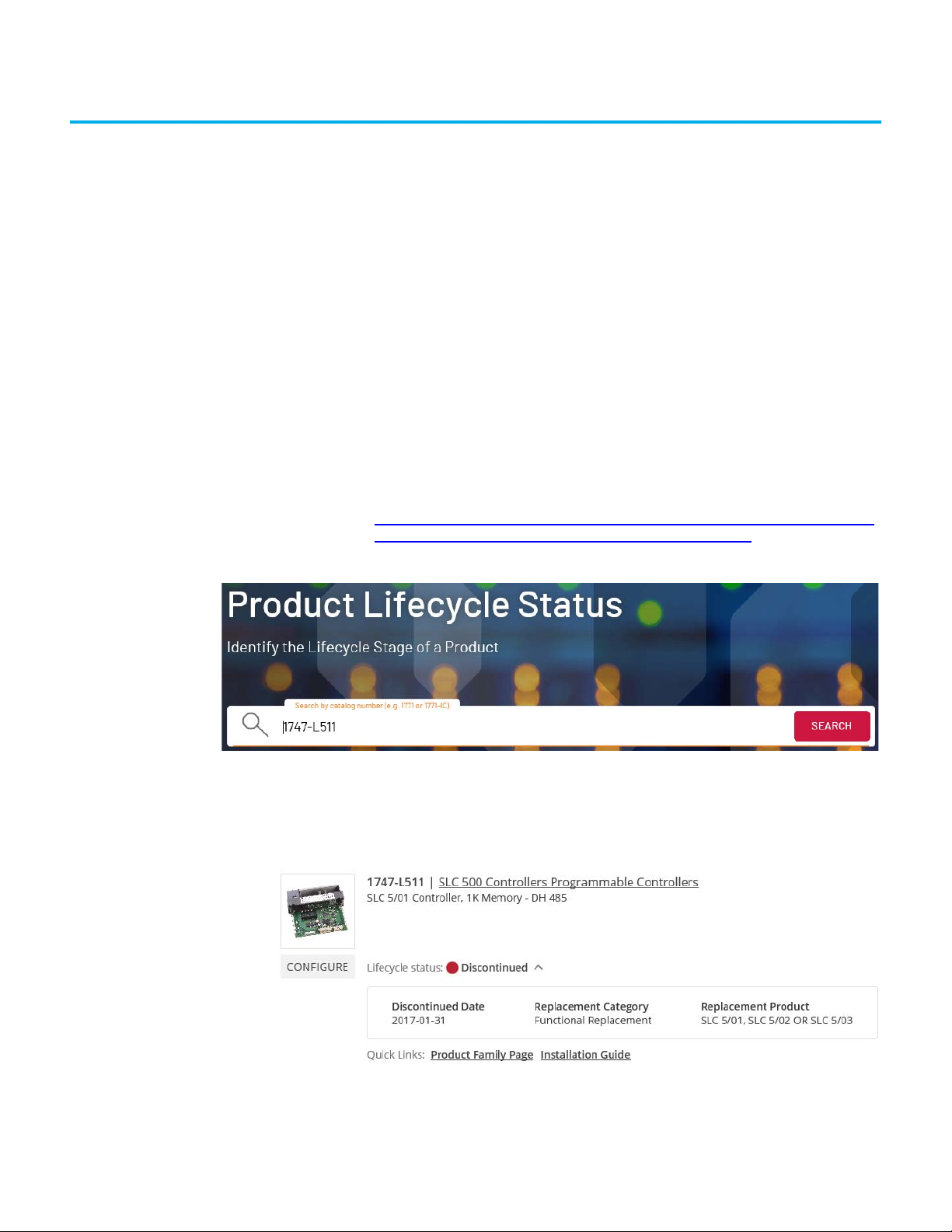

Product Lifecycle Status Website

The Rockwell Automation Product Lifecycle Status website allows you to proactively plan and manage the transition from existing equipment to leadingedge products and technologies. Using the search tool, you can view up-to-date

product lifecycle status and identify the most contemporary Rockwell

Automation products.

The product lifecycle status may be Active, Active Mature, End of Life, or

Discontinued.

To view the lifecycle information for a product:

1. On your web browser, open the Product Lifecycle Status website:

https://www.rockwellautomation.com/en-us/support/product/productcompatibility-migration/product-lifecycle-status.html.

2. In the Catalog Number field, enter the catalog number of the product.

3. Click Search.

The product lifecycle data displays.

If the lifecycle status of the product is End of Life or Discontinued, you

can view the recommended replacement.

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 9

Page 10

Chapter 1 Overview

SLC 500 System The SLC 500 system is a small chassis-based family of programmable

controllers, discrete, analog, and specialty I/O, and peripheral devices. The SLC

500 family delivers power and flexibility with a wide range of communication

configurations, features, and memory options.

SLC 500 programmable controllers provide value with extensive capabilities to

address a broad range of applications including material handling, HVAC

control, high-speed assembly operations, small process control, simple motion

control, and SCADA. With SLC 500 Modular Hardware Style controllers, you

select the processor, power supply, and I/O modules to fit your application.

Modular style chassis are available in 4, 7, 10, and 13-slot versions.

Digital I/O modules, analog I/O modules, and specialty temperature, counting,

and process control modules are available to help you create a custom solution

for your application.

CompactLogix 5370 Controllers

CompactLogix 5380 Controllers

CompactLogix 5370 controllers provide scalable controller solutions to address

a wide variety of applications. All CompactLogix 5370 controllers provide the

following functionality:

• Two EtherNet/IP™ ports

• One USB port

• Support for local expansion modules

• Control of local and distributed I/O modules

• Use of 1784-SD1 or 1784-SD2 Secure Digital (SD) card for nonvolatile

memory

• A battery is no longer necessary because of the internal energy-storage

solution

Some CompactLogix 5370 controllers provide the following functionality:

• Built-in power supply

• Some combination of embedded digital, analog, and high-speed counter

modules

• Support for Integrated Motion over an EtherNet/IP network

• Access to DeviceNet® networks.

CompactLogix 5380 controllers can operate in various applications that range

from standalone systems or in more complex systems with devices that are

connected to the controller via an EtherNet/IP network. All CompactLogix

5380 controllers provide the following functionality:

• Two EtherNet/IP ports

• One USB port

• Support for local expansion modules

• Control of local and distributed I/O modules

• Support Device Level Ring (DLR), Star, and Linear EtherNet/IP network

topologies.

• Support up to 180 EtherNet/IP nodes, depending on catalog number.

• Support Linear/DLR and Dual-IP EtherNet/IP modes.

10 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 11

Chapter 1 Overview

• Support Generic ASCII, Modbus RTU/ASCII, and legacy DF1 and DH-485

protocols.

Some CompactLogix 5380 controllers provide the following functionality:

• Support for Integrated Motion up to 32 axes over an EtherNet/IP

network

Compact I/O Modules The Compact I/O modules can be used in the following applications:

• With a CompactLogix controller

• In an assembly with a 1769-ADN DeviceNet adapter

• In an assembly with a 1769-AENTR Ethernet adapter.

Each I/O module includes a built-in removable terminal block with fingersafe

cover for connections to I/O sensors and actuators. The terminal block is

behind a door at the front of the module. I/O wiring can be routed from

beneath the module to the I/O terminals.

• Once the modules are locked together, the system becomes a rugged

assembly.

• Upper and lower tongue-and-groove slots guide the module during

installation and secure the module within the system.

• Removable terminal blocks help ease the wiring task.

• Self-lifting, field-wire pressure plates cut installation time.

• The patented bus connector with the lock function enables consistent

system communication.

• A color bar is provided on the front of the module.

• Digital and field circuits are optically isolated.

Compact 5000 I/O Modules The Compact 5000 I/O architecture provides a wide range of input and output

modules to span many applications, from high-speed digital to process

control. The architecture uses Producer/Consumer technology that allows

input information and output status to be shared among multiple

Logix 5000 controllers.

Compact 5000 I/O systems are used as local I/O modules in

CompactLogix 5380 controller systems or as remote I/O modules with

CompactLogix 5380 controllers and some other Logix 5000 controllers. The

modules are configured with the Studio 5000 Logix Designer application.

The serial module provides two independent channels that function as

network interface using RS232C, RS422, or RS485 to serial devices

communicating on Generic ASCII, Modbus RTU/ASCII, DF1, or DH-485

protocol.

The I/O module requires a removable terminal block (RTB) to connect fieldside wiring. RTBs are not included with the I/O modules. You must order

RTBs separately.

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 11

Page 12

Chapter 1 Overview

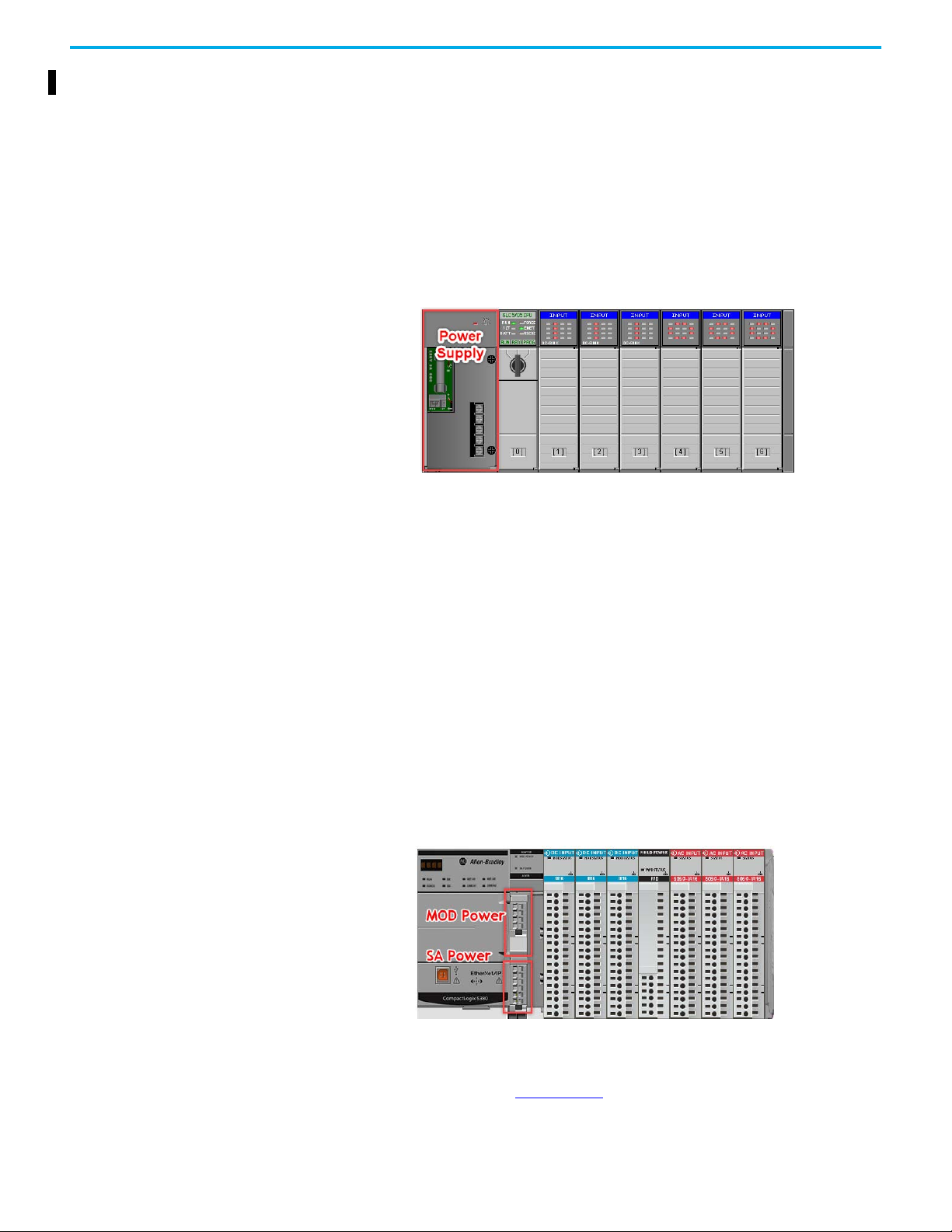

Power Considerations SLC 500 Controllers

The SLC 500 controllers require an SLC power supply module on the leftmost

slot to provide power to all modules on the chassis. This powers up the

controller and the I/O modules. This also facilitates communication through

the backplane.

Though all 1746 input modules and most 1746 output modules receive the

necessary power that they need from the backplane, some 1746 output

modules, such as relay modules and AC modules, require additional power to

be supplied to the module terminal block.

CompactLogix 5380 Controllers

The CompactLogix 5380 controllers require a 24V DC source supply that is

connected to the MOD power terminal to provide power to all modules. Unlike

the SLC 500 controller, the CompactLogix 5380 controller does not require

a chassis.

Backplane connection is at the side of each module and it is necessary to cover

the side with a 5069-ECR end cap (shipped with the CompactLogix 5380

controllers and Compact 5000 EtherNet/IP adapters) to help prevent

electrical hazards.

The 24V DC source to MOD power terminal can be from any external power

supply. You do not require additional power supply connections to each I/O

module

(1)

if connecting field devices are in the same operating voltage range.

For more information about MOD power and SA power considerations, see

chapter 2 of the CompactLogix 5380 and Compact GuardLogix® 5380

Controllers User Manual, 5069-UM001

(1) Except for 5069-OB8, 5069-OB16 and 5069-OB16F.

12 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

.

Page 13

Chapter 1 Overview

The CompactLogix 5380 I/O power system if sensors/actuators have a common operating voltage.

The CompactLogix 5380 I/O power system if sensors/actuators have different operating voltages.

Sensor Actuator Power for CompactLogix 5380

The CompactLogix 5380 I/O power system has a common sensor actuator (SA)

bus where a single power source can be shared among all attaching I/O

modules using the backplane. This helps reduce wiring effort and is

convenient if all I/O devices operate at the same operating voltage. If the SA

has two different operating voltages (see following figures), the SA power bus

can be separated with a Field Potential Distributor Module, such as the 5069FPD.

IMPORTANT

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 13

The 5069-OW16 module uses DC SA power. You must connect DC power

to the component, that is, controller, adapter, or field potential

distributor, that provides SA power to the module.

Page 14

Chapter 1 Overview

Other Considerations

The SLC 500 system was designed more than 30 years ago and electronic

components have evolved over time. To help avoid potential electromagnetic

interference (EMI) and transient EMI that could cause problems in your

existing system conversion, see the Industrial Automation Wiring and

Grounding Guidelines, publication 1770-IN041

.

To fully migrate your SLC 500 systems you also need to

convert your SLC 500

application code. For more information on software conversion, see the SLC to

CompactLogix Programming Migration Application Profile, publication

5069-AP001.

14 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 15

Chapter 2

Replace an SLC 500 Controller

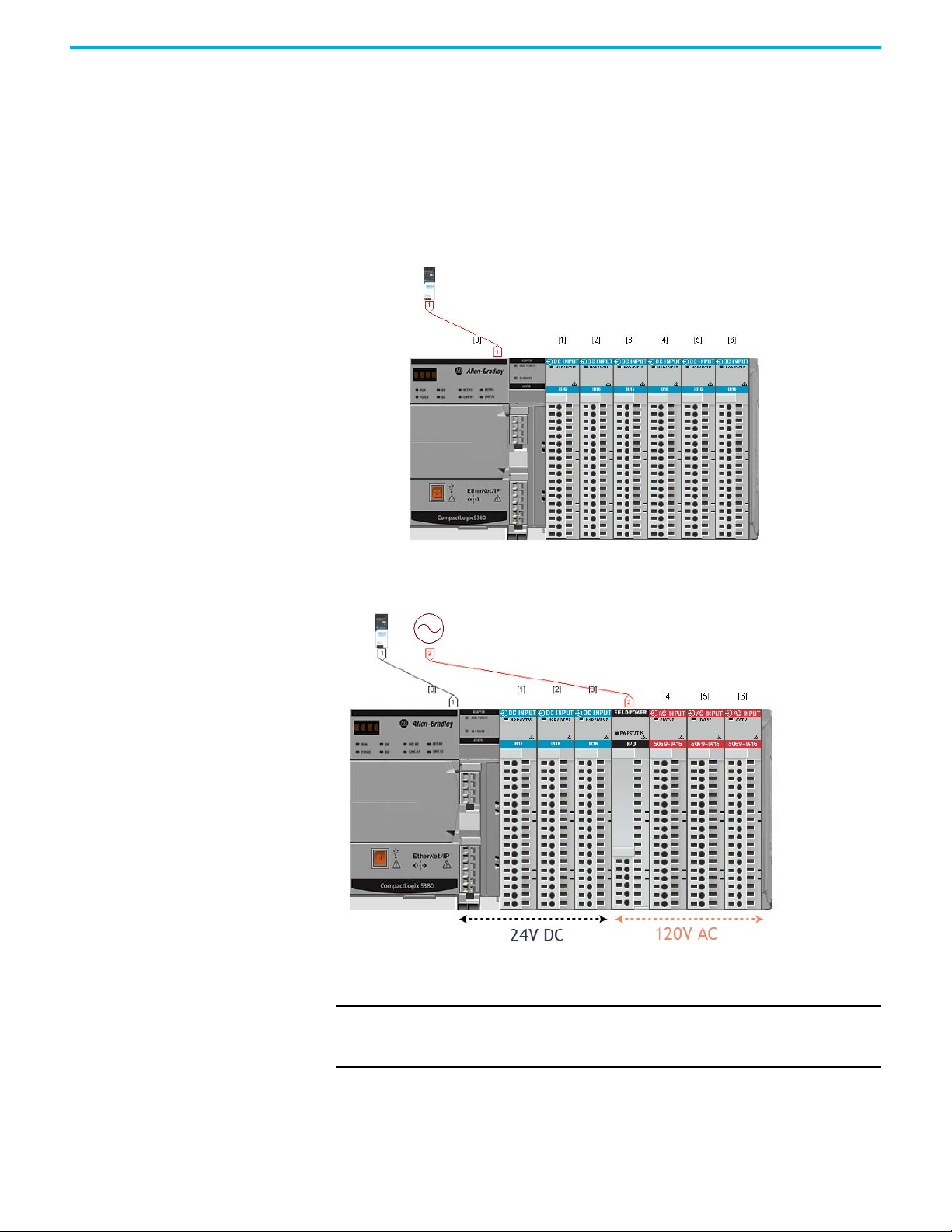

This chapter provides information about the recommended replacement for

your existing SLC 500 controller.

Due to the discontinuation of SLC 5/01 and SLC 5/02 controllers in

January 2017, a replacement CompactLogix controller is recommended.

You can view the lifecycle status of your SLC product on the Rockwell

Automation Product Lifecycle Status website:

https://www.rockwellautomation.com/en-us/support/product/productcompatibility-migration/product-lifecycle-status.html.

Upgrade to a CompactLogix 5370 Controller

Table 1 lists the recommended replacement CompactLogix 5370 controller to

your existing SLC 500 controller. These recommendations exclude Motion and

Safety applications, consult your local sales office for more info.

Table 1 - Recommended CompactLogix 5370 Replacement Controllers

Catalog Number

1747-L511 SLC 5/01 1K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L514 SLC 5/01 4K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L524 SLC 5/02 4K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L531 SLC™ 5/03 8K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L532 SLC 5/03 16K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L533 SLC 5/03 32K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L541 SLC 5/04 16K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L542 SLC 5/04 32K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L543 SLC 5/04 64K Controller 1769-L30ER CompactLogix 5370 L3 Controller, 1 MB Memory, Dual Ethernet Port - SD Card

1747-L551 SLC 5/05 16K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L552 SLC 5/05 32K Controller 1769-L24ER-QB1B CompactLogix 5370 L2 Controller, 750 KB Memory, 16 DC Inputs, 16 DC Outputs

1747-L553 SLC 5/05 64K Controller 1769-L30ER CompactLogix 5370 L3 Controller, 1 MB Memory, Dual Ethernet Port - SD Card

(1) The general rule

5069-AP001.

Alternatively, you may validate the controller based on memory estimation by the code conversion tool (RSLogix Project Migrator).

SLC Controller

Description

of thumb for memory estimation can be found under “SLC to Logix Memory Comparison” in the SLC to CompactLogix Programming Migration Application Profile, publication

Recommended CompactLogix

5370 Controller Replacement

CompactLogix 5370 Controller Description

(1)

For technical specifications of the recommended CompactLogix 5370

controller, see CompactLogix Controllers Specifications Technical Data,

publication 1769-TD005

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 15

.

Page 16

Chapter 2 Replace an SLC 500 Controller

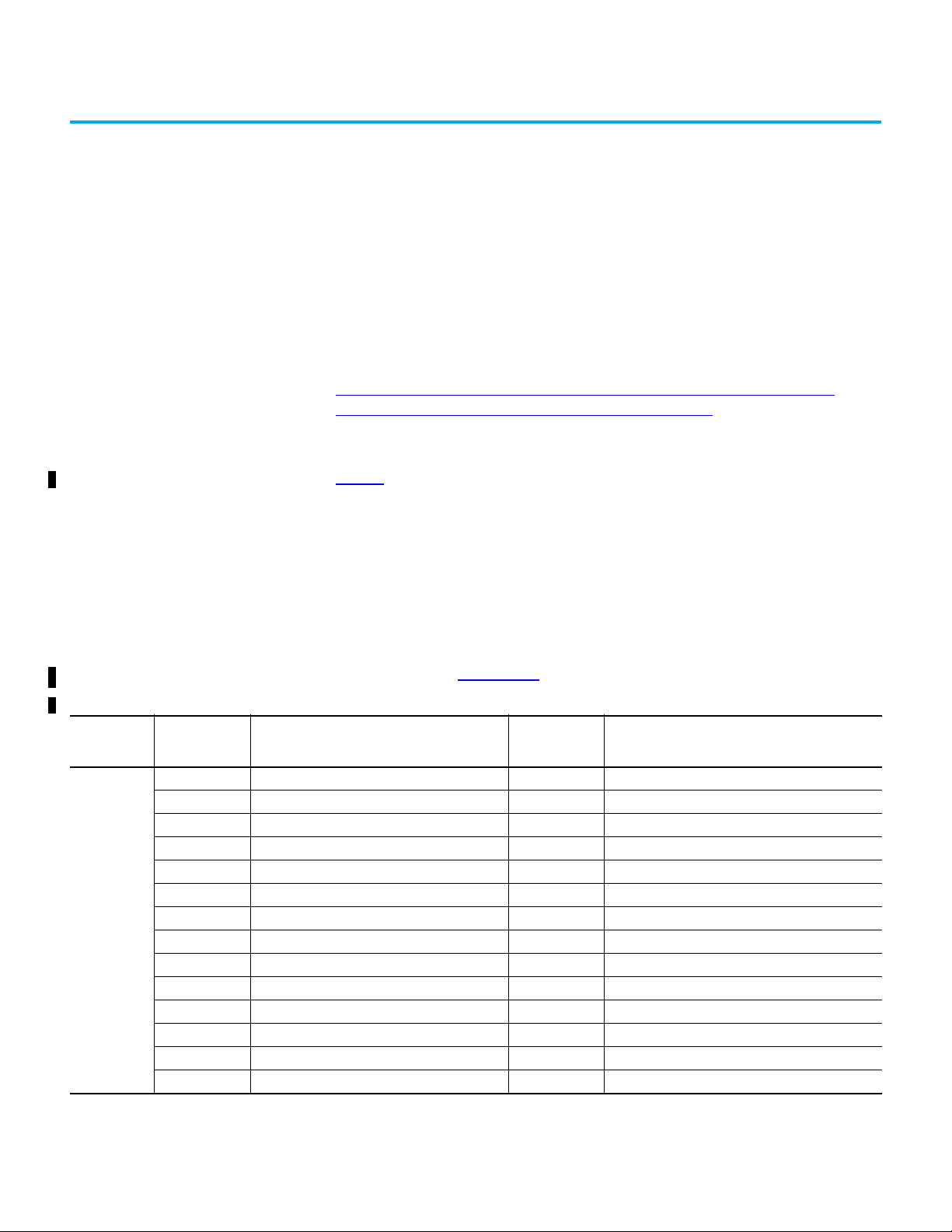

Upgrade to a CompactLogix 5380 Controller

Table 2 lists the recommended replacement CompactLogix 5380 controller to

your existing SLC 500 controller. These recommendations exclude Motion

applications, consult your local sales office for more information.

Table 2 - Recommended CompactLogix 5380 Replacement Controllers

Catalog Number

1747-L511 SLC 5/01 1K Controller

1747-L514 SLC 5/01 4K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L524 SLC 5/02 4K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L531 SLC 5/03 8K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L532 SLC 5/03 16K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L533 SLC 5/03 32K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L541 SLC 5/04 16K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L542 SLC 5/04 32K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L543 SLC 5/04 64K Controller 5069-L310ER CompactLogix 5380 Controller, 1 MB, 8 I/O, 24 nodes, Standard

1747-L551 SLC 5/05 16K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L552 SLC 5/05 32K Controller 5069-L306ER CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

1747-L553 SLC 5/05 64K Controller 5069-L310ER CompactLogix 5380 Controller, 1 MB, 8 I/O, 24 nodes, Standard

(1) To include safety on the control, you can upgrade any recommended CompactLogix 5380 replacement controller to Compact GuardLogix 5380 SIL 2 and Compact GuardLogix 5380 SIL 3

safety controllers.

(2) The general rule of thumb for memory estimation can be found under “SLC to Logix Mem

5069-AP001.

Alternatively, you can validate the controller based on memory estimation by the code conversion tool (RSLogix™ Project Migrator).

SLC Controller

Description

Recommended CompactLogix

5380 Controller Replacement

5069-L306ER

(1)(2)

CompactLogix 5380 Controller Description

CompactLogix 5380 Controller, 600 KB, 8 I/O, 16 nodes, Standard

ory Comparison” in the SLC to CompactLogix Programming Migration Application Profile, publication

For technical specifications of the recommended CompactLogix 5380

controller, see CompactLogix Controllers Specifications Technical Data,

publication 5069-TD002

.

16 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 17

Chapter 3

Replace an SLC 500 I/O Module

This chapter provides information about the recommended replacement for

your existing SLC 500 I/O module.

The lifecycle status for Rockwell Automation products is maintained and

published in the Rockwell Automation Product Lifecycle Status website:

https://www.rockwellautomation.com/en-us/support/product/productcompatibility-migration/product-lifecycle-status.html.

Upgrade an SLC I/O Installation by Replacing it with Compact I/O

Table 3 lists the recommended replacement Compact I/O module to your

existing SLC 500 I/O module.

Before upgrading, take note of the following:

• When replacing an SLC I/O with a Compact I/O, a CompactLogix 5370

• There might be technical differences between the SLC I/O and

Table 3 - Recommended Compact I/O Replacement

Module Type

Digital input

Catalog Number

1746-IA4 100/120V AC 4 120V AC input module 1769-IA8I 8 inputs, individually isolated, 100/120V AC input module

1746-IA8 100/120V AC 8 120V AC input module 1769-IA8I 8 inputs, individually isolated, 100/120V AC input module

1746-IA16 100/120V AC 16 120V AC input module 1769-IA16 16 inputs, 100/120V AC input module

1746-IB8 24V DC 8 current sinking DC input module 1769-IQ16 16 inputs, 24V DC sink/souce input module

1746-IB16 24V DC 16 current sinking DC input module 1769-IQ16 16 inputs, 24V DC sink/souce input module

1746-IB32 24V DC 32 current sinking DC input module 1769-IQ32 32 inputs, 24V DC sink/souce input module

1746-IC16 48V DC 16 current sinking DC input module No replacement —

1746-IG16 5V DC 16 current sourcing TTL input module 1769-IG16 16 inputs, 5V DC TTL input module

1746-IH16 125V DC 16 current sinking DC input module No replacement —

1746-IM4 200/240V AC 4 240V AC input module 1769-IM12 12 inputs, 200/240V AC input module

1746-IM8 200/240V AC 8 240V AC input module 1769-IM12 12 inputs, 200/240V AC input module

1746-IM16 200/240V AC 16 240V AC input module 1769-IM12 12 inputs, 200/240V AC input module

1746-IN16 24V AC/DC 16 24V AC/DC input module No replacement —

1746-ITB16 24V DC 16 fast response DC sinking input module 1769-IQ16F 16 inputs, high-speed 24V DC sink/source digital input module

(1)

SLC Module Description

controller must be used.

Compact I/O. Verify the specifications to meet your application needs.

For wiring diagrams and technical specifications of Compact I/O

modules, see Compact I/O Modules Specifications Technical Data,

publication 1769-TD006

.

Recommended

Compact I/O

Replacement

Compact I/O Module Description

(2)

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 17

Page 18

Chapter 3 Replace an SLC 500 I/O Module

Table 3 - Recommended Compact I/O Replacement (Continued)

Module Type

Digital input

Digital output

Digital

combination

Catalog Number

1746-ITV16 24V DC 16 fast response DC sourcing input module 1769-IQ16F 16 inputs, high-speed 24V DC sink/source digital input module

1746-IV8 24V DC 8 current sourcing DC input module 1769-IQ16 16 inputs, 24V DC sink/source input module

1746-IV16 24V DC 16 current sourcing DC input module 1769-IQ16 16 inputs, 24V DC sink/source input module

1746-IV32 24V DC 32 current sourcing DC input module 1769-IQ32 32 inputs, 24V DC sink/source input module

1746-OA8 120/240V AC 8 120/240V AC output module 1769-OA8 8 outputs, 100/240V AC input module

1746-OA16 120/240V AC 16 120/240V AC output module 1769-OA16 16 outputs, 100/240V AC input module

1746-OAP12 120/240V AC 12 high current 120/240V AC output module No replacement —

1746-OB6EI

1746-OB8 24V DC 8 current sourcing DC output module 1769-OB8 8 outputs, 24V DC source output module

1746-OB16 24V DC 16 current sourcing DC output module 1769-OB16 16 outputs, 24V DC source output module

1746-OB16E

1746-OB32 24V DC 32 current sourcing DC output module 1769-OB32 32 outputs, 24V DC source output module

1746-OB32E

1746-OBP8 24V DC 8 high current sourcing DC output module 1769-OB8 8 outputs, 24V DC source output module

1746-OBP16 24V DC 16 high current sourcing DC output module No replacement —

1746-OG16 5V DC 16 current sourcing TTL output module 1769-OG16 16 outputs, 5V DC TTL output module

1746-OV8 24V DC 8 current sinking DC output module 1769-OV16 16 outputs, 24V DC sink output module

1746-OV16 24V DC 16 current sinking DC output module 1769-OV16 16 output, 24V DC sink output module

1746-OV32 24V DC 32 current sinking DC output module 1769-OV32T 32 terminated outputs, 24V DC sink output module

1746-OVP16 24V DC 16 high current sinking DC output module No replacement —

1746-OW4 AC/DC relay 4 relay (hard contact) output module 1769-OW8 8 outputs, 5...265V AC/5...125V DC relay output module

1746-OW8 AC/DC relay 8 relay (hard contact) output module 1769-OW8 8 outputs, 5...265V AC/5...125V DC relay output module

1746-OW16 AC/DC relay 16 relay (hard contact) output module 1769-OW16 16 outputs, 5...265V AC/5...125V DC relay output module

1746-OX8 AC/DC relay 8 relay (hard contact) output module No replacement —

1746-IO4

1746-IO8

1746-IO12

1746-IO12DC

(1)

SLC Module Description

24V DC 6 electronically protected isolated sourcing DC

output module

24V DC 16 electronically protected current sourcing DC

output module

24V DC 32 electronically protected current sourcing DC

output module

120V AC (inputs) 100/120V AC (relay contact outputs) 2-in

2-out combination input/output module

120V AC (inputs) 100/120V AC (relay contact outputs) 4-in

4-out combination input/output module

120V AC (inputs) 100/120V AC (relay contact outputs) 6-in

6-out combination input/output module

240V DC (inputs) 100/120V AC (relay contact outputs) 6-in

6-out combination input/output module

Recommended

Compact I/O

Replacement

No replacement —

1769-OB16P 16 outputs, protected, 24V DC source output module

No replacement —

No replacement —

No replacement —

No replacement —

1769-IQ6XOW4

Compact I/O Module Description

(2)

6 inputs, 4 outputs, 24V DC sink/source input AC/DC

normally open, relay contact output module

18 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 19

Table 3 - Recommended Compact I/O Replacement (Continued)

Module Type

Analog input

Analog output

Analog

combination

Catalog Number

1746-INT4

1746-NI4 High resolution (4) analog input module 1769-IF4

1746-NI8 High resolution (8) analog input module 1769-IF8

1746-NI16I -20 mA to +20 mA high resolution (16) analog input module 1769-IF16C

1746-NI16V

1746-NR4 4-channel RTD/resistance input module 1769-IR6

1746-NR8 8-channel RTD/resistance input module 1769-IR6

1746-NT4

1746-NT8

1746-NIO4I

1746-NIO4V

1746-NO4I 0...20 mA (4) analog current output module 1769-OF4

1746-NO4V -10V DC to +10V DC (4) analog current output module 1769-OF4

1746-NO8I 0...20 mA (8) analog current output module 1769-OF8C

1746-NO8V -10V DC to +10V DC (8) analog current output module 1769-OF8V

1746-FIO4I (2) Fast analog input, (2) analog current output module 1769-IF4XOF2

1746-FIO4V (2) Fast analog input, (2) analog voltage output module 1769-IF4XOF2

(1)

SLC Module Description

4-channel thermocouple (J, K, T, E, R, S, B, N, C, D)/mV

input module

-10V DC to +10V DC high resolution (16) analog input

module

4-channel thermocouple (J, K, T, E, R, S, B, N)/mV

input module

8-channel thermocouple (J, K, T, E, R, S, B, N)/mV

input module

High resolution (2) analog input, (2) analog current

output module

High resolution (2) analog input, (2) analog voltage

output module

Chapter 3 Replace an SLC 500 I/O Module

Recommended

Compact I/O

Replacement

1769sc-IT6I Isolated thermocouple or millivolt input module

1769-IF16V

1769-IT6

1769-IT6

1769-IF4XOF2

1769-IF4XOF2

Compact I/O Module Description

(2)

4 inputs, differential or single-ended, ±10V/0...10V/0...5V/1...5V/

0...20 mA/4...20 mA analog input module

8 inputs, differential or single-ended, ±10V/0...10V/0...5V/1...5V/

0...20 mA/4...20 mA analog input module

16 inputs, single-ended 0...20 mA/ 4...20 mA analog

input module

16 inputs, single-ended, ±10V/0...10V/0...5V/1...5V analog

input module

6 RTD inputs, 100, 200, 500, 1000 Platinum 385/3916, 120 ohm

Nickel 618/672, 10 ohm Nickel-iron, 0...150/500/1000/3000 ohm

module

6 RTD inputs, 100, 200, 500, 1000 Platinum 385/3916, 120 ohm

Nickel 618/672, 10 ohm Nickel-iron, 0...150/500/1000/3000 ohm

module

6 thermocouple, thermocouple types B, C, E, J, K, N, R, S, T/

±50V/±100V module

6 thermocouple, thermocouple types B, C, E, J, K, N, R, S, T/

±50V/±100V module

4 inputs, differential or single-ended, 2 outputs, single-ended

analog module

4 inputs, differential or single-ended, 2 outputs, single-ended

analog module

4 outputs, single-ended, ±10V/0...10V/0...5V/1...5V/0...20 mA/

4...20 mA analog output module

4 outputs, single-ended, ±10V/0...10V/0...5V/1...5V/0...20 mA/

4...20 mA analog output module

8 outputs, single-ended, 0...20 mA/4...20 mA analog

output module

8 outputs, single-ended, ±10V/0...10V/0...5V/1...5V analog

output module

4 inputs, differential or single-ended, 2 outputs, single-ended

analog module

4 inputs, differential or single-ended, 2 outputs, single-ended

analog module

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 19

Page 20

Chapter 3 Replace an SLC 500 I/O Module

Table 3 - Recommended Compact I/O Replacement (Continued)

Module Type

Specialty 1747-ACN15 ControlNet® adapter No replacement —

(1) The product may be in Active Mature, End of Life, or Discontinued state. To view the most up-to-date product lifecycle status, search for the catalog number on the Product Lifecycle Status

website.

(2) The recommended replacements that are indicated in this table are for reference only. There may be slight differences in specifications between the existing 1746 SLC I/O module and

recommended 1769 Compact I/O module. Consult your local sales team for further assistance.

Catalog Number

1747-ACNR15 ControlNet adapter, redundant No replacement —

1747-ASB SLC 500 remote I/O adapter No replacement —

1746-BAS B asic module No replacement —

1746-BAS-T High-s peed basic module No replacement —

1746-BLM Blow molding module No replacement —

1746-BTM Barrel temperature module No replacement —

1746-HS IMC 110 motion module No replacement —

1746-HSCE High-speed counter encoder module No replacement —

1746-HSCE2 Multi-channel high-speed counter encoder module 1769-HSC High-speed counter module

1746-HSTP1 1-axis stepper module No replacement —

1746-N2 Empty slot filler 1769-ARM Compact address reserve module

1746-QS Synchronized axis module No replacement —

1746-QV Open loop velocity control module No replacement —

1747-SCNR ControlNet scanner No replacement —

1747-SDN DeviceNet scanner 1769-SDN Compact I/O DeviceNet scanner

1746-SIM 16-point input simulator modul e No replacement —

1747-SN Remote I/O scanner No replacement —

(1)

SLC Module Description

Recommended

Compact I/O

Replacement

Compact I/O Module Description

(2)

Upgrade an SLC I/O Installation by Replacing it with Compact 5000 I/O

Table 4 lists the recommended replacement Compact 5000 I/O module to your

existing SLC 500 I/O module.

Before upgrading, take note of the following:

• When replacing an SLC I/O with a Compact 5000 I/O, a

CompactLogix 5380, CompactLogix 5480, or ControlLogix® 5580

controller must be used.

• There might be technical differences between the SLC I/O and

Compact 5000 I/O. Verify the specifications to meet your application

needs. For wiring diagrams and technical specifications of Compact

5000 I/O modules, see Compact 5000 I/O Modules Specifications

Technical Data, publication 5069-TD001

.

20 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 21

Table 4 - Recommended Compact 5000 I/O Replacement

Chapter 3 Replace an SLC 500 I/O Module

Module Type

Digital input

Digital output

Digital output

(cont)

Recommended

Compact 5000 I/O

Replacement

(2)

Compact 5000 I/O Module Description

Catalog Number

(1)

SLC Module Description

1746-IA4 100/120V AC 4 120V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IA8 100/120V AC 8 120V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IA16 100/120V AC 16 120V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IB8 24V DC 8 current sinking DC input module 5069-IB16 16-point, 24V DC sinking digital input module

1746-IB16 24V DC 16 current sinking DC input module 5069-IB16 16-point, 24V DC sinking digital input module

1746-IB32 24V DC 32 current sinking DC input module

5069-IB16 x 2

(3)

16-point, 24V DC sinking digital input module

1746-IC16 48V DC 16 current sinking DC input module No replacement —

1746-IG16 5V DC 16 current sourcing TTL input module No replacement —

1746-IH16 125V DC 16 current sinking DC input module No replacement —

1746-IM4 200/240V AC 4 240V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IM8 200/240V AC 8 240V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IM16 200/240V AC 16 240V AC input module 5069-IA16 16-point, 120/240V AC digital input module

1746-IN16 24V AC/DC 16 24V AC/DC input module No replacement —

1746-ITB16 24V DC 16 fast response DC sinking input module 5069-IB16 16-point, 24V DC sinking digital input module

1746-ITV16 24V DC 16 fast response DC sourcing input module No replacement —

1746-IV8 24V DC 8 current sourcing DC input module No replacement —

1746-IV16 24V DC 16 current sourcing DC input module No replacement —

1746-IV32 24V DC 32 current sourcing DC input module No replacement —

1746-OA8 120/240V AC 8 120/240V AC output module 5069-OA16 16-point, 120/240V AC digital output module

1746-OA16 120/240V AC 16 120/240V AC output module 5069-OA16 16-point, 120/240V AC digital output module

1746-OAP12 120/240V AC 12 high current 120/240V AC output module No replacement —

1746-OB6EI

24V DC 6 electronically protected isolated sourcing DC

output module

No replacement —

1746-OB8 24V DC 8 current sourcing DC output module 5069-OB8 8-point, 24V DC high current digital output module

1746-OB16 24V DC 16 current sourcing DC output module 5069-OB16 16-point, 24V DC sourcing digital output module

1746-OB16E

24V DC 16 electronically protected current sourcing DC

output module

1746-OB32 24V DC 32 current sourcing DC output module

1746-OB32E

24V DC 32 electronically protected current sourcing DC

output module

5069-OB16 16-point, 24V DC sourcing digital output module

(3)

5069-OB16 x 2

5069-OB16 x 2

16-point, 24V DC sourcing digital output module

(3)

16-point, 24V DC sourcing digital output module

1746-OBP8 24V DC 8 high current sourcing DC output module 5069-OB8 8-point, 24V DC high current digital output module

(4)

1746-OBP16 24V DC 16 high current sourcing DC output module

5069-OB8 x 2

16-point, 24V DC high current digital output module

1746-OG16 5V DC 16 current sourcing TTL output module No replacement —

1746-OV8 24V DC 8 current sinking DC output module No replacement —

1746-OV16 24V DC 16 current sinking DC output module No replacement —

1746-OV32 24V DC 32 current sinking DC output module No replacement —

1746-OVP16 24V DC 16 high current sinking DC output module No replacement —

1746-OW4 AC/DC relay 4 relay (hard contact) output module

1746-OW8 AC/DC relay 8 relay (hard contact) output module

1746-OW16 AC/DC relay 16 relay (hard contact) output module

1746-OX8 AC/DC relay 8 relay (hard contact) output module

5069-OW4I

5069-OW16

5069-OW16

5069-OX4I

(5)(6)

(5)(6)

(5)(6)

(5)(6)

4-point, normally open, isolated relay output module

16-point, non-isolated, high-density relay output module

16-point, non-isolated, high-density relay output module

4-point, normally open/normally closed, isolated relay

output module

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 21

Page 22

Chapter 3 Replace an SLC 500 I/O Module

Table 4 - Recommended Compact 5000 I/O Replacement (Continued)

Module Type

Digital

combination

Analog input

Analog output

Analog

combination

Specialty

(1)

Catalog Number

1746-IO4

1746-IO8

1746-IO12

1746-IO12DC

1746-INT4

1746-NI4 High resolution (4) analog input module 5069-IY4

1746-NI8 High resolution (8) analog input module 5069-IF8 8-channel, analog input module, differential inputs only

1746-NI16I -20 mA to +20 mA high resolution (16) analog input module 5069-IF8 8-channel, analog input module, differential inputs only

1746-NI16V -10V DC to +10V DC high resolution (16) analog input module 5069-IF8 8-channel, analog input module, differential inputs only

1746-NR4 4-channel RTD/resistance input module 5069-IY4

1746-NR8 8-channel RTD/resistance input module 5069-IY4

1746-NT4

1746-NT8

1746-NIO4I

1746-NIO4V

1746-NO4I 0...20 mA (4) analog current output module 5069-OF4 4-channel, analog output module

1746-NO4V -10V DC to +10V DC (4) analog current output module 5069-OF4 4-channel, analog output module

1746-NO8I 0...20 mA (8) analog current output module 5069-OF8 8-channel, analog output module

1746-NO8V -10V DC to +10V DC (8) analog current output module 5069-OF8 8-channel, analog output module

1746-FIO4I (2) Fast analog input, (2) analog current output module No replacement —

1746-FIO4V (2) Fast analog input, (2) analog voltage output module No replacement —

1747-ACN15 ControlNet adapter No replacement —

1747-ACNR15 ControlNet adapter, redundant No replacement —

1747-ASB SLC 500 remote I/O adapter No replacement —

1746-BAS Basic module No replacement —

1746-BAS-T High-speed basic module No replacement —

1746-BLM Blow molding module No replacement —

1746-BTM Barrel temperature module No replacement —

SLC Module Description

120V AC (inputs) 100/120V AC (relay contact outputs) 2-in

2-out combination input/output module

120V AC (inputs) 100/120V AC (relay contact outputs) 4-in

4-out combination input/output module

120V AC (inputs) 100/120V AC (relay contact outputs) 6-in

6-out combination input/output module

240V DC (inputs) 100/120V AC (relay contact outputs) 6-in

6-out combination input/output module

4-channel thermocouple (J, K, T, E, R, S, B, N, C, D)/mV

input module

4-channel thermocouple (J, K, T, E, R, S, B, N)/mV

input module

8-channel thermocouple (J, K, T, E, R, S, B, N)/mV

input module

High resolution (2) analog input, (2) analog current

output module

High resolution (2) analog input, (2) analog voltage

output module

Recommended

Compact 5000 I/O

Replacement

No replacement —

No replacement —

No replacement —

No replacement —

No replacement —

5069-IY4

5069-IY4

No replacement —

No replacement —

(2)

Compact 5000 I/O Module Description

4-channel, universal analog input module, differential

inputs only

4-channel, universal analog input module, differential

inputs only

4-channel, universal analog input module, differential

inputs only

4-channel, universal analog input module, differential

inputs only

4-channel, universal analog input module, differential

inputs only

22 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 23

Table 4 - Recommended Compact 5000 I/O Replacement (Continued)

Chapter 3 Replace an SLC 500 I/O Module

Module Type

Specialty

(cont)

(1) The product may be in Active Mature, End of Life, or Discontinued state. To view the most up-to-date product lifecycle status, search for the catalog number on the Product Lifecycle Status

website.

(2) The recommended replacements that are indicated in this table are for reference only. There may be slight differences in specifications between the existing 1746 SLC I/O module and

recommended 5069 Compact 5000 I/O module. Consult your local sales team for further assistance.

(3) 1746-IB32 modules can be replaced with two 5069-IB16 modules.

(4) 1746-OBP16 modules can be replaced with two 5069-OB8 modules.

(5) 5069-OW16 is a DC module.

(6) The 5069-OW16 does not come with an internal snubber, an external surge suppressor is required. For more information on selecting and adding surge suppressors, see the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

Catalog Number

1746-HS IMC 110 motion module No replacement —

1746-HSCE High-speed counter encoder module 5069-HSC2XOB4

1746-HSCE2 Multi-channel high-speed counter encoder module 5069-HSC2XOB4

1746-HSTP1 1 axis stepper module No replacement —

1746-N2 Empty slot filler 5069-ARM Address reserve module

1746-QS Synchronized axis module No replacement —

1746-QV Open loop velocity control module No replacement —

1747-SCNR ControlNet scanner No replacement —

1747-SDN DeviceNet scanner No replacement —

1746-SIM 16-point input simulator module No replacement —

1747-SN Remote I/O scanner No replacement —

(1)

SLC Module Description

.

Recommended

Compact 5000 I/O

Replacement

(2)

Compact 5000 I/O Module Description

High-speed counter, 2-axis, 4-point sourcing digital

output module

High-speed counter, 2-axis, 4-point sourcing digital

output module

SLC I/O Installation Using a Conversion Kit

You can use a conversion system to connect the existing SLC I/O wiring to the

Compact 5000 I/O modules without disturbing the field wiring connections,

reducing labor time and eliminating downtime that could result from wiring

mistakes during the migration. With a conversion system I/O can be swapped

one rack at a time, giving you the option to run both new and old I/O networks

simultaneously.

Table 5 - SLC I/O to Compact 5000 I/O Conversion System Selection

SLC I/O Module Catalog Number

(To be converted)

1746-IA16

1746-IM16 240VAC Input Module

1746-IB16

1746-ITB16 Fast Response DC Sinking Input Module

1746-OA16 5069-OA16 1492-CM1746-M02 120/240V AC Output Module

1746-OB16

1746-OB16E Current Sourcing DC Output Module

1746-OW16 5069-OW16 1492-CM1746-M04 AC/DC Relay Output Module

1746-NI8 5069-IF8 1492-CM1746-M05 High Resolution (8) Analog Input Module

1746-NI4

1746-NR4 1492-CM1746-M07 SLC 500 RTD/Resistance Input Module

1746-NT4 1492-CM1746-M09 4-Channel Thermocouple/mV Input Module

1746-NO4I

1746-NO4V 4 Point Analog Output Module (Voltage)

Compact 5000 I/O Modules

Catalog Number (To be

used)

Conversion Module Catalog

Number

5069-IA16

1492-CM1746-M01

5069-IB16

5069-OB16 1492-CM1746-M03

1492-CM1746-M06 High Resolution (4) Analog Input Module

5069-IY4

5069-OF4 1492-CM1746-M10

Conversion Module Description

120VAC Input Module

Current Sinking DC Input Module

Current Sourcing DC Output Module

4 Point Analog Output Module (Current)

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 23

Page 24

Chapter 3 Replace an SLC 500 I/O Module

Table 5 - SLC I/O to Compact 5000 I/O Conversion System Selection

SLC I/O Module Catalog Number

(To be converted)

1746-NO8I

1746-NO8V 8 Point Analog Output Module (Voltage)

1746-IB32 5069-IB16 (2x) 1492-CM1746-M12 Current Sinking DC Input Module

1746-OB32

1746-OB32E Current Sourcing DC Output Module

Compact 5000 I/O Modules

Catalog Number (To be

used)

5069-OF8 1492-CM1746-M11

5069-OB16 (2x) 1492-CM1746-M13

Conversion Module Catalog

Number

Conversion Module Description

8 Point Analog Output Module (Current)

Current Sourcing DC Output Module

Table 6 - SLC to Compact 5000 Chassis Conversion System Selection

SLC 500 Chassis 1492 Conversion Chassis 1792 Slots max Chassis Length Usable Length

1746-A4 1492-CH1746-4 4 235 mm (9.25 in.) 203 mm (8.00 in.) 4

1746-A7 1492-CH1746-7 7 339 mm (13.33 in.) 307 mm (12.08 in.) 9

1746-A10 1492-CH1746-10 10 454 mm (17.88 in.) 422 mm (16.63 in.) 14

1746-A13 1492-CH1746-13 13 559 mm (22.00 in.) 527 mm (20.75 in.) 19

For more information on choosing the appropriate conversion chassis and

conversion system for your system, see 1746 SLC I/O to Compact 5000 I/O

Conversion System Selection Guide, publication 1492-SG010

For more information on installing the 1492 conversion system chassis, see

1746-to-5069 I/O Conversion System Instruction Sheet, publication 1492-IN132

Number of Compact 5000

I/O Cards max

.

.

24 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 25

Appendix A

RUN

FLT

BATT

FORCE

RUN REM PROG

DH485

SLC 5/03 CPU

RS232

9-pin female 25-pin 9-pin

DCD.IN 1 8 1

RXD.IN 2 3 2

TXD.OUT 3 2 3

DTR.OUT 4 20 4

SIG.GND 5 7 5

DSR.IN 6 6 6

RTS.OUT 7 4 7

CTS.IN 8 5 8

SLC 5/03, 5/04, 5/05

Serial Port

5069-SERIAL

Serial Module

Wiring Diagram Comparisons

This appendix provides wiring diagram comparisons of the recommended

replacement for your existing SLC 500 I/O module.

Replace an SLC 5 Processor Serial Port with a Compact I/O Serial Module

See the installations instructions and technical data of the associated catalogs

for the detailed wiring instruct

ions.

SLC 5/03, SLC 5/04, or SCL 5/05 to 5069-SERIAL

6

7

8

9

RS-232C

Pin

1 Data Carrier Detect (DCD) (i)

2 Receive Data (RXD) (i) A

3 Transmit Data (TXD) (o)

Data Terminal Ready

4

(DTR)

5 Common (COM) 6 Data Set Ready (DSR) (i) - 7 Request To Send (RTS) (o)

8 Clear To Send (CTS) (i) - A

9 - ---

Input (i)/Output (o)

(o) B

Wiring

No Handshaking Handshaking

1

2

3

4

5

--

A

A

A

B

A

B

A

A

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 25

Page 26

Appendix A Wiring Diagram Comparisons

AC

COM 0

IN 0

AC

COM 1

AC

COM 2

IN 1

IN 2

AC

COM 3

AC

COM 4

AC

COM 5

AC

COM 6

AC

COM 7

NC

NC

IN 3

IN 4

IN 5

IN 6

IN 7

100/120V AC

100/120V AC

100/120V AC

L1a

L2a

L1b

L2b

L1c

L2c

1769-IA8I

100/120V AC Input Module

AC

COM 0

IN 0

AC

COM 1

AC

COM 2

IN 1

IN 2

AC

COM 3

AC

COM 4

AC

COM 5

AC

COM 6

AC

COM 7

NC

NC

IN 3

IN 4

IN 5

IN 6

IN 7

100/120V AC

100/120V AC

100/120V AC

L1a

L2a

L1b

L2b

L1c

L2c

1769-IA8I

100/120V AC Input Module

Replace an SLC 500 I/O with a Compact I/O

100/120V AC

L1

100/120V AC

L2

See the installations instructions and technical data of the associated catalogs

for the detailed wiring instruct

ions.

1746-IA4 to 1769-IA8I

1746-IA4

NOT

USED

NOT

USED

NOT

USED

NOT

USED

IN 0

IN 1

IN 2

IN 3

AC COM

1746-IA8 to 1769-IA8I

1746-IA8

100/120V AC

L1

100/120V AC

L2

Internally Connected

Commons

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

AC COM

AC COM

26 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 27

1746-IA16 to 1769-IA16

PLC

SLC

IN 1

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

AC COM

AC COM

0

1

2

4

6

IN 8

10

12

14

16

11

13

15

17

3

5

7

L1

L2

100/120V AC

1746-IA16

100/120V AC

Internally Connected

Commons

1769-IA16

100/120V AC Input Module

1769-IQ16

24V DC Sink/Source Input Module

L1

L2

100/120V AC

Appendix A Wiring Diagram Comparisons

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

AC

COM

COM

AC

Commons are

connected internally.

+DC

-DC

1746-IB8

24V DC Sinking

24V DC

Internally Connected

Commons

1746-IB8 to 1769-IQ16

+DC (sinking)

-DC (sourcing)

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

DC COM

DC COM

+DC (sinking)

-DC (sourcing)

24V DC

+DC (sinking)

-DC (sourcing)

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 27

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

IN 13

IN 15

DC

COM 2

IN 0

IN 2

IN 4

IN 6

DC

COM 1

IN 8

IN 10

IN 12

IN 14

24V DC

+DC (sinking)

-DC (sourcing)

Page 28

Appendix A Wiring Diagram Comparisons

-DC

PLC

SLC

+DC

IN 1

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 11

IN 12

IN 13

IN 14

IN 15

DC COM

DC COM

0

1

2

4

6

IN 8

10

14

11

13

15

17

3

5

7

24V DC

6

IN 10

12

16

1746-IB16

24V DC Sinking

Internally Connected Commons

24V DC

IN 1

DC

COM 2

IN 5

IN 7

IN 0

IN 2

IN 4

IN 6

DC

COM 1

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 3

24V DC

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 9

IN 11

IN 8

IN 13

IN 15

IN 14

IN 10

IN 12

1769-IQ16

24V DC Sink/Source Input Module

PLC

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 10

IN 1 1

IN 12

IN 13

IN 14

DC COM

0

1

2

4

6

10

12

14

16

11

13

15

IN 15

17

3

5

7

+DC

-DC

SLC

+5V DC

IN 8

IN 1

+5 DC

1746-IG16

TTL Input (Low = True)

1769-IG16

5V DC TTL Input Module

1746-IB16 to 1769-IQ16

1746-IG16 to 1769-IG16

28 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

Page 29

1746-IM4 to 1769-IM12

Do not use the NC terminals as a connection.

200/240V AC

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

NC

NC

AC

COM

AC

COM

Common s are

connected internally.

L2

L1

IN 0

IN 2

IN 4

IN 6

IN 8

IN 10

NC

NC

NOT

USED

NOT

USED

NOT

USED

NOT

USED

IN 0

IN 1

IN 2

IN 3

AC COM

L1

L2

200/240V AC

1746-IM4

200/240V AC

1769-IM12

200/240V AC Input Module

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

AC COM

L1

L2

AC COM

200/240V AC

1746-IM8

200/240V AC

Internally Connected

Commons

Do not use the NC terminals as a connection.

200/240V AC

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

NC

NC

AC

COM

AC

COM

Common s are

connected internally.

L2

L1

IN 0

IN 2

IN 4

IN 6

IN 8

IN 10

NC

NC

1769-IM12

200/240V AC Input Module

Appendix A Wiring Diagram Comparisons

1746-IM8 to 1769-IM12

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 29

Page 30

Appendix A Wiring Diagram Comparisons

Do not use the NC terminals as a connection.

200/240V AC

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

NC

NC

AC

COM

AC

COM

Common s are

connected internally.

L2

L1

IN 0

IN 2

IN 4

IN 6

IN 8

IN 10

NC

NC

1769-IM12

200/240V AC Input Module

-DC

PLC

SLC

+DC

IN 1

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 1 1

IN 12

IN 13

IN 14

IN 15

DC

COM

DC COM

0

1

2

4

6

IN 8

10

14

11

13

15

17

3

5

7

24V DC

6

IN 10

12

16

1746 -ITB16

24V DC Sinking

Internally Connected Commons

1769-IQ16F

24V DC Sink/Source Input Module

1746-IM16

200/240V AC

L1

IN 0

IN 2

IN 4

200/240V AC

L2

IN 6

IN 8

IN 10

IN 12

IN 14

AC COM

Internally Connected

Commons

1746-IM16 to 1769-IM12

0

IN 1

1

IN 3

2

3

IN 5

4

5

IN 7

6

7

IN 9

10

11

IN 11

12

13

IN 13

14

15

IN 15

16

17

AC COM

SLC

PLC

1746-ITB16 to 1769-IQ16F

30 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

+DC (sinking)

-DC (sourcing)

24V DC

+DC (sinking)

-DC (sourcing)

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

IN 13

IN 15

DC

COM 2

IN 0

IN 2

IN 4

IN 6

DC

COM 1

IN 8

IN 10

IN 12

IN 14

+DC (sinking)

-DC (sourcing)

24V DC

+DC (sinking)

-DC (sourcing)

Page 31

1746-ITV16 to 1769-IQ16F

PLC

SLC

-DC

+DC

IN 1

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 10

IN 1 1

IN 12

IN 13

IN 14

IN 15

VDC

VDC

0

1

2

4

6

IN 8

10

12

14

16

11

13

15

17

3

5

7

24V dc

Internally

Connected V DC

1746-ITV16

24V DC Sourcing

1769-IQ16F

24V DC Sink/Source Input Module

24V DC

IN 1

DC

COM 2

IN 5

IN 7

IN 0

IN 2

IN 4

IN 6

DC

COM 1

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 3

24V DC

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 9

IN 11

IN 8

IN 13

IN 15

IN 14

IN 10

IN 12

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

VDC

-DC

+DC

VDC

24V dc

1746-IV8

24V DC Sourcing

Internally

Connected V DC

1769-IQ16

24V DC Sink/Source Input Module

+DC (sinking)

-DC (sourcing)

24V DC

+DC (sinking)

-DC (sourcing)

Appendix A Wiring Diagram Comparisons

+DC (sinking)

-DC (sourcing)

IN 0

IN 1

IN 3

IN 5

IN 7

IN 9

IN 11

IN 13

IN 15

DC

COM 2

IN 2

IN 4

IN 6

DC

COM 1

IN 8

IN 10

IN 12

IN 14

24V DC

+DC (sinking)

-DC (sourcing)

1746-IV8 to 1769-IQ16

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 31

Page 32

Appendix A Wiring Diagram Comparisons

24V DC

IN 1

DC

COM 2

IN 5

IN 7

IN 0

IN 2

IN 4

IN 6

DC

COM 1

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 3

24V DC

+DC (sinking)

-DC (sourcing)

+DC (sinking)

-DC (sourcing)

IN 9

IN 11

IN 8

IN 13

IN 15

IN 14

IN 10

IN 12

PLC

SLC

-DC

+DC

IN 1

IN 0

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 9

IN 10

IN 1 1

IN 12

IN 13

IN 14

IN 15

VDC

VDC

0

1

2

4

6

IN 8

10

12

14

16

11

13

15

17

3

5

7

24V dc

Internally

Connected V DC

1746-IV16

24V DC Sourcing

1769-IQ16

24V DC Sink/Source Input Module

OUT6

OUT4

VAC 2

OUT2

OUT0

OUT7

OUT5

OUT3

OUT1

VA C 1

CR

CR

CR

CR

CR

CR

CR

CR

1769-OA8

100/240V AC Input Module

100…240V AC

CR

CR

VAC 1

OUT 0

OUT 1

OUT 2

OUT 3

VAC 2

OUT 4

OUT 5

OUT 6

OUT 7

CR

CR

L2

L1

L2

L1

100…240V AC

1746-OA8

100...240V AC Triac Output

1746-IV16 to 1769-IQ16

32 Rockwell Automation Publication 1746-RM003E-EN-E - August 2020

1746-OA8 to 1769-OA8

L1

100…240V AC

L2

L1

100…240V AC

L2

Page 33

1746-OA16 to 1769-OA16

1769-OA16

100/240V AC Input Module

OUT0

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 9

OUT 8

OUT 1 1

OUT 10

OUT 14

OUT 12

0

2

4

6

11

13

16

10

12

14

3

5

L1

PLC

SLC

CR

CR

L2

CR

CR

CR

CR

L2

CR

CR

100…240V AC

OUT 7

7

OUT 1

1

VAC 1

100…240V AC

L1

OUT 15

17

OUT 13

15

VAC 2

1746-OA16

100...240V AC Triac Output

OUT10

OUT 8

VAC 2

OUT6

OUT4

OUT11

OUT 9

OUT 7

OUT 5

OUT 3

CR

CR

CR

CR

CR

CR

CRCRCR

CR

CR

CR

CR

CR

VAC 1

OUT 1

OUT 0

OUT 2

CR

CR

CRCRCR

CRCRCR

OUT 12

OUT 14

OUT 13

OUT 15

1769-OB8

24V DC Source Output Module

DC+

DC-

OUT 6

OUT 4

NC

NC

NC

OUT 2

OUT 0

OUT 7

OUT 5

+VDC 2

NC

NC

NC

OUT 3

OUT 1

+VDC 1

CR

CR

CR

CR

DC COM

2

DC COM

1

CR

CR

DC -

DC+

Appendix A Wiring Diagram Comparisons

L1

100…240V AC

L2

L1

100…240V AC

L2

10...50V DC Transistor Output-sourcing

1746-OB8

VDC

OUT 0

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

DC

COM

CR

CR

CR

CR

10…50V DC

Rockwell Automation Publication 1746-RM003E-EN-E - August 2020 33

1746-OB8 to 1769-OB8

+DC

-DC

Page 34

Appendix A Wiring Diagram Comparisons

1769-OB16

24V DC Source Output Module