Page 1

Application Techniques

Original Instructions

Industry Installation Guidelines for Pulse Width Modulated (PWM)

AC Drives

Industries discussed in this application technique include:

Automotive Marine and Offshore

Chemical/Specialty Chemical Mining and Steel

Food and Beverage Tire Manufacturing

Forest Products/Converting Water/Waste Water

Page 2

Summary of Changes

This manual has been extensively revised to reduce redundancies in previous version. There are different requirements in applications for

specific industries. The unique requirements of the Marine Industry are in Chapter 4 Marine and Offshore Industry. Other industries which

have more in common are discussed in Chapters 1…3 and Appendix B: Sample Requirements and Enclosure Specifications for Specific

Industry Types, which provides bulleted lists of the requirements for each of these industries. These industries include:

• Automotive

• Forest and pulp paper products

•Metal products

• Mining process products

• Oil and gas products

• Open pit mining products

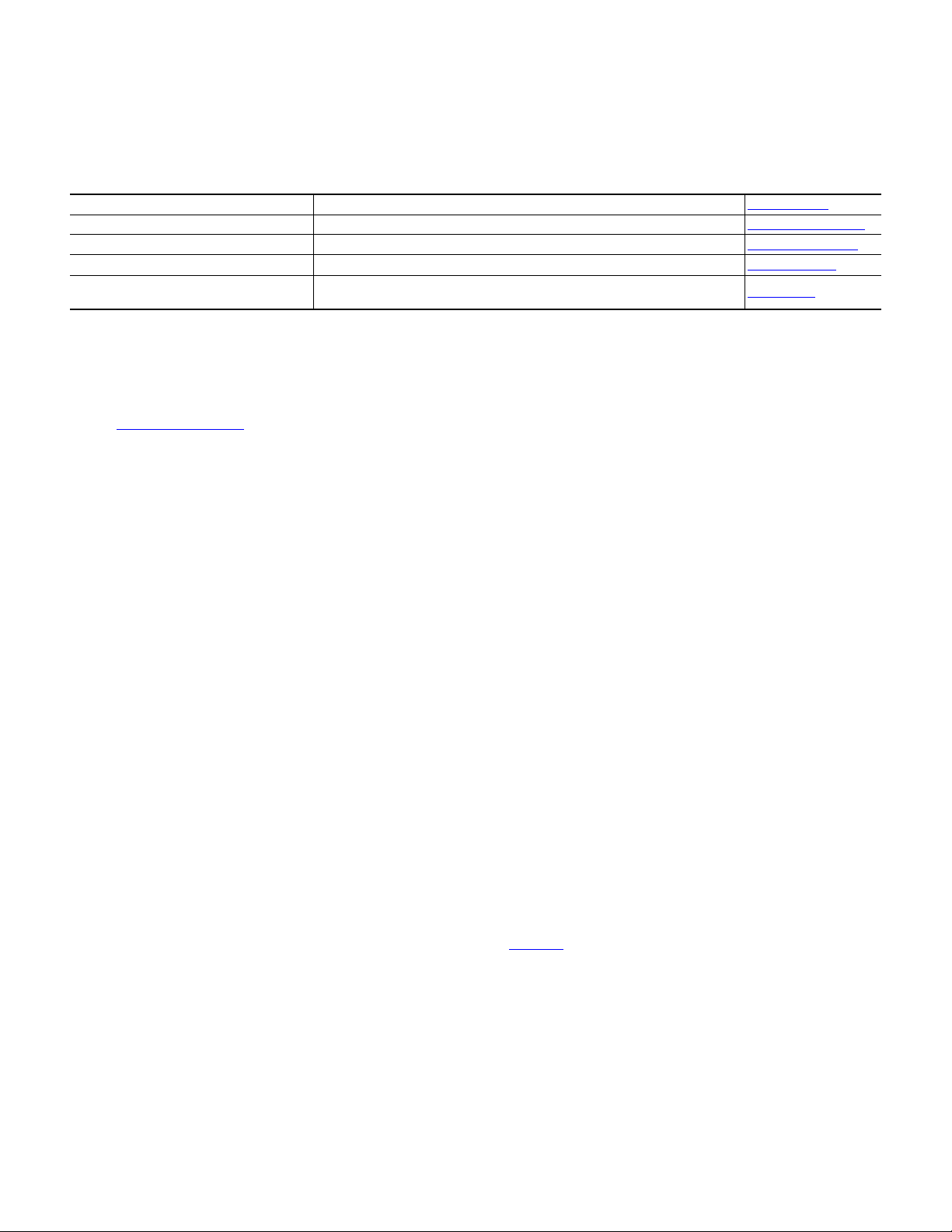

This manual contains new and updated information as indicated in the following table.

Top ic Pa ge

Updated Safety Information link in Degree of Protection section of Chapter 1 and in the

Additional Resources table.

Added Control System Packaging for Corrosion Mitigation Design and Installation Guideline,

publication TIRE-RM001 and Control System Packaging for Corrosion Mitigation White Paper,

publication WWW-WP001 to Additional Resources table.

Moved General Precautions from Preface to Chapter 2. 21

Consolidation of common information between industries into first three chapters rather

than spread across 10 chapters as in previous version

Moved Marine and Offshore Industry information from Chapter 7 in original document to

Chapter 4.

Creation of Sample Drive Installation Requirements Appendix to list standard drive

requirements.

Creation of Sample Requirements and Enclosure Specifications for S pecific Industry Types

Appendix to list unique requirements of cer tain industries.

10, 59

59

Var iou s

37

41

47

2 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 3

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Recommended Agencies and Standards Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

National Electrical Manufacturers Association (NEMA) . . . . . . . . . . . . . . . . . . . . . . . 5

Underwriters Laboratories, Inc. (UL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Canadian Standards Association (CSA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

National Fire Protection Association (NFPA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

International Society of Automotive Engineers (SAE). . . . . . . . . . . . . . . . . . . . . . . . . 6

The Institute of Electrical and Electronics Engineers, Inc. (IEEE). . . . . . . . . . . . . . . 6

American Bureau of Shipping (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

The International Society of Automation (ISA). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

International Electrotechnical Commission (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Environmental Considerations General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Enclosure Types and Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

North American Standards Organizations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

International Standards Organizations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Degree of Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

IEC Enclosure Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Abridged Descriptions of IEC Enclosure Test Requirements. . . . . . . . . . . . . . . . . . . . . . 11

Tests for Protection Against Access to Hazardous Parts (first

characteristic numeral) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tests for Protection Against Water (second characteristic numeral) . . . . . . . . . . 13

Abridged Descriptions of NEMA Enclosure Test Requirements. . . . . . . . . . . . . . . . . . . . 14

6.2 Rod Entry Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 Drip Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4 Rain Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5.1.1 (2) Outdoor Dust Test (Alternate Method) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5.1.2 (2) Indoor Dust Test (Alternate Method) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.6 External Icing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.7 Hosedown Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.8 Rust Resistance Test (Applicable Only to Enclosures Incorporating

External Ferrous Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.9 Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.11 (2) Air Pressure Test (Alternate Method) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.12 Oil Exclusion Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Abridged Descriptions of UL Standard 698 Test Requirements . . . . . . . . . . . . . . . . . . . 16

Explosion Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hydrostatic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Temperature Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Dust Penetration Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Temperature Test with Dust Blanket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Enclosure Type Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 1

Page 4

Table of Contents

Industry Related Installation

Considerations

Type 1 – General Purpose Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 1 – Flush Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 3 – Rainproof Dusttight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 3R – Rainproof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 4 – Watertight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 4X – Non-metallic, Corrosion-resistant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Type 6P – For Prolonged Submersion at a Limited Depth . . . . . . . . . . . . . . . . . . . . 18

Type 7 – For Hazardous Gas Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Type 9 – For Hazardous Dust Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Type 12 – Dusttight Industrial Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Type 13 – Oiltight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Enclosure Type Descriptions for Non-hazardous Locations. . . . . . . . . . . . . . . . . . . . . . 19

Enclosures Offered by Rockwell Automation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2

General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contaminants and Conditions by Industry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Environmental and Atmospheric Considerations by Location. . . . . . . . . . . . . . . . . 23

Explanation of Contaminant Severity Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Explanation of Contaminant Severity Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Relative Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Duty Rating of the AC Drive Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Periodic Duty Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Short-time Duty Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Non-periodic Duty Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Continuous Duty Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Protecting Electronic Modules From Contaminants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Shielding by Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Source Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ventilation Control and Removal Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Outdoor Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Protecting Electronic Modules During Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sources of Reactive Contaminants and Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3

System Configurations,

Grounding, Application, and

Control

2 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System Configurations and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Delta/Wye with Grounded Wye Neutral. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Delta/Delta with Grounded Leg or Four-wire Connected Secondary Delta . . . . . . 32

Three-phase Open Delta with Single-phase Center Tapped . . . . . . . . . . . . . . . . . . 32

Ungrounded Secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

High Resistance Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Application and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Automotive Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chemical and Specialty Chemical Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Food and Beverage Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Forest Products and Converting Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mining and Steel Industry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Page 5

Table of Contents

Tire Manufacturing Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Water and Waste Water Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 4

Marine and Offshore Industry Typical Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Typical Hazardous Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shielding by Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Protecting Electronic Modules During Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

System Configurations and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ungrounded Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ungrounded Secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Application and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Design and Implementation Considerations . . . . . . . . . . . . . . . . . . . . . . . . 40

Appendix A

Sample Drive Installation

Requirements

Design Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Input Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Grounding and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Motor Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Encoder Feedback Signal Wiring – Rockwell Automation’s Recommended Shielding

Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dynamic Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Wire Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pre-Installation Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

AC Supply SourceInput Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Grounding and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Mounting Considerations and Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Control and Signal Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dynamic Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Motor Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Encoder Feedback Signal Wiring – Rockwell Automation’s Recommended Shielding

Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Post Installation Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

AC Supply Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Input Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Grounding and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Mounting Considerations and Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control and Signal Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dynamic Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Motor Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Encoder Feedback Signal Wiring – Rockwell Automation’s Recommended Shielding

Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 3

Page 6

Table of Contents

Appendix B

Sample Requirements and

Enclosure Specifications for

Specific Industry Types

Automotive Industry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Forest Products/Converting (Pulp Paper Products) Industry . . . . . . . . . . . . . . . . . . . . . 48

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Marine and Offshore Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Metals Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Mining Process Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Oil, Gas, and Chemical Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Open Pit Mining Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Enclosure Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Welded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Frame and Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index

4 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 7

Preface

About This Publication

The purpose of this application technique is to provide basic information for different enclosure systems and environmental/location

considerations (to help protect against environmental contaminants), and power and grounding considerations needed to properly install a

Pulse Width Modulated (PWM) AC drive. The industry-specific guidelines in this document are meant to be used as examples - specific

locations are unique and the guideline examples should be adapted accordingly.

Pulse width modulation is a form of control used to generate a waveform necessary to operate an induction motor. With PWM control it is

possible to change the speed of the motor by varying the frequency sent to the motor. PWM drives are also known as Variable Frequency

Drives, and Adjustable Speed Drives.

Who Should Use This Manual

This manual is intended for qualified personnel who plan and design installations of PWM AC drives.

Recommended Agencies and Standards Publications

The following agencies and standards publications provide general information for installing drives and drive enclosures in regards to

environmental conditions and degrees of protection against ingress of contaminants.

National Electrical Manufacturers Association (NEMA)

1300 North 17th Street

Suite 1847

Rosslyn, VA 22209, USA

www.nema.org

• NEMA Standards Publication No. 250, Enclosures for Electrical Equipment (1000 Volts Maximum)

• NEMA Standards Publication No. ICS6, Enclosures for Industrial Controls and Systems

Underwriters Laboratories, Inc. (UL)

333 Pfingsten Road

Northbrook, IL 60062, USA

www.ul.com

• UL 50 Enclosures for Electrical Equipment, Non-Environmental Considerations (Type 1)

• UL 50E Enclosures for Electrical Equipment, Environmental Considerations (Remaining Types)

• UL 94 Flammability of Plastic Materials

• UL 414 Meter Sockets

• UL 497 Protectors for Paired Conductor Communication Circuits

• UL 508A Industrial Control Panels

• UL 870 Wireways, Auxiliary Gutters and Associated Fittings

•UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 5

Page 8

Preface

• UL 1773 Termination Boxes

• UL 1863 Communication Circuit Accessories

• UL 2279 Electrical Equipment for Use in CLI Zone 1 and 2 Hazardous Locations

Canadian Standards Association (CSA)

178 Rexdale Boulevard

Rexdale (Toronto), Ontario, Canada

M9W 1R3

www.csa.ca

CSA Standard C22.2:

• No. 0 General Requirements - Canadian Electrical Code, Part II

• No. 0.4 Bonding and Grounding of Electrical Equipment (Protective Equipment)

• No. 14 Industrial Control Equipment for Use in Ordinary (Non- Hazardous) Locations

• No. 25 Enclosures for Use in Class 11 Groups E, F, and G Hazardous Locations

• No. 26 Construction and Test of Wireways, and Auxiliary Gutters, and Associated Fittings

• No. 40 Cutout, Junction, and Pull Boxes

•No. 76 Splitters

• No. 94 Special Purpose Enclosures

• No. 182.4 Plugs, Receptacles, and Connections for Communications Systems

National Fire Protection Association (NFPA)

Batterymarch Park

Quincy, MA 02169-7471, USA

www.nfpa.org

• NFPA 70 National Electrical Code

• NFPA 70e Standard for Electrical Safety Requirements for Employee Workplaces

• NFPA 79 Electrical Standard for Industrial Machinery

• NFPA 496 Purged and Pressurized Enclosures for Electrical Equipment

International Society of Automotive Engineers (SAE)

400 Commonwealth Drive

Warrendale, PA 15096-0001, USA

www.sae.org

• SAE HS 1738 SAE Standard - Electrical Equipment for Automotive Industrial Machinery

The Institute of Electrical and Electronics Engineers, Inc. (IEEE)

3 Park Avenue,

New York, NY 10016-5997, USA

www.ieee.org

• IEEE 45, Recommended Practice for Electrical Installations on Shipboard

6 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 9

American Bureau of Shipping (ABS)

ABS Plaza

16855 Northchase Drive

Houston, TX 77060, USA

www.eagle.org

• Rules for Building and Classing Steel Vessels 2009, Part 4, Vessel Systems and Machinery

The International Society of Automation (ISA)

67 Alexander Drive

Research Triangle Park, NC 27709, USA

www.isa.org

• ISA-71.04-2013, Environmental Conditions for Process Measurement and Control Systems: Airborne Contaminants

International Electrotechnical Commission (IEC)

Preface

3, rue de Varembé

P.O. Box 131

CH - 1211 Geneva 20 - Switzerland

www.iec.ch

• IEC Publication 529, contains descriptions and associated test requirements that define the degree of protection each IP numeral

specifies

• IEC Publication 60079, standard for installations in hazardous areas

• IEC Publication 60079-20, section for flammability group and temperature class of equipment installed in hazardous areas

• IEC Publication 60529, describes the complete test procedures for standard degrees of protection ratings

Conventions Used in This Manual

These conventions are used throughout this manual.

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 7

Page 10

Preface

Notes:

8 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 11

Chapter 1

Environmental Considerations

This chapter describes environmental considerations, standards, and agency requirements for enclosures for different environments. This

is not meant to be a comprehensive guide but provide information that can let you know the different regulations that need to be further

studied and complied with for your location. Please contact your local Rockwell Automation representative for assistance in selecting or

addressing environmental concerns.

General Information

You must evaluate the environment where your AC drive will be installed, identify any contaminants, and provide the correct degree of

protection for the AC drive and electronics in either a stand-alone installation or when mounting the drive inside an enclosure. This

evaluation and degree of protection helps to make sure the drive functions correctly and reliably. If the drive is going to be placed into an

environmental setting that is harsher than defined by the specified rating of the drive, it must be installed in the proper type of protective

enclosure. If the drive is not installed in the proper type of protective enclosure it can suffer failure from atmospheric contaminants which

produce corrosion.

Corrosion failures of industrial electronic equipment is a concern, especially in industry groups such as water/waste water, paper making,

steel, and tire manufacturing. For these industries, sulfur compounds that can attack electrical components and lead to failure are typical.

These failures can be unexpected because the relatively low levels of sulfur concentration that can lead to electronic failure are often not

perceived as severe by workers in those facilities. Electronic assemblies can fail due to several corrosion mechanisms. This corrosion can

occur with or without electrical voltage being present, and can also compromise insulated systems, if and when they become conductive.

Conformal coating of printed circuit boards can prevent some of the contamination challenges faced in the field; but, because all

components are not coated, there is still a need to review the applications and environments. Refer to Conformal Coating for Variable Speed

Drives, publication DRIVES-WP021

.

Enclosure Types and Ratings

What's in an Enclosure Rating?

As a way of standardizing enclosure performance, organizations like National Electrical Manufacturers Association (NEMA), Underwriters

Laboratories, Inc. (UL), Canadian Standards Association (CSA), International Electrotechnical Commission (IEC), and Association for Electrical,

Electronic and Information Technologies (Verband der Elektrotechnik, Elektronik und Informationstechnik [VDE]) use rating systems to

identify the ability of an enclosure to resist external environmental influences. Resistance to everything from dripping liquid, to hosedown, to

total submersion is defined by the rating systems. While all these rating systems are intended to provide information to help you make a

safer, more informed enclosure choice, there are notable differences between the rating systems.

North American Standards Organizations

In North America, NEMA, UL, and CSA are the commonly recognized standards organizations. Their ratings are based on similar application

descriptions and expected performance. UL and CSA both require enclosure testing by qualified evaluators in UL- and CSA-certified labs.

They also send site inspectors to verify that a manufacturer adheres to prescribed manufacturing methods and material specifications.

NEMA does not require independent testing and does not verify the compliance of the manufacturer.

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 9

Page 12

Chapter 1 Environmental Considerations

North American enclosure rating systems also include a 4X rating that indicates corrosion resistance. This rating is based on the ability of

the enclosure to withstand prolonged exposure to saltwater spray. While a 4X rating is a good indicator that an enclosure can resist

corrosion, it does not provide information on how a specific corrosive agent will affect a given enclosure material. It is best to conduct a full

analysis of the specific application and environment to determine the best enclosure choice.

International Standards Organizations

Like NEMA, IEC does not require independent testing and does not verify the compliance of the manufacturer. Nevertheless, there are

differences in how enclosure performance is interpreted. For example, UL and CSA test requirements specify that an enclosure fails the

water-tight test if even a single drop of water enters the enclosure. In the IEC standards for each level of ingress protection (IP), a certain

amount of water is allowed to enter the enclosure.

IEC 60529 IP ratings do not specify construction requirements or degrees of protection against corrosive atmospheres, risk of explosion, or

conditions such as moisture or corrosive vapors. NEMA Type ratings do specify construction and performance requirements for most

environmental conditions. Because of this difference in construction requirements, and because the tests and evaluations for other

characteristics are not identical, the IEC enclosure classification designations cannot be exactly equated with NEMA enclosure Type

numbers.

Enclosure materials and construction must consider the following:

• Environmental considerations include moisture, temperature, solar affect, airborne particulate matter, and harsh or corrosive

chemicals present in the atmosphere.

• Safety issues including electrical code requirements, grounding needs, and others.

Choosing the incorrect solution can be costly and can adversely affect the performance of your installation.

Degree of Protection

IEC Publication 60529 describes standard Degrees of Protection that enclosures are designed to provide when properly installed.

Summary

The publication defines Degrees of Protection with respect to:

•Persons

• Equipment within the enclosure

• Ingress of water

It does not define:

• Protection against risk of explosion

• Environmental protection (for example: against humidity, corrosive atmospheres or fluids, fungus, or the ingress of vermin)

Note: The IEC test requirements for Degrees of Protection against liquid ingress refer only to water. The products on the Safety Products

page (https://ab.rockwellautomation.com/Safety

Nitrile seals. Nitrile seals have good resistance to a wide range of oils, coolants, and cutting fluids; however, some of the available lubricants,

hydraulic fluids, and solvents can cause severe deterioration of Nitrile and other polymers. Some of the products listed are available with

seals of Viton or other materials for improved resistance to such liquids. For specific advice on enclosure seals and protection against liquid

ingress, contact your local Rockwell Automation sales office.

) that have a high degree of protection against ingress of liquid include, in most cases,

10 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 13

Chapter 1 Environmental Considerations

IEC Enclosure Classification

The IEC enclosure classification for degree of protection is indicated by two letters and two numerals (IP_ _). International Standard IEC

60529 contains descriptions and associated test requirements that define the degree of protection that each numeral specifies. Table 1

indicates the general degree of protection indicated by the value and position of each numeral in the enclosure classification.

See the Abridged Descriptions of IEC Enclosure Test Requirements below for brief descriptions of the test requirements.

Note: For complete test requirements refer to IEC 60529.

Abridged Descriptions of IEC Enclosure Test Requirements

Refer to IEC 60529 for complete test specifications (for example: test apparatus configuration, tolerances, etc). For metric conversion

factors, see Safety Products page (https://ab.rockwellautomation.com/Safety

Tests for Protection Against Access to Hazardous Parts (first characteristic numeral)

).

The first characteristic numeral of the IP number indicates compliance with the following tests for the degree of protection against access

to hazardous parts. It also indicates compliance with tests shown in Tests for Protection Against Solid Foreign Objects (first characteristic

numeral) on page 12.

The protection against access to hazardous parts is satisfactory if adequate clearance is kept between the specified access probe and

hazardous parts. For voltage less than 1000V AC and 1500V DC, the access probe must not touch the hazardous live parts. For voltage

exceeding 1000V AC and 1500V DC, the equipment must be capable of withstanding specified dielectric tests with the access probe in the

most unfavorable position.

Table 1 - Numeric Conventions for Protection Against Access to Hazardous Parts

First Numeral

Protection of persons against access to hazardous

parts and protection against penetration of solid

foreign objects.

0 – Non-protected 0 – Non-protected

1 – Back of hand; objects greater than 50 mm in diameter 2 – Vertically falling drops of water

3 – Finger; objects greater than 12.5 mm in diameter 4 – Vertically falling drops of water with enclosure tilted 15°

5 – Tools or objects greater than 2.5 mm in diameter 6 – Spraying water

7 – Tools or objects greater than1.0 mm in diameter 8 – Splashing water

9 – Dust-protected (dust can enter during specified test

but must not interfere with operation of the equipment or

impair safety)

11 – Dusttight (no dust observable inside enclosure at

end of test)

Example: IP41 describes an enclosure that is designed to protect against the entry of tools or objects greater than 1 mm

in diameter and to protect against vertically dripping water under specified test conditions.

Note: All first numerals and second numerals up to and including characteristic numeral 6, imply compliance also with

the requirements for all lower characteristic numerals in their respective series (first or second). Second numerals 7 and

8 do not imply suitability for exposure to water jets (second characteristic numeral 5 or 6) unless dual coded; e.g., IP_5/

IP_7.

(1) The IEC standard permits use of certain supplementary letters with the characteristic numerals. If such letters are

used, refer to IEC 60529 for the explanation.

(1)

Second Numeral

Protection against ingress of water under test conditions

specified in IEC 60529.

10 – Water jets

12 – Powerful water jets

13 – Temporary submersion

14 – Continuous submersion

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 11

Page 14

Chapter 1 Environmental Considerations

IP0_ No test required.

IP1_

A rigid sphere 50 mm in diameter shall not completely pass through any

opening. Force = 50 N.

A jointed test finger 80 mm long and 12 mm in diameter can penetrate to its

IP2_

80 mm length, but shall have adequate clearance as specified above, from

hazardous live parts, in every possible position of the test finger as both

joints are bent through an angle up to 90°. Force = 10 N.

A test rod 2.5 mm in diameter shall not penetrate and adequate clearance

IP3_

shall be kept from hazardous live parts

(as specified in Table 1

). Force = 3 N.

A test wire 1 mm in diameter shall not penetrate and adequate clearance

IP4_

shall be kept from hazardous live parts

(as specified in Table 1

). Force = 1 N.

A test wire 1 mm in diameter shall not penetrate and adequate clearance

IP5_

shall be kept from hazardous live parts

(as specified in Table 1

). Force = 1 N.

A test wire 1 mm in diameter shall not penetrate and adequate clearance

IP6_

shall be kept from hazardous live parts

(as specified in the Table 1

). Force = 1 N.

Tests for Protection Against Solid Foreign Objects (first characteristic numeral)

For first numerals 1, 2, 3, and 4, the protection against solid foreign objects is satisfactory if the full diameter of the specified probe does not

pass through any opening. Note that for first numerals 3 and 4, the probes are intended to simulate foreign objects which can be spherical.

Where shape of the entry path leaves any doubt about ingress or a spherical object capable of motion, it can be necessary to examine

drawings or to provide special access for the object probe. For first numerals 5 and 6, see test descriptions below for acceptance criteria.

IP0_ No test required.

IP1_

IP2_

IP3_

The full diameter of a rigid sphere 50 mm in diameter must not pass through

any opening at a test force of 50 N.

The full diameter of a rigid sphere 12.5 mm in diameter must not pass

through any opening at a test force of 30 N.

A rigid steel rod 2.5 mm in diameter must not pass through any opening at a

test force of 3 N.

12 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 15

Chapter 1 Environmental Considerations

IP4_

IP5_

IP6_

A rigid steel wire 1 mm in diameter must not pass through any opening at a

test force of 1 N.

The test specimen is supported inside a specified dust chamber where

talcum powder, able to pass through a square-mesh sieve with wire

diameter 50 mm and width between wires 75 mm, is kept in suspension.

Enclosures for equipment subject to thermal cycling effects (category 1) are

vacuum pumped to a reduced internal pressure relative to the surrounding

atmosphere: maximum depression = 2 kPa; maximum extraction rate = 60

volumes per hour. If extraction rate of 40 to 60 volumes/hr is obtained, test

is continued until 80 volumes have been drawn through or 8 hours has

elapsed. If extraction rate is less than 40 volumes/hr at 20 kPa depression,

test time = 8 hr.

Enclosures for equipment not subject to thermal cycling effects, and

designated category 2 in the relevant product standard, are tested for 8

hours without vacuum pumping.

Protection is satisfactory if talcum powder has not accumulated in a

quantity or location such that, as with any other kind of dust, it could

interfere with the correct operation of the equipment or impair safety, and

no dust has been deposited where it could lead to tracking along creepage

distances.

All enclosures are tested as category 1, as specified above for IP5_. The

protection is satisfactory if no deposit of dust is observable inside the

enclosure at the end of the test.

Tests for Protection Against Water (second characteristic numeral)

The second characteristic numeral of the IP number indicates compliance with the following tests for the degree of protection against

water. For numerals 1 through 7, the protection is satisfactory if any water that has entered does not interfere with satisfactory operation,

does not reach live parts not designed to operate when wet, and does not accumulate near a cable entry or enter the cable. For second

numeral 8, the protection is satisfactory if no water has entered the enclosure.

IP_0 No test required.

Water is dripped onto the enclosure from a “drip box” having spouts spaced

IP_1

IP_2

IP_3

IP_4 Same as test for IP_3 except spray covers an arc of 180° from vertical.

on a 20 mm square pattern, at a “rainfall” rate of 1 mm/min The enclosure is

placed in its normal operating position under the drip box. Test time = 10 min

Water is dripped onto the enclosure from a “drip box” having spouts spaced

on a 20 mm square pattern, at a “rainfall” rate of 3 mm/min The enclosure is

placed in 4 fixed positions tilted 15° from its normal operating position,

under the drip box. Test time = 2.5 min for each position of tilt.

Water is sprayed onto all sides of the enclosure over an arc of 60° from

vertical, using an oscillating tube device with spray holes 50 mm apart (or a

hand-held nozzle for larger enclosures). Flow rate, oscillating tube device =

0.07 l/min per hole x number of holes; for hand-held nozzle = 10 l/min Test

time, oscillating tube = 10 min; for hand-held nozzle = 1 min/m2 of enclosure

surface area, 5 min minimum.

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 13

Page 16

Chapter 1 Environmental Considerations

Enclosure is sprayed from all practicable directions with a stream of water

IP_5

IP_6

IP_7

IP_8

at 12.5 l/min from a 6.3 mm nozzle from a distance of 2.5 to 3 m. Test time =

1 min/m2 of enclosure surface area to be sprayed, 3 min minimum.

Enclosure is sprayed from all practicable directions with a stream of water

at 100 l/min from a 12.5 mm nozzle from a distance of 2.5 to 3 m. Test time =

1 min/m2 of enclosure surface area to be sprayed, 3 min minimum.

Enclosure is immersed in water in its service position for 30 min Lowest

point of enclosures less than 850 mm tall = 1000 mm below surface of water.

Highest point of enclosures more than 850 mm tall = 150 mm below surface

of water.

Test conditions are subject to agreement between manufacturer and user,

but shall be at least as severe as those for IP_7.

Abridged Descriptions of NEMA Enclosure Test Requirements

NEMA is a commonly recognized standards organization in North America and publishes standards for enclosures. It does not require

independent verification of these tests.

6.2 Rod Entry Test

A 3.18 mm (0.125 in.) diameter rod must not be able to enter enclosure except at locations where nearest live part is more than 102 mm (4 in.)

from an opening — such opening shall not permit a 13 mm (0.5 in.) diameter rod to enter.

6.3 Drip Test

Water is dripped onto enclosure for 30 minutes from an overhead pan having uniformly spaced spouts, one every 12,900 mm (20 in.) of pan

area, each spout having a drip rate of 20 drops per minute.

Evaluation 6.3.2.2: No water shall have entered enclosure.

6.4 Rain Test

Entire top and all exposed sides are sprayed with water at a pressure of

0.35 kg/cm2 (5 psi) from nozzles for one hour at a rate to cause water to rise 457 mm (18 in.) in a straight-sided pan beneath the enclosure.

Evaluation 6.4.2.1: No water shall have reached live parts, insulation, or mechanisms.

Evaluation 6.4.2.2: No water shall have entered enclosure.

6.5.1.1 (2) Outdoor Dust Test (Alternate Method)

Enclosure and external mechanisms are subjected to a stream of water at 170.5 liters (45 gallons) per minute from a 25.4 mm (1 in.) diameter

nozzle, directed at all joints from all angles from a distance of 3…3.7 m (10…12 ft). Test time is 48 seconds times the test length (height +

width + depth of enclosure in feet), or a minimum of 5 minutes. No water shall enter enclosure.

14 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 17

Chapter 1 Environmental Considerations

6.5.1.2 (2) Indoor Dust Test (Alternate Method)

Atomized water at a pressure of 2.11 kg/cm2 (30 psi) is sprayed on all seams, joints and external operating mechanisms from a distance of

305…381 mm (12…15 in.) at a rate of 11 liters (3 gallons) per hour. No less than 142 gms

(5 oz) of water per linear foot of test length (height + length + depth of enclosure) is applied. No water shall enter enclosure.

6.6 External Icing Test

Water is sprayed on enclosure for one hour in a cold room 2 °C (36 °F); then room temperature is lowered to approximately –5 °C (–23 °F) and

water spray is controlled so as to cause ice to build up at a rate of 6.4 mm (0.25 in.) per hour until 19 mm (0.75 in.) thick ice has formed on top

surface of a 25.4 mm (1 in.) diameter metal test bar, then temperature is maintained at –5 °C (–23 °F) for 3 hours.

Evaluation 6.6.2.2: Equipment shall be undamaged after ice has melted (external mechanisms not required to be operable while iceladen).

6.7 Hosedown Test

Enclosure and external mechanisms are subjected to a stream of water at 246 liters (65 gallons) per minute from a 25.4 mm (1 in.) diameter

nozzle, directed at all joints from all angles from a distance of 3…3.7 m (10...12 ft). Test time is 48 seconds times the test length [height +

width + depth] of enclosure in meters (feet), or a minimum of 5 seconds. No water shall enter enclosure.

6.8 Rust Resistance Test (Applicable Only to Enclosures Incorporating External Ferrous Parts)

Enclosure is subjected to a salt spray (fog) for 24 hours, using water with five parts by weight of salt (NaCI), at 35 °C (95 °F), then rinsed and

dried. There shall be no rust except where protection is impractical (for example, machined mating surfaces, sliding surfaces of hinges,

shafts, etc.).

6.9 Corrosion Protection

Sheet steel enclosures are evaluated per Underwriter's Laboratories (UL) 50, Part 13 (test for equivalent protection as G-90 commercial zinc

coated sheet steel). Other materials per Underwriter's Laboratories (UL) 508, 6.9 or 6.10.

6.11 (2) Air Pressure Test (Alternate Method)

Enclosure is submerged in water at a pressure equal to water depth of 2 m (6 ft), for 24 hours. No water shall enter enclosure.

6.12 Oil Exclusion Test

Enclosure is subjected to a stream of test liquid for 30 minutes from a 9.5 mm (0.375 in.) diameter nozzle at 7.57 liters (2 gallons) a minute.

Water with 0.1% wetting agent is directed from all angles from a distance of 305…457 mm (12…18 in.), while any externally operated device is

operated at 30 operations per minute. No test liquid shall enter the enclosure.

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 15

Page 18

Chapter 1 Environmental Considerations

Abridged Descriptions of UL Standard 698 Test Requirements

The following descriptions are based on the descriptions in the UL Standard 698 Test Requirements.

Explosion Test

During a series of tests in which gas-air mixtures of the specific gas, over its range of explosive concentrations, are ignited inside the

enclosure, the enclosure shall prevent the passage of flame and sparks capable of igniting a similar gas-air mixture surrounding the

enclosure. In addition, there shall be no mechanical damage to enclosed electrical mechanisms or the enclosure.

Hydrostatic Test

The enclosure shall withstand for one minute a hydrostatic test based on the maximum internal explosion pressure developed during the

explosion tests, as follows: cast metal, four times the explosion pressure without rupture or permanent deformation; fabricated steel, twice

the explosion pressure without permanent deformation and three times the explosion pressure without rupture. Exception: Hydrostatic tests

can be omitted if calculations show safety factor of 5:1 for cast metal, and 4:1 for fabricated steel.

Temperature Test

The enclosed device is subjected to a temperature test to determine maximum temperature at any point on the external surface. The device

must be marked with a temperature code based on the result only if the temperature exceeds 100 °C (212 °F).

Dust Penetration Test

The device is operated at full rated load until equilibrium temperatures are attained, then allowed to cool to ambient (room) temperature,

through six heating and cooling cycles covering at least 30 hours, while continuously exposed to circulating dust of specified properties in a

test chamber. No dust shall enter the enclosure.

Temperature Test with Dust Blanket

This test is conducted as described for the Dust Penetration test except that the re-circulating dust nozzles are positioned so that the dust

is not blown directly on the device under test. The device is operated at full rated load (and under abnormal conditions for equipment subject

to overloading) until equilibrium temperatures are attained. Dust in contact with the enclosure shall not ignite or discolor from heat, and the

exterior surface temperatures based on 40 °C (104 °F) ambient shall not exceed the values listed below.

Class II, Group Normal Operating Conditions Abnormal Operating Conditions

E 200 °C (392 °F) 200 °C (392 °F)

F 150 °C (302 °F) 200 °C (392 °F)

G 120 °C (248 °F) 165 °C (329 °F)

Enclosure Type Descriptions

This section provides enclosure type descriptions for hazardous and non-hazardous locations.

16 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 19

Chapter 1 Environmental Considerations

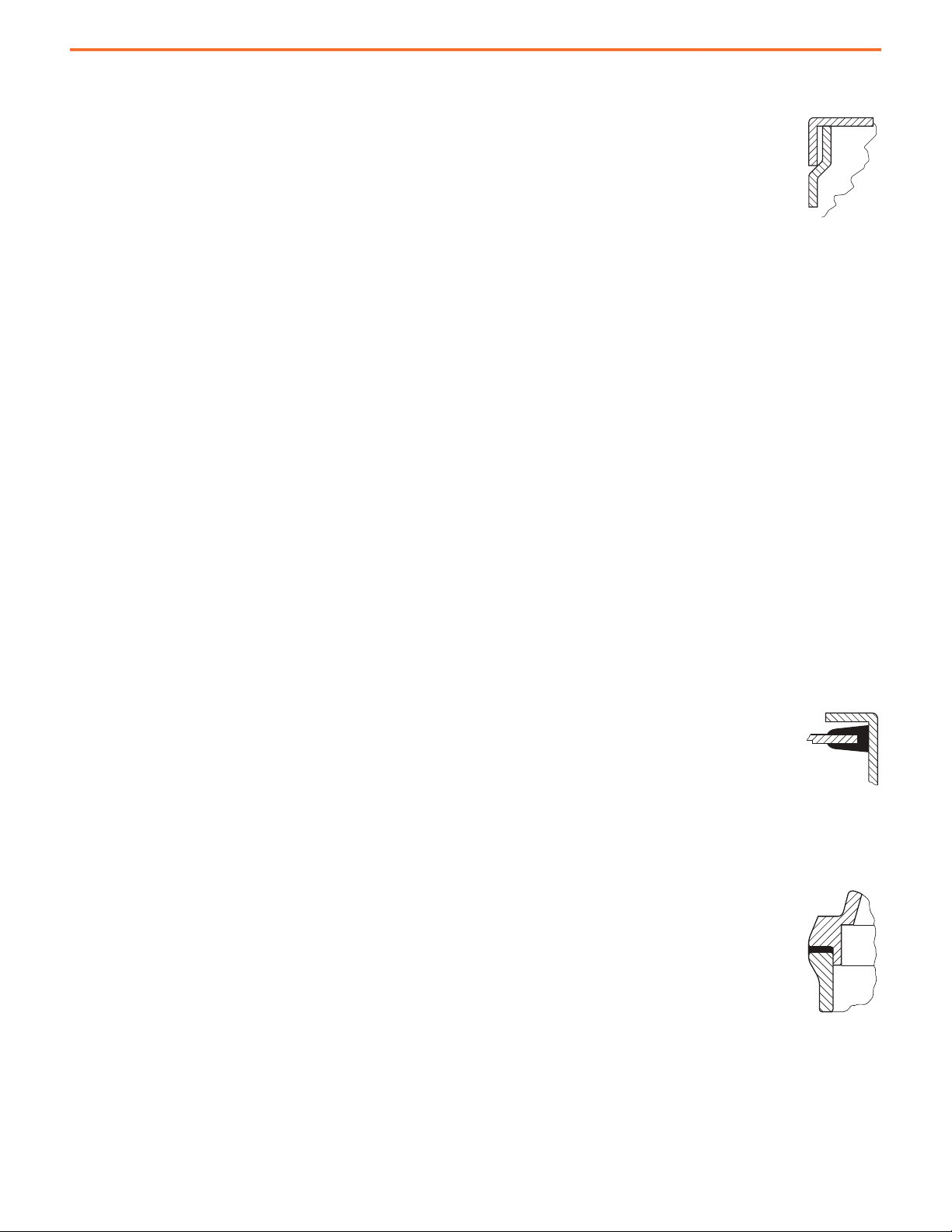

Type 1 – General Purpose Surface Mounting

Type 1 enclosures are intended for indoor use primarily to provide a degree of protection against contact with the enclosed

equipment in locations where unusual service conditions do not exist. The enclosures are designed to meet the rod-entry and

rust-resistance design tests. Enclosure is sheet steel, treated to resist corrosion.

Type 1 – Flush Mounting

Type 1 Flush Mounting enclosures for installation in machine frames and plaster wall. These enclosures are for similar applications and are

designed to meet the same tests as Type 1 surface mounting.

Type 3 – Rainproof Dusttight

Type 3 enclosures are intended for outdoor use primarily to provide a degree of protection against windblown dust, rain, and sleet; and to

be undamaged by the formation of ice on the enclosure. They are designed to meet rain

(1)

, external icing

tests. They are not intended to provide protection against conditions such as internal condensation or internal icing.

(2)

, dust, and rust-resistance design

Type 3R – Rainproof

Type 3R enclosures are intended for outdoor use primarily to provide a degree of protection against falling rain, and to be undamaged by

the formation of ice on the enclosure. They are designed to meet rod entry, rain

(3)

external icing

(4)

, and rust resistance design tests. They are

not intended to provide protection against conditions such as dust, internal condensation, or internal icing.

Type 4 – Watertight

Type 4 enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against windblown dust

and rain, splashing water, and hose-directed water; and to be undamaged by the formation of ice on the enclosure. They are

(4)

designed to meet hosedown, dust, and external icing tests

. They are not intended to provide protection against conditions

such as internal condensation or internal icing.

Type 4X – Non-metallic, Corrosion-resistant

Type 4X enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against corrosion,

windblown dust and rain, splashing water, and hose-directed water; and to be undamaged by the formation of ice on the

(4)

enclosure. They are designed to meet the hosedown, dust, external icing

not intended to provide protection against conditions such as internal condensation or internal icing.

, and corrosion-resistance design tests. They are

(1) Evaluation criteria: No water has entered enclosure during specified test.

(2) Evaluation criteria: Undamaged after ice buildup during specified test has melted. (Note: Not required to be operable while iceladen.)

(3) Evaluation criteria: No water shall have reached live parts, insulation or mechanisms.

(4) Evaluation criteria: Undamaged after ice buildup during specified test has melted. (Note: Not required to be operable while iceladen.)

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 17

Page 20

Chapter 1 Environmental Considerations

Type 6P – For Prolonged Submersion at a Limited Depth

Type 6P enclosures are intended for indoor or outdoor use primarily to provide a degree of protection against the entry of water during

prolonged submersion at a limited depth; and to be undamaged by the formation of ice on the enclosure. They are designed to meet air

(1)

pressure, external icing

such as internal condensation or internal icing.

, hosedown and corrosion-resistance design tests. They are not intended to provide protection against conditions

Type 7 – For Hazardous Gas Locations

Type 7 enclosures are for indoor use in locations classified as Class I, Groups C or D, as defined in the U.S. National Electrical

Code. Type 7 enclosures are designed to be capable of withstanding the pressures resulting from an internal explosion of

specified gases, and contain such an explosion sufficiently that an explosive gas-air mixture existing in the atmosphere

surrounding the enclosure will not be ignited. Enclosed heat generating devices are designed not to cause external surfaces

to reach temperatures capable of igniting explosive gas-air mixtures in the surrounding atmosphere. Enclosures are

designed to meet explosion, hydrostatic, and temperature design tests. Finish is a special corrosion-resistant, gray enamel.

Type 9 – For Hazardous Dust Locations

Type 9 enclosures are intended for indoor use in locations classified as Class II, Groups E, F, or G, as defined in the U.S.

National Electrical Code. Type 9 enclosures are designed to be capable of preventing the entrance of dust. Enclosed heat

generating devices are designed not to cause external surfaces to reach temperatures capable of igniting or discoloring dust

on the enclosure or igniting dust-air mixtures in the surrounding atmosphere. Enclosures are designed to meet dust

penetration and temperature design tests, and aging of gaskets. The outside finish is a special corrosion-resistant gray

enamel.

Type 12 – Dusttight Industrial Use

Type 12 enclosures are intended for indoor use primarily to provide a degree of protection against dust, falling dirt, and

dripping non-corrosive liquids. They are designed to meet

(2)

drip

, dust, and rust-resistance tests. They are not intended to provide protection against conditions such as internal

condensation.

Type 13 – Oiltight

Type 13 enclosures are intended for indoor use primarily to provide a degree of protection against dust, spraying of water,

oil, and noncorrosive coolant. They are designed to meet oil exclusion and rust-resistance design tests. They are not intended

to provide protection against conditions such as internal condensation.

(1) Evaluation criteria: No water has entered enclosure during specified test.

(2) Evaluation criteria: Undamaged after ice buildup during specified test has melted. (Note: Not required to be operable while iceladen.)

18 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 21

Chapter 1 Environmental Considerations

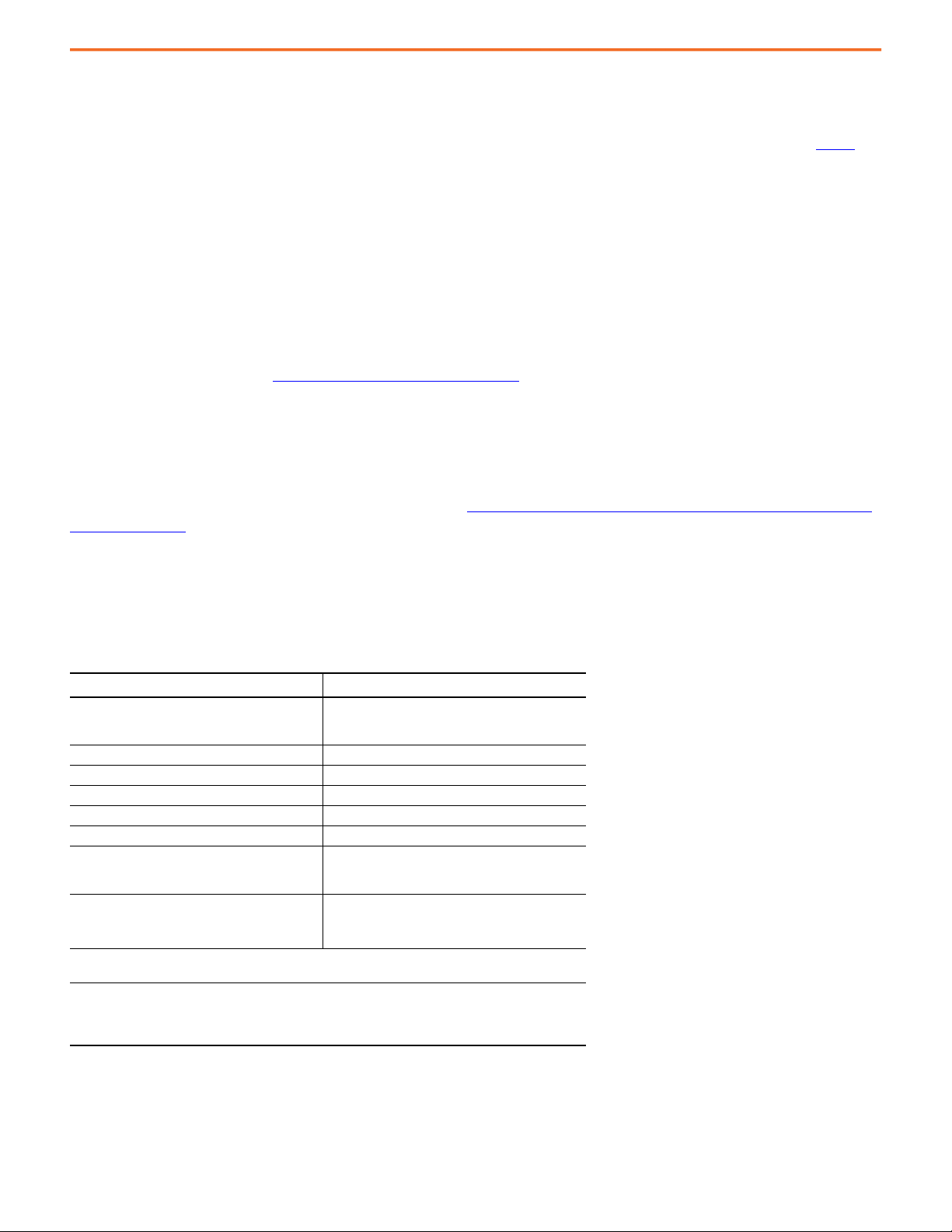

Enclosure Type Descriptions for Non-hazardous Locations

This section compares the enclosure type descriptions for non-hazardous locations between NEMA, UL, and CSA standards.

Location Enclosure Type

NEMA

(1)

Indoor Type 1 Enclosures are intended for indoor use

primarily to provide a degree of protection

against contact with the enclosed equipment

(2) (3)

UL

Indoor use primarily to provide protection

against contact with the enclosed equipment

and against a limited amount of falling dirt.

(4)

CSA

General purpose enclosure. Protects against

accidental contact with live par ts.

or locations where unusual service conditions

do not exist.

Indoor Type 12 Enclosures are intended for indoor use

primarily to provide a degree of protection

against dust, falling dirt and dripping

noncorrosive liquids.

Indoor use to provide a degree of protection

against dust, dirt, fiber flyings, dripping water

and external condensation of noncorrosive

liquids.

Indoor use; provides a degree of protection

against circulating dust, lint, fibers and

flyings; dripping and light splashing of noncorrosive liquids; not provided with

knockouts.

Indoor Type 12K Enclosures with knockouts are intended for

indoor use primarily to provide a degree of

protection against dust, falling dirt and

dripping noncorrosive liquids.

Indoor use to provide a degree of protection

against dust, dirt, fiber flyings, dripping water

and external condensation of noncorrosive

liquids.

Indoor use; provides a degree of protection

against circulating dust, lint, fibers and

flyings; dripping and light splashing of

noncorrosive liquids; not provided with

knockouts.

Indoor Type 13 Enclosures are intended for indoor use

primarily to provide a degree of protection

against dust, spraying of water, oil and

noncorrosive coolant.

Outdoor Type 3 Enclosures are intended for outdoor use

primarily to provide a degree of protection

against windblown dust, rain and sleet;

undamaged by the formation of ice on the

Indoor use to provide a degree of protection

against lint, dust seepage, external

condensation and spraying of water, oil and

noncorrosive liquids.

Outdoor use to provide a degree of protection

against windblown dust and windblown rain;

undamaged by the formation of ice on the

enclosure.

Indoor use; provides a degree of protection

against circulating dust, lint, fibers and

flyings; seepage and spraying of noncorrosive liquids, including oils and coolants.

Indoor or outdoor use; provides a degree of

protection against rain, snow and windblown

dust; undamaged by the external formation

of ice on the enclosure.

enclosure.

Outdoor Type 3R Enclosures are intended for outdoor use

primarily to provide a degree of protection

against falling rain and sleet; undamaged by

the formation of ice on the enclosure.

Outdoor Type 3RX Enclosures are intended for outdoor use

Outdoor use to provide a degree of protection

against falling rain; undamaged by the

formation of ice on the enclosure.

Indoor or outdoor use; provides a degree of

protection against rain and snow; undamaged

by the external formation of ice on the

enclosure.

Not specifically defined. Not specifically defined.

primarily to provide a degree of protection

against corrosion, falling rain and sleet;

undamaged by the formation of ice on the

enclosure.

Outdoor Type 4 Enclosures are intended for indoor or outdoor

use primarily to provide a degree of protection

against windblown dust and rain, splashing

water and hose-directed water; undamaged

by the formation of ice on the enclosure.

Outdoor Type 4X Enclosures are intended for indoor or outdoor

use primarily to provide a degree of protection

against corrosion, windblown dust and rain,

splashing water and hose-directed water;

undamaged by the formation of ice on the

Either indoor or outdoor use to provide a

degree of protection against falling rain,

splashing water and hose-directed water;

undamaged by the formation of ice on the

enclosure.

Either indoor or outdoor use to provide a

degree of protection against falling rain,

splashing water and hose-directed water;

undamaged by the formation of ice on the

enclosure; resists corrosion.

Indoor or outdoor use; provides a degree of

protection against rain, snow, windblown

dust, splashing and hose-directed water;

undamaged by the external formation of ice

on the enclosure.

Indoor or outdoor use; provides a degree of

protection against rain, snow, windblown

dust, splashing and hose-directed water;

undamaged by the external formation of ice

on the enclosure; resists corrosion.

enclosure.

Outdoor Type 6P Enclosures are intended for use indoors or

outdoors where occasional submersion is

encountered; limited depth; undamaged by

the formation of ice on the enclosure.

(1) Reprinted from NEMA 250-2008, Enclosure Type Non-Hazardous Location, Enclosure Type descriptions, by permission of the National Electrical Manufacturers Association.

(2) © 1995 (UL 50), 2001 (UL 508A), and 2007 (UL 50E) Underwriters Laboratories Inc. Reprinted with permission. This material is not the complete and official position of UL on the

referenced subject, which is represented only by the UL Standard in its entirety.

(3) Underwriters Laboratories Inc. (UL) shall not be responsible for the use of or reliance upon a UL Standard by anyone. UL shall not incur any obligation or liability for damages,

including consequential damages, arising out of or in connection with the use, interpretation of, or reliance upon a UL Standard.

(4) Reproduced with the permission of CSA from CSA C22.2 No. 94.2-07 Enclosures for Electrical Equipment, Environmental Considerations (Tri-National Standard, with NMX-J-235/2-

ANCE-2007 and UL 50E) which is copyrighted by CSA. While use of this material has been authorized, CSA shall not be responsible for the manner in which the information is

presented, nor for any interpretations thereof.

Indoor or outdoor use to provide a degree of

protection against entry of water during

temporary submersion at a limited depth;

undamaged by the external formation of ice

on the enclosure.

Indoor or outdoor use; provides a degree of

protection against the entry of water during

temporary submersion at a limited depth.

Undamaged by the external formation of ice

on the enclosure; resists corrosion.

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 19

Page 22

Chapter 1 Environmental Considerations

Enclosures Offered by Rockwell Automation

See Selection Criteria for Non-hazardous Locations and Selection Criteria for Hazardous Locations (division 1 or 2) for the types of

enclosures offered by Rockwell Automation. For definitions, descriptions, and test criteria, see National Electrical Manufactures Association

(NEMA) Standards Publication No. 250. Also see individual product listings within the Safety Products page,

(https://ab.rockwellautomation.com/Safety

Note: Enclosures do not normally protect devices against conditions such as condensation, icing, corrosion, or contamination that can occur

within the enclosure or enter via the conduit or unsealed openings. You must make adequate provisions to safeguard against such

conditions and be sure that the equipment is properly protected.

Selection Criteria for Non-hazardous Locations

), for available enclosure types and for any additional information relating to these descriptions.

For a Degree of Protection Against:

Incidental contact with enclosed equipment 6.2 xxxxxxxx

Falling dirt 6.2 xxxxxxxx

Rust 6.8 xxxxxxxx

Circulating dust, lint, fibres, and flyings

Windblown dust 6.5.1.1 (2) x x x x

Falling liquids and light splashing 6.3.2.2 x x x x x x

Rain (Test evaluated per 6.4.2.1) 6.4.2.1 x x x x x

Rain (Test evaluated per 6.4.2.2) 6.4.2.2 x x x x

Snow and sleet 6.6.2.2 x x x x x

Hosedown and splashing water 6.7 x x x

Occasional prolonged submersion 6.11 (2) x

Oil and coolant seepage 6.3.2.2 x x

Oil or coolant spraying and splashing 6.12 x

Corrosive agents 6.9 x x x x x

(1) Non-hazardous materials, not Class III ignitable or combustible.

(2) See Enclosure Type Descriptions for Non-hazardous Locations on page 19. Refer to NEMA Standards Publication No. 250 for complete test specifications.

(2)

Designed to

Meet Test No.

6.5.1.2 (2) x x x x x x

Type

For Indoor Use For Outdoor Use Indoor or Outdoor

(1)

112133R344X6P

Selection Criteria for Hazardous Locations (division 1 or 2)

For a Degree of Protection Against

Atmospheres Typically Containing:

Acetylene Explosion Test

Hydrogen, Manufactured Gas X X

Diethyl Ether, Ethylene, Hydrogen Sulfide X

Acetone, Butane, Gasoline, Propane, Toluene X X

Metal dusts and other combustible dusts with

resistivity of less than 10

Carbon black, charcoal, coal or coke dusts with

resistivity between 10

Combustible dusts with resistivity of 105 -cm or

greater

Fibers, flyings

(1) For indoor locations only, unless cataloged with additional NEMA Type enclosure number(s) suitable for outdoor use as shown in the table on this page. Some control devices (if so

listed in the catalog) are suitable for Division 2 hazardous location use in enclosures for nonhazardous locations. For explanation of CLASSES, DIVISIONS and GROUPS, refer to the

National Electrical Code.

(2) For listing of additional materials and information noting the properties of liquids, gases and solids, refer to NFPA 497M-1991, Classification of Gases, Vapors, and Dusts for

Electrical Equipment in Hazardous (Classified) Locations.

(3) See Enclosure Type Descriptions for Non-hazardous Locations on page 19. For complete requirements, refer to UL Standard 698, compliance with which is required by NEMA

enclosure standards.

(4) UL 698 does not include test requirements for Class III. Products that meet Class II, Group G requirements are acceptable for Class III.

-cm

…10 -cm

(1)(2)

Designed to Meet

(3)

Tes ts

Hydrostatic Test

Temperature Test

Dust Penetration Test

Tem pe ra tu re Test wi th D us t

Blanket

(4)

Class (National

Electrical Code)

IX

II X

III X

7, Class I Group 9, Class II Group

ABCDEFG

X

X

20 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 23

Chapter 2

Industry Related Installation Considerations

This section describes different installation considerations for specific industries. It is not meant to be a comprehensive list and you must

take into account conditions at your specific location.

General Precautions

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of

the system. Failure to comply can result in personal injury and/or

equipment damage.

ATTENTION: An incorrectly applied or installed drive can result in

component damage or a reduction in product life. Wiring or

application errors such as under sizing the motor, incorrect or

inadequate AC supply, or excessive surrounding air temperatures can

result in malfunction of the system.

ATTENTION: Severe injury or death can result from electrical shock,

burn, or unintended actuation of controlled equipment. Hazardous

voltages can exist in the drive enclosure even with the circuit breaker

in the off position. Recommended practice is to disconnect and lock

out control equipment from power sources. If it is necessary to work

in the vicinity of energized equipment, the safety related work

practices of NFPA 70E, Electrical Safety Requirements for Employee

Workplaces, must be followed. DO NOT work alone on energized

equipment.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing any

work on the drive. Measure the DC bus voltage at the +DC and -DC

terminals of the Power Terminal Block. The voltage must be zero.

General Information

As with any AC drive installation there are many items that must be considered. In general, the selection of an enclosure for an AC drive is

based on the type of environment in which the AC drive will be applied. Specific industries have known contaminants which can contain

particulate matter (solids) and/or harsh chemical gases, and potentially higher ambient temperatures that can require filtering, additional

air flow, or complete sealing of an enclosure to protect the AC drive from the contaminant source.

Contaminants and Conditions by Industry

There are known contaminants in the atmosphere based on the type of application, location of the facility, or location (placement) of the AC

drive (for example: indoor vs. outdoor). This section lists some typical contaminants present in various industries.

Also see Environmental and Atmospheric Considerations by Location

Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020 21

on page 23) and Table 5 on page 28.

Page 24

Chapter 2 Industry Related Installation Considerations

Automotive Industry

In the Automotive industry the AC drive is typically an indoor installation. The airborne contaminants that can be present are:

• Hydrogen fluoride

• Oxides of nitrogen

• Hydrocarbons

•Sulfur dioxide

Chemical/Specialty Chemical

In the Chemical/Specialty Chemical industries, the AC drive can be found in both indoor and outdoor installations. The airborne contaminants

that can be present are:

• Organic dust (elemental chemicals such as sulfur)

• Oil-based distillates, which can create an oily film, further attracting other contaminants.

• High humidity levels in outdoor installations

• Caustic cleaners and / or concentrates (for example, ammonia, sodium chloride)

• High-pressure wash down

• NEMA4/4X environment

• Alcohol (Class1, Div 1, environment)

• Hose-directed water which can contain cleaning and other chemicals

Food and Beverage

In the Food and Beverage industry the AC drive is typically an indoor installation. The airborne contaminants that can be present are:

• Organic dust (grains, sugars, etc.)

• Caustic cleaners and/or concentrates (ammonia, sodium chloride, syrups)

• High-pressure wash down

• NEMA4/4X environment

• Alcohol (Class 1, Div 1, environment)

• High temperature/industrial cooking and baking 35 °C (95 °F)

Forest Products Industry/Converting

In the Forest Products/Converting industries, the AC drive is typically an indoor installation. The airborne contaminants that can be present

are:

• Hydrogen sulfide

• Active organic nitrogen

• Carbon monoxide

•Chlorine

• Chlorine dioxide

• Hydrocarbons

•Phosphates

• High moisture or humidity

Mining and Steel

In the Mining and Steel industry the AC drive is typically an indoor installation. The airborne contaminants that can be present are:

• Hydrogen sulfide,

• Hydrogen fluoride,

22 Rockwell Automation Publication DRIVES-AT003C-EN-P - October 2020

Page 25

Chapter 2 Industry Related Installation Considerations

•Carbon,

• Carbon monoxide,

• Inorganic dust,

• Pickle line acid,

• Hydrochloric acid,

• Moisture or humidity

Tire Manufacturing

In the Tire Manufacturing industry the AC drive is typically an indoor installation. The airborne contaminants that can be present are:

• Hydrogen sulfide

•Mercaptans

•Carbon black

Water/Waste Water

In the Water/Waste Water industry the AC drive can be installed either indoors or outdoors. With an indoor installation the airborne

contaminants that can be present are:

• Hydrogen sulfide

• Active organic nitrogen

• Carbon monoxide

•Chlorine

• Chlorine dioxide

• Hydrocarbons

• Moisture or humidity

Marine and Offshore

In the Marine and Offshore industry the AC drive can be installed either indoor (controlled), indoor (uncontrolled or ventilated), or outdoor