Page 1

PowerFlex 750-Series AC Drives with TotalFORCE Control

Catalog Number 20G

Quick Start

Original Instructions

Page 2

PowerFlex 750-Series AC Drives with TotalFORCE Control Quick Start

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 3

Table of Contents

Preface Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Supported Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Step 1: Gather the Required

Information

Step 2: Validate the Drive

Installation

Step 3: Power Up, Configure the

Modular Control Profiles

Step 4: Configure the Line Side

Converter

Step 5: Enter Motor Data Enter Motor Nameplate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Step 6: Set Up Velocity Feedback

for Flux Vector Control

Record System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Record Velocity Reference and Start/Stop Sources . . . . . . . . . . . . . . . . 9

Verify the Setting of the ENABLE and SAFETY Jumpers . . . . . . . . 12

Verify Power Source Ratings and Wiring Configurations . . . . . . . . . 13

Verify Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Verify Power Jumper Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Verify I/O Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

How to Use the HIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HIM Navigation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HIM Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HIM Single Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

HIM Alarms and Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

For Drives Without 24V Auxiliary Power . . . . . . . . . . . . . . . . . . . 19

For Drives With 24V Auxiliary Power. . . . . . . . . . . . . . . . . . . . . . . 19

Select the Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configure the Motor Side Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enter the Voltage Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enter the Duty Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Enter the Velocity Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Enter the Motor Control Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Enter the Application Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enter the Embedded Logic Selection . . . . . . . . . . . . . . . . . . . . . . . . 23

Enter the Motor Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Enter the Motor Side Bus Regulation Mode . . . . . . . . . . . . . . . . . 25

Reset Device and Verify the Configurations . . . . . . . . . . . . . . . . . . . . . 25

Configure Embedded EtherNet/IP Communication Adapter. . . . . 26

Set the Embedded Ethernet Adapter IP Address Switches. . . . . . . . . 27

Enter Line Side Converter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Enter Motor Poles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Enter Motor Overload Hertz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Enter Motor Protection Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Enter Motor Hot Start Coefficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Enter Motor Cooling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Record Encoder Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure Motor Encoder Velocity Feedback. . . . . . . . . . . . . . . . . . . . 34

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 3

Page 4

Table of Contents

Step 7: Tune the Motor Side

Inverter Control

Enable the HIM Start Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set Maximum Velocity for Permanent Magnet Motor . . . . . . . . . . . . 35

Perform the Direction Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Select the Source of Motor Control Parameter Values . . . . . . . . . . . . 38

Enter Motor Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Motor Inertia Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Perform the Motor ID Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rotate Motor ID Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Static Motor ID Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Autotune Bandwidth Calculations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Step 8: Set Up Velocity Reference Default Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Door Mounted or Remote Mounted HIM . . . . . . . . . . . . . . . . . . . . . . 44

Connections on 11-Series and 22-Series I/O Modules . . . . . . . . . . . . 44

Embedded EtherNet/IP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Step 9: Set Up Start/Stop Human Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control on 11-Series and 22-Series I/O Modules . . . . . . . . . . . . . . . . 46

Three-Wire Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Two-Wire Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Embedded EtherNet/IP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Step 10: Set Acceleration and

Acceleration and Deceleration Times . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Deceleration Times

Step 11: Configure Outputs Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Step 12: Verify Drive Operation Configuration Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Contact Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

After Basic Setup Configure Predictive Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Advanced Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Reference Information Reset Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cycle Power to the Drive and Control Pod . . . . . . . . . . . . . . . . . . 53

Use the HIM Reset Device Function . . . . . . . . . . . . . . . . . . . . . . . . 53

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Setting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Line Side Converter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

LCL Filter Capacitor Resonance Alarms . . . . . . . . . . . . . . . . . . . . 57

High Inertia Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Acceleration Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Deceleration Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Disable the HIM Start Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Using the HIM CopyCat Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Calculating AC Line Impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 5

Preface

Introduction

This Quick Start is designed to guide you through the basic steps that are required to start up your PowerFlex® 755TL

low harmonic, or PowerFlex 755TR regenerative standalone AC drives, for the first time, for simple applications. This

procedure uses the Human Interface Module (HIM) to configure parameters. However, you can use Connected

Components Workbench™ (CCW) (version 11 or later) software and the associated PowerFlex 755T Wizards to

configure parameters, instead of using the HIM.

Who Should Use This Manual

This manual is intended for qualified personnel.

• You must understand the hazards that are associated with electromechanical equipment installations.

• You must understand and follow all applicable local, national, and/or international electrical codes.

• You must be able to program and operate Adjustable Frequency AC Drive devices.

• You must have an understanding of the parameter settings and functions.

Equipment

The following equipment requirements apply to the use of this publication:

• The drive is a PowerFlex 755TL or PowerFlex 755TR standalone installation.

• The motor is either an induction motor, a synchronous reluctance motor, or a permanent magnet motor.

• No load sharing or multiple motors on a single drive.

• The drive has all required circuit protection installed.

• The drive and motor are connected and ready to have AC power applied.

• The drive is equipped with either a PowerFlex 20-HIM-A6 or a 20-HIM-C6S Human Interface Module (HIM).

• If used, the motor feedback device is a quadrature (AqB) incremental encoder.

Supported Applications

This publication is intended for use on simple velocity control applications with fans, pumps, compressors, and

conveyors.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 5

Page 6

Preface

Installation

The content of this manual assumes that the drive is installed according to the guidelines in the following publications:

• Wiring and Grounding for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

• PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100

The following is assumed:

• The drive installation meets mechanical requirements for drive orientation, cooling airflow, and mounting

hardware.

• The drive installation meets environmental requirements for surrounding air temperature, ambient atmosphere,

and the enclosure rating.

• The drive installation meets electrical requirements for AC supply, motor sizing, wiring and grounding, and

overload and short circuit protection.

• The drive installation is compliant with all applicable local, national, and international codes, standards, and

requirements.

Summary of Changes

This publication contains the following new or updated information. This list includes substantive updates only and is

not intended to reflect all changes. Translated versions are not always available for each revision.

Topic Page

Made changes regarding firmware revision 10 Throughout

Reorganized and added information to incorporate steps unique to Flux Vector motor control into the main

start-up procedure

Added information regarding permanent magnet motors 5, 15, 22, 35, 40

Added information regarding synchronous reluc tance motors 5, 15, 22

Added information on Motor Protection Class, Motor Hot Start Coefficient, and Motor Cooling Time parameters 8, 31, 32

Added information regarding oil well applications 15, 23

Added information regarding the Embedded Logic Select parameter 15, 23

Changed the Perform the Direction Test procedures 36

Added Autotune Bandwidth Calculation section for Flux Vector motor control 43

Added After Basic Setup section to reference predictive maintenance and advanced configuration resources 52

Updated status indicator information 54

Added information on calculating AC line impedance for a system with a line reactor 60

Througho ut

6 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 7

Step 1: Gather the Required Information

When you apply power to your drive for the first time, you must enter specific information about your application. This

step helps you to verify that you have the needed information before drive power-up.

Table 1 on page 8

provides a place to record the data you need for the rest of the steps in this document.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 7

Page 8

Step 1: Gather the Required Information

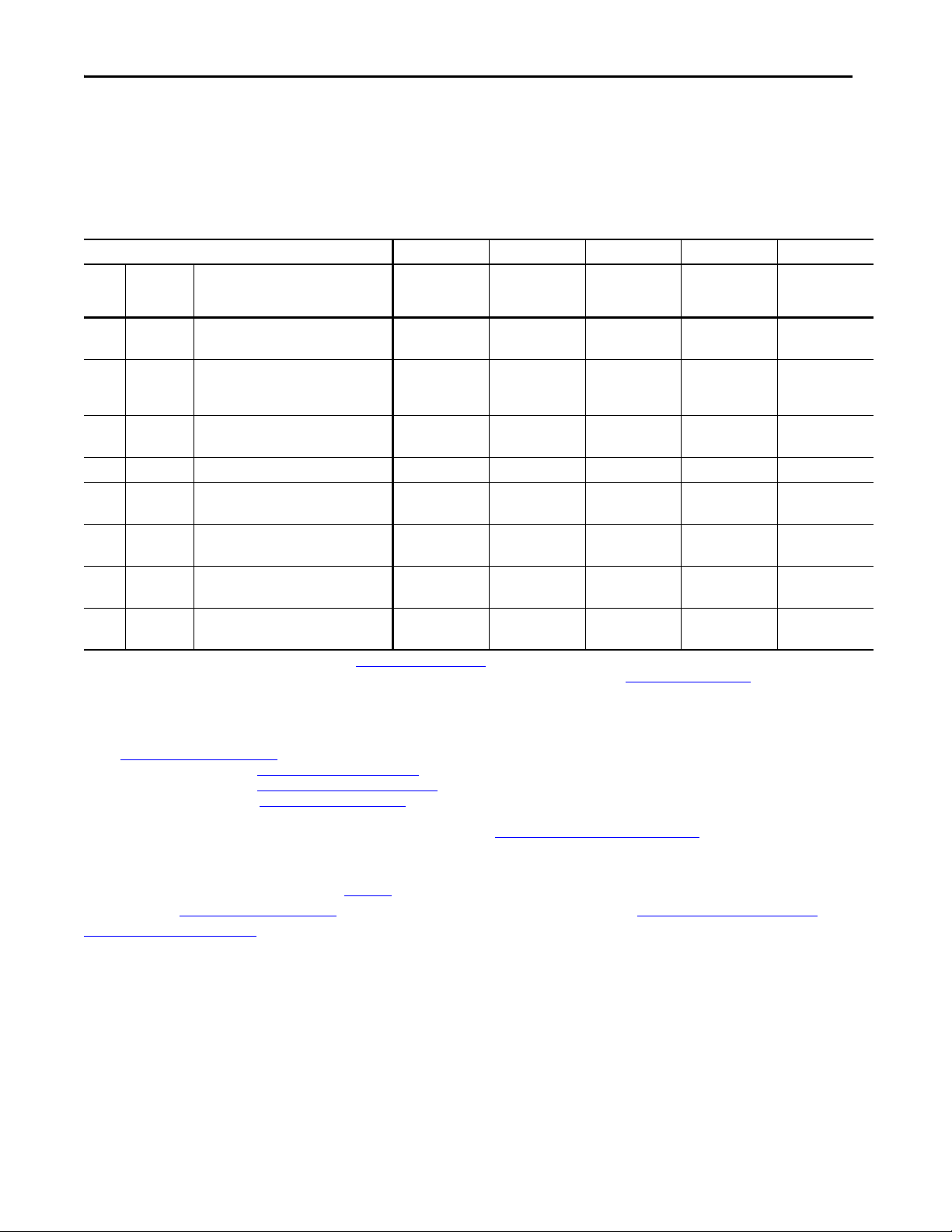

Record System Data

Record the data that will be used to configure system parameters. This includes motor nameplate data, AC power data,

and other motor data. Use this table to record a descriptive name, and parameter values for each drive/motor

combination. You can record data for up to five drive/motor combinations.

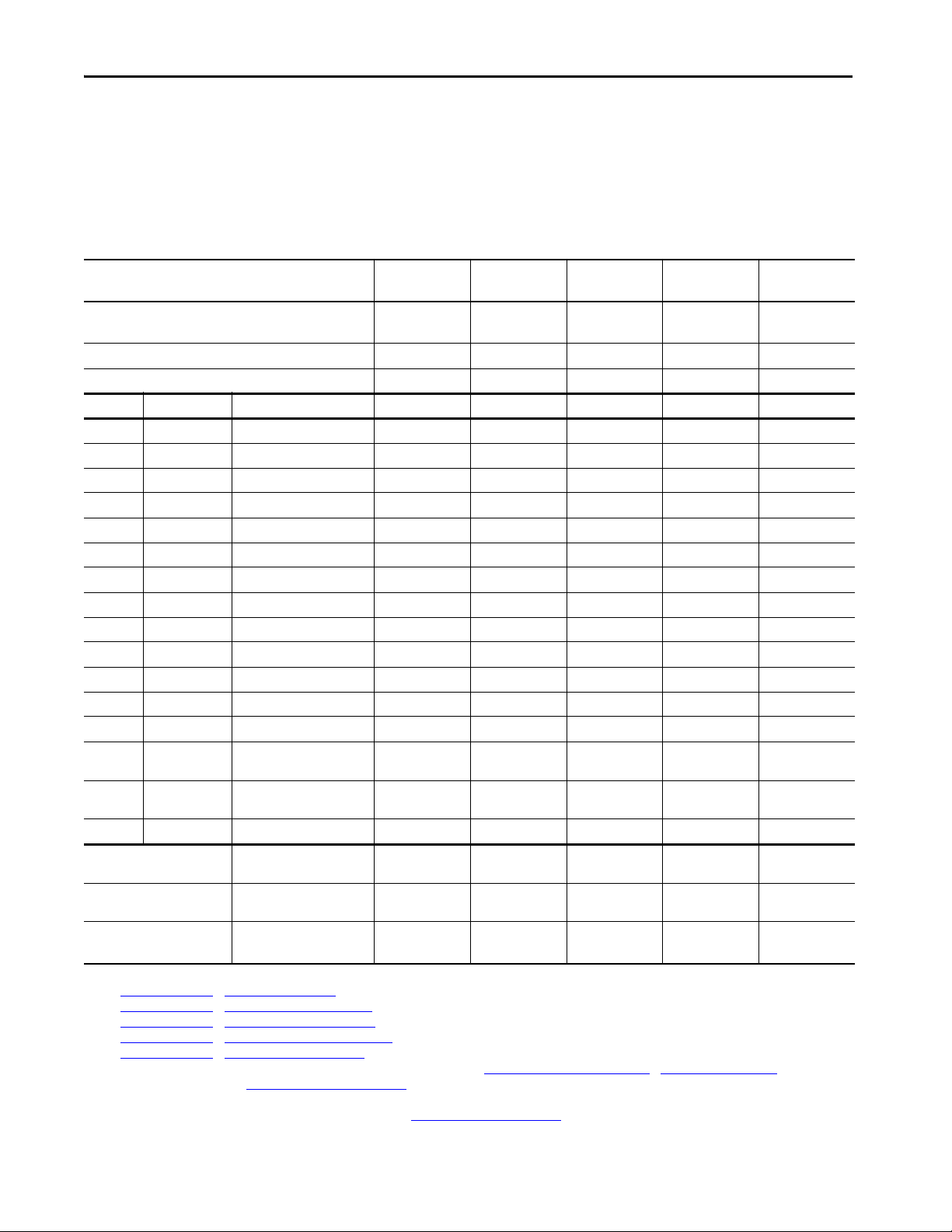

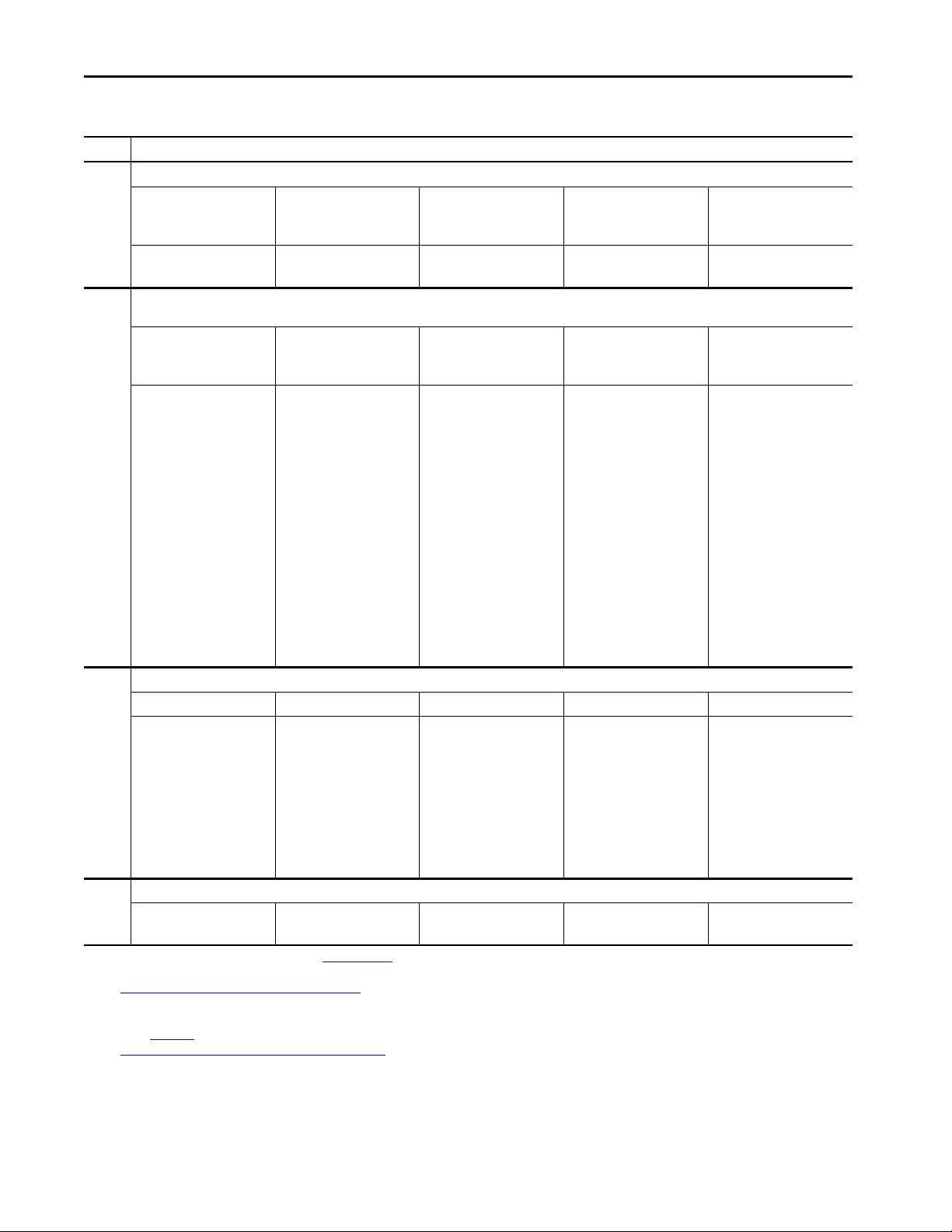

Table 1 - System Data

Drive/Motor Identifier (example, Main Exhaust Fan) Drive/Motor 1: Drive/Motor 2: Drive/Motor 3: Drive/Motor 4: Drive/Motor 5:

Drive Type

❑

❑

755TL

755TR

❑

❑

755TL

755TR

❑

❑

755TL

755TR

❑

❑

755TL

755TR

Drive Catalog Number 20G1 20G1 20G1 20G1 20G1

Transformer Identifier

Port No. Parameter No. Description

(1)

Drive/Motor 1: Drive/Motor 2: Drive/Motor 3: Drive/Motor 4: Drive/Motor 5:

10 400 Motor Nameplate Volts

10 401 Motor Nameplate Amps

10 402 Motor Nameplate Hertz

10 403 Motor Nameplate RPM

10 405 Motor Nameplate Power Units

❑

kW ❑ Hp

❑

kW ❑ Hp

❑

kW ❑ Hp

❑

kW ❑ Hp

10 406 Motor Nameplate Power

10 407 Motor Poles

10 204 Motor Overload Hertz

10 209 Motor Protection Class

10 210 Motor Hot Start Coefficient

10 210 Motor Cooling Time

10 900 Motor Inertia

(2)

(7)

(3)

(4)

(5)

(6)

(kg•m2)

0 33 AC Line Voltage nom (V AC)

13 30 AC Line Frequency nom

❑

50 Hz ❑ 60 Hz❑ 50 Hz ❑ 60 Hz❑ 50 Hz ❑ 60 Hz❑ 50 Hz ❑ 60 Hz❑ 50 Hz ❑ 60 Hz

(50 Hz or 60 Hz)

13 32 AC Line Transformer Rating

(kVA)

13 34 AC Line Impedance (%)

Power jumpers configuration. AC Power Source Grounding

Method

(9)

Braking Chopper (only if used) External Brake Chopper and

(8)

❑

—

❑

—

❑

—

❑

—

DB Resistor Data

Motor Encoder, also known as a

Motor Encoder Data

Feedba ck Device (only if use d)

(1) Motor parameters with descriptions that do not include “Motor Nameplate” are typically not present on the motor nameplate.

(2) See Step 5: Enter Motor Data

(3) See Step 5: Enter Motor Data

(4) See Step 5: Enter Motor Data

(5) See Step 5: Enter Motor Data

(6) See Step 5: Enter Motor Data

(7) Only needed for Flux Vector motor control mode. Methods to determine motor inertia are covered in Step 7: Tune the Motor Side Inverter Control

(8) If your system uses a line reactor, see Calculating AC Line Impedance on page 60

(9) For example, solid (low res), non-solid (high res).

(10) Only needed if a motor encoder is used. For more information, see Appendix A > Line Side Converter Settings on page 57

> Enter Motor Poles on page 30 .

> Enter Motor Overload Her tz on page 31.

> Enter Motor Protec tion Class on page 31.

> Enter Motor Hot Start Coefficient on page 32.

> Enter Motor Cooling Time on page 32.

(10)

❑

—

PPR: _____

.

❑

—

PPR: _____

❑

—

PPR: _____

.

❑

—

PPR: _____

> Enter Motor Inertia on page 39.

❑

755TL

❑

755TR

❑

kW ❑ Hp

❑

—

❑

—

PPR: _____

8 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 9

Step 1: Gather the Required Information

3

4

Sh

Sh

PTC–

PTC+

Ao0–

Ao0+

Ao1–

Ao1+

–10V

10VC

+10V

Ai0–

Ai0+

Ai1–

Ai1+

24VC

+24V

DiC

Di0

Di1

Di2

Di3

Di4

Di5

7

55

66

1

2

1010

89

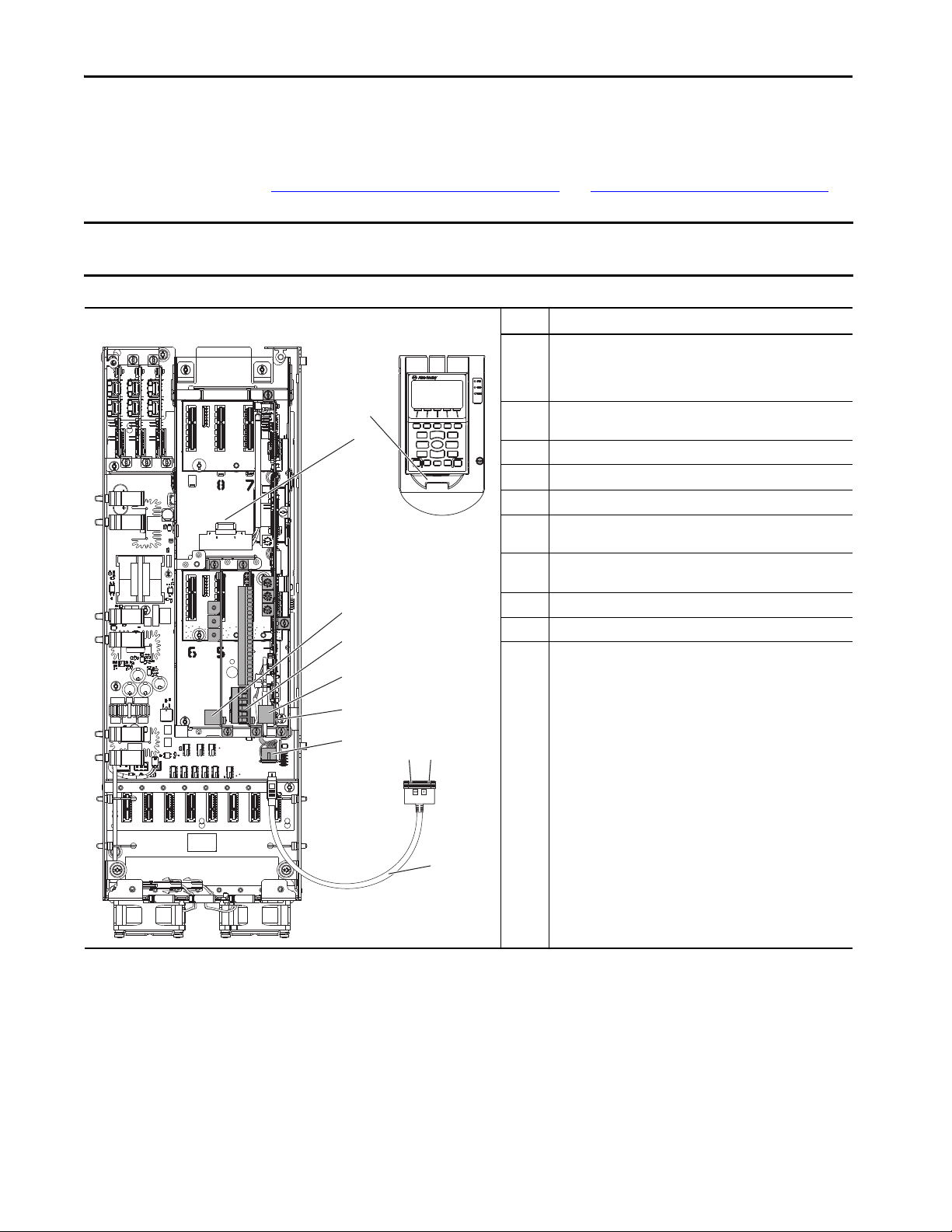

Record Velocity Reference and Start/Stop Sources

Use this diagram to help determine where signal and control sources are connected in each of your drives. You need this

information when you get to Step 8: Set Up Velocity Reference on page 44

IMPORTANT PowerFlex® 755T products use the term ‘port’ to designate (in firmware and software) the physical location where hardware is

located to make it easier to select hardware or functions to program.

and Step 9: Set Up Start/Stop on page 46.

Figure 1 - Basic Subset of Signal Source and Port Locations

Items Descriptions

1 Port 1 connection on the drive-mounted Human Interface Module

(HIM) (The drive-mounted HIM is shown not installed. When it is

installed, the drive-mounted HIM is mounted to the HIM cradle,

connecting at item 2.)

2 Port 1 connection on the HIM cradle (where the drive-mounted HIM

is installed and item 1 connects)

3 Communication option module (shown installed at port 5)

4 Expansion I/O module (shown installed at port 4)

5 Embedded EtherNet/IP™ connectors

6 Terminal block TB1 behind port 0 (the EtherNet/IP port) on the main

control board

7 Port 2 for handheld HIM connection, remote HIM connection, or a

splitter cable (item 10)

8 Splitter cable connection to port 2

9 Splitter cable connection to port 3

10 Splitter cable that connec ts to port 2 (item 7) and provides a port 2

splitter cable connection (item 8) and port 3 splitter cable

connection (item 9)

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 9

Page 10

Step 1: Gather the Required Information

Table 2 - Velocity Reference and Start/Stop Control Sources

(1)

Item

03 Are signal sources connected to a communication option module installed in your drive? If yes, note the catalog number and port number for the module.

Drive 1:

❑

Yes: Port No. _____❑ No

Cat. No.: 20-750-_____

Drive 2:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Address Information: Address Information: Address Information: Address Information: Address Information:

Drive 3:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Drive 4:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Drive 5:

❑

Yes: Port No. _____❑ No

Cat. No.: 20-750-_____

(2)

04 Are signal sources connected to the digital and analog inputs of an I/O option module that is installed in your drive?

If yes, note the catalog number, port number and wiring terminal information for the module.

Drive 1:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Vel Ref Term: Ai ___

DI 0 Term: _____

DI 1 Term: _____

DI 2 Term: _____

DI 3 Term: _____

DI 4 Term: _____

DI 5 Term: _____

Ao0 Term: _____

Ao1 Term: _____

R0 Term: _____

R1 Term: _____

T0 Term: _____

T1 Term: _____

Drive 2:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Vel Ref Term: Ai ___

DI 0 Term: _____

DI 1 Term: _____

DI 2 Term: _____

DI 3 Term: _____

DI 4 Term: _____

DI 5 Term: _____

Ao0 Term: _____

Ao1 Term: _____

R0 Term: _____

R1 Term: _____

T0 Term: _____

T1 Term: _____

Drive 3:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Vel Ref Term: Ai ___

DI 0 Term: _____

DI 1 Term: _____

DI 2 Term: _____

DI 3 Term: _____

DI 4 Term: _____

DI 5 Term: _____

Ao0 Term: _____

Ao1 Term: _____

R0 Term: _____

R1 Term: _____

T0 Term: _____

T1 Term: _____

(3)

Drive 4:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Vel Ref Term: Ai ___

DI 0 Term: _____

DI 1 Term: _____

DI 2 Term: _____

DI 3 Term: _____

DI 4 Term: _____

DI 5 Term: _____

Ao0 Term: _____

Ao1 Term: _____

R0 Term: _____

R1 Term: _____

T0 Term: _____

T1 Term: _____

05 Is there a connection to the Embedded EtherNet/IP Adapter? If yes, note the IP address and other applicable information.

Drive 1: ❑ Yes ❑ No Drive 2: ❑ Yes ❑ No Drive 3: ❑ Yes ❑ No Drive 4: ❑ Yes ❑ No Drive 5: ❑ Yes ❑ No

Por t No. 0

IP Address:

___:___:___:___

Port No. 0

IP Address:

___:___:___:___

Port No. 0

IP Address:

___:___:___:___

Por t No. 0

IP Address:

___:___:___:___

Drive 5:

❑

Yes: Port No._____ ❑ No

Cat. No.: 20-750-_____

Vel Ref Term: Ai ___

DI 0 Term: _____

DI 1 Term: _____

DI 2 Term: _____

DI 3 Term: _____

DI 4 Term: _____

DI 5 Term: _____

Ao0 Term: _____

Ao1 Term: _____

R0 Term: _____

R1 Term: _____

T0 Term: _____

T1 Term: _____

(4)

Port No. 0

IP Address:

___:___:___:___

Subnet Mask:

___:___:___:___

Gateway Address (if used):

___:___:___:___

Subnet Mask:

___:___:___:___

Gateway Address (if used):

___:___:___:___

Subnet Mask:

___:___:___:___

Gateway Address (if used):

___:___:___:___

Subnet Mask:

___:___:___:___

Gateway Address (if used):

___:___:___:___

Subnet Mask:

___:___:___:___

Gateway Address (if used):

___:___:___:___

01, 02 Are you using the drive HIM to set the speed reference or for Start/Stop control? If yes, note the HIM port number.

Drive 1:

❑

Yes: Port No._____ ❑ No

(1) Item numbers are referenced to the control pod diagram, Figure 1 on page 9.

(2) See the user manual for the communication option module installed in the drive.

(3) See Connections on 11-Series and 22-Series I/O Modules on page 44

wiring diagrams to determine the functions of digital and analog I/O that are wired to various I/O option module terminals. Possible motor side control functions that can be assigned to the digital

inputs include; Stop, Start, and Run. See the PowerFlex Drives with TotalFORCE Control Programming Manual,

publication 750-PM100

(4) See Configure Embedded EtherNet/IP Communication Adapter on page2 6

, for all motor side control functions available for assignment to digital inputs.

Drive 2:

❑

Yes: Port No._____ ❑ No

for information regarding analog I/O parameter assignments. Leave unused digital and analog assignments blank. See application

Drive 3:

❑

Yes: Port No._____ ❑ No

for information regarding methods to set the embedded EtherNet adapter IP address.

Drive 4:

❑

Yes: Port No._____ ❑ No

Drive 5:

❑

Yes: Port No._____ ❑ No

10 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 11

Step 2: Validate the Drive Installation

Step 2: Validate the Drive Installation

It is important that you thoroughly inspect each of your drive installations before applying power for the first time. This

is especially important if you did not personally perform the installation tasks. Verify that each drive is ready to be

energized when you get to Step 3: Power Up, Configure the Modular Control Profiles on page 14

ATTENTION: To avoid an electric shock hazard, the drive must be locked and tagged before you start Step 2: Validate the Drive

Installation. Failure to comply can result in personal injury and/or equipment damage.

.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 11

Page 12

Step 2: Validate the Drive Installation

Verify the Setting of the ENABLE and SAFETY Jumpers

• If the ENABLE jumper is removed, then to enable the product to operate, you must apply control power to the

main control board, port 0 TB1 terminal <Di0> and <DiC>. No modification of drive parameters is required.

Port 0 TB1 terminal <Di0> becomes the dedicated product enable input. For more information, see the

PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100

• If the SAFETY jumper is removed, install the ENABLE jumper and install a safety option module in a valid

control pod port. Configuring a safety option module is beyond the scope of this document. See the manual for

the safety option that is installed:

– Catalog number 20-750-S: PowerFlex 750-Series Safe Torque Off User Manual, publication 750-UM002

– Catalog number 20-750-S1: Safe Speed Monitor Option Module for PowerFlex 750-Series AC Drives Safety

Reference Manual, publication 750-RM001

– Catalog number 20-750-ATEX: PowerFlex 750-Series ATEX Option Module User Manual,

publication 750-UM003

.

– Catalog number 20-750-S3: PowerFlex 755 Integrated Safety - Safe Torque Off User Manual,

publication 750-UM004

.

– Catalog number 20-750-S4: PowerFlex 755/755T Integrated Safety Functions Option Module, publication

750-UM005

.

.

.

.

1

2

3

4

5

6

9

8

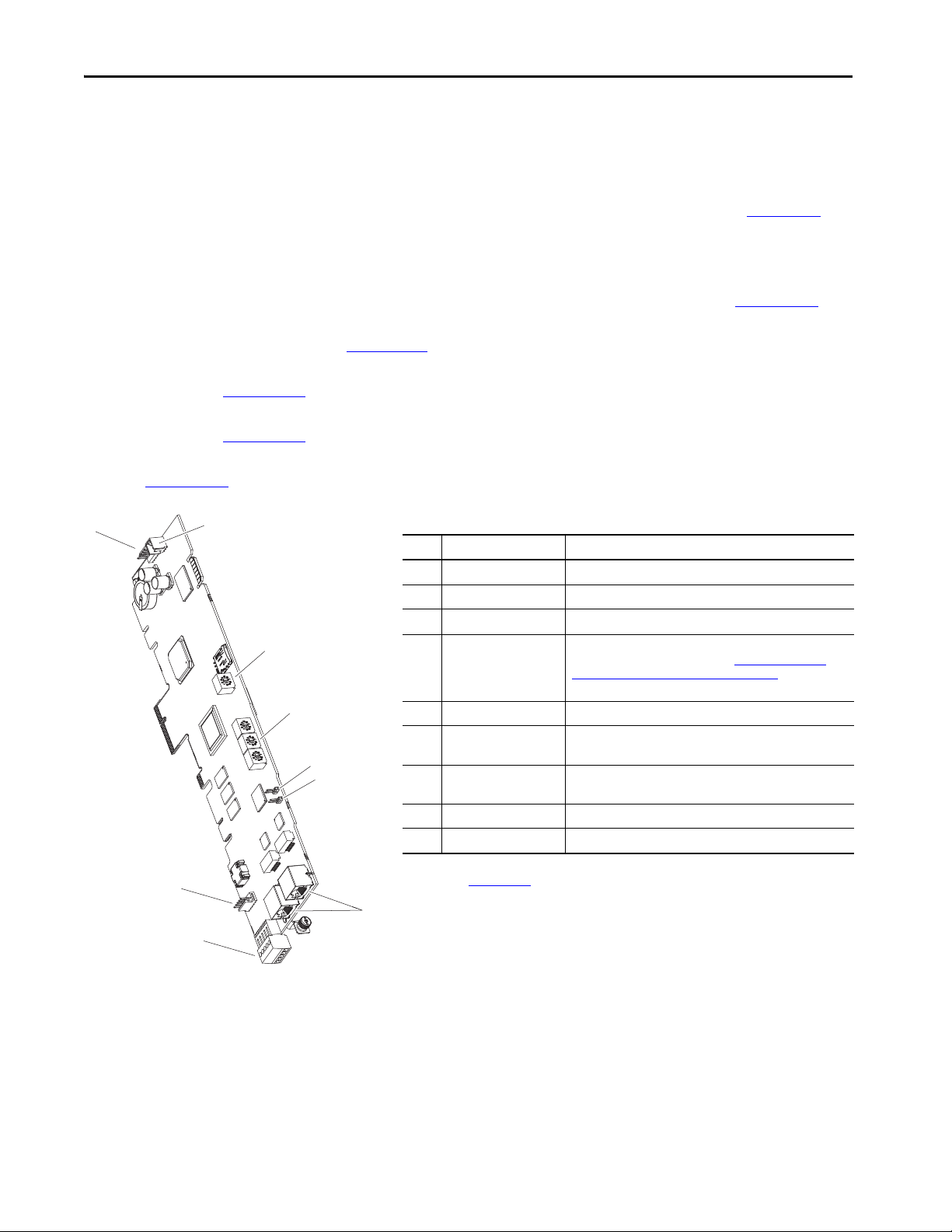

Figure 2 - Main Control Board

Item Name Description

1 HIM Connector DPI port 01 (HIM Cradle) connection.

2 Fan Connector Power supply for internal cooling fan.

3 Control Selector Rotary switch for setting the programming mode.

4 Embedded EtherNet/IP

Address Selectors

5 SAFETY Jumper Safety enable jumper. Removed when safety option is installed.

6 ENABLE Jumper Hardware enable jumper. TB1 becomes an Enable when this

7 Built-in EtherNet/IP

Adapter

8TB1 I/O terminal block.

9 DPI port 2/3 Cable connection for handheld and remote HIM options.

(1) See the PowerFlex Drives with TotalFORCE Control Built-in EtherNet/IP Adapter User Manual,

publication 750COM-UM009

7

(1)

Rotary switches for setting lowest octet of EtherNet address

(forces address to 192.168.1.xxx). See Configure Embedded

EtherNet/IP Communication Adapter on page 26 for instructions

on setting the IP address.

jumper is removed.

A single adapter with dual EtherNet/IP network cable

connecti ons.

.

12 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 13

Step 2: Validate the Drive Installation

Verify Power Source Ratings and Wiring Configurations

The installation must conform with the guidelines that are given in the PowerFlex 750-Series Products with

TotalFORCE Control Installation Instructions, publication 750-IN100

If any of the following conditions exist, confirm that these items have been addressed and that the power source and

cabling is suitable for operation of the PowerFlex 755TL/TR drives.

• The power-source-short-circuit-current capacity must not exceed 100,000 A rms symmetrical amperes at 400/

480/600V systems, and 65,000 A rms symmetrical amperes for 690V systems.

• The PowerFlex 755TL/TR drives must not be used on undersized or high impedance supply systems. The supply

system kVA must be equal to or greater than the drive kW, and the system impedance must be less than 10%.

• Other drives share the AC input source transformer with the PowerFlex 755TL/TR drive, certain measures may

be required for proper operation of the PowerFlex 755TL/TR drive.

• The power source grounding method is not the recommended wye secondary with solid (low resistance) X0

ground with cable that is connected to the drive PE terminal. DC bus conditioning filters and other devices may

be required.

• The motor output cable length is greater than the recommendations in Appendix A of the Wiring and Grounding

for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

cable length in comparison to the recommendations, consider the following:

– Motor insulation rating

– PWM switching frequency

– Any reflected wave protection devices, such as an RWR filter, if any such devices have been installed

.

. When assessing the motor output

See the Wiring and Grounding for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

, for

important information regarding installation of AC drives.

Verify Power Wiring

Visually inspect the power wiring connections to each drive. Be sure that you are satisfied that the correct wires are

connected to the input terminals and to the output terminals and are tightened with the correct torque.

See the PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100

more information on where these connections are made and torque requirements.

See the Wiring and Grounding for Pulse Width Modulated (PWM) AC Drives, publication DRIVES-IN001

important information regarding installation of AC drives.

Verify Wiring Drive 1

AC input power is on L1, L2, L3 / R, S, T. ❑❑ ❑❑❑

Output motor connection is on T1, T2, T3 / U, V, W. ❑❑ ❑❑❑

Proper ground wire terminations at PE ground studs. ❑❑ ❑❑❑

The motor output cable length does not exceed the max

recommended length.

Wiring is Correct

❑❑ ❑❑❑

Drive 2

Wiring is Correct

Drive 3

Wiring is Correct

Drive 4

Wiring is Correct

Wiring is Correct

for

, for

Drive 5

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 13

Page 14

Step 3: Power Up, Configure the Modular Control Profiles

Verify Power Jumper Configuration

PowerFlex 755T drives contain protective MOVs and common mode capacitors that are referenced to ground. To guard

against drive damage and/or operation problems, these devices must be configured based on the AC power source

grounding method that is recorded in Tab le 1 on pa ge 8

IMPORTANT The drive-power-source-grounding method must be accurately determined and the jumpers must be configured for the power

source. See the PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100

more information on common power source types. See the Power Jumper Configuration sections for the proper jumper

configuration for your power source and the locations of power jumpers in the drives.

.

for

Drive 1

Power jumpers are

configured correctly.

❑❑❑❑❑

Drive 2

Power jumpers are

configured correctly.

Drive 3

Power jumpers are

configured correctly.

Drive 4

Power jumpers are

configured correctly.

Drive 5

Power jumpers are

configured correctly.

Verify I/O Wiring

To configure a drive correctly, you must know the source of the velocity reference and the start/stop commands. There

are four places where signal sources (such as push buttons, potentiometers, communication network cabling, or HIM)

are connected to the drive:

1. The main control board.

• Embedded EtherNet/IP port

• Terminal block TB1 (Di0)

2. An I/O option module. This is where an analog input or preset speed would connect.

3. A communication option module.

4. A HIM.

Step 3: Power Up, Configure the Modular Control Profiles

In this step, you power up the drive and configure the drive modular control profiles and system properties. Modular

Control Profiles are parts of the drive that change to match your application needs. A power cycle or drive reset is

required for the new configuration to be applied. Modular Control Profiles improve the user interface and performance.

14 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 15

Step 3: Power Up, Configure the Modular Control Profiles

Preparation

Use the following table to record your configurations and preferences. See the detailed description below the table for

more information about what to record in this table.

Table 3 - Configurations and Preferences

Drive/Motor Name (example, Main Exha ust Fan)

Por t

Related

No.

Param eter

No.

033 Voltage Class

035 Duty Rating Class

0 46 Velocity Units

0 65 Primary Motor Control Mode

0 70 Application Select

0 72 Embedded Logic Select

10 110 Stop Mode

10 116 Motor Side DC Bus Regulation Mode

(1) Low for 400V and 600V drives. High for 480V and 690V drives. See Enter the Voltage Class on page 20 for more information about this setting.

(2) Depends on the application overload requirements. LD = 110% for 60 s, ND = 110%/150% for 60 s/3 s, HD = 150%/180% for 60 s/3 s. See Enter the Duty Rating on page 21

setting.

(3) Motor control mode options include: Induction Volts Per Hertz, Induc tion Sensorless Vector, Induction Economizer, Induction Flux Vector, Interior Permanent Magnet Flux Vector, Surface Permanent Magnet

Flux Vec tor, Perman ent Magn et Volts Per H ertz, Pe rmanent Magnet Sensorless Vector, Synchronous Reluctance Volts Per Hertz, and Synchronous Reluctance Sensorless Vector. For most applications, select

an SV (Sensorless Vector) or Econ (Econ SV) motor control mode. If your application requires closed loop velocity control with encoder feedback, select an FV (Flux Vector) motor control mode.

See Enter the Motor Control Mode on page22

(4) For most applications, select ‘None‘. See Enter the Application Selection on page 23

(5) For most applications, select ‘None’. S ee Enter the Embedded Logic Selection on page 23

(6) For most applications, select ‘Ramp’. See Enter the Motor Stop Mode on page 24

Device procedure changes parameters that are associated with port 10.

(7) For PowerFlex 755TL drives, select ‘Adjust Frequency’. For PowerFlex 755TR drives, select ‘Disabled’. See Enter the Motor Side Bus Regulation Mode on page 25

parameter 0:65 is changed, then performing a Reset Device procedure changes parameters that are associated with por t 10.

Description Drive/Motor 1: Drive/Motor 2: Drive/Motor 3: Drive/Motor 4: Drive/Motor 5:

(1)

(Low, High)

(2)

(Light Duty [LD], Normal Duty [ND], Heavy

Duty [HD])

(Hertz, RPM)

(3)

(4)

(None, PID, Torque Prove, OilWell Pump)

(5)

(None, DeviceLogix™)

(6)

(Coast, Ramp, Current Limit, Decel Hold)

(7)

(Disabled, Adjust Frequency)

for more information about this

for more information about this setting.

for more information about this setting.

for more information about this setting.

for more information about this setting. If parameter 0:65 (port 0, parameter 65) is changed, then performing a Reset

for more information about this setting. If

Some of the parameters that are listed in Ta b l e 3 require you to reset the device to change the value of the parameter. See

Appendix A > Reset Device on page 53

. The parameters that require reset are listed in Reset Device and Verify the

Configurations on page 25.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 15

Page 16

Step 3: Power Up, Configure the Modular Control Profiles

ESC

VIEW

REF

PAR #

TEXT

Soft Key Labels

Soft Keys

How to Use the HIM

The PowerFlex 20-HIM-A6 / -C6S HIM User Manual, publication 20HIM-UM001, provides detailed instructions on

how to use the Human Interface Module (HIM) capabilities for configuring PowerFlex 750-Series drive settings.

The PowerFlex 755T product does not support Assisted Startup using the HIM. You must manually select parameters as

directed in the following procedure.

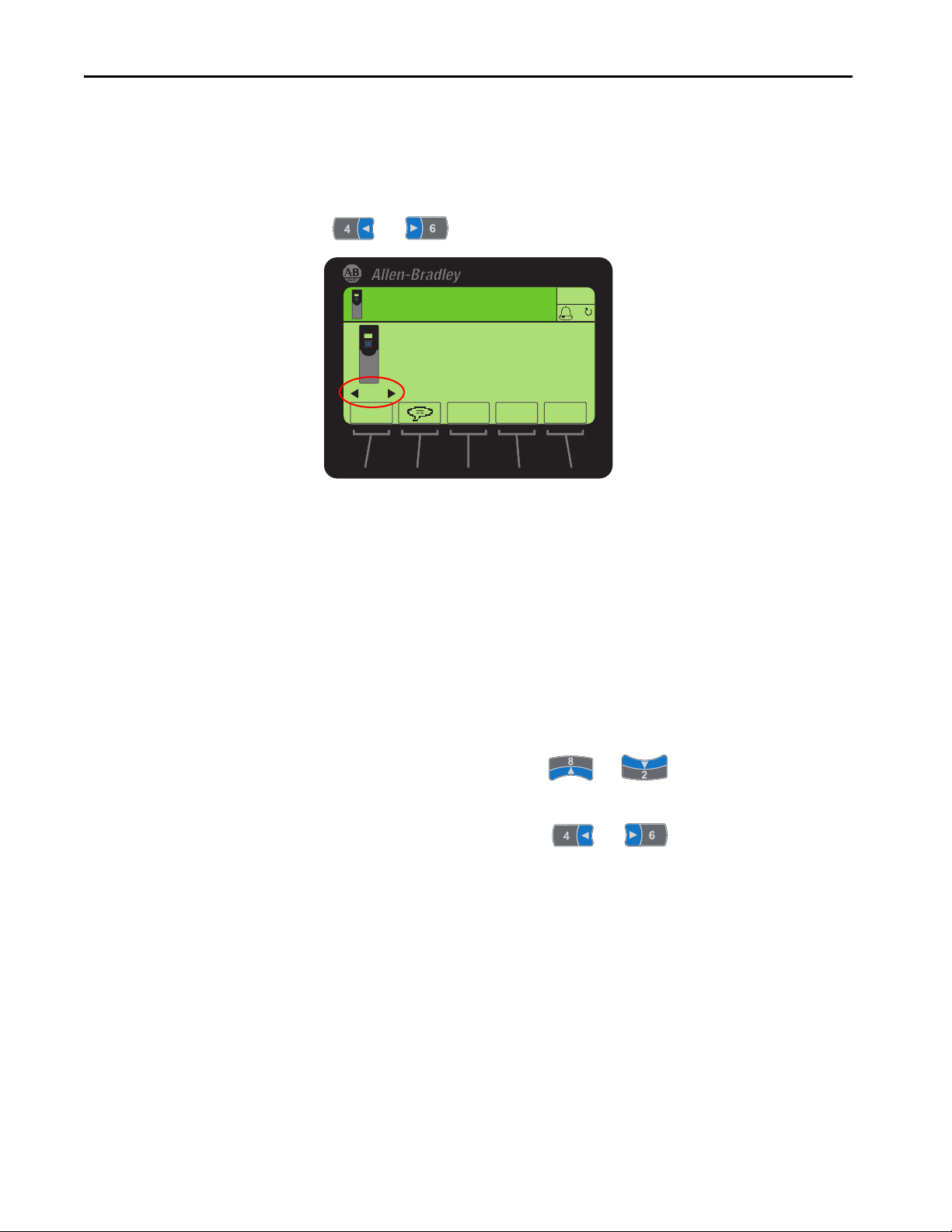

HIM Navigation Keys

The navigation keys are the blue keys (2, 4, 5, 6, 8). The navigation keys are also used for entering numeric values.

•Use the

or

to scroll up or down through selection lists shown on the LCD display.

• Use the or keys to scroll left or right through selection options that are shown on the LCD display.

• Use the key to accept selections.

HIM Soft Keys

The HIM soft keys are the top row of gray unmarked keys. Soft key function depends on context. The function that a key

currently has is shown by the corresponding soft key label at the bottom of the LCD display. When prompted to use a

soft key function, use the key label to determine which soft key button to press.

16 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 17

Step 3: Power Up, Configure the Modular Control Profiles

Stopped

0.00 Hz

AUTO

Fault Code 81

Port 1 DPI Loss

Elapsed Time 01:26:37

– – FAULTED – –

ESC

CLR

HIM Single Function Keys

There are four single-function keys, which are highlighted. Each single-function key always performs only its dedicated

function.

• The key is the drive Start push button.

• The key is the drive Stop push button and can be used to clear alarms and faults.

• The key accesses folder for parameters, diagnostics, memory functions, preferences, and other tasks.

• The key accesses drive control such as jog, direction, auto/manual and other functions.

HIM Alarms and Faults

The HIM displays various alarm and fault codes. When alarm and fault codes display, you have the following options:

• Correct the cause of the fault and then clear the fault code by pressing the drive Stop push button or the CLR soft

key. Once the fault is corrected and cleared, the fault no longer exists, and normal drive operation can resume.

• Do not correct the cause of the fault and just press the drive Stop push button or the CLR soft key. If the fault is

cleared, but not corrected, whatever condition is causing the fault still exists, but the fault is removed from the

HIM display.

• Do not clear faults and just exit the fault screen by pressing the ESC soft key.

Normal drive operation cannot be resumed until any faults that exist are both corrected and cleared. See the PowerFlex

Drives with TotalFORCE Control Programming Manual, publication 750-PM100

for Fault/Alarm code information.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 17

Page 18

Step 3: Power Up, Configure the Modular Control Profiles

00

Stopped

0.00 Hz

AUTO

Host Drive

480V 740 A

20G...D740

ESC

REF TEXT

PAR#PAR#

Navigating to a Port and Parameter

Throughout this document you are prompted to ‘Navigate to parameter nn:xxxx [name]’. ‘Parameter nn:xxxx’ means

port nn, parameter xxxx. When prompted to access a parameter, use the following procedure.

1. From the Status screen, use the or navigation keys to scroll to the indicated port number.

2. Press the PAR# soft key.

3. Use the numeric keys to enter the indicated parameter number. Entry of leading zeroes is not required.

4. Press the ENTER soft key.

Edit a value

When prompted to Edit a value, use the following procedures.

1. When the parameter display screen appears, press the EDIT soft key.

2. Depending on the parameter properties, you can enter the parameter value directly with the numeric keys or there

may be a list of available selections.

If there is a list of available selection use the HIM navigation keys or , to scroll up or down

through selection list that is shown on the LCD display.

Other settings such as bit selections use the HIM navigation keys or to scroll let or right to the

indicated value or bit number.

3. To accept the entered data or selection, press the ENTER soft key.

Depending on the parameter properties, there may be multiple selection lists that appear each time you press the

ENTER soft key.

4. If you do not want to accept a value or selection, press the ESC soft key.

5. To return to the Status screen, press the ESC soft key. Multiple presses may be required.

18 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 19

Step 3: Power Up, Configure the Modular Control Profiles

Power the Drive

Use one of the following procedures to energize your drive.

ATTENTION: Power must be applied to the drive to perform the following start-up procedure. Some of the voltages present are

at incoming line potential. To avoid electric shock hazard or damage to equipment, allow only qualified service personnel to

perform the following procedure. Thoroughly read and understand the procedure before beginning.

For Drives Without 24V Auxiliary Power

1. Energize the 3-phase power source to the drive.

2. For Frames 7…15, turn the Fused Disconnect handle on the drive input bay to the ON position.

3. After the drive boots up, if there are any faults, correct and clear them.

TIP The drive should remain energized for the next procedure, but if you ever want to de-energize the drive, do so as follows:

1. For Frames 7…15, turn the Fused Disconnect handle on the drive input bay to the OFF position.

2. De-energize the 3-phase power source to the drive.

For Drives With 24V Auxiliary Power

1. Energize the three-phase power source to the drive.

2. For Frames 7…15, turn the Fused Disconnect handle on the drive input bay to the ON position.

3. After the drive boots up, if there are any faults, correct and clear them.

4. Energize the 24V Auxiliary Power supply source.

5. Keep the 24V Auxiliary Power source energized even if the AC power is de-energized. This maintains operation of

the control pod port devices and communication adapters.

TIP The drive should remain energized for the next procedure, but if you ever want to de-energize the drive, do so as follows:

1. For Frames 7…15, turn the Fused Disconnect handle on the drive input bay to the OFF position.

2. De-energize the 3-phase power source to the drive.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 19

Page 20

Step 3: Power Up, Configure the Modular Control Profiles

Stopped

0.000 Hz

AUTO

Select Language to Use

English

Francaise

Espanol

Italiano

ENTER

Select the Language

If you are prompted to select the language, use the following procedure.

1. Use the HIM navigation keys to scroll through the list of selections to highlight the desired display language.

2. To accept the setting, press the ENTER soft key.

Configure the Motor Side Inverter

IMPORTANT If the drive was previously configured for a different application, and is being repurposed for this application, you must reset the

parameters to factory defaults. Do this before configuring the motor side inverter. See Appendix A > Setting Factory Defaults on

page 55.

Enter the following data, which was gathered in Table 3 on page 15.

IMPORTANT Some parameter settings and related control mode changes only take effect after you perform a Reset Device procedure. You

only need to perform the Reset Device procedure once, after entering all settings to configure the motor side inverter.

Enter the Voltage Class

A change to this parameter is needed only when you are applying a drive on a voltage other than what the catalog number

specifies.

• For 400/480V products, ‘Low Voltage’ selects 400V and ‘High Voltage’ selects 480V.

• For 600/690V products, ‘Low Voltage’ selects 600V and ‘High Voltage’ selects 690V.

1. Navigate to parameter 0:33 [VoltageClass Cfg].

2. Press the EDIT soft key.

3. Edit the value to either 0 ‘Low Voltage’ or 1 ‘High Voltage’, choosing the option corresponding to the data

collected in Ta b l e 3

4. Press the ENTER soft key.

20 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

.

Page 21

Step 3: Power Up, Configure the Modular Control Profiles

Enter the Duty Rating

The duty class parameter allows you to select the continuous and overload modes of operation. The value of this

parameter affects the continuous current rating of the drive.

• Normal Duty (ND) - Selects the normal continuous rating, with overload ratings of 110% for 60 seconds and

150% for 3 seconds.

• Heavy Duty (HD) - Provides a lower continuous rating, with overload ratings of 150% for 60 seconds and 180%

for 3 seconds.

• Light Duty (LD) - provides the highest continuous rating, with an overload rating of 110% for 60 seconds. Not

available on all drive ratings.

1. Navigate to parameter 0:35 [Duty Rating Cfg].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘Normal Duty’, 1 ‘Heavy Duty’, or 2 ‘Light Duty’, choosing the option corresponding to the data

collected in Table 3 on page 15

4. Press the ENTER soft key.

.

Enter the Velocity Units

This parameter allows you to select either Hertz (Hz) or Revolutions per Minute (RPM) as the units for velocity (speed).

1. Navigate to parameter 0:46 [Velocity Units].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘Hz’ or 1 ‘RPM’, choosing the option corresponding to the data collected in Ta b l e 3

4. Press the ENTER soft key.

.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 21

Page 22

Step 3: Power Up, Configure the Modular Control Profiles

Enter the Motor Control Mode

Setting the motor control mode determines how the drive controls the motor. There are four basic control modes. Some

of them have different variations for different motor types. The four basic modes are as follows:

• Volts per Hertz (VHz) - The most basic form of motor control. Useful for variable torque applications such as

pumps, fans, and multiple motors in parallel.

• Sensorless Vector (SV) - An enhanced form of VHz control with better low speed operation and better torque

control at low frequencies. Useful for variable torque and simple constant torque applications. If you choose an SV

control mode, we recommend that you run a Motor ID test.

• Economize (Econ) - An enhanced form of Sensorless Vector control designed to reduce energy consumption when

the drive is not accelerating. If you choose Econ, we recommend that you run a Motor ID test.

• Flux Vector (FV) - The highest performance control mode. A control mode that is designed for precise Torque,

Velocity, and/or Position regulation. Usually uses a motor feedback device. Useful for variable torque, constant

torque, and constant power applications. Provides precise position and velocity tracking. Provides excellent

disturbance rejection. This mode is required for position and load sharing applications. If you choose an FV

control mode, it is required that you run a Motor ID test. You may also have to run a Motor Inertia test. We

recommend that you use a Flux Vector control mode for both encoder and encoderless control of permanent

magnet motors.

For the control modes where a Motor ID test or Motor Inertia is recommended or required, these tests are performed

during Step 7: Tune the Motor Side Inverter Control on page 35

.

The motor-type-specific motor control modes are as follows. Choose from these options based on your type of motor

and application:

• Induction Volts Per Hertz (InductionVHz)

• Induction Sensorless Vector (Induction SV)

• Induction Economize (Induct Econ)

• Induction Flux Vector (Induction FV)

• Interior Permanent Magnet Flux Vector (IPM FV)

• Surface Permanent Magnet Flux Vector (SPM FV)

• Permanent Magnet Volts Per Hertz (PM VHz)

• Permanent Magnet Sensorless Vector (PM SV)

• Synchronous Reluctance Volts Per Hertz (SynR VHz)

• Synchronous Reluctance Sensorless Vector (SynR SV)

1. Navigate to parameter 0:65 [Pri MtrCtrl Mode].

2. Press the EDIT soft key.

3. Edit the value to one of the following, choosing the option corresponding to the data collected in Table 3 on

page 15: 1 ‘InductionVHz’, 2 ‘Induction SV’, 3 ‘Induct Econ’, 4 ‘Induction FV’, 5 ‘IPM FV’, 6 ‘SPM FV’, 7 ‘PM

VHz’, 8 ‘PM SV’, 9 ‘SynR VHz’, or 10 ‘SynR SV’.

4. Press the ENTER soft key.

22 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 23

Step 3: Power Up, Configure the Modular Control Profiles

Enter the Application Selection

You can add Process PID, Torque Prove, or Oil Well Pump application functionality to determine which application

parameters are present in virtual port 9. This is only needed when you are using Process PID, Torque Prove, or Oil Well

Pump. The following options are available:

• None - leaves port 9 empty. This is the default setting

• Process PID only - provides a PID regulator for process applications in port 9. Use Process PID for pressure or

flow transducers on fan or pump applications; you can also use it for tension transducers on winding applications.

• Torque Prove - provides a mechanism for coordinating the motor and mechanical brake on lifting applications.

This selection loads these parameters and the Process PID parameters into port 9.

• Oil Well Pump - provides a mechanism for pump jack and progressive cavity pump applications

1. Navigate to parameter 0:70 [Application Sel].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘None’, 1 ‘ProcPID Only’, 2 ‘Torque Prove’, or 3 `OilWell Pump', choosing the option

corresponding to the data collected in Table 3 on page 15

4. Press the ENTER soft key.

.

Enter the Embedded Logic Selection

Selecting DeviceLogix as the embedded logic source loads embedded logic parameters into port 9 following a reset or

power cycle. These parameters contain the default values.

1. Navigate to parameter 0:72 [Emb Logic Select].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘None’ or 1 ‘DeviceLogix’, choosing the option corresponding to the data collected in Ta b l e 3

4. Press the ENTER soft key.

.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 23

Page 24

Step 3: Power Up, Configure the Modular Control Profiles

Enter the Motor Stop Mode

Select how the drive executes a stop command. For operation with a controller, Stop Mode A (parameter 10:110

[Mtr Stop Mode A]) defines the method that is used for a Normal Stop. The default motor stop mode is ‘Ramp’.

• Coast - the motor side inverter immediately stops modulating (stops gating its power devices), and stops the motor

side inverter from powering the motor. In most applications, Coast causes the motor to coast to a standstill.

• Ramp - the motor side inverter decelerates the motor from the Base speed to the Zero Speed threshold,

10:146 [Zero Speed Limit]. Active Decel Time (10:1917 [VRef Decel Time1] or 10:1918

[VRef Decel Time2]) controls the rate of deceleration. Active Decel Time sets the amount of time it takes for the

motor to decelerate from Base speed to the Zero Speed threshold. Once the motor reaches the Zero Speed

threshold, modulation is stopped (stops gating its power devices). Decel rate is defined as motor Base speed/Decel

time.

• Current Limit - the motor side inverter decelerates the motor at a rate where the Decel Time is 0.1 seconds.

Deceleration does not exceed the Current Limit to stop at this rate.

• Decel To Hold - the motor side inverter decelerates the motor from the Base speed to the Zero Speed threshold,

10:146 [Zero Speed Limit]. Active Decel Time (10:1917 [VRef Decel Time1] or 10:1918

[VRef Decel Time2]) controls the rate of deceleration. Active Decel Time sets the amount of time it takes for the

motor to decelerate from Base speed to the Zero Speed threshold. Once the motor reaches the Zero Speed

threshold, the motor side inverter holds by continuing to modulate with a zero speed (zero frequency) output.

Hold continues until there is a new start command, new run command, or another kind of stop command. Decel

rate is defined as motor Base speed/Decel time.

1. Navigate to parameter 10:110 [Mtr Stop Mode A].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘Coast’, 1 ‘Ramp’, 2 ‘Current Lmt’, or 3 ‘DecelToHold’, choosing the option corresponding to

the data collected in Table 3 on page 15

.

4. Press the ENTER soft key.

24 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 25

Step 3: Power Up, Configure the Modular Control Profiles

Enter the Motor Side Bus Regulation Mode

Selects how the motor side inverter attempts to mitigate rising DC bus voltage during motor regeneration.

• Disabled - the motor side inverter does nothing to regulate the DC bus voltage. In this mode, the regenerative line

side converter or an external DC bus voltage control (brake resistor, regen module) is required to regulate the DC

bus voltage during motor regeneration.

– Disabled is the typical setting for a 755TR regenerative drive.

– Disabled is the required setting if you have installed an external brake chopper and dynamic brake resistor.

• Adjust Output Frequency - the motor side inverter adjusts its fundamental output frequency or torque, depending

on the motor control mode, to reduce the amount of motor regeneration. The use of this option may result in

extended deceleration times.

– Adjust Output Frequency is the typical setting for a 755TL low harmonic drive.

– Adjust Output Frequency is default motor side bus regulation mode.

1. Navigate to parameter 10:116 [Bus Reg Mode A].

2. Press the EDIT soft key.

3. Edit the value to 0 ‘Disabled’ or 1 ‘Adjust Freq’, choosing the option corresponding to the data collected in Ta b l e 3

on page 15.

4. Press the ENTER soft key.

Reset Device and Verify the Configurations

For the setting changes you entered earlier to be accepted, you must perform a Reset Device procedure. You can cycle

power to the drive and control pod or use the HIM. See Appendix A > Reset Device on page 53

IMPORTANT You must perform a Reset Device procedure to load the modified values of these parameters.

To verify the configurations, verify the values of the following parameters:

0:34 [VoltageClass Act] 0:47 [Vel Units Act] 0:71 [Application Act]

0:36 [Duty Rating Act] 0:66 [Pri MtrCtrl Act] 0:73 [Emb Logic Act]

, for more information.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 25

Page 26

Step 3: Power Up, Configure the Modular Control Profiles

Configure Embedded EtherNet/IP Communication Adapter

If you are using a communication adapter, configure the address so that it corresponds to the data collected in Table 2 on

page 10.

If you are using a communication option module (20-750 series), refer to the appropriate 750COM-UM user manual for

more information about setting communication addresses.

See PowerFlex Drives with TotalFORCE Control Built-in EtherNet/IP Adapter User Manual, publication 750COM-

UM009, for more information about configuring the embedded EtherNet/IP adapter.

Active IP addresses are shown in the diagnostic items, parameters 0:49…60.

There are three methods for configuring the embedded EtherNet/IP IP address in the adapter:

1. Adapter Rotary Switches - Use the switches when working on a simple, isolated network (for example,

192.168.1.xxx). The three adapter switches are read when the drive powers up, and represent three decimal digits

from top to bottom (see Figure 3 on page 27

a. Set the rotary switches to a valid address (001-254) corresponding to the data collected in Ta b l e 2

uses that value as the lower octet of its IP address (192.168.1.xxx, where xxx = rotary switch settings), along

with a subnet mask of 255.255.255.0. No gateway is configured. Also, the setting for adapter parameter 0:300

[Net Addr Sel] is automatically ignored.

b. To accept the changes to IP address switches, perform a Reset Device procedure. See Appendix A > Reset

Device on page 53 for more information.

).

. The adapter

2. BOOTP or DHCP Server - If you prefer to control the IP addresses of devices using a server, use BOOTP/

DHCP. The IP address, subnet mask, and gateway addresses are then provided by the BOOTP/DHCP server. If

the address is invalid, DHCP is used.

3. Adapter Parameters - Use adapter parameters when you want more flexibility in configuring the IP address, or

when you must communicate outside the control network using a gateway. When adapter parameters are used, the

IP address, subnet mask, and gateway addresses come from the adapter parameters you set.

a. Set the adapter rotary switches to 999. See Figure 3

and their related descriptions.

b. Navigate to parameter 0:300 [Net Addr Sel]. Press the EDIT soft key. Edit to a value of 1 'Parameters'. Press the

ENTER soft key.

c. Navigate to parameters 0:302…305 [IP Addr Cfg 1…4]. Press the EDIT soft key. Edit the value of each IP

address octet corresponding to the data collected in Ta b l e 2

IP address to 10.20.3.123, you would set the parameters as follows:

– 0:302 [IP Addr Cfg 1] = 10

– 0:303 [IP Addr Cfg 2] = 20

– 0:304 [IP Addr Cfg 3] = 3

– 0:305 [IP Addr Cfg 4] = 123

and its accompanying table for all possible switch settings

. Press the ENTER soft key. For example, to set the

26 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 27

Step 3: Power Up, Configure the Modular Control Profiles

Hundreds

Ten s

Ones

d. Navigate to parameters 0:306…309 [Subnet Cfg 1…4] corresponding the data collected in Ta ble 2 on page 10.

Press the EDIT soft key. Edit the value of each subnet mask octet. Press the ENTER soft key. The subnet mask

cannot be set to 0.0.0.0. If you set the subnet incorrectly, the drive uses DHCP.

e. Navigate to parameters 0:310…313 [Gateway Cfg 1…4] corresponding to the data collected in Ta b l e 2

. Press

the EDIT soft key. Edit the value of each gateway address octet. Press the ENTER soft key.

If the gateway address is set to 0.0.0.0, the drive can only communicate with devices on the same subnet as the

drive. It is not able to communicate with devices on other subnets. If the gateway address is not set to 0.0.0.0,

then it must be set to an address that is on the same subnet as the IP address of the drive. If you set the gateway

incorrectly, the drive uses DHCP.

f. To accept the changes to the switch and parameter settings, perform a Reset Device procedure. See Appendix A

> Reset Device on page 53

for more information.

g. Verify the entered values of parameters 0:301…313. Active IP addresses are shown in the diagnostic items,

parameters 0:49…60.

IMPORTANT Regardless of the method used to set the IP address on the adapter, each node on the EtherNet/IP network must have a unique

IP address. To accept IP address changes, you must perform a Reset Device procedure.

Set the Embedded Ethernet Adapter IP Address Switches

Set the embedded Ethernet adapter IP address switches using Figure 3 and the information in Ta b l e 4 .

Figure 3 - Location of Ethernet Adapter IP Address Switches

Table 4 - Ethernet Adapter IP Address Switches

Possible Settings Description

000, 255…887,

889…999

001…254 Adapter uses the rotary switch settings for the IP address (192.168.1.xxx, where xxx = rotary switch settings).

888 Resets the adapter IP address function to factory defaults. This setting also resets most parameters to factory defaults on a drive or bus supply.

(1) 999 is the default setting and disables the rotary switches.

(1)

Adapter uses, depending on 0:300 [Net Addr Sel], BOOTP setting, DHCP setting, or the adapter parameter settings for the IP address.

Thereafter, the drive must be powered down, the switches set to a setting other than 888, and then the drive must be powered up again to accept the

new address.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 27

Page 28

Step 4: Configure the Line Side Converter

Step 4: Configure the Line Side Converter

In this step, you configure the line side converter. The line-side-converter-regulation parameters can usually be left at the

default values. If you are having issues or alarm/faults, refer to Appendix A > Line Side Converter Settings on page 57

Enter Line Side Converter Settings

1. Navigate to parameter 13:30 [Nom Line Freq]. Press the EDIT soft key.

.

2. Edit the nominal line frequency in Hertz, corresponding to the data collected in Table 1 on pag e 8

3. Press the ENTER soft key.

4. Navigate to parameter 13:32 [AC Line kVA A]. Press the EDIT soft key.

5. Edit the supply transformer power rating in kVA, corresponding to the data collected in Ta b l e 1

6. Press the ENTER soft key.

7. Navigate to parameter 13:34 [AC Line Imped% A]. Press the EDIT soft key.

8. Edit the power source line impedance in percent, corresponding to the data collected in Ta b l e 1

9. Press the ENTER soft key.

10. At this point, the basic line side converter settings required for most applications are configured. You may

configure additional parameters such as:

• Current Rate Limit, parameter 10:227 [Current Rate Lim].

• Regen Power Limit, parameter 10:229 [Regen Power Lim]. Only for Flux Vector motor control modes.

• Motor Power Limit, parameter 10:230 [Motor Power Lim]. Only for Flux Vector motor control modes.

To determine the settings for these parameters, refer to either of the following:

• Connected Components Workbench™ (version 11 or later) software and the associated PowerFlex 755T

Startup Wizard.

• The PowerFlex Drives with TotalFORCE Control Programming Manual, publication 750-PM100

.

.

.

.

28 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 29

Step 5: Enter Motor Data

Step 5: Enter Motor Data

In this step, you configure the Motor Side Inverter Control using the motor data recorded in Ta b l e 1 on pag e 8 .

Enter Motor Nameplate Data

1. Navigate to parameter 10:400 [Motor NP Volts]. Press the EDIT soft key.

2. Edit the motor nameplate voltage to match the data recorded in Tab l e 1

3. Press the ENTER soft key.

4. Navigate to parameter 10:401 [Motor NP Amps]. Press the EDIT soft key.

5. Edit the motor nameplate full load current in amps, to match the data collected Ta b l e 1

key.

6. Navigate to parameter 10:402 [Motor NP Hertz]. Press the EDIT soft key.

7. Edit the motor nameplate fundamental frequency in Hertz, to match the data collected Ta b l e 1

8. Press the ENTER soft key.

9. Navigate to parameter 10:403 [Motor NP RPM]. Press the EDIT soft key.

10. Edit the motor nameplate base speed in RPM, to match the data collected Tab l e 1

11. Press the ENTER soft key.

12. Navigate to parameter 10:405 [Mtr NP Pwr Units]. Press the EDIT soft key.

13. Edit the value to 0 ‘HP’ or 1 ‘kW’, to match the motor nameplate power units collected Ta b l e 1

14. Press the ENTER soft key.

15. Navigate to parameter 10:406 [Motor NP Power]. Press the EDIT soft key.

16. Edit the motor nameplate power, to match the data collected Ta b l e 1

.

. Press the ENTER soft

.

.

.

.

17. Press the ENTER soft key.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 29

Page 30

Step 5: Enter Motor Data

Enter Motor Poles

If the number of motor poles is not on the motor nameplate, contact the motor manufacturer and confirm the number of

motor poles. The number of motor poles is ALWAYS an even integer multiple of 2.

Use this table to help determine the number of poles. The motor NP RPM is always less than the Sync RPM by the

amount of motor slip RPM. If the motor NP Hertz is not 50 Hz or 60 Hz, or if the motor has a low NP RPM, contact

the motor manufacturer and confirm the number of poles.

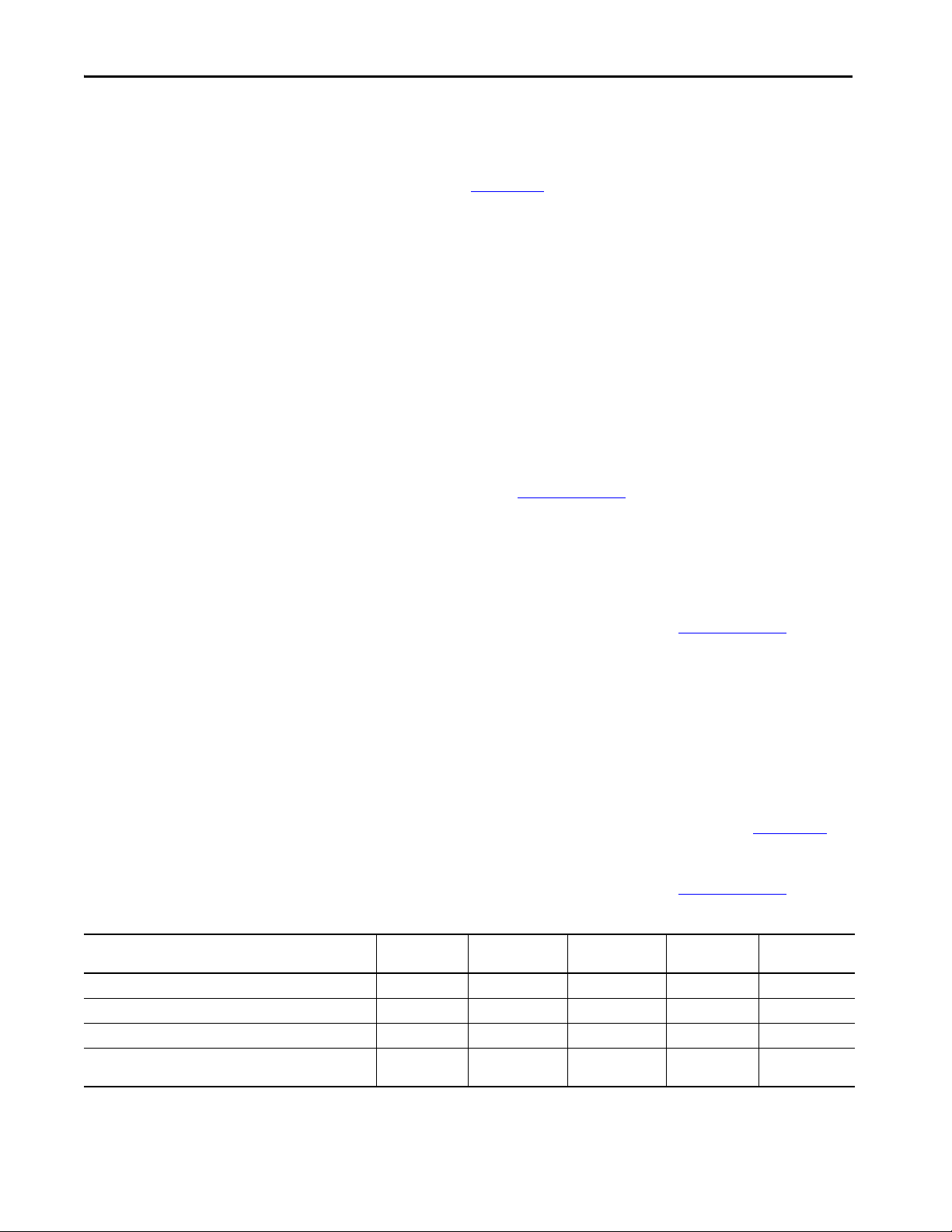

No. Poles Sync RPM

NP Hertz = 60 Hz

2 3600 3000

4 1800 1500

6 1200 1000

8900750

10 720 600

12 600 500

Sync RPM

NP Hertz = 50 Hz

1. Navigate to parameter 10:407 [Motor Poles]. Press the EDIT soft key.

2. Edit the number of motor poles to match the data collected Ta b l e 1 o n pa g e 8

.

3. Press the ENTER soft key.

30 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 31

Step 5: Enter Motor Data

Enter Motor Overload Hertz

The motor OL Hertz is typically not on the motor nameplate. This information is available from the motor

manufacturer data sheets. Motor OL Hertz is the fundamental frequency below which the motor cannot deliver rated

torque continuously without the possibility of overheating. This is sometimes referred to as the 'speed turn-down ratio'.

Self-cooled motors with Totally Enclosed Non-Ventilated (TENV) enclosures, Drip Proof Guarded (DPG) enclosures,

and Totally Enclosed Fan Cooled (TEFC) enclosures, have shaft driven cooling fans. These fans cannot produce the

volume and pressure of cooling air that is required to produce rated motor torque continuously, without the motor

overheating when operated below the minimum speed turn-down frequency. Motors with separately powered cooling

fans, such as those with Totally Enclosed Blower Cooled (TEBC) enclosures, and Drip Proof Guarded Force Ventilated

(DPG-FV) enclosures, can typically be operated to zero speed without overload Hertz derating.

For example, a 60 Hz base speed TEFC motor with 4:1 speed turndown ratio can only produce rated torque

continuously down to 60 Hz / 4 = 15 Hz. In this example, parameter 10:204 [Mtr OL Hertz] would be set to 15 Hz.

Another example is a 60 Hz base speed TEBC blower cooled motor with a 1000:1 speed turndown ratio. In this case,

parameter 10:204 [Mtr OL Hertz] would be set to 60 Hz / 1000 = 0.06 Hz or 0 Hz.

Setting parameter 10:204 [Mtr OL Hertz] does not affect the drives capability to deliver motor current or limit output

current in any way. Parameter 10:204 only sets the threshold where the motor overload counter begins to increment.

1. Navigate to parameter 10:204 [Mtr OL Hertz]. Press the EDIT soft key.

2. Edit the overload threshold frequency in Hertz, based on the data collected in Ta ble 1 on page 8

calculations. Press the ENTER soft key.

and the previous

Enter Motor Protection Class

This parameter is available in firmware revision 10 and higher. The motor protection class, or trip class, defines the

length of time it takes to trip the system in an overload condition. The Motor Protection Class parameter can have a

value between 1 and 60. This value is the maximum number of seconds until the motor trips off when it is in an overload

condition. An overload condition is defined as the current being over 600% of the maximum thermal current rating (or

600% of the actual dial setting on adjustable overloads). So if the motor current is over 600% of the maximum thermal

current rating, and the motor protection class is 60, the motor will trip in 60 seconds or less.

The default value for Motor Protection Class is 11. Many industrial loads, particularly high inertia loads, require Class

30. Use a protection class appropriate for your application, considering motor thermal curves, operating conditions, and

inertia of the load. For more information on motor protection class, refer to the Low Voltage Motor Protection White

Paper, publication 193-WP008

1. Navigate to parameter 10:209 [Mtr Protn Class]. Press the EDIT soft key.

2. Enter the Motor Protection Class that is recorded in Ta ble 1 on pag e 8

. To set Motor Protection Class, use the following procedure.

. Press the ENTER soft key.

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 31

Page 32

Step 5: Enter Motor Data

Enter Motor Hot Start Coefficient

This parameter is available in firmware revision 10 and higher. The Motor Hot Start Coefficient parameter allows you to

set the hot state overload curve to some percent of the cold curve representing the motor protection class. This

accommodates requirements for both cold start and hot start. Running from a cold state, the cold curve is used. The

motor is considered to be in a hot state if it has been running above the rated current for at least 20 minutes. Once the

motor is considered to be in a hot state, the hot curve is used for any overload condition. The parameter can have a value

in the range of 0.1…1. A value of 1 makes the hot state overload curve equivalent to the cold curve. A value of 0.1 makes

the hot state overload curve equivalent to 10% of the cold curve.

The default value for Motor Hot Start Coefficient is 0.33. To set Motor Hot Start Coefficient, use the following

procedure.

1. Navigate to parameter 10:210 [Mtr HotStrtCoeff ]. Press the EDIT soft key.

2. Enter the Motor Hot Start Coefficient that is recorded in Table 1 on page 8

. Press the ENTER soft key.

Enter Motor Cooling Time

This parameter is available in firmware revision 10 and higher. The Motor Cooling Time parameter allows you to set the

decay time for the motor to go from a hot state to a cool state. The parameter value is the time in minutes. The motor is

considered to be in a hot state if it has been running above the rated current for at least 20 minutes. A hot state occurs

when a motor overload condition appears and the overload count reaches 100%. If the motor was just in a hot state, and

is no longer running above the rated Amps, the motor cooling time begins. This could be because the motor was tripped

off due to an overload, was turned off by a user, or it could still be running, but below the rated Amps. Once the full

length of the motor cooling time has passed, the motor overload count reaches 0%, and the motor is considered to be in a

cool state.

The default value for Motor Cooling Time is 20 minutes. To set Motor Cooling Time, use the following procedure.

1. Navigate to parameter 10:211 [Mtr Cooling Time]. Press the EDIT soft key.

2. Enter the Motor Cooling Time in minutes, that is recorded in Table 1 on page 8

. Press the ENTER soft key.

32 Rockwell Automation Publication 750-QS100B-EN-P - August 2020

Page 33

Step 6: Set Up Velocity Feedback for Flux Vector Control

Step 6: Set Up Velocity Feedback for Flux Vector Control

Perform this step only if your application uses Flux Vector motor control and closed loop (encoder) feedback. If your

application uses open loop (encoderless) feedback, skip this section. Default velocity feedback values are for open loop

feedback, so no setup is required for open loop feedback.

Record Encoder Information

If your application uses Flux Vector motor control and closed loop (encoder) feedback, record the system information for

the encoder feedback option modules and wiring terminals in Ta b l e 5

.

Additional information is available in PowerFlex 755T Flux Vector Tuning, publication 750-AT006

.

Examples of wiring encoder feedback devices to option modules can be found in the PowerFlex 750-Series I/O,

Feedback, and Power Option Modules Installation Instructions, publication 750-IN111

Table 5 - Encoder Information

Enter the encoder feedback module catalog number, port number, and wiring terminals.

Drive 1: _____

Port No. _____

Cat. No.: 20-750- ________

Encoder Term: _____ A…Z

Drive 2:_____

Port No. _____

Cat. No.: 20-750-________

Encoder Term:_____ A…Z

Drive 3:_____

Port No. _____

Cat. No.: 20-750- ________

Encoder Term:_____ A…Z

Drive 4:_____

Port No. _____

Cat. No.: 20-750- ________

Encoder Term: _____ A…Z

.

Drive 5:_____

Port No. _____

Cat. No.: 20-750-________

Encoder Term: _____ A…Z

Rockwell Automation Publication 750-QS100B-EN-P - August 2020 33

Page 34

Step 6: Set Up Velocity Feedback for Flux Vector Control

Configure Motor Encoder Velocity Feedback

This procedure is needed only if you are using closed loop Flux Vector motor control with a motor-incremental-encoderfeedback device. In this procedure, you configure the motor incremental encoder feedback.