Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

6180 Industrial

Computer

User

Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. "Safety Guidelines for t he Application, Installation, and

Maintenance of Solid State Controls" (Publication SGI-1.1) describes some important

differences between solid state equ ipment and hard-wired electromechanical devices.

Because of this difference, and because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy themselves

that each intend ed application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associ ated with any particular

installation, Rockwell Automation cannot assume responsibility or liability for actual use

based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect to use of the

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation is prohibited.

Throughout this manual, we use notes to make you aware of safety considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage, or economic loss.

Important: Identifies information that is especially important for successful application

and understanding of the product.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

Table of Contents

Table of Contents

Table of ContentsTable of Contents

Using this Manual

System Features

Preface

Who Should Use This Manual...................................................P-1

Purpose of this Manual..............................................................P-1

Contents of this Manual.............................................................P-2

Manual Conventions..................................................................P-4

Allen-Bradley Support...............................................................P-4

Chapter 1

Chapter Objectives.................................................................... 1-1

6180 Computer Versions ........................................................... 1-1

64−Key Standard Keypad........................................................ 1-13

Full Alphanumeric Keypad..................................................... 1-15

68−Key Standard Keypad........................................................ 1-17

70−Key Standard Keypad........................................................ 1-18

Configurable Keys................................................................... 1-19

Re-legendable Keys................................................................. 1-19

Keyboard Interface Controller Card........................................ 1-19

Integral Mouse......................................................................... 1-19

LED Indicators........................................................................1-20

Backlight Brightness Control <<graphics needed>>...............1-20

Chassis Locks.......................................................................... 1-21

Installation

Chapter 2

Chapter Objectives.................................................................... 2-1

European Union Compliance.....................................................2-1

Environmental Considerations .................................................. 2-1

Mounting Hardware................................................................... 2-2

Tools Required........................................................................... 2-2

Mounting Clearances................................................................. 2-3

Mounting Dimensions............................................................... 2-4

Mounting Cutout ....................................................................... 2-9

Panel Mounting (with Studs)...................................................2-11

Panel Mounting (with Clips) ................................................... 2-13

Rack Mounting........................................................................ 2-15

Connecting a Mouse & Keypad (Side Panel).......................... 2-16

Connecting a Mouse & Keyboard (Front Panel)..................... 2-19

Power Connections (6180 AC unit).........................................2-21

Power Connections (6180 DC unit).........................................2-23

Configuring the Power Supply Jumper ................................... 2-23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

toc-ii Table of Contents

Initial Operation and Setup

Adding and Removing

System Components

Chapter 3

Chapter Objective......................................................................3-1

Operating Objectives..................................................................3-1

Operator Access.........................................................................3-1

Keypad Operation......................................................................3-2

System Checkout........................................................................3-3

System Reset..............................................................................3-3

System Hot Keys........................................................................3-4

Legend Strip for Configurable Keypad......................................3-5

Using IrDA.................................................................................3-7

Using USB.................................................................................3-7

Chapter 4

Chapter Objective......................................................................4-1

Safety Precautions......................................................................4-1

Removing the Back Panel and Accessory Drive Cover.............4-2

Adding and Removing Add-in Boards.......................................4-3

Installing and Removing the Processor Board...........................4-7

Adding and Removing

Memory

Adding and Removing

Processors

Adding and Removing

Removable Media

Adding and Removing Data

Storage Drives

Chapter 5

Chapter Objective......................................................................5-1

Installing and Removing Memory .............................................5-1

Guidelines for Adding and Removing Memory.........................5-3

Chapter 6

Chapter Objective......................................................................6-1

Installing and Removing Processors..........................................6-1

Chapter 7

Chapter Objective......................................................................7-1

Installing and Removing Removable Media..............................7-1

Chapter 8

Chapter Objective......................................................................8-1

Installing and Removing Data Storage Drives...........................8-1

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Table of Contents toc-iii

Adding and Removing

Power Supplies

Adding and Removing

Displays and Backlights

Allen-Bradley Video

Controller Boards

Chapter 9

Chapter Objective...................................................................... 9-1

Installing and Removing Power Supplies.................................. 9-1

Chapter 10

Chapter Objective.................................................................... 10-1

Installing and Removing Displays and Backlights.................. 10-1

Replacing the 10.4 inch Display Backlight.............................10-1

Replacing the 12.1 inch Display Backlight.............................10-3

Replacing the 15 inch Display Backlight ................................ 10-3

Replacing the Display and No Display Bezel.......................... 10-3

Chapter 11

Chapter Objective.....................................................................11-1

Adding and Removing the Video Board...................................11-1

Descriptions..............................................................................11-1

Video Drivers............................................................................11-1

Allen-Bradley Keypad

Interface Cards

Keypad Configuration Utility

Software

Touchscreen Utilities

Chapter 12

Chapter Objective.................................................................... 12-1

Chapter 13

Chapter Objective.................................................................... 13-1

Overview ................................................................................. 13-1

System Requirements.............................................................. 13-2

Installing the Keypad Configuration Utility............................ 13-2

File Ty p es................................................................................ 13-3

Connecting the Keyboard to the 6180 Computer.................... 13-3

Using the KIC Utility .............................................................. 13-4

Chapter 14

Chapter Objective.................................................................... 14-1

Touchscreen IRQ Configuration.............................................. 14-1

Touchscreen Software Installation........................................... 14-2

DOS Systems........................................................................... 14-2

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

toc-iv Table of Contents

System Troubleshooting

Maintenance

Specifications

European Union Di rective

Compliance

Chapter 15

Chapter Objective....................................................................15-1

LANDesk Summary.................................................................15-1

Troubleshooting Procedure......................................................15-3

Troubleshooting Check Lists ...................................................15-4

Chapter 16

Chapter Objective....................................................................16-1

Cleaning the Display................................................................16-1

Cleaning the Chassis Fan Filters..............................................16-2

Cleaning the Power Supply Fan Filter.....................................16-4

Replacement Parts....................................................................16-6

Appendix A

Appendix B

European Union Directive Compliance....................................B-1

Field Replacement Uni t s

(FRU)

Glossary

Appendix C

Overview................................................................................... C-1

Appendix D

Index

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Using this Manual

Using this Manual

Using this ManualUsing this Manual

Read this preface to familiarize yourself with the rest of the manual. The

preface covers the following topics:

• who should use this manual

• the purpose of the manual

• contents of the manual

• conventions used in this manual

• Allen-Bradley support

PPPPreface

reface

refacereface

Who Should Use This

Manual

Purpose of this Manual

Use this manual if you are responsible for installing, using, or

troubleshooting the 6180 Industrial Computer.

You should have a basic understanding of computers and the specific

Microsoft Windows operating system that the 6180 Industrial Computer

will run.

This manual is a user guide for the 6180 Industrial Computer. It gives an

overview of the system and describes procedures you use to:

• install the 6180 Computer in a rack, panel or enclosure

• install and remove system components

• run the system

• troubleshoot the system

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

P–2 Using this Manual

Contents of this Manual

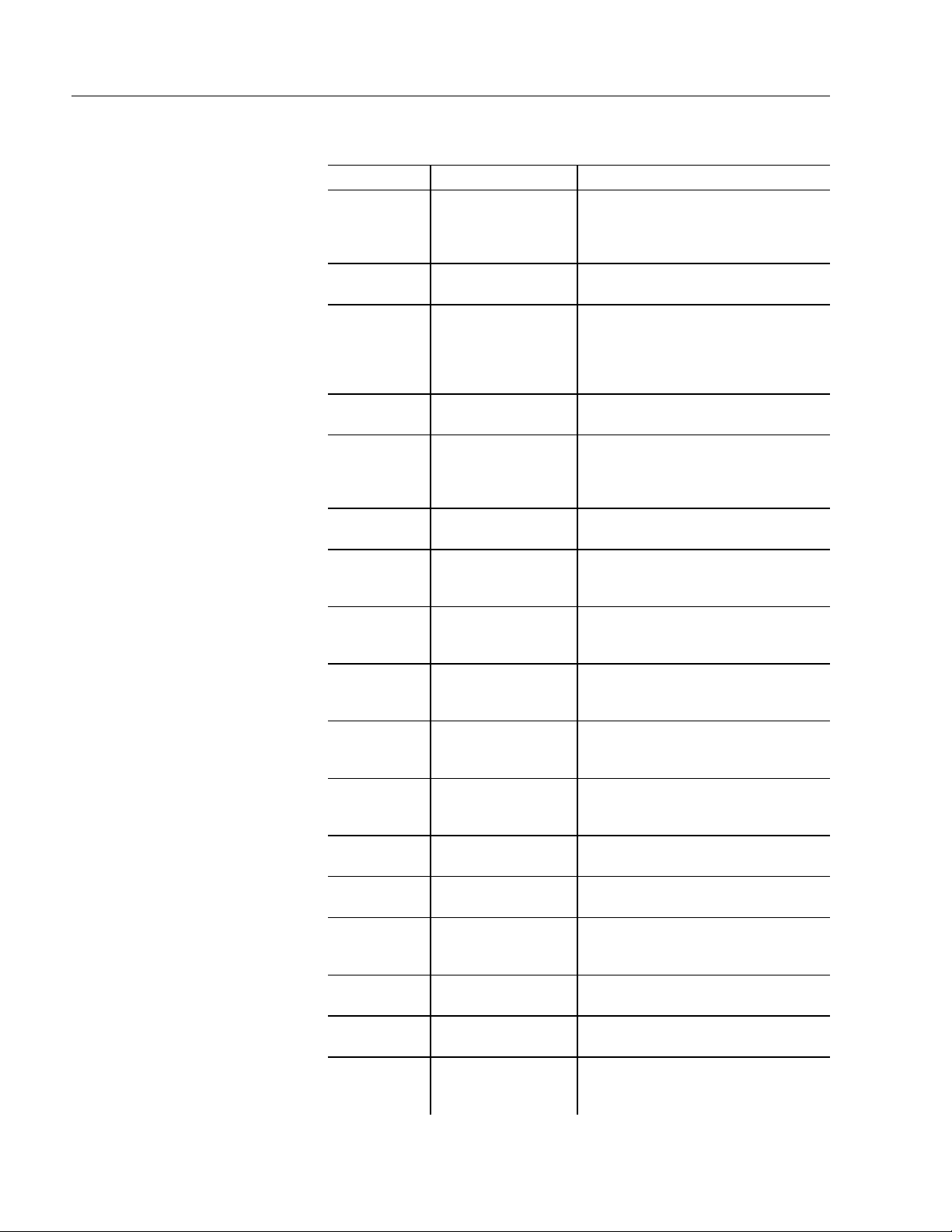

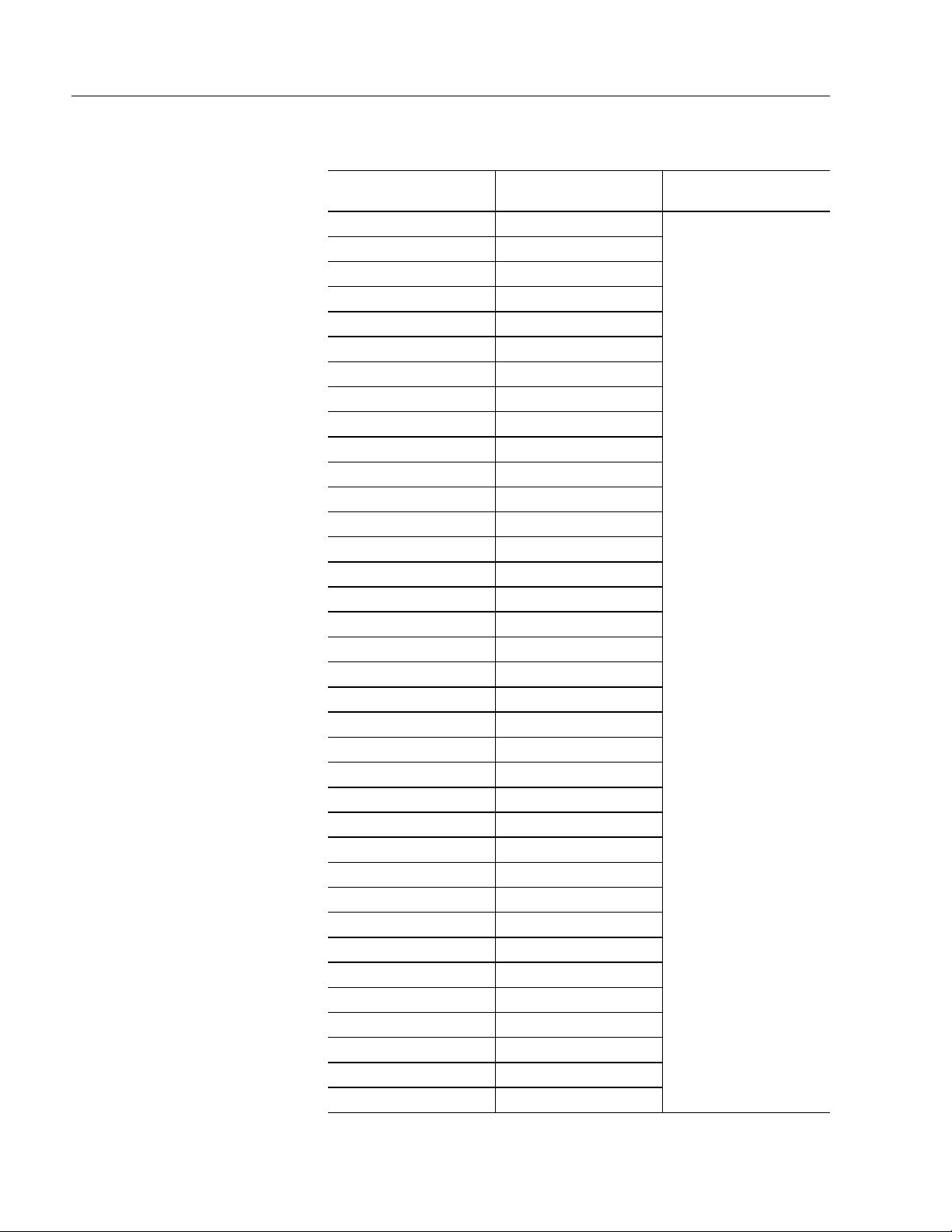

Chapter Title Contents

Preface

1 System Features

2 Installation

3

4

5

6

7

8

9

10

11 AB Video Cards

12

13

14

15

16 Maintenance

Initial Operation and

Setup

Adding and

Removing System

Components

Adding and

Removing memory

Adding and

Removing

Processors

Adding and

Removing

Removable Media

Adding and

Removing Data

Storage Drives

Adding and

Removing Power

Supplies

Adding and

Removing Displays

And Backlights

AB Keypad Interface

Cards

Keypad

Configuration Utility

Software

Touchscreen Drivers

and Utilities

System

Troubleshooting

Describes the purpose, background,

and scope of this manual. Also

specifies the audience for whom this

manual is intended.

Shows the different versions of the

6180 Computer and system features.

Describes how to install the 6180

Computer in a panel or enclosure.

Also tells how to connect devices

(such as mouse or keyboard) to the

system.

Tells how to start and check out the

system.

Gives procedures for adding and

removing the back panel accessory

drive cover, add–in boards, and

processor board.

Gives procedures for adding and

removing memory

Gives procedures for adding and

removing processors.

Gives procedures for adding and

removing removable media.

Gives procedures for adding and

removing data storage drives.

Gives procedures for adding and

removing power supplies.

Gives procedures for adding and

removing displays and backlights.

Explains how to use video cards in

the 6180 Computer.

Explains how to use keypad interface

cards in the 6180 Computer.

Gives procedures on how to use the

Keypad Configuration Utility software

in the 6180 Computer.

Explains how to use touchscreens in

the 6180 Computer.

Explains how to interpret and correct

problems with the 6180 Computer.

Gives procedures for cleaning the

6180 Computer display, and other

components.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

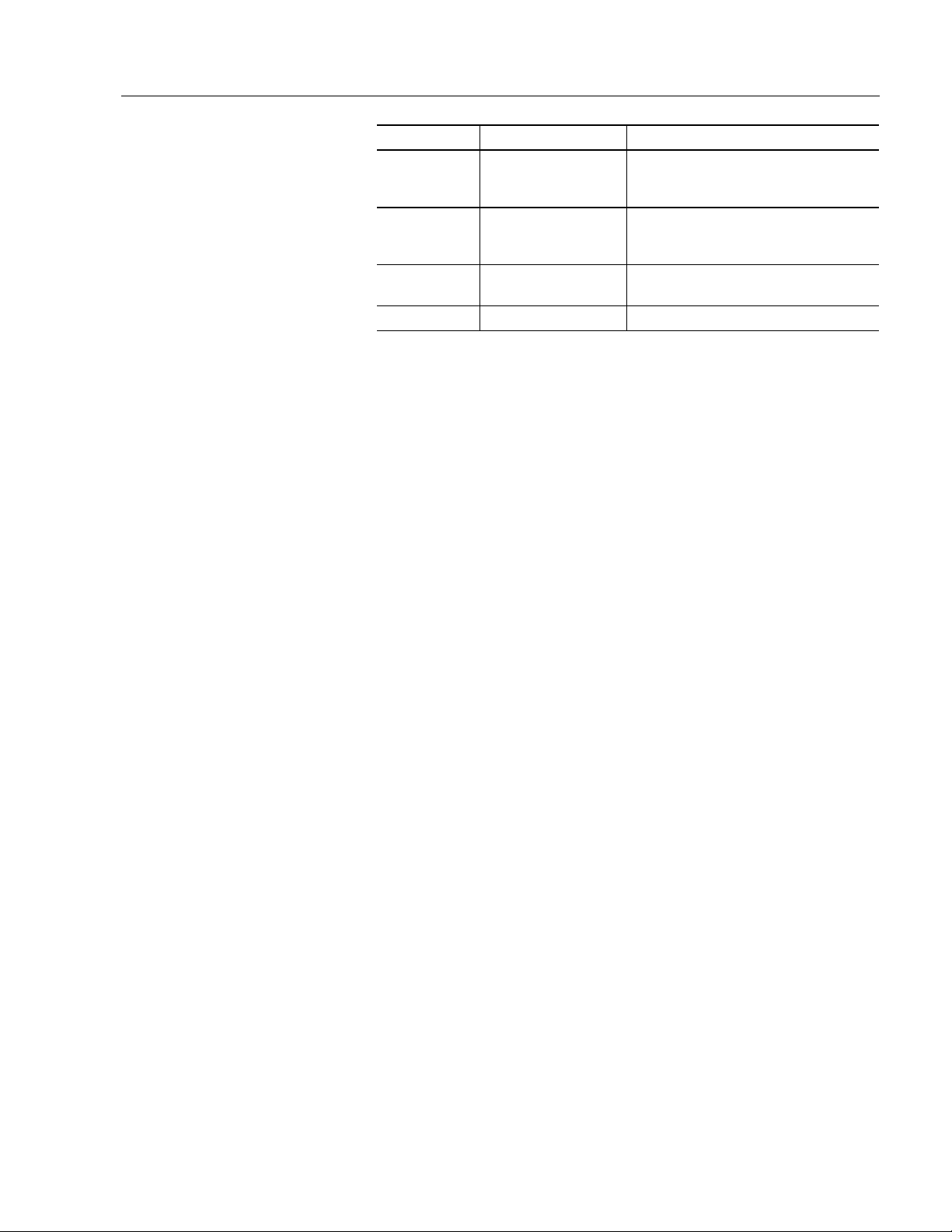

Using this Manual P–3

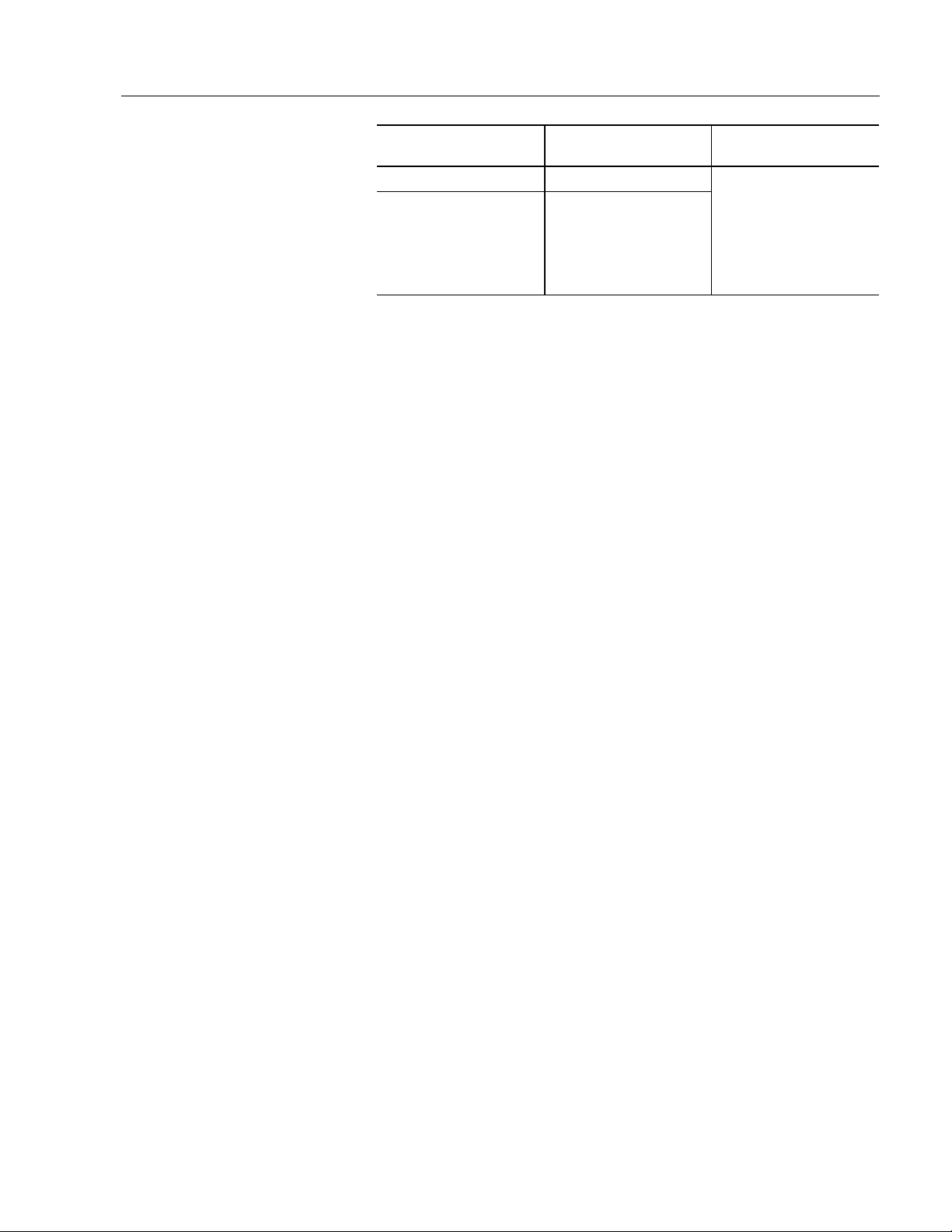

Chapter Title Contents

Appendix A Specifications

Appendix B

Appendix C

Appendix D Glossary List of terms

European Union

Directive

Compliance

Field Replacement

Units

Provides physical, electrical,

environmental, and functional

specifications.

????

????

<<WRITER: Update contents>>

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

P–4 Using this Manual

Manual Conventions

Allen-Bradley Support

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural

steps.

• Numbered lists provide sequential steps or hierarchical information.

Allen-Bradley offers support services worldwide, with over 75 Sales and

Support Offices, 512 authorized Distributors and 260 authorized Sy stems

Integrators located throughout the United States alone, plus AllenBradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the System Troubleshooting chapter first.

Then call your local Allen-Bradley representative or contact AllenBradley technical support at (440) 646-5800.

For additional product information and a description of the technical

services available, visit the Rockwell Automation/Allen-Bradley Internet

site at: http://www.ab.com.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

Chapter

Chapter 1

Chapter Chapter

System Features

System Features

System FeaturesSystem Features

Chapter Objectives

6180 Computer Versions

Feature

Pentium (Socket

7) Processor

Board

(Slot 1) Pentium

III Processor

Board

Pentium

III/Celeron (FlipChip PGA 370)

Processor

Board

Hard Drive

1.44 Mbyte

Floppy Drive

External Video

Driver

Integral Flat

Panel Display

Front Panel

Access to

Removable

Media (Floppy,

CD, or Tape)

NDM

Version

No

Display,

Metal

Bezel

√ √ √ √ √ √ √

√ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

Version

Display,

NDP

No

Plastic

Bezel

√

This chapter is an overview of the 6180 industrial computer including:

• available versions

• standard keypad

• full alphanumeric keypad

• software

• additional catalog items

The following table summarizes the options for each version:

SD104

Version

10.4-inch

(264 mm)

Display,

64−−−−key

Standard

Keypad

√

√

SD104 Version

10.4-inch

(264 mm)

Display, 96−−−−key

Full

Alphanumeric

Keypad

√

√

SD121 Version

12.1-inch (307

mm) Display,

69−−−−key

Standard

Keypad

√

SD150 Version

15-inch

(381 mm)

Display,

70−−−−key

Standard

Keypad

√ √

√

SD150 Version,

15-inch

(381 mm)

Display, No

Keypad

√

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

1–2 System Features

Feature

Front Panel

Access to

Mouse and

Keyboard Ports

Front Panel

Keypad

Integrated Front

Panel Mouse

Standard 19inch Rack

Mounting

Panel Mount

with Studs or

Clips

Infrared (IrDA)

Receiver/

Transmitter

Touch Screen

Option

Field

Replaceable

Backlight

NDM

Version

No

Display,

Metal

Bezel

√

NDP

Version

No

Display,

Plastic

Bezel

√

√

√

√

SD104

Version

10.4-inch

(264 mm)

Display,

64−−−−key

Standard

Keypad

√

√ √ √ √

√

√

√

√

√

√

SD104 Version

10.4-inch

(264 mm)

Display, 96−−−−key

Full

Alphanumeric

Keypad

√

√

√

√

√

SD121 Version

12.1-inch (307

mm) Display,

69−−−−key

Standard

Keypad

√

√

√

√

√

√

SD150 Version

15-inch

(381 mm)

Display,

70−−−−key

Standard

Keypad

√

√

√

√

√

SD150 Version,

15-inch

(381 mm)

Display, No

Keypad

√

√

√

√

√

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

System Features 1–3

Common 6180 Computer Features

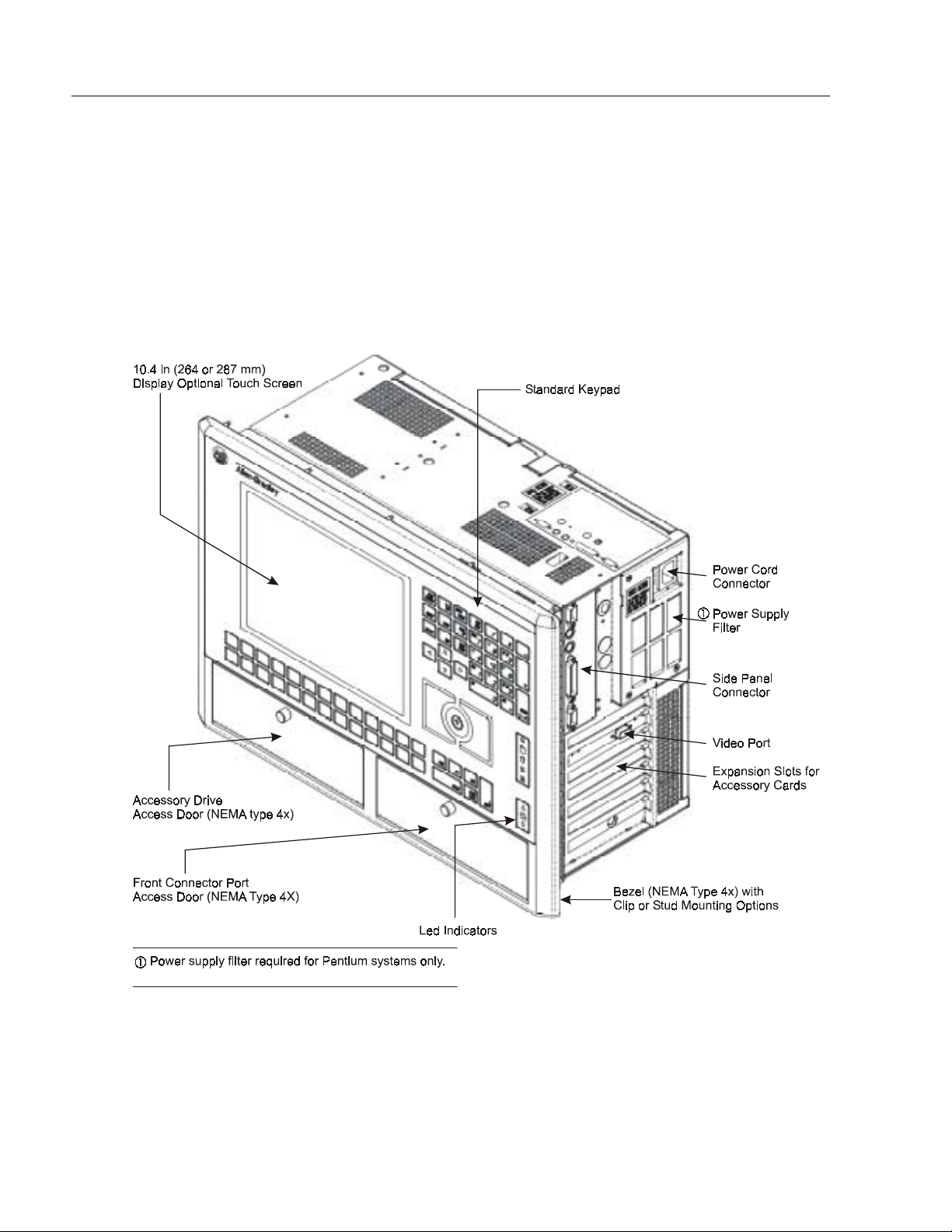

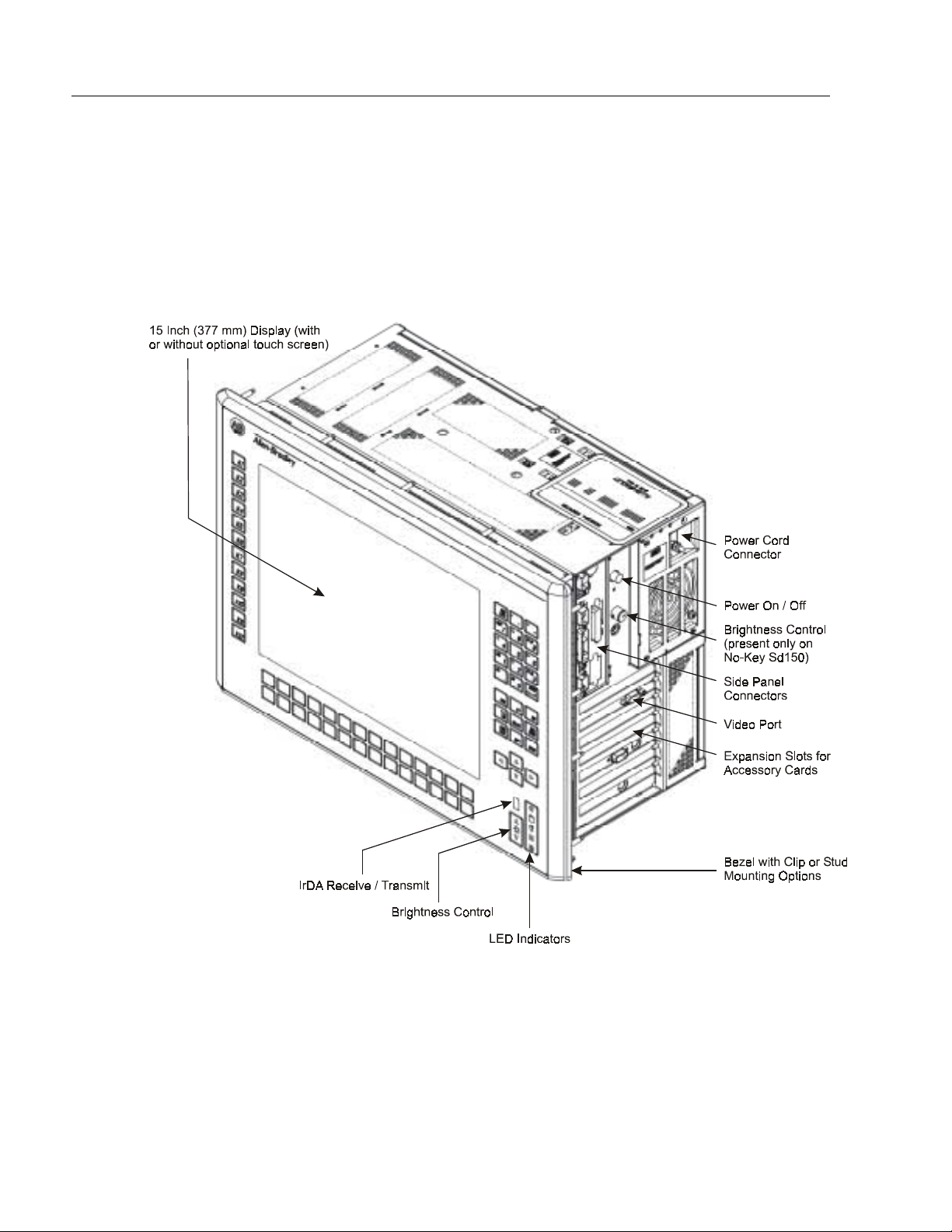

Figure 1- 1

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

1–4 System Features

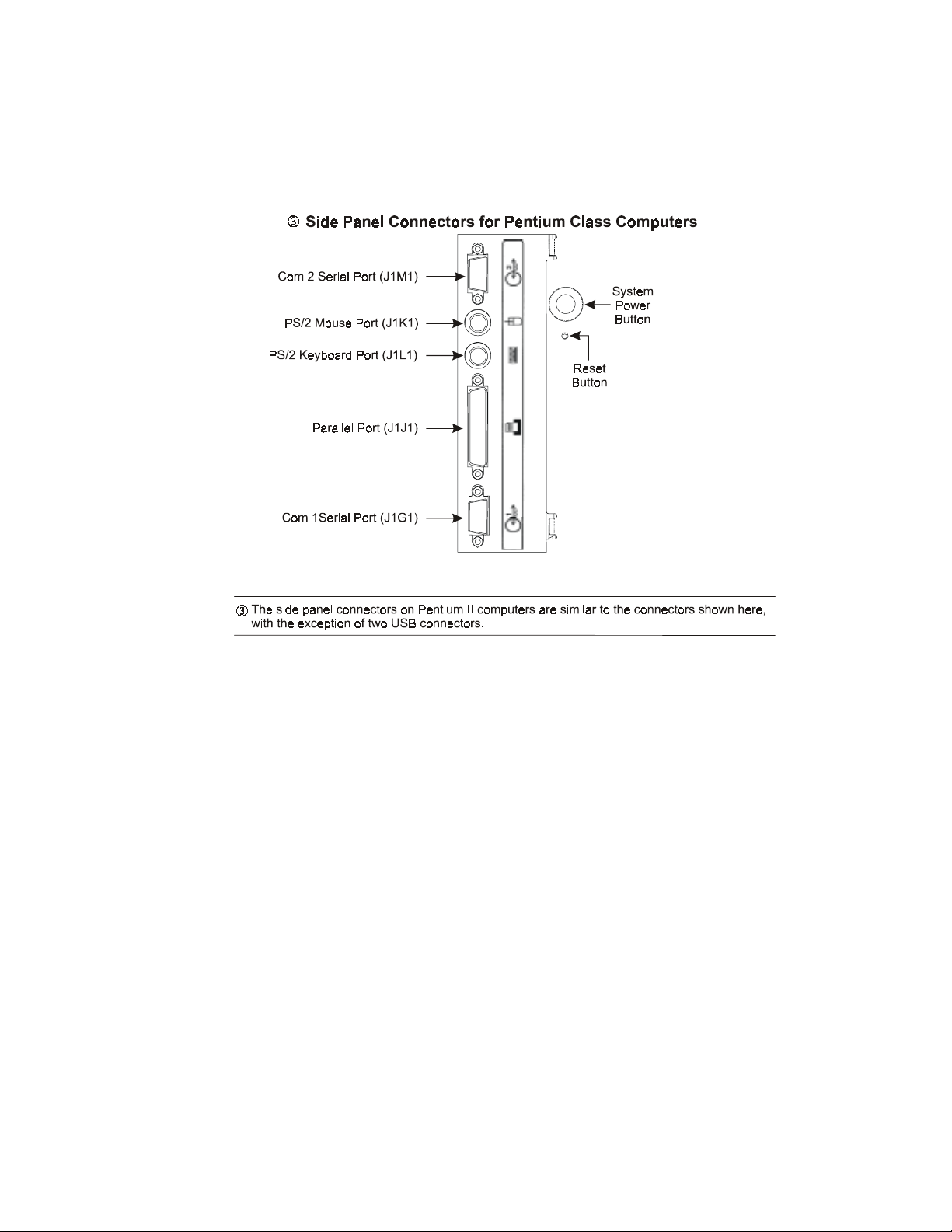

Figure 1- 2

Figure 1- 3

Need drawing for: Side Panel Connectors for Pentium II Class Computers (use illus. From Seattle II

(see engineering)

Figure 1- 4

Need drawing for: Side Panel Connectors for Pentium III/Celeron Class Computers (use illus. From

ITOX (see engineering)

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

System Features 1–5

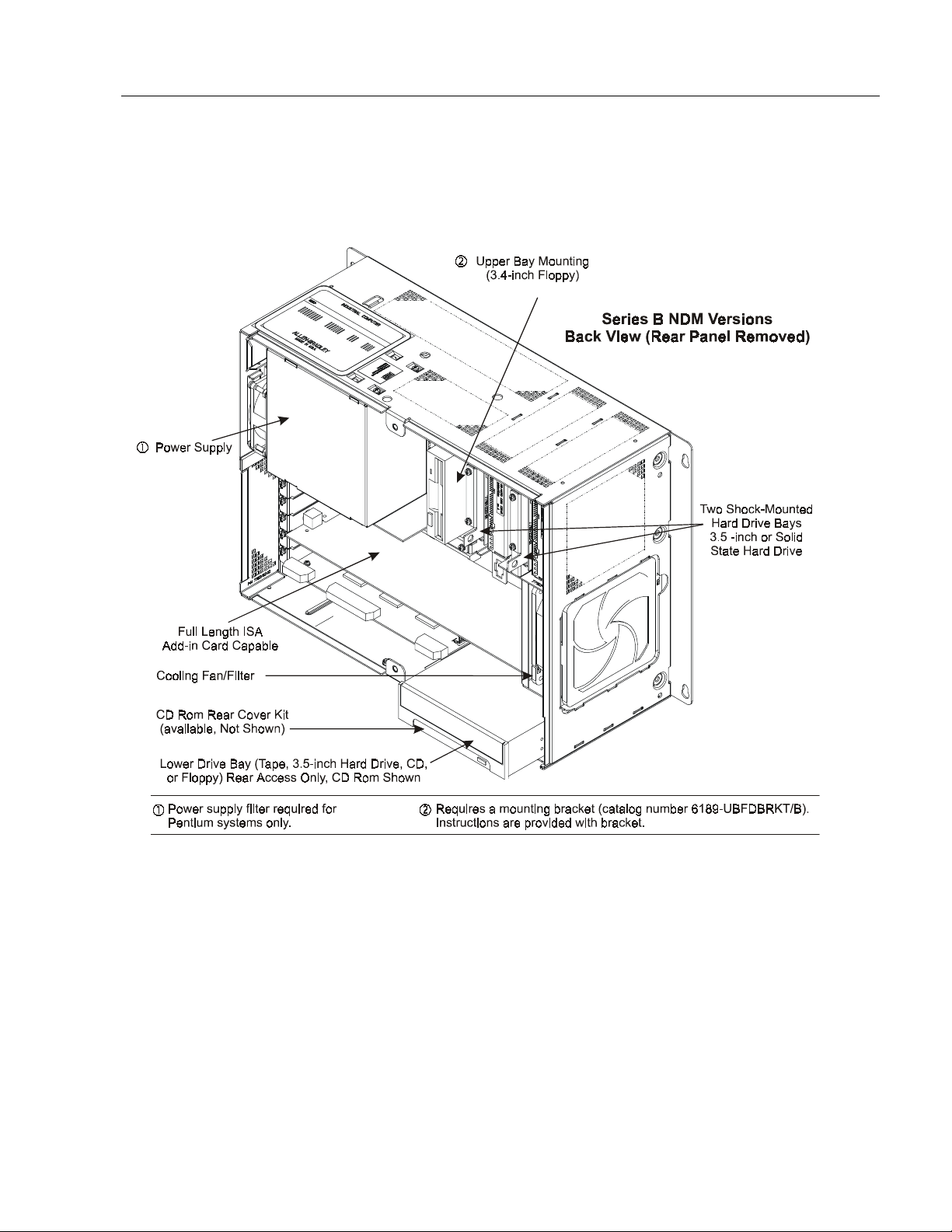

NDM Version with No Display & Metal Bezel

The following illustrations show the major features and controls of the

non–display, metal bezel versions of the 6180 Computer

(6180-xxAxxxxxxxx).

Figure 1- 5

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

1–6 System Features

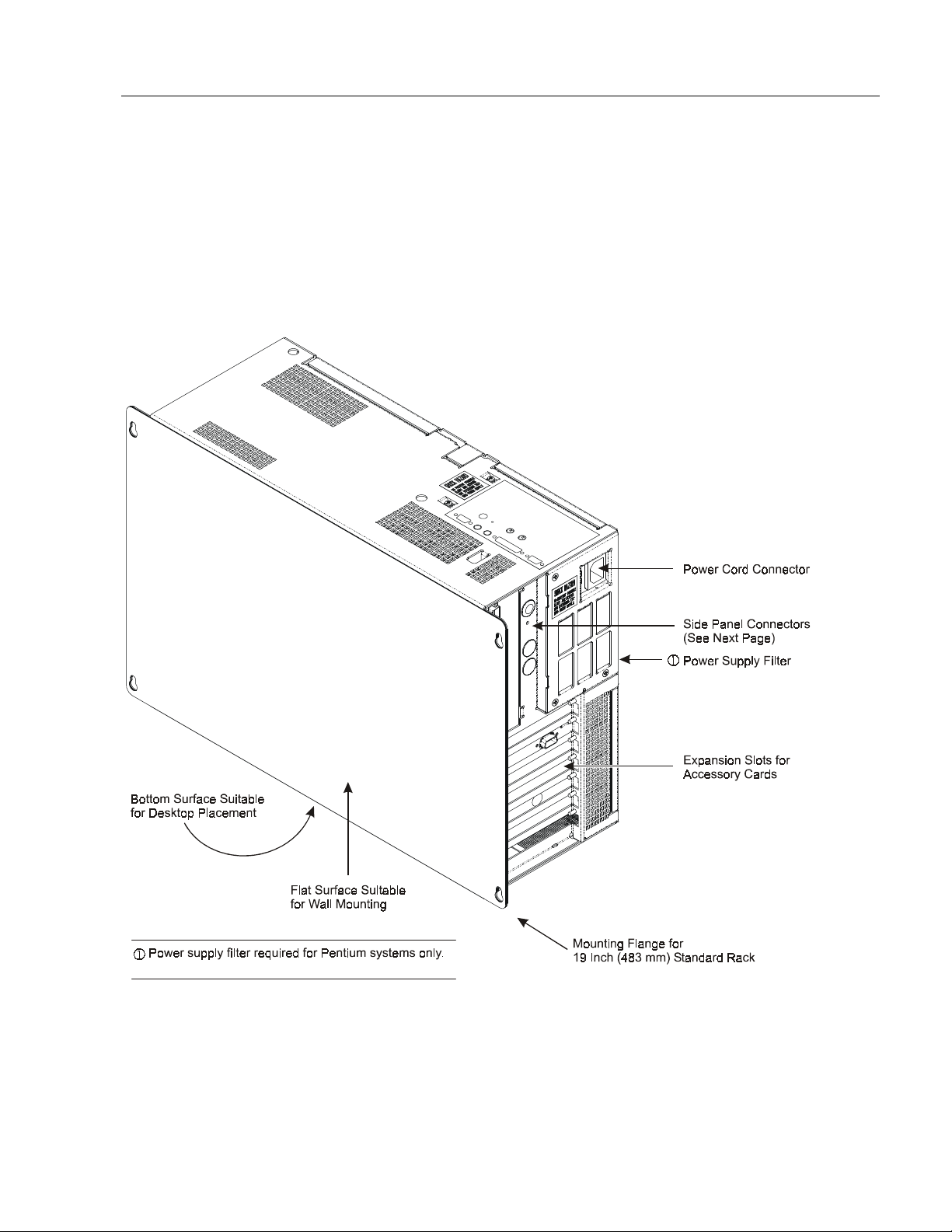

NDP Version with No Display & Plastic Bezel

The following illustration shows the major features and controls of the

non–display, plastic bezel versions of the 6180 Computer

(6180-xxBxxxxxxxx).

Figure 1- 6

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

System Features 1–7

SD104 Version with

Display and 64-Key

Standard Keypad

The following illustration shows the major features and controls of the

display, plastic bezel versions of 6180 Computer (6180-xxCxxxxxxxx, xxDxxxxxxxx).

Figure 1- 7

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

1–8 System Features

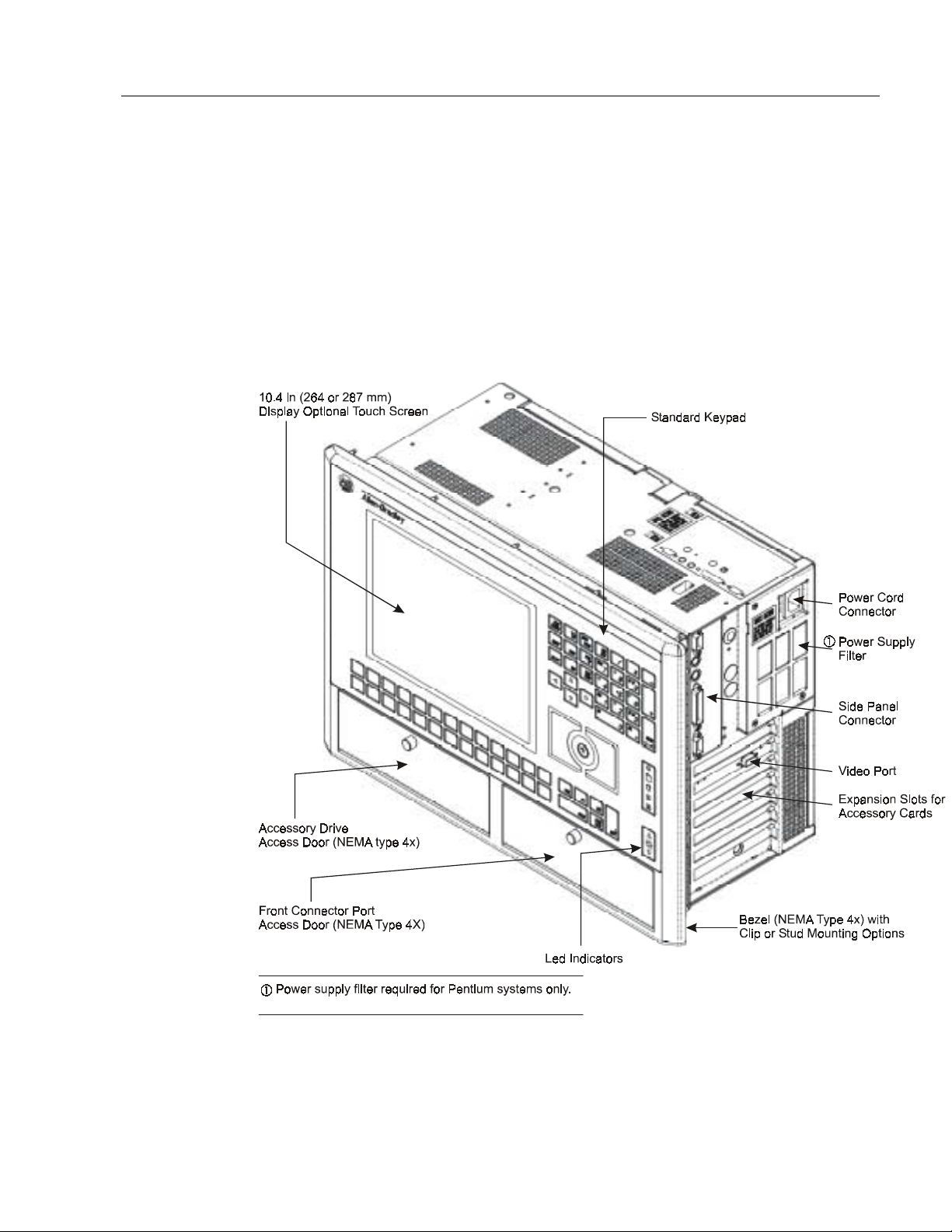

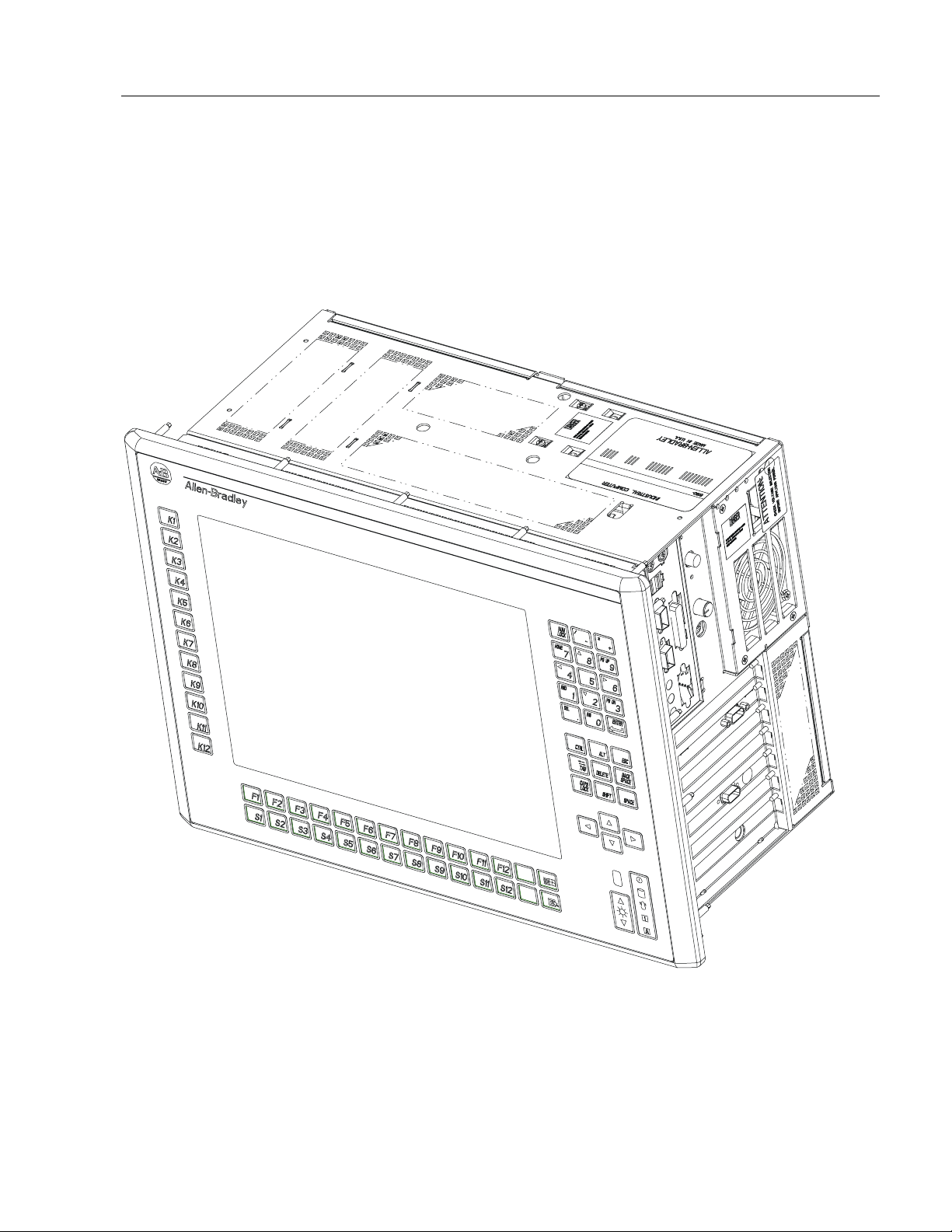

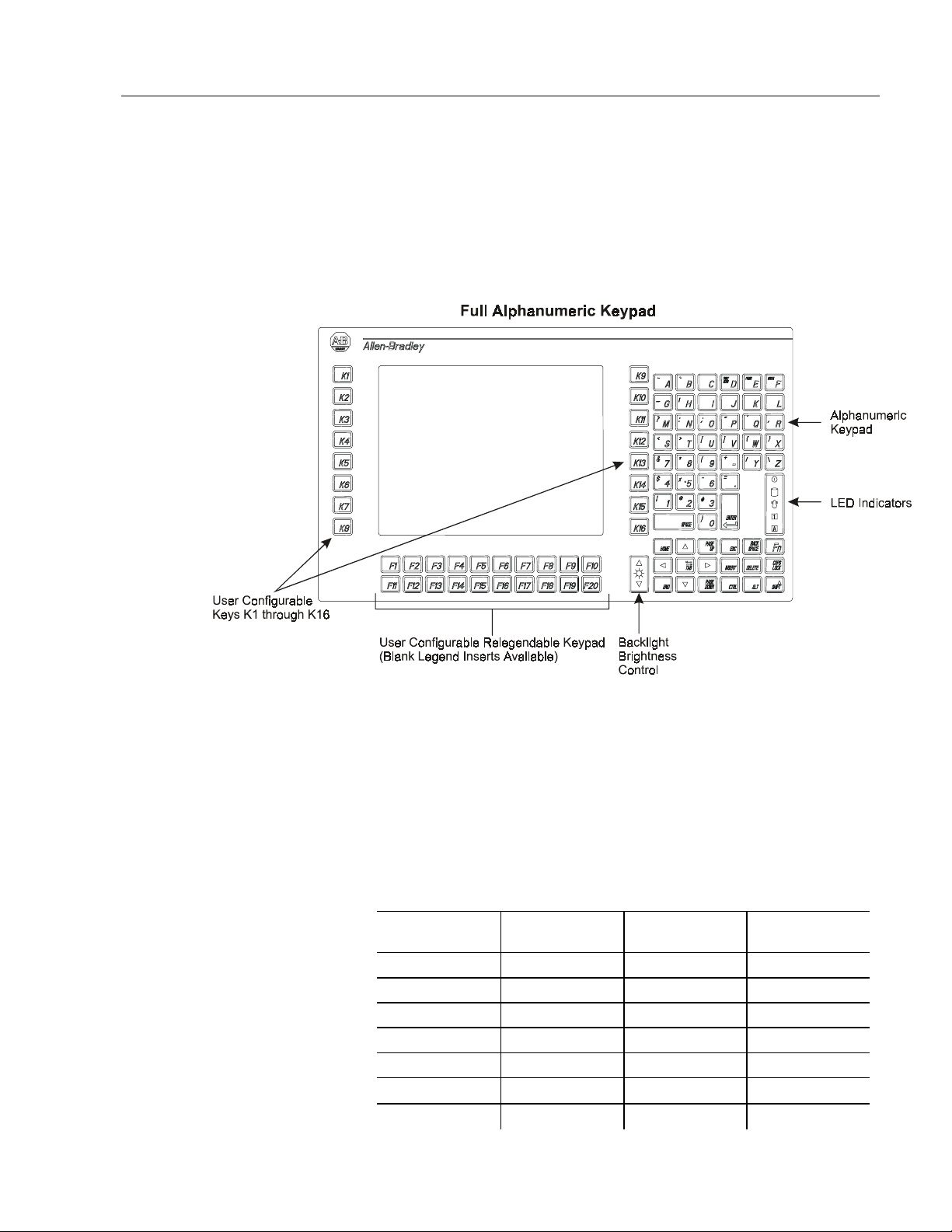

SD104 Version with Display and Full Alphanumeri c Keypad

The following illustration shows the major features and controls of the

full alphanumeric keypad versions of 6180 Computer

(6180-xxGxxxxxxxx).

Figure 1- 8

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

System Features 1–9

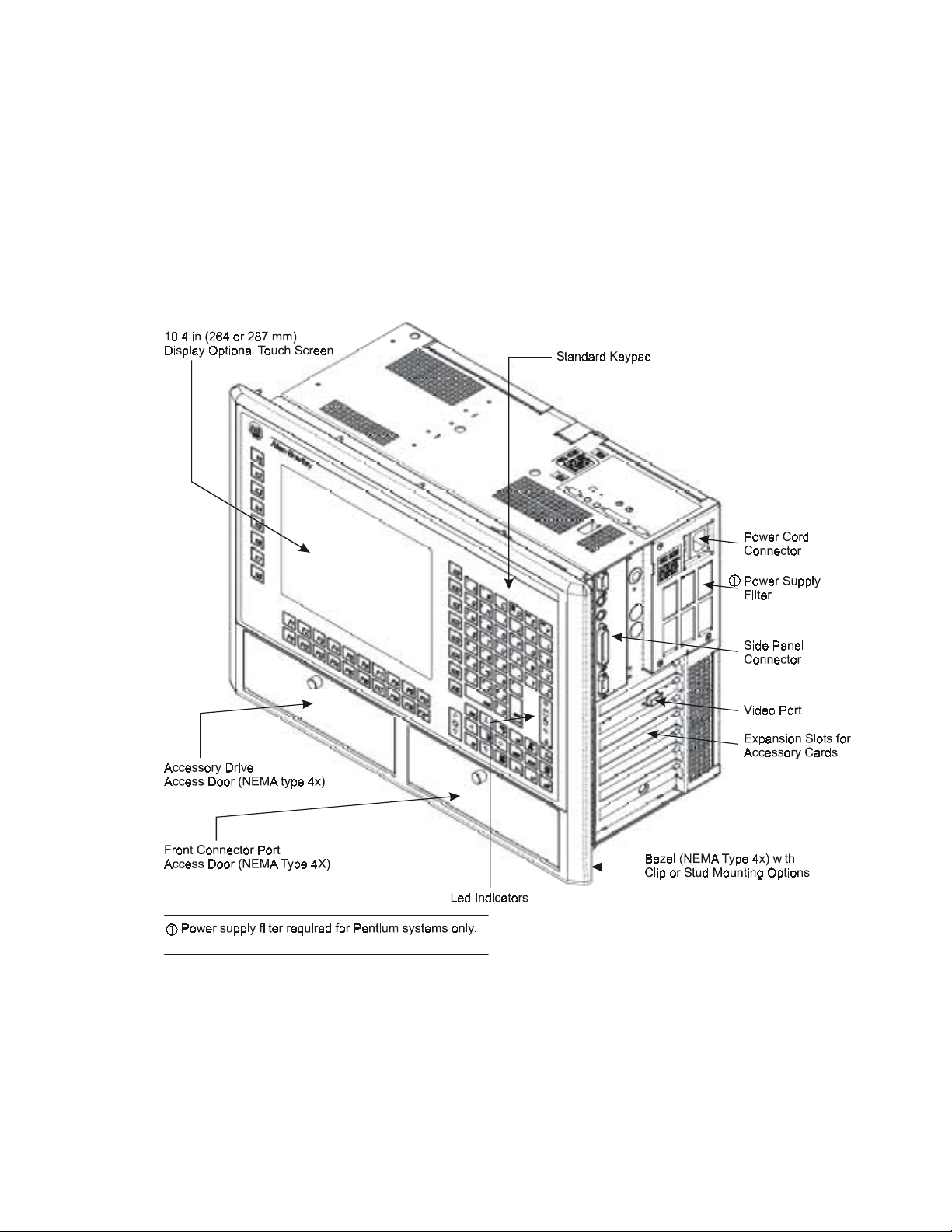

SD121 Version with Display and 69-Key Standard Keypad

The following illustrations show the major features and controls of the

12.1 in. keypad versions of 6180 Computer (6180-xxLxxxxxxxx, 6180xxMxxxxxxxx).

Figure 1- 9

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

1–10 System Features

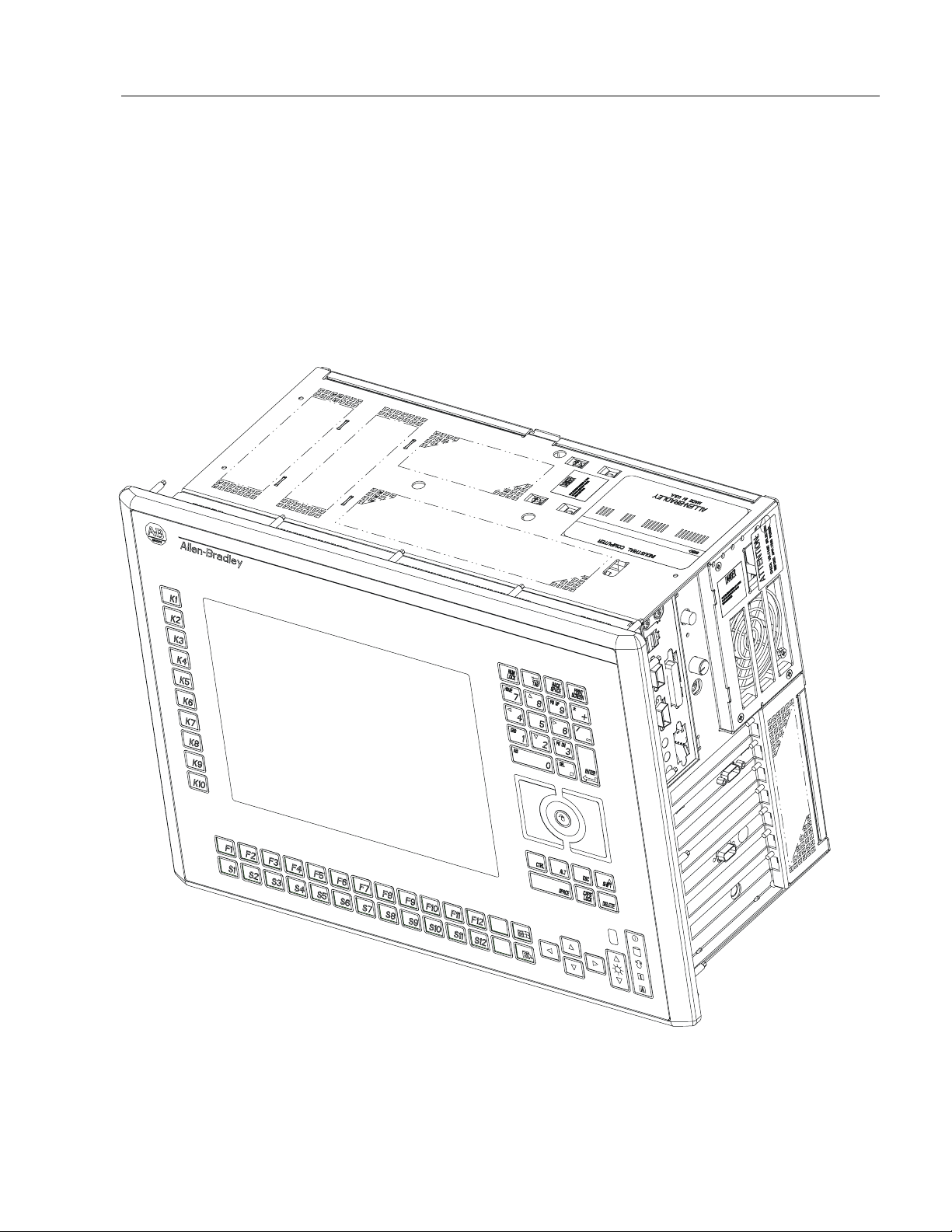

SD150 Version with Display and 70-Key Standard Keypad

The following illustration shows the major features and controls of the

70-key keypad versions of 6180 Computer (6180-xxHxxxxxxxx, xxIxxxxxxxx).

Figure 1- 10

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

System Features 1–11

SD150 Version with Display and no Keypad

The following illustrations show the major features and controls of the

15 in. no keypad versions of 6180 Computer (6180-xxJxxxxxxxx, 6180xxKxxxxxxxx).

Figure 1- 11

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

1–12 System Features

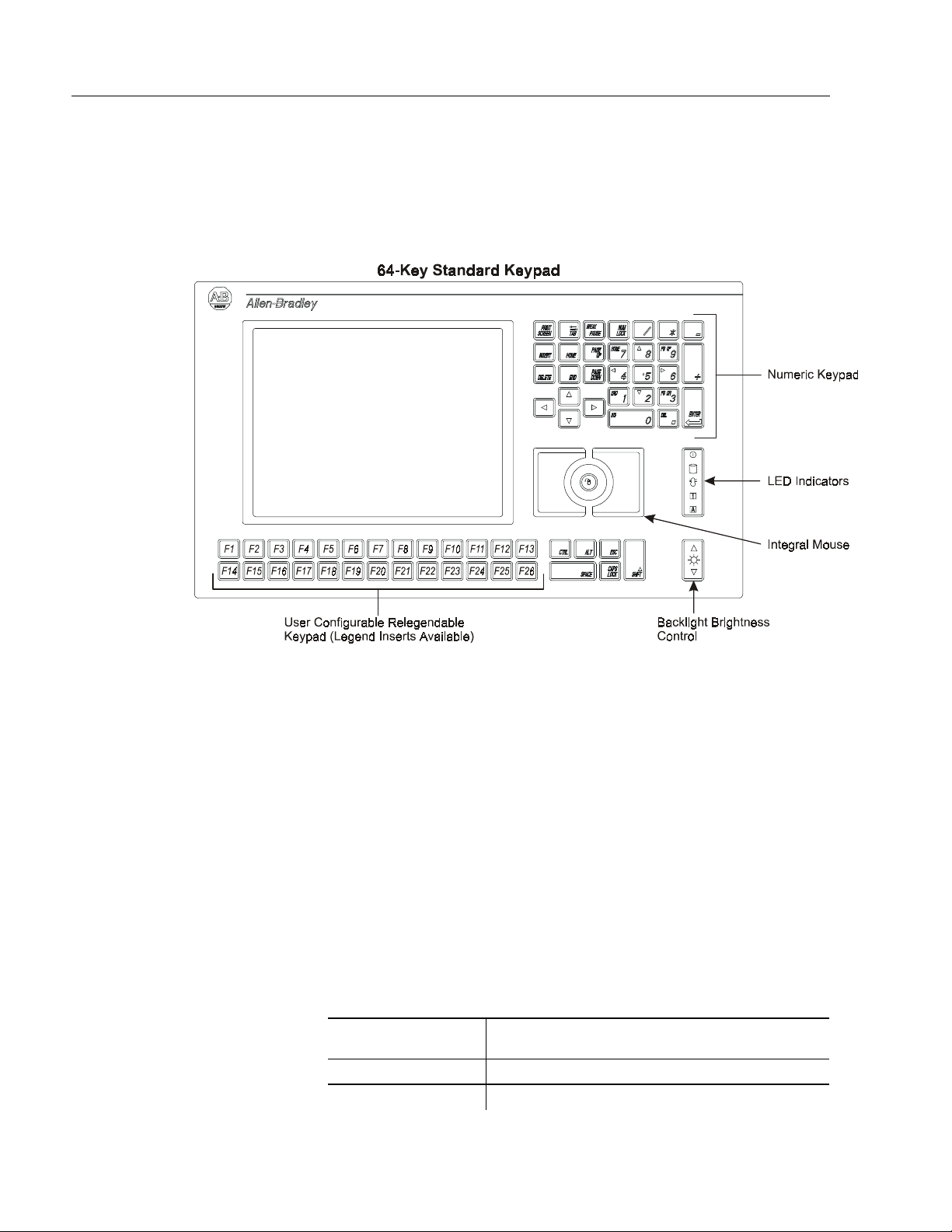

64−−−−Key Standard Keypad

The standard SD104 keypad provides integrated keyboard and mouse

control functionality.

Figure 1- 12

Numeric Keys

The NUM LOCK key allows you to use the same set of keys on the

numeric keypad for alternate Number and Cursor Control functions.

Press the NUM LOCK key to select the Number function for these keys.

The NUM LOCK LED on the keypad will be lit to indicate the Number

function is active. Press the NUM LOCK key again to select the Cursor

Control function for these keys. The NUM LOCK LED will be lit to

reflect the function.

For example, with the NUM LOCK key active (i. e. lit), the numeric

key “4” allows you to enter the number “4”. With the NUM LOCK key

inactive, the numeric key “4” allows you to move the cursor to the left

on the display.

NUM LOCK “On”

Number Function

1 End

2 Down Arrow

NUM LOCK “Off” Cursor Control Function

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

System Features 1–13

NUM LOCK “On”

Number Function

3 Page Down

4 Left Arrow

5 None

6 Right Arrow

7 Home

8 Up Arrow

9 Page Up

0 Insert

. Delete

Configurable Keys

User Configurable

Key Legend

F1 F1

F2 F2

F3 F3

F4 F4

F5 F5

F6 F6

F7 F7

F8 F8

F9 F9

F10 F10

F11 F11

F12 F12

F13 Left Windows Key

F14 SHIFT + F1

F15 SHIFT + F2

F16 SHIFT + F3

F17 SHIFT + F4

F18 SHIFT + F5

F19 SHIFT + F6

F20 SHIFT + F7

F21 SHIFT + F8

F22 SHIFT + F9

F23 SHIFT + F10

NUM LOCK “Off” Cursor Control Function

Default User Defined Options

Any alphanumeric

character or string

(restricted by KCU)

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

1–14 System Features

User Configurable

Key Legend

F24 SHIFT + F11

F25 SHIFT + F12

F26

Default User Defined Options

Any alphanumeric

character or string

(restricted by KCU)

Windows Application

Key

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

System Features 1–15

SD104 Alphanumeric

Keypad

The SD104 alphanumeric keypad provides full keyboard functionality.

Figure 1- 13

Alphanumeric Keys

The “Fn” key allows you to use the same set of keys on the keypad for

alternate functions. The “Fn” key must be pressed and held while

pressing another key to activate the other functions.

For example, if you press the “D” key, the letter “D” is entered on the

display. If you press and hold the Fn key while pressing the “D” key,

you activate the other function for that key, which is to print the screen.

Alphanumeric

Key

A ~ W {

B ` X }

D Print Screen Y /

E Pause Z \

F Break 1 !

G

H | 3 #

Alternate

Function

−

Alphanumeric

Key

2 @

Alternate

Function

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

1–16 System Features

Alphanumeric

Key

M ? 4 $

N : 5 %

O ; 6 ^

P “ 7 &

Q ‘ 8 *

R , 9 (

S < 0 )

T >

U [ . =

V ]

Alternate

Function

Alphanumeric

Key

−

Alternate

Function

+

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

System Features 1–17

69−−−−Key Standard Keypad

The SD121 keypad provides keyboard functionality.

Figure 1- 14

INSERT GRAPHIC HERE

Numeric Keys

The NUM LOCK key allows you to use the same set of keys on the

numeric keypad for alternate Number and Cursor Control functions.

Press the NUM LOCK key to select the Number function for these keys.

The NUM LOCK LED on the keypad will be lit to indicate the Number

function is active. Press the NUM LOCK key again to select the Cursor

Control function for these keys. The NUM LOCK LED will be lit to

reflect the function.

For example, with the NUM LOCK key active (i. e. lit), the numeric

key “4” allows you to enter the number “4”. With the NUM LOCK key

inactive, the numeric key “4” allows you to move the cursor to the left

on the display.

NUM LOCK “On”

Number Function

1 End

2 Down Arrow

3 Page Down

4 Left Arrow

5 None

6 Right Arrow

7 Home

8 Up Arrow

9 Page Up

0 Insert

. Delete

NUM LOCK “Off” Cursor Control Function

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

1–18 System Features

Configurable Keys

User Configurable

Key Legend

K1 F1

K2 F2

K3 F3

K4 F4

K5 F5

K6 F6

K7 F7

K8 F8

K9 F9

K10 F10

A A

B B

C C

D D

E E

F F

G G

H H

I I

J J

K K

L L

M M

N N

O O

P P

Q Q

R R

S S

T T

U U

V V

W W

X X

Y Y

Z Z

Default User Defined Options

Any alphanumeric

character or string

(restricted by KCU)

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

System Features 1–19

User Configurable

Key Legend

Windows Logo Left Windows Key

Windows App

Windows Application

Default User Defined Options

Any alphanumeric

Key

character or string

(restricted by KCU)

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

1–20 System Features

70−−−−Key Standard Keypad

The SD150 keypad provides keyboard functionality.

Figure 1- 15

The NUM LOCK key allows you to use the same set of keys on the

numeric keypad for alternate Number and Cursor Control functions.

Press the NUM LOCK key to select the Number function for these keys.

The NUM LOCK LED on the keypad will be lit to indicate the Number

function is active. Press the NUM LOCK key again to select the Cursor

Control function for these keys. The NUM LOCK LED will be lit to

reflect the function.

For example, with the NUM LOCK key active (i. e. lit), the numeric

key “4” allows you to enter the number “4”. With the NUM LOCK key

inactive, the numeric key “4” allows you to move the cursor to the left

on the display.

NUM LOCK “On”

Number Function

1 End

2 Down Arrow

NUM LOCK “Off” Cursor Control Function

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

System Features 1–21

NUM LOCK “On”

Number Function

3 Page Down

4 Left Arrow

5 None

6 Right Arrow

7 Home

8 Up Arrow

9 Page Up

0 Insert

. Delete

Configurable Keys

User Configurable

Key Legend

K1 F1

K2 F2

K3 F3

K4 F4

K5 F5

K6 F6

K7 F7

K8 F8

K9 F9

K10 F10

A A

B B

C C

D D

E E

F F

G G

H H

I I

J J

K K

L L

M M

N N

NUM LOCK “Off” Cursor Control Function

Default User Defined Options

Any alphanumeric

character or string

(restricted by KCU)

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

1–22 System Features

User Configurable

Key Legend

O O

P P

Q Q

R R

S S

T T

U U

V V

W W

X X

Y Y

Z Z

Windows Logo Left Windows Key

Windows App

Windows Application

Default User Defined Options

Any alphanumeric

character or string

(restricted by KCU)

Key

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

System Features 1–23

Configurable Keys

Re-legendable Keys

Using the Keyboard Configuration Utility software program, you can

assign alpha characters or other functions to the keys in the configurable

section of Model 6180 keypads. For more information, refer to Chapter

13, for the Keyboard Configuration Utility.

The Legend Strip Kit (Catalog No. 6189-KEYKIT1) contains legend

strips for the following computers. .

64-Key Standard Keypad

Versions with an SD104 standard keypad (6180-xxC, -xxD) are shipped

with the 26 configurable keys assigned to function keys F1 through F12,

and shifted function keys S1 through S12. Removable inserts provide

standard or custom legends for these keys.

Full Alphanumeric Keypad

Versions with an SD104 alphanumeric keypad (6180-xxG) are shipped

with the 36 configurable keys assigned to Function Keys K1 through

K16 and F1 through F20. Removable inserts provide standard or custom

legends for the F1 through F20 keys.

Keyboard Interface

Controller Card

69-Key Standard Keypad

Versions with an SD104 keypad (6180-xxL, -xxM) are shipped with the

lower 28 configurable keys assigned to function keys F1 through F12

and shifted function keys S1 through S12. Removable inserts provide

standard or custom legends for the 28 relegendable and reprogrammable

keys. (i.e. A-Z keys, Windows key, and Application key).

70-Key Keypad

Versions with an SD121 keypad (6180-xxH, -xxI) are shipped with the

lower 28 keys assigned to the A-Z keys, Windows key, and Application

key.

Removable inserts provide standard or custom legends for the 28 relegendable and re-programmable keys.

The 6180 keypad can work simultaneously with an external keyboard.

The 6180 Keyboard Interface Controller multiplexes information from

both the 6180 keypad and the external keyboard. Refer to Chapter 12,

for information on the 6189-KICxxx card.

Integral Mouse

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

On the SD104 and SD121 standard keypads, the integral mouse consists

of left, right, and cursor control buttons. Control the movement of the

screen cursor by pressing the edge of the cursor button in the direction

Publication 6180-6.0

Page 35

1–24 System Features

you want the cursor to move. The integral mouse can work

simultaneously with the optional touchscreen.

Figure 1- 16

LED Indicators

Backlight Bright ness

Control <<graphics

needed>>

Indicator Color Indicates

<<graphic needed>>

<<graphic needed>>

<<graphic needed>>

<<graphic needed>>

<<graphic needed>>

Green Power On

Green Hard Drive Operating

Red

Green Num Lock On

Green Caps Lock On

Overtemperature. Temperature inside

the 6180 Computer enclosure is above

1400 F (600 C)

Use the backlight brightness control to vary the screen lighting for

optimal viewing.

On SD150 versions without keypads (6180-xxJ and 6180-xxK), a

backlight brightness adjustment knob is located on the right side of the

chassis.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

System Features 1–25

Chassis Locks

Two chassis locking holes restrict unauthorized access to the 6180

Computer internal components. Standard padlocks may be used (user

supplied).

Figure 1- 17

ATTENTION: The chassis locking hole on the bottom

of the chassis has been plugged with a steel cap for

compliance with UL 1950 fire enclosure requirements.

Removal of this plug will result in a failure to comply

with UL 1950 safety requirements. It is up to the user to

determine if removal of the plug raises fire containment

issues with individual installation(s), and to provide

suitable preventive measures as necessary.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

1–26 System Features

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Installation

Installation

InstallationInstallation

Chapter

Chapter 2

Chapter Chapter

Chapter Objectives

European Union

Compliance

Environmental

Considerations

This chapter describes installation of the 6180 Computer including how

to:

• install the 6180 Computer in a rack

• install the 6180 Computer in a panel using mounting studs

• install the 6180 Computer in a panel using mounting clips

• change the voltage input setting

The 6180 Computer meets the European Union Directive requirements

when installed within the European Union or EEA regions and has the

CE mark. A copy of the Declaration of Conformity is available at the

Rockwell Automation / Allen–Bradley Internet site: www.ab.com

Mount the 6180 Computer in a panel or enclosure to protect the internal

circuitry. Versions with a gasketed bezel meet NEMA Type 1, 12, 13

and 4/4X (indoor use) and IEC IP54, IP65 only when mounted in a panel

or enclosure having an equivalent rating. The No Display, Metal Bezel

(NDM) version has a NEMA Type 1 and IEC IP2X rating.

Allow enough room within the enclosure for adequate ventilation. Also

consider heat produced by other devices in the enclosure. The ambient

temperature around the 6180 Computer must be maintained between 5°

and 50°C (41° to 122°F). The 6180 Computer is intended for use in

Pollution Degree 2 environments.

Make sure you provide provisions for accessing the back and side panels

of the 6180 Computer to install and remove components.

The 6180 Computer must be mounted in a vertical position as illustrated

in this manual. Installing the 6180 Computer in any other orientation

may result in overheating due to improper airflow.

ATTENTION: The bottom of the chassis has a knockout

panel. This knockout was provided for special

applications with other Allen–Bradley products. Do not

remove this knockout. If the knockout is removed, the

6180 Computer will not meet UL 1950 standards for

flammability containment.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

2–2 Installation

Mounting Hardware

The 6180 Computer is shipped with the following mounting hardware

installed on the bezel.

Item Description Quantity Use For

<<graphic

needed>>

1.265−inch long

mounting studs with

integral spacer

Self-locking nuts 18

18

Panel or enclosure

mounting

Panel, enclosure, or

rack mounting

Mounting clips can be used instead of the mounting studs and are

ordered separately.

Item Description Quantity Use For

Mounting Clips

Catalog No. 2711NP1

Each

Package

Contains

10 Clips

Panel or enclosure

mounting

Tools Required

In addition to the tools required to make the cutout, you will need the

following tools:

• 3/8 inch socket

• 14 inch (36 cm) extension rod (minimum)

• Socket driver (in/lb torque wrench recommended)

• 7/32 hex wrench

• Ruler

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

Installation 2–3

Mounting Clearances

Allow adequate space for mounting, air flow, and maintenance. The

figure below shows recommended minimum clearances to other

components within the rack or enclosure.

ATTENTION: The 6180 Computer should not be

operated within a confined space of the dimensions

shown below unless adequate ventilation or other cooling

methods are used to lower the air temperature within the

enclosure.

Figure 2- 1

ATTENTION: Before installing the 6180 Computer in a

panel, check the clearances of any add–in boards. If your

system has an Ethernet card installed, the card must be

checked for clearance before installation. Failure to

follow this caution may result in damage to the 6180

Computer and/or panel.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

2–4 Installation

Mounting Dimensions

The following figures show the mounting dimensions.

Versions with a Metal Bezel (No Display)

Figure 2- 2

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

Installation 2–5

Figure 2- 3

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

2–6 Installation

Versions with a Plastic Bezel (With or Without Display)

Figure 2- 4

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

Installation 2–7

Versions with a Plastic Bezel (With or Without Display)

Figure 2- 5

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

2–8 Installation

Mounting Cutout

The following figure provides the dimensions for making the panel or

enclosure cutout. If you are using mounting clips, the mounting studs

are removed and the 18 stud holes are not necessary.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

Installation 2–9

Figure 2- 6

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

2–10 Installation

Panel Mounting

(with Studs)

To install the 6180 Computer in a panel using 18 mounting studs:

ATTENTION: Disconnect all electrical power from the

panel before making cutout.

Make sure the area around the panel cutout is clear.

Take precautions so that metal cuttings do not enter any

components that are already installed in the panel.

Failure to follow these warnings may result in personal

injury or damage to the panel components.

To install the 6180 Computer in a panel using mounting studs:

1. Cut an opening in the panel using the panel cutout dimensions

provided on page 28. Carefully drill eighteen 1/4 inch (6.35 mm)

holes for studs as indicated.

2. The 18 mounting studs are factory installed. In the event studs were

removed for clip mounting, you can re–install studs using a 1/8 inch

socket on the end of the stud. Turn stud clockwise to tighten to

approximately 10 inch pounds (1.1 N•m).

Gasket

Figure 2- 7

Bezel

Mounting Studs

(Qty 18)

Spacer

Panel or Enclosure

Self-Locking Nuts

ATTENTION: Be careful not to damage the sealing

gasket when installing or removing studs. A damaged

seal may result in damage to the 6180 Computer and

other panel components due to a leaking seal.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

Installation 2–11

3. Make sure the sealing gasket is properly positioned on the terminal.

This gasket forms a compression type seal (NEMA Type 4x), do not

use sealing compounds.

4. Place the 6180 Computer in the panel cutout aligning the studs with

the mounting holes. The 6180 Computer will snap into the panel as

the temporary retaining tabs lock against the panel (see note

following).

Note:

Versions of the 6180 Computer designed for panel

mounting have metal tabs that temporarily lock the 6180

Computer against the panel. These tabs only facilitate

installation of the mounting hardware. The tabs are not

designed to provide permanent mounting.

5. Install the 18 self–locking nuts hand tight.

ATTENTION: Tighten mounting nuts to a torque of 10

inch pounds (10 inch–pounds, 1.1 N•m) to provide a

proper seal and prevent damage to the 6180 Computer.

Allen–Bradley assumes no responsibility for water or

chemical damage to the terminal or other equipment

within the enclosure because of improper installation.

6. Alternately tighten the self–locking nuts (use 3/8 inch socket) until

the 6180 Computer is held firmly against the panel (see

recommended tightening sequence below). The studs have an

integral spacer that prevents the gasket from being over–compressed.

The amount of torque required increases significantly as the gasket

reaches the proper compression. Tighten nuts to a torque of 10 inch–

pounds (1.1 N•m).

Figure 2- 8

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

2–12 Installation

Panel Mounting (with

Clips)

To install the 6180 Computer in a panel using mounting clips:

ATTENTION: Disconnect all electrical power from the

panel before making cutout.

Make sure the area around the panel cutout is clear.

Take precautions so that metal cuttings do not enter any

components that are already installed in the panel.

Failure to follow these warnings may result in personal

injury or damage to the panel components.

1. Cut an opening in the panel using the panel cutout dimensions

provided on page 2-8.

2. If the mounting studs are present, they should be removed. To

remove a stud, use a 1/8 inch socket and turn counterclockwise to

remove.

ATTENTION: Be careful not to damage the sealing

gasket when installing or removing studs. A damaged

seal may result in damage to the 6180 Computer and

other panel components due to a leaking seal.

3. Make sure the 6180 Computer sealing gasket is properly positioned

on the terminal. This gasket forms a compression type seal, do not

use sealing compounds.

Publication 6180-6.0

4. Place the 6180 Computer in the panel cutout. The 6180 Computer

will snap into the panel as the temporary retaining tabs lock against

the panel (see note below).

Note:

Versions of the 6180 Computer designed for panel

mounting have metal tabs that temporarily lock the 6180

Computer against the panel. These tabs only facilitate

installation of the mounting hardware. The tabs are not

designed to provide permanent mounting.

5. Install the 10 mounting clips (Catalog No. 2711–NP1). The

mounting clips slide into the slots on the sides, top and bottom of the

6180 Computer as indicated by the arrows shown on the following

diagram (3 top, 3 bottom, 2 sides). Gradually tighten the clips one at

a time around the bezel (see tightening sequence next page). Repeat

this process at least three times

until the clips are hand tight and the

gasket is compressed uniformly against the panel.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

Installation 2–13

Figure 2- 9

6. Tighten mounting clips to a torque of 10 inch–pounds (1.1 N•m) in

the sequence shown above. Do not over–tighten.

ATTENTION: Tighten mounting clips to a torque of 10

inch pounds (1.1 N•m) to provide a proper seal and

prevent damage to the 6180 Computer. Allen–Bradley

assumes no responsibility for water or chemical damage

to the terminal or other equipment within the enclosure

because of improper installation.

Note:

The mounting clips on the hinge side interfere with the

opening of the hinge. Remove the clips before opening the

hinge.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 51

2–14 Installation

Rack Mounting

The 6180 Computer mounts in a standard EIA 19 inch (48.3 cm) rack.

The 6180 Computer occupies 8U EIA units.

Rack Mounting Guidelines

Observe the following precautions before installing the 6180 Computer

in a rack:

Disconnect all electrical power from the rack before

installing the 6180 Computer.

If installing the 6180 Computer in an enclosed rack, make

sure the ambient temperature stays within 5° to 50° C

(41° to 122° F). Be aware of other nearby devices which

may raise the ambient temperature in the rack. Make sure

there is adequate room for air flow through the 6180

Computer chassis vents.

Verify that the addition of the 6180 Computer does not

cause uneven loading (instability) of the rack.

Check that the power supply limits for the rack

components will not be exceeded by the addition of the

6180 Computer.

Make sure the installation of the 6180 Computer

maintains proper earth grounding of the rack components.

The 6180 Computer requires connection to a power

source having an earth ground (three prong outlet).

Failure to follow these warnings may result in personal

injury or damage to the rack components.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

Installation 2–15

Rack Mounting Procedures

To install the Plastic Bezel versions of the 6180 Computer in a rack:

Note:

1. The 18 mounting studs are factory installed. In the event studs were

removed for clip mounting, you can re–install studs using a 1/8 inch

socket on the end of the stud. Turn stud clockwise to tighten to

approximately 10 inch pounds (1.1 N•m).

Figure 2- 10

The metal bezel versions of the 6180 Computer have

mounting holes in the bezel. User must provide rack

mounting hardware (see example illustrated next).

Connecting a Mouse &

Keypad (Side Panel)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2. Place the 6180 Computer in the rack aligning the studs with the

mounting holes.

3. Install the 8 self–locking nuts hand tight.

4. Alternately tighten the self–locking nuts until the 6180 Computer is

held firmly against the rack. Tighten nuts to a torque of 10 inch–

pounds (1.1 N•m).

The mouse and keyboard plug directly into the side panel mouse and

keyboard ports, or the front panel connectors as shown below. When

connected to the processor board ports, it does not matter if the keyboard

Publication 6180-6.0

Page 53

2–16 Installation

and mouse cables are interchanged, the 6180 Computer will

automatically detect them.

Figure 2- 11

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Important:

If the mouse and keyboard are connected to the side panel

connectors, the keypad (if present) on the front of the 6180

Computer is disabled. The mouse and keyboard jumpers

must be installed for operation of the keypad (see next

page).

Page 54

Installation 2–17

Note:

The Keyboard Interface Card (KIC) has a keyboard

connector. If you use the processor board or front panel

keyboard/ mouse connectors, the KIC keyboard port is

overridden (disabled).

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 55

2–18 Installation

Connecting a Mouse &

Keyboard (Front Panel)

If you are using the front panel connectors, you must install jumper

cables as shown below. These jumpers route the keyboard and mouse

ports from the processor board to the front panel connectors. Make sure

the correct ports are used.

Figure 2- 12

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

ATTENTION: When a keyboard or mouse is connected

to the front panel connectors, you lose the NEMA 4x and

NEMA 12 rating while the access door is open.

Page 56

Installation 2–19

Note:

The Keyboard Interface Card (KIC) has a keyboard

connector. If you use the processor board or front panel

keyboard/ mouse connectors, the KIC keyboard port is

overridden (disabled).

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 57

2–20 Installation

Indirect Motherboard

Connections

Add text……

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 58

Installation 2–21

Power Connections (6180

AC unit)

A standard IEC 320 power cord provides power to the 6180 Computer.

The power supply input will accept 120/240V AC.

ATTENTION: If the power supply has a manual input

voltage selection switch, check voltage selection before

applying power.

ATTENTION: The power cord must be connected to an

outlet having an earth ground (three prong outlet).

Failure to follow this warning could result in severe

electrical shock.

Use the cord retainer to prevent accidental interruption of power to the

6180 Computer. Pull the cord retainer over the cord plug as shown

below.

The following illustration pertains to 6180 Computers equipped with a

Pentium Class CPU.

Figure 2- 13

1

The power cord connector is recessed on 6180 Computers equipped with a

Pentium III CPU.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 59

2–22 Installation

Power Connections (6180

DC unit)

Configuring the Power

Supply Jumper

A standard IEC 320 power cord??? provides power to the 6180

Computer. The power supply input will accept ?????.

The

either power up using the on/off switch, or to automatically turn on when

AC power is applied to the unit. An internal jumper on the power supply

wiring harness controls the configuration. The factory default setting

enables the on/off switch. To change the configuration, perform the

following steps:

1. Remove power from the 6180 Computer. Disconnect the power

2. Remove the 6180 Computer back cover. Locate the power supply,

3. If the power switch bypass mode is desired, then connect the white

Computer 120/240VAC power supply can be configured to

6180

cord.

and look for a single white wire not connected on the power supply

wiring harness. The white wire is shipped not connected from the

factory, because this position enables the power switch to be used.

wire to its mating connector.

4. Replace the back cover. Reconnect power to the 6180 Computer.

5. Press and hold the on/off switch for at least 10 seconds.

6. Unplug the 6180 Computer and wait 5 seconds before plugging back

in. This clears the soft-start logic on the 6180 Computer

motherboard.

7. Plug in the unit again. The on/off switch bypass mode is enabled.

When using Microsoft Windows NT, a normal shut down and power

cycle will restart the computer regardless if the computer needs the

power button turned back on; steps 2 and 3 need to return to bypass

mode. A power outage in Windows 95/98 will still automatically reboot

the computer.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 60

Installation 2–23

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 61

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 62

Initial Operation a

Initial Operation and Setup

Initial Operation aInitial Operation a

nd Setup

nd Setupnd Setup

Chapter

Chapter 3

Chapter Chapter

Chapter Objective

Operating Objecti ves

This chapter provides information on:

• Operating recommendations

• Bootup sequence

• System reset and power on/off buttons

• System hot keys

We recommend these operating guidelines:

• Avoid turning the system on and off frequently.

• Never turn the system off when the hard drive indicator light is

illuminated.

• After shutting the system off, do not turn it back on again until the

hard drive has come to a complete stop (about 30 seconds).

• If using an external monitor, turn on the monitor first.

• Always use the proper power down procedures as required by your

operating system such as the Shut Down command in the Microsoft

Windows operating system.

• Do not operate the 6180 Computer without the back panel installed.

An electrical shock hazard exists. In addition, removing the back

panel disrupts air flow and may result in overheating. The back panel

also functions as an EMI shield.

Operator Access

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Operator access is limited to the front panel of the 6180 Computer. This

includes the display, front panel, keys, and front panel doors (accessory

drive and mouse/keyboard connectors). Access to components behind

the rack or panel that the 6180 Computer is installed in is restricted to

authorized and properly trained personnel.

ATTENTION: Operator access is limited to the front

panel controls and access doors of the 6180 Computer.

Failure to observe this caution could result in severe

electrical shock and/or damage to the 6180 Computer.

Page 63

3–2 Initial Operation and Setup

Keypad Operation

If your computer has a front panel keypad, note the following:

• Mouse and keyboard jumpers must be installed to activate the front

panel, keypad, and mouse (see page 2-17).

• The KIC card has a jumper (P1) that enables/disables the keypad.

The default position is enabled (pins 2–3 jumpered). For more

information, refer to Chapter 13, Keyboard Configuration Utility.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 64

Initial Operation and Setup 3–3

System Checkout

To boot up the system:

1. Apply power and press the on/off button. The 6180 Computer

performs a Power On Self Test (POST) in which it tests the

processor board, memory, keyboard, and certain peripheral devices.

2. The 6180 Computer displays the progress of the POST and

initialization of accessory devices. This display varies depending on

the system configuration and BIOS version, but will look similar to

this:

Figure 3- 1

System Reset

3. If your system does not boot up, or you notice other problems, refer

to Chapter 15, System Troubleshooting.

4. The 6180 Computer will then run any preloaded operating system

software such as Windows 95/98 or Windows NT. If no operating

system is preloaded, the following prompt is displayed:

Insert bootable media in the appropriate drive.

The three ways to reset the 6180 Computer are to:

• use the side mounted CPU reset button

• press [Ctrl] [Alt] [Delete]

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 65

3–4 Initial Operation and Setup

• use power switch on front or side panel

After resetting, the 6180 Computer will begin the Power On Self Test

(POST). During reset, the 6180 Computer:

• clears RAM

• starts the POST

• initializes peripheral devices, such as drives and printers

• loads the operating system (if pre–loaded)

System Hot Keys

The keyboard controller supports the following hot key sequences:

Use this key

sequence:

[Ctrl][Alt][Del]* Perform a software reset of the system.

[Ctrl][Alt][+]

[Ctrl][Alt][−]

[Ctrl][Alt][Defined

in Setup]

[Ctrl][Alt][Defined

in Setup]

* May be inhibited (user configured) through KCU. The default is Ctrl-Act-Del

enabled.

Set the system to turbo mode (Default setting). In turbo

mode, the system bootup occurs at full speed.

Switching to turbo mode may be prohibited by the

operating system, or when the CPU is in protected mode

or virtual x86 mode under DOS.

Set the system to deturbo mode. In deturbo mode, the

system operates at a slower speed (emulating a 23 MHz

AT).

Enter energy saving standby mode. Standby mode

reduces the system’s power consumption while still

responding to external interrupts, such as FAXs or

network messages.

Any keyboard or mouse activity brings the system out of

standby mode.

The Power Management hot key is defined in the

Advanced screen of the Setup program.

Lock the keyboard (and clear the screen) until a User

Password is entered. The keyboard LEDs flash to

indicate the keyboard is locked. After entering the User

Password, you do not have to press the [Enter] key.

The security hot key is entered in the Security screen of

the Setup program.

The security hot key will not function unless a User

Password is also defined in the Security screen of the

Setup program.

To:

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 66

Initial Operation and Setup 3–5

Legend Strip for

Configurable Keypad

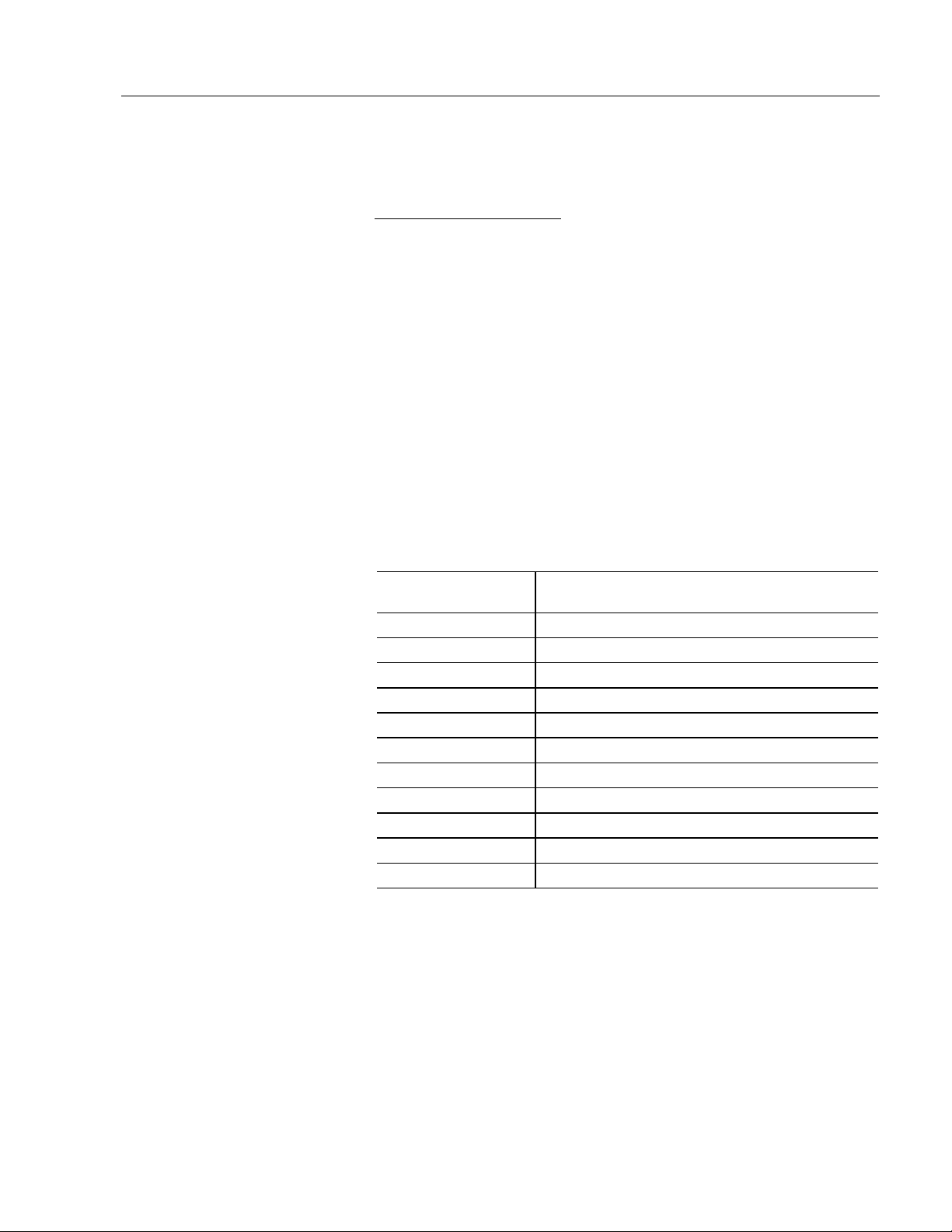

The 6189-KEYKIT1 legend kit contains legend strips for the following

computers:

Computer

Catalog Number

6180-xxCxxxxxxxx

6180-xxDxxxxxxxx

6180-xxGxxxxxxxx

6180-xxLxxxxxxxx

6180-xxMxxxxxxx

6180-xxHxxxxxxxx

6180-xxIxxxxxxxx

Computer Type

6180 Industrial

Computer, 10.4 inch

Color Screen

6180 Industrial

Computer, 10.4 inch

Color Screen

6180 Industrial

Computer, 12.1 inch

Color Touchscreen

6180 Industrial

Computer, 15 inch

Color Touchscreen

Standard

Full Alphanumeric

Standard

Standard

Keypad

The 6180 Computer models 6180-xxC, -xxD, xxG (with 10.4 inch

screen) are provided with a keypad strip installed display ing function k ey

labels F1 - F12 and S1 - S12. The reverse side of this strip has labels for

letters A - Z. Custom legend strips can also be created using blank

legend labels.

The 6180 Computer models 6180-xxL and -xxM (with a 12.1 inch

screen) are provided with an alpha keypad strip installed. The reverse

side of this strip has labels for function keys F1 - F12 and S1 - S12.

The 6180 Computer models 6180-xxH and -xxI (with a 15 inch screen)

are provided with an alpha keypad strip installed. The reverse side of

this strip has labels for function keys F1 - F12 and S1 - S12.

Legend kit contents

The Legend Strip Kit (Catalog No. 61 89-KEYKIT1) contains legend

strips for both the standard and full alphanumeric keypad versions of the

6180 Computer. The standard keypad legend strips are longer than the

strips for the full alphanumeric keypad. The kit contains:

• Two preprinted legend strips for standard keypads. These strips are

preprinted on both sides. One side has function key labels. The

reverse side of this strip is preprinted with labels for letters A-Z.

• Three blank legend strips for standard keypads. The strips are blank

on both sides and may be marked for custom legends.

• Three Preprinted/Blank legend strips for full alphanumeric keypads.

These strips are preprinted on one side with function key labels Fl —

F20. The reverse side of the strips are blank for marking custom

legends.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 67

3–6 Initial Operation and Setup

Marking the legend strip

When custom labeling the legend strips, use an indelible type of marker.

All printing must appear within the white text areas. We recommend that

you test print the legends on a separate sheet of paper to verify that the

insert has adequate space for the legends.

To reverse or change a legend strip:

1. Carefully pull the legend strip from the left side behind the bezel.

Figure 3- 2

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2. If you are using the blank legend strips, mark the legends on the matt

surfaces provided for marking.

3. Re–insert the tab into the slot. Here are some helpful hints:

• Grip the legend strip near the point where the strip enters the slot

and use short “pushes”. This helps prevent buckling of the

legend strip.

• It may be helpful to “cup” the legend strip slightly as you hold it.

This will stiffen the legend strip and also prevent buckling.

Page 68

Initial Operation and Setup 3–7

Using IrDA

Using USB

The IrDA receiver / transmitter (version 2.0 compatible) located behind

the front connector access panel or directly on the front panel overlay

(see pages 1–6 and 1−11) allows you to communicate with other devices

also having an IrDA receiver / transmitter, such as printers or note book

computers. The IrDA link has a maximum baud rate of 115

kilobytes/sec. Both devices must be no more than 1 meter apart.

Also note the following when using IrDA:

• Microsoft Windows needs to be configured for IrDA support

(software drivers loaded into operating system).

• In BIOS setup, the Serial Port 2 IR Mode (in Peripheral

Communication submenu) must be enabled.

• You must be running a software application that uses IrDA.

Some 6180 motherboards are provided with USB connectors.

The Universal Serial Bus (USB) is an external bus standard that supports

data transfer rates of 12Mbps (12 million bits per second). A single USB

port can be used to connect up to 127 peripheral devices, such as mice,

modems, and keyboards. USB also supports Plug-and-Play installation

and hot plugging.

Refer to the USB peripheral documentation for installing any required

software on the 6180 Computer. Microsoft Windows 95, Windows 98,

and Windows 2000 operating systems offer plug and play support for

USB devices.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 69

3–8 Initial Operation and Setup

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 70

Adding and Removing System

Adding and Removing System

Adding and Removing System Adding and Removing System

Components

Components

ComponentsComponents

Chapter

Chapter 4

Chapter Chapter

Chapter Objective

Safety Precautions

This chapter describes how to remove and install:

• back panel and accessory drive cover

• add–in boards

• processor board

The 6180 Computer contains line voltages. Make sure you disconnect

all power to the 6180 Computer before performing any of the operations

described in this chapter.

ATTENTION: Disconnect all power from the 6180

Computer before removing components. Failure to

disconnect power could result in severe electrical shock

or damage to the 6180 Computer.

ATTENTION: Wear an ESD wrist strap (well grounded)

and perform work in a static safe environment.

Electrostatic discharge can damage the 6180 Computer

and components.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 71

4–2 Adding and Removing System Components

Removing the Back Panel

and Accessory Drive

Cover

This section shows how to remove the back cover to access internal

components.

ATTENTION: Review safety precautions on page 4-1

before proceeding. Failure to follow proper safety

procedures could result in severe electrical shock or

damage to the 6180 Computer.

To remove the back panel:

1. Disconnect power from the 6180 Computer.

2. Loosen the 2 screws securing the back panel. The screws are

retained and cannot be removed from the panel.

Figure 4- 1

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 72

Adding and Removing System Components 4–3

3. To re–install back panel, position back panel tabs over the chassis

and tighten the 2 screws (6-8 in./lb.)

Adding and Removing

Add-in Boards

ISA compatible boards may be installed in any of the ISA slots or the

ISA/PCI shared slot. PCI compatible boards may be installed in any one

of the PCI slots or the ISA/PCI shared slot.

Note:

If a floppy or other device is installed in the lower bay, the

lower three slots are restricted to half-length cards.

Refer to the Processor Board manual for the type and number of slots

supported by your computer.

ATTENTION: Review safety precautions on page 4−1

before proceeding. Failure to follow proper safety

procedures could result in severe electrical shock or

damage to the 6180 Computer.

ATTENTION: Add-in boards may be sensitive to ESD

and require careful handling. Hold boards only by the

edges, do not touch connectors. After removing a board,

place the board on a flat static free surface, component

side up. Do not slide the board over any surface.

To remove a slot cover (to add a board):

Figure 4- 2

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 73

4–4 Adding and Removing System Components

1. Remove the back panel. See page 4-2.

2. Locate the slot cover you want to remove. We recommend that you

remove adjacent add–in boards.

3. Remove the screw securing the slot cover and remove cover.

To install a slot cover (after removing a board)

1. Insert the end of the cover into the slot in the chassis.

2. Install the screw securing the slot cover, tighten to 6–8 in–lbs (.7–.9

N•m)

To install an add–in board:

1. Remove the board from its anti–static packaging and place on a

grounded, static free surface.

2. Set any board jumpers or switches as described in the instructions for

the board.

3. Hold the board by the edges and firmly press the board into the

connector on the processor board.

Figure 4- 3

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 74

Adding and Removing System Components 4–5

4. Align the notch in the board retainer with the threaded hole and

install the screw. Hold the notch tightly against the screw before

tightening (6-8 in./lb.).

Note:

If you do not install the retainer tight against the screw, you

may have problems inserting an adjacent board.

5. Connect any board cables (if required).

6. Install the back panel. See page 4-2.

To remove an add–in board:

1. Disconnect the cables to the Keypad Interface Card (KIC) and video

card.

2. Remove the screw securing the board retainer.

3. Hold the board at each end and carefully rock the board back and

forth until the edge connectors pull free.

Installing and Removing

the Processor Board

4. Store the board in an anti-static wrapper.

5. Remove any unused cable associated with the board.

6. Install a slot cover over the open slot.

Removal of the processor board may be required for repairs or future

board upgrades.

Refer to the Processor Board Manual for board specifications.

ATTENTION: Disconnect all power from the 6180

Computer before removing components. Failure to

disconnect power could result in severe electrical shock

or damage to the 6180 Computer.

Wear an ESD wrist strap (well grounded) and perform

work in a static safe environment. Electrostatic discharge

can damage the 6180 Computer and components.

To remove the processor board:

1. Remove the back panel. See page 4-2.

2. Remove the power supply. See page 9-1.

3. Remove all add-in boards. See page 4-7.

Publication 6180-6.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 75

4–6 Adding and Removing System Components

Figure 4- 4

4. Disconnect the hard drive IDE cable connector.

5. Disconnect the floppy drive connector.

6. Disconnect the front header panel connector.

7. The side board (shown previous page) restricts access to the upper

left mounting screw of the processor board. Remove the 3 screws

that secure the board, you do not need to unplug any connectors from