Page 1

User Manual

Original Instructions

Compact 5000 I/O Digital Modules

Catalog Numbers 5069-IA16, 5069-IB8S, 5069-IB8SK, 5069-IB16, 5069-IB16F, 5069-IB16K, 5069-IB6F-3W, 5069-OA16,

5069-OB8, 5069-OBV8S, 5069-OBV8SK, 5069-OB16, 5069-OB16F, 5069-OB16K, 5069-OW4I, 5069-OW16, 5069-OX4I

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Digital Module Operation in

a Control System

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Graphics Indicate Feature Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 1

Controller and Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . 18

Controller Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Types of Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Local I/O Modules or Remote I/O Modules. . . . . . . . . . . . . . . . . . . . . 24

Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Secure Access to the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ownership. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Multiple Owners of Compact 5000 I/O Digital

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuration Changes in an Input Module with

Multiple Owners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Construct a System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Use a 5069-ARM Address Reserve Module to

Reserve a Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Use a 5069-FPD Field Potential Distributor to

Establish New SA Power Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Requirements When You Use Compact 5000 I/O

Safety Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connections with Compact 5000 I/O Digital Modules. . . . . . . 40

Connections with Compact 5000 I/O Safety Modules. . . . . . . . 44

Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connection Over an EtherNet/IP Network . . . . . . . . . . . . . . . . . 48

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 3

Page 4

Table of Contents

Input Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Local Compact 5000 I/O Digital Input Modules. . . . . . . . . . . . . 49

Trigger Events for Standard Input Modules. . . . . . . . . . . . . . . . . . 49

Remote Compact 5000 I/O Digital Input Modules . . . . . . . . . . 50

Output Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Local Compact 5000 I/O Digital Output Modules . . . . . . . . . . . 52

Remote Compact 5000 I/O Digital Output Modules. . . . . . . . . 53

Listen Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Protected Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Considerations Specific to Safety Modules. . . . . . . . . . . . . . . . . . . . . . . 58

Overall System Safety Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Single-channel or Dual-channel Mode. . . . . . . . . . . . . . . . . . . . . . . 59

Use with Safety Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Determine Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Obtain Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Safety Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Safe State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Configuration Signature and Ownership . . . . . . . . . . . . . . . . . . . . 65

Reset Compact 5000 I/O Safety Modules to

Out-of-Box State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Features Common to Compact

5000 I/O Digital Modules

Chapter 2

Input Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Output Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Software Configurable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Module Data Quality Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Module Inhibiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Module Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Producer/Consumer Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Use CIP Sync Time with Fast

I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Timestamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 5

Table of Contents

Chapter 3

Input Module Features Multiple Input Module Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Data Transfer at RPI or Change of State . . . . . . . . . . . . . . . . . . . . . . . . 83

Software Configurable Input Filters and Delays. . . . . . . . . . . . . . . . . . 84

Compact 5000 I/O Standard Input Modules . . . . . . . . . . . . . . . . 84

Compact 5000 I/O Safety Input Modules . . . . . . . . . . . . . . . . . . . 85

Input Filter with Compact 5000 I/O Fast Input Modules. . . . . 86

Module Health Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Compact 5000 I/O Standard Input Modules . . . . . . . . . . . . . . . . 88

Compact 5000 I/O Safety Input Module . . . . . . . . . . . . . . . . . . . . 89

Simple Count Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Sequence of Events Per Point Timestamping . . . . . . . . . . . . . . . . . . . . 91

Chatter Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Event Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Independent Point Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pattern Match Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Additional Event Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Pulse Latching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Field Power Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Muting Lamp Fault and Short Circuit

Diagnostics Triggered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Test Output Recovery After Overload or Short

Circuit to Ground Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Thermal Shutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Chapter 4

Output Module Features Multiple Output Module Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Module Health Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Data Echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Field Power Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

No Load Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Short Circuit Protection with Standard

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Short Circuit Protection with Safety Output Modules. . . . . . . 116

Other Conditions That Can Trigger the Short

Circuit Diagnostic on the 5069-OBV8S or

5069-OBV8SK Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Output Recovery After Overload or Short Circuit to

Ground Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 5

Page 6

Table of Contents

Thermal Shutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Thermal Shutoff with Standard Output Modules . . . . . . . . . . . 119

Thermal Shutoff with a Safety Output Module . . . . . . . . . . . . . 120

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Compact 5000 I/O Standard Output Modules. . . . . . . . . . . . . . 121

Compact 5000 I/O Safety Output Modules . . . . . . . . . . . . . . . . 122

Output State Change Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Configurable Channel-level Output State in Program

Mode or Fault Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Connection Fault Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Output Behavior Immediately After a Connection

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Fault State Duration After Connection Fault . . . . . . . . . . . . . . . 125

Final Fault State Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Output State Once Connection Is Re-established . . . . . . . . . . . 125

Forcing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Enable Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Disable or Remove a Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Check Force Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

GSV Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Time-scheduled Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Use an MAOC Instruction with a 5069-OB16F

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Isolated and Non-isolated Varieties of Output Modules . . . . . . . . . 132

Chapter 5

Safety Module Features Safety Input Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Safety Application Suitability Levels. . . . . . . . . . . . . . . . . . . . . . . . 133

Use Test Output with a Safety Input . . . . . . . . . . . . . . . . . . . . . . . 135

Single-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Safety Input Fault Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Safety Input Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Muting Lamp Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Safety Output Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Safety Application Suitability Levels. . . . . . . . . . . . . . . . . . . . . . . . 143

Safety Output with Test Pulse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Single-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Dual-channel Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Safety Output Fault Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

6 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 7

Table of Contents

Chapter 6

Configure a Standard Module Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Create a New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Discover Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

New Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Discover Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

New Remote I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Reserve an I/O Module Slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Add the 5069-ARM Module to the Project . . . . . . . . . . . . . . . . . 159

Delete the 5069-ARM Module from the Project . . . . . . . . . . . . 160

Edit the Module Configuration Common Categories . . . . . . . . . . . 162

General Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Connection Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Module Info Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Edit 5069-IA16 Module Configuration Categories. . . . . . . . . . . . . . 167

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Edit 5069-IB16 Module Configuration Categories. . . . . . . . . . . . . . 168

Counters Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Edit 5069-IB16F Module Configuration Categories. . . . . . . . . . . . . 169

Counters Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Events Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Time Sync Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Edit 5069-IB6F-3W Module Configuration Categories . . . . . . . . . 176

Counters Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Events Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Time Sync Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Edit 5069-OA16 Module Configuration Categories . . . . . . . . . . . . 182

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Edit 5069-OB8 Module Configuration Categories . . . . . . . . . . . . . . 183

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Edit 5069-OB16 Module Configuration Categories. . . . . . . . . . . . . 184

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Edit 5069-OB16F Module Configuration Categories . . . . . . . . . . . 185

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Edit 5069-OW4I Module Configuration Categories . . . . . . . . . . . . 186

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Edit 5069-OW16 Module Configuration Categories. . . . . . . . . . . . 187

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Edit 5069-OX4I Module Configuration Categories. . . . . . . . . . . . . 188

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

View the Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 7

Page 8

Table of Contents

Configure and Replace

Safety Modules

Chapter 7

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Create a New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

New Local Safety Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

New Remote I/O Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Edit the Module Configuration Common Categories . . . . . . . . . . . 196

General Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Connection Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Safety Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Module Info Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Edit the 5069-IB8S and 5069-IB8SK Module

Configuration Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Input Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Test Output Points Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Edit the 5069-OBV8S and 5069-OBV8SK Module

Points Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

View the Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Replace a Safety Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Set the SNN Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Reset to Out-of-Box Configuration . . . . . . . . . . . . . . . . . . . . . . . . 208

Replace a Module in a Logix 5000 System. . . . . . . . . . . . . . . . . . . 209

Appendix A

Troubleshoot Your Module Module Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Compact 5000 I/O Standard Input Modules

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Compact 5000 I/O Standard Output Modules

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Compact 5000 I/O Safety Input Module Status

Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

SA Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

I/O Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Compact 5000 I/O Safety Output Module Status

Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

SA Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

I/O Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Use the Logix Designer Application for Troubleshooting . . . . . . . . 223

Warning Signal in the I/O Configuration Tree . . . . . . . . . . . . . 223

Status and Fault Information in Module

Properties Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Module and Point Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Logix Designer Application Tag Editor. . . . . . . . . . . . . . . . . . . . . 228

InternalFault Triggered on the Safety Output Module. . . . . . . . . . . 229

8 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 9

Table of Contents

Appendix B

Module Tag Definitions Name Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Access the Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

5069-IA16 Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

5069-IB16 Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

5069-IB16F Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Event Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Event Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

5069-IB6F-3W Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Event Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Event Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

5069-OA16 Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

5069-OB8 Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

5069-OB16 Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

5069-OB16F Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

5069-OW4I, 5069-OW16, and 5069-OX4I Module Tags. . . . . . . 266

Configuration Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 9

Page 10

Table of Contents

5069-IB8S and 5069-IB8SK Module Tags. . . . . . . . . . . . . . . . . . . . . . 268

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

5069-OBV8S and 5069-OBV8SK Module Tags . . . . . . . . . . . . . . . . 270

Input Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Output Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix C

Application and Wiring

Examples for Safety Modules

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

5069-IB8S or 5069-IB8SK Module Wiring Diagrams . . . . . . . . . . . 274

5069-OBV8S and 5069-OBV8SK Module Wiring Diagrams . . . . 277

Bipolar Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Sourcing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Wiring Faults on Safety Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Appendix D

Safety Data for Safety Modules Compact 5000 I/O Safety Input Module Safety Data . . . . . . . . . . . 288

Compact 5000 I/O Safety Output Module Safety Data. . . . . . . . . . 289

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .291

10 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 11

Preface

This manual describes how to use Compact 5000™ I/O digital modules in

Logix 5000™ control systems.

Make sure that you are familiar with the following:

• Use of a controller in a Logix 5000 control system.

• Use of an EtherNet/IP™ network, if the digital I/O modules are

used remotely.

• Use of safety systems.

• Use Studio 5000 Logix Designer® environment.

IMPORTANT In this manual, we use standard module to indicate a standard digital I/O

module. We use safety module to indicate a safety digital I/O module.

Further, we use Compact 5000 I/O digital module to indicate when a

concept or task applies to both the standard and safety digital I/O modules.

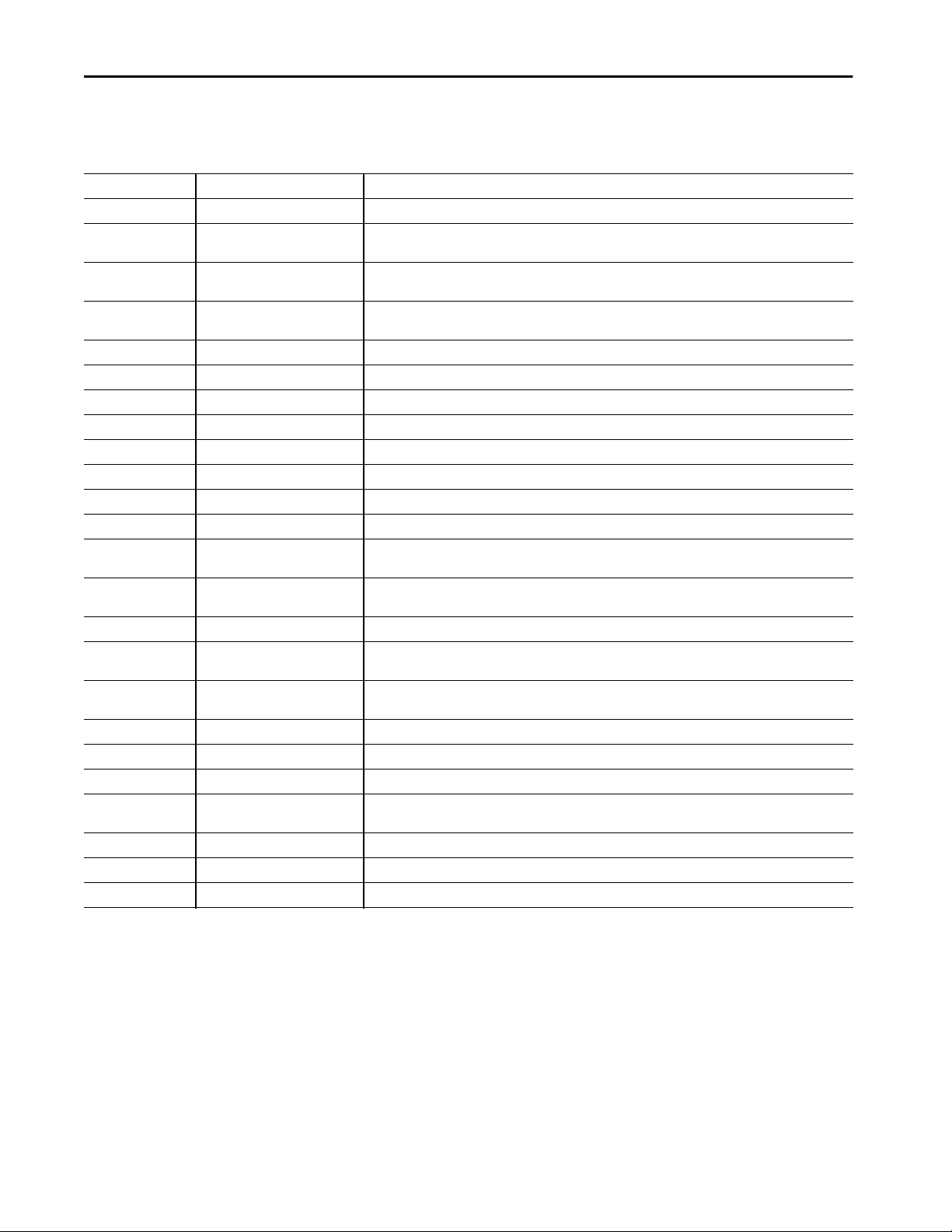

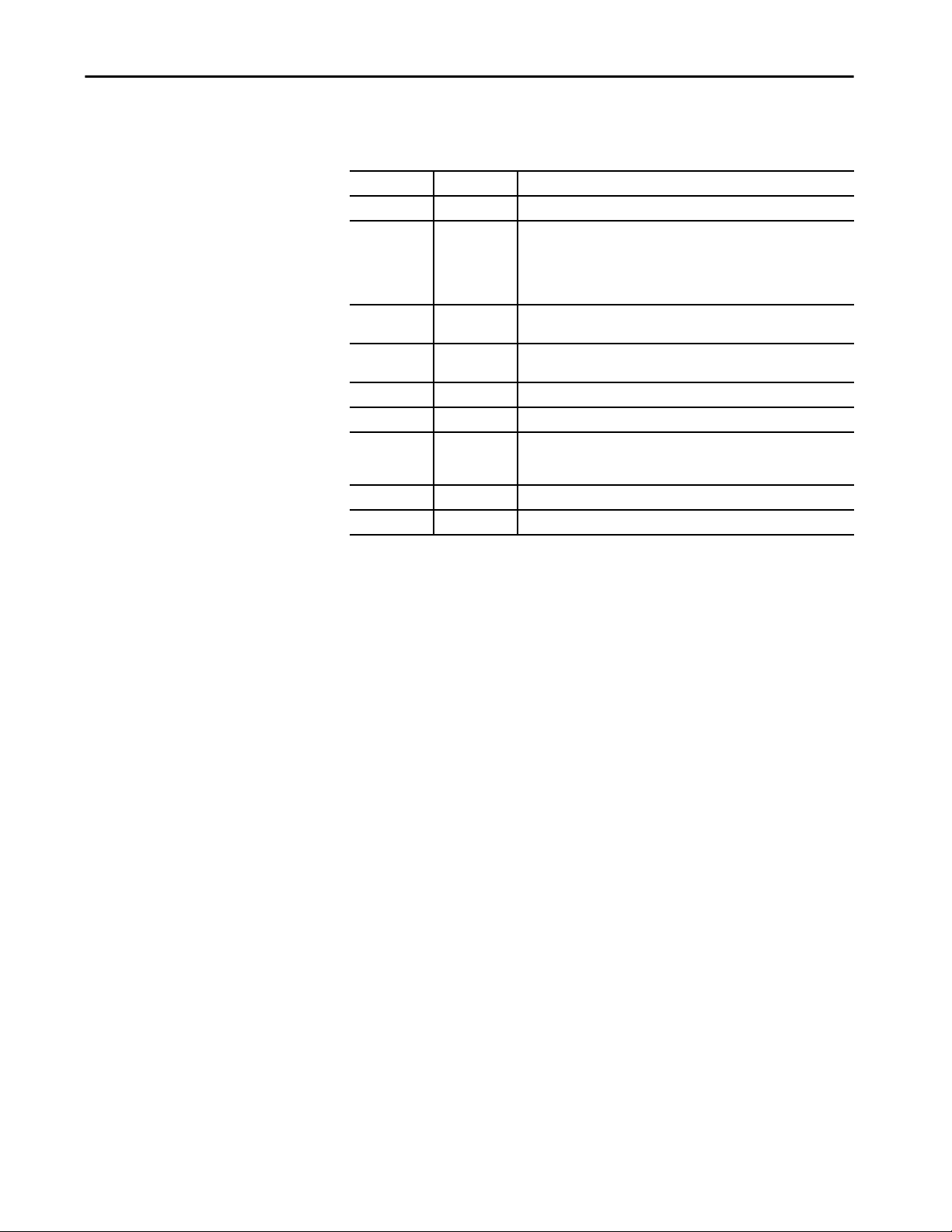

Summary of Changes

This manual was revised to add information listed in this table. Some minor

changes were made in the manual that are not listed here.

Topic Page

Added Compact 5000 I/O conformal coated digital modules, 5069-IB16K and 5069-OB16K Throughout

Secure Access to the System 28

Configuration Changes in an Input Module with Multiple Owners 30

Use a 5069-ARM Address Reserve Module to Reserve a Node Address 33

Power Requirements When You Use Compact 5000 I/O Safety Modules 37

Connections with Compact 5000 I/O Safety Modules 44

Considerations Specific to Safety Modules 58

Use with Safety Controllers 60

Safety Precautions 62

Safety Application Requirements 63

Safe State 64

Configuration Signature and Ownership 65

Reset Compact 5000 I/O Safety Modules to Out-of-Box State 65

Safety Module Features Chapter 5, page 133

Configure and Replace Safety Modules Chapter 7, page 191

Compact 5000 I/O Safety Input Module Status Indicators 219

Compact 5000 I/O Safety Output Module Status Indicators 221

5069-IB8S and 5069-IB8SK Module Tags 268

5069-OBV8S and 5069-OBV8SK Module Tags 270

Application and Wiring Examples for Safety Modules Appendix C, page 273

Safety Data for Safety Modules Appendix D, page 287

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 11

Page 12

Preface

Graphics Indicate Feature Support

Throughout this manual, graphics appear with section titles to indicate the

digital I/O modules that support the feature that is described in that section.

If both standard and safety modules support a feature, you see icons for

both types.

If only one type of module, standard or safety, supports a feature, you see only

one type of icon.

12 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 13

Preface

Terminology

The following table defines terms that are used in this manual.

Table 1 - Terminology Used throughout the Manual

Abbreviation Full Term Definition

1oo2 One out of Two Identifies the programmable electronic controller architecture.

CIP™ Common Industrial Protocol An industrial communication protocol that is used by Logix 5000-based automation systems on EtherNet/IP,

CIP Safety™ Common Industrial Protocol –

Safety Certified

— Connection Logical communication channel for communication between nodes. Connections are maintained and controlled

CL Claim Limit The maximum safety integrity level (SIL) that can be achieved.

DC Diagnostic Coverage The ratio of the detected failure rate to the total failure rate.

EN European Norm. The official European Standard.

GSV Get System Value A ladder logic instruction that retrieves specified controller status information and places it in a destination tag.

— Multicast The transmission of information from one sender to multiple receivers.

MTTF Mean Time to Failure The length of time that a device or other product is expected to remain reliable in operation.

NAT Network Address Translation The translation of an Internet Protocol (IP) address to another IP address on another network.

ODVA Open DeviceNet Vendor Association A nonprofit association of vendors that are established for the promotion of CIP networks.

PFD Probability of a dangerous failure on

demand

PFH Average frequency of a dangerous

failure per hour

PL Performance Level ISO 13849-1 safety rating.

— Proof test Periodic test that detects failures in a safety-related system so that, if necessary, the system can be restored to an

SC Systematic Capability A confidence that the systematic safety integrity meets the requirements of the specified safety integrity level

SFF Safe Failure Fraction The sum of safe failures plus the sum of dangerous detected failures divided by the sum of all failures.

SIL Safety Integrity Level A relative level of risk-reduction that is provided by a safety function, or to specify a target level of risk reduction.

SIL CL SL Claim Limit The maximum safety integrity level (SIL) that can be achieved.

SNN Safety Network Number Safety network number, which uniquely identifies a network across all networks in the safety system. You are

SRT Safety Reaction Time A consideration of delays or latencies within the safety system.

— Standard Devices or portions of devices that do not participate in the safety function.

— Unicast The transmission of information from one sender to one receiver.

ControlNet®, and DeviceNet® communication networks.

SIL-rated version of CIP.

between masters and slaves.

The average probability of a system to fail to perform its design function on demand.

The probability of a system to have a dangerous failure occur per hour.

as-new condition or as close as practical to this condition.

(SIL). (from IEC 61508-4)

responsible for assigning a unique number for each safety network or safety subnet within a system.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 13

Page 14

Preface

Additional Resources

The following resources contain information about related products from

Rockwell Automation.

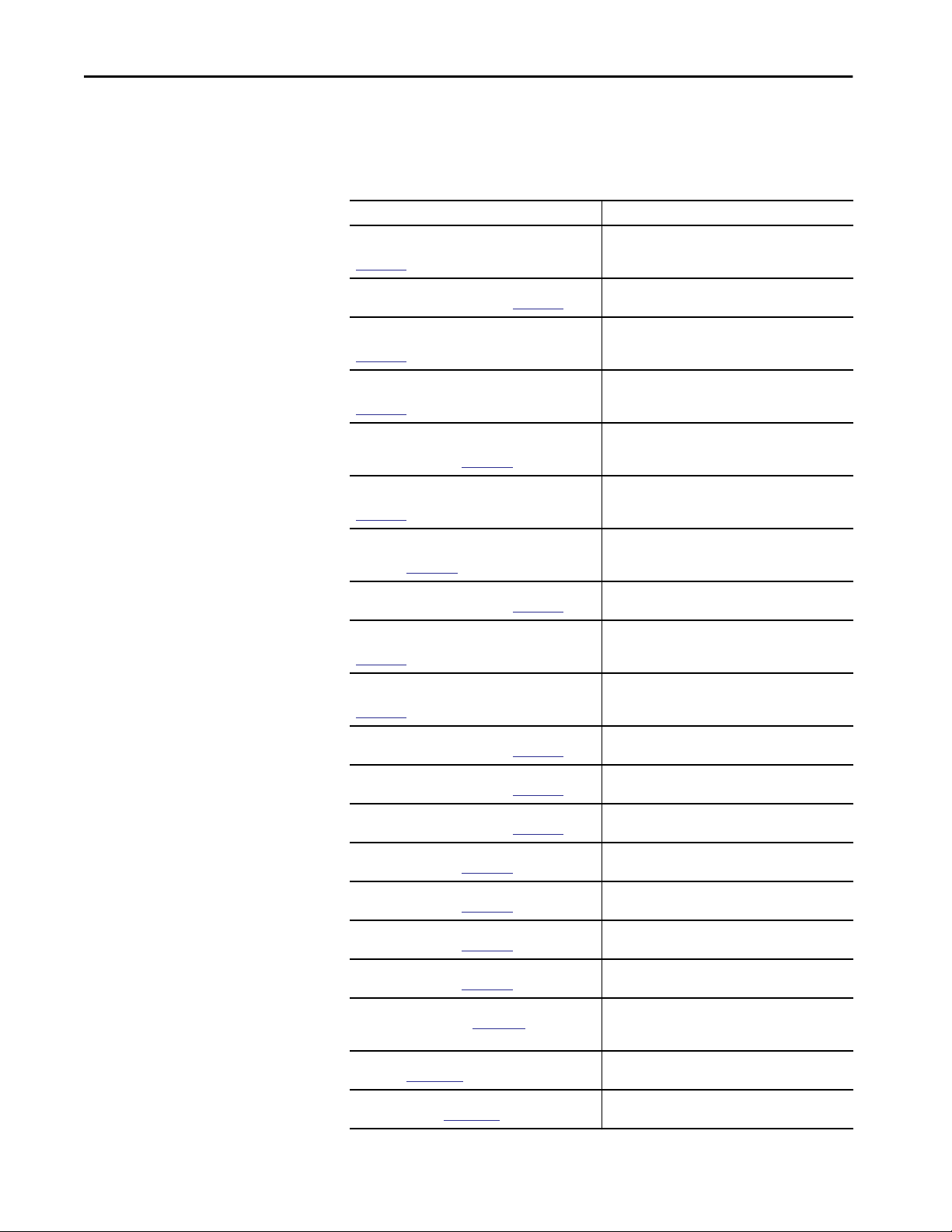

Table 2 - Additional Resources to Use with Compact 5000 I/O Digital Modules

Resource Description

Compact 5000 I/O Digital 16-point Sinking Input

Modules Installation Instructions, publication

5069-IN004

Compact 5000 I/O Digital 3-wire Sinking Input Module

Installation Instructions, publication

Compact 5000 I/O Digital 16-point Sourcing Output

Modules Installation Instructions, publication

5069-IN007

Compact 5000 I/O Digital 4-point Isolated Relay Output

Module Installation Instructions, publication

5069-IN008

Compact 5000 I/O Digital 4-point Isolated Normallyopen/Normally-closed Relay Output Module Installation

Instructions, publication

Compact 5000 I/O Analog 8-channel Current/Vole Input

Module Installation Instructions, publication

5069-IN010

Compact 5000 I/O Analog 4-channel Current/Vole/RTD/

Thermocouple Input Module Installation Instructions,

publication

Compact 5000 I/O Analog Current/Vole Output Modules

Installation Instructions, publication

Compact 5000 I/O Digital 16-point 120/240V AC Input

Module Installation Instructions, publication

5069-IN015

Compact 5000 I/O Digital 16-point 120/240V AC Output

Module Installation Instructions, publication

5069-IN016

Compact 5000 I/O Digital 8-point 24V DC Output Module

Installation Instructions, publication

Compact 5000 I/O Digital 16-point Relay Output Module

Installation Instructions, publication

Compact 5000 I/O Safety Sinking Input Module

Installation Instructions, publication

Compact 5000 I/O Safety Output Module Installation

Instructions, publication

Compact 5000 I/O Field Potential Distributor Installation

Instructions, publication

Compact 5000 I/O Address Reserve Module Installation

Instructions, publication

Compact 5000 I/O EtherNet/IP Adapter Installation

Instructions, publication

Compact 5000 I/O Modules and EtherNet/IP Adapter

Technical Data, publication

Compact 5000 I/O Analog Modules User Manual,

publication

Compact 5000 I/O High-speed Counter Module User

Manual, publication

5069-IN011

5069-UM005

5069-IN009

5069-IN021

5069-IN001

5069-IN002

5069-IN003

5069-UM006

5069-IN006

5069-IN012

5069-IN017

5069-IN018

5069-IN020

5069-TD001

Describes how to install and wire the 5069-IB16,

5069-IB16F, and 5069-IB16K input modules.

Describes how to install and wire the 5069-IB6F-3W

input module.

Describes how to install and wire the 5069-OB16,

5069-OB16F, and 5069-OB16K output modules.

Describes how to install and wire the 5069-OW4I output

module.

Describes how to install and wire the 5069-OX4I output

module.

Describes how to install and wire the 5069-IF8 analog

input module.

Describes how to install and wire the 5069-IY4 and

5069-IY4K analog input modules.

Describes how to install and wire the 5069-OF4,

5069-OF4K, and 5069-OF8 analog output modules.

Describes how to install and wire the 5069-IA16 input

module.

Describes how to install and wire the 5069-OA16 output

module.

Describes how to install and wire the 5069-OB8 output

module.

Describes how to install and wire the 5069-OW16

output module.

Describes how to install and wire the 5069-IB8S and

5069-IB8SK safety input module.

Describes how to install and wire the 5069-OBV8S and

5069-OBV8SK safety output modules.

Describes how to install and wire the 5069-FPD field

potential distributor.

Describes how to install the 5069-ARM address reserve

module.

Describes how to install and wire the Compact 5000 I/O

EtherNet/IP adapters.

Provides specifications, wiring diagrams, and module

block diagrams for Compact 5000 I/O modules and

EtherNet/IP adapters

Describes how to configure, operate, and troubleshoot

Compact 5000 I/O analog modules.

Describes how to configure, operate, and troubleshoot

the Compact 5000 I/O high-speed counter module.

14 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 15

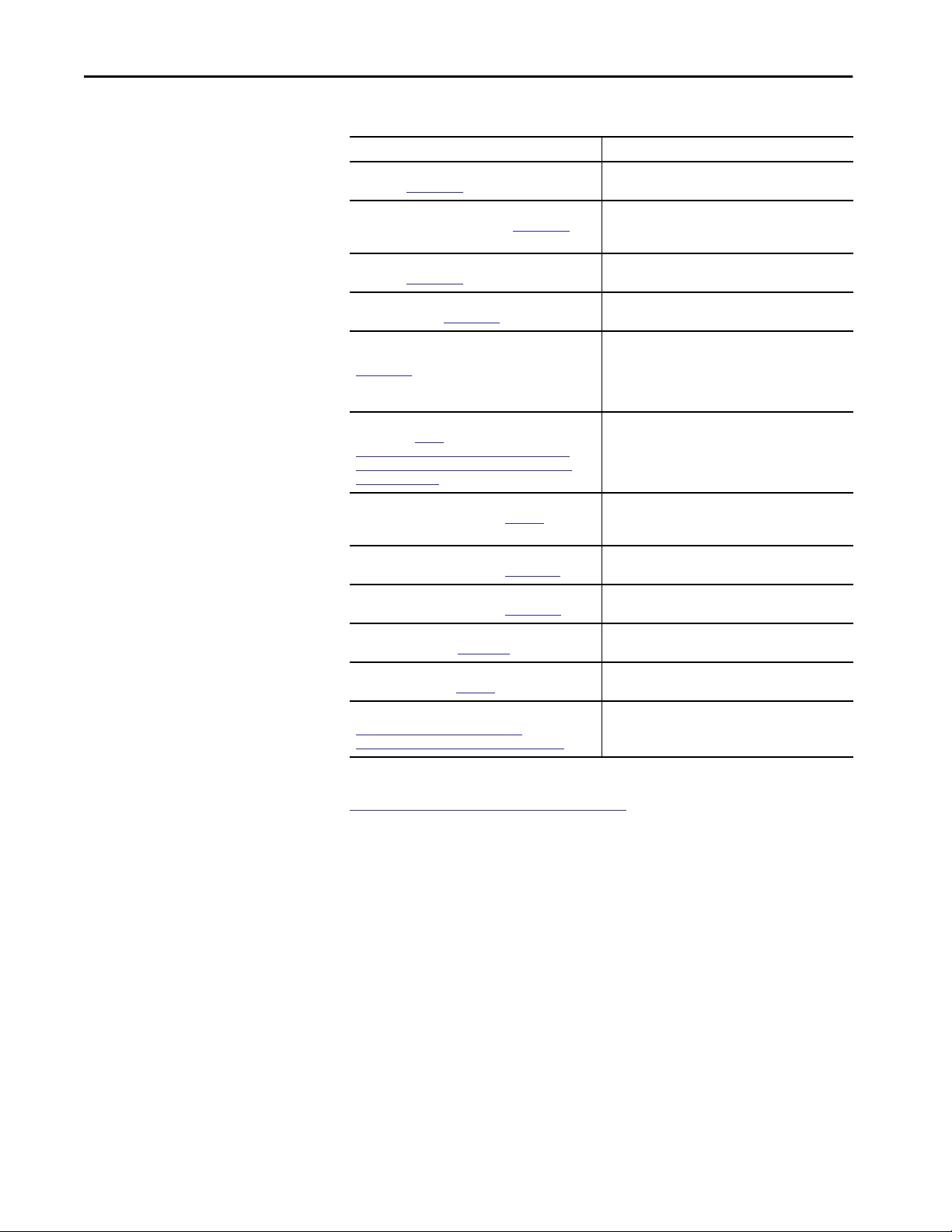

Table 2 - Additional Resources to Use with Compact 5000 I/O Digital Modules

Resource Description

Compact 5000 EtherNet/IP Adapters User Manual,

publication 5069-UM007

CompactLogix 5380 and Compact GuardLogix 5380

Controllers User Manual, publication

CompactLogix 5480 Controllers User Manual,

publication

ControlLogix 5580 and GuardLogix 5580 Controllers User

Manual, publication

GuardLogix and Compact GuardLogix 5380 Controller

Systems Safety Reference Manual, publication

1756-RM012

SISTEMA Performance Level Calculator, available for

download at:

www.marketing.rockwellautomation.com/safetysolutions/en/MachineSafety/ToolsAndDownloads/

sistema_download

Integrated Architecture and CIP Sync Configuration

Application Technique, publication

Electronic Keying in Logix5000 Control Systems

Application Technique, publication

Logix5000 Controllers Tasks, Programs, and Routines

Programming Manual, publication

Position-based Output Control with the MAOC

Instruction, publication

Industrial Automation Wiring and Grounding

Guidelines, publication

Product Certifications website,

http://www.rockwellautomation.com/

rockwellautomation/certification/overview.page

5069-UM002

1756-UM543

http://

1756-AT017

1770-4.1

5069-UM001

IA-AT003

LOGIX-AT001

1756-PM005

Describes how to configure, operate, and troubleshoot

the Compact 5000 I/O EtherNet/IP adapters.

Describes how to configure, operate, and troubleshoot

CompactLogix™ 5380 and Compact GuardLogix® 5380

controllers.

Describes how to configure, operate, and troubleshoot

CompactLogix 5480 controllers.

Describes how to configure, operate, and troubleshoot

ControlLogix® 5580 and GuardLogix 5580 controllers.

Describes requirements for achieving and maintaining

Safety Integrity Level (SIL) 2 and Performance Level (PL)

d requirements with the GuardLogix 5580 controller

system, using the Studio 5000 Logix Designer

application.

The SISTEMA tool automates calculation of the attained

Performance Level from the safety-related parts of a

machine’s control system to (EN) ISO 13849-1.

Provides information about CIP Sync™ technology and

how to synchronize clocks within the Rockwell

Automation® Integrated Architecture® system.

Describes how to use electronic keying in Logix 5000

control system applications.

Provides more information on event tasks and event

task configuration.

Describes how to configure time-scheduled output

control with the MAOC instruction.

Provides general guidelines for installing a Rockwell

Automation® industrial system.

Provides declarations of conformity, certificates, and

other certification details.

Preface

You can view or download publications at

http://literature.rockwellautomation.com/. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or Rockwell

Automation® sales representative.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 15

Page 16

Preface

Notes:

16 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 17

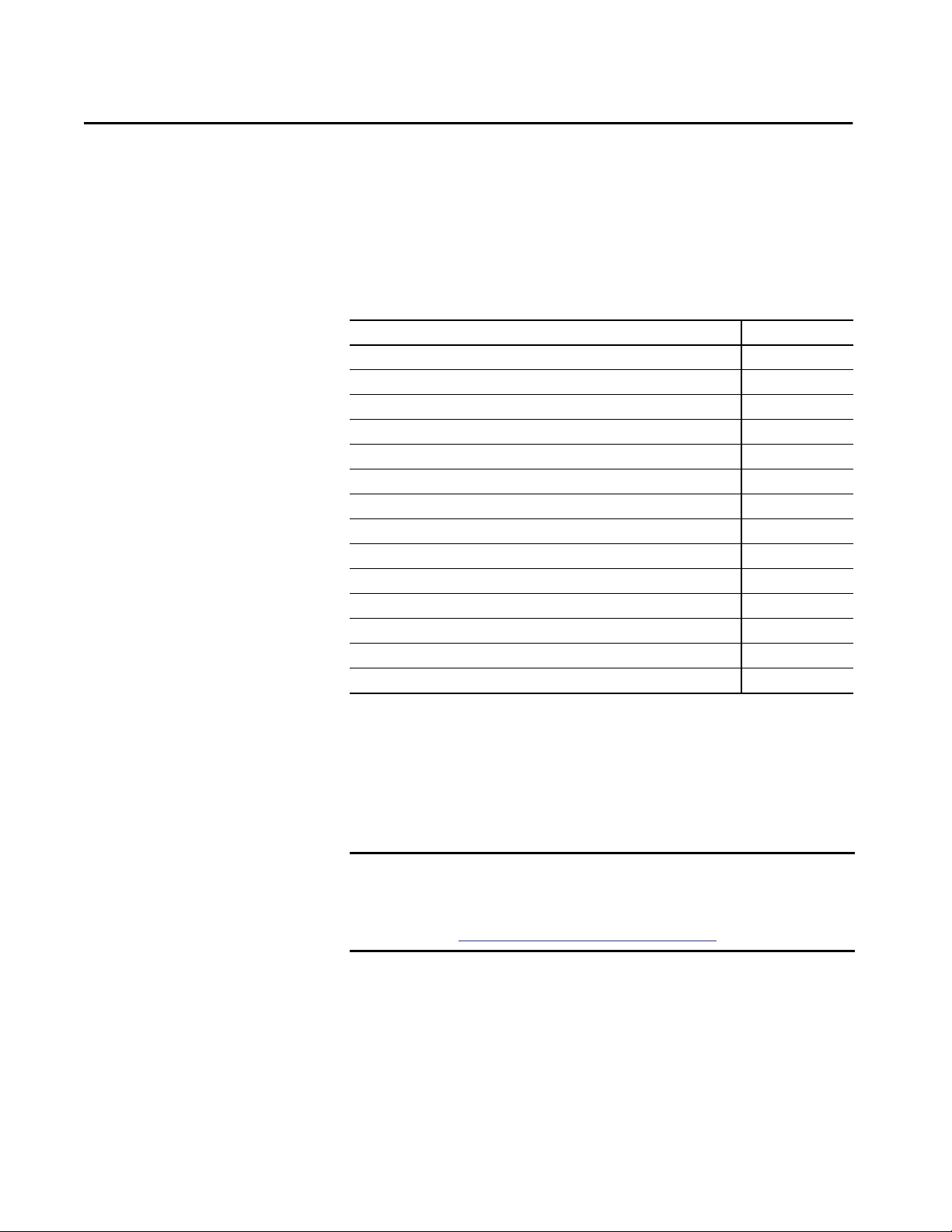

Chapter 1

Digital Module Operation in a Control System

Topic Page

Controller and Software Compatibility 18

Types of Modules 21

Module Overview 22

Local I/O Modules or Remote I/O Modules 24

Secure Access to the System 28

Ownership 29

Construct a System 31

Power the Modules 34

Configure the Modules 40

Input Module Operation 49

Output Module Operation 51

Listen Only 56

Protected Operations 57

Considerations Specific to Safety Modules 58

Logix 5000™ controllers use Compact 5000™ I/O digital modules to control

devices in a control system.

Compact 5000 I/O digital modules use removable terminal blocks (RTBs) to

connect field-side wiring. You use the Studio 5000 Logix Designer® application

to configure the modules.

IMPORTANT Controller and programming software compatibility requirements apply

when you use Compact 5000 I/O digital modules.

For more information on controller and software compatibility, see

Controller and Software Compatibility on page 18.

Compact 5000 I/O digital modules use the Producer/Consumer network

communication model. This communication is an intelligent data exchange

between modules and other system devices in which each module produces

data without first being polled.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 17

Page 18

Chapter 1 Digital Module Operation in a Control System

Controller and Software Compatibility

Standard Modules

DC OUTPUT

DC INPUT

5069-IB16

SA Power MOD Power

CONTROLLER

5069-L46ERMW

UPS

R

R

OK

FAN 1

B

B

RUN

SD

F

F

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

A1

LINK A2

1

2

CompactLogix 5480

A2

MP

SA

SPEED X1

LINK X1

™

Safety Modules

SIL2 CPU

5069-L3100ERMS2

ANALOG INPUT

DC INPUT

5069-IB16

DC INPUT

5069-IB16

5069-IB8S5069-IB8S

5069-OB16

DC INPUT

5069-IB16

5069-OBV8S

5069-IY4

DC OUTPUT

5069-OB16

OUTPUT OUTPUT

ANALOG OUTPUT

5069-OF8

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OBV8S

Controller and programming software compatibility requirements apply when

you use Compact 5000 I/O digital modules. A module type and how it is used

affect which requirements apply.

You must also consider Logix Designer application version requirements when

you design your system. For example, you can use safety modules only with the

Logix Designer application, version 32 or greater.

Controller Compatibility

Compatibility between Logix 5000 controllers and Compact 5000 I/O digital

modules varies based on module type and location. That is, whether the

module is standard or safety and whether it is local or remote.

For example, CompactLogix™ 5380 and CompactLogix 5480 controllers are

compatible with local or remote Compact 5000 I/O standard modules.

Compact GuardLogix® 5380 controllers are compatible with local or remote

Compact 5000 I/O digital modules.

Software Compatibility

Compact GuardLogix

Compact 5000 I/O digital modules are supported in different minimum

versions of the Logix Designer application.

SA Power MOD Power

For example, Compact 5000 I/O standard modules support the Logix

Designer application, version 28 or later. Compact 5000 I/O safety modules

support the Logix Designer application, version 32 or later.

IMPORTANT Logix 5000 controllers support different minimum versions of Logix Designer

application. You must consider the different device requirements when you

design your system.

For example, to use a 5069-IB16 input module with a 5069-L330ERM

controller, you can use the Logix Designer application, version 29 or later.

However, to use a 5069-IB16 input module with a 5069-L350ERM controller,

you can use the Logix Designer application, version 30 or later.

For more information on compatibility requirements, see

Table 3 on page 19

18 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 19

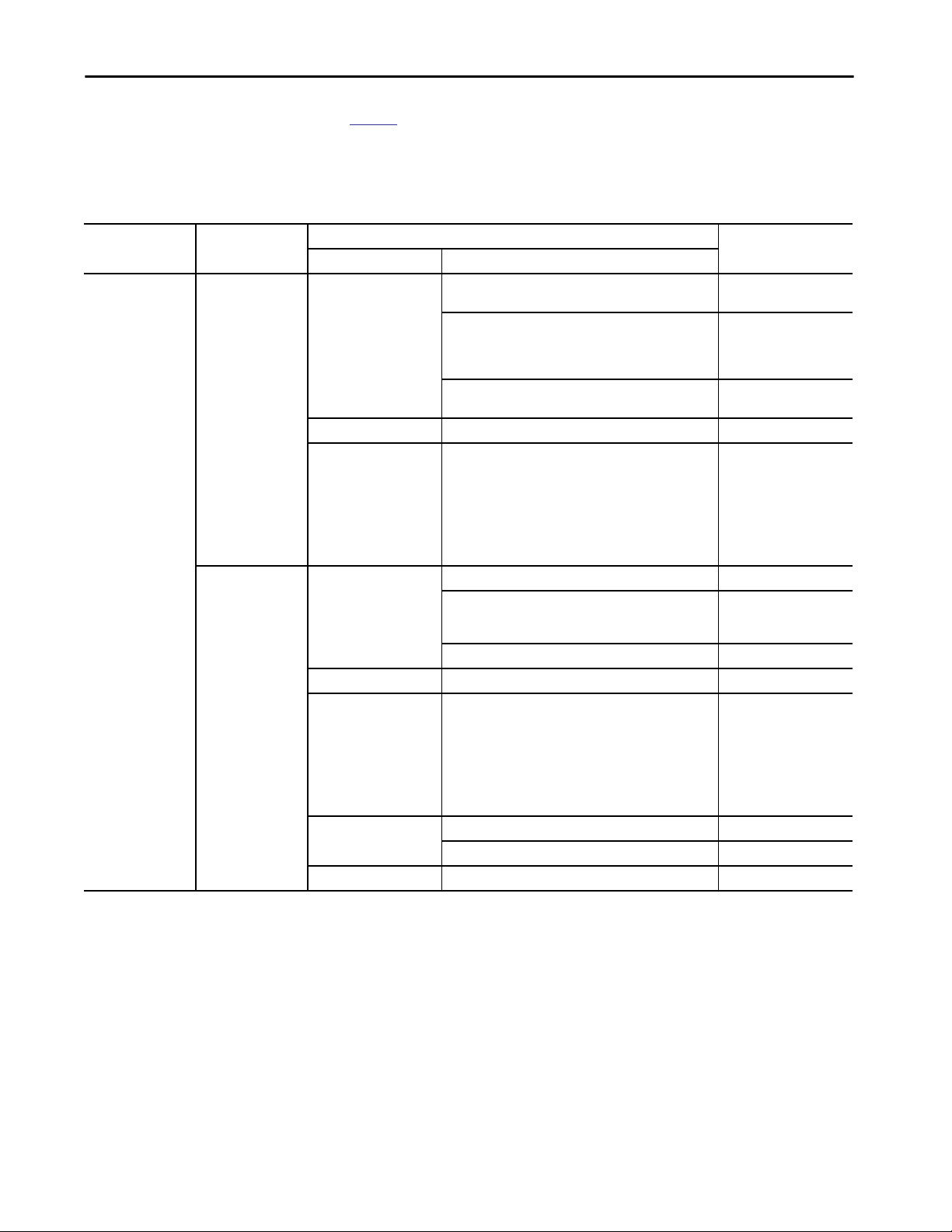

Table 3 describes the module compatibility requirements when you use

Compact 5000 I/O digital modules with Logix 5000 controllers.

Table 3 - Compact 5000 I/O Digital Modules Controller and Software Compatibility Requirements

Digital Module Operation in a Control System Chapter 1

Modules Location

Standard Modules

5069-IA16, 5069-IB16,

5069-IB16F, 5069IB16K, 5069-IB6F-3W,

5069-OA16, 5069-OB8,

5069-OB16, 5069OB16F, 5069-OB16K,

5069-OW4I, 5069OW16, 5069-OX4I

Local I/O modules CompactLogix 5380 5069-L320ER, 5069-L320ERMK, 5069-L330ERMK,

Remote I/O modules CompactLogix 5380 5069-L320ER, 5069-L340ERM Version 28.00.00 or later

Controllers

5069-L340ERM, 5069-L350ERMK

5069-L306ER, 5069-L306ERM, 5069-L310ER, 5069-L310ERM,

5069-L310ER-NSE, 5069-L310ERS2, 5069-L320ERM,

5069-L320ERMK, 5069-L330ER, 5069-L330ERM,

5069-L330ERMK, 5069-L340ER

5069-L350ERM, 5069-L350ERMK, 5069-L380ERM,

5069-L3100ERM

CompactLogix 5480 5069-L46ERMW Version 32.00.00 or later

Compact GuardLogix 5380 5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2, 5069-

L310ERMS2, 5069-L320ERS2, 5069-L320ERS2K, 5069L320ERMS2, 5069-L320ERMS2K, 5069-L330ERS2, 50695069-L330ERS2K, L330ERMS2, 5069-L330ERMS2K, 5069L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069L350ERS2K, 5069-L350ERMS2, 5069-L350ERMS2K, 5069L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2, 5069L3100ERMS2

5069-L306ER, 5069-L306ERM, 5069-L310ER, 5069-L310ERM,

5069-L310ER-NSE, 5069-L310ERS2, 5069-L320ERM, 5069L330ER, 5069-L330ERM, 5069-L340ER

5069-L350ERM, 5069-L380ERM, 5069-L3100ERM Version 30.00.00 or later

CompactLogix 5480 5069-L46ERMW Version 32.00.00 or later

Compact GuardLogix 5380 5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2, 5069-

L310ERMS2, 5069-L320ERS2, 5069-L320ERS2K, 5069L320ERMS2, 5069-L320ERMS2K, 5069-L330ERS2, 50695069-L330ERS2K, L330ERMS2, 5069-L330ERMS2K, 5069L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069L350ERS2K, 5069-L350ERMS2, 5069-L350ERMS2K, 5069L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2, 5069L3100ERMS2

ControlLogix® 5580 1756-L83E, 1756-L85E Version 28.00.00 or later

1756-L81E, 1756-L82E, 1756-L84E Version 29.00.00 or later

GuardLogix 5580 1756-L81ES, 1756-L82ES, 1756-L83ES, 1756-L84ES Version 31.00.00 or later

Logix Designer

ApplicationSystem Cat. Nos.

Version 28.00.00 or later

Version 29.00.00 or later

Version 30.00.00 or later

Version 31.00.00 or later

Version 29.00.00 or later

Version 31.00.00 or later

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 19

Page 20

Chapter 1 Digital Module Operation in a Control System

Table 3 - Compact 5000 I/O Digital Modules Controller and Software Compatibility Requirements

Modules Location

Safety Modules

5069-IB8S,

5069-IB8SK,

5069-OBV8S,

5069-OBV8SK

Local Compact GuardLogix 5380 5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2, 5069-

Remote Compact GuardLogix 5380 5069-L306ERS2, 5069-L306ERMS2, 5069-L310ERS2, 5069-

Controllers

L310ERMS2, 5069-L320ERS2, 5069-L320ERS2K, 5069L320ERMS2, 5069-L320ERMS2K, 5069-L330ERS2, 50695069-L330ERS2K, L330ERMS2, 5069-L330ERMS2K, 5069L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069L350ERS2K, 5069-L350ERMS2, 5069-L350ERMS2K, 5069L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2, 5069L3100ERMS2

L310ERMS2, 5069-L320ERS2, 5069-L320ERS2K, 5069L320ERMS2, 5069-L320ERMS2K, 5069-L330ERS2, 50695069-L330ERS2K, L330ERMS2, 5069-L330ERMS2K, 5069L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069L350ERS2K, 5069-L350ERMS2, 5069-L350ERMS2K, 5069L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2, 5069L3100ERMS2

GuardLogix 5580 1756-L81ES, 1756-L82ES, 1756-L83ES, 1756-L84ES

Logix Designer

ApplicationSystem Cat. Nos.

Version 32.00.00 or later

20 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 21

Digital Module Operation in a Control System Chapter 1

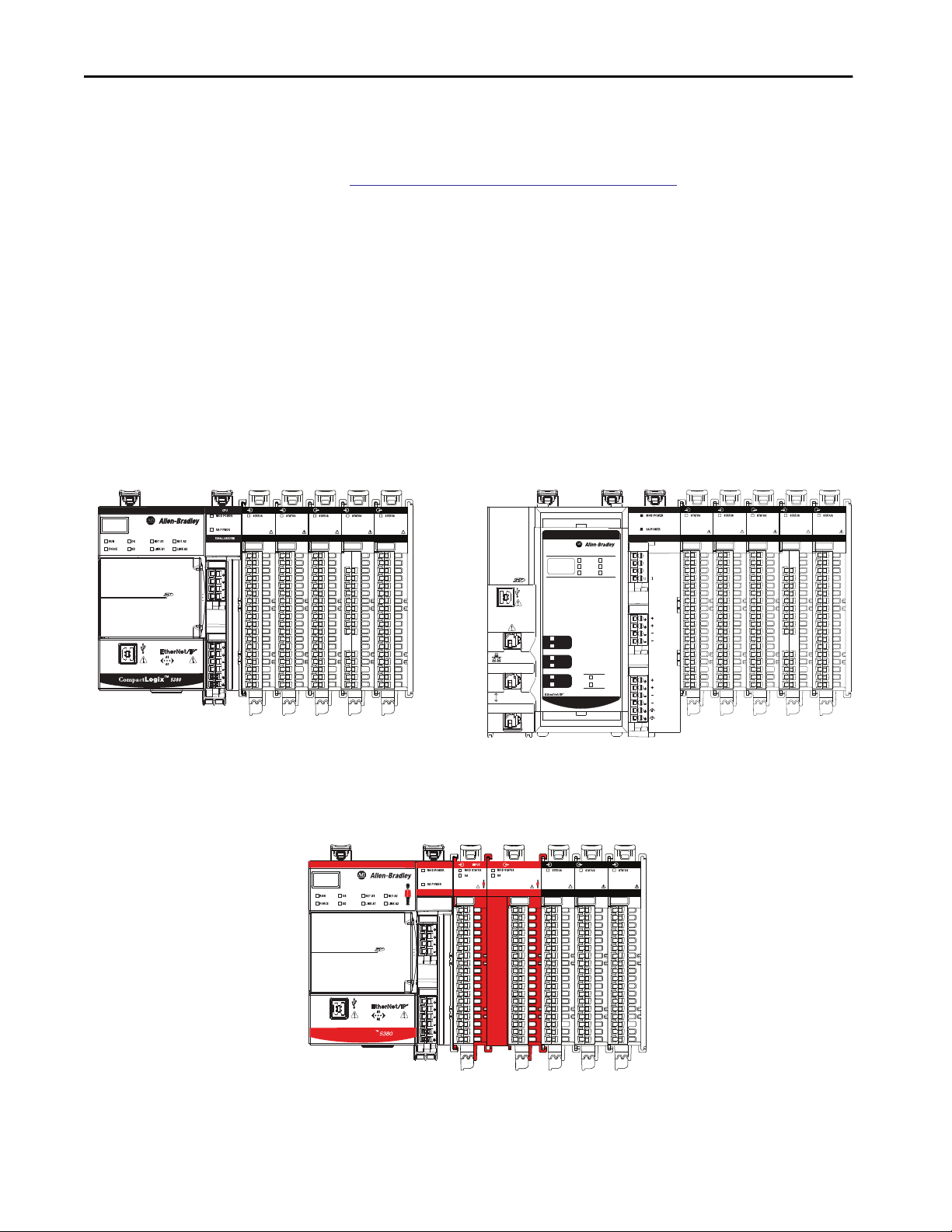

Types of Modules

Standard Modules

DC INPUT

DC INPUT

5069-IB16

5069-IB16

SA Power MOD Power

CONTROLLER

DC INPUT

5069-IB16

5069-L46ERMW

UPS

R

R

OK

FAN 1

B

B

RUN

SD

F

F

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

A1

LINK A2

1

2

CompactLogix 5480

A2

Compact GuardLogix

MP

SA

SPEED X1

LINK X1

™

Safety Modules

SIL2 CPU

5069-L3100ERMS2

SA Power MOD Power

5069-IB8S5069-IB8S

DC OUTPUT

5069-OB16

DC INPUT

5069-IB16

5069-OBV8S

ANALOG INPUT

5069-IY4

DC OUTPUT

5069-OB16

OUTPUT OUTPUT

Table 4 describes the Compact 5000 I/O digital modules.

Table 4 - Compact 5000 I/O Digital Modules

ANALOG OUTPUT

5069-OF8

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OBV8S

Module Type Cat. No. Description

Standard 5069-IA16 79…264V AC 16-point, input module

5069-IB16 10…32V DC 16-point, sinking input module

5069-IB16K 10…32V DC 16-point, conformal coated sinking input module

5069-IB16F 10…32V DC 16-point, sinking fast input module

5069-IB6F-3W 10…32V DC 6-point, 3-wire, sinking fast input module

5069-OA16 85…264V AC 16-point, output module

5069-OB8 10…32V DC 8-point, sourcing high-current output module

5069-OB16 10…32V DC 16-point, sourcing output module

5069-OB16K 10…32V DC 16-point, conformal coated sourcing output

module

5069-OB16F 10…32V DC 16-point, sourcing fast output module

5069-OW4I 5…264V AC /125V DC 4-point, isolated normally open relay

output module

5069-OW16 5…264V AC/125V DC 16-point, normally open relay output

module

5069-OX4I 5…264V AC /125V DC 4-point, isolated normally open/

normally closed relay output module

Safety

(1)

5069-IB8S 18…32V DC 8-point, safety sinking input module

5069-IB8SK 18…32V DC 8-point, conformal coated safety sinking

input module

5069-OBV8S 18…32V DC 8-point, safety output module that can be used as

follows:

• Bipolar output module

• Sourcing output module

5069-OBV8SK 18…32V DC 8-point, conformal coated safety output module

that can be used as follows:

• Bipolar output module

• Sourcing output module

(1) You can use the safety modules in applications that are rated up to, and including, SIL CL3, PLe, Cat. 4 as defined in IEC 61508, IEC

61511, IEC 62061, and ISO 13849-1.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 21

Page 22

Chapter 1 Digital Module Operation in a Control System

Module Overview

Standard Modules

DC INPUT

DC INPUT

5069-IB16

5069-IB16

SA Power MOD Power

CONTROLLER

DC INPUT

DC INPUT

5069-IB16

5069-IB16

5069-L46ERMW

UPS

R

R

OK

FAN 1

B

B

RUN

SD

F

F

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

A1

LINK A2

1

2

CompactLogix 5480

A2

MP

SA

SPEED X1

LINK X1

™

Safety Modules

SIL2 CPU

5069-L3100ERMS2

5069-IB8S5069-IB8S

DC OUTPUT

5069-OB16

DC OUTPUT

5069-OB16

OUTPUT OUTPUT

5069-OBV8S

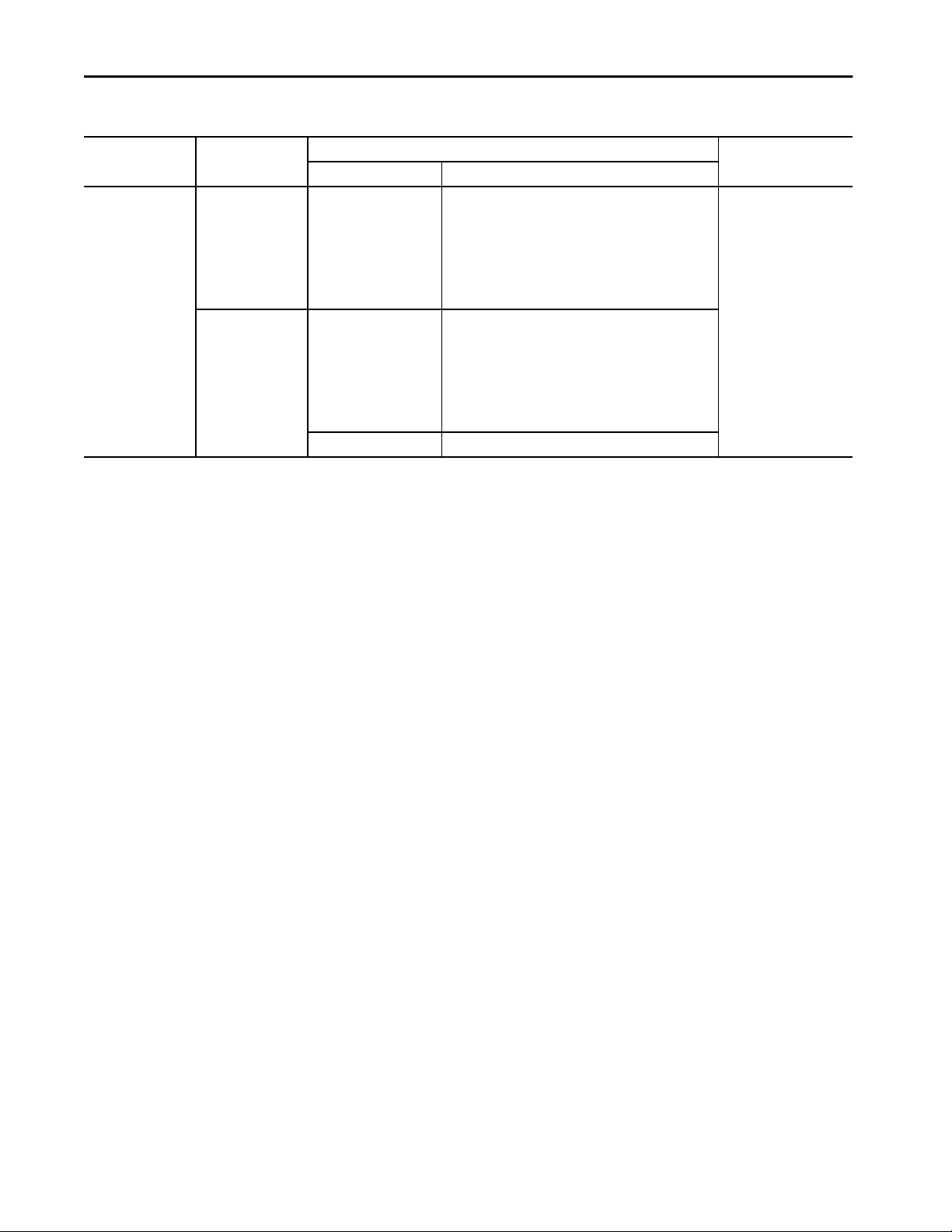

Figure 1 shows the parts of a Compact 5000 I/O digital module.

IMPORTANT Compact 5000 I/O safety modules look the same from the front with the

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

exception that the safety modules have a red

Figure 1 - Example Compact 5000 I/O Digital Modules

1

2

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

DC INPUT

5069-IB16

3

4

5069-OBV8S

1

2

3

housing.

5069-IB8S

4

Compact GuardLogix

SA Power MOD Power

5

6

7

8

22 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

9

Page 23

Digital Module Operation in a Control System Chapter 1

Table 5 - Compact 5000 I/O Digital Module Parts

Item Item Description

1 DIN rail latch Locks the module on the DIN rail.

2 Module and

power status

indicators

3 I/O status

indicators

4 Interlocking

pieces

5 RTB handle Anchors the RTB on the module.

6 RTB Provides a wiring interface for the module.

7 MOD Power bus

and SA Power

bus connectors

8 RTB lower tab Hooks RTB onto the module to begin installation.

9 Lower hook Used with cable tie after you wire the module.

Standard modules:

• STATUS - Displays the status of communication and module health.

Safety modules:

• MOD Status - Displays the status of communication and module health.

• SA - Displays whether SA power is applied to the module.

Displays the status of the input/output point.

Securely installs Compact 5000 I/O digital modules in the system.

Pass system-side and field-side power across the internal circuitry of the

module in a Compact 5000 I/O system. The connectors are isolated from

each other.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 23

Page 24

Chapter 1 Digital Module Operation in a Control System

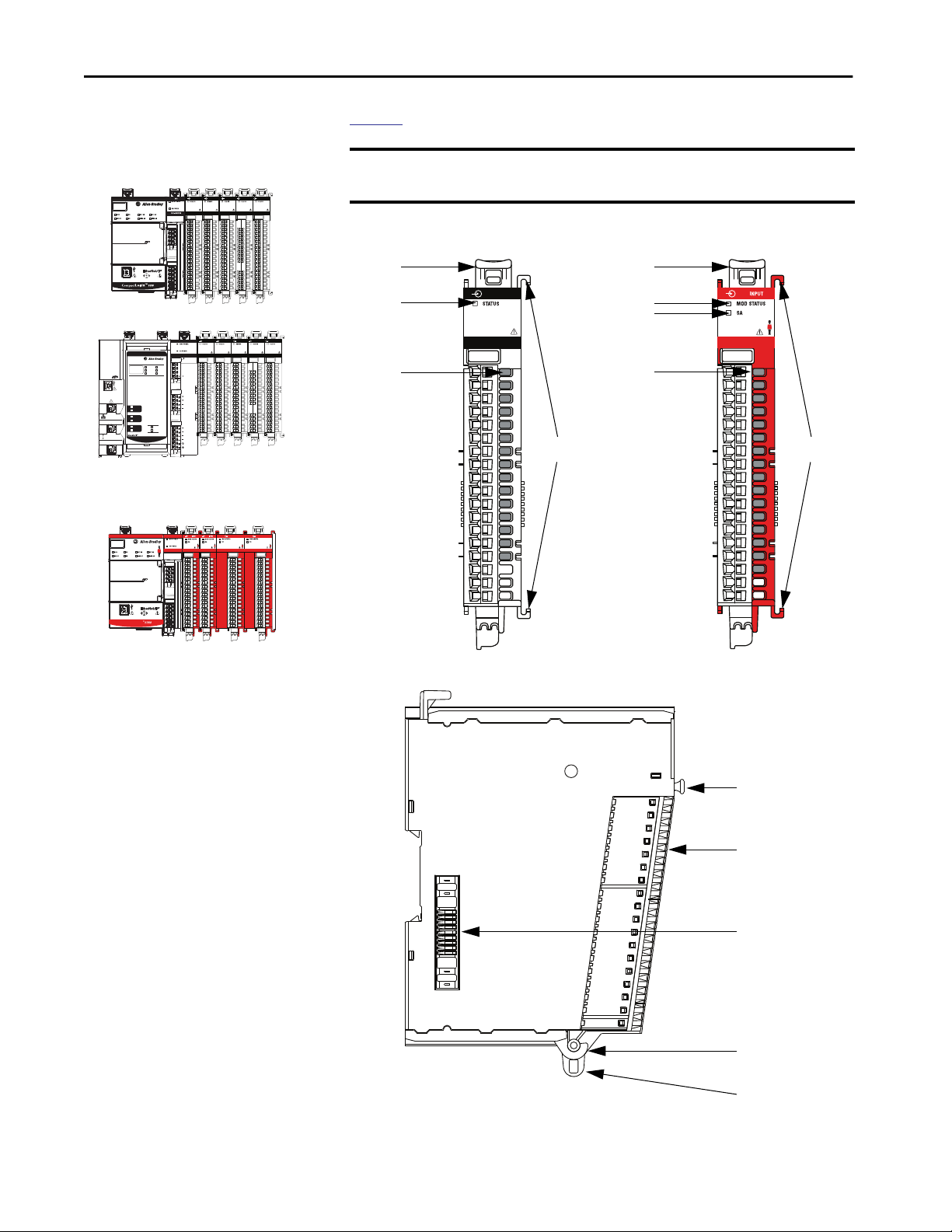

Local I/O Modules or Remote I/O Modules

CompactLogix 5380 Controller Local Compact 5000

I/O Standard Modules

DC INPUT

DC INPUT

5069-IB16

5069-IB16

DC OUTPUT

5069-OB16

You can use Compact 5000 I/O digital modules as local or remote

I/O modules, with some restrictions that are based on the module and

controller type. Compatibility requirements apply and are described in

Controller and Software Compatibility on page 18.

Local I/O Modules

When Compact 5000 I/O digital modules reside in the same system as the

controller, the modules are local I/O modules.

Local I/O modules are installed to the right of the controller and exchange

data with the controller over the system backplane.

Figure 2 - Local Compact 5000 I/O Digital Modules

ANALOG INPUT

5069-IY4

ANALOG OUTPUT

5069-OF8

CompactLogix 5480 Controller Local Compact 5000 I/O

CONTROLLER

5069-IB16

5069-L46ERMW

UPS

R

OK

FAN 1

RUN

SD

FORCE

FAN 2

R

B

B

F

F

DC INPUT

Standard Modules

DC OUTPUT

DC INPUT

5069-IB16

5069-OB16

ANALOG INPUT

5069-IY4

ANALOG OUTPUT

5069-OF8

MP

B1

SA Power MOD Power

A1

1

2

NET B1

LINK B1

NET A1

LINK A1

NET A2

LINK A2

CompactLogix 5480

SPEED X1

LINK X1

™

SA

A2

Compact GuardLogix 5380 Controller Local Compact 5000 I/O

Digital Modules

OUTPUT

Compact GuardLogix

SIL2 CPU

5069-L3100ERMS2

DC INPUT

5069-IB16

5069-OBV8S

5069-IB8S

SA Power MOD Power

ANALOG OUTPUT

5069-OF8

COUNTER

5069-HSC2xOB4

24 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 25

Digital Module Operation in a Control System Chapter 1

Remote I/O Modules

When Compact 5000 I/O digital modules reside in a separate location from

Logix 5000 controllers, they are remote I/O modules. Remote Compact 5000

I/O digital modules are accessible over an EtherNet/IP™ network via a

Compact 5000 I/O EtherNet/IP adapter.

The modules are installed to the right of the adapter and exchange data across

the remote system backplane. The data is then exchanged with the controller

over the EtherNet/IP network.

IMPORTANT Remember, some restrictions apply when you use the I/O modules remotely.

For example, you can use Compact 5000 I/O safety modules as remote I/O

modules only in Compact GuardLogix 5380 or GuardLogix 5380 control

systems.

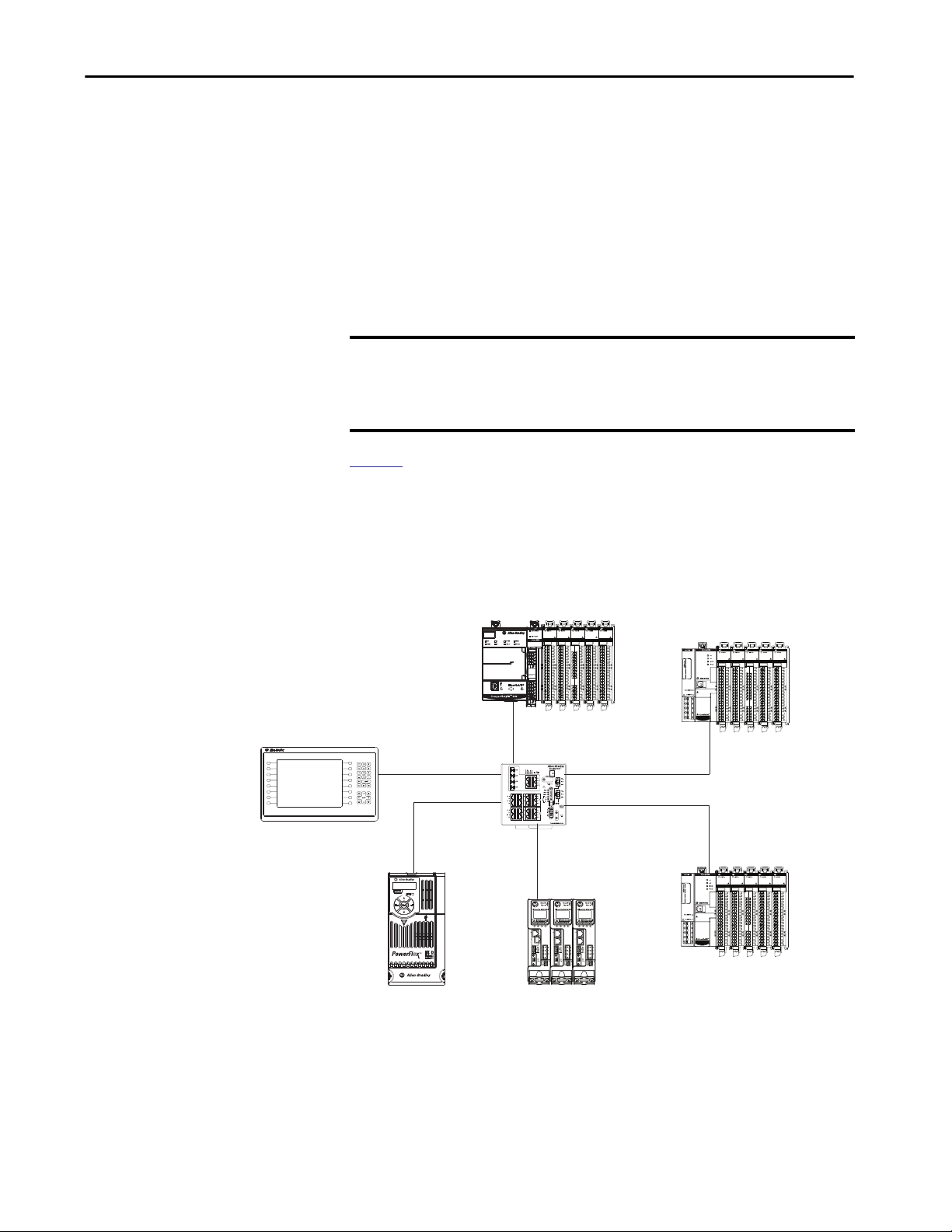

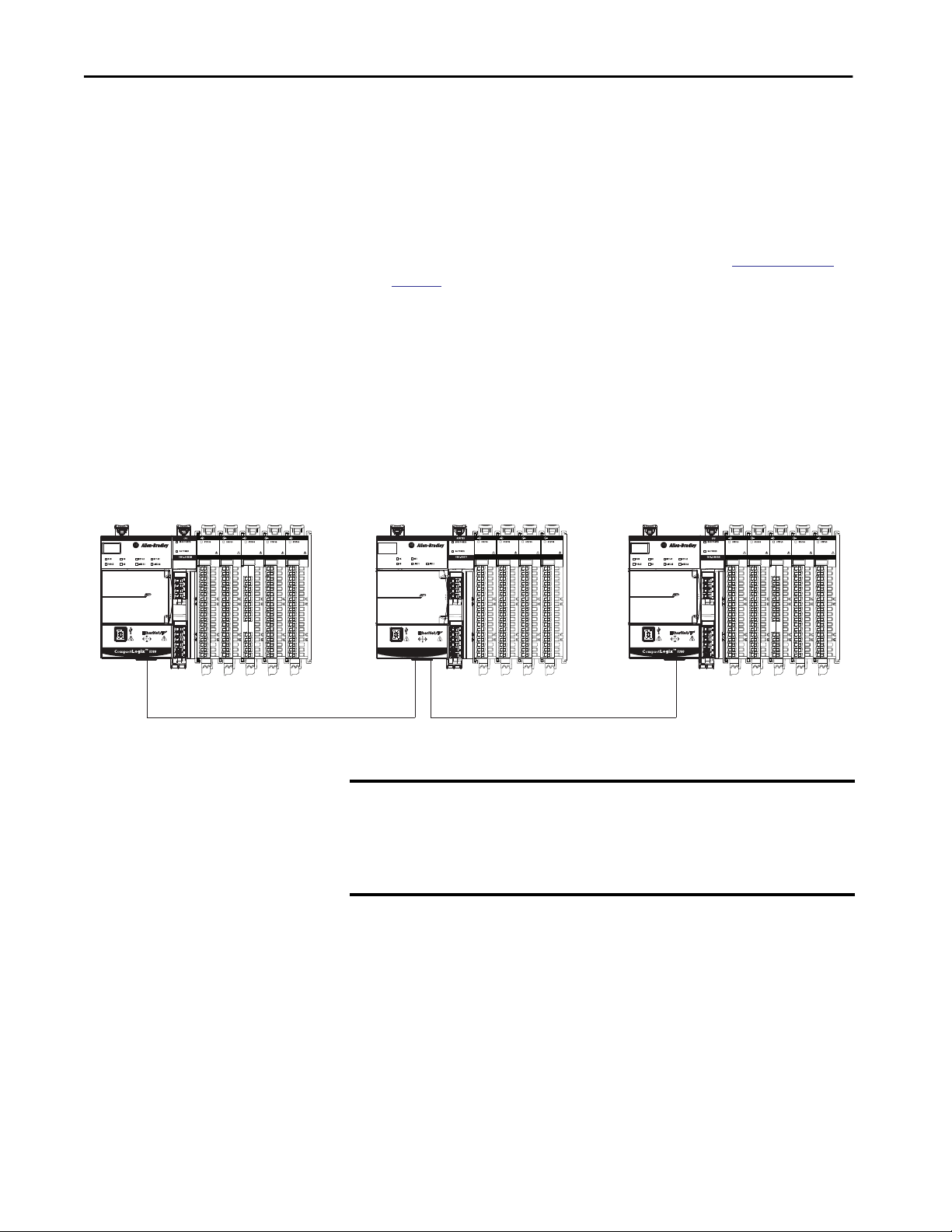

Figure 3 shows remote Compact 5000 I/O standard modules in an example

CompactLogix 5380 control system.

Figure 3 - Remote Compact 5000 I/O Standard Modules in a CompactLogix 5380

Control Applications

F1

F2

F3

F4

F5

F6

F7

F8

PanelView™ Plus 7 Terminal

F9

F10

F11

F12

F13

F14

F15

F16

PowerFlex® 527 Drive Kinetix® 5500 Drive

CompactLogix 5380 Controller

Compact 5000 I/O Standard Modules

Compact 5000 I/O EtherNet/IP Adapter

DC OUTPUT

DC INPUT

5069-IB16

SA Power MOD Power

COUNTER

ANALOG INPUT

ANALOG OUTPUT

5069-HSC2xOB4

5069-IY4

5069-OF8

5069-OB16

Compact 5000 I/O Standard Modules

DC OUTPUT

DC INPUT

5069-IB16

1

2

Compact 5000™ I/O

Compact 5000™ I/O

COUNTER

ANALOG INPUT

ANALOG OUTPUT

5069-HSC2xOB4

5069-IY4

5069-OF8

5069-OB16

Stratix® 5400 Switch

DC OUTPUT

DC INPUT

5069-IB16

1

2

Compact 5000™ I/O

Compact 5000™ I/O

527

COUNTER

ANALOG INPUT

ANALOG OUTPUT

5069-HSC2xOB4

5069-IY4

5069-OF8

5069-OB16

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Standard Modules

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 25

Page 26

Chapter 1 Digital Module Operation in a Control System

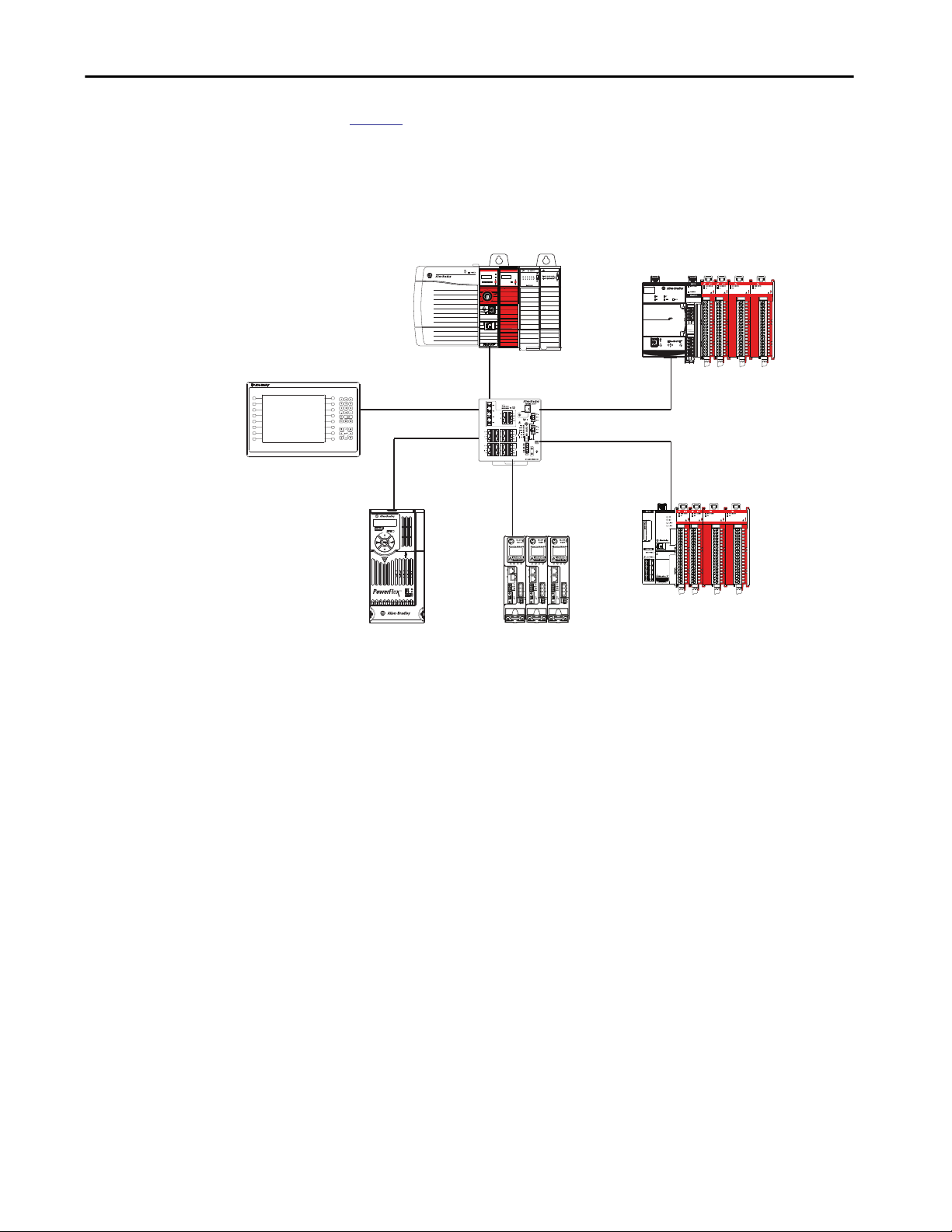

Figure 4 shows remote Compact 5000 I/O safety modules in a

Compact GuardLogix 5380 control application.

Figure 4 - Remote Compact 5000 I/O Safety Modules in a Compact GuardLogix 5380

Control Application

Compact GuardLogix 5380 Controller

Compact 5000 I/O Digital Modules

OUTPUT

SIL2 CPU

5069-L3100ERMS2

5069-IB8S 5069-IB8S

ANALOG OUTPUT

5069-HSC2xOB4

5069-OF8

5069-OBV8S

COUNTER

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Safety Modules

OUTPUT OUTPUT

5069-OBV8S

5069-IB8S 5069-IB8S

5069-OBV8S

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

PanelView Plus 7 Terminal

Compact GuardLogix

SA Power MOD Power

Stratix 5400 Switch

527

PowerFlex 527 Drive Kinetix 5500 Drive

SA Power MOD Power

Compact 5000™ I/O

OUTPUT OUTPUT

5069-OBV8S

5069-IB8S 5069-IB8S

Compact 5000™ I/O

5069-OBV8S

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Safety Modules

26 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 27

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

PanelView Plus 7 Terminal

Digital Module Operation in a Control System Chapter 1

Figure 5 shows remote Compact 5000 I/O safety modules in a

GuardLogix 5580 control application.

Figure 5 - Remote Compact 5000 I/O Safety Modules in a GuardLogix 5580 Control Application

GuardLogix 5580 Safety Controller

GuardLogix 1756-L8SP Safety Partner

Logix5584ES™

NET

LINK

FORCESD OK

RUN

REM

PROG

RUN

DC INPUT

Logix55L8SP™

OK

Stratix 5400 Switch

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Safety Modules

OUTPUT OUTPUT

5069-OBV8S

OUTPUT OUTPUT

5069-OBV8S

5069-OBV8S

5069-OBV8S

Compact 5000™ I/O

5069-IB8S 5069-IB8S

SA Power MOD Power

5069-IB8S 5069-IB8S

527

PowerFlex 527 Drive Kinetix 5500 Drive

Compact 5000™ I/O

Compact 5000 I/O EtherNet/IP Adapter

Compact 5000 I/O Safety Modules

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 27

Page 28

Chapter 1 Digital Module Operation in a Control System

Secure Access to the System

Standard Modules

DC OUTPUT

DC INPUT

5069-IB16

SA Power MOD Power

CONTROLLER

5069-L46ERMW

UPS

R

R

OK

FAN 1

B

B

RUN

SD

F

F

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

A1

LINK A2

1

2

CompactLogix 5480

A2

MP

SA

SPEED X1

LINK X1

™

Safety Modules

SIL2 CPU

5069-L3100ERMS2

ANALOG INPUT

DC INPUT

5069-IB16

DC INPUT

5069-IB16

5069-IB8S5069-IB8S

5069-OB16

DC INPUT

5069-IB16

5069-OBV8S

5069-IY4

DC OUTPUT

5069-OB16

OUTPUT OUTPUT

ANALOG OUTPUT

5069-OF8

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OBV8S

To secure access to a Logix 5000 controller, Compact 5000 EtherNet/IP

adapter, or I/O module by authorized users only, consider the

following options:

• Password protect the source and execution of the control program.

• Deploy EtherNet/IP devices in accordance with recommended

architectures and concepts. See the Converged Plantwide Ethernet

(CPwE) Design and Implementation Guide, publication

ENET-TD001.

• Implement physical barriers, such as locked cabinets.

To secure access to the system, consider the following options:

• Follow industry best practices to harden your PCs and servers, including

anti-virus/anti-malware and application whitelisting solutions.

The recommendations are published at the Rockwell Automation®

technical support center in Knowledgebase article Rockwell

Automation Customer Hardening Guidelines, #546987.

The technical support center is available at:

https://

rockwellautomation.custhelp.com/

Compact GuardLogix

SA Power MOD Power

• Develop and deploy backup and disaster recovery policies and

procedures. Test backups on a regular schedule.

• Minimize network exposure for all control system devices and systems,

and make sure that they are not accessible from the Internet.

• Locate control system networks and devices behind firewalls and isolate

them from the business network.

• Subscribe to Knowledgebase article Industrial Security Advisory Index,

#54102 at the Rockwell Automation technical support center so you

have access to information about security matters that affect Rockwell

Automation products.

The technical support center is available at:

https://

rockwellautomation.custhelp.com/

28 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 29

Digital Module Operation in a Control System Chapter 1

Ownership

Standard Modules

OK

FAN 1

RUN

SD

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

Compact GuardLogix

SPEED X1

LINK A2

LINK X1

™

CompactLogix 5480

Safety Modules

A1

1

2

A2

Every I/O module in a Logix 5000 control system must be owned by a

controller, also known as the owner-controller. When a Compact 5000 I/O

digital module is used in a Logix 5000 control system, the owner-controller

performs the following:

DC OUTPUT

DC INPUT

5069-IB16

ANALOG INPUT

DC INPUT

5069-IB16

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OB16

• Stores configuration data for every module that it owns.

• Can reside in a location that differs from the Compact 5000 I/O

SA Power MOD Power

digital modules.

• Sends the I/O module configuration data to define module behavior

CONTROLLER

5069-L46ERMW

UPS

R

R

B

B

F

F

MP

DC OUTPUT

DC INPUT

5069-IB16

ANALOG INPUT

DC INPUT

5069-IB16

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OB16

and begin operation in the control system.

Each Compact 5000 I/O digital module must continuously maintain

communication with its owner-controller during normal operation.

SA

Typically, each I/O module in a system has only one owner-controller. Output

modules are limited to one owner-controller.

SIL2 CPU

5069-L3100ERMS2

OUTPUT OUTPUT

5069-OBV8S

5069-IB8S5069-IB8S

5069-OBV8S

Multiple Owners of Compact 5000 I/O Digital Input Modules

Typically only one owner-controller is connected to a Compact 5000 I/O

digital input module. However, multiple Logix 5000 controllers can connect to

SA Power MOD Power

Compact 5000 I/O digital input modules as owner-controllers.

In this case, the following conditions must exist:

• The controllers maintain the same configuration.

• The configuration in each controller uses a Data connection to the

input module.

• The first controller to make a connection to the input module is the

only controller that can change the connection. Therefore, it is ‘owns’

the module configuration.

IMPORTANT If the controller that owns the module configuration changes the

configuration, the other controllers are not notified of the changes.

For more information, see

Configuration Changes in an Input

Module with Multiple Owners on page 30.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 29

Page 30

Chapter 1 Digital Module Operation in a Control System

• The controllers that do maintain, but do not ‘own’, the module

configuration are similar to Listen-only controllers.

The difference between the controllers is that the controllers that

maintain, but do not own, the module configuration can use a Multicast

or Unicast connection over the EtherNet/IP network.

Configuration Changes in an Input Module with Multiple Owners

DC OUTPUT

DC INPUT

5069-IB16

5069-OB16

SA Power MOD Power

ANALOG INPUT

5069-IY4

ANALOG OUTPUT

5069-OF8

COUNTER

5069-HSC2xOB4

For more information on Listen-only controllers, see

Listen Only on

page 56.

You must be careful when changing the configuration data of an input module

in a multiple-owner scenario. If the configuration data is changed in owner A

and sent to the module, the changed configuration data is accepted as the new

configuration for the module. Owner B continues to listen unaware that any

changes have been made in the behavior of the input module, as illustrated.

Figure 6 - Module Configuration Changes with Multiple Owners

DC OUTPUT

DC OUTPUT

DC INPUT

Compact 5000™ I/O

DC INPUT

5069-IB16

5069-IB16

5069-OB16

5069-OB16

SA Power MOD Power

DC OUTPUT

DC INPUT

5069-IB16

5069-OB16

SA Power MOD Power

COUNTER

ANALOG INPUT

ANALOG OUTPUT

5069-HSC2xOB4

5069-IY4

5069-OF8

Controller A sends new configuration to the module. Controller B is unaware of any configuration changes.

IMPORTANT A message in Logix Designer application alerts you to the possibility of a

multiple owner-controller situation and lets you inhibit the connection

before changing the module configuration. When changing the

configuration for a module with multiple owners, we recommend that you

inhibit the connection.

30 Rockwell Automation Publication 5069-UM004A-EN-P - April 2019

Page 31

Digital Module Operation in a Control System Chapter 1

To help prevent other owner-controllers from receiving potentially erroneous

data, use the following steps when changing the configuration of a module in a

multiple owner scenario while online.

1. For each owner-controller, inhibit the connection to the module either

in the software on the Connection tab or the message dialog box

warning you of the multiple owner condition.

2. Make the appropriate configuration data changes in the software.

For more information on how to use the Logix Designer application to

change the configuration, see the following:

– Standard modules - Chapter 6,

Configure a Standard Module on

page 149

– Safety modules - Chapter 7,

Configure and Replace Safety Modules

on page 191

Construct a System

Standard Modules

DC OUTPUT

DC INPUT

DC INPUT

5069-IB16

5069-IB16

5069-OB16

SA Power MOD Power

CONTROLLER

DC INPUT

DC INPUT

5069-IB16

5069-IB16

5069-L46ERMW

UPS

R

R

OK

FAN 1

B

B

RUN

SD

F

F

FORCE

FAN 2

NET B1

B1

LINK B1

NET A1

LINK A1

NET A2

A1

LINK A2

1

2

CompactLogix 5480

A2

MP

SA

SPEED X1

LINK X1

™

3. Repeat

step 1 and step 2 for all owner-controllers, to make the exact

same changes in each.

4. Clear the Inhibit checkbox in each owner-controller configuration.

Before you use your Compact 5000 I/O digital modules, you must complete

tasks that are based on the way that you use the modules. That is, if the

modules are used locally, remotely or both locally and remotely.

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

Local I/O Modules

Complete the following:

1. Install a CompactLogix 5380, CompactLogix 5480, or

DC OUTPUT

ANALOG INPUT

ANALOG OUTPUT

5069-IY4

5069-OF8

5069-OB16

Compact GuardLogix 5380 controller.

IMPORTANT Remember, you must use a Compact GuardLogix 5380 controller if

the local Compact 5000 I/O digital modules includes safety

modules.

For more information on controller compatibility, see

Controller and

Software Compatibility on page 18.

Compact GuardLogix

Safety Modules

SIL2 CPU

5069-L3100ERMS2

5069-IB8S5069-IB8S

SA Power MOD Power

OUTPUT OUTPUT

5069-OBV8S

2. Install the modules to the right of the controller.

5069-OBV8S

3. Install the end cap on the last module in the local system.

IMPORTANT The end cap in a CompactLogix 5380, CompactLogix 5480, or

Compact GuardLogix 5380 control system covers the exposed

interconnection on the last module on the DIN rail.

If you do not install an end cap on the last module on the DIN rail,

equipment damage or injury can occur.

Rockwell Automation Publication 5069-UM004A-EN-P - April 2019 31

Page 32

Chapter 1 Digital Module Operation in a Control System

Remote I/O Modules

Complete the following:

1. Install a controller that is compatible with the remote Compact 5000

I/O digital modules to be used in the application via an EtherNet/IP

network.