Page 1

Installation Instructions

44.5

(1.75)

44.5

(1.75)

25 (1) 25 (1)

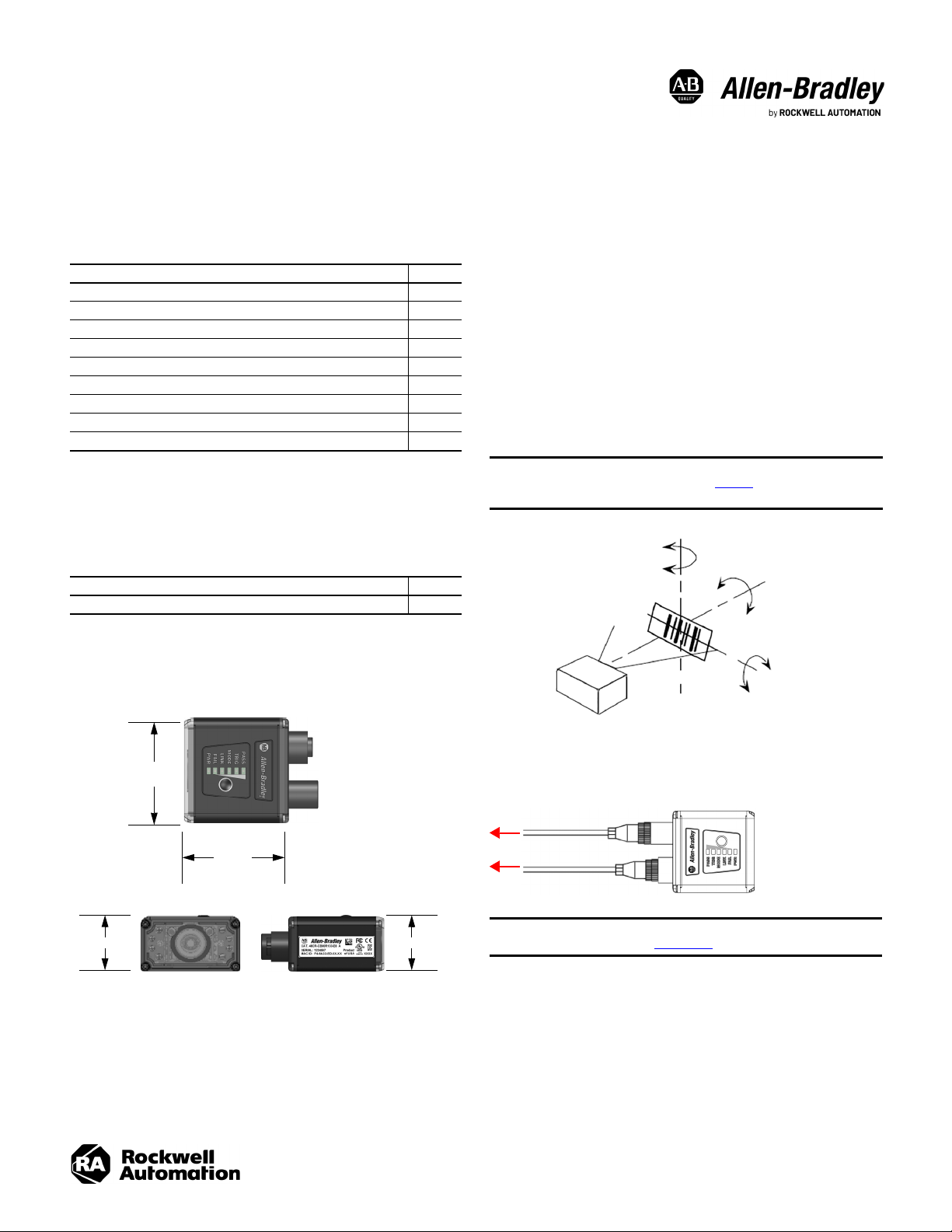

Symbol

Skew

Tilt

Pitch

To H ost

To P ower

Original Instructions

Bulletin 48CR Code Reader

Catalog Number 48CR-CB16R400-E8, 48CR-CB52R102-E8, 48CR-CB80R133-E8, 48CR-CB80R190-E8, 48CR-CC16RAF-E8, 48CR-CC50RAF-E8,

48CRCC77RAF-E8

Top ic Pa ge

Summary of Changes 1

Dimensions 1

Mount and Position the Reader 1

Connect the System 1

Power Requirements and Pin Assignments 1

Status Indicators 2

Connect to Code Reader 2

Product Selection 3

Specifications 4

Summary of Changes

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

Translated versions are not always available for each revision.

Top ic Pa ge

Updated Connectivity in the Specifications table. 4

Dimensions

Figure 1 - Approximate Dimensions [mm (in.)]

Mount and Position the Reader

1. Position the reader several inches from the symbol. The focal distance

varies depending on the code reader catalog number and the 1D/2D

barcode size. If needed, you can reposition the reader a few times to

find the ideal distance.

2. Tip the reader relative to the symbol to avoid the glare of direct

(specular) reflection.

3. Symbols can be rotated (tilted) at any angle. However, for best results,

symbols must be aligned with the field of view. If there are linear

symbols, align the bars in the direction of their movement (ladder

orientation) to help minimize the chance of blurring. This alignment

results in more consistent decodes.

IMPORTANT

Figure 2 - Skew, Pitch, and Tilt

Avoid excessive skew or pitch. Maximum skew is ±30°;

maximum pitch is ±30°. Figure 2 shows approximate

skew axis, pitch axis, and tilt axis.

Connect the System

Figure 3 - 48CR Code Reader– Standalone Ethernet Configuration

IMPORTANT

The 48CR code reader is an EtherNet/IP™ reader. See

publication 48CR-UM001 for more details.

Power Requirements and Pin Assignments

4.75…30V; 150 mA at 24V DC (typical)

Page 2

Bulletin 48CR Code Reader Installation Instructions

5

6

7

8

4

3

1

2

3

2

1

4

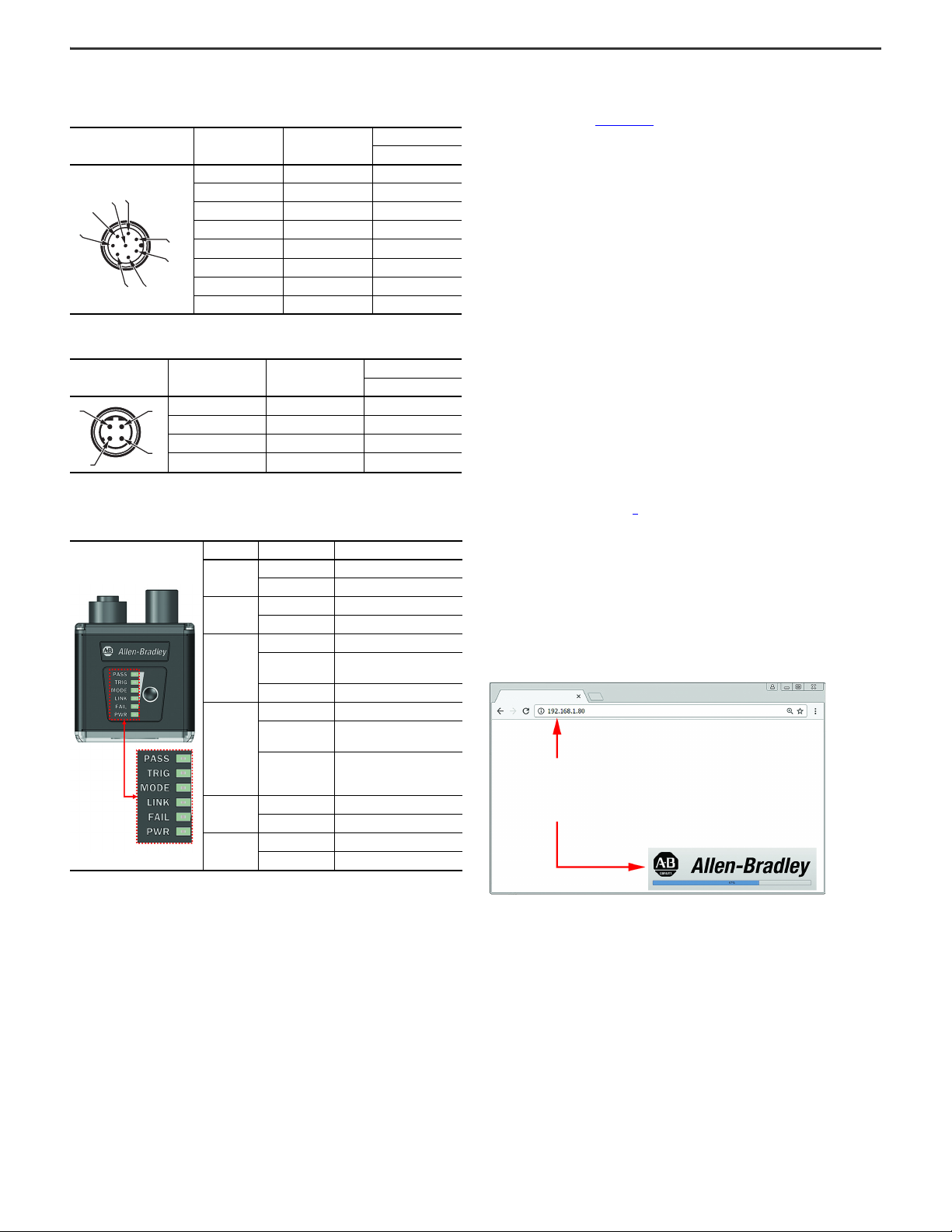

Type 192.168.1.80 in the address

bar of the web browser. The Web

Connect session launches after

the IP address has been entered.

I/O Connectors

Table 1 - Power I/O Connection

Face View of

Male DC Micro

Table 2 - Ethernet Connection

Face View of

Female DC Micro

Color Pin Number

White-Orange 1 TxData +

White-Green 2 TxData -

Orange 3 Recv Data +

Green 4 Recv Data -

Status Indicators

Color Pin Number

White 1 Trigger input

Brown 2 +24V DC

Green 3 Input 1

Yell ow 4 Out put 1

Gray 5 Output 2

Pink 6 Output common

Blue 7 0V DC

Red 8 Input common

Indicator Status Description

PASS

TRIG

MODE

LINK

FAIL

PWR

Off Inactive status

Steady green Active status

Off Waiting for trigger event

Flashing yellow Trigger event

Off Unit not ready

Flashing yellow

(0.5 Hz)

Steady yellow Unit is configured

Off No power or no IP address

Steady yellow

Flashing yellow

Off Inactive status

Steady red Active status

Off No power is applied to unit

Steady green Power on

Unit is not configured

Connected in normal

(No network connection,

only power is connected).

Signal

Receiver

Signal

Receiver

operation

Standby.

Connect to Code Reader

You can connect to your 48CR code reader via Web Connect or Add-on Profile

(AOP). See publication 48CR-UM001 for details.

Ethernet Communication Options

There are two options to make a static connection to your code reader.

Option 1 — Initiate IP Address (DHCP Default)

1. The code reader IP address configuration state defaults to dynamic and

requires a Dynamic Host Configuration Protocol (DHCP) server to assign

the IP address automatically.

2. Manually assign the IP address through the Rockwell Automation®

BootP/DHCP server tool.

Option 2 — Change Static IP Address

1. Navigate to Control Panel > Network and Sharing Center on your

computer.

2. Click Local Area Connection 4. In the Status dialog box, click Properties.

3. In the Local Area Connection Properties dialog box, select Internet

Protocol Version 4 (TCP/IPv4) and click Properties again. Set the IP

address to 192.168.1.x (for example, 192.168.1.80).

4. Click OK.

5. Open a web browser and type the IP address of the code reader that was

established in step 3

The code reader connects to Web Connect.

Initialize Web Connect

When you enter the IP address of the code reader directly in the address bar of

your web browser, Web Connect loads and starts.

Figure 4 - Initiate Web Connect in Browser

.

2 Rockwell Automation Publication 48CR-IN001B-EN-P - January 2021

Page 3

Bulletin 48CR Code Reader Installation Instructions

Once Web Connect has launched, the initial view is the Start View (Figure 5). The

connected code reader is shown along with user-defined name, IP address, model,

serial number, MAC ID, firmware revision, sensor, optics, decoder, and speed. This

initial view allows you to choose either Assisted Setup, New Setup, or to load a

setup. For details on use of Web Connect, see publication 48CR-UM001

.

Figure 5 - Web Connect View

IMPORTANT

Web Connect and Studio 5000® Add-on Profiles are

the preferred user interfaces to configure and test

your 48CR code reader.

Add-on Profile (AOP)

Figure 6 - AOP

Table 4 - Advanced Auto-focus Code Readers (1.2 MP Resolution)

Lens

[mm (in.)]

5.0 (0.2) Standard density

7.7 ( 0.3) High den sity

16 (0.6) Ultra high density

Optics Imager

SXGA 1D, 2D, and DPM

Decode

Algorithms

Cat. No.

48CR-CC50RAF-E8

48CR-CC77RAF-E8

48CR-CC16RAF-E8

Table 5 - Accessories

Description Cat. No.

Polarizer — lens cover kit

Diffuser — lens cover kit

L-bracket mounting

Adjustable mounting bracket

Right-angle mirror

T-p ort

48CR-POLARIZER

48CR-DIFFUSER

48CR-LBKT

48CR-ADJBKT

48CR-45MIRROR

879D-F8D4M

Table 6 - Cables

Style Connector Type Pins Shield

EtherNet/IP Cables

M12 male straight

to RJ45 male

M12 D Code

Patchcords

Power Cables

DC Micro

(M12) QD Code

Cordset

DC Micro

(M12) QD Code

Patchcord

(1) The x represents the cable length. Available in lengths of 0.15, 0.2, 0.3, 0.6, 1, 2, 2.5, 3, 4, 5, 10, 15, 20,

30, and 40 m (0.5, 0.7, 1, 2, 3.3, 6.6, 8.2, 9.8, 13.1, 16.4, 32.8, 49.2, 65.6, 98.4, and 131.2 ft) in increments

of 5 m (16.4 ft) up to 75 m (246.1 ft).

(2) The x represents the cable length. Available in lengths of 0.3, 1, 2, 5, 10, and 15 m (1, 3.3, 6.6, 16.4, 32.8,

and 49.2 ft) in increments of 5 m (16.4 ft) up to 75 m (246.1 ft).

straight

M12 male right

angle to RJ45

male straight

M12 female

straight to flying

lead

M12 female

straight to M12

male straight

4 Unshielded 24

Unshielded

8

Shielded

Unshielded

8

Shielded

Wire Size

[AWG]

24

24

Cat. No.

1585D-M4TBJM-x

1585D-E4TBJM-x

889D-F8AB-x

889-F8FB-x

889D-F8ABDM-x

889D-F8FBDM-x

(1)

(1)

(2)

(2)

(2)

(2)

For details on the use of AOP, see publication 48CRUM001

.

Product Selection

Table 3 - Standard Fixed-focus Code Readers (0.3 MP Resolution)

Lens

[mm (in.)]

5.2 (0.2)

8 (0.3)

8 (0.3)

16 (0.6)

Optics Imager

Standard

density

High

density

High

density

Ultra high

density

WVGA

Focu s

Distance

[mm (in.)]

102 (4.02)

133 (5.24)

190 (7.48)

400 (15.75)

Decode

Algorithms

1D, 2D, and

DPM

48CR-CB52R102-E8

48CR-CB80R133-E8

48CR-CB80R190-E8

48CR-CB16R400-E8

Rockwell Automation Publication 48CR-IN001B-EN-P - January 2021 3

Cat. No.

IMPORTANT

See ab.rockwellautomation.com/Connection-Devices/

Cables-and-Cordsets and online configuration tools for

more cable and cordset offerings.

Page 4

Specifications Additional Resources

Table 7 - Specifications

Attribute Standard Advanced

Certifications

Decoder

Speed High speed (up to 60 fps) High speed (up to 42 fps)

Sensor (CMOS) WVGA (0.34 MP, 752 x 480) SXGA (1.2 MP, 1280 x 980)

Shutter Global

Frames per second (FPS) WVGA (60 FPS) SXGA (42 FPS)

Exposure 50…100,000 µs (default 2500 µs)

Focal length

Connectivity M12 8-pin power, M12 4-pin Et hernet

Illumination 16 red inner light-emitting diode (LEDs)

Light source, type High output LED

Light source,

wave length

Light source,

operating life

Digital I/O 2 opto-isolator inputs, 2 opto-isolator outputs

Electrical 4.75…30V DC, 200 mV p-p max ripple, 150 mA at 24V DC (typical)

Operating temperature 0…40 °C (32…104 °F)

Storage temperature -50…+75 °C (-58…+167 °F)

Humidity 5…95% (noncondensing)

Dimensions 25 x 45 x 45 mm (1 x 1.75 x 1.75 in.)

Weig ht 68 g (2 .4 oz)

Enclosure IP65/67, aluminum

Indicators Target pattern, good read (green flash), performance status indicators

Emissions EN 55022:2010 Class A limits

•FCC and CE Marked

• RoHS compliant

• Plus (high-contrast 1D/2D)

• X-mode (poor or damaged 1D/2D = DPM)

Fixed focus:

•102 mm (4.02 in.)

•133 mm (5.24 in.)

• 190 mm (7.48 in.)

•400 mm (15.75 in.)

625 nm (inner red) nominal, 617 nm (outer red) nominal

50,000 hr @ 25 °C (77 °F)

Liquid lens auto focus:

•102 mm (4.02 in.)

• 190 mm (7.48 in.)

•400 mm (15.75 in.)

These documents contain additional information concerning related products from

Rockwell Automation.

Resource Description

48CR Code Reader User Manual,

publication 48CR-UM001

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

rok.auto/certifications

You can view or download publications at rok.auto/literature.

Provides information on the installation and

configuration of 48CR code readers.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit rok.auto/support.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uygundur

Allen-Bradley, expanding human possibility, Rockwell Automation, Rockwell Software, and Studio 5000 are trademarks of Rockwell Automation, Inc.

Ethernet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 48CR-IN001B-EN-P - January 2021 | Supersedes Publication 48CR-IN001A-EN-P - November 2019

Copyright © 2021 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

10002830370 Ver 02

Loading...

Loading...