Allen-Bradley 45LSP-2LNA1-P3, 45LSP-2LNA2-P4, 45LSP-2LNA1-P4, 45LSP-2LNA2-P3, 45LSP-2LNA3-P3 Installation Instructions Manual

...Page 1

Installation Instructions

IMPORTANT

45LSP Optical Fork PHOTOSWITCH Photoelectric Sensors

Installation Instructions

Catalog Numbers: 45LSP-2LNA1-P3, 45LSP-2LNA1-P4, 45LSP-2LNA2-P3, 45LSP-2LNA2-P4, 45LSP-2LNA3-P3,

45LSP-2LNA3-P4, 45LSP-2LNA4-P3, 45LSP-2LNA4-P4, 45LSP-2LPA1-P3, 45LSP-2LPA1-P4, 45LSP-2LPA2-P3,

45LSP-2LPA2-P4, 45LSP-2LPA3-P3, 45LSP-2LPA3-P4, 45LSP-2LPA4-P3, 45LSP-2LPA4-P4

SAVE THESE INSTRUCTIONS FOR FUTURE USE. Refer to http://ab.rockwellautomation.com/ for additional information.

Description

The 45LSP is a family of optical fork sensors housed in a plastic

enclosure. Fork sensors offer self-contained transmitted beam sensing,

ideal for applications that require reliable parts detection. A simple

push button teach-in sensitivity adjustment, several connection options

and multiple mounting features (via side thru-holes, rear threaded

inserts or optional dovetail bracketry) make the 45LSP an economical,

easy-to-use solution for typical applications such as small part

detection, edge detection, part counting, gear tooth detection and

dimension verification.

Features

• Detection of objects as small as 0.2 mm (0.0078 in.)

• Highly visible power and output LED indicators with output

indication along both sides of the fork

• Remote teach and teach button lock on 4-pin models

• Light or dark operate selectable

• Multiple mounting options: thru-holes, threaded holes and

dovetail

• Easy installation with no alignment required

• IP67 enclosure

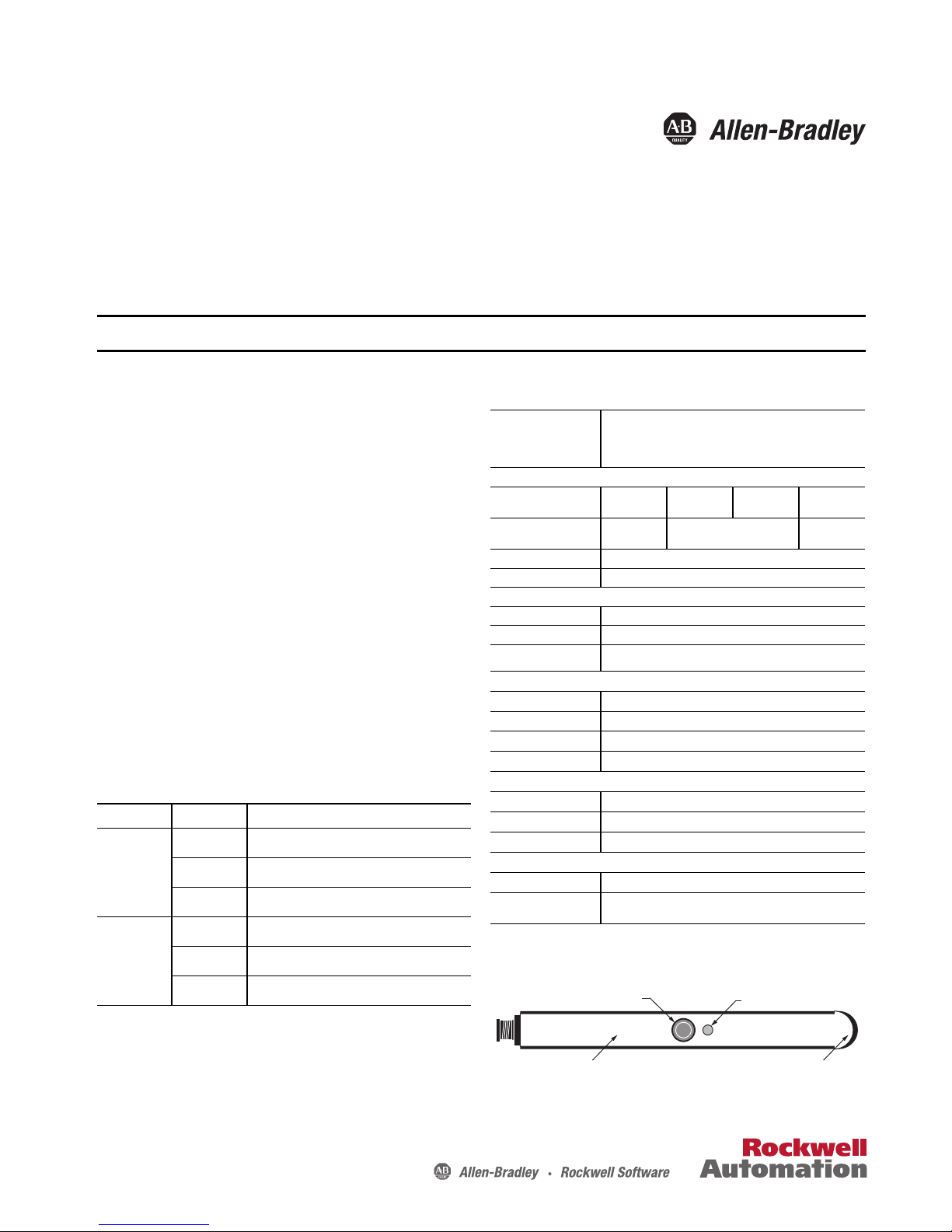

User Interface

LED Color State Status

OFF Output de-energized

Orange

Green

ON Output energized

Flashing Teach mode or short circuit protective active

OFF Power is OFF

ON Power is ON

Specifications

cULus and CE Marked for all applicable directives

Certifications

Optical

Sensing Gap

Smallest Detectable Target

Light Source Visible red (640 nm)

Sensitivity Adjustment Teach button and remote teach

Electrical

Voltage 10…30V DC

Current Consumption 30 mA maximum

Protection Reverse Polarity and short circuit

Outputs

Response Time 250 µs

Output Type PNP or NPN

Output Mode Light or dark operate selectable

Output Current 100 mA maximum

Mechanical

Housing Material Polycarbonate

Connection Types 3-pin pico QD, 4-pin pico QD

Optional Accessories 44B-BKT dovetail mounting bracket and cordsets

Environmental

Environmental Rating IP67

Operating Temperature

[C(F)]

1

For detection of objects less than 0.9 m (0.035 in.), the object should be placed ≥ 10 mm

(0.39in.) away from the LED light source.

For use in NFPA 79 applications only

Adapters providing field wiring means are available from the

manufacturer. Refer to manufacturers information.

30 mm

(1.18 in.)

0.2 mm

(0.07 in.)

-10…+60 ° (14…140 °

1

50 mm

(1.97 in.)

0.2 mm (0.007 in.)

80 mm

(3.15 in.)

120 mm

(4.72 in.)

0.4 mm

(0.02 in.)

Flashing Teach mode

Teach button

Orange LED

Green LED

Orange LED

Page 2

45LSP Optical Fork PHOTOSWITCH Photoelectric Sensors Installation Instructions

Brown (1)

+

–

Black (4)

White (2)

Blue (3)

Load

Brown (1)

Black (4)

White (2)

Blue (3)

Load

Brown (1)

+

–

Black (4)

Blue (3)

Load

Brown (1)

Black (4)

Blue (3)

Load

+

–

+

–

3

1

4

3

4

2

1

3-Pin

NPN ModelsPNP Models

4-pin3-pin4-pin

♦

♦

Operational Instructions

Sensitivity Adjustment

With no target present, press the teach button for approximately three

seconds until orange LEDs are flashing synchronously: first threshold is

taught. With the target present, press the teach button for

approximately one second. If the green LED flashes and stays on then

thresholds have been taught, and the sensor is ready to operate. If both

LEDs are flashing synchronously then the sensor cannot detect the

object and no thresholds have been taught.

Sensitivity Adjustment During a Running Process (optimum detection

of very small parts)

With the chosen running process being the only thing in the scanning

area, press the teach button for approximately three seconds until

orange LEDs are flashing synchronously. Press the teach button until a

minimum of one process cycle is completed. If the green LED flashes

and stays on then thresholds have been taught, and the sensor is ready to

operate. If both LEDs are flashing synchronously then the sensor

cannot detect the target and no thresholds have been taught.

L.O./D.O. Setup

Press the teach button for approximately 13 seconds. Orange LEDs

should flash alternately. When you release the button, the green LED

should remain flashing. When the green LED is flashing , the output is

inverted by pressing the button. The orange LED shows active

function. Do not press the button for 10 seconds. The green LED stops

flashing and the present output function is saved. The sensor is ready to

operate.

Maximum Sensitivity

With no target present, press the teach button for approximately three

seconds until orange LEDs are flashing synchronously. Again, with no

target present, press the teach button for one second. The sensor is set

to maximum sensitivity and is ready to operate.

Maximum Stability—Factory Setting (maximum resistance to

contamination)

Cover the light source. Press and hold the teach button until the orange

LEDs are flashing synchronously. Keep the light source covered, press

the teach button for one second. The sensor is set to maximum stability

and is ready to operate.

Modification of the Emitter Frequency in Case of Mutual Interference

Switch one sensor off. Press the teach button during power ON. The

orange LED flashes one time; frequency one, normal operation

(switching frequency 2 kHz). Keep the button pressed for another

three to five seconds. The orange LED flashes twice; frequency two,

normal operation (switching frequency 2 kHz). Keep the button

pressed for another three to five seconds. The orange LED flashes three

times; frequency one, detection of very small parts possible (switching

frequency 2 kHz). Keep the button pressed for another three to five

seconds. The orange LED flashes four times; frequency two, detection

of very small parts possible (switching frequency 1.5 kHz). Release the

button to place the sensor in operating mode. Switch other sensor on

again.

Wiring Diagrams

2 Rockwell Automation Publication 45LSP-IN001C-EN-P – November 2015

Page 3

45LSP Optical Fork PHOTOSWITCH Photoelectric Sensors Installation Instructions

C

Teach-in

button

4

E

D

A

B

GF

10

(0.39)

5

(0.2)

4.5 (0.18)

12 (0.47)

4.5 (0.18)

8 (0.31)

4.2 (0.17) 3x Dia.

Dimensions [mm (in.)]

Fork Type A B C D E F G H I

30 mm 30 (1.18) 50 (1.97) 30 (1.18) 34 (1.34) 59.5 (2.34) 20 (0.78) — 62.2 (2.45) 71.7 (2.82)

50 mm 50 (1.97) 70 (2.76) 50 (1.97) 54 (2.13) 79.5 (3.13) 20 (0.78) 28 (1.10) 82.2 (3.24) 91.7 (3.61)

80 mm 80 (3.15) 100 (3.93) 80 (3.15) 54 (2.13) 79.5 (3.13) 20 (0.78) 2 x 28 (2.20) 112.2 (4.42) 91.7 (3.61)

120 mm 120 (4.72) 140 (5.51) 120 (4.72) 54 (2.13) 79.5 (3.13) 20 (0.78) 3 x 28 (3.30) 152.2 (5.99) 91.7 (3.61)

Optional Accessories

Description Cat.

Dovetail mounting bracket 44B-BKT

2 m (6.5 ft) 3-pin DC pico QD

2 m (6.5 ft) 4-pin DC pico QD

No.

889P- F3AB -

889P- F4AB -

2

2

Rockwell Automation Publication 45LSP-IN001C-EN-P – November 2015 3

Page 4

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

You can also visit our Support Center at https://rockwellautomation.custhelp.com/

information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact your local

distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual. Yo u ca n c ont ac t

Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada

Use the Worl dwide Locato r

Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing facility. However,

if your product is not functioning and needs to be returned, follow these procedures.

you can find technical and application notes, sample code, and links to software service packs.

for software updates, support chats and forums, technical

.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local Rockwell

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your distributor to complete

the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete this

form, publication RA-DU002

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com

Online: www.ab.com/support/abdrives.

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

, available at http://www.rockwellautomation.com/literature/.

.

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respec tive companies.

Publication 45LSP-IN001C-EN-P – November 2015 10000033147 Ver 02

Copyright © 2015 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...