Page 1

Installation and Operating Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

This publication does not include all specifications, dimensions, or any special installation

considerations. Refer to the product catalog pages for additional information.

To avoid electrical shock and unintended operation of equipment,

disconnect all power to the limit switch and the controlled

equipment before proceeding with any repair or adjustment of

the limit switch.

Improper selection or installation of the devices affect the integrity of the safety

systems.

Personnel injury or death, property damage or economic loss can result.

Comply with ISO 14119 including selection, accessibility to the installation,

arrangement and fastening, possible substitute actuation, access to the escape release,

motivation to defeat, and actuation mode.

Management controls, working procedures, training, and additional protective

measures should be used to minimize the motivation to defeat and to manage the use

and availability of spare actuators.

Comply with ISO13857 and ISO13855 for guard openings and minimum (safe)

distances.

Comply with IEC 62061 or ISO 13849-1 and ISO 13849-2 for functional safety.

Installation of Allen-Bradley Guardmaster products should be in

accordance with local and/or national codes. Servicing energized

industrial control equipment can be hazardous if not in accordance with recommended

safety procedures.

ENISO14119 replaces EN 1088 as the harmonized standard for interlocking devices

associated with guards.

Functional safety information: http://literature.rockwellautomation.com/idc/groups/

literature/documents/sr/safety-sr001_-en-e.pdf

Bulletin 440P Small Metal Safety Position Switches

ATTENTION

General Data

• Safety contacts: 1 N.C.

• Auxiliary contacts: 1 N.O.

•Enclosure rating:

• NEMA 1

• IP66, IP67, IP69K

• Rugged die cast housing

• 2 m prewired cable

• Compact profile for access limited installation

Principles, Standards, and Implementation

Before installation in a safety application, perform a risk

assessment to determine whether the specifications of this device

are suitable for foreseeable operational and environmental

characteristics of the machine which is to be controlled. Only the

normally closed set of contacts are considered safety contacts.

When deploying these limit switches in a safety system

application, all applicable standards for application should be

followed. Operating specifications must be followed. The actuator

must be placed beyond the point where Direct Opening Action

occurs. Do not use these devices to directly control a motor.

Specifications

Safety Ratings

Standards

Safety Classification

Certifications cULus Listed, TÜV and CE Marked for all applicable directives

Functional Safety Data

IMPORTANT

EN 13849-1, EN ISO 14119, EN 60204-1, NFPA 79, ISO 14119,

EN 60947-5-1, ANSI B11.19 AS 4024.1

Cat. 1 Device per ISO 13849-1 Dual channel limit switch suitable for

Cat. 3 or 4 systems

6

operations

B10d: 2x10

Outputs

Safety Contacts 1 N.C. snap acting

Auxiliary Contacts 1 N.O. snap acting

Thermal Current (/

Rated Insulation Voltage (ui) 300 AC

Short Circuit Protection 10 A max. fast acting fuse IEC 269 type gG or equivalent

)

lth

10 A

Contact Ratings

Maximum AC Contact Rating Per Pole (50/60 hz) Same Polarity

NEMA Rating

Designation

AC15/ B300 120 30 3 5 3600 360

AC15/ B300 240 15 1.5 5 3 600 360

DC13/ Q300 240 0.27 0.27 2.5 69 69

Operating Characteristics

Actuation Speed, Max. 250 mm/s

Actuation Speed, Min. 100 mm/min

Actuation Frequency, Max. 6000 ops/hr

Mechanical Life

Environmental

Enclosure Type Rating NEMA 1, IP66/IP67/IP69K

Operating Temperature [C (F)] 2…70 ° (35.6…158 °)

Pollu tion De gree 3

Physical Characteristics

Housing Material Die cast alloy

Actuator Material Various polymers and metals

Mounting 2 x M4, any position

Vibration IEC 60068-2-6 (10…55 Hz, 0.35 mm amplitude)

Shock IEC 60068-2-7 (30 Gn 3 pulses per axis)

Connection 2 m (6.5 ft) cable

Enclosure Color Red body/black head

Max.

Volta ge

Maximum AC Contact Rating Per Pole (50/60 hz) Same Polarity

Amperes Continuous

Make Break Make Break

1 x 10

Carrying Current

(Amp.)

7

operation s at room temperature

Voltamp eres

Electrical life is dependent on load, therefore, operations are not

applicable and withdrawn.

Product Intended Use

440P Cam actuated

ISO 14119 defines types of interlocking devices and coding:

Product Type Coding

440P 1 Uncoded

The products shown on this document conform with the Essential Health and

Safety Requirements (EHSRs) of the European Machinery Directive. They are third party

certified to EN60947-5-1 and EN ISO 14119.

Declaration of Conformity and certification: www.rockwellautomation.com/

certification/ce.page

Page 2

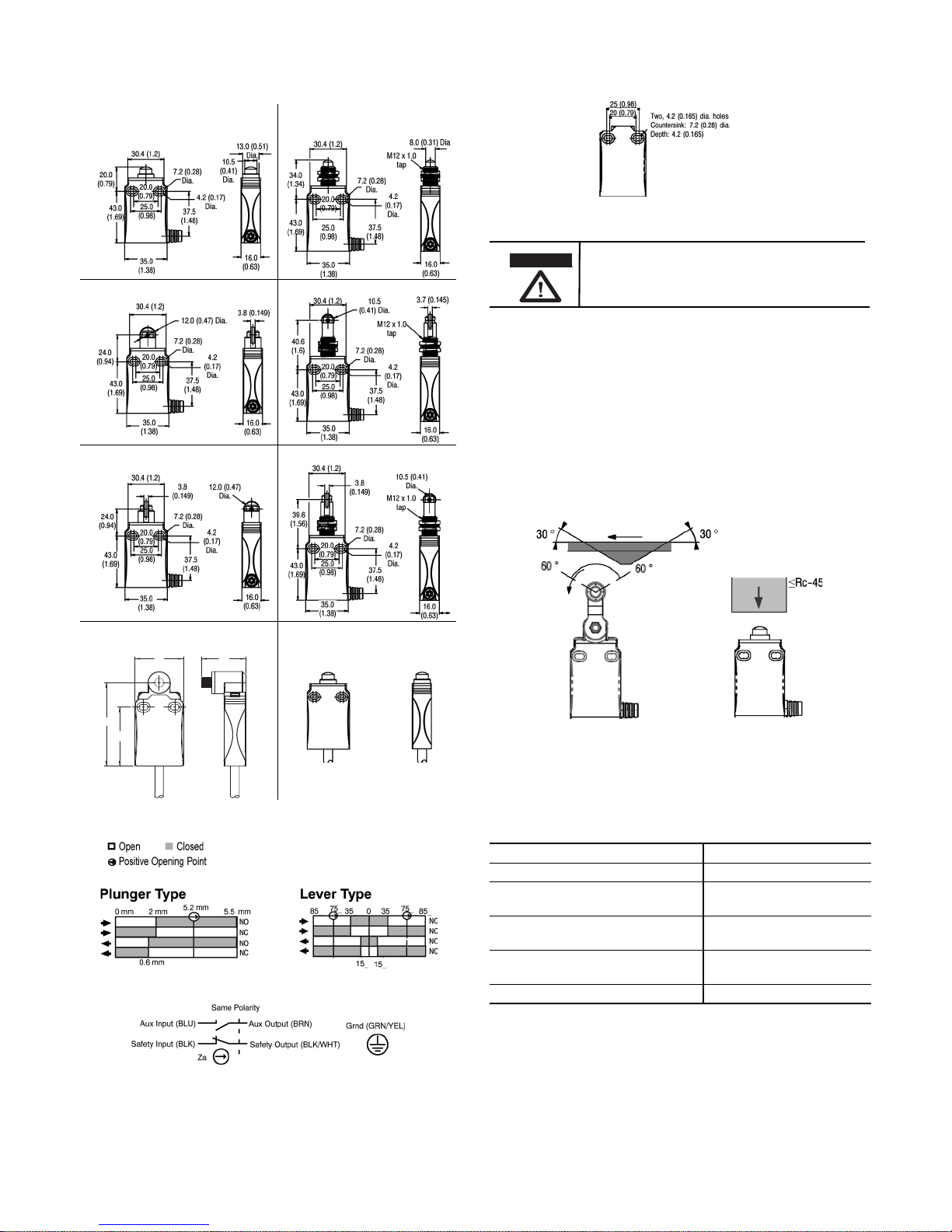

Mounting Dimensions [mm]

Nonpanel Mount Panel Mount

Dome

Plunger

Cross Roller Plunger

Bottom Cable Style

32.2

(1.27)

35.0

(1.37)

43.0

(1.69)

6.10

(2.40)

Replacement Switch, without

a Lever (440P-NX10)

Roller Plunger

Under no circumstances must the switch be actuated beyond

the mechanical travel specified. Serious damage to the device

and property could result.

Countersink Hole

\

• Panel mount clearance hole = 13 mm (0.51 in.) max.

ATTENTION

Maintenance

These devices require little maintenance, but routine visual

inspection is recommended to keep foreign debris from

collecting on the exterior actuators and rollers. Removing the

operator head is not recommended as loose internal components

may be lost or improperly re-installed.

Actuation Guidelines

The method of actuation and over travel has significant influence

on the service life of the limit switch. To maximize the service life,

it is recommended to provide an actuator with a 30° pressure

angle and a surface hardness of Rc-45 max.

Contact Opening Characteristics

Wiring Diagram

Lever Positioning

Some rotary switches are supplied with levers that are

mechanically coupled to the actuating shaft. The lever may be

removed and re-installed to adjust cam tracking. See table below

for torque recommendations.

Torque Specifications

Location Torque

3.5 mm Operator Head Phillips Screws 0.8 N•m (7.1 lb•in)

Short and Wide Roller Lever A rm

8 mm Hex Nut

Adjustable Lever Arm

4 mm Allen Head Screw

Adjustable Lever Arm Collar

3 mm Allen Head Screw

12 mm Panel Mount Nut 1.5 N•m (13.28 lb•in)

1.0 N•m (8.85 lb•in)

1.8…2.8 N•m

(15.93…24.78 lb•in)

3.2 N•m (28.32 lb•in)

2

Page 3

Mounting Dimensions [mm (in.)]

20

(0.79)

35 (1.38)

43

(1.69)

18

(0.71)

25

(0.98)

25

(0.98)

30.4 (1.2)

16 (0.63)

35.15 (1.38)

25.4 (1)

Ø13.5

(0.53)

Ø7.2

(0.28)

Ø4.2

(0.17)

Ø13.5

(0.53)

25

(0.98)

Wide Roller Lever Arm

8 mm Hex Nut

20

(0.79)

35 (1.38)

43

(1.69)

18

(0.71)

25

(0.98)

25

(0.98)

30.4 (1.2)

16 (0.63)

35.8 (1.41)

5.2

(0.2)

Ø13.5

(0.53)

Ø7.2

(0.28)

Ø4.2

(0.17)

Short Lever Arm

8 mm Hex Nut

Note: Lever arm versions are nonpanel mount only.

Operator heads with adjustable actuators should NOT be used for

safety applications.

IMPORTANT

18

(0.71)

43

(1.69)

35 (1.38)

Ø16.5 (0.65)x7

R27 (Min)

R105 (Max)

Adj. Lever Arm 4 mm

Allen Head Screw

Two 4.2 (0.17) Dia. Holes

Countersink: 7.2 (0.28) Dia.

Depth: 4.2 (0.17)

Adj. Lever Arm Collar

3 mm Allen Head Screw

20 (0.79)

25 (0.98)

43.4 (1.71)

38.2 (1.5)

16 (0.63)

3.5 mm Operator Head

Philips Screw

3

Page 4

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 440P-IN002C-EN-P—10000020920 Ver 06—May 2015

Copyright © 2015 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...