Page 1

Installation Instructions

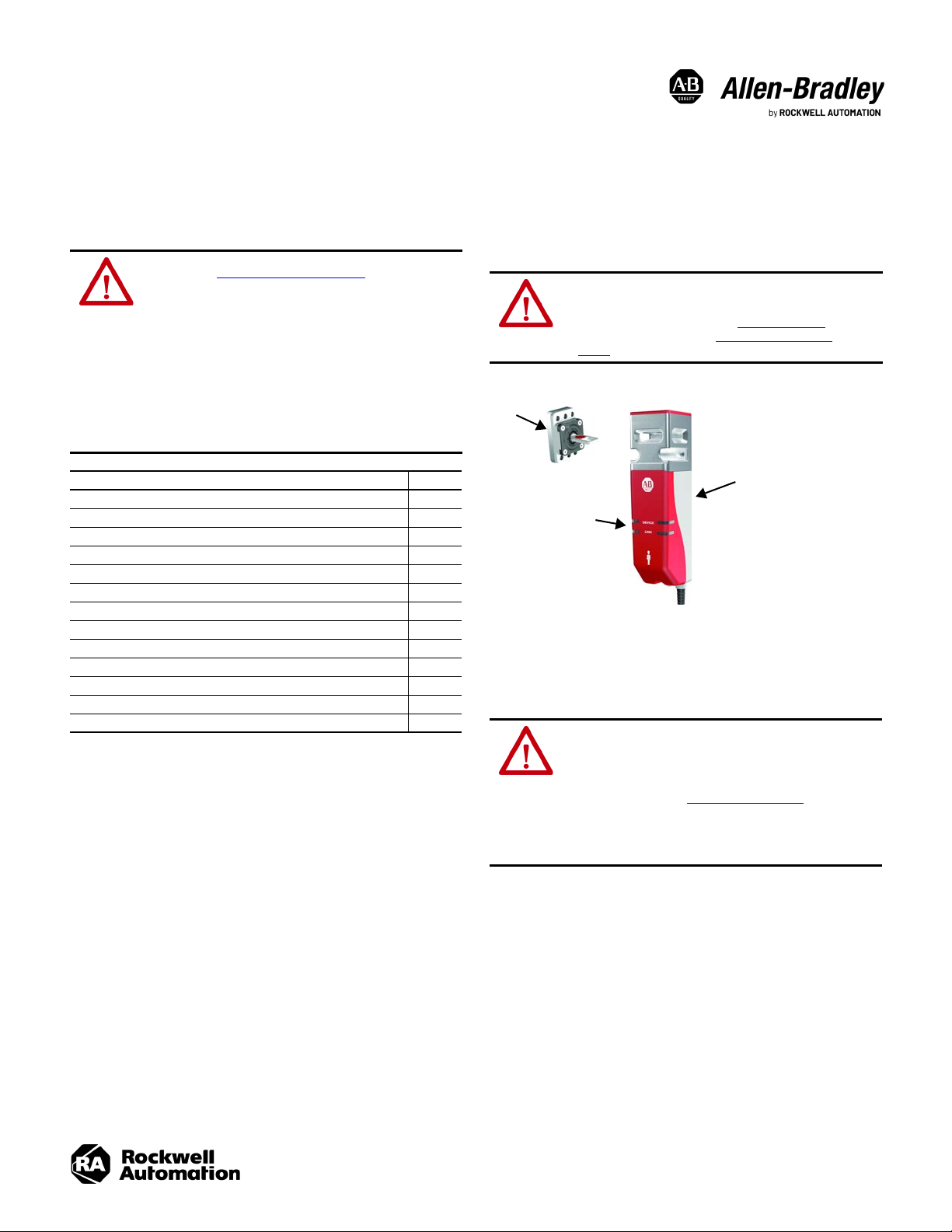

Actua tor

Switch body

LINK and DEVICE

status indicators

Original Instructions

440G-MZ Guardmaster Safety Switches

Catalog Numbers

Top ic Pa ge

Introduction 1

Installation 2

Commissioning — Unique Coded Models 2

Auxiliary Release 3

Approximate Dimensions 3

Pin Assignment 4

Connection in a GuardLink System 4

Specifications 4

Status Indicators 5

Lock Command 5

Catalog Number Explanation 5

Accessories 5

Additional Resources 5

440G-MZS20SNRJ, 440G-MZS20UNRJ, 440G-MZS20SNLJ, 440GMZS20UNLJ

ATTENTION: Read this document and the documents that

are listed in Additional Resources on page 5 about

installation, configuration, and operation of this equipment

before you install, configure, operate, or maintain this

product. Users are required to familiarize themselves with

installation and wiring instructions, and requirements of all

applicable codes, laws, and standards.

Only suitably trained personnel must perform activities

including installation, adjustments, commissioning, use,

assembly, disassembly, and maintenance in accordance

with applicable code of practice.

If this equipment is used in a manner that the manufacturer

does not specify, the protection that is provided by the

equipment may be impaired.

Introduction

ATTENTION: Do not attempt to install this device unless the

installation instructions have been studied and understood.

This document acts as a guide for a typical installation and

is available in some languages at rok.auto/literature. A user

manual is also available (see Additional Resources on

page 5).

Figure 1 - Assembly Overview

The 440G-MZ Guardmaster® Guard Locking Switch locks a guard door in the closed

position and does not release it until the hazardous machine functions that are

covered by the guard are in a safe condition. The safety control system only allows

the hazardous machine functions to operate when the guard is closed and locked.

Qualified personnel must install the switch in accordance with these instructions.

ATTENTION: This device is intended to be part of the safetyrelated control system of a machine. Before installation, a

risk assessment must be performed to determine whether

the specifications of this device are suitable for all

foreseeable operational and environmental characteristics

of the application. See Specifications on page 4 for

certification information and ratings.

Use appropriate screws, bolts, or nuts that are fitted by tools

to mount the switch and actuators to avoid the risk of

tampering. Do not over torque the mounting hardware.

Page 2

440G-MZ Guardmaster Safety Switches Installation Instructions

3 x M5

2 x M5

100 (3.94)

1

2

3

White

Gray

NC

Gnd 0V

NC

NC

+24V DC

Blue

Black

Brown

889D-F5NC-x

or

889D-F5BC-x

DEVICE

LINK

Installation

ATTENTION: Do not defeat, tamper, remove, or bypass this

unit. Severe injury to personnel could result.

The presence of spare actuators can compromise the

integrity of the safety systems. Personal injury or death,

property damage, or economic loss can result. Appropriate

management controls, working procedures, and alternative

protective measures should be introduced to control their

use and availability.

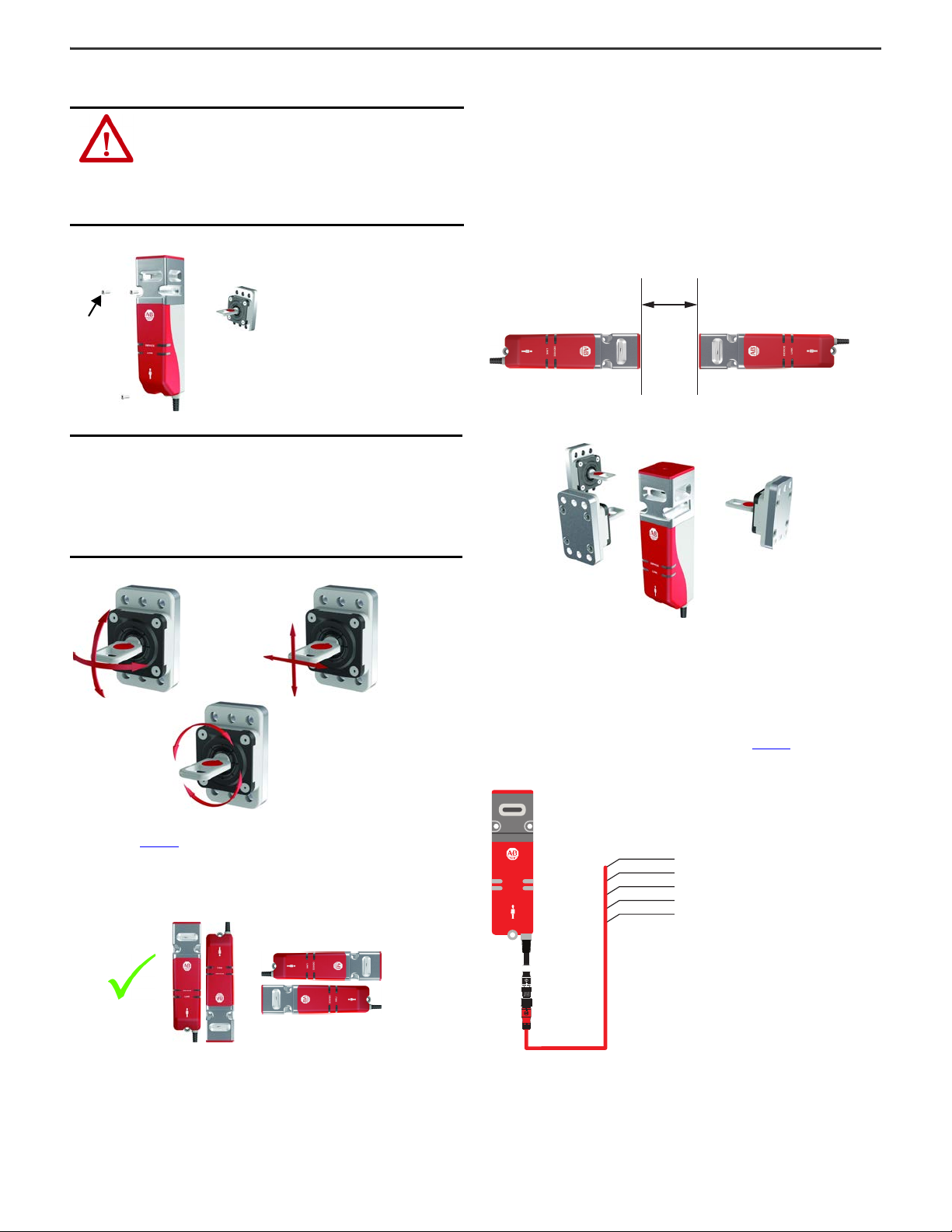

Figure 2 - Required Mounting Hardware for Switch and Actuator

IMPORTANT

Washers are not required and if used can cause the

mounting holes on the switch body to crack. If standard

thread locking compound is used on the mounting

screws of the switch body, check the manufacturer’s

specification. Many standard thread-locking compounds

can attack the plastic feet of the switch body, which can

cause stress cracks. It is recommended to use

cyanoacrylate-type thread-locking compounds.

Minimum Distance Between Switches

If a pair of 440G-MZ safety switches are mounted too close to one another, the two

magnetic fields interact causing crosstalk, which results in nuisance faults and

false operation.

A minimum of 100 mm (3.94 in.) must separate a pair of switches to help achieve

correct operation.

This restriction applies to any pair of Guardmaster safety switches that use RFID

sensing technology, including 440N-Z SensaGuard™ interlocks, or TLS-Z and

440G-LZ guard locking switches.

Figure 5 - Minimum Distance between Switches [mm (in.)]

Figure 6 - Three Directions of Approach

Figure 3 - Actuator Function

The flexible actuator bends, rotates, and slides to accommodate guard door

misalignment (Figure 3

). For optimal performance, verify that the locking bolt can

enter and withdraw from the tongue actuator without binding. A separately

mounted door latch is recommended to avoid door misalignment.

Figure 4 - Orientation of Assembled Switch

Commissioning — Unique Coded Models

The actuator teach process is not performed at the factory and must be performed

when the switch is first put into use. After the first-time learn, this process can be

repeated up to seven more times with unique coded replacement actuators.

During commissioning, connect the switch as shown in Figure 7

Figure 7 - Wiring

.

2 Rockwell Automation Publication 440G-IN018B-EN-P - April 2020

Page 3

440G-MZ Guardmaster Safety Switches Installation Instructions

5 (0.2)

Top View

2 x Ø5.5

(0.22)

33

(1.3)

6

(0.24)

153 (6.02)

134.5 (5.3)

33 (1.3)

14.9 (0.59)

22.5

(0.89)

176.8 (6.96)

15 (0.59)

5.9

(0.23)

15

(0.59)

Ø5.1

(0.2)

22.6

(0.89)

25.3

(1)

50

(1.97)

47.5

(1.87)

39.5

(1.56)

0.3

(0.01)

153 (6.02)

134.5 (5.3)

182.7 (7.19)

45.2

(1.78)

9.9

(0.39)

12.5

(0.49)

4

(0.16)

59.3

(2.33)

4 x Ø6.5

(0.26)

6 x Ø6.3 (0.25)

30

(1.18)

15

(0.59)

65 (2.56)

30

(1.18)

Ø32.9 (1.3)

50 (1.97)

7.5

(0.3)

7.3 (0.28)

25.6 (1.01)

12.8 (0.5)

10

(0.39)

14

(0.55)

14

(0.55)

20

(0.79)

10

(0.39)

23.7

(0.93)

Ø12.4

(0.49)

3 (0.12)

40

(1.57)

23.8

(0.94)

32.5

(1.28)

First Time Learn

Apply power to the switch without the actuator present. After the switch completes

the power sequence (approximately 8 seconds), the status indicator flashes green

eight times, which indicates the total number of times a new actuator can be

learned. This status indicator sequence repeats until an actuator is inserted in the

switch (in the guard closed position).

Table 1 - Commissioning Process for Unique Coded Switches

Step State Approximate Duration LED Indicators

1Actuator Present 15 s

• Flashing 8x green, repeating

• Solid red (learning a

replacement actuator)

2Verifying Actuator 15 s Flashing red/green, slow

3 Programming Switch 15 s Flashing red/green, fast

4 Program Finalization 15 s

Run Mode

(2)

After teaching a new actuator, a power cycle is required

5

(1) Out of box condition only.

(2) When teaching an actuator, the switch must be unlocked to insert the actuator. At the completing

program finalization, the switch remains unlocked and in the safe state.

IMPORTANT

—Solid red

Flashing green (number of times

a new actuator can be learned)

to complete the process.

Learn Additional Replacement Actuators

The switch automatically starts a new teach process (Table 1) when a unique coded

replacement actuator is inserted in the switch (in the guard closed position).

Auxiliary Release

Operation of the auxiliary release causes a fault condition.

To reset the switch, cycle the power or issue a RESET command over the link in a

GuardLink® safety system.

Figure 8 - Auxiliary Release Operation [mm (in.)]

(1)

Approximate Dimensions

Figure 9 - Switch Body [mm (in.)]

IMPORTANT

When the switch learns a new actuator, it no longer

recognizes previously learned actuators.

Lock the Actuator Code

If the actuator is removed from the switch and then reinserted into the switch

during the 15-second Program Finalization stage (see Step 4 in Table 1), this action

triggers the switch to LOCK the actuator code. This action can be performed during

any of the eight unique coded actuator learn cycles.

IMPORTANT

After a unique coded actuator is locked using this

method, the switch cannot learn additional replacement

actuators for the remaining life of the switch. If the

actuator is lost or damaged, the switch must be

replaced.

Error Codes

The following indicator patterns repeat until a Power Off/On cycle is completed.

Status/Diagnostic Indicator Error Code

Red-red-red-green Cannot learn a standard actuator

Red-red-red-green-green Actuator already learned

Red-red-red-green-green-green Bad RFID; actuator moved out of range

Red-red-red-green-green-green-green Exceeded learning eight actuators

Red-red-red-green-green-green-green-green Unit locked: cannot learn another actuator

Rockwell Automation Publication 440G-IN018B-EN-P - April 2020 3

Figure 10 - Actuator [mm (in.)]

Page 4

440G-MZ Guardmaster Safety Switches Installation Instructions

440G-MZ

5-wire Patchcord

(1), (2)

889D-F5NCDM-

x

Cordset

(3)

889D-F4NE-

y

4-wire Patchcord

(2), (4)

889D-F4NEDM-x

440S-PF5D

Brown

Blue

+24V DC

0V

440R-ENETR 440R-DG2R2T

White (S12) Black (S22)

OSSD

Unlock

Reset

Pin Assignment

Table 2 - 5-pin Micro (M12)

Pin Color

1 Brown +24V +24V

2 White Safety A Safety In

3Blue 0V 0V

4Black Safety B Safety Out

5GrayLock Command

(1) The recommended cordset is catalog number 889D-F5AC-2 (2 m [6.5ft]). For additional lengths,

replace the 2 with 5 [5 m (16.4 ft)] or 10 [10 m (32.8 ft)] for standard cable lengths.

The recommended patchcord for use with ArmorBlock® Guard Safety I/O is the 2 m (6.5 ft) catalog

number 889D-F5ACDM-2. Replace the 2 with 0M3 [0M3 (0.98 ft)], 1 [1 m (3.28 ft)], 5 [5 m (16.4 ft)], or 10

[10 m (32.8 ft)] for standard cable lengths.

Connection in a GuardLink System

The 440G-MZ safety switch can be connected to a GuardLink system via a passive

tap (catalog number 440S-PF5D shown in Figure 11) or a passive power tap (catalog

number 440S-PF5D4).

Figure 11 - Connect 440G-MZ Switch to a GuardLink System with a Passive Tap

(1) 10 m (32.8 ft) length, max.

(2) Replace

(3) Replace

(4) 30 m (98.4 ft) length, max

x

with 0M3 (300 mm [0.98 ft]), 0M6 (600 mm [1.97 ft]), 1 (1 m [3.3 ft]), 2 (2 m [6.6 ft]),

5 (5 m [16.4 ft]), or 10 (10 m [32.8 ft]) for standard cable lengths.

y

in order number with 2 (2 m [6.6 ft]), 5 (5 m [16.4 ft]), 10 (10 m [32.8 ft]), 15 (15 m [49.2 ft]),

20 (20 m [65.6 ft]), or 30 (30 m [98.4 ft]) for standard cable lengths.

(1)

5

3

2

1

4

Function

OSSD Mode GuardLink Mode

Command, Lock, and

Unlock (CLU)

Specifications

Attribute Value

Standards IEC 60947-5-3, IEC 61508, ISO 13849-1, IEC 62061, ISO 14119, UL 508

Type 4 interlocking device with guard locking per ISO 14119 with

Safety classification

Functional safety data See publication SAFETY-SR001

Certifications CE Marked for all applicable EU directives, c-UL-us, TÜV

Operating Characteristics

Torque for M5 mounting of switch

and actuator mounting bracket

Locking bolt alignment tolerance

X, Y, Z

Holding force F

(ISO 14119)

Holding force F

(ISO 14119)

Output current, max (each output) 200 mA

Quiescent power consumption,

locked or unlocked

Lock signal current 1 mA

Peak current and duration, at turn

on or after lock/unlock operation

Steady state current, max

Operating voltage Ue 24V DC +10% / -15% Class 2 PELV

Operating cycle frequency, max 0.2 Hz

Dwell time between subsequent

locking/unlocking

Response time (Off)

(IEC 60947-5-3)

Start up time (availability) 8 s

Utilization category

(IEC 60947-5-2)

Insulation voltage U

(IEC 60947-5-1)

Impulse withstand voltage U

(IEC 60947-5-1)

Pollution degree

(IEC 60947-5-1)

Auxiliary release Built in

Protection class

(IEC 61140)

Mechanical life 500,000 cycles

Outputs (Guard door is closed and locked)

Safety outputs 2 x PNP, 0.2 A max / ON (+24V DC)

Environmental

Operating temperature 0…55 °C (32…131 °F)

Storage temperature -25…+75 °C (-13…+167 °F)

Operating humidity 5…95%, noncondensing

Enclosure ingress rating IP65, IP66, IP67, IP69K

Shock and vibration

Radio frequency/EMC IEC 60947-5-3, FCC-1 (Parts 18 and 15), RED

General

Materials

Weig ht

Protection Type

max

zh

i

low (standard) and high (unique) coding per ISO 14119

Suitable for use in applications up to and including PLe Cat 4 per

ISO 13849-1, SIL CL 3 per IEC 62061, and SIL 3 per IEC 61508.

2 N•m (17.7 lb•in) max

±5 mm (0.2 in.) max

3250 N

2500 N

1.5 W

150 mA for approximately 800 ms following lock/unlock operation.

OSSD mode: 40 mA

GL mode: 50 mA

2.5 s

275 ms

DC-13 24V 200 mA

75V

imp

1 kV

3

Class II

IEC 60068-2-27, 30 g (1.1 oz), 11 ms/IEC 60068-2-6, 10…55 Hz,

1mm(0.4in.)

• Switch: Housing - ABS, front brace – SS304 (machined), SS316

(cast)

• Actuator: Housing and housing cover – SS304, spring – SS302,

grommet – nitrile rubber, screws - stainless steel, tongue –

SS410

• Brackets: High Strength Low Alloy Steel

• Padlock Accessory: SS410

• Switch: 0.75 kg (1.7 lb)

• Actuator: 0.27 kg (0.6 lb)

• Actuator L mounting bracket: 0.27 kg (0.6 lb)

• Actuator Z bracket: 0.54 kg (1.2 lb)

• Switch L bracket: 1 kg (2.2 lb)

Short-circuit, current limitation, overload, reverse polarity,

overvoltage (up to 60V max), thermal shutdown/restart

4 Rockwell Automation Publication 440G-IN018B-EN-P - April 2020

Page 5

Status Indicators

Table 3 - Output Status and LED Indication

440G-MZ Guardmaster Safety Switches Installation Instructions

Guard Status Lock Command Lock Status

Open or Closed Unlock Unlocked Solid red Off Off Safe

Open Lock Unlocked Flashing amber Off Off Ready. Close guard door to lock.

Closed Lock Locked Solid green On On Operational

Open or Closed Lock or Unlock

(1) The LINK status indicator is OFF in OSSD mode, and conditional on the status of other devices in Guardlink mode. See publication 440R-UM015 for information about the operation of a GuardLink safety system.

(2) See publication 440G-UM004

for additional information about Diagnostic and Fault Codes.

Locked or

Unlocked

Device Indicator

Flashing red Off Off

(1)

OSSD Mode

(Safety A and B)

Lock Command

Table 4 - Lock Command Function (OSSD mode)

Lock Type OSSD Mode Cat. No.

Power to Release

Power to Lock

IMPORTANT

24V = Unlock

0V = Lock

0V = Unlock

24V = Lock

In Guardlink mode, LOCK and UNLOCK commands are

sent via the GuardLink CLU signal. This function is the

440G-MZS20*NR*

440G-MZS20*NL*

Output Status

Guardlink Mode

(Safety Out)

Fault present. Cycle power or issue a RESET command

Accessories

Description Catalog No.

Standard code actuator (Low level to EN ISO 14119)

Unique code actuator (High level to EN ISO 14119)

Actuator mounting

bracket

State

over the link in a Guardlink system

440G-MZAS

440G-MZAU

L-shaped

Z-shaped

440G-MZAM1

440G-MZAM2

(2)

same for both Power to Release and Power to Lock

models.

Switch mounting bracket

440G-MZAM3

Catalog Number Explanation

440G-MZS 20 S N R J

abc de

abc

Outputs (Safety/Auxiliary) Actuator Code Auxiliary Type

Code Description Code Description Code Description

20 Two safety/no aux S Standard code NNo auxiliary

UUnique code

de

Lock Type Connection Type

Code Description Code Description

RPower to Release JM12 5-pin

LPower to Lock

Padlock accessory

440G-MZAL

Additional Resources

These documents contain additional information concerning related products from

Rockwell Automation.

Resource Description

440G-MZ Guard Locking Switch User Manual,

publication 440G-UM004

Guardmaster DG Safety Relay and GuardLink

System User Manual, publication 440R-UM015

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website:

rok.auto/certifications

You can view or download publications at rok.auto/literature.

Provides general guidelines for installing a

Rockwell Automation® guard locking

switch.

Provides general guidelines for configuring

a Rockwell Automation Guardlink safety

system.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

Rockwell Automation Publication 440G-IN018B-EN-P - April 2020 5

Page 6

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit rok.auto/support.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uygundur

Allen-Bradley, ArmorBlock, expanding human possibility, GuardLink, Guardmaster, Rockwell Automation, Rockwell Software, and SensaGuard are

trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 440G-IN018B-EN-P - April 2020 | Supersedes Publication 440G-IN018A-EN-P-February 2020

Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

*PN-539600*

PN-539600

PN-539600

10005220453 Ver 01

Loading...

Loading...