Allen-Bradley 440G-LZS21SJRJ, 440G-LZS21SPLA, 440G-LZS21SJLJ, 440G-LZ, 440G-LZS21SPLB Installation Instructions Manual

...Page 1

Installation Instructions

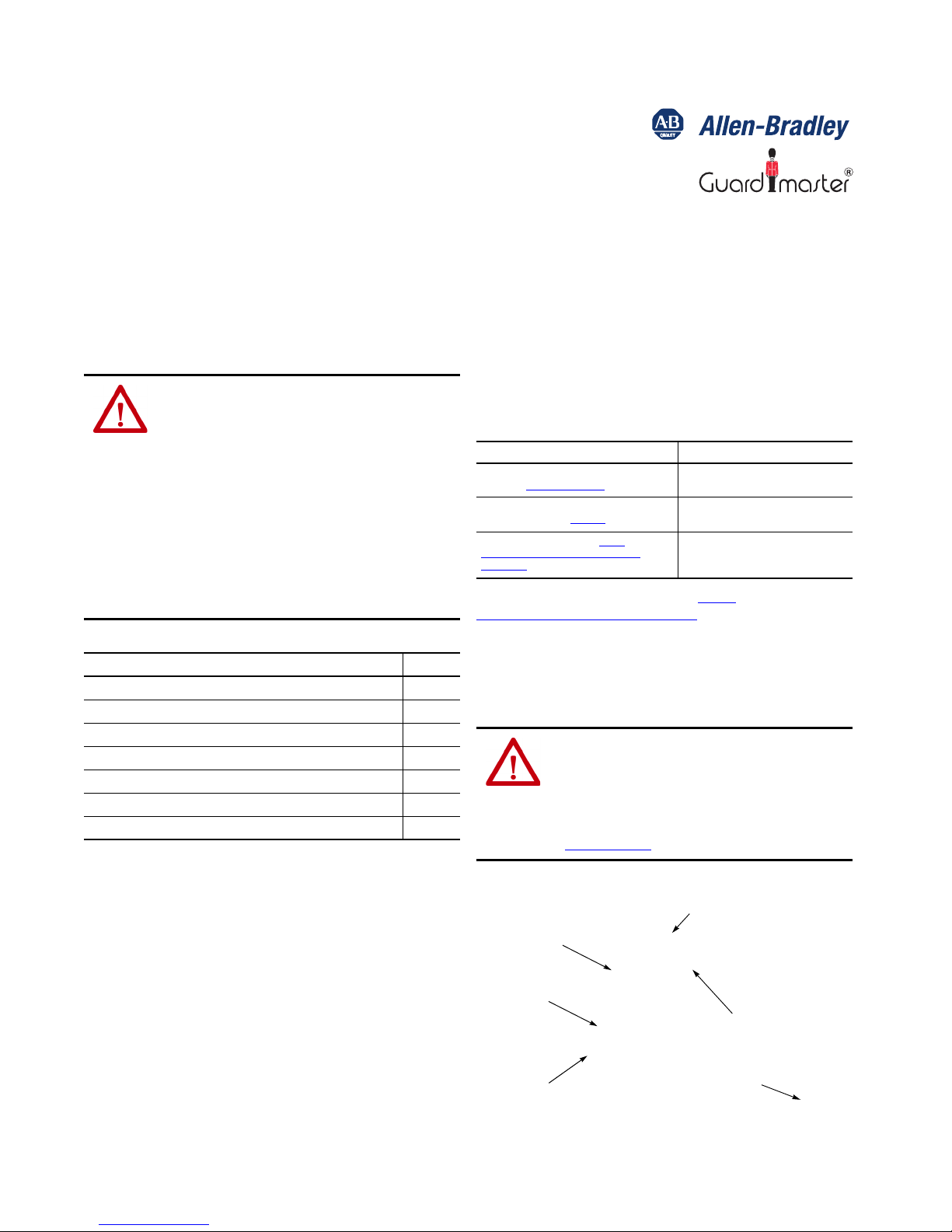

Locking b olt

Actu ator

Switch body

Actuator mounting

bracket

QR Code

Alignment

guide

Original Instructions

440G-LZ Guard Locking Safety Switch

Catalog Numbers

440G-LZS21SJLJ, 440G-LZS21SJRJ, 440G-LZS21SPLA, 440G-LZS21SPLB, 440G-LZS21SPLH, 440G-LZS21SPRA, 440G-LZS21SPRB,

440G-LZS21SPRH, 440G-LZS21STLA, 440G-LZS21STLB, 440G-LZS21STLH, 440G-LZS21STRA, 440G-LZS21STRB, 440G-LZS21STRH, 440G-LZS21UJLJ,

440G-LZS21UJRJ, 440G-LZS21UPLA, 440G-LZS21UPLB, 440G-LZS21UPLH, 440G-LZS21UPRA, 440G-LZS21UPRB, 440G-LZS21UPRH, 440G-LZS21UTLA,

440G-LZS21UTLB, 440G-LZS21UTLH, 440G-LZS21UTRA, 440G-LZS21UTRB, 440G-LZS21UTRH

Additional Resources

ATT EN TI ON : Read this document and the documents that are listed

in the Additional Resources section about installation,

configuration, and operation of this equipment before you install,

configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions,

and requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service,

use, assembly, disassembly, and maintenance are required to be

carried out by suitably trained personnel in accordance with

applicable code of practice.

If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Topi c Page

Summary of Changes 1

Additional Resources 1

Introduction 1

Mounting 2

Installation Considerations 2

Auxiliary/Manual Release 3

Connections 4

The QR code on the switch provides a link to publication

440G-UM001A-EN-P.

Resource Description

440G-LZ Guard Locking Switch User Manual,

publication 440G-UM001A-EN-P

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, http://

www.rockwellautomation.com/products/

certification

You can view or download publications at http://

www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor

or Rockwell Automation sales representative.

Provides general guidelines for installing a

Rockwell Automation guard locking switch.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity,

certificates, and other certification details.

Introduction

ATT EN TI ON : Do not attempt to install this device unless the

installation instructions have b een studied and u nderstood. This

document acts as a guide for a typical installation and is available in

some languages at

Select the publication language and type 440G-LZ in the search

field. A user manual is also available, publication

440G-UM001A-EN-P

www.rockwellautomation.com/literature.

.

Summary of Changes

Added required minimum distance between switches and detail for 5pin quick-disconnect models.

Figure 1 - Assembly Overview

Page 2

440G-LZ Guard Locking Safety Switch

For proper installation, a

minimum of two fasteners

must be used, at least one of

which must be fitted to the top

row of holes, closest to the

bend in the actuator mounting

bracket.

2 x M5/M6 CSK

3 x M5

The locking bolt must always enter

the actuator mounting bracket first.

200 mm (7.87 in.) minimum

Align the white triangles

0.4 N•m

2 x T10

Torx screws

This 440G-LZ Guard Locking switch is for use on guards that are

engineered to be rigid without sag. A separately mounted latch (for

example, magnetic, mechanical) and mechanical stop is required.

Installation must be in accordance with these instructions and must be

carried out by qualified personnel.

ATT EN TI ON : After installation, ensu re that there is no p ossibility

of lifting the ac tuator over the extended locki ng bolt. Adherence to

the recommended maintenance instructions forms part of the

warr anty.

This device is intended to be part of the safety-related control system of

a machine. Before installation, a risk assessment must be performed to

determine whether the specifications of this de vice are suitable for all

foresee able ope rational and environmental characteristi cs of the

application. See Specifications on page 5

and ratings.

Use appropriate screws, bolts, or nuts that are fitted by tools to mount

the switch and actuators to avoid the risk of tampering. Do not over

torque the mounting hardware.

for certification information

Mounting

Figure 2 - Switch Body and Actuator

Installation Considerations

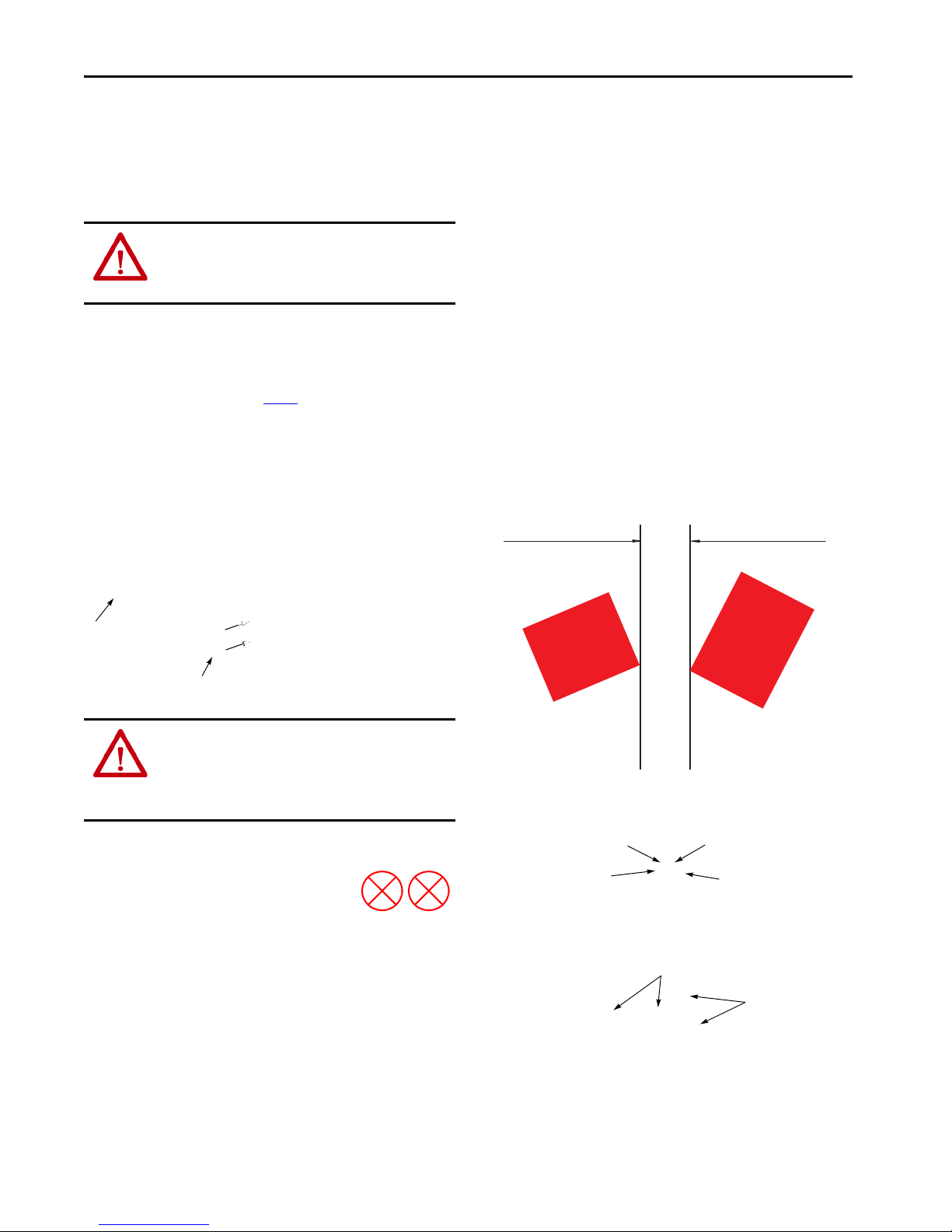

Figure 4 - Orientation of Assembled S

Minimum Distance Between Switches

If a pair of 440G-LZ switches is mounted close to each other, the two

inductive fields interact causing crosstalk, which results in nuisance

faults and false operation.

An absolute minimum of 200 mm (8 in.) must be used to help achieve

correct operation.

The restriction applies if a 440G-LZ switch is mounted close to the

TLS-Z guard locking and the 440N-Z SensaGuard™ switches.

Figure 5 - Minimum Distance between Switches

witch

ATT EN TI ON : For the switch, actuator and actuator mounting

bracket:

• Only use the designated mounting holes.

• Never drill or use to support other structures such as conduit,

cable wa ys, or other hardware.

Figure 3 - Actuator Mounting Possibilities

2 Rockwell Automation Publication 440G-IN011B-EN-P - October 2018

Figure 6 -

Four Directions of Approach

Page 3

440G-LZ Guard Locking Safety Switch

G

H

2.5 (0.098)

dia.

25

(0.98)

50

(1.97)

22.5

(0.89)

45 (1.77)

8

(0.31)

10

(0.39)

22.9

(0.90)

140 (5.51)

10

(0.39)

9.5

(0.37)

9.525

(0.37) dia.

22.5

(0.88)

134.5 (5.29)

33

(1.29)

2 x 5.5

(0.22) dia.

Figure 7 - Actuator Alignment (Three Methods)

1. By setting gap

2.5 mm (0.09 in.)

[

0…5 mm (0…0.19 in.)

2. By mounting hole alignment

H”

6.5 mm (0.25 in.)

“

[4…9 mm (0.15…0.35 in.)]

3. By use of the

Alignment

“G”

]

Guide

Auxiliary/Manual Release

Operation

To reset the switch, cycle the power.

Figure 8 - Manual Release Operation [mm (in.)]

Figure 9 - Dimensions [mm

of the

auxiliary release caus

(in.)]

es

a fault condition.

IMPORTANT It might be easier to achieve actuator alignment by first

mounting just the actuator mounting bracket to the guard/

door and then fit the actuator to its mounting bracket.

It is not possible to mechanically extend the locking bolt

during installation, this can only be done electrically (see

Commissioning in the user manual).

ATT EN TIO N: After installation, be sure that there is no possibility

of lifting the actuator over the extended locking bolt.

After installation, be sure that there is no possibility of collision

when the actuator approaches the switch body.

51.5 (2.03)

40 (1.57)

40

(1.57)

65

(2.56)

47

(1.85)

3

(0.12)

Act uato rs.

25.4

(1.0)

7

(0.28)

25 (0.98)

6 x 6.35

(0.25) dia.

12.5

(0.5)

See publication 440G-UM001, for configuring Unique

Rockwell Automation Publication 440G-IN011B-EN-P - October 2018 3

Page 4

440G-LZ Guard Locking Safety Switch

2 24V DC+

1 Aux

7 0V

6 Safety B

3 Lock Command

8 Safety A+

4 Safety B+

5 Safety A

Keyway

5

4

3

1

2

Connections

Figure 10 - Eight-pin Micro (M12) or Cable Version

Color Function Pin

White Aux 1

Brown 24V DC+ 2

Green Lock 3

Yel low Saf et y B+ 4

Grey Safety A 5

Pink Sa fety B 6

Blue Gnd/0V 7

Red Safety A+ 8

The recommended cordset is catalog number 889D-F8AB-2 (2 m

[6.5ft]). For additional lengths, replace the 2 with a 5 (5 m [16.4 ft]), or

10 m (32.8 ft) for standard cable lengths.

Five-pin Micro (M12)

Pin Color Function

1Brown+24

2 White Safety OSSD 1 Output

3Blue0V

4 Black Safety OSSD2 Output

5GrayLock Command

The recommended cordset is catalog number 889D-F5AC-2 (2 m

[6.5ft]). For additional lengths, replace the 2 with 5 [5 m (16.4 ft)] or

10 [10 m (32.8 ft)] for standard cable lengths.

The recommended patchcord for use with ArmorBlock® Guard Safety

I/O is the 2 m (6.5 ft) catalog number 889D-F5ACDM-2. Replace the

2 with 0M3 [0M3 (0.98 ft)], 1 [1 m (3.28 ft)], 5 [5 m (16.4 ft)], or 10

[10 m (32.8 ft)] for standard cable lengths.

4 Rockwell Automation Publication 440G-IN011B-EN-P - October 2018

Page 5

440G-LZ Guard Locking Safety Switch

Specifications

Standards

Safety classification: Guard door sensi ng

and lock monitoring

Functional Safety Data: G uard door sensing

and lock monitoring

Certifications

Operating Characteristics Protection class (IEC 61140) Class II

Torque for M5 mounting of switch and

actuator mounting bracket

Locking bolt insertion for assured locking

and holding force

Locking bolt alignment tolerance

X, Y, Z

Holding force Fmax (EN/ISO 14119) 1690 N Auxiliary outputs 1 x PNP, 0.2 A max / OFF (0V DC)

Holding force Fzh (EN/ISO 14119) 1300 N Environmental

Maximum output current (each outputs) 200 mA Operating temperature 0…55 °C (32…131 °F)

Quiescent power consumption, locked or

unlocked

Lock signal current 3.5 mA signal on green lock/unlock wire Operating humidity 5…95% relative

Peak current and duration, at turn on or

after lock/unlock operation

Operating voltage Ue 24V DC +10% / -15% Class 2 SELV Shock and vibration IEC 60068-2-27 30 g, 11 ms/IEC 60068-2-6 10…55 Hz

Maximum frequency of operating cycles 0.2 Hz Hygienic

Dwell time between subsequent locking/

unlocking

Response time (Off) 100 ms first switch, 50 ms additional for each switch Radio frequency / EMC IEC 60947-5-3, FCC-1(Parts 18&15), R&TTE

Risk time 100 ms (according to IEC 60947-5-3)

Start up time (availability) 5 s General

Maximum length of a chain of switches 10 km (Dependent on cable/connection/ required response time) Materials ABS, locking bolt and mounting bracket 304 stainless steel

Utilization category (IEC 60947-5-2) DC-13 24V 200 mA Weight switch/actuator Switch 400 g, actuator 150 g, actuator mounting bracket 60 g

Insulation voltage Ui (IEC 60947-1) 75V Protection Type

IEC 60947-5-3, IEC 60947-5-1, IEC 61508, EN ISO 13849-1, IEC

62061, ISO 14119, UL 508

PLe Category 4 per ISO 13849-1, SIL 3 per IEC 61508 and IEC 62061

-10

PFHd: 9.1 x 10

application up to PLe (according to ISO 13849-1) a nd for use up to

SIL3 systems (according to IEC 62061 and IEC 61508) depending on

application characteristics. Mission time/PTI: 20 years

CE Marked for all applicable EU directives, c-UL-us (UL 508), TÜV,

C-tick

2 N•m (17.7 lb•in) max Mechanical life 500,000 cycles

5 mm (0.19 in.) min, 10 mm (0.39 in.) max Outputs (Guard door closed and locked)

±2.5 mm (0.09 in.) max Safety outputs 2 x PNP, 0.2 A max / ON (+24V DC)

2.5 W Storage temperature -25…+75 °C (-13…+167 °F)

400 mA/100 ms Enclosure ingress rating NEMA 3, 4X, 12, 13, IP66, IP67, IP69K

2.5 s Washdown Sodium Hydroxide based washdown fluids

; Dual channel interlock can be suitable for use in

Operating Characteristics (continued)

Impulse withstand voltage Uimp

(IEC 60947-1)

Pollution degree (IEC 60947-1) 3

Manual (auxiliary) relea se Built in

1 kV

ISO 14159:2004 and EN 1672-2005, (for that part of the machine

defined as “food splash area”)

Short-circuit, current limitation, overload, reverse polarity,

overvoltage (up to 60V max.), thermal shutdown/restar t

Status/Diagnostic Operating LED Indicators

The switch has two pairs of LEDs. Status LEDs are green and diagnostic LEDs are red.

Power to Lock Versions Door/Guard Status Lock Com mand OSSD Input Lock Status LED Status OSSD Status

Power on and lock command off Open or closed Off Off or on Unlocked

Lock command on and door open Open On Off or on Unlocked Fast flash green Off

Lock command on and door closed Closed On Off Locked Slow flash green Off

Lock command on and door closed Closed On On Locked Solid green On

Power to Release Versions

Power on with door open Open Off Off or on Unlocked

Power on with door closed Closed Off Off Locked

Power on with door closed and OSSD

input active

Unlock command on and door closed or

open

Door/Guard

Status

Closed Off On Locked

Open or closed On Off or on Unlocked Solid red Off

Blinks 6 x green then

solid red

Off

Unlock Command OSSD Input Lock Status LED Status OSSD Status

Blinks 6 x green then 1 x blink red

followed by fast flash green

Blinks 6 x green then 1 x blink red

followed by slow flash green

Blinks 6 x green then 1 x blink red

followed by solid green

Off

Off

On

Rockwell Automation Publication 440G-IN011B-EN-P - October 2018 5

Page 6

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Catalog Numbers for Complete Switches

Rockwell Automation Support

Use the following resources to access support information.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

How Are We Doing? form at http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf.

Technical Support Center

Knowledgebase Articles, How-to Videos, FAQs, Chat, User

Forums, and Product Notification Updates.

https://rockwellautomation.custhelp.com/

Local Technical Support Phone Numbers Locate the phone number for your country. http://ww w.rockwellautomation.com/global/support/get-suppor t-now.page

Direct Dial Codes

Find the Direct Dial Code for your product. Use the code to

route your call directly to a technical support engineer.

http://www.rockwellautomation.com/global/support/direct-dial.page

Literature Library

Installation Instructions, Manuals, Brochures, and

Technical Data.

http://www.rockwellautomation.com/global/literature-library/overview.page

Product Compatibility and Download

Center (PCDC)

Get help determining how products interact, check

features and capabilities, and find associated firmware.

http://www.rockwellautomation.com/global/support/pcdc.page

440G-LZS21

abcd

abcd

S Standard Coding J No Auxiliary (5-pin models) R Power-to-Release A 3 m Cable

U Unique Coding P Auxiliary—Lock Status L Power-to-Lock B 10 Cable

T Auxiliary—Door Proximity H M12 8-pin

J M12 5-pin

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately

from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley, ArmorBlock, Rockwell Automation, Rockwell Software, and SensaGuard are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

.

Publication 440G-IN011B-EN-P - October 2018 PN-212379

Supersedes Publication 440G-IN011B-EN-P - June 2015 10000818284 Ver 04

Copyright © 2018 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...