Allen-Bradley 42GRU-9000-QD, 42GRP-9040-QD, 42GRU-9202-QD, 42GRF-9000-QD, 42GRP-9000-QD Installation Manual

...Page 1

Installation Instructions

Original Instructions

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors

Catalog Number 42G

Specifications

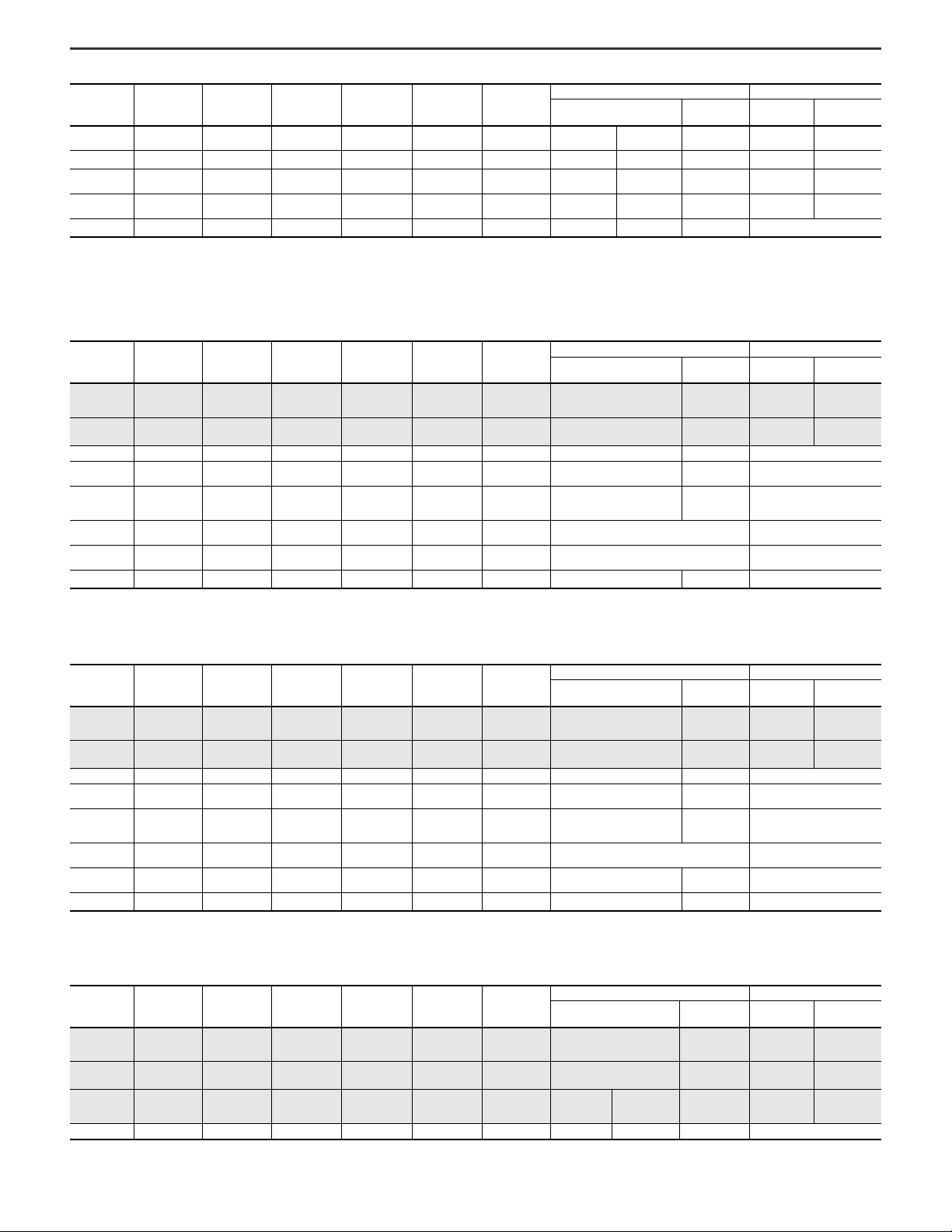

Table 1 - All Photoelectric Sensors

(2)

(3)

(4)

Polarized

Retroreflective

(2)

4.9 m (16 ft)

(3)

2 m (6.5 ft)

(4)

1 m (3 ft)

Visible Red

660 nm

Yellow: Power

Green: Output

Red: Margin/SCP

(5)

ClearSight Standard Diffuse

1.2 m (4 ft) 1.5 m (5 ft) 3.0 m (10 ft) 4.2 m (14 ft) 61 m (200 ft) 152 m (500 ft)

Visible Red

660 nm

Yellow: Power

Green: Output

Red: Margin/SCP

(5)

Infrared

880mn

Yellow: Power

Green: Output

Red: Margin/SCP

(5)

Specification Retroreflective

Sensing

distance

9.1 m (30 ft)

3.6 m (12 ft)

3 m (10 ft)

Transmi tting

status

indicator

Indicators

Visible Red

660 nm

Yellow: Power

Green: Output

Red: Margin/SCP

(5)

Field of view 1.5° 1.5° 1.5° 3.5° 6.5° 3.5° 1.5° 1.5° 1.5° Depends on fiber-optic selected

Sensitivity

adjustment

Operating

temperature

Relative

humidity

Housing/lens

material

Operating

environment

Approvals

Protections

Vibration

Shock

(1) Transmitted beam source rated 10…264V AC/DC.

(2) 78 mm (3 in.) reflector

(3) 32 mm (1.25 in.) reflector

(4) 16 mm (0.625 in.) reflector

(5) Red: Illuminates when margin ≤0.5x (no target) and ≥2.5x (target).

(6) Except models with solid-state and relay output (see page 8).

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

(6)

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

(6)

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

(6)

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

5…95% 5…95% 5…95% 5…95% 5…95% 5…95% 5…95% 5…95% 5…95% 5…95% 5…95%

Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic Valox/acrylic

NEMA 3, 4X, 6P,

12, 13, IP67

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions:

False Pulse

Solid-state

output versions:

Short circuit and

overlo ad

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

NEMA 3, 4X, 6P,

12, 13, IP67

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions:

False Pulse

Solid-state

output versions:

Short circuit and

overload

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

NEMA 3, 4X, 6P, 12,

13, IP67

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions: False

Pulse

Solid-state

output versions:

Short circuit and

overload

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

NEMA 3, 4X, 6P, 12,

13, IP67

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions: False

Pulse

Solid-state

output versions:

Short circuit and

overlo ad

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

Long Range

Yellow: Power

Green: Output

Red: Margin/SCP

Single-turn

Potentiometer

-34…+70 °C

(6)

(-29…+158 °F)

NEMA 3, 4X, 6P, 12,

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions: False

Solid-state

output versions:

Short circuit and

overloa d

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

Diffuse

Infrared

880mn

(5)

13, IP67

Pulse

Extended Range

Yellow: Power

Green: Output

Red: Margin/SCP

Single-turn

Potentiometer

-34…+70 °C

(6)

(-29…+158 °F)

NEMA 3, 4X, 6P,

12, 13, IP67

UL Listed

CSA certified

CE marked for all

applicable

directives

All Versions:

False Pulse

Solid-state

output versions:

Short circuit and

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.)

amplitude

Meets or exceeds

IEC 947-5-2

30G with 1 ms

pulse duration

Meets or exceeds

IEC 947-5-2

Diffuse

Infrared

880mn

(5)

overlo ad

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

NEMA 3, 4X, 6P,

Table 2 - 10…30V DC Photoelectric Sensors — NPN and PNP

Specification Retroreflective

Cat. No.

2 m (9.84 ft)

300V cable

Cat. No.

4-pin DC micro

Cat. No.

4-pin micro QD

QD

42GxU-9000

42GxU-9000-QD

(2)

42GxU-9000-QD1

(2)

Polarized

Retroreflective

(2)

42GxU-9200

42GxU-9200-QD

42GxU-9200-QD1

(2)

(2)

ClearSight

42GxC-9200

42GxC-9200-QD

(2)

42GxC-9200-QD1

(2)

Supply current 30 mA 30 mA 30 mA 30 mA 30 mA 50 mA 15 mA 15 mA 25 mA 30 mA 30 mA

(2)

42GxP-9000

42GxP-9000-QD

42GxP-9000-QD1

Standard

Diffuse

(3)

(3)

Long Range

Diffuse

(3)

42GRP-9040 42GRP-9070 42GRL-9000 42GRL-9040

Extended

Range Diffuse

42GRP-9040-QD 42GRP-9070-QD 42GRL-9000-QD 42GRL-9040-QD

42GRP-9040-QD1 42GRP-9070-QD1 42GRL-9002-QD 42GRL-9042-QD

Transmitted Beam Fiber-optic

(1)

Source

Infrared

880mn

12, 13, IP67

CE marked for all applicable directives

Infrared

880mn

Yellow: Power

Green: Output

Red: Margin/SCP

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

NEMA 3, 4X, 6P,

12, 13, IP67

UL Listed

CSA certified

Potentiometer

(-29…+158 °F)

NEMA 3, 4X, 6P,

Receiver

Depends on

light source

selected

Single-turn

-34…+70 °C

12, 13, IP67

Plastic Visible

Depends on fiber-optic selected

Visible Red

—

660 nm

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

NEMA 3, 4X, 6P,

12, 13, IP67

CE marked for all applicable

All Versions: False Pulse All Versions: False Pulse

Solid-state output versions:

Short circuit and overload

DC versions:

Reverse polarity

10…55 Hz

1 mm (0.04 in.) amplitude

Meets or exceeds IEC 947-5-2

30G with 1 ms pulse duration

Meets or exceeds IEC 947-5-2

Solid-state output versions:

Short circuit and overload

1 mm (0.04 in.) amplitude

Meets or exceeds IEC 947-5-2

30G with 1 ms pulse duration

Meets or exceeds IEC 947-5-2

Transmitted Beam Fiber-optic

(2)

(2)

Plastic Visible

(2)

42GxF-9100

42GxF-9100- QD

42GxF-9100- QD1

Source

(1)

Receiver

42GxR-9000

42GxR-9000-QD

42GxR-9000-QD1

Red

Yellow: Power

Green: Output

Red: Margin/SCP

UL Listed

CSA certified

directives

DC versions:

Reverse polarity

10…55 Hz

Red

(2)

(2)

(2)

Glass Infrared

Infrared

880mn

Single-turn

Potentiometer

-34…+70 °C

(-29…+158 °F)

NEMA 3, 4X, 6P,

12, 13, IP67

Glass Infrared

42GxF-9000

42GxF-9000-QD

(2)

42GxF-9000-QD1

(2)

(2)

Page 2

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

Table 2 - 10…30V DC Photoelectric Sensors — NPN and PNP (Continued)

Transmitted Beam Fiber-optic

(1)

Source

——

Receiver

Light/dark

selectable

Plastic Visible

Red

Light/dark

selectable

(4)

(5)

Polarized

Retroreflective

Light/dark

selectable

(4)

250 mA

(5)

2 ms

ClearSight

Light/dark

selectable

250 mA

2 ms

Specification Retroreflective

Output

energized

Load current

Leakage

current

Power

consumption

Response time

(1) Transmitted beam source rated 10…264V AC/DC.

(2) x = R: On/Off, or T: timer version.

(3) x = L: Linear sense potentiometer, S: Teachable version, R: Nonlinear sense potentiometer, or T: Timer version.

(4) 100 mA for 42GSP, 9000, and 42GLP-9000 models.

(5) 5 ms for timer versions.

Light/dark

selectable

250 mA

10 µA 10 µA 10 µA 10 µA 10 µA 10 µA — — 10 µA 10 µA 10 µA

4VA max 4VA ma x 4VA m ax 4VA max 4 VA ma x 4VA max 4VA m ax 4 VA max 4VA m ax 4VA max 4 VA max

2 ms

Standard

Diffuse

Light/dark

selectable

(4)

250 mA

(5)

2 ms

Long Range

Diffuse

Light/dark

selectable

(4)

(5)

(4)

250 mA

2 ms 2 ms — — 5 ms 2 ms

Extended

Range Diffuse

Light/dark

selectable

250 mA — — 250 mA 250 mA 250 mA

Table 3 - 10…55V DC/20…40V AC Photoelectric Sensors — SPDT EM Relay

Specification Retroreflective

Cat. No.

2 m (9.84 ft)

300V cable

Cat. No.

5-pin micro QD

42GxU-9001

42GxU-9001-QD

(2)

Retroreflective

(2)

42GxU-9201

42GxU-9201-QD

Polarized

(2)

ClearSight

(2)

—

—

Standard

Diffuse

42GxP-9001

42GxP-9001-QD

(2)

Long Range

Diffuse

(2)

42GRP-9041 — — 42GRR-9001

Extended

Range Diffuse

42GRP-9041-QD — — 42GRR-9001-QD

Supply current 40 mA 40 mA — 40 mA 40 mA — — 35 mA 40 mA

Output

energized

Load current

Leakage

current

Power

consumption

Response time

(1) Transmitted beam source rated 10…264V AC/DC.

(2) x = R: On/Off, or T: timer version.

(3) 18 ms for timer versions.

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

—

—

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

——

——

—————— — —

2.2 watts/

1.6VA max

15 ms

2.2 watts/

1.6VA max

(3)

15 ms

(3)

—

—

2.2 watts/

1.6VA max

15 ms

2.2 watts/

1.6VA max

(3)

15 ms — — 23 ms 15 ms

—— 3VA max

Transmitted Beam Fiber-optic

Source

(1)

Receiver

Plastic Visible

Red

42GxF-9101

42GxF-9101- QD

(2)

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

(2)

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Glass Infrared

Light/dark

selectable

Glass Infrared

42GxF-9001

42GxF-9001-QD

(2)

(2)

Table 4 - 70…264V DC/60…264V AC Photoelectric Sensors — SPDT EM Relay

Specification Retroreflective

Cat. No.

2 m (9.84 ft)

300V cable

Cat. No.

5-pin micro QD

42GxU-9002

42GxU-9002-QD

(2)

Retroreflective

(2)

42GxU-9202

42GxU-9202-QD

Polarized

(2)

(2)

42GxC-9202

42GxC-9202- QD

ClearSight

(2)

(2)

42GxP-9002

42GxP-9002-QD

Standard

Diffuse

(2)

Long Range

Diffuse

(2)

42GRP-9042 42GRP-9072 —

Extended

Range Diffuse

42GRP-9042-QD 42GRP-9072-QD —

Supply current 15 mA 15 mA 15 mA 15 mA 15 mA 15 mA — 10 mA 15 mA

Output

energized

Load current

Leakage

current

Power

consumption

Response time

(1) Transmitted beam source rated 10…264V AC/DC.

(2) x = R: On/Off, or T: timer version.

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

—

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Light/dark

selectable

——

—————— — —

4 watts/

4VA max

15 ms

(3)

4 watts/

4VA max

15 ms

4 watts/

(3)

4VA max

15 ms

(3)

4 watts/

4VA max

15 ms

4 watts/

(3)

4VA max

15 ms 15 ms — 23 ms 15 ms

4VA max — 4VA max 4VA max

(3) 18 ms for timer versions.

Transmitted Beam Fiber-optic

(2)

Plastic Visible

(2)

42GxF-9102

42GxF-9102 -QD

Red

(2)

Source

—

(1)

Receiver

42GxR-9002

42GxR-9002-QD

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

(2)

Light/dark

selectable

2A/132V AC

1A/264V AC

1A/150V DC

Table 5 - 70…264V AC/DC Photoelectric Sensors — Solid-state Isolated N.O.

Specification Retroreflective

Cat. No.

2 m (9.84 ft)

300V cable

Cat. No.

4-pin micro QD

Cat. No.

4-pin AC micro

QD

42GxU-9003

42GxU-9003-QD

(2)

42GxU-9003-QD1

(2)

Retroreflective

(2)

42GxU-9203

42GxU-9203-QD

42GxU-9203-QD1

Polarized

(2)

(2)

(2)

42GxC-9203

42GxC-9203-QD

42GxC-9203-QD1

ClearSight

(2)

(2)

(2)

42GxP-9003

42GxP-9003-QD

42GxP-9003-QD1

Standard

Diffuse

(2)

(2)

Long Range

Diffuse

(2)

42GRP-9043 — — 42GRR-9003

Extended

Range Diffuse

42GRP-9043-QD — — 42GRR-9003-QD

42GRP-9043-QD1 — — 42GRL-9043-QD1 42GRR-9003-QD1

Supply current 15 mA 15 mA 15 mA 15 mA 15 mA — — 15 mA 15 mA 15 mA

Transmitted Beam Fiber-optic

Source

(1)

Receiver

Plastic Visible

Red

42GxF-9103

42GxF-9103- QD

(2)

42GxF-9103- QD1

(2)

(2)

Glass Infrared

42GxF-900 2

42GxF-9002 -QD

(2)

Glass Infrared

42GxF-900 3

42GxF-9003-QD

(2)

42GxF-900 3-QD1

(2)

(2)

(2)

2 Rockwell Automation Publication 42G-IN003B-EN-P - October 2021

Page 3

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

(+)

(--)

Brown

White: NPN

Black: PNP

Blue

Load

Load

(+)

(--)

1

2

4

1 Brown

2 White: NPN

4 Black: PNP

3 Blue

Load

Load

4

1

3

(+)

(--)

3

3 Brown

4 White: NPN

1 Black: PNP

2 Blue

Load

Load

(+)~

(--)~

(1) Load can be placed on either black or whit e wire to create sourcing or sinking respectively.

(1)

Brown

White

Black

Blue

Load

1

2

4

(+)

~

(--)~

(1) Load can be placed on either black or whit e wire to create sourcing or sinking respectively.

(1)

3 Brown

4 White

1 Black

2 Blue

Load

1

32

4

3

(+)~

(--)~

2 Red/White

4 Green No Conn.

3 Red

1 Red/Black

Load

(+)

~

(--)

~

Brown

Black (N.O.)

White (NC)

Orange (C)

Blue

1

3

2

4

5

(+)

~

(--)

~

4 Brown

1 Black (N.O.)

5 White (NC)

3 Orange (C)

2 Blue

T

(+)~

(--)~

Brown

Blue

T

1

2

4

(+)

~

(--)~

3 Brown

1 Black

4 White

2 Blue

Not Used

Not Used

1

2

4

T

3

(+)~

(--)~

1 Brown

2 White

4 Black

3 Blue

Not Used

Not Used

1

32

4

T

(+)

~

(--)

~

1 Red/Black

4 Green

3 Red

2 Red/White

Not Used

Not Used

Table 5 - 70…264V AC/DC Photoelectric Sensors — Solid-state Isolated N.O. (Continued)

Transmitted Beam Fiber-optic

Source

(1)

Receiver

Light/dark

selectable

1 mA at

264V AC/DC

Plastic Visible

Red

Light/dark

selectable

264V AC/DC

(3)

Polarized

Retroreflective

Light/dark

selectable

1 mA at

264V AC/DC

4 watts/

4VA max

(3)

2 ms

ClearSight

Light/dark

selectable

1 mA at

264V AC/DC

4 watts/

4VA max

2 ms

Specification Retroreflective

Output

energized

Load current 300 mA 300 mA 300 mA 300 mA 300 mA — — 300 mA 300 mA

Leakage

current

Power

consumption

Response time

(1) Transmitted beam source rated 10…264V AC/DC.

(2) x = R: On/Off, or T: timer version.

(3) 5 ms for timer versions.

Light/dark

selectable

1 mA at

264V AC/DC

4 watts/

4VA max

2 ms

Conductor Size (AWG) Max Current/Min Voltage of Overcurrent Protection

20 5 A/300V

22 3 A/300V

24 2 A/300V

26 1 A /300V

28 0.8 A/300V

30 0.5 A/300V

Standard

Diffuse

Light/dark

selectable

1 mA at

264V AC/DC

4 watts/

(3)

4VA max

2 ms

Long Range

Diffuse

Light/dark

selectable

1 mA at

264V AC/DC

4 watts/

(3)

4VA max

2 ms — — 15 ms 2 ms

Extended

Range Diffuse

——

——

——4VA max4VA max 4VA max

Figure 6 - AC/DC Micro QD Model: 9xx3-QD11

Figure 7 - Cable Model: 9xx1, 9xx2

Wiring Diagrams

Shows all models except transmitted beam source.

Figure 1 - Cable Model: 9xx0

Figure 8 - 5-pin AC/DC Mini QD Model: 9xx1-QD, 9xx2-QD

Glass Infrared

1 mA at

Figure 2 - 4-pin DC Micro QD Model: 9xx0-QD

Figure 3 - 4-pin DC Mini QD Model: 9xx0-QD1

Figure 4 - Cable Model: 9xx3

Figure 5 - AC/DC Mini QD Model: 9xx3-QD

Figure 9 - Transmitted Beam Source Cable Model: 42GRL-90x

Figure 10 - AC/DC Mini QD Model: 42GRL-90x2-QD

Figure 11 - DC Micro QD Model: 42GRL-90x0-QD

Figure 12 - 4-pin DC Micro QD Model: 42GRL-90x3-QD1

Rockwell Automation Publication 42G-IN003B-EN-P - October 2021 3

Page 4

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

300

(12)

51

(2)

15000

(600)

1500

(60)

600

(24)

3000

(120)

76 (3)

32 (1.25)

16 (0.625)

100

1

2

4

8

10

20

40

80

Operating Margin

Operating Distance

Reflector

Reflector

Reflector

16 (0.625)

76 (3)

32 (1.25)

100

1

2

4

8

10

20

40

80

300

(12)

51

(2)

15000

(600)

1500

(60)

3000

(120)

6000

(240)

150

(6)

Operating Margin

Operating Distance

Reflector

Reflector

Reflector

1

10

92-39

92-90

25.4

(1)

254

(10)

2540

(100)

Operating Margin

Operating Distance

Reflector

Reflector

216 x 279.4

(8.5 x 11)

100

1

2

4

8

10

20

40

80

300

(12)

51

(2)

1500

(60)

3000

(120)

6000

(240)

150

(6)

600

(24)

Operating Margin

Operating Distance

White Paper,

1

1000

10

100

42GRP-907x

42GRP-904x

25.4

(1)

254

(10)

25400

(996)

2500

(98.4)

Operating Margin

Operating Distance

0.3m

(1ft)

10

4

1

100

40

1000

400

10000

4000

1.8m

(5ft)3m(10ft)

15m

(50ft)

30m

(100ft)

150m

(500ft)

Operating Margin

Operating Distance

25.4mm

(1.0in)

2.3mm (0.09in)GlassFiber

1.0mm (0.04in)Plastic Fiber

0.5mm (0.02in)Plastic Fiber

0.5mm (0.02inPlastic Fiber Bundle

WhitePaper

216mm X279.4mm

(8.5 x 11)

0.6m

(24in)

2.54mm

(0.1in)

0.3m

(12in)

1.0mm (0.04in)Pla sticFiber‐Coiled

76.2mm

(3.0in)

10000

1

4

10

40

100

400

1000

4000

Operating Margin

Operating Distance

1.5mm (0.6in)Glass Fiber

1.0mm (0.04in)Plastic Fiber

1.0mm (0.04in)Pla sticFiber‐Coiled

0.5mm (0.02in)Plastic Fiber

0.5mm (0.06in)Plastic

Fiber‐Coiled

10000

1

4

10

40

100

400

1000

4000

25mm

(1.0in)

0.6m

(24in)

2.5mm

(0.1in)

0.3m

(12in)

76mm

(3.0in)

Operating Margin

Operating Distance

Typical Response Curves

Figure 13 - Retroreflective [mm (in.)]

Figure 14 - Polarized Retroreflective [mm (in.)]

Figure 17 - Long Range Diffuse

Figure 18 - Transmitted Beam, 61 m (200 ft), 152 m (500 ft) Light Source

[mm (in.)]

Figure 15 - ClearSight Clear Object Detector [mm (in.)]

Figure 19 - Visible Red Fiber-optic Standard Diffuse

Figure 20 - Visible Red Fiber-optic Transmitted Beam

Figure 16 - Standard Diffuse [mm (in.)]

4 Rockwell Automation Publication 42G-IN003B-EN-P - October 2021

Page 5

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

1.0mm (0.04I)

Plastic Fiber

2.3mm (0.09I)

Glass Fiber

With 76mm (3

)

Reflector

0.02 (0.5mm)

Plastic Fiber

Coiled

1.0mm (0.04I)

Plastic Fiber Coiled

0.5mm (0.02I)

Plastic Fiber

25.4mm

(1.0in)

0.6m

(23in)

2.54mm

(0.1in)

0.3m

(12in)

76.2mm

(3.0in)

1.5m

(59in)

10000

1

4

10

40

100

400

1000

4000

OperatingDistance

Operating Margin

White Paper

216mm x 279.4mm

(8.5x11

)

3.18mm (0.125

) Glass Fiber

1.52mm (0.06)GlassFiber

0.69m (0.027) Glass Fiber

10000

1

4

10

40

100

400

1000

4000

25mm

(1.0in)

0.6m

(24in)

2.5mm

(0.1in)

0.3m

(12in)

150mm

(6.0in)

OperatingDistance

Operating Margin

0.69mm (0.027) Glass Fiber

3.18mm (125 )Glass Fiber

1.52mm (0.060)GlassFiber

25mm

(1.0in)

0.6m

(24in)

2.5mm

(0.1in)

0.3m

(12in)

150mm

(6.0in)

10000

1

4

10

40

100

400

1000

4000

OperatingDistance

Operating Margin

0.060 (1.52mm)

Glass Fiber

0.125(3.18mm)

Glass Fiber

0.027(0.69mm)

GlassFiber

With 78mm (3)

Reflector

25mm

(1.0in)

0.6m

(24in)

2.5mm

(0.1in)

0.3m

(12in)

150mm

(6.0in)

1.5m

(59in)

10000

1

4

10

40

100

400

1000

4000

OperatingDis tance

Operating Margin

41.91

(1.650)

5.46

(0.215)

32.66 (1.286)

74.93

(2.950) Ref

55.62

(2.190)

16.76 (0.660)

M30 X 1.5

External Thread

1/2

NPSM

Internal Thread

24.69

(0.970)

30.35

(1.195)

15.87

(0.625)

42.41

(1.670)

20.96

(0.825)

7.62 (0.300)

15.24 (0.600)

5.21 (0.205) X 8.13

(0.320)

Slot, 2 PLCS

Cable Length

2m (6.5ft )

6.5 (0.255/0.245) Dia.

103.63

(4.080) Max.

Travel

40.00

(1.575)

Mounting Hole

Centerline

6.12

(0.241)

103.63

(4.080) Max.

Travel

41.91

(1.650)

Cable Length 2m (6.5ft)

6.47/6.22

6.25 (0.25) Dia.

32.66 (1.286)

74.93

(2.950)

Ref

2.190

(55.62)

16.76 (0.660)

M30 X 1.5

External Thread

1/2

NPSM

Internal Thread

24.64 (0.970)

30.35 (1.195)

15.87(0.625)

5.46

(0.215)

42.42

(1.670)

20.96

(0.825)

7.62 (0.300)

5.21(0.205) X

8.13 (0.320)

Slot, 2 Plcs

Mounting Hole

Centerline

40.00

(1.575)

Cable Length

2m (6.5ft)

6.47/6.22 (0.255/0.245)

Dia.

9 (1.283)

65.23

(2.568)

32.89

(1.295)

100.6 (3.96)

Max. Travel

120

2.54

(0.10)

79.63

(3.135)

M30 x 1.5 External

Thread 1/2 NPSM

Internal Thread

25.1

(0.99)

39.5

(1.55)

42.41

(1.670)

15.87 (0.625)

47.88

(1.885)

5.46 (0.215)

5.21 (0.205

8.13 (0.32

Slot, 2 Plc

24.64 (0.97)

30.35 (1.195)

Centerlin

}

13.41 (0.528

20.96 (0.82

41.91

(1.65)

68.07

(2.68)

Figure 21 - Visible Red Fiber-optic Retroreflective

Figure 22 - Infrared Fiber-optic Standard Diffuse

Approximate Dimensions

Figure 25 - All Cable Versions Except Fiber-optic [mm (in.)]

Figure 26 - Fiber-optic [mm (in.)]

Figure 23 - Infrared Fiber-optic Transmitted Beam

Figure 24 - Infrared Fiber-optic Retroreflective

Figure 27 - ClearSight 9000 Versions [mm (in.)]

Rockwell Automation Publication 42G-IN003B-EN-P - October 2021 5

Page 6

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

13.97 (0.550)

1/2-20 UNF

2 Keyways (AC)

M12 x 1

1 Keyway (DC)

17.78 (0.700)

7/8-16UN

1 Keyway

50.08

(2.0)

57.15

(2.25)

28.6

(1.13)

7.95

(0.31)

10 _ Adjustment in

each direction

28.6

(1.13)

7.95

(0.31)

50.08

(2.0)

87.0

(3.42)

101.6

(4.0)

22.2

(1.88)

139.7

(5.5)

H

#602721

= height 4 inches

#602722 = height 6 inches

#602723 = height 8 inches

#602724 = height 10 inches

152.4

(6.0)

7.0

(0.275)

80

45

50

55

60

65

70

75

06201101206160

Supply Voltage, V AC/DC

Ambient Temperature,__C

40

M5 x 0.8 x 53

Combination

Screws and Nuts

(Supplied)

Hardware Kit

(Supplied)

Unlock

Lock

Figure 28 - Connector Version [mm (in.)]

Accessories

Figure 29 - Swivel/tilt Mounting Assembly #60-2439 [mm (in.)]

Figure 30 - Swivel/tilt Mounting Assembly #60-2681 for ClearSight 9000

[mm (in.)]

determined from Figure 32. The temperature is based on the supply voltage that is

fed to the photoelectric sensor. For example, if the operating voltage is 120V AC,

the maximum operating temperature would be 70 °C (158 °F). An operating voltage

of 220V AC would limit the ambient operating temperature to 55 °C (131 °F).

Operation of the photoelectric sensor at ambient temperatures that exceed these

limits could result in sensor failure.

Mounting and Wiring

Securely mount the photoelectric sensor on a firm, stable surface or support. A

mount that is subject to excessive vibration or shifts can cause intermittent

operation. Rockwell Automation offers a wide variety of fixed and adjustable

mounting brackets and reflectors and quick disconnect cables. The photoelectric

sensor is supplied with the hardware kit #129-130, which contains a plastic

mounting nut, lock washer, and two M5 x 0.8 x 53 screws and nuts. Once securely

mounted, the photoelectric sensor can be wired as indicated in the wiring

diagrams.

Figure 31 - Vertical Height Adjustment Brackets [mm (in.)]

Operational Notes

Figure 32 - Ambient Temperature Ratings

All models of the Series 9000 photoelectric sensor, except for models with the

solid-state output (catalog number 42Gxx-9xx3) and the EM-relay output (catalog

number 42Gxx-9xx2), have a maximum operating temperature of 70 °C (158 °F). The

maximum operating temperature of models 42Gxx-9xx3 and 42Gxx-9xx2 can be

6 Rockwell Automation Publication 42G-IN003B-EN-P - October 2021

Install Fiber-Optic Cables (42GxF-9xxx models only)

1. Confirm that the fiber-optic cable

locking lever on the photoelectric

sensor is in the unlocked position.

2. Insert the fiber-optic cable until the

internal clip mechanism is engaged

3. Rotate the locking lever to the lock

position.

4. Mount the fiber-optic cable sensing tip end as appropriate.

Wiring the Photoelectric Sensor

The Series 9000 photoelectric sensor is available in one of three different

connection types as identified in Specifications

of the 889 Series of cordsets and patchcords on the quick disconnect models. All

on page 1. We recommend the use

Page 7

PHOTOSWITCH Series 9000 On/Off and Timing Photoelectric Sensors Installation Instructions

Sensitivity Adjustment

Status Indicators

Light/Dark

Operate Switch

external wiring must conform to the National Electrical Code and all applicable

local codes.

Align and Configure the Photoelectric Sensor

All Models Except 42GSP-9000

User Interface

To gain access to the user interface panel, use a screwdriver to open the top cover

of the photoelectric sensor. This panel contains a single-turn sensitivity

adjustment knob, a two-position mode selector switch, and three status indicators.

Use the screwdriver to increase (clockwise) or decrease (counterclockwise) the

sensitivity to meet the application requirements. The factory default setting for all

versions is maximum sensitivity.

IMPORTANT Damage to the single-turn sensitivity adjustment knob

Figure 33 - 42GRx Top Vie w Detai l

The Series 9000 photoelectric sensor also contains a two-position selector switch.

This switch is used to select either Light- or Dark-operate mode of the

photoelectric sensor. In Light-operate mode, the photoelectric sensor output turns

on when light is being reflected back to it (reflector for retroreflective, source for

transmitted beam, or target for diffuse). In Dark-operate mode, the photoelectric

sensor output turns off when no light is being reflected back to it. See Table 6

Photoelectric Sensor Alignment

The red status indicator is an alignment aid, which indicates that a margin of 2.5X,

is reached. At this margin, the photoelectric sensor is receiving at least 2.5 times

the signal strength back from the target that triggers an output signal. A higher

margin is recommended to help overcome any deteriorating environmental

conditions, such as dust buildup on the lens of the photoelectric sensor. When

aligning the photoelectric sensor, the best performance is obtained if the margin

indicator illuminates with the target in place. We recommend leaving the

sensitivity at the default maximum setting and change the setting only when

necessary.

Table 6 - Status Indicators

Label Color State Status

Output Green

Margin Red

Power Yellow

Transmitted Beam Versions

1. Visually align the emitter and receiver units (fibers) until the green output

status indicator turns on (with Light-operate mode) or turns off (with Darkoperate mode).

2. To be certain that the beam is centered, sweep the emitter or receiver in

the horizontal and vertical plane and determine at what position the

output indicator turns on and then turns off. Set the sensor

(or fiber-optics) midway between both positions. The red margin status

indicator is on when the beam is unbroken.

occurs if it is turned beyond the in/max steps.

After initial photoelectric sensor configuration, confirm

that the user interface cover is closed tightly to maintain

specified environmental ratings.

.

OFF Output de-energized, SCP active

ON Output energized

OFF Margin <2.5

ON Margin >2.5

Flashing Output SCP active

OFF Sensor not powered

ON Sensor powered

2. To be certain that the beam is centered, sweep the sensor in the

horizontal and vertical plane and determine at what position the output

indicator goes turns and then turns off. Set the sensor (or fiber-optics)

midway between both positions.

3. Break the beam with the object to be detected and check if the output

status indicator turns on (Dark-operate mode). If necessary, turn down the

sensitivity adjustment until the output status indicator turns on. Remove

the object to restore the light beam and check if the output status

indicator turns off again and that the red margin status indicator turns on.

If the status indicates do not change, increase the size of the reflector or

decrease the distance between the reflector and the photoelectric sensor.

Diffuse Mode

1. Visually align the sensor (or fiber-optic cable) on the object until the green

output status indicator turns on (with Light-operate mode) or turns off

(Dark-operate mode).

2. To be certain that the beam is centered, sweep the sensor in the

horizontal and vertical plane and determine at what position the output

indicator goes on and then goes off. Set the sensor (or fiber-optics)

midway between both positions.

3. Remove the object in front of the sensor and eliminate any existing

background signals by turning down the sensitivity adjustment. Replace

the object and verify that the output status indicator turns on and that the

margin status indicator is on. If the sensor continues to pick up

background reflections, you must either eliminate those reflections (paint

with a nonreflective color), or replace the photoelectric sensor with a

background suppression, a sharp cutoff diffuse, or a Retroreflective

Sensing mode version.

42GSP- 9000 Models

User Interface

Use a screwdriver to open the top cover of the photoelectric sensor to gain access

to the user interface panel. This panel contains two push buttons and three status

indicators. The left push button puts the photoelectric sensor into Teach mode

while the right-hand button is for light/dark operate selection.

Teach M ode

The Teach mode of the 42GSP-9000 photoelectric sensor enables the it to learn

both the light and dark conditions that are presented to it and to automatically

adjust sensitivity to the optimal level for the application. This mode replaces the

sensitivity adjustment knob of a conventional photoelectric sensor.

With the photoelectric sensor pointed at the light condition (target), momentarily

press the Teach button until the red status indicator turns on. After 3 seconds, this

status indicator flashes, which indicates that it is ready to receive the dark

condition (background). The red status indicator momentarily remains steady, then

turns off, which indicates that the teach operation was successful.

The 42GSP-9000 photoelectric sensor also contains a two-position push button.

This button selects either Light- or Dark-operate mode of the photoelectric sensor.

In Light-operate mode, the photoelectric sensor output turns on when light is

reflected back to it (indicated by the output status indicator being on). In

Dark-operate mode, the photoelectric sensor output turns on when no light is

reflected back to it.

describes the function of the three status indicators.

Table 34

Figure 34 - Status Indicators

Label Color State Status

OUT Yellow

SET/SCP Red

PWR/STAB Green

OFF Output de-energized

ON Output energized

OFF Normal operation

ON

Flashing

OFF Sensor not powered

ON Sensor powered

Flashing Unstable margin condition

Teach mode active present dark

condition

Teach mode active present light

condition, output SCP active

Retroreflective and Polarized Retroreflective Versions

1. Visually align the sensor (or fiber-optic cable) on the reflector until the

green output status indicator turns on (with Light-operate mode) or turns

off (with Dark-operate mode). Also verify that the red margin status

indicator is on.

Rockwell Automation Publication 42G-IN003B-EN-P - October 2021 7

Page 8

Figure 35 - 42GSP Top View Detail

Teach Button

Status Indicators

Light/Dark Operate

Pushbutton

PWR 9003 DEFAULT

Tar g e t

ON/OFF

Timin g: O FF De lay

Timin g: O N Del ay

Timing: ON /OFF Delay

ON DELAY

OFF D ELAY

Tar g et

One-Shot

Delayed One-Shot

T2

T1

T1 is adjusted via the off delay potentiometer with either a long (0…15 s) or short (0…1.5 s) DIP switch setting.

T2 is adjusted via the on delay potentiometer with either a long (0…15 s) or short (0…1.5 s) DIP switch setting.

42GTx Models

Some versions of the Series 9000 photoelectric sensor also contain a four-bank

DIP switch (S1...S4) and two rotary knobs (R2 and R3). These devices are used to

configure internal on, off, and one-shot time delays making it possible to provide

some degree of local control in an application.

Figure 36 - Timing Photoelectric Sensors Top View Detail

Short/Long

Off Delay

Short/Long

On Delay

Light/Dark

Operate

One Shot/

Time Delay

S1 S2 S3 S4

Sensitivity

Adjustment

Red Margin/

SCP Indicator

Green Output

Indicator

Yellow Power

Indicator

Figure 37 - Typical ON/OFF Timing Diffuse (Light-operate) Nonretriggerable

Figure 38 - Typical One-Shot Timing Diffuse (Light-operate) Nonretriggerable

On Delay Adjustment

Off Delay Adjustment

The timers are nonretriggerable. The timing can be set for short (0…1.5 s) or long

(0…15 s) duration using the DIP switches and adjusted via the two 15-turn rotary

knobs. See Figure 37 and Figure 38 to configure these timers.

IMPORTANT After initial photoelectric sensor configuration, confirm

that the user interface cover is closed tightly to maintain

specified environmental ratings.

42GRL Models

For the 9003 model photoelectric sensors, the

switch must be pushed to the left, towards 9003.

For all other models, the switch must be pushed to

Application Example

Product travels down a conveyor. If the product is a white box, a kicker located 3

seconds down the conveyor activates to push the box down another conveyor. The

kicker must extend and retract for 1 second. The sensor is a 42GTP-9000

photoelectric sensor. In this application, an on and off delay are required. Set the

first DIP switch (S1) to TD position. Switch (S2) is set to LT position. Switch (S3) is

set to L position for a 3 second delay. Switch (S4) is set to the S position. The delay

is adjusted by turning the on delay pot clockwise until the proper delay time is set.

The off delay pot is turned clockwise so to set the 1 second off delay.

the right, towards default.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec.

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback.

For technical support, visit rok.auto/support.

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine Uygundur

Allen-Bradley, expanding human possibility, PHOTOSWITCH, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 42G-IN003B-EN-P - October 2021 | Supersedes Publication 42G-IN003A-EN-P - August 2014

Copyright © 2021 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

*PN-158404*

PN-158404

PN-158404

DIR 10000321004 Ver 02

Loading...

Loading...